Patents

Literature

227results about "Ammonium carbonates/bicarbonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

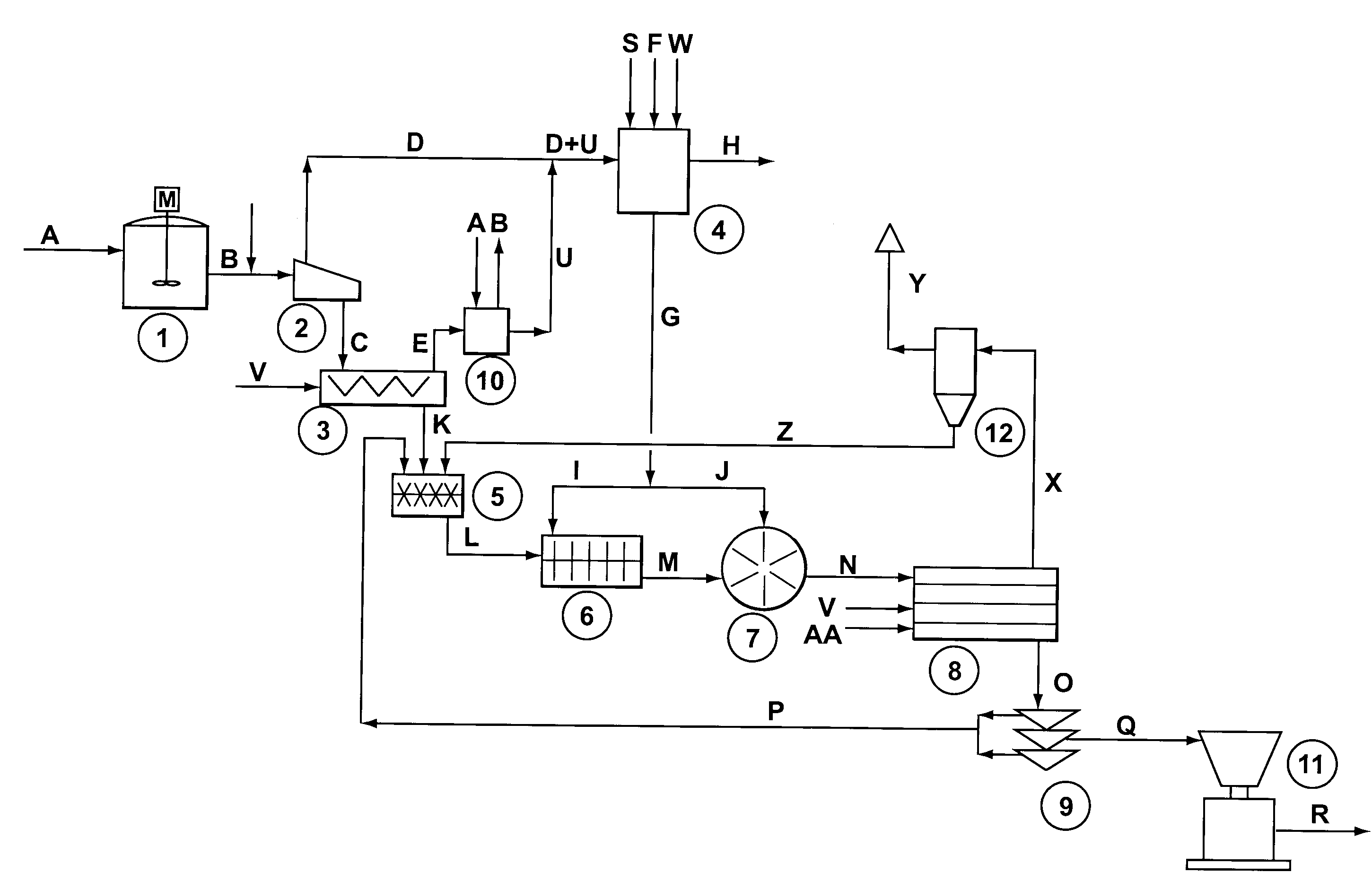

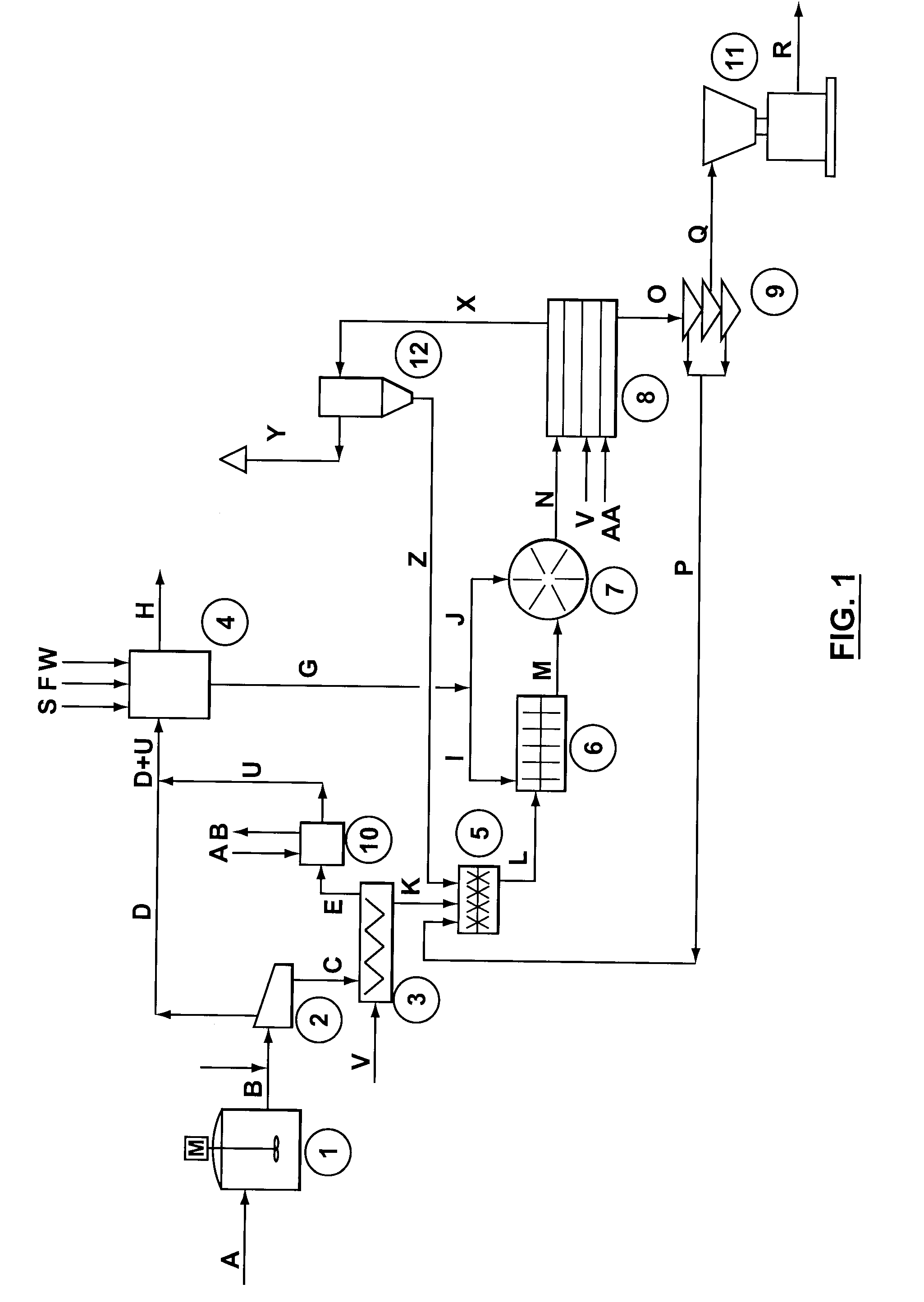

Organics and nutrient recovery from anaerobic digester residues

Sludge from an anaerobic digester is treated to recover one or more of fibers, or solids or liquids with a high nutrient content. The solids or liquids can be used as a fertilizer. The fibers can be used in a plant growing medium. Solids are separated from liquids in the sludge and dried. The solids may be dried to produce a flake or pellet. Ammonia in the liquids is recovered and used to produce a concentrated acidic ammonium salt solution. This solution may be mixed with the solids to produce a nitrogen enhanced solid. The fibers and solids or liquids can also be used in combination to produce an enhanced plant growing medium. A device and process for removing ammonia from a liquid can be used in the system or separately.

Owner:ANAERGIA

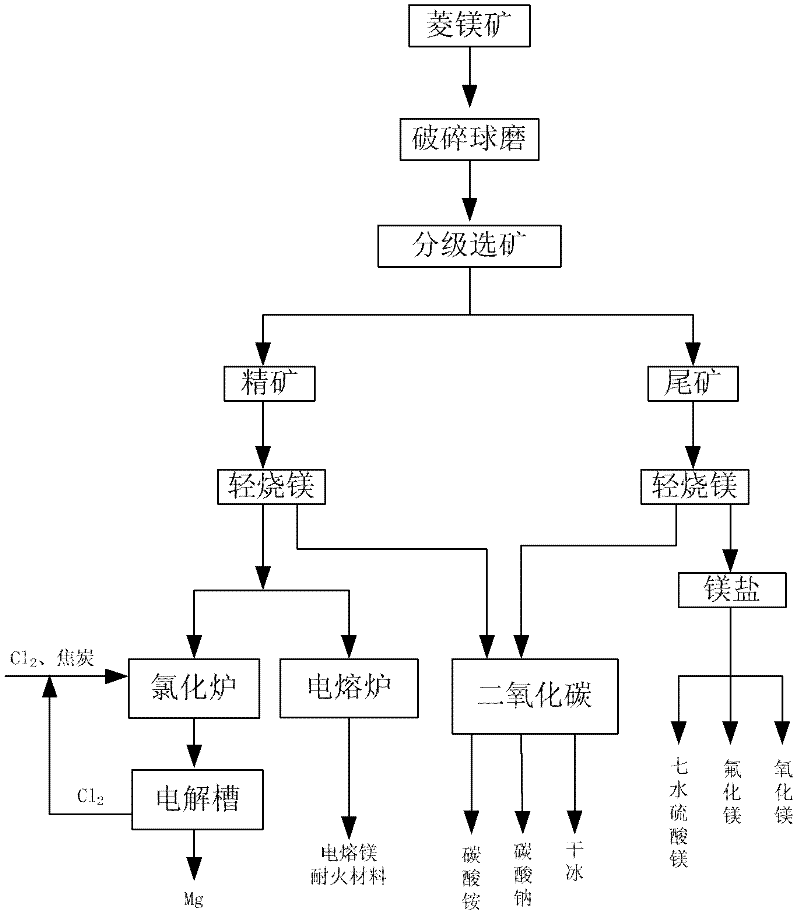

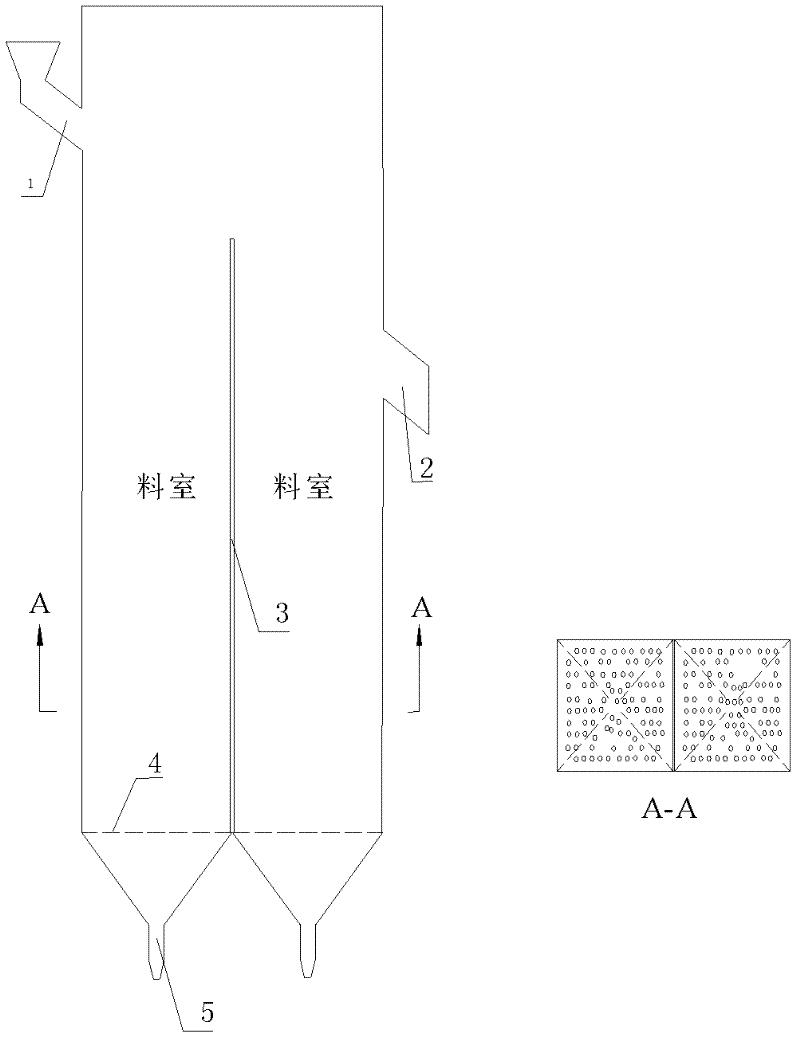

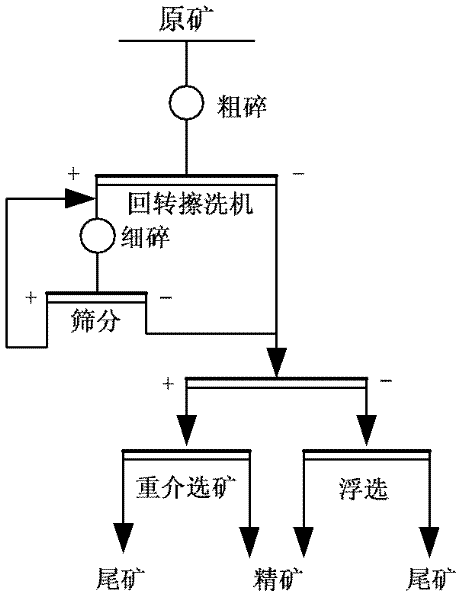

Integrated utilization method of low grade magnesite

InactiveCN102515213ASave raw materialsSimple processCarbon compoundsAmmonium carbonates/bicarbonatesElectrolysisMagnesium salt

The invention belongs to the fields of integrated utilization technology of magnesite and environmental protection, and relates to an integrated utilization method of low grade magnesite. The method comprises steps of: magnesite fragmentation; ore grinding; ore dressing; ore dressing product calcining; conversion of calcined useful components into magnesium salt to prepare high purity magnesium oxide or direct electrolysis of the calcined useful components into magnesium metal or preparation of refractory material; and recovery utilization of gas generated by calcination. The invention comprehensively utilizes useful ingredients in the magnesite, realizes zero discharge of magnesite mine tailing, increases utilization rate of low grade magnesite and efficiently utilizes ore resource; and especially, fluidized roasting by a horizontal fluidized bed saves energy consumption and maximize economic benefit.

Owner:UNIV OF SCI & TECH BEIJING

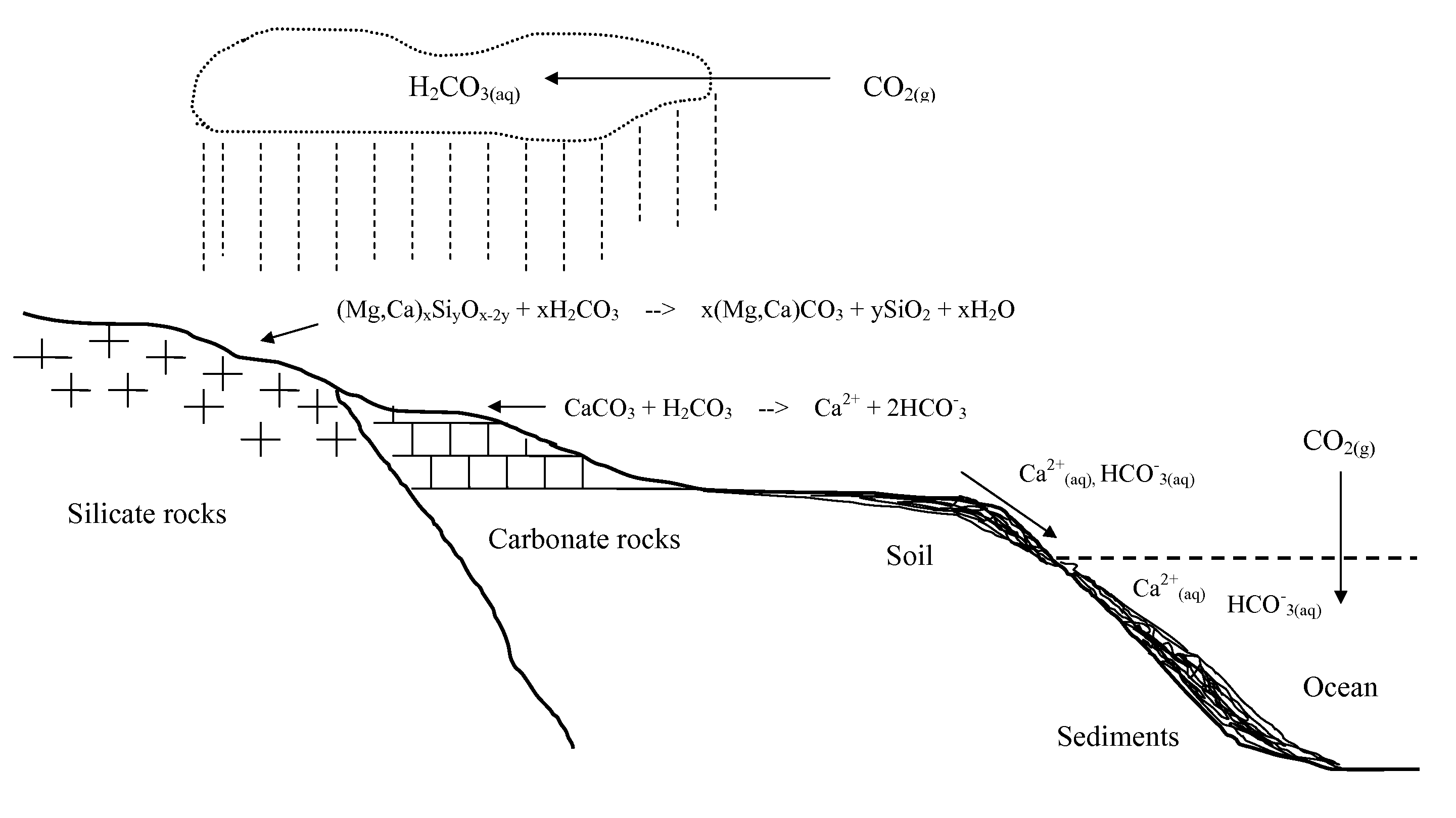

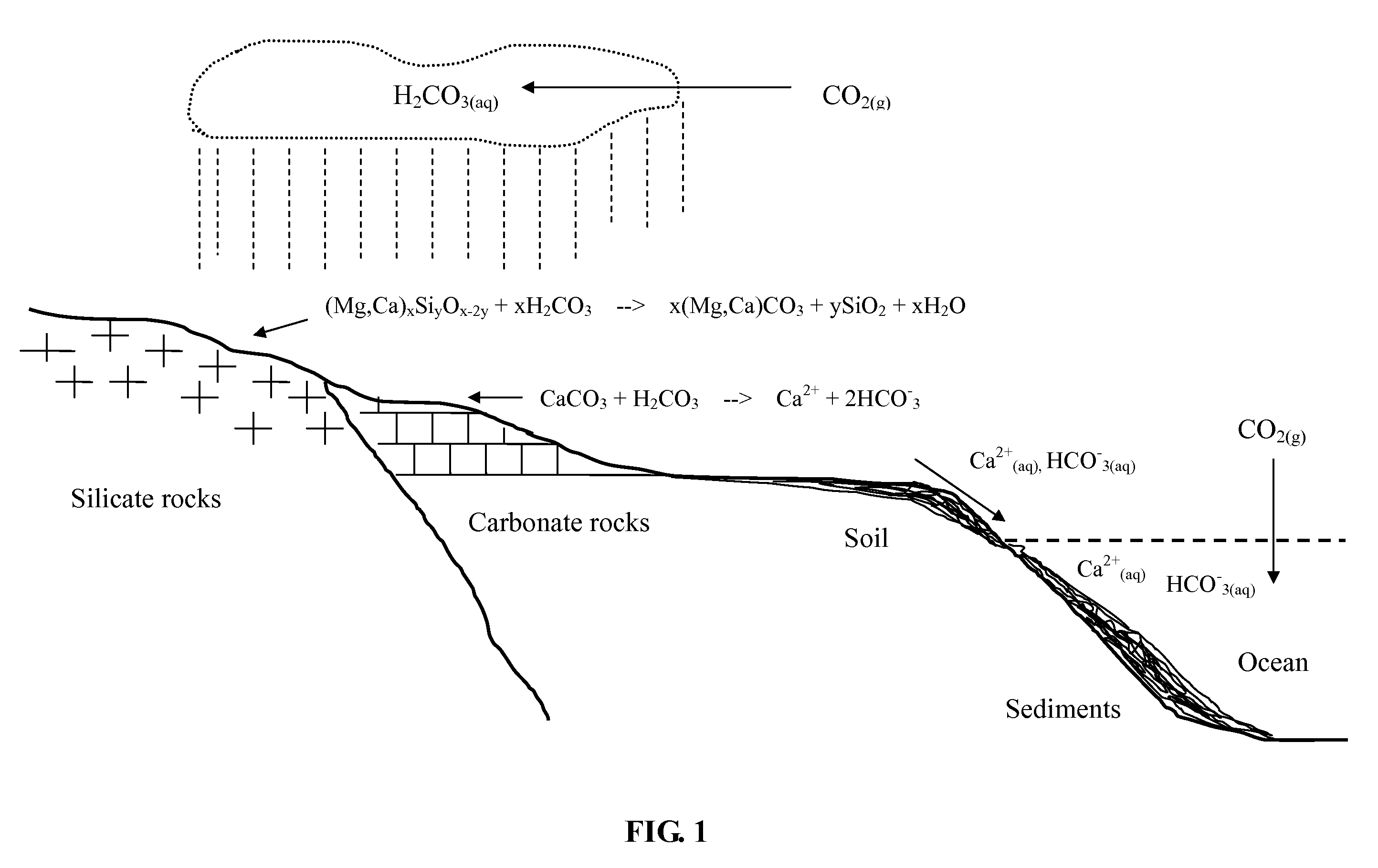

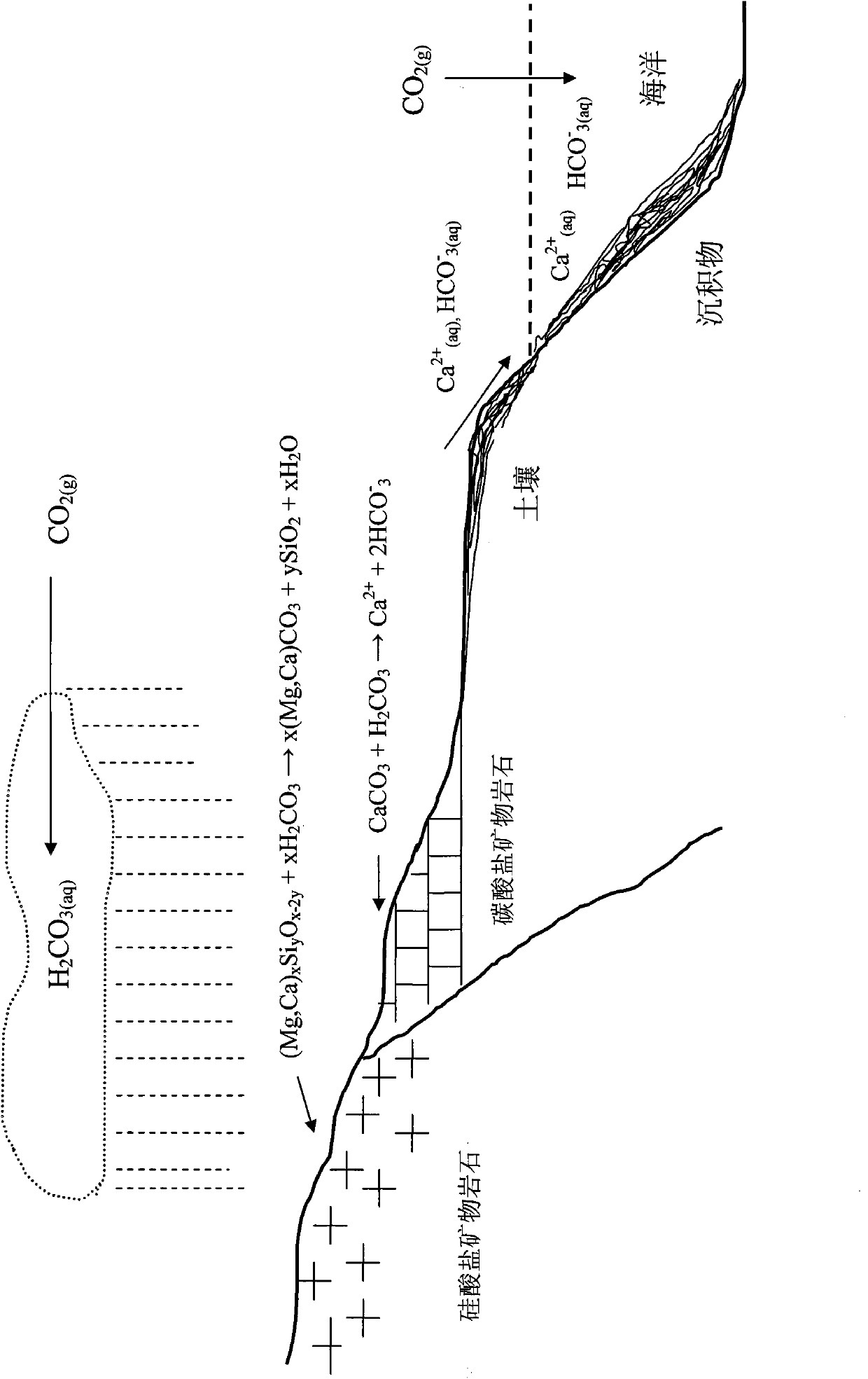

Method for Sequestering Carbon Dioxide

InactiveUS20110038774A1Enhance CO dissolutionMitigate local ocean acidificationCalcium/strontium/barium carbonatesProductsSodium bicarbonateSlag

Owner:ZHONG SHAOJUN

Method for treating wastewater of dilute thiamine

ActiveCN101092265AEfficient removalReduce dosageCalcium/strontium/barium sulfatesAmmonium carbonates/bicarbonatesIon exchangeIon-exchange resin

This invention relates to a method for treating diluted ammonium sulfate wastewater. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, and difficult ammonium sulfate recovery. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater, adjusting the pH value to 6.5-7.5, performing flash evaporation, stripping or rectification, removing lightweight organic fractions at the overhead, collecting heavy fractions at the bottom, and extracting the rest ammonium sulfate wastewater at 1st-5th theoretical plates from the overhead; (2) sending the rest ammonium sulfate wastewater to ion exchange reaction, and removing NH4+; (3) treating regenerated liquid of the ion exchange resin with Ca(OH)2 aqueous solution to produce CaSO4 and diluted ammonia solution, performing solid-liquid separation, reacting CaSO4 and diluted ammonia solution with CO2 to obtain ammonium carbonate or ammonium hydrogen carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

