Patents

Literature

315results about "Safety devices for fibre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

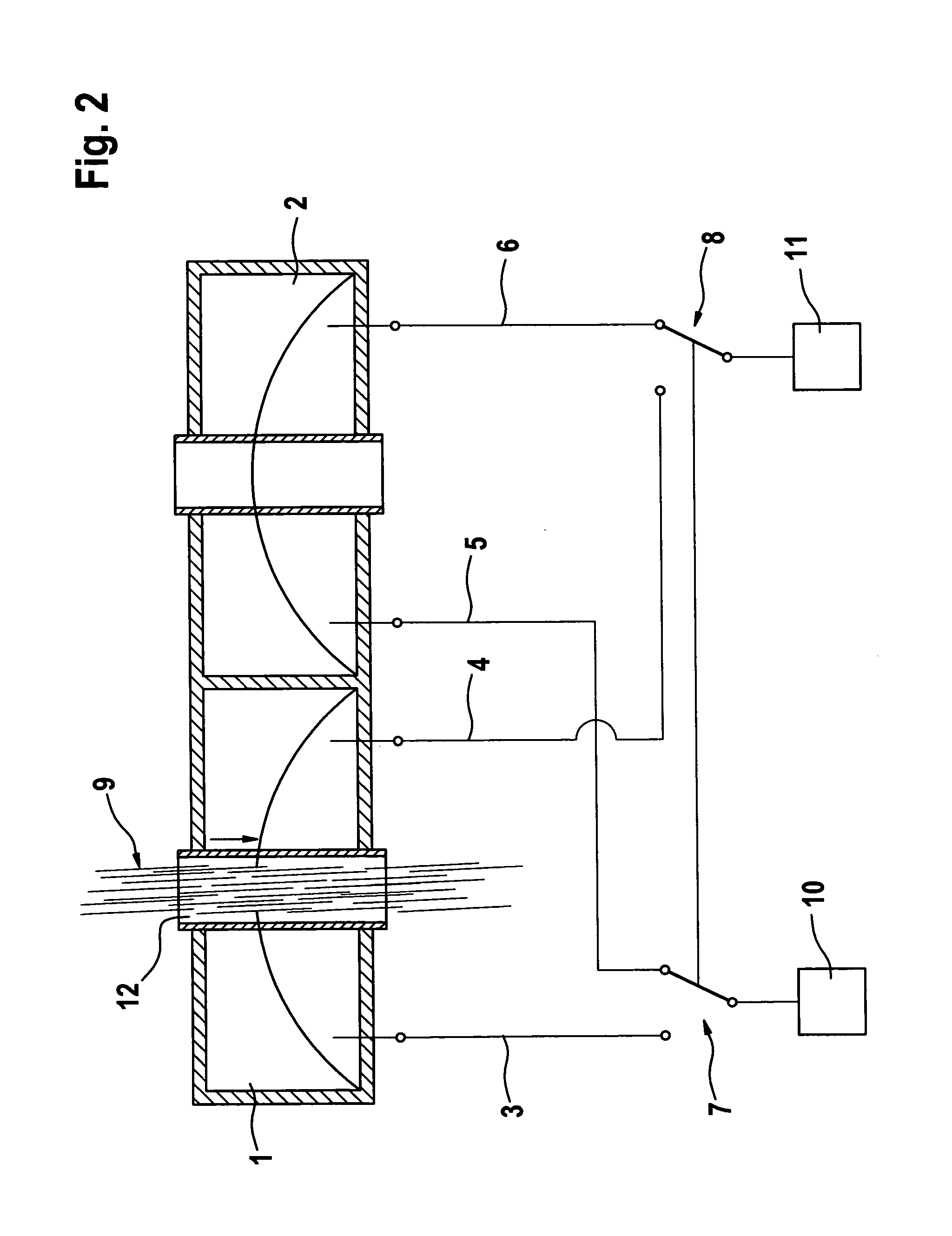

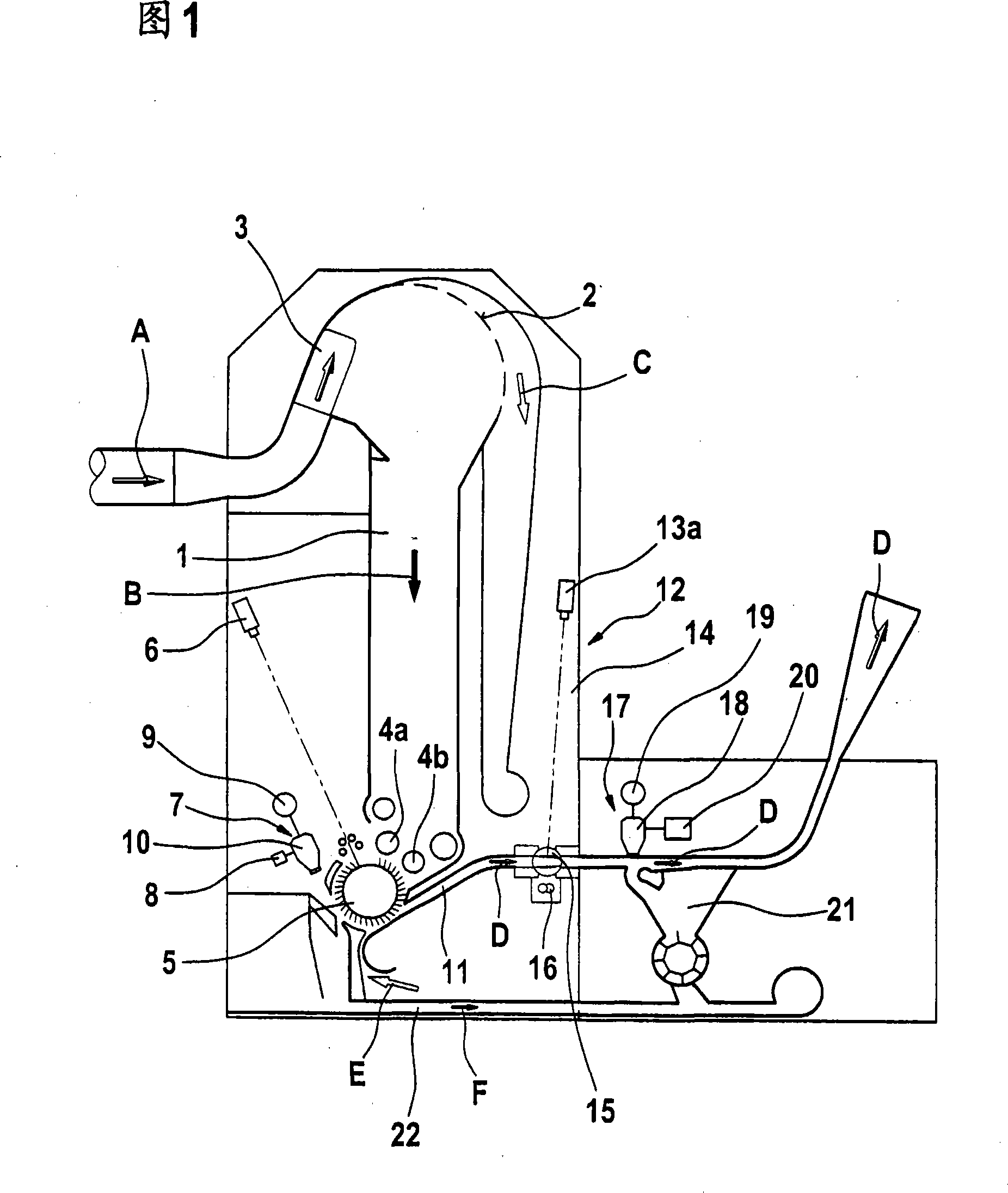

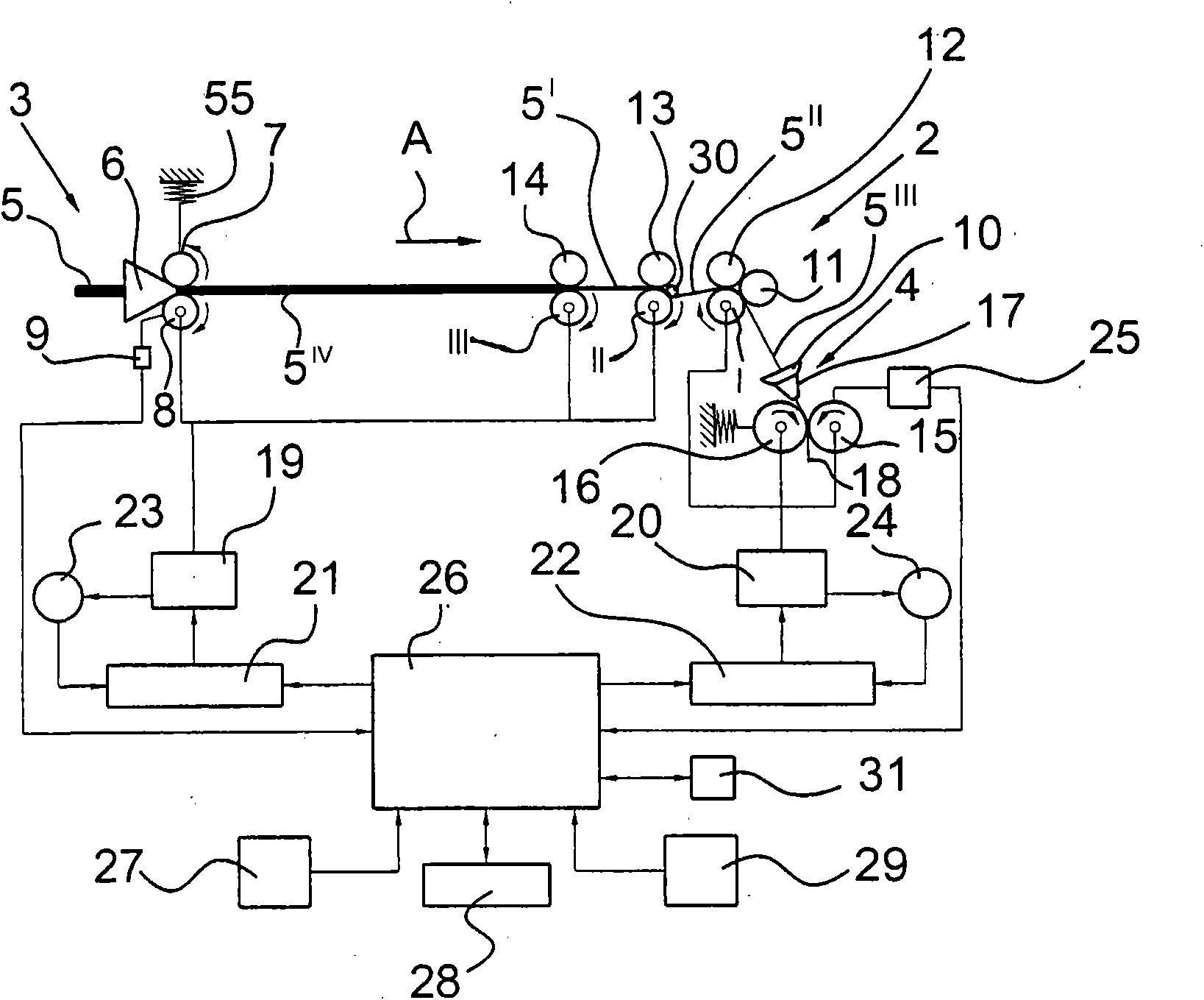

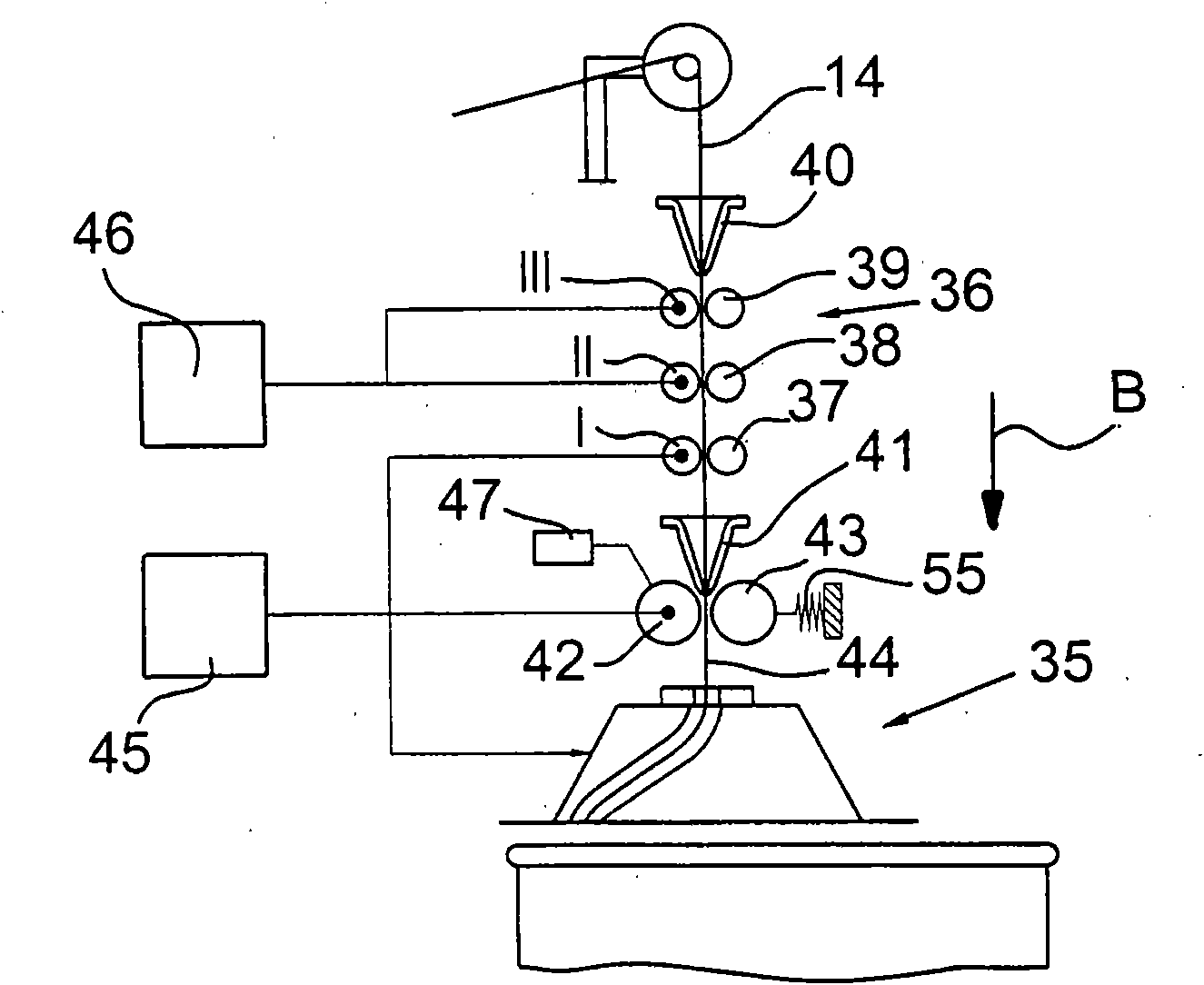

Apparatus on a spinning preparation machine for ascertaining the mass and/or fluctuations in the mass of a fibre material

InactiveUS20060260100A1Improved and accurate measurementSmall dimensionSafety devices for fibre treatmentMeasurement devicesEngineeringDistance sensors

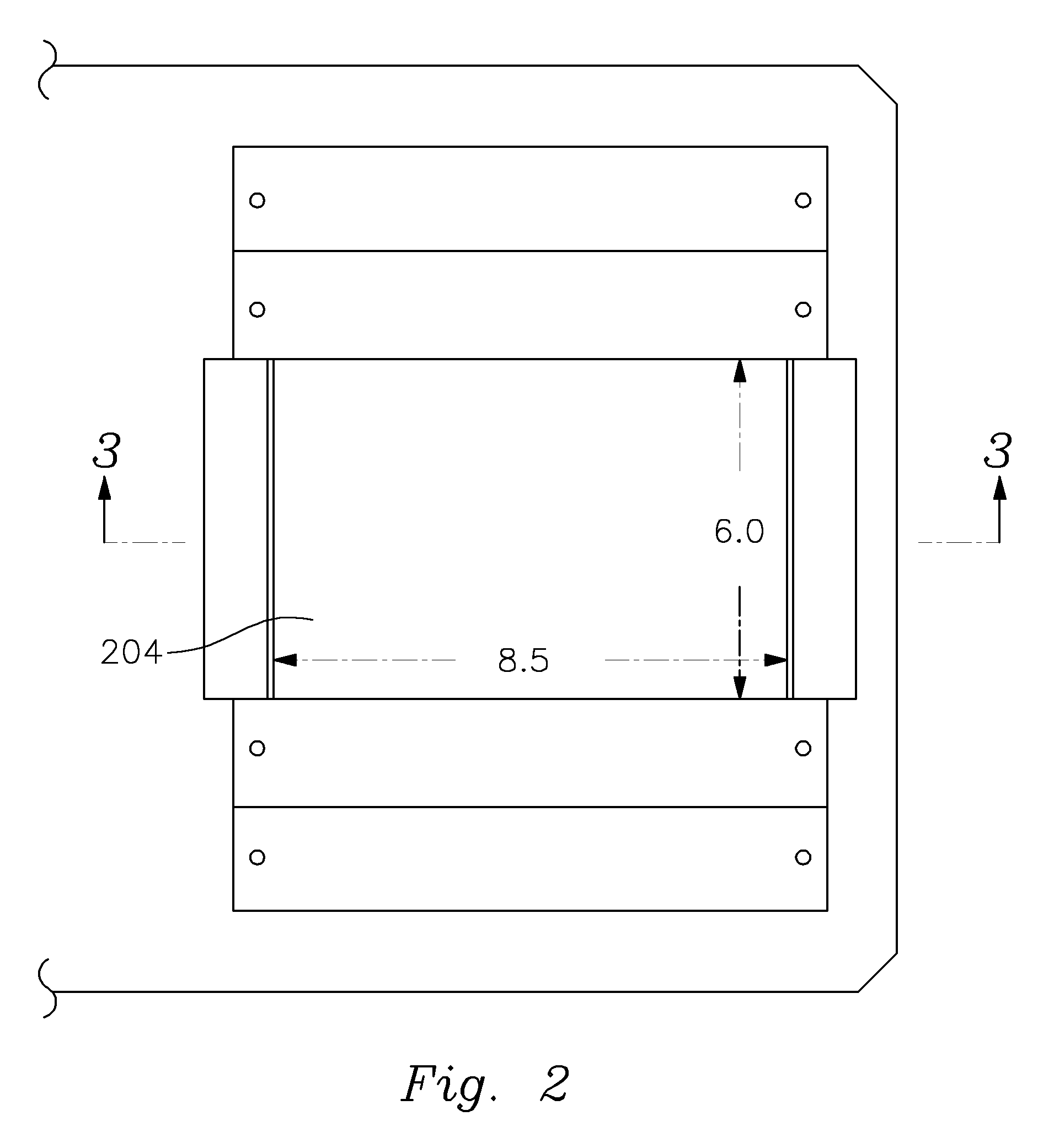

In an apparatus on a spinning preparation machine, for example a flat card, roller card, draw frame, combing machine or the like, for ascertaining the mass and / or fluctuations in the mass of a fibre material, for example at least one fibre sliver, fibre web or the like, of cotton, synthetic fibres or the like, the fibre material is scanned mechanically by a feeler element the excursions of which are converted into electrical signals. In order to facilitate improved and more accurate measurement of the fibre in a way that is simple in terms of structure and installation, a contactless distance sensor is provided for detecting the position of the feeler element, the sensor being a sensor that measures distance using transmitted waves, and is connected to an electronic evaluating device.

