Patents

Literature

884 results about "Ammonium Hydrogen Carbonate" patented technology

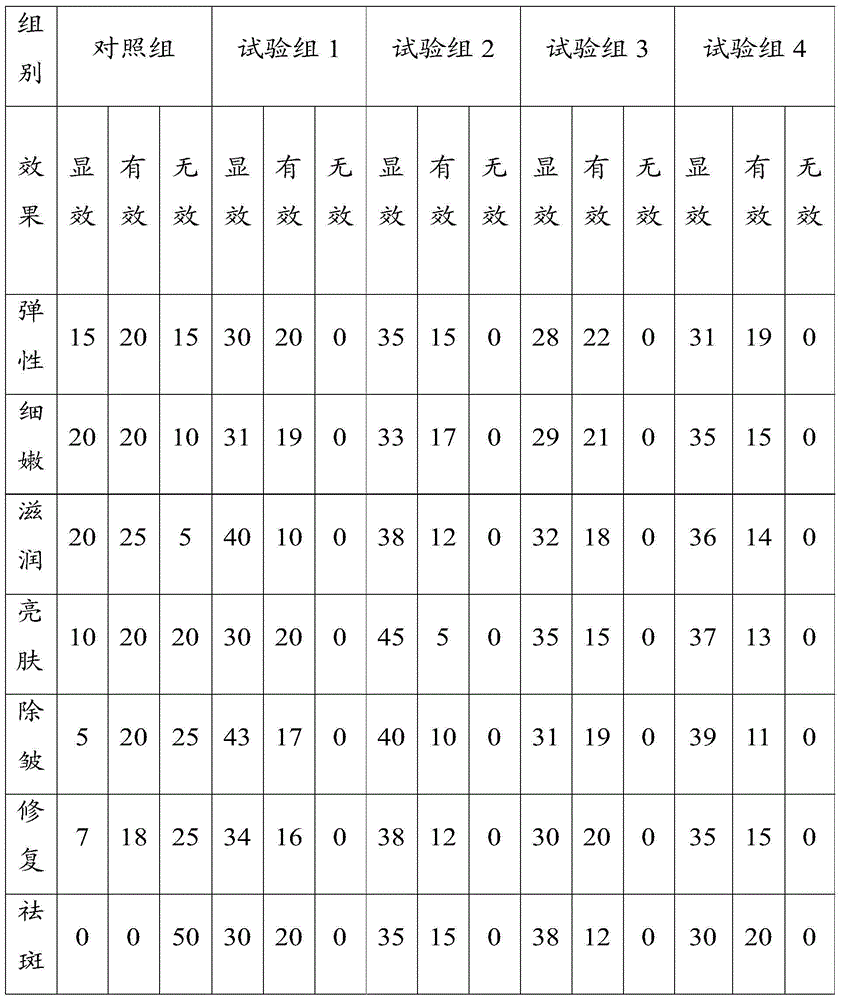

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium hydrogen carbonate. Other names Bicarbonate of ammonia, ammonium hydrogen carbonate, hartshorn, AmBic, powdered baking ammonia, Baking soda. Identifiers CAS Number. ... Ammonium bicarbonate is an inorganic compound with formula (NH 4)HCO 3, simplified to NH 5 CO 3. The compound has many names, reflecting its long history.

Special organic-inorganic composite biological pesticide-fertilizer for flowers and preparation method thereof

The invention provides a special organic-inorganic composite biological pesticide-fertilizer for flowers. The special organic-inorganic composite biological pesticide-fertilizer for flowers comprises the following raw materials in parts by weight: 80-90 parts of municipal sludge, 10-20 parts of fruit peel, 10-20 parts of fallen leaves, 10-15 parts of poultry manure, 10-14 parts of bagasse, 20-30 parts of iron ore slag, 10-12 parts of animal feathers, 10-15 parts of tree ash, 10-15 parts of monoammonium phosphate, 20-25 parts of urea, 10-12 parts of ammonia sulfate, 8-10 parts of ammonium hydrogen carbonate, 8-10 parts of potassium chloride, 5-7 parts of carboxymethyl chitosan, 20-30 parts of modified bentonite, 5-8 parts of lignite, 2-4 parts of black dye tree, 9-11 parts of celastrus angulatus, 9-11 parts of common carpesium fruit, 9-11 parts of radix sophorae flavescentis, 4-6 parts of lilac daphne flower bud, 3-5 parts of coptis root, 10-12 parts of powder of root of stellera chamaejasme, 2-4 parts of vegetable oil, 1-3 parts of zinc sulfate, 3-4 parts of ferrous sulfate, 0.8-1.2 parts of borax, 20-26 parts of potassium fulvate and 0.3-0.4 part of EM (effective microorganism) strain. The pesticide-fertilizer disclosed by the invention has the advantages of scientific ratio of nitrogen, phosphorus and potassium, easiness in absorption by crops, obvious yield-increasing benefit and the like. By applying the pesticide-fertilizer, the nutrient absorption of plants can be balanced, the quality of flowers can be effectively improved, plants are green in leaves and bright in flower, and the flowering phase is also prolonged.

Owner:东至县神山化肥有限责任公司 +1

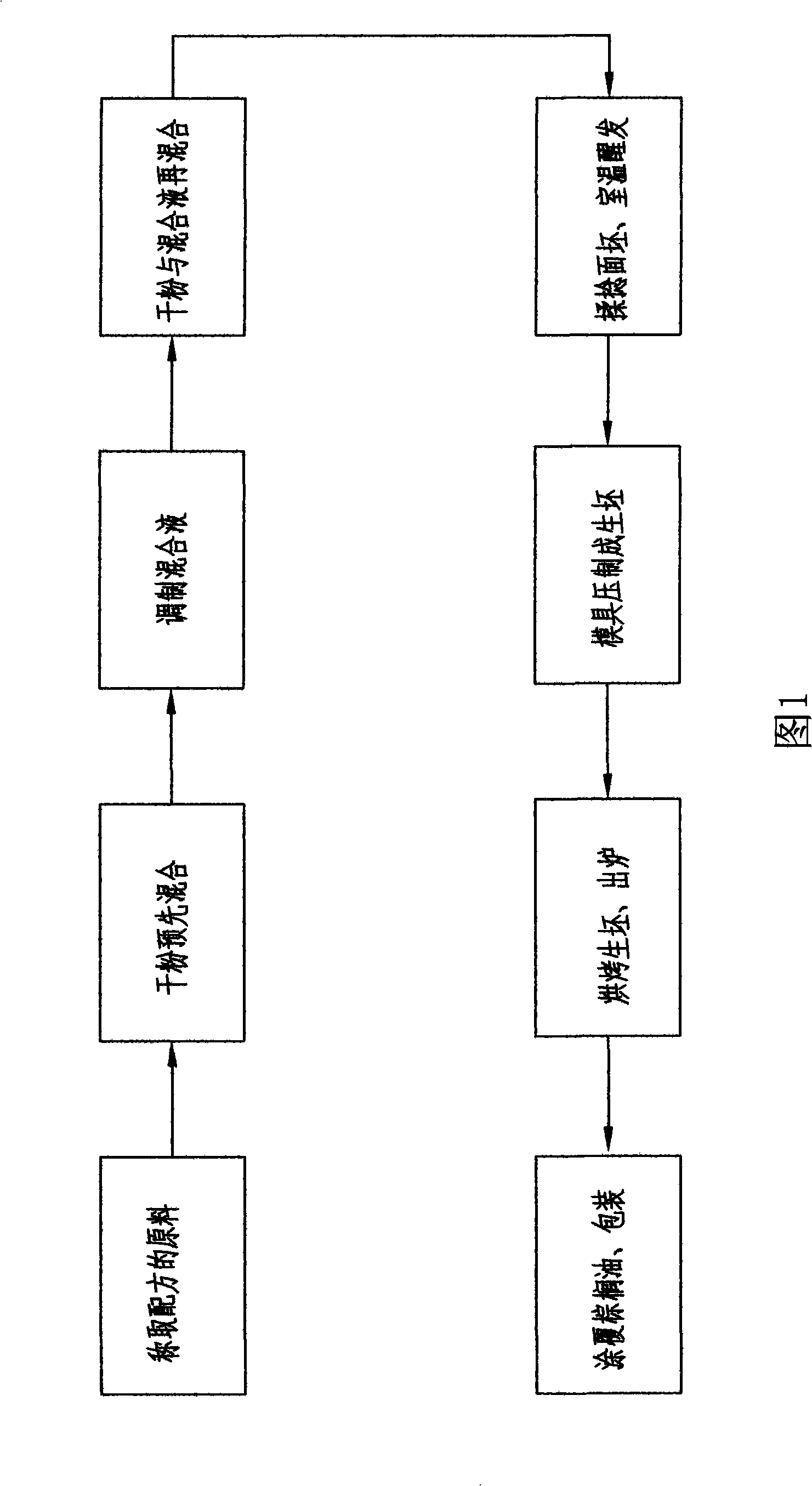

Coarse grain biscuit and preparation method thereof

The invention relates to a coarse grain biscuit and a preparation method thereof. The formula of the coarse grain biscuit comprises 15 to 18 percent of coarse grain special flour, 30 to 38 percent of gluten flour, 8 to 15 percent of edible vegetable oil, 12 to 20 percent of white granulated sugar, 2 to 3 percent of dried whole milk, 0.2 to 0.25 percent of sodium bicarbonate, 0.2 to 0.35 percent of ammonium bicarbonate, 0.1 to 0.25 percent of edible salt, 0.1 to 0.25 percent of coarse grain essence, 2 to 3.5 percent of egg and the balance being water. The preparation method comprises the following steps that: needed raw materials are taken and mixed in advance by means of dry powder; a mixed liquid is prepared and then is added in the premixed dry powder so as to be mixed; water is added in the mixture so as to knead the mixture into a dough; the dough is kneaded, fermented and pressed into a dough which is fed into an oven to be roasted; and the roasted dough is coated with palm oil after and is packaged after airing. The coarse grain biscuit adopts coarse grain special flour made of coarse grain of natural corns, beans and tubers, and has easily controlled mixture ratio of raw materials, low cost and stable quality; moreover, the coarse grain biscuit is suitable for large-scale production, and has a nice chewy texture and the efficacies of heal care and weight reducing.

Owner:田丰

Foamed concrete and preparation method thereof

ActiveCN103304200AReduce voidsImprove waterproof performanceCeramicwareIsolation effectFoam concrete

The invention provides foamed concrete and a preparation method thereof, and belongs to the technical field of building materials. The foamed concrete provided by the invention consists of the following components in percentage by mass: 25-55 percent of a gel material, 18-50 parts of light aggregate, 13-36 parts of water, 0.5-5 parts of a foaming agent, 0.03-0.5 part of a thickening agent and 0.03-0.5 part of enhanced fiber, wherein the gel material consists of cement and coal ash or superfine slag powder; the light aggregate consists of coarse light aggregates and fine light aggregates; the foaming agent is a hydrogen peroxide solution or an ammonium hydrogen carbonate; the thickening agent is powdered carboxymethylcellulose; the enhanced fiber is a lignin fiber or a polypropylene fiber or an alkali resistance glass fiber which is 5-20 mm long. The water prevention, sound isolation and heat isolation effects of the foamed concrete prepared by the invention are better than those of the existing foamed concrete. According to the method, the foaming process of processing various batches and scales of foamed concrete can be precisely controlled by in-situ foaming; the method can be suitable for large-scale production of high-quality foamed concrete.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

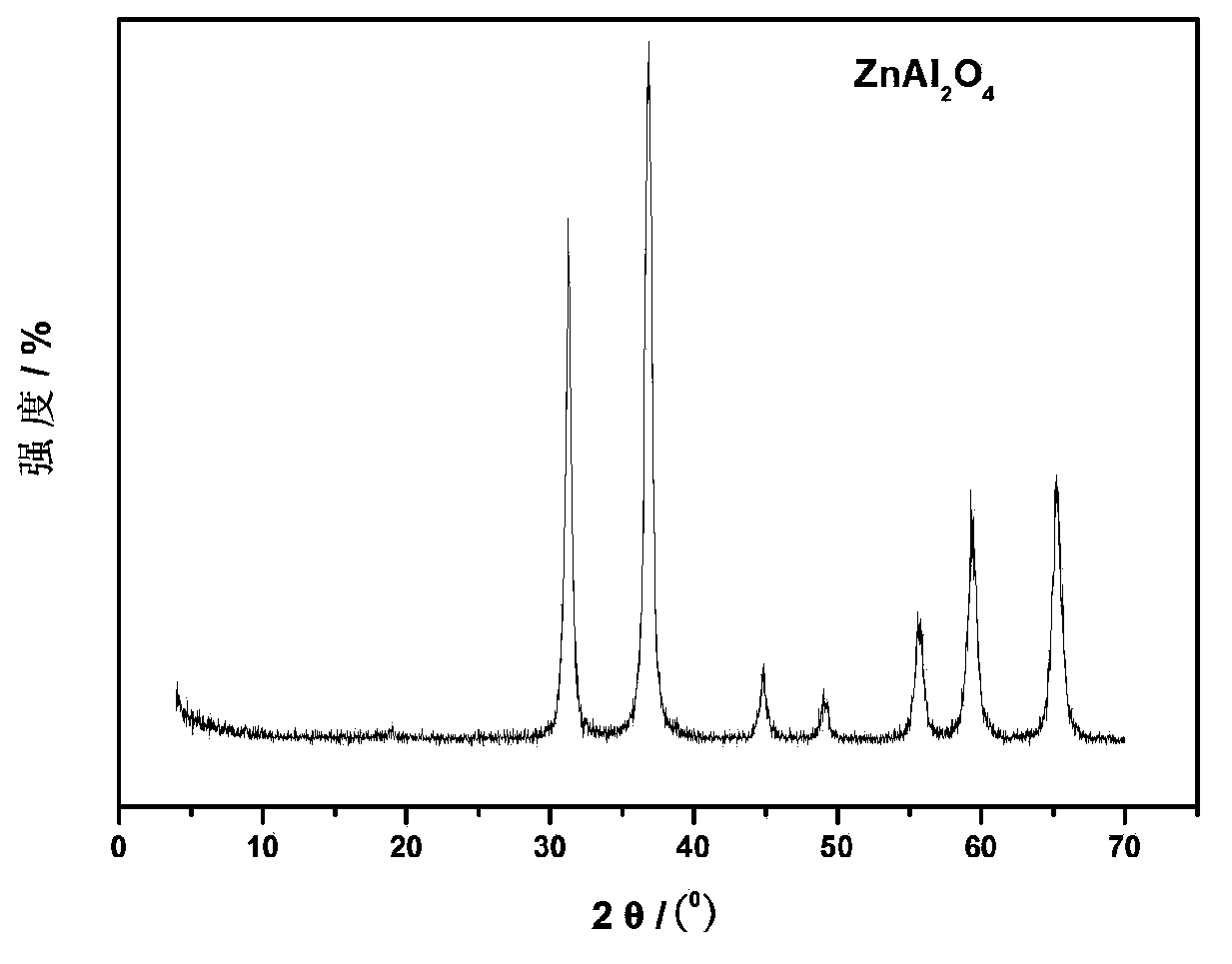

Method for preparing nanometer gahnite

ActiveCN103449503AReduce pollutionGood quality powderZinc oxides/hydroxidesNanotechnologySucroseGlycerol

A method for preparing nanometer gahnite. The preparation method is as below: dissolving zinc salt in water, adding an aluminum source, stirring for 10-30 min, adding a pore-enlarging agent, stirring, ageing at 20-100 DEG C for 30-60 min, drying, and calcining at 500-1200 DEG C. The molar ratio of the raw materials is as below: Zn:Al:water=1:2:16-35; calculated by the weight of zinc oxide being 100%, the addition amount of the pore-enlarging agent is 0.5-30%; and the pore-enlarging agent is one or more selected from sucrose, glycerol, ammonium carbonate, ammonium hydrogen carbonate, polystyrene latex and polyethylene glycol.