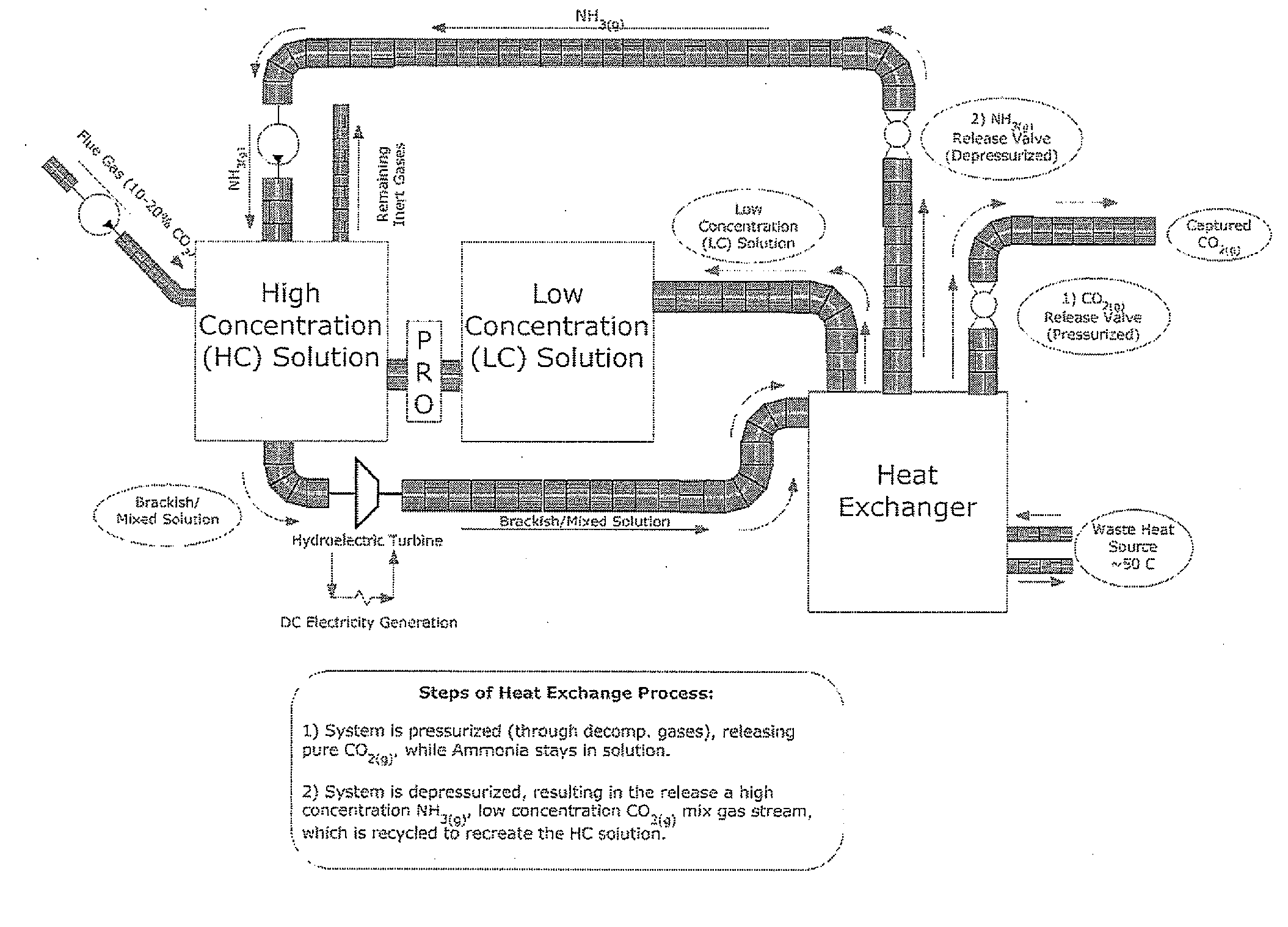

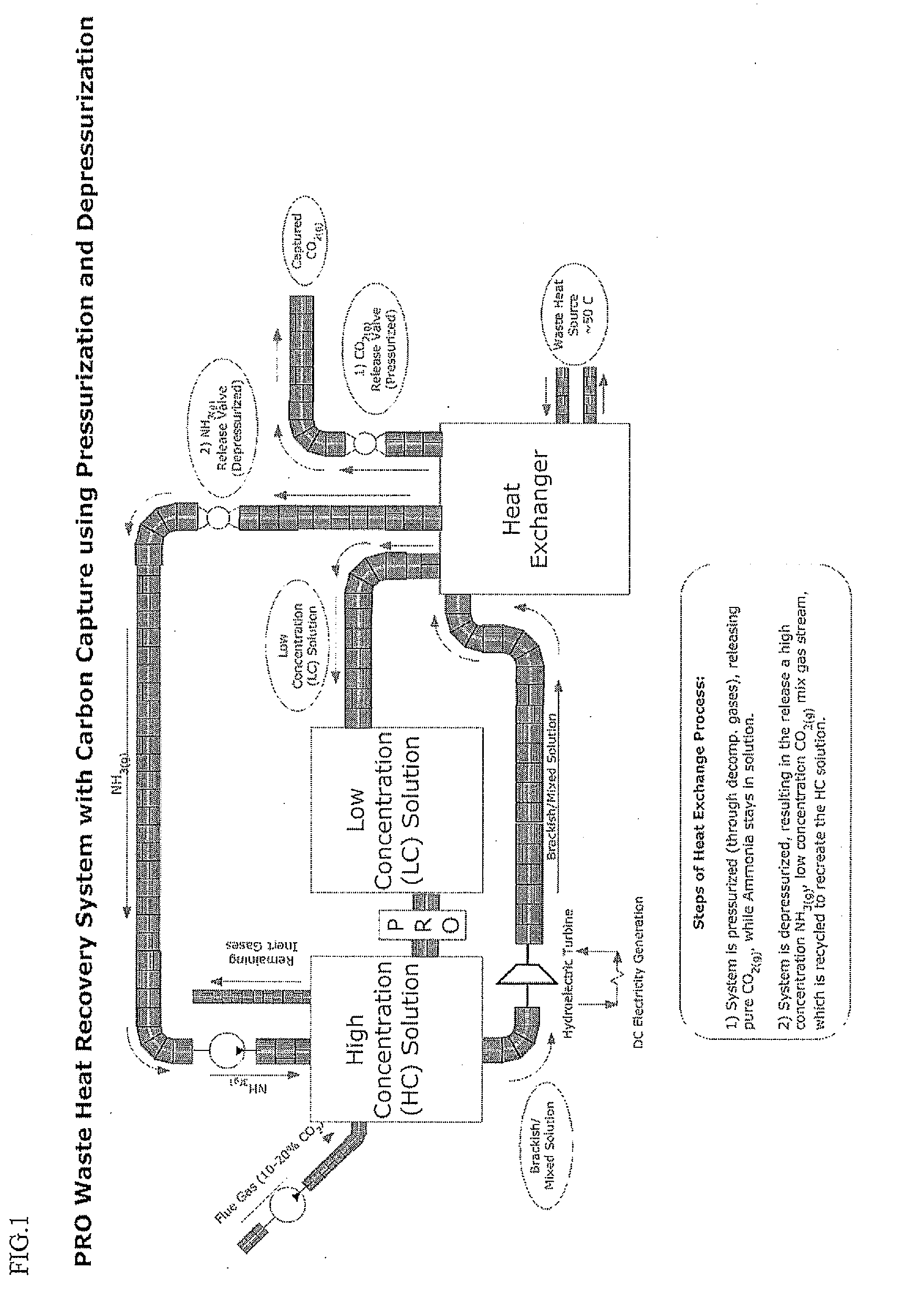

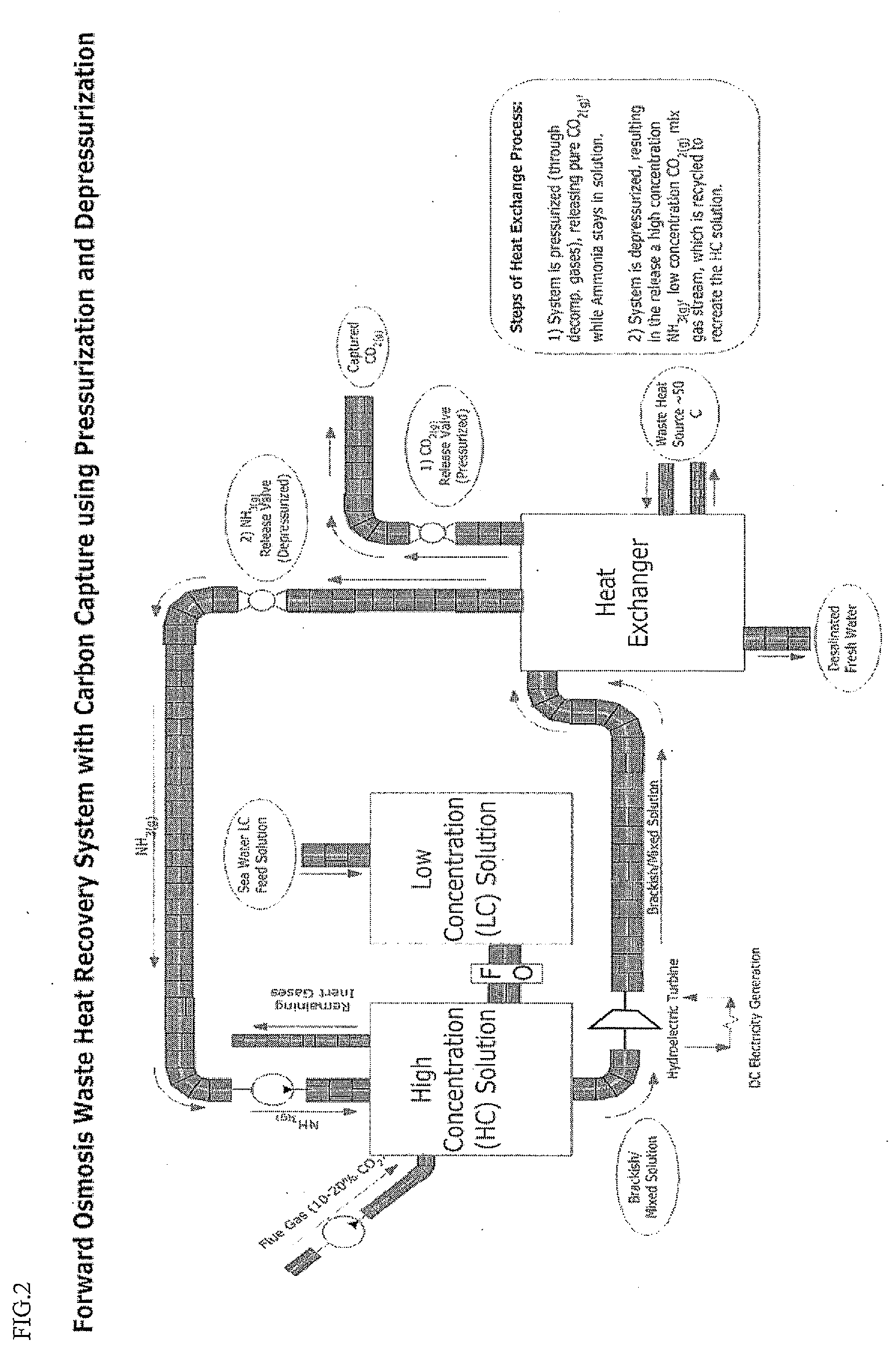

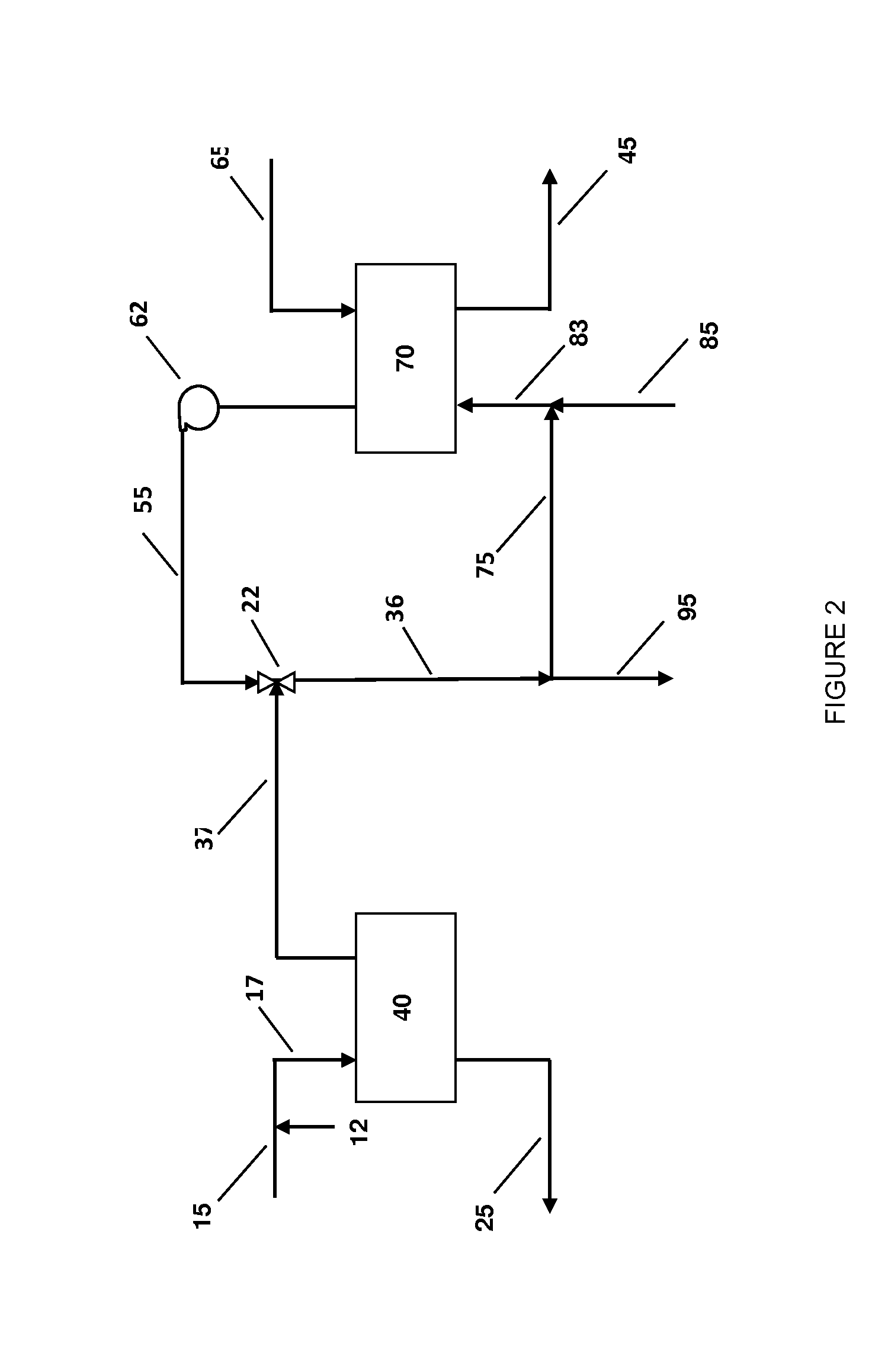

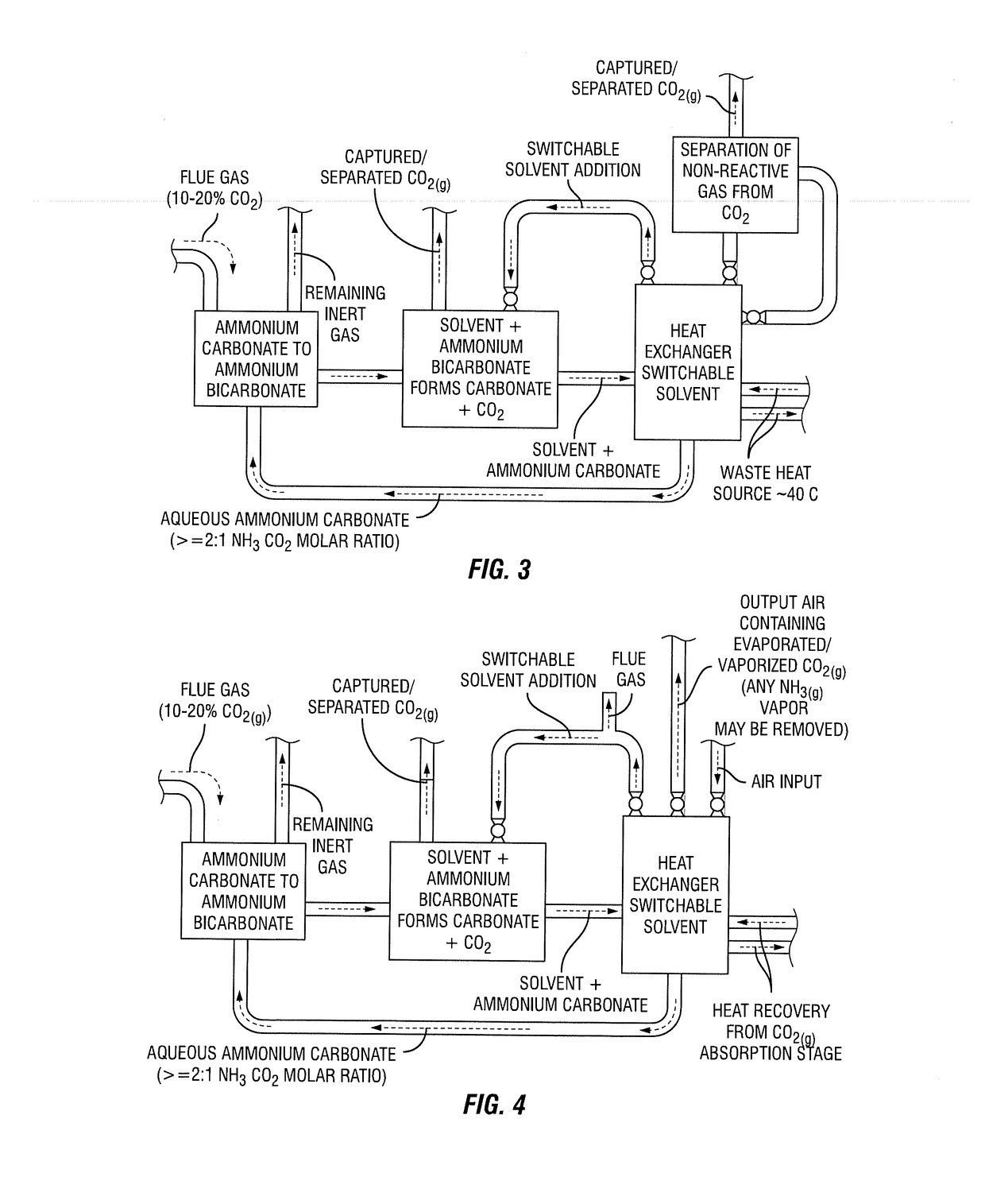

Integrated process for carbon capture and energy production

ActiveUS20160167974A1Urea derivatives preparationCarbamic acid derivatives preparationPhysical chemistryAmmonium carbonate

The present invention pertains to new methods for generating energy and useful nitrogen compounds from captured carbon dioxide. It involves employing an osmotic engine, draw solution, and feed solution. An osmotic gradient between the solutions assists in generating energy and a solution of ammonium carbonate, ammonium bicarbonate or mixture thereof. This solution may be decomposed to form ammonia, carbon dioxide, a precipitate, or a mixture thereof.

