Patents

Literature

84 results about "Biodiesel feedstock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

InactiveCN101280328AReduce consumptionReduce releaseFatty acid esterificationUnicellular algaeBiodiesel feedstockOil and grease

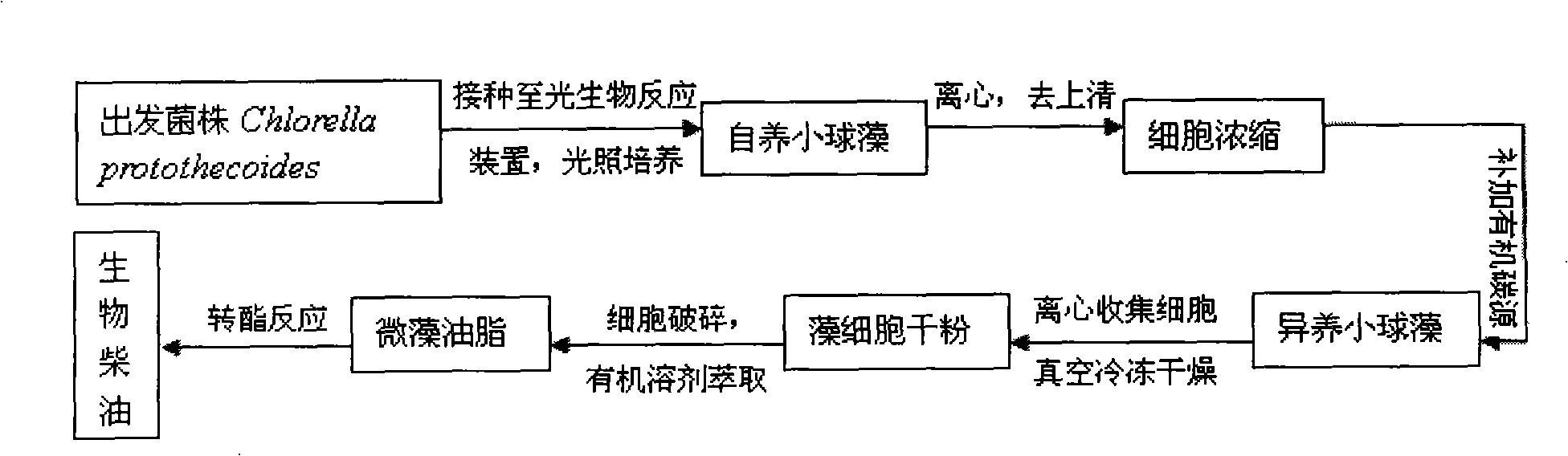

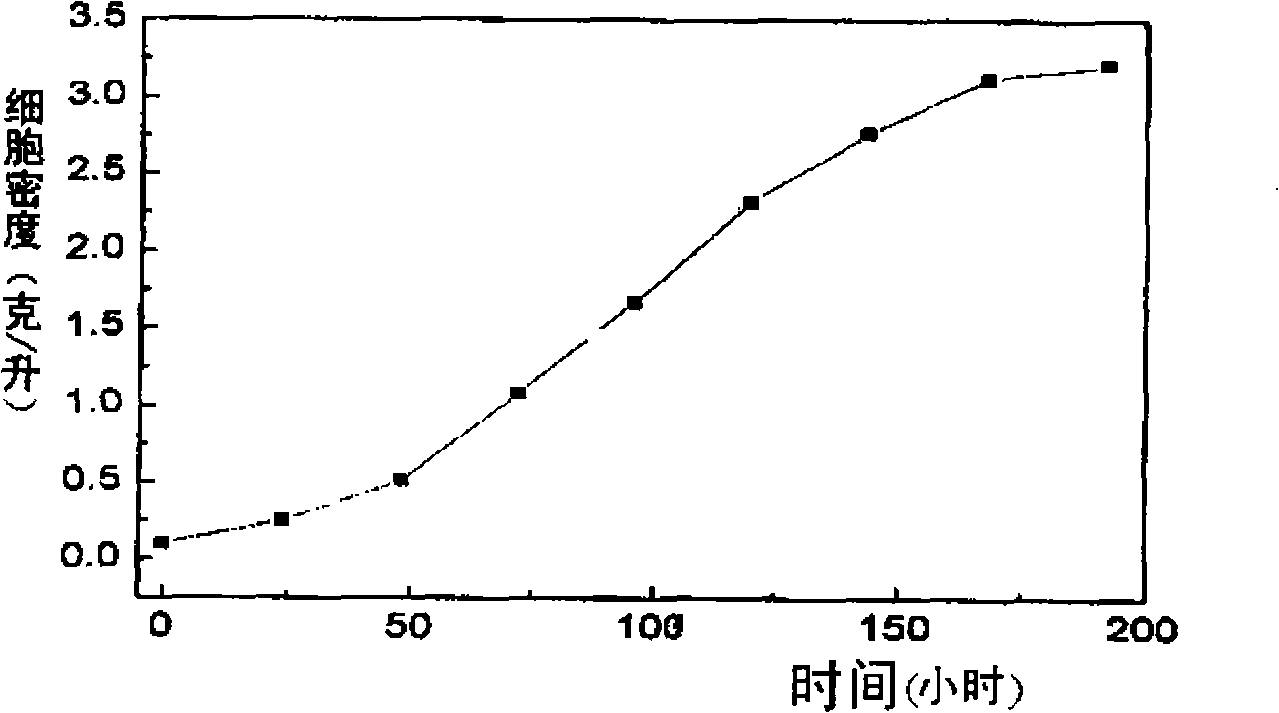

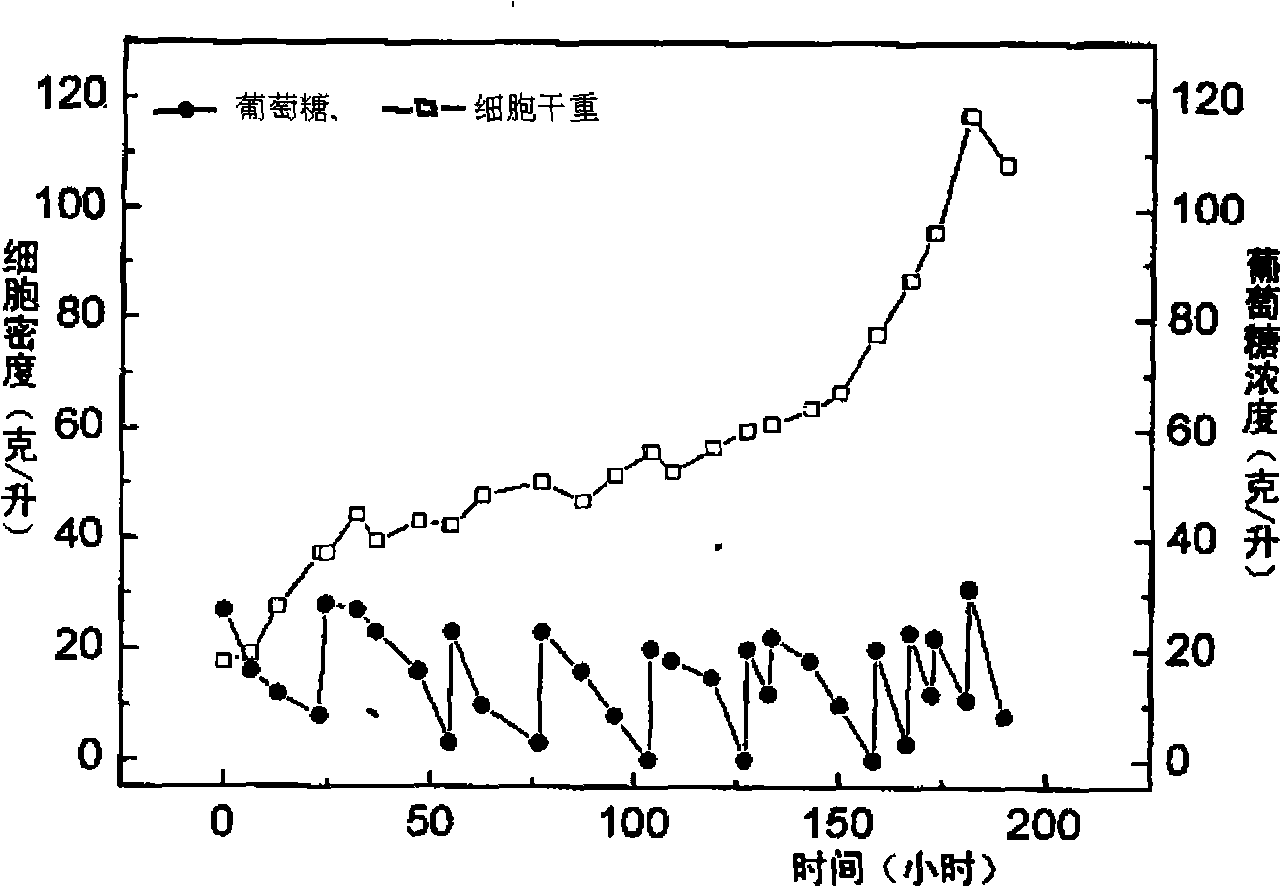

The invention discloses a method for producing biological diesel oil by two steps of culture of chlorellas, namely, autotrophy and heterotrophy, which belongs to the renewable biological energy field. Concentrated autotrophic algae is put into a fermentation tank to perform heterotrophic growth from the processes of autotrophic culture, cell concentration and fermentation pollution controlling of the chlorellas, to ensure the chlorellas to be synthesized into neutral fat. Effective feeding strategy is established to ensure the fat to be synthesized into optimal after the optimization of the fermentation conditions and the process control. The biomass can reach 108g.L-1, and the grease content can reach 52 percent of cell dry weight. After the culturing is finished, biological diesel oil can be prepared after extracting algal oil and transesterification reaction. The cell concentration technology adopted by the invention can effectively avoid the problem of light restriction during the high density culture process Not only is the carbon dioxide emission reduced, but also the organic carbon source consumption is reduced, thus the preparation cost of the biological diesel oil material is saved. The whole technical line is environmental friendly, high efficient, and can meet the industrial application requirements of the microalgae biological diesel oil.

Owner:TSINGHUA UNIV

Method for producing biodiesel by high-density fermentation of heterotrophic chlorella

InactiveCN101230364ALow raw material costOptimizing conditions for heterotrophic fermentationFatty acid esterificationUnicellular algaeBiodiesel feedstockBiodiesel

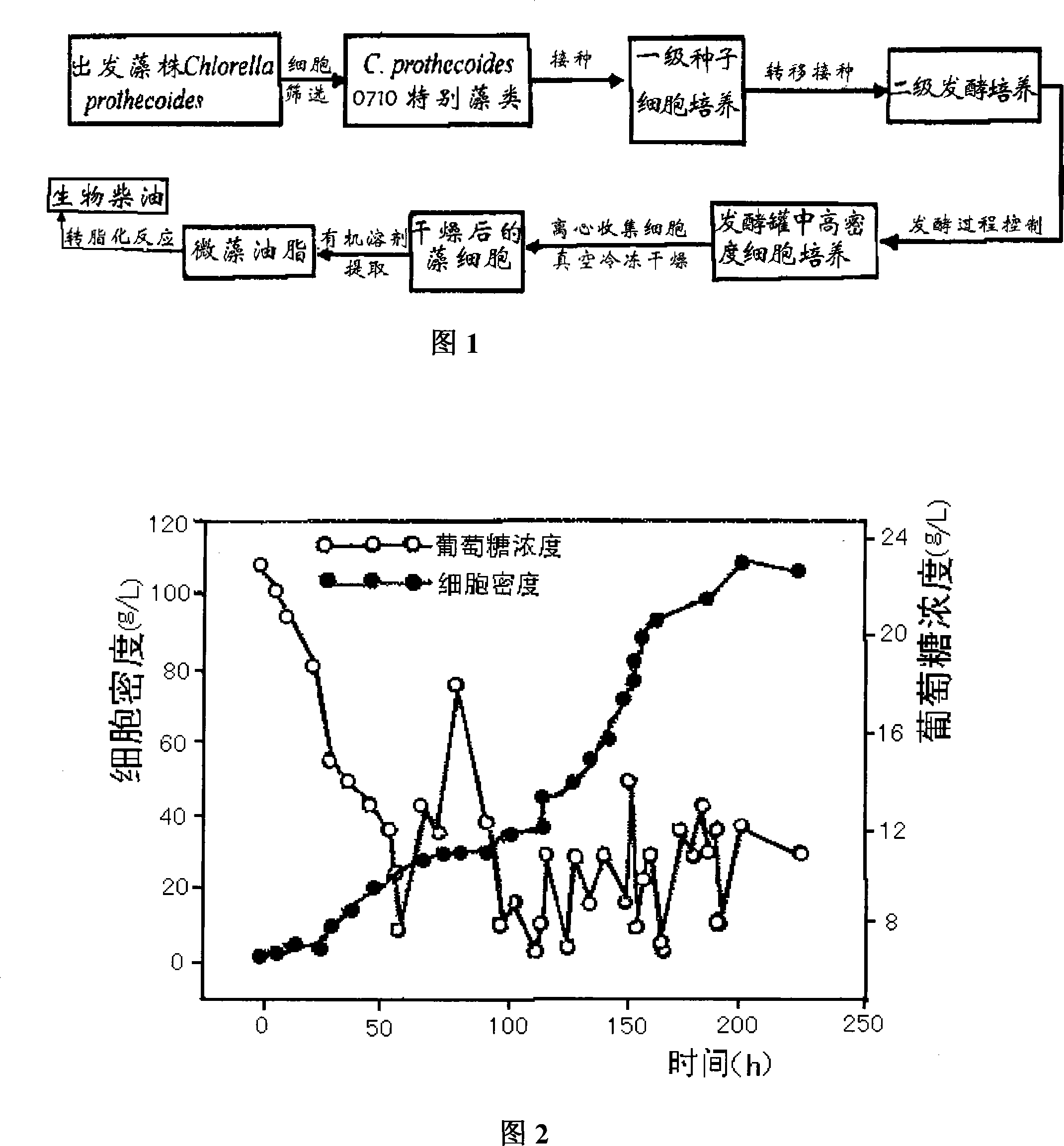

The invention discloses a method of producing bio-diesel by fermenting the heterotrophic chlorella in high density which belongs to the renewable biological energy field. The method uses the heterotrophic chlorella fermented in high density in the bio-reactor as a raw material, which screens the chlorella species having high growth rate and high oil content, directly inoculates into the bottle as the first-class germ to culture then transfers to the fermentation cylinder to undergo the second-glass high density fermentation; the reaction condition is then optimized, and the process is controlled; the culture containing the carbohydrate is dripped to provide the nutrition for the cell growth, therefore the heterotrophic chlorella cells cultured in high density with density of 108g / L and oil content of 61 percent are separated, collected and dried; the algae oil is extracted, and the bio-diesel is produced by transesterification reaction; the invention reduces the cost for the raw material of bio-diesel, and satisfies the demand of industrialized application of producing bio-diesel by heterotrophic chlorella cells, therefore the technique of the invention becomes an economical and effective way of making oils from bio-diesel materials.

