Technique for processing mixed type iron ore

A kind of iron ore and mixed technology, applied in the direction of magnetic separation, solid separation, filtration and screening, etc., can solve the problems of complex pharmaceutical system, susceptibility to interference from other minerals, and inability to effectively recover hematite, so as to achieve easy operation and flow good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

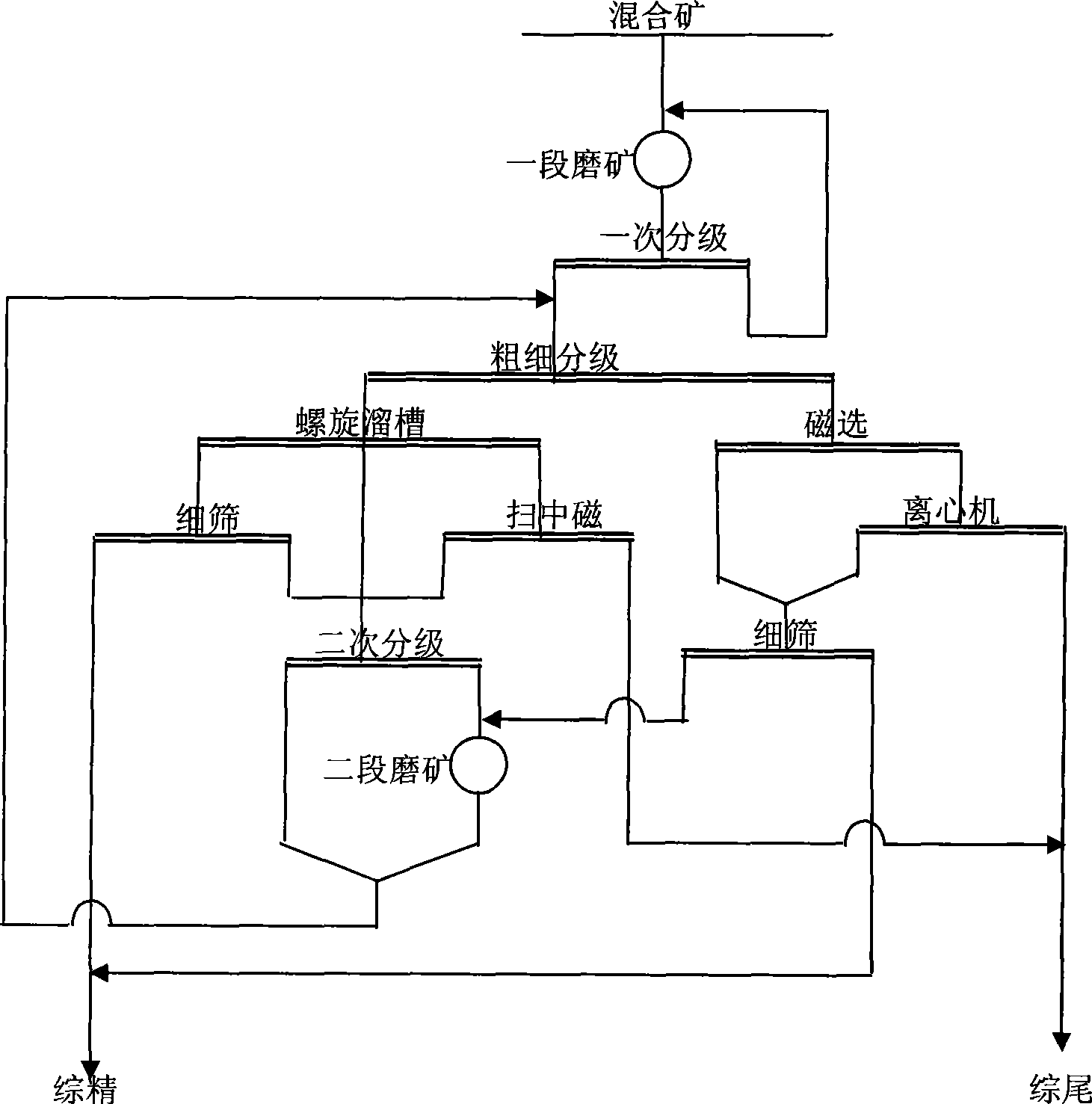

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, a ball mill and a cyclone form a closed-circuit grinding. After the primary overflow is classified by a coarse and fine grading cyclone, the coarse particles are separated by two sections of spiral chutes, and the fine spiral concentrate is sent to a fine screen, and the bottom of the screen is gravity separation. Concentrate, fine snail medium ore self-circulation, after the coarse snail tail is swept by the magnetic tail, the magnetic fine and fine snail tail are swept, and the sieve becomes the medium ore of the coarse part, and the medium ore of the coarse part is sent to the secondary classification The cyclone and rotary sinking are fed into the second-stage grinding; after the fine particles are separated by the magnetic separator, if the tailings are of low grade, the tailings will be thrown directly, if the tailings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com