Integrated process for carbon capture and energy production

a carbon capture and energy production technology, applied in the direction of energy input, machine/engine, energy input, etc., can solve the problems of increasing the cost of current methods, and the inability to meet the needs of current methods, etc., to reduce and/or eliminate co2 emissions, less complex equipment, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples of specific embodiments

Example 1

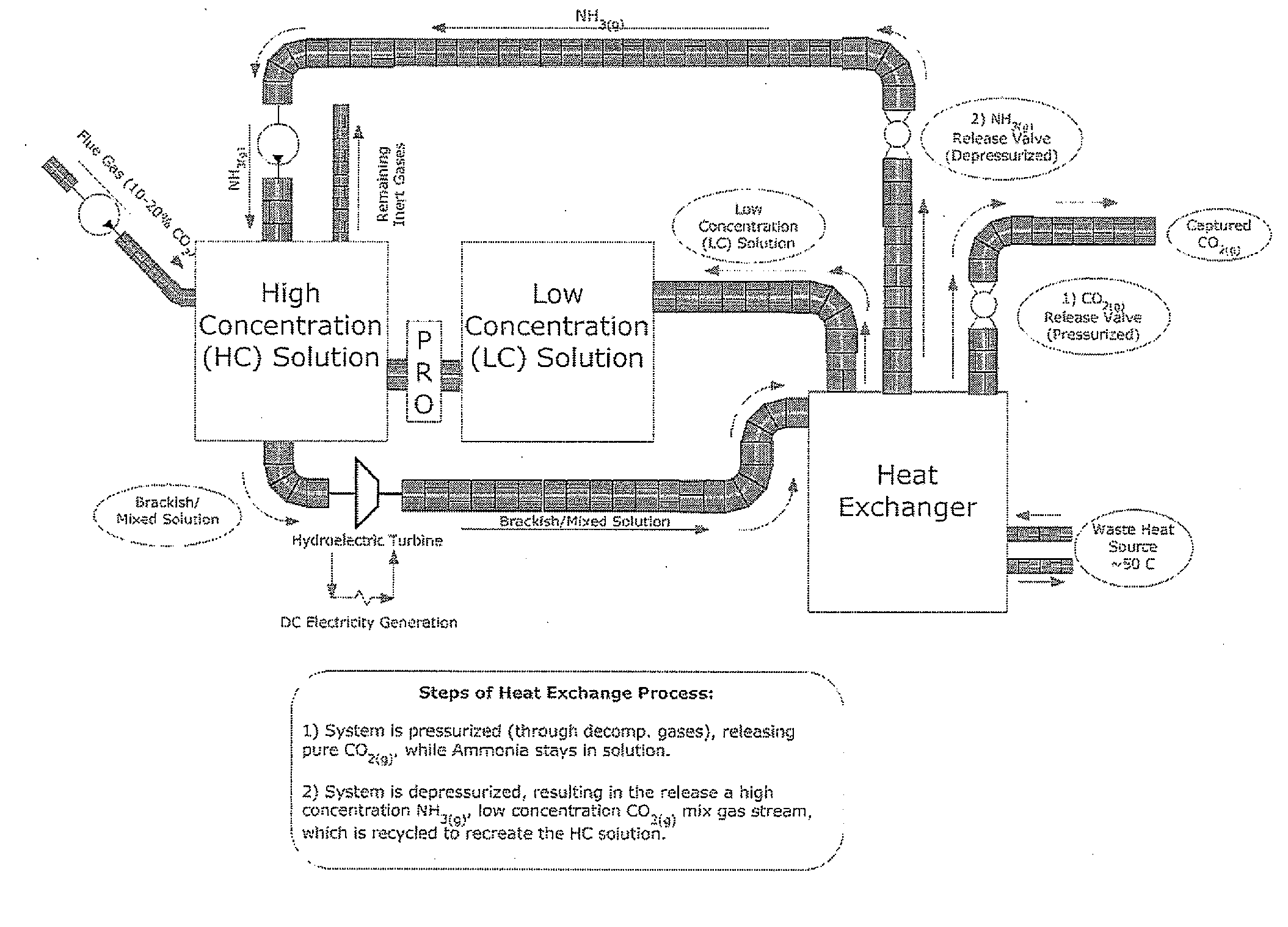

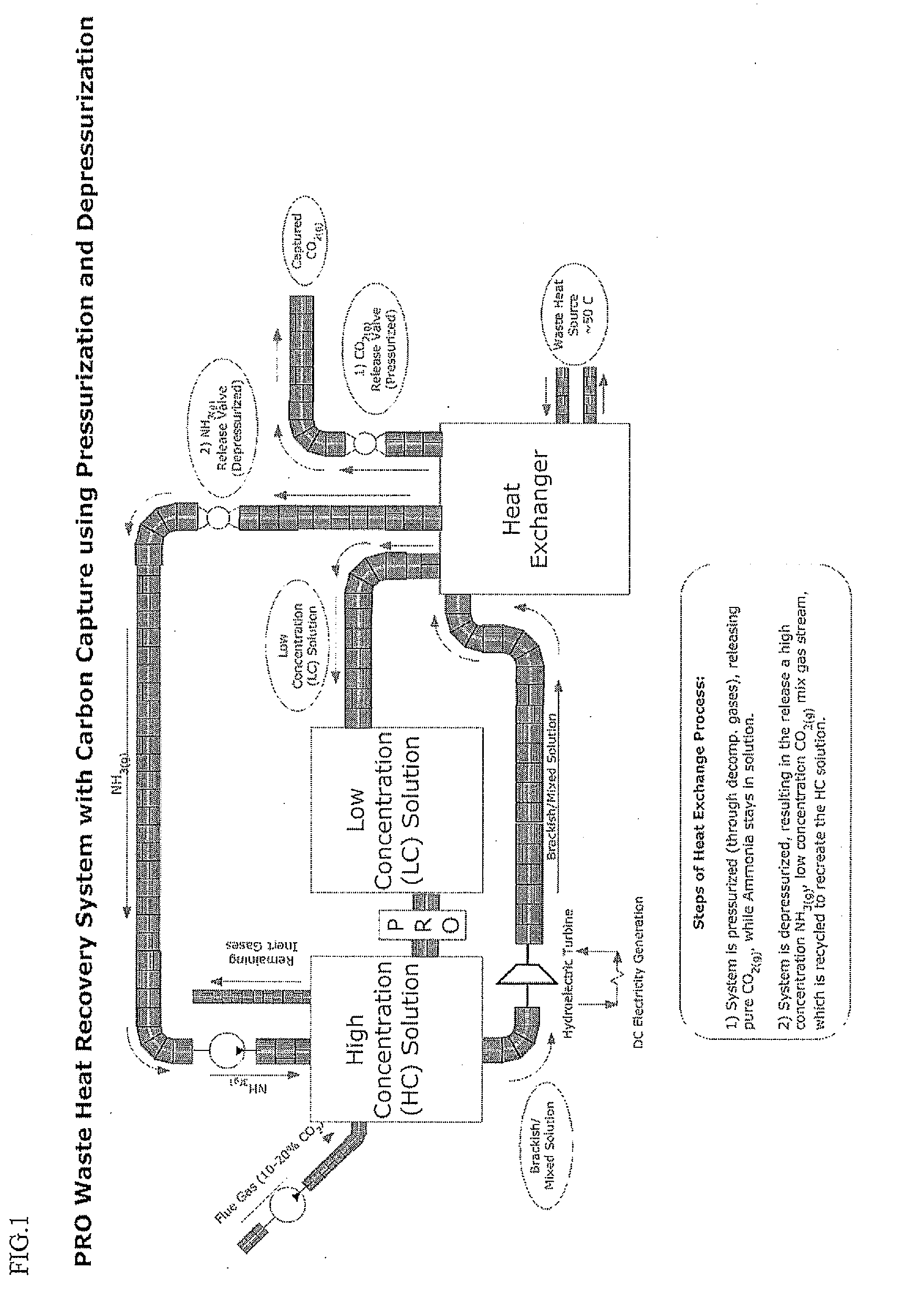

Pressure Retarded Osmosis Waste Heat Recovery System with Carbon Capture Using Pressurization and Depressurization

[0073]A specific embodiment of the instant invention is shown in FIG. 1. In this embodiment low grade heat is used to simultaneously capture carbon dioxide and generate electricity using osmotic gradients engineered using a heat exchange process. As shown, flue gas comprising carbon dioxide is contacted with ammonia to form the High Concentration Solution. The High Concentration Solution is used as a draw solution and comprises ammonium carbonate, ammonium bicarbonate or mixture thereof formed from at least a portion of captured carbon dioxide. The heat exchange process uses a pressurization and depressurization system, which pressurizes the system to release CO2(g) during carbon capture and depressurizes the system to release NH3(g) to recreate the high concentration draw solution.

[0074]Specifically, pressure retarded osmosis (PRO) and a thermolytic salt (e.g. ...

