Copper oxide loaded attapulgite catalyst and preparation method and applications thereof

The technology of attapulgite and catalyst is applied in the field of attapulgite-supported copper oxide catalyst, which can solve the problems of high carrier cost and high desulfurization activity temperature, and achieve the effects of high mechanical strength, low operating cost and increased added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

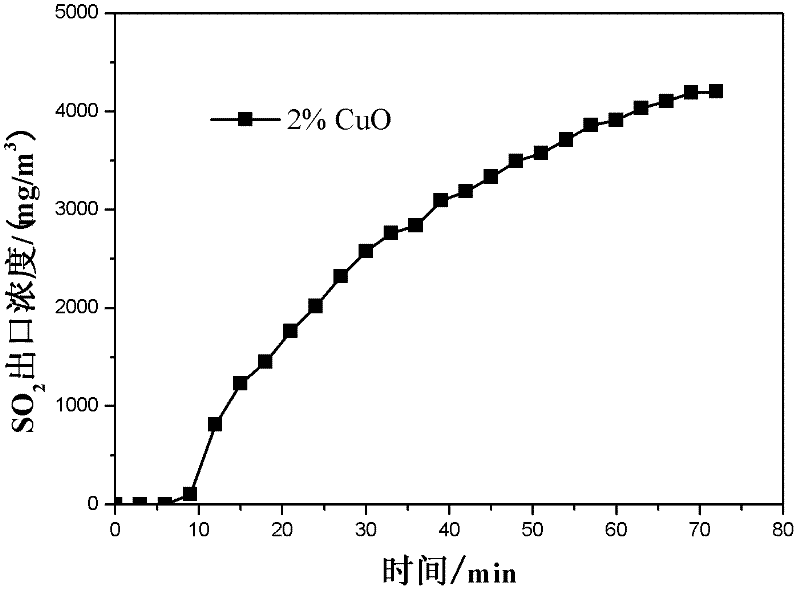

[0033] Example 1: CuO2 / PG

[0034] The preparation of catalyst carrier in the present embodiment:

[0035] Mix 30g of 200-mesh attapulgite powder with 200mL of distilled water, stir to form a suspension, and then dry at 105°C for 12 hours to obtain attapulgite samples; crush and sieve the attapulgite samples to obtain a preparation with a particle size of 20-40 mesh. Supplies: put the spares into a fixed-bed reactor, and heat-treat at 300°C for 2 hours under the atmosphere of nitrogen gas to obtain the catalyst carrier.

[0036] The preparation of catalyst in the present embodiment:

[0037] Take 1g of catalyst carrier, after adding water by equal-volume impregnation method, measure its solid-liquid ratio as 1g: 1.5mL; take Cu(NO 3 ) 2 Solution 1.4mL, containing Cu(NO 3 ) 2 0.97g, dilute to 30mL with distilled water, add evenly to 20g catalyst carrier, let it stand at room temperature for 48 hours, then dry at 70°C for 5h, 110°C for 12 hours, and finally place it in an ai...

Embodiment 2

[0040] Example 2: CuO5 / PG

[0041] The preparation method of the catalyst carrier in this example is the same as that in Example 1.

[0042] The preparation of catalyst in the present embodiment:

[0043] Take 1g of catalyst carrier, after adding water by equal-volume impregnation method, measure its solid-liquid ratio as 1g: 1.5mL; take Cu(NO 3 ) 2 Solution 3.5mL, which contains Cu(NO 3 ) 22.4g, dilute to 30mL with distilled water, add evenly to 20g catalyst carrier, let it stand at room temperature for 48 hours, then dry at 70°C for 5h, 110°C for 12 hours, and finally place it in an air atmosphere and calcinate at 300°C for 3h to obtain Finished CuO5 / PG catalyst.

[0044] Put 3 g of the CuO5 / PG catalyst prepared in this example into a fixed-bed reactor, raise the temperature to 300° C. under a nitrogen atmosphere, pretreat at 300° C. for 1 hour, then lower the temperature to 200° C. Flue gas, simulated flue gas composition is 4380mg / m 3 SO 2 , O 2 4vol%, nitrogen is...

Embodiment 3

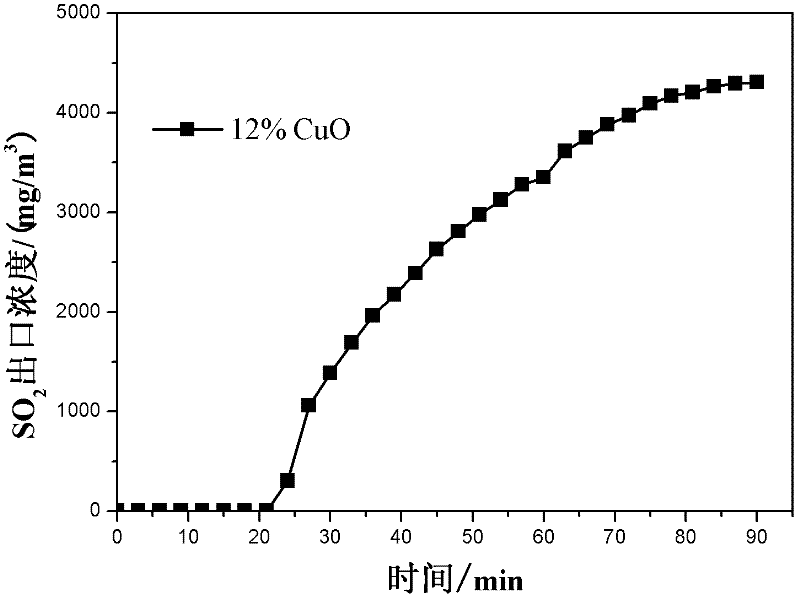

[0046] Example 3: CuO12 / PG

[0047] The preparation method of the catalyst carrier in this example is the same as that in Example 1.

[0048] The preparation of catalyst in the present embodiment:

[0049] Take 1g of catalyst carrier, after adding water by equal-volume impregnation method, measure its solid-liquid ratio as 1g: 1.5mL; take Cu(NO 3 ) 2 Solution 8.4mL, which contains Cu(NO 3 ) 2 5.8g, dilute to 30mL with distilled water, add evenly to 20g catalyst carrier, let it stand at room temperature for 48 hours, then dry at 70°C for 5h, 110°C for 12 hours, and finally place it in an air atmosphere and calcinate at 300°C for 3h to obtain CuO12 / PG catalyst finished product.

[0050] Put 3 g of the CuO12 / PG catalyst prepared in this example into a fixed-bed reactor, raise the temperature to 300° C. under a nitrogen atmosphere, pretreat at 300° C. for 1 hour, then lower the temperature to 200° C. Flue gas, simulated flue gas composition is 4380mg / m 3 SO 2 , O 2 4vol%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com