Patents

Literature

54results about How to "Reduce lateral distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

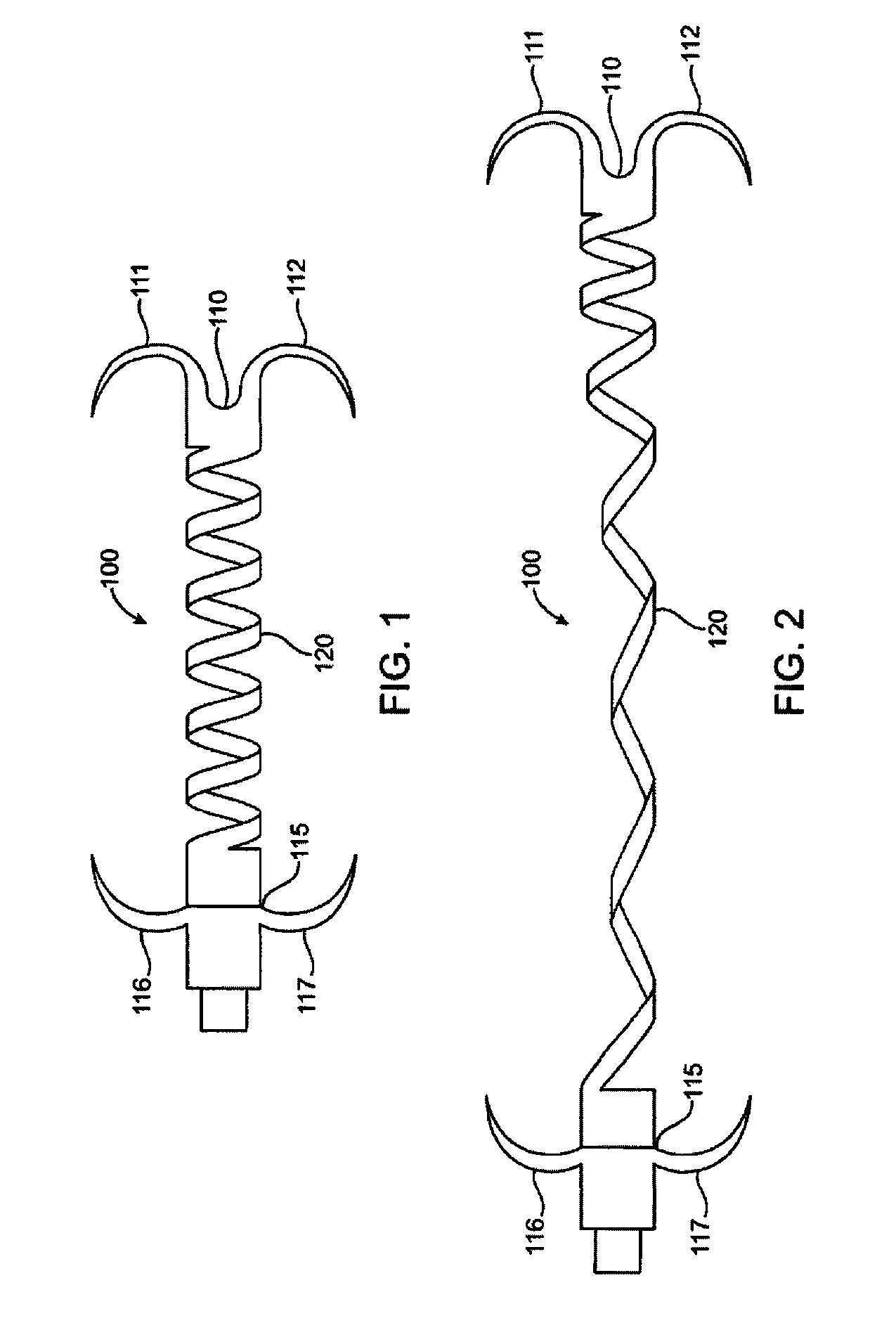

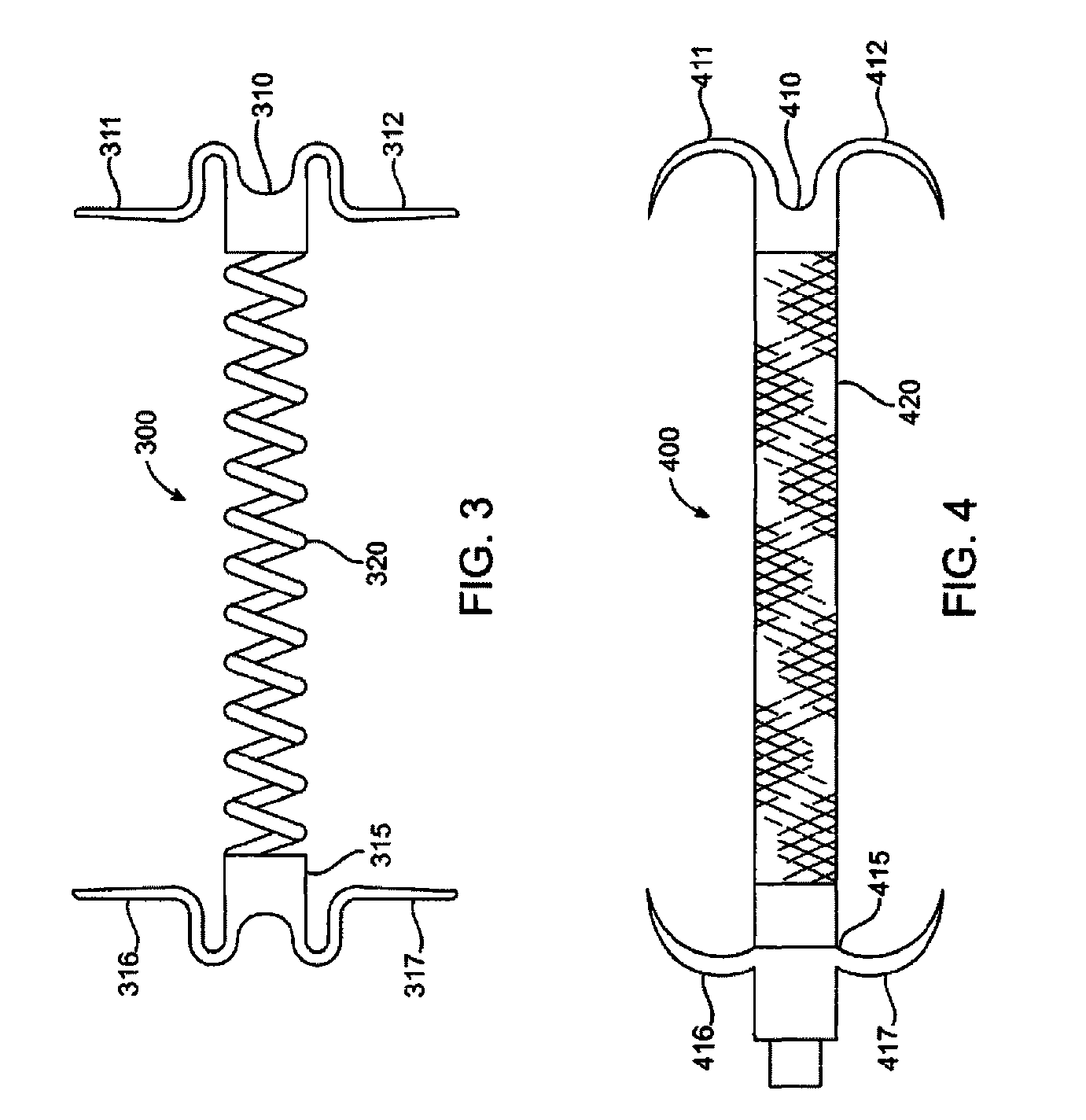

System for Treating Mitral Valve Regurgitation

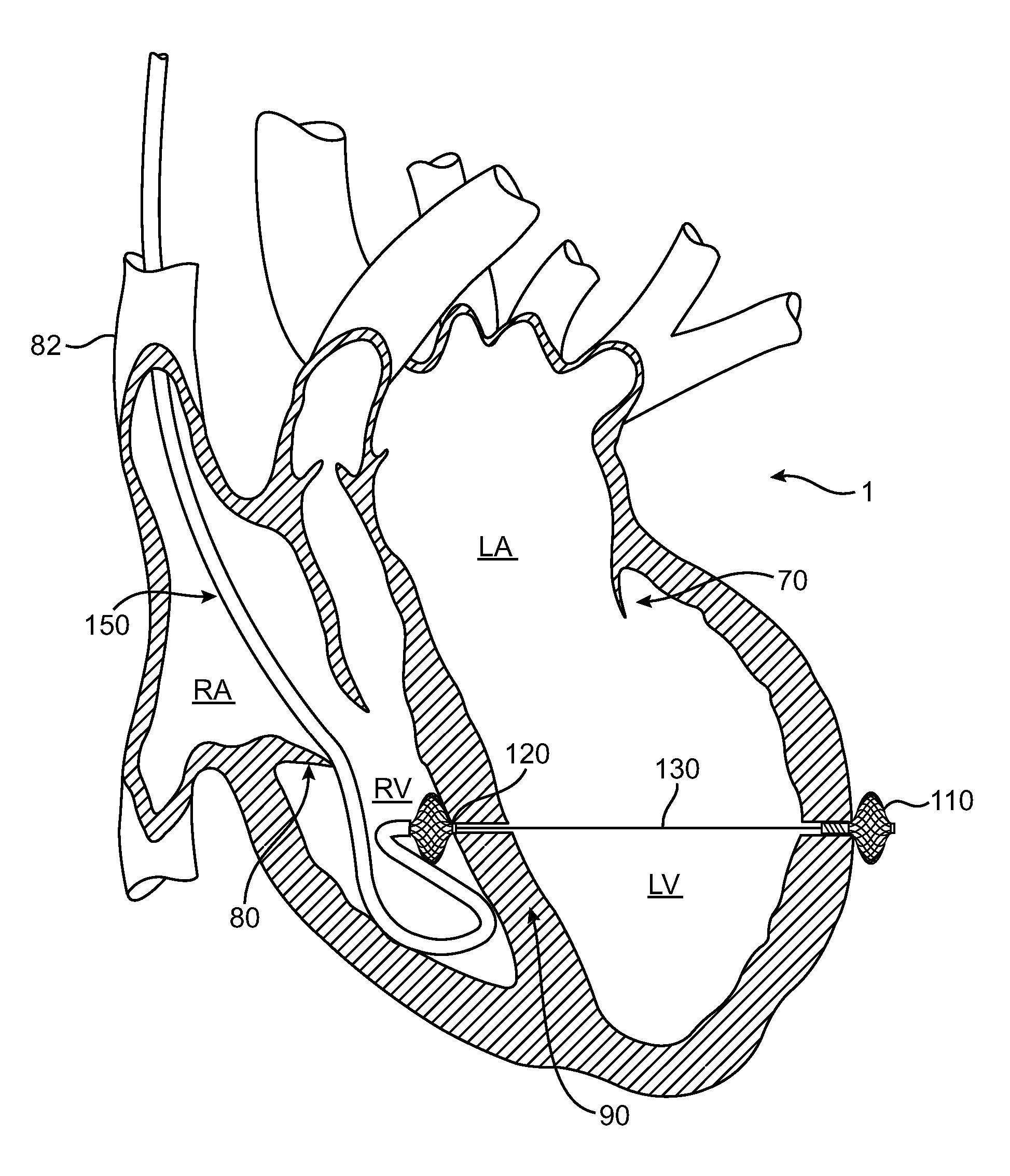

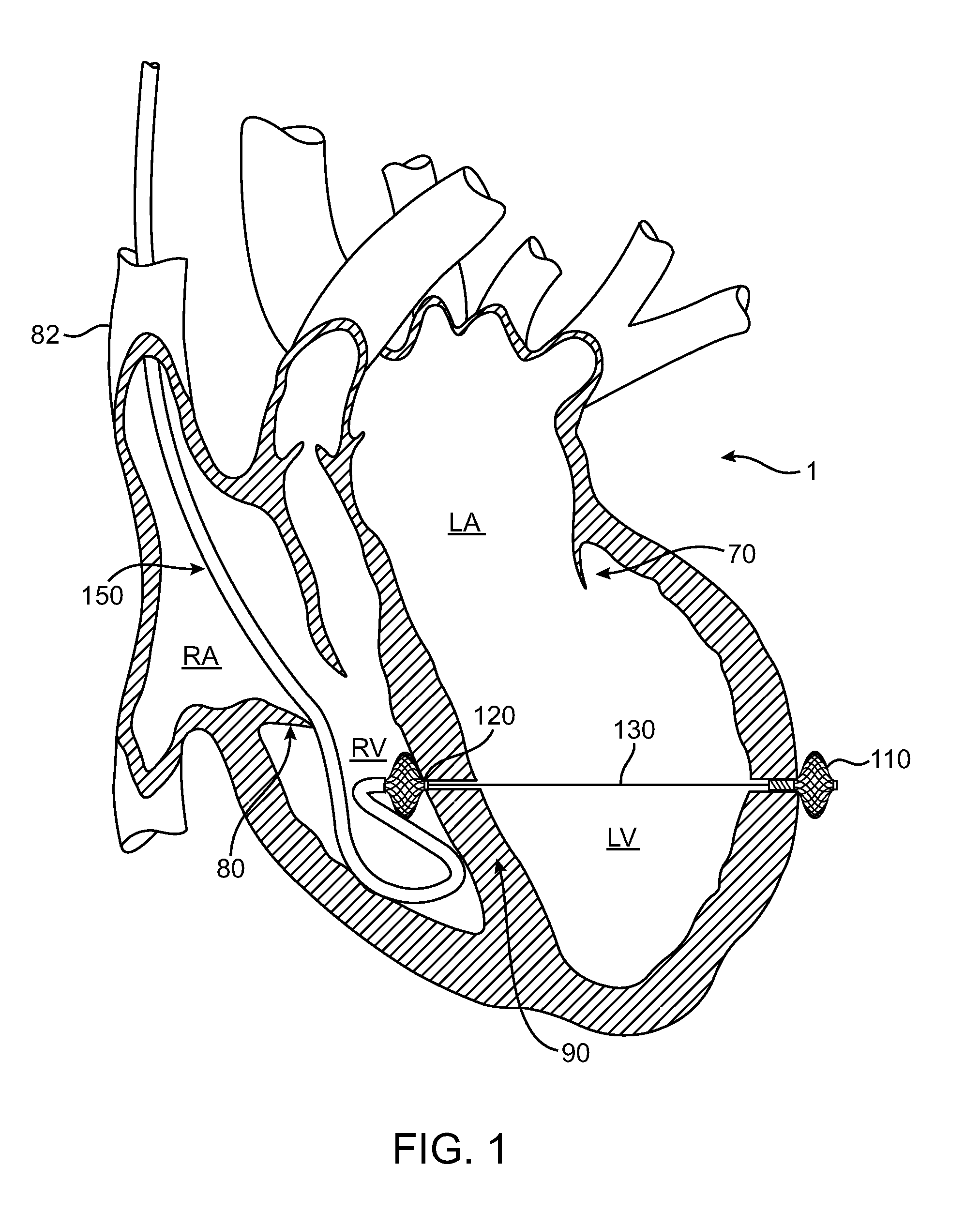

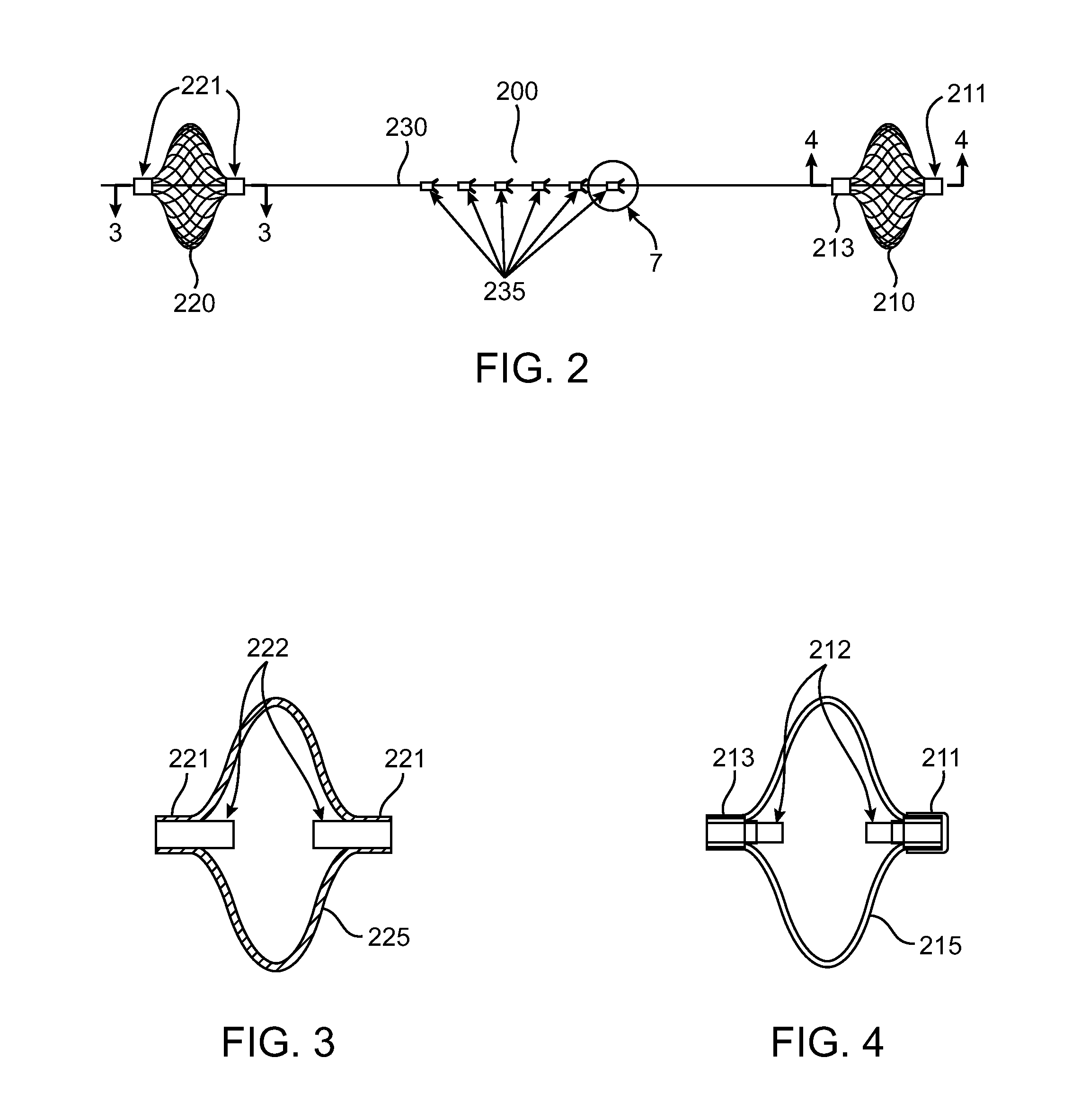

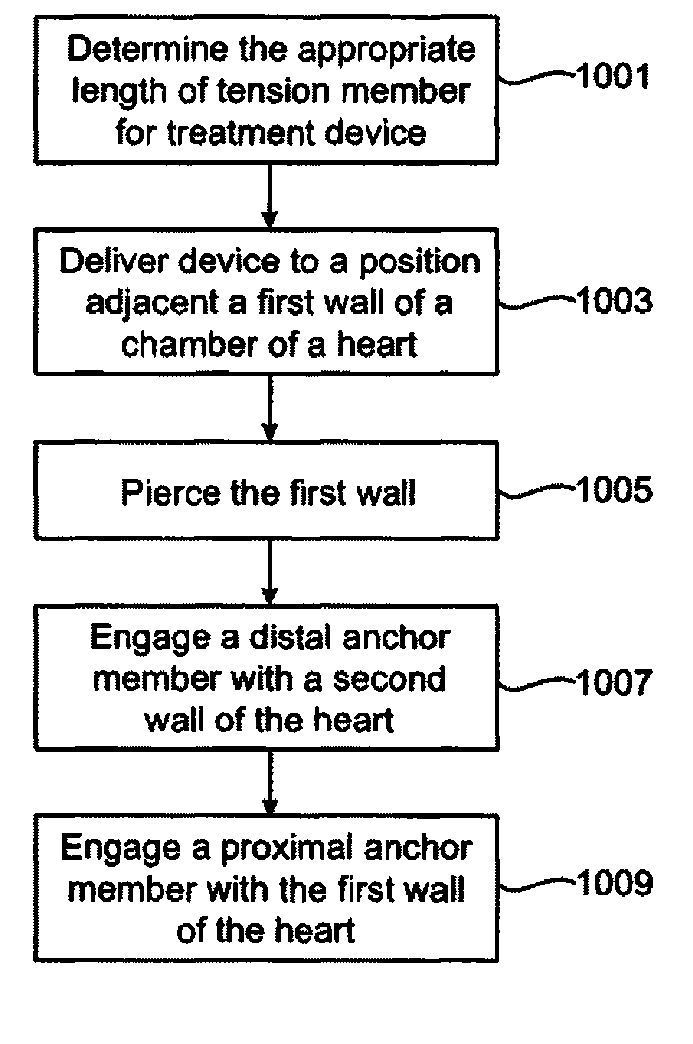

InactiveUS20070203391A1Reduce lateral distanceConstant tensionSuture equipmentsSurgical needlesTension memberLeft Ventricles

A system for treating mitral valve regurgitation comprising at least delivery catheters, puncture catheters, and tensioning devices. The devices include tension members linking a proximal anchor and distal anchor that can be constructed from a tubular braded material and have internal reinforcing members. In some embodiments, the anchors and tension members may flex in response to a heart beat. The system can also include temporary anchors so a clinician can review and adjust the vector of the tension member. Delivery catheters can also include temporary anchors to secure the catheter in position. When positioned across the left ventricle of a heart, the device can reduce the lateral distance between the walls of the ventricle and thus allow better coaption of the mitral valve leaflets thereby reducing heart valve regurgitation.

Owner:MEDTRONIC VASCULAR INC

Device for Treating Mitral Valve Regurgitation

InactiveUS20070078297A1Reduce lateral distanceEasy to deploySuture equipmentsHeart valvesHeart chamberTension member

