Patents

Literature

129results about How to "Reduce the amount of exhaust gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

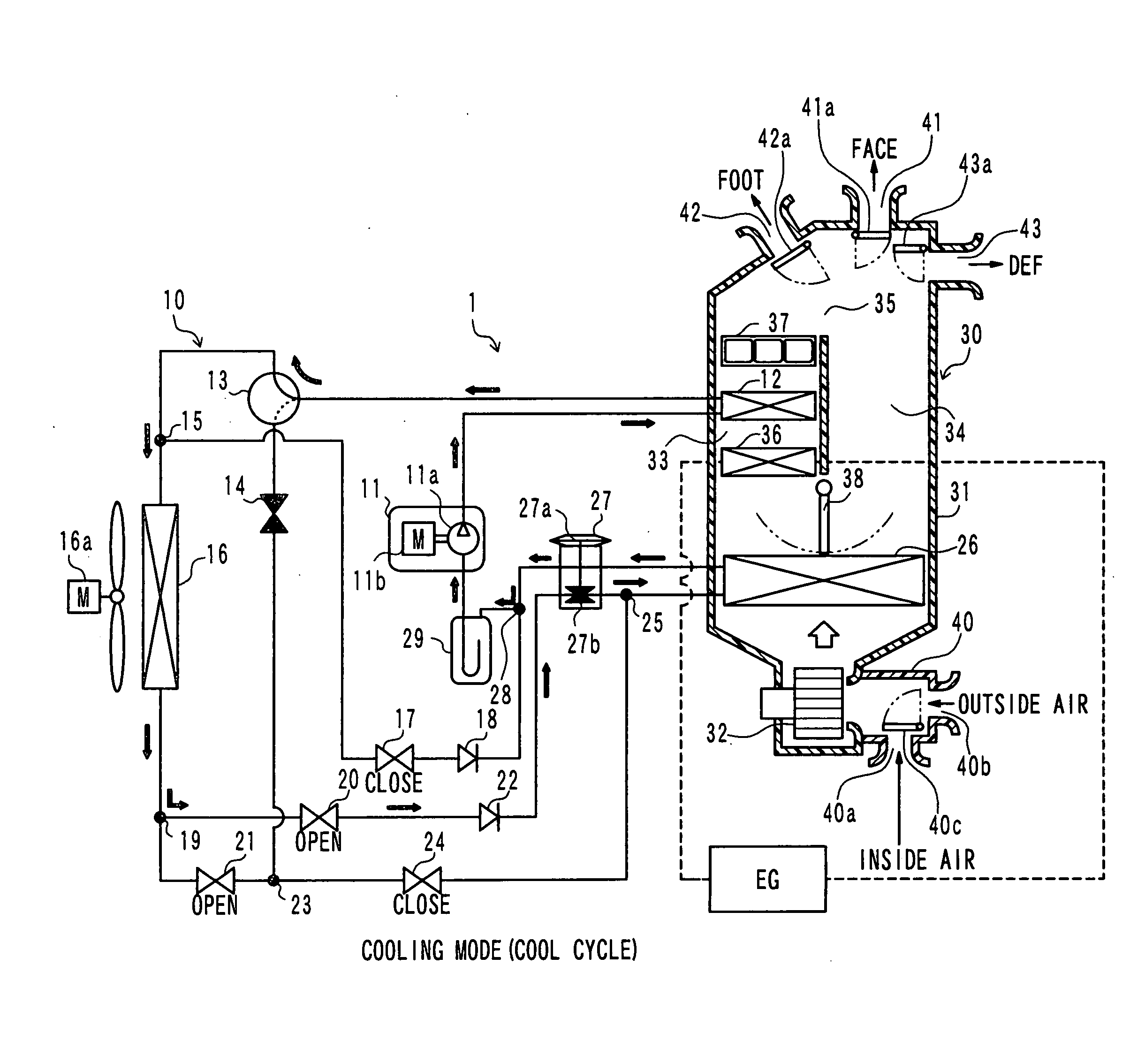

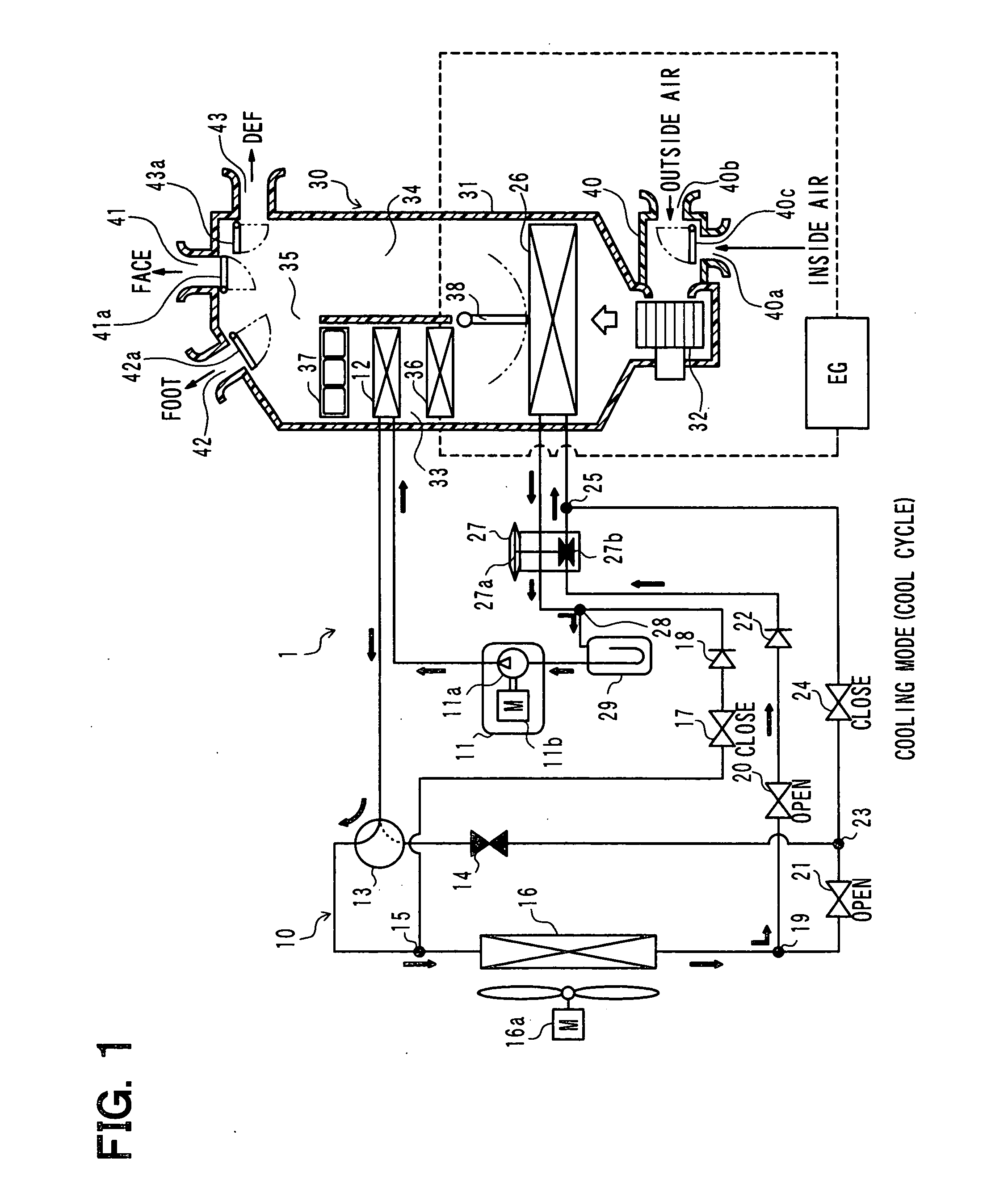

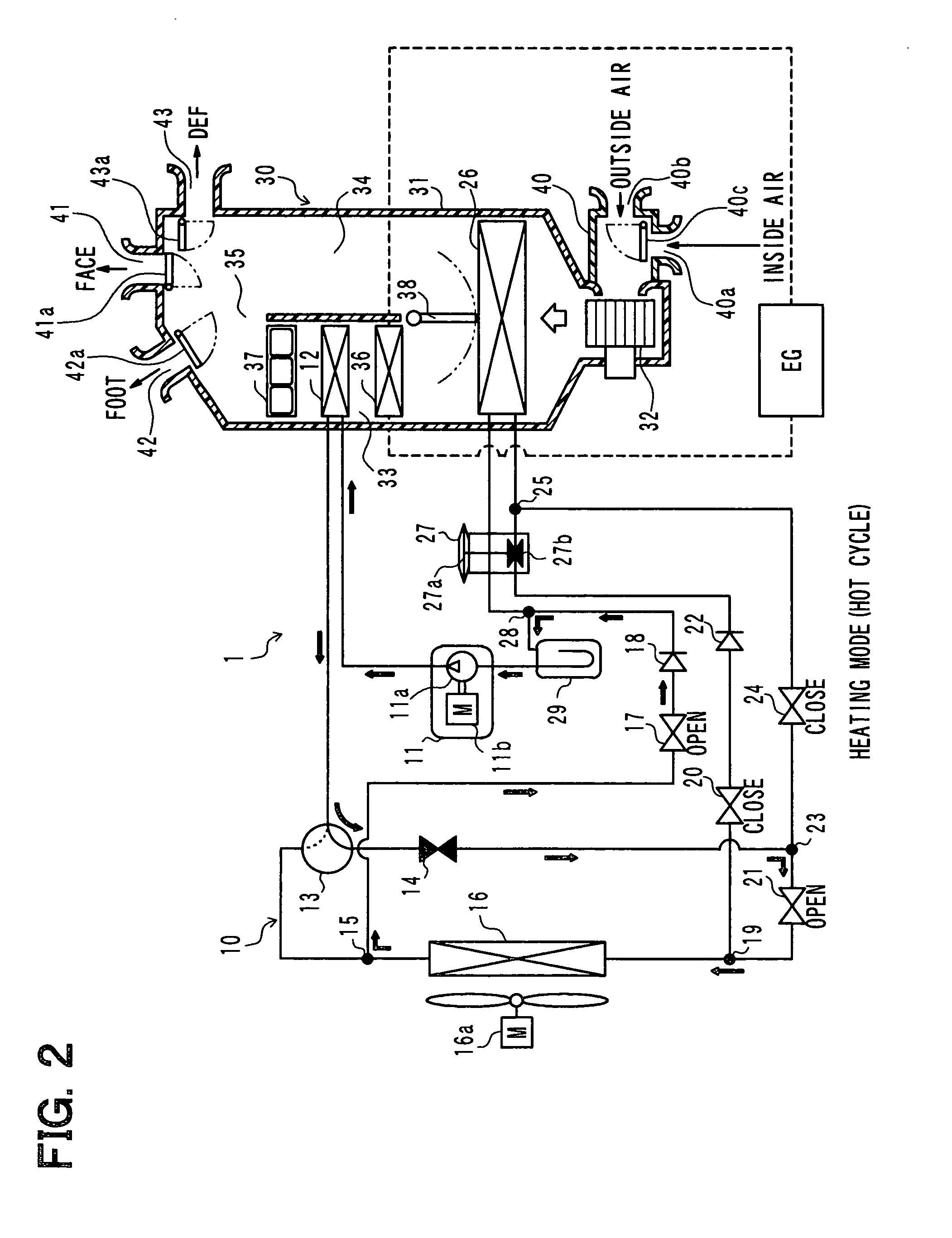

Air conditioner for vehicle with heat pump cycle

InactiveUS20110016896A1Prevent heatDefrost time be reduceMechanical apparatusHeat pumpsCooling cycleChiller

An air conditioner for a vehicle includes a vapor compression refrigeration cycle switchable between a heat pump cycle and a cooler cycle, a heat core configured to heat air to be blown into a vehicle compartment by using coolant of an engine of the vehicle as a heat source, and a controller configured to control operation of the vapor compression refrigeration cycle. The controller controls the vapor compression refrigeration cycle to be operated as the cooler cycle so as to perform a defrosting control of the outdoor heat exchanger, and outputs an operation request signal to the engine, when the controller determines that the outdoor heat exchanger is frosted.

Owner:DENSO CORP

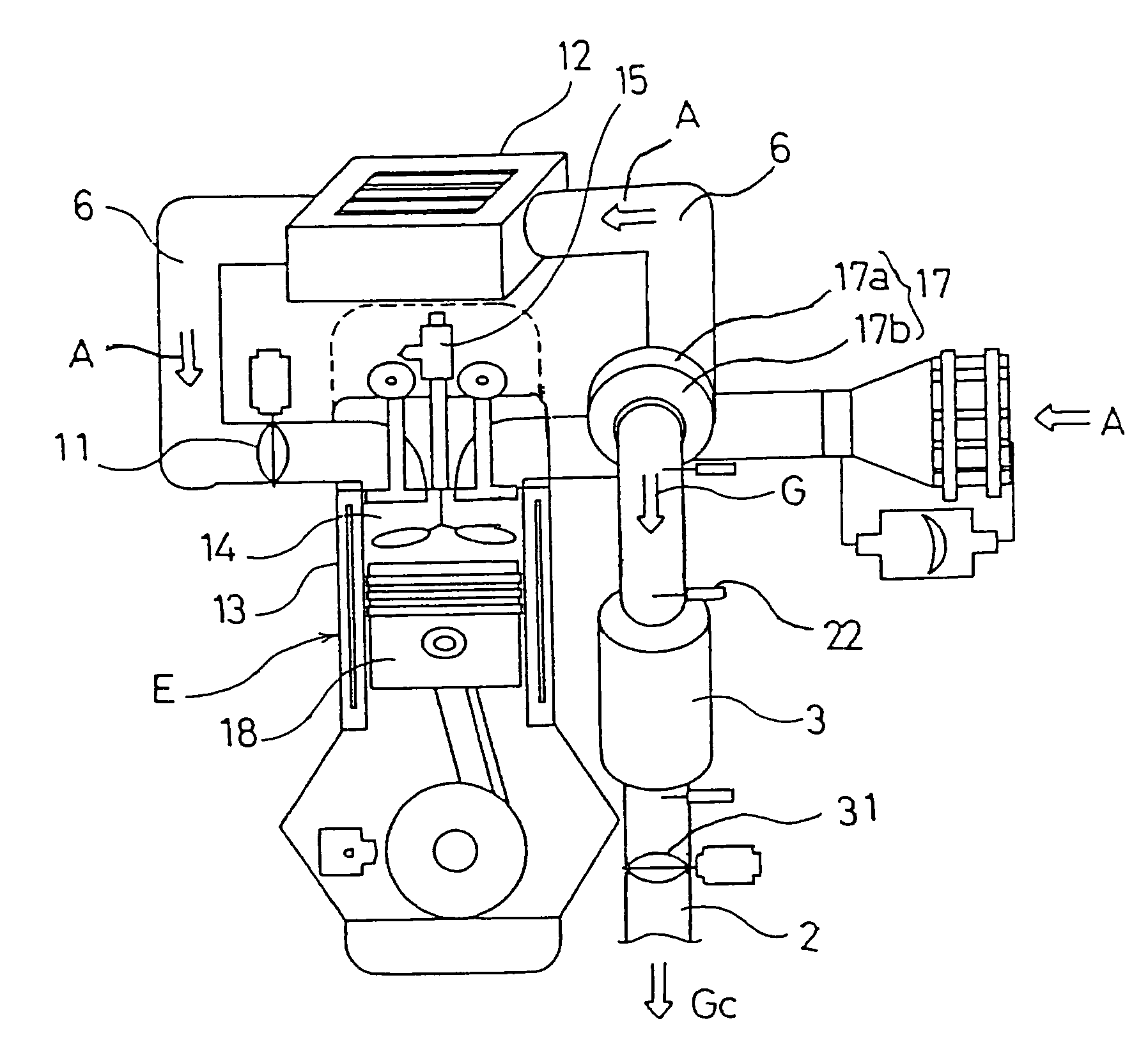

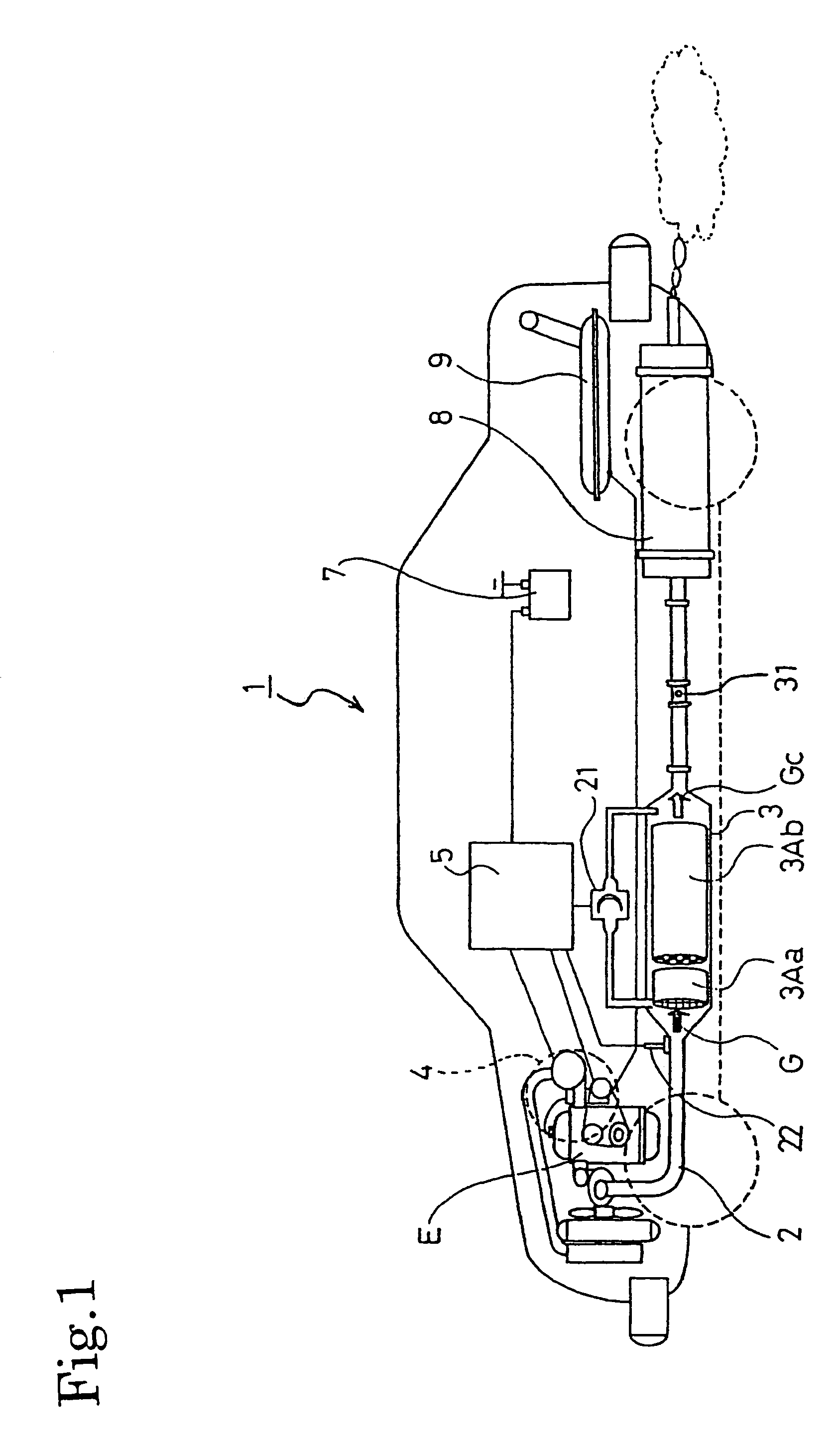

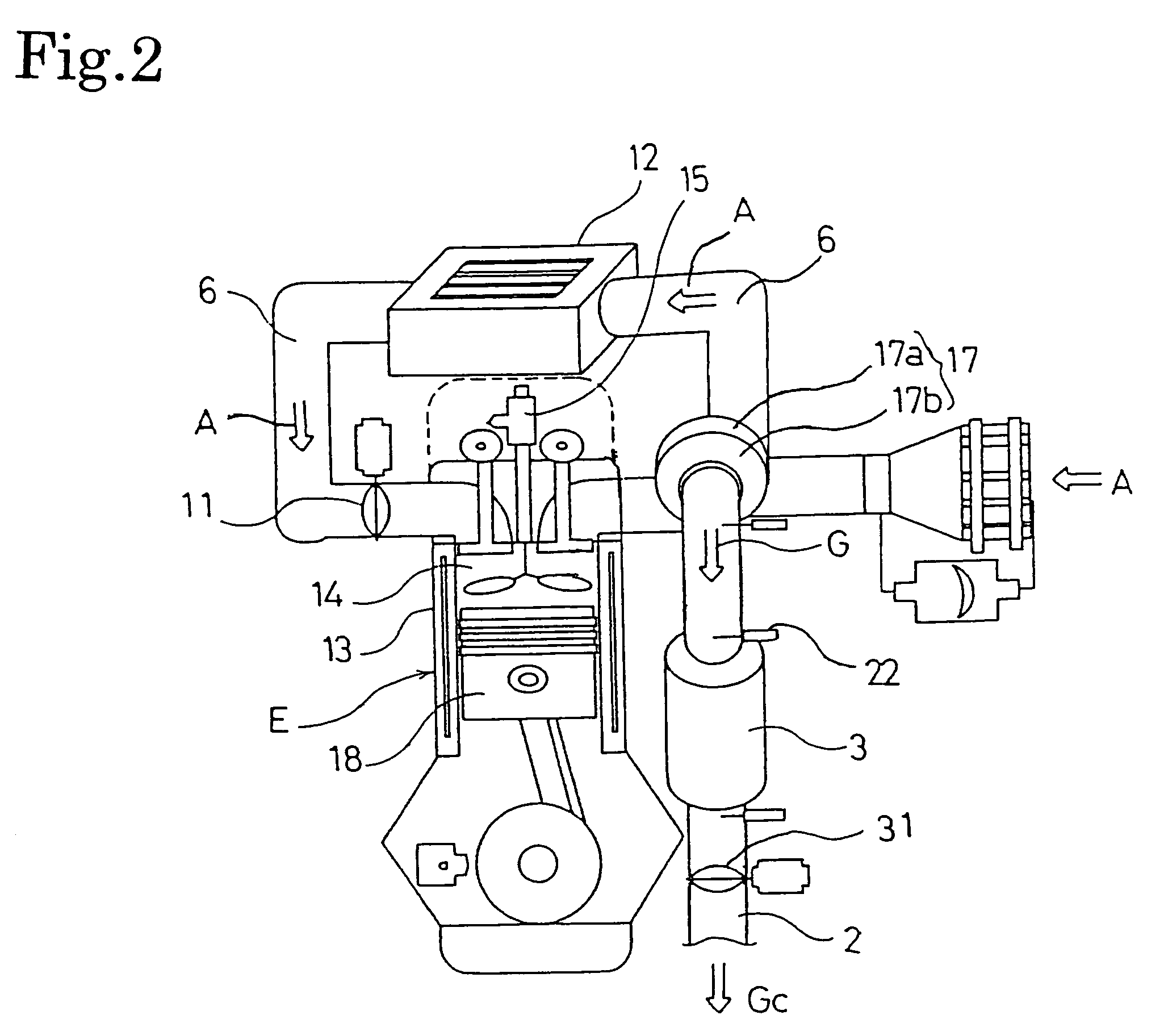

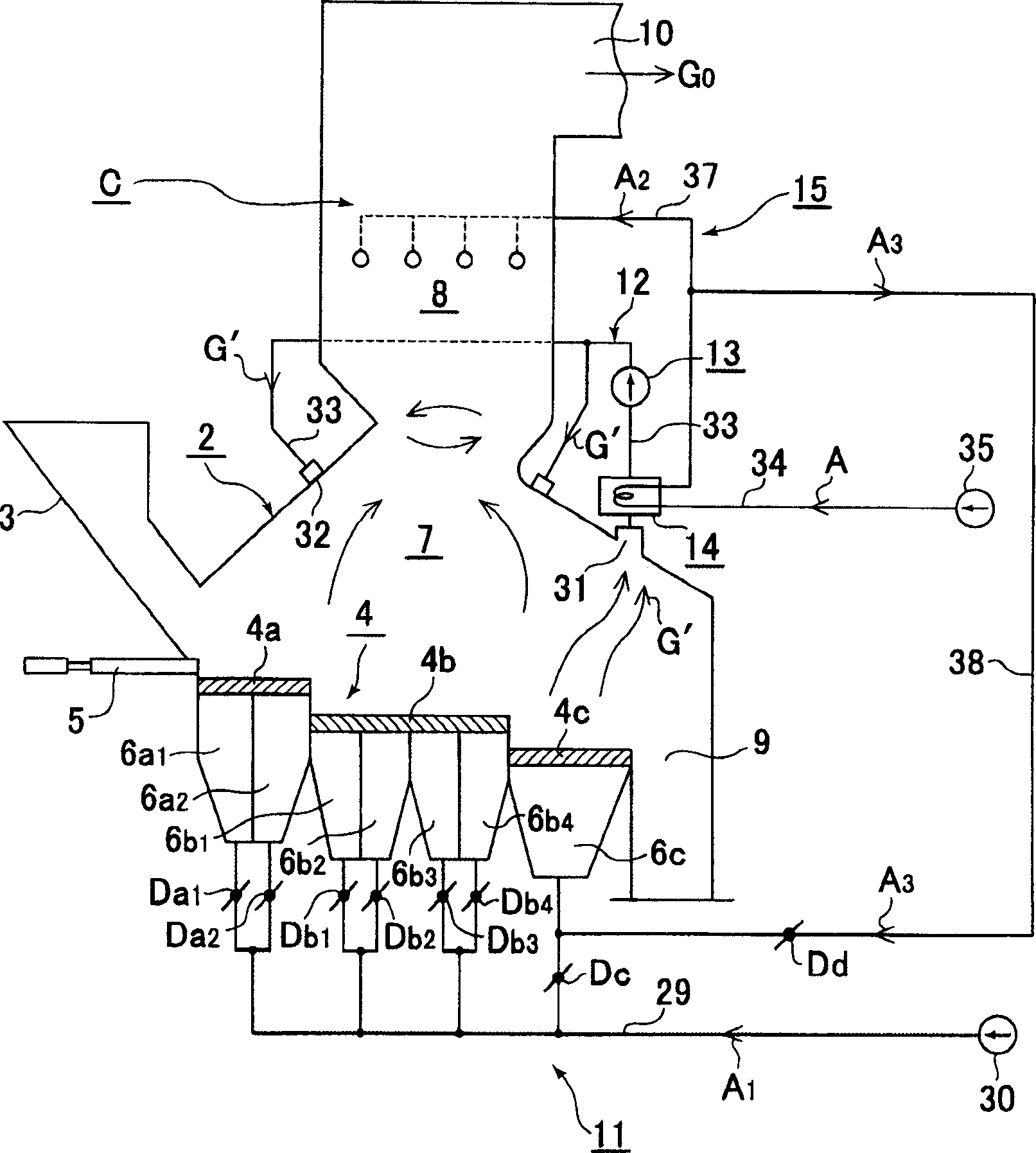

Exhaust gas purifying system

ActiveUS6966179B2Efficiently raising temperature of exhaust gasLower outlet temperatureElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