Owner:TRUETZSCHLER GMBH & CO KG

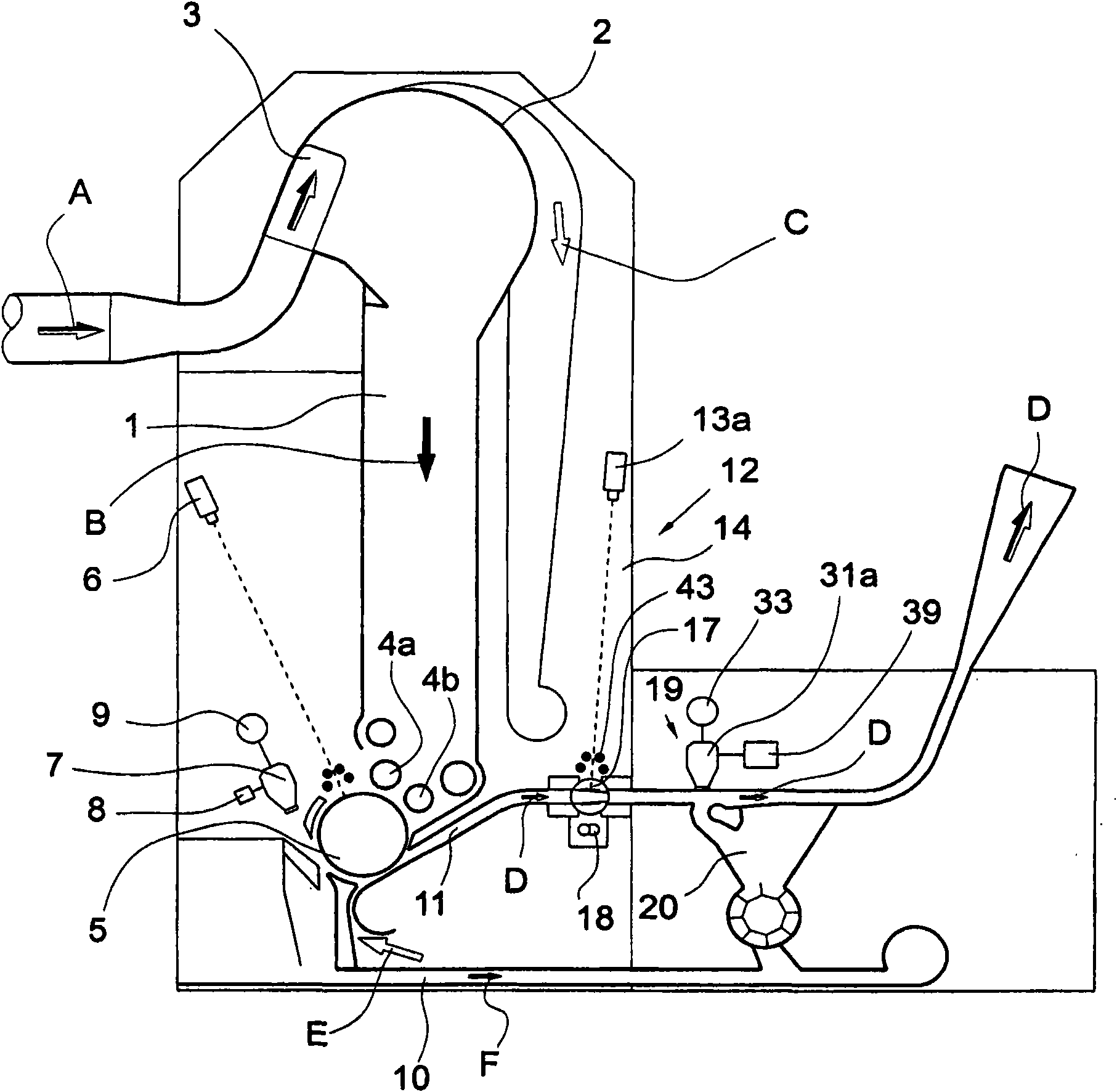

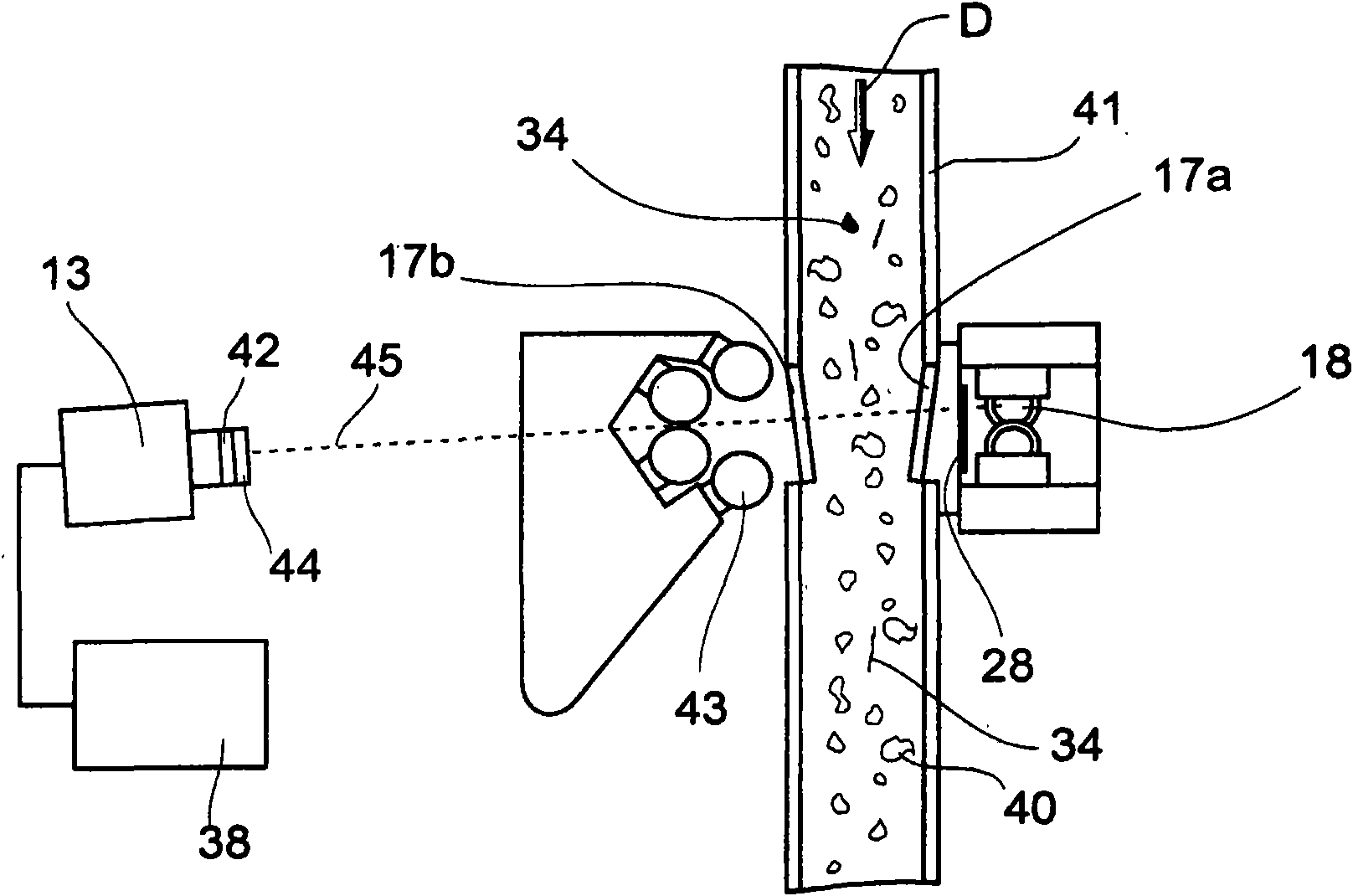

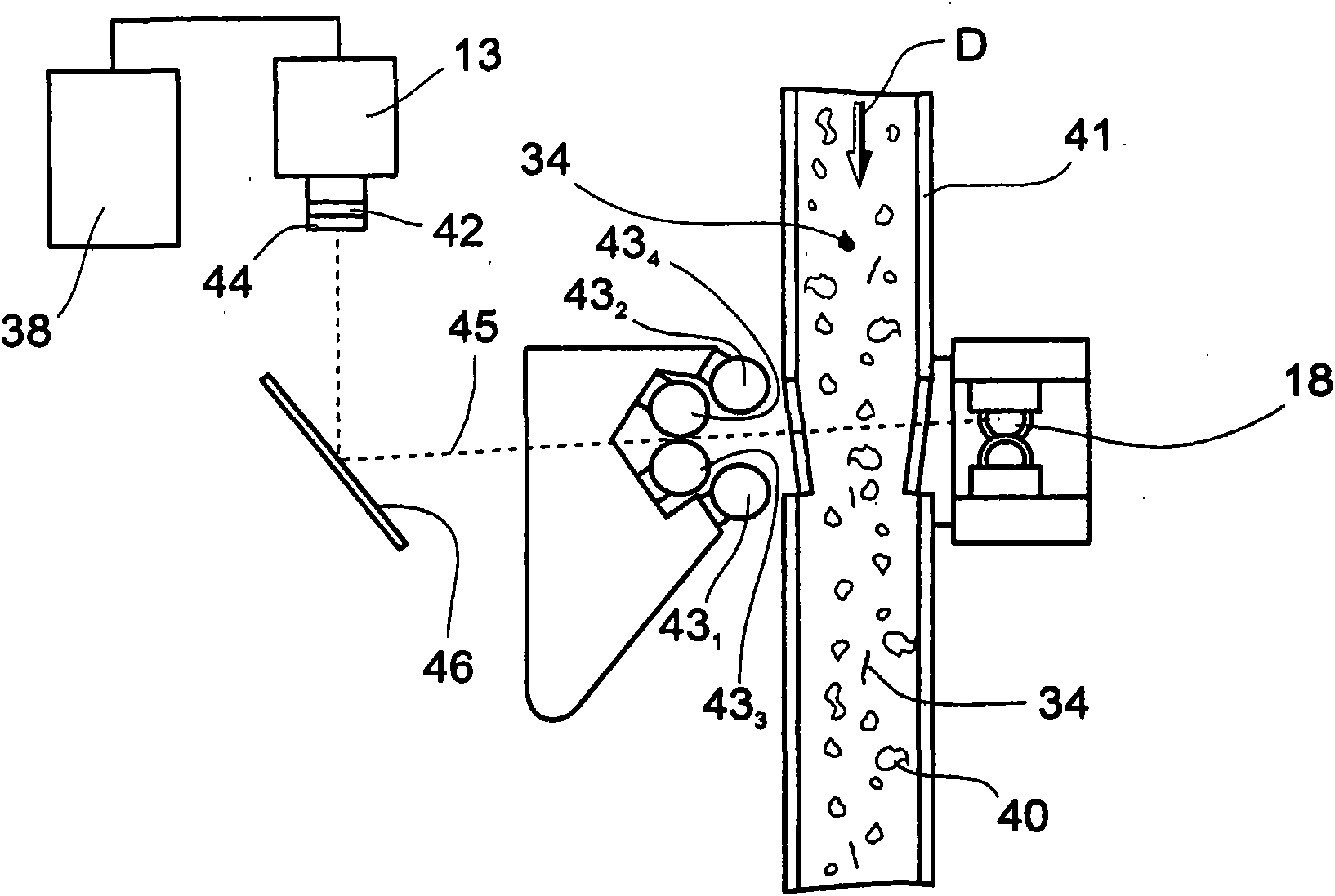

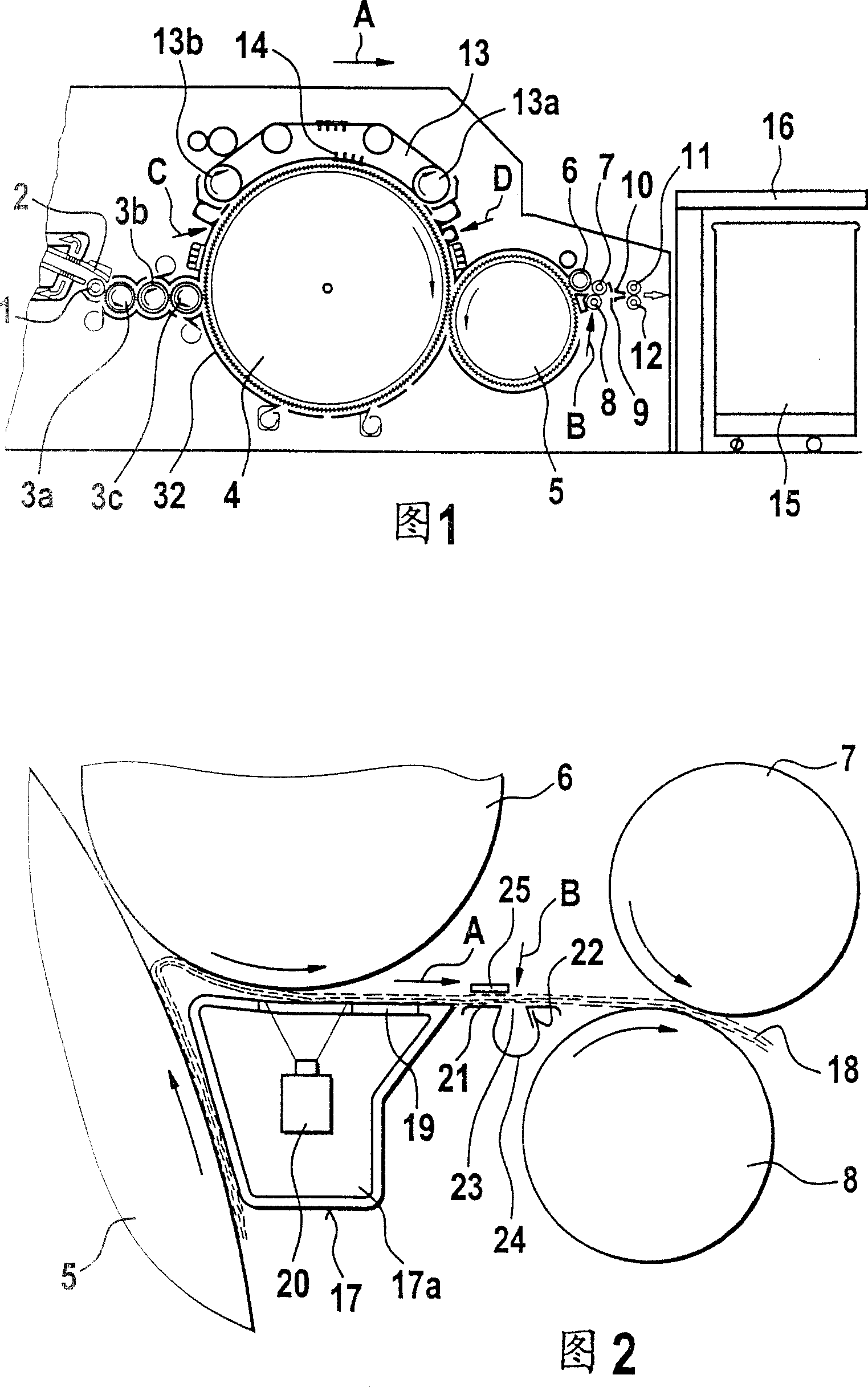

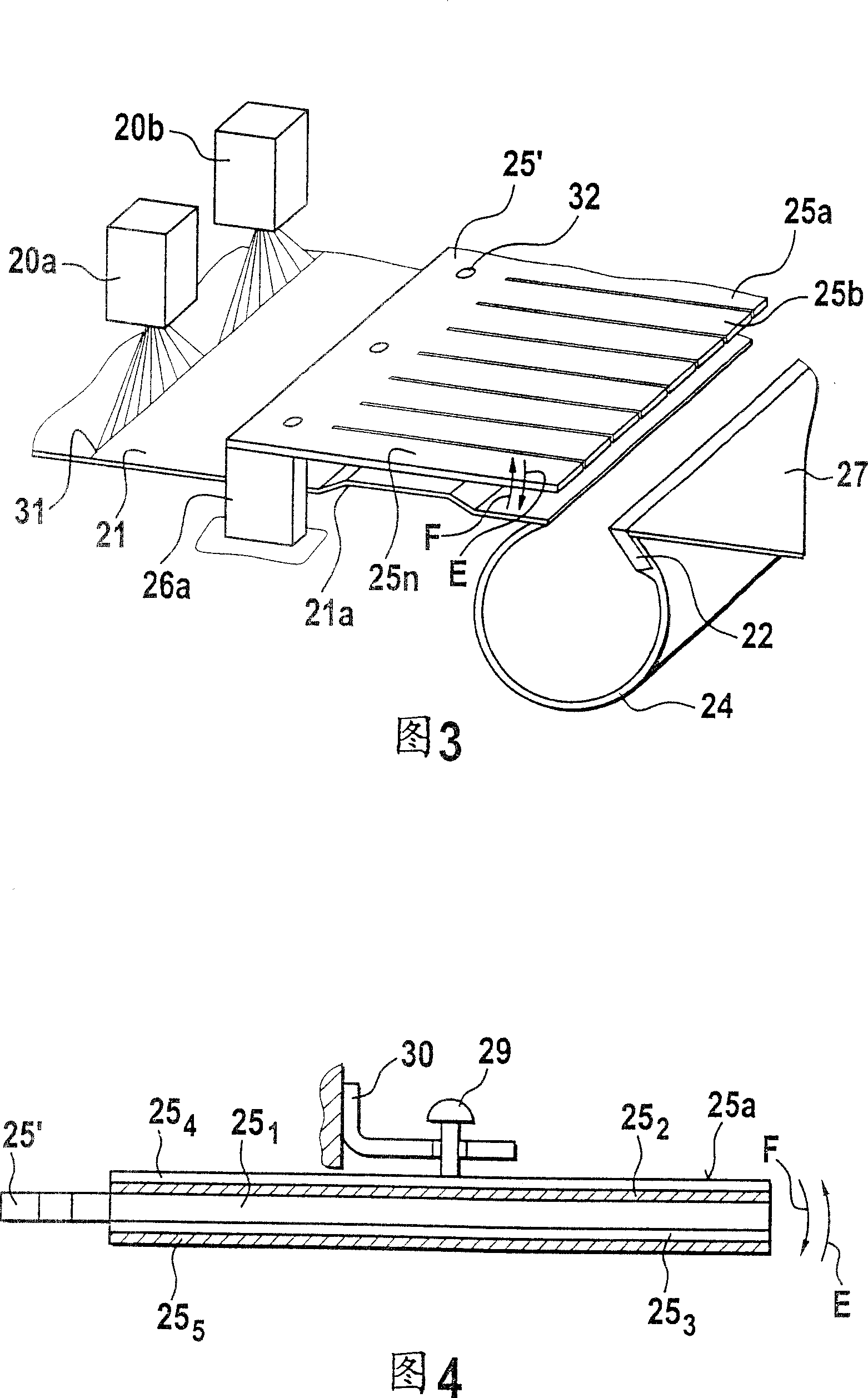

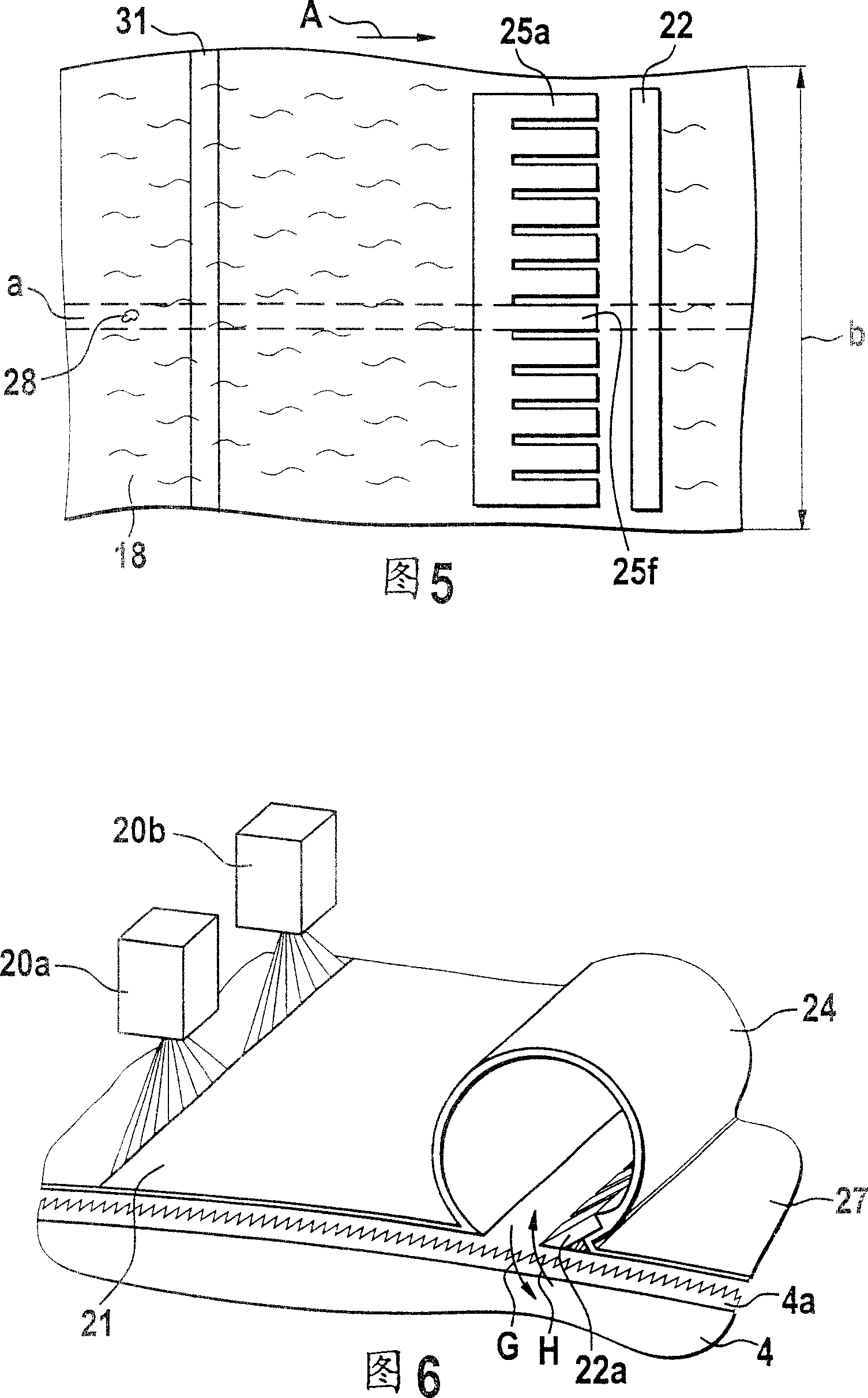

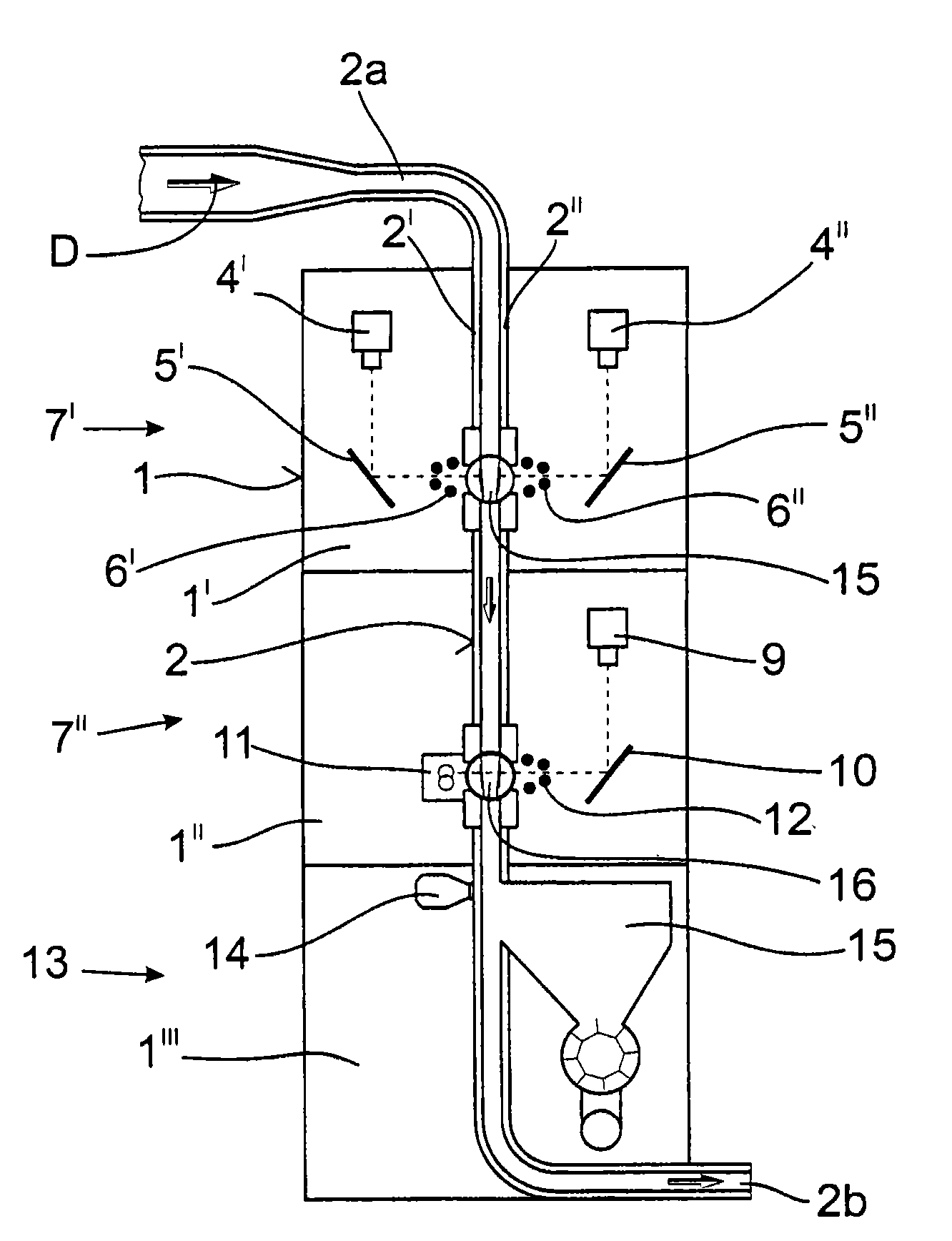

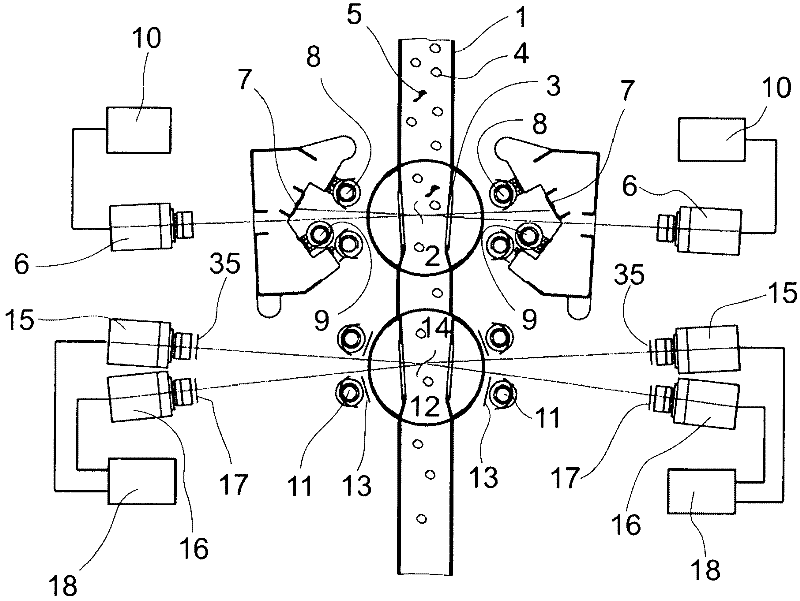

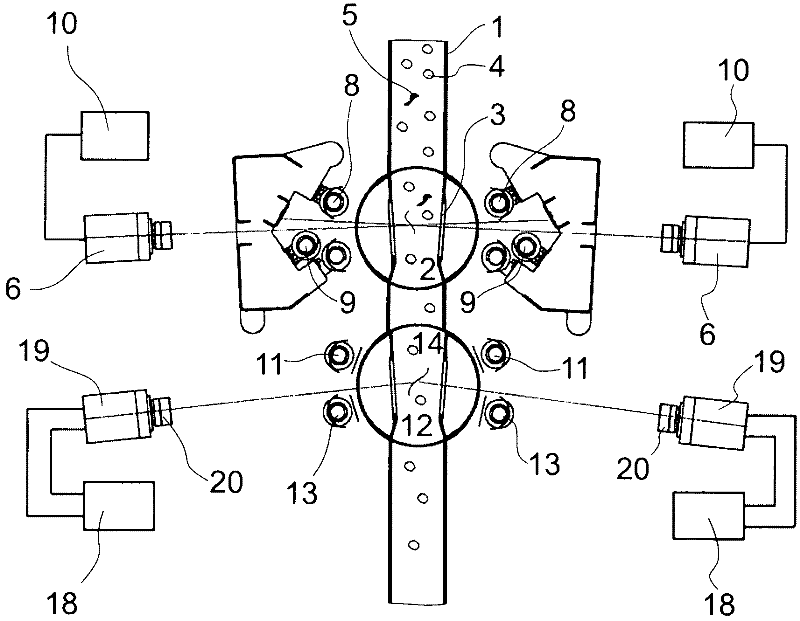

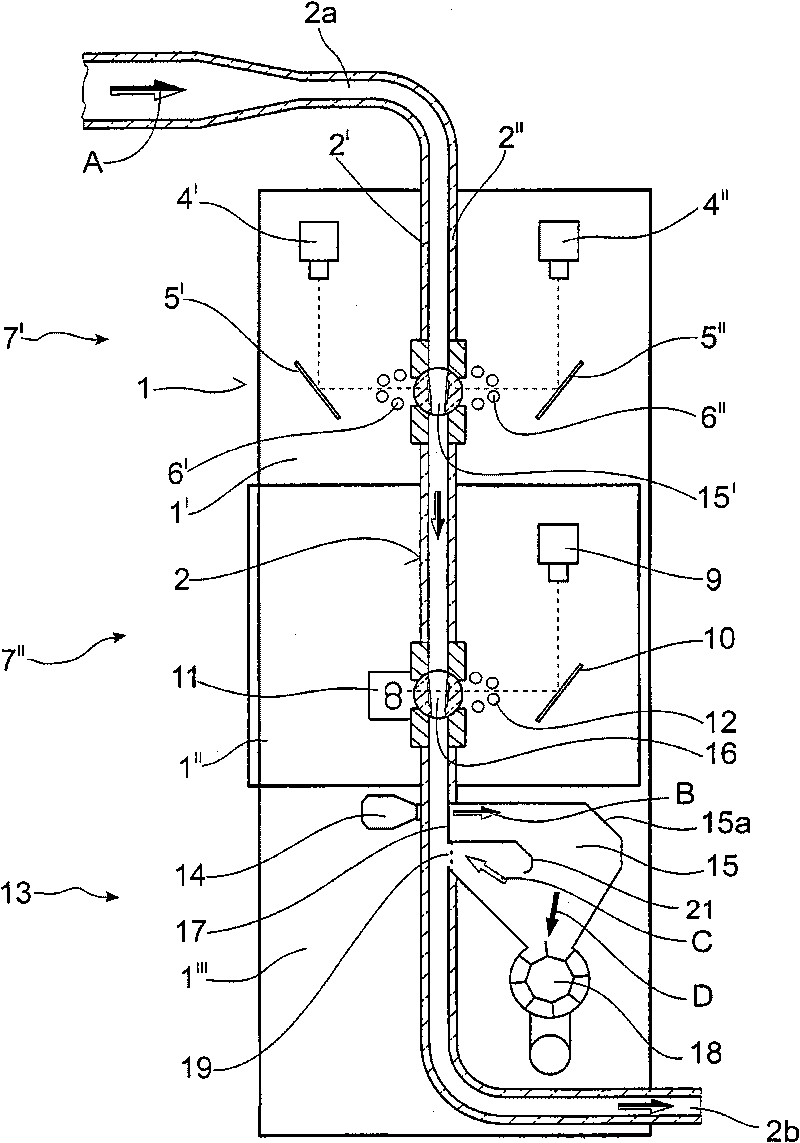

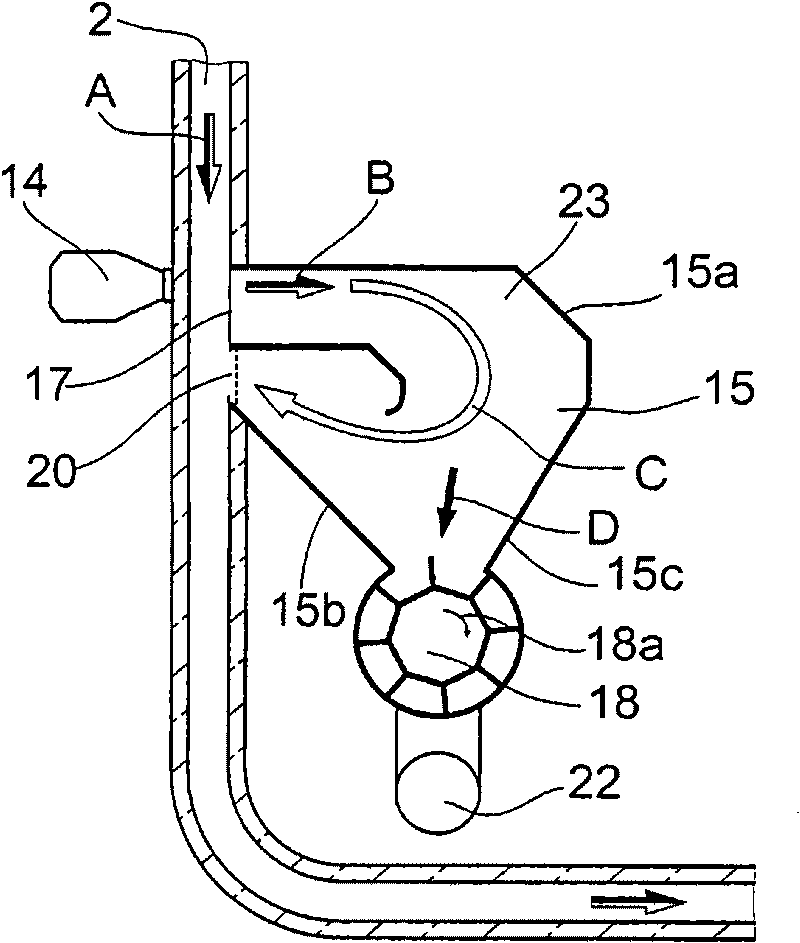

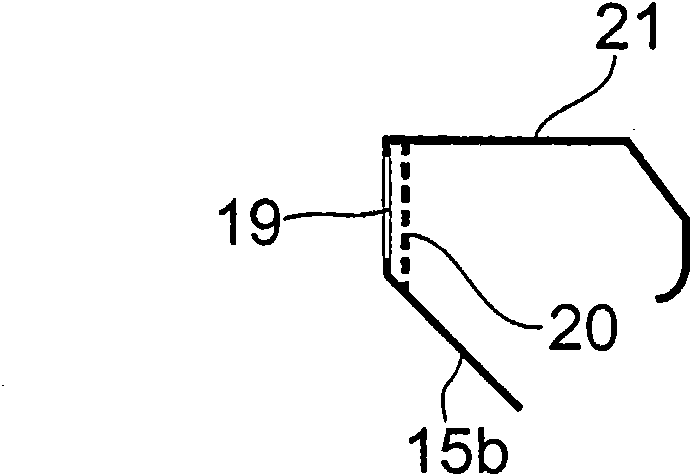

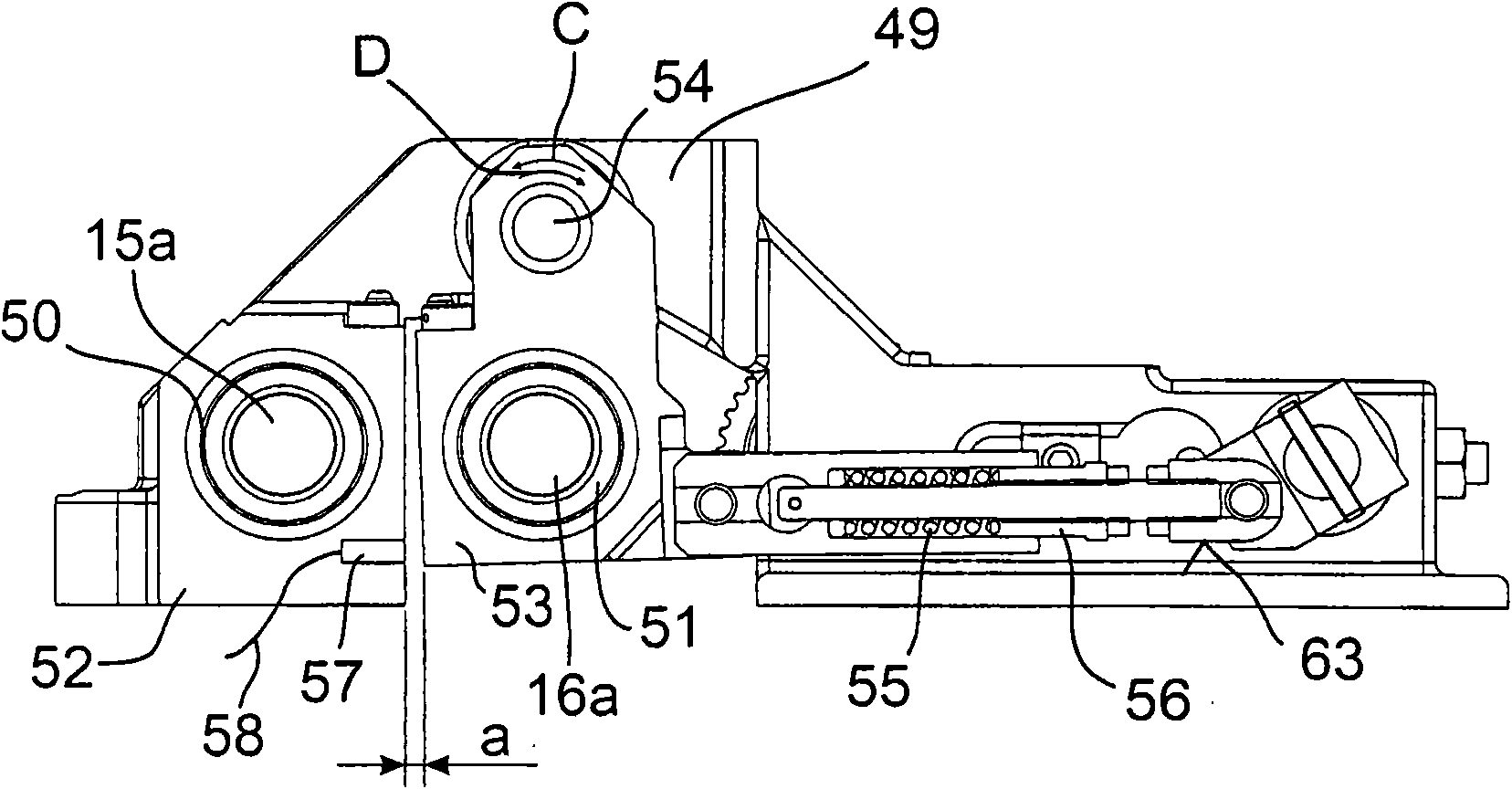

Apparatus at a spinning preparation machine for detecting waste separated out from fibre material

InactiveUS7173207B2Automatic detectionEasy to adjustSafety devices for fibre treatmentCarding machinesForeign matterEngineering

In an apparatus at a spinning preparation machine, for example a cleaner, opener, carding machine or the like, for detecting waste which is separated out from fibre material, for example cotton, and consists of foreign matter and good fibres and which is collected in a collecting device, there is provided an optical measuring device having a brightness sensor, which measuring device examines the waste.In order to make it possible, by simple means, for the content of good fibres in the waste to be detected and to allow optimum adjustment of the composition of the waste, especially with a high content of trash and low content of good fibres, the waste material is moved past at least one sensor arrangement responding to good fibres, and the sensor arrangement comprises a light source, the light reflected by the moving good fibres being detected by the brightness sensor and being converted into electrical signals, from which the good fibre content can be determined.

Owner:TRUETZSCHLER GMBH & CO KG

Ultra rapid conditioning of cotton fiber for testing and processing

InactiveUS20020178547A1Increase speedSafety devices for fibre treatmentCarding machinesFiberEngineering

<heading lvl="0">Abstract of Disclosure< / heading> Machines for ultra-rapidly conditioning cotton fiber. In one embodiment, a machine includes a conditioning chamber for receiving cotton fiber formed into a sheet-like body. The conditioning chamber is defined on one side by an impervious plate and on an opposite side by a perforated plate. The sheet-like body of cotton fiber is pressed between the impervious and perforated plates. An air conditioner is connected for driving a conditioned gas flow through the perforations and then laterally through the sheet-like body of cotton fiber. In another embodiment, a conditioning chamber is defined on one side by an impervious plate and on an opposite side by a distribution plate having a series of alternating passages connected for respectively delivering gas flow to the cotton and for allowing gas flow to exit from the cotton. As a result, relatively short path lengths are achieved. An air conditioner is connected for driving a conditioned gas flow through the passages for delivering gas flow. In a processing embodiment for conditioning fiber being pneumatically transported by a gas flow, fibers are collected to form a thin mat. Aerosolized liquid is delivered to the thin mat, and then conditioned fiber from the thin mat is re-delivered into the gas flow.

Owner:SHOFNER ENG ASSOC INC

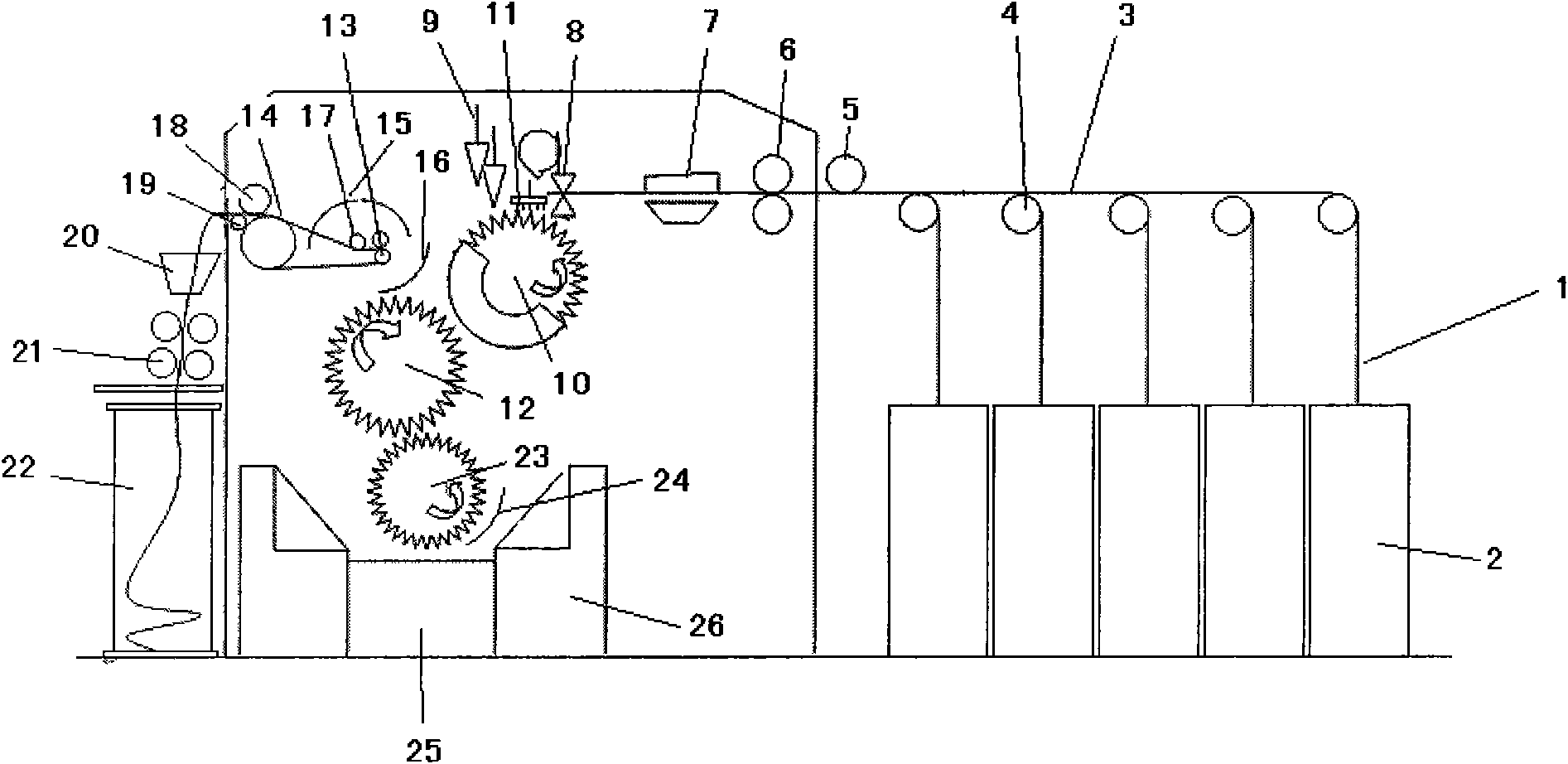

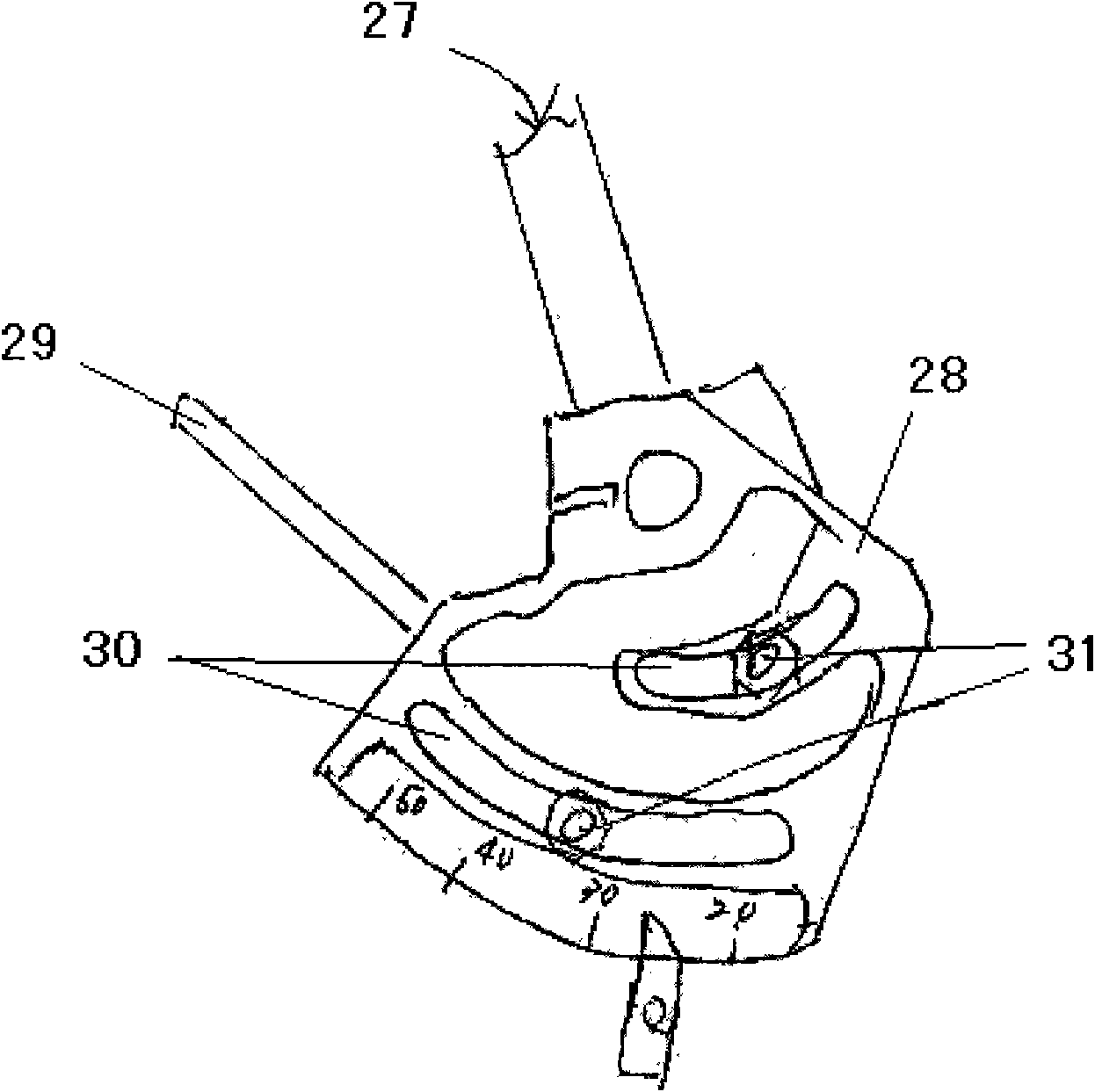

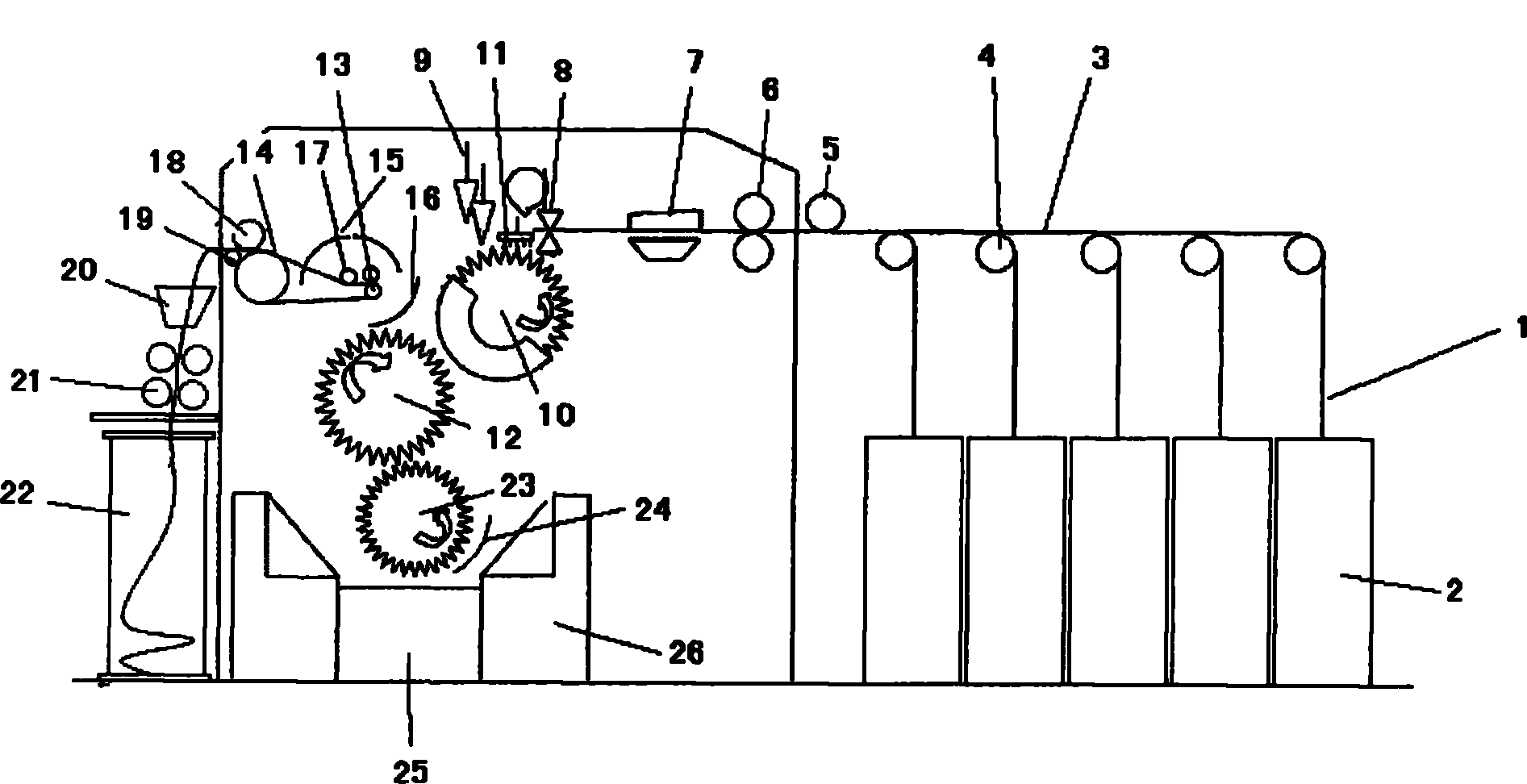

Sesaron combing and sorting method and device

ActiveCN101824676AEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesCombingEngineering

The invention relates to a sesaron combing and sorting method and a device; combed ramie stripes with different specifications and lengths are obtained through a plurality of layers of combing; the split degree of the ramie stripes is decided by comb needle models used in all the layers of combing; and the lengths of the ramie stripes are changed by adjusting a pulling vehicle. In a combing and sorting mechanism of the device, circular comb needle strips are lined in a circumference of 0 to 270 degrees respectively through a rack method and a rack and needle row combined method, and top combs are in a single row or a plurality of rows. A pulling separation mechanism comprises the pulling vehicle, the pulling vehicle is arranged on a regulation frame, the regulation frame is provided with a rod and a circular arc-shaped chute, a bolt is inserted into the circular arc-shaped chute, the bolt is fastened on a frame, the bolt is loosened, and the regulation frame can slide along the circular arc-shaped chute by triggering the rod. At least two pairs of curl rollers are arranged in a strip discharge mechanism. The ramie stripe fibers processed by the method and the device are even and uniform, have short fiber rate, uniform fiber length and low ultra-long length fiber content, so that the fibers are more parallel and straighter, the operation is convenient, the efficiency is high, and the labor intensity is low.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Apparatus for detection of foreign matter in plastic material in spinning room preparation, ginning or the like installation

ActiveCN101619537ASave installation spaceMomentary loss of clarityFibre cleaning/opening by air draught arrangementsSafety devices for fibre treatmentForeign matterFiber

The present invention relates to an apparatus in a spinning room preparation, ginning or the like installation for detection of foreign objects of plastics material, such as polypropylene, weaving plastic, plastic sheet and the like, in or between a stream of fibre material, especially cotton. In the apparatus, the foreign objects in or between the stream of fibre material are arranged to be penetrated by a polarised light source cooperating with a detector, preferably a camera, weak color and / or transparent foreign objects are penetrated, and the light from another light source is applied on the stream of the fibre material. For effectively detecting the white and / or transparent plastic material sheets by a simple structure, the foreign objects in or between the stream of the fibre material are arranged to be illuminated by an ultraviolet light source or reflected light, and the ultraviolet light source cooperates with the detector, wherein the detector is capable of detecting the penetrated and illuminated foreign objects and separating them from the fibre material.

