Patents

Literature

531results about "Electrode assembly manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic-glass composite electrode and fluorescent lamp having the same

InactiveUS20120212121A1Low costSimple structureDischarge tube luminescnet screensLamp detailsGlass compositesAdhesive

The present invention provides a ceramic-glass composite electrode and a fluorescent lamp having the same. The ceramic-glass composite electrode according to the present invention is a ceramic-glass composite, which is disposed at the ends of a glass tube of the fluorescent lamp. A stopper is disposed at the end of the glass tube for pushing against the ceramic-glass composite electrode and limiting the position of the ceramic-glass composite electrode slipped on the glass tube. Thereby, flowing of adhesives into the glass tube is avoided when the adhesives are used for gluing the glass tube and the ceramic-glass composite electrode, and hence extending the lifetime of the fluorescent lamp.

Owner:SANTOMA

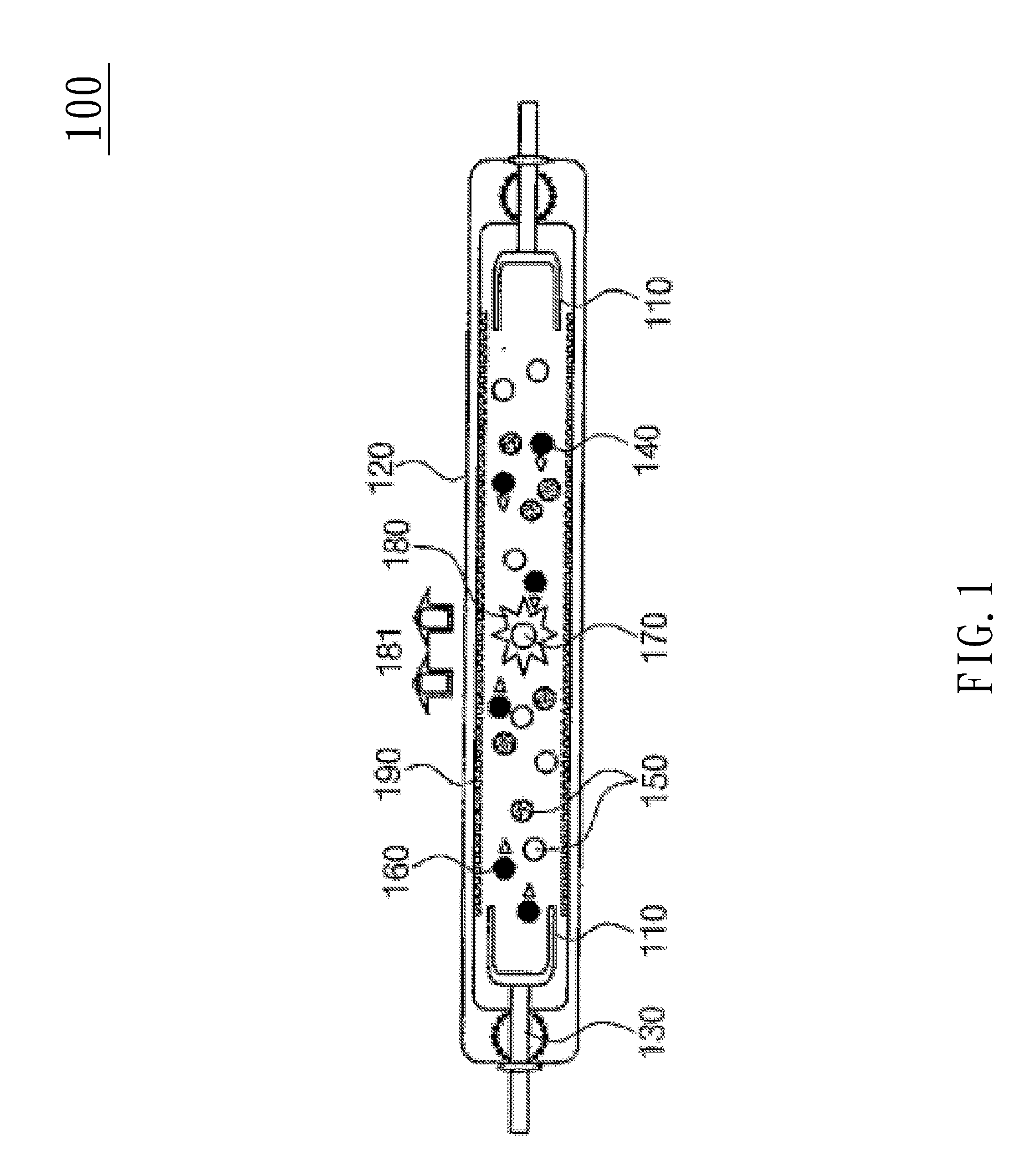

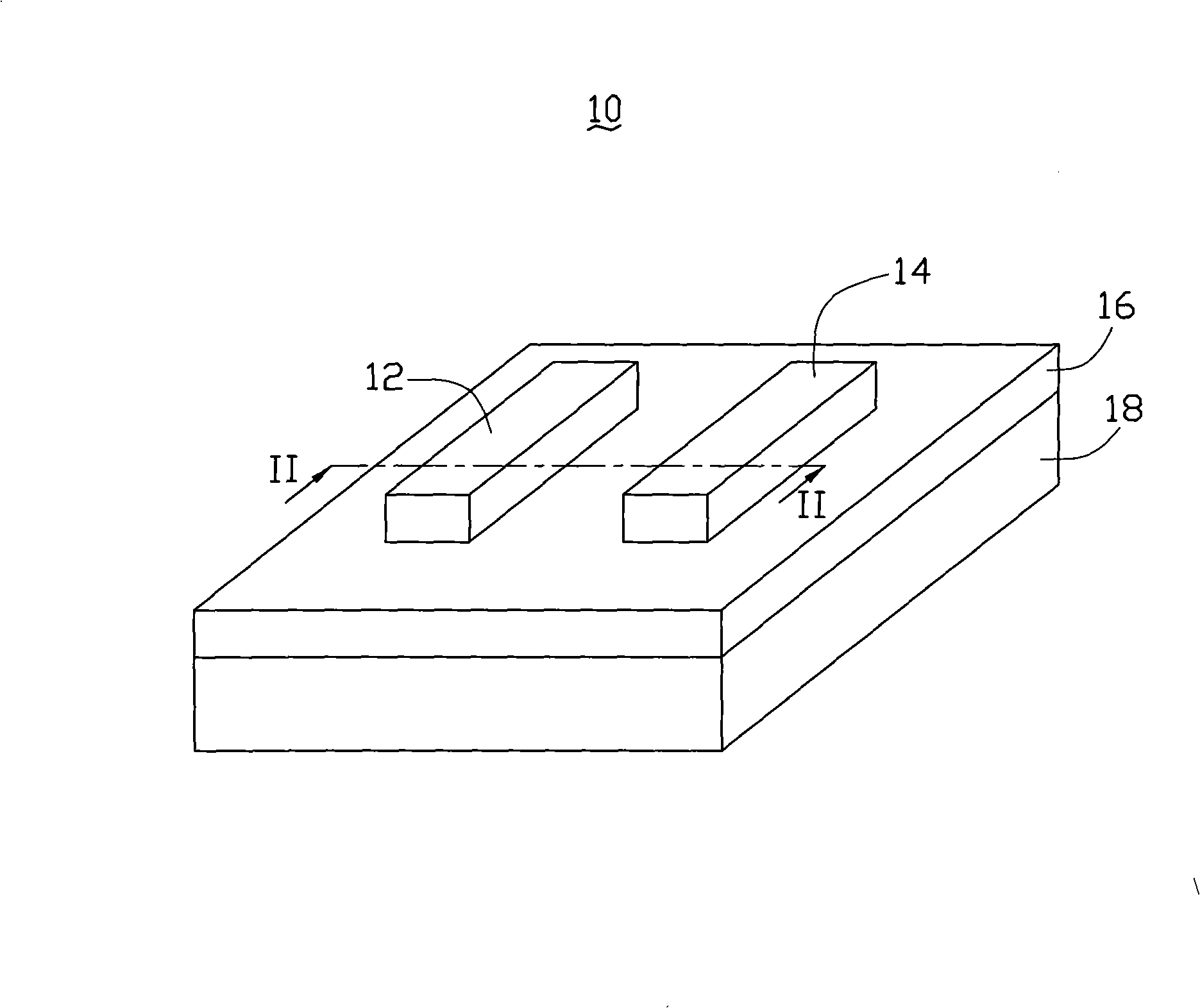

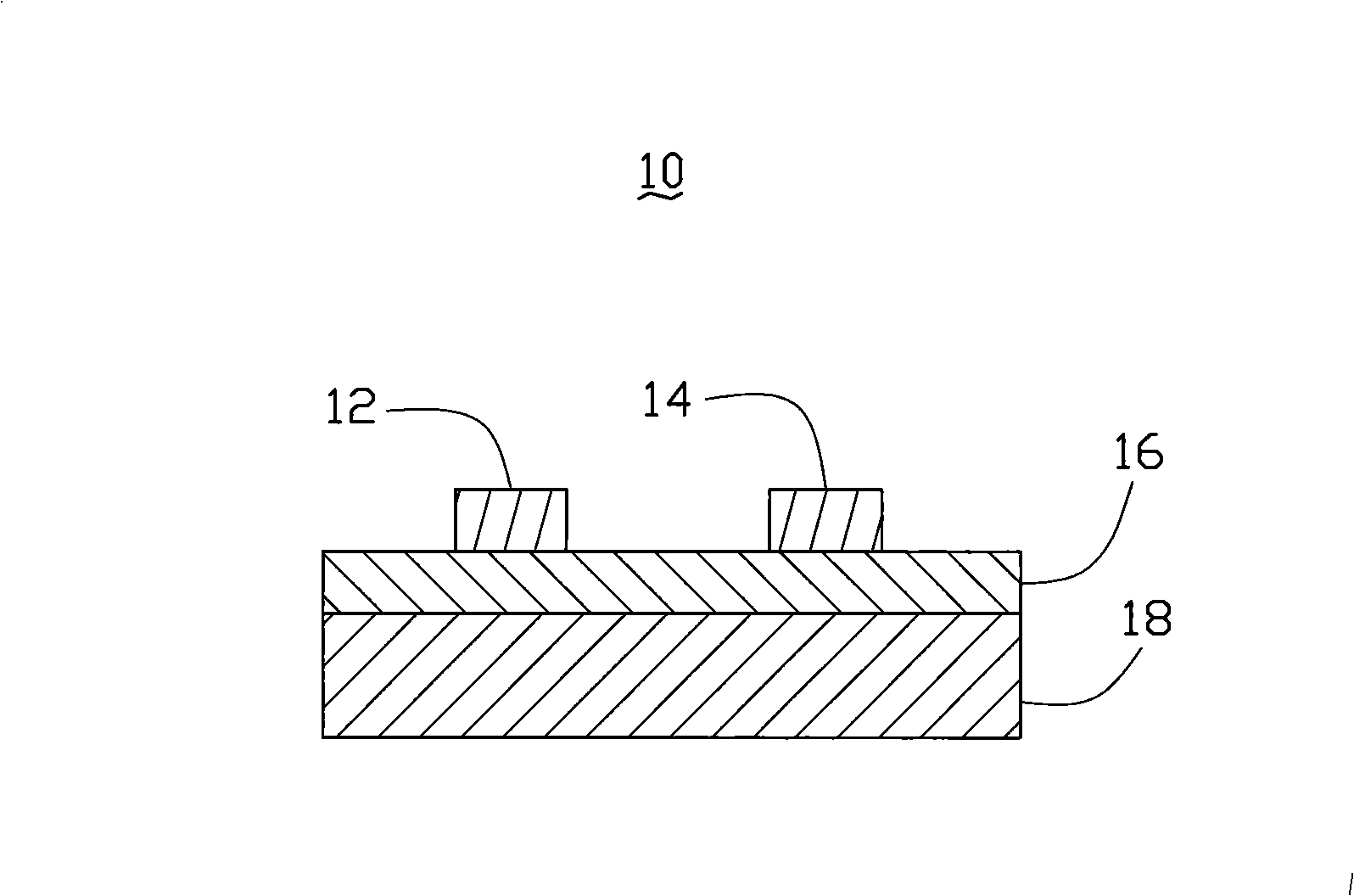

Sheet-shaped heat and light source, method for making the same and method for heating object adopting the same

InactiveUS20090096348A1Efficient use ofNanotechDischarge tube luminescnet screensCarbon nanotubeOptoelectronics

The present invention relates to a sheet-shaped heat and light source. The sheet-shaped heat and light source includes a carbon nanotube film and at least two electrodes. The at least two electrodes are separately disposed on the carbon nanotube film and electrically connected thereto. Moreover, a method for making the sheet-shaped heat and light source and a method for heating an object adopting the same are also included.