Owner:SOLVCOR TECH LLC

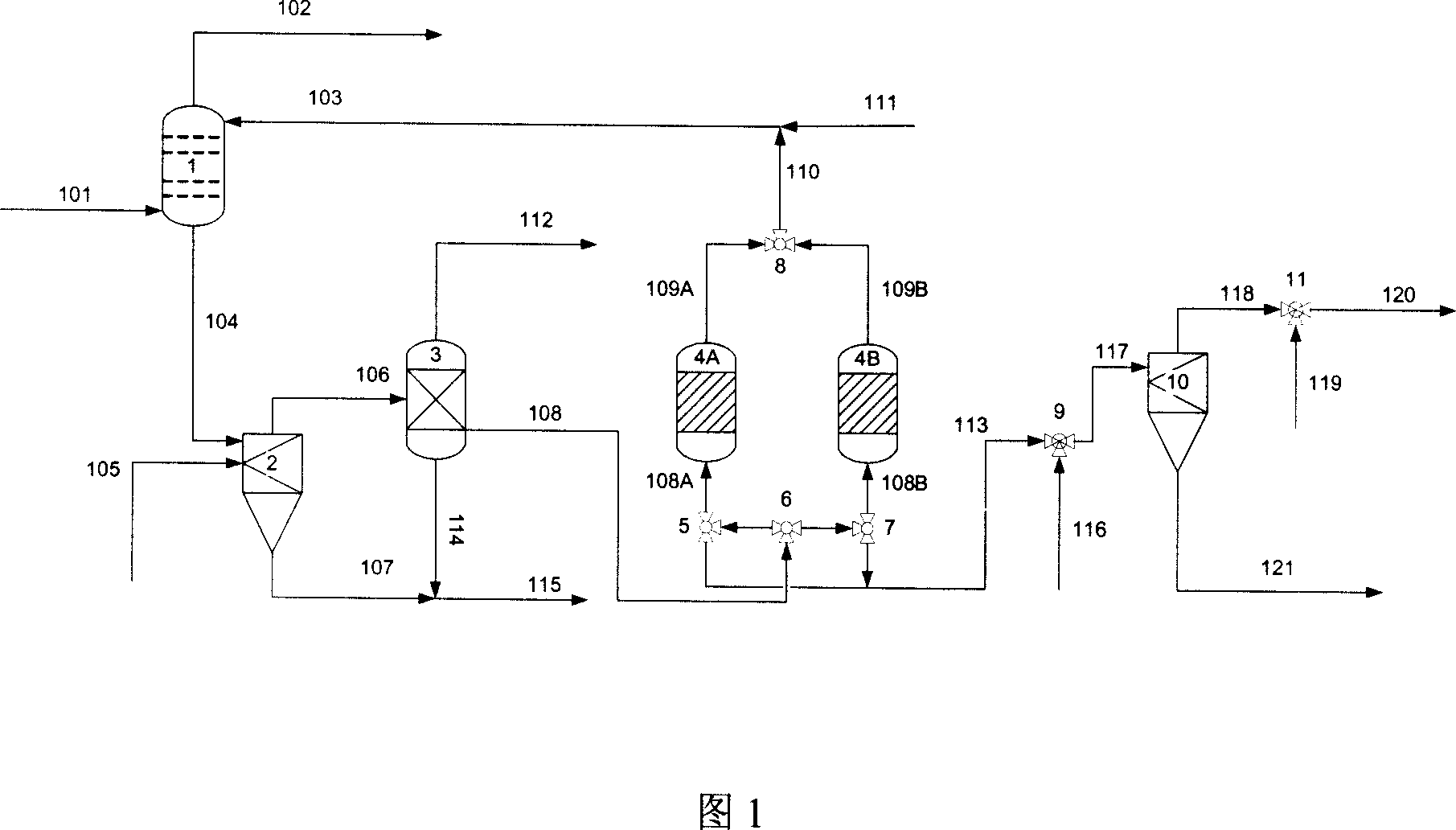

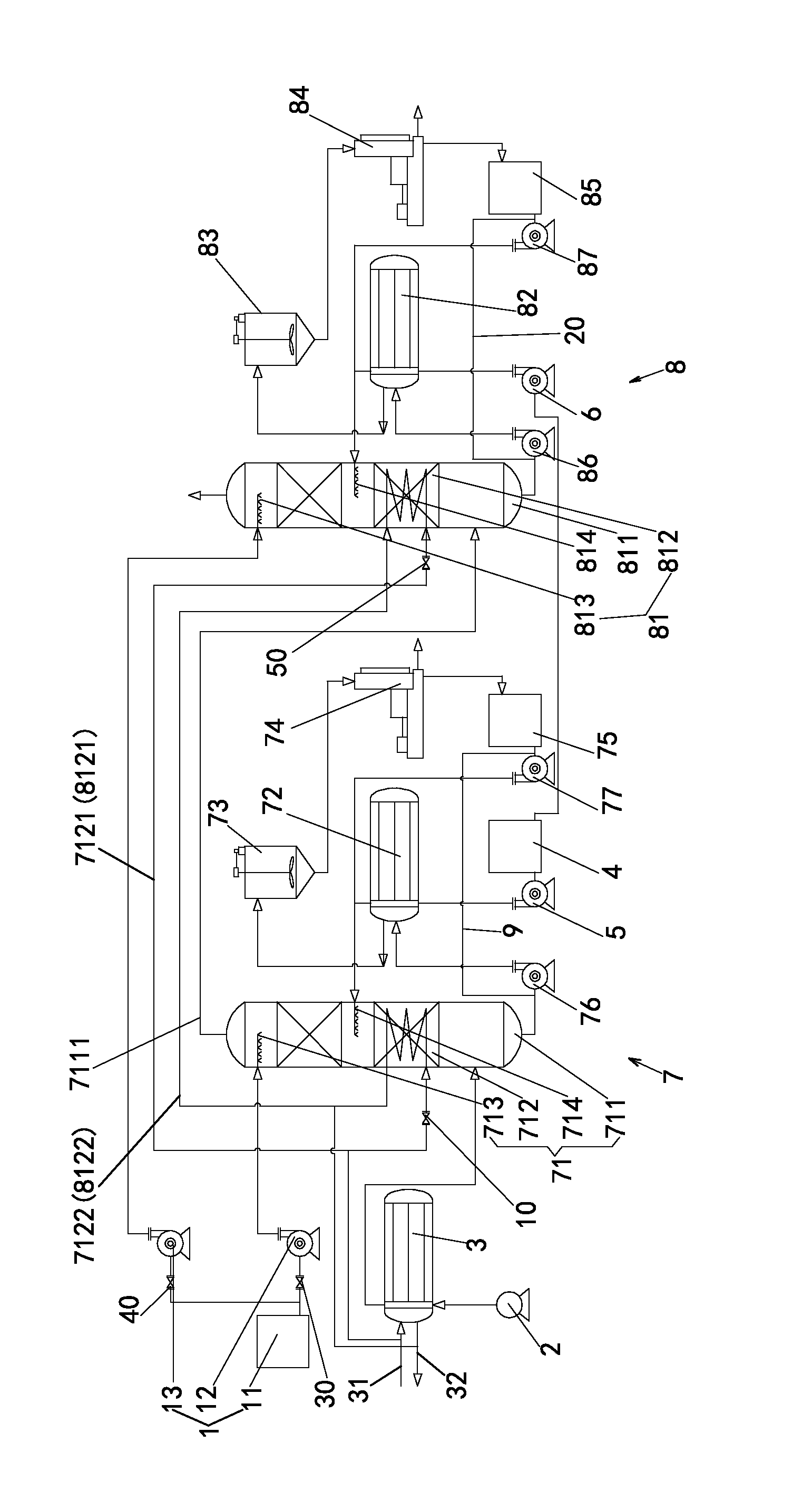

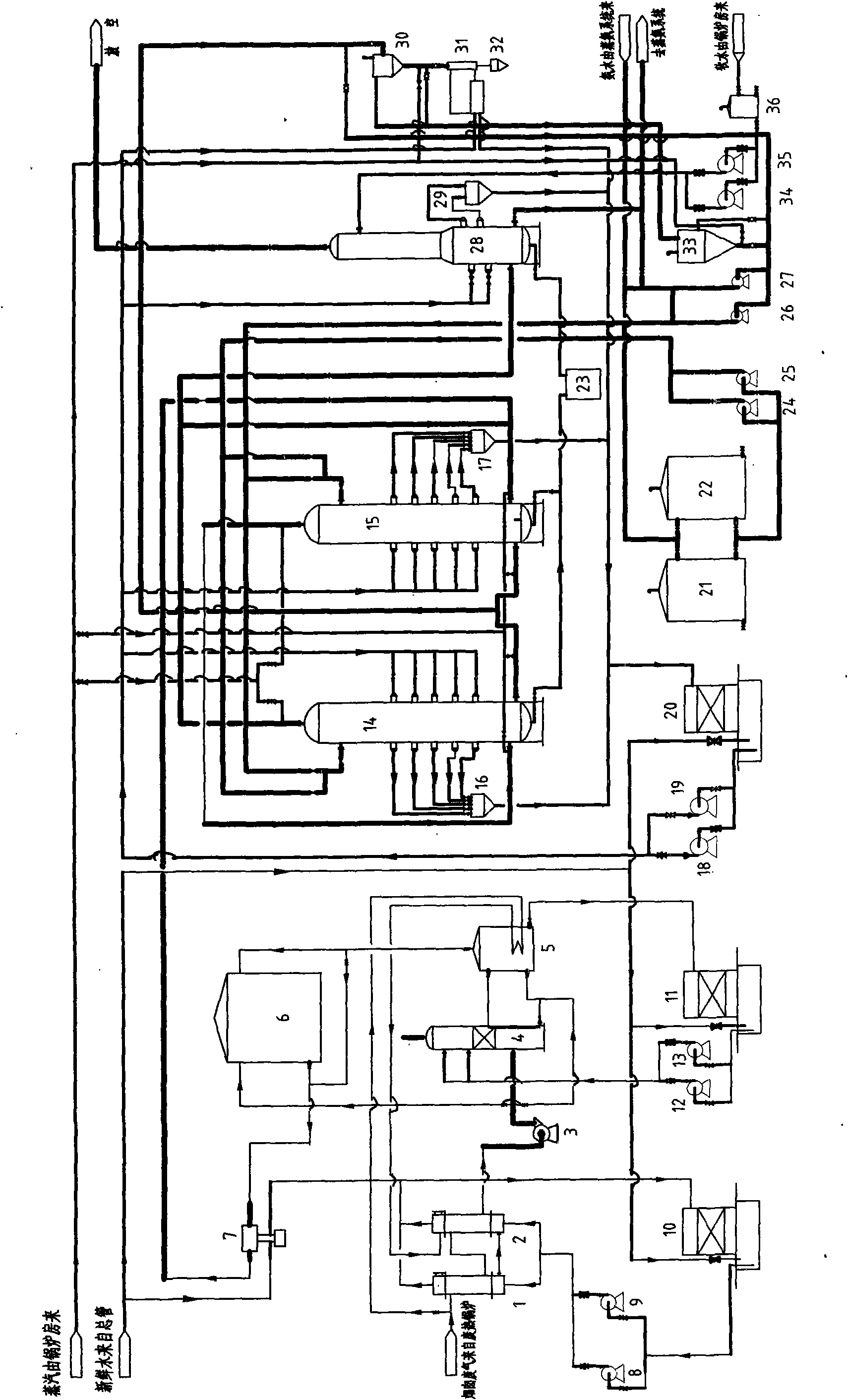

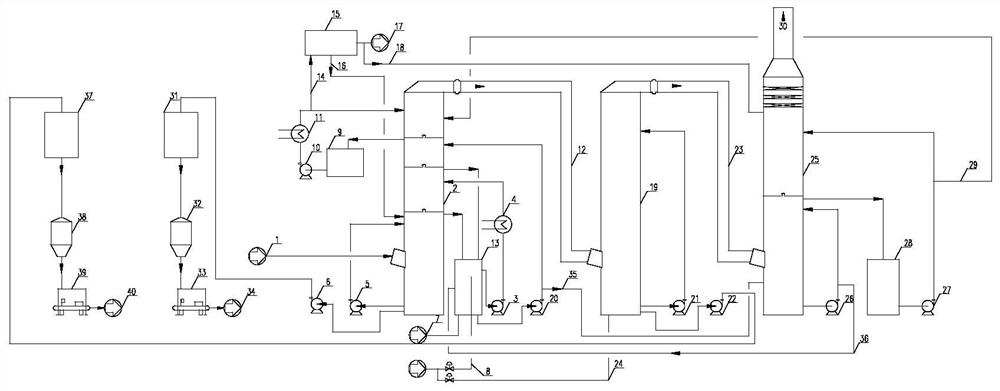

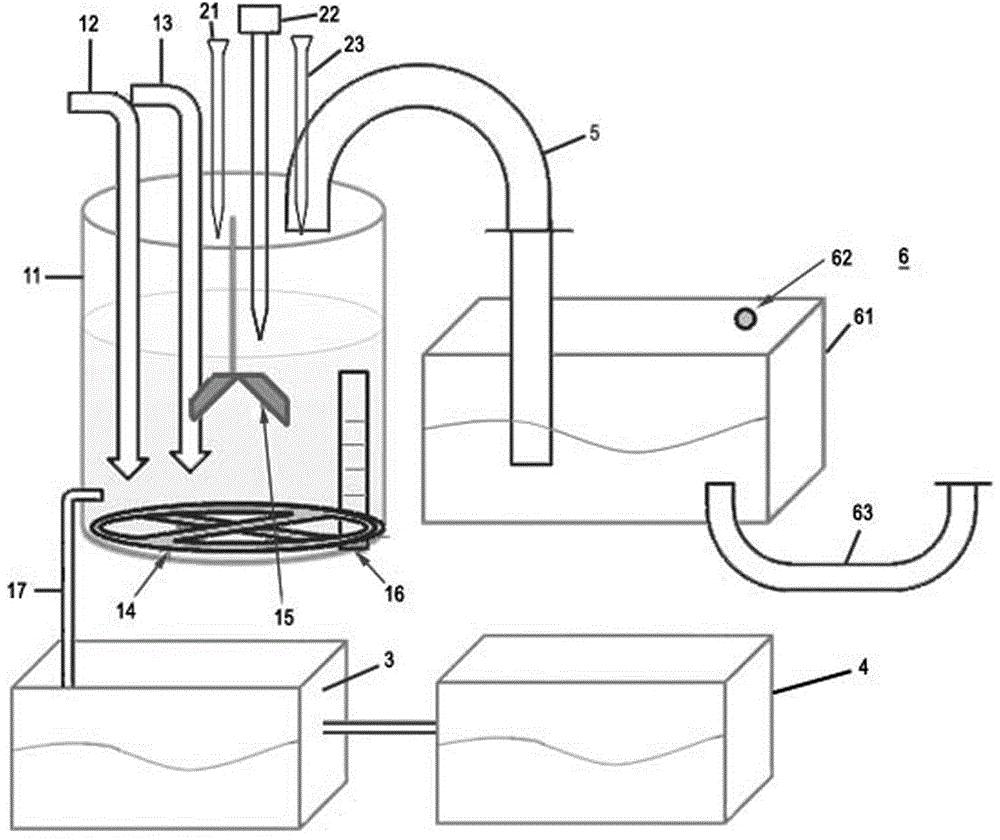

System and process for trapping sulfur dioxide and carbon dioxide by ammonia absorption at atmospheric pressure

InactiveUS20140050651A1High desulfurizationHigh carbon reduction efficiencyCombination devicesGas treatmentCo2 absorptionWater concentration

A system and a process for capture and absorption of sulfur dioxide and carbon dioxide by an ammonia method at normal pressure are disclosed. The system has a dilute ammonia water supply device connected with sulfur dioxide and carbon dioxide absorption devices; an induced draft fan is connected with a heat exchanger connected with the sulfur dioxide absorption device; a sulfur dioxide absorption tower is connected with a carbon dioxide absorption tower; cooling devices in the sulfur dioxide and carbon dioxide absorption towers share a cooling water inlet and outlet pipe; the sulfur dioxide and carbon dioxide absorption devices respectively restore ammonia concentration to original ammonia water concentration by supplementing concentrated ammonia water; the sulfur dioxide and carbon dioxide absorption devices respectively pump solutions into the heat exchangers, then the solutions enter crystallization tanks; solid-liquid separation is performed through centrifuges, and the liquid continues to circulate in the system.

Owner:ANHUI HUAIHUA

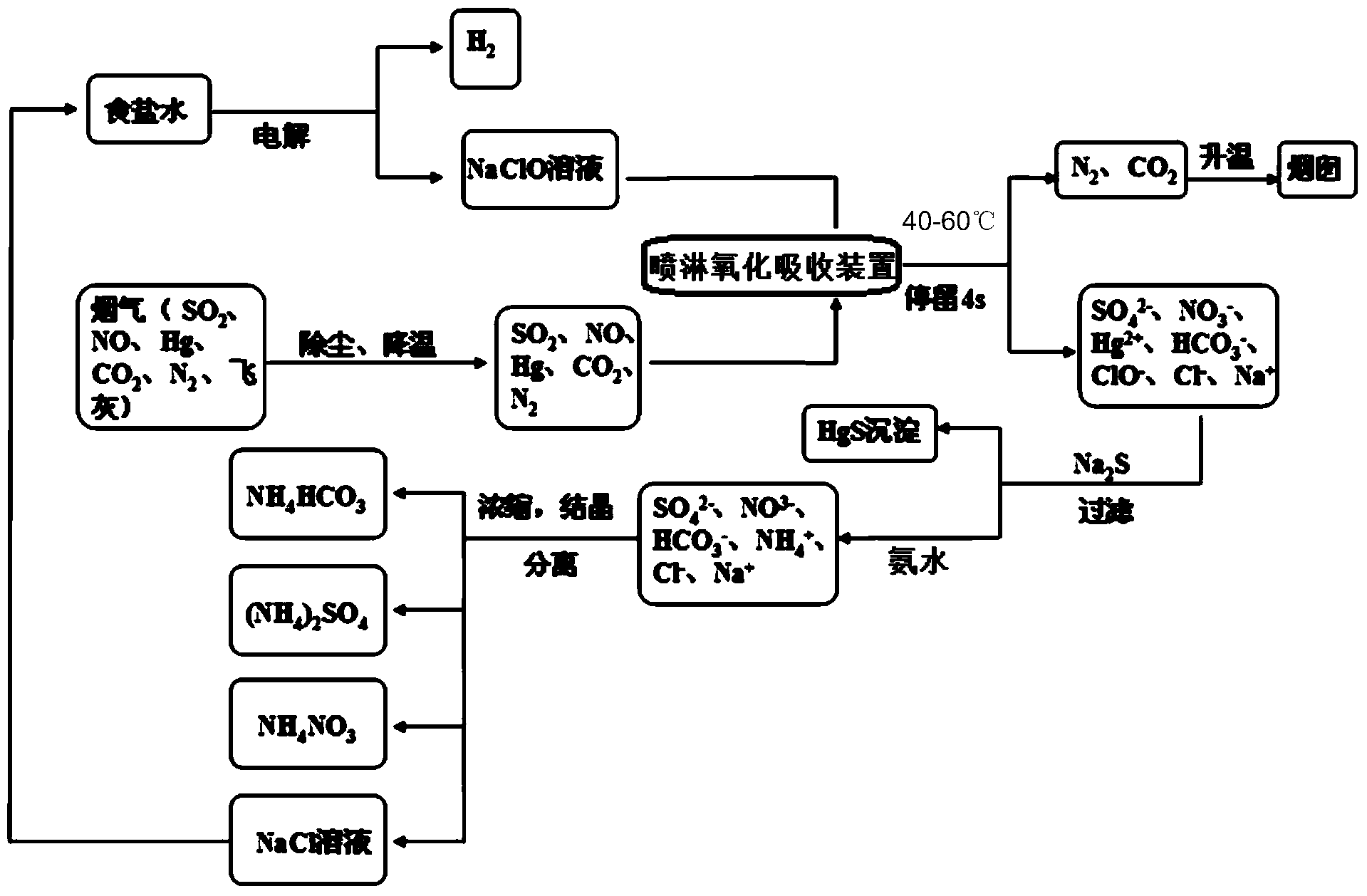

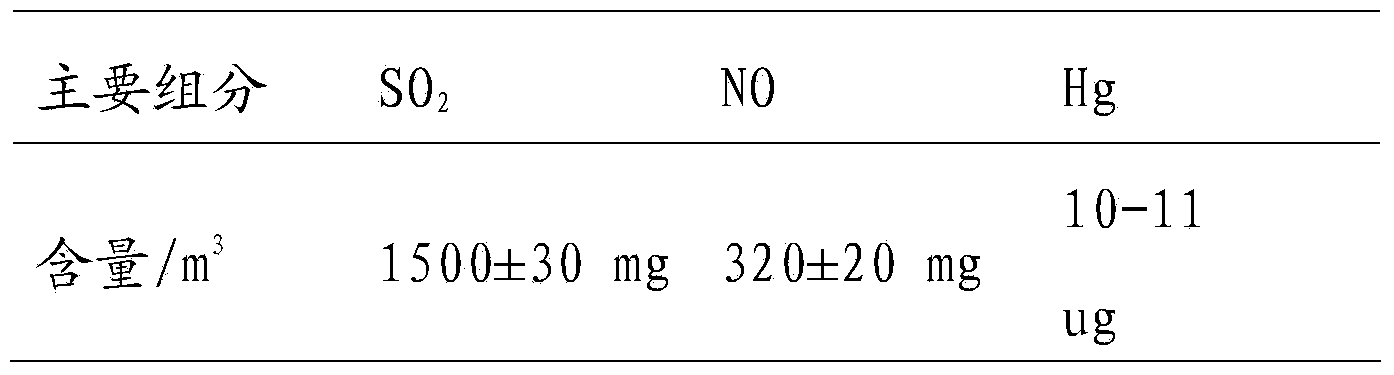

Comprehensive treatment method for carrying out desulfurization, denitration, mercury removal and recycling on flue gas of boiler

The invention discloses a comprehensive treatment method for carrying out desulfurization, denitration, mercury removal and recycling on the flue gas of a boiler. Sodium hypochlorite which is low in price serves as an oxidation absorbent for purifying flue gas pollutants; SO2, NOx and Hg in the flue gas are oxidized by virtue of a wet oxidization process; oxidation products and part of CO2 in the flue gas are converted into ammonium bicarbonate, ammonium sulfate, ammonium nitrate and mercuric sulfide products with certain economical values; a reduction product of the sodium hypochlorite, namely sodium chloride, is reused as a production raw material of the sodium hypochlorite, and the method is a green process for purification treatment on the flue gas of the boiler. The removal rate of SO2 in the flue gas treated by virtue of the method exceeds 99 percent, the removal rate of NOx exceeds 90 percent, the removal rate of Hg exceeds 95 percent, and the obtained products such as ammonium bicarbonate, ammonium sulfate, ammonium nitrate and HgS are industrial first-grade products, so that recycling is realized.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

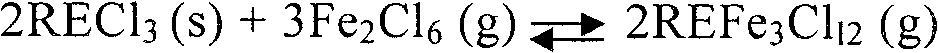

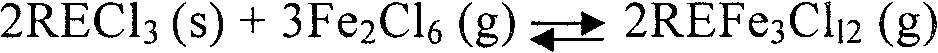

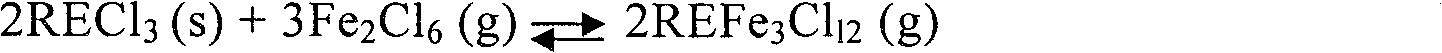

Method for recovering mixed rare earth chlorides from neodymium iron boron permanent magnet material scraps

InactiveCN101817547AReduce varietyReduce dosageAmmonium carbonates/bicarbonatesRare earth metal compoundsRare earthClosed tube

The invention provides a method for recovering mixed rare earth chlorides from neodymium iron boron permanent magnet material scraps, which is characterized in that: grinding the neodymium iron boron permanent magnet material scraps in an environment of an inert gas to obtain a powdered material, adding a proper amount of carbon powder into the powdered material, introducing a dry chlorine gas into the mixed powder to perform chlorination and performing two closed-tube chemical vapor transport processes for the chlorinated product to obtain the mixed rare earth chlorides which contain over 95 percent of rare earth and anhydrous ferric chloride with a purity of about 98 percent respectively; and using oxalate to perform precipitation and obtaining cobalt oxide with a purity of about 99 percent by washing, dehydration and roasting. When the method is used for recovering the mixed rare earth chlorides and valuable elements such as iron and cobalt from the neodymium iron boron permanent magnet material scraps, the varieties and using amount of chemical raw materials can be reduced in a recovery process, the discharge of waste gases and water can be reduced, and the waste gases can be absorbed by ammonia water so as to be reused.

Owner:SHENYANG POLYTECHNIC UNIV

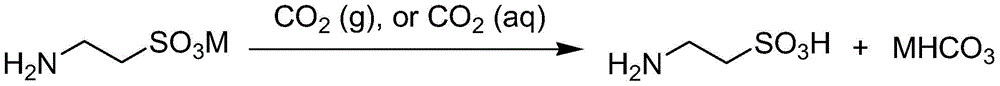

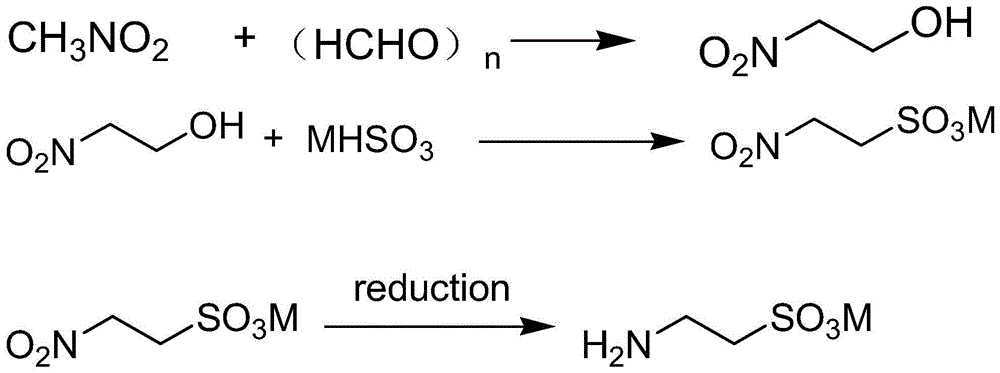

Method for preparing taurine and co-producing bicarbonate

ActiveCN105693559ASolve the dangerSolve the problems that need to be dealt withChemical industryAmmonium carbonates/bicarbonatesTaurineAlkali metal

The invention discloses a method for preparing taurine and co-producing bicarbonate. The method comprises the step of leading carbon dioxide gas or adding a carbon dioxide water solution to an amino ethyl sulfonate water solution of alkali metal or ammonium to regulate a pH value so as to obtain the taurine and the bicarbonate. The method can replace an existing taurine preparation method of using sulfuric acid or sulfur dioxide to regulate the pH value, meanwhile can treat boiler exhaust gas, turns the carbon dioxide in the exhaust gas into wealth, co-produces the bicarbonate and is a safe, environmentally-friendly and energy-saving method for producing the taurine and co-producing the bicarbonate.

Owner:HUBEI GRAND LIFE SCI & TECH CO LTD

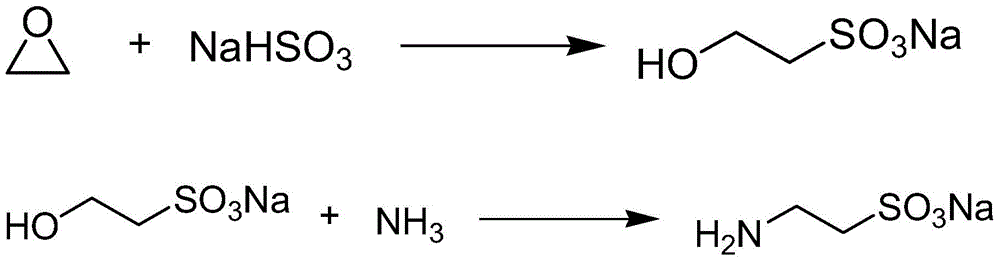

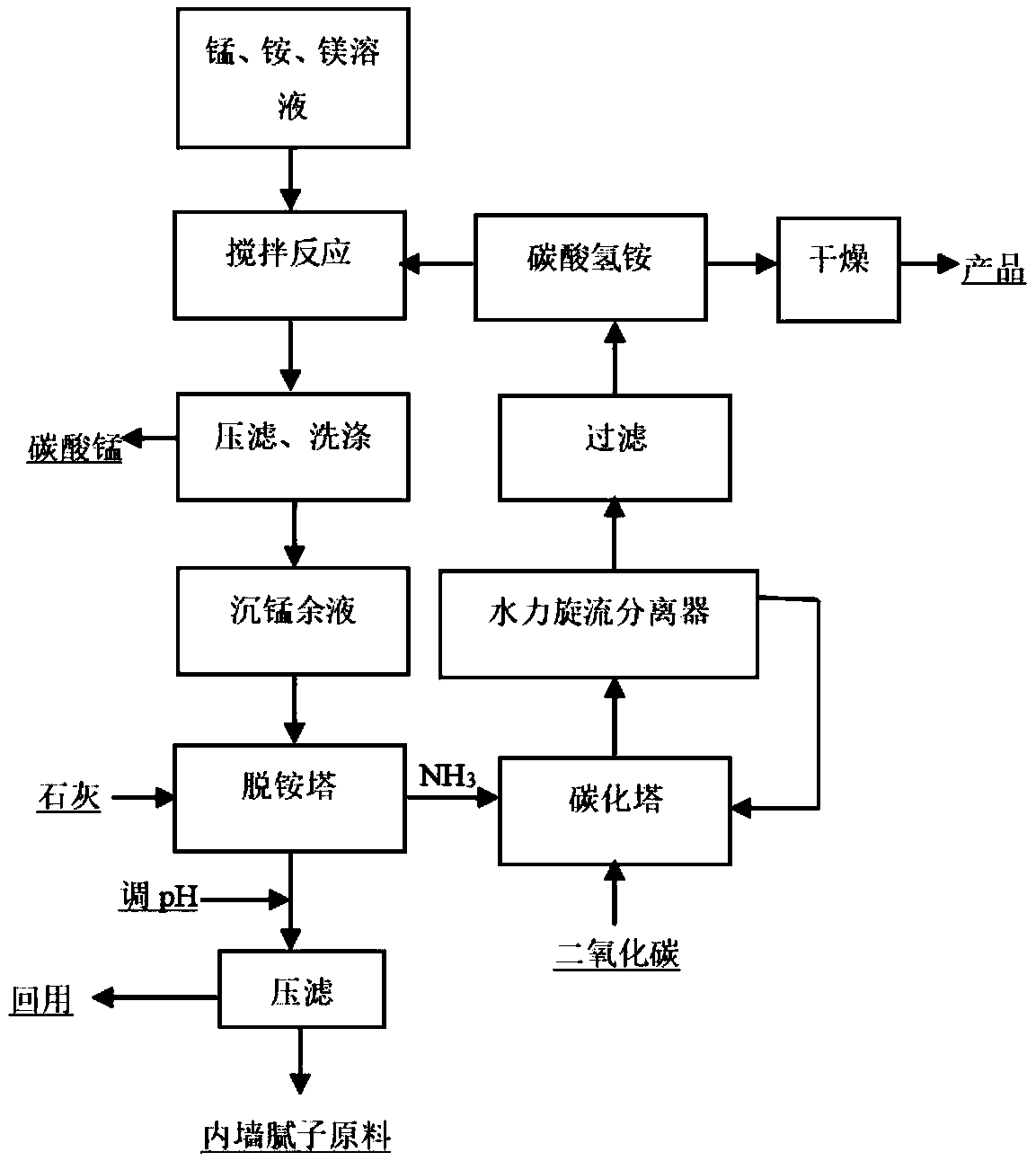

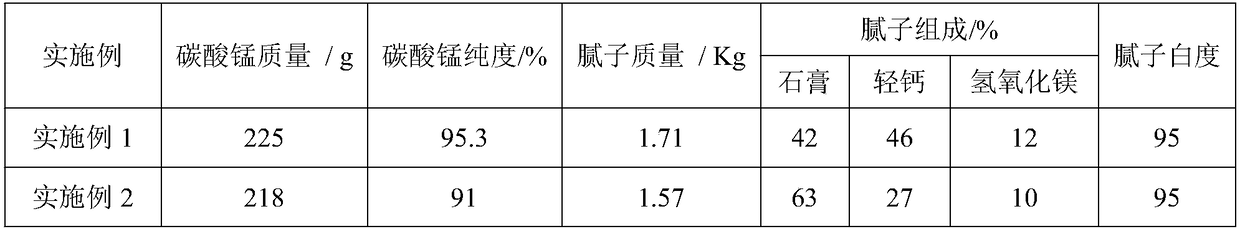

Comprehensive utilization method of electrolytic manganese residue washing liquid

ActiveCN108483501ANo secondary pollutionReduce pollutionAmmonium carbonates/bicarbonatesFilling pastesElectrolysisManganese

The invention relates to a comprehensive utilization method of electrolytic manganese residue washing liquid. The comprehensive utilization method comprises the following steps: (1) purifying, namelyadding a heavy metal precipitator and activated carbon into electrolytic manganese residue washing liquid, stirring for reaction, and filtering; (2) carrying out manganese precipitation, namely addingammonium hydrogen carbonate to precipitate manganese into manganese carbonate, and carrying out pressure filtering washing and drying, so as to obtain crude manganese carbonate; (3) carrying out deamination, namely adding lime into the manganese precipitation residual liquid to generate precipitation and deamination reaction, carrying out solid-liquid separation, adjusting the pH value of solids,carrying out pressure filtering drying to obtain putty powder, pumping filtrate into a deamination tower, carrying out deamination, adjusting the pH value of solution with carbon dioxide, and reusingthe solution for washing residue; and (4) carrying out carbonization, namely reacting by virtue of ammonia gas exhausted from the deamination tower and carbon dioxide, so as to generate ammonium hydrogen carbonate. By virtue of a circulating production process, a manganese carbonate product is obtained, meanwhile, two products including ammonium hydrogen carbonate and a gypsum-base internal wallputty raw material can be further produced, and soluble substances in the manganese residue are adequately recycled and comprehensively utilized, so that the treatment cost is greatly lowered, and thecomprehensive utilization method has good economic benefits.