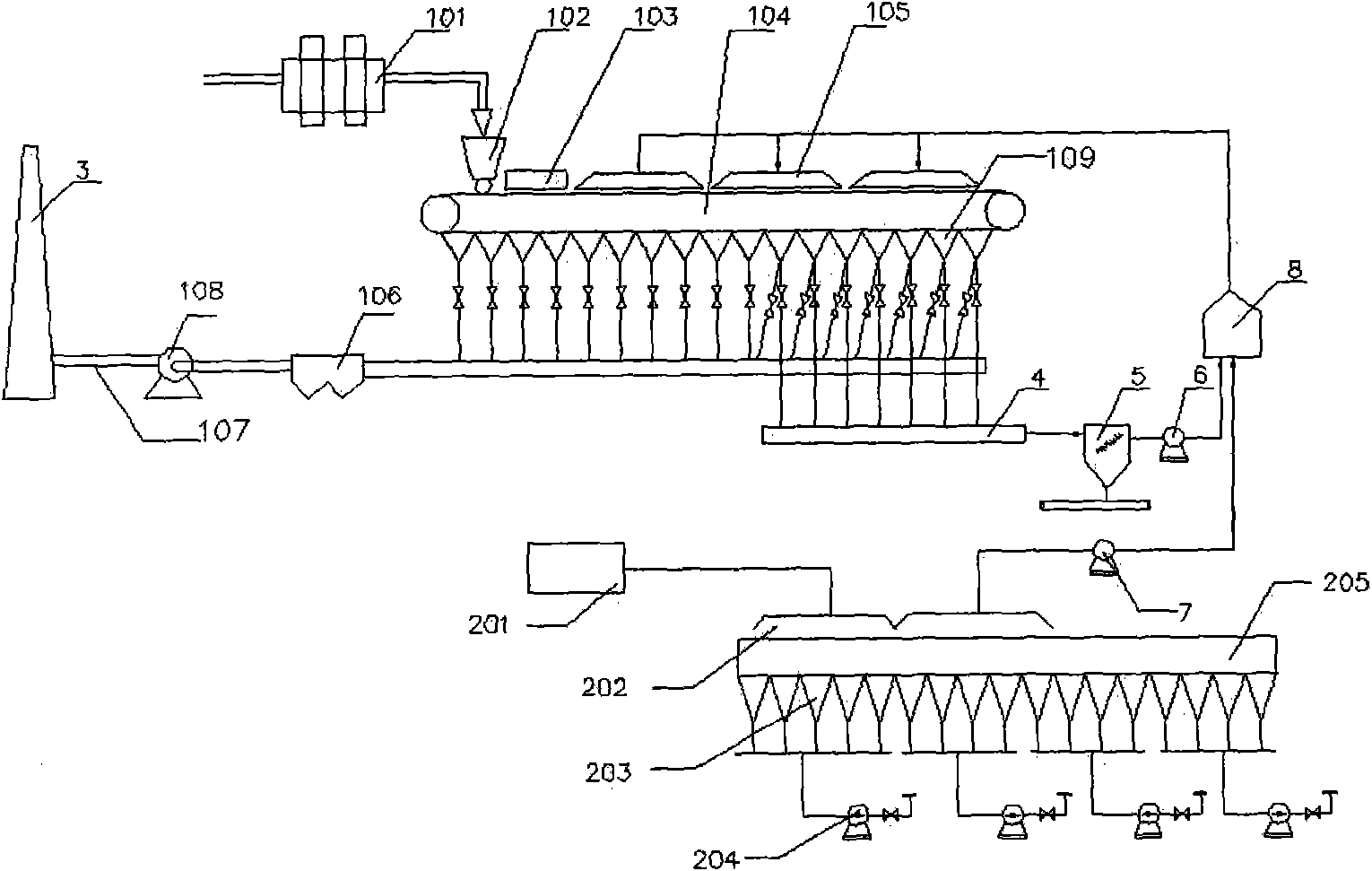

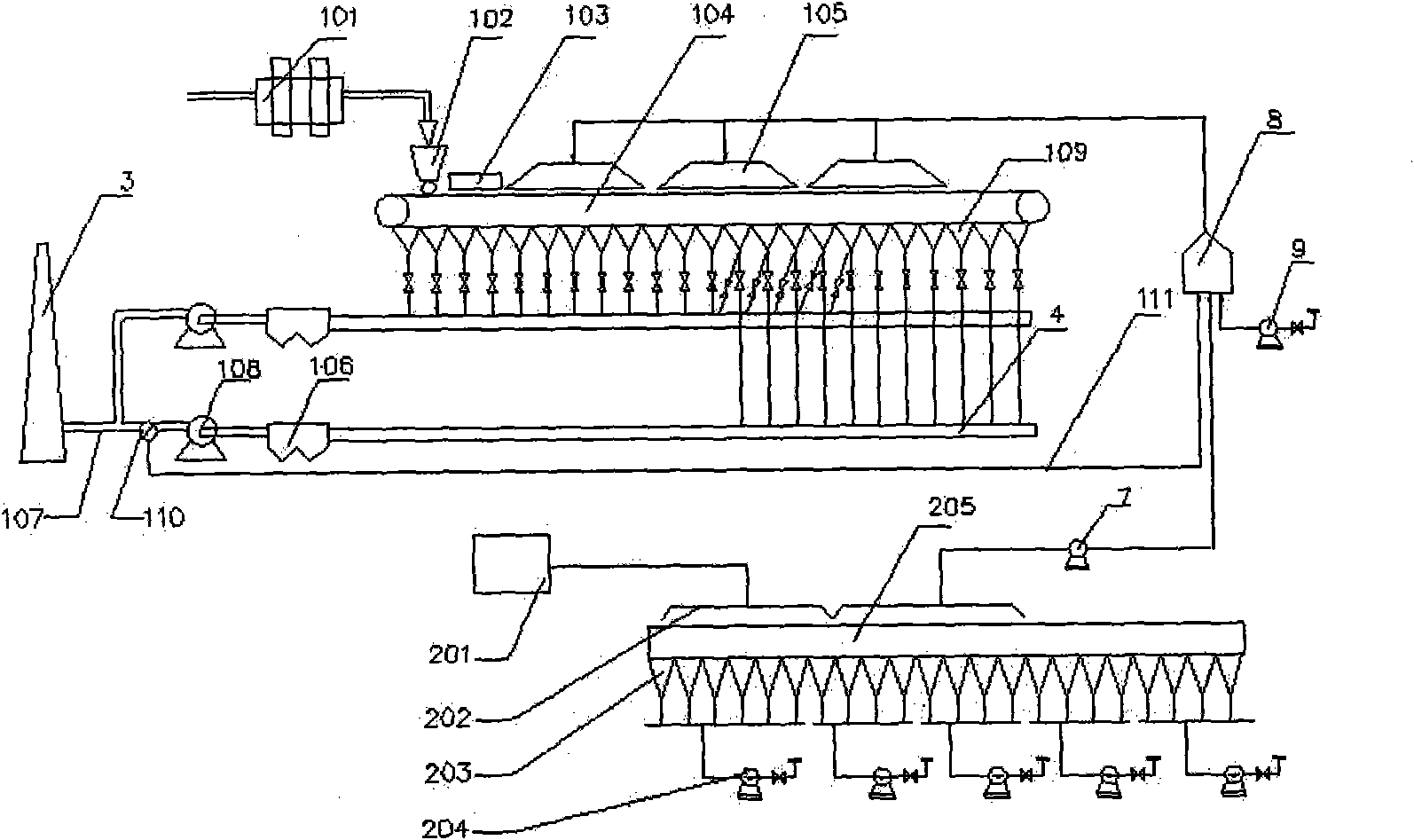

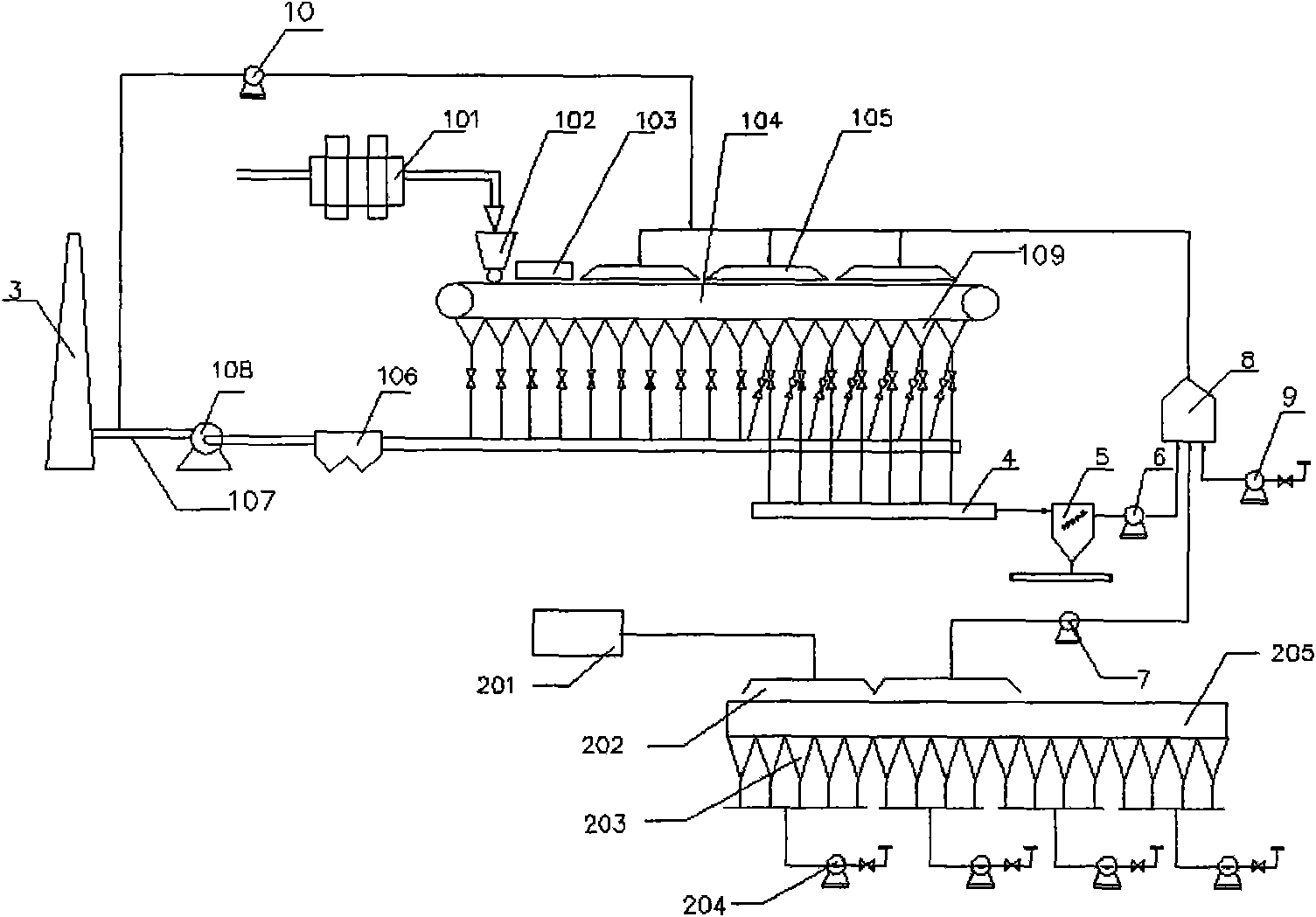

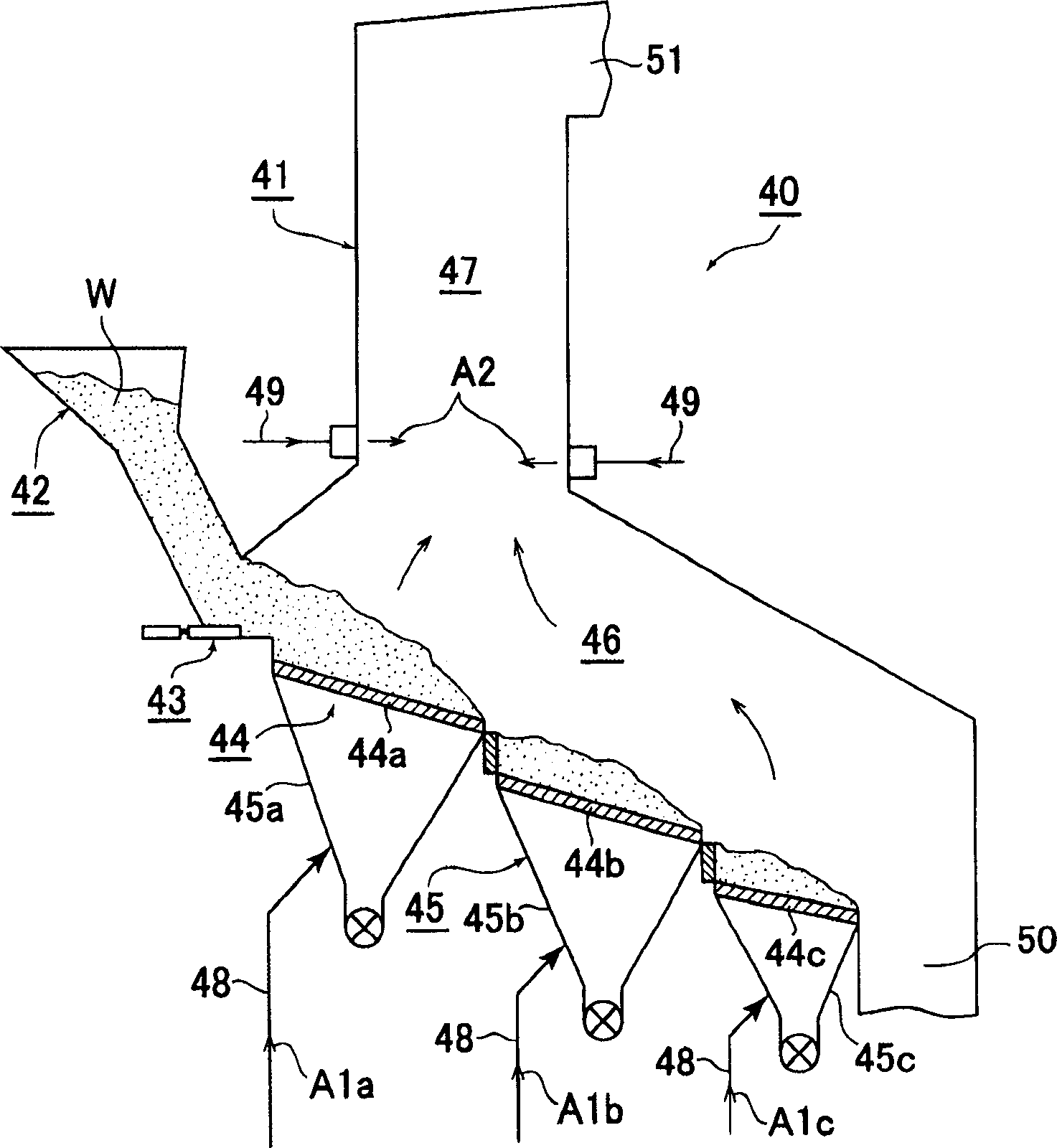

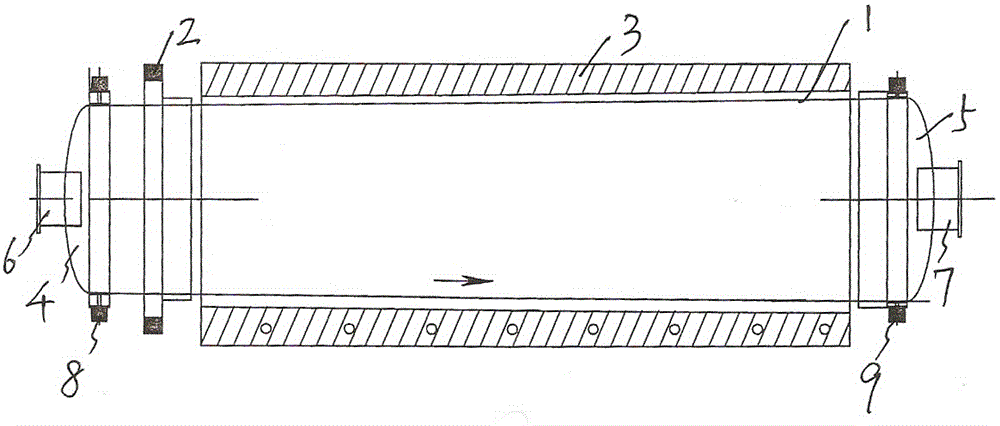

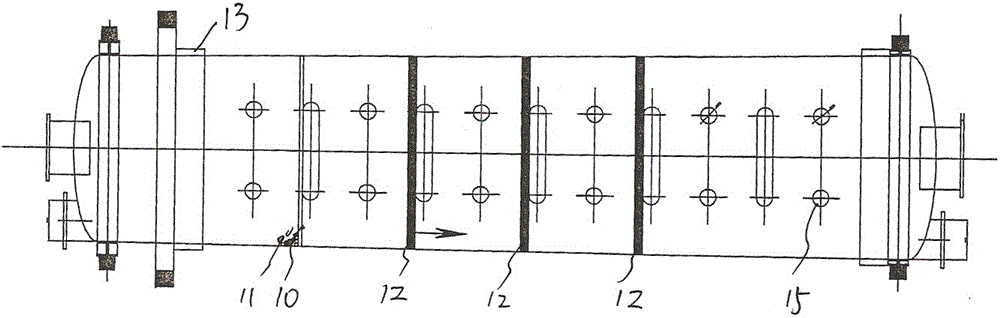

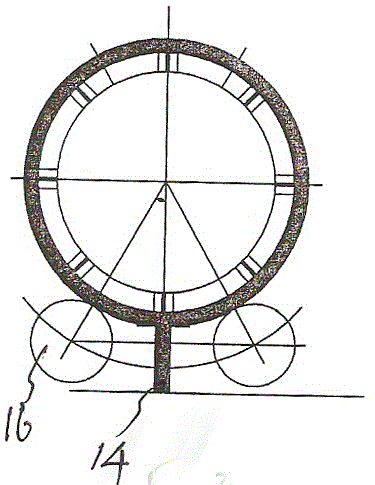

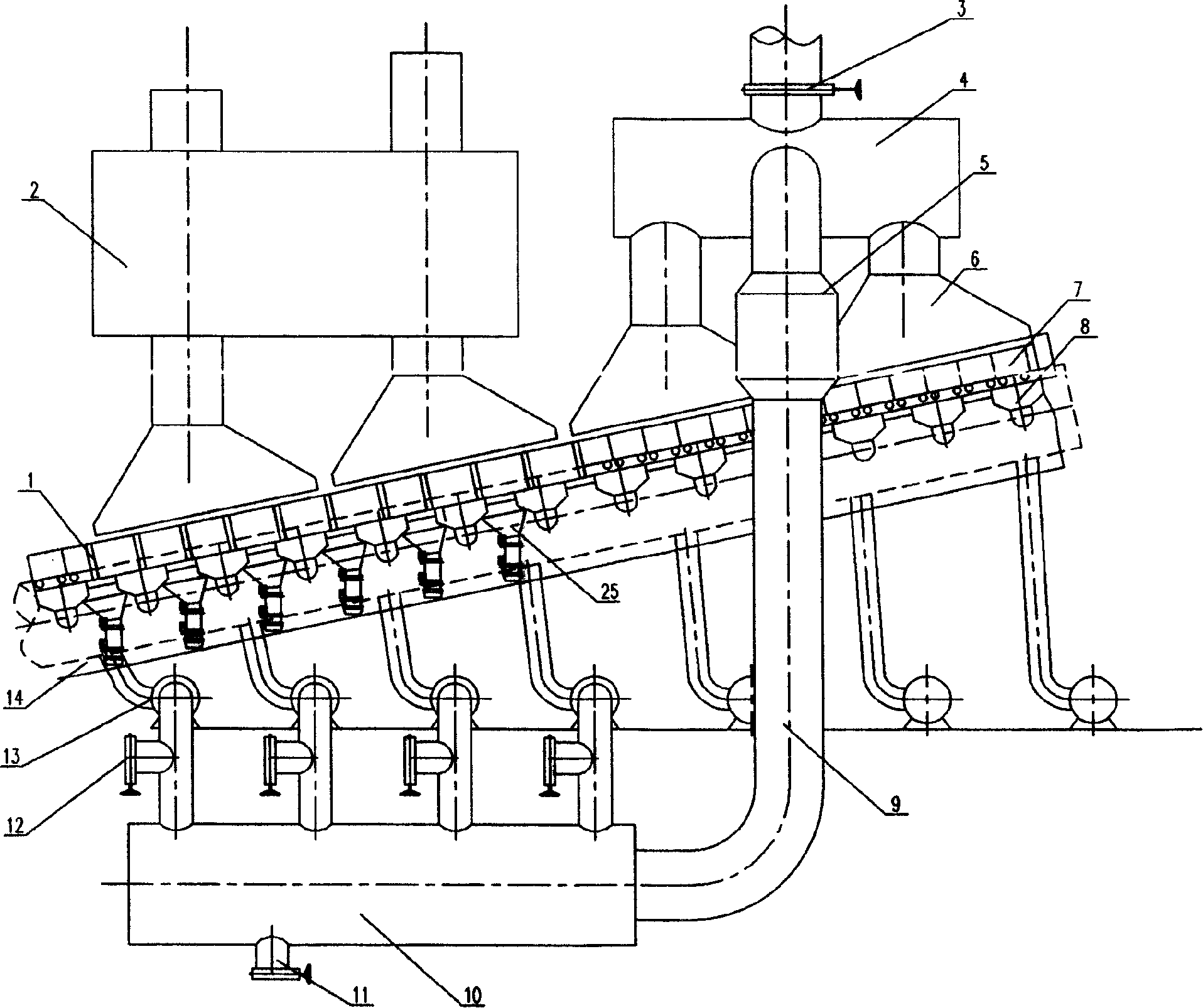

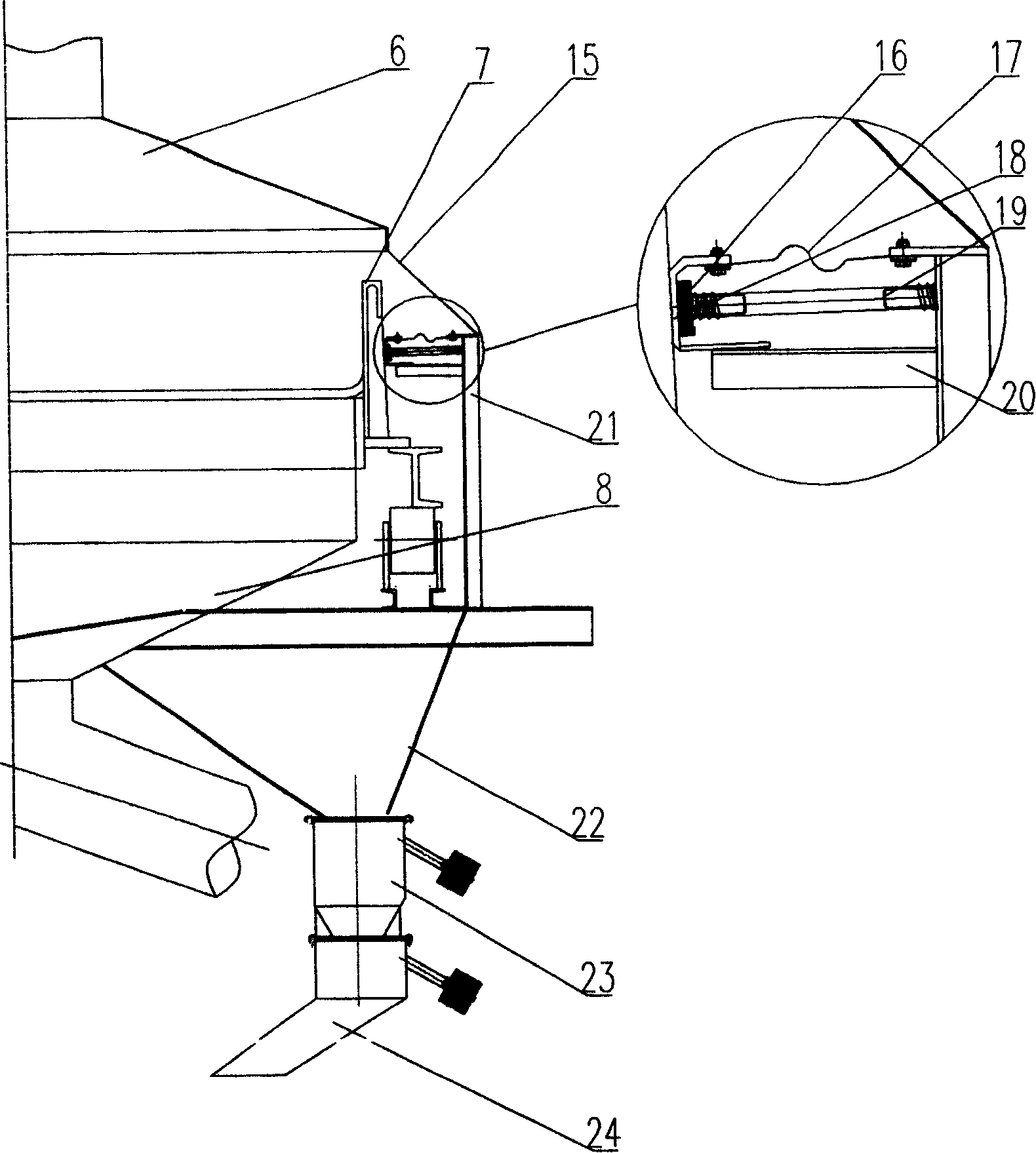

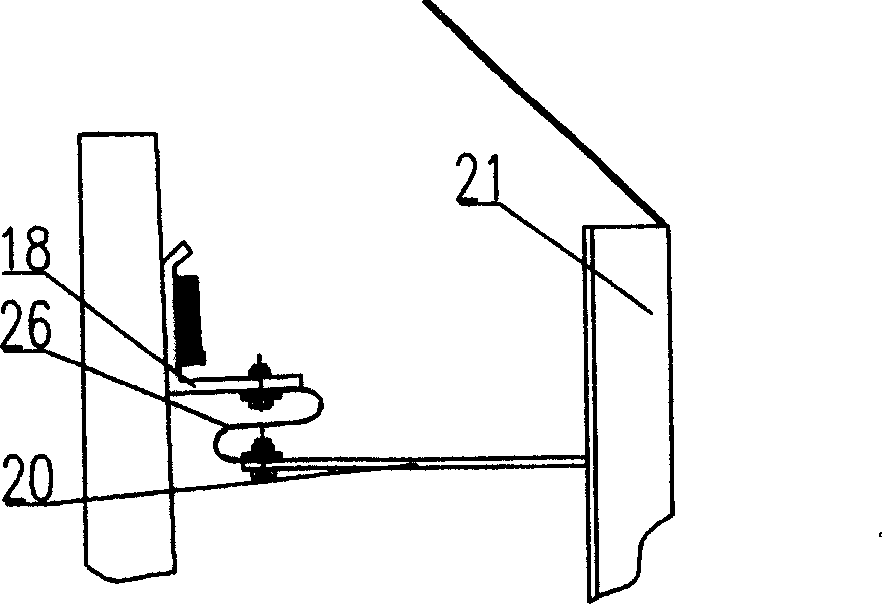

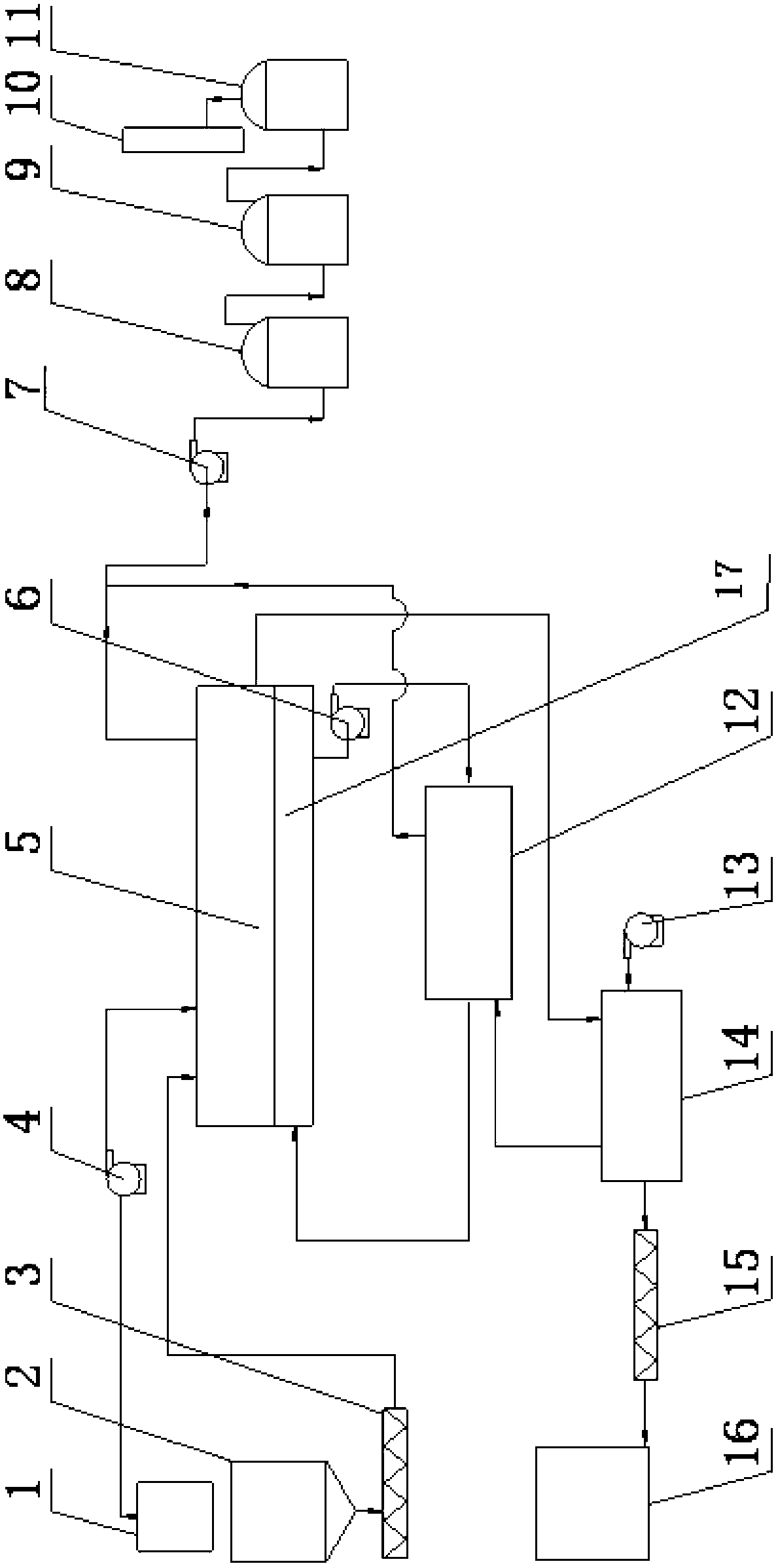

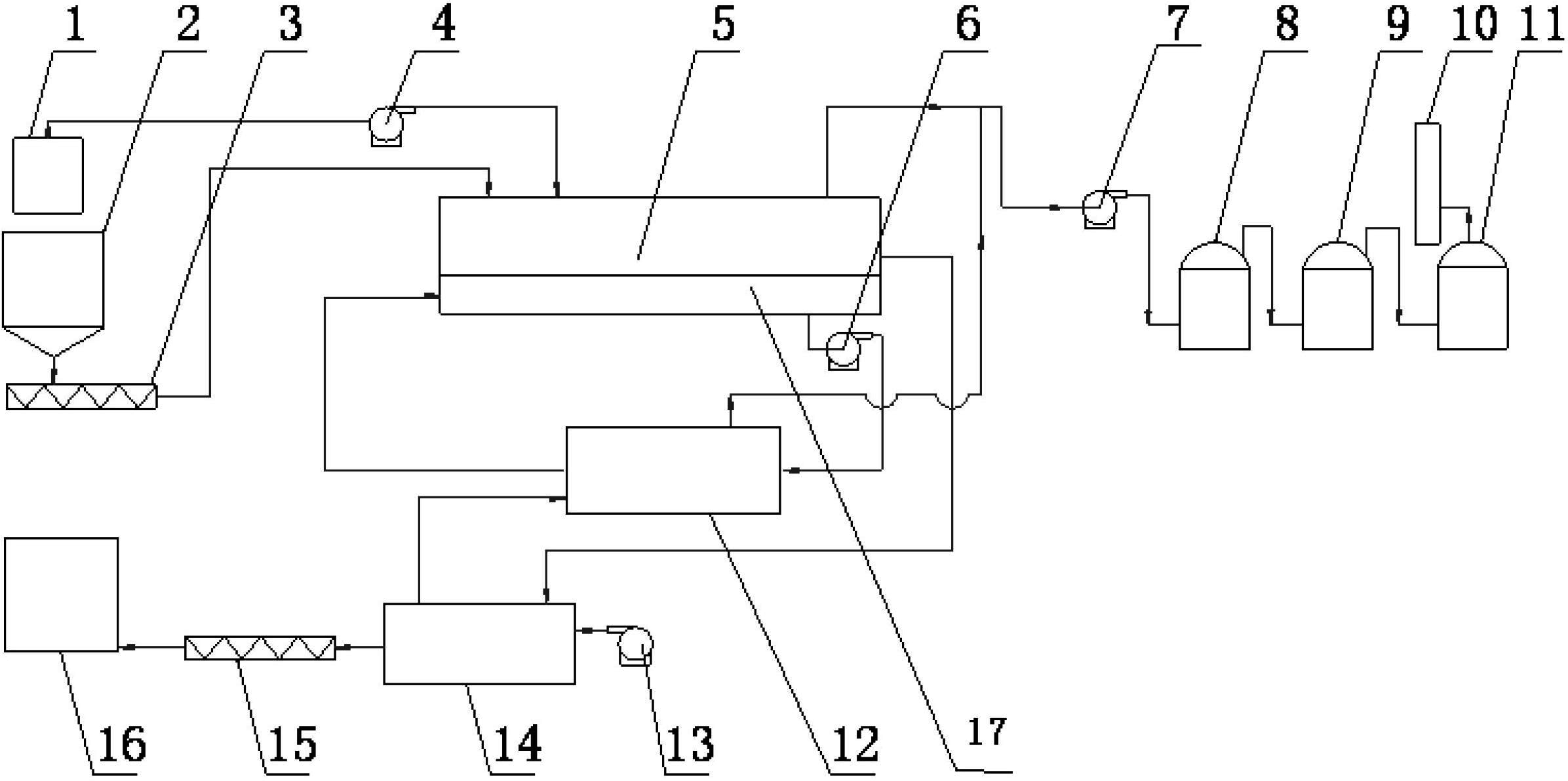

Method of sintering low temperature waste heat circulation and discharged waste gas reduction and device thereof

InactiveCN101893384AReduce process energy consumptionConducive to environmental protectionWaste heat treatmentFluePollutant

The invention discloses a method of sintering low temperature waste heat circulation and discharged waste gas reduction and a device thereof. The method comprises the following steps: drawing out flue gas having a high temperature in an air bellow on the rear part of the main-flue of a sintering machine; dedusting; mixing the flue gas with hot waste gas extracted from a sintering cool machine into a mixer to form the mixed hot waste gas; and transmitting the mixed hot waste gas on the surface of the material layer of the sintering machine for circular sintering. The device comprises a high temperature flue gas circulation pipeline of the sintering machine connected with a high temperature flue of the sintering machine, a hot waste gas circulation pipeline of a sintering cool machine connected with the sintering cool machine and a total circulation pipeline connected with a sintering machine fan cover. By using the invention, the waste gas discharging total amount and the pollutants discharging amount produced in a sintering process can be greatly reduced, the low temperature waste heat in the flue gas can be recycled and energy consumption of the sintering process can be saved, thus, the method of the invention has significant energy saving and emission reduction value.

