Method for producing biodiesel by high-density fermentation of heterotrophic chlorella

A high-density fermentation and heterotrophic chlorella technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of low microalgae cell yield and industrial application of oil content, and achieve the goal of reducing raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

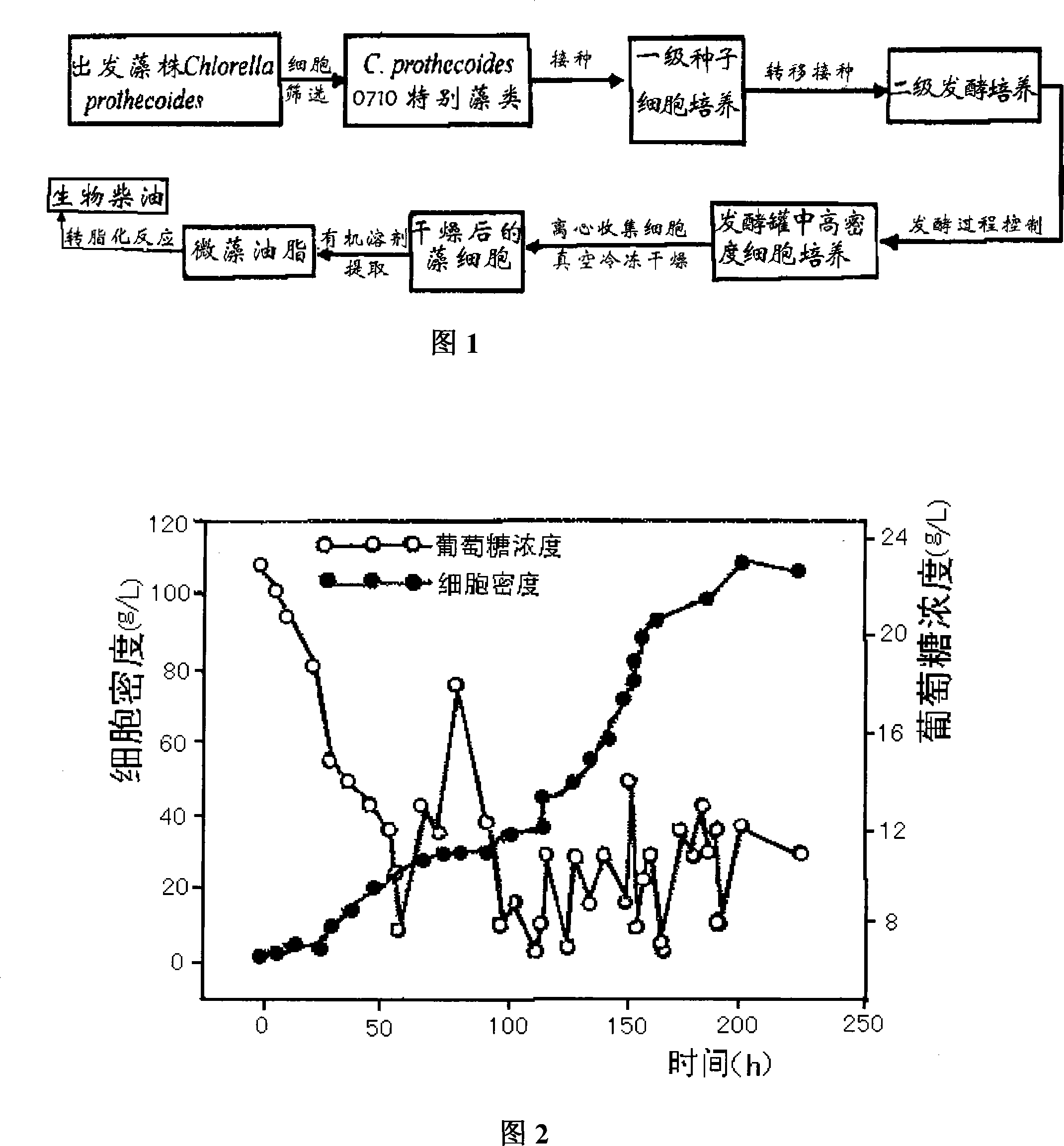

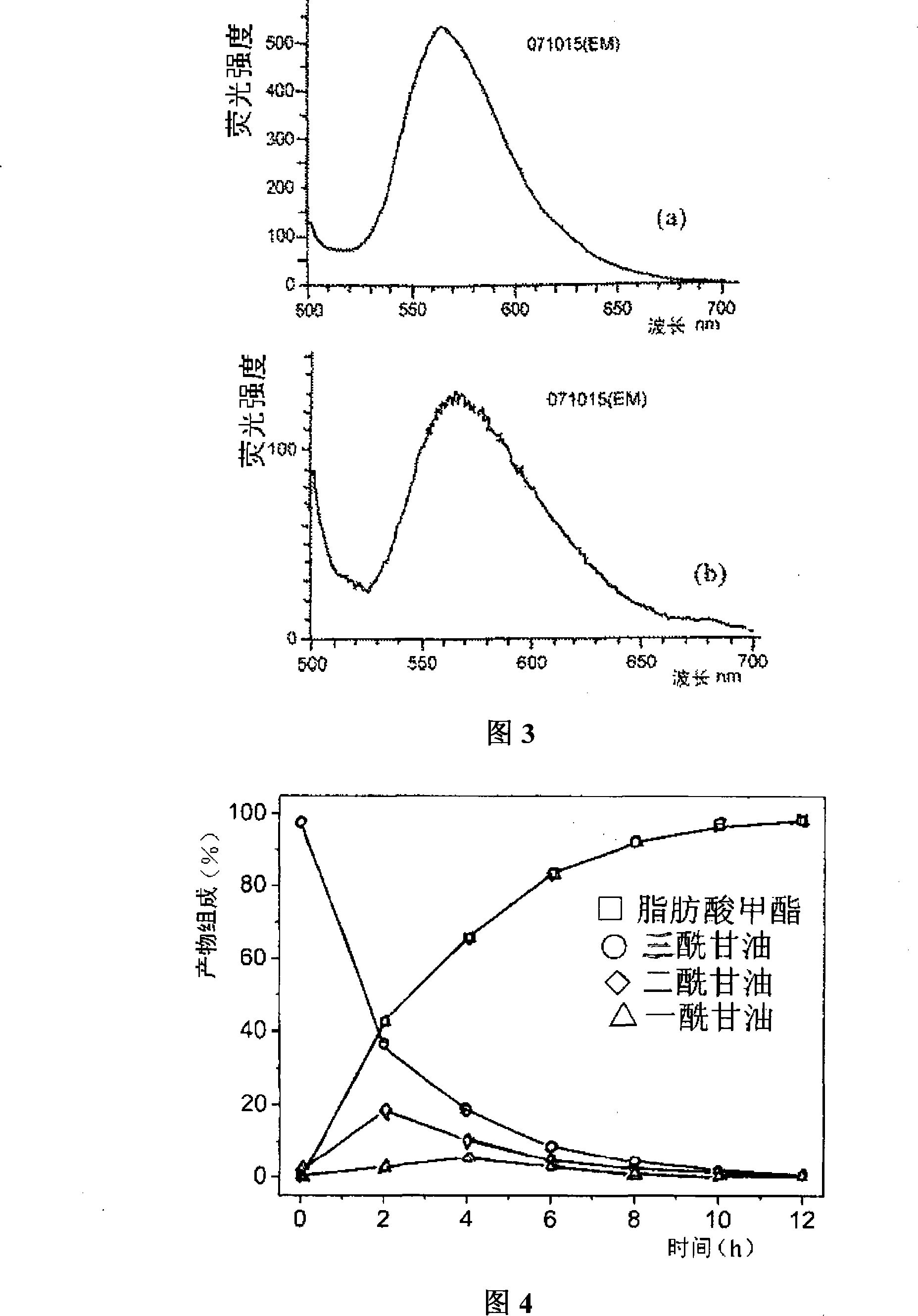

Method used

Image

Examples

Embodiment

[0063] The starting algae strain of Chlorella protothecoides was purchased from the Algae Center of the University of Texas in the United States. Since 1990, the Microalgae Bioenergy Laboratory of the Department of Biological Science and Technology, Tsinghua University has cultivated the algae for long-term bioenergy research. Its basal medium formula is as follows:

[0064] K H 2 PO 4 0.7g / L, K 2 HPO 4 0.3g / L, MgSO 4 ·7H 2 O 0.3g / L, FeSO 4 ·7H 2 O 3mg / L, glycine 0.1g / L, vitamin B 1 0.01mg / L, A5 trace element solution 1ml / L.

[0065] Among them, the A5 trace element solution contains H 3 BO 3 , Na 2 MoO 4 2H 2 O, ZnSO 4 ·7H2 O, and MnCl 2 4H 2 O, CuSO 4 ·5H 2 O and other components. The optimized A5 trace element solution contains: H 3 BO 3 2.86g.L -1 , Na 2 MoO 4 2H 2 O 0.039g.L -1 , ZnSO 4 ·7H 2 O 0.222g.L -1 , MnCl 2 4H 2 O 1.81g.L -1 , CuSO 4 ·5H 2 O 0.074g.L -1 .

[0066] Through the directional screening technique described in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com