Owner:TRUETZSCHLER GRP SE

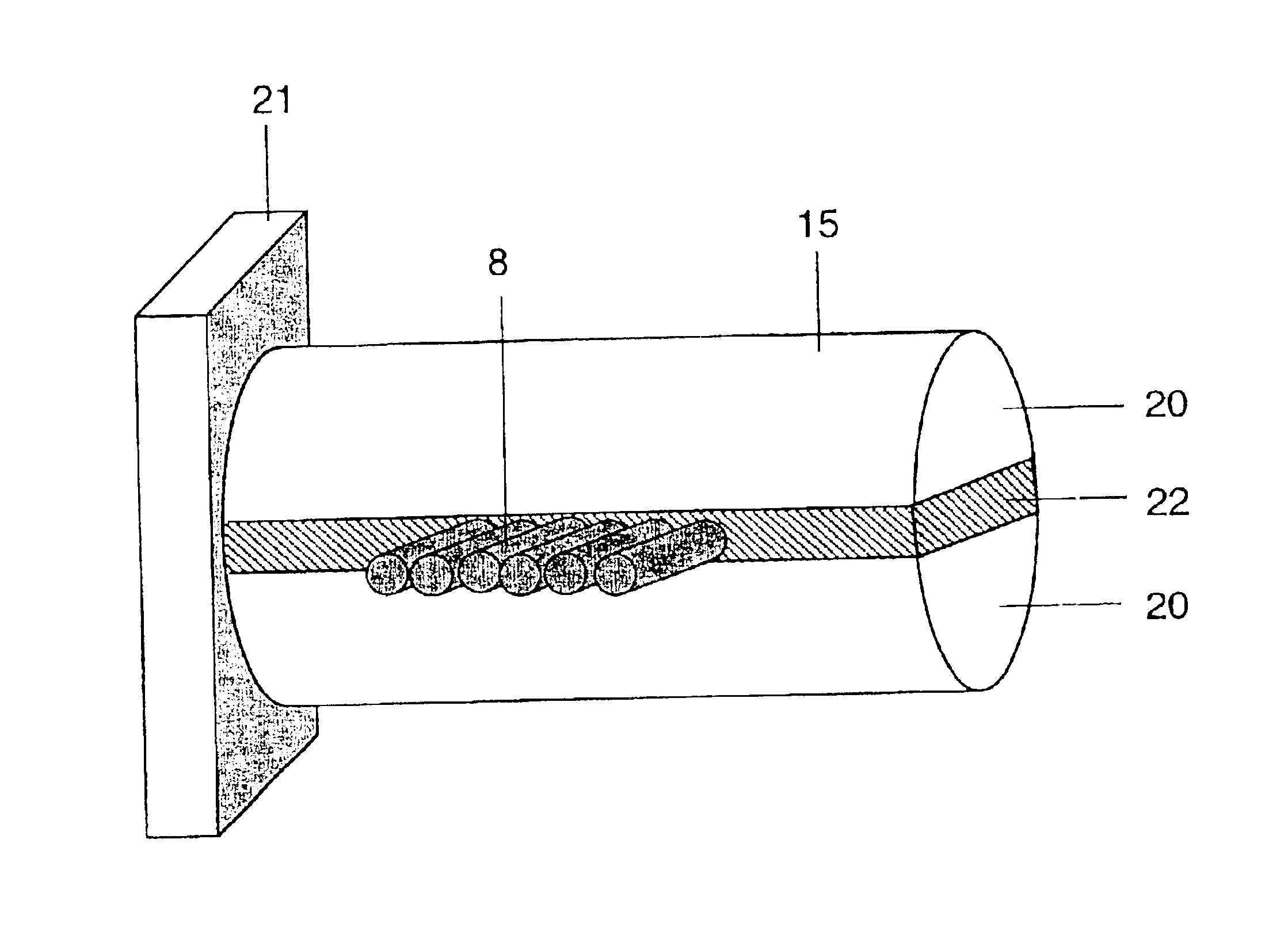

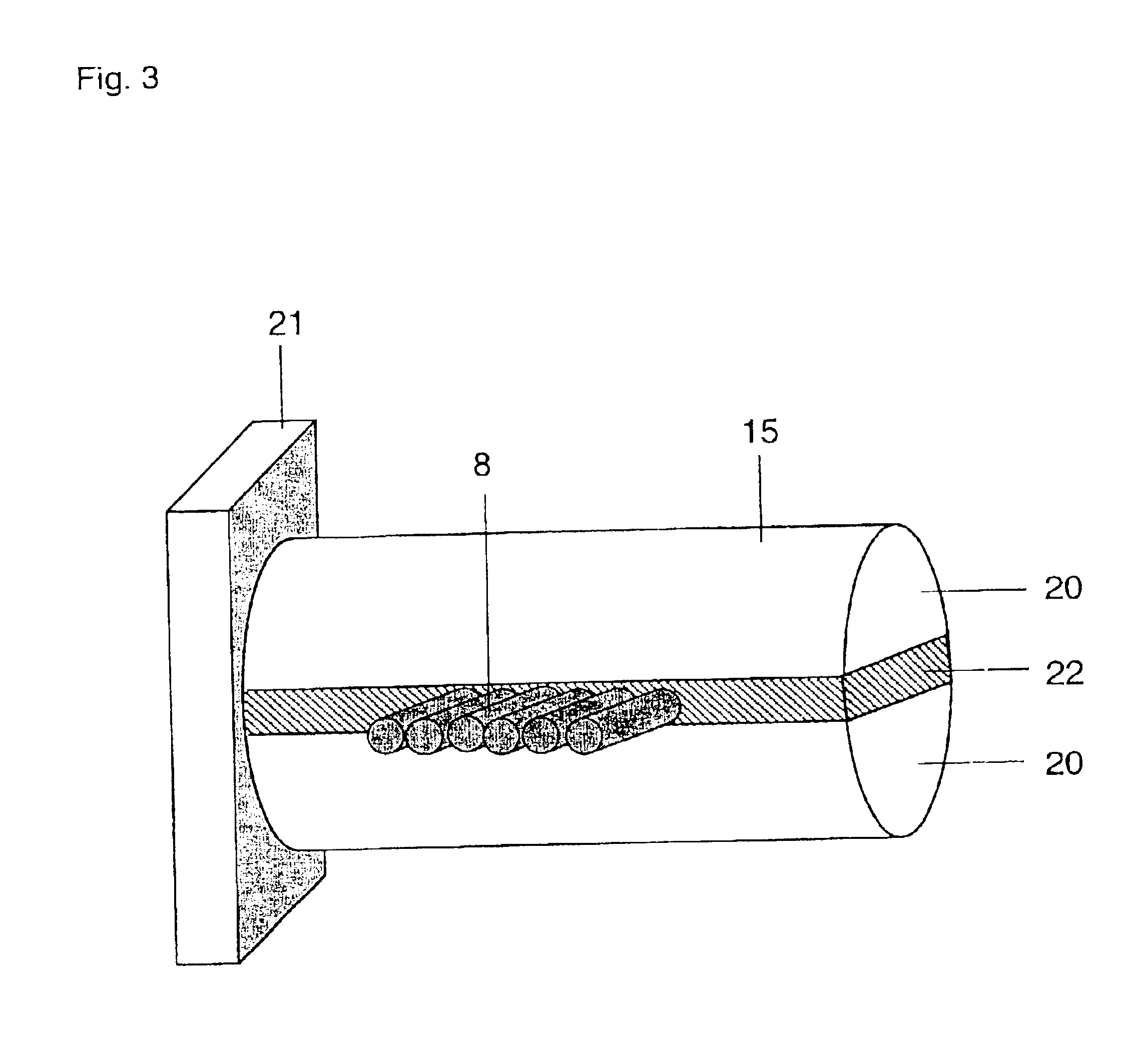

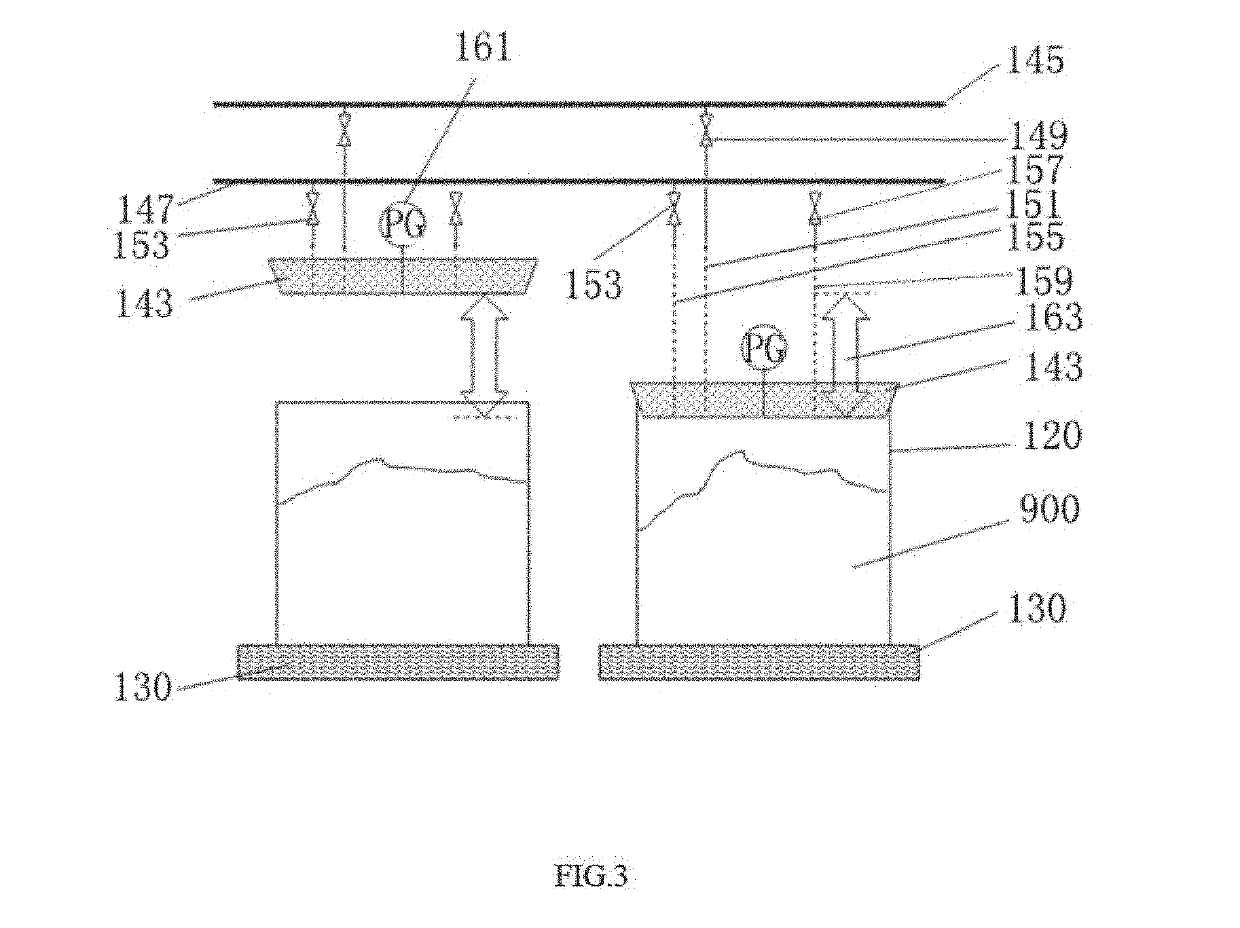

Device and method for detecting the mass and the moisture content for spinning preparation machines

InactiveUS6837122B2Fine time resolutionReliable measurementSafety devices for fibre treatmentResistance/reactance/impedenceEngineeringMoisture

The device for measuring the mass and / or the moisture of a material running through a spinning preparation machine is distinguished in that it has a microwave resonator (15, 18) and associated adapted measurement electronics. The method for measuring the mass and / or the moisture of a material running through a spinning preparation machine is distinguished in that the measurement is carried out with the aid of microwaves.

Owner:TEWS ELEKTRONIK GMBH & CO KG

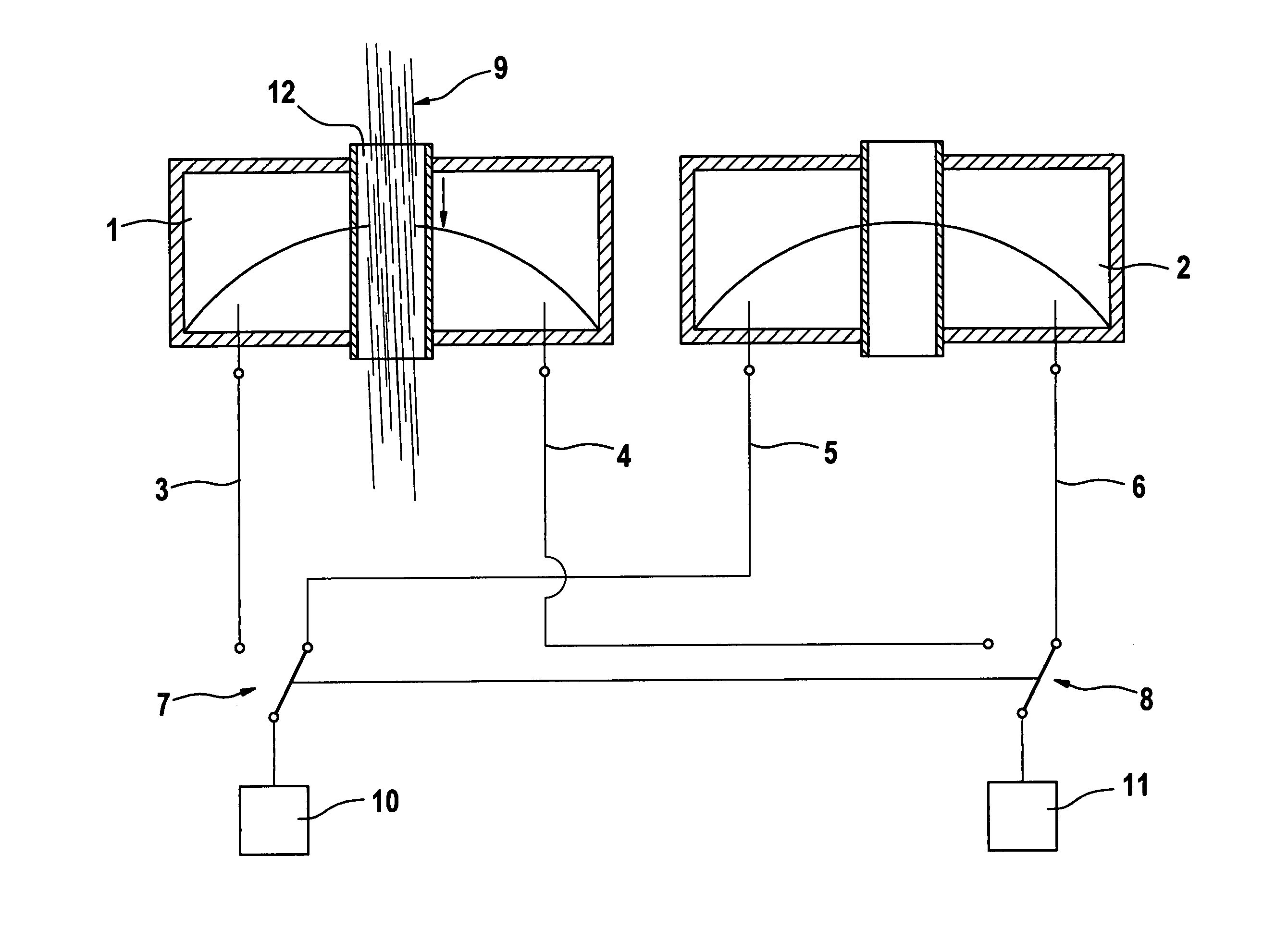

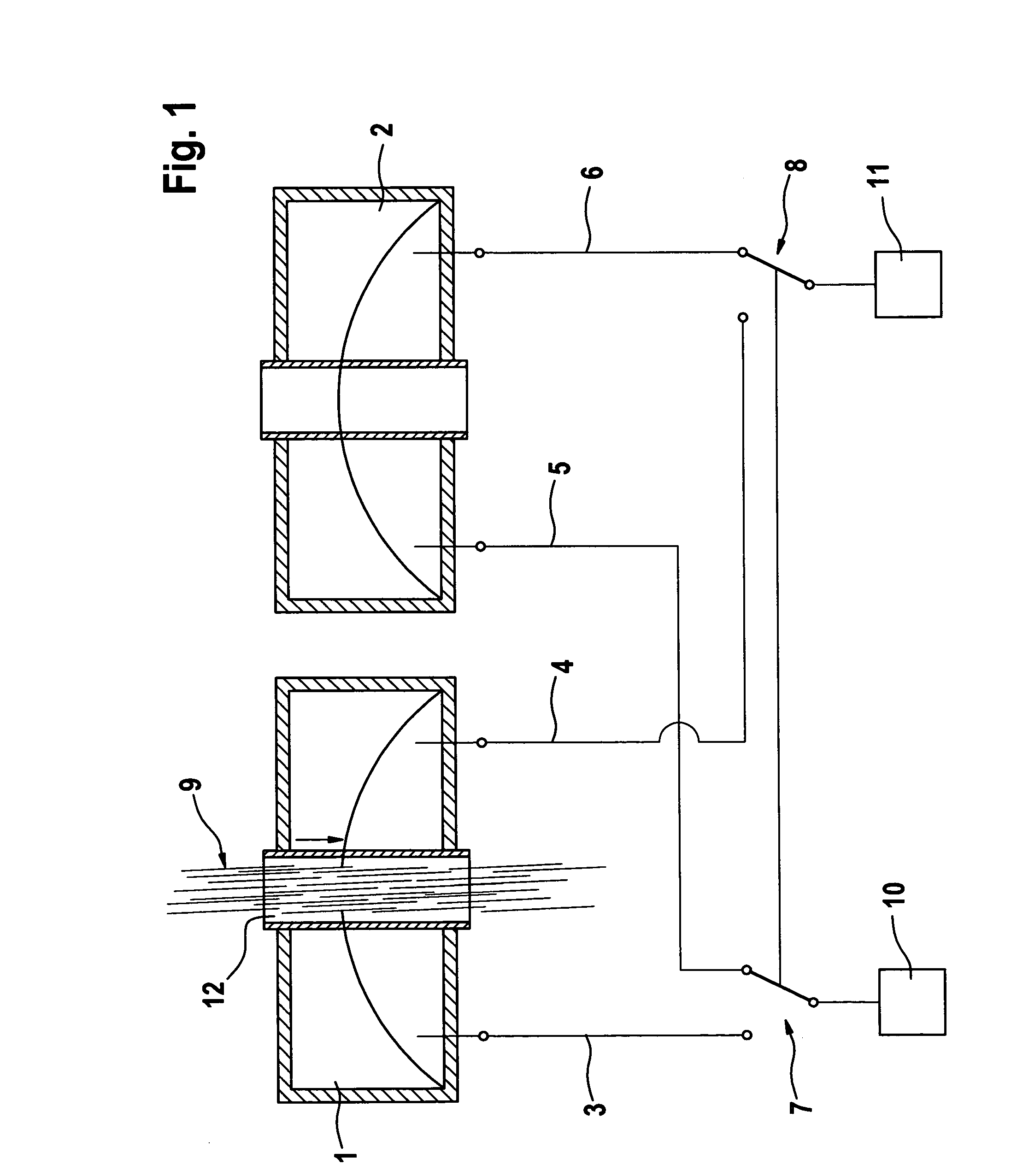

Microwave measuring arrangement for product density measurement

InactiveUS7132836B2Safety devices for fibre treatmentResistance/reactance/impedenceMeasurement deviceEnvironmental effect

The invention relates to a measuring arrangement for measuring the density of a product by means of microwaves. The measuring arrangement comprises a first microwave resonator, from which, in operation, microwaves enter a product area, and a device for compensating for environmental influences and disturbance variables affecting the measuring signal of the first microwave resonator. According to the invention, the compensation device comprises a second microwave resonator, which is shielded towards the product area with respect to microwave radiation.

Owner:TRUETZSCHLER GMBH & CO KG

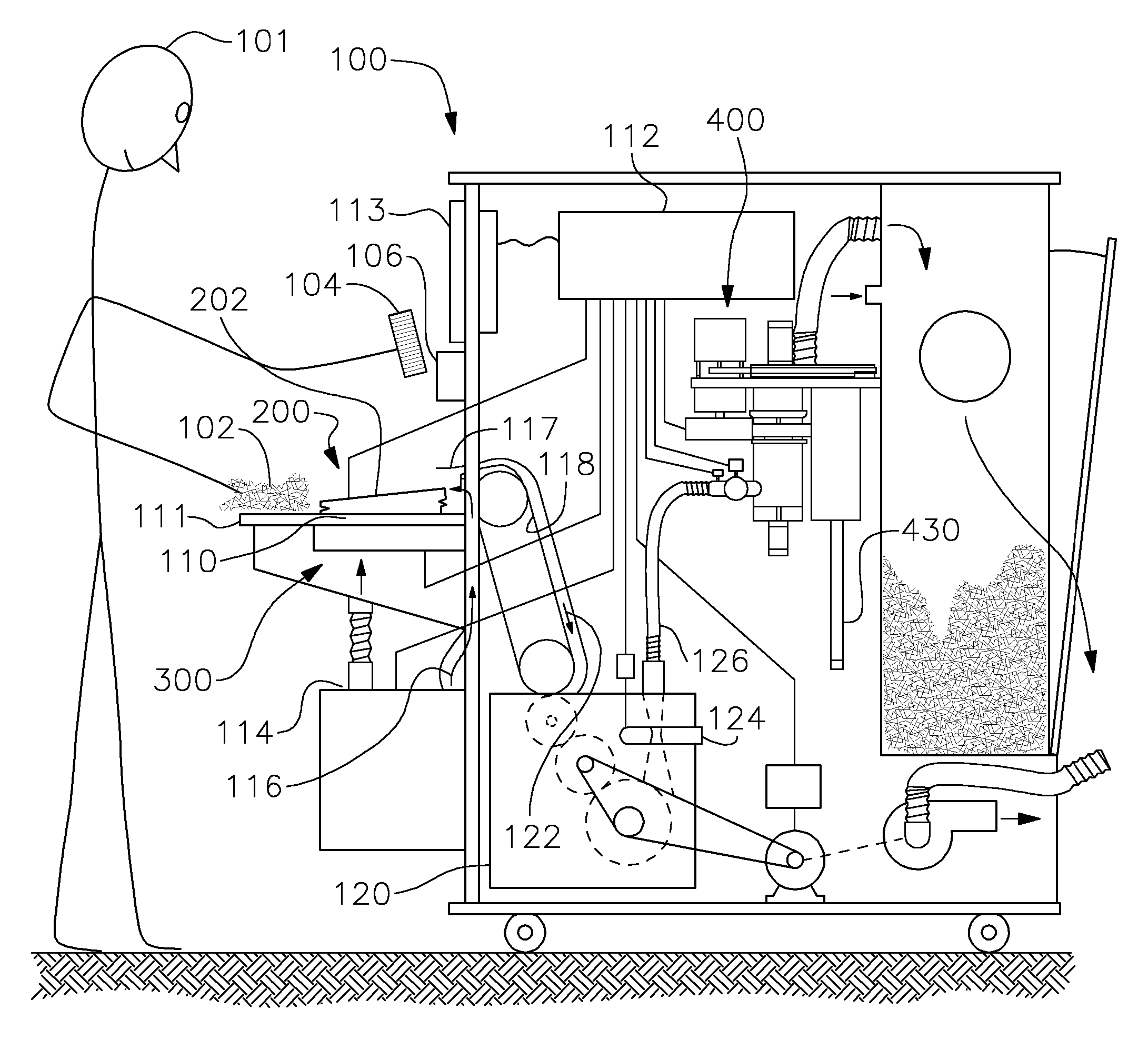

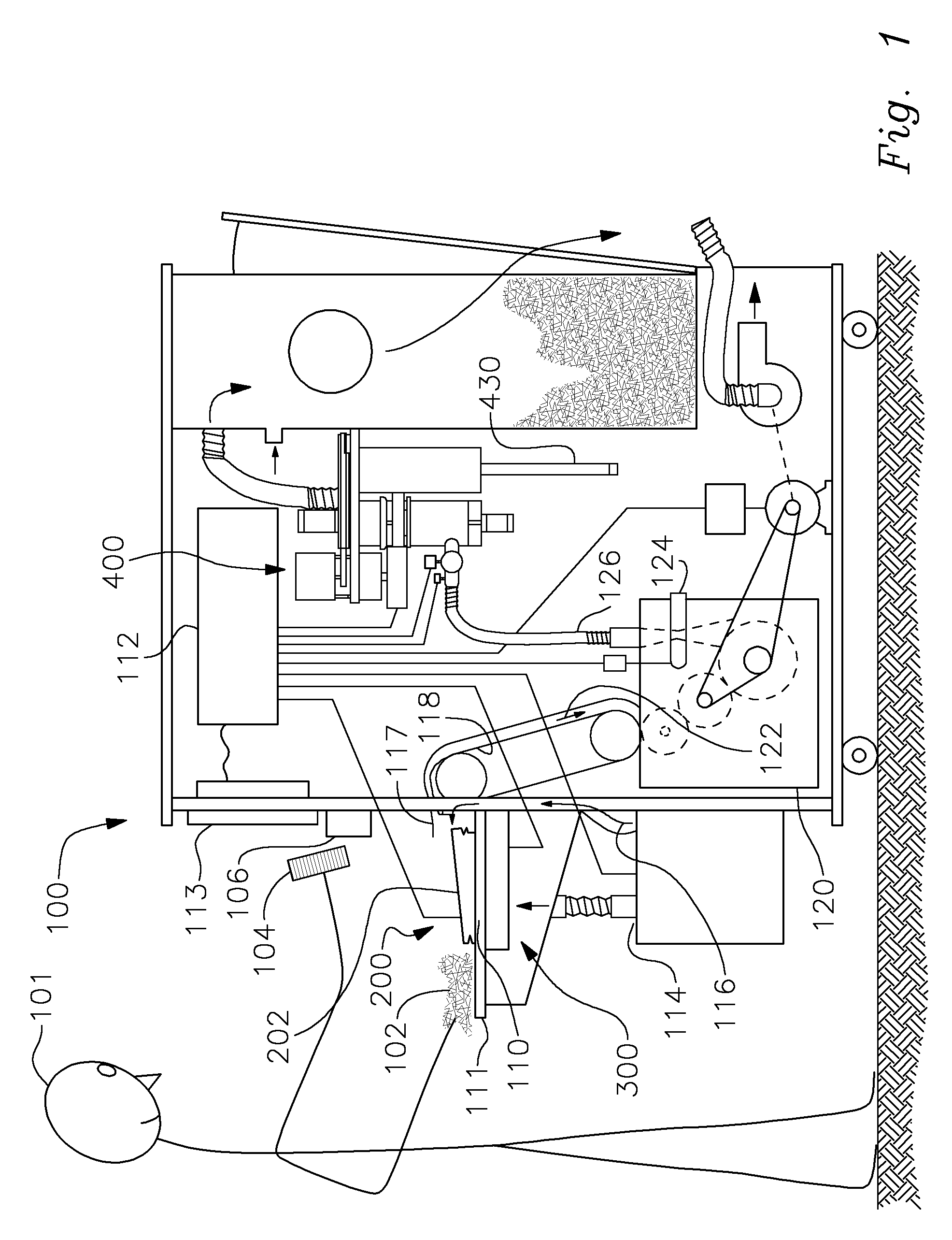

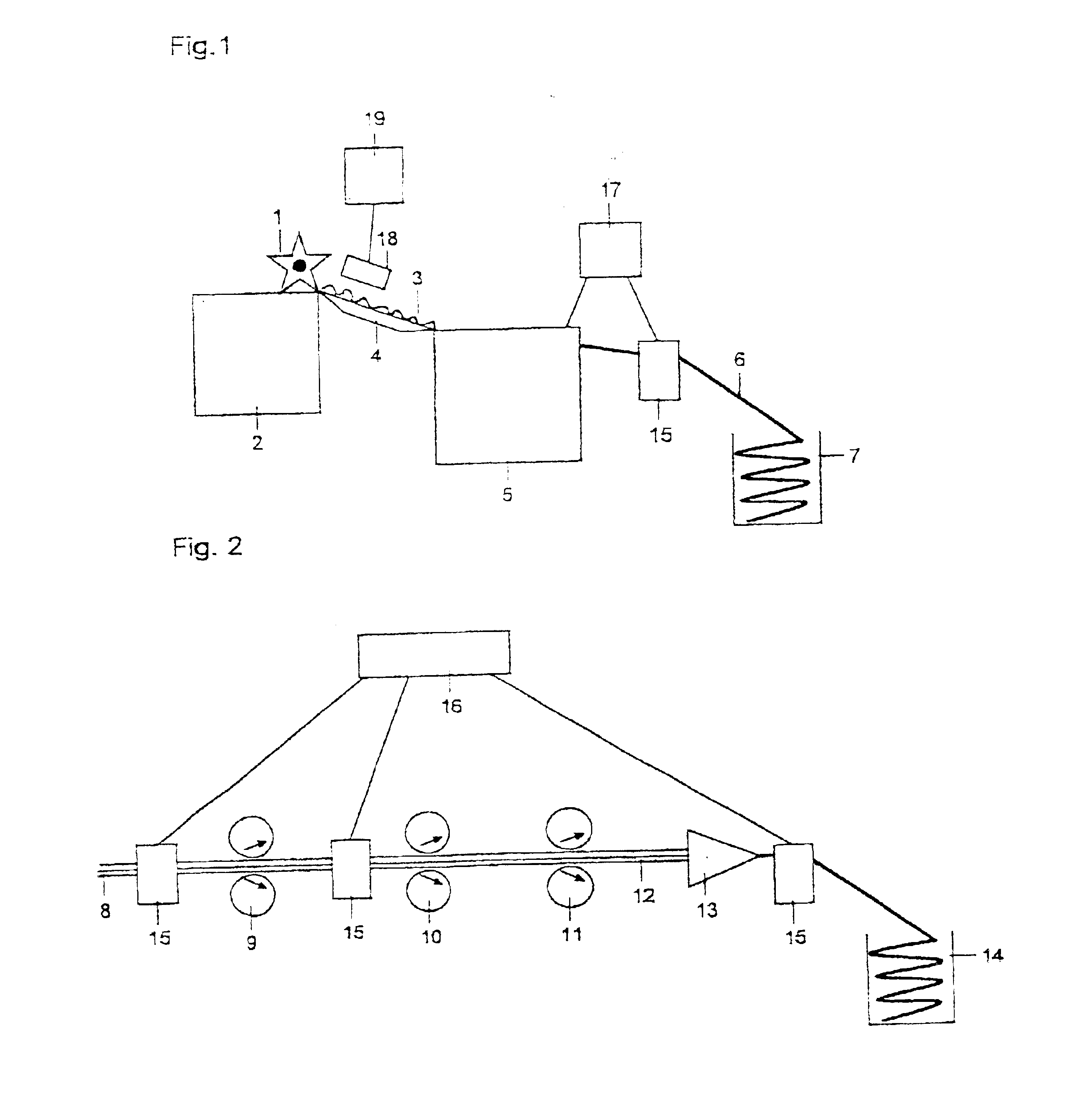

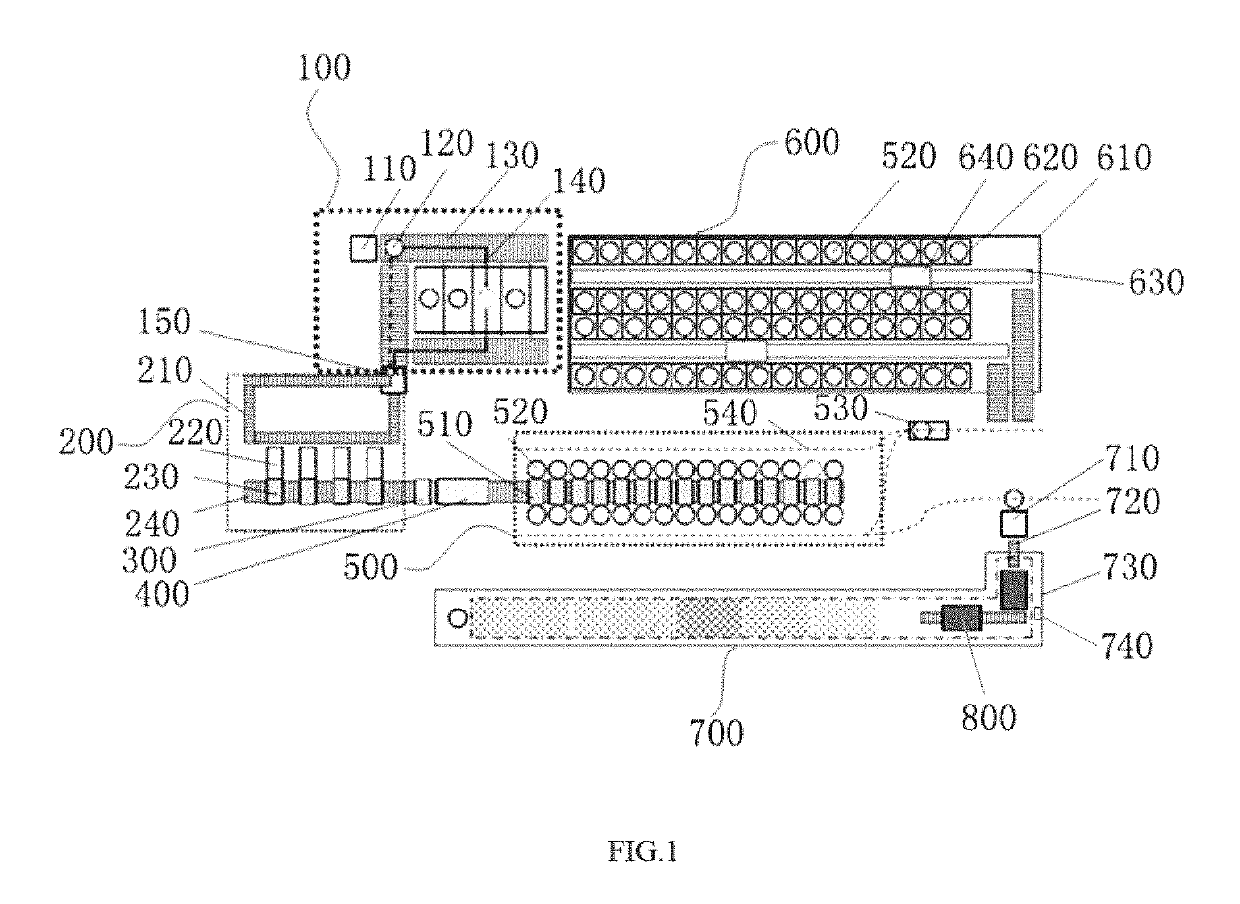

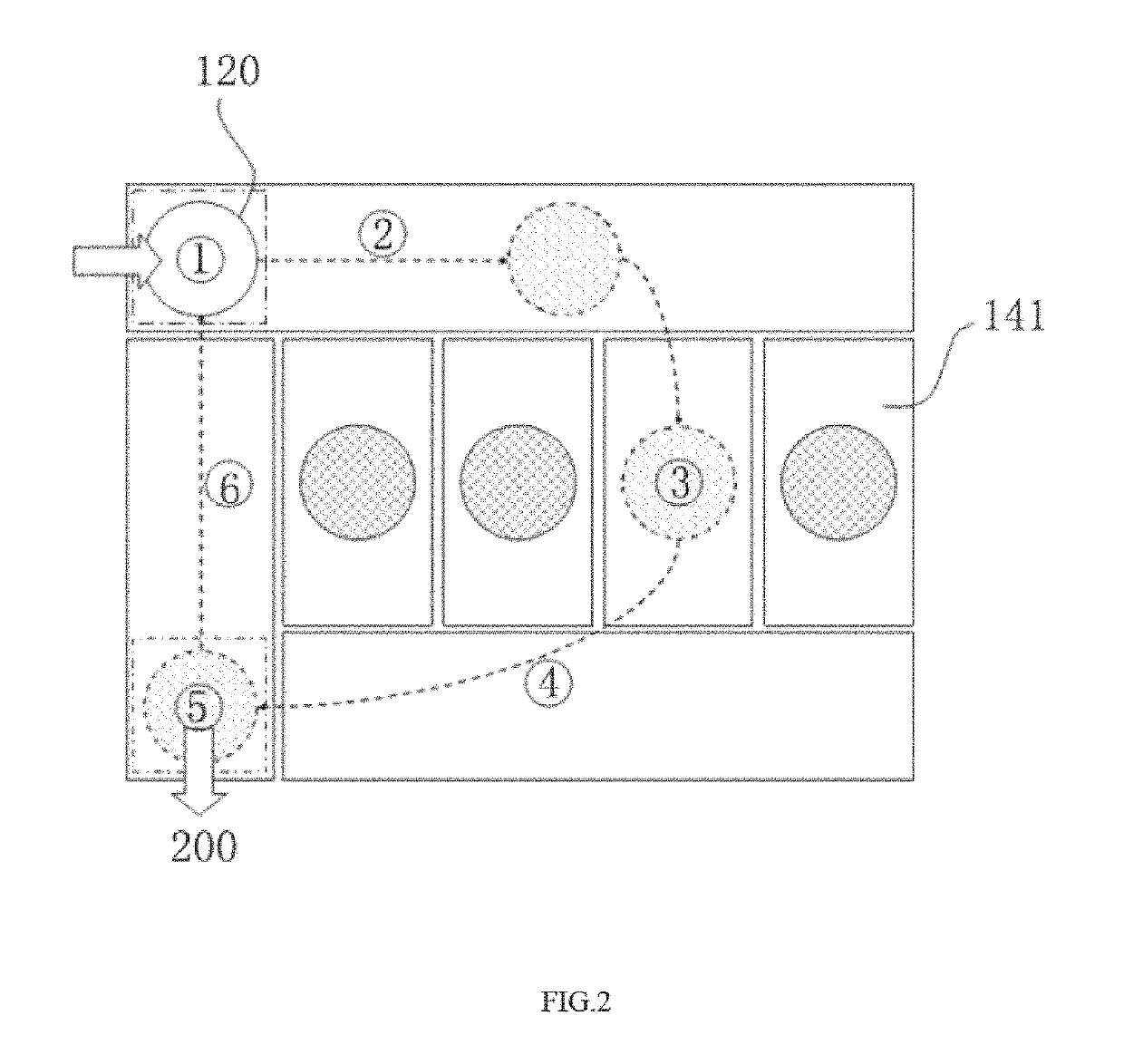

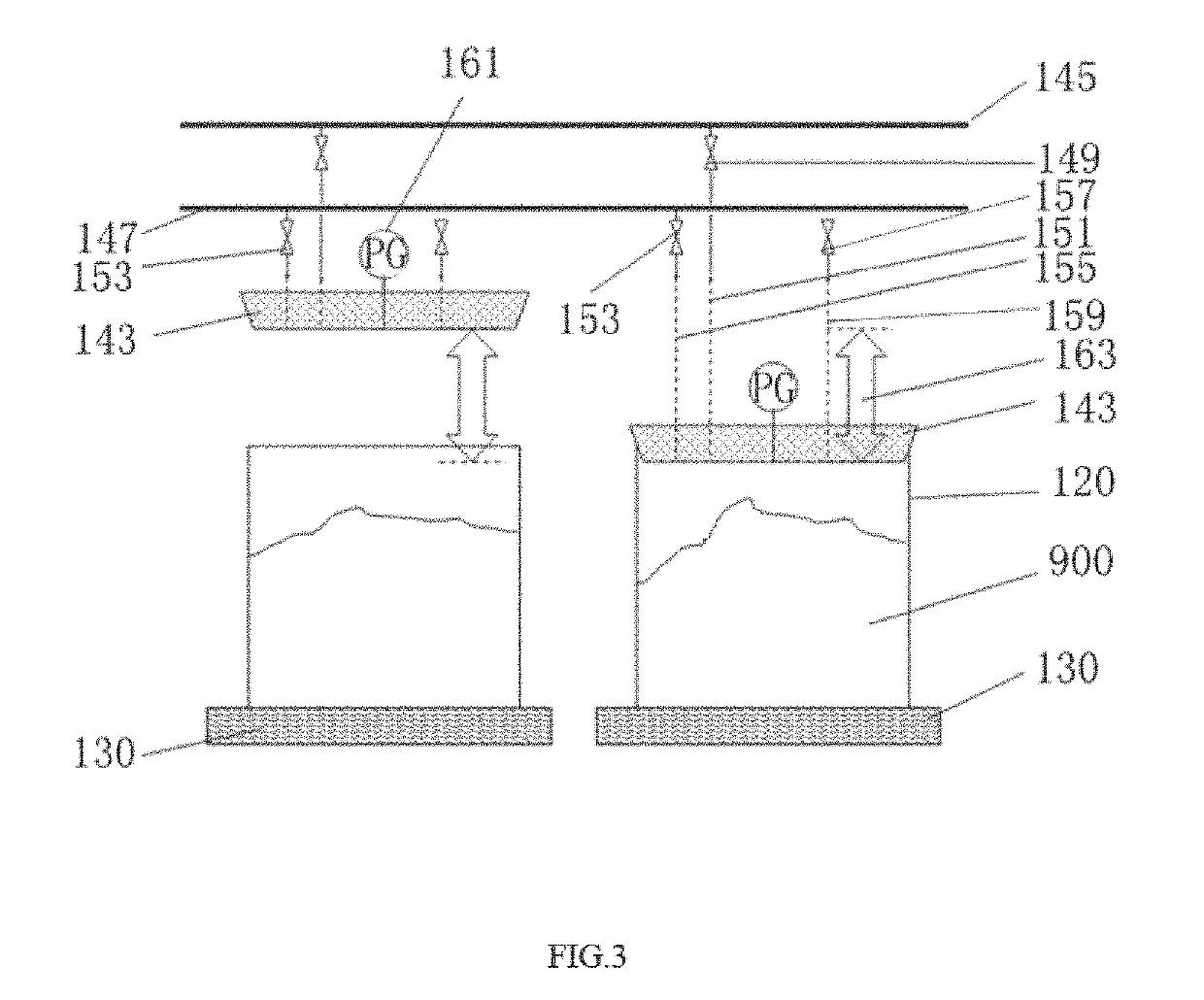

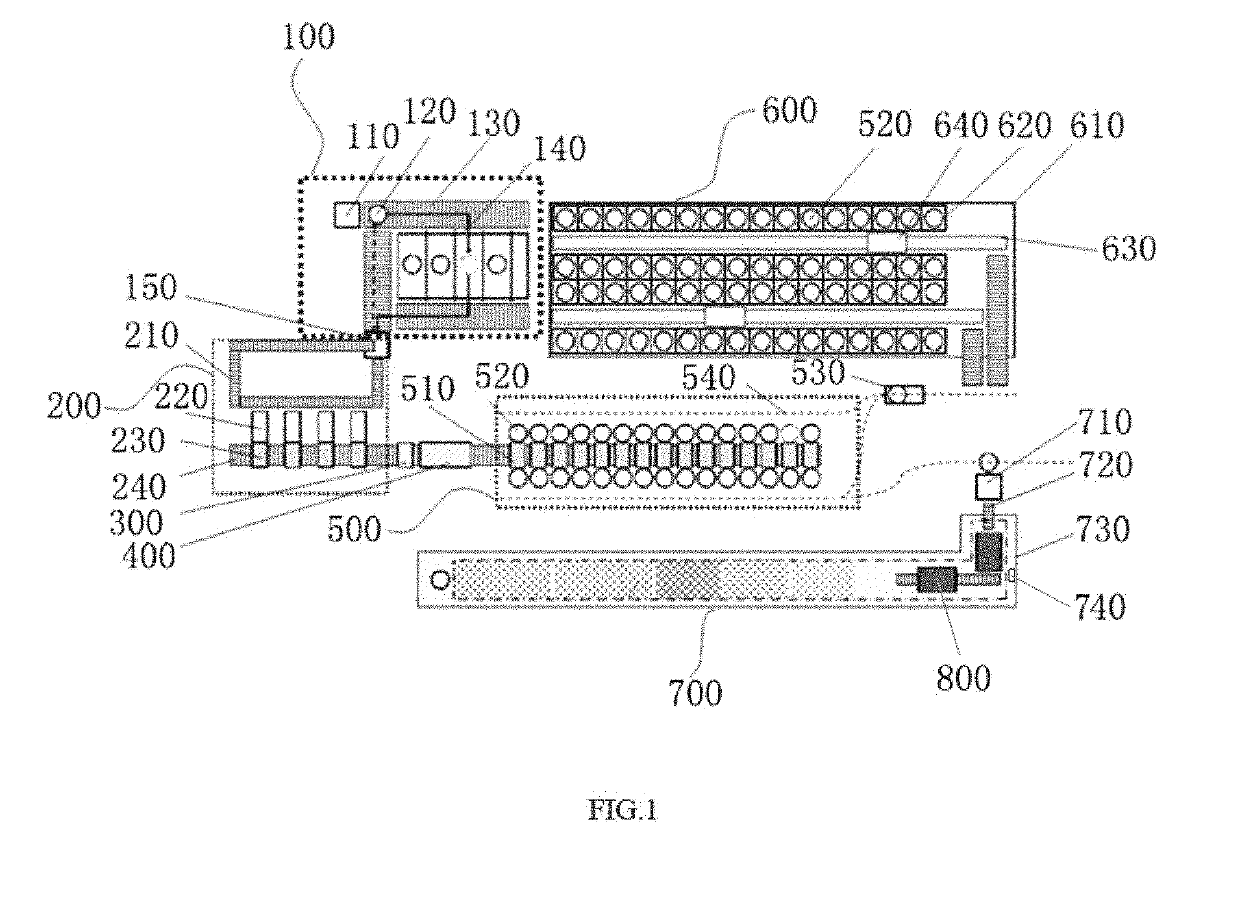

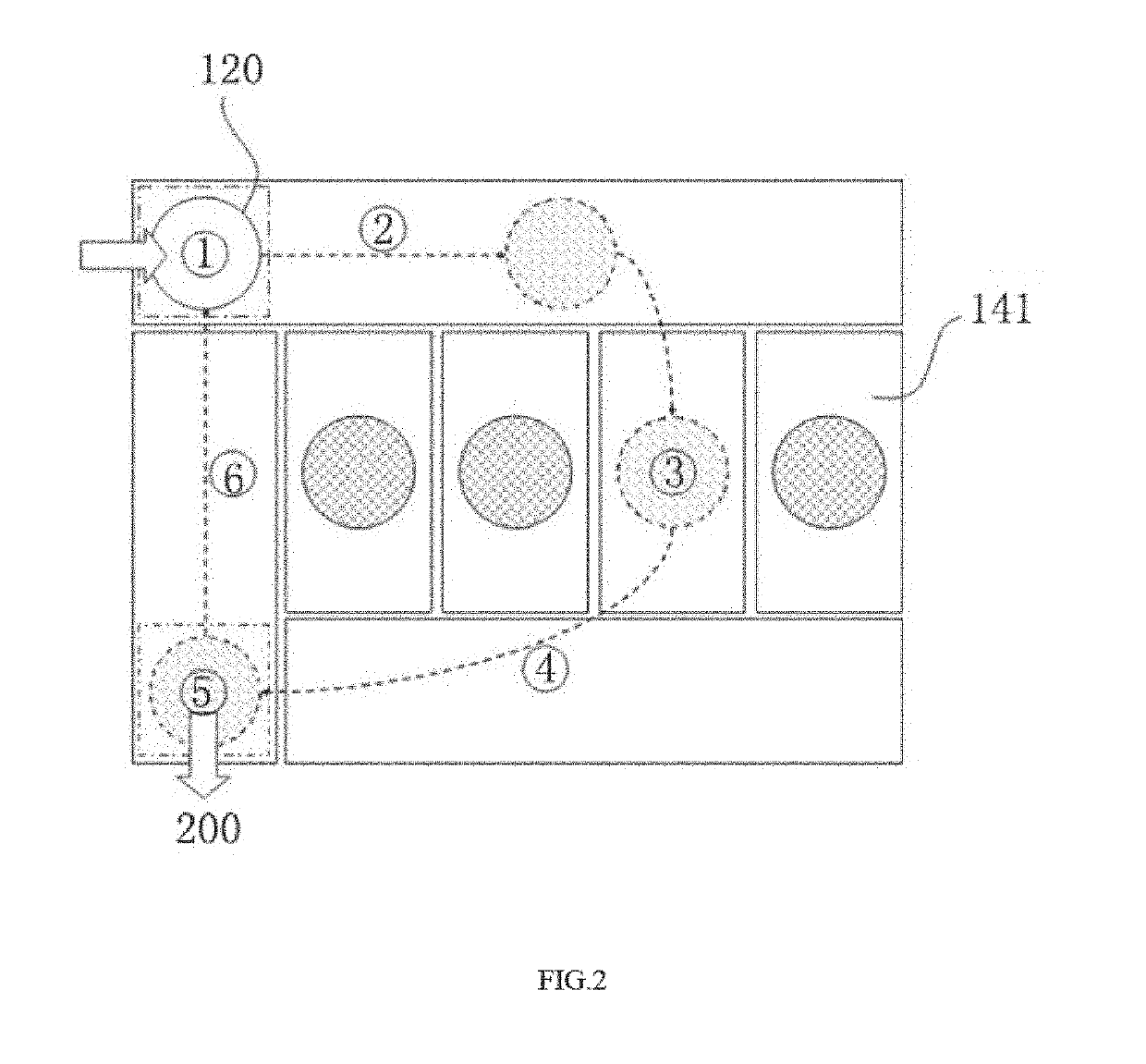

System and method for recycling fibers from textiles waste

ActiveUS10458047B2Fibre cleaning and opening machine combinationsSolid waste disposalFiberPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

Microwave sensor for measuring a dielectric property of a product

InactiveUS20050179443A1Prevent crashReduce the total massSafety devices for fibre treatmentResistance/reactance/impedenceVolumetric Mass DensityHigh field

The application relates to a microwave sensor for measuring a dielectric property, especially the density and / or moisture content of a product, having a microwave resonator, wherein a product introduced into the resonator interacts with a resonant microwave field generated in the resonator in order to determine suitable measured quantities, and is characterised in that at least two half-waves of the electric field are formed in the resonator in one direction, the product feed being effected in at least one region of high field intensity of one of the half-waves of the electric field.

