Continuous production device for lamp tripod

A technology for producing devices and lamp pins, which is applied in the manufacture of electrical components and electrode components, can solve the problems of difficult quality assurance and low production efficiency, and achieve the effects of saving manpower, high production efficiency and stable processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

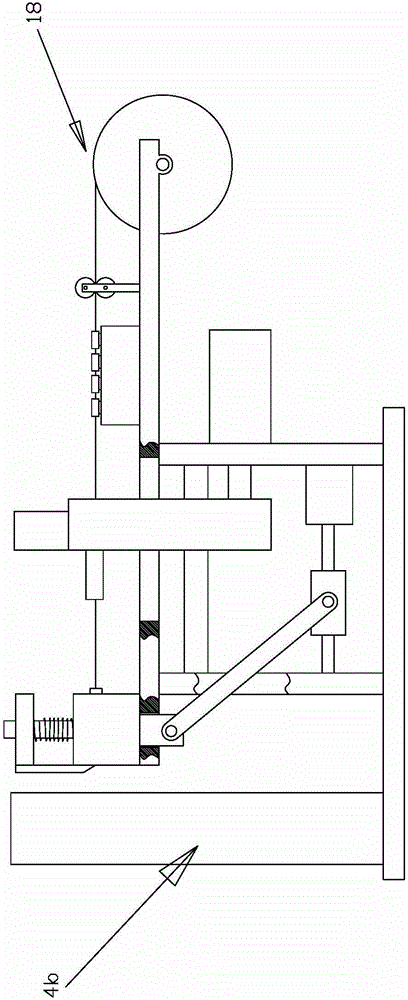

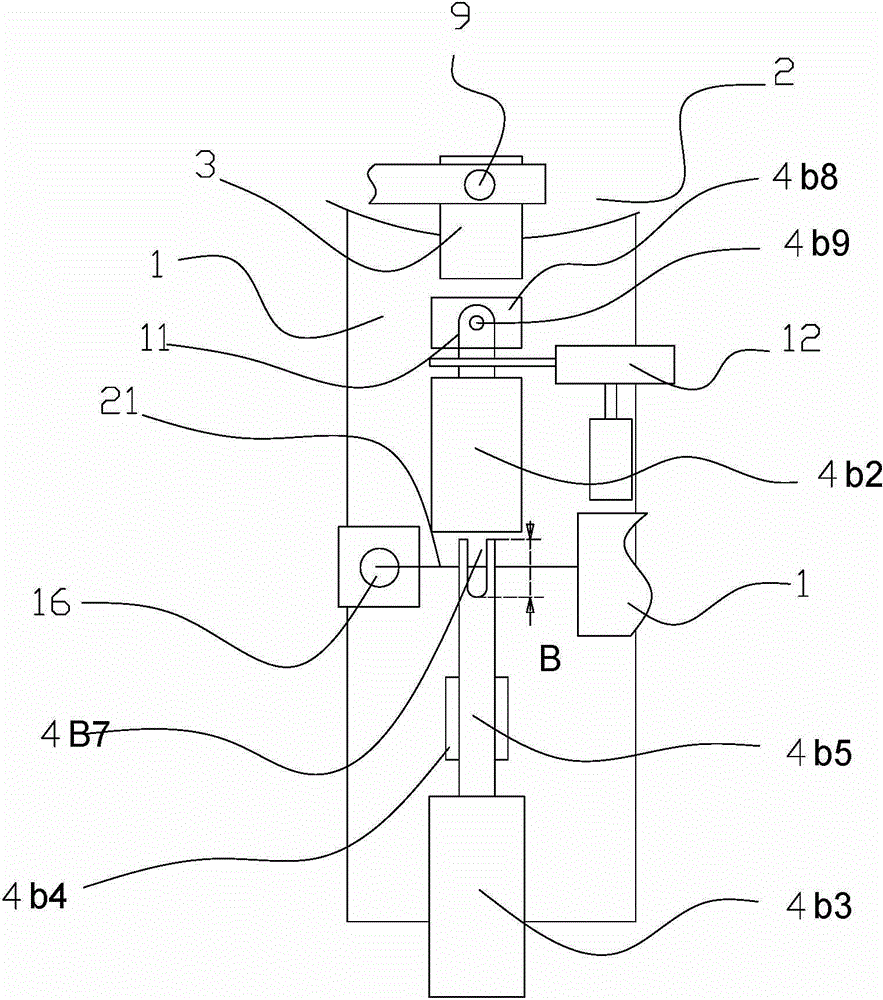

[0027] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

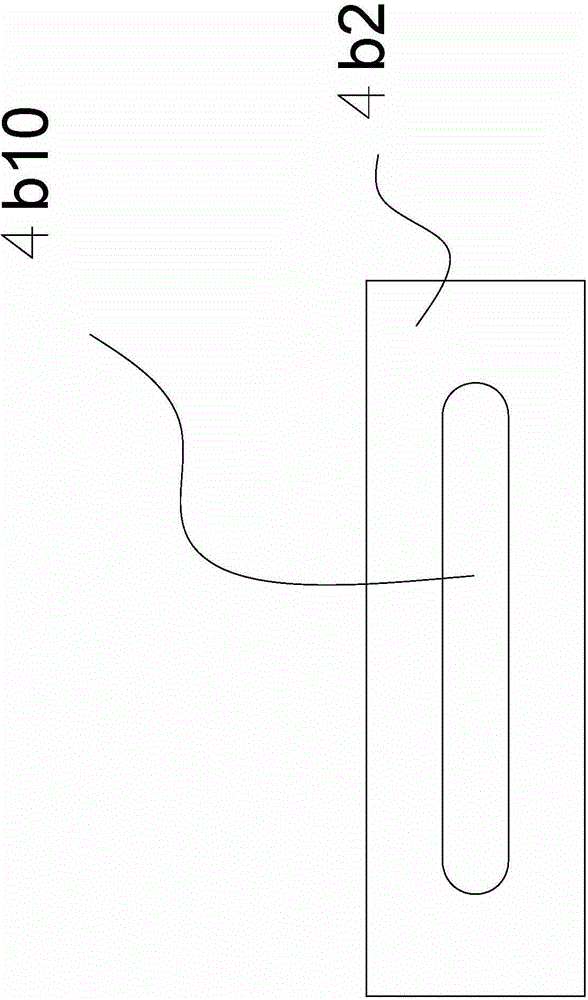

[0028] As shown in the figure, the present invention includes a frame 1, a turntable 2 driven by power arranged on the The U-shaped lamp foot forming station 4, the metal sheet welding station 5, the metal wire welding station 6, and the metal cylinder welding station 7 are arranged along the outer periphery of the turntable 2 to bend the metal wire 21 into a U-shaped metal wire 11. , blanking station 8, U-shaped lamp foot forming station 4 includes a wire feeding and cutting mechanism 18, a U-shaped lamp foot forming mechanism 4b located at the outlet end of the wire feeding and cutting mechanism 18, and a U-shaped lamp foot forming mechanism The pinching mechanism 12 at the exit of 4b, the clip opening driving mechanism 9 (as disclosed in Chinese patent application 2013102185722), the U-shaped lamp foot forming mechanism 4b includes a U-shaped metal wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com