Patents

Literature

1441 results about "Diode array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diode array is a type of electronic component that consists of multiple diodes within a single package.

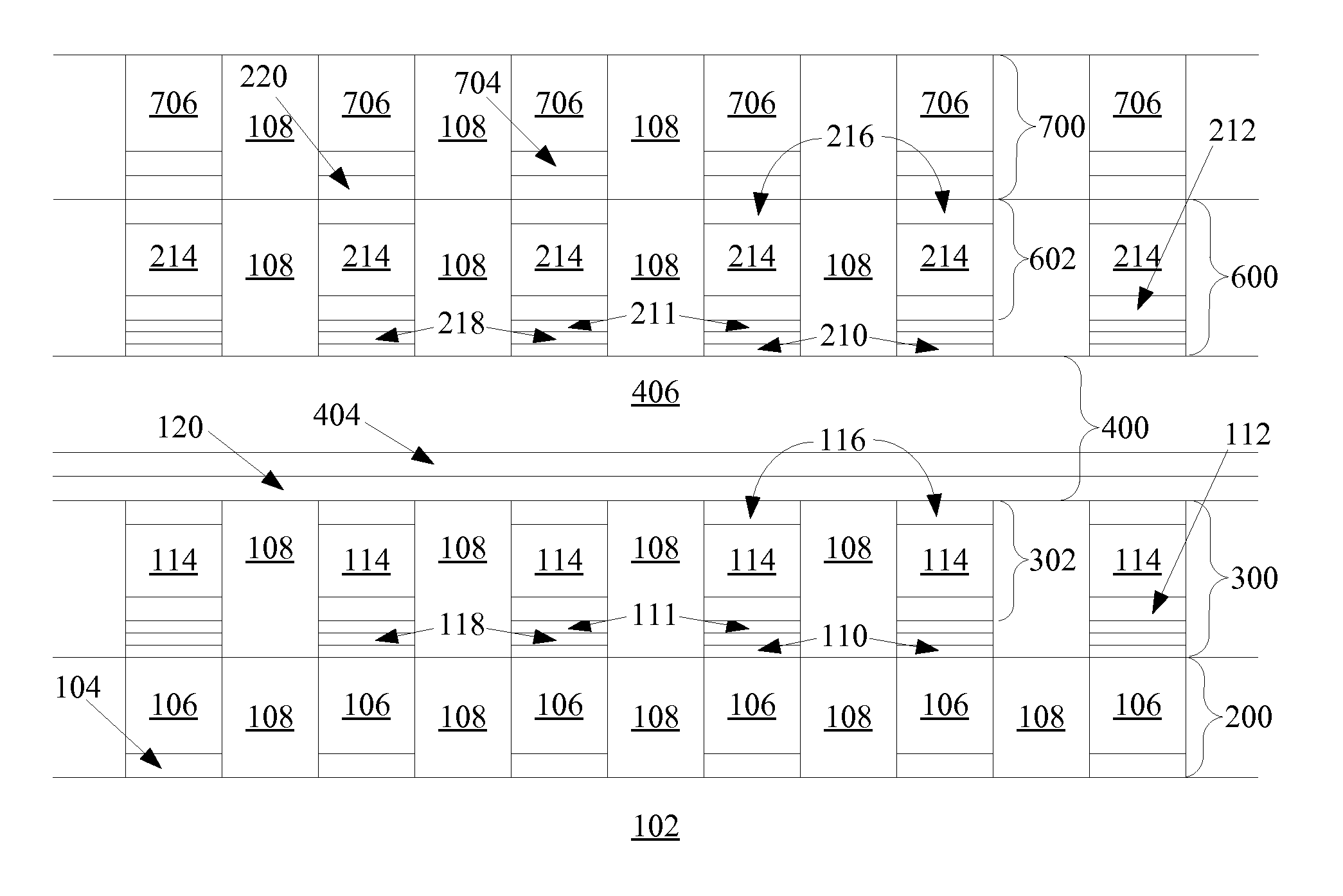

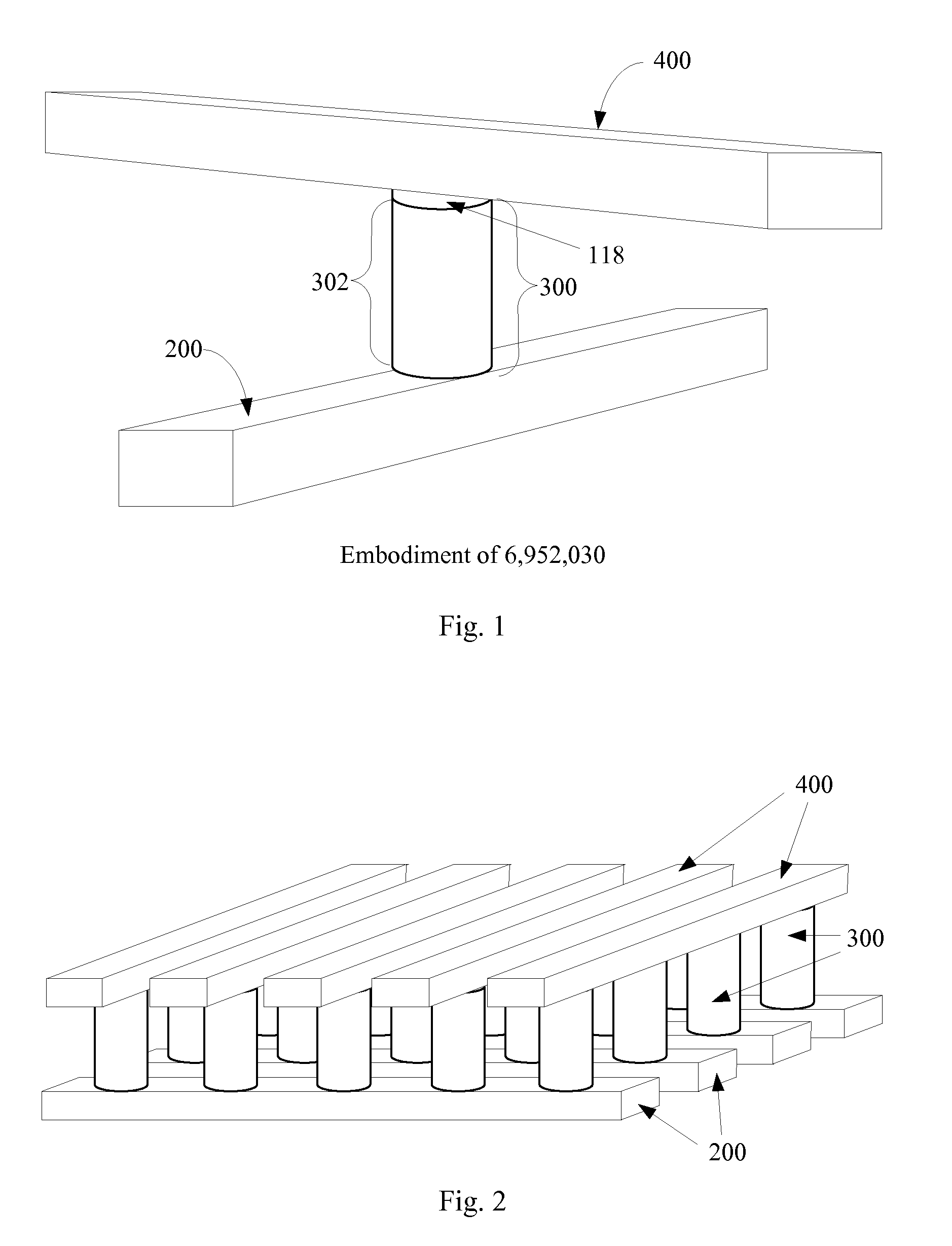

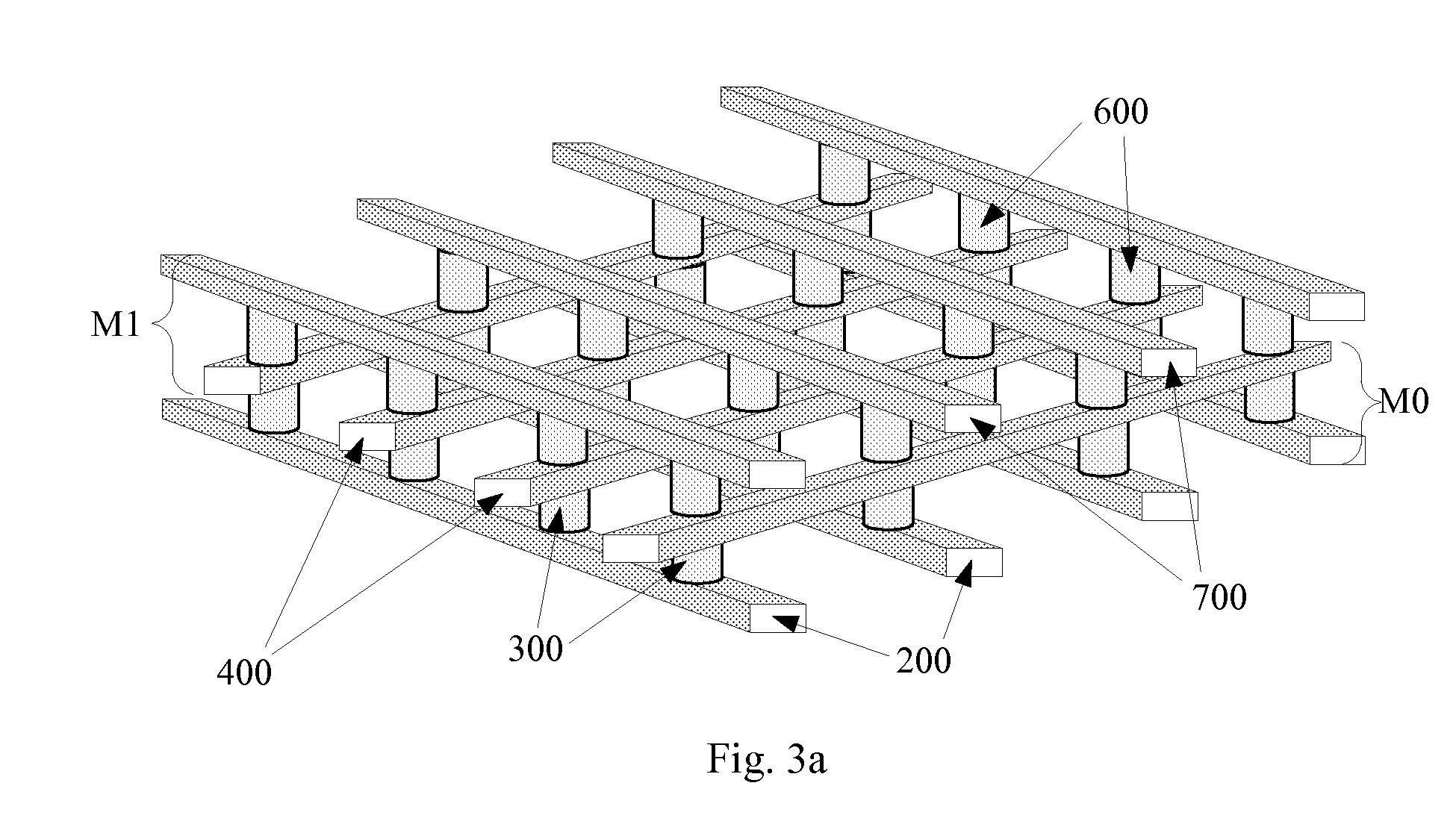

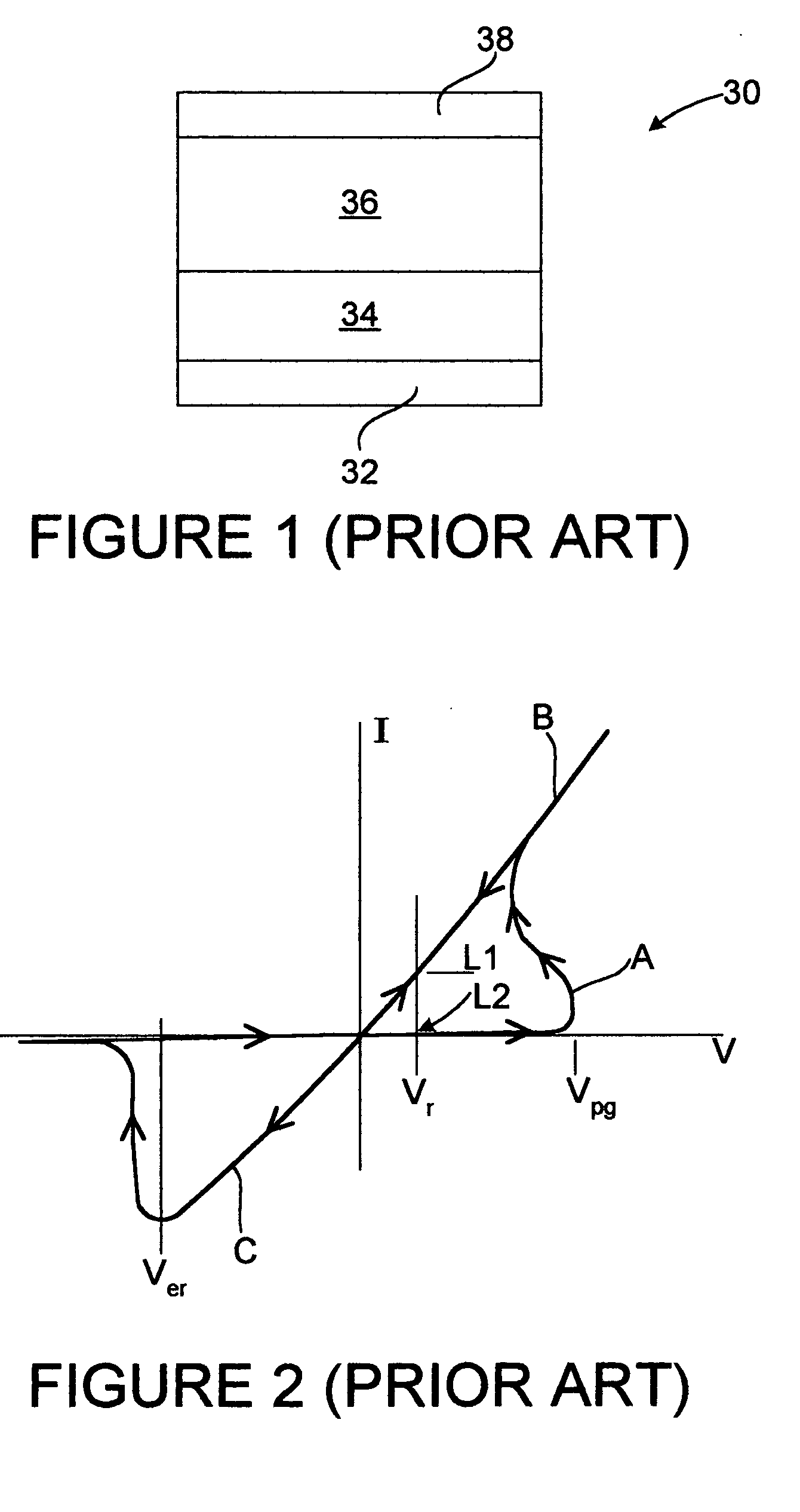

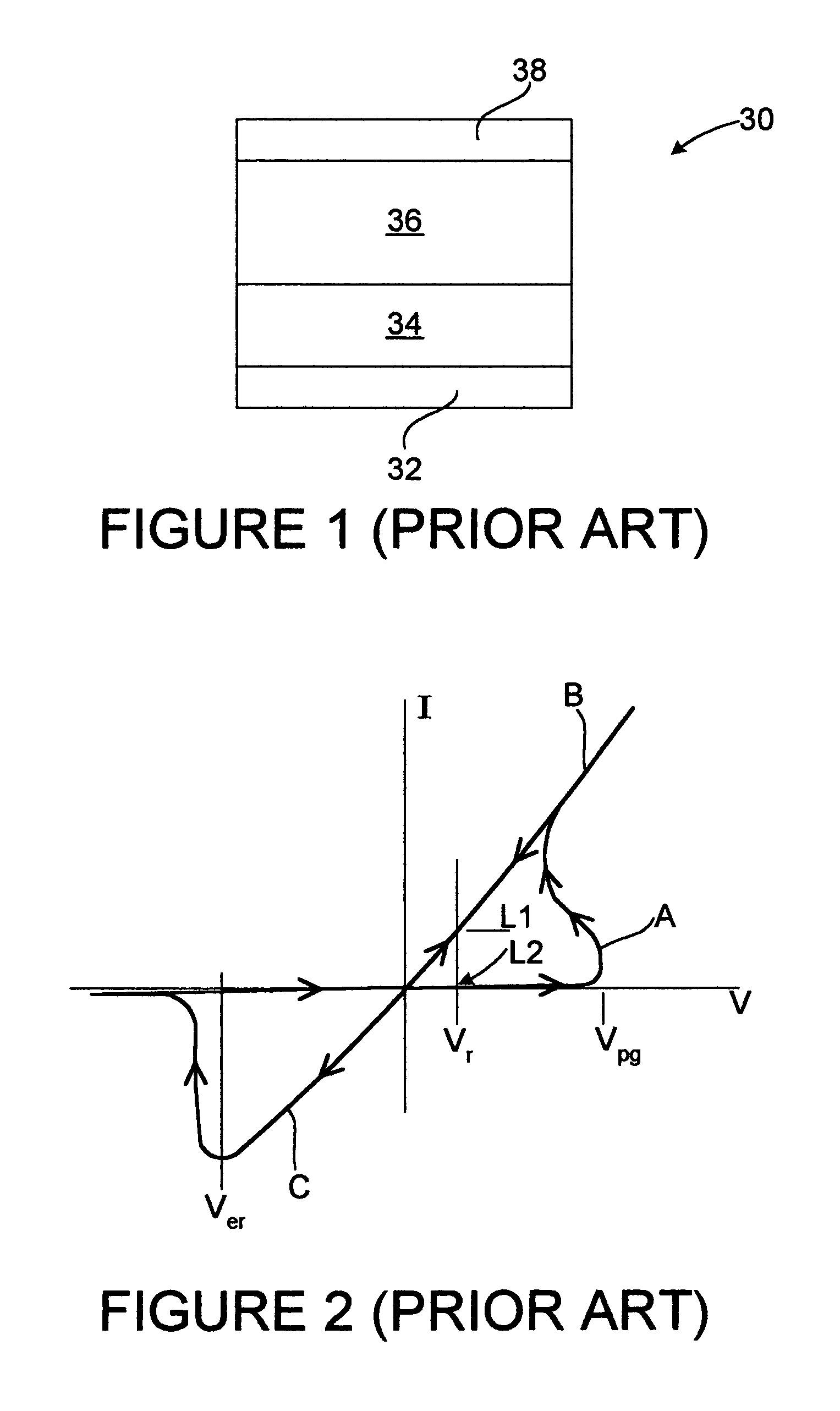

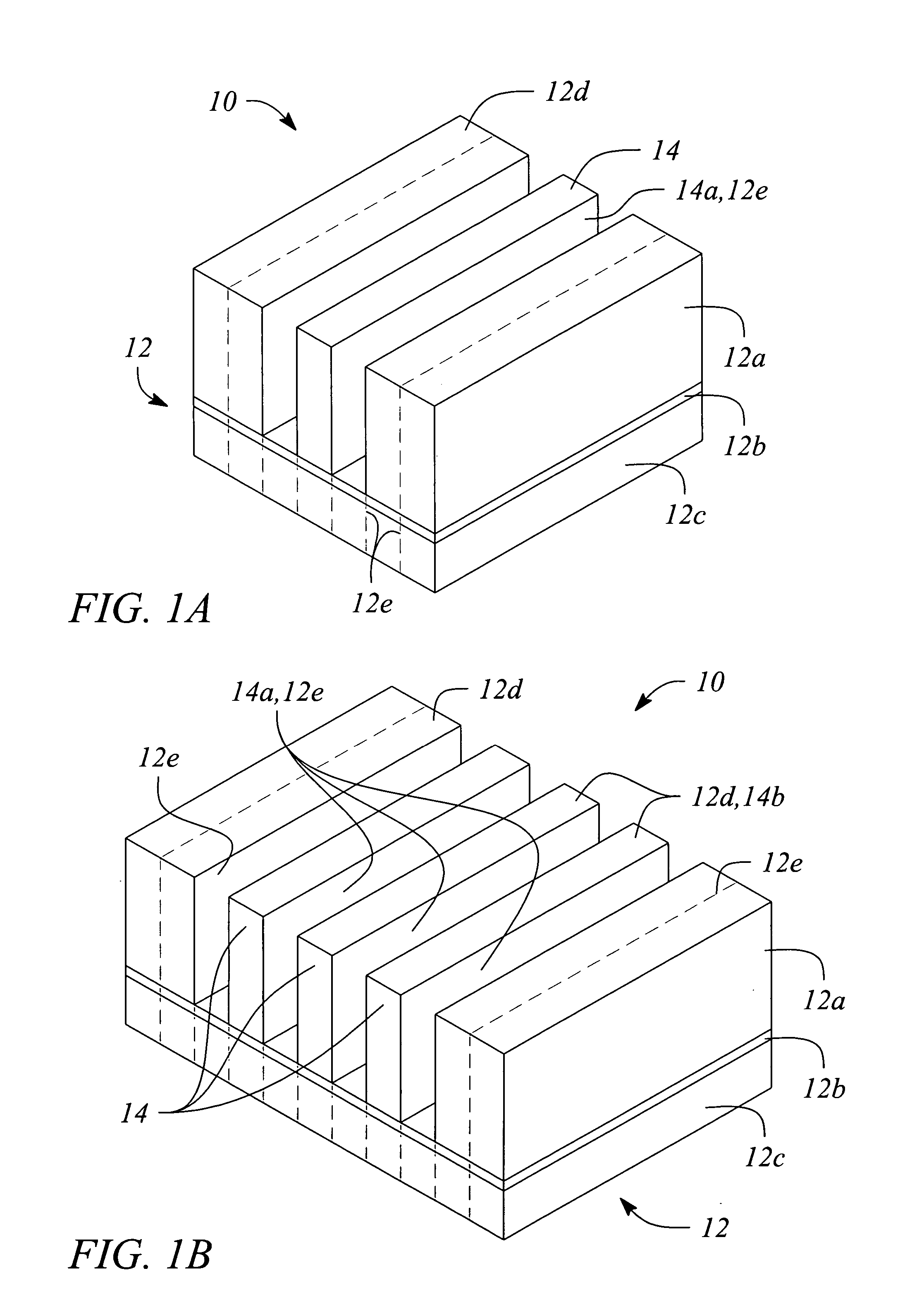

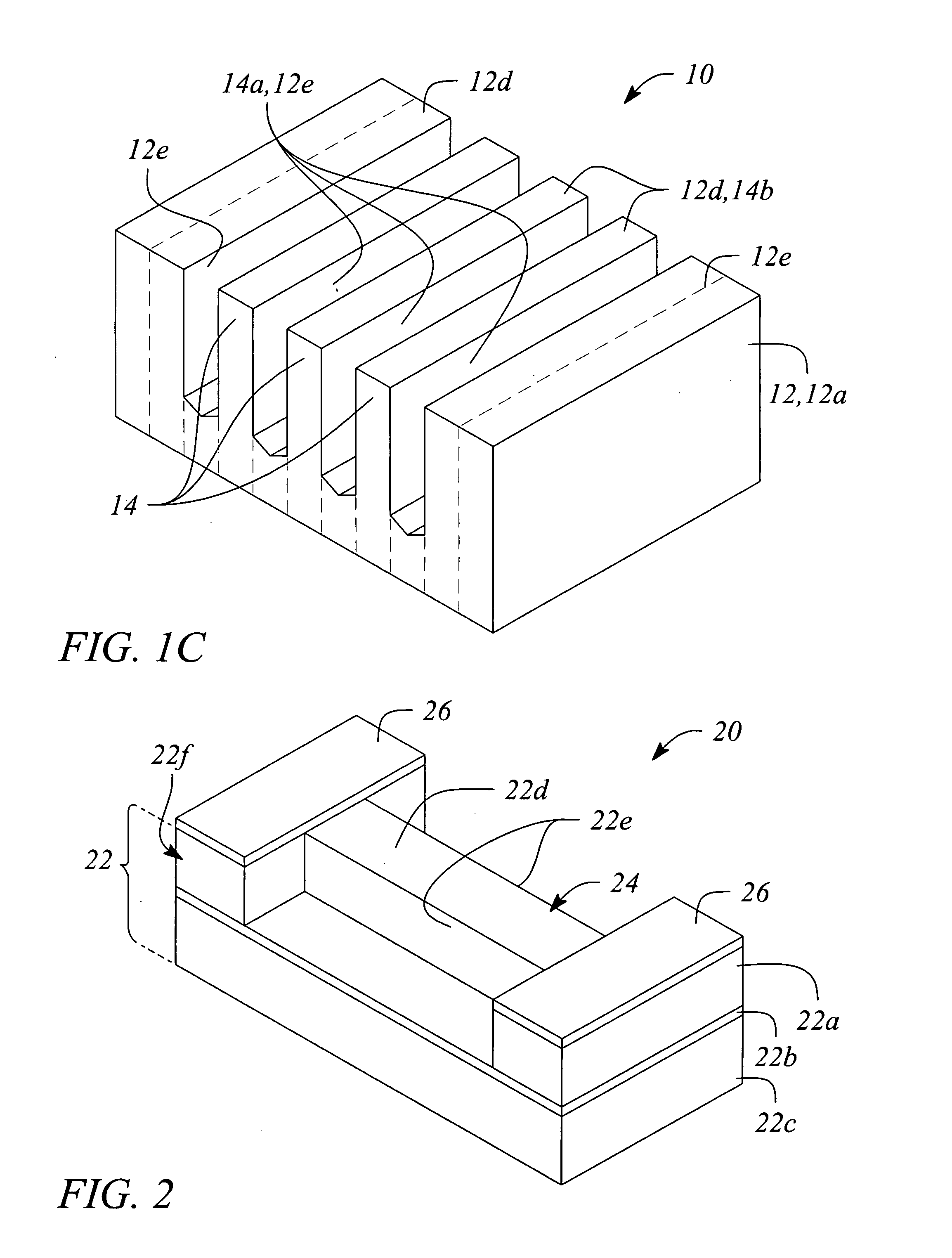

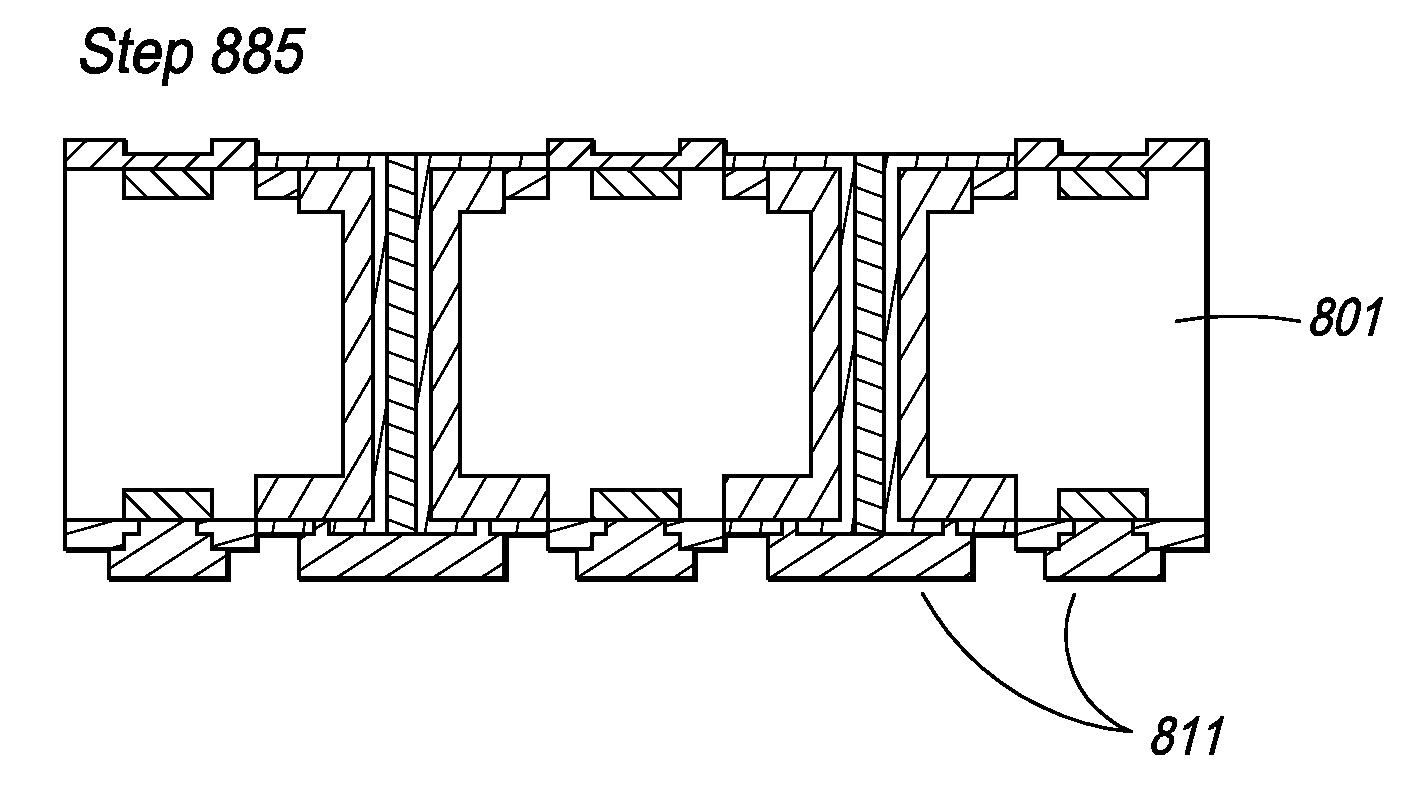

Method to form upward pointing p-i-n diodes having large and uniform current

A method is disclosed to form an upward-pointing p-i-n diode formed of deposited silicon, germanium, or silicon-germanium. The diode has a bottom heavily doped p-type region, a middle intrinsic or lightly doped region, and a top heavily doped n-type region. The top heavily doped p-type region is doped with arsenic, and the semiconductor material of the diode is crystallized in contact with an appropriate silicide, germanide, or silicide-germanide. A large array of such upward-pointing diodes can be formed with excellent uniformity of current across the array when a voltage above the turn-on voltage of the diodes is applied. This diode is advantageously used in a monolithic three dimensional memory array.