Owner:TRUETZSCHLER GMBH & CO KG

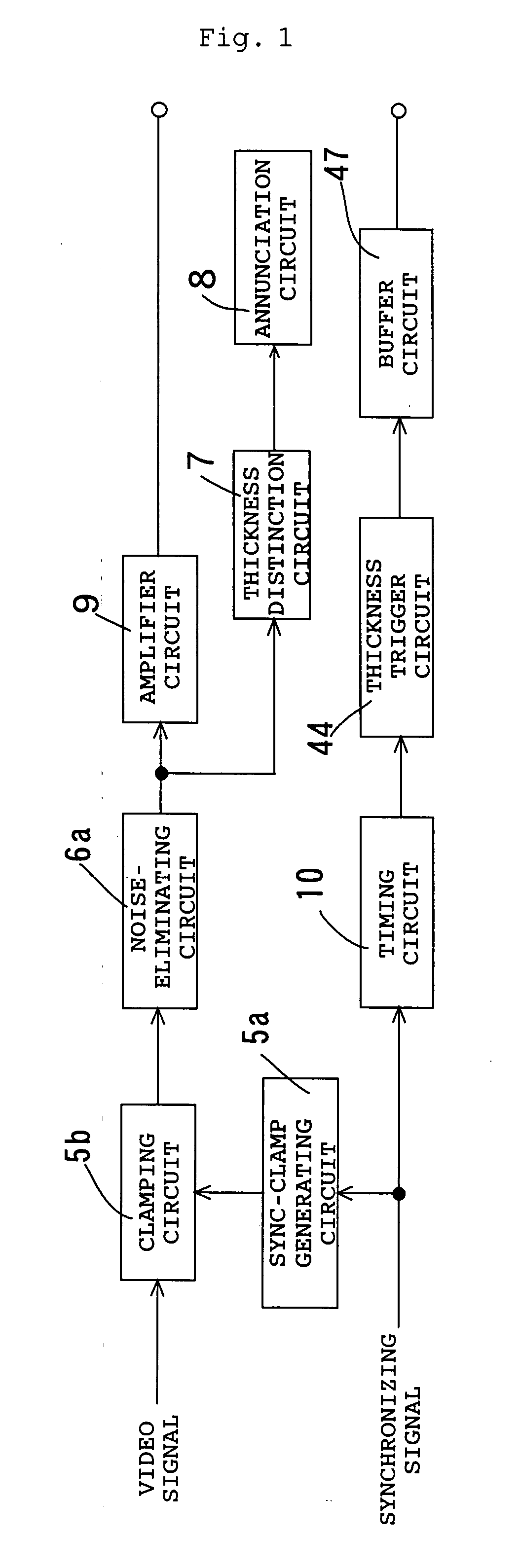

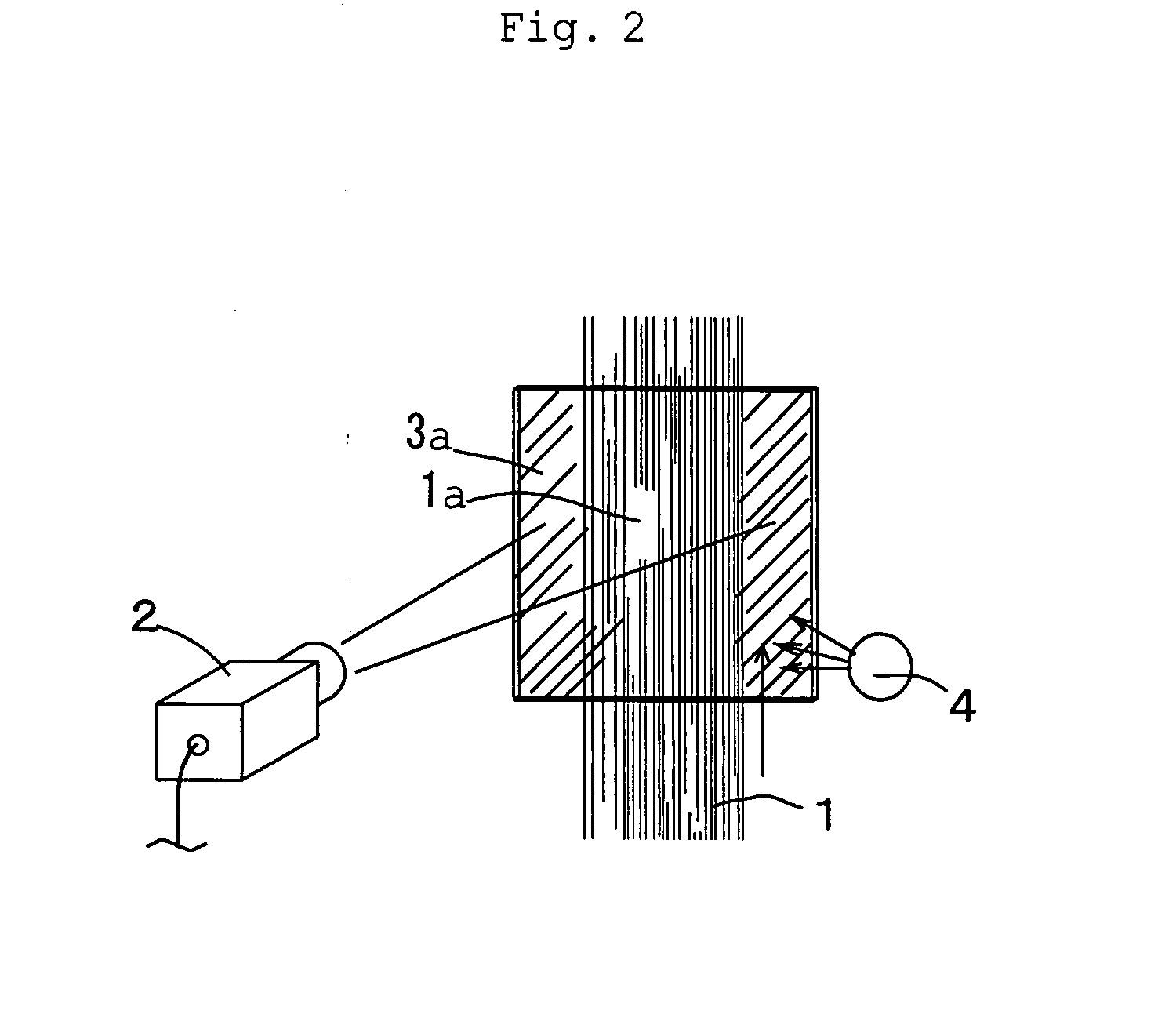

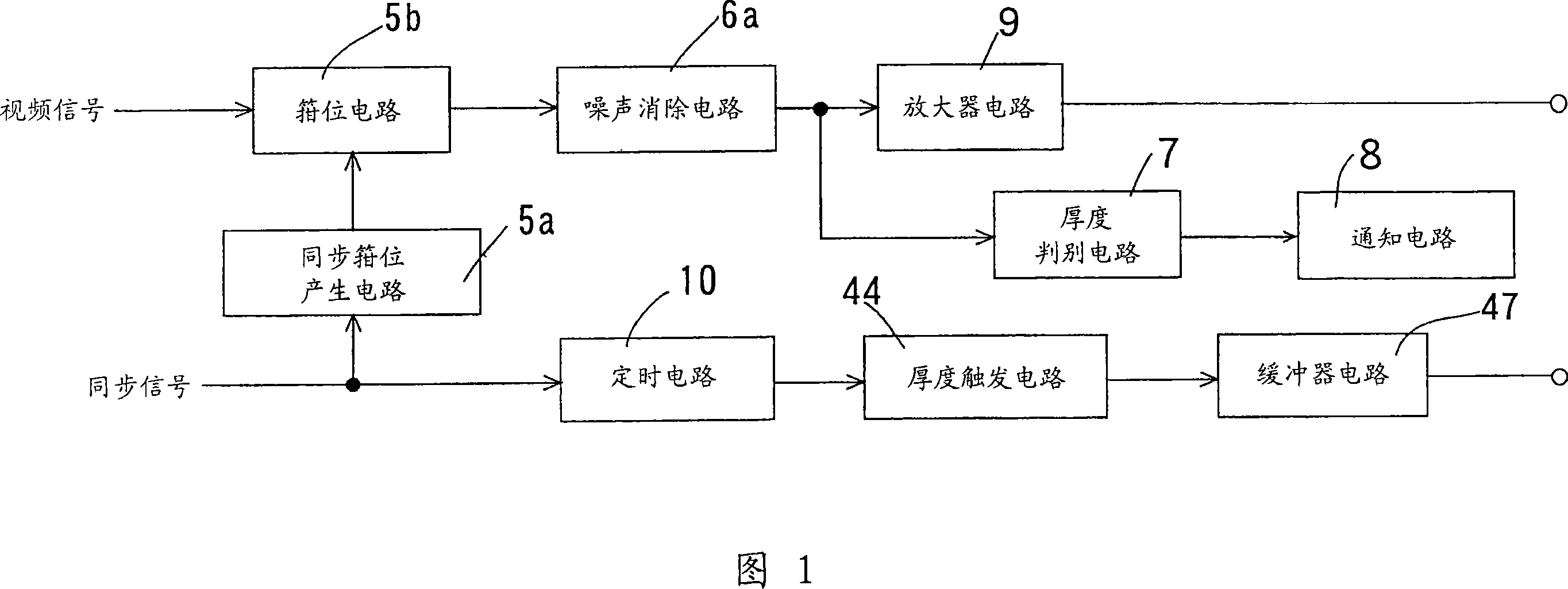

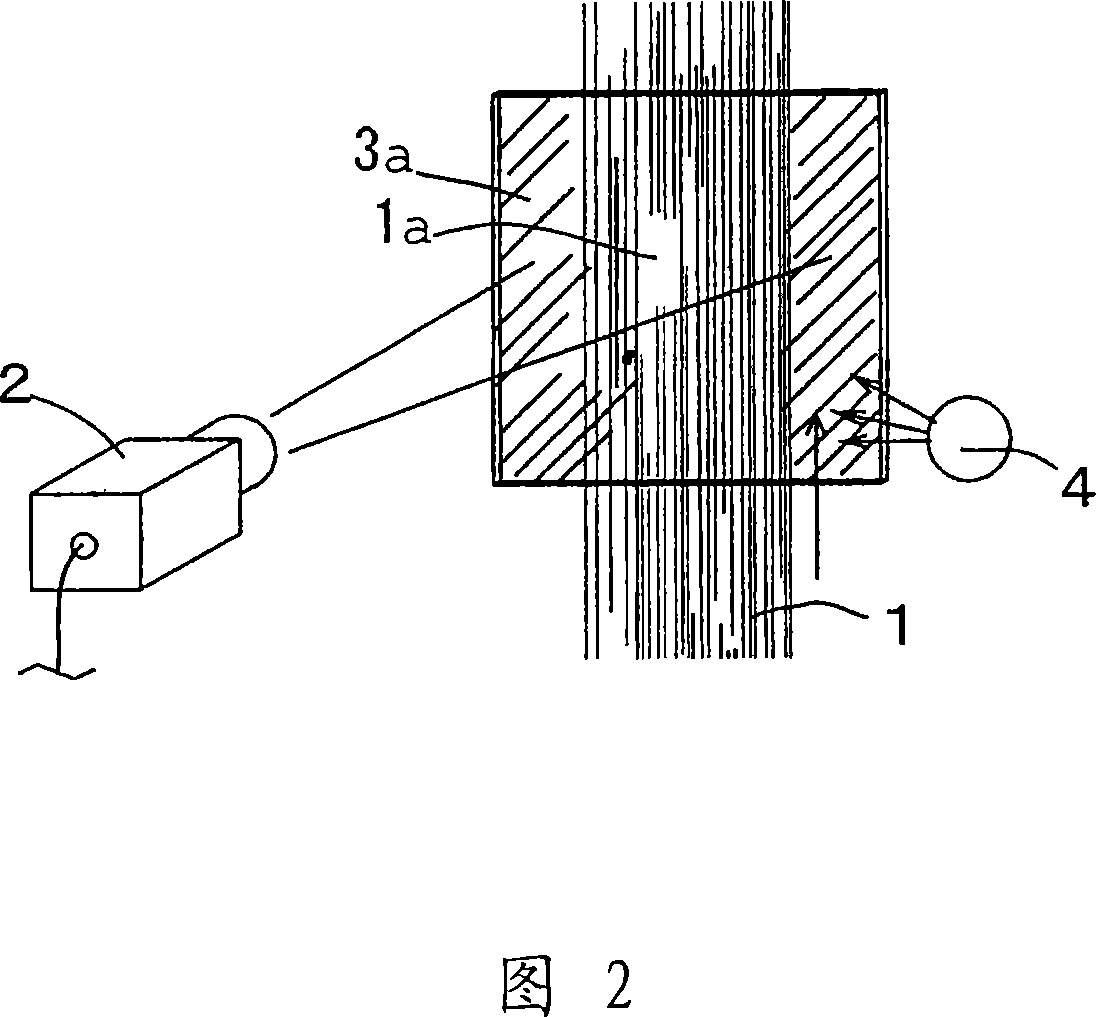

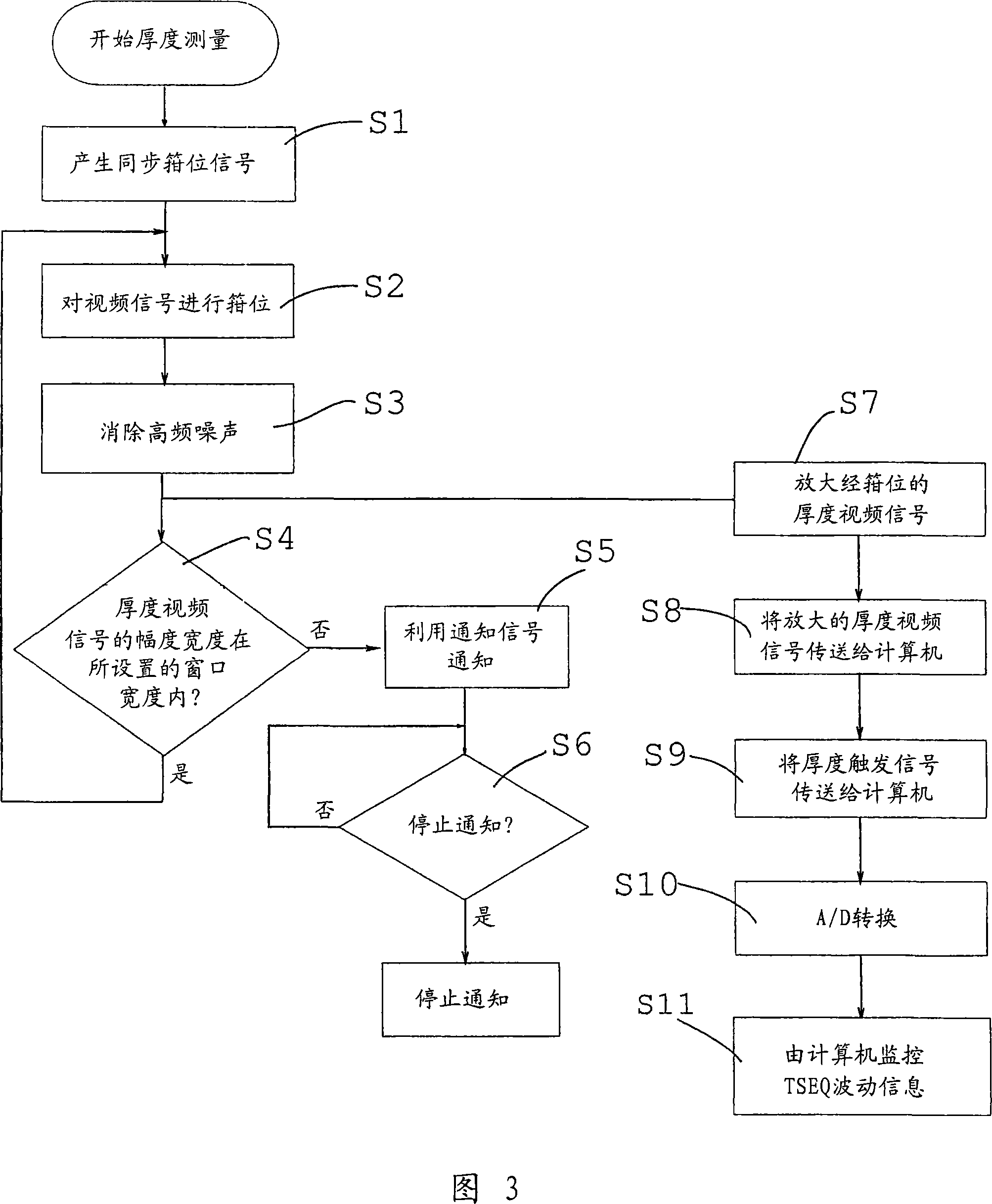

Auto Distinction System And Auto Distinction Method

InactiveUS20070286471A1Efficient extractionIncrease speedSafety devices for fibre treatmentInspecting textilesLine sensorEngineering

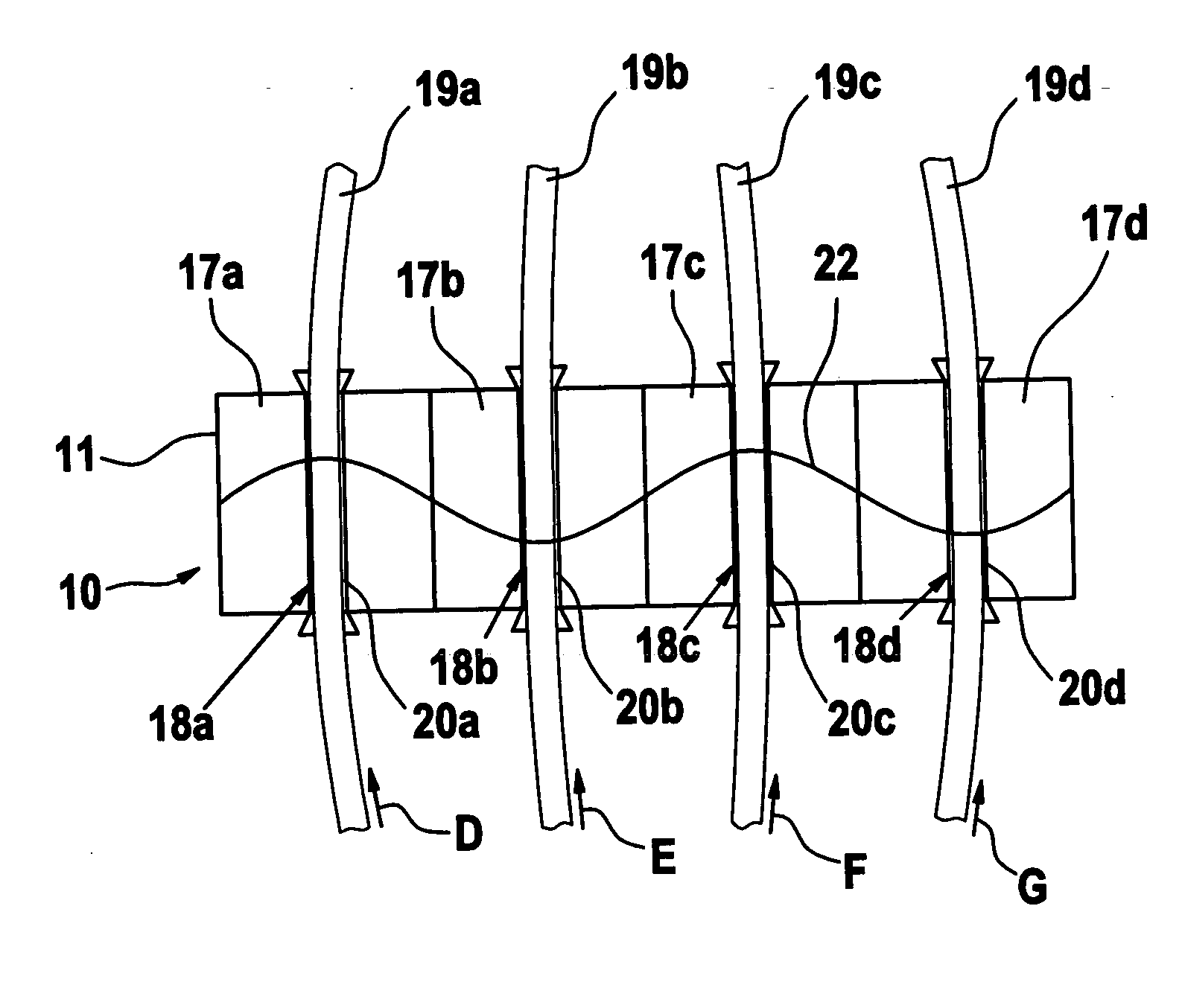

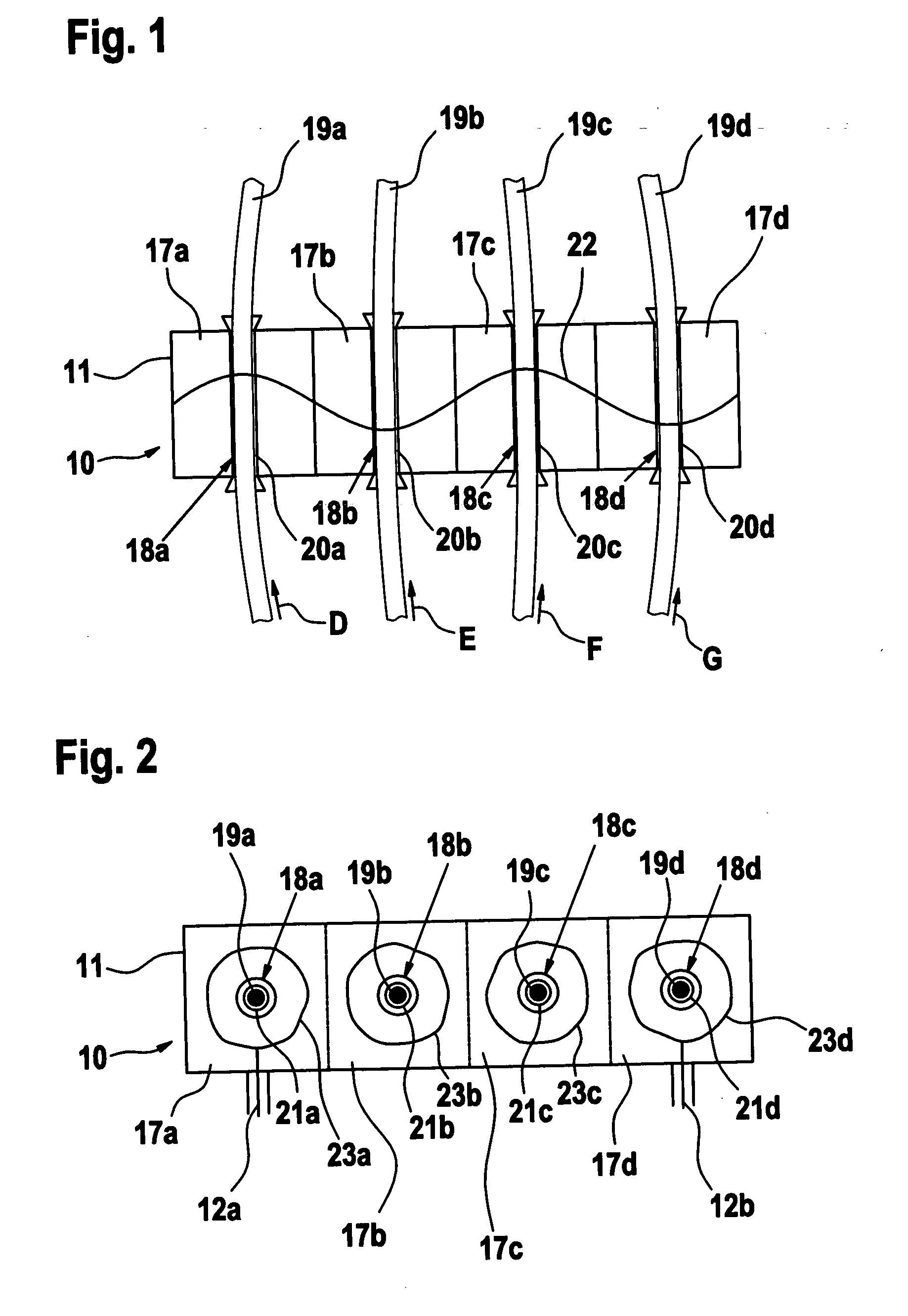

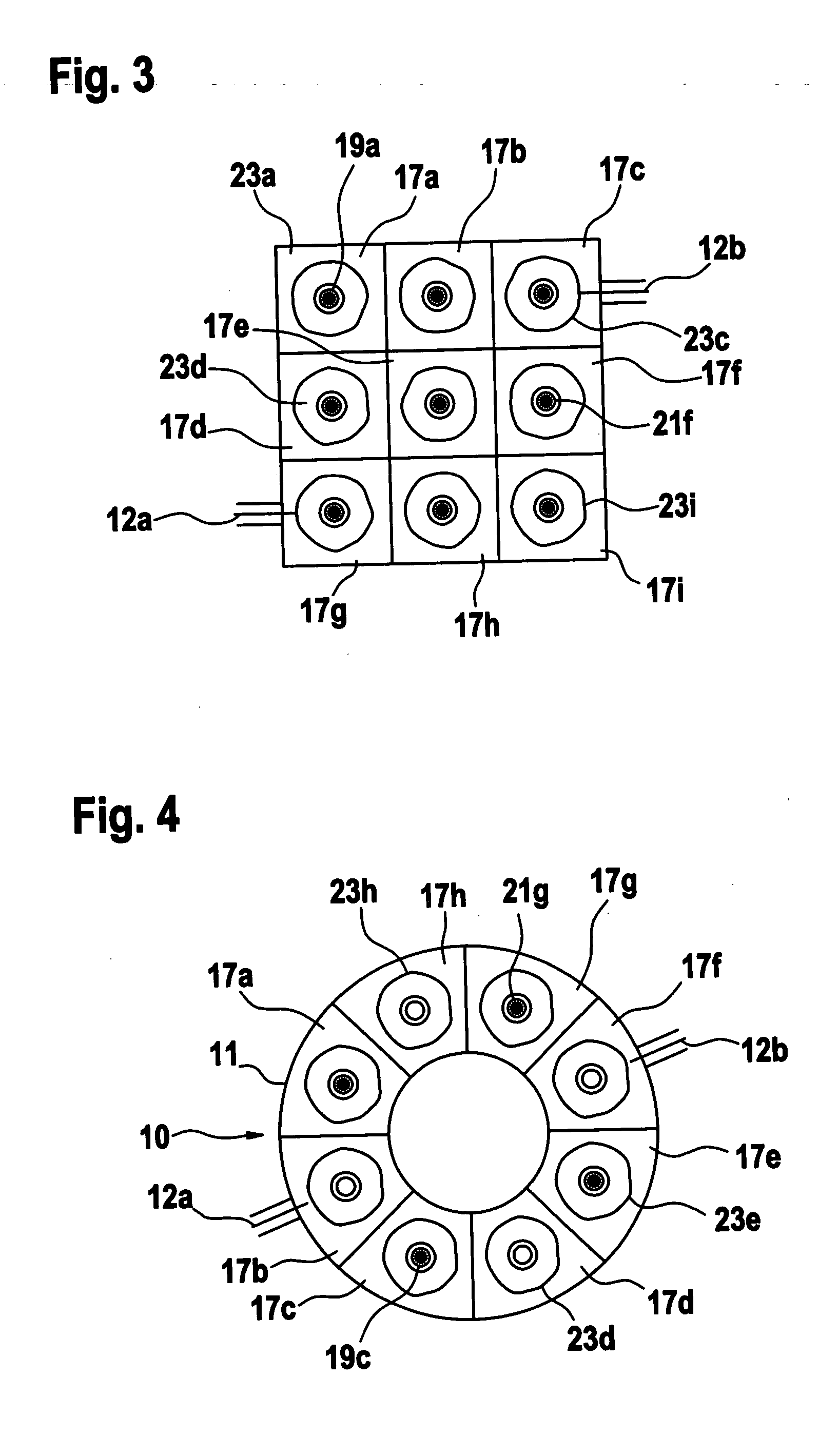

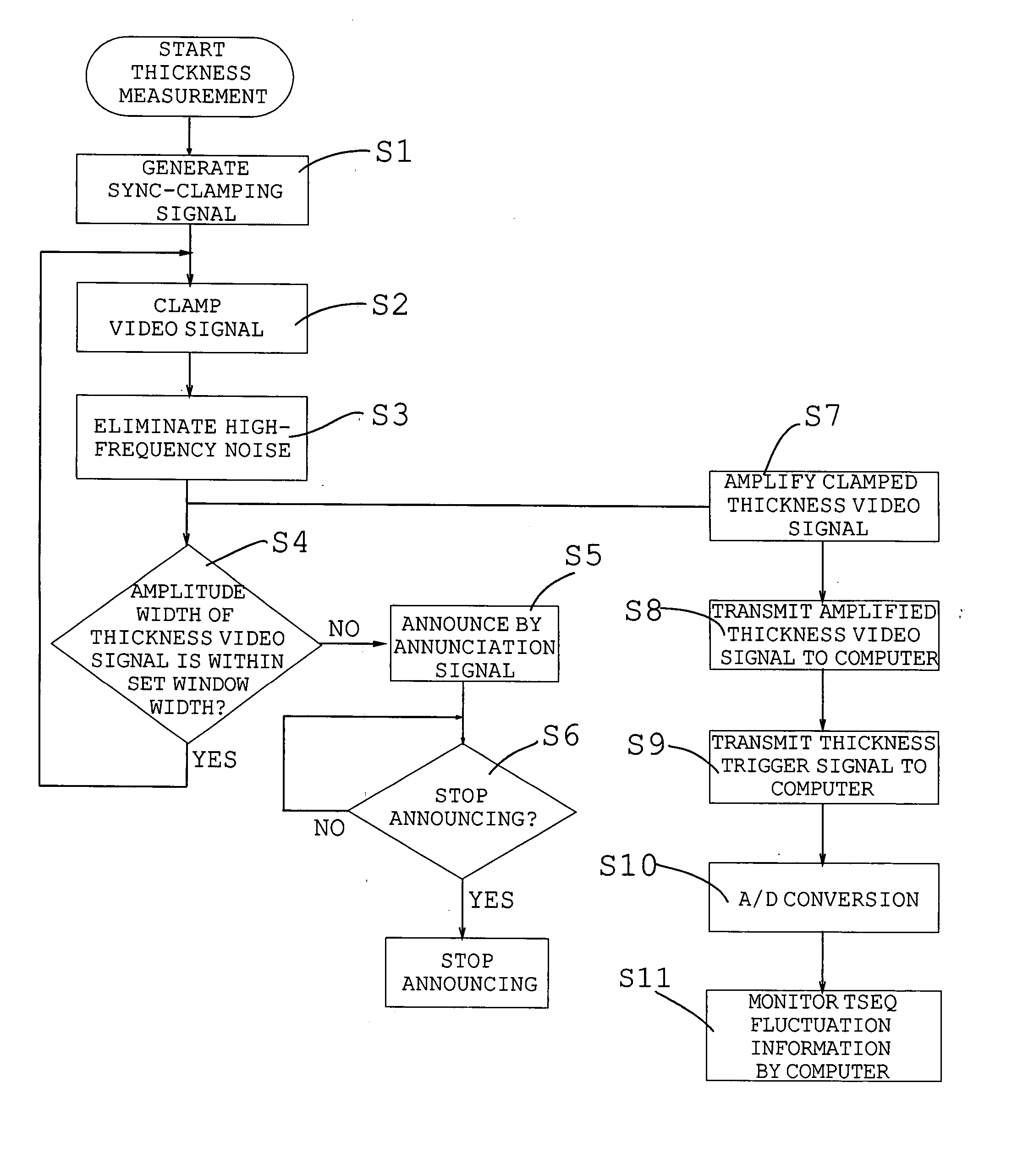

The present invention provides an auto distinction system and an auto distinction method with which suitability of a width, a thickness, and a stain of a continuously moving assembled fiber band can be accurately distinguished. An assembled fiber band such as a filter tow which continuously moves on the front side of a background plate is imaged by a line sensor. Based on the produced video signal, a characteristic information containing a defect information concerning a thickness, a width, and a stain of the assembled fiber band is detected, and the defect information is extracted from the characteristic information. Thus suitability of the assembled fiber band is distinguished. For example, the video signal is supplied to a noise-eliminating circuit 6a and a defect signal concerning the thickness of the assembled fiber band is extracted. Based on the extracted signal and a reference signal with respect to the information, suitability of the defect information is distinguished by a distinction circuit 7. When the results of distinction are defective, the results are announced by an annunciation circuit 8. The video signal may be clamped by a clamping circuit 5b, and based on the clamped video signal, the defect information of the assembled fiber band may be extracted. The characteristic information or the defect information may be supplied to an external computer and used for process control.