Owner:BAOSHAN IRON & STEEL CO LTD

Exhaust gas purifying system

ActiveUS20050044845A1Increase exhaust pressureImprove combustion performanceElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

Efficient energy-saving steam cabinet

ActiveCN102631131AEmission reductionImprove energy savingCooking vesselsBoiler controlCombustion chamberProcess engineering

The invention discloses an efficient energy-saving steam cabinet. The efficient energy-saving steam cabinet comprises an oven body, wherein a plurality of combustion heads are arranged inside the oven body; the plurality of combustion heads are located in a combustion chamber; a steam generating pot is arranged on the combustion chamber; a horizontal discharge flue is arranged at the lateral wall of the combustion chamber; a smoke discharge port is arranged on the side wall of the combustion chamber; and a burner port is arranged at the bottom of the combustion chamber. The efficient energy-saving steam cabinet disclosed by the invention has the beneficial effects of being obvious in energy-saving effect, very little in exhausted air quantity, very high in energy utilization rate and very obvious in national energy-saving and emission-reducing effects, and the utilization efficiency of the heat energy can be up to over 90%, the discharge temperature is close to ambient temperature, and the discharge of greenhouse gas is greatly reduced.

Owner:浙江合隆智能设备有限公司

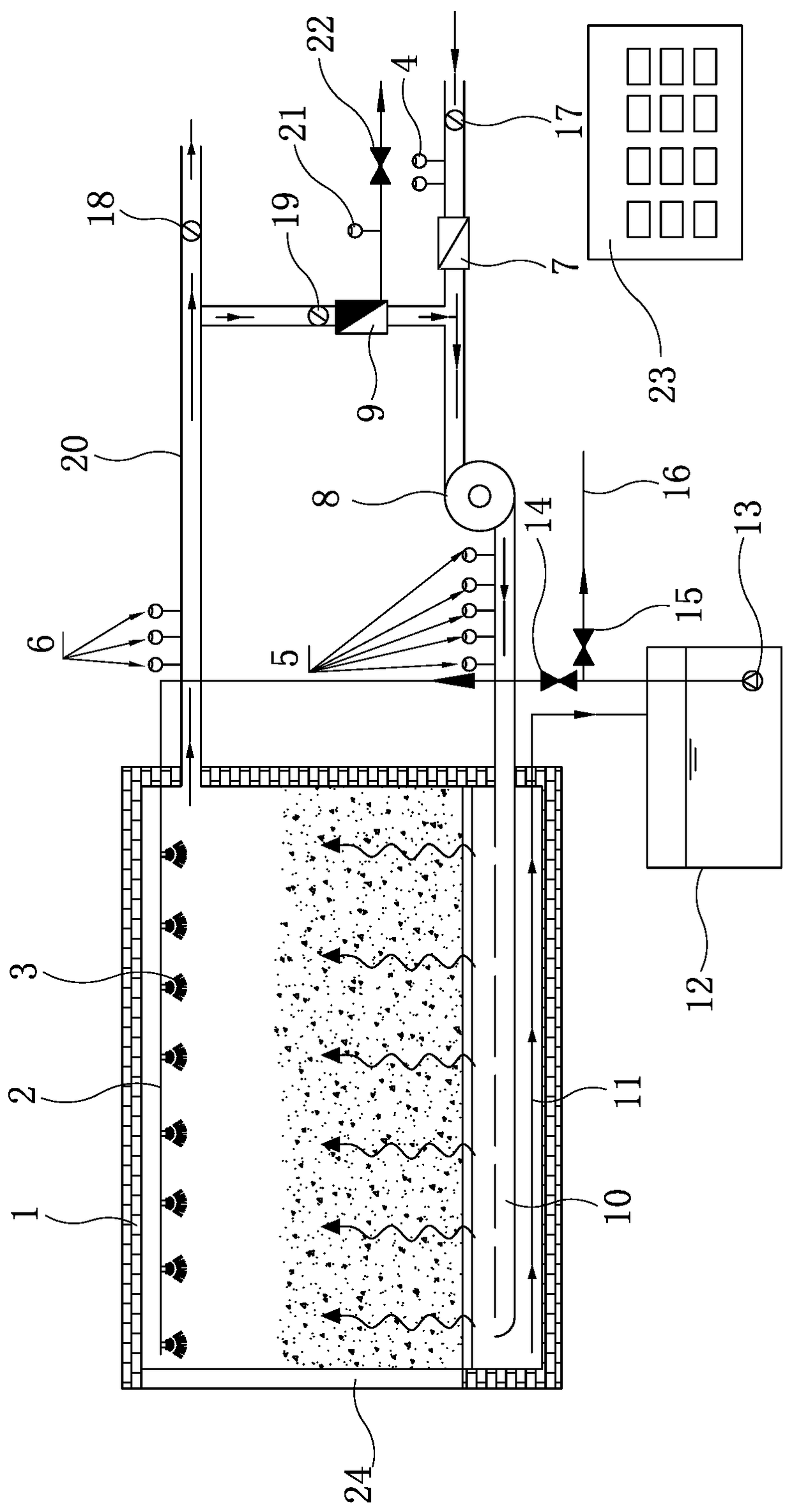

Biological drying treatment device and method for domestic garbage

PendingCN109201706AAchieve harmless purposeTo achieve the purpose of reducingSolid waste disposalHigh concentrationAir monitoring

The invention discloses a biological drying treatment device and method for domestic garbage. The biological drying treatment device comprises a biological drying chamber, a wastewater evaporation system, a condensation conversion system, an auxiliary system, an online exhaust gas and supply air monitoring system, an exhaust gas and supply air cyclic utilization system, and an automatic productionand distribution control system. According to the invention, wastewater evaporation and condensation conversion technologies of the invention can convert high-concentration percolate wastewater intolow-concentration condensed wastewater, so wastewater treatment difficulties and treatment cost are lowered; online monitoring and cyclic utilization technologies can reduce the supply volume of a fresh air source, decrease the amount of exhaust gas treated by an end exhaust gas treatment system and lower the cost of exhaust gas treatment; and an automatic distribution control system (DCS) can realize on-line monitoring of the parameters of a biological drying production process, centralized control of remote terminals and automatic execution of procedures, so the automation management level of a project is improved.