Owner:TSINGHUA UNIV +1

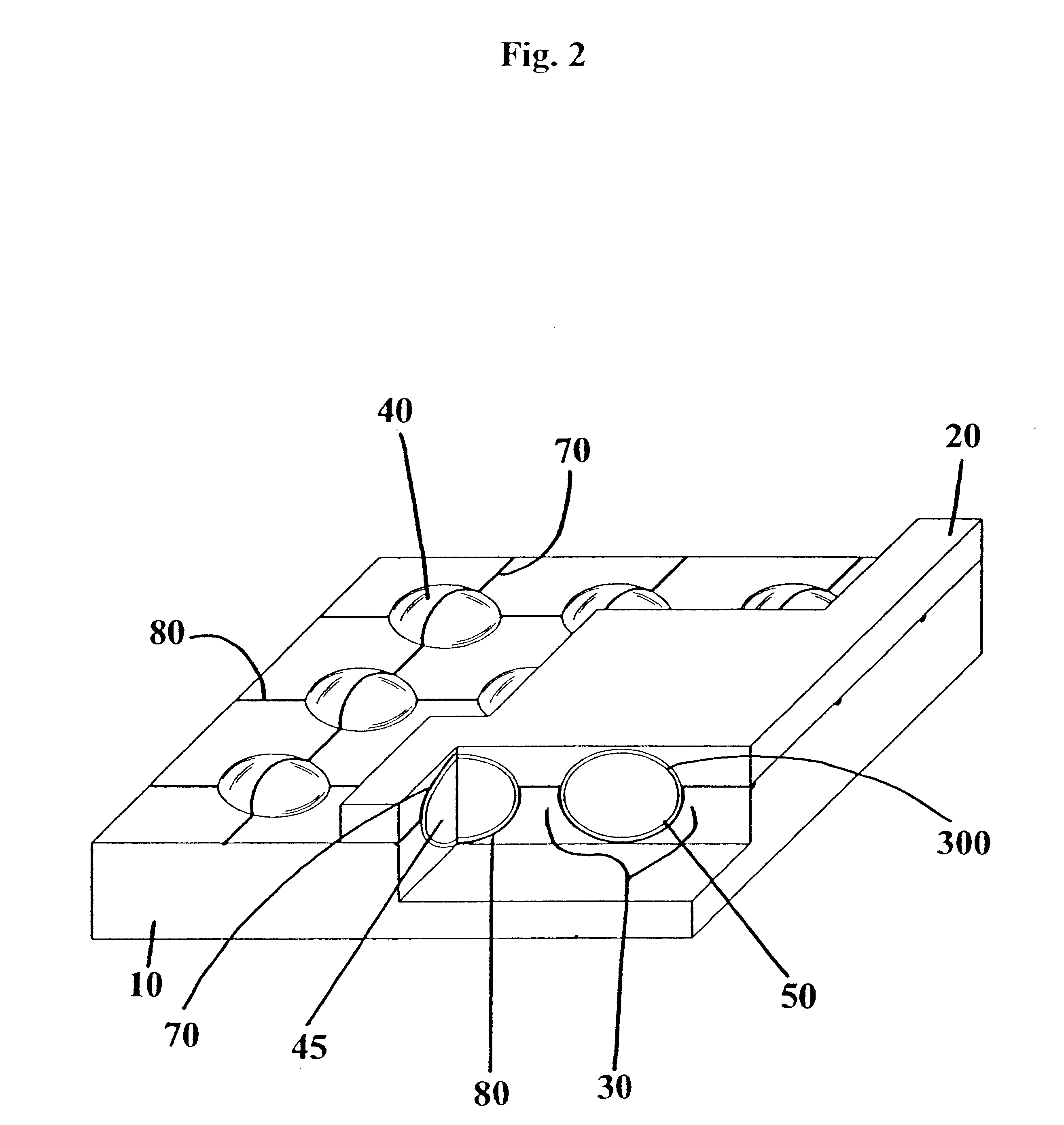

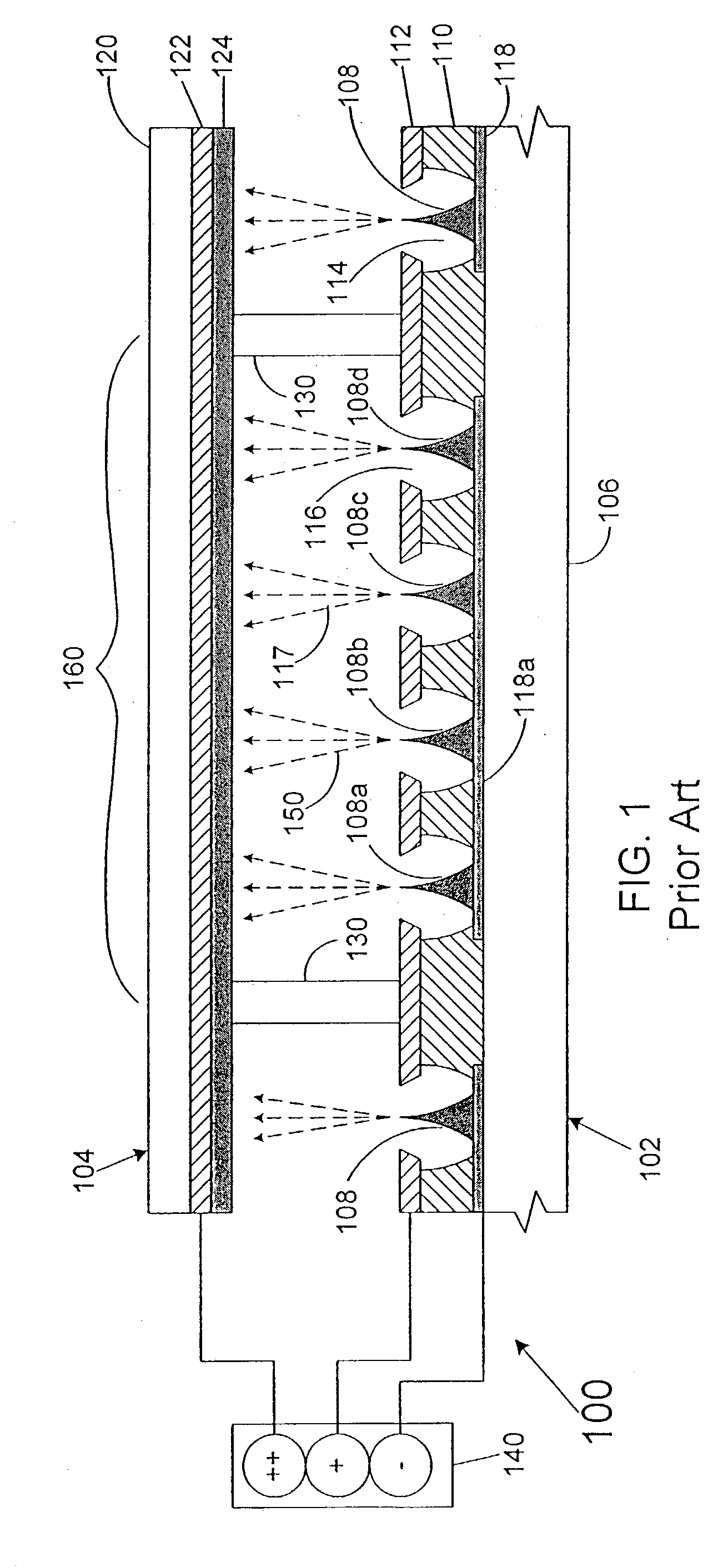

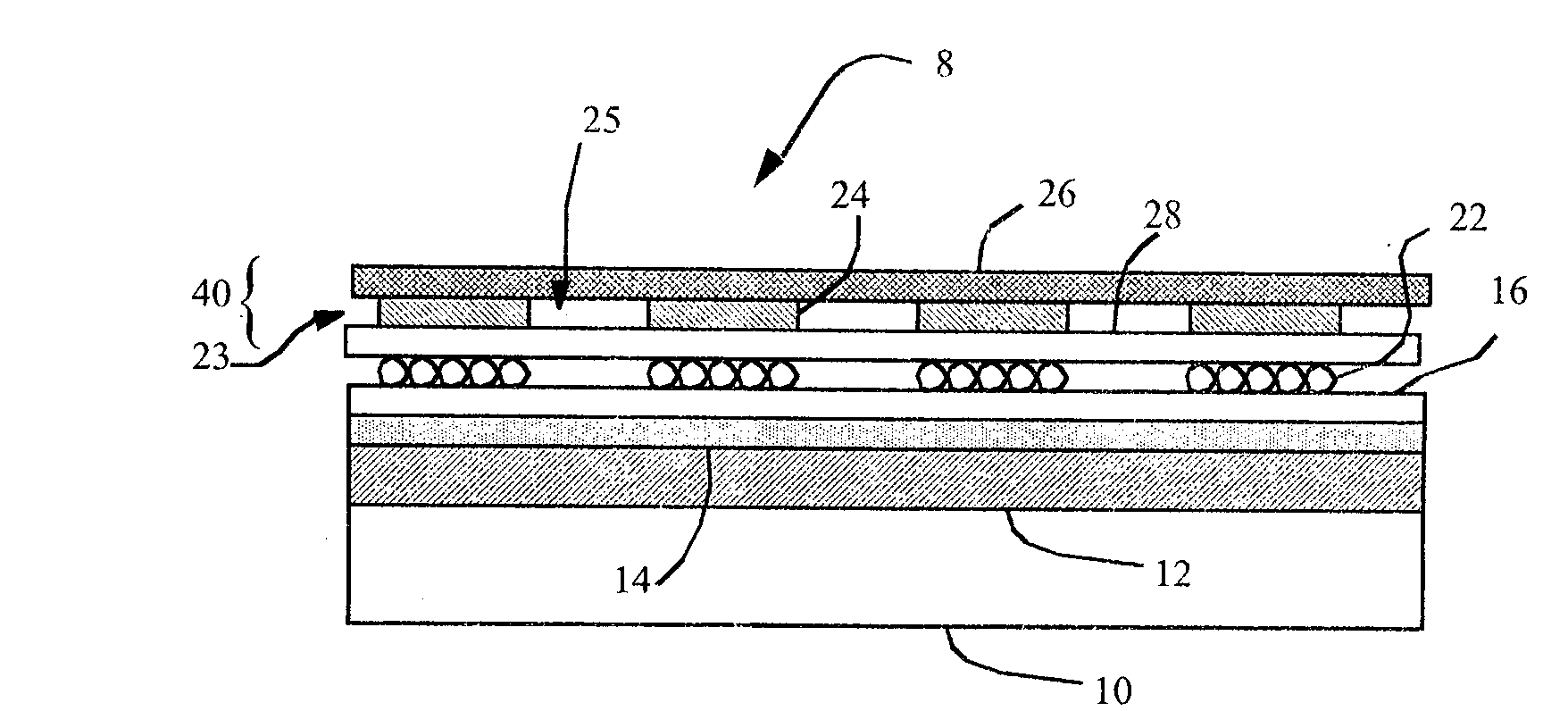

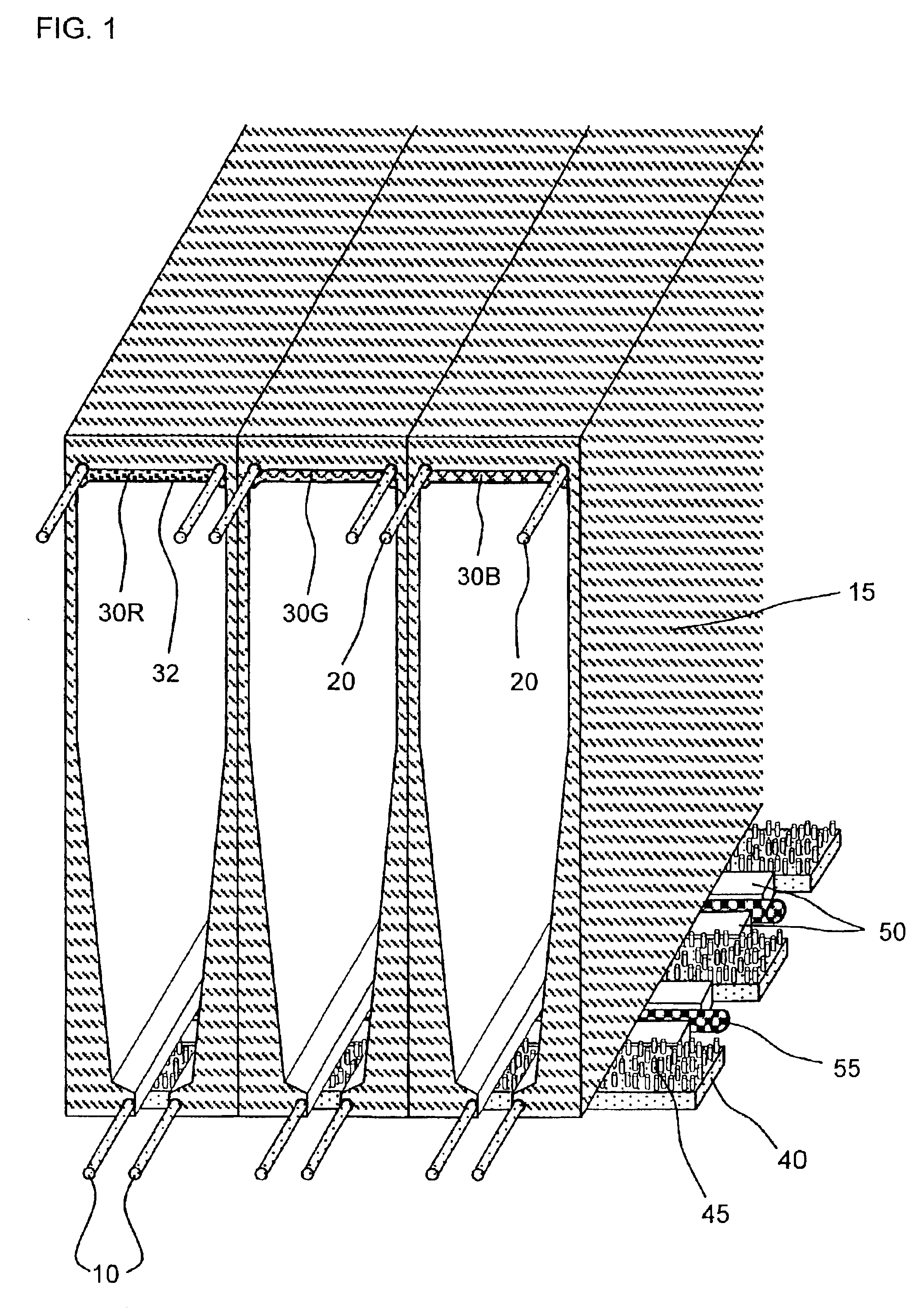

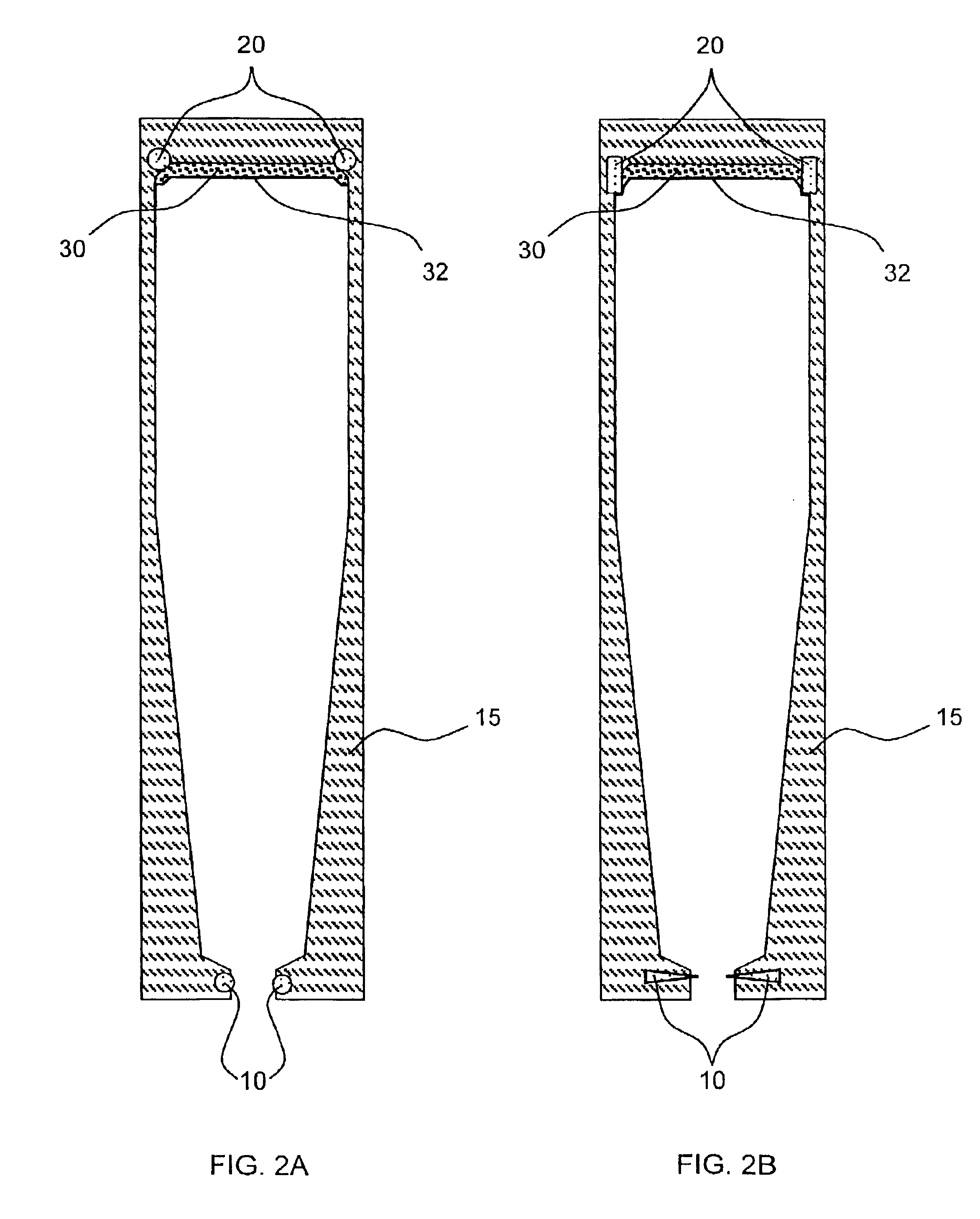

Socket for use with a micro-component in a light-emitting panel

InactiveUS6545422B1Sufficient resolutionManufactured very thinEmission spectroscopyStatic indicating devicesIonizationVoltage

An improved light-emitting panel having a plurality of micro-components at least partially disposed in a socket and sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes.