Owner:DAICEL CHEM IND LTD

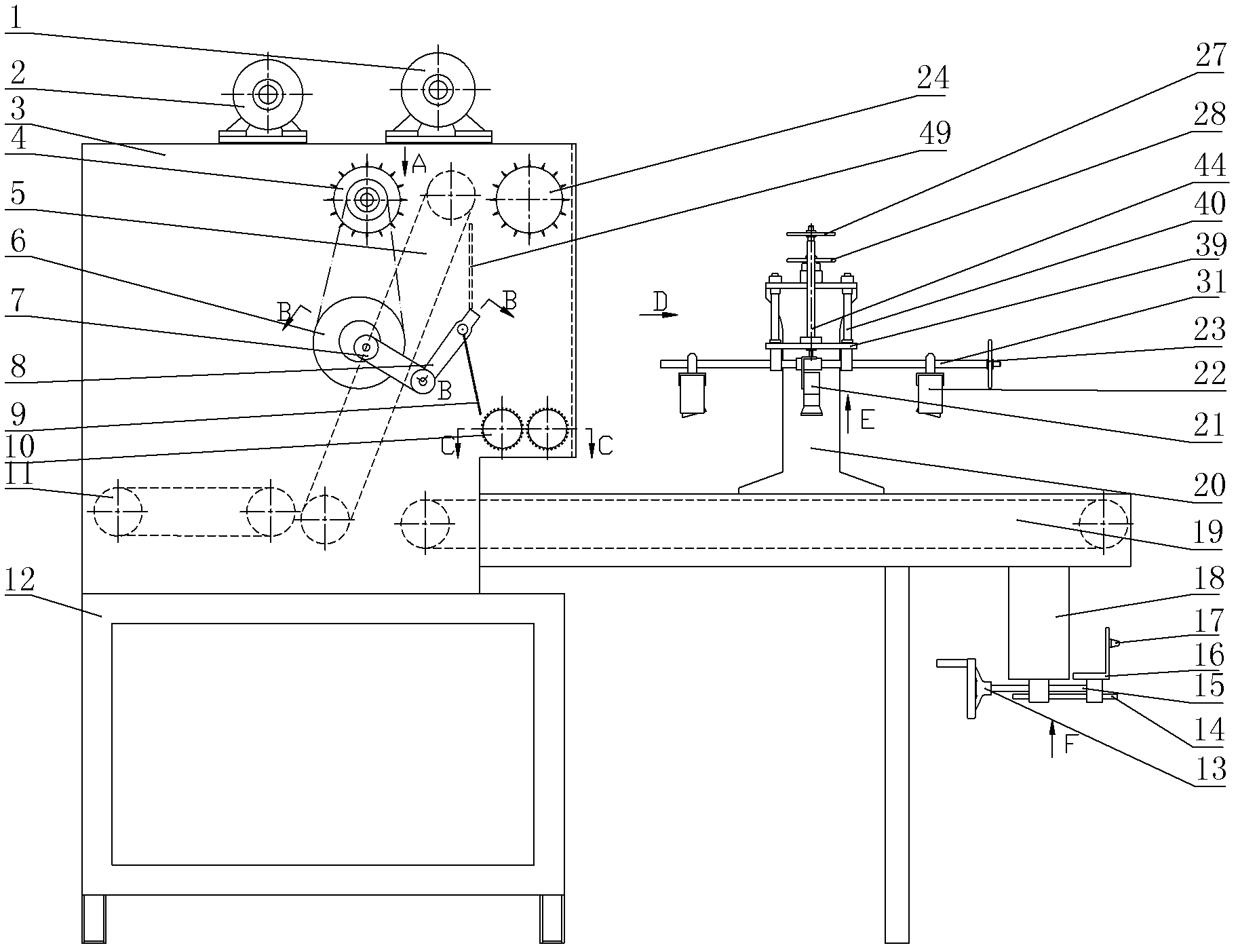

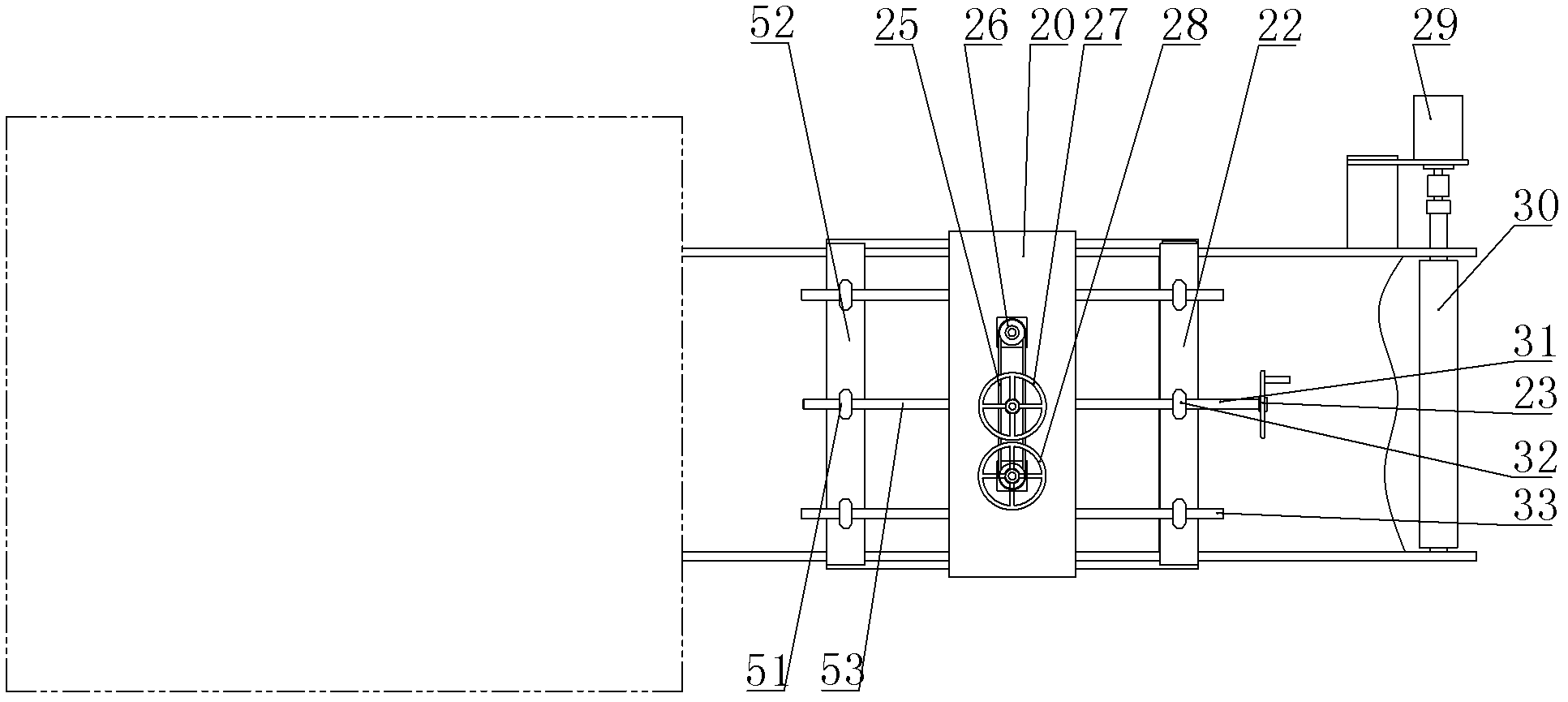

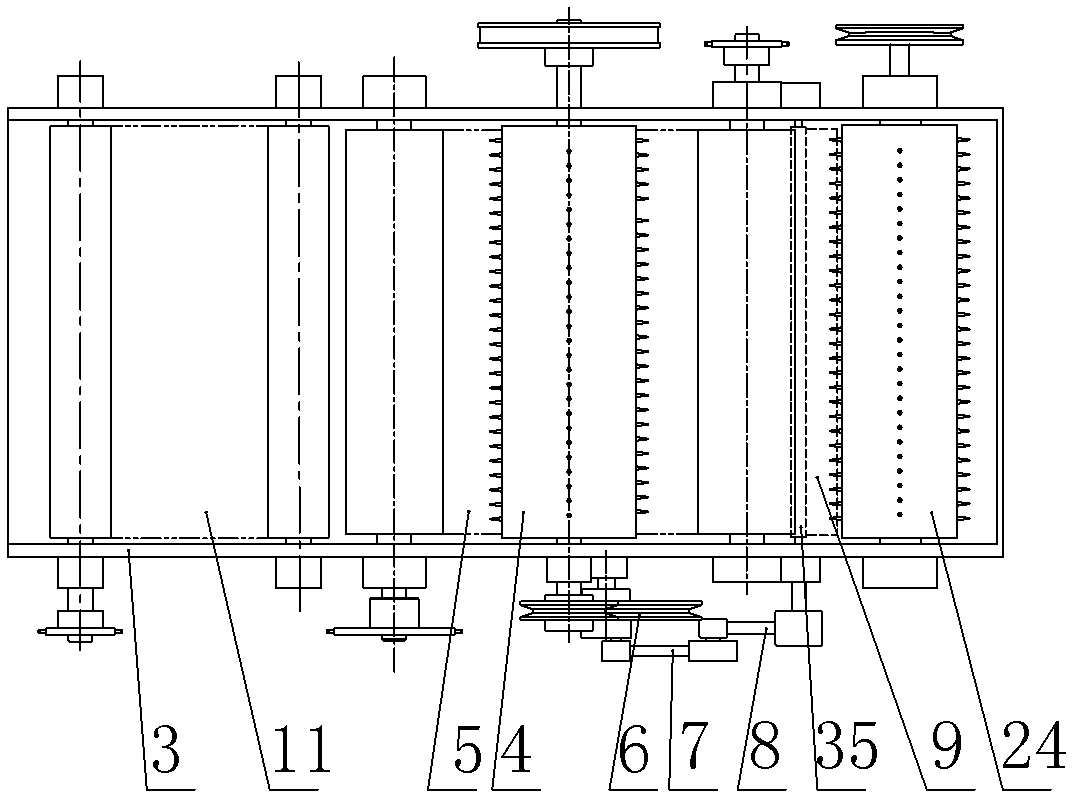

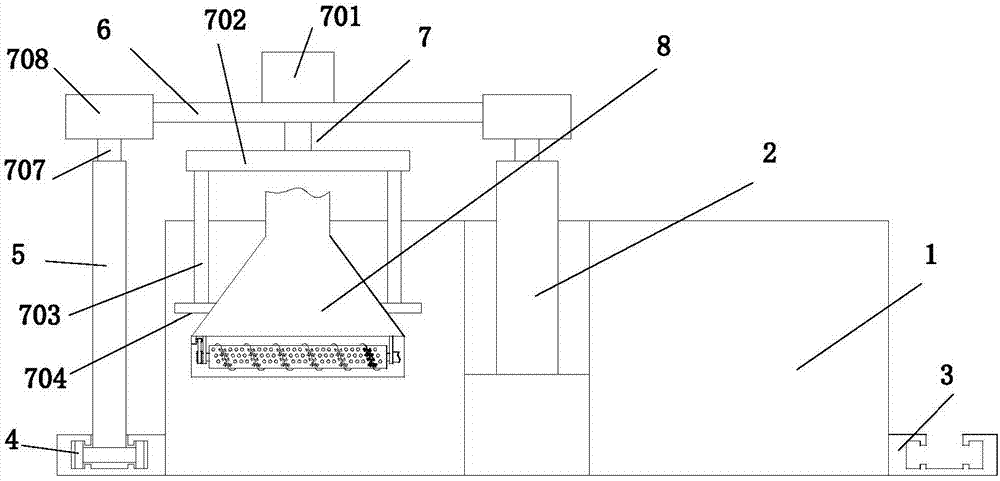

Device and method for detecting foreign fibers in raw cotton

The invention discloses a device for detecting foreign fibers in raw cotton. The device comprises a mechanical part and a control part; the mechanical part comprises a machine frame, a paving mechanism, a discharging conveying belt, a detection mechanism and a pneumatic removal mechanism; the feed end of the discharging conveying belt is positioned below the discharging end of the paving mechanism; the detection mechanism comprises a charge coupled device (CCD) camera and an illumination mechanism and is positioned above the middle part of the discharging conveying belt; the pneumatic removal mechanism is positioned below the discharging end of the discharging conveying belt; the control part comprises a programmable logical controller (PLC) and a CCD image processor; the PLC controls the CCD image processor to acquire raw cotton image signals from the CCD camera; and the CCD image processor judges whether foreign fibers are mixed in the raw cotton and feeds back a judgment result to the PLC, and the PLC controls the pneumatic removal mechanism to act. The invention also discloses a method for detecting the foreign fibers in the raw cotton by using the device. By the device and the method, the foreign fibers in the raw cotton are detected and removed.

Owner:TIANJIN POLYTECHNIC UNIV

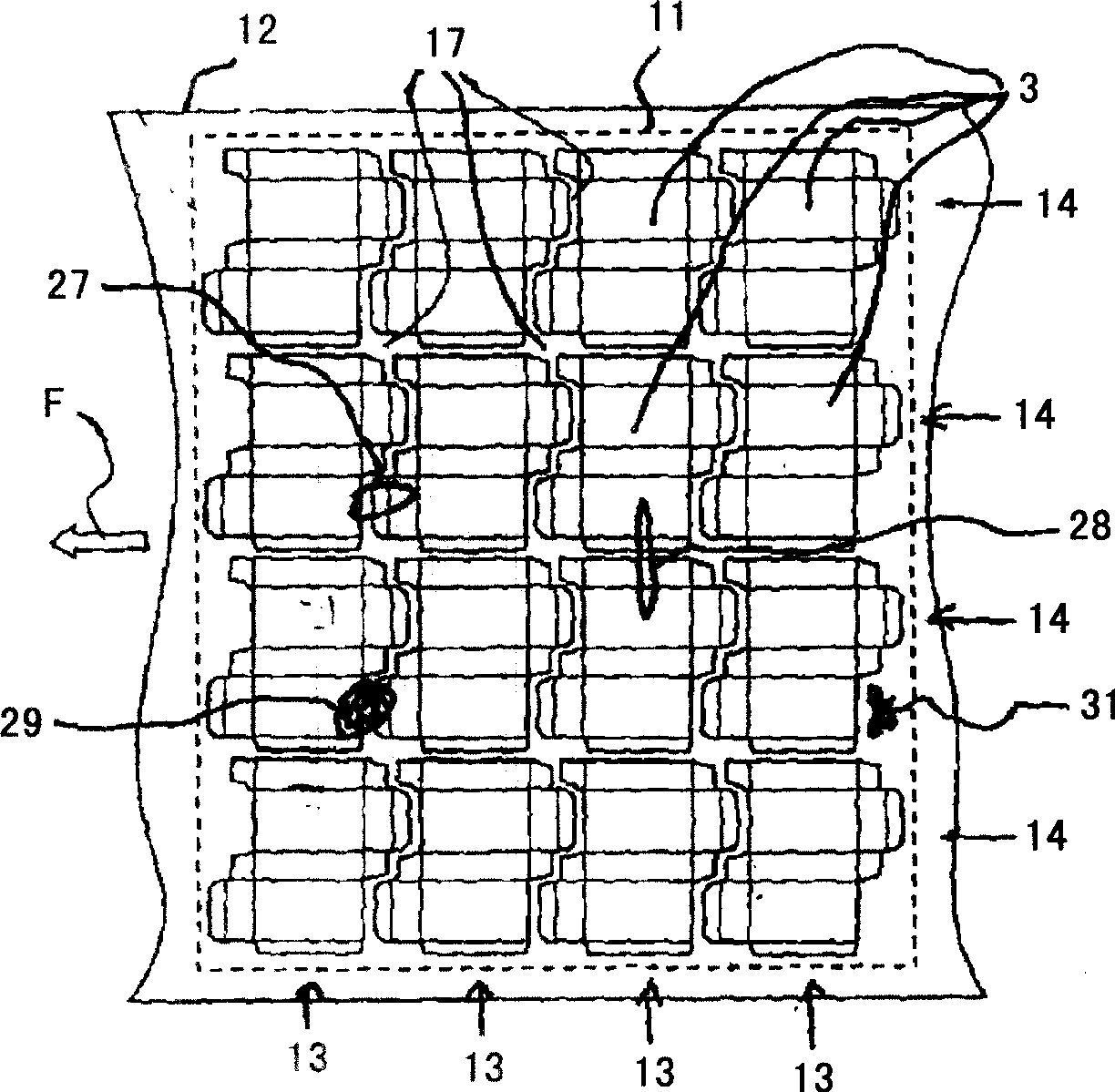

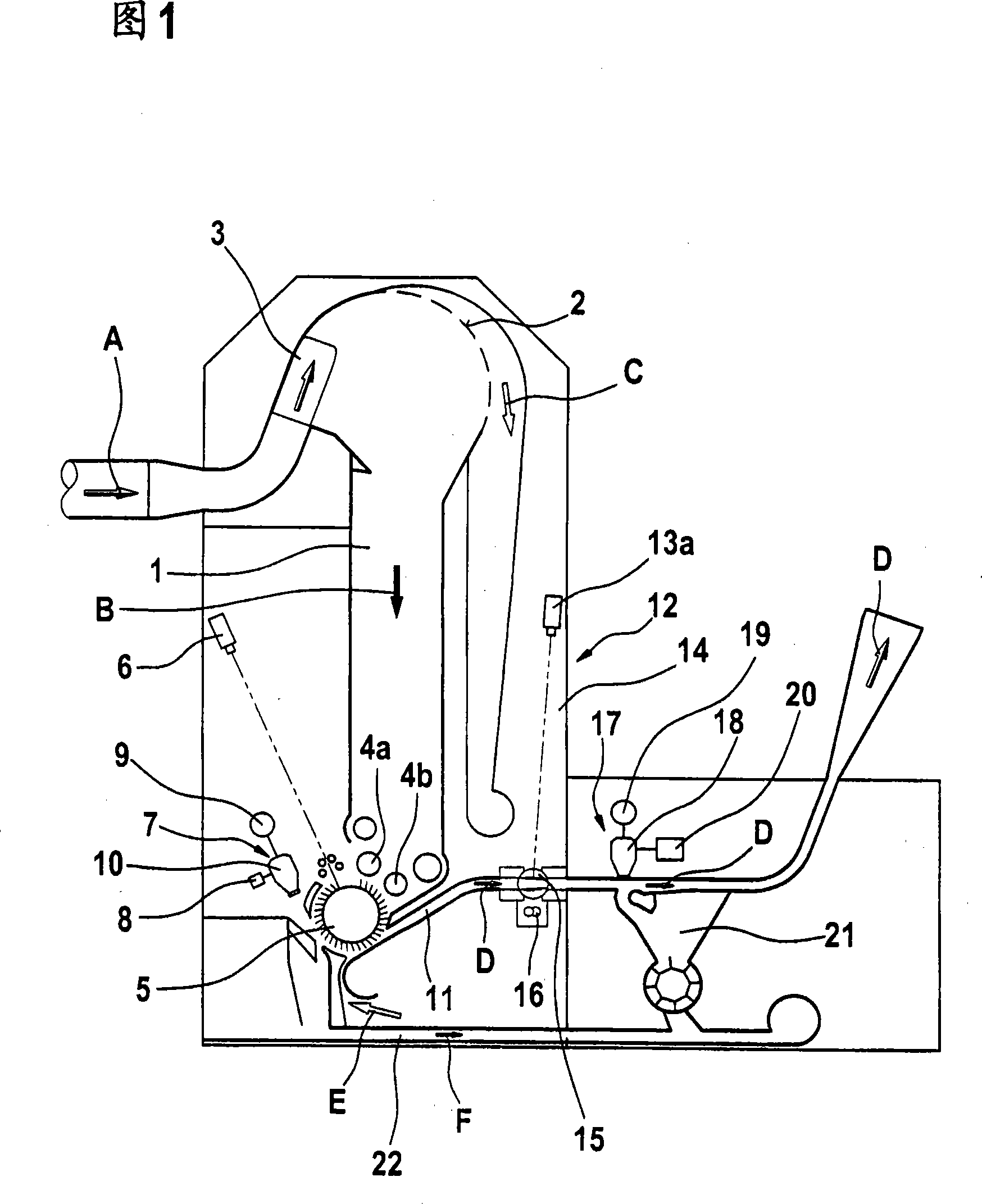

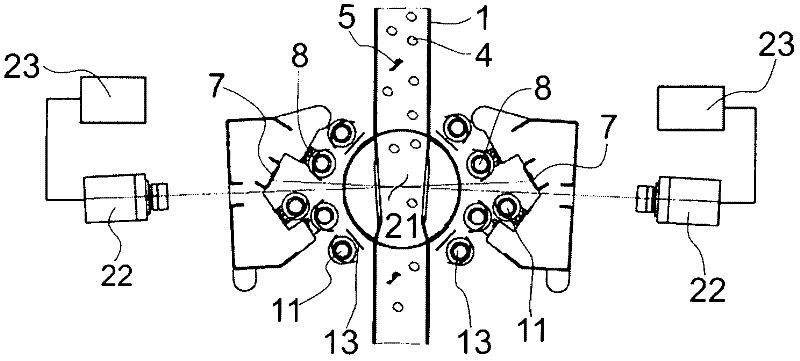

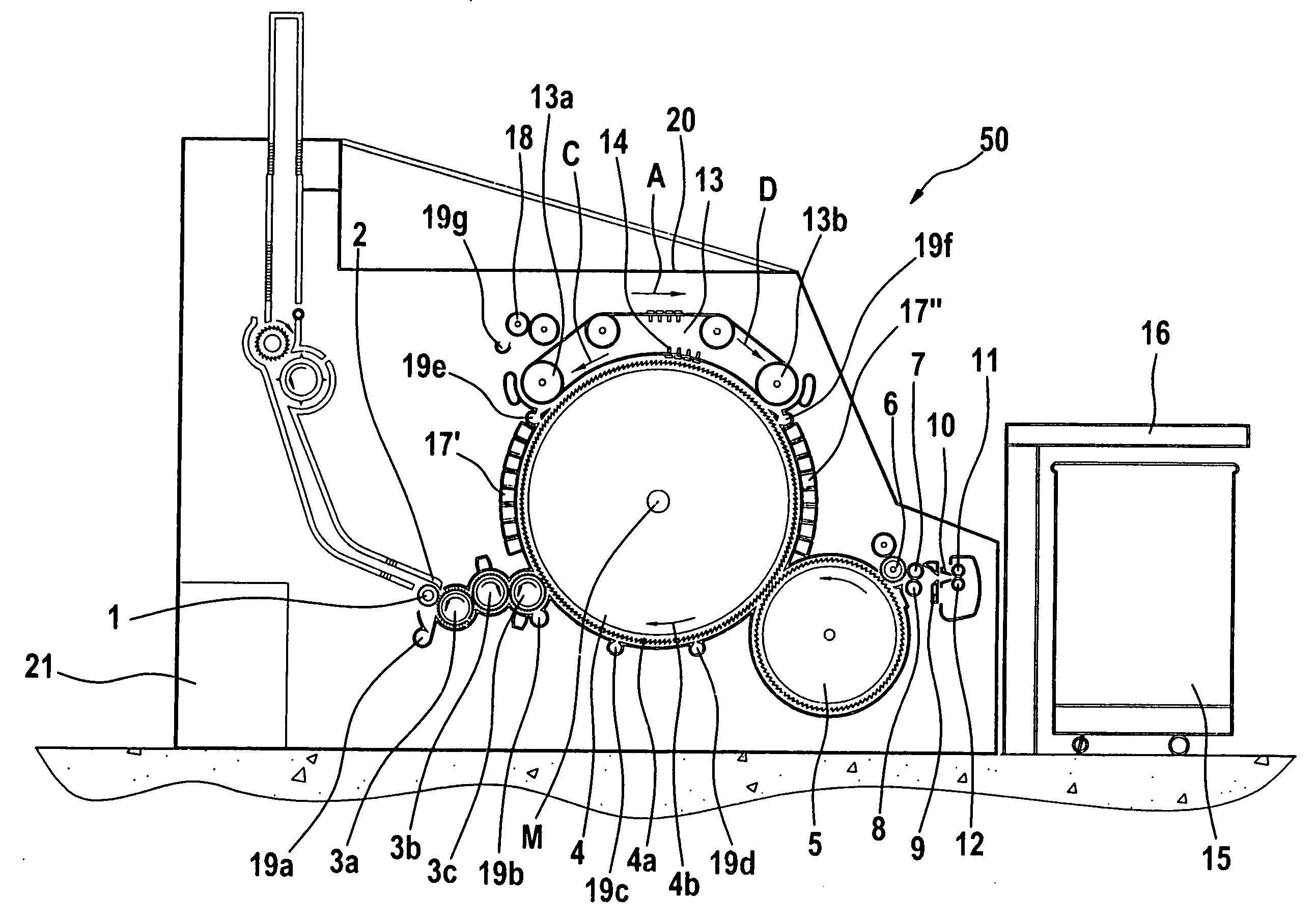

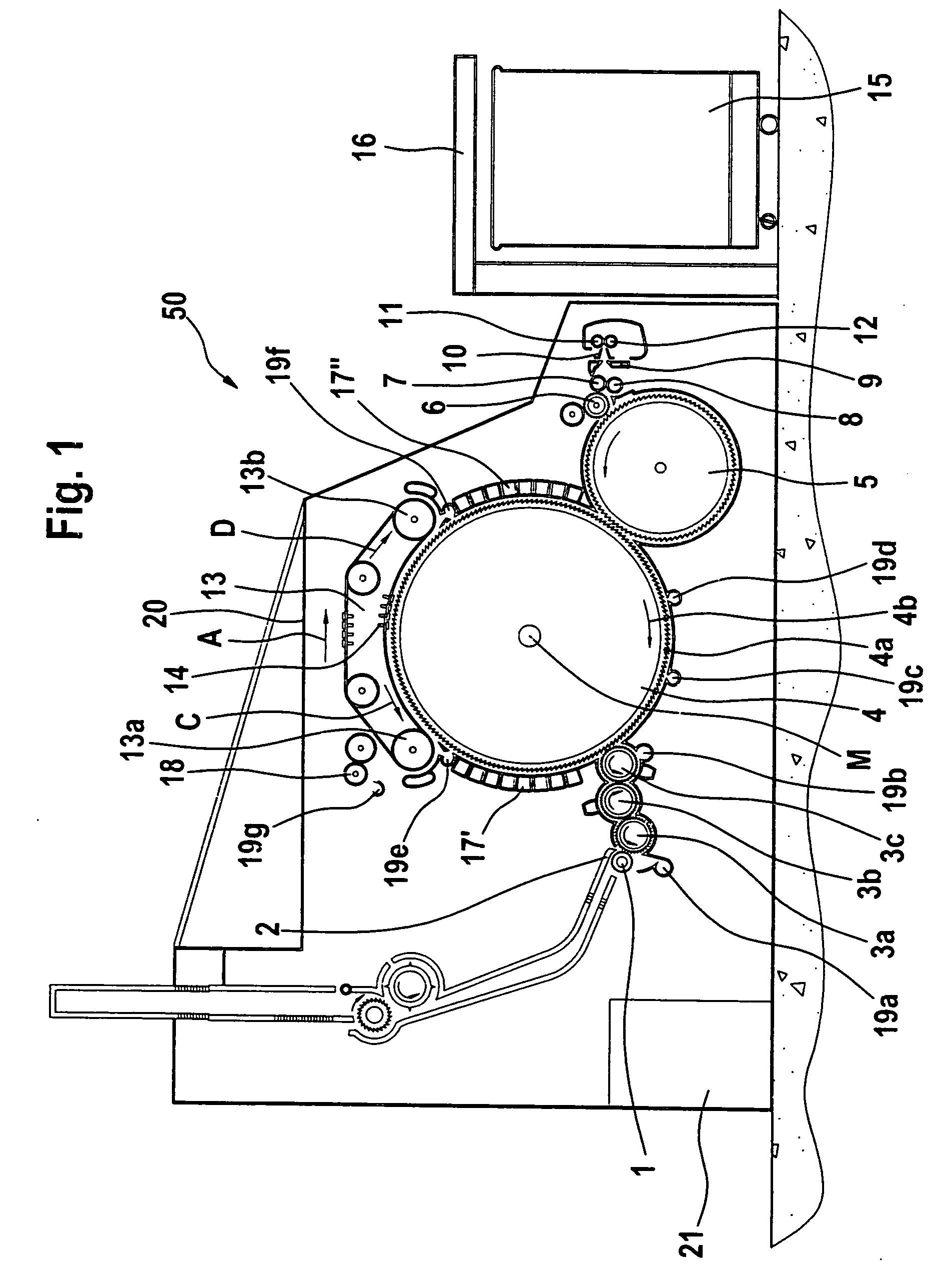

Device for cleaning and opening textile material, especially cotton at clearer, carding machine

InactiveCN1327057CEasy to separateGood effectSafety devices for fibre treatmentCarding machinesTextile fiberEngineering

In order to detect and remove interfering particles, particularly trash particles, husk naps, seed remnants and the like, from textile fiber goods, a device on a carding machine, a cleaner or the like is provided across the width of the carding machine, cleaner or the like with at least one detection device, for example, a camera with an electronic evaluation device for the detection, and a downstream-connected separating device for removing the particles. A plurality of guide elements are provided across the width, which can selectively deflect the fiber goods regions containing the interfering particles to improve the effect of the separating device in a simple manner.

Owner:TRUETZSCHLER GMBH & CO KG

Use of microwaves in the spinning industry

InactiveCN1606692AReduce integral lengthIncrease effective resolutionSafety devices for fibre treatmentTextile testingForeign matterSpinning

The invention uses microwaves in the spinning industry in order to determine the band mass of an elongated, substantially non-twisted fiber structure. In addition, a method for measuring the sliver mass from the frequency detuning and the damping of resonance signals of a microwave sensor while taking into consideration the moisture of the fiber structure with a computer is suggested. Likewise, a corresponding spinning preparation machine and a laboratory device for measuring the sliver mass are part of the invention. Lastly, a method and a spinning preparation machine for recognizing foreign matter in a moved fiber structure with the aid of microwaves is suggested.

Owner:利特英格纺织机械制造股份公司

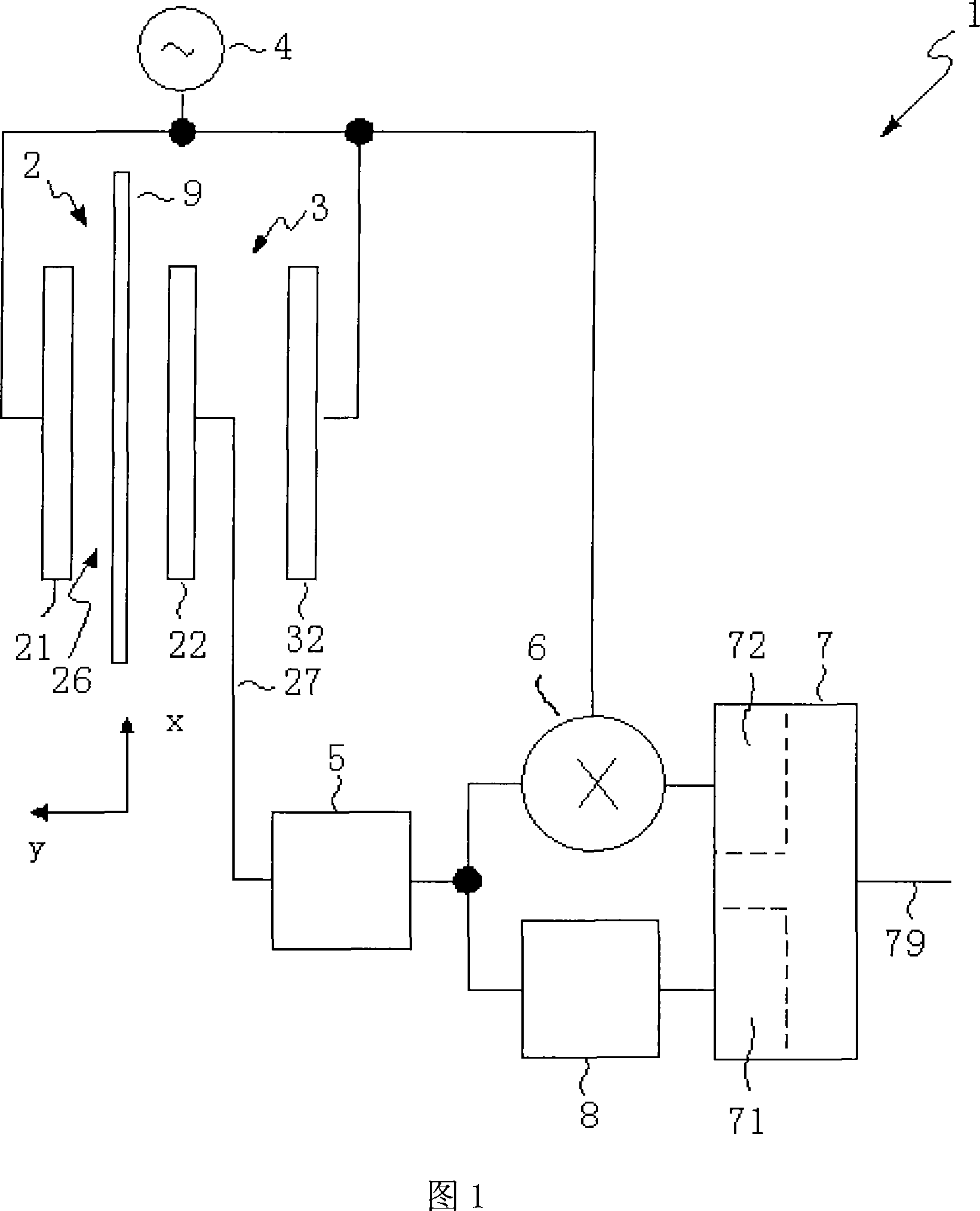

Automatic judging device and automatic judging method

InactiveCN101103246AImprove discriminationSafety devices for fibre treatmentInspecting textilesLine sensorFiber

An automatic judging device and method for precisely judging the adequateness of the width, thickness, and stain of a continuously moving fiber aggregate. A fiber aggregate such as filter tow continuously moving on the front side of a background plate is imaged with a line sensor. Characteristic information including defect information on the thickness, width, and stain of the fiber aggregate is detected according to the generated video signal, and the defect information is extracted to judge the adequateness of the fiber aggregate. For example, the video signal is fed to a noise removing circuit (6a), and a defect signal concerning the thickness is extracted. On the basis of the extracted signal and a reference signal concerning the information, a judging circuit (7) judges the adequateness of the defect information. If the fiber aggregates is judged to be defective, an annunciating circuit (8) annunciates it. The video signal is clamped by a clamp circuit (5b), and defect information on the fiber aggregate may be extracted from the clamped video signal. The characteristic information or the defect information can be given to an external computer and used for process control.

Owner:DAICEL CHEM IND LTD

Method for determining the surface quality of a support and machine for transforming the associated support

ActiveCN101393141AQuality improvementSafety devices for fibre treatmentOptically investigating flaws/contaminationMachining processComputer science

Owner:BOBST SA

Apparatus in spinning preparation for separating foreign objects at conveying equipment for fibre material

InactiveCN101230505AEasy to integrateEasy to assembleSafety devices for fibre treatmentCarding machinesWaste materialForeign body

In an apparatus in spinning preparation for separating foreign objects at conveying equipment for fibre material, at least one separation device is associated with the conveying equipment. The separation device comprises an arrangement for producing a blast of air that flows in the direction onto the conveying equipment and generates an air flow that detaches the foreign objects from the conveyed fibres and carries them away. The arrangement comprises a plurality of blast nozzles arranged across the width of the conveying equipment and connected to a compressed air pipe and to valves. To reduce the proportion of good fibres in the waste in a simple manner, and to allow a more selective action of the blast air current, a bar member for mounting the blast nozzles is present and the nozzles are integrated in the bar member.

Owner:TRUETZSCHLER GMBH & CO KG

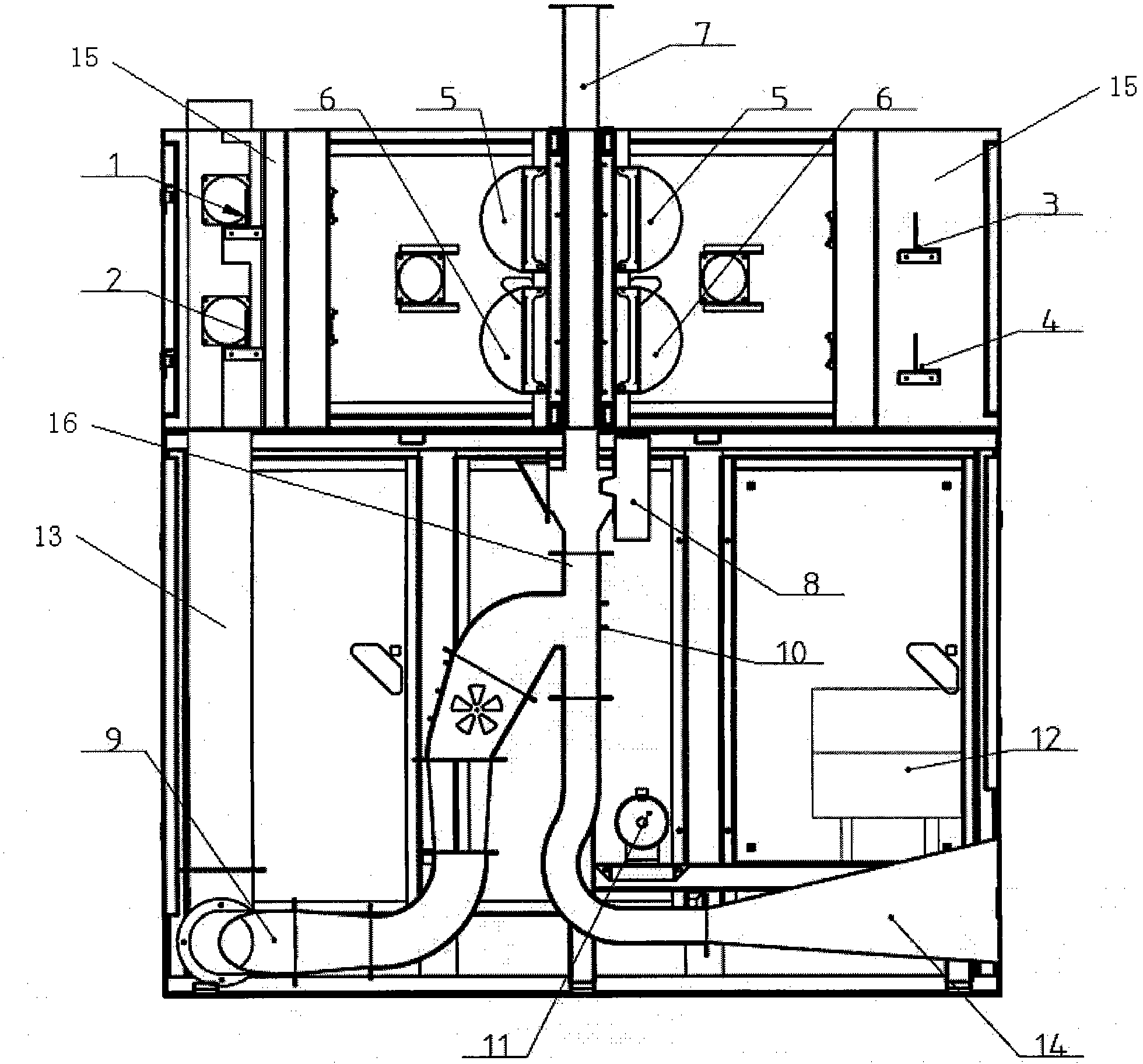

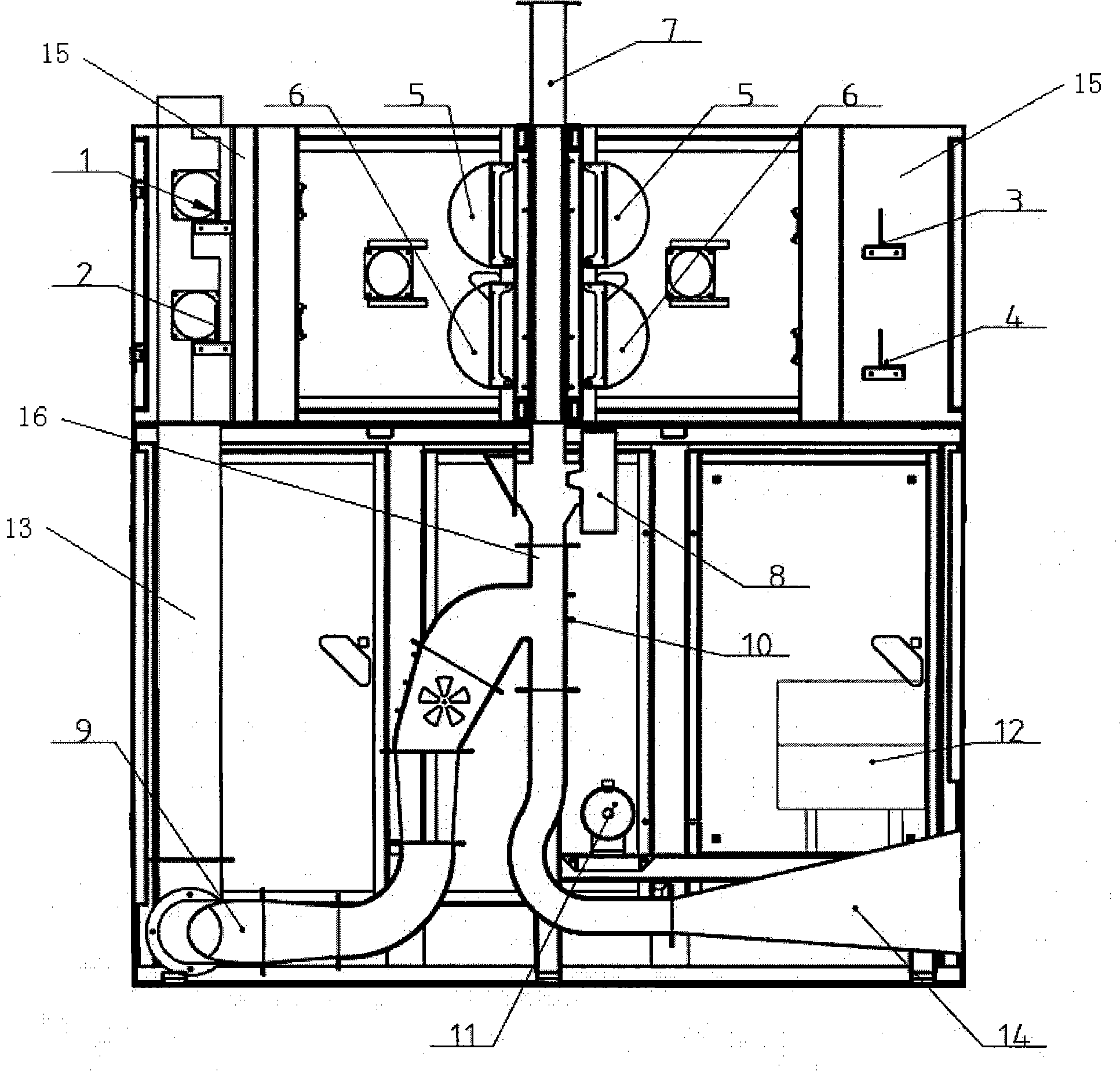

Multi-channel detection foreign fiber sorting machine with CCD camera and ultrasonic sensor

InactiveCN101979730AImprove sorting efficiencyFast sortingSafety devices for fibre treatmentCcd cameraAnti jamming

The invention relates to a multi-channel detection foreign fiber sorting machine with a CCD camera and an ultrasonic sensor. The machine comprises a box body, wherein the centre region of the box body is provided with a cotton passage pipeline; the end, positioned in the box body, of the cotton passage pipeline is provided with a connecting pipe; the connecting pipe is provided with a foreign fiber pipeline and an outlet pipeline; the junction between the connecting pipe and the foreign fiber pipeline is provided with a high-pressure electromagnetic valve; the inlet of the high-pressure electromagnetic valve is connected with a high-pressure air storage tank; the two sides, corresponding to the cotton passage pipeline, in the box body are both provided with mounting blocks; the mounting blocks are provided with a first color linear array scanning CCD camera, a second color linear array scanning CCD camera, a first black and white linear array scanning CCD camera and a second black and white linear array scanning CCD camera; the cotton passage pipeline is also provided with a first lighting device and a second lighting device; and the end, corresponding to the adjacent cotton passage pipeline, of the connecting pipe is provided with the ultrasonic sensor. The machine has large cotton passage number, high sorting speed, high sorting efficiency, high anti-jamming capacity, high detection accuracy, safety and reliability.

