Antimicrobial coat on surface of water system, and its preparation method

A surface coating and water system technology, applied in coatings, conduits, etc., can solve problems such as environmental pollution, hidden production hazards, and harm to workers' health, and achieve the effects of protecting the environment, reducing safety hazards, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

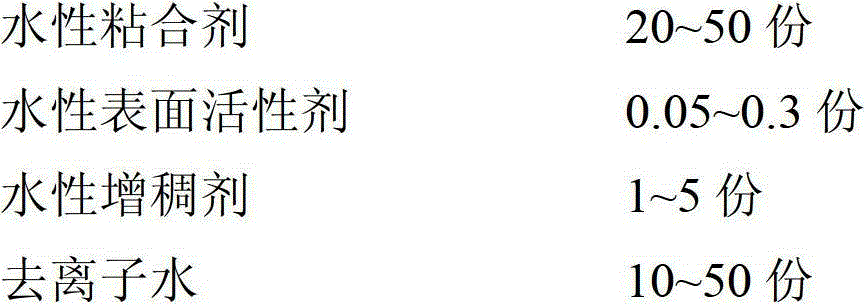

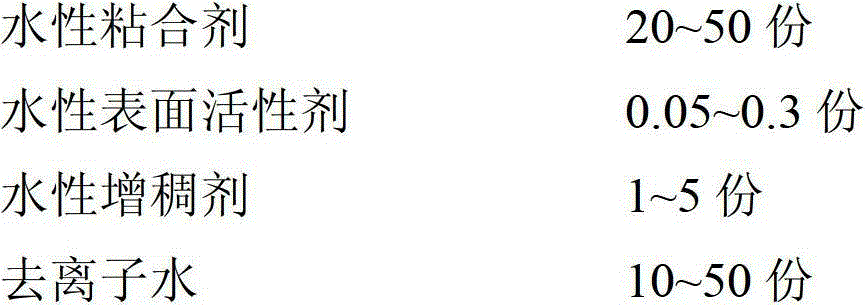

[0032] Primer coating preparation: Weigh 20 g of water-based polyurethane resin (produced by DSM, with a solid content of 40%), 0.1 g of sodium lauryl sulfate, 1 g of carboxymethyl cellulose, and 20 g of deionized water, mix well, and statically After standing for 24 hours for defoaming, the bottom coating mixture was obtained.

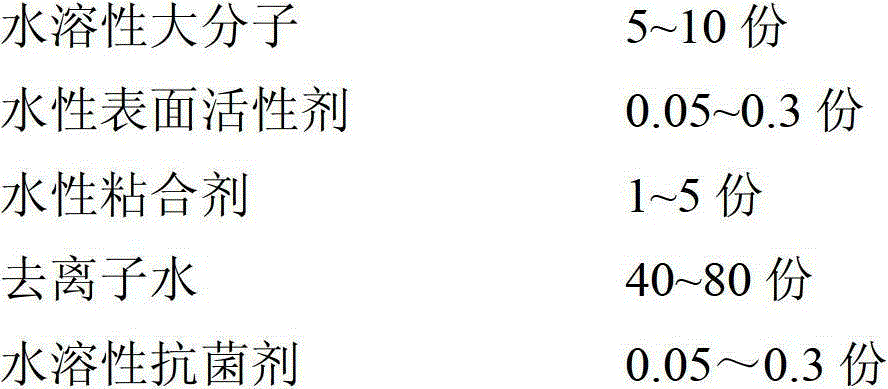

[0033] Surface coating preparation: Weigh 5g of polyvinylpyrrolidone, 5g of water-based polyurethane resin (solid content 40%), 0.1g of sodium lauryl sulfate, and 0.3g of organic silicon quaternary ammonium salt (produced by Guangzhou Nuokang Chemical Co., Ltd., model HM98) , 40 g of deionized water, mixed evenly, and allowed to stand for 24 hours for defoaming to obtain a surface coating mixture for use.

[0034] Immerse the PVC catheter in ethanol, ultrasonically clean it at 40KHz for 10 minutes, remove the dirt on the surface, and dry it; then immerse it in the prepared bottom coating mixture for 10 seconds, take it out and bake it at 70°C for 6 mi...

Embodiment 2

[0037] Primer coating preparation: Weigh 20g of water-based polyacrylic resin (produced by DSM, solid content 40%), 0.15 of trisodium phosphate, 1.5g of carboxymethyl cellulose, 30g of deionized water, mix well, and let stand for 24 hours After defoaming, the bottom coating mixture is obtained.

[0038] Surface coating preparation: weigh 6g of polyvinylpyrrolidone, polyacrylic acid resin (manufactured by DSM, solid content 40%) 2g, trisodium phosphate 0.15, deionized water 50g, 3-(trimethoxysilyl) propyl Dimethyloctadecylammonium chloride (Dow Corning DC-5700, USA) 0.15 g, mixed evenly, and left to stand for 24 hours for degassing to obtain the surface coating mixture.

[0039] Immerse the latex catheter in ethanol, ultrasonically clean it at 45KHz for 7 minutes, remove the dirt on the surface, and dry it; then immerse it in the prepared bottom coating mixture for 10 seconds, take it out and bake it at 60°C for 10 minutes until it is completely dry; The thickness of the under...

Embodiment 3

[0041] Primer coating preparation: Weigh 20 g of water-based bisphenol A epoxy resin (produced by DSM, solid content 40%), 0.15 g of polyoxyethylene alkyl ester, 1.5 g of carboxymethyl cellulose, and 30 g of deionized water , mix well, let stand for 24 hours to defoam and obtain the bottom coating mixture;

[0042]Surface coating preparation: weigh 6g of polyvinylpyrrolidone, 1g of water-based polyurethane resin (produced by DSM, solid content 40%), 1g of water-based polyacrylic resin (produced by DSM, solid content of 40%), polyoxyethylene Alkyl ester 0.15g, deionized water 50g, nano-silver (manufactured by Beijing Jieershuang, model SCJ-951) 0.05g, mix well, stand for 24 hours to get the surface layer coating mixture after defoaming.

[0043] Immerse the silicone catheter in ethanol, ultrasonically clean it at 50KHz for 5 minutes, remove the dirt on the surface, and dry it; then soak it in the bottom coating mixture for 10 seconds, take it out and bake it at 90°C for 3 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com