Patents

Literature

86results about How to "Friendly working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

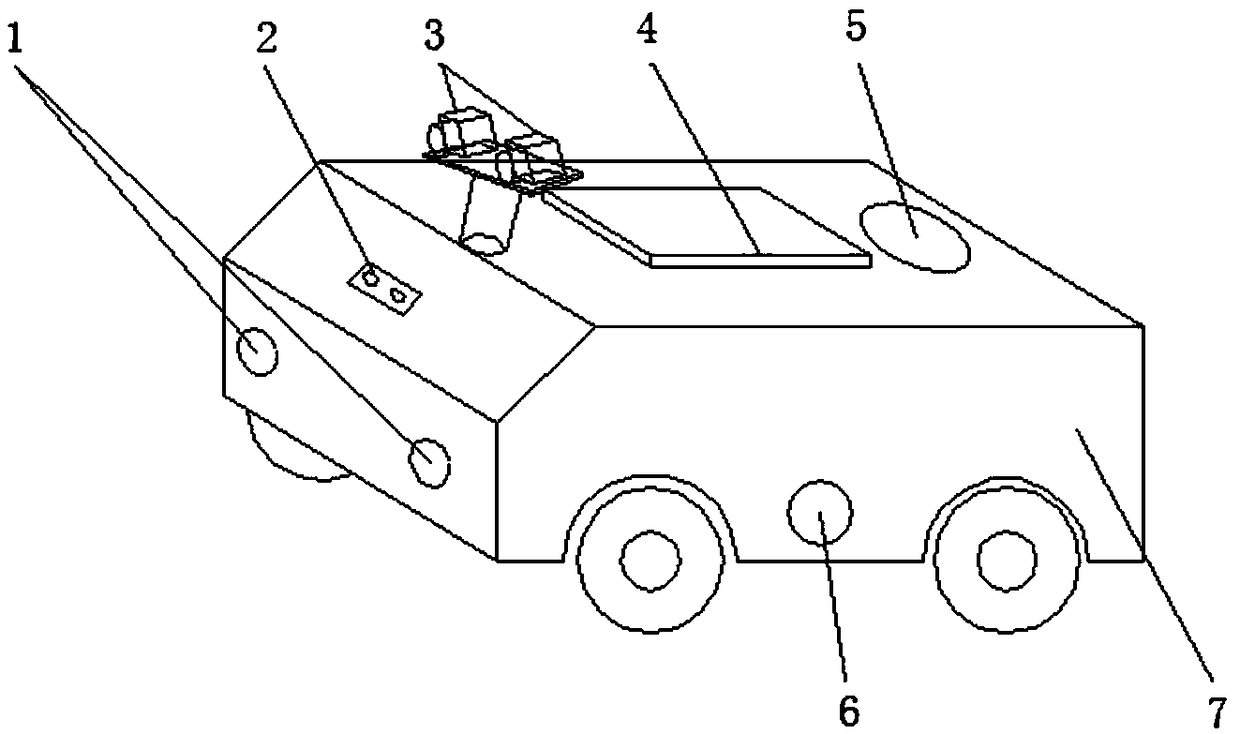

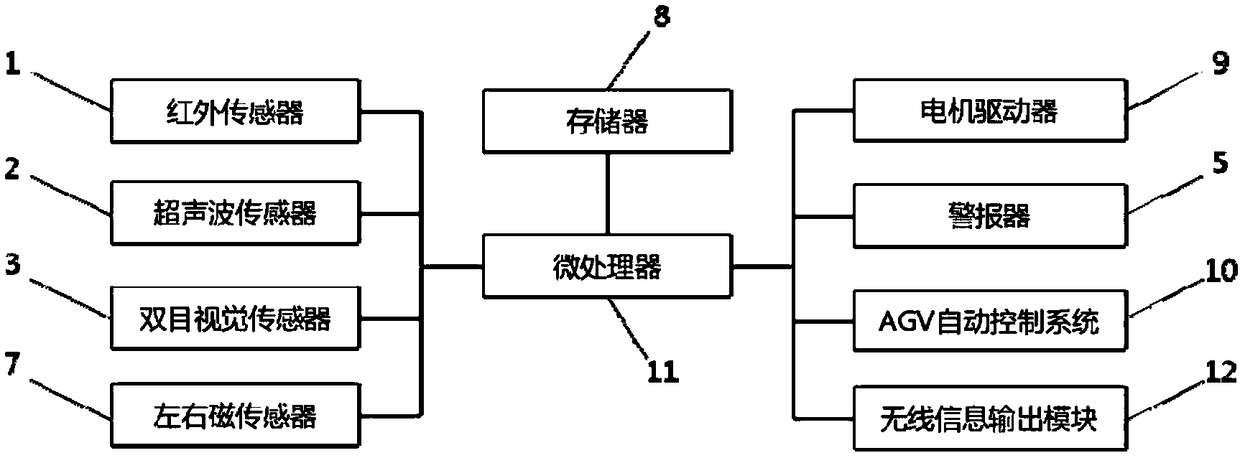

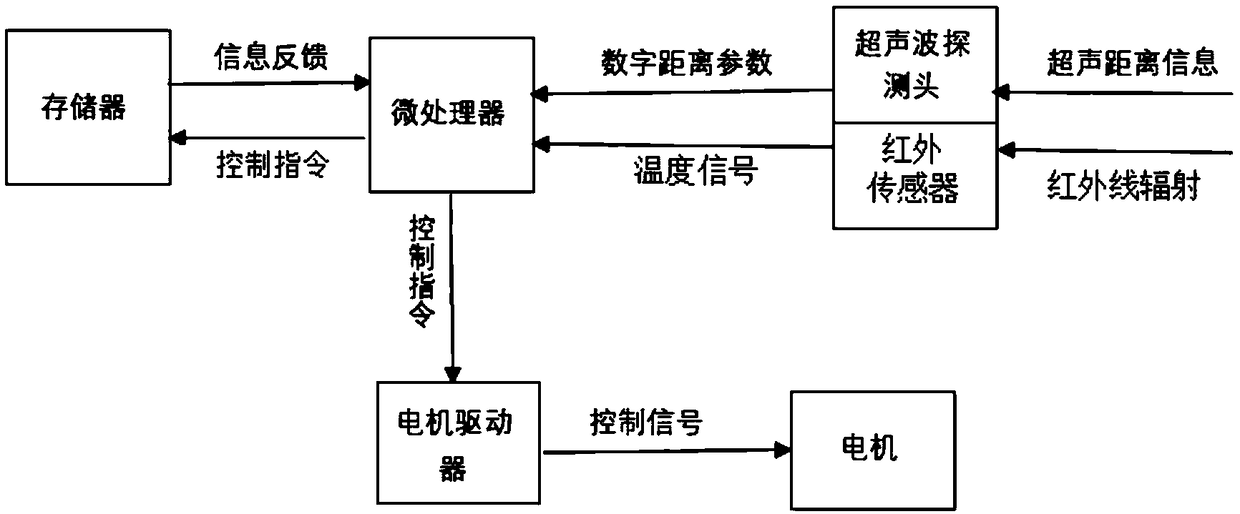

Automatic rail deviation correction device and automatic rail deviation correction method for AGV trolley

ActiveCN108762276ARealize automatic off-track correction functionIncrease productivityPosition/course control in two dimensionsVehiclesMicrocontrollerAutomatic control

The invention discloses an automatic rail deviation correction device and automatic rail deviation correction method for an AGV trolley. The automatic rail deviation correction device is composed of an infrared sensor, an ultrasonic sensor, a binocular vision sensor, left and right electromagnetic sensors, an alarm device, a printed circuit board, a microcontroller, a wireless information transmission module, a power source module, a motor driver, a memory, and an AGV automatic control system. The microcontroller is configured to identify a magnetic track landmark based on an image acquired bythe binocular vision sensor, analyze the magnetic track direction based on the magnetic track landmark, and send a corresponding instruction to the motor driver to carry out trolley deviation correction. According to the invention, the automatic people avoidance and alarming as well as automatic rail deviation correction function of the SGV trolley is realized; the human-machine friendly workingenvironment is created; the staff is protected from being injured; and the production efficiency of the AGV trolley is improved.

Owner:ANHUI UNIV OF SCI & TECH

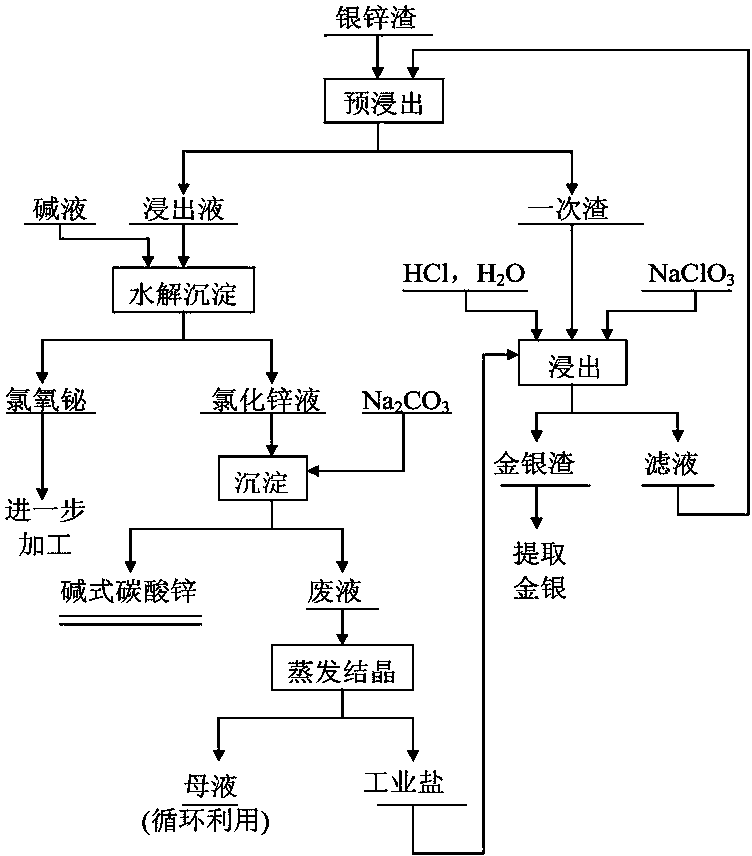

Method for recovering valuable metals from silver-zinc slag

ActiveCN103589873AHigh recovery rateReduce consumptionProcess efficiency improvementSlagEconomic benefits

The invention discloses a method for recovering valuable metals from silver-zinc slag. The method is characterized in that the method comprises the following steps: carrying out oxidation leaching of the silver-zinc slag by adopting a NaClO3-NaCl-HCl system through a pre-leaching and leaching stage countercurrent extracting technology; allowing base metals comprising bismuth, zinc and the like to enter a solution, carrying out hydrolysis precipitation to obtain bismuth oxychloride, and precipitating a zinc chloride solution with soda ash to obtain basic zinc carbonate; and enriching gold and silver in slag, and extracting. The method has the advantages of reasonable technology, short and feasible flow, high metal recovery rate, good comprehensive recovery and substantial economic benefit.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

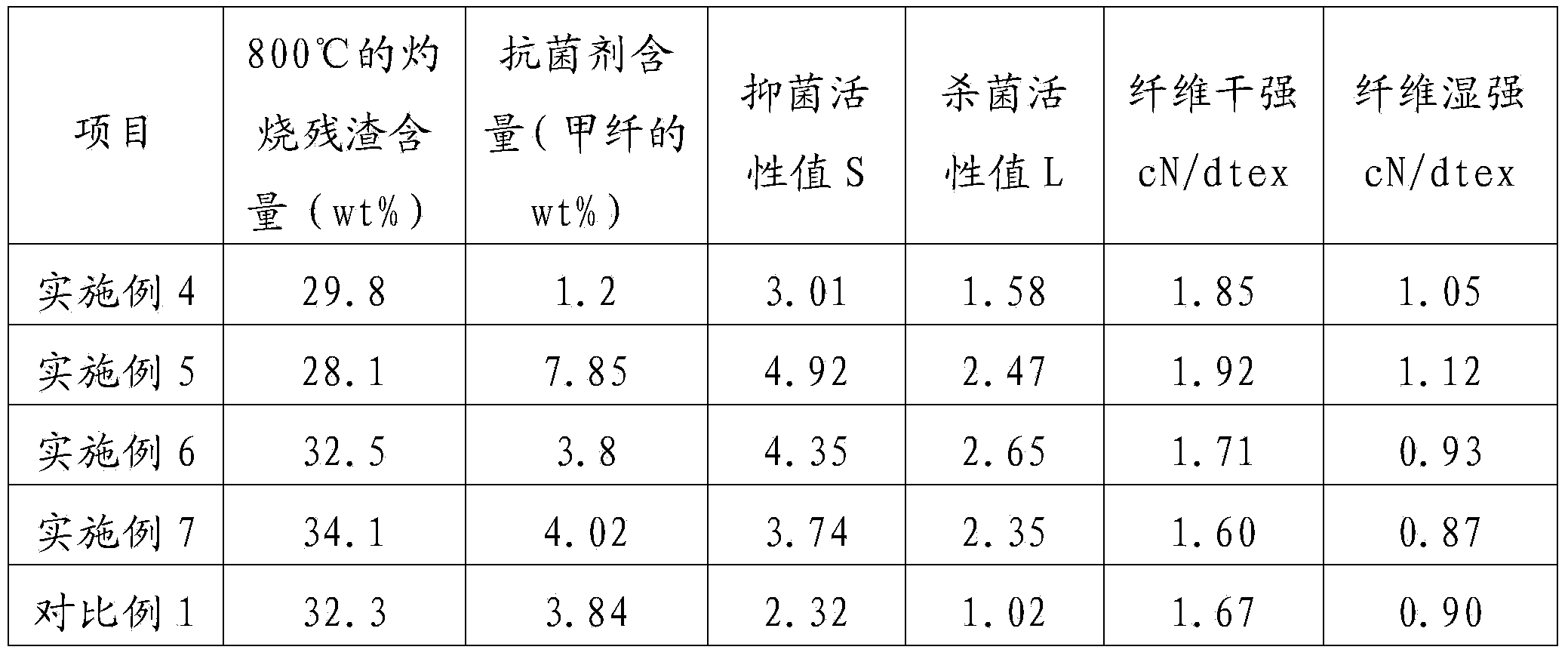

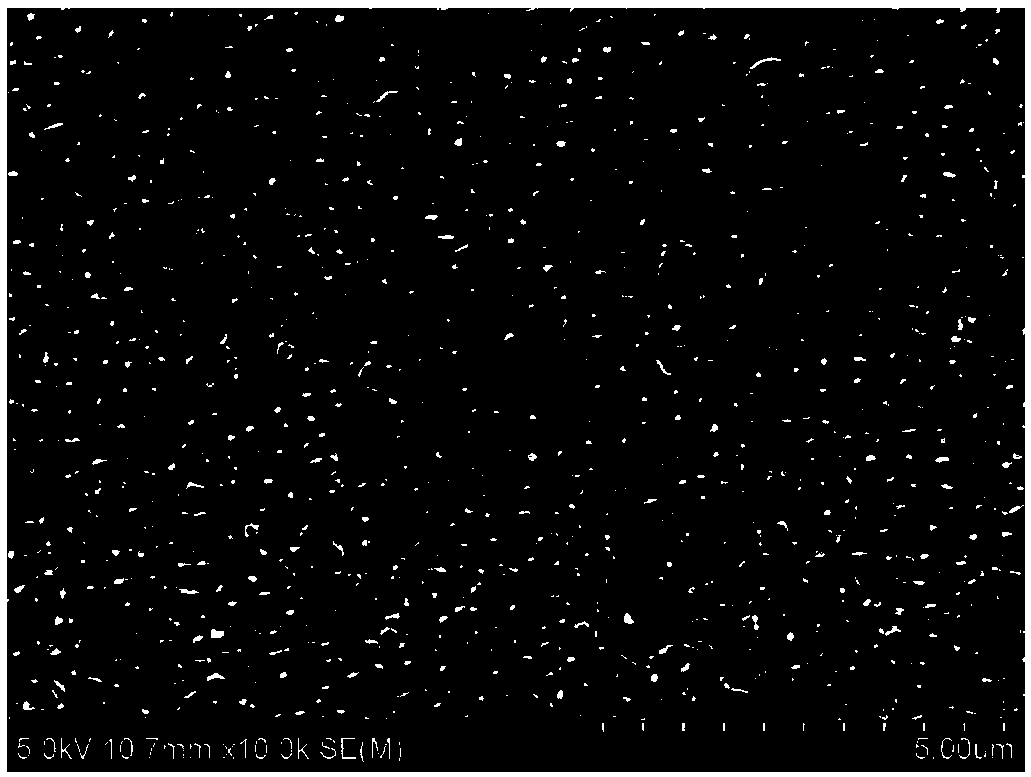

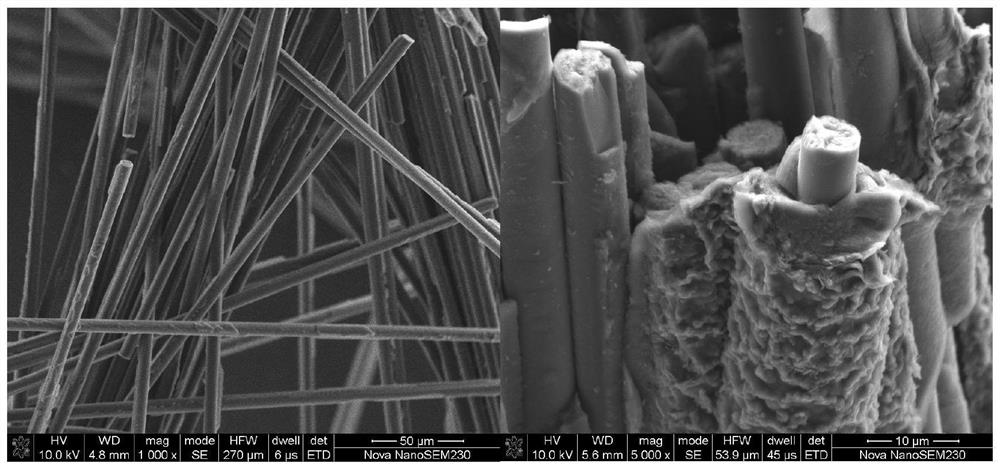

Functional composite fiber and preparation method thereof

ActiveCN103643332AGood antibacterial effectPromote degradationArtificial filaments from viscoseWet spinning methodsCellulose pulpSilicon dioxide

The invention discloses a functional composite fiber and a preparation method thereof. The functional composite fiber comprises 15wt%-45wt% of silicon dioxide and 0.5wt%-10wt% of chitosan quaternary ammonium salt. The preparation method comprises the following steps: (1) preparing an antiseptic solution from the chitosan quaternary ammonium salt, deionized water and sodium hydroxide; (2) preparing alkali cellulose from cellulose pulp, yellowing the alkali cellulose and dissolving the yellowed alkali cellulose in a sodium hydroxide solution of the silicon dioxide, wherein the solid content of spinning viscose containing silicon dioxide is 9.5wt%-11.5wt%; (3) adding the antiseptic solution into the viscose solution containing silicon dioxide in any step from yellowing to spinning to prepare a blended viscose solution, wherein the weight of the chitosan quaternary ammonium salt in the added antiseptic solution accounts for 0.5%-10% of that of the solid in the viscose solution; and (4) performing spinning forming and after-treating on the blended viscose solution to obtain the functional composite fiber. The functional composite fiber prepared by the method has both flame retardant and antibacterial properties.

