Patents

Literature

47results about How to "Match resource" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-specific-surface-area porous graphitic nanocarbon plate with coconut shells serving as raw materials

InactiveCN103011129ASolve pollutionSimple equipmentMaterial nanotechnologyNano-carbonResource utilizationDistilled water

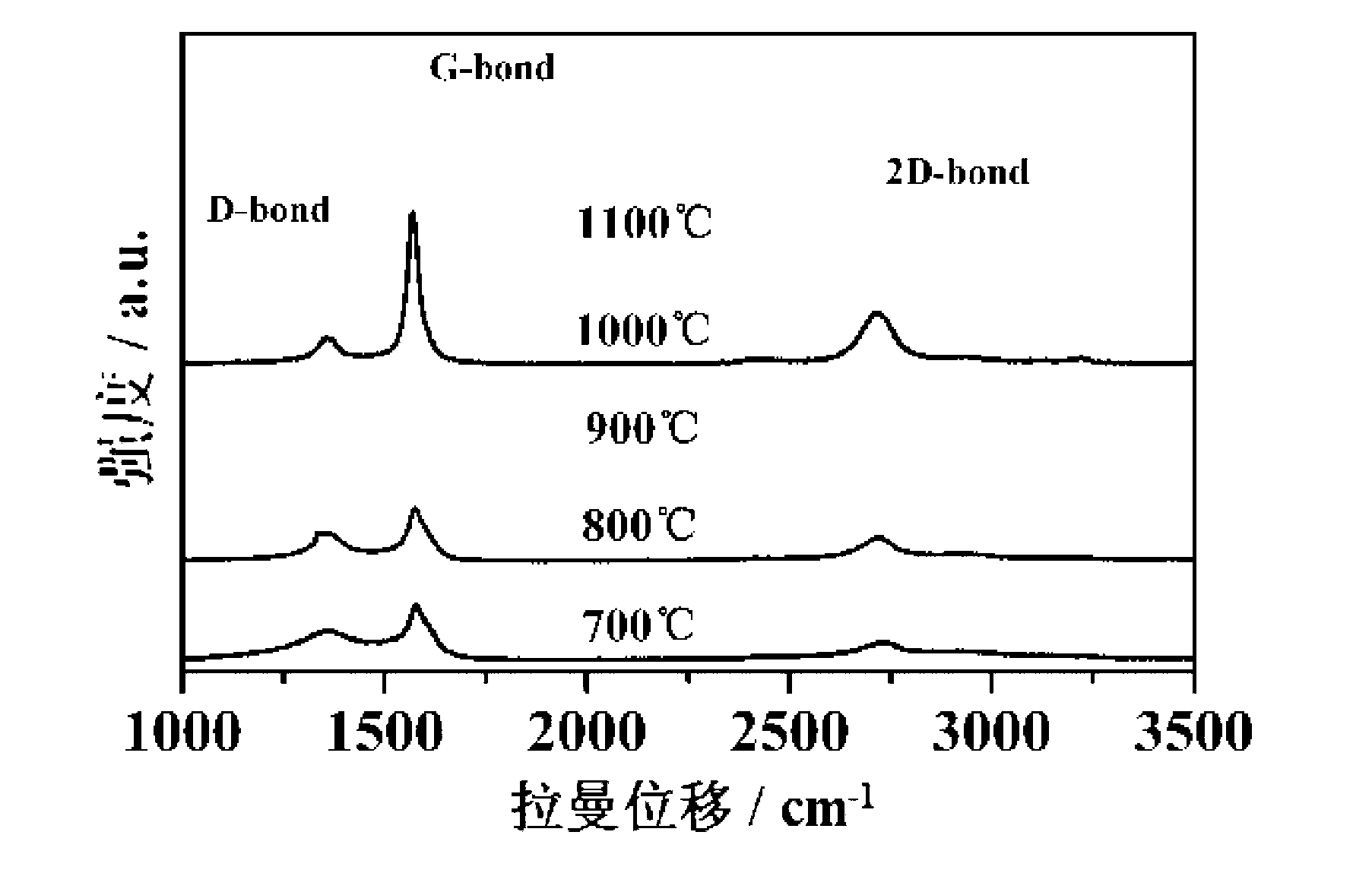

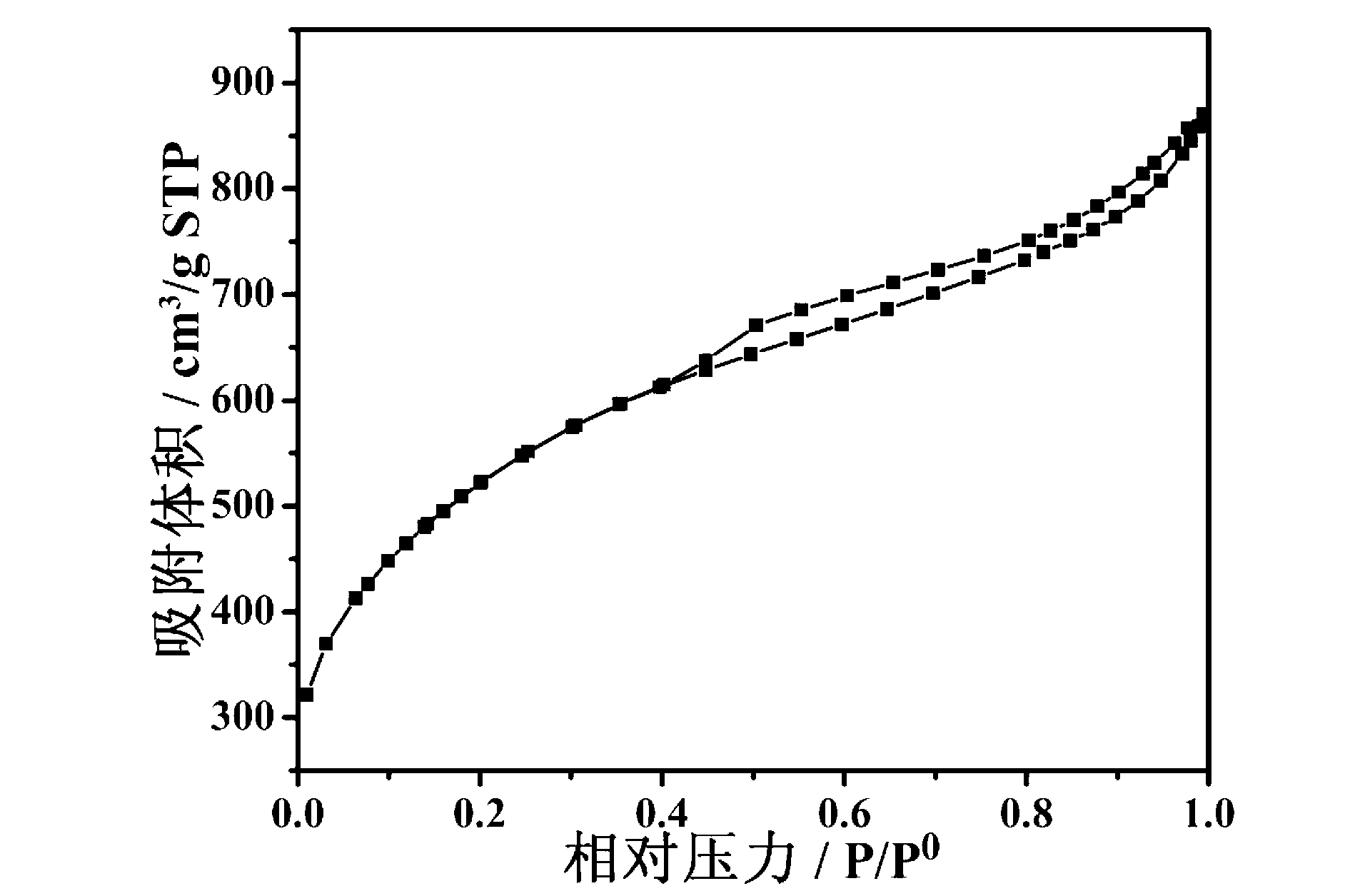

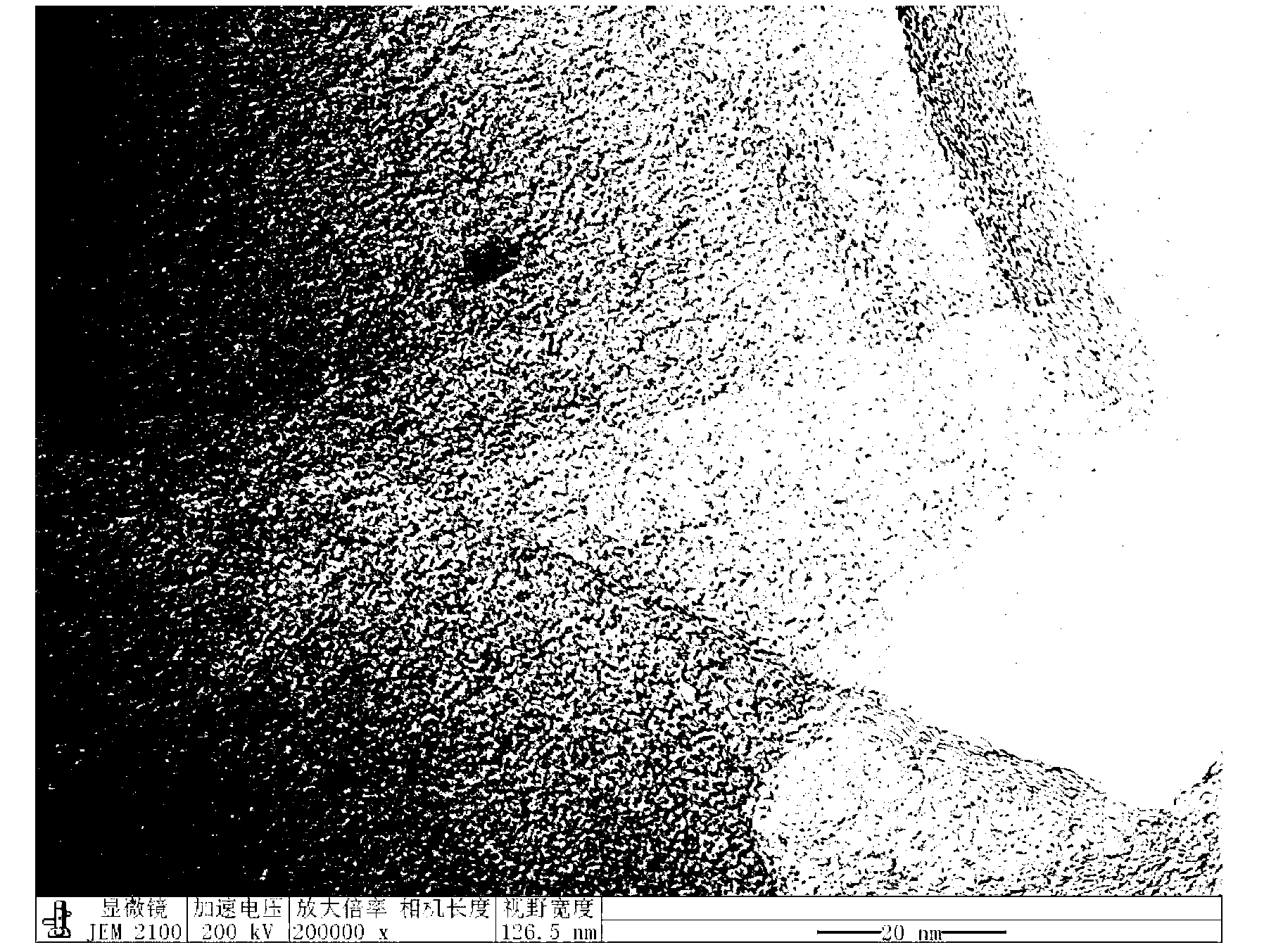

The invention provides a method for preparing a high-specific-surface-area porous graphitic nanocarbon plate with coconut shells serving as raw materials, and relates to a preparation method of a graphitic nanocarbon material, and the method is used for solving the problems of conventional preparation method of the graphitic nanocarbon material that the production cost is high, the process is complex, the safety is poor, the output is low, the industrialization is hard to realize, and the prepared graphitic nanocarbon material is low in specific surface area and poor in graphitic degree. The preparation method comprises the following steps: 1, preprocessing the raw materials; 2, coordinating the raw materials with catalysts and activating agents; 3, curing the coordination compound; 4, thermally treating under an inert gas condition; and 5, carrying out acid leaching, washing by distilled water, and drying, so as to obtain the high-specific-surface-area porous graphitic nanocarbon plate. The porous graphitic nanocarbon plate prepared by the method provided by the invention is high in specific surface area, high in graphitic degree and excellent in electrochemical performance; the method is simple, low in energy consumption, high in safety, and suitable for industrial production; and a scientific way is provided for realizing the resource utilization of biological wastes like the coconut shells.

Owner:HEILONGJIANG UNIV

Filter material for biological aerated filter and preparation method thereof

InactiveCN101798140ALarge specific surface areaAvoid secondary pollutionTreatment using aerobic processesSustainable biological treatmentHigh carbonSludge

The invention relates to a filter material for a biological aerated filter, which comprises the following raw materials by mass part: 10-40 parts of sludge from a waterworks, 25-80 parts of sludge from a sewage treatment works, 3-15 parts of pore-forming agent, and 7-20 parts of binder. Since the sludge from the sewage treatment works has higher carbon content, and the particle surface forms a porous state by adding right amount of pore-forming agent, the filer material has better adsorption and removal effects for pollutants in wastewater. The prepared filter material has huge specific surface area, is favorable for the attached growth of microorganisms, and is a novel efficient filter material for the biological aerated filter.

