Heat insulation paint with plurality of properties

A thermal insulation coating and performance technology, applied in the direction of reflection/signal coating, coating, etc., can solve the problems of poor thermal insulation effect, complicated production steps, single performance, etc., and achieve easy promotion, good physical and mechanical stability, The effect of surface self-cleaning ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

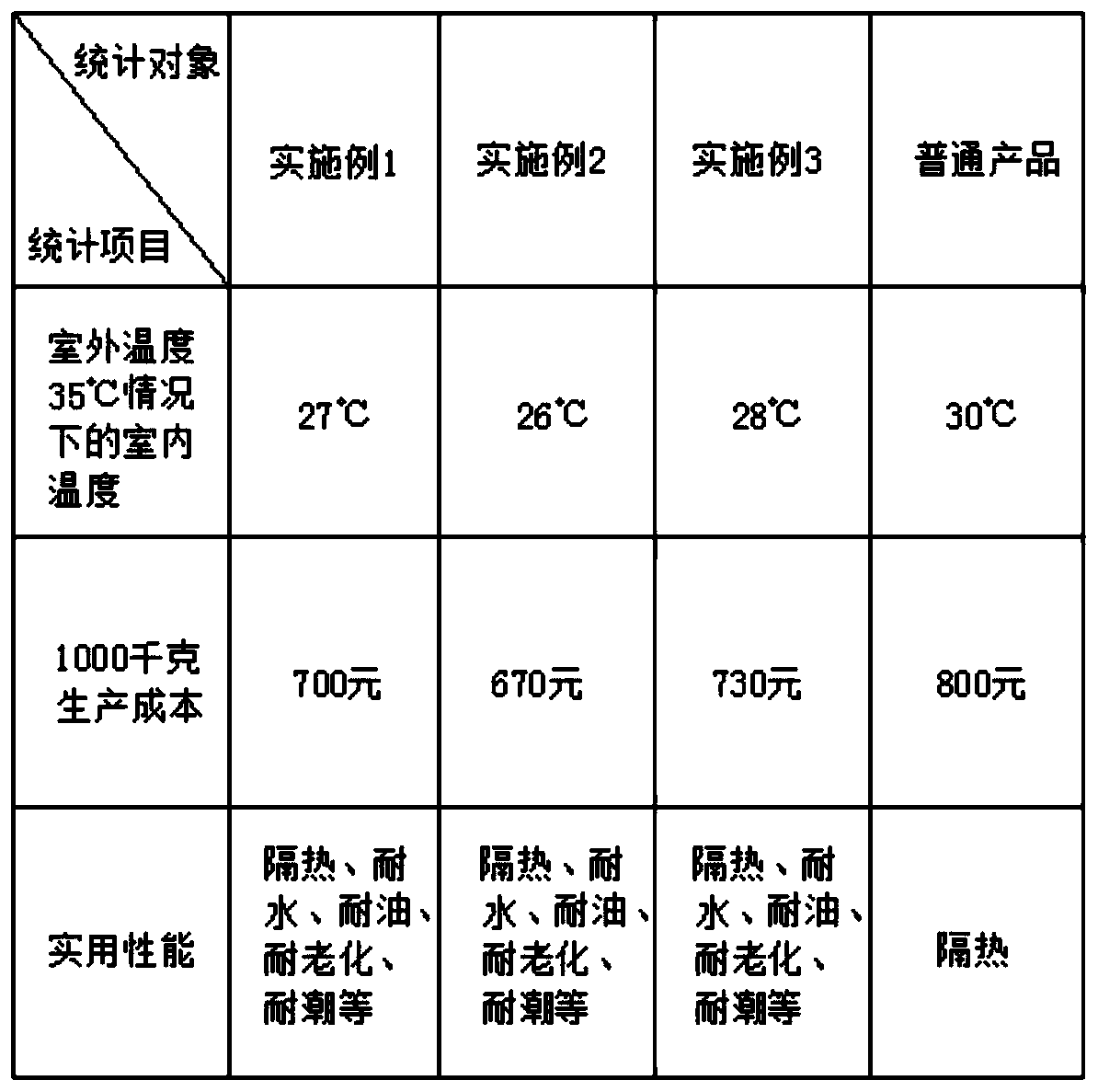

Examples

Embodiment 1

[0031] S1. Selection of raw materials: select 25 parts of original styrene-acrylic emulsion, 10 parts of bamboo charcoal fiber, 15 parts of silicon dioxide, 3 parts of heat-reflecting heat-insulating powder, 8 parts of heat-resistant mixture, 7 parts of wear-resistant reinforcing agent, and defoamer 3 parts, 3 parts of bactericide, 3 parts of thickener, 8 parts of ultraviolet absorber, 6 parts of titanium dioxide and 9 parts of talcum powder, take raw material by weight ratio;

[0032] S2. Preparation of semi-finished products: add 10 parts of bamboo charcoal fiber, 15 parts of silicon dioxide, 3 parts of heat-reflecting and heat-insulating powder, 8 parts of heat-resistant mixture, 6 parts of titanium dioxide and 9 parts of talcum powder weighed in S1 into the grinder , Grind it to the required fineness requirements to obtain mixed fine powder, add 25 parts of styrene-acrylic emulsion weighed in S1 into the mixing and heating mixer, and at the same time add the mixed fine powd...

Embodiment 2

[0036] S1. Selection of raw materials: Select 30 parts of styrene-acrylic emulsion, 7 parts of bamboo charcoal fiber, 13 parts of silicon dioxide, 5 parts of heat-reflecting heat-insulating powder, 11 parts of heat-resistant mixture, 5 parts of wear-resistant reinforcing agent, and defoamer 2 parts, 2 parts of bactericide, 2 parts of thickener, 6 parts of ultraviolet absorber, 7 parts of titanium dioxide and 10 parts of talcum powder, the raw materials are weighed by weight;

[0037] S2. Preparation of semi-finished products: Add 7 parts of bamboo charcoal fiber, 13 parts of silicon dioxide, 5 parts of heat-reflecting heat-insulating powder, 11 parts of heat-resistant mixture, 7 parts of titanium dioxide and 10 parts of talc powder weighed in S1 into the grinder , Grind it to the required fineness to obtain mixed fine powder, add 30 parts of styrene-acrylic emulsion weighed in S1 to the mixing and heating mixer, and at the same time add the mixed fine powder to the mixing and h...

Embodiment 3

[0041]S1. Selection of raw materials: Select 36 parts of styrene-acrylic emulsion, 5 parts of bamboo charcoal fiber, 10 parts of silicon dioxide, 6 parts of heat-reflective heat-insulating powder, 14 parts of heat-resistant mixture, 2 parts of wear-resistant reinforcing agent, and defoamer 1 part, 1 part of bactericide, 1 part of thickener, 4 parts of ultraviolet absorber, 8 parts of titanium dioxide and 12 parts of talcum powder, the raw materials are weighed by weight;

[0042] S2. Preparation of semi-finished products: add 5 parts of bamboo charcoal fiber, 10 parts of silicon dioxide, 6 parts of heat-reflecting and heat-insulating powder, 14 parts of heat-resistant mixture, 8 parts of titanium dioxide and 12 parts of talc powder weighed in S1 into the grinder , grind it to the required fineness requirement to get mixed fine powder, add 36 parts of styrene-acrylic emulsion weighed in S1 into the mixing and heating mixer, and at the same time add the mixed fine powder into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com