Owner:WUXI HENGJIU ELECTRICAL TECH

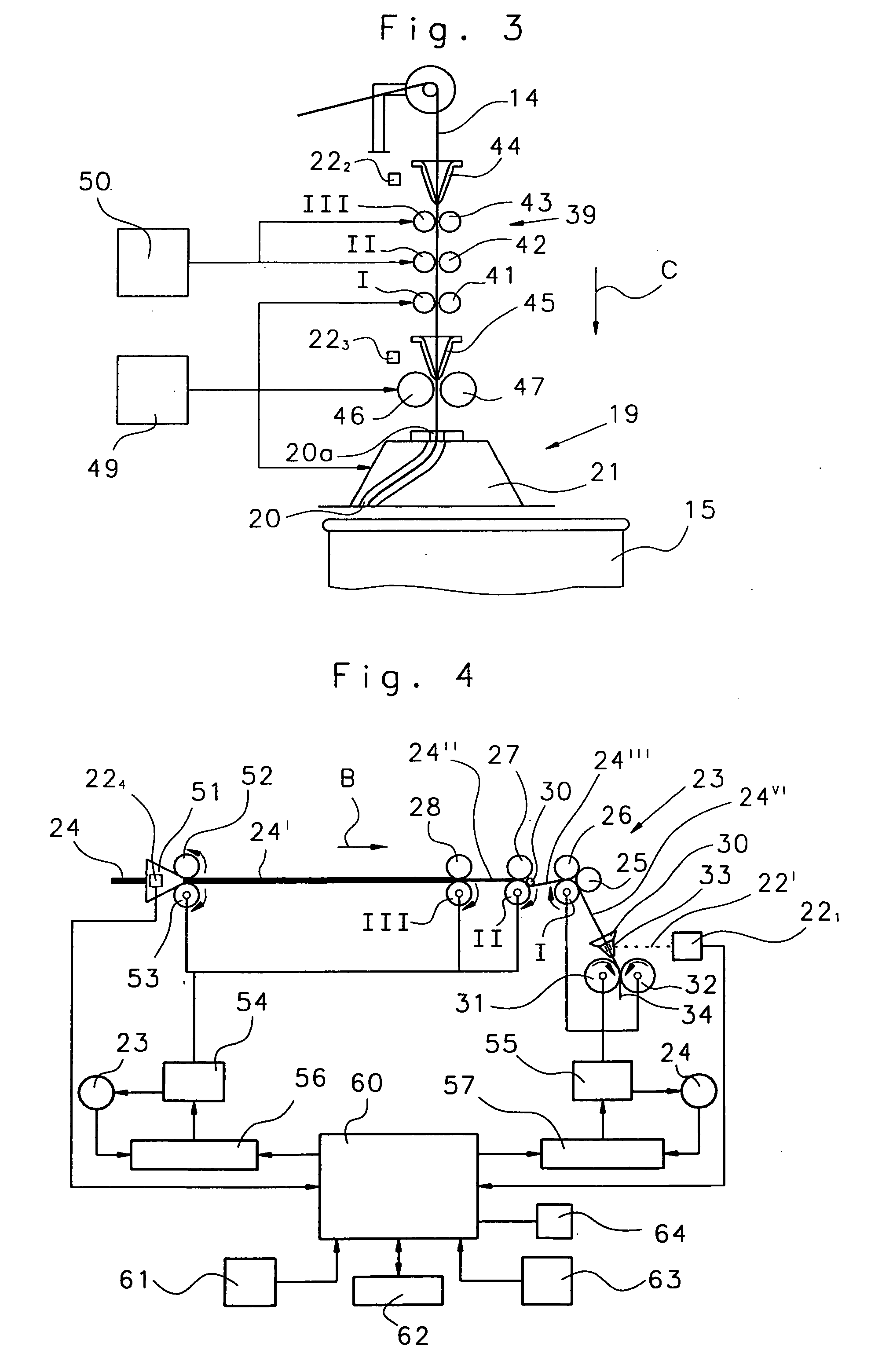

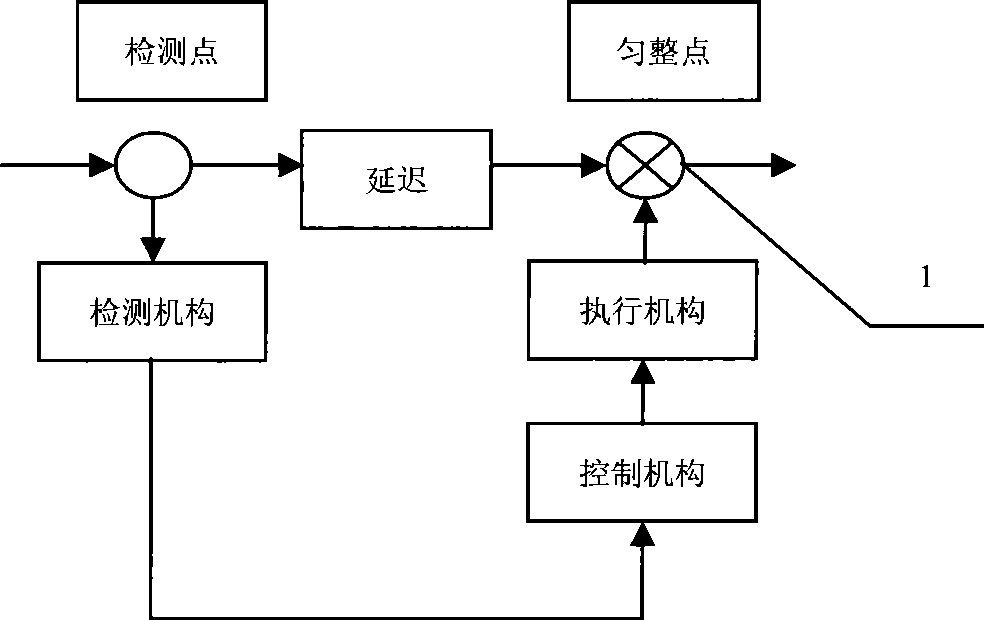

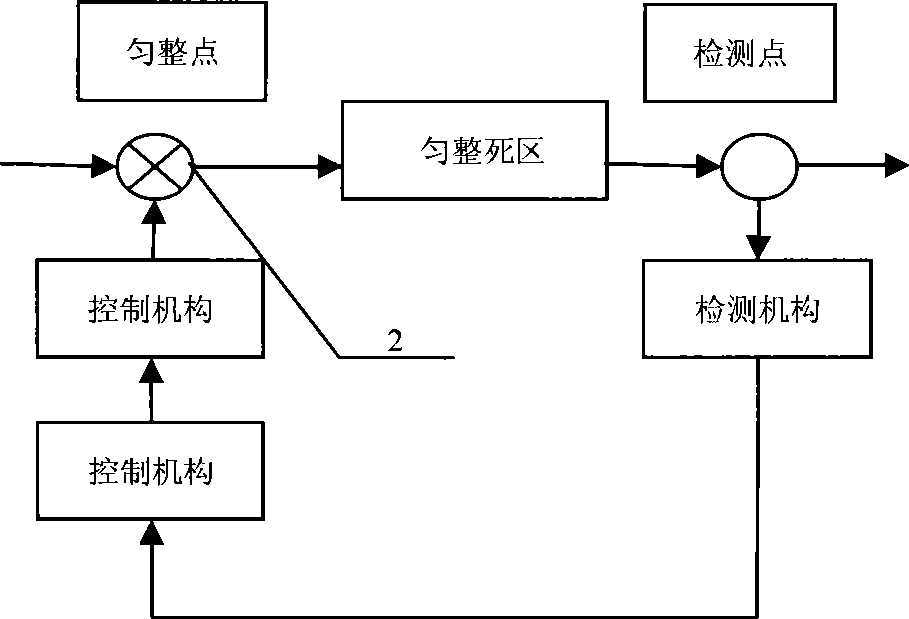

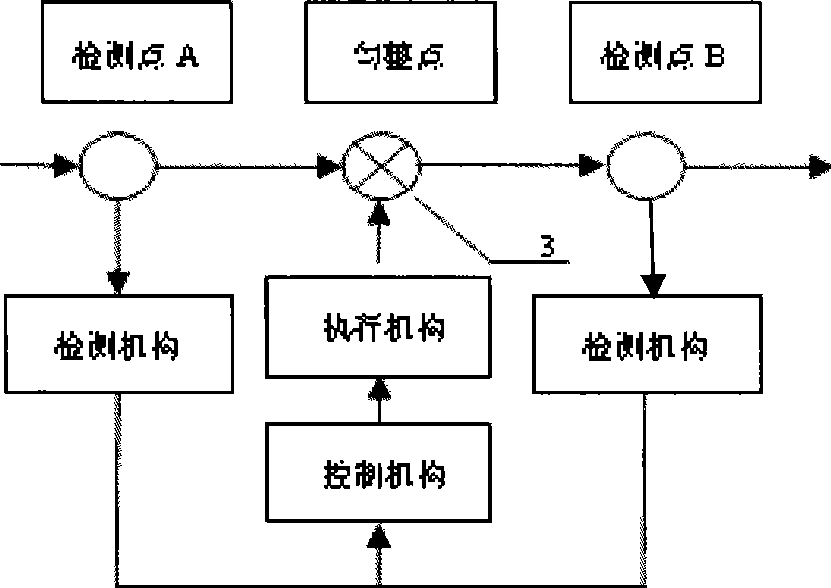

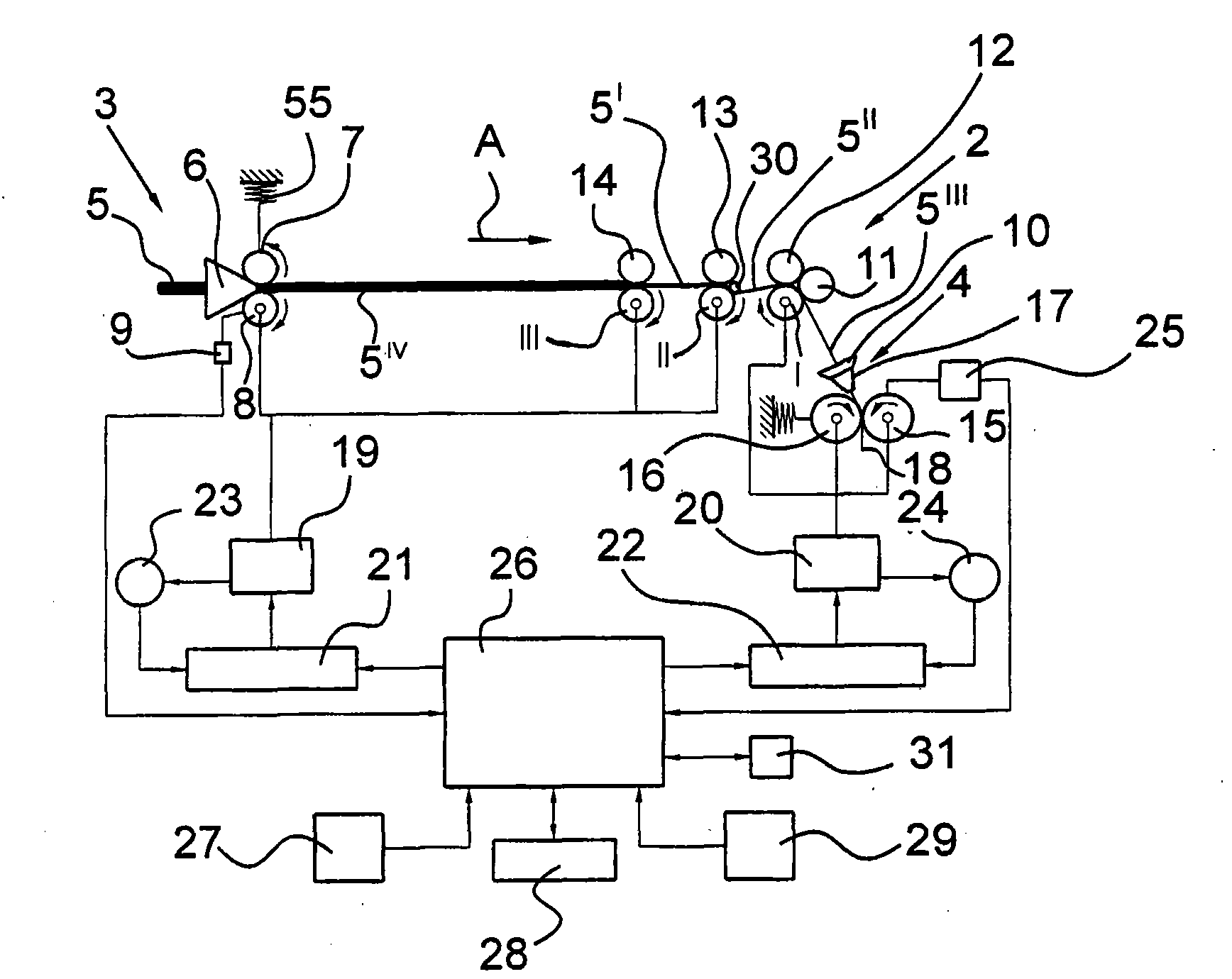

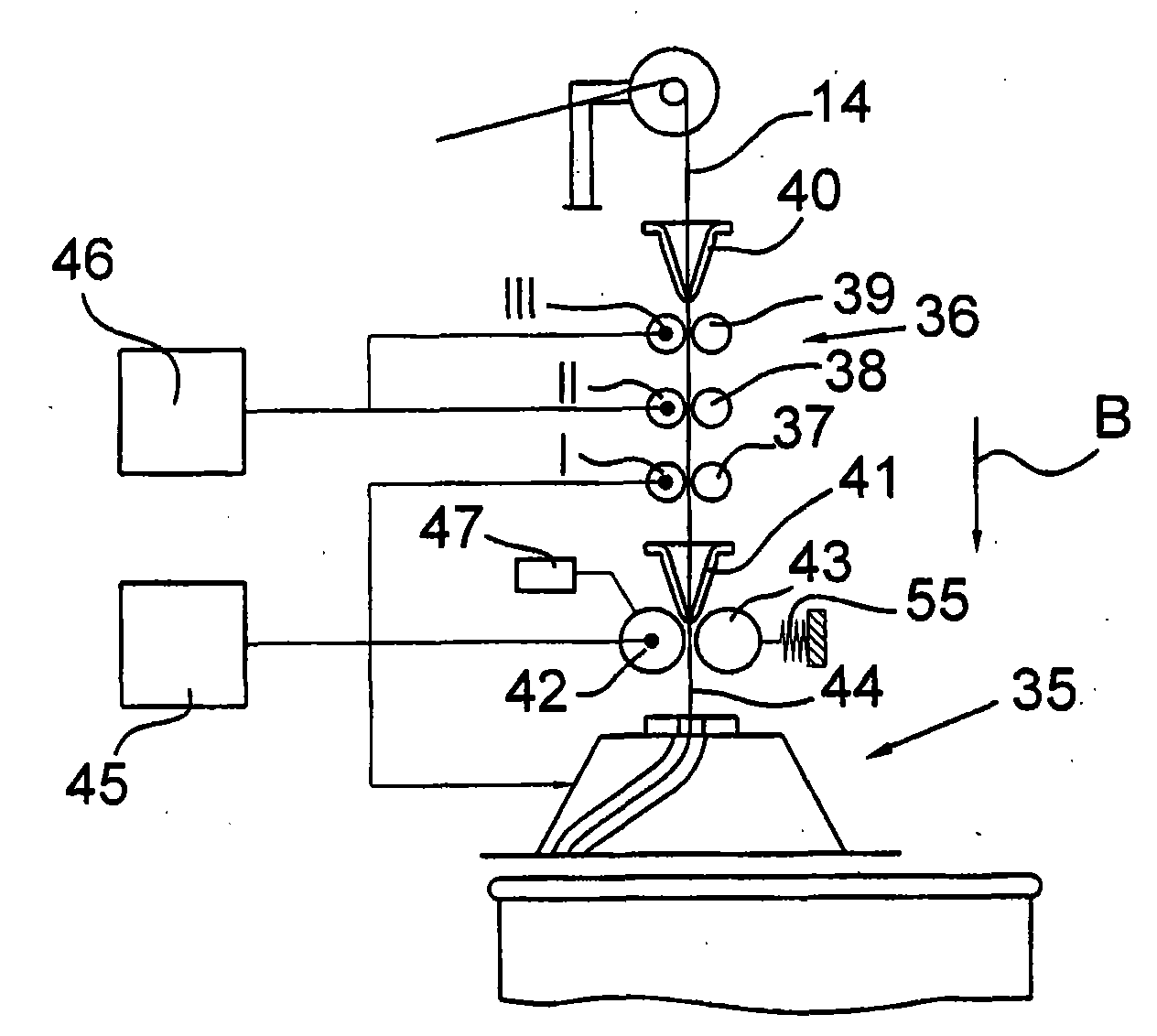

Double-open ring control device and method applied to self-regulating technology

InactiveCN101509159AGuaranteed uniformityQuality assuranceSafety devices for fibre treatmentCarding machinesEngineeringConnection control

The invention provides a dual opening ring control device and a method which are applied to self-adjusting regulating technology. The device of the invention comprises a rear roller, a group of middle rollers are arranged in front of the rear roller, a front roller is arranged in front of the middle rollers, a first detecting mechanism is arranged behind the rear roller, the rear roller and the front roller are respectively connected with a first executing mechanism and a second executing mechanism, a second detecting mechanism is arranged among the middle rollers, the output ends of the first detecting mechanism and the second detecting mechanism are connected with the input end of a control mechanism, and the output end of the control mechanism is connected with the input ends of the first executing mechanism and the second executing mechanism respectively. The method comprises the following steps: cotton strips firstly pass through the rear roller and the middle rollers to finish ring opening regulating for the first time, and then pass through the middle rollers and the front roller to finish ring opening regulating for the second time. The advantages of the invention are: the invention is particularly suitable for strip combining machines, and eliminates the problems existing in the original system such as blind area, dead area as well as advanced or postponed regulating.

Owner:DONGHUA UNIV

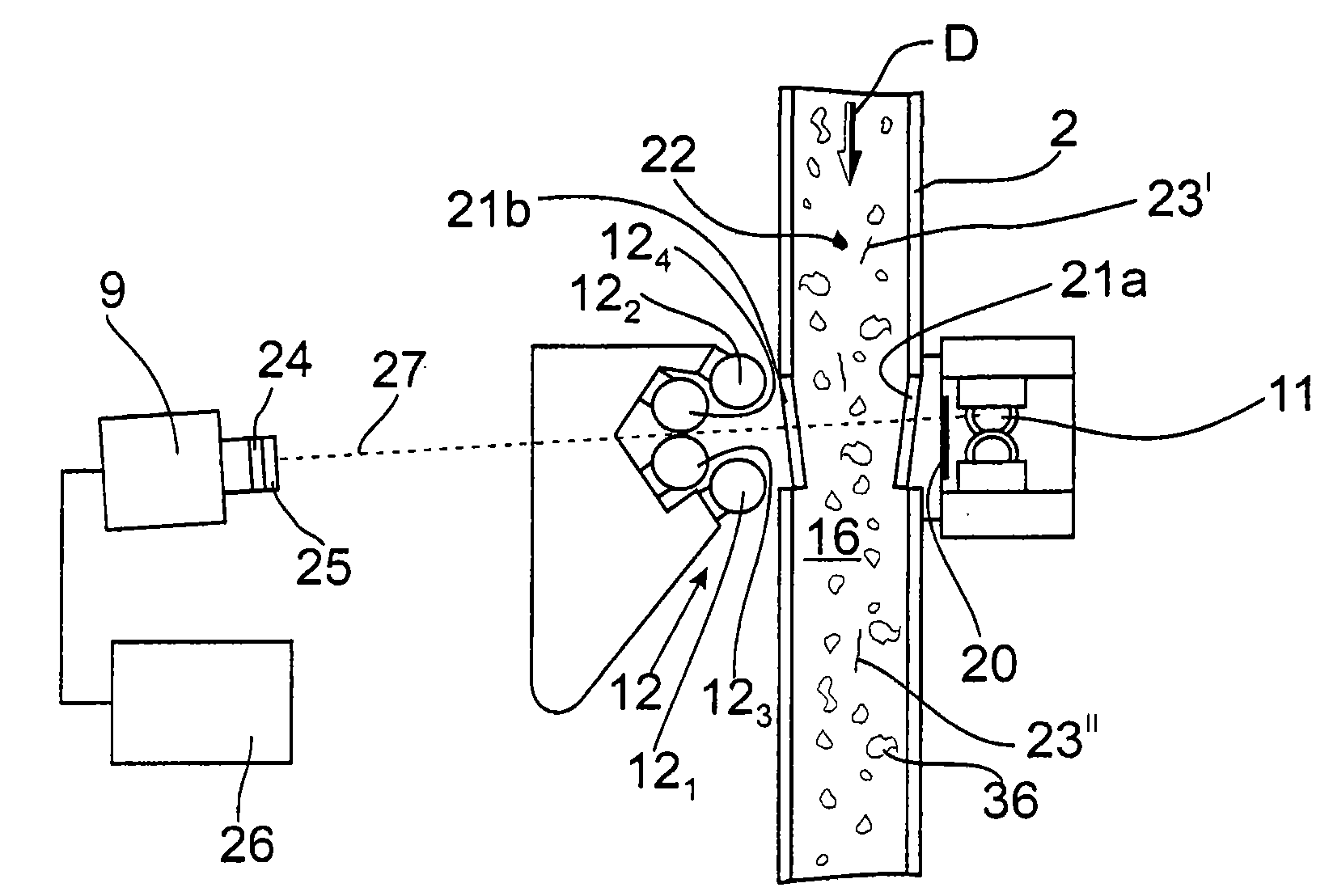

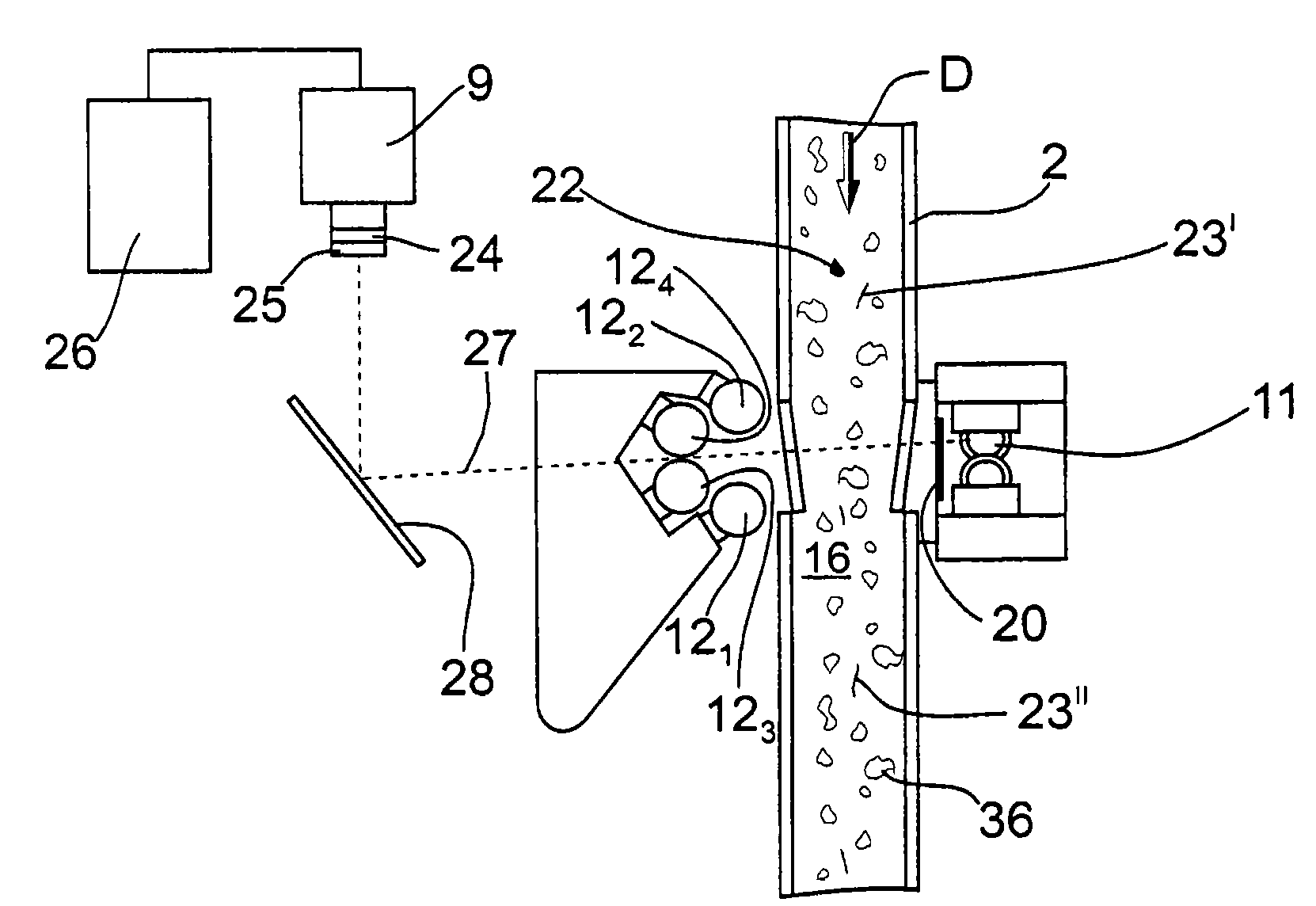

Apparatus in a spinning room preparation, ginning or the like installation for detection of foreign matter in fibre material

ActiveCN101634103ANo transient loss of claritySave installation spaceFibre cleaning/opening by air draught arrangementsSafety devices for fibre treatmentFiberForeign matter

Owner:TRUETZSCHLER GRP SE

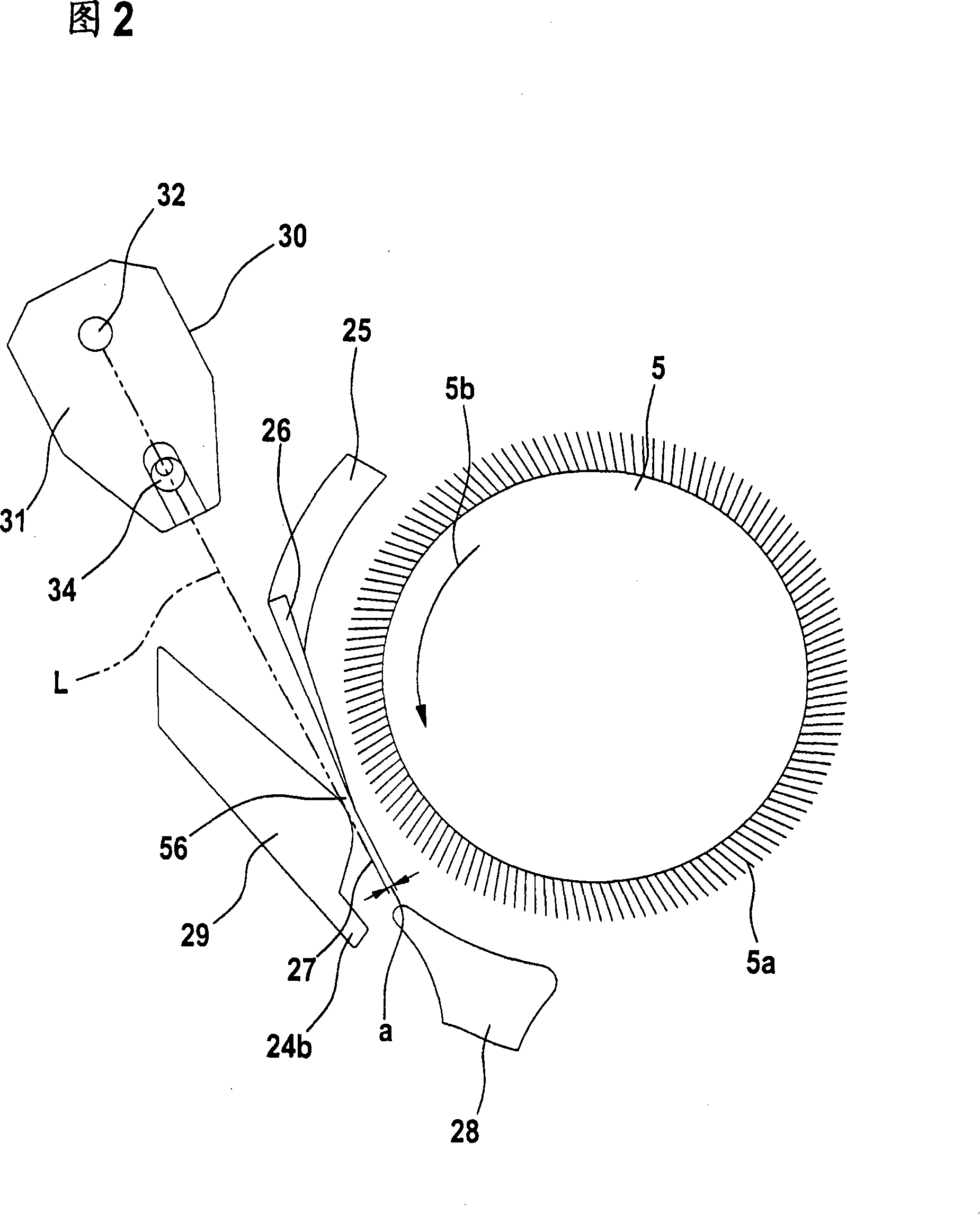

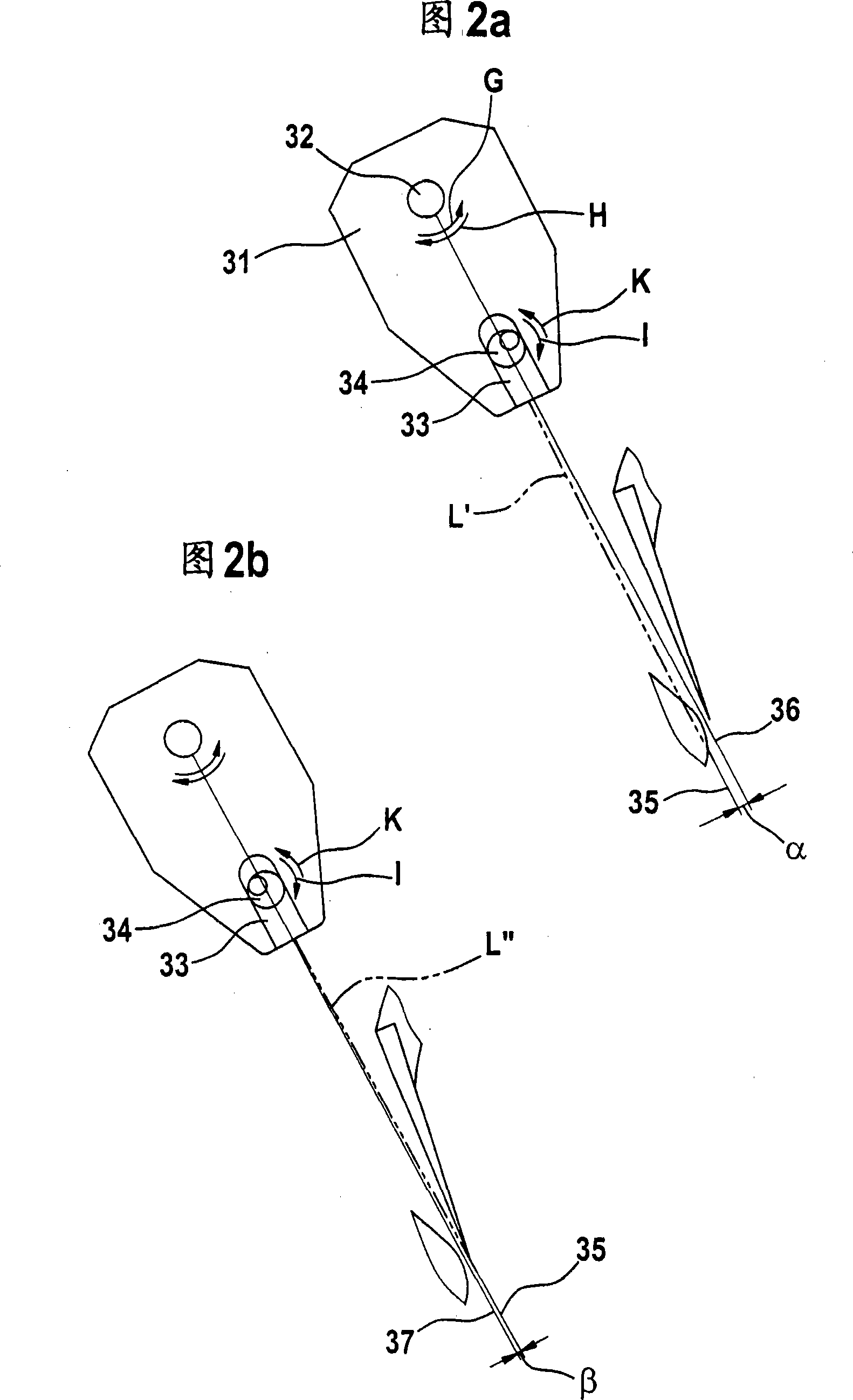

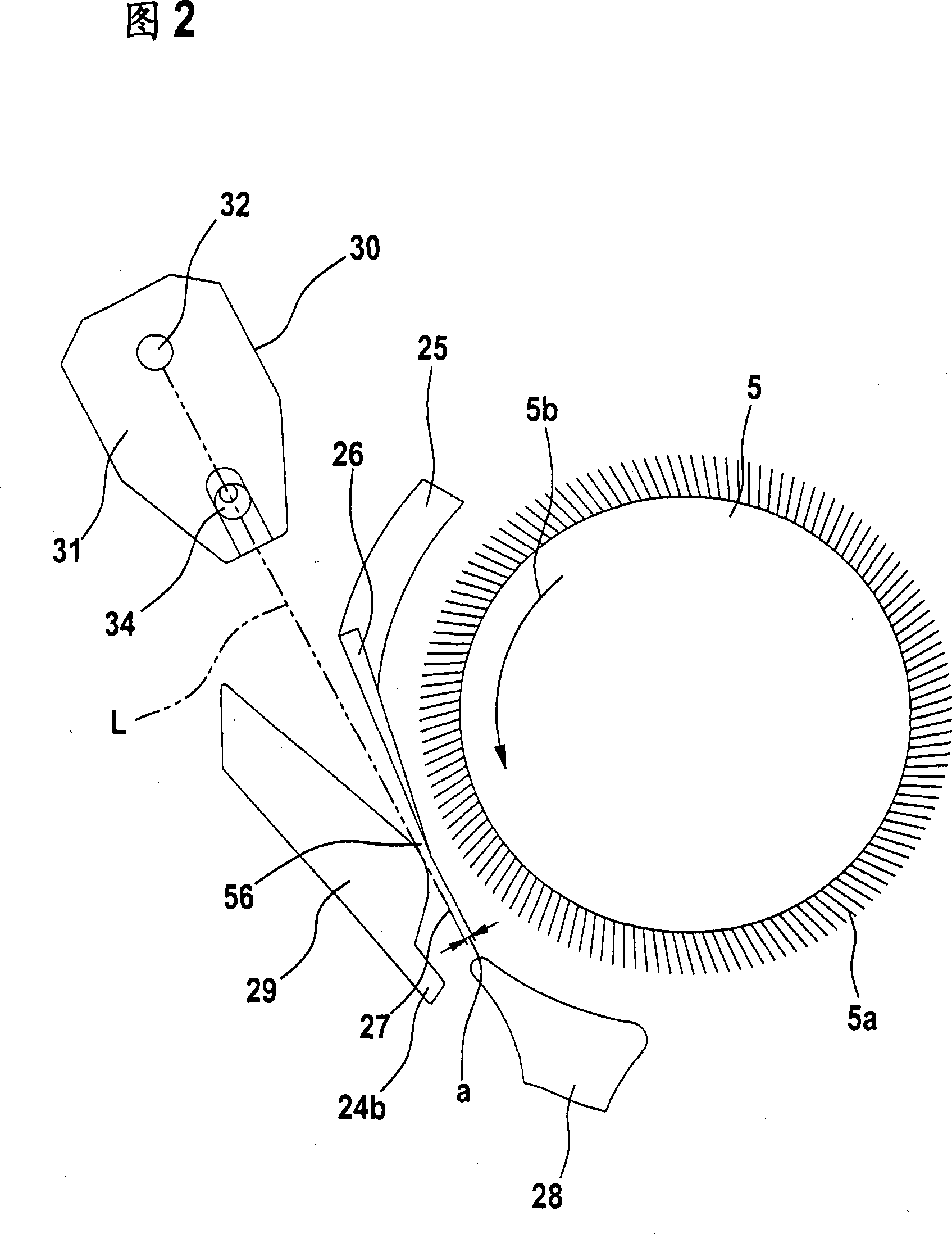

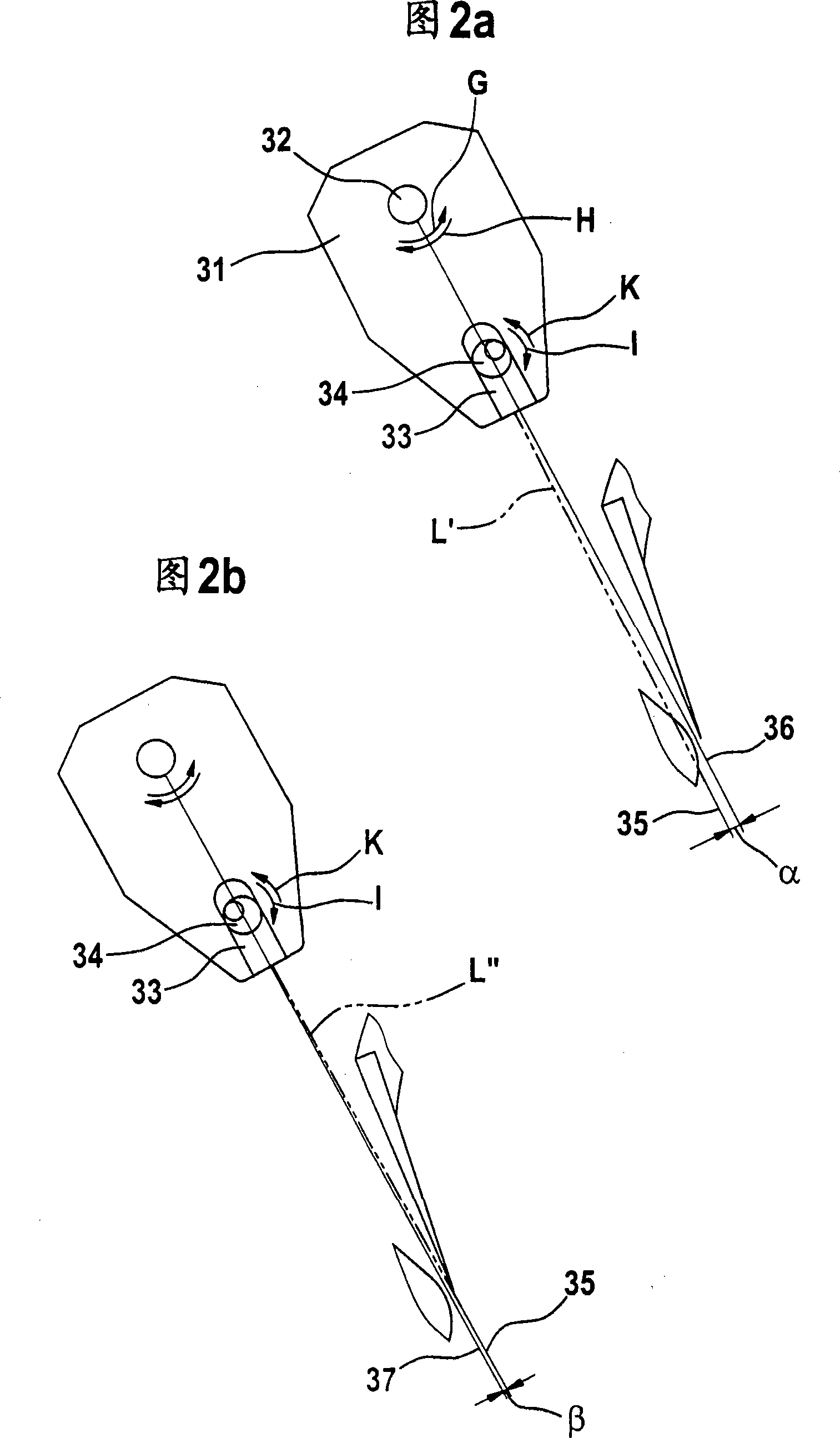

Apparatus in spinning preparation for separating foreign objects at a high-speed roll for opening or doffing fibre material

InactiveCN101230504AEasy to adjustQuality improvementSafety devices for fibre treatmentCarding machinesForeign bodyWaste material

In an apparatus in spinning preparation for separating foreign objects at a roll for opening or doffing fibre material, at least one device for separating the foreign objects is associated with a face of the roll. That device comprises an arrangement for producing a current of blast air flowing onto the face for detaching the foreign objects and carrying them away. The arrangement comprises a plurality of blast nozzles arranged across the width of the roll. To permit separation and allow rapid changes of the action of the blast air current, a bar for mounting the blast nozzles is present and the outlet of the blast nozzles is locally displaceable in relation to the face of the roll.