Owner:MIANYANG TEACHERS COLLEGE

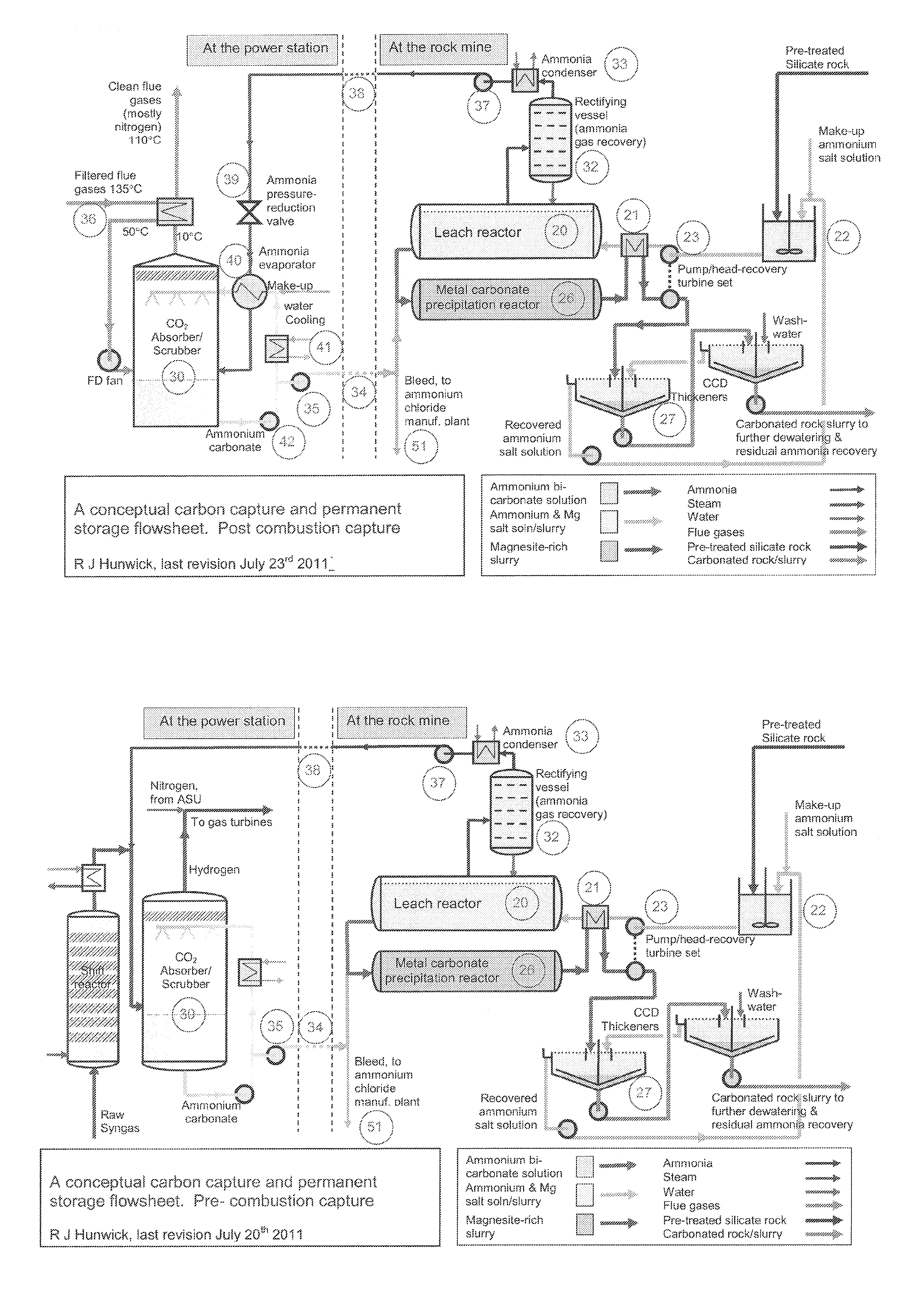

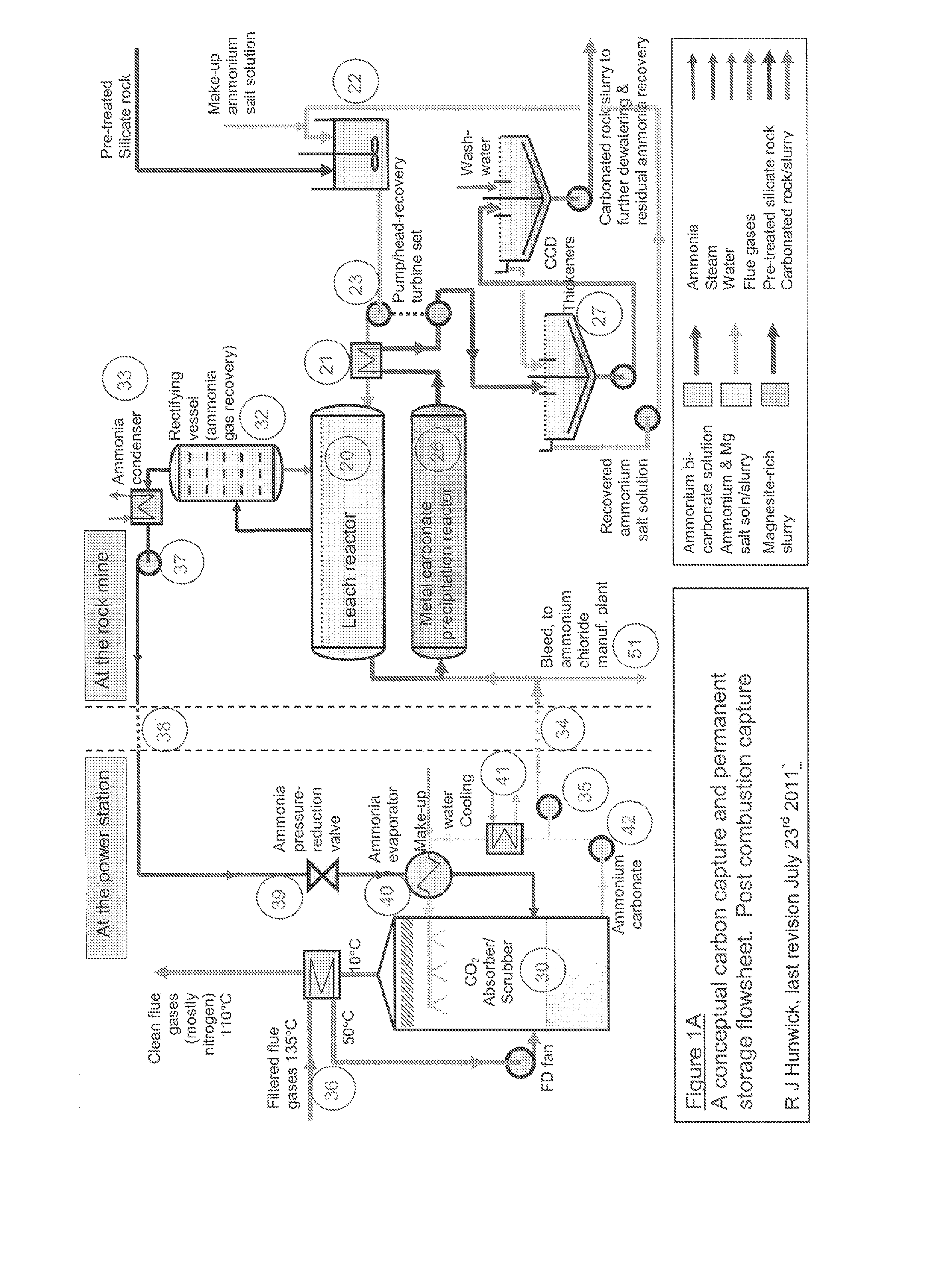

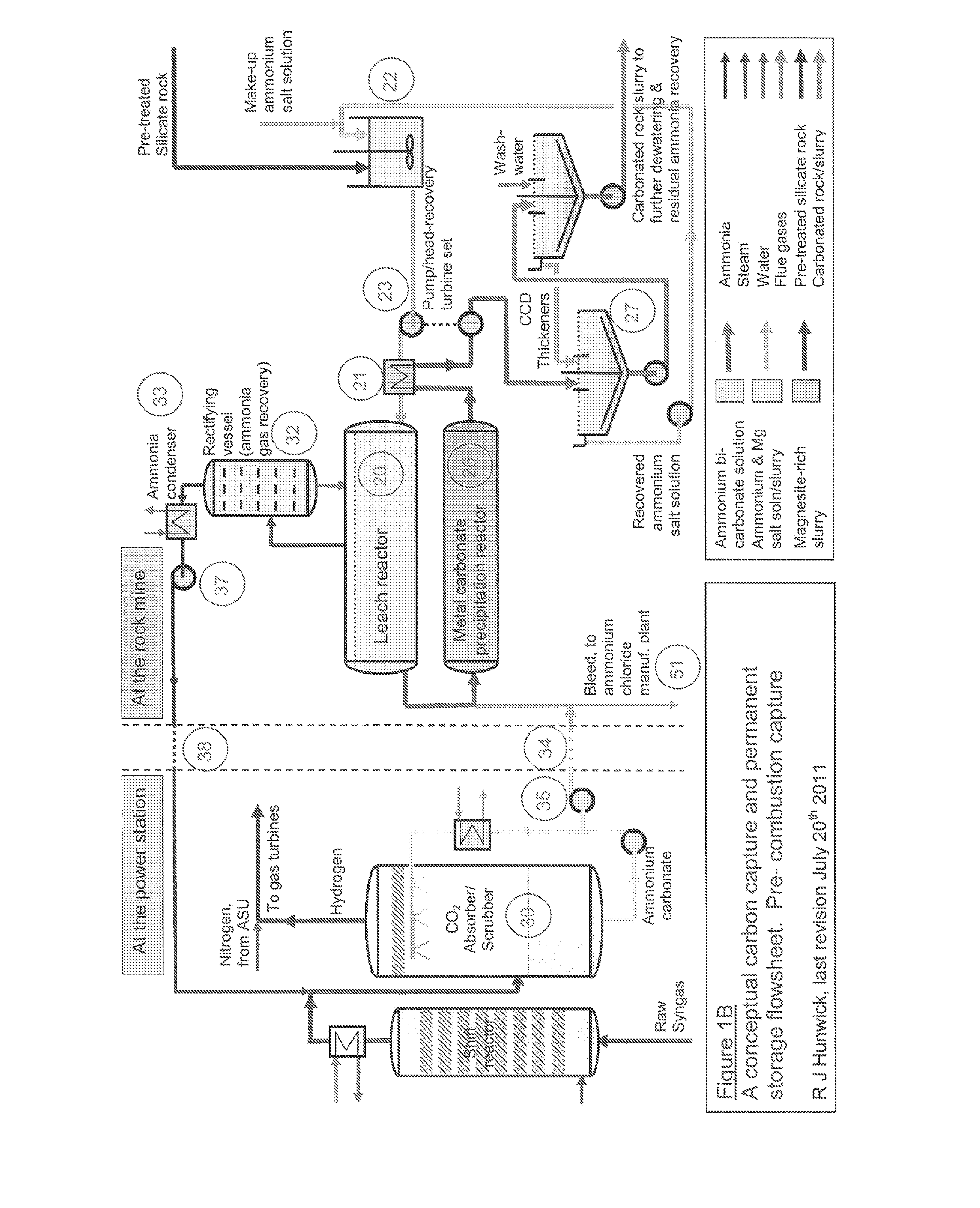

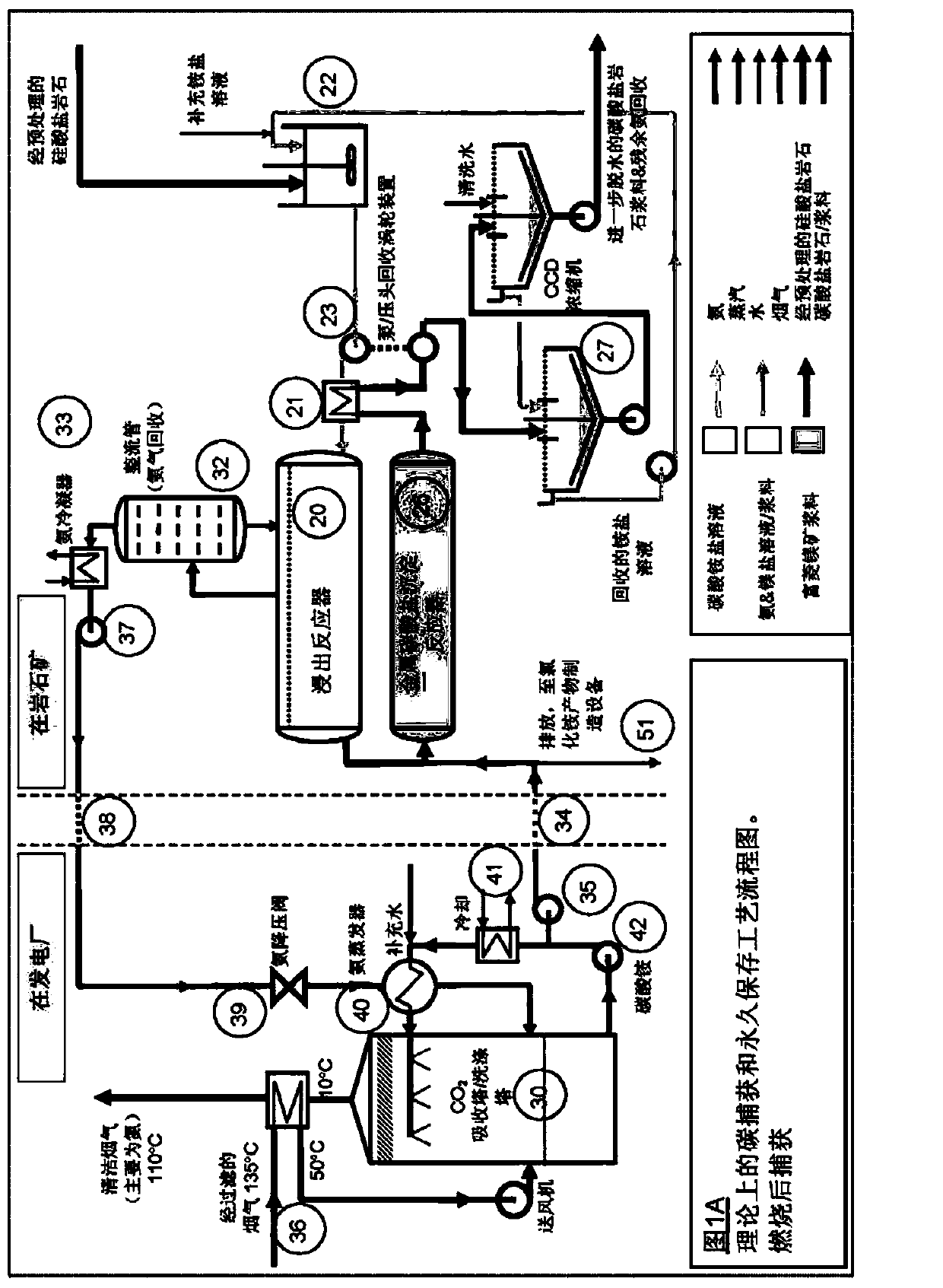

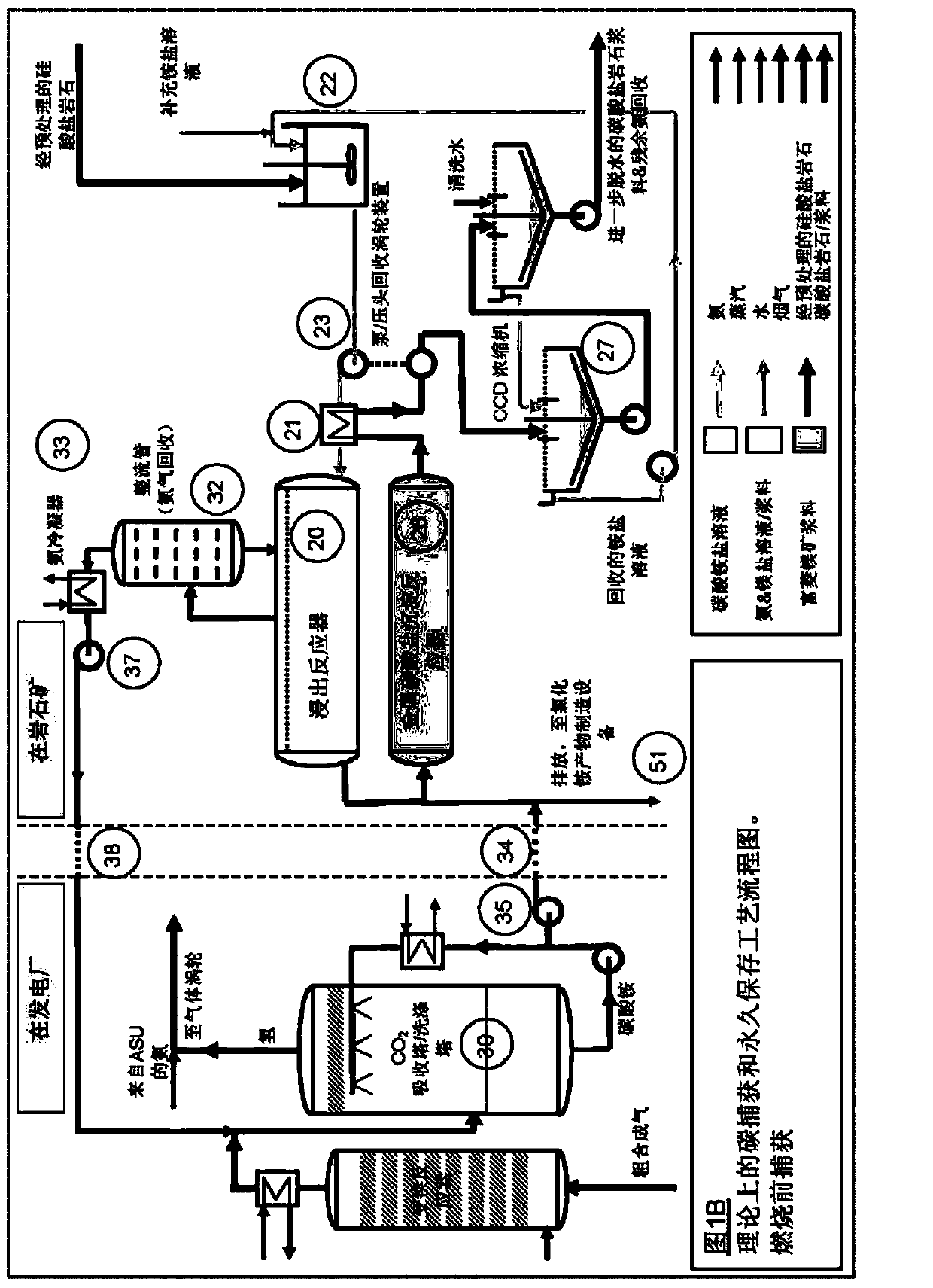

Process and system for capturing carbon dioxide from a gas stream

InactiveUS20140356267A1Quick fixPrevent scalingMaterial nanotechnologyCombination devicesSlurryAmmonium carbonate

A process and system are disclosed for capturing carbon dioxide from a gas stream. The process and system comprises a first reactor in which a slurry of a metal silicate is reacted together with an ammonium salt in aqueous solution. The salt is one that does not form a precipitate with the metal silicate. In the first reactor the metal silicate reacts with the solution to produce a slurry of silica in an aqueous solution of a salt of the metal and ammonia. Ammonia gas is drawn off directly from the first reactor, and ammonia, including the ammonia drawn off from the first reactor, is added to the gas stream. The process and system also comprises scrubbing the gas stream, including with the added ammonia, with an aqueous solution, whereby the carbon dioxide and ammonia are absorbed into the solution and ammonium carbonate salt(s) are produced.

