Ammonia recovery method of high-ammonia-and-nitrogen waste water

A technology for high ammonia nitrogen and ammonia recovery, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of insufficient biological treatment efficiency, failure of resource utilization, low ammonia removal efficiency, etc. problem, to achieve the effect of improving the deamination efficiency and deamination effect, increasing the proportion of ammonia, and complete precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

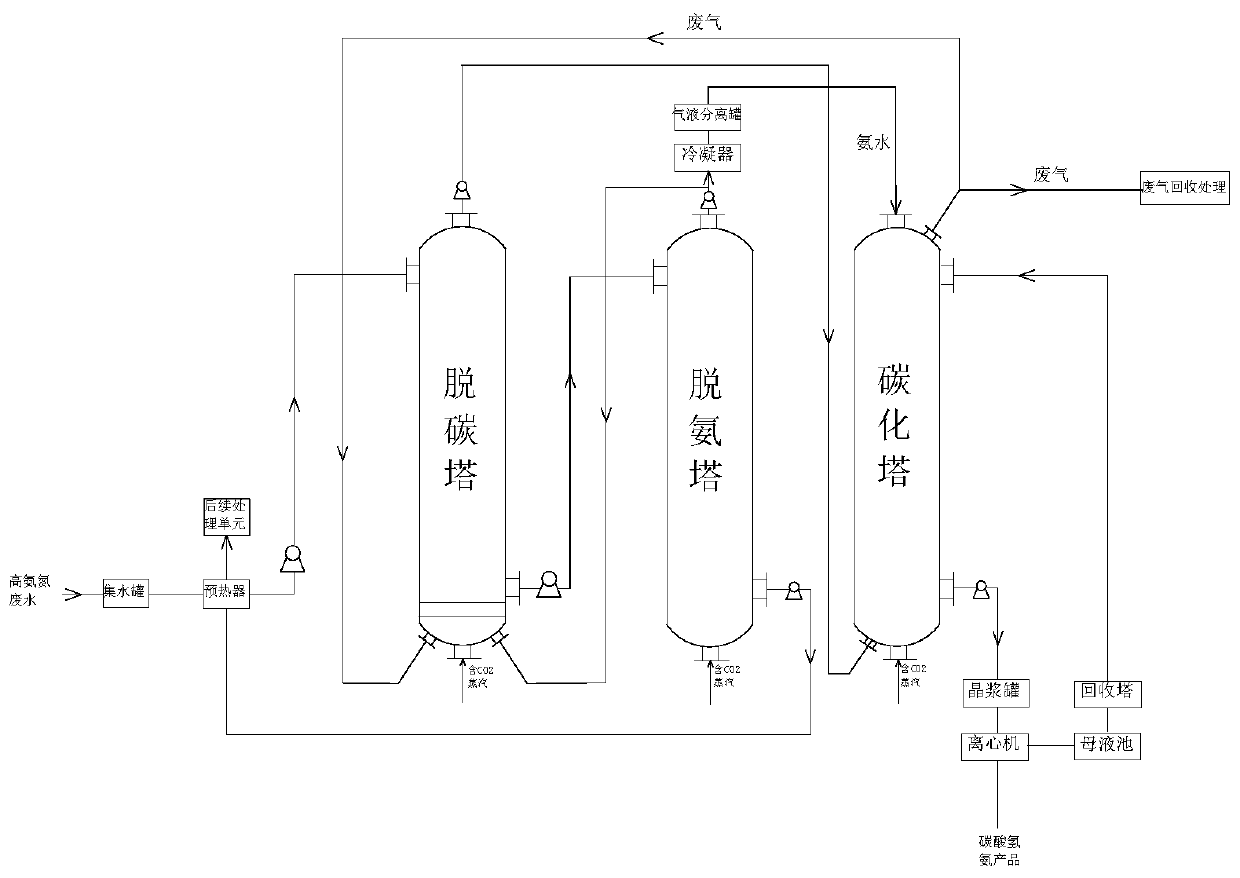

[0021] Combine figure 1 , A specific embodiment of the present invention is described in detail, but does not limit the claims of the present invention in any way.

[0022] Such as figure 1 As shown, a method for recovering ammonia from wastewater with high ammonia nitrogen includes the following steps:

[0023] (1) The high ammonia nitrogen wastewater is preheated by the preheater and pumped to the upper part of the decarburization tower. From the lower part of the decarburization tower, carbon dioxide-containing steam and ammonia-containing steam are introduced. Among them, carbon dioxide and ammonia are contained in the carbon dioxide-containing steam and ammonia-containing steam. The quantity ratio of the substance is 1:1. The ammonia-containing steam includes the ammonia-containing steam returned from the deammification tower and part of the waste gas returned from the carbonization tower. The decarburization tower is a plate tower, and the temperature of the decarburization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com