Owner:赛得利(盐城)纤维有限公司

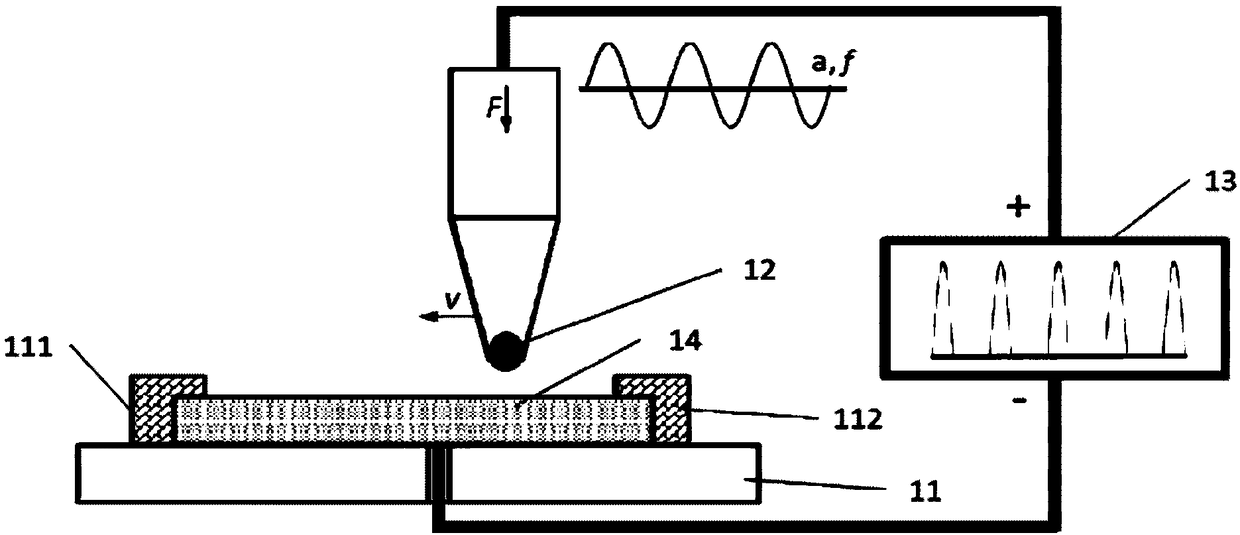

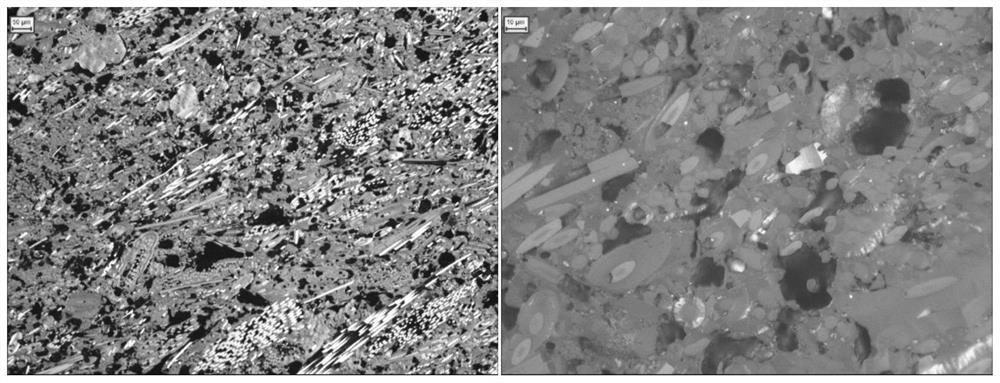

Metal component optimization method based on additive process forming and forming equipment with same

InactiveCN109158829AHigh densityExcellent surface hardnessAdditive manufacturing apparatusManufacturing technologyStressed state

The invention relates to the technical field of metal component additive manufacturing, and discloses a metal component optimization method based on additive process forming and forming equipment withthe same. The metal component optimization method comprises the following steps that a metal component prepared by an additive process is arranged, and a cladding layer is arranged on the metal component; ultrasonic rolling treatment is performed on the cladding layer; and a pulse current is applied to the metal component. According to the method and the equipment, an internal structure of the metal component can be regulated, the defects of holes, microcracks and the like can be reduced, the compactness of a base body can be improved, the stress state of the component is regulated, the surface quality, the precision and the stability of the metal component are improved, the comprehensive service performance of the metal component, such as the surface hardness, the wear resistance, the fatigue resistance and the corrosion resistance, can further be improved, extra heat treatment is not needed, and the metal component optimization method based on the additive process forming and the forming equipment with the same have the advantages of being efficient, stable in the process, safe, reliable, friendly in working environment, energy-saving, environmentally friendly, green and pollution-free and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

High-speed environment-friendly chemical copper plating solution

InactiveCN102337527AFriendly working environmentIncreased chemical deposition rateLiquid/solution decomposition chemical coatingCopper platingHydantoin derivatives

The invention discloses a high-speed environment-friendly chemical copper plating solution, which relates to a chemical copper plating solution and solves the technical problem of low copper plating speed of the conventional chemical copper plating solution. The high-speed environment-friendly chemical copper plating solution consists of copper sulfate, sodium hypophosphite, guanidine monohydrochloride, a catalyst, a combined coordination agent, a combined stabilizing agent and water, wherein the catalyst is metal salt containing nickel, cobalt and iron; the combined coordination agent consists of iminodiacetic acid, dimethyl hydantoin and potassium sodium tartrate, the mass ratio of the dimethyl hydantoin to the potassium sodium tartrate is 1:(2-3), and the mass ratio of the dimethyl hydantoin to the iminodiacetic acid is 1:(7-8); and the combined stabilizing agent consists of thiocarbamide and 2,2'-bipyridyl in the mass ratio of 1:(5-6). In the invention, the plating solution has the chemical deposition speed of 10 to 40 micrometers / hour, and can be used for chemically plating copper on the surfaces of matrixes such as printed circuit board holes, ceramics, plastics and the like.

Owner:HARBIN INST OF TECH

Light thermal insulation coating

InactiveCN102674865AImprove thermal stabilityImprove sintering performanceAluminateThermal insulation

The invention relates to a light thermal insulation coating, which is characterized by consisting of refractory cellucotton, aluminate cement, flint clay powder, micro-porous light mullite powder, clay and solid water glass powder, wherein the materials are stirred by adding water and then subjected to coating construction. The light thermal insulation coating is characterized by comprising the following coating raw materials in percentage by weight: 15-30 percent of refractory cellucotton, 15-20 percent of micro-porous light mullite powder, 20-30 percent of aluminate cement, 10-20 percent of flint clay powder, 3-10 percent of clay and 3-6 pecent of solid water glass. The proportioned mixture is uniformly stirred, 20-45 percent of water is added, the mixture is stirred to a proper state to perform coating construction, and the materials are adhered to a construction body. The light thermal insulation coating has the advantages of good thermal insulation effect, high extreme cold and heat resistance, easiness in improvement on strength and coating, friendliness to operation environment, manual direct coating, high adhesion and capability of being constructed on a wall surface and a steel plate without an anchor member at any angle.

Owner:山国强

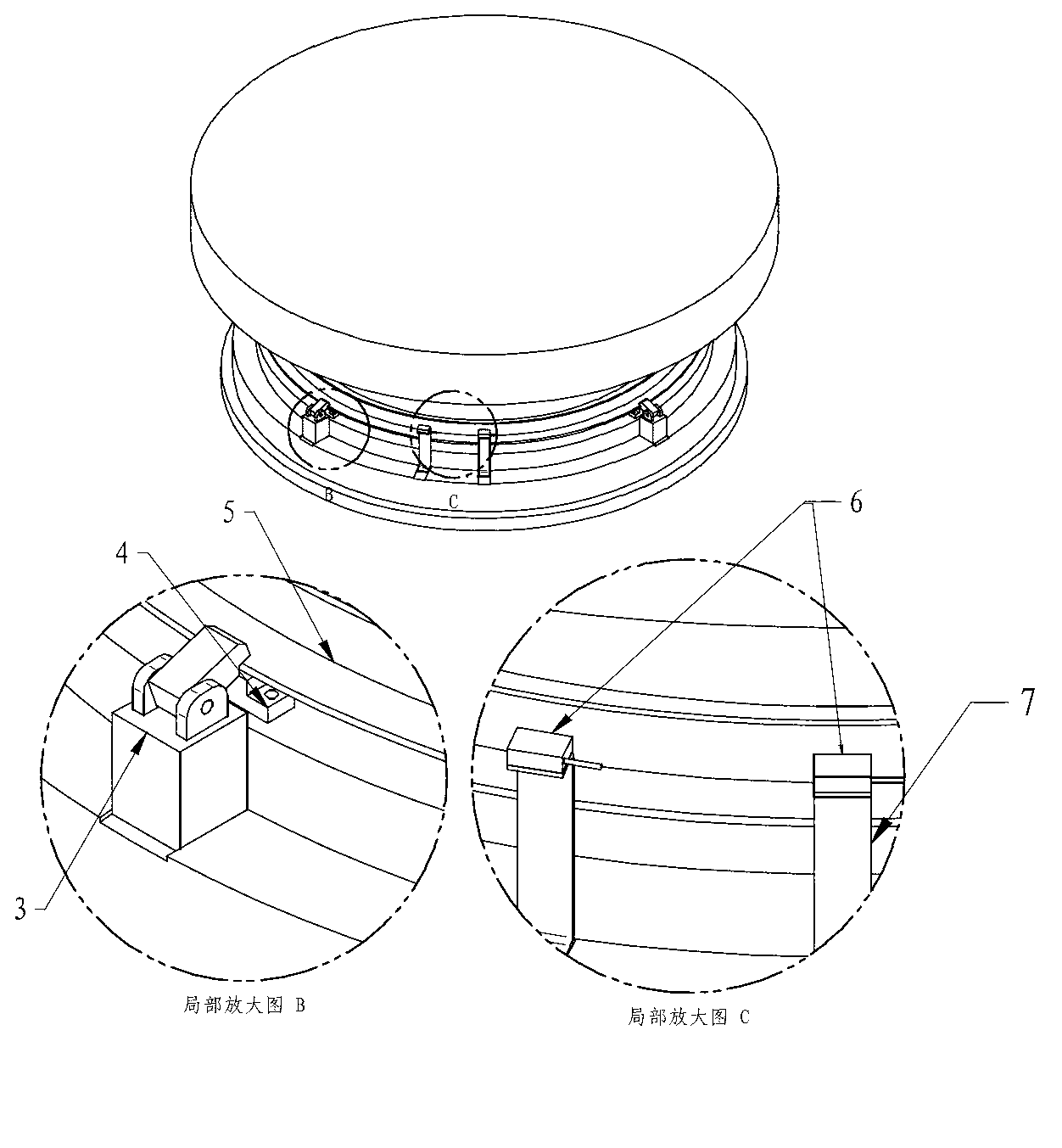

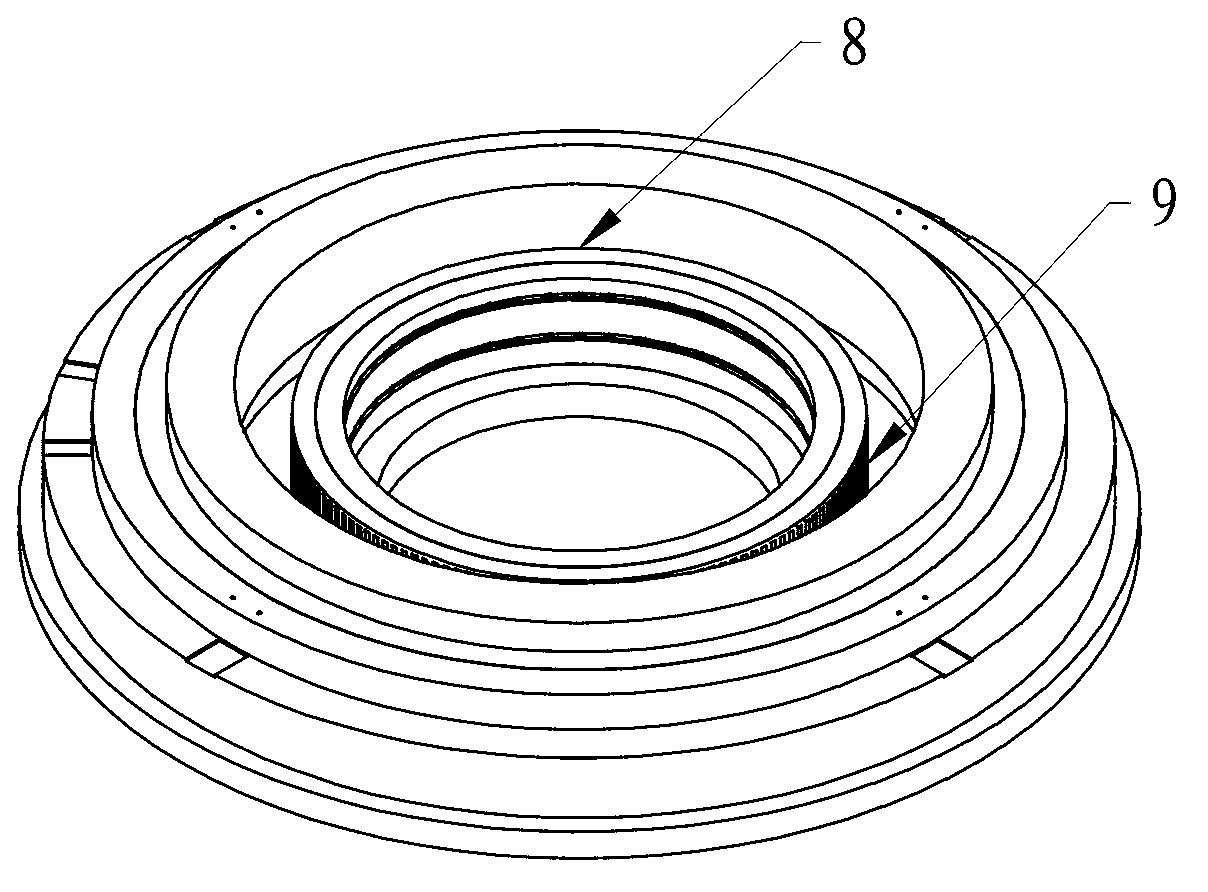

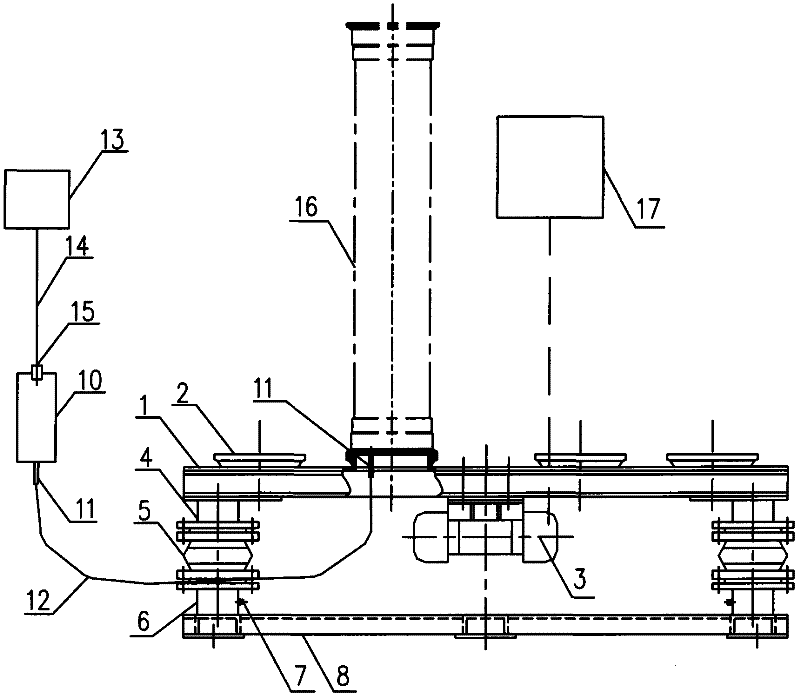

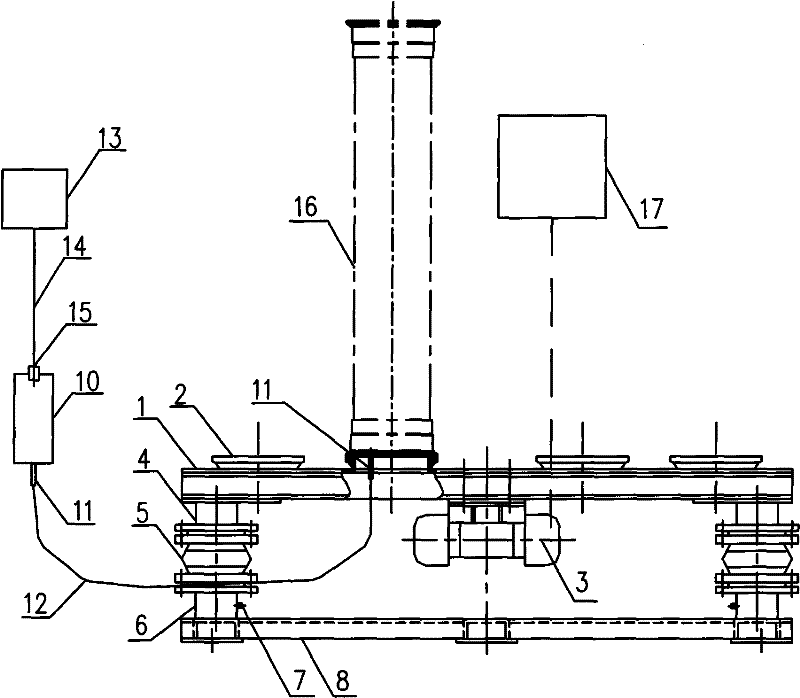

Large-moment direct-drive plane rotary platform device

InactiveCN102794755AEliminate Symptoms of Low AccuracyReduce precision errorWork benchesHydraulic cylinderWorking environment

