Patents

Literature

671results about How to "High light conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

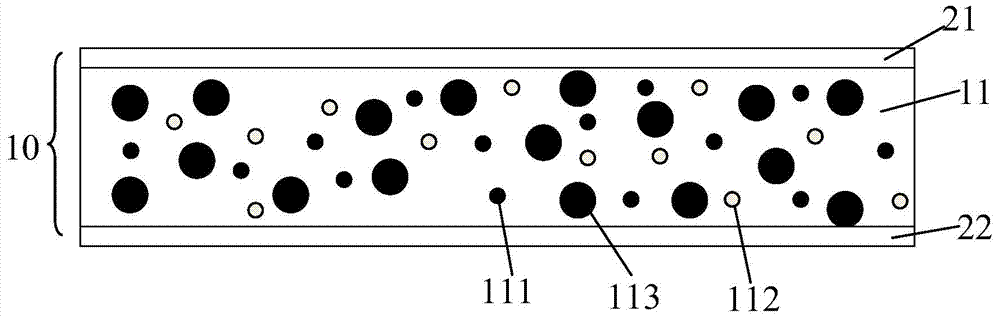

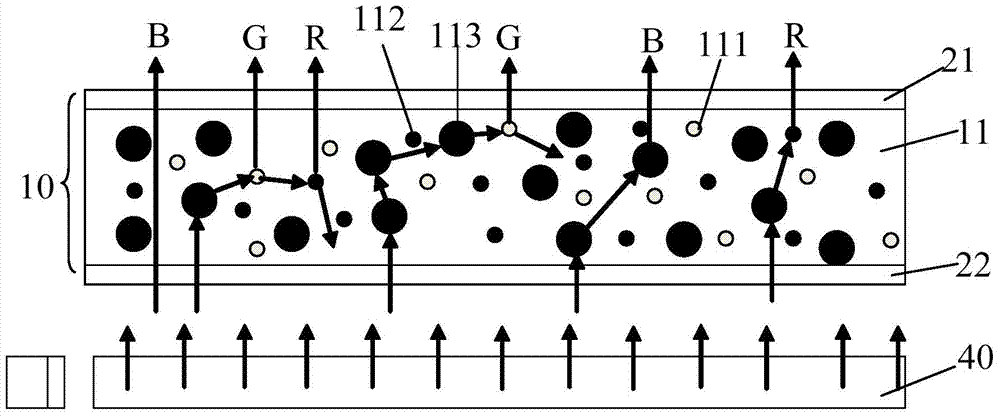

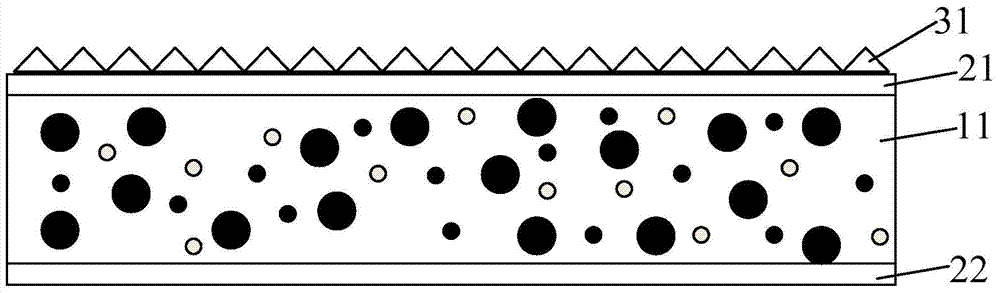

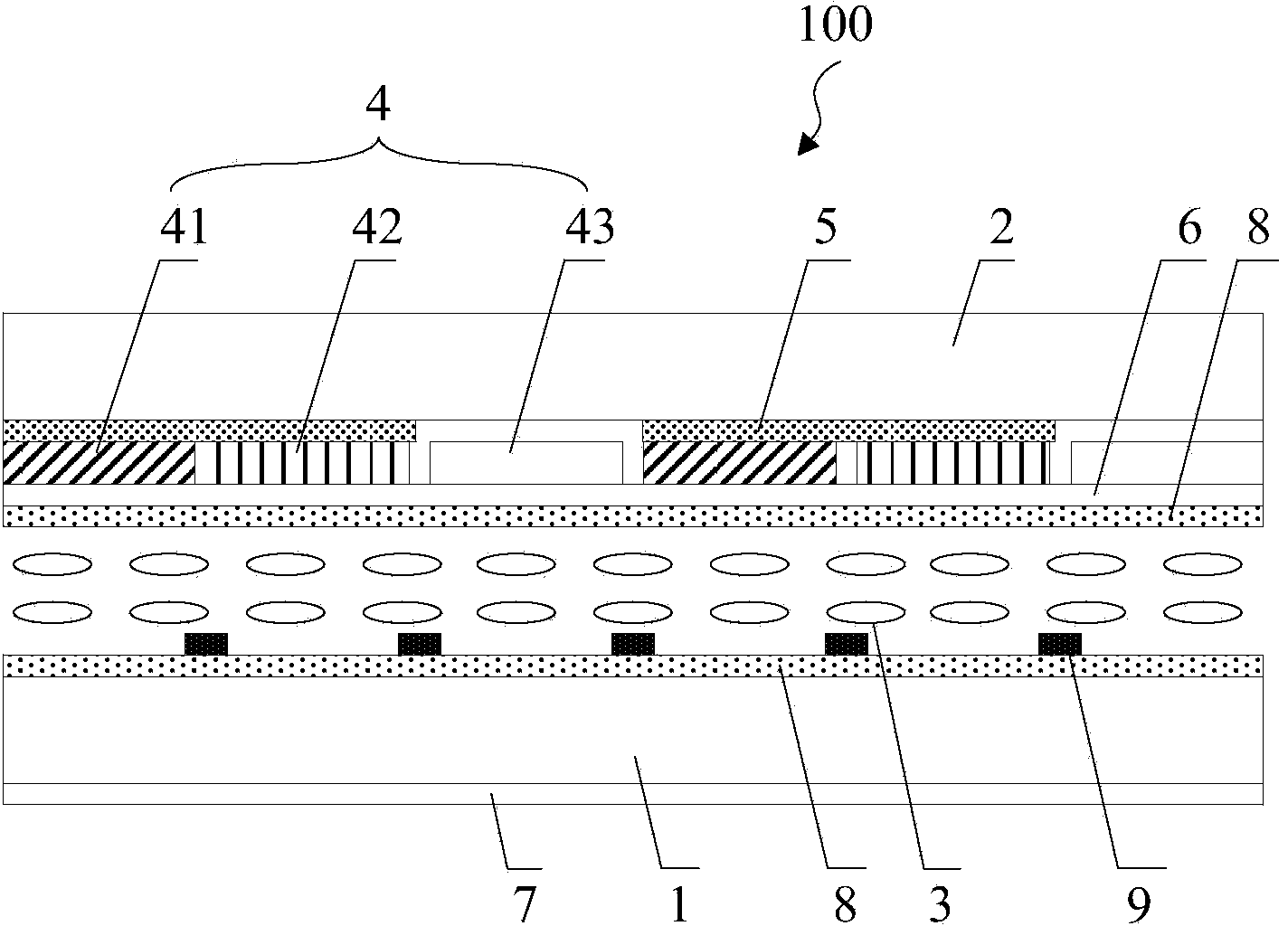

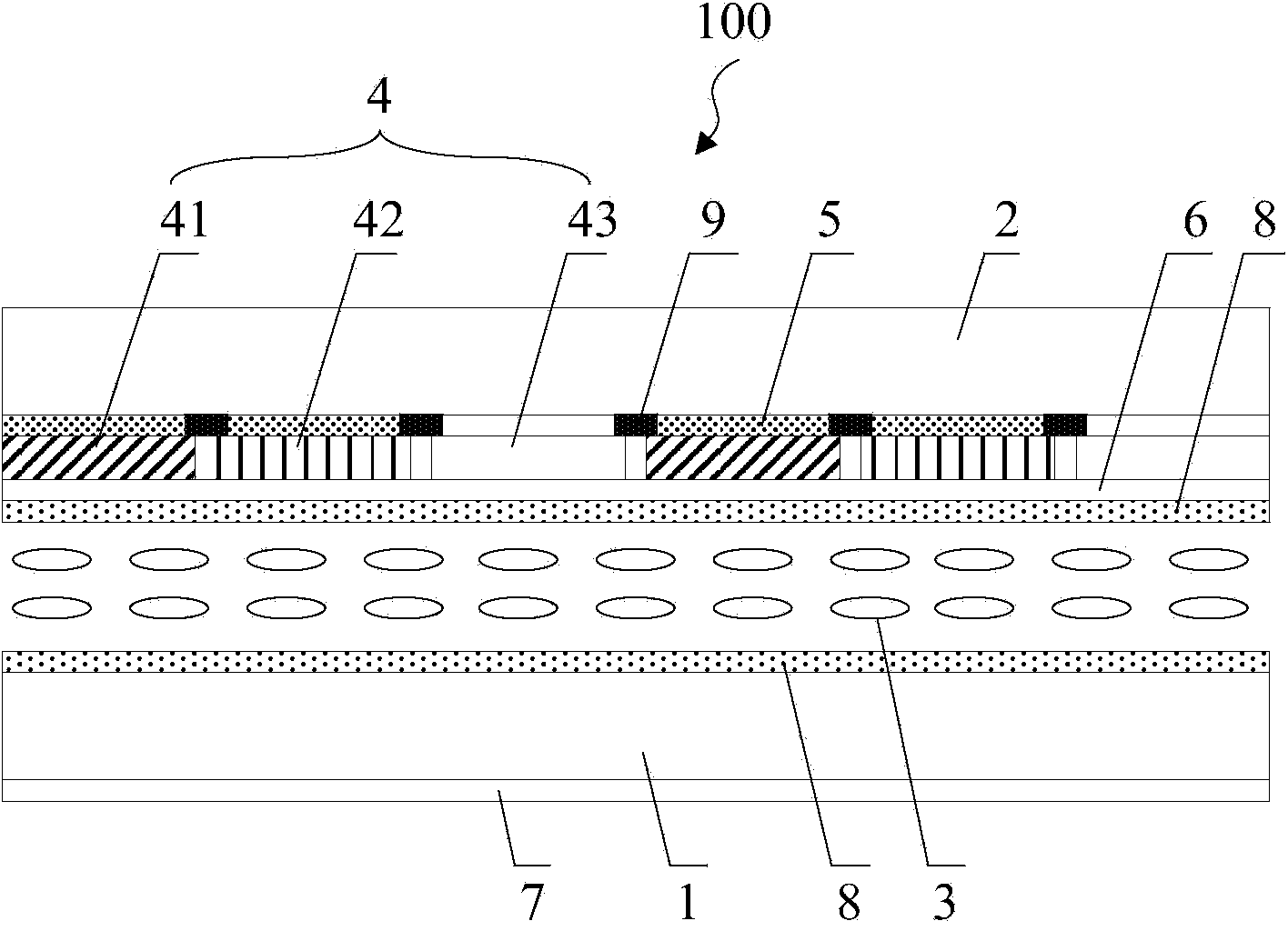

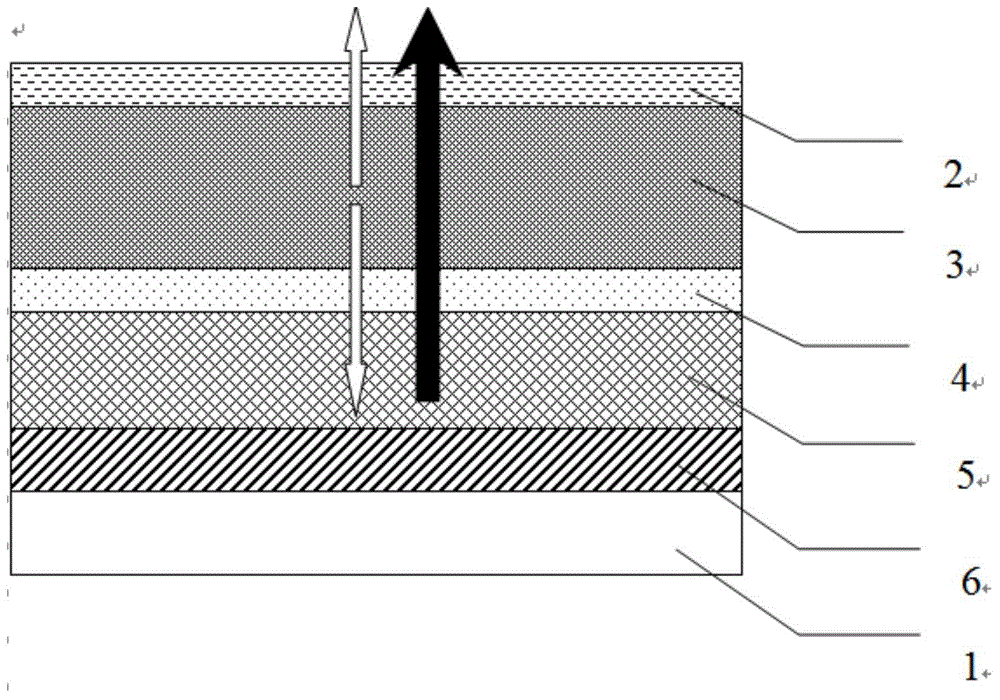

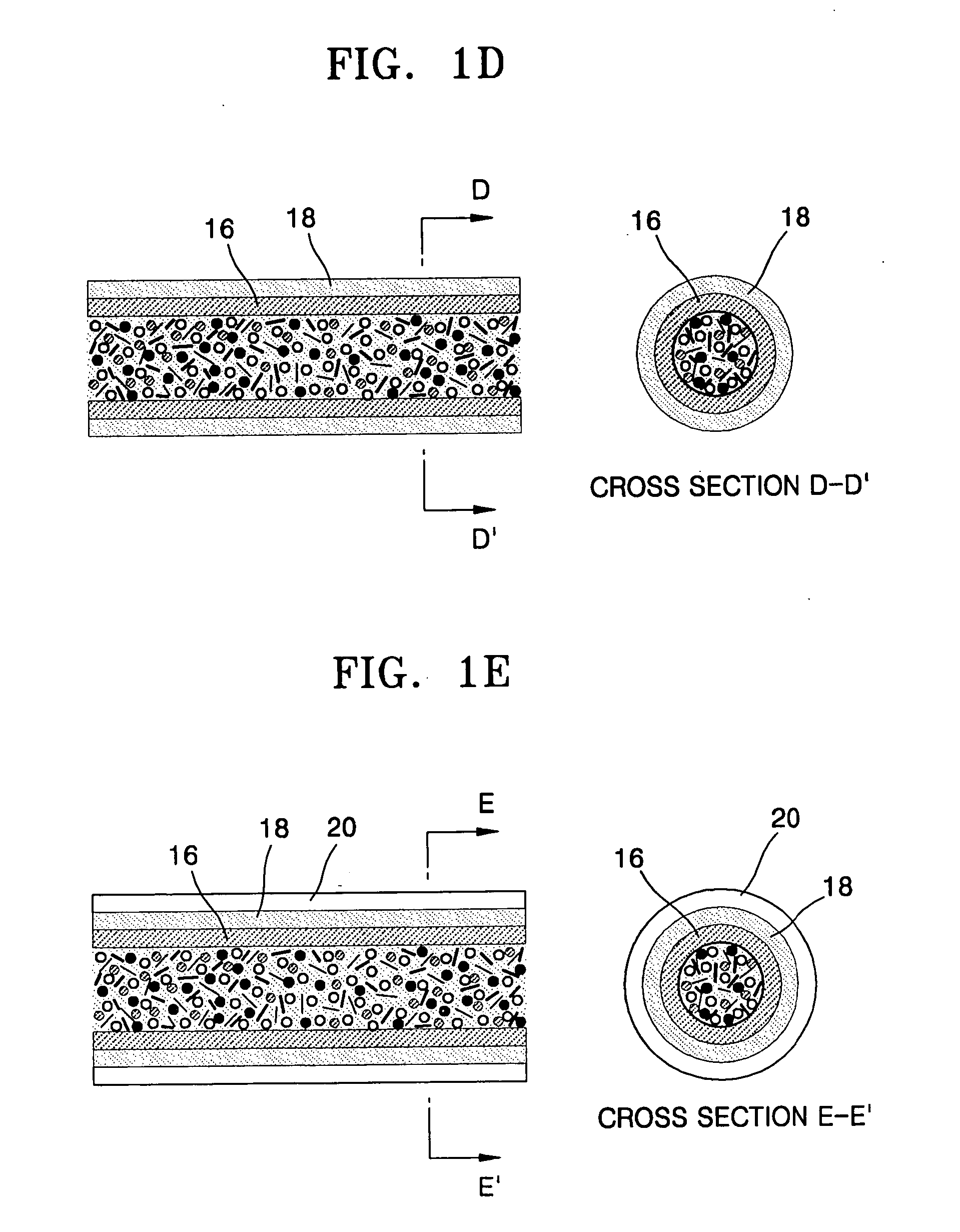

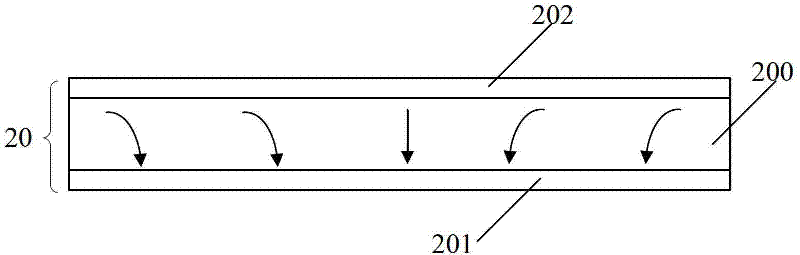

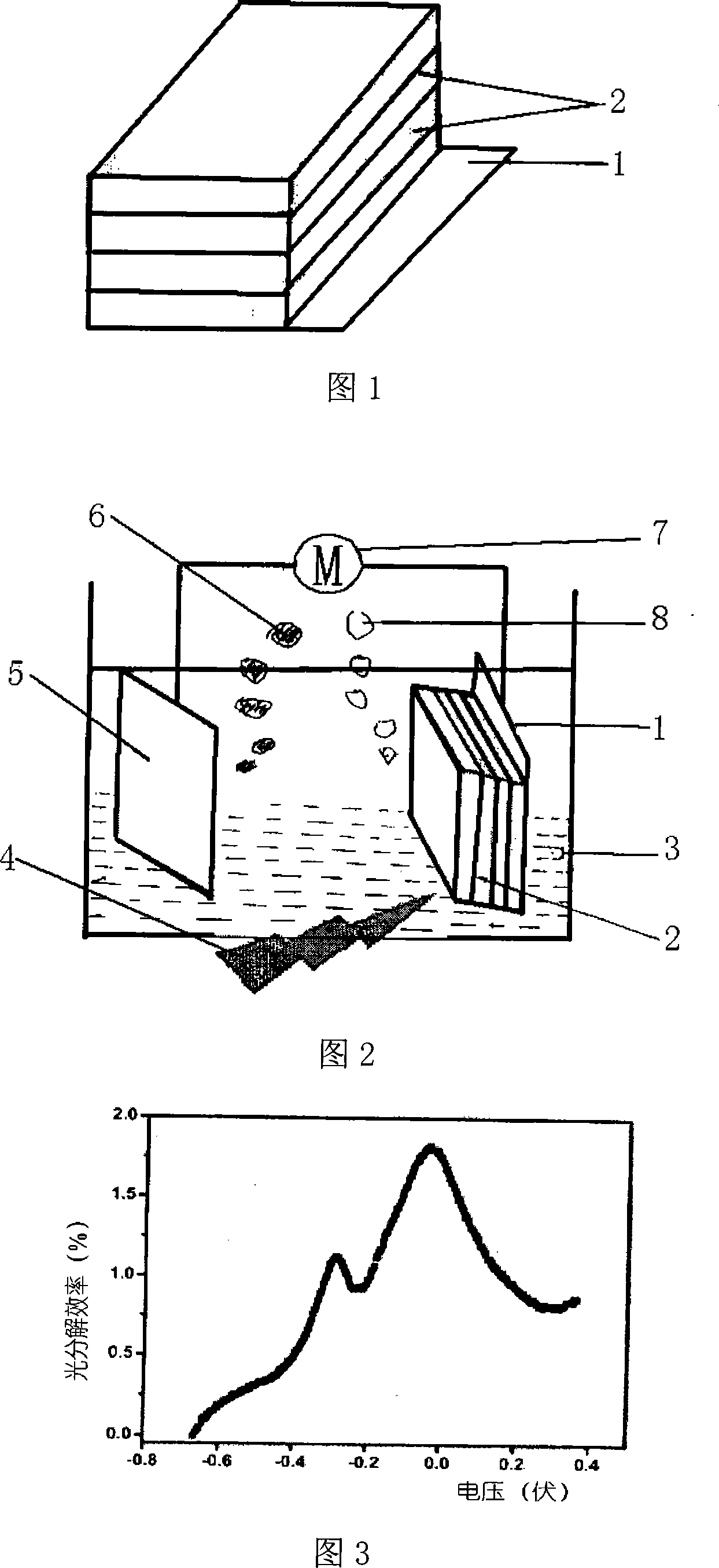

Quantum dot film and backlight module

InactiveCN103487857AIncrease profitImprove light conversion efficiencyDiffusing elementsNon-linear opticsOptical pathMultiple quantum

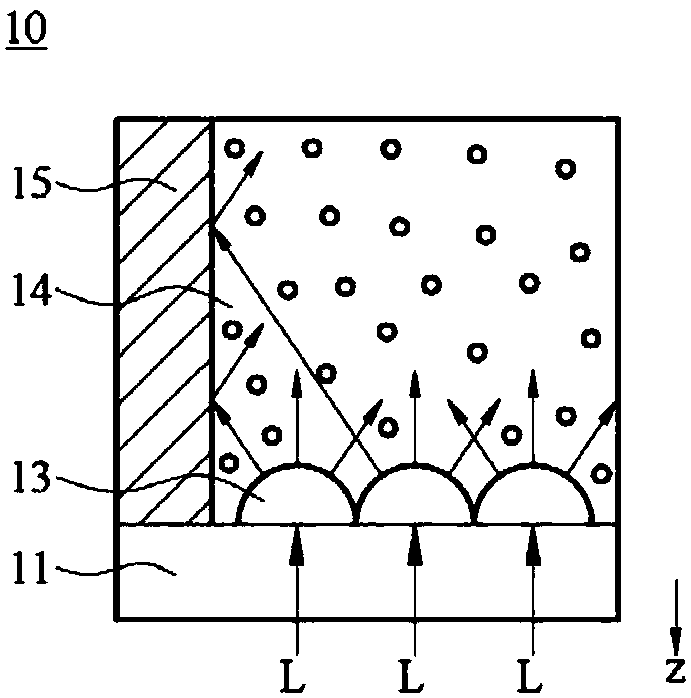

The invention discloses a quantum dot film and a backlight module. The quantum dot film comprises a quantum dot layer, wherein the quantum dot layer comprises a matrix and multiple quantum dots which are uniformly dispersed in the matrix; multiple diffusion particles which are uniformly dispersed are arranged in the matrix; a refractive index difference between the diffusion particles and the matrix is more than 0.01; the diffusion particles are used for scattering incident rays in the matrix; an optical path through which the rays pass the quantum dot layer is increased. According to the quantum dot film, the optical path through which the rays pass the quantum dot layer can be increased, the quantum dot utilization rate is increased, the light conversion efficiency is improved, and the cost is reduced. Moreover, three effects of light conversion, atomization and brightness enhancement can be provided, and the thickness of the backlight module is reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Display panel and display device

InactiveCN104330918AHigh light conversion efficiencyNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display panel and a display device, capable of improving light conversion efficiency of the display panel. The display panel comprises an array substrate and a color film substrate which are oppositely arranged as well as a liquid crystal layer between the array substrate and the color film substrate, wherein a quantum dot excitation layer is arranged on the color film substrate; an upper polarizing layer is arranged between the color film substrate and the liquid crystal layer; a lower polarizing layer is arranged on one surface, not adjacent to the liquid crystal layer, of the array substrate; and through the upper polarizing layer, linearly polarized light transmitted from the lower polarizing layer can reach the quantum dot excitation layer by keeping the state of the linearly polarized light.