Owner:TRUTZSCHLER GMBH & CO KG

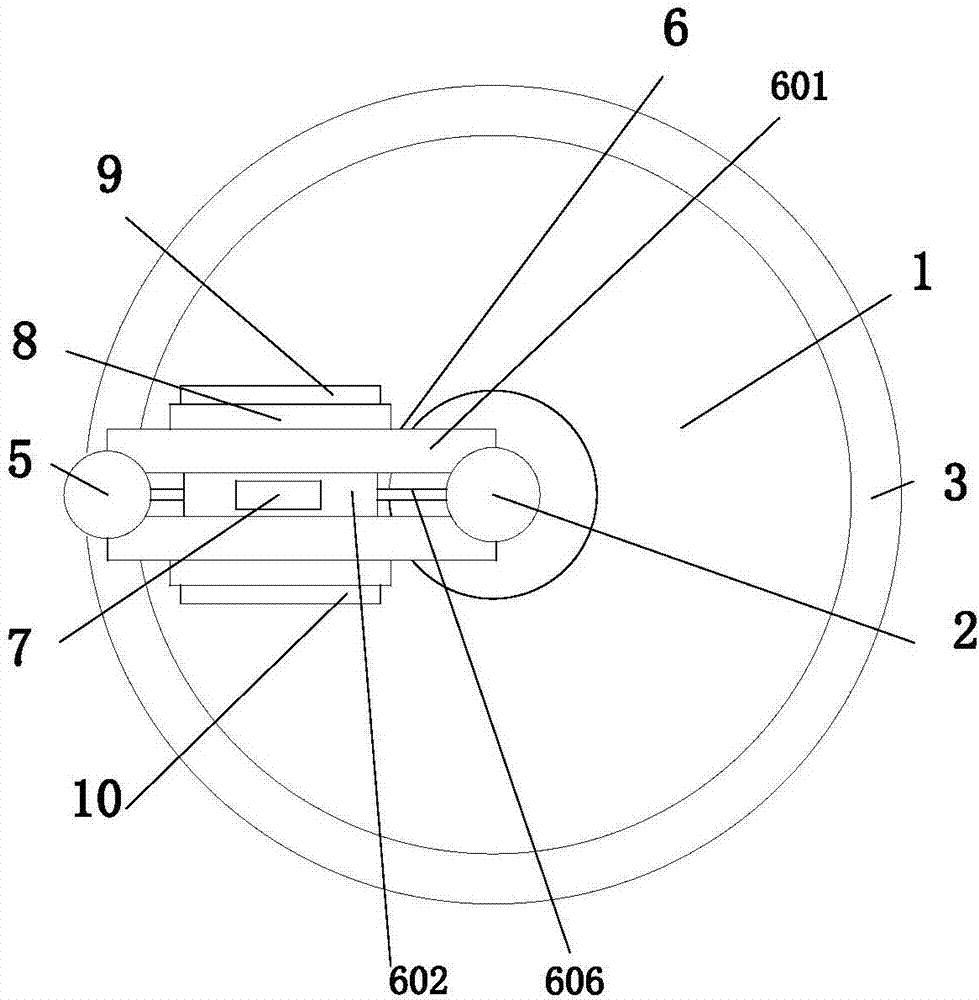

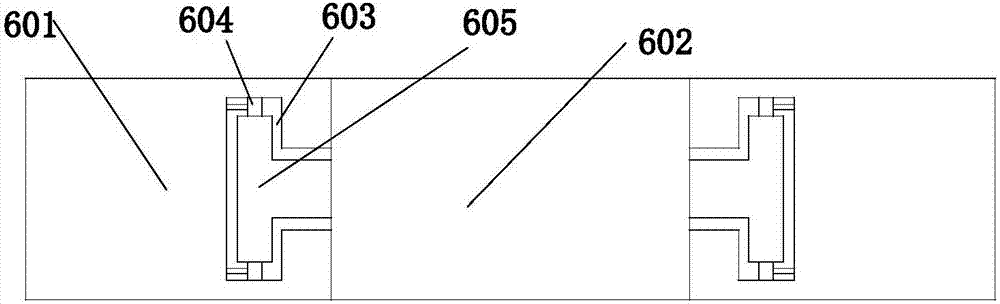

Disk plucker

InactiveCN107217336AIncrease contact areaIncrease contact frictionSafety devices for fibre treatmentFibre breaking machinesCircular discPlucker

The invention discloses a disc plucking machine, which comprises a silo (1), a rotating column (2) is arranged at the central position of the silo (1), an annular guide rail (3) is arranged on the outer wall of the silo (1), and the annular guide rail (3) is provided with a driving trolley (4), a driving column (5) is provided above the driving trolley (4), and a supporting sliding device (6) is provided between the driving column (5) and the rotating column (2) to support sliding The device (6) is provided with a lifting device (7), and the bottom of the lifting device (7) is provided with a cotton collection device (8), and the bottom of the cotton collection device (8) is respectively provided with an impurity removal device (9) and a humidification device (10) . The invention has the characteristics of improving cotton grasping efficiency, improving the impurity removal effect and reducing the clogging frequency of the cotton receiving hopper.

Owner:湖州南浔凯普纺织有限公司

Device in spinning room preparaed for detecting foreign bodies made of plastics, such as polypropylene tapes, fabrics and films and the like

ActiveCN102534875ASafety devices for fibre treatmentPolarisation-affecting propertiesFiberFluorescence

The invention relates to a device in a spinning room preparaed for detecting foreign bodies made of plastics, such as polypropylene tapes, fabrics and films and the like, in or between fibre tufts, for example of cotton, in particular for detecting in fibre materials those packaging materials and waste plastics which are not detectable using polarised light (non-transparent) or detectable using UV light (non-fluorescent), by illuminating the fibre material on the one hand with non-polarised light of one wavelength range and at the same time with polarised light of a different wavelength range in such a way that both kinds of light can be used together in one machine at closely adjacent inspection stations.

Owner:TRUETZSCHLER GRP SE

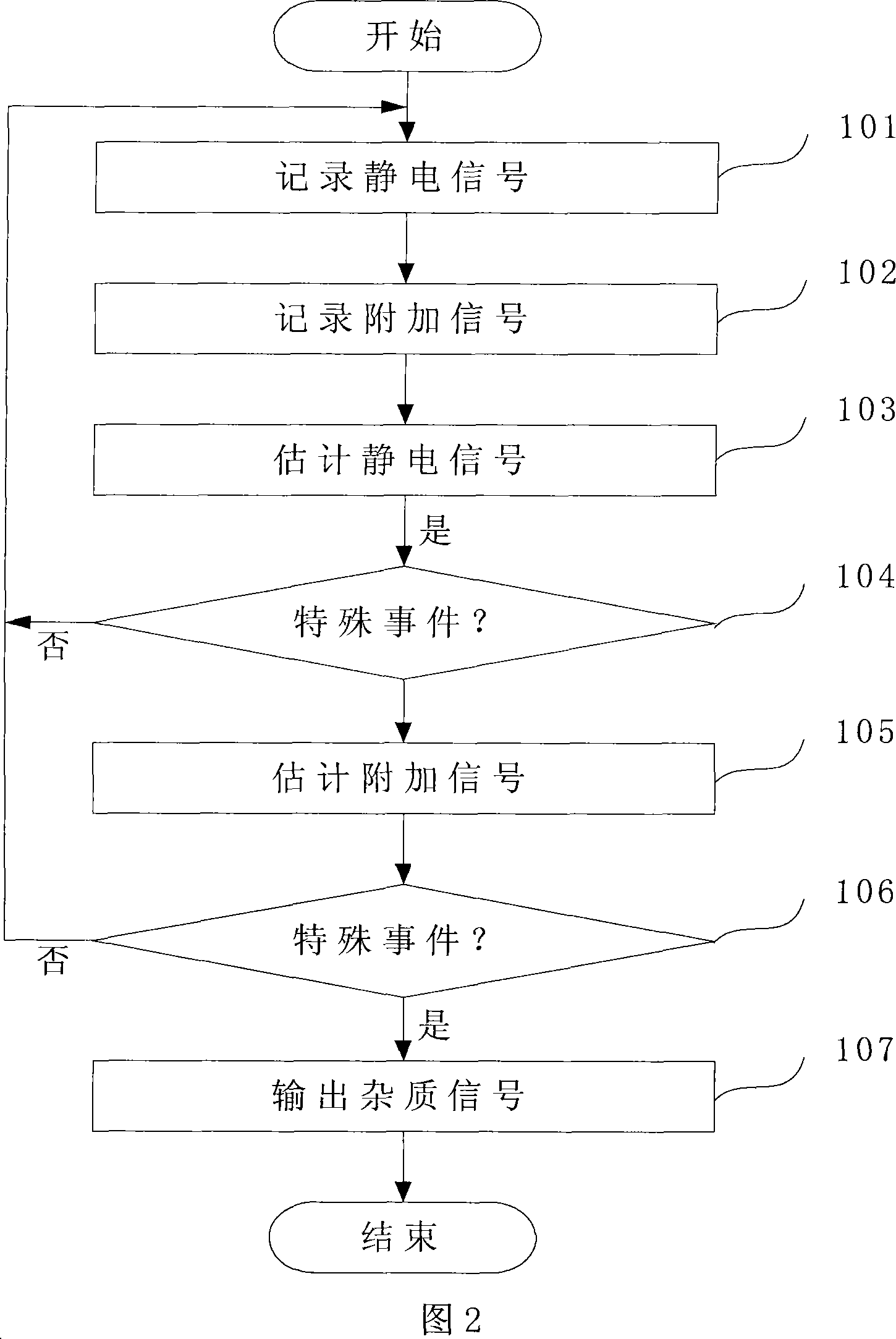

Method and device for detecting foreign matter in a moving solid elongated test object

InactiveCN101180535ASimple methodSave spaceSafety devices for fibre treatmentTextile testingYarnForeign matter

A device (1) for detecting foreign matter in a moving solid elongated test object (9), for example a yarn, comprises a sensor (2) for picking up an electrostatic signal from the test object (9). The sensor (2) is suitable for picking up an electrostatic signal from such excess charges that were already previously present on the test object (9). The device (1) also comprises a sensor (2) for picking up a further signal, for example a capacitive signal, from the test object (9). Furthermore, evaluation means (7) are present to evaluate the electrostatic signal and the further signal and to detect foreign matter. The combination of the electrostatic signal and the further signal produces an improvement in selectivity. False alarms are reduced, and greater reliability and sensitivity are achieved.

Owner:USTER TECHNOLOGIES

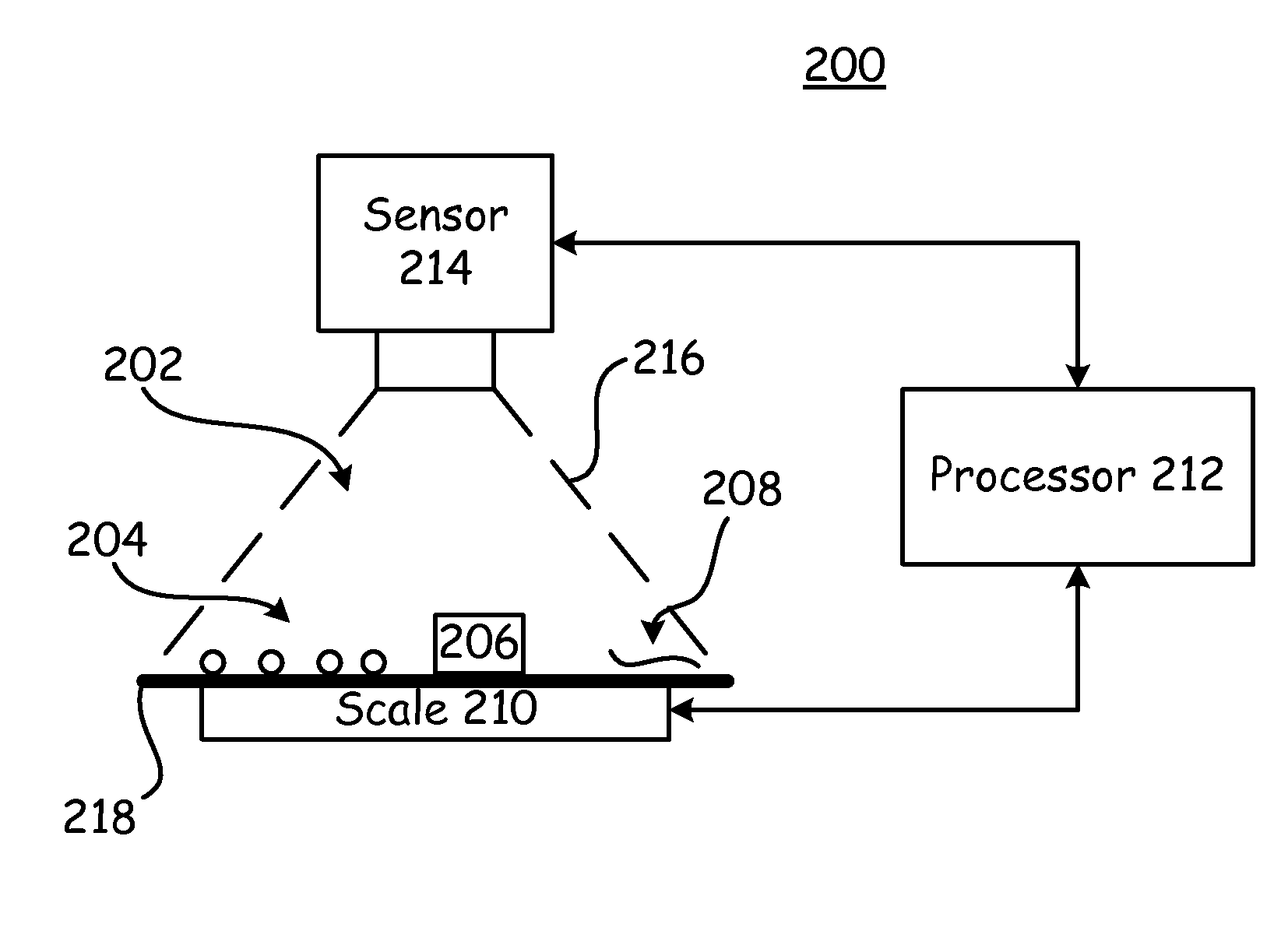

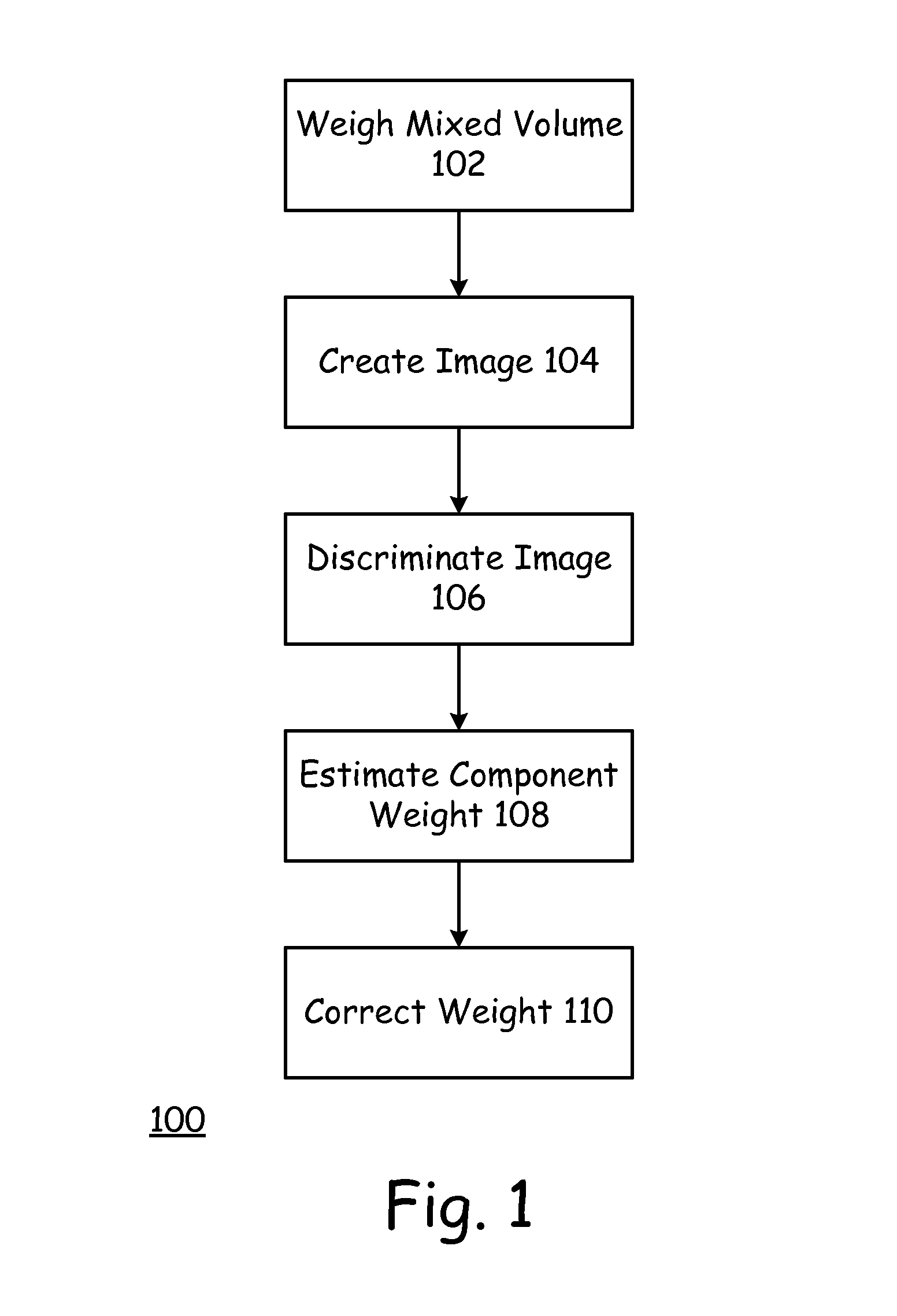

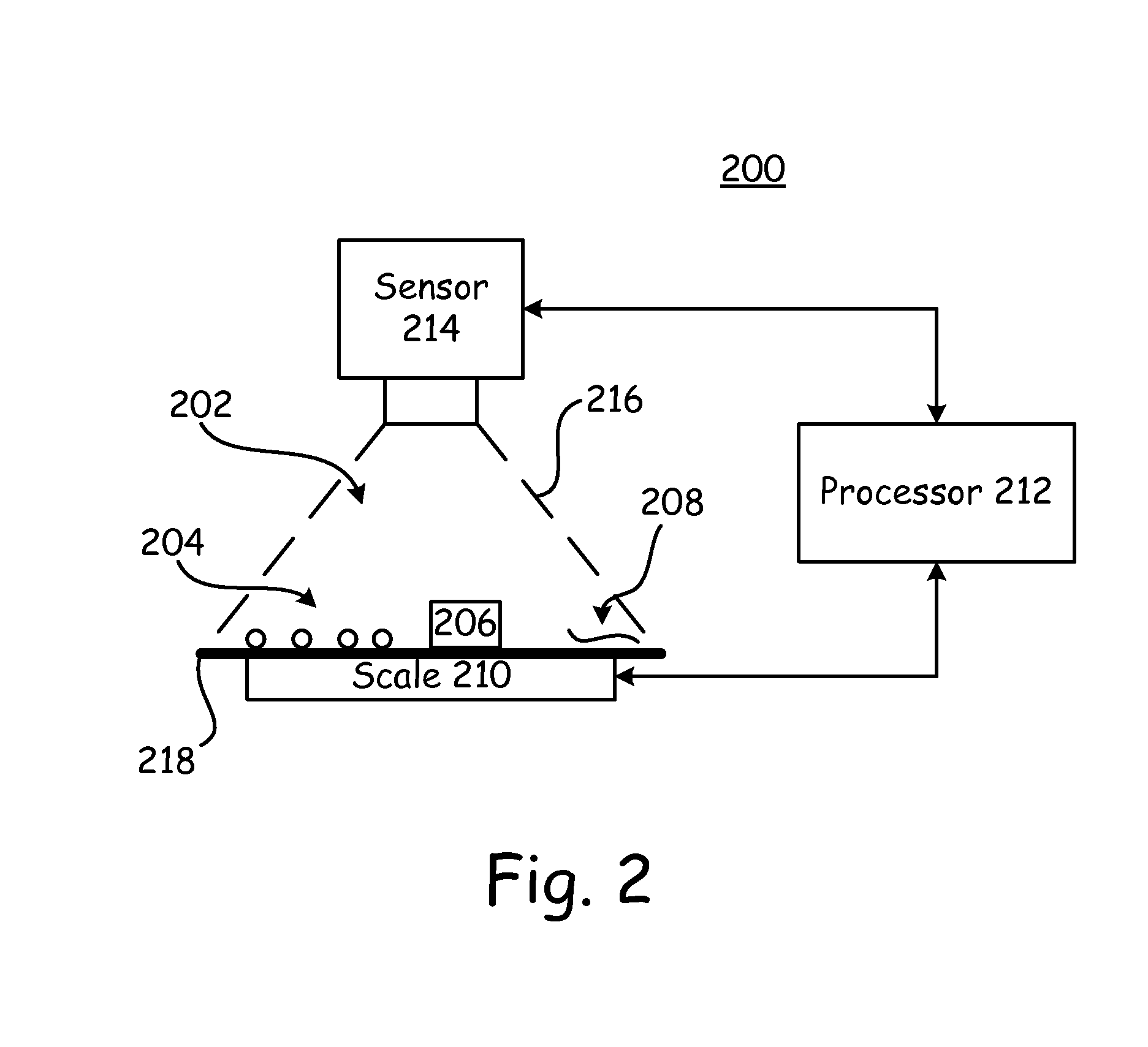

Visual weight compensation

InactiveUS8301410B2Quickly and easily and automatically generatedGuaranteed mixMaterial analysis by optical meansCharacter and pattern recognitionComputer scienceVisual perception