Owner:厦门市联谊吉源环保工程有限公司

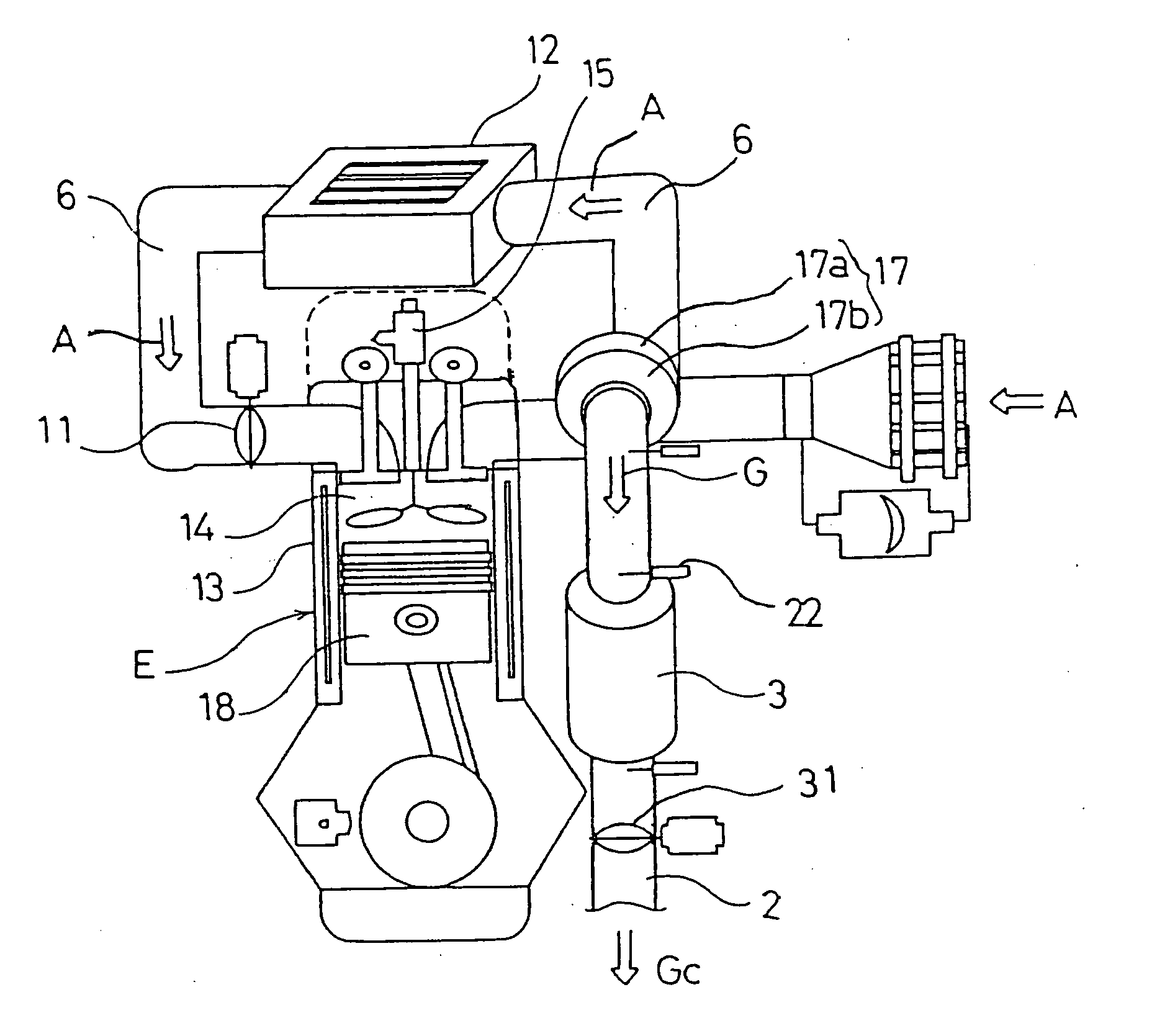

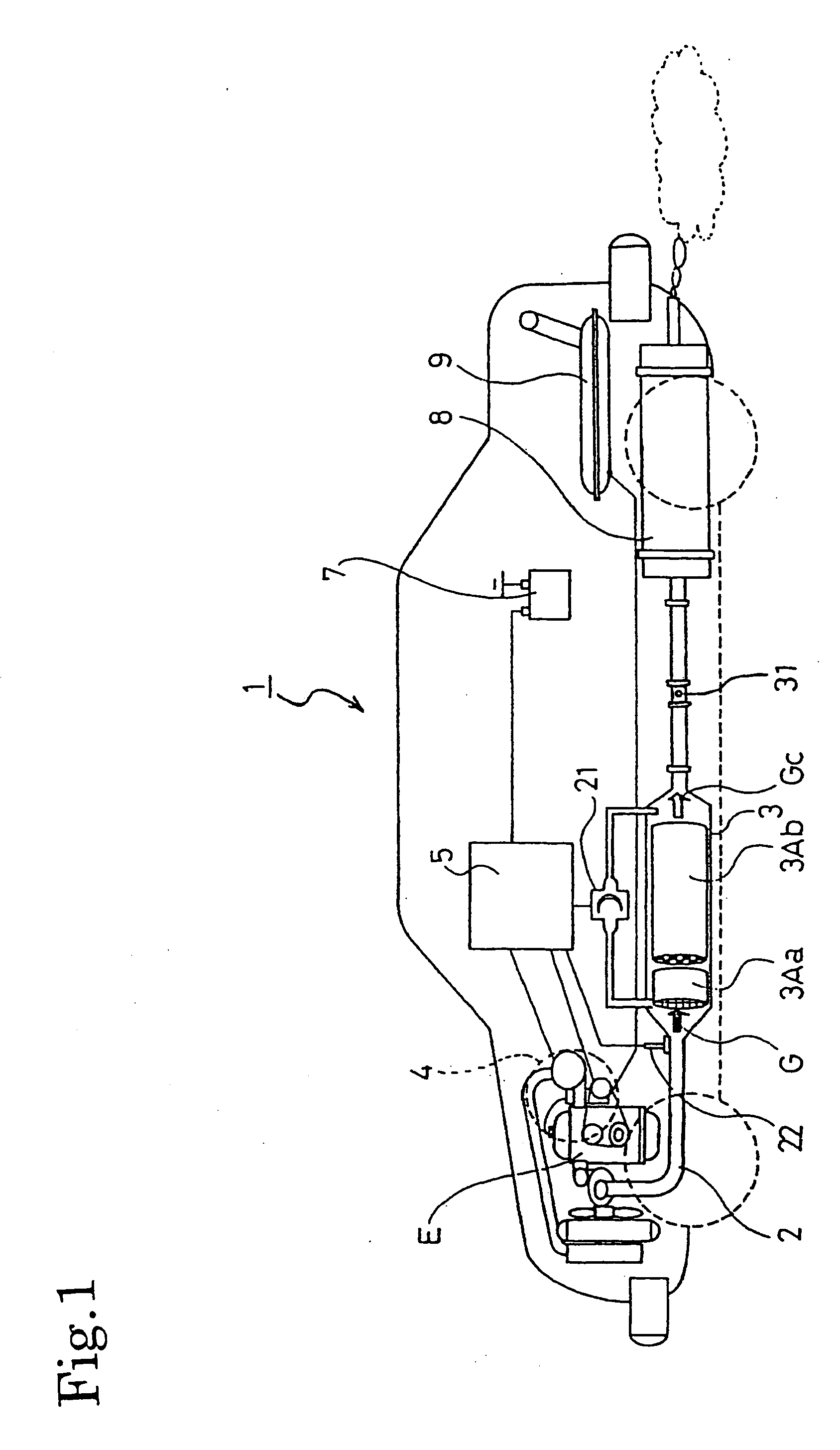

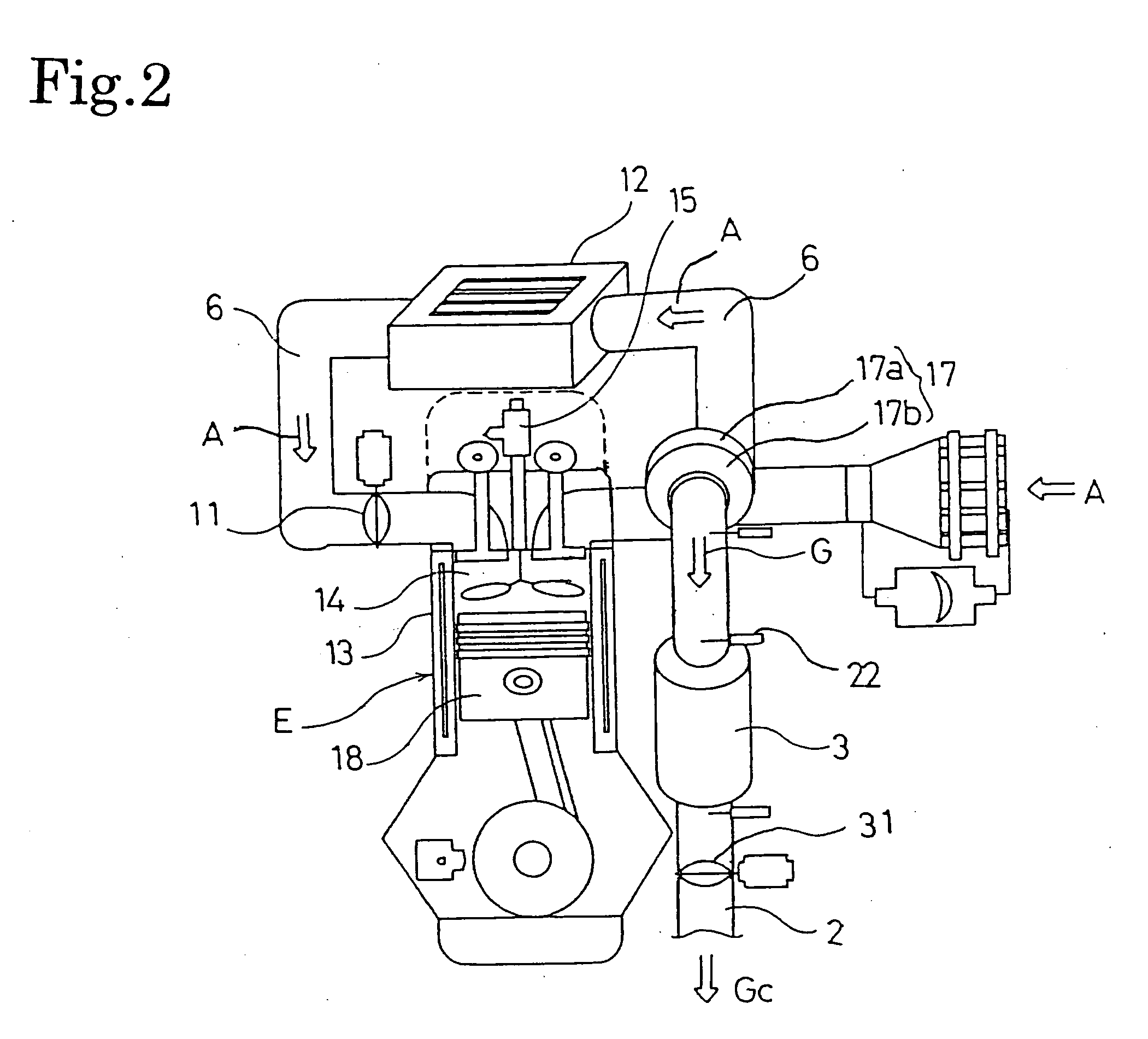

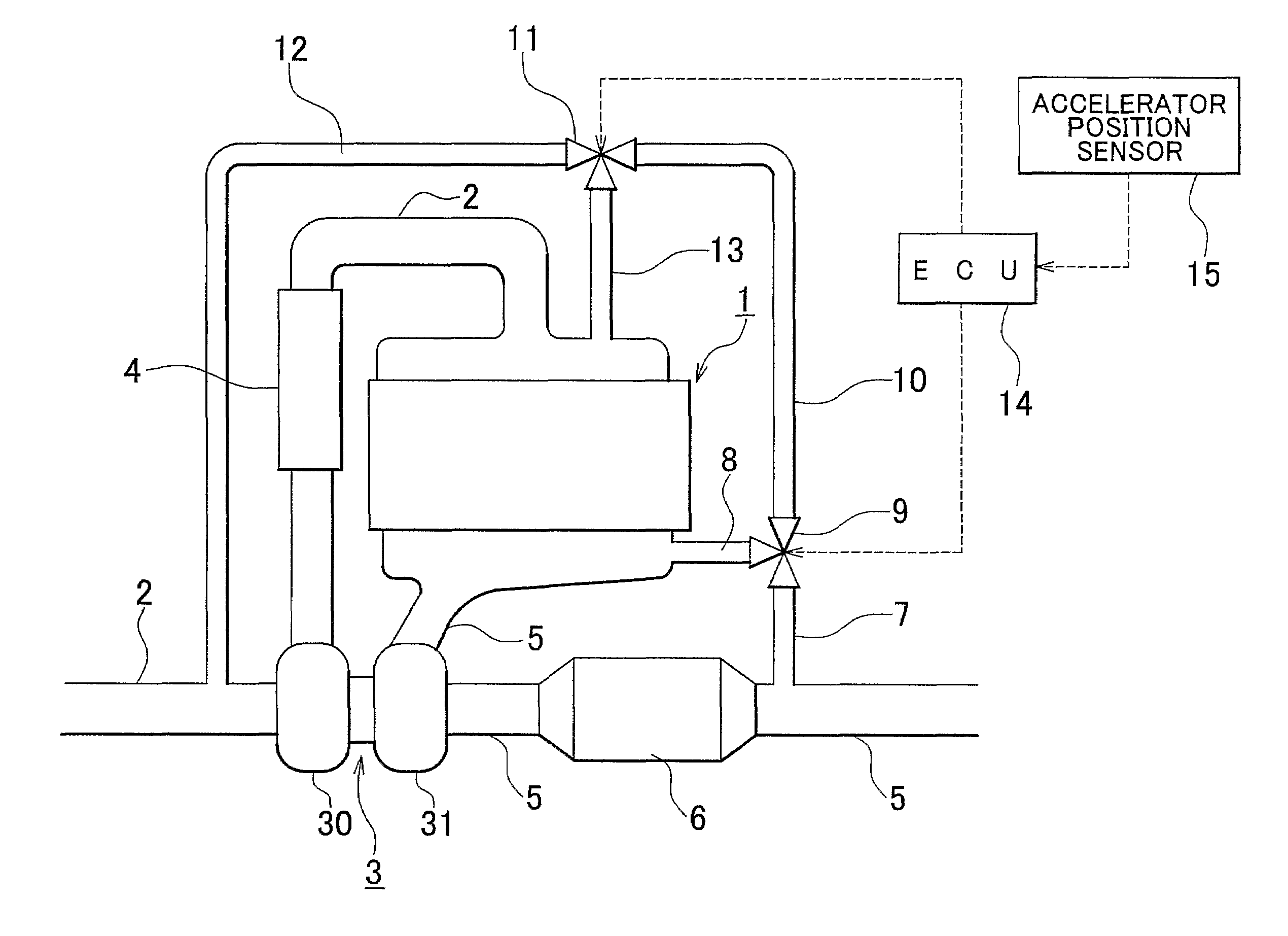

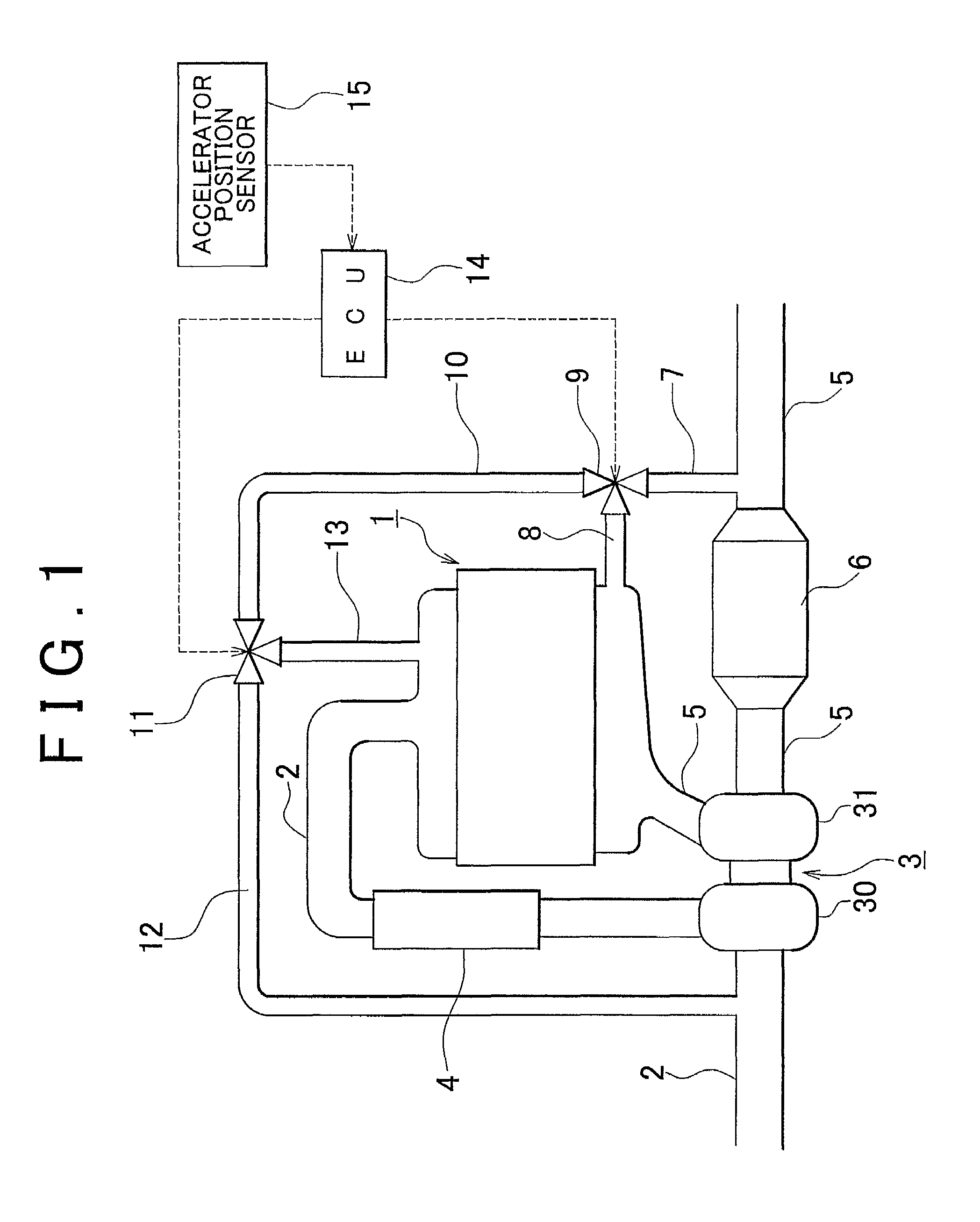

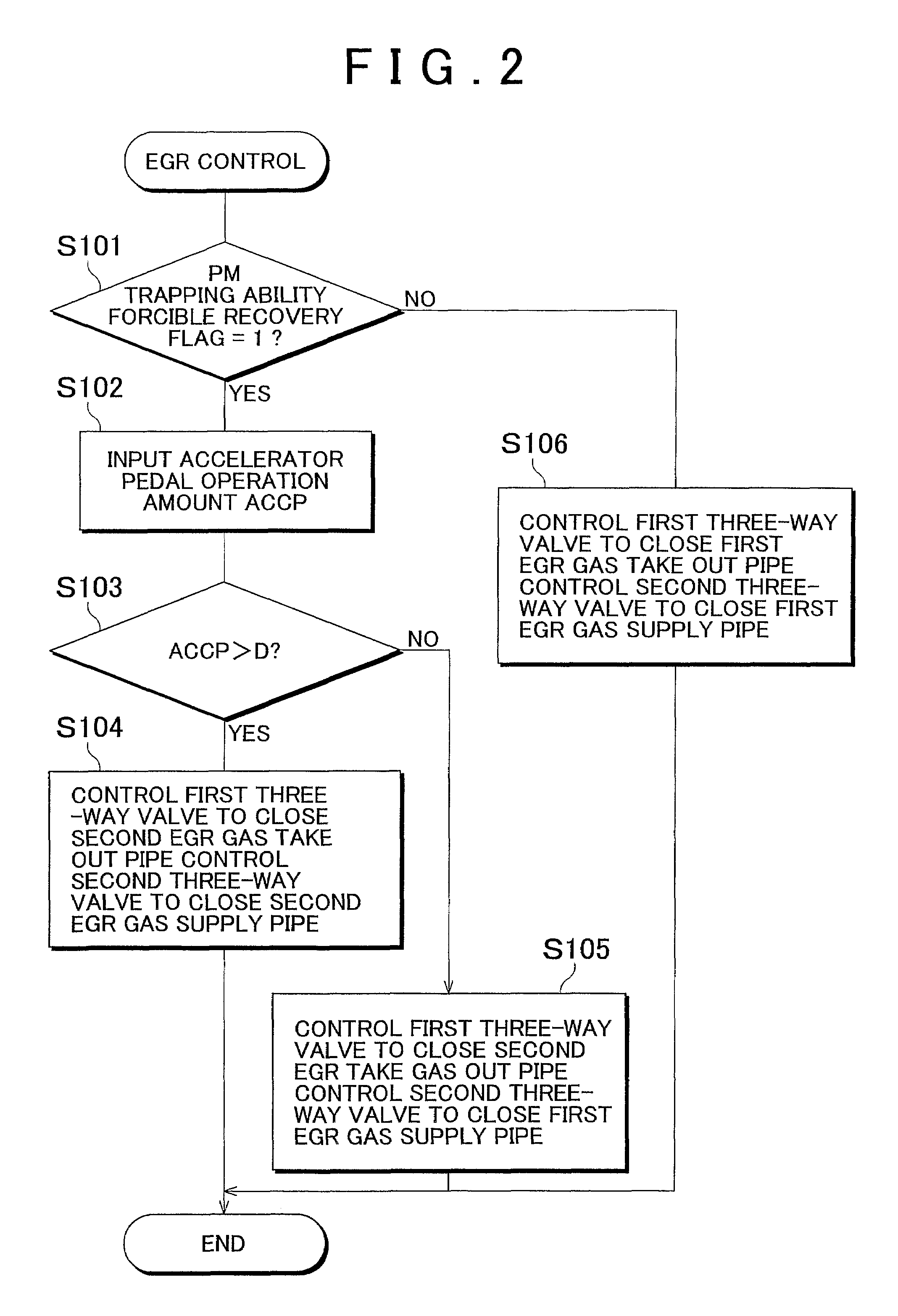

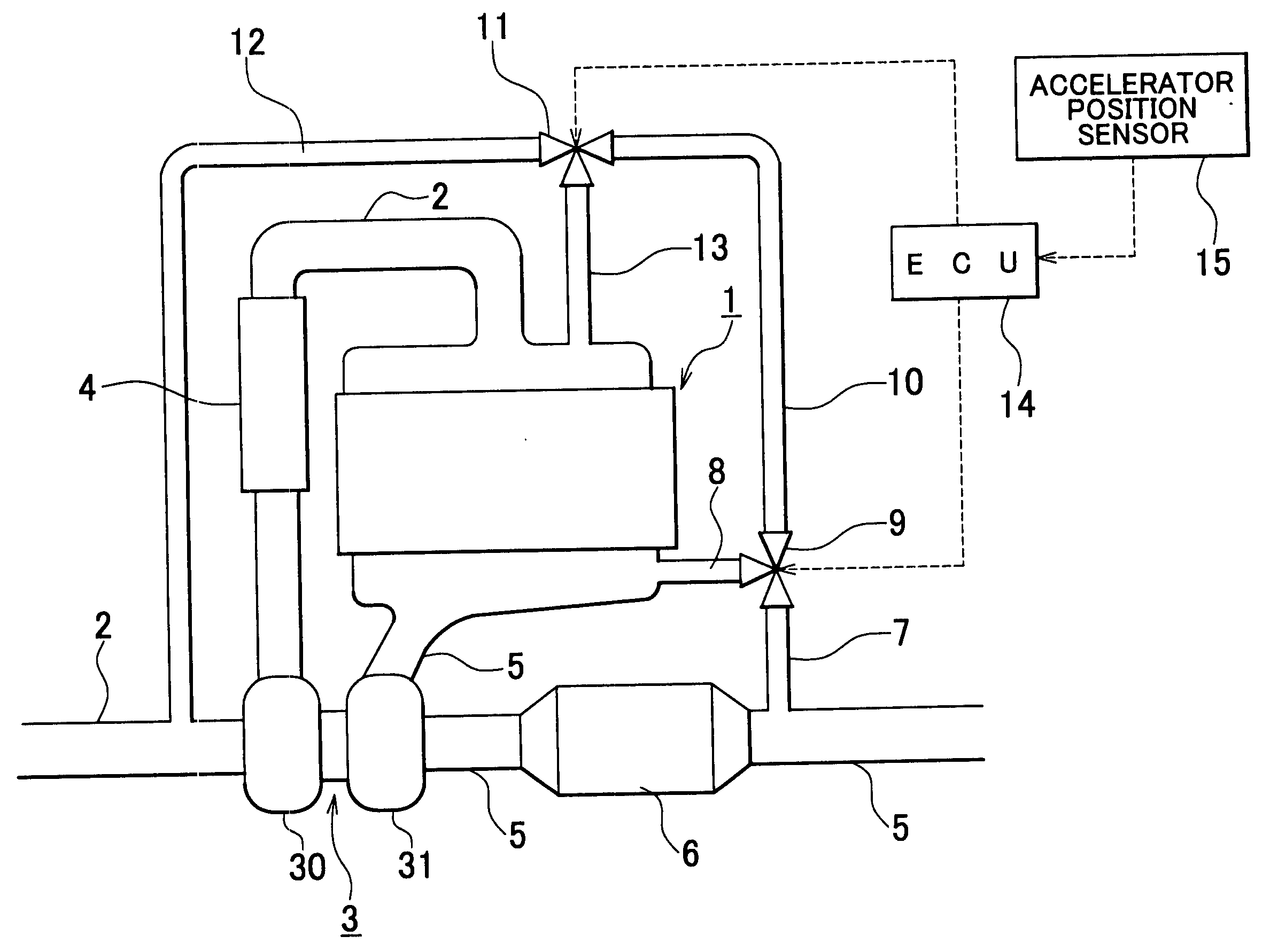

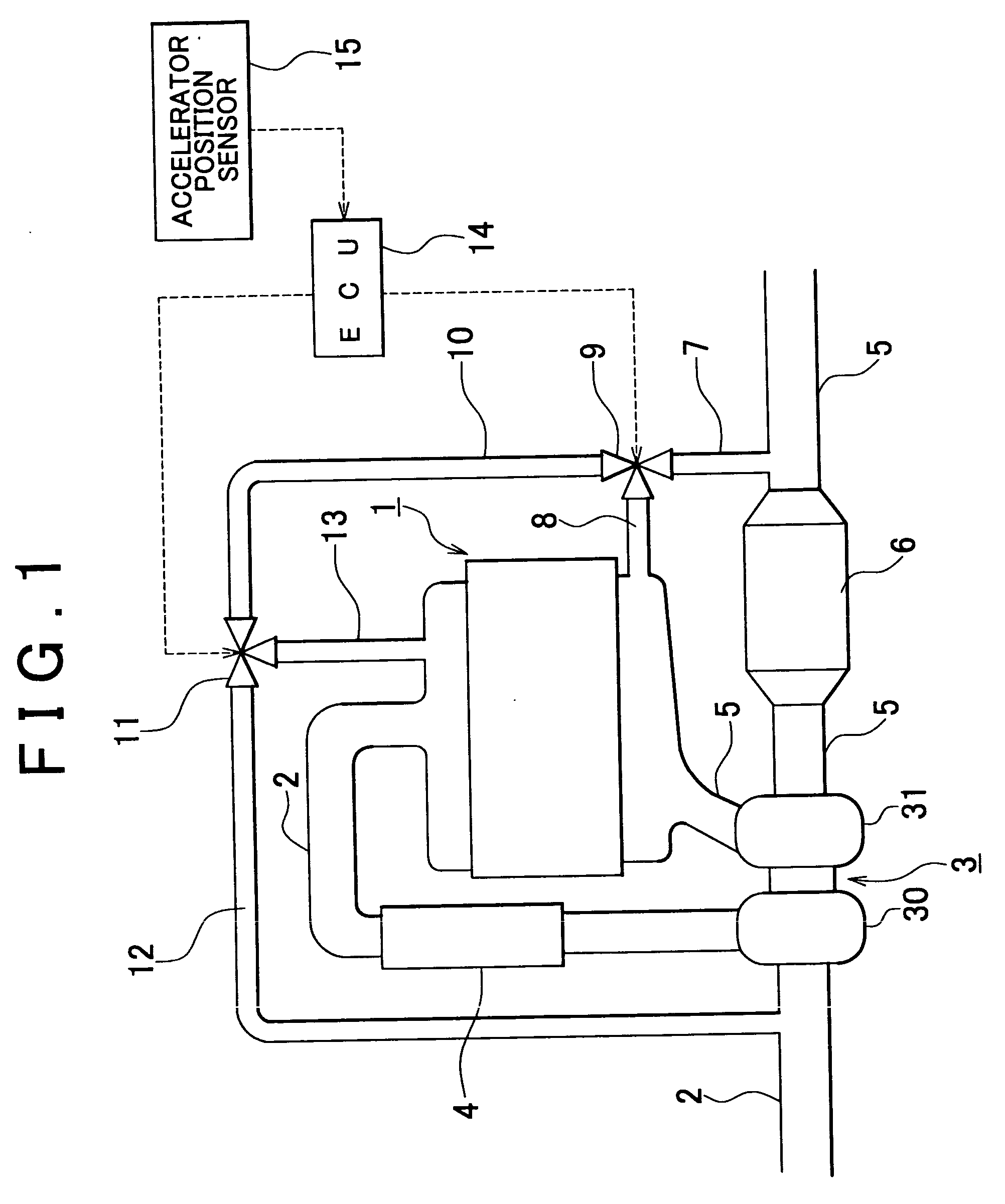

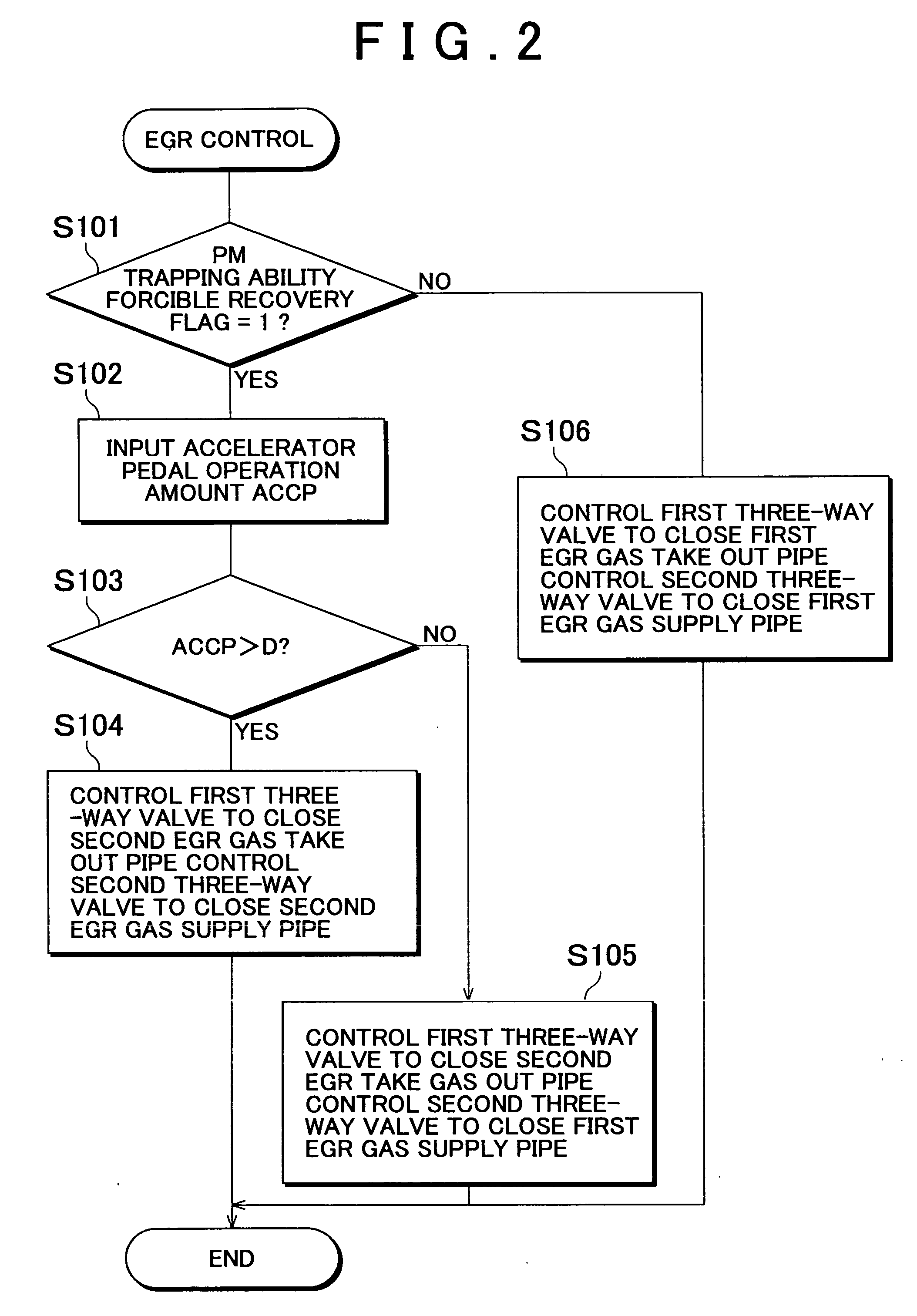

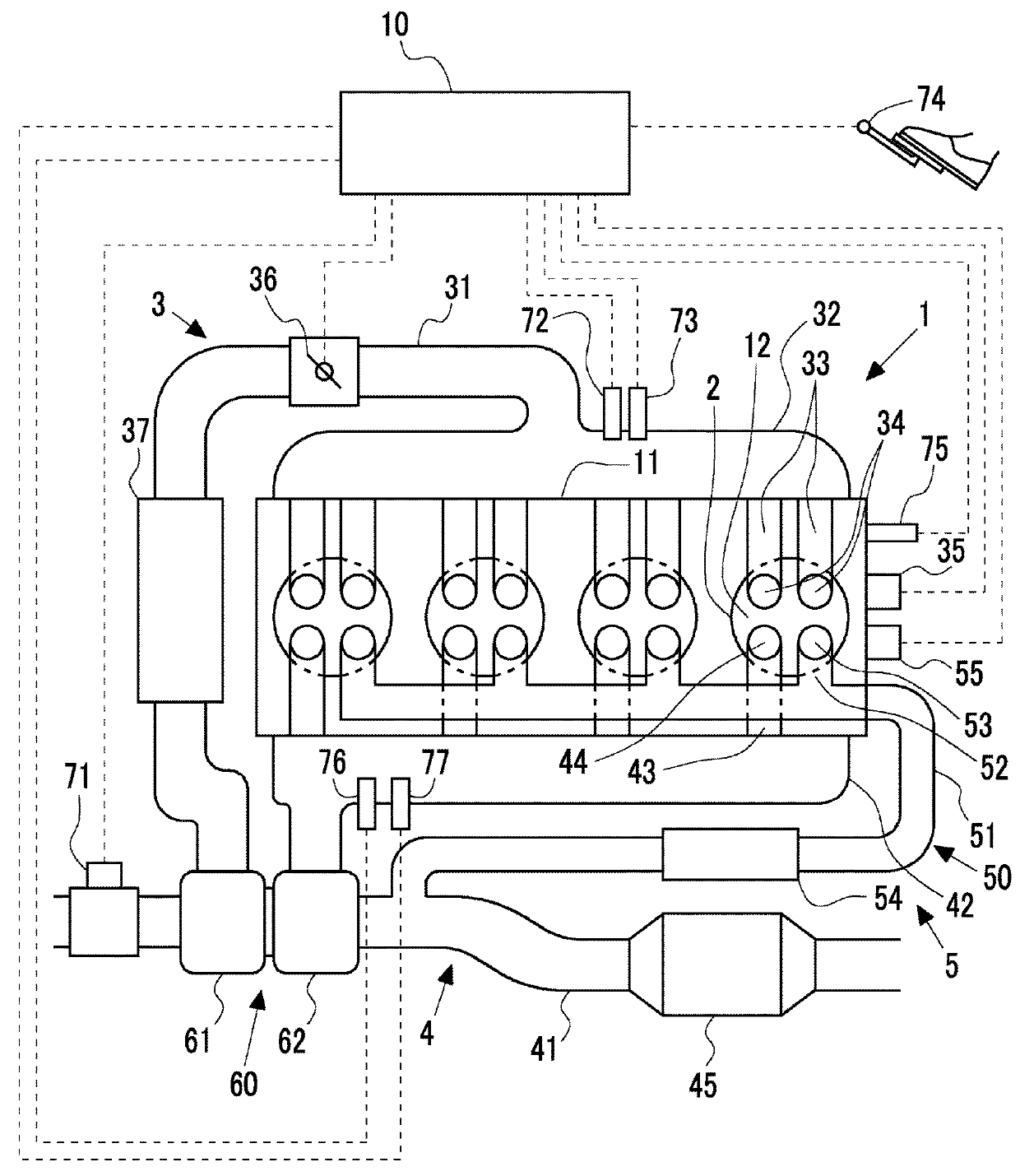

Exhaust gas control apparatus for internal combustion engine

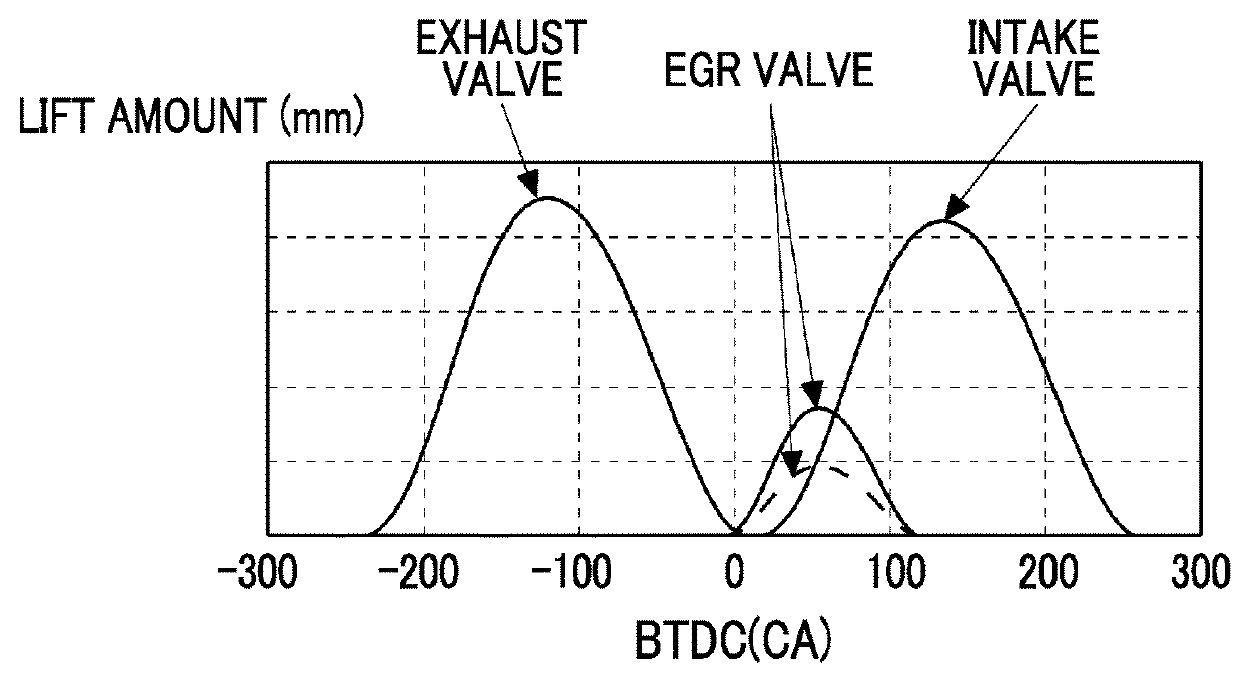

InactiveUS7444804B2Reduce the amount of exhaust gasIncrease temperatureElectrical controlInternal combustion piston enginesExternal combustion engineLow load

In an exhaust gas control apparatus for an internal combustion engine, in a case where an internal combustion engine is in a high load operating state while a PM trapping ability forcible recovery process for a particulate filter is being performed, EGR gas is caused to flow back from a portion downstream of the particulate filter in an exhaust passage to a portion upstream of a compressor housing in an intake passage, whereby the EGR gas is cooled by an intercooler. In a case where the internal combustion engine is in a low load operating state while the PM trapping ability forcible recovery process is being performed, the EGR gas is caused to flow back from the portion downstream of the particulate filter in the exhaust passage to a portion downstream of the intercooler in the intake passage, whereby the EGR gas is prevented from being unnecessarily cooled.

Owner:TOYOTA JIDOSHA KK

Exhaust gas control apparatus for internal combustion engine

InactiveUS20070186536A1Increase temperatureRaise the combustion temperatureElectrical controlInternal combustion piston enginesParticulatesLow load

In an exhaust gas control apparatus for an internal combustion engine, in a case where an internal combustion engine is in a high load operating state while a PM trapping ability forcible recovery process for a particulate filter is being performed, EGR gas is caused to flow back from a portion downstream of the particulate filter in an exhaust passage to a portion upstream of a compressor housing in an intake passage, whereby the EGR gas is cooled by an intercooler. In a case where the internal combustion engine is in a low load operating state while the PM trapping ability forcible recovery process is being performed, the EGR gas is caused to flow back from the portion downstream of the particulate filter in the exhaust passage to a portion downstream of the intercooler in the intake passage, whereby the EGR gas is prevented from being unnecessarily cooled.

