Coating composition and film prepared therefrom

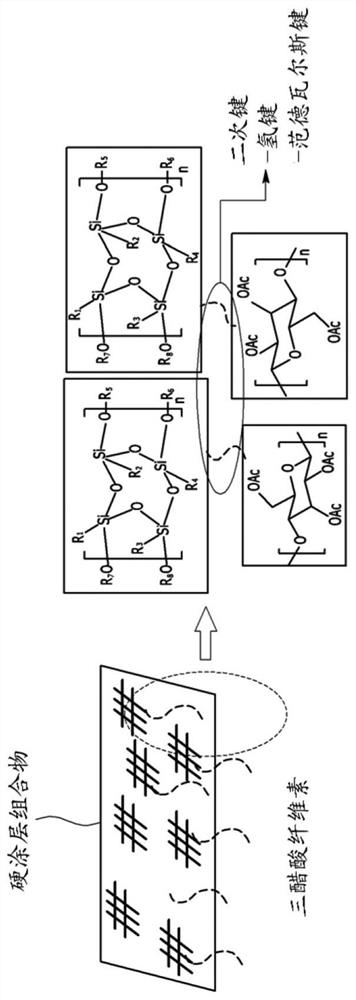

A coating composition and oligomer technology, applied in the direction of coating, can solve the problems of high moisture permeability and poor durability, and achieve the effects of improving moisture permeability resistance and surface hardness, simple coating process, and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0059] Add dropwise the prepared catalyst of 10 parts by weight of distilled water, 20 parts by weight of acetonitrile (Oi Chemical and Metal Co., Ltd.), 2 parts by weight of the dry flask with condenser tube and stirrer, and stir at normal temperature for 1 hour , then dropwise add 20 parts by weight of 2-(3,4-epoxycyclohexyl) ethyltrimethoxymethane (2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane, Shin-Etsu Chemical, product name: KBM-303) and stir further 6 hours. After the reaction is completed, wash twice to extract the catalyst and impurities, and finally obtain a silsesquioxane oligomer with a ratio of clathrate silsesquioxane and trapezoidal silsesquioxane of 10:90.

Synthetic example 2

[0061] Add dropwise the prepared catalyst of 10 parts by weight of distilled water, 50 parts by weight of acetonitrile (Oi Chemical and Metal Co., Ltd.), 2 parts by weight of the dry flask with condenser tube and stirrer, and stir at normal temperature for 1 hour , and then dropwise added 20 parts by weight of 2-(3,4-epoxycyclohexyl)ethyltrimethoxymethane (Shin-Etsu Chemical, product name: KBM-303) and stirred for further 6 hours. After the reaction is completed, wash twice to extract the catalyst and impurities, and finally obtain a silsesquioxane oligomer with a ratio of clathrate silsesquioxane and trapezoidal silsesquioxane of 30:70.

Synthetic example 3

[0063] Add dropwise the prepared catalyst of 10 parts by weight of distilled water, 90 parts by weight of acetonitrile (Oi Chemical and Metal Co., Ltd.), 2 parts by weight of the dry flask with condenser tube and stirrer, and stir at normal temperature for 1 hour , and then dropwise added 20 parts by weight of 2-(3,4-epoxycyclohexyl)ethyltrimethoxymethane (Shin-Etsu Chemical, product name: KBM-303) and stirred for further 6 hours. After the reaction is completed, wash twice to extract the catalyst and impurities, and finally obtain a silsesquioxane oligomer with a ratio of clathrate silsesquioxane and trapezoidal silsesquioxane of 50:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com