Owner:TSINGHUA UNIV

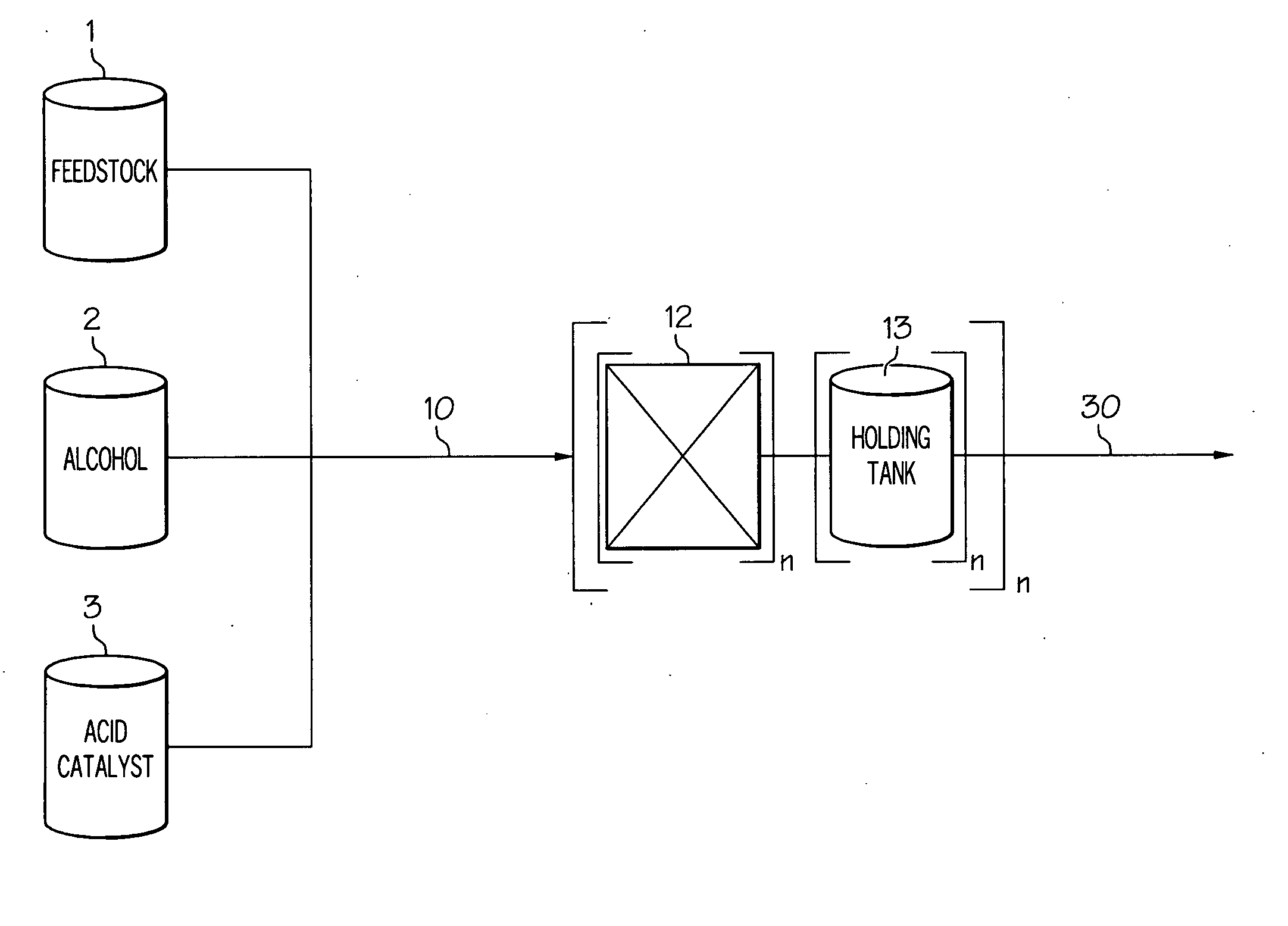

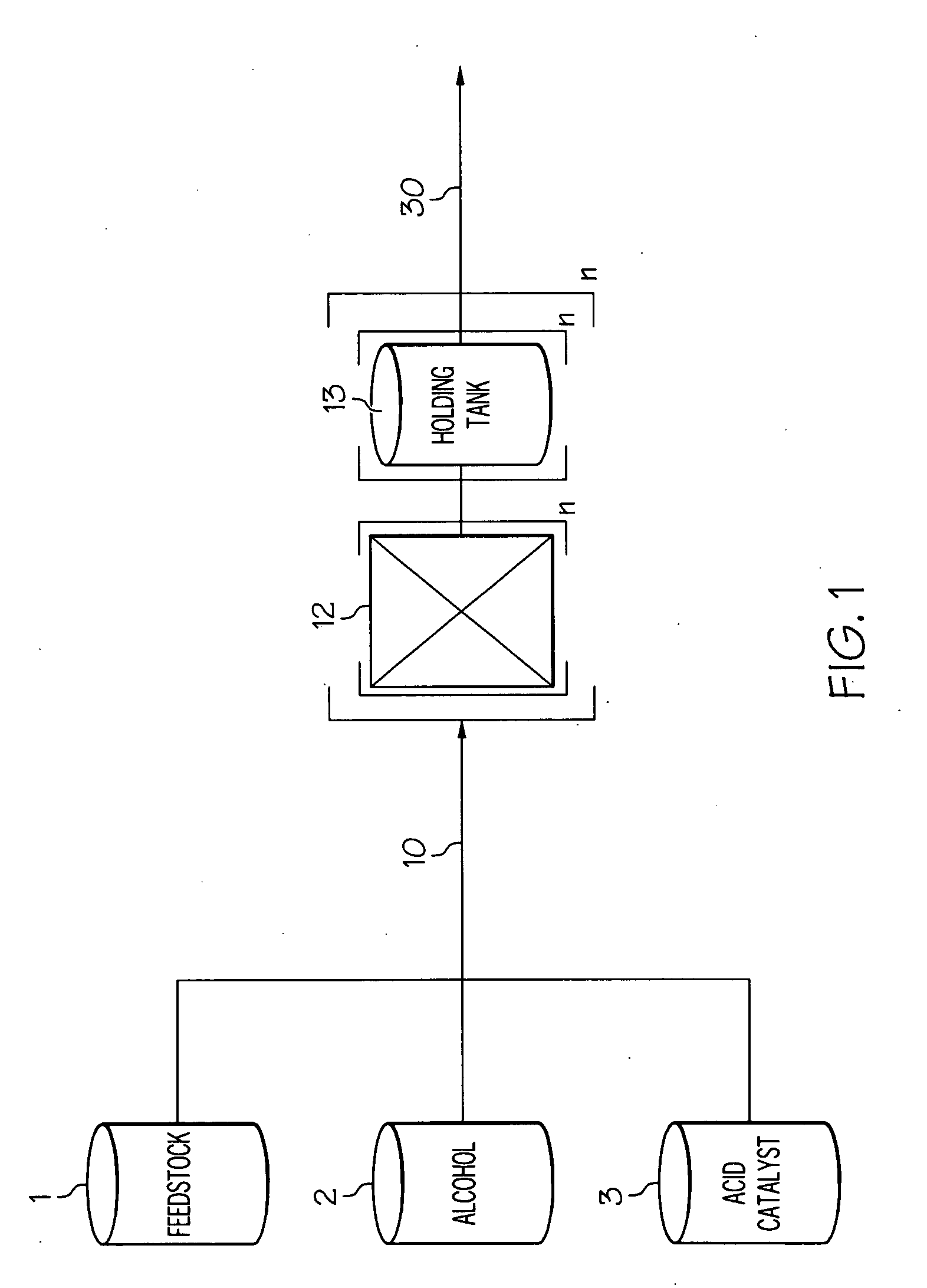

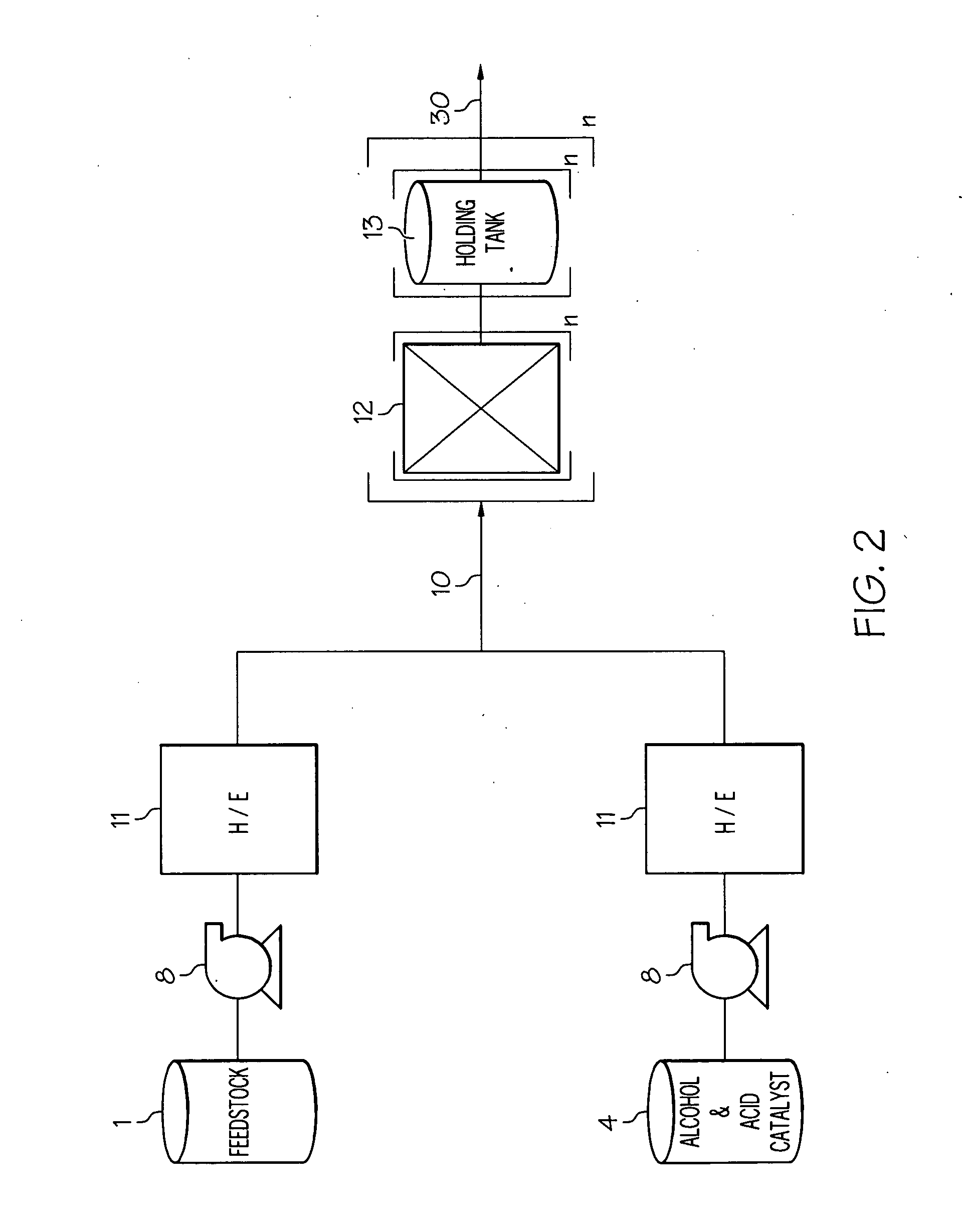

Method for reducing free fatty acid content of biodiesel feedstock

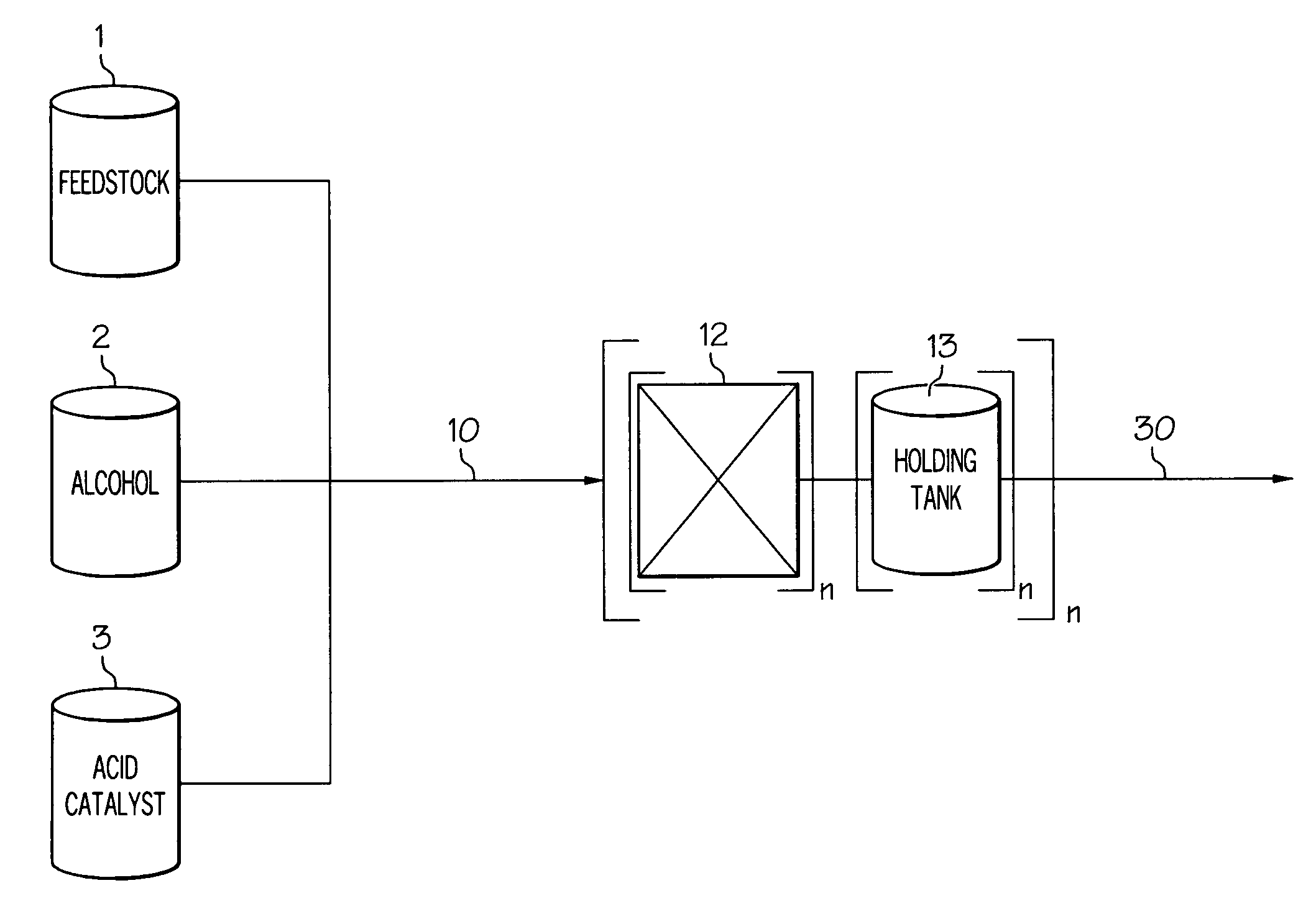

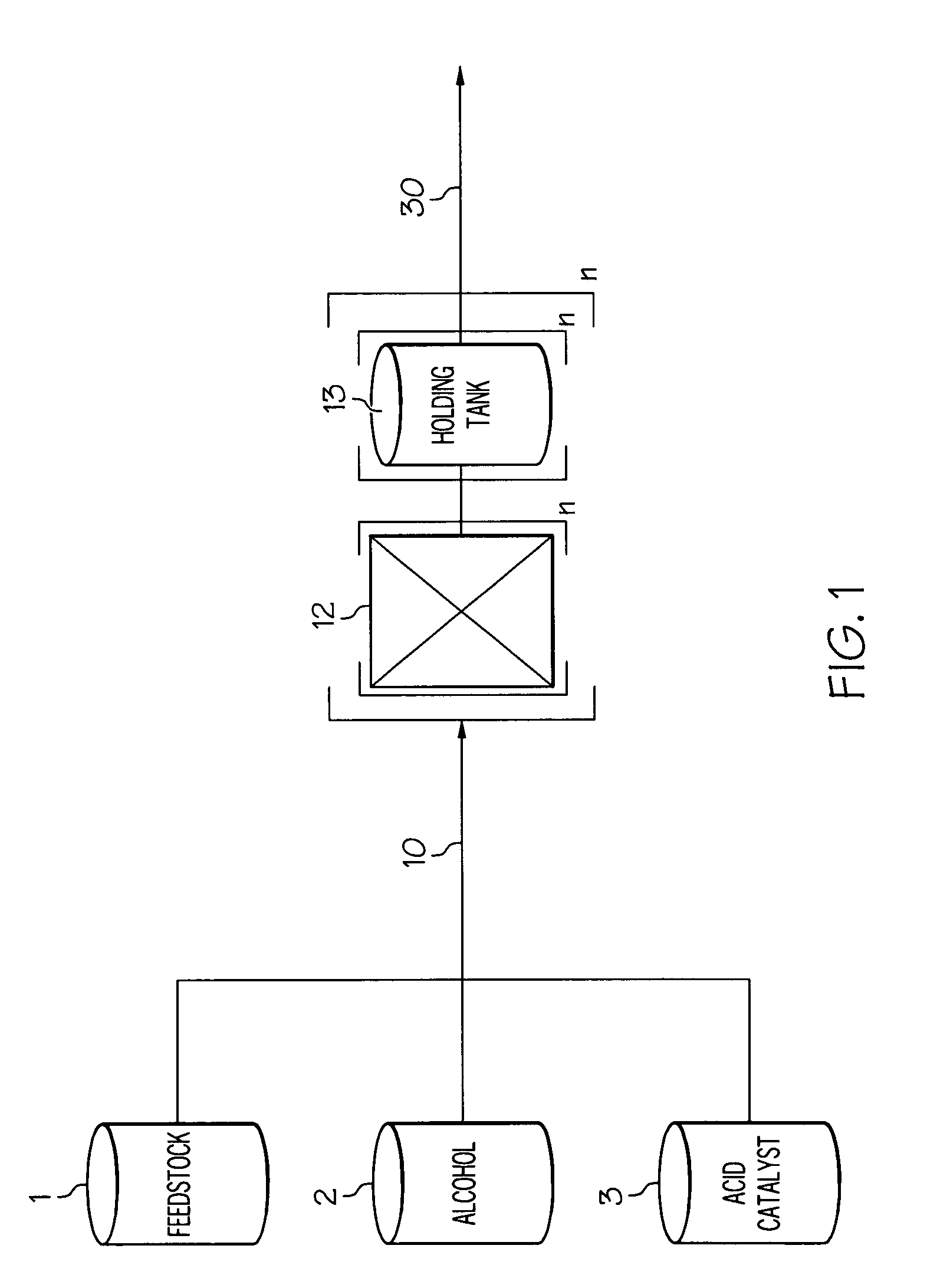

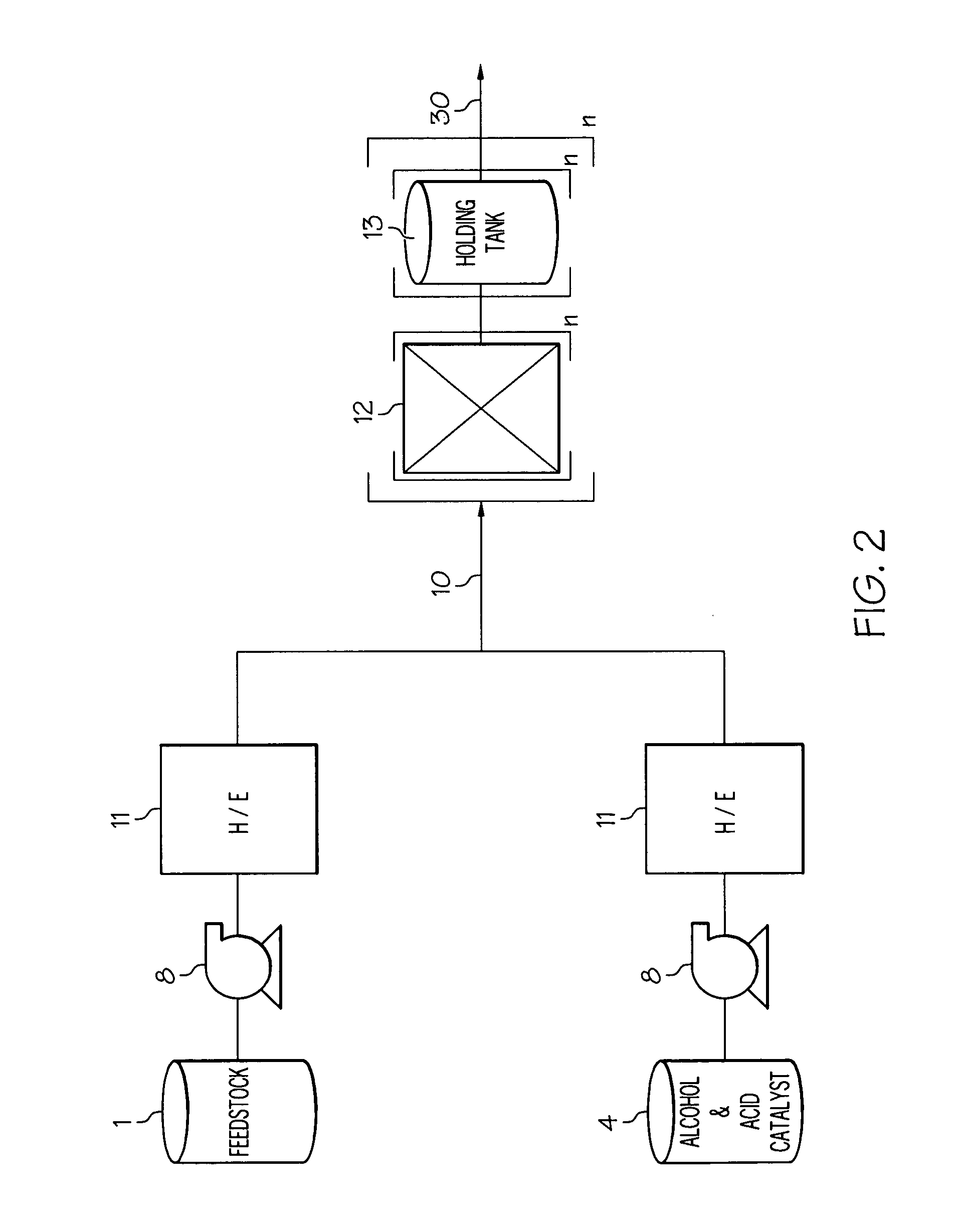

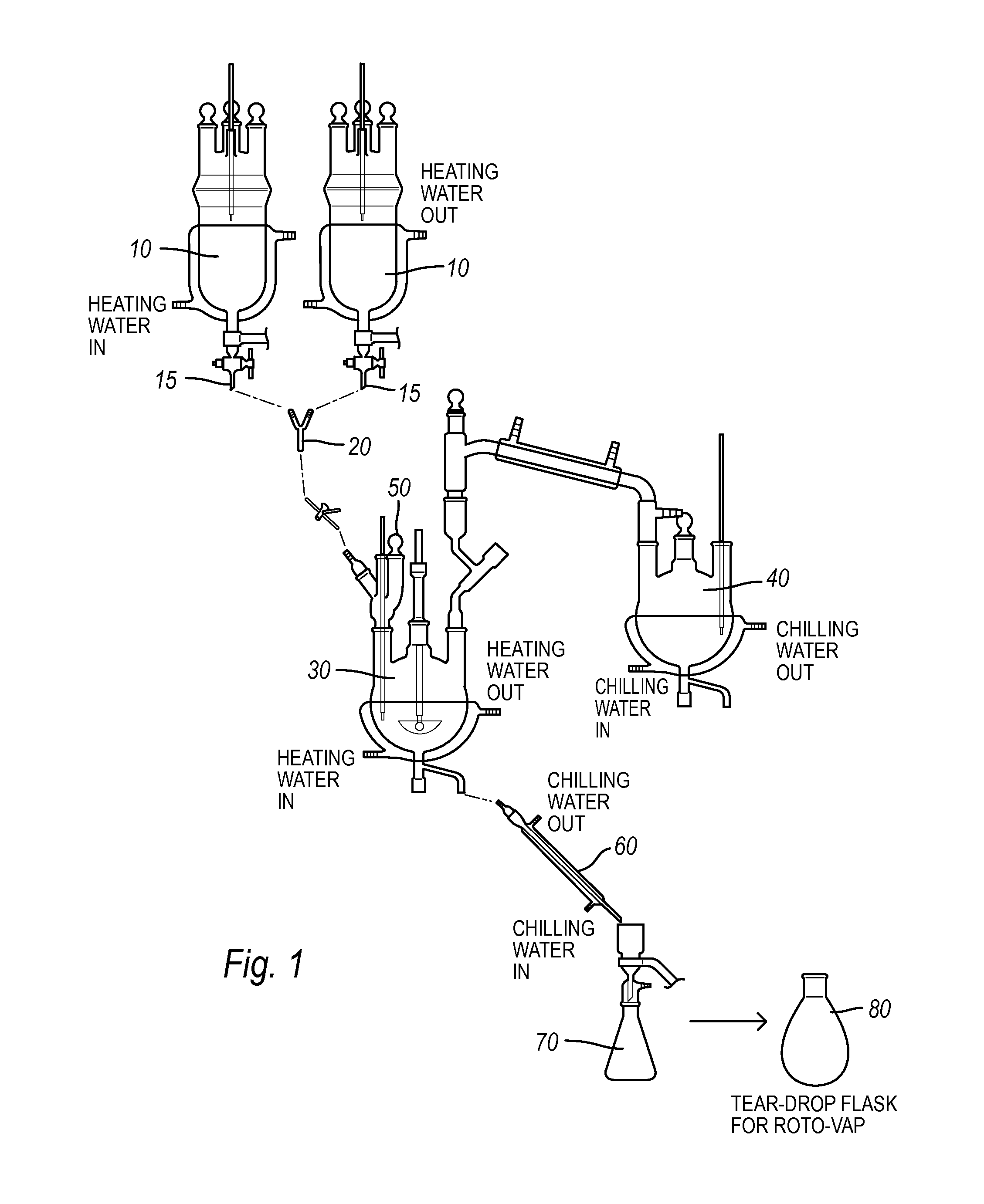

InactiveUS20090038210A1Reduce decreaseReduce free fatty acid contentFatty oils/acids recovery from wasteFatty acid esterificationBiodiesel feedstockCavitation

A method comprising applying controlled flow cavitation apparatuses and holding tanks to a pretreatment process in order to reduce the free fatty acid content of a biodiesel feedstock. A feedstock comprising a high content of free fatty acids can be passed through controlled flow cavitation apparatuses and holding tanks at a velocity capable of generating hydrodynamic cavitation zones and subsequent dwell times where the free fatty acid content can be reduced to below 2%.

Owner:ARISDYNE STSTEMS INC

Oleaginous yeast strain and method for preparing biological oil using the same

InactiveCN101434912APromote growthHigh oil contentFungiMicroorganism based processesBiodiesel feedstockBiodiesel

The invention relates to an oil-producing yeast strain and a method for preparing biological grease; the oil-producing yeast strain is Trichosporon cutaneum CX1 with the collection No. of CGMCC No. 2527; the method for producing the biological grease by using the oil-producing yeast is as follows: hydrolyzate of stalks is generated after pretreatment and the hydrolysis of crop stalks; a basic inorganic salt component is added in the hydrolyzate, and the oil-producing yeast can utilize sugar and other organic matters in the hydrolyzate for growth and metabolism, thereby generating the grease; the generated grease is stored in cells, and then the biological grease is obtained by extracting the grease in the cells. The invention has the advantages that the composition of the generated grease is similar to vegetable oil, and the grease can be used as the raw material for producing biodiesel; compared with the existing other processes, the invention greatly expands the sources of the grease raw material of the biodiesel and significantly reduces the costs of the raw material grease of the biodiesel.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for reducing free fatty acid content of biodiesel feedstock

InactiveUS7935157B2Fatty oils/acids recovery from wasteFatty acid esterificationBiodiesel feedstockCavitation

A method comprising applying controlled flow cavitation apparatuses and holding tanks to a pretreatment process in order to reduce the free fatty acid content of a biodiesel feedstock. A feedstock comprising a high content of free fatty acids can be passed through controlled flow cavitation apparatuses and holding tanks at a velocity capable of generating hydrodynamic cavitation zones and subsequent dwell times where the free fatty acid content can be reduced to below 2%.

