Patents

Literature

37results about How to "Control rheology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmentally Friendly Solvent Systems/Surfactant Systems For Drilling Fluids

InactiveUS20140005079A1Good for healthImprove securityFlushingDrilling compositionGlutaric acidActive agent

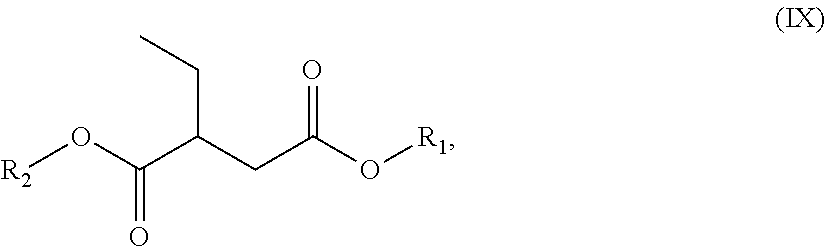

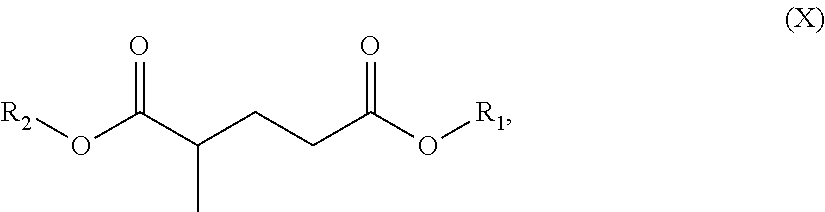

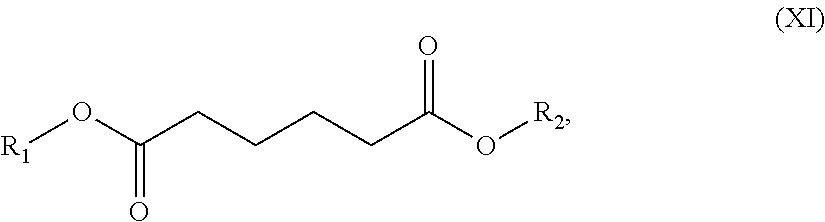

A oil field production fluid, namely a drilling mud composition, comprising a mixture of: (a) at least one base oil component; and (b) an additive component comprising a blend of dibasic esters. The functional fluid can optionally comprise additional additive components. The blend of dibasic esters comprises two or more of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate.

Owner:RHODIA OPERATIONS SAS

Fluid loss additive for drilling fluid and preparation method thereof

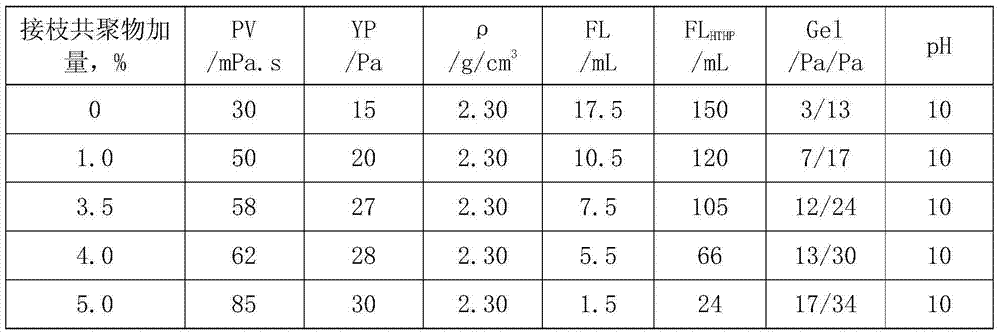

ActiveCN102766240AControl rheologyReduce high temperature and high pressure filtration lossDrilling compositionSide chainWell drilling

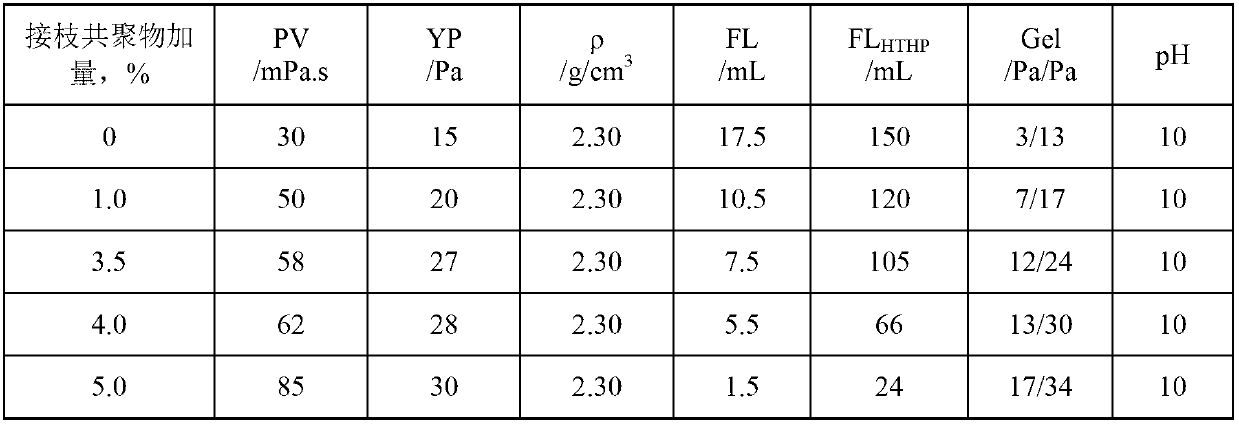

The invention discloses a fluid loss additive for drilling fluid and a preparation method thereof, belonging to the technical field of chemical drilling fluid treating agents for oilfields. The method comprises the following steps of: carrying out one-step reaction on phenol, formaldehyde, humate, pyrosulfite and anhydrous sulfite so as to obtain a sulfonated phenolic humic acid resin; in the presence of an initiator, carrying out graft copolymerization on the sulfonated phenolic humic acid resin and a mixture of sodium hydroxide, 2-acrylamide-2-methyl-propyl sulfonate, acrylamide and dodecylacrylamide; and carrying out drying and crushing on the obtained product so as to obtain sulfonated phenolic humic acid resin-alkenyl monomer graft copolymer. The fluid loss additive disclosed by the invention has the functions of controlling the rheological property of drilling fluid and reducing the high-temperature and high-pressure filter loss of drilling fluid, not only enhances the thermal stability of side chains of a chain polymer, but also improves the salt tolerance of a sulfonated phenolic resin, and guarantees that products have good properties under high temperature and high salt conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic silicon lubricating grease and preparation method thereof

ActiveCN101870905AImprove the lubrication effectNo dielectric constantThickenersAdditivesBase oilThermal stability

The invention relates to the technical field of lubricating grease, in particular to organic silicon lubricating grease and a preparation method thereof. The organic silicon lubricating grease comprises the following components in percentage by mass: 10 to 80 percent of base oil, 1 to 30 percent of modifier and 5 to 25 percent of thickening agent. The organic silicon lubricating grease has the advantages of wide application range, excellent dielectric property, insulating property, sealing property, thermal stability, shockproof property and lubricating property, and obvious improvement on lubricating property and thermal stability particularly.

Owner:东莞太平洋博高润滑油有限公司

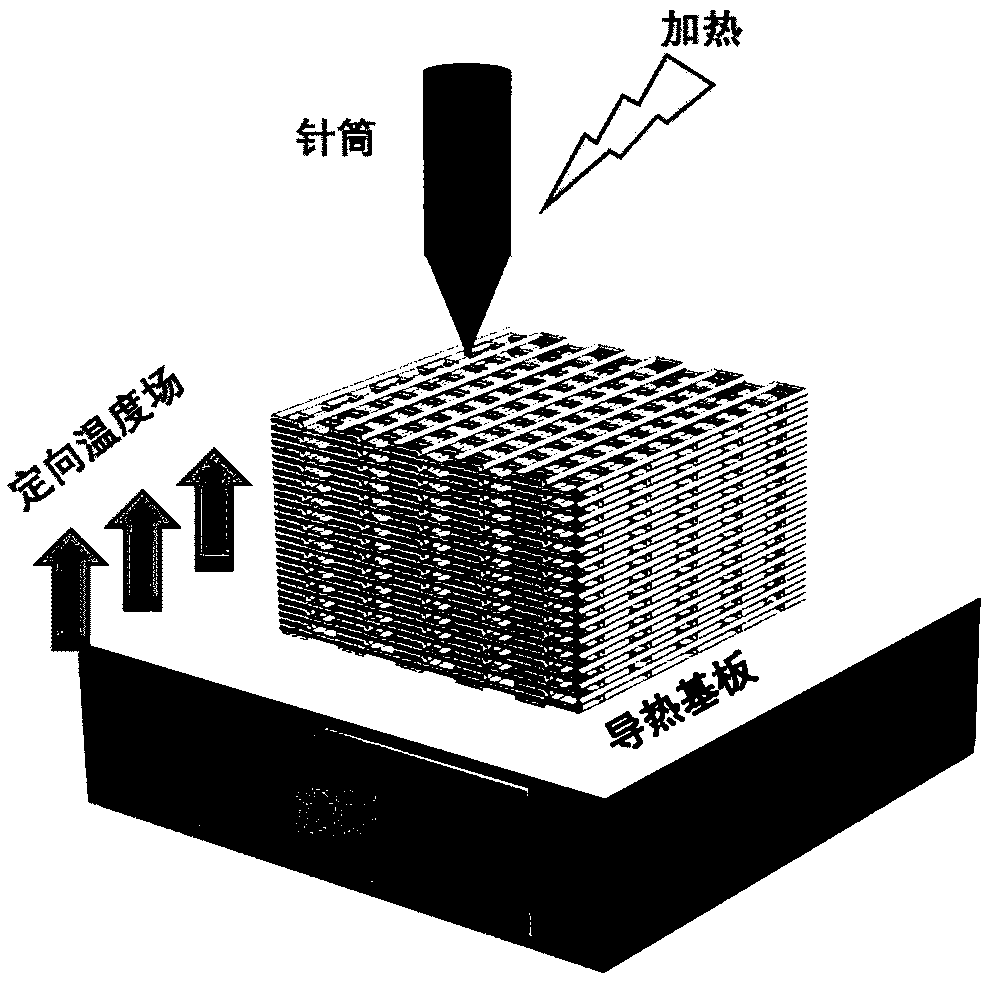

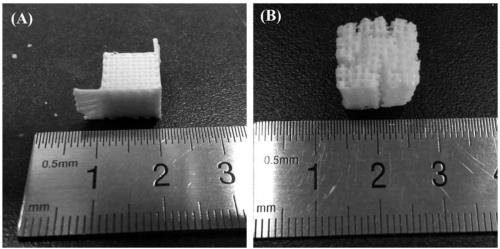

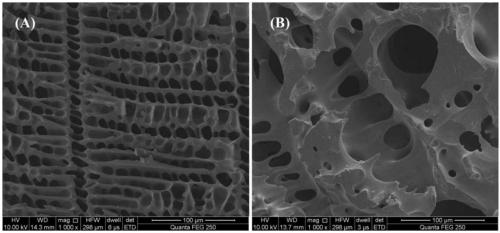

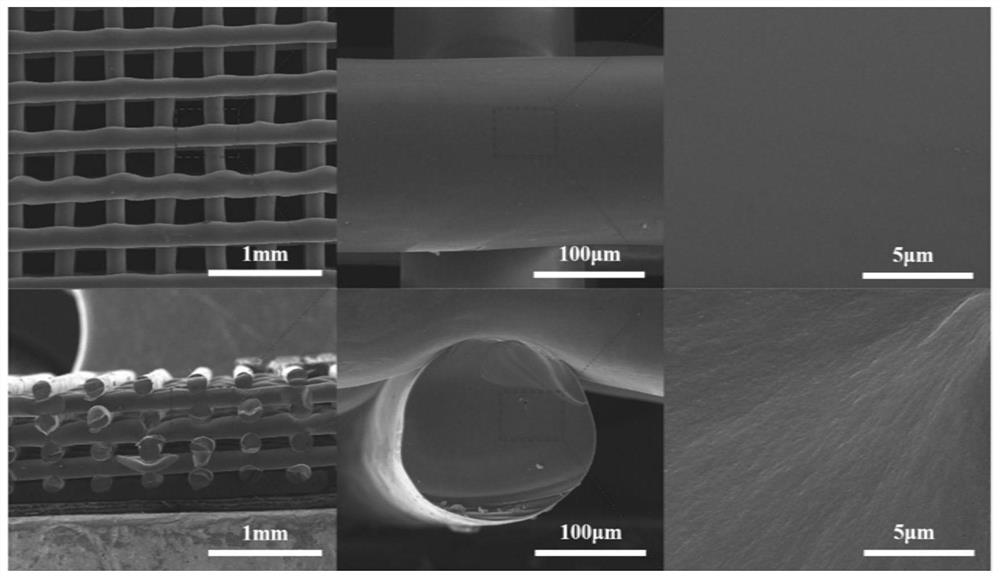

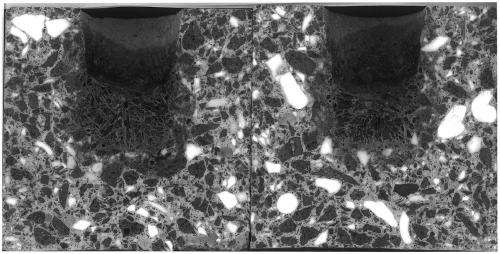

Preparation method of bionic porous ceramic with complex three-dimensional structure

ActiveCN109485430ARheology controlAchieve preparationAdditive manufacturing apparatus3D object support structuresFreeze-dryingSlurry

The invention belongs to the field of molding of three-dimensional structures and specifically relates to a preparation method of a bionic porous ceramic with a complex three-dimensional structure. The preparation method comprises the steps: dissolving a ceramic precursor into a solvent, and carrying out a partial crosslinking reaction to obtain direct writing slurry; degasifying the direct writing slurry, and then, carrying out direct writing molding in an environment of an oriented cold field; and then, carrying out processes such as freeze-drying and crosslinking-cracking to obtain the bionic porous ceramic with the three-dimensional structure. By using the preparation method, the efficient combination of a direct writing molding technology and a freeze-pouring technology is firstly realized; and the limit of a traditional preparation technology on the aspect of achieving a multi-scale hole structure and the complex three-dimensional structure is overcome.

