System and method for reducing ash content of pyrolysis carbon black of waste tires and recovering Zn

A technology of waste tires and carbon black, which is applied in the direction of fibrous fillers, etc., can solve the problems of large water consumption, unresolved Zn efficient recovery, unresolved chemical consumption, etc., and achieve the effects of reduced ash content, high recovery rate, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

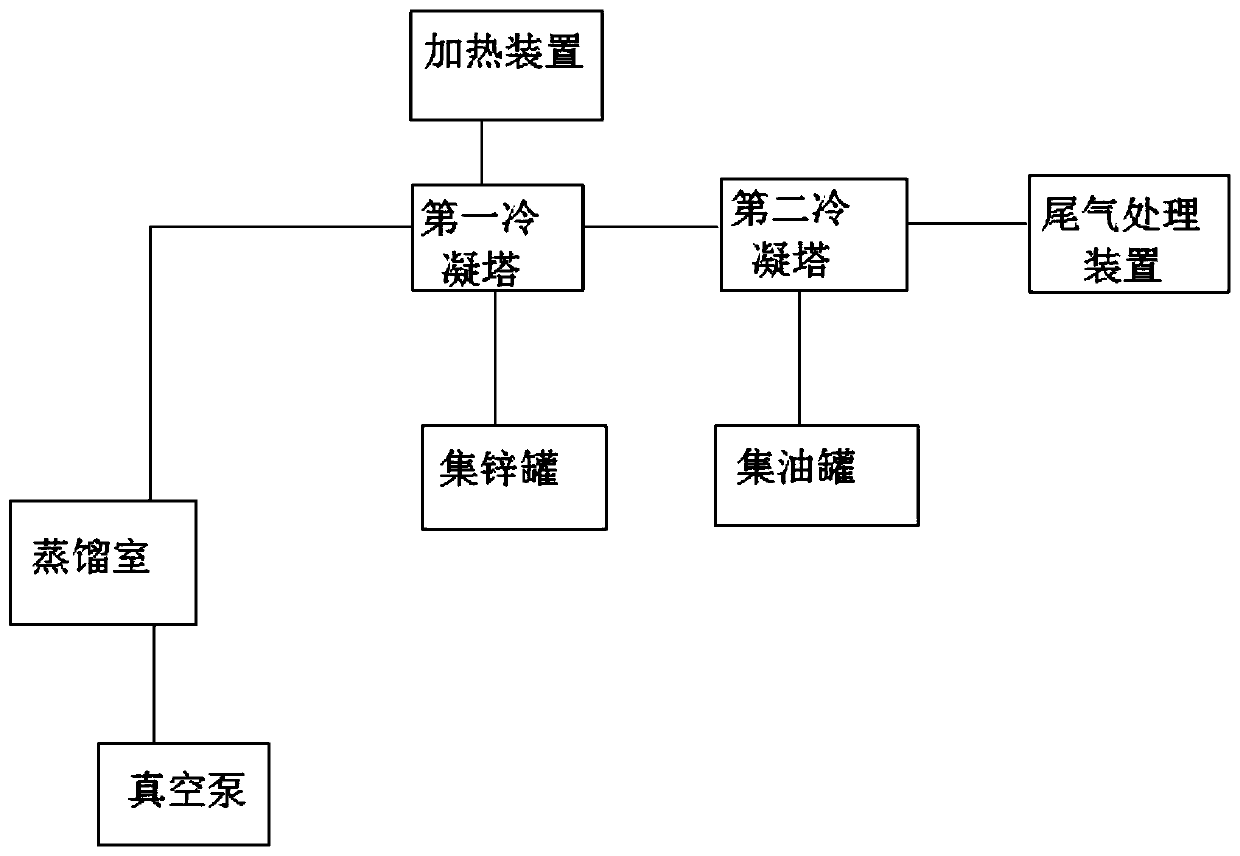

[0042] Such as figure 1As shown, a kind of system of reducing waste tire pyrolysis carbon black ash and reclaiming Zn of the present embodiment, described system comprises the distillation chamber connected in sequence, the first condensing tower, the second condensing tower, described first condensing tower A zinc collection tank is also connected, the second condensation tower is also connected with an oil collection tank and a tail gas treatment device, and the distillation chamber is connected with a vacuum pump. A vacuum valve is arranged between the distillation chamber and the vacuum pump, and the vacuum control of the distillation chamber can be realized by controlling the opening or closing of the vacuum valve. A check valve that only allows gas to enter the first condensation tower from the distillation chamber in one direction is arranged between the distillation chamber and the first condensation tower. The check valve of the present invention can make the gas in t...

Embodiment 2

[0045] The total ash content in the waste tire pyrolysis carbon black described in this example is 16.8%, and the content of zinc oxide is 8.5%.

[0046] A kind of method of utilizing the system of embodiment 1 to reduce waste tire pyrolysis carbon black ash and reclaim Zn of the present embodiment, described method comprises the steps:

[0047] (1) Send waste tire pyrolysis carbon black to the distillation chamber through the feed port, and close the feed port;

[0048] (2) Turn on the vacuum pump, vacuumize the distillation chamber to 30-40Pa to achieve a basic anaerobic environment, close the vacuum pump and the vacuum valve, and preheat the first condensation tower to 200°C through the heating device;

[0049] (3) start to heat the distillation chamber, and along with the raising of temperature, the oil part in the pyrolysis carbon black begins to volatilize and pass through the first condensation tower and the second condensation tower successively, the temperature of the...

Embodiment 3

[0053] The total ash content in the waste tire pyrolysis carbon black described in this example is 16.8%, and the content of zinc oxide is 8.5%.

[0054] A kind of method of utilizing the system of embodiment 1 to reduce waste tire pyrolysis carbon black ash and reclaim Zn of the present embodiment, described method comprises the steps:

[0055] (1) Send waste tire pyrolysis carbon black to the distillation chamber through the feed port, and close the feed port;

[0056] (2) Turn on the vacuum pump, vacuumize the distillation chamber to 10-30Pa to achieve a basic anaerobic environment, close the vacuum pump and the vacuum valve, and preheat the first condensation tower to 300°C through the heating device;

[0057] (3) start to heat the distillation chamber, and along with the raising of temperature, the oil part in the pyrolysis carbon black begins to volatilize and pass through the first condensation tower and the second condensation tower successively, the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com