Owner:HUNWICK RICHARD J

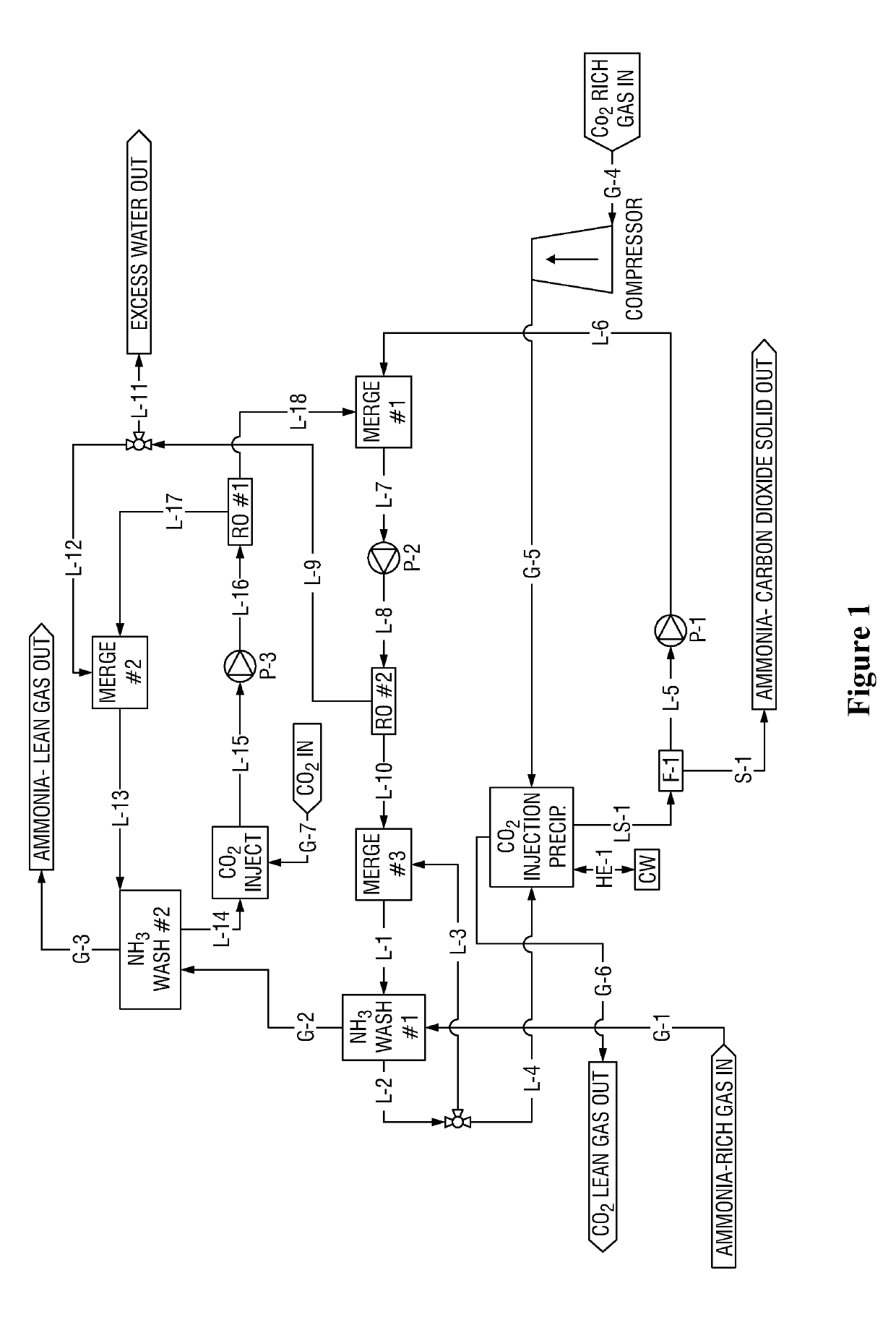

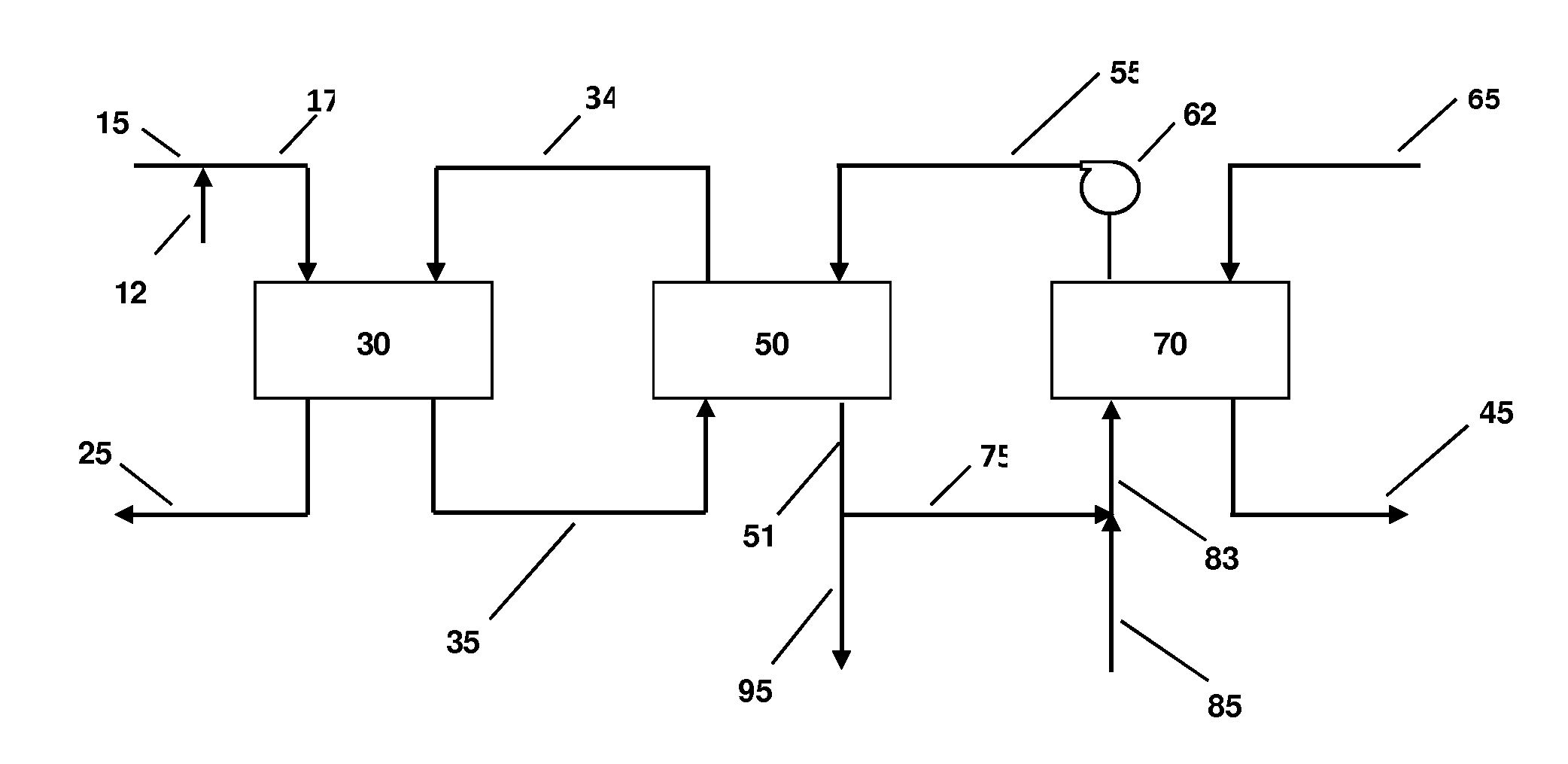

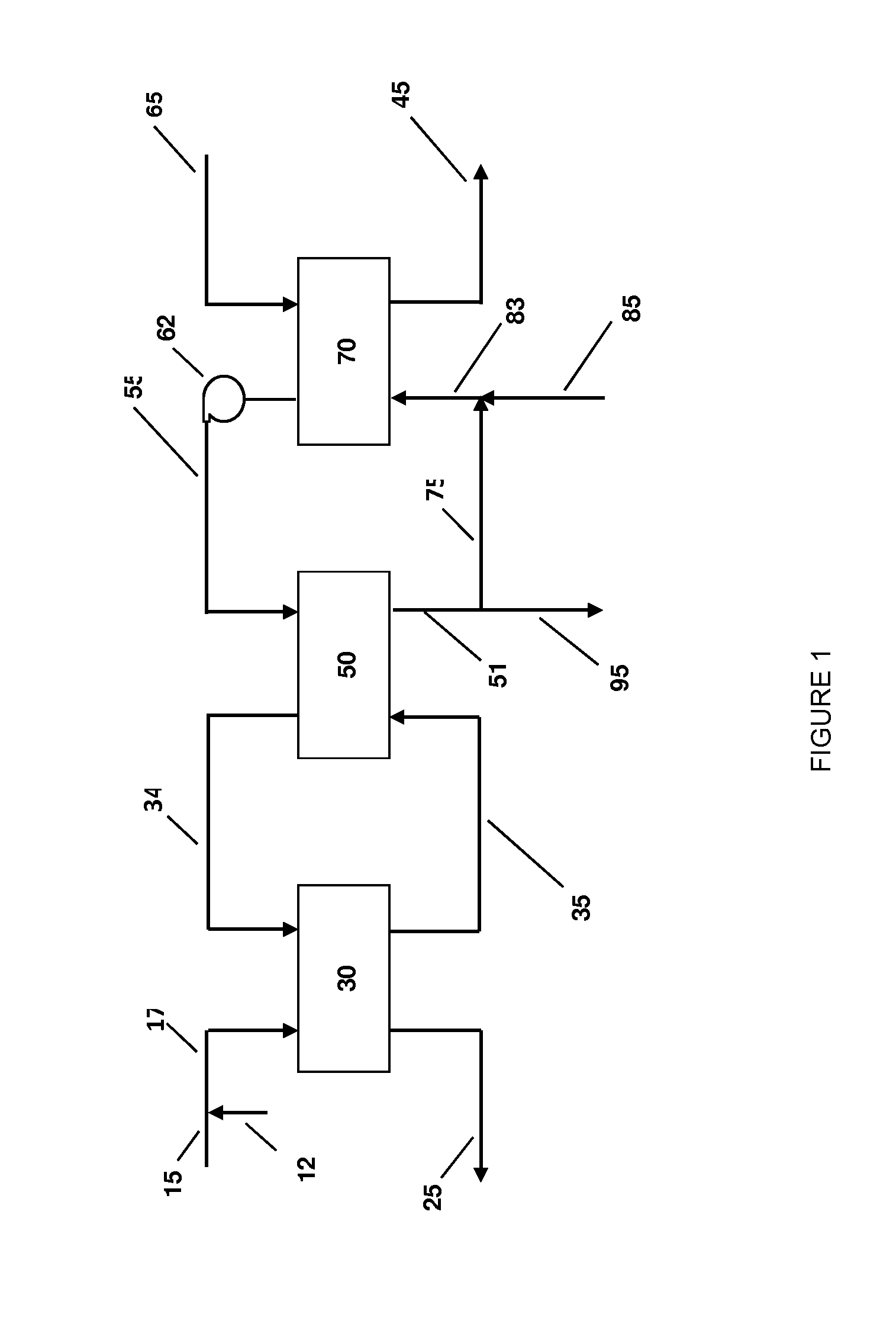

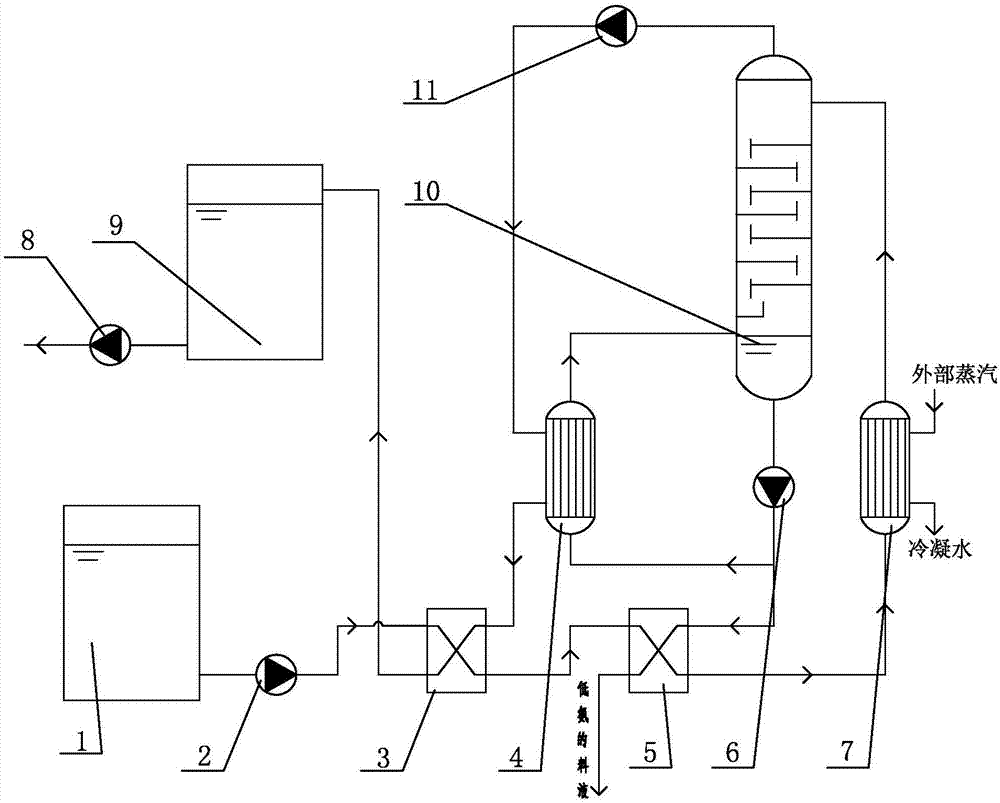

Process to recover ammonium bicarbonate from wastewater

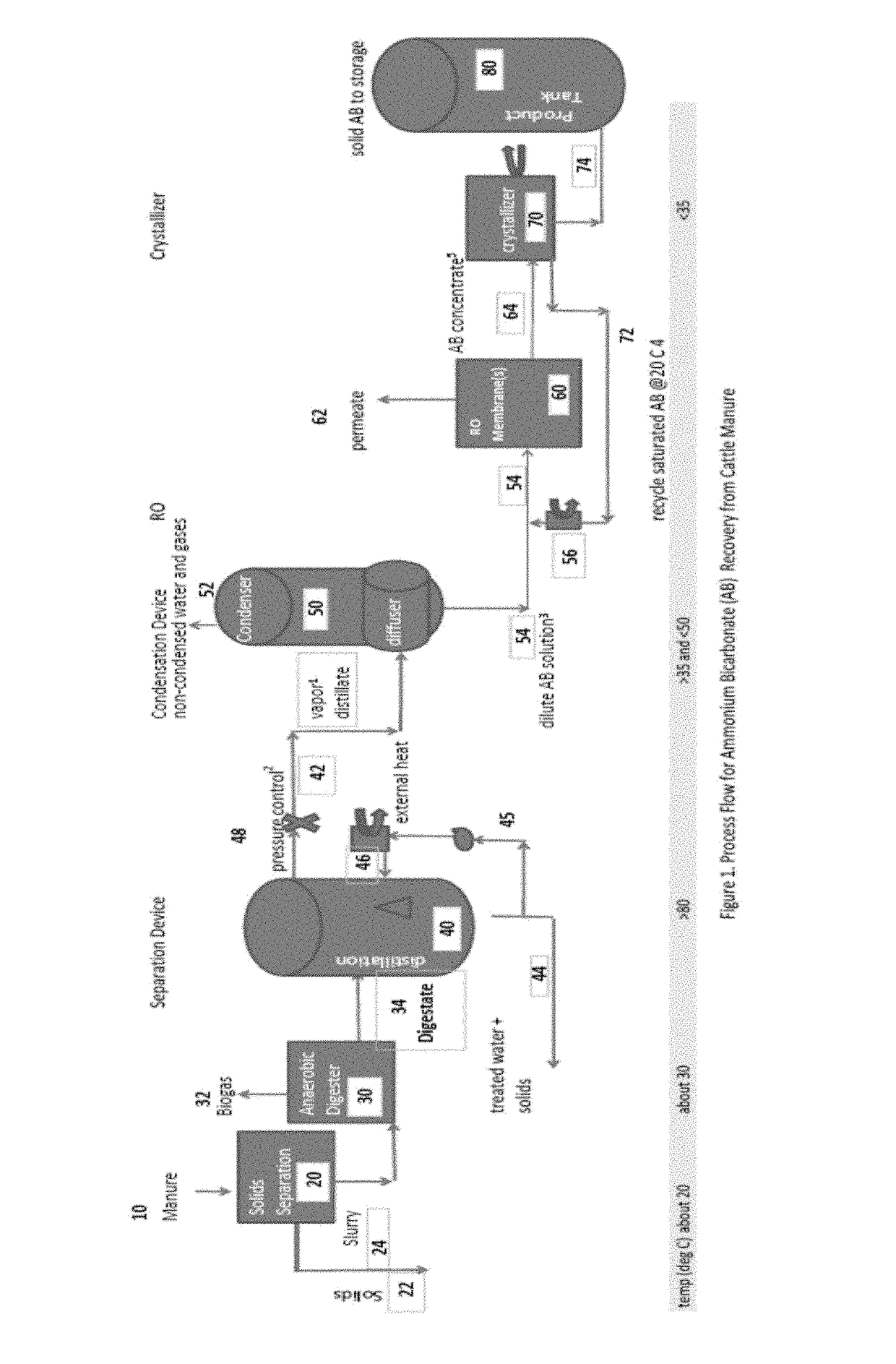

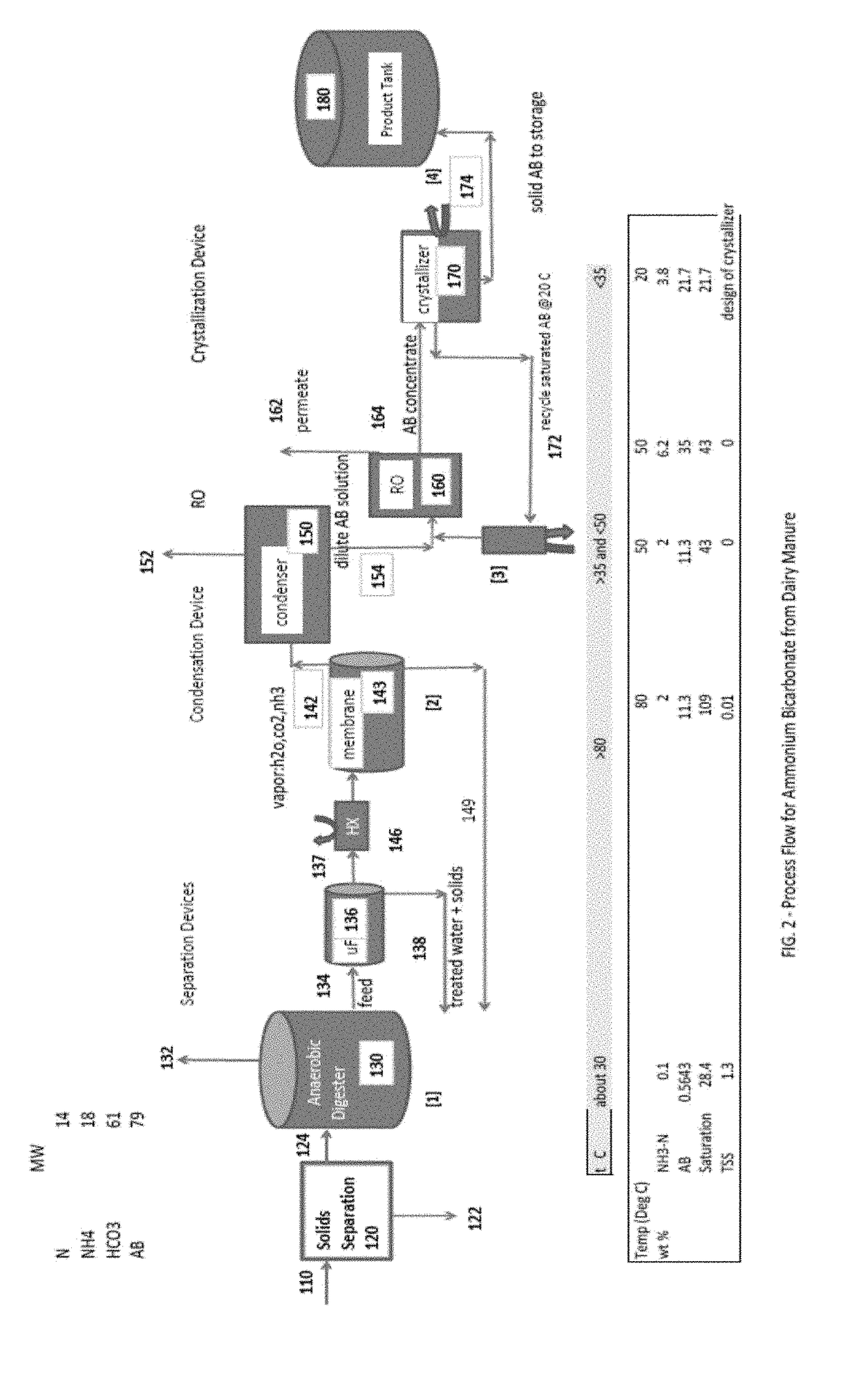

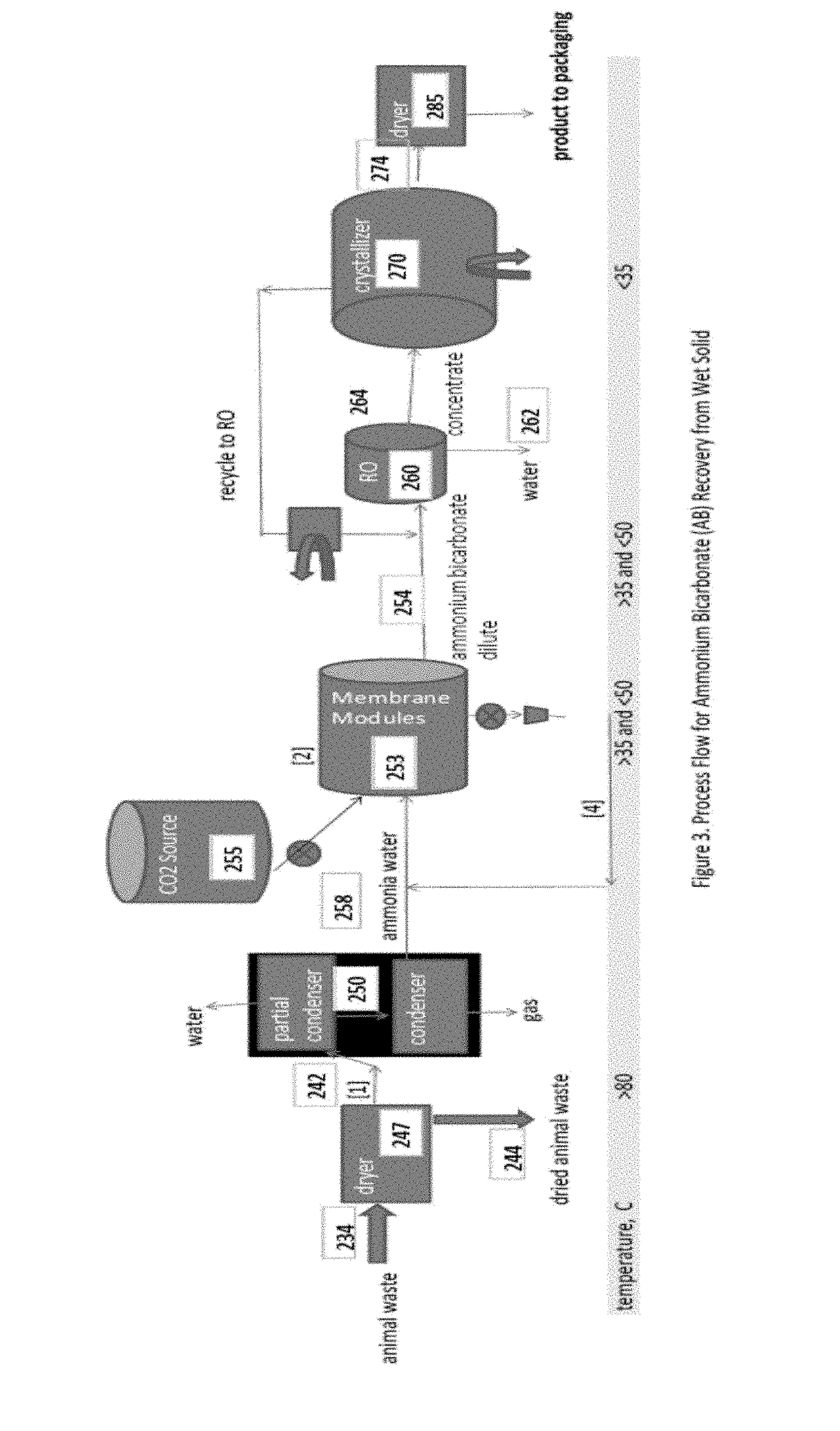

ActiveUS20190071338A1Eliminate needConcentrates dissolved ammonium carbonate and ammonium bicarbonate more efficientlyWater treatment parameter controlSpecific water treatment objectivesCelsius DegreeSludge

The present invention is a process, a method, and system for recovery and concentration of dissolved ammonium bicarbonate from a wastewater containing ammonia (NH3) using gas separation, condensation, and crystallization, each at controlled operating temperatures. The present invention includes 1) removal of ammonia from waste (sludges, semi-solids, and solids and liquids) without the use of chemicals at a temperature of at least 80 degrees Celsius, 2) condensing the gaseous containing ammonia, carbon dioxide and water vapor to remove water vapor concentrating the amount of gaseous ammonia and carbon dioxide, 3) concentrating the ammonia and carbon dioxide in the water by established means, such as concentrating the gas using partial condensation followed by passing the concentrated gas through an absorption column at a temperature of between about 20 and 50 degrees Celsius to form dissolved ammonium carbonate and ammonium bicarbonate, or total condensation followed by dewatering using reverse osmosis, and 4) crystallizing concentrated dissolved ammonium carbonate and ammonium bicarbonate at a temperature of less than about 35 degrees Celsius to form solid ammonium bicarbonate and ammonium carbonate.

Owner:BION ENVIRONMENTAL TECH

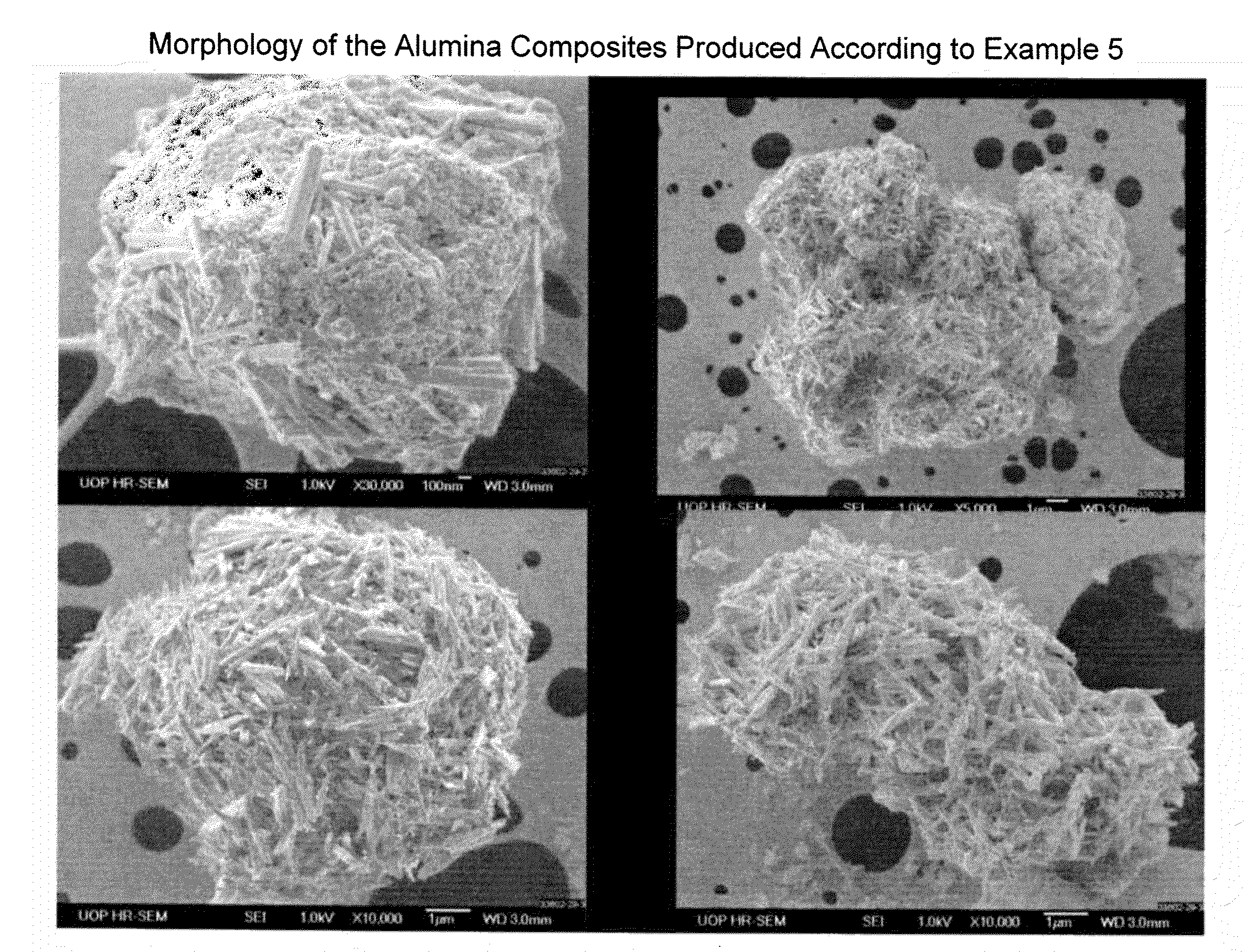

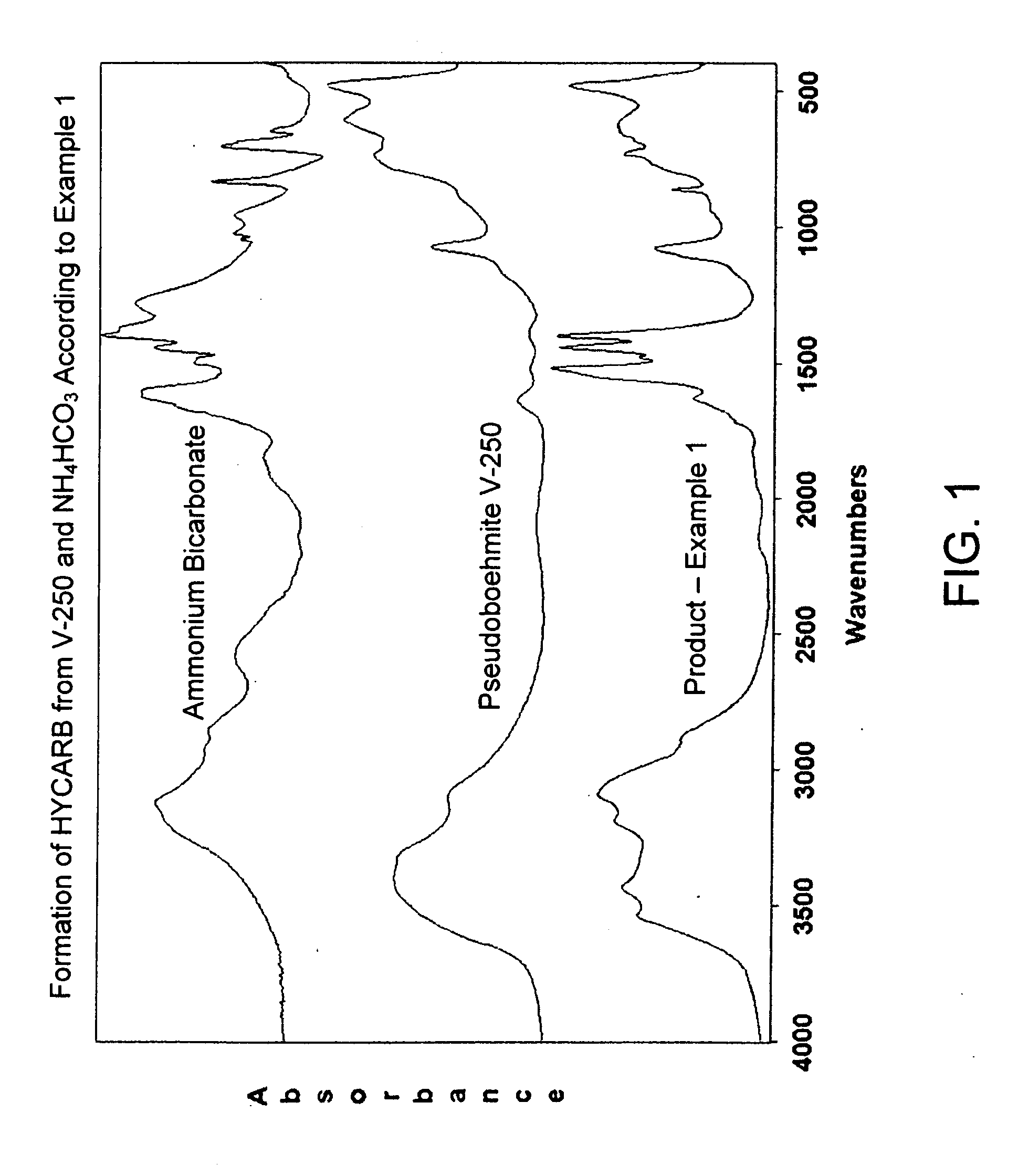

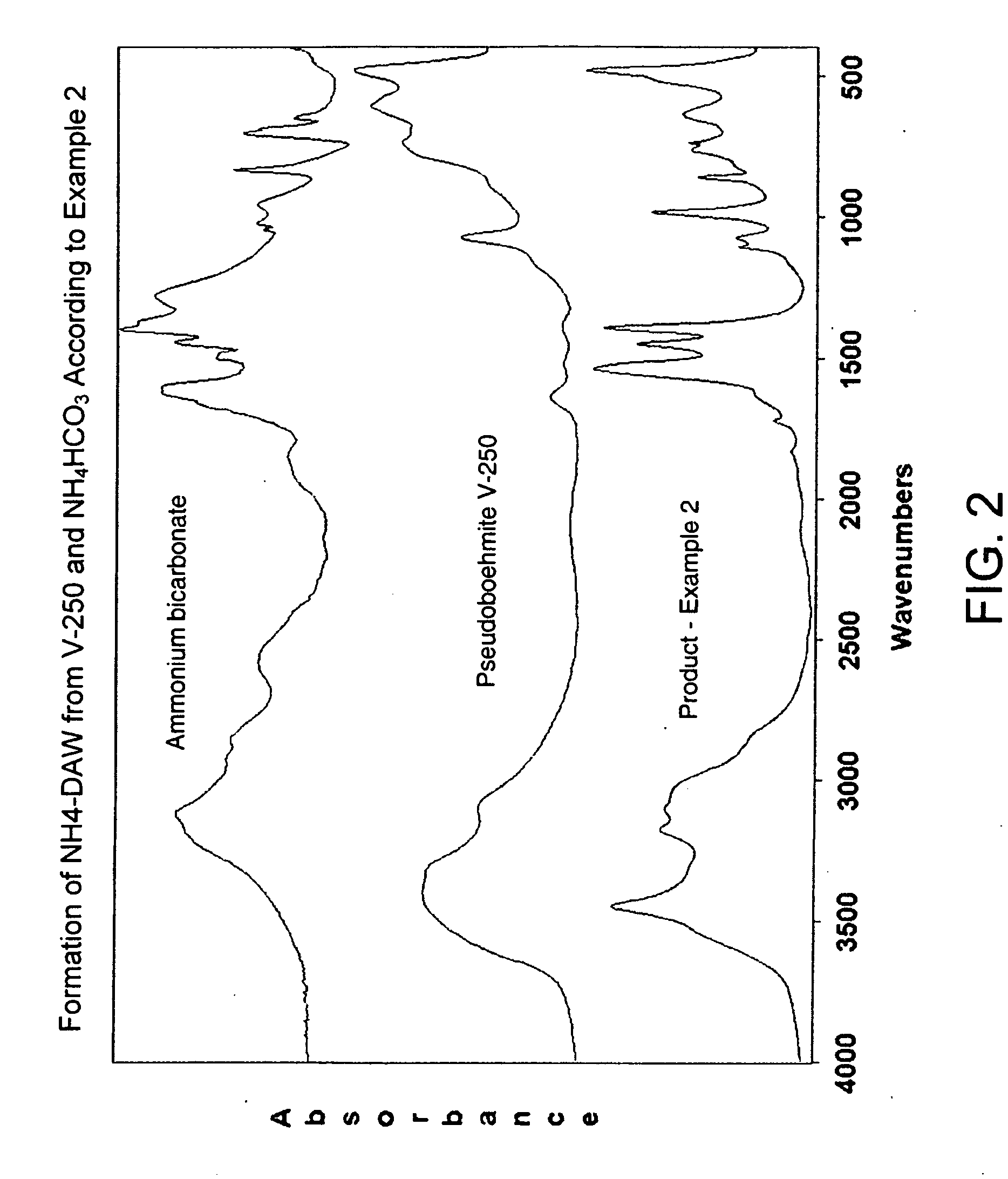

Process for Conversion of Aluminum Oxide Hydroxide

ActiveUS20100148116A1Other chemical processesAmmonium carbonates/bicarbonatesAluminium hydroxideAluminum oxide hydroxide

The present invention is a process for the conversion of aluminum oxide hydroxide (AlOOH) to aluminum oxide. About 30 to 70 wt-% of AlOOH, about 30 to 70 wt-% ammonium hydrogencarbonate NH4HCO3 and 0 to 20 wt-% water are combined to produce a mixture. This mixture is then cured at a temperature from about 30° to about 90° C. to convert at least 5% of the AlOOH to a ammonium hydroxycarbonate (dawsonite-type) intermediate and then the dawsonite-type intermediate is decomposed at a temperature from about 130° to 320° C. to produce aluminum oxide. The aluminum oxide can be further calcined at 500° to 800° C. to produce a gamma-theta phase alumina.