Owner:HOHAI UNIV

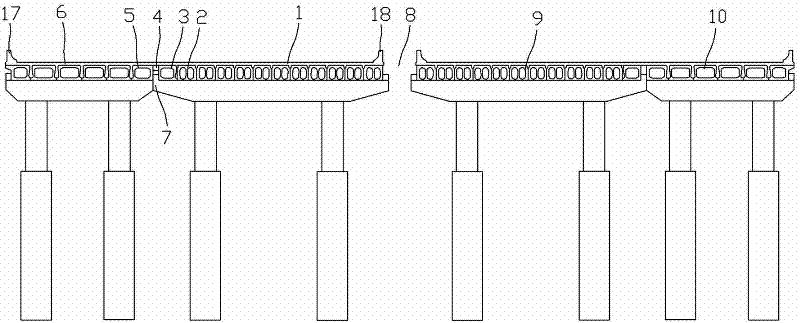

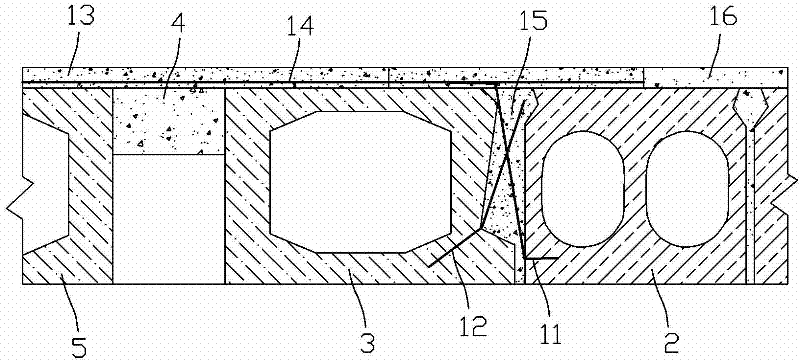

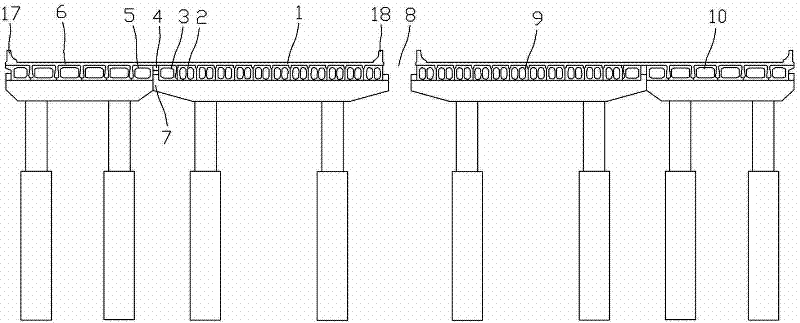

Bridge widening splicing structure and its construction method

InactiveCN102286921AEnsure connection integrityExtended service lifeBridge erection/assemblyBuilding energyResource saving

The invention relates to a bridge widening splicing structure and a construction method thereof. The present invention adopts the design principle of "connecting at the top and not connecting at the bottom", that is, the wet joint of cast-in-situ concrete is realized between the upper hollow slabs of the new and old bridges, the bridge deck is continuous, and the lower piers and foundations are no longer connected, and they are relatively independently stressed. To adapt to the differential settlement between the new and old bridges; the outer side plate of the old bridge is replaced, and the pier cover beam is not removed, only the anti-collision guardrail of the old bridge is removed. After the old bridge plate is replaced, the plate is replaced next to the old bridge The edge of the rear beam slab is connected with the beam slab of the new bridge by planting bars, so that the old and new bridges form a solid whole. The inventive method combines many advantages such as simple construction, short construction period, low construction cost, new and old bridges are formed into a whole to bear the force together, etc. The hollow slabs can be replaced by centralized prefabrication and factory construction, and are suitable for highway bridges of all grades. Wide construction, in line with the requirements of building energy saving, building a resource-saving, environment-friendly society, after promotion, it has good economic benefits and social value.

Owner:河南省九建工程有限公司 +1

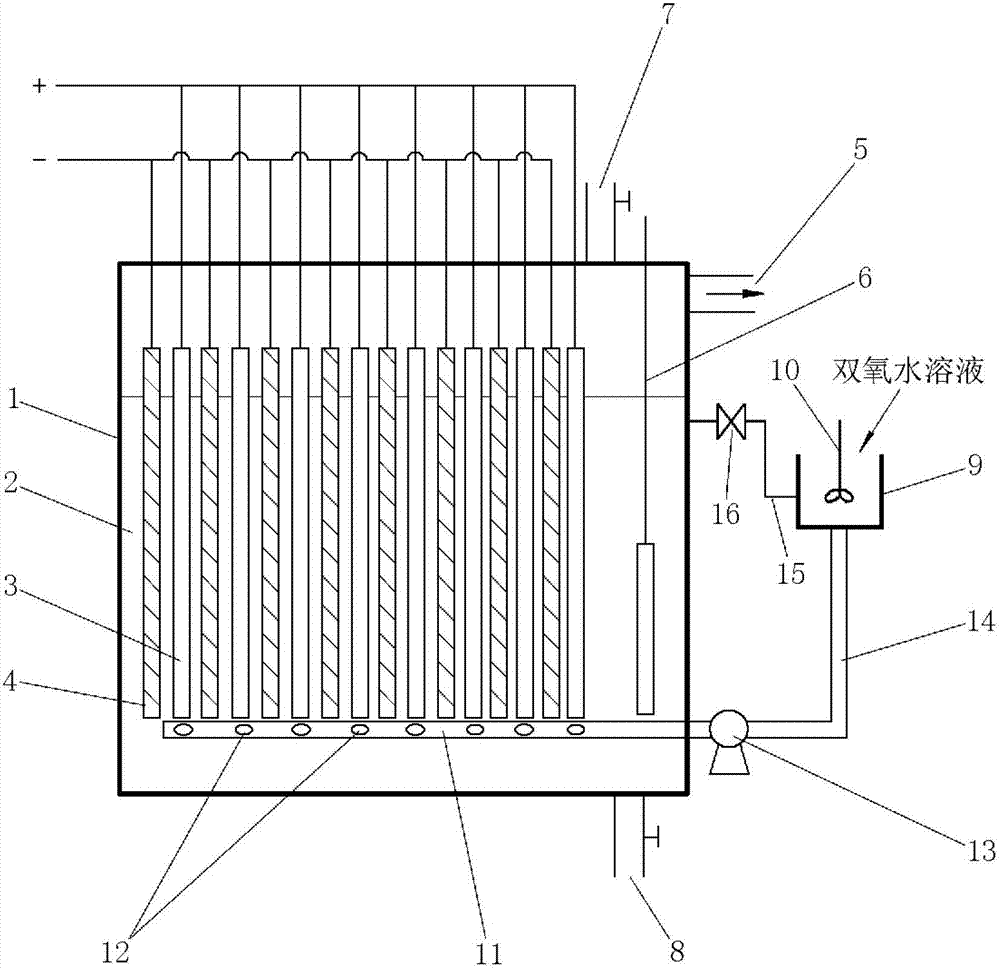

Method for carrying out electrolytic treatment on copper-containing electroplating wastewater and recycling copper

InactiveCN103011347AHigh removal rateSimple processPhotography auxillary processesWaste water treatment from metallurgical processCopperElectroplating wastewater

The invention relates to a method for carrying out electrolytic treatment on copper-containing electroplating wastewater and recycling copper. Compared with the existing copper-containing electroplating wastewater treatment methods, the method provided by the invention has the advantages of simple process, easiness in control, no secondary pollution, high removal ratio, recyclable precipitated copper and reusable outlet water. The method for carrying out electrolytic treatment on copper-containing electroplating wastewater and recycling copper is achieved through the following manners: the copper-containing electroplating wastewater electrolysis treatment is carried out through a copper-containing electroplating wastewater electrolysis treatment device, wherein the device comprises an electrolysis bath and an electrolyte stirring device; and the method comprises the following steps of: adding quicklime to the copper-containing electroplating wastewater so as to adjust the pH value of the wastewater, removing precipitates from the copper-containing electroplating wastewater so as to obtain an electrolyte, and adding a certain amount of NaCl and KCl to the electrolysis bath containing the electrolyte; during electrolysis, slowly adding a right amount of hydrogen peroxide liquid to the electrolysis bath; and after the copper is precipitated from the negative electrode, recycling the precipitated copper.

Owner:ZHEJIANG NORMAL UNIVERSITY

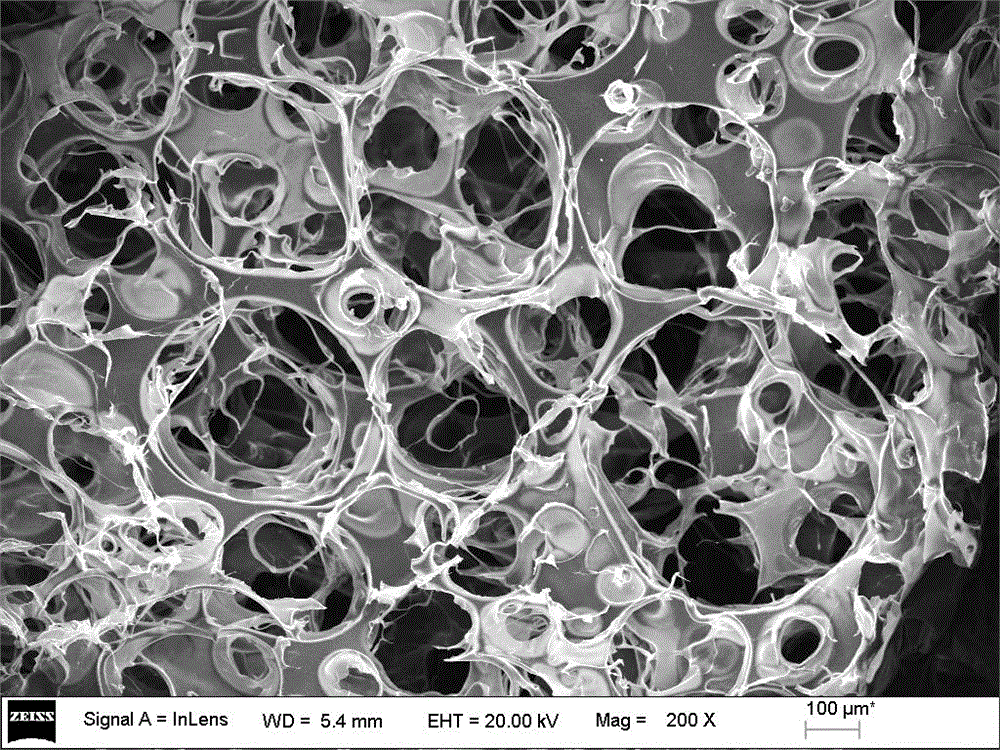

Compound dressing with high liquid absorption performance and preparation method of compound dressing

InactiveCN106344952AGood tissue compatibilityImprove the ability to absorb exudatePharmaceutical delivery mechanismAbsorbent padsFreeze-dryingMechanical property

The invention relates to compound dressing with high liquid absorption performance and a preparation method of the compound dressing. The compound dressing is prepared from chitosan serving as a raw material and consists of a supporting layer and a functional layer, wherein the supporting layer is functional nonwoven cloth; the functional layer is prepared by performing water dissolving, macromolecular crosslinking, foaming, freeze drying and the like on carboxymethyl chitosan. The compound dressing is high in mechanical property and pore-forming property; furthermore, by the compound design of a dual-layer structure, the liquid absorption performance is higher than that of common dressing, and the compound dressing is suitable for perpendicular absorption application. Chitosan is a natural macromolecular polymer and belongs to aminopolysaccharide, so that the dressing is high in mechanical property, high in seepage absorption, and also high in biological compatibility, degradability and nontoxicity, can induce tissue regeneration and remodeling, can effectively promote healing of a wound, and is a more ideal healing promotion material.

Owner:QINGDAO CHENLAND MARINE BIOTECH CO LTD

Method for preparing building materials by virtue of sludge pyrolyzation

The invention relates to a method for preparing building materials by virtue of sludge pyrolyzation. The method comprises the following steps: (1) drying sludge in a solar greenhouse; (2) sending the sludge processed in the step (1) into a drying chamber, drying the sludge by virtue of any heat source (preferable flue gas of a system), sending the sludge into a pyrolyzation chamber, pyrolyzing the sludge so as to produce combustible gas and sludge carbon, introducing combustible gas into a combustion chamber for combustion, introducing high temperature flue gas produced during the combustion into the drying chamber to preheat and dry the sludge, introducing exhaust gas produced during drying and cooled flue gas into gas purifying equipment, and discharging exhaust gas and flue gas into a chimney after purification; (3) sending high temperature sludge carbon prepared in the step (2) into a cooling chamber, cooling, and breaking cooled sludge carbon into particles with the particle sizes less than 20mm in a breaking machine; and (4) stirring the following mixed materials in parts by weight, molding by casting in a mold, carrying out natural drying and maintenance in the mold, removing the mold, and drying. By preparing the building materials from the sludge, the cost is lowered, the land source is saved, and the pollution problem caused by the sludge to surrounding environments is solved.

Owner:SHAANXI UNIV OF SCI & TECH

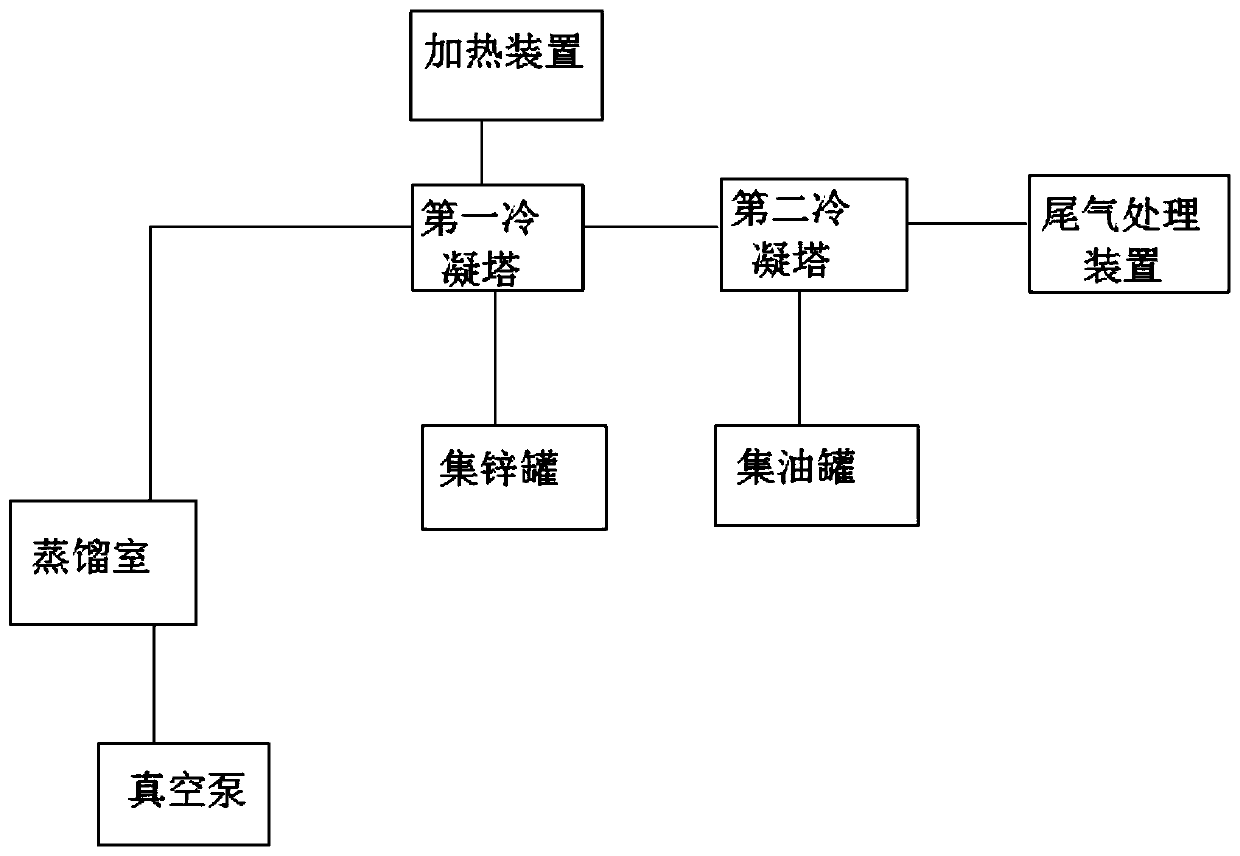

System and method for reducing ash content of pyrolysis carbon black of waste tires and recovering Zn

ActiveCN110760204AEfficient recyclingImprove the performance of pyrolysis carbon blackPigmenting treatmentProcess engineeringResidual oil

The invention relates to a system and a method for reducing the ash content of pyrolysis carbon black of waste tires and recovering Zn. The system comprises a distillation chamber, a first condensation tower and a second condensation tower which are sequentially connected, wherein the first condensation tower is also connected with a zinc collecting tank; the second condensation tower is also connected with an oil collecting tank and a tail gas treatment device; and the distillation chamber is connected with a vacuum pump. According to the method disclosed by the invention, the pyrolysis carbon black is reprocessed by using a vacuum distillation chamber, carbon black and zinc oxide in the pyrolysis carbon black are subjected to a carbothermic reduction reaction under a high-temperature vacuum environment to generate zinc and vaporize at a high temperature, condensation recovery is realized, and residual oil in the carbon black is removed by high-temperature vaporization at the same time; according to the method disclosed by the invention, the ash content of the pyrolysis carbon black can be reduced, the performance of the pyrolysis carbon black is greatly improved, meanwhile, the purposes of recovering zinc and removing excess oil are achieved, the treated carbon black achieves the purposes of deodorization and oil removal, the ash content of the treated carbon black can be obviously reduced, and the recovery rate of crude zinc and oil is high.

