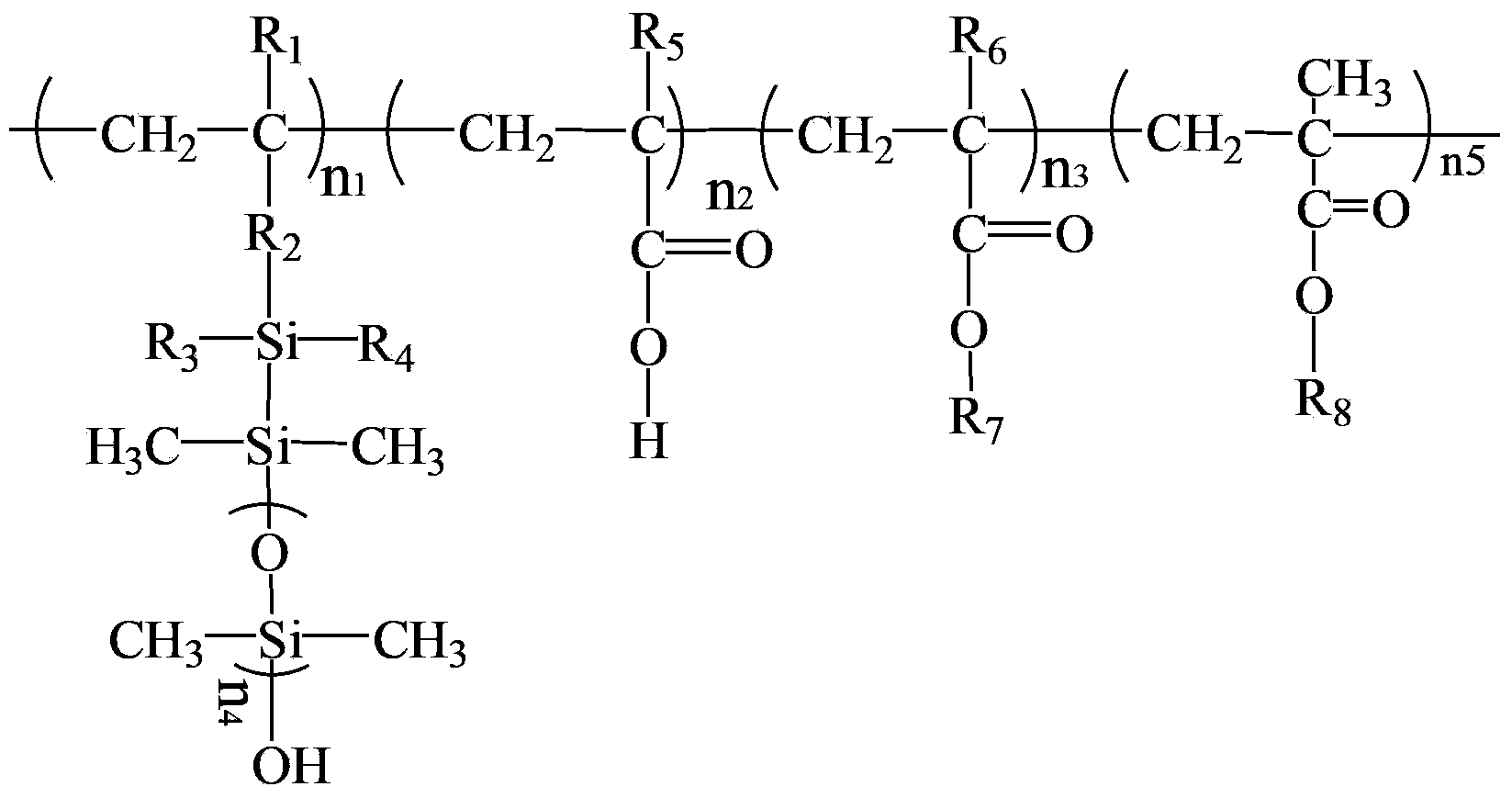

Organosilicone modified fluorine-containing (methyl) acrylic resin with long side chain

A technology of acrylic resin and silicone, applied in the direction of coating, etc., can solve the problems of affecting the scope of application, stain resistance, water resistance, toughness, and heat resistance, etc., to improve water resistance, good water resistance, Effect of improved stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of silicone-modified fluorine-containing (meth)acrylic resin with long side chains

