Patents

Literature

1042results about "Fruits/vegetable preservation using acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

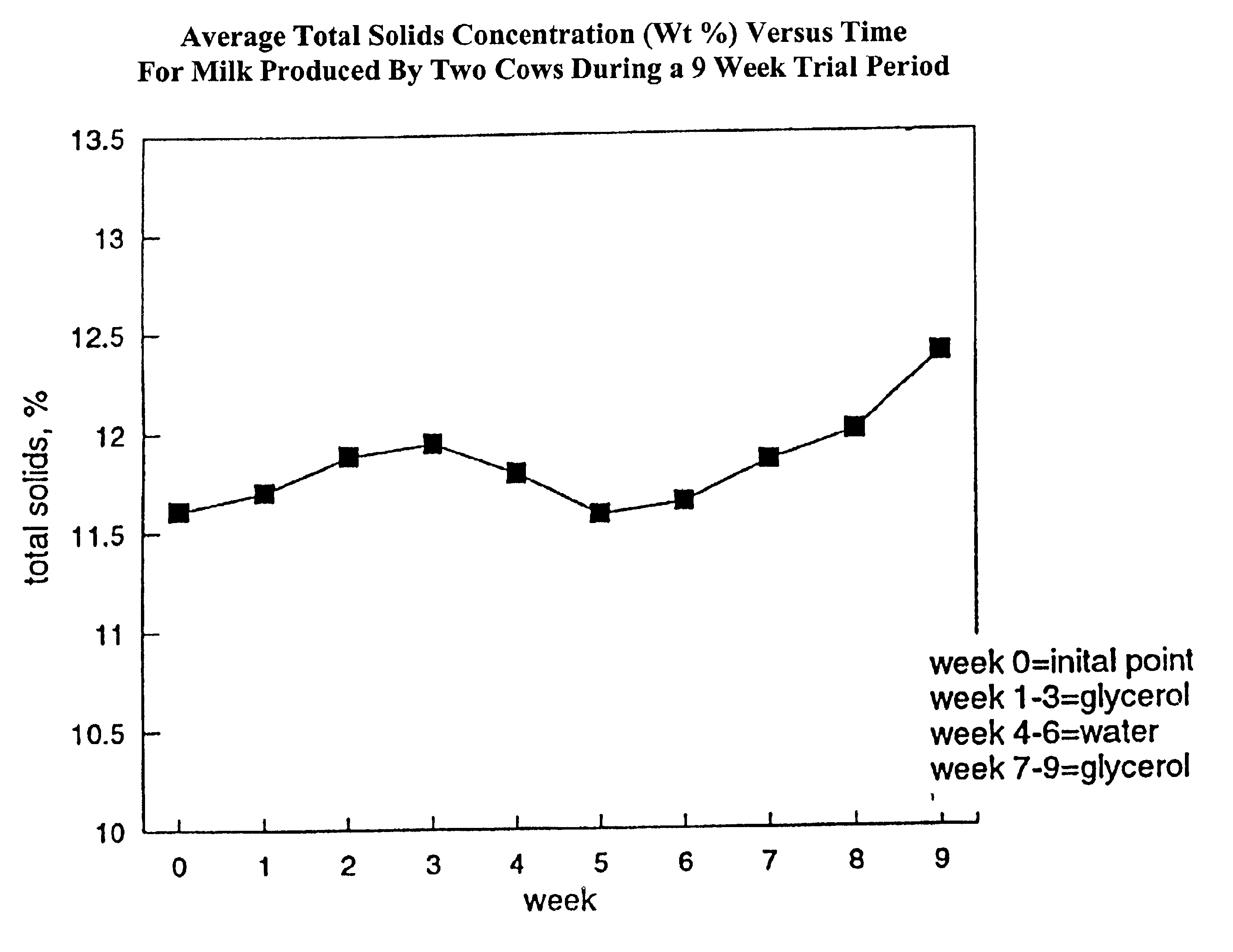

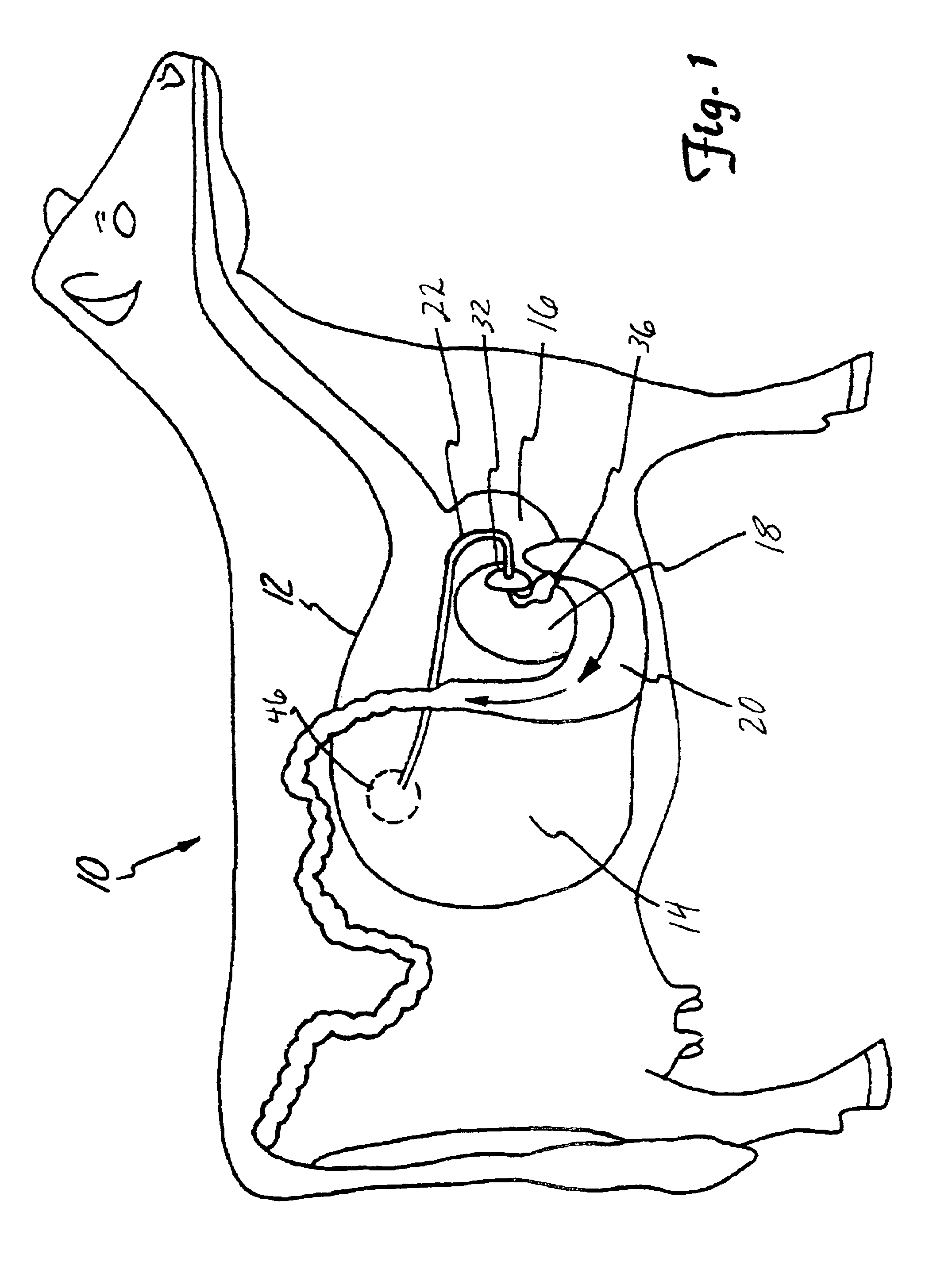

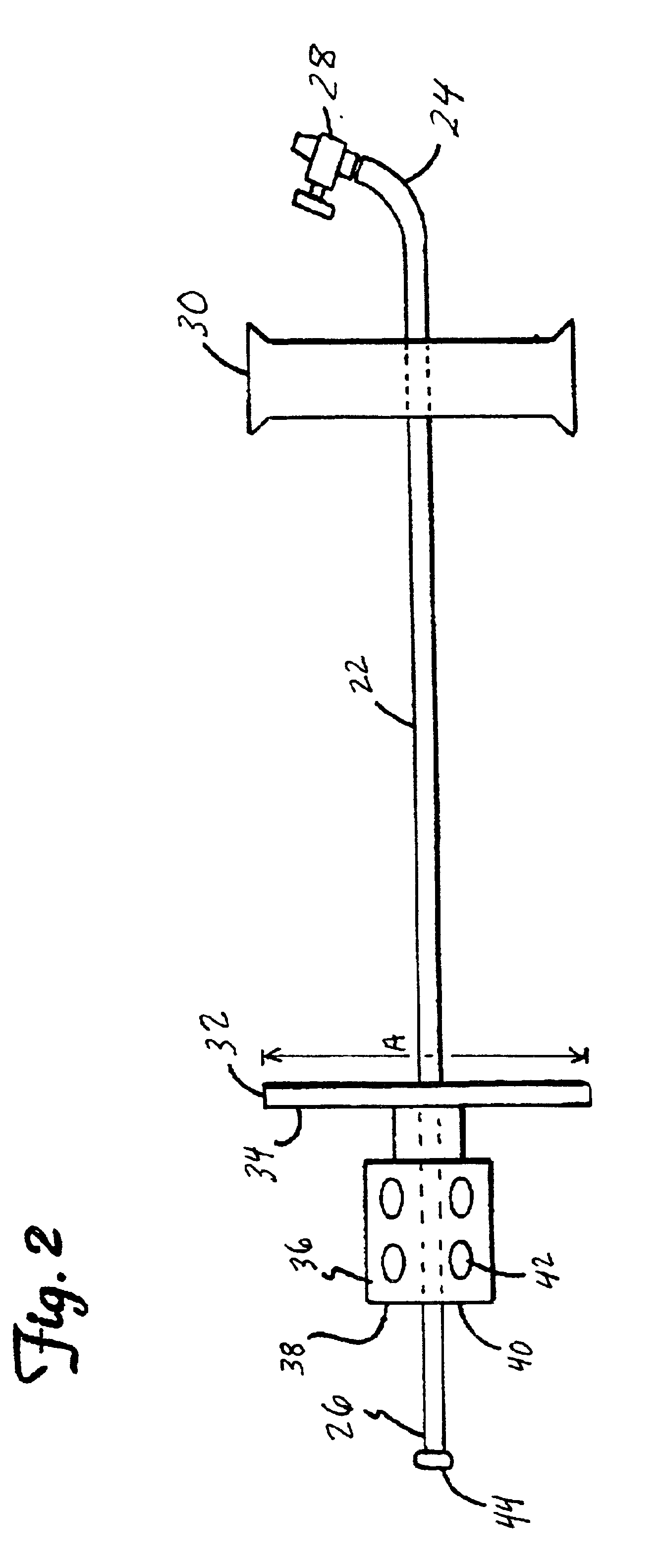

Method and composition for enhancing milk component concentrations

InactiveUS6866861B1Enhancing milk component productionEnhance milk component productionBiocideHydroxy compound active ingredientsAdditive ingredientAlcohol sugars

Owner:LAND O'LAKES

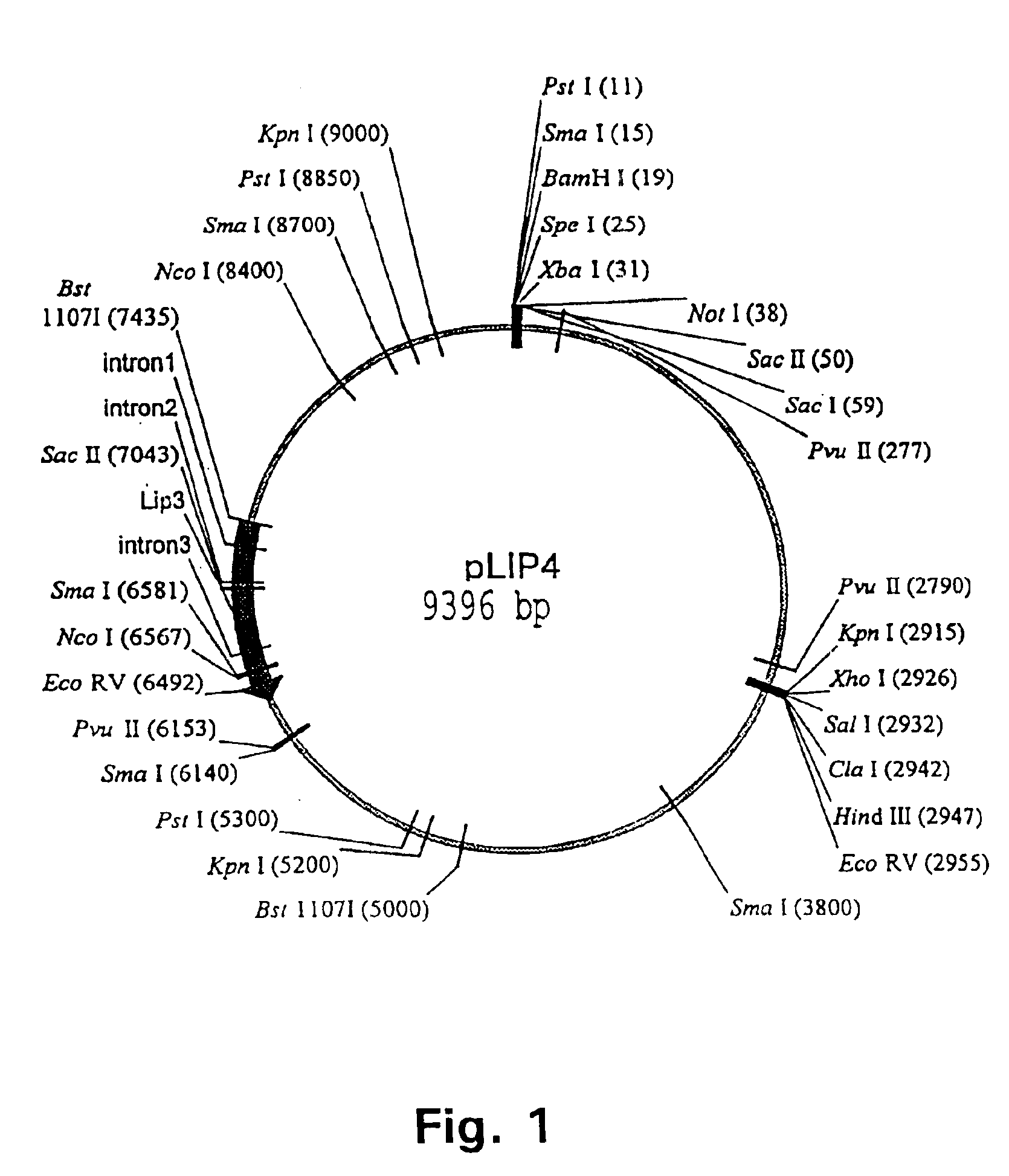

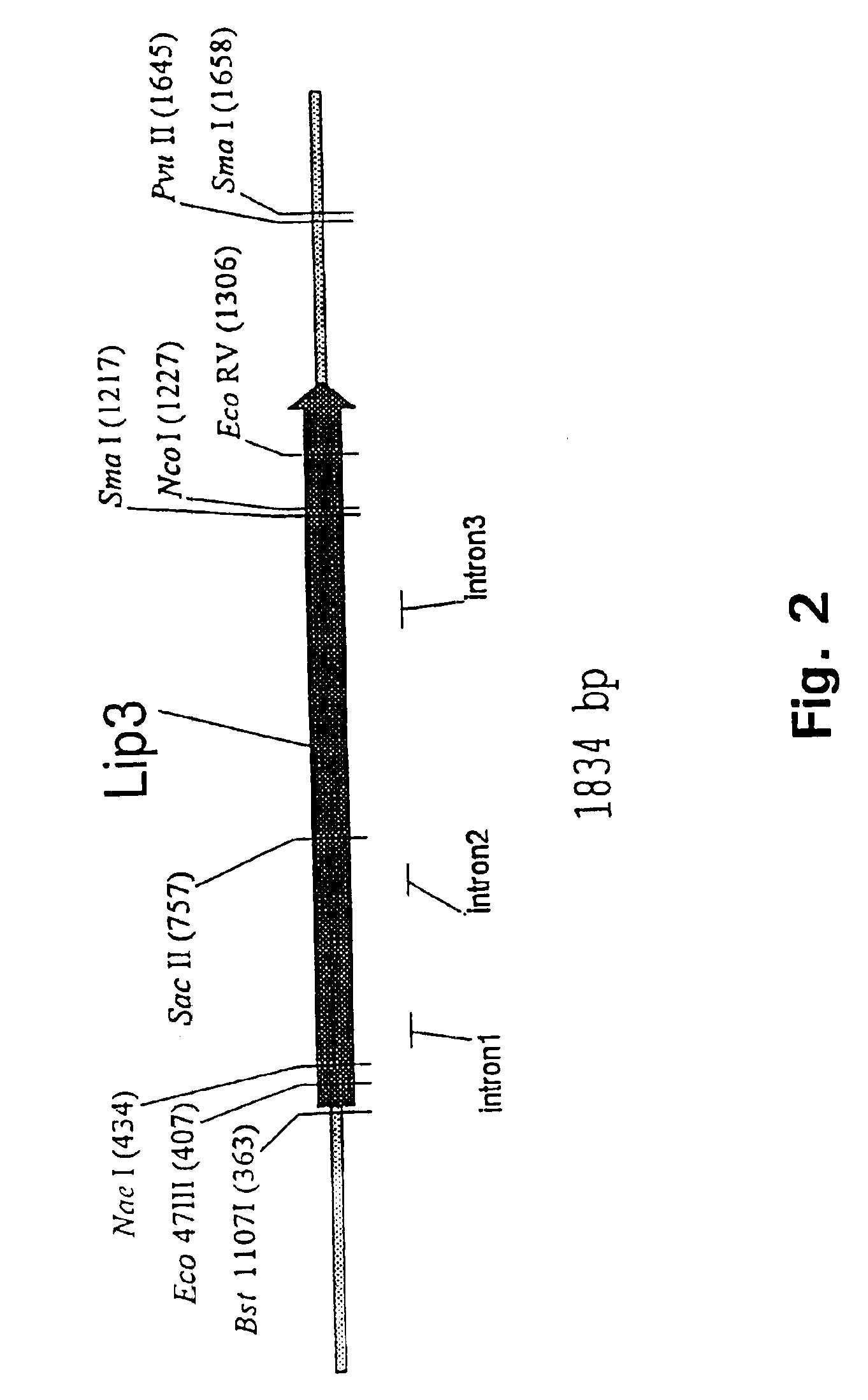

Nucleotide sequences and corresponding polypeptides conferring modulated plant characteristics

InactiveUS20110167514A1Increase the number ofIncrease biomassLibrary screeningFruits/vegetable preservation using acidsNucleotidePlant cell

The present invention relates to isolated nucleic acid molecules and their corresponding encoded polypeptides. The present invention further relates to the uses of these nucleic acid molecules and polypeptides. For example, the nucleic acid molecules and polypeptides could be used in making enzymes or used to make plants, plant cells, plant materials or seeds of a plant having such modulated growth or phenotype characteristics that are altered with respect to wild type plants grown under similar conditions.

