Method for Operating a Bale Opener and Such a Bale Opener

a bale opener and bale technology, applied in mechanical equipment, packaging, transportation and packaging, etc., can solve the problems of high risk for the person operating the machine, cumbersome operation practice in subdividing the enclosure of the beam of light, and difficulty in staking out hazardous areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006]The invention is thus based on the object of creating a method for operating a bale opener and such a bale opener that avoids the disadvantages of the prior art.

[0007]The invention is also based on the object of creating a method for operating a bale opener and such a bale opener, which are less susceptible to interference, more reliable and less expensive than the methods and the systems offered in the prior art.

[0008]The invention is also based on the object of creating a method for operating a bale opener and such a bale opening, which can be used as collision monitoring in rotation of the stripping element.

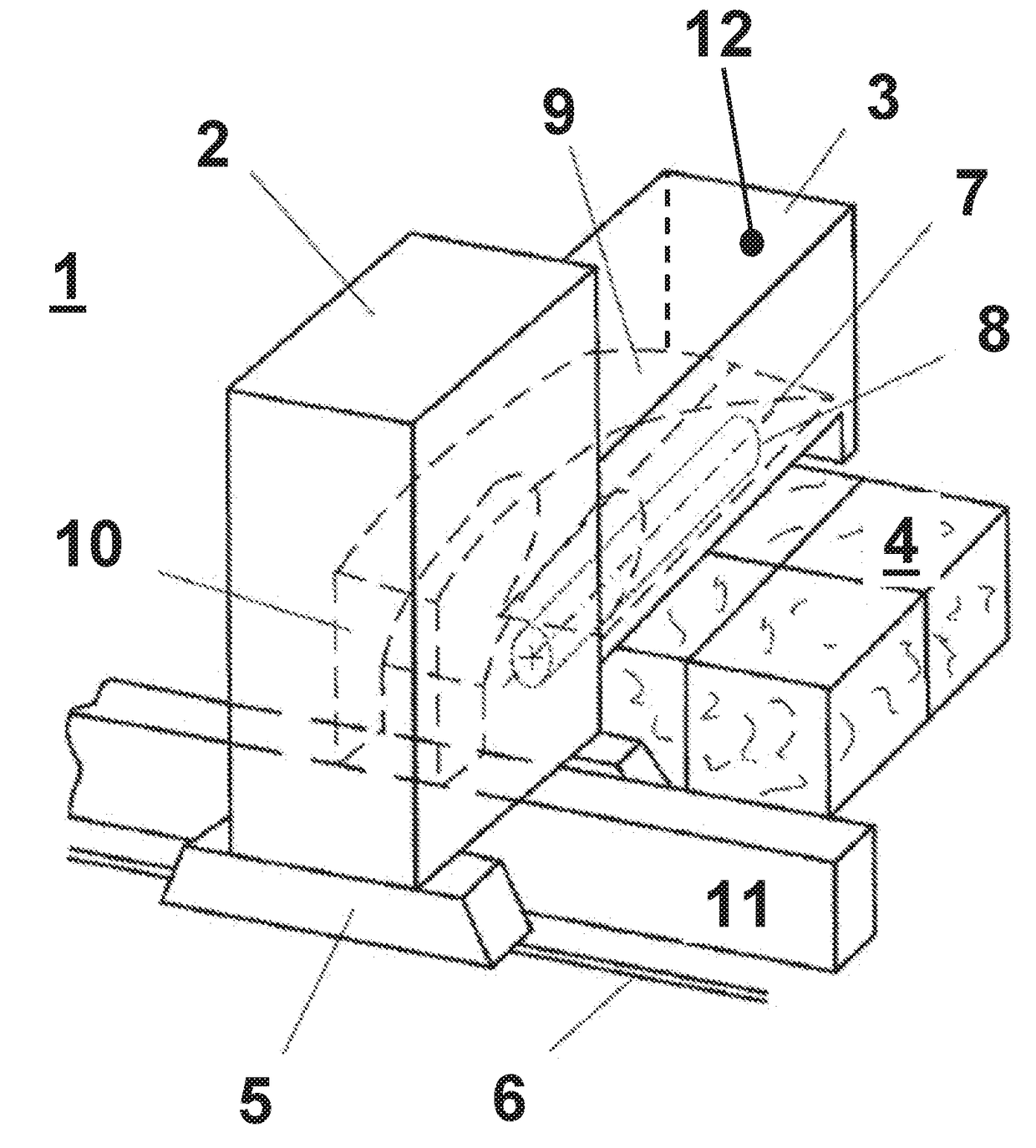

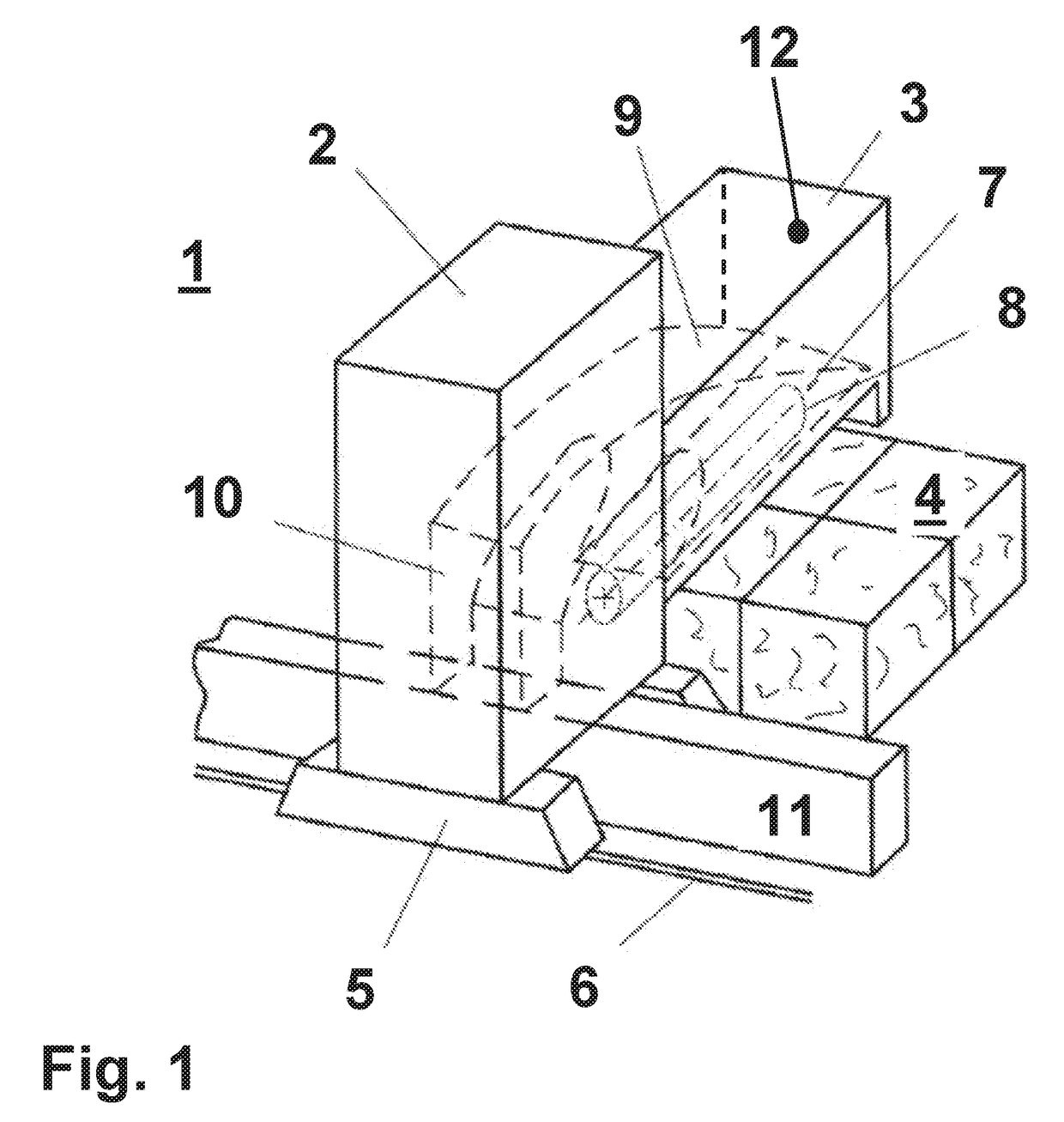