Owner:BOE TECH GRP CO LTD

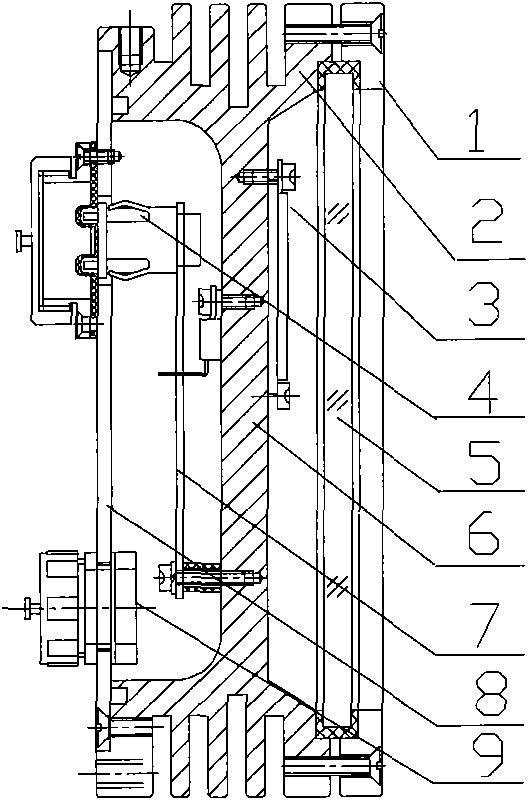

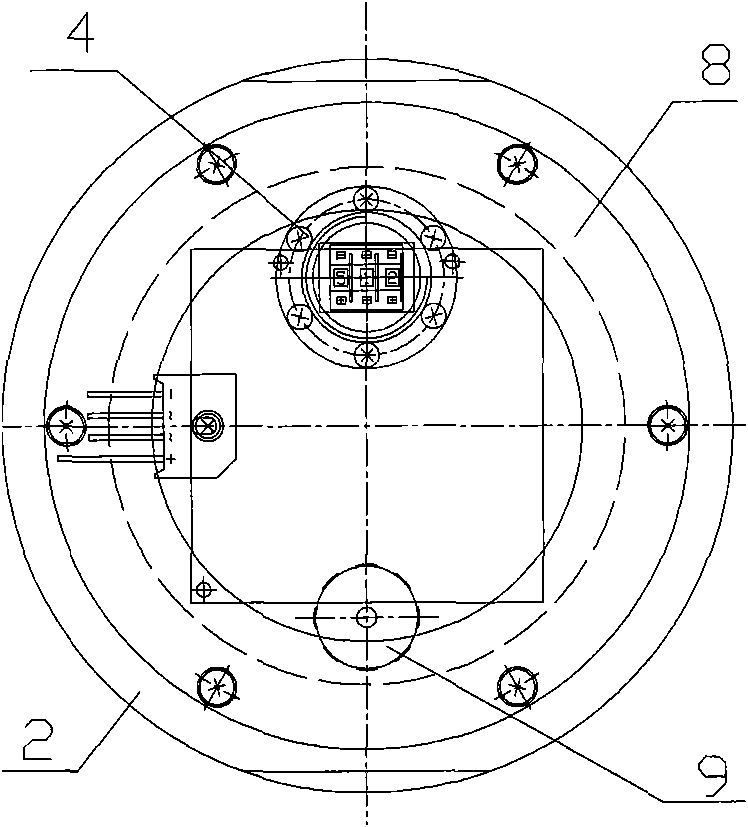

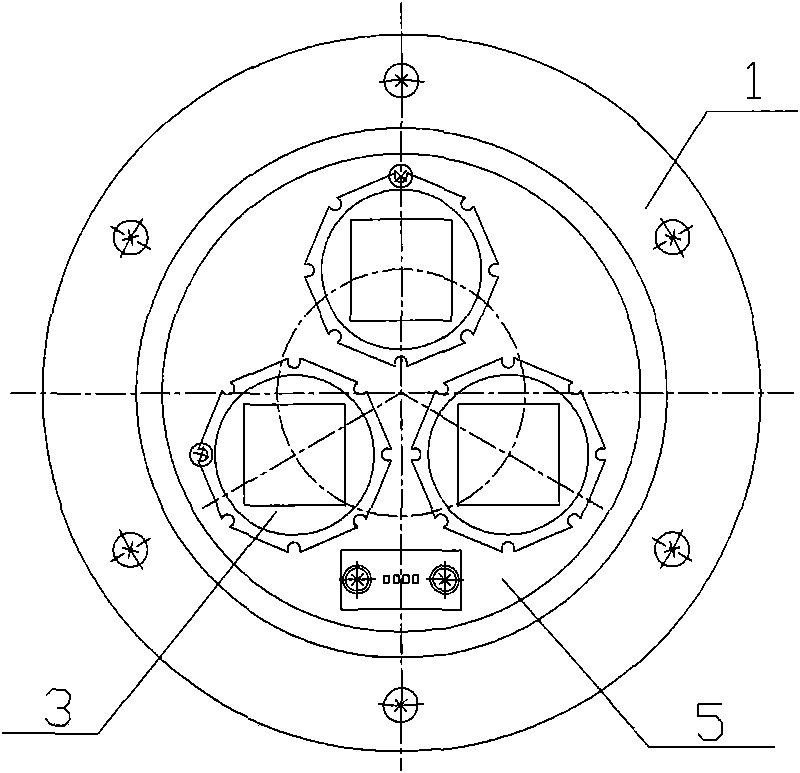

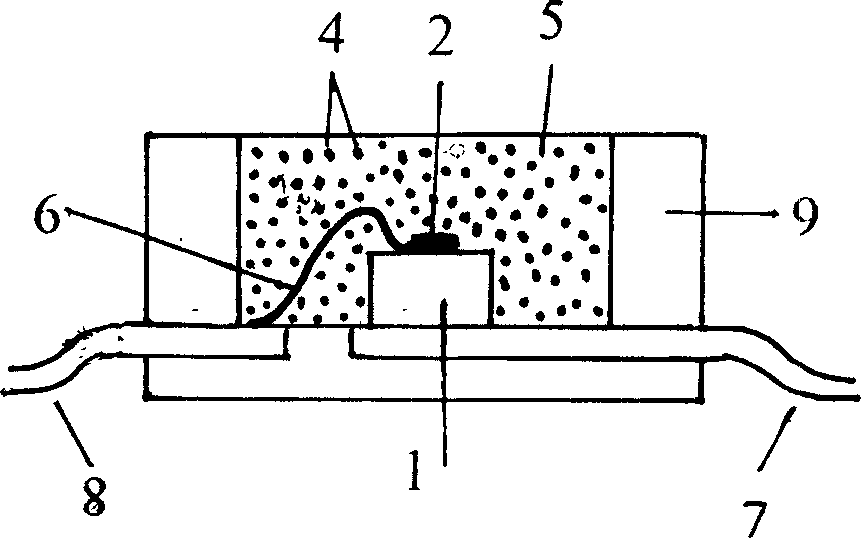

High-brightness LED underwater energy saving lamp

InactiveCN101608781ARealize direct coolingReduce adverse effectsPoint-like light sourceElectric circuit arrangementsDecreased energyEngineering

The invention relates to a high-brightness LED underwater lamp with low energy consumption and numerically controlled light color. A groove surface of a double-sided groove type lamp housing is provided with one or more LED chips. A transparent cover is arranged on and matched with one side, where an LED is arranged, of the double-sided groove type lamp housing by a rubber sealing ring in a waterproof sealed manner. Another groove cavity of the double-sided groove type lamp housing is internally provided with a control circuit board, a signal end of which is respectively connected with signal ends of one or more LED chips. A wiring terminal is sealed and connected on a sealing cover plate and a lead of the wiring terminal is connected with the signal end of the control circuit board. The sealing cover plate is sealed and matched with the other side of the double-sided groove type lamp housing. The energy saving lamp has the advantages of firstly, not only avoiding unfavorable effect of the control circuit board on the LED chip, but also considerably improving the optical conversion efficiency of the LED chip; secondly, realizing the direct temperature reduction to the LED chip, decreasing energy consumption, improving the optical conversion efficiency of the LED chip and considerably prolonging the service life of the LED chip; and thirdly, realizing the purpose of direct water-cooled temperature reduction.

Owner:杭州亿奥光电有限公司

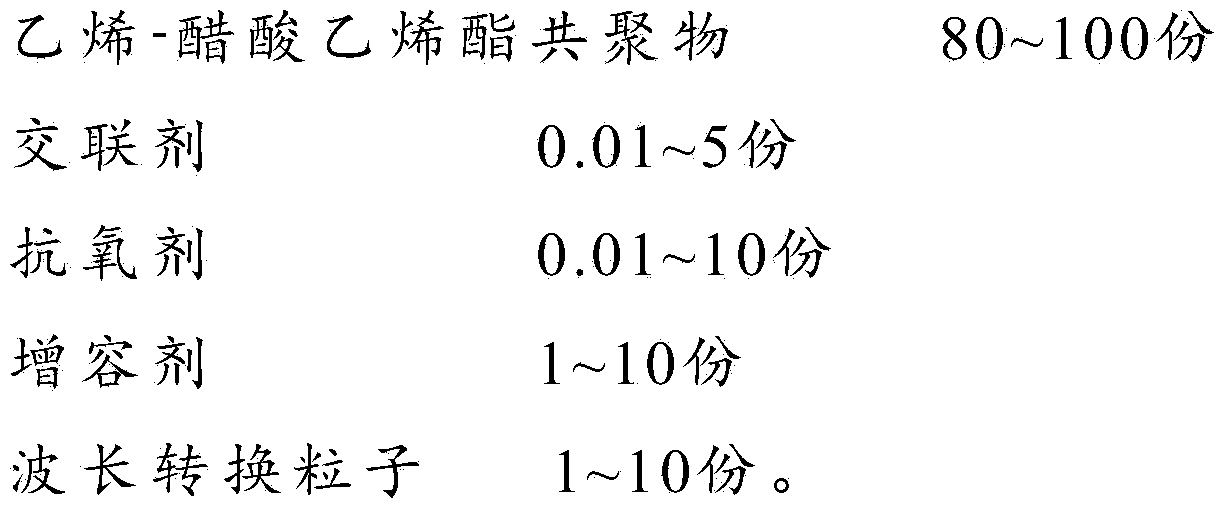

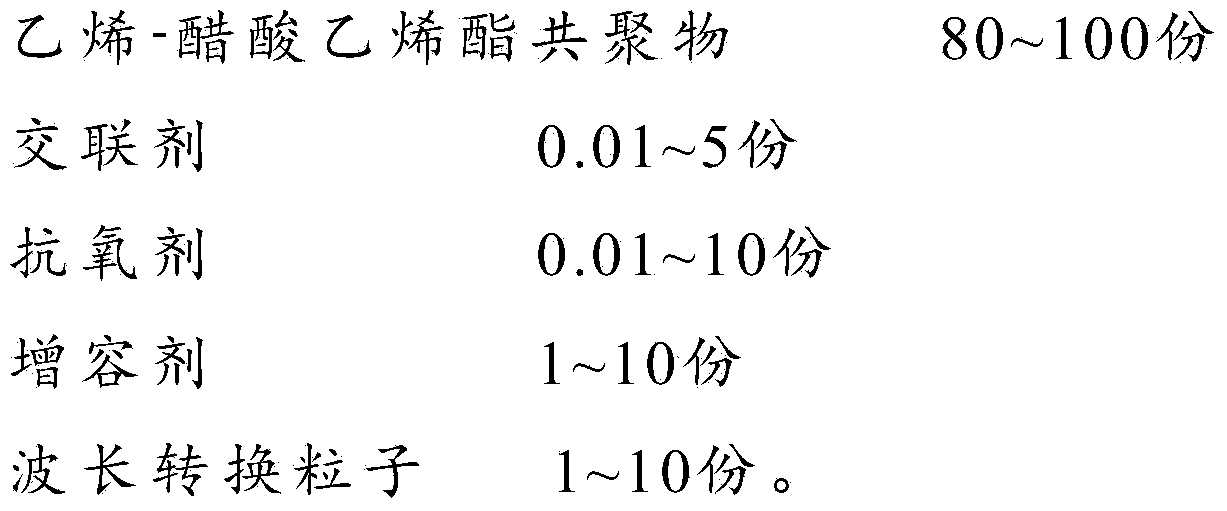

Optical-transfer packaging adhesive film, and preparation technique and application thereof

InactiveCN104194661AIncrease powerIncrease incomeNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantOptical transmittance

The invention discloses an optical-transfer packaging adhesive film which is prepared from the following raw materials in parts by weight: 80-100 parts of ethylene-vinyl acetate copolymer, 0.01-5 parts of crosslinking agent, 0.01-10 parts of antioxidant, 1-10 parts of solubilizer and 1-10 parts of wavelength conversion particle. The adhesive film has the advantages of favorable light transmittance, high optical-transfer efficiency and uniform dispersion.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Optical conversion luminous film and preparation method thereof

ActiveCN101571235AGood luminous consistencyPrevent glareLuminescent paintsSynthetic resin layered productsChemistryColor rendering index

The invention relates to an optical conversion luminous film and a preparation method thereof. The optical conversion luminous film is formed by a diffusion film and a mixed paint layer on the diffusion film; the optical conversion luminous film has the thickness of 30-200mum, wherein, the thickness of the diffusion film is 20-70mum; the mixed paint layer is made of 10.000-30.000% of yellow luminous fluorescent material, 0.001-2.000% of red luminous fluorescent material, 60.000-89.000% of polymer resin, 1.000-5.000% of bi-amino silane, 0.000-20.000% of diluting agent and 0.000-5.000% of accessory ingredient. By combining the yellow luminous fluorescent material and the red luminous fluorescent material, the invention can realize the aim of regulating chromaticity coordinate, color temperature and color rendering index, thus preparing the optical conversion luminous film which is made of the fluorescent materials and has the advantages of high color rendering index of the photodiffusion effect, good property of uniform light, anti-dazzle, high light conversion efficiency, low cost, excellent aging characteristic and simple production technique.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

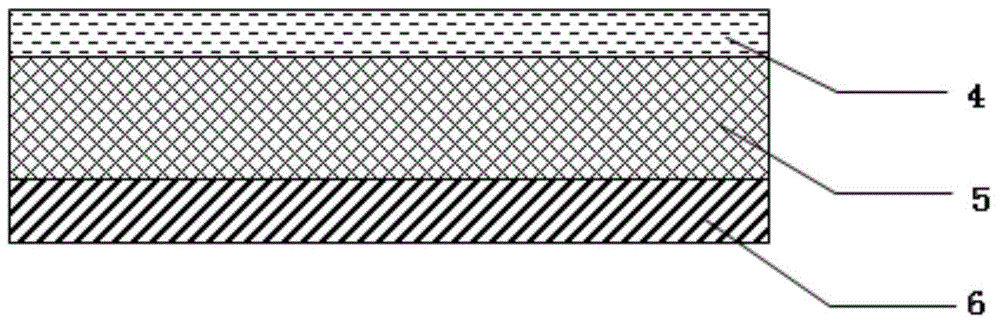

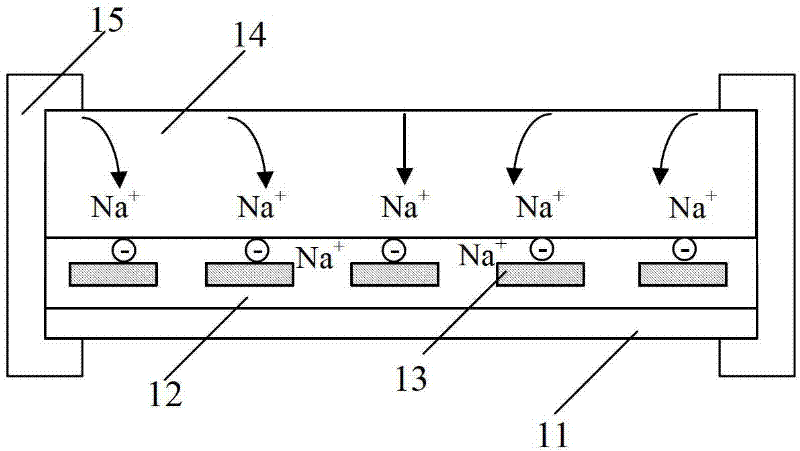

Light conversion unit having color conversion function and application thereof

InactiveCN104466026AIncrease light field intensityHigh light conversion efficiencyOLED manufacture/treatment processesSolid-state devicesOrganic electroluminescenceLight conversion efficiency

The invention discloses a light conversion unit having a color conversion function. The light conversion unit comprises a semi-permeant semi-reflecting conductive layer, a color conversion layer and a reflecting layer, wherein the semi-permeant semi-reflecting conductive layer, the color conversion layer and the reflecting layer are arranged in an overlaid mode. The invention further relates to an organic electroluminescence device with the light conversion unit. The organic electroluminescence device comprises the light conversion unit, an organic function layer and a second electrode layer, wherein the light conversion unit, the organic function layer and the second electrode layer are arranged in an overlaid mode, and the semi-permeant semi-reflecting conductive layer of the light conversion unit is close to the organic function layer. The organic electroluminescence device with the light conversion unit has high light conversion efficiency and light extraction efficiency.

Owner:BEIJING VISIONOX TECH

A kind of electronic silver paste and its preparation process

ActiveCN102290118ALow melting pointLow softening pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteElectricity

The invention relates to electronic silver paste and a preparation process thereof, belonging to the technical field of production of such base materials as electronic ceramic components, thick film hybrid circuits, touch components and the like. The electronic silver paste is prepared by mixing and stirring 4-9% of glass powder, 63-80% of silver powder, 12-28% of organic carrier and 0.2-2% of additive, rolling, dispersing and grinding the mixture, then adding 1-2wt% of bismuth stearate, stirring the mixture uniformly and filtering the mixture with a screen. The electronic silver paste and the preparation process have the following beneficial effects: the glass powder system does not contain lead; the minimum grain size and shape of the silver powder are not strictly required; and the silver paste is especially suitable for the positive electrodes of the solar cells on the crystalline silicon solar cell silicon substrates produced in large batch and has excellent electrical property and mechanical property..

Owner:郴州雄风环保科技有限公司

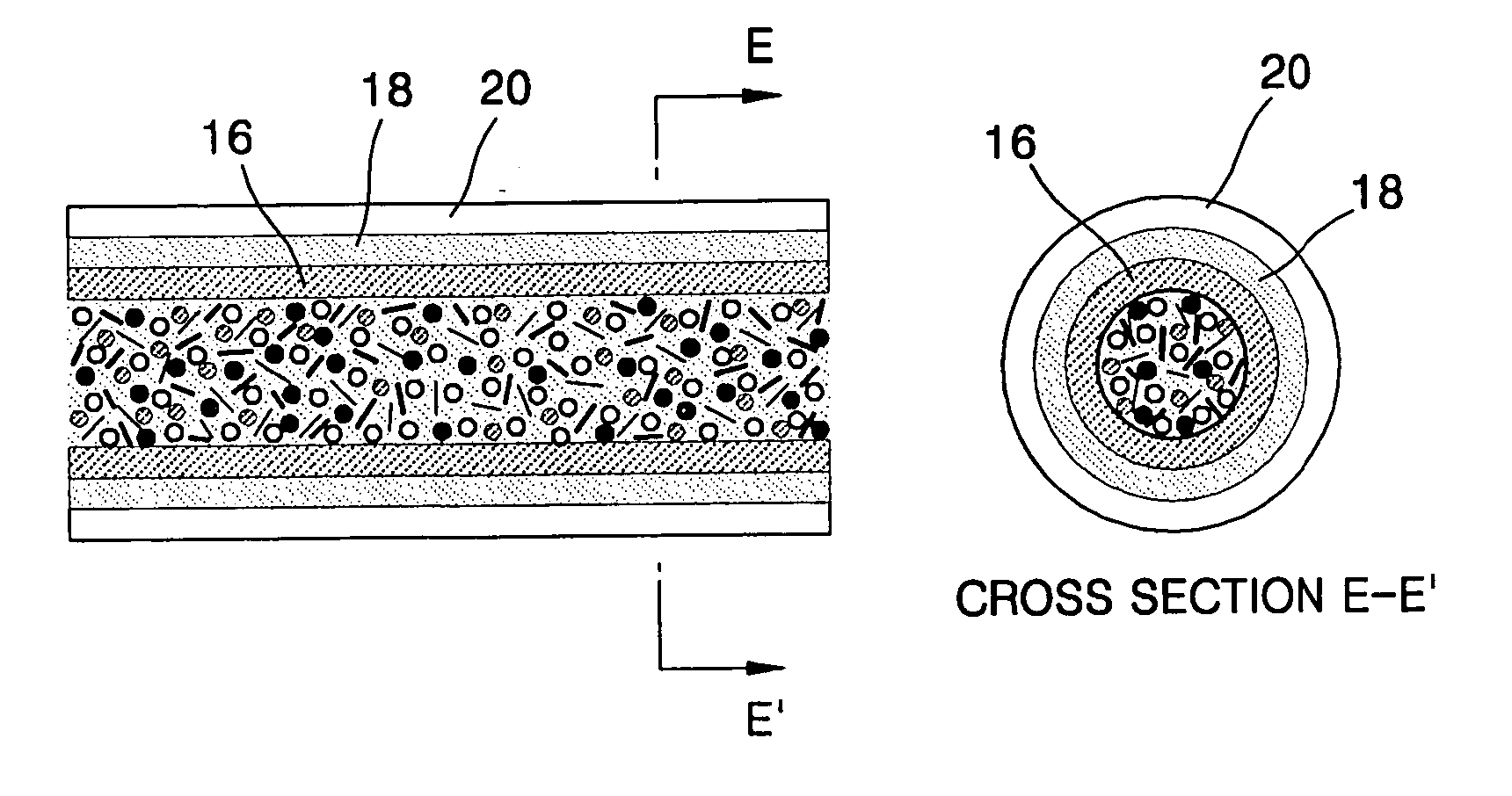

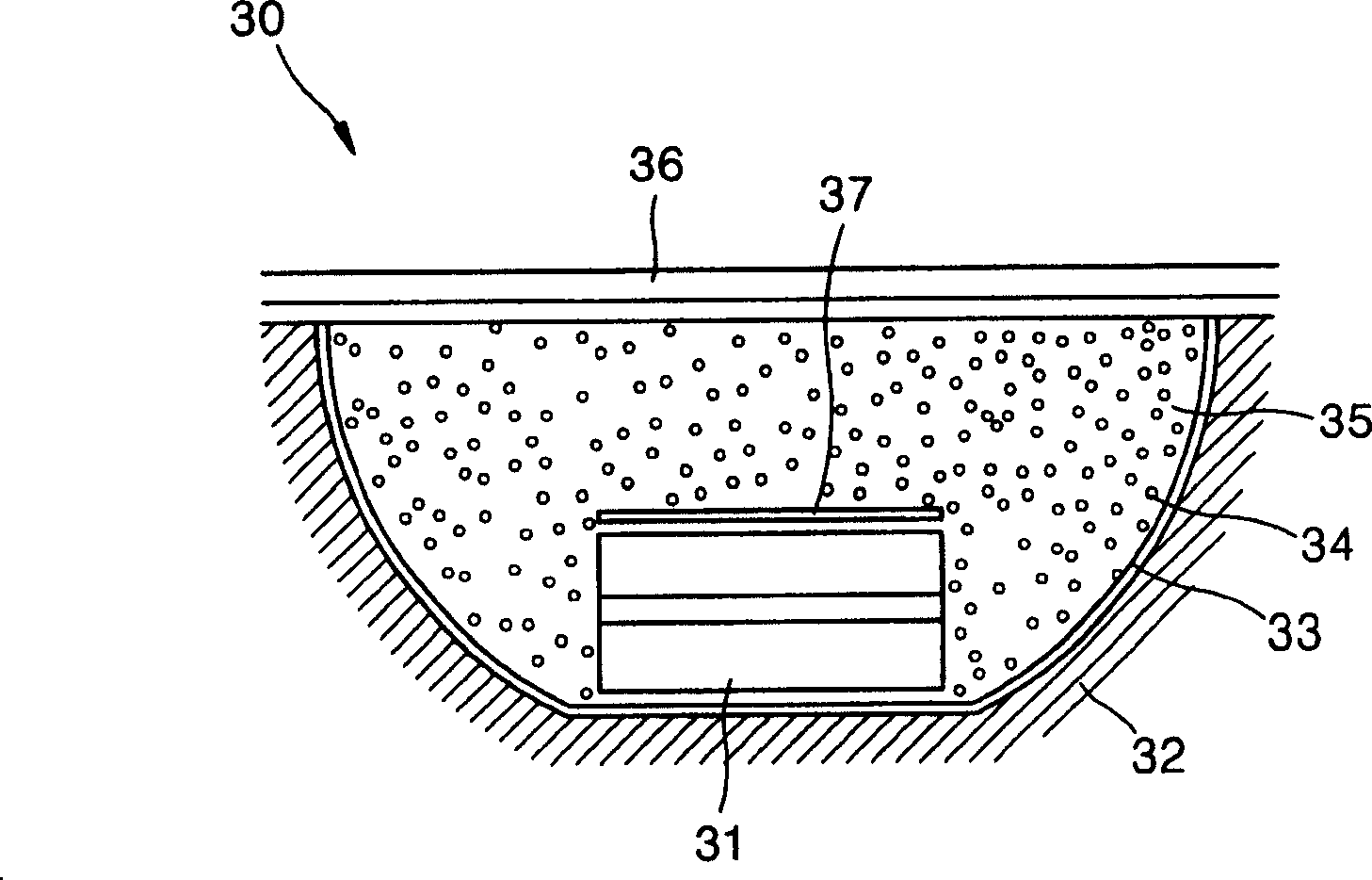

Fibril solar cell and method of manufacture

InactiveUS20050194035A1Reduce manufacturing costHigh light conversion efficiencyLight-sensitive devicesFinal product manufactureFibrilCarbon nanotube

A fibril solar cell includes: a fiber-shaped inner core having a porous fiber composed of first carbon nanotubes and a cathode material, in which pores of the porous fiber are filled with second carbon nanotubes, titanium dioxide, a photosensitive dye, and an electron transfer electrolyte; a photoconductive layer formed on a surface of the fiber-shaped inner core and composed of at least one photoconductive polymer; a transparent electrode layer formed on a surface of the photoconductive layer; and a transparent protective layer formed on a surface of the transparent electrode layer and composed of at least one transparent polymer. The fibril solar cell can be mass-produced inexpensively using a polymer. Also, the fibril solar cell has a high efficiency and can be converted into various shapes. The fibril solar cell can be attached to clothing, and be used as a portable power source for mobile electronics.