Owner:SANDISK TECH LLC

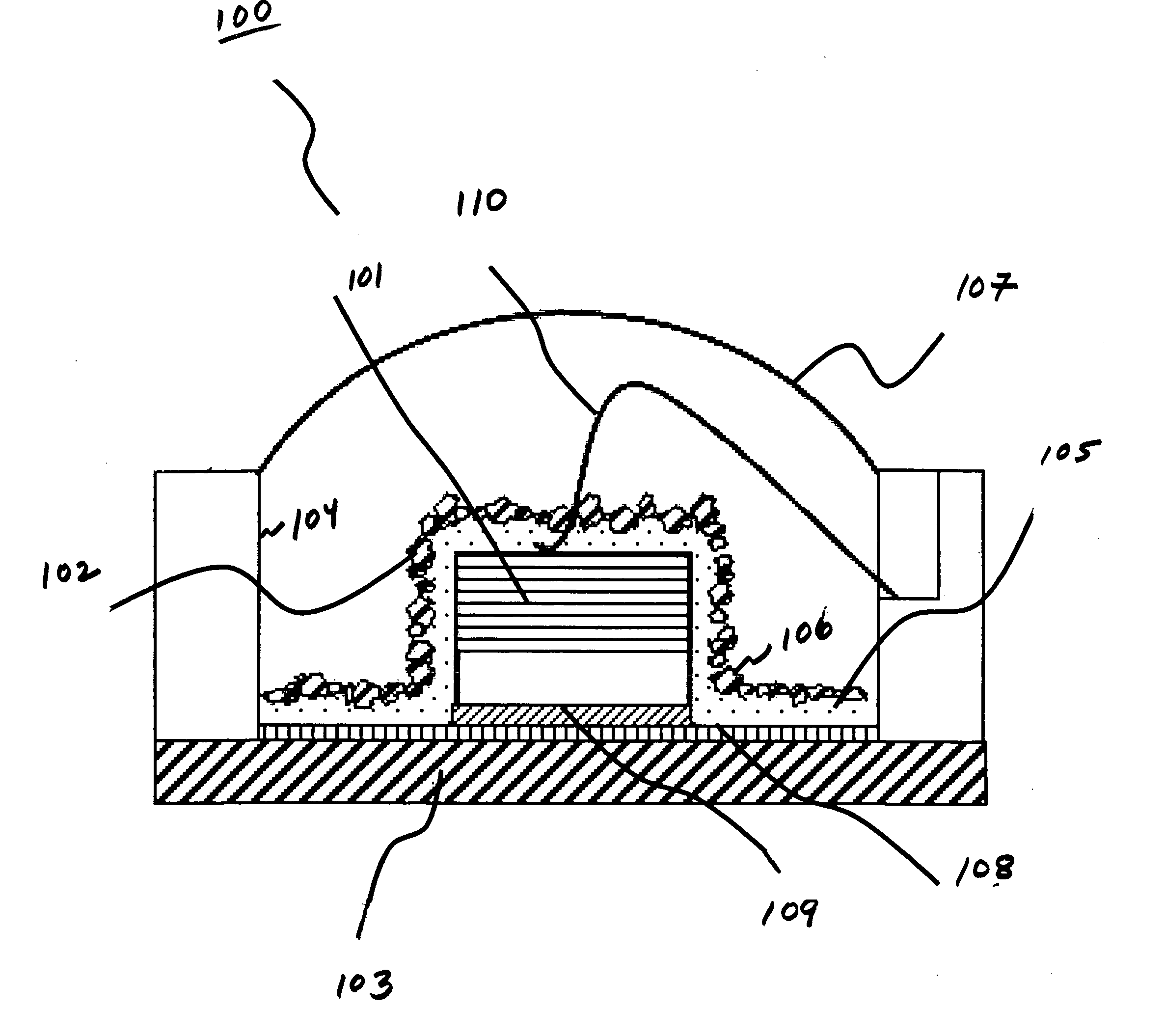

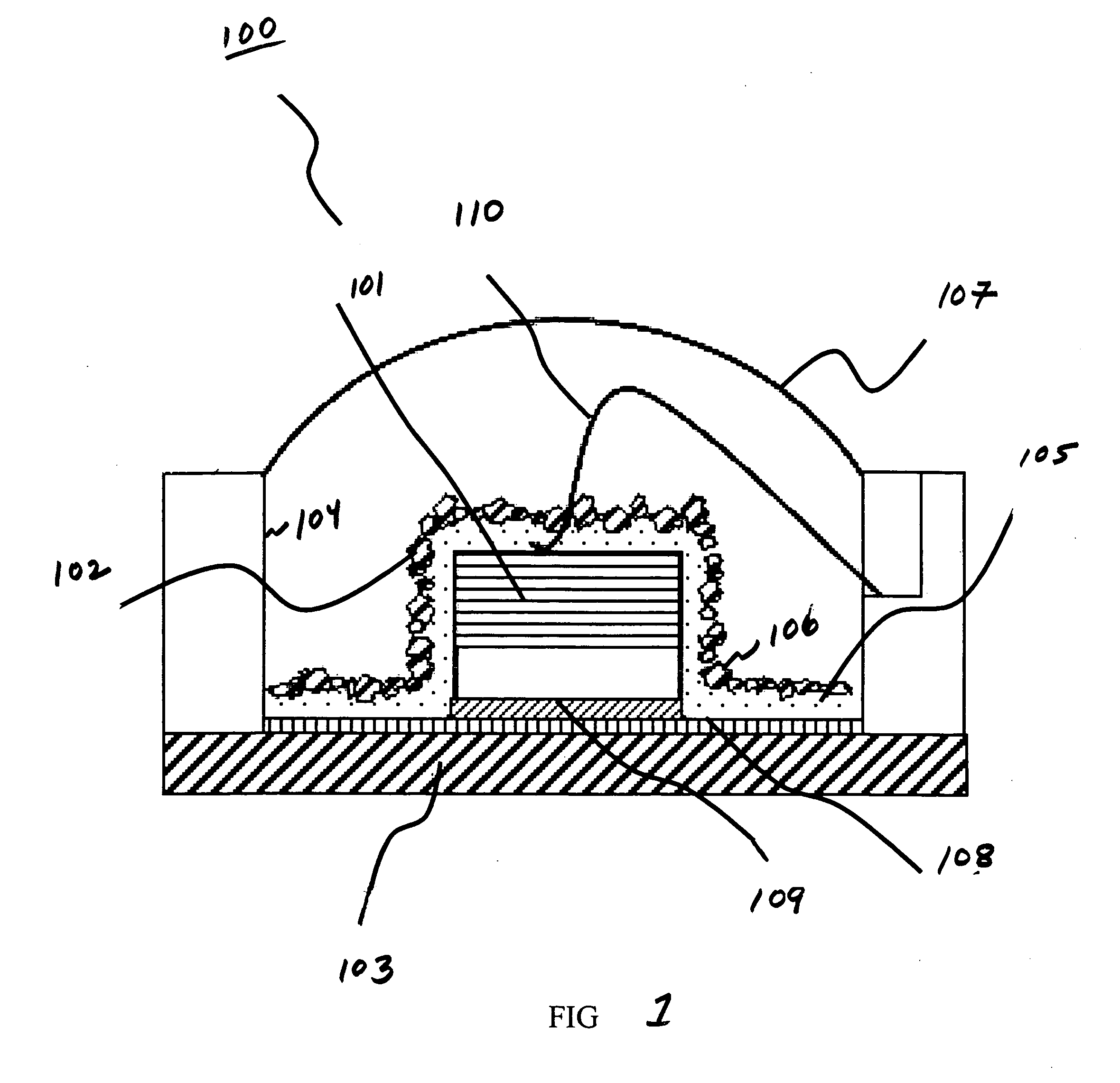

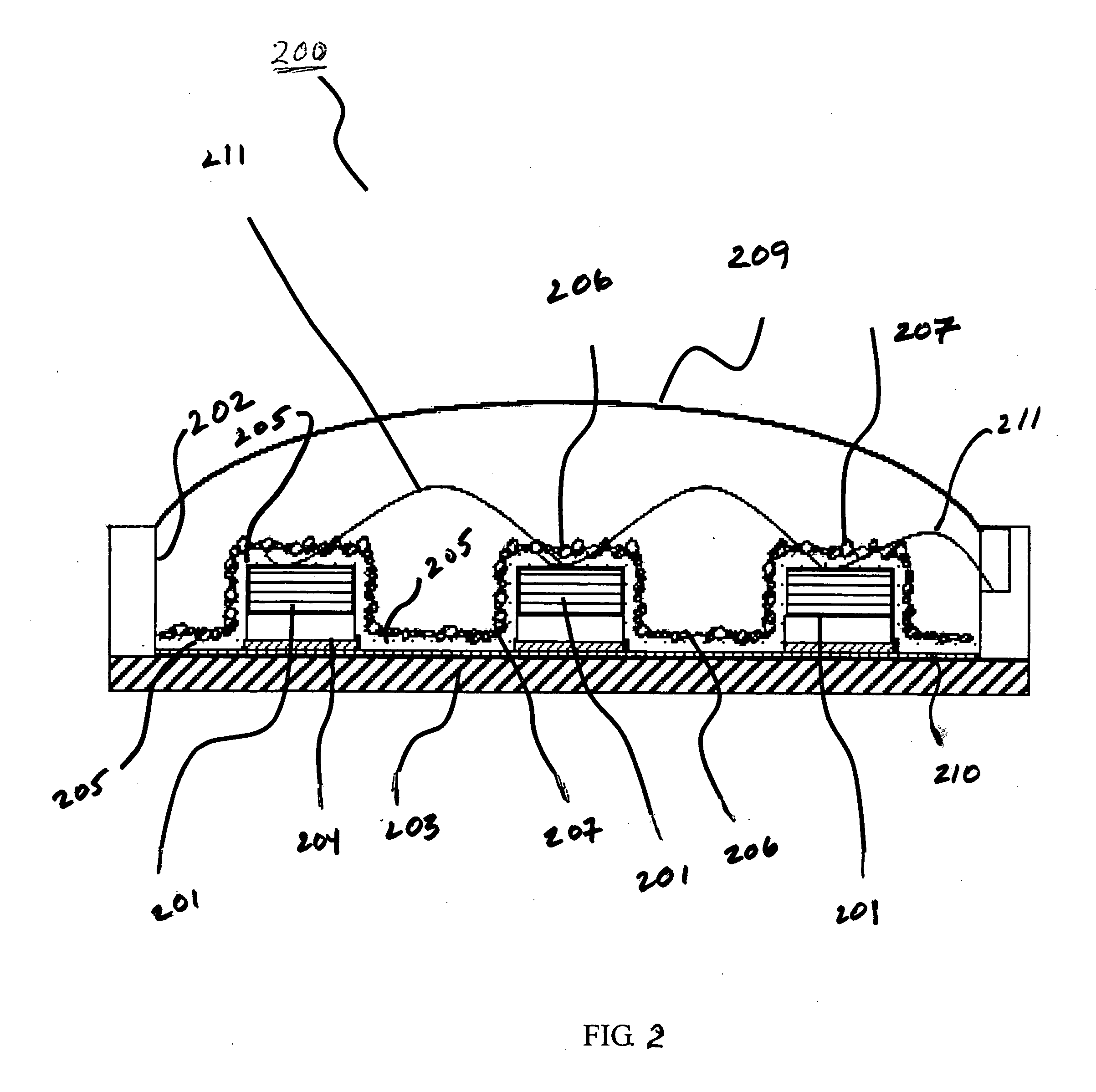

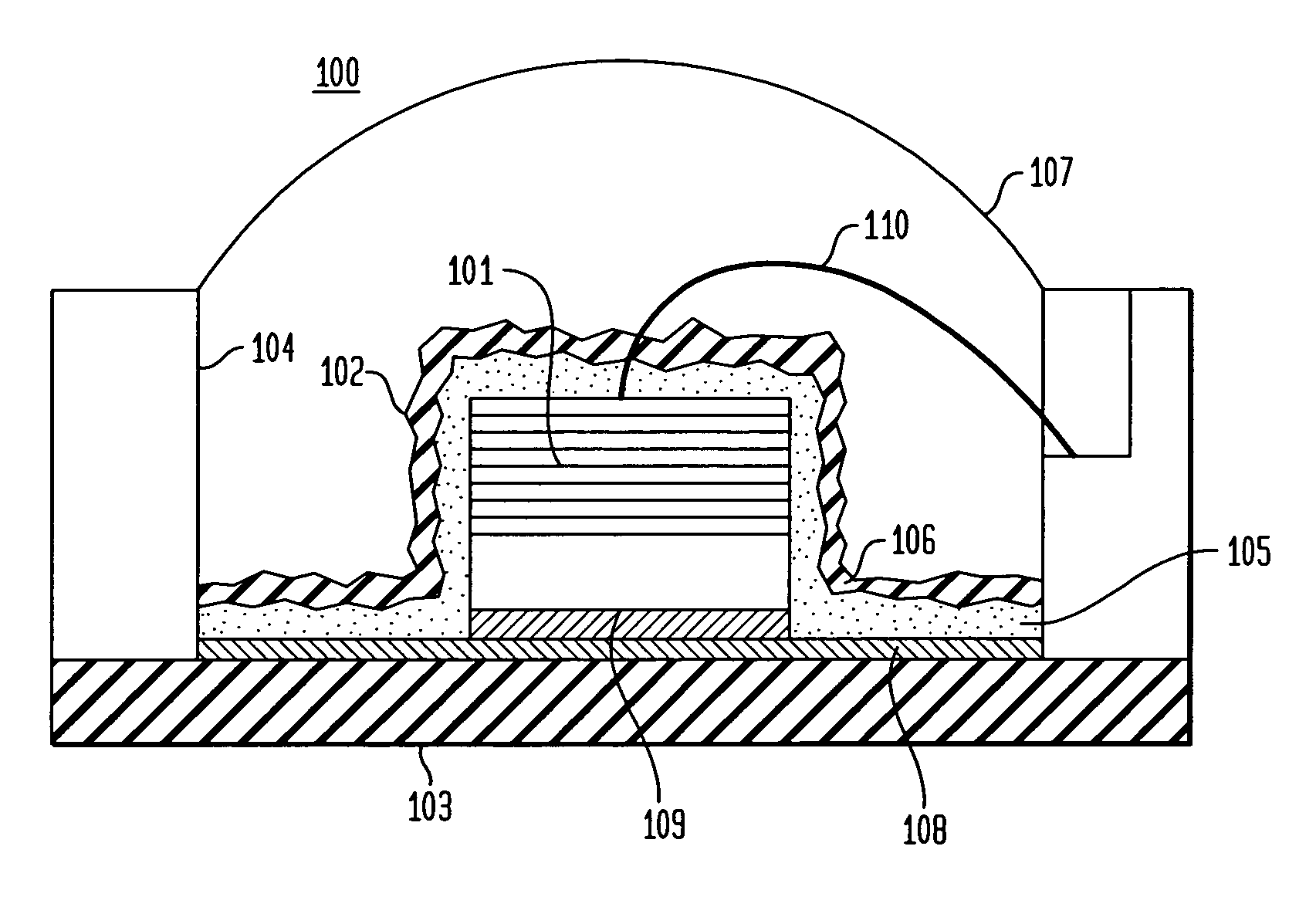

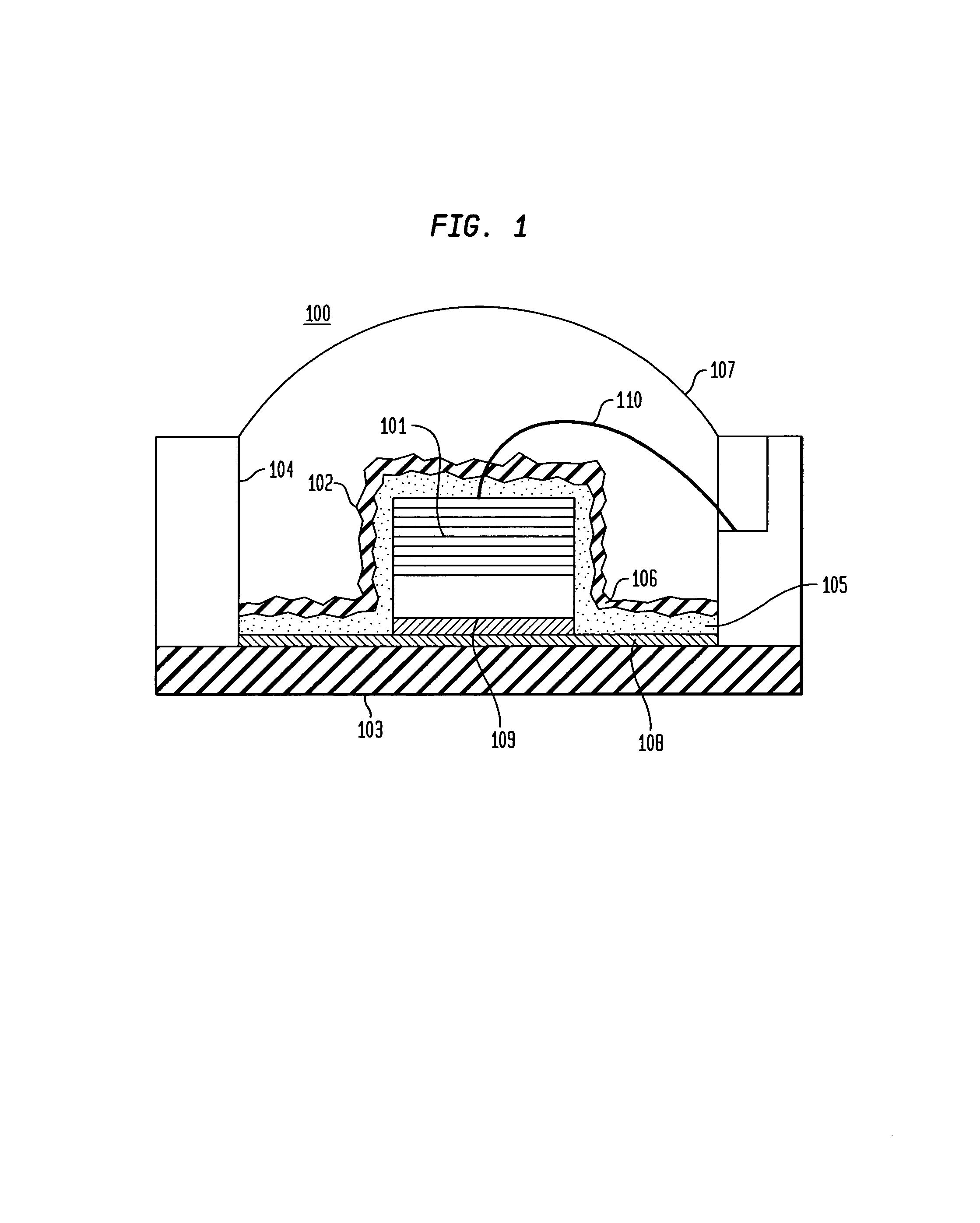

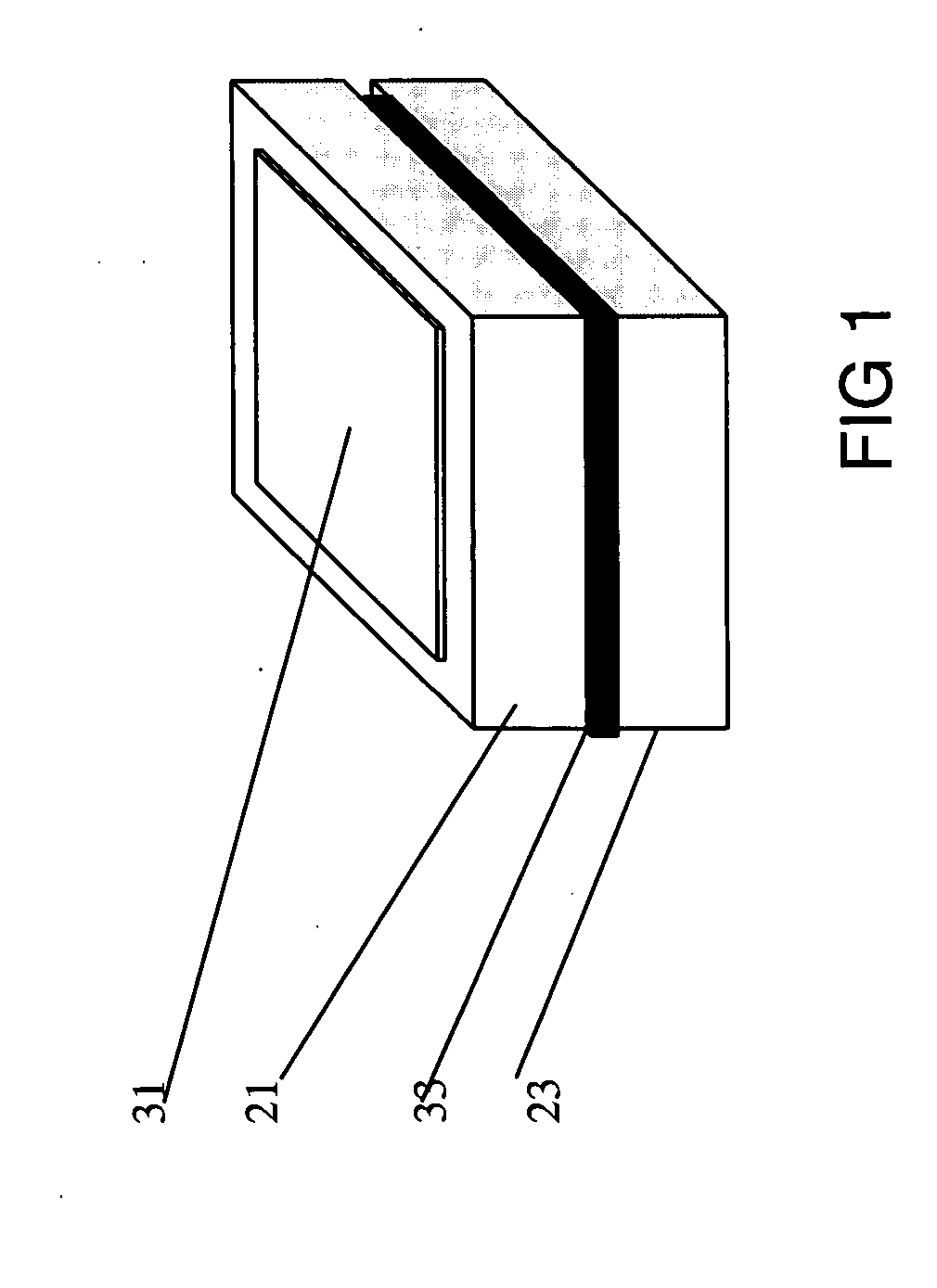

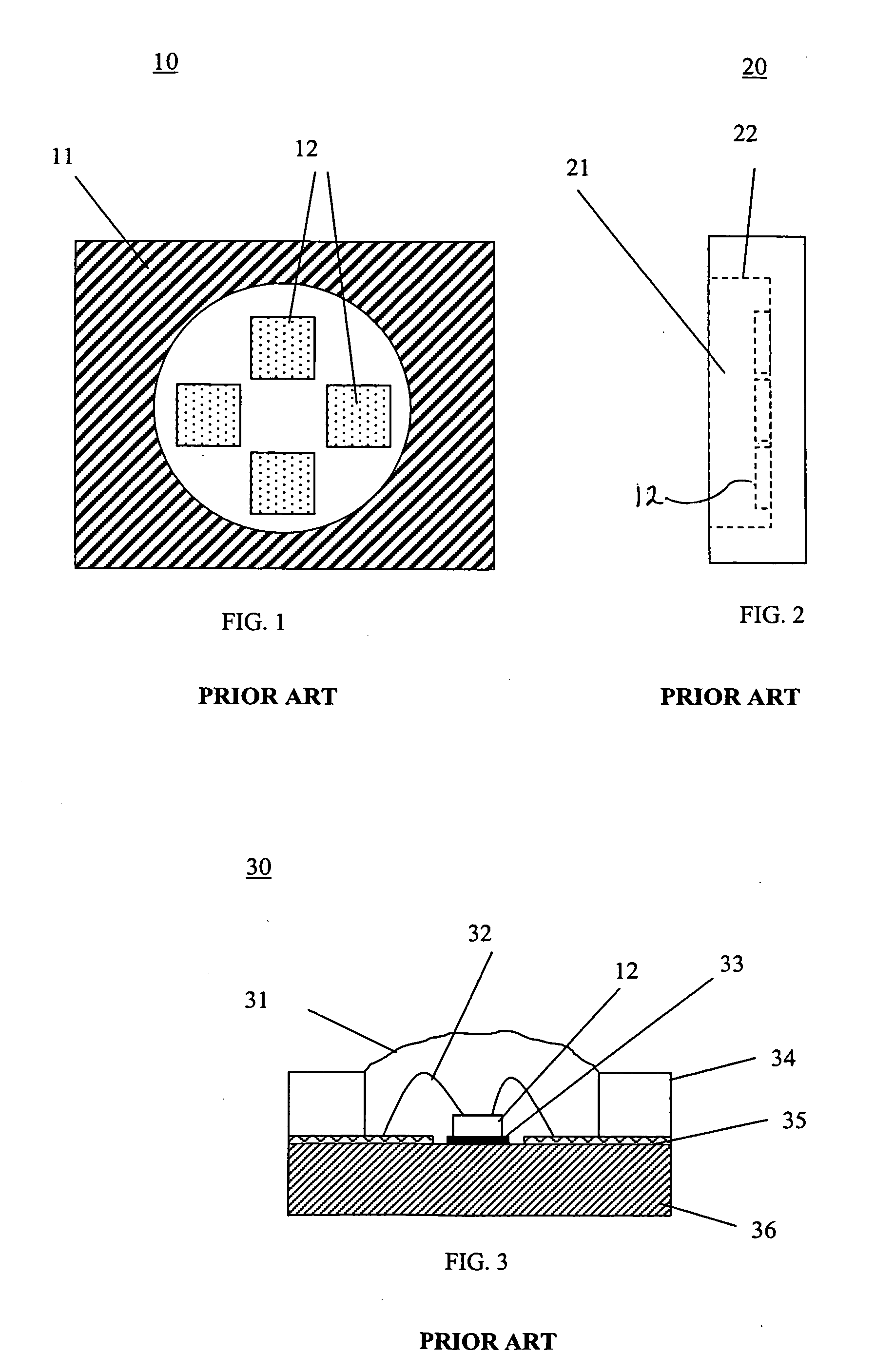

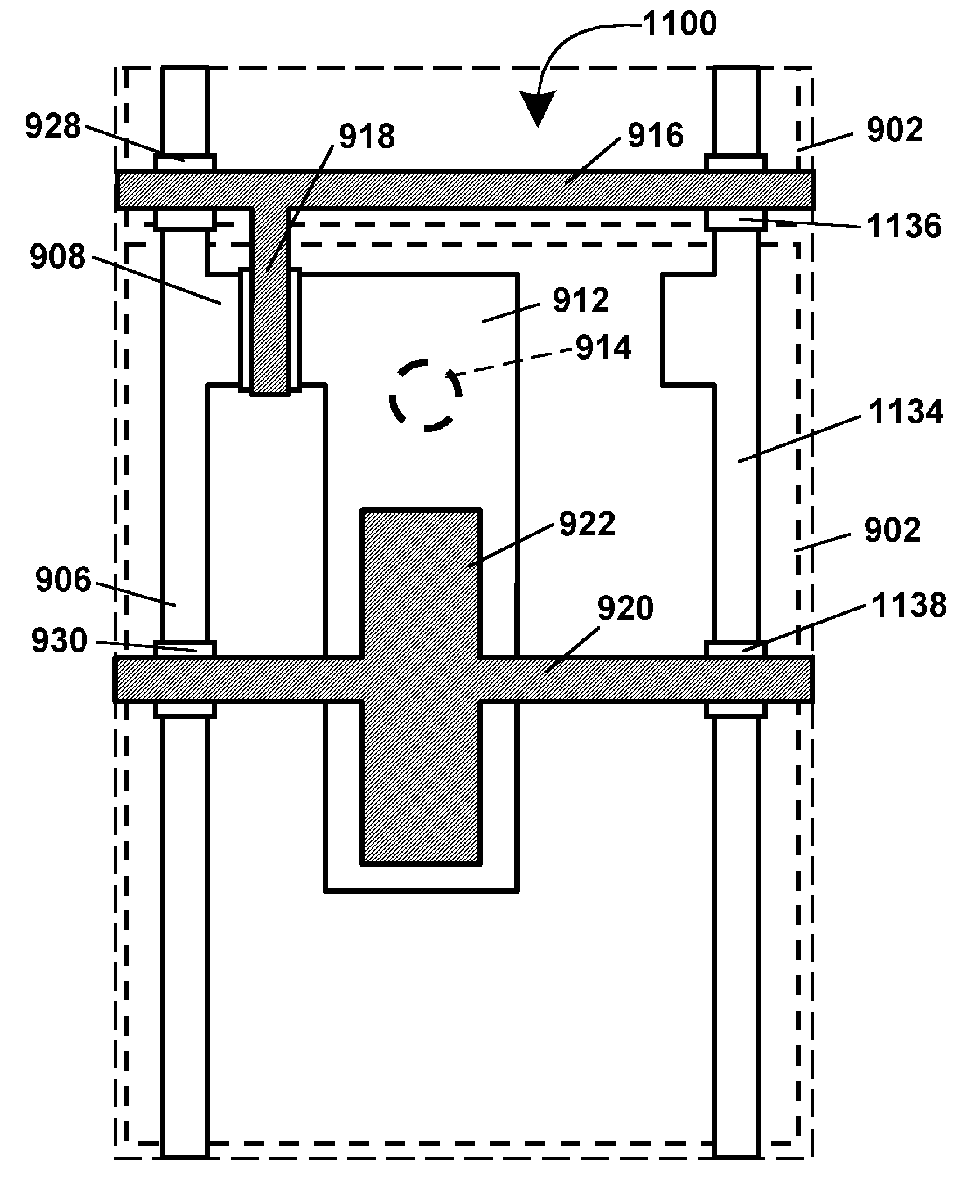

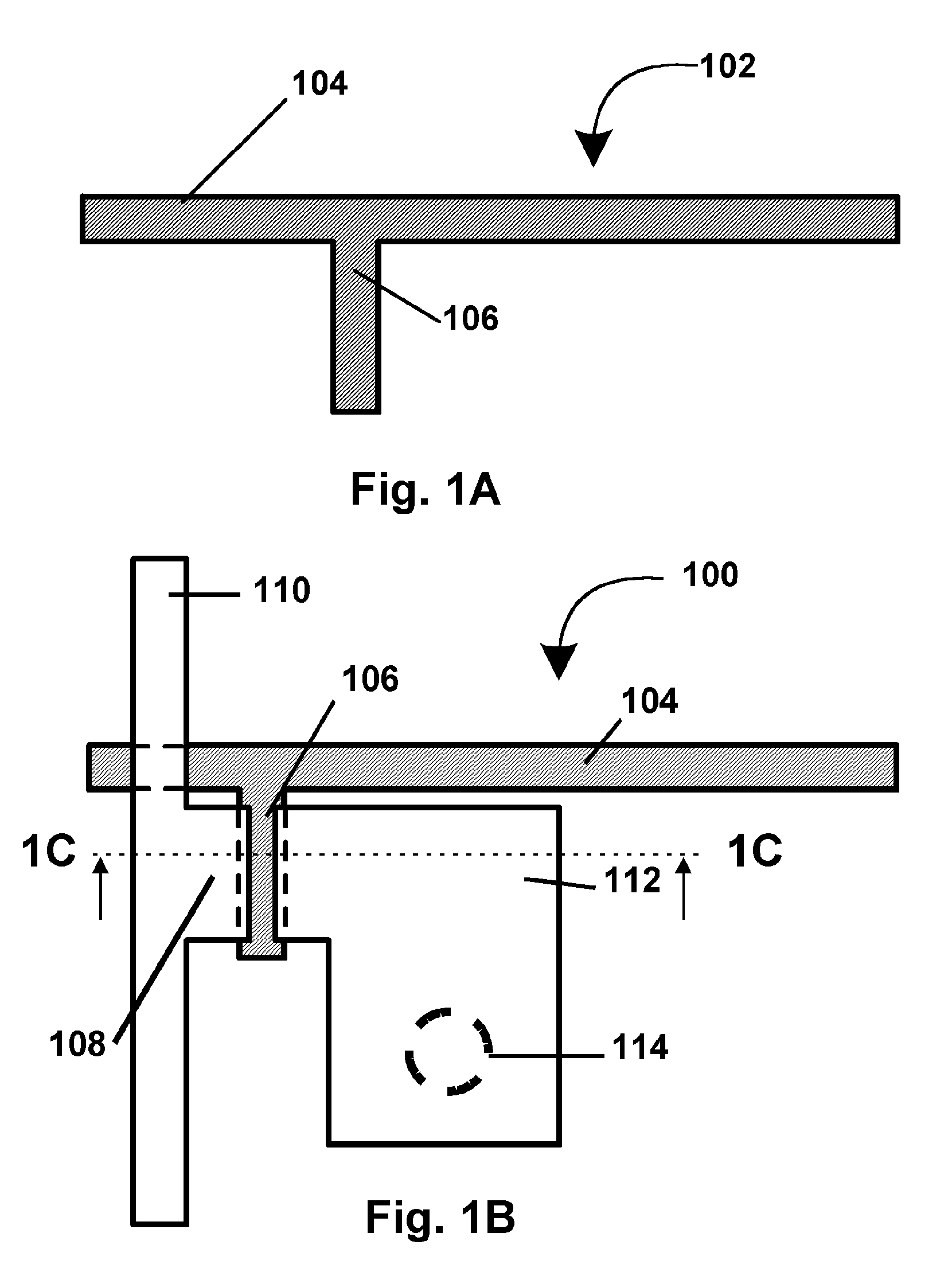

Illumination devices comprising white light emitting diodes and diode arrays and method and apparatus for making them

In accordance with the invention, an illumination device comprises a substrate having a surface and a cavity in the surface. At least one light emitting diode (“LED”) is mounted within the cavity, and a monolayer comprising phosphor particles overlies the LED. The phosphor monolayer is adhered to the LED by a monolayer of transparent adhesive material. An optional optical thick layer of transparent material overlies the phosphor monolayer to encapsulate the LED and optionally to form a lens. Methods and apparatus for efficiently making the devices are disclosed.

