Process for producing biodiesel

a biodiesel and process technology, applied in the direction of fatty oil/fat refining, fatty acid chemical modification, milk preparation, etc., can solve the problem of heavy subsidies and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

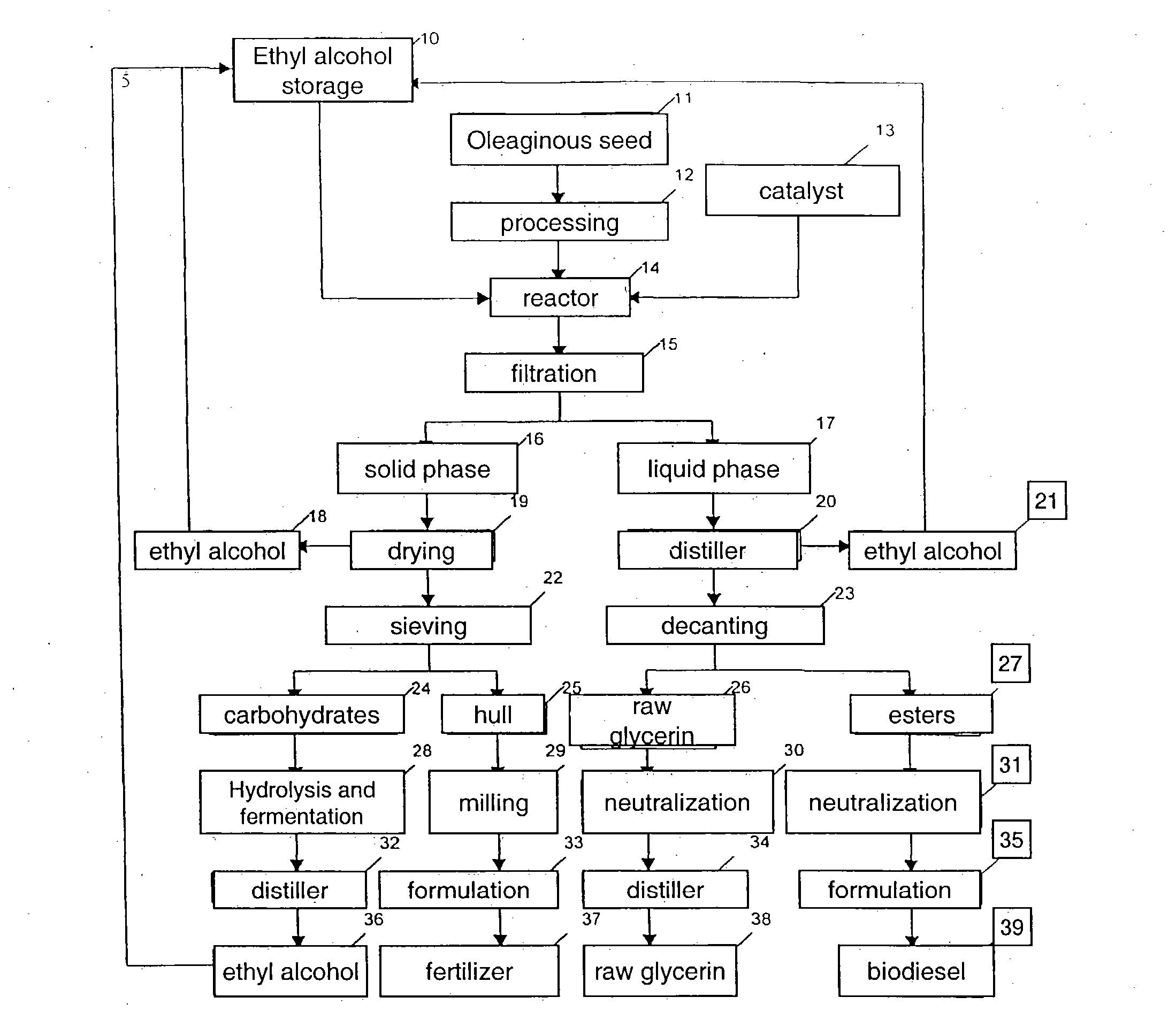

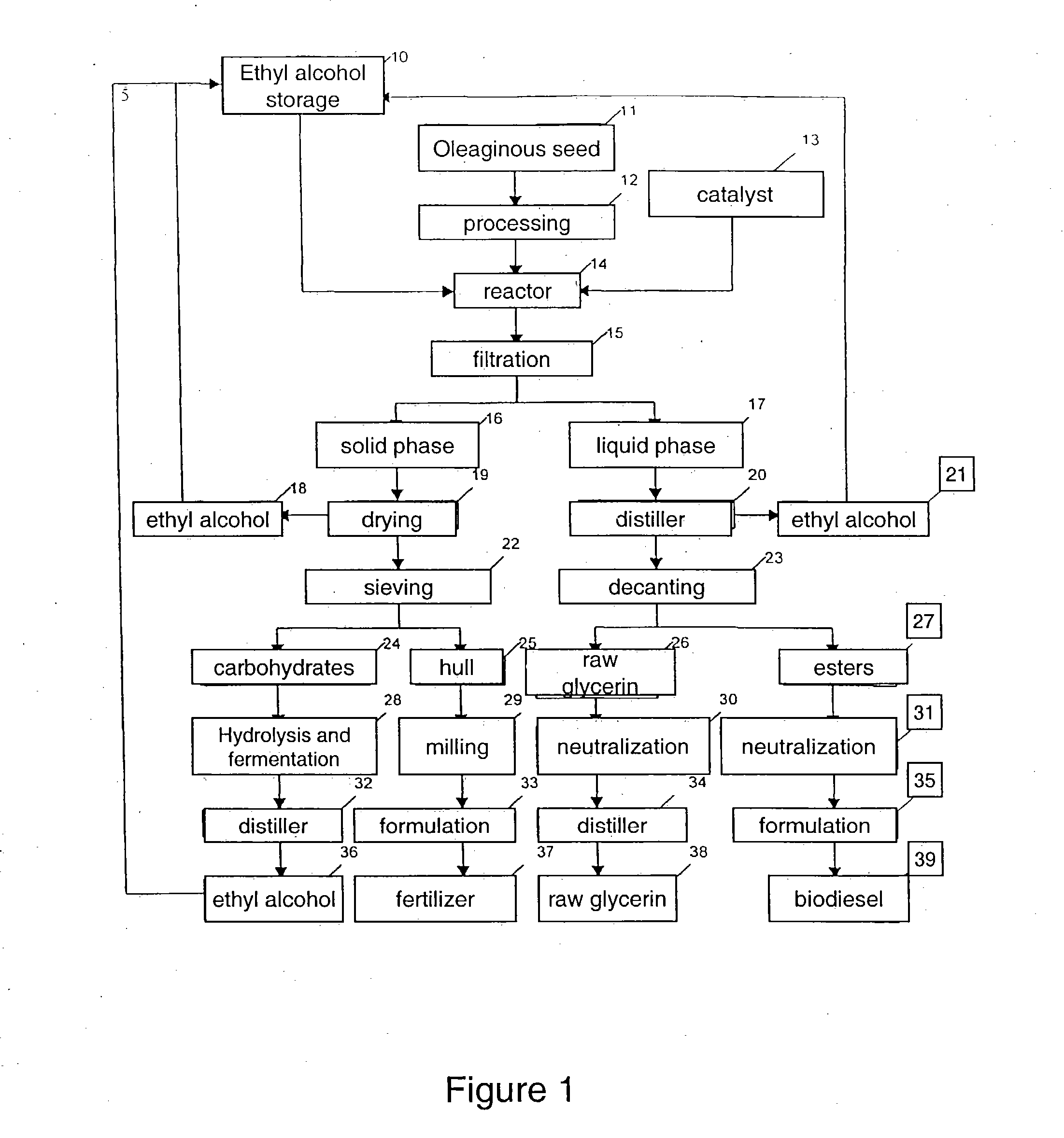

Method used

Image

Examples

example

[0049] 1000 g of raw castor bean seeds (Ricinus Communis L) of the Brazilian variety known as “Bull Heart”, processed as described above were added to a reactor together with 800 g ethyl alcohol and comminuted under vigorous agitation, at ambient temperature, until the reaction mass was a fluid, homogeneous suspension.

[0050] Then 40 g of sodium alkoxide catalyst were incorporated to the mixture and for 1 hour under moderated agitation and reflux, under atmospheric pressure and constant temperature of 50° C., the transesterification reaction of said seeds was carried out.

[0051] Then, the reactor charge was cooled to 40° C. and filtered, yielding 600 g of solid phase and 1240 g of a filtrate that after being distilled at atmospheric pressure, provided the recovery of 680 g raw ethyl alcohol condensate and 560 g of a liquid residue, remaining in the distiller, made up of a mixture of esters, glycerin and other by-products.

[0052] Once transferred to a decanter where it was kept for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com