Novel air film hole with improved cooling efficiency

A technology of cooling efficiency and air film holes, applied in the field of new air film holes, can solve the problems of combination, unrealized expansion holes and opening transverse grooves, etc., to achieve the effect of good cooling effect, wide coverage of cold air, and high transverse cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

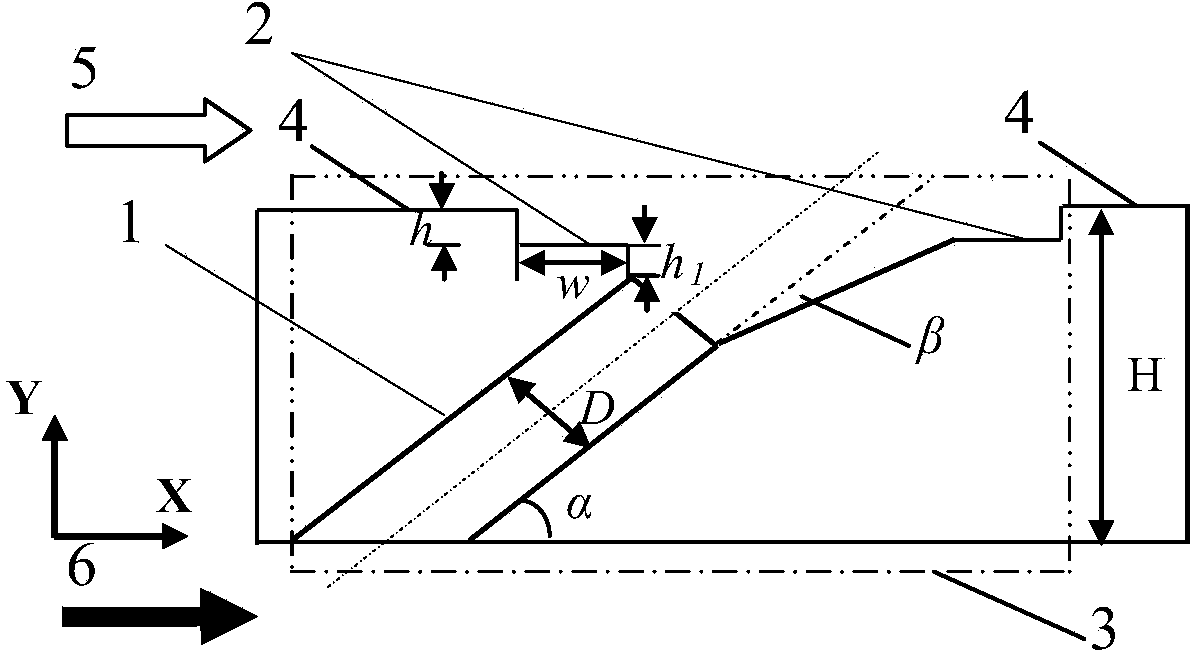

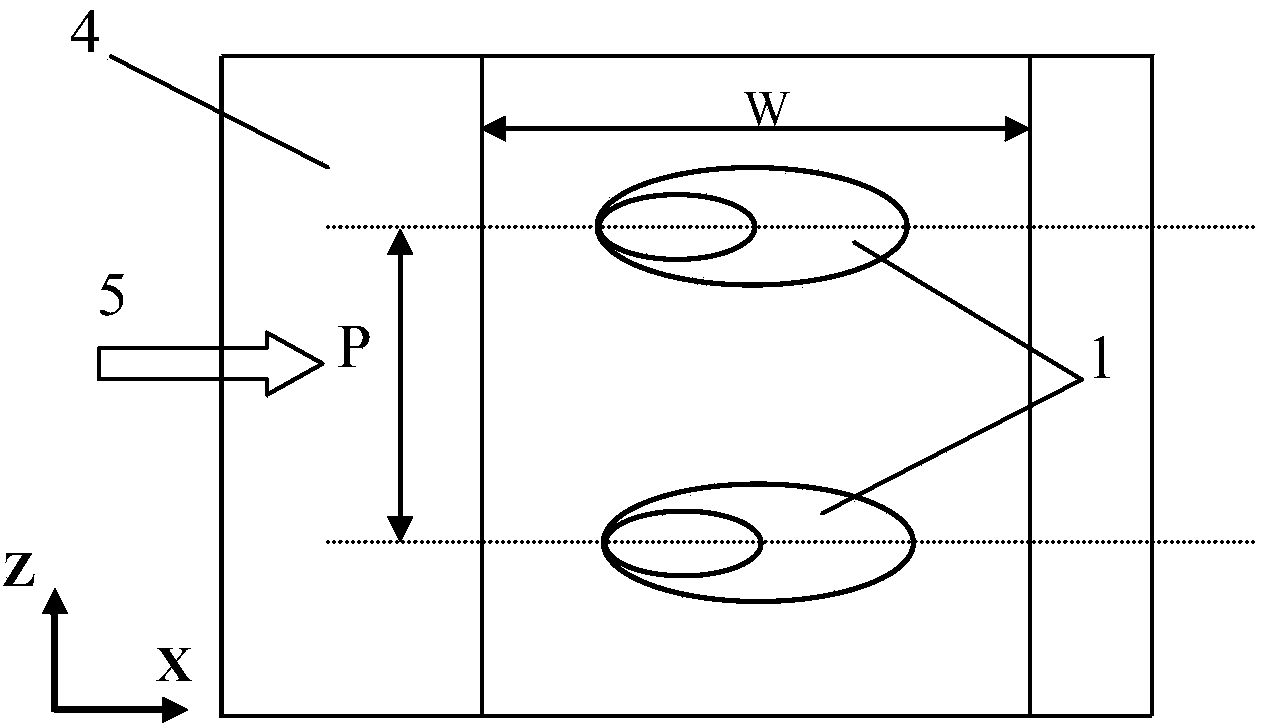

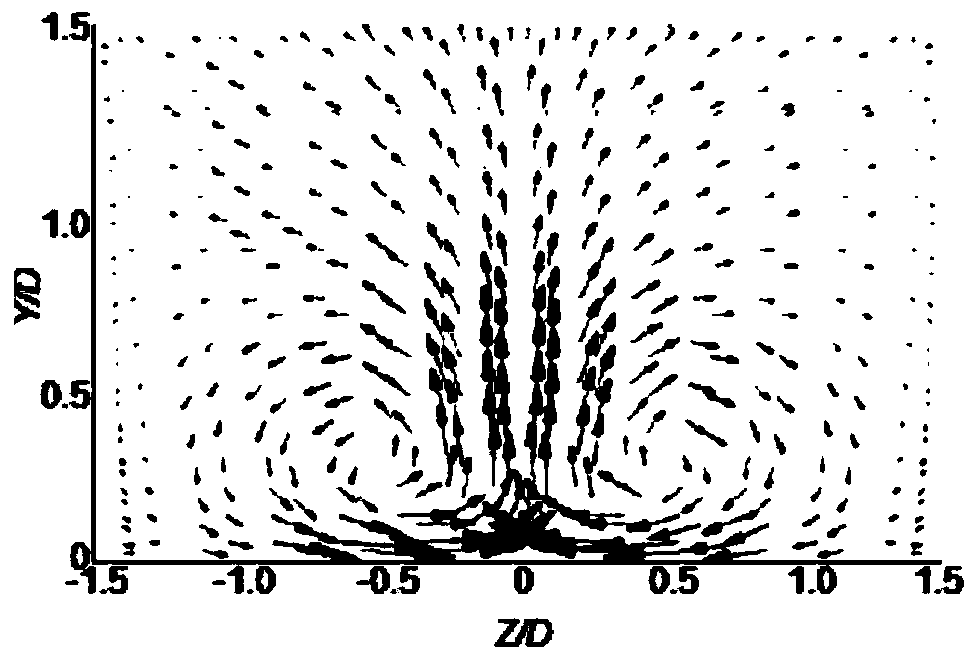

[0022] refer to figure 1 , shown in 2, is a side view and a top view of a novel hole for improving film cooling efficiency of the present invention, including a conical hole 1, a transverse groove 2 and a minimum unit body (new hole) 3. The angle α between the hole axis and the flow direction of the novel hole 3 of the present invention is between 10°~40°, the angle β between the conical opening and the hole axis is between 10°~20°, and the upstream is a height h1( 0.5D~1.0D), the height of the gas film hole 3 is expressed as 2.5D~3.5D by H, the depth h of the transverse groove 2 is between 0.5D~1.0D, the vertical solid wall on the upper and lower reaches of the transverse groove and The distance w at the opening of the conical air film hole 1 is between 1.0D and 1.5D, the width of the transverse groove 2 is W, and the distance P between the holes is between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com