The invention belongs to the technical field of an operation platform and relates to a large-moment direct-drive plane rotary platform device. A base, a core shaft, a coil winding, a hydraulic cylinder, a hydraulic seat, a reading head seat and a reading head are fixed through bolts to integrally form a stator; a rotor is formed by a tabletop, a hydraulic sheet, a magnet yoke and a magnetic railing ruler; the stator is coupled with the rotor through a bearing and is fixed in an inner ring of the bearing by a bolt; the rotor is fixed on an outer ring of the bearing by a bolt; glue is filled into the coiling winding to be encapsulated, and magnetic steel is stuck on the magnet yoke by glue; stamp gum is coated on the back face of the magnetic railing ruler, and magnetic railing rule is directly adhered to the tabletop; the hydraulic cylinder and the hydraulic seat are sequentially fixed on the base; the hydraulic sheet is fixed between the hydraulic seat and a pressing head of the hydraulic cylinder of the tabletop; the reading head and the reading head seat are sequentially fixed on the base; the coil winding is uniformly wound and fixed on the core shaft; and the magnetic railing ruler is fixed on the side face of the tabletop. The large-moment direct-drive plane rotary platform device disclosed by the invention has the advantages of simple structure, easiness in control, large moment, stability in rotation, high positioning precision, long service life and friendly working environment.

Owner:青岛同日电机有限公司

Method for recovering metal lead from solid lead oxide

ActiveCN104711637AFriendly working environmentEasy to operatePhotography auxillary processesElectrolysisPower flow

The invention relates to a method for recovering metal lead from solid lead oxide. The method is characterized by comprising the following steps: (1) subjecting vulcanized lead concentrate to chlorination leaching, and crystallizing the leachate to obtain solid lead chloride; (2) carrying out first conversion on the solid lead chloride by using calcium oxide to generate basic lead chloride PbOHCl, and then carrying out second conversion between PbOHCl and a sodium hydroxide solution to obtain solid lead oxide; (3) preparing a sodium hydroxide solution as the electrolyte, mixing a proper amount of electrolyte and lead oxide, stirring to obtain paste, evenly painting the paste on a negative electrode plate, installing the negative electrode plate and a positive electrode plate into an electrolysis tank, and carrying out electrolysis; (4) after the electrolysis, peeling off the sponge lead from the negative electrode plate, pressing the sponge lead into balls, and casting the lead balls into lead ingots. The provided method can solve the problems existing in the process of recovering lead from chlorinated leachate of vulcanized lead concentrate through a conversion-solid electrolysis technology, and has the advantages of friendly operation environment, strong operability, high current efficiency, and low production cost.

Owner:SHENYANG RES INST OF NONFERROUS METALS

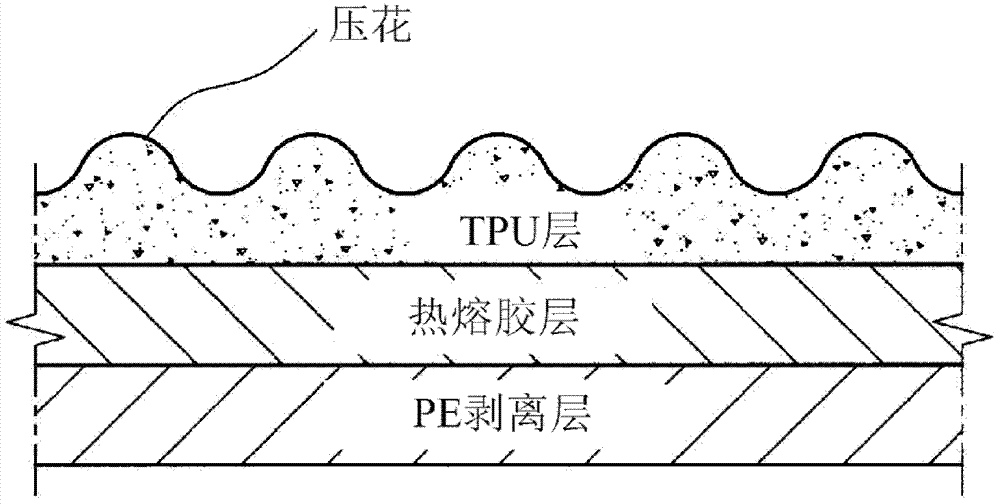

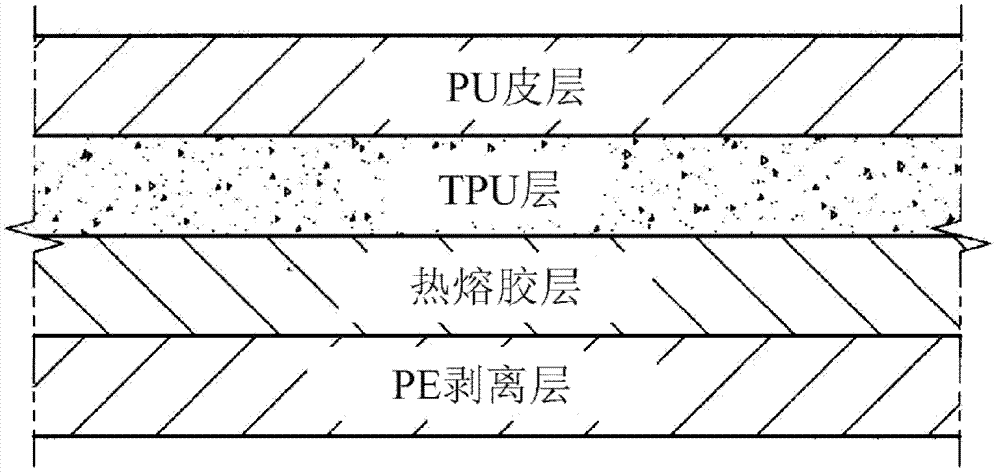

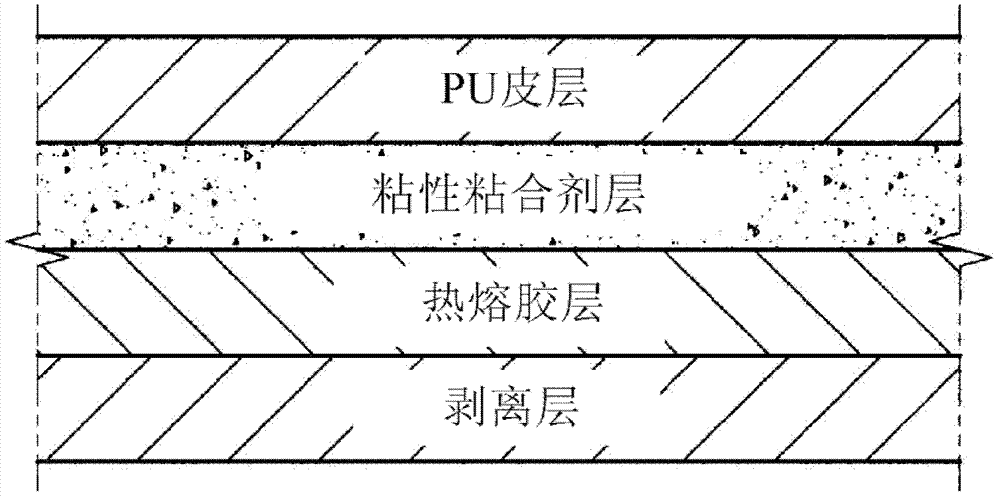

Method for manufacturing colorful multilayer sheets

InactiveCN103085403AHealth injuryFriendly working environmentSynthetic resin layered productsThermoplastic polyurethaneSolvent

The invention discloses a method for manufacturing colorful multilayer sheets. The method does not use tacky adhesions, concretely the tacky adhesions containing DMF or MEK solvents, during the manufacturing of mono-color or multicolor multilayer sheets used for vamps, thereby preventing formation of bubbles in the sheet materials and creases in sheet layers, and improving road holding of frictional forces. The method further comprises embossing appearance designs such as patterns on surfaces of thermoplastic polyurethane so as to improve adhesion stress of a TPU layer and a PU layer, thereby preventing the PU layer from separating from a hot melt adhesive layer.

Owner:朴喜大

Method for preparing glass fiber reinforced plastic through vacuum flow guide

The invention discloses a method for preparing glass fiber reinforced plastic through vacuum flow guide. The method comprises the following steps: laying a fiber cloth in a die, starting a vacuum pumpand vacuumizing to enable the vacuum degree of a sealed space in the die to achieve 0.08-0.1MPa, pouring matrix resin into the die, and curing to form the glass fiber reinforced plastic. The processis simple, green and pollution-free; and the composite material has the advantages of being high in mechanical property, wide in application prospect and the like, and is wide in application field.

Owner:徐卫国

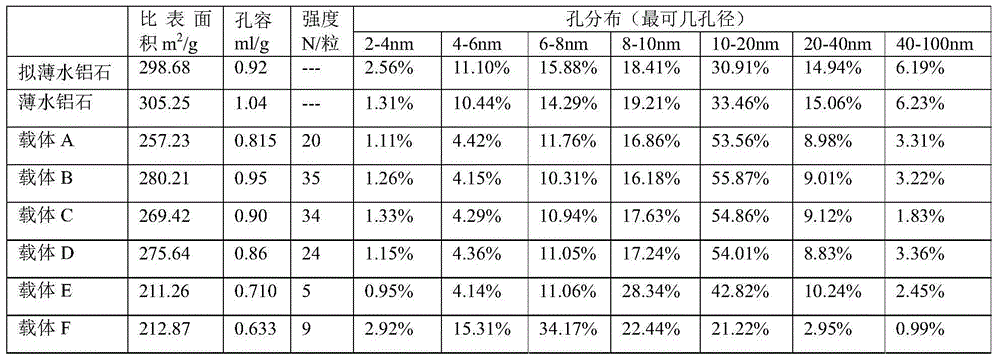

Spherical alumina carrier and preparation method thereof

The invention discloses a spherical alumina carrier and a preparation method thereof. Specifically, the method comprises the steps of: (1) subjecting first raw material powder and a binder to mixing granulation to form wet balls with a particle size of 0.1-3mm; (2) contacting second raw material powder with the wet balls formed in step (1), and then conducting pre-drying, drying, sieving and roasting in order; wherein, the first raw material powder and the second raw material powder are the same or different, and are pseudo-boehmite or a mixture of pseudo-boehmite and boehmite respectively. The spherical alumina carrier prepared by the method provided by the invention has significantly increased strength, the particles size of the formed balls is easily controllable, and the time is short. Also, the preparation method provided by the invention is easy to operate, as strong acid or other peptizers are not added in the granulation process, a large pore volume carrier can be obtained. And the method provided by the invention is carried out in a mixing granulator, the work environment is friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

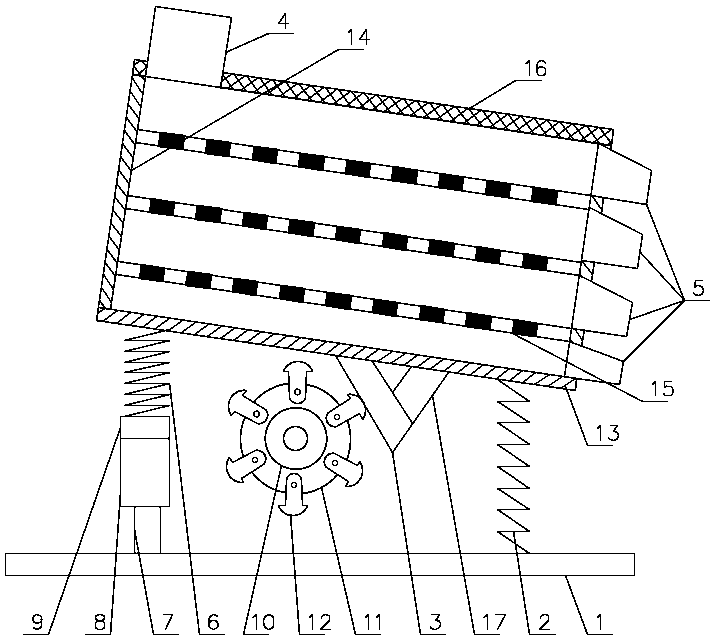

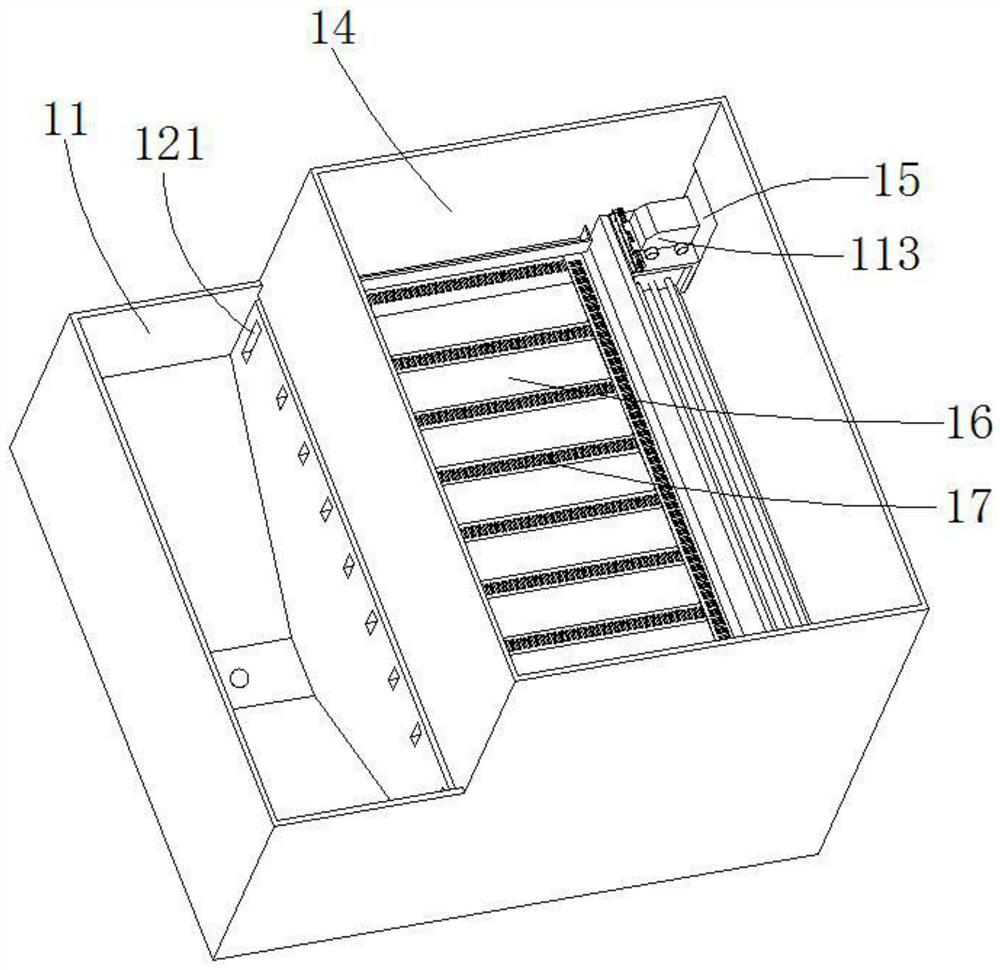

Angle-adjustable multilayer linear vibrating screen for engineering plastic granules

PendingCN110449343AReach screeningTo achieve the purpose of gradingSievingScreeningEngineering plasticEngineering

The invention provides an angle-adjustable multilayer linear vibrating screen for engineering plastic granules. The angle-adjustable multilayer linear vibrating screen comprises a mounting base, wherein one side of the mounting base is connected with a sieve body through two return springs; the other side of the mounting base is connected with the other end of the sieve body through two springs with adjustable heights; a vibration exciting plate with an angle of 45 degrees with the bottom of the sieve body is arranged at the central position of the bottom of the sieve body; a vibration exciterfor striking the vibration exciting plate is arranged on the mounting base; the upper part of the sieve body is provided with a feeding inlet; and the bottom of the inclined side is provided with a discharging outlet. According to the invention, , the vibration excitation in two directions is realized by only one vibration exciter; the equipment is simple in structure, more energy-saving and environment-friendly.

