Blends of synthetic distillate and biodiesel for low nitrogen oxide emissions from diesel engines

a biodiesel and diesel engine technology, applied in biofuels, liquid carbonaceous fuels, fuels, etc., can solve the problems of reducing the efficiency of diesel engines, affecting the quality of ignition, so as to achieve the effect of reducing nox emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

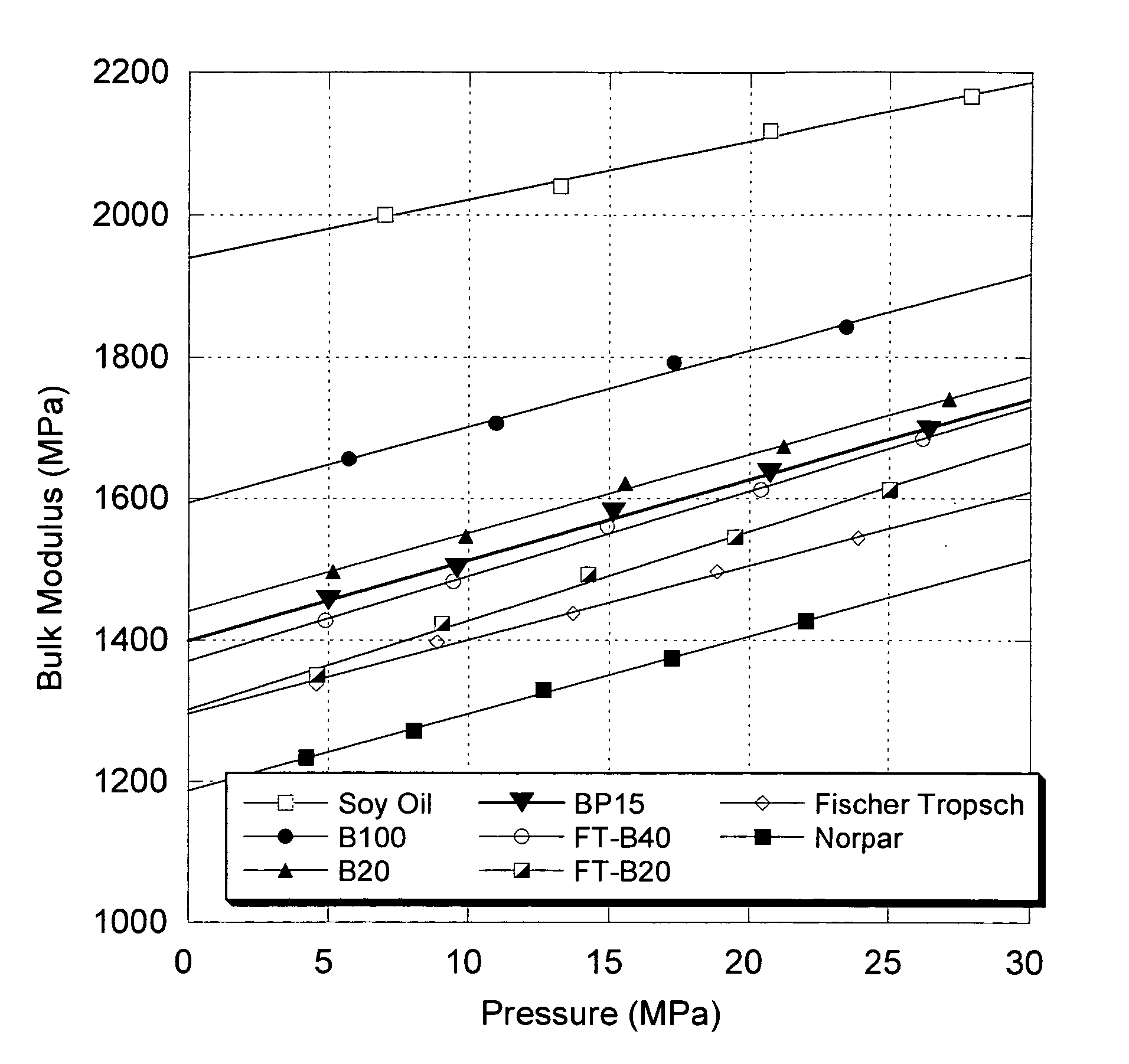

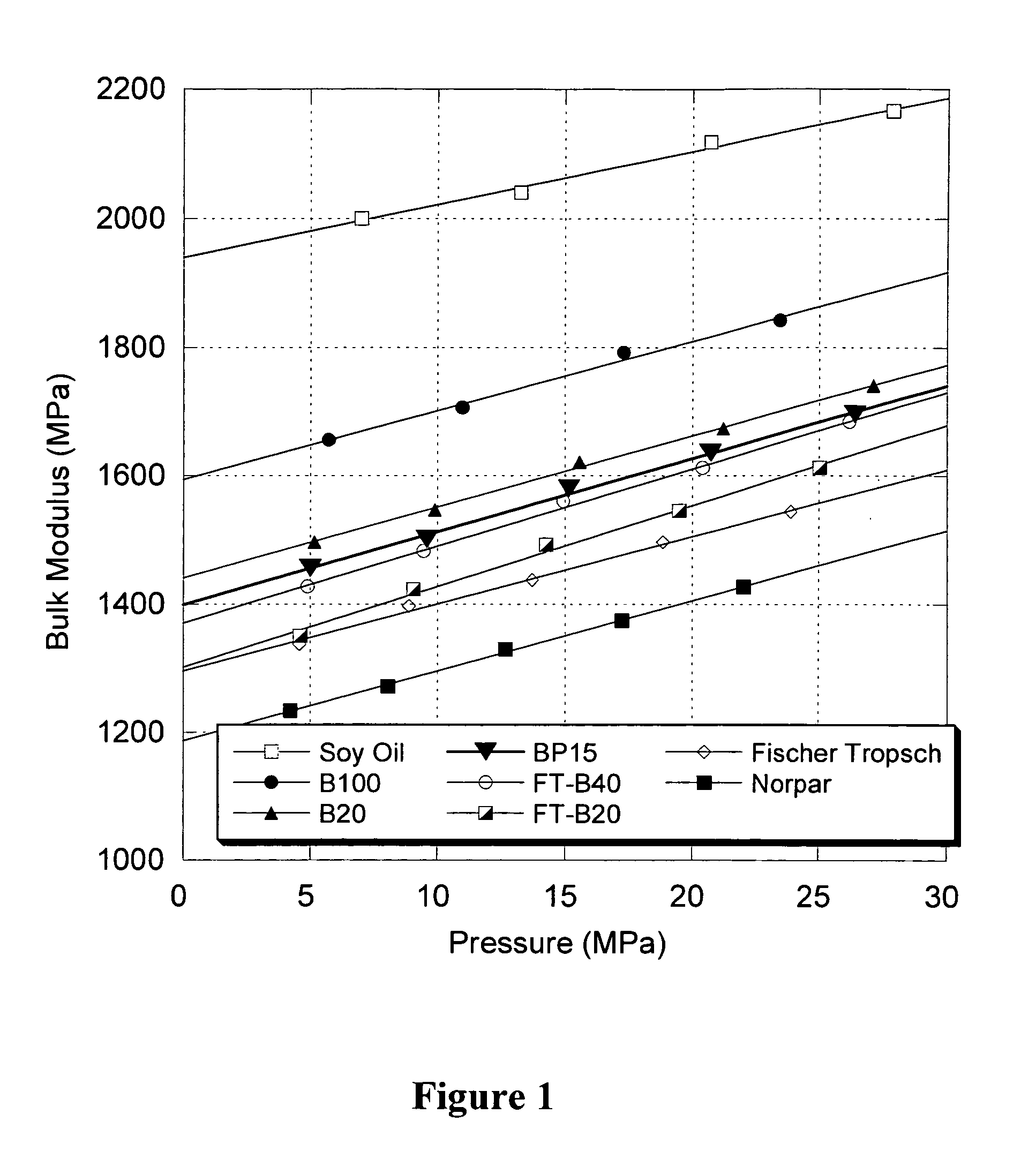

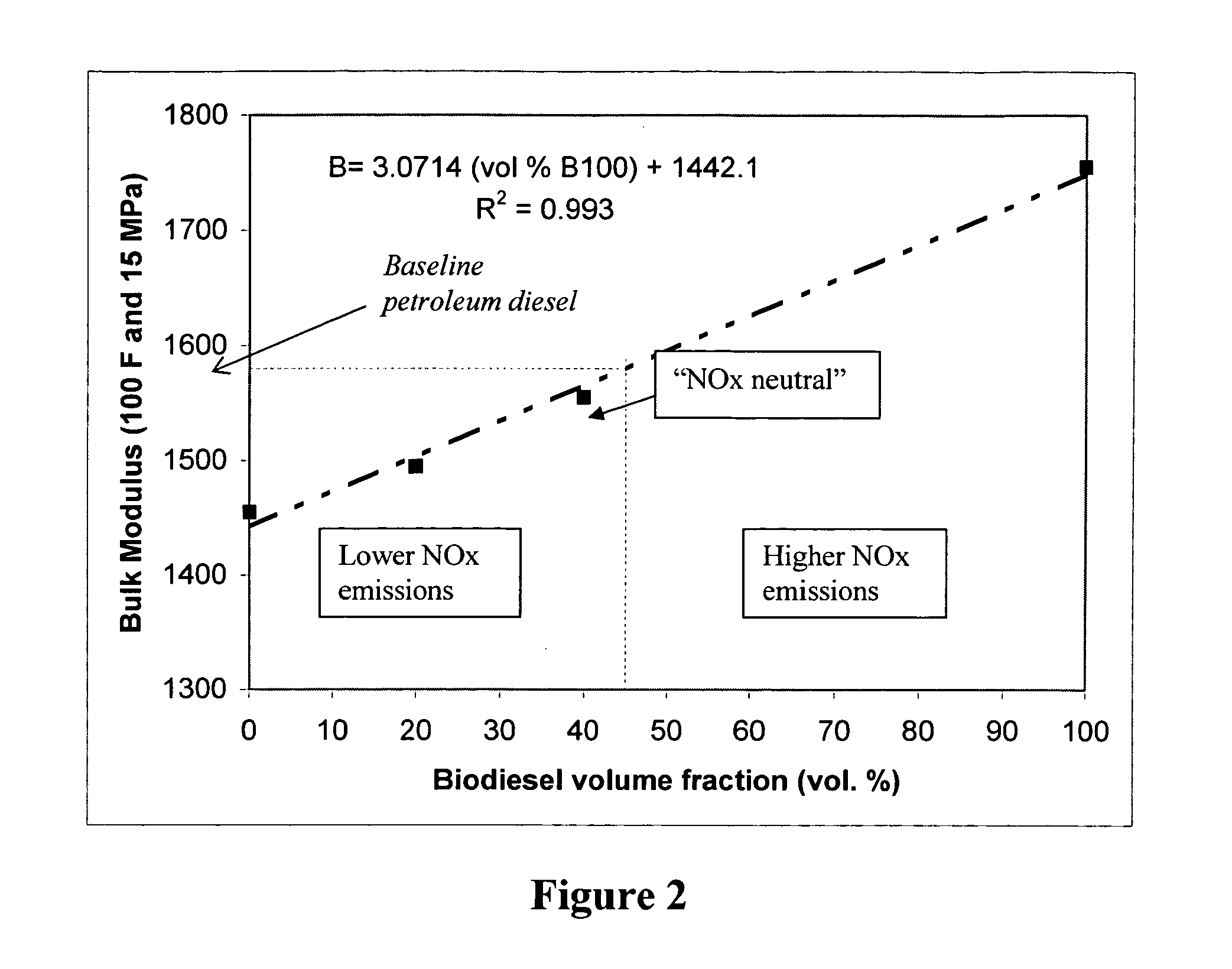

[0121] The interaction between the bulk modulus of compressibility of various fuel samples and their effect on fuel injection timing was examined. The fuels considered ranged from biodiesel B100 (as methyl soyate, i.e., the methyl ester of soybean oil), unrefined soybean oil, paraffinic solvent, Fischer-Tropsch derived diesel, and ultra low sulfur diesel fuel. Both the impact on injection timing and the variation in the bulk modulus of compressibility were measured so that correlation between fuel composition, fuel properties and injection timing could be observed and quantified.

[0122] Two different experimental systems were used: a high-pressure viscometer, capable of measuring the bulk modulus of compressibility with the use of a pycnometer; and a highly instrumented, single-cylinder direct injection (DI) diesel engine, with an accompanying spray visualization chamber. The bulk modulus of various fuels was measured, and corresponding measurements were made of the impact of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk modulus | aaaaa | aaaaa |

| bulk modulus | aaaaa | aaaaa |

| bulk modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com