Owner:CERES INC

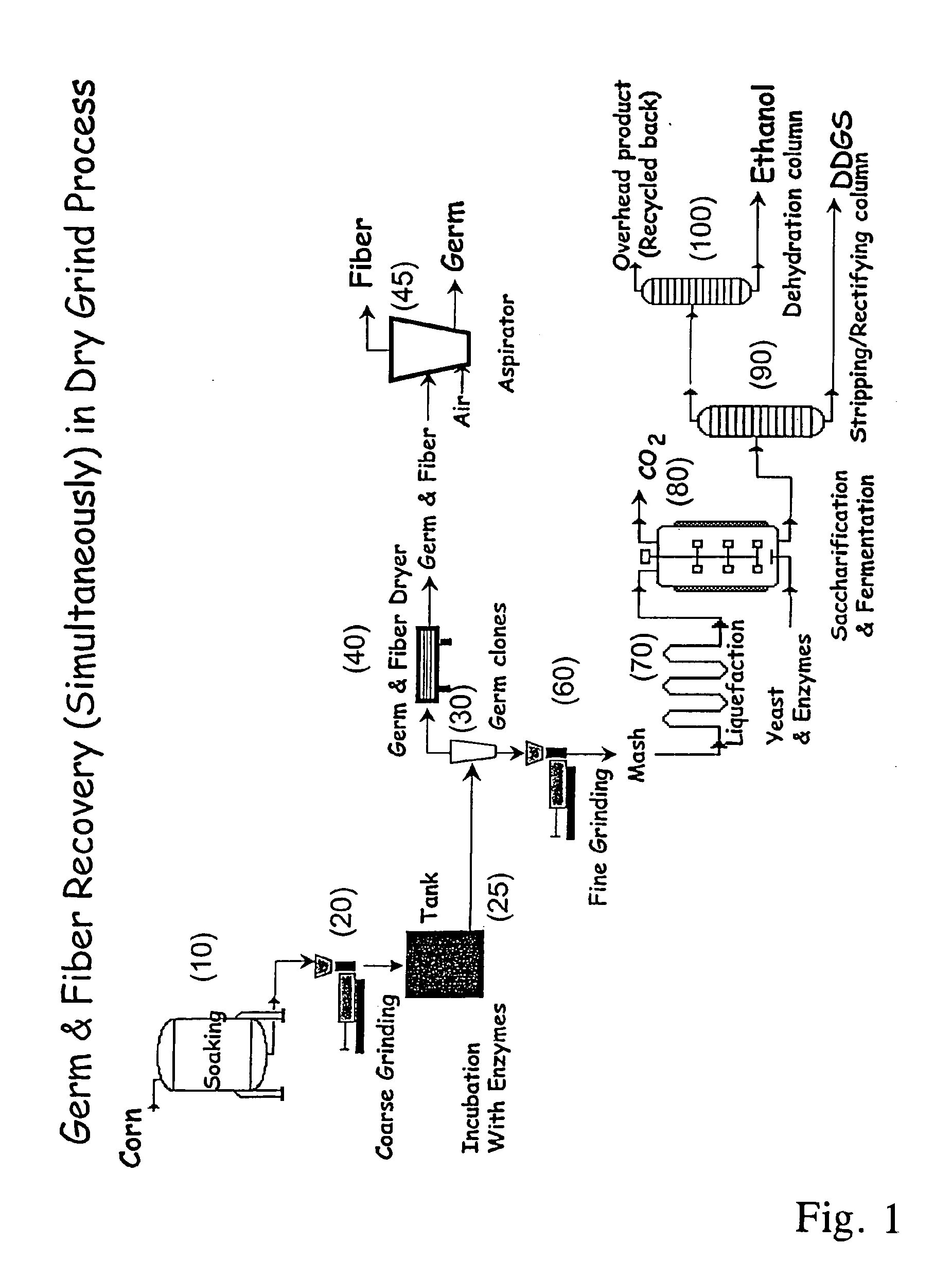

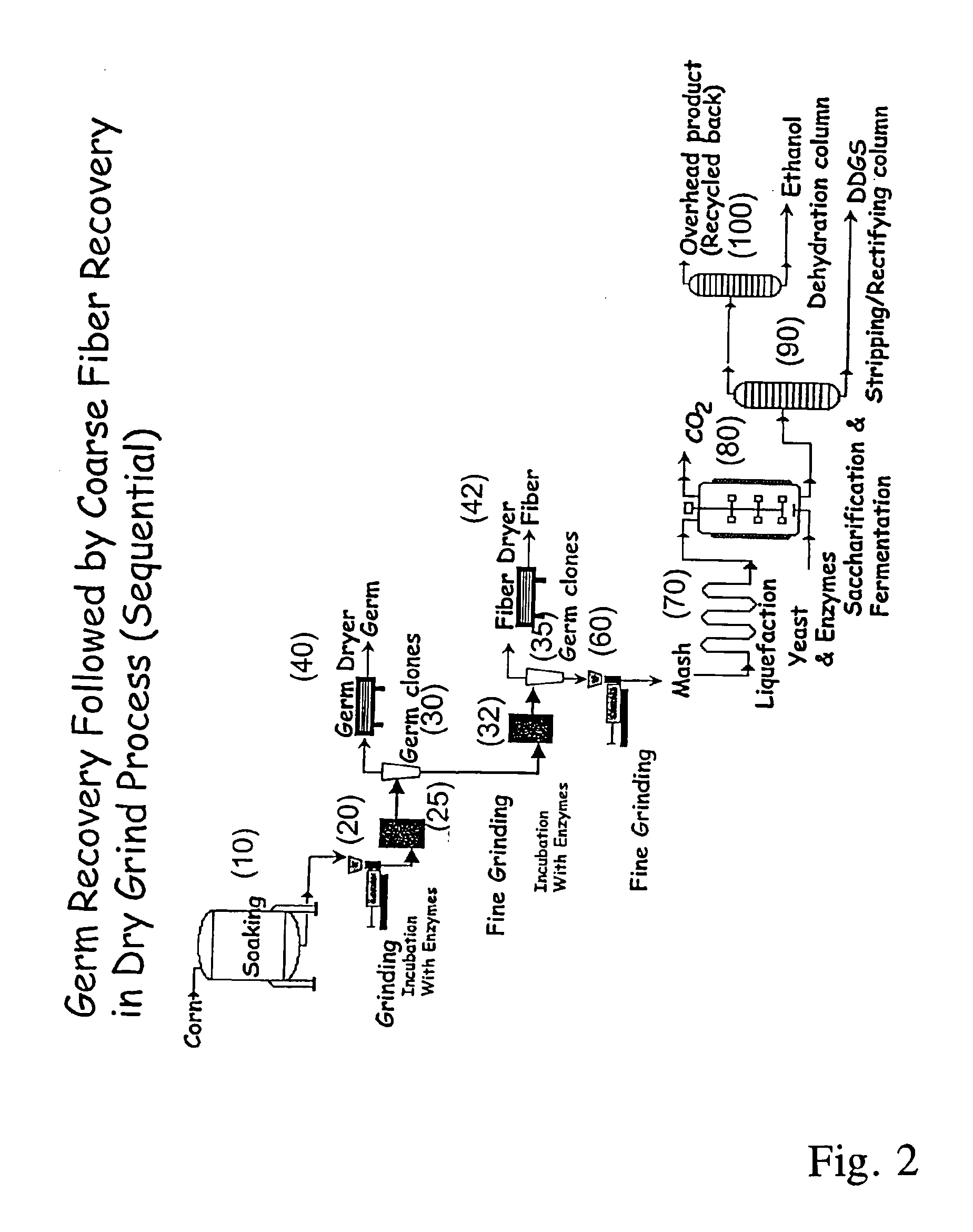

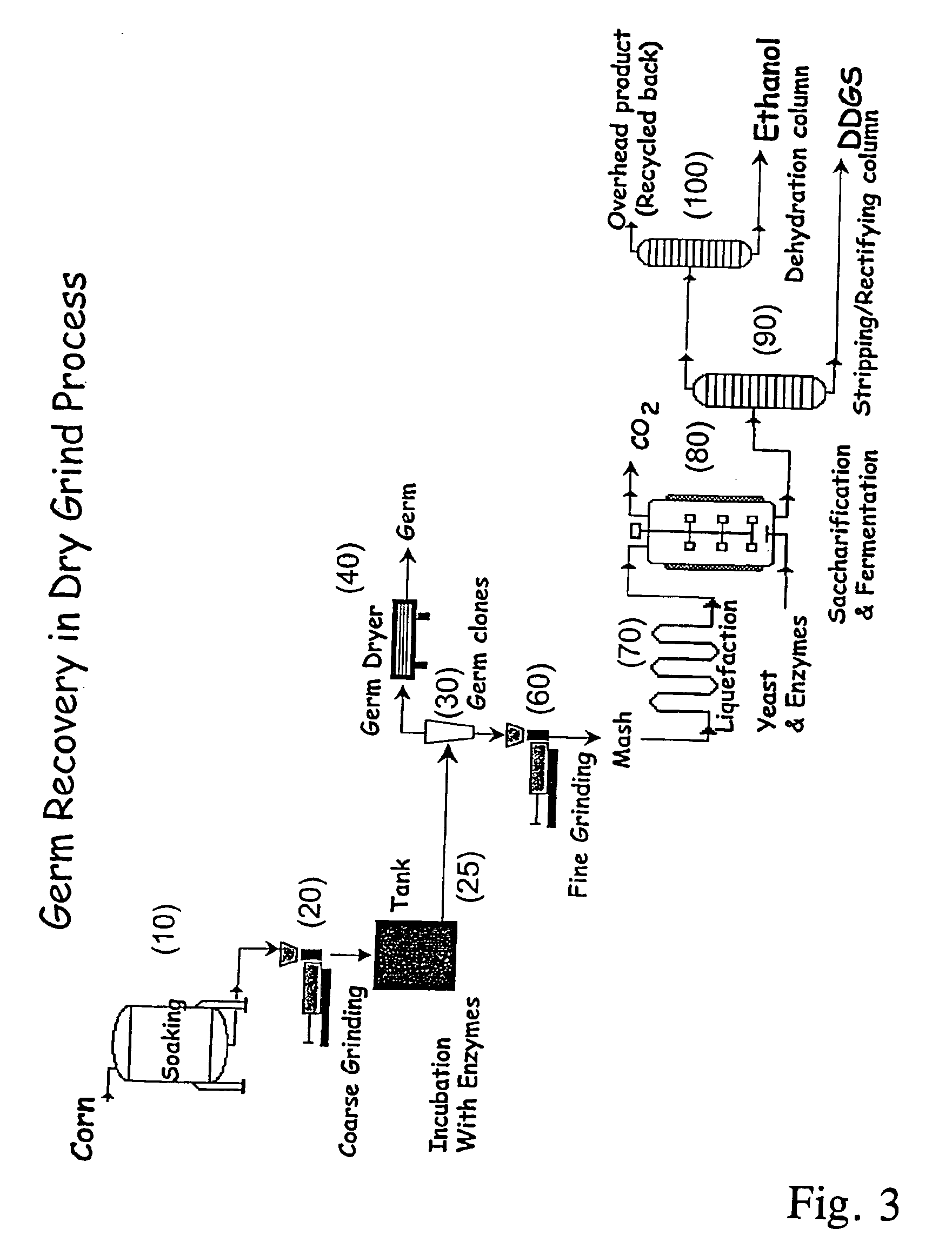

Processes for recovery of corn germ and optionally corn coarse fiber (pericarp)

A process for recovering corn germ and corn coarse fiber from corn in a dry grind process, involving soaking corn kernels in water to produce soaked corn kernels, grinding the soaked corn kernels to produce a ground corn slurry, and incubating the ground corn slurry with at least one enzyme (amylase(s), protease(s), cell wall degrading enzyme(s), or mixtures thereof, and optionally other enzyme(s)) to increase the specific gravity of the slurry to about 10-about 16 Baume so that the corn germ and corn coarse fiber floats to the top of the slurry, recovering the corn germ and the corn coarse fiber, and optionally producing ethanol from the slurry no longer containing the corn germ and corn coarse fiber. The process does not involve the addition of starch, a salt, a sugar syrup, or mixtures thereof to the slurry.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

Morinda citrifolia (Noni) enhanced animal food product

The present invention advances prior art animal food products by providing an animal food product formulated with Morinda Citrifolia, or Noni, from the Indian Mulberry plant. The addition of Noni to the animal food product of the present invention serves to provide significant health advantages not found in prior art animal food products.

Owner:TAHITIAN NONI INT INC

Protein beverage and method of making the same

An improved protein beverage / drink composition which may provide a relatively high protein content, ranging from about 0.01% by weight to about 15% by weight, while optionally employing a carbonation concentration between about 0.1 volumes of carbonation (per volume of liquid drink solution or liquid drink suspension) to about 6 volumes of carbonation. Preferably the protein is a protein, such preferably as whey protein, or others. The protein beverage may contain juice and / or an additive which provides energy generation enhancement. The protein beverage may be heat treated to inactivate pathogenic microbes in the presence of the carbonation which may be used to provide taste and mouth feel for the drink. Typically, the treatment for pathogenic microbe inactivation is carried out in the individual package used for storage and handling of the protein drink.

Owner:DAVINAS LLC

Method for extracting juice from plant material containing terpene glycosides and compositions containing the same

Processes for extracting juice from plant material containing terpene glycosides comprising the steps of crushing a plant material comprising terpene glycosides, blanching the crushed plant material in acidified water to obtain a puree, the puree comprising a juice extract and a plant solids residue, separating the juice extract from the plant solids residue, mixing enzymes with the juice extract, and separating the juice extract to obtain a sweet juice.

Owner:THE PROCTER & GAMBLE COMPANY

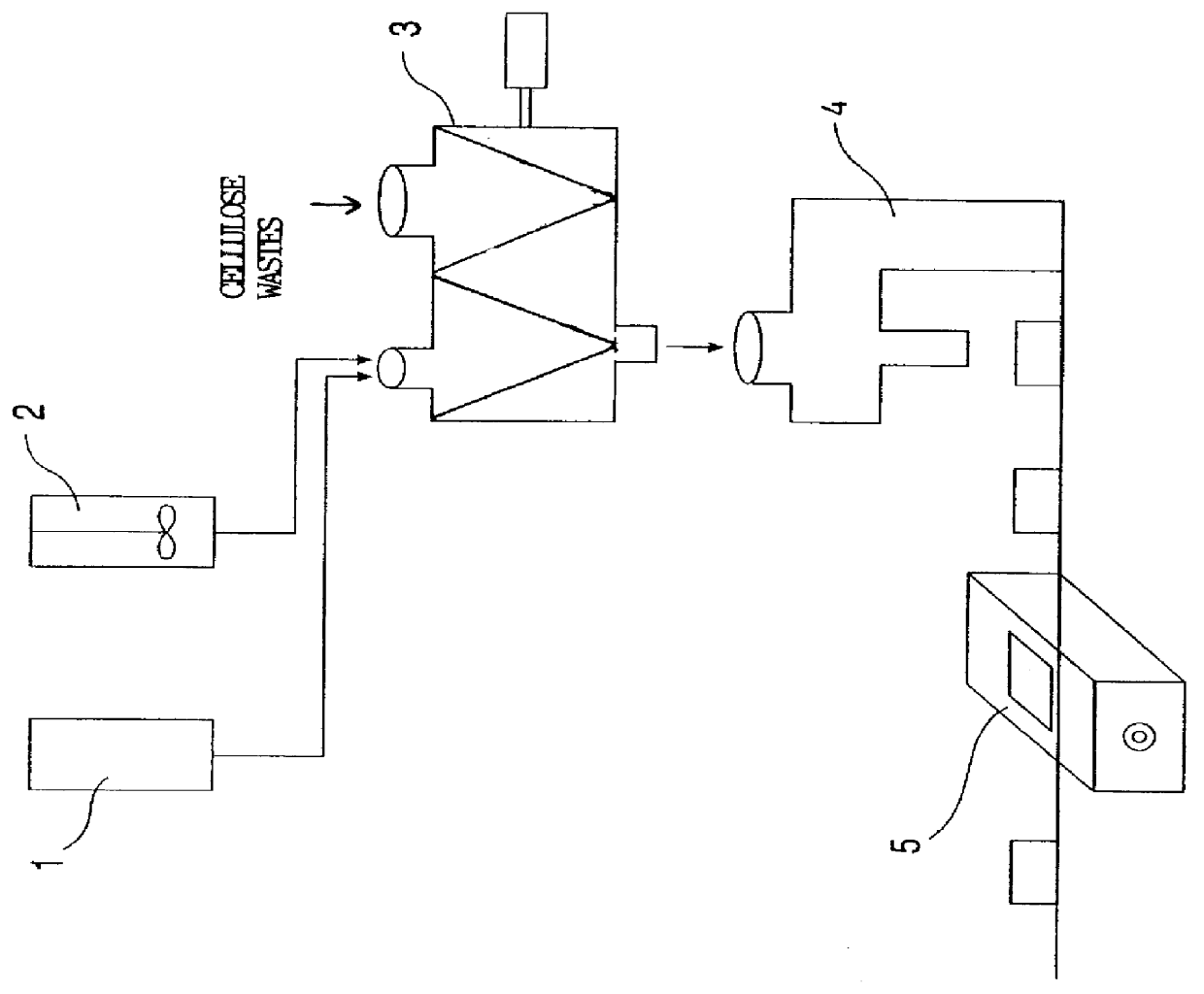

Method of bioconversion of industrial or agricultural cellulose containing wastes

InactiveUS6159510ADrawback mentionedHigh in proteinMilk preparationFood processingCelluloseMicroorganism

PCT No. PCT / IL98 / 00437 Sec. 371 Date Feb. 8, 2000 Sec. 102(e) Date Feb. 8, 2000 PCT Filed Sep. 10, 1998 PCT Pub. No. WO99 / 12429 PCT Pub. Date Mar. 18, 1999A method of bioconversion of organic industrial or agricultural cellulose containing wastes into proteinaceous product. The method comprises comminution of the wastes with moistening and addition of a starting culture inducing their biological degradation and conversion into simple carbohydrates. The carbohydrates are fermented into digestible products. The starting culture comprises cleaving enzymes produced by edible microorganisms such as fungus and bacteria selected from the group consisting of Ilumicola grisea, Trichoderma harzanum, Ruminococcus albus.