Owner:PETROCHINA CO LTD

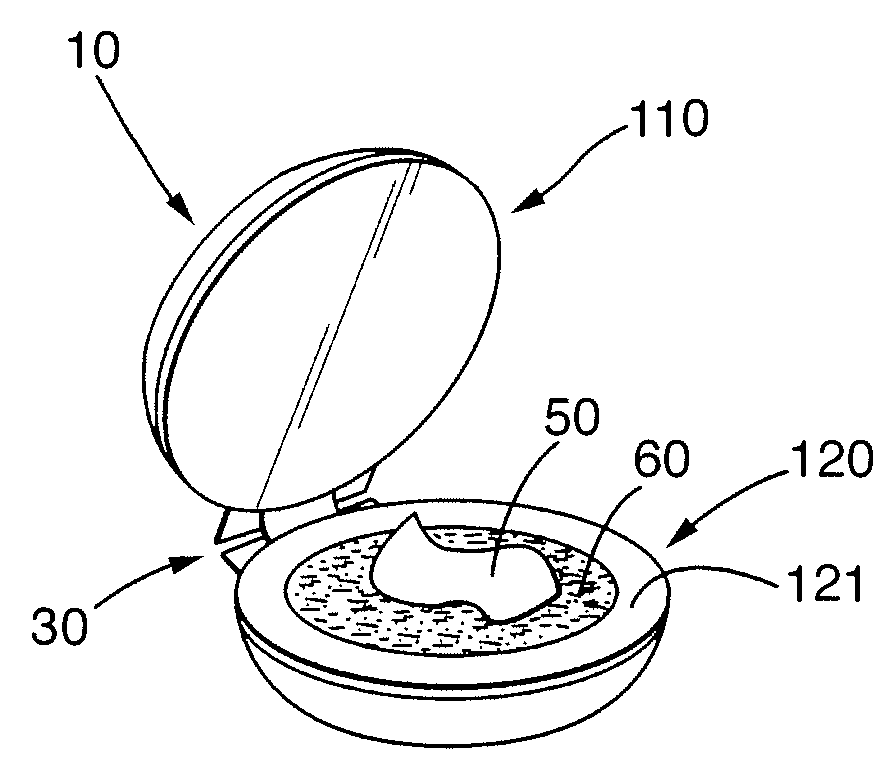

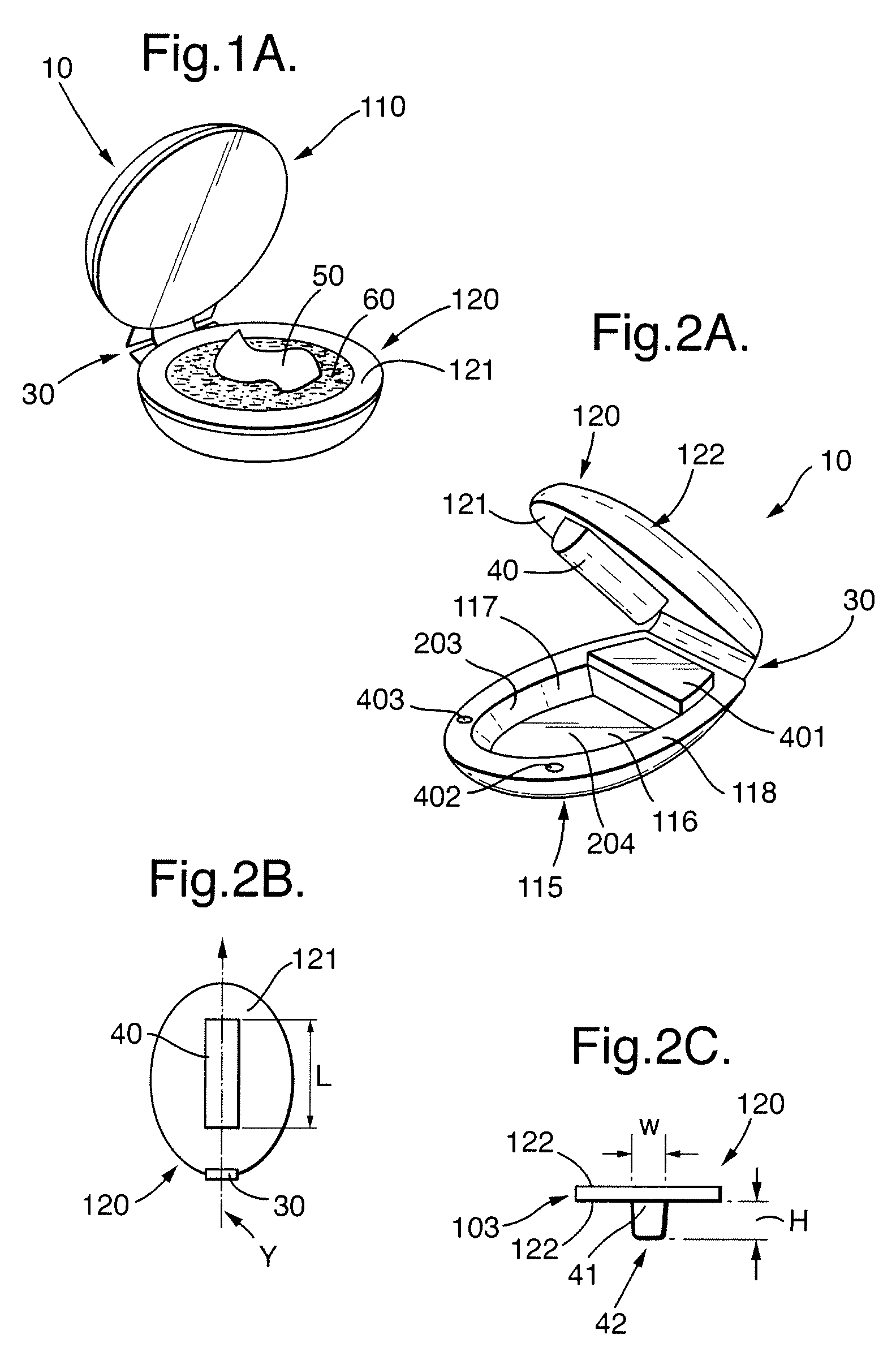

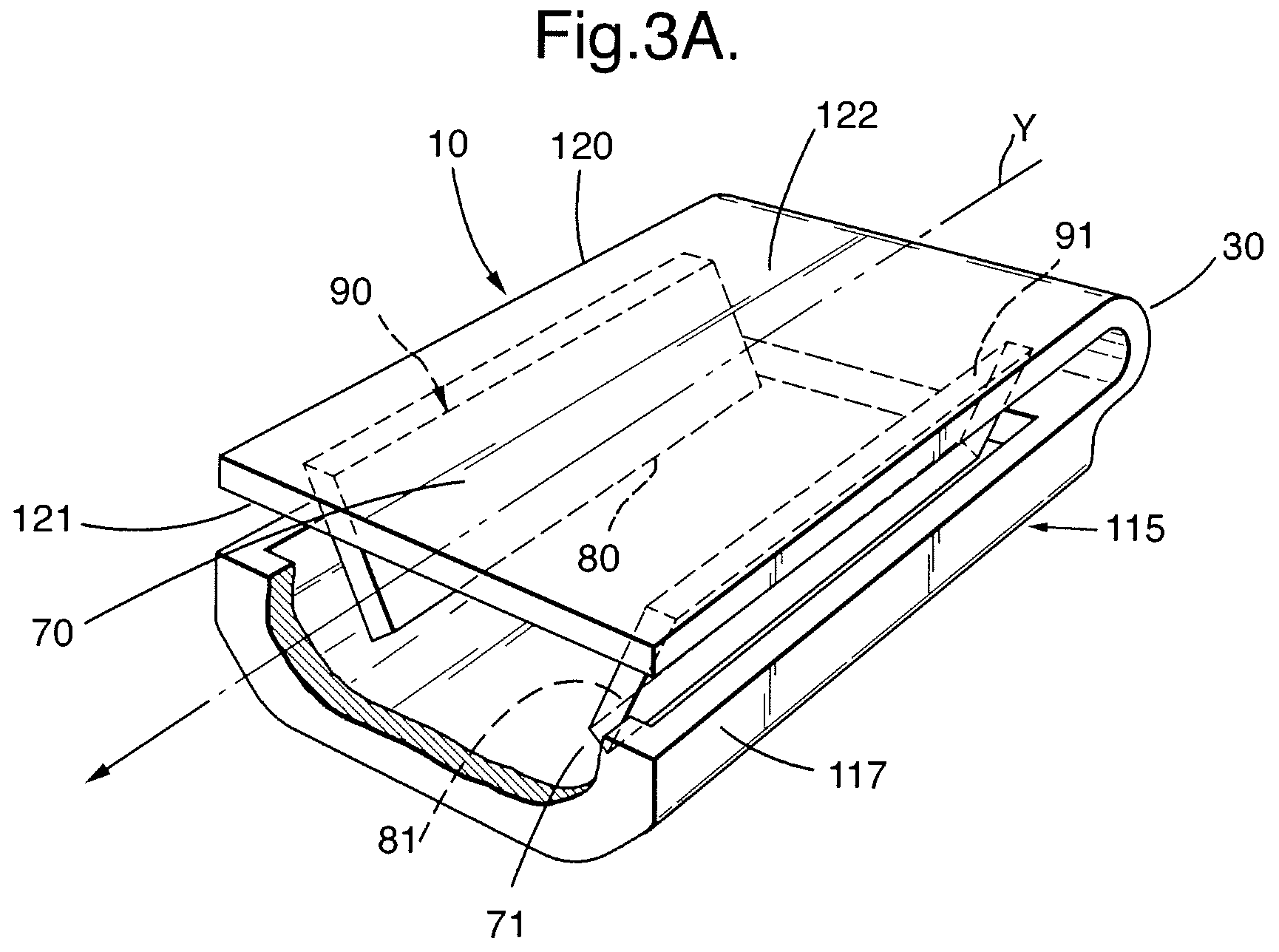

System for Highlighting Hair

The present invention relates to a system to highlight the hair. The system comprises a device (10) and a composition (50). Device (10) comprises a first portion movably joined to a second portion. Composition (50) comprises a percentage of hydrogen peroxide and a percentage of an alkalizer by weight of said composition (50). The weight percentages of hydrogen peroxide and of an alkalizer are defined by equation (I): X+1.5Y≧15 (I) wherein X is the percentage by weight of hydrogen peroxide by weight of the composition (50) and wherein Y is the percentage by weight of an alkalizer by weight of the composition (50). Said composition (50) comprises at least 2% of hydrogen peroxide by weight of said composition (50) and said alkalizer is an inorganic salt selected from the group consisting of sodium silicate, sodium metasilicate, potassium hydrogen carbonate, ammonium carbonate, ammonium hydrogen carbonate and sodium hydrogen carbonate and mixtures thereof. Said composition (50) allows to perform highlighting when applied with the device (10) as described herein.

Owner:WELLA OPERATIONS US LLC

Lotus leaf defatting cake and preparing method

InactiveCN1586219ASolve the single functionLower serum triacylglycerol-lipoproteinDough treatmentConfectionerySugarWheat flour

The slimming lotus leaf biscuit is produced with material including wheat flour, sugar, milk powder, ammonium bicarbonate, salt, crushed dewatered lotus leaf, plant butter, baking soda, calcium carbonate, starch and egg. The production process includes treating lotus leaf via eliminating ribs, washing, scalding, stoving and crushing; mixing all the material to form dough; rolling, molding and stoving. The slimming lotus leaf biscuit is convenient in carrying about and eating and has the slimming and defatting function of lotus leaf, which maintains its green color in biscuit.

Owner:王锋

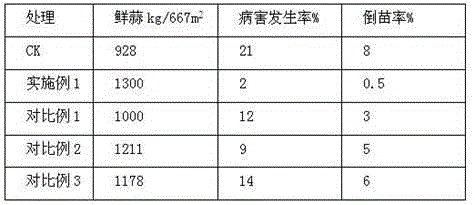

Special organic microbial bacterial manure for garlic and preparation method thereof

ActiveCN104016807ABalanced nutritionMeet the nutritional requirements for growthFertilizer mixturesEcological environmentMicrobial agent

The invention belongs to the technical field of manure, and in particular relates to special organic microbial bacterial manure for garlic and a production method for the special organic microbial bacterial manure for garlic. The special organic microbial bacterial manure for garlic comprises the following components: furfural residue, mushroom bran, composite microbial agent, ammonium hydrogen carbonate, calcium superphosphate, potassium chloride, zinc sulfate, plant ash, potassium sulfate, animal manure, potassium humate, rice hull powder and rape seed cakes. The special organic microbial bacterial manure for garlic, prepared by adopting the method disclosed by the invention, contains a large amount of nutrients required for the growth of garlic and various trace elements and amino acids, and has the effects of efficiently, synergistically and enduringly improving soil, improving the fertility, resisting diseases and the like; in addition, soil probiotic floras are added into organic matters, so that the nutrients can be better absorbed and utilized, and the micro-ecological environment of the soil can be continually repaired. Through testing, the special organic microbial bacterial manure for garlic, disclosed by the invention, can be used for effectively improving the yield of garlic by 20-30%.