Owner:TOYOTA JIDOSHA KK

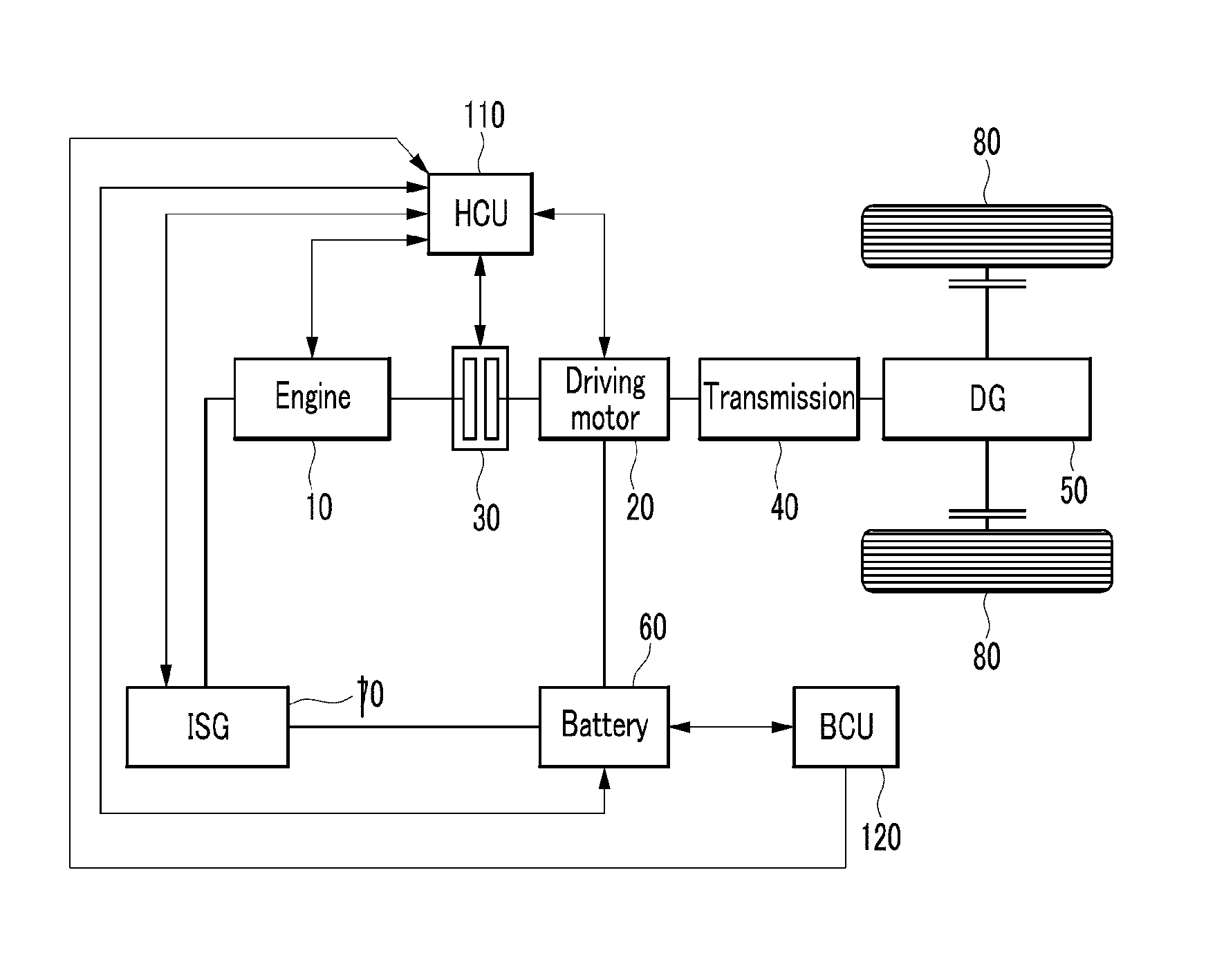

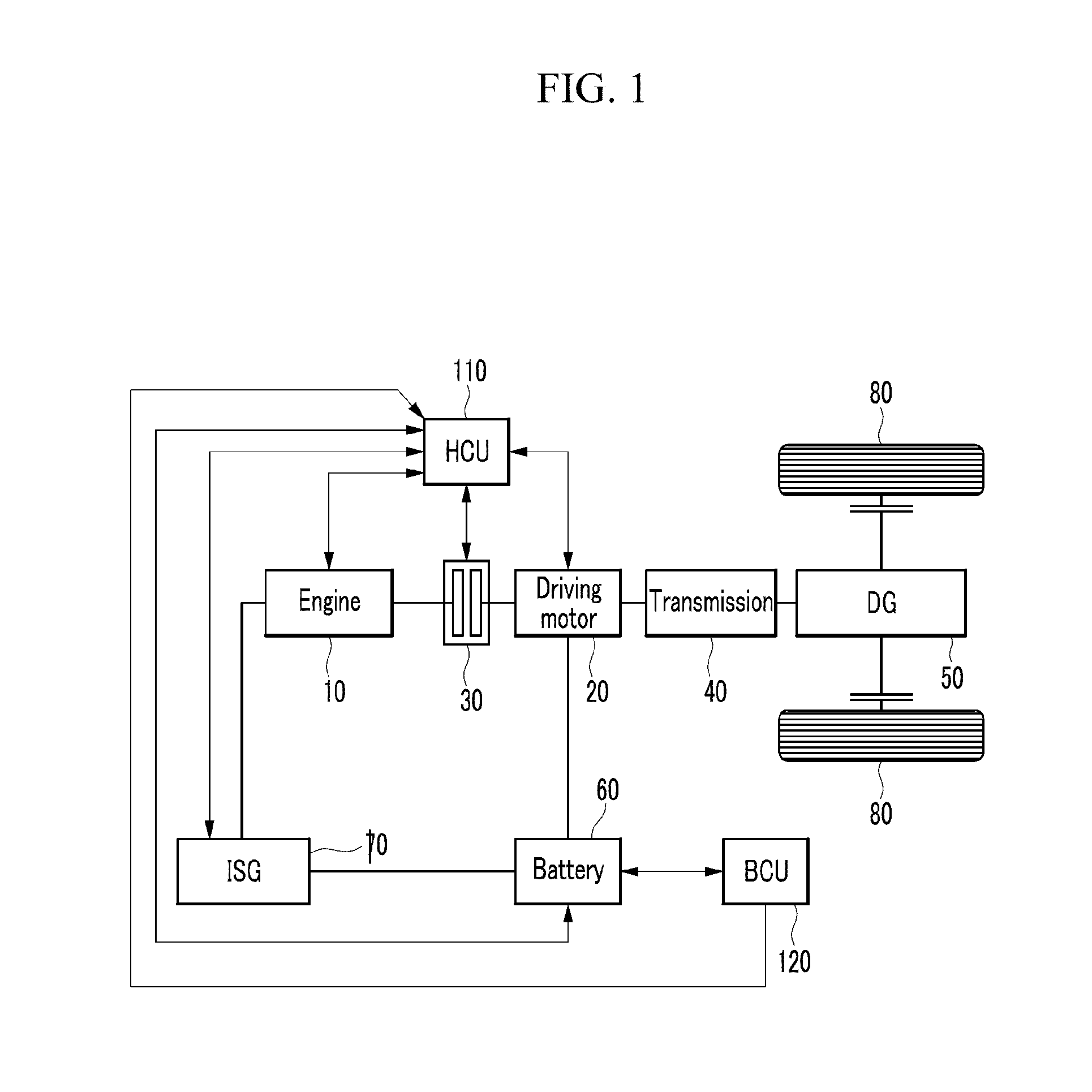

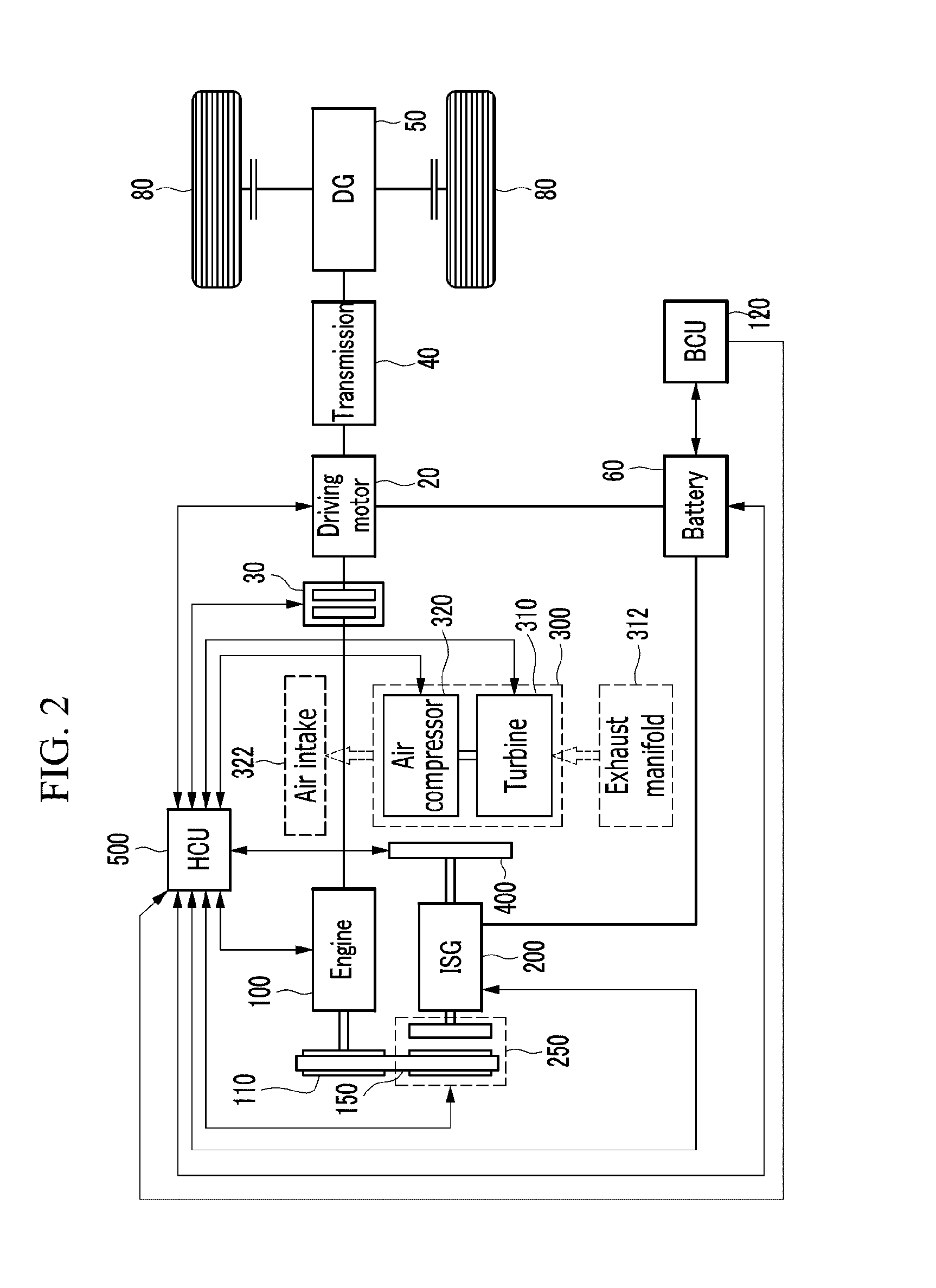

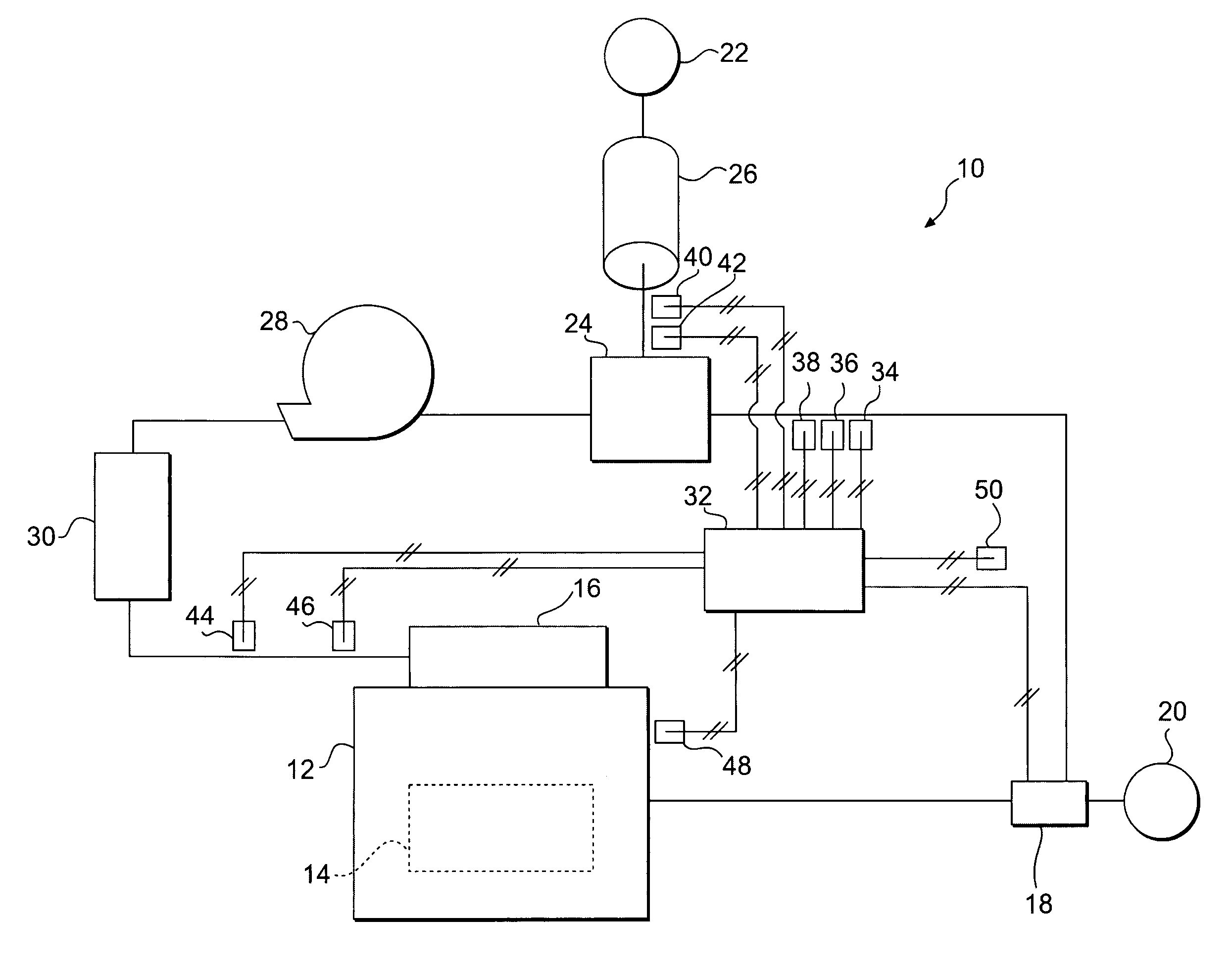

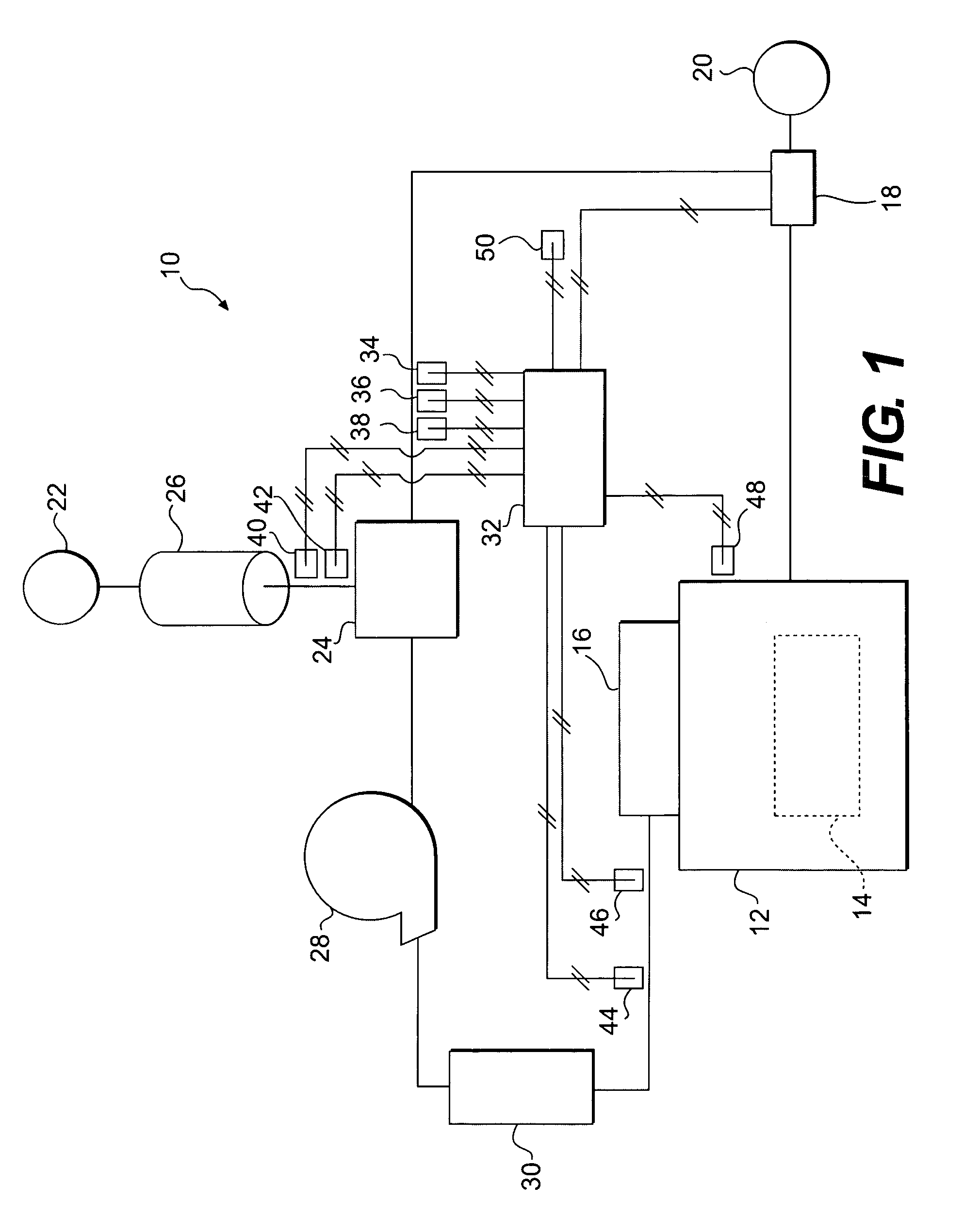

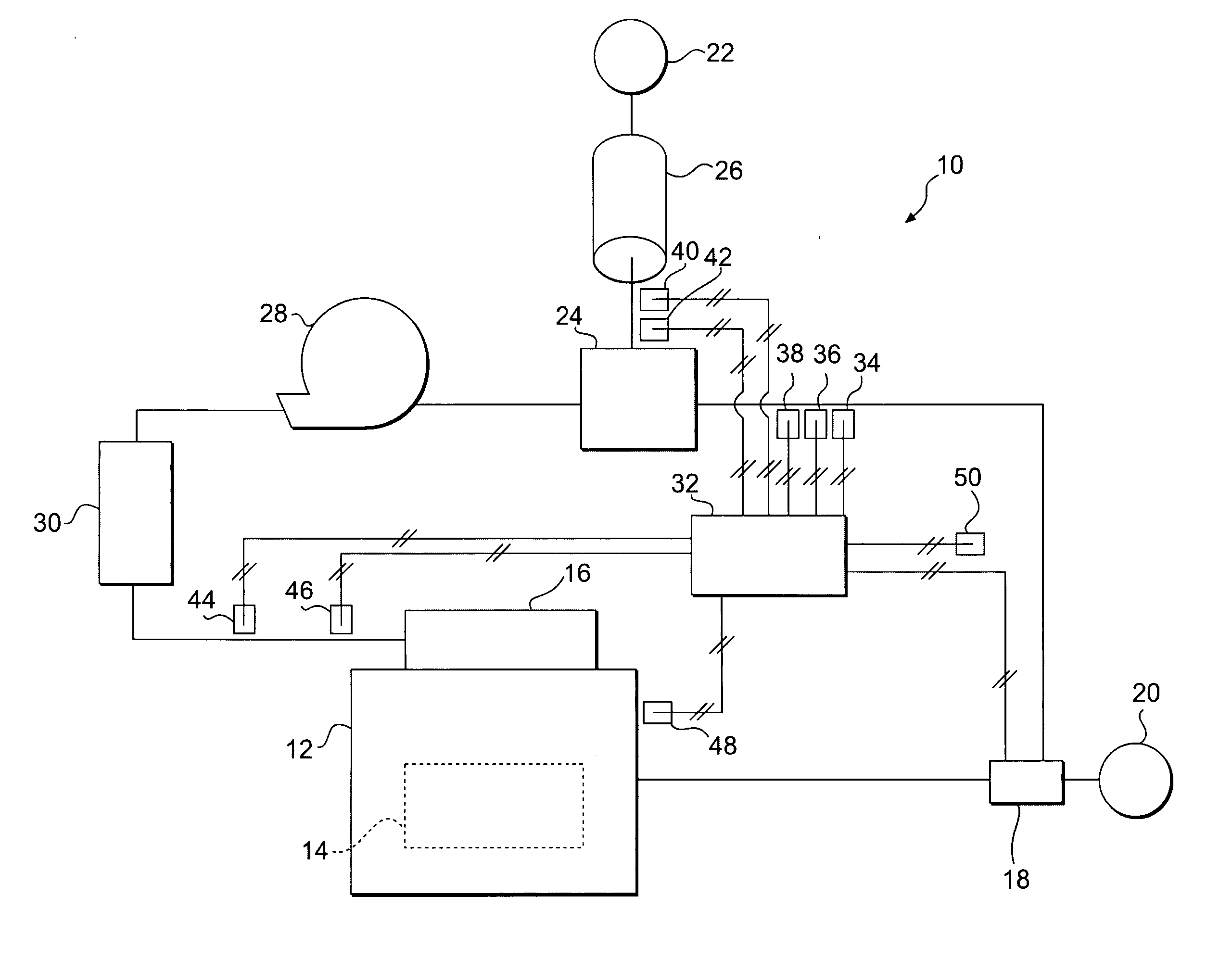

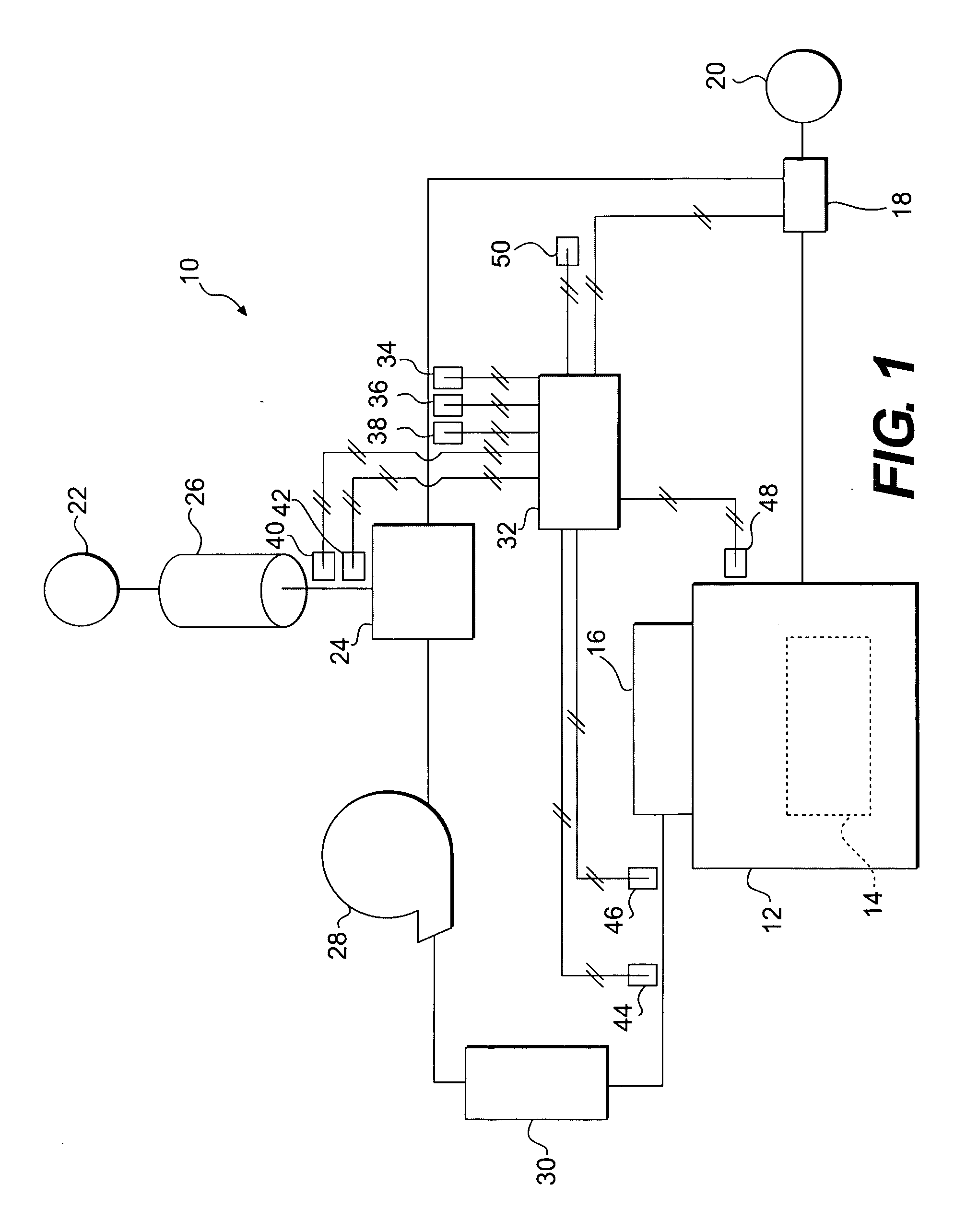

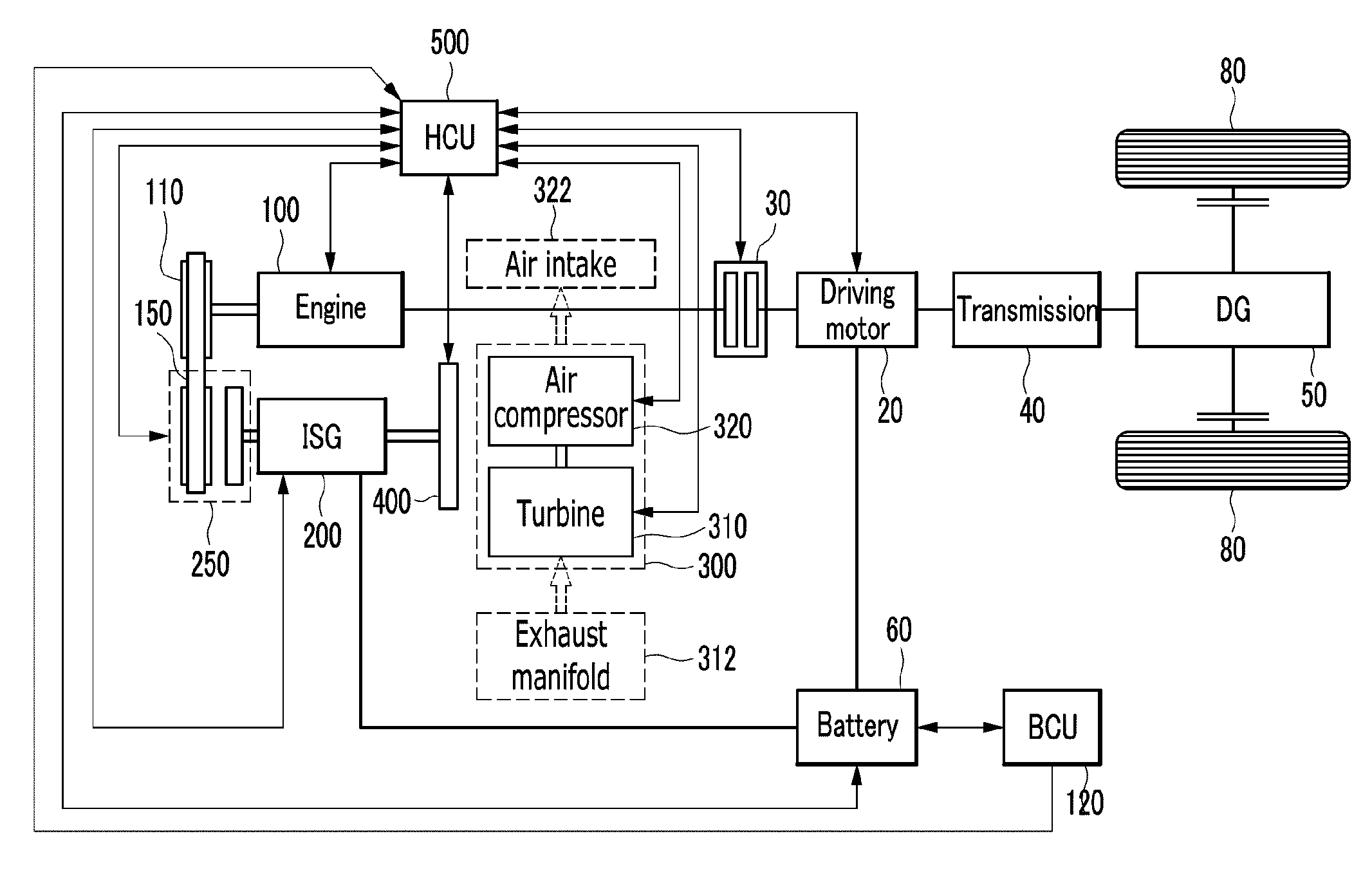

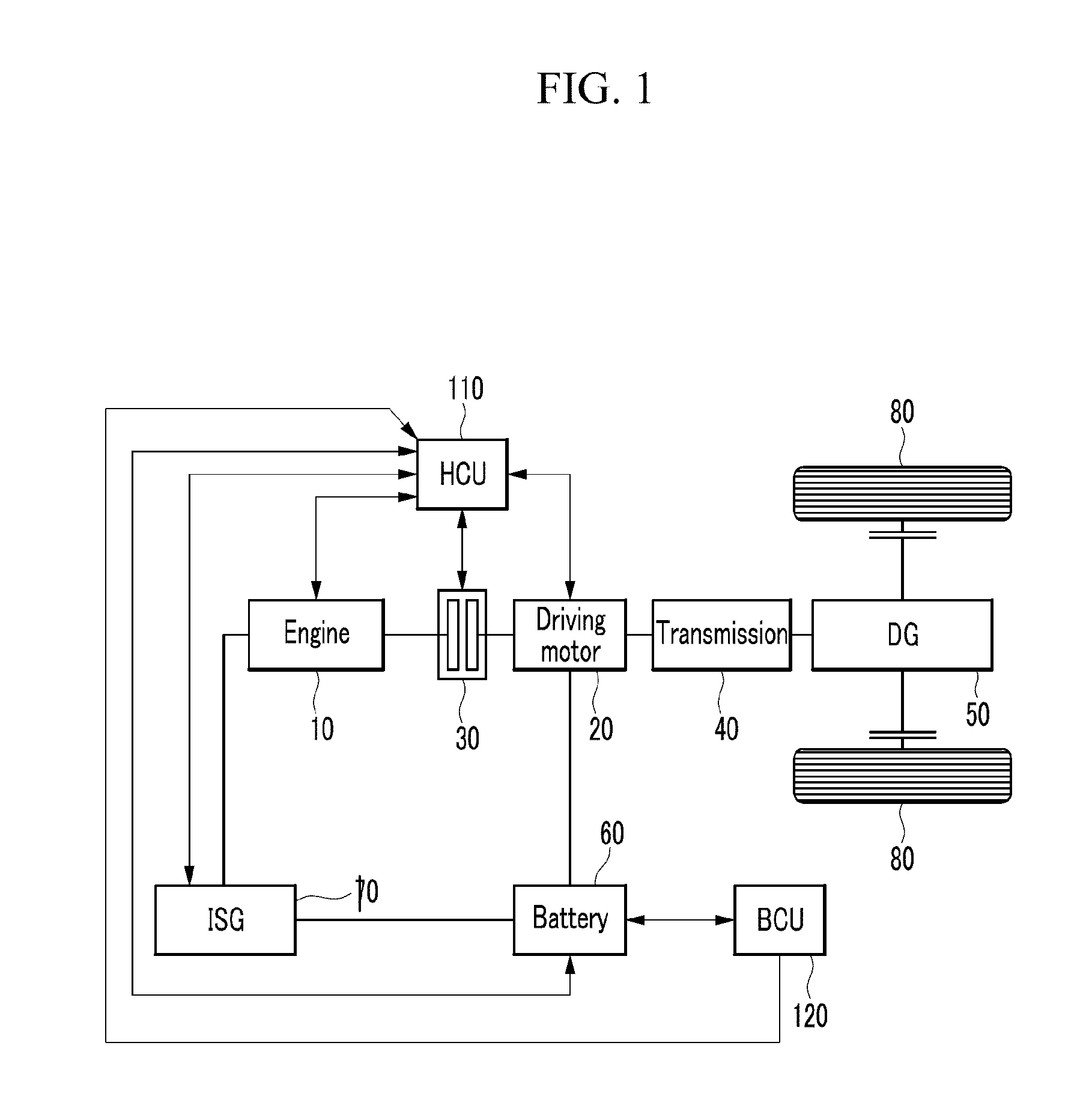

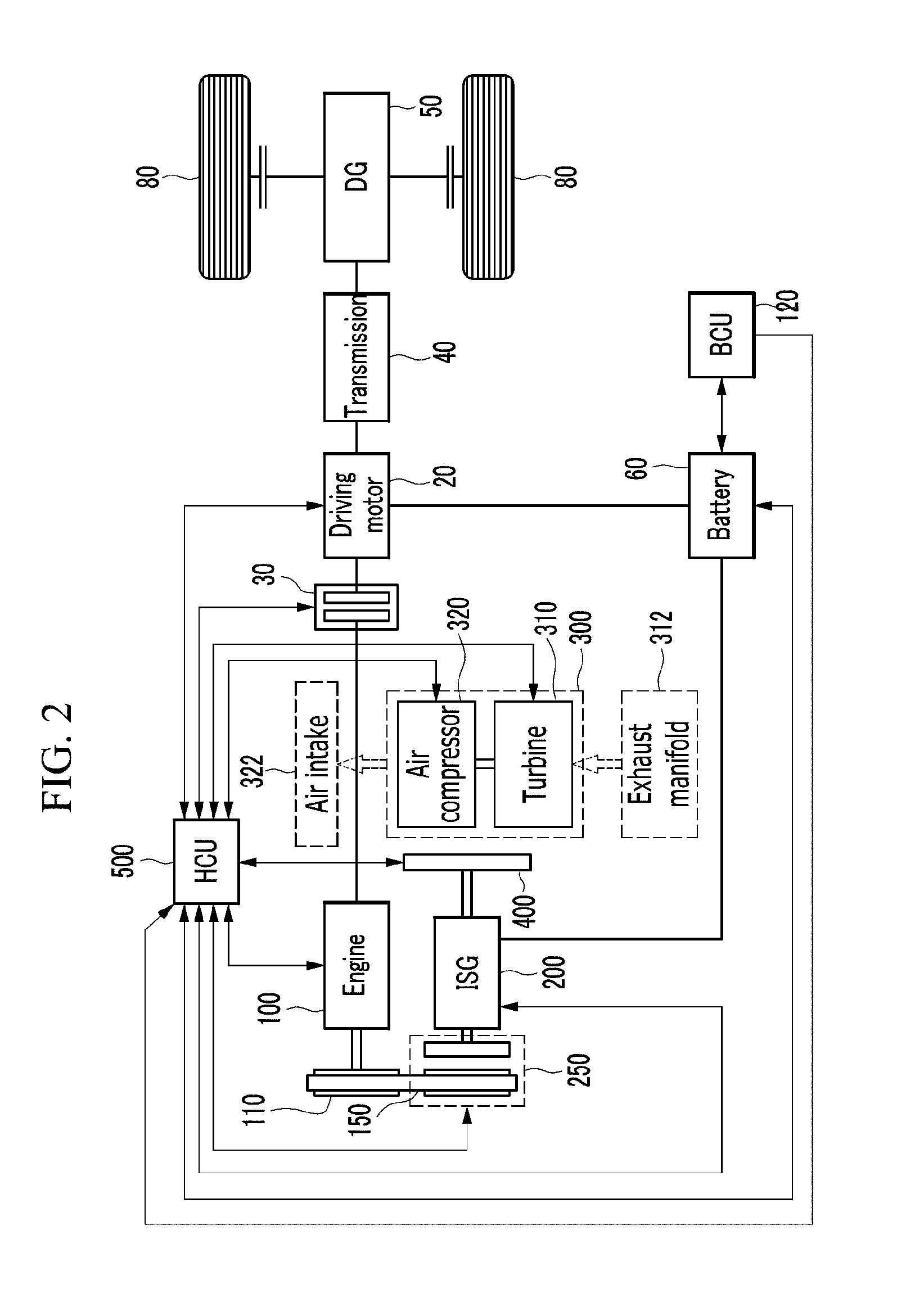

Hybrid electric vehicle and method of controlling driving of the same

ActiveUS20140100729A1Improve engine performanceReduce the amount of exhaust gasHybrid vehiclesBatteries circuit arrangementsTurbochargerReduction drive

Provided is a hybrid electric vehicle that includes a turbocharger and a method for controlling driving of the hybrid electric vehicle accordingly. In particular, an engine and a motor are configured to generate power respectively. An engine clutch may be positioned between the engine and the driving motor to engage and disengage the engine and the driving motor. An integrated starter and generator (ISG) starts the engine or generates power, and a turbocharger is provided therein. A decelerator adjusts revolution speeds and torque of the turbine and the air compressor of the turbocharger and the integrated starter and generator between the turbine and the air compressor of the turbocharger and the integrated starter and generator. Finally, a controller controls the integrated starter and generator, the engine clutch, the turbo charter, and the decelerator based on states of the engine, the driving motor, and the battery accordingly.

