Origin fermentation method and origin fermentation product prepared by same

A kind of origin and fermenter technology, applied in the direction of fermentation, skin care preparations, pharmaceutical formulas, etc., can solve the problems of complex enzyme preparation process steps, consumption of many types of excipients, increased production costs, etc., to achieve reasonable composition, small molecular weight, step-by-step simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

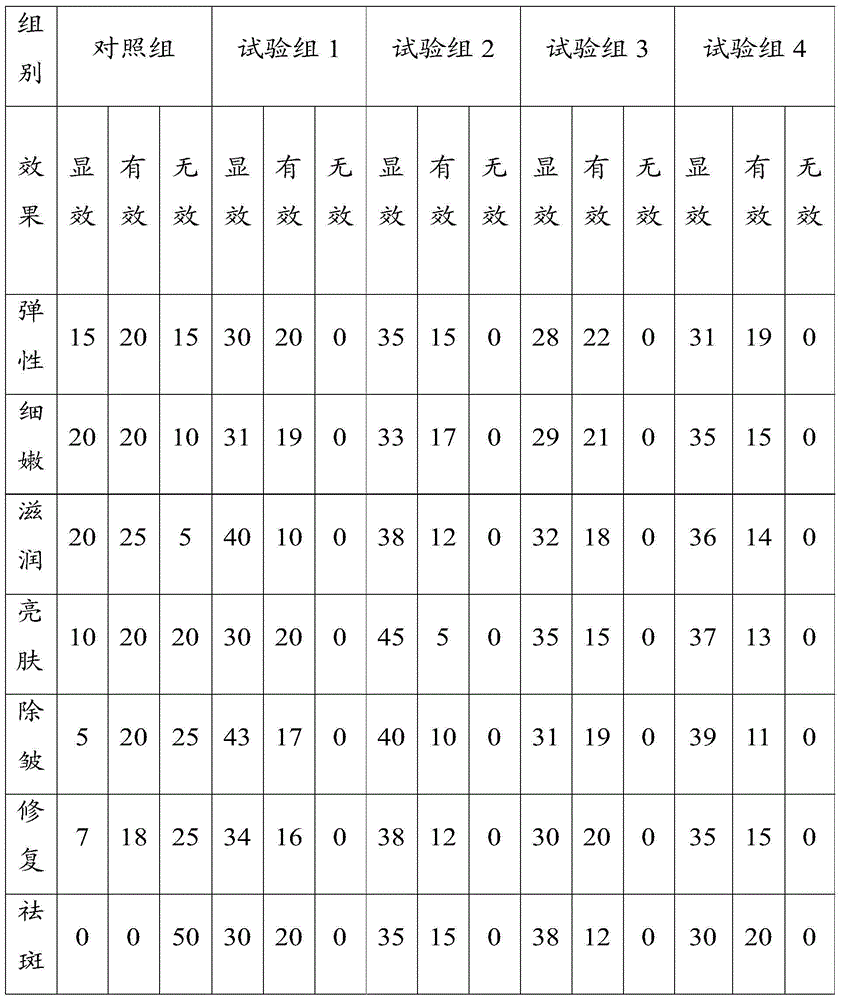

Examples

Embodiment 1

[0055] Get fresh aloe leaves, beating and crushing to obtain leaf slurry, and the crushed particle size is greater than 15 mesh;

[0056] Put the leaf slurry into the fermentation tank, add the aqueous solution of ammonium sulfate, ammonium dihydrogen phosphate, ammonium bicarbonate, and corn steep liquor dry powder into the fermentation tank after continuous sterilization. The composition of the fermentation tank is: by mass percentage, the leaves 40% of slurry, 1.9% of ammonium sulfate, 0.7% of ammonium dihydrogen phosphate, 1.1% of ammonium bicarbonate, 0.5% of corn steep liquor dry powder, the balance is water, and the substances contained in the fermentation tank account for 1 / 3 of the volume of the fermentation tank;

[0057] The early stage of fermentation is 2 hours, the middle stage is 4 hours, and the late stage is 2 hours; the temperature in the early stage is 35°C, the temperature in the middle stage is 37°C, and the temperature in the late stage is 38°C. The relati...

Embodiment 2

[0060] Get fresh ginkgo tender leaves, beating and crushing to obtain leaf slurry, and the crushed particle size is greater than 15 mesh;

[0061] Put the leaf slurry into a fermentation tank, add the aqueous solution of ammonium sulfate, ammonium dihydrogen phosphate, ammonium bicarbonate, and corn steep liquor dry powder into the fermentation tank after continuous sterilization, and the composition of the fermentation tank is: by mass percentage , 50% of leaf slurry, 2.0% of ammonium sulfate, 0.8% of ammonium dihydrogen phosphate, 1.2% of ammonium bicarbonate, 0.6% of corn steep liquor dry powder, the balance is water, and the substances contained in the fermentation tank account for 1 / 2 of the volume of the fermentation tank ;

[0062] The early stage of fermentation is 3 hours, the middle stage is 6 hours, and the late stage is 3 hours; the temperature in the early stage is 36°C, the temperature in the middle stage is 36°C, and the temperature in the late stage is 37°C. Th...

Embodiment 3

[0065] Take fresh young verbena leaves, beat and crush to obtain leaf slurry;

[0066] Put the leaf slurry into a fermenter, add sterilized ammonium sulfate, ammonium dihydrogen phosphate, ammonium bicarbonate, corn steep liquor dry powder aqueous solution into the fermenter, the composition of the fermenter is as follows: In terms of mass percentage, 60% of leaf slurry, 2.1% of ammonium sulfate, 0.8% of ammonium dihydrogen phosphate, 1.3% of ammonium bicarbonate, 0.7% of corn steep liquor dry powder, and the balance is water. 2 / 3;

[0067] The early stage of fermentation is 2.5 hours, the middle stage is 5 hours, and the late stage is 2.5 hours; the temperature in the early stage is 35.5°C, the temperature in the middle stage is 36°C, and the temperature in the late stage is 37°C. The relative dissolved oxygen in the early stage is 70%, and the relative dissolved oxygen in the middle stage The amount is 70%, and the relative dissolved oxygen amount in the later stage is 0%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com