Owner:QILU UNIV OF TECH

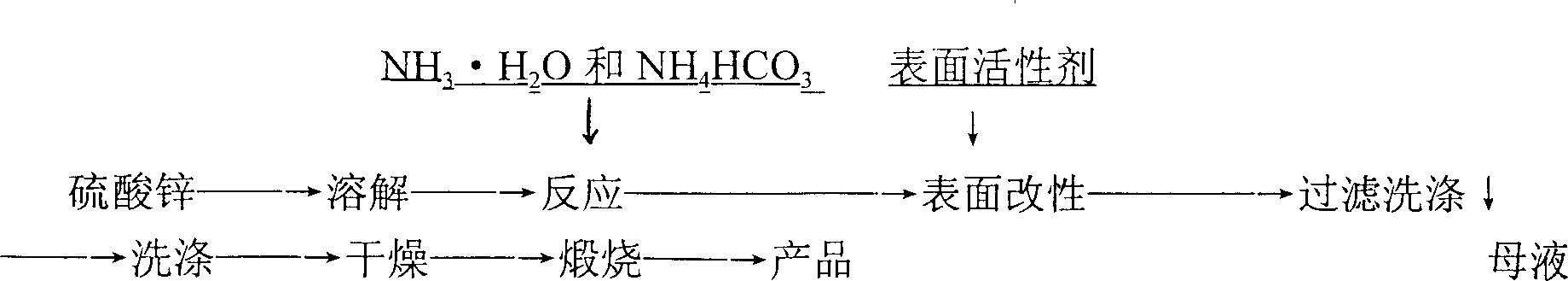

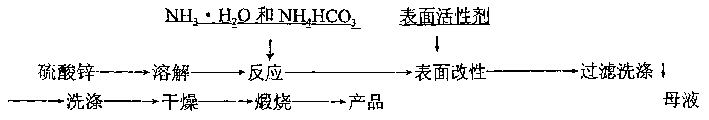

Process for preparing nano zinc oxide

InactiveCN1396117ASmall specific surface areaLarge specific surface areaZinc oxides/hydroxidesAmmonium salt fertilisersDispersitySulfate

A process for preparing nanometre zinc oxide includes such steps as proportionally dropping ammonia water to a zinc sulfate solution, adding ammonium hydrogen carbonate to obtain ZnCO3.Zn(OH)2 deposit, separation, washing with deionized water, vacuum drying to obtain a composite presoma, and then calcining at 150-600 deg.C for 1.5-2.5 hr to obtain the product. Its advantages are low cost and high dispersity of product in water.

Owner:SHANDONG XIAOYA GRP CO LTD

Method of comprehensively utilizing serpentine

InactiveCN101235440ATake advantage ofFull controlSilicon oxidesProcess efficiency improvementFerric hydroxideSoluble glass

The invention relates to a method for comprehensively utilizing serendipities, which comprises: magnetically separating the serpentinites in a strong magnetic field, obtaining amorphous silica powder which contains silicon dioxide more than 90% through filtering acid dipping solution, dissolving the amorphous silica powder through using caustic soda under high temperature, which is used for manufacturing soluble glass with medium high modulus or taken as raw materials for producing white carbon black, then, mixing sulphuric acid and hydrochloric acid or nitric acid or mixing the sulphuric acid, the hydrochloric acid and nitric acid, adding acid dipping additive to carry out compound alternative and circulating acid dipping for ore powder which is magnetically separated and processed, fractionally depositing, filtering, and removing impurity for magnesium sulfate solution which is filtered through the acid dipping and contains the impurity, through adjusting the pH value, obtaining inorganic industrial dyes which mainly contain iron oxide yellow, ferric hydroxide and aluminum hydroxide, enriching the nickel, which is convenient for abstracting the nickel from the serpentinites, finally obtaining high purity magnesium oxide through refining refined magnesium sulfate solution whose impurity is removed after ammonium hydrogen carbonate and ammonial solution or sodium sulfide is used to deposit, and also obtaining ammonium sulfate or sodium sulfate which contains magnesium and calcium after liquid which is filtered is evaporated.

Owner:刘湘霖 +1

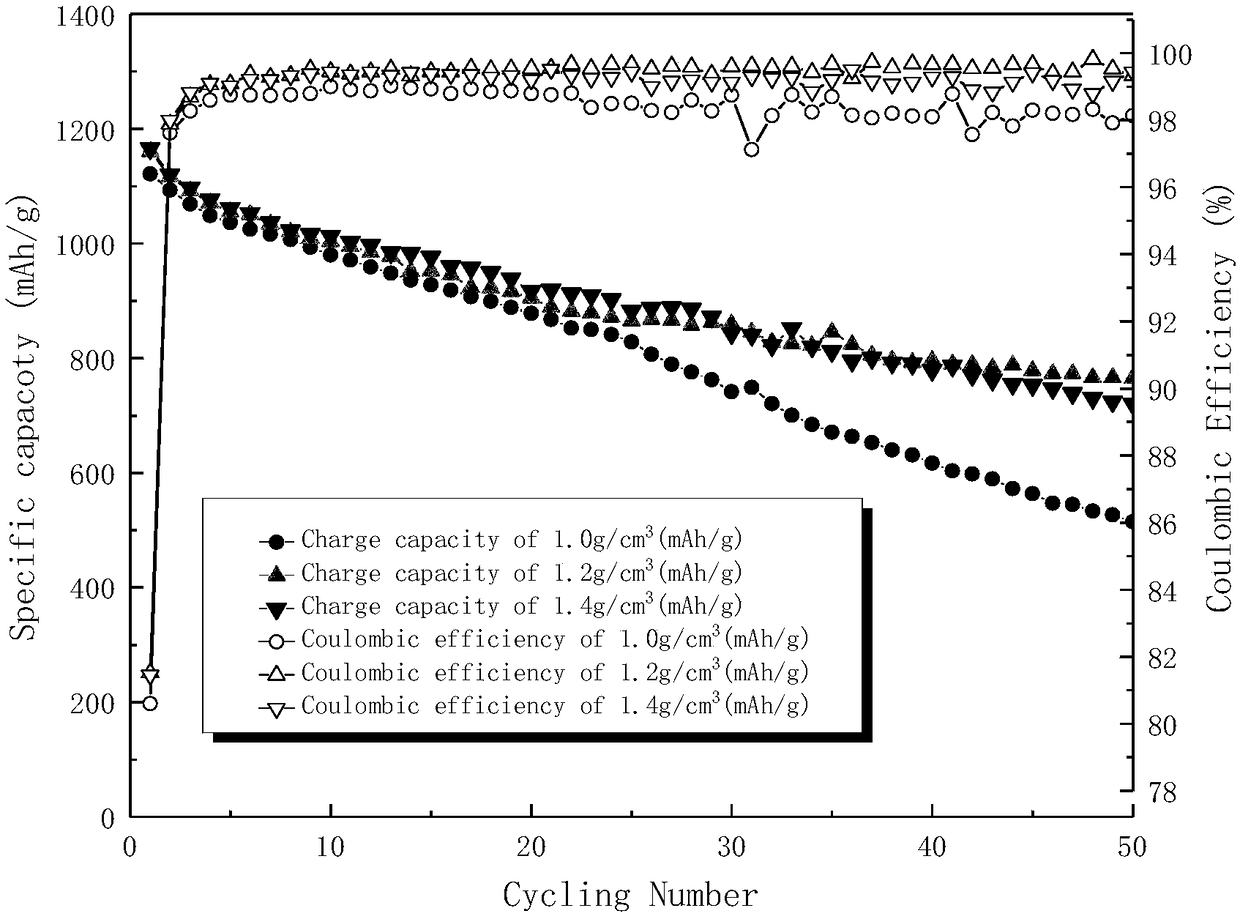

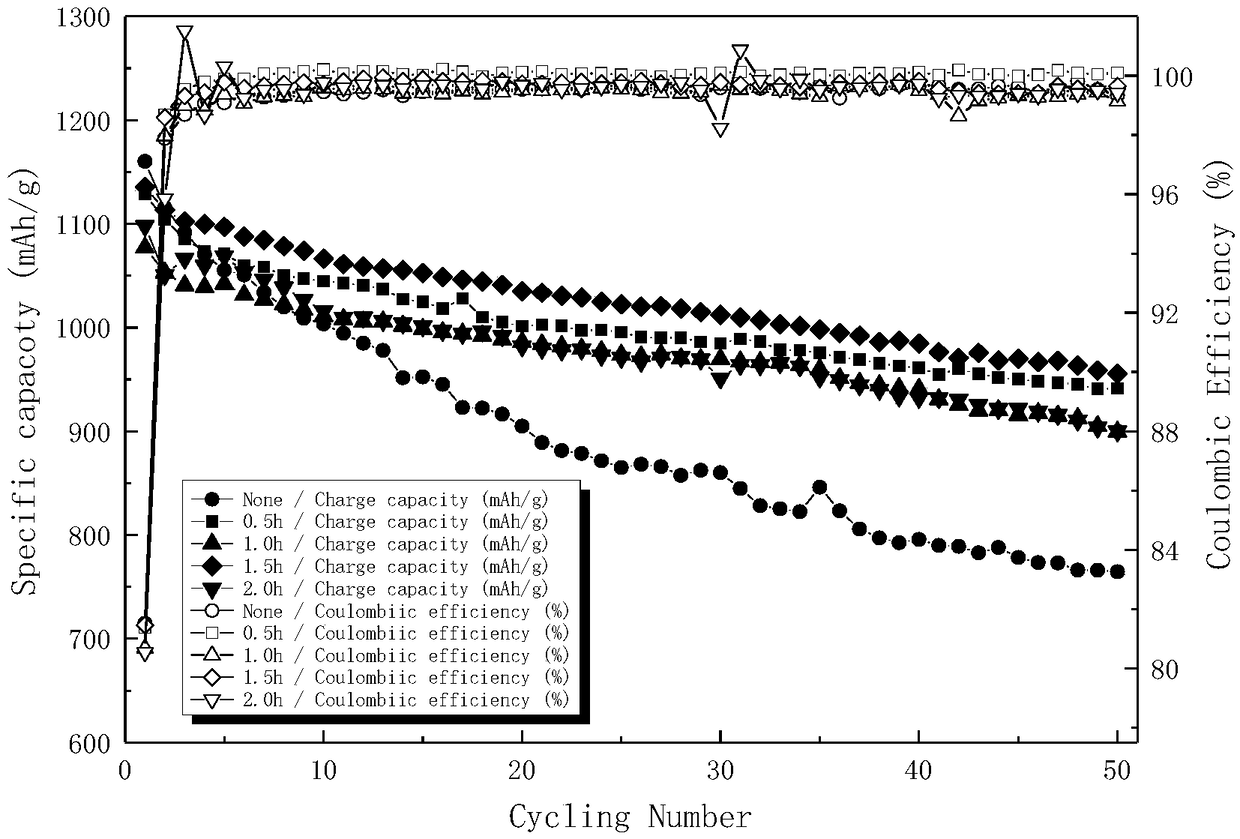

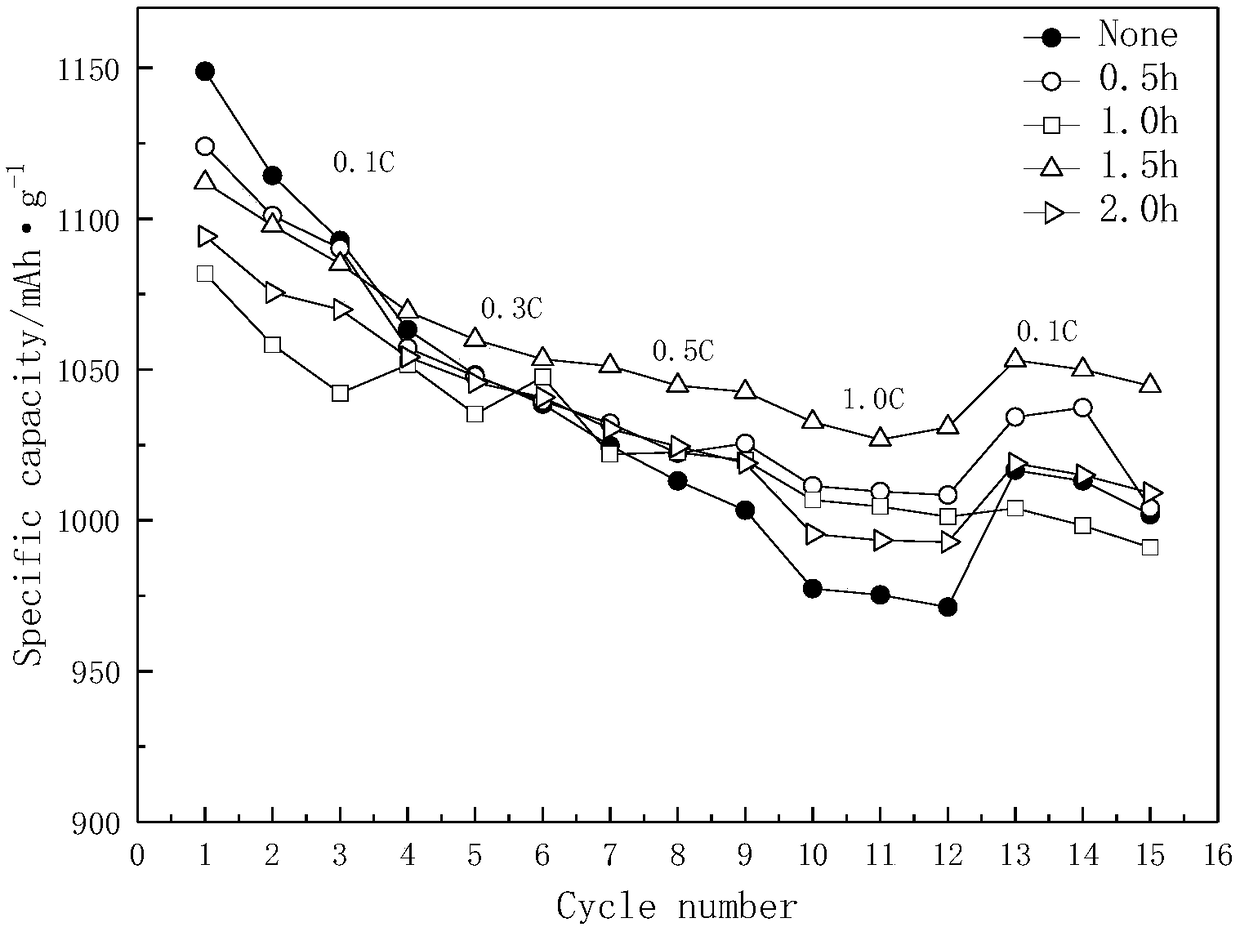

Silicon-based electrode with adjustable pore structure and preparation method of silicon-based electrode