Owner:BIOFEED

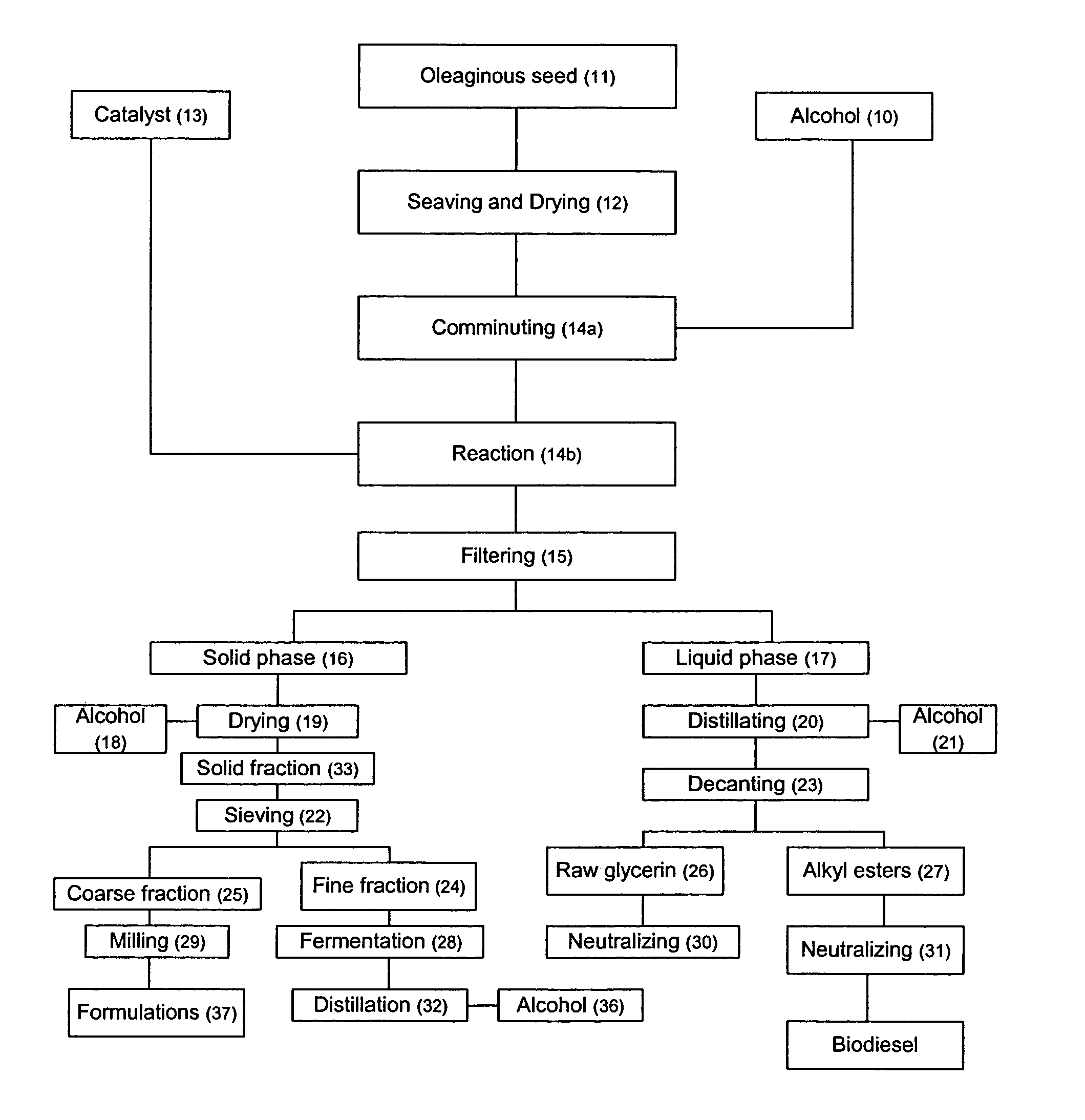

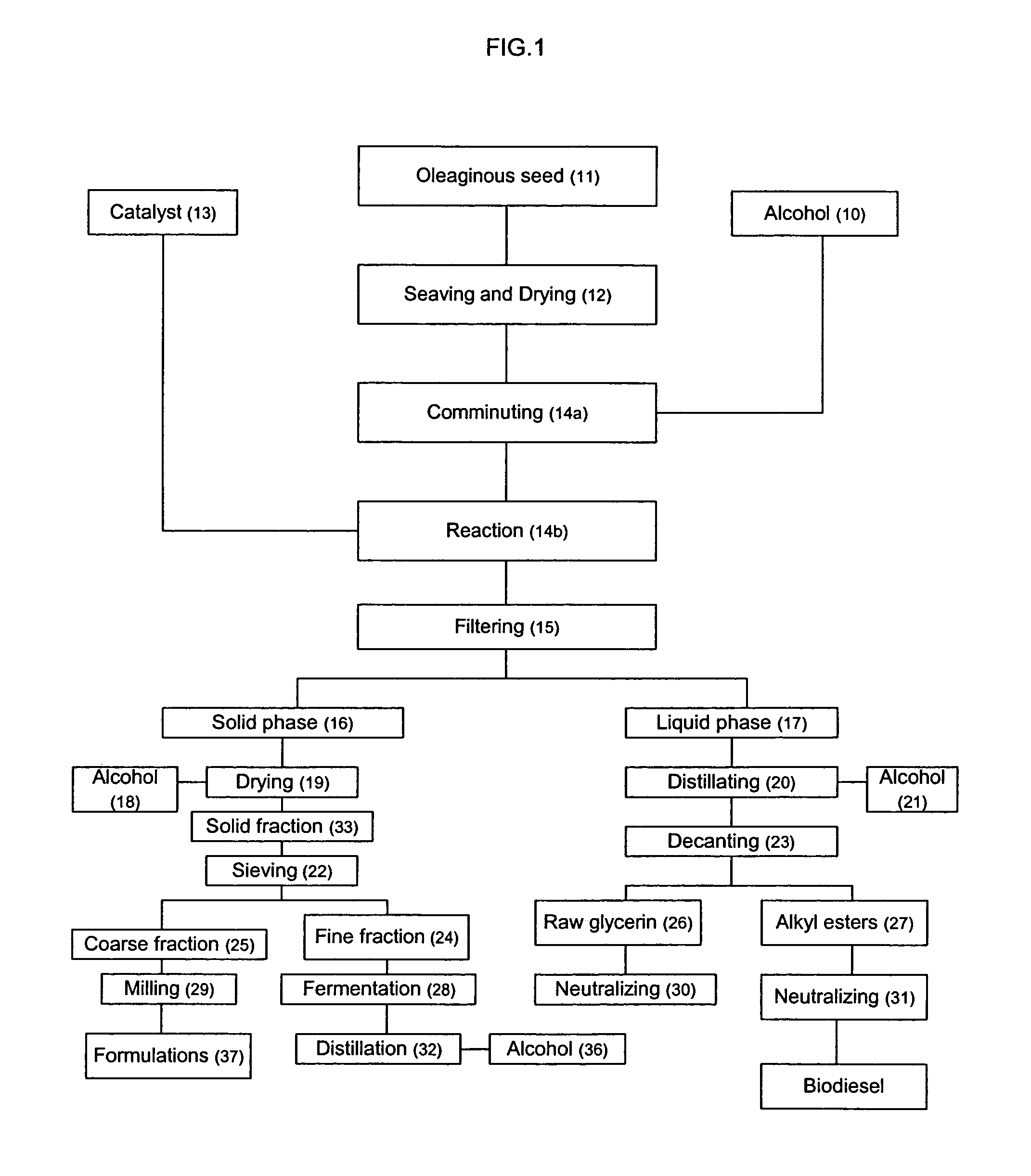

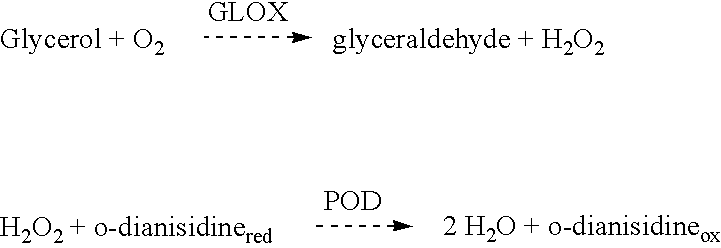

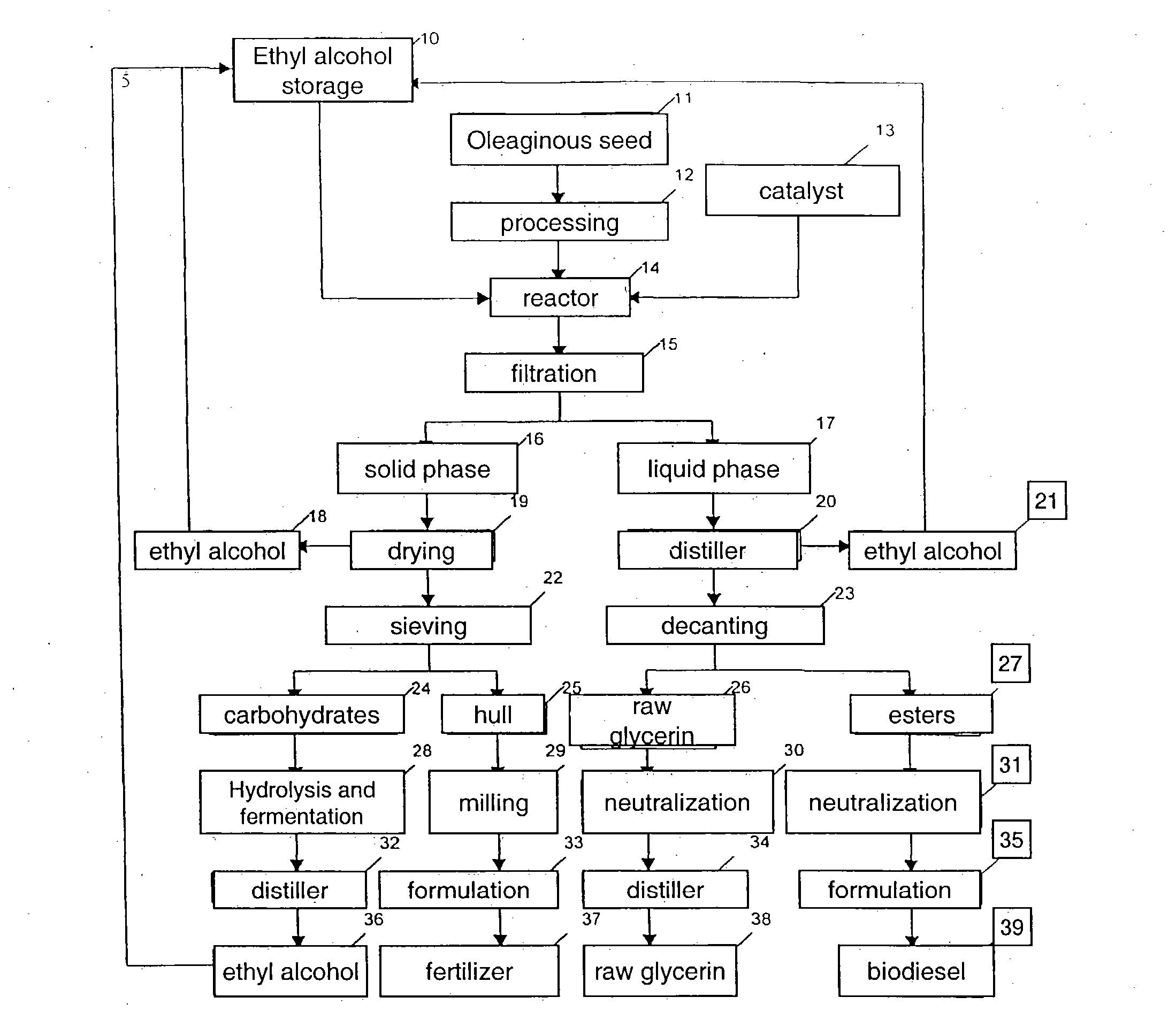

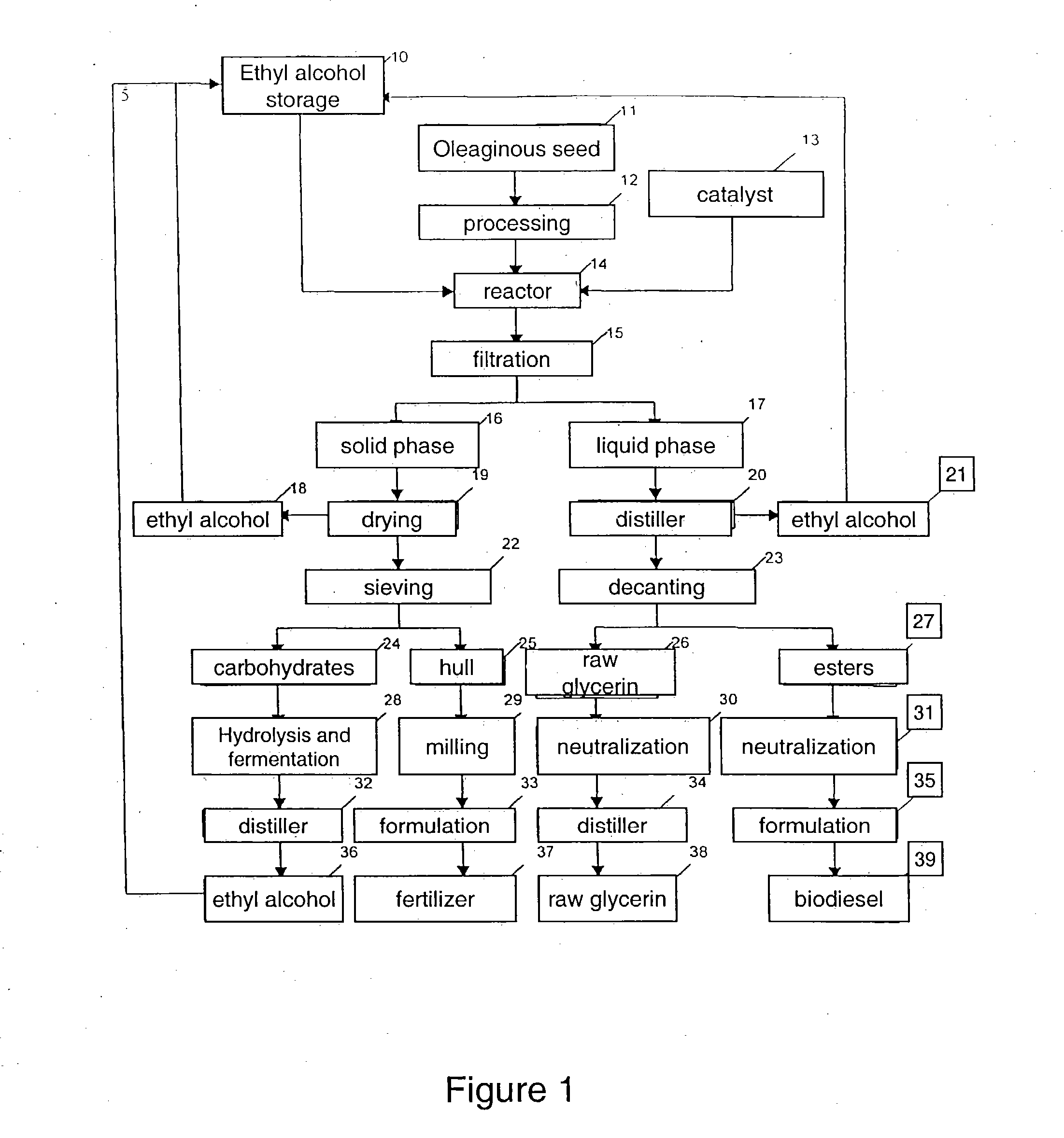

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method for preparing flour doughs and products made from such doughs using lipase

InactiveUS6852346B2Improve the immunityLess-prone to mechanical deformationFungiDough treatmentPore diameterSpecific volume