Owner:ARISDYNE STSTEMS INC

Method for preparing microorganism grease by fermenting steam-exploded straw hemicellulose hydrolysate

InactiveCN101148630AIncrease productionImprove use valueMicroorganism based processesFermentationBiodiesel feedstockMicrobial oil

The process of preparing microbial oil with steam blasted stalk hemicellullose hydrolysate includes the following steps: water soaking steam blasted stalk and filtering to obtain the steam blasted stalk hemicellullose hydrolysate, sterilizing, inoculating oil microbe seed liquid in 1-5 vol%, fermentation at 25-32 deg.c for 5-8 days, filtering to obtain mycelium and stoving, and extracting with organic solvent to obtain the microbial oil. The microbial oil containing high unsaturated fatty acid is applied in producing biodiesel oil. The present invention has best utilization of stalk material and low production cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

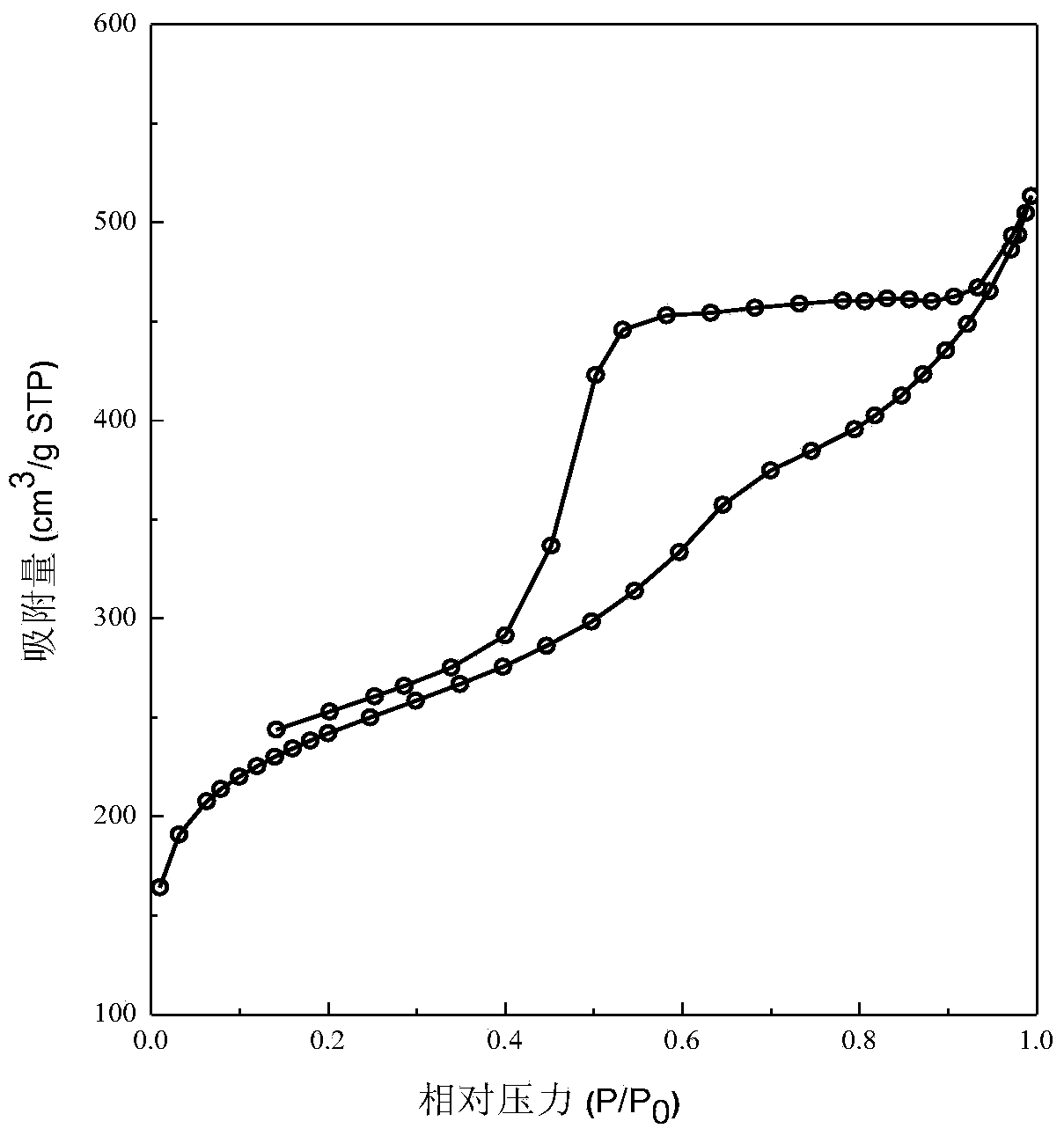

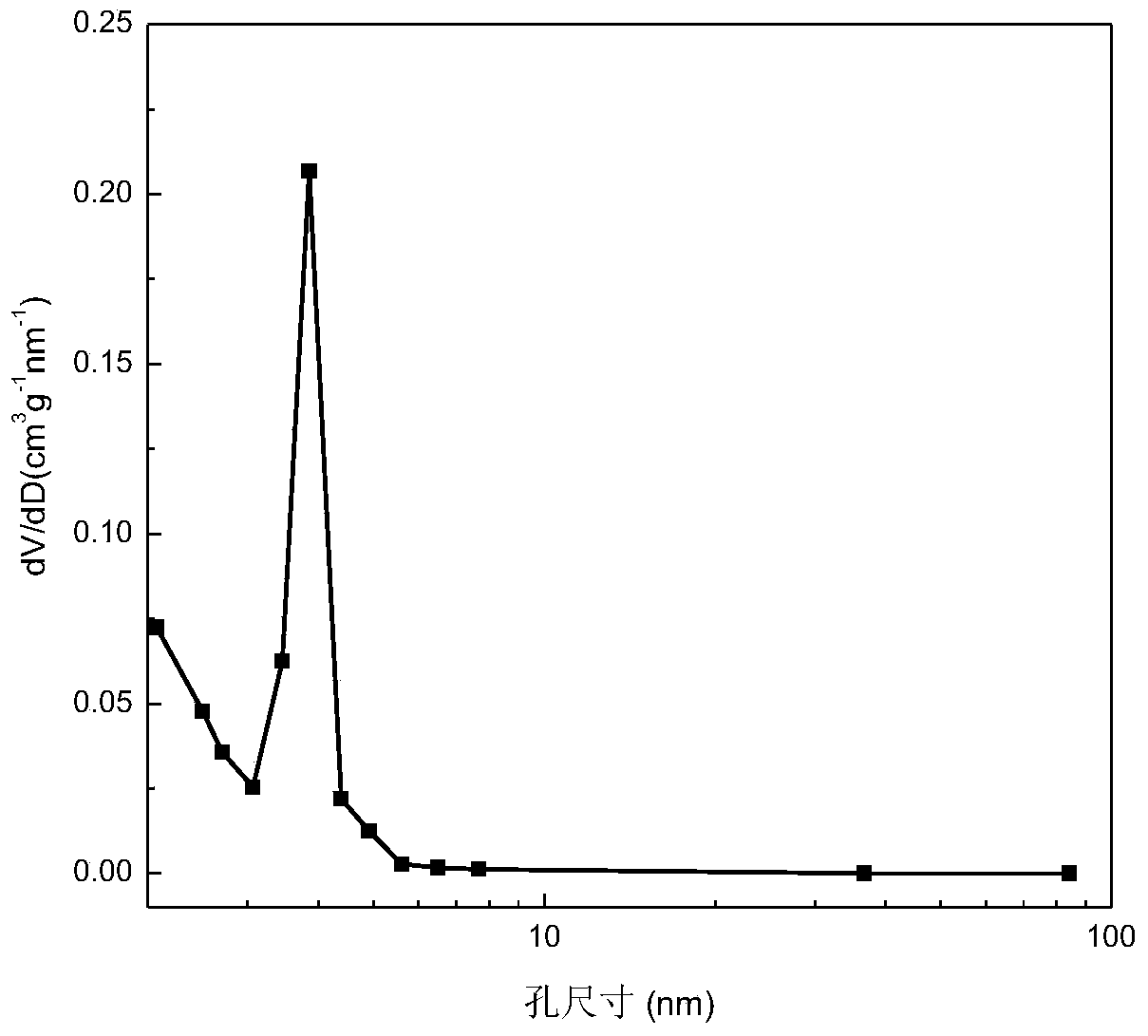

Preparation method for mesoporous carbon-based solid acid catalyst and application of mesoporous carbon-based solid acid catalyst

ActiveCN103691454ALarge specific surface areaLarge pore volumeFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodiesel feedstockSolid acid

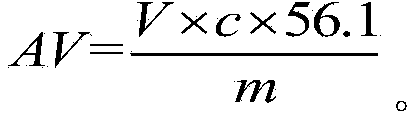

The invention relates to a preparation method for a mesoporous carbon-based solid acid catalyst and application of the mesoporous carbon-based solid acid catalyst. Under an acidic condition, saccharides or oligomerization phenolic aldehyde serving as a carbon source is dissolved through supercritical carbon dioxide serving as a solvent to perform pouring filling on a silicon dioxide template according to the special property of supercritical fluid; under inert atmosphere, the silicon dioxide template is carbonized at high temperature to obtain a carbon-silicon composite; a silicon dioxide casting is removed through a strong acid or strong alkaline solution; then the mesoporous carbon-based solid acid catalyst is obtained through acid modification. The mesoporous carbon-based solid acid catalyst prepared by the preparation method disclosed by the invention has a regularly ordered mesoporous duct structure with proper intensity, is larger in specific surface area and the pore volume and is higher in acid density. The catalyst is used for catalyzing the esterification acid reduction reaction of biological diesel raw materials; after the reaction, the oil acid value is reduced to be smaller than 2 mgKOH / g, and excellent solid acid catalysis performance is achieved.