Owner:CENT SOUTH UNIV

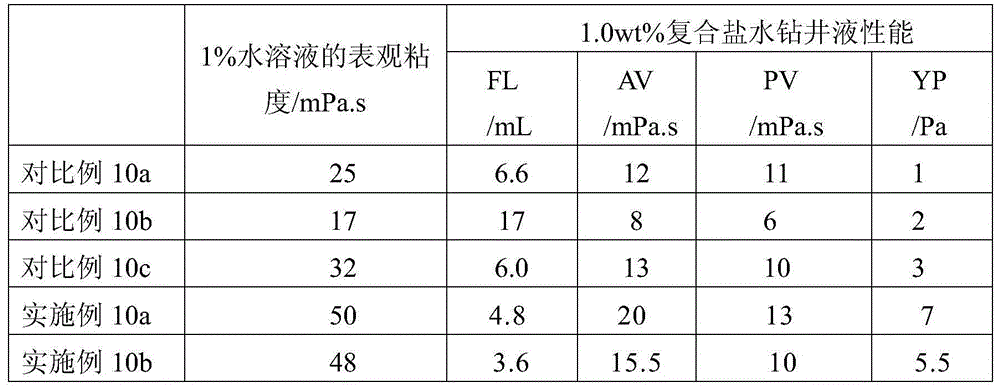

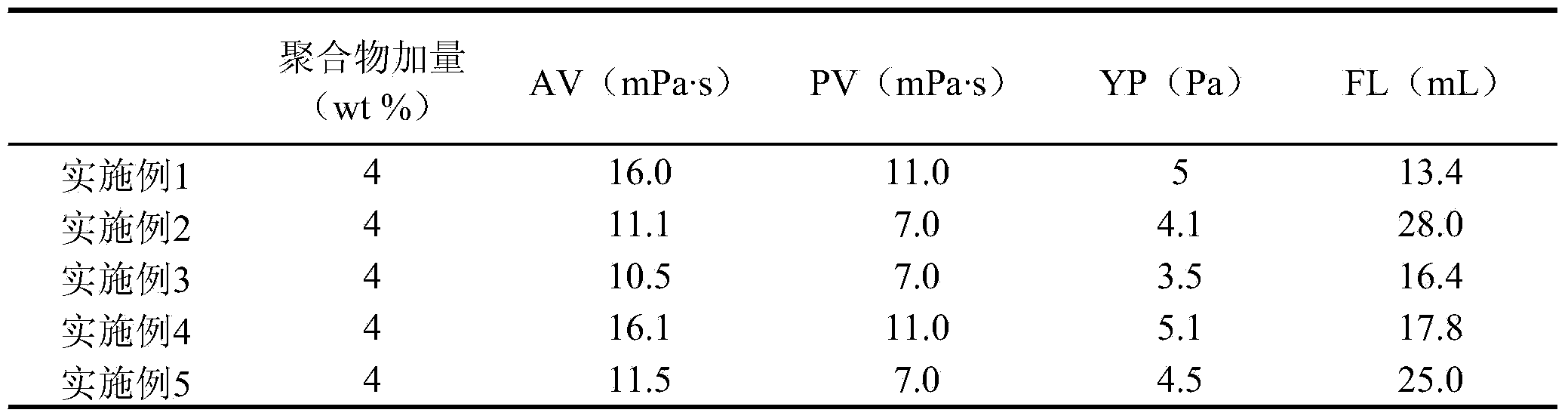

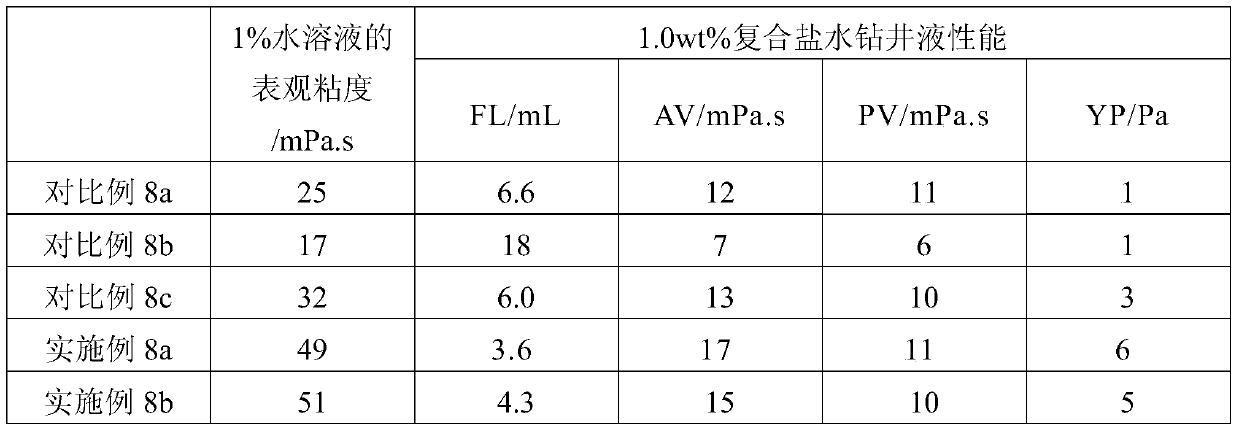

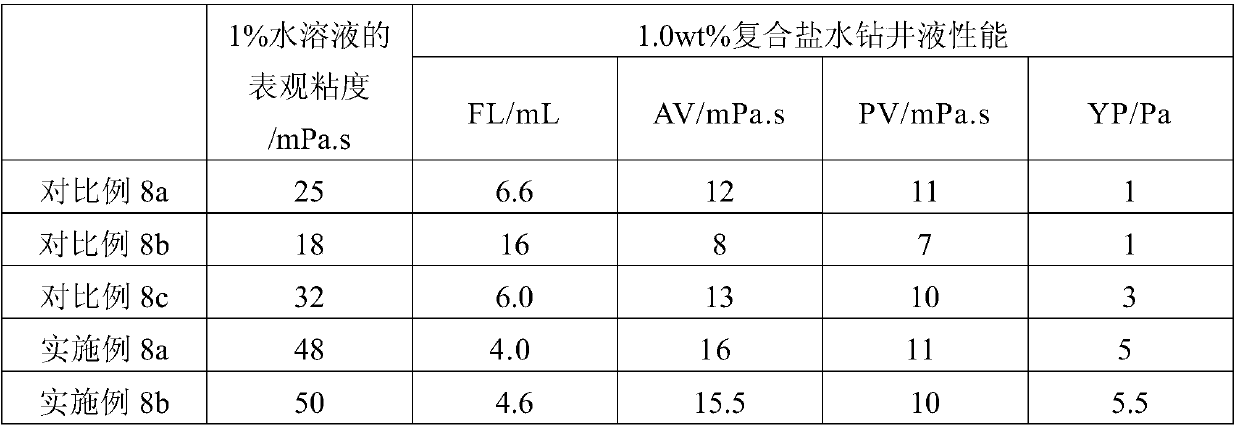

Inorganic-organic polymer processing agent for drilling fluid and preparation method thereof

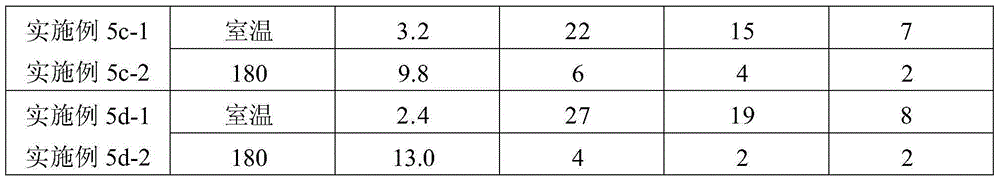

ActiveCN105154030AParticipation responds wellIncrease the amount of introductionDrilling compositionPolymer scienceFiltration

The invention provides an inorganic-organic polymer processing agent for drilling fluid polymerized from sulfonic acid monomer, carboxylic acid monomer, nonionic monomer and inorganic material in the presence of initiator, and the inorganic material includes bentonite. The inorganic-organic polymer processing agent for drilling fluid has good effect on filtration reduction effect in fresh water drilling fluid, brine drilling fluid, saturated brine drilling fluid and compound brine drilling fluid. The inorganic-organic polymer processing agent for drilling fluid has strong anti-sloughing capability and high permeability recovery, can control hydration and dispersion of the shale effectively, can control mud making of the clay effectively, and has good effect on hydrocarbon reservoir protection. Moreover, the preparation method is simple, the sources of raw materials are wide, and the promotion prospect is wide. The invention also provides a preparation method of inorganic-organic polymer processing agent for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

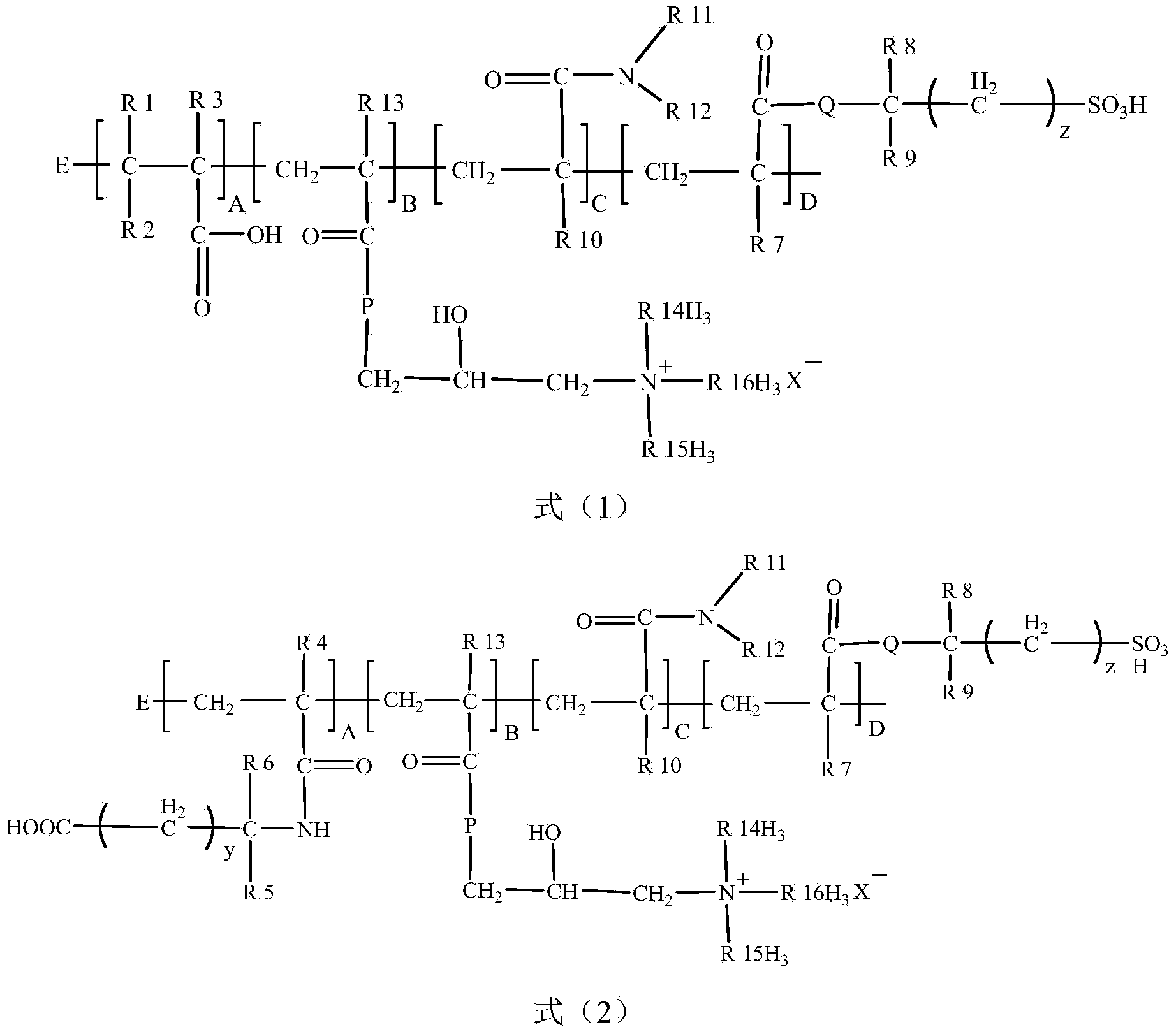

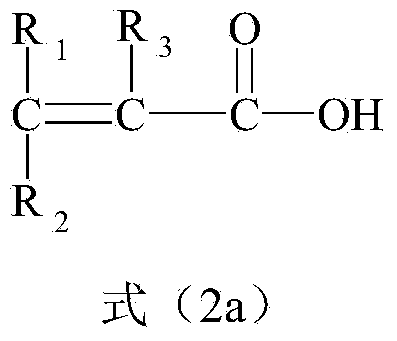

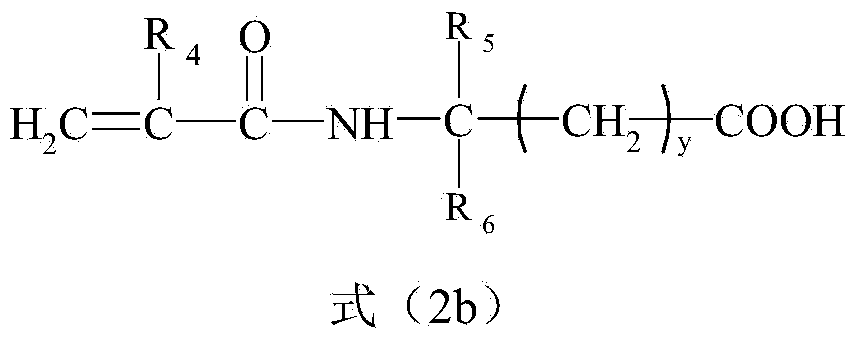

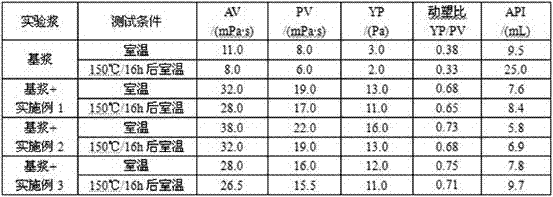

Treating agent for zwitter-ion inorganic-organic monomer polymer drilling fluid and preparation method of treating agent

ActiveCN104357026AImprove thermal stabilityExcellent calcium resistanceDrilling compositionCarboxylic acidSolvent

The invention relates to a treating agent for a zwitter-ion inorganic-organic monomer polymer drilling fluid and a preparation method of the treating agent, and belongs to the technical field of synthesis and preparation of a water-soluble polymer material. The preparation method comprises the following steps: adopting carboxylic acid monomers A, sulfonic acid monomers B, nonionic monomers C, cationic monomers D and inorganic material monomers E as raw materials; feeding the raw materials, wherein the ratio of the amounts of substances of the carboxylic acid monomers A to the sulfonic acid monomers B to the nonionic monomers C to the cationic monomers D is (5-40):(25-10):(65-35):(5-15), and the dosage of inorganic material monomers E is 5%-25% of the total mass of the carboxylic acid monomers A, the sulfonic acid monomers B, the nonionic monomers C, the cationic monomers D and the inorganic material monomers E; adopting water as a solvent, and initiating polymerization through an oxidation-reduction initiation system to obtain the treating agent. The treating agent has higher anti-collapse ability, can effectively control hydration and dispersion of clay shale and mud making of clay, has a better hydrocarbon reservoir protection effect, and is high in permeability recovering value, simple in production technology, extensive in raw material sources and wide in popularization prospects.