Owner:HYUNDAI MOTOR CO LTD +1

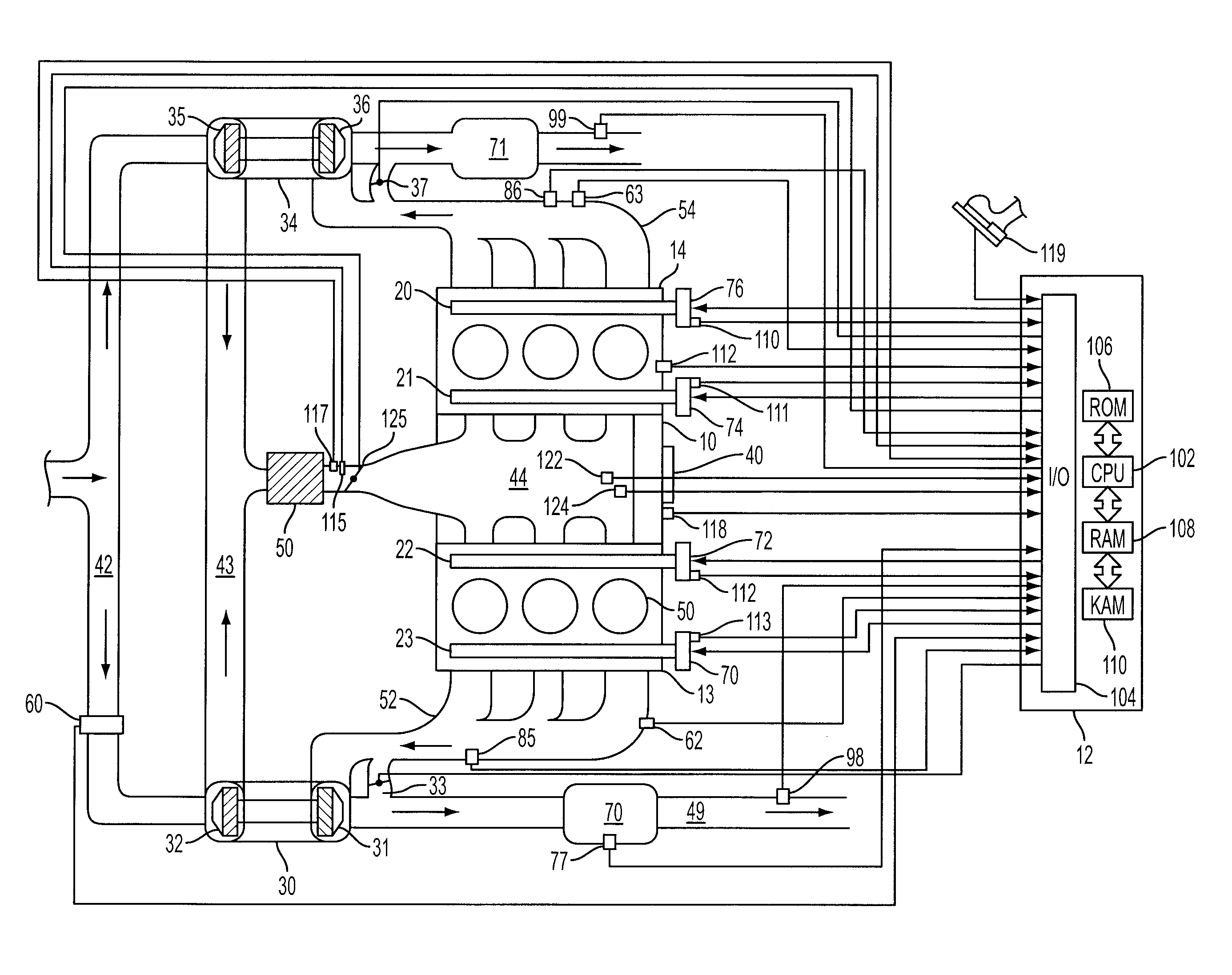

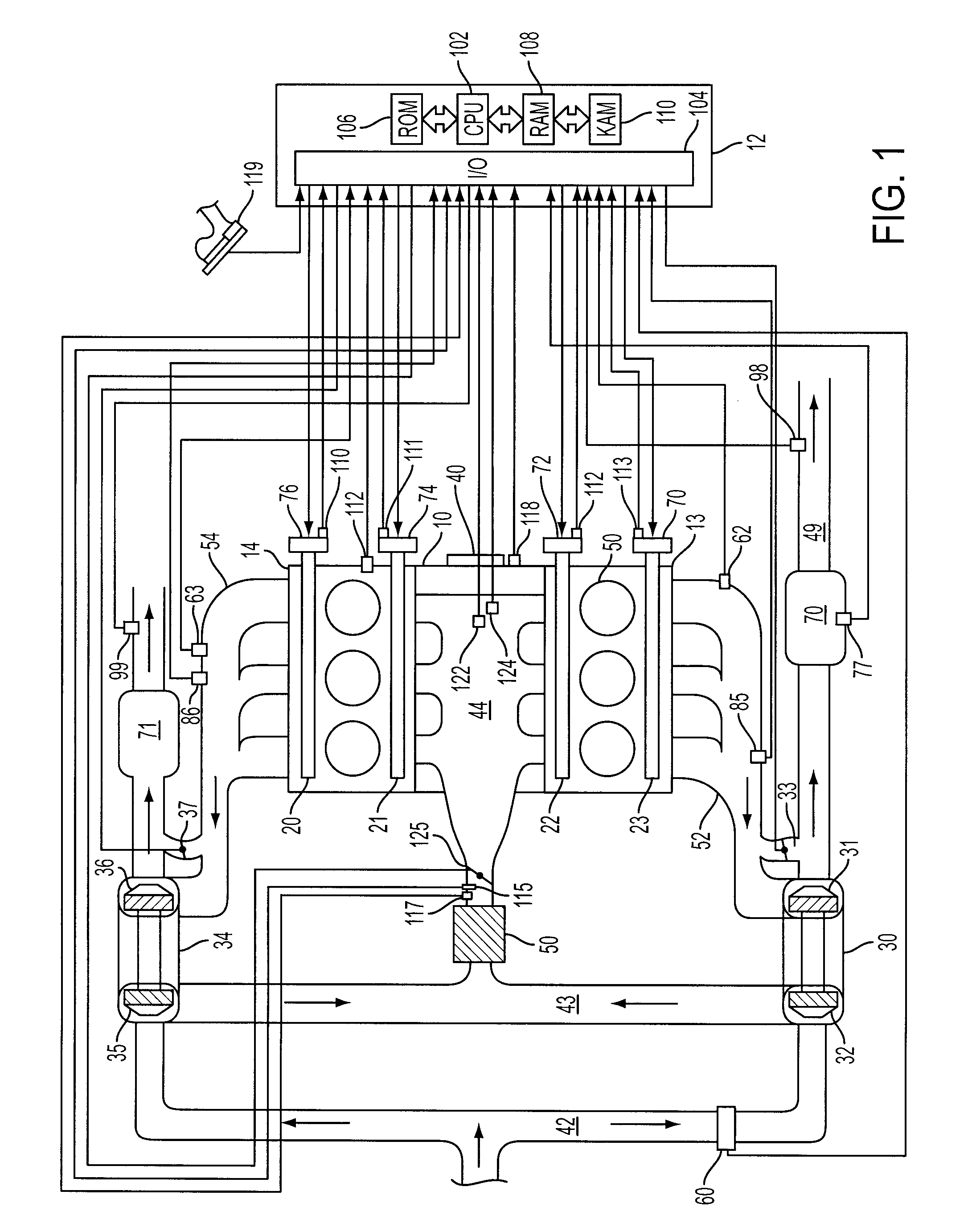

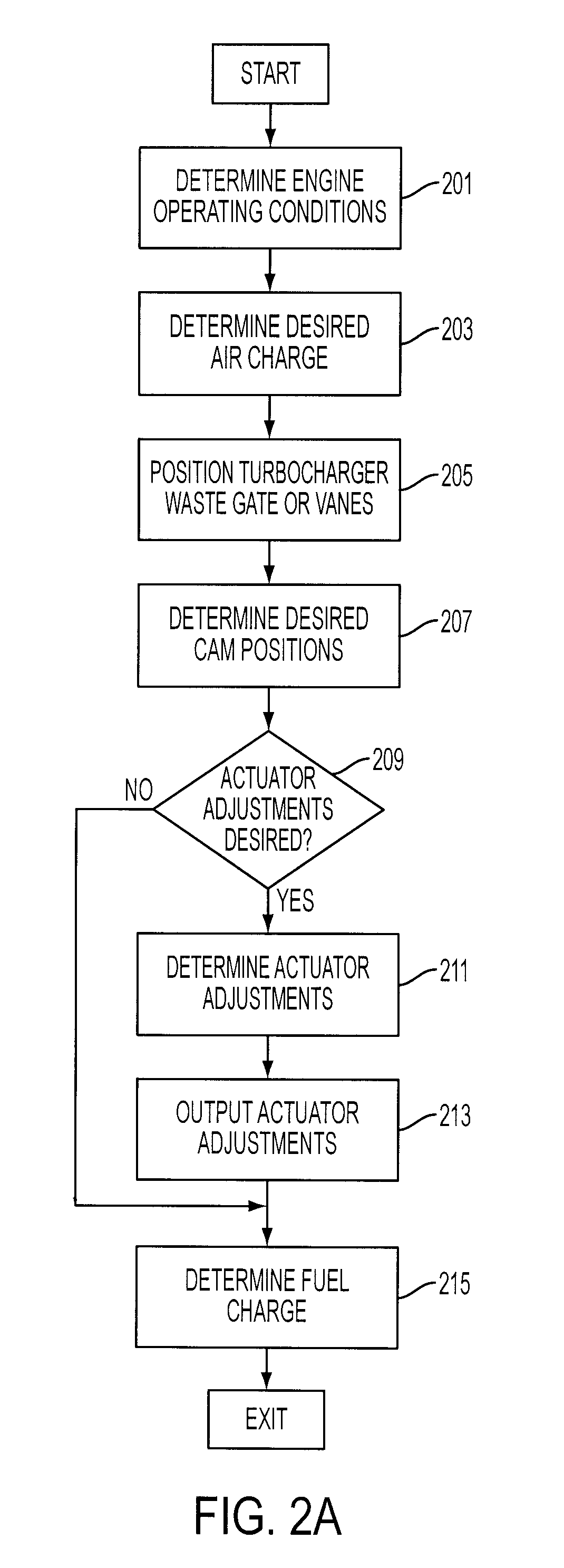

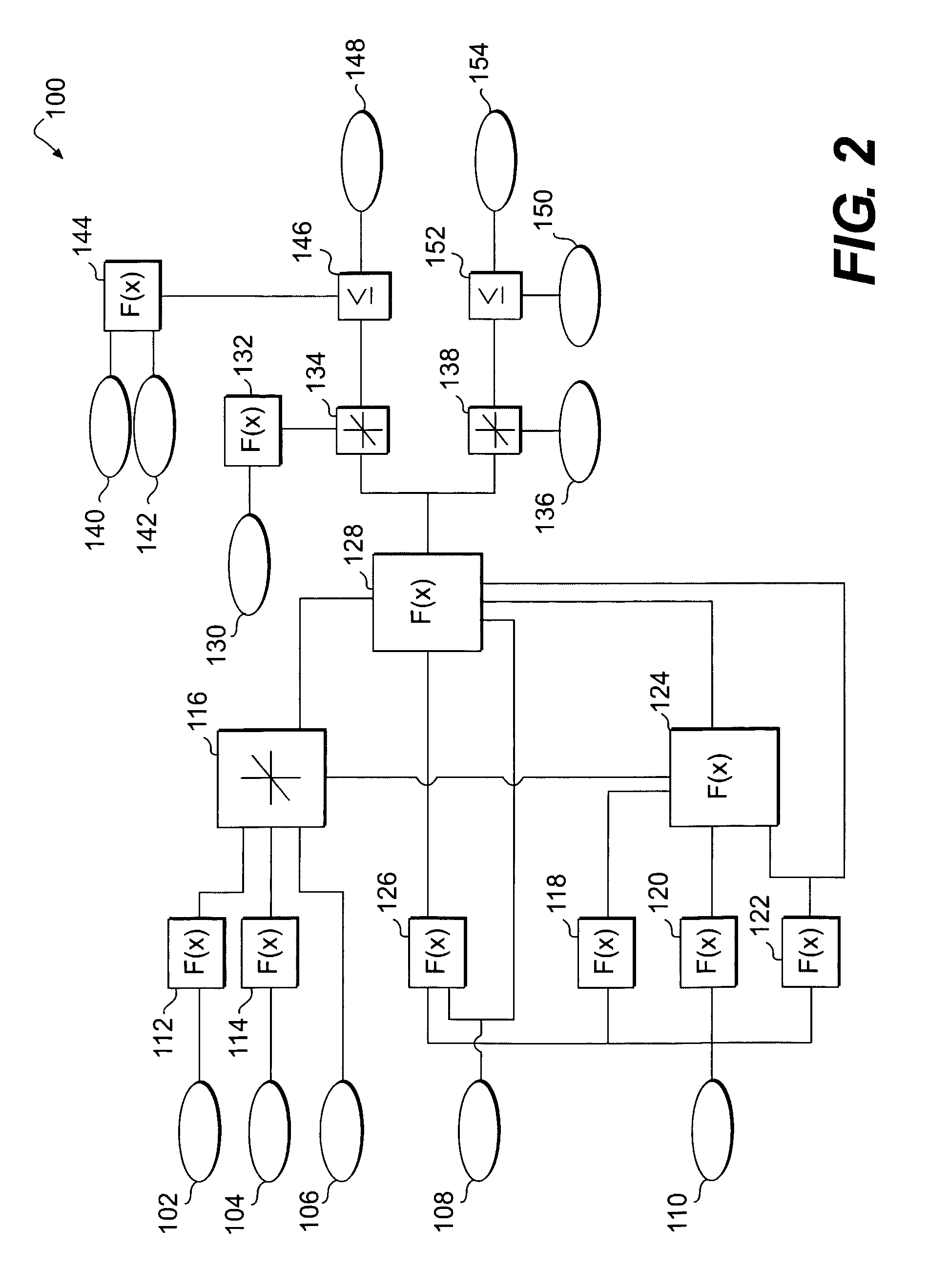

Controlling cylinder mixture and turbocharger operation

ActiveUS7987040B2Less variationReduce the differenceElectrical controlInternal combustion piston enginesTurbochargerExhaust gas

A method for controlling differences in exhaust gas residual amount for a two cylinder bank engine having at least one turbocharger is presented. In one example, the description includes a method for adjusting valve timing to reduce cylinder exhaust gas residual variation.

Owner:FORD GLOBAL TECH LLC

Method for preparing titanium-rich material from titanium-containing slag

InactiveCN101768673AReduce the amount of exhaust gasThe process method is simpleProcess efficiency improvementSlagBall mill

The invention relates to a method for preparing titanium-rich material from titanium-containing slag, comprising the following steps: 1. carrying out ball-milling on titanium-containing slag, then adding Na2CO3 or NaOH and mixing evenly; 2. carrying out calcination on the mixture obtained in step 1, then adding HC1 solution for leaching; 3. filtering the leached solution, concentrating and then recycling the filtrate; 4. calcining the filter residue to obtain titanium-rich material with grade of TiO2 being more than 90%.In the invention, Na2CO3, NaHCO3 or NaOH are added into the titanium-containing slag, then SiO2, Al203 in the slag are converted into NaSiO3 and NaAlO2 which are later leached by HC1 solution, so that SiO2, Al2O3 and MgO which are not converted are leached into the solution and grade of TiO2 in leached slag is improved by a big margin. The technique of the invention features simple method, convenient operation, environmental-friendliness, good economic benefits, high level of resource utilization and adaptability to industrialized production; in addition, the technique is especially suitable for recovering titanium in titanium-containing slag produced by the direct iron process.

Owner:CENT SOUTH UNIV

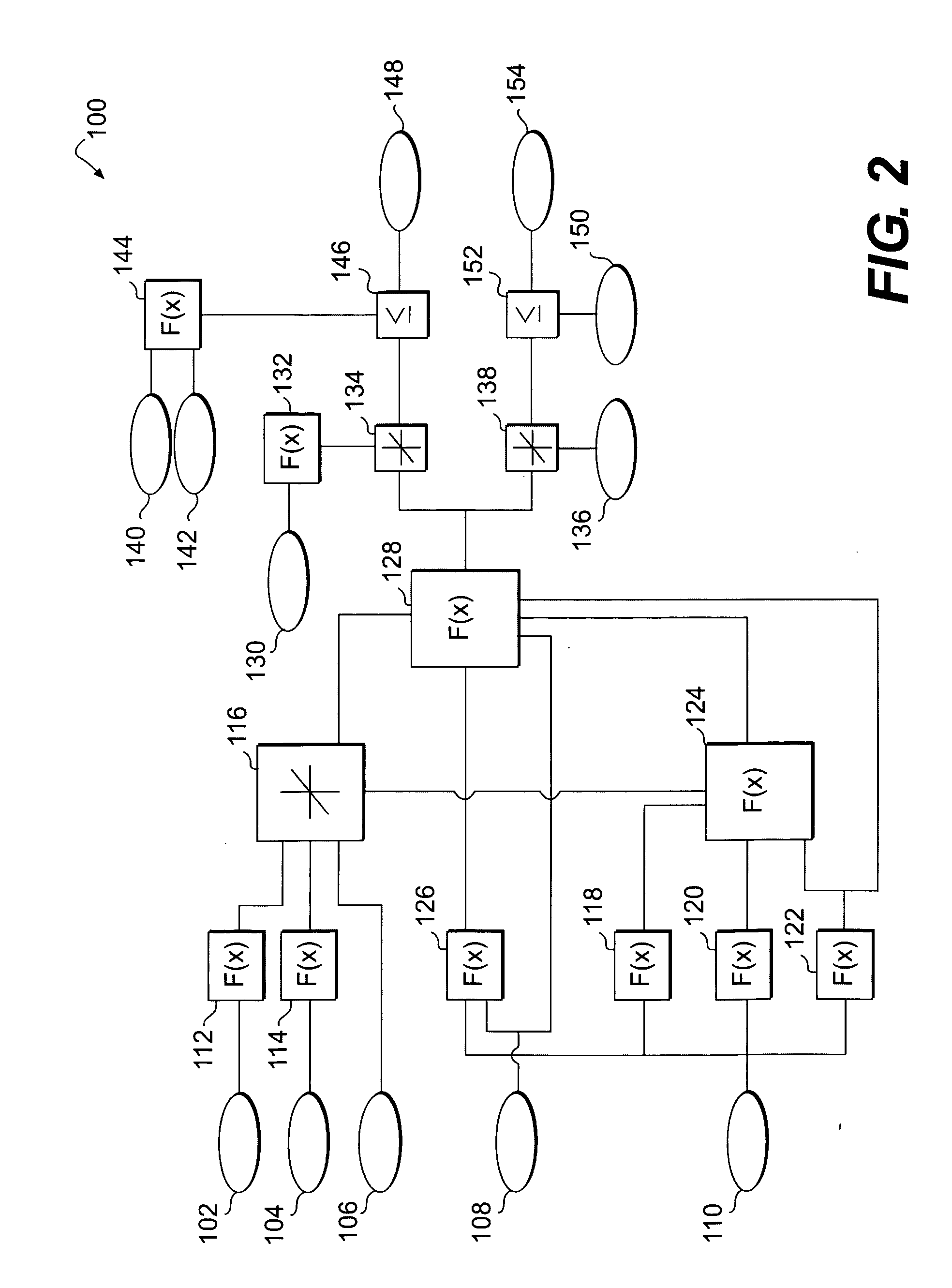

System for a virtual dew point sensor

InactiveUS7292929B2Reduce the amount of exhaust gasElectrical controlInternal combustion piston enginesCombustionHumidity ratio

A system for a virtual dew point sensor is disclosed including a method for operating the virtual dew point sensor. The method includes determining a first humidity ratio indicative of the humidity associated with an ambient air as a function of at least a relative humidity associated with the ambient air. The method also includes determining a second humidity ratio indicative of the humidity associated with an exhaust gas as a function of at least one engine parameter. The method also includes determining a third humidity ratio indicative of combustion air directed toward an inlet manifold of an engine as a function of the first and second humidity ratios. The method further includes determining at least one dew point indicative of the combustion air as a function of the third humidity ratio and a pressure indicative of the combustion air.

Owner:CATERPILLAR INC

System for a virtual dew point sensor

InactiveUS20070239344A1Reduce the amount of exhaust gasElectrical controlInternal combustion piston enginesCombustionHumidity ratio

A system for a virtual dew point sensor is disclosed including a method for operating the virtual dew point sensor. The method includes determining a first humidity ratio indicative of the humidity associated with an ambient air as a function of at least a relative humidity associated with the ambient air. The method also includes determining a second humidity ratio indicative of the humidity associated with an exhaust gas as a function of at least one engine parameter. The method also includes determining a third humidity ratio indicative of combustion air directed toward an inlet manifold of an engine as a function of the first and second humidity ratios. The method further includes determining at least one dew point indicative of the combustion air as a function of the third humidity ratio and a pressure indicative of the combustion air.

Owner:CATERPILLAR INC

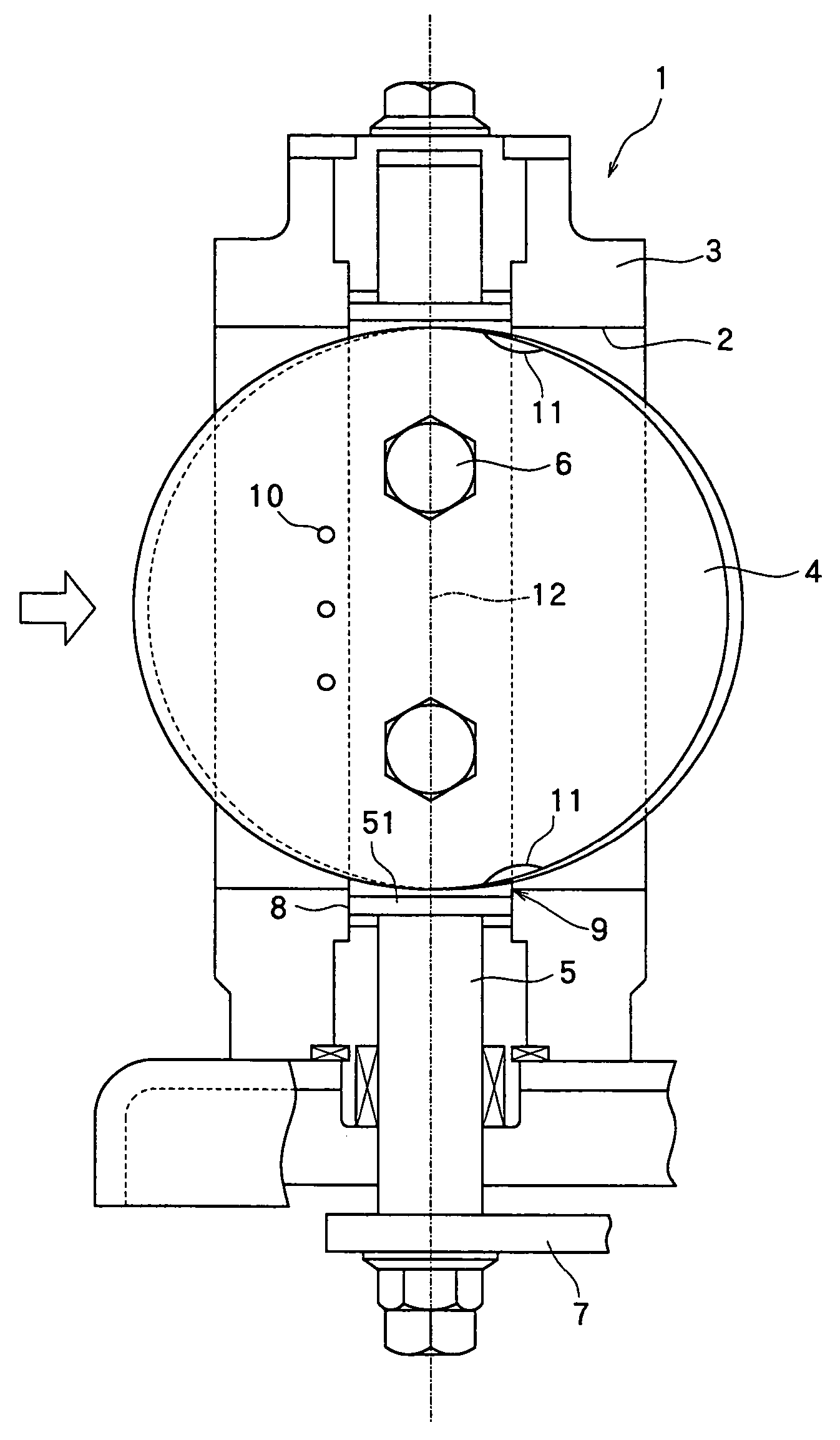

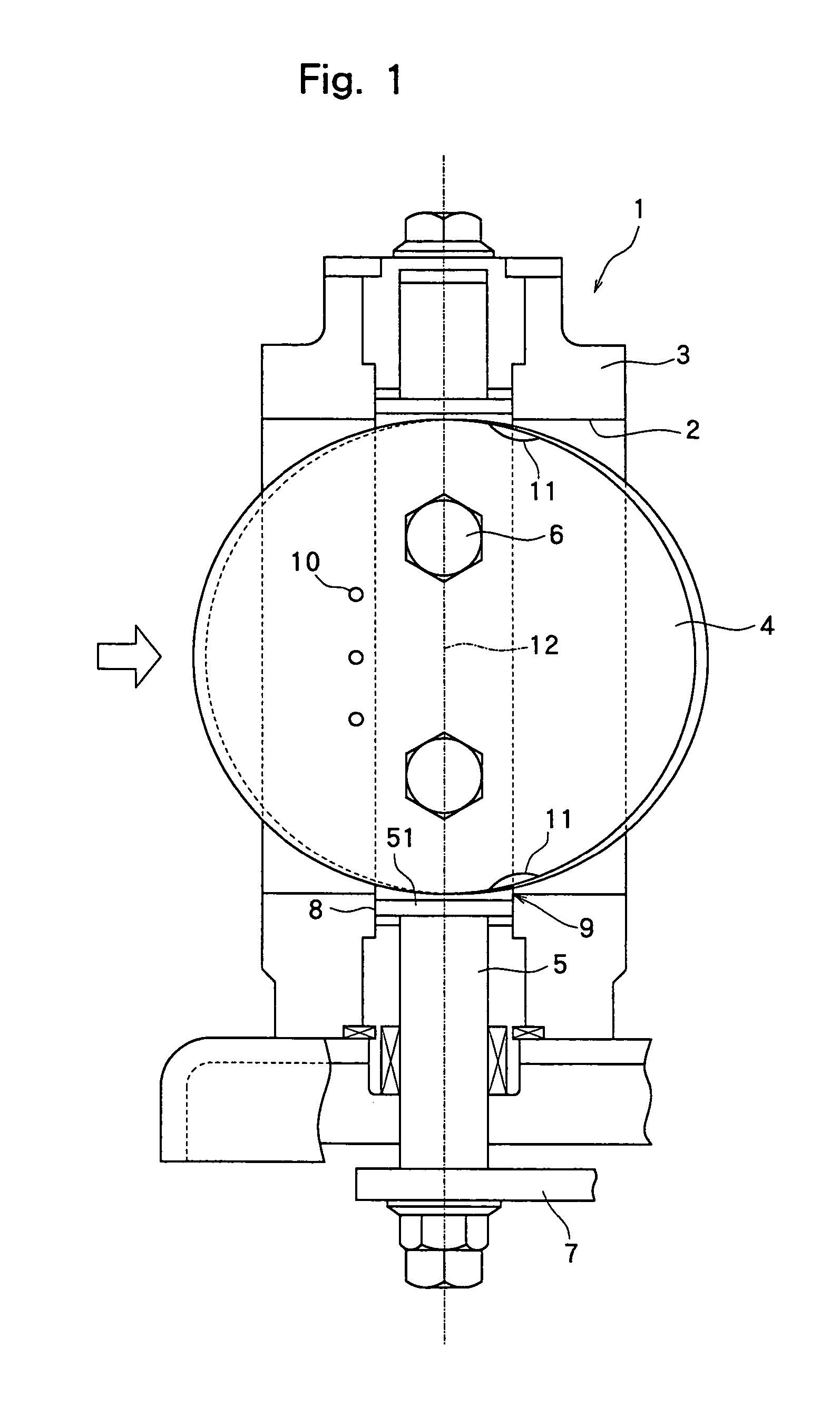

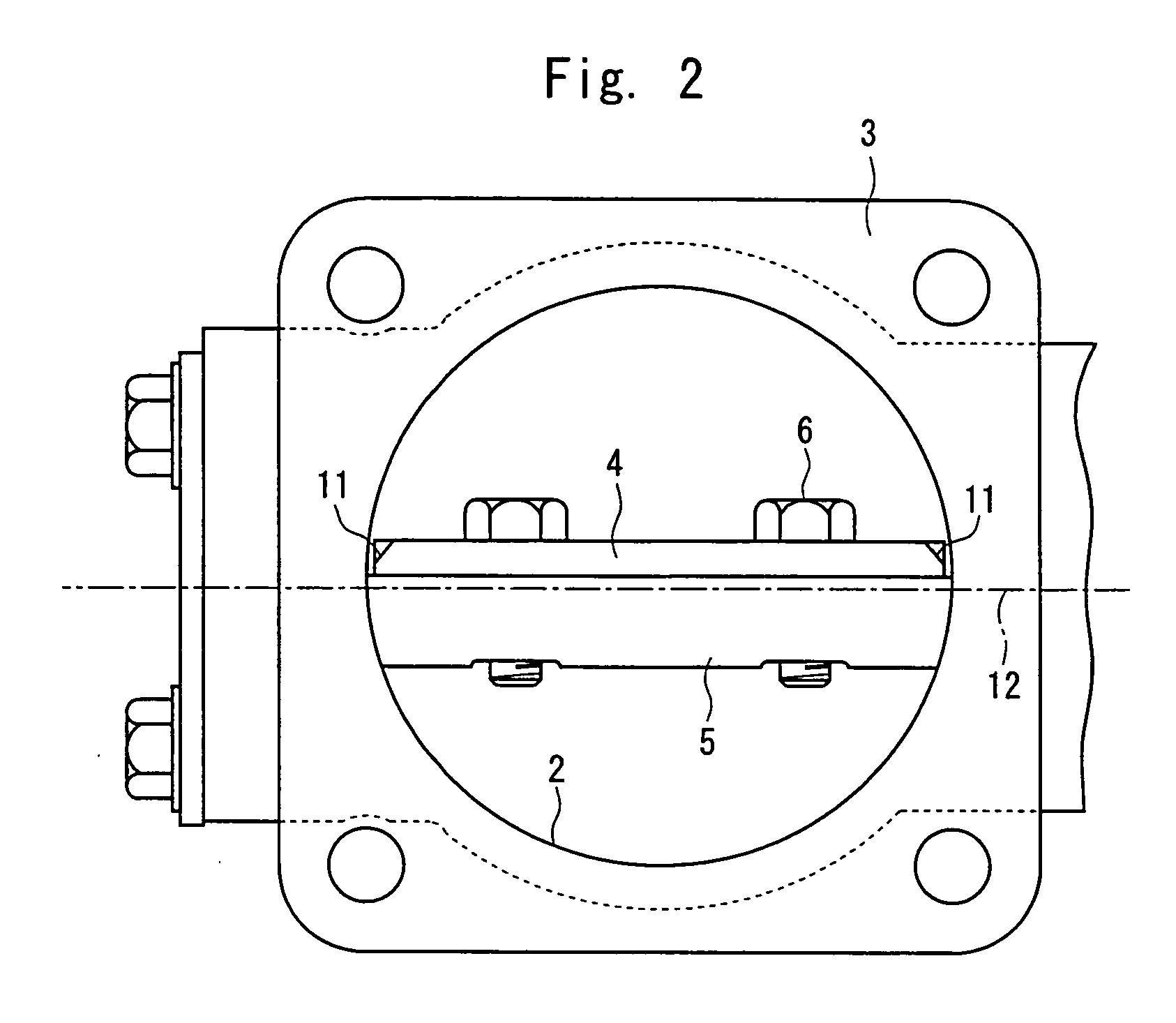

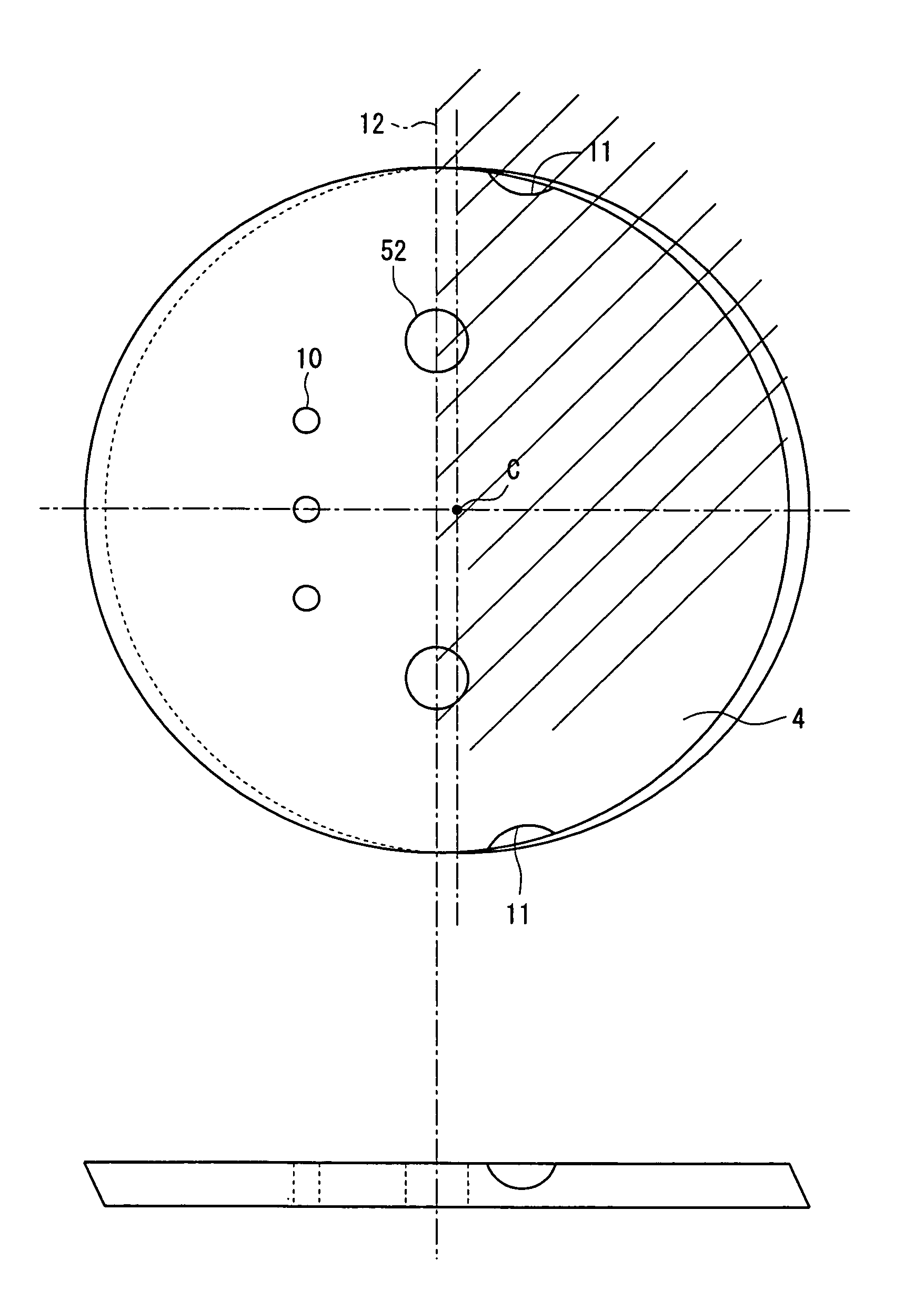

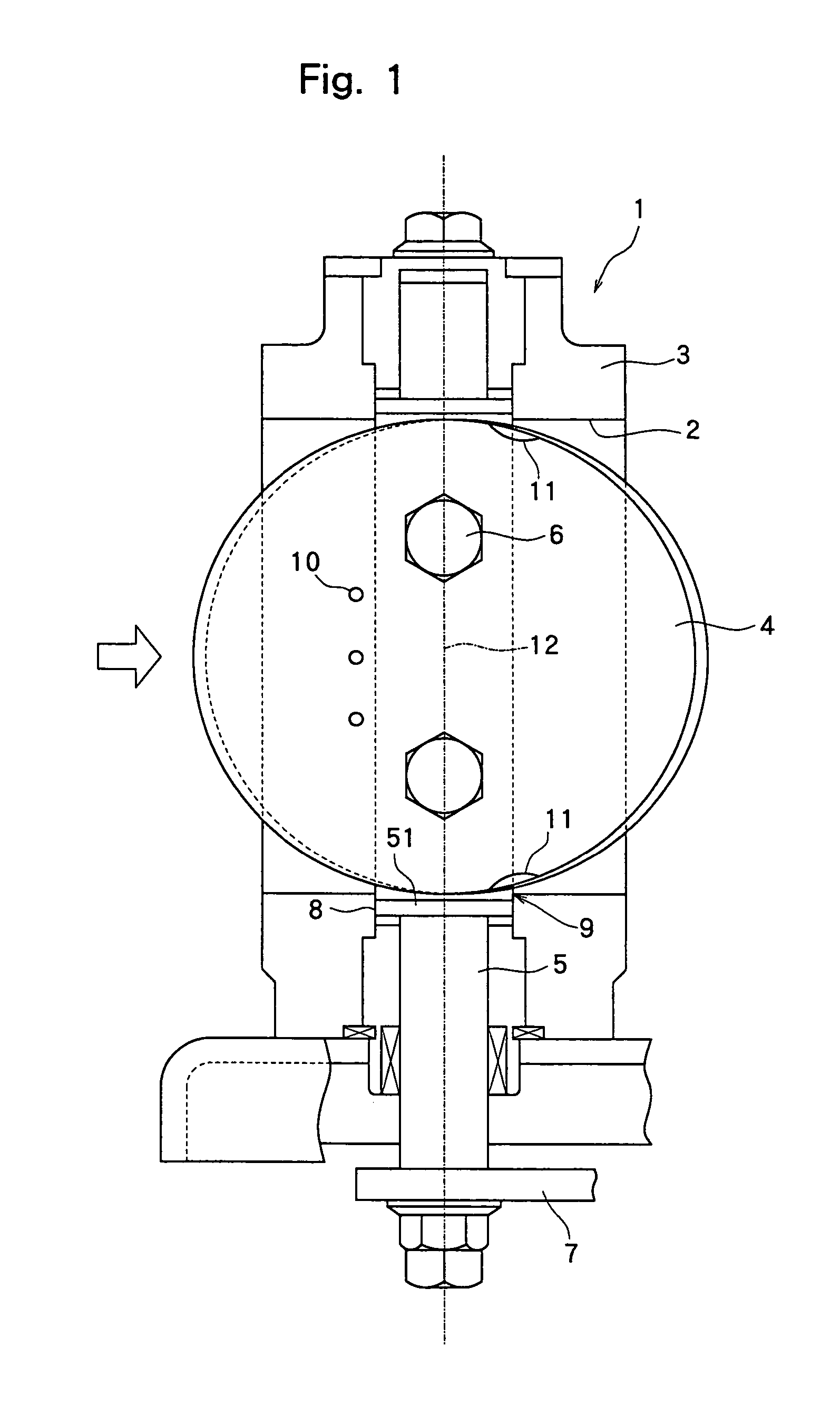

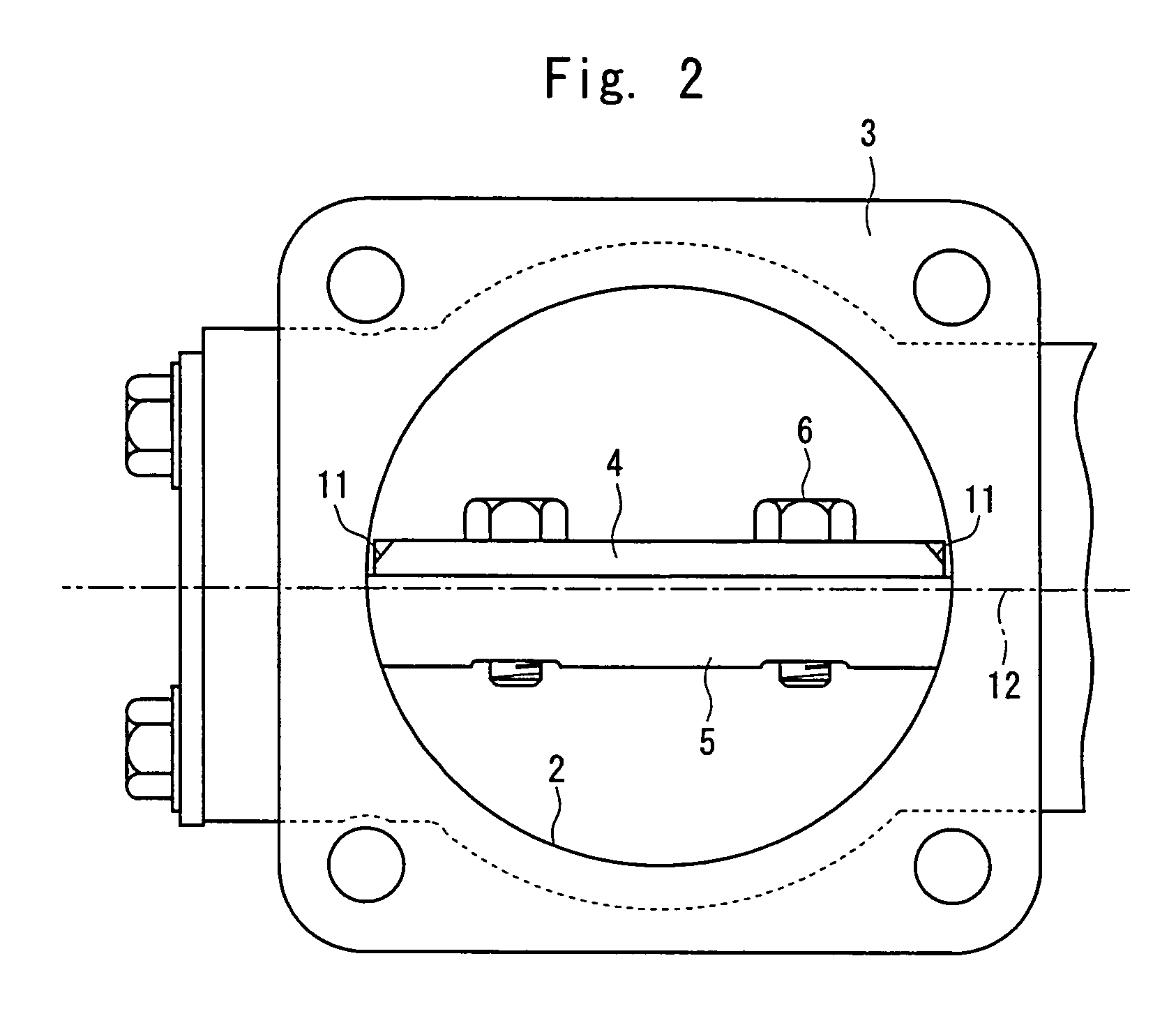

Exhaust gas throttle valve for engines

InactiveUS20060048505A1Good effectReduce the degree of openingInternal combustion piston enginesDispersed particle filtrationThermal expansionThrottle

An exhaust gas throttle valve disposed in the exhaust system of an engine, wherein the center axis of rotation of a valve shaft 5 is set at a position deviated from the center axis of the exhaust gas passage, and two recessed portions 11 are symmetrically formed in the circumferential portion of a valve body 4 by cutting the surface thereof. The positions where the recessed portions 11 are formed are on the side of the center axis of the exhaust gas passage beyond the center axis 12 of rotation, and at where the peripheral portion of the valve body 4 faces the edge portions 9 where insertion holes 8 for the valve shaft 5 are opened in the exhaust gas passage. At these positions, the distance is a minimum between the peripheral portion of the valve body 4 and the edge portions 9. The recessed portions 11 work to increase the gap relative to the edge portions 9 at that positions. It is therefore made possible to approximate the peripheral portion of the valve body 4 to the tubular wall of the exhaust gas passage 2 when the exhaust gas throttle valve is closed preventing the valve body 4 and the edge portions 9 from coming in contact together despite of the thermal expansion.