ActiveCN108767195AIntegrity guaranteedImprove distributionElectrode rolling/calenderingSecondary cellsPorosityCyclic process

The invention provides a silicon-based electrode with an adjustable pore structure; the porosity of the silicon-based electrode is 30%-60%; the pore structure of the silicon-based electrode is adjusted by controlling the compaction density of the electrode and adding a pore-forming additive, wherein the pore-forming additive is one or more of ammonium carbonate, ammonium hydrogen carbonate, ammonium acetate, ammonium nitrate and ammonium chloride. The invention further provides a preparation method of the silicon-based electrode. The porosity of the electrode is controlled by changing the compaction density, and the appropriate porosity can be consistent with the volume expansion rate of a high specific capacity silicon carbon negative electrode material in a lithium intercalation state, so that the integrity of the structure is kept in the circulation process of the electrode; and the volume change of silicon can be effectively buffered through the high-capacity silicon-based negativeelectrode with the variable pore structure, so that the diffusion speed of lithium ions and electrons is increased, the cycling stability of the electrode is obviously improved, and the large-currentdischarge performance of the electrode is improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

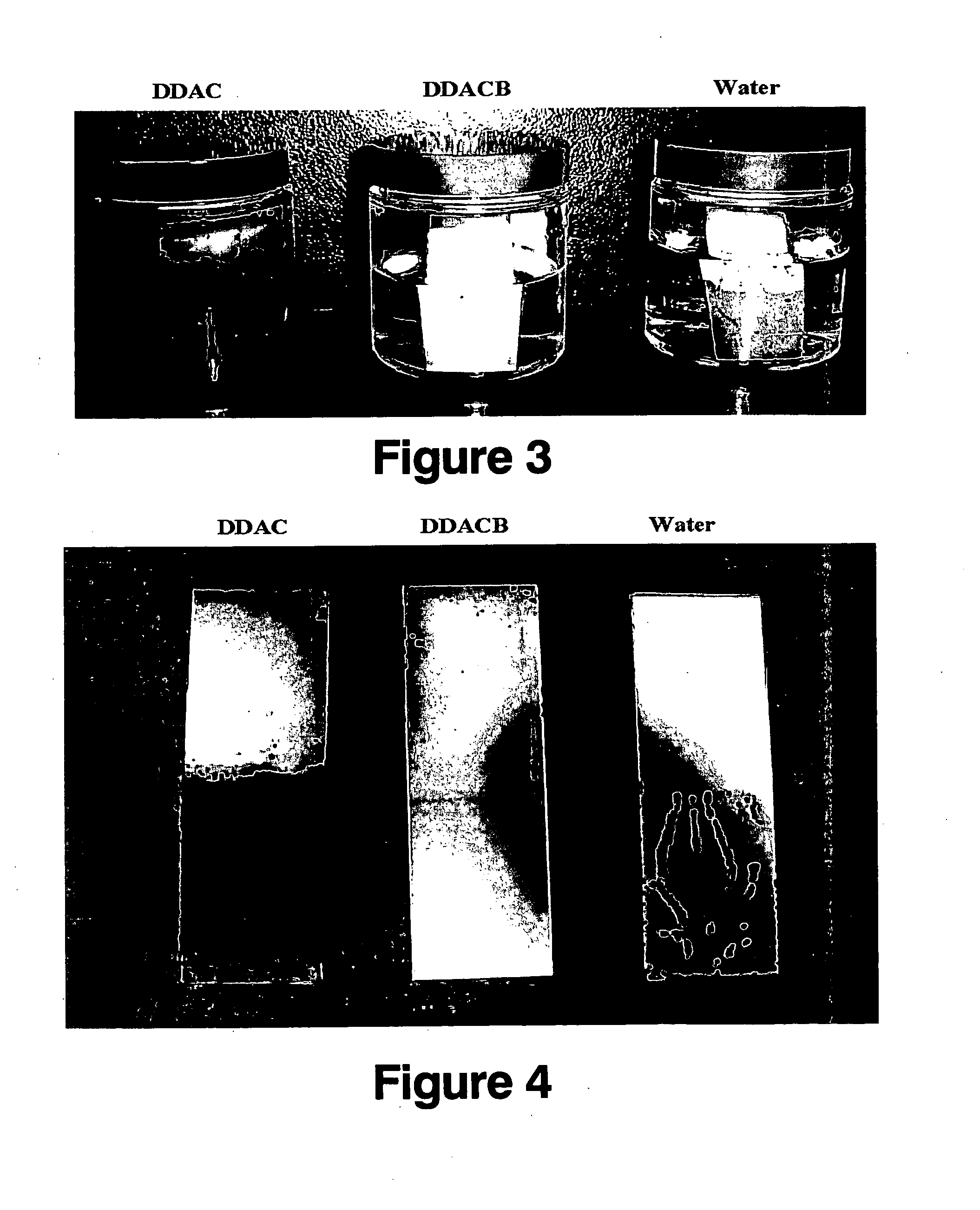

Quaternary ammonium carbonates and bicarbonates as anticorrosive agents

InactiveUS20050003978A1Avoid corrosionInorganic/elemental detergent compounding agentsCationic surface-active compoundsBicarbonateMetal substrate

Quaternary ammonium carbonates, bicarbonates, and mixtures thereof as anti-corrosive agents. The present disclosure relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds, to metal substrates having these anticorrosive coatings, and to aqueous cleaning solutions containing these compounds.

Owner:LONZA INC

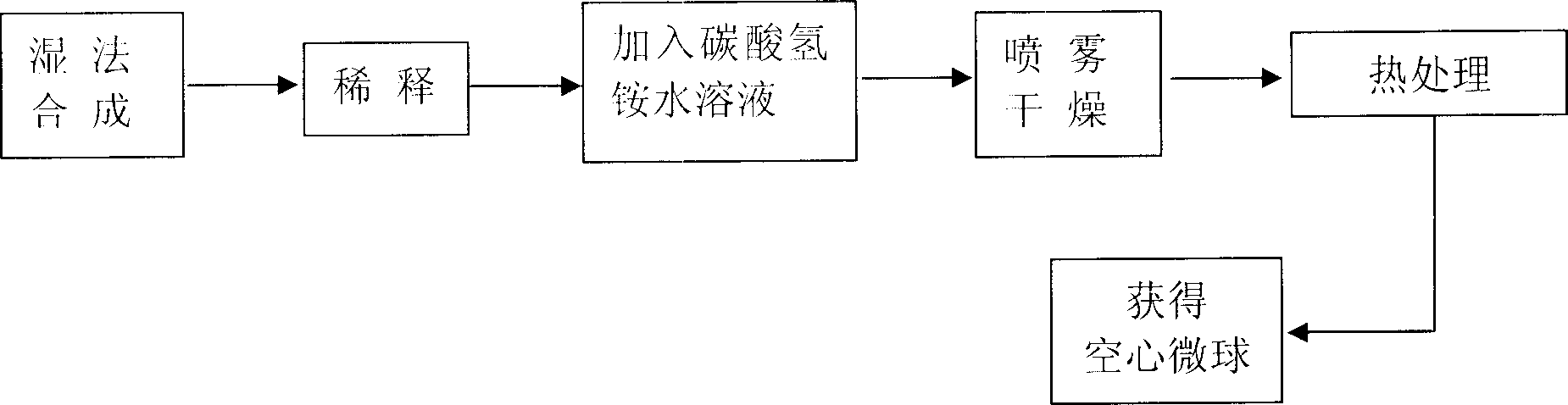

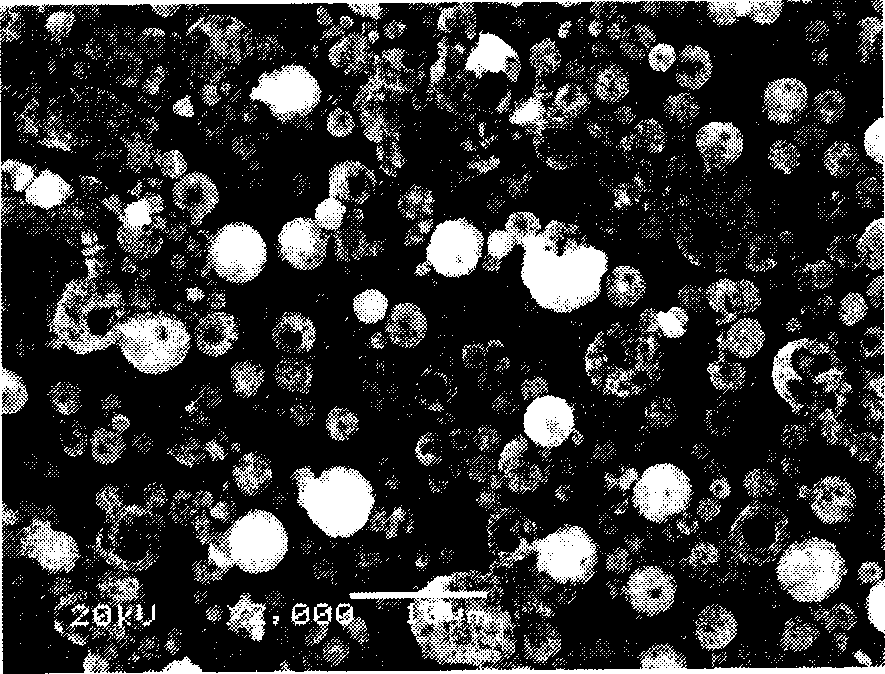

Preparation method of hydroxy phosephorite hollow microball

InactiveCN1903706AHigh purityReduce crystallinityPhosphorus compoundsProsthesisCalcium nitrate tetrahydrateApatite

The present invention discloses a method for preparing hydroxyapatite hollow microsphere. Said method includes the following steps: using tetrahydrate calcium nitrate and ammonium hydrogen phosphate as raw material, adopting chemical precipitation method to prepare hydroxyapatite slurry, then diluting said hydroxyapatite slurry by using distilled water, adding ammonium hydrogen carbonate as additive, uniformly stirring them, spray drying, making following heat treatment so as to obtain the hydroxyapatite hollow microsphere formed from nano grains.

Owner:SHANDONG UNIV

Nitrogen-doped hierarchical pore carbon and preparation method and application thereof

ActiveCN106179440AImprove usabilityLarge specific surface areaOrganic reductionPreparation by hydroxy compound hydrogenationNano catalystSodium bicarbonate

The invention discloses a preparation method of nitrogen-doped hierarchical pore carbon. The preparation method includes: using biomass as a raw material, and mixing the biomass with a composite activator; heating for calcining, mixing a calcining product with deionized water, standing for precipitation, and filtering to obtain precipitate; performing after-treatment to obtain the nitrogen-doped hierarchical pore carbon, wherein the composite activator is sodium hydrogen carbonate / nitrogen-containing compound, a mass ratio of sodium hydrogen carbonate to the nitrogen-containing compound is 0.25-4:1, the nitrogen-containing compound comprises at least one of ammonium oxalate, ammonium hydrogen carbonate, ammonium chloride and ammonium nitrate, and a mass ratio of the biomass to the composite activator is 1:2-16. The composite activator is utilized to activate the biomass to obtain a functionalized nitrogen-doped hierarchical pore carbon material, the preparation method is simple and easy to operate, the biomass existing in nature can be utilized directly, the obtained carbon material has rich hierarchical pore structure and can be used as a catalyst carrier to prepare high-performance nano catalysts, and utilization value of the biomass is increased greatly.

Owner:ZHEJIANG UNIV

Alumina supporter and preparation method thereof

ActiveCN101462074AImprove hydrogenation reactivityLower Diffusion LimitsCatalyst carriersPore distributionSlurry

The invention relates to an alumina carrier and a preparation method thereof. The pore distribution of the alumina carrier is as follows: the pore volume of holes with the pore diameter of less than 10 nanometers accounts for less than 10 percent of the total pore volume; the pore volume of holes with the pore diameter between 10 and 50 nanometers accounts for 40 to 80 percent of the total pore volume; the pore volume of holes with the pore diameter between 100 and 1,000 nanometers accounts for 1 to 40 percent of the total pore volume; and the pore volume of holes with the pore diameter between 5,000 and 10,000 nanometers accounts for 1 to 20 percent of the total pore volume. The preparation method for the alumina carrier comprises: adopting a small quantity of starch and / or carbon black as crystal seeds, adopting a method of co-current flow first and swing then to prepare a serum containing aluminum hydroxide, using ammonium carbonate and / or ammonium bicarbonate to adjust the pH value, and finally preparing the alumina carrier. Alumina obtained by the method still maintains high strength under the condition of enlarged pore volume and pore diameter. The alumina carrier is particularly suitable to be a carrier of a residual oil hydrotreating catalyst.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Origin fermentation method and origin fermentation product prepared by same

ActiveCN104152514AShort fermentation timeSimple stepsCosmetic preparationsToilet preparationsAdditive ingredientUltrafiltration

The invention relates to the field of biological fermentation and in particular relates to an origin fermentation method and an origin fermentation product prepared by the same. The origin fermentation method comprises the following steps: acquiring fresh leaves, pulping and crushing to obtain a leaf slurry; placing the leaf slurry into a fermentation tank, adding sterilized ammonium sulphate, ammonium dihydrogen phosphate, ammonium hydrogen carbonate and an aqueous solution of corn steep liquor dry powder into a fermentation tank so as to be fermented; carrying out cell breakage, ultrafiltration, low-temperature drying and concentrating on a fermentation product, and packaging, so that the origin fermentation product is obtained. The origin fermentation method provided by the invention has the advantages that fresh leaves are crushed, bacteria and enzymes carried by the leaves are directly utilized for carrying out fermentation, no organic solvent, saccharifying enzyme or yeast is added in a fermentation process, the fermentation time is short, main ingredients of the obtained origin fermentation product are active substances beneficial to skin, such as micromolecule plant proteins, plant growth factors, plant activity auxin and part of cell growth factors, and the quality of the obtained origin fermentation product is high.