Owner:CHINA PETROCHEMICAL CORP +1

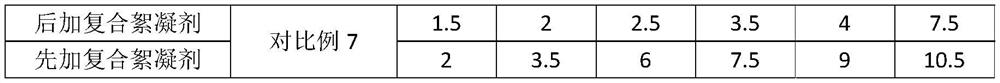

Application of cellulose nanofiber as flow pattern regulator for drilling fluids

Owner:CHINA PETROCHEMICAL CORP +3

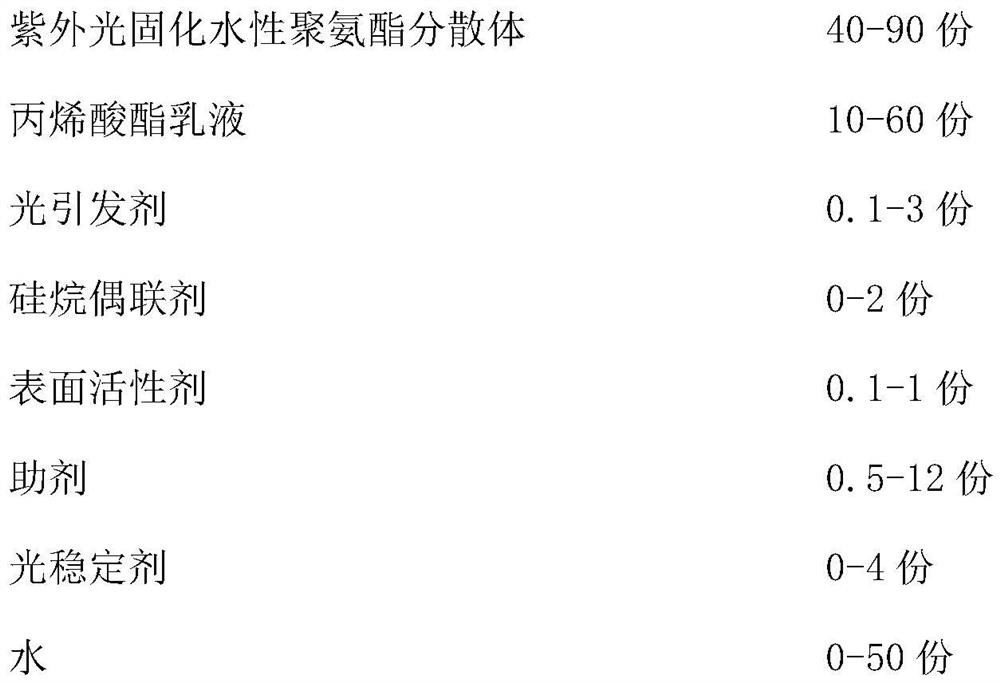

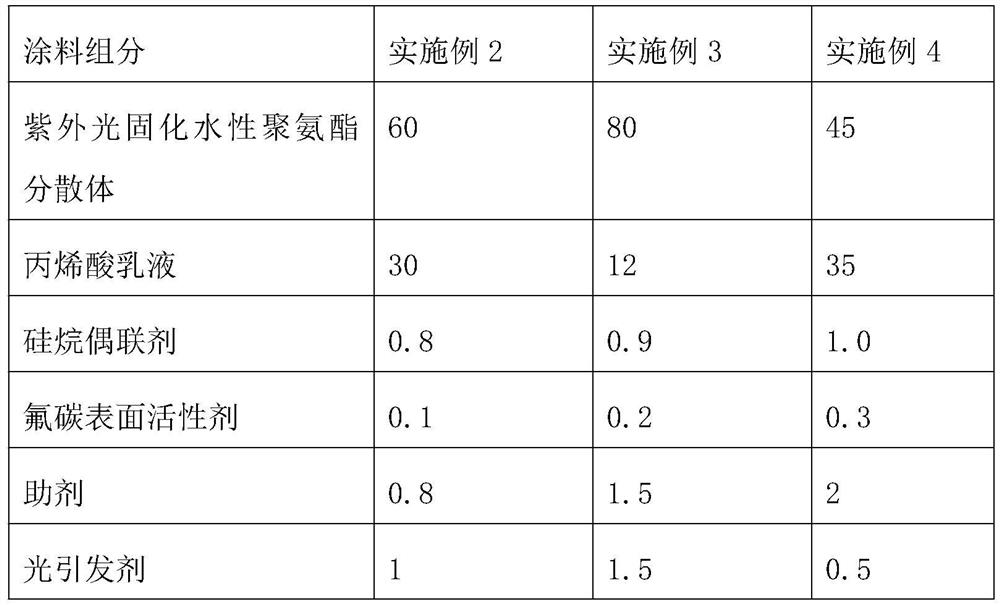

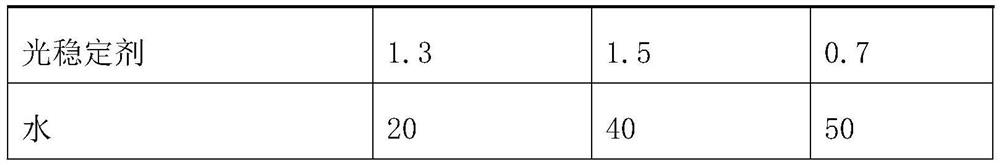

Water-based UV printing ink used for gravure printing and production technology thereof

The invention discloses water-based UV printing ink used for gravure printing and belongs to the field of printing materials. The water-based UV printing ink used for gravure printing is prepared from the following raw materials in parts by weight: 30-60 parts of waterborne polyurethane resin, 3-5 parts of a photoinitiator, 10-30 parts of pigment, 5-20 parts of filler, 0.05-0.5 part of a defoaming agent, 0.2-3.0 part of a wetting dispersant and 5-30 parts of water. The invention also provides a production technology of the water-based UV printing ink used for gravure printing. The water-based UV printing ink is non-inflammable and unexplosive and does not belong to dangerous chemicals, so that the security in printing, transportation and storage is enhanced; meanwhile, the water-based UV printing ink is not added with a quick-drying auxiliary or ethyl alcohol, zero release is realized, and the printing effect of the water-based UV printing ink can be equivalent to that of alcohol soluble printing ink and solvent type printing ink. The water-based UV printing ink has good adhesion and strong water resistance after being printed, so that the water-based UV printing ink is especially applicable to packaging printing materials for food, drink and medicines.