Owner:珠海格力绿色再生资源有限公司

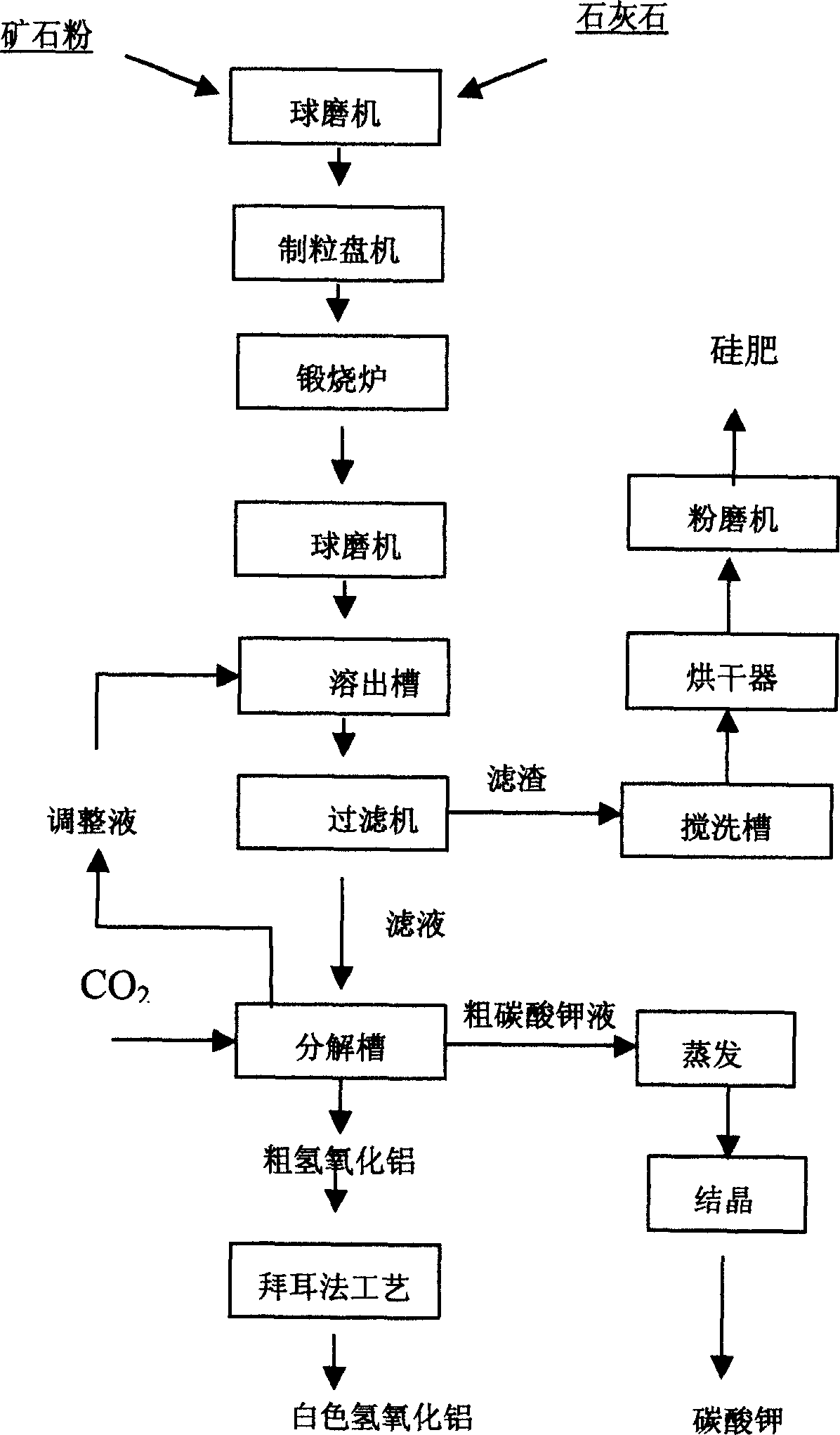

Formula and technique for extracting potassium carbonate and aluminum hydroxide and preparing siliceous fertilizer using slate with rich kalium

InactiveCN1603234AIncrease economic value addedProtect the environmentAlkali metal carbonatesAluminium oxides/hydroxidesAluminium hydroxidePotassium

The invention relates to a compounding recipe and technology to distill potassium carbonate and aluminum hydroxide by potassium-rich slate and to produce siliceous fertilizer. It belongs to fertilizer producing field. Its feature is that putting the potassium-rich slate ore and limestone into ball mill, cuber, rotary kilncalcnaton furnace, ball mill, digestion tank and filter according to calcium-silicon mol ratio. Then, part of rough potassium carbonate is used to confect correction liquor, and the other is used to gain potassium carbonate after concentration and crystallizing. The leached residue is rough potassium hydroxide, and pure potassium hydroxide would be gained by Bayer process technology. And other part is used to gain siliceous fertilizer after passing washer tank, drying apparatus and pulverizer. The invention could make the extraction rate of alumina reach to over 60% and that of kali reach to over 80%. It can transform the silicon element into siliceous fertilizer. The invention would not produce exhausted water and waste residue. Thus, the purpose of comprehensive utilization of resource would be realized.

Owner:包头市科技开发研究院

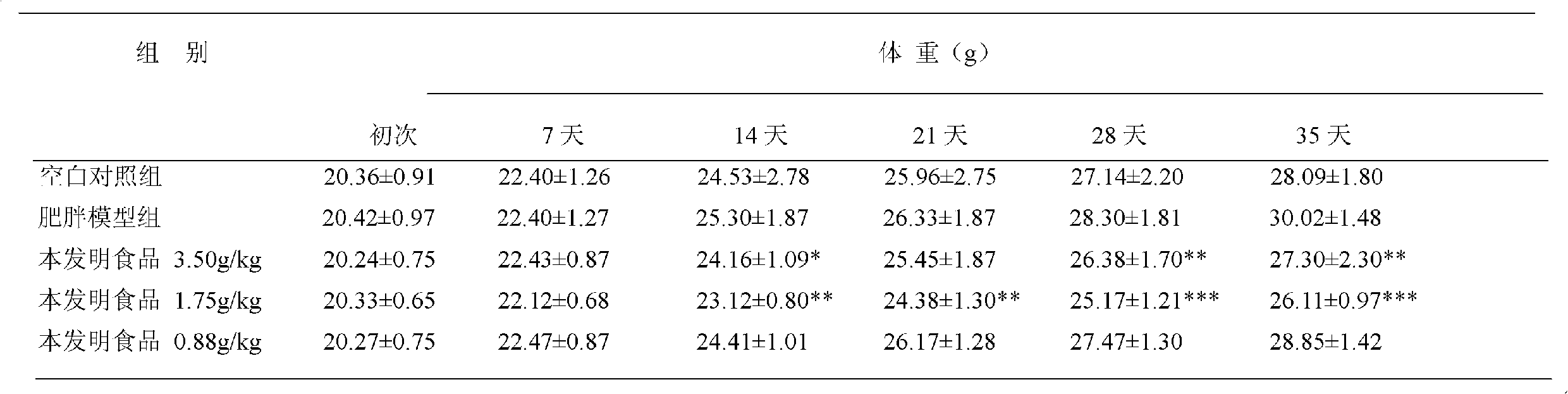

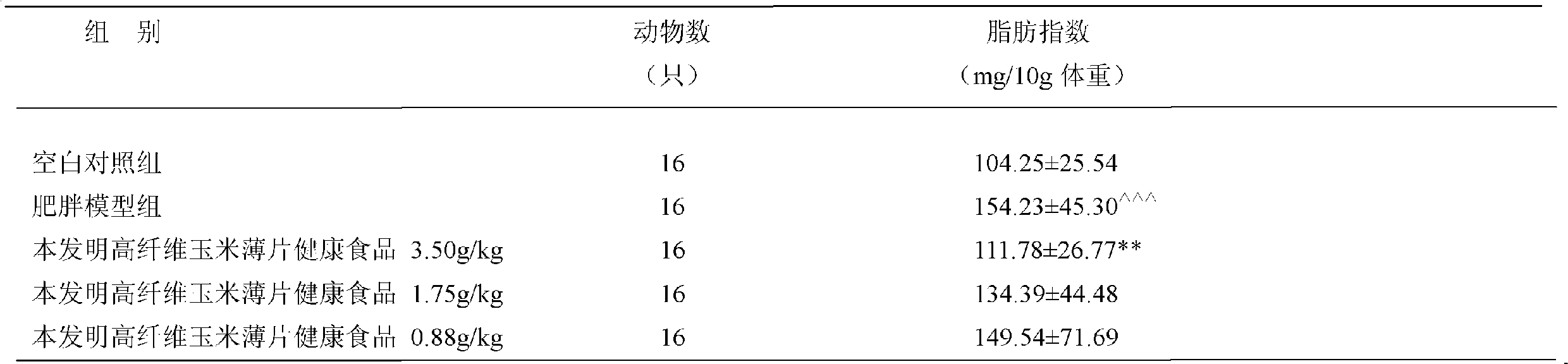

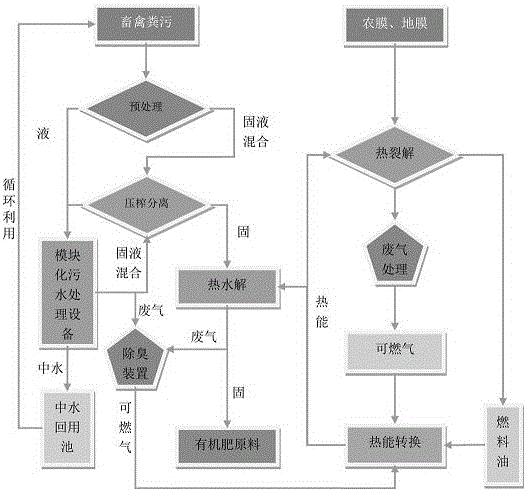

High-fiber corn flake healthy food and production method thereof

The invention relates to high-fiber corn flake healthy food and a production method thereof, belonging to the food processing technology. The method comprises the following steps of: screening corn seeds to remove inedible impurities; rinsing, drying and crushing to obtain pure corn meal; adding a proper amount of high-quality corn dietary fiber, flavor endowing agent and the like, and adjusting the components; and preparing the corn flake healthy food with abnormal metabolism regulation functions such as shaping, resisting constipation and the like by the technology integrating separation and recombination, quick cropping and forming. The product is crispy, has good flavor, is suitable for all consumer groups, and can be taken as leisure food as well as snack or staple food. In the production process, the raw materials are completely used, the production of pollution, waste slag, waste gas and harmful substances is avoided, and the food is safe to eat because no chemical reagent is used.

Owner:吉林省长吉图开发建设现代农业投资有限公司

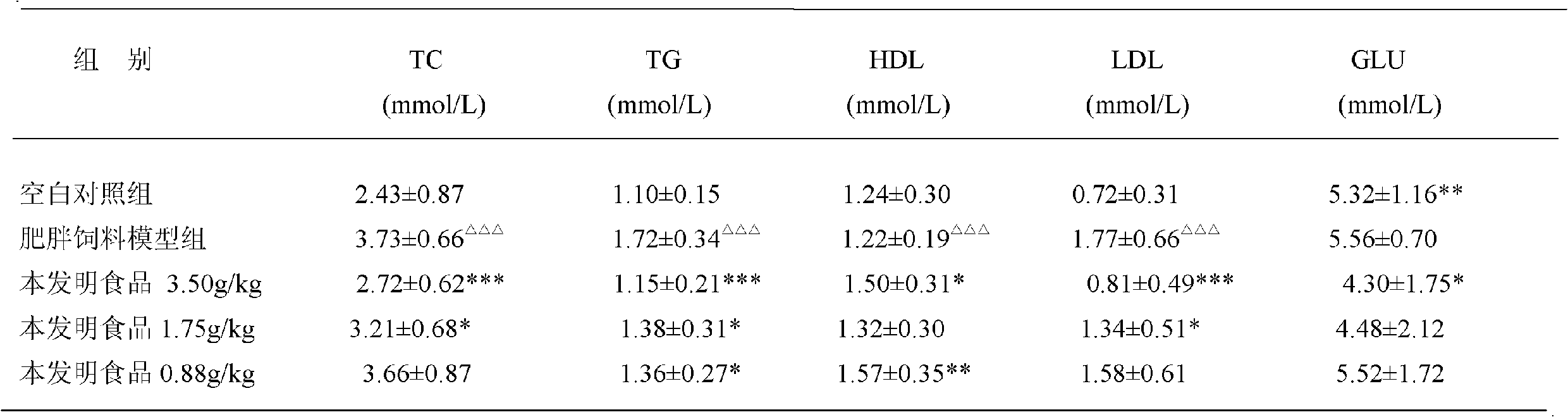

Comprehensive treatment technology of farming excrement and mulching film non-point source pollution

InactiveCN106145608AAchieve deacidification and deodorizationAchieve inactivation and sterilizationByproduct vaporizationWaste water treatment from animal husbandryEnvironmental resistanceFlocculation

The invention discloses a comprehensive treatment technology of farming excrement and mulching film non-point source pollution. The technology comprises the following steps: (1) with a livestock excrement flocculation concentration squeezed separation treatment technology, adding a flocculating agent into the livestock excrement, separating the livestock excrement added with the flocculating agent by a mechanical roller screen, and dehydrating with a screw extrusion dehydrator; (2) performing sewage treatment by a modular sewage treatment equipment, wherein a modular A / O device, a flocculating agent adding device, a flocculation separation and disinfection integrated device and a solid-liquid separation squeezing device are adopted; (3) with a solid excrement acid removal thermal hydrolysis technology, performing solid excrement treatment in an acid removal thermal hydrolysis way; and (4) with a mulching film cracking technology, selecting the heating rate, pyrolysis temperature and catalyst and determining the heating rate and pyrolysis temperature of the technology and corresponding product recycling and environment-friendly treatment technology to realize an environmental protection effect of 'treating waste with waste' and avoiding secondary pollution.