Owner:LIGHTING SCI GROUP

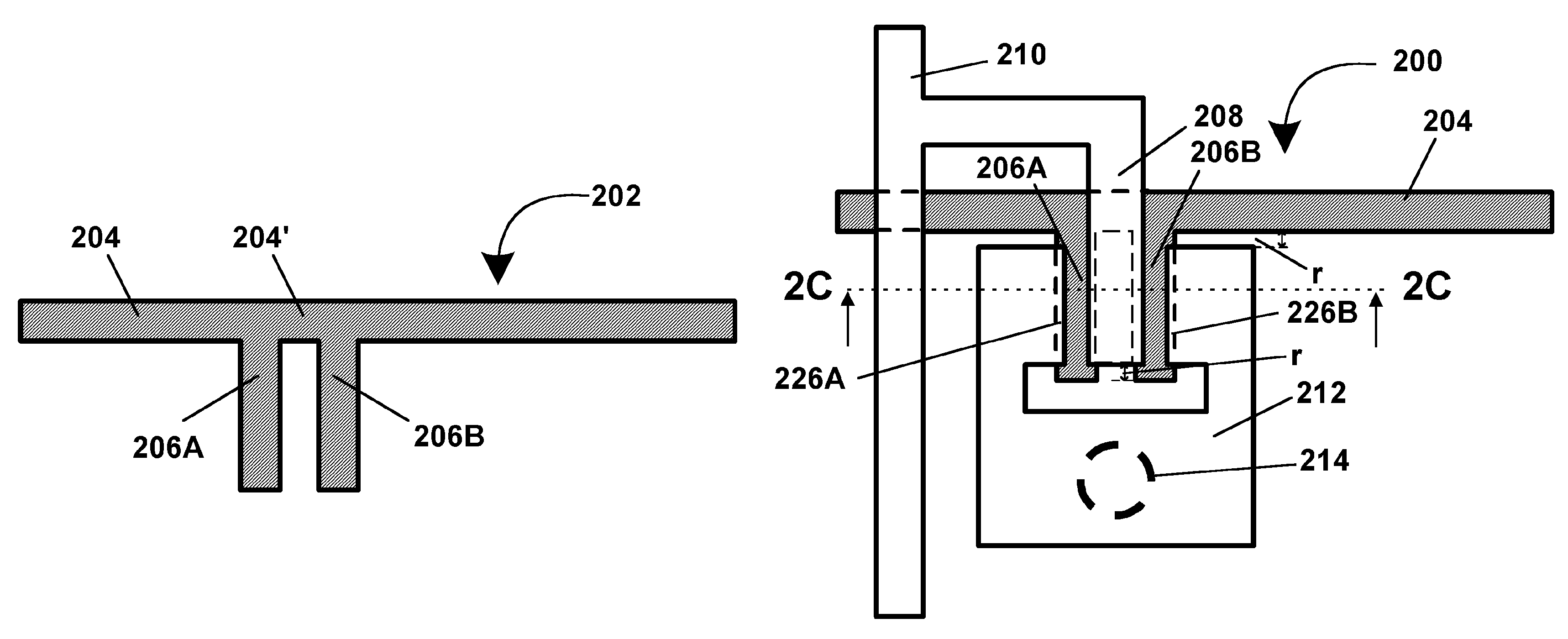

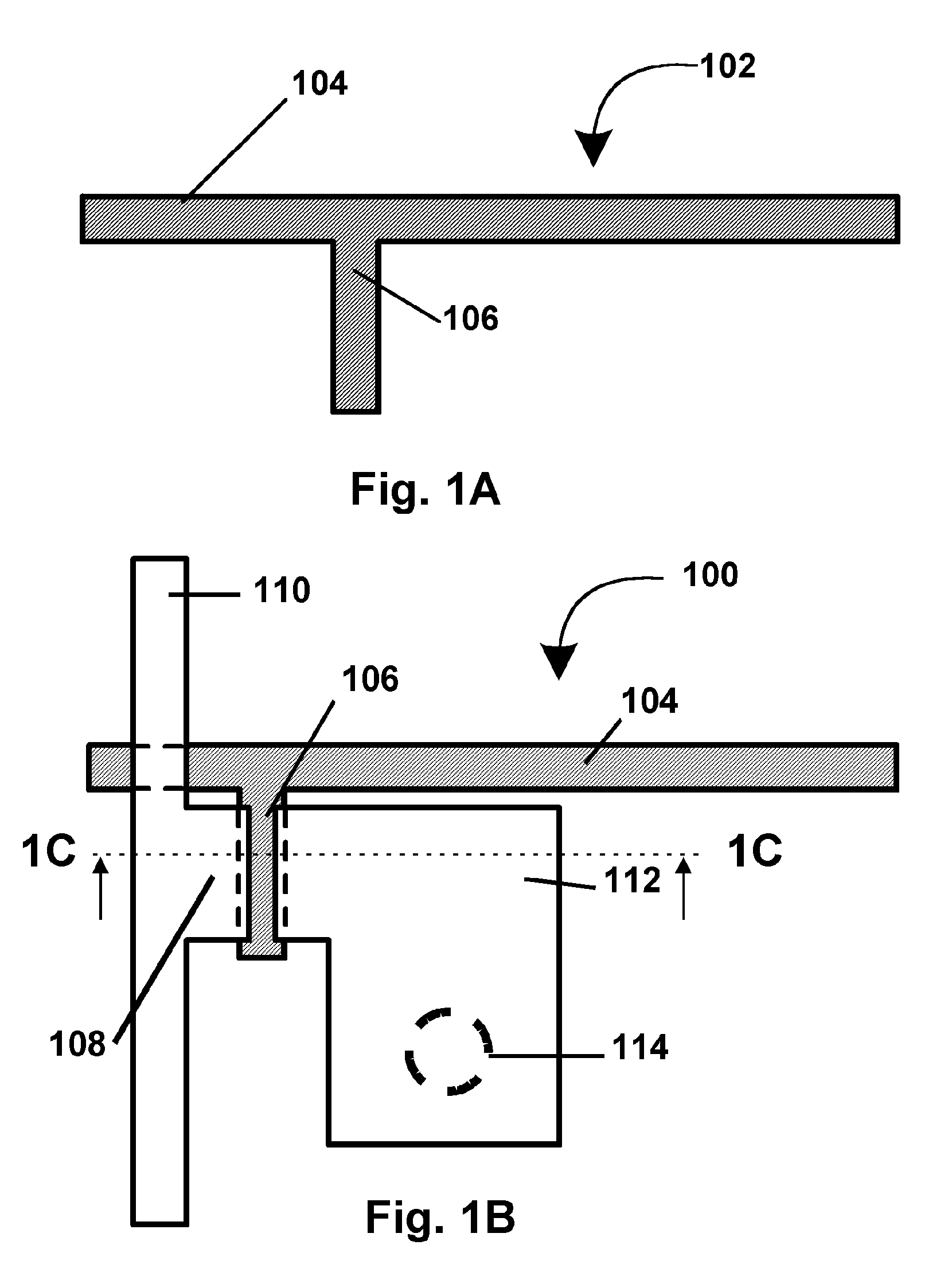

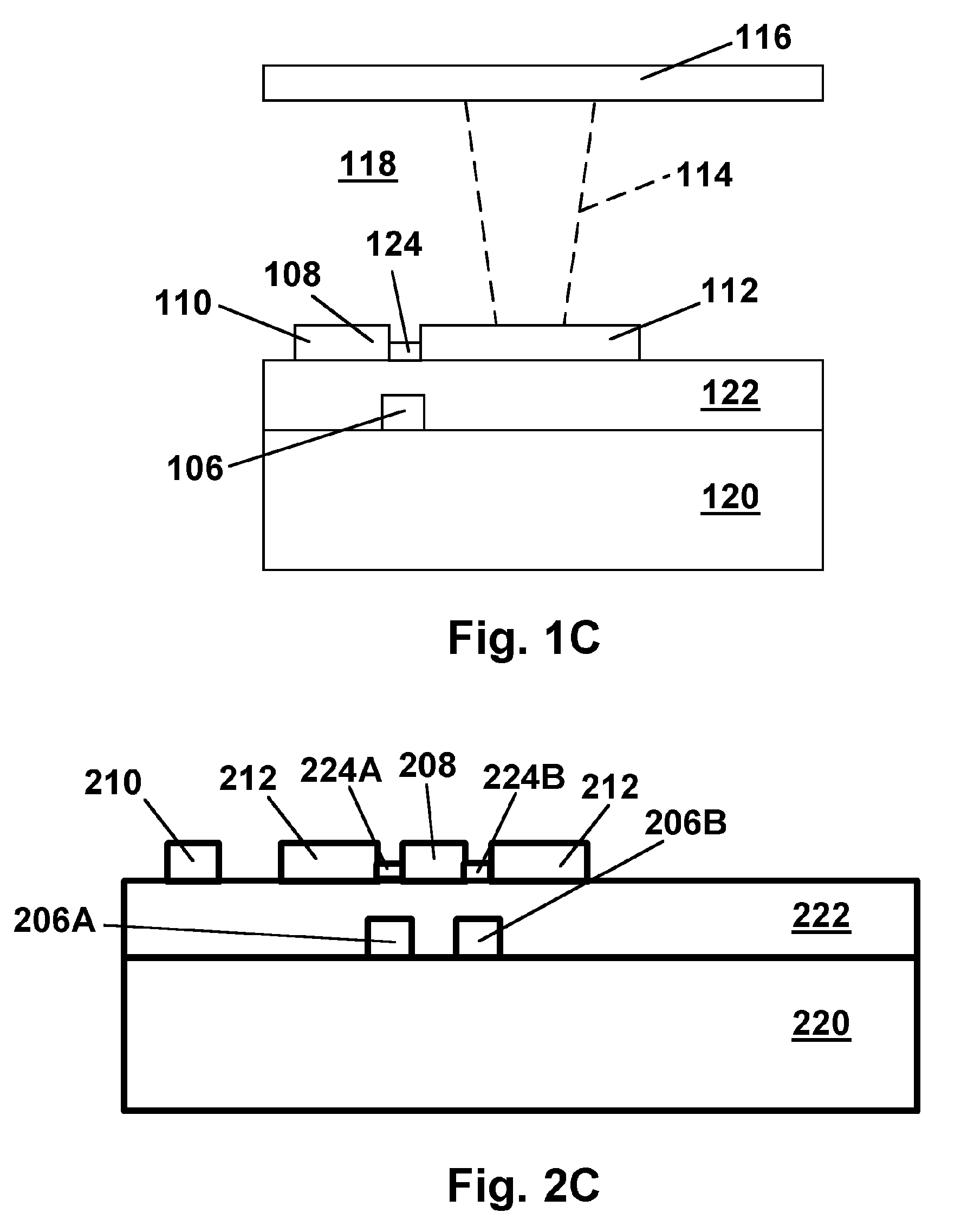

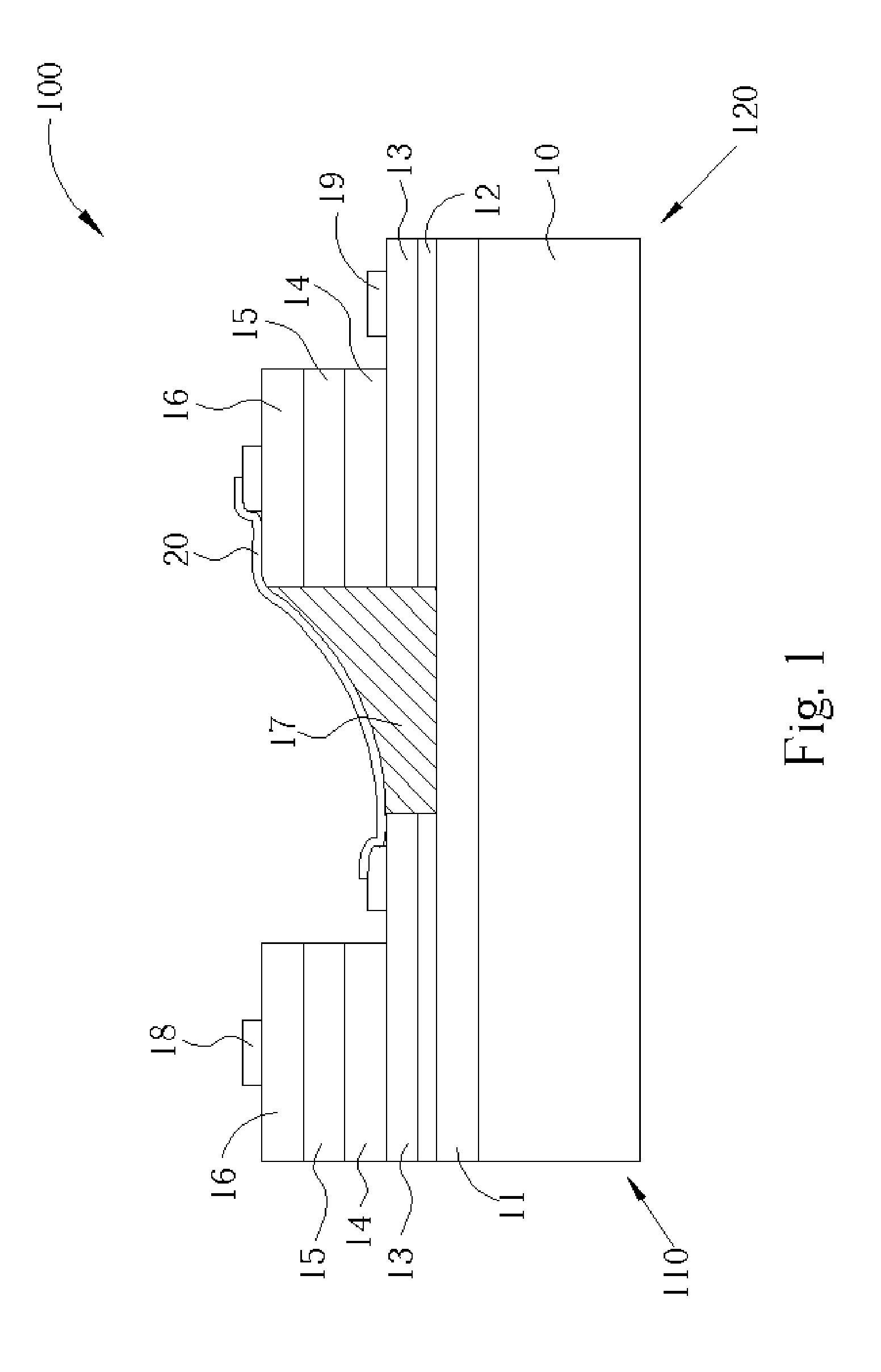

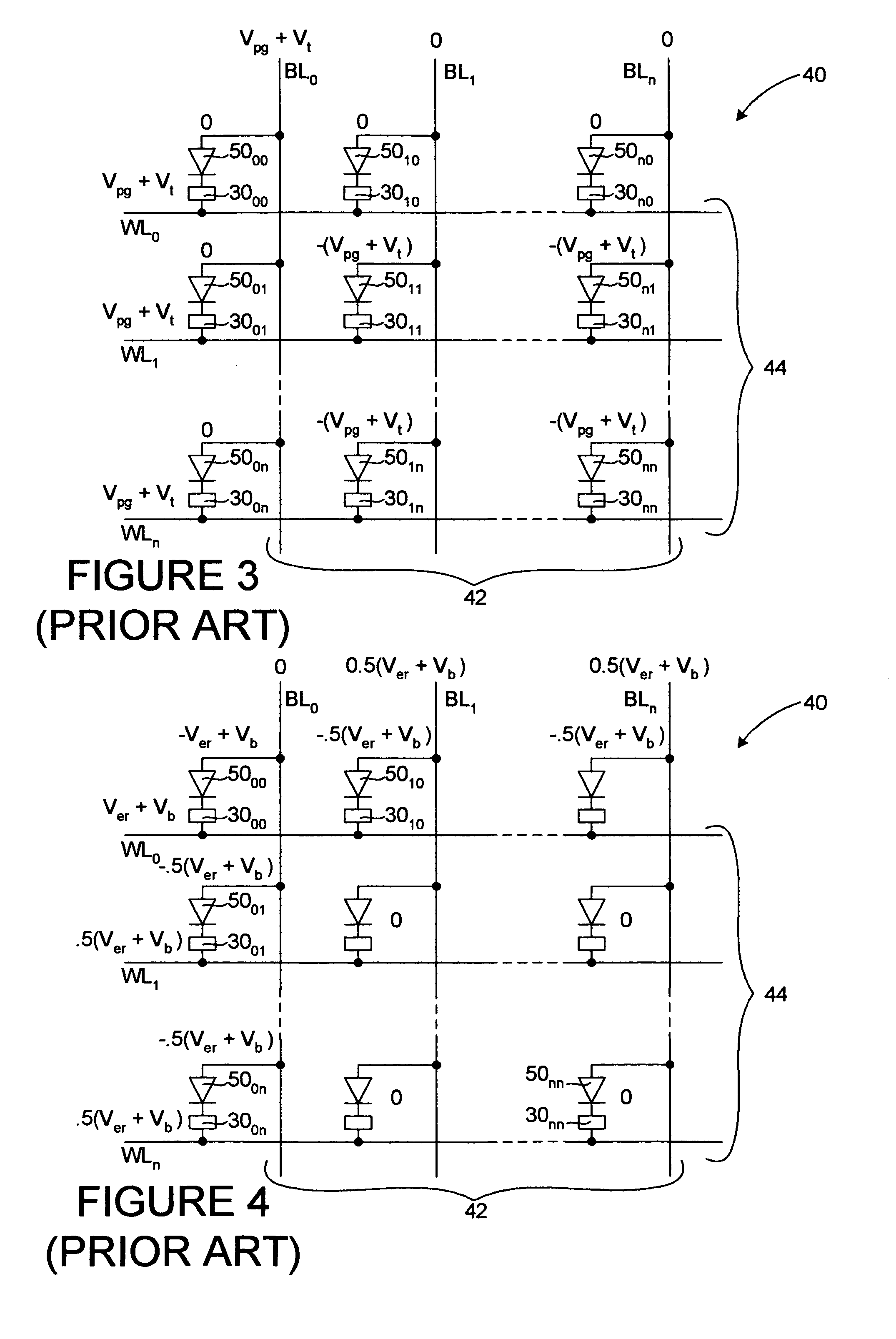

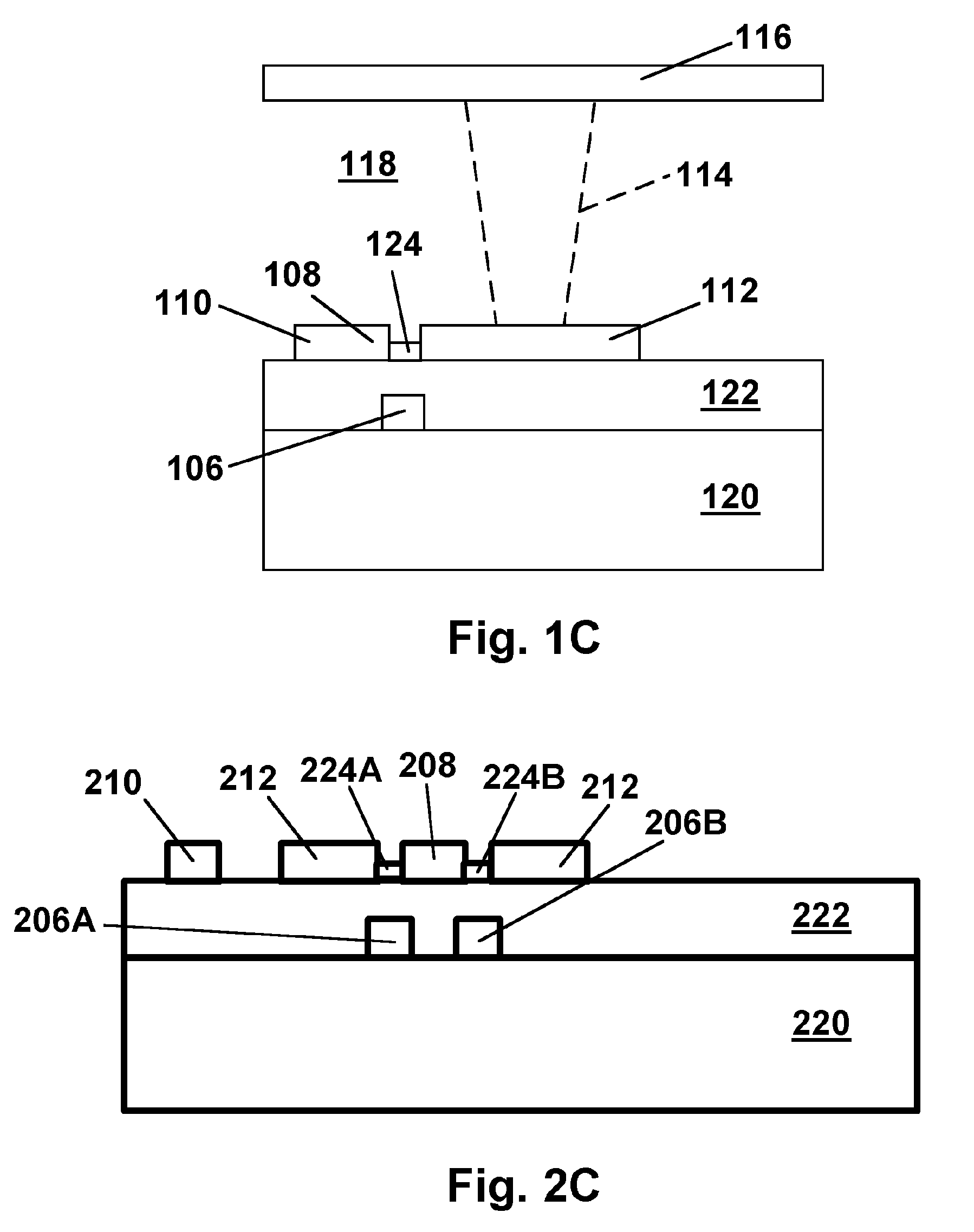

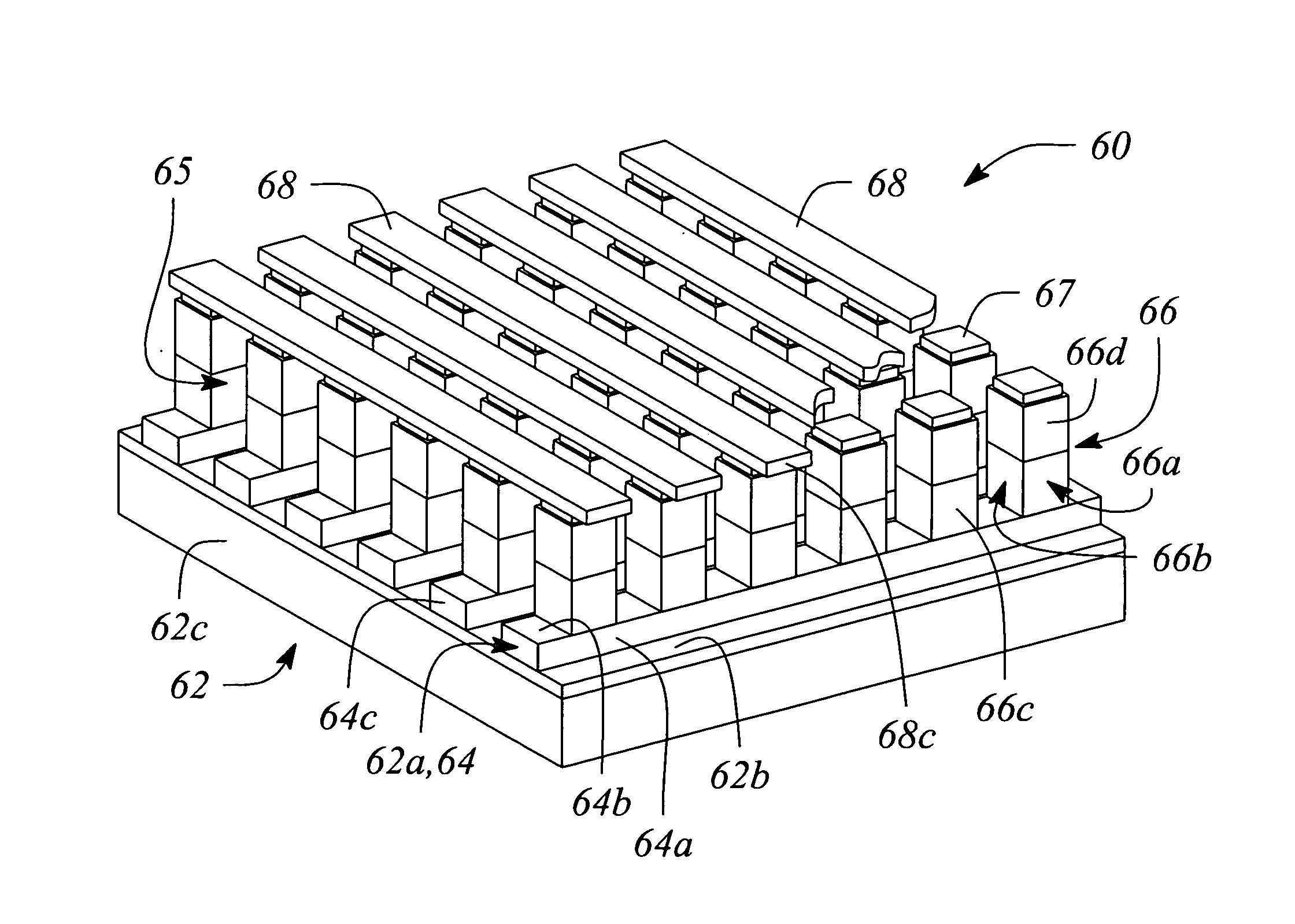

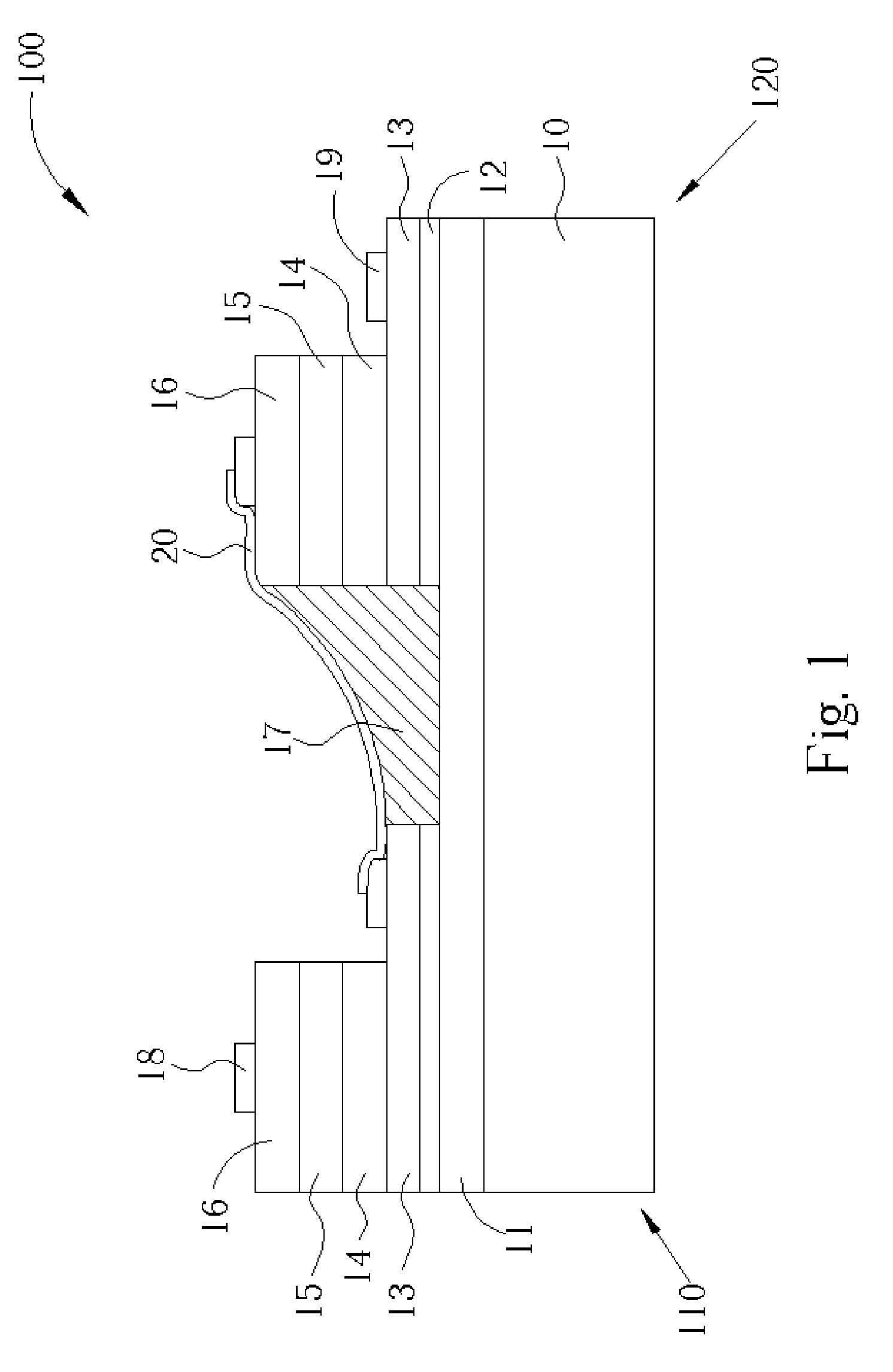

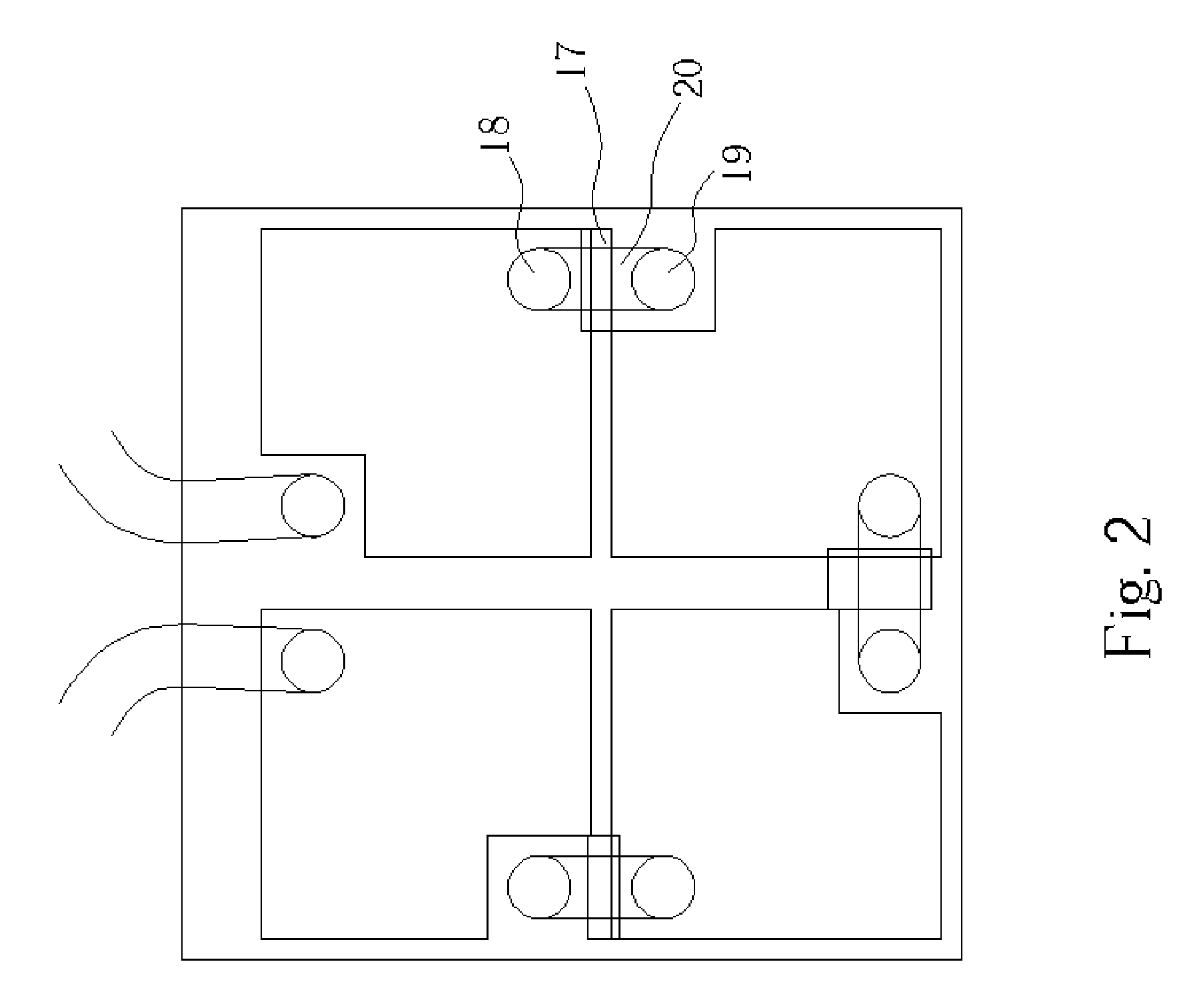

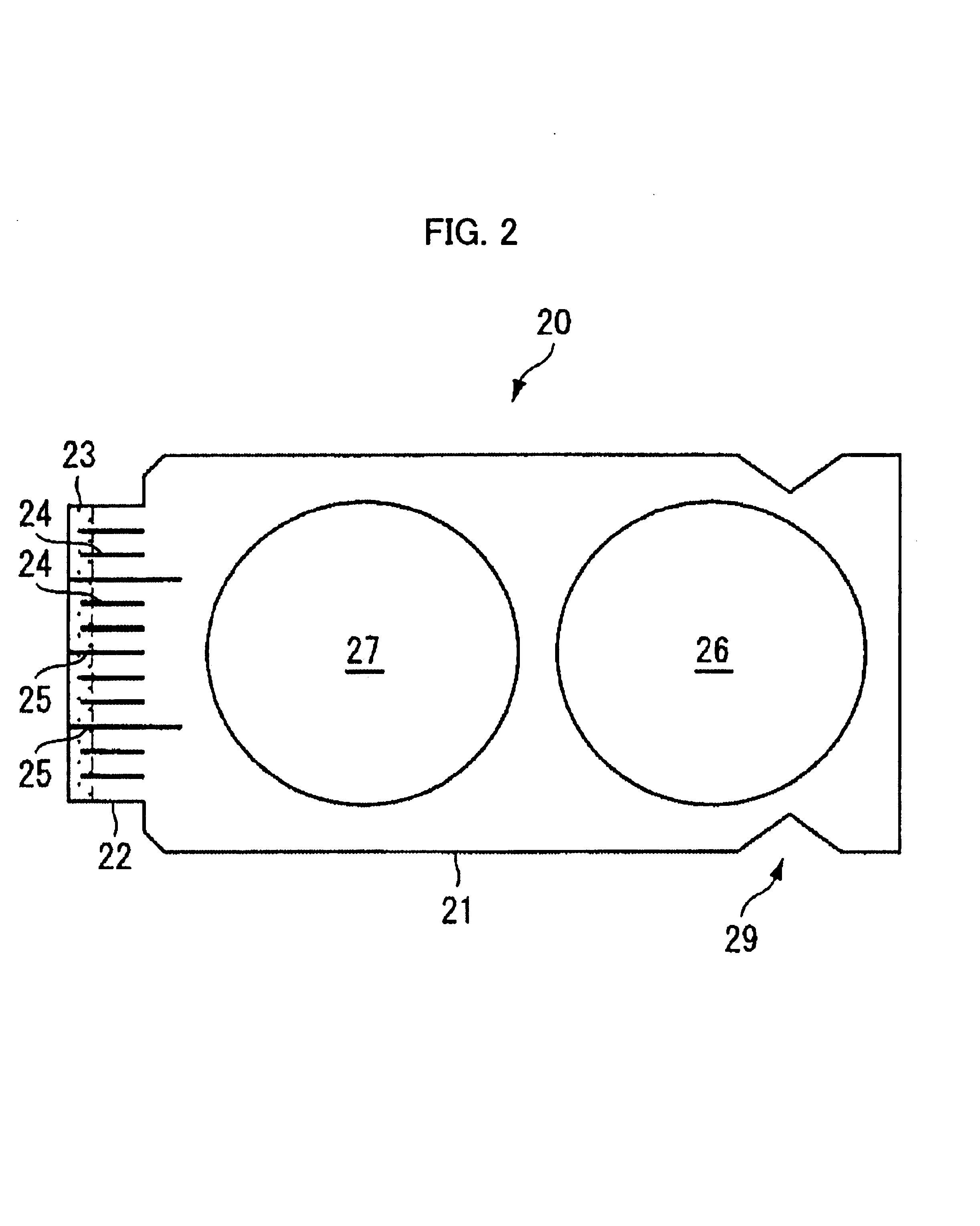

Backplanes for display applications, and components for use therein

InactiveUS7605799B2Slow changeLow cost manufacturingTransistorStatic indicating devicesCapacitanceDisplay device

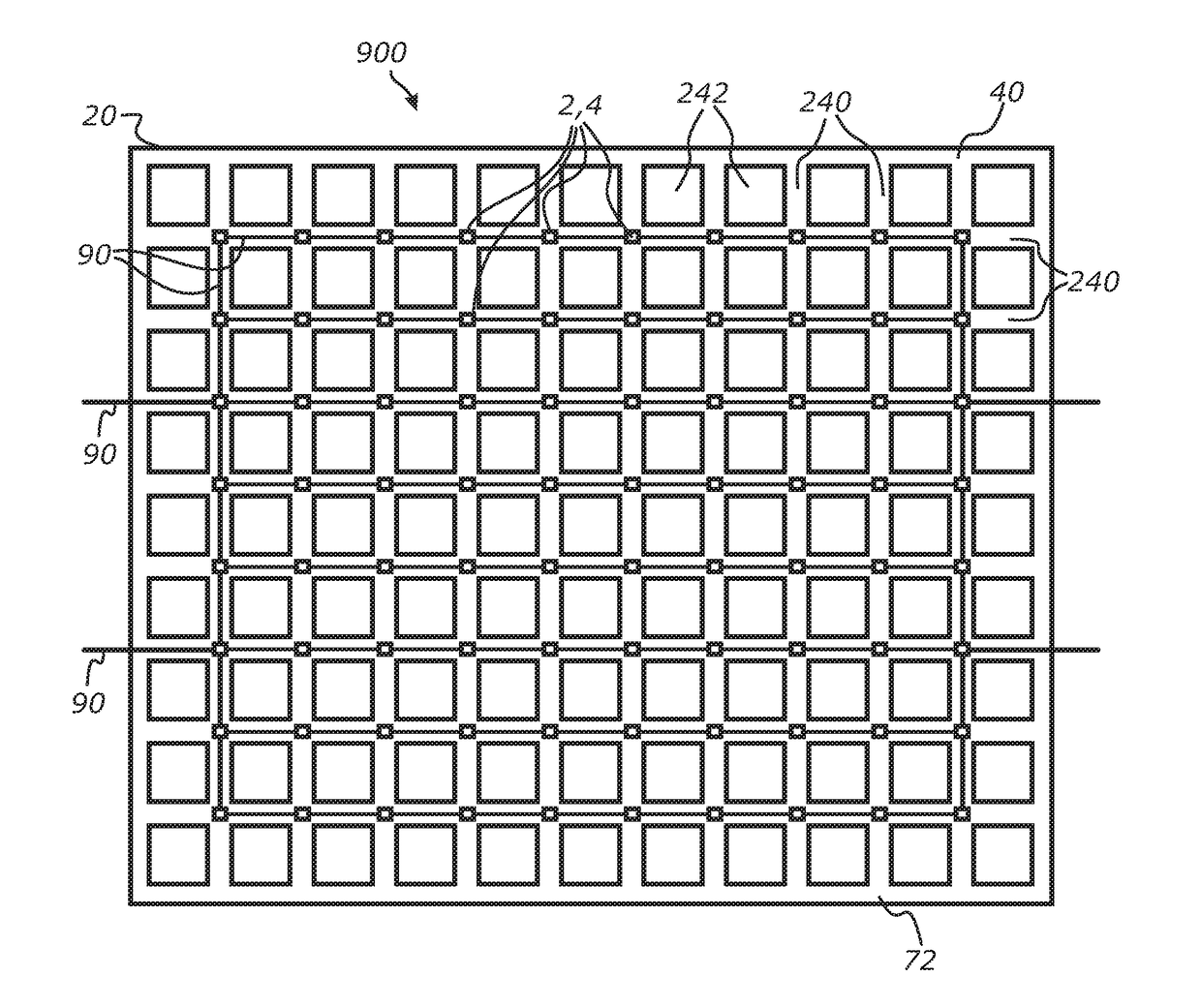

A thin-film transistor includes a gate electrode having first and second gate electrode edges on opposed sides, and a drain electrode having a first edge that overlaps the first gate electrode edge, and a second edge that overlaps the second gate electrode edge. A diode array is fabricated by successive deposition of a conductive layer, a doped semiconductor layer and an undoped semiconductor layer adjacent to the substrate. A display pixel unit provides reduced capacitative coupling between a pixel electrode and a source line. The source line includes an extension that provides a source for the transistor. A patterned conductive portion is disposed adjacent to the source line. Another display pixel unit provides reduced pixel electrode voltage shifts using a source line and a balance line.

Owner:E INK CORPORATION

Illumination devices comprising white light emitting diodes and diode arrays and method and apparatus for making them

ActiveUS7157745B2Solid-state devicesSemiconductor/solid-state device manufacturingPhosphorAdhesive materials

In accordance with the invention, an illumination device comprises a substrate having a surface and a cavity in the surface. At least one light emitting diode (“LED”) is mounted within the cavity, and a monolayer comprising phosphor particles overlies the LED. The phosphor monolayer is adhered to the LED by a monolayer of transparent adhesive material. An optional optical thick layer of transparent material overlies the phosphor monolayer to encapsulate the LED and optionally to form a lens. Methods and apparatus for efficiently making the devices are disclosed.

Owner:LIGHTING SCI GROUP

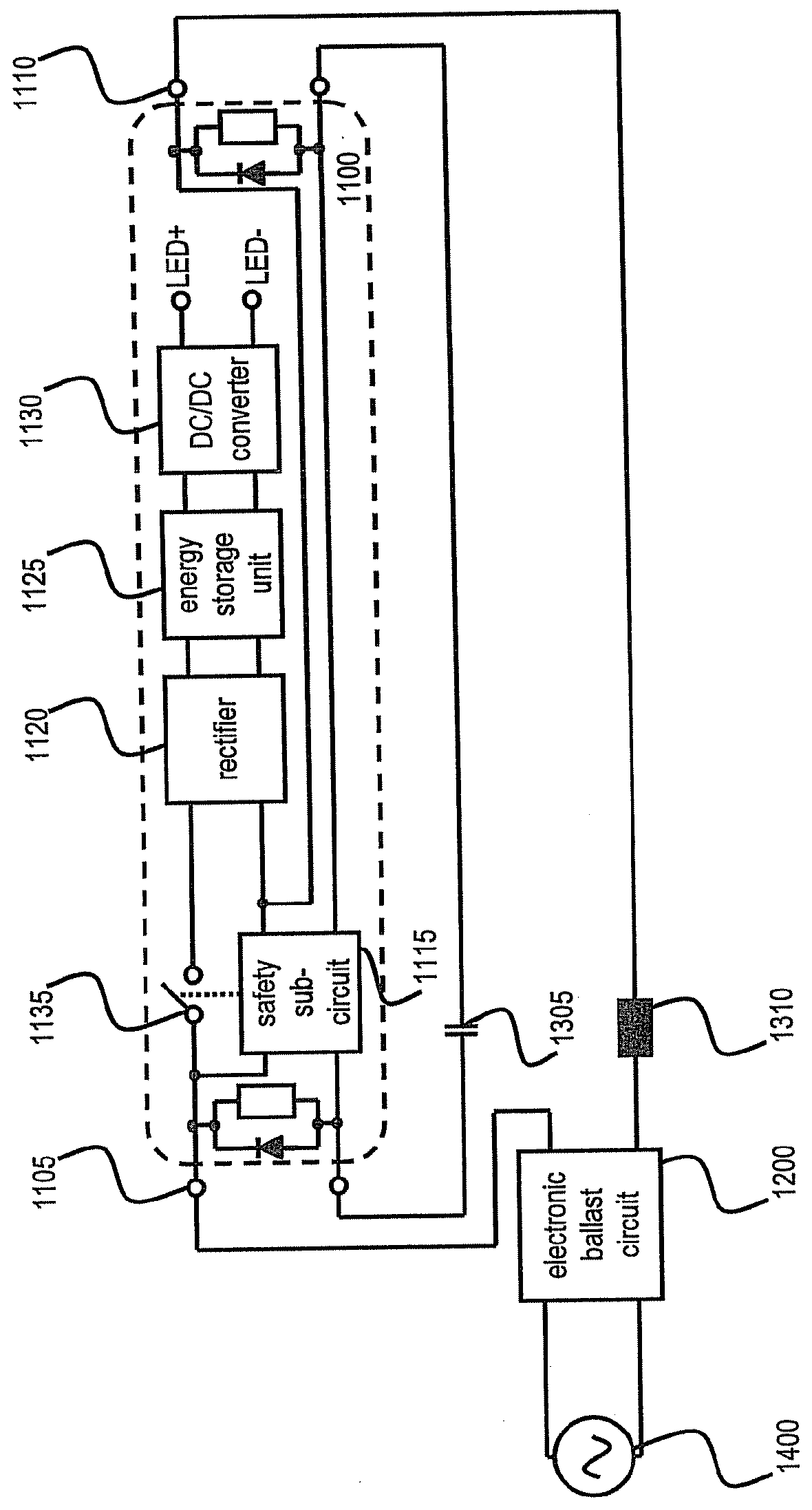

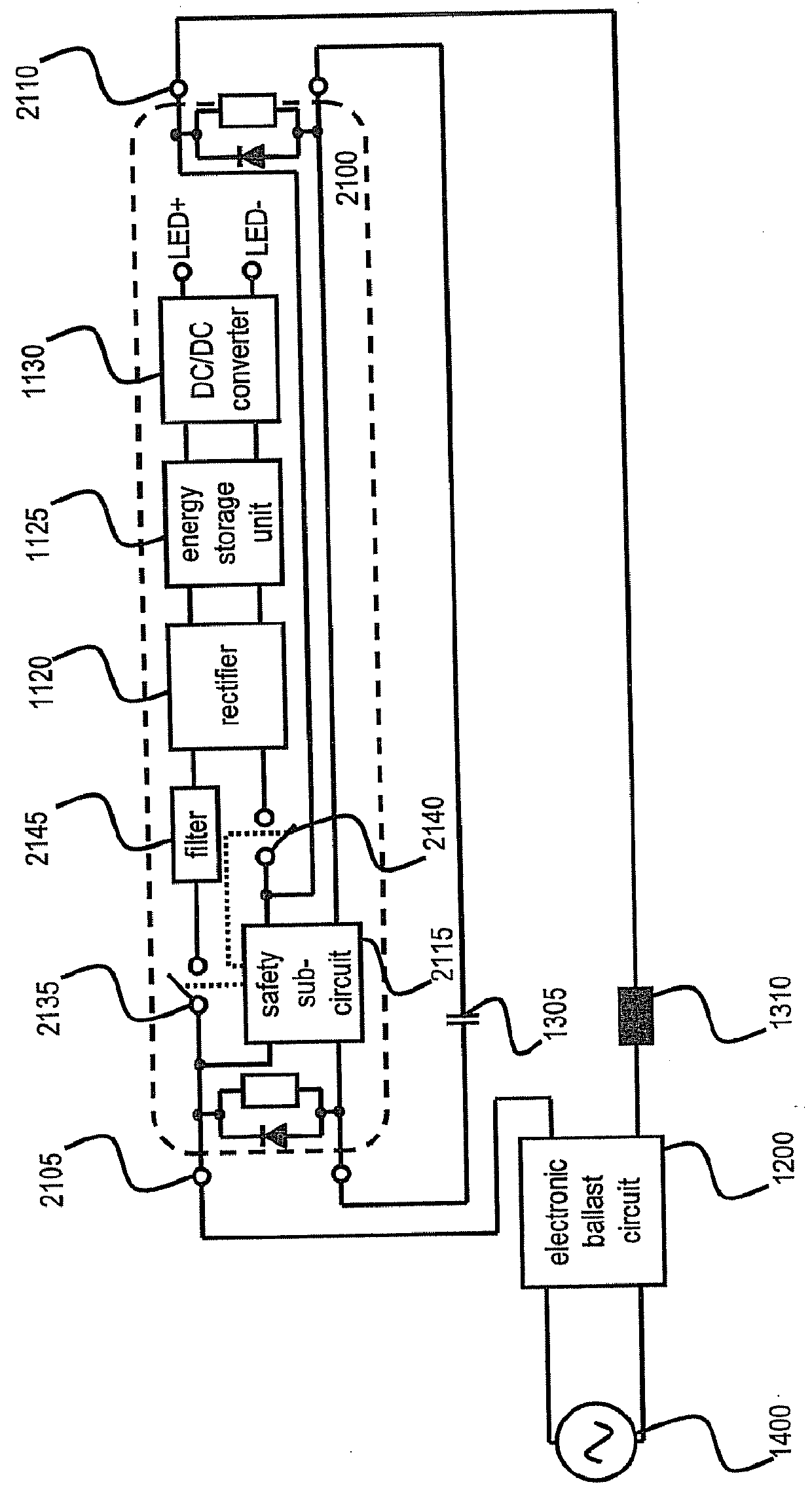

Drive circuit for light-emmiting diode array

InactiveUS20120181952A1Safe installationAvoid flowElectrical apparatusElectroluminescent light sourcesPower flowDc current

The invention relates to a drive circuit for driving an LED array. In order to allow driving the LED array based on an AC current supplied by an electronic ballast circuit for driving a fluorescent lighting device, the invention provides for a power supply sub-circuit converting the supplied AC current to a DC current and at least partially storing energy of the converted DC current for driving the LED array. Further, the power supply sub-circuit is connected / disconnected to / from at least one of first or second terminals in response to the presence / absence of the AC current supplied via a terminal of at least one of the first or second terminals. Accordingly, the power supply sub-circuit is connected to the first and second terminals only when the supplied AC current is simultaneously supplied via a terminal of each of the first and second pair of terminals.

Owner:ROEER NORBERT

Light-emitting diode array having an adhesive layer

ActiveUS20050224822A1Semiconductor/solid-state device detailsSolid-state devicesLight-emitting diodePhysics

A light-emitting diode array includes a substrate, an adhesive layer formed on the substrate, and a plurality of electrically connected epitaxial light-emitting stack layer disposed on the adhesive layer. Each of the epitaxial light-emitting stack layer has a P-contact and an N-contact coplanar to the P-contact. The light-emitting diode array has improved heat ventilation characteristics.

Owner:EPISTAR CORP

Solid state lighting device

InactiveUS20060038542A1Effectively white lightEffective lightingElectroluminescent light sourcesSolid-state devicesLow voltageEngineering

A light assembly for use with a low voltage power source. The light assembly semiconductor photo-emitters are electrically in series with a higher forward voltage drop than the associated low voltage power supply. To provide the necessary voltage the light assembly includes a current regulated step-up DC / DC converter. The semiconductor photo-emitters that are electrically in series are in the form of a monolithic light emitting diode array with a plurality of light emitting diode elements electrically and mechanically in series with a conductive, rigid bond region between the cathode region of the first light emitting diode element and the anode region of the second light emitting diode element. The first and second light emitting diode elements may differ in band gaps to emit different colors, that are additive to a non-primary color, such as white.

Owner:TESSERA INC

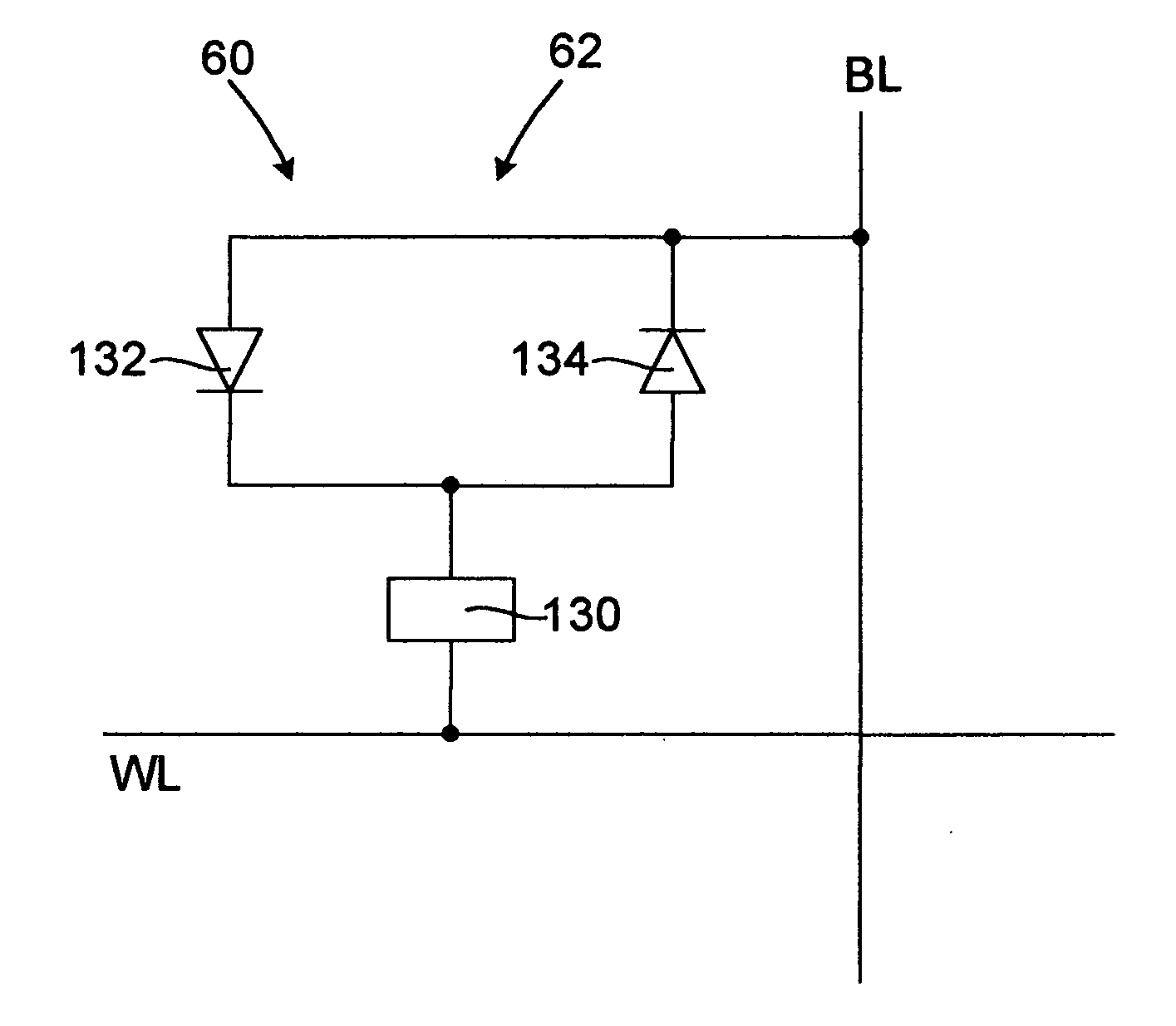

Diode array architecture for addressing nanoscale resistive memory arrays

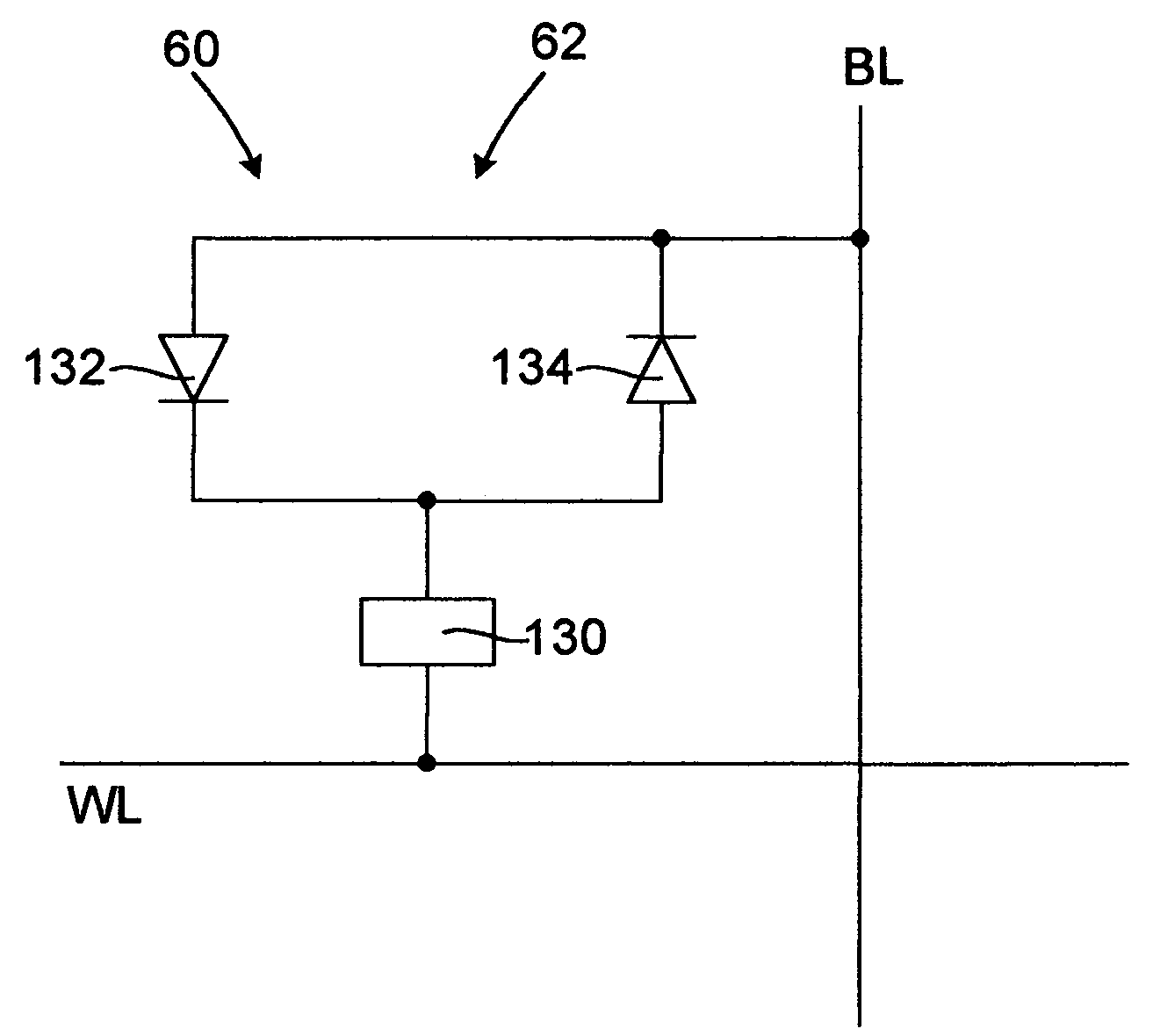

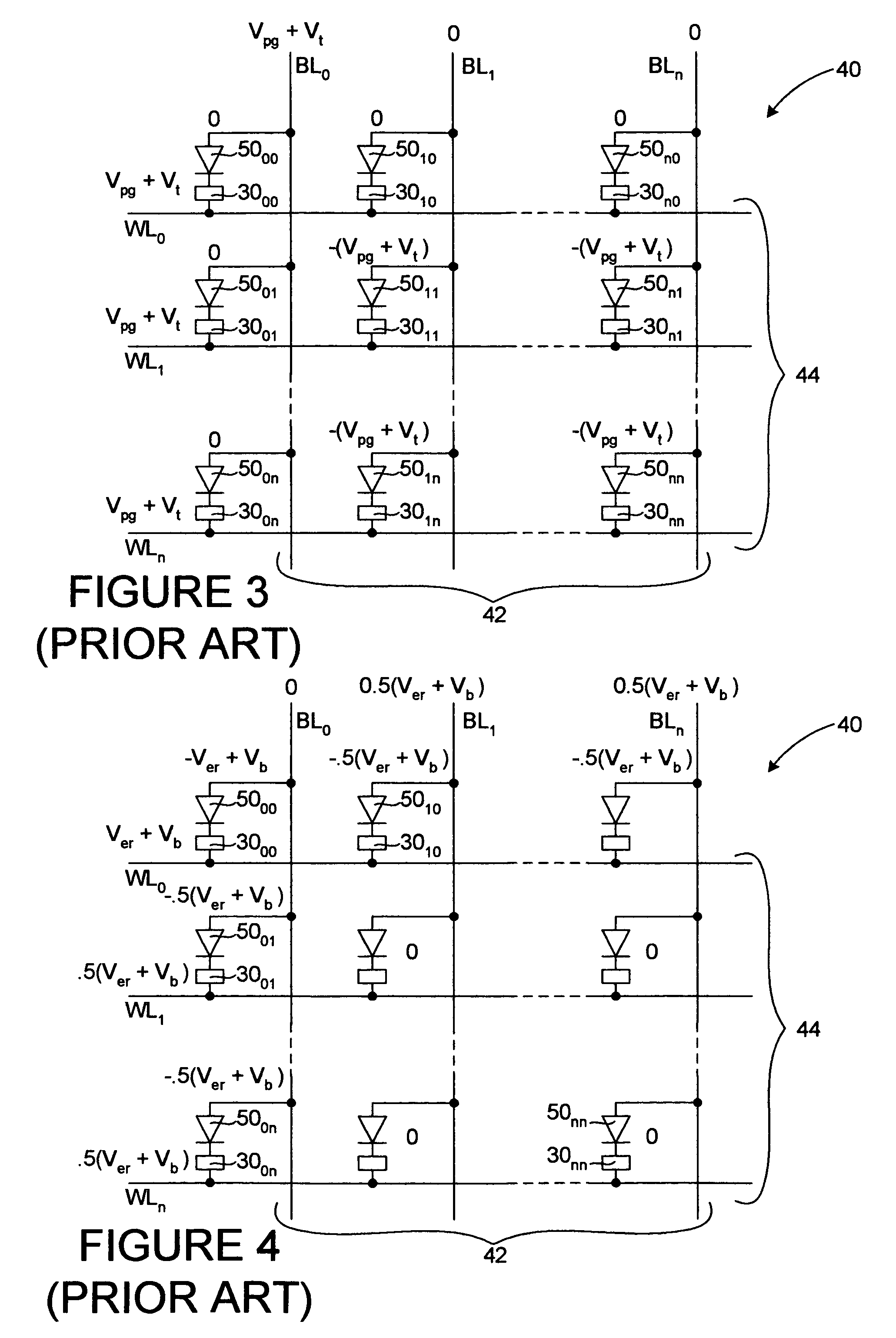

The present memory structure includes thereof a first conductor, a second conductor, a resistive memory cell connected to the second conductor, a first diode connected to the resistive memory cell and the first conductor, and oriented in the forward direction from the resistive memory cell to the first conductor, and a second diode connected to the resistive memory cell and the first conductor, in parallel with the first diode, and oriented in the reverse direction from the resistive memory cell to the first conductor. The first and second diodes have different threshold voltages