Owner:UOP LLC

Treatment method for sludge in municipal sewage treatment plant

ActiveCN104671621AHighlight substantiveSignificant progressSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMedicineMunicipal sewage

The invention discloses a treatment method for sludge in a municipal sewage treatment plant and belongs to the technical field of sludge treatment. The technical scheme adopted by the treatment method is as follows: the treatment method is characterized in that sludge in the municipal sewage treatment plant is subjected to harmless processing and treatment through the processing steps of dehydration, modification and heavy metal treatment, and treated sludge conforms to the national pollutant control standard of agricultural sludge. Compared with the prior art, the treatment method is novel, reliable and free of secondary pollution, changes waste into valuable, realizes harmless treatment of sludge, realizes the outstanding substantial characteristic of resourceful treatment and makes remarkable progress.

Owner:徐明好

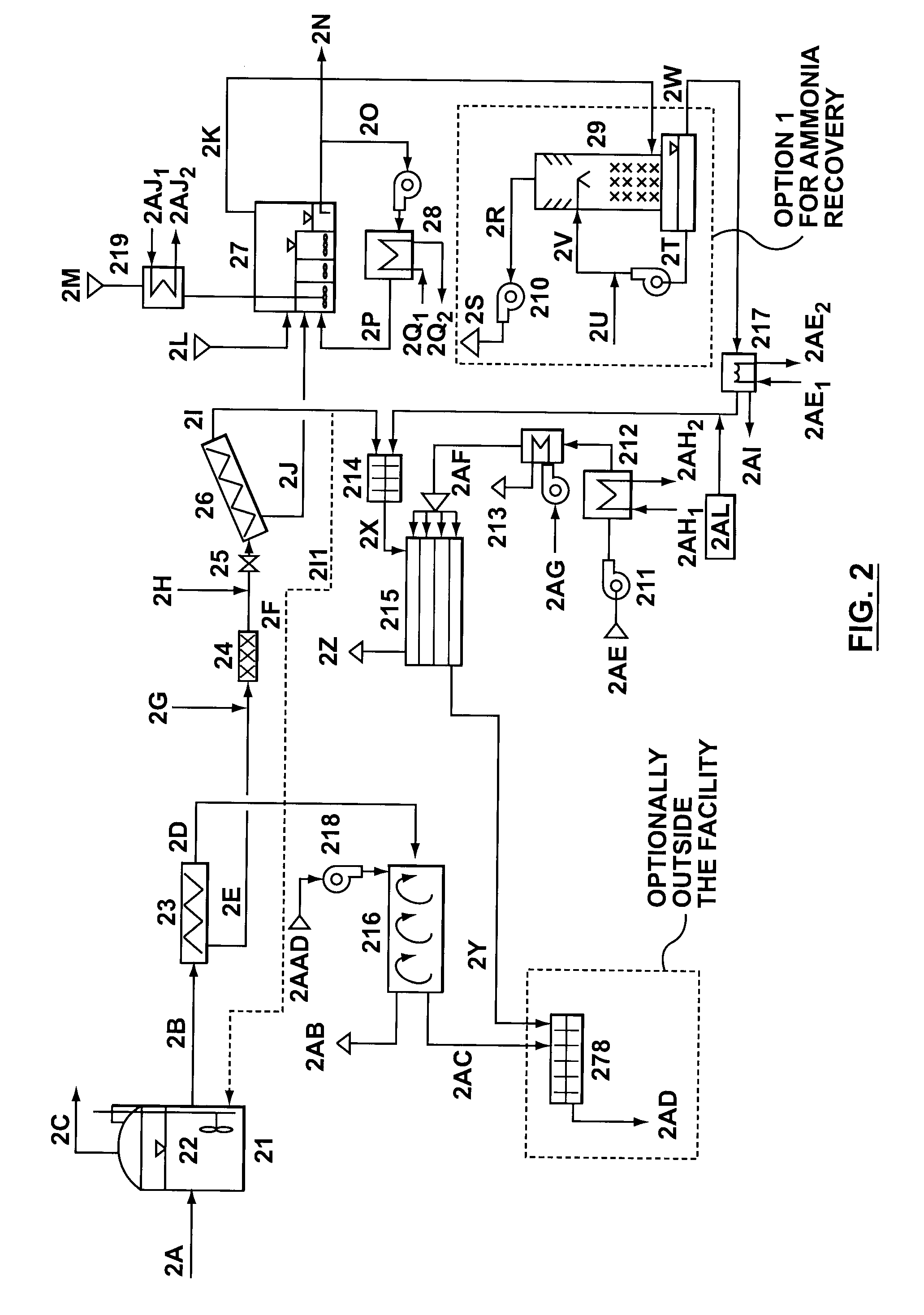

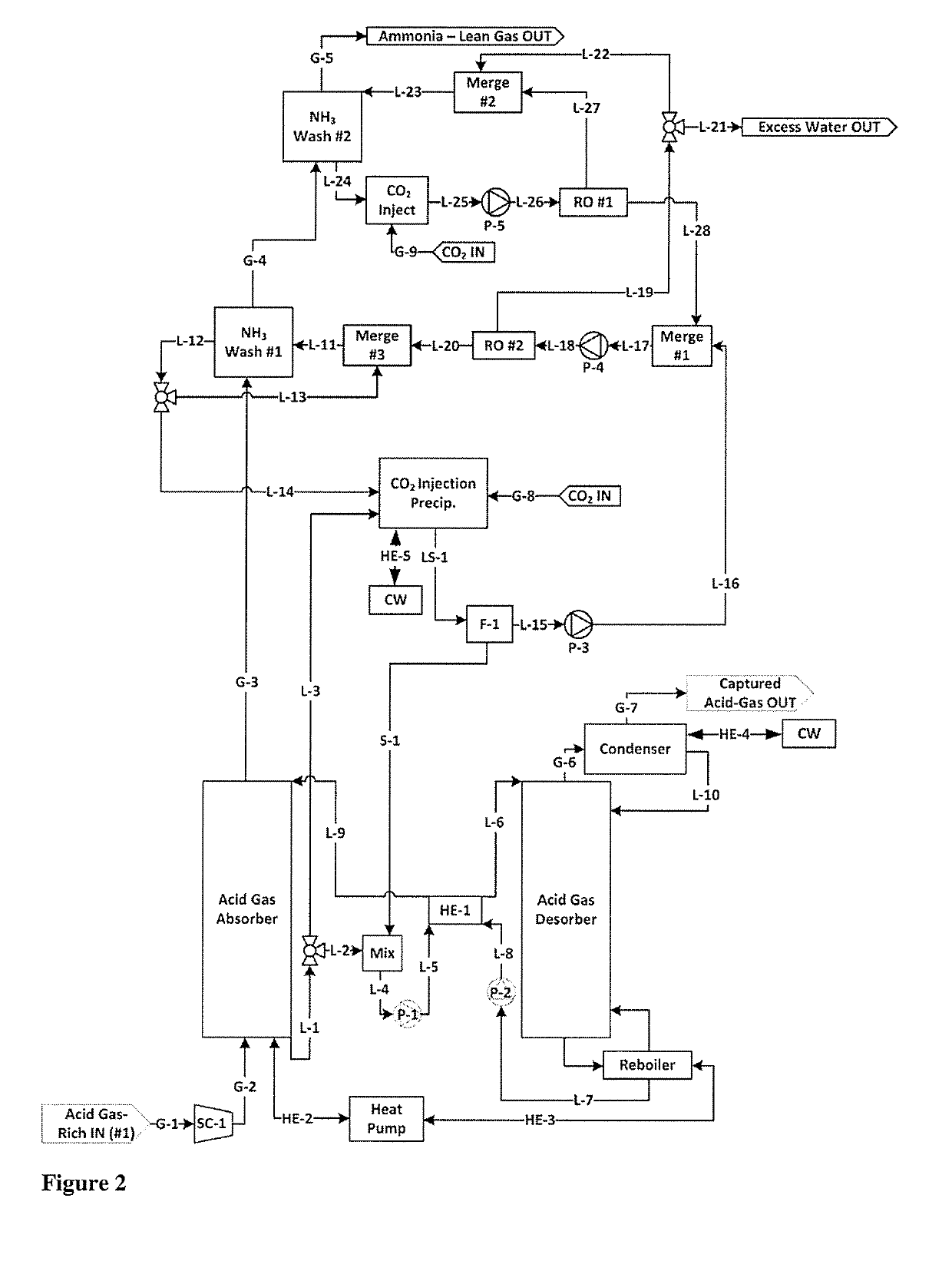

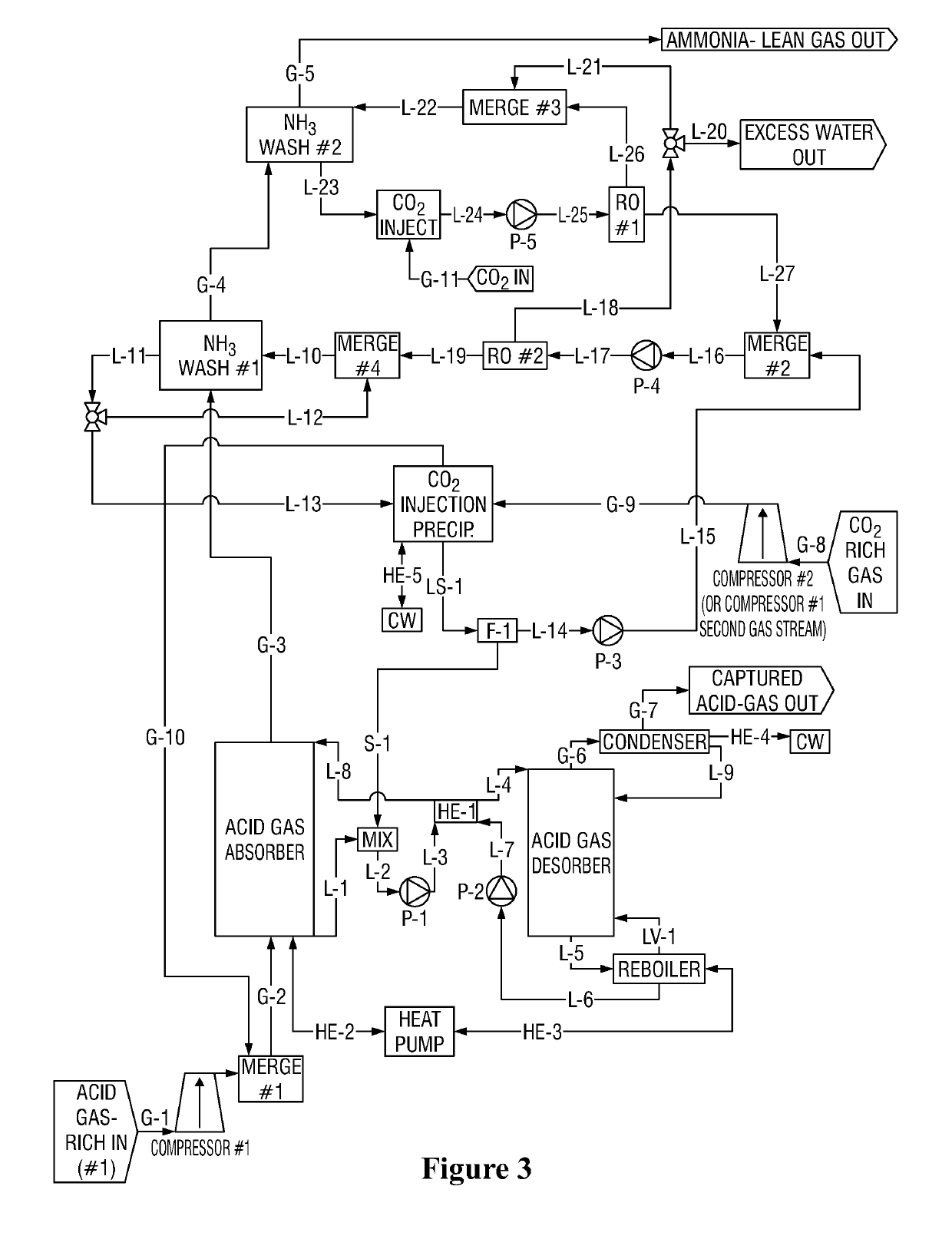

Systems and methods for ammonia recovery, acid gas separation, or combination thereof

ActiveUS20190233296A1Reduce and eliminates challengeFast absorptionProductsMembranesDesorptionReverse osmosis

The present invention relates to processes and systems for ammonia recovery and / or acid-gas separation. In some embodiments, a system for acid gas separation may be integrated with an ammonia abatement cycle employing a high temperature absorber. In some embodiments, a system for acid gas separation may employ a higher temperature absorber due to the lower energy consumption and cost of the integrated ammonia abatement cycle. Advantageously, heat may be recovered from the absorber to power at least a portion of any acid gas desorption in the process. Reverse osmosis or other membranes may be employed.

Owner:INNOVATOR ENERGY LLC

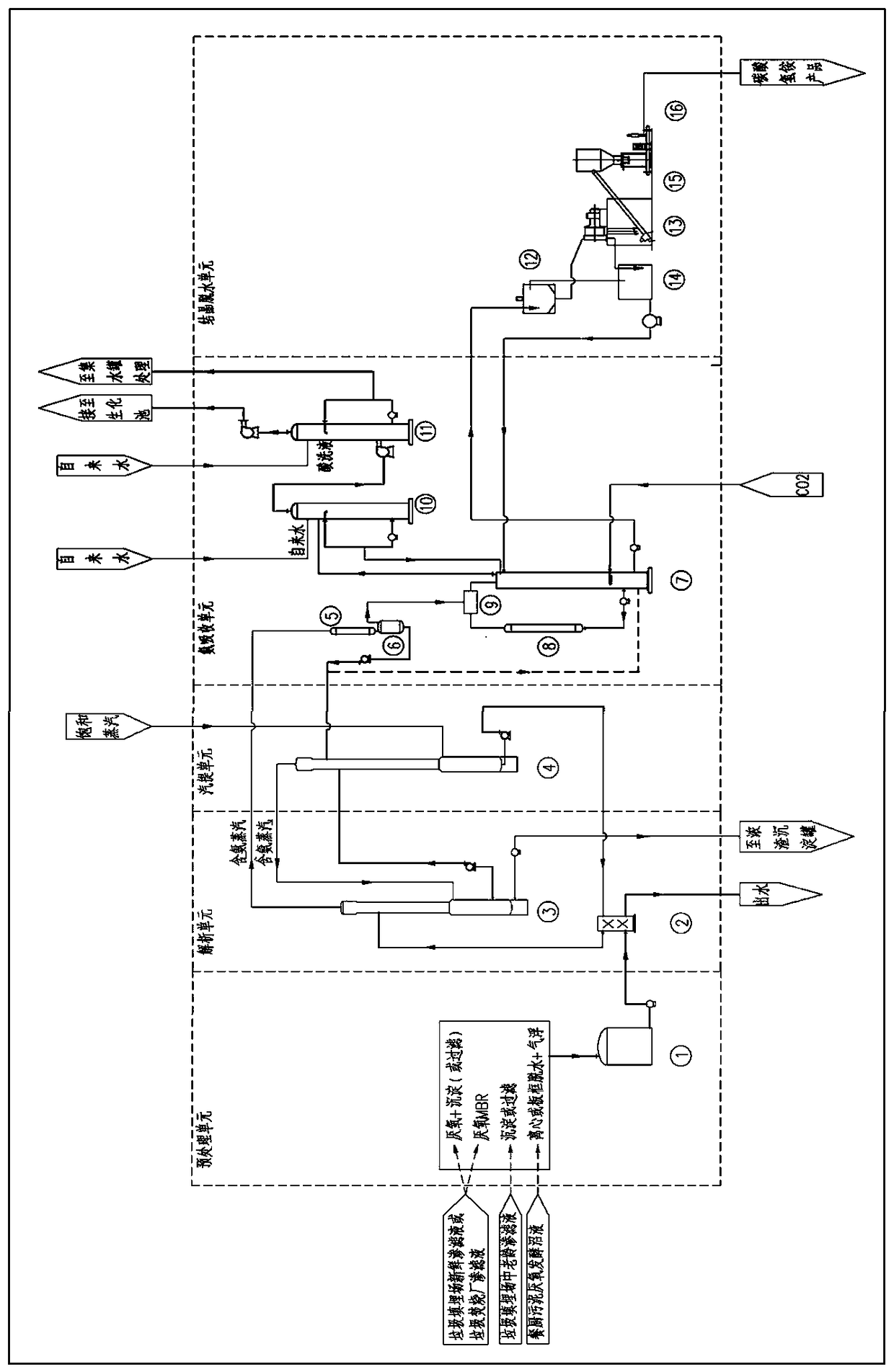

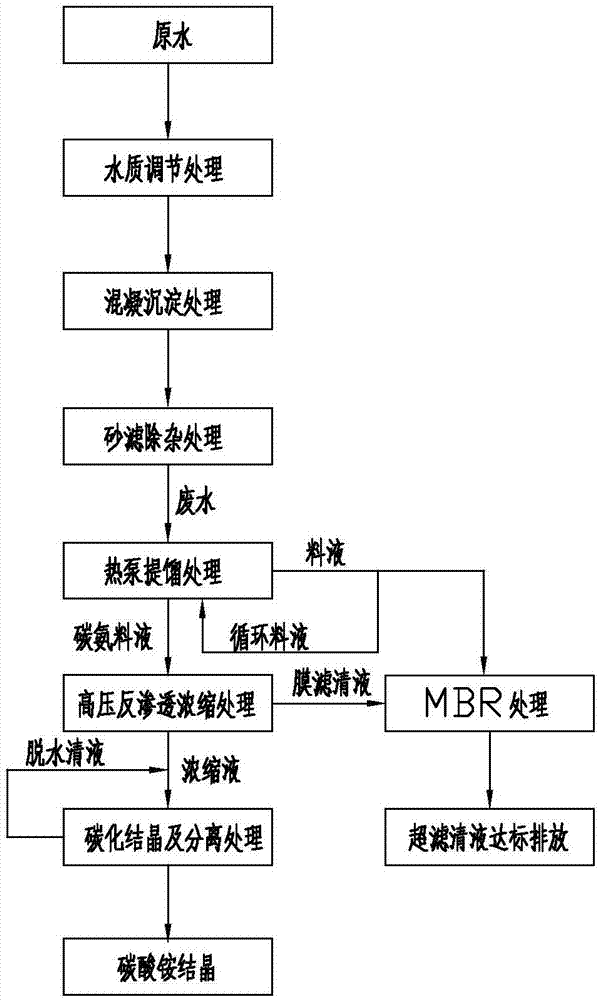

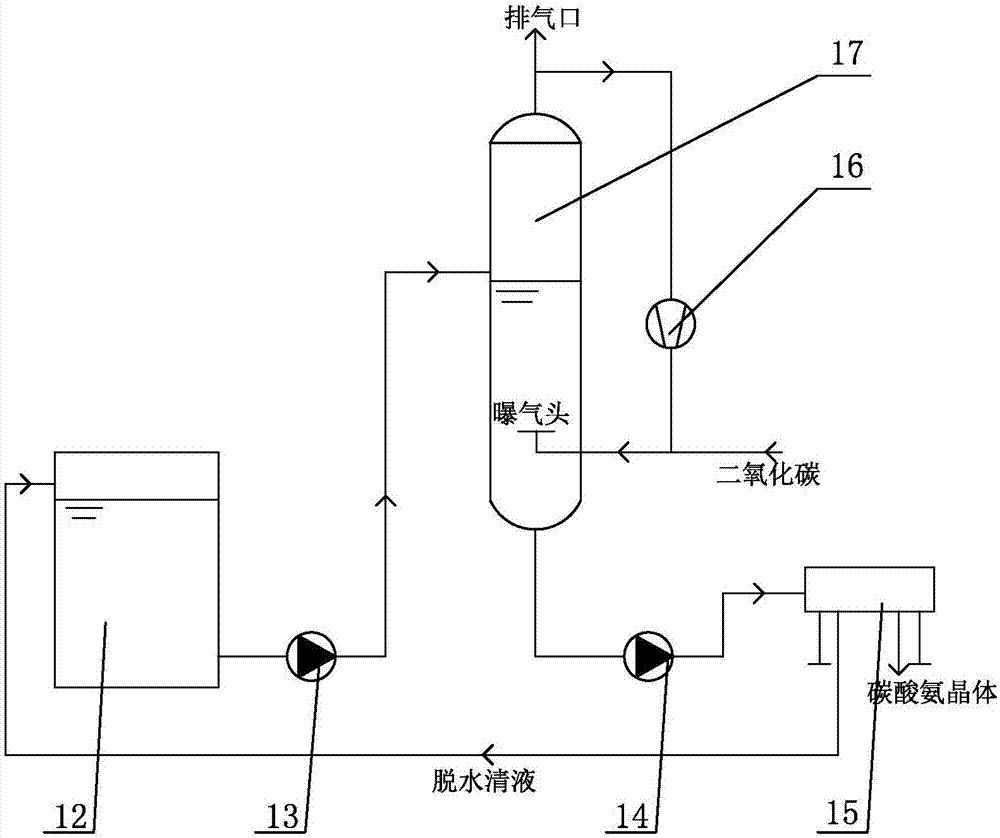

Nitrogen resource heat-extraction recovery method

PendingCN109455885AReduced nitrogen loadImprove stabilityTreatment involving filtrationWaste based fuelRecovery methodChemical reaction

The invention discloses a nitrogen resource heat-extraction recovery method. Through a pretreatment unit, an analytical unit, a deamination unit, an ammonia absorption unit and a crystallization dewatering unit which are sequentially connected, ammonia nitrogen in a liquid phase is transferred to a vapor phase through a physical method, then by additionally adding CO2, the ammonia nitrogen and ammonia nitrogen in the vapor phase generate a chemical reaction in the liquid phase to generate an ammonium bicarbonate solution, the ammonium bicarbonate solution separates crystals out after supersaturation, and solid ammonium bicarbonate is obtained by centrifugal dewatering. According to the nitrogen resource heat-extraction recovery method, nitrogen resources in leachate of refuse landfills andkitchen sludge anaerobic fermentation biogas liquid are recovered, meanwhile, engineering investment and the operation cost of a subsequent sewage treatment system are greatly lowered, and the goalsof energy saving and consumption reduction are achieved. The nitrogen resource heat-extraction recovery method is also suitable for recovery of nitrogen resources in other types of high-ammonia-nitrogen wastewater in the coal chemical industry.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Ammonium recovery methods

ActiveUS20130029405A1Increase energy densityIncrease volumeMicroorganismsDispersed particle separationWater useRecovery method

The methods are utilized to recover ammonium from waste water using CO2 acidified absorption water. The process is particularly suited for utilization of cellular matter and a CO2 rich tail gas from a syngas fermentation process and derives significant benefit from the recovery of ammonium bicarbonate and ammonium carbonate. Ammonia and ammonium are recovered from the treatment of the syngas as an ammonium rich solution, at least a portion of which is recycled to the fermentation zone to aid in the production of liquid products. A carbon dioxide rich gas produced by fermentation is used to capture the ammonia and ammonium, forming the ammonium rich solution.

Owner:SYNATA BIO INC

Process and system for capturing carbon dioxide from a gas stream

InactiveCN103974757AMaterial nanotechnologyChemical/physical/physico-chemical processesSlurryAqueous solution

A process and system are disclosed for capturing carbon dioxide from a gas stream. The process and system comprises a first reactor in which a slurry of a metal silicate is reacted together with an ammonium salt in aqueous solution. The salt is one that does not form a precipitate with the metal silicate. In the first reactor the metal silicate reacts with the solution to produce a slurry of silica in an aqueous solution of a salt of the metal and ammonia. Ammonia gas is drawn off directly from the first reactor, and ammonia, including the ammonia drawn off from the first reactor, is added to the gas stream. The process and system also comprises scrubbing the gas stream, including with the added ammonia, with an aqueous solution, whereby the carbon dioxide and ammonia are absorbed into the solution and ammonium carbonate salt(s) are produced.