Owner:MEDTRONIC VASCULAR INC

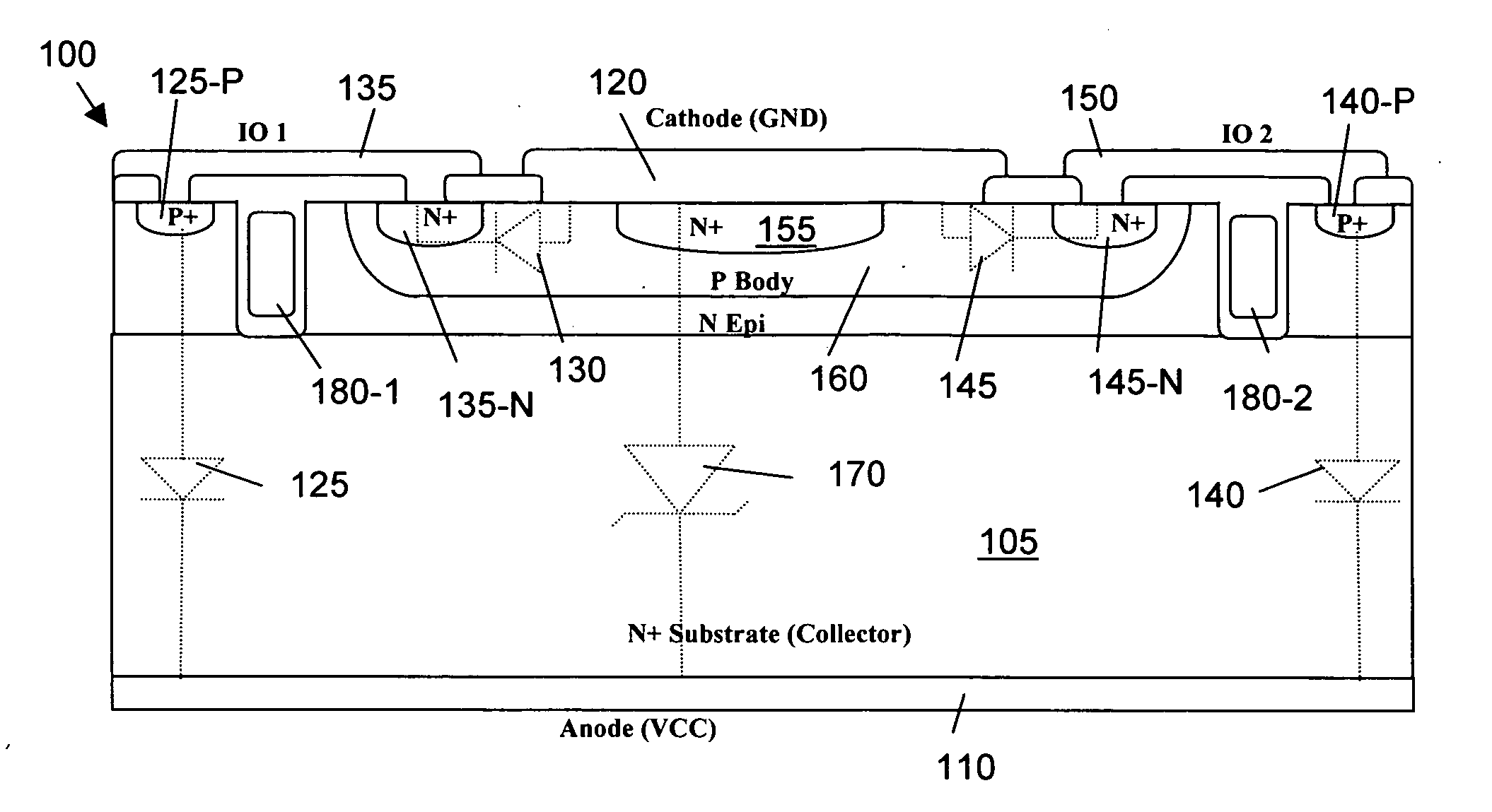

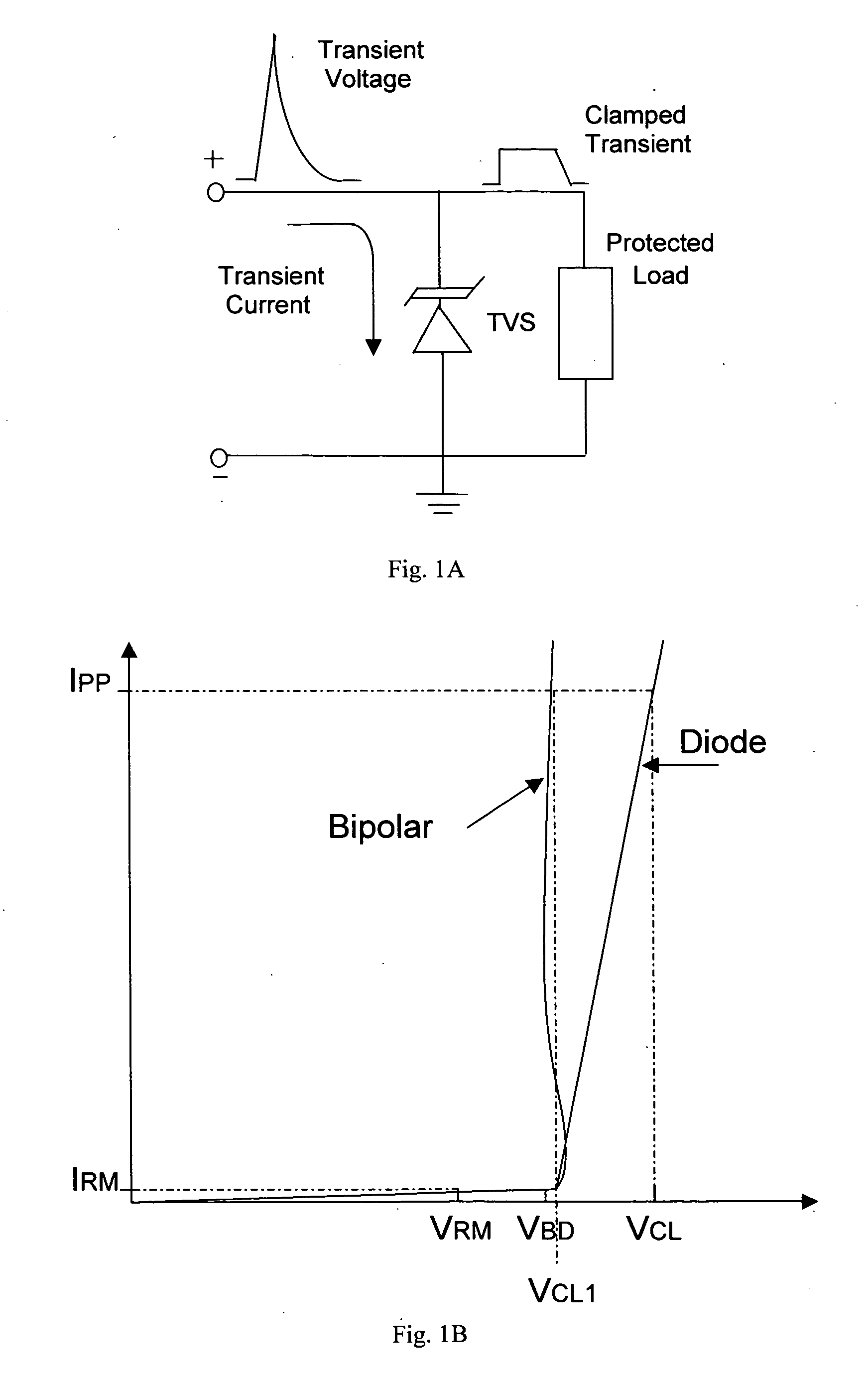

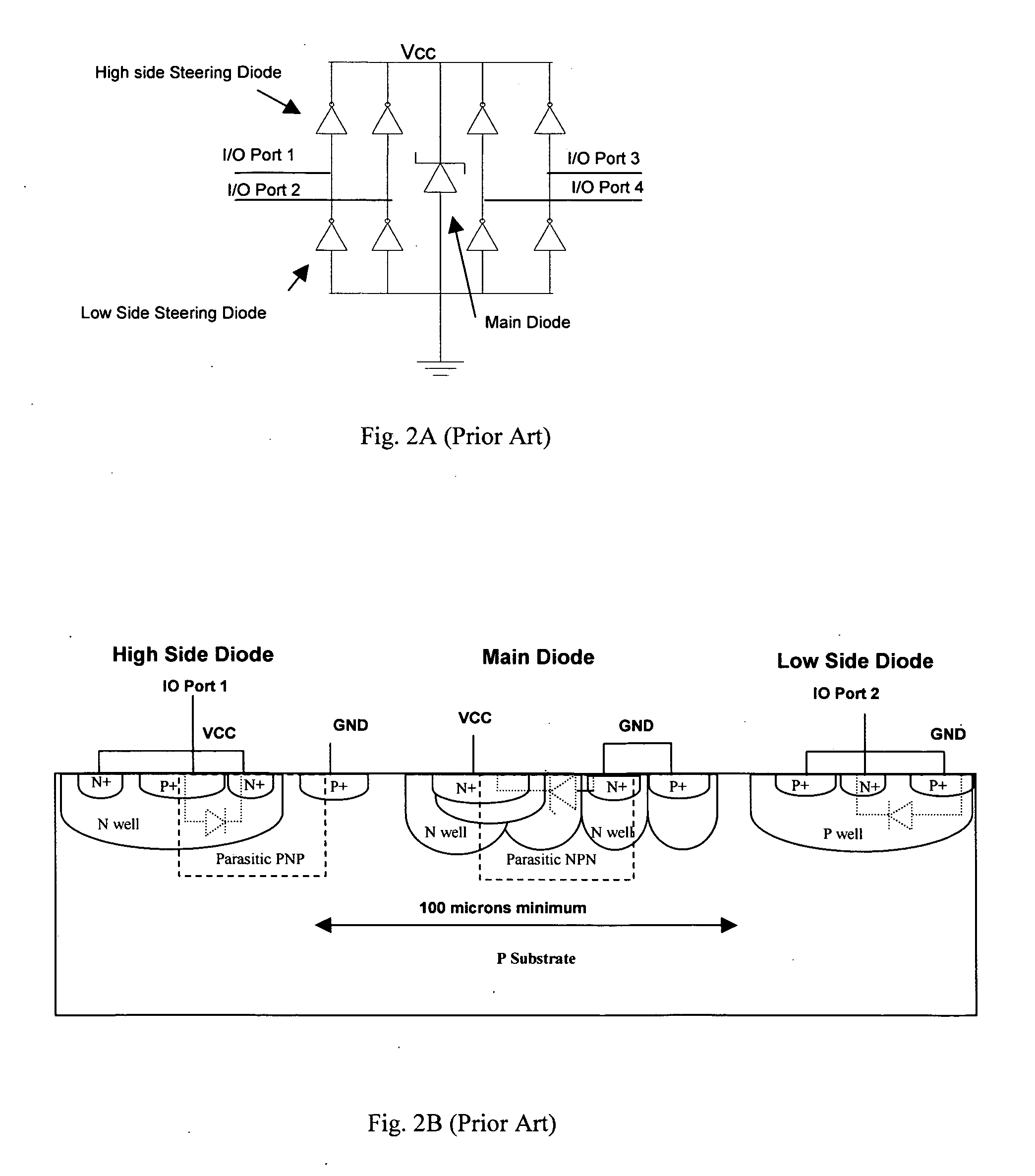

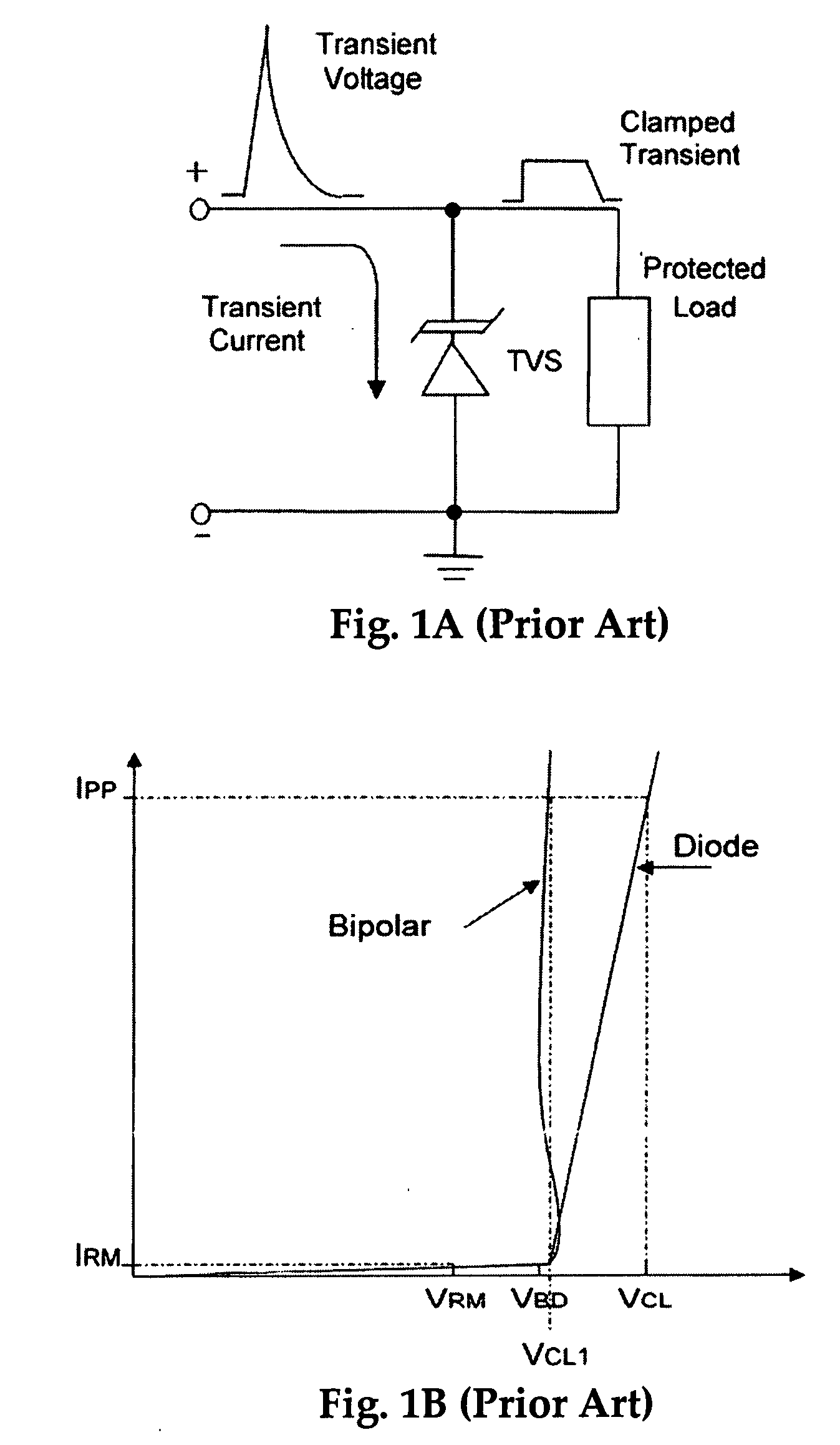

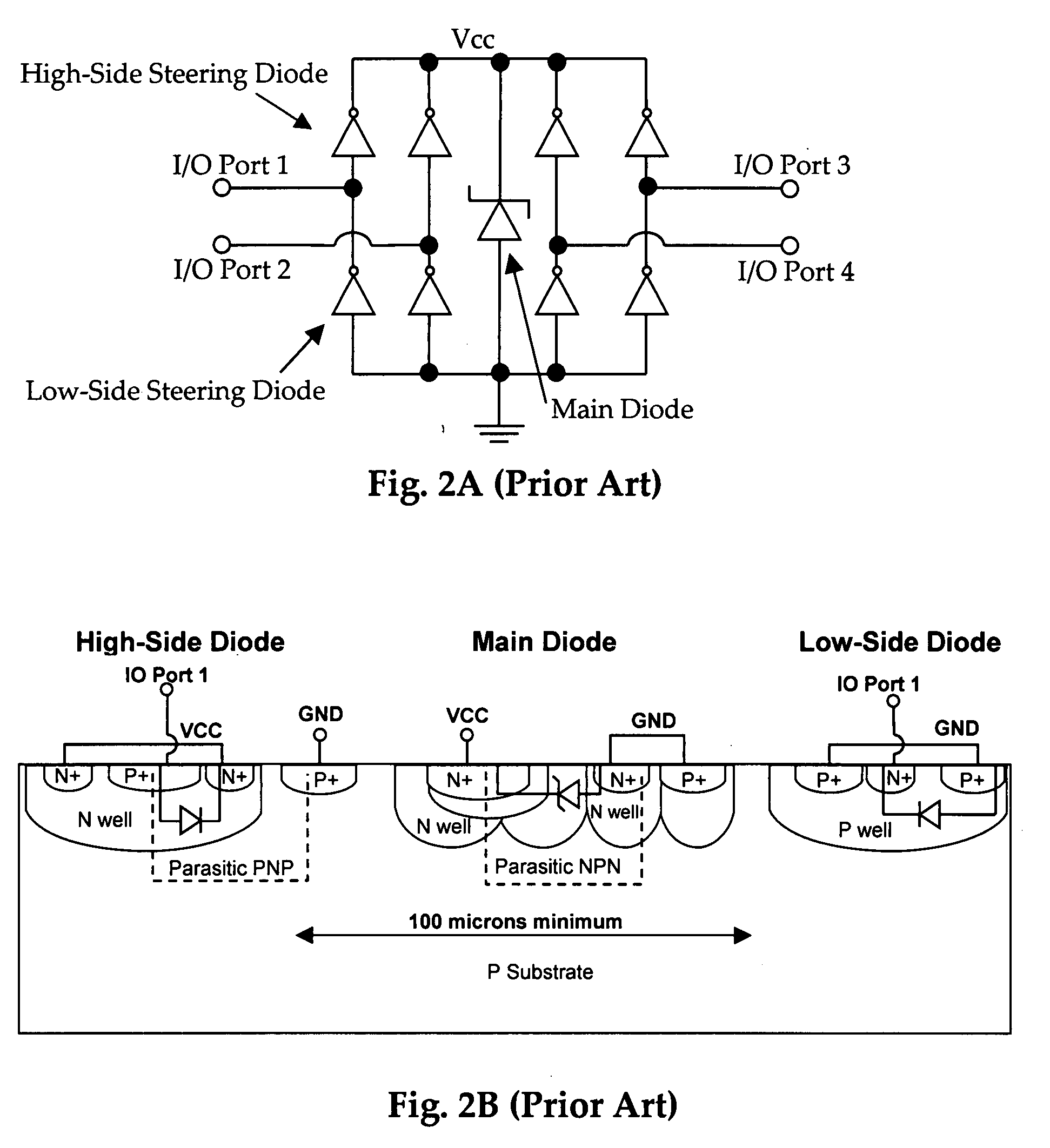

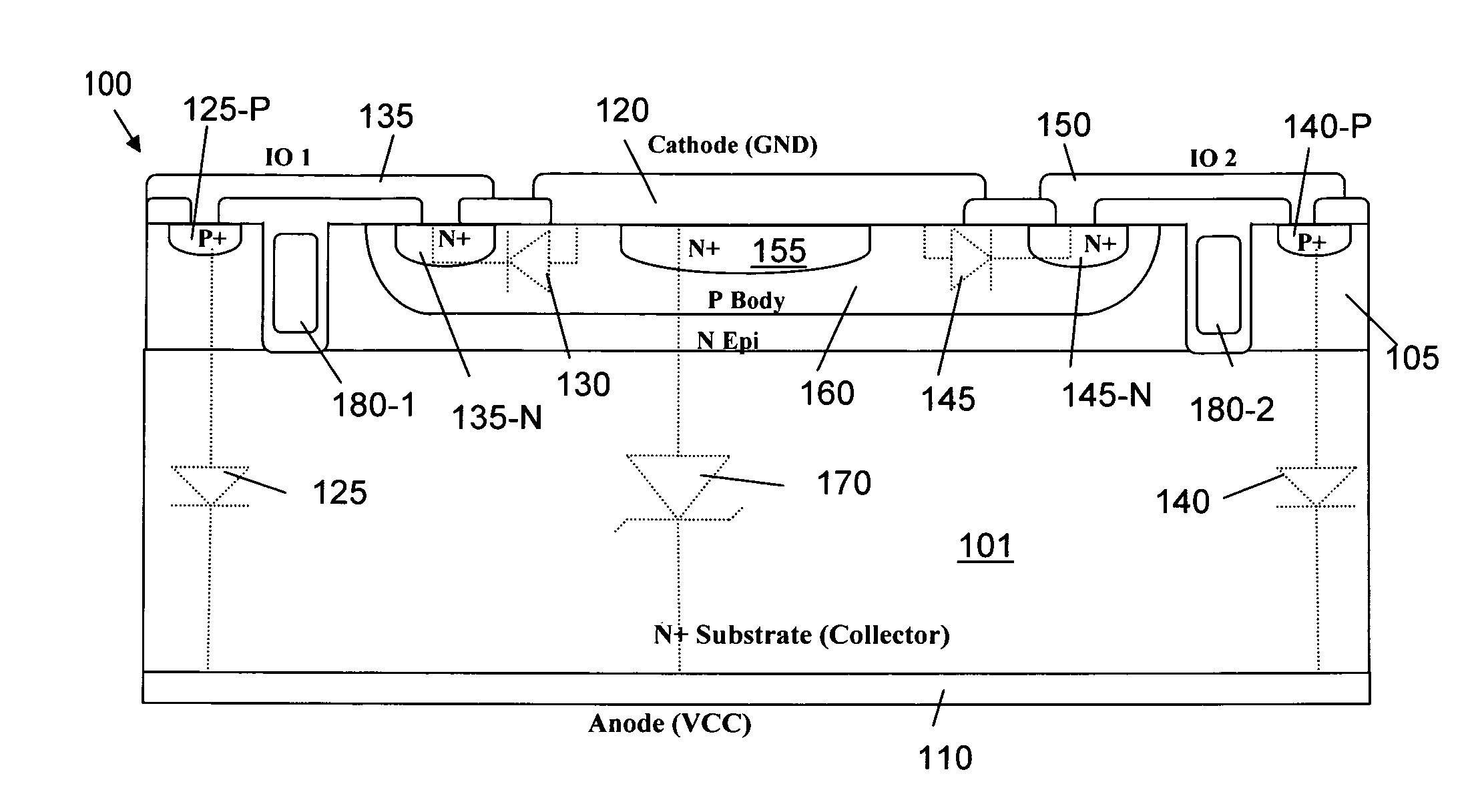

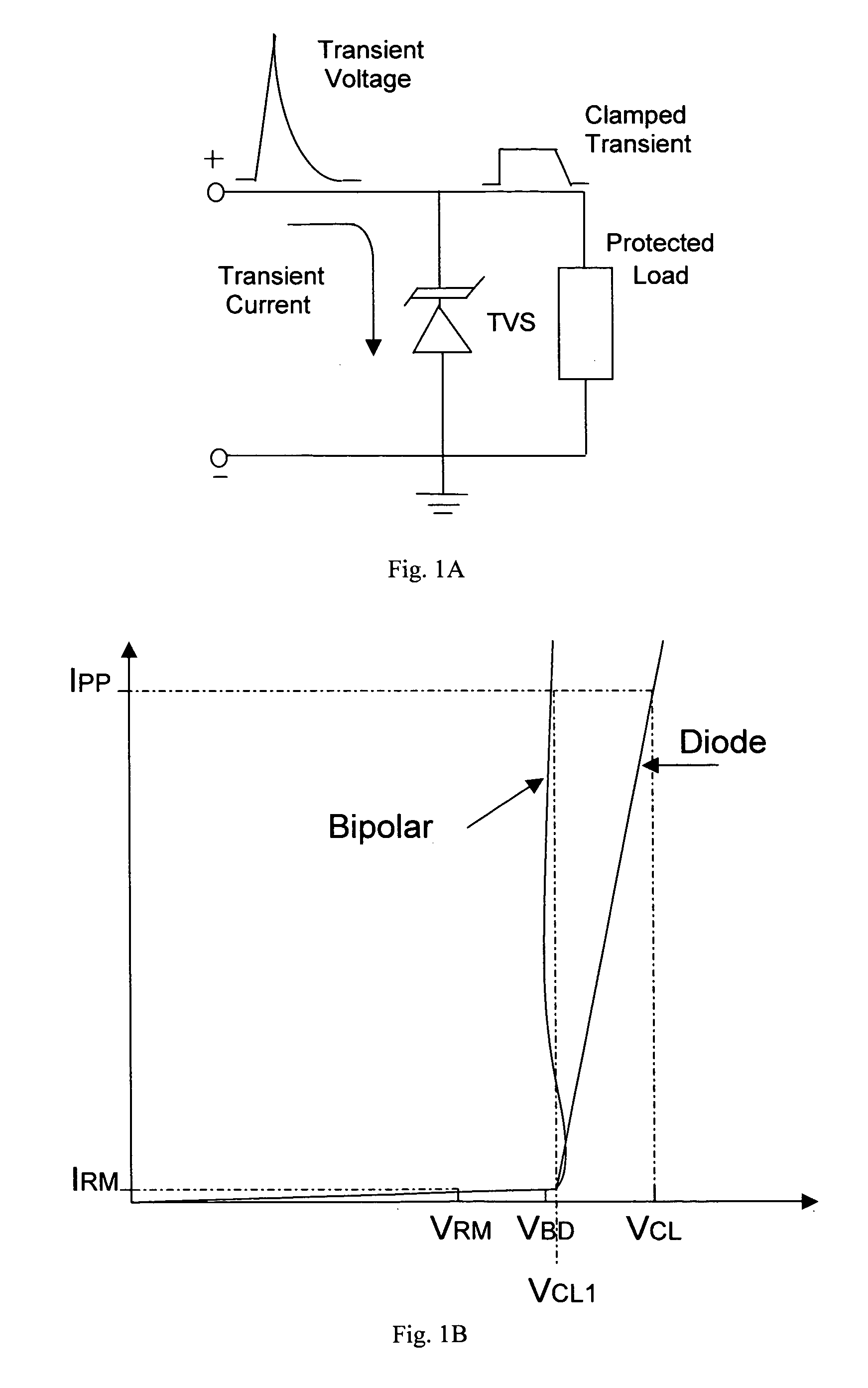

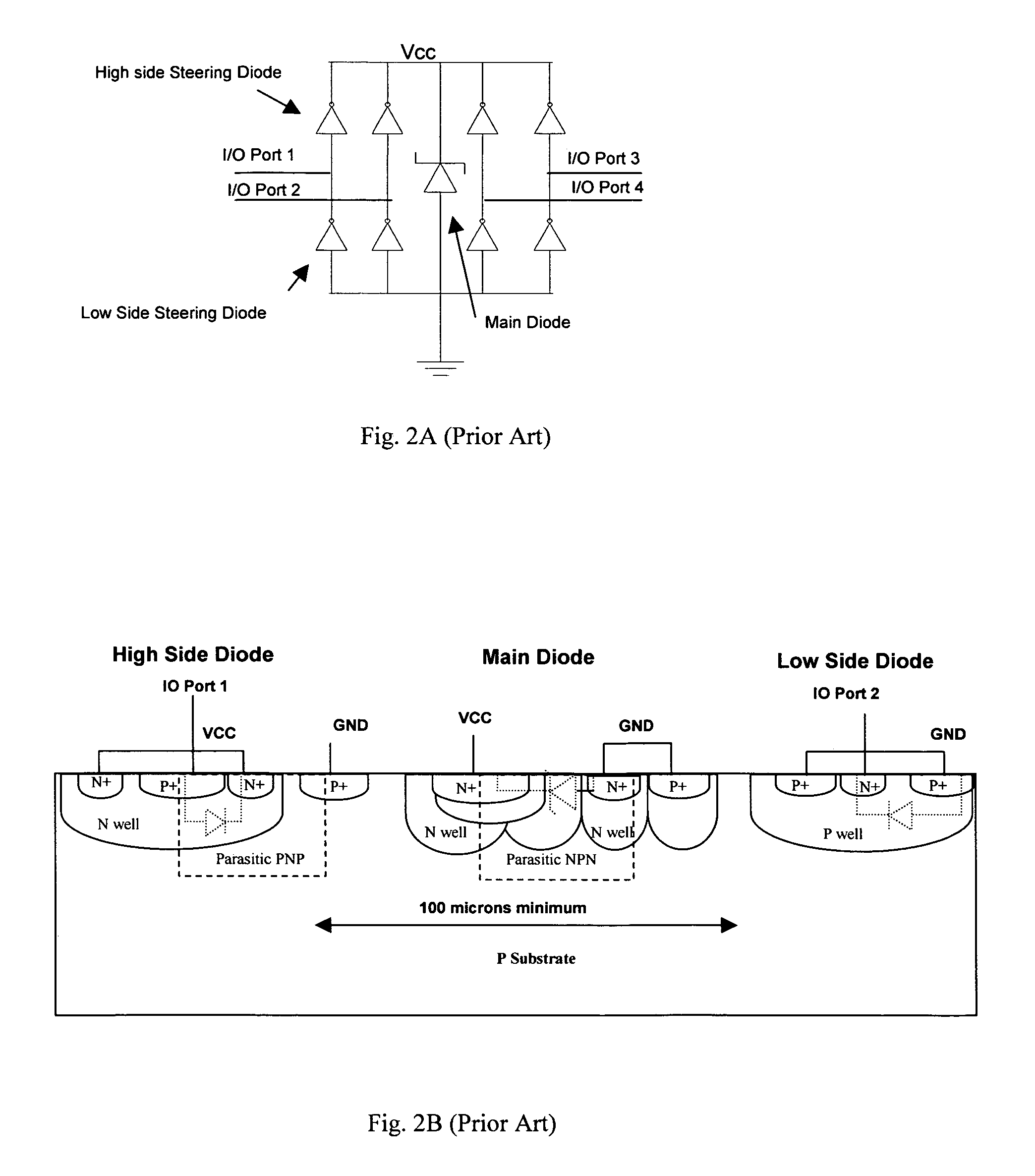

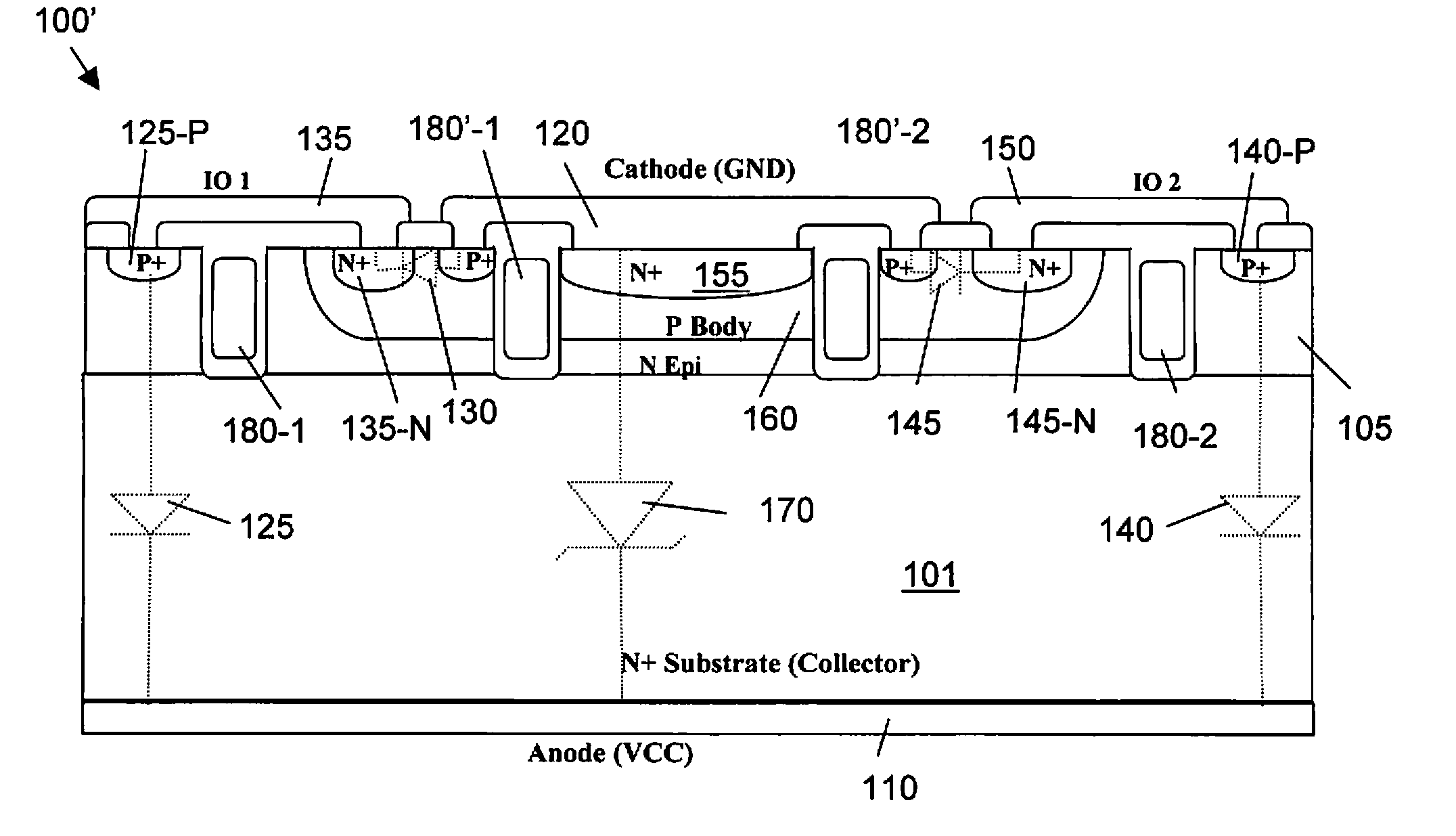

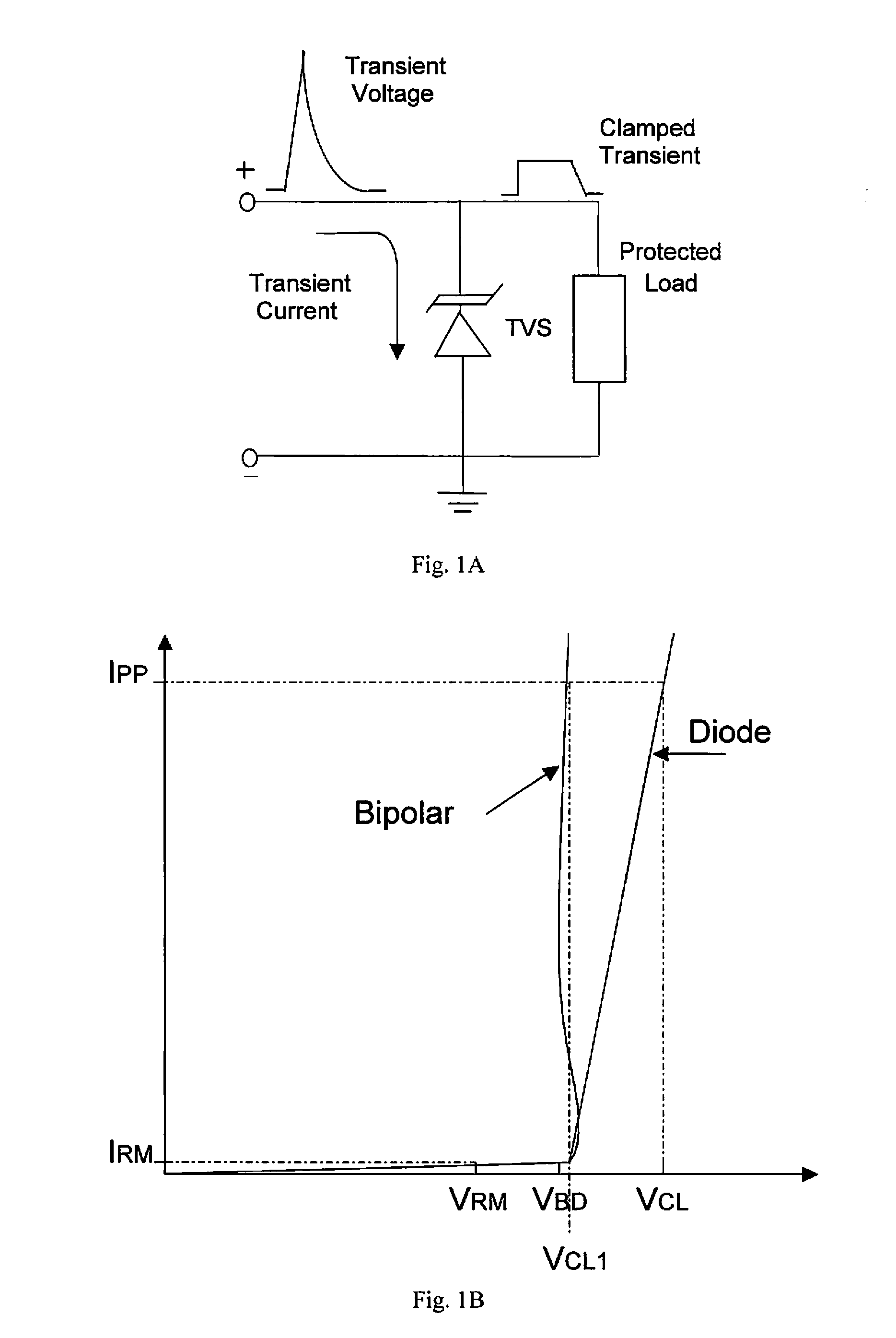

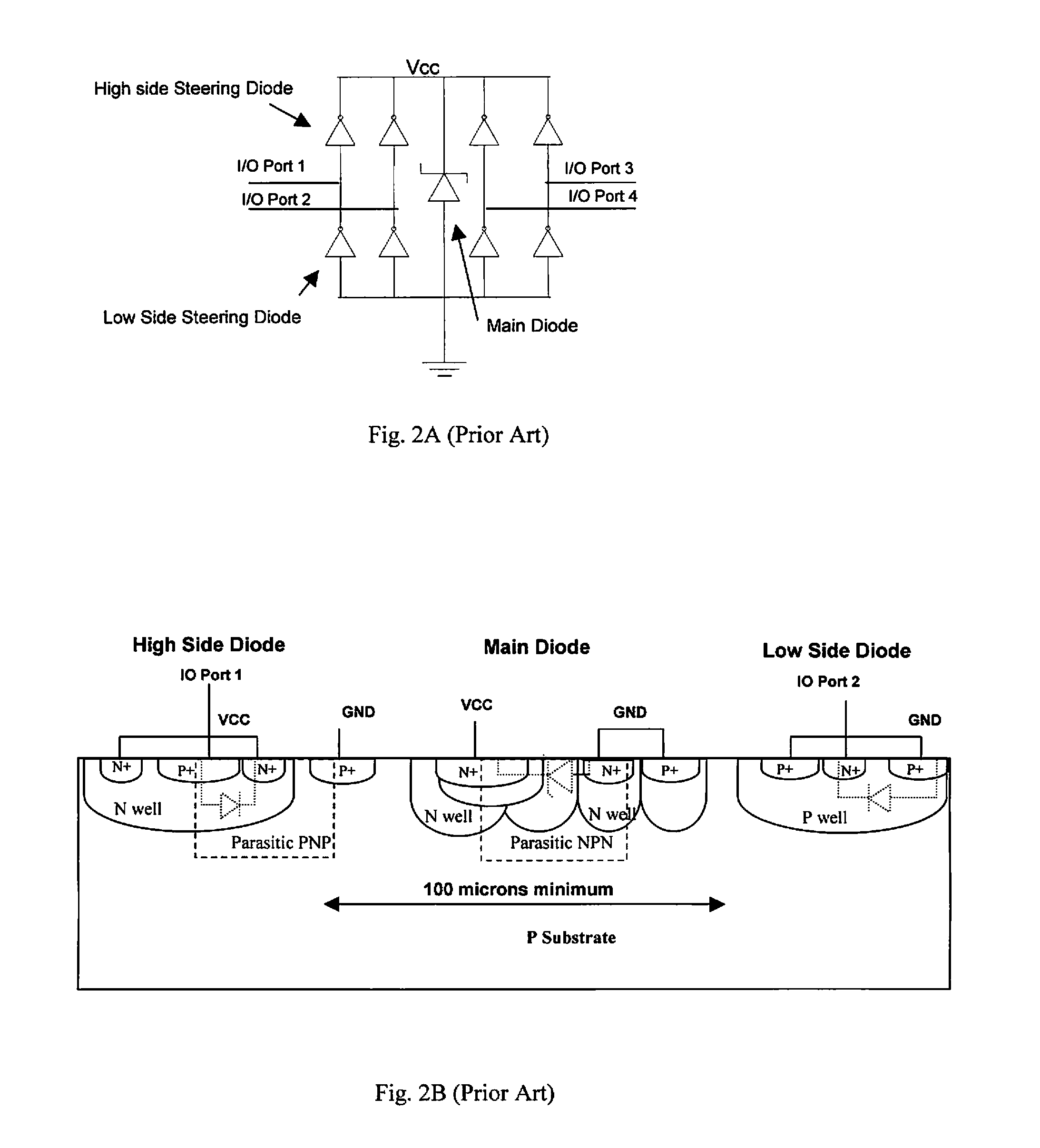

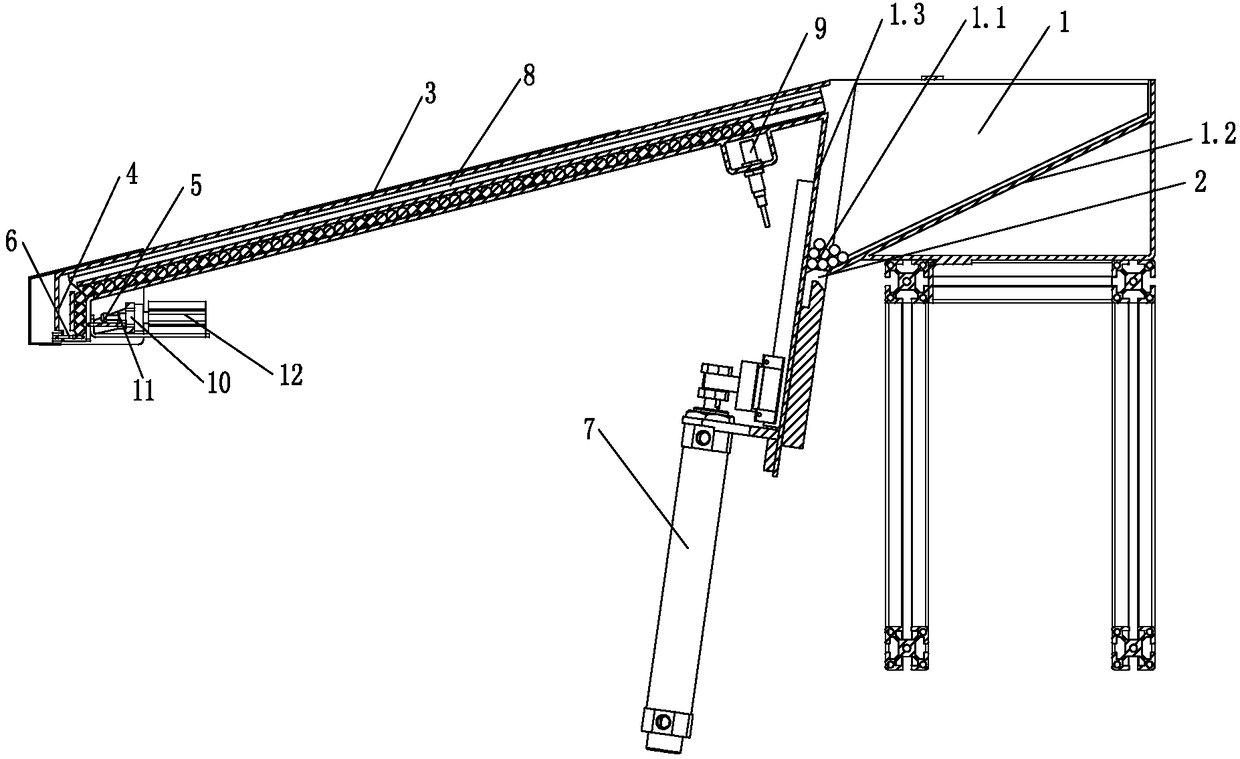

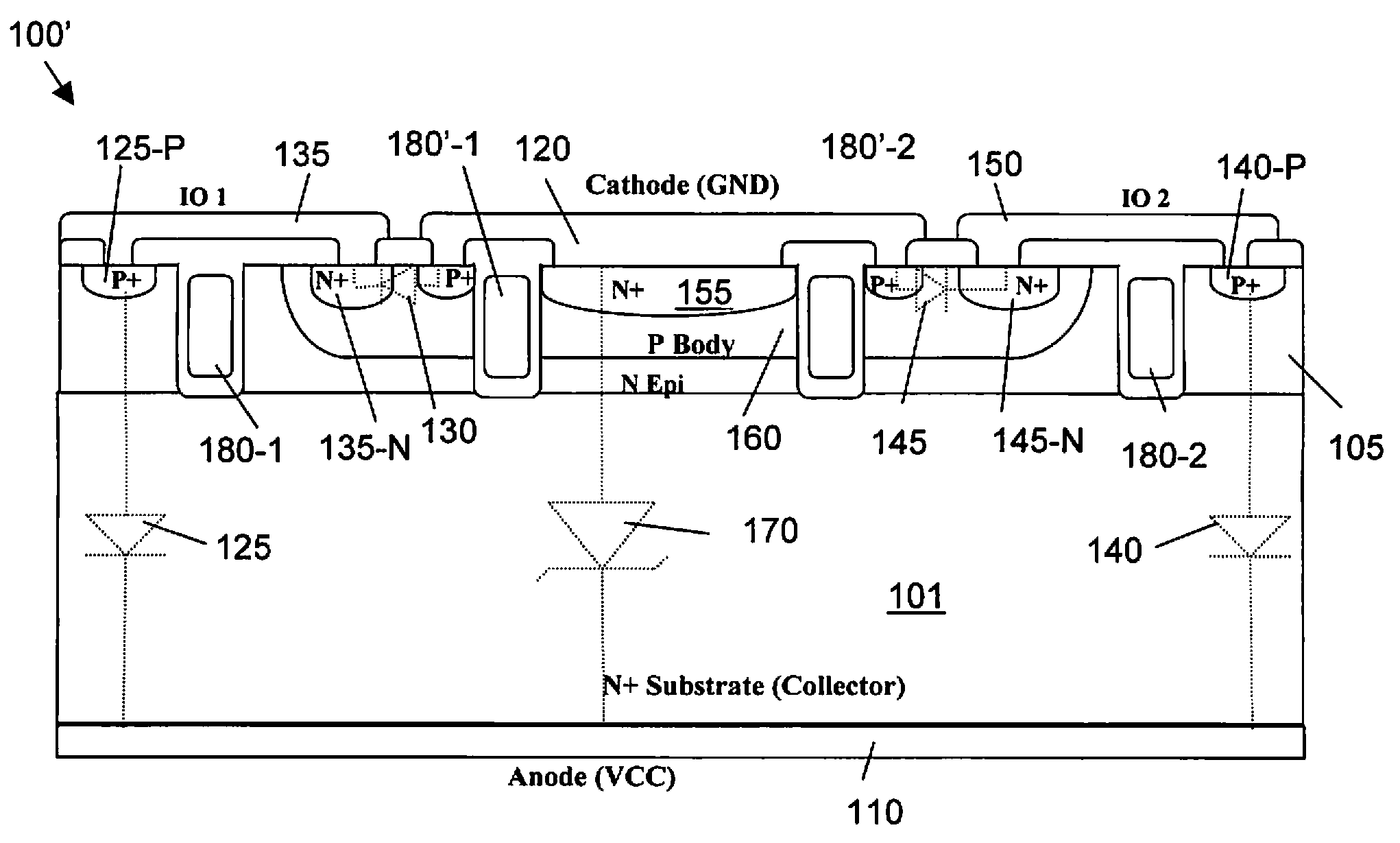

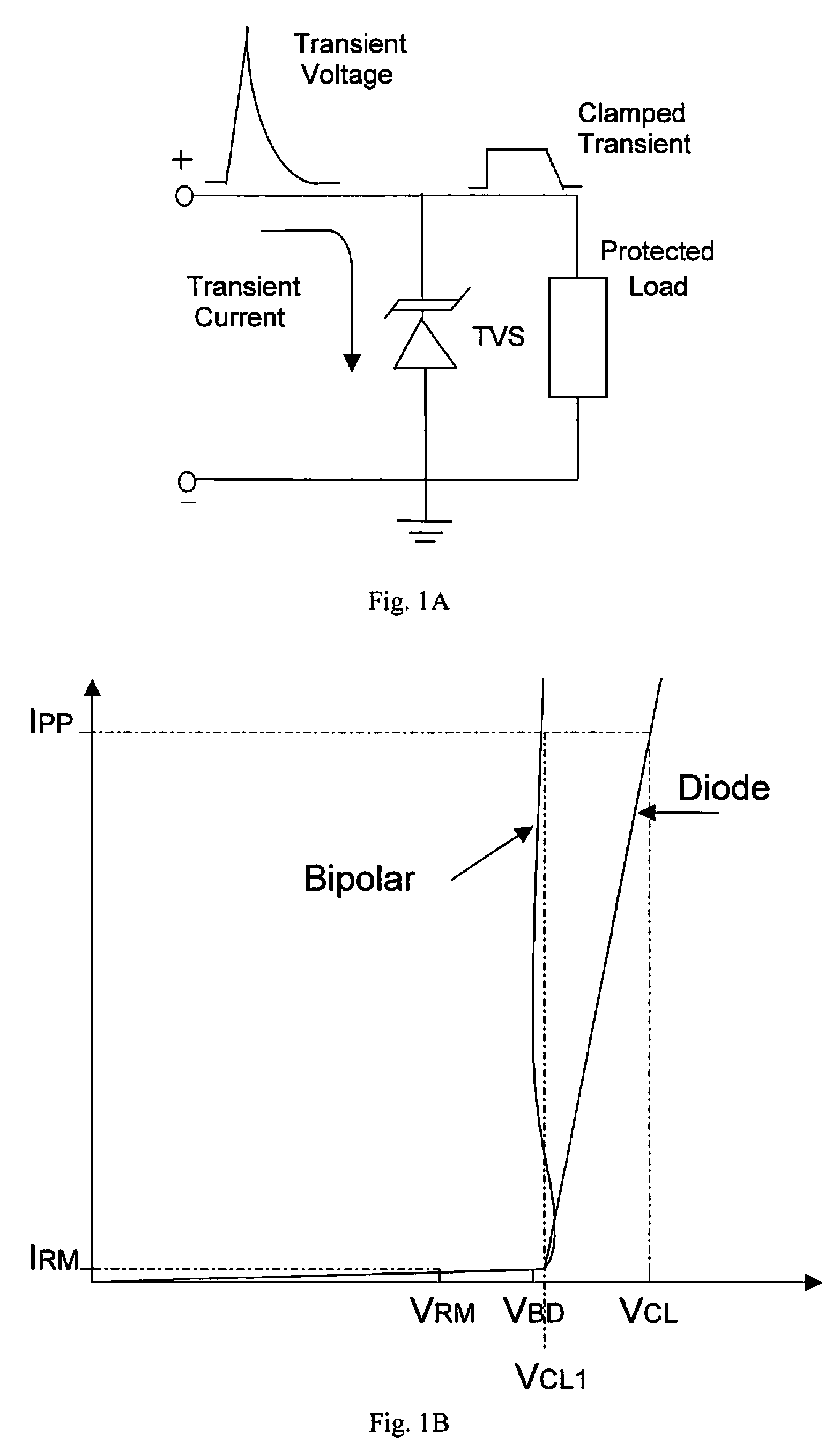

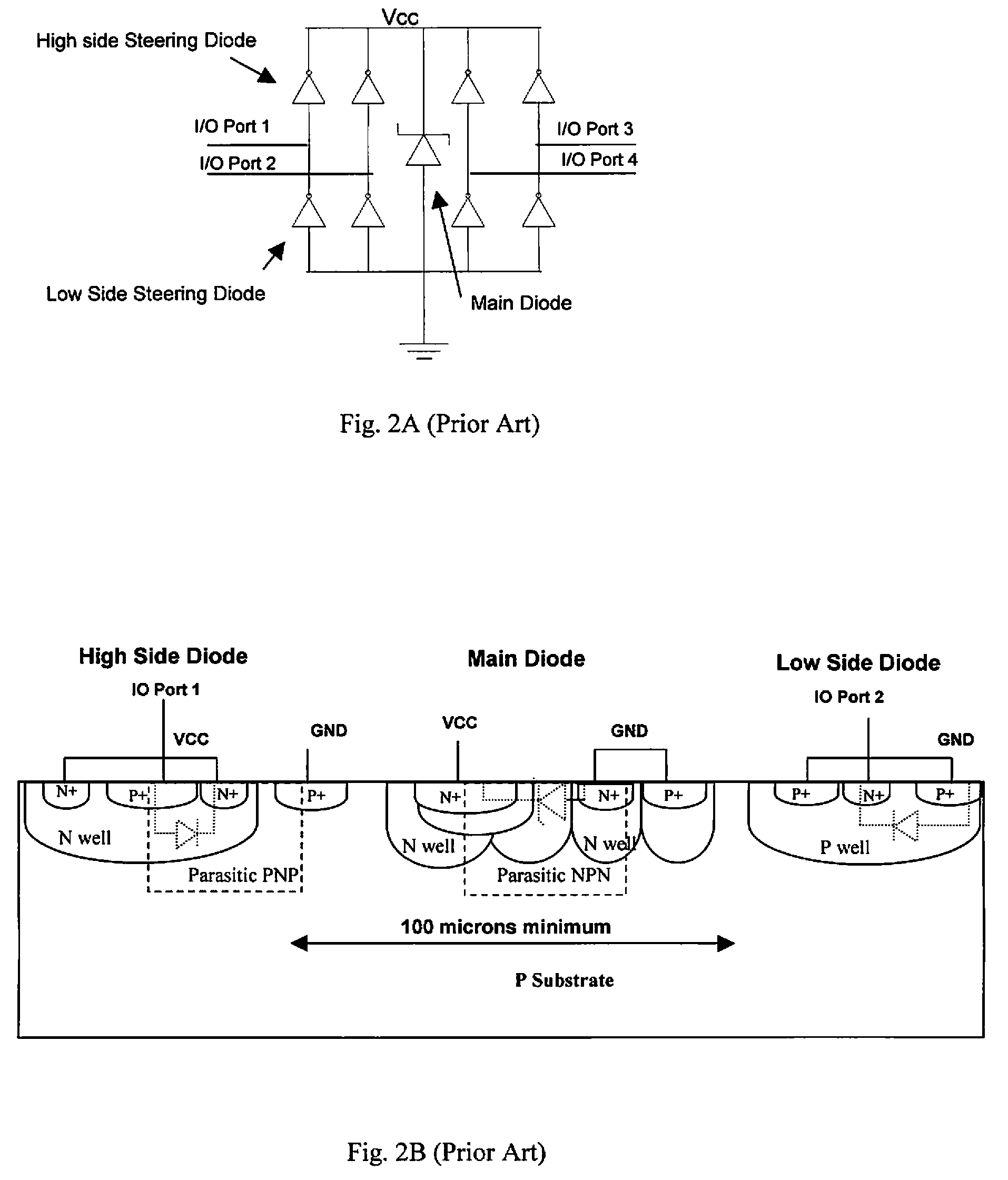

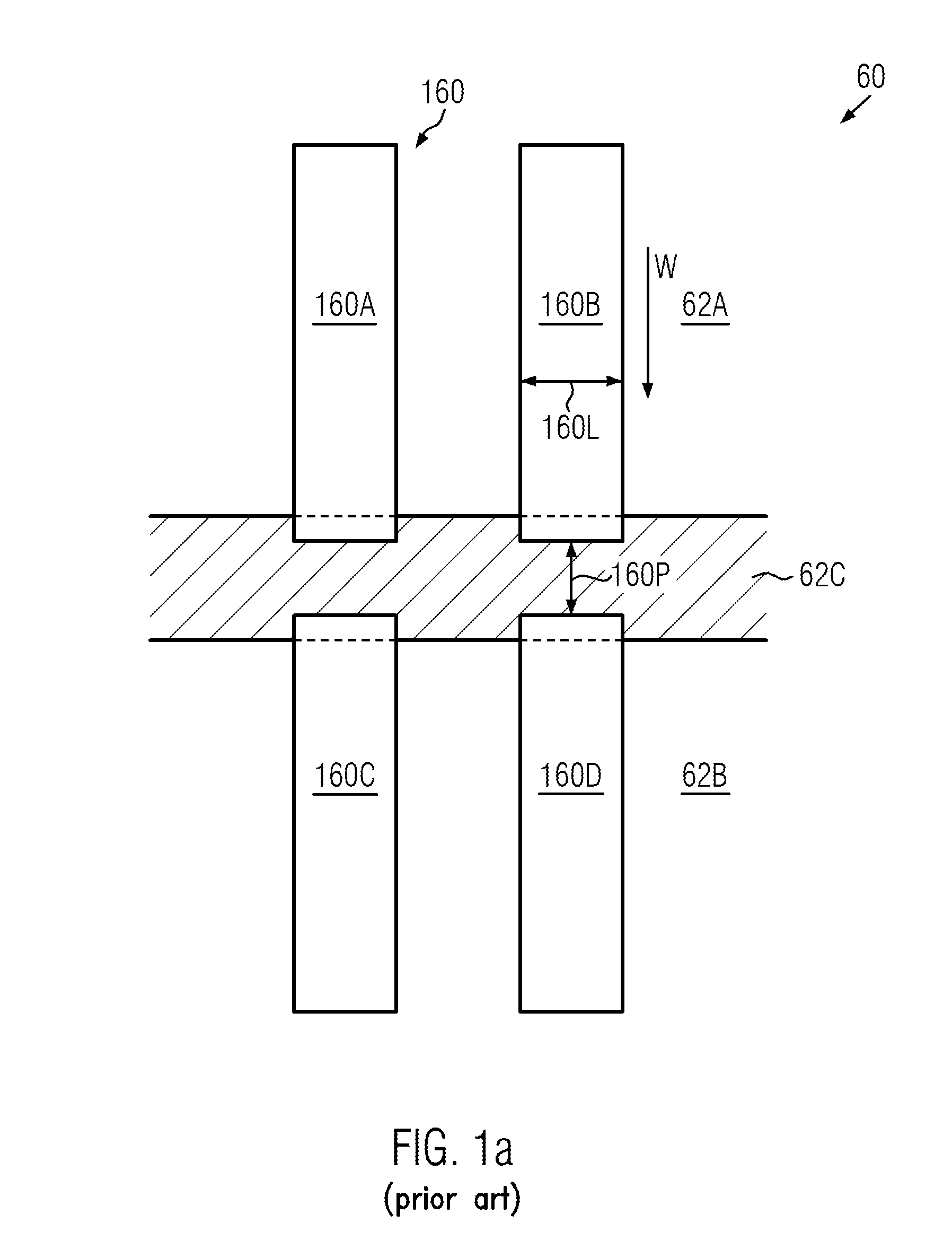

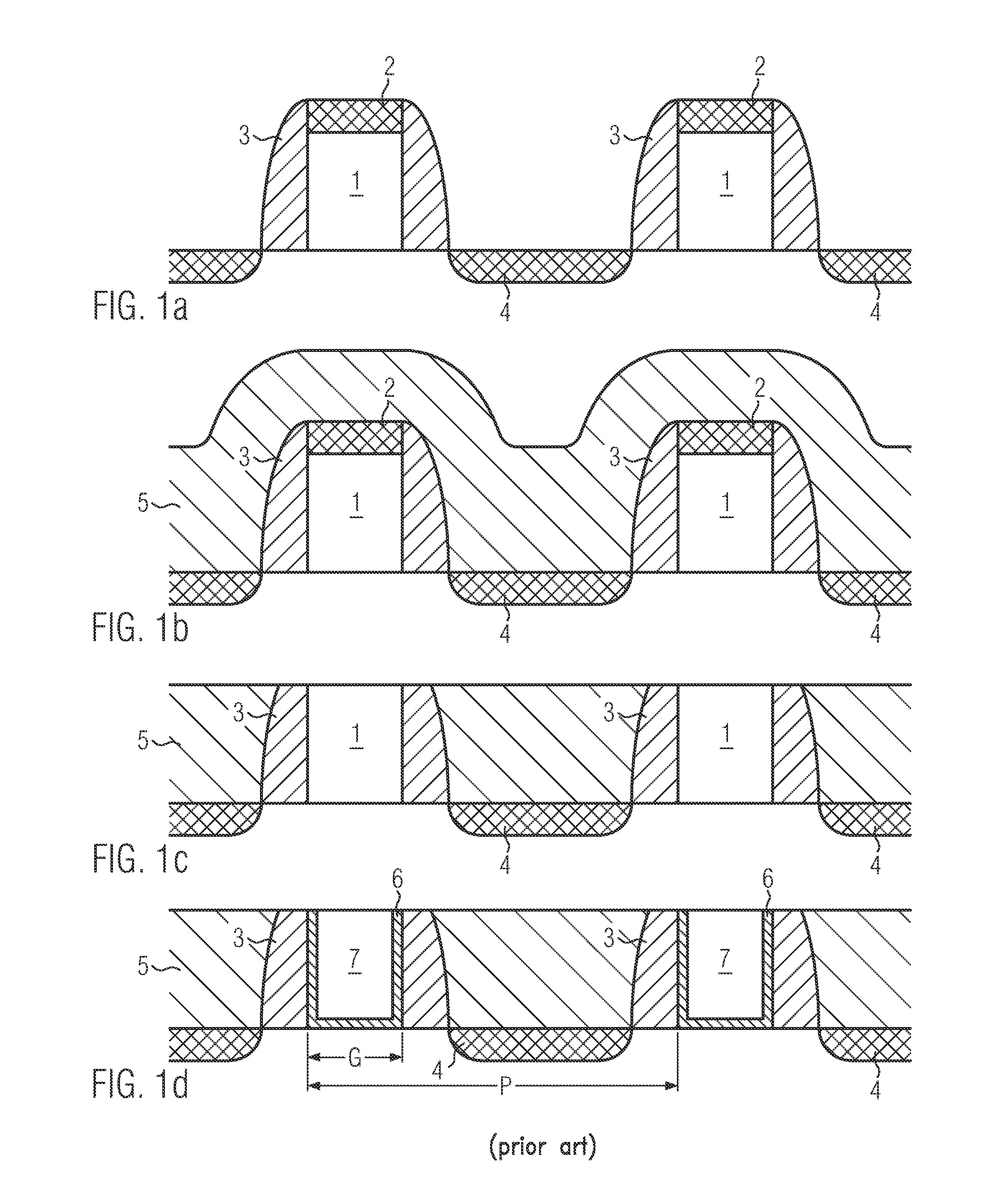

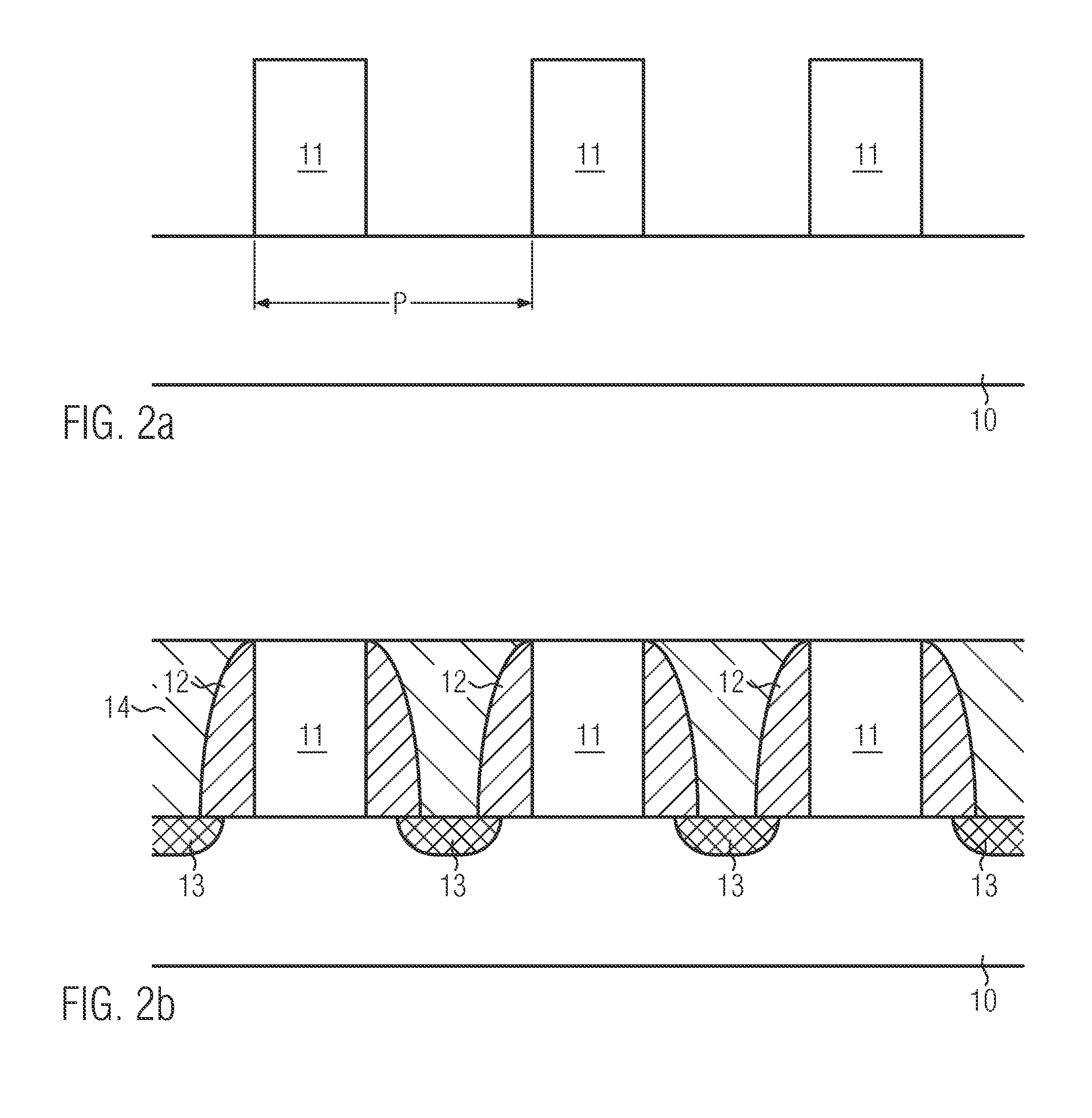

Latch-up free vertical TVS diode array structure using trench isolation

ActiveUS20070073807A1Lateral distanceReduce lateral distanceTransistorSemiconductor/solid-state device detailsEngineeringBody region

A method for manufacturing a transient voltage suppressing (TVS) array substantially following a manufacturing process for manufacturing a vertical semiconductor power device. The method includes a step of opening a plurality of isolation trenches in an epitaxial layer of a first conductivity type in a semiconductor substrate followed by applying a body mask for doping a body region having a second conductivity type between two of the isolation trenches. The method further includes a step of applying an source mask for implanting a plurality of doped regions of the first conductivity type constituting a plurality of diodes wherein the isolation trenches isolating and preventing parasitic PNP or NPN transistor due to a latch-up between the doped regions of different conductivity types.

Owner:ALPHA & OMEGA SEMICON LTD

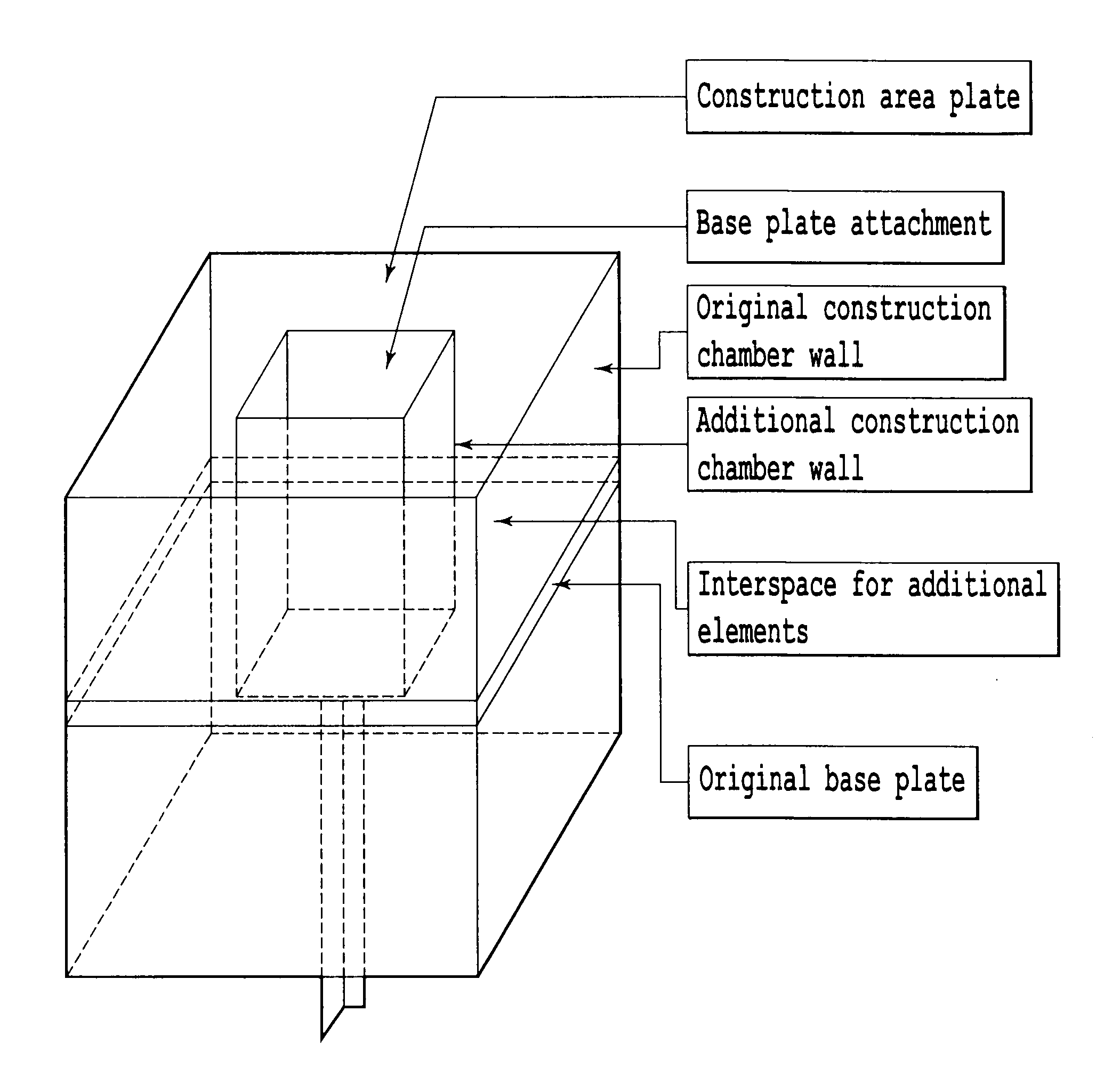

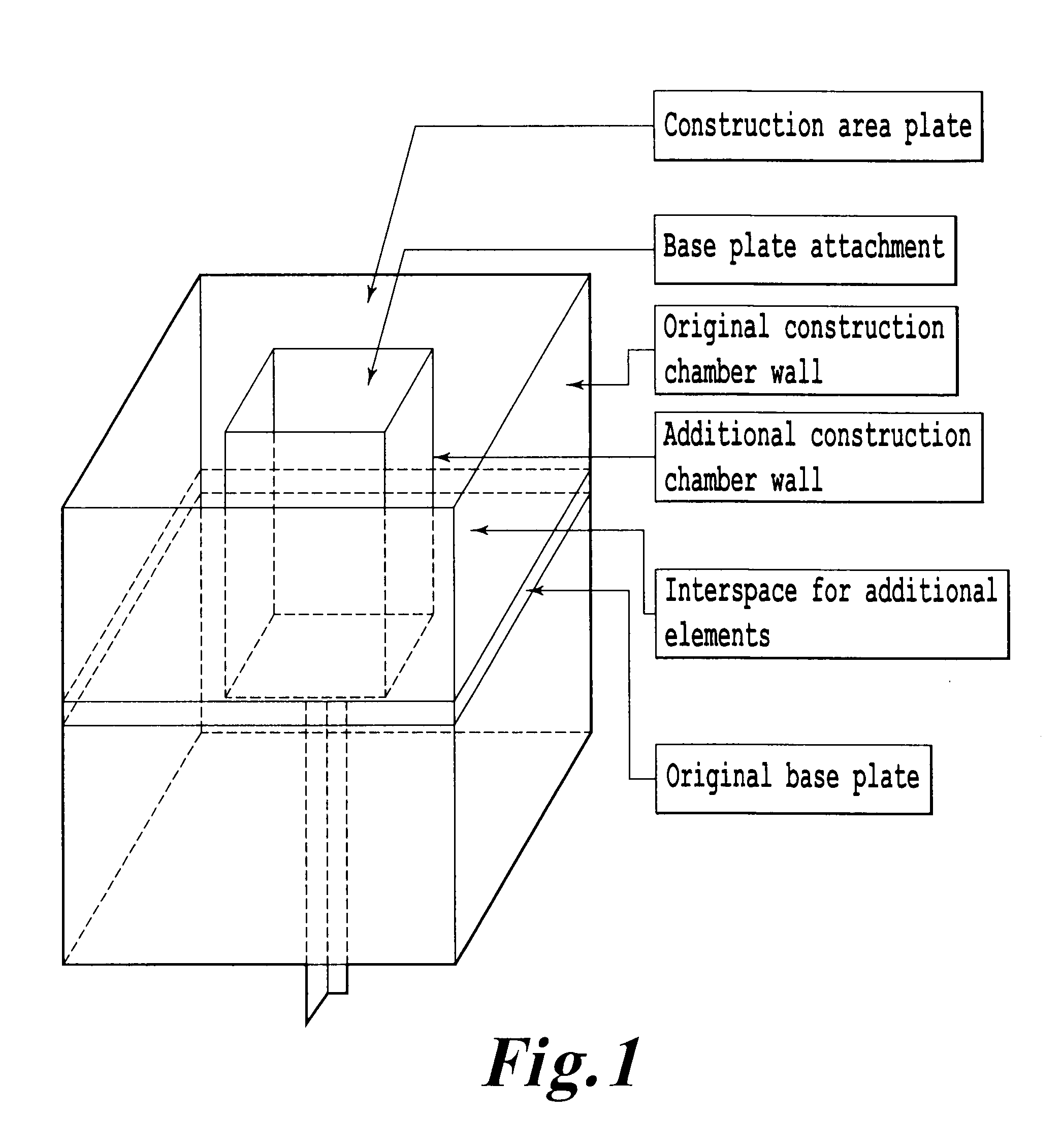

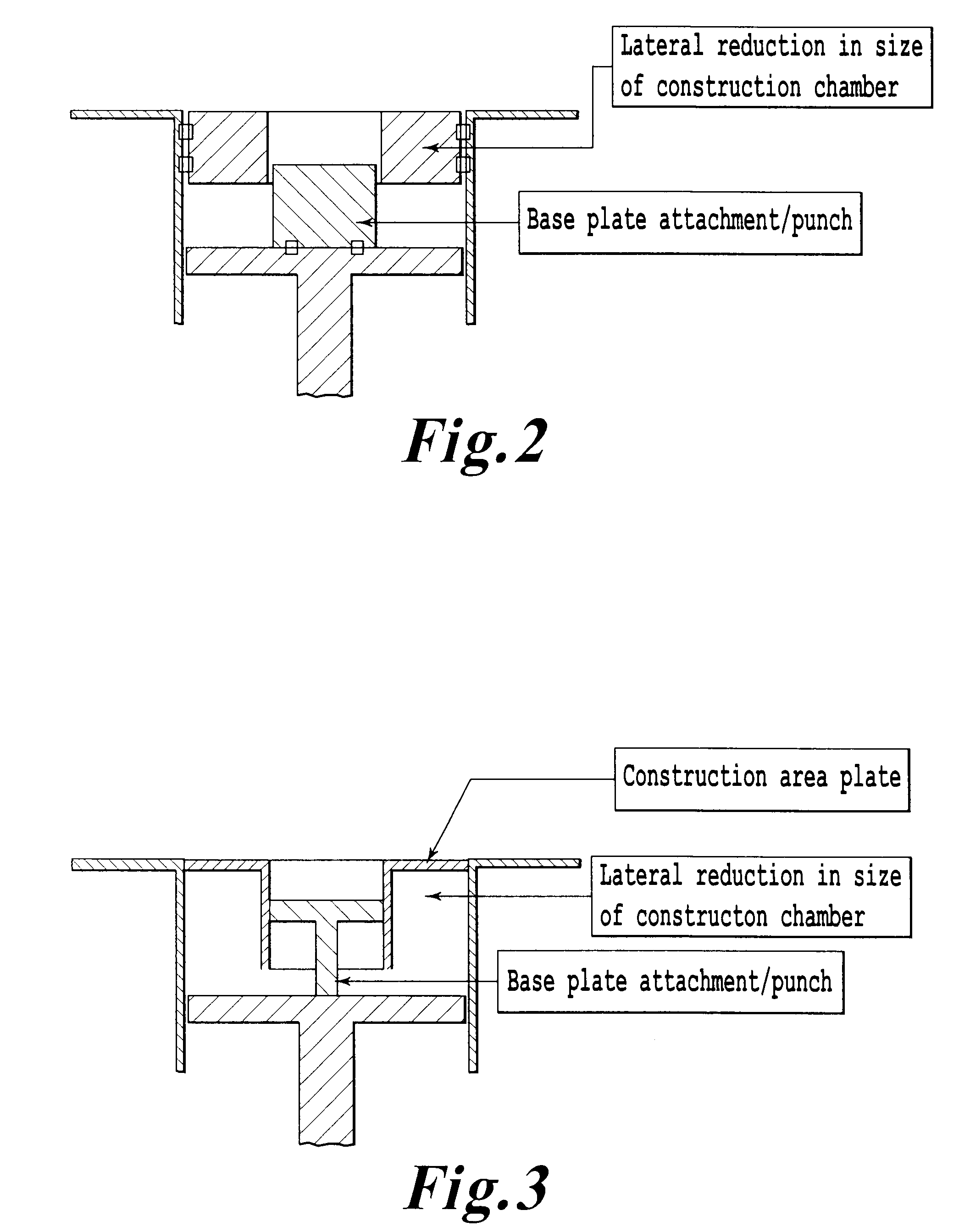

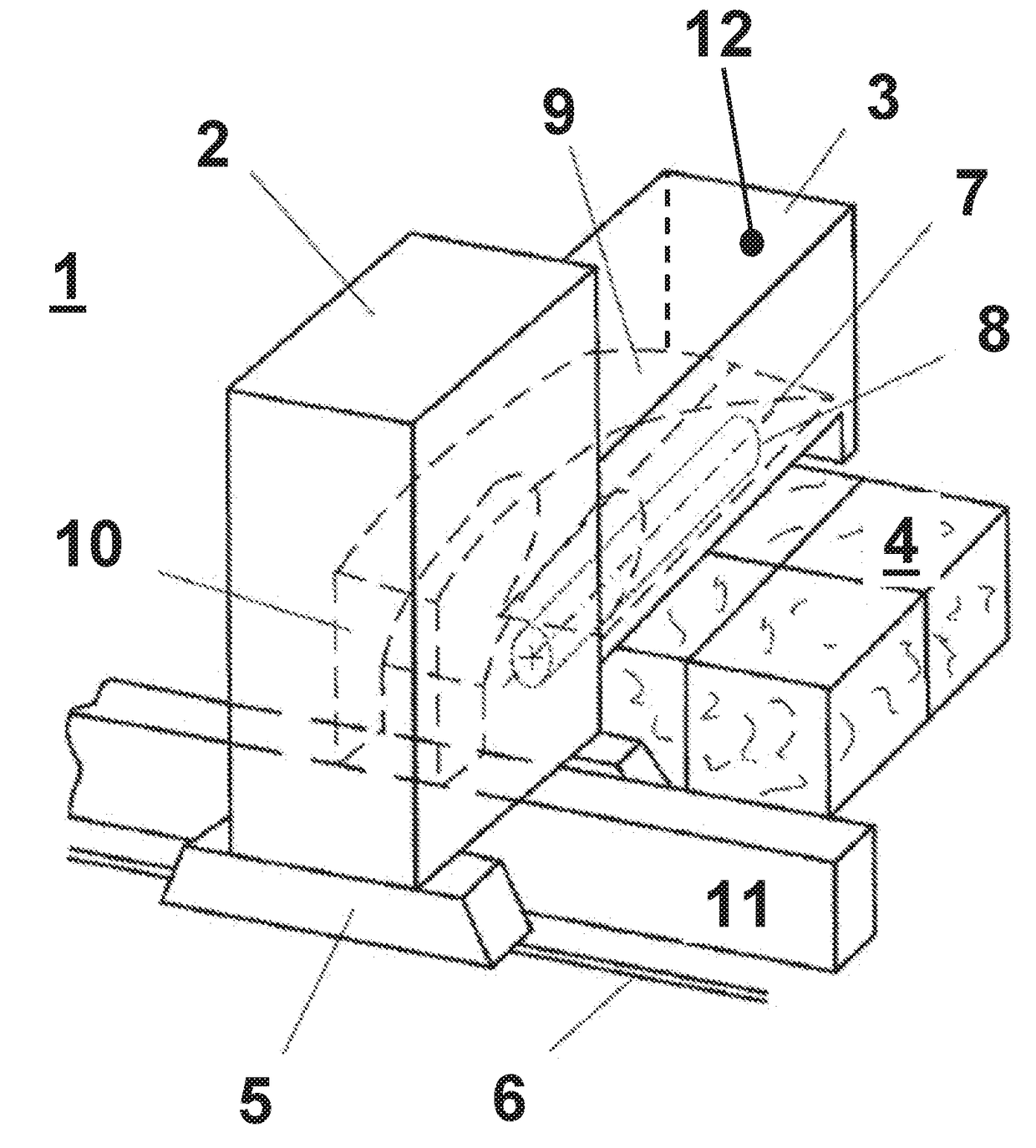

Apparatus for reducing the size of the lower construction chamber of a laser sintering installation

InactiveUS20110252618A1Reduce lateral distanceSmall sizeOther manufacturing equipments/tools3D object support structuresOptoelectronicsMaterials science

An apparatus for the reduction in size of the lower construction chamber of a laser sintering installation is provided. Also provided is a method to reduce the size of the lower construction chamber of a laser sintering installation by insertion of the apparatus of the invention. The invention thereby provides for reduction in the demand for material for specific laser sintering requirements. In addition, a new degree of sintering process control is obtained when the apparatus contains heating or cooling units.

Owner:EVONIK DEGUSSA GMBH

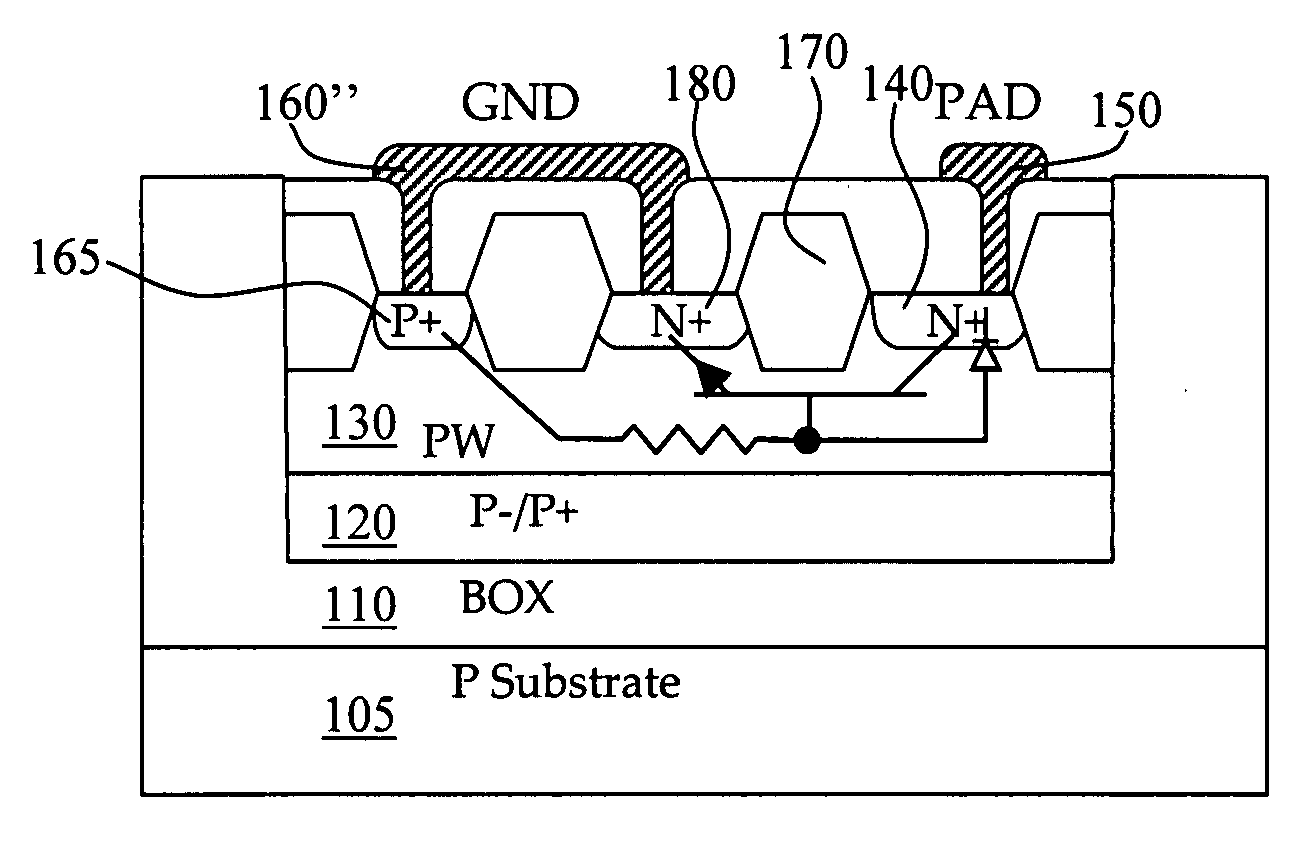

Transient voltage suppressor manufactured in silicon on oxide (SOI) layer