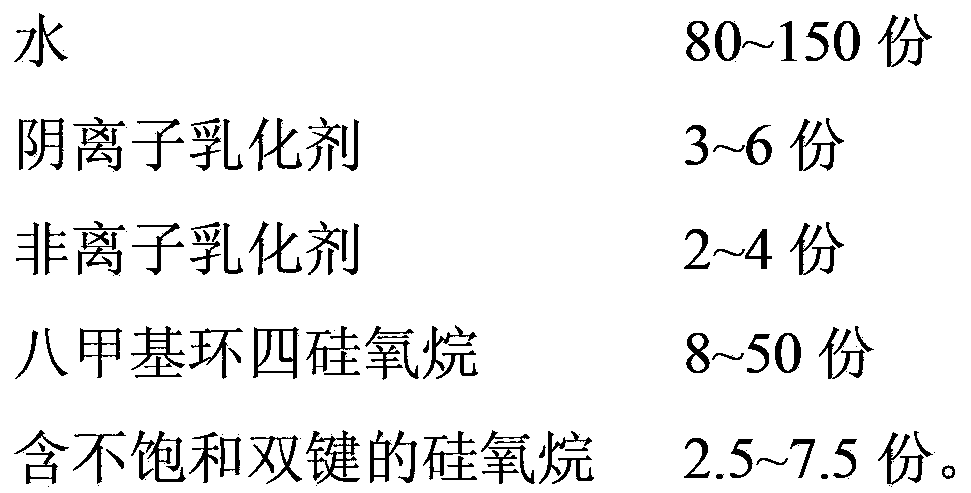

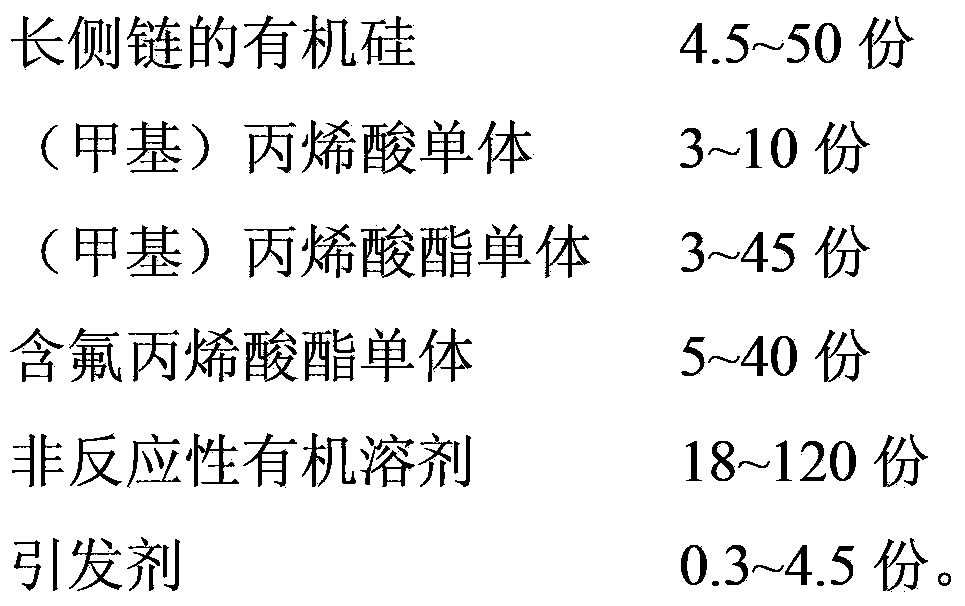

[0039] (1) Add 80g of deionized water, 3g of dodecylbenzenesulfonic acid (DBSA), 2g of alkylphenol polyoxyethylene ether into a four-neck flask equipped with a stirrer, thermometer, condenser tube and nitrogen gas inlet tube (NP-9), 8g octamethylcyclotetrasiloxane, blow nitrogen, react at 70°C for 9h, then add 2.5g γ-methacryloyloxypropyltrimethoxysilane (KH-570), in React at 75 for 9 hours to obtain a silicone emulsion with long side chains, cool to room temperature, then add the obtained emulsion dropwise to ethanol whose volume is 2 to 4 times its volume, break the emulsion by ultrasonic vibration, and pour off the supernatant to obtain long side chains of silicone.

[0040] (2) Add 3g of methacrylic acid, 3.0g of isooctyl methacrylate, 5.0g of trifluoroethyl methacrylate, and 4.5g of a reaction vessel equipped with a stirrer, a thermometer, a condenser tube, ...

Embodiment 2

[0046] Example 2: Preparation of silicone-modified fluorine-containing (meth)acrylic resin with long side chains

[0047] (1) Add 110g of deionized water, 4g of dodecylbenzenesulfonic acid (DBSA), 2g of polyoxyethylene alkyl ether, 25.4 g octamethylcyclotetrasiloxane, feed nitrogen, react at 75°C for 7h, then add 4.5g allyltrimethoxysilane, react at 80°C for 7h to obtain a silicone emulsion with long side chains, take it out and air-cool to room temperature, and then drop the obtained emulsion into ethanol whose volume is 2 to 4 times its volume, ultrasonically oscillate to break the emulsion, and pour off the supernatant to obtain long side chain silicone.

[0048](2) Add 10.4g methyl methacrylate, 5g acrylic acid, 15.0g trifluoroethyl methacrylate, 20.5g step (1) The obtained long side chain organosilicon, 79g methyl ethyl ketone, 1.6g azobisisobutyrocyanide, nitrogen gas, reacted at 63°C for 5h, then air-cooled and discharged, to obtain long side chain organosilicon modifi...

Embodiment 3

[0054] Example 3: Preparation of silicone-modified fluorine-containing (meth)acrylic resin with long side chains

[0055] (1) Add 130g of deionized water, 5g of cetylbenzenesulfonic acid, 3g of polyoxyethylene sorbitan oleate, 30.4 g octamethylcyclotetrasiloxane, feed nitrogen, react at 80°C for 5h, then add 5.3g allyltriethoxysilane, react at 85°C for 5h, obtain a silicone emulsion with long side chains, take it out and air-cool to room temperature, and then drop the obtained emulsion into ethanol whose volume is 2 to 4 times its volume, ultrasonically oscillate to break the emulsion, and pour off the supernatant to obtain organosilicon with long side chains.

[0056] (2) Add 7g of acrylic acid, 26.6g of ethyl acrylate, 15.0g of hexafluorobutyl methacrylate, and 30.5g of Silicone with long side chains, 92g methyl ethyl ketone, 2.4g azobisisobutylcyanide, nitrogen gas, react at 68°C for 4 hours, and then air-cool the material to obtain long side chain silicone-modified fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com