Owner:SAMSUNG SDI CO LTD

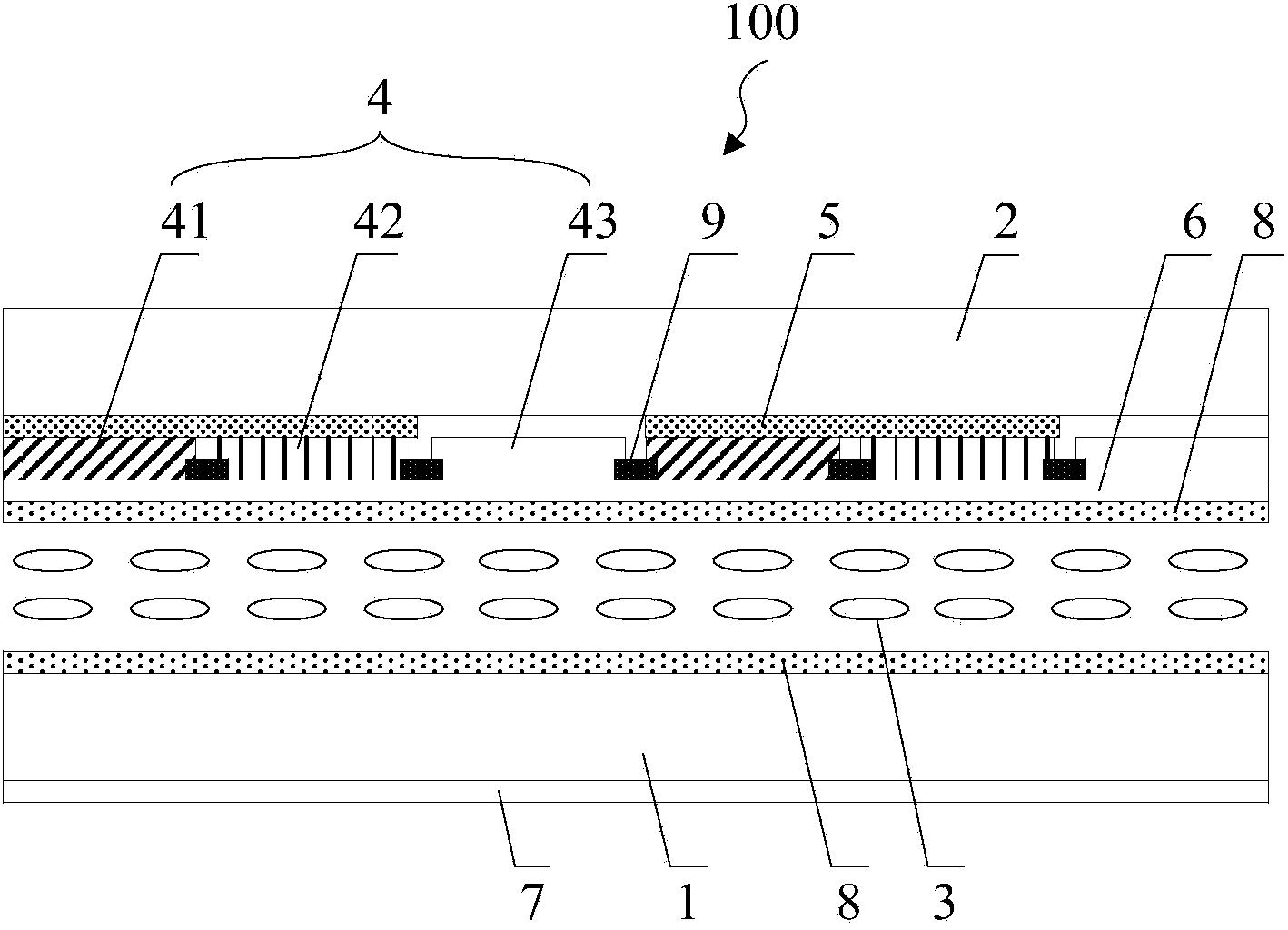

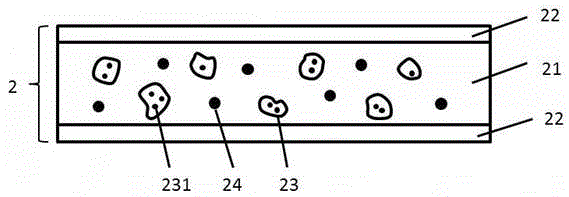

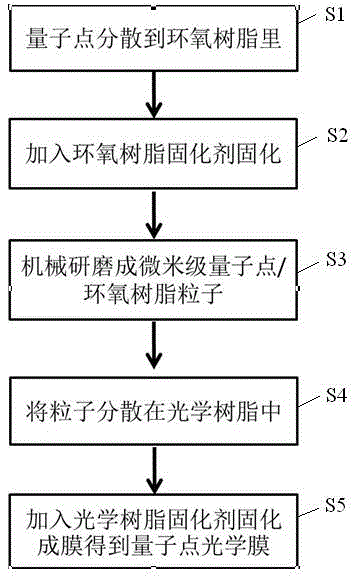

Quantum dot/epoxy resin particle, preparation method thereof, quantum dot optical film and backlight module

The invention discloses a quantum dot / epoxy resin particle, a preparation method thereof, a quantum dot optical film and a backlight module. The preparation method of the quantum dot / epoxy resin particle comprises the following steps: pre-dispersing and packaging quantum dots in an epoxy resin block, and grinding the obtained epoxy resin block. The structure of the quantum dot / epoxy resin particle effectively reduces the quantum dot agglomeration and the possibility of interference and destroy caused by agglomeration, and allows the quantum dots to be uniformly dispersed in the obtained optical film, so the quantum dot utilization rate is obviously improved. The phototransformation efficiency and the brightening effect of the backlight module made by using the quantum dot optical film are obviously improved. The backlight module can be applied to a display to realize pure color, high saturation and high color gamut of the R / G / B color sub-pixel units corresponding to color filters and improve the luminescence efficiency.

Owner:TCL CORPORATION

White light LED and light converting luminophore

InactiveCN1585141AHigh color rendering indexHigh light conversion efficiencyGas discharge lamp usageLuminescent compositionsFluorescenceManganese

The diode is comprised of the luminous chip electrode, phosphor and sealing material. The phosphor is comprised of the silicon chloride acid Mg Zn Ca (CMZSC) and alkali earth silicate and pyrosilicate phosphor. This phosphor with the other phosphor of the visible light combines the UV white light and LD. The CMZSC green phosphor can transform the blue light transmitted by the semiconductor compound into yellow light. Thus the transmitting spectrum covered area is broadened and the optical transform effect is improved.

Owner:刘行仁 +1

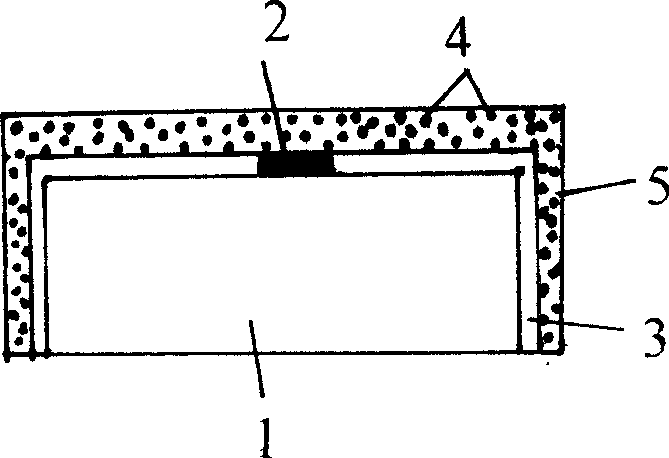

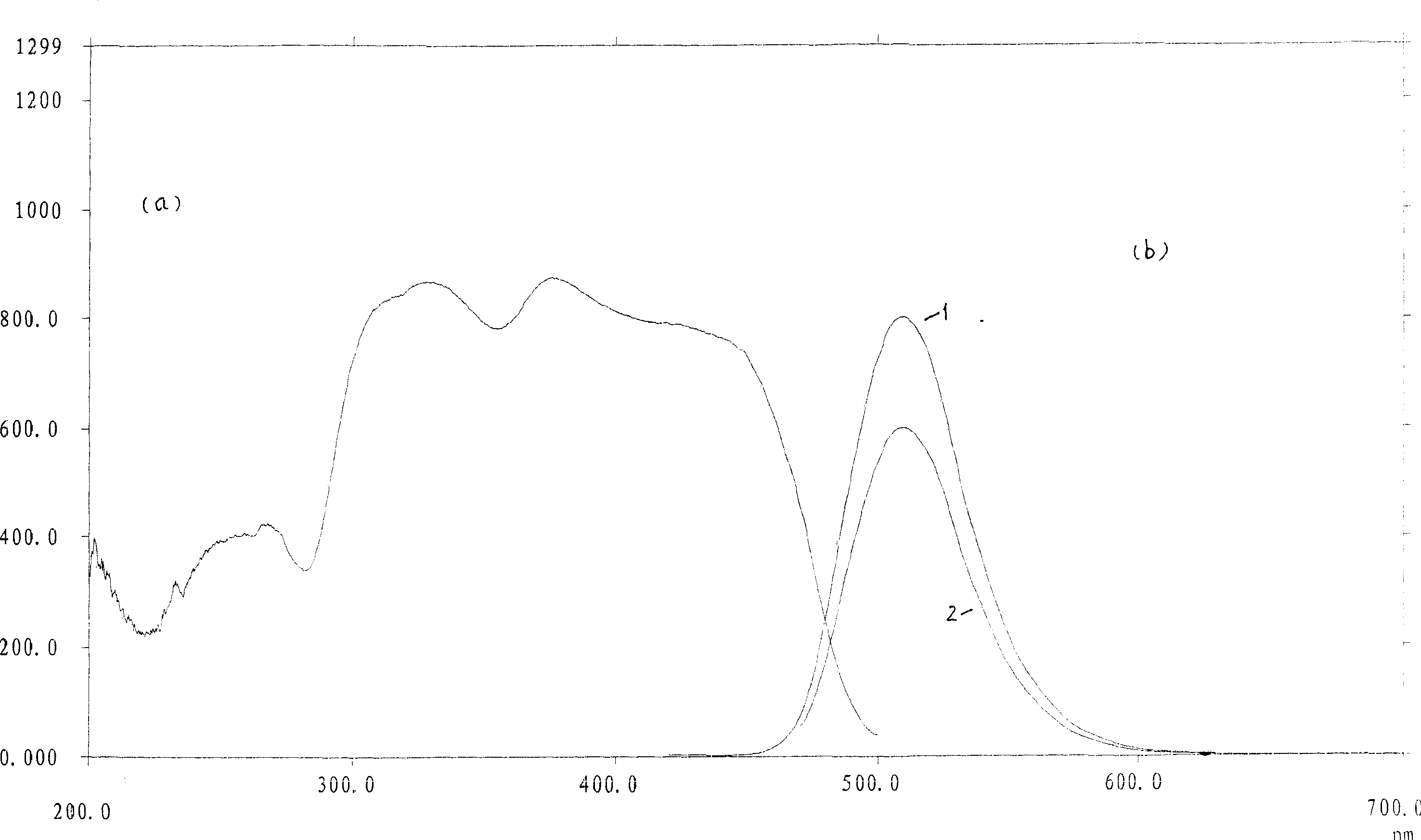

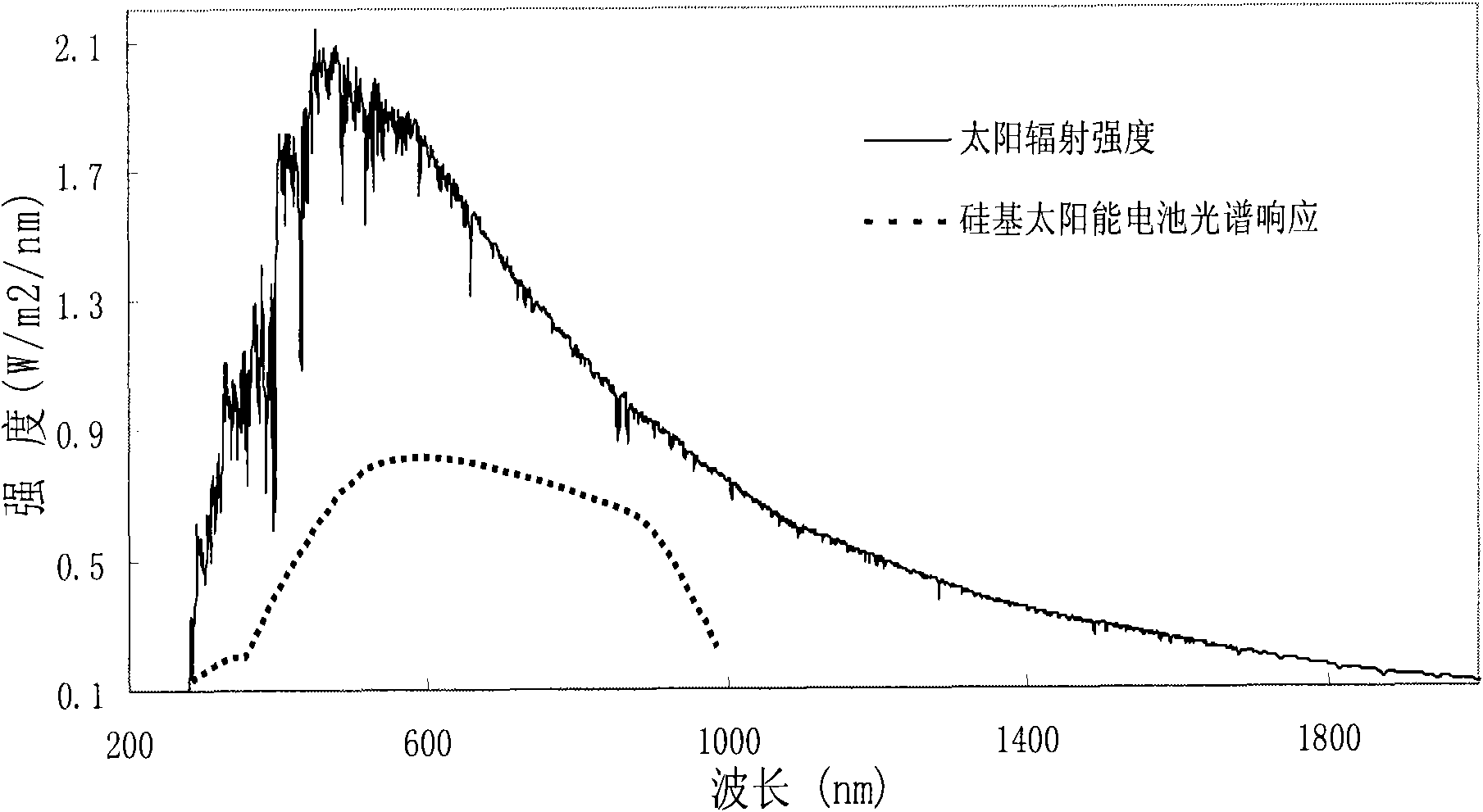

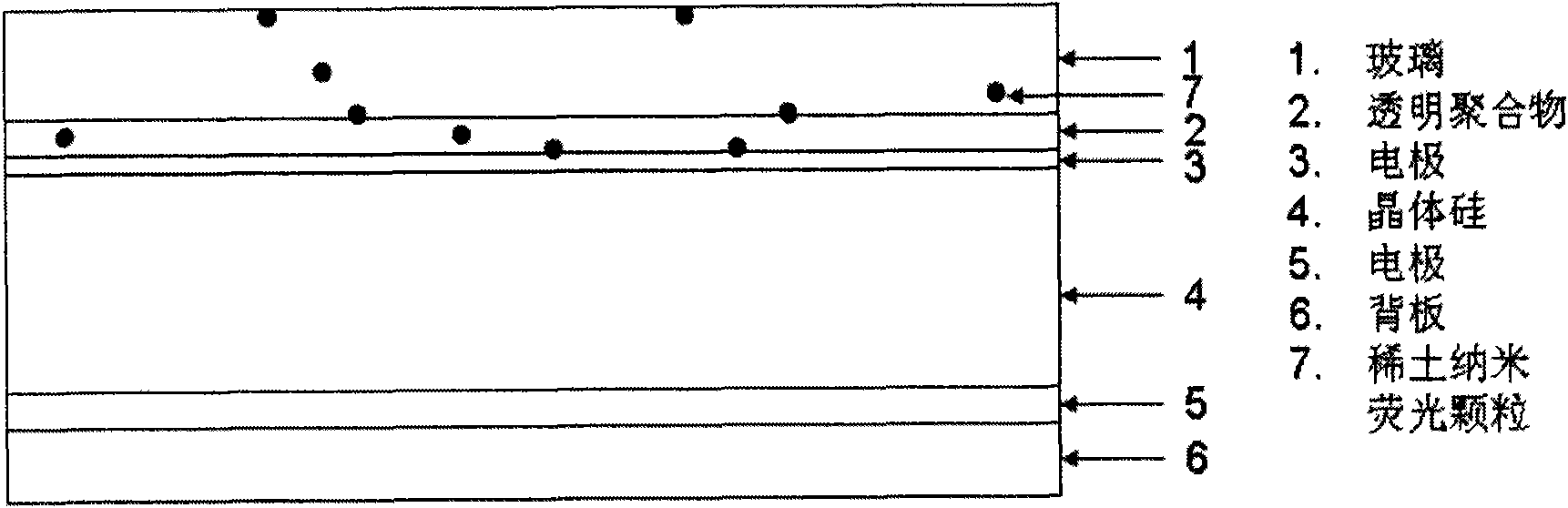

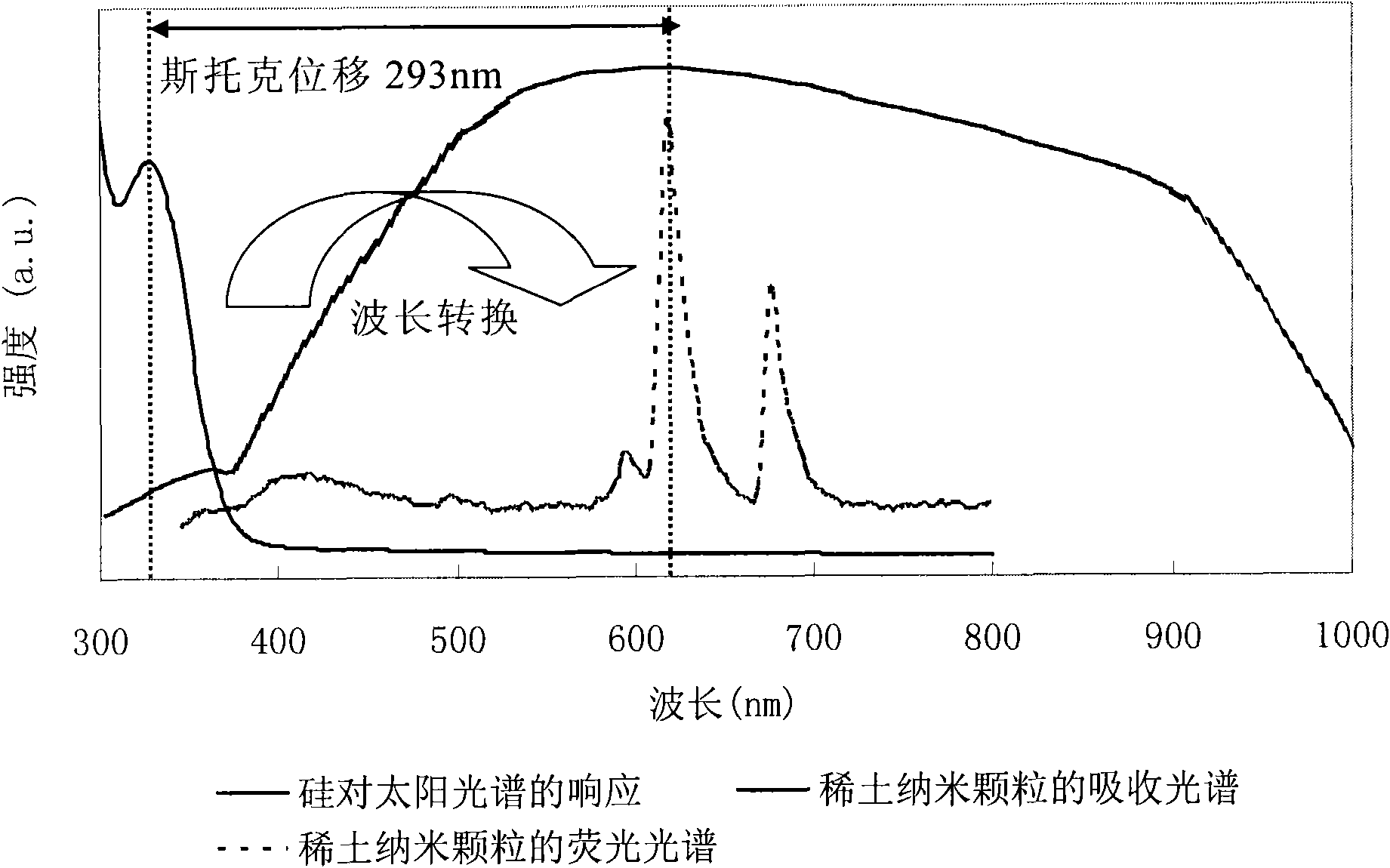

Nano fluorescent particles doping with rare-earth ions and relevant application thereof

InactiveCN101787272AHigh fluorescence efficiencyEffective absorptionTenebresent compositionsPhotovoltaic energy generationMischmetalRare earth ions

The invention provides nano fluorescent particles doping with rare-earth ions. The grain size of the nano particles is 1-200nm, and the nano particles comprise a nano particle matrix and rare-earth ions. The invention also provides a solar battery containing the nano particles.