Owner:TIANJIN UNIV

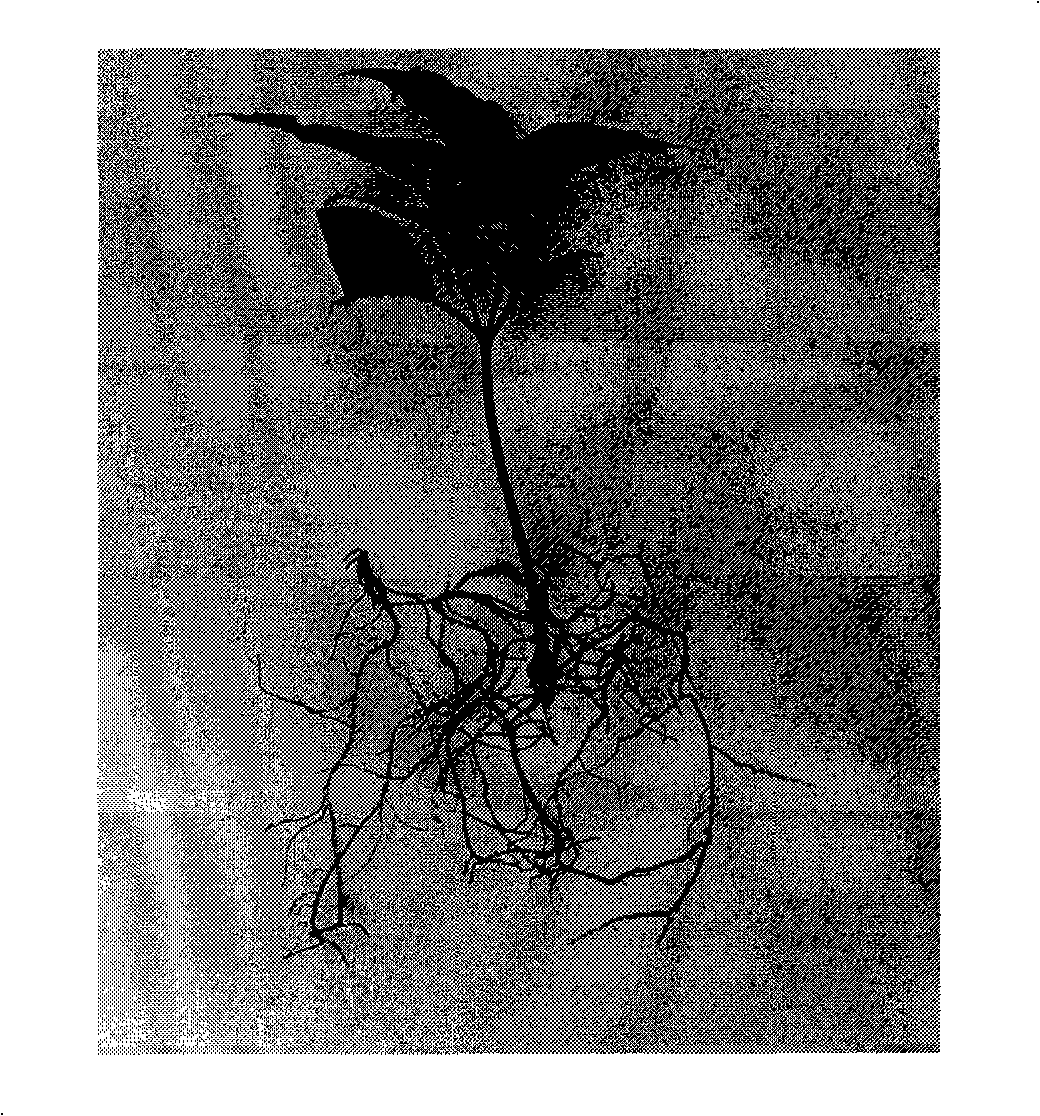

Cuttage replication method on tree without bark

InactiveCN101341827ABreed fastEasy constructionCultivating equipmentsSoilless cultivationBiodiesel feedstockReplication method

The invention relates to a fast reproduction technology of cornus wisoniana. The fast reproduction method of cornus wisoniana provided by the invention comprises the following process: (1) the selection of cutting materials: semi lignified cutting materials are selected; (2) the hormone pre-treatment of cutting materials; (3) the preparation of sticking matrix; (4) the sticking of the cutting materials: the cutting materials after hormone pre-treatment are stuck in the matrix, and disinfectant is poured; (5) seedling period management. The fast reproduction method of cornus wisoniana provided by the invention can realize the fast reproduction of the cornus wisoniana, and plays a very important role and is significant in speeding up the cornus wisoniana excellent clone promotion and promotes the construction of biological diesel raw material construction.

Owner:HUNAN ACAD OF FORESTRY

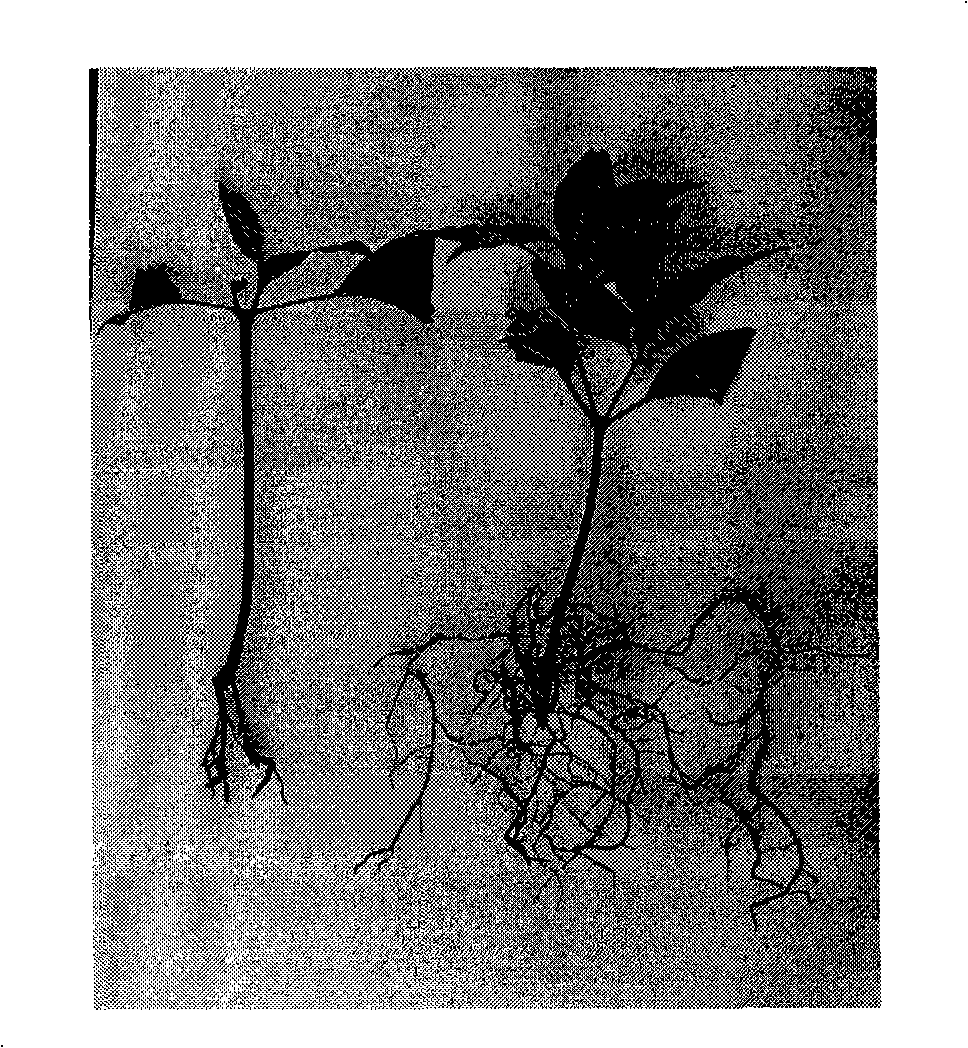

Method for carrying out asexual cuttage propagation on vernicia fordii

InactiveCN102138482AHigh rooting rateIncrease the number of rootsCultivating equipmentsBiodiesel feedstockVernicia fordii

The invention discloses a method for carrying out asexual cuttage propagation on vernicia fordii, belonging to the technical field of asexual propagation of plants. The method comprises the following steps of: (1) branch collecting time; (2) seedbed preparation and cuttage environment; (3) selection of cuttings and treatment of cutting branches; (4) pretreatment of a growth regulator; (5) cuttage; and (6) management after cuttage. The method provided by the invention is simple and feasible, has the advantages of low cost and short cycle and can conduce to realization of effective and rapid asexual propagation of the vernicia fordii. The method has the beneficial effect of solving the problem that the vernicia fordii can not root during cuttage, and has very important effects on and significance for accelerating popularization of excellent clone of the vernicia fordii and promoting construction of biodiesel raw material forests.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

Method for high yield, prematurity and dwarfing cultivation of jatropha curcas

InactiveCN101663996AImprove site conditionsPromote growthPlant growth regulatorsBiocideBiodiesel feedstockBiodiesel

The invention discloses a biodiesel raw tree, in particular to a method for high yield, prematurity and dwarfing cultivation of jatropha curcas. Plants with excellent biological and economical properties are selected out of numerous wild jatropha curcas or cultivated excellent variant strains; furthermore, by preferential selection, individual system breeding and artificial cultivation, domestication and breeding for many years, the plants are cultivated to excellent tree species; subsequently, by adopting adaptive tests for many years and multi-technologies, the jatropha curcas bears fruits in the transplanting year and can bear fruits more than five times per year; the oil content of the kernel of the jatropha curcas is 58.2-64.4%, the dry seeds per plant is 2-3kg, the yield per Mu in the transplanting year is 200-300kg (equivalent to the output of general wild adult tree after 3-4 years), and the yield per Mu can achieve 600-1000kg after growing up.

Owner:北京国林能源科技有限公司

Method for producing microbial grease by fermenting inulin serving as raw material

InactiveCN102417915AExpand sourceLow costBiofuelsMicroorganism based processesBiodiesel feedstockBiodiesel

Owner:HENAN UNIV OF SCI & TECH

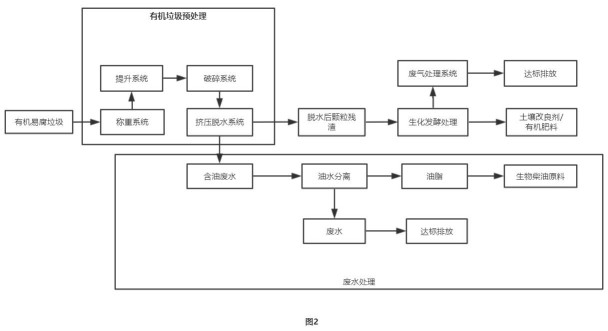

Urban catering pigwash industrialized treatment method

ActiveCN101579684AAchieving processing powerRealize comprehensive utilizationFatty oils/acids recovery from wasteFood processingBiodiesel feedstockSocial benefits

The invention relates to an urban catering pigwash industrialized treatment method which can effectively solve the problems that urban pigwash is used to comprehensively produce biodiesel raw materials and fodder raw materials and prevented from polluting the environment and wasting the resource; the technical proposal provided by the invention comprises the following steps: small and big impurities are firstly screened from the pigwash, different impurities are separated by a separation device to store separately; the mixture of the pigwash is smashed and washed by water while solid and liquid are separated by centrifugal separation to store separately; after separating solid from liquid, the separated liquid is sent to a centrifugal device to separate oil from water; the separated pigwash oil is used to prepare biodiesel raw materials, and the separated water is recycled; after separating the solid and liquid of the pigwash, the separated solid is shaped into dregs to prepare fodder raw materials, thus realizing the pigwash industrialized treatment. The invention has the advantages that a simple and advanced method is used and the pigwash comprehensive treatment and application is effectively realized, therefore the pollution of the pigwash on urban environment is prevented and the pigwash resource is fully used with enormous economic benefit and social benefit.

Owner:河南华泰粮油机械股份有限公司

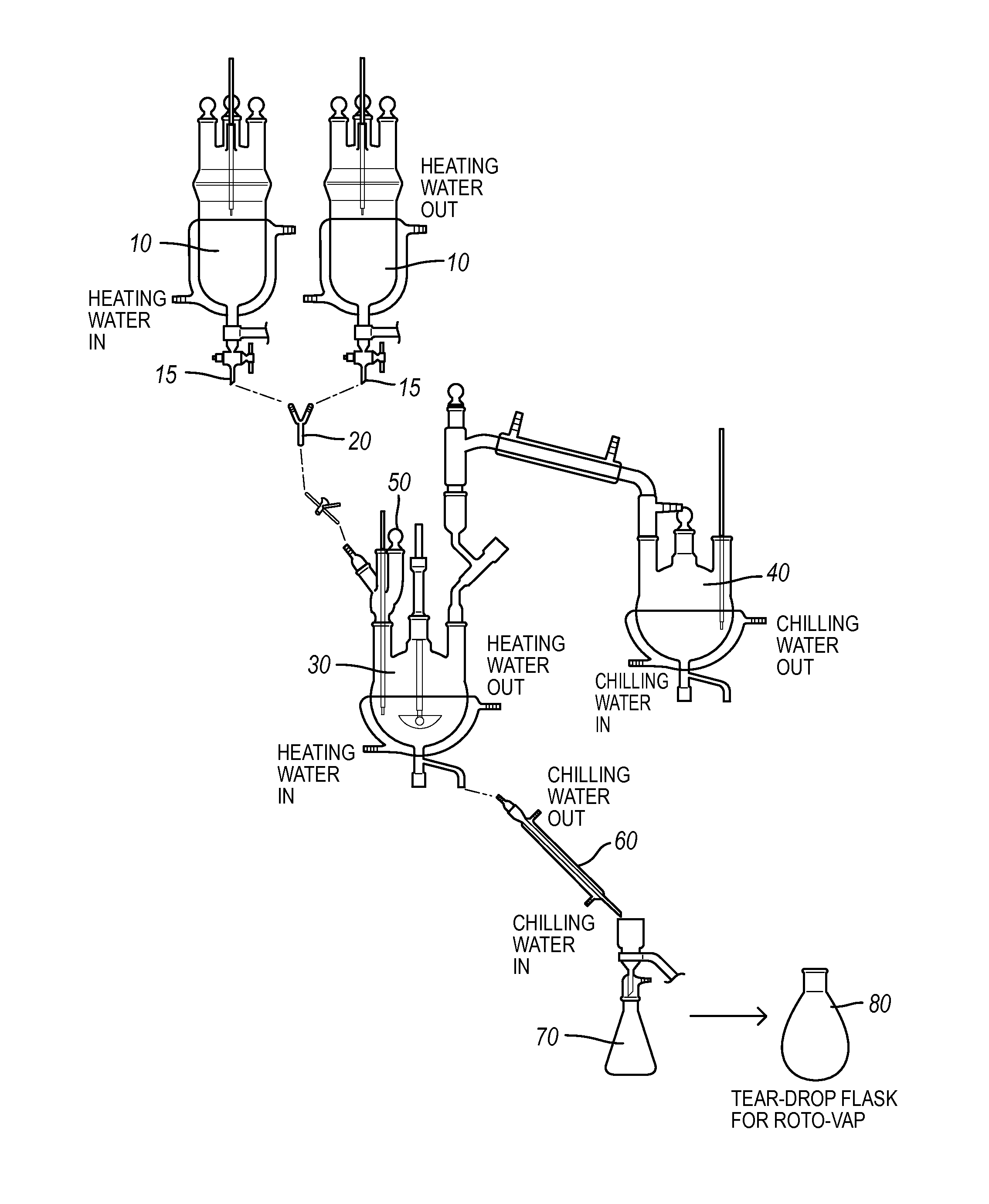

Single step transesterification of biodiesel feedstock using a gaseous catalyst

InactiveUS20110245523A1Improve responseEasy to produceFatty acid esterificationFatty acids production/refiningBiodiesel feedstockTransesterification

Embodiments of the present application provide methods for processing biodiesel from feedstock using a single-step process. The methods can include, for example, use of a gaseous catalyst as part of the esterification / transesterification process. Embodiments of the present application also provide systems for the methods thereof.