Owner:新东方油墨有限公司

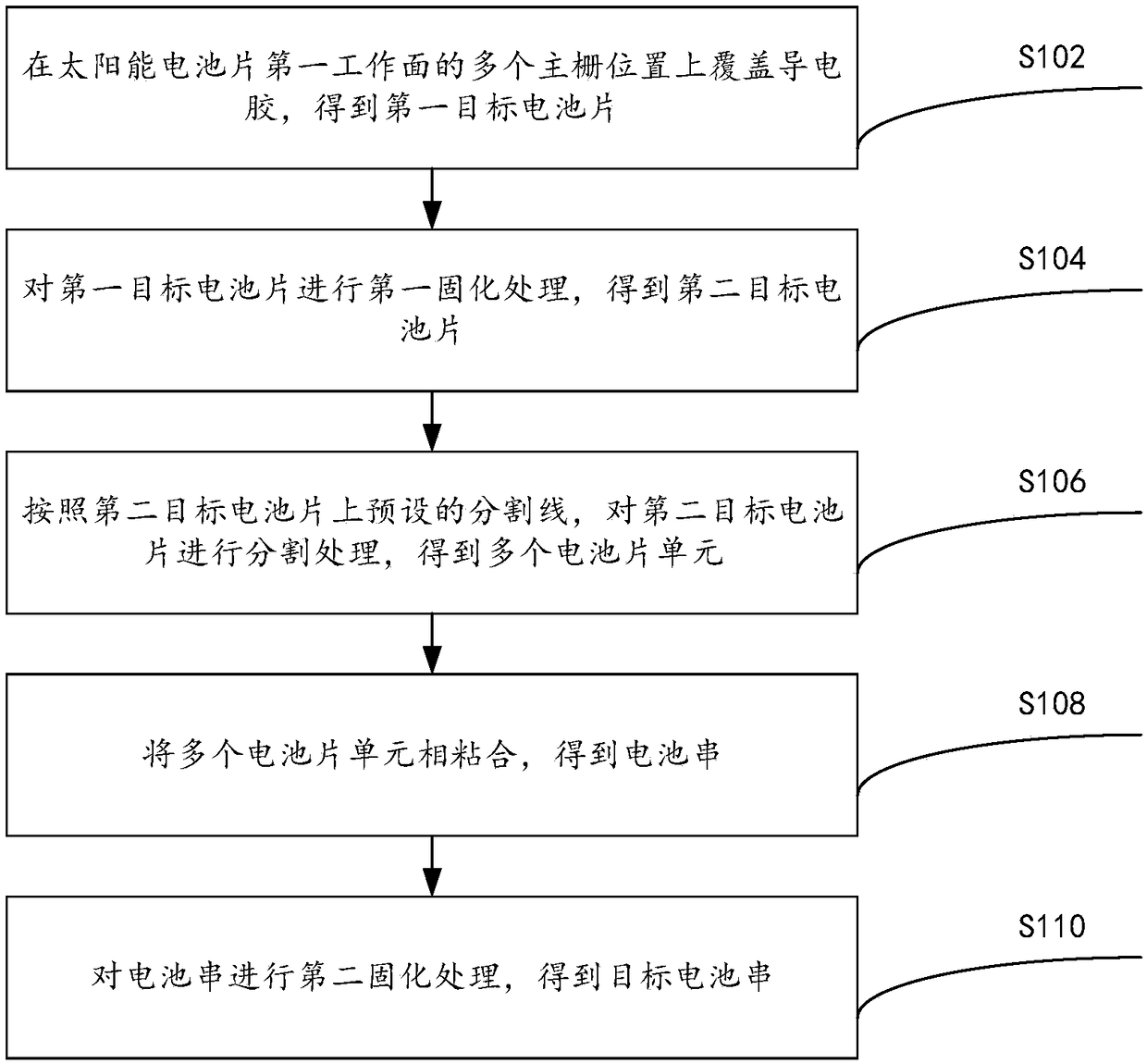

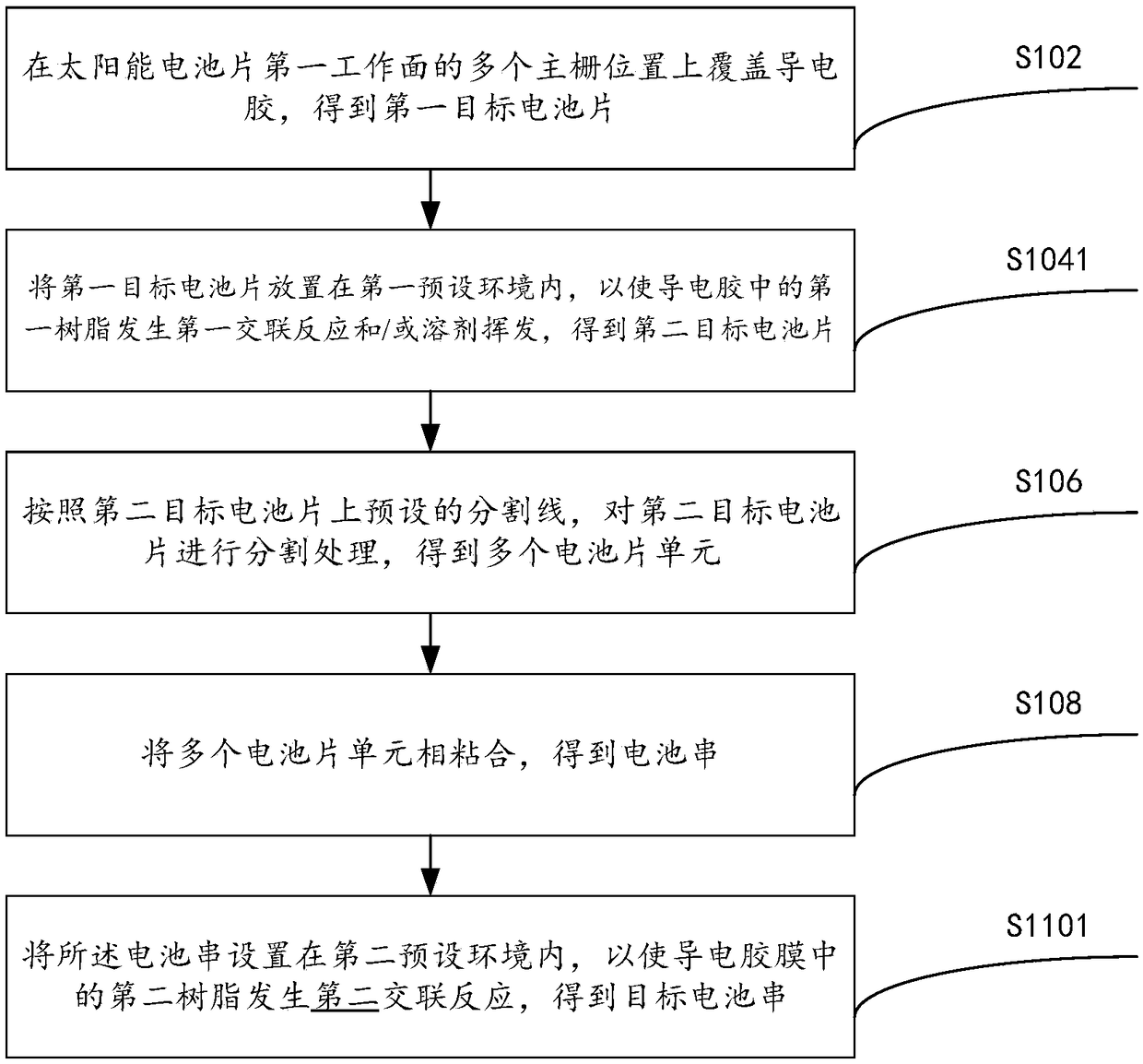

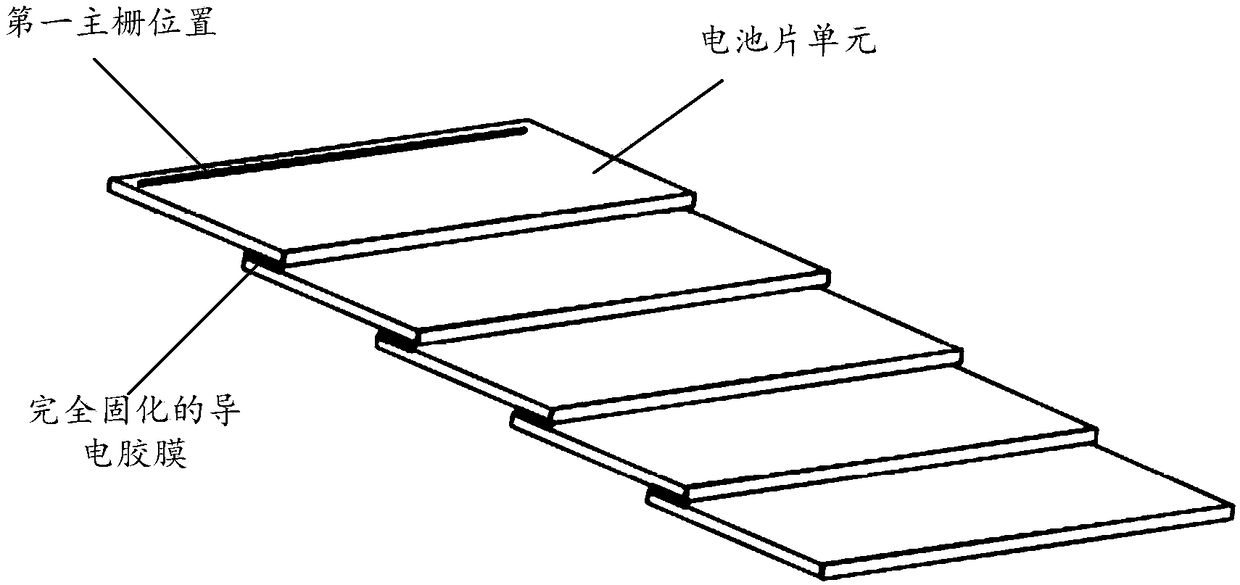

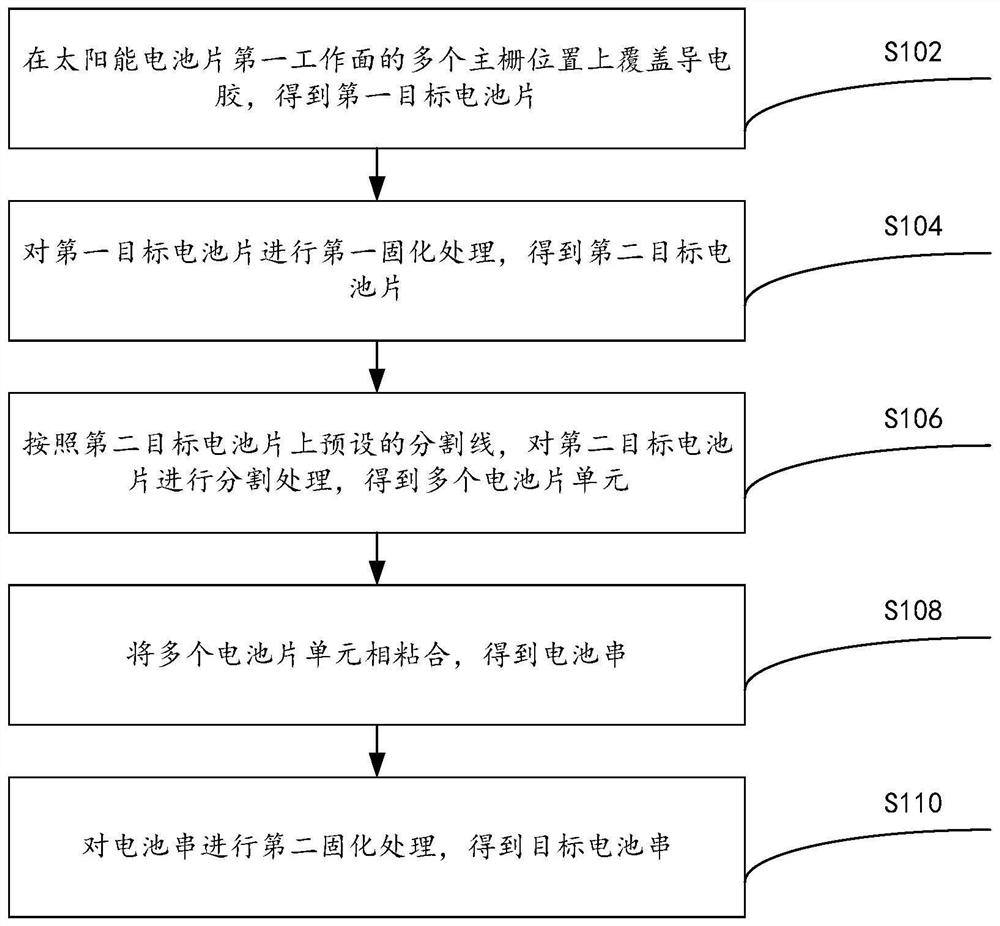

Connection method of conducting glue capable of being online transformed into glue film in time and solar cell piece

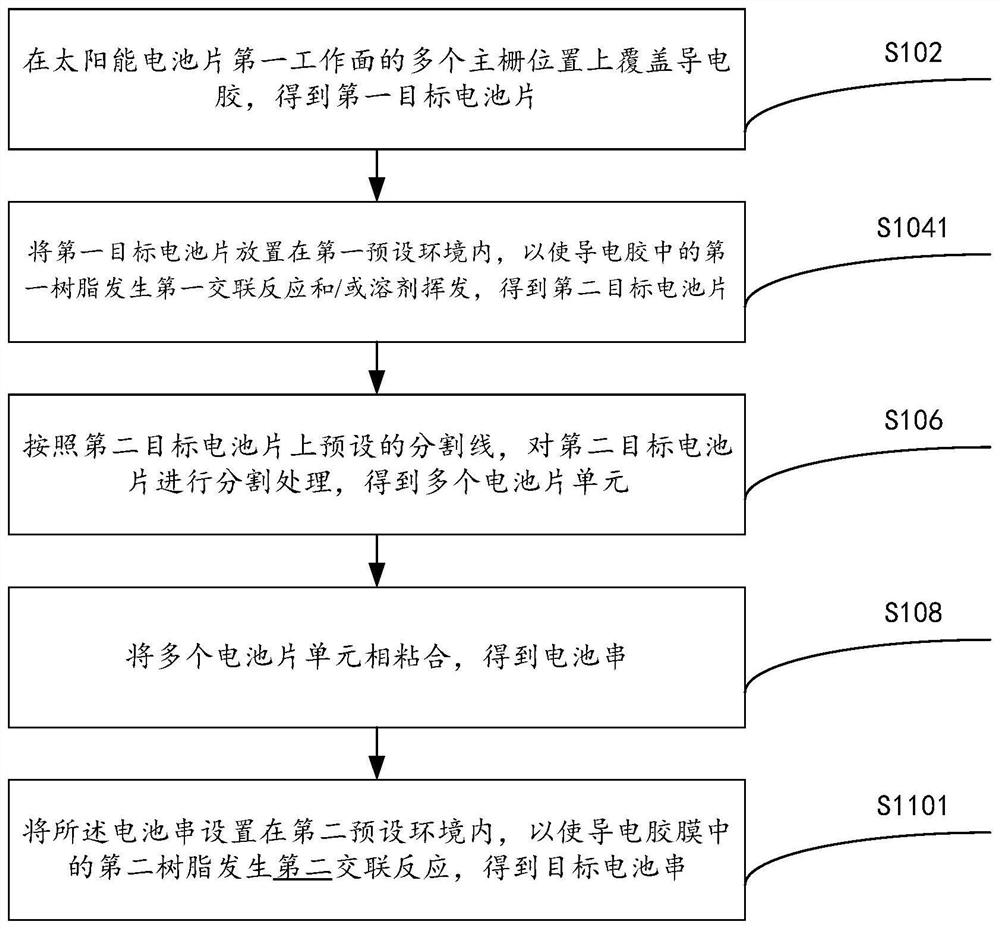

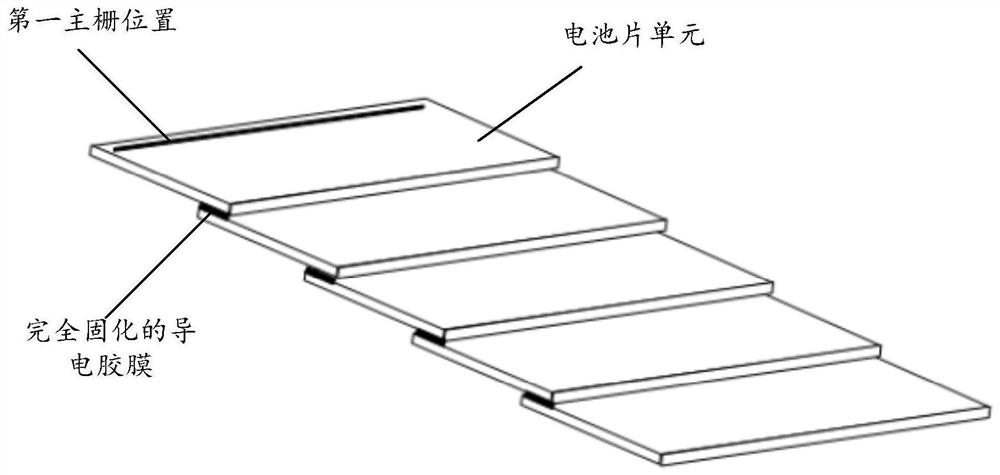

ActiveCN108899387AControl overlap areaReduce overlap areaPhotovoltaic energy generationSemiconductor devicesSplit linesEngineering

The invention provides a connection method of conducting glue capable of being online transformed into a glue film in time and a solar cell piece and relates to the technical field of solar power generation. The method comprises the following steps: covering a plurality of main grid positions of a first working surface of the solar cell piece with the conducting glue, so as to obtain a first target cell piece; carrying out first curing treatment on the first target cell piece, so as to obtain a second target cell piece; carrying out cutting treatment on the second target cell piece according to pre-set division lines on the second target cell piece, so as to obtain a plurality of cell piece units; sticking the plurality of cell piece units to obtain a cell string; carrying out second curing treatment on the cell string to obtain a target cell string. By adopting the connection method disclosed by the invention, the technical problems in the prior art that when the cell piece units areconnected, the overlapping area between the two adjacent cell piece units is relatively large, the light illumination conversion rate is relatively low, and the reliability of an imbrication assemblycomposed of the target cell piece is relatively low, caused by the fact that the thickness of a glue layer between each two point battery piece units is not enough or the thickness of the glue layer is not uniform are solved.

Owner:彭延岩

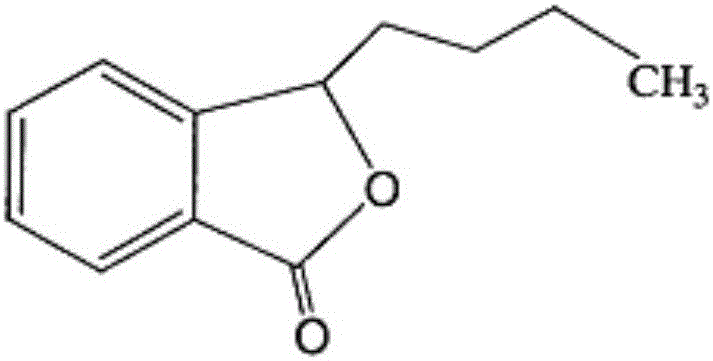

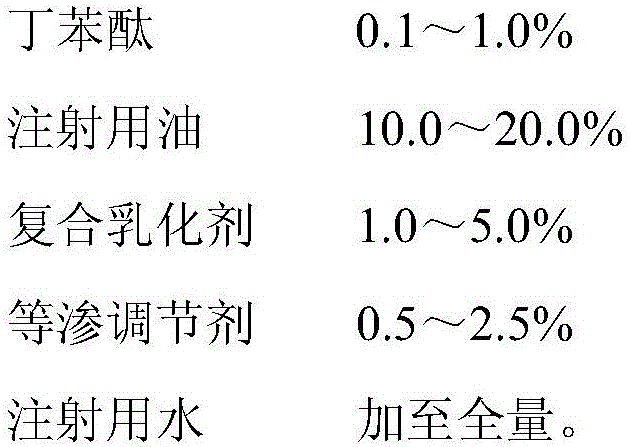

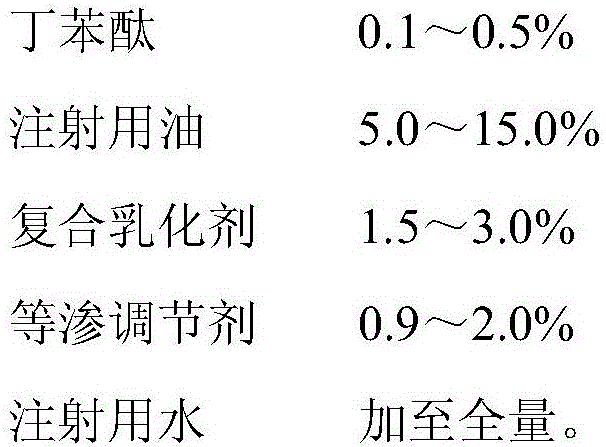

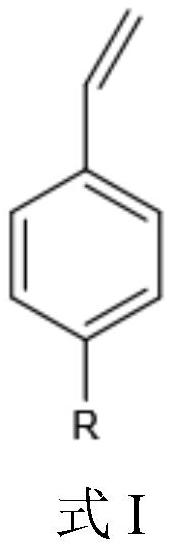

Butylphthalide fat emulsion injection and preparation process thereof

InactiveCN105796486AGood solubilization effectAccurate doseOrganic active ingredientsPharmaceutical non-active ingredientsSide effectMicrometer

The invention discloses a butylphthalide fat emulsion injection and a preparation process thereof.The butylphthalide fat emulsion injection is prepared from 0.1-1.0% of refined butylphthalide, 10.0-20.0% of oil for injection, 1.0-5.0% of a compound emulsifier, 0.5-2.5% of an isotonic regulator and the balance water for injection, wherein the grain size of an obtained milk white emulsion solution ranges from 0.1 micrometer to 1.0 micrometer.Butylphthalide is dissolved in an oil phase, a better solubilization effect can be achieved after the oil phase and a water phase are fully emulsified under the action of the compound emulsifier at a specific proportion, the divided dose is accurate, and no solubilizer or cosolvent needs to be added; meanwhile, stability is improved, and the toxic and side effects of the butylphthalide fat emulsion injection are reduced.