InactiveUS20090115018A1Reduce parasitic capacitanceAvoid latchSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerMicrometer

A transient voltage-suppressing (TVS) device supported on a semiconductor substrate is applied to protect an electronic device from a transient voltage. The TVS device includes a clamp diode functions with a high-side and a low side diodes for clamping a transient voltage disposed on a top layer of the semiconductor substrate insulated by a insulation layer constituting a TVS on silicon-on-insulator (SOI) device. In an exemplary embodiment, the insulator layer further includes a thick body oxide (BOX) layer having a thickness in the range of 250 Angstroms to 1 micrometer to sustain an application with a breakdown voltage higher than 25 volts. In another exemplary embodiment, the clamp diode further surrounded by a P-well and the P-well is formed on top of a P− / P+ substrate layer disposed above the insulator layer.

Owner:ALPHA & OMEGA SEMICON LTD

Latch-up free vertical TVS diode array structure using trench isolation

ActiveUS7880223B2Lateral distanceReduce lateral distanceTransistorSemiconductor/solid-state device detailsEngineeringBody region

A method for manufacturing a transient voltage suppressing (TVS) array substantially following a manufacturing process for manufacturing a vertical semiconductor power device. The method includes a step of opening a plurality of isolation trenches in an epitaxial layer of a first conductivity type in a semiconductor substrate followed by applying a body mask for doping a body region having a second conductivity type between two of the isolation trenches. The method further includes a step of applying an source mask for implanting a plurality of doped regions of the first conductivity type constituting a plurality of diodes wherein the isolation trenches isolating and preventing parasitic PNP or NPN transistor due to a latch-up between the doped regions of different conductivity types.

Owner:ALPHA & OMEGA SEMICON LTD

Latch-up free vertical tvs diode array structure using trench isolation

ActiveUS20140363930A1Lateral distanceReduce lateral distanceTransistorSolid-state devicesEngineeringBody region

A method for manufacturing a transient voltage suppressing (TVS) array substantially following a manufacturing process for manufacturing a vertical semiconductor power device. The method includes a step of opening a plurality of isolation trenches in an epitaxial layer of a first conductivity type in a semiconductor substrate followed by applying a body mask for doping a body region having a second conductivity type between two of the isolation trenches. The method further includes a step of applying an source mask for implanting a plurality of doped regions of the first conductivity type constituting a plurality of diodes wherein the isolation trenches isolating and preventing parasitic PNP or NPN transistor due to a latch-up between the doped regions of different conductivity types.

