Kitchen waste treatment equipment system

A technology for kitchen waste and equipment, applied in the field of kitchen waste treatment equipment system, can solve the problems of difficulty in feeding materials, high operating costs, and inability to run continuously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

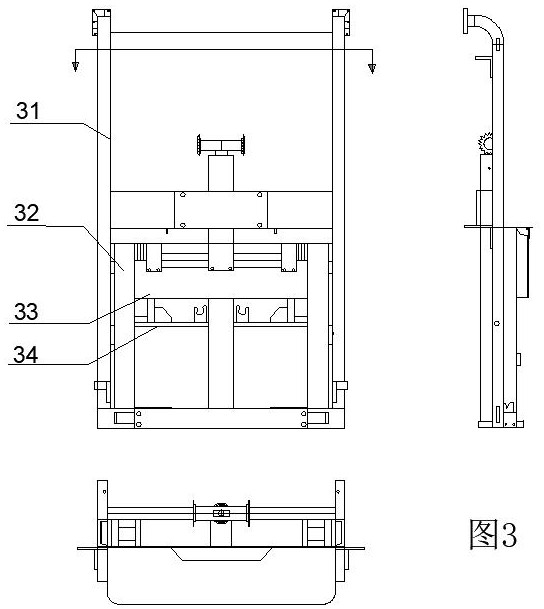

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the equipment system of the present invention, but they do not limit the present invention.

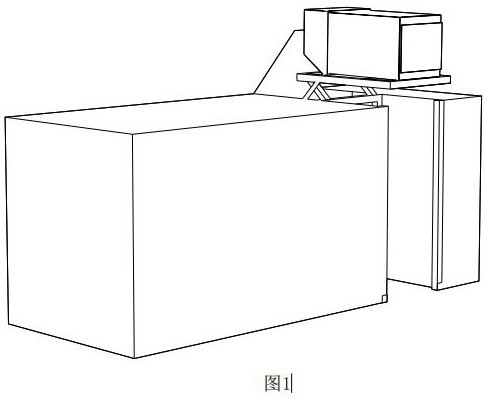

[0033] Such as figure 1 The illustrated embodiment provides a food waste treatment equipment system, including:

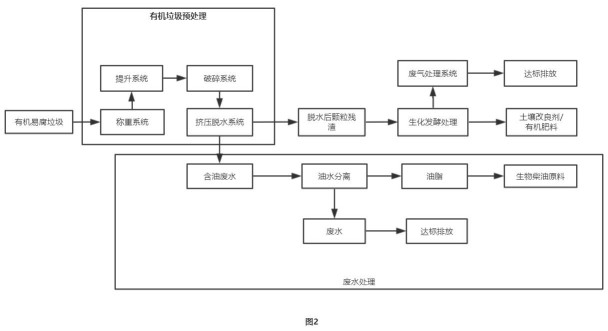

[0034] The pretreatment and biochemical degradation system is used to degrade the particle residue generated by microbial fermentation after the material is pretreated by strong crushing, extrusion and dehydration;

[0035] The waste gas treatment system is used to treat the waste gas generated after degradation and discharge it after reaching the standard;

[0036] The special shed body meets the requirements of airtight space during equipment installation;

[0037] The oil-water separator is used to separate oil-water from the oil-containing wastewater after extrusion dehydration, and then treat the separated wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com