Owner:北京翰若生物科技有限公司

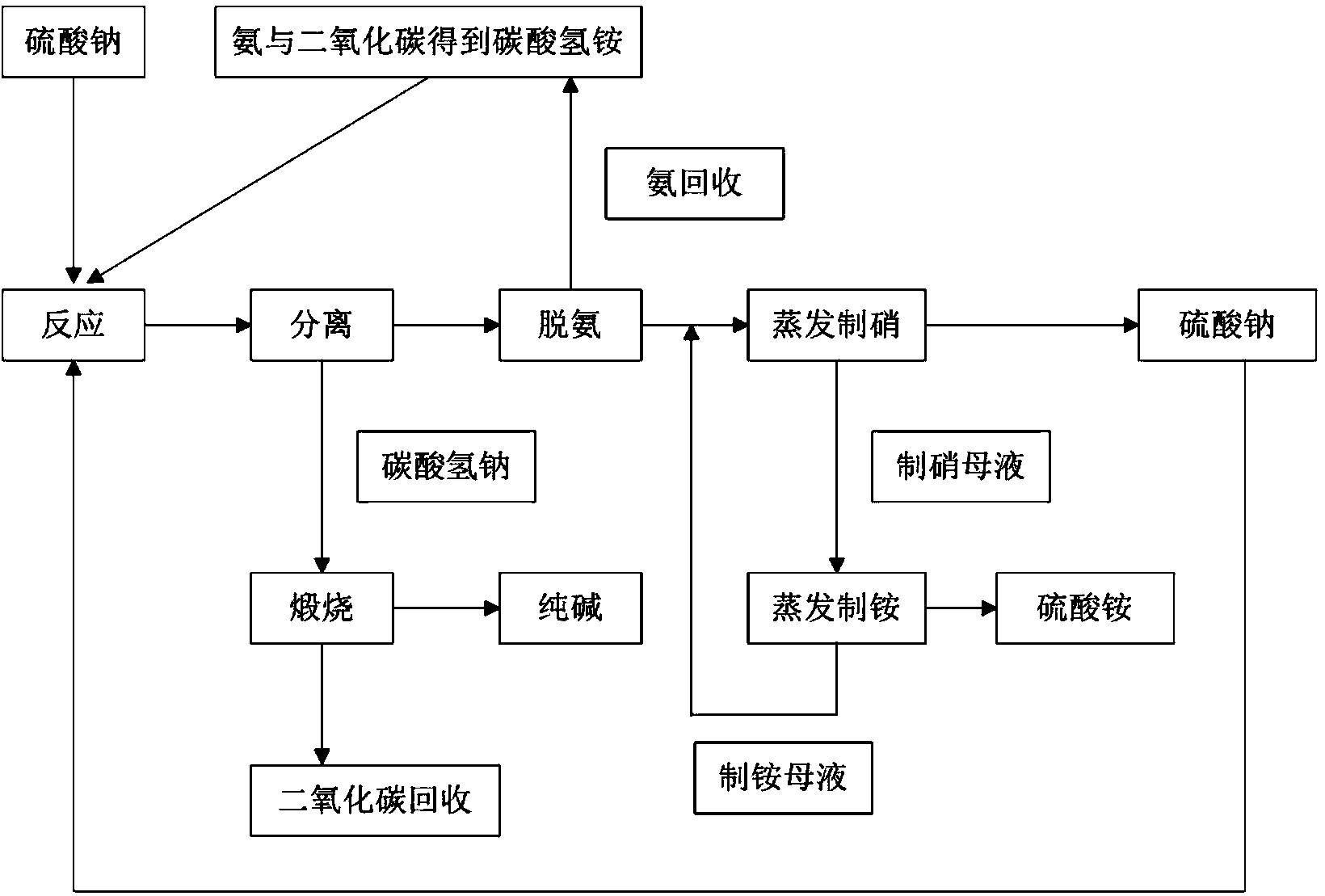

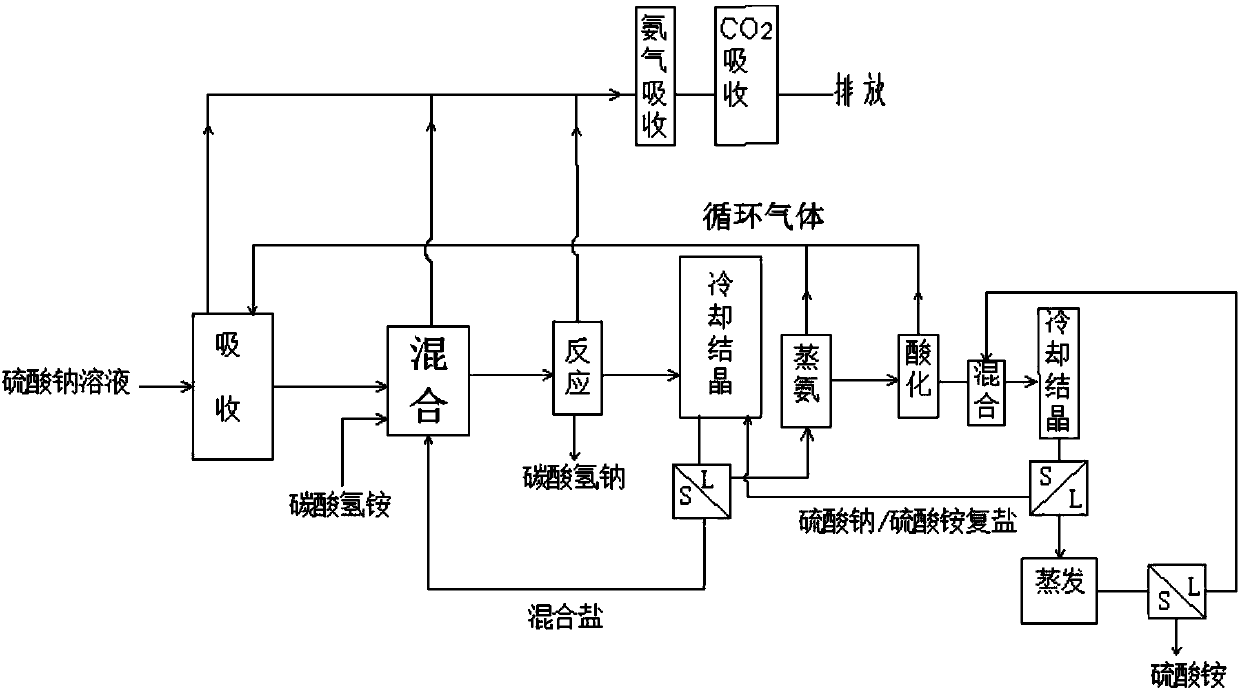

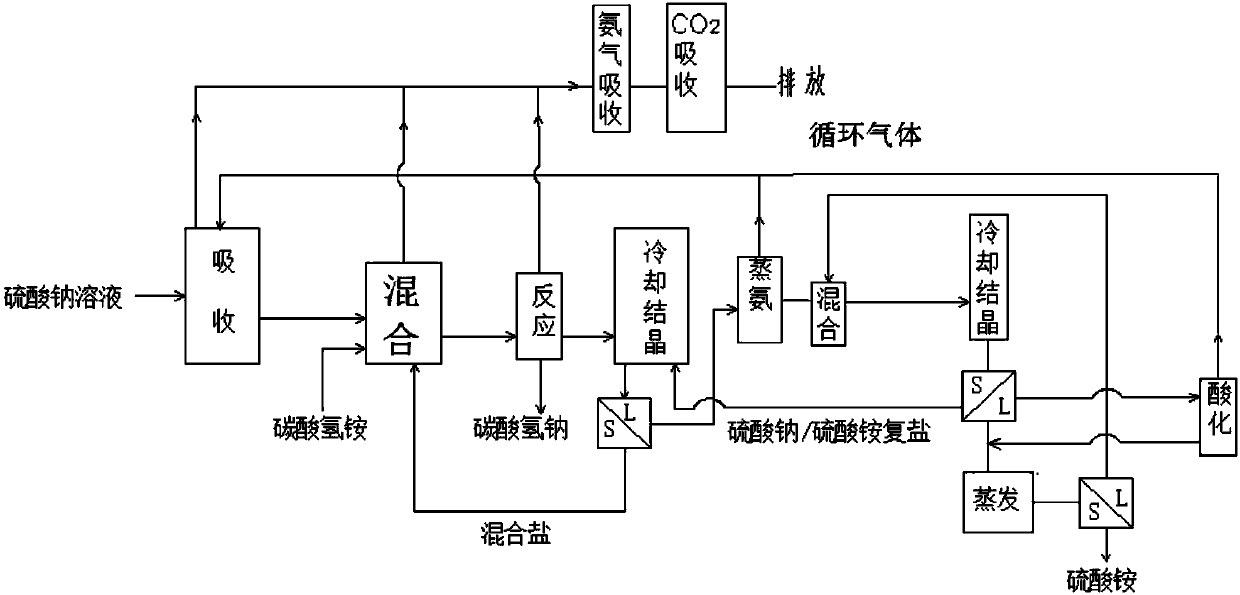

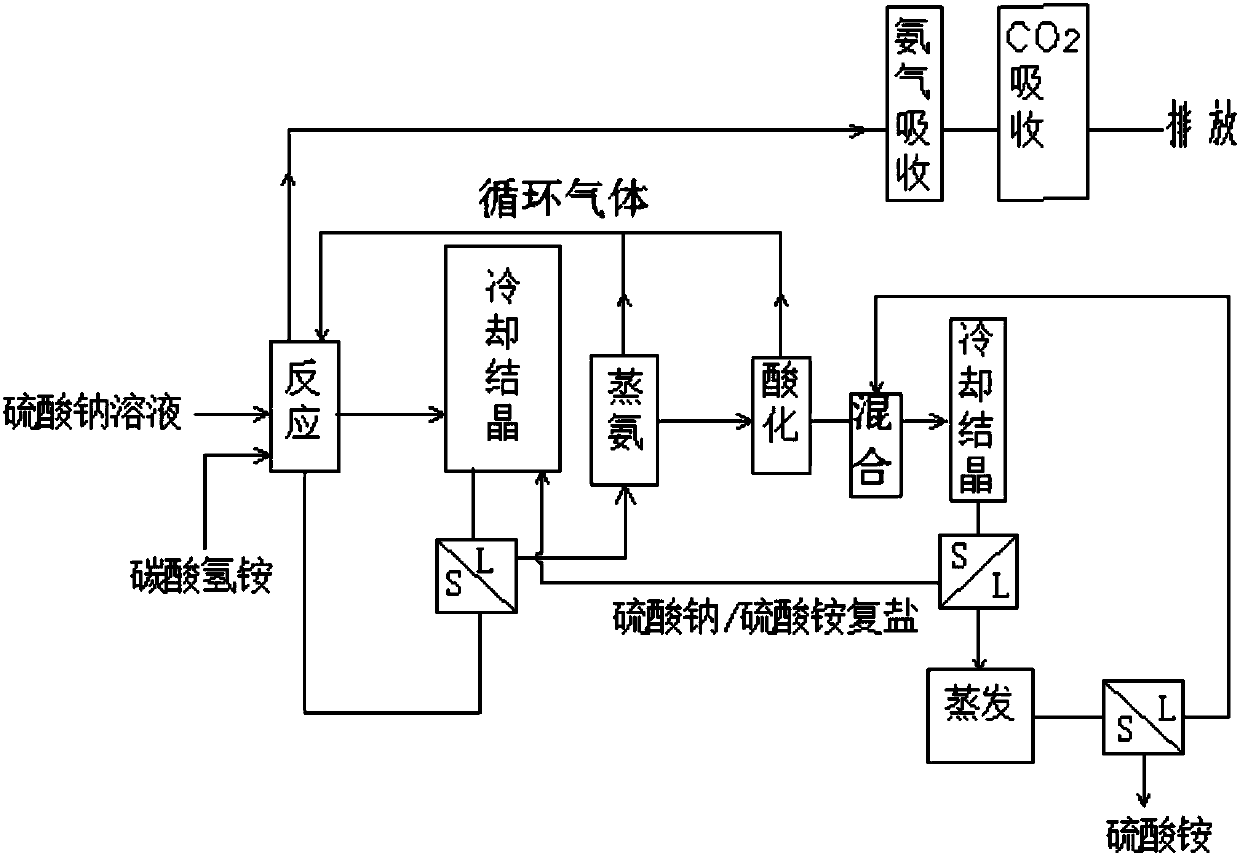

Thermal circulation technology of utilizing sodium sulfate solution or carrier to cogenerate sodium carbonate and ammonium sulfate

ActiveCN104355326AIncrease added valueReduce energy consumptionAmmonium sulfatesCarbonate preparationAmmonium Hydrogen CarbonateSodium sulfate

The invention provides a thermal circulation technology of utilizing sodium sulfate solution or a carrier to cogenerate sodium carbonate and ammonium sulfate. The thermal circulation technology comprises the following steps: regarding an ammonium hydrogen carbonate solution prepared from sodium sulfate, ammonia and carbon dioxide as a raw material to be conducted with a replacement reaction, then carrying out separation to obtain sodium hydrogen carbonate (which can be calcined to obtain a pure alkali product) and an alkali preparing mother solution containing ammonium sulfate, sodium sulfate, ammonium hydrogen carbonate and ammonium carbonate; preheating the alkali preparing mother solution to a high temperature to remove ammonium hydrogen carbonate and ammonium carbonate, and then obtaining the deaminized mother solution containing ammonium sulfate and sodium sulfate; evaporating the deaminized mother solution at a high temperature to obtain sodium sulfate and a niter preparing mother solution; evaporating the niter preparing mother solution at a low temperature to obtain ammonium sulfate and an ammonium preparing mother solution; circulating the sodium sulfate to the replacement reaction working procedure; circulating the ammonium preparing mother solution to the deaminized mother solution high-temperature evaporation working procedure. The main products and byproducts prepared by thermal circulation technology disclosed by the invention are high in quality and added value; the thermal circulation technology is well-adapted in raw materials, low in sodium sulfate theoretical use ratio, production cost and energy consumption, closed circulating, free of three-waste discharge, and capable of saving energy and reducing emission.

Owner:CHINA LIGHT IND INT ENG CO LTD

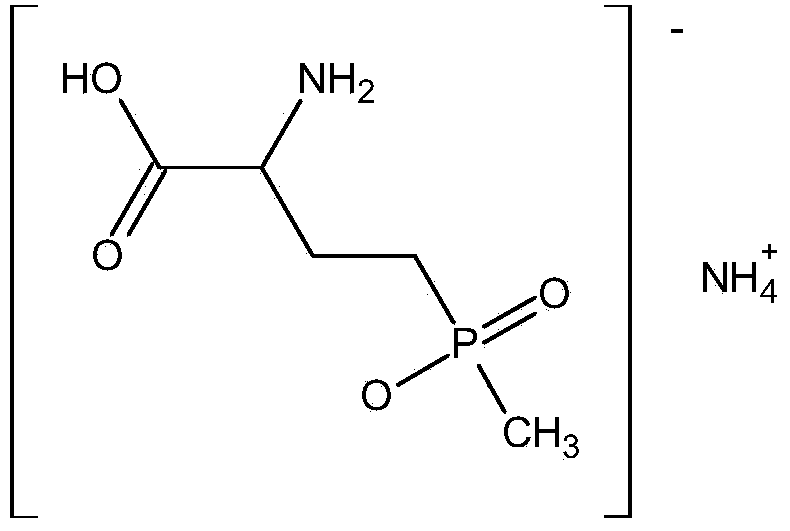

Solid glyphosate-formulation and manufacturing process

Disclosed is a solid formulation of the herbicidal active agent glyphosate [N-(phosphonomethyl)glycine] compressed into tablet form. It is applied in the agricultural and horticultural sectors to destroy unwanted vegetation. The solid formulation according to the invention consists essentially of free glyphosate acid, salifying agents (alkali or ammonium hydrogencarbonate or carbonate in conjunction with solid organic acids), biological activating agents and diluents. A suitably sized tablet can consequently be adapted to supply an appropriate dose of spray mixture per surface unit for small-scale users. Submerging in water causes the glyphosate to convert into a soluble salt. The resulting carbon dioxide facilitates rapid disintegration of the tablet.