Owner:USTER TECHNOLOGIES

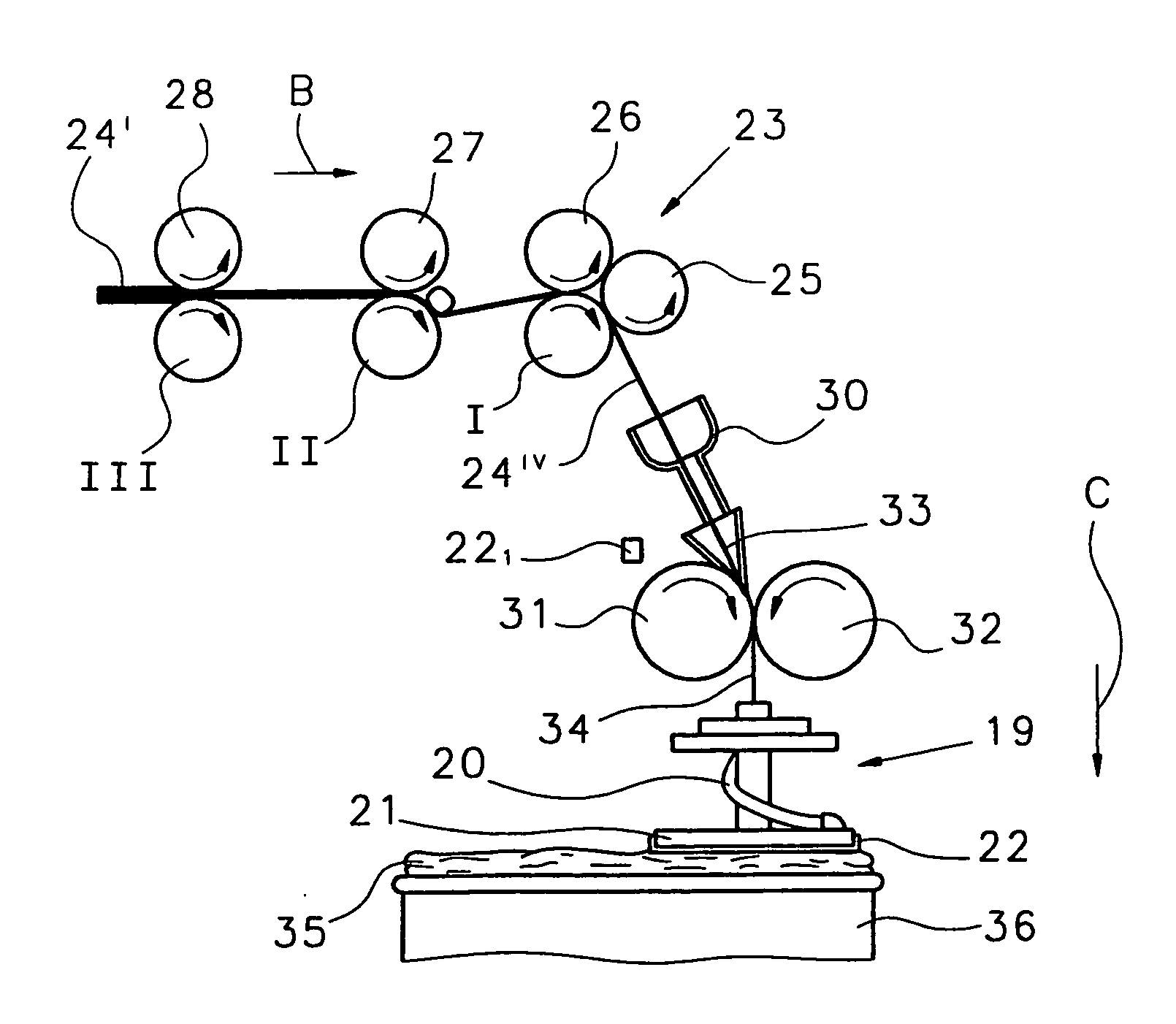

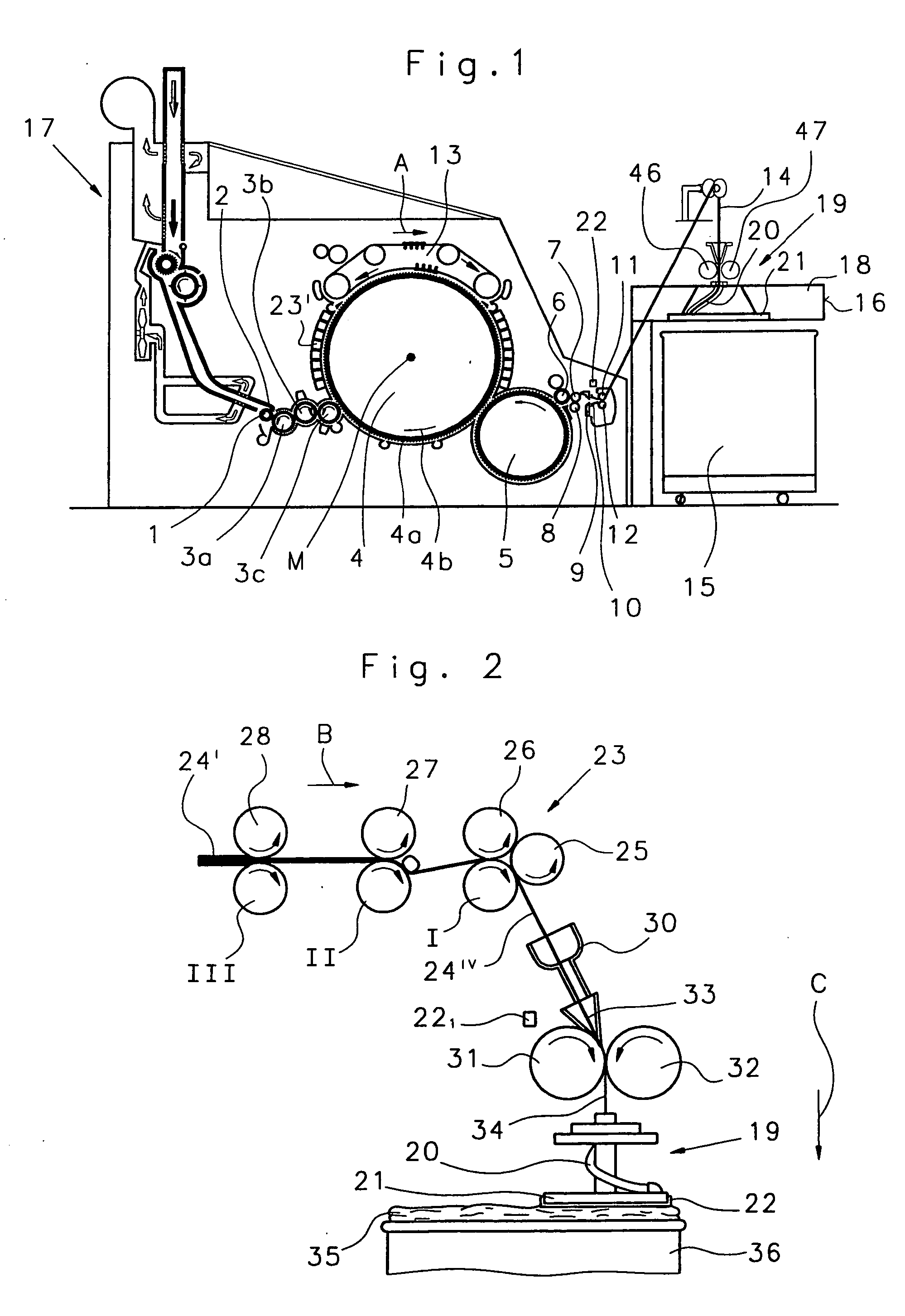

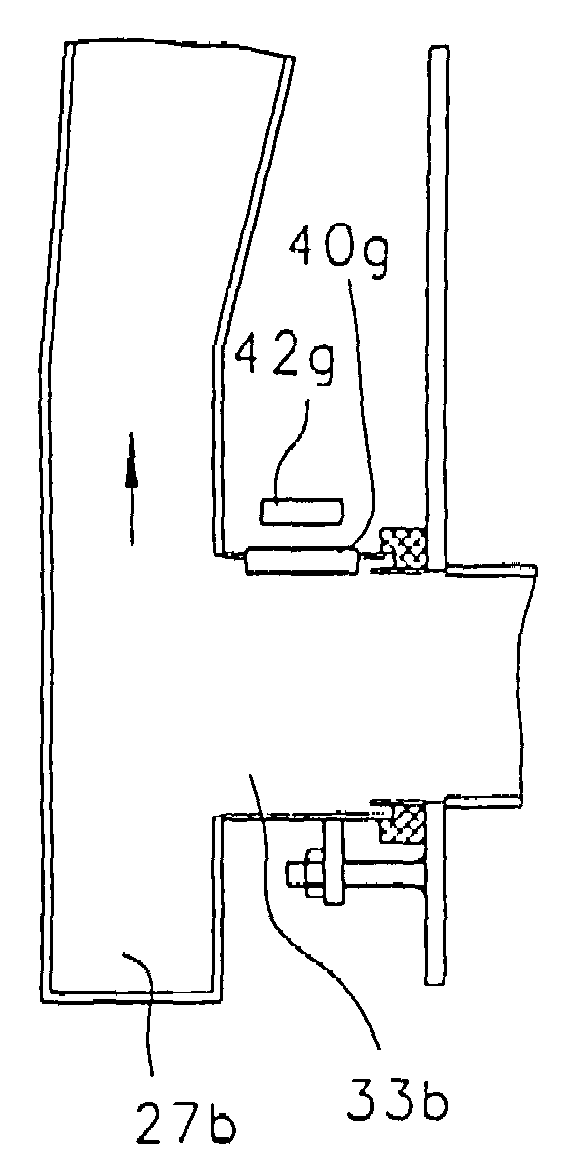

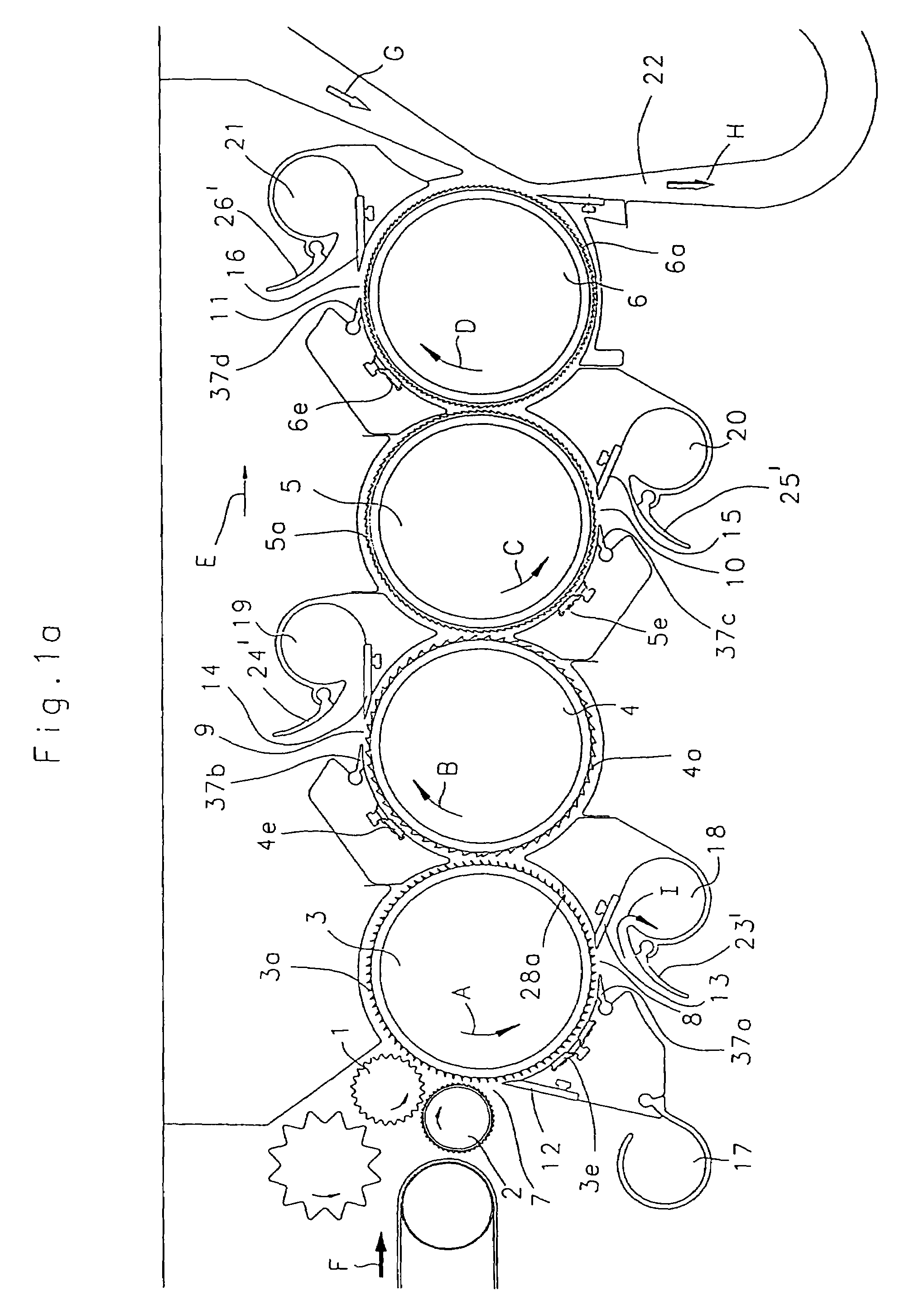

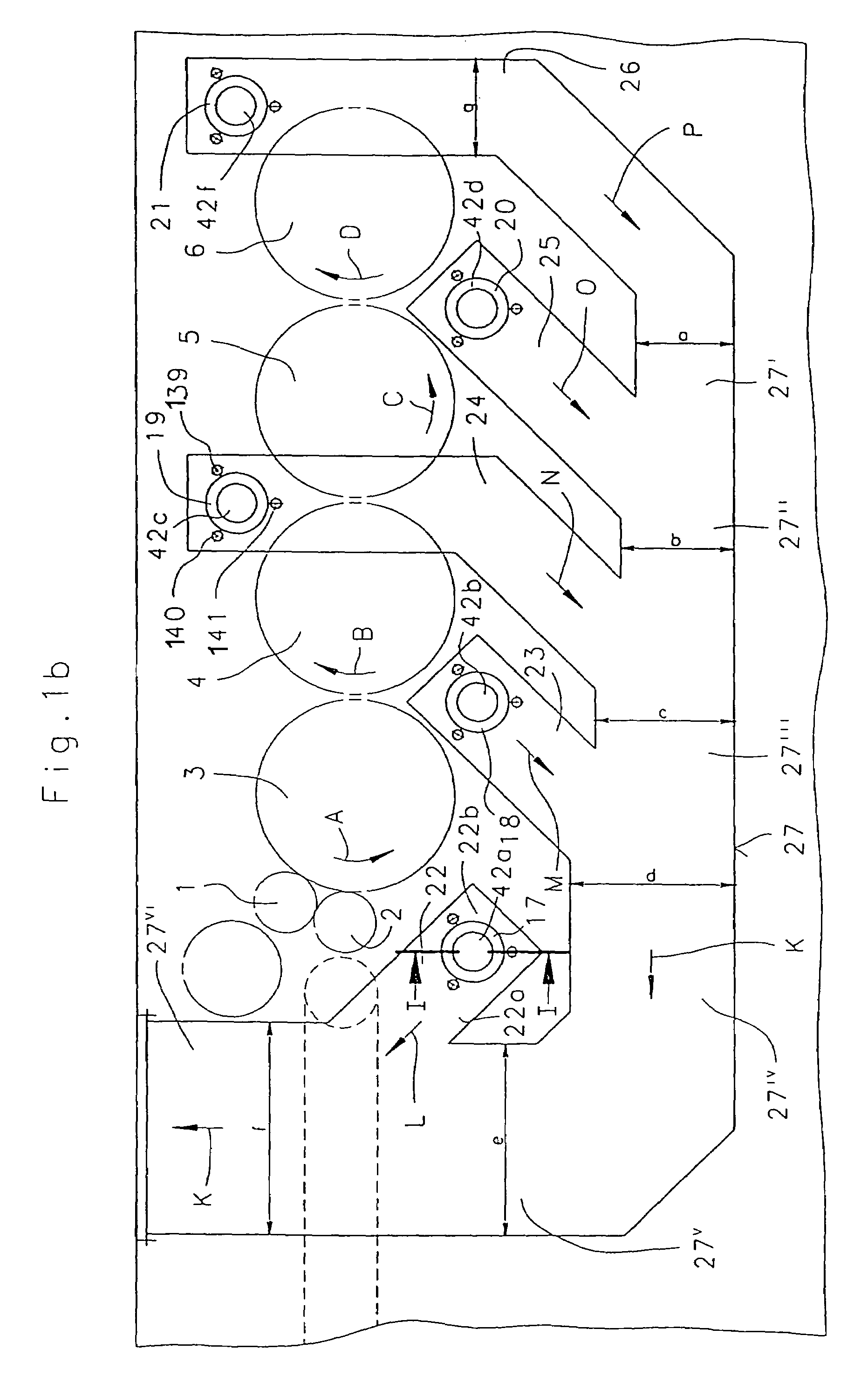

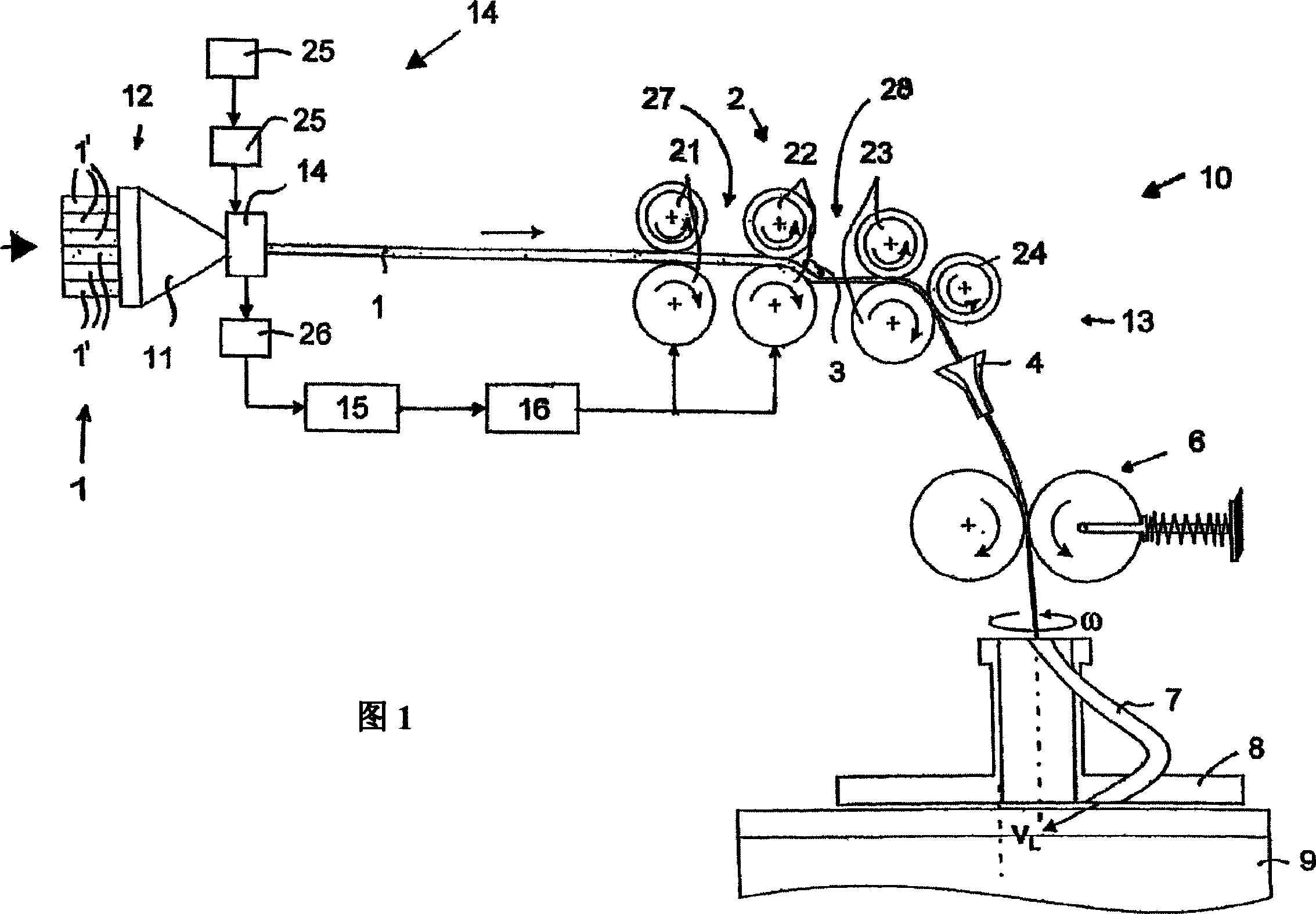

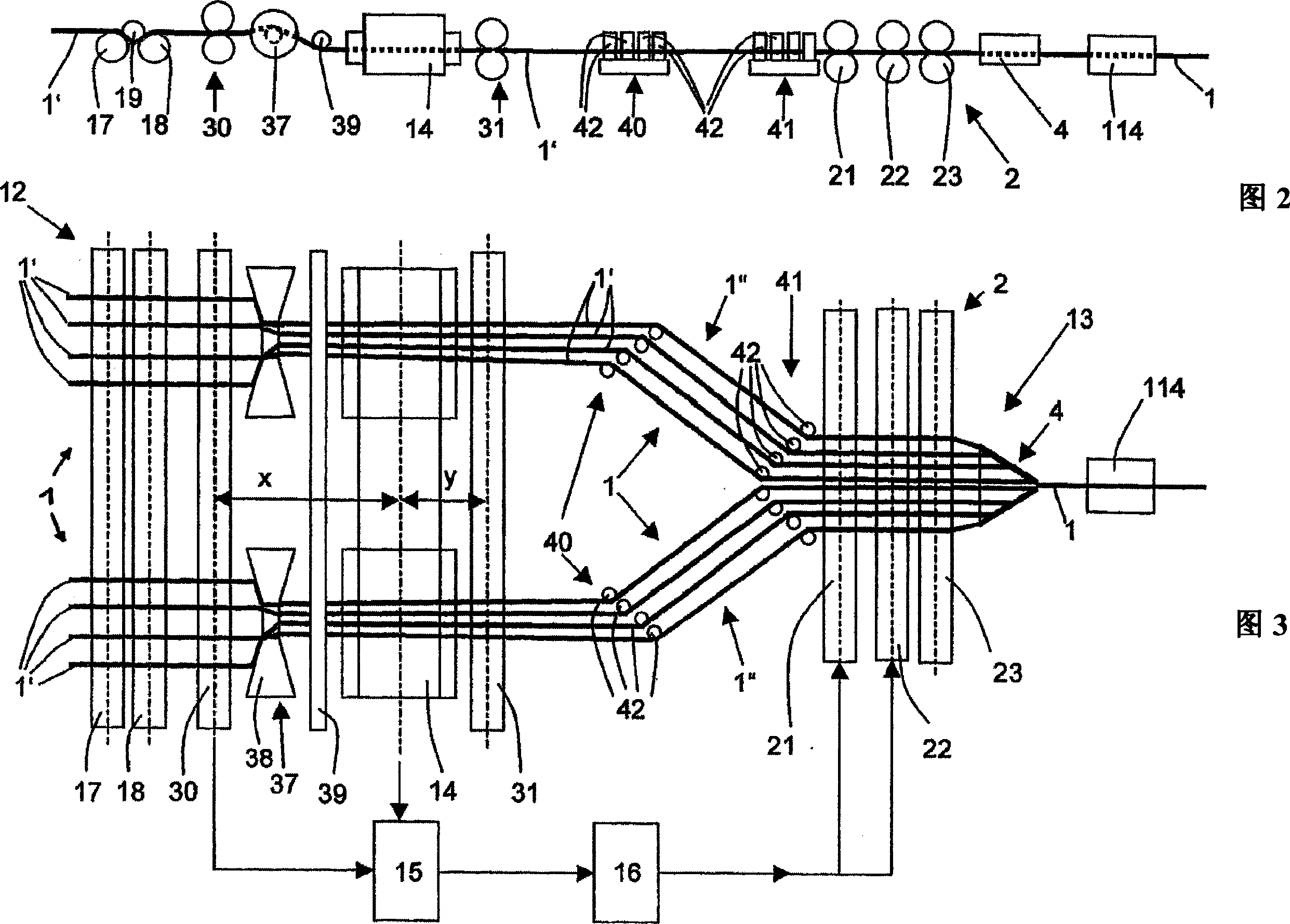

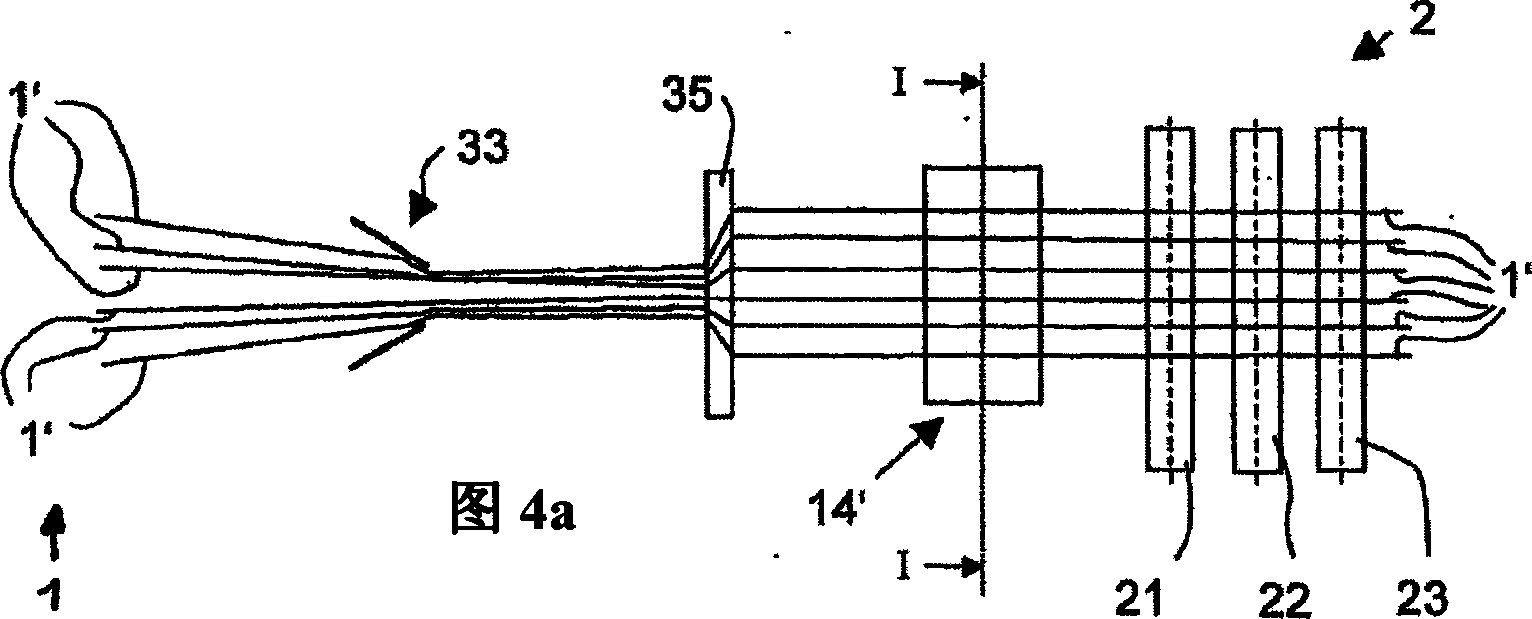

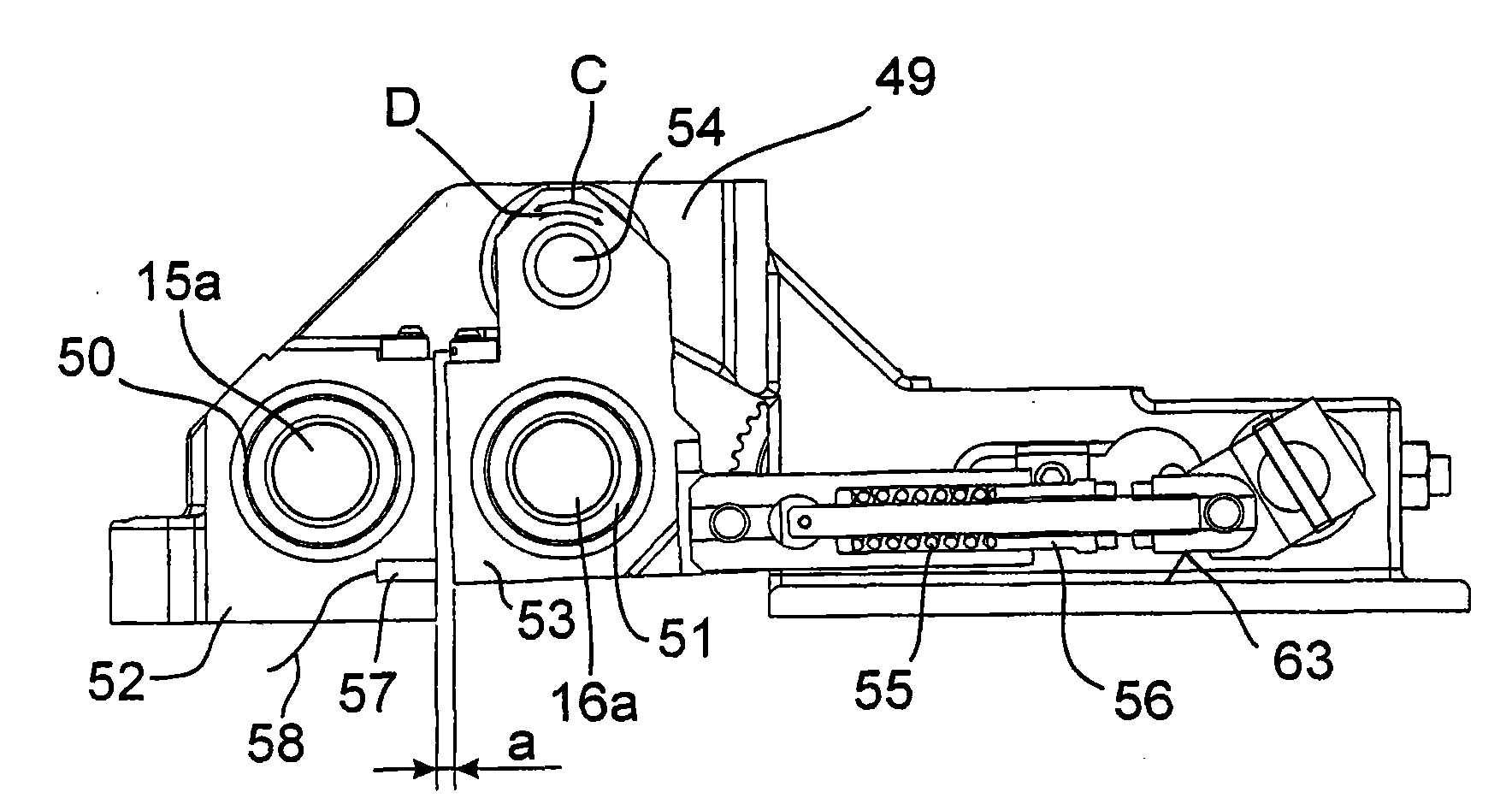

Apparatus used on a spinning room preparation machine having a drafting mechanism for drafting strand fibre materials,

ActiveCN101654820ASavings RegulatorSimplified adjustment procedureSafety devices for fibre treatmentDrafting machinesFiberEngineering

An apparatus used on a spinning room preparation machine, which is specially a carding mechine, a draw frame, a combing machine or a bobbiner and has a drafting mechanism for drafting strand fibre materials, has a pair of scanning rollers pressed against one another for continuously recording the cross-sectional area and / or fibre amount of at least one fibre strip, wherein one of the rollers is immovable and the other roller is arranged that it can deviate from the immovable roller. The apparatus has a non-contact spacing sensor for measuring the spacing from the corresponding surface (sensedsurface). In order to arrange the spacing sensor in simple modus specially in limited spacing and improve the connection between the spacing sensor and the sensed surface, the spacing sensor is integrated to the holding element of the roller.

Owner:TRUETZSCHLER GRP SE

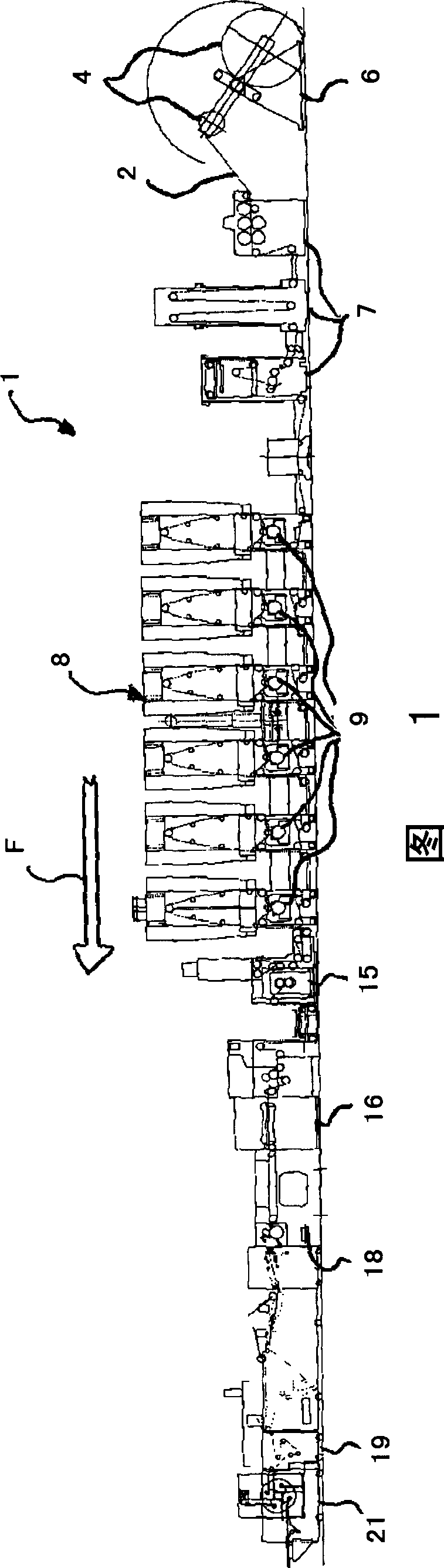

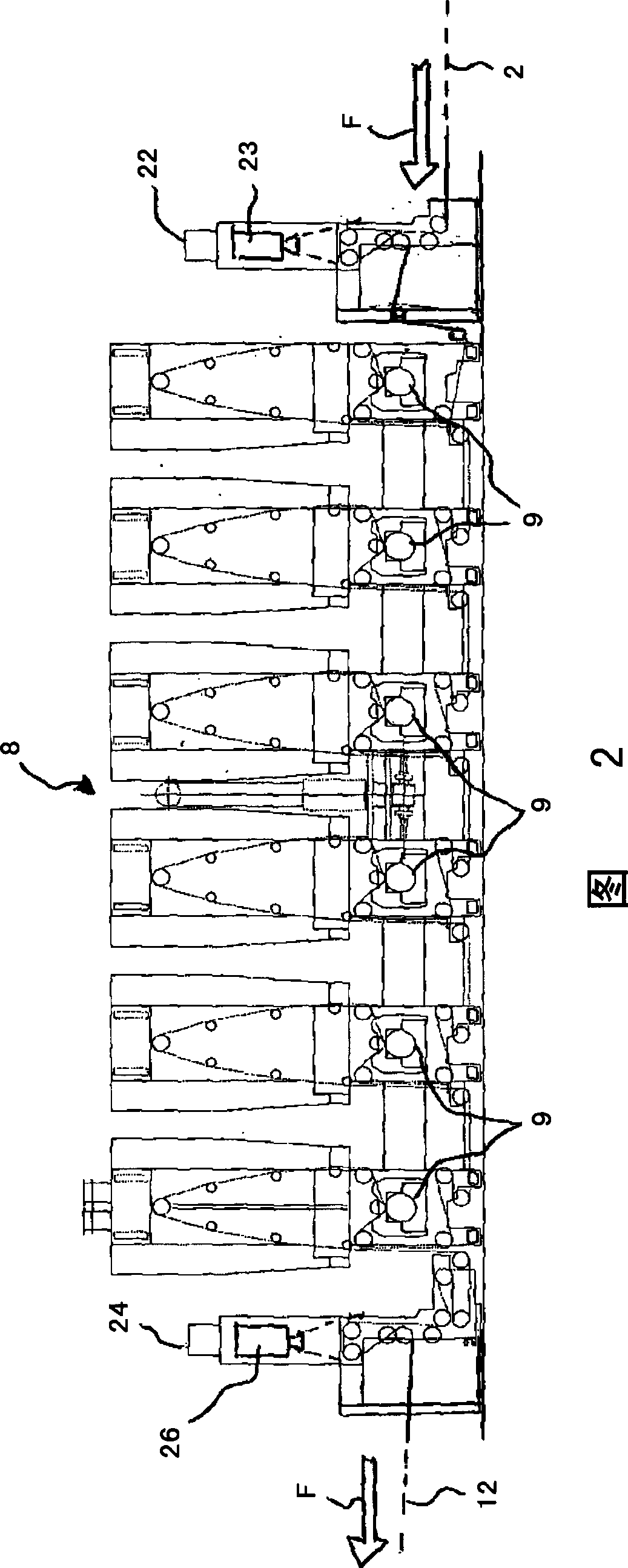

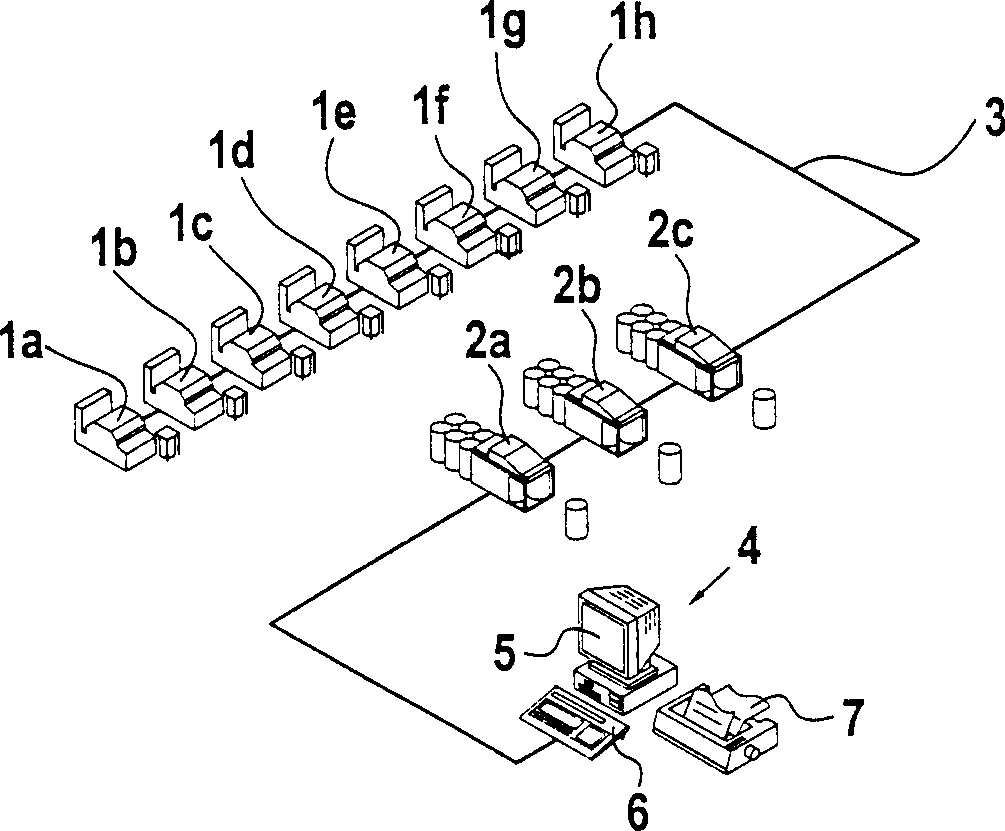

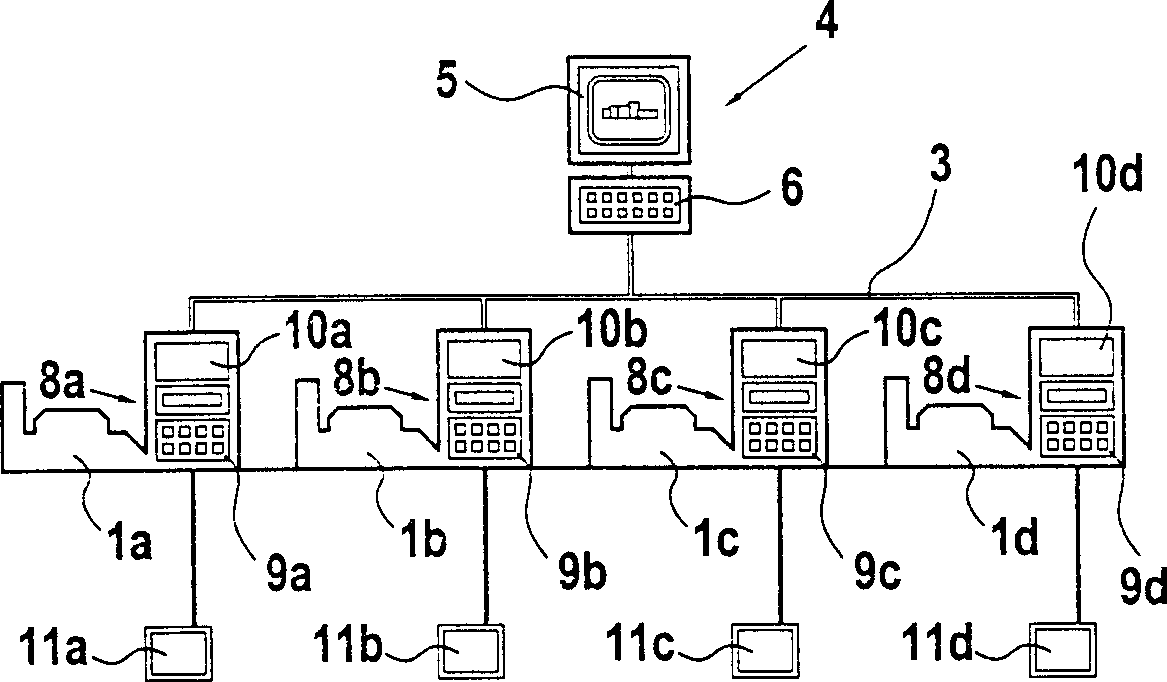

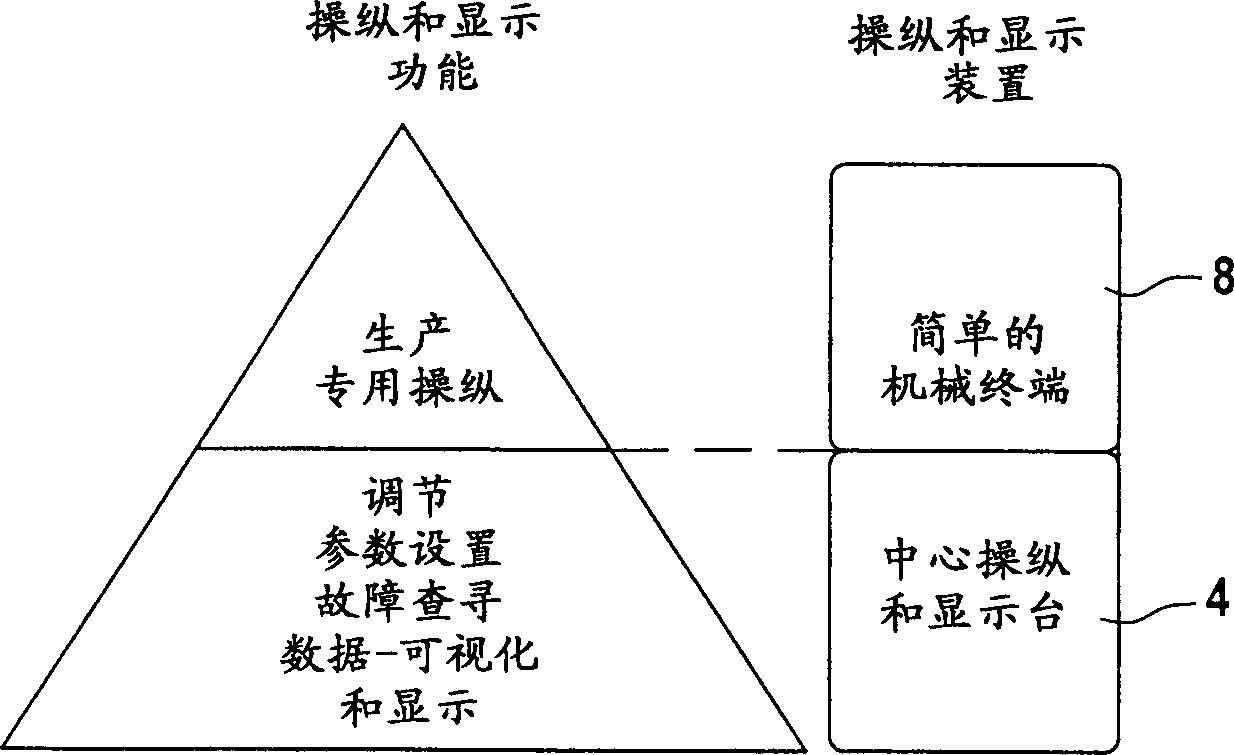

Equipment for proceeding control and display of spinning and weaving equipment and spinning and weaving machine

A control and display arrangement for a spinning preparation system comprising a plurality of machines, e.g. carding machines and / or draw frames, comprises at least one control and display device and the machines each have a machine-related control and display device, all the control and display devices connected to one another via a network. The control and display devicehas a first stationary unit, which substantially comprises a power supply, communications with the network, data storage and management and a computer, and a second mobile unit comprising an operating and display unit .

Owner:TRUETZSCHLER GMBH & CO KG

Device for detecting and separating impurity in or between fiber materials on spinning preparation machine

ActiveCN101736450AAvoid pollutionImprove separation efficiencySafety devices for fibre treatmentInvestigating moving fluids/granular solidsImpuritySensor system

The present invention provides a device used for detecting and separating impurity in or between fiber materials on a spinning preparation machine (or a cotton gin or analog). The device is provided with a fiber transmission pipe. A sensor system for detecting the impurity and a separation device are sequentially provided along the pipe in the transmission direction. The separation device is provided with at least one compression air nozzle (for blowing air) which operates transversely with the fiber transmission pipe. The fiber transmission pipe is provided with a first opening opposite with the compression air nozzle. The first opening is introduced to a separation chamber connected with a waste discharge device. Furthermore the blowing air from at least one compression air nozzle can be supplied to the conveying air flow in a closed system from the separation chamber through an additional opening. For reliably insulating the impurity from the fiber material flow with a mode with simple structure and preventing generating negative influence for the air balance, the separation chamber is integrally connected with the fiber transmission pipe. Furthermore the blowing air passes through a filter, a sieve or analog before returning to the conveying air flow.

Owner:TRUETZSCHLER GRP SE

System and method for recycling fibers from textiles waste

ActiveUS20190226125A1Fibre cleaning and opening machine combinationsSolid waste disposalFibre treatmentPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

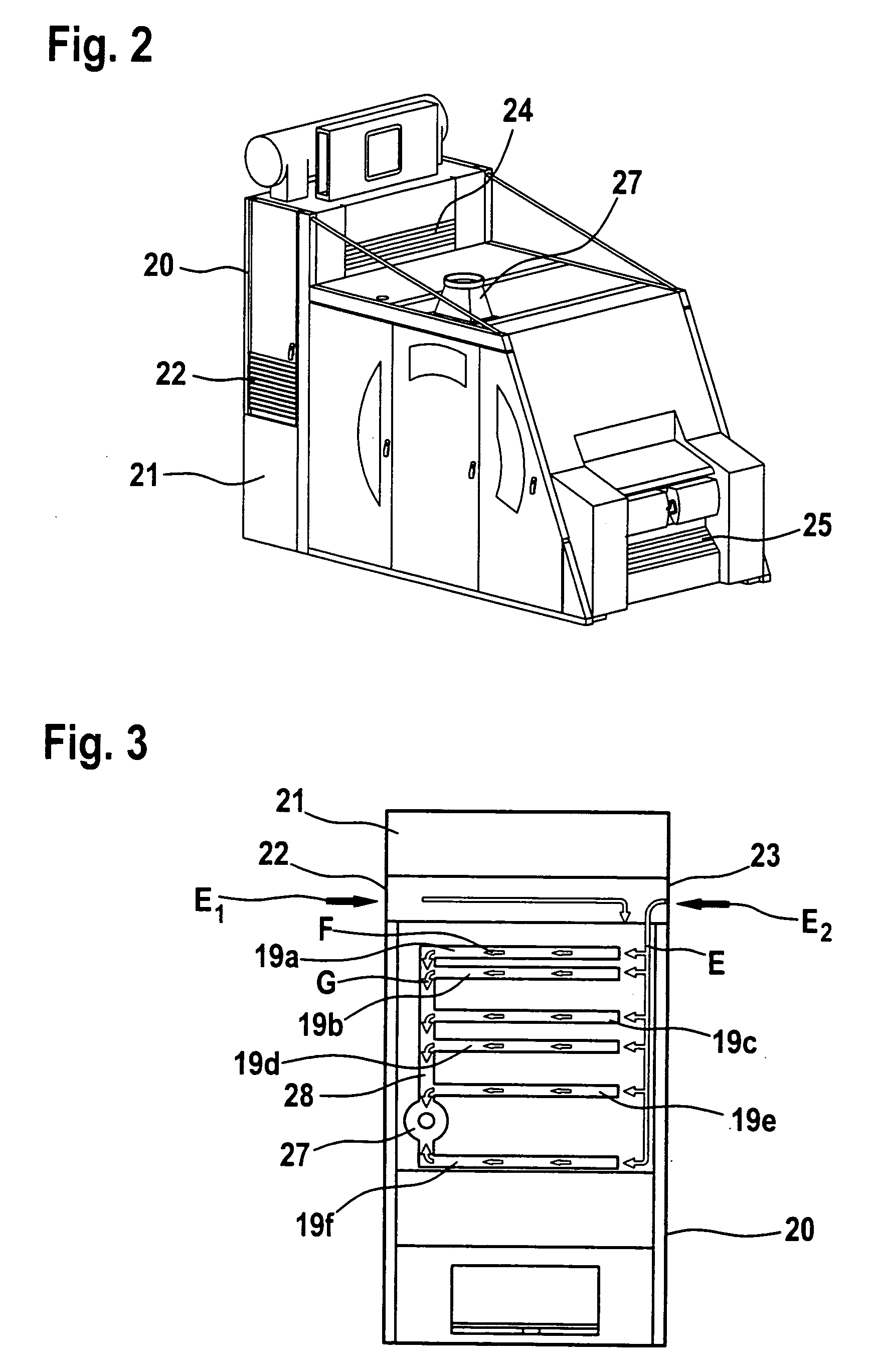

Device on a textile machine, especially a spinning preparation machine, for cooling heat-emitting electrical components

InactiveUS20080236178A1Economical and low-maintenanceImprove productivitySafety devices for fibre treatmentLighting and heating apparatusElectrical switchingAirflow

In a device on a textile machine, for cooling heat-emitting electrical components, for example electrical switching devices and / or switch cabinets, the heat-emitting components are cooled by an air stream. In order to provide a device that ensures the necessary cooling in a structurally simple way and is economical and low-maintenance, at least one partial air stream of the supply air to the machine is guidable towards the heat-emitting components and the supply air is able to absorb heat from the components and subsequently flow via outlet through components of the textile machine.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus used on spinning room preparation machine

ActiveCN101654819ASavings RegulatorSimplified adjustment procedureSafety devices for fibre treatmentDrafting machinesFiberEngineering

An apparatus used on a spinning room preparation machine, which is specially a carding mechine, a draw frame, a combing machine or a bobbiner and has a drafting mechanism for drafting strand fibre materials, has a pair of scanning rollers pressed against one another for continuously recording the cross-sectional area and / or fibre amount of at least one fibre strip, wherein one of the rollers is immovable and the other roller is arranged that it can deviate from the immovable roller. The apparatus has a non-contact spacing sensor for measuring the spacing from the corresponding surface (sensedsurface), used to be integrated into the holding element of one of the rolls. In order to arrange the spacing sensor in simple modus specially in limited spacing and improve the connection between thespacing sensor and the sensed surface, the spacing sensor and the corresponding surface are arranged at the mutually faced lateral parts of the holding element.

Owner:TRUETZSCHLER GRP SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com