Owner:NANJING QINGYAN POLYMER NEW MATERIAL CO LTD

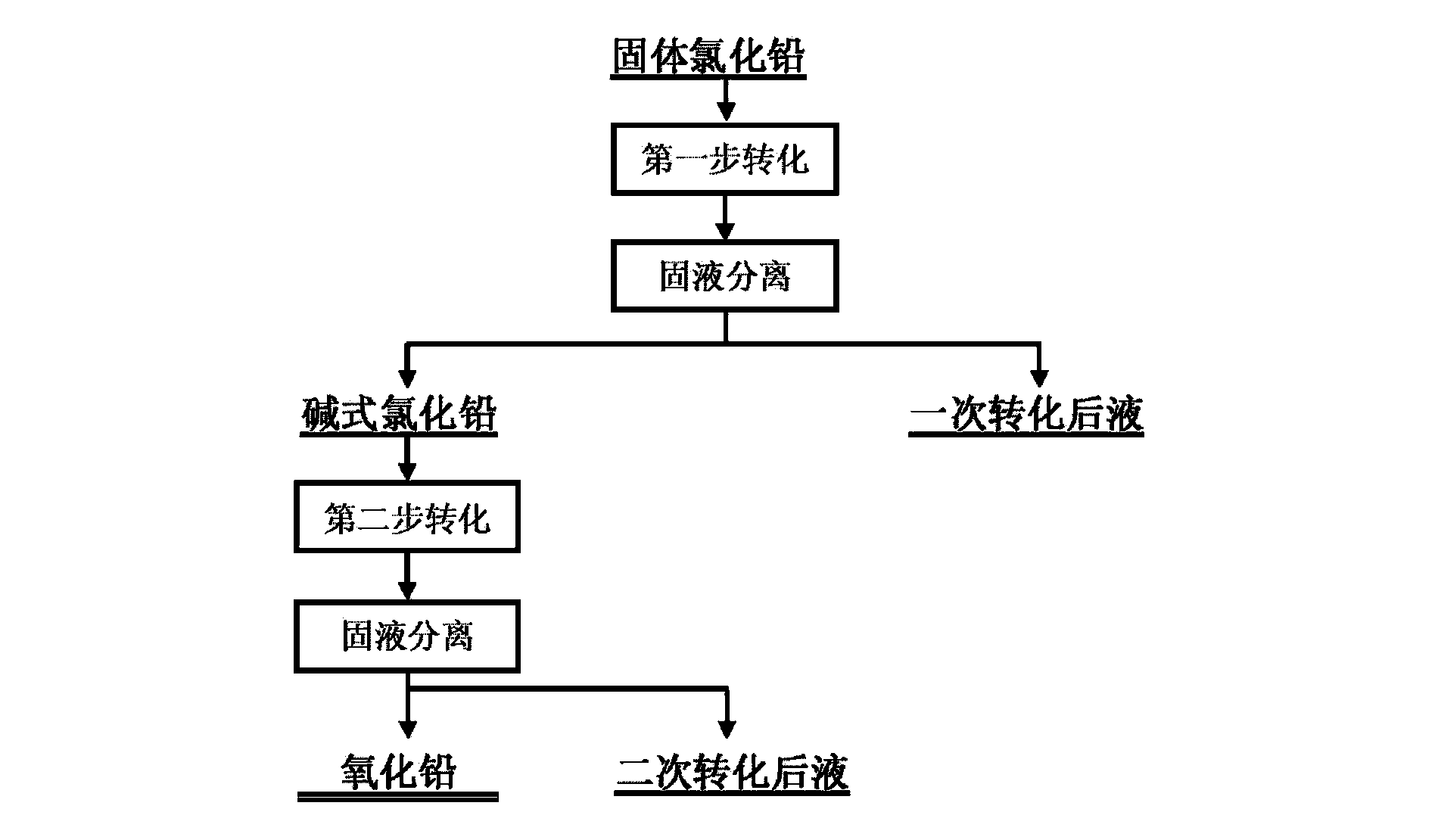

Method for converting solid lead chloride into lead oxide

ActiveCN103570058AAvoid escapes and leaksFriendly working environmentLead monoxideLead chlorideLead oxide

A method for converting solid lead chloride into lead oxide is characterized by comprising the following steps: (1) placing solid lead chloride and calcium oxide according to a liquid-solid ratio of 4-7:1 into a conversion tank with a stirrer to perform a first step conversion; and (2) reacting basic lead chloride PbOHCl generated in the first step conversion with sodium hydroxide solution to perform a second step conversion and further to generate solid lead oxide and a secondary conversion liquid. According to the method, the wet-process metallurgy technology is employed for converting lead chloride into lead oxide, lead oxide subjected to purification can be used as a chemical product, also can be used to prepare lead acid batteries, and also can be further processed into metallic lead.

Owner:SHENYANG RES INST OF NONFERROUS METALS

Method for gradient separation and comprehensive recovery of gold concentrate containing carbon and arsenic

ActiveCN113755704ACrack Recycling ImpactAchieve nudityPhotography auxillary processesProcess efficiency improvementSulfideRoasting

The invention belongs to the technical field of gold dressing and smelting, and relates to a method for gradient separation and comprehensive recovery of gold concentrate containing carbon and arsenic. A flotation technology and a smelting technology are effectively combined for pre-flotation of the gold concentrate containing carbon and arsenic, the obtained carbon concentrate is independently cyanided to extract gold, silver and copper, the gold, silver and copper in the carbon concentrate are comprehensively recycled, the influence of carbon minerals on roasting and the influence of subsequent cyaniding on gold recycling are eliminated, and carbon concentrate leaching residues are subjected to non-waste comprehensive treatment through a nonferrous smelting production process. By effectively combining low-temperature arsenic removal, acid leaching treatment and high-temperature desulfurization of the carbon separation tailings, through granulation, low-temperature reduction roasting, fine grinding of cinder and an acid leaching process, the defects are overcome that in a conventional two-stage roasting process, arsenic minerals are not roasted completely and gold is wrapped by metal oxides and sulfides, so that the gold is exposed to the maximum extent, the leaching rates of gold and silver in the cyaniding process is remarkably improved, and economic benefits are remarkable.

Owner:SHANDONG GUODA GOLD

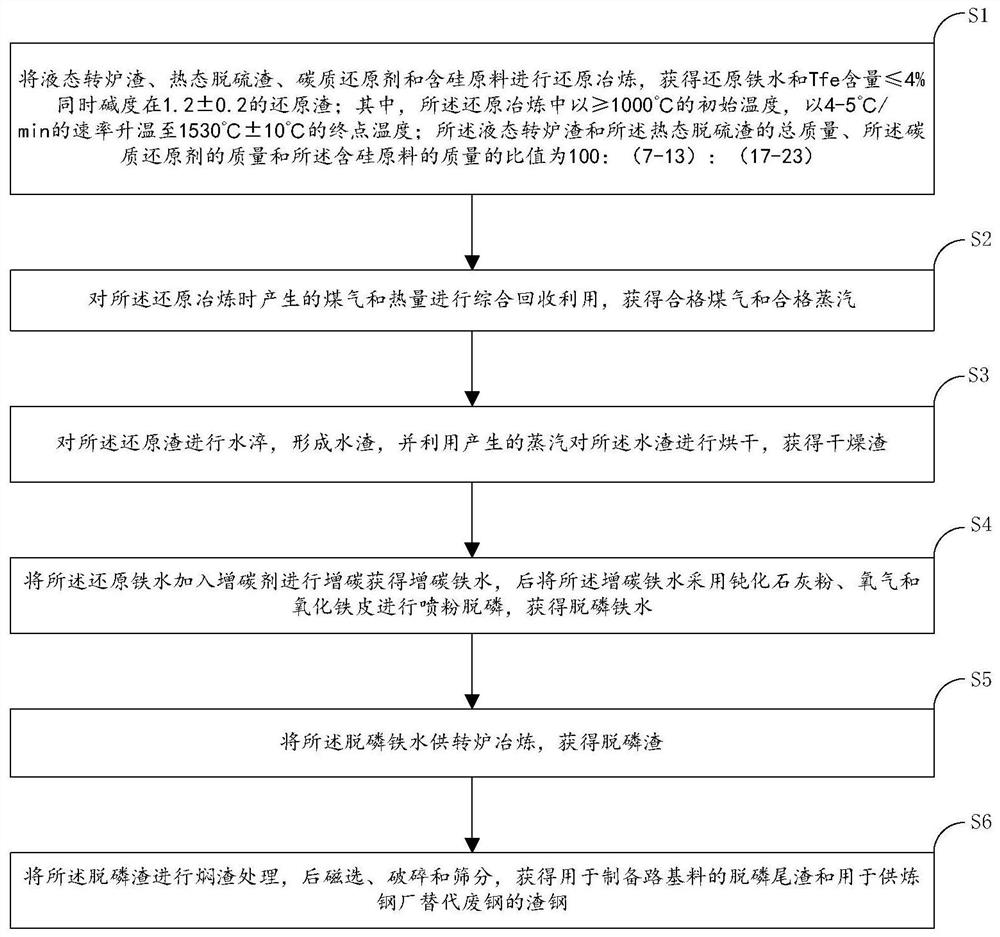

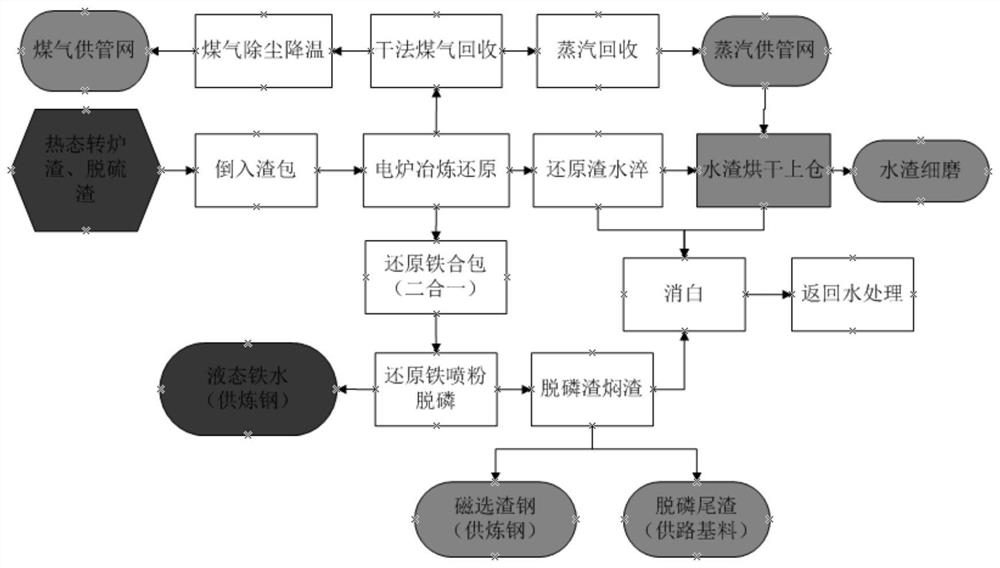

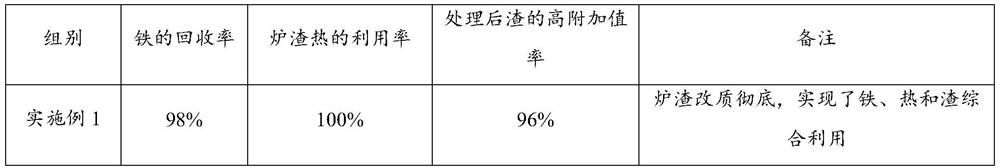

Comprehensive utilization method of iron, heat and slag of converter slag and desulfurization slag

ActiveCN113462840AHigh recovery rateEasy to recycleExhaust gas handlingManufacturing convertersSlagMolten steel

The invention discloses a comprehensive utilization method of iron, heat and slag of converter slag and desulfurization slag. The comprehensive utilization method comprises the steps of reducing and smelting the liquid converter slag, the hot desulfurization slag, a carbonaceous reducing agent and silicon-containing raw materials to obtain reduced molten iron and reduced slag with a Tfe content of less than or equal to 4% and alkalinity of 1.2+ / -0.2, increasing an initial temperature of greater than or equal to 1000 DEG C to a final temperature of 1530+ / -10 DEG C at a rate of 4-5 DEG C / min during reduction and smelting, enabling a ratio of the total mass of the liquid converter slag and the hot desulfurization slag to the mass of the carbonaceous reducing agent to the mass of the silicon-containing raw materials to be 100:(7-13):(17-23), recovering the generated heat and coal gas to obtain qualified coal gas, performing water quenching on the reduced slag to form water granulated slag, performing dephosphorization converter smelting after performing dephosphorization on the reduced molten iron to obtain dephosphorized molten steel and dephosphorized slag, and performing slag hot disintegration, magnetic separation, crushing and screening on the dephosphorized slag to obtain dephosphorized tailings and slag steel. The method solves the problem of comprehensive utilization of the iron, heat and slag of the converter steel slag and the desulfurization slag.

Owner:吉立鹏

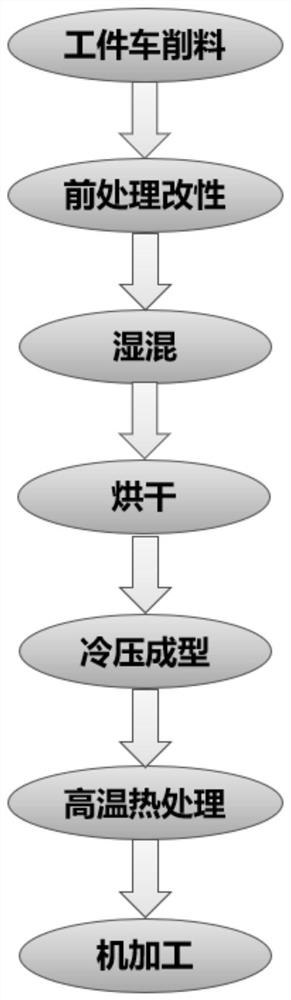

Preparation method of chopped carbon fiber composite material

The invention mainly relates to a method for preparing a carbon fiber composite material by taking a turning material of a carbon / carbon composite material as a main raw material and commercial chopped carbon fibers as a reinforcing phase, mainly aiming at the problems of resource recovery and reutilization in the production process of the carbon / carbon composite material. According to the method, turning materials and leftover materials generated in the workpiece turning process serve as main raw materials, the raw materials are subjected to pretreatment modification, wet mixing, drying, cold press forming, heat treatment and the like, the carbon / carbon composite material with high mechanical performance is prepared, and the material has wide application in the photovoltaic field, the heat treatment field, the friction field and the like. According to the invention, the effective utilization of resources is realized, the production cost is reduced, the solid wastes generated in the production process are effectively reduced, and the problem of environmental pollution is also well improved.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

