High propylene yield catalytic conversion method

A catalytic conversion method, propylene technology, applied in catalytic cracking, chemical instruments and methods, cracking, etc., can solve the problems of high yield of dry gas and coke, small contribution of propylene yield, increase of coke and dry gas yield, etc. Achieve the effects of increasing propylene yield, reducing energy consumption, and reducing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

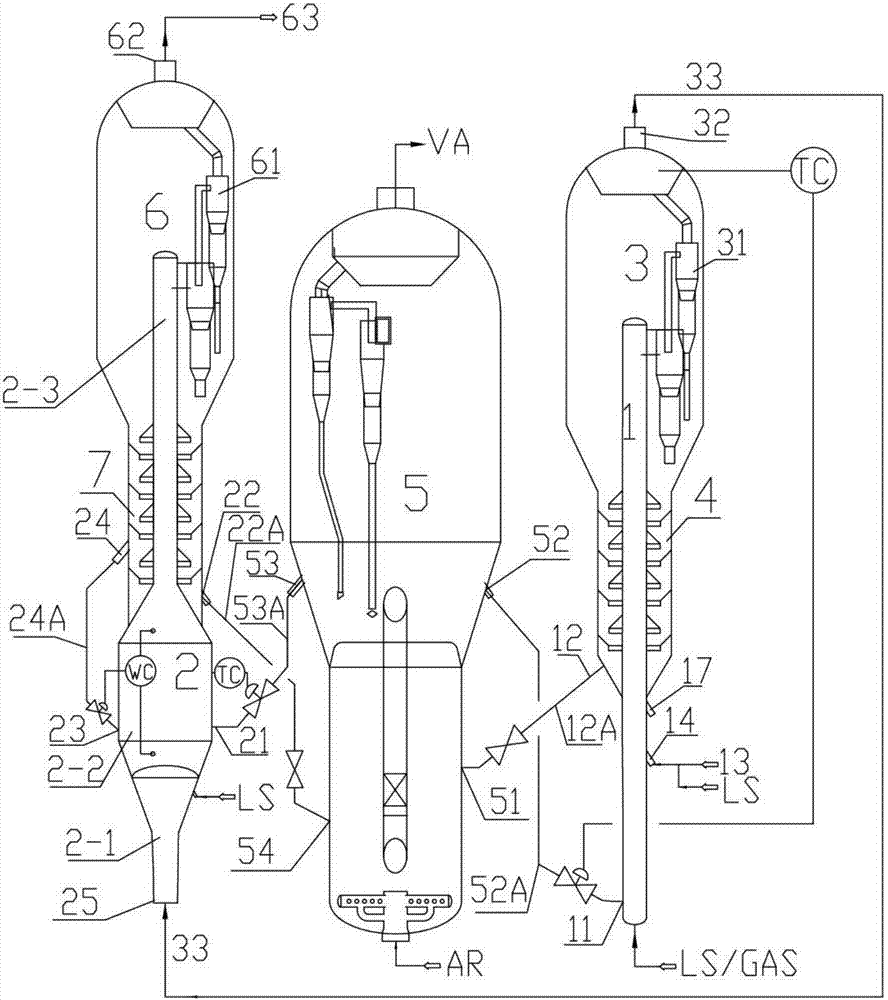

[0045] Such as figure 1 As shown, a catalyst regenerator and two reaction systems are set;

[0046] The raw oil is catalyzed in the first reaction system, and the reaction product, namely the first reaction oil gas 33, enters the second reaction system in gaseous state for further catalytic reaction; the two reaction systems use the same catalyst; the first reaction system is composed of the first The reactor 1, the first settler 3, and the first stripper 4 are composed; the second reaction system is composed of a separate second reactor 2, the second settler 6, and the second stripper 7;

[0047] After the fresh raw oil 13 is atomized by the steam LS, it enters the first reactor 1 through the raw oil inlet pipe 14, and is gasified after being in contact with the first reactor regeneration agent 52A sent through the first regeneration inclined pipe 11 and the regenerator 5 , and flow upward along the riser of the first reactor 1 to complete the reaction, and the first reactio...