Owner:ALPHA & OMEGA SEMICON INC

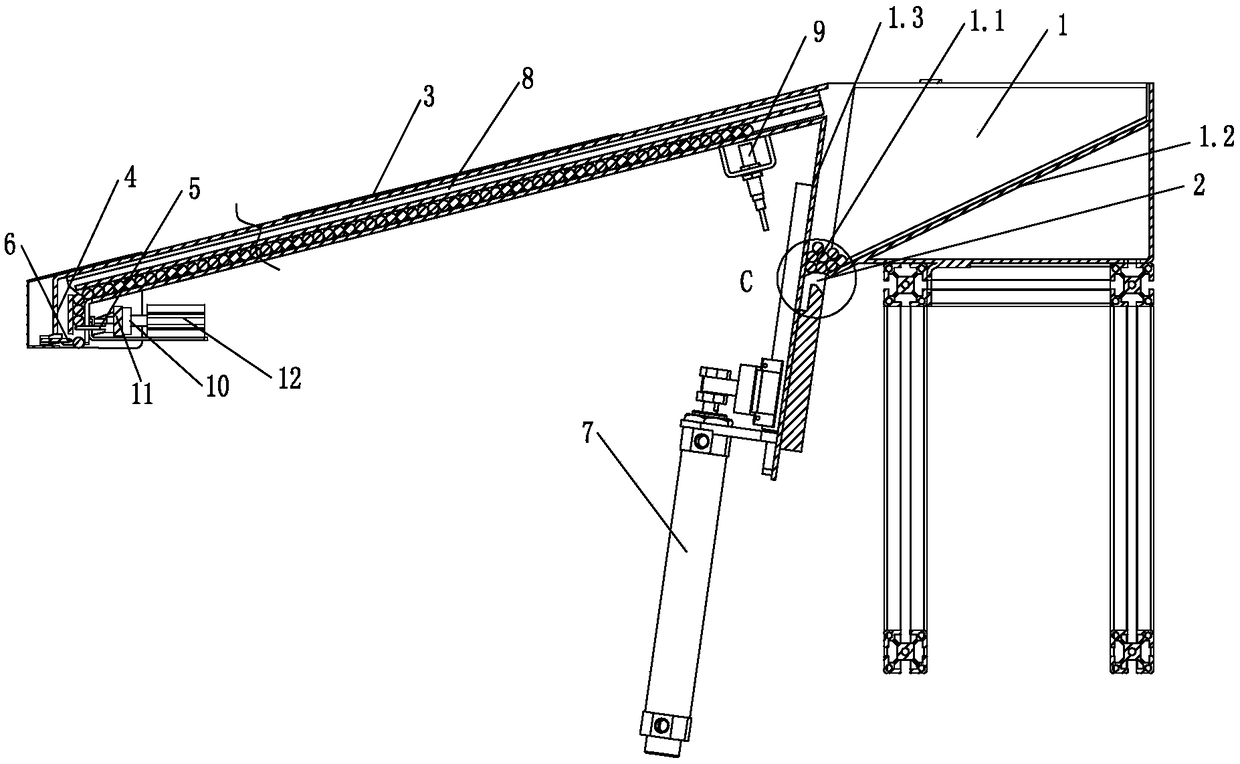

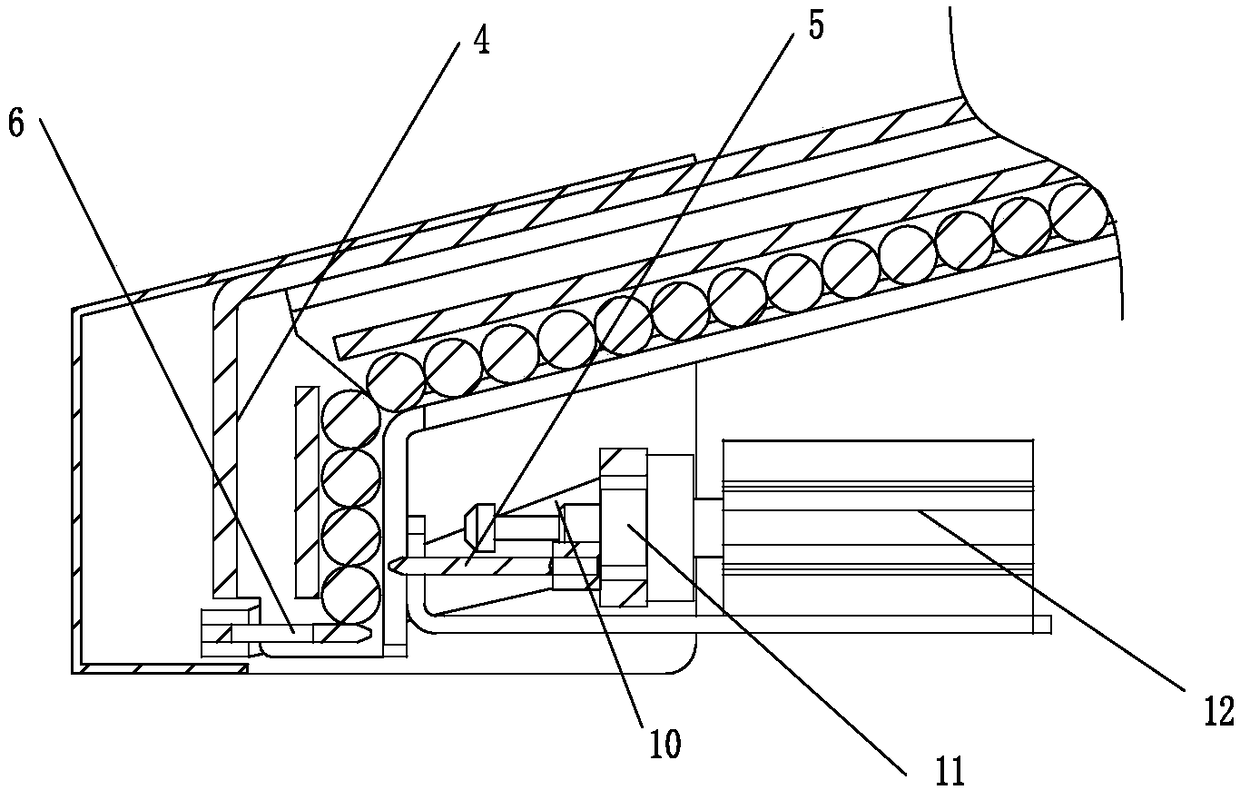

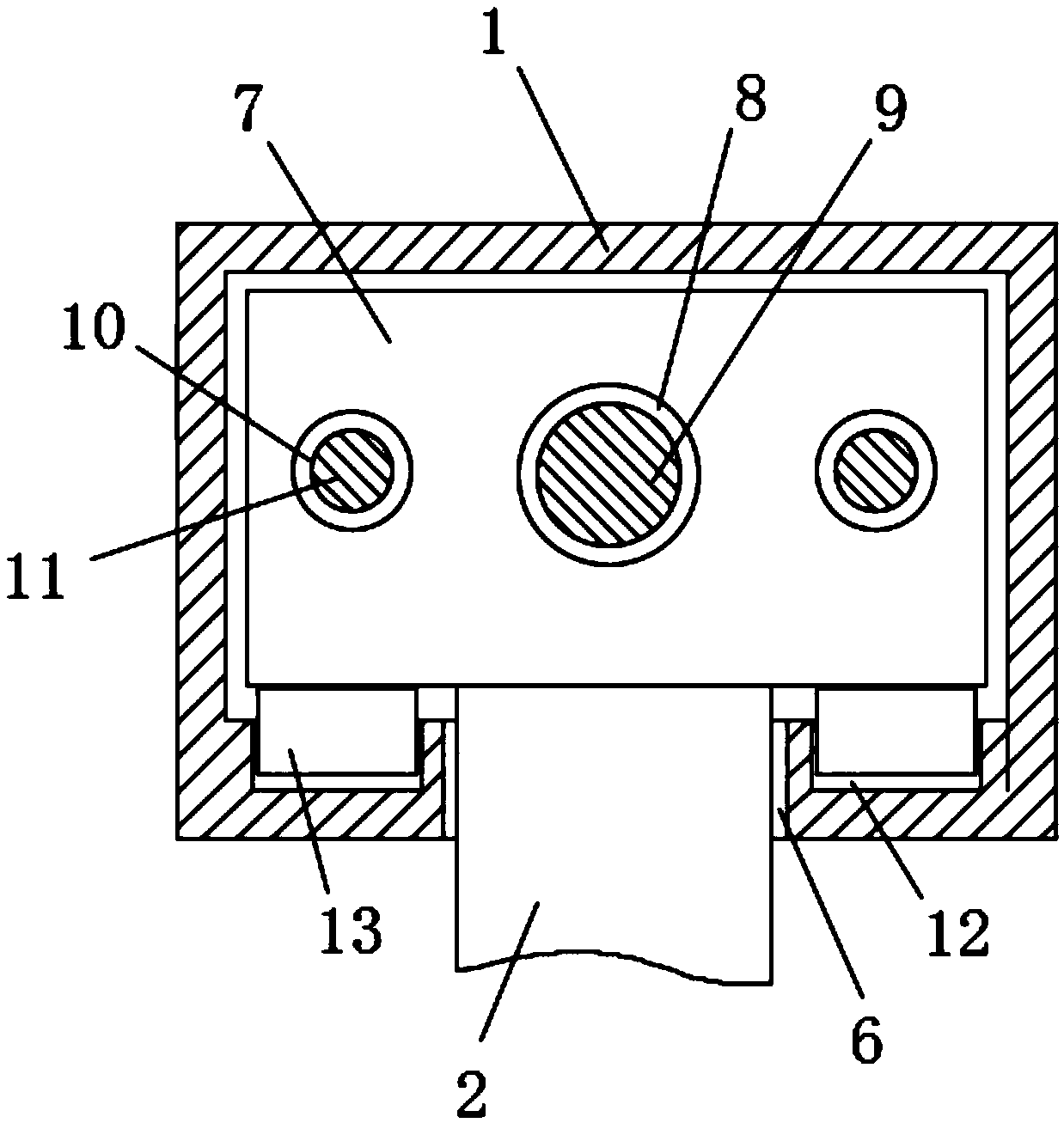

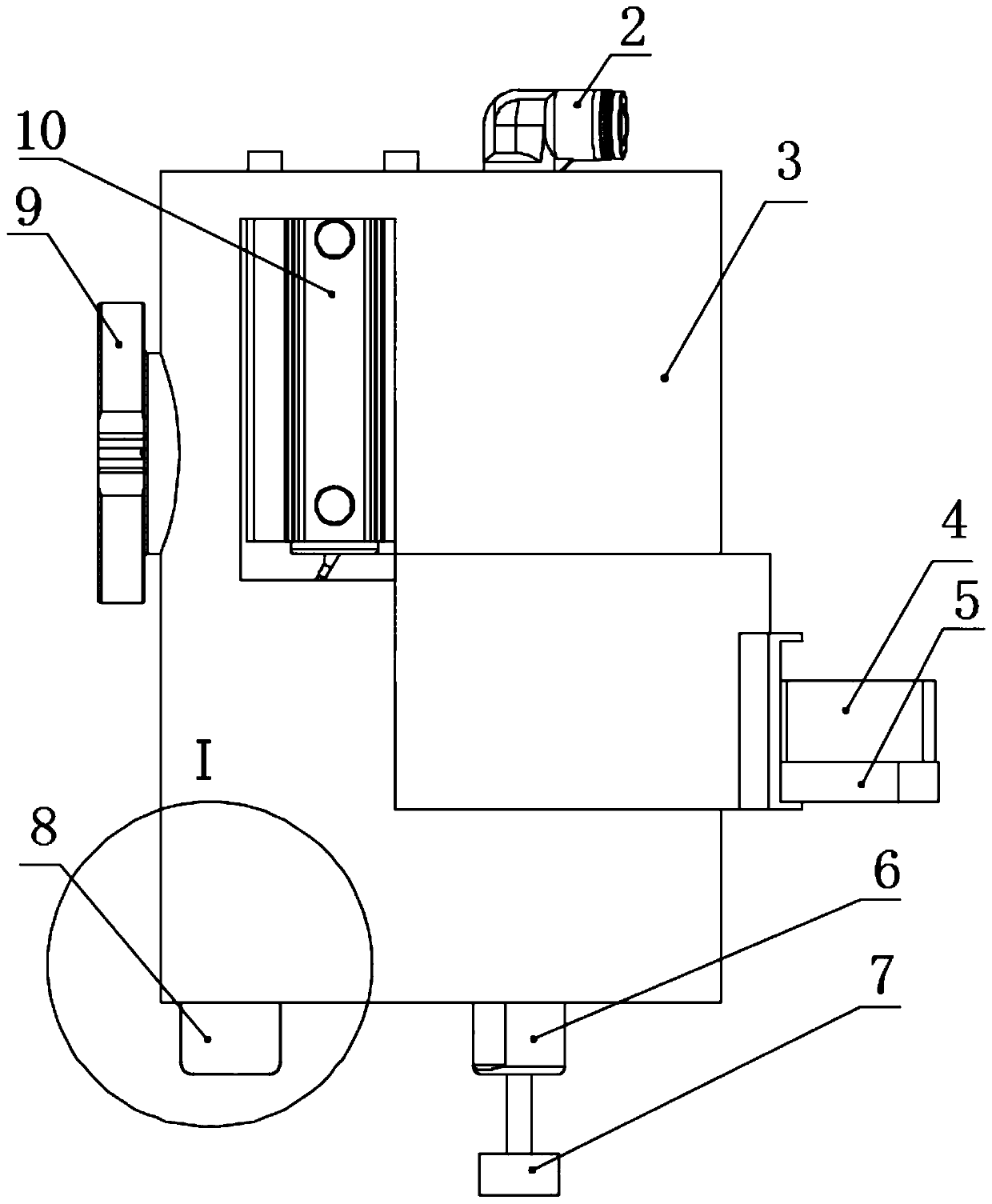

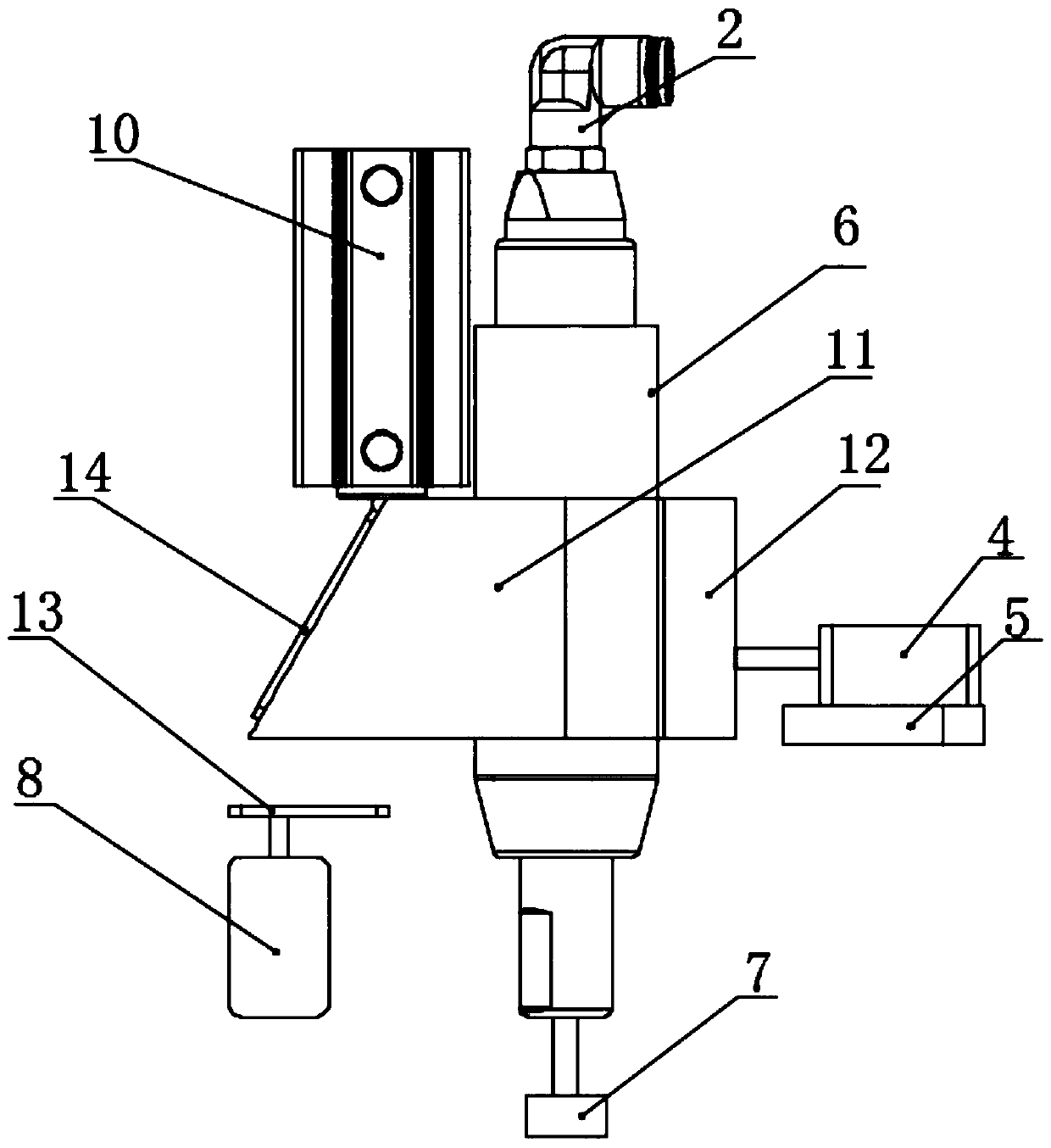

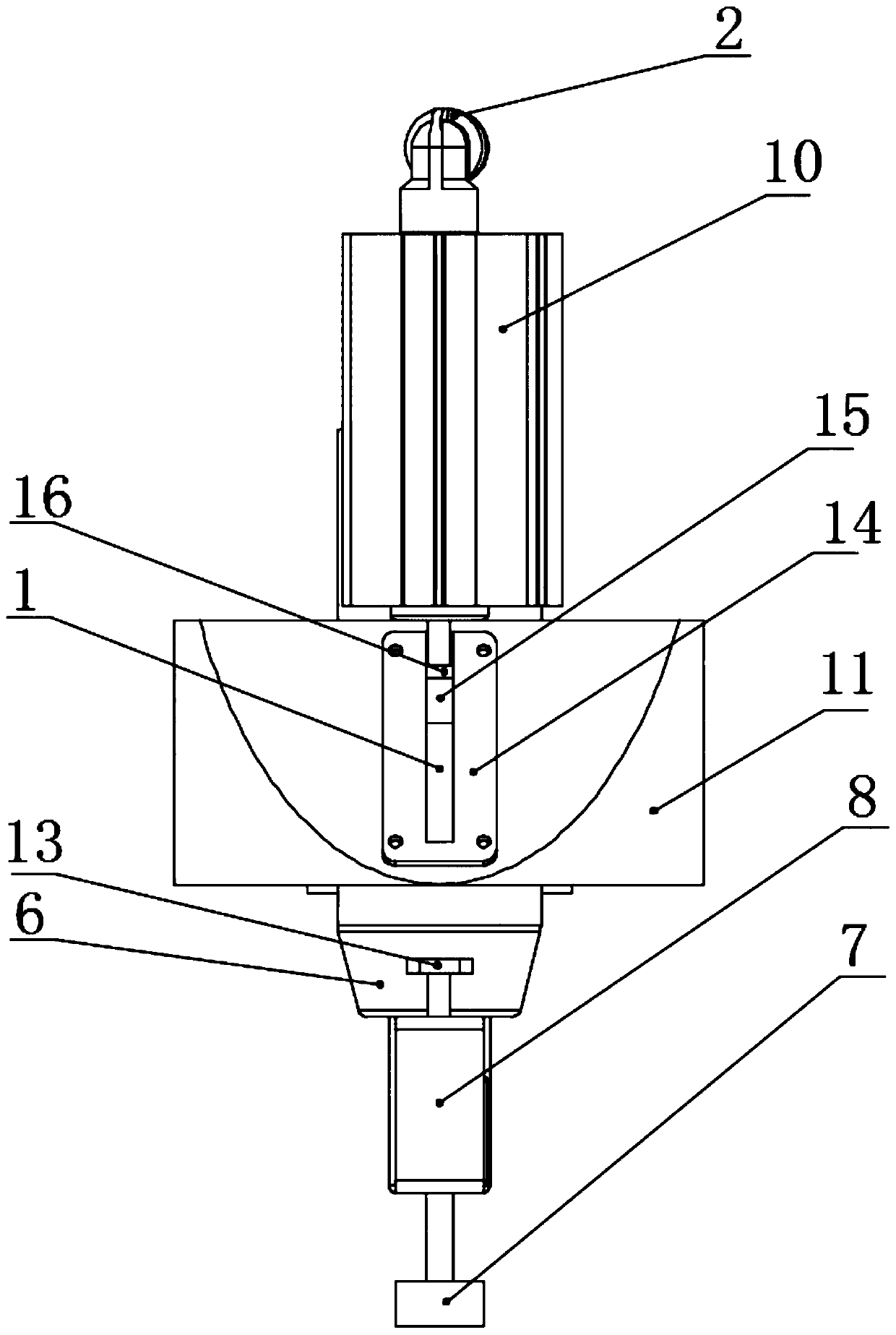

Automatic arranging and feeding device

The invention discloses an automatic arranging and feeding device. The device is characterized by comprising a storage bin (1) which is in a funnel shape and is used for accommodating rod and shaft like products, a material port (1.1) is formed in the bottom of the storage bin (1), the bottom of the material port (1.1) is provided with a material ejecting block (2) which is capable of ejecting a product of the storage bin (1) to be attached to the side wall of the storage bin (1) to move upwards, the device further comprises a first conveying rail (3) which is obliquely arranged and a second conveying rail (4) which is vertically arranged, wherein the first conveying rail (3) and the second conveying rail (4) are used for allowing a single-row product to pass through, the top end of the first conveying rail (3) is connected with the storage bin (1), the bottom top end of the first conveying rail (3) is connected with the top end of the second conveying rail (4), and a material distributing mechanism and a material falling mechanism are both connected to a driving mechanism which linearly stretch and retract back and forth. The device is simple in structure, good in reliability andgood in safety, and can be mounted on an existing machine tool, and the transverse distance is not added.

Owner:宁波宫铁智能科技有限公司

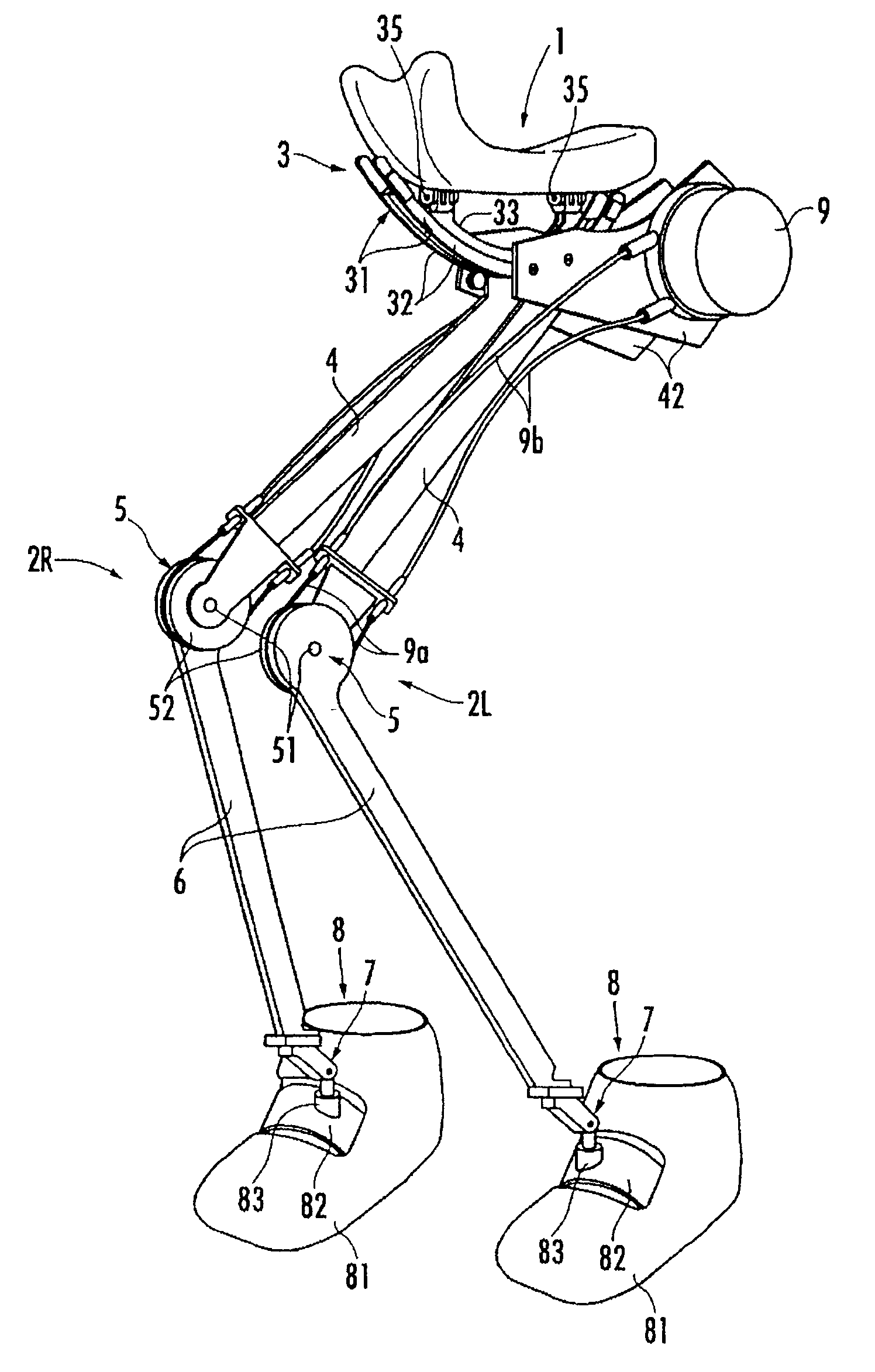

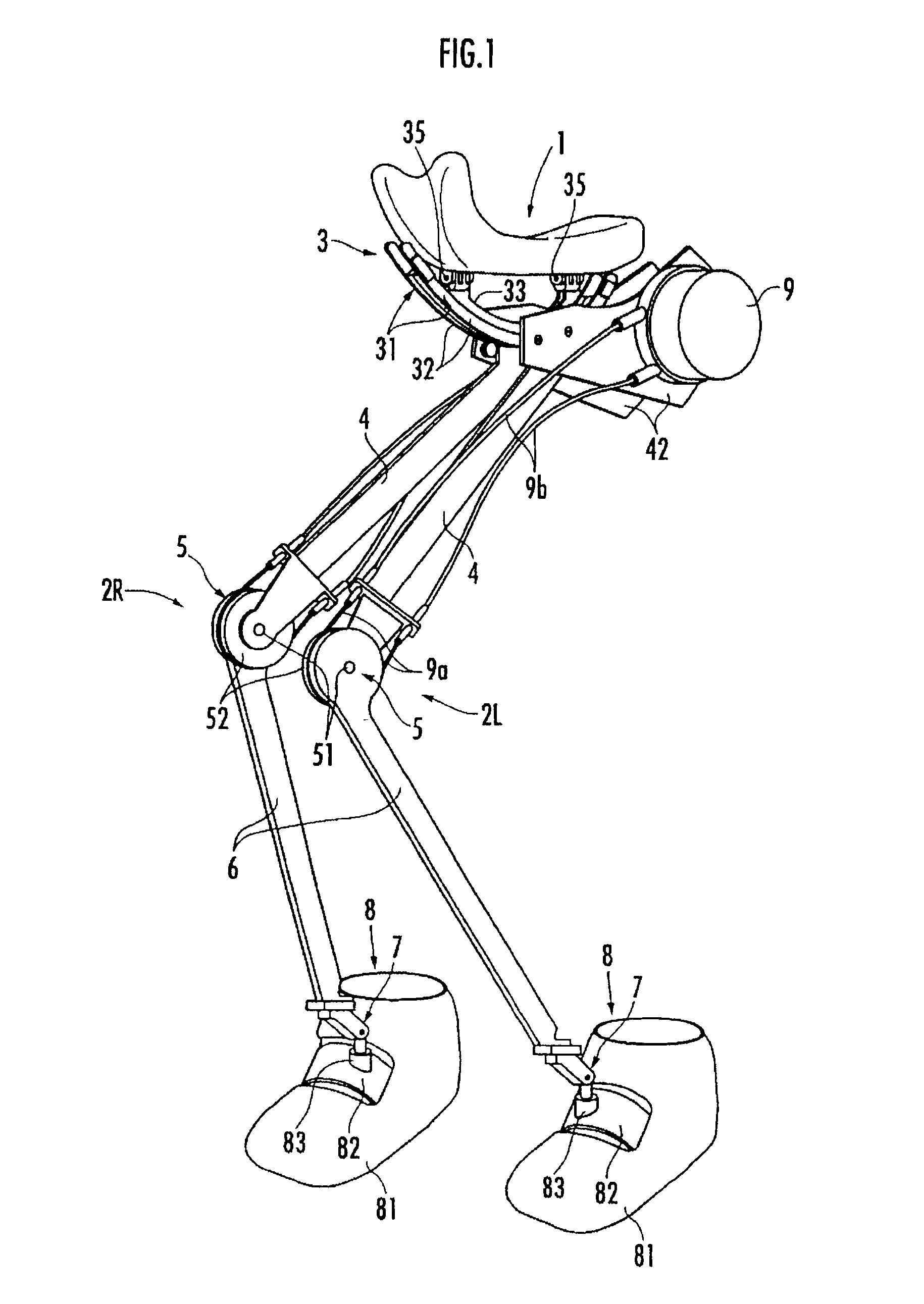

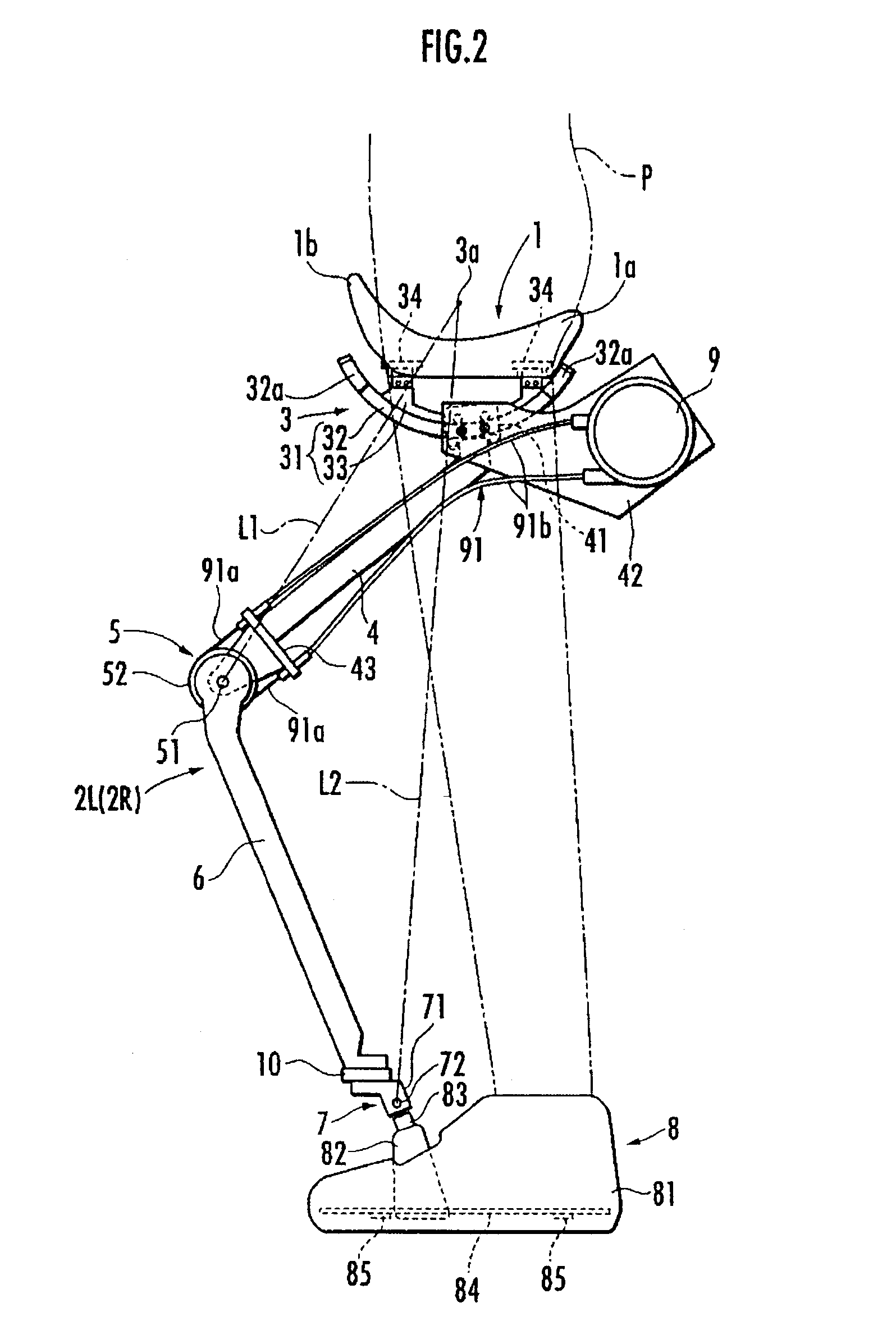

Walking assisting device

ActiveUS8114034B2Reduce torqueLateral distanceProgramme-controlled manipulatorWalking sticksEngineeringAssistive device

Owner:HONDA MOTOR CO LTD

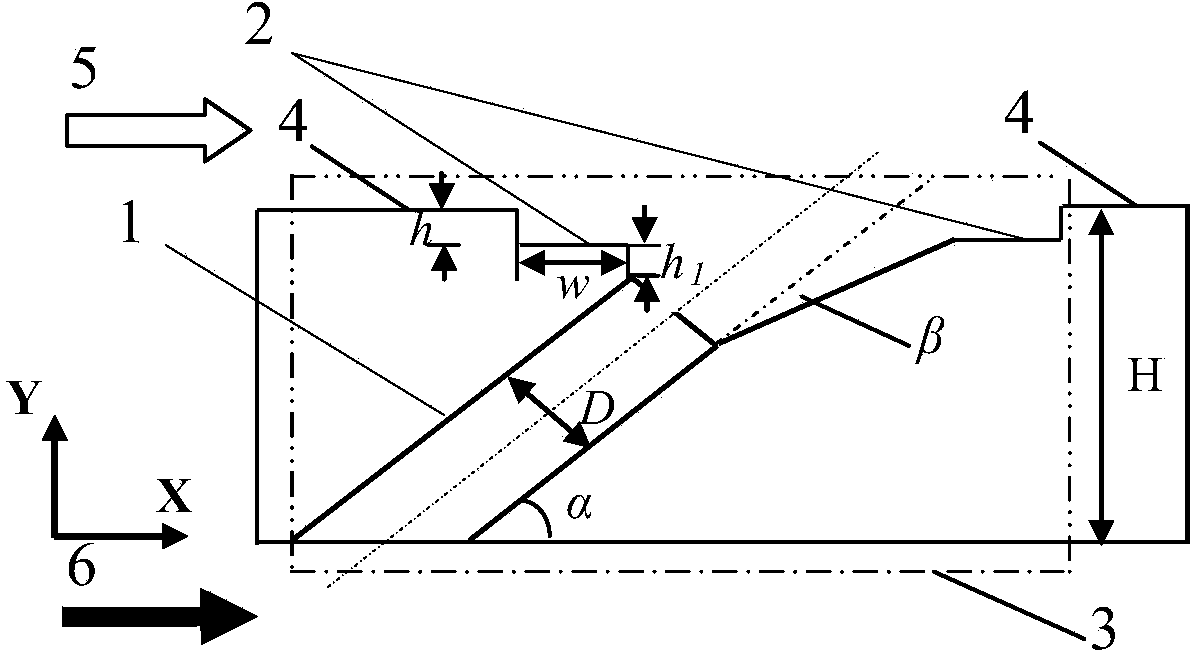

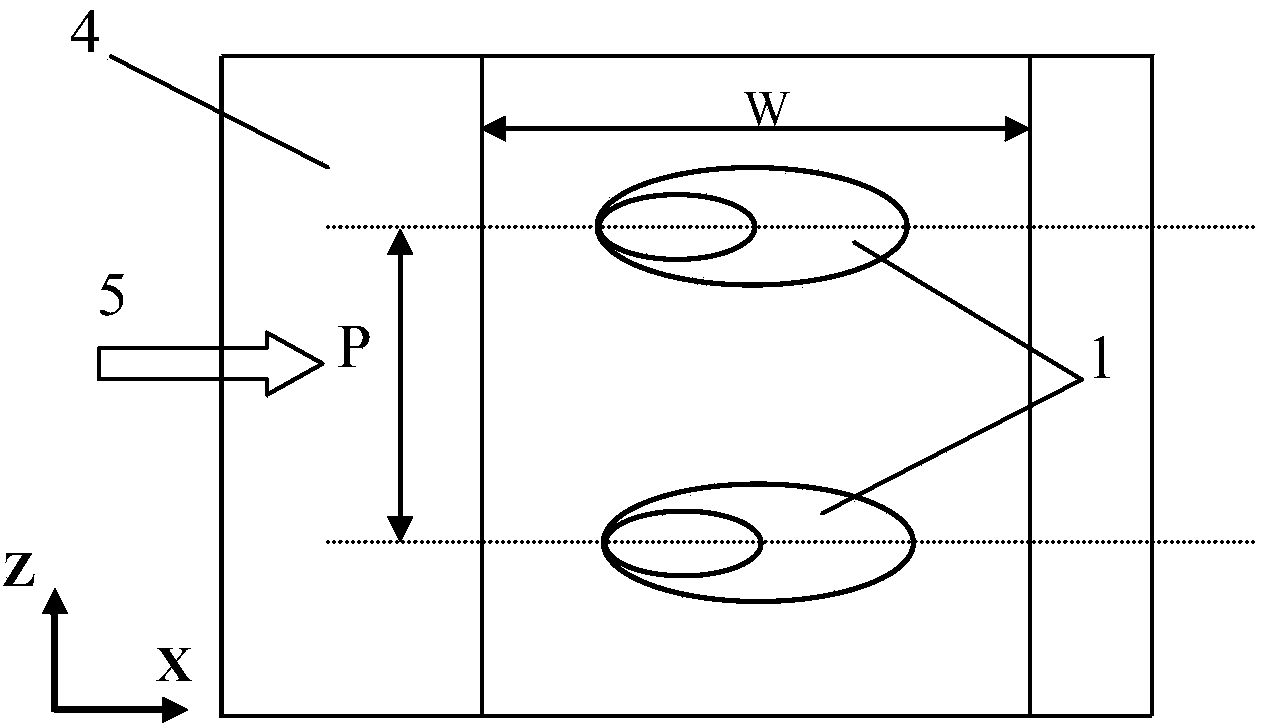

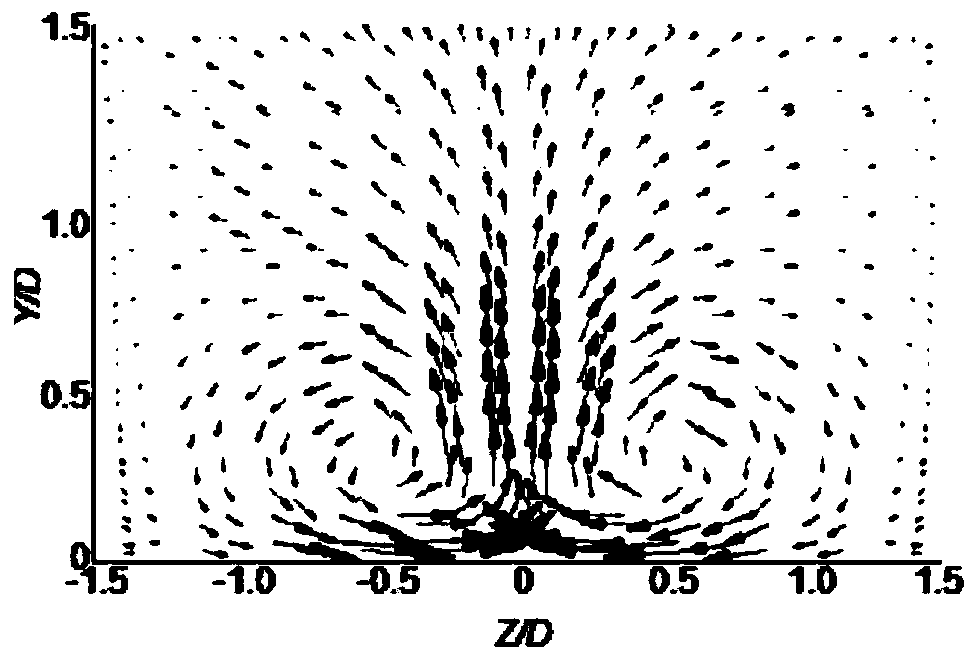

Novel air film hole with improved cooling efficiency

InactiveCN103452595AImprove cooling effectWide air-conditioning coverageContinuous combustion chamberTurbine/propulsion engine coolingAirflowCold air

The invention discloses a novel cooling hole capable of improving the cooling efficiency of an air film of a turbine engine. The novel cooling hole structurally comprises conical holes and a rectangular transverse groove. The rectangular transverse groove is formed in the conical holes along the direction perpendicular to the flowing direction of cold air. An included angle between the axis of each hole and a plane ranges from 10 degrees to 40 degrees, the conical holes are machined on the basis of cylindrical holes, an orifice of each conical hole is a conical opening with an opening angle which ranges from 10 degrees to 20 degrees, and the depth of the transverse groove ranges from 0.5D to 1.0D. Compared with conventional cylindrical air film hole structures, the novel cooling hole has the advantages that the exit sectional area is increased by the conical nozzle holes, so that the main flow penetrating ability of jet flow is reduced, reverse vortex pairs around the nozzle holes can be effectively suppressed, and accordingly the cooling efficiency can be improved; vertical fixed walls of the transverse groove at the lower edges of the conical holes can stop cooling air flow from flowing, so that parts of the cooling air flow flow to two sides of the novel cooling hole, and the novel cooling hole is favorable for transversely diffusing the cooling air flow; the cooling efficiency of the novel cooling hole can be improved by about 300% as compared with the traditional cylindrical air film hole under the condition of a certain blowing ratio.