Owner:MONTEREY RES LLC

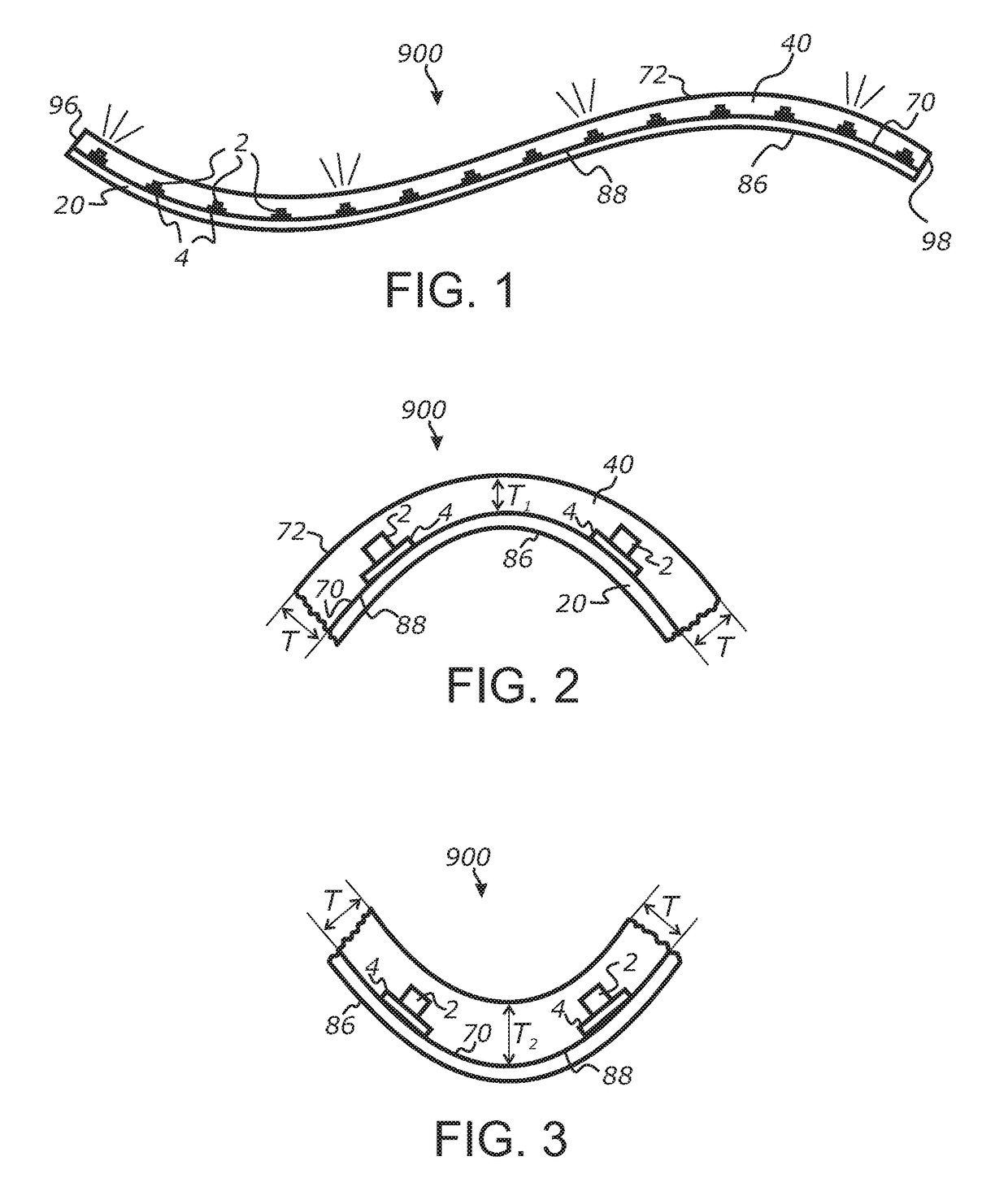

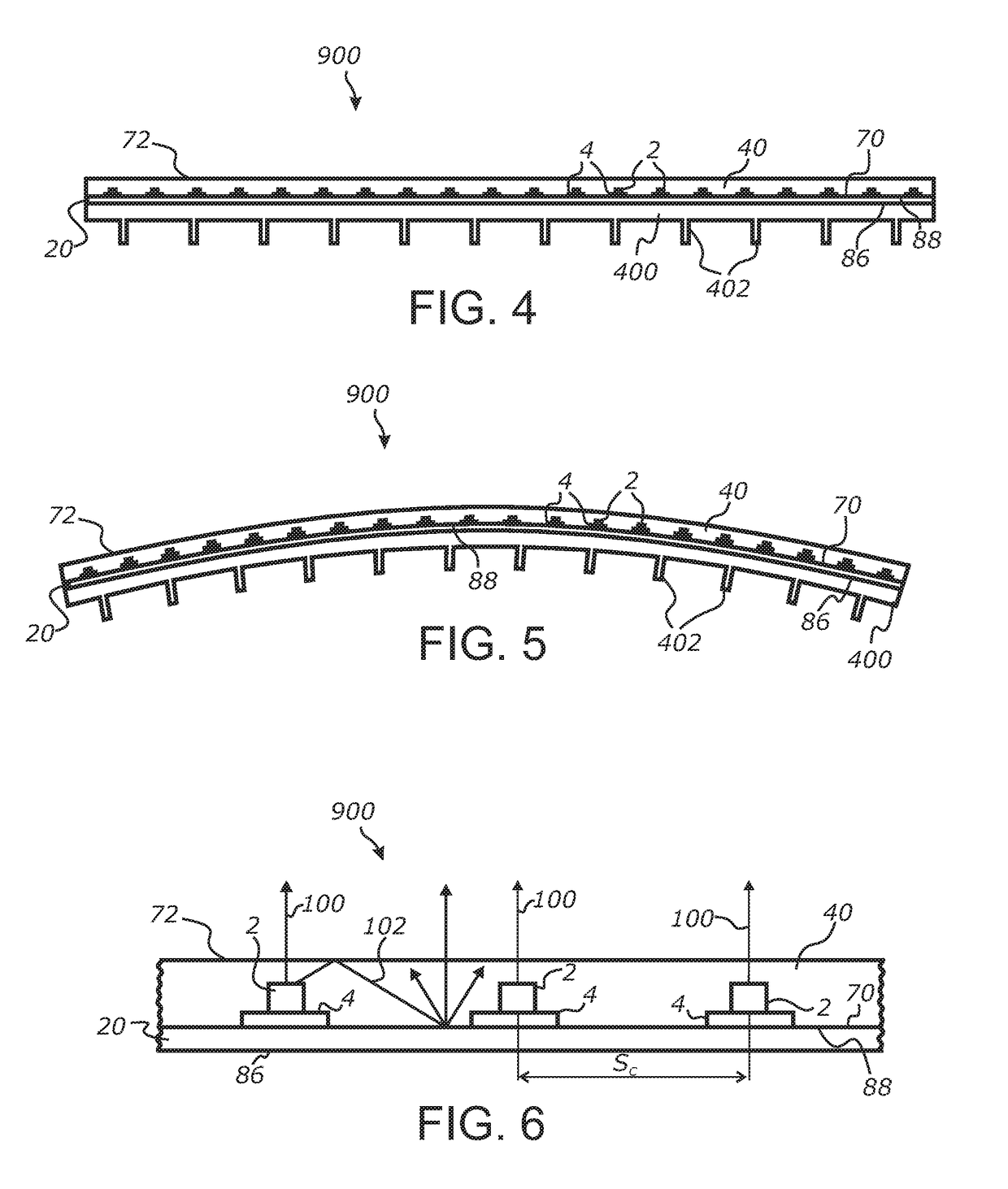

Flexible solid-state illumination devices

ActiveUS20170254518A1Increasing the thicknessPlanar light sourcesMechanical apparatusEngineeringSolid-state lighting

Owner:S V V TECH INNOVATIONS

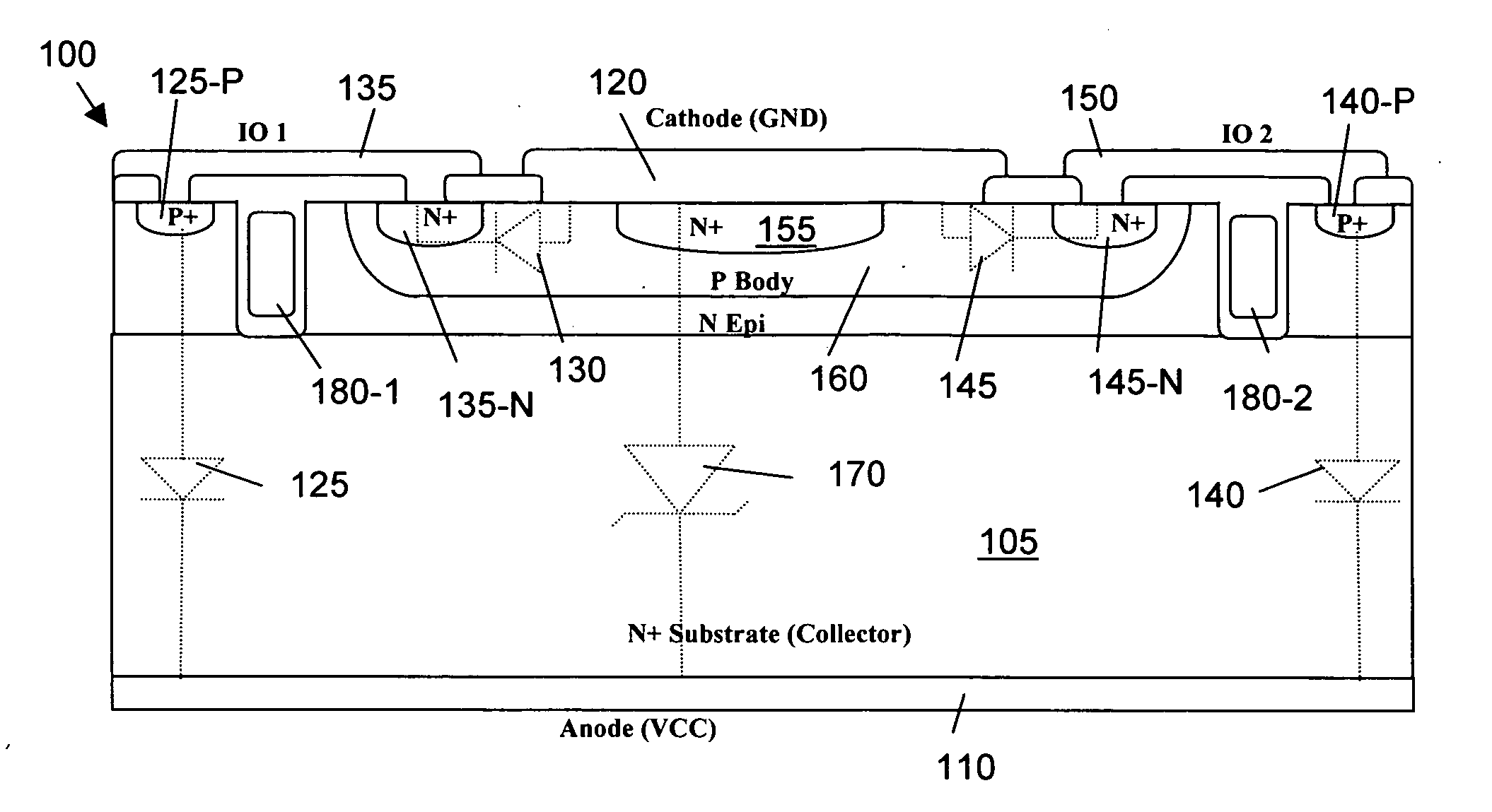

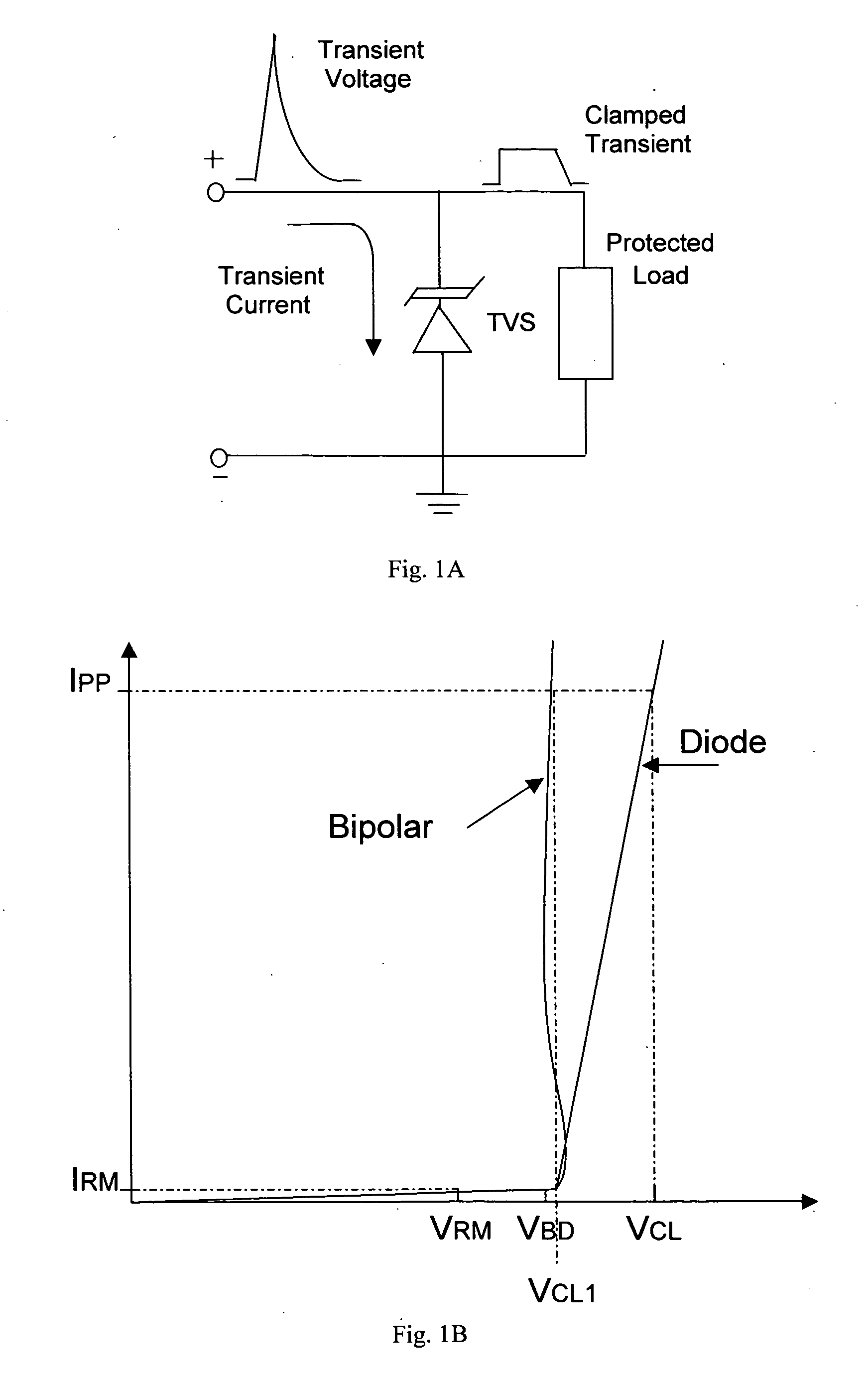

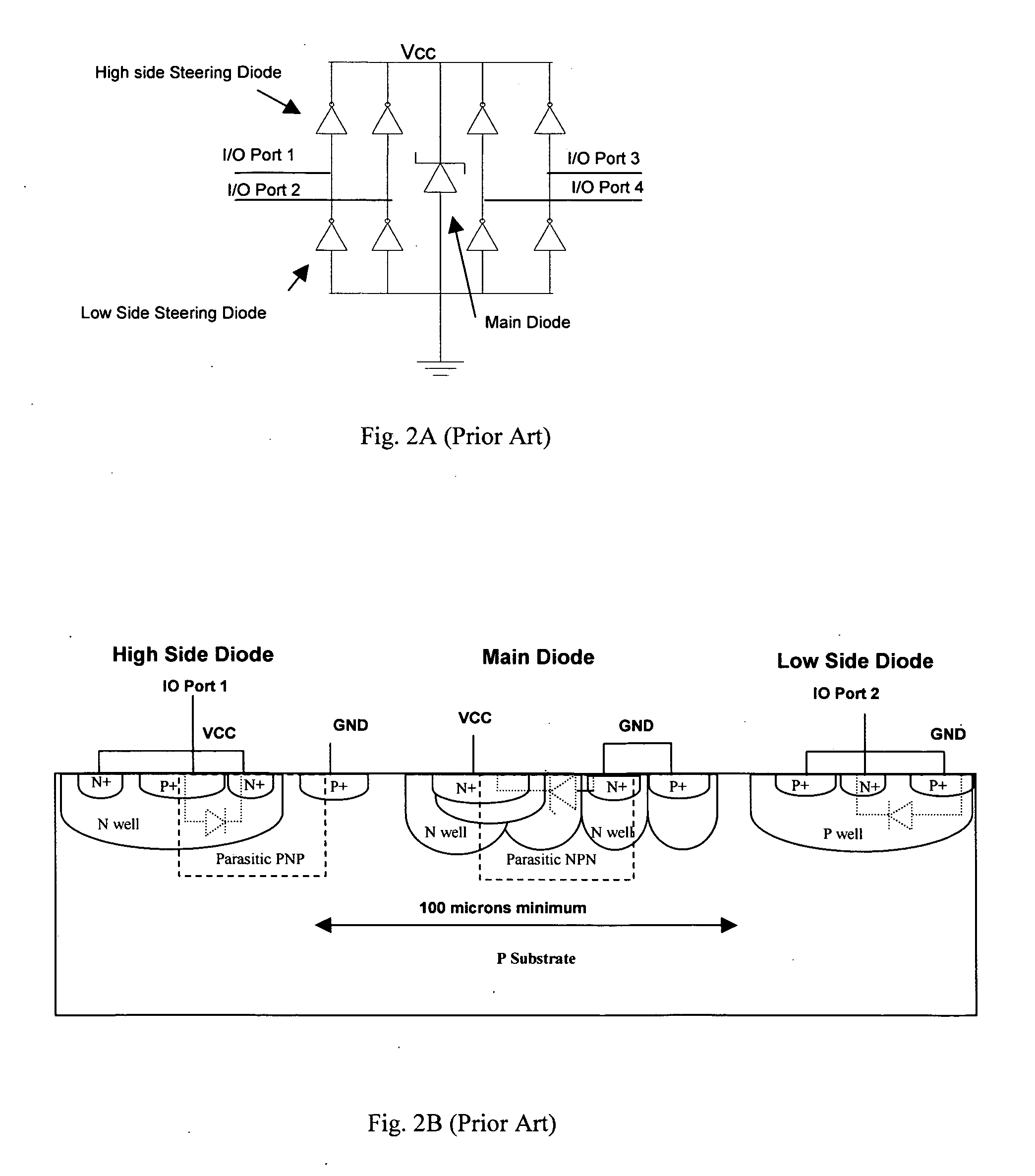

Latch-up free vertical TVS diode array structure using trench isolation

ActiveUS20070073807A1Lateral distanceReduce lateral distanceTransistorSemiconductor/solid-state device detailsEngineeringBody region

A method for manufacturing a transient voltage suppressing (TVS) array substantially following a manufacturing process for manufacturing a vertical semiconductor power device. The method includes a step of opening a plurality of isolation trenches in an epitaxial layer of a first conductivity type in a semiconductor substrate followed by applying a body mask for doping a body region having a second conductivity type between two of the isolation trenches. The method further includes a step of applying an source mask for implanting a plurality of doped regions of the first conductivity type constituting a plurality of diodes wherein the isolation trenches isolating and preventing parasitic PNP or NPN transistor due to a latch-up between the doped regions of different conductivity types.

Owner:ALPHA & OMEGA SEMICON LTD

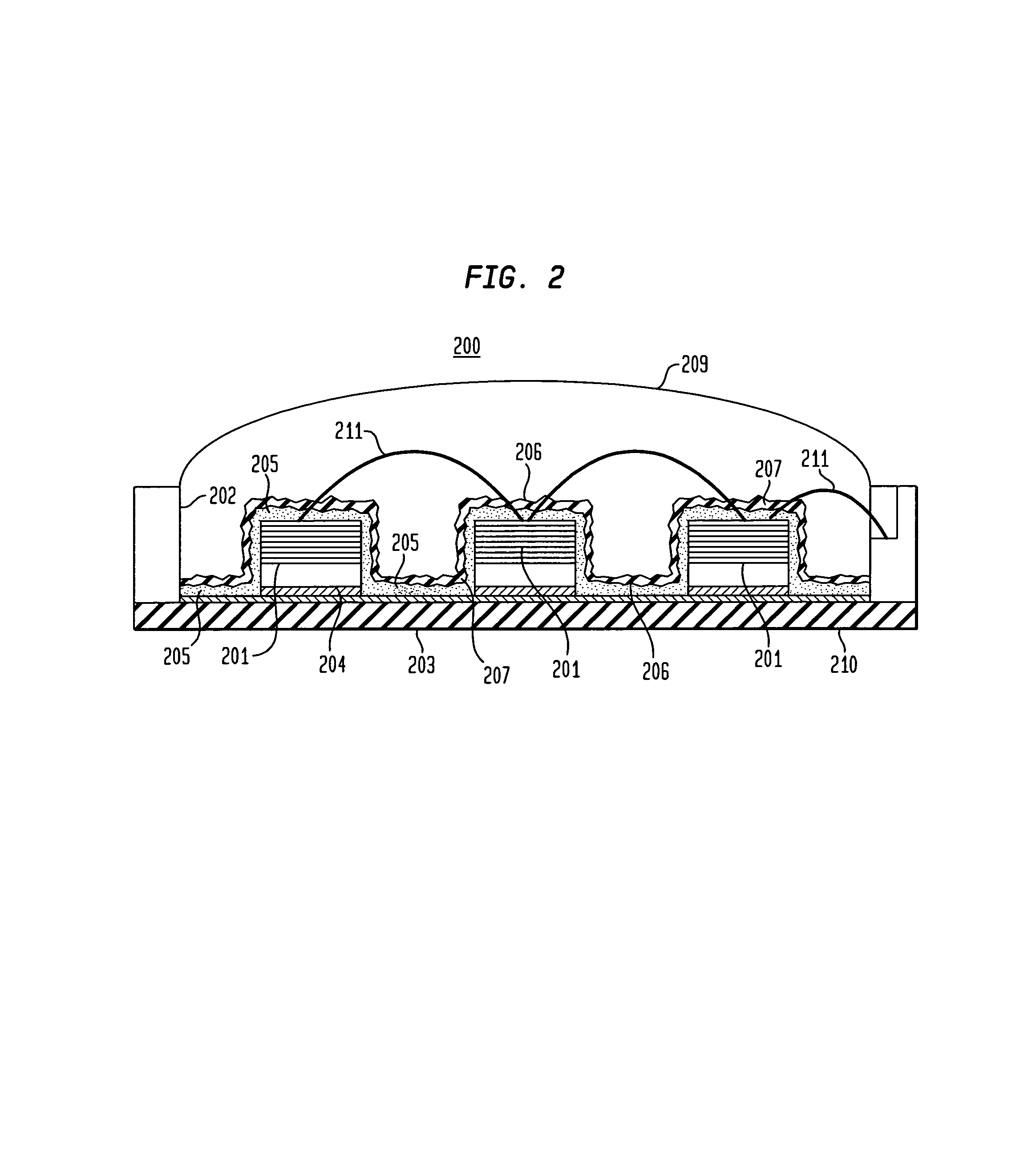

Light emitting diode arrays with improved light extraction

InactiveUS20050225222A1Discharge tube luminescnet screensElectric discharge tubesLight-emitting diodeMetal

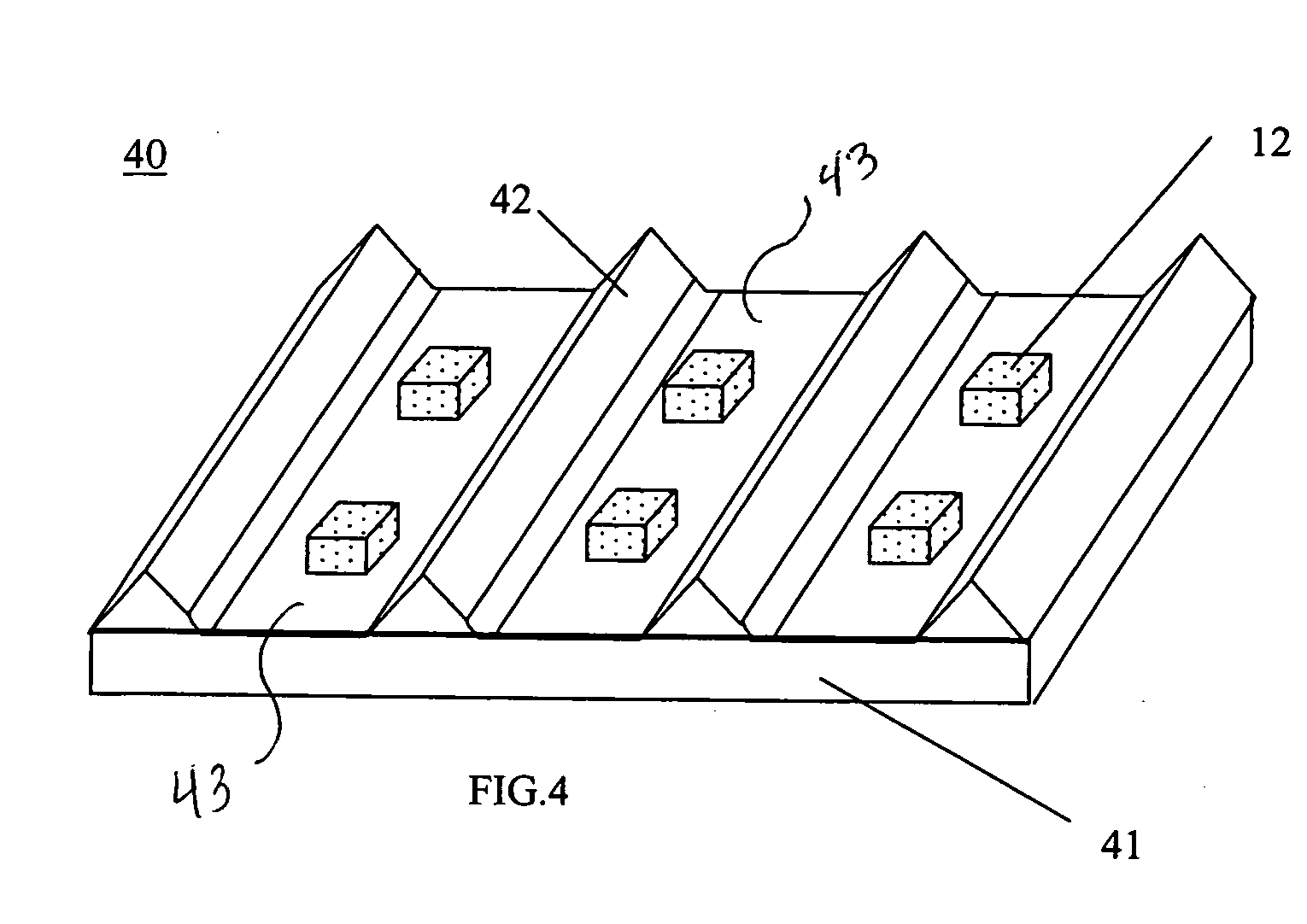

In accordance with the invention, an illumination device comprises a highly thermally conductive substrate having a surface, a plurality of light emitting diodes (LEDs) supported by the surface and arranged in an array to provide illumination. At least one reflective barrier at least partially surrounds each LED. The reflective barrier is shaped to reflect away from the LED light emitted by other LEDs in the array. Advantageously the substrate and reflective barrier are thermally coupled to a heat spreader to dissipate heat generated by the LEDs. The substrate preferably comprises an LTTC-M heat spreader, and the reflective thermal barriers preferably comprise metal ridges or cups.

Owner:LAMINA CERAMICS

Diode array architecture for addressing nanoscale resistive memory arrays

The present memory structure includes thereof a first conductor, a second conductor, a resistive memory cell connected to the second conductor, a first diode connected to the resistive memory cell and the first conductor, and oriented in the forward direction from the resistive memory cell to the first conductor, and a second diode connected to the resistive memory cell and the first conductor, in parallel with the first diode, and oriented in the reverse direction from the resistive memory cell to the first conductor. The first and second diodes have different threshold voltages.

Owner:MONTEREY RES LLC

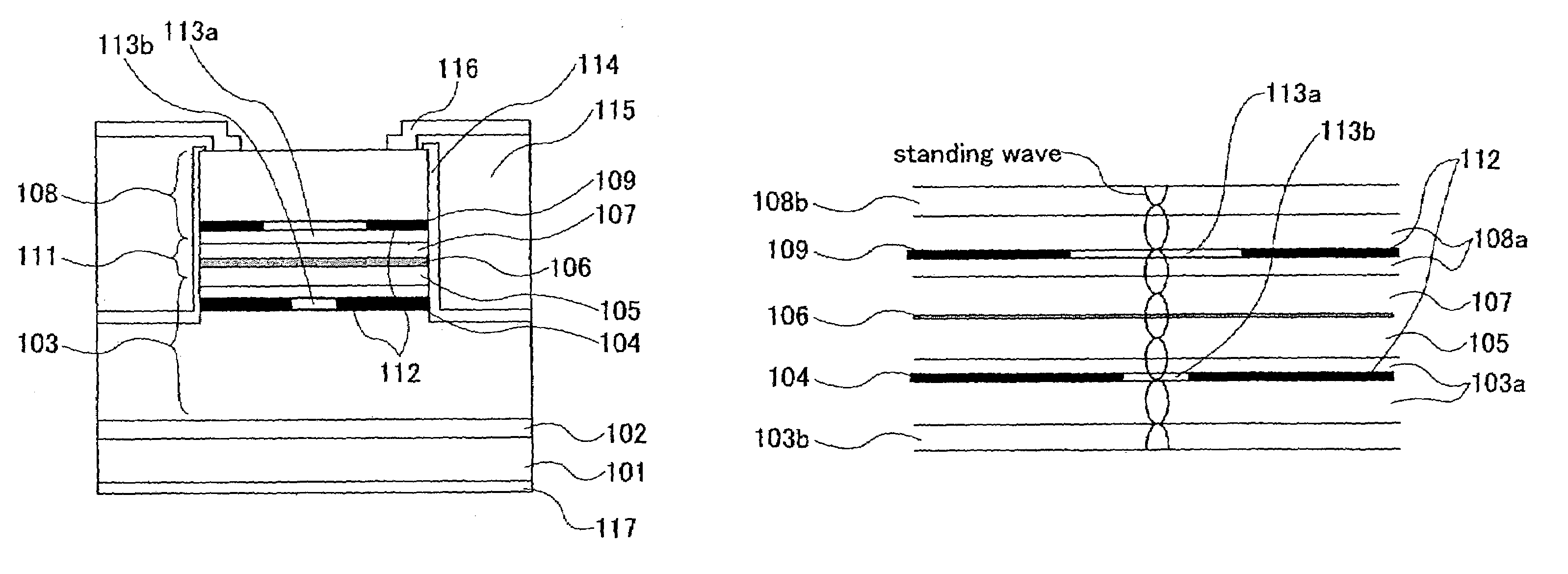

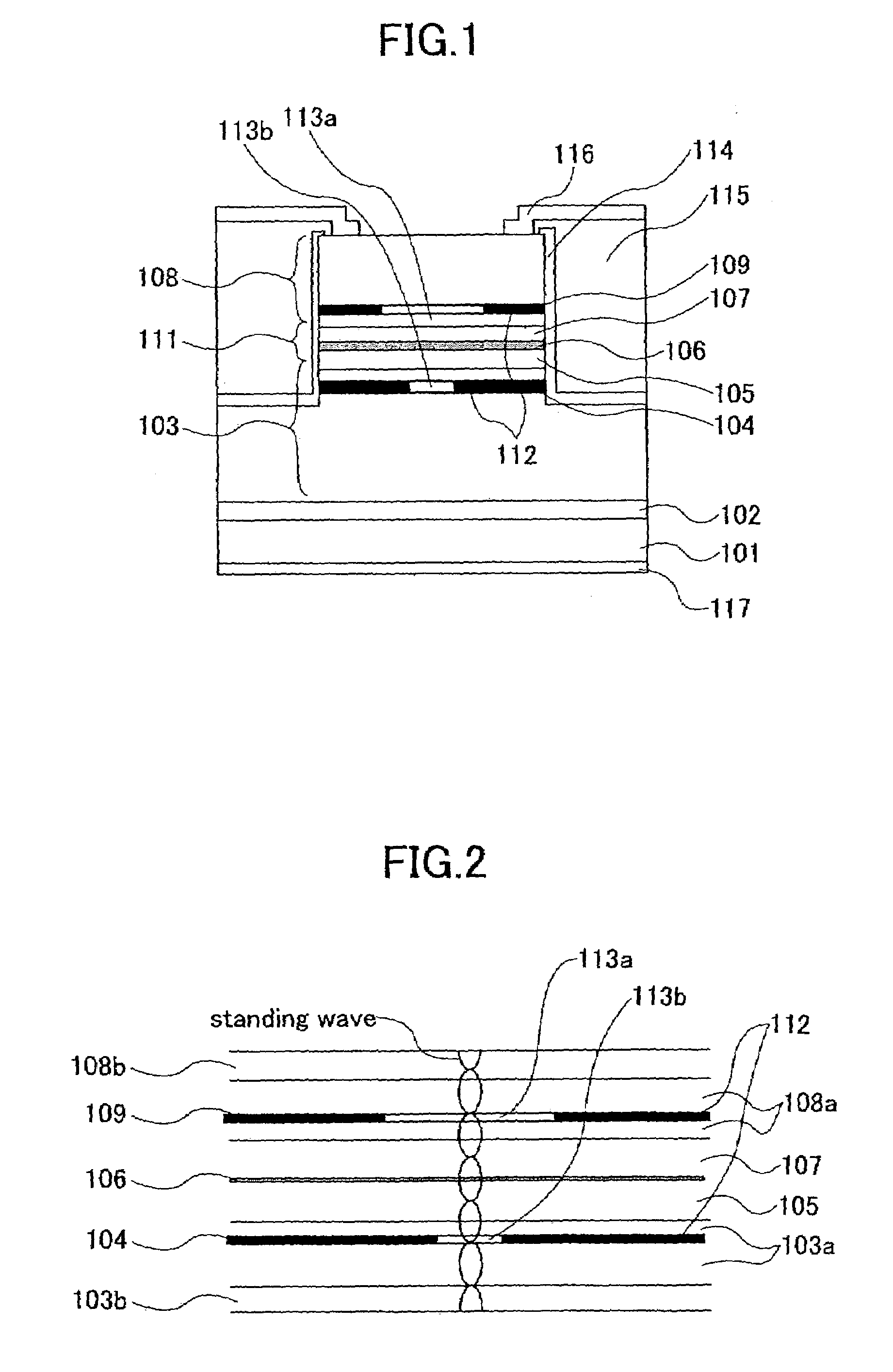

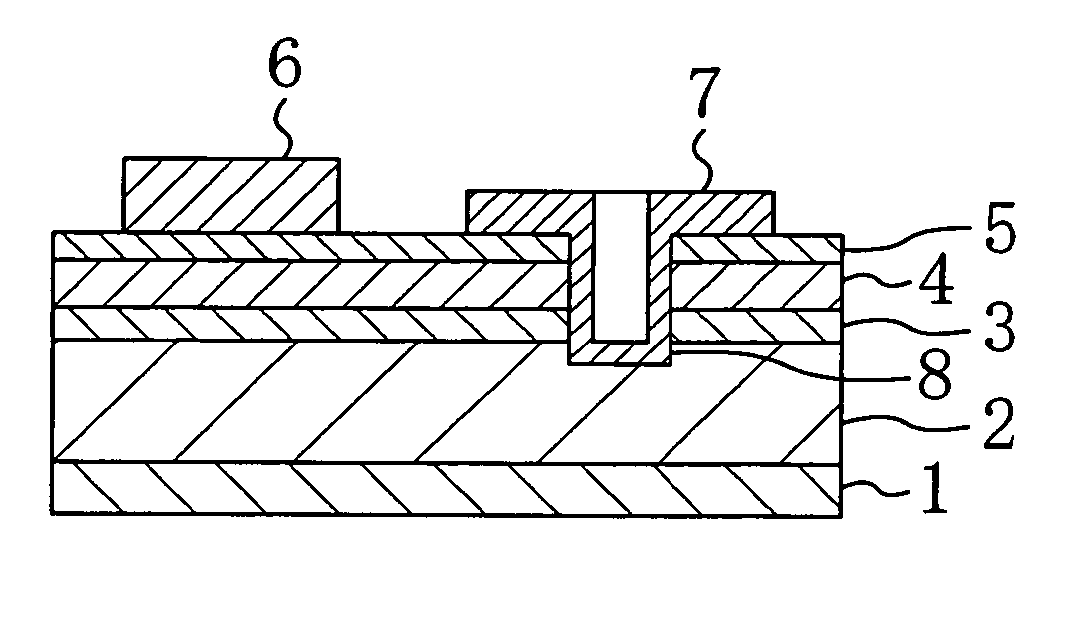

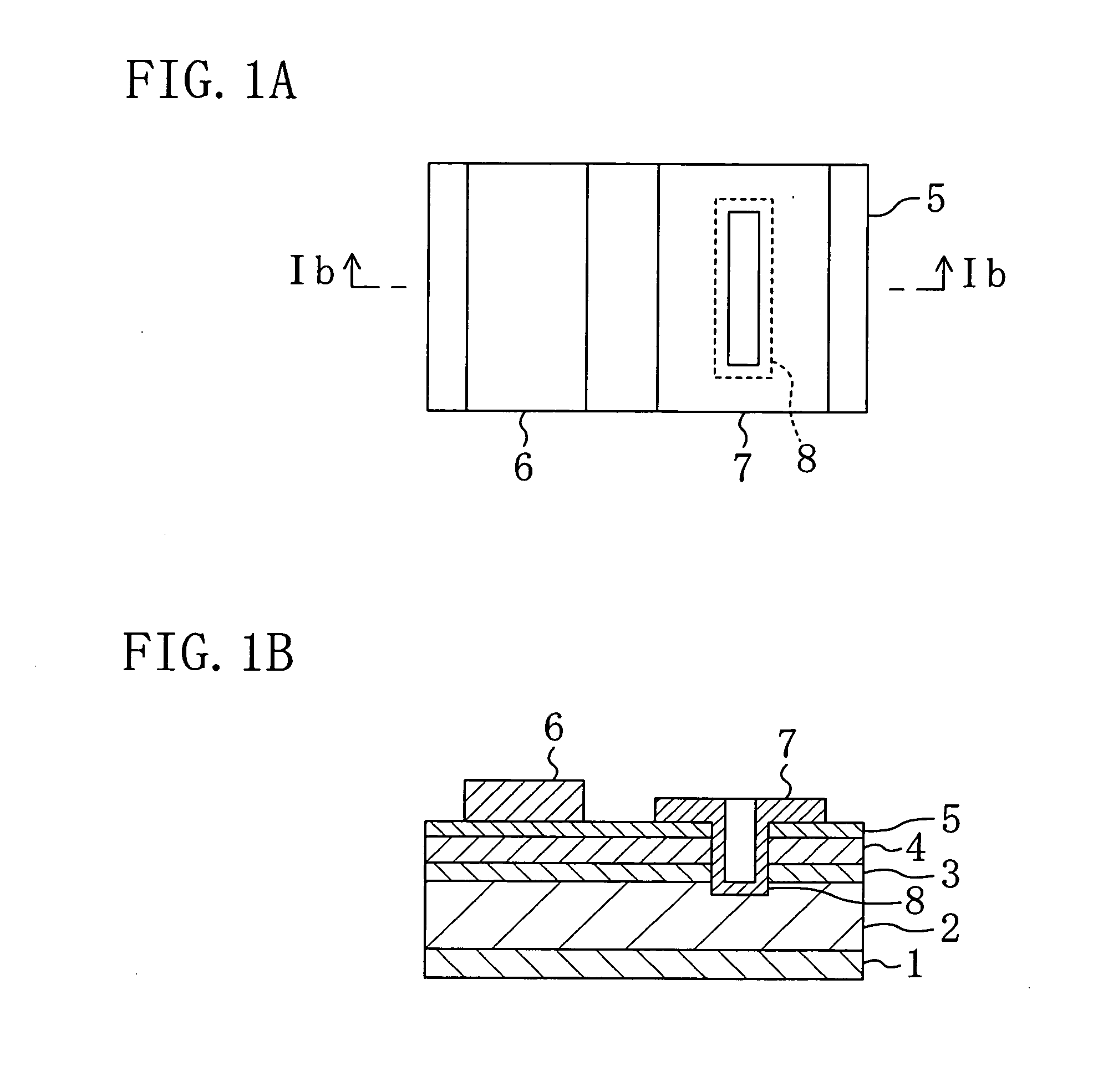

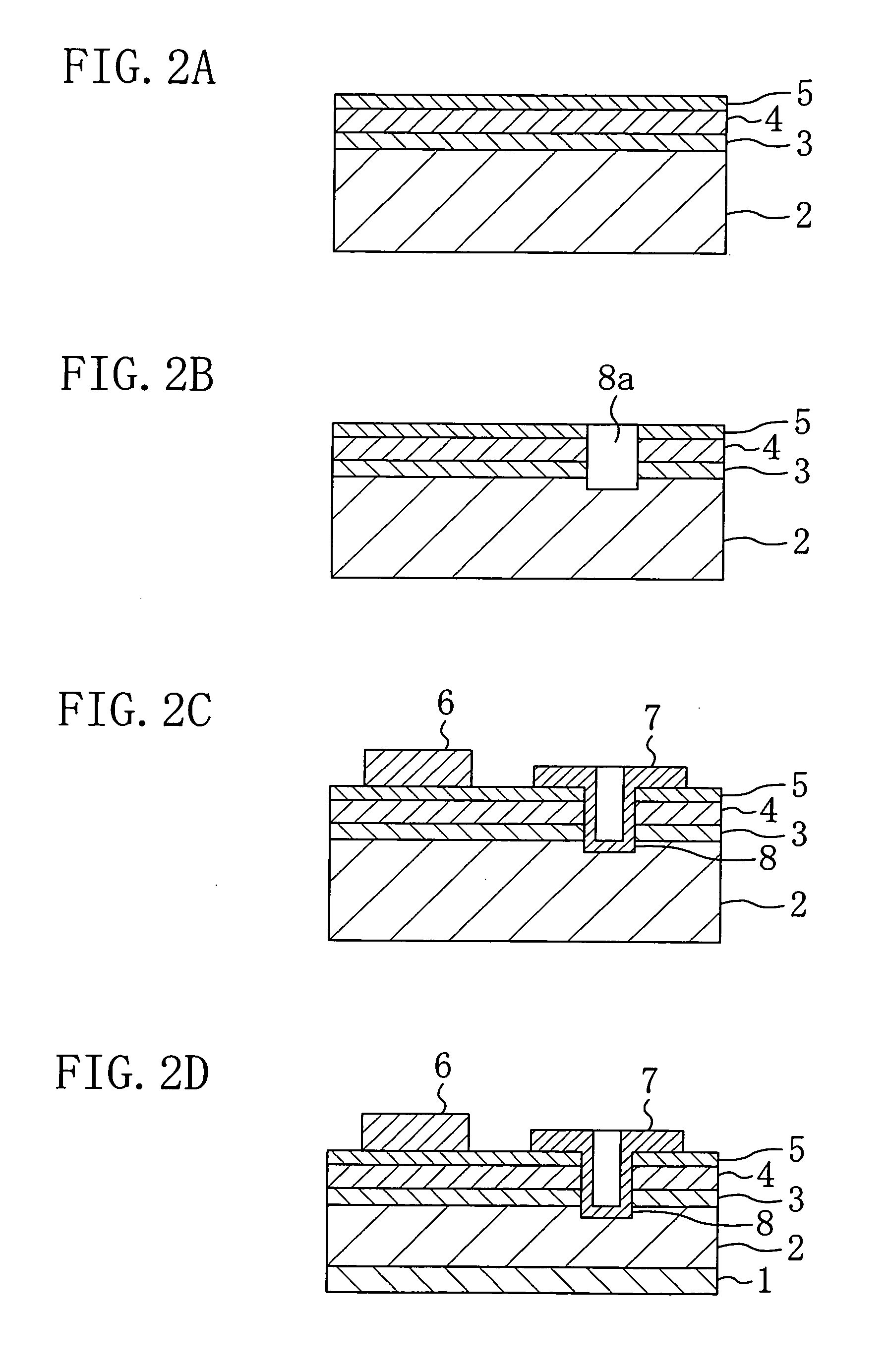

Surface-emitting laser diode having reduced device resistance and capable of performing high output operation, surface-emitting laser diode array, electrophotographic system, surface-emitting laser diode module, optical telecommunication system, optical interconnection system using the surface-emitting laser diode, and method of fabricating the surface-emitting laser diode

ActiveUS6959025B2Lower resistanceHigh-output operationOptical wave guidanceOptical resonator shape and constructionMode controlDistributed Bragg reflector

A surface-emitting laser diode device that oscillates in a direction perpendicular to the substrate is provided. This surface-emitting laser diode device includes: an active layer; a resonator structure including a first distributed Bragg reflector and a second distributed Bragg reflector that face each other and sandwich the active layer; a hole passage that extends from a first electrode to the active layer; an electron passage that extends from a second electrode to the active layer; a hole restricting structure that is located in the hole passage and defines a region for confining holes to the active layer; and an optical mode control structure that includes a non-oxide region provided in the resonator structure and an oxide region surrounding the non-oxide region, each region containing Al as a constituent element. In this surface-emitting laser diode, the area of the non-oxide region is smaller than the area of the hole restricting structure.