Owner:NANJING TIANXIANG PHARMA TECH

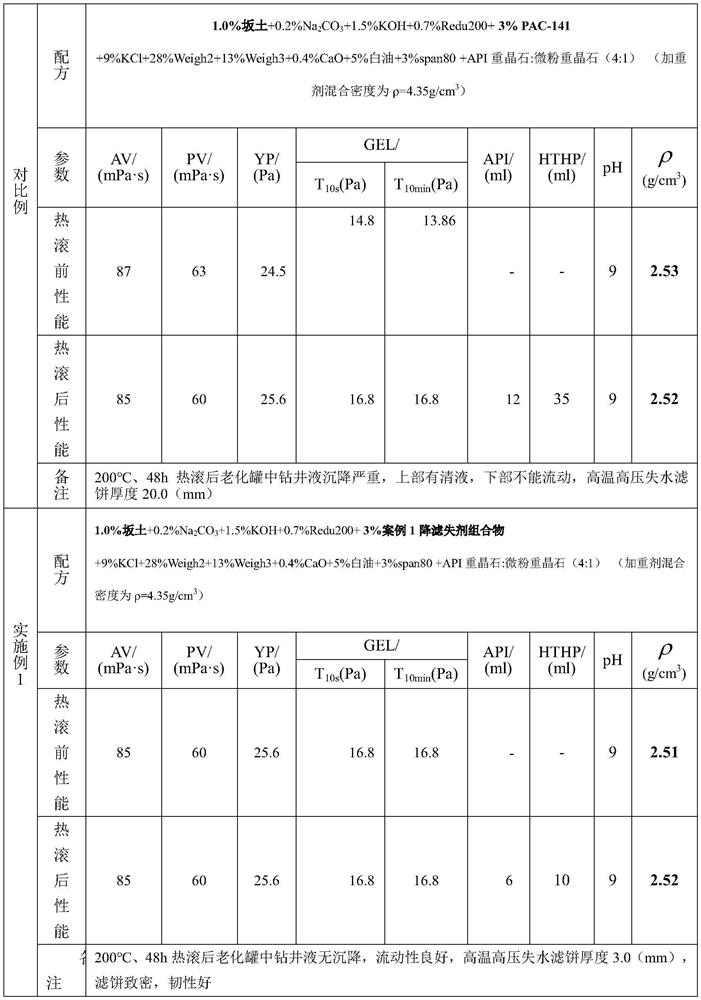

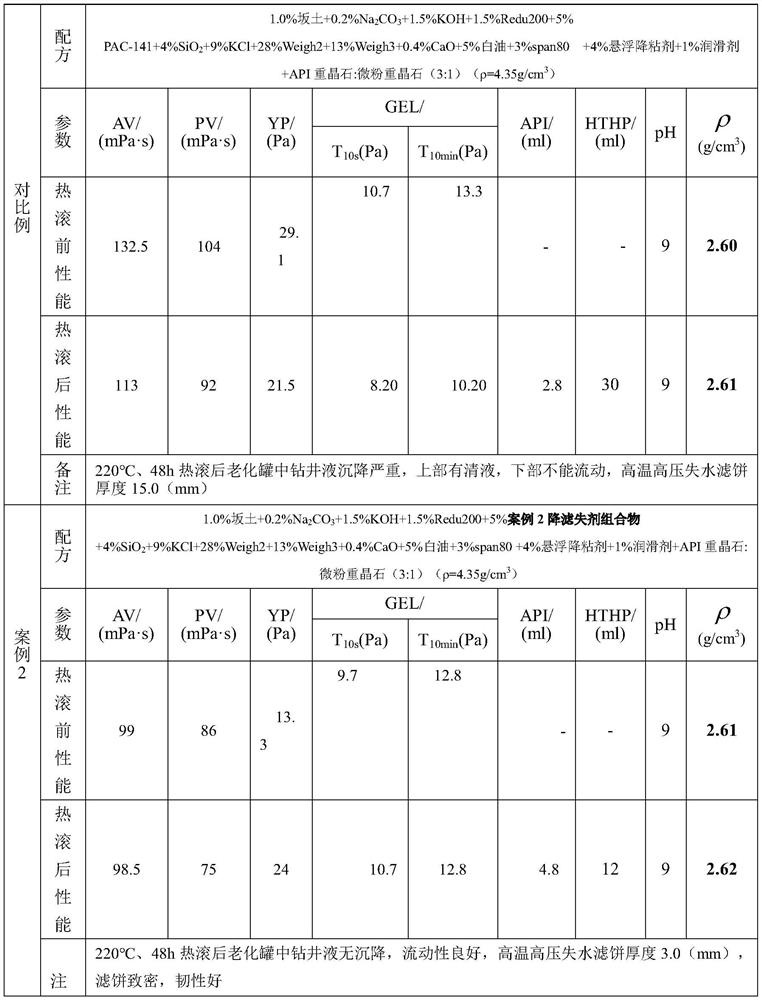

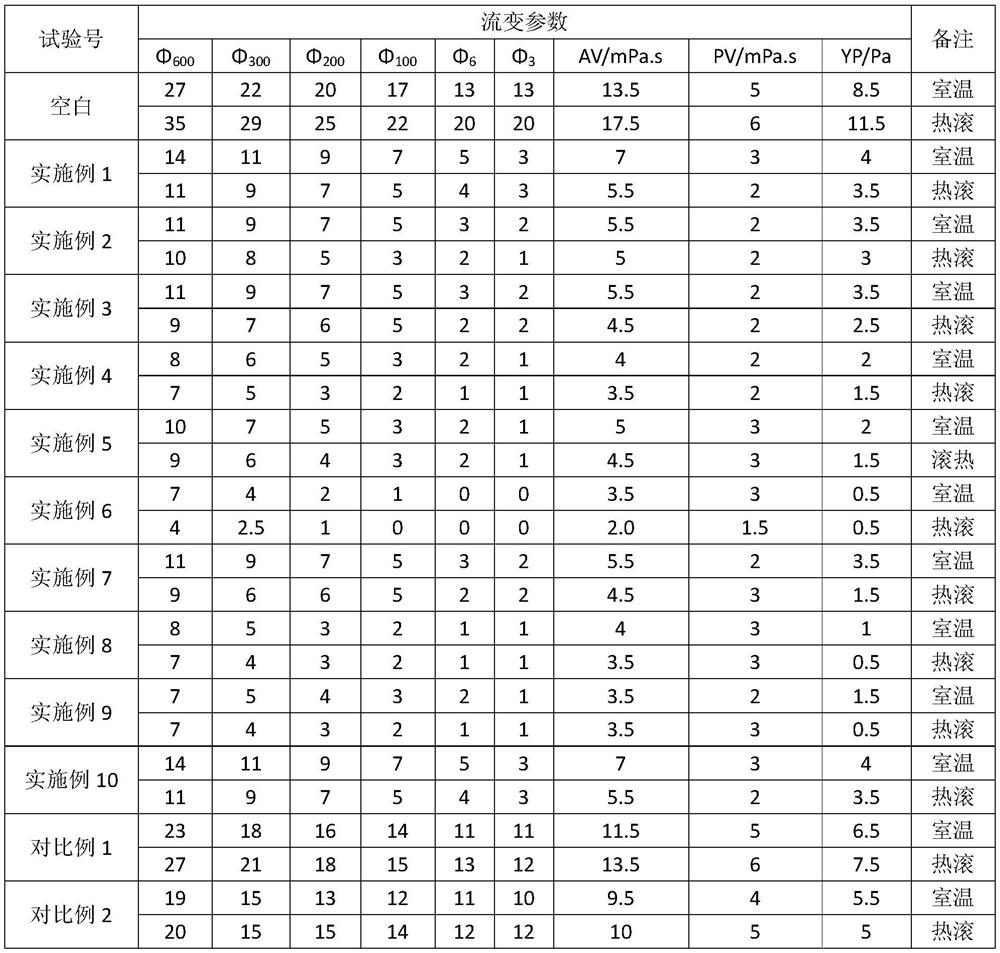

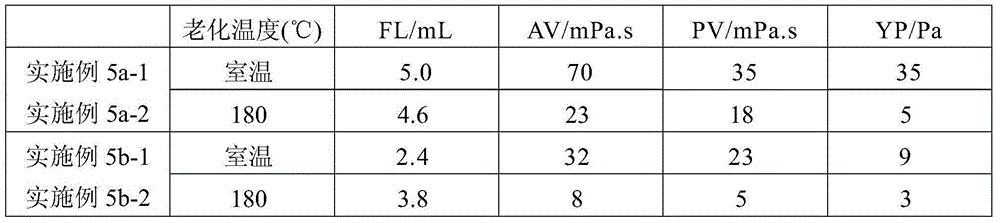

Preparation method of high-temperature high-density water-based drilling fluid filtrate reducer composition

PendingCN114736659AIncrease resistance to movementAvoid curlDrilling compositionHydrophilic monomerMicrosphere

The invention discloses a preparation method of a high-temperature and high-density water-based drilling fluid filtrate reducer composition, which belongs to the technical field of oilfield chemical agents, and is characterized in that the filtrate reducer composition is formed by combining a low-molecular-weight linear polymer and temperature-sensitive polymer particle microspheres, the preparation method of the low-molecular-weight linear polymer comprises the following steps: reacting an acrylamide hydrophilic monomer, a sulfonic acid group-containing temperature-resistant monomer, a rigid hydrophobic monomer, a cationic monomer, an initiator I and a polymerization inhibitor under a deoxidizing condition, washing a reaction product, drying and crushing to obtain the low-molecular-weight linear polymer. The preparation method of the temperature-sensitive polymer particle microspheres comprises the following steps: dissolving a temperature-sensitive monomer, a cationic monomer, a dispersing agent, a cross-linking agent and an initiator II in a mixed solution of deionized water and polyethylene glycol, reacting under a deoxidizing condition, and washing and drying a reaction product to obtain the polymer particle microspheres. The method is mainly used for synthesizing the high-temperature high-density water-based drilling fluid filtrate reducer composition.

Owner:YANGTZE UNIVERSITY +1

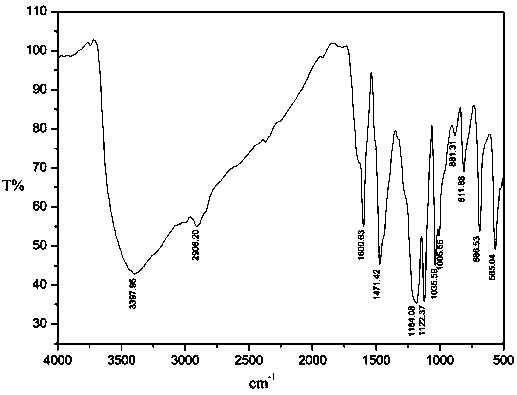

Filtrate reducer for oil field drilling fluid and preparation method thereof

InactiveCN103614120AAchieve rheologyImprove thermal stabilityDrilling compositionReaction temperatureHigh pressure

The invention relates to a filtrate reducer for an oil field drilling fluid for a petroleum enterprise and a preparation method thereof. The filtrate reducer can be used for favorably controlling the rheological property of the drilling fluid and decreasing the filter loss of high-temperature and high-pressure basic mud of the drilling fluid so as to improve the salt tolerance of the drilling fluid. According to the technical scheme, the filtrate reducer is a quadripolymer prepared by polymerizing the following monomers by mass percent: 3.2% to 16.1% of p-sulfanilic acid, 16% to 29.1% of p-methylbenzene sulfonic acid, 26% to 31.8% of phenol and 35.9% to 41.7% of formaldehyde. The preparation method comprises the following steps: adding a sodium hydroxide solution with the mass percentage concentration being 50% into the monomers; regulating the pH (Power Of Hydrogen) of a reaction system to reach 9; performing a thermostatic reaction for 4 to 7 hours by setting the reaction temperature at 70 DEG C to 90 DEG C; washing the mixture with absolute ethyl alcohol until separating out precipitates; and drying the precipitates for 24 hours at the temperature of 85 DEG C, thereby preparing the filtrate reducer. The filtrate reducer has the good performance under high-temperature and high-salt conditions. The preparation method is simple in process, easy to control and low in cost. The filtrate reducer is used for the oil field drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Use of polyurethane powder as inner additive of redispersible polymer powder

ActiveUS20140288202A1High bonding strengthMinimize water infiltrationPlastic recyclingAdhesiveWater insoluble

A powdered polyurethane, preferably a powdered recycled polyurethane rigid foam is co-dried with a water insoluble film-forming polymer to obtain a redispersible polymer powder composite for use in hydraulic binders or cementitious compositions to improve performance of cementitious compositions or mortar, in applications such as cement based the adhesives (CBTA), or external thermal insulating composite systems (ETICS).

Owner:THE DOW CHEM CO

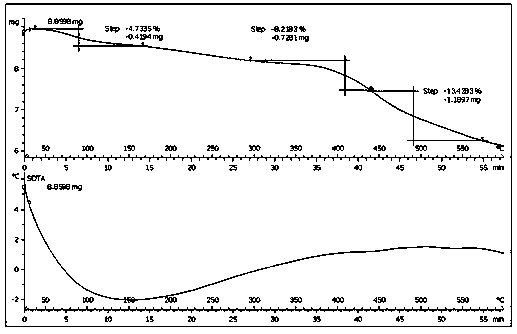

High-temperature-resisting water-based well-drilling fluid filtrate reducer and preparation method thereof

InactiveCN109321216AControl rheologyControl suspension stabilityDrilling compositionCross-linkWater based

The invention discloses a high-temperature-resisting water-based well-drilling fluid filtrate reducer and a preparation method thereof. The high-temperature-resisting water-based well-drilling fluid filtrate reducer is prepared from the following raw materials in parts by mass: 700 parts of sulfomethylated phenol formaldehyde resin, 3-8 parts of formaldehyde, 6-15 parts of melamine, 8-20 parts ofa sulfonate monomer, 40-80 parts of an acrylamide monomer, 0.5-2 parts of a cross-linking agent, 0.3-0.6 part of an initiator, and 60-80 parts of water. The sulfomethylated phenol formaldehyde resin is modified and then subjected to a copolymerization with the multiple monomers, namely the high-temperature-resisting water-based well-drilling fluid filtrate reducer is synthesized by increasing hydration groups of a product and introducing new sulfonic groups and aromatic ring structures, thus the demand of safe well-drilling construction in a downhole high-temperature environment can be met, the rheological property and suspension stability of water-based well-drilling fluid under the high-temperature and high-pressure conditions can be controlled, and the high-temperature and high-pressurefilter loss of the well-drilling fluid is effectively decreased.