Owner:INITIO FUELS

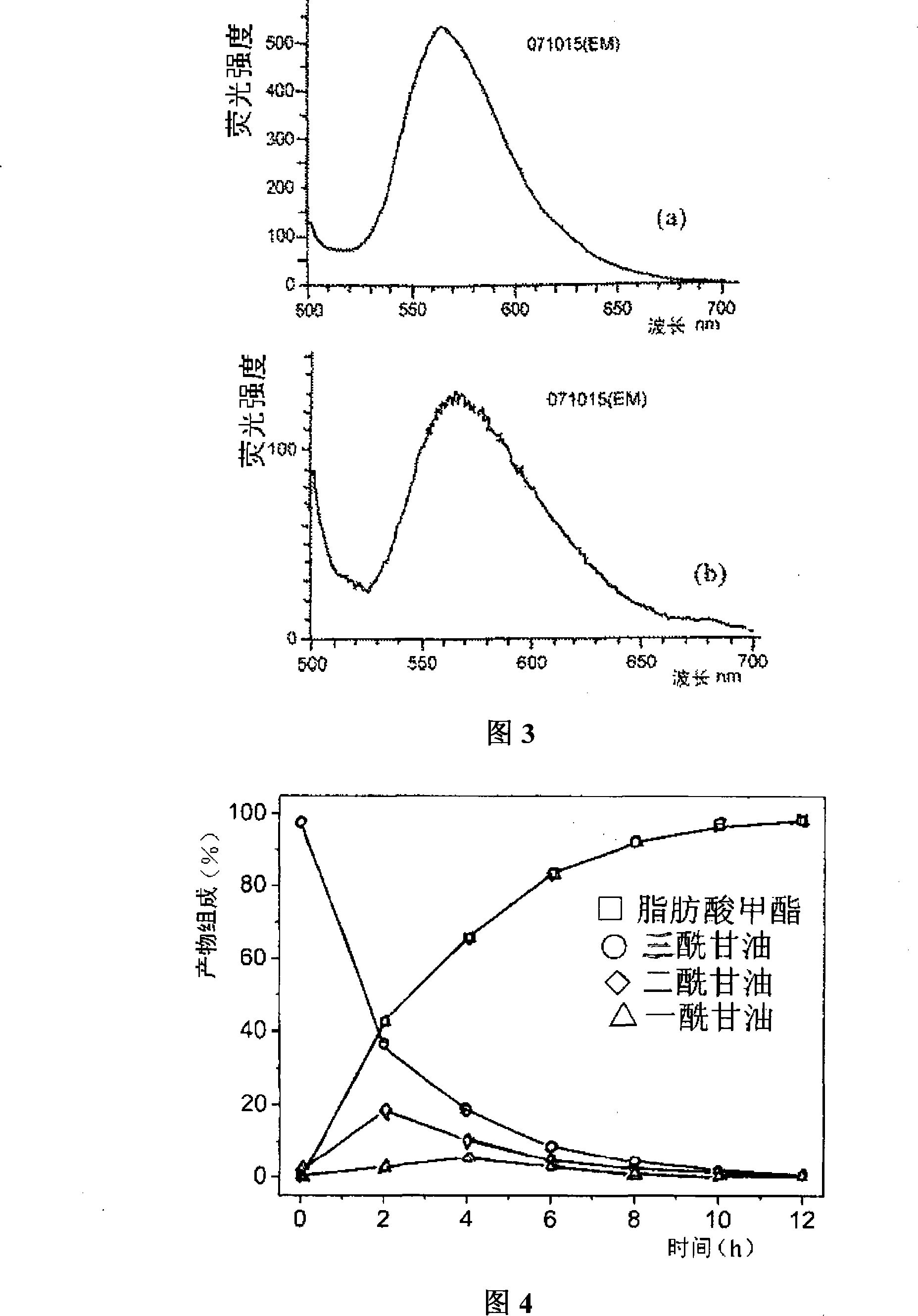

Method for producing diesel oil by esterification deacidification of rice bran oil

InactiveCN102453613AEliminate pollutionImprove refining yieldFatty acid esterificationFatty-oils/fats refiningChemical industryBiodiesel feedstock

The invention relates to a rice bran oil, specifically to a method for producing diesel oil by esterification deacidification of the rice bran oil, and belongs to the technical field of chemical industry. By the adoption of zinc oxide as a catalyst, the rice bran crude oil with high acid value undergoes esterification deacidification and is deacidified into a biodiesel material. The acid value of the rice bran oil can be decreased from 38.14mg / g to 5.17mg / g. Free fatty acid in the rice bran oil can react with glycerin at high temperature under vacuum in the presence of a catalyst to generate triacylglycerol, diacylglyeerol and monoglyceride. According to the chemical principle to design a chemical catalysis method, a lot of free fatty acid in the rice bran crude oil undergoes resterification to generate neutral oil. And simultaneously, the purpose of deacidification is achieved and the pollution of soap stock to the environment is eliminated. Additional loss is greatly reduced. And in the meanwhile, inevitable loss caused by free fatty acid which must be removed during the above chemical alkali refining and physical deacidification refining processes is changed into neutral rice bran grease, so as to raise the refining yield of the grease.

Owner:姚昂

Method for producing biodiesel raw materials from Botryococcus braunii

InactiveCN106929550APromote rapid growthPromote accumulationUnicellular algaeBiofuelsBiodiesel feedstockBiology

The invention discloses a method for producing biodiesel raw materials from Botryococcus braunii. The method includes the steps of (1), seed culture, (2), seed collection, (3), photoautotrophic culture, (4), microalgae harvest and (5) grease extraction. The method is used for culturing algae cells capable of controlling the oil content and the high-grease quality through introduction of indexes for representing the biodiesel quality, such as a cetane number and a ratio of unsaturated fatty acid to saturated fatty acid in terms of a culture condition and a culture technology of microalgae, and the grease content of the finally obtained algae cells is above 30%, a CN value is stabilized above 50, and the ratio of the unsaturated fatty acid to the saturated fatty acid between 1.5 and 2.5. The method is capable of effectively controlling the output and the quality of biodiesel from source raw materials and meets the application requirements of microalgae biodiesel industrialization.

Owner:PETROCHINA CO LTD

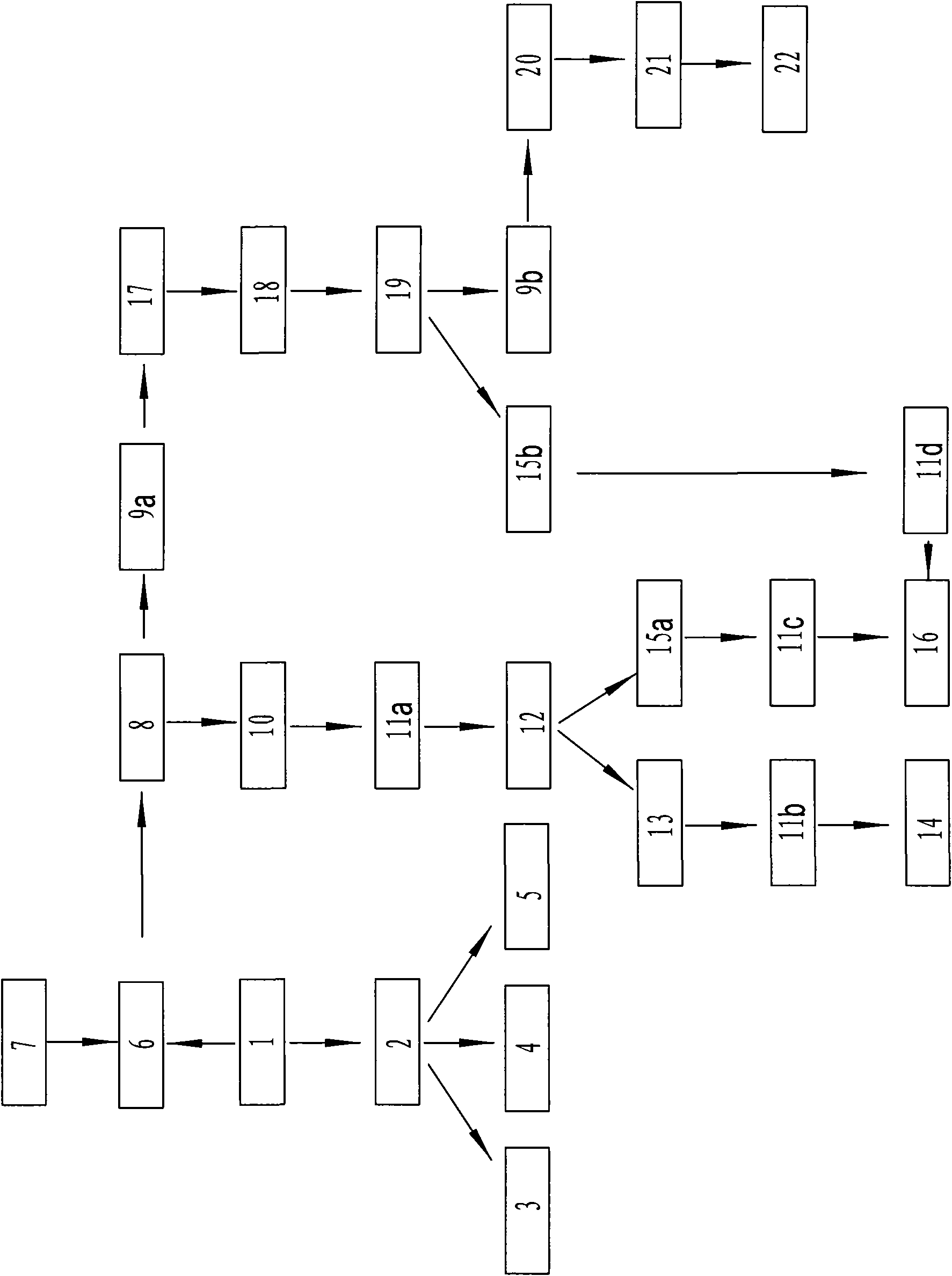

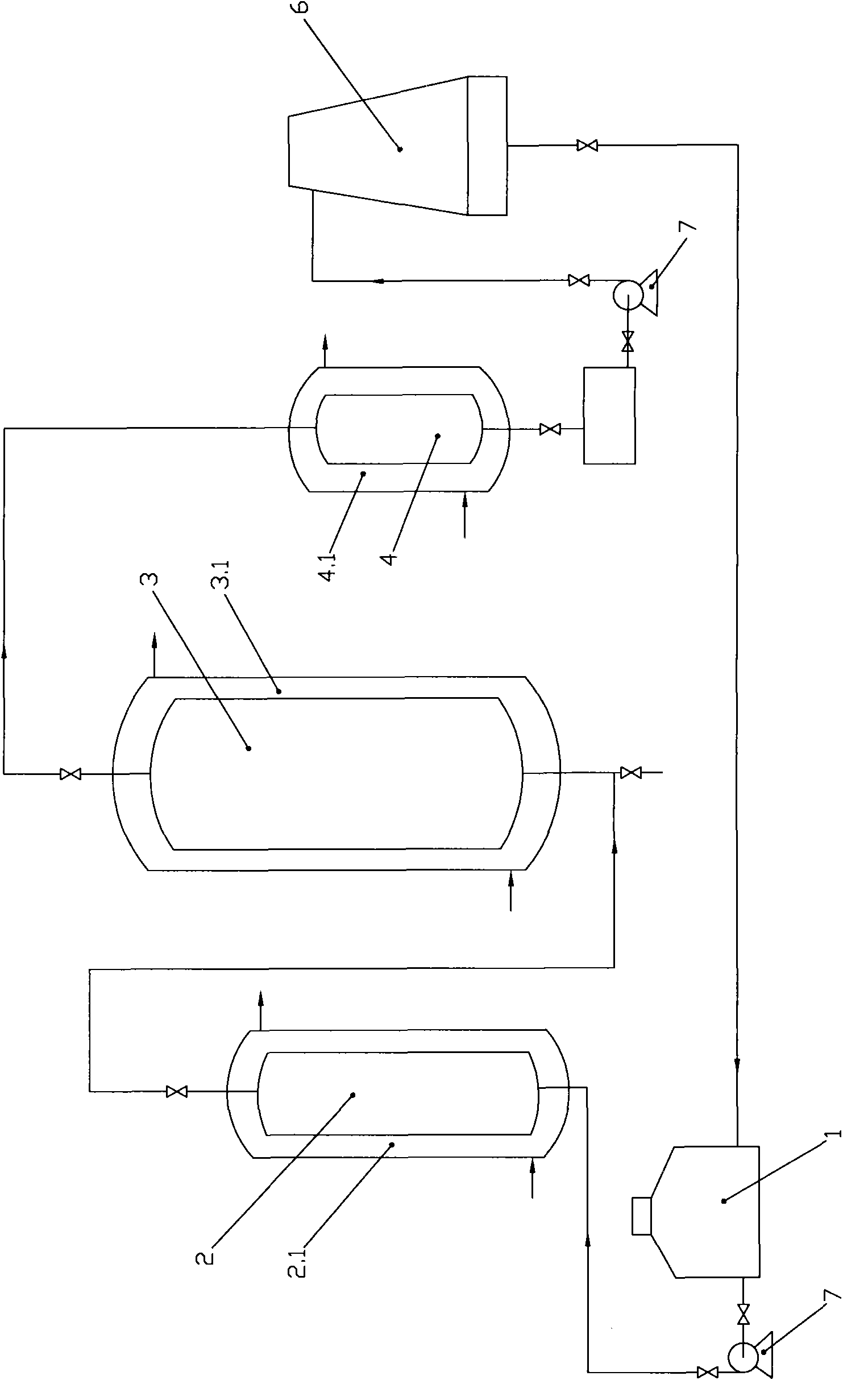

Gaseous phase circulation production method for biodiesel and device therefor

InactiveCN101654624AReduce consumptionIncrease temperatureFatty acid esterificationBiofuelsProduction rateBiodiesel feedstock

The invention discloses a gaseous phase circulation production method for biodiesel, which comprises that: firstly, a biodiesel raw material is sent into a reaction kettle, and the biodiesel raw material is heated while a catalyst is added into the reaction kettle; and then, methanol vapor after vaporization is injected into the reaction kettle, and the methanol vapor and the raw material are subjected to ester exchange reaction to generate the biodiesel. The invention also discloses a device for implementing the gaseous phase circulation production method for the biodiesel, which comprises the reaction kettle; a lower part of the reaction kettle is connected with an upper part of a methanol generator; an upper part of the reaction kettle is connected with a cooler which is connected witha methanol recovery tower through a storage tank; the methanol recovery tower is connected with a methanol storage tank through a pump; and the methanol storage tank is connected with a lower part ofthe methanol generator. The gaseous phase circulation production method improves the temperature in the reaction kettle so as to shorten the esterification time, improve the oil rate of the biodiesel,reduce ethanol consumption by 50 percent and greatly improve productivity.

Owner:庞汝瑞 +1

Microemulsified biodiesel and preparation method thereof

InactiveCN102417840AWide range of sources, safe and non-toxicSimple recipeLiquid carbonaceous fuelsBiodiesel feedstockBiodiesel

The invention discloses microemulsified biodiesel and a preparation method thereof. The microemulsified biodiesel comprises: by weight, 88 to 92% of biodiesel, 1.0 to 2.0% of an emulsifier EL-12 (castor oil-ethylene oxide condensation product), 1.0 to 2.0% of Span 80 (sorbitan monooleate), and 5 to 10% of water, wherein a use amount ratio of the emulsifier EL-12 to the Span 80 is in a range of 0.9 to 1.1. The preparation method comprises the following steps of uniformly mixing the biodiesel, the emulsifier EL-12 and the Span 80 according to the above ratios, and adding a certain amount of water into the mixture with stirring. The microemulsified biodiesel has wide raw material sources, needs simple preparation processes and has a low cost. After microemulsification, the microemulsified biodiesel has low viscosity, good stability and a high combustion ratio, and can be used widely.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