Owner:DUPONT NUTRITION BIOSCIENCES APS

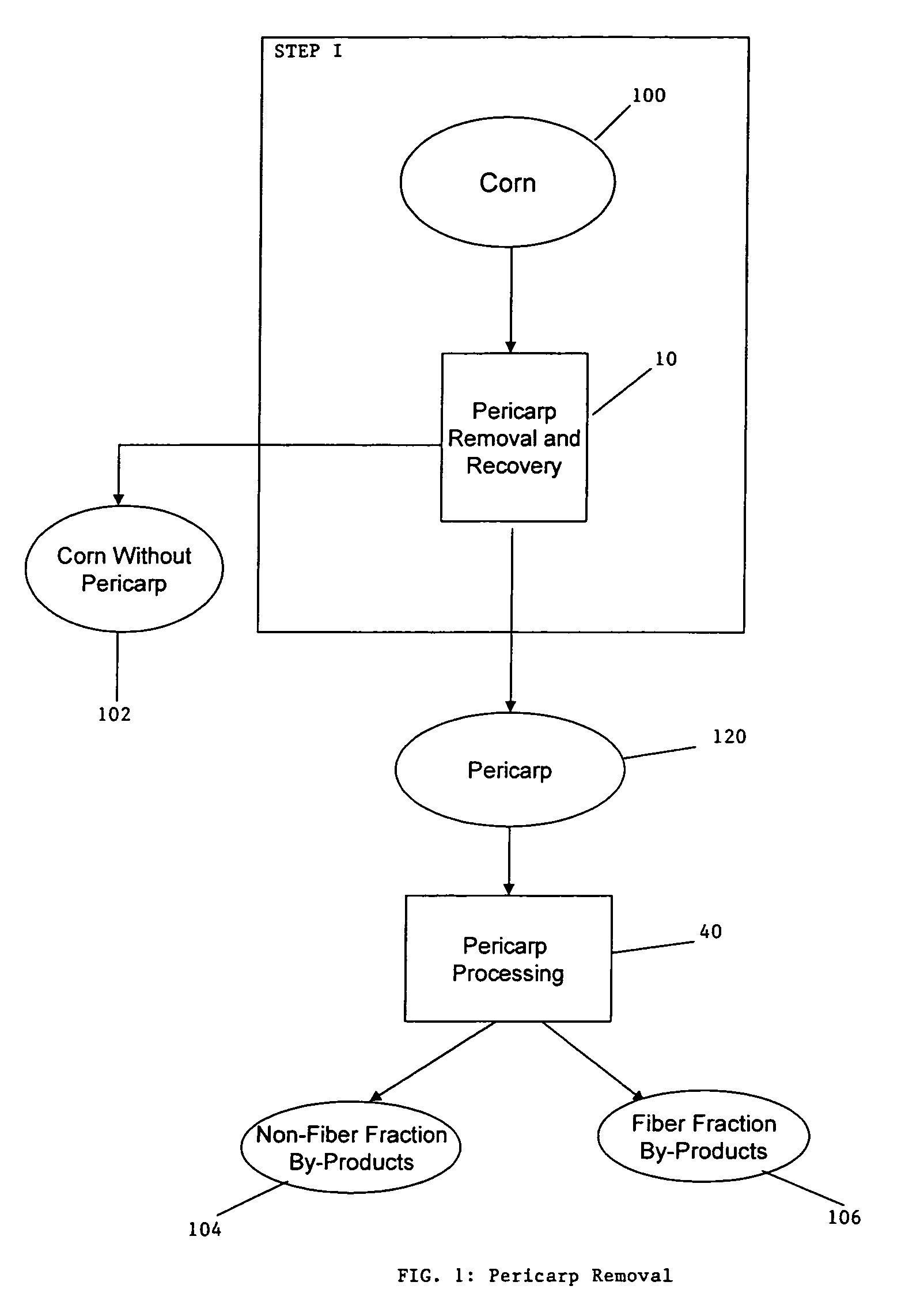

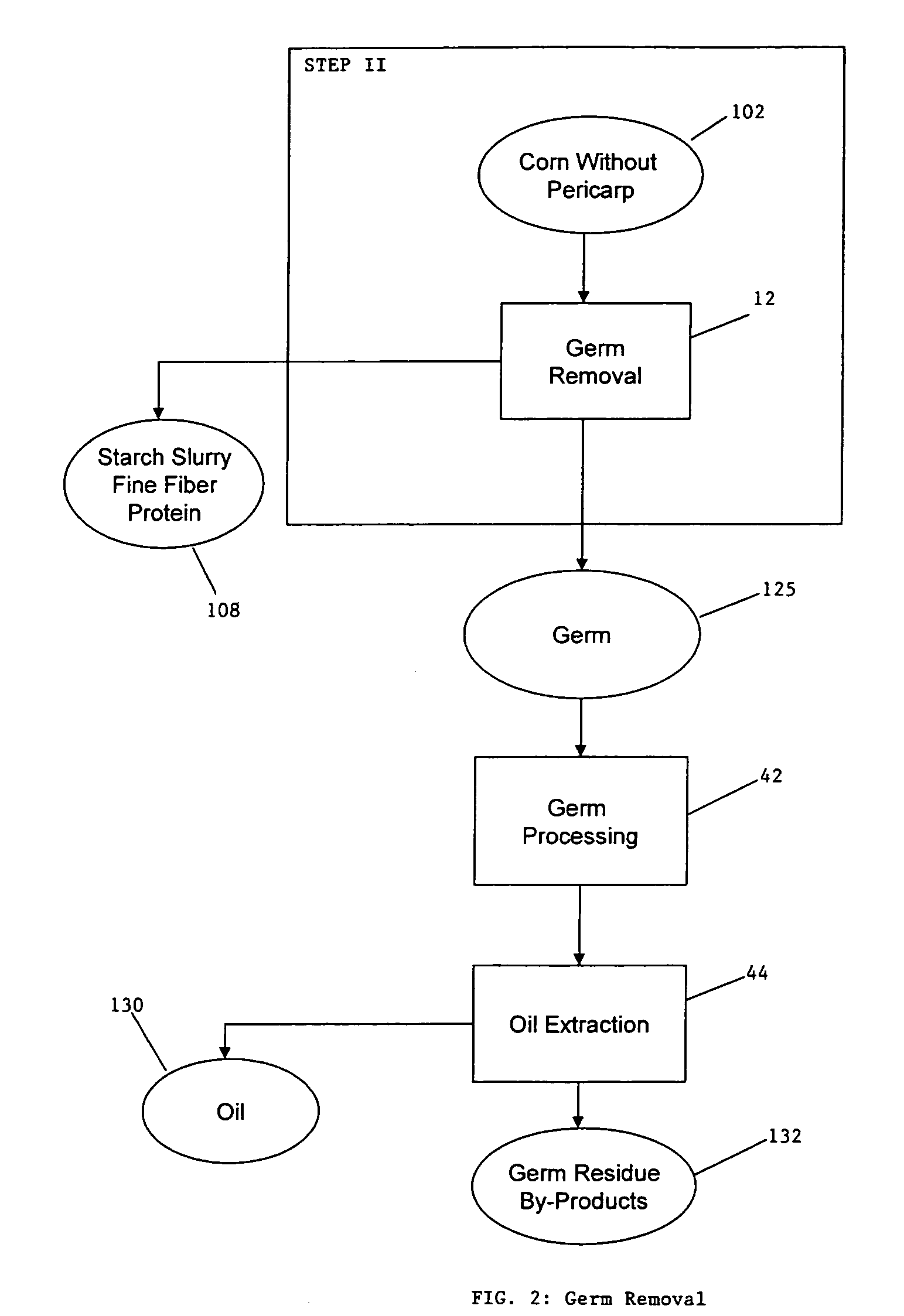

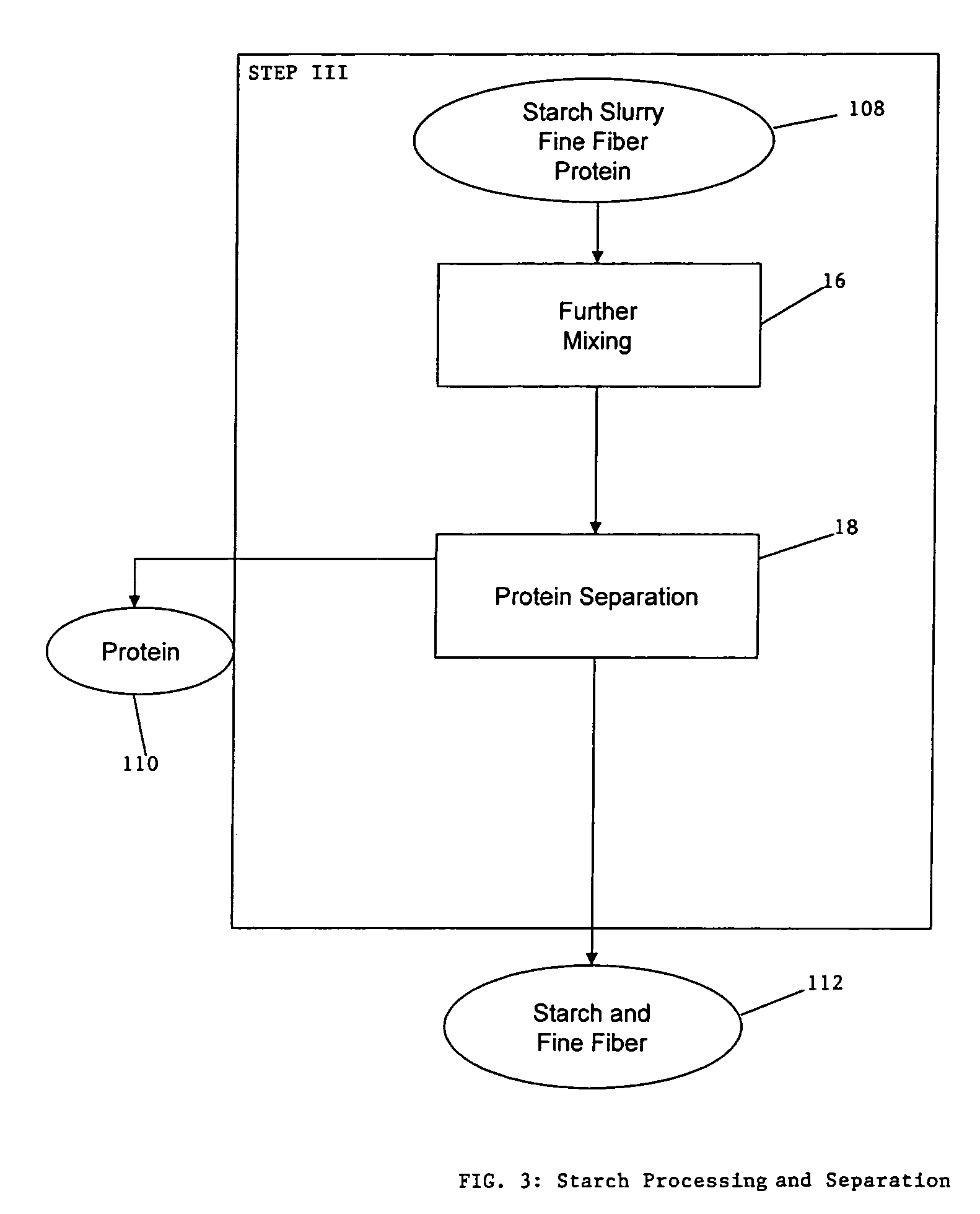

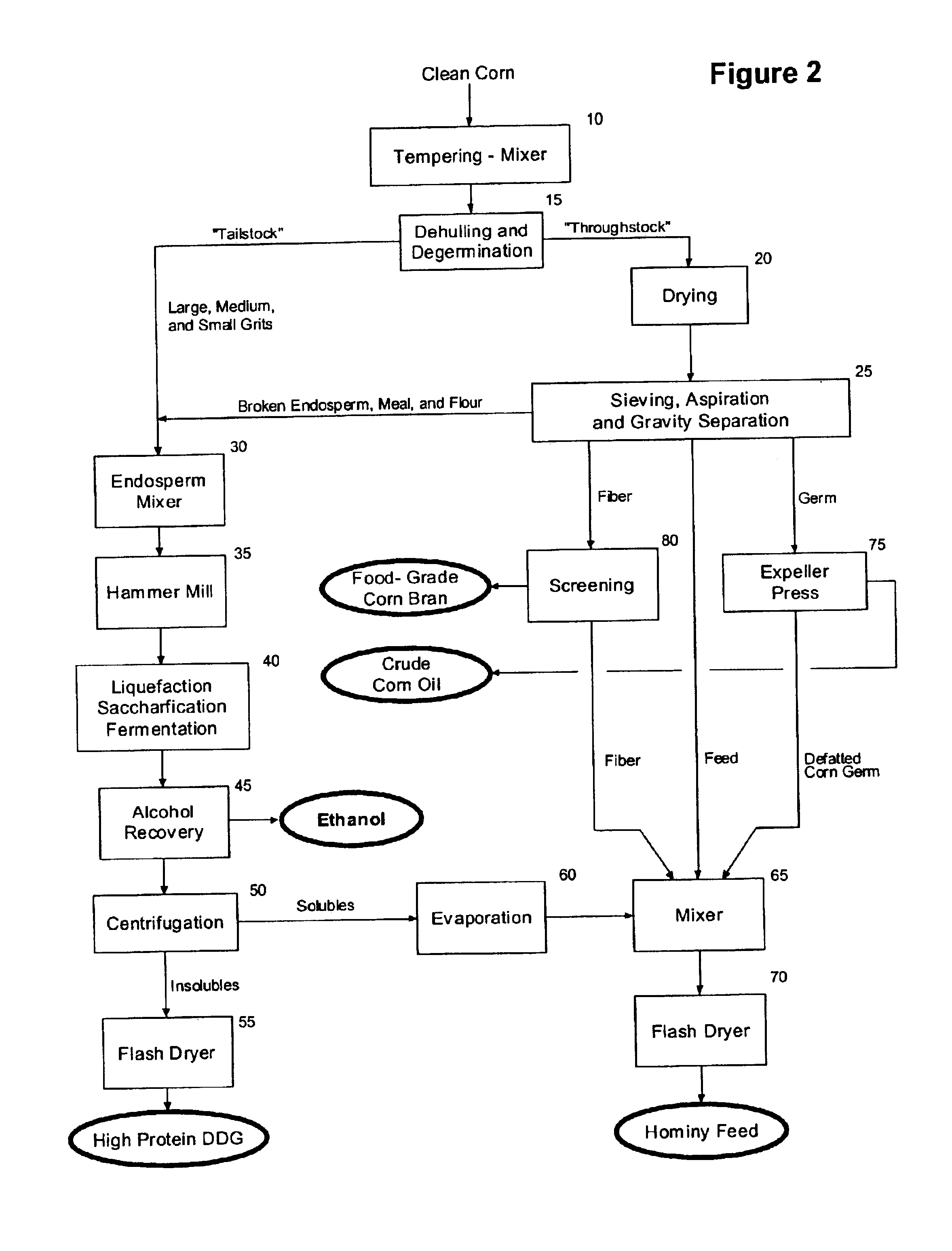

Process for the production of animal feed and ethanol and novel animal feed

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

Refrigeration-shelf-stable ultra-pasteurized or pasteurized infant formula

InactiveUS6194009B1Maintain qualityReduce degradationSugar food ingredientsVitamin food ingredientsPasteurizationRefrigeration

Refrigeration-shelf-stable ready-to-feed and concentrated infant formulas can be prepared through a ultra-pasteurization and / or pasteurization process. The ultra-pasteurized and / or pasteurized infant formulas contain complete balanced quantities of nutrients.

Owner:KAMAREI ARZHANG +1

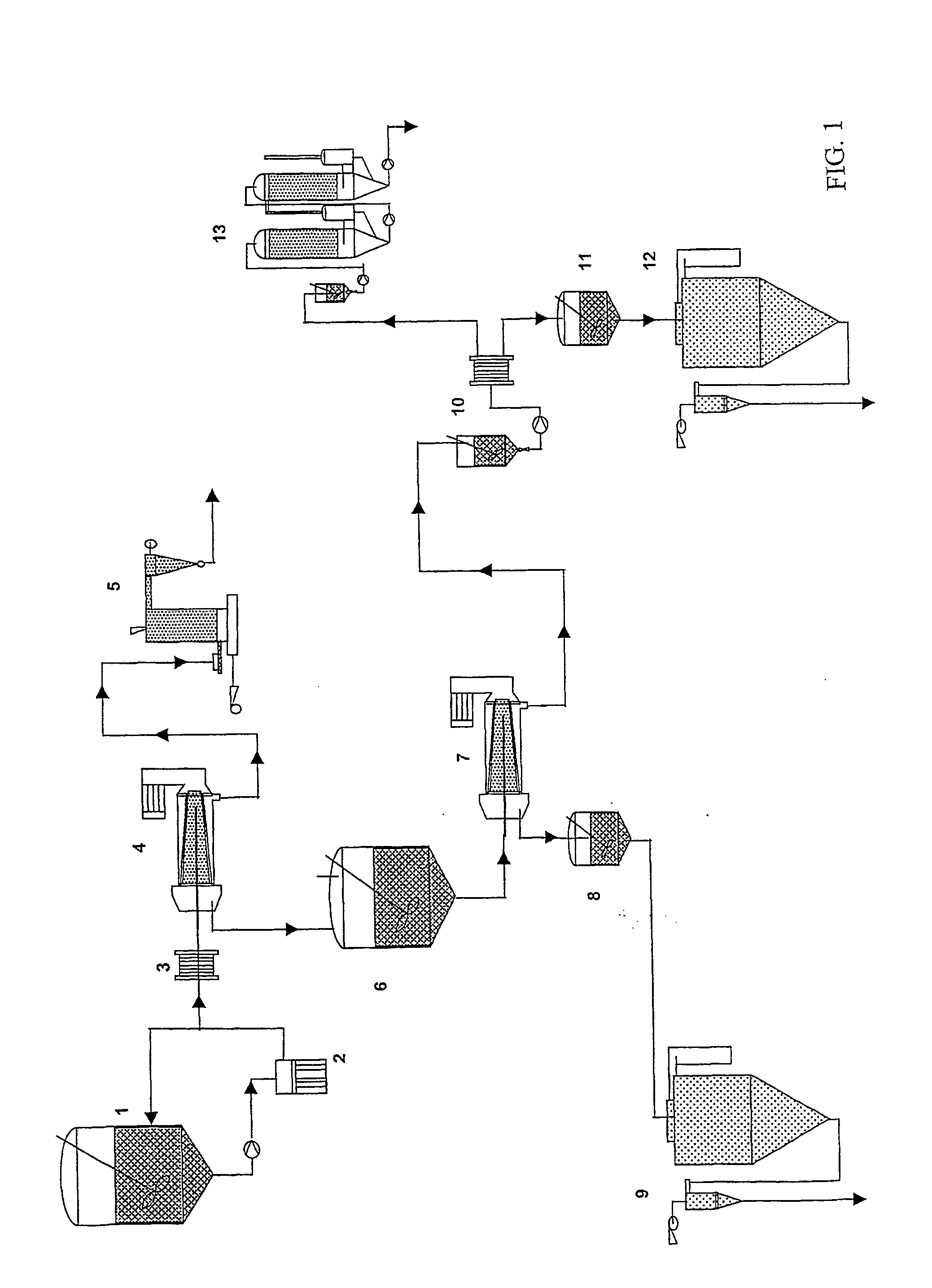

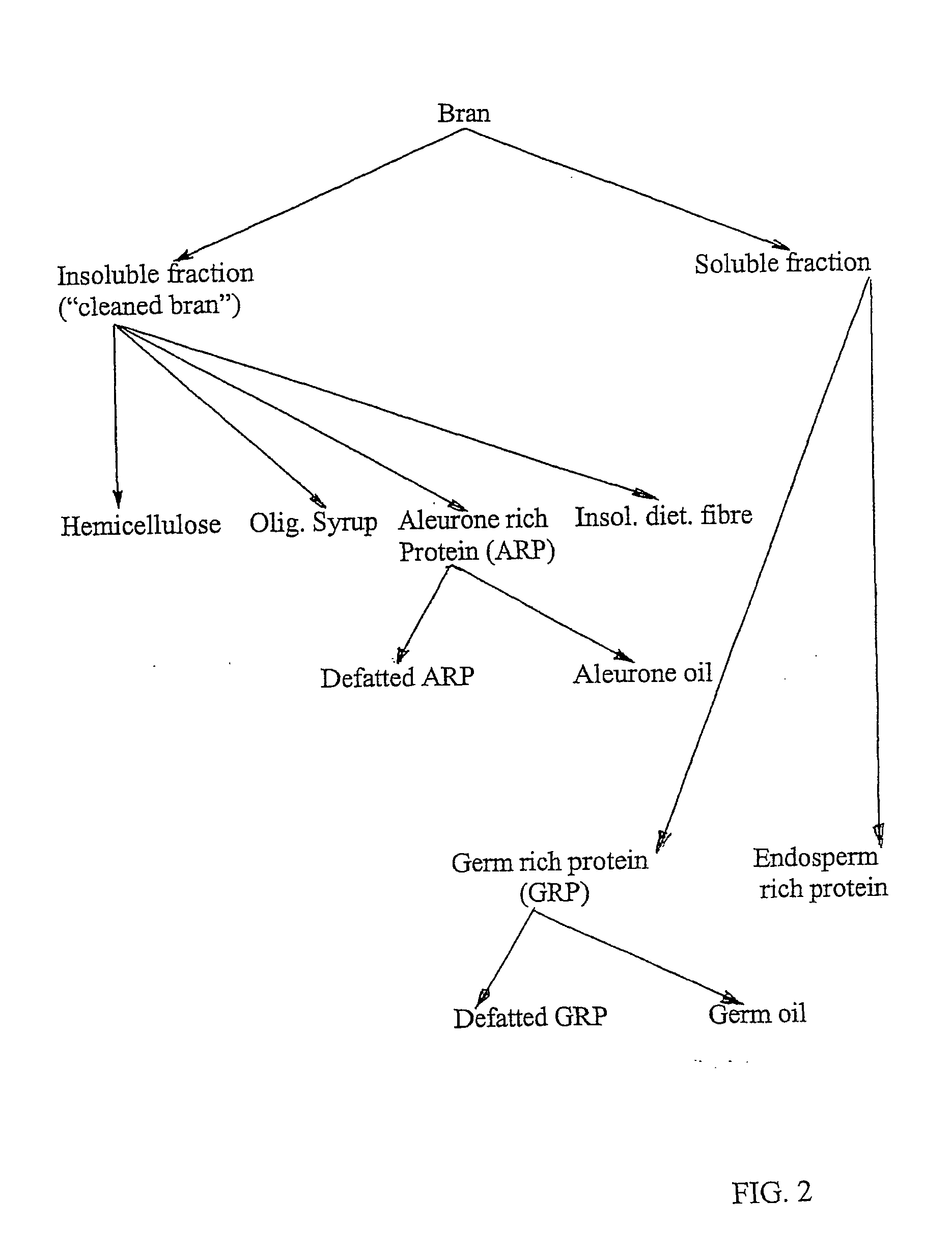

Process for the fractionation of cereal brans

InactiveUS20050089602A1Minimal contaminationImprove efficiencyTea extractionProtein composition from vegetable seedsUltrafiltrationHordeum vulgare