Owner:RICOH KK

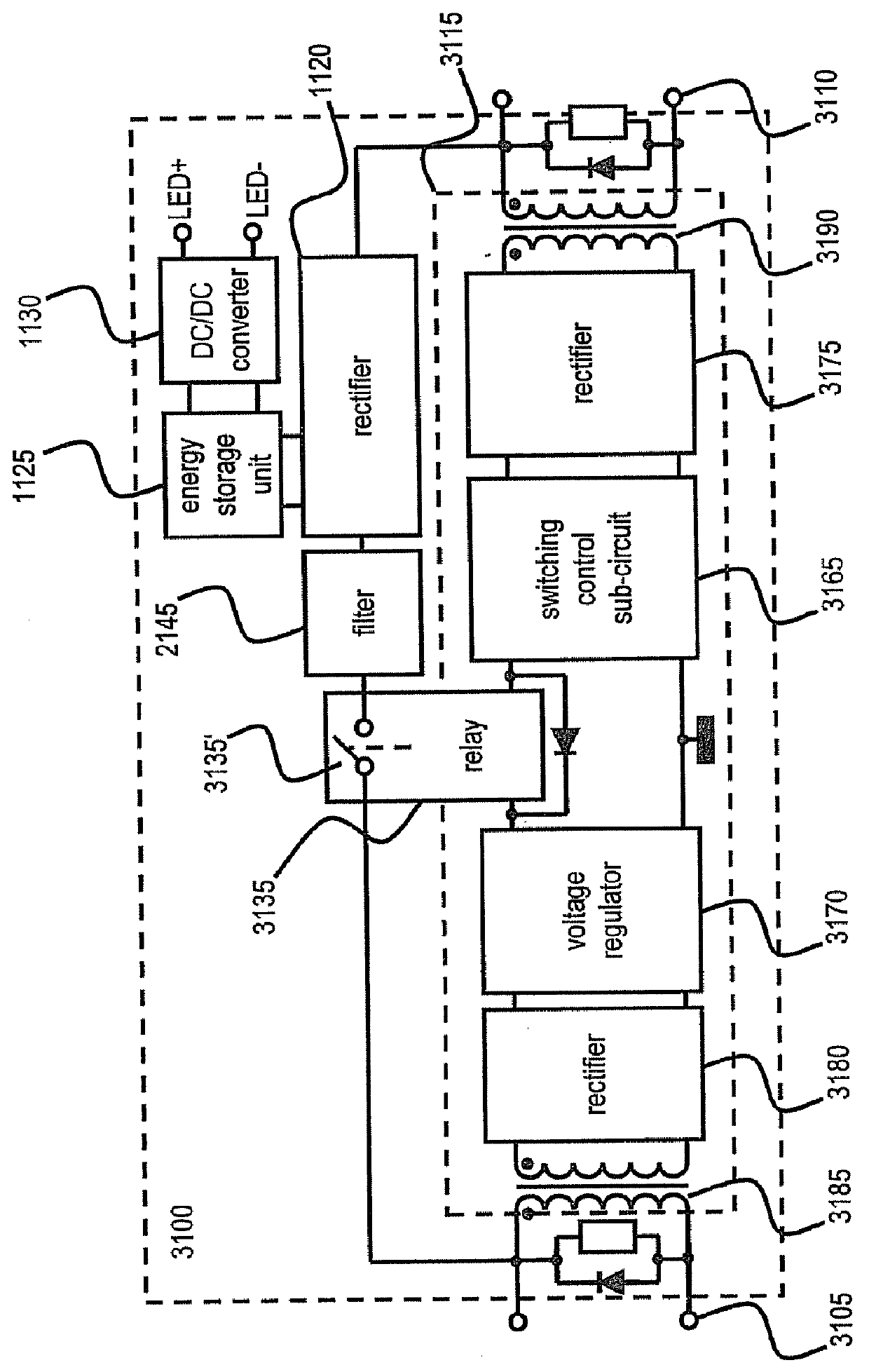

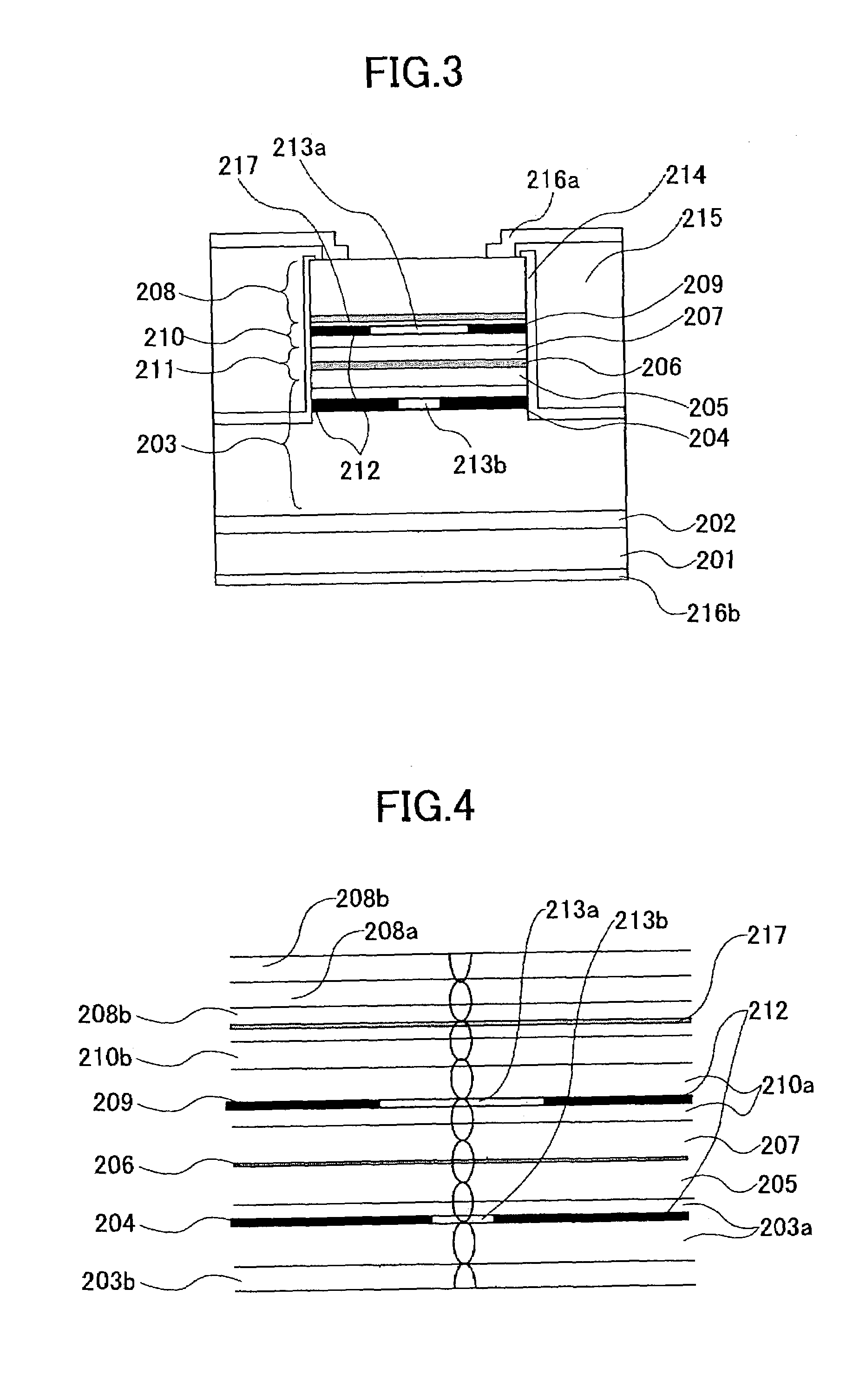

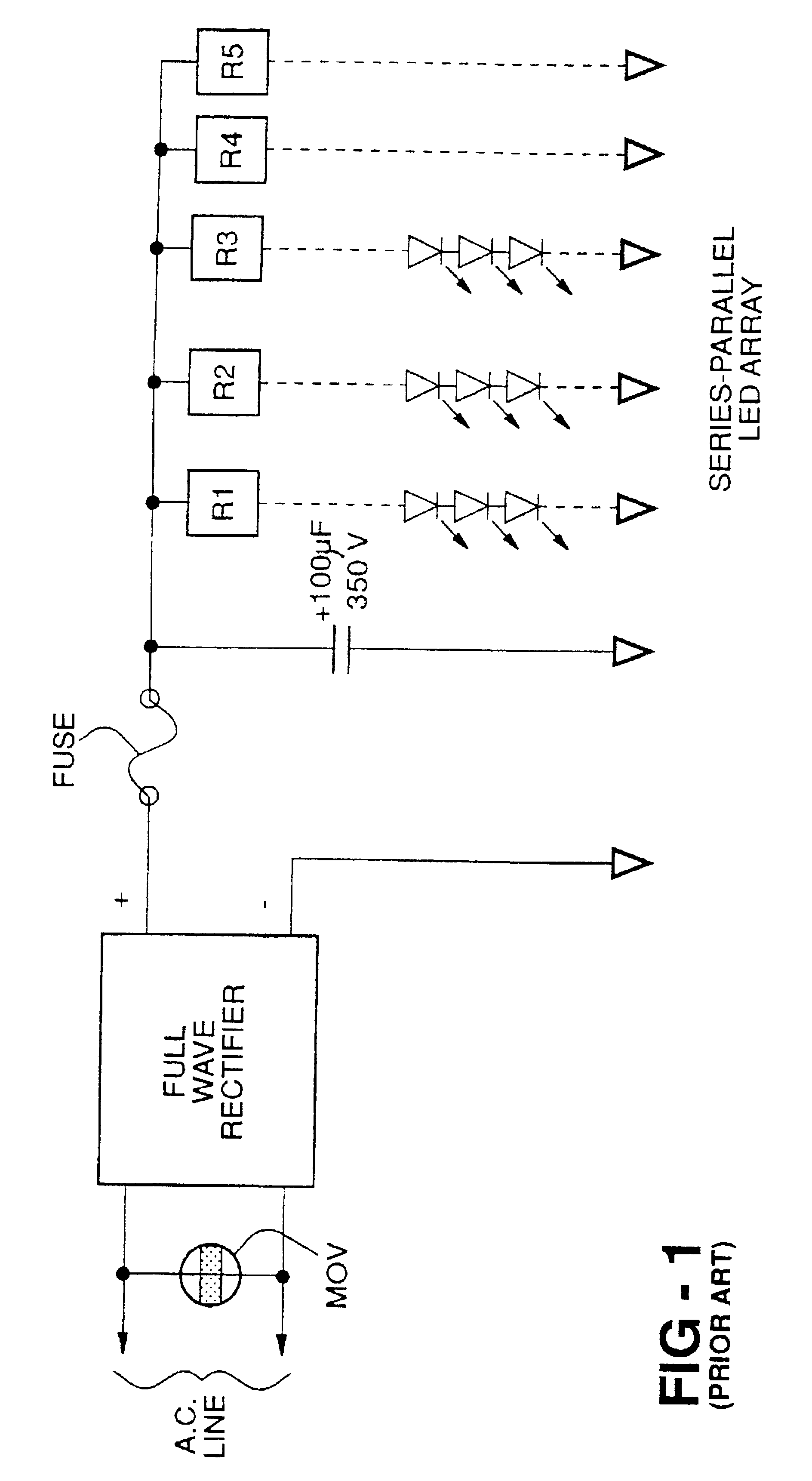

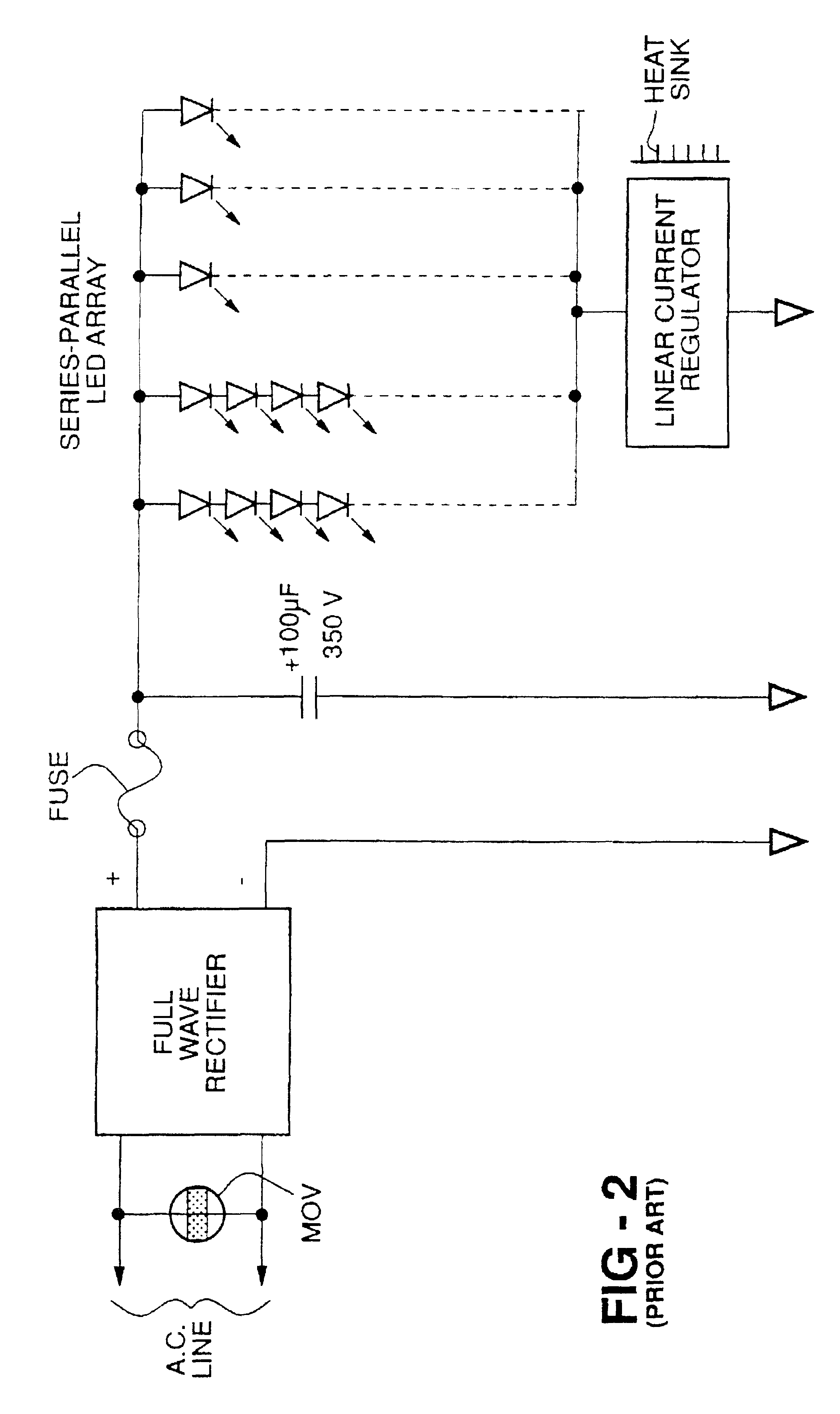

Power supply for light emitting diode array

InactiveUSRE42161E1Eliminate leakage currentEliminate the problemAc-dc conversion without reversalEfficient power electronics conversionLed arrayPower detector

An apparatus (10) for supplying regulated voltage d.c. electrical power to an LED array (12) includes a rectifier (32) responsive to a.c. power for generating rectified d.c. power and a power factor correcting and voltage regulating buck / boost switchmode converter (38) responsive to the rectified d.c. power for generating regulated voltage d.c. power to illuminate the LED array (12). A battery backup system (62) receives the a.c. power applied to the rectifier (32) for charging a rechargeable battery (66) and sensing an a.c. power failure. A switch-over relay (82) is connected between the battery backup system (62) and the rectifier. Upon sensing a failure of the a.c. power, the battery backup system (62) controls the switch-over relay (82) to connect the battery backup system (62) to the rectifier (32) to provide d.c. power to the switchmode converter (38) to illuminate the LED array (12). A half wave power detector (88) causes the apparatus (10) to reduce regulated d.c. power to dim the LED array (12).

Owner:AGREEMENT & DECLARATION OF TRUST DATED JUNE 1 2009

Backplanes for display applications, and components for use therein

InactiveUS20070035532A1Slow changeLow cost manufacturingTransistorSolid-state devicesCapacitanceCoupling

Owner:E INK CORPORATION

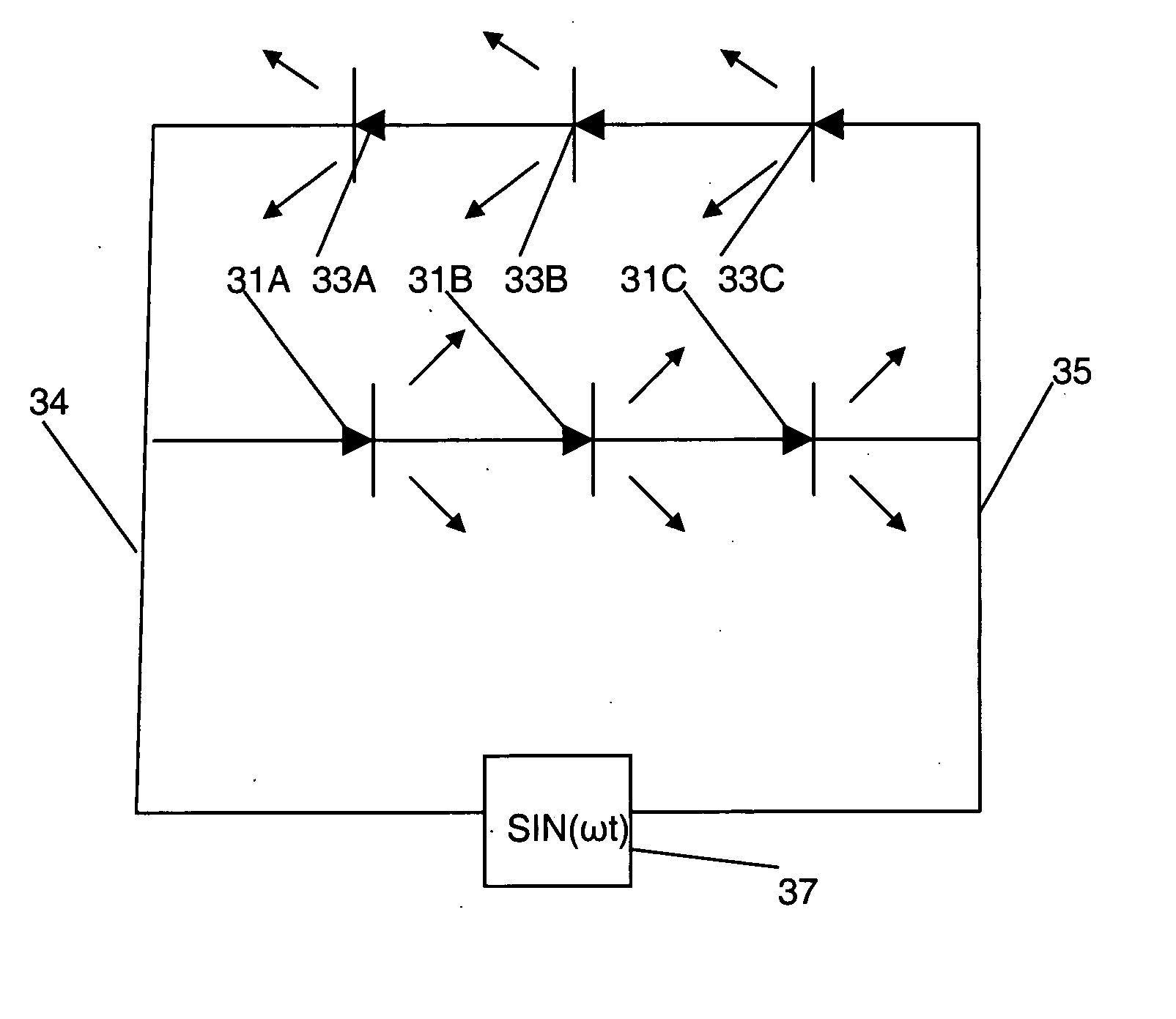

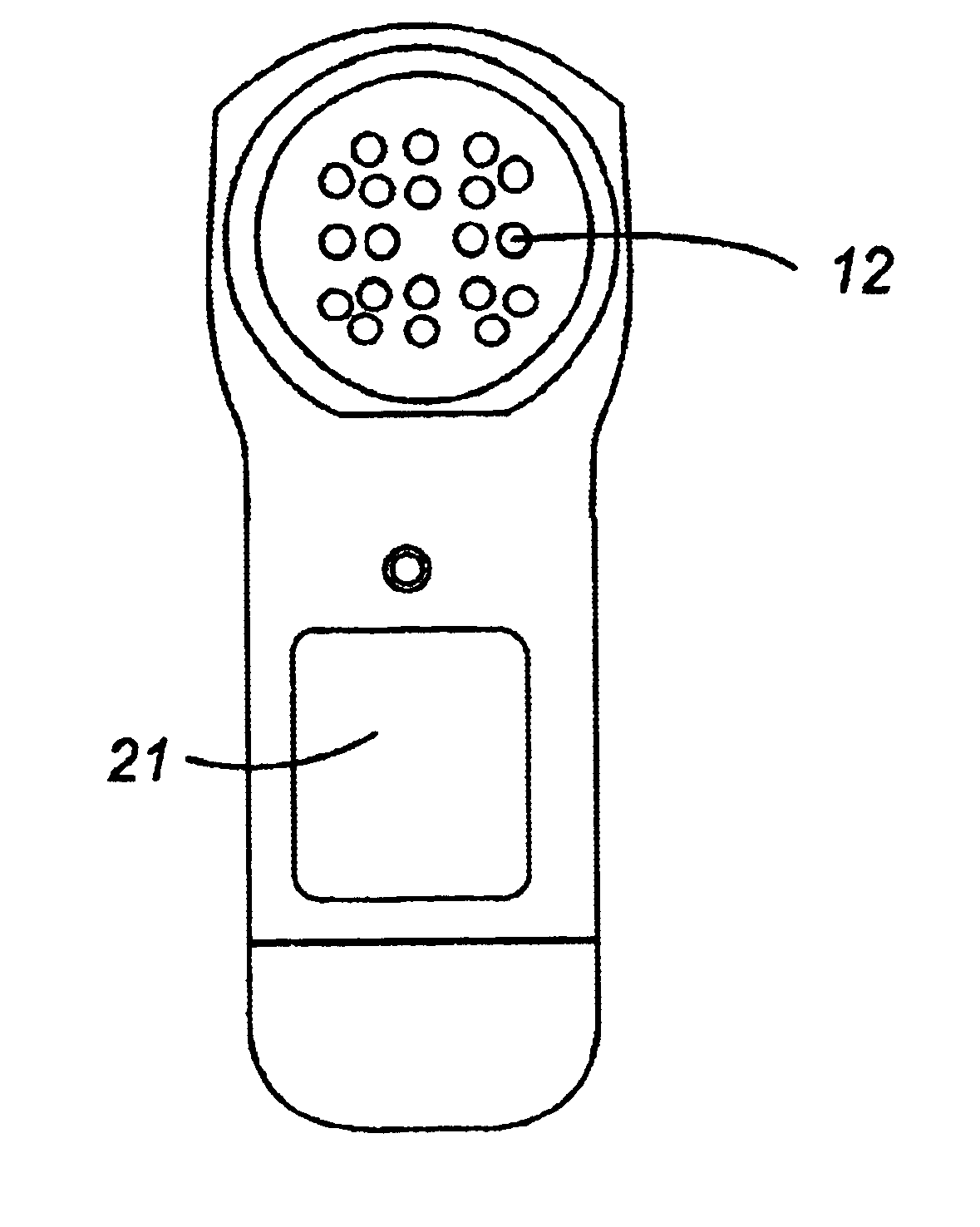

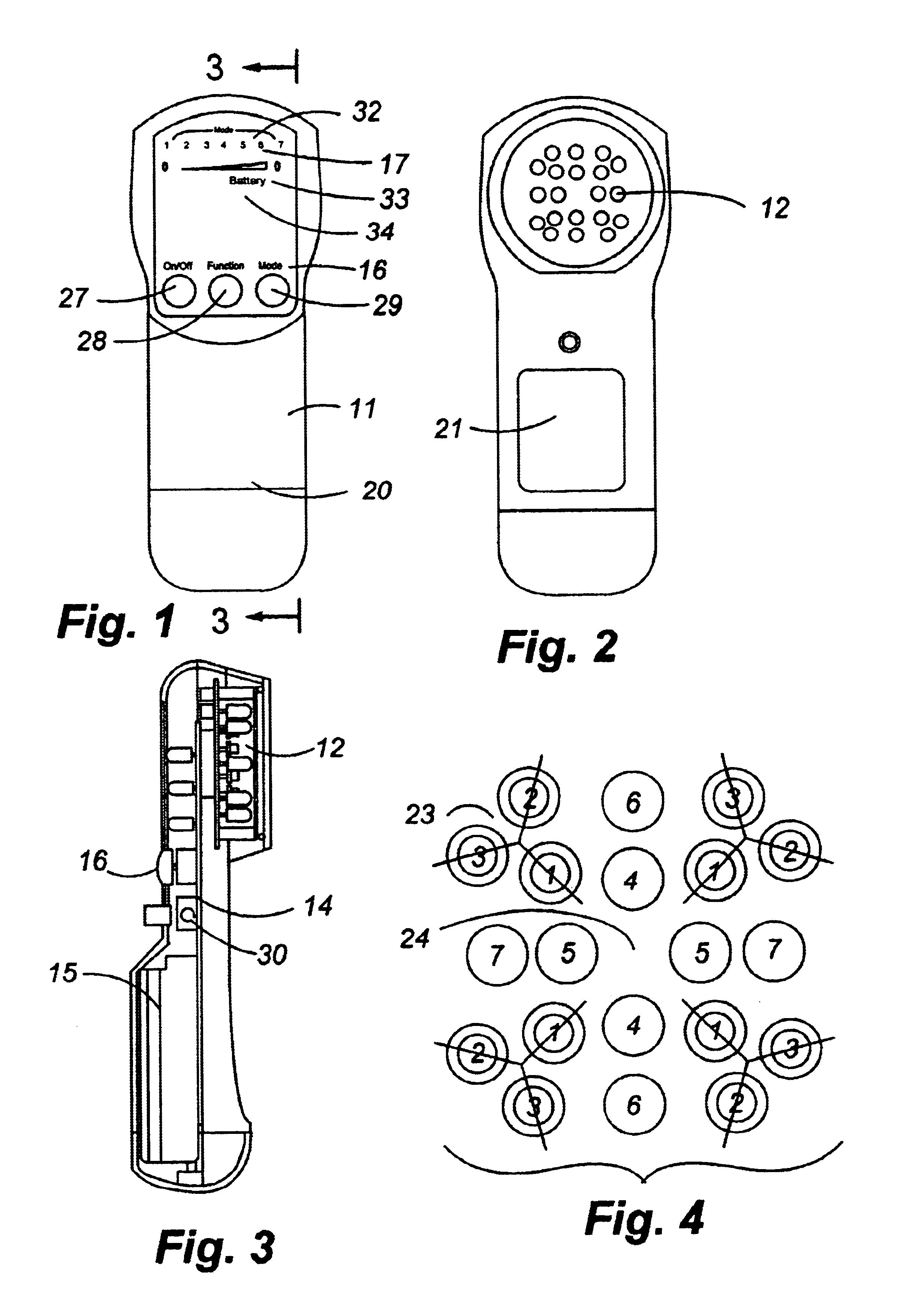

Therapeutic low level laser apparatus and method

Apparatus for therapeutic low level laser treatment has a diode array with sets of laser diodes of three wavelengths, and with light emitting diodes of four wavelengths. The emitted laser and light beams overlap in a selected configuration. The method includes pulsing the diodes in one of several available selected frequency sequences. One of the available frequency sequences includes increasing frequency pulsing.