Owner:LEIDOS

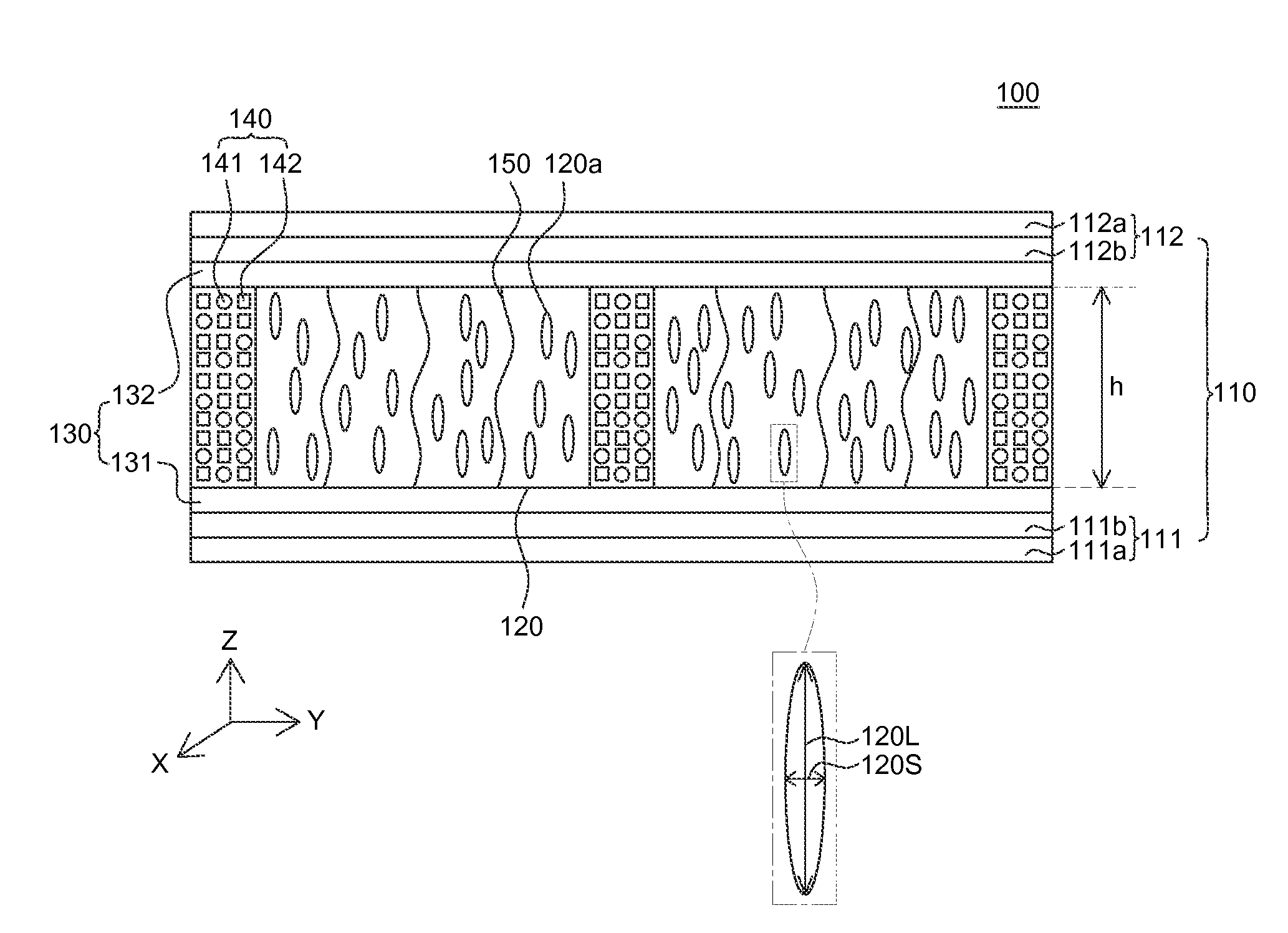

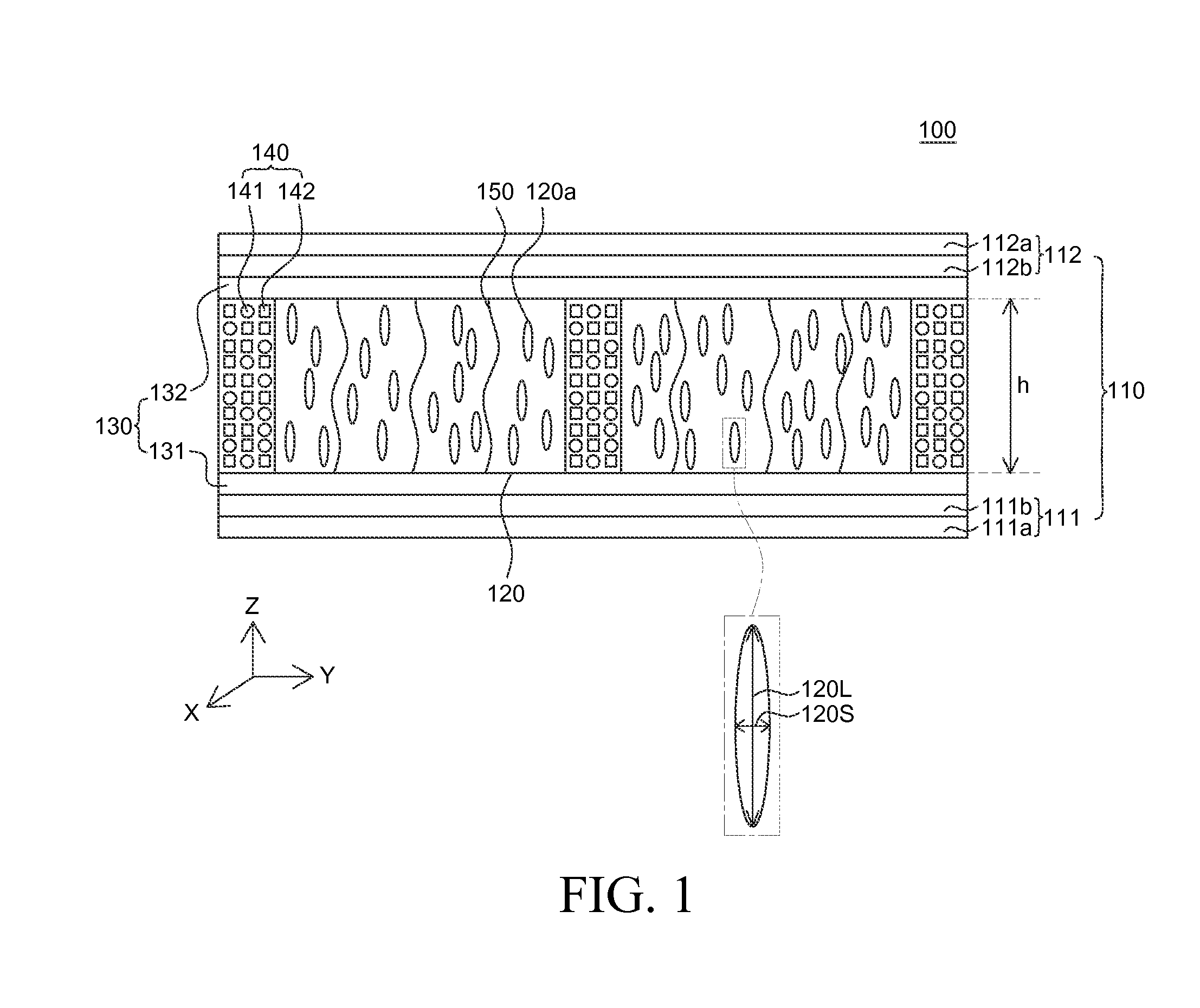

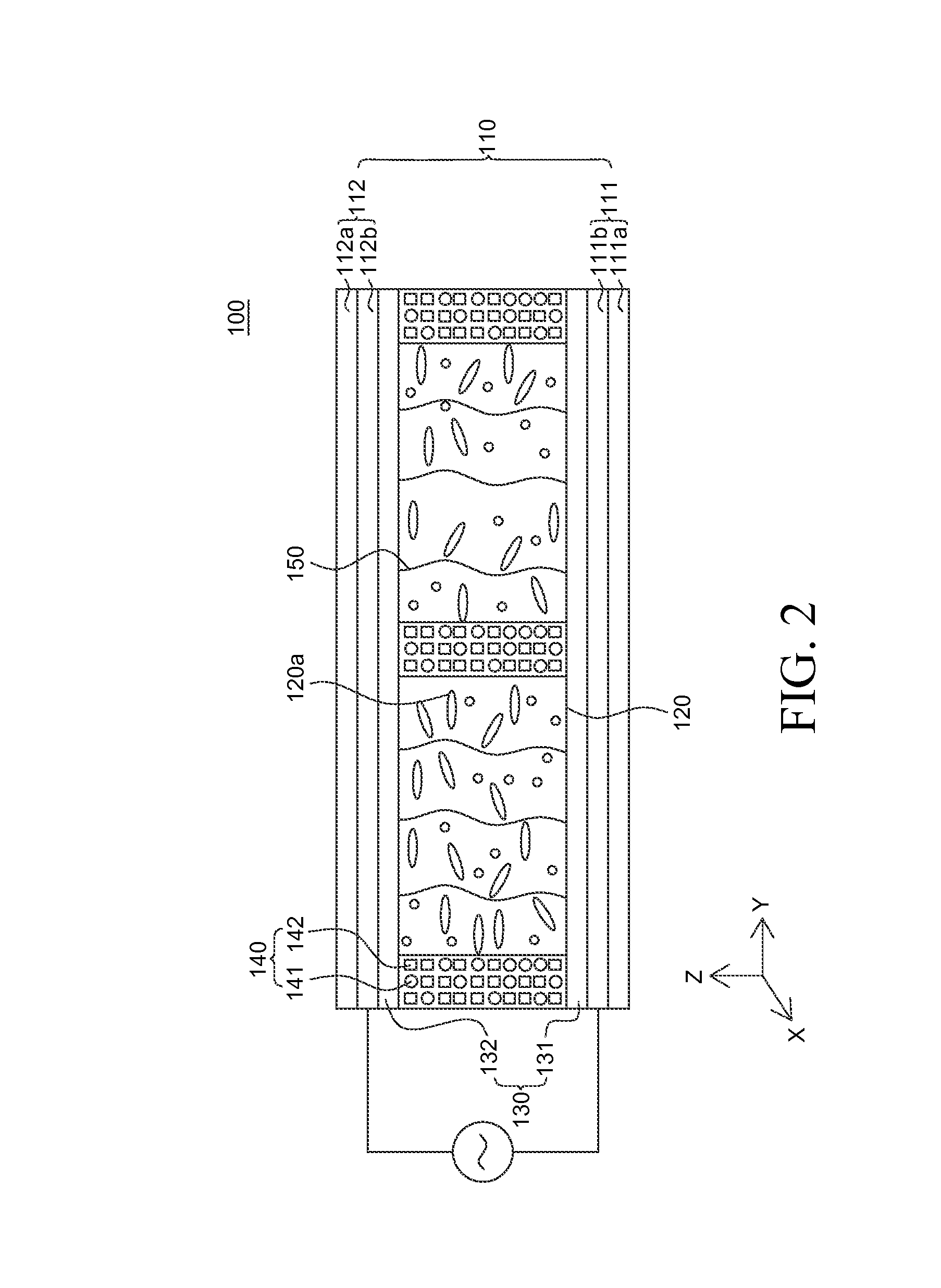

Light controlling apparatus and method of fabricating the same

ActiveUS20160154259A1Reduce power consumptionHigh light transmittanceLiquid crystal compositionsStatic indicating devicesEngineeringControl equipment

Provided are a light controlling apparatus and a method of fabricating the same. The light controlling apparatus comprises: a first electrode unit and a second electrode unit facing each other; a liquid crystal unit between the first electrode unit and the second electrode unit, the liquid crystal unit including: a liquid crystal; a network having a first polymer polymerized from a first monomer having a similar shape as the liquid crystal and a second polymer polymerized from a second monomer having a shape different from the first monomer; and a wall having the first polymer and the second polymer.