Owner:QINGDAO UNIV OF SCI & TECH

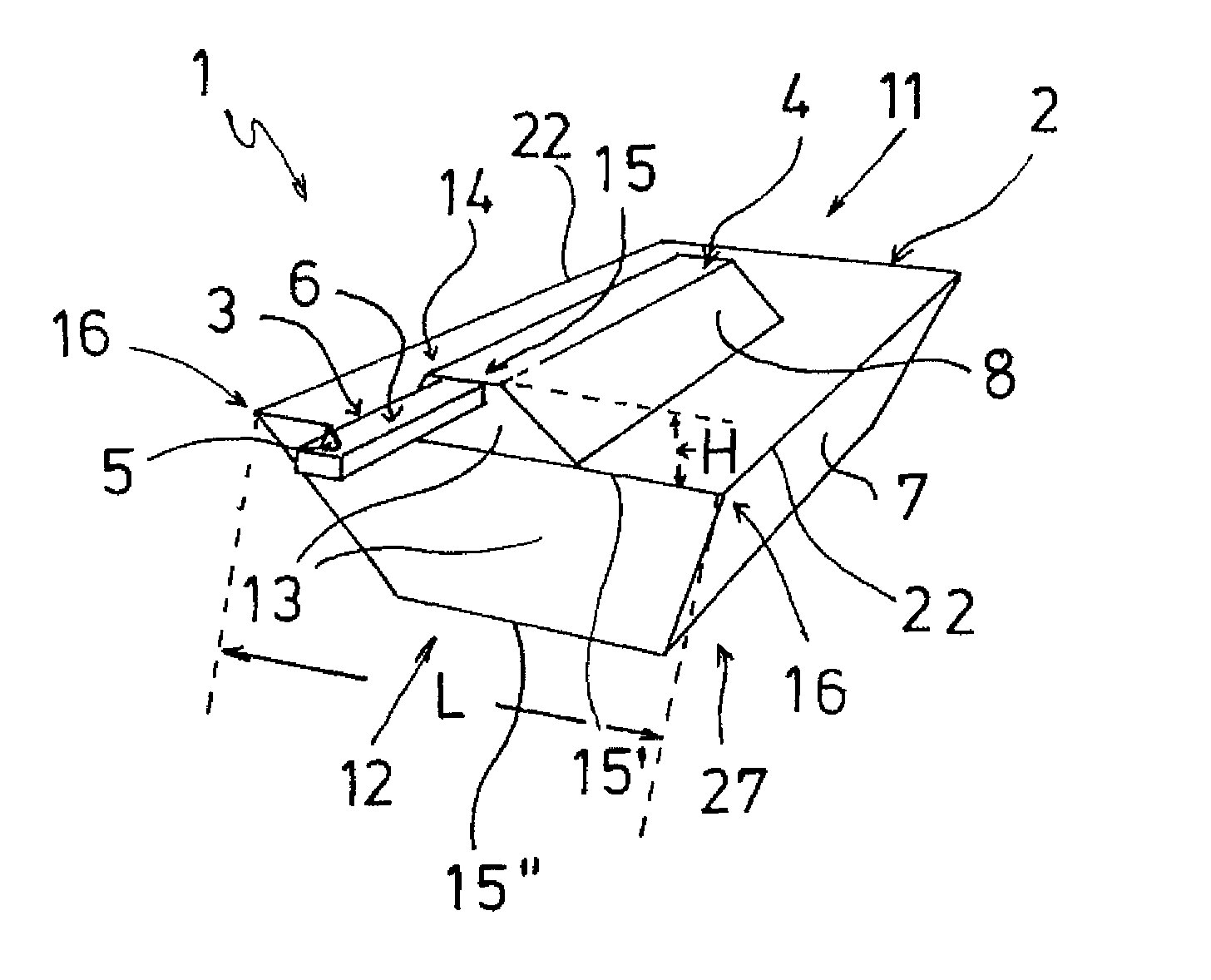

Spm probe with shortened cantilever

InactiveUS20090241233A1Reduce lateral distanceIncrease distanceMaterial analysis using wave/particle radiationNanotechnologyEngineeringCantilever

An SPM probe with an elongated support element and a cantilever projecting beyond the front face of the support element and carrying a scanning tip, with the cantilever arranged at a front face side of the support element of the probe, protruding there from a front face side flank, and with the support element having an essentially trapezoidal cross-section with a longer and a shorter transverse edge at the face side flank, and also with critical corners at one of the transverse edges of the face side flank that are closest to a sample during the scanning process, wherein the support element has an elongated raised portion extending in the longitudinal direction of the support element and of the cantilever, with the raised portion having an essentially trapezoidal cross-section, and with the cantilever arranged on the face side on a narrow transverse edge of the raised portion of the support element, and with the raised portion with the cantilever arranged preferably at the longer transverse edge of the face side flank of the support element, and with the plane extending between the scanning tip and a theoretical straight line passing through one of the critical corners, parallel to the lateral longitudinal edges of the underside of the support element, forming an angle of tilt of at least 5 degrees relative to the transverse edge.

Owner:NANOWORLD

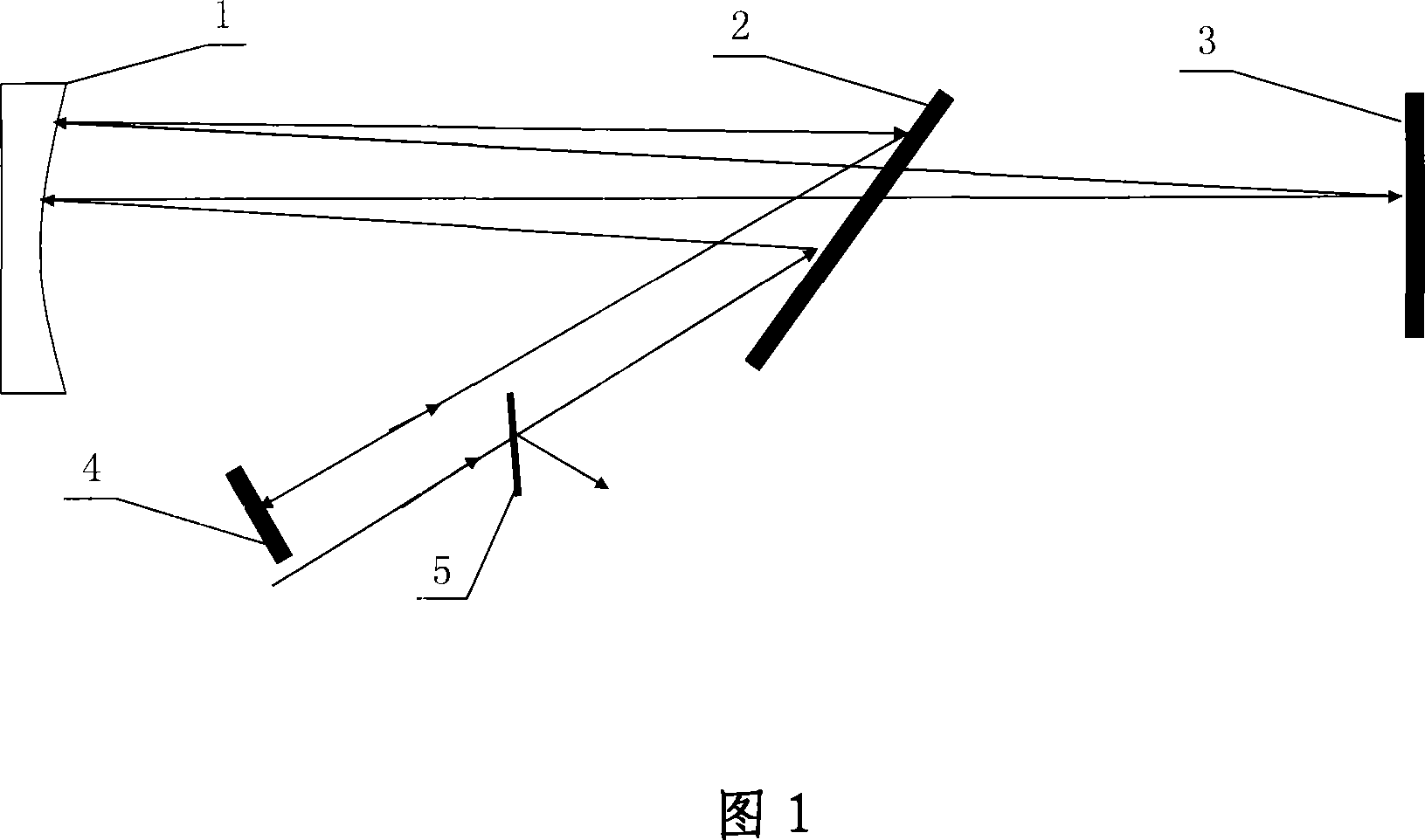

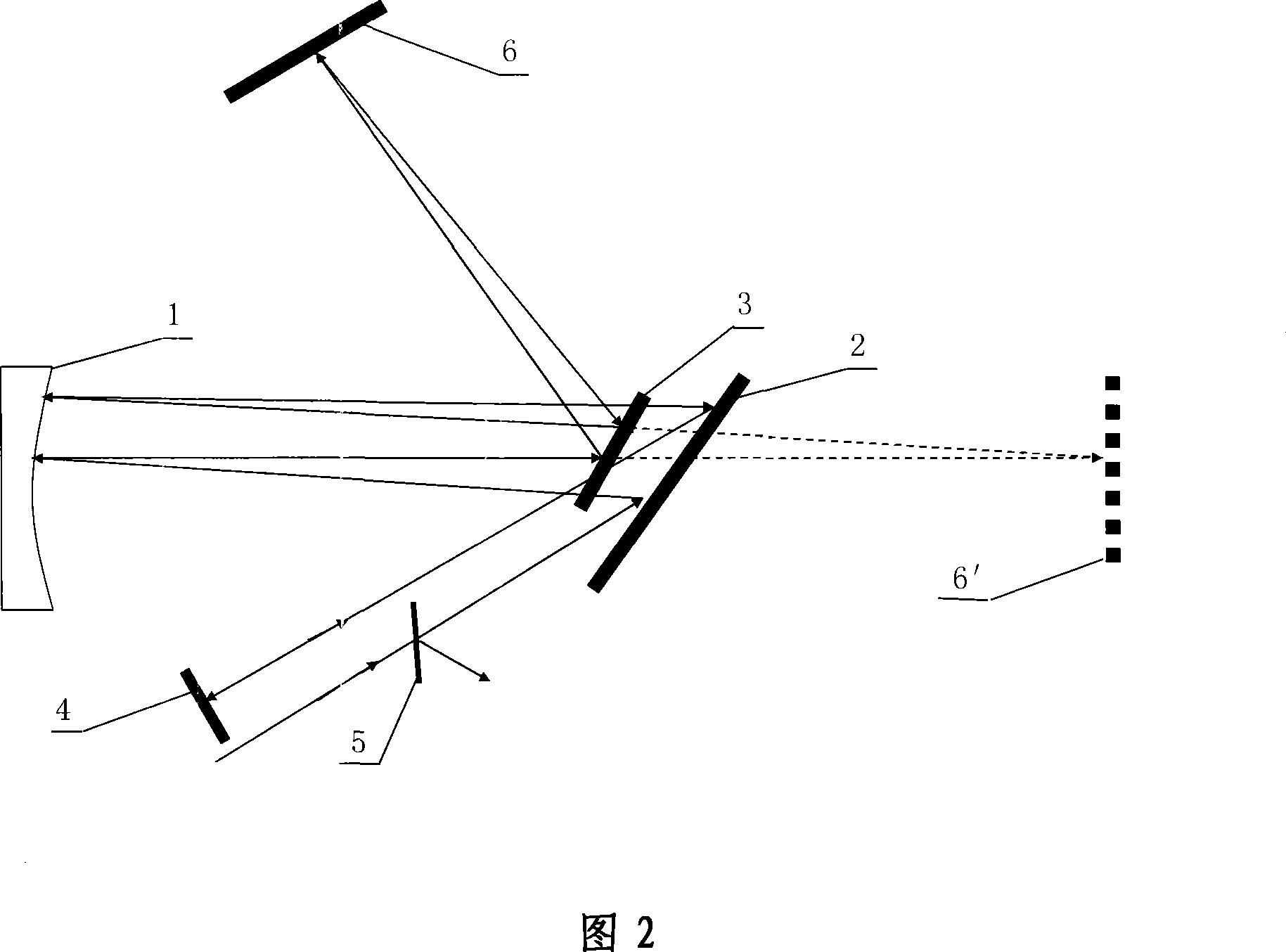

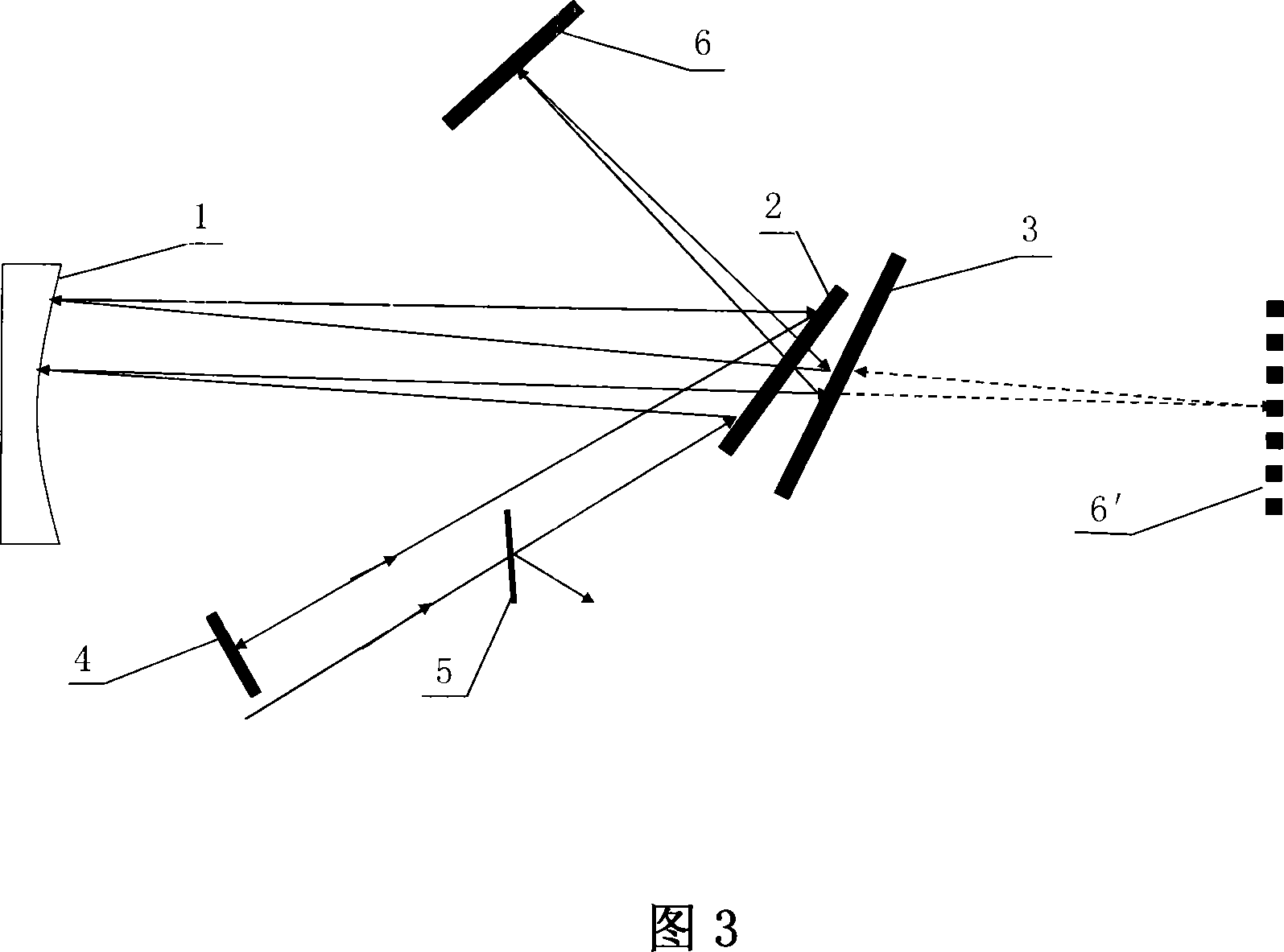

Folding reflective single optical grating expending device

The invention relates to folded reflecting single grating spreading device. It includes column type concave mirror, grating, 1 / 2 lambada wave plate, the first and second plane reflecting mirror. The 1 / 2 lambada wave plate is set on the light beam input and output way. Its feature is that it has the third plane reflecting mirror. The first plane reflecting mirror is set at the optical axis between the column type concave mirror and the grating and close to the latter; or it is set at their optical axis extending line. The first plane reflecting mirror image about the third one is set at the focal plane of the column type concave mirror. The included angle between the first plane reflecting mirror and the optical axis is 45-90 degree. The invention has the advantages of compact structure, flexible using. And it can satisfy the demand of laser pulse big spreading ratio for high power large energy super strength super short laser system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

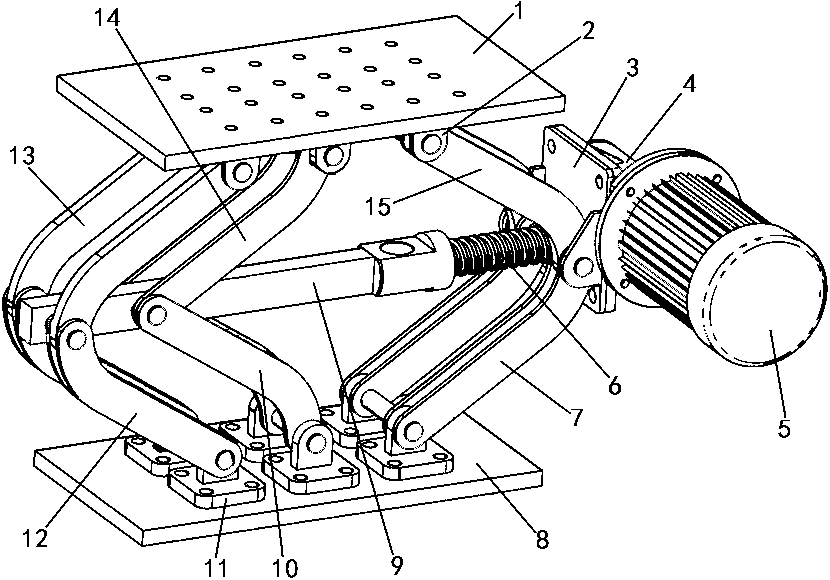

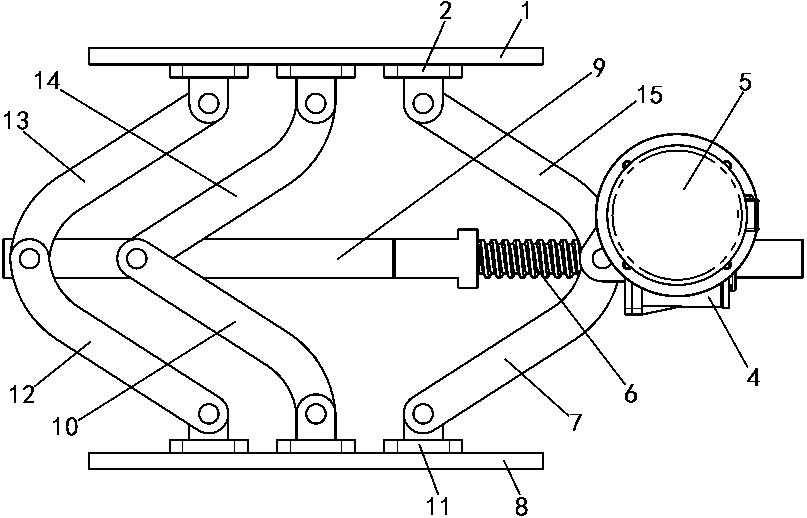

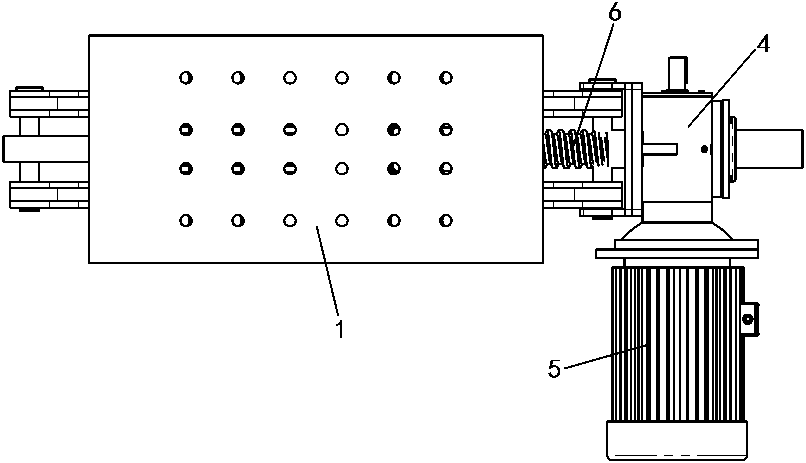

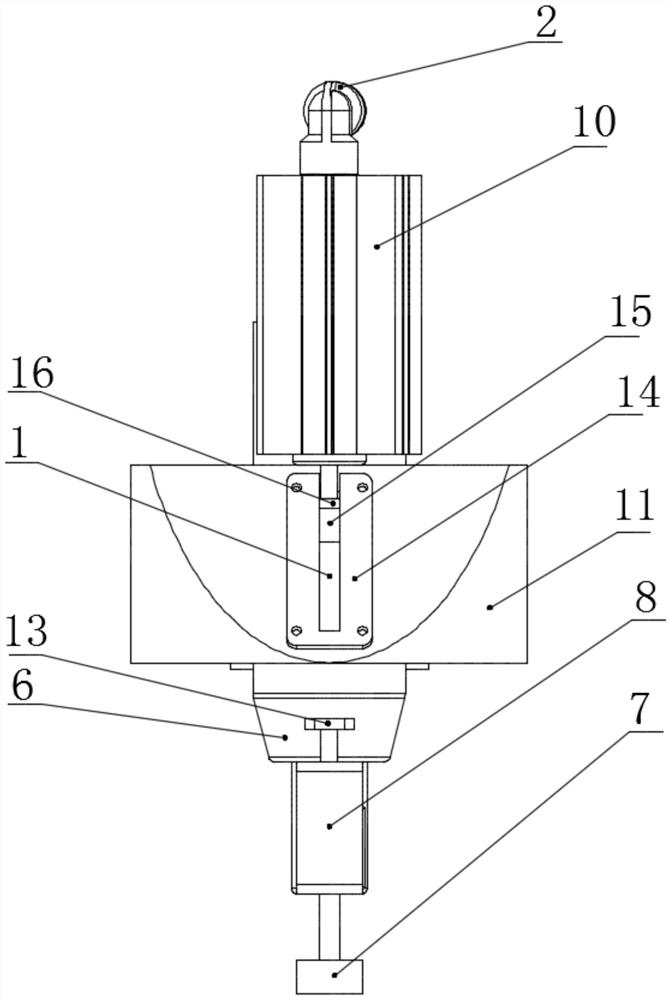

Crane main beam connecting rod lifting device

InactiveCN111115488AGuaranteed translational actionGuaranteed to pan up and downLifting devicesEngineeringMechanical engineering

The invention provides a crane main beam connecting rod lifting device. The crane main beam connecting rod lifting device comprises a base, a bracket, a lead screw, a power driving mechanism, a firstupper connecting rod, a first lower connecting rod, a second upper connecting rod, a second lower connecting rod, a third upper connecting rod and a third lower connecting rod. The bottom end of the first upper connecting rod is hinged to the top end of the first lower connecting rod, and the lead screw straightly moves left and right under the action of the power driving mechanism. The bottom endof the second upper connecting rod and the top end of the second lower connecting rod are hinged to the lead screw at the same time, and the bottom end of the third upper connecting rod and the top end of the third lower connecting rod are hinged to the lead screw at the same time. A parallelogram mechanism is formed by the base, the second lower connecting rod, the third lower connecting rod andthe lead screw, and a parallelogram mechanism is formed by the bracket, the second upper connecting rod, the third upper connecting rod and the lead screw. The crane main beam connecting rod liftingmechanism has the advantages that the connecting rods are hinged, the connecting rods and the other components are hinged, tooth structure do not need to be machined on the connecting rods, and machining and manufacturing are convenient; and meanwhile the problem that the tooth structures are adopted for keeping the synchronization action of the connecting rods, and consequently the use effect ispoor is avoided.

Owner:HENAN MINE CRANE

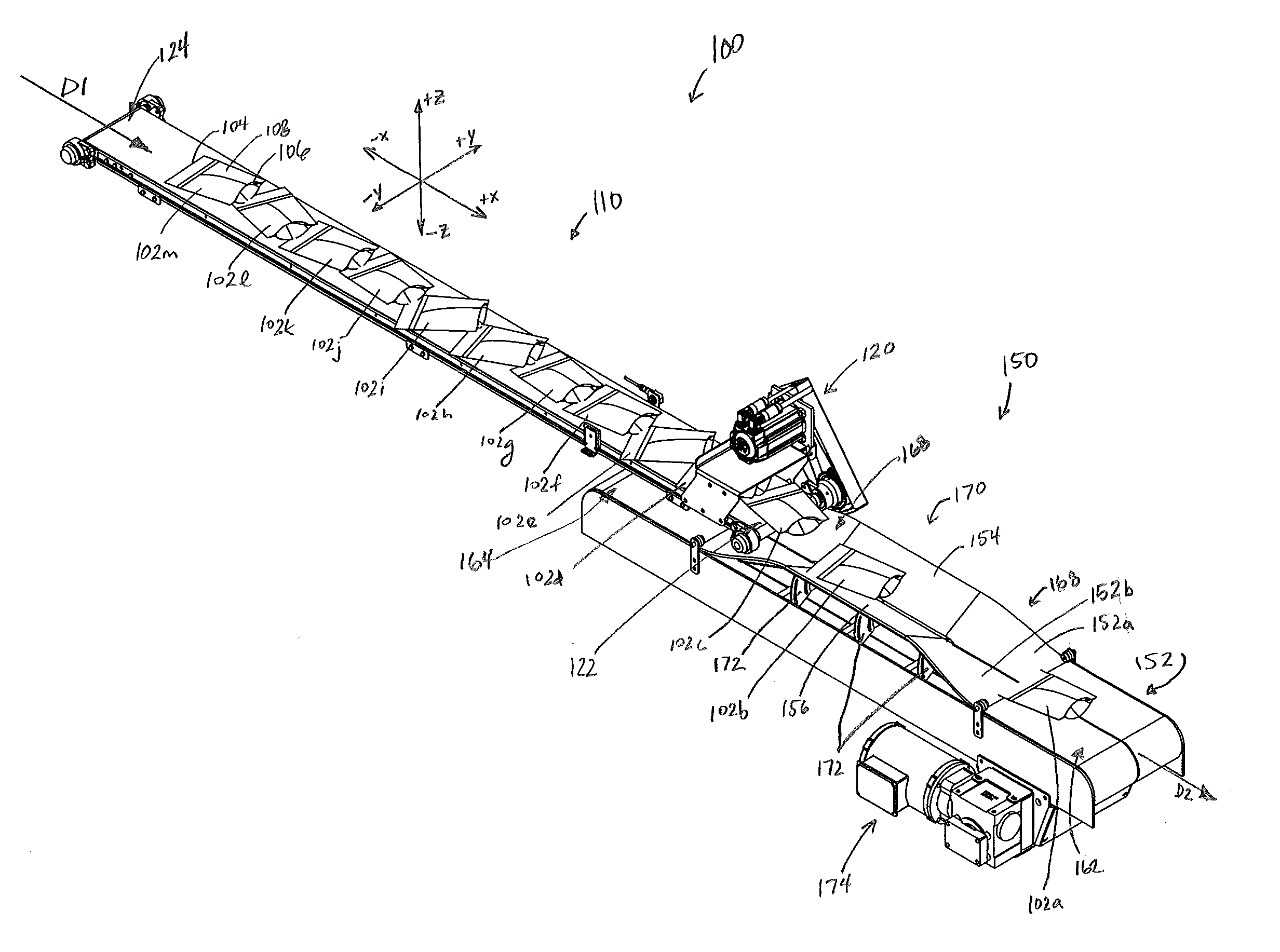

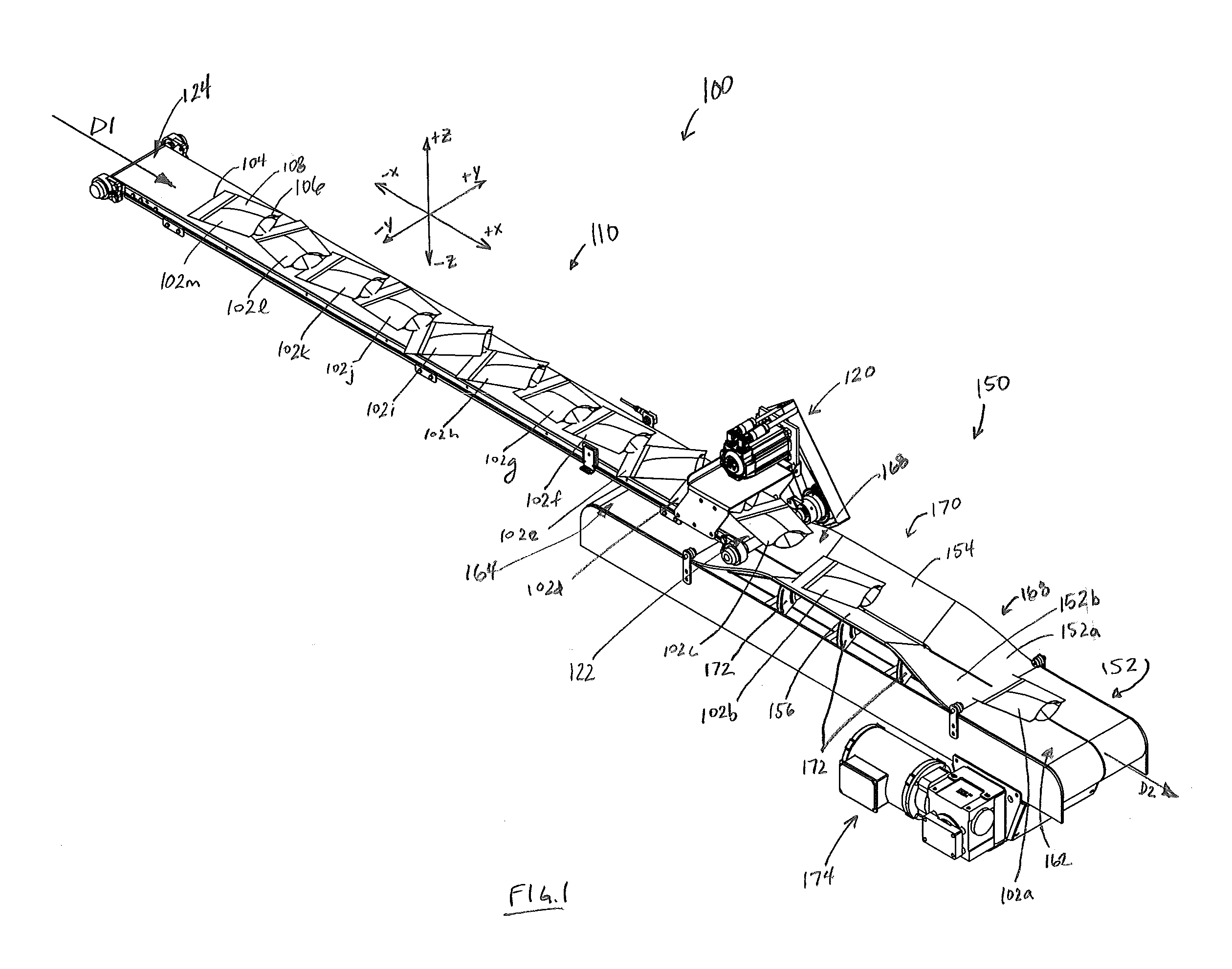

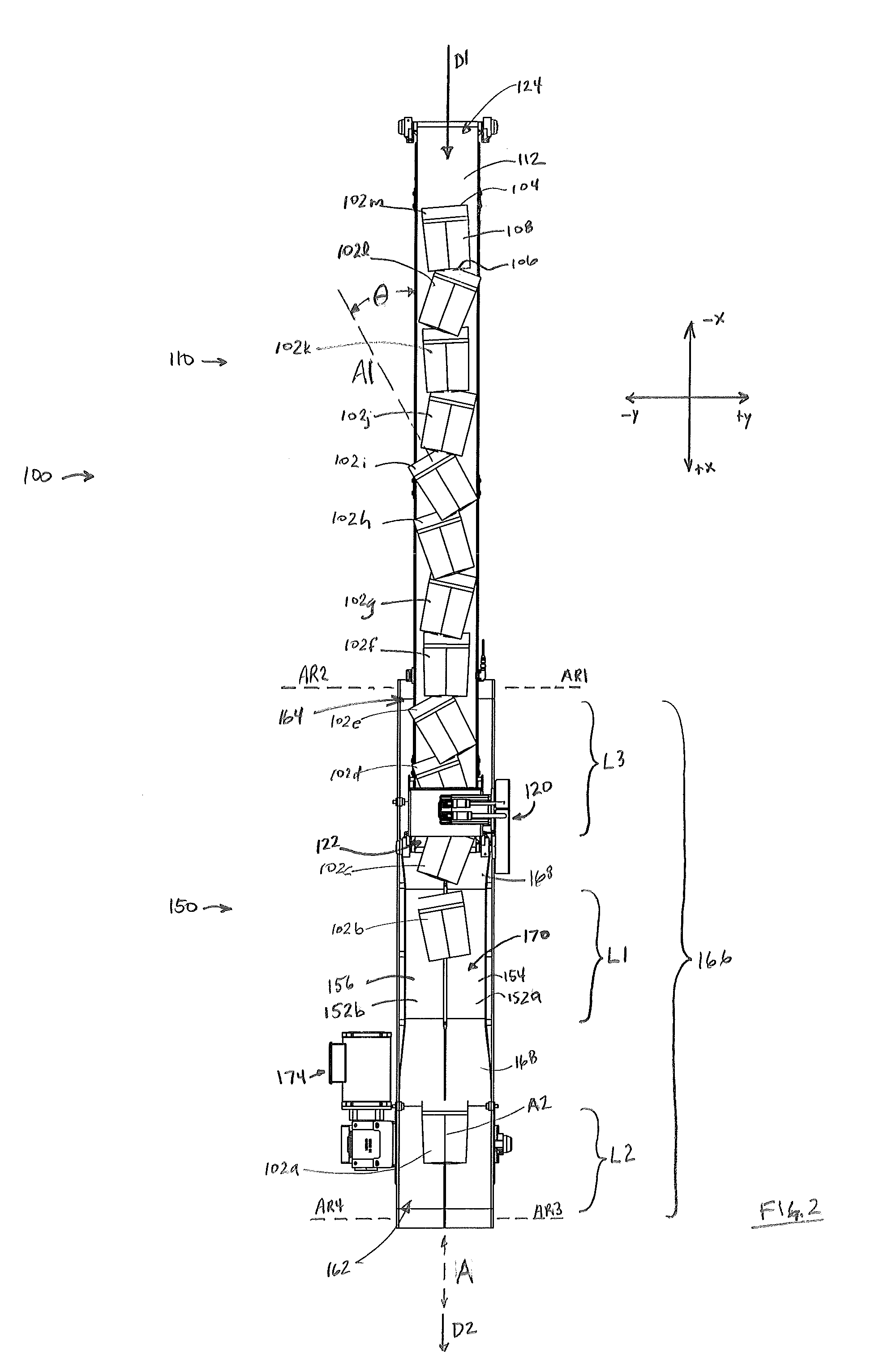

Handling Systems and Methods

InactiveUS20150314965A1Reduce lateral distanceConveyor partsMechanical conveyorsEngineeringHandling system

One or more systems for handling one or more articles, wherein at least one article has a first orientation that deviates from a desired orientation. One or more systems include an infeed conveyor system including an infeed conveyor belt moving at a first speed and an aligning conveyor system including an aligning conveyor belt moving at a second speed and / or a static surface and having portions that form a trough in which an article may be oriented in a sliding engagement to a second orientation that deviates from the desired orientation less than the first orientation. One or more methods include contacting an aligning conveyor system having an aligning conveyor belt and / or a static surface that forms a trough with an article that has a first orientation that deviates from a desired orientation and allowing the article to move laterally within the trough to a second orientation that deviates from a desired orientation less than the first orientation.