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

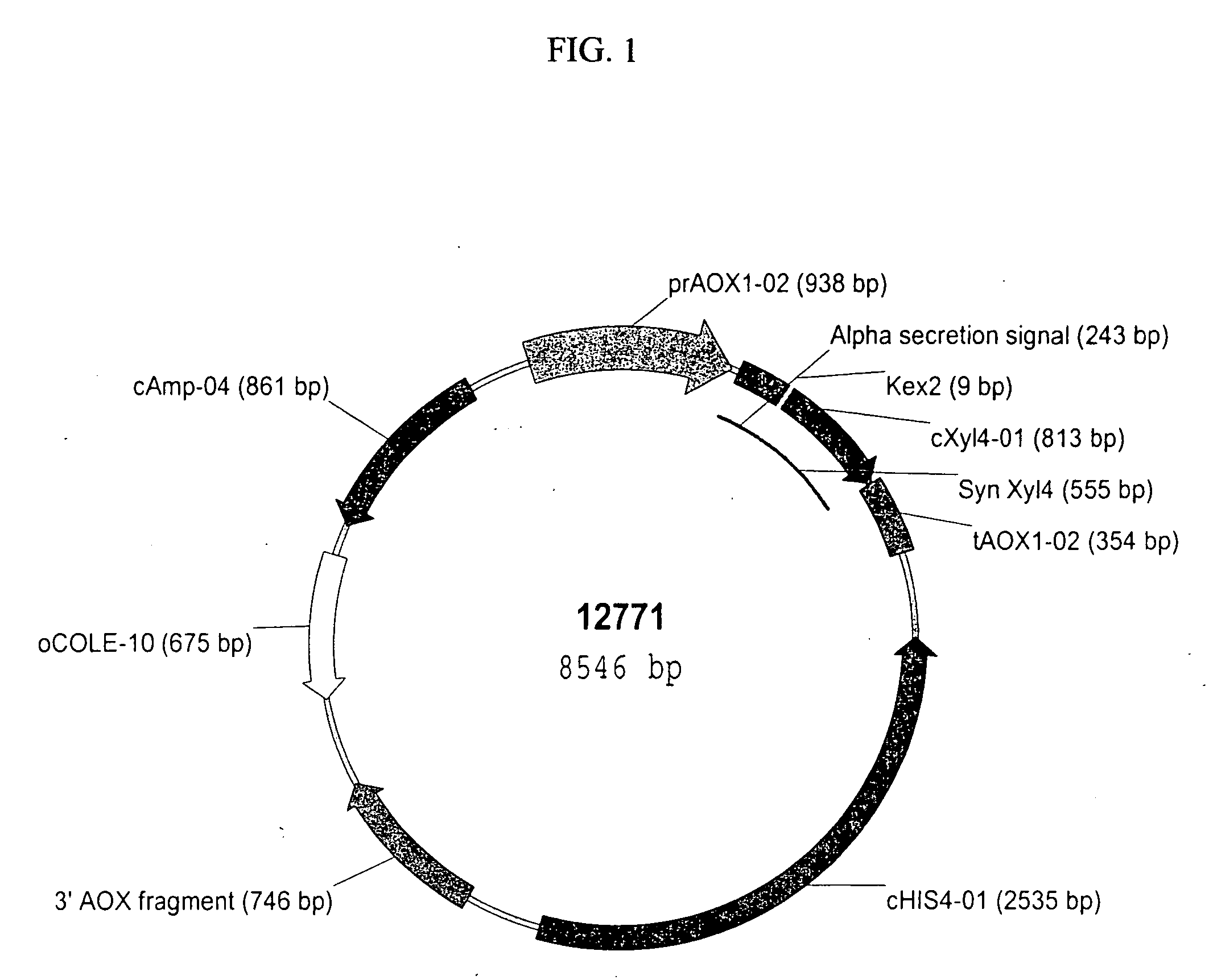

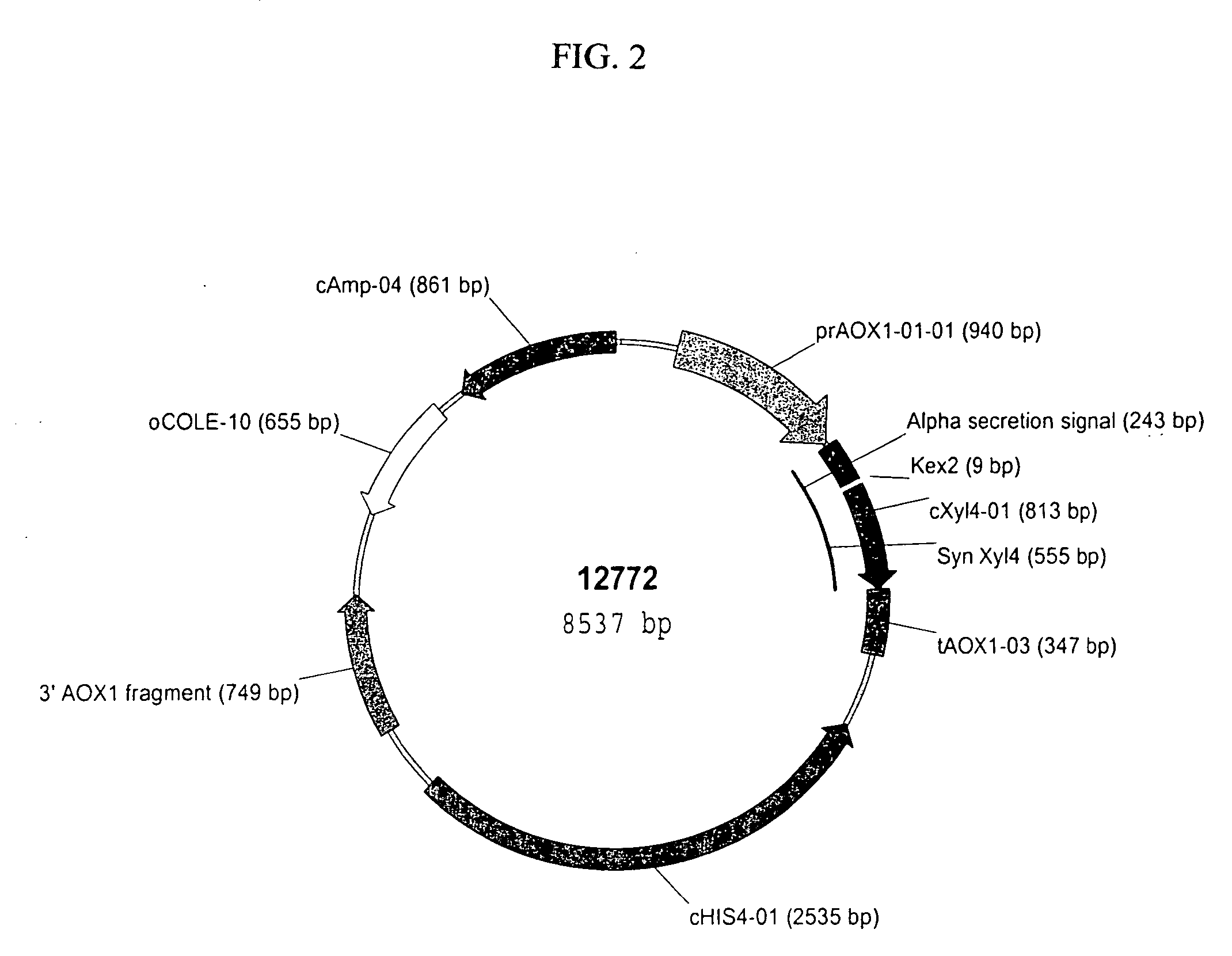

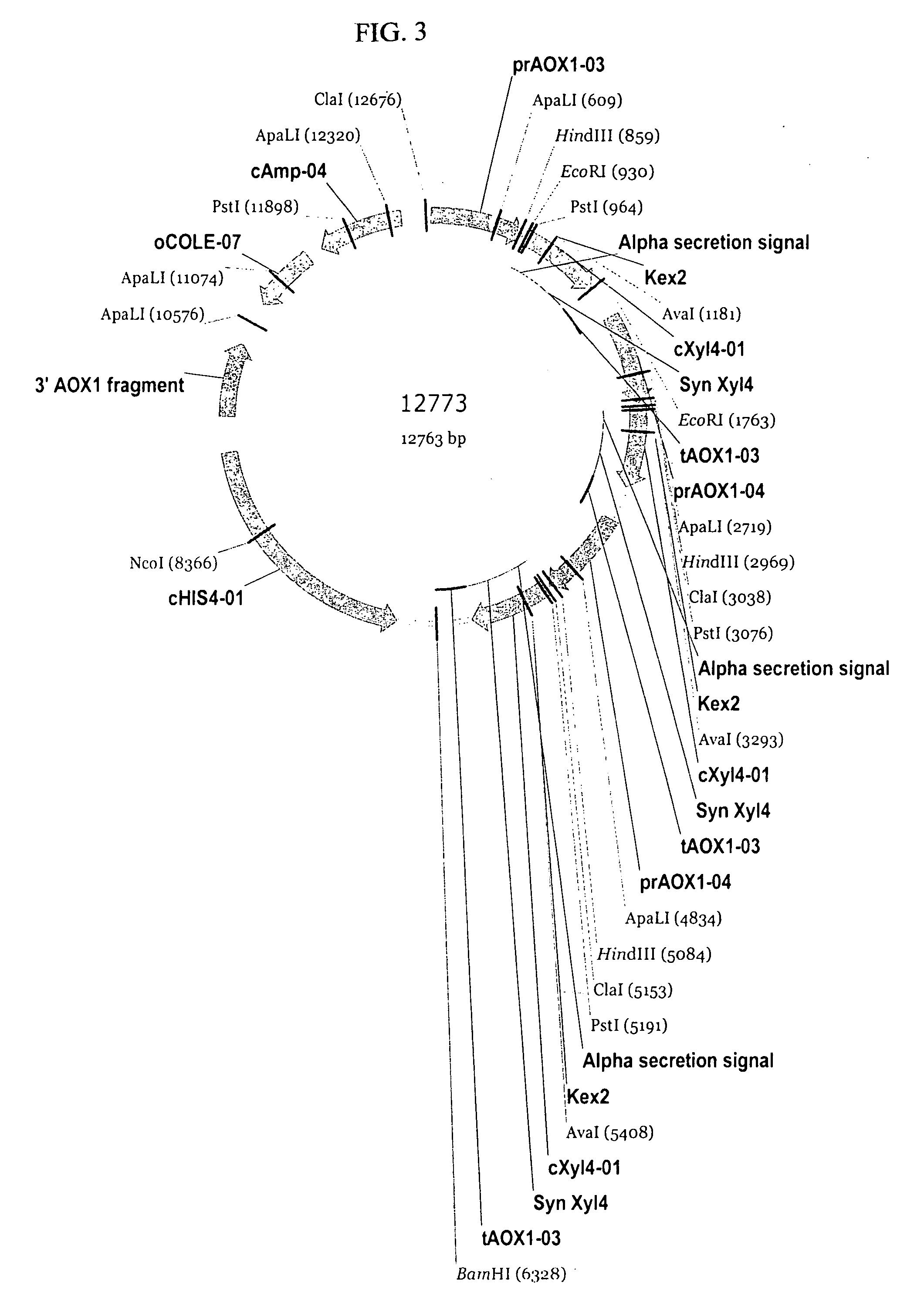

Microbially expressed xylanases and their use as feed additives and other uses

The present invention relates to codon-optimized xylanase coding sequences and the expression of xylanases in microbes and yeast. The invention further relates to using multiple copies of the xylanase expression construct for high levels of protein expression. The invention also relates to the use of xylanases as feed or food additives. The invention also relates to methods of expression of enzymes to increase thermotolerance by expressing them in organisms that glycosylate proteins compared to expression that the same enzyme without the glycosylation. Further, the invention relates to methods of preparing feed, enzyme feed additives, and methods of reducing the feed conversion ration or increasing weight gain of animals.

Owner:SYNGENTA PARTICIPATIONS AG

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS20040005399A1Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

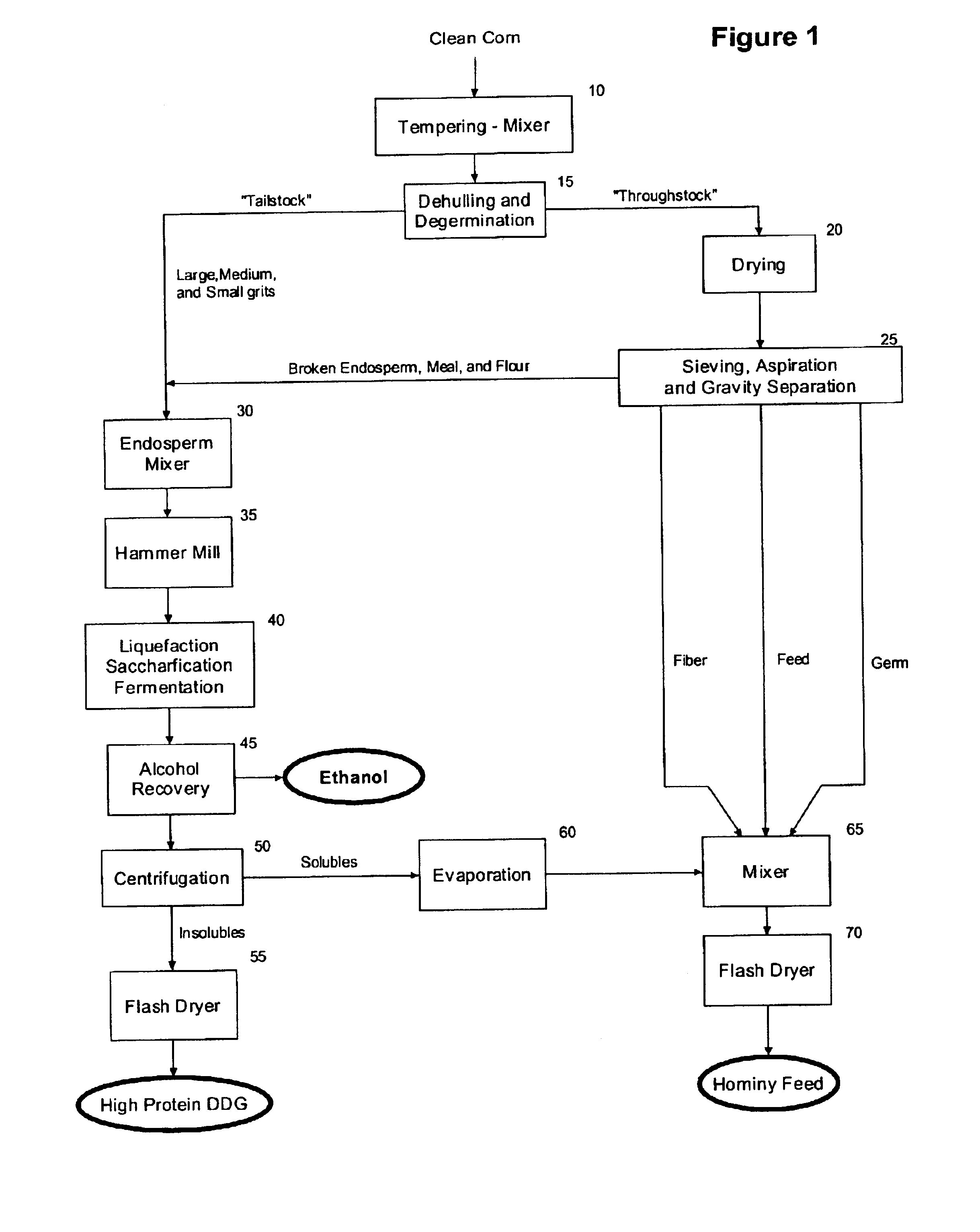

High protein corn product production and use

InactiveUS6962722B2Improve palatabilityImprove digestibilityFood processingClimate change adaptationWeight gainingFiber

The present invention relates to the production of a highly digestible, high protein product (high protein distillers dried grains or high protein DDG) from corn endosperm, and more particularly to a method for the recovery of high protein DDG by using: (i) dehulling and degermination to isolate a low fat, low fiber corn endosperm fraction, (ii) enzymatic hydrolysis to solubilize and alcoholic fermentation to assimilate the starch and non-starch carbohydrates present in the corn endosperm, and (iii) filtration and / or centrifugation to recover the dealcoholized insoluble solids that remain after fermentation of the corn endosperm. The present invention provides an alternative to the traditional dry mill method of processing corn to produce ethanol, and results in the production and recovery of a distillers' by-product (high protein DDG) with increased value and range of use as an ingredient in feeds for farm-raised ruminants and non-ruminants and pet foods. The product of the present invention contains less than about 2.0 weight percent starch, from about 55.0 to about 65.0 weight percent protein, from about 4.5 to about 7.5 weight percent fat, from about 3.0 to about 5.0 weight percent crude fiber, and from about 78.0 to about 90.0 percent total digestible nutrients, and improves the palatability and digestibility of animal feeds and / or pet foods into which it is incorporated, and aids in the management of the health and weight gain of the animal.

Owner:GREENSTOCK RESOURCES

Method for increasing the tenderness of a meat product

A method for preserving a food product, such as meat, including the steps of inoculating meat with an effective amount of euhygienic non-pathogenic, non-spoilage bacteria in order to competitively inhibit the growth of undesired pathogenic and spoilage bacteria. Edible films that incorporate and / or cover euhygenic bacteria on the food product are used to ensure competitive inhibition of undesired spoilage and pathogenic bacteria.

Owner:SWIFT BEEF +1

Frozen food product

Plant anti freeze proteins can advantageously be incorporated into frozen confectionery products, provided they have the capability of limiting the growth of ice crystals

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

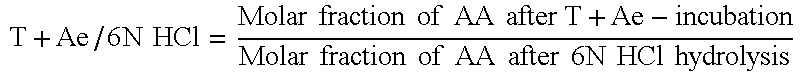

Protein hydrolysates

The present invention describes protein hydrolysates: obtainable by the hydrolysis of a protein containing substrate; comprising free amino acids and peptides; and wherein the molar fraction of at least one free amino acid, present in the protein hydrolysate is at least a factor 2.5, preferably at least a factor 3, more preferably at least a factor 3.5 times higher than in a hydrolysate of the same protein containing substrate which has been completely hydrolysed to free amino acids, wherein the molar fraction of the at least one free amino acid in the protein hydrolysate is at least 25%; and wherein the Amino Acid Quotient (AAQ) in the protein hydrolysate is at least 10%. These protein hydrolysates can be used in the preparation of food compositions, wherein these protein hydrolysates provide for novel and unexpected flavours. Moreover these protein hydrolysates are applicable in personal care applications.