Owner:EI DU PONT DE NEMOURS & CO

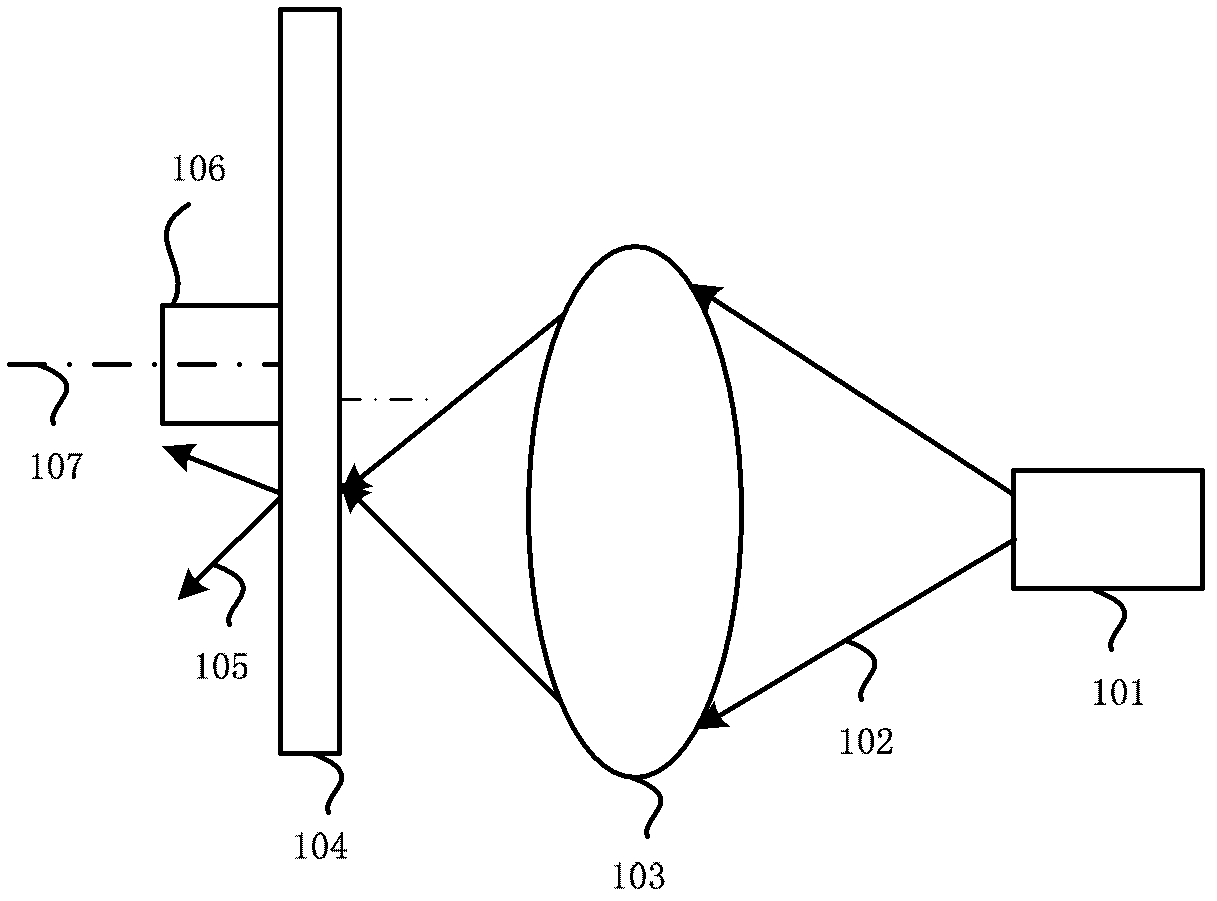

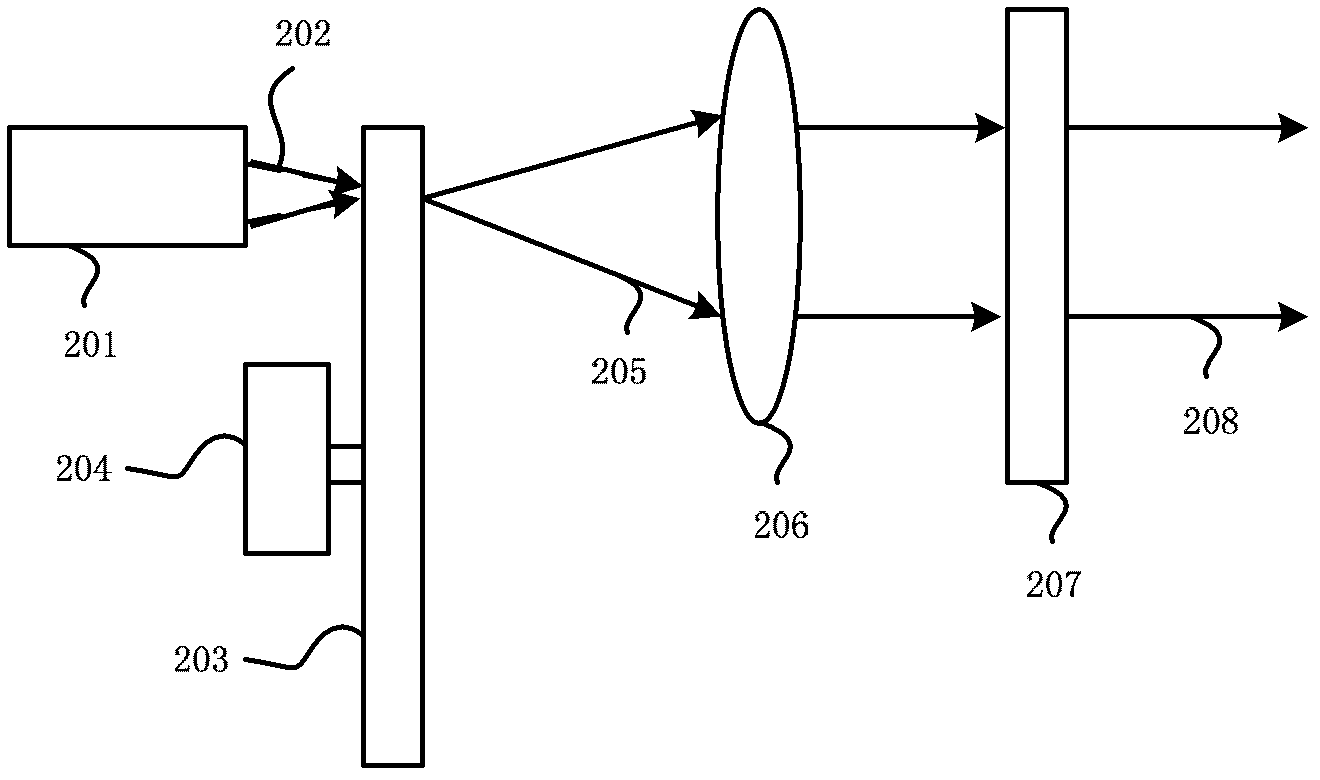

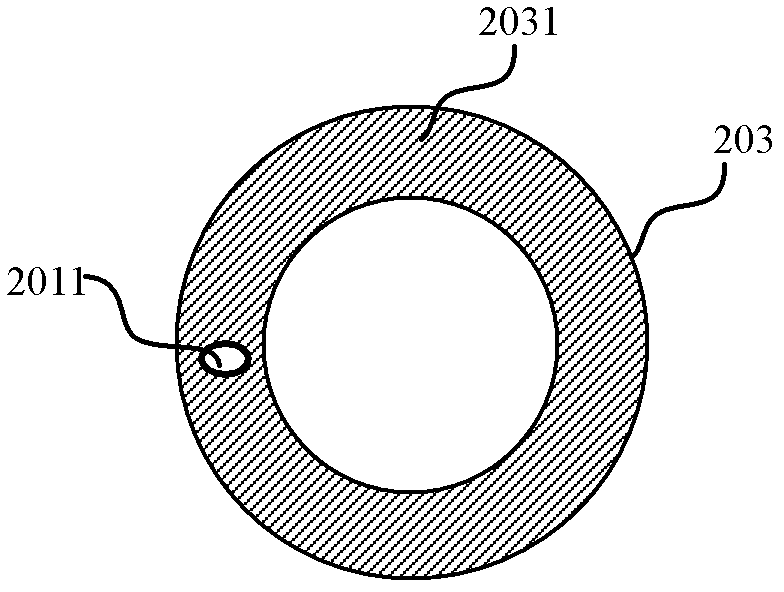

Light source component, light source system and projection device

ActiveCN102650812ALow costHigh light conversion efficiencyProjectorsMountingsLight filterColor wheel

The invention relates to a light source component, a light source system and a projection device. The light source component comprises an exciting light source, a color wheel and a light filter. The exciting light source is used to generate exciting light; first wavelength conversion material which converts the exciting light to first color light is arranged on the color wheel; and the light filter is provided with a first light filtering area which filters the first color light so as to produce second color light, wherein the difference between the dominant wavelengths of the first color light and the second color light is bigger than or equal to 3nm. According to the invention, through the manner, the first wavelength conversion material capable of converting the exciting light to the first color light cooperates with the light filter to generate the second color light, thus avoiding the use of wavelength conversion material which is relatively high in price or poor in performance and directly absorbs the exciting light to generate second color light. Therefore, the cost of the light source system is reduced and the light conversion efficiency of the light source system is improved.

Owner:APPOTRONICS CORP LTD

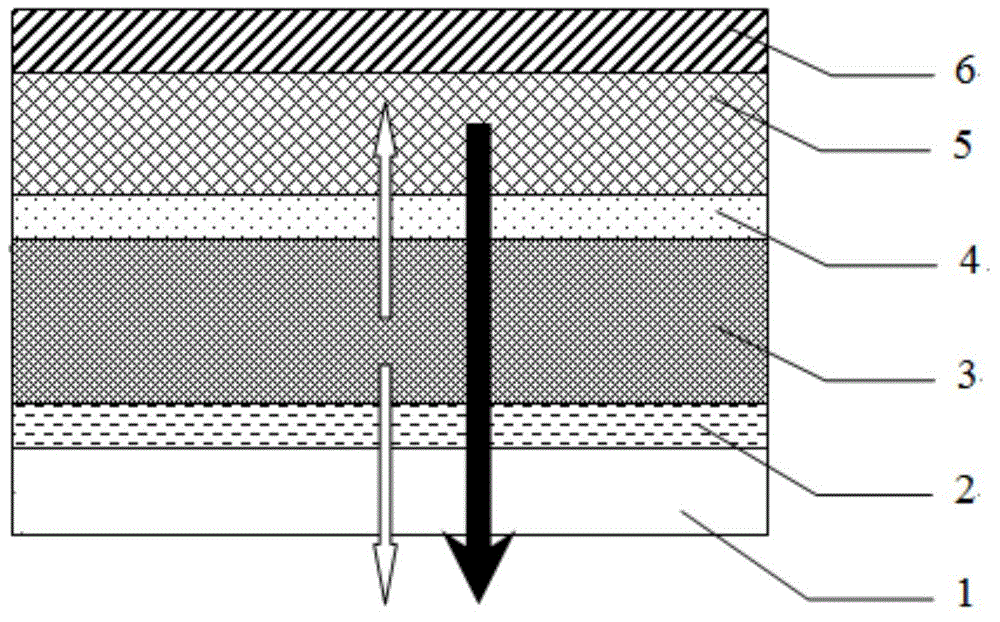

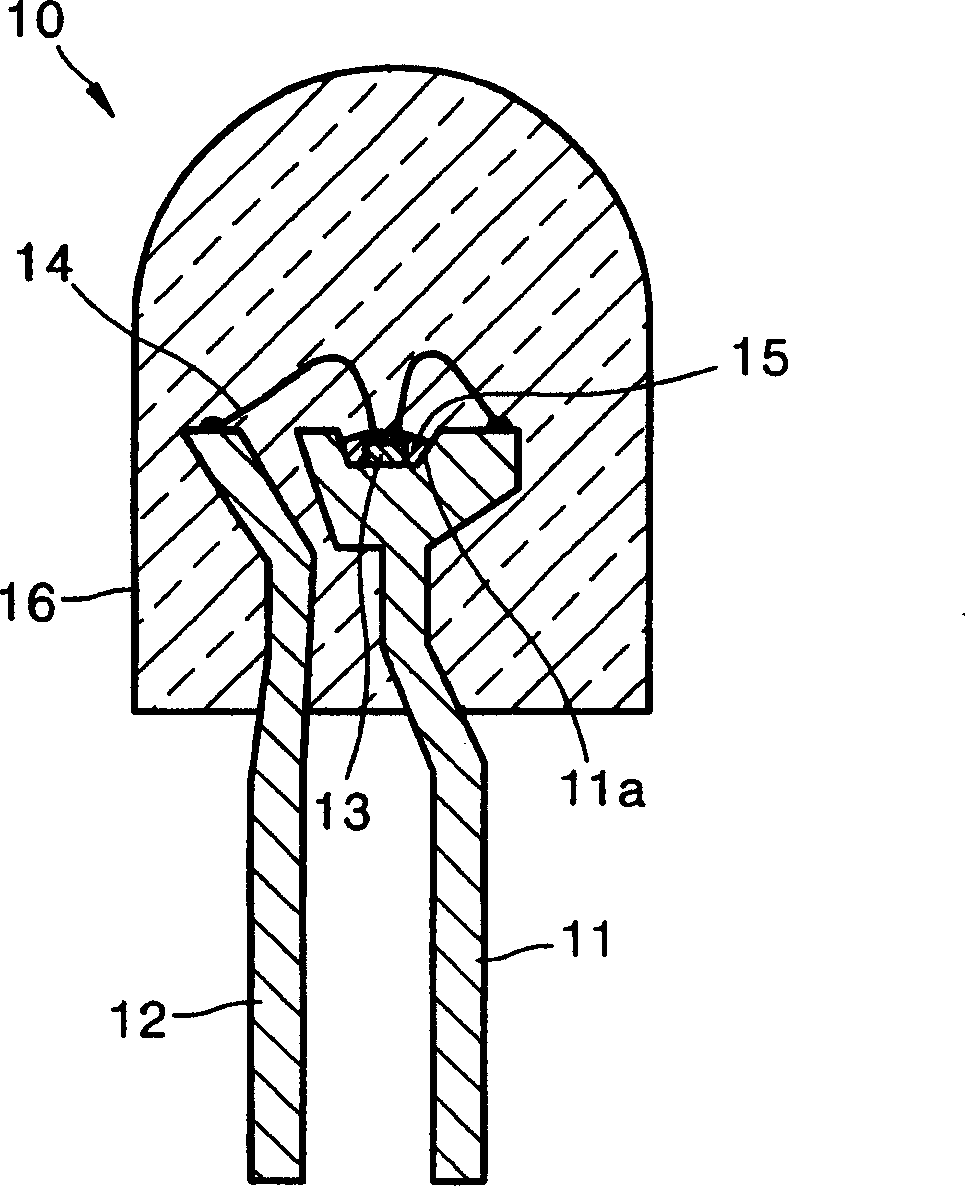

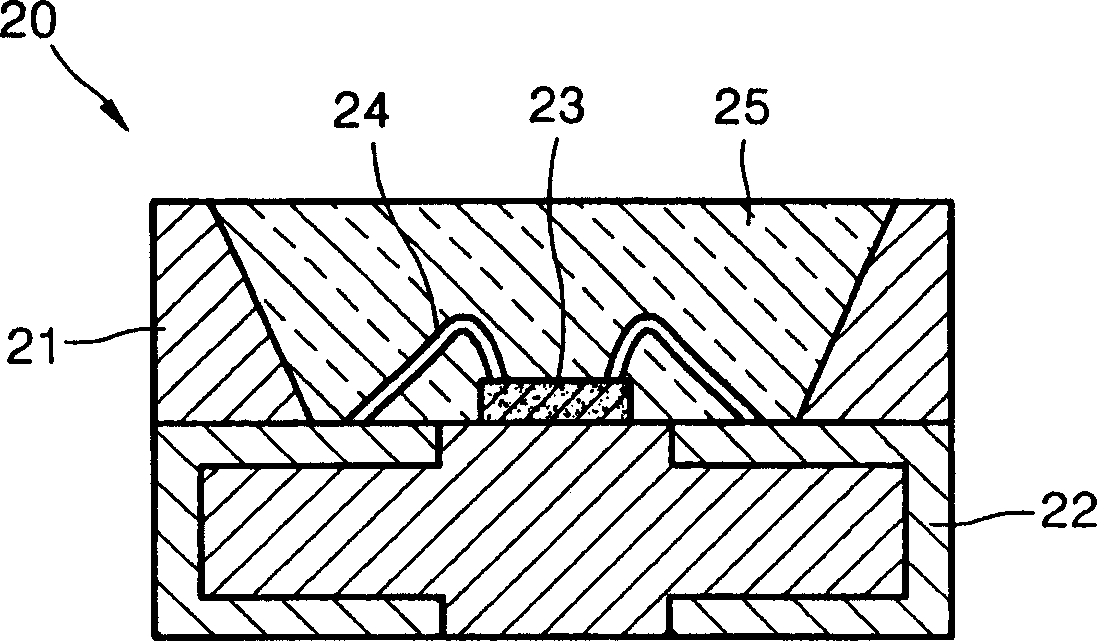

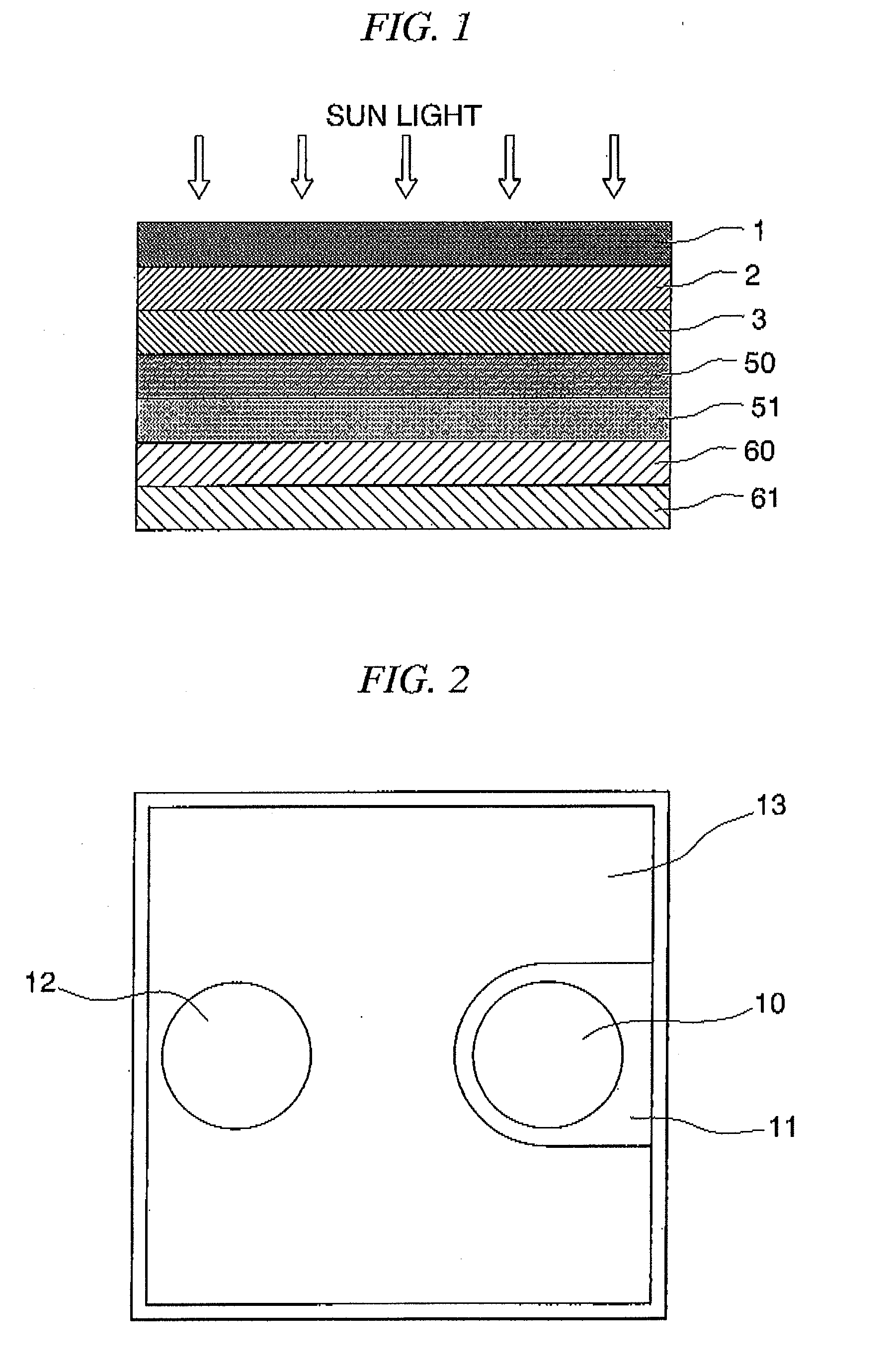

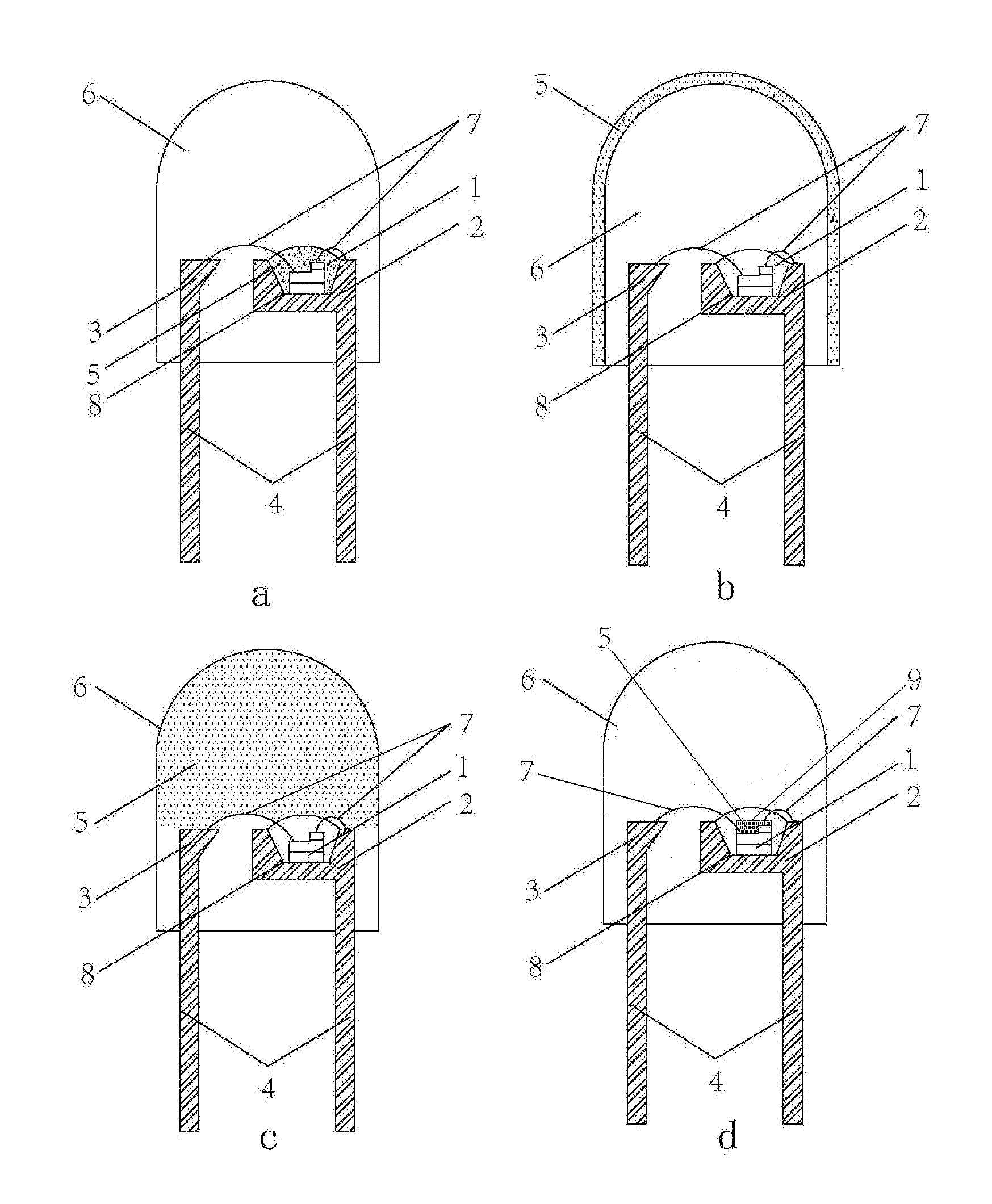

Light emitting device having fluorescent multilayer

InactiveCN1542991AIncrease the number of outputsHigh light conversion efficiencySolid-state devicesLuminescent compositionsFluorescenceLength wave

A light emitting diode (LED) device having a fluorescent multilayer is provided. The LED device includes an LED chip, which emits excitation light, and a fluorescent multilayer, which is comprised of a plurality of fluorescent layers that emit different colors from one another when being excited by excitation light. Light of a longer wavelength is emitted from a portion of the fluorescent multilayer closer to the LED chip, and light of a shorter wavelength is emitted from a portion of the fluorescent multilayer farther away from the LED chip. Accordingly, it is possible to increase the entire light conversion efficiency of the LED device and the amount of light output from the LED device.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of carbon quantum dot fluorescent material

The invention provides a preparation method of a carbon quantum dot fluorescent material. The method involves an ignitable plant leaf material, a combustion supporting substance, a solid fiber adsorption material layer, and a combustion furnace body. The method is characterized in that: the combustion furnace body is composed of an air inlet, a combustion chamber, and an exhaust gas outlet, and the solid fiber adsorption material layer is arranged at the exhaust gas outlet; when the plant leaf material combusts, the carbon quantum dot fluorescent material can be generated, is carried by gas and is adsorbed in the solid fiber adsorption material layer, when the solid fiber adsorption material is placed in water or a solvent, the carbon quantum dot fluorescent material can separate and precipitate out by itself. The method provided in the invention can directly use urban waste fallen leaves to prepare the carbon quantum dot fluorescent material and does not employ any chemical means to extract. The carbon quantum dot fluorescent material adsorbed in the solid fiber adsorption material layer is convenient for transportation and carrying, is pollution-free and nonhazardous, can be released by an aqueous solvent or static electricity, so that the carbon quantum dot fluorescent material can be taken out directly.