Owner:陈永进

Gas combustion-supporting device of recirculating fluidized bed and combustion control device of recirculating fluidized bed

InactiveCN102353044AResolve Insufficient CombustionSolve the landfill problemFluidized bed combustionDirect carbon-dioxide mitigationCombustion systemCombustion chamber

The invention relates to the technical field of fluidized bed combustion, and in particular relates to a gas combustion-supporting device of a recirculating fluidized bed and a combustion control device of the recirculating fluidized bed. The combustion-supporting device comprises a fluidized bed combustion chamber and a gas compression device; the gas compression device is communicated with the fluidized bed combustion chamber through a pipeline, and gas is introduced into the fluidized bed combustion chamber; and the top end of the pipeline is provided with a gas compression ejector. Through the gas combustion-supporting device of the recirculating fluidized bed provided by the invention, the problem of insufficient combustion brought by the calorific value, less than 2500kcal / kg, of the recirculating fluidized bed of fuel material (mud) can be solved effectively, thus the combustion is fuller, and the desulfurization and deslagging operations are easier, and clean combustion is realized; simultaneously the emission of carbon dioxide is reduced effectively, and the tail gas treating cost is lowered; and in addition, the sufficient combustion of fuel materials in the fluidized bed enables the fuel material waste residue to be decreased greatly, the problem of land occupation by landfill of waste residue is solved effectively, the comprehensive benefit is good, and the device and the system accord with the principles of reduction, harmlessness and resource utilization of mud treatment.

Owner:北京君达能源投资有限公司

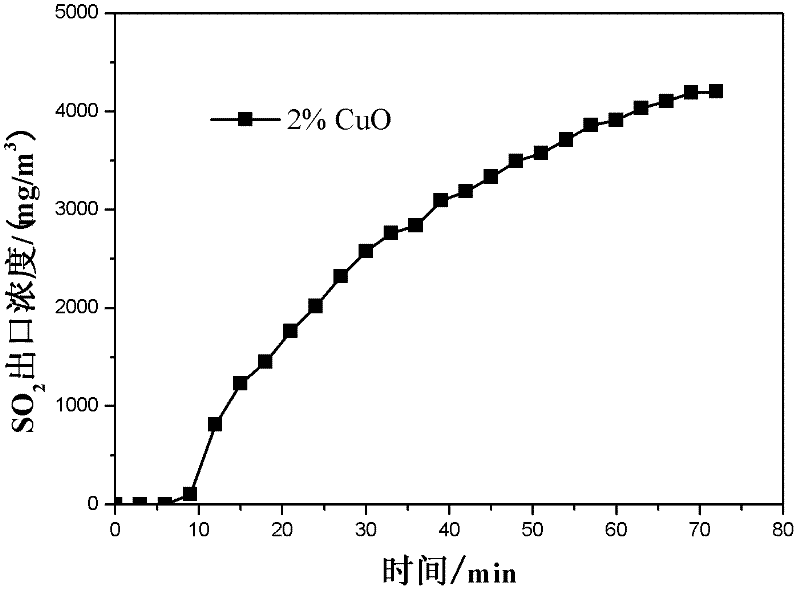

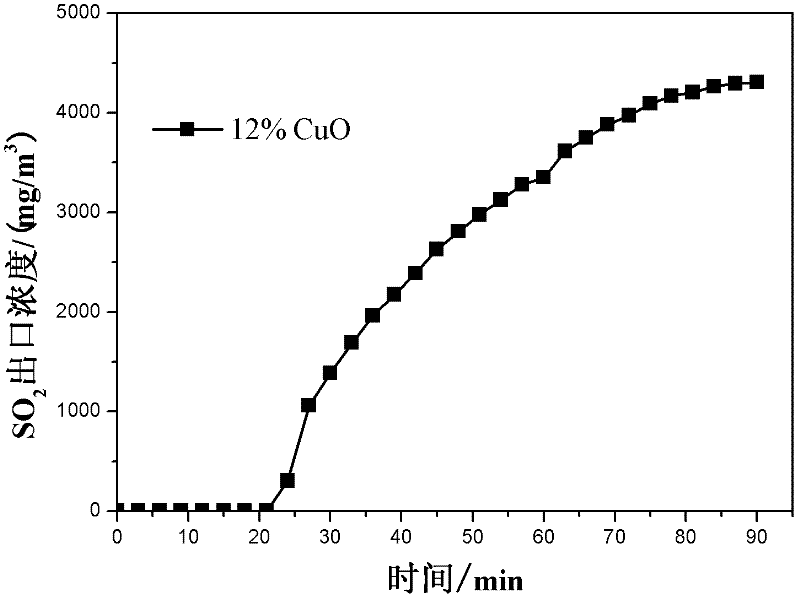

Copper oxide loaded attapulgite catalyst and preparation method and applications thereof

InactiveCN102500372AImprove desulfurization efficiencyWide variety of sourcesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention discloses a copper oxide loaded attapulgite catalyst and a preparation method and applications thereof. The copper oxide loaded attapulgite catalyst is a composite which uses the calcined attapulgite as the catalyst carrier and is loaded with copper oxide; and the weight of copper oxide accounts for 2-20% of the weight of the catalyst carrier. The preparation method of the catalyst comprises the following steps: adopting the isovolumetric impregnation method to load a catalyst precursor on the surface of the catalyst carrier, drying and calcining to obtain the copper oxide loaded attapulgite catalyst, wherein the catalyst precursor is Cu(NO3)2. The catalyst disclosed by the invention is used to remove SO2 in the flue gas. The cheap and available attapulgite is used as the catalyst carrier, thus reducing the cost of the catalyst and the environmental load; and attapulgite has better formability and thermal stability, and the catalyst which is loaded with the copper active component has higher sulfur capacity.

Owner:HEFEI UNIV OF TECH

Lightweight wallboard manufactured by utilizing paper mill sludge and manufacturing method thereof

The invention belongs to the technical field of lightweight wallboards and in particular relates to a lightweight wallboard manufactured by utilizing paper mill sludge and a manufacturing method thereof. The lightweight wallboard is manufactured from the following raw materials in parts by weight: 50-60 parts of paper mill sludge, 30-50 parts of construction wastes, 40-60 parts of potassium feldspar powder, 10-40 parts of fly ash and 40-60 parts of cement. The adopted paper mill sludge dispenses with dehydration and drying and can be used directly, therefore the energy is saved, the cost is low and the production efficiency is high; the manufactured lightweight wallboard has low shrinkage, light weight and high compression strength; the compression strength is as high as 60-120MPa; the lightweight wallboard has better physical and mechanical properties than the common natural stones; and plenty of construction wastes, paper mill sludge and fly ash are used, therefore the manufactured product has low cost and high economic benefit, and the method not only can be used for turning wastes into wealth, but also is beneficial to reduction of environmental pollution and has obvious economic and social benefits.

Owner:广东春天生态科技集团有限公司

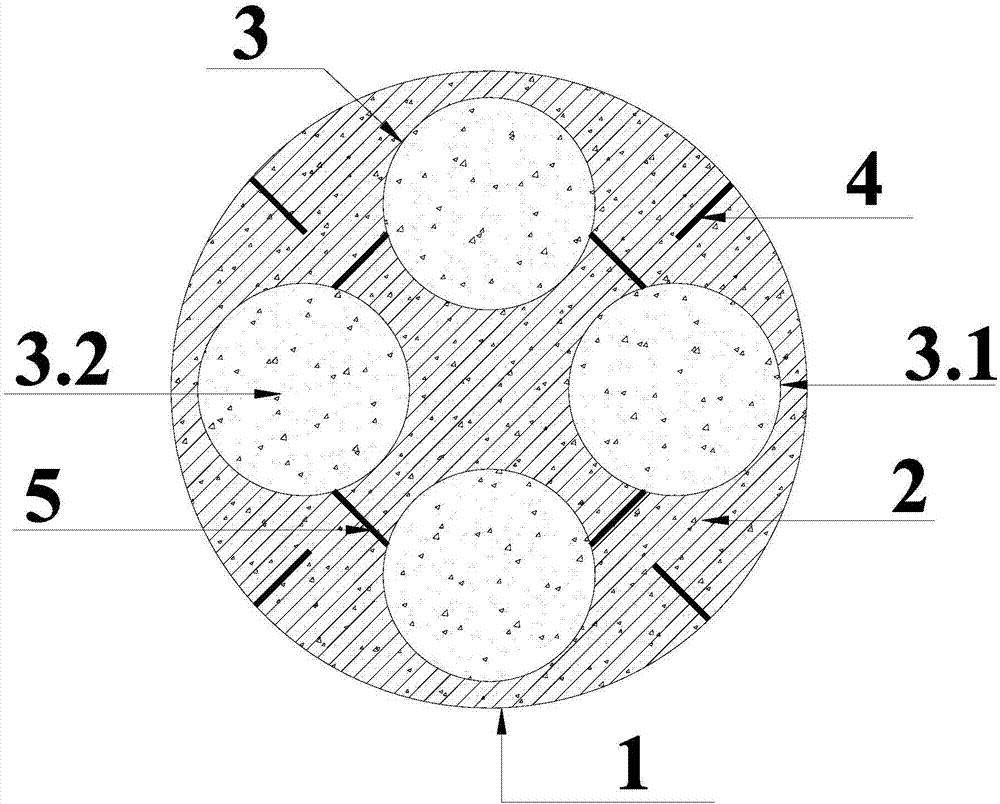

Composite steel pipe concrete column with built-in steel pipe beam tube

The invention discloses a composite steel pipe concrete column with a built-in steel pipe beam tube. The composite steel pipe concrete column comprises an outer tube steel pipe, wherein a plurality of inner tube steel pipe concrete columns are arranged in the outer tube steel pipe; each inner tube steel pipe concrete column comprises an inner tube steel pipe; inner tube concrete is filled in the inner tube steel pipe; the inner tube steel pipe concrete columns are connected through connecting lacing elements; a plurality of enhanced bonding ribs are arranged on the inner wall of the outer tube steel pipe; between-pipe concrete is filled between the outer tube concrete pipe and the inner tube concrete columns; The composite steel pipe concrete column with the built-in steel pipe beam tube has the advantages that the carrying force is high; the intensity storage is great; the durability is higher; the cross section dimension and the dead weight of the column component are reduced; the high-intensity materials are sufficiently utilized; the energy sources and the energy sources are saved; the sustainable development requirements are met.

Owner:HUBEI ENG UNIV

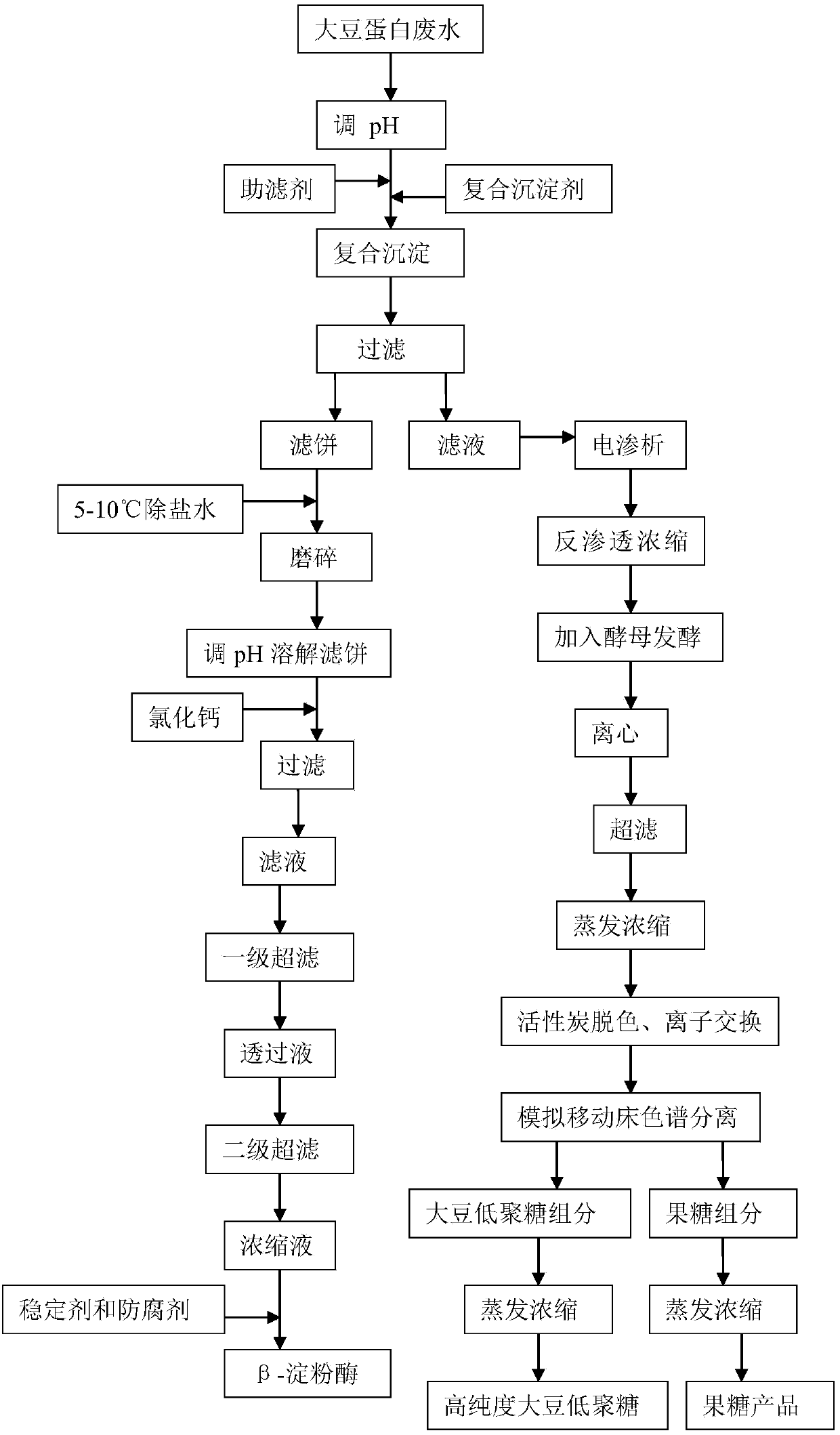

Method for preparing beta-amylase and soybean oligosaccharides

ActiveCN103756987ATake advantage ofReduce processing costsSugar derivativesChemical industryChromatographic separationAmylase

The invention discloses a method for preparing beta-amylase and high-purity soybean oligosaccharides at the same time. The method comprises the following steps: (1) adjusting the pH value of soybean protein wastewater, and adding a filter aid and a composite precipitator; (2) adding desalting water and calcium salt; (3) performing ultrafiltration membrane treatment; (4) performing ultrafiltration membrane treatment to prepare beta-amylase; (5) reducing the electric conductance by an electrodialysis method; (6) fermenting by yeasts and ultra-filtering; (7) performing chromatographic separation by a simulated moving bed to obtain soybean oligosaccharides and fructose. The method has the benefits as follows: 1, the soybean protein wastewater is taken as a raw material, so that the resources are fully utilized and the wastewater treatment cost is saved; 2, obtained beta-amylase is high in activity and good in acid resistance and temperature resistance; 3, the process is simple, the cost is low, and obtained soybean oligosaccharides are high in purity.

