Gaseous phase circulation production method for biodiesel and device therefor

A biodiesel, gas phase cycle technology, applied in the production of biological raw materials, biofuels, bulk chemicals, etc., can solve problems such as the loss of raw materials and methanol, and achieve the effects of reducing consumption, shortening lipidation time, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

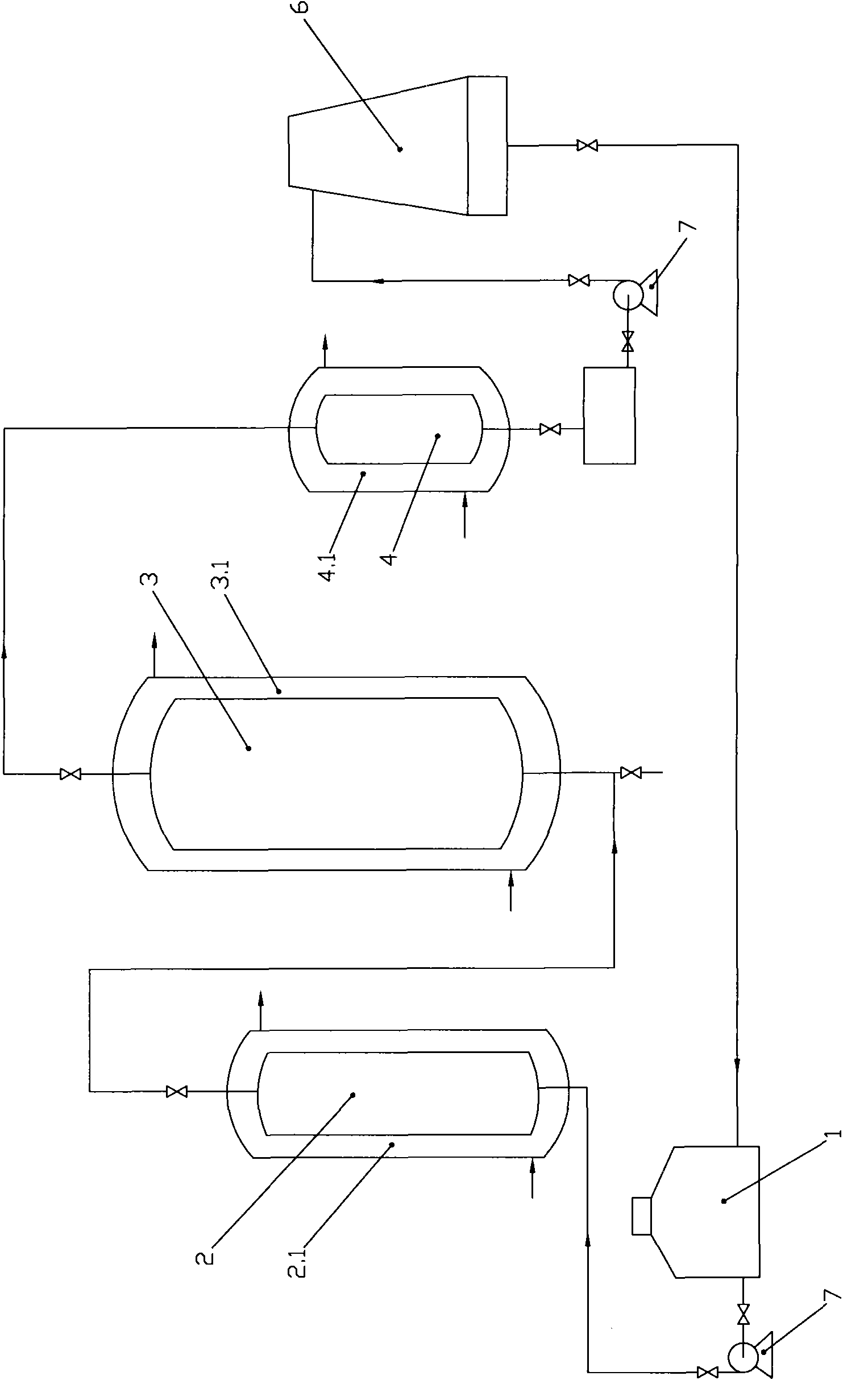

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0017] A gas-phase cycle production method of biodiesel, comprising the following steps:

[0018] (1) 5 tons of raw materials of acidified oil made from saponins are sent into the reactor through the input pump, the heat medium of the jacket of the reactor is used to heat the raw materials, and the sulfuric acid catalyst of 0.3 tons of raw materials weight is added to the kettle while heating, and fully stir;

[0019] (2) When the temperature in the still rose to 90°C, the methanol vapor from the methanol generator was delivered to the liquid level in the still, and the amount of methanol vapor introduced was the amount after 0.45 tons of liquid methanol was vaporized. Lipid exchange reaction for 1 hour;

[0020] (3) Part of the methanol vapor with moisture in the raw material enters the coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com