Owner:DELKOR SYST

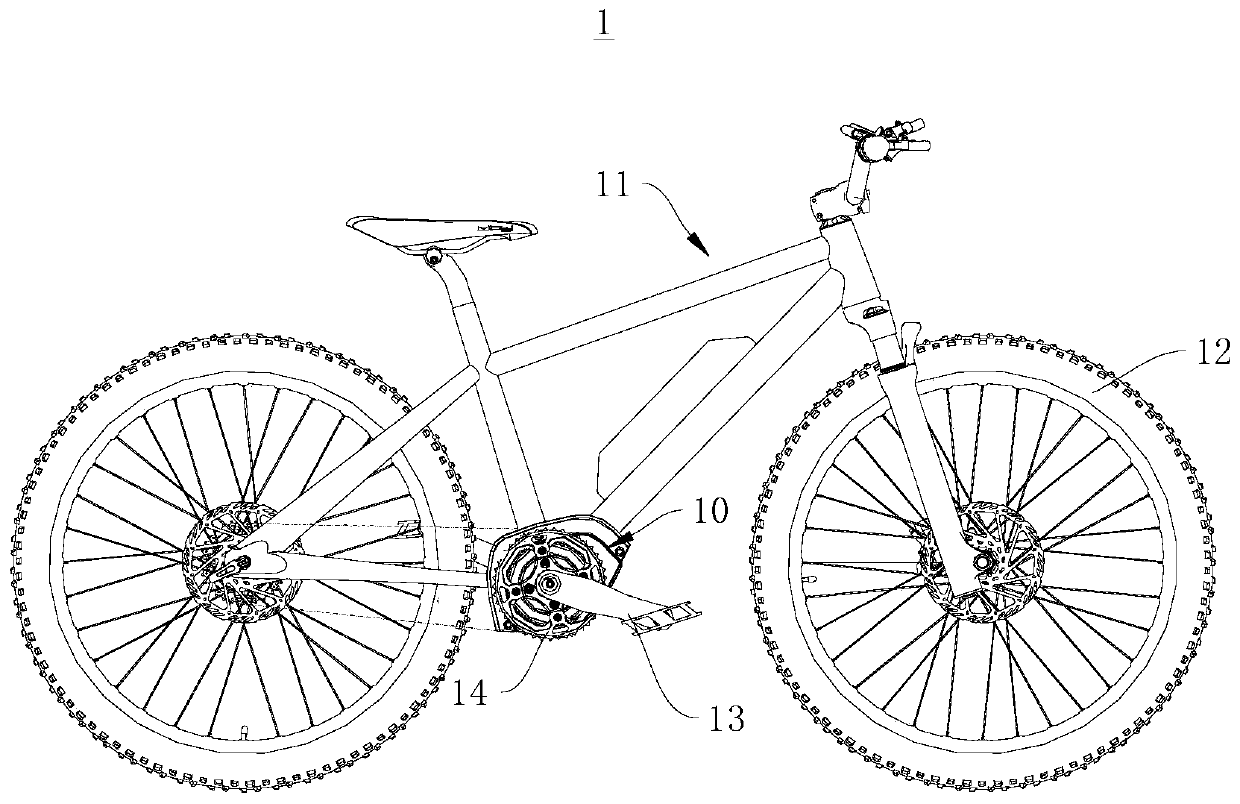

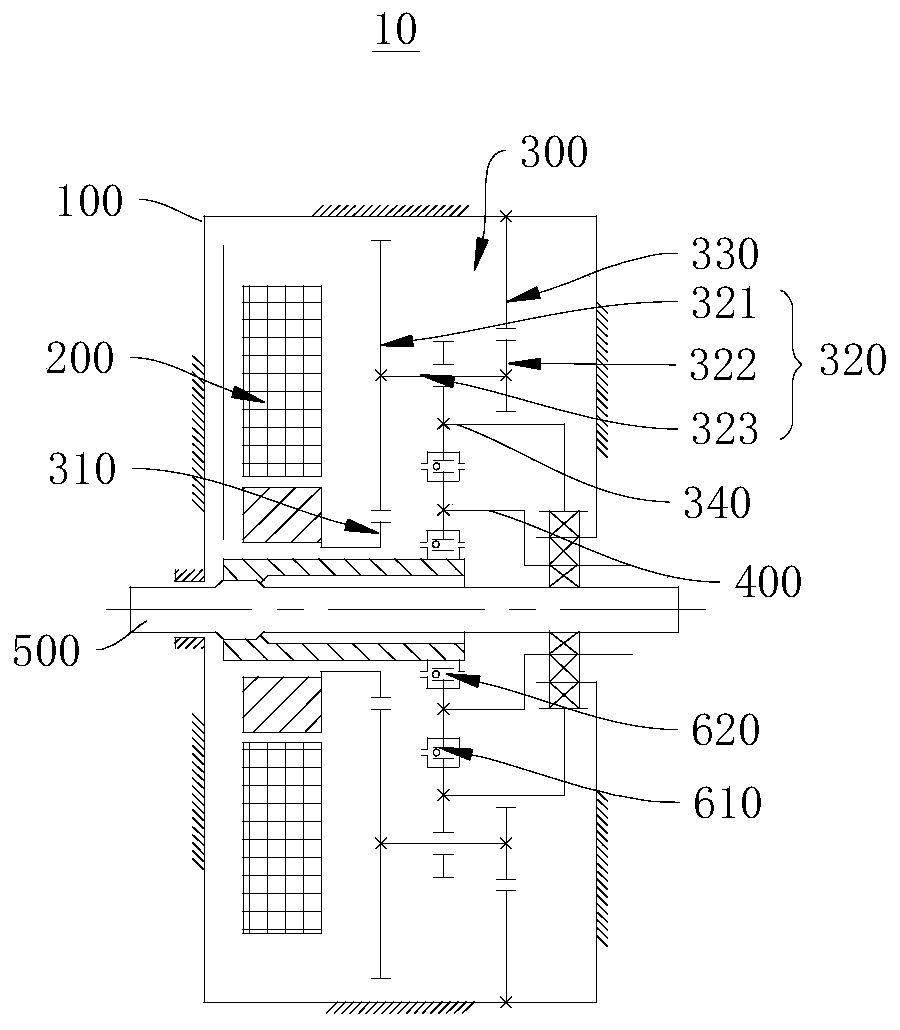

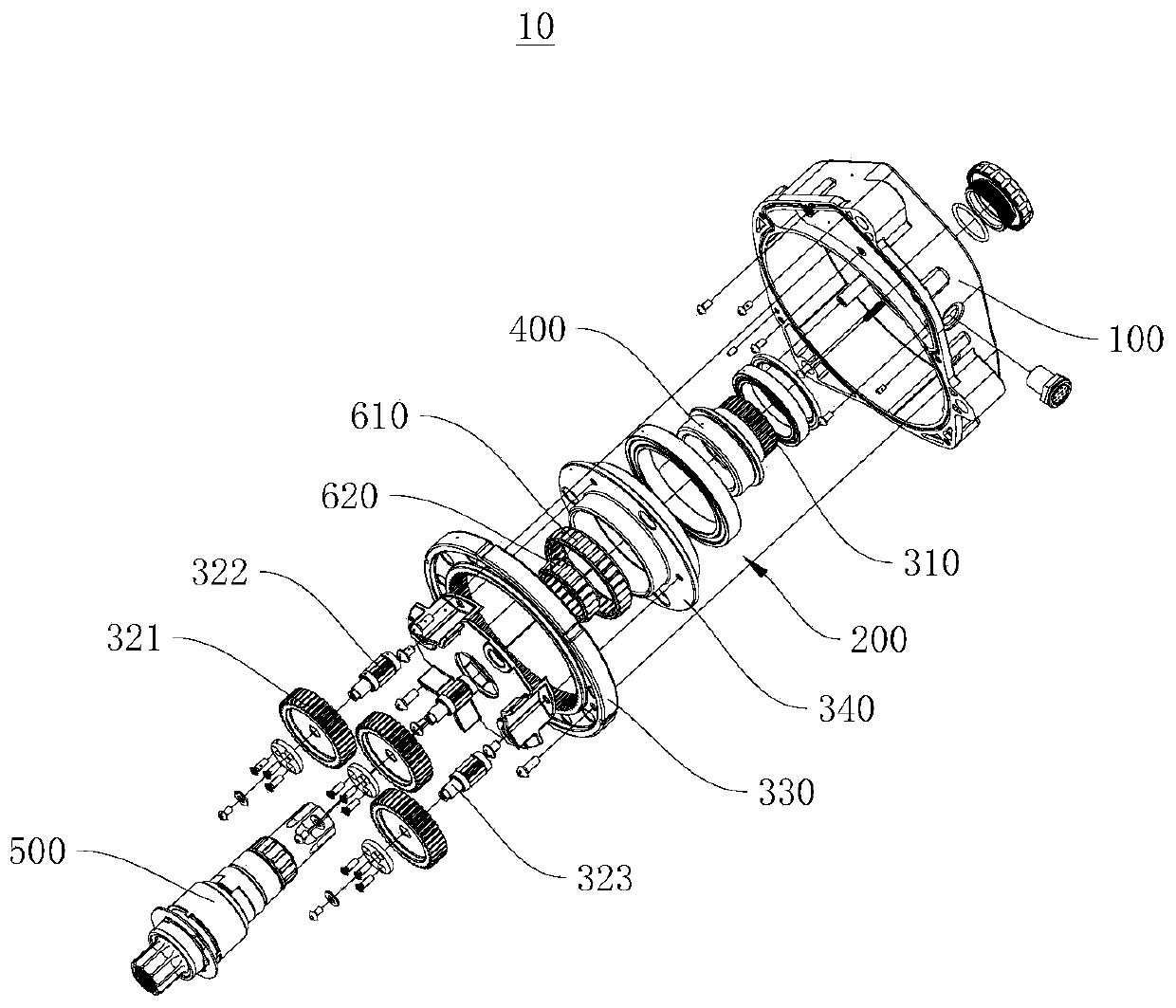

Power-assisted vehicle coaxially middle-mounted motor and power-assisted bicycle

The invention provides a power-assisted vehicle coaxial middle-mounted motor and a power-assisted bicycle, and relates to the technical field of power-assisted bicycles. The power-assisted vehicle coaxial middle-mounted motor comprises a shell, a central shaft core, an output structure, a power-assisted motor, a sun gear, a duplex planetary gear, an inner gear ring and a planet carrier, wherein the central shaft core is arranged in the shell, and the sun gear is connected to the power-assisted motor. The duplex planetary gear comprises a first planetary gear and a second planetary gear which are coaxial and fixed, and the first planetary gear and the second planetary gear are rotatably connected to the planet carrier. The first planetary gear is meshed with the sun gear, the second planetary gear is meshed with the inner gear ring, and the inner gear ring is fixed to the shell. The planet carrier can drive the output structure, and the central shaft core can drive the output structure.A power-assisted motor shaft core, the central shaft core, the sun gear, the planet carrier, the inner gear ring and the output structure are coaxially arranged. The invention further provides the power-assisted bicycle, and the coaxial middle-mounted motor is adopted in the power-assisted bicycle. According to the power-assisted vehicle coaxial middle-mounted motor and the power-assisted bicycle, the volume can be reduced and the power output performance can be increased.

Owner:深圳市奥酷曼智能技术有限公司

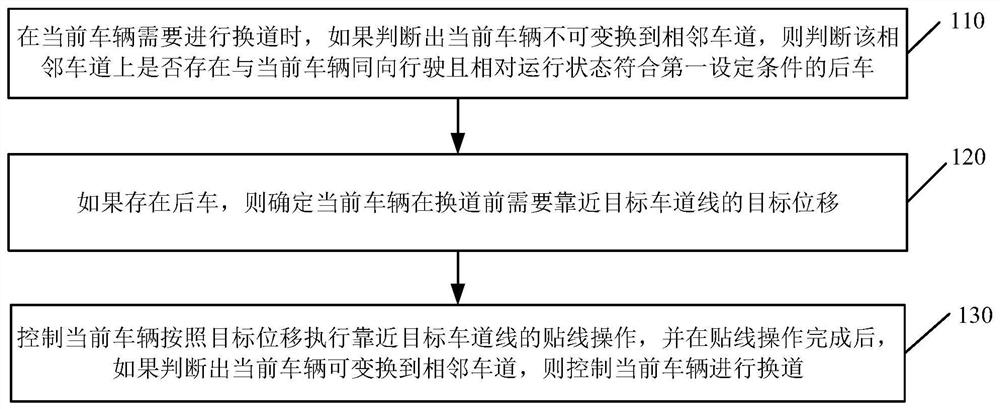

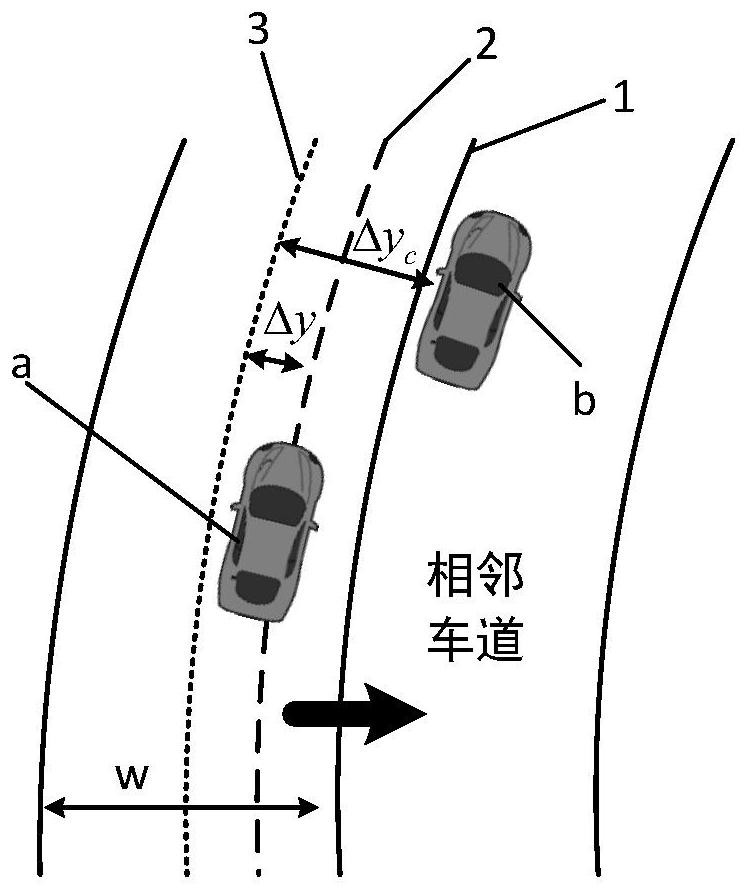

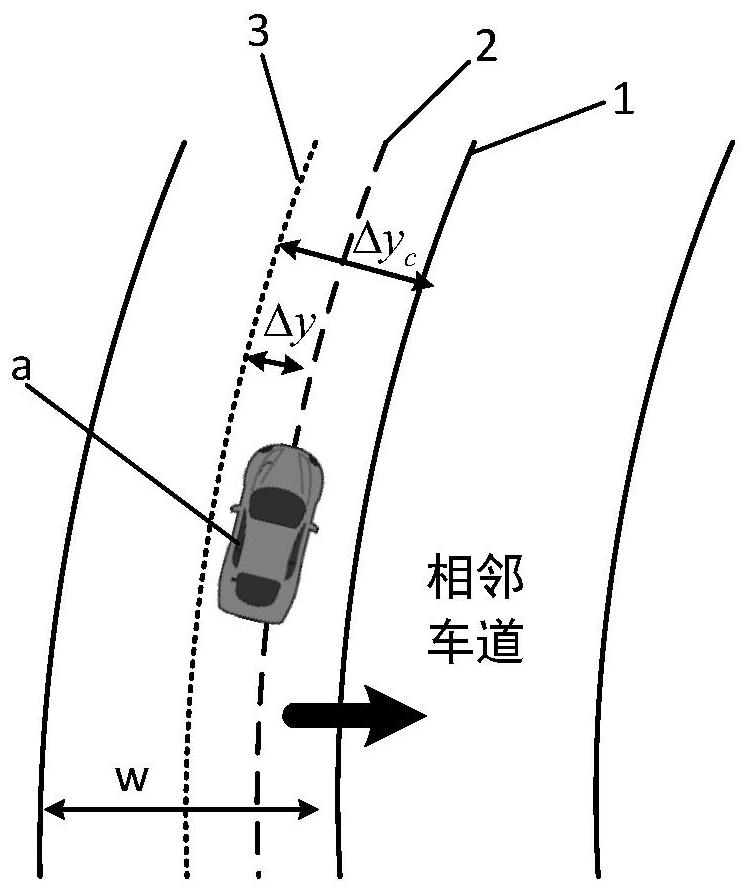

Vehicle lane changing method and device

The embodiment of the invention discloses a vehicle lane changing method and device, and the method comprises the steps: judging whether there is a rear vehicle which runs in the same direction as a current vehicle and has a relative running state meeting a first set condition on an adjacent lane or not if the current vehicle is judged not to be able to change to the adjacent lane when the currentvehicle needs to change a lane, wherein the relative operation state comprises a relative speed and a relative distance; if the rear vehicle exists, determining that the current vehicle needs to getclose to a target lane line before lane changing, the target lane line being a lane line between the current lane and an adjacent lane; and controlling the current vehicle to execute the line approaching operation close to the target lane line according to the target displacement, and after the line approaching operation is completed, if it is judged that the current vehicle can be changed to theadjacent lane, controlling the current vehicle to change the lane. By the adoption of the technical scheme, the success rate of autonomous lane changing of an automatic driving vehicle in a dense traffic scene is increased.

Owner:MOMENTA SUZHOU TECH CO LTD

Latch-up free vertical TVS diode array structure using trench isolation

ActiveUS9202938B2Lateral distanceReduce lateral distanceTransistorSolid-state devicesEngineeringBody region

A method for manufacturing a transient voltage suppressing (TVS) array substantially following a manufacturing process for manufacturing a vertical semiconductor power device. The method includes a step of opening a plurality of isolation trenches in an epitaxial layer of a first conductivity type in a semiconductor substrate followed by applying a body mask for doping a body region having a second conductivity type between two of the isolation trenches. The method further includes a step of applying an source mask for implanting a plurality of doped regions of the first conductivity type constituting a plurality of diodes wherein the isolation trenches isolating and preventing parasitic PNP or NPN transistor due to a latch-up between the doped regions of different conductivity types.

Owner:ALPHA & OMEGA SEMICON INC

SPM probe with shortened cantilever

InactiveUS8011016B2Reduce lateral distanceIncrease distanceMaterial analysis using wave/particle radiationNanotechnologyEngineeringCantilever

An SPM probe with an elongated support element and a cantilever projecting beyond the front face of the support element and carrying a scanning tip, with the cantilever arranged at a front face side of the support element of the probe, protruding there from a front face side flank, and with the support element having an essentially trapezoidal cross-section with a longer and a shorter transverse edge at the face side flank, and also with critical corners at one of the transverse edges of the face side flank that are closest to a sample during the scanning process, wherein the support element has an elongated raised portion extending in the longitudinal direction of the support element and of the cantilever, with the raised portion having an essentially trapezoidal cross-section, and with the cantilever arranged on the face side on a narrow transverse edge of the raised portion of the support element, and with the raised portion with the cantilever arranged preferably at the longer transverse edge of the face side flank of the support element, and with the plane extending between the scanning tip and a theoretical straight line passing through one of the critical corners, parallel to the lateral longitudinal edges of the underside of the support element, forming an angle of tilt of at least 5 degrees relative to the transverse edge.

Owner:NANOWORLD

LED plant growth lamp adjusting device and method

InactiveCN108826111AReduce lateral distanceShorten height distanceSaving energy measuresHorticulture methodsGrowth plantSurface mounting

The invention discloses an LED plant growth lamp adjusting device and method. The LED plant growth lamp adjusting device comprises a growth lamp body. The growth lamp body is composed of a supportingbox, a sliding column, a universal column and a lamp post. A plurality of sets of LED lamp pieces are mounted on the surface of the lamp post. A sliding groove is formed in the lower surface of the supporting box in the length direction of the box. The upper end of the sliding column is movably inserted into the sliding groove. A sliding block is slidably arranged in the supporting box. A first driving motor is fixedly mounted on the side, adjacent to a transmission box, of the lower surface of the supporting box. A limiting tube is fixedly mounted at the lower end of the sliding column, a sleeve is mounted on the front side surface of the limiting tube, and a second driving motor is fixedly mounted on the rear side wall of the limiting tube. According to the LED plant growth lamp adjusting device and method, the transverse distance between the LED lamp and a plant can be shortened, the second driving motor is started, the universal column is swung to the lower end of the sliding column, the height distance between the LED lamp and the plant can be shortened, the irradiation effect of the LED lamplight is improved, and the growth efficiency of the plant can be improved.

Owner:ANHUI SHILIN LIGHTING

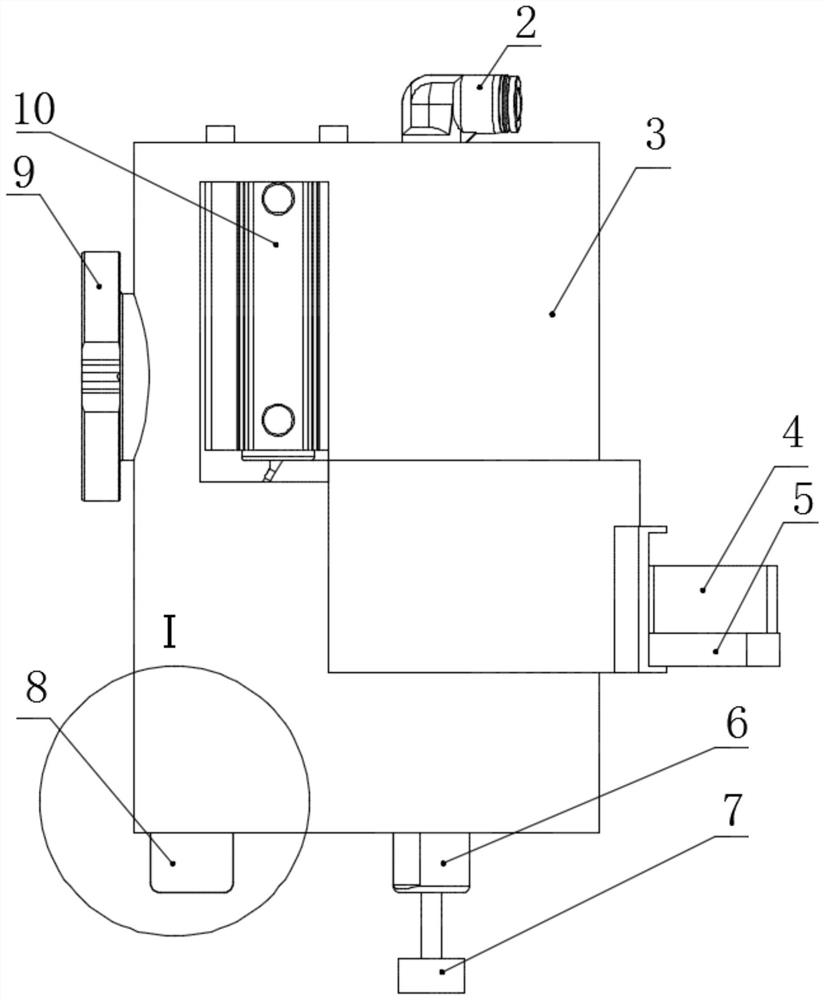

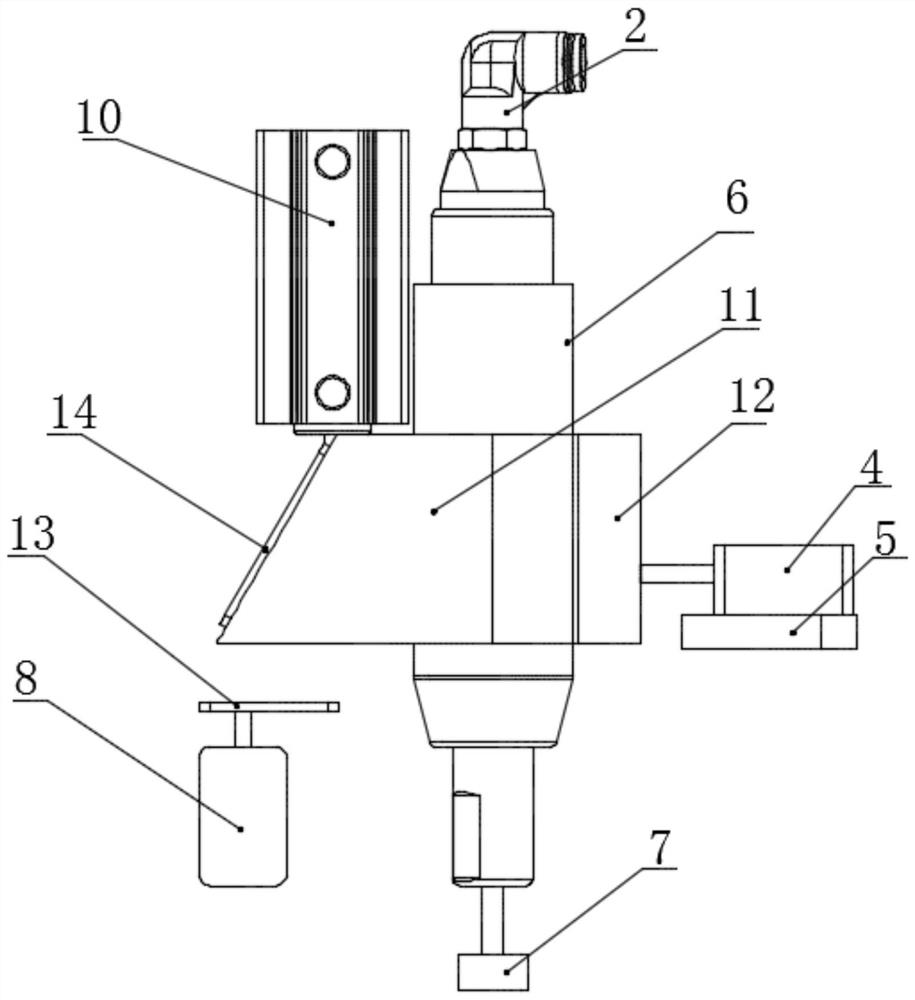

Grinding and polishing force control end execution device

ActiveCN111136543AAvoid interferenceSimple structurePolishing machinesGrinding drivesAir pumpEngineering

The invention provides a grinding and polishing force control end execution device. The grinding and polishing force control end execution device comprises an outer shell, a pneumatic spindle, a grinding wheel, a cylinder, a movable piston, a tension and pressure sensor, a first limiting part and a second limiting part, wherein the pneumatic spindle vertically penetrates through the outer shell and is not fixed to the outer shell; the tail end of the pneumatic spindle is exposed to the outer shell and is fixedly provided with the grinding wheel; the air inlet end of the pneumatic spindle is insealing connection with an external air tank or an air pump; the movable piston is sleeved on a cylinder barrel of the pneumatic spindle and located in the outer shell; the cylinder is located in theouter shell, and the tension and pressure sensor is fixed to a telescopic rod of the cylinder; the tail end of the telescopic rod of the cylinder can apply horizontal and vertical force to the movable piston; the sidewall of the outer shell is provided with an arc-shaped square hole, and an outer cover is arranged at the arc-shaped square hole of the outer shell; and the first limiting part and the second limiting part are used for limiting the movable piston in the horizontal direction and the vertical direction correspondingly. The grinding and polishing force control end execution device realizes motion of the piston in the horizontal and vertical directions through one cylinder, and also realizes force control over the grinding wheel in two dimensionalities.

Owner:HEBEI UNIV OF TECH

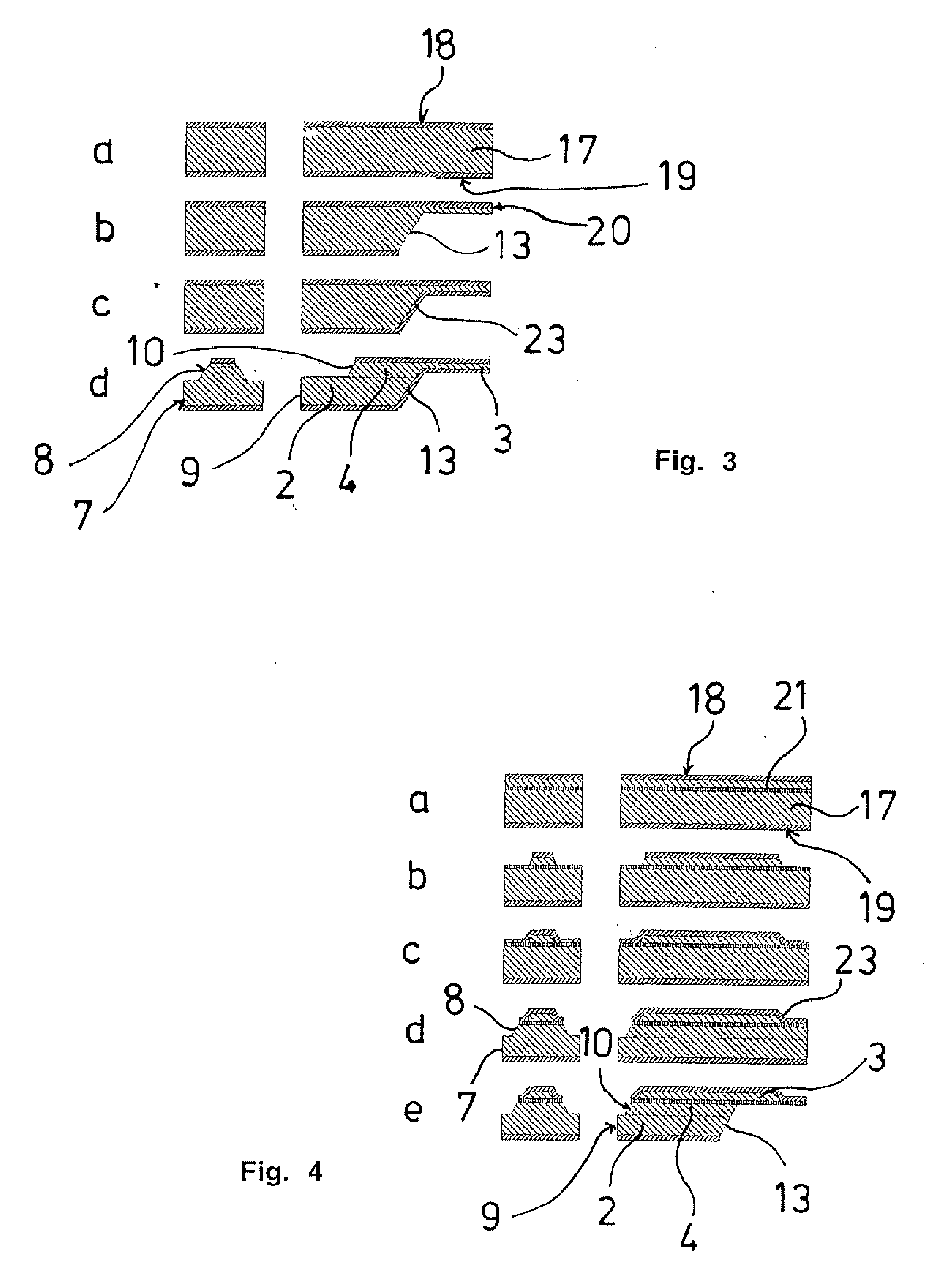

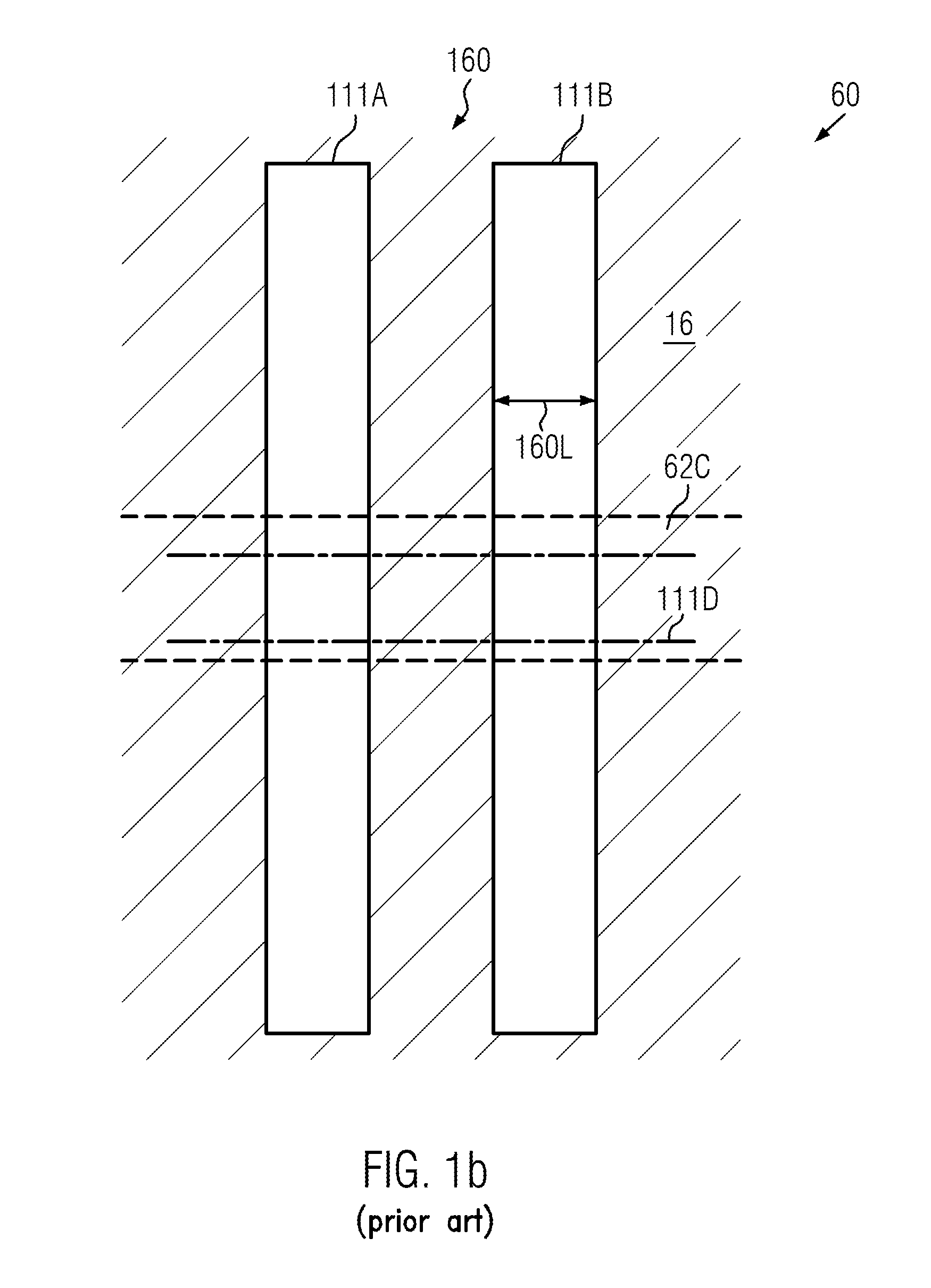

Gate electrode with a shrink spacer

InactiveUS9040405B2Improve controllabilityImprove scalabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor packageCondensed matter physics

A method of forming a semiconductor device including forming a dielectric material layer on a semiconductor layer, forming a gate electrode material layer on the dielectric material layer, forming mask features on the gate electrode material layer, forming a spacer layer on and at sidewalls of the mask features and on the gate electrode material layer between the mask features, removing the spacer layer from the gate electrode material layer between the mask features, and etching the gate electrode material layer and dielectric material layer using the hard mask features as an etch mask to obtain gate electrode structures. A semiconductor device including first and second gate electrode structures, each covered by a cap layer that comprises a mask material surrounded at the sidewalls thereof by a spacer material different from the mask material, and the distance between the first and second electrode structures is at most 100 nm.