Owner:山东绿健生物技术有限公司

Lightweight wallboard manufactured by using urban sludge and manufacturing method for lightweight wallboard

The invention belongs to the technical field of lightweight wallboards, and in particular relates to a lightweight wallboard manufactured by using urban sludge and a manufacturing method for the lightweight wallboard. The lightweight wallboard comprises the following raw materials in part by weight: 40 to 60 parts of urban sludge, 30 to 50 parts of building garbage, 40 to 60 parts of potassium feldspar powder, 10 to 40 parts of fly ash, and 40 to 60 parts of cement. The adopted urban sludge does not need to be dehydrated and dried and can be directly used, so that the energy is saved, the cost is low and the production efficiency is high. The manufactured lightweight wallboard has low shrinkage, light weight and high compressive strength; the compressive strength reaches 60 to 120MPa; andthe lightweight wallboard has more excellent physical and mechanical properties compared with common natural stones. By using massive building garbage, urban sludge and fly ash, the manufactured product has low cost and high economic benefit, wastes are changed into valuable, environmental pollution is improved, and the lightweight wallboard has remarkable economic benefit and social benefit.

Owner:广东春天生态科技集团有限公司

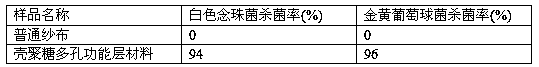

Chitosan porous functional layer of dustproof and antibacterial mask and preparation method of chitosan porous functional layer

PendingCN110628075AGood moisture absorption and air permeabilityHigh porosityProtective garmentCross-linkFreeze-drying

The invention discloses a chitosan porous functional layer of a dustproof and antibacterial mask and a preparation method of the chitosan porous functional layer, and belongs to the technical field ofhygienic product material preparation. The preparation method comprises the following steps: 1) preparing a cross-linking agent solution with a proper concentration, then slowly adding the cross-linking agent solution into a sodium periodate solution, mechanically stirring, adding ethylene glycol, stirring to react, and freeze-drying to obtain a macromolecular cross-linking substance; 2) preparing a carboxymethyl chitosan solution, wherein uniformly mixing the macromolecular crosslinking substance with a proper amount of glycerol for reaction, adding a surfactant, and stirring at a high speed; 3) pouring the carboxymethyl chitosan solution obtained after the reaction on a mold, coating, and freeze-drying a coated material; and 4) after vacuum drying, curing the coated material to obtain the chitosan porous functional layer material, which has the advantages of excellent mechanical properties, favorable moisture absorption, favorable air permeability, favorable antibacterial properties, favorable biocompatibility, favorable degradability and no toxicity, and is an ideal mask functional layer material.

Owner:HANGZHOU DIANZI UNIV

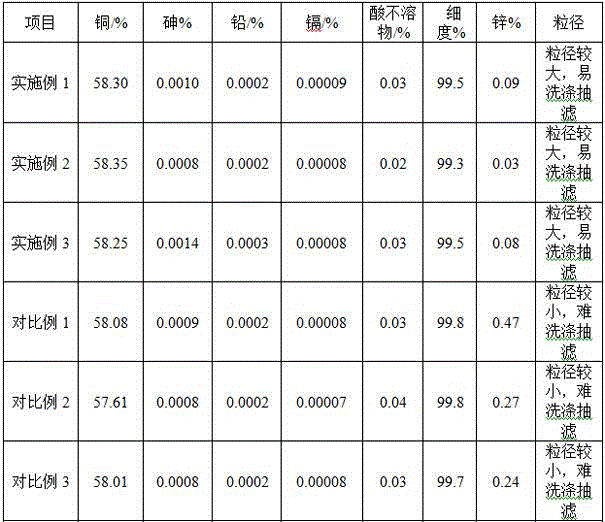

Technology for preparing tribasic copper chloride and tetrabasic zinc chloride by utilization of brass slag and zinc-containing flue ash

ActiveCN105399132AImprove utilizationReduce processing costsZinc halidesCopper chloridesTribasic copper chlorideCopper chloride

The invention relates to a technology for preparing tribasic copper chloride and tetrabasic zinc chloride by utilization of brass slag and zinc-containing flue ash. The technology comprises steps of acid dipping, synthesis of tribasic copper chloride and synthesis of tetrabasic zinc chloride. The technology achieves effective recovery of the copper element and the zinc element in brass slag and zinc-containing flue ash. When the provided technology is compared with technologies wherein brass slag or zinc-containing flue ash can be only processed individually, and only copper or zinc can be recovered, the resource utilization degree is raised greatly. Tribasic copper chloride and tetrabasic zinc chloride prepared through the whole technology meet feed-grade standards. Only one kind of production waste is produced, waste water processing burden is reduced, and circular economy and resource comprehensive utilization principles are met.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

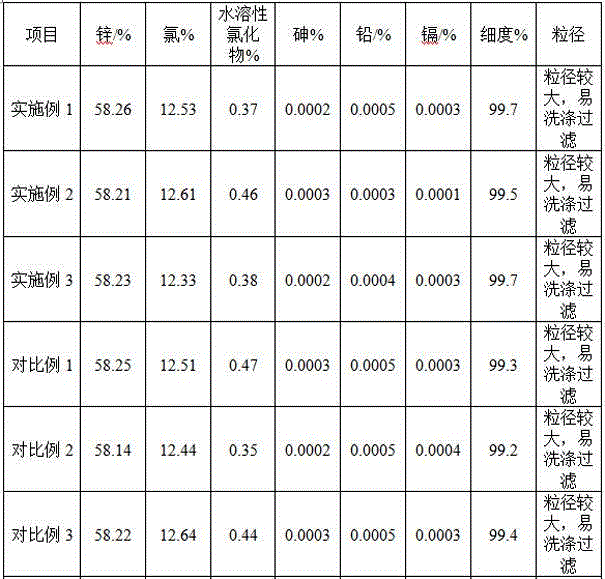

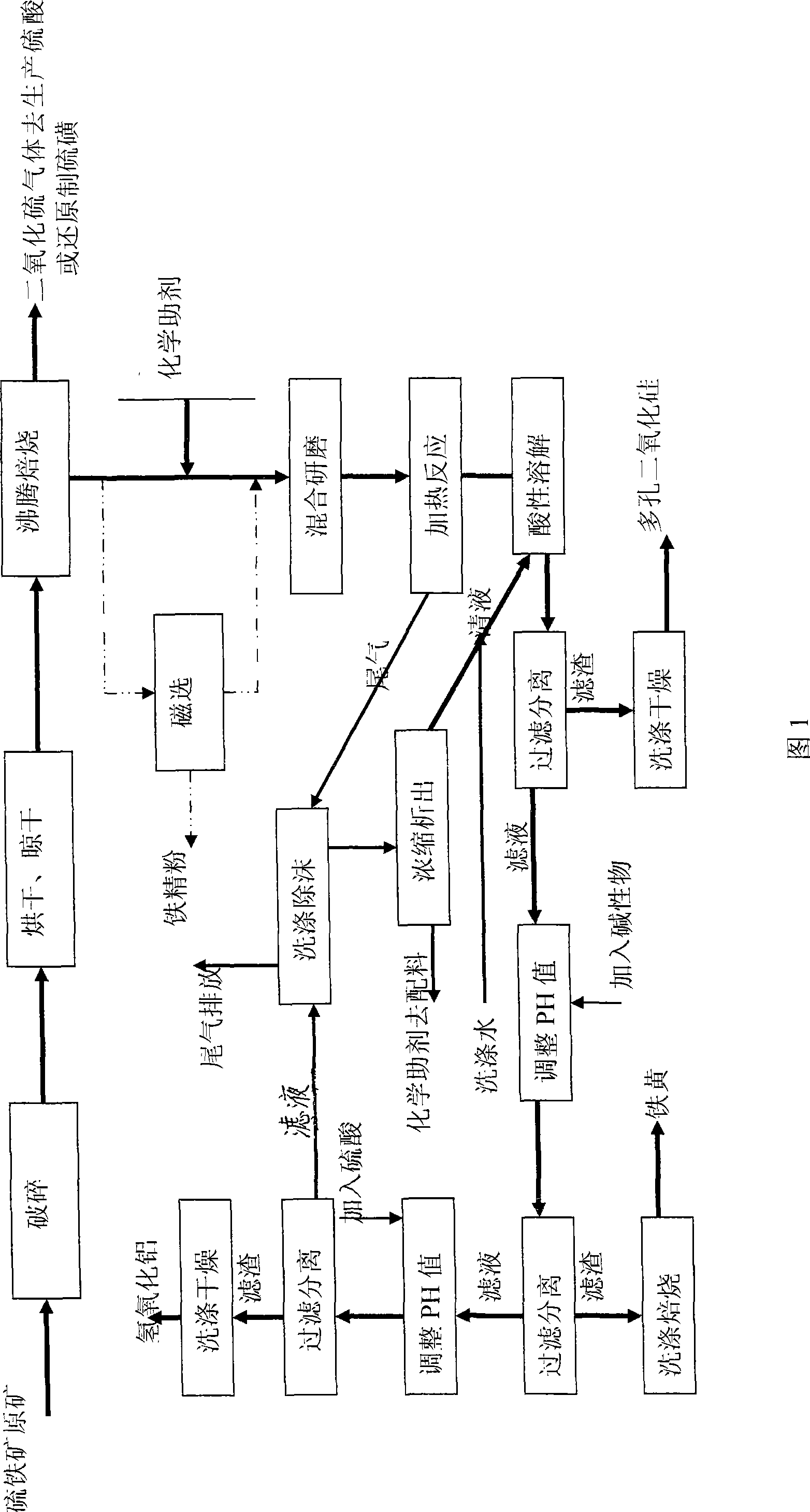

Method for by-producing porous silicon dioxide, aluminum hydroxide and ferrite yellow from middle and low grade ferro-sulphur ore

InactiveCN101456559ARealize full layer miningAchieve recyclingSilicaSulfur-dioxide/sulfurous-acidFerric hydroxideFiltration

The invention relates to a method for coproducing porous silicon dioxide, aluminum hydroxide and ferrite yellow when producing medium and low grade sulfurous iron ores, which comprises: the sulfurous iron ores are crushed and directly enter a fluidized bed furnace for roasting to obtain sulfur dioxide gas and cinder; the sulfur dioxide gas is used for further producing sulfuric acid or reducing production of sulfur; the cinder is subjected to magnetic separation to obtain iron concentrate or directly added with a chemical additive and then subjected to grinding and heating reaction, wherein the addition of the chemical additive is 2 to 4 times of the weight of the cinder; the cinder is dissolved for 1 to 3 hours under the acid condition after heating reaction, and the porous silicon dioxide is obtained after filtration and separation; the pH value of filtrate is adjusted to be between 9 and 12, the filtrate stands and is filtrated, and filter residue ferric hydroxide is washed and roasted to obtain a high-purity ferrite yellow pigment; and the pH value of the filtrate for filtrating the ferric hydroxide is adjusted to be between 4 and 6.5, the filtrate stands and is filtrated and separated to obtain aluminum hydroxide, and the aluminum hydroxide finished product is obtained after washing and drying the aluminum hydroxide. The method can improve the sulfur utilization rate by 40 to 50 percent, solves the problem of environmental pollution in the prior art, and fully utilizes all the compositions coproduced with the medium and low grade sulfurous iron ores.

Owner:云南常青树投资有限公司

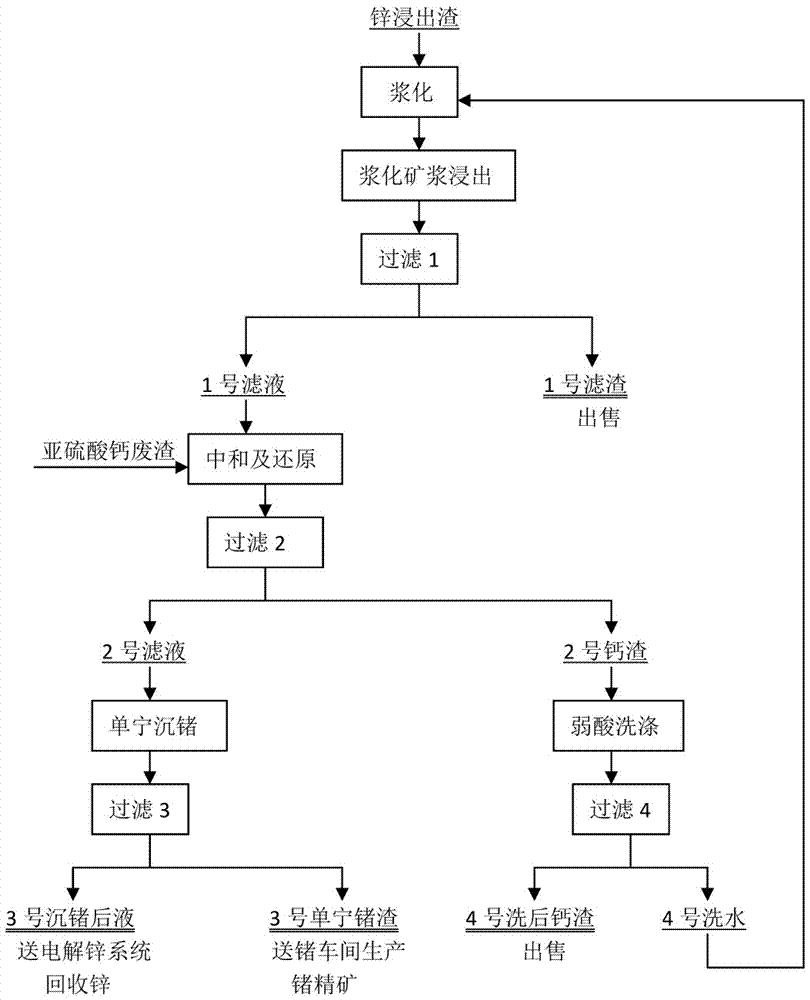

Comprehensive treatment method for zinc hydrometallurgy high-germanium raw material and calcium sulfite residues

ActiveCN106884095AImprove environmental benefitsAchieve restorationProcess efficiency improvementAcid washingHydrometallurgy

The invention discloses a comprehensive treatment method for a zinc hydrometallurgy high-content germanium raw material and calcium sulfite residues. The method comprises the following steps that 1), pulpifying of zinc leaching residues is performed; 2), pulpified ore pulp leaching is performed; 3), neutralization and reduction are performed; 4), calcium residue weak acid washing is performed; and 5), tannic germanium precipitation is performed. According to the comprehensive treatment method, when germanium is directly recycled in the zinc hydrometallurgy process, the simple and convenient method is adopted, the calcium sulfite residues generated when sulfur dioxide is absorbed through a double-alkali method during volatilization of a rotary kiln are comprehensively treated, and a marketable calcium sulfite industrial raw material is obtained; and recycling of resources is achieved, the environmental protection risk is eliminated, the production cost is saved, and meanwhile it is effectively guaranteed that the germanium is smoothly recycled from the zinc hydrometallurgy high-germanium raw material.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