Owner:LG DISPLAY CO LTD

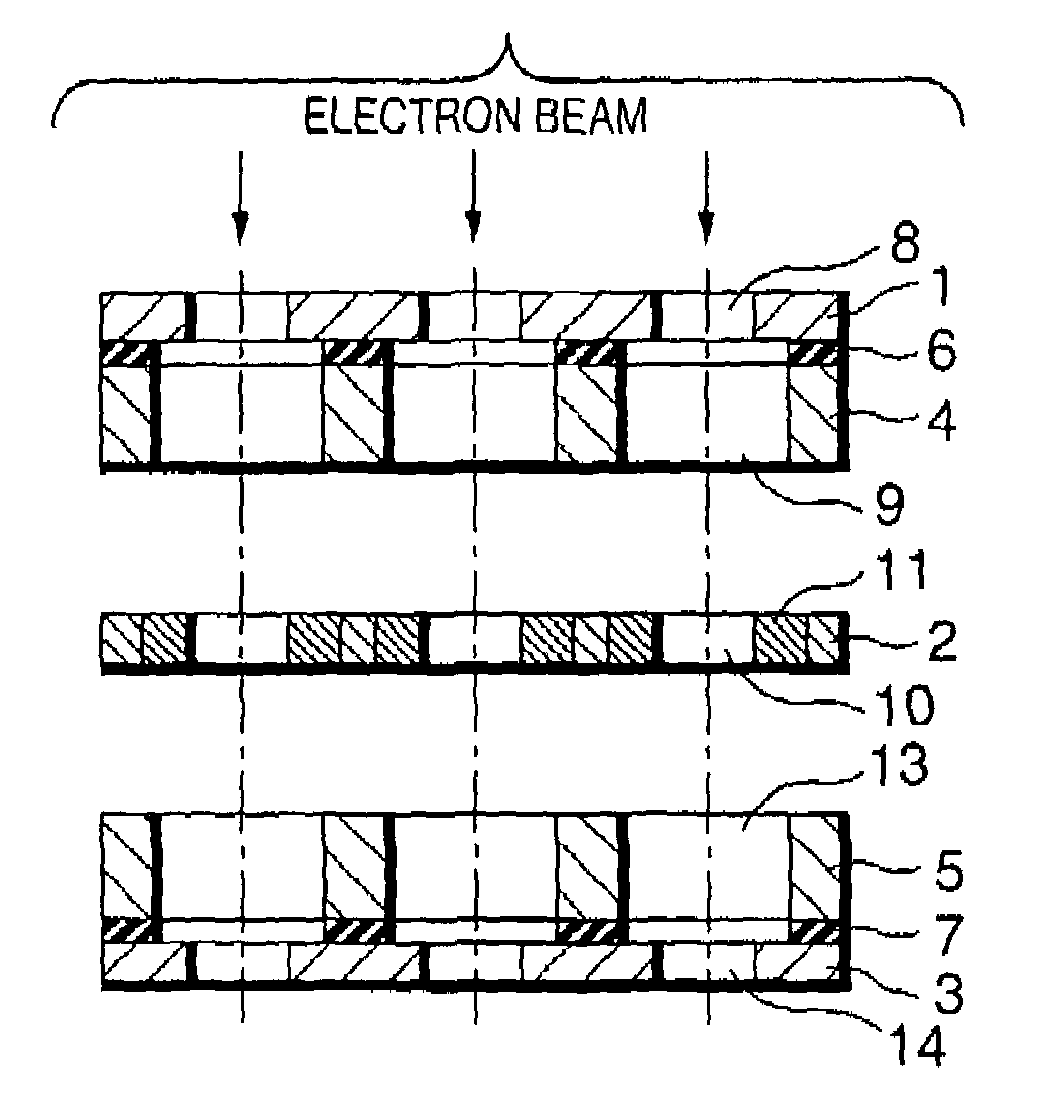

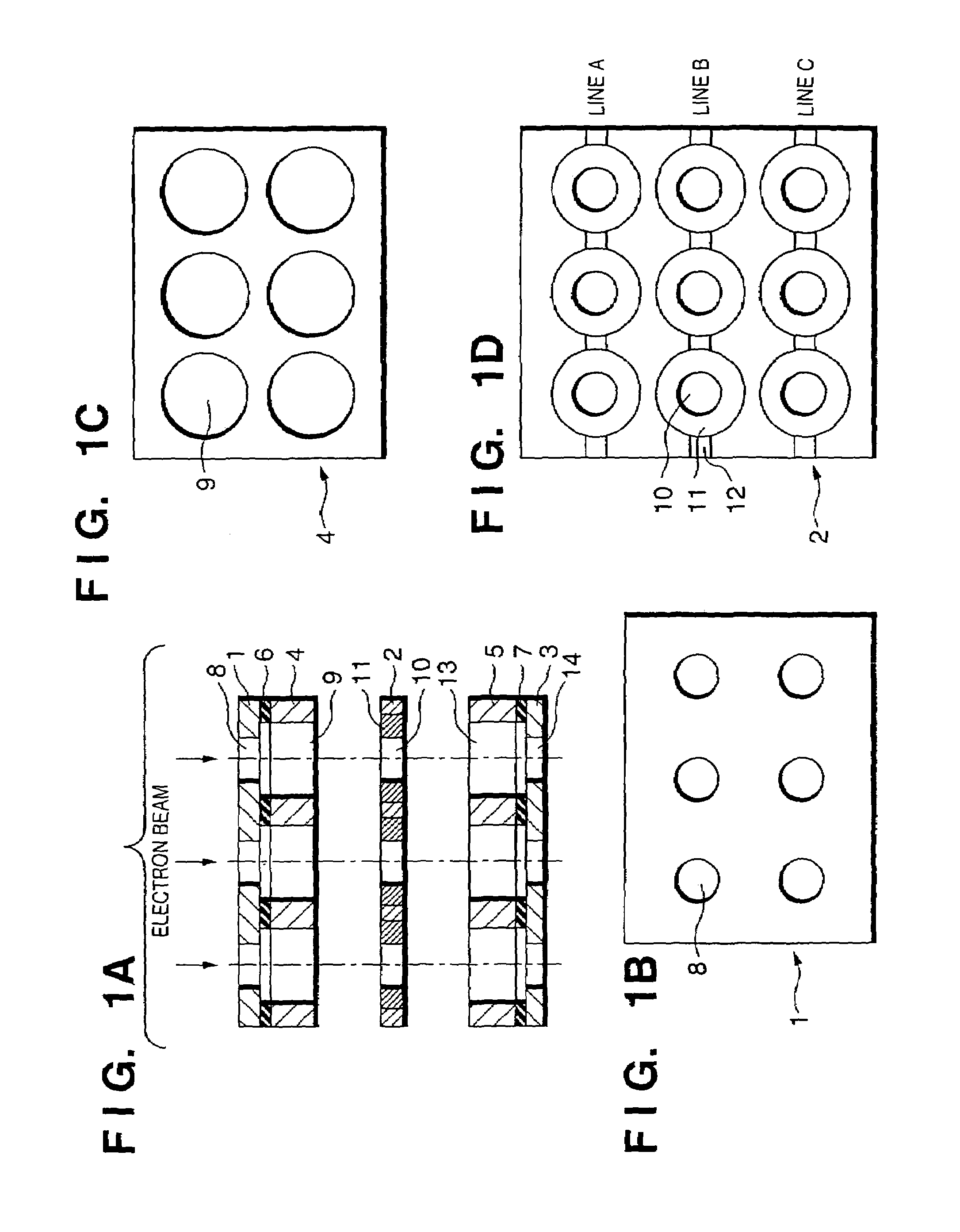

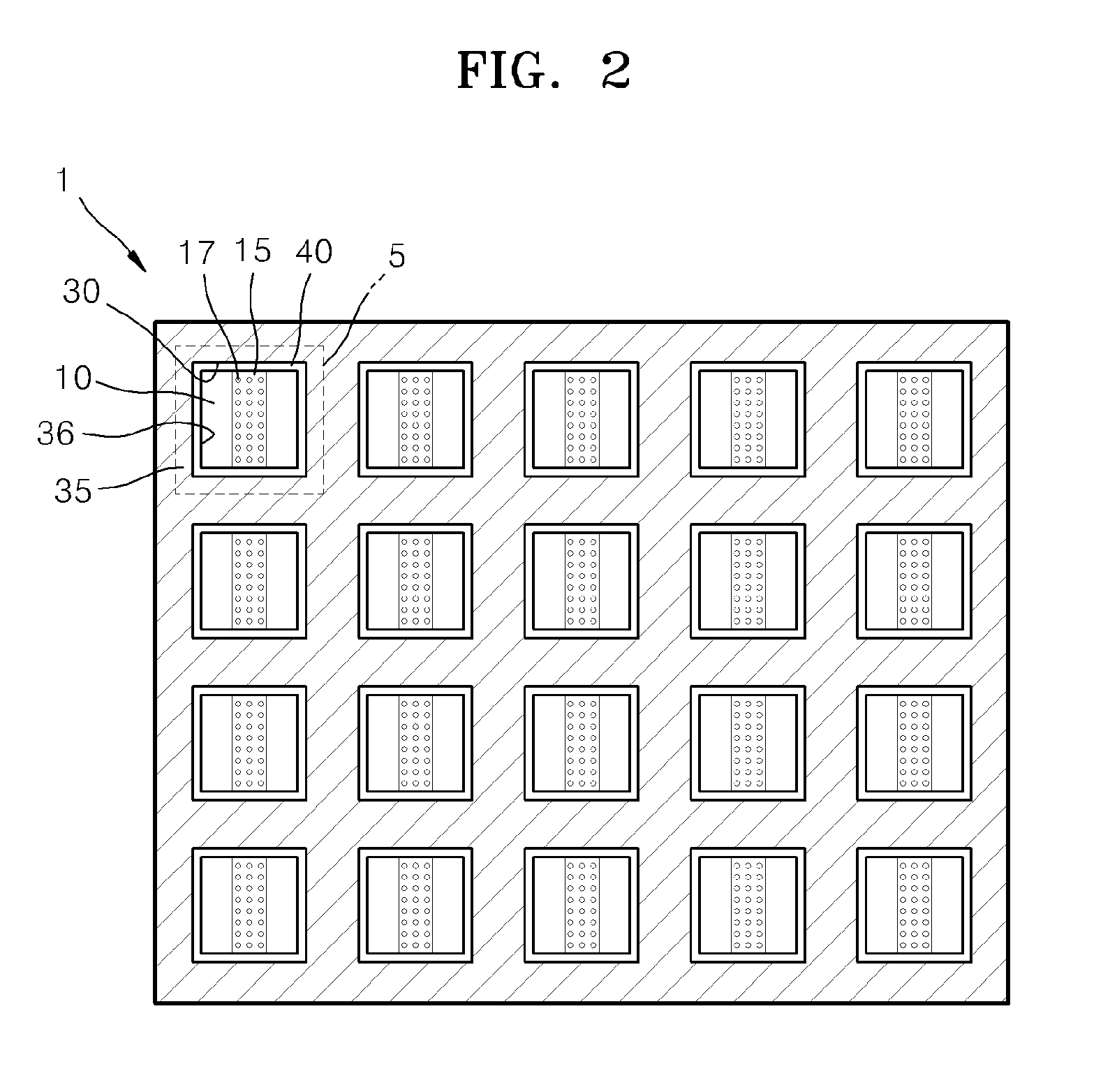

Electrooptic system array, charged-particle beam exposure apparatus using the same, and device manufacturing method

InactiveUS6965153B1Reduce crosstalkImprove accuracySemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringElectron lenses

This invention relates to an electrooptic system array having a plurality of electron lenses. The electrooptic system array includes upper, middle, and lower electrodes arranged along the paths of a plurality of charged-particle beams, the upper, middle, and lower electrodes having pluralities of apertures on the paths of the plurality of charged-particle beams, an upper shield electrode which is interposed between the upper and middle electrodes and has a plurality of shields corresponding to the respective paths of the