Owner:GLOBALFOUNDRIES INC

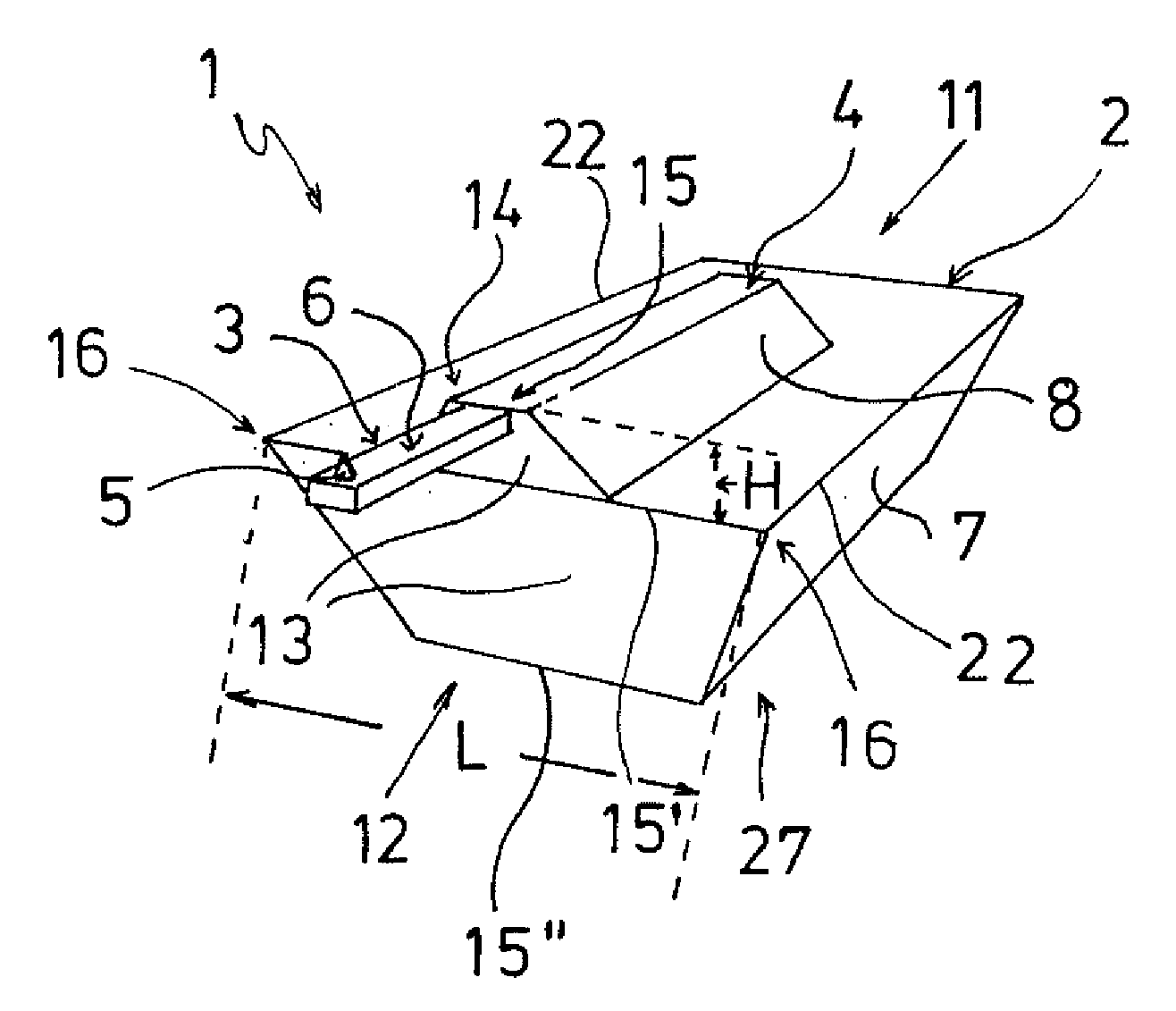

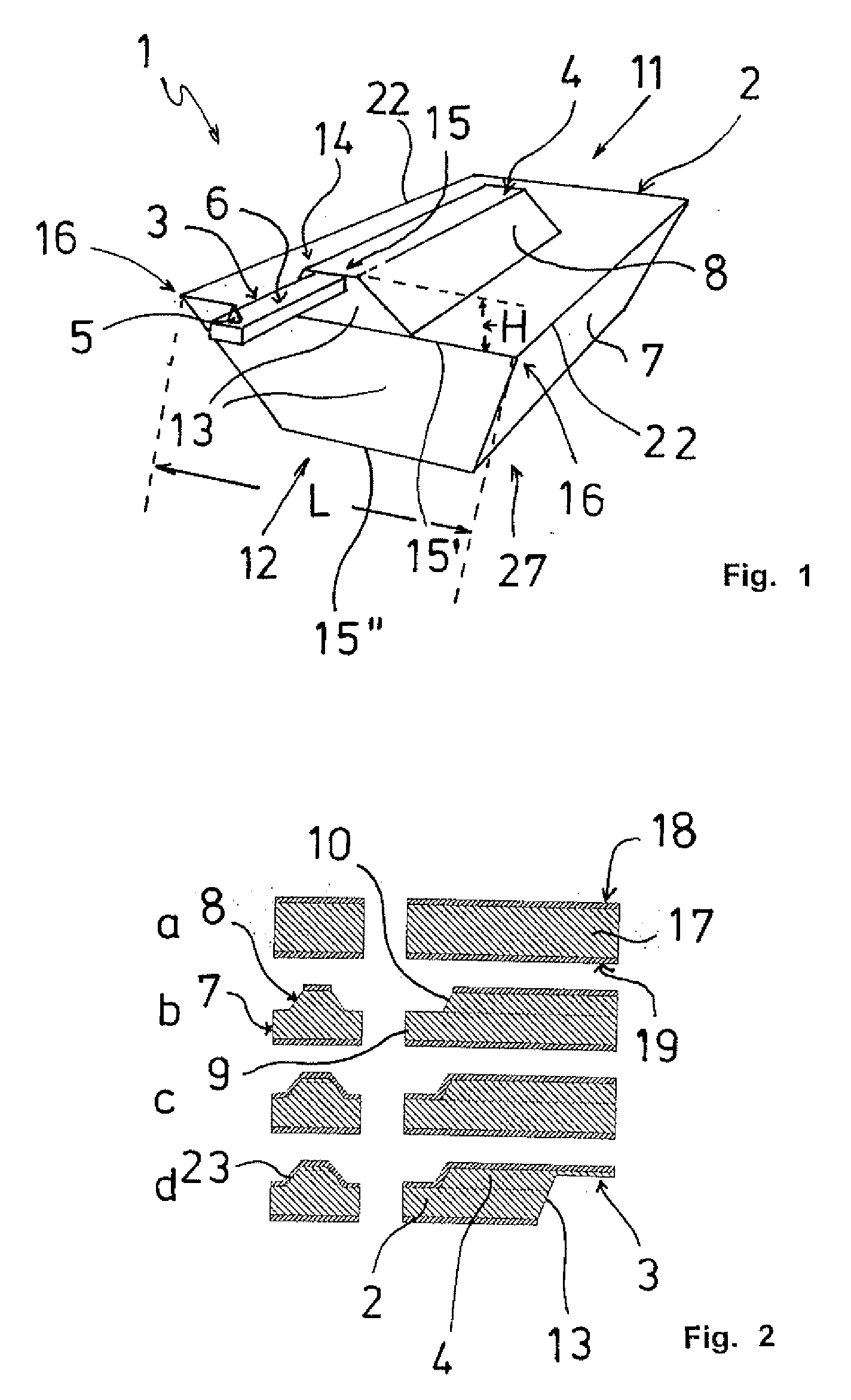

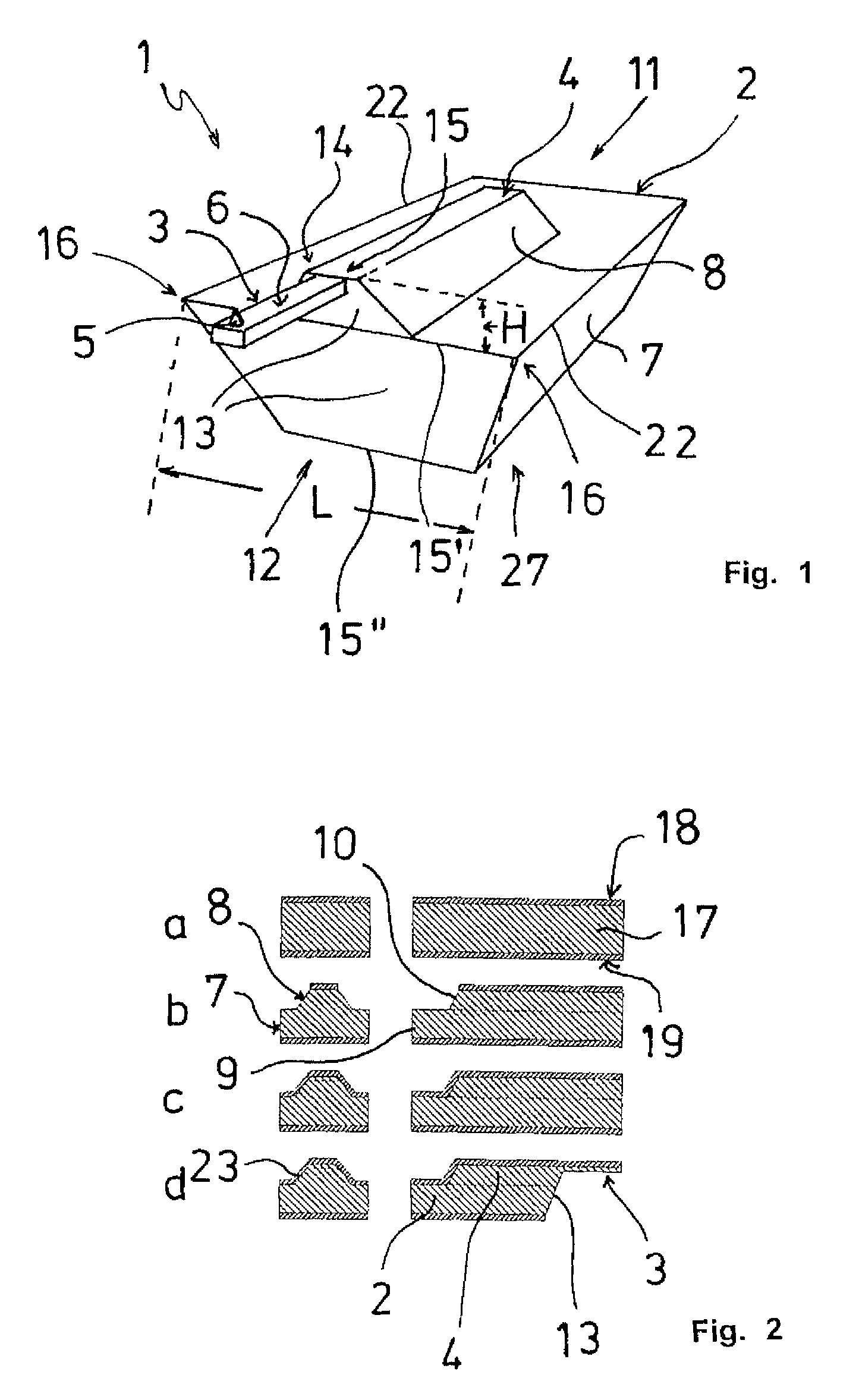

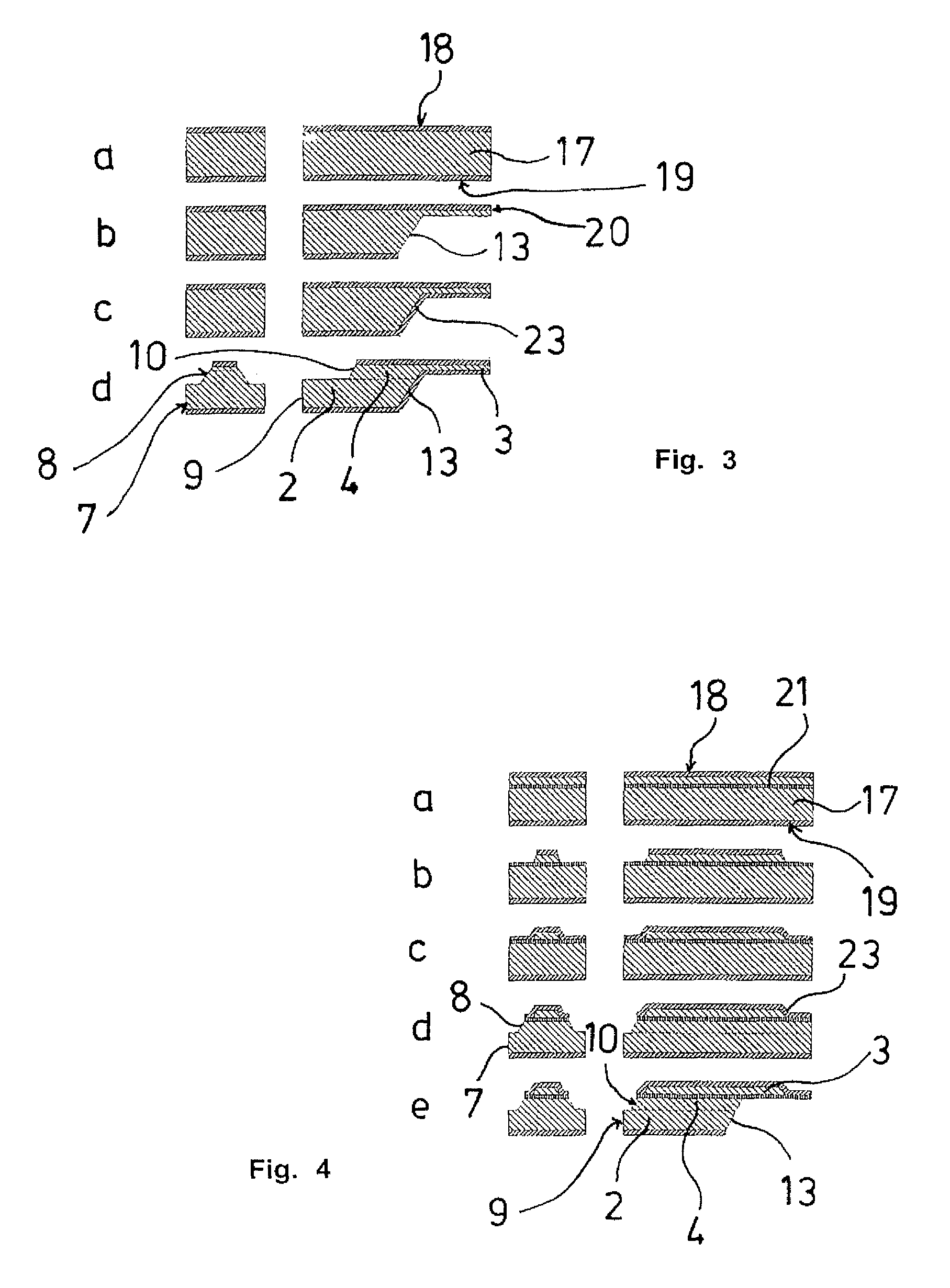

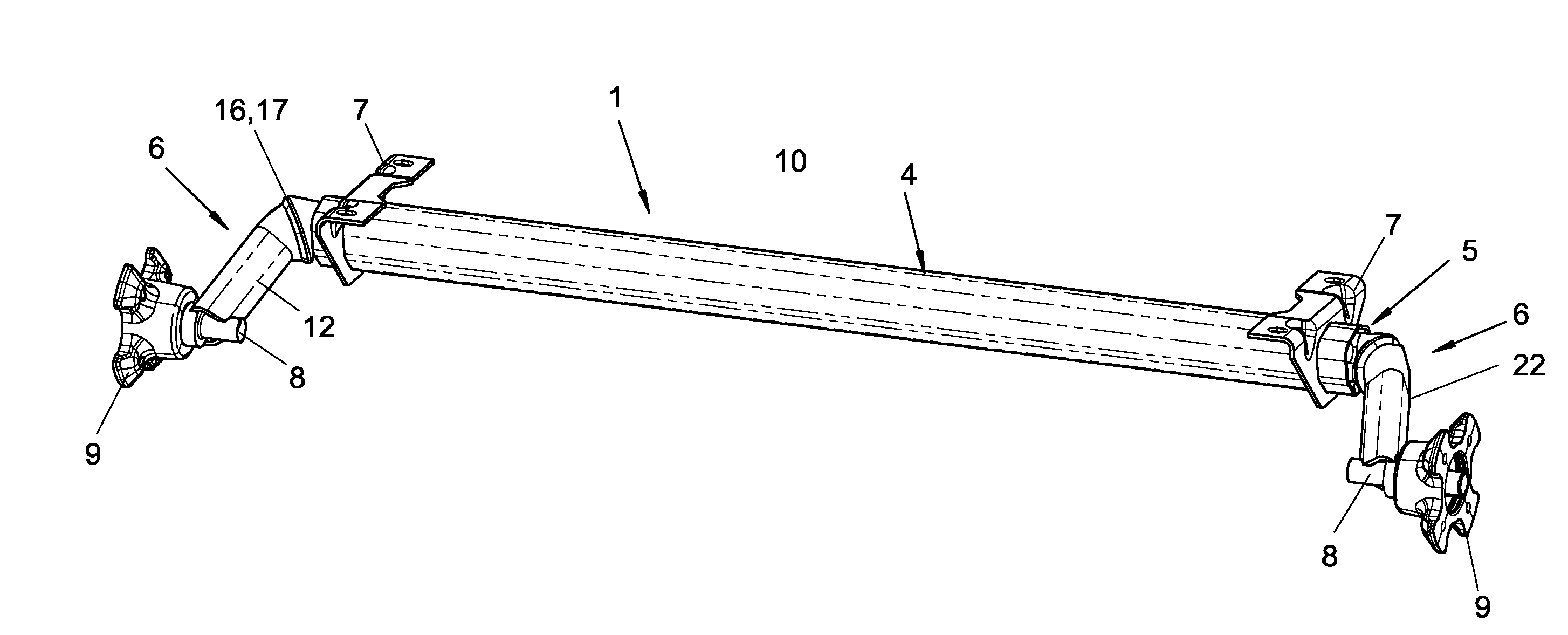

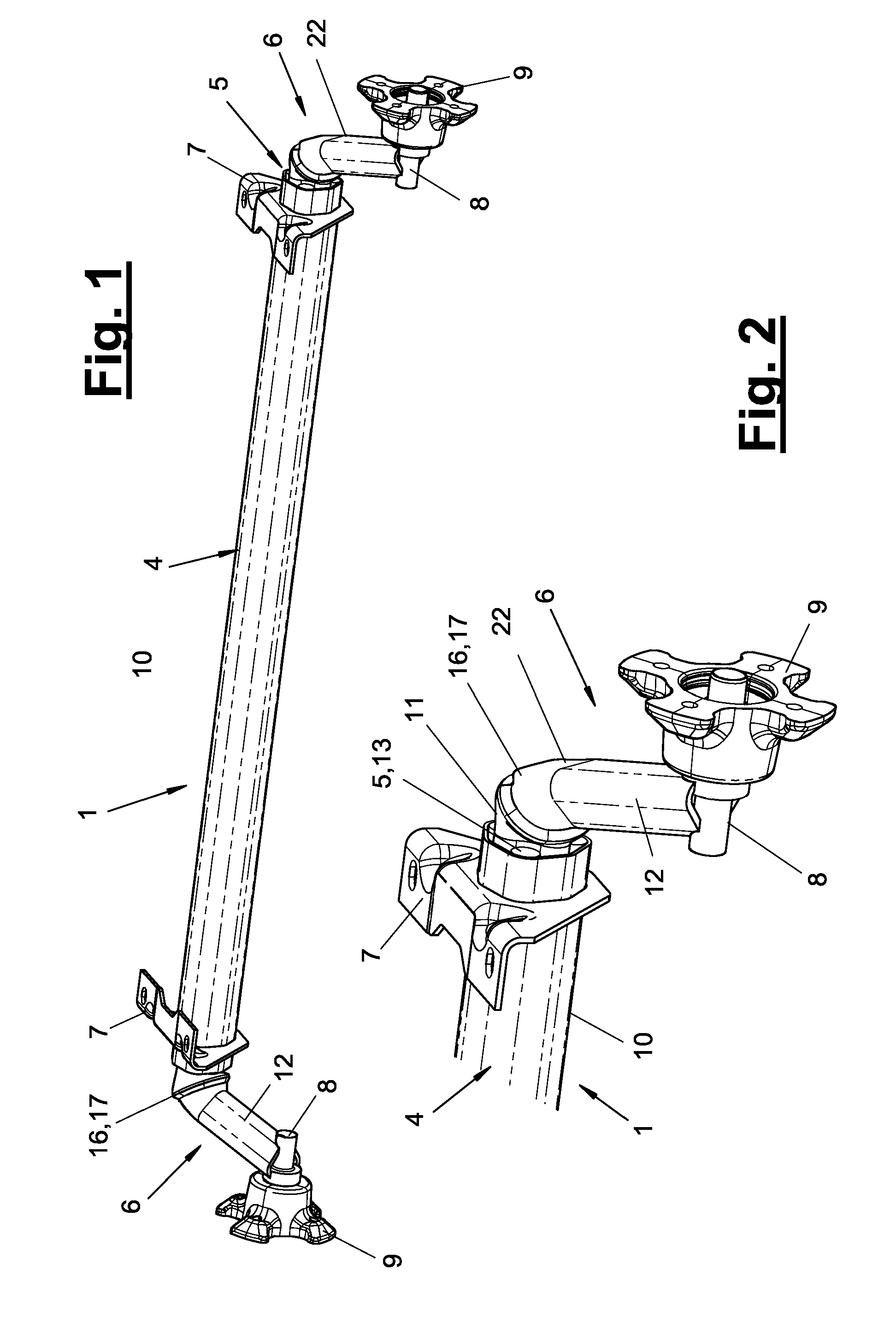

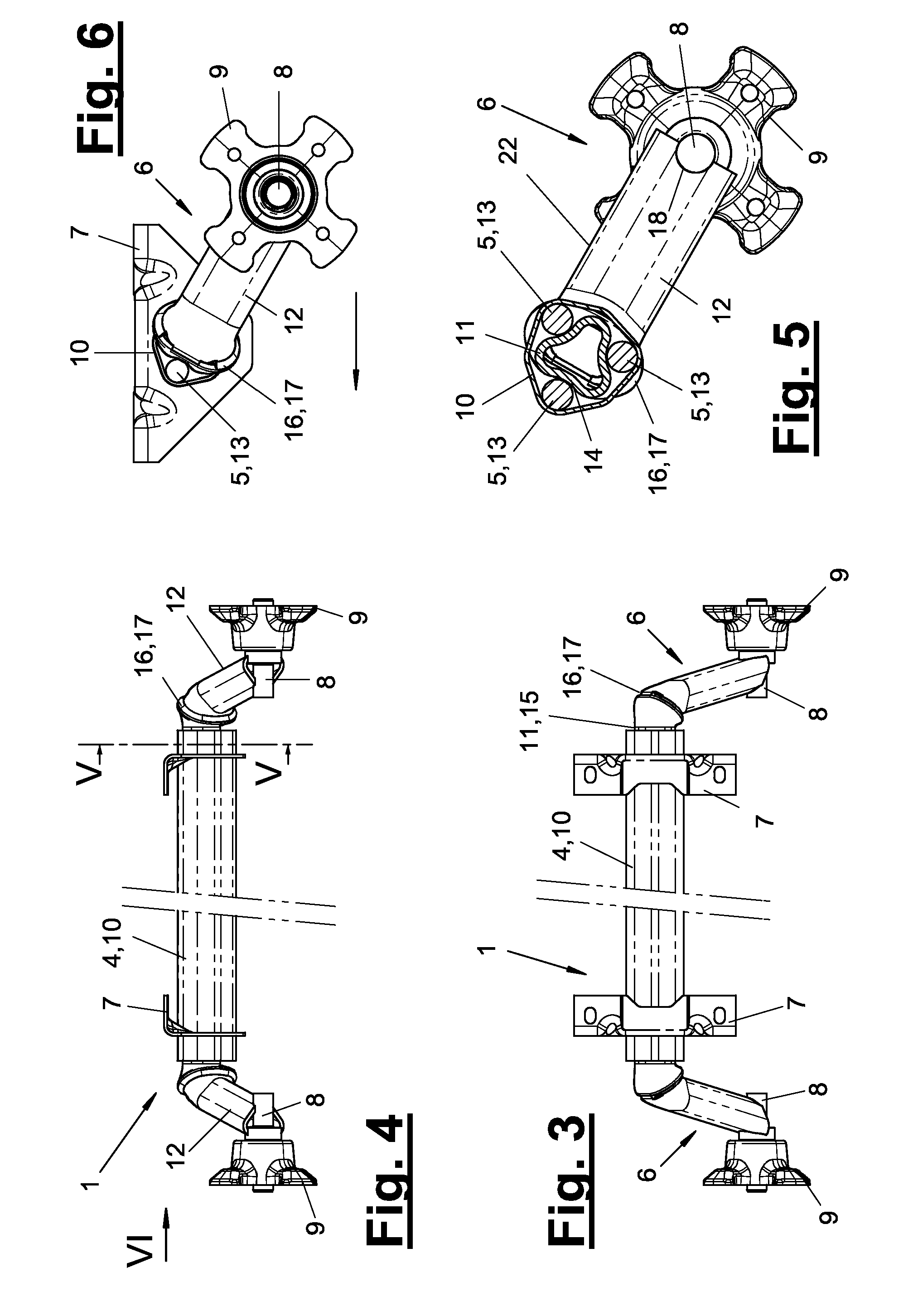

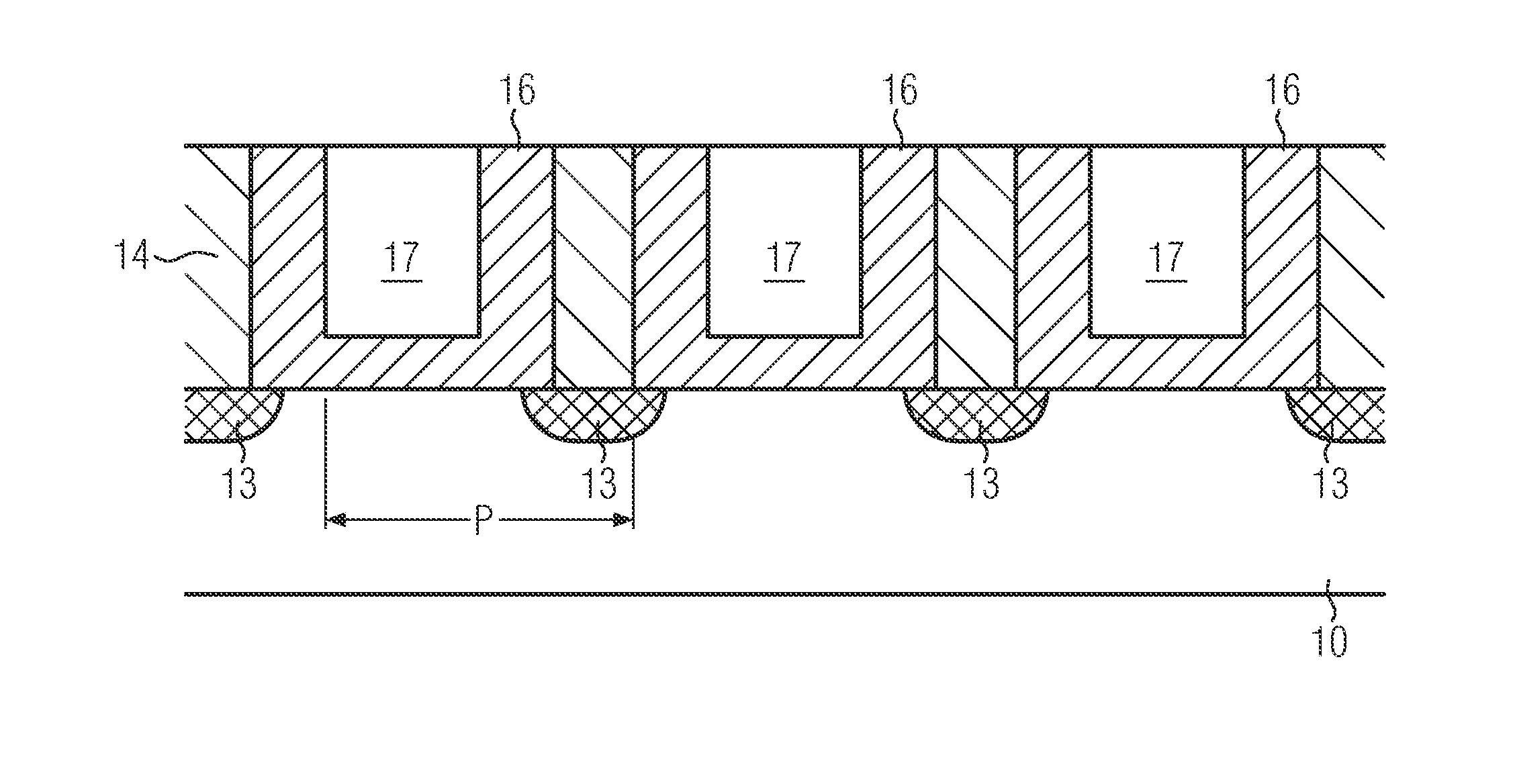

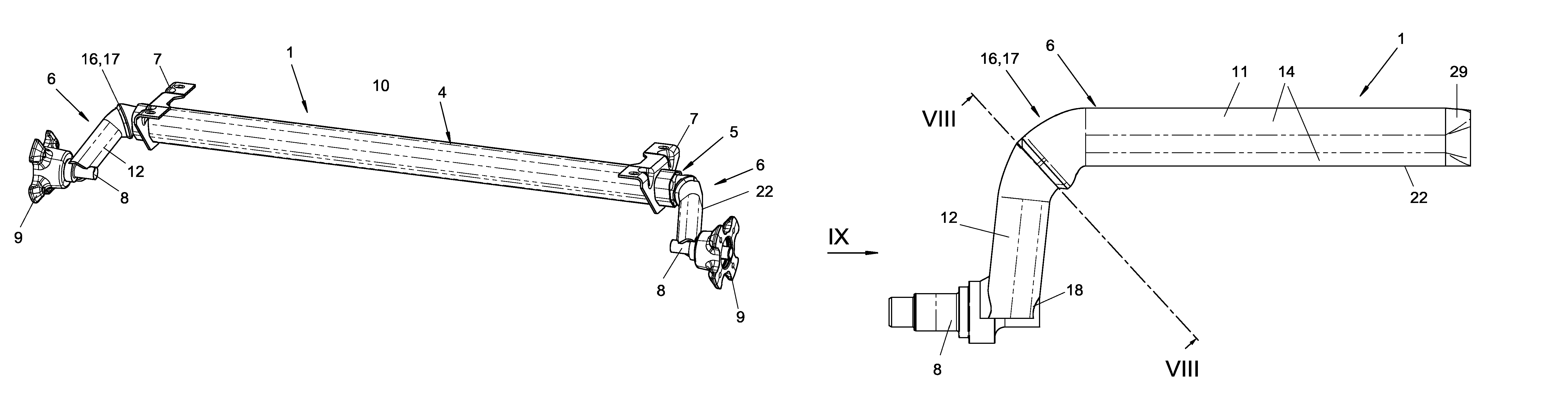

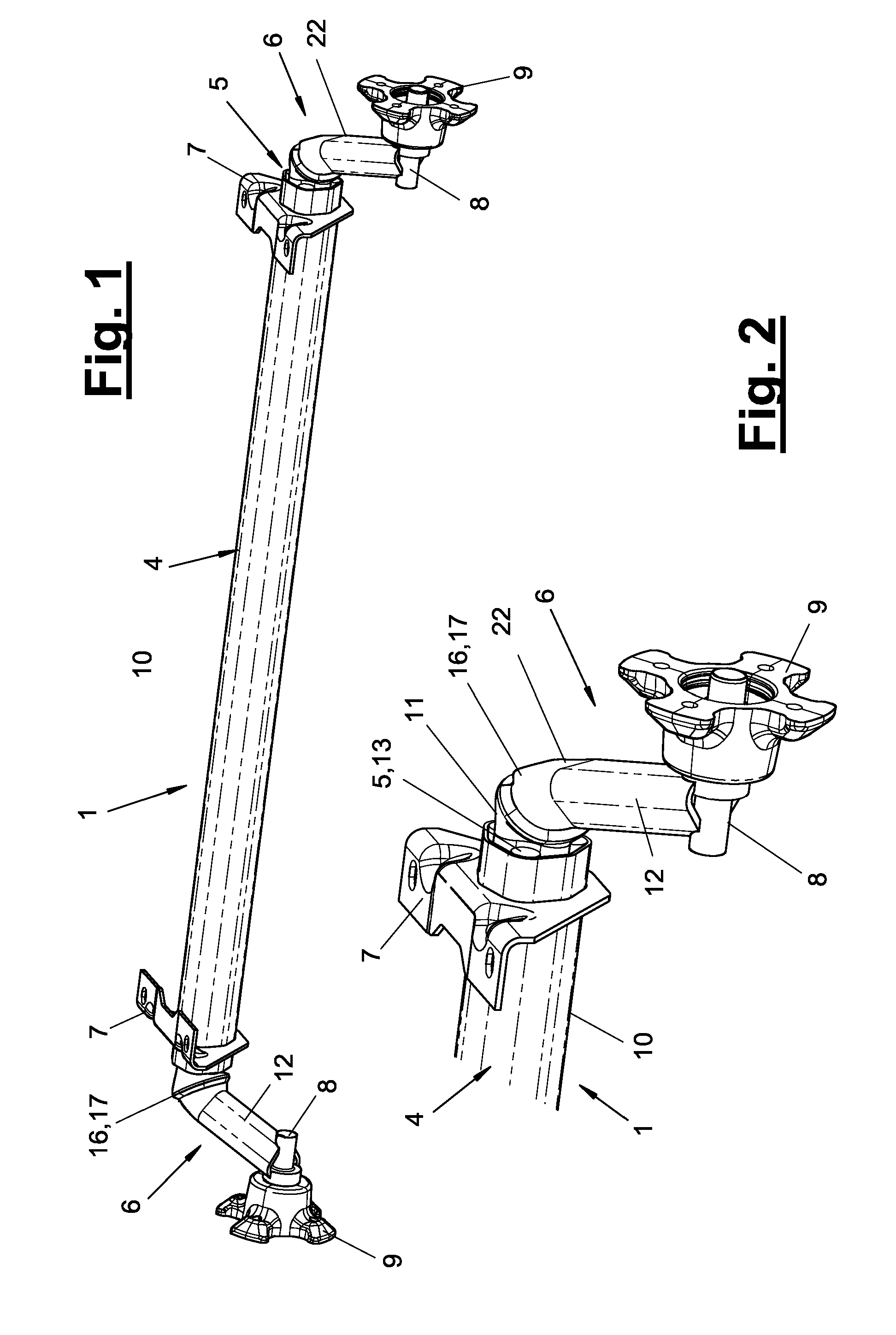

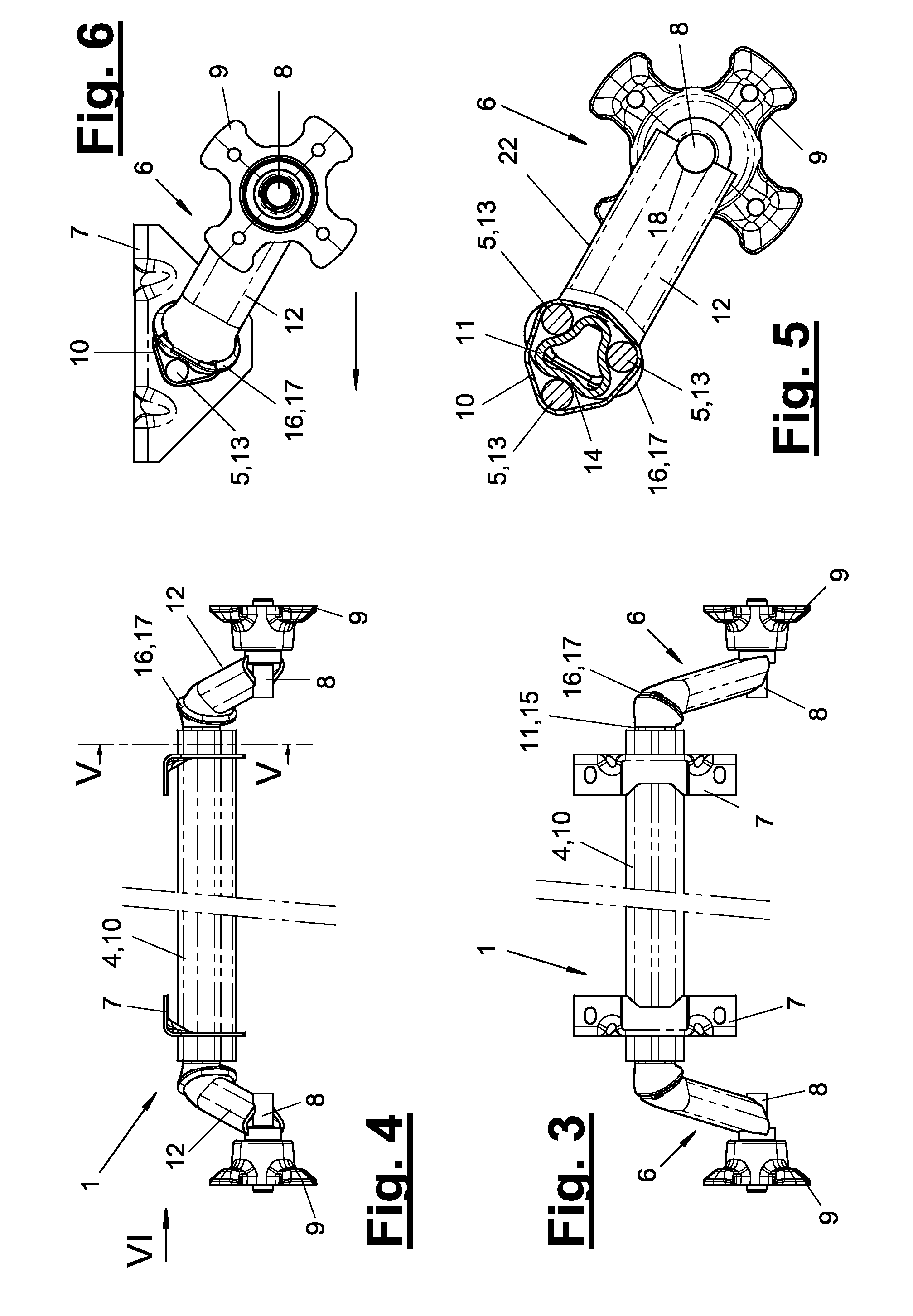

Axle and production method thereof

InactiveUS20140138930A1High product precisionCost- and effort-reducingInterconnection systemsResilient suspensionsEngineeringRocker arm

A carrying axle (1) for trailers and a method for the production thereof are provided. The axle (1) includes an axle body (4) having an outer supporting axle tube (10) in which a rocker arm assembly (6), which is bent once or several times, is introduced. The rocker arm assembly (6) is produced as a metal, tubular stamped and bent single piece. The rocker arm assembly is stamped from a platine (21) or a sheet metal strip (23) and is bent in order to form an angled tube (22).