Owner:DSM IP ASSETS BV

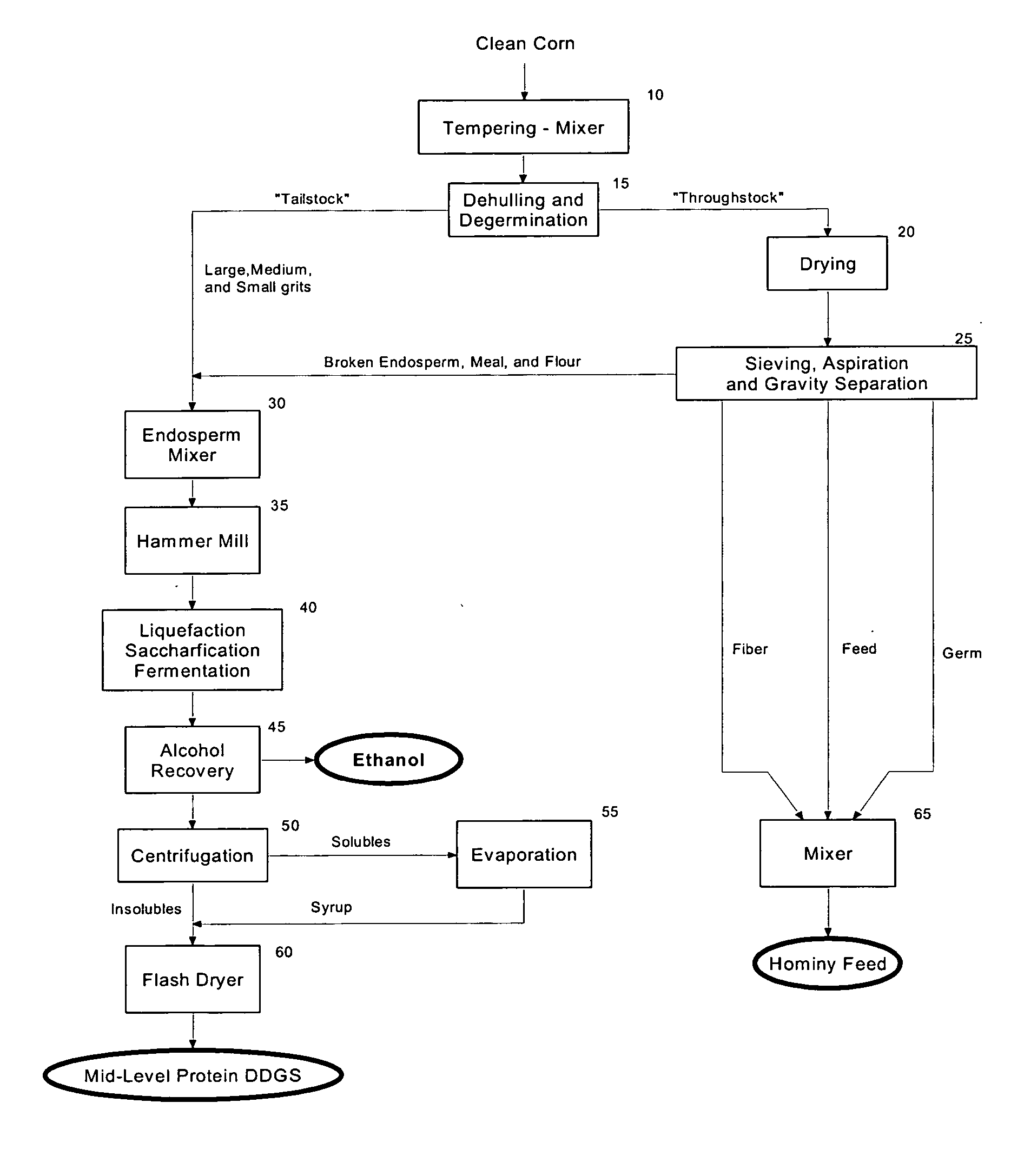

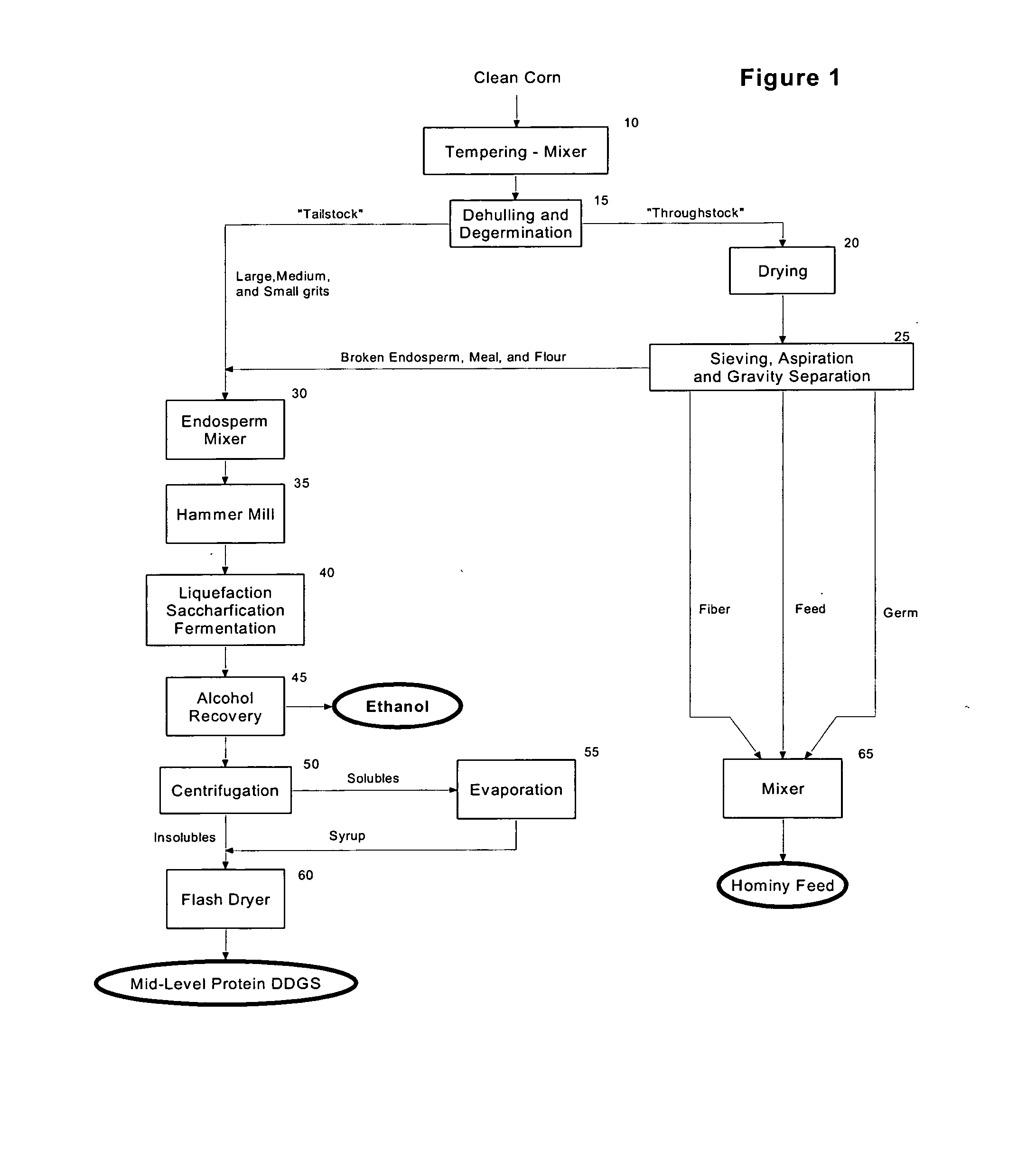

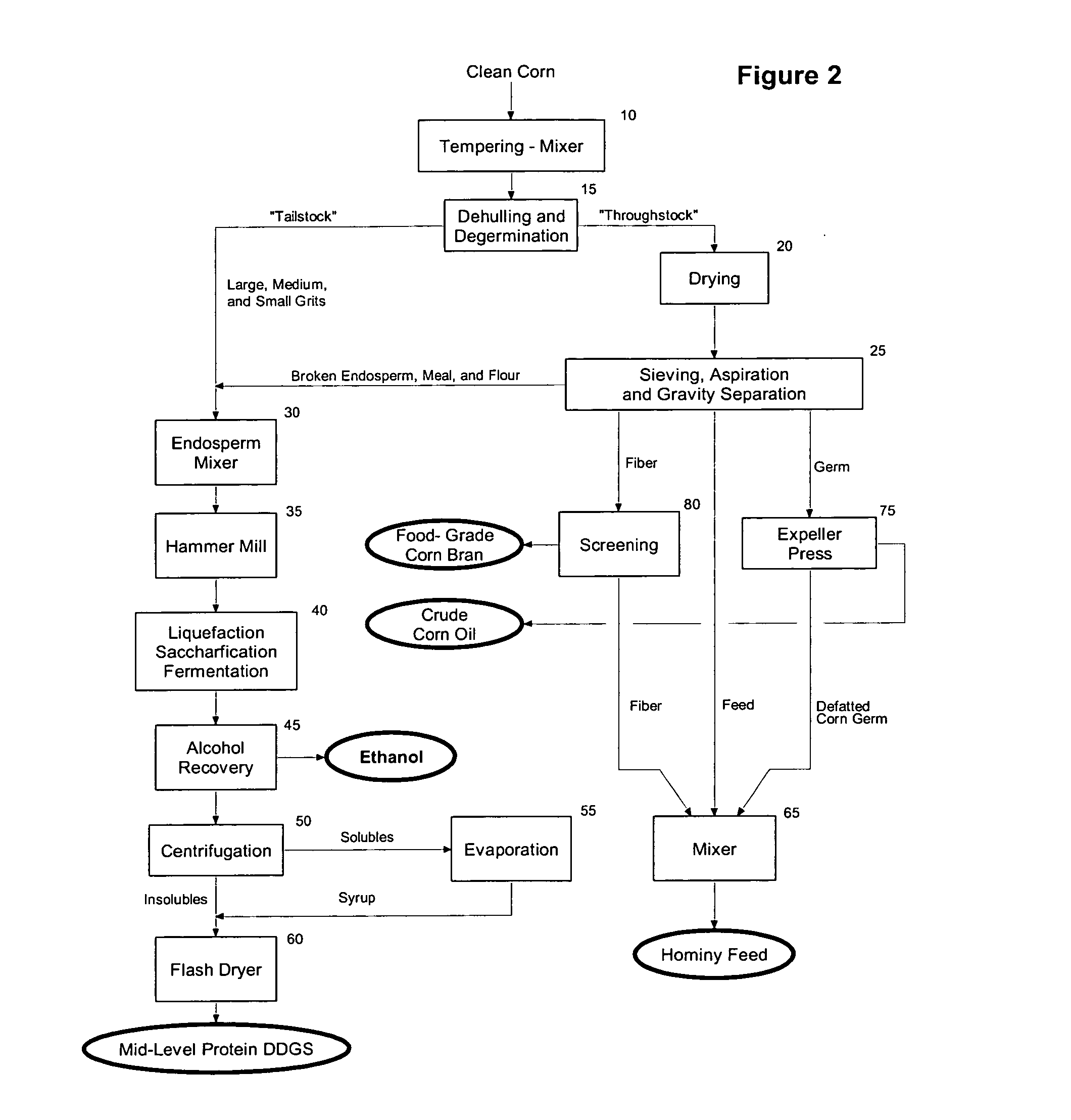

Mid-level protein distillers dried grains with solubles (DDGS) - production and use

InactiveUS20060057251A1Improve palatabilityImprove digestibilityFood processingClimate change adaptationFiberFiltration

The present invention relates to the production of a highly digestible, mid-level protein DDGS from corn endosperm, and more particularly to a method for the recovery of mid-level protein DDGS by using: (i) dehulling and degermination to isolate a low fat, low fiber corn endosperm fraction, (ii) enzymatic hydrolysis to solubilize and alcoholic fermentation to assimilate the starch and non-starch carbohydrates present in the corn endosperm, and (iii) filtration, centrifugation and / or evaporation to recover the dealcoholized insoluble and soluble solids that remain after fermentation of the corn endosperm. The product of the present invention contains less than about 5.0 weight percent starch, from about 40.0 to about 52.5 weight percent protein, from about 4.5 to about 8.5 weight percent fat, from about 3.0 to about 6.0 weight percent crude fiber, and from about 78.0 to about 90.0 percent total digestible nutrients.

Owner:GREENSTOCK RESOURCES

Process for producing biodiesel

InactiveUS20050011112A1Fatty oils/acids recovery from wasteFatty acid esterificationBiodieselSolid fraction

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds, comprising a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Green tea formulations and methods of preparation

ActiveUS20050287278A1Large doseWell received naturalTea extractionTea substituesIntracellular substanceFood flavor

Green tea formulations and methods for the preparation thereof are disclosed and described. Generally speaking, the method of preparation includes the mixing of fresh tea leaves in an amount of cold water, followed by pulverization of the leaves to release their intracellular material from the cells of the green tea leaves into the water and form an aqueous extract component. The remaining cellular material forms a leaf residue component which is removed from the mixture. Once the leaf residue is removed, the aqueous extract component is collected and may be dried or further processed to produce a final tea extract that has good natural color, robust natural flavor, and pleasant organoleptic properties, which also is high in polyphenol content, and may be used for various purposes such as the creation of a green tea beverage.

Owner:XEL HERBACEUTICALS INC

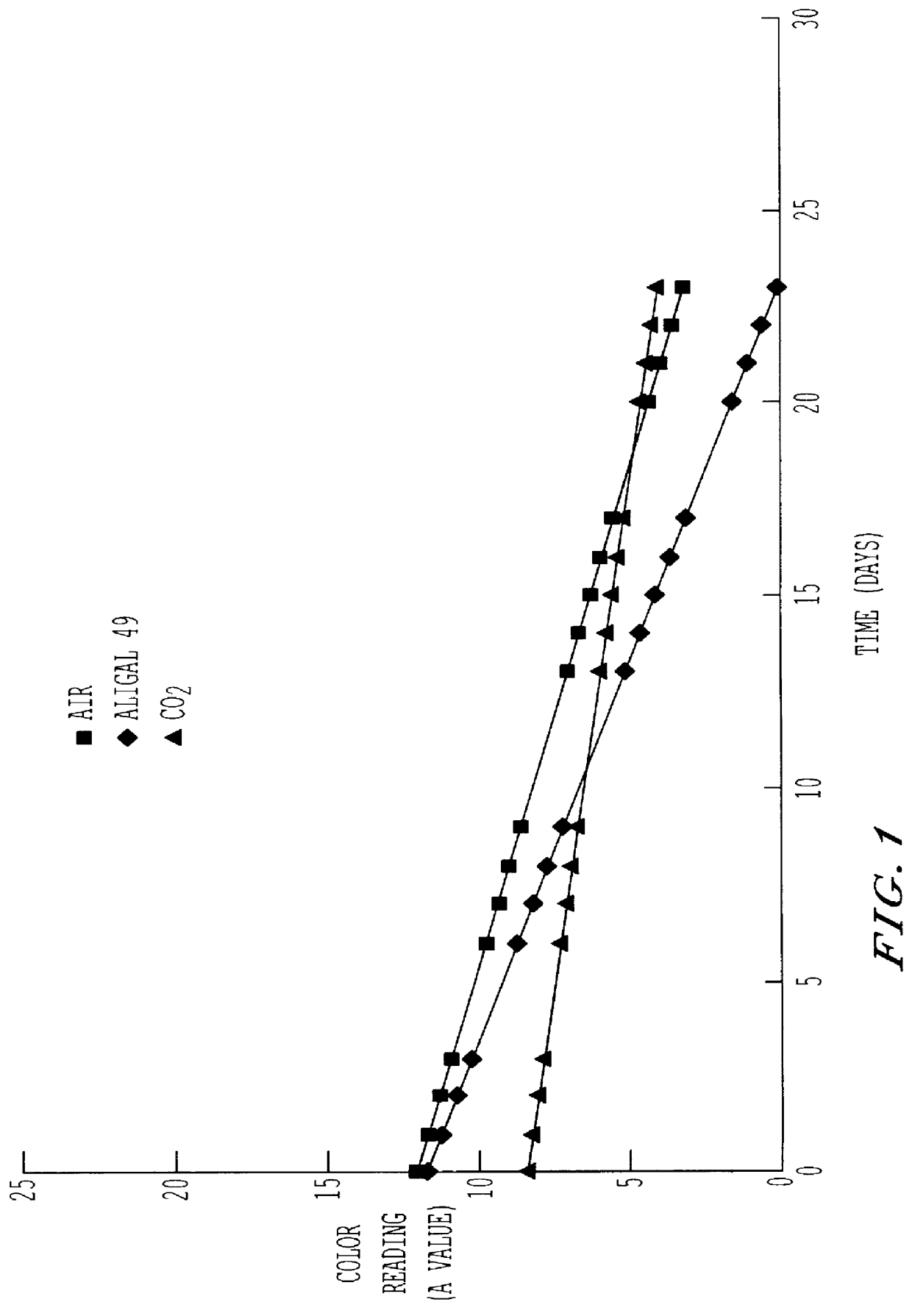

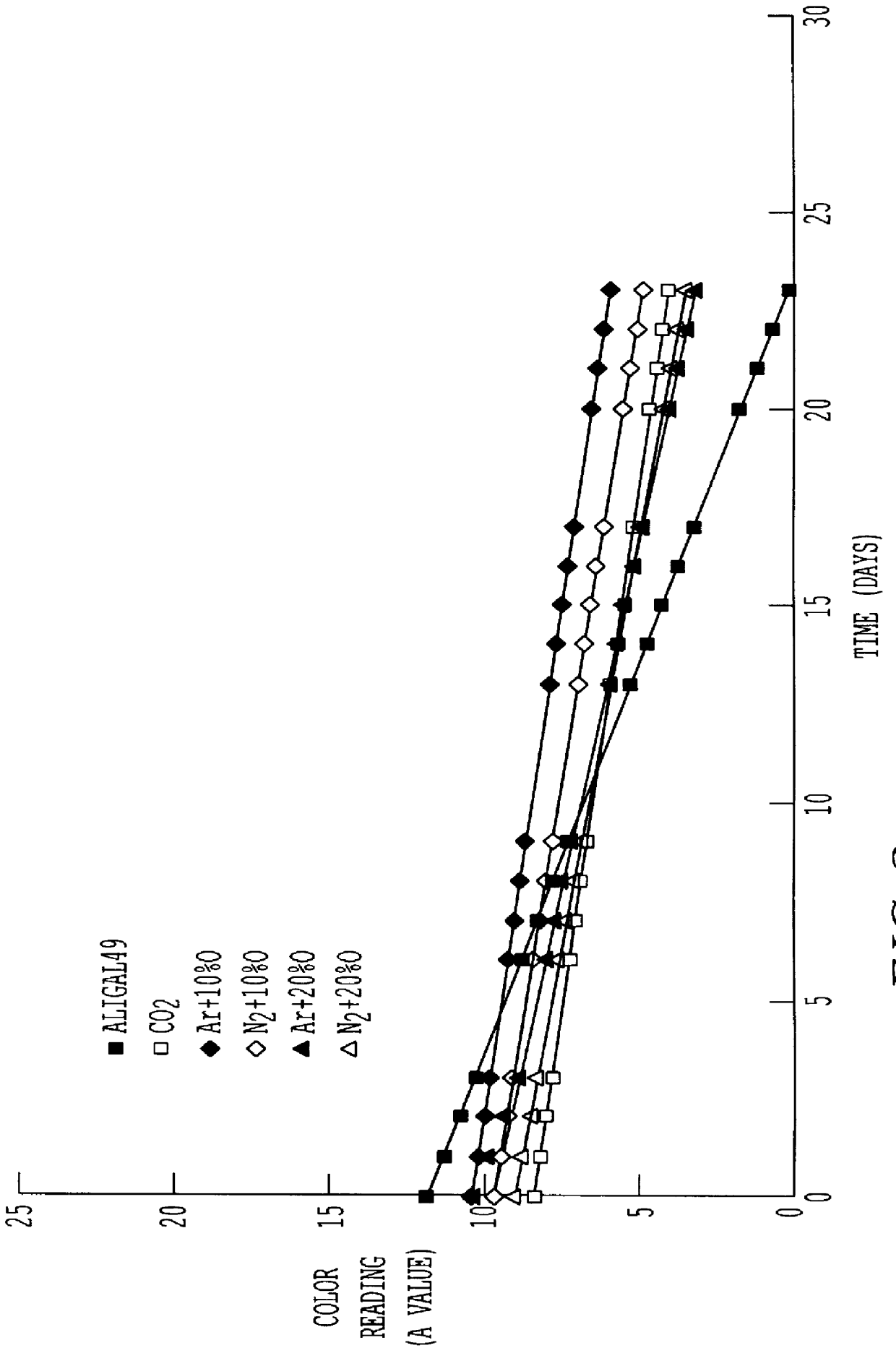

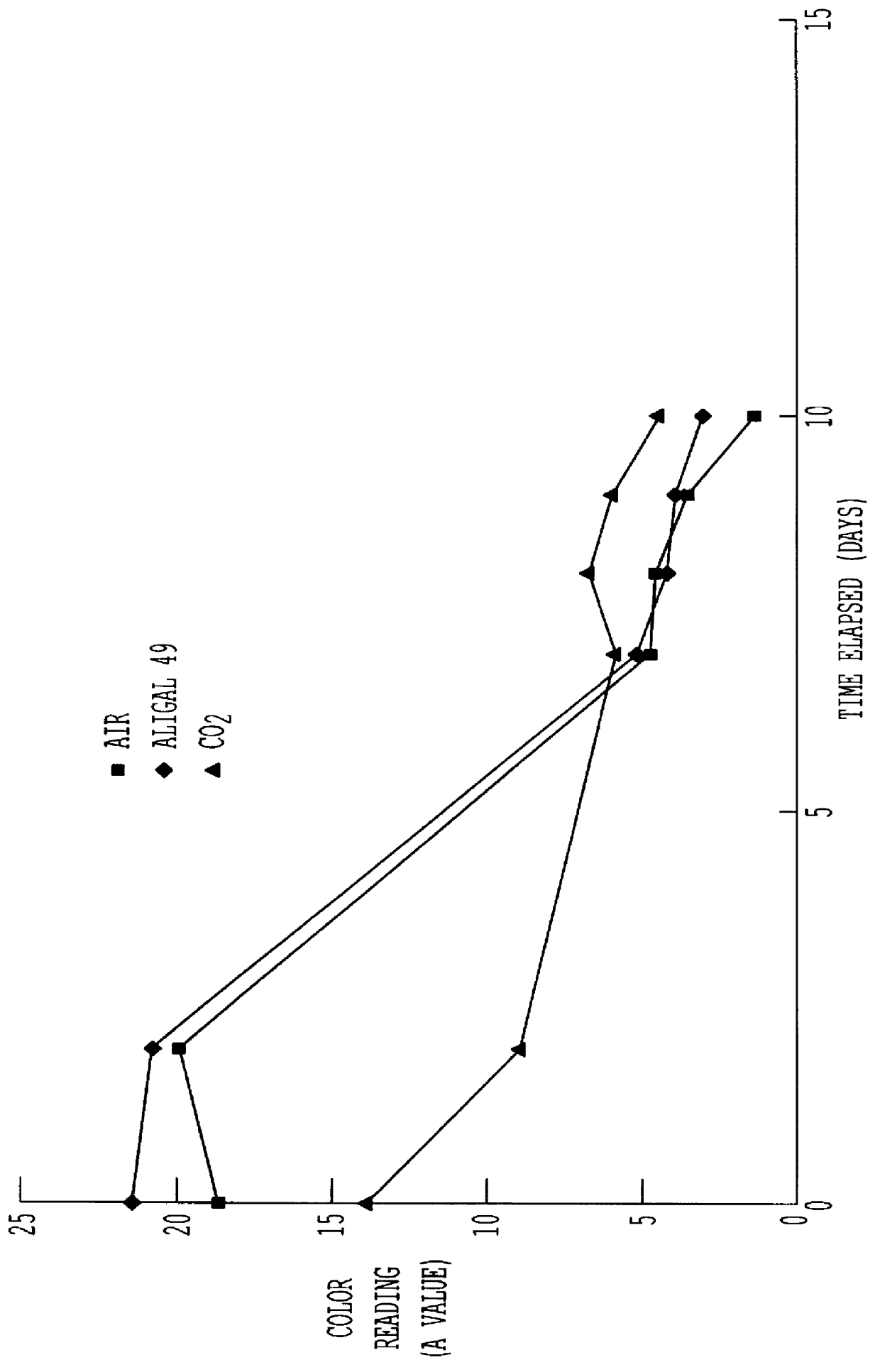

Preservation of color of stored meat using noble gases

A process for preserving the color of red meat, which entails contacting the meat with an effective amount of an atmosphere selected from the group consisting of a noble gas, a mixture of noble gases and a mixture containing at least one noble gas and a carrier gas, the noble gas in the mixture with the carrier gas being selected from the group consisting of argon, neon, xenon an krypton and being present in said mixture in an amount of greater than about 10% by volume.