Owner:SCHIRM AG

Soybean dedicated biological organic green fertilizer and preparation method thereof

ActiveCN104045425AIncrease profitSufficient nutritionFertilizer mixturesRapeseedAmmonium Hydrogen Carbonate

The invention discloses a soybean dedicated biological organic green fertilizer which is characterized by being prepared from the following raw materials in parts by weight: 100-120 parts of human and animal excreta, 50-60 parts of corn straw, 35-50 parts of rapeseed cake meal, 25-30 parts of urea, 21-25 parts of ammonium hydrogen carbonate, 35-40 parts of diammonium phosphate, 10-13 parts of a limestone powder, 1-2 parts of zinc oxide, 29-35 parts of animal urine, 17-23 parts of potassium chloride, 24-28 parts of peanut cake meal, 5-7 parts of brown sugar, 5-7 parts of an EM agent, 8-10 parts of a soil improvement agent, and a proper amount of water. The organic fertilizers are fermented and then are mixed with the general chemical fertilizers, and the melting urea is utilized to coating the surface, so that a slow release effect is played, subsequent nutrients for soybean are allowed to be sufficient, the utilization rate of the fertilizer is improved, the fertilization cost is substantially reduced, the yield of the soybean is improved, and economic benefits are also correspondingly improved; and the soybean dedicated biological organic green fertilizer is green and environmentally friendly, and is convenient to popularize and apply.

Owner:广西三合生态农业发展有限公司

Special microbial bacterial fertilizer for potato and preparation method thereof

InactiveCN106748341APromote growthImprove disease resistanceCalcareous fertilisersMagnesium fertilisersPhosphateMicrobial agent

The invention discloses a preparation method of a special microbial bacterial fertilizer for potato. The special microbial bacterial fertilizer for potato comprises the following raw materials: potassium sulfate, monoammonium phosphate, urea, ammonium sulfate, ammonium hydrogen carbonate, calcium sulfate, sodium borate, copper sulfate, magnesium sulfate, ferrous sulfate, ammonium molybdate, zinc sulfate, cottonseed cake powder, straw compost, biochar, corn starch sugar residue and animal manure; and the preparation method comprises the following steps: proportionally mixing the raw materials in water to obtain a base fertilizer solution; uniformly mixing the base fertilizer solution with a composite microbial agent, and stacking in a greenhouse for fermentation; and piling up for 3-4 days to obtain the special microbial bacterial fertilizer for potato. The invention also discloses a special microbial bacterial fertilizer for potato prepared by the preparation method of special microbial bacterial fertilizer for potato; in the special microbial bacterial fertilizer for potato, the ratio of N to P2O5 to K2O is 8:4:12, and total content of the three is greater than or equal to 24%; and experiments prove that the special microbial bacterial fertilizer for potato can effectively enhance the disease resistance, thus the tuber grows vigorously, and the product quality is good.

Owner:安徽莱姆佳生物科技股份有限公司

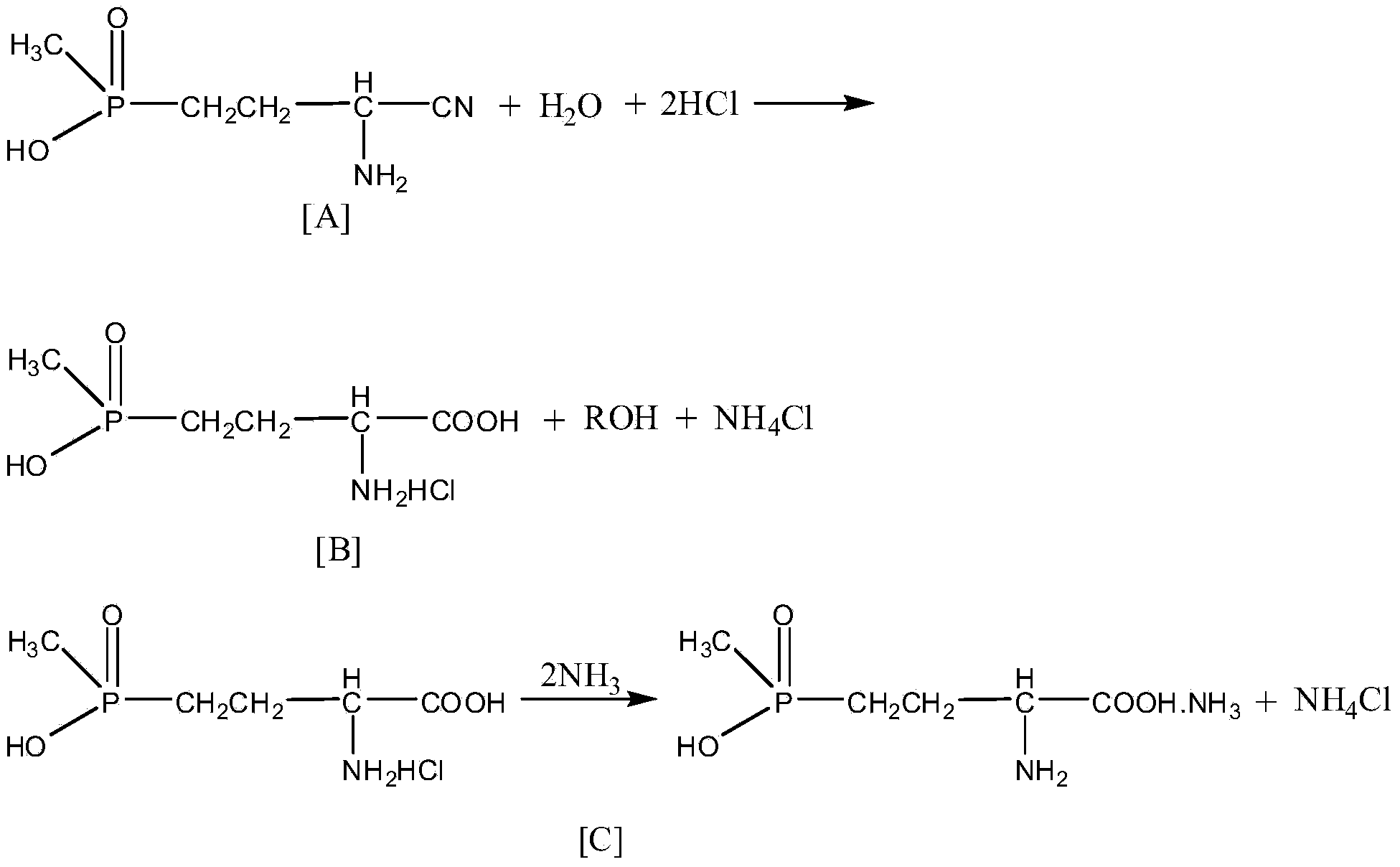

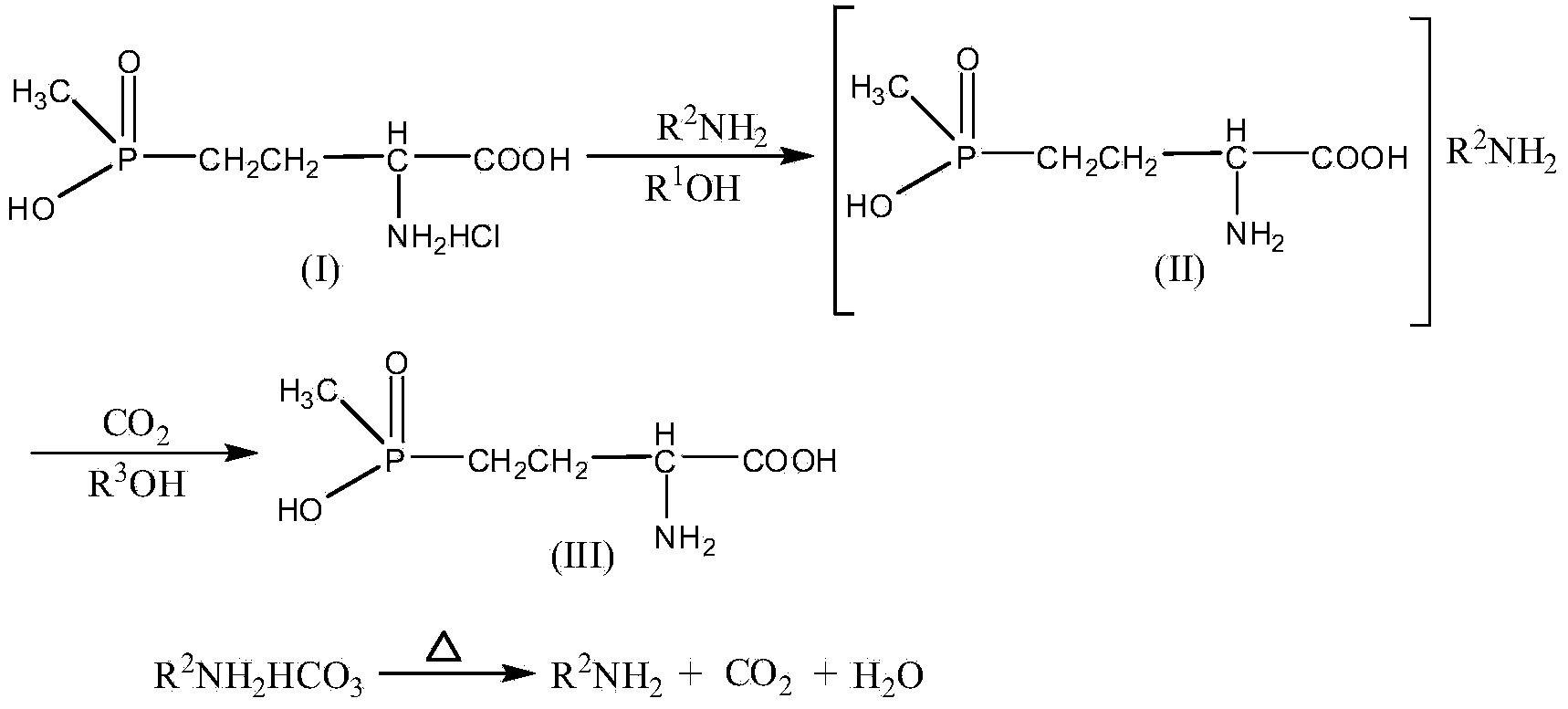

Glufosinate purifying technology

ActiveCN103819503AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsDecompositionSolvent

The invention provides a glufosinate purifying technology including the following steps: (1) adding glufosinate hydrochloride to alcohol R1OH, adding R2NH2 for ammoniation, adjusting the pH to 7.0-14.0, cooling and filtering, removing a solvent from a filtrate to obtain glufosinate ammonium salt and a small amount of organic impurities; (2) dissolving the glufosinate ammonium salt obtained by the steps (1) in an appropriate amount of water, leading in CO2 for neutralizing to the pH of 2.0-5.0, adding a proper amount of alcohol R3OH for precipitation of glufosinate acid, centrifugally filtrating to obtain the glufosinate acid which contains a small amount of ammonium hydrogen carbonate or organic amine carbonates; (3) heating for drying a glufosinate acid filtering cake obtained by the step (2) for decomposition and volatilization of the ammonium hydrogen carbonate or organic amine carbonates to obtain high purity glufosinate acid. The glufosinate purifying technology is simple in steps, the obtained glufosinate is low in inorganic salt content and high in purity, and compared with a traditional technology using epoxy ethane and epoxy propane, the purifying technology using carbon dioxide for separation of glufosinate hydrochloride and HCl is more economical, and high in safety, and has a higher industrialization prospect.