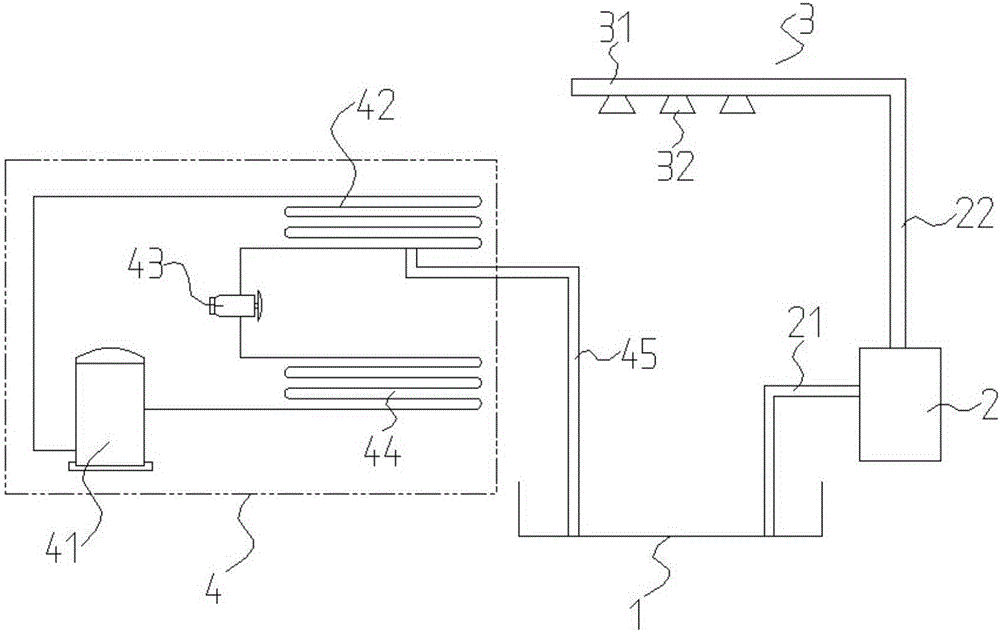

Temperature and humidity control device and standard curing box

InactiveCN106696067AReduce wasteAchieve recyclingCeramic shaping apparatusTemperature controlAssistive device/technology

The invention relates to a temperature and humidity control device and a standard curing box, and relates to the technical field of auxiliary equipment for buildings. The temperature and humidity control device is designed in order to solve the problem that the existing humidity control method for the standard curing box is complicated. The temperature and humidity control device comprises a high-pressure water pump, a reservoir communicated with a water inlet pipe of the high-pressure water pump, a spraying device communicated with a water outlet pipe of the high-pressure water pump, a temperature control device for adjusting the ambient temperature, and a power supply device for supplying electric energy to the high-pressure water pump and the temperature control device. The standard curing box comprises the temperature and humidity control device. The standard curing box provided by the invention is used for curing concrete test blocks.

Owner:长江重庆航道工程局

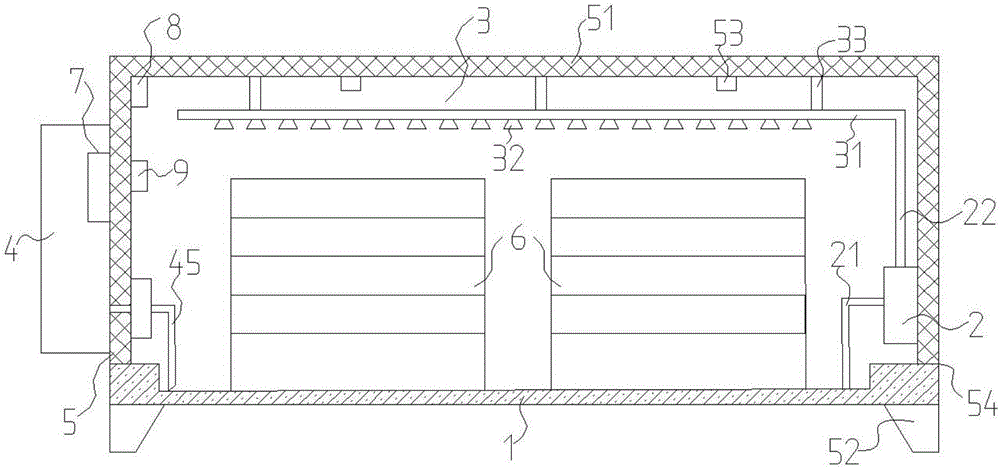

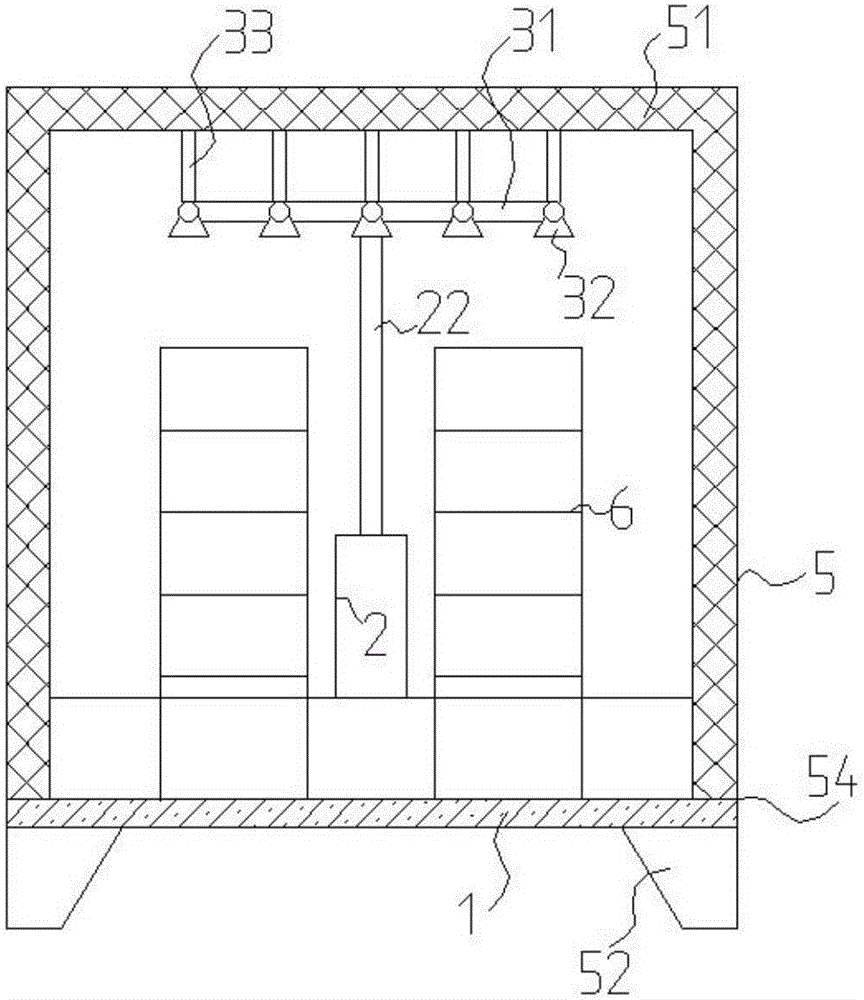

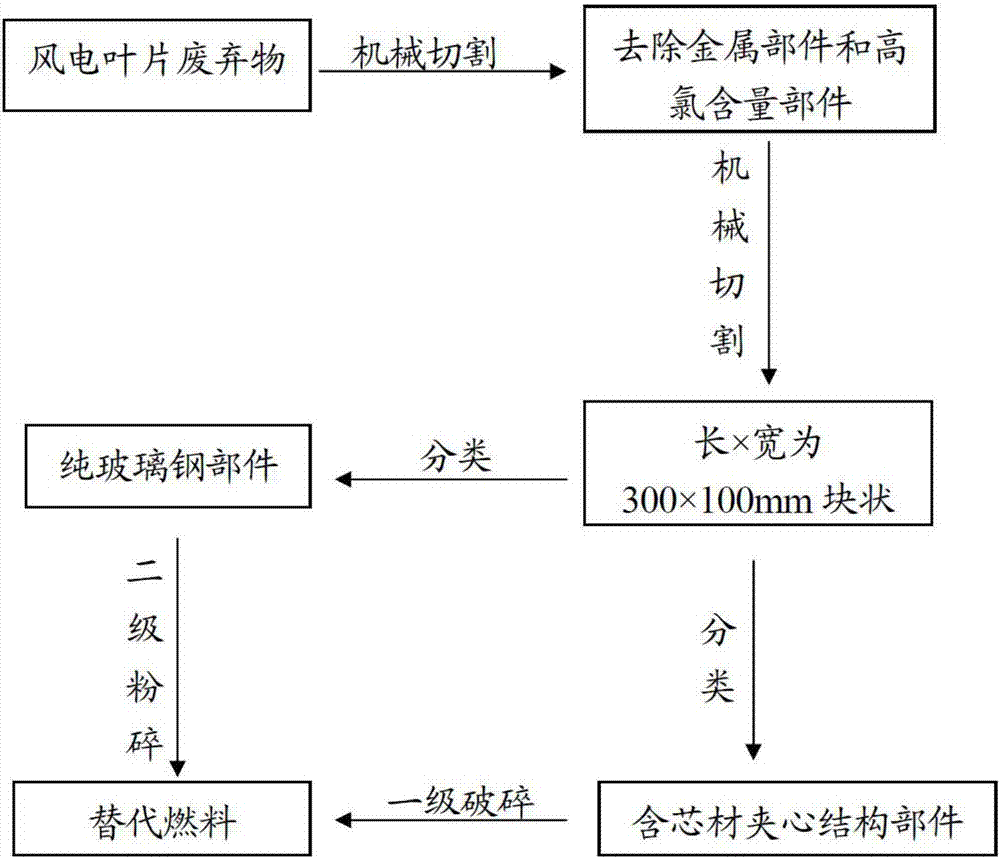

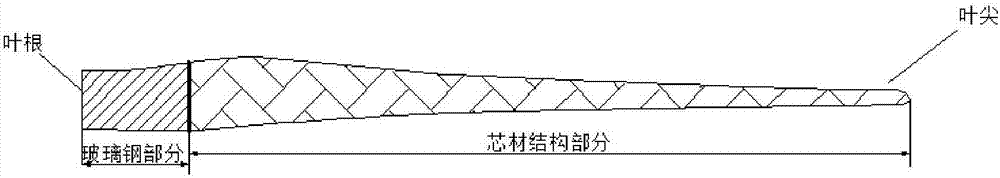

Method for absorbing wind turbine blade wastes in cement kiln

InactiveCN107305010AConsumptionReduce wearIncinerator apparatusCombined combustion mitigationAlternative fuelsHigh energy

The invention provides a method for absorbing wind turbine blade wastes in a cement kiln. The method comprises the following steps: separating metal parts and high-chlorine content parts in the wind turbine blade wastes, and segmenting the remaining wind turbine blade wastes as massive wastes; grinding the massive wastes into particles so as to obtain ground materials; and taking the ground materials as alternative fuel of the cement kiln, and combusting the fuel in a cement kiln decomposing furnace. The method disclosed by the invention is simple, practical, less in initial investment and subsequent maintenance cost, environment-friendly and harmless, belongs to a circular economy manner, accords with the treatment policy of 'reduction, recycling and harmlessness' of municipal wastes, can thoroughly implement and carry out the national policy of cooperatively treating non-medical wastes and industrial wastes in the cement kiln, solves the thermosetting material waste disposal difficulty problem troubling the society for a long time, provides alternative fuel and raw materials for the high-energy-consumption cement industry and has wide application prospects.

Owner:SINOMATECH WIND POWER BLADE

Lightweight high-strength ceramic particles manufactured by using urban sludge and manufacturing method for lightweight high-strength ceramic particles

InactiveCN102336580ALight weightHigh strengthSludge treatmentConstruction waste recoverySocial benefitsResource utilization

The invention belongs to the technical field of sludge reclaiming resource utilization, and in particular relates to lightweight high-strength ceramic particles manufactured by using urban sludge and a manufacturing method for the lightweight high-strength ceramic particles. The method comprises the following steps of: crushing 30 to 50 parts of building garbage to obtain crushed building garbage; and mixing the crushed building garbage, 40 to 60 parts of urban sludge and 40 to 60 parts of potassium feldspar powder uniformly, roasting the mixture for 20 to 120 minutes at the temperature of between 1,150 and 1,500 DEG C, cooling, and thus obtaining the lightweight high-strength ceramic particles. The urban sludge, the building garbage and the potassium feldspar powder are mixed in a certain ratio and coordinated, so that the strength of the lightweight high-strength ceramic particles reaches 60 to 120MPa, and the ceramic particles have more excellent physical and mechanical properties compared with common natural stones. According to the ceramic particles and the manufacturing method, wastes can be changed into valuable, environmental pollution is improved, and the innocent, reduction and recycle principles of Chinese solid waste treatment are met; and the invention has remarkable economic benefit and social benefit.

Owner:DONGGUAN BAOYUANDA REAL ESTATE DEV

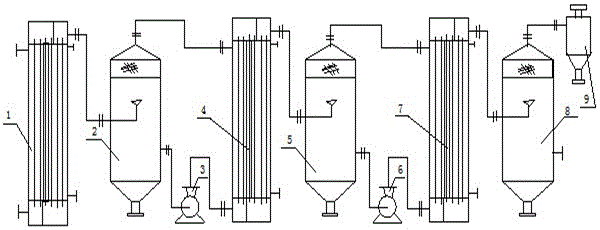

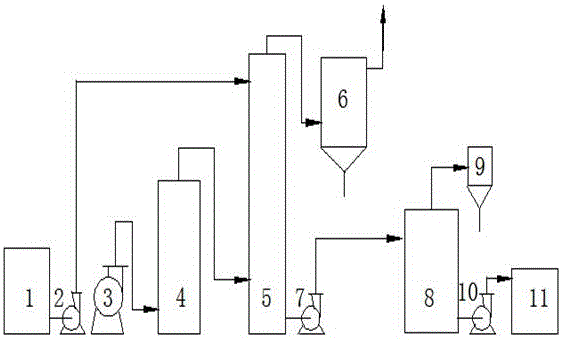

External circulation multi-effect evaporator for titanium dioxide waste acid

ActiveCN106178564AHighlight substantive featuresSignificant progressSulfur compoundsEvaporation by sprayingSulfateEngineering

The invention relates to an external circulation multi-effect evaporator for titanium dioxide waste acid. The titanium dioxide waste acid is pressed into a tube pass of a single-effect heater, and the waste acid flows in a plurality of tube passes back and forth and is subjected to heat exchange with steam in a shell pass of the single-effect heater; the waste acid is heated and is conveyed into a single-effect flash evaporation crystallization tank through a waste acid outlet pipe of the single-effect heater; in a vacuum environment in the tank, the waste acid is sprayed by a nozzle to form mist to suddenly cause flash evaporation; a lot of moisture in the waste acid is evaporated to form water steam and the titanium dioxide waste acid is concentrated; the concentration of the waste acid is improved and the temperature is reduced, so that one part of ferrous sulfate is separated out; supernatant liquor is conveyed into a tube pass of a double-effect heater through a single-effect acid conveying pump, and reaches the last effect according to the flow; finally, water steam in a last-effect flash evaporation crystallization tank enters a water spraying vacuum pump and the water steam is condensed; then the last-effect flash evaporation crystallization tank is vacuumized, and the concentrated titanium dioxide waste acid is discharged from a concentrated acid outlet pipe of the last-effect flash evaporation crystallization tank. The external circulation multi-effect evaporator for the titanium dioxide waste acid has the advantages of low energy consumption of a technical process, simple and convenient process, effectiveness, low possibility of blocking equipment, safety and reliability in operation and the like.