Owner:理查德·J·洪威克

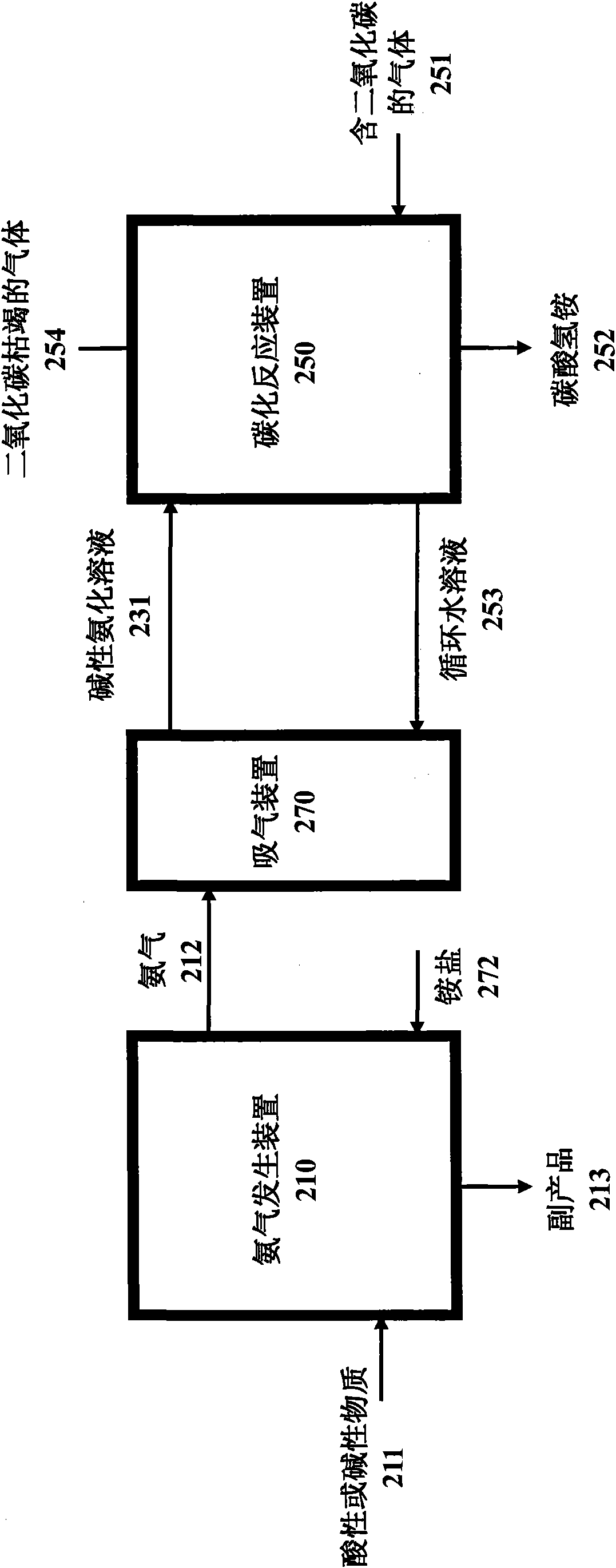

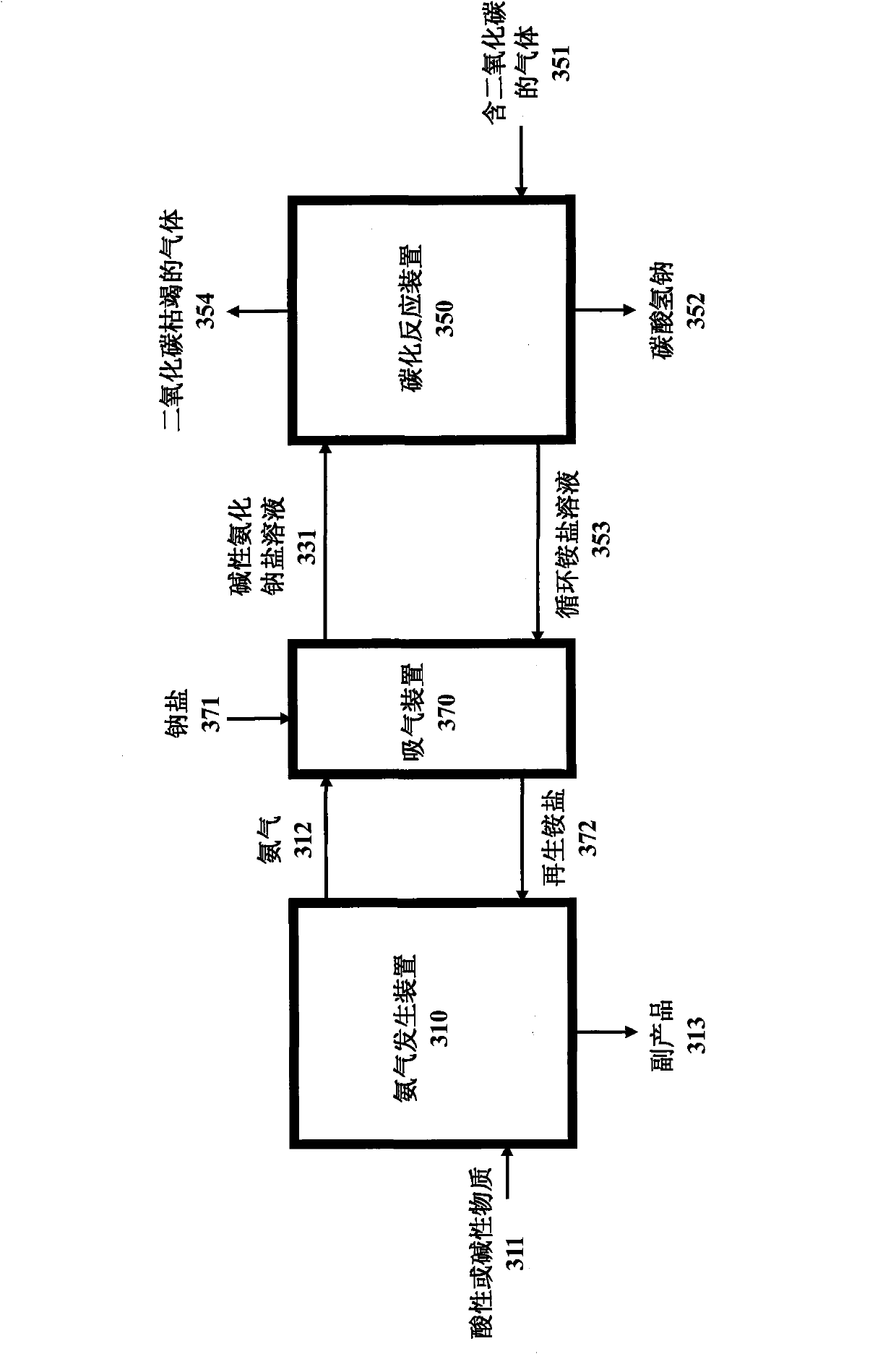

Method for sequestering carbon dioxide

InactiveCN101992015AEase acidificationPromote absorptionCalcium/strontium/barium carbonatesProductsSodium bicarbonateSlag

The present invention discloses a method for sequestering carbon dioxide (CO2) that includes generating ammonia from an ammonium salt to make a basic ammoniated aqueous solution and using the solution to remove at least a portion of CO2 from a CO2-bearing gas and precipitate the removed CO2 as bicarbonate. The aqueous solution is recycled. Various valuable byproducts, including sodium bicarbonate, sodium carbonate, ammonium bicarbonate, and hydrochloric acid, are produced. Ammonia is generated by reacting an ammonium salt with either acidic or basic materials. Non-limiting examples of suitable ammonium salt include ammonium chloride, ammonium sulfate, ammonium bisulfate, and ammonia nitrate, those of the acidic material include ammonium bisulfate and sulfuric acid, and those of the basic material include calcium oxide, limestone, dolomite, cement kiln dust, calcium-rich fly ash, steel and iron slag, and silicate rocks or mining wastes that are rich in serpentine, olivine or wollastonite.

Owner:钟少军

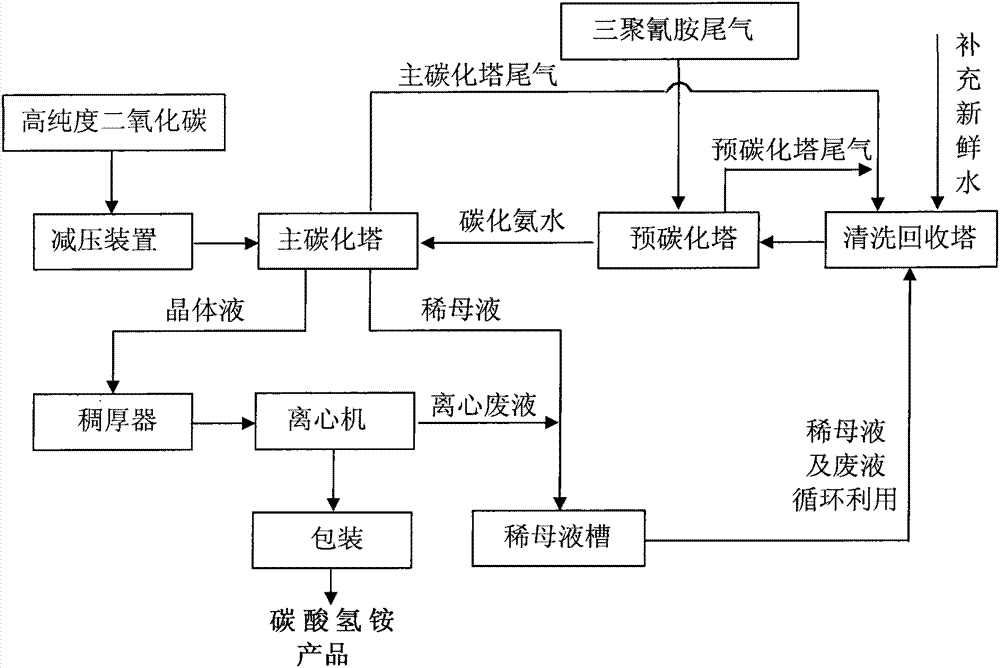

Clean production method for co-production of ammonium bicarbonate through combination of high purity carbon dioxide and melamine tail gas

InactiveCN102897796AIncrease concentrationIncrease production capacityAmmonium carbonates/bicarbonatesCarbonizationCarbon dioxide binding

The present invention relates to a clean production method for co-production of ammonium bicarbonate through combination of high purity carbon dioxide and melamine tail gas. According to the clean production method, carbon dioxide gas in a large nitrogen fertilizer device is subjected to decompression; the decompressed carbon dioxide gas and melamine tail gas are subjected to a reaction in a main carbonization tower, wherein the melamine tail gas is subjected to absorption condensation; and then a thickener treatment, centrifugation separation and packaging are performed to obtain an ammonium bicarbonate product, wherein the carbonized dilute mother liquor and the centrifugated waste liquid enter recycling. According to the present invention, high purity carbon dioxide gas is adopted, such that the effective concentration of the carbon dioxide actually participating in the reaction is increased, and production capacity is significantly increased compared with the carbonation equipment having the same size; the dilute mother liquor from the ammonium bicarbonate production is recycled so as to achieve clean production; and the purity of the carbon dioxide gas is high, and the impurity content is significantly reduced so as to easily improve product quality.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

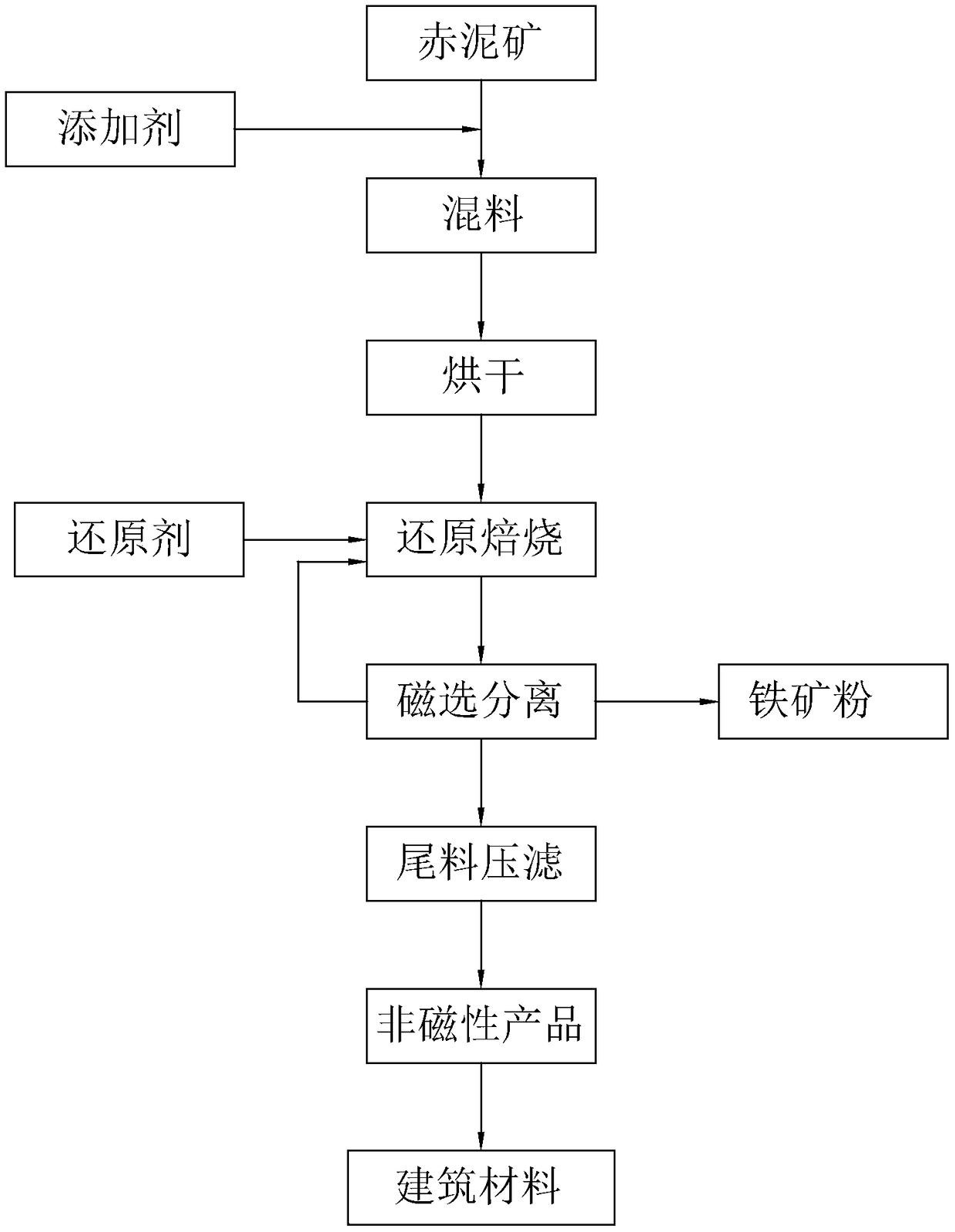

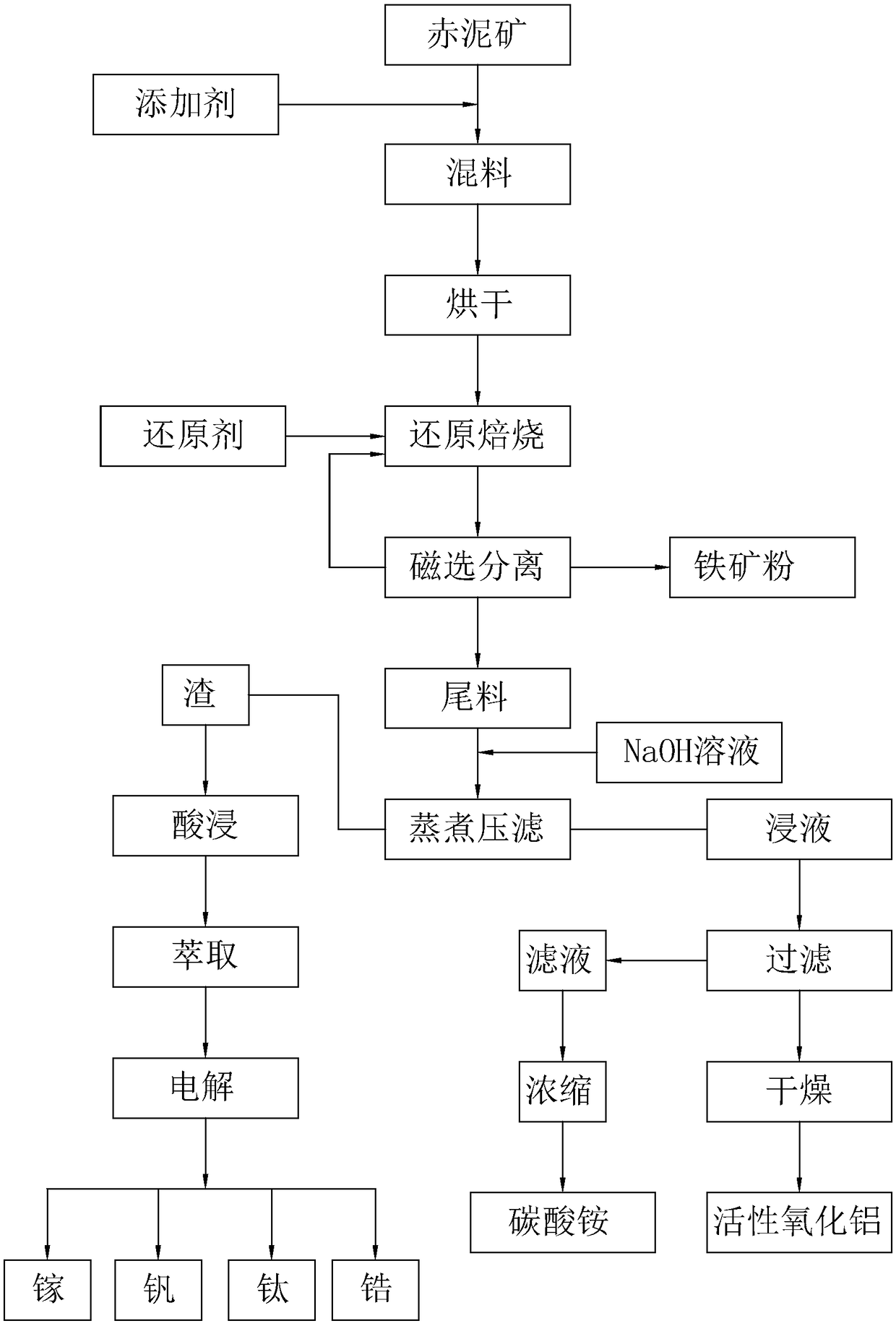

Chemical metallurgical method for comprehensive treatment and utilization of red mud

InactiveCN108118141AFull restorationGuaranteed conversion of carbonation structureAmmonium carbonates/bicarbonatesNanotechnologyRed mudSlag

The invention relates to a chemical metallurgy method for comprehensive treatment and utilization of red mud. Lignite is used as a reducing agent for Fe2O3 in the red mud, limestone is taken as a dispersant and a conversion agent for Al2O3 in the red mud, and the lignite and the limestone are finely ground and uniformly mixed with the red mud for carrying out reduction magnetization and conversionroasting. Fe3O4 and Fe obtained by the magnetization are subjected to magnetic separation enrichment to obtain an iron concentrate, and second reduction magnetization can be further carried out on the iron concentrate and then precision magnetic separation is performed to prepare reduced iron powder. After the magnetic separation, Al2O3 is converted into Al2(CO3)3 aluminum-rich slag for performing oxidative cooking and desilication to dissolve Al2(CO3)3. Silicon slag containing a small amount of aluminum and calcium can be used as a raw material of ceramic or white cement. An Al2(CO3)3 solution is used for synthesizing NH4Al(OH)2CO3(inverted arrow) with ammonia water. After carrying out solid-liquid separation, solid-phase NH4Al(OH)2CO3 is dried and roasted and reduced to obtain nano-active alumina; liquid-phase (NH4)2CO3 is concentrated and crystallized and then dried to obtain a sodium carbonate by-product.

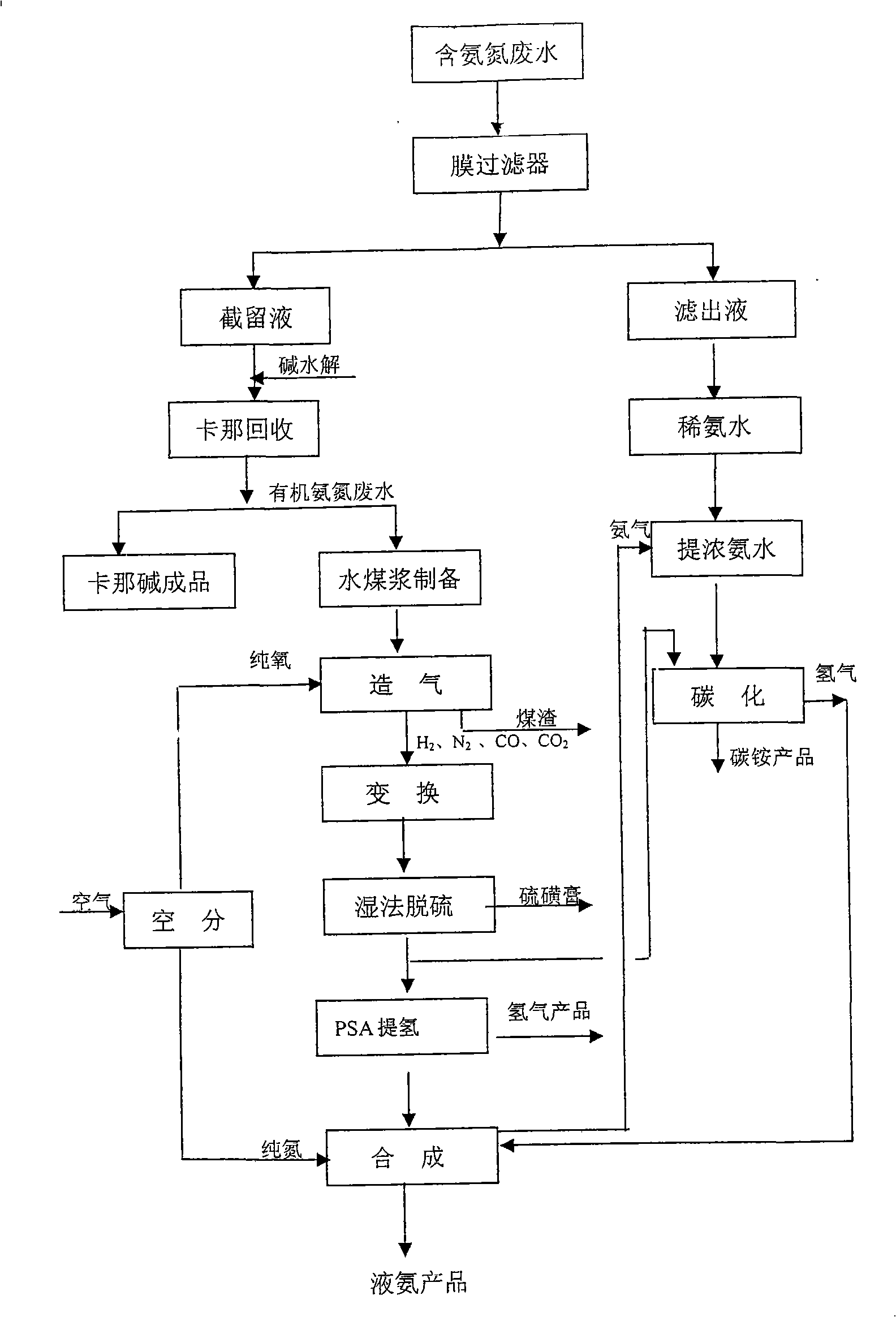

Process for treating ammonia-nitrogen waste water

ActiveCN101289238AEmission reductionReduce pollutionHydrogenAmmonium carbonates/bicarbonatesWater vaporCarbonization

A method for treating ammonia nitrogen wastewater is disclosed. The ammonia nitrogen wastewater is firstly filtered by a membrane filter, and dilute ammonia water filtered out is processed by isobaric pressure recycling to prepare concentrated ammonia water which is carbonized to produce ammonium bicarbonate. Trapped solution is firstly hydrolyzed to extract Kana alkali, and organic wastewater which contains ammonia nitrogen and is produced by the recycling of the trapped solution is used for preparing coal water slurry; the coal water slurry prepared, the concentration of which is 60 percent, together with pure oxygen by air separation are gasified and cracked at the temperature of 1350 DEG C to 1450 DEG C and the pressure of 1.3 MPa to produce CO, CO2, H2, N2 and water gas with trace amount of hydrogen sulfide; by changing the process, CO and water vapor react and produce CO2 and H2; trace amount of hydrogen sulfide is removed by carrying out desulfurization by a wet process; some gas is treated by carbonization process to remove CO2, and ammonium carbonate is produced at the same time. The left gas is treated by PSA hydrogen-extraction process to prepare high-purity hydrogen as finished product or for preparing product liquid ammonia. The method of the invention changes waste into valuable and requires low operating cost.

Owner:ZHEJIANG FENGDENG CHEM

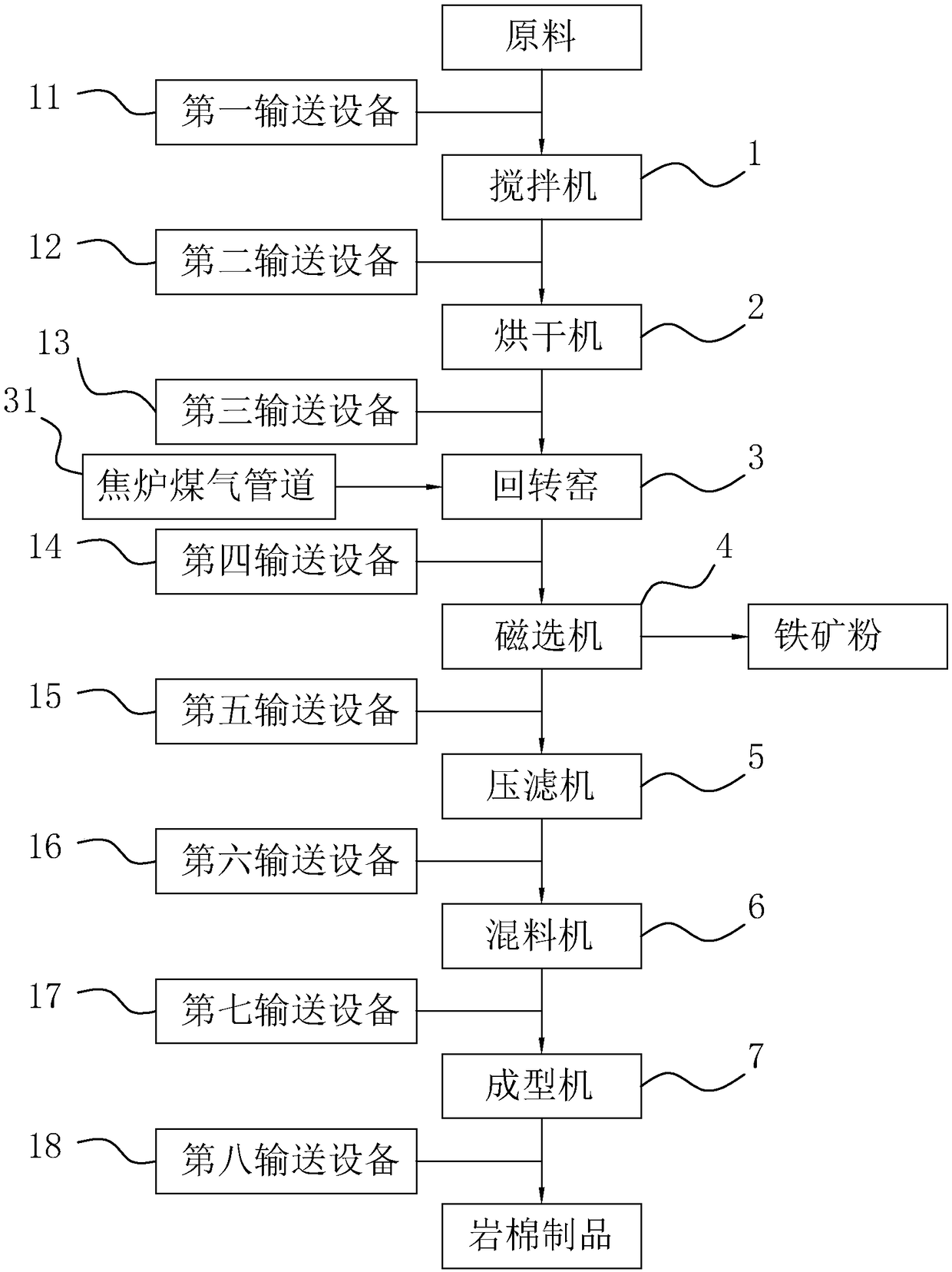

Red mud magnetizing roasting comprehensive utilization system and technology

PendingCN109160744ARaise the gradeWill not bondGlass making apparatusPhotography auxillary processesResource utilizationRed mud

The invention discloses a red mud magnetizing roasting comprehensive utilization system and a red mud magnetizing roasting comprehensive utilization technology, and relates to the technical field of mineral resource utilization. The red mud magnetizing roasting comprehensive utilization technology is characterized by the following steps: performing detecting analysis and proportioning materials: sampling red mud for detecting analysis, and proportionally adding an additive for inhibiting high-temperature bonding of silicon titanium aluminum and iron into the red mud; stirring and drying: stirring the proportioned red mud for 30-60min so as to uniformly mix the materials, and then drying, wherein the drying temperature is 180-200 DEG C; performing roasting reduction: performing roasting reduction on the dried materials, wherein the reduction temperature is controlled at 750-1150 DEG C and the reduction time is 15-60 min; performing magnetic separation: cooling a product obtained after the roasting reduction, then grinding, and then sequentially sieving through two stages of magnetic fields to separate out magnetic iron ore powder and non-magnetic tailings. Through the red mud magnetizing roasting comprehensive utilization system and the red mud magnetizing roasting comprehensive utilization technology, the problem of low reaction efficiency due to high ash content during use ofbrown coal for reducing the red mud in conventional magnetizing roasting is solved, magnetizing roasting equipment is optimized and improved, and the comprehensive utilization rate of the red mud is increased.