Owner:ISUZU MOTORS LTD

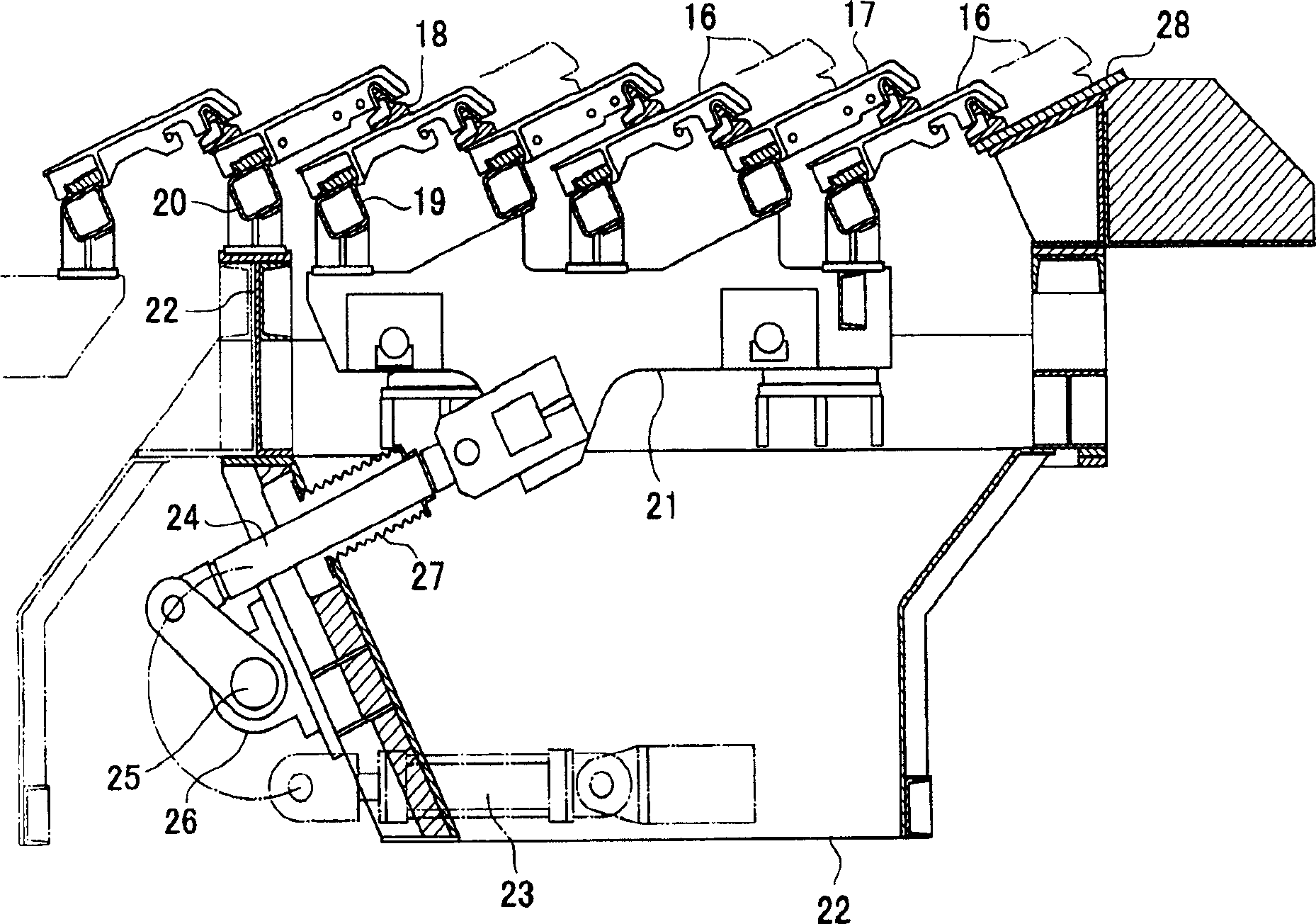

Mechanical stoker type destructor and refuse burning method

InactiveCN1521448AReduce the amount of exhaust gasEfficient combustionIncinerator apparatusExhaust fumesCombustible gas

A mechanical stoker type refuse burning furnace, wherein the dehydration mechanical stokers, combustion mechanical stokers and rear combustion mechanical stoker in horizontal position are configured into step-form, so as to lower the height of the main block of the furnace. Furthermore, the primary combustion-air, the secondary combustion-air supplied into the main block of the mechanical stoker refuse burning furnace and the quantity of burning gas extracted from the upper side downstream the main block are adjusted so as to decrease the waste gas displacement from the furnace main block. The invention can facilitate the complete combustion of non-combustible gas and abate the occurrence of NO[X].

Owner:TAKUMA

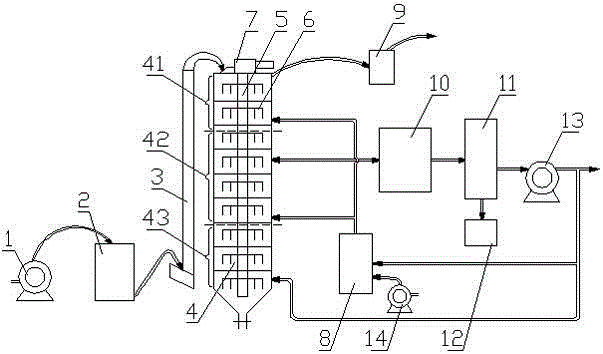

High molecular waste pyrolysis catalysis conical rotary reaction kettle

InactiveCN102875837AReduce deflectionReduce olefin contentPlastic recyclingChemical/physical/physico-chemical moving reactorsEngineeringSteel ball

The invention discloses a high molecular waste pyrolysis catalysis conical rotary reaction kettle which comprises a rotary reaction kettle cylinder and a rotary reaction kettle power large gear ring, wherein the cylinder is conical, the smaller end is positioned at the inlet end, and the bigger end is positioned at the outlet end; a heating furnace body is sheathed outside the cylinder, and a clearance is arranged between the heating furnace body and the cylinder; both ends of the cylinder are respectively provided with a spherical crown end socket, and the two spherical crown end sockets are respectively provided with an inlet tube and an outlet tube; both ends of the cylinder are respectively provided with an inlet support rolling ring and an outlet support rolling ring matched with corresponding supporting idlers; the front part of the cylinder is provided with a radial fence net; steel balls for ball milling are arranged in front of the fence net; a plurality of catalyst trays are arranged behind the fence net; and a catalyst is arranged on each catalyst tray. The invention has a reasonable structure, and has the functions of pyrolysis, catalytic modification, ball milling and gas-solid separation.

Owner:赵旭荣 +1

All-sealing circulating cooling machine for clinker production

InactiveCN101236052AIncrease temperatureSolve wasteFurnace coolingWaste heat treatmentAir blowerDistributor

Owner:QINHUANGDAO XINLV ENERGY SAVING TECH

Exhaust gas throttle valve for engines

InactiveUS7406823B2Reduce the amount of exhaust gasReduce noiseInternal combustion piston enginesDispersed particle filtrationThermal expansionEngineering

Owner:ISUZU MOTORS LTD

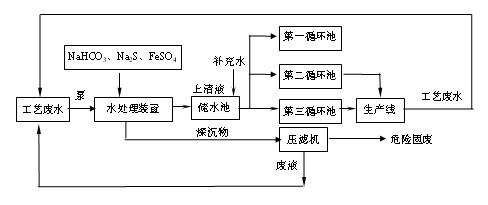

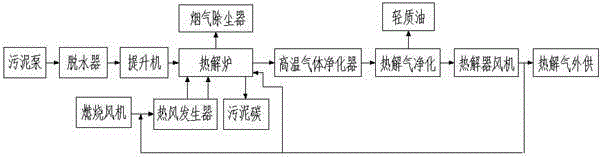

Method and device for comprehensively treating sludge generated by sewage treatment plant and kitchen waste oil

InactiveCN102701559AShorten drying timeDry fastSludge treatment by de-watering/drying/thickeningBurn unitsSludge

The invention relates to a method for comprehensively treating sludge generated by a sewage treatment plant and kitchen waste oil, which comprises the following steps of: (1) sludge formation; (2) frying dehydration; (3) burning and heat exchange; (4) tail gas processing; and (5) slag collection. The invention also relates to a comprehensive treatment device which consists of a sludge forming unit, a frying and drying unit, a burning unit, a heat exchange unit, a solid slag processing unit and a waste gas processing unit. A discharge port of the sludge forming unit is connected to a feed inlet of the frying and drying unit; a discharge port of the frying and drying unit is connected with a feed inlet of the burning unit; a slag outlet of the burning unit is connected to a slag inlet of the solid slag processing unit; a high temperature flue gas exhaust port of the burning unit is connected with the heat exchange unit; the heat exchange unit is connected to a heating chamber of the frying and drying unit; and the frying and drying unit and a waste gas exhaust port of the heat exchange unit are connected to the waste gas processing unit. According to the method and device provided by the invention, the resource recovery, the reduction and the harmless treatment of two types of wastes in towns, i.e. the kitchen waste oil and the sludge generated by the sewage treatment plant, can be implemented.

Owner:TIANJIN UNIV OF SCI & TECH

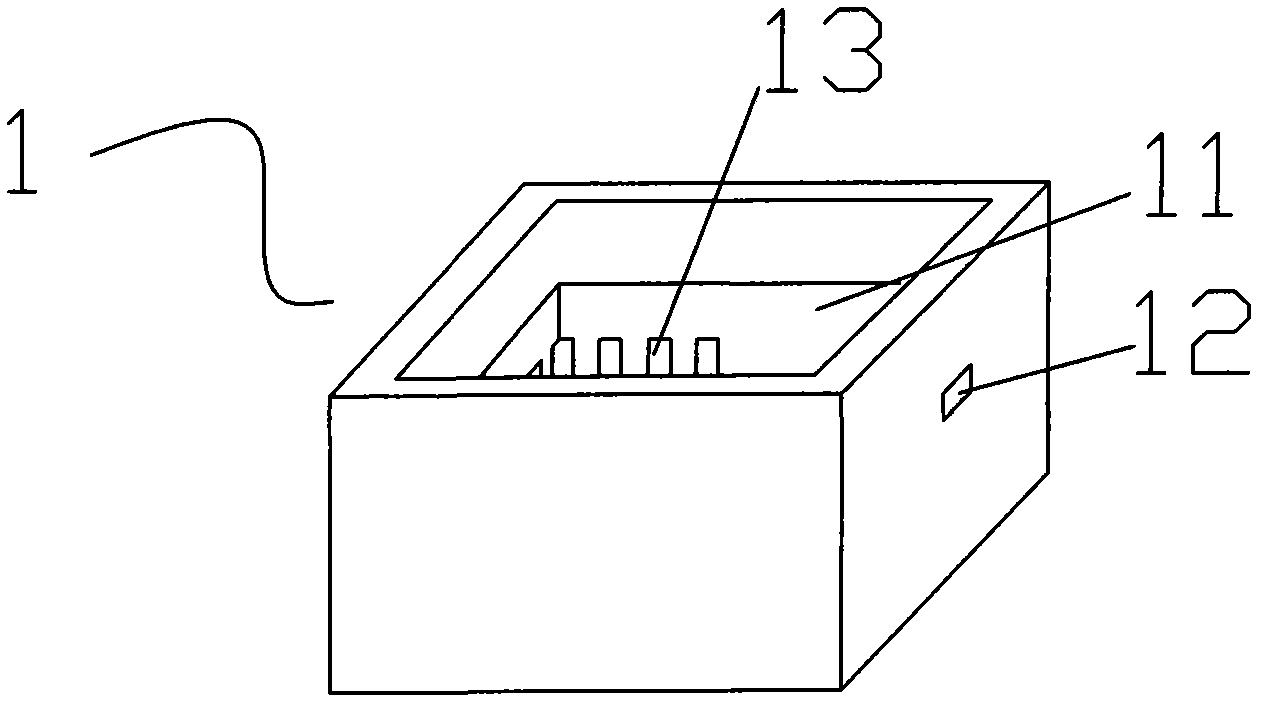

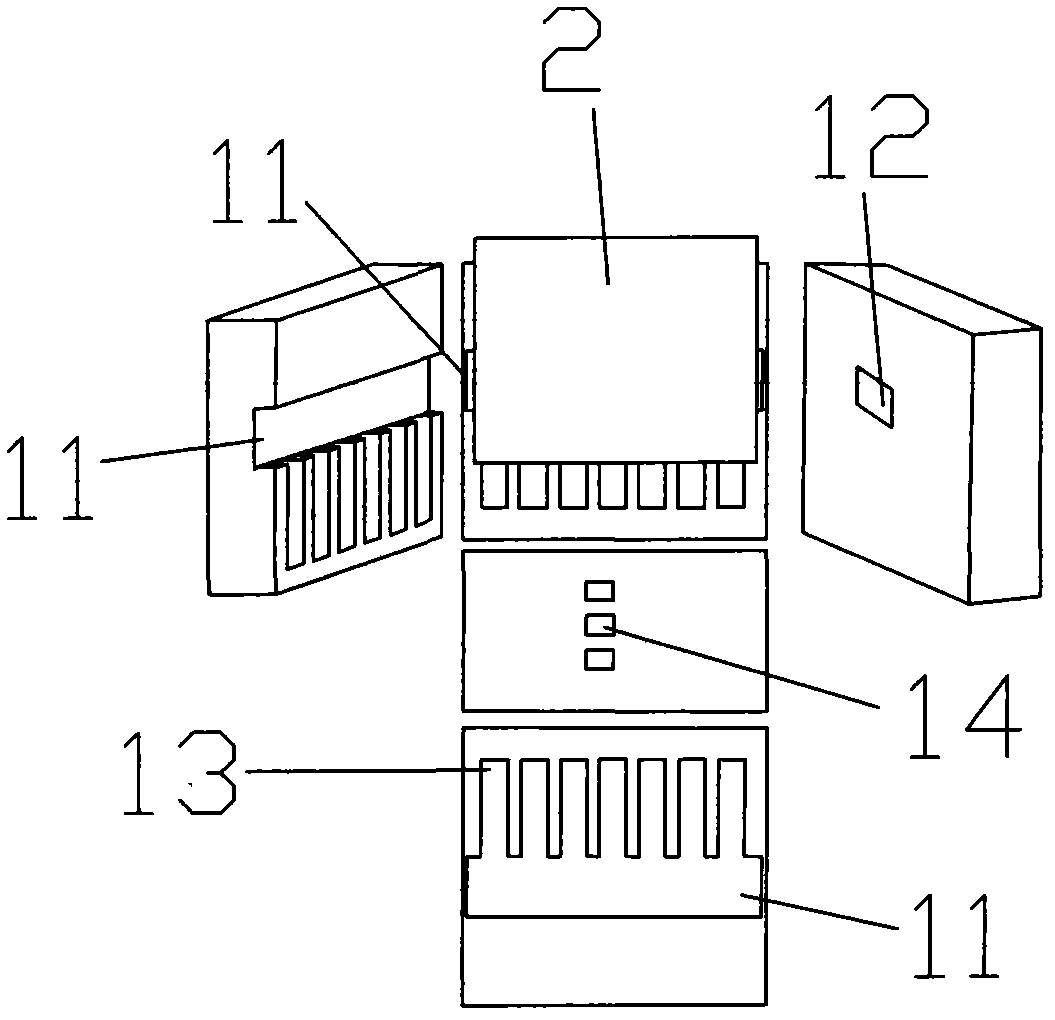

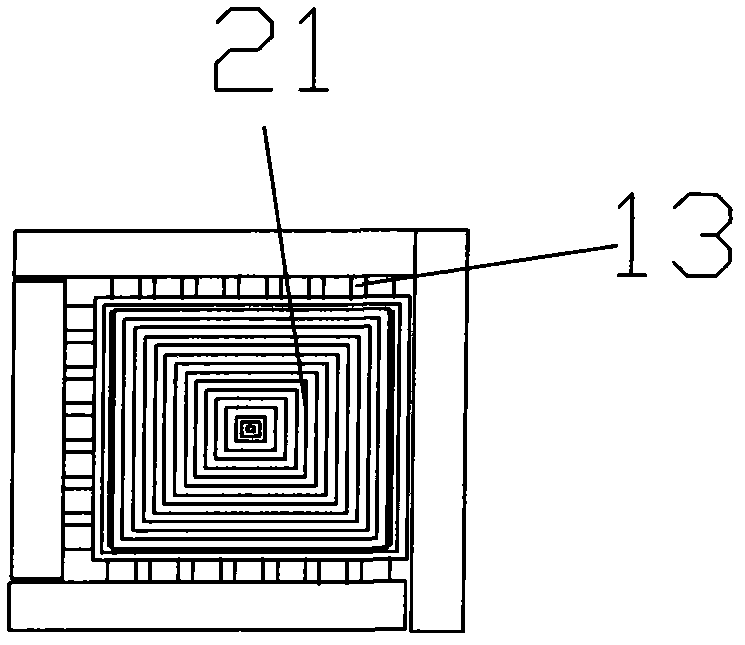

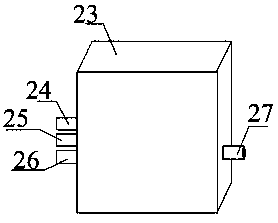

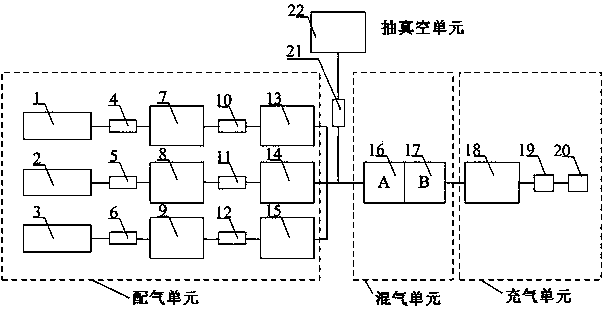

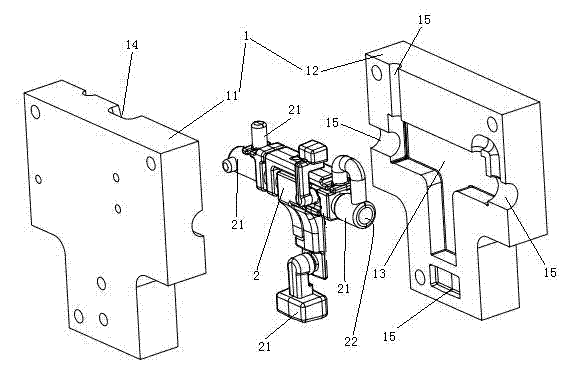

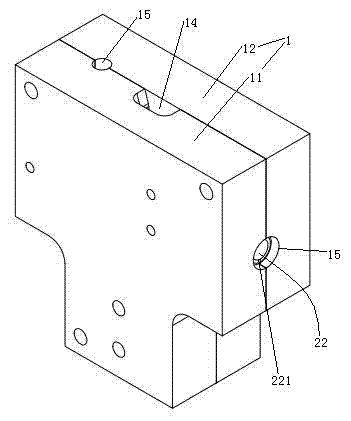

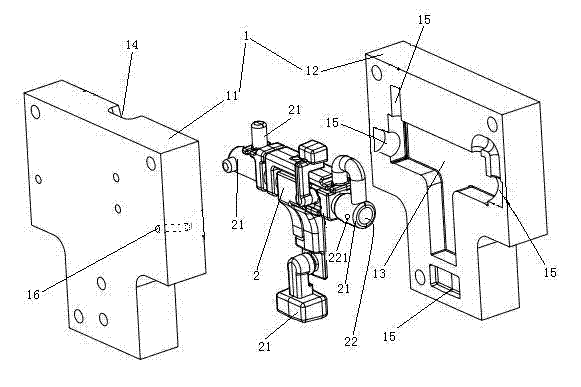

Mixing insulating gas dynamic gas distribution device

PendingCN108514846ARealize mixed gas distributionSimple structureTransportation and packagingMixer accessoriesProcess engineeringUltimate tensile strength

The invention discloses a mixing insulating gas dynamic gas distribution device. The device comprises a protective shell body, a gas distribution unit, a gas mixing unit and an air inflation unit, wherein the gas distribution unit, the gas mixing unit and the air inflation unit are arranged in the protective shell body; the gas distribution unit comprises at least one first gas distribution branchused for distributing the first class of gas and at least one second gas distribution branch used for distributing the second class of gas, and the dielectric strength and liquefying temperature of the first class of gas are higher than those of the second class of gas; the air mixing unit is connected with the gas distribution unit and used for mixing the first class of gas and the second classof gas; and the air inflation unit is connected with the gas mixing unit and used for delivering the mixed gas to electrical equipment or experimental equipment after pressurization. The mixing insulating gas dynamic gas distribution device has the advantages that the structure is simple, the mixing efficiency is high, a mixing chamber is merged with a buffer standing chamber, the exhausted air quantity during the air inflation can be reduced, and the mixed gas distribution of three ways of gas or above can be achieved.

Owner:SHENZHEN POWER SUPPLY BUREAU

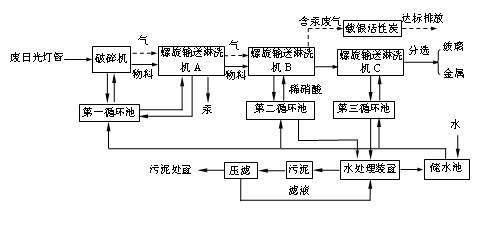

Innocent treatment method for mercury-containing waste tube

ActiveCN102110560ALow costAvoid Volatile PollutionGlass recyclingElectronic waste recyclingActivated carbonSulfur

The invention relates to the improvement on an innocent treatment method for a mercury-containing waste tube. The method is characterized by comprising the following steps of: crushing the waste tube in water; performing at least three processes of washing, namely water washing, dilute nitric acid washing and water washing on the crushed tube in turn; separating and removing mercury on tube fragments; separating tube head metal from glass fragments through magnetic separation, wherein the whole treatment process is linked up in an airtight way and is performed in a sealed state; performing air draft guidance on gas emitted from the water surface under negative pressure; performing water and dilute nitric acid drip washing; and filtering and separating the mercury by using silver-carried activated carbon or sulfur-carried activated carbon, and discharging. The method has a simple and practical process, is energy saving, is suitable for automatic operation, and has the advantages of lowcost, simple and practicable process and the like; and by the method, the mercury is not released to the outside, and automatic treatment can be realized.