Owner:中科宝辰(北京)科技有限公司

Fluid loss additive for drilling fluid and preparation method thereof

ActiveCN102766240BControl rheologyReduce high temperature and high pressure filtration lossDrilling compositionSide chainWell drilling

The invention discloses a fluid loss additive for drilling fluid and a preparation method thereof, belonging to the technical field of chemical drilling fluid treating agents for oilfields. The method comprises the following steps of: carrying out one-step reaction on phenol, formaldehyde, humate, pyrosulfite and anhydrous sulfite so as to obtain a sulfonated phenolic humic acid resin; in the presence of an initiator, carrying out graft copolymerization on the sulfonated phenolic humic acid resin and a mixture of sodium hydroxide, 2-acrylamide-2-methyl-propyl sulfonate, acrylamide and dodecylacrylamide; and carrying out drying and crushing on the obtained product so as to obtain sulfonated phenolic humic acid resin-alkenyl monomer graft copolymer. The fluid loss additive disclosed by the invention has the functions of controlling the rheological property of drilling fluid and reducing the high-temperature and high-pressure filter loss of drilling fluid, not only enhances the thermal stability of side chains of a chain polymer, but also improves the salt tolerance of a sulfonated phenolic resin, and guarantees that products have good properties under high temperature and high salt conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

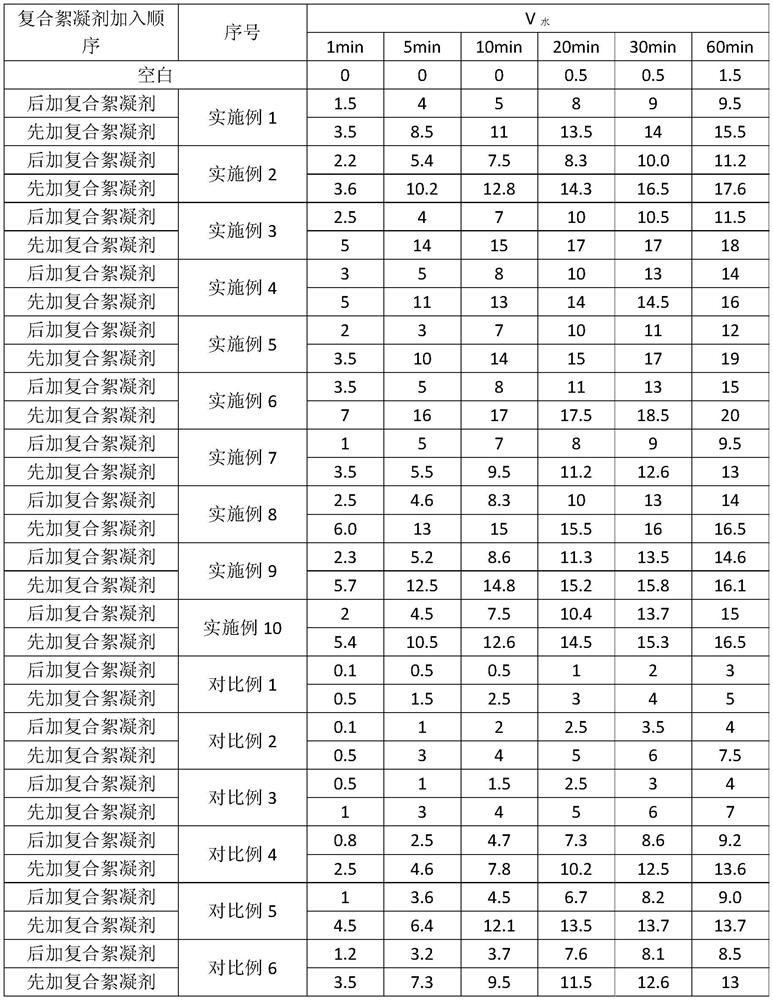

Composite flocculant, water-based drilling fluid and application of water-based drilling fluid

ActiveCN112760087AGood synergyGood flocculation effectDrilling compositionInorganic saltsFlocculation

The invention relates to the technical field of petroleum drilling fluids, in particular to a composite flocculant, a water-based drilling fluid and application of the water-based drilling fluid. The composite flocculant disclosed by the invention is prepared from the following components in parts by weight: 0.05-0.3 parts of polyacrylamide, 2-20 parts of inorganic salt and 1-10 parts of a polyamine inhibitor. According to the composite flocculant disclosed by the invention, the flocculation effect of the composite flocculant is improved by mainly utilizing the synergistic effect of the macromolecular polyacrylamide and the polyamine inhibitor. The composite flocculant can reduce clay hydration and accelerate solid-phase particle flocculation and sedimentation, is used for rapid drilling of an upper stratum, improves the flocculation degree and realizes effective solid-phase control.

Owner:中石化石油工程技术服务有限公司 +2

Polyquaternary amine salt with rheologic modification function and application thereof

ActiveCN103030747AWith rheology modification functionGood rheology modification functionCosmetic preparationsHair cosmeticsSulfite saltPolyethylene glycol

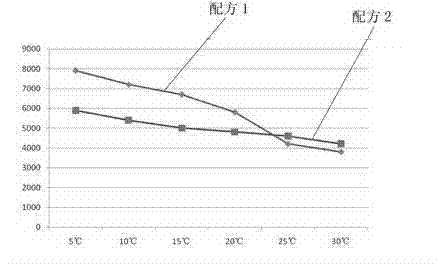

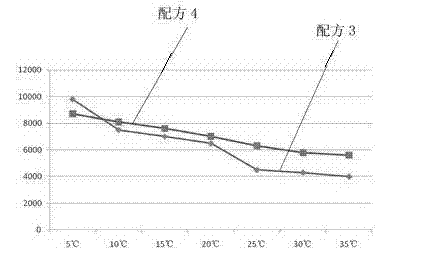

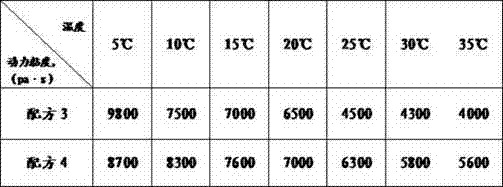

The invention provides a synthetic cationic high-polymer polyquaternary amine salt with rheologic modification function, which is polymerized from the following components in parts by weight in a water solution environment: 7-14 parts of dimethylaminoethyl methacrylate, 3-10 parts of acrylic acid, 0.5-5 parts of allyl polyethyleneglycol, 0.3-3 parts of ammonium persulfate, 1-7 parts of hydrochloric acid, 0.1-6 parts of 10% sodium sulfite water solution and 53-88 parts of deionized water. On the premise of not losing cationic polyquaternary amine salt characteristics, the polyquaternary amine salt provided by the invention has favorable rheologic modification function, and can be used as a conditioner in liquid washing products, such as shampoo, body wash, liquid soap and the like. Due to the properties, the polyquaternary amine salt can enable the liquid washing product to have stable rheological properties in both high and low temperature environments, and is especially suitable for improving the rheological properties under low temperature conditions, thereby enhancing the service convenience of the product.

Owner:汕头市大千高新科技研究中心有限公司

Inorganic-organic polymer treatment agent for drilling fluid and preparation method therefor

ActiveCN105295857AParticipation responds wellIncrease the amount of introductionDrilling compositionAluminum magnesium silicateCarboxylic acid

The present invention provides an inorganic-organic polymer treatment agent for a drilling fluid, wherein the treatment agent is polymerized and formed by a sulfonic acid monomer, a carboxylic acid monomer, a nonionic monomer and inorganic material under the action of an initiator; and the inorganic material contains an aluminum-magnesium silicate inorganic gel. The inorganic-organic polymer treatment agent provided by the present invention has a relative strong reduction fluid loss effect in a fresh water drilling fluid, a saline water drilling fluid, a saturated saline water drilling fluid and a composite saline water drilling fluid, and further has a relative strong collapse prevention capability to control hydration and dispersion of mud shale and clay mud-making effectively. The recover value of permeability is high. The treatment agent has a relatively good hydrocarbon reservoir protecting effect. The inorganic-organic polymer treatment agent is simple in production process, wide in raw material sources, and vast in popularizing prospect. The present invention further provides a preparation method for the inorganic-organic polymer treatment agent for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

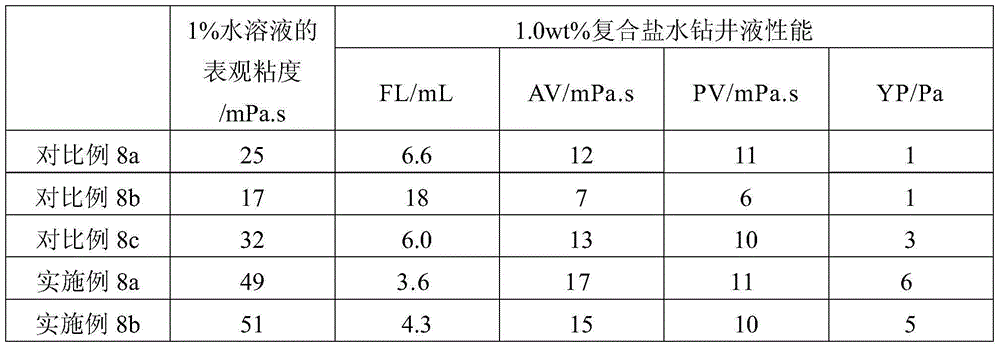

Molten 3D direct-writing printing slurry as well as preparation method and application thereof

ActiveCN111646803AControl rheologyReduce adverse effectsAdditive manufacturing apparatusCeramic shaping apparatusMolten stateSolvent free

The invention discloses molten-state 3D direct-writing printing slurry as well as a preparation method and application thereof, the molten-state 3D direct-writing printing slurry is a molten-state substance obtained by modifying a ceramic precursor with a modifier and then heating the obtained modified ceramic precursor powder to 250-300 DEG C, wherein the ceramic precursor is polycarbosilane, andthe modifier is selected from at least one of polypropylene, hyperbranched liquid polycarbosilane, liquid polyvinyl silane and polydimethylsiloxane. The invention, for the first time, provides the 3Ddirect-writing printing slurry in a molten state, wherein the 3D direct-writing printing slurry is completely solvent-free, and the rheological property of the slurry can be simply controlled by controlling the temperature. Compared with solutions and suspension slurry, the ceramic structure prepared from the molten 3D direct-writing printing slurry is very smooth in surface and hardly has defects inside, the process that a solvent needs to be removed from a printed green body is removed, and the adverse effect of the solvent on the green body is overcome.

