Grinding and polishing force control end execution device

An end effector, grinding and polishing technology, applied in the direction of grinding drive device, grinding/polishing equipment, grinding machine, etc., can solve the problems of less freedom, air spring vibration, complex structure, etc., to reduce the lateral distance, reduce the The effect of overturning moment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the present application.

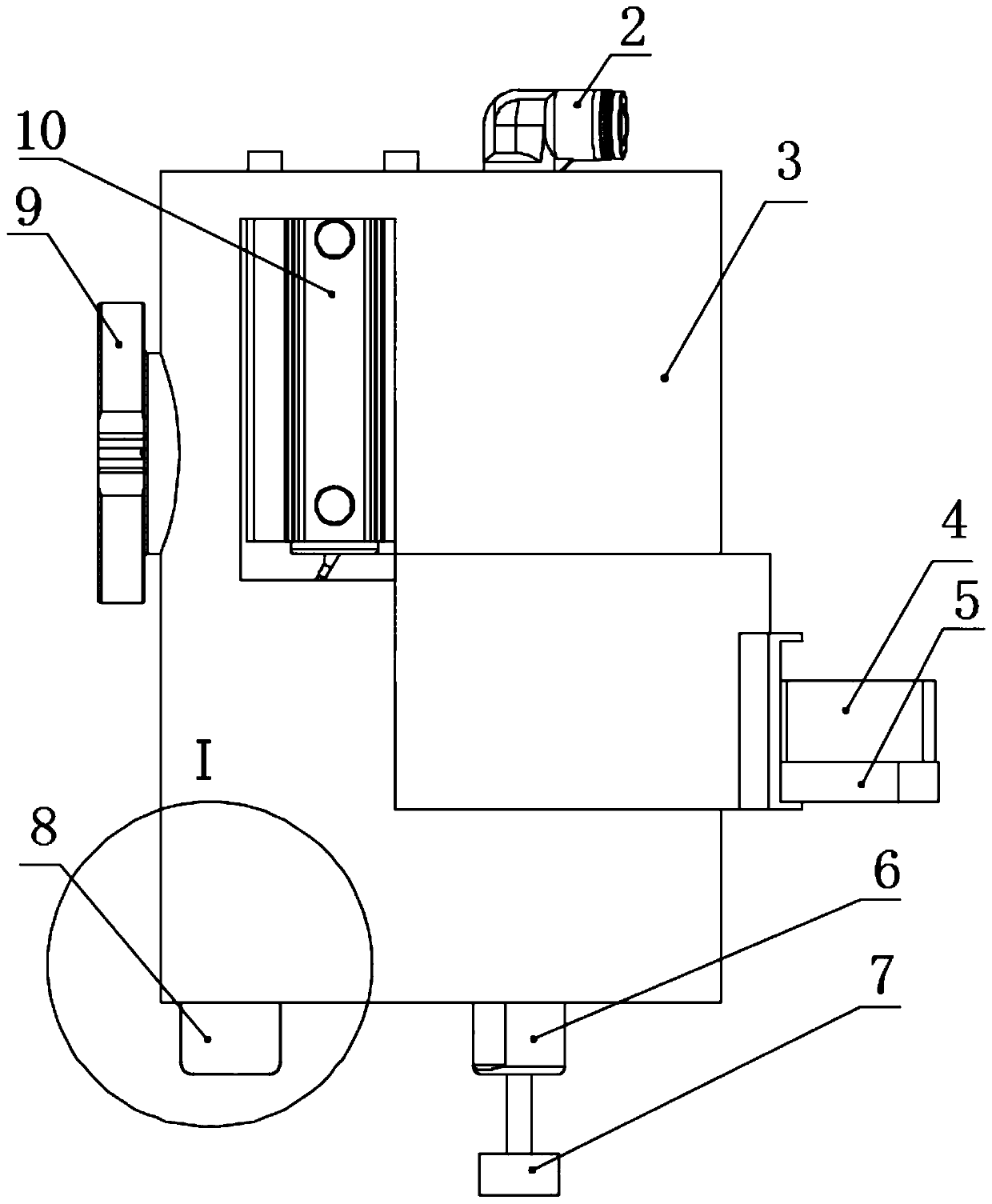

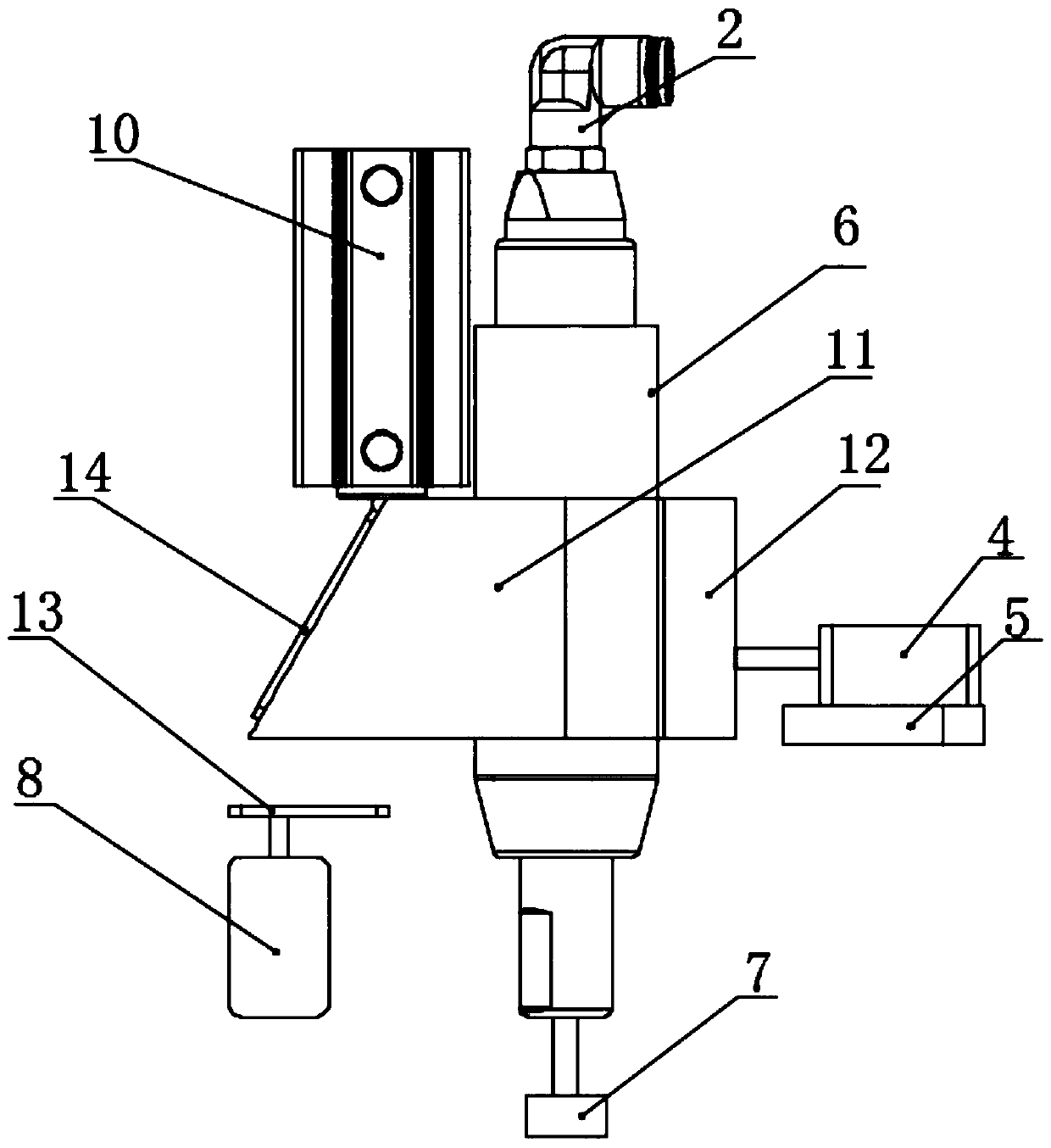

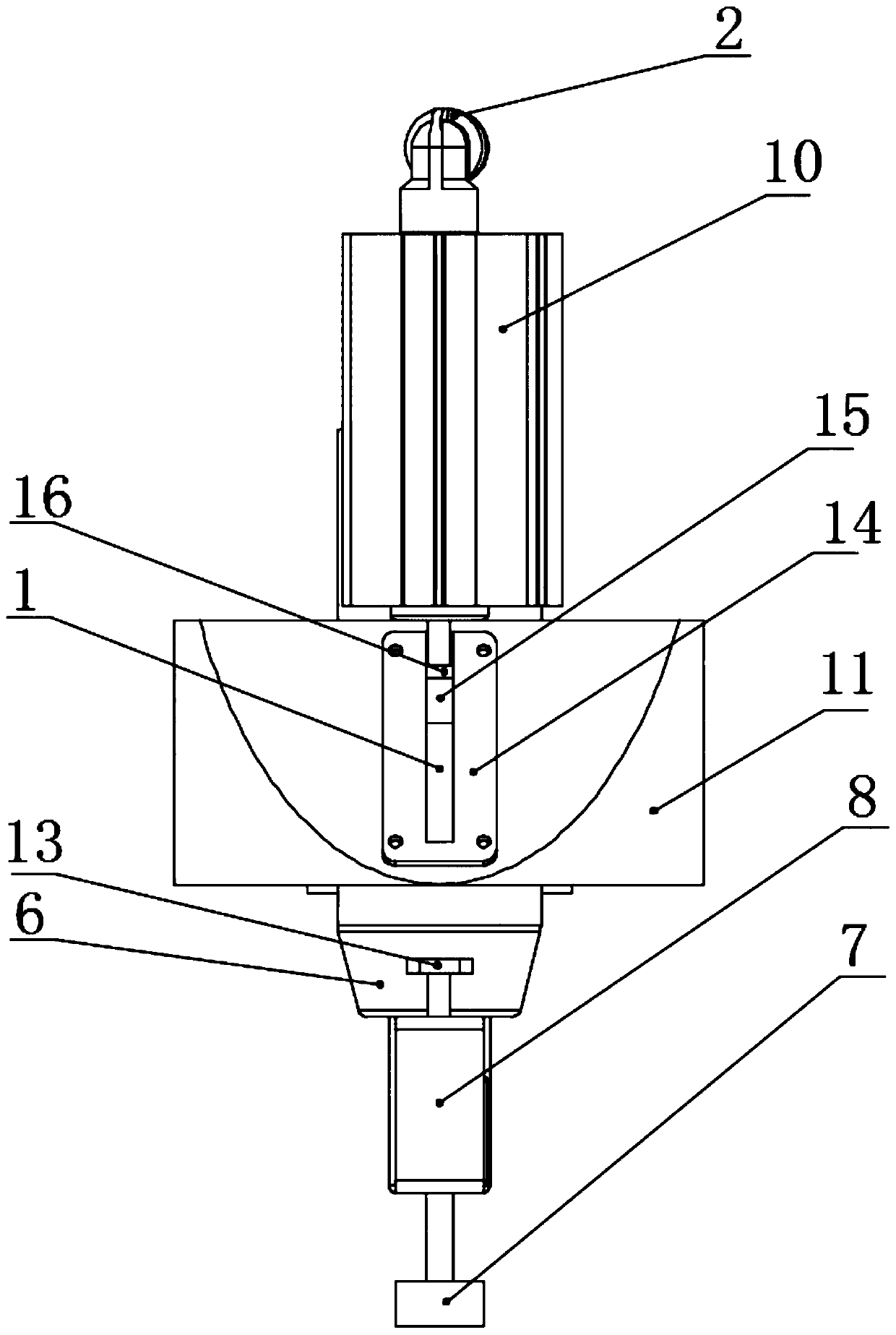

[0028] The present invention provides a grinding and polishing force control end effector (executive device for short, refer to Figure 1-7 ), including a housing 3, a pneumatic spindle 6, a grinding wheel 7, a cylinder 10, a moving piston 11, a pull pressure sensor 16, a first limiting portion and a second limiting portion;

[0029] The shell 3 is hollow, with an opening at the bottom, and the middle part of the shell 3 is fixedly connected with the end of the mechanical arm through a flange 9; the pneumatic main shaft 6 runs through the shell 3 vertically, and is not fixed with the shell 3; the end of the pneumatic main shaft 6 is exposed on the shell 3 and fixed with a grinding wheel 7, the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com