Production apparatus of high cleanness biodiesel, and method thereof

A technology of biodiesel and production method, applied in the direction of biofuel, petroleum industry, fat production, etc., can solve the problems of inconvenient use, high manufacturing cost, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

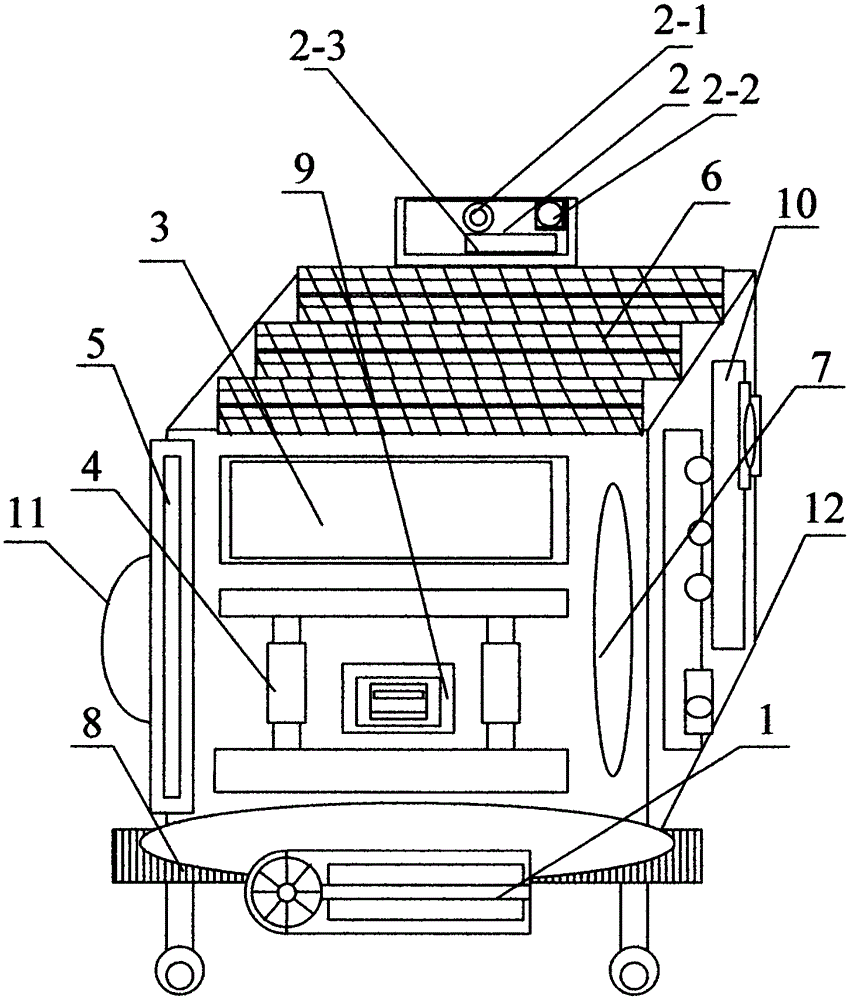

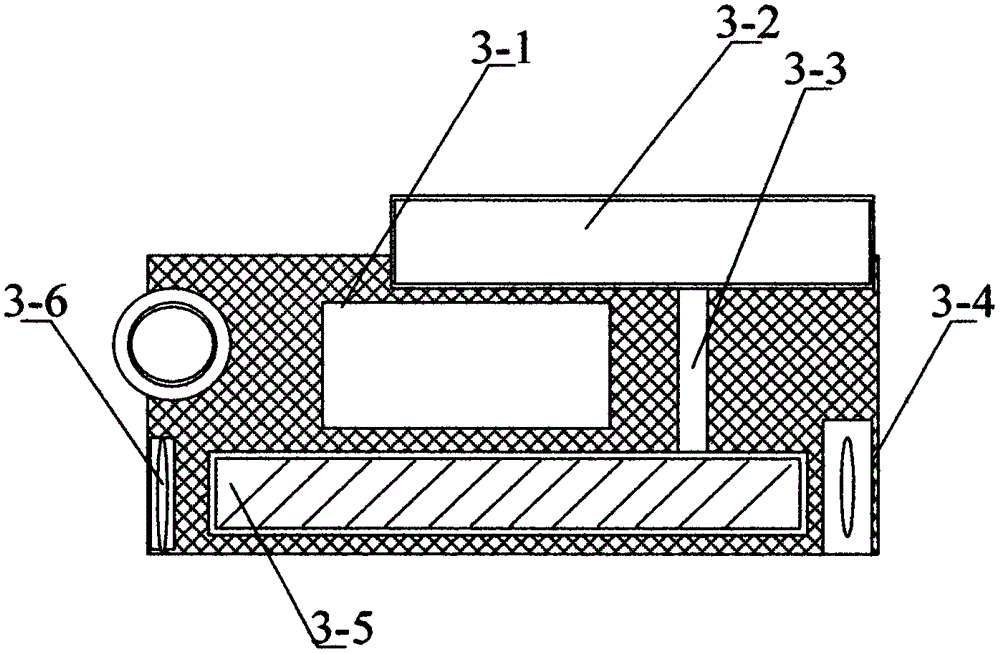

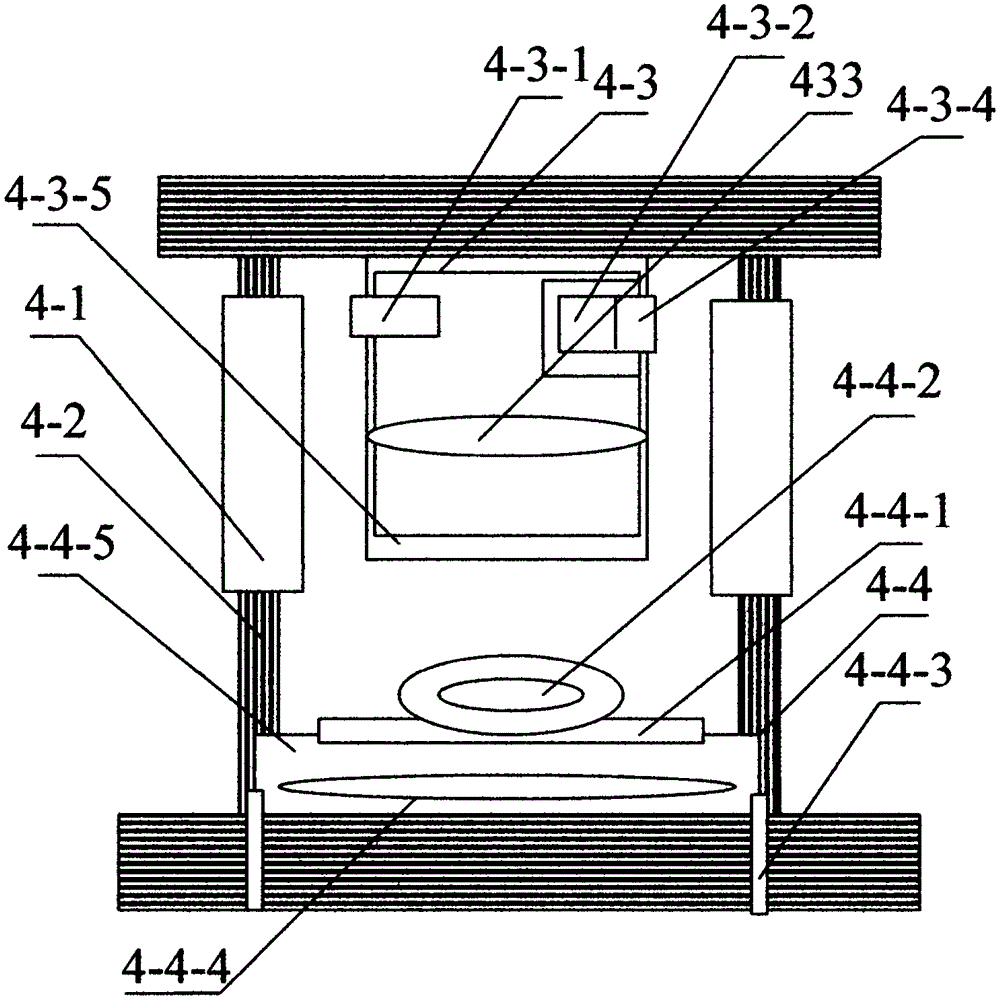

[0048] The present invention will be further described below in conjunction with accompanying drawing:

[0049] A high-clean biodiesel production method uses a generator to generate electricity, powers the power supply substrate, and through the cooperation of the regulating valve input and the container, removes foreign substances and dehydrates the biodiesel feedstock oil containing low fatty acids with an adsorbent; through heating wire and The heat storage plate is heated, and the temperature monitoring device is used for infrared temperature monitoring; after being heated to the specified temperature, the dehydrated biodiesel feedstock oil passes through the reactant and esterification reaction device equipped with cation exchange resin to adjust the pH, and through the real-time online monitoring module Collect reaction data and remotely control experimental parameters.

[0050] The dehydrated biodiesel feedstock oil is passed through a solid acid catalyst reaction guard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com