Owner:AIR LIQUIDE AMERICA INC

Process for the Manufacture of a Tea Product and Products Obtained Thereby

A process is provided for the manufacture of a tea product which is readily infusible and has improved red colour. The process comprises contacting black tea with ascorbic acid and / or its salts, an oxidizing agent and water for a period of at least 5 minutes followed by drying to prepare a tea product that is infusible in water at 5 to 100° C.

Owner:CONOPCO INC D B A UNILEVER

Pharmaceutical compositions containing herbal-based active ingredients; methods for preparing same and uses of same for medical and veterinary purposes

InactiveUS6106838AHigh yieldLow costBiocideHydroxy compound active ingredientsCoccidiosisAdditive ingredient

PCT No. PCT / GR96 / 00016 Sec. 371 Date Dec. 29, 1997 Sec. 102(e) Date Dec. 29, 1997 PCT Filed Jun. 27, 1996 PCT Pub. No. WO97 / 01348 PCT Pub. Date Jan. 16, 1997Methods for treating and preventing coccidiosis in poultry, and inflammation, infection, and diarrhea in mammals are provided utilizing an antimicrobial pharmaceutical composition comprising an herbal essential oil which contains thymol and carvacrol as its main ingredients. The essential oil is preferably obtained from the genus Origanum, especially Origanum vulgare ssp. hirtum.

Owner:ECOPHARM USA

Supplemented fruit or vegetable product

Owner:MCHANEY BLAIR C +1

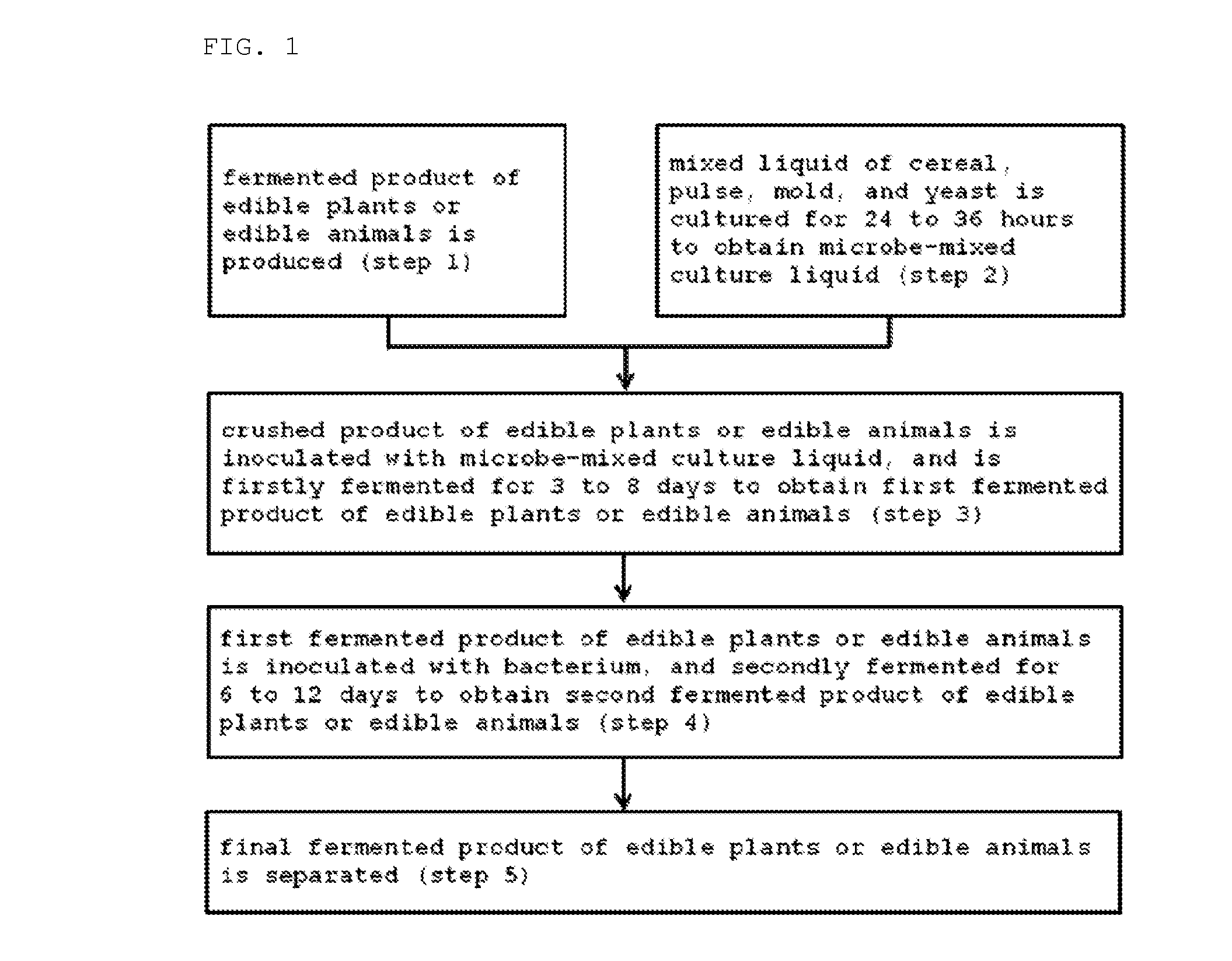

Method for producing fermented edible plants or edible animal/plants, fermented edible plants or edible animal/plants produced by same, and foods containing same

ActiveUS20100316763A1Increase heightPrevent invasionDough treatmentEdible seed preservationFood flavorOrganism

The present invention relates to a method for producing fermented edible plants or edible animal / plants, to fermented edible plants or edible animal / plants produced by same, and to foods containing same. The method for producing fermented edible plants or edible animal / plants includes the steps of: producing crushed edible plants or edible animal / plants; culturing a liquid mixture of grains, saccharides, filamentous fungi, and yeast for 24 to 36 hours to produce a mixed microbial broth; inoculating the edible plants or edible animal / plants with the mixed microbial broth, and firstly fermenting the edible plants or edible animal / plants for 3 to 8 days to produce first fermented edible plants or edible animal / plants; and inoculating the first fermented edible plants or edible animal / plants with bacteria, and secondly fermenting the first fermented edible plants or edible animal / plants for 6 to 12 days to produce second fermented edible plants or edible animal / plants. Whereby, a fermentation period can be shortened, and food deterioration and the growth of pathogenic microorganisms can be suppressed. Further, adding the fermented edible plants or edible animal / plants produced by the above-described method into foods can provide storage stability, increase bioavailability, and improve flavor.

Owner:PHARVIS R&D KOREA

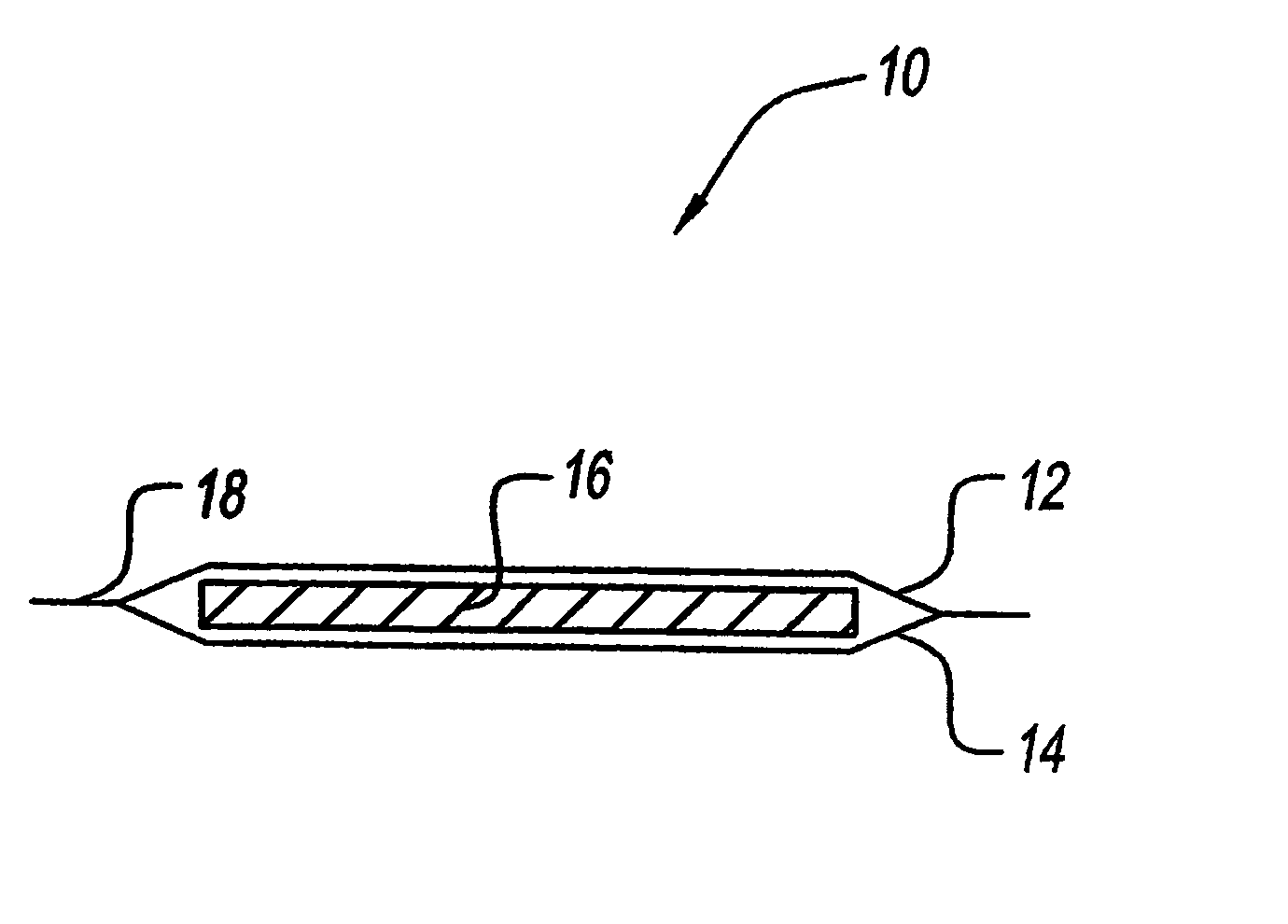

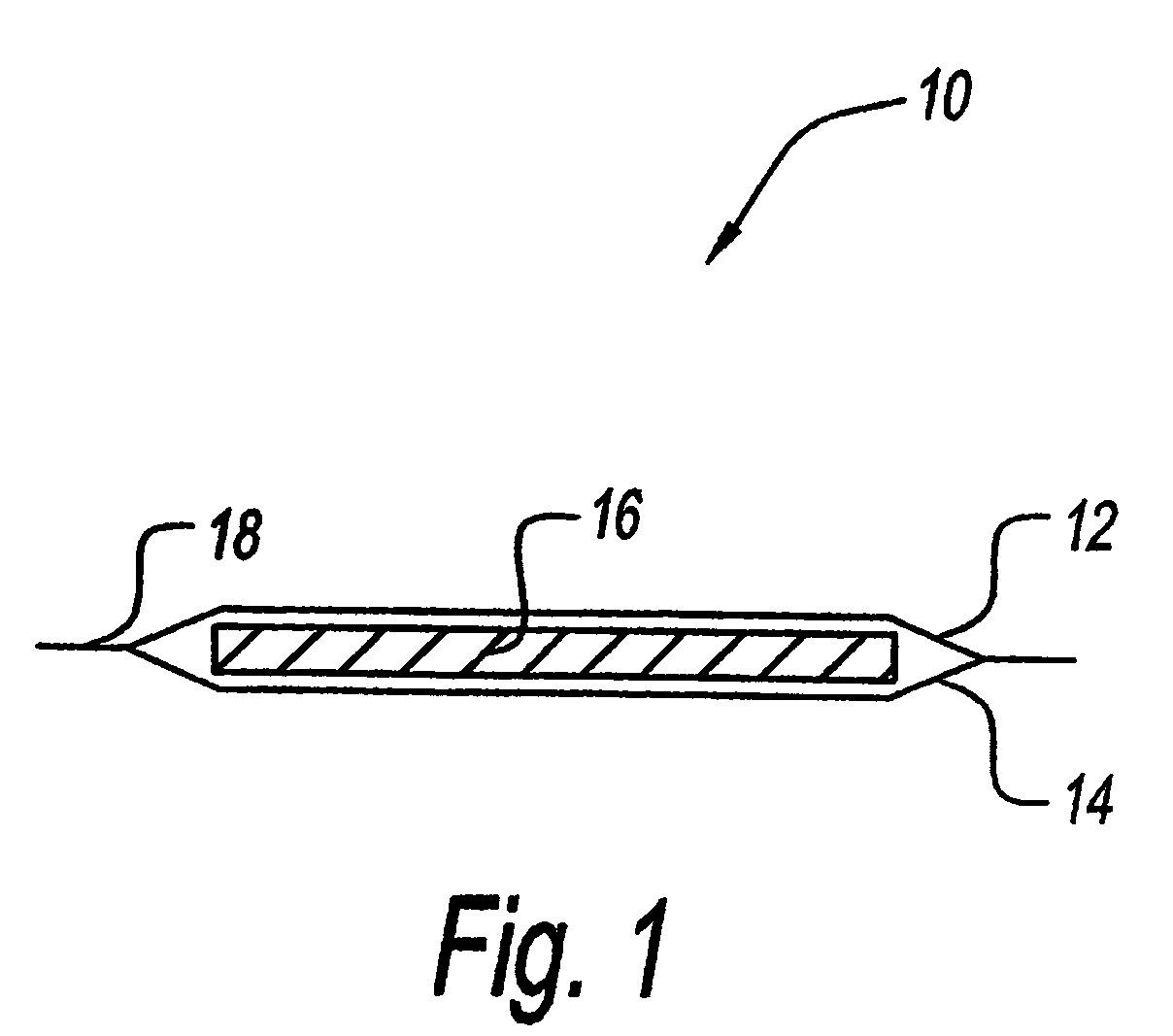

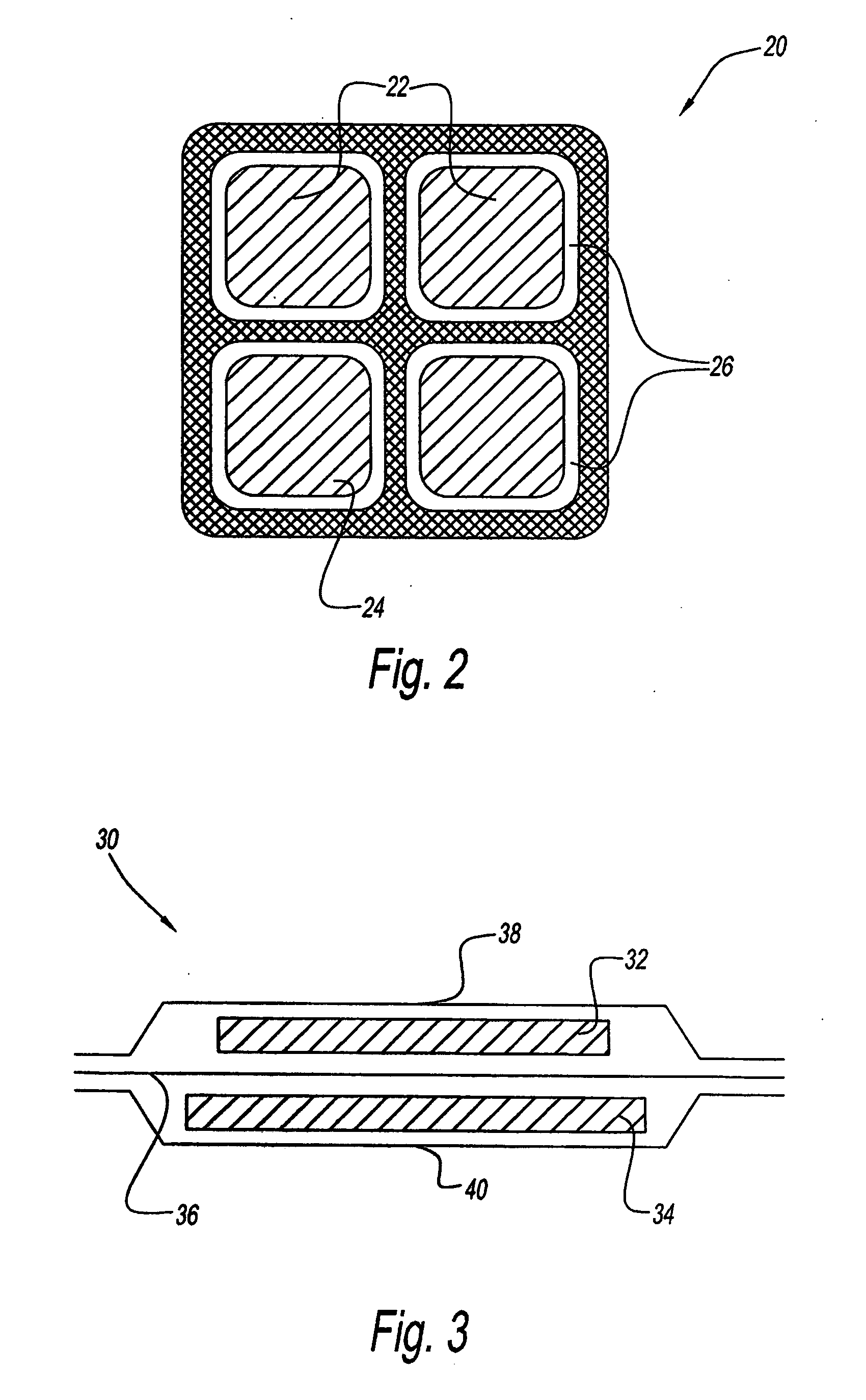

Food preservation systems

ActiveUS20060172048A1Large capacityIncreased physical sizeContainer/bottle contructionFruits/vegetable preservation using acidsFood safetyFood preservation

The present invention provides a food preservation system that includes a multi-phase bacterial inhibition food pad. The food pad includes absorbent media and / or material to absorb fluids emanating from the packaged food. The absorbent media / material includes one or more bacterial inhibitors that may possess bacteriostatic and / or bactericidal properties. In addition, the food pad may also include an atmosphere modification system capable of modifying an atmosphere in a food package. Optionally, one or more reaction promoters and / or one or more mechanisms to protect the food preservation system may also be included in the food pad. Overall, the food preservation system inhibits bacterial growth, thereby enhancing food preservation and / or food safety.

