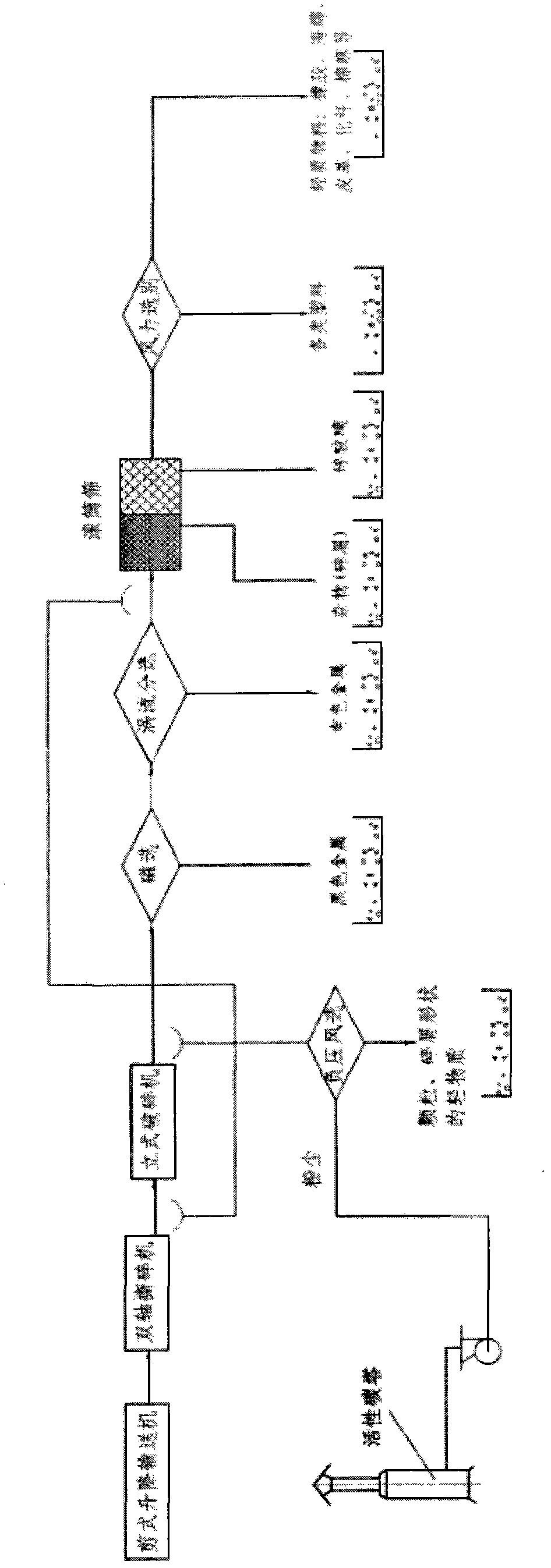

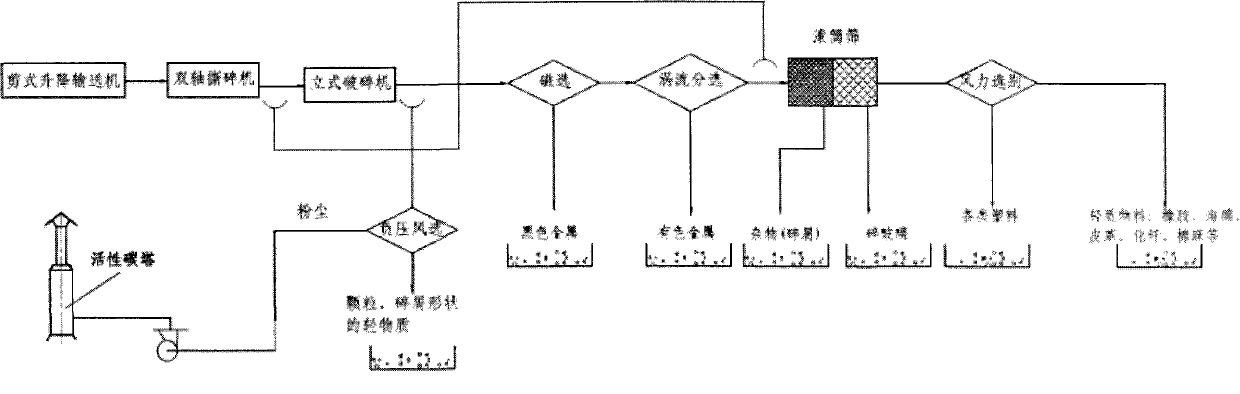

Fragmentation separation process flow for end-of-life automobile body

A technology for scrapping automobiles and technological processes, applied in the fields of comprehensive utilization of resources and environmental protection, can solve the problems of high labor intensity, low processing efficiency, environmental pollution, etc., and achieve the effects of high degree of automation, low noise, and friendly working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Referring to the accompanying drawings, the crushing and sorting process of the scrapped automobile body of the present invention is as follows: the scrapped automobile body is put into the feed hopper of the primary crusher through the elevator, and the primary crusher adopts a double-shaft shredder to crush the automobile body into strips. Fragments, generally between 5-20cm×20-60cm in size, are sent to the secondary crusher through the primary belt conveyor. The secondary crusher adopts a vertical crusher to further crush the strip-shaped fragments into more The small fragments are generally 3-20cm in size, which is convenient for later selection. There is a negative pressure system at the outlet of the secondary crusher, which is used to send the crushed light materials to the cyclone separator and bag filter, and the heavier materials are sent to the magnetic separator by the secondary belt conveyor to separate the black materials. The metals are separated, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com