Owner:GUANGXI DETIAN CHEM CYCLE CO LTD

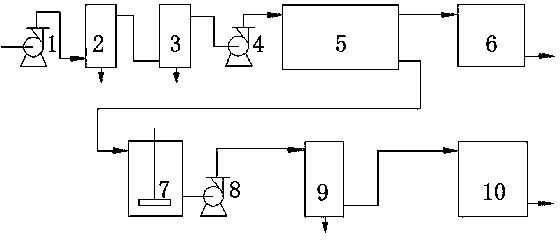

Method for concentrating titanium dioxide waste acid by adopting reverse osmosis process

ActiveCN104176714AHighlight substantive featuresSignificant progressSulfur compoundsSulfate radicalsReverse osmosis

The invention relates to a method for concentrating titanium dioxide waste acid by adopting a reverse osmosis process. The method comprises the following steps: pressing titanium dioxide waste acid with acid concentration of about 20% in a filter to remove micro-grained suspended matters, pressurizing through a high-pressure pump, enabling a small part of titanium dioxide waste acid to penetrate through a reverse osmosis membrane through a reverse osmosis device to prepare clean fresh water, and feeding the clean fresh water to a clean fresh water storage tank for later use; reserving sulfate radicals and other impurities for a large part of titanium dioxide waste acid, feeding into a cooling crystallizing groove, stirring, fully separating out and settling the impurities, conveying concentrated waste acid into a pressure filter, and putting concentrated waste acid subjected to impurity removal into a circulating groove for reverse osmosis treatment; when the acid concentration is more than 40%, feeding titanium dioxide waste acid to a sulfuric acid production device, mixing with concentrated acid for increasing the concentration, and removing the impurities to prepare 98% concentrated sulfuric acid. According to the method, titanium dioxide waste acid is effectively concentrated until 98% concentrated sulfuric acid is prepared, so that the difficult problem of recycling of titanium dioxide waste acid is solved; and the method has the advantages of being low in process energy consumption, simple, effective, stable to perform, remarkable in economic and environmental benefits and the like.

Owner:梧州佳源实业有限公司

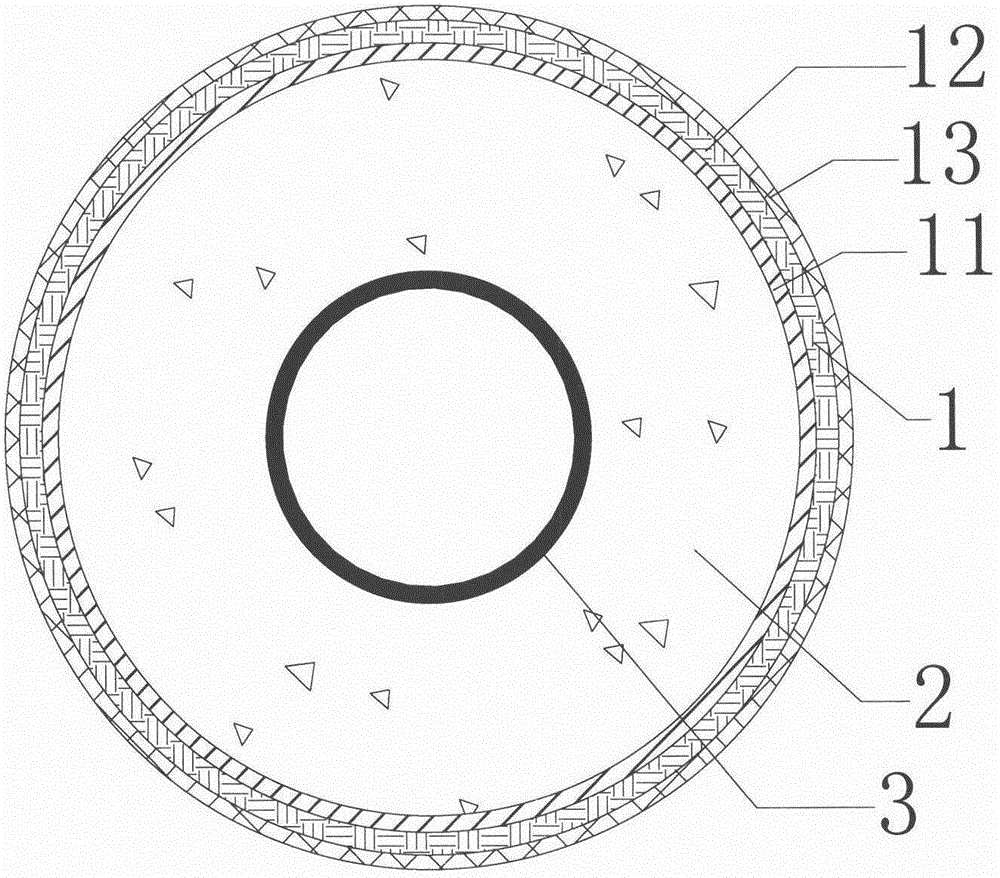

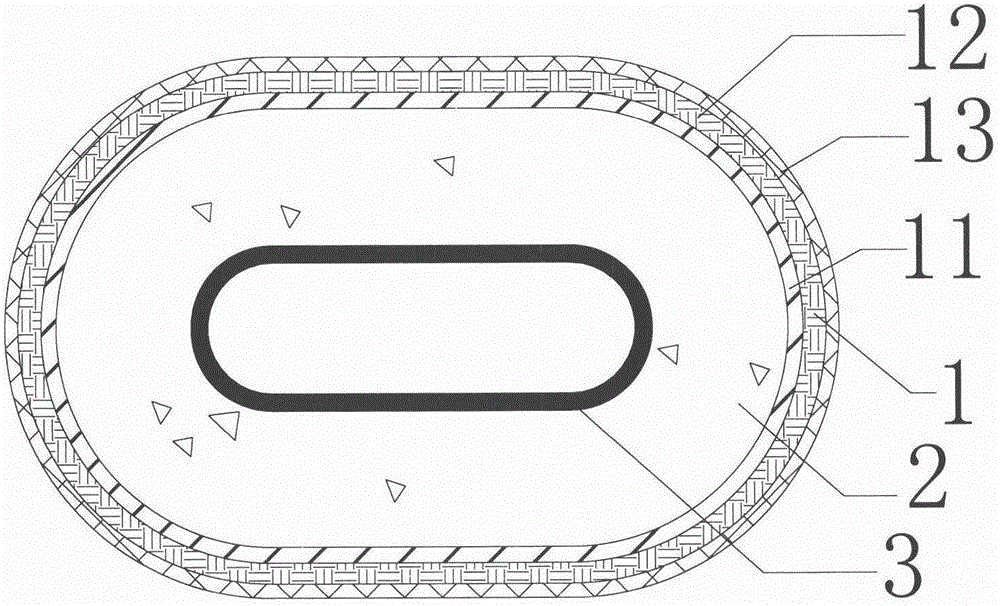

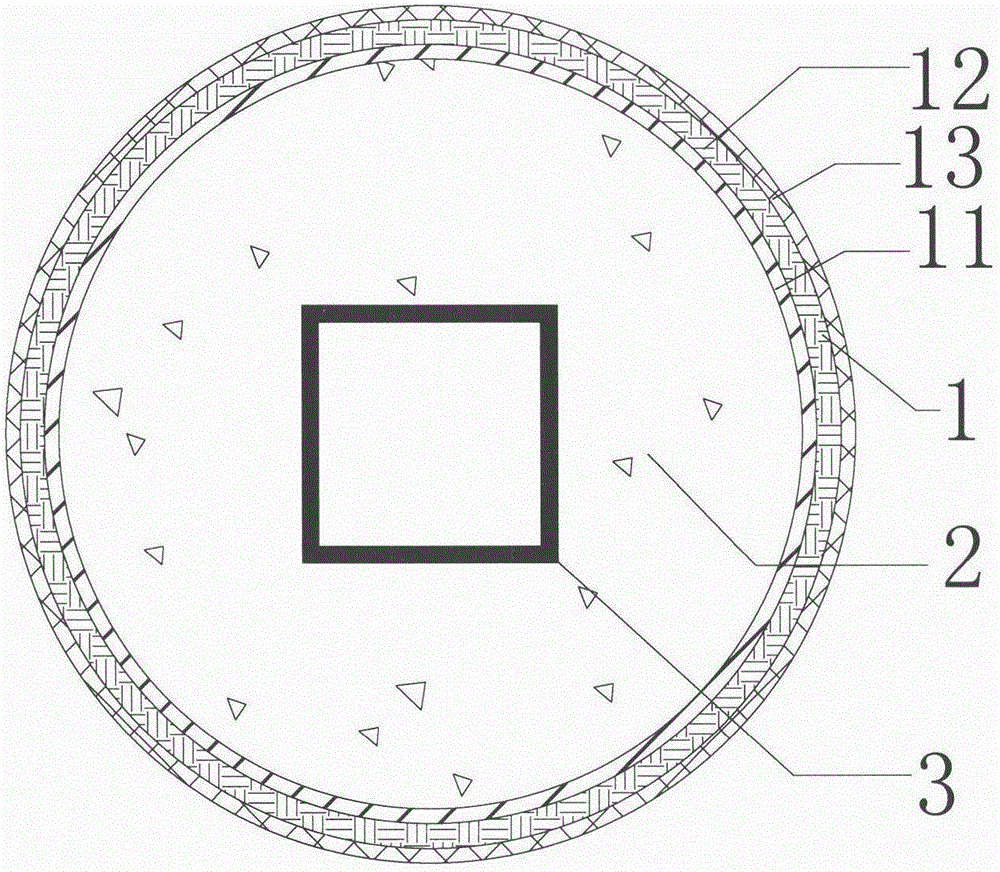

Bamboo composite pipe-steel pipe internal-external constraint concrete composite structure

PendingCN106592869AReduce dosageImprove bearing capacityStrutsPillarsShock resistanceFiber orientation

The invention discloses a bamboo composite pipe-steel pipe internal-external constraint concrete composite structure. The bamboo composite pipe-steel pipe internal-external constraint concrete composite structure is characterized in that the cross section of the bamboo composite pipe-steel pipe internal-external constraint concrete composite structure is sequentially composed of a bamboo composite pipe (1), sandwich concrete (2) and an inner steel pipe (3) from outside to inside; the bamboo composite pipe (1) sequentially comprises an isolating layer (11), a bamboo fiber strengthened composite layer (12) and an outer protective layer (13) from inside to outside; the bamboo fiber strengthened composite layer (12) is formed by continuously and evenly winding and solidifying one or more layers of bamboo fibers which are impregnated with resin adhesive on the outer wall of the isolating layer (11); the included angle between the fiber direction of the bamboo fibers and the circumferential direction of the bamboo composite pipe (1) ranges from minus 45 degrees to 45 degrees; the outer surface of the bamboo fiber strengthened composite layer (12) is coated with the outer protective layer (13); the inner steel pipe (3) is located in the cross section; the space between the bamboo composite pipe(1) and the inner steel pipe (3) is filled with the sandwich concrete (2); and the inner steel pipe (3) is internally hollow. The structure is high in bearing capacity, good in stiffness, ductility and shock resistance and has good construction performance and durability, the cross section inertia moment is large, concrete consumption is low, and construction cost is low; and the sustainable bamboo source in China is sufficiently utilized, and property advantages good toughness and high longitudinal tension strength of bamboo t are brought into play to the maximum extent.

Owner:NANJING FORESTRY UNIV

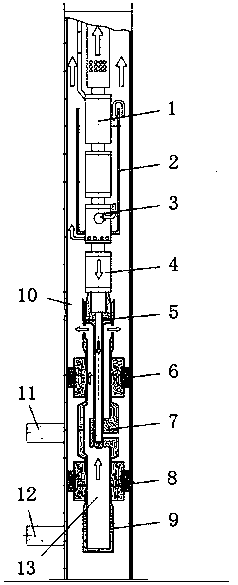

Water-gas separation technology for production and injection in same well through electric submersible pump

ActiveCN109296351AIncrease gas productionSolve environmental problems that cannot be dischargedFluid removalSealing/packingVapor–liquid separatorSeparation technology

The invention discloses a water-gas separation technology for production and injection in the same well through an electric submersible pump. The water-gas separation technology includes an electric submersible pump unit, a gas-liquid separation guiding device, a gas-liquid diversion device, a gas-liquid channel and a packer layered sealing system, the packer layered sealing system is composed ofa first packer, a second packer and a screen pipe, and the first packer is located on the upper part of the second packer; and the gas-liquid diversion device is located between the first packer and the second packer. According to the water-gas separation technology for production and injection in the same well through the electric submersible pump, the advantages of wide displacement range and high delivery head of the electric submersible pump are used, well fluid is subjected to water-gas separation coordinated with a gas-liquid separator, separated gas continues up along a casing pipe anddischarges from a wellhead through an oil pipe or the casing pipe, and separated water is pressurized by a centrifugal pump and injected into an injection layer; and wide application fields are achieved, the current vigorously advocated requirements for building a resource-conserving and environment-friendly society are met, a good technology for drainage and gas production fields is provided, themarket demands are met, and the bright prospects are achieved.

