Method for generating third harmonic laser

A generation method and sub-harmonic technology, applied in lasers, laser parts, optics, etc., can solve the problems of large fundamental wave loss and poor stability of the resonator, and achieve the effects of avoiding damage, good stability, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

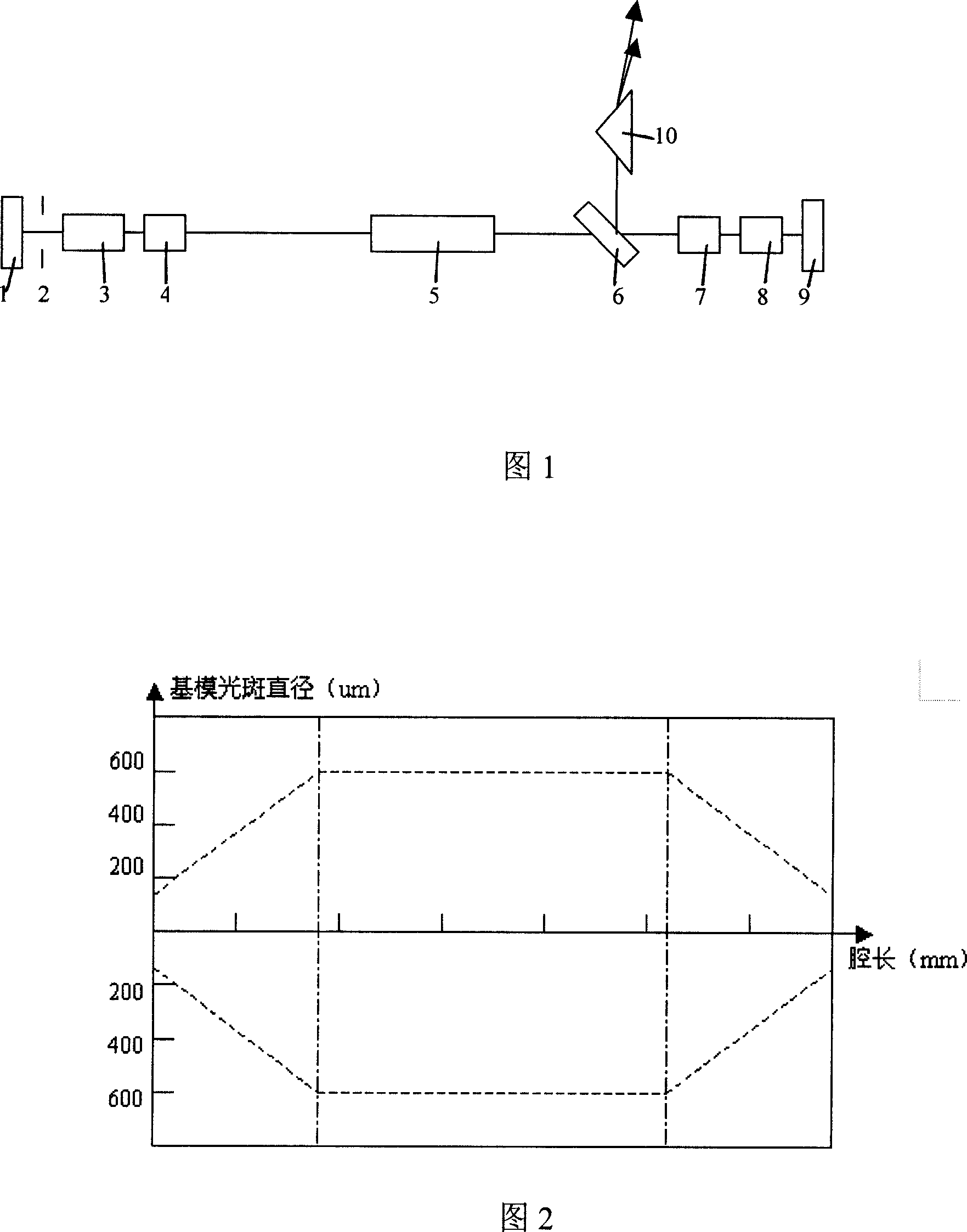

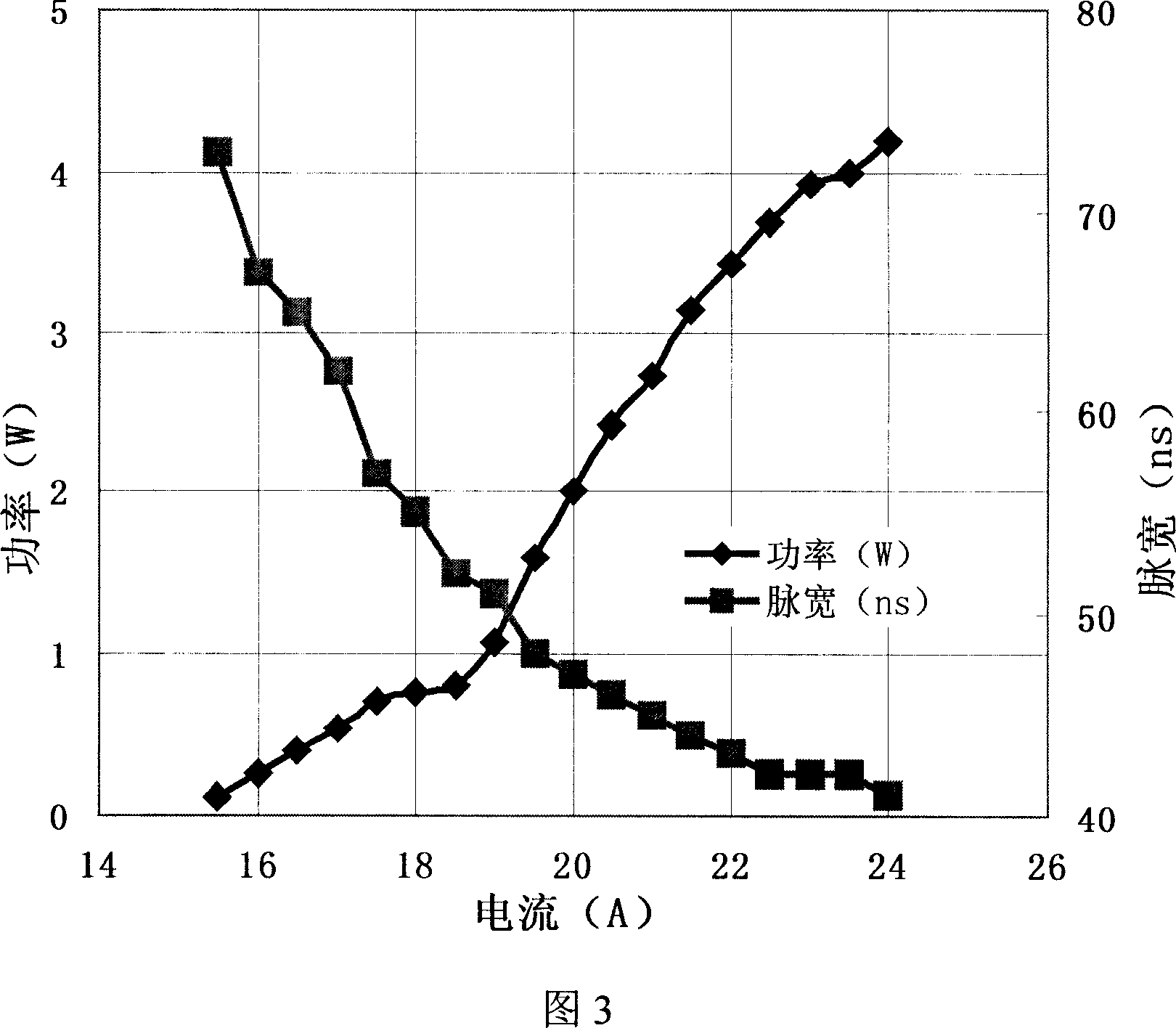

[0030] The principle of the third harmonic laser generation method is shown in Figure 1. The fundamental wave is an oscillator with a wavelength of 1064nm, which is composed of a pump source 5, a Q switch 3, a polarizer 4, a mode-limiting aperture 2, a total reflection mirror 1, 9, and a 45-degree reflection mirror 6 on the end face. The pumping source 5 adopts the Nd:YAG rod pumped by the side of the high-power laser diode array. The thermal lens effect of the Nd:YAG rod is calculated and measured under different pump powers, and the optical matrix method is used to calculate the thermal lens effect of the laser resonator. The spatial distribution of the Gaussian mode transmission, the optimal cavity length and the curvature of the end total reflection mirrors 1 and 9 are designed, so that the infrared laser resonator can still maintain stable oscillation under a wide range of changes in the thermal lens. The calculation results are shown in Figure 2. The mode limiting apert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com