Owner:SHANGHAI KERUN PHOSPHOR TECH

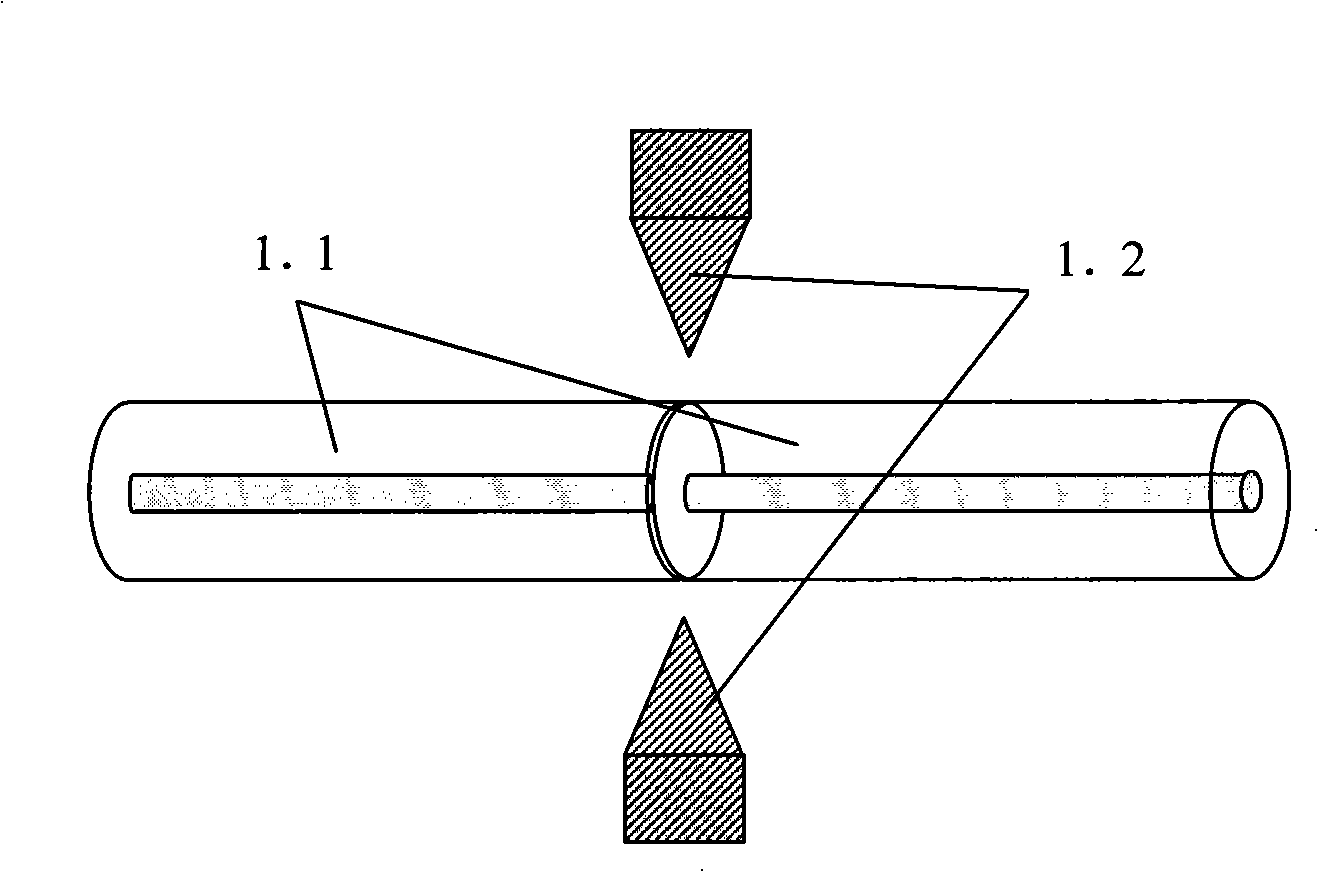

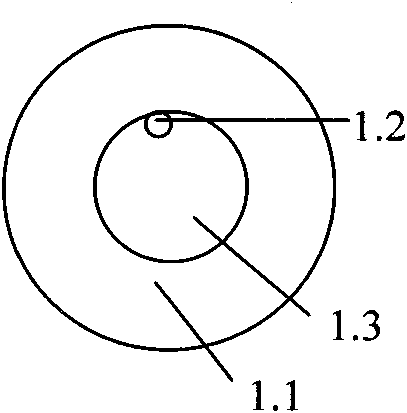

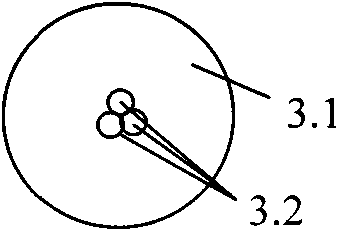

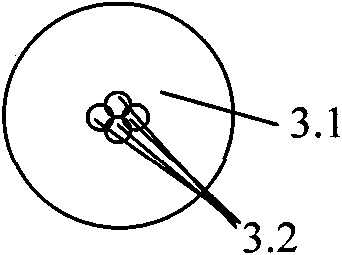

Capillary pipe optical fibre and standard optical fibre connecting method

InactiveCN101339275AResolve connectionEasy to manufactureCladded optical fibreCoupling light guidesLight energyCoupling

The invention provides a connecting method for a capillary optical fiber and a standard optical fiber, which comprises the following steps: stripping and washing the coating layer at one end of the capillary optical fiber, the standard optical fiber or a multimode optical fiber respectively and cutting a tidy optical fiber head face; fusing and welding through an optical fiber welder; preheating for Delta t seconds at the position where a welding point leans a distance of delta from the standard optical fiber or the multimode optical fiber (the value range of Delta is 0.1 - 3.5mm, the value range of Delta t is 3 - 12 seconds); implementing fused biconical taper to form a tapered light energy distribution area; carrying out optical power monitoring to one end of the capillary optical fiber in the process of fused biconical taper so as to form a tapered coupling area; sheathing a quartz protection sleeve outside of the tapered coupling area and sealing the both ends of the quartz protection sleeve with the standard optical fiber and the capillary optical fiber. The method solves the connection problem of the standard optical fiber and the hollow capillary optical fibers with the same diameter but different cross-sectional area ratio, and has the advantages of easy manufacturing and high light-wave conversion efficiency.

Owner:HARBIN ENG UNIV

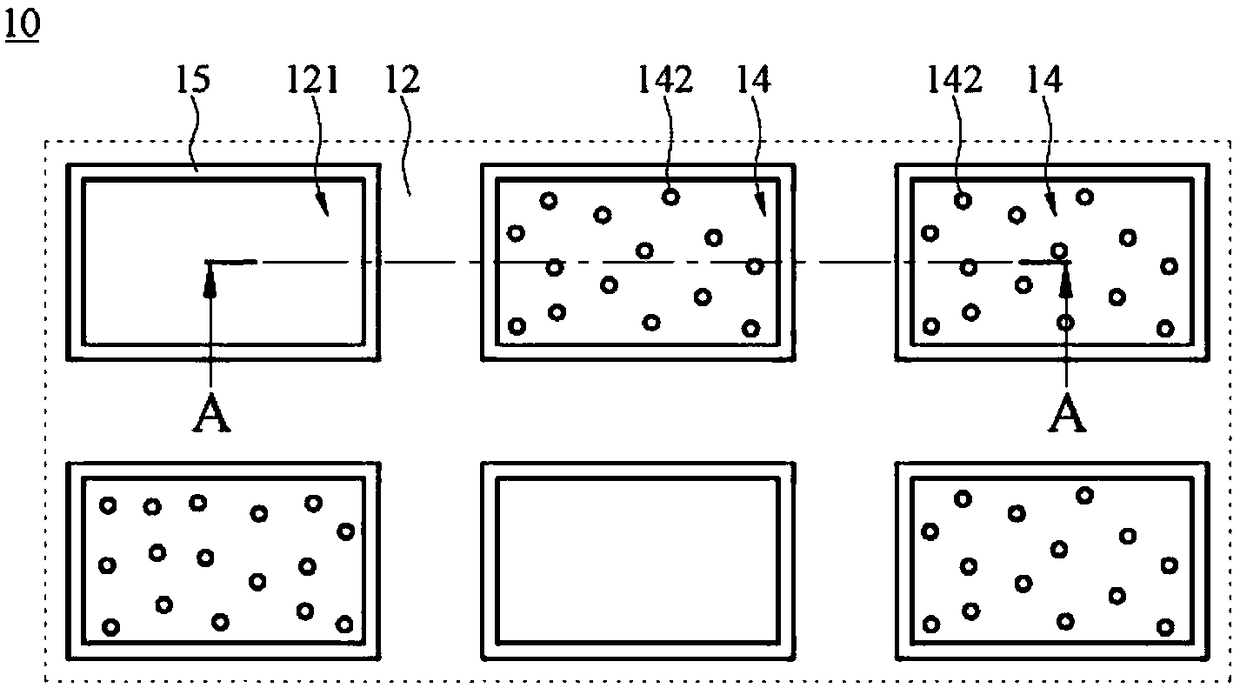

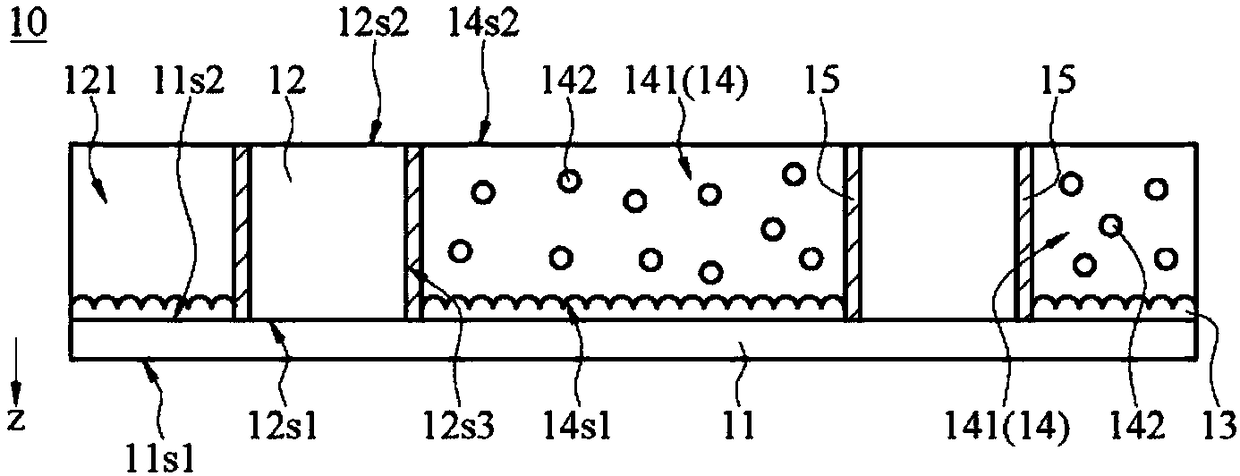

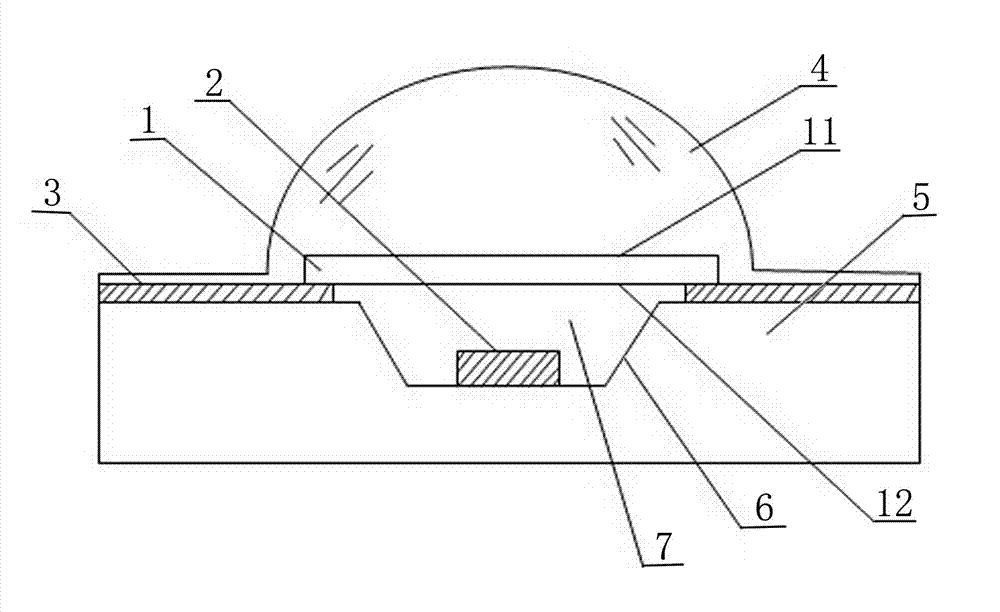

Display panel and optical sheet applying same

ActiveCN108107627AHigh light conversion efficiencyAvoid reflectionsNon-linear opticsQuantum dotBiological activation

The invention provides a display panel and an optical sheet applying the same. The optical sheet comprises a substrate layer, a light shielding layer, a color light-filtering structure, a scattering layer and a first reflection layer. The light shielding layer is located on the substrate layer. Additionally, the light shielding layer has multiple openings. The color light-filtering structure is installed in at least a part of openings. Additionally, the color light-filtering structure comprises multiple quantum dots. The scattering layer is arranged between the color light-filtering structureand the first reflection layer. The first reflection layer is arranged between the color light-filtering structure and the light shielding layer. Accordingly, the likelihood of activation of the quantum dots is increased through the scattering layer and the first reflection layer. Therefore, light conversion efficiency of the display panel is improved.

Owner:AU OPTRONICS CORP

Solar-electothermal united prodn appts

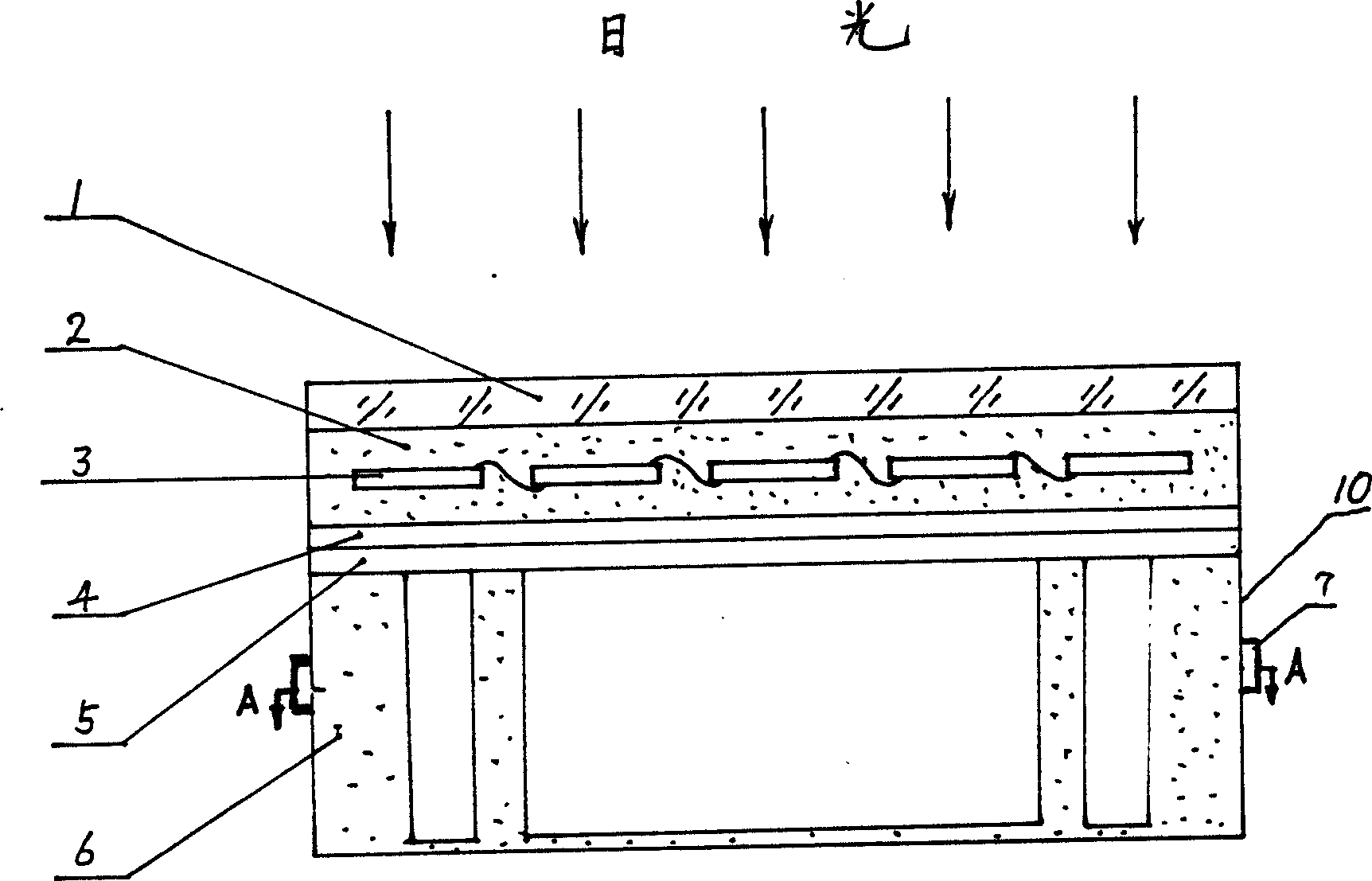

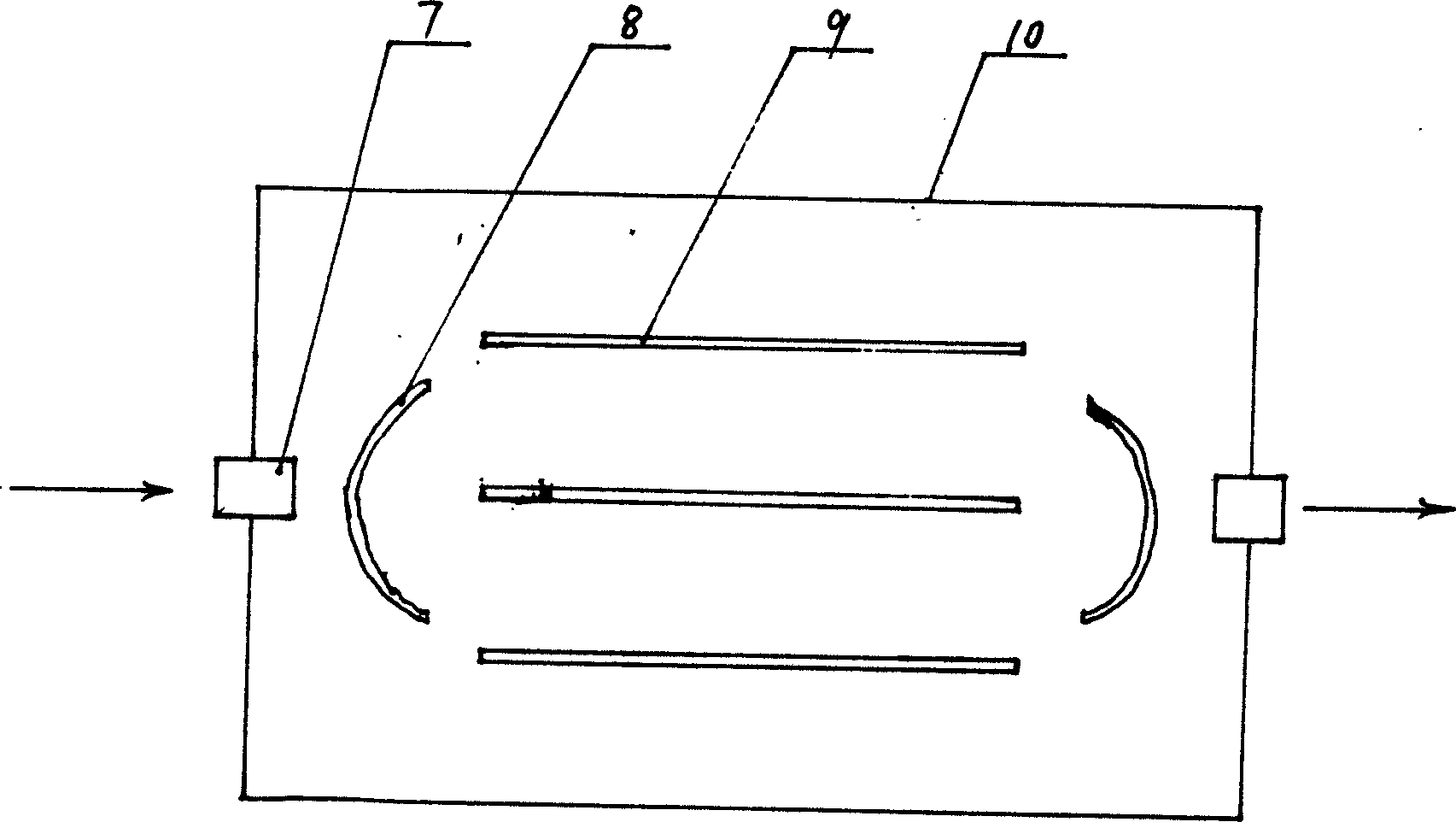

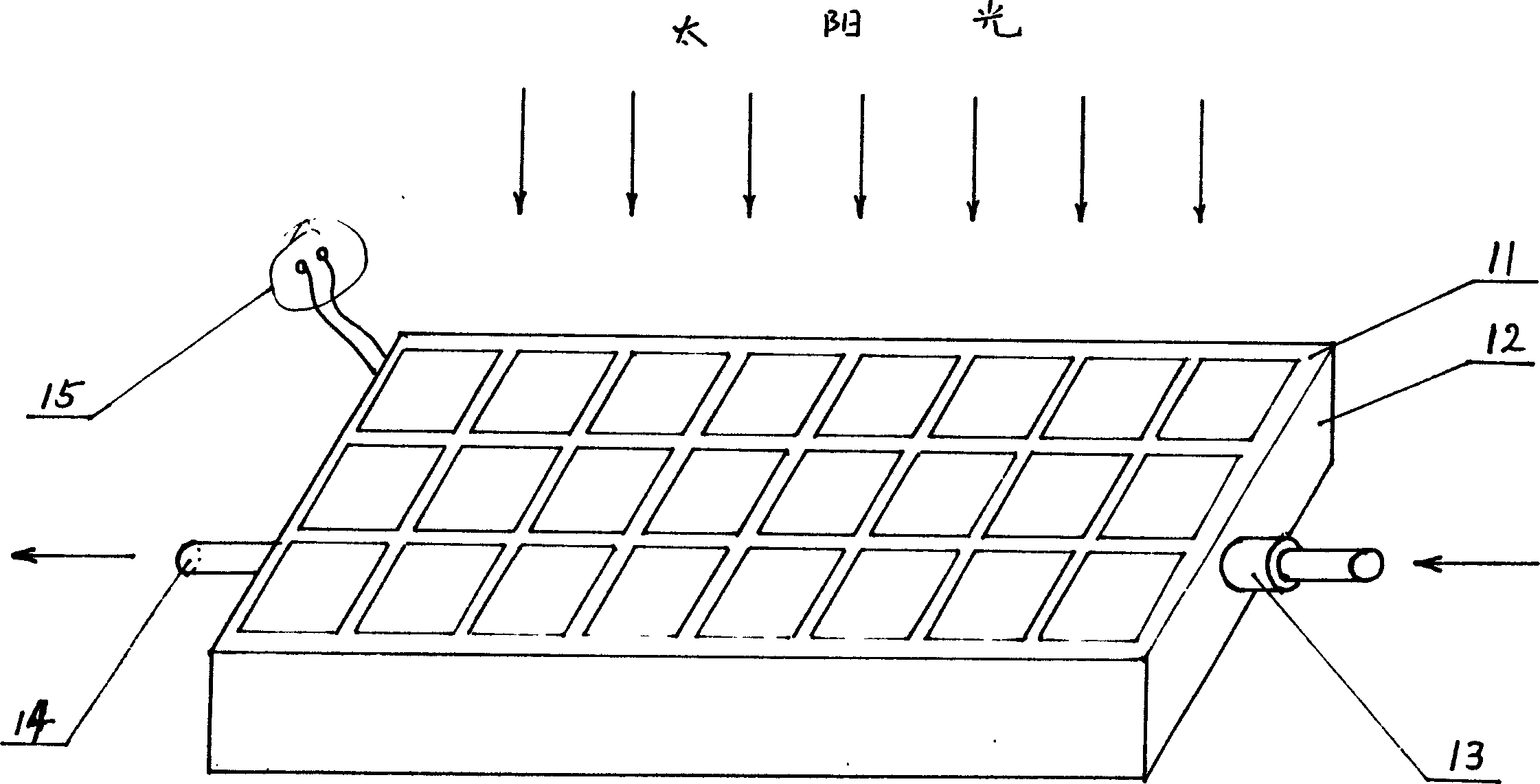

InactiveCN1563844AIncrease power generationTemperature stays the same or even dropsSolar heat devicesPhotovoltaicsHeat sinkCurrent limiting

The disclosed equipment consists of integrated day lighting generating board and heat production box. The generating board is composed of sunlight transparent sheets and solar cell pieces. Heat sink layer, heat conducting layer and heat transferring working medium are setup under solar call pieces. Structure of heat production box includes following parts: heat transferring working medium through current limiting valve enters into the box, balanced allocator of guiding flow splits flows; heat transferring flow deflectors are as channel walls; heat energy from sun collected and transferred by heat sink layer, heat conducting layer are conducted to working medium; thus, temp of solar cell pieces are unchanged basically in order to raise electric-power output of solar cell pieces.