Owner:SHANDONG BINNONG TECH

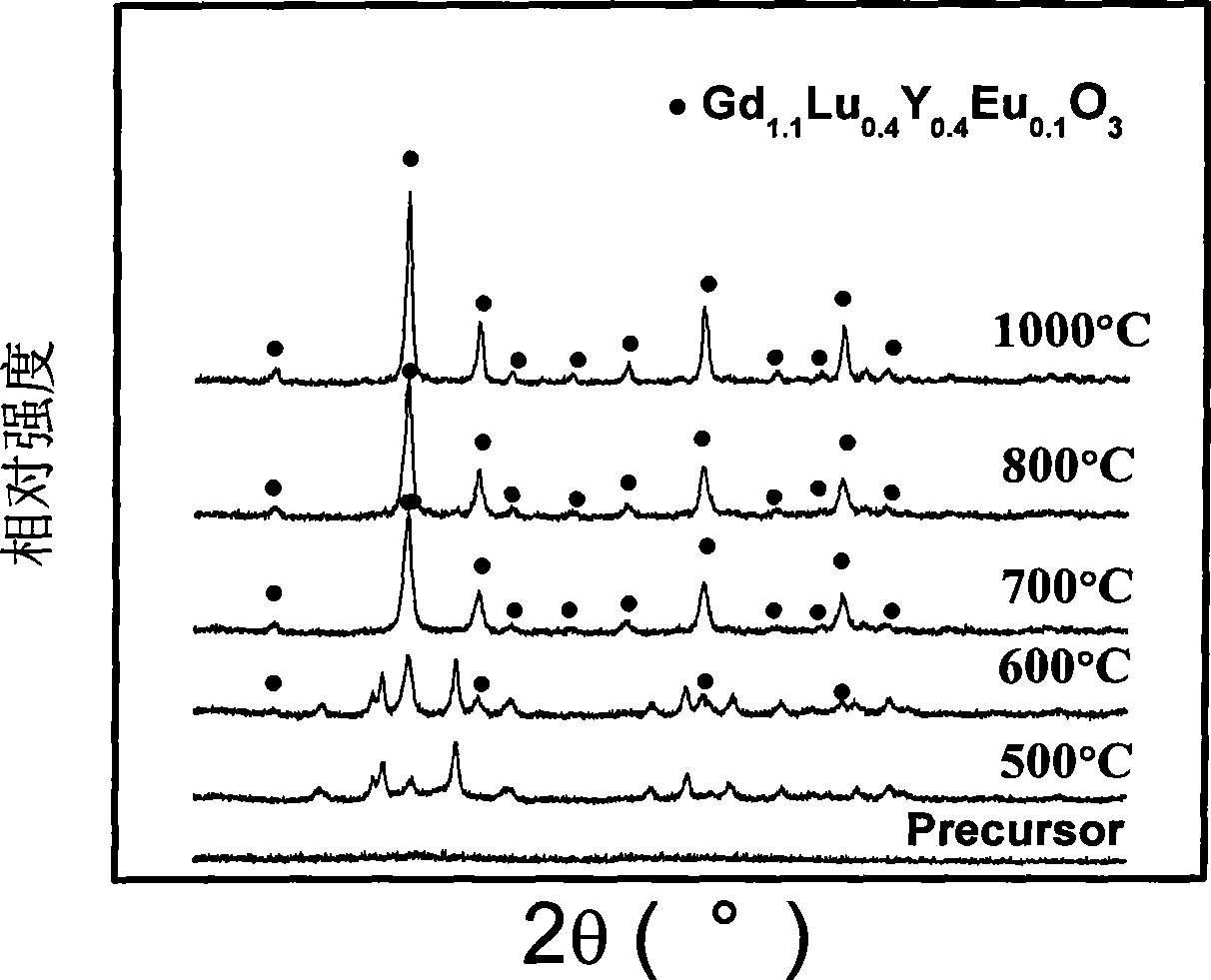

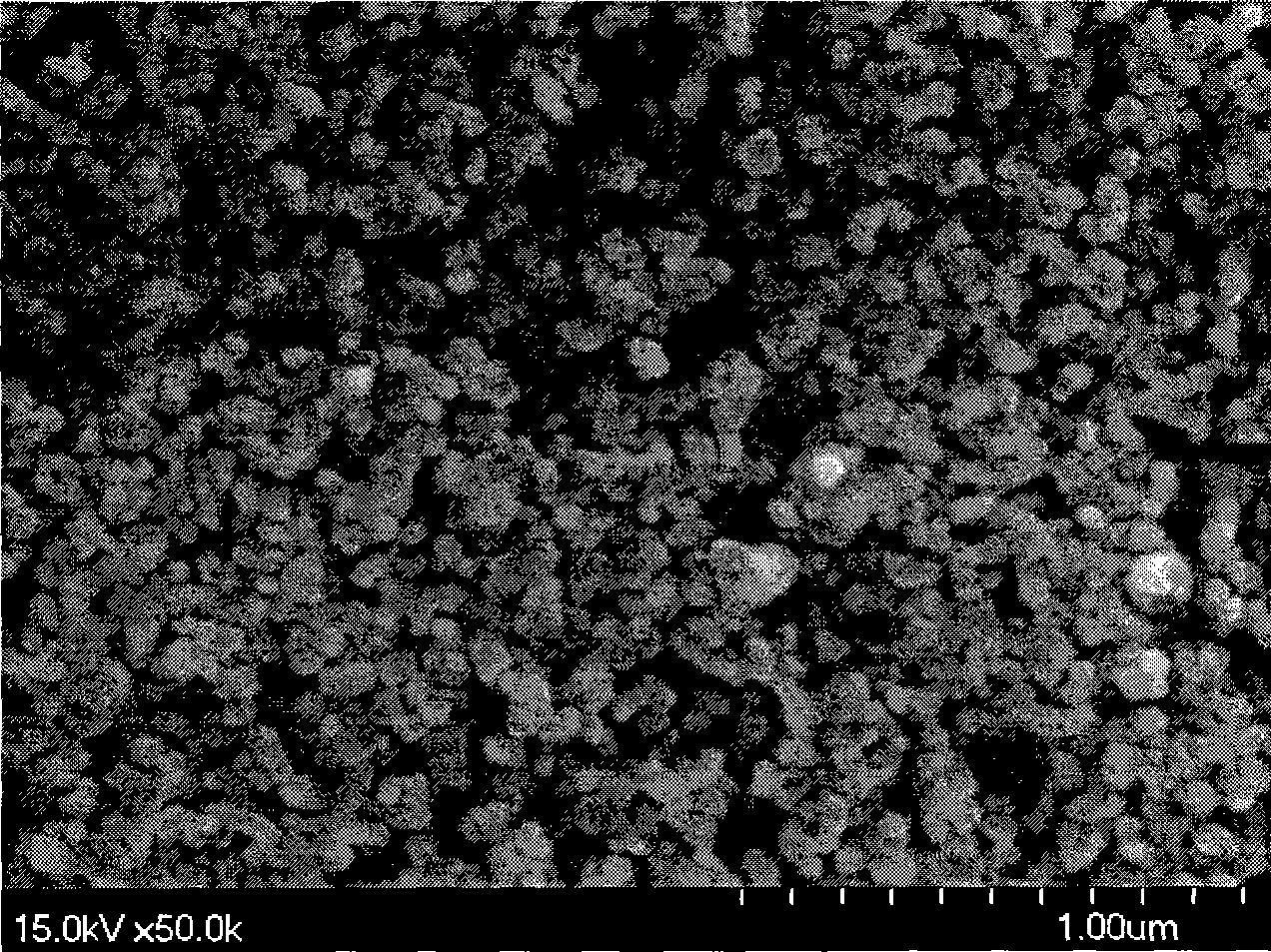

Rare earth oxide solid solution ceramic scintillator and preparation method thereof

The invention discloses a rare earth oxide solid solution ceramic scintillator and a preparation method thereof. The main component of the ceramic scintillator is Gd2xLu2yY2(1-x-y-z)Eu2zO3 (the x is more than or equal to 0.1 and less than or equal to 0.6, the y is more than or equal to 0.1 and is less than or equal to 0.4, and the z is more than or equal to 0.01 and less than or equal to 0.1), and the ceramic scintillator has a crystal structure with a cubic Ia3 point group. Ceramic powder can be synthesized by a chemical coprecipitation method. The coprecipitation method adopts ammonia, ammonium hydrogen carbonate or a mixed solution of the ammonium water and the ammonium hydrogen carbonate as a precipitating agent, titrates the precipitating agent into a solution of gadolinium nitrate, lutecium nitrate, yttrium nitrate and europium nitrate to obtain a precipitate, and then the precipitate is dried and calcined to obtain nano-powder. The obtained powder is pressed into a ceramic blank through an isostatic compaction method, then the pressureless sintering is performed in vacuum or hydrogen atmosphere, the sintering temperature is between 1,600 and 1,900 DEG C, transparent Gd2xLu2yY2(1-x-y-z)Eu2zO3 ceramic can be obtained, a ceramic product with the needed dimension is prepared after the cutting, grinding and polishing, and the transmission rate of the ceramic in a visible region (400-800 nanometers) is more than or equal to 65 percent. The ceramic scintillator emits red light with a main wavelength of 610 nanometers under the excitation of ultraviolet light or X rays, and can be used for scintillating materials of imaging and detection of medical and industrial X rays.

Owner:CHINA JILIANG UNIV

Wet production process for feed-grade active zinc oxide

The invention discloses a novel wet production process for feed-grade active zinc oxide, belonging to the field of feed additives. The process comprises steps such as neutral leaching, ammonia leaching, acid leaching, primary purifying, secondary purifying, carbonization reaction, washing and filtering, drying, heating for decomposing, and the like. In the process, active zinc oxide is produced by directly carbonizing an acid immersion liquid and an ammonia immersion liquid, so that cheap zinc flue dust is utilized, ammonia water in the ammonia immersion liquid and ammonium hydrogen carbonateare taken as carbonization precipitating agents of the acid immersion liquid, ammonia water and ammonium hydrogen carbonate are not additionally used, an ammonia evaporation step is eliminated, and production cost is reduced greatly; the bulk density of the obtained active zinc oxide can be up to 0.9-1.1 g / cm<3> and even higher, the higher requirements of the feed additive industry on the fluidity and bulk density of active zinc oxide are met; and the moisture content is lowered, so that the drying cost on every ton of product is lowered by about 200 yuan.

Owner:GUANGHAN LONGDA FEED

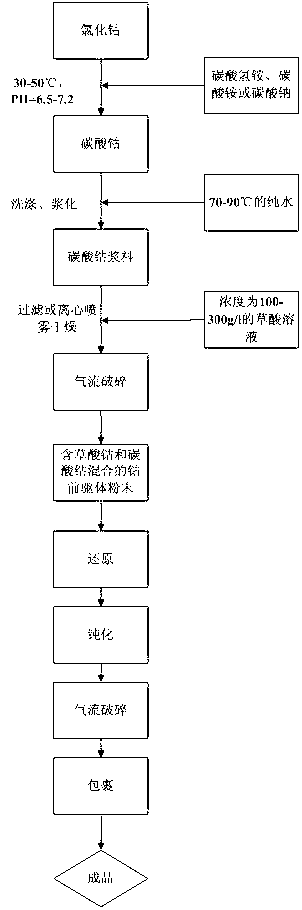

Preparation method of high-gravity spherical cobalt carbonate

InactiveCN101973592AHigh degree of sphericityProportionally largeCobalt carbonatesPh controlReaction temperature

The invention relates to a preparation method of high-gravity spherical cobalt carbonate, comprising the following steps of: with a water-soluble cobalt salt as a raw material and ammonium hydrogen carbonate as a precipitant adding a cobalt salt aqueous solution and an ammonium hydrogen carbonate aqueous solution into a reactor at the same time by adopting a first-slow and rear-quick stage feeding manner at reaction temperature of 60-90DEG C under a stirring condition, wherein a feeding speed ratio of the cobalt salt aqueous solution of a slow feeding stage to a quick feeding stage is 1:2.5-1:10, and the feeding volume of the slow feeding stage occupies 25-60 percent of the total feeding volume; controlling pH of a reaction solution between 7.0 and 7.5; then, reducing the temperature to carry out heat preservation reaction; and filtering, drying and washing a reaction product to obtain the high-gravity spherical cobalt carbonate. Under the condition of high temperature, a first-slow and rear-quick stage speed-control feeding manner is adopted to prepare cobalt carbonate which has the advantages of high spherical degree, high gravity, controllable grain diameter, good dispersive property and good flow property and can satisfy different product requirements; meanwhile, the invention has short reaction time and is beneficial to the increasing of the production efficiency.

Owner:安徽寒锐新材料有限公司

Pesticide water effervescent dispersible tablet and preparation method thereof

InactiveCN102823589AAvoid degradation of active ingredientsReduce the use effectBiocideFungicidesAmmonium Hydrogen CarbonateAmmonia gas

The invention discloses a pesticide water effervescent dispersible tablet and a preparation method thereof. According to the pesticide water effervescent dispersible tablet and the preparation method thereof, ammonium hydrogen carbonate is used as a gas source, and an acid source or alkali source is selected according to the physical property of different raw materials, i.e. the acid source and the ammonium hydrogen carbonate are added into the acid-resistant raw materials, and tablets are put into water to produce carbon oxide during use; and the alkali source and the ammonium hydrogen carbonate are added into the alkali-resistant raw materials, and tablets are put into water to produce ammonia gas. The pesticide water effervescent dispersible tablet can rapidly boil and disintegrate in water and therefore avoid the reduction of application effect caused by degradation of effective components of the pesticide effervescent dispersible tablet, so that the pesticide water effervescent dispersible tablet with stable chemical properties is obtained.

Owner:FIVESTAR NANTONG CHEM

Special fertilizer for rape base fertilizer

InactiveCN102816021AIncrease the chelating structureReduce invalid releaseBio-organic fraction processingOrganic fertiliser preparationPhosphateManganese

The invention discloses a special fertilizer for a rape base fertilizer. The special fertilizer is prepared by biogas residue, rape cake, decomposed coal, gelatin, biological bacteria, ammonium hydrogen carbonate, monoammonium phosphate, potassium sulfate, tea seed meal, carboxymethylcellulose, 35% of sulfuric acid, lime, ferrous sulfate, ammonium molybdate, manganese sulfate, nanocarbon, nanometer rock phosphate powder, neem bark, leaf extract and liquid paraffin according to a certain weight ratio. According to the special fertilizer, amino acid is generated by feathers after acid hydrolysis, trace elements or secondary elements are cheated, and a chelate structure of the trace elements or the secondary elements is reinforced by the carboxymethylcellulose, so that the trace elements or the secondary elements can be effectively utilized and ineffective releases of the trace elements or the secondary elements can be reduced; an inorganic slow release component and a soil improvement component, namely the gelatin and the decomposed coal, are added in a formula of the special fertilizer to improve the soil and to be beneficial to the effective release of fertilizer efficiency and full absorption of the fertilizer by the crops; biological insecticide components, namely the nanocarbon, the nanometer rock phosphate powder, the neem bark and the leaf extract, can effectively reduce pest and disease damage on the soil, are safe and pollution-free, and do not pollute an environment or the crops; and the special fertilizer has the advantages that the formula is reasonable, the nutrition is more comprehensive and balanced, the use effect is good, the utilization rate of fertilizer efficiency can be remarkably increased, the yield and the quality of rape are greatly improved, and the economic benefit of the rape is increased.