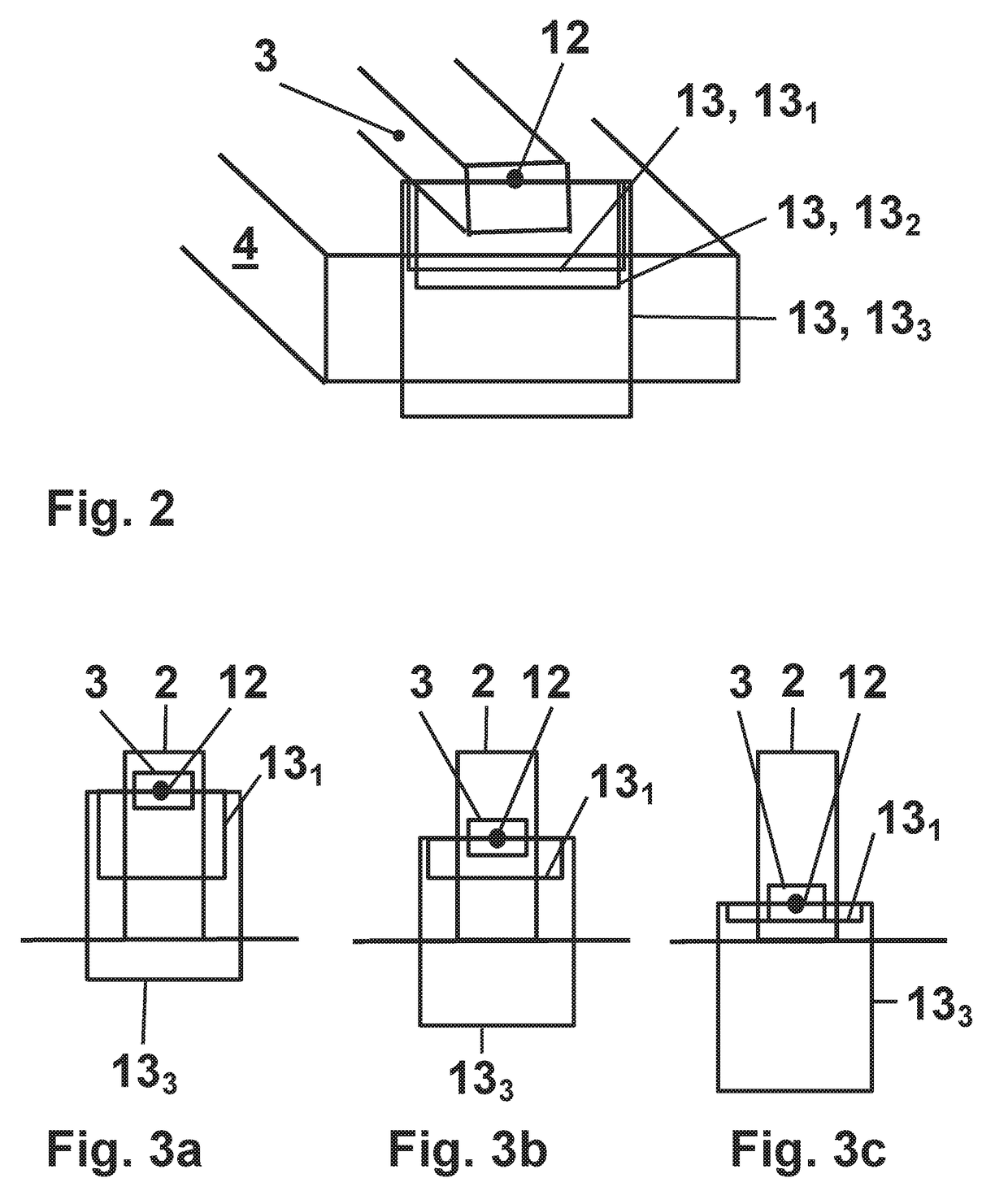

[0009]These objects are achieved by a method and a bale opener corresponding to the preamble of the independent claims, which are characterized in that the safety equipment comprises at least one two-dimensional laser scanner, on which at least one monitoring area that is adjustable and variable over time is monitored.

[0010]These objects are also achieved first by a comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| lateral distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com