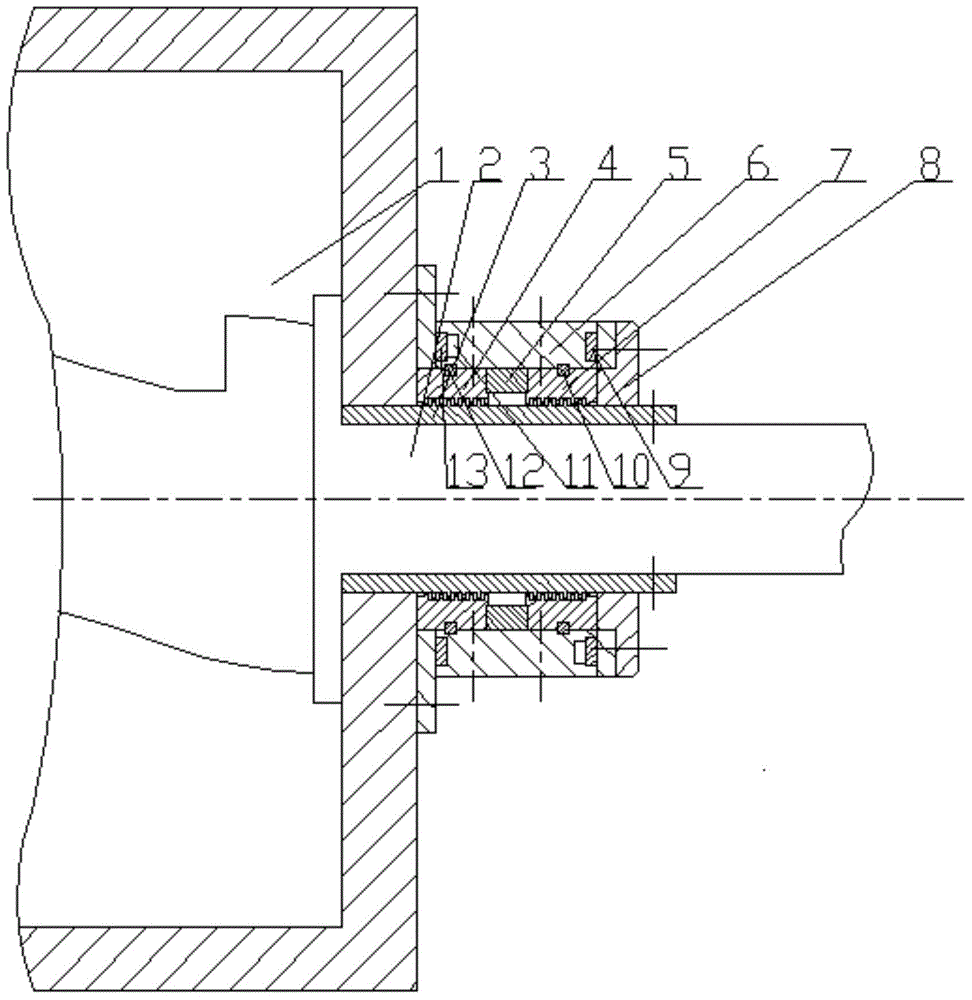

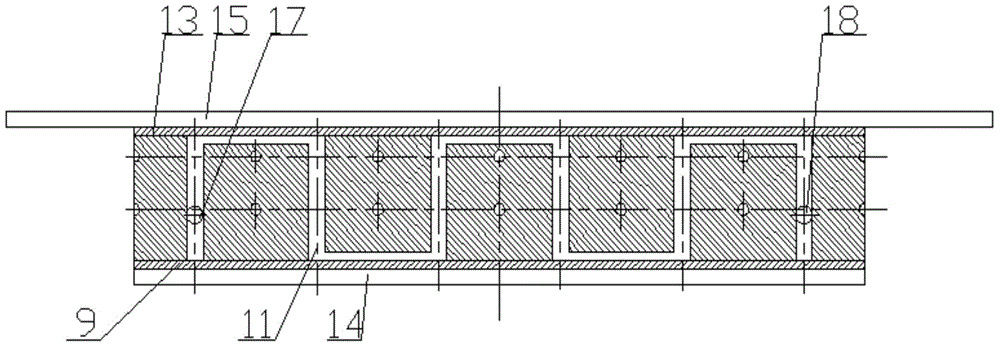

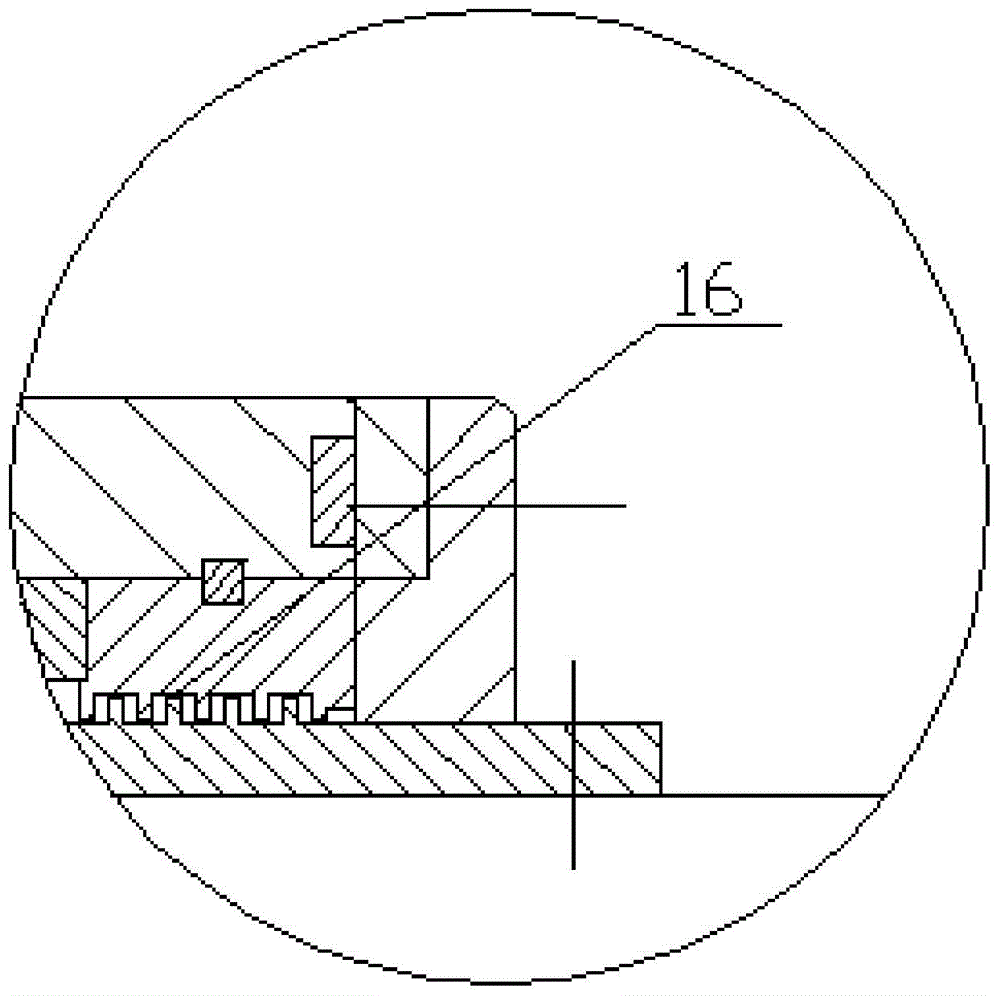

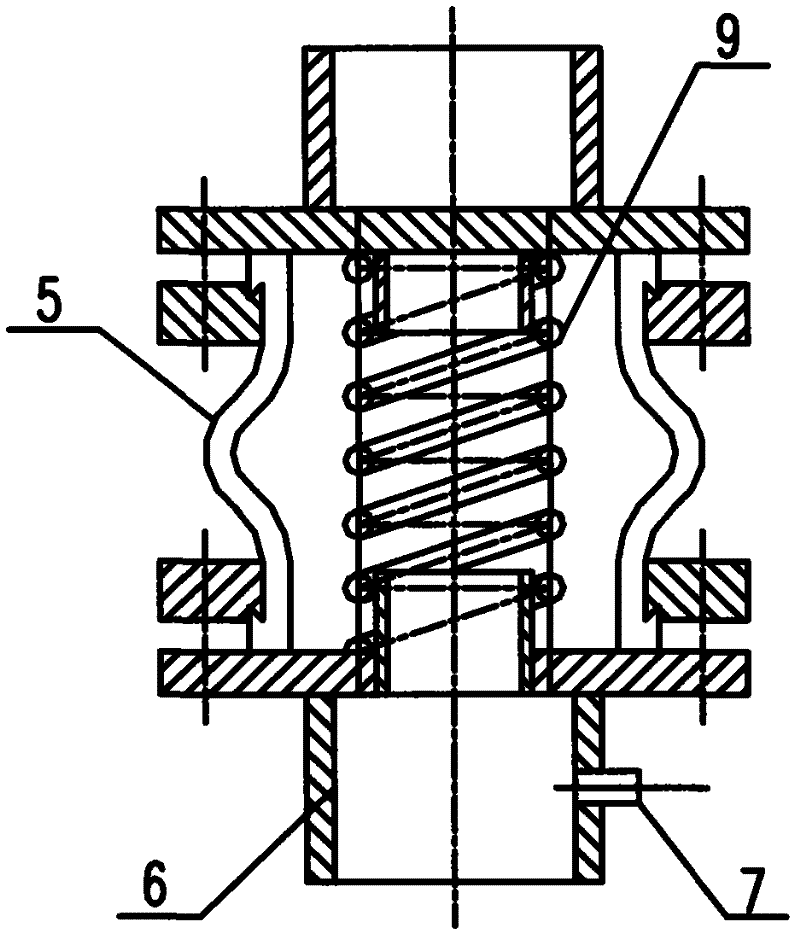

Internal mixer rotor sealing device

The invention belongs to the technical field of the sealing of a rubber device, and relates to a novel internal mixer rotor sealing device. A threaded shaft sleeve fixedly sleeves a rotor shaft, one end of a shell is fixedly connected to the outer wall of an internal mixing chamber, the other end of the shell is fixedly butt-jointed to an end cover, a first pole shoe and a second pole shoe are fixed on the wall of an inner cavity of the shell, and a permanent magnet is installed in a space between the two pole shoes in an embedding manner; a second O-shaped sealing ring and a first O-shaped sealing ring are respectively arranged on the junctions between the inner cavity wall of the shell and the two pole shoes, a clearance between each pole shoe and the outer wall of the threaded shaft sleeve is filled with a magnetic medium; a cooling passage with a liquid inlet and a liquid outlet in two ends is formed in the inner cavity of the shell, a second sealing cover plate and a first sealing end cover are respectively welded on the cooling passage on the end, which is butt-jointed with the outer wall of the internal mixing chamber, of the shell and the end, which is butt-jointed with the end cover, of the shell, and an end flange and a fixed flange are welded on the periphery of the shell. The novel internal mixer rotor sealing device is simple in structure, novel in design, high in operability, good in sealing effect and long in service life.

Owner:QINGDAO UNIV OF SCI & TECH

A method for recovering metallic lead from solid lead oxide

ActiveCN104711637BFriendly working environmentEasy to operatePhotography auxillary processesElectrolysisLead dioxide

The invention relates to a method for recovering metal lead from solid lead oxide. The method is characterized by comprising the following steps: (1) subjecting vulcanized lead concentrate to chlorination leaching, and crystallizing the leachate to obtain solid lead chloride; (2) carrying out first conversion on the solid lead chloride by using calcium oxide to generate basic lead chloride PbOHCl, and then carrying out second conversion between PbOHCl and a sodium hydroxide solution to obtain solid lead oxide; (3) preparing a sodium hydroxide solution as the electrolyte, mixing a proper amount of electrolyte and lead oxide, stirring to obtain paste, evenly painting the paste on a negative electrode plate, installing the negative electrode plate and a positive electrode plate into an electrolysis tank, and carrying out electrolysis; (4) after the electrolysis, peeling off the sponge lead from the negative electrode plate, pressing the sponge lead into balls, and casting the lead balls into lead ingots. The provided method can solve the problems existing in the process of recovering lead from chlorinated leachate of vulcanized lead concentrate through a conversion-solid electrolysis technology, and has the advantages of friendly operation environment, strong operability, high current efficiency, and low production cost.

Owner:SHENYANG RES INST OF NONFERROUS METALS

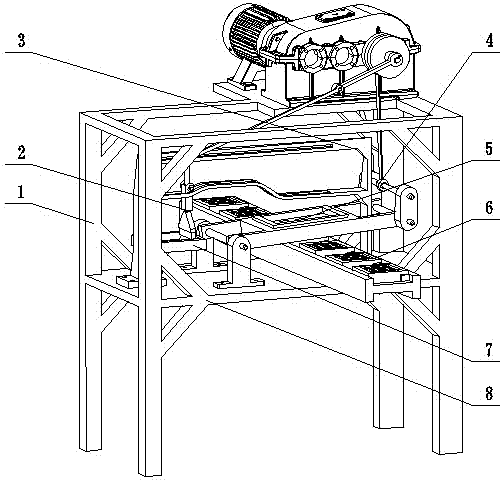

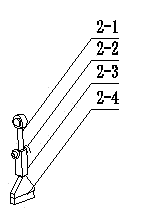

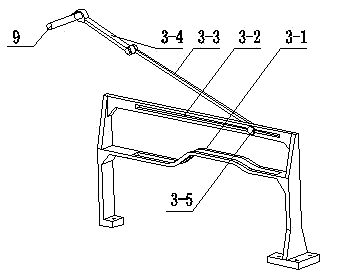

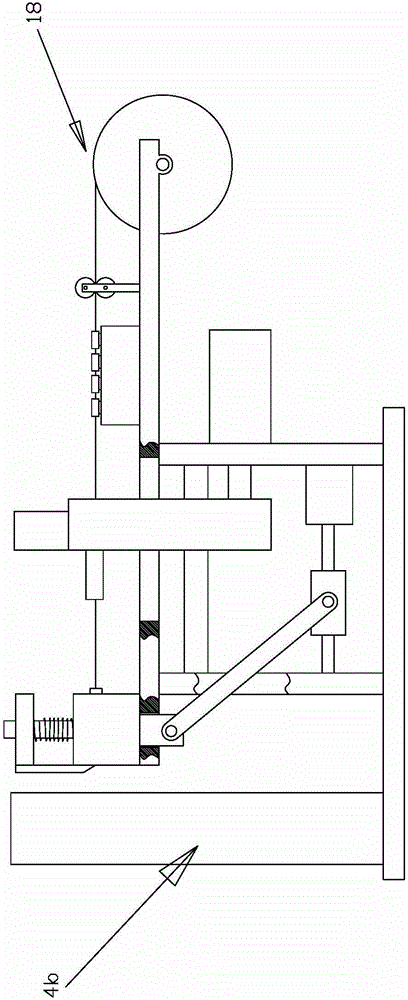

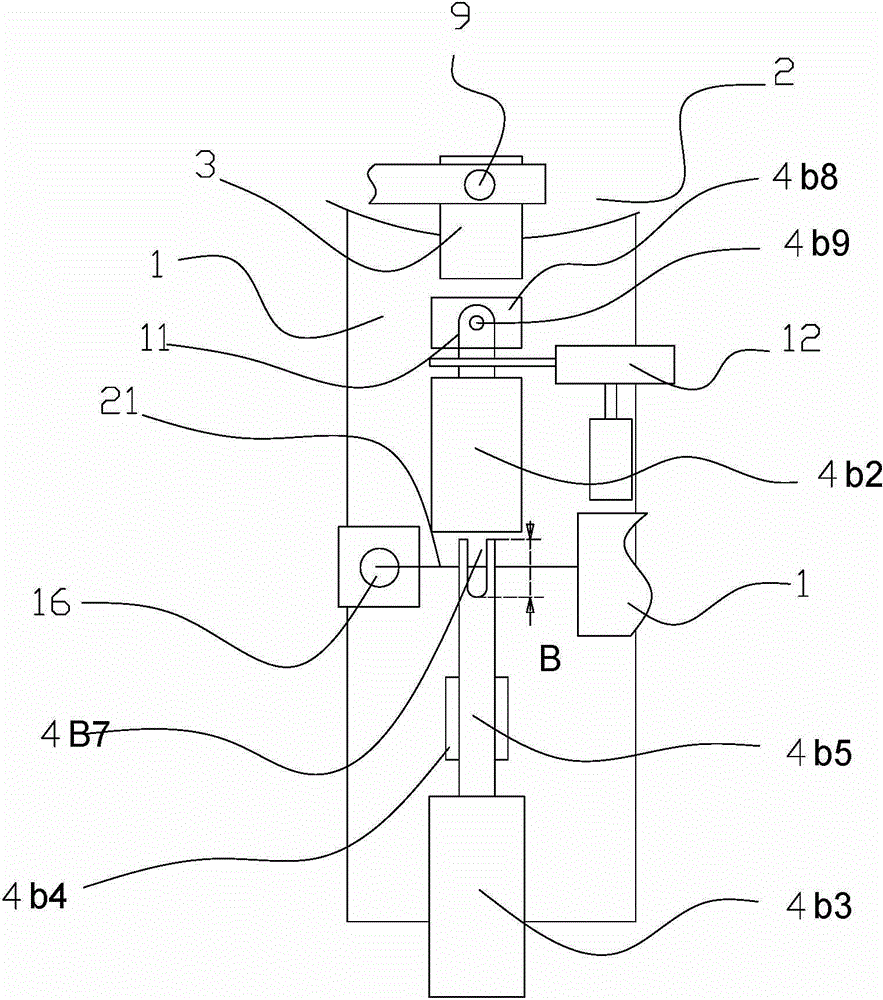

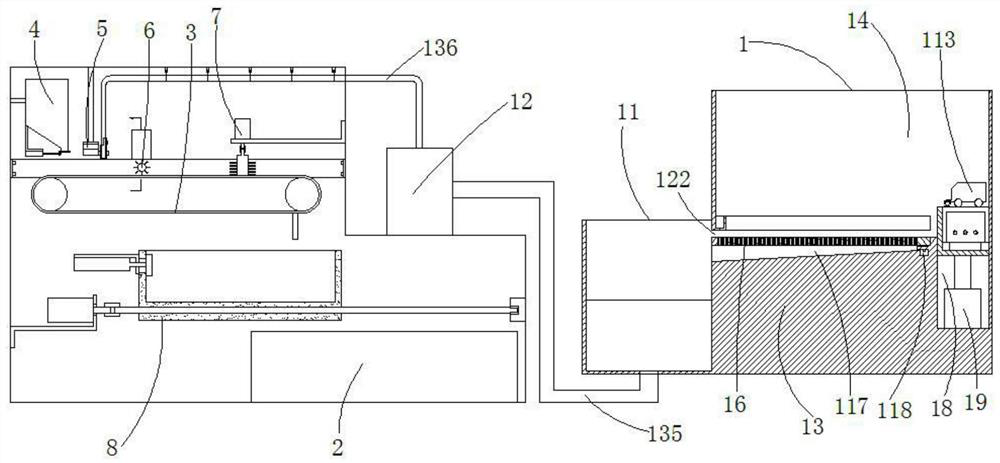

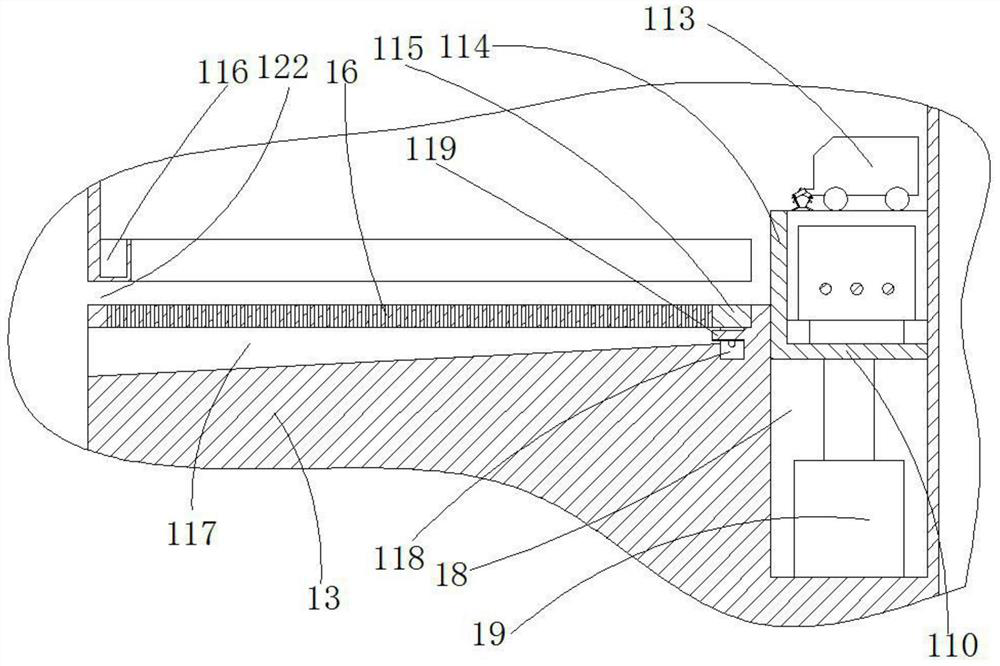

Automatic printing equipment

ActiveCN103085457ARealize continuous printingNo artificial contamination requiredTransfer printingSurface patternAutomatic test equipment