Owner:ALOIS KOBER

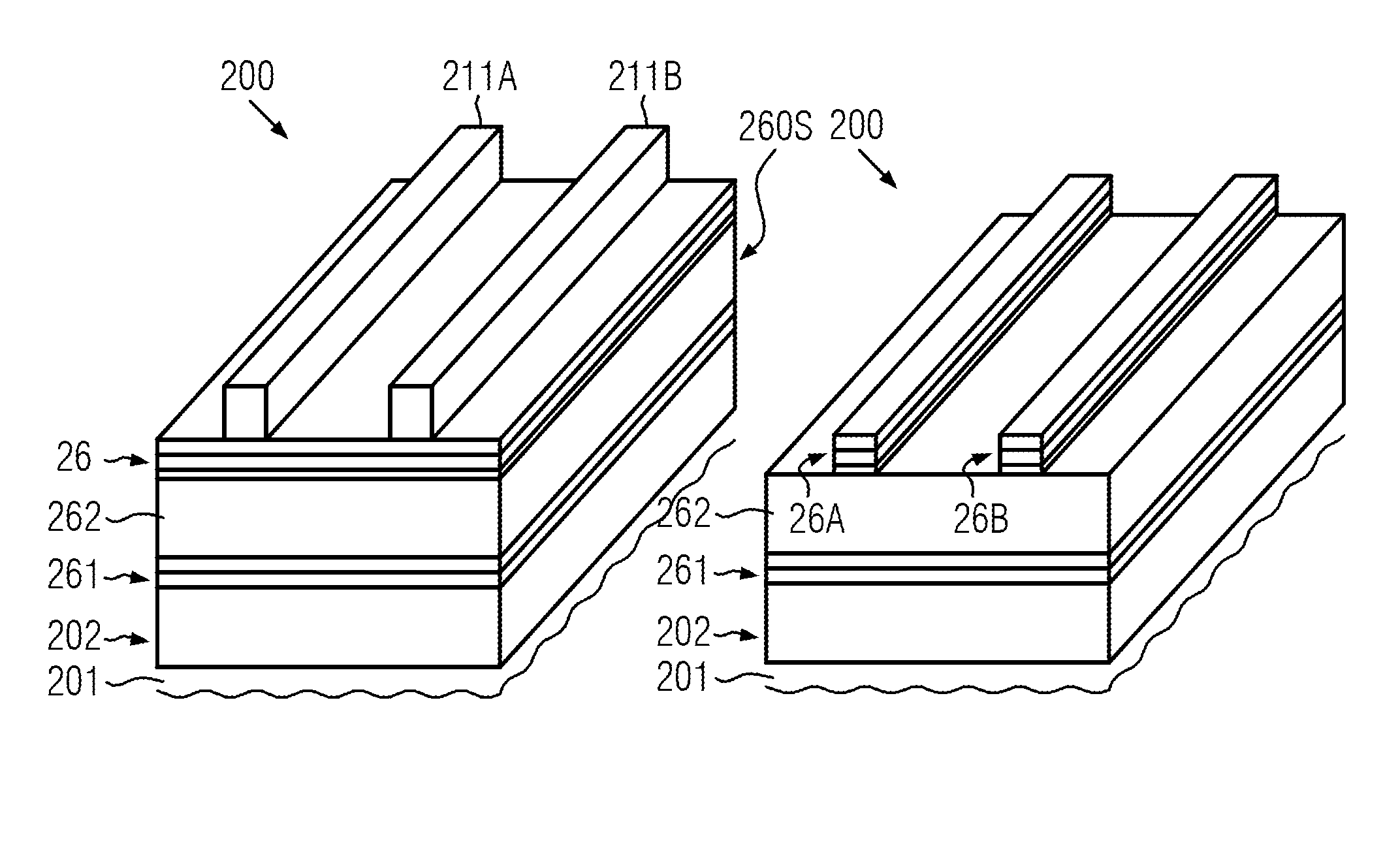

Densely packed transistor devices

InactiveUS20160300928A1Reduce distanceReduce lateral distanceTransistorSemiconductor/solid-state device manufacturingEngineeringDielectric layer

A method of manufacturing a semiconductor device is provided including forming replacement gates over a semiconductor layer, forming sidewall spacers at sidewalls of the replacement gates, forming a dielectric layer in interspaces between the sidewall spacers of neighboring replacement gates, removing the replacement gates and sidewall spacers to form openings in the dielectric layer, and forming gate electrodes in the openings.

Owner:GLOBALFOUNDRIES INC

A roller guide and a method for guiding stock

ActiveCN107000004AAdjust the lateral distanceReduce lateral distanceGuiding/positioning/aligning arrangementsMeasuring devicesEngineeringMechanical engineering

Owner:MORGARDSHAMMAR AB

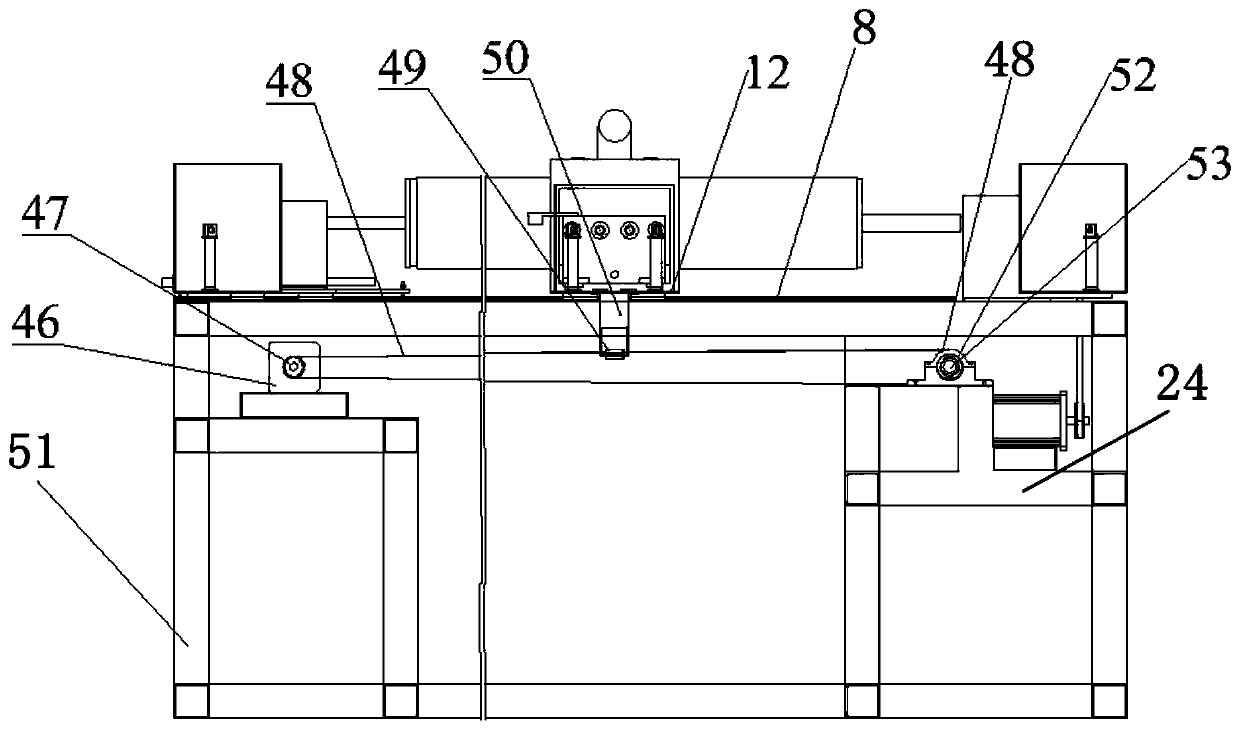

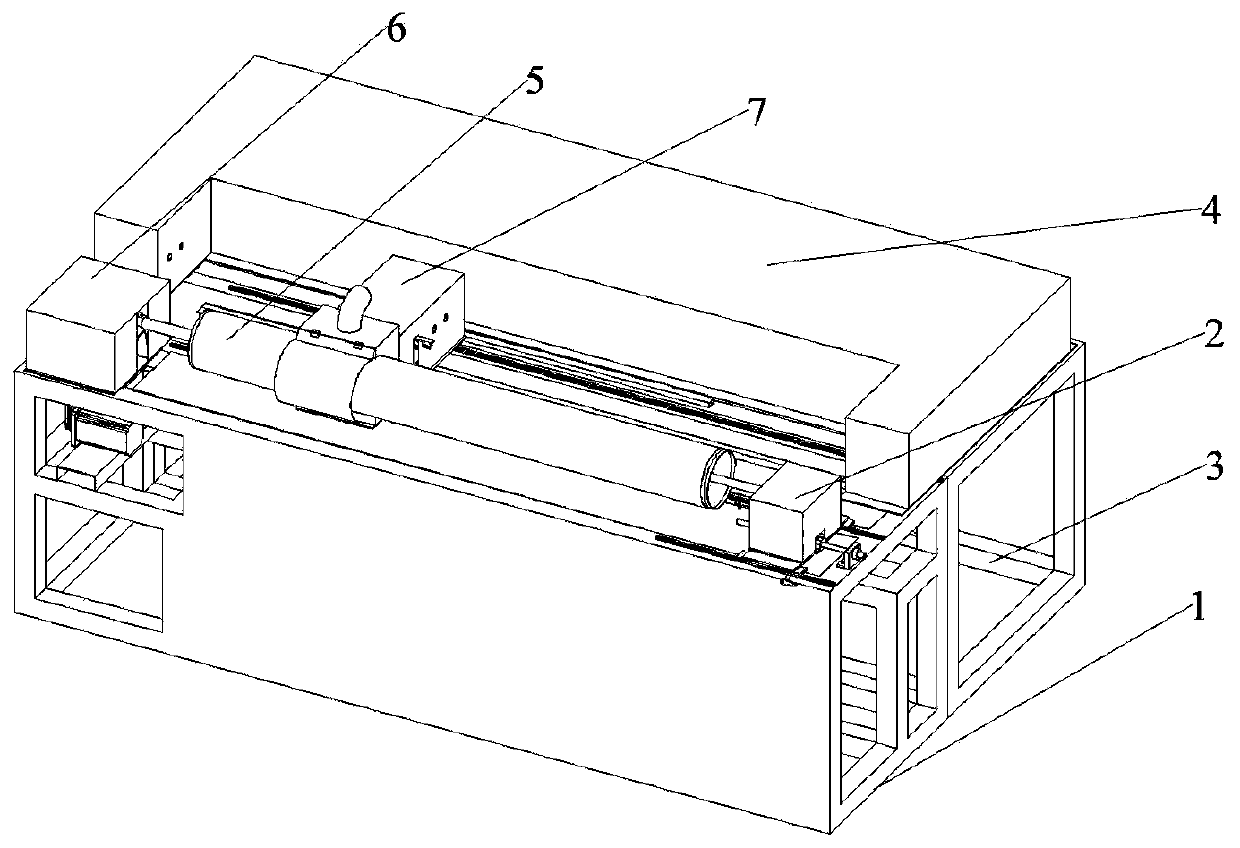

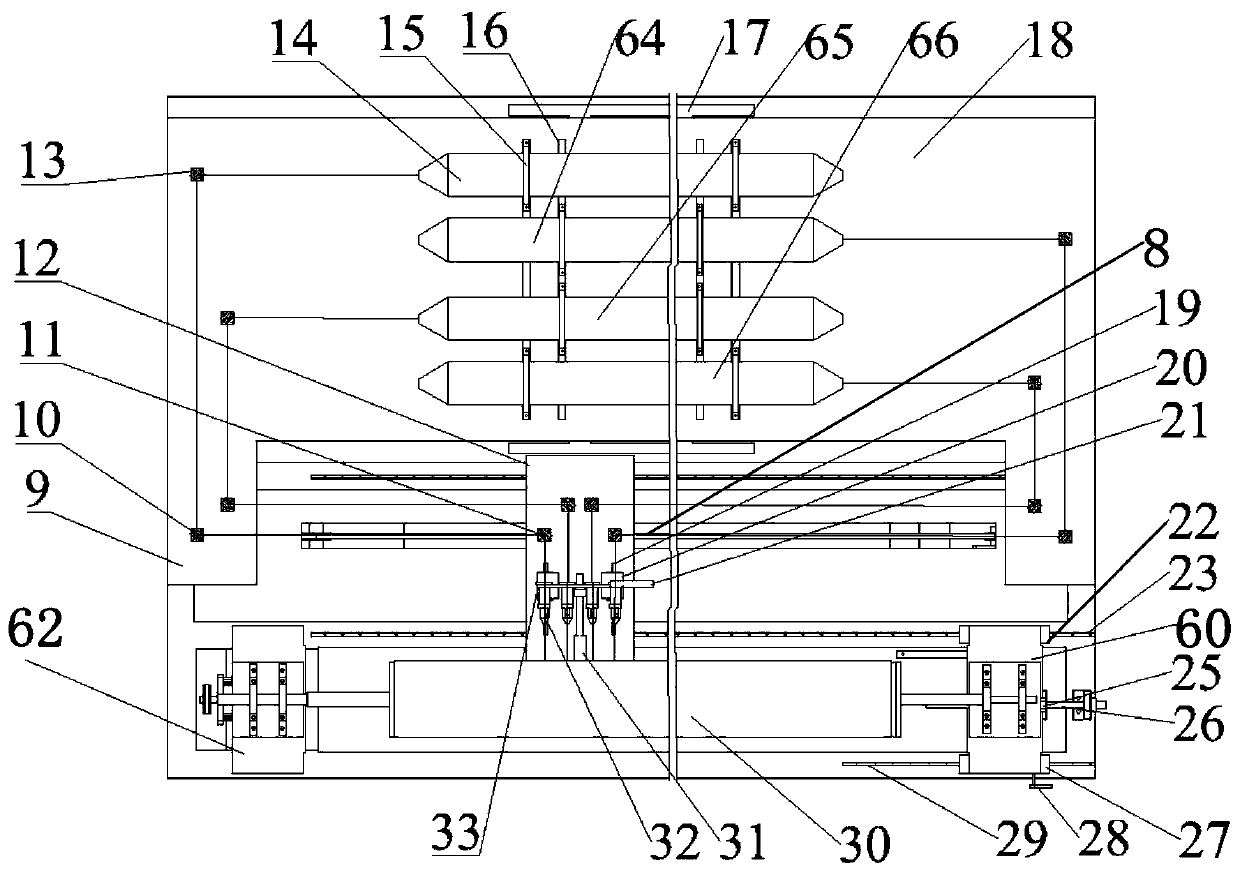

Laser cleaning machine for cylindrical nickel screen

ActiveCN111085507ASmall footprintReduce lateral distanceCleaning processes and apparatusPrinting press partsElectric machineryBeam direction

The invention relates to a laser cleaning machine for a cylindrical nickel screen, and belongs to the technical field of laser cleaning devices. The laser cleaning machine comprises a machine body front portion, a machine body rear portion, a cylindrical nickel screen rotating mechanism, a tail bracket mechanism, a laser emission mechanism, a motor driving mechanism, a cleaning mechanism and a transmission mechanism. By using three groups of reflectors, through the reflective cooperation of the reflectors, the directions of the beams emitted by laser tubes are changed. In the cleaning process,the cylindrical nickel screen is rotated simply by moving the cleaning mechanism, and the space occupation of the device is reduced by fixing the laser tubes and changing the arrangement way of the laser tubes. An original arrangement way that the laser tubes are perpendicular to the nickel screen is replaced. The transverse distance between the beam focuses when lasers reach the cylindrical nickel screen is shortened, that is, when the cylindrical nickel screen is cleaned, the cleaning mechanism can move a shorter distance, and by means of the structure, the cleaning efficiency can be effectively improved. By using the cleaning structure which can move independently without moving the laser tubes or a power supply thereof, the load of a motor is greatly reduced, therefore, the motor which has lower technical parameters can be selected, and the cost is saved.

Owner:NANTONG UNIVERSITY

Axle and production method thereof

InactiveUS9199522B2High product precisionCost- and effort-reducingResilient suspensionsPivoted suspension armsEngineeringRocker arm

A carrying axle (1) for trailers and a method for the production thereof are provided. The axle (1) includes an axle body (4) having an outer supporting axle tube (10) in which a rocker arm assembly (6), which is bent once or several times, is introduced. The rocker arm assembly (6) is produced as a metal, tubular stamped and bent single piece. The rocker arm assembly is stamped from a platine (21) or a sheet metal strip (23) and is bent in order to form an angled tube (22).

Owner:ALOIS KOBER

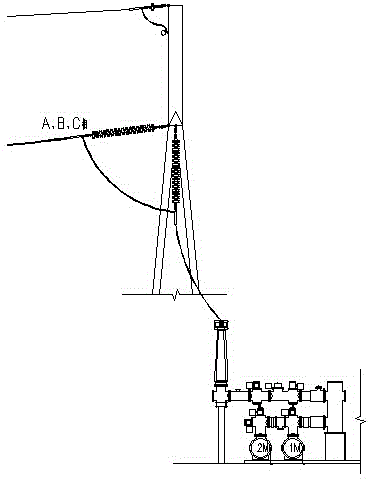

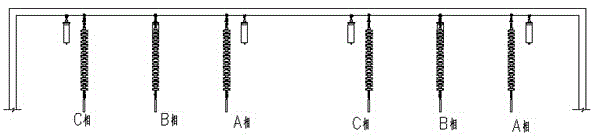

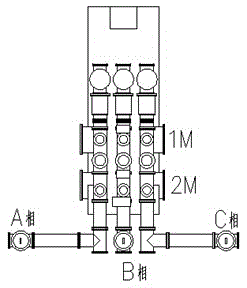

Triangular GIS outgoing line layout structure for voltage grade of 500kV and below

ActiveCN105610081AReduce horizontal sizeShorten the lengthBus-bar/wiring layoutsSwitchgear arrangementsEngineeringStructural engineering

The invention relates to a triangular GIS outgoing line layout structure for a voltage grade of 500kV and below. Compared with the prior art, the defect that the GIS outgoing line layout structure is relatively low in utilization rate of floor area is overcome. A B-phase tension insulator string is arranged at a line outlet side of an upper triangular beam; a B-phase inverted post insulator is arranged at the lower part of the upper triangular beam; an A-phase tension insulator string and a C-phase tension insulator string are arranged at the line outlet side of a lower triangular beam; a B-phase cross-arm insulator is arranged at one side, opposite to the line outlet side, of the lower triangular beam; and a center point between the suspension point of the A-phase tension insulator string and the suspension point of the C-phase tension insulator string corresponds to a fixed point of the B-phase cross-arm insulator. The lateral dimension of a power distribution device area is reduced, so that the length of a main bus-bar cylinder of GIS equipment is reduced; the equipment cost is reduced; and the floor area of the equipment is saved.

Owner:ANHUI ELECTRIC POWER DESIGN INST CEEC

A grinding and polishing force-controlled end effector

ActiveCN111136543BAvoid interferenceSimple structurePolishing machinesGrinding drivesAir pumpEngineering

The invention provides a grinding and polishing force control end execution device. The grinding and polishing force control end execution device comprises an outer shell, a pneumatic spindle, a grinding wheel, a cylinder, a movable piston, a tension and pressure sensor, a first limiting part and a second limiting part, wherein the pneumatic spindle vertically penetrates through the outer shell and is not fixed to the outer shell; the tail end of the pneumatic spindle is exposed to the outer shell and is fixedly provided with the grinding wheel; the air inlet end of the pneumatic spindle is insealing connection with an external air tank or an air pump; the movable piston is sleeved on a cylinder barrel of the pneumatic spindle and located in the outer shell; the cylinder is located in theouter shell, and the tension and pressure sensor is fixed to a telescopic rod of the cylinder; the tail end of the telescopic rod of the cylinder can apply horizontal and vertical force to the movable piston; the sidewall of the outer shell is provided with an arc-shaped square hole, and an outer cover is arranged at the arc-shaped square hole of the outer shell; and the first limiting part and the second limiting part are used for limiting the movable piston in the horizontal direction and the vertical direction correspondingly. The grinding and polishing force control end execution device realizes motion of the piston in the horizontal and vertical directions through one cylinder, and also realizes force control over the grinding wheel in two dimensionalities.

Owner:HEBEI UNIV OF TECH

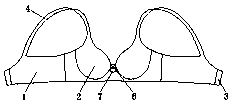

Adjustable seamless inflatable bra

The invention relates to the technical field of bras, and discloses an adjustable seamless inflatable bra. The adjustable seamless inflatable bra comprises integrated side parts, cups, back buckles and straps; two communicated air bag bodies are arranged in the cups; a deflating switch and a pressing air pump which are communicated with the air bag bodies are arranged on the front surface betweenthe two cups; massage mechanisms are embedded in joints of the cups and the side parts; and magnetic sheets are embedded into the inner side parts corresponding to the massage mechanisms. According tothe adjustable seamless inflatable bra, the sizes of the left and right cups can be automatically adjusted through the characteristic that the air bag bodies arranged in the middle layers of the cupscan be communicated left and right, so that the trouble of left and right breasts in different sizes is thoroughly avoided; and people do not need to replace bras frequently.

Owner:杨玉华

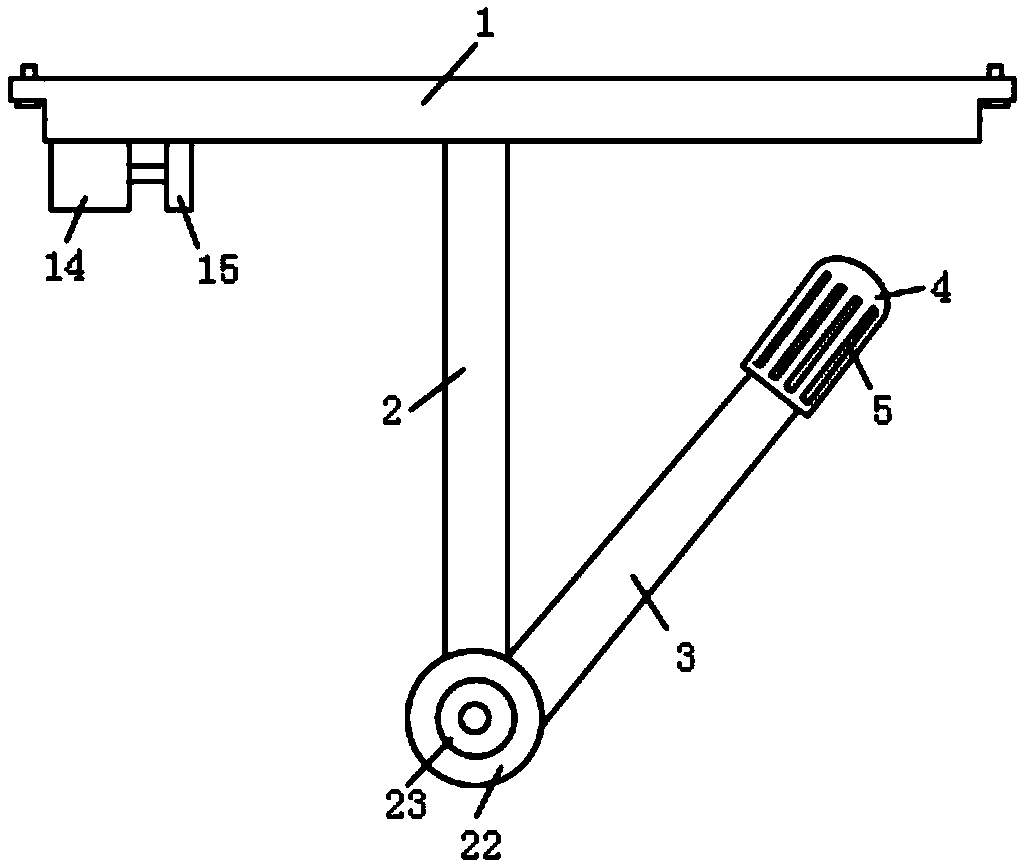

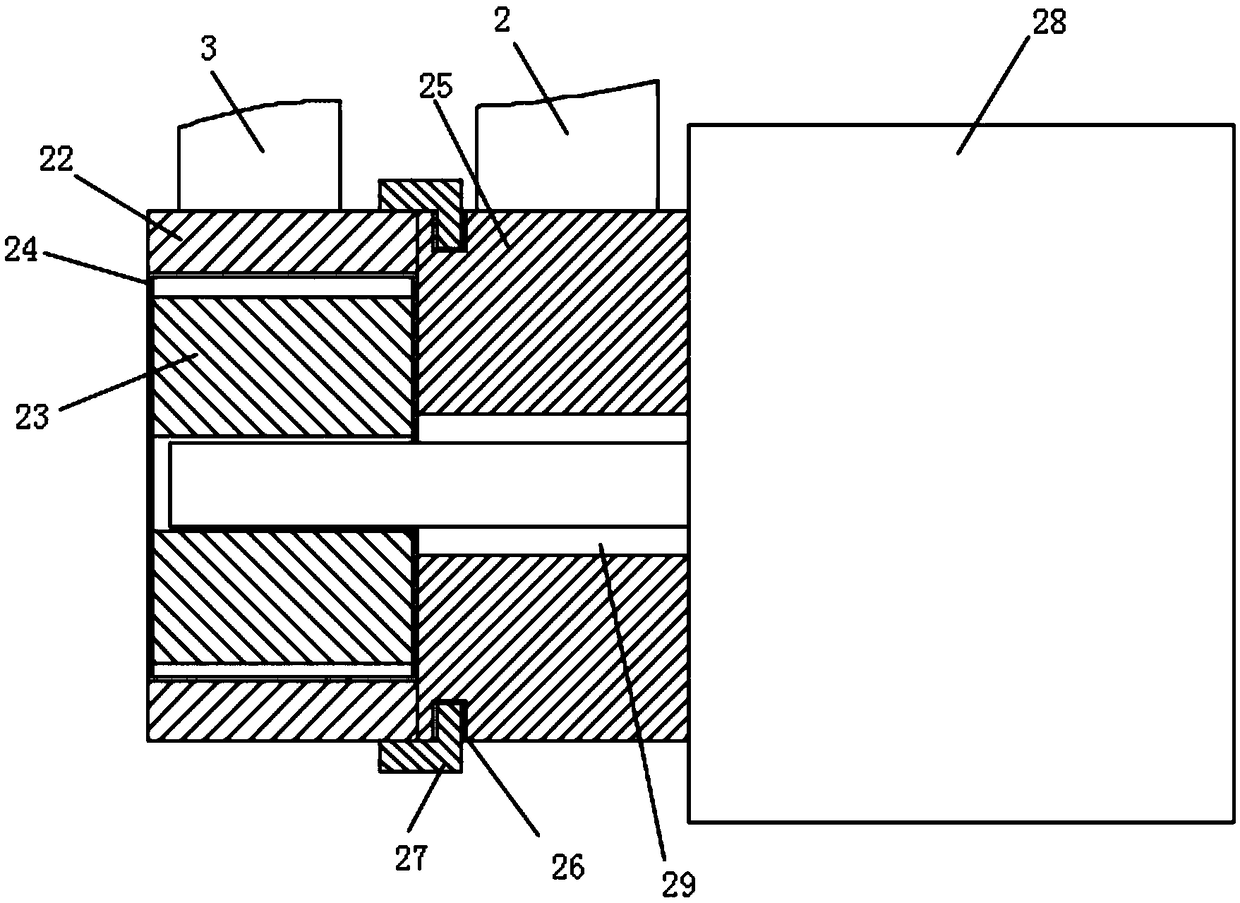

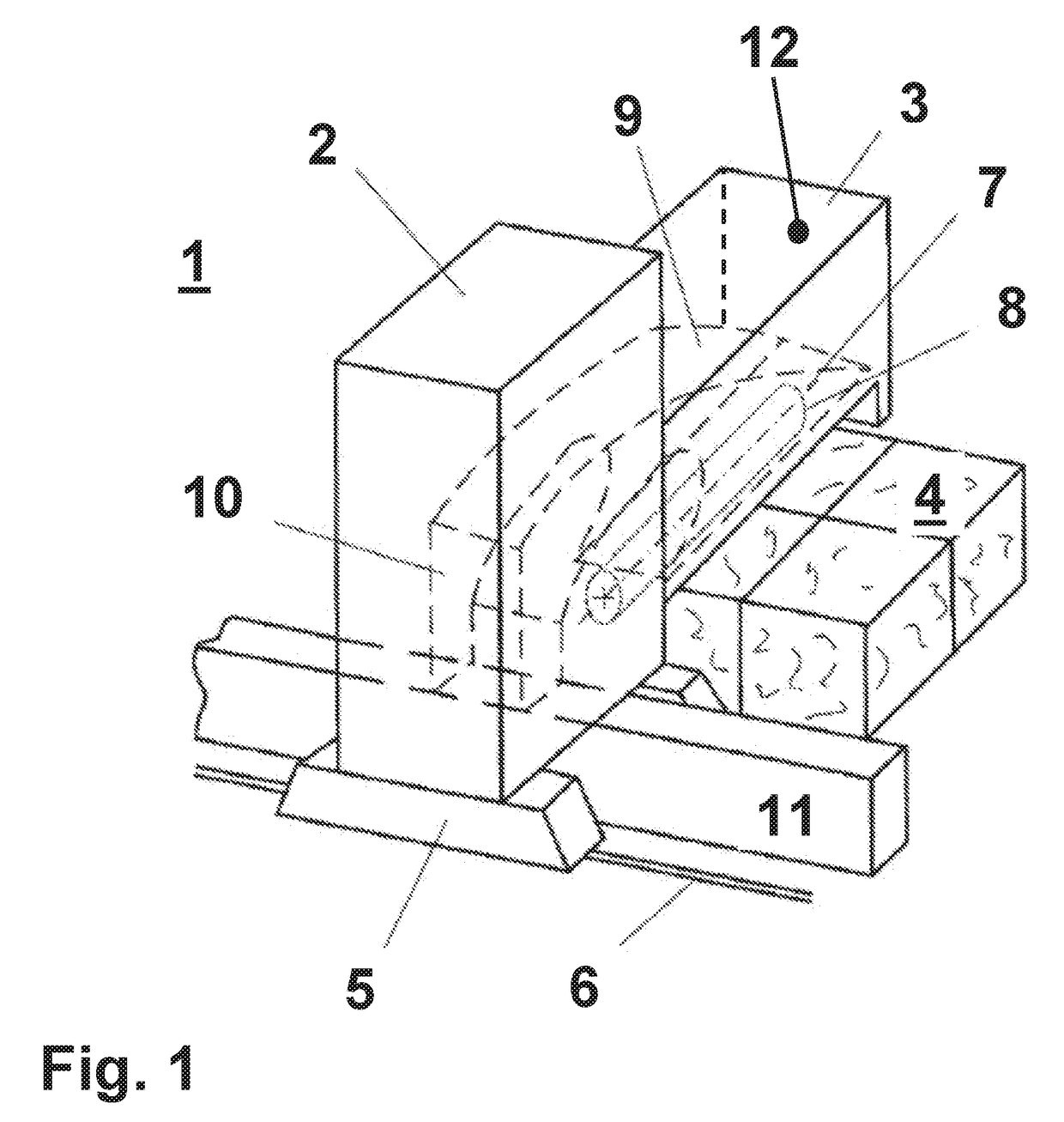

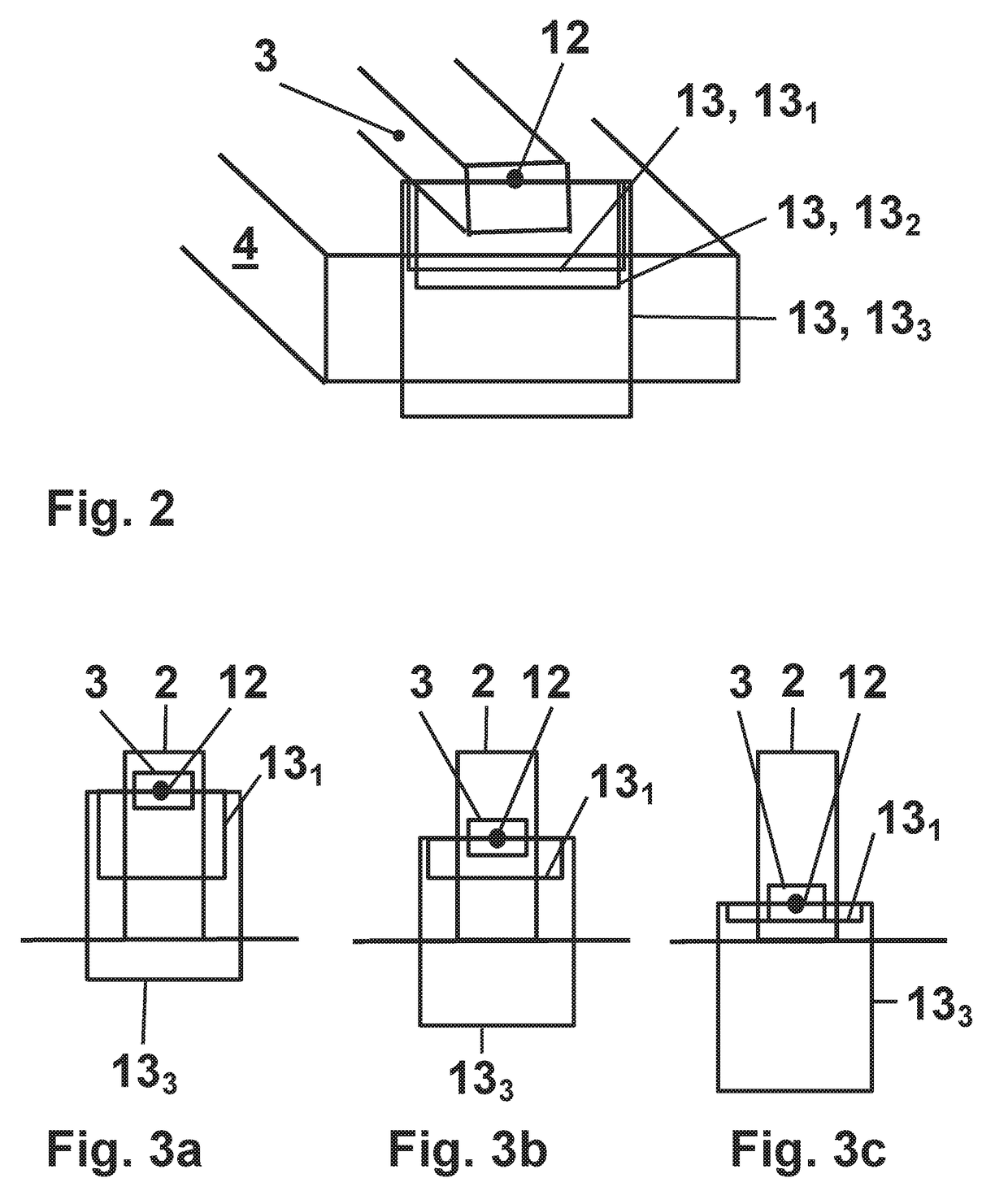

Method for Operating a Bale Opener and Such a Bale Opener

InactiveUS20170298540A1Less susceptibleMore reliableSafety devices for fibre treatmentArticle unpackingEngineeringLaser

The invention relates to a method for operating a bale opener (1) having a stripping element (3) and a safety device for protection against penetration into a hazardous zone of the stripping element (3), said safety device consisting of sensory safety means, wherein a monitoring region (13, 131, 132, 133) at the front beneath the stripping element is detected and wherein the stripping element (3) is mounted on a stripping tower (2). According to the invention the safety device is at least one two-dimensional laser scanner (12), on which at least one monitoring region (13, 131, 132, 133), which is adjustable and variable over time, is monitored. The invention also relates to a corresponding bale opener (1).

Owner:MASCHINENFABRIK RIETER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com