Owner:青岛盈坤源矿业科技有限公司

Process method for co-producing ammonium bicarbonate by using coking plant waste

ActiveCN101857246AAvoid pollutionTo achieve comprehensive recyclingChemical industryAmmonium carbonates/bicarbonatesDistillationPollution

The invention discloses a process method for co-producing ammonium bicarbonate by using coking plant waste, comprising the following steps: exchanging heat of flue gas in a coke oven flue channel to lower the temperature to 40-50 DEG C, absorbing and concentrating by a washing tower to obtain CO2 gas the volume concentration of which is 25%-28%, and lowering the temperature to below 35 DEG C; carrying out distillation pretreatment on coking plant waste ammonia water; and leading the pretreated strong ammonia water and CO2 gas into a synthetic tower to react to generate ammonium bicarbonate. In the invention, waste water and waste gas exhausted by coking industry are fully utilized to synthesize ammonium bicarbonate suitable for the growth of crops, the investment is low no matter a new factory is built or an old factory is transformed, the process is simple, convenient, mature and reliable, the cost is greatly reduced, and the method has higher economic yield. By the comprehensive utilization of waste gas and waste water, the pollution to atmosphere is significantly reduced, thus achieving the purposes of energy saving and emission reduction, being in line with the policy of developing low-carbon economy implemented by China currently, and having great social benefit.

Owner:泰安金冠机械工程有限公司

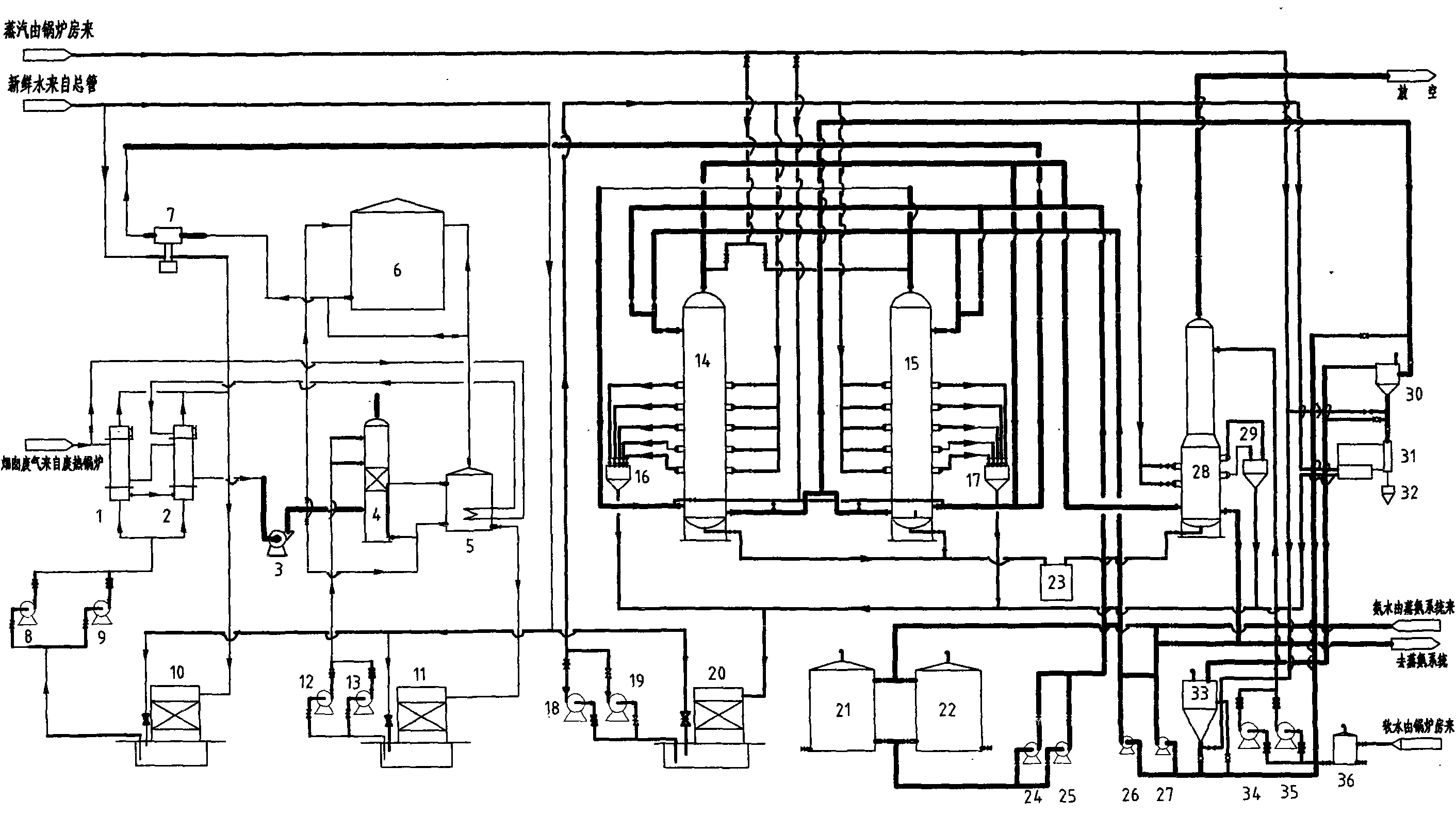

Treatment method for high-ammonia-nitrogen wastewater

ActiveCN107399876AReduce turbidityGuaranteed uptimeWater contaminantsAmmonium carbonates/bicarbonatesParticulatesCarbonization

The invention relates to a treatment method for high-ammonia-nitrogen wastewater. The treatment method comprises the following steps: performing water quality regulation treatment on raw water, performing coagulating sedimentation treatment on the regulated raw water; intercepting macromolecular particulate matters, colloids and suspended matters in liquid supernatant subjected to coagulating sedimentation treatment on a sand filter; feeding wastewater with high ammonia nitrogen discharged from the sand filter to a heat pump stripping system; heating and pressurizing low-temperature carbon ammonia steam which enters the tower top in a rectifying tower through heat exchange in a steam compressor, performing stripping ammonia removal with wastewater in the rectifying tower; feeding a carbon ammonia stock solution into a high-pressure reverse osmosis membrane element to perform concentration-extracting treatment; and feeding a reverse osmosis membrane concentrated solution into a carbonization tower to react with carbon dioxide gas to continuously crystallize, and performing centrifugal separation to obtain ammonium carbonate crystal for being recycled. The treatment method has the characteristics of being good in ammonia removal effect, relatively low in investment and operation cost and low in energy consumption.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Ammonia-process desulfurization and decarbonization integrated device and method

PendingCN113262625AWaste water treatment from gaseous effluentsAmmonium salt fertilisersAmmonium sulfateDecarburization

The invention is applied to desulfurization and decarburization of process gas containing sulfur oxides and CO2, and belongs to the field of environmental protection, ammonia is used as a desulfurization and decarbonization agent, the gas firstly enters a desulfurization device for desulfurization to generate ammonium sulfate fertilizer, the desulfurized gas enters a decarbonization device to remove carbon dioxide in the gas to generate ammonium bicarbonate fertilizer, the decarbonized gas contains free ammonia, is washed with a desulfurization circulating solution and then is washed with water, and the washing solution returns to a desulfurization tower and is used as an absorbent for desulfurization. A desulfurization unit is provided with a cooling device for cooling the flue gas, so that the subsequent decarburization requirement is met. Condensate water generated in the desulfurization cooling process is used as ammonia washing replenishing water or used for other purposes after being subjected to film separation and purification, concentrated water returns to a desulfurization area, and no waste water is generated. According to the technology, decarburization and desulfurization technologies are organically integrated, ammonia washing efficiency is high by adopting acidic desulfurization circulating liquid to wash ammonia, the problem of ammonia escape in the decarburization process is successfully solved, the process is simpler, investment and operation cost is low, by-products of ammonium sulfate and ammonium bicarbonate fertilizer are produced, CO2 does not need to be reinjected underground for storage, by-product ammonia water can be used, and the purposes of treating waste with waste and recycling economy are really achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

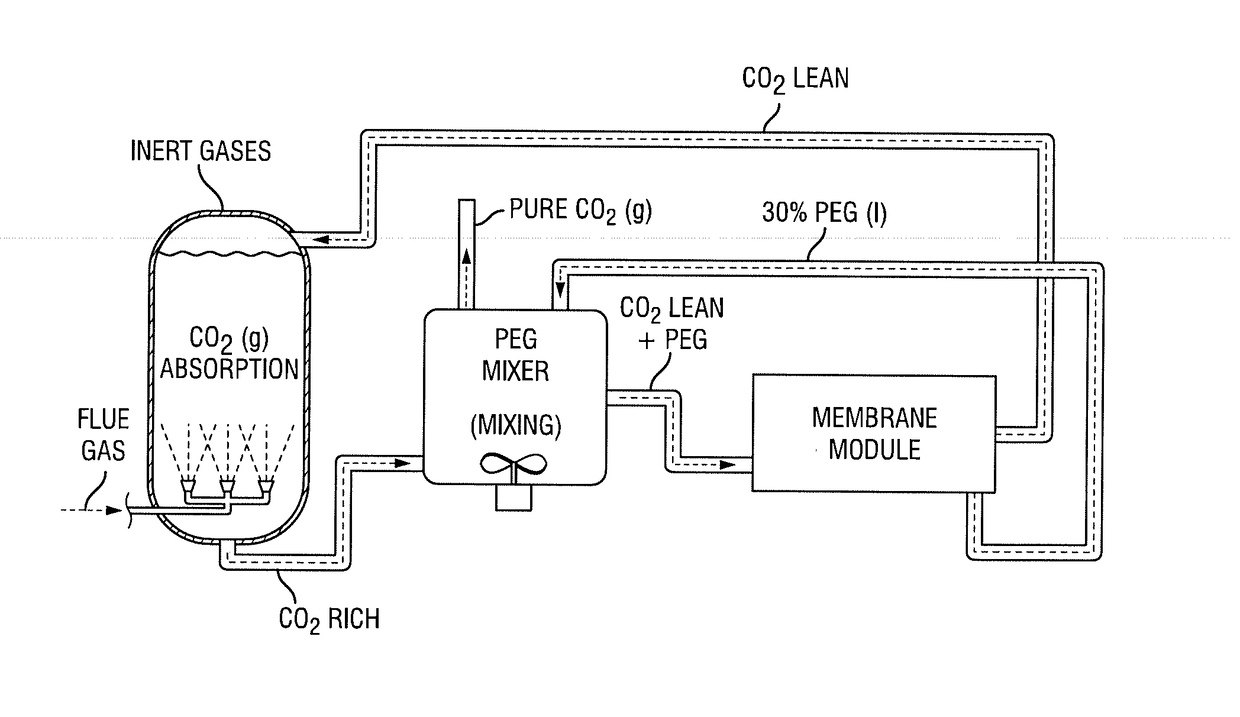

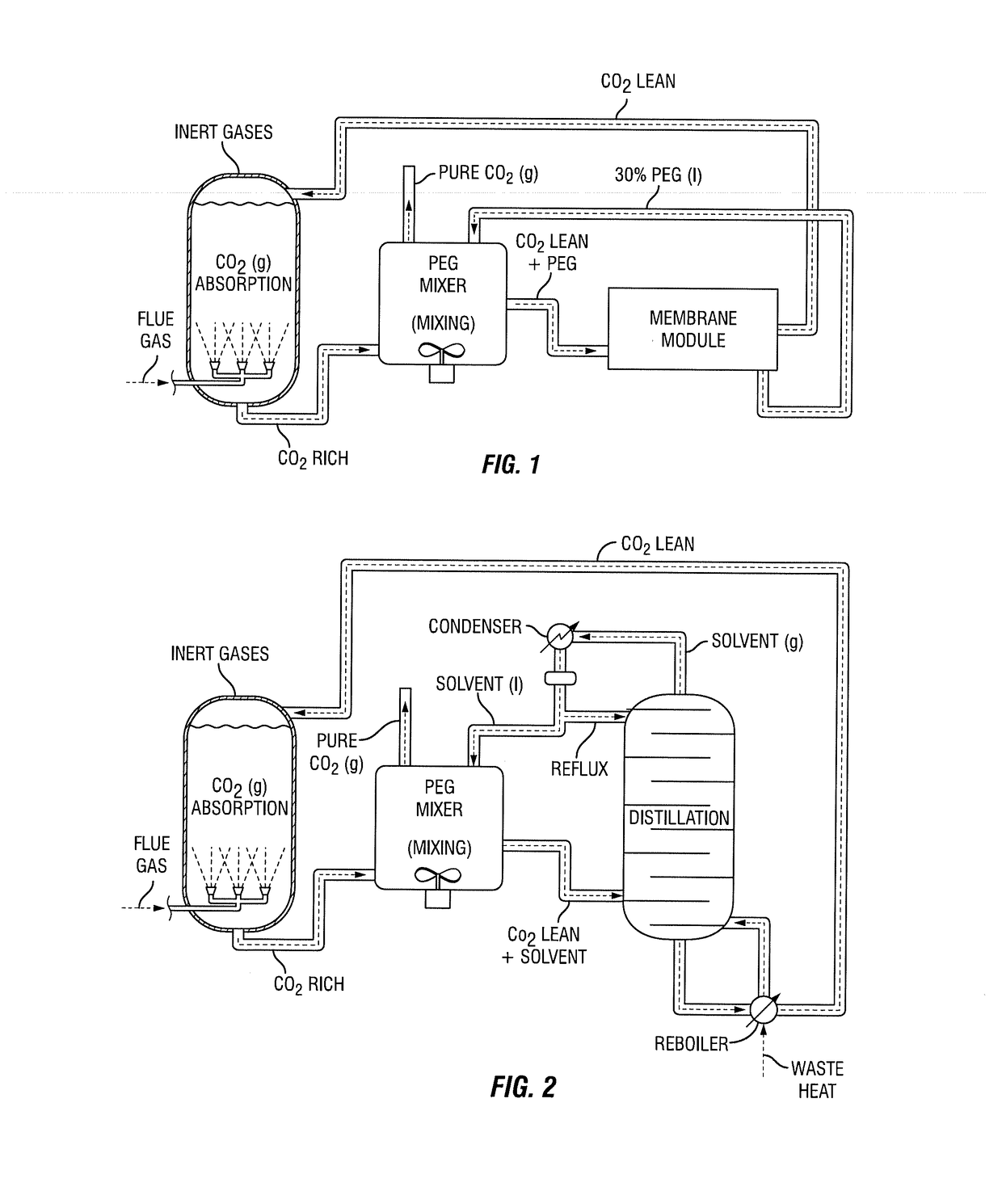

Integrated process for capturing carbon dioxide

InactiveUS20170267538A1Reduce carbon dioxide emissionsLower cost of capitalUrea derivatives preparationCarbamic acid derivatives preparationCarbamateDistillation

The invention pertains to an integrated process for capturing CO2. The process involves desorbing gaseous CO2 from a CO2 containing aqueous solution comprising carbonate, bicarbonate, sesquicarbonate, carbamate, or a mixture thereof. The desorbing of gaseous CO2 is conducted in the presence of a suitable water soluble substance. If desired, the process may also at least partially recover the soluble substance using a membrane, distillation, or another technique.

Owner:SOLVCOR TECH LLC

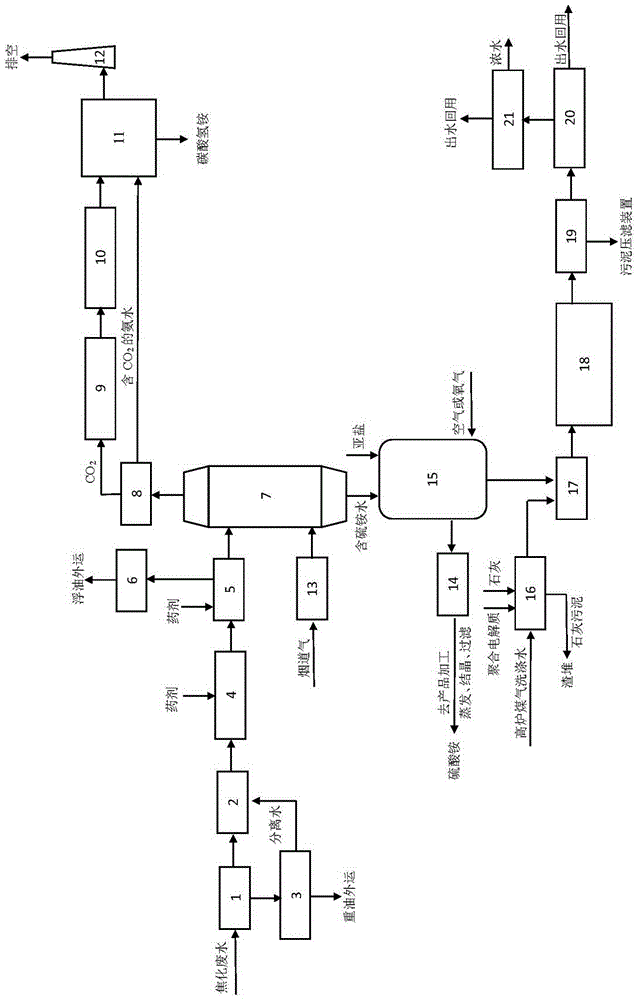

Coking wastewater treatment method

InactiveCN106477825AReduce processing costsEliminate treatment facilitiesTreatment using aerobic processesGeneral water supply conservationCyanideFlue gas

The invention relates to a coking wastewater treatment method. The coking wastewater treatment method includes: firstly, performing pretreatment on coking wastewater by the aid of flue gasses, organically combining flue gas desulfurization and CO2 recovery with coking wastewater treatment, and obtaining fertilizer; secondly, performing joint treatment on drainage subjected to pretreatment and scrubbing water of blast furnace gases and performing dephenolization and cyanide treatment on the drainage and the scrubbing water of the blast furnace gases with a biological contact oxidation process; finally, performing depth treatment on the drainage subjected to biochemical treatment with aerated biofiltration and reverse osmosis methods, outflowing water subjected to treatment reaches reuse standard, no wastewater is discharged during the entire process, and cyclic use of water resources can be realized.

Owner:NORTHEASTERN UNIV

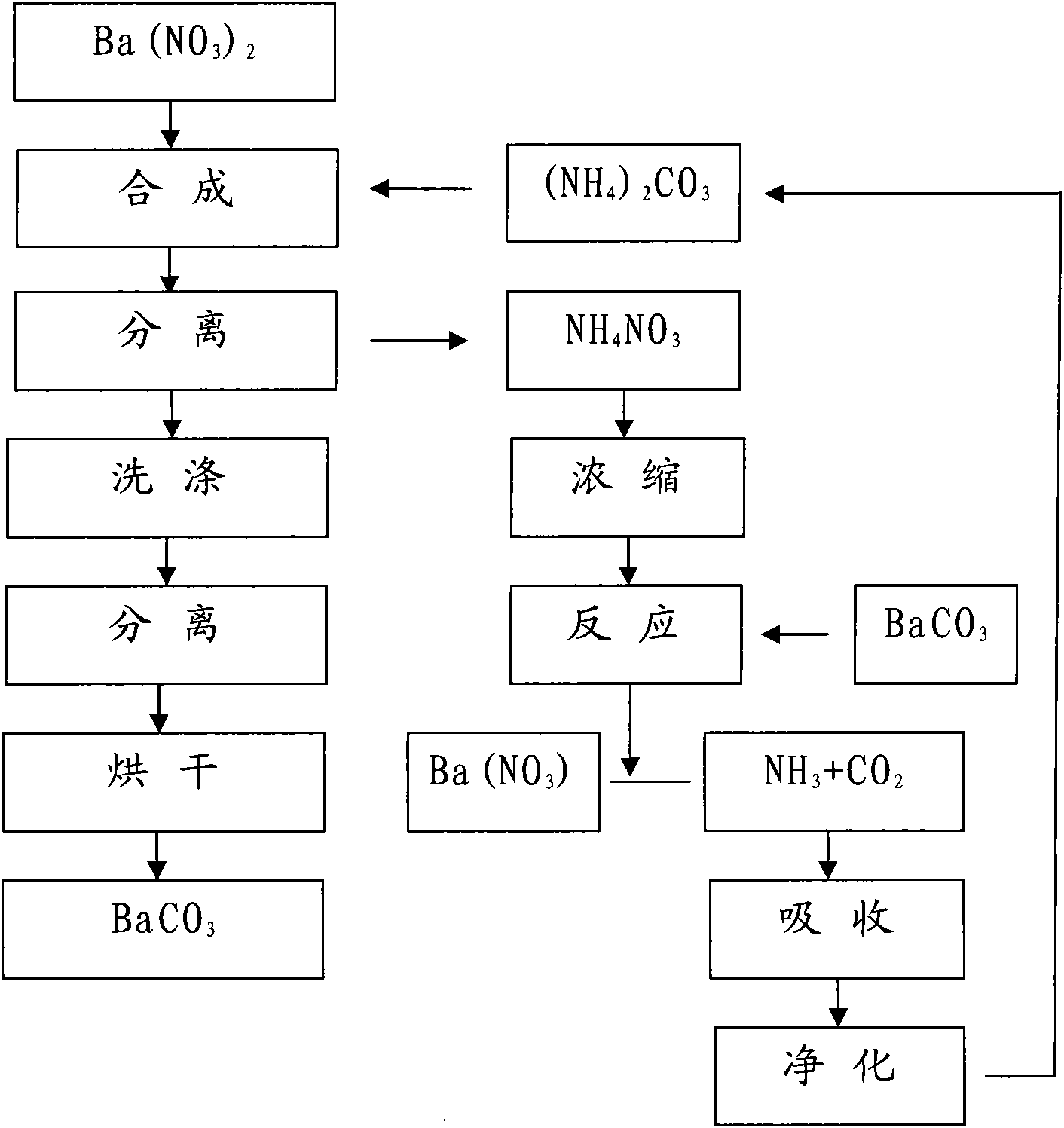

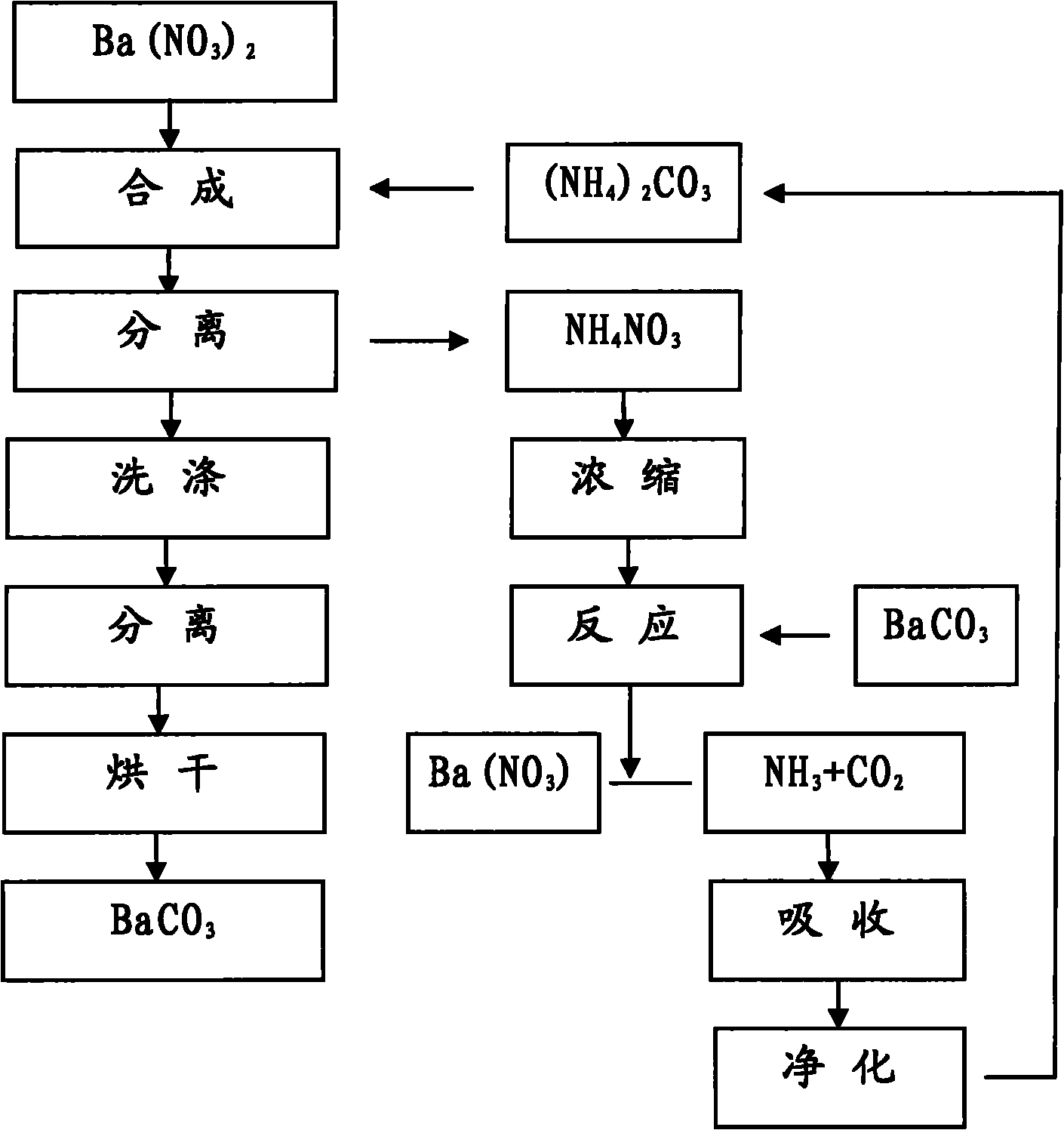

Method for producing BaCO3 through cyclically recovering and reusing (NH4)2CO3

ActiveCN101774622AEasy to washReduce energy consumptionCalcium/strontium/barium carbonatesAmmonium carbonates/bicarbonatesChemistryMother liquor

The invention relates to a method for producing BaCO3 through cyclically recovering and reusing (NH4)2CO3, which comprises the following steps: rising the temperature for boiling 0.4 to 0.85 mol / L Ba(NH3)2 solution; stopping heating; adding 2 to 3.5 mol / L (NH4)2CO3 under the agitation for reaction; carrying out solid and liquid separation; carrying out hot washing on obtained filter cake by deionized water; then, carrying out solid and liquid separation; obtaining BaCO3 products after baking the solid; evaporating and concentrating the obtained mother liquid to 400 to 500 g / L; then, carrying out heating reaction for the mother liquid and the BaCO3 in a sealed container; controlling the reaction temperature in a range between 70 and 118 DEG C; introducing NH3 and CO2 released in the reaction in the step C into an absorption device to be absorbed; detecting the concentration of CO3<2-> and NH<4+> in absorption liquid; and supplementing a proper amount of lime-kiln gas for synthesizing (NH4)2CO3. The invention can cyclically utilize the NH4CO3 for preparing BaCO3 products with low strontium content and low calcium magnesium content.

Owner:GUIZHOU REDSTAR DEVING

Method for treating spent etching solution and treating equipment thereof

ActiveCN104556467AAchieving safe complianceEnable recyclingAmmonium carbonates/bicarbonatesMultistage water/sewage treatmentSuspended particlesEmission standard

The invention provides a method for treating a spent etching solution and treating equipment thereof. The method, provided by the invention, for treating the spent etching solution comprises the following steps: mixing an acidic spent etching solution with an alkaline spent etching solution; regulating a pH value of the mixed spent etching solution and heating to ensure that the acidic spent etching solution reacts with the alkaline spent etching solution; adding a flocculating agent in filtrate to flocculate suspended particles and suspension colloidal arsenic in the filtrate. According to the method or equipment provided by the invention, the spent etching solution is massively treated in a simple low-cost manner, so that the recycling of copper and ammonia is realized; meanwhile, COD of the spent etching solution is reduced to be below 40mg / L, and the content of the arsenic is reduced to be below 0.8ppm, so that the state specified emission standard of waste water is reached.

Owner:NEW FOUNDER HLDG DEV LLC +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com