The invention relates to automatic printing equipment, in particular to a continuous automatic printing equipment which comprises a rack (1), a supportive plate (8) fixedly linked in the rack (1), an printing ink box (7) arranged on the supportive plate (8) and an automatic feeding mechanism (6). The automatic printing equipment further comprises a printing brush transmission mechanism (3) and a printing transmission mechanism (4), a printing box (5) arranged on the upper surface of the printing transmission mechanism (4) and a printing brush mechanism (2) hinged on the printing brush transmission mechanism (3), wherein both the printing brush transmission mechanism (3) and the printing transmission mechanism (4) are arranged on the supportive plate (8). With the continuous automatic printing equipment, patterns can be continuously printed on surfaces of an eraser and the like. The continuous automatic printing equipment is compact in structure, capable of automatically stacking and printing, free of printing impact, high in production efficiency, stable in product quality, free of manual printing ink applying, clean, hygienic and working-environment-friendly.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

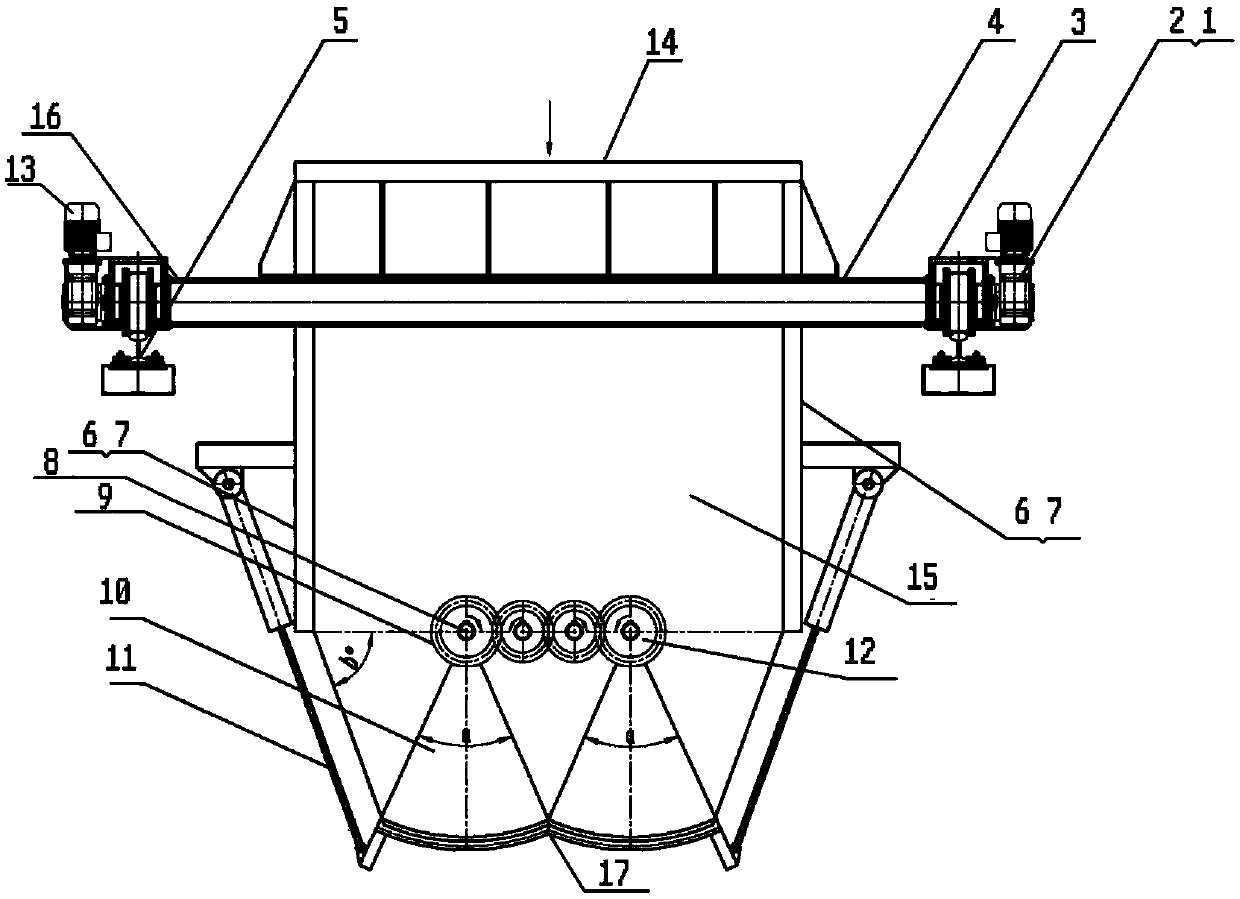

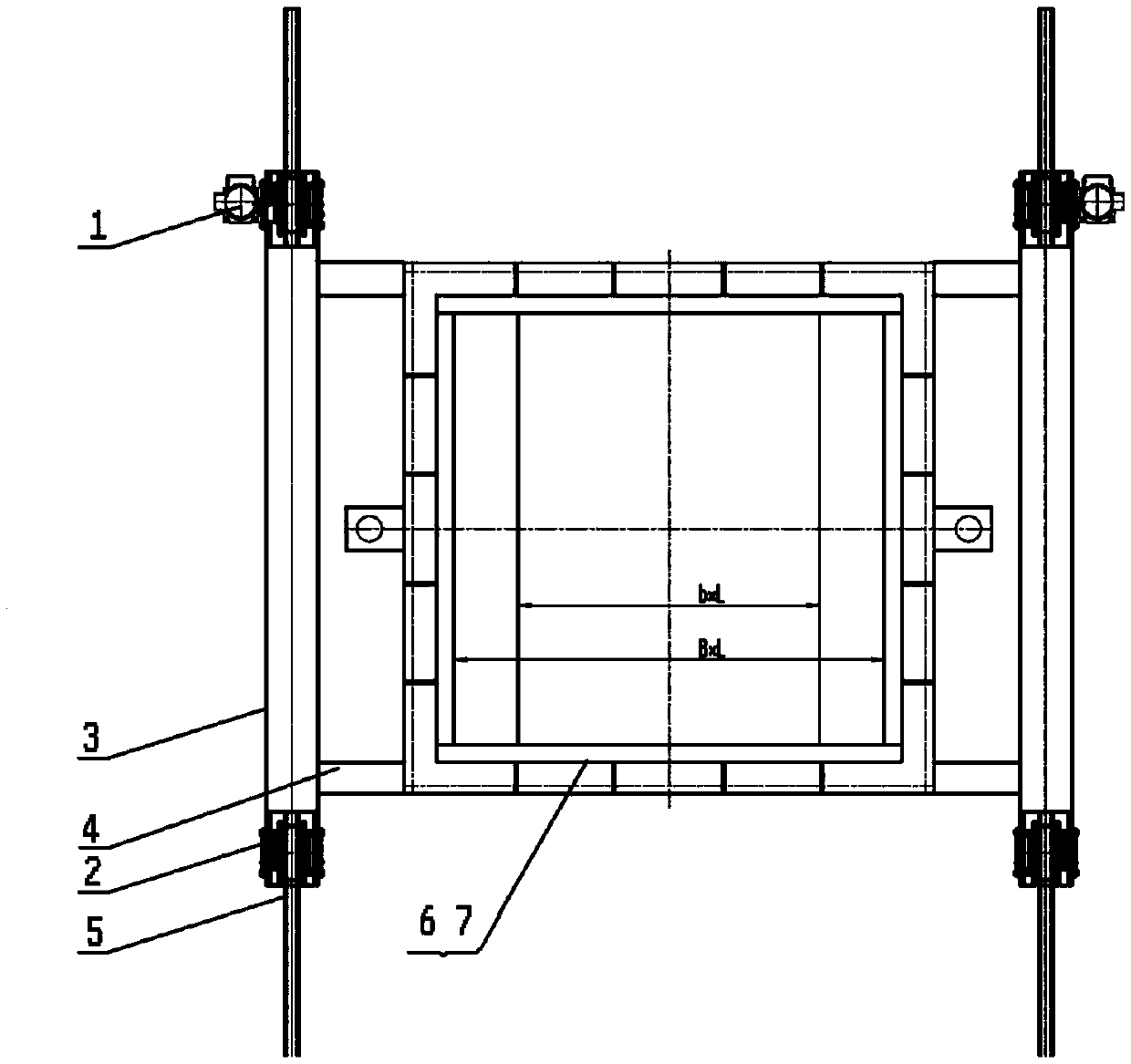

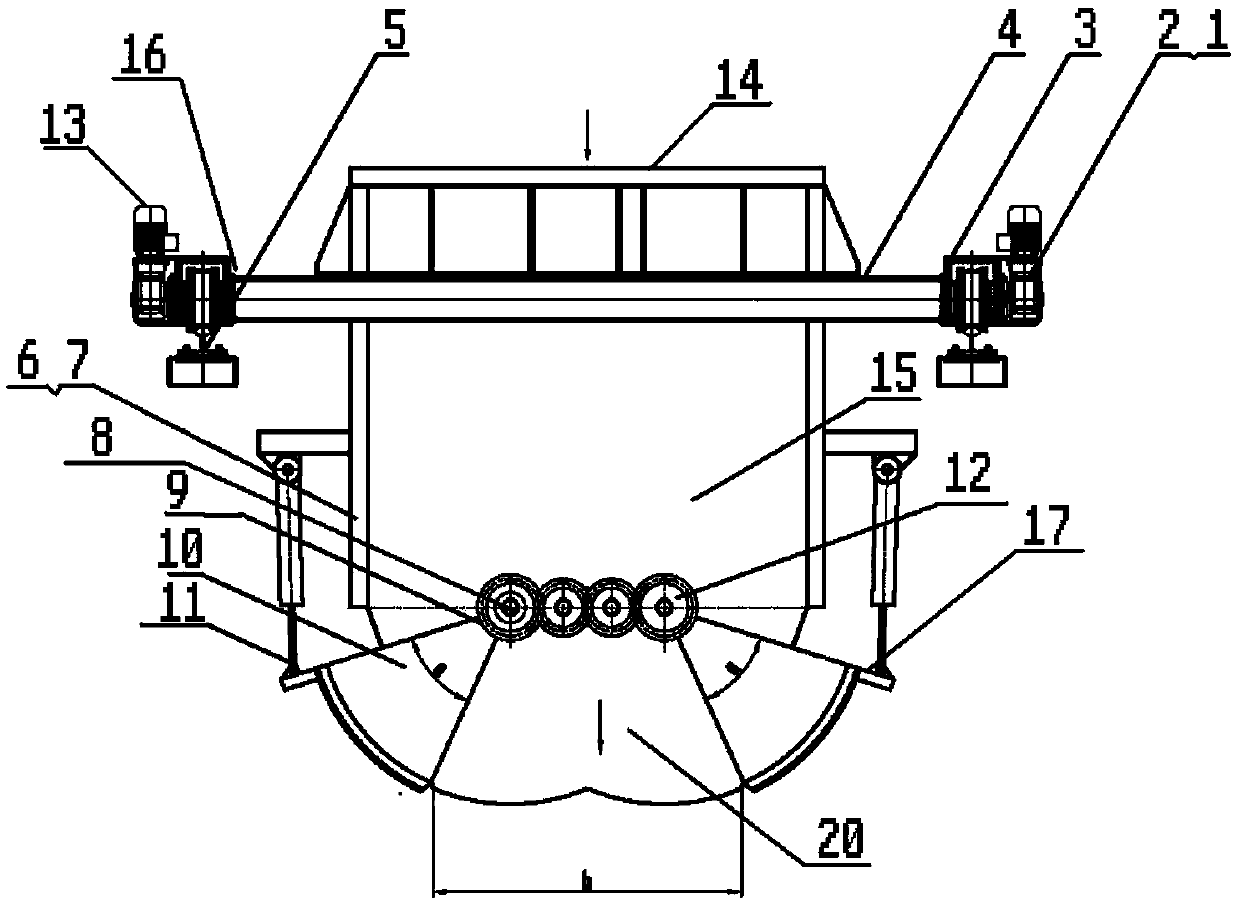

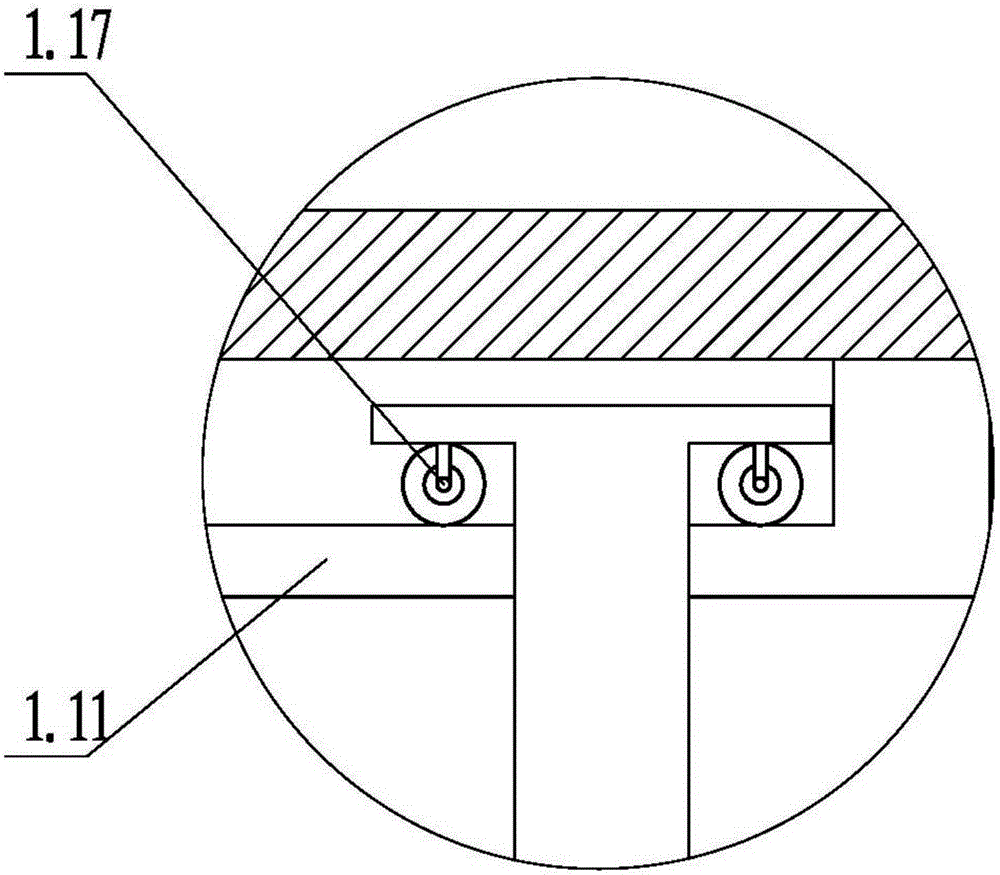

Movable sludge material conveying box

PendingCN109516114AGuaranteed uptimeStrong conveying capacityLoading/unloadingMechanical conveyorsElectronic controllerDrive wheel

The invention provides a movable sludge material conveying box. The movable sludge material conveying box comprises rails, a material trolley, a sludge self-discharging material box and an electroniccontroller, wherein the rails are two parallel suspended steel rails; the material trolley comprises a driving device, a driven wheel set and a driving wheel set; the sludge self-discharging materialbox is fixed on the material trolley, an open feeding port is arranged at the top, discharging doors which are opened oppositely are arranged at the bottom, and a box body is symmetrically distributedwith respect to the rails on the two sides; a discharging door unit comprises a pair of the symmetrically distributed discharging doors and a reciprocating mechanism connected with the discharging doors, and the discharging doors synchronously move to two sides to be opened or synchronously move oppositely to be closed; and the electronic controller is connected with the driving device and the reciprocating mechanism, controls the material trolley to walk or stand still on the rails and controls opening and closing of the discharging doors. The movable sludge material conveying box has a large-volume conveying function, achieves material reciprocating conveying according to the line distance between the conveying starting point and the final point and achieves automatic running and operation. The discharging doors are closed and opened automatically, and discharging is thorough.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