Owner:胜利油田胜利泵业有限责任公司

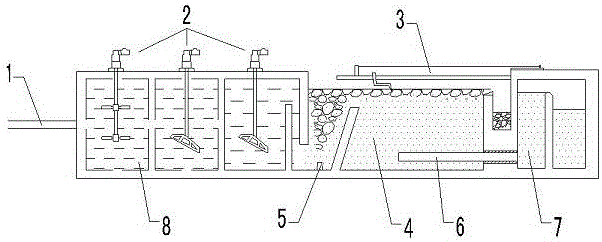

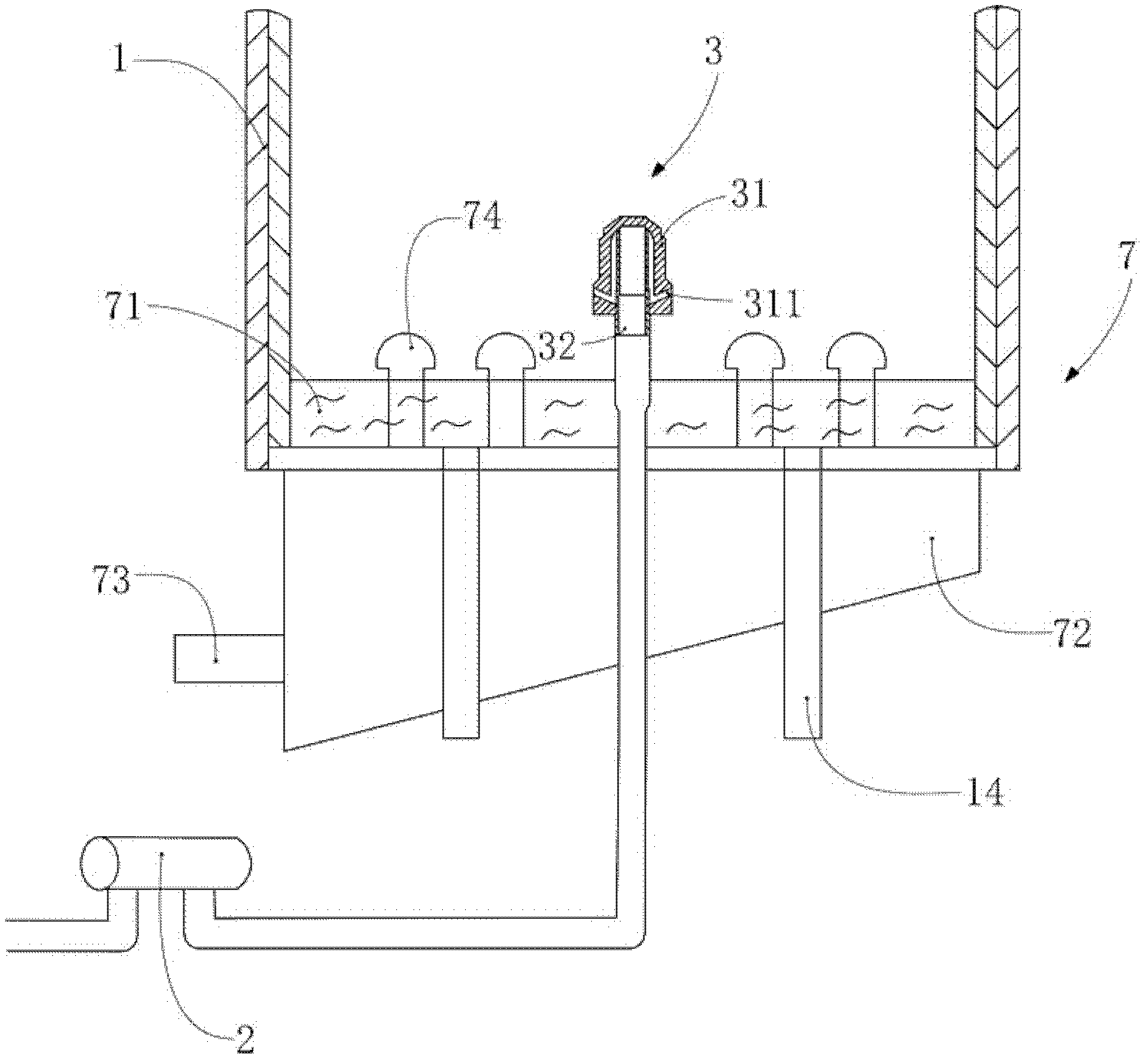

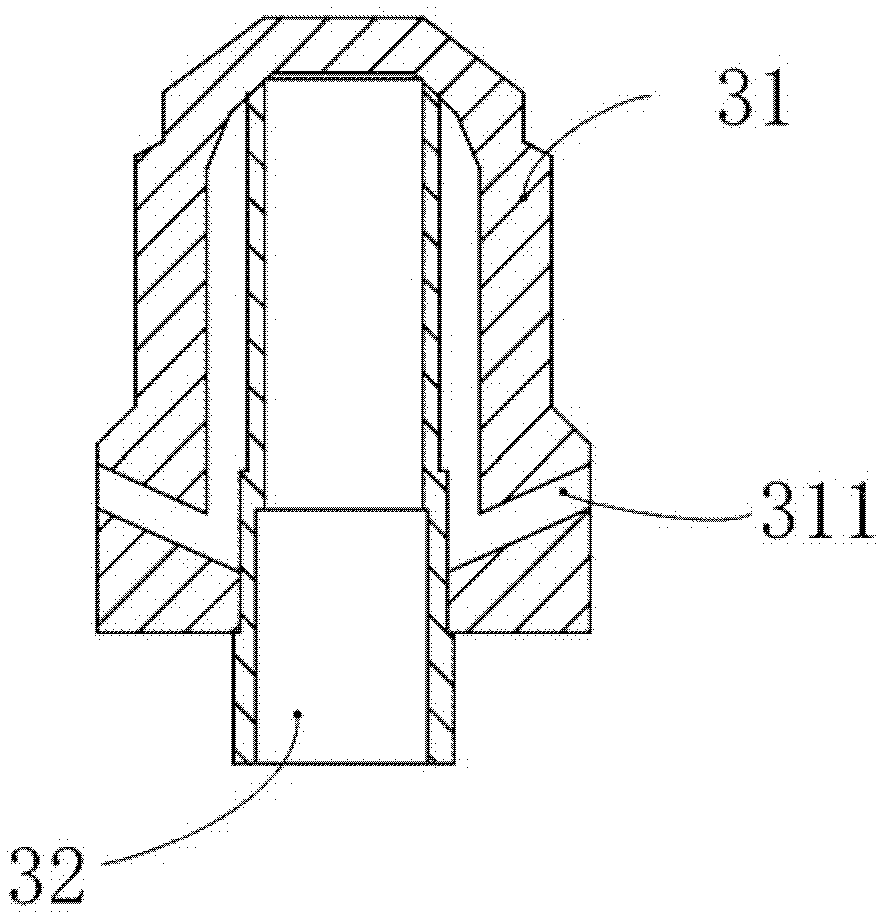

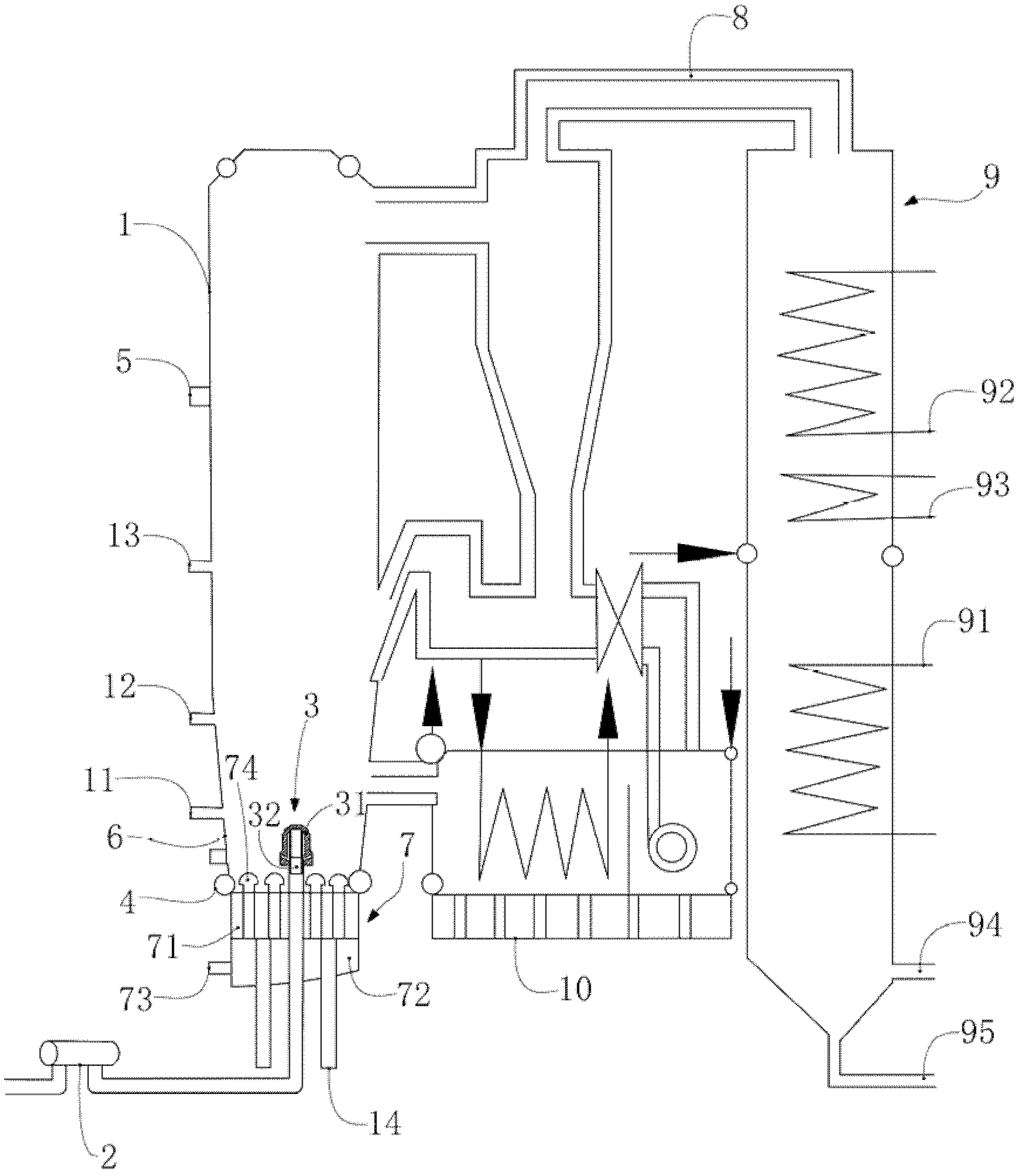

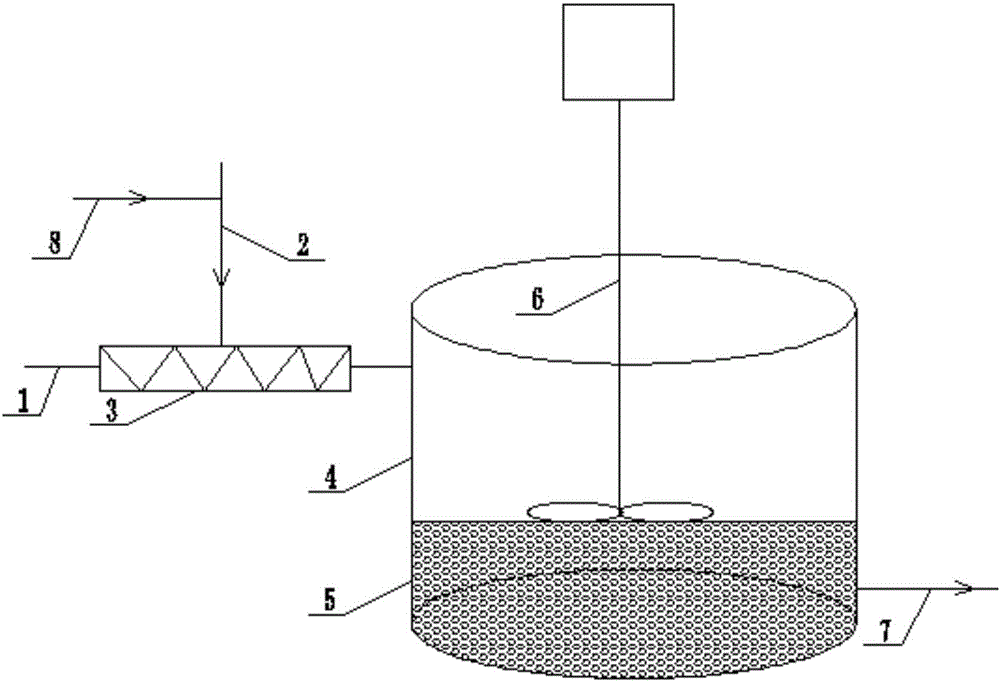

Black and odorous water bottom mud passivation system

PendingCN106430869ACompliant with harmless disposalMatch resourceWater contaminantsSludge processingChemical oxygen demandEconomic benefits

The invention belongs to the technical field of water treatment, and particularly relates to a black and odorous water bottom mud passivation system. The system comprises a feed pipe, a pipe mixer, a reactor and a discharge pipe which are sequentially communicated, the pipe mixer is provided with a feeding pipeline for supplying first multifunctional nano-composite materials, the feeding pipeline is provided with a water supply pipeline, a stirrer is arranged in the reactor, a bottom mud layer is arranged at the bottom of the reactor and internally filled with second multifunctional nano-composite materials, the first multifunctional nano-composite materials include 10-20 parts of COD (chemical oxygen demand) removing materials and 80-90 parts of heavy metal removing materials, and the second multifunctional nano-composite materials include 10-20 parts of COD (chemical oxygen demand) removing materials and 80-90 parts of heavy metal removing materials. The black and odorous water bottom mud passivation system is mainly used for performing heterotopic reinforcement treatment for endogenous pollutants in black and odorous water treatment and performing in-situ passivation for the pollutants, passivated bottom mud can serve as fertilizers to be applied, and economic benefits are generated.

Owner:格丰环保科技有限公司

Method for concentrating titanium white waste acids through gas-liquid contact technology

InactiveCN105858621AHighlight substantive featuresSignificant progressSulfur-trioxide/sulfuric-acidVapor–liquid separatorTitanium

The invention relates to a method for concentrating titanium white waste acids through a gas-liquid contact technology. The method concretely comprises the following steps: the white waste acids are pressed in a titanium white waste acid tank into a gas-liquid contact evaporator, the titanium white waste acids are jetted through nozzles to form mist, high temperature hot wind is sent to a gas-liquid contact evaporator through a blower, directly upwardly contact titanium white waste acid droplets jetted by the nozzles and is rapidly cooled, and water in the waste acids is massively evaporated to concentrate diluted waste acids; a gas and liquid mixture at the upper portion of the gas-liquid contact evaporator enters a gas-liquid separator and undergoes rotation and separation, the obtained gas is discharged through the discharge port of the gas-liquid separator, and condensed water is recovered; the concentrated waste acids at the lower portion of the gas-liquid contact evaporator are sent to a vacuum flash evaporation tank, and are concentrated and cooled; and the flash-evaporated steam enters a vacuum condensation jet pump, and the concentrated waste acids are sent to a storage tank, and are stored to be treated. The method effectively solves the titanium white waste acid recycling problem, and has the advantages of low energy consumption, simplicity, effectiveness, stable operation, and substantial economy and environment benefits.

Owner:钮德明

Water-soluble food packaging film

The invention discloses a water-soluble food packaging film. The water-soluble food packaging film is prepared from, by weight, 10 to 50 parts of polyvinyl alcohol, 30 to 80 parts of oxidized starch, 0.5 to 5 parts of a filling material, 1 to 10 parts of a plasticizer, 0.5 to 10 parts of a modifier, 0.5 to 10 parts of metallocene, 3 to 10 parts of linear polyethylene, and 0.1 to 2 parts of a food colouring. The water-soluble food packaging film can be degraded quickly after using, is capable of reducing stress on the environment, and according with requirements of construction of resource-conserving and environment-friendly society; a preparation method is simple; raw materials are cheap; and the water-soluble food packaging film is convenient for large-scale popularization and application.

Owner:NANNING JUXIANG PLASTIC PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com