Owner:2035 INC

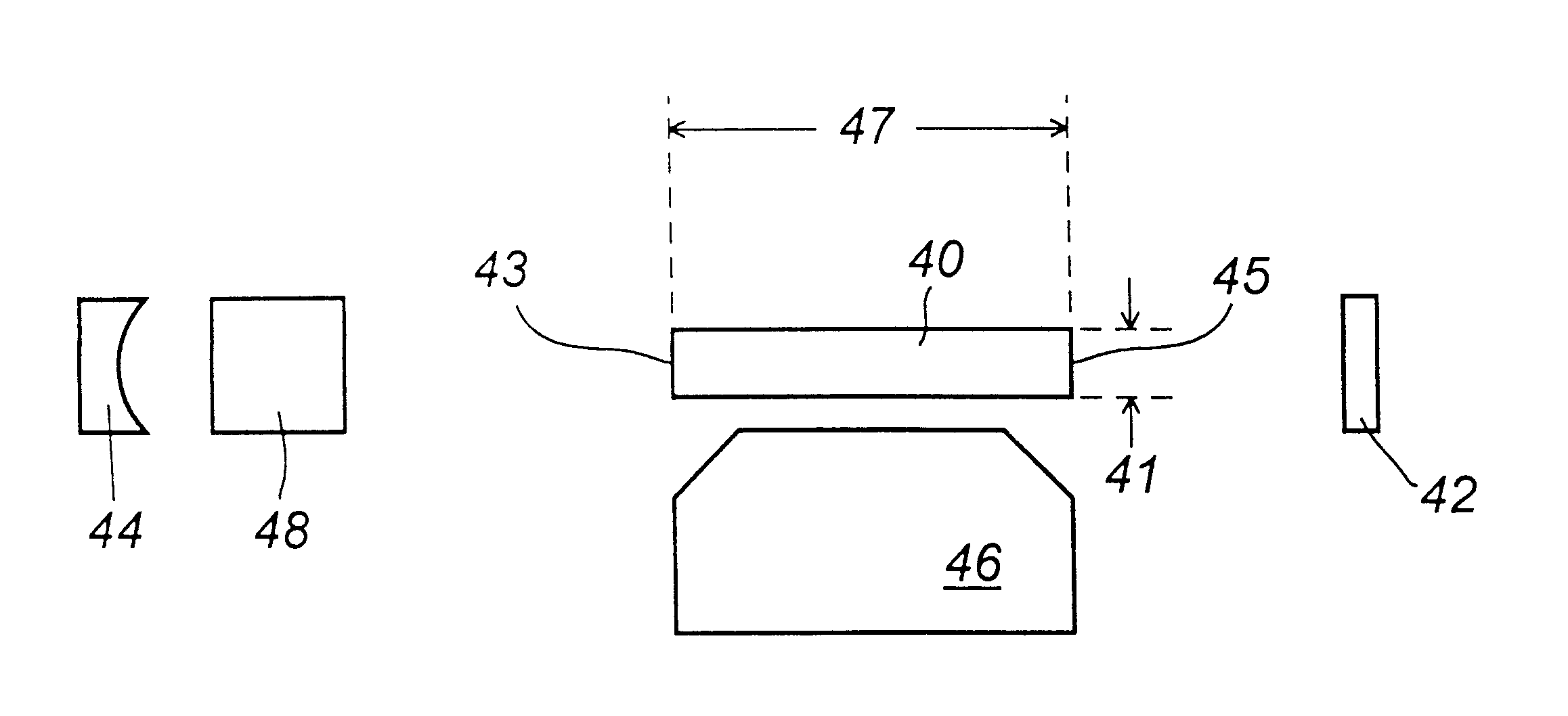

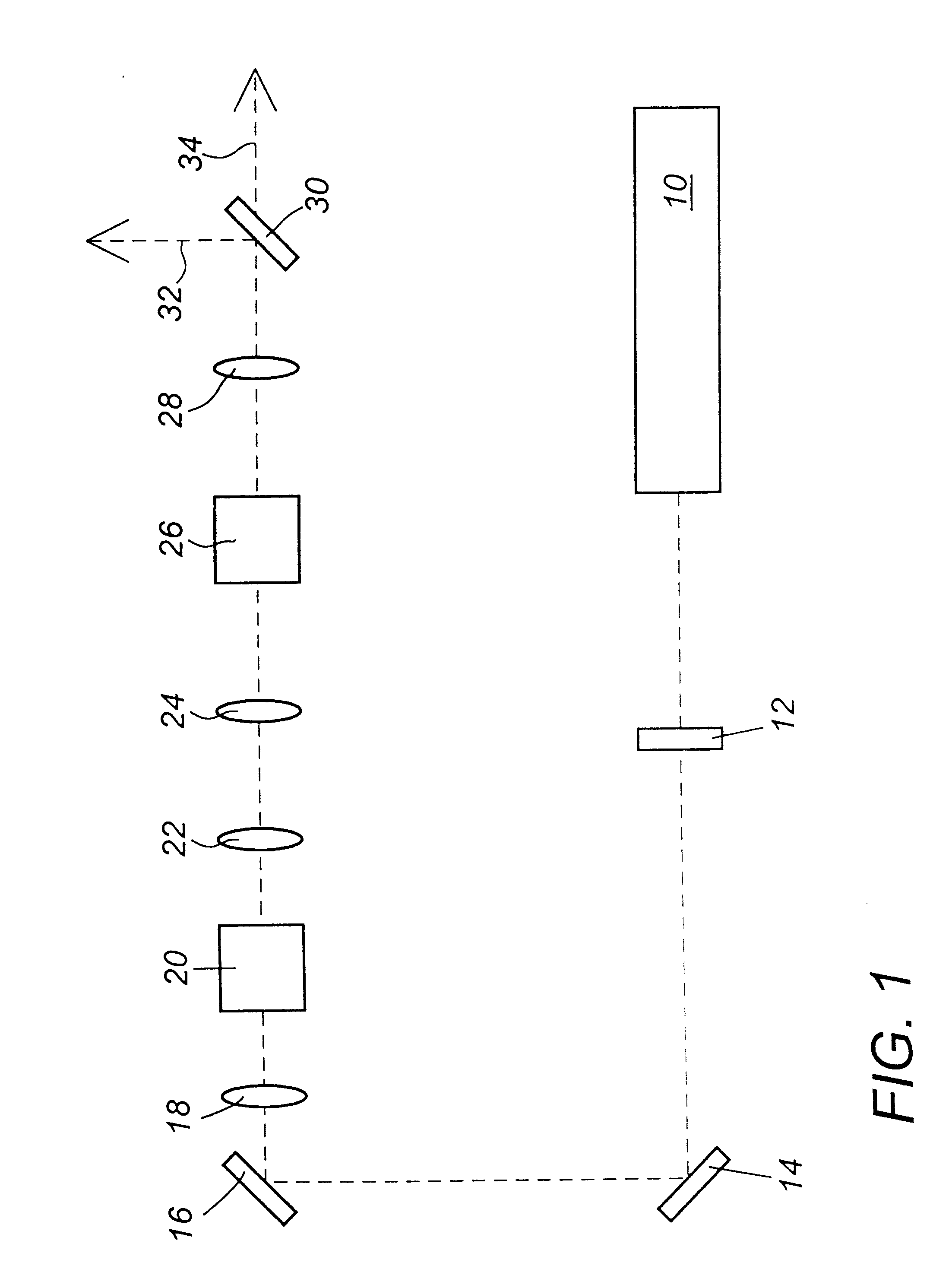

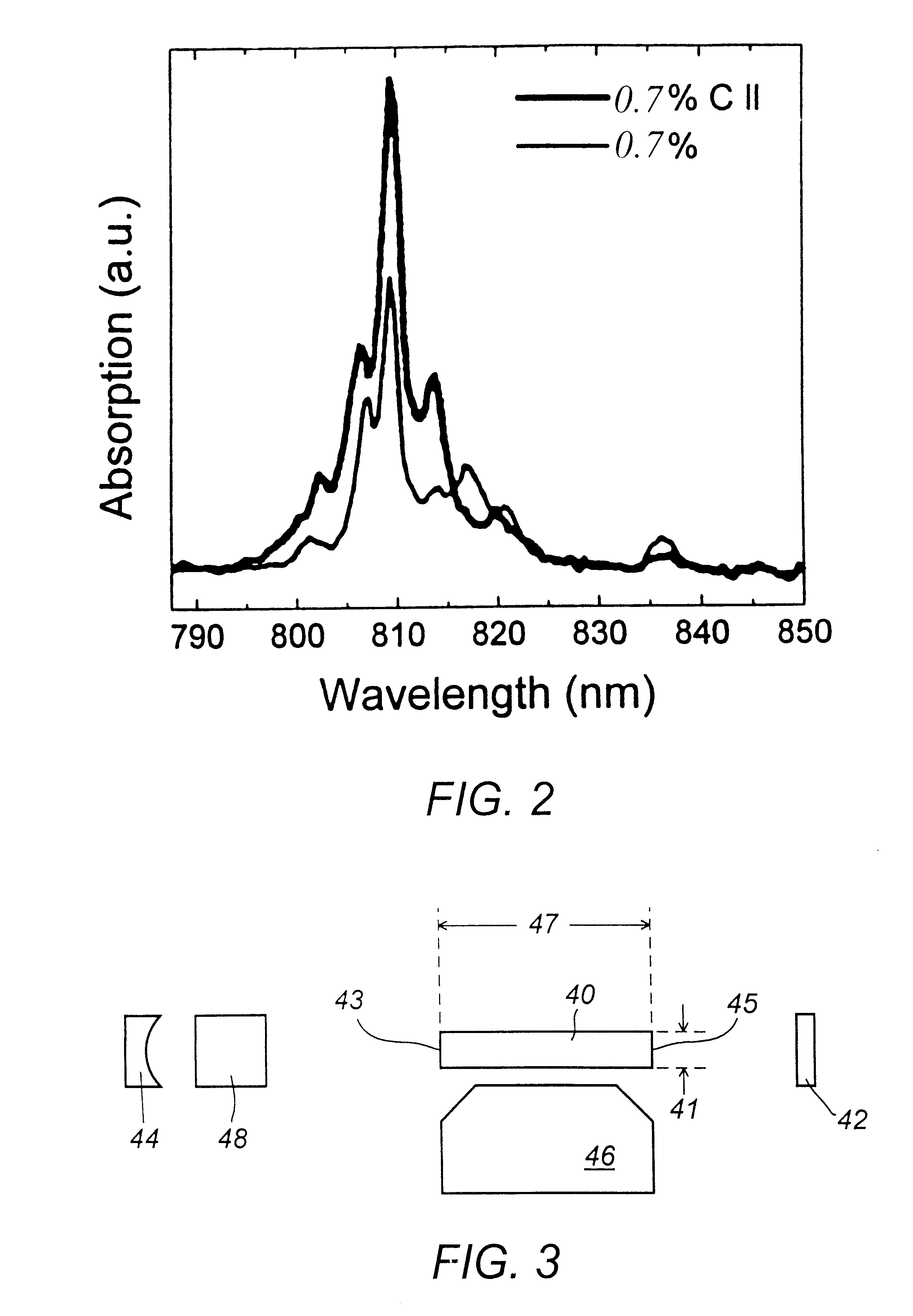

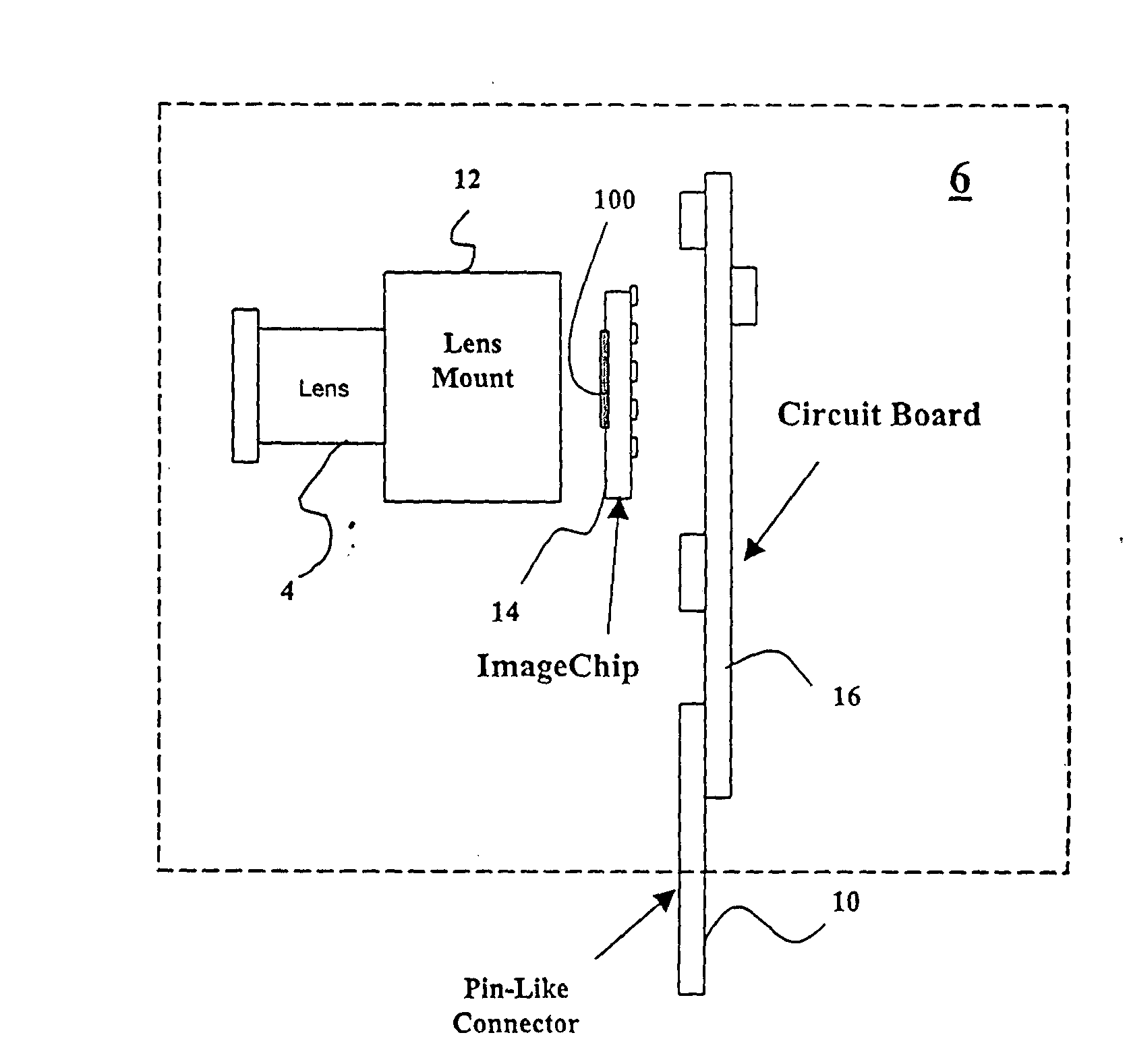

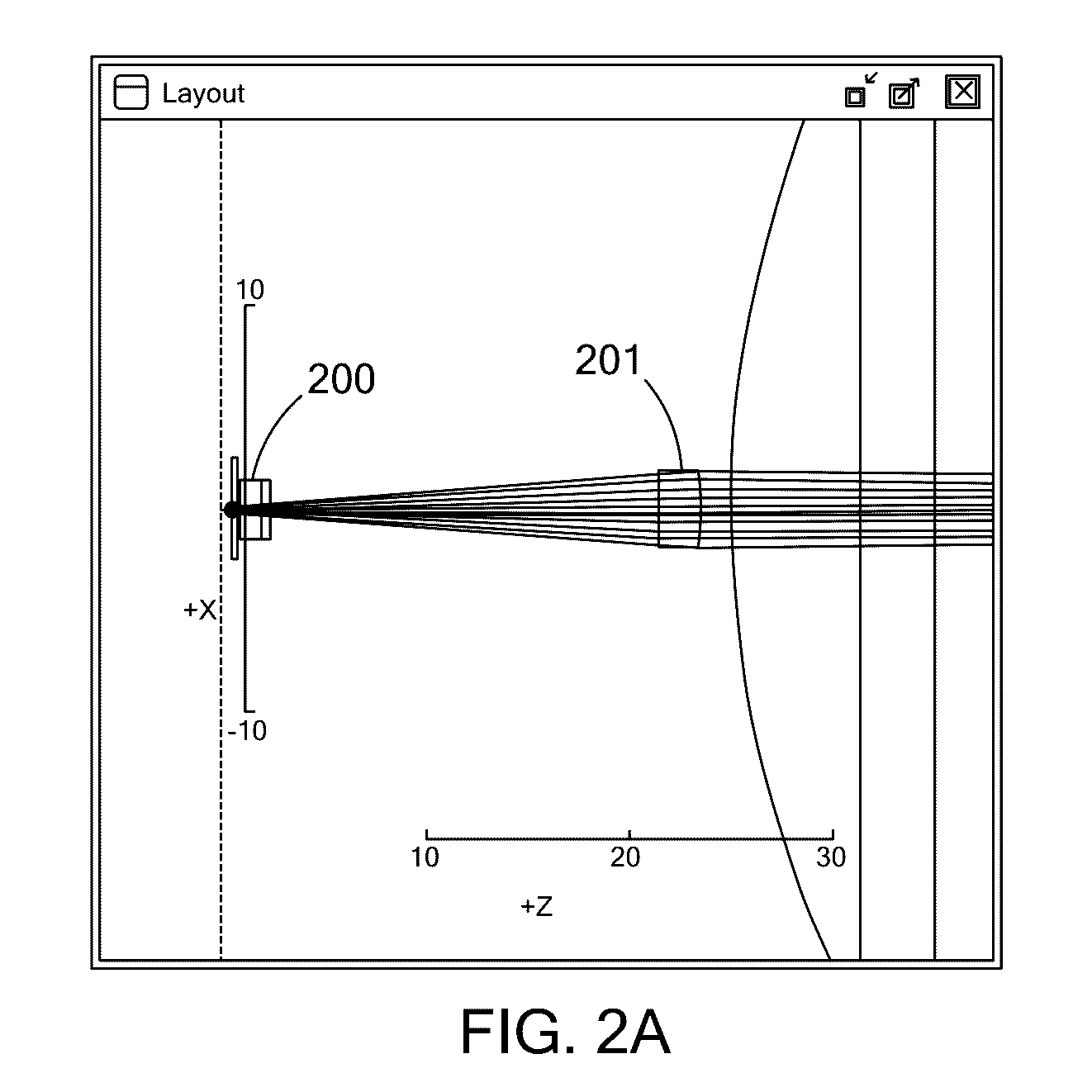

Laser with absorption optimized pumping of a gain medium

InactiveUS6347101B1Improve the level ofEasy maintenanceAdditive manufacturing apparatusOptical resonator shape and constructionResonant cavityHigh absorption

A solid state laser includes a high absorption coefficient solid state gain medium such as Nd:YVO4 that is side pumped with a semiconductor laser diode array. The resonant cavity of the solid state laser is positioned so that the TEM00 mode is spaced from the face of the laser through which the laser is pumped by a distance sufficient to reduce diffraction losses but sufficiently near to allow coupling of pump light into the gain mode. The gain medium, the doping level of the gain medium, and the operating temperature of the pump laser are selected to efficiently couple pump light into the gain mode. The pump laser is positioned to side pump the gain medium without collimating or focusing optics between the pump laser and the face of the gain medium. A gap between the pump laser and the gain medium is empirically selected to match the angular extent of the pump laser output light to the height of the gain mode at the position of the gain mode fixed to optimize coupling and diffraction losses.

Owner:3D SYST INC

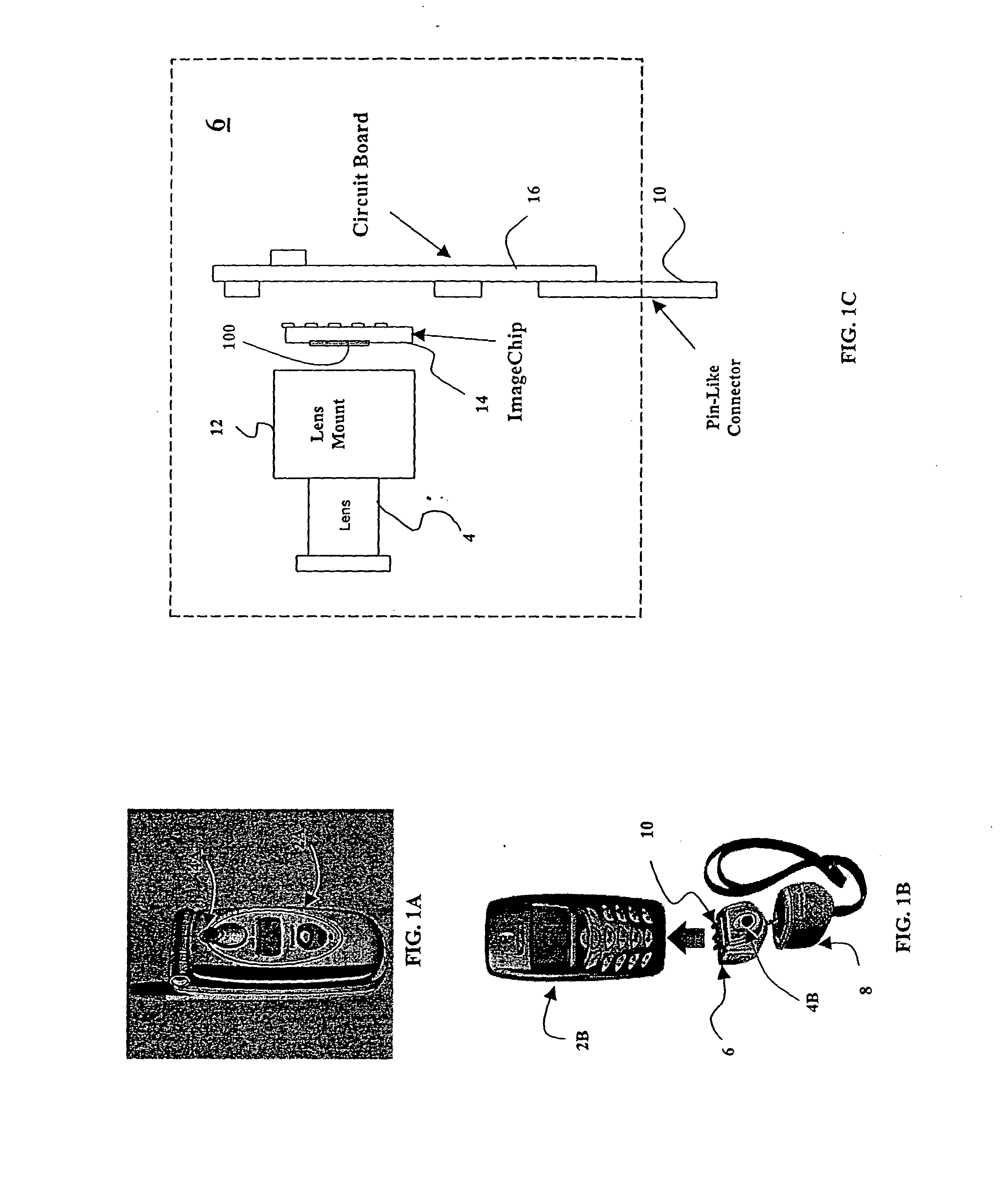

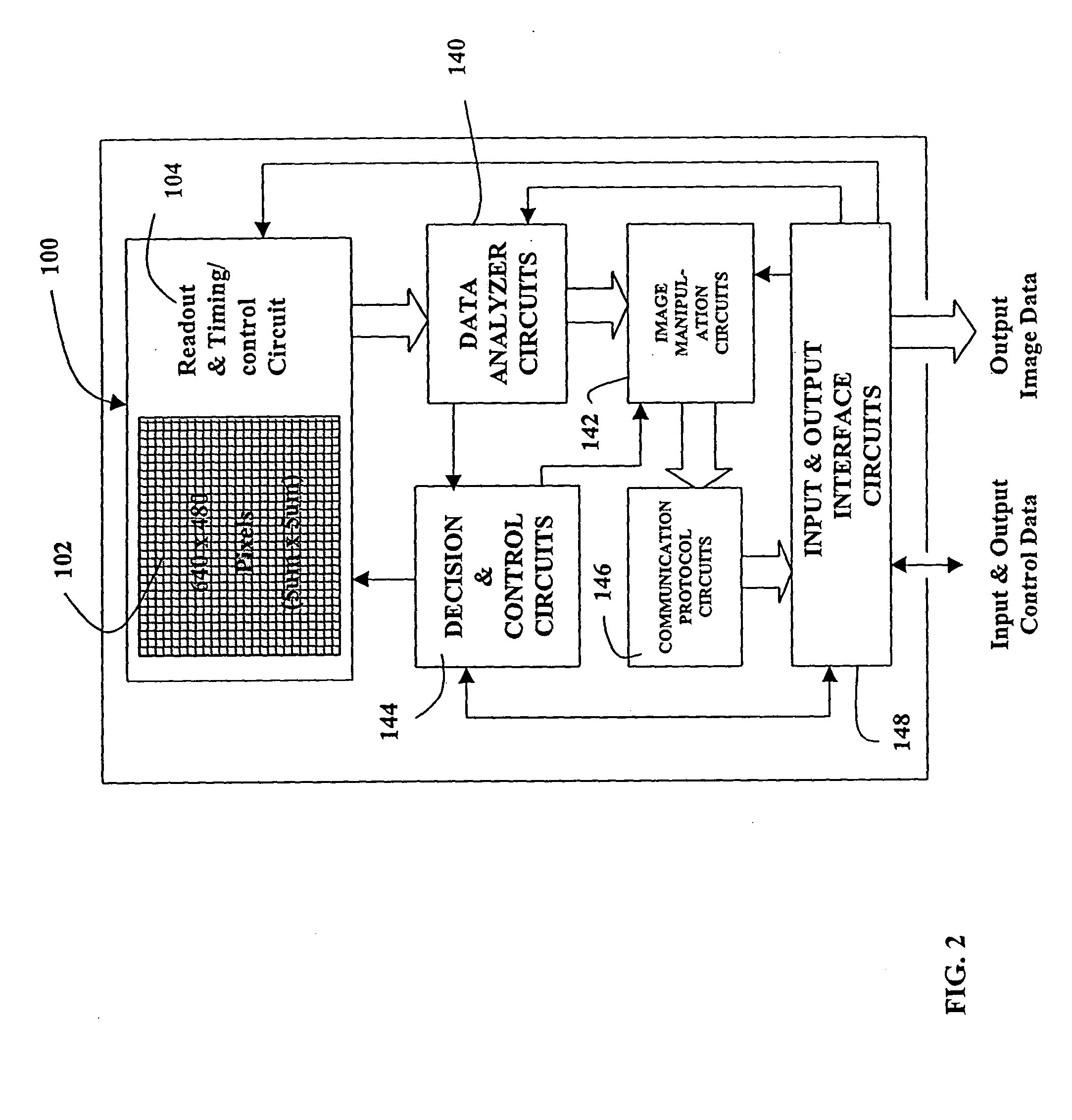

Photoconductor on active pixel image sensor

InactiveUS20040036010A1Low costMass productionTelevision system detailsTelevision system scanning detailsSemiconductor materialsSpectral response

A MOS or CMOS based photoconductor on active pixel image sensor. Thin layers of semi-conductor material, doped to PIN or NIP photoconducting layers, located above MOS and / or CMOS pixel circuits produce an array of layered photodiodes. Positive and negative charges produced in the layered photodiodes are collected and stored as electrical charges in the MOS and / or CMOS pixel circuits. The present invention also provides additional MOS or CMOS circuits for reading out the charges and for converting the charges into images. With the layered photodiode of each pixel fabricated as continuous layers of charge generating material on top of the MOS and / or CMOS pixel circuits, extremely small pixels are possible with almost 100 percent packing factors. MOS and CMOS fabrication techniques permit sensor fabrication at very low costs. In preferred embodiments all of the sensor circuits are incorporated on or in a single crystalline substrate along with the sensor pixel circuits. Techniques are disclosed for tailoring the spectral response of the sensor for particular applications.

Owner:E PHOCUS

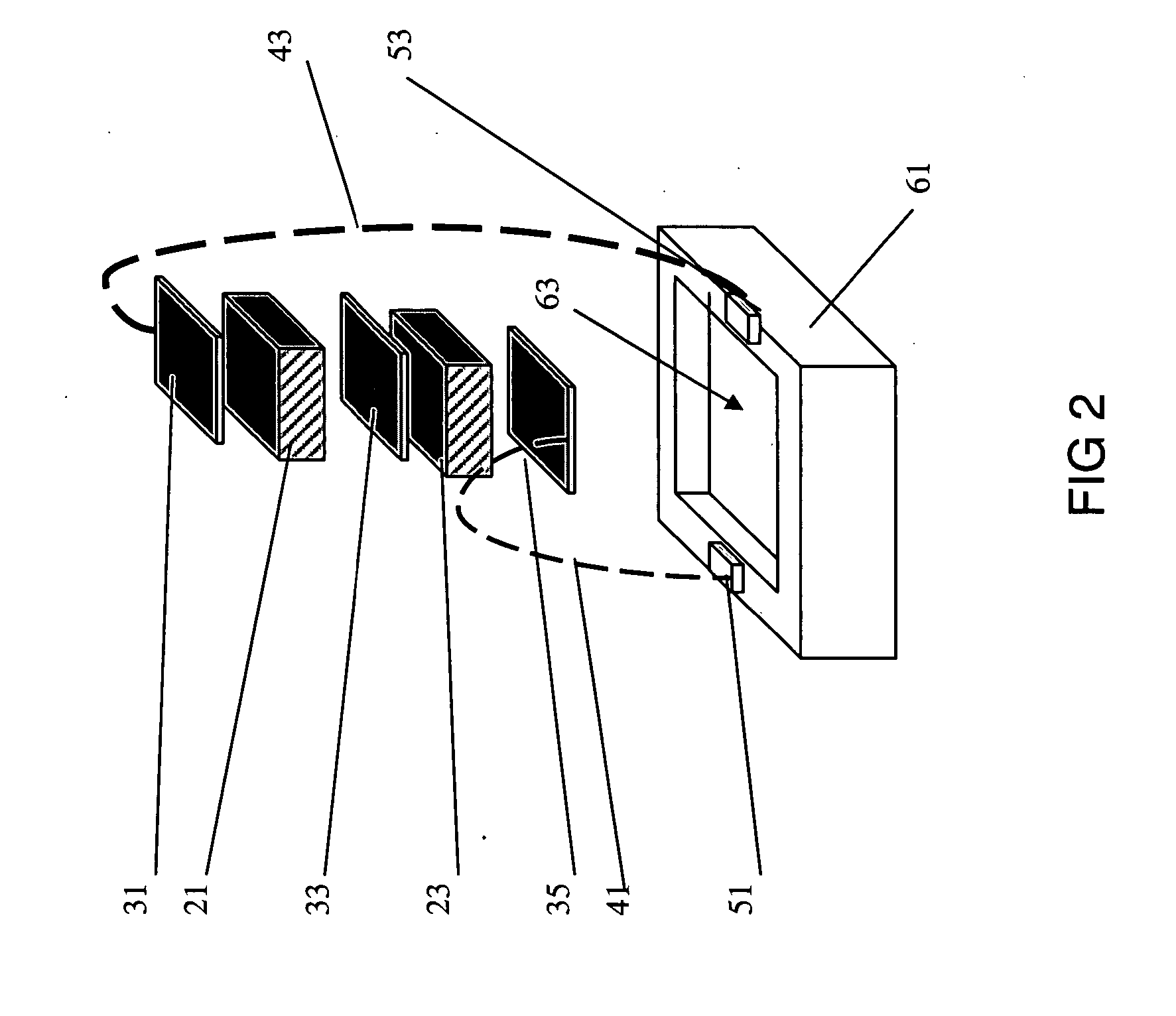

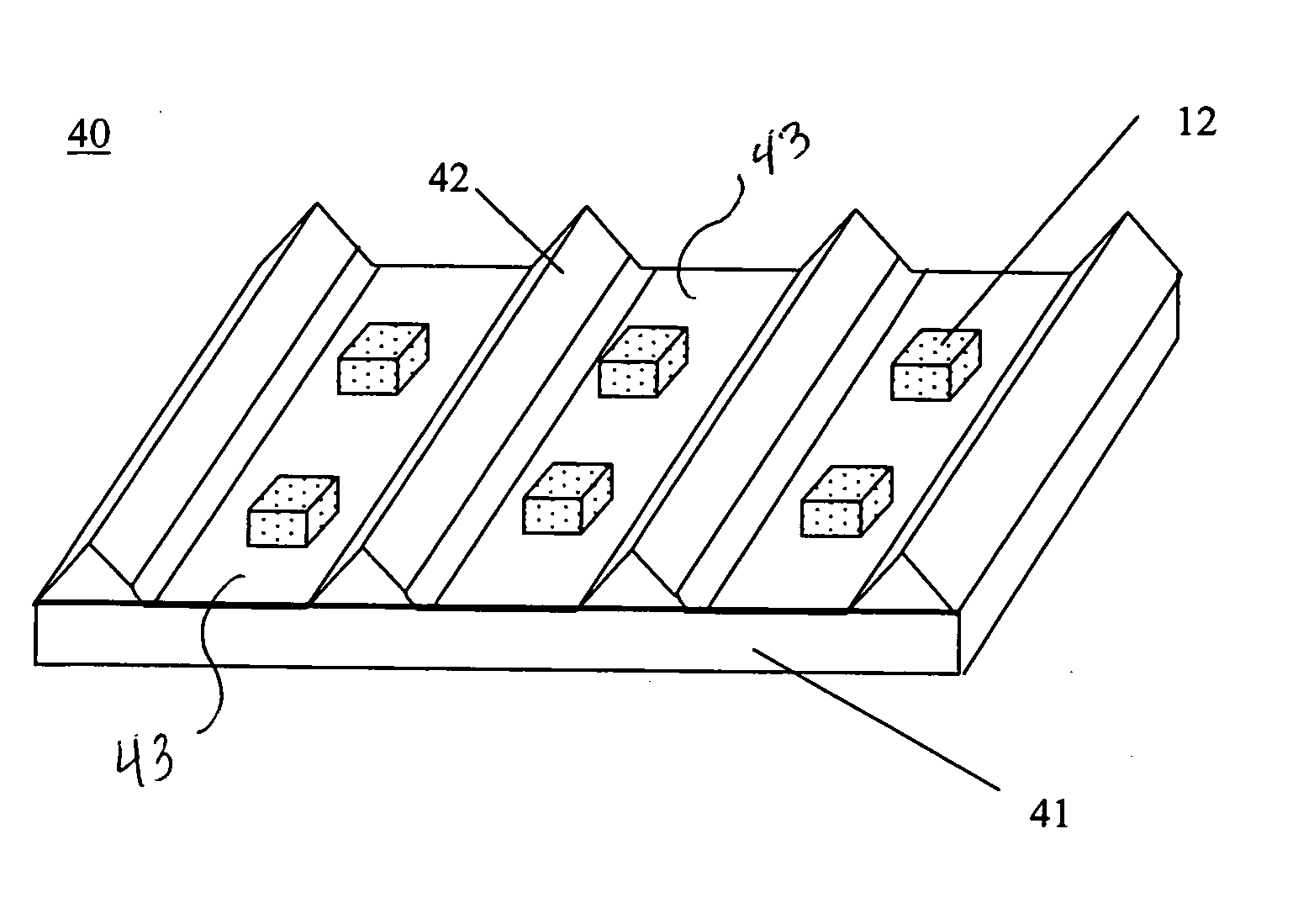

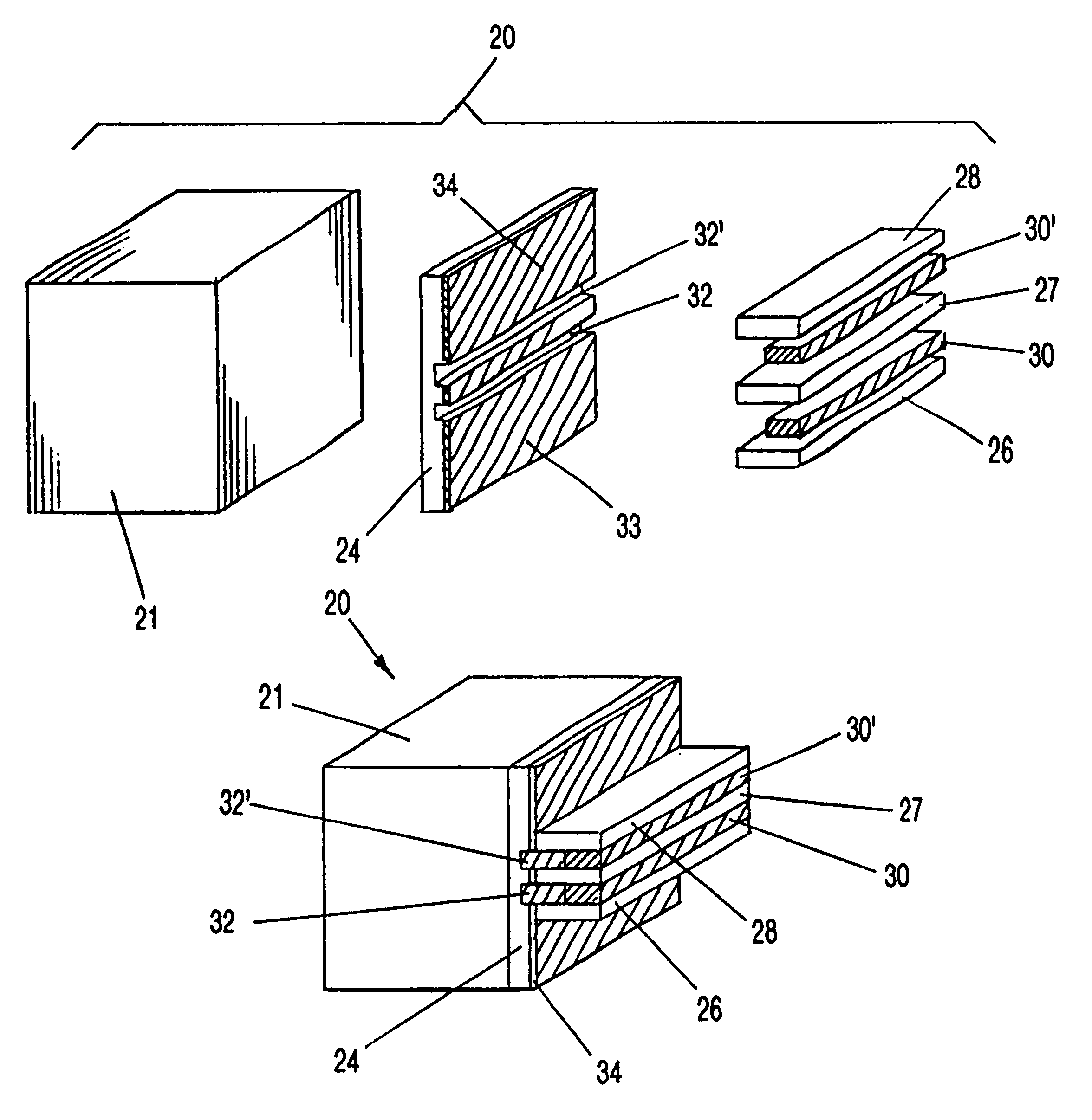

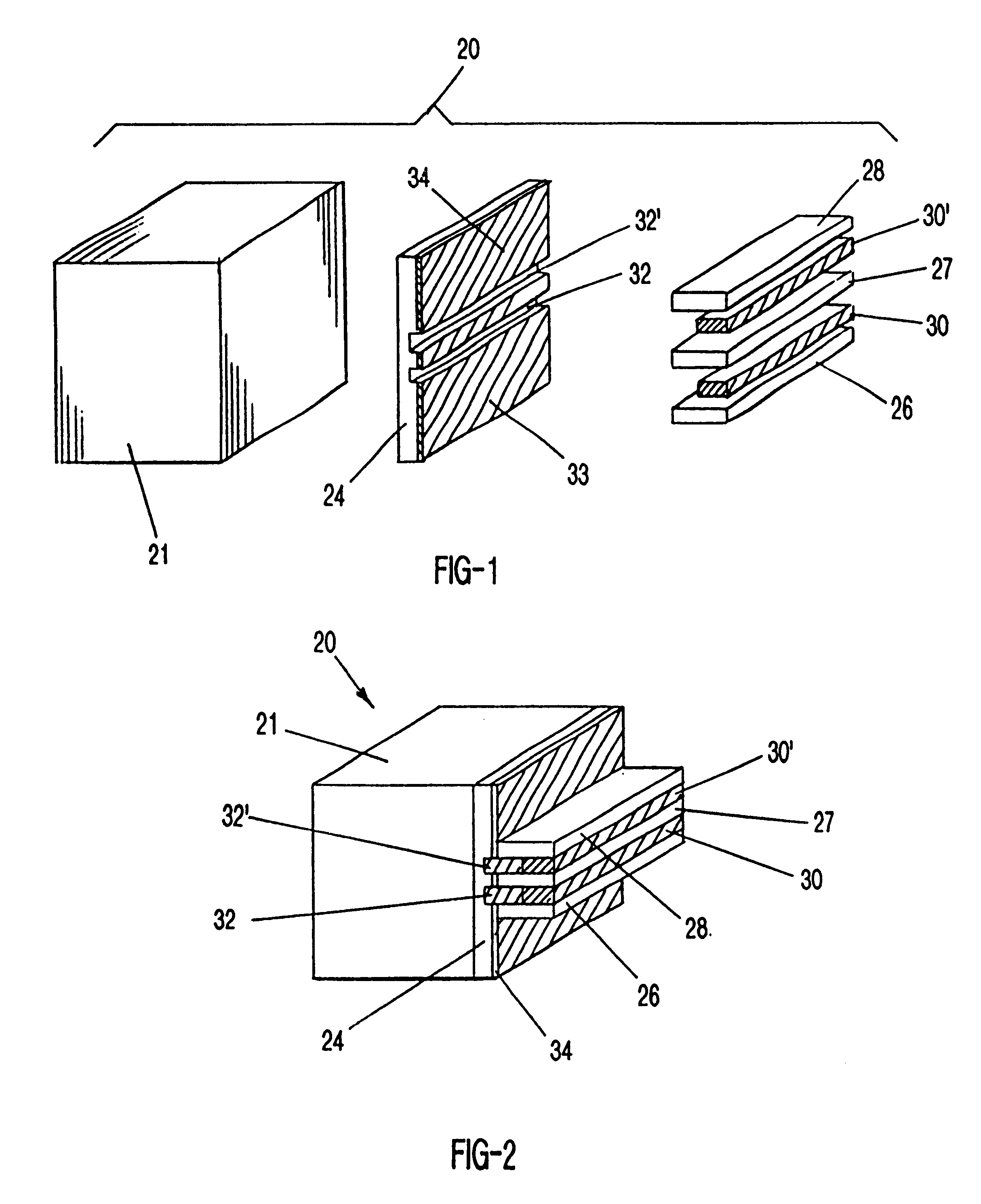

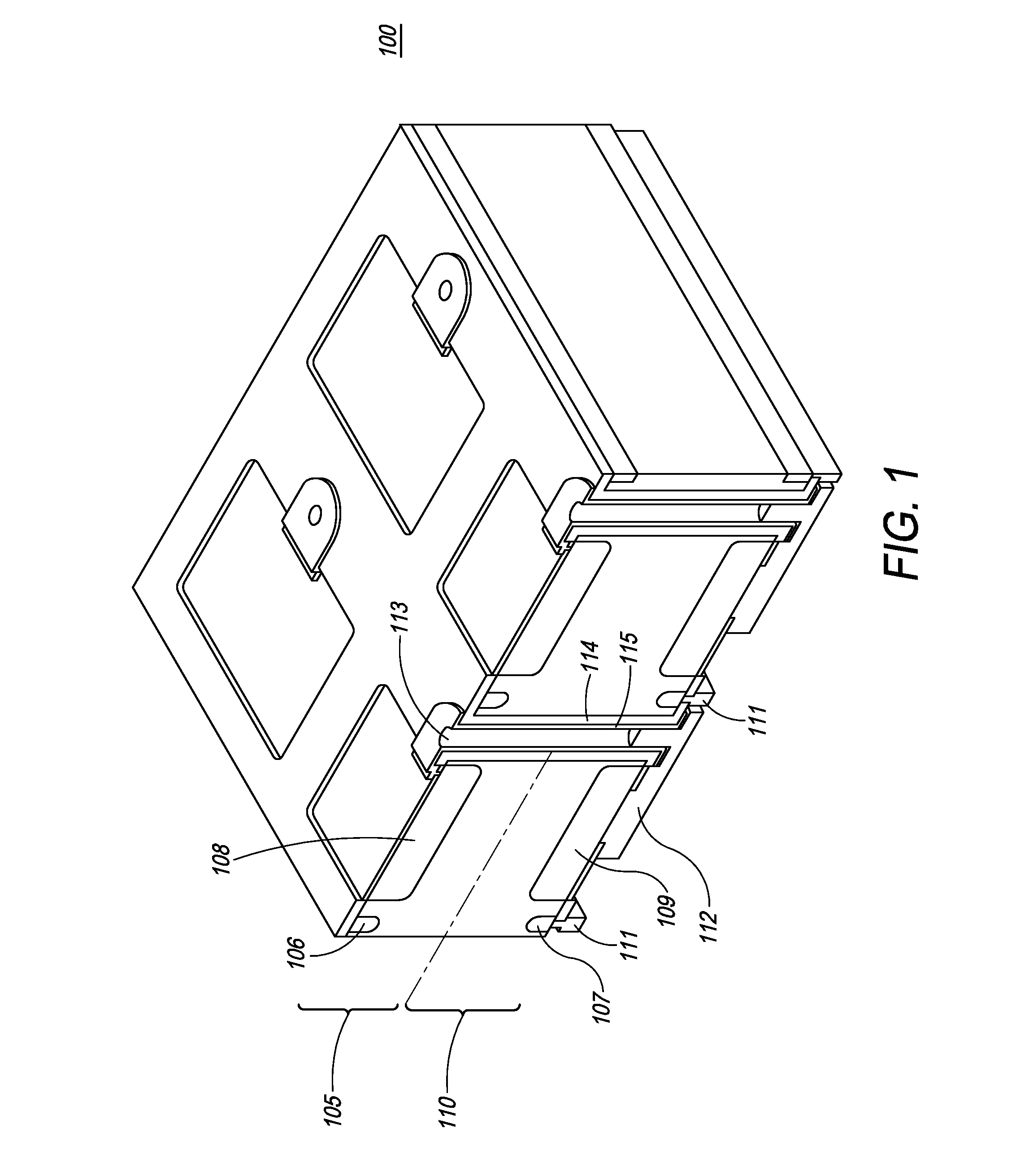

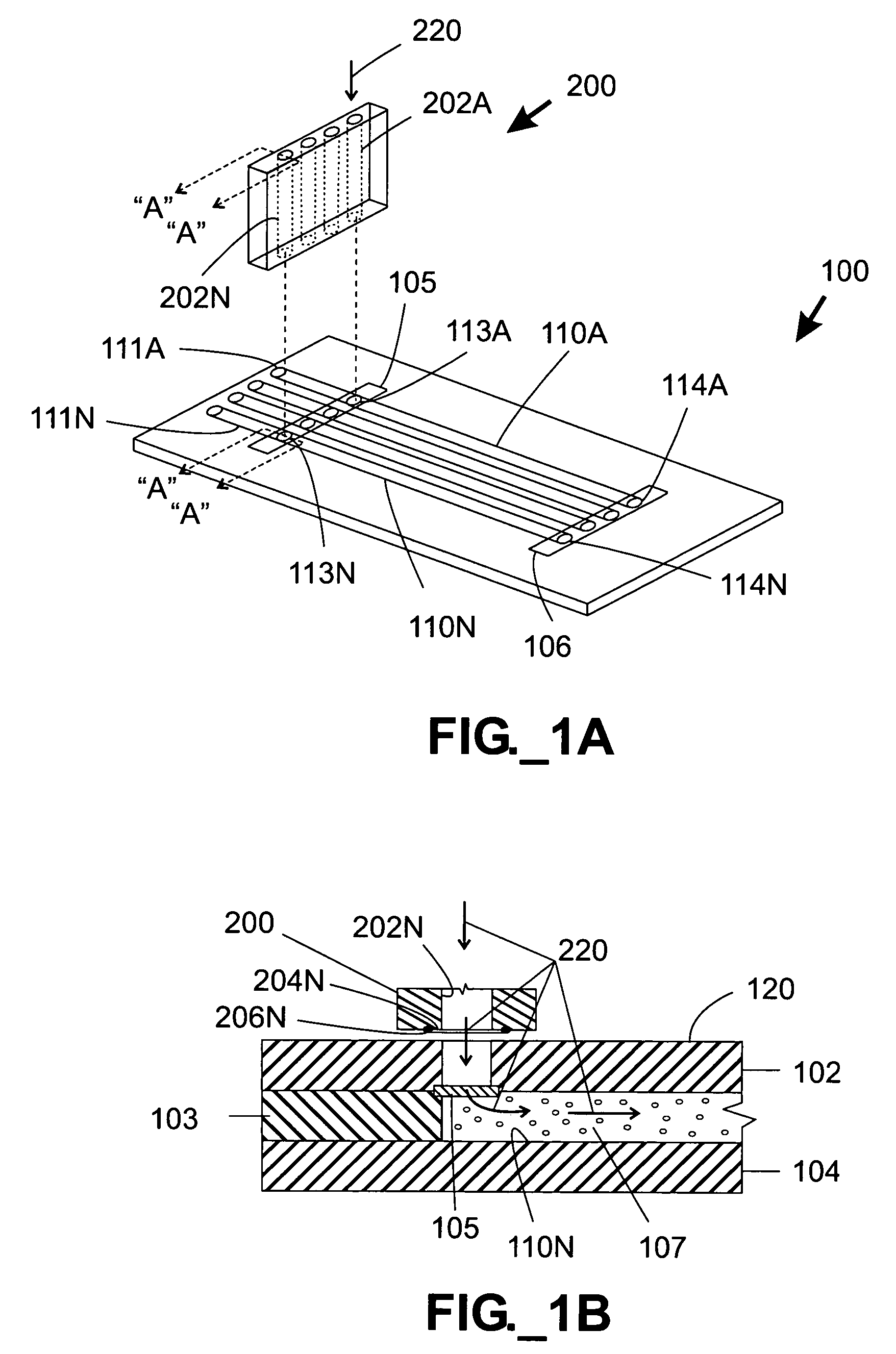

Method for modular laser diode assembly

InactiveUS6352873B1Semiconductor laser arrangementsSemiconductor laser structural detailsElectrical connectionEngineering

A method for laser diode bar assembly. A method for assembling a modular stacked diode array is disclosed, whereby a diode bar is bonded between a pair of conductive spacers, as by soldering, to create a diode submodule. Each submodule, prior to being affixed to a substrate, may be individually pre-tested. Any number of diode bar submodules then may be affixed to a substrate to construct a diode bar array. A stacked array embodiment assembled according to the method provides for efficient cooling of the diode bars and electrical connection between diode bars while maximizing alignment of the diode bars. The spacers are connected to a conductive surface on a heat spreader. In the stacked array, one or more diode bars are alternated in series with two or more conductive spacers, with a series circuit provided from diode bar to diode bar. The spacers hold the diodes spaced apart from insulating grooves in the conductive layer on the substrate. Alternatively, thermally conductive separator fins extend from the heat spreader substrate to contact the diode bars situated between the spacers to promote rapid heat transfer from the diodes while maintaining the diode bars electrically isolated from tie conductive layer on the substrate.