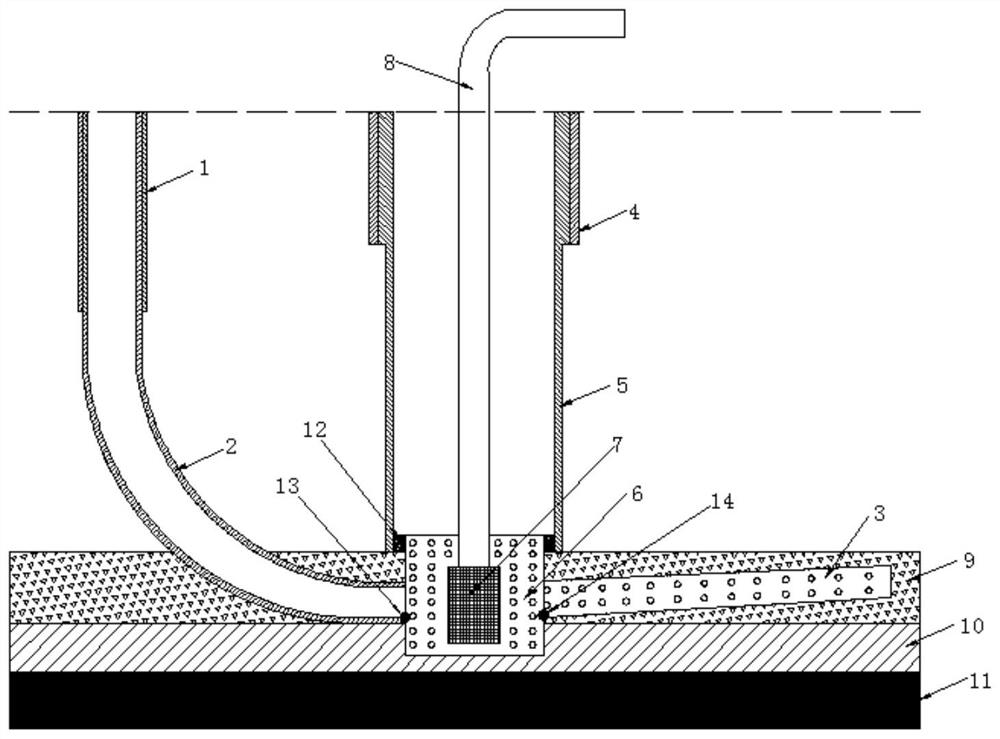

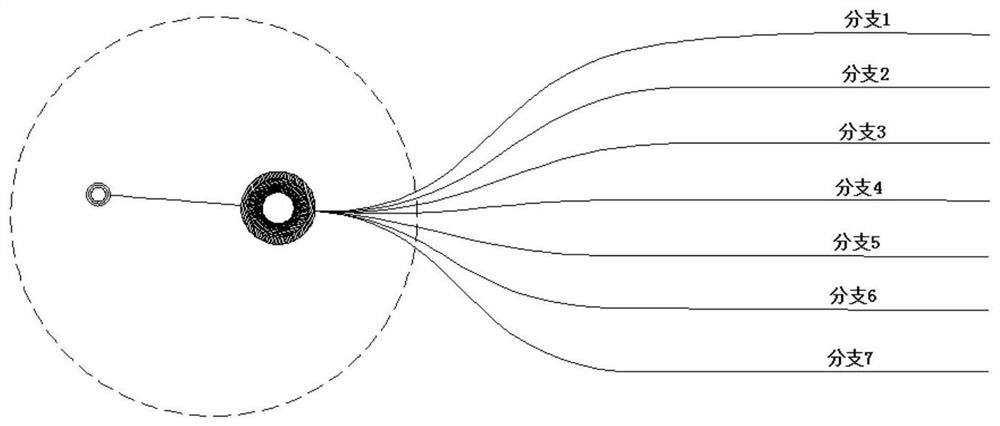

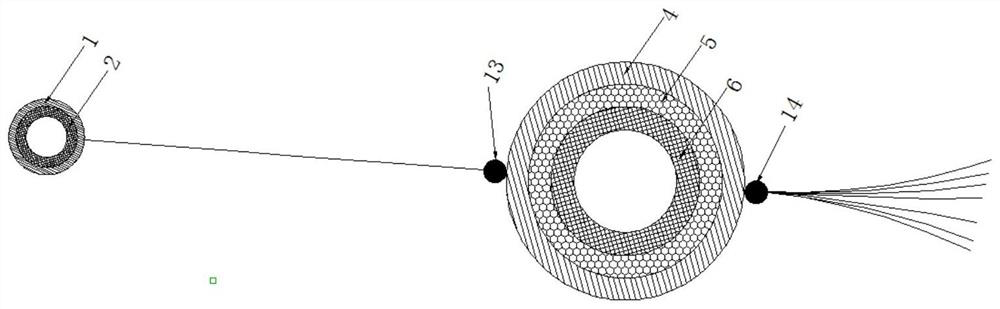

Coal seam roof aquifer ground advanced pre-drainage method

ActiveCN113107589AFulfilling the water hazard threatSafe and efficient continuous miningFluid removalDrainageMining engineeringHorizontal wells

The invention relates to a coal seam roof aquifer ground advanced pre-drainage method. The method comprises the steps that a ground multi-branch updip horizontal well is constructed, and each branch hole of the updip horizontal well penetrates through an enriched water area of a roof aquifer; a large-diameter drainage well leading to the enriched water area of the roof aquifer is constructed, and the large-diameter drainage well is in communication with the updip horizontal well; and a drainage device is put into the large-diameter drainage well, and drainage treatment is conducted through the drainage device. The method can overcome the defects of the existing coal seam roof water disaster treatment technology, can completely remove hidden dangers of the coal seam roof aquifer to be mined before a regional coal mine is not well-built, guarantees that no roof water disaster influence exists in the whole coal mine from well building to well shut-in, and realizes safe, efficient and continuous coal seam mining.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

