A method for connecting conductive adhesive and solar cells that can be converted into an adhesive film on-line in real time

A technology of solar cells and connection methods, which is applied in the field of conductive adhesives, can solve problems such as large overlapping area, low light conversion power, and insufficient thickness of the glue layer, and achieve the effects of enhancing reliability, increasing light conversion power, and reducing overlapping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

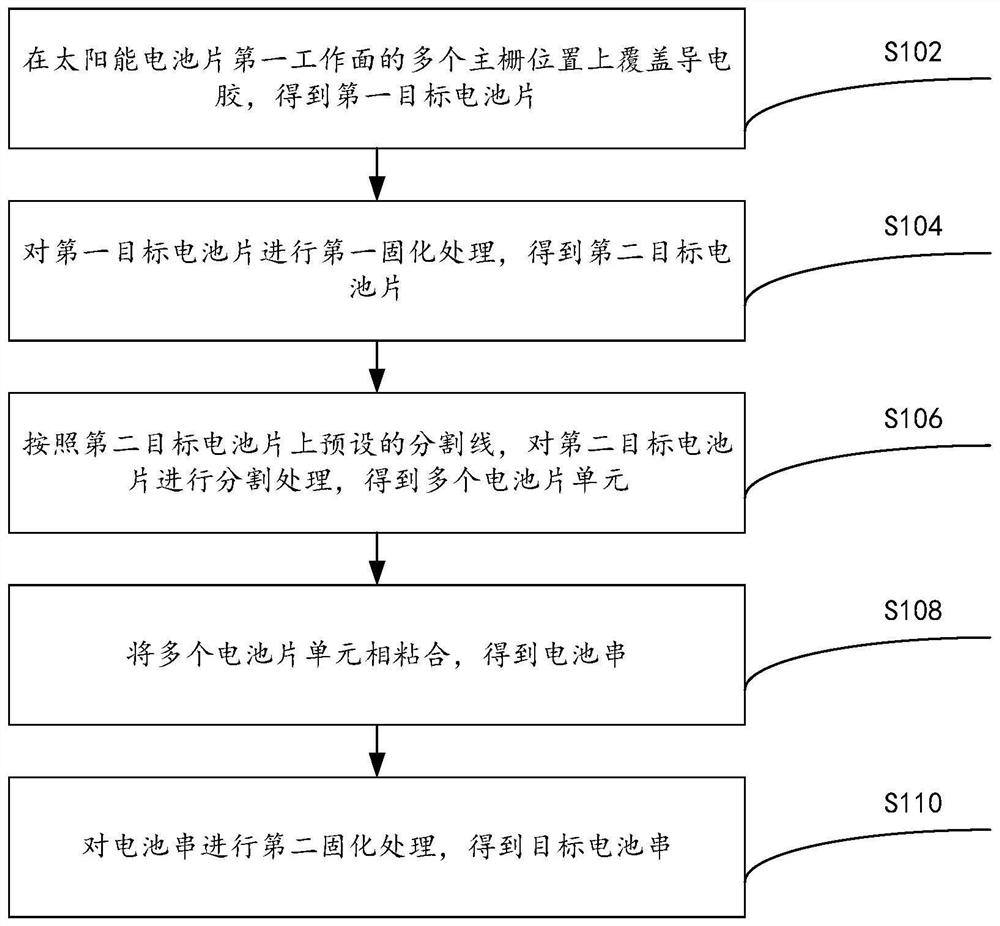

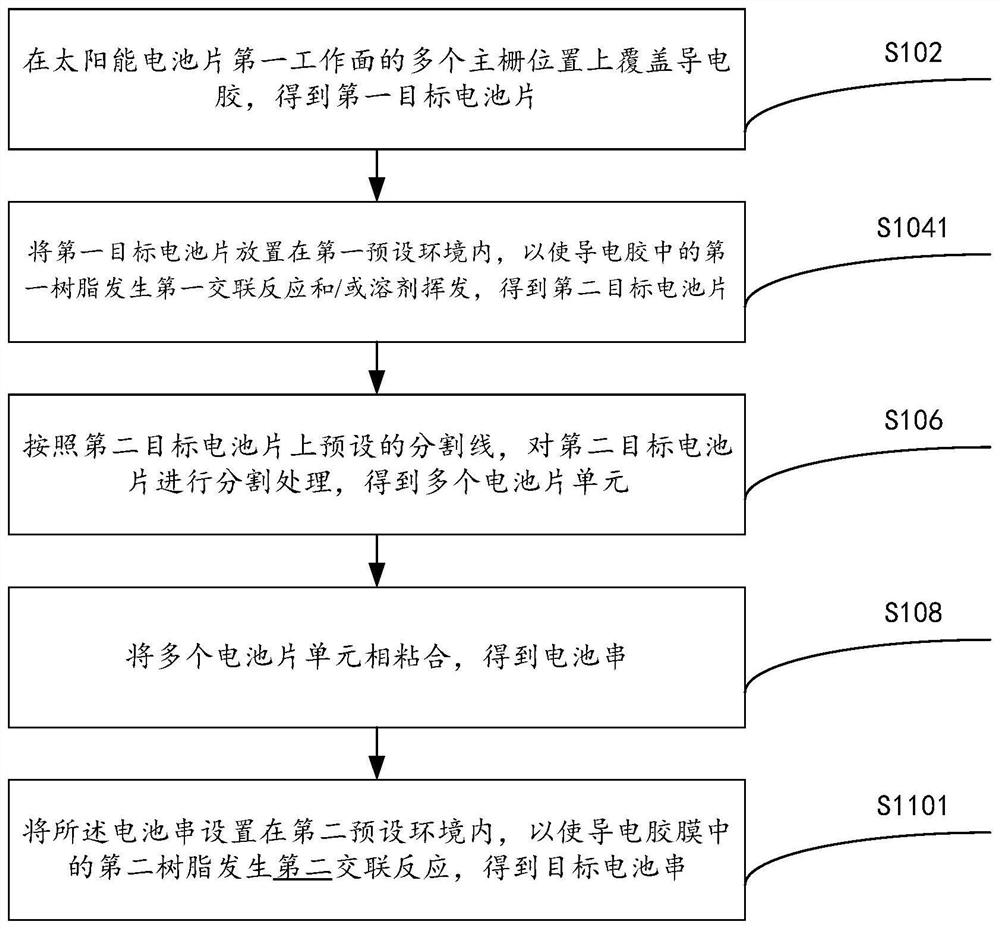

[0026] According to an embodiment of the present invention, an embodiment of a method for connecting solar cells is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and , although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0027] figure 1 is a method for connecting solar cells according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

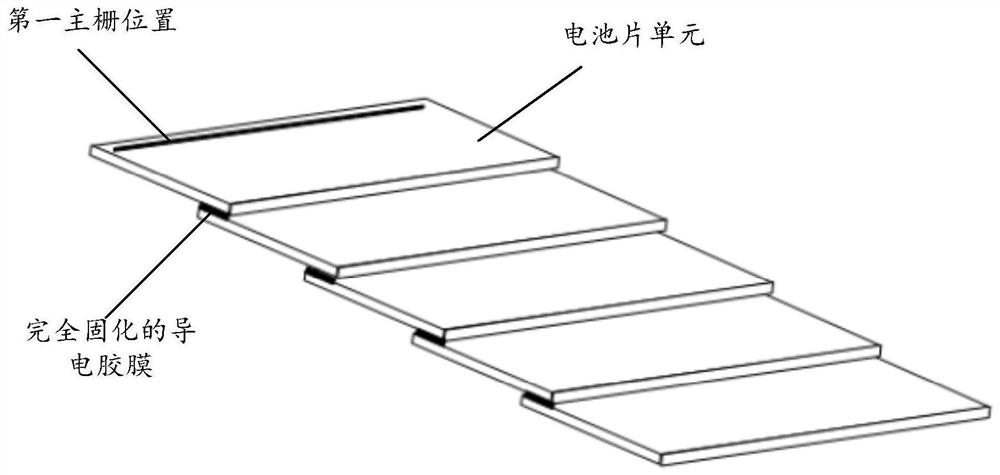

[0028] Step S102, covering a plurality of busbar positions on the first working surface of the solar cell with conductive glue to obtain a first target cell, wherein both the first working surface and the second working surface of the solar cell include multiple main grid position.

[0029] It should be noted that the position ...

Embodiment 2

[0069] The embodiment of the present invention also provides a conductive adhesive, which is applied to the above-mentioned method for connecting solar cells. The following is a specific introduction of the conductive adhesive provided by the embodiment of the present invention.

[0070] In the embodiment of the present invention, the conductive glue includes: target resin 10, conductive particles, 20 solvent 30, wherein:

[0071] The proportion of the target resin 10 in the unit weight of the conductive adhesive is 5%-30%;

[0072] The conductive particles 20 include at least one of the following: silver particles, copper particles, and silver-coated particles, wherein the proportion of the conductive particles in the conductive adhesive per unit weight is 45%-85%;

[0073] The solvent 30 is a solvent capable of dissolving the target resin, wherein the proportion of the solvent in the unit weight of the conductive adhesive is 0%-10%.

[0074] Optionally, the conductive adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com