Owner:如皋市玺运生态农业科技有限公司

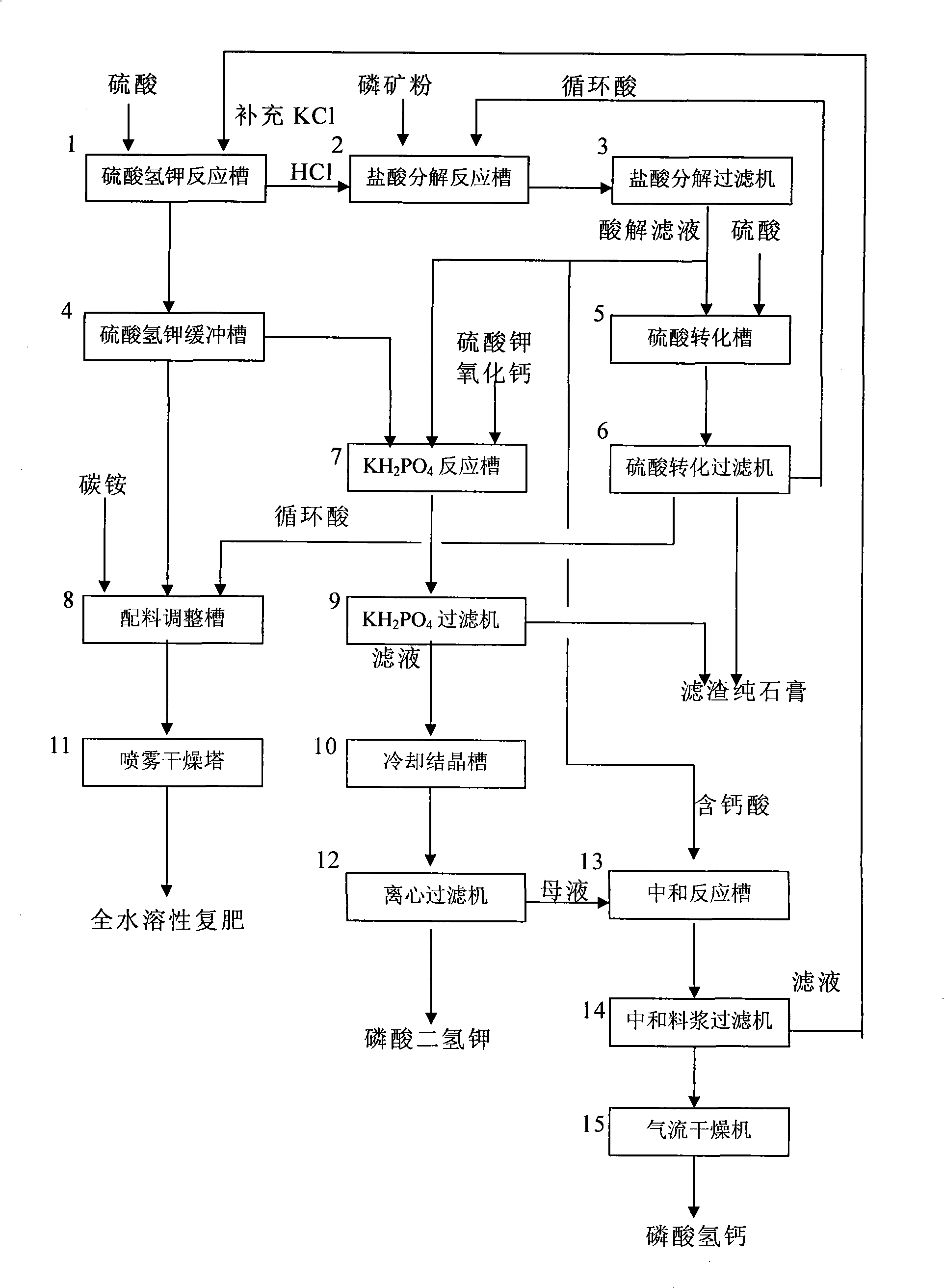

Process for disassembling phosphate ore by mixed acid and coproducing potassium dihydrogen phosphate, hydrogen phosphate and combined fertilizer

InactiveCN101337657ASolve processing problemsSolving Phosphogypsum ProblemsChlorine/hydrogen-chlorideSulfate/bisulfate preparationSolubilitySlurry

A method for the joint production of monopotassium phosphate, calcium hydrophosphate and compound fertilizers through by subjecting phosphorite to mixed acid resolution is characterized in that the method comprises the steps of taking sulphuric acid and potassium chloride to prepare chlorine hydride and acid potassium sulfate; conducting acidolysis reaction after phosphorite slurry absorbs chlorine hydride; preparing monopotassium phosphate through the reaction between an acidolysis filtrate and calcium oxide and lemery; agitating a mixture of the acidolysis fitrate with monopotassium phosphate crystallization mother liquor to neutralize and prepare calcium hydrophosphate; preparing recycle acid through the reaction between the acidolysis filtrate with sulphuric acid; preparing full water-solubility compound fertilizers through the reaction between recycle acid and an acid potassium sulfate solution and ammonium hydrogen carbonate or ammonia, etc. The method can successfully solve the impurity interference problem in the production of phosphate by using phosphorite of middle-low grade, and increase the reclaim rate of phosphorus pentoxide to approximate 100%. The method has the advantages of fully utilizing resources, simplifying process and devices, reducing corrosion, saving energy, reducing acid consumption and cost, eliminating pollution, and achieving good technical and economic effects.

Owner:黄明科 +1

Preparation method of semi-micrometer cobalt powder

The invention provides a preparation method of semi-micrometer cobalt powder. The preparation method of the semi-micrometer cobalt powder is low in cost and simple and practical, and products by means of the preparation method are high in purity. The preparation method includes that cobalt carbonate sediments are produced through reaction of cobalt chloride and ammonium hydrogen carbonate, reaction of the cobalt carbonate sediments and oxalate solution is carried out, when the reaction is stopped, reaction products are directly crushed through drying and air flow by centrifugal spray drying equipment, and therefore precursor powder which is fine and even in particle size and sphere-like in particle shape and mixed by oxalate cobalt and cobalt carbonate. The precursor powder is reduced in a superfine powder hydrogen reduction furnace and then comes out of the furnace after reduction, and then the precursor powder is kept in nitrogen or carbon dioxide for 12-24 hours for passivating treatment. Afterwards, the precursor powder is crushed by the air flow, paraffin wax and oleic acid are added in the precursor powder, the precursor powder is packaged so as to prevent cobalt powder from oxidation, and finally superfine cobalt powder is obtained by vacuum package. The semi-micrometer cobalt powder obtained by means of the preparation method has the advantages of superfine cobalt powder and sphere-like cobalt powder, is fine in particle size, narrow in distribution, small and even in partical size and can be widely used in battery industries and hard alloy products like numerical blades, bar materials, holding-up hammers and drills.

Owner:GEM CO LTD

Method for producing sodium hydrogen carbonate and ammonium sulfate by using sodium sulfate solution

ActiveCN108046295ASolve pollutionImprove absorption rateCarbonate preparationAmmonia compoundsSodium bicarbonateHydrogen

The invention relates to a method for producing sodium hydrogen carbonate and ammonium sulfate by using a sodium sulfate solution, and belongs to the technical field of chemical engineering. The method comprises the following steps: a, absorbing circulating gas by using the sodium sulfate solution at -5 to 10 DEG C to obtain absorbing liquid; b, mixing the absorbing liquid, ammonium hydrogen carbonate and / or mixed salt at -5 to 20 DEG C to obtain mixed slurry; c, performing sealed reaction on the mixed slurry to obtain sodium hydrogen carbonate and reaction mother liquid; d, mixing the reaction mother liquid and complex salt to obtain salt mixture and primary frozen mother liquid after freezing; e, distilling the primary frozen mother liquid to obtain carbon dioxide, ammonium circulating gas and ammonium steaming mother liquid; f, adjusting the ammonium steaming mother liquid by acid to obtain an acidified solution and gas; g, mixing and freezing the acidified solution and crystallizedmother liquid to obtain complex salt and secondary frozen mother liquid; and h, evaporating and concentrating the secondary frozen mother liquid to separate out ammonium sulfate. The method is low inenvironmental pollution and high in raw material utilization rate.

Owner:SICHUAN UNIV

Efficient compound fertilizer for greening flowers and preparation method thereof

InactiveCN104072268AImprove the ecological environmentImprove long-term effectFertilizer mixturesDiseaseEcological environment

The invention discloses an efficient compound fertilizer for greening flowers and a preparation method thereof. The compound fertilizer is prepared from the following raw materials in parts by weight: 40-50 parts of human excreta, 15-25 parts of peony seed meal, 10-15 parts of coffee grounds, 20-30 parts of corn meal, 10-15 parts of peanut meal, 12-16 parts of chestnut shell, 18-24 parts of melon peel, 5-10 parts of gleditsia sinensis powder, 4-8 parts of hoof powder, 3-6 parts of illite powder, 5-10 parts of kieselguhr, 10-15 parts of alcohol waste liquid, 17-23 parts of ammonium hydrogen carbonate, 10-15 parts of ammonium sulfate, 14-18 parts of calcium dihydrogen phosphate, 3-6 parts of potassium humate, 8-16 parts of modified attapulgite, 4-6 parts of jade powder and 3-5 parts of ochre powder. The compound fertilizer is reasonable and scientific in raw material proportioning, contains nutrients required by the growth of the greening flowers, is quick in response and long and comprehensive in fertility, has high activity and long fertility of organic fertilizers and biological fertilizers, fast-acting property of inorganic fertilizers and specificity of bacterial manures, promotes the photosynthesis of plants, greatly increases the utilization rate and the fertility, can also improve the ecological environment of the flowers, inhibit diseases and insect pests of soil and improve the soil structure, and can be widely applied to fertilization management of the greening flowers.

Owner:MINGGUANG HEZHONG IND ENG INSTALLATION

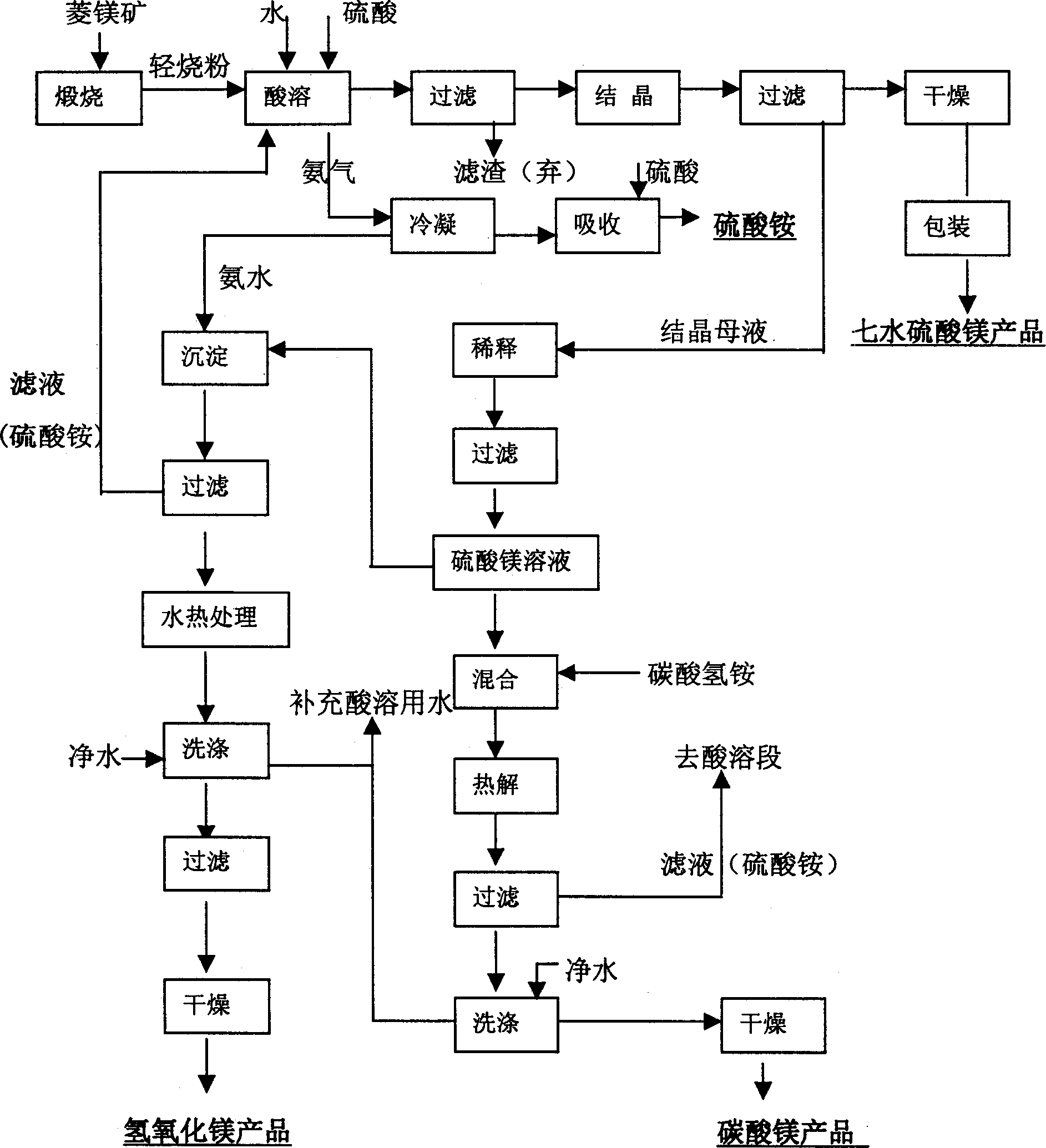

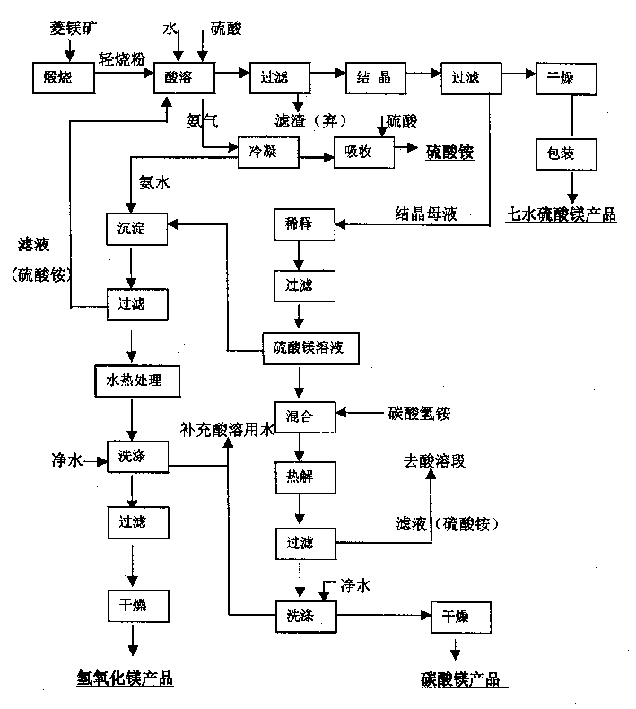

Method for integrated production of magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite

InactiveCN1401573AImprove protectionReduce manufacturing costMagnesium carbonatesMagnesium sulfatesAmmonium Hydrogen CarbonateCarbonate

A process for preparing magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite includes reaction of light-burned magnesium oxide powder obtained by calcining magnesite, the solution of ammonium sulfate as the by-product obtained by reaction with magnesium carbonate and magnesium hydroxide precipitate and industrial concentrated sulfuric acid, evaporating ammonia gas, dissolving in water, depositing to obtain magnesium hydroxide, controlling acidity and temp. filtering to remove impurities, cooling crystallizing to obtain magnesium sulfate heptahydrate, diluting the mother liquid, preparing alkaline magnetic carbonate by ammonium hydrogen carbonate method, and sulfuric acid absorption to residual ammonia water to obtain ammonium sulfate as by-product. Its advantage is no generation of gas and liquid pollutants.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com