Owner:LASERTEL

Nanowire device with (111) vertical sidewalls and method of fabrication

A nano-scale device and method of fabrication provide a nanowire having (111) vertical sidewalls. The nano-scale device includes a semiconductor-on-insulator substrate polished in a [110] direction, the nanowire, and an electrical contact at opposite ends of the nanowire. The method includes wet etching a semiconductor layer of the semiconductor-on-insulator substrate to form the nanowire extending between a pair of islands in the semiconductor layer. The method further includes depositing an electrically conductive material on the pair of islands to form the electrical contacts. A nano-pn diode includes the nanowire as a first nano-electrode, a pn-junction vertically stacked on the nanowire, and a second nano-electrode on a (110) horizontal planar end of the pn-junction. The nano-pn diode may be fabricated in an array of the diodes on the semiconductor-on-insulator substrate.

Owner:HEWLETT PACKARD DEV CO LP

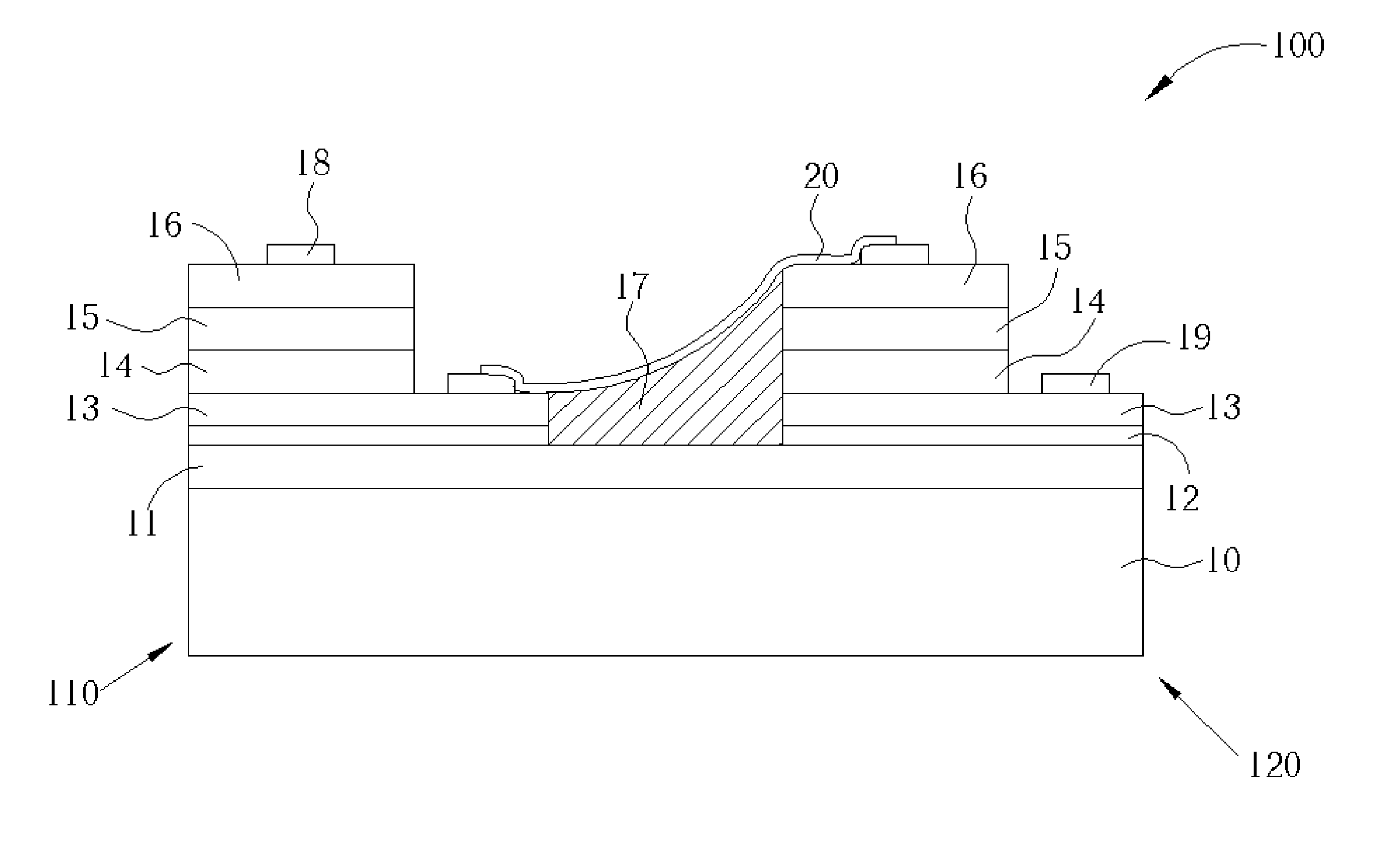

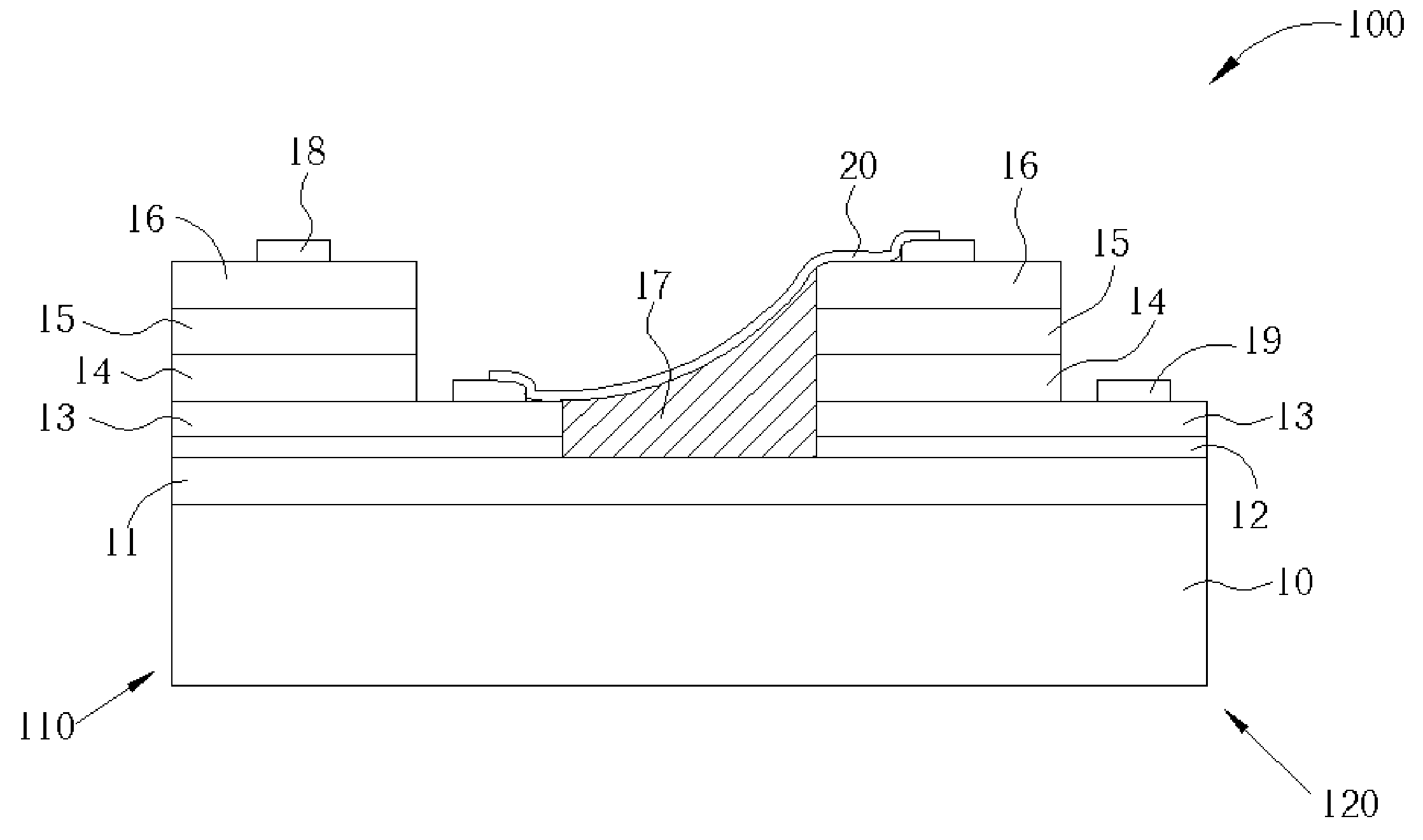

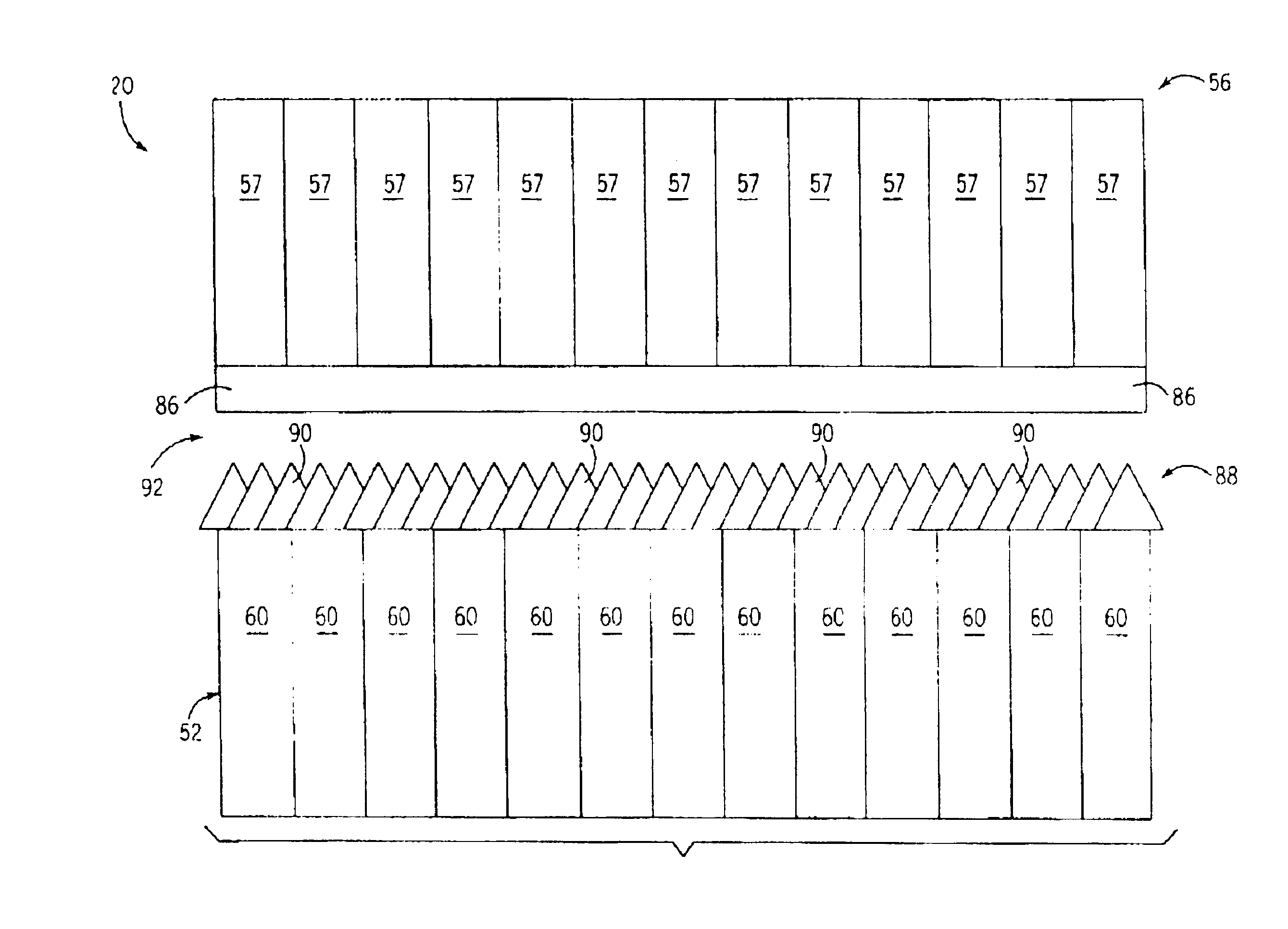

Light-emitting diode array having an adhesive layer

ActiveUS7560738B2Semiconductor/solid-state device detailsSolid-state devicesLight-emitting diodeDiode array

A light-emitting diode array includes a substrate, an adhesive layer formed on the substrate, and a plurality of electrically connected epitaxial light-emitting stack layer disposed on the adhesive layer. Each of the epitaxial light-emitting stack layer has a P-contact and an N-contact coplanar to the P-contact. The light-emitting diode array has improved heat ventilation characteristics.

Owner:EPISTAR CORP

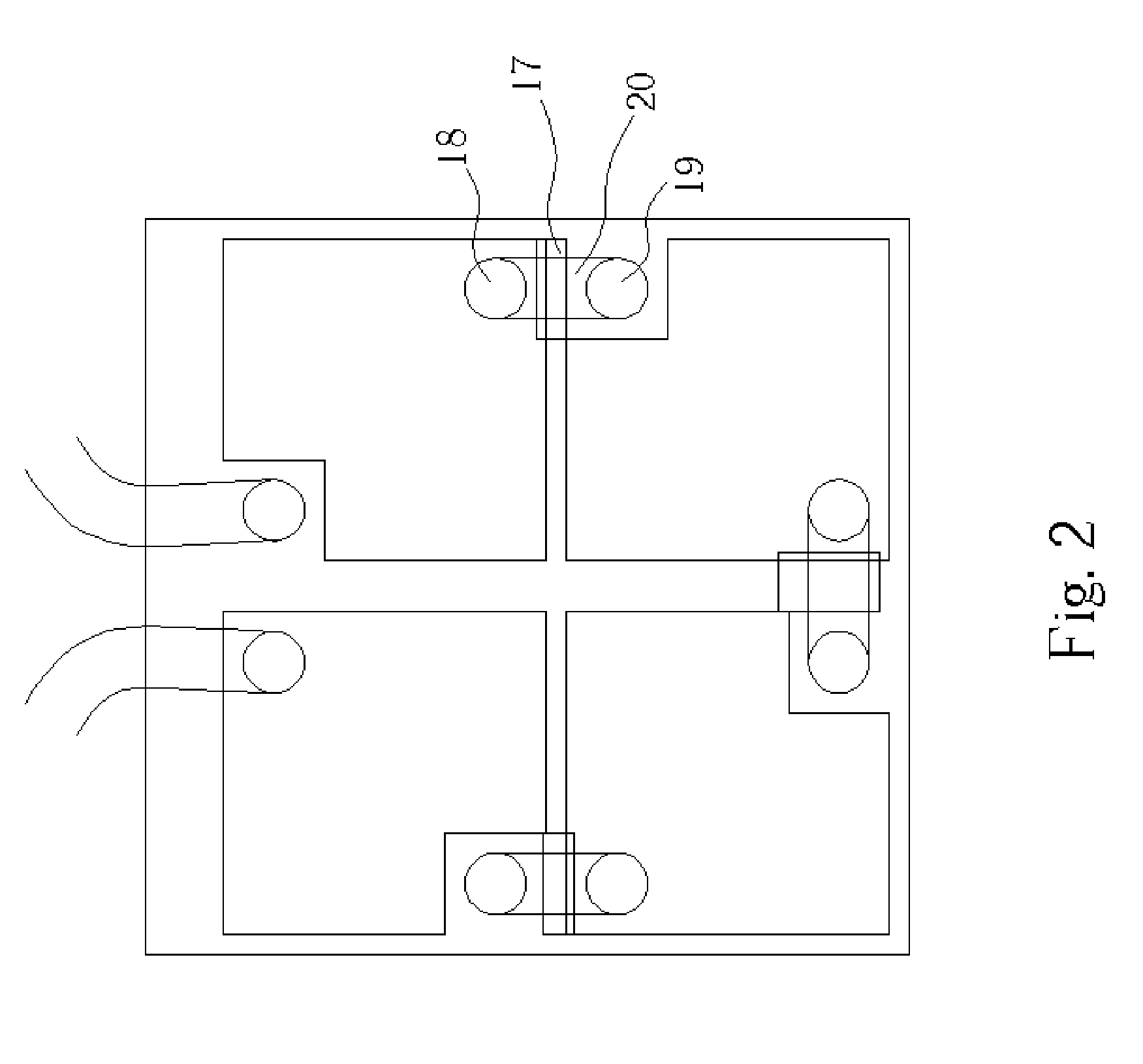

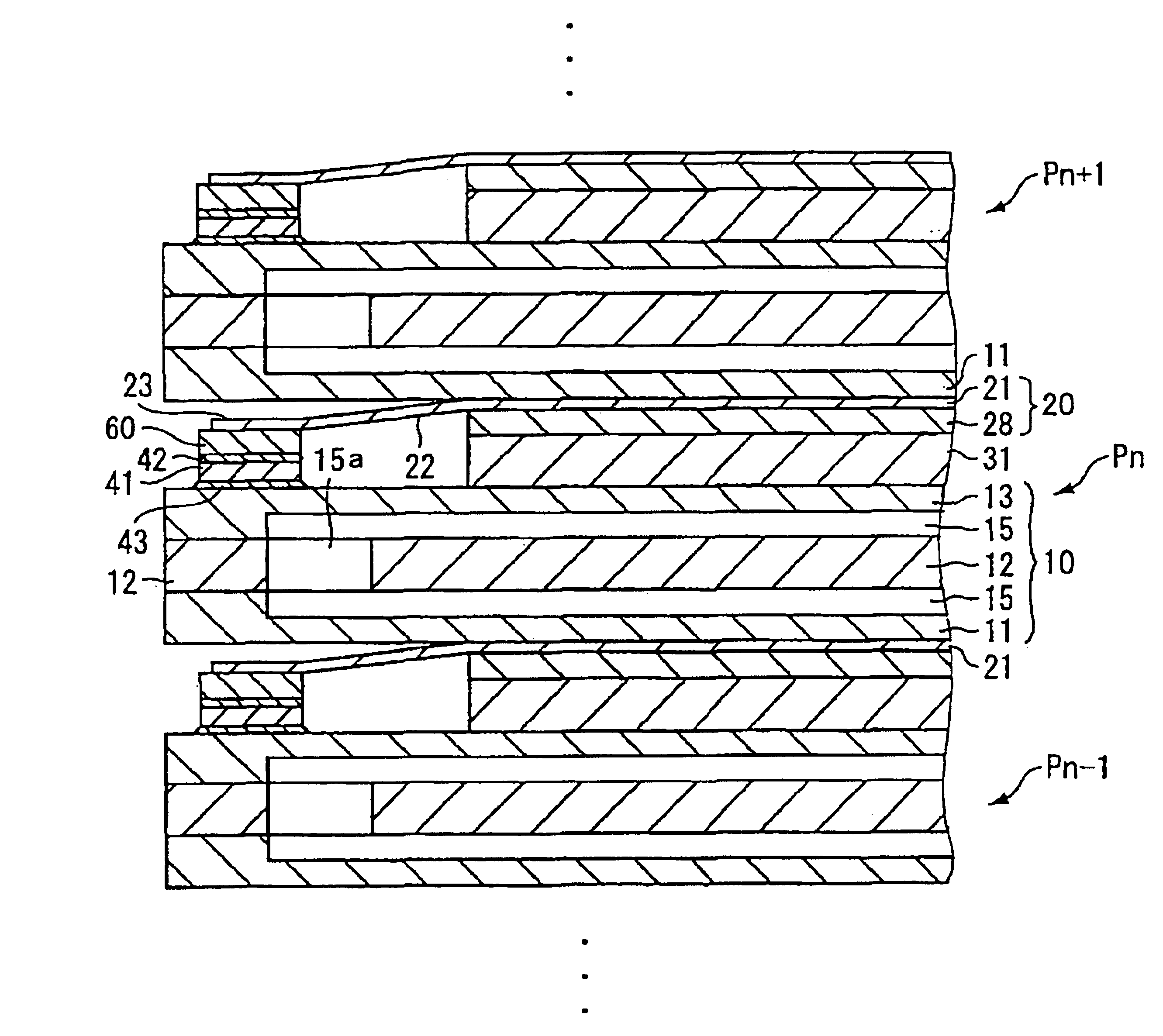

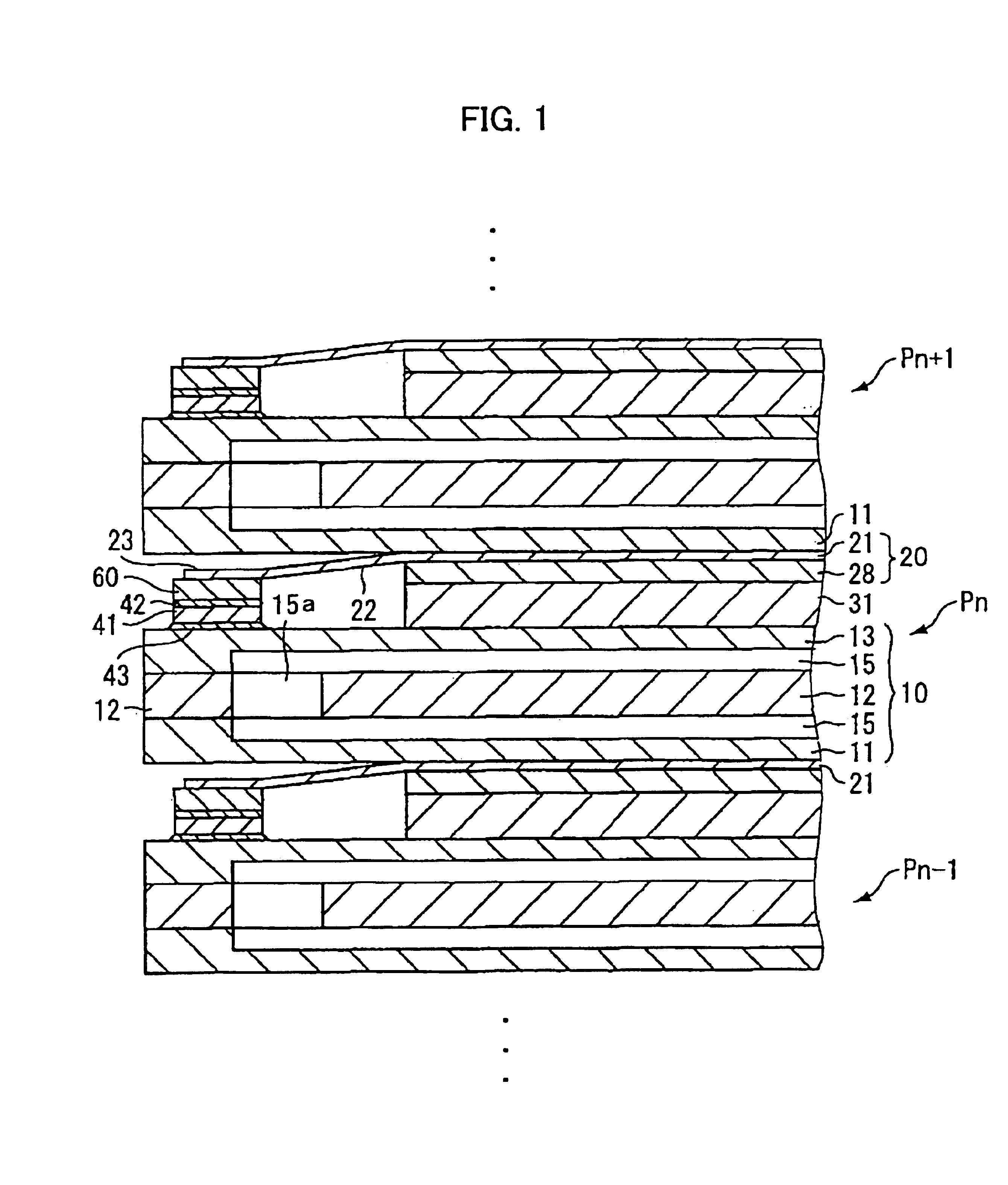

Two-dimensional laser diode array light-emitting device

InactiveUS6934309B2Reduce manufacturing costSimplify the electrical connection structureOptical wave guidanceSemiconductor laser arrangementsManufacturing cost reductionElectrical connection

A two-dimensional LD (laser diode) array light-emitting device constituted by stacking light-emitting units each having a LD bar and a cooling assembly for cooling the LD bar with a simplified electrical connection structure to reduce manufacturing cost. The cooling assembly is electrically connected with one electrode of the LD bar through the die spacer so that a part of the cooling assembly serves as one electrode of the light-emitting unit. The other electrode of the LD bar is electrically connected with a webbed extending section of a conductive layer of a TAB (tape-automated bonding) sheet so that the conductive layer serves as the other electrode of the light-emitting unit. A space between the adjacent cooling assemblies for arranging the LD bar is adjusted by the spacer sheet intervened between the TAB sheet and the cooling assembly.

Owner:FANUC LTD

Front-side illuminated, back-side contact double-sided pn-junction photodiode arrays

ActiveUS20080099871A1Maintain performanceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceSignal-to-noise ratio (imaging)

The present invention is a photodiode detector array for use in computerized tomography (CT) and non-CT applications. Specifically, the present invention is a high-density photodiode arrays, with low dark current, low capacitance, high signal to noise ratio, high speed, and low crosstalk that can be fabricated on relatively large substrate wafers. More specifically the photodiode array of the present invention is fabricated such that the PN-junctions are located on both the front side and back side surfaces of the array, and wherein the front side PN-junction is in electrical communication with the back side PN-junction. Still more specifically, the present invention is a photodiode array having PN-junctions that are electrically connected from the front to back surfaces and which can be operated in a fully depleted mode at low reverse bias.

Owner:UDT SENSORS +1

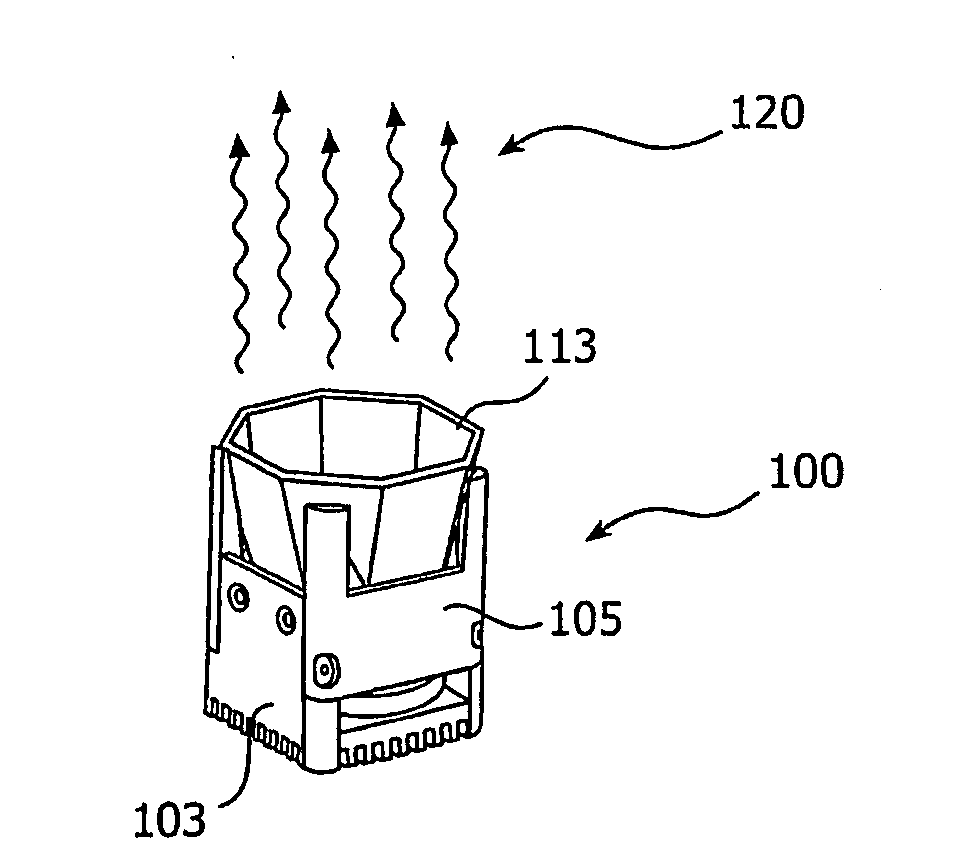

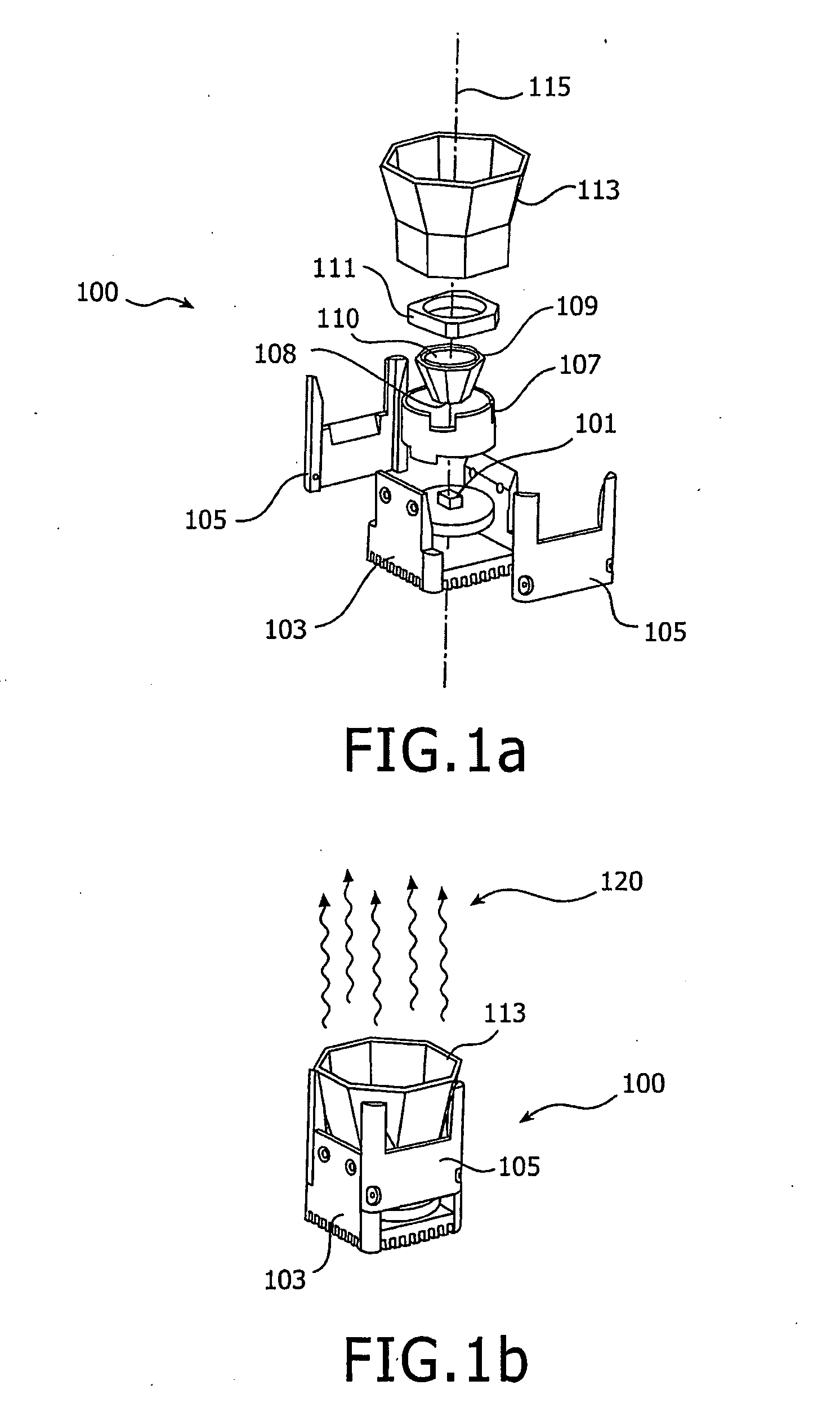

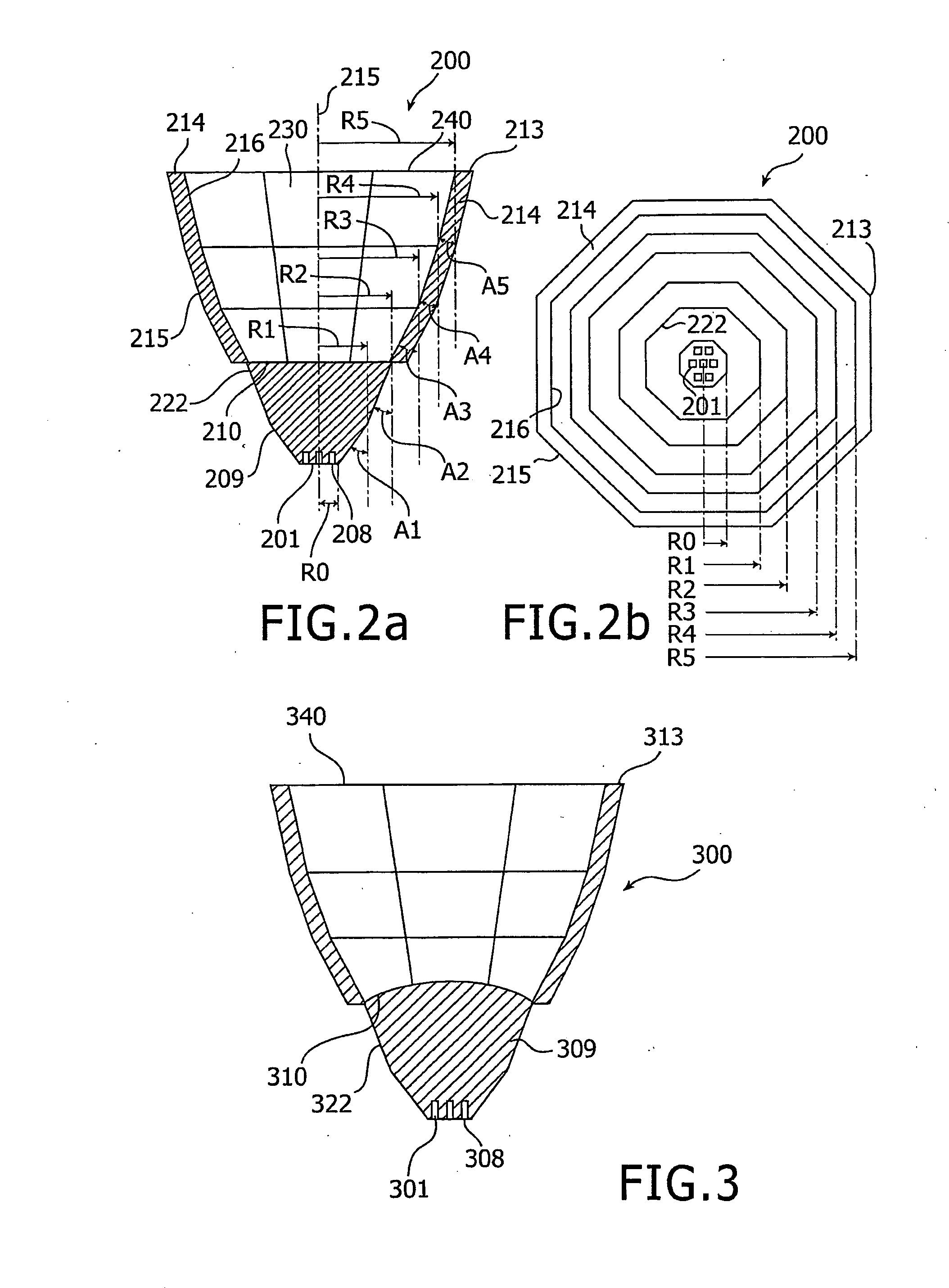

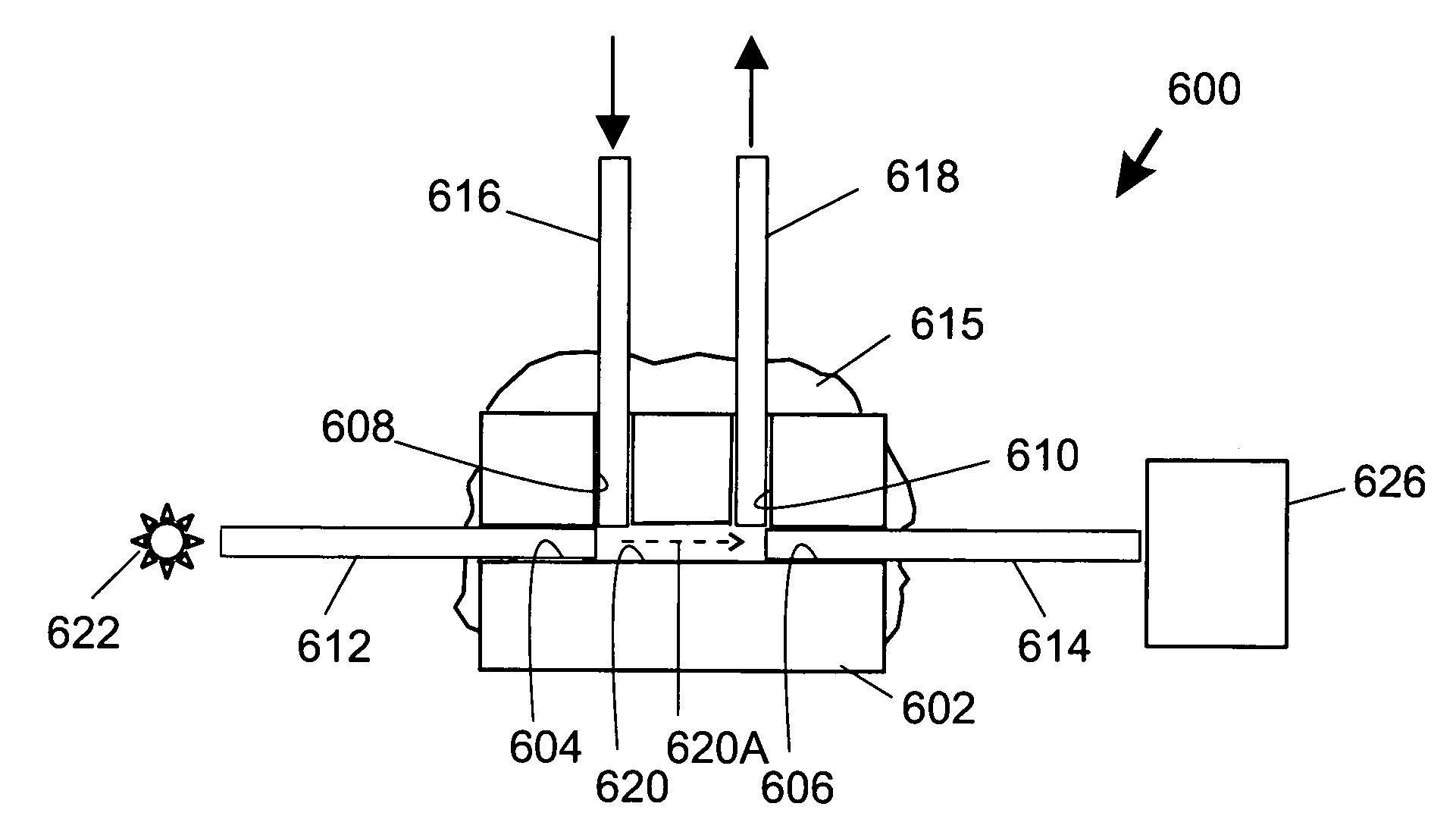

High efficiency LED light source arrangement

InactiveUS20090201677A1Improve efficiencyLittle loss in color homogeneityMirrorsPoint-like light sourceElectricityTotal internal reflection

A light source (100) comprises a number of optical components aligned concentrically along an optical axis (115). The optical components include an array of light emitting diodes (101), a dielectric collimator (109) having surfaces configured to provide total internal reflection of light emitted from the array of diodes, and a second stage reflector (113) to further collimate the beam and which also may be based on total internal reflection by a prism structure on the outside.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Parallel detection chromatography systems

High throughput liquid chromatography systems include multiple separation columns and multiple flow-through detection regions in sensory communication with a common radiation source and a multi-channel detector. Preferred detector types include a multi-anode photomultiplier tube, a charge-coupled device detector, a diode array, and a photodiode array. In certain embodiments, separation columns are microfluidic and integrated into a unitary microfluidic device. The optical path through a detection region is preferably coaxial with the path of eluate flow along a flow axis through a detection region. On-board or off-board detection regions may be provided.