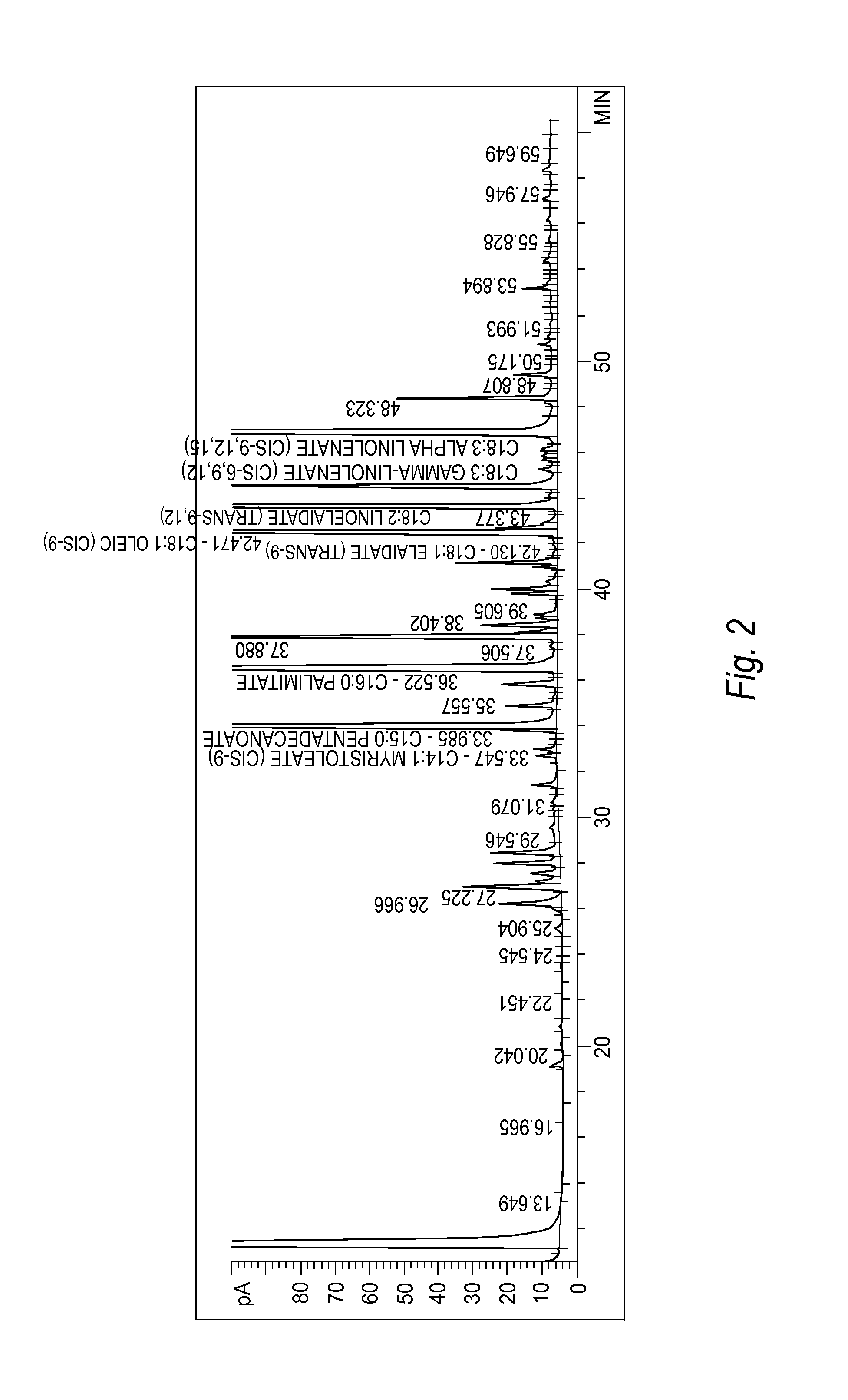

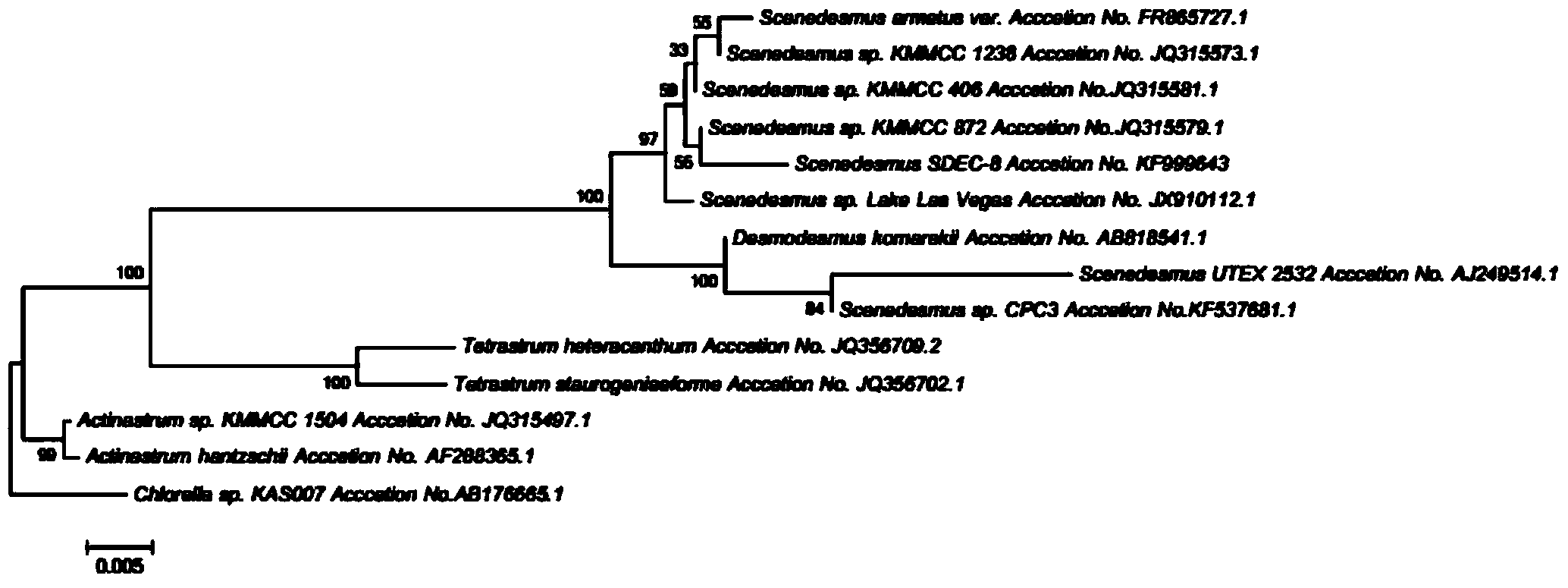

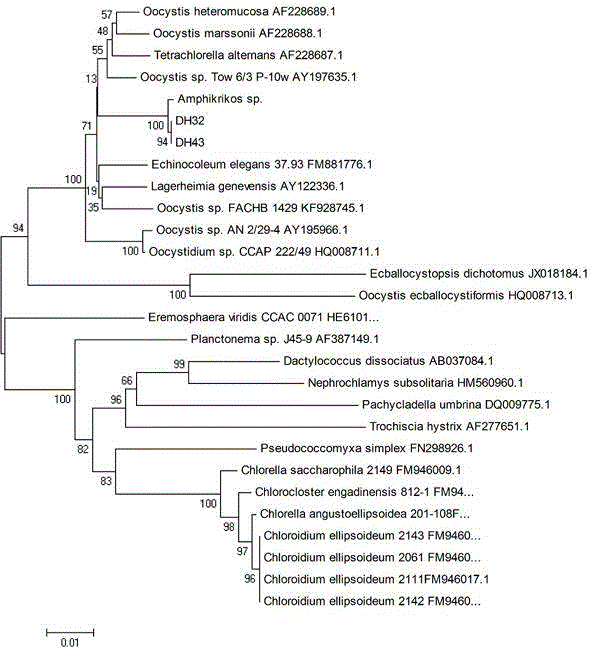

Scenedesmus capable of highly yielding oil as well as culture method and application thereof

InactiveCN104328053AWell mixedImprove light energy utilizationUnicellular algaeWater contaminantsBiodiesel feedstockSequence analysis

The invention relates to scenedesmus capable of highly yielding oil as well as a culture method and application thereof. An alga variety separated from a eutrophic water region is subjected to 18S rDNA sequence analysis and microstructure morphology identification so that the alga is determined as the member of Scenedesmus sp. and the sequence number is KF999043. The alga strain is named as Scenedesmus quadricauda SDEC-8 and is preserved in China Center for Type Culture Collection on October 8, 2014; and the preservation number is CCTCC NO: M2014448. An oil production culture method comprises the following steps: separating single alga cells of the Scenedesmus quadricauda SDEC-8 and carrying out aeration enlarged cultivation on obtained pure cells under laboratory conditions. The Scenedesmus quadricauda SDEC-8 contains rich high-quality oil; and the oil content can be up to 31.8% of the dry weight of the cells and the content of saturated fatty acids in fatty acids can be up to 80%, so that the Scenedesmus quadricauda SDEC-8 can be used as the raw material of biodiesel. Based on a high cetane number (61.38) and a low iodine number (29.38gI2 / 100g), the biodiesel prepared by taking the microalga as the raw material has good oxidization stability.

Owner:SHANDONG UNIV

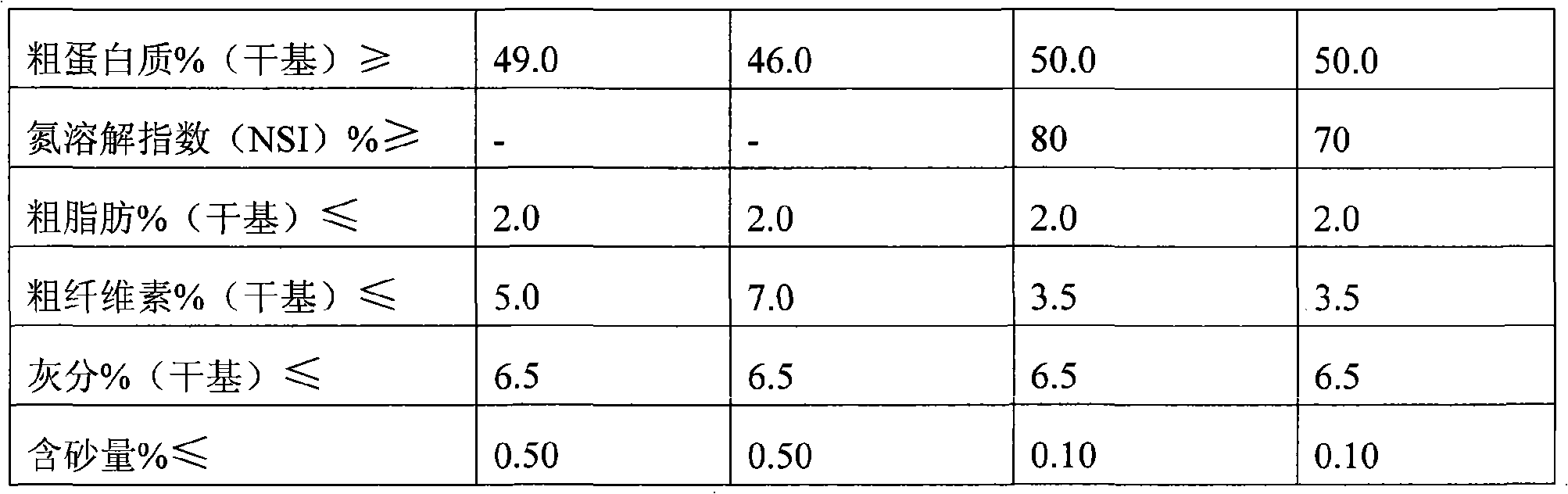

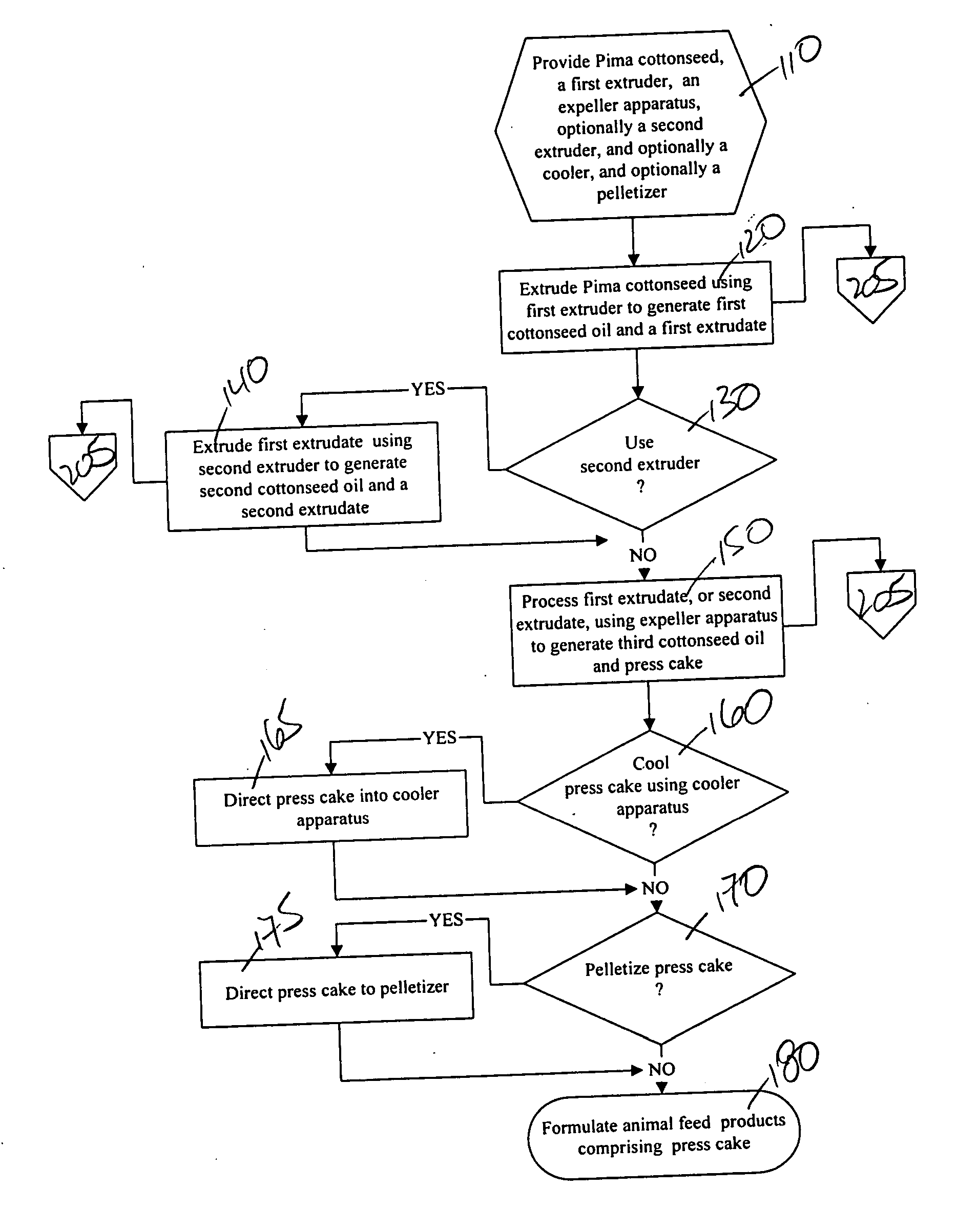

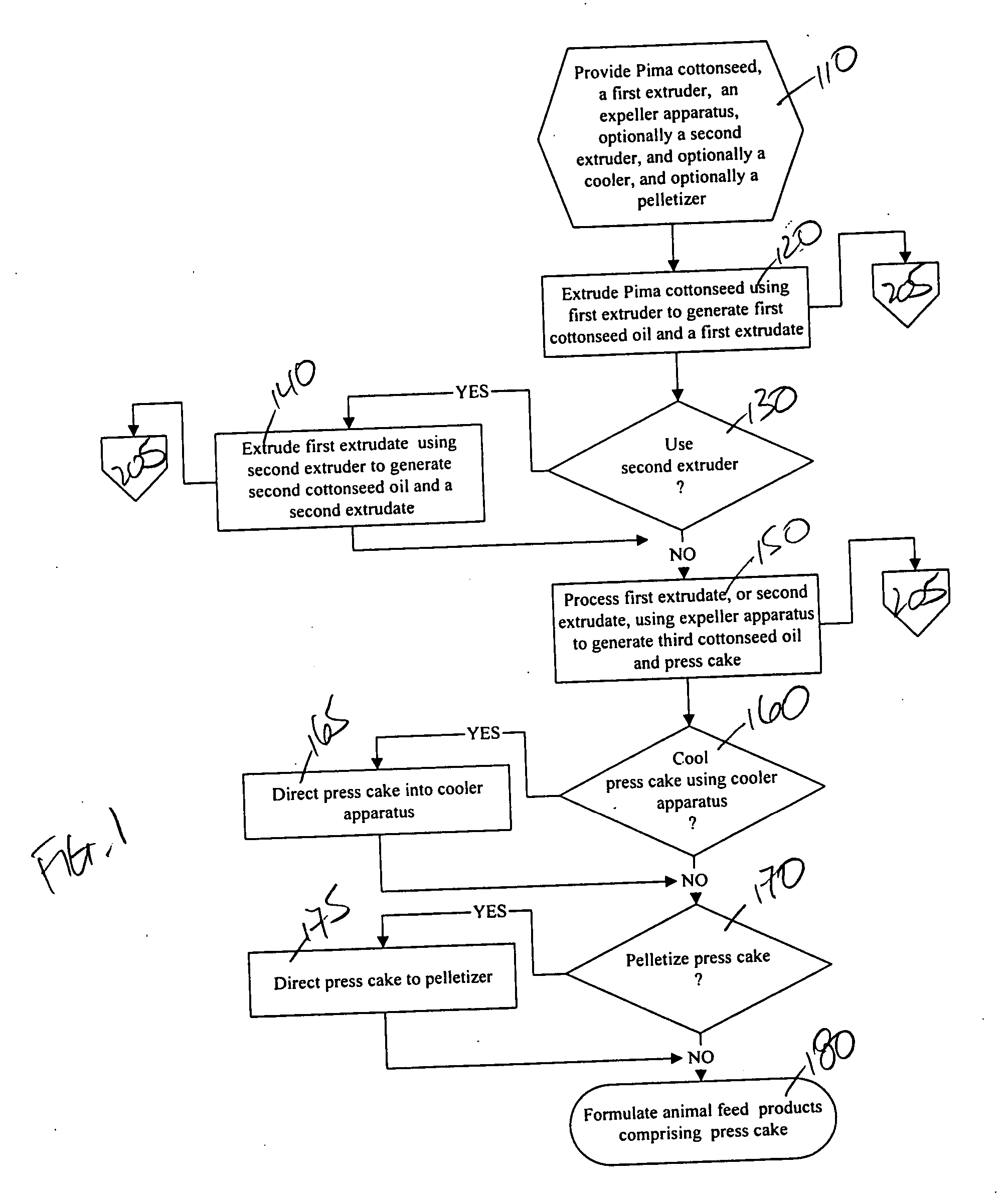

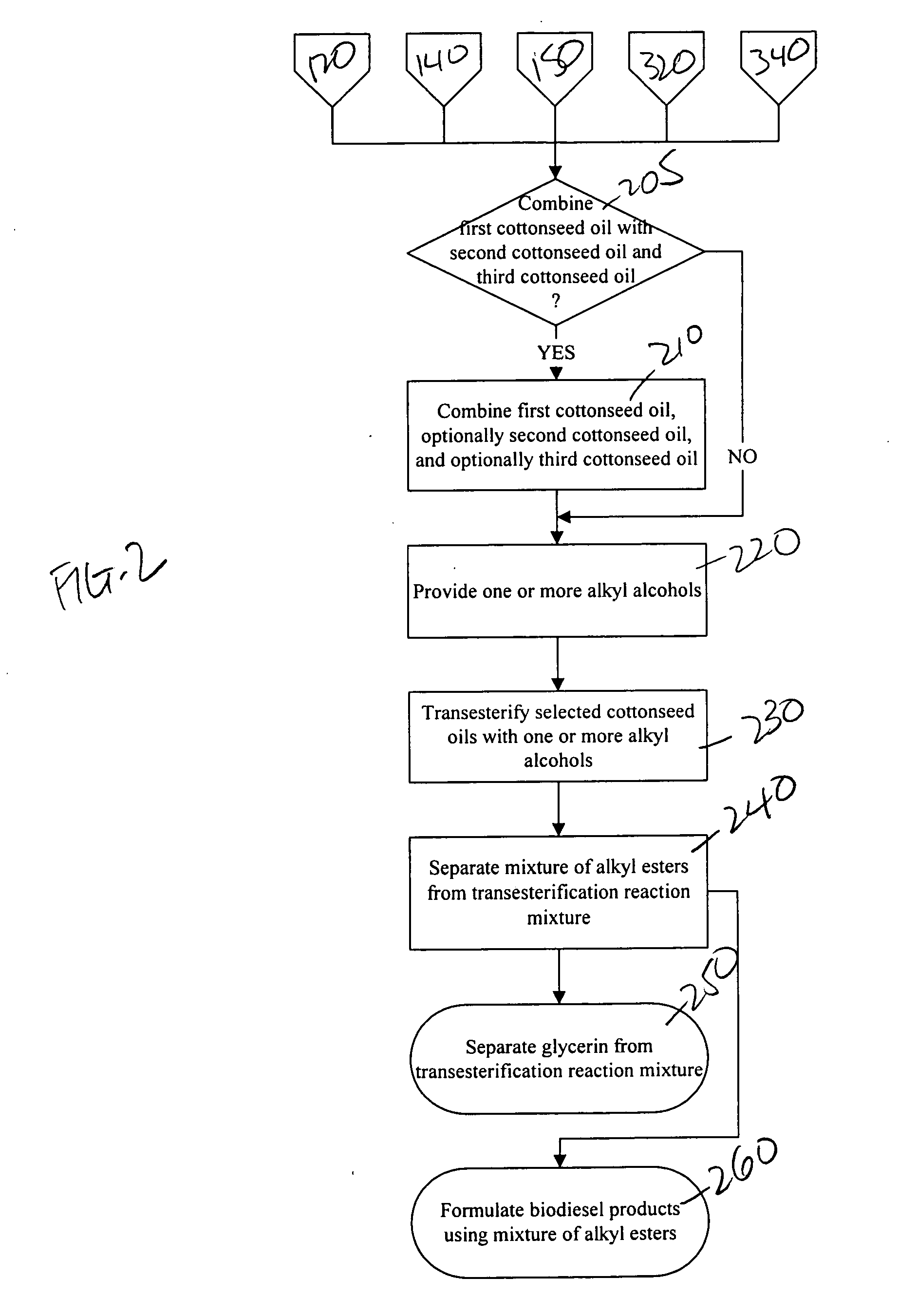

Method to form an animal feed and biodiesel feedstock from Pima cottonseed

A method is disclosed to form an animal feed from cottonseed. The method provides cottonseed and an extruder, and extrudes the cottonseed using temperatures greater than 260° F. to form an extrudate. The method extracts from the extrudate oil suitable for a biodiesel feedstock, and then forms an animal feed comprising the extrudate.

