Multi-channel detection foreign fiber sorting machine with CCD camera and ultrasonic sensor

A sensor and ultrasonic technology, applied in the field of multi-channel detection foreign fiber sorting machine, can solve the problems that impurities cannot be detected and removed, and affect the quality of cotton, etc., and achieve the effect of simple and convenient maintenance, strong anti-interference ability and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

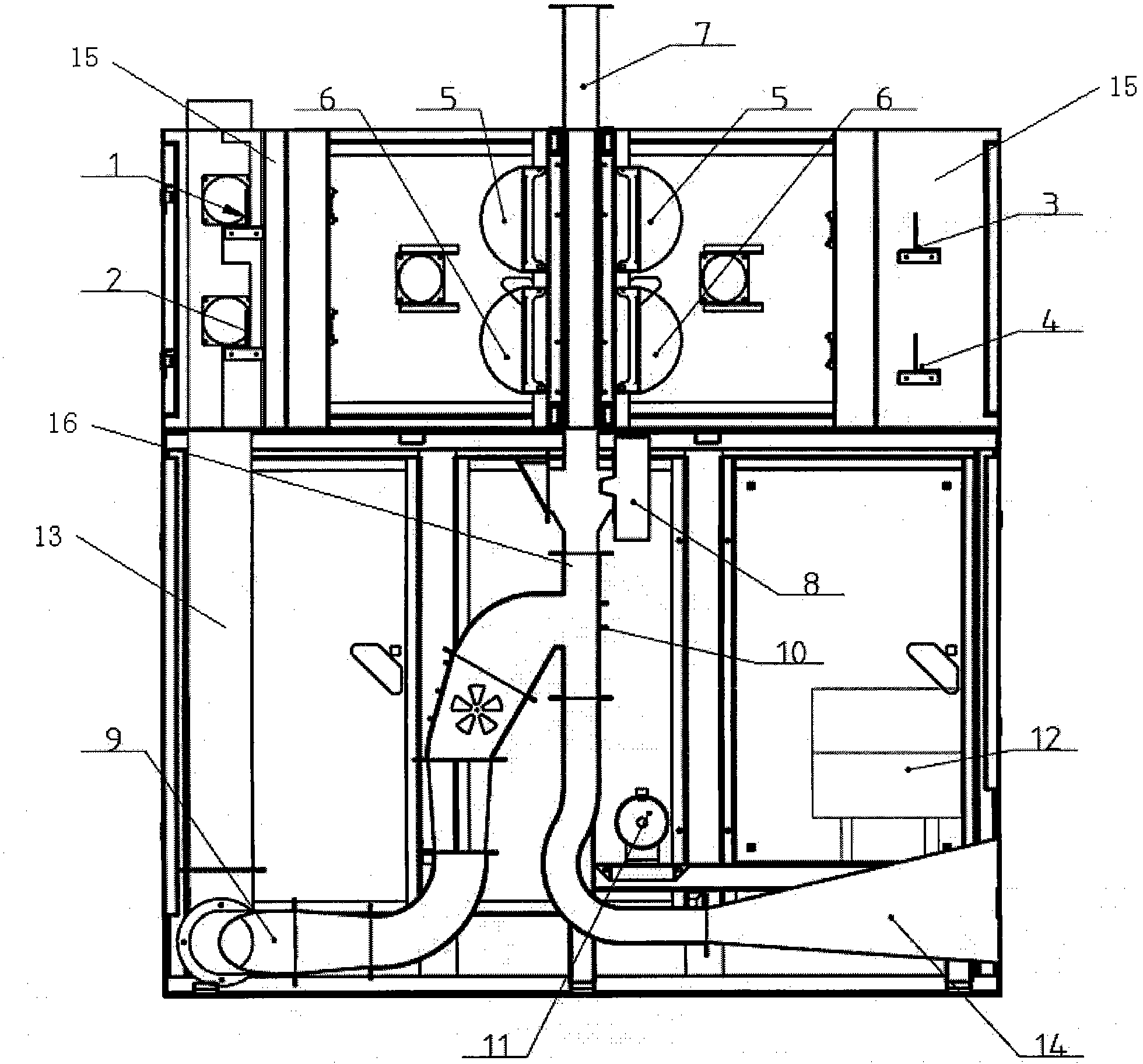

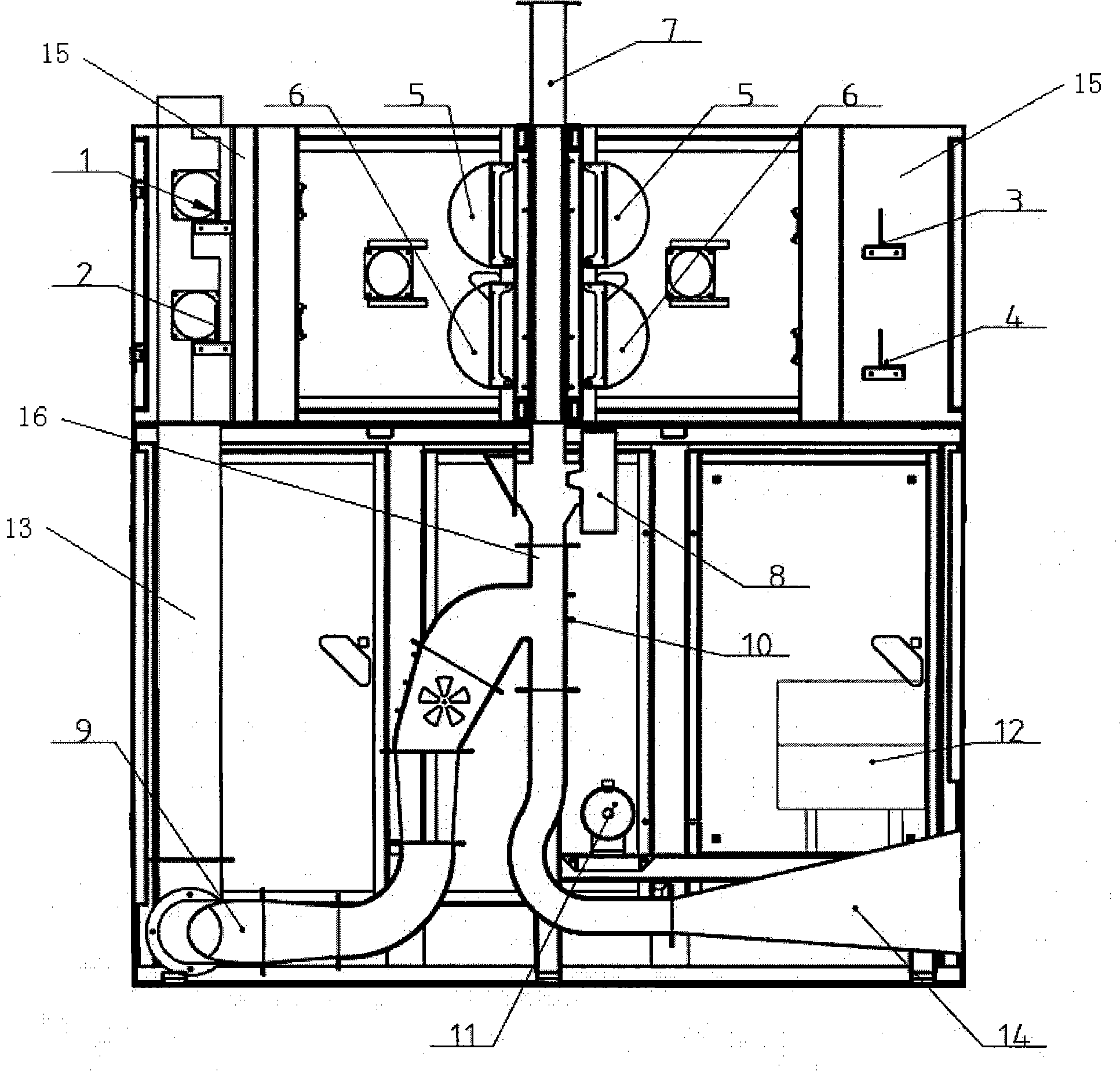

[0011] Such as figure 1 Shown: the present invention includes a first color line scan CCD camera 1, a first black and white line scan CCD camera 2, a second color line scan CCD camera 3, a second black and white line scan CCD camera 4, and a first lighting device 5. The second lighting device 6, the cotton pipe 7, the ultrasonic sensor 8, the foreign fiber pipe 9, the high-pressure solenoid valve 10, the high-pressure gas storage tank 11, the industrial control box 12, the box body 13, the outlet pipe 14, the installation block 15 and the connection Tube 16.

[0012] Such as figure 1 As shown: the central area of the box body 13 is provided with a cotton passing pipe 7, and one end of the cotton passing pipe 7 penetrates into the box body 13. The two sides corresponding to the cotton pipe 7 in the casing 13 are provided with installation blocks 15, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com