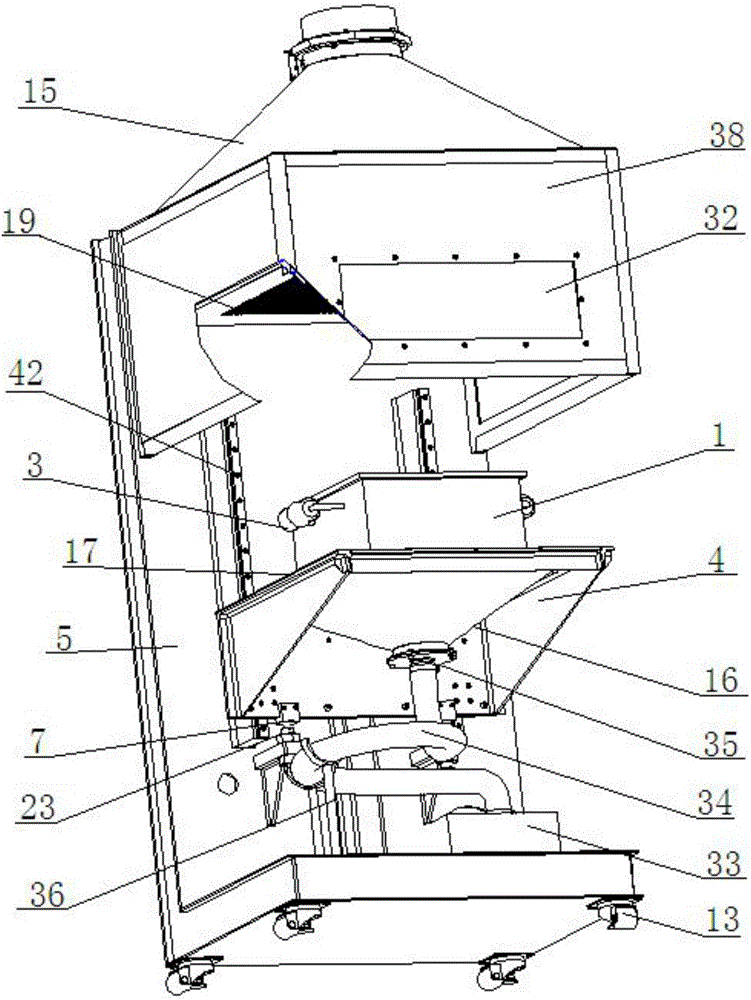

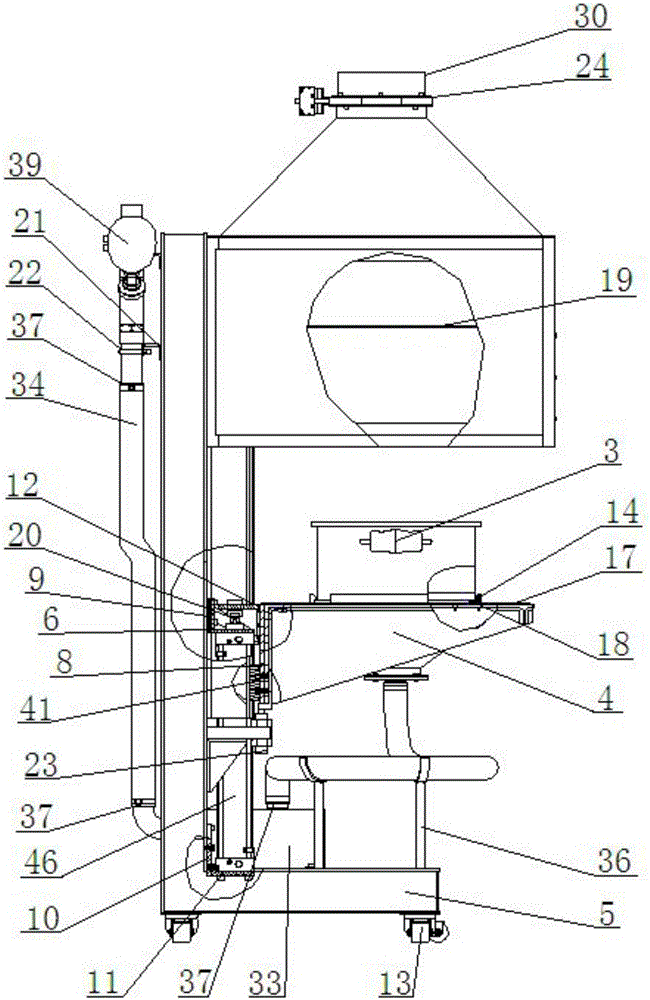

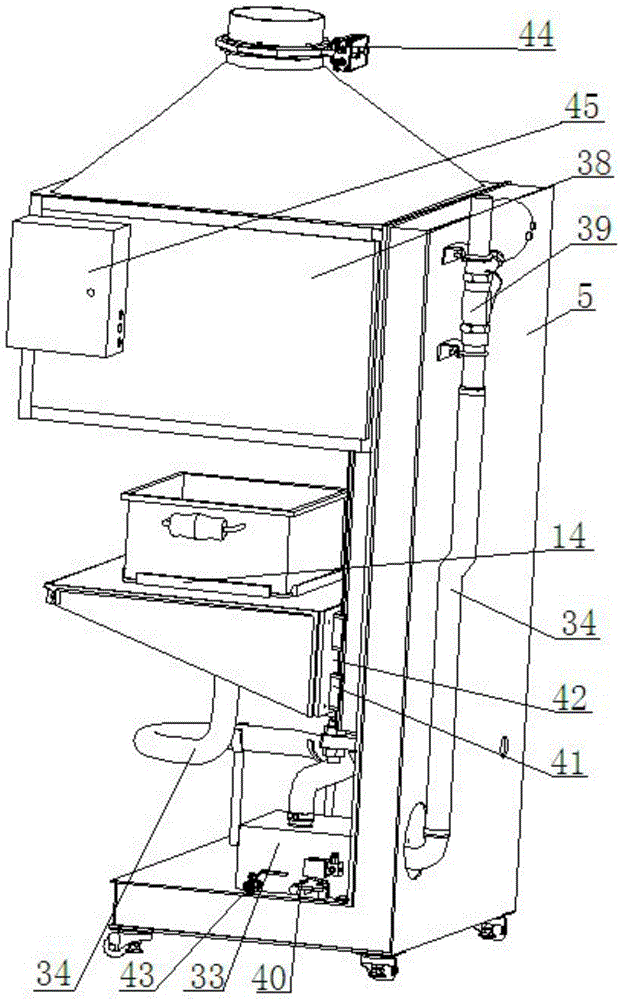

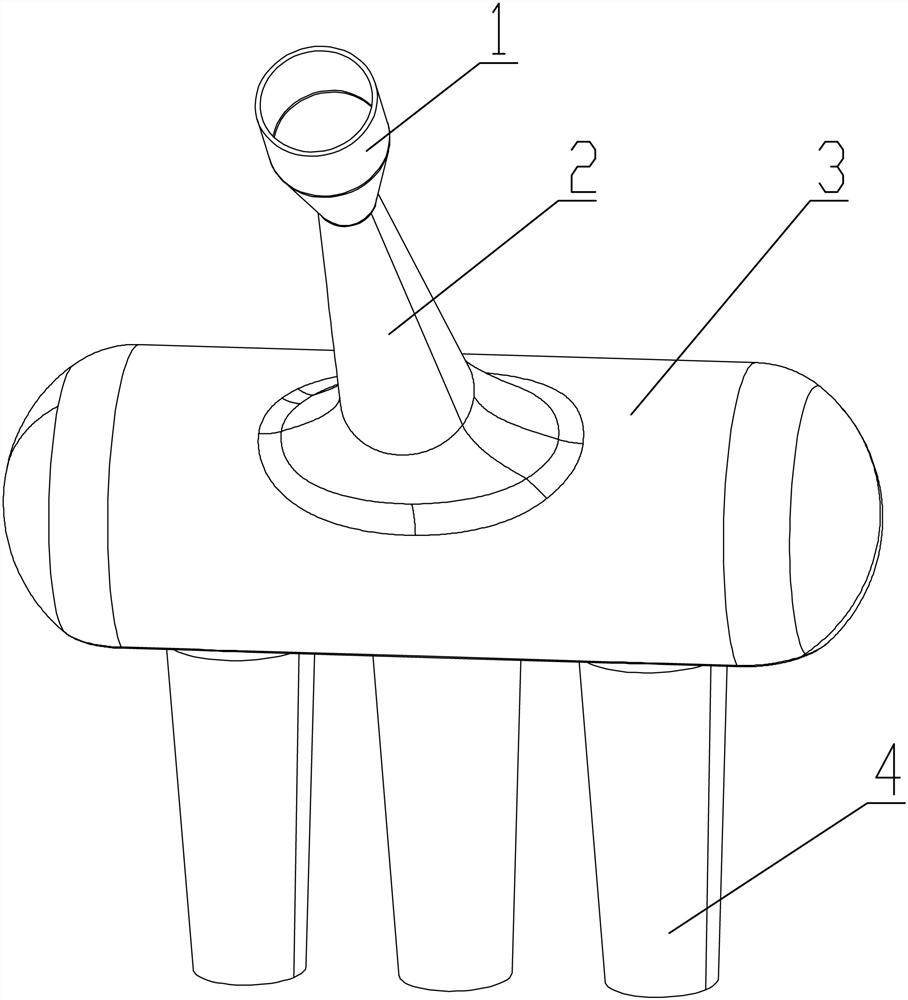

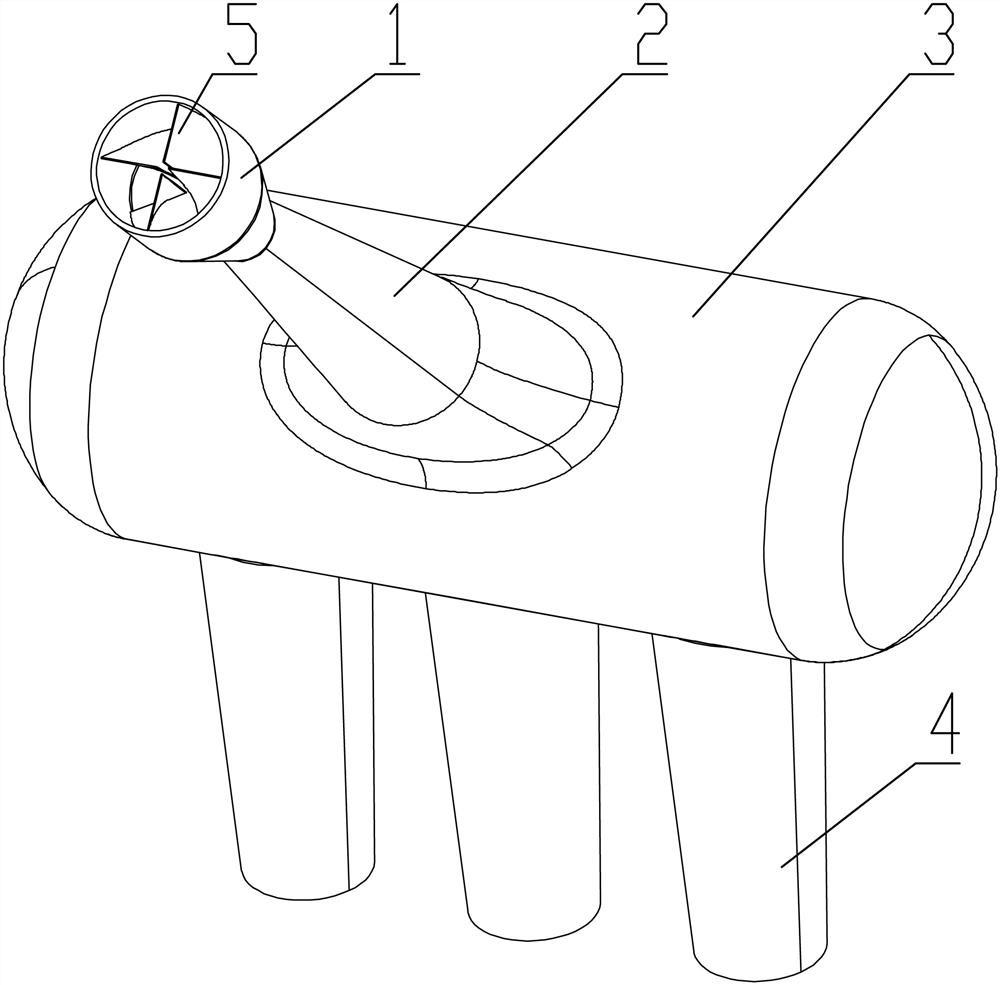

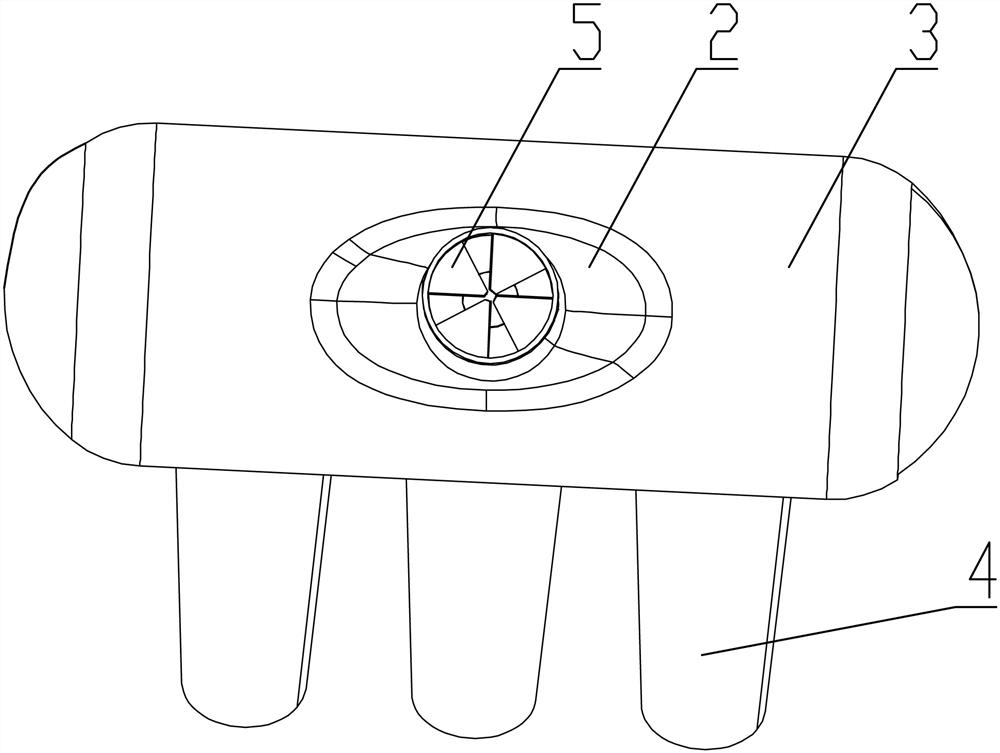

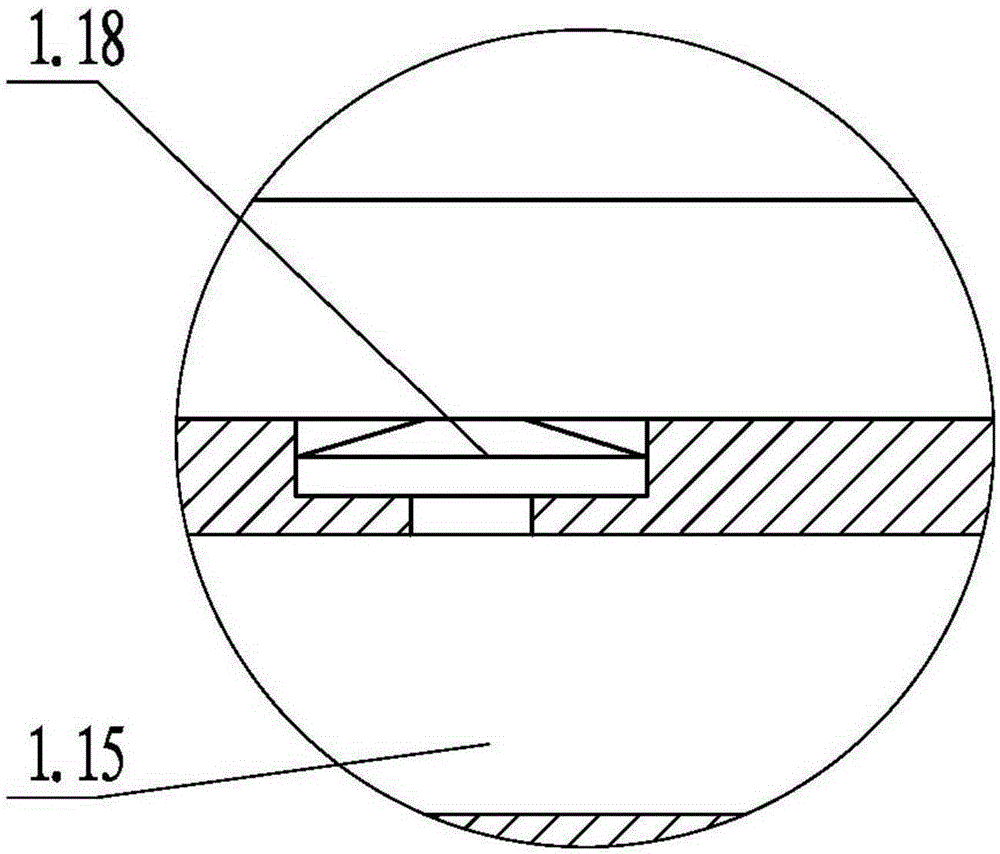

A closed type tea steaming and pressing device

ActiveCN104996609AReduce labor intensityPrecise control of steaming timePre-extraction tea treatmentProduction lineStructural engineering

The present invention relates to a closed type tea steaming and pressing device. The device comprises a body frame, an air drawing hood, a movable bracket, a tea steaming box, a water gathering tank, a pipeline, a rotating cylinder, two sets of sliders, an electric control box and cylinder, a upper fixing frame is fixedly arranged at the upper end of the inside of a side board of the body frame, the air drawing hood is arranged at the top of the upper fixing frame, a switch body is arranged at the top of the air drawing hood, the switch body is connected with the rotating cylinder, both sides of the movable bracket are respectively connected with the two sets of sliders through bracket base plates, the two sets of sliders are in slip connection with two rail lines of the inside of the side board of the body frame, a bracket connecting base is connected with the head of a piston rod of the cylinder through connecting blocks, a vapour hood is arranged at the bottom of a top tray of the movable bracket, the tea steaming box is arranged on the top tray of the movable bracket, the pipeline is arranged at the upper end of the outer side of the side board of the body frame by crossing one end of the water gathering tank, and the other end of the pipelinr is arranged in the vapour hood. The steaming time can be set without additional timing, the steaming is uniform and good in effect; and vapour movement is limited in the closed type device with good operating environment; and the closed type device can be used for automatic production line.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

Method for rectifying dimethyl phosphite

ActiveCN107722053AIncrease vacuumReduce corrosionGroup 5/15 element organic compoundsDimethyl phosphitePhosphate

The invention relates to a method for rectifying dimethyl phosphite. The method comprises the following steps that after raw materials are fully reacted in an esterification reaction kettle, crude ester enters the rectification kettle, a first rectifying tower and a second rectifying tower are arranged at the top of the rectifying kettle, and the first rectifying tower and the second rectifying tower are continuously heated; the first rectifying tower firstly collects low-boiling-point substances in the materials into a low-boiling-point substance storage tank, and tower bottom discharge liquid enters the second rectification tower for further separation; a vacuum unit is started for vacuum concentration, high-purity dimethyl phosphate is collected into a product storage tank, and tower bottom residual liquid is high-boiling-point substances. The technical process is simple, the production time is short, the product purity is high, the yield is high, continuous production can be achieved, the cost is low, the fuel utilization rate is high, emission is basically avoided, the environmental pollution is small, the reaction operation safety is high, the labor intensity is low, the labor efficiency is high, the product quality is good, and industrialization is facilitated.

Owner:HENAN HDF CHEM CO LTD

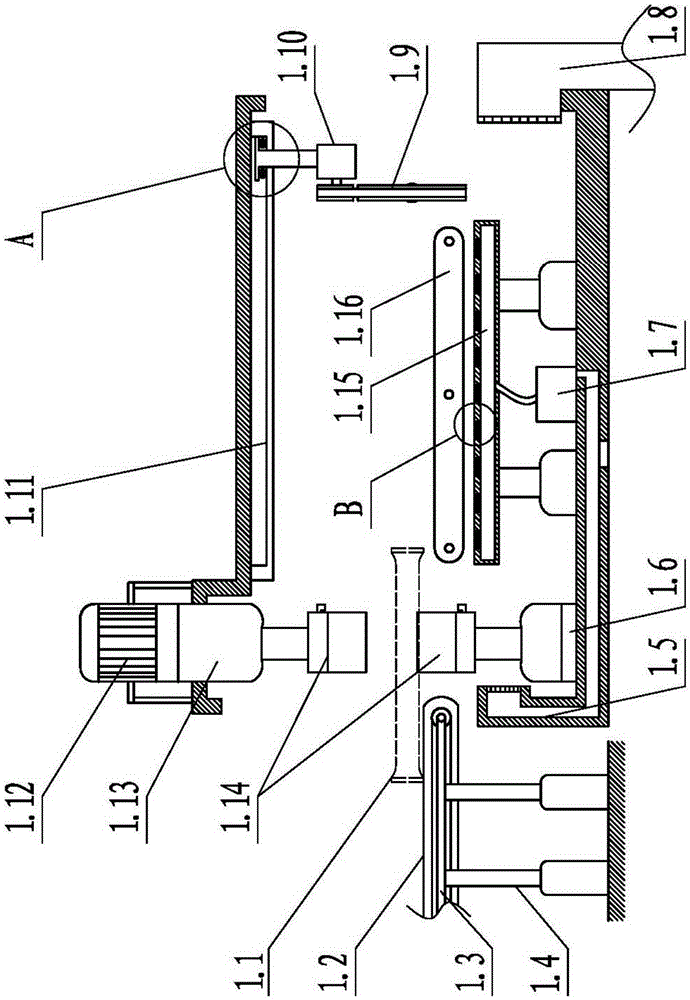

Continuous production device for lamp tripod

ActiveCN104599939ASave human effortIncrease productivityElectrode assembly manufactureEngineeringFully automatic

The invention provides a continuous production device for a lamp tripod. The device is characterized by comprising a rack, a rotating plate which is arranged on the rack and driven through power, a clamp which is arranged in the periphery of the rotating plate to clamp the lamp tripod, an U-shaped lamp tripod forming station, a metal plate welding station, a metal wire welding station, a metal barrel welding station and a blanking station, wherein all the stations are arranged on the rack and sequentially positioned along the peripheral outer sides of the rotating plate. Compared with the prior art, the device has the advantages of being fully automatic to produce the lamp tripod, labor saving, high in production efficiency, stable in processing quality, and working environmentally friendly.

Owner:徐州博创建设发展集团有限公司

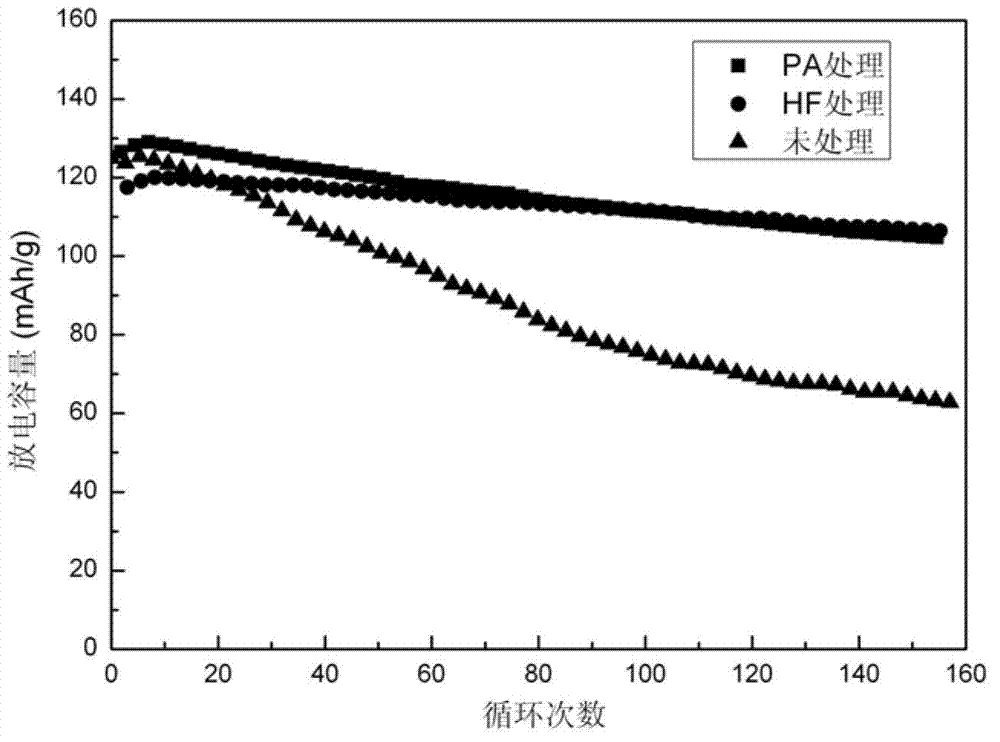

Surface passivating treatment method of spinel type manganese-based positive pole material

InactiveCN102738460AImprove high temperature cycle performanceAvoid erosionCell electrodesCyclic processStrong acids

The invention relates to a surface passivating treatment method of a spinel type manganese-based positive pole material, which is characterized by comprising the following steps: (1) soaking spinel type manganese-based positive pole material powder in a strong acid solution to carry out acid treatment; (2) repeatedly cleaning the material subjected to the acid treatment in water until the pH value of water ranges between 7 and 8, then filtering out, and drying; (3) carrying out heat treatment on the dried material, and cooling to obtain the spinel type manganese-based positive pole material subjected to surface passivating treatment. By soaking the spinel type manganese-based positive pole material in the acid solution, Ni ions, Mn ions and other ions which are soluble in the surface of the positive pole material are removed; and through the heat treatment, an even passivation layer is generated on the surface of the positive pole material, thereby effectively preventing the electrolyte from corroding the positive pole material, inhibiting the dissolution of Ni and Mn ions in the positive pole material in the high-temperature cyclic process, and improving the high-temperature cyclic performance of the spinel type manganese-based positive pole material. Besides, the invention has low requirement for equipment, is non-poisonous and harmless to human bodies and is friendly to working environment.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Method for statically casting membrane element

The invention belongs to the technical field of casting of rubber and plastic material membrane elements, and relates to a technical process method for statically casting a membrane element. The method comprises the following steps of: assembling the membrane element onto a membrane shell fixing ring by using a membrane element static casting device, and tightly clamping by using a hoop; communicating a glue injection nozzle with a glue injection kettle by using a glue injection pipe, and fastening by using a broken filament rope or a filament wire; pouring epoxy resin into the glue injection kettle, and stuffing up a rubber stopper by exerting force; and making compressed air pass through a compressed air pipe to enter the glue injection kettle, slowly pressing the epoxy resin into the glue injection nozzle at the lower end of the membrane element along the glue injection pipe, injecting into the membrane element, statically solidifying, and then casting the other end of the membrane element according to the same process to form a product. The method has the advantages that: the process is simple, the principle is reliable, the automation degree is high, the casting effect is good, the static casting time is short, work load is low, labor cost is saved, production efficiency is high, the mechanical abrasion degree of the membrane element is low and working environment is friendly.

Owner:QINGDAO SEACON WATER SERVICE TECH

Engine air intake system with air inlet flow guiding blade grid and simulated analysis method

InactiveCN112855393AFriendly working environmentIncrease the total air intakeInternal combustion piston enginesDesign optimisation/simulationWorking environmentEngineering

The invention provides an engine air intake system with an air inlet flow guiding blade grid and a simulated analysis method. The system comprises a pressure stabilizing cavity, wherein an air inlet main pipe is connected to a middle position of one side of the top of the pressure stabilizing cavity, a current limiting valve is mounted at an inlet end of the air inlet main pipe, a plurality of air inlet manifolds are parallelly mounted on one side of the bottom of the pressure stabilizing cavity, and an air flow guiding sheet for guiding an inlet air flow and converting the same into a rotary flow is mounted in the inlet end of the current limiting valve or the air inlet main pipe. By additionally mounting the air flow guiding sheet based on the existing current limiting valve, an air flow entering the pressure stabilizing cavity from the air inlet main pipe is converted from a direct current into the rotary current, so that the air inlet air flow is higher in flow rate and the total air inlet amount is increased. The rotary flow entering the pressure stabilizing cavity can fill the pressure stabilizing cavity quickly, and thus, air flow amounts of the pressure stabilizing cavity entering the air inlet manifolds are more balanced, and a working environment of an engine is more environmental-friendly.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Pruning and fixed-length pretreatment equipment for folding fan bamboo material

ActiveCN105150313ASimple processAdaptableCane mechanical workingPower driven reciprocating sawsEngineeringAutomation

The invention discloses pruning and fixed-length pretreatment equipment for a folding fan bamboo material, and belongs to the field of mechanical automation equipment. The pruning and fixed-length pretreatment equipment is characterized by comprising a bamboo material conveying device, a bamboo material fixing device and a branch knot removing linear cutting tool. Due to the growth characteristics of bamboos, branch knots can only grow in the positions of bamboo knots; the equipment can clamp the middle of the bamboo material, then the bamboo material is rotated through a reversing motor, and thus the branch knots at the two ends of the bamboo material can be processed. The technique is simple, and processing reliability and precision are both excellent.

Owner:TAIZHOU LIKE TECH CO LTD

Back-and-forth scraping and brushing type large pig raising system

InactiveCN111642405AImprove working environmentFriendly working environmentRotary stirring mixersTransportation and packagingPig farmsPig breeding

The invention discloses a back-and-forth scraping and brushing type large pig raising system. The back-and-forth scraping and brushing type large pig raising system comprises a pig farm, a material collecting chamber, a pump, a linear motor, a conveying belt, a material stirring chamber, a first stirring device, a second stirring device, a material receiving device and a second treatment chamber,wherein the pig farm comprises a feeding farm, a first base plate is paved in the feeding farm, pigs are raised on the first base plate, a movable transverse moving table is arranged on the feeding farm, a sweeper is arranged on the transverse moving table, the bottom of the material collecting chamber is connected with the pump through a feeding pipe, an outlet of the pump is connected with a discharging pipe, the end of the discharging pipe is connected to the linear motor, and the material stirring chamber, the linear motor, the first stirring device and the second stirring device are distributed along the conveying belt from front to back, a material baffle in clearance fit with the conveying belt is arranged on the lower portion of the conveying belt, the material receiving device isarranged below the material baffle, and the second treatment chamber is arranged below the material receiving device. The pig farm can be swept by only one person, excrement of pigs is automatically treated subsequently, the whole process is time-saving and labor-saving, the working efficiency is high, and the economic benefit is good.

Owner:王慧文

Crushing and sorting process of scrapped car body

InactiveCN108043559AImprove mechanizationHigh degree of automationVortex flow apparatusGrain treatmentsPower flowEngineering

The invention discloses a crushing and sorting process of a scrapped car body. The crushing and sorting process comprises the following steps of (1) gradually crushing the scrapped car body into preliminary dimensions in a two-stage crushing mode; (2) respectively separating and recycling light substances, magnetic metals, non-ferrous metals, micro powder substances, glass, rubber and plastic in sequence after the car body is crushed by adopting a negative pressure-cyclone separation process, a magnetic sorting process, an eddy current sorting process and a roller screening process. Accordingto the crushing and sorting process, the scrapped car body is crushed and sorted in a two-stage crushing and multi-sorting mode. The requirement of disassembling operation of an enterprise for disassembling the scrapped car body is fully satisfied, and the crushing and sorting process is an initiative technological process in the domestic existing same disassembling industry.

Owner:湖北天银报废汽车回收拆解有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com