Owner:KERKMAN TIMOTHY M

Preparation method of super-high specific surface area activated carbon

InactiveCN106495152ALarge specific surface areaRatio of high and high holesCarbon compoundsBiodiesel feedstockBiodiesel

The invention relates to the technical field of functional materials, in particular to a preparation method of super-high specific surface area activated carbon. Soapberry residues with raw biodiesel extracted are washed by 80% ethanol water solution, dried, crushed and impregnated by ethanol, unstable carbonaceous organic materials in the soapberry residues are removed, a framework, the carbon yield and the strength of activated carbon are enhanced, the treated soapberry residues are placed into a microwave reactor and carbonized, carbonized materials of the activated carbon are mixed with a composite activator comprising KOH and K2CO3, mixture is uniformly grinded, 10g of the grinded mixture is placed into a tubular furnace, the carbonized materials are activated under N2 protection, the activated carbon is firstly soaked in 1mol / L of hydrochloride acid solution for 2 hours and then washed with distilled water after cooling until a pH (potential of hydrogen) value is unchanged, and the activated carbon is placed into a 110 DEG C thermostatic blast drying oven and dried to obtain an activated carbon test sample. The activated carbon has super-high specific surface area and high mesoporous proportion and can be used for electrode materials of super-capacitors.

Owner:SHAANXI SHENGMAI PETROLEUM

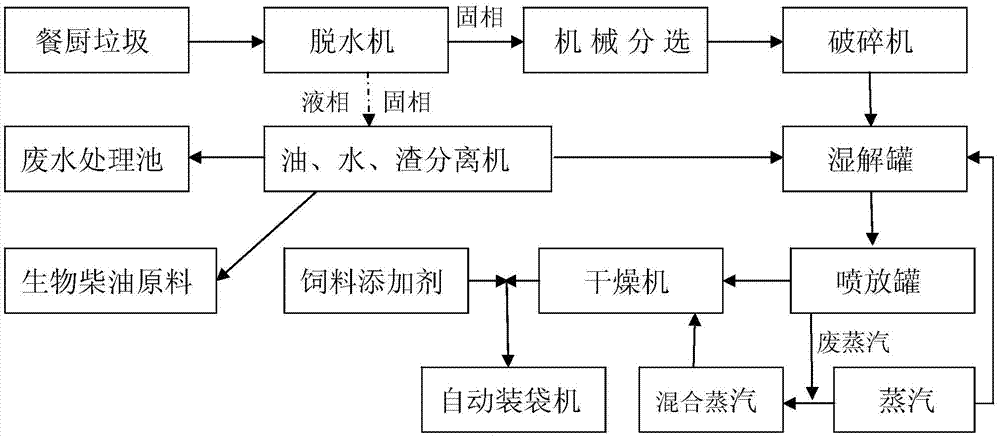

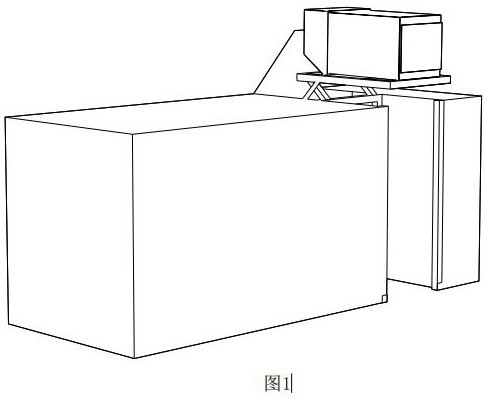

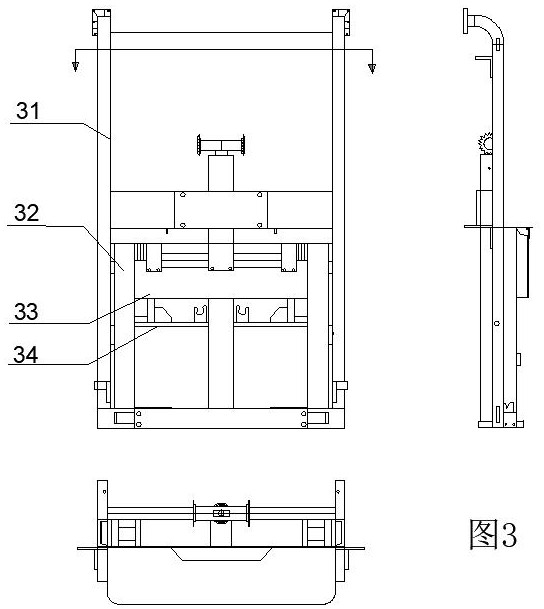

Method and device for co-production of animal feed and biodiesel feedstock by using kitchen waste through hydrothermal treatment

ActiveCN103480634AMeet the protection requirementsGuaranteed uptimeFatty oils/acids recovery from wasteSolid waste disposalBiodiesel feedstockBiodiesel

The invention discloses a method and a device for co-production of an animal feed and a biodiesel feedstock by using kitchen waste through the hydrothermal treatment. According to the method, processes of one-time mechanical dehydration, crushing, hydrothermal treatment, flash vaporization for dehydration and drying processing are carried out, and the method has the characteristics of short running time and low energy consumption; a step-by-step moisture removal drying method is adopted in the systematically technological process, so that more than 50% energy is saved compared with a one-stage direct thermal drying process; after the hydrothermal, high-temperature and high-pressure treatment, bacteria are treated, perishable parts are converted into a liquid phase for producing oil, and the produced feed has the characteristic low salt content (less than 1%), is free from influencing of animal growth, germ-free, safe and easy to store, and realizes the poly-generation purpose of the biodiesel feedstock recycling and the animal feed production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

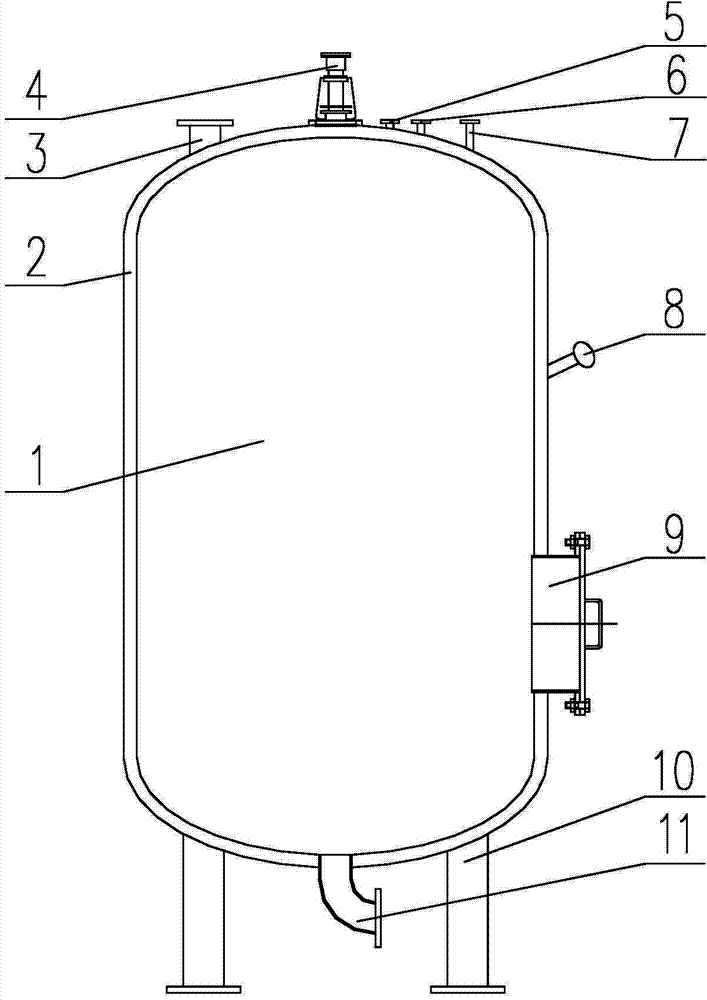

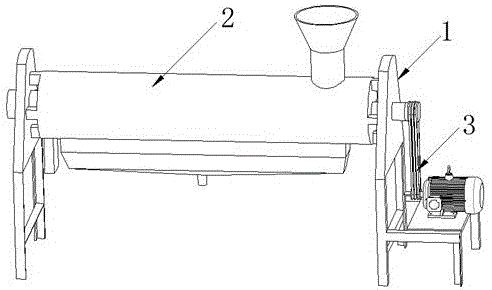

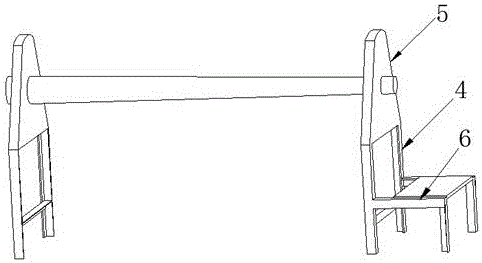

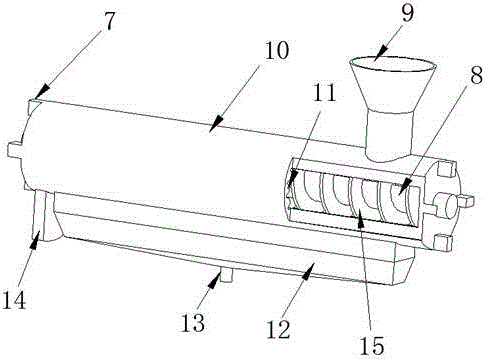

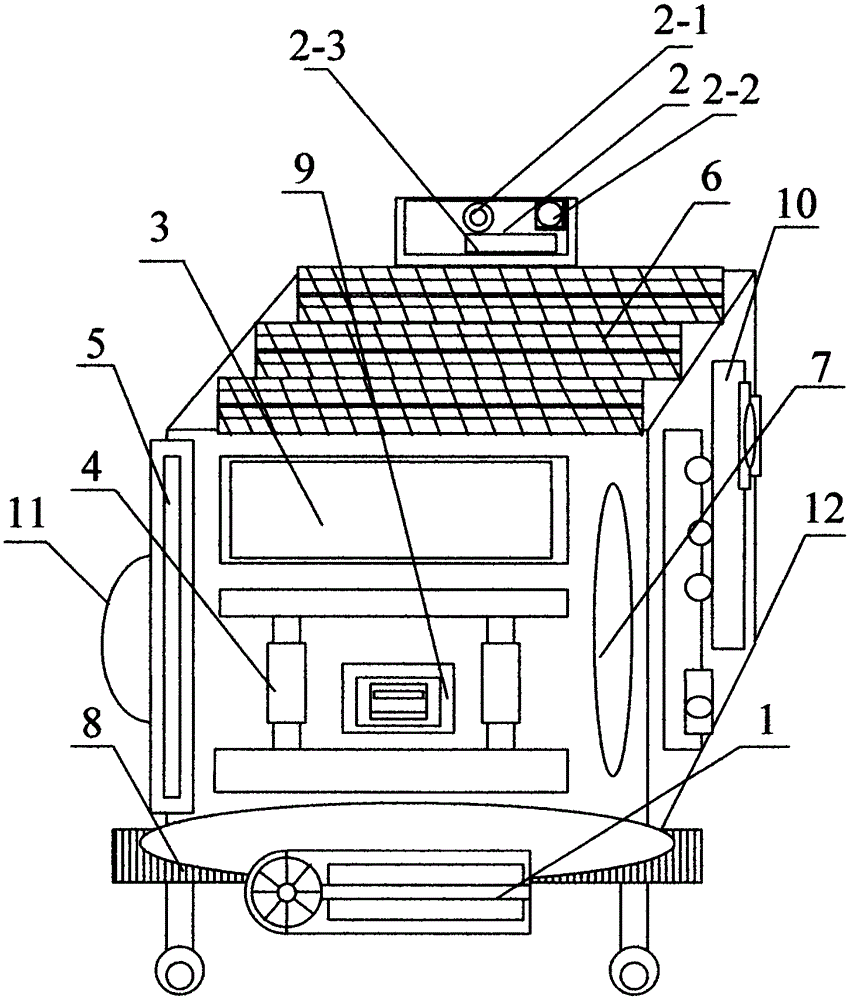

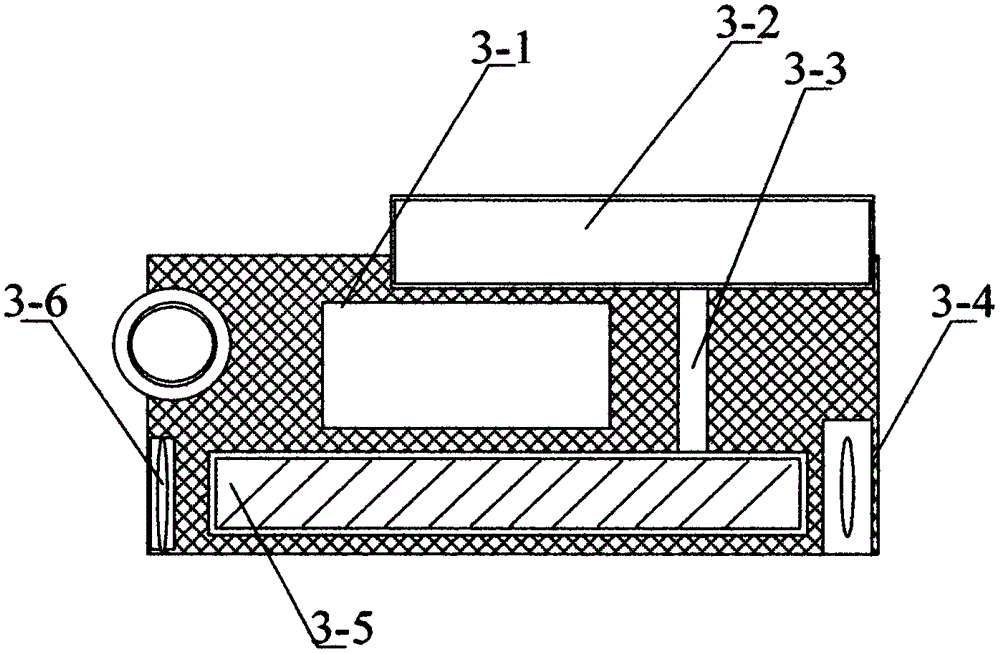

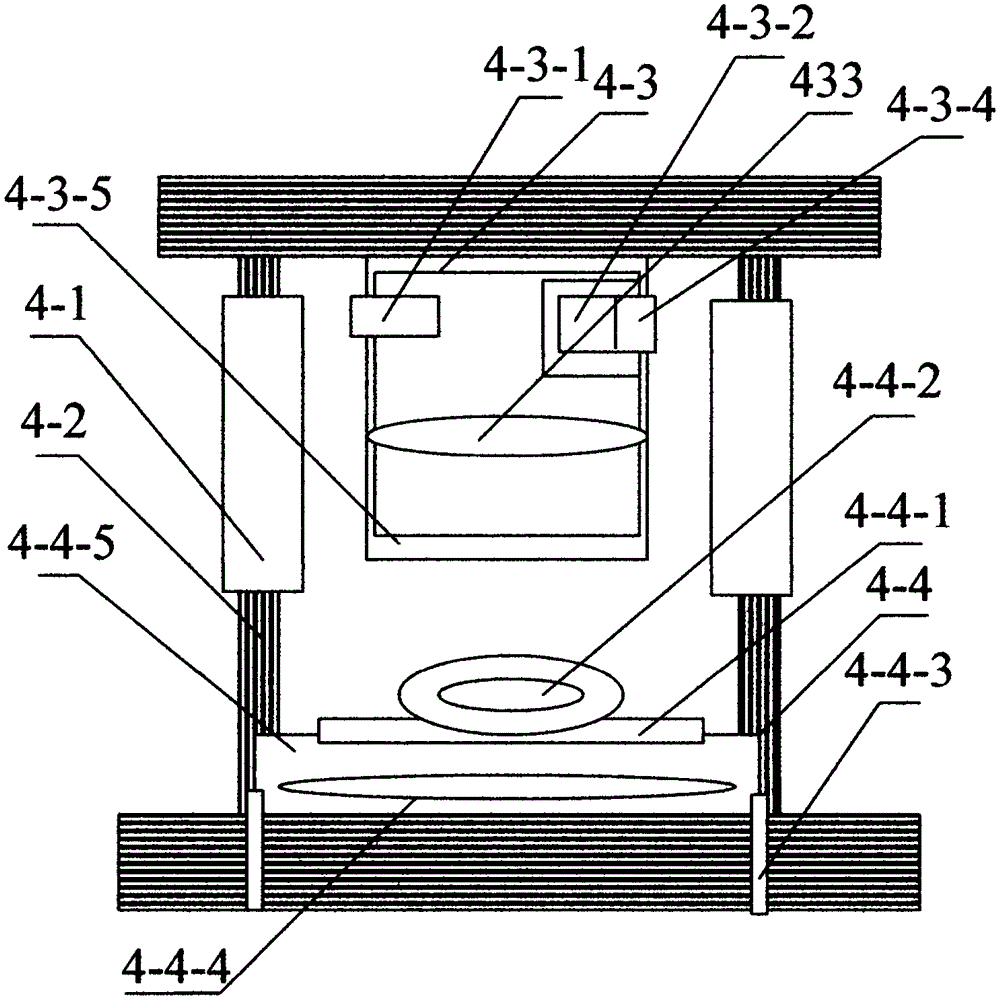

Spiral-type jatropha curcas crude oil extraction machine

ActiveCN107175841ASimple structureSimple and fast operationBiofuelsFatty-oils/fats productionBiodiesel feedstockBiodiesel