Owner:NOVIPAX INC

Food Containing a Probiotic and an Isolated Beta-Glucan and Methods of Use Thereof

ActiveUS20080193485A1Reduce allergiesReduce colonizationAntibacterial agentsBiocideNatural sourceDisease

The invention features a food product containing a probiotic and β-glucan isolated from a natural source, methods of treating a disease or disorder by administering the food product, and a package containing separated components of the food product.

Owner:GORBACH SHERWOOD L +1

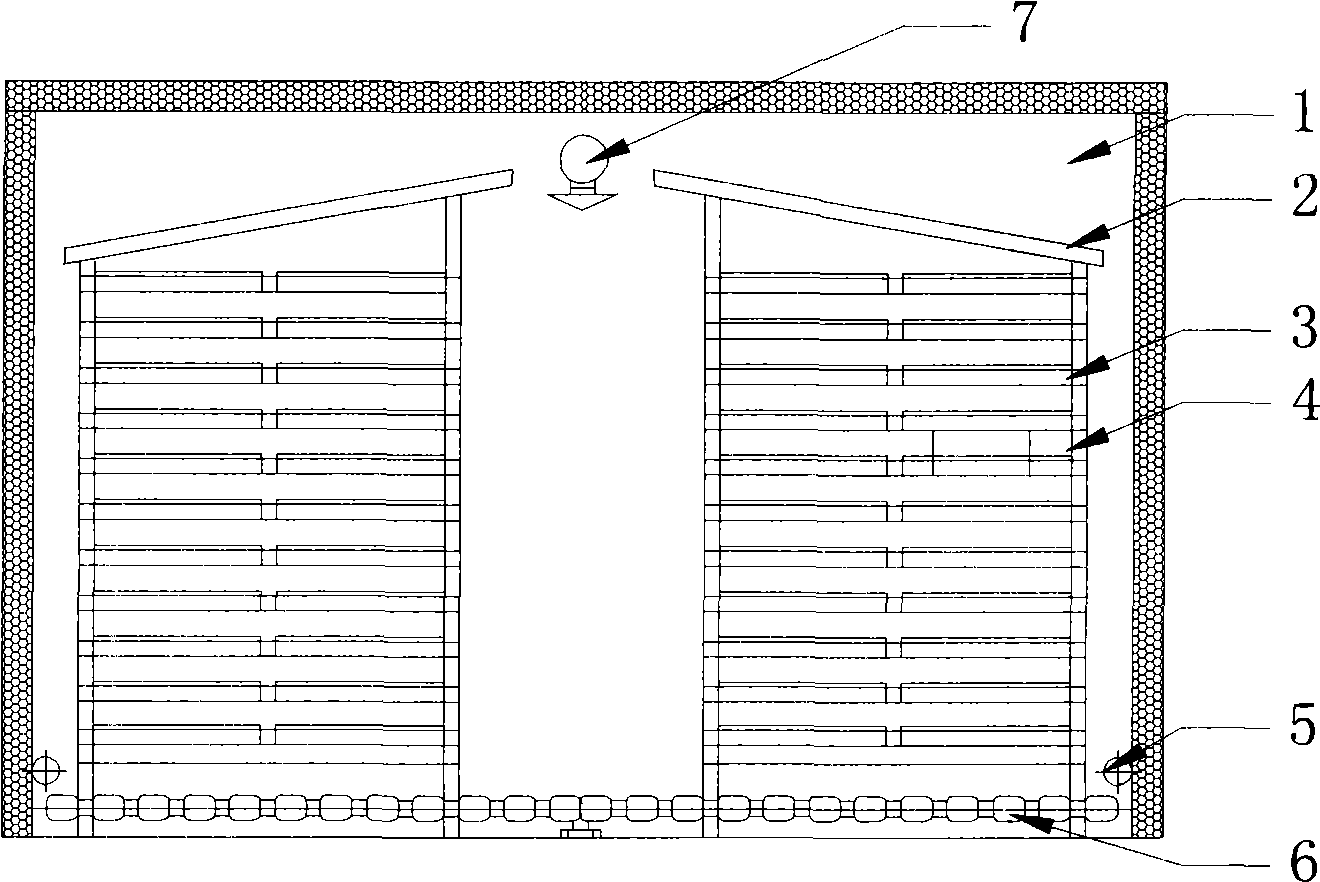

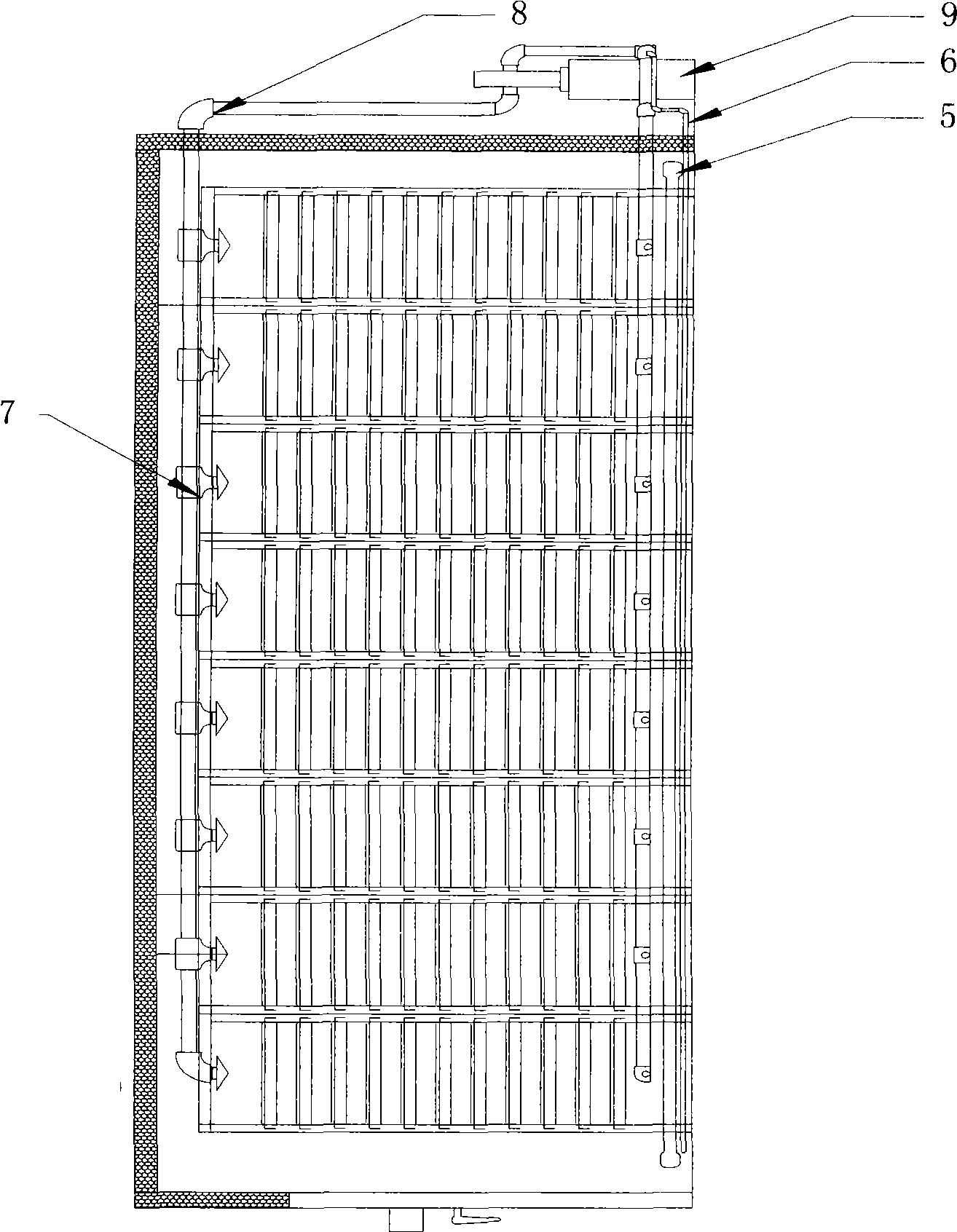

Black garlic, process and device for fermenting same

InactiveCN101518319AEasy to peel offNo irritating odorClimate change adaptationFruits/vegetable preservation using acidsS-Allyl cysteinePesticide residue

The invention discloses black garlic, a process and a device for fermenting the same, which overcomes technical defects of the prior product, processing method and processing device. The black garlic is integral in bulk, dry in outer peel and easy to peel. Garlic cloves are in preserved fruit paste shape, are free from pungent taste, have jelly taste, taste good and are easy to preserve. Every 100 grams of ripening black garlic contains 140 milligrams of isoleucine, 250 milligrams of leucine, 170 milligrams of lysine, 160 milligrams of cystine, S-allyl cysteine and polyphenol of which the content is 22 times that of raw garlic, 36 milligrams of sodium, 930 milligrams of potassium, 52 milligrams of magnesium and 13 milligrams of calcium. The black garlic has the advantages of low heavy-metal content, no pesticide residue and no additive. The fermenting process comprises the steps of taking integral garlic as raw material, initially washing the raw material with clear water, soaking the raw material in brine, placing the raw material in a tray, fermenting, steaming and baking the raw material, performing aging treatment, sterilizing and disinfecting the obtained product, and packing the obtained product in vacuum or with nitrogen. The fermenting process has the advantages of adopting mineral water vapor and discharging air in the whole process, along with few links and low cost. The fermenting device is heated by a steam boiler, has a humidifying vapor pipe, and uses all-wooden fermentation frame and a container.

Owner:DALIAN HUAGU GARLIC

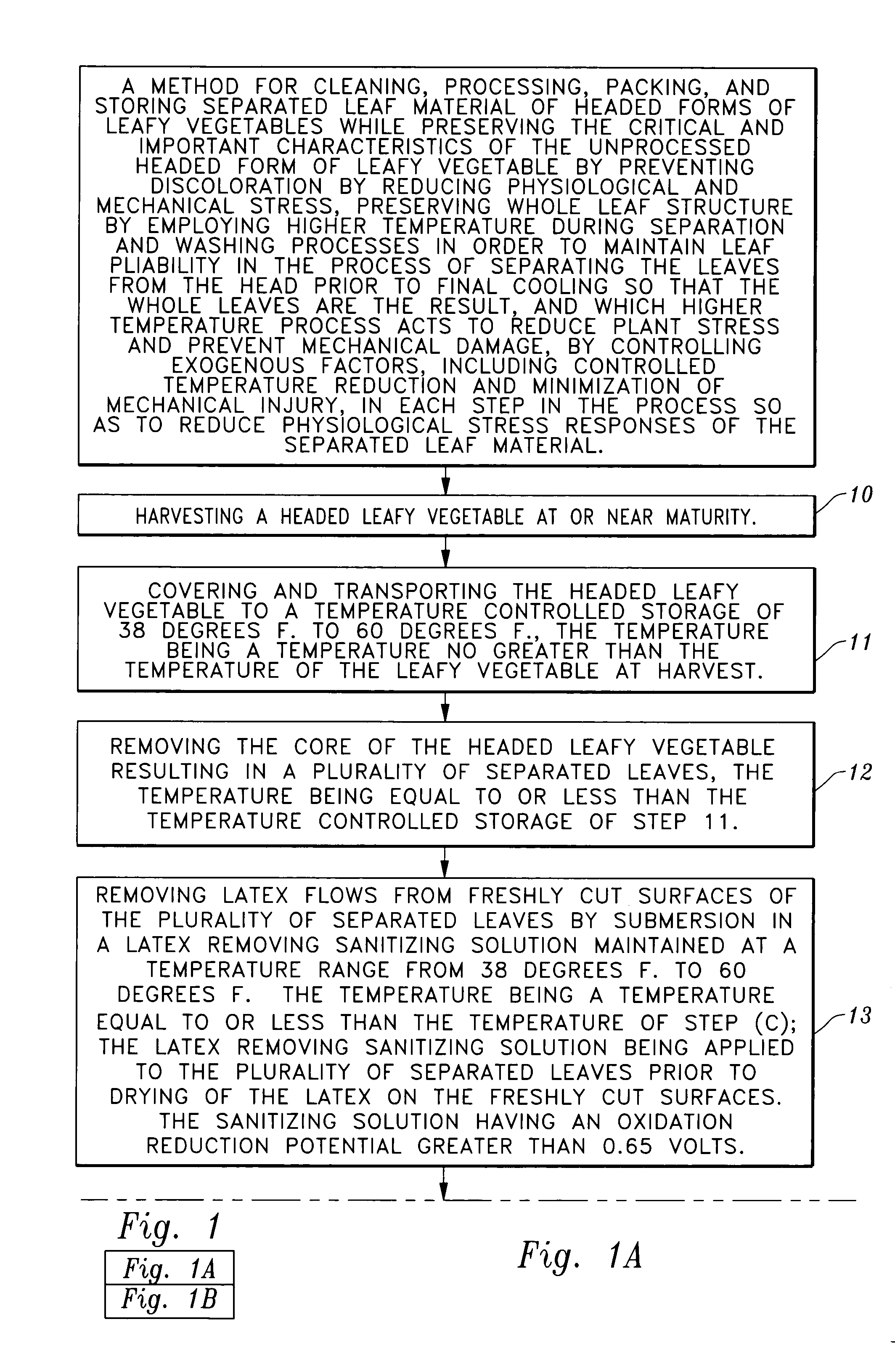

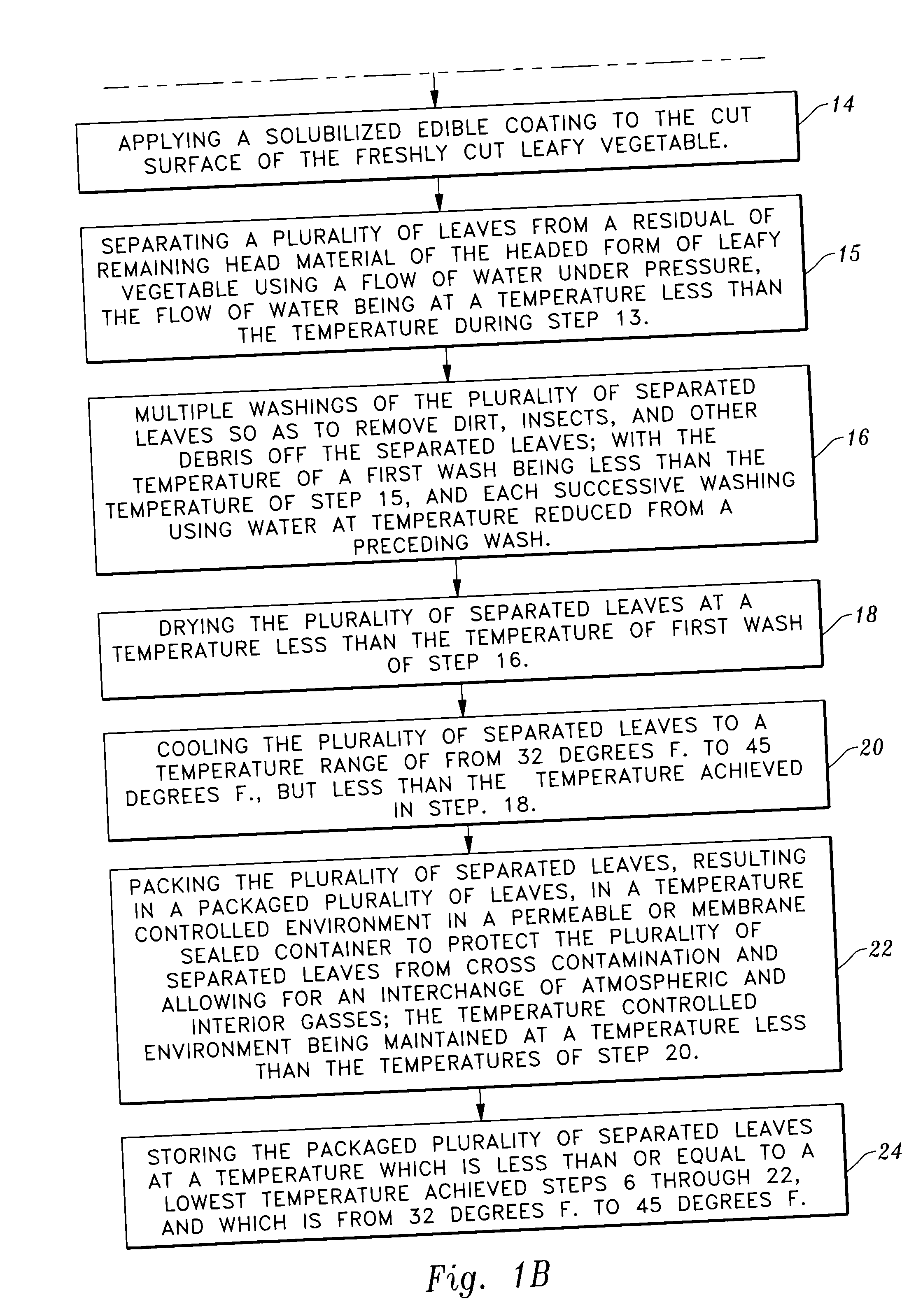

Method for cleaning, packing, and transporting vegetables

InactiveUS20050233039A1Relieve pressureIncrease pressureMilk preservationAlcoholic beverage preparationWater flowReady to use

A method for processing headed varieties of vegetables such as iceberg lettuce so as to remove all dirt, insects, and other debris from the vegetable and to allow shipping and transport of the vegetable while preserving the characteristics and versatility of the vegetable in a fresh form. The method comprises harvesting (10) the vegetable at or near maturity and then coring the vegetable (12). Latex is removed from cut surfaces (13) and a solubilized edible coating may be applied (14). A plurality of cored and separated leaves are made by separation of the leaves using a flow of water (15). The cored and separated leaves are then washed multiple times with each successive wash done using successively reduced water temperature (16). The plurality of separated leaves are maintained in a cool environment, preferably from 32 to 45 degrees F. The separated leaves are then packaged (22) in a permeable film or membrane sealed container allowing for the interchange of atmospheric gasses and gasses from the interior of the film or container, and stored (24) at a temperature which is equal to or less than the lowest temperature achieved in the preceding steps.

Owner:WOLFE STEVEN K +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com