Photocurable translucent composition for adhesive sheet, and optical adhesive sheet

A photocurable, adhesive sheet technology, applied in non-polymer organic compound adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of not being able to obtain foam resistance and corrosion resistance. , whitening-resistant adhesive compositions, whitening of adhesive sheets, etc., to achieve good visibility, prevent whitening, and inhibit corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

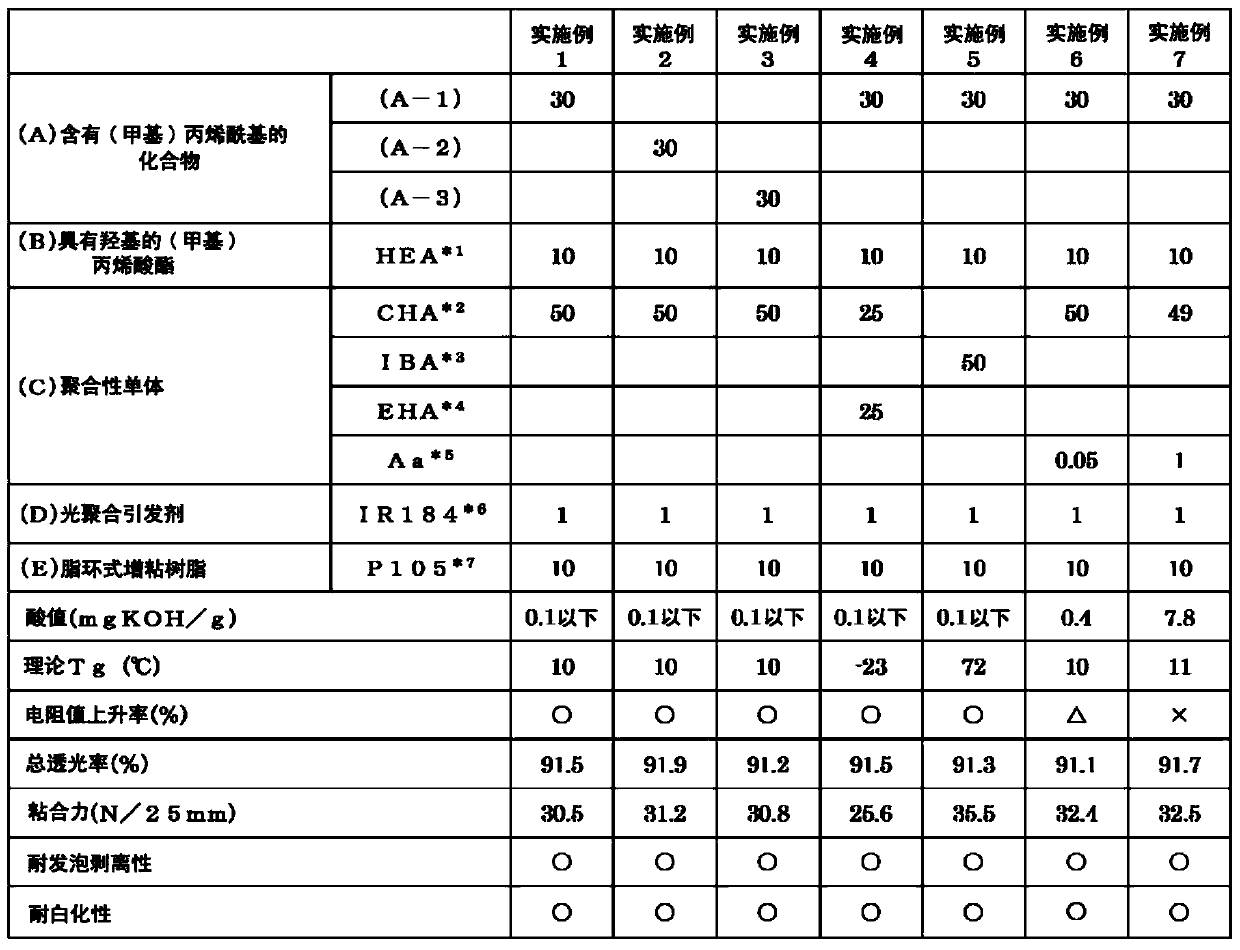

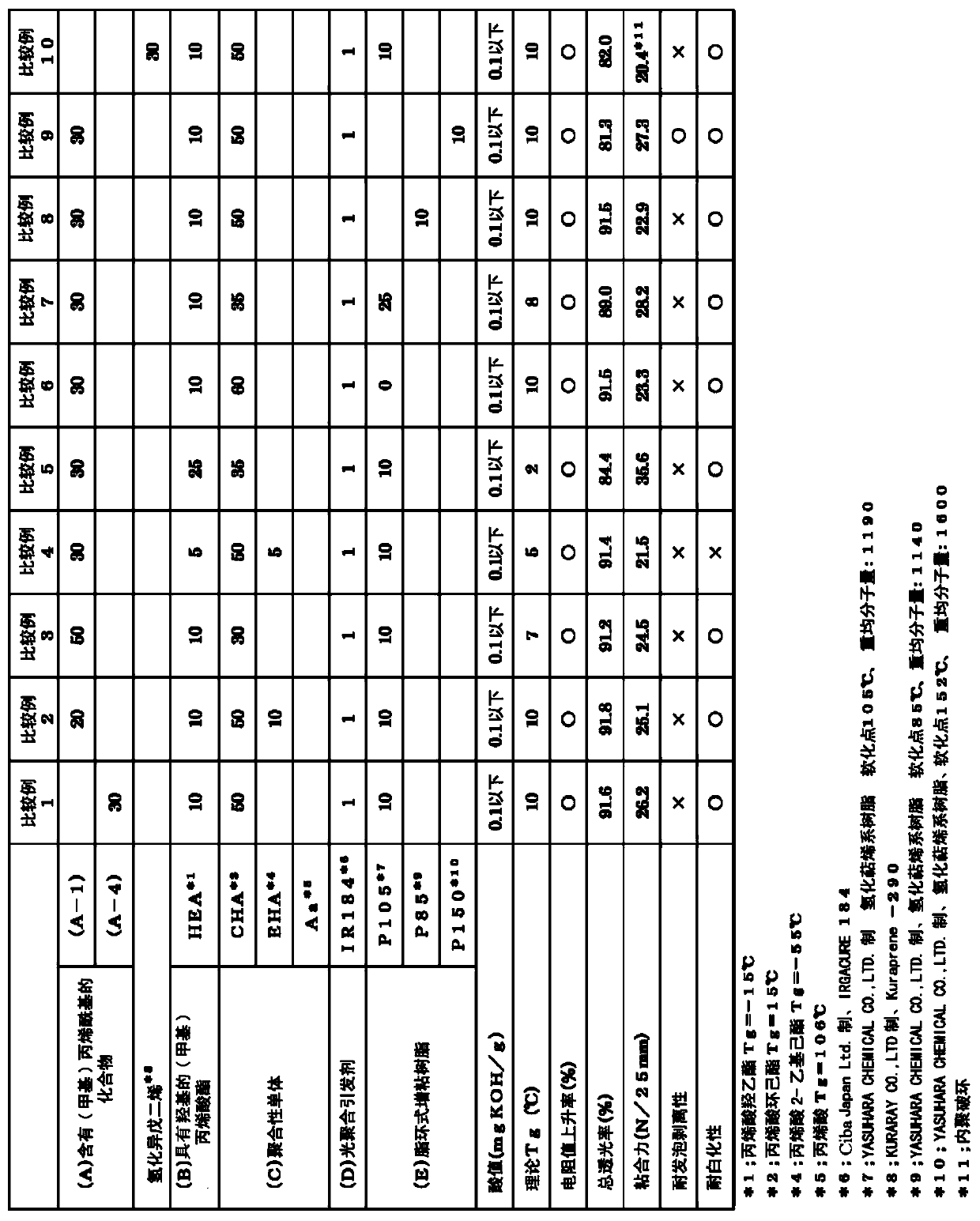

Embodiment 1~7、 comparative example 1~10

[0102] The compositions shown in Table 1 and Table 2 were mixed separately and mixed using a dispenser at room temperature to prepare a uniform composition for a photocurable transparent pressure-sensitive adhesive sheet. The prepared composition for a photocurable transparent adhesive sheet was applied to a release PET film (100 mm × 100 mm × 100 μm) using an applicator so that the film thickness became 200 μm, and the upper surface was covered with a release PET film with a thickness of 25 μm After that, use an ultraviolet irradiation device (UV irradiation device manufactured by Nippon Battery Co., Ltd. 4kw×1, output: 160W / cm, metal halide lamp), at an irradiation distance of 12cm, a lamp moving speed of 20m / min, and an irradiation dose of about 1000mJ / cm 2 It was cured by irradiating ultraviolet rays under certain conditions to obtain an adhesive sheet with a film thickness of about 200 μm sandwiched by a release PET film.

[0103] (calculation of theoretical glass transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com