The invention relates to a spiral-type jatropha curcas crude oil extraction machine, and belongs to the field of biodiesel raw material oil extraction machines. The spiral-type jatropha curcas crude oil extraction machine comprises a machine frame, a squeezing oil extraction device and a power device. The machine frame is composed of bearing supports, plated grillages and a motor rack. The plated grillages are welded to the upper ends of the bearing supports. The plated grillages and the bearing supports form brackets, and the number of the brackets is two. The squeezing oil extraction device is installed on the two plated grillages. The motor rack is installed on the side wall of the bearing support of one of the brackets in a welding mode. The power device is installed on the motor rack. The power device and the squeezing oil extraction device are connected. According to the spiral-type jatropha curcas crude oil extraction machine, power is transmitted to the squeezing oil extraction device through the power device, squeezing oil extraction of jatropha curcas is achieved through the squeezing oil extraction device, oil and residues are separated, and therefore the jatropha curcas crude oil yield is greatly increased, the jatropha curcas crude oil quality is greatly improved, jatropha curcas crude oil extraction efficiency is also improved, and distribution and collection of the oil and the residues are guaranteed; and the structure is simple, operation is easy and convenient, parts can be installed and replaced easily, and the spiral-type jatropha curcas crude oil extraction machine can further be used for squeezing shell cracking oil extraction operation of oil crops with the seed particles and dimensions being similar to those of the jatropha curcas.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Method for preparing rosin methyl ester and compound biodiesel raw material through pine oleoresin

InactiveCN102358844ALow priceReduce manufacturing costBiofuelsLiquid carbonaceous fuelsBiodiesel feedstockBiodiesel

The present invention relates to the technical fields of forest product deepening and processing, and renewable energy resources, and a method for preparing rosin methyl ester and a compound biodiesel raw material through pine oleoresin. The method comprises: mixing the pine oleoresin and turpentine oil according to a mass ratio of the pine oleoresin to the turpentine oil of 1:0.4-1.2; heating, melting and filtering; adding the resulting filtrate and methanol to an autoclave according to the mass ratio of the filtrate to the methanol of 1:0.05-0.5, introducing 0-4 MPa of CO2 to the autoclave, wherein the CO2 is adopted as a cosolven to carry out a reaction under a supercritical state or a subcritical state; carrying out standing and demixing for the product after completing the reaction, wherein the upper layer is an alcohol phase, and is subjected to atmospheric distillation to recover the methanol, the lower layer is an oil phase, is subjected to atmospheric distillation to recover the methanol, and then is subjected to a CO2 circulating gas introducing method or a super heating steam method to carry out vacuum distillation and separation to obtain the rosin methyl ester and the compound biodiesel raw material. The method provided by the present invention has advantages of simple production process, environmentally friendly property, no requirement of the catalysts, improvement of the economic feasibility of the biodiesel preparing through the pine oleoresin, and the like.

Owner:GUANGXI UNIV

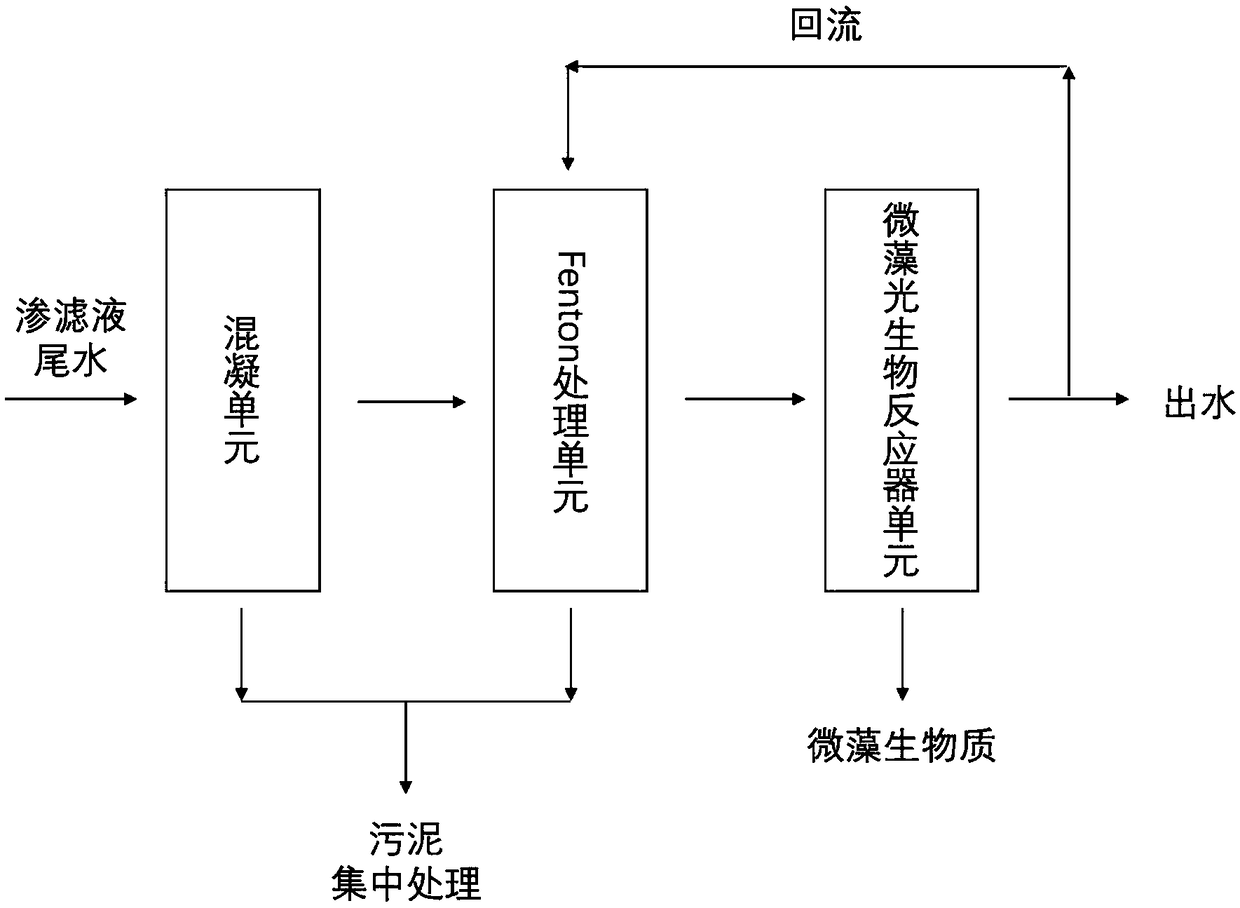

Treatment method of leachate tail water based on advanced oxidation combination technology

InactiveCN108793588AImprove water qualitySolve processing problemsWater/sewage treatment by irradiationWater treatment compoundsWater basedBiodiesel feedstock

The invention provides a treatment method of landfill leachate tail water based on an advanced oxidation combination technology. The treatment method comprises the following steps: (1) putting a certain amount of coagulant in the landfill leachate tail water, standing, and realizing separation in a coagulation unit; (2) enabling a supernatant of the coagulation unit to enter a Fenton unit, addingFeSO4 and H2O2, and fully mixing and reacting with the supernatant; (3) enabling effluent of the Fenton unit to enter a microalgae photobioreactor, and carrying out deep treatment. According to the treatment method of the landfill leachate tail water, provided by the invention, a traditional nitrification / denitrification aerated biological filter unit can be replaced, the microalgae photobioreactor is utilized for carrying deep treatment on the effluent treated by the Fenton unit, residual pollutants such as COD (Chemical Oxygen Demand), organic matters, ammonia nitrogen, nitrate nitrogen andphosphorus in water can be removed, and various indexes of the effluent can be comprehensively upgraded; meanwhile, generated microalgae biomass can be used as animal feed or a biological diesel raw material, so that the treatment cost of leachate is reduced.

Owner:中节能工程技术研究院有限公司

Method for preparing biodiesel by using FCC spent catalyst loaded acid to catalyze cracking of black rosin

ActiveCN103484143AAchieve recyclingIncrease added valueBiofuelsLiquid hydrocarbon mixture productionBiodiesel feedstockBiodiesel

The invention discloses a method for preparing biodiesel by using FCC (fluid catalytic cracking) spent catalyst loaded acid to catalyze cracking of black rosin. The method mainly adopts the technical scheme that the method comprises the steps of using a roasted activated FCC spent catalyst as a carrier to load acid with a dipping method, drying, obtaining a high-activity FCC spent catalyst loaded acid catalyst, using the low-grade residue black rosin produced in a rosin production process as a raw material and the loaded acid modified FCC spent catalyst as the catalyst, charging CO2 or N2 as protective gas, performing a black rosin ordinary pressure catalytic cracking reaction for 0.5-4h at 250-300 DEG C and at a stirring rate of 100-500r*min<-1>, washing, filtering, obtaining a compound rosinyl biodiesel raw material, mixing, and compounding with 0# petroleum diesel to form the rosinyl biodiesel. According to the method, the FCC spent catalyst modifies the low-grade industrial by-product black rosin of a rosin enterprise to prepare renewable new energy with a high added value, and the method has economic and environmental benefits.

Owner:GUANGXI UNIV

Kitchen waste treatment equipment system

InactiveCN112808735AImprove the level of industrial designSolve various problems of in-situ processing equipmentTransportation and packagingSolid waste disposalBiodiesel feedstockOil and grease

The invention discloses a kitchen waste treatment equipment system. The kitchen waste treatment equipment system comprises a pretreatment and biochemical degradation system, a waste gas treatment system, a special shed body and an oil-water separator, wherein the pretreatment and biochemical degradation system is used for degrading particle residues generated after pretreatment such as strong crushing and extrusion dehydration of materials in a microbial fermentation manner; the waste gas treatment system is used for treating waste gas generated after degradation and discharging the waste gas after the waste gas reaches the standard; the special shed body is used for meeting the requirement of space sealing during equipment installation; and the oil-water separator is used for performing oil-water separation on oil-containing wastewater after extrusion dehydration and respectively treating wastewater and oil which are separated from each other, the treated wastewater is discharged after reaching the standard, and the oil is taken as a biodiesel raw material. According to the kitchen waste treatment equipment system, a high-temperature aerobic fermentation process is adopted, and the treatment effect of organic waste is improved. The kitchen waste treatment equipment system has the advantages of low energy consumption, low operation cost, small occupied area and the like.

Owner:宁国圣韬实业发展有限公司

Production apparatus of high cleanness biodiesel, and method thereof

InactiveCN105567434AEasy to detectImprove consistencyProgramme controlFatty acid esterificationBiodiesel feedstockBiodiesel

The invention provides a production apparatus of high cleanness biodiesel, and a method thereof. The method comprises the following steps: carrying out foreign water removal and dehydration on lower fatty acid-containing biodiesel raw oil with an adsorbent through generating power by using a power generator, through supplying power by using a power supply substrate and through using cooperation of regulating valve input and a container; heating through using a heating wire and a heat accumulation plate, and carrying out infrared temperature monitoring by adopting a temperature monitoring device; and allowing the hydrated biodiesel raw oil to go through a reaction agent provided with cationic exchange resin and an esterification reaction device after the raw oil is heated to an assigned temperature, adjusting the pH value, and acquiring reaction data and remote control experiment parameters through a real-time online monitoring module. The infrared temperature monitoring is carried out through the temperature monitoring device, and the reaction data and remote control experiment parameters are acquired through the real-time online monitoring module, so real-time optimum reaction parameters are guaranteed, the detection performances of produced biodiesel are excellent, and the consistence of the above product is good.

Owner:SHANDONG TAIDE NEW ENERGY

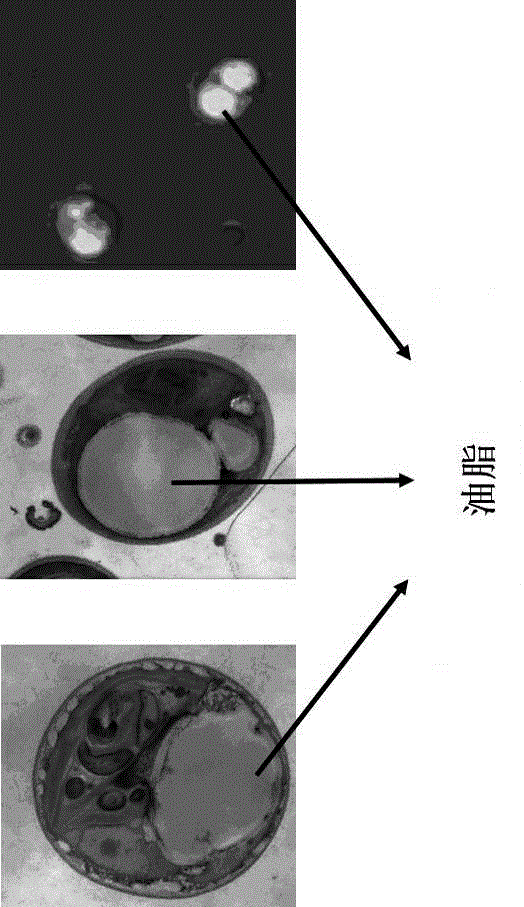

Amphikrikos marinus as well as application and culture method thereof

InactiveCN104560720AReduce manufacturing costHigh fat contentUnicellular algaeBiofuelsBiodieselHigh fat

The invention discloses amphikrikos marinus as well as an application and a culture method thereof. The amphikrikos marinus is separated from the seawater of the Yellow Sea and classified and named amphikrikos marinus and collected in the China General Microbiological Culture Collection Center on October 22, 2014; and the collection number of the strain is CGMCC No.9814. A collection method of the amphikrikos marinus is to enable phytoplankton to get rid of the net; and a separation method adopts a micropipette for absorption, step-by-step dilution and separation and a spread-plate method. The amphikrikos marinus disclosed by the invention has the beneficial effects that compared with other algae species serving as a biodiesel raw material, the amphikrikos marinus has remarkably high fat content and growth speed, and the production cost of biodiesel can be effectively reduced.

Owner:OCEAN UNIV OF CHINA

Elaeagnus angustifolia oil, method for preparing same and application of elaeagnus angustifolia oil used as raw material for biodiesel

ActiveCN109439426AIncrease productionReduce usageBiofuelsFatty-oils/fats refiningBiodieselUltrasonic assisted

The invention relates to a method for preparing grease raw materials for biodiesel from elaeagnus angustifolia pit. The method includes 1 cleaning, 2 smashing and separating, 3 ultrasonic-assisted Soxhlet extraction, 4 impurity removing and grease separating, 5 grease degumming, 6 grease deacidifying and 7 grease purifying. The method has the advantages that the extraction efficiency can be improved by the aid of smashing and separating and ultrasonic-assisted extraction processes, the grease raw materials can be applied to preparing the biodiesel and can be reasonably utilized as compared with existing discarded elaeagnus angustifolia pit, the method is beneficial to applying natural renewable resources on a large scale, and the problems in the aspect of the requirements of the mankind onenergy sources can be solved by the aid of the method; experiment procedures are simple, biomass resources can be sufficiently effectively utilized, the method has low requirements on equipment, andthe grease raw materials can be industrially produced by the aid of the method.

Owner:HEILONGJIANG UNIV

Method for extracting carclazyte oil

PendingCN111254019ASimple processHigh recovery rateFatty oils/acids recovery from wasteFatty substance recoveryBiodiesel feedstockBiodiesel

The invention discloses a method for extracting carclazyte oil, which belongs to the technical field of grease refining waste treatment. The method comprises the following steps: mixing waste carclazyte obtained after oil decolorization and refining with biodiesel accounting for 10-20% of the weight of the waste carclazyte, frying and mixing in a frying pan to 80-100 DEG C, and then putting a mixture into a squeezer for squeezing while the mixture is hot, and using the obtained mixture of biodiesel and carclazyte oil to be directly used as a biodiesel raw material for biodiesel production. Themethod disclosed by the invention has the characteristics of simple process, high recovery rate (more than 90%), no wastewater discharge, no use of dangerous chemicals and the like, and is particularly suitable for industrial transformation and popularization of carclazyte oil refining.

Owner:常州市金坛区维格生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com