Owner:CENT SOUTH UNIV

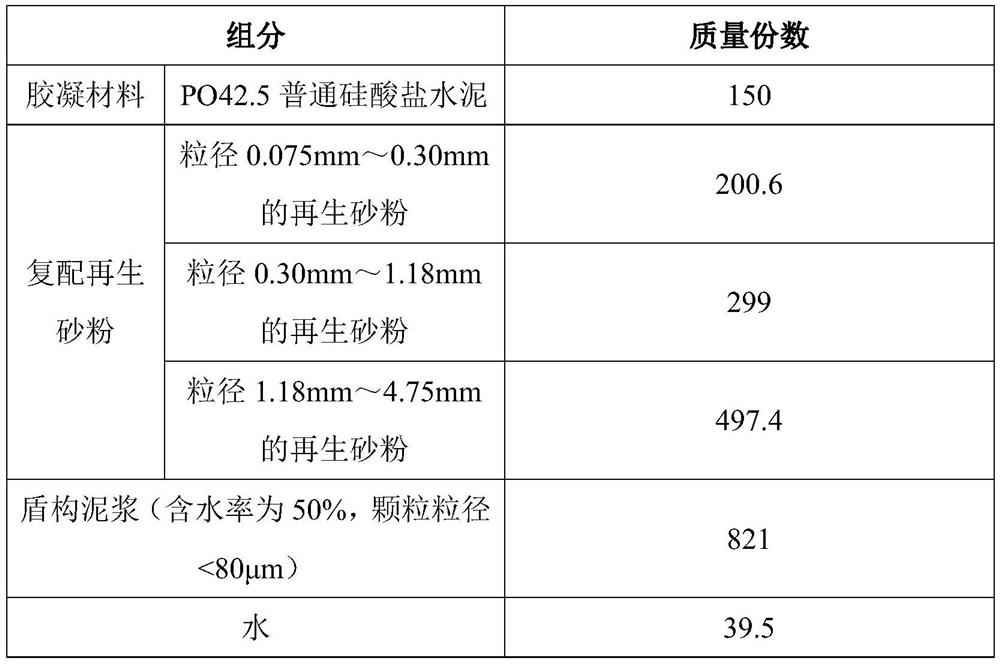

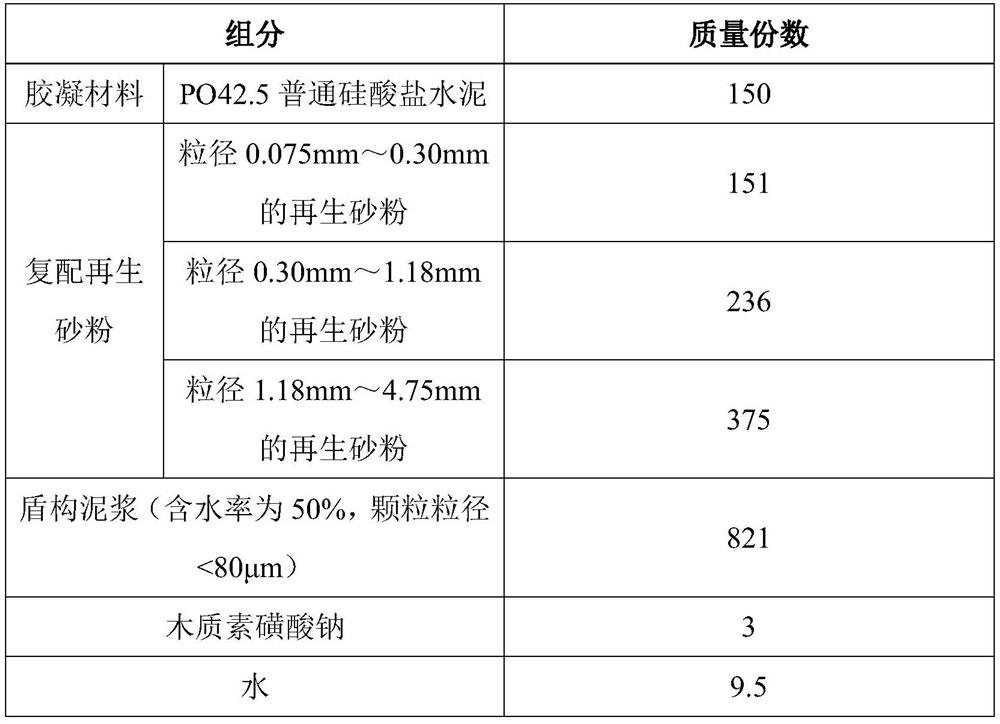

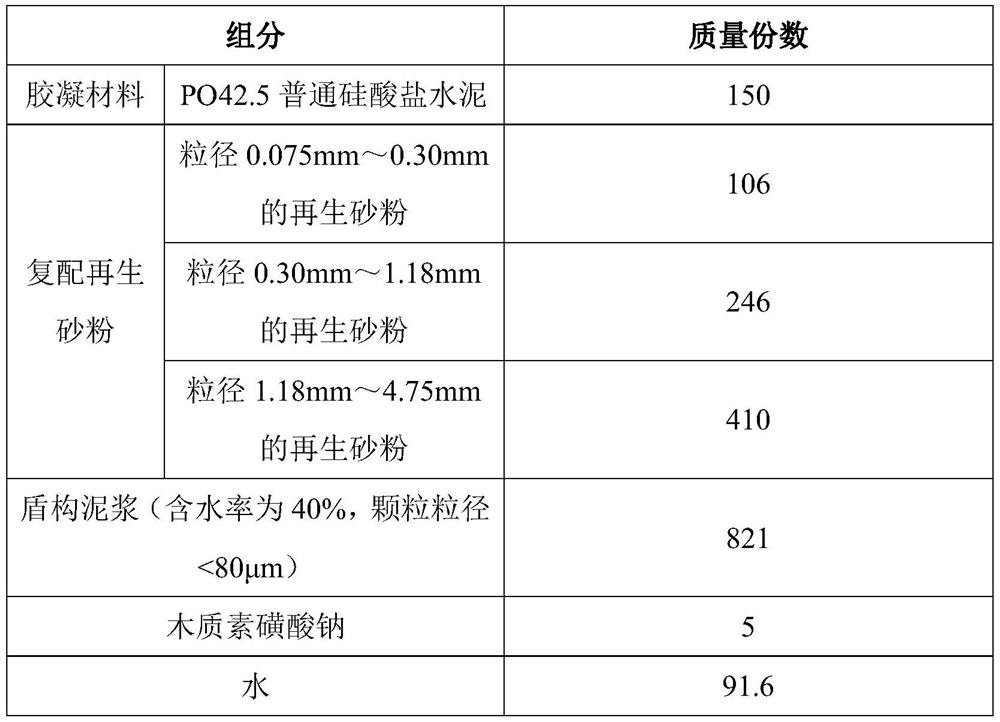

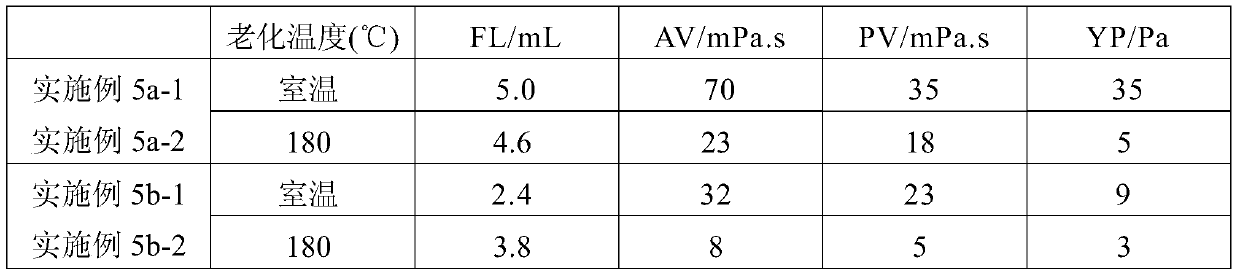

Controllable low-strength material based on shield slurry and regenerated sand powder as well as preparation method and application of controllable low-strength material

ActiveCN114213077AImprove liquidityImprove stabilityRoadwaysSolid waste managementPowderWater reducer

The invention discloses a controllable low-strength material based on shield slurry and regenerated sand powder as well as a preparation method and application of the controllable low-strength material. The controllable low-strength material based on the shield slurry and the regenerated sand powder comprises a cementing material, compound regenerated sand powder, the shield slurry, a water reducing agent, a coagulant and water, wherein the compound regenerated sand powder is formed by compounding regenerated sand powder with the particle size of 0.075-0.30 mm, regenerated sand powder with the particle size of 0.30-1.18 mm and regenerated sand powder with the particle size of 1.18-4.75 mm. The preparation method of the controllable low-strength material comprises the following steps: uniformly mixing the cementing material, the compound regenerated sand powder, the shield slurry, the water reducing agent, the coagulant and the water. The controllable low-strength material is high in fluidity, high in stability and controllable in strength, bleeding is avoided while high fluidity is guaranteed, and the controllable low-strength material is simple in preparation process and low in cost and has remarkable social benefits and economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

Inorganic-organic polymer treatment agent for drilling fluid and preparation method thereof

ActiveCN105295857BParticipation responds wellIncrease the amount of introductionDrilling compositionAluminum magnesium silicateSalt water

The invention provides an inorganic-organic polymer treatment agent for drilling fluid, wherein the treatment agent is formed by polymerization of sulfonic acid monomers, carboxylic acid monomers, nonionic monomers and inorganic materials under the action of an initiator; And the inorganic material includes aluminum magnesium silicate inorganic gel. The inorganic-organic polymer treatment agent provided by the invention has strong fluid loss reducing effect in freshwater drilling fluid, brine drilling fluid, saturated brine drilling fluid and composite brine drilling fluid. It also has a strong anti-collapse ability, can effectively control the hydration and dispersion of mud shale, control clay slurry, and has a high permeability recovery value, which has a good oil and gas layer protection effect. Moreover, the production process is simple, the source of raw materials is wide, and the promotion prospect is broad. The invention also provides a preparation method of an inorganic-organic polymer treatment agent for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coating technology of finishing varnish on integrated plate

ActiveCN111715492AStrong adhesionEasily control rheologyChemical industryPretreated surfacesThermal treatmentVarnish

The invention belongs to the field of the finishing varnish coating technology and particularly discloses a coating technology of finishing varnish on an integrated plate. The coating technology comprises drying and solidifying; drying comprises dewatering for dry flash-over and later thermal treatment; dewatering for dry flash-over refers to rapid determing treatment before solidification; and later thermal treatment refers to heating treatment after solidification. The coating technology is suitable for the field of outer wall integrated plates and is excellent in coating effect, high in coating adhesion and small in color difference.

Owner:NIPPON PAINT CHINA +1

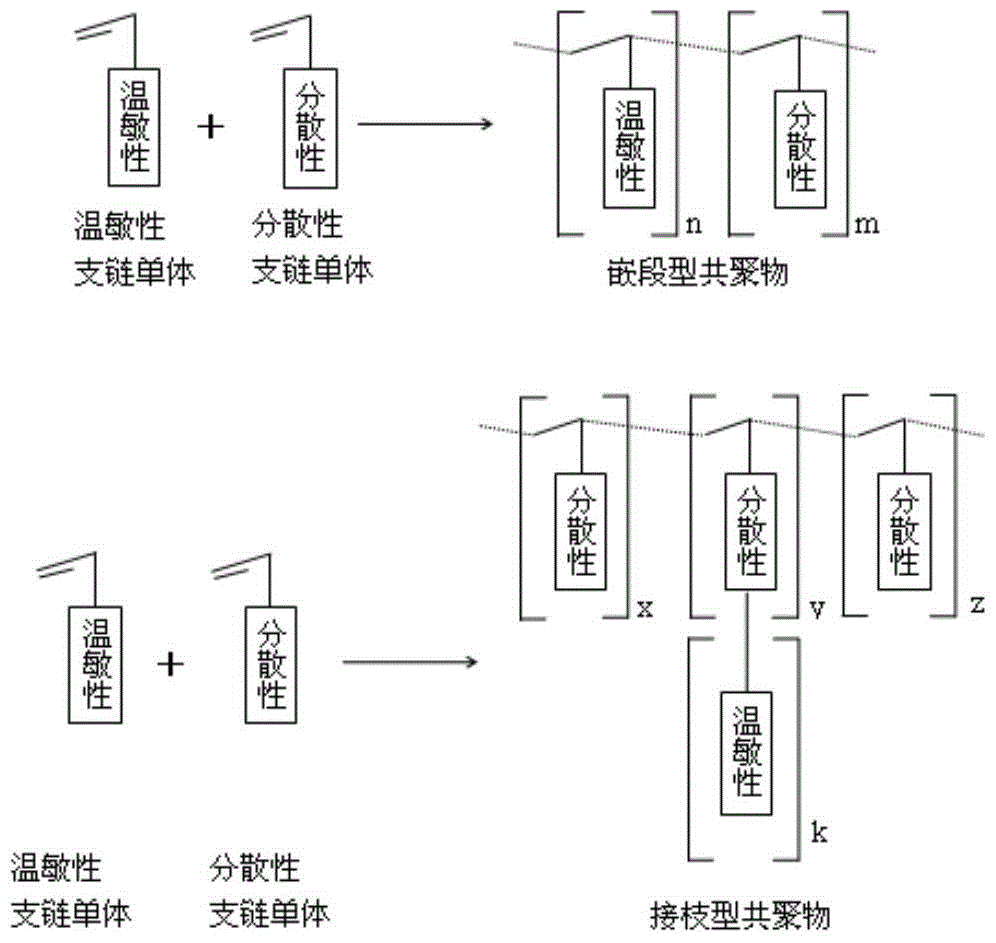

A kind of temperature-sensitive dispersant and temperature-sensitive suspension and their application

The invention discloses a temperature-sensitive dispersing agent, a temperature-sensitive suspending liquid and application of temperature-sensitive dispersing agent and temperature-sensitive suspending liquid. The temperature-sensitive dispersing agent is a graft copolymer prepared by grafting a temperature-sensitive monomer on the homopolymerized main polymer chain of a dispersive monomer or a block polymer prepared by carrying out block copolymerization on the temperature-sensitive monomer and a dispersive monomer. The prepared temperature-sensitive dispersing agent has the hydrophilic-hydrophobic interconversion characteristic under the stimulation of different temperatures and can be prepared into the temperature-sensitive suspending liquid by being ground and dispersed with a power material; the prepared temperature-sensitive suspending liquid has good dispersity, the rheological property of the temperature-sensitive suspending liquid can be regulated and controlled by controlling temperature change, and the temperature-sensitive suspending liquid can be widely applied to the fields of ceramic wet forming, cement grouting, orifice well plugging of well drilling and the like.

Owner:CENT SOUTH UNIV

A breathable brick prepared from industrial by-product aluminum chrome slag and its production method

The invention discloses a breathable brick produced from an industrial byproduct aluminum chrome slag and a production method thereof. The byproduct aluminum chrome slag produced during metal chromium smelting is used as a raw material, and according to components and performance characteristics of the aluminum chrome slag, the aluminum chrome slag is reasonably matched with other refractory materials, so that the water demand and the rheological property of a castable are controlled and a breathable brick product with good scouring resistance, erosion resistance and stripping resistance is produced; compared with the prior art, the invention has the advantages as follows: the industrial byproduct aluminum chrome slag is successfully applied to the field of the breathable brick products having relatively high technical requirements, so that on one hand, the significance of turning wastes into treasures and recycling is achieved, and on the other hand, the application range of the aluminum chrome slag is widened.

Owner:LUOYANG XUANSHI HIGH TEMPERATURE MATERIALS CO LTD +1

Inorganic-organic polymer treatment agent for drilling fluid and preparation method thereof

ActiveCN105219358BParticipation responds wellIncrease the amount of introductionDrilling compositionSlurryCarboxylic acid

The invention provides an inorganic-organic polymer treating agent used for drilling fluid. The treating agent is prepared from a sulfonic acid monomer, a carboxylic acid monomer, a non-ionic monomer and an inorganic material by polymerization under the action of an initiator, wherein the inorganic material contains lithium magnesium silicate inorganic gel. The inorganic-organic polymer treating agent provided by the invention has strong effect of reducing filtrate loss in fresh-water drilling fluid, saltwater drilling fluid, saturated saltwater drilling fluid and compound saltwater drilling fluid. The treating agent also has strong anti-sloughing ability, can effectively control hydration dispersion of clay-shale and slurry making of clay, and has high permeability recovery rate and good hydrocarbon reservoir protection effects. Meanwhile, the treating agent has the advantages of simple production process, wide raw material sources and extensive popularization prospects. The invention also provides a preparation method for the inorganic-organic polymer treating agent used for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

