Method for preparing special cement by circulating fluidized bed combustion ash

A technology of circulating fluidized bed and sulfur-fixing ash, which is applied in the direction of cement production, etc., can solve the problems of polluting air, water, soil and biological environment, environmental secondary pollution, and endangering human health, so as to solve the shortage of resources and reduce production Low cost and good wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

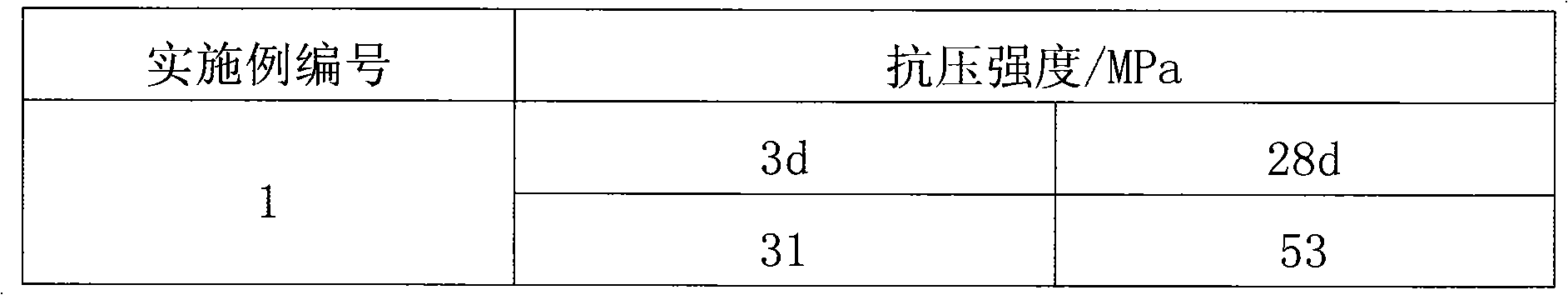

Embodiment 1

[0030] A method for preparing special cement by utilizing a circulating fluidized bed sulfur-fixing ash, comprising the following steps:

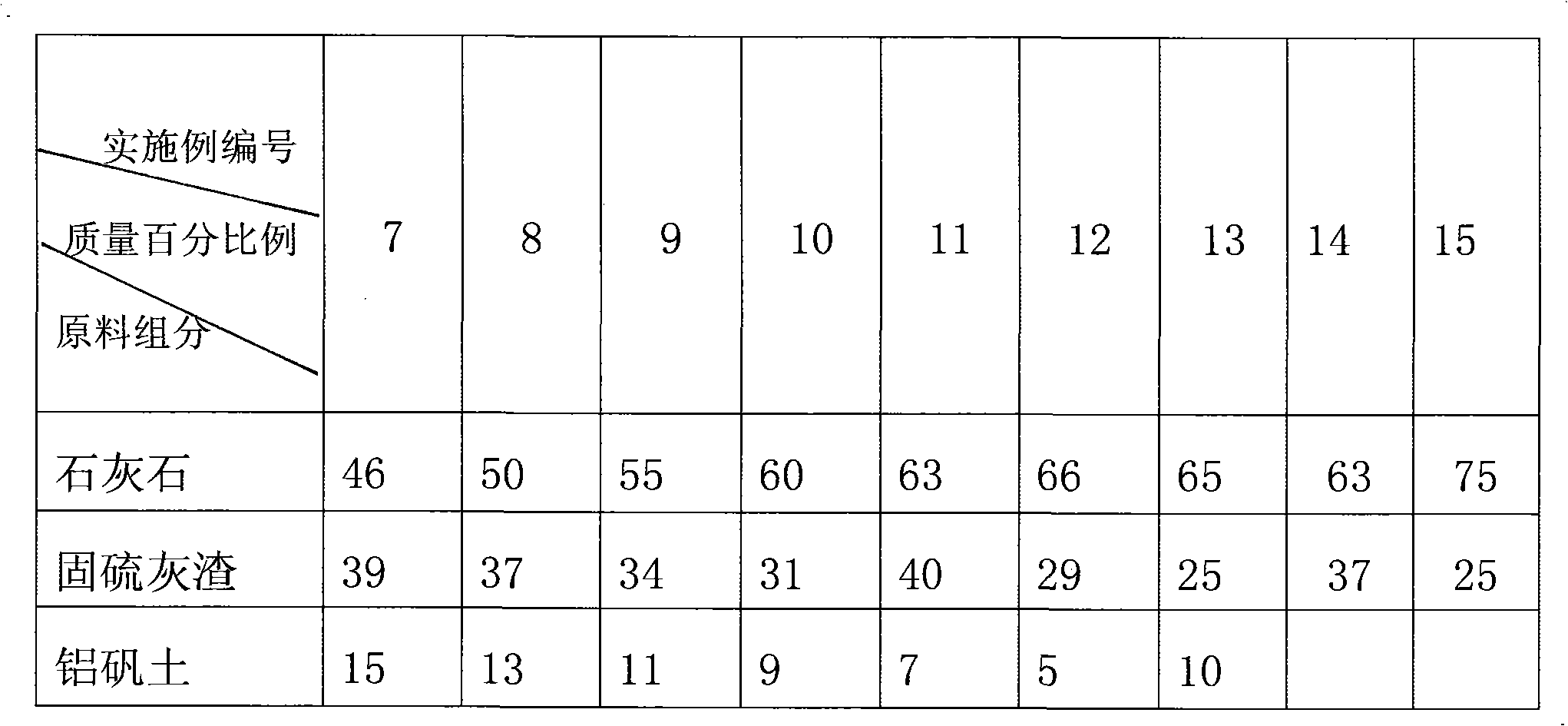

[0031] a, batching: take each component according to the raw material composition and mass percentage example of limestone 45%, sulfur-fixing ash slag 40%, bauxite 15%, respectively broken and ground (broken and ground to 80 μ m sieve residue is less than 6%) after Mix evenly to obtain a mixture;

[0032] b. Calcining: place the mixed material at a temperature of 1100-1450° C. for 60 minutes, and cool (preferably place in air for rapid cooling) to obtain clinker;

[0033] c. Cement making: Take clinker and grind it finely (ground until the specific surface area is 350-450m3) 2 / kg), that is, to make special cement.

Embodiment 2

[0035] A method for preparing special cement by utilizing a circulating fluidized bed sulfur-fixing ash, comprising the following steps:

[0036] a, batching: take each component according to the raw material composition and mass percentage of limestone 70%, sulfur-fixing ash 25%, bauxite 5%, after crushing and grinding (crushing and grinding to 80 μm sieve is less than 6%) Mix evenly to obtain a mixture;

[0037] b. Calcination: place the mixture at a temperature of 1100-1450°C for 30 minutes and then cool to obtain clinker;

[0038] c. Cement making: Take clinker and grind it finely (ground until the specific surface area is 350-450m3) 2 / kg), that is, to make special cement.

Embodiment 3

[0040] A method for preparing special cement by utilizing a circulating fluidized bed sulfur-fixing ash, comprising the following steps:

[0041] a. Ingredients: take each component according to the raw material composition and mass percentage of 60% limestone, 30% sulfur-fixing ash slag, and 10% bauxite, and crush and grind them respectively (the crushed and ground to 80 μm sieve is less than 6%) Mix evenly to obtain a mixture;

[0042] b. Calcination: place the mixture at a temperature of 1100-1450°C and calcinate for 50 minutes, then cool to obtain clinker;

[0043] c. Cement making: Take clinker and grind it finely (ground until the specific surface area is 350-450m3) 2 / kg), that is, to make special cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com