Embodiment approach 2

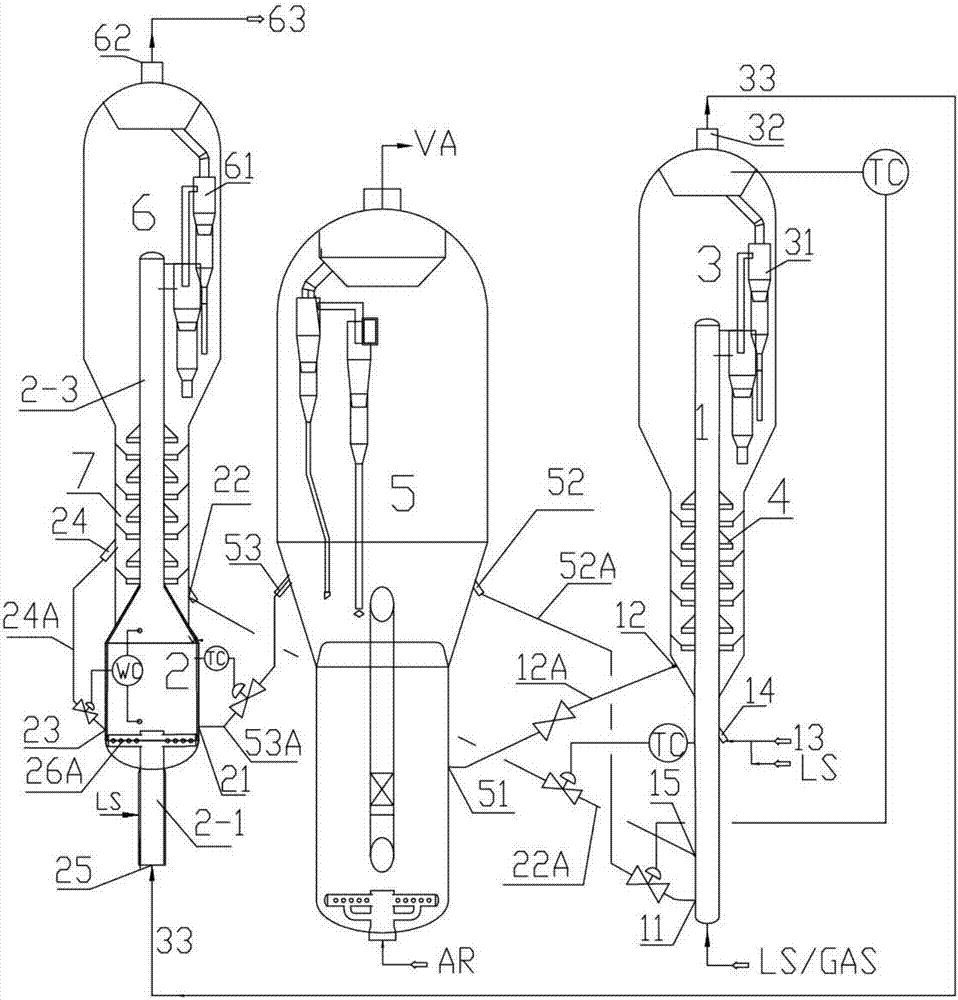

[0052] Such as figure 2 As shown, a catalyst regenerator and two reaction systems are set;

[0053] The raw oil is catalyzed in the first reaction system, and the reaction product, namely the first reaction oil gas 33, enters the second reaction system in gaseous state for further catalytic reaction; the two reaction systems use the same catalyst;

[0054] After the fresh raw oil 13 is atomized by the steam LS, it enters the first reactor 1 through the raw oil inlet pipe 14, and is gasified after being in contact with the first reactor regeneration agent 52A sent through the first regeneration inclined pipe 11 and the regenerator 5 , and react upwards along the riser of the first reactor 1; part of the second reactor’s standby agent 22A is drawn from the second standby standpipe 22, enters the first reactor 1, and flows upwardly with the first reactor The regeneration agent 52A is mixed and continues to be used in the reaction of the raw material oil, and the reaction temper...

Embodiment approach 3

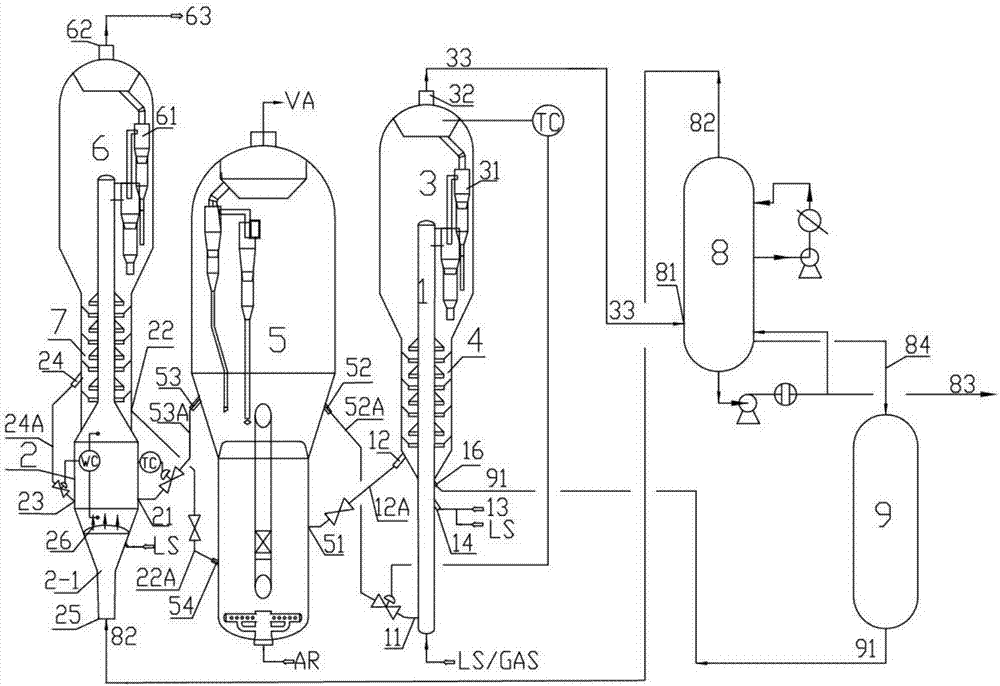

[0057] Such as image 3 As shown, a catalyst regenerator and two reaction systems are set;

[0058] The raw oil is catalyzed in the first reaction system, and the reaction product, namely the first reaction oil gas 33, enters the second reaction system in gaseous state for further catalytic reaction; the two reaction systems use the same catalyst; the first reaction system is composed of the first The reactor 1, the first settler 3, and the first stripper 4 are composed; the second reaction system is composed of a separate second reactor 2, the second settler 6, and the second stripper 7;

[0059] After the fresh raw oil 13 is atomized by the steam LS, it enters the first reactor 1 through the raw oil inlet pipe 14, and is gasified after being in contact with the first reactor regeneration agent 52A sent through the first regeneration inclined pipe 11 and the regenerator 5 , and flow upward along the riser of the first reactor 1 to complete the reaction, and the first reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com