Owner:YIXING SUNAN SOLID WASTE TREATMENT

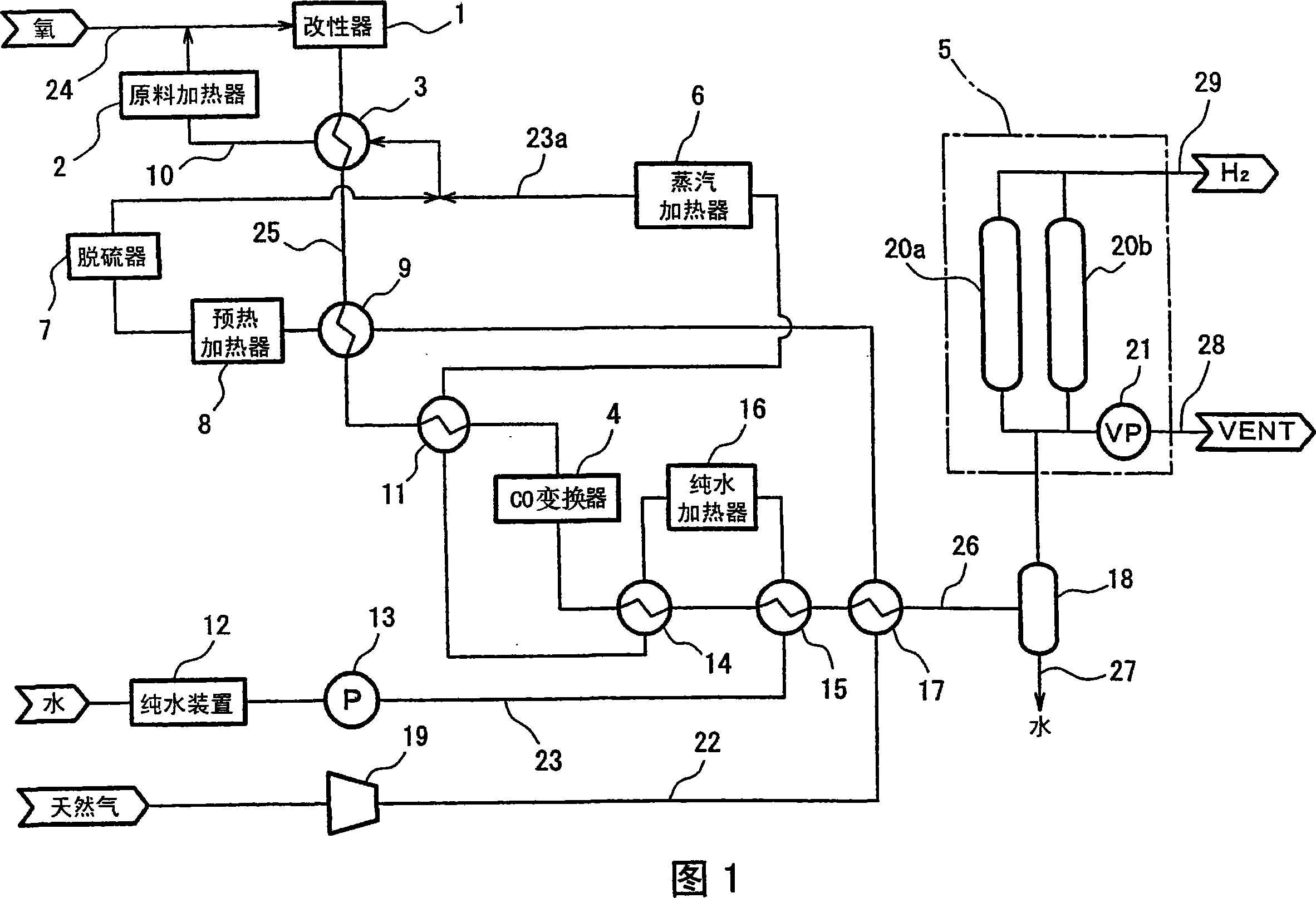

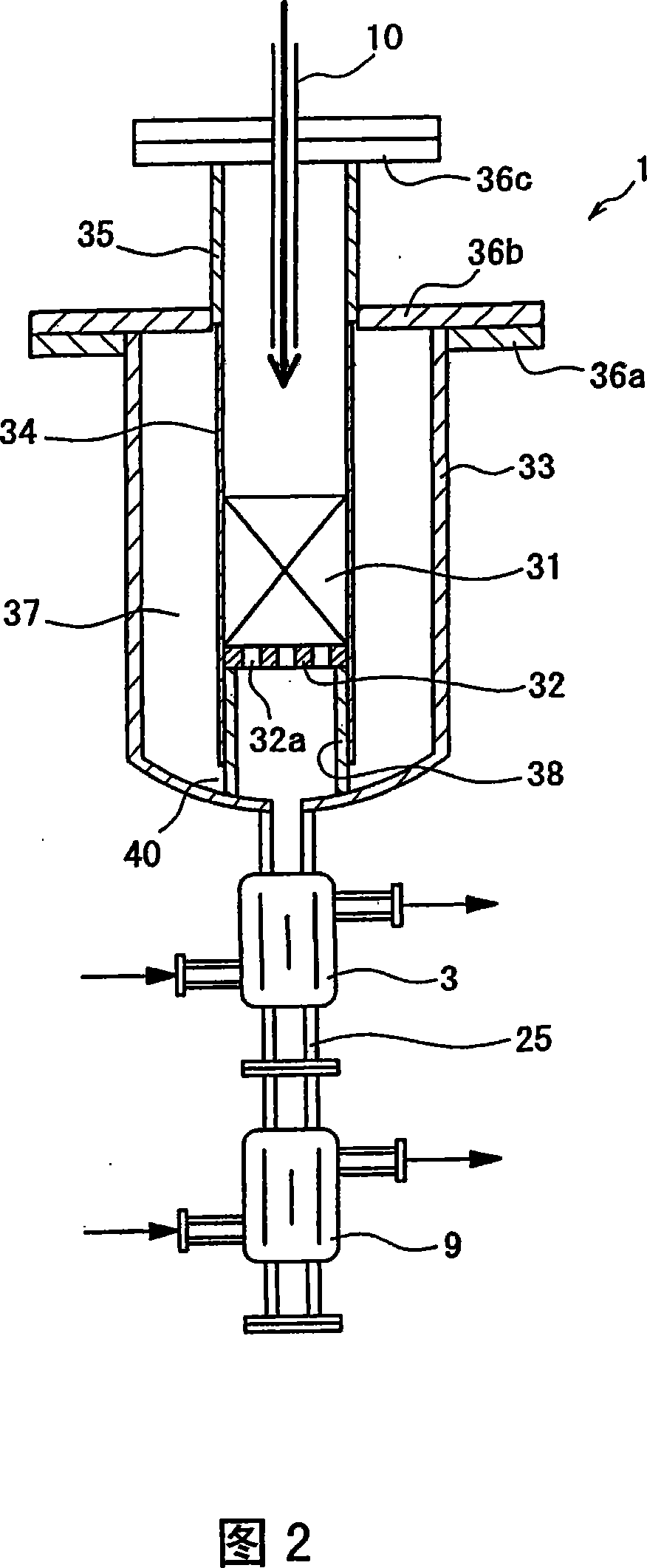

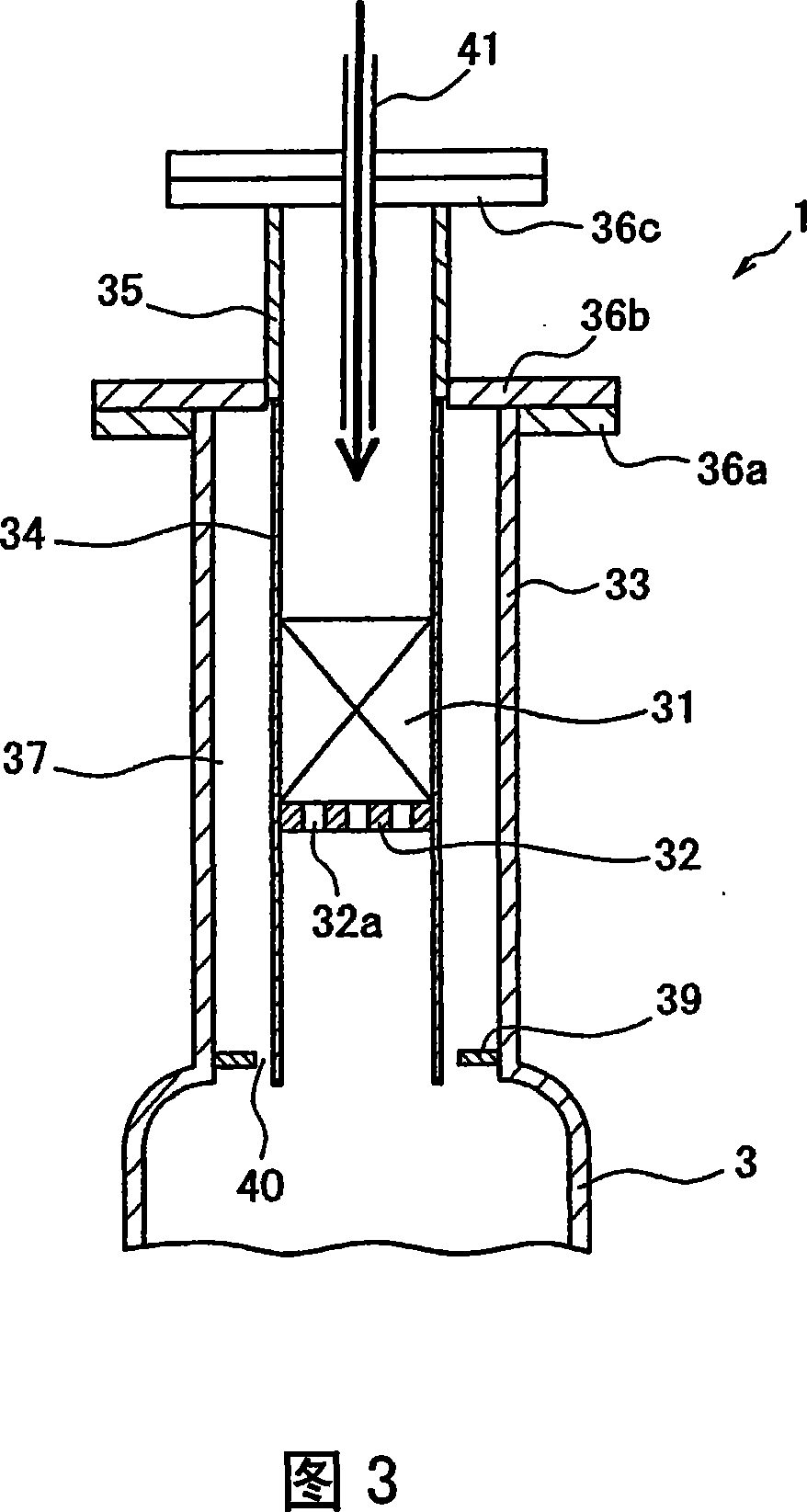

Apparatus and method for hydrogen generation

ActiveCN101111452AImprove energy efficiencyLarge adsorption capacityHydrogenChemical industryThermal energyHydrogen

This invention provides a hydrogen generator that has excellent energy efficiency and can reduce equipment cost. In the hydrogen generator, a hydrocarbon gas is reformed to produce a hydrogen-rich reformed gas. The hydrogen generator comprises a reformer (1) for catalytically reacting the hydrocarbon gas together with oxygen with a catalyst to perform combustion and reforming of the hydrocarbon gas and a first heat exchanger (3) for heating the hydrocarbon gas to be introduced into the reformer (1) after heat exchange between the reformed gas and the hydrocarbon gas in a reformed gas passage (25) provided on the downstream side of the reformer (1). According to the above construction, the raw material gas to be introduced into the reformer (1) is heated by the heat of the reformed gas produced by the combustion and the reforming, without the need to externally supply heat energy necessary for reforming by a burner or the like. Accordingly, the energy efficiency is improved. Further, since the need to provide any burner in the reformer (1) is eliminated, the structure of the reformer (1) per se can be simplified, and, at the same time, the structure for imparting heat resistance and pressure resistance can also be simplified. This advantageously leads to a reduction in equipment cost.

Owner:AIR WATER INC

Exhaust gas control apparatus of internal combustion engine

InactiveUS20180266365A1Improve responsivenessIncrease temperatureExhaust gas recirculationMachines/enginesExternal combustion engineTurbocharger

An exhaust gas control apparatus of an internal combustion engine includes a turbocharger including a turbine in an exhaust passage of the internal combustion engine, a post-processing device configured to control exhaust gas, the post-processing device being disposed in the exhaust passage downstream of the turbine, an EGR passage configured to connect the exhaust passage downstream of the turbine and upstream of the post-processing device with a cylinder of the internal combustion engine, and an EGR device including an EGR valve which is disposed in an end portion on the cylinder side of the EGR passage and opens or closes the EGR passage in the cylinder.

Owner:TOYOTA JIDOSHA KK

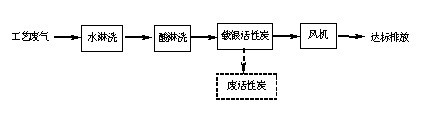

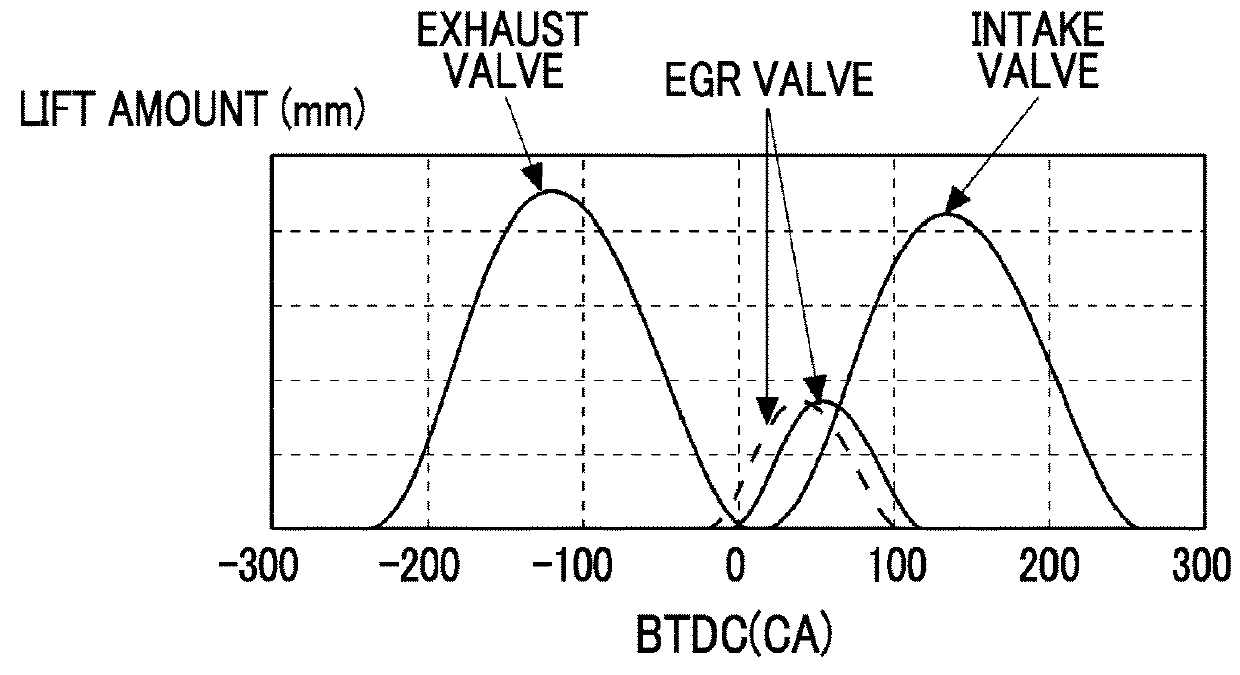

Pyrolysis treatment process for domestic sludge

InactiveCN105174678AIncrease profitHigh capacity reduction rateSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisParticulatesResource utilization

The invention discloses a pyrolysis treatment process for domestic sludge. The process comprises: sludge is fed into a dehydrator through a sludge pump to be dehydrated; the dehydrated sludge is fed into a pyrolyzing furnace; high-temperature flue gas generated by combustion in a hot air producer indirectly enters a destructive distillation section of the pyrolyzing furnace, and then flue gas of the destructive distillation section directly enters a preheating drying section; the flue gas that enters the preheating drying section is subjected to heat dissipation and is dedusted and discharged; the flue gas that enters the destructive distillation section is mixed with dry distillation gas and the mixture enters a high-temperature gas purifier; tar and saturated water coal gas are separated out through a purification system; and sludge carbon is cooled through circulating saturated water coal gas and is discharged. The sludge pyrolytic technique adopted by the process is an effective way for sludge reduction, stabilization, harmless treatment and resource utilization, and has the advantages of high utilization ratio of energy sources, high volume reduction rate and low operating cost; after combustion, the amount of exhaust gas needed to be treated is small; sludge needs not to be buried, and an incomplete incineration process is converted into a gas complete combustion process, so that the discharge amount of sludge carbon solid particulate matters is extremely small, and the process is more environmental-friendly.

Owner:ANHUI ZHUOXIN CLEAN ENERGY TECH CO LTD

Hybrid electric vehicle and method of controlling driving of the same

ActiveUS9102325B2Improve engine performanceReduce the amount of exhaust gasHybrid vehiclesBatteries circuit arrangementsTurbochargerDrive motor

Owner:HYUNDAI MOTOR CO LTD +1

System and method for recycling water vapor during roasting aluminum hydroxide

ActiveCN105000582AReduce generationReduce consumptionAluminium compoundsWater vaporAluminium hydroxide

The invention belongs to the technical field of aluminum hydroxide production, and particularly relates to a system and method for recycling water vapor during roasting aluminum hydroxide. The system for realizing the aim of recycling the water vapor during roasting the aluminum hydroxide of the invention comprises a water vapor recycling device, a main furnace, a suspension separation heat exchanger and a heat transfer device. The system provided by the invention recycles crystal water and attached water produced during the roasting process of the aluminum hydroxide for reusing, so that the consumption of electric energy and heat energy during the roasting process is reduced, the energy conservation and emission reduction are promoted, and the economic benefits of enterprises are increased.

Owner:SHENYANG XINBO IND TECH

Metal gravity casting mould and method

InactiveCN102699274AReduce process stepsImprove compactnessFoundry mouldsFoundry coresMetallurgyMaterials science

The invention relates to a metal gravity casting mould which comprises a metal mould and an inner cavity core. A plurality of positioning heads is arranged on the inner cavity core; the inner cavity core is internally provided with an exhaust channel; and the outlet of the exhaust channel is located on the positioning heads and communicated with the outside of the metal mould. Due to the adoption of the metal gravity casting mould and method, the production processes of the casts are reduced, and the amount of the exhaust emitted in the casting process is low. The metal gravity casting mould and method solve the problems of the existing metal gravity casting mould and method that the casts have unwanted structures and the exhaust emission amount is high.

Owner:MAIN PLAN NINGBO BATHROOM COLLECTIONS

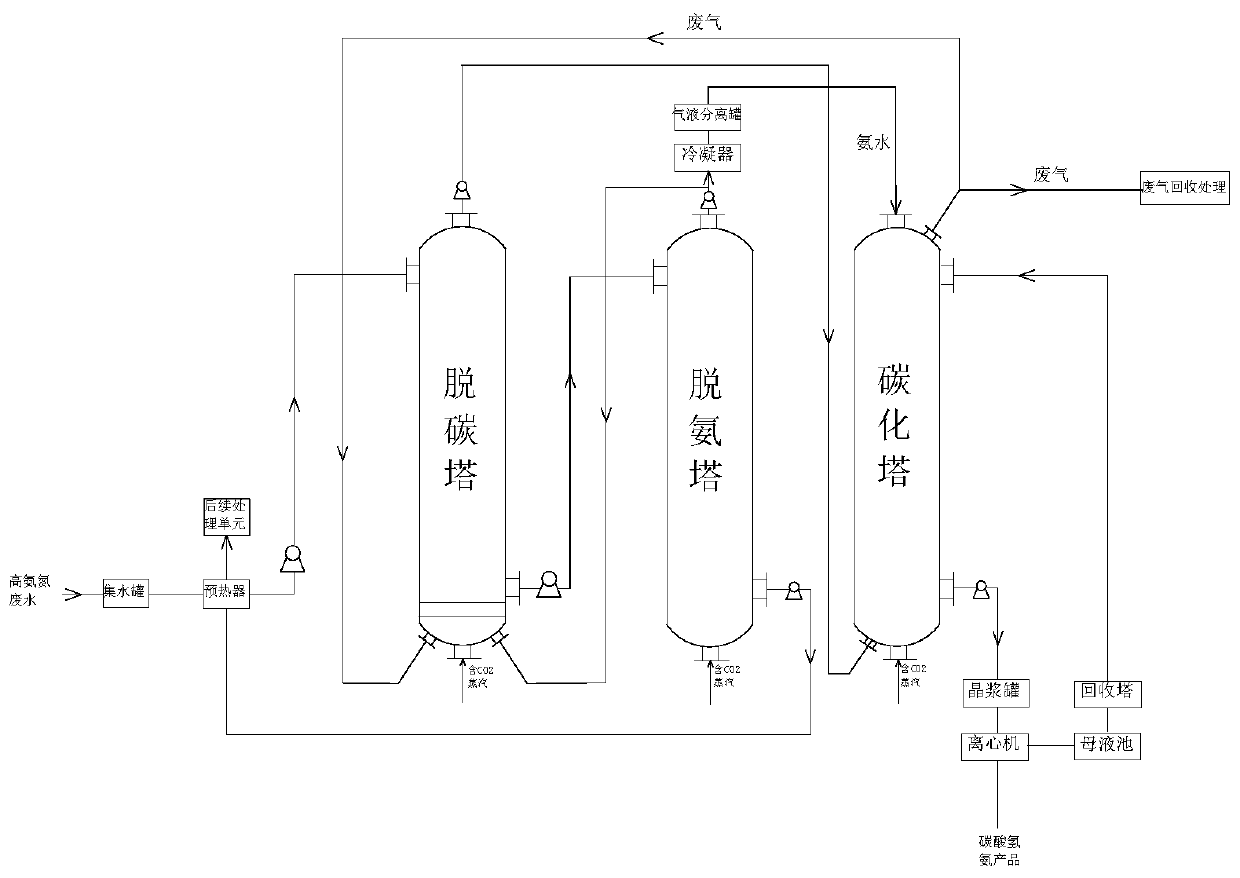

Ammonia recovery method of high-ammonia-and-nitrogen waste water

ActiveCN109879510APrecipitation completePrevent sedimentation and scalingWater contaminantsAmmonium carbonates/bicarbonatesRecovery methodHigh concentration

The invention discloses an ammonia recovery method of high-ammonia-and-nitrogen waste water, and belongs to the technical field of sewage treatment. The ammonia recovery method comprises the steps: firstly, the high-ammonia-and-nitrogen waste water passes through a decarburization tower where carbon-dioxide-containing steam and ammonia-containing steam are introduced, and calcium and magnesium ions in the waste water are removed; then the high-ammonia-and-nitrogen waste water passes through a deamination tower, steam-stripping deamination is carried out at 80-90 DEG C, ammonia and nitrogen inthe waste water enter a steam phase, high-concentration ammonia-containing mixed steam is formed and collected at the top of the deamination tower, one part of the ammonia-containing mixed steam flowsback to the decarburization tower, and the remaining part of ammonia-containing mixed steam is introduced into a condenser to be condensed and then subjected to gas-liquid separation; and finally, effluent of the deamination tower enters a subsequent treatment facility to be subjected to biochemical treatment, separated ammonia water enters a carburization tower where the carbon-dioxide-containing steam is introduced, and ammonium bicarbonate is formed and serves as a recycled product. By adopting the method for high-ammonia-and-nitrogen waste water treatment and ammonia recovery, the deamination effect and ammonia recovery efficiency of the high-ammonia-and-nitrogen waste water can be improved greatly, and additionally treatment equipment can further be prevented from being scaled.

Owner:TONGJI UNIV

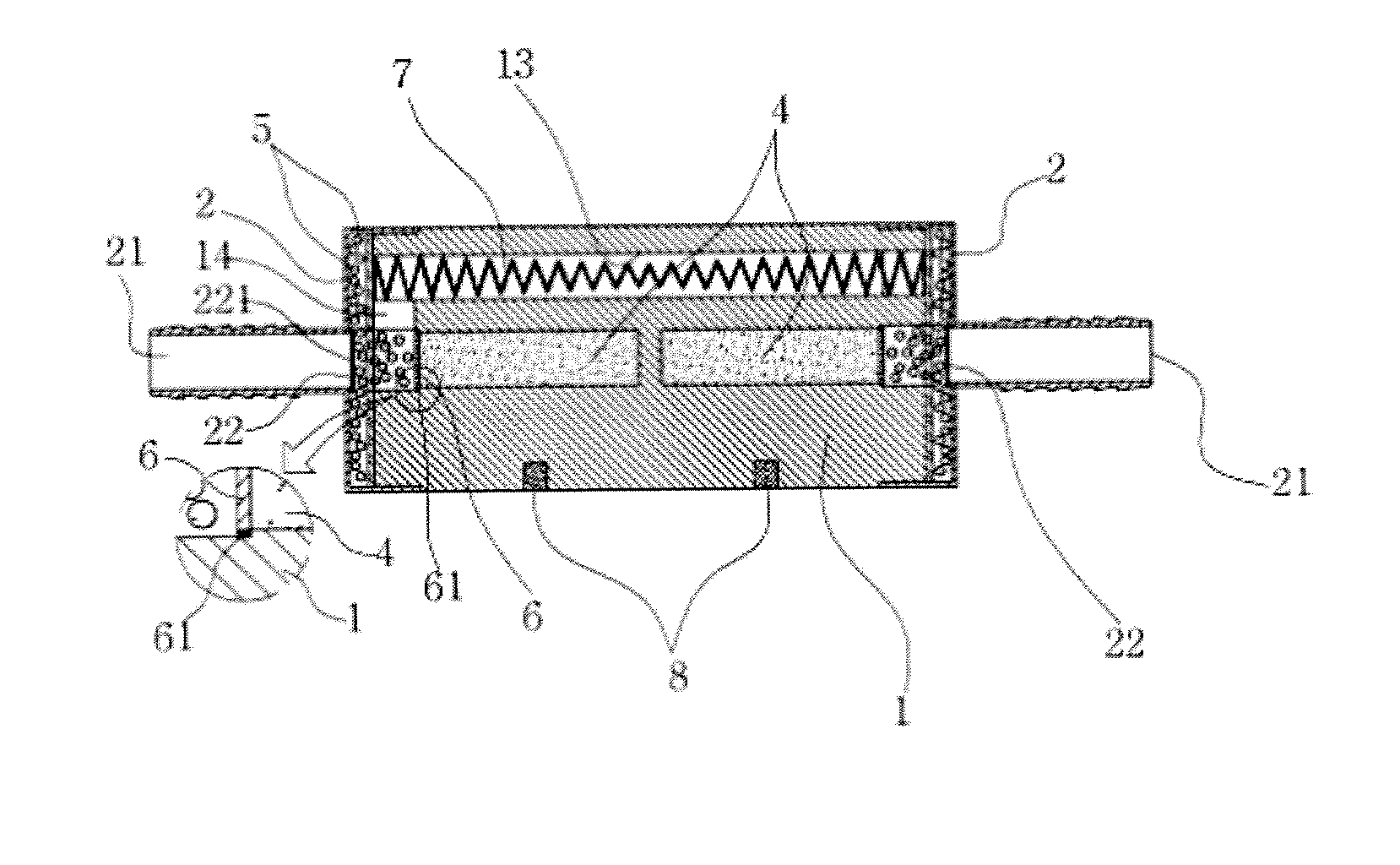

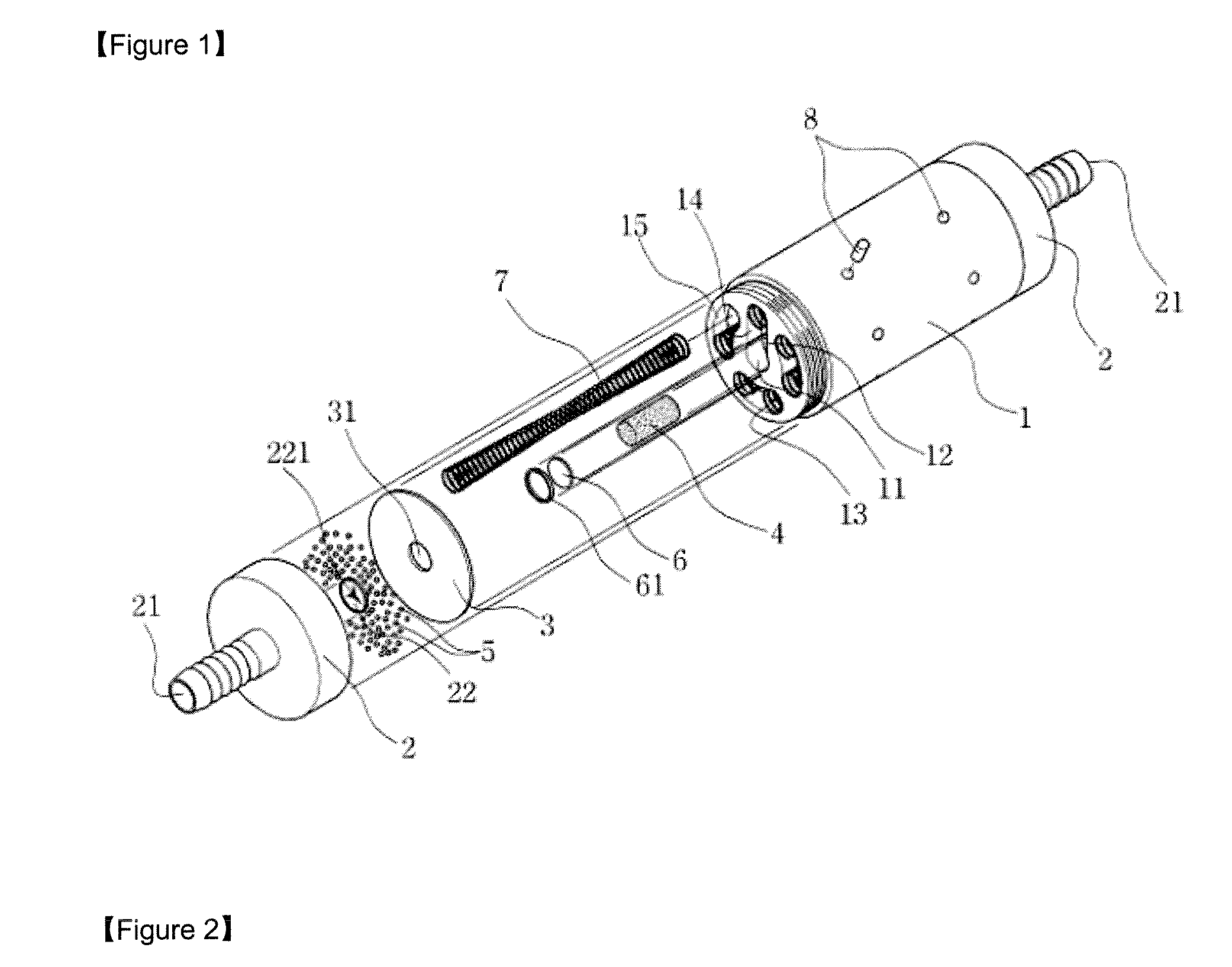

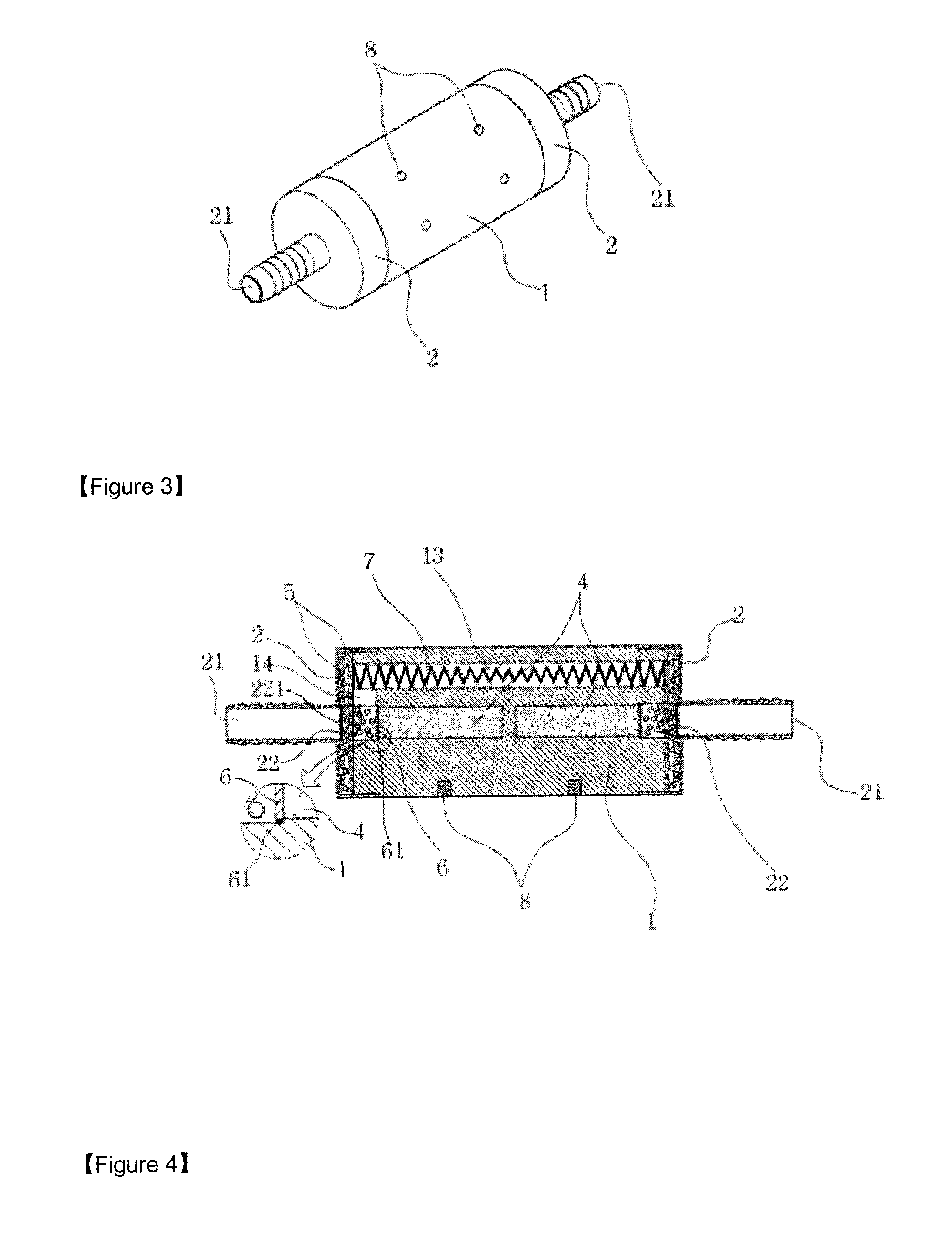

Multi-purpose liquid atomizer utilizing catalyst, turbulence, and collision

InactiveUS20090071449A1Improve combustion efficiencyReduce fuel consumptionFuel re-atomisation/homogenisationMachines/enginesPotable waterEngineering

The present invention relates to a multi-purpose liquid atomizer utilizing a catalyst, turbulence, and collision. More specifically, the present invention relates to a multi-purpose liquid atomizer using a catalyst, turbulence, and collision, involving forming ceramic serving as a catalyst in inlet and outlet caps, such that the liquid fuel can be reformed into a liquid fuel satisfying a maximized contact area with air or oxygen for effective combustion of the liquid fuel, thereby promoting combustion reaction and remarkably enhanced surface area by liquid atomization; packing ceramic fillers into a central part of a main body; forming an uneven number of flow holes for liquid fuel by which the liquid fuel can be reformed while flowing along inside passages of the main body for an adequate period of time; furnishing mortar-shaped special metal springs within the flow holes such that the liquid fuel can be whirled and collided; and arranging specially-designed plural rows of permanent magnets along the outer circumference of the main body such that the liquid fuel can be reformed. As such, the multi-purpose liquid atomizer in accordance with the present invention provides effects such as improved heat efficiency of the liquid carbon fuel leading to reduction of fuel consumption, clarification, and induction of a fuel system leading to reduction in discharged exhaust gas, and supply of clean, potable water necessary, by ionization of water molecules.

Owner:CHOI OK

Air conditioner for vehicle with heat pump cycle

InactiveUS9250005B2Increase heatIncrease fuel consumptionAir-treating devicesMechanical apparatusEngineeringVapor-compression refrigeration

An air conditioner for a vehicle includes a vapor compression refrigeration cycle switchable between a heat pump cycle and a cooler cycle, a heat core configured to heat air to be blown into a vehicle compartment by using coolant of an engine of the vehicle as a heat source, and a controller configured to control operation of the vapor compression refrigeration cycle. The controller controls the vapor compression refrigeration cycle to be operated as the cooler cycle so as to perform a defrosting control of the outdoor heat exchanger, and outputs an operation request signal to the engine, when the controller determines that the outdoor heat exchanger is frosted.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com