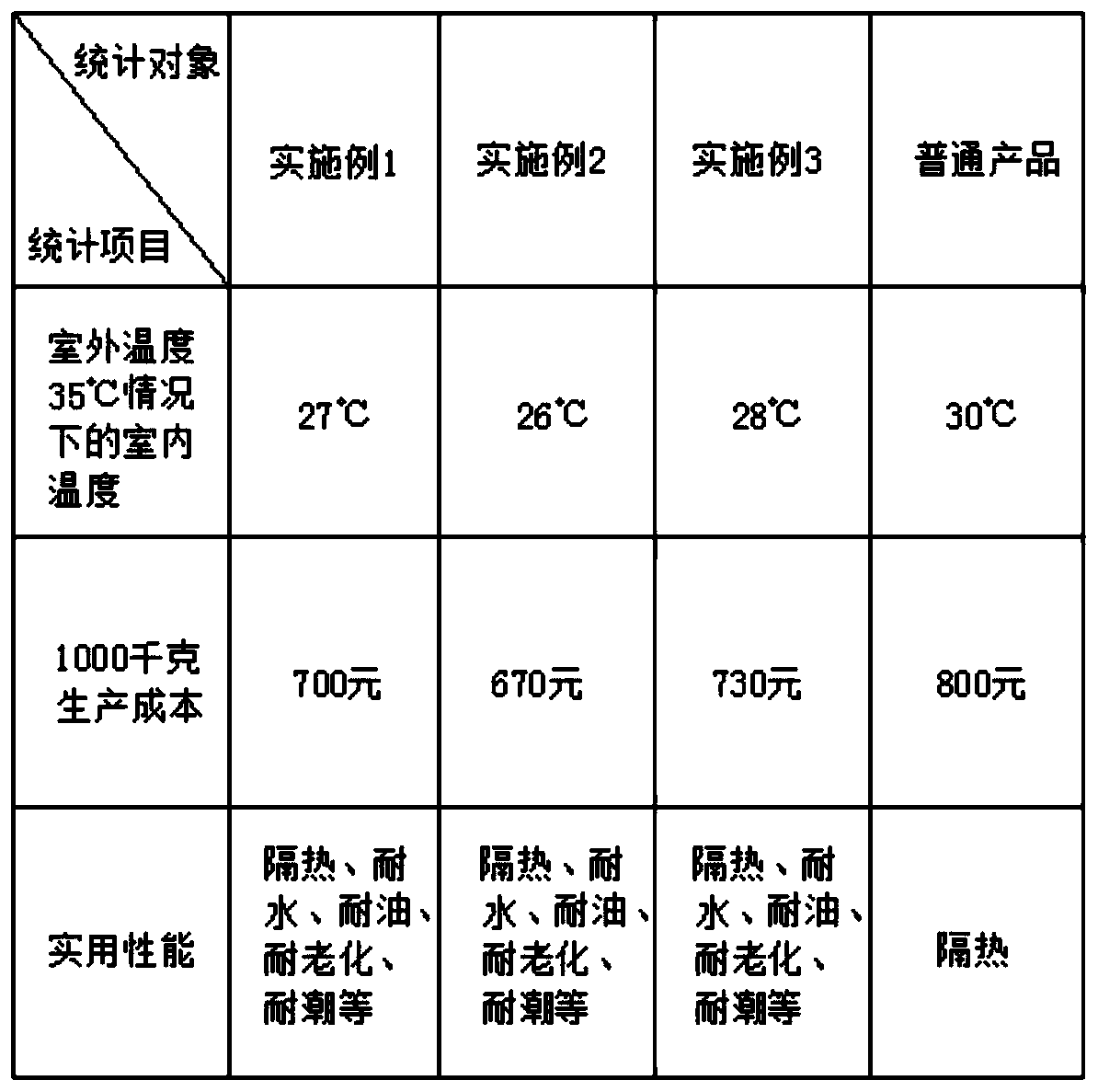

Heat insulation paint with plurality of properties

PendingCN110105820AGood water resistanceHigh bonding strengthReflecting/signal paintsEmulsionBamboo charcoal

The invention discloses a heat insulation paint with plurality of properties, and belongs to the field of building materials technology. The heat insulation paint with plurality of properties comprises, by weight, 25 to 36 parts of styrene-acrylic emulsion, 5 to 10 parts of bamboo charcoal fiber, 10 to 15 parts of silica, 3 to 6 parts of a heat-reflecting heat-insulating powder, 8 to 14 parts of aheat-resistance mixture, 2 to 7 parts of a wear-resistant reinforcing agent, 1 to 3 parts of a defoaming agent, 1 to 3 parts of a bactericide, 1 to 3 parts of a thickener, 4 to 8 parts of an ultraviolet absorber, 6 to 8 parts of titanium dioxide, and 9 to 12 parts of talcum powder. According to a preparation method, styrene-acrylic emulsion, the heat-reflecting heat-insulating powder, the heat-resistance mixture, and the wear-resistant reinforcing agent are added, so that the heat insulation paint is provided with excellent water resistance, oil resistance, heat resistance and aging resistance; bamboo charcoal fiber is added, so that the heat insulation paint is capable of absorbing moisture, drying, deodorizing, and preventing bacteria; the thickener is added to prevent filler precipitation, and control the rheological property of construction process. The heat insulation paint possesses various properties; the suitable application range is very wide; the production steps simple; andit is convenient for popularization.

Owner:江门市涂霸建材实业有限公司

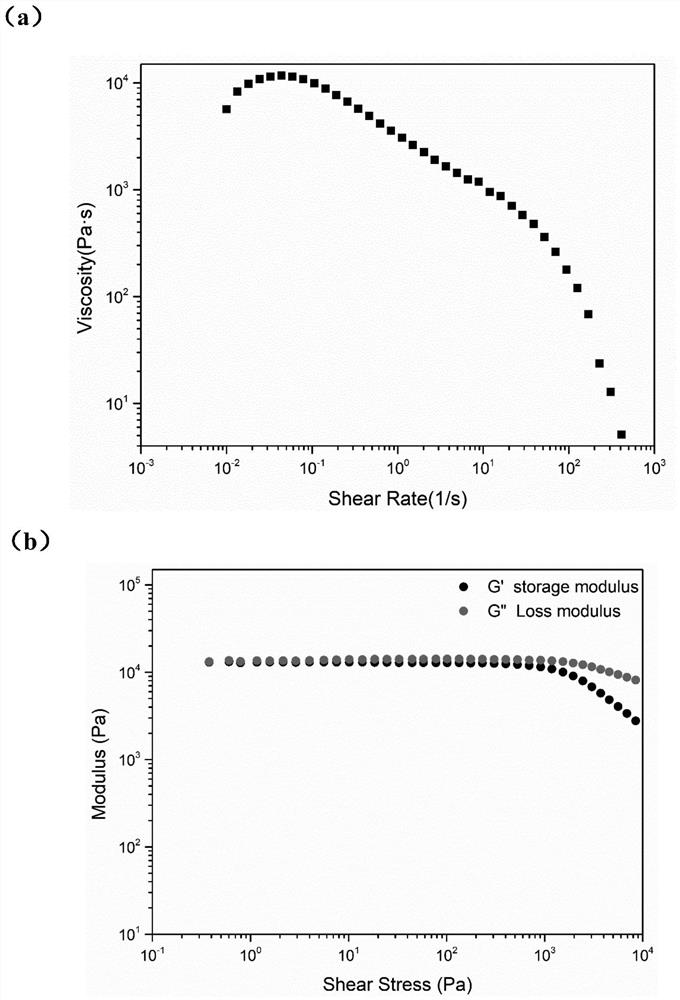

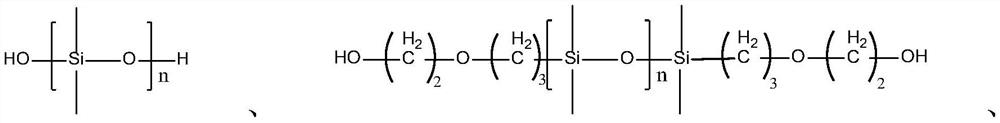

Polyurethane/silicone rubber hybrid material capable of 3D printing and preparation method thereof

ActiveCN114752222AControl rheologyImprove mechanical propertiesAdditive manufacturing apparatusPolymer scienceHybrid material

The invention provides a polyurethane / silicone rubber hybrid material. The polyurethane / silicone rubber hybrid material is formed by compounding vinyl silicone oil, silicon dioxide and micro-crosslinked vinyl terminated polyurethane, the mass ratio of the vinyl silicone oil to the silicon dioxide to the micro-crosslinked vinyl terminated polyurethane is 100: (30-40): (15-25); the micro-crosslinked vinyl-terminated polyurethane is prepared by enabling vinyl-terminated polyurethane to react for 20 to 30 hours at the temperature of 65 to 75 DEG C under the vacuum pressure of 0.05 to 0.15 MPa. The silicone rubber is compounded with polyurethane with a specific structure and a specific crosslinking degree, so that the rheological property of the silicone rubber is successfully regulated and controlled, and the silicone rubber has the shear thinning rheological property while having excellent mechanical properties, meets the conditions of 3D printing, and has a very good application prospect as 3D printing ink.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS +1

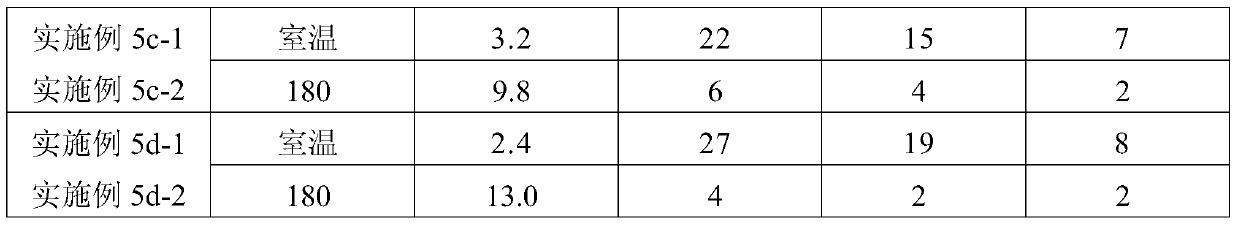

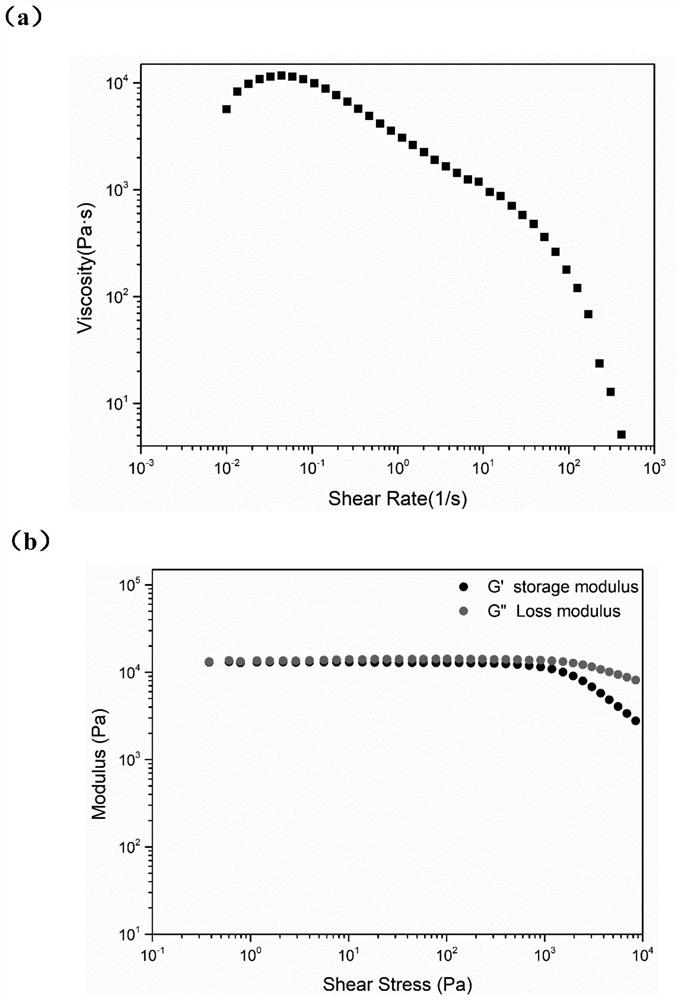

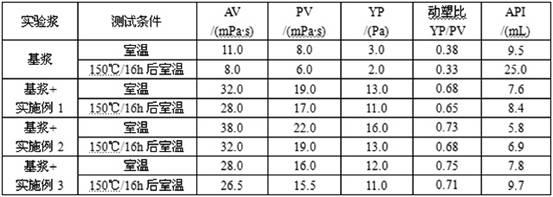

Application of Cellulose Nanofibers as Flow Regulators for Drilling Fluids

The invention relates to the application of a cellulose nanofiber as a flow pattern regulator for drilling fluid. The technical proposal is: the cellulose nanofiber is used as a flow pattern regulator for drilling fluid, and the filling amount of the cellulose nanofiber in the drilling fluid is 0.1-3.0%, according to the volume ratio. The beneficial effects are: the cellulose chains of the present invention are entangled with each other to form a three-dimensional net-like space grid structure, which achieves the purpose of "increasing viscosity and lifting cut". At the same time, this space grid structure is easily destroyed under the action of external force It will recover when the external force is removed, and has the characteristics of "rapid weak gel", which helps to enhance the shear dilution and thixotropy of the drilling fluid system, thereby effectively regulating the rheological properties of the drilling fluid system; the invention provides As a flow pattern regulator for drilling fluid, cellulose nanofibers not only have good drilling fluid "viscosity increase and shearing" performance, but also have the advantages of being renewable, non-toxic and degradable, and low cost.

Owner:CHINA PETROCHEMICAL CORP +3

Preparing method of auxiliary additive beneficial for oil transport

InactiveCN110408363AGood dispersionControl rheologyOther chemical processesPipeline systemsOil and greaseBall mill

The invention discloses a preparing method of an auxiliary additive beneficial for oil transport. The method includes the steps of adding dipropylene glycol methyl ether and N,N-diethylethanamine to tetrahydrofuran, slowly dropwise adding acryloyl chloride, raising the temperature to the room temperature 1 hour later, continuing the reaction for 12 hours, filtering out precipitates generated in reaction after the reaction ends, washing out a product in filtrate through petroleum ether, dissolving 4-10 parts of the product and 5-20 parts of polyethylene imine in methyl alcohol for stirring reaction for 20 hours, conducting rotary evaporating on the reaction product after the reaction stops to remove part of the solvent, settling out the concentrated product from the petroleum ether, conducting centrifuging and drying to obtain a solvent, and adding the solvent and mica powder to deionized water to be ball-milled to prepare suspension, namely the auxiliary additive.

Owner:王豫园

A method for connecting conductive adhesive and solar cells that can be converted into an adhesive film on-line in real time

ActiveCN108899387BControl overlap areaReduce overlap areaPhotovoltaic energy generationSemiconductor devicesElectrical batteryEngineering

The invention provides a method for connecting a conductive adhesive that can be transformed into an adhesive film on-line in real time and a solar cell, and relates to the technical field of solar power generation. Covering the conductive glue to obtain the first target cell; performing the first curing treatment on the first target cell to obtain the second target cell according to the preset dividing line on the second target cell; Segmentation processing to obtain multiple battery slice units; bonding multiple battery slice units to obtain a battery string; performing a second curing treatment on the battery string to obtain a target battery string. It solves the problem that when the cell units in the prior art are connected, the overlapping area between two adjacent cell units is large, the light conversion power is low, and the thickness of the glue layer or the glue between each cell unit is insufficient. The uneven layer thickness leads to the technical problem of low reliability of the shingled module composed of the target cells.

Owner:彭延岩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com