Owner:XI AN JIAOTONG UNIV

Coupling method for suspended-core optical fibers

InactiveCN101852894AHigh light conversion efficiencyResolve connectionCoupling light guidesCouplingOptical power

Owner:HARBIN ENG UNIV

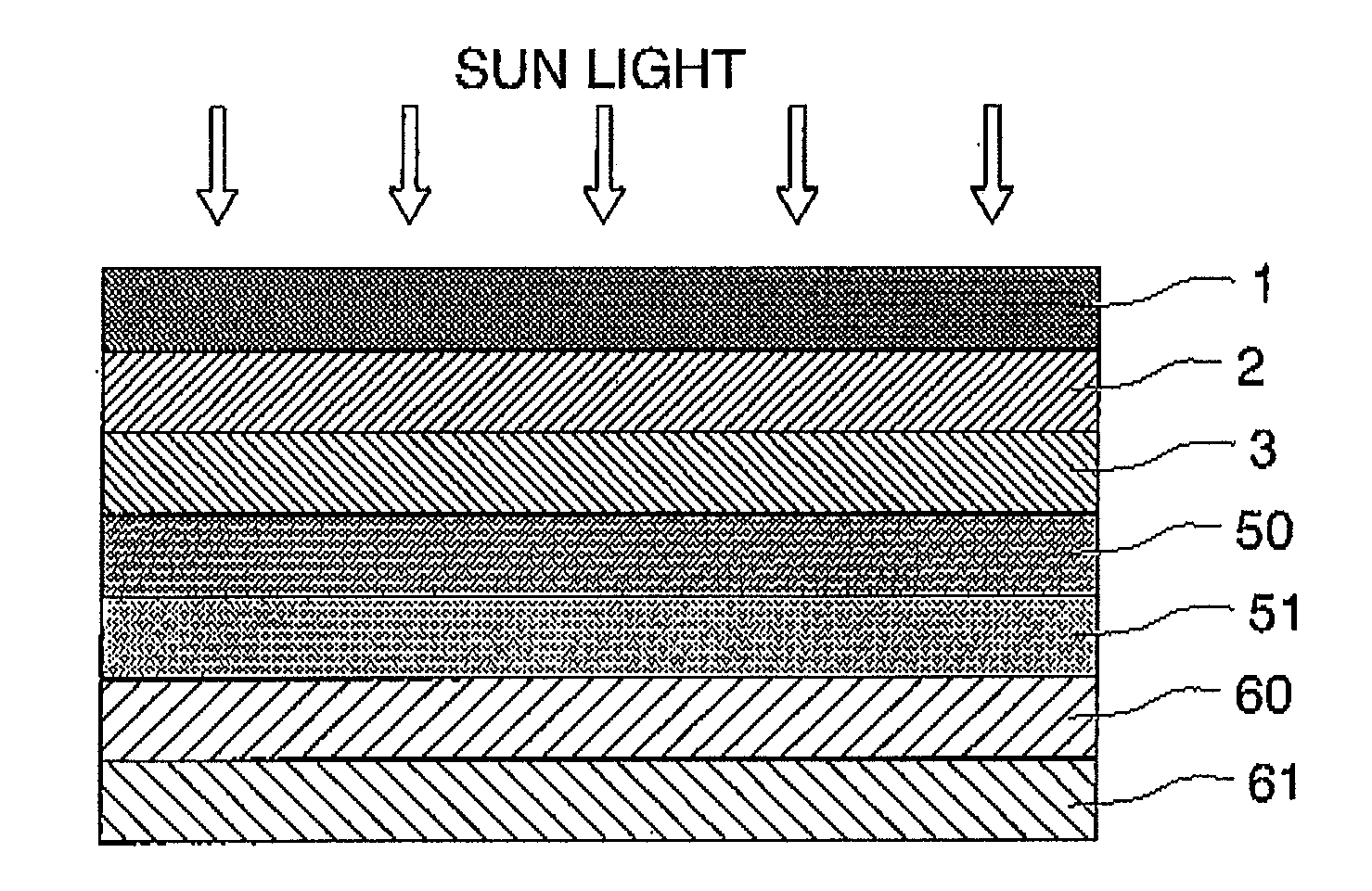

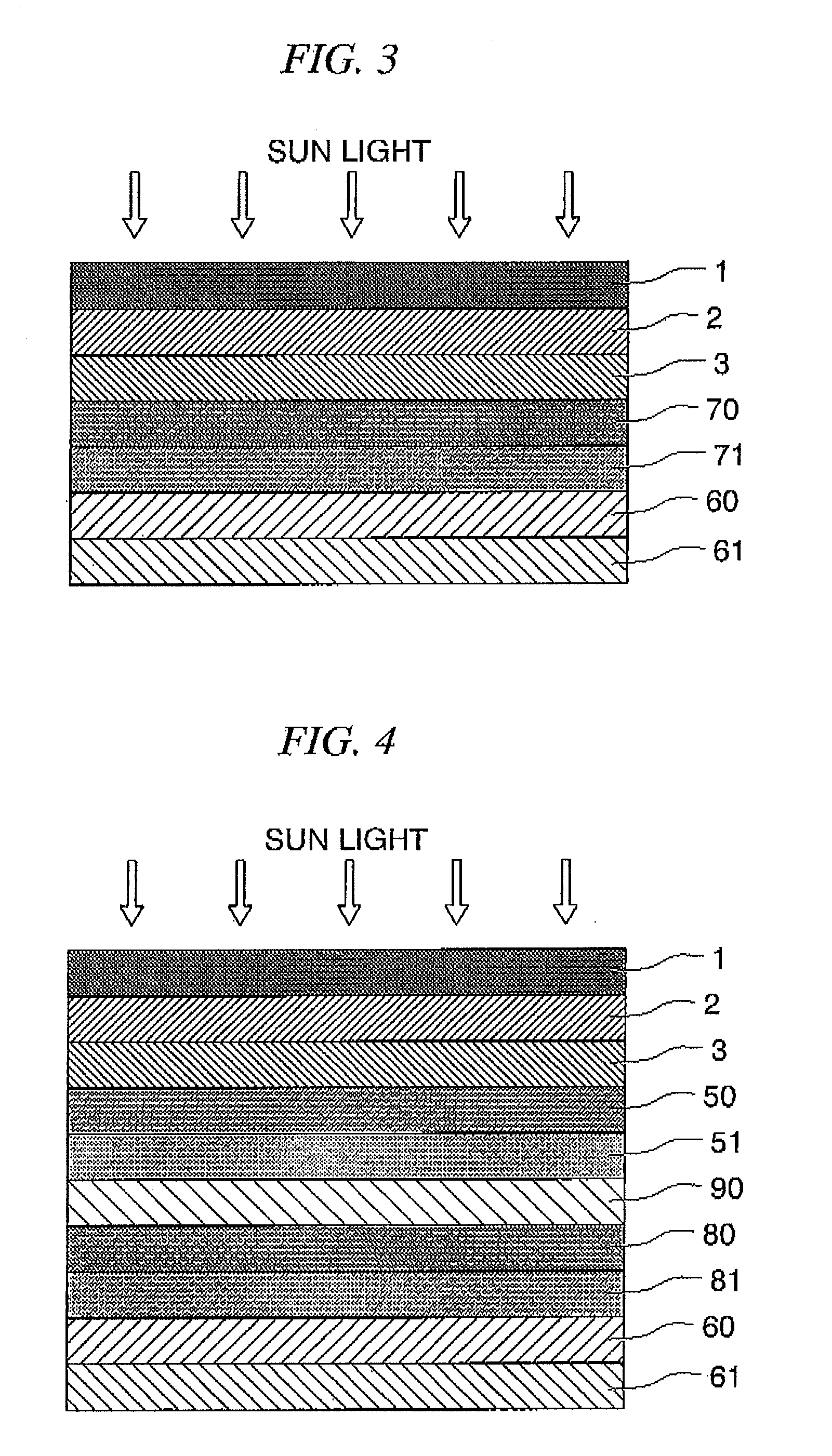

Solar cell and method for producing the same

InactiveUS20090205707A1High light conversion efficiencySolve the real problemFinal product manufactureSemiconductor/solid-state device manufacturingLight conversion efficiencySolar cell

The object of the present invention is to provide a solar cell which is industrially beneficial and has high light conversion efficiency; and a method for producing a solar cell; and the present invention provides a solar cell comprising a substrate, a power generation layer for converting received light into electrical power, a translucent electrode, and another electrode, when light travels through each member from a first surface thereof, a surface opposite to the first surface is defined as a second surface, the power generation layer is formed at a second surface side of the substrate, the translucent electrode is formed on one surface of the power generation layer, and another electrode is formed on the other surface of the power generation layer, wherein the translucent electrode comprises hexagonal In2O3 crystal.

Owner:SHOWA DENKO KK

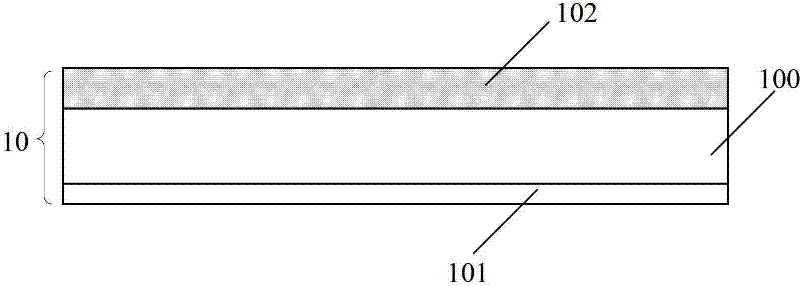

Cover plate, manufacturing method of cover plate, solar glass and photovoltaic device

InactiveCN102655178ABlock escapeAvoid enteringPhotovoltaic energy generationSemiconductor devicesDevice formEngineering

The invention discloses a cover plate, a manufacturing method of the cover plate, solar glass and a photovoltaic device. The cover plate is suitable for covering a work device, and the work device forms an electric field on the cover plate. The cover plate comprises a light-transmitting matrix, a barrier layer and an anti-reflex layer, wherein the light-transmitting matrix is provided with a first surface and a second surface which are opposite to each other, and the first surface is adjacent to and connected with the work device; the barrier layer is positioned on the first surface of the light-transmitting matrix and is used for preventing substances in the light-transmitting matrix from escaping under the action of the electric field so as to inhibit the performance degradation of the work device; and the anti-reflex layer is positioned on the second surface of the light-transmitting substrate and is used for reducing the reflection of incident light on the second surface of the light-transmitting substrate. The barrier layer is positioned on the first surface adjacent to the work device and can be used for preventing the substances in the light-transmitting substrate from escaping from the first surface under the action the electric field, thereby preventing the substances in the light-transmitting matrix from entering into the work device, and inhibiting the performance degradation, caused by the substances in the light-transmitting matrix, of the work device.

Owner:SAINT-GOBAIN GLASS FRANCE

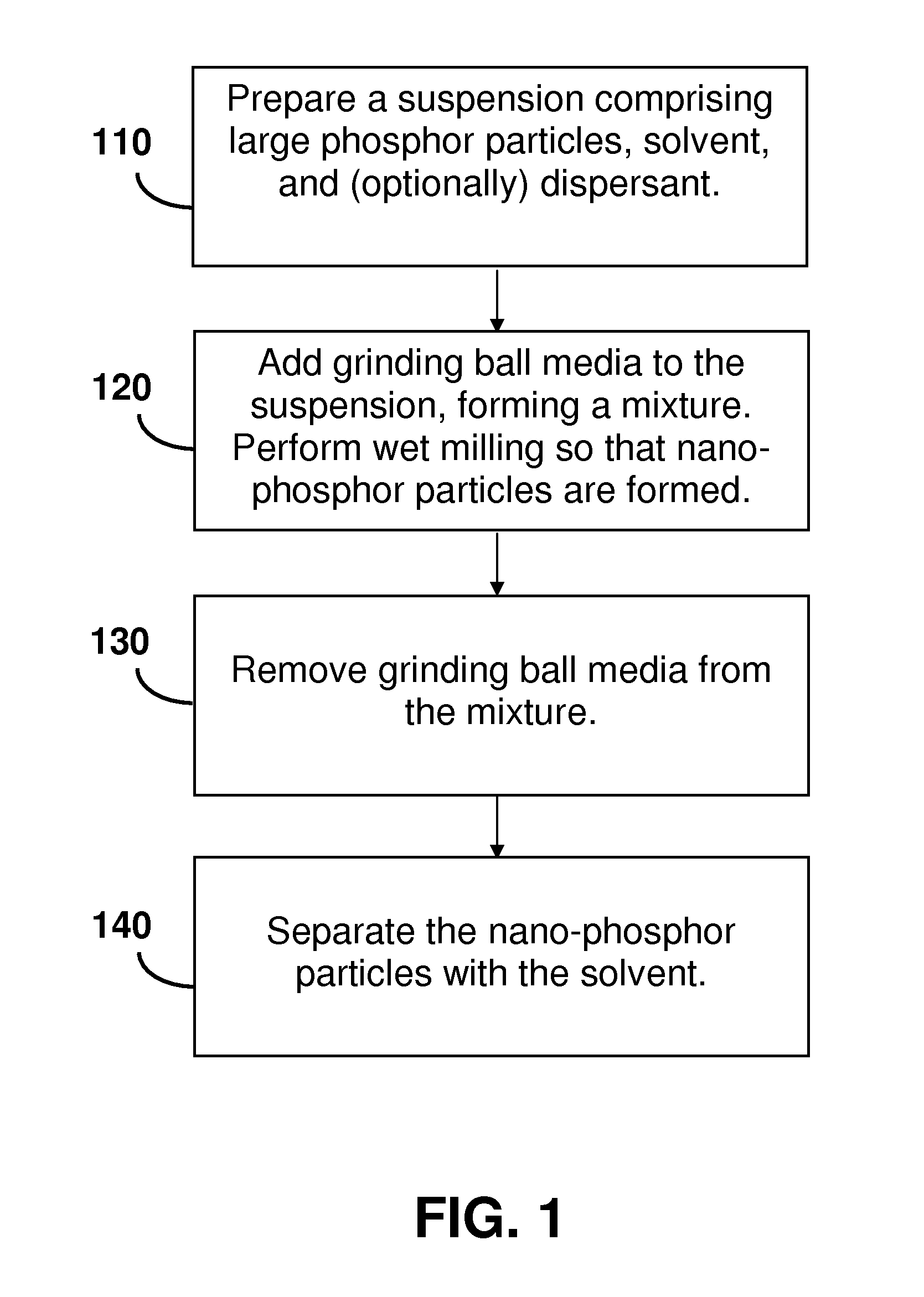

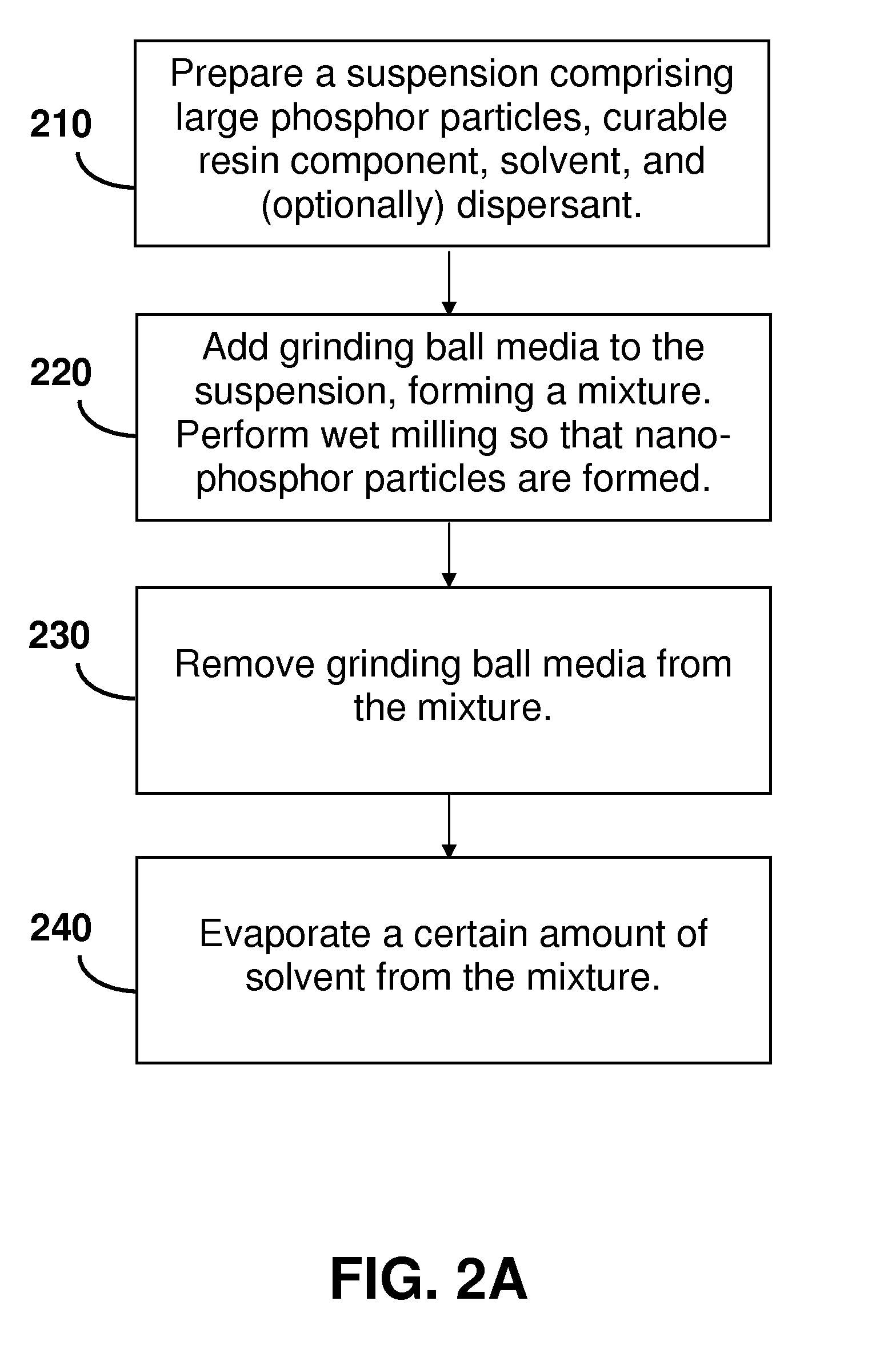

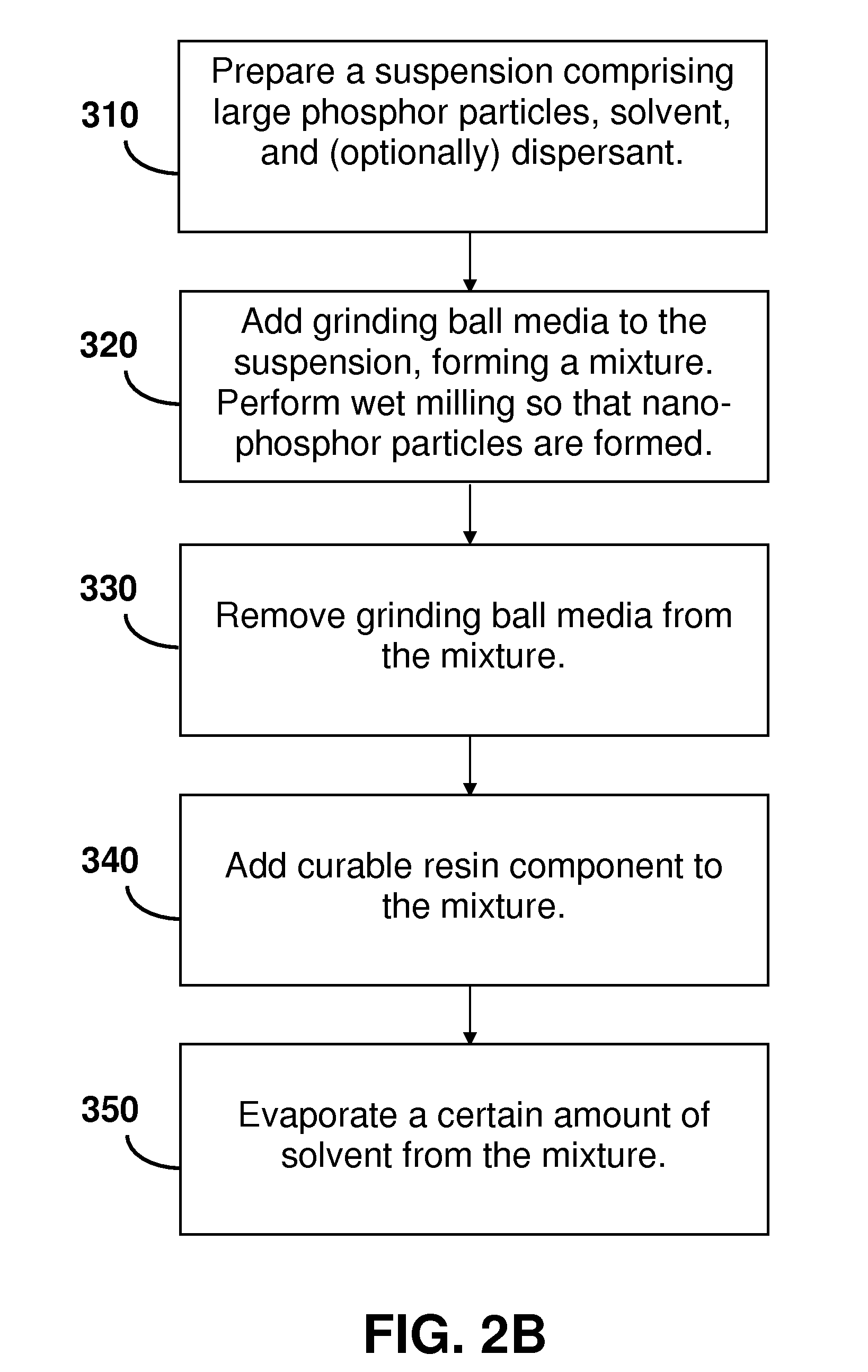

Phosphor ink composition

InactiveUS20120286208A1High light conversion efficiencyLoss in light conversion efficiencyMaterial nanotechnologySolid-state devicesPhosphorMicrometer

The present invention provides phosphor inks configured to achieve high efficiency in converting LED light from one wavelength to another. The phosphor ink composition for deposition on an LED device comprises a phosphor component having nano-phosphor particles on the order of 100 to 1000 nanometers, and a curable resin component. In particular, the nano-phosphor particles are uniformly dispersed throughout the ink composition. The nano-phosphor particles may be formed by a size reduction process carried out on larger phosphor particles on the order of 1 to 50 micrometers. Preferably, the size reduction process is based on solvent wet milling. Methods for preparing the phosphor inks based on forming the nano-phosphor particles from larger particles by solvent wet milling are also provided.

