Device in spinning room preparaed for detecting foreign bodies made of plastics, such as polypropylene tapes, fabrics and films and the like

A technology of polypropylene tape and foreign matter, which is applied in the field of devices in spinning workshops, and can solve problems such as large machines, low optical contrast, and separators that cannot be detected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

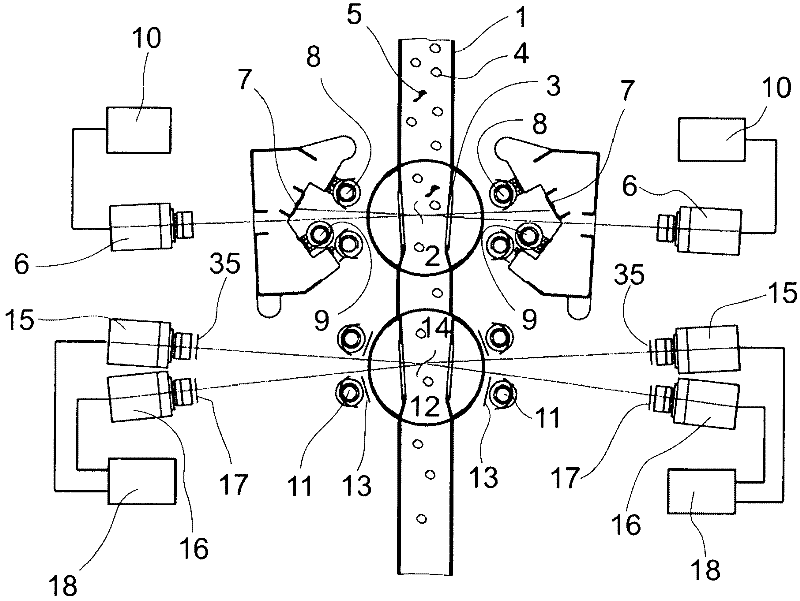

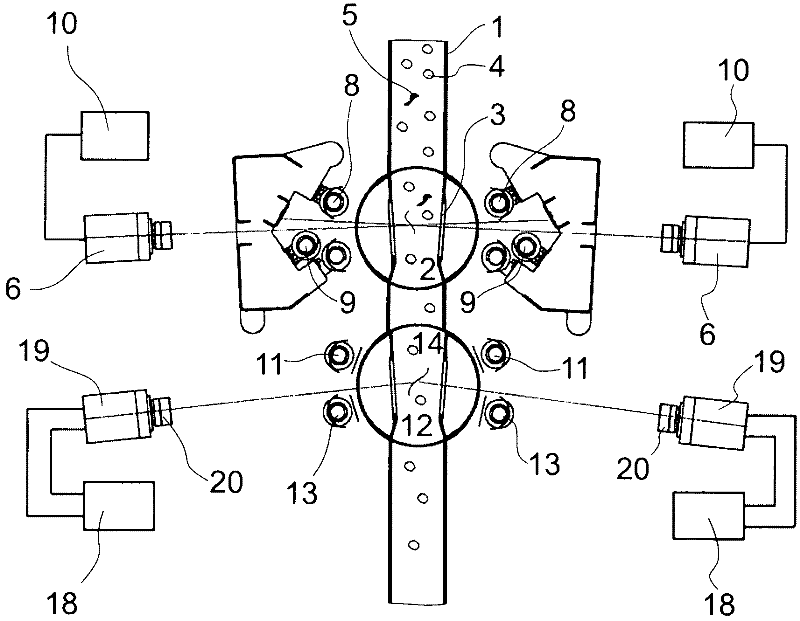

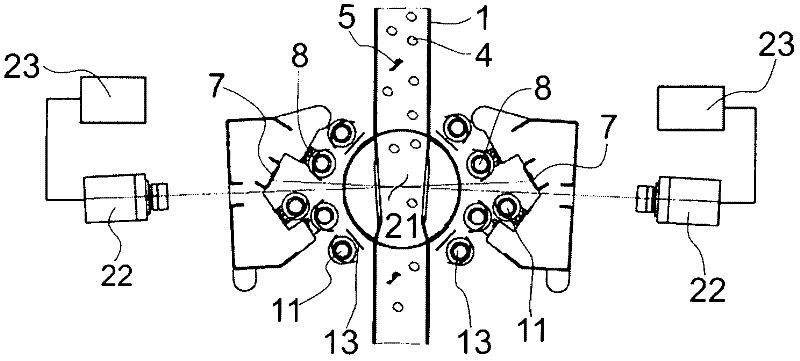

[0020] figure 1 A test channel 1 with a transparent wall 3 is shown in the test region 2 , through which the fiber bundles 4 to be tested and foreign bodies 5 flow. Two cameras 6 (one on each side) are pointed into the tunnel and encounter a material-coloured background plate 7 on the respective other side. For the illumination, for example a light emitting tube 8 is used, which emits white unpolarized light in the visible wavelength range. Another luminous tube 9 illuminates the background plate 7 . The light reflected by the fiber tuft 4 or the foreign object 5 is received by a camera 6 and analyzed by an evaluator 10 for brightness and color. It is preferred here that the cameras are able to receive light in the red, green or blue wavelength range of the channel and further process it separately, but in simple cases black / white cameras can also be used if their sensitivity For example if limited to the visible part of the spectrum by using filters.

[0021] Using one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com