Owner:AGILENT TECH INC

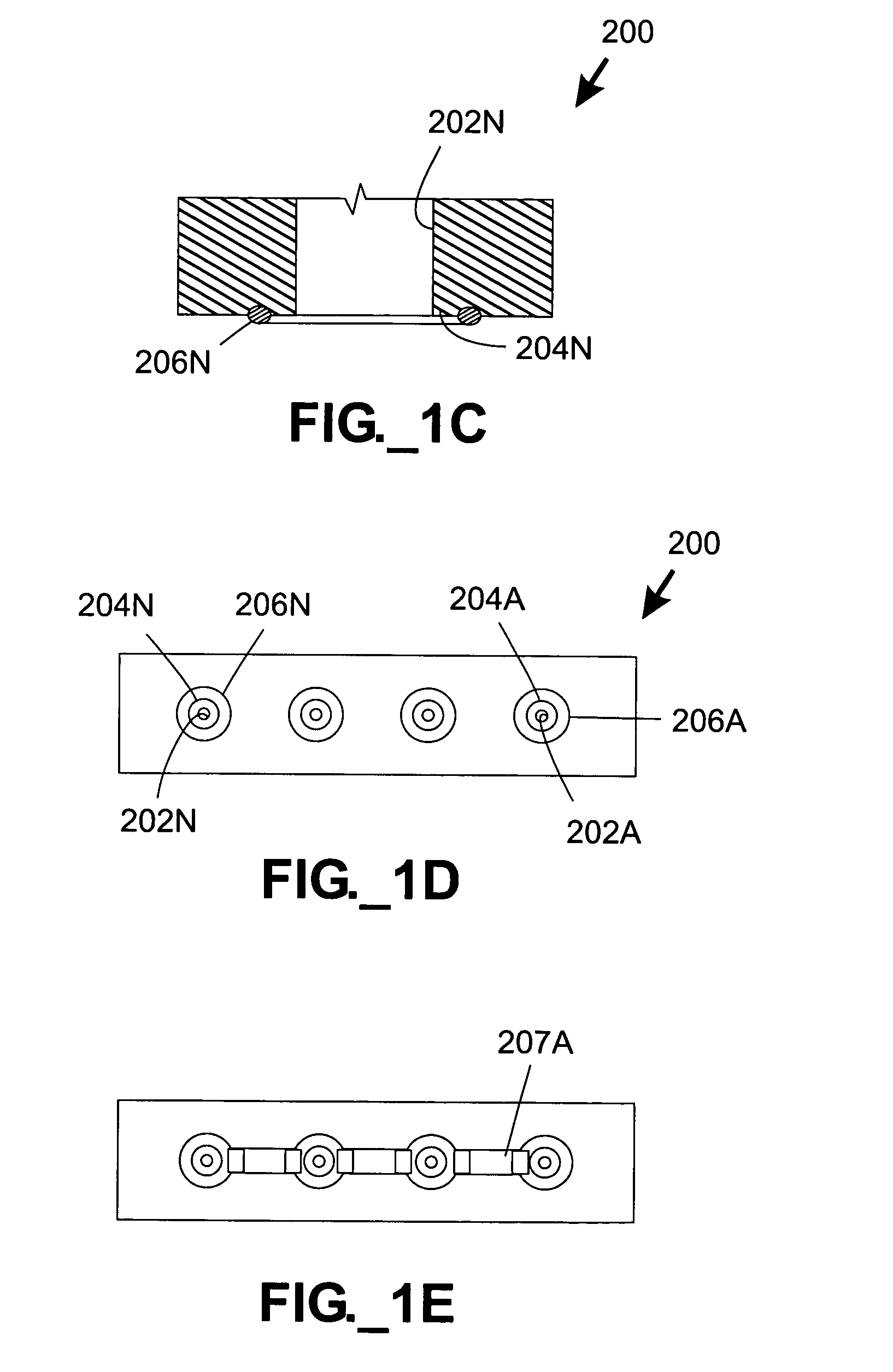

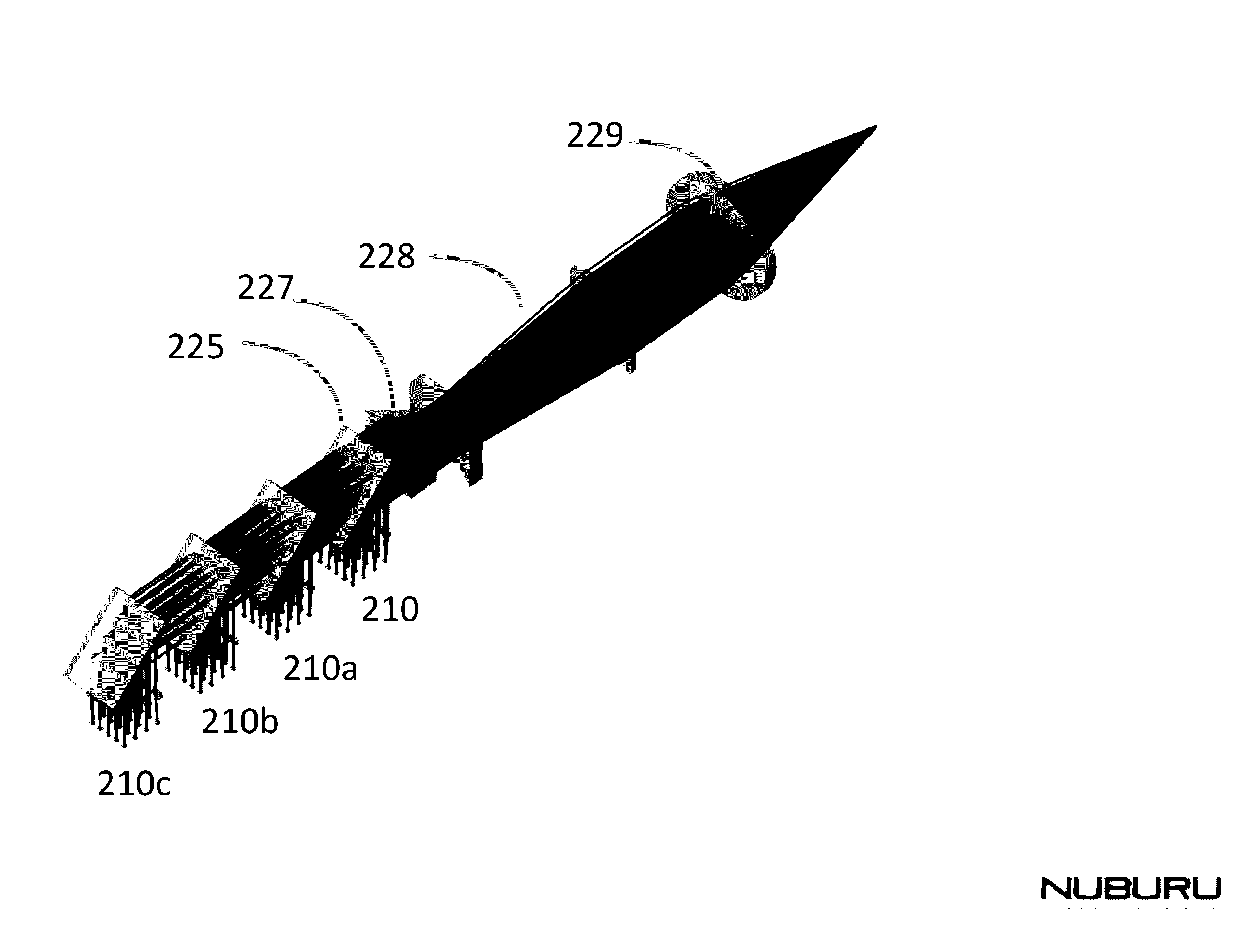

Applications, methods and systems for a laser deliver addressable array

ActiveUS20160322777A1Improve Raman conversion efficiencyHinders its propagationAdditive manufacturing apparatusLaser using scattering effectsLaser processingLaser array

There is provided assemblies for combining a group of laser sources into a combined laser beam. There is further provided a blue diode laser array that combines the laser beams from an assembly of blue laser diodes. There are provided laser processing operations and applications using the combined blue laser beams from the laser diode arrays and modules.

Owner:NUBURU INC

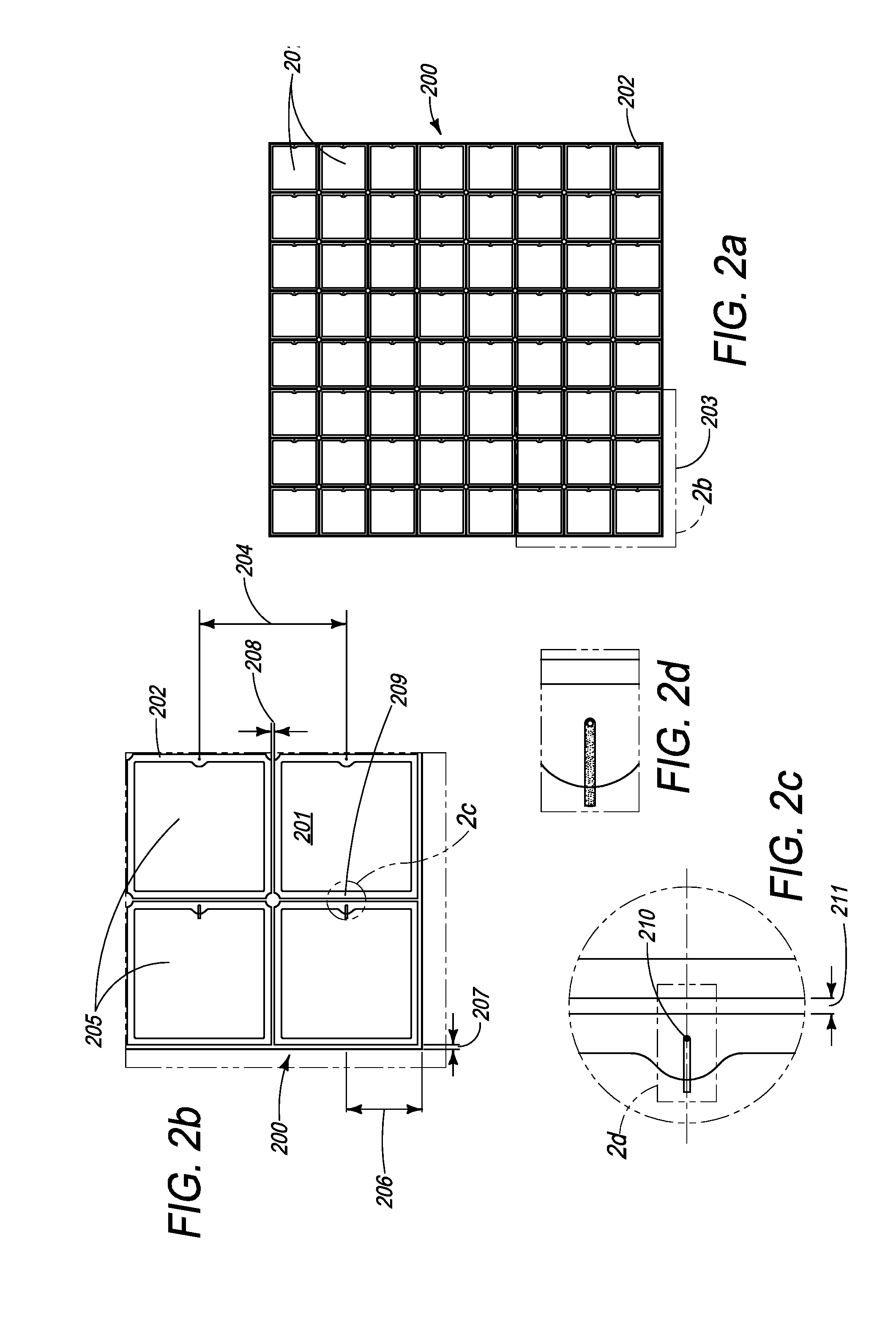

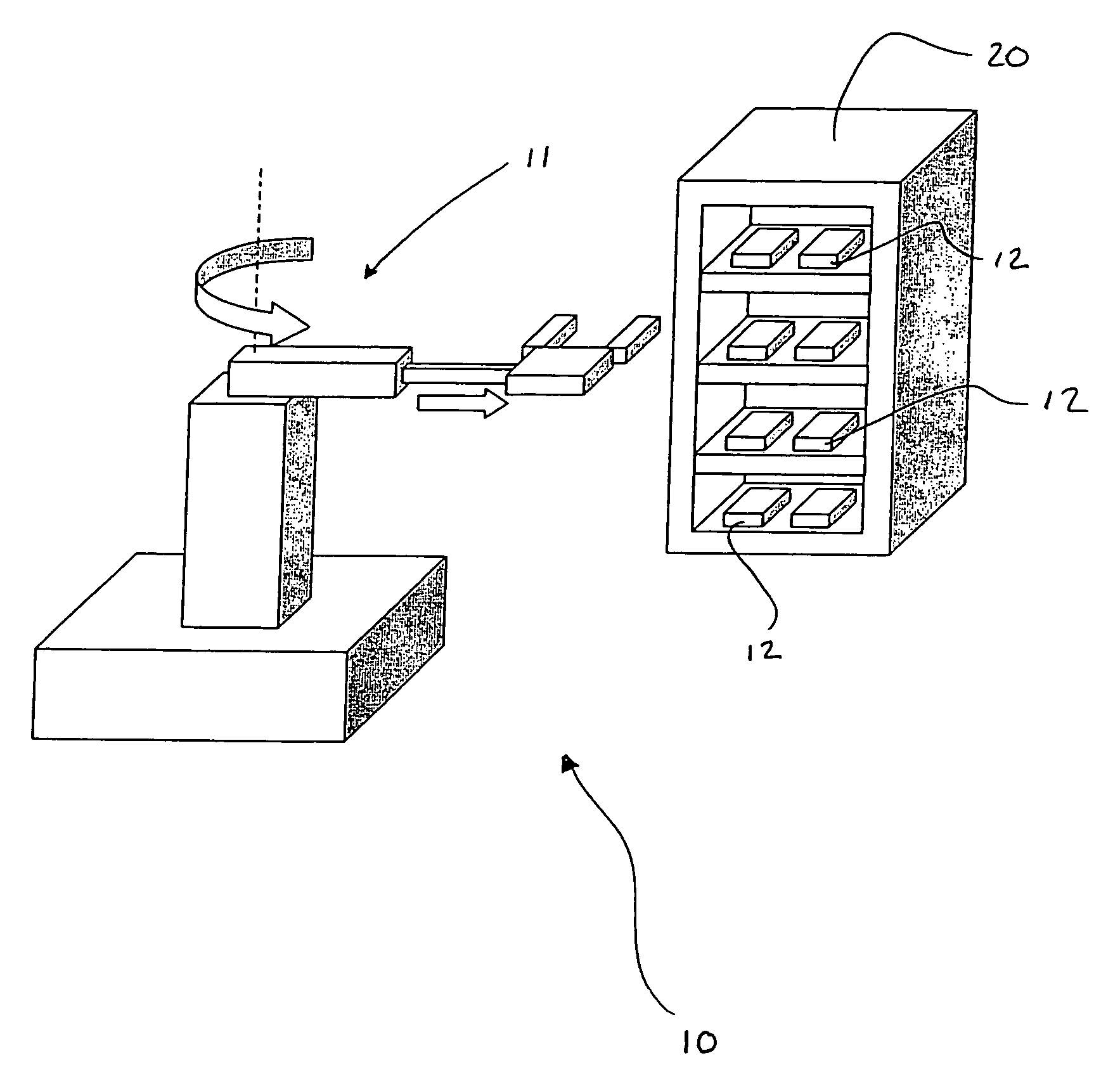

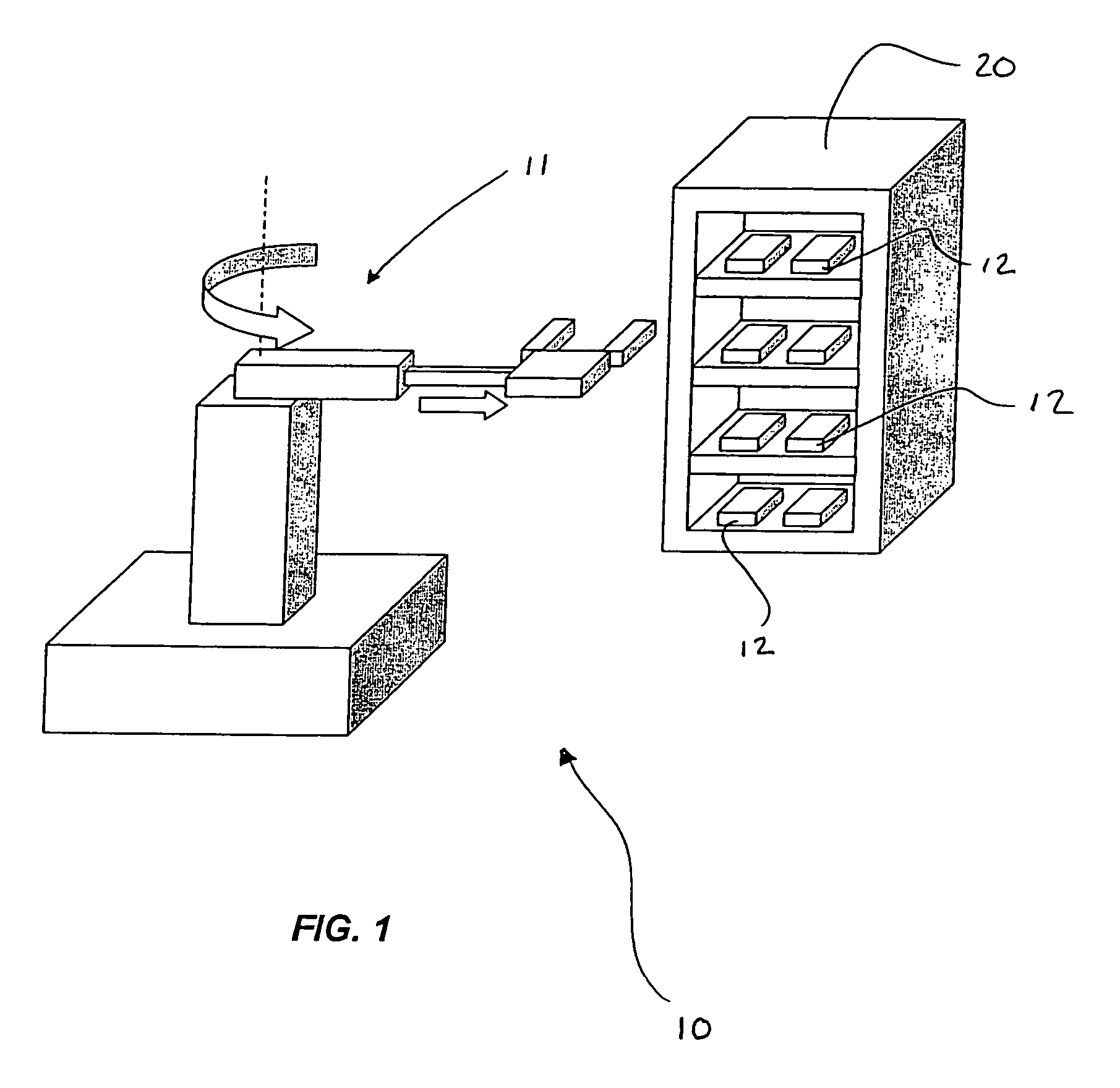

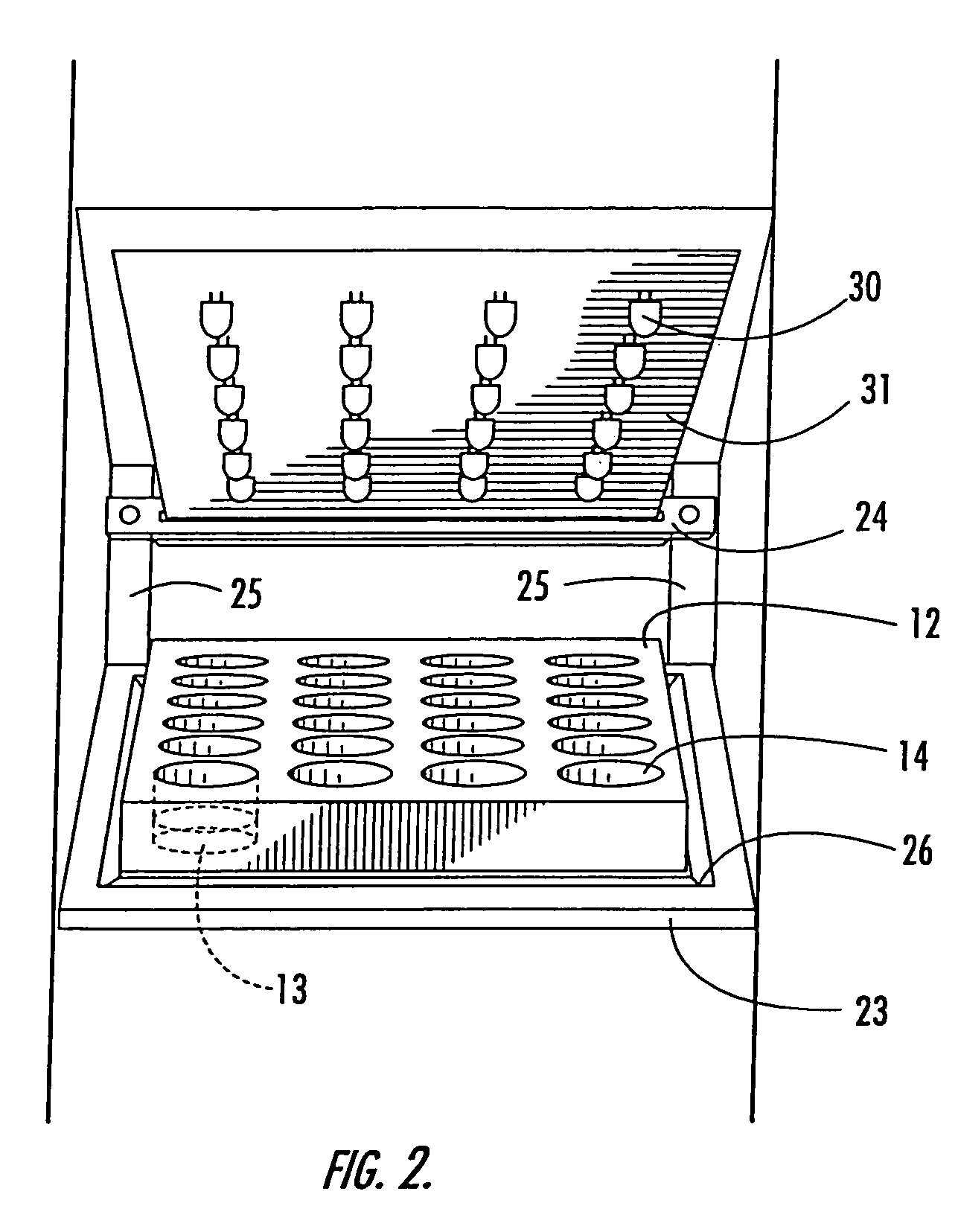

LED array for illuminating cell well plates and automated rack system for handling the same

InactiveUS7160717B2Improve storage efficiencyReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellPlant tissue

An assembly for promoting the growth of plant tissues that includes a plurality of plates each defining an array of wells wherein each of the wells contains a tissue sample. Support for the plates is provided by a rack having a plurality of vertically stacked shelves that may include one or more register depressions that urge the plates into predetermined positions. Light for the tissue samples is provided by a plurality of light-emitting diode arrays each mounted on a circuit board. Each circuit board is supported by a respective card edge connector of the rack so that the light-emitting diodes are in proximity to the plates supported on one of the shelves therebelow. Preferably, the light-emitting diode array corresponds to the well array supported in the registered position on the shelf therebelow so that each light-emitting diode is centered above a respective one of the wells.

Owner:BIOLEX THERAPEUTICS INC

Schottky barrier diode and diode array

ActiveUS20060108659A1Lower resistanceReduce chip areaSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSchottky barrier

A Schottky barrier diode includes a first semiconductor layer and a second semiconductor layer successively formed above a semiconductor substrate with a buffer layer formed between the first and second semiconductor layers and the semiconductor substrate. A Schottky electrode and an ohmic electrode spaced from each other are formed on the second semiconductor layer, and a back face electrode is formed on the back face of the semiconductor substrate. The Schottky electrode or the ohmic electrode is electrically connected to the back face electrode through a via penetrating through at least the buffer layer.

Owner:PANASONIC CORP

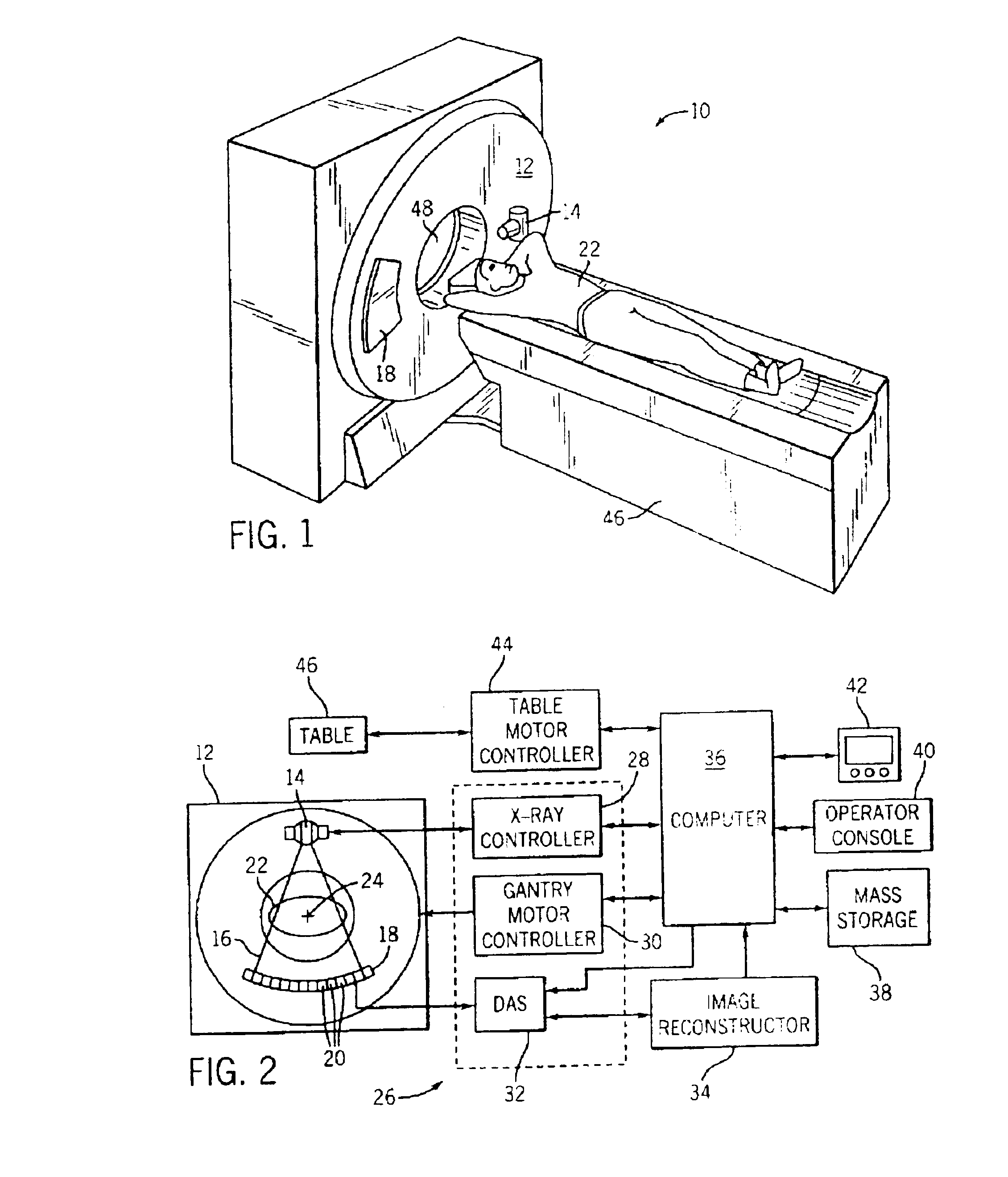

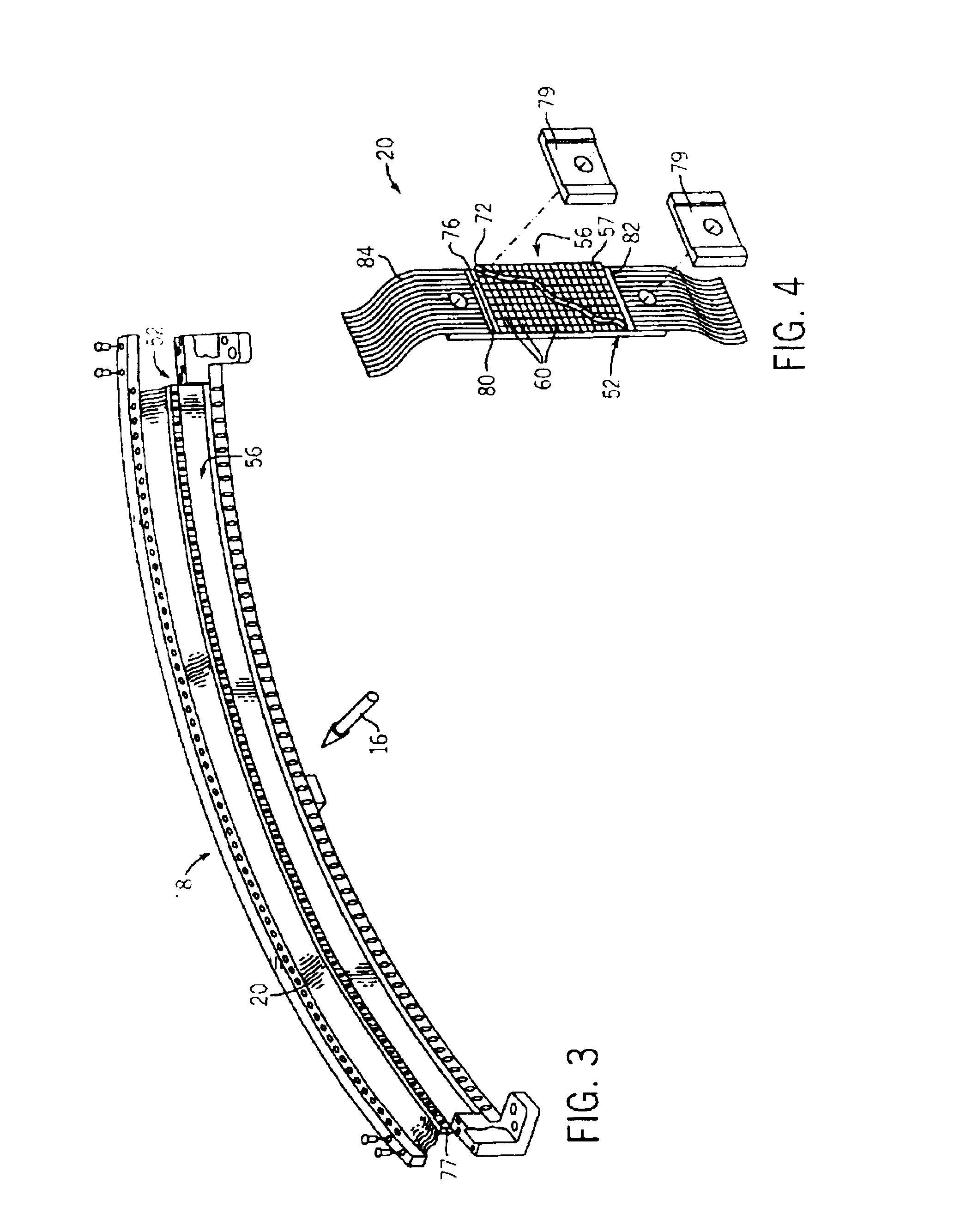

CT detector with integrated air gap

InactiveUS6907101B2Enhanced light absorptionImprove light collectionTelevision system detailsSolid-state devicesScintillatorPhotodiode

The present invention is directed to an improved CT detector scintillator to photodiode optical coupling. The CT detector utilizes a controlled air gap between the photodiode array and the scintillator array together with an anti-reflective layer on the scintillator array. To improve the absorption of light at the photodiode array, the photodiode array includes a textured light reception surface. By incorporating a textured layer with the photodiode array, the light collection efficiency of the photodiodes is improved. The textured layer may extend along an x- and / or z-axis and the texturing may be in different forms. For example, the textured layer may include a series of pyramidally-shaped protrusions.

Owner:GENERAL ELECTRIC CO

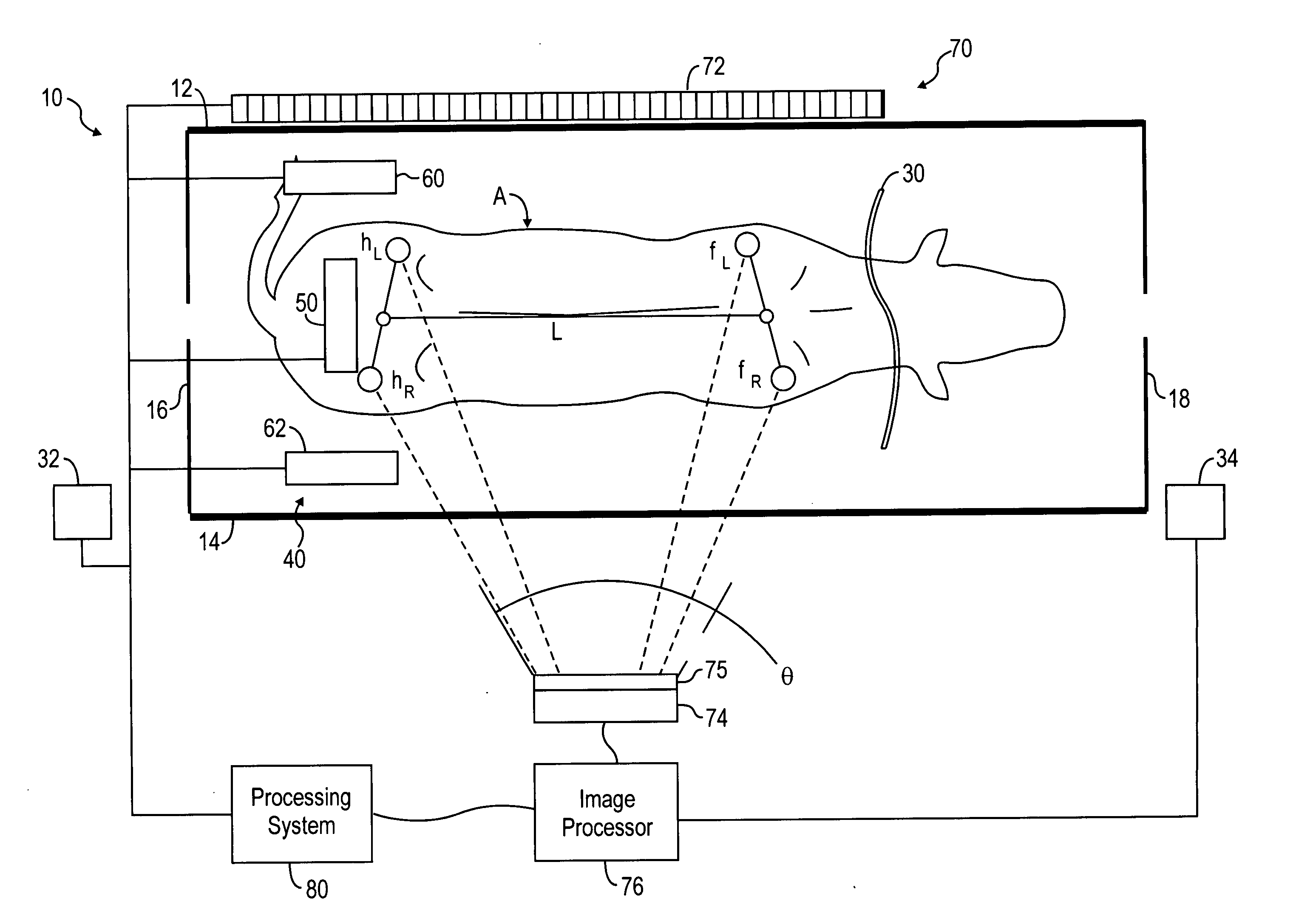

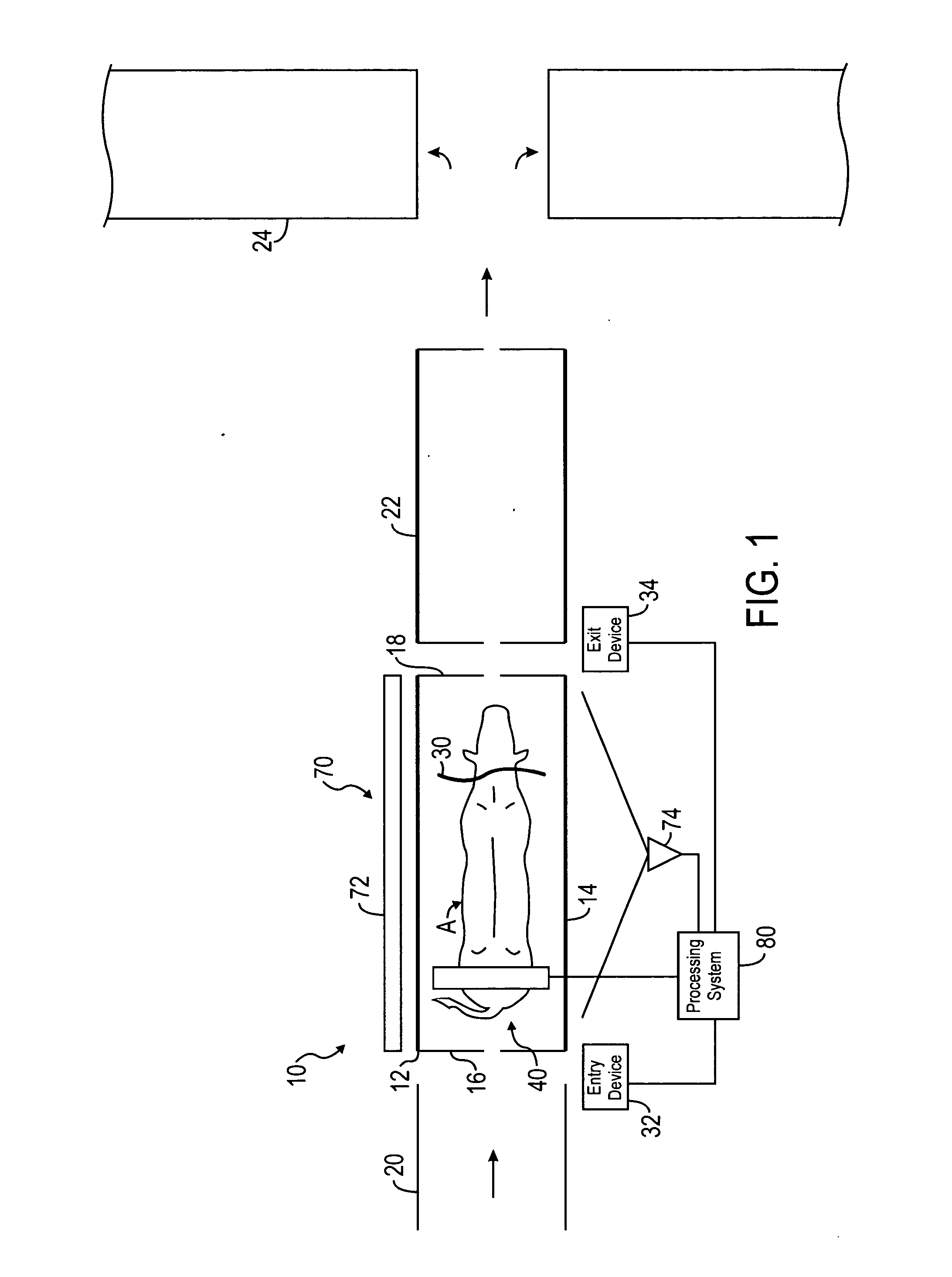

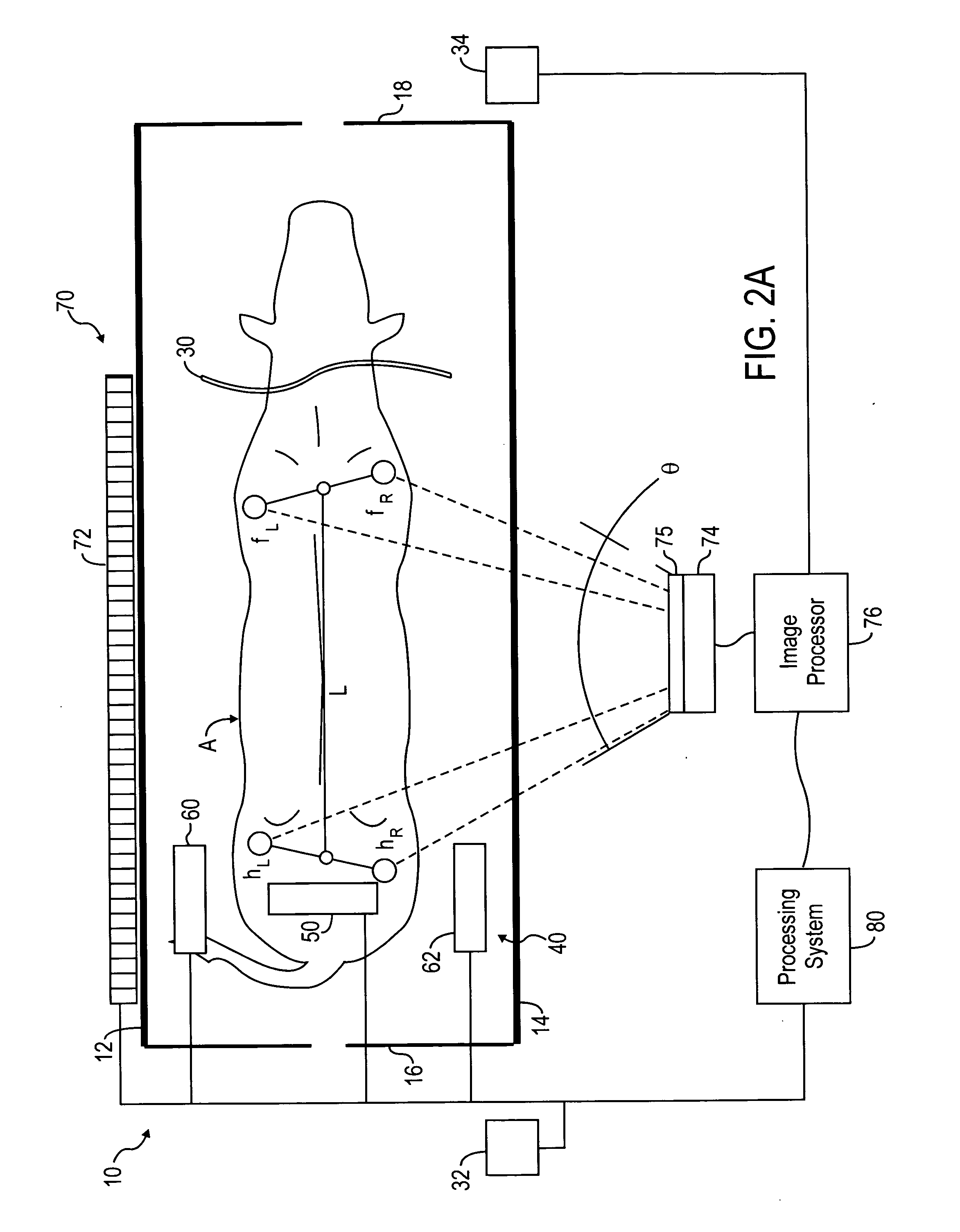

System and method for measuring animals

A system and method for measuring an animal includes a light source and an optical source. The light source, which is preferably an array of monochromatic light emitting diodes, at least partially backlights one or more of the animal's legs. The optical sensor or device, which is preferably a single dimension camera or charged-coupled device, opposes the light source and obtains an image that includes silhouettes of one or more legs of the animal. A processor, such as a computer with software and data storage, determines measurements, such as the approximate skeletal trunk length of the animal, from the silhouetted legs in the image. One or more first ultrasound transducers can be arranged to determine an approximate height of the pelvic region, and one or more second ultrasound transducers can be arranged to determine an approximate width of the pelvic region.

Owner:DOYLE II JOHN CONAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com