Elaeagnus angustifolia oil, method for preparing same and application of elaeagnus angustifolia oil used as raw material for biodiesel

A technology of jujube and crude oil, applied in the fields of biofuel, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of large amount of solvent, high energy consumption of solvent recovery, waste of solvent, etc., to reduce extraction time, The effect of solving energy shortage and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Cleaning: Cleaning the core of Rhododendron, washing away the pulp and mud remaining on it, and drying to remove water. Random sampling was used to analyze the proportion of the woody shells of Elaeagnus sativa.

[0035] (2) Pulverization and separation: get 1kg of dried Rhizoma sylvestris and put it into a pulverizer to pulverize, and sieve to remove the large particles that are not pulverized. Weigh the uncrushed large particles.

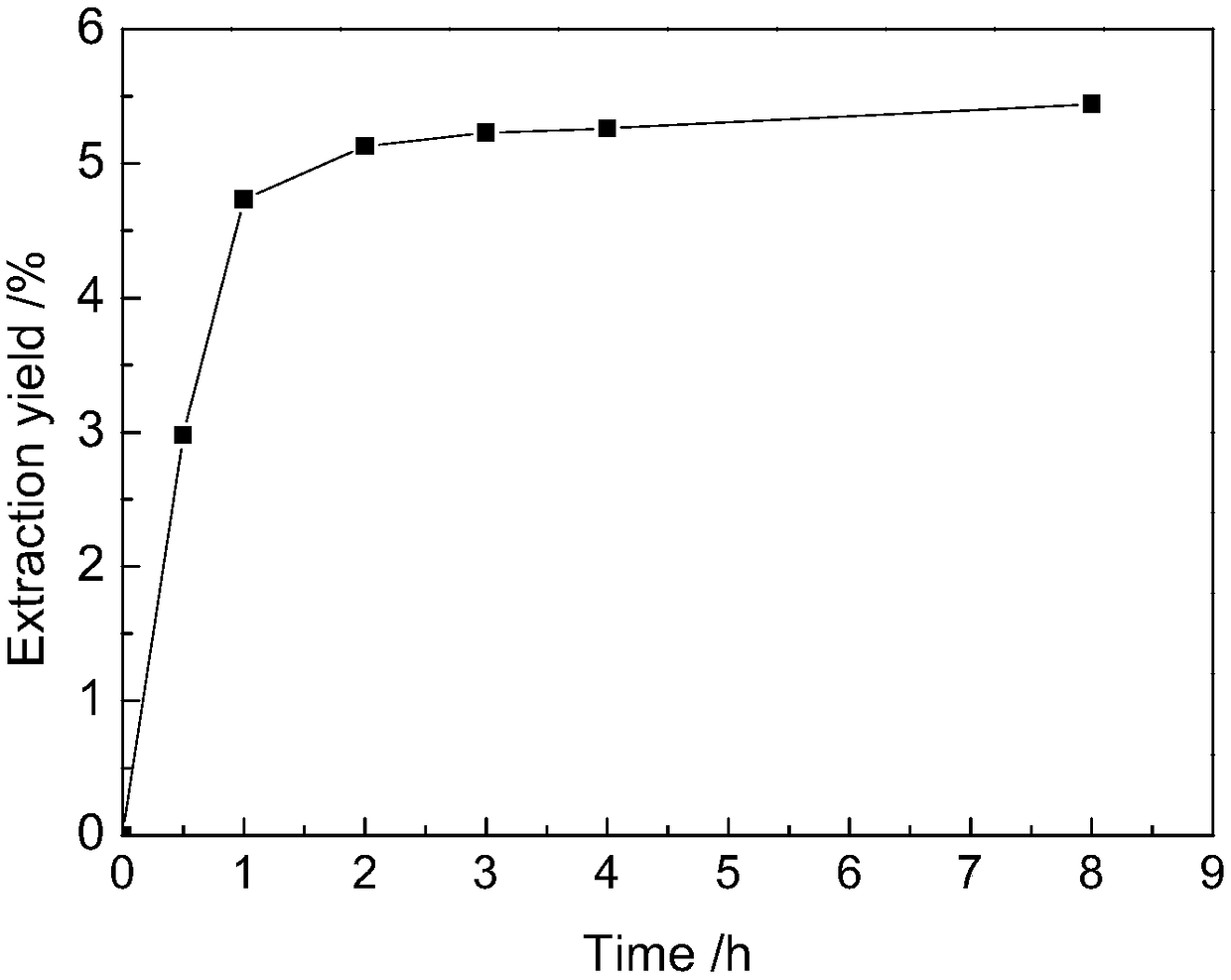

[0036] (3) Ultrasonic-assisted Soxhlet extraction: Take part of the pulverized Jujube seed and n-hexane at a mass-volume ratio of 1:4, ultrasonicate for 15 minutes in a 100W ultrasonic frequency of 40KHz, then pour it into a filter bag, and pour the solvent into the bottom bottle , put the filter bag into the Soxhlet extractor, maintain a cycle of 6 minutes, and extract for 8 hours. After all the extracts of Elaeagnus sativa powder are completed, proceed to the next step.

[0037] (4) Removal of impurities, separation of grease: filt...

Embodiment 2

[0054] (1) Cleaning: Cleaning the core of Rhododendron, washing away the pulp and mud remaining on it, and drying to remove water. Random sampling was used to analyze the proportion of the woody shells of Elaeagnus sativa.

[0055] (2) Pulverization and separation: get 1kg of dried Rhizoma sylvestris and put it into a pulverizer to pulverize, and sieve to remove the large particles that are not pulverized. Weigh the uncrushed large particles.

[0056] (3) Ultrasound-assisted Soxhlet extraction: Take part of the pulverized Jujube seed and n-hexane at a mass-volume ratio of 1:6, sonicate in a 50W frequency of 40KHz ultrasound for 25min, then pour it into a filter bag, and pour the solvent into the bottom bottle , filter the bag into the Soxhlet extractor, maintain a cycle of 5min, and extract for 2h. After all the extracts of Elaeagnus sativa powder are completed, proceed to the next step.

[0057] (4) Removal of impurities, separation of grease: filter to remove its insolubl...

Embodiment 3

[0062] (1) Cleaning: Cleaning the core of Rhododendron, washing away the pulp and mud remaining on it, and drying to remove water.

[0063] (2) Pulverization and separation: get 1kg of dried Rhizoma sylvestris and put it into a pulverizer to pulverize, and sieve to remove the large particles that are not pulverized.

[0064] (3) Ultrasonic-assisted Soxhlet extraction: Take part of the pulverized Jujube seed and n-hexane with a mass-volume ratio of 1:5, ultrasonicate in a 100W ultrasonic frequency of 40KHz for 10min, then pour it into a filter bag, and pour the solvent into the bottom bottle , filter the bag into the Soxhlet extractor, maintain a cycle of 5min, and extract for 1.5h. After all the extracts of Elaeagnus sativa powder are completed, proceed to the next step.

[0065] (4) Removal of impurities, separation of grease: filter to remove its insoluble solid impurities, the solution is poured into a distillation device, and the solvent is separated to obtain the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com