Owner:HONG KONG APPLIED SCI & TECH RES INST

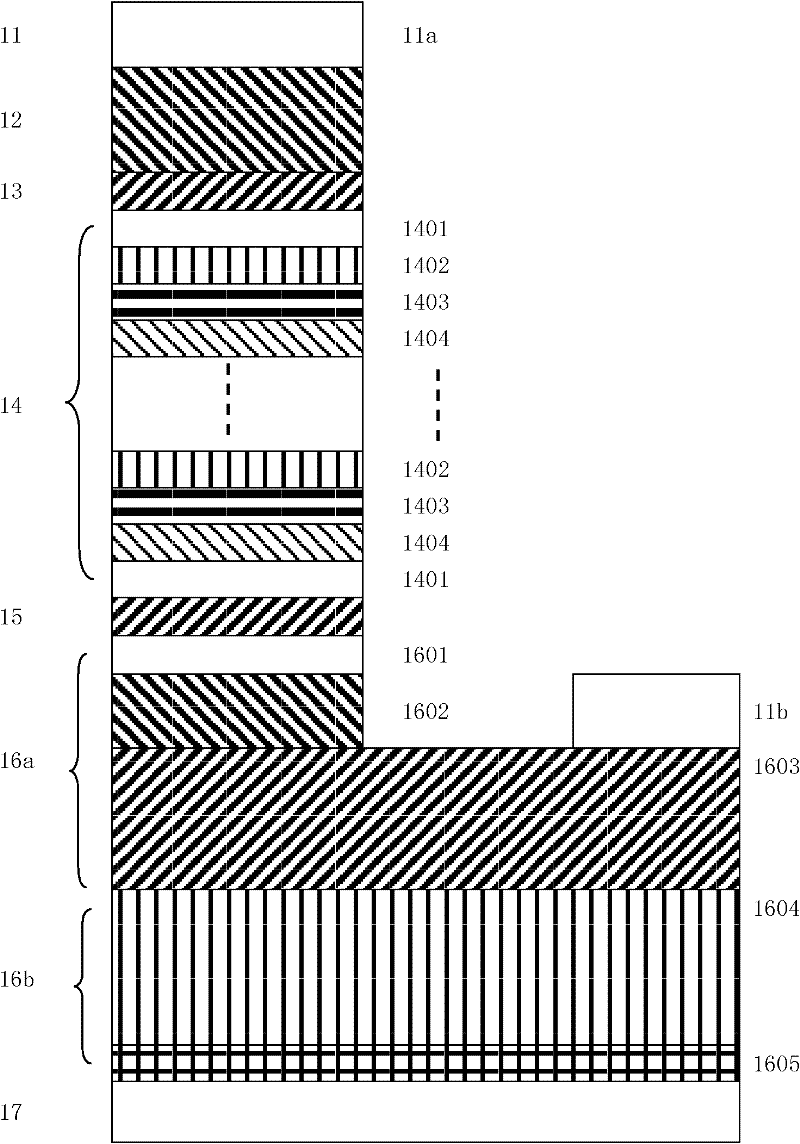

Method for using solar energy decomposing water to prepare hydrogen nanometer electrode

InactiveCN101143712AAchieve dopingImprove photocatalytic efficiencyEnergy inputCatalyst activation/preparationSemiconductor materialsMicrosphere

The invention discloses a preparation art, which belongs to the preparation art of photo-hydrolysis nanometer electrode. Particularly, the invention relates to a preparation method, which utilizes solar energy for water decomposition and production of hydrogen nanometer electrode. The invention uses the synthetic titanium oxide nanometer microspheres and other semiconductor materials, such as zinc oxide , to construct lamellar nanometer electrode. The application of lamellar doping method accelerates an efficient separation of electron and cavity, the titanium oxide nanometer microsphere structure increases contact area of the electrode surface and the electrolyte, the material is provided with high light conversion efficiency and photolysis efficiency, which improve the photo-hydrolysis efficiency. The preparation method has a simple manufacturing process, which decreases the manufacturing difficulty of semiconductor nanometer composite material and simplifies the implementation process of the electrode. Thus, the invention has a potential application value.

Owner:TSINGHUA UNIV

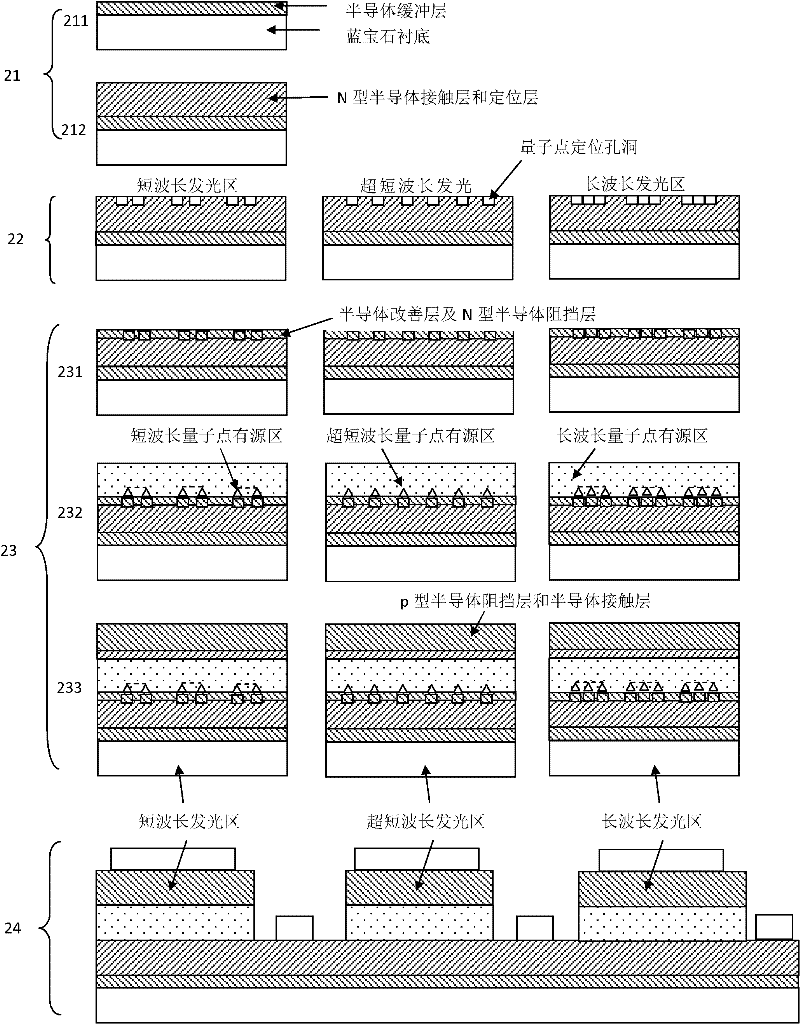

A multi-source integrated color-tunable light-emitting element and its preparation method

InactiveCN102270716AAvoid integration processHigh light conversion efficiencySemiconductor devicesQuantum dotEngineering

The invention relates to a multi-source integrated color-adjustable light-emitting component and a preparation method thereof. The multi-source integrated color-adjustable light-emitting component and preparation method have the advantages of effectively prolonging the service life of products and increasing the light conversion efficiency of light emitting diodes. The multi-source integrated color-adjustable light-emitting component comprises an electrode layer, a p-type semiconductor contact layer, a p-type semiconductor barrier layer, an active layer, an n-type semiconductor barrier layer,an n-type semiconductor contact layer, and a substrate, which are arranged in sequence from top to bottom, wherein the electrode layer is formed by a plurality of p electrodes and a plurality of n electrodes, which are spaced according to different light wavelength regions, and at least one type of electrodes are insulated from one another to independently regulate and control the regions of different light wavelengths; the energy gap of the p-type semiconductor barrier layer is wider than that of the p-type semiconductor contact layer; the light wavelength range of the active layer is from red light to blue light, the active layer has a light-emitting structure formed by quantum dots and quantum wells, and the positions of the quantum dots are restricted in corresponding regions; and theenergy gap of the n-type semiconductor barrier layer is wider than that of the n-type semiconductor contact layer.

Owner:楼刚

Fluorescent and transparent polycarbonate grating for LED (light-emitting diode) and preparation method for same

InactiveCN103044892AControl shapeControl thicknessGrain treatmentsSemiconductor devicesColloidal silicaGrating

The invention provides a preparation method for a fluorescent and transparent polycarbonate grating for an LED (light-emitting diode). The materials of the fluorescent and transparent polycarbonate grating for an LED are composed of polycarbonate, fluorescent powder, an antioxidant, a coupling agent and a light dispersing agent. The fluorescent and transparent polycarbonate grating for an LED is formed by performing the preparation processes of sieving, preparing, mixing, drying, matching with auxiliaries, mixing, banburying, forming, annealing, cutting, etching and the like on the composition materials. The fluorescent and transparent polycarbonate grating can be used for an LED lamp bead / lamp, for adjusting the colour temperature of the LED, and solving the problems of the glare of the LED, the non-uniform distribution of the traditional silica gel fluorescent powder, and the like. The problem of non-uniform coating of the fluorescent powder is effectively solved, so that the light-emitting efficiency, the service life and the light spectrum stability of the white-light LED are improved; and moreover, the fluorescent and transparent polycarbonate grating is relatively simple in structure and preparation process, high in reliability, low in cost, good in plasticity and capable of being widely applied to LED manufacturing, as well as opens up unprecedented flexibility and creativity for the field of light sources.

Owner:SOUTH CHINA NORMAL UNIVERSITY

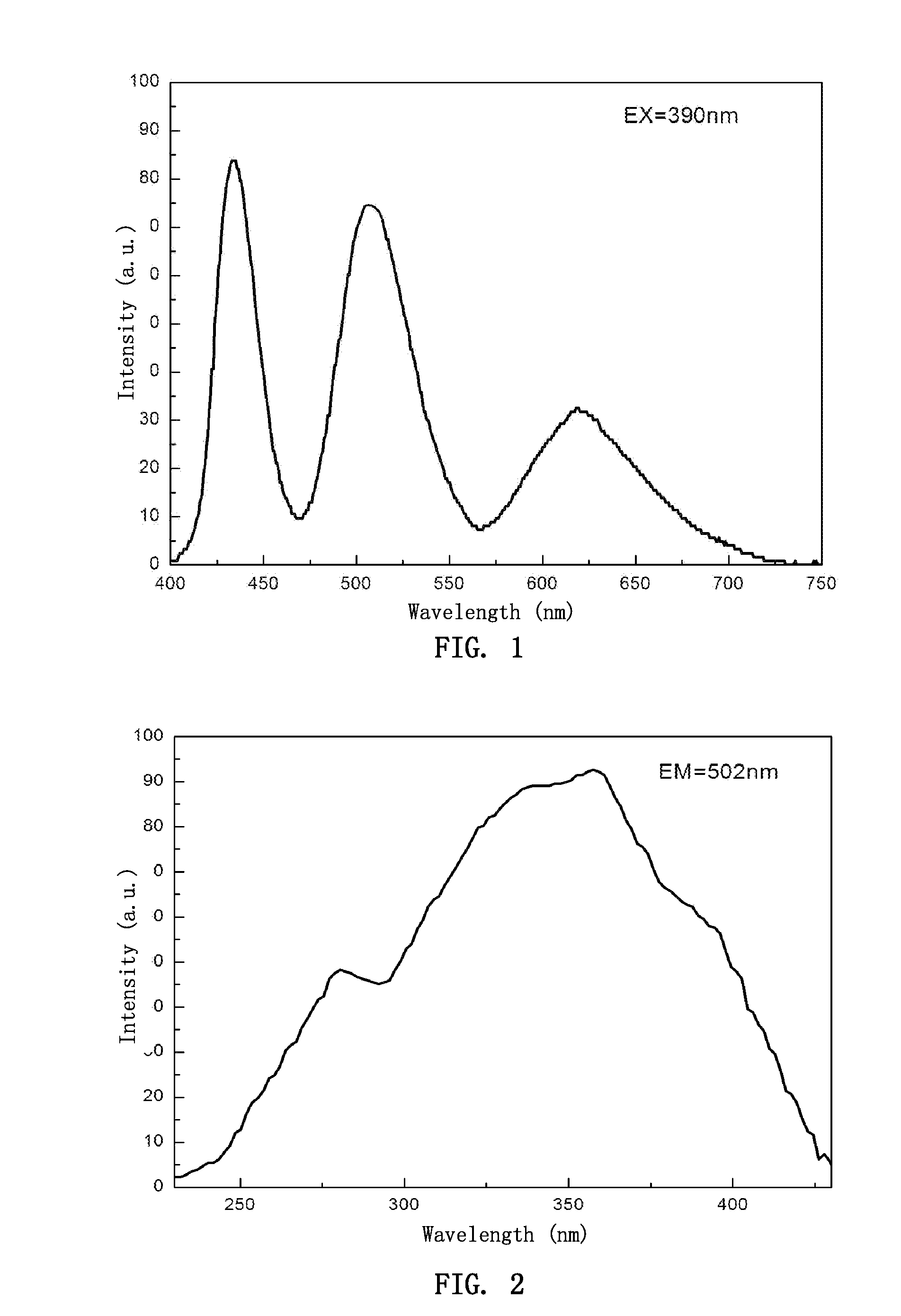

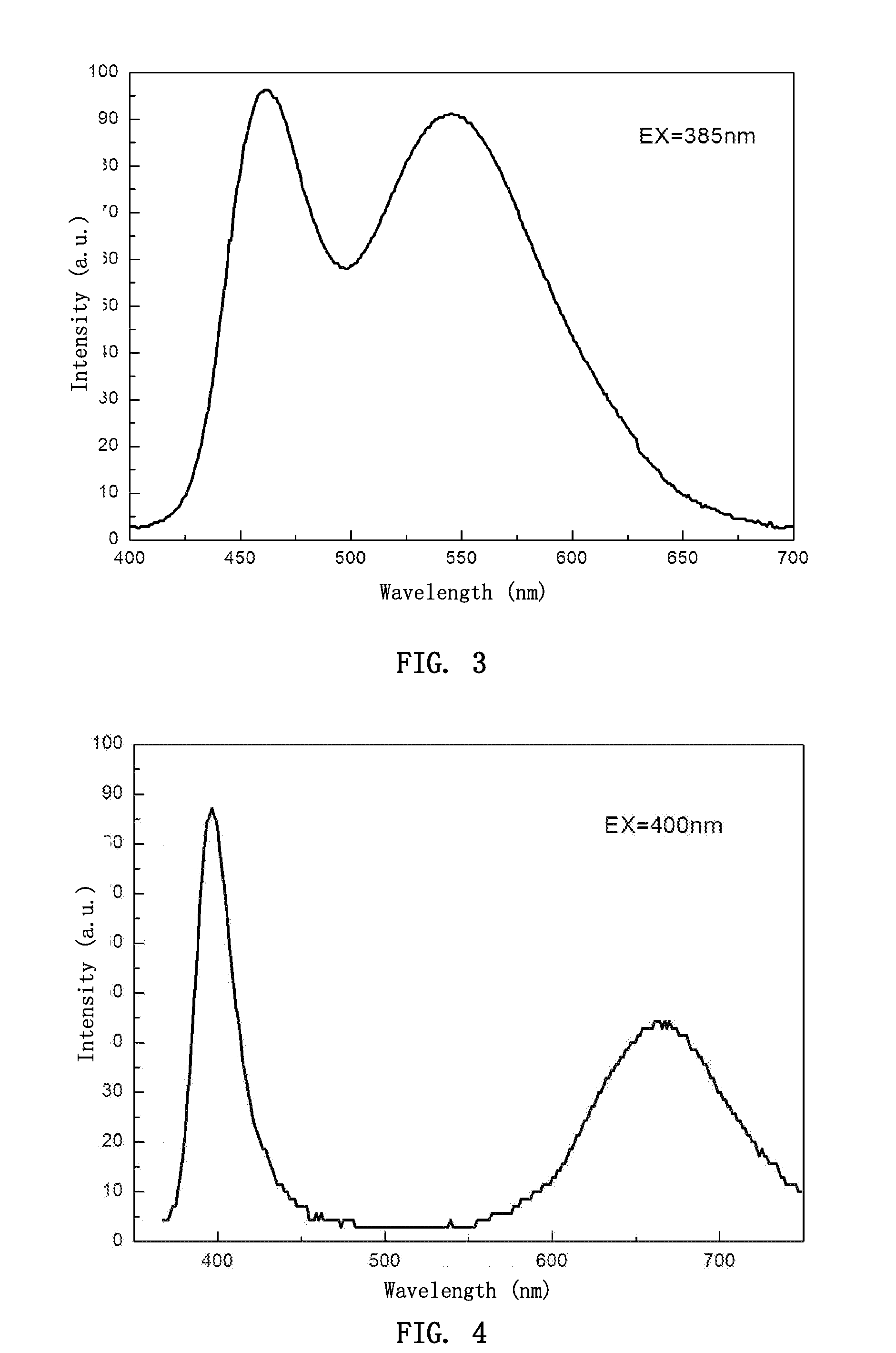

Silicate base luminescent materials having multiple emission peaks, processes for preparing the same and light emitting devices using the same

ActiveUS20100052513A1High light conversion efficiencyImprove aging resistanceDischarge tube luminescnet screensLamp detailsLight emitting deviceLight-emitting diode

A silicate luminescent material excitable by an excitation light source having emissions in UV to blue light region, a process for producing the same, and a white light emitting device. The luminescent material has an emission spectrum with at least two peaks in a range of from 370 to 760 nm, and has a general chemical composition formula of aAO.bA′O.cSiO2:xEu.yLn.zM.δN, wherein A is selected from the group consisting of Sr, Ca, Ba, and combinations thereof; A′ is selected from the group consisting of Mg, Zn, and combinations thereof; Ln is selected from the group consisting of Nd, Dy, Ho, Tm, La, Ce, Er, Pr, Bi, Sm, Sn, Y, Lu, Ga, Sb, Tb, Mn, Pb and combinations thereof; M is one or a combination of halogen ions; N is selected from the group consisting of Li+, Na+, K+, Ag+, and combinations thereof; and a, b, c, x, y, z, and δ are molar coefficients.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