example 2

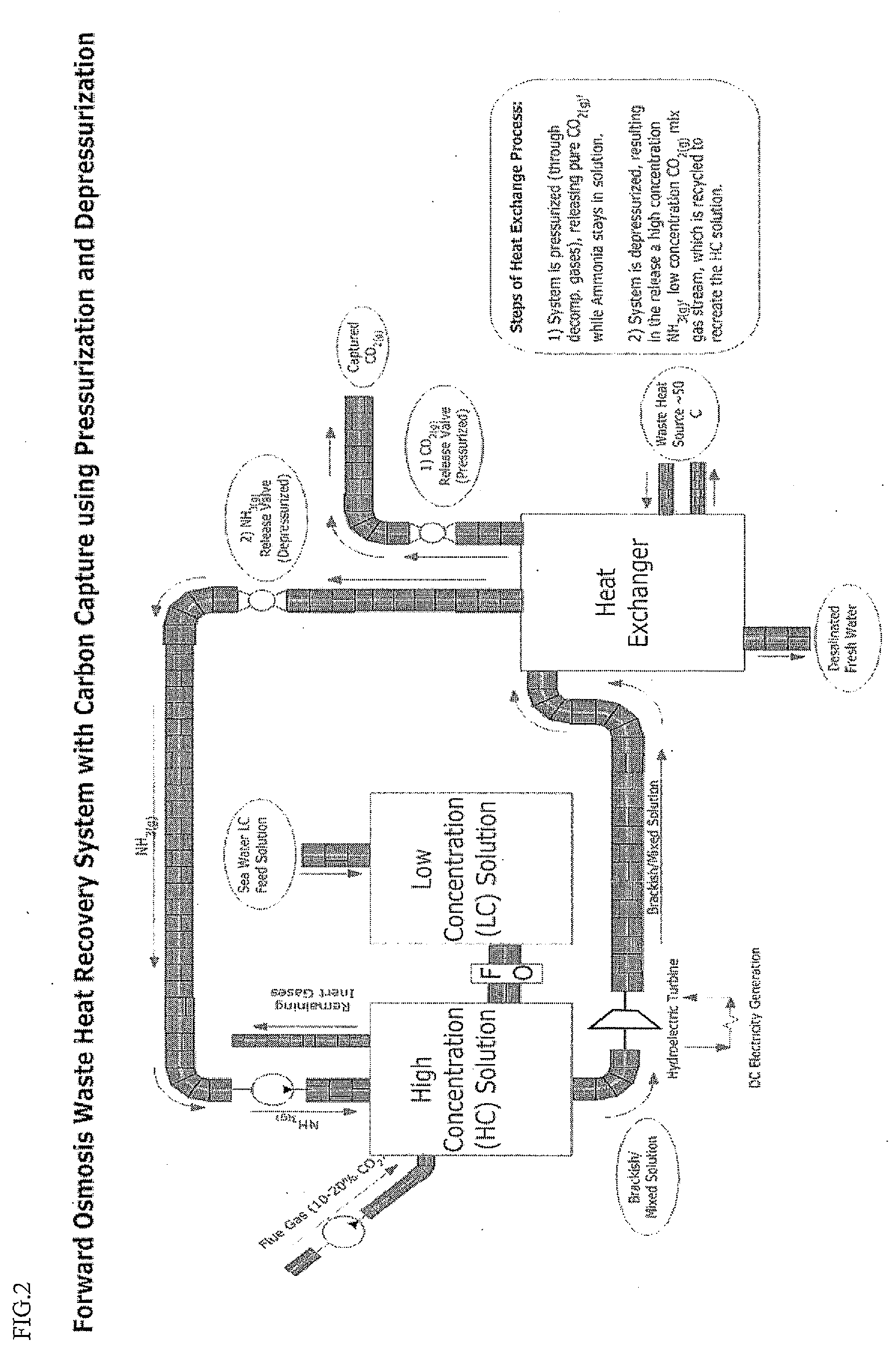

Forward Osmosis Waste Heat Recovery System with Carbon Capture Using Pressurization and Depressurization

[0077]Another specific embodiment of the instant invention is shown in FIG. 2. The system previously described above in Example 1 can be used as a forward osmosis water purification / desalination process that recovers heat in the system through electricity production, water desalination, and carbon capture. The system in Example 1 can be converted to a forward osmosis process by utilizing saline water (e.g. sea water or waste water) as the LC feed solution and sending desalinated water out of the system for sale or other purpose following the heat exchange process, rather than recycling the water to replenish the feed / LC solution. The system has all of the functionalities of the system in example 1 and desalinates water through forward osmosis.

example 3

Pressure Retarded Osmosis Waste Heat Recovery System with Carbon Sequestration Through the Production of Urea

[0078]Another specific embodiment of the instant invention is shown in FIG. 3. The system uses low grade heat to simultaneously generate electricity, and capture and sequester CO2 in the form of ammonium carbamate, which is subsequently converted to urea. The pressurization and depressurization heat exchange process is employed to concentrate NH3 and capture excess CO2. The concentrated NH3 and low concentration CO2 gas stream created in the heat exchange process is contacted with an organic solvent to react and form ammonium carbamate.

[0079]The system continuously feeds NH3(g) and CO2(g) to recreate the HC draw solution in the electricity generation process. Therefore, in a version of the ammonium carbamate / urea production system, NH3 is not recycled, although NH3 may be recycled or recovered if desired. The concentrated NH3 and lower concentration CO2 (Note: the concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com