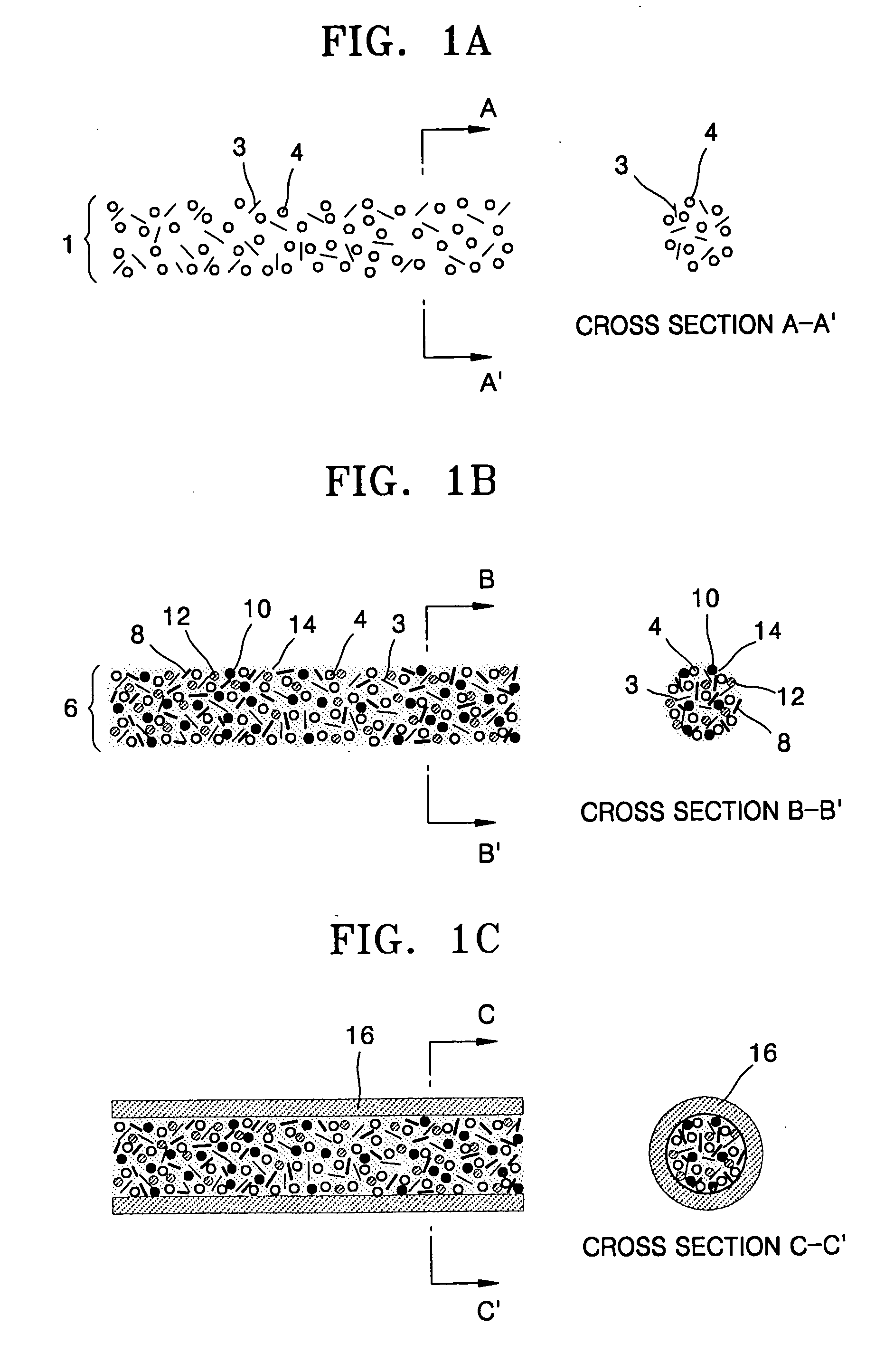

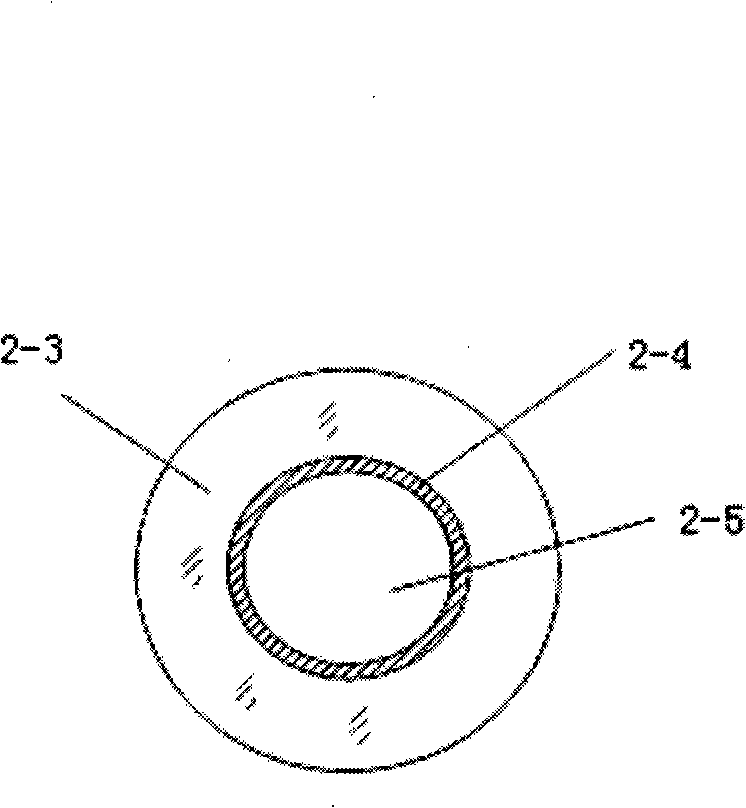

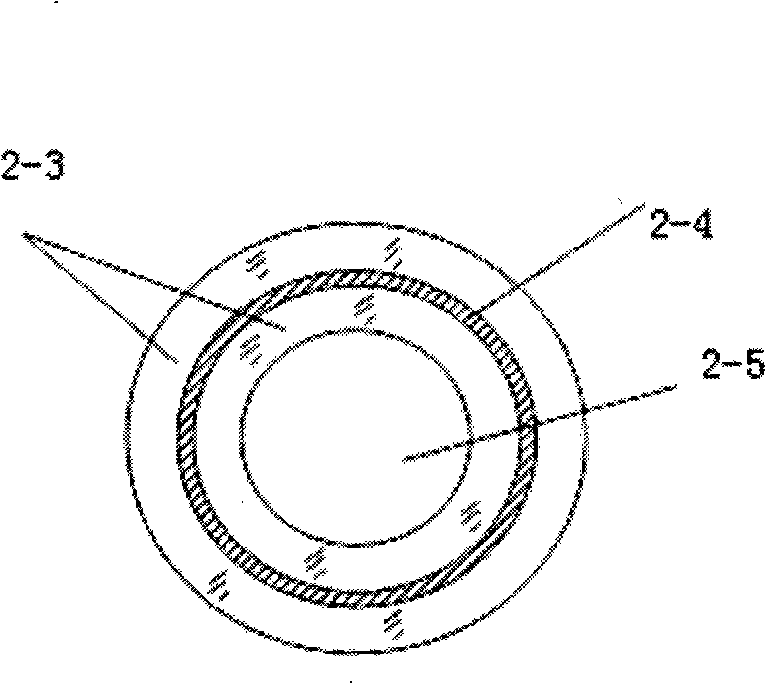

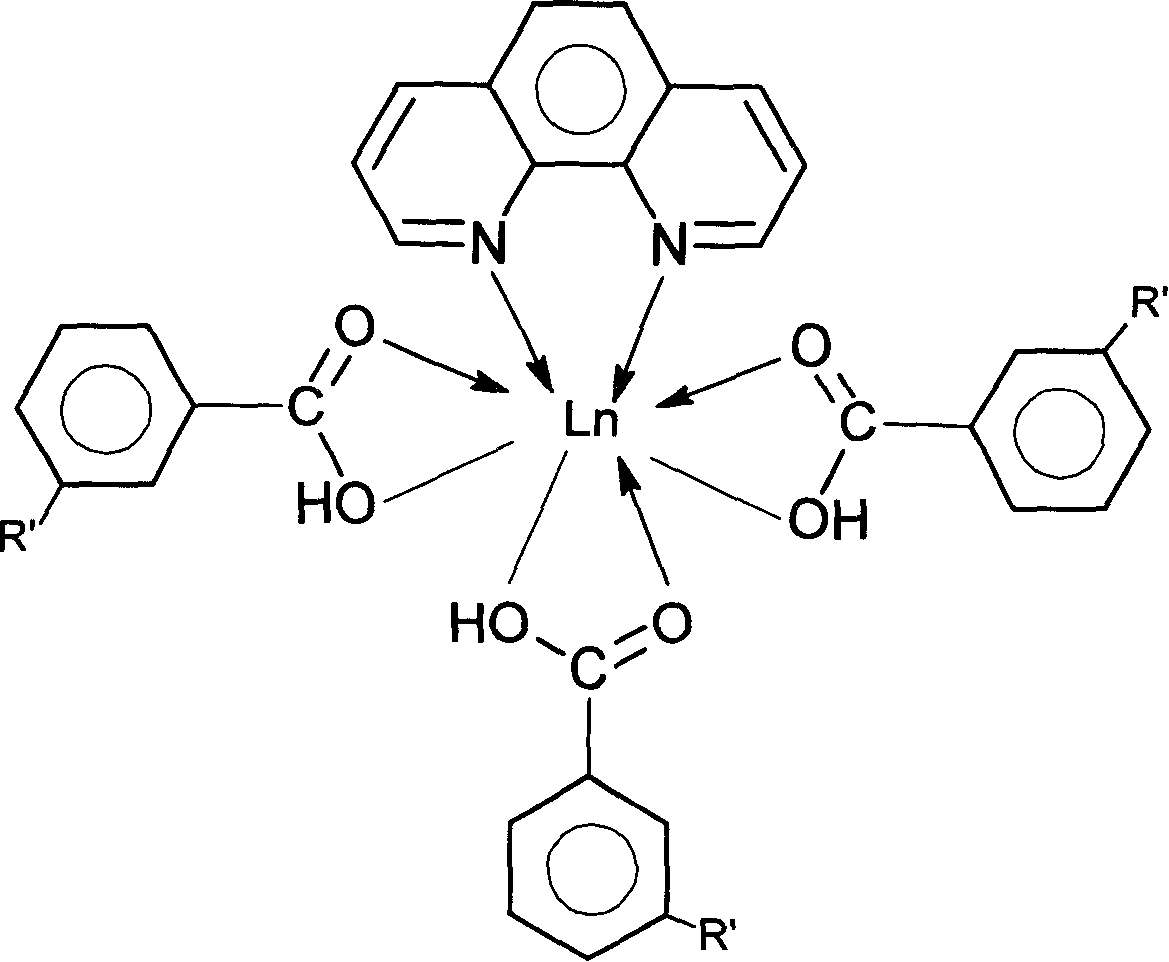

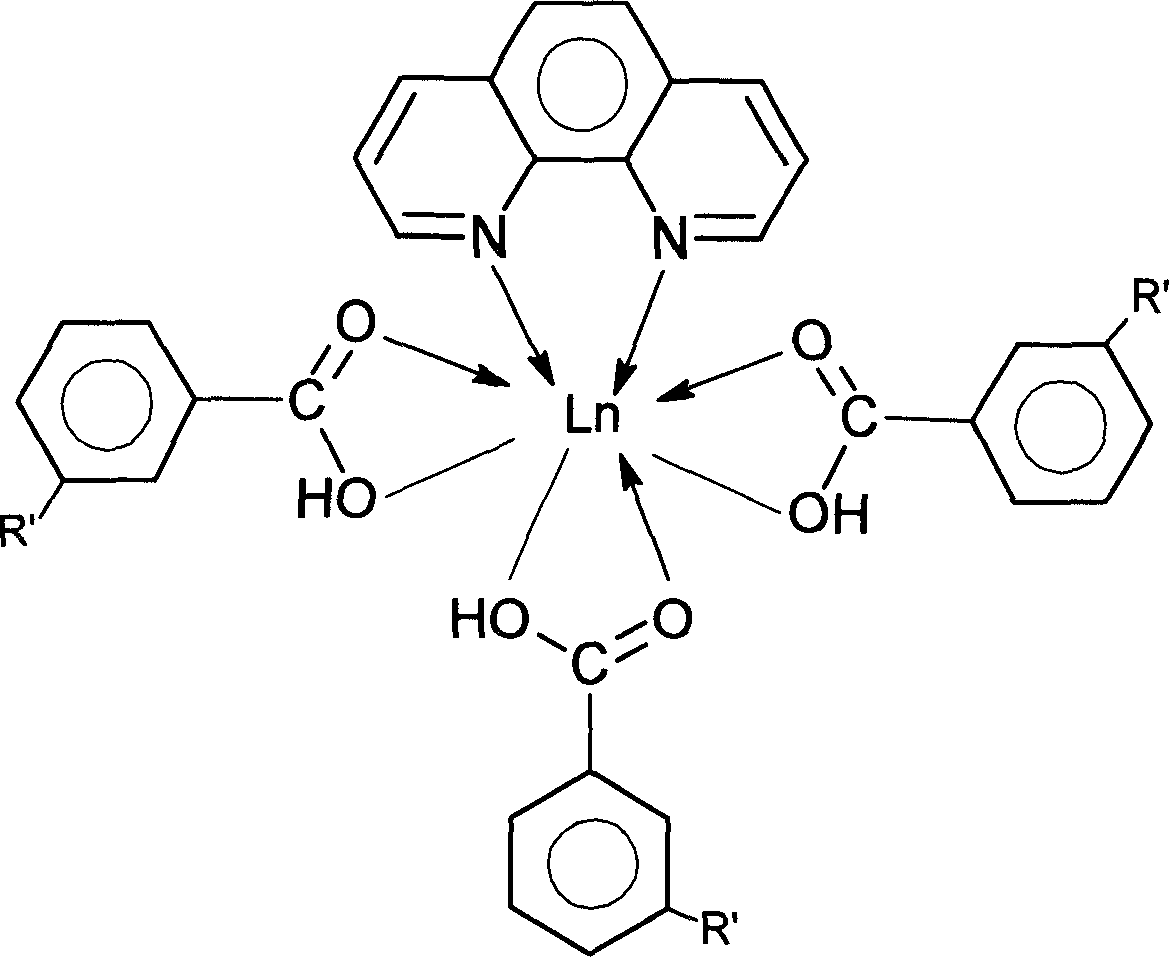

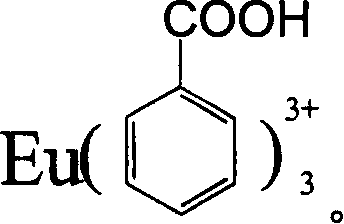

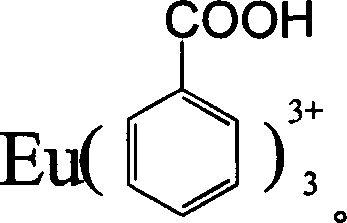

Inorganic-organic core-shell type rare earth high polymer material and its preparation method

InactiveCN1966534AHigh light conversion efficiencyLong fluorescence lifetimeLuminescent compositionsBenzoic acidFluorescence

The invention relates to a preparation method for an inorganic-organic core-shell rare-earth (RE) polymer material, wherein core-shell RE-organic complex is a ternary RE-organic complexes LnM1 (M2R') 3R synthesized by a single substituted-benzoic acid compounds (L) and 1, 10-phenanthroline as ligand, as shown in the right figure. The said method includes: (1) preparation of organic RE complexes, (2) preparation of organic RE complexes emulsion, and (3) preparation of core-shell organic RE complexes / PMMA organic RE polymer light-conversion agent. The RE polymer composite has excellent characteristics of high optical conversion efficiency, strong fluorescence, longer fluorescence lifetime and complexes of high transparency, and can be used as a new optical materials in agriculture, biology, electrical and electronics, etc. arious fields. The preparation process is simple.

Owner:DONGHUA UNIV

Fluorescent powder for white LED and its prepn process

InactiveCN1931958AImprove consistencyEnhance light absorptionGas discharge lamp usageLuminescent compositionsLight fluxLight-emitting diode

The present invention is fluorescent powder for white LED and its preparation process, and the fluorescent powder has torispherical structure and high light converting efficiency. The fluorescent powder has the composition of (Y1-xGdx)3-z(Al1-yGay)5O12:Cez3+, with the activator including RE activator Ce3+ and other activator. The preparation process includes preparing torispherical precursor of granularity of 1-2 micron, adding flux into the precursor, synthesis in H2 / N2, acid prickling, alkali washing, water washing, crushing, sieving, detecting and packing. The fluorescent powder has high light emitting efficiency and light flux up to 80 lm / w.

Owner:王锦高

Weather resistant light-converting luminous farm film and its making process

InactiveCN1887942AHigh light conversion efficiencyTransition spectral widthLuminescent compositionsPlant protective coveringsDiseasePolymer science

The present invention belongs to the field of one kind of weather resistant light-converting luminous farm film and its making process. The farm film contains base resin and following added components: at least one kind of visible light excited long afterglow light-converting agent, at least one kind of red light-converting agent, at least one kind of blue light-converting agent, and one compatible antiaging agent. The farm film has the light-converting and luminous characteristics, can luminesce at night stably for long time, so that plant can utilize sunlight effectively for increasing yield, fast maturing and reducing diseases and pests.

Owner:SHANGHAI NORMAL UNIVERSITY

Process for etching solar cells by combining acid and alkali

InactiveCN101515611AReduce the surface complexReduce reflectivityFinal product manufactureSemiconductor devicesSilicon chipChemistry

The invention relates to the technical field of solar cells manufacturing, in particular to a process for etching solar cells by combining acid and alkali. The process comprises the following steps: a, acid-etching: carrying out light-etching on the surface of a silicon chip with HF and HNO3; and b, alkali-etching: cleaning the light-etched silicon chip and further carrying out deep-etching with potassium hydroxide solution or sodium hydroxide solution to finish etching the silicon chip. The invention solves the problem that the performance of the solar cells is affected by the high surface recombination of the silicon chip in the existing etching process.

Owner:TRINASOLAR CO LTD

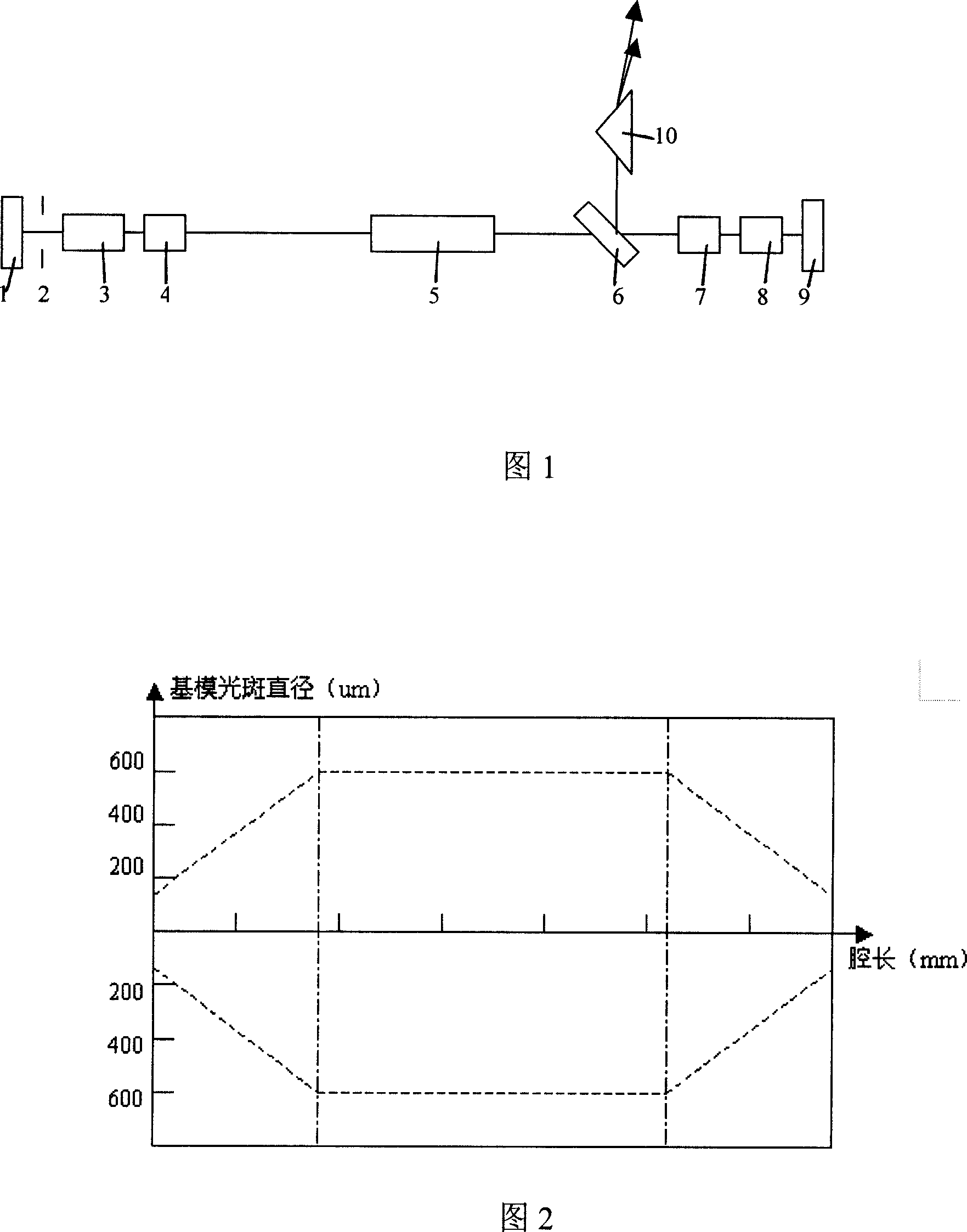

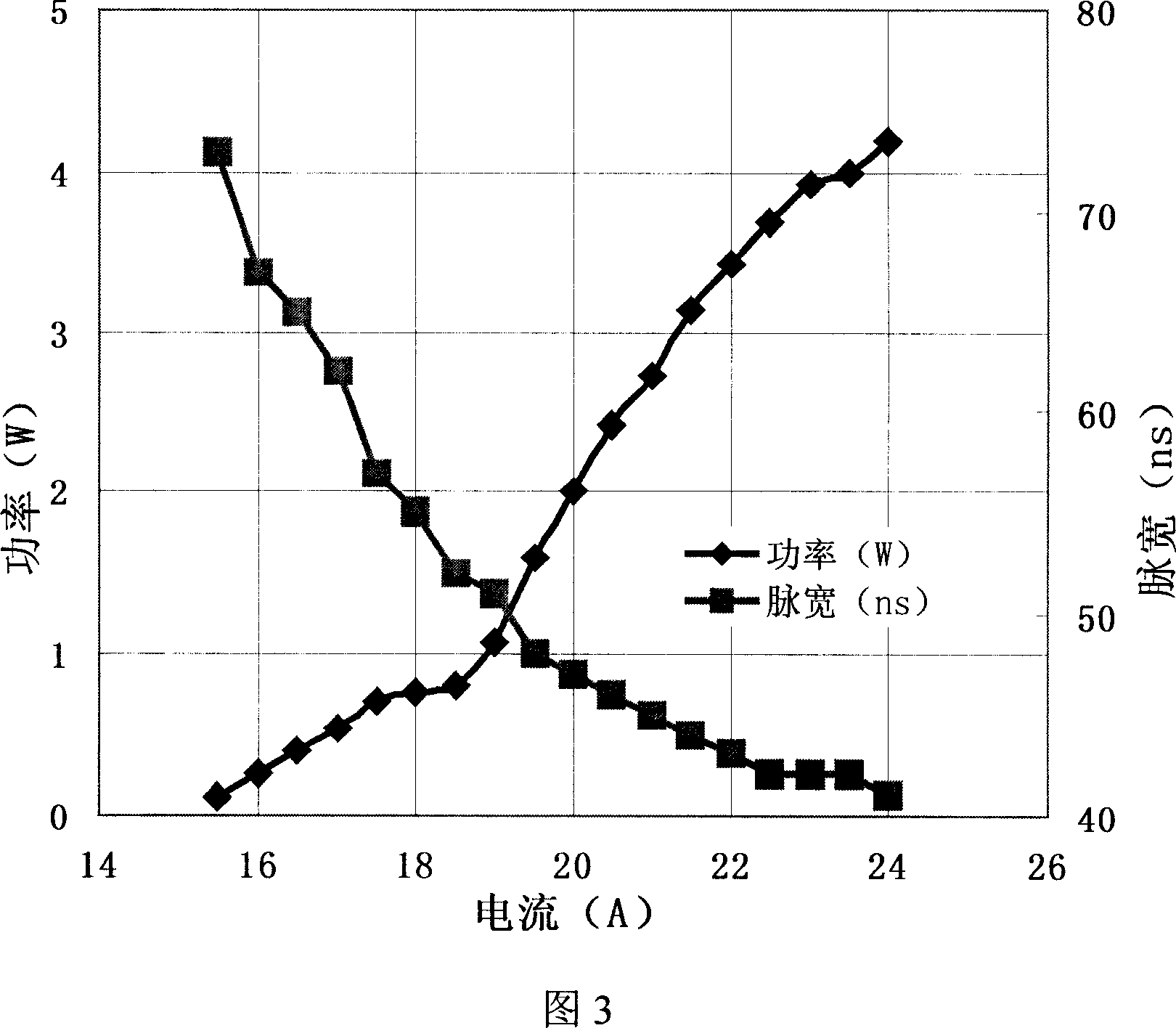

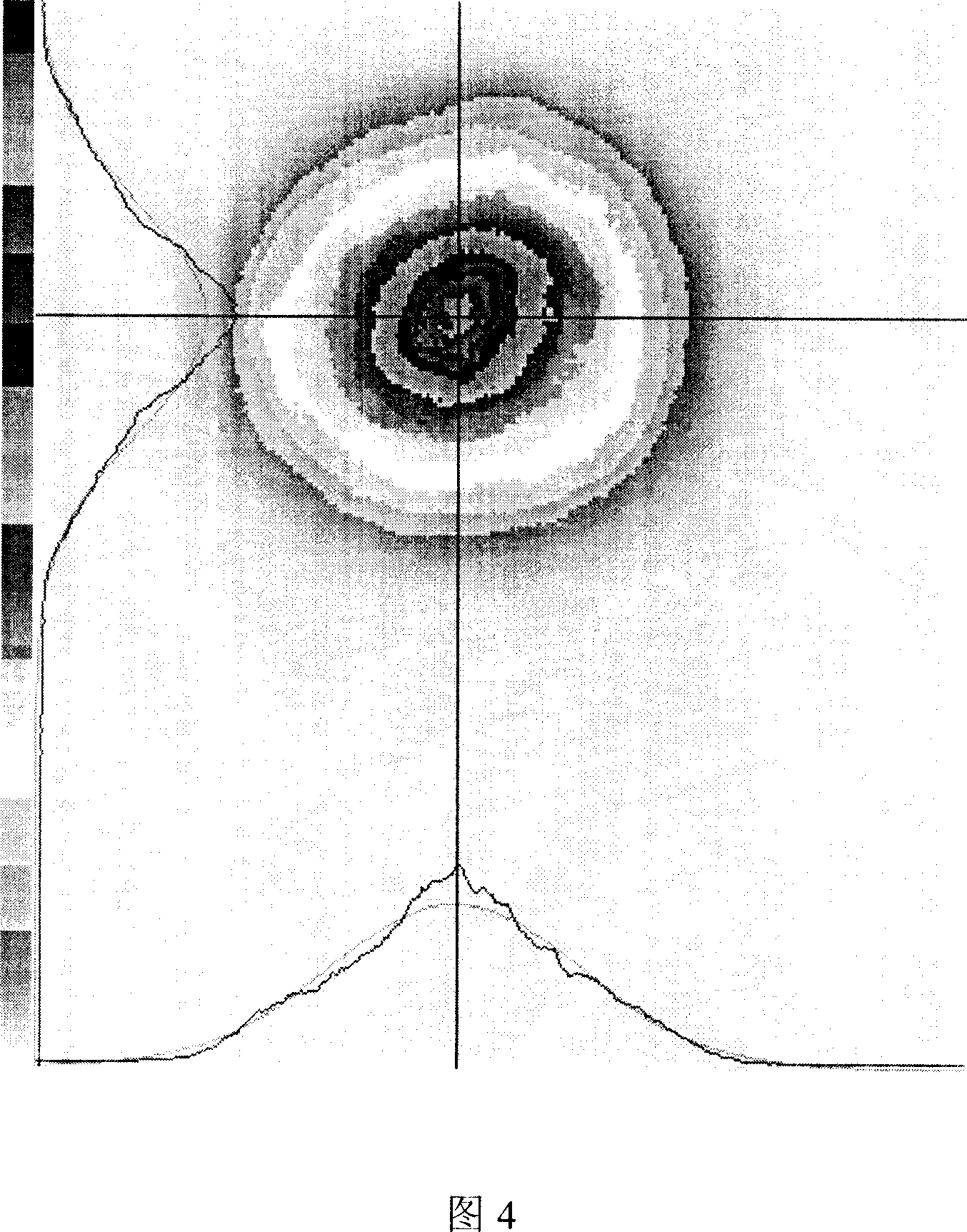

Method for generating third harmonic laser

InactiveCN101119009AAvoid destructionImprove laser lifeLaser detailsNon-linear opticsThird harmonicHigh power density

The invention relates to a third harmonic laser generating method, which comprises a pumping resource, a Q switch, a duplex frequency nonlinear crystal, a triplicate frequency nonlinear crystal and a plurality of reflecting mirrors. The high power density fundamental wave light generated by the pumping resource pump acts on the duplex frequency nonlinear crystal so as to generate second harmonic laser; the second harmonic laser and the high power density fundamental wave light generated by the pumping resource pump synchronically is emitted into the triplicate frequency nonlinear crystal to be summed so as to generate third harmonic laser to be output out of a laser resonance cavity; the duplex frequency nonlinear crystal, the triplicate frequency nonlinear crystal and the pumping resource are all positioned in the laser renounce cavity. The present invention develops a diode array side pumping ultraviolet 355nm laser so as to get ultraviolet 355nm laser output with high basic mold and light conversion rate and long service life.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com