charged-particle beams, and a lower shield electrode which is interposed between the lower and middle electrodes and has a plurality of shields corresponding to the respective paths of the charged-particle beams.

Owner:CANON KK

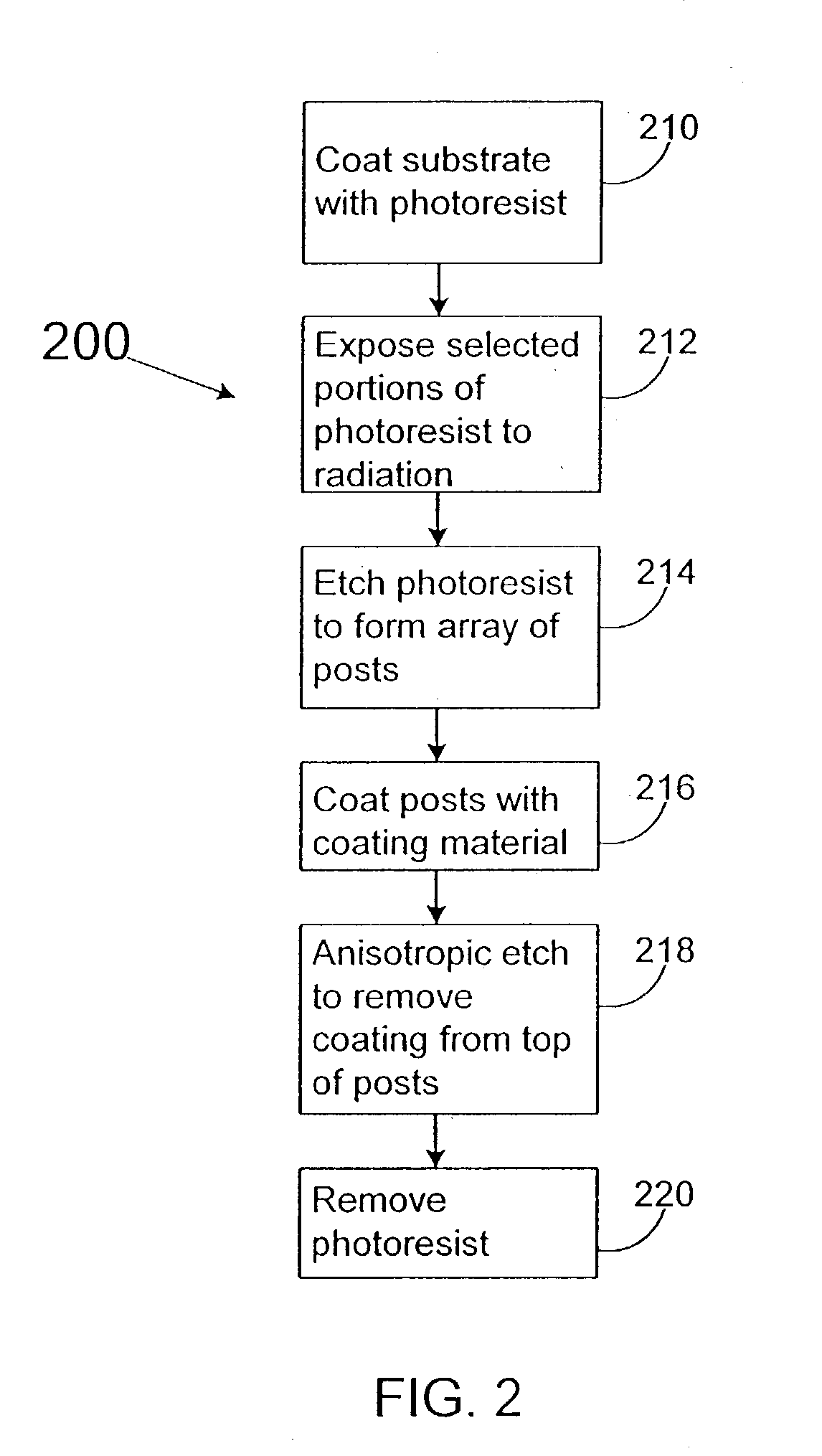

Spacers for field emission displays

InactiveUS20030085650A1Precise positioningQuality improvementCathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsField emission displayDisplay device

The disclosed method for forming a field emission display includes forming a cathode and an anode, forming a plurality of photoresist posts over the cathode, and coating the posts with a coating material. The coating material forms sidewalls around the posts. The photoresist posts may then be removed from within the sidewalls. The anode may then be fitted onto the sidewalls so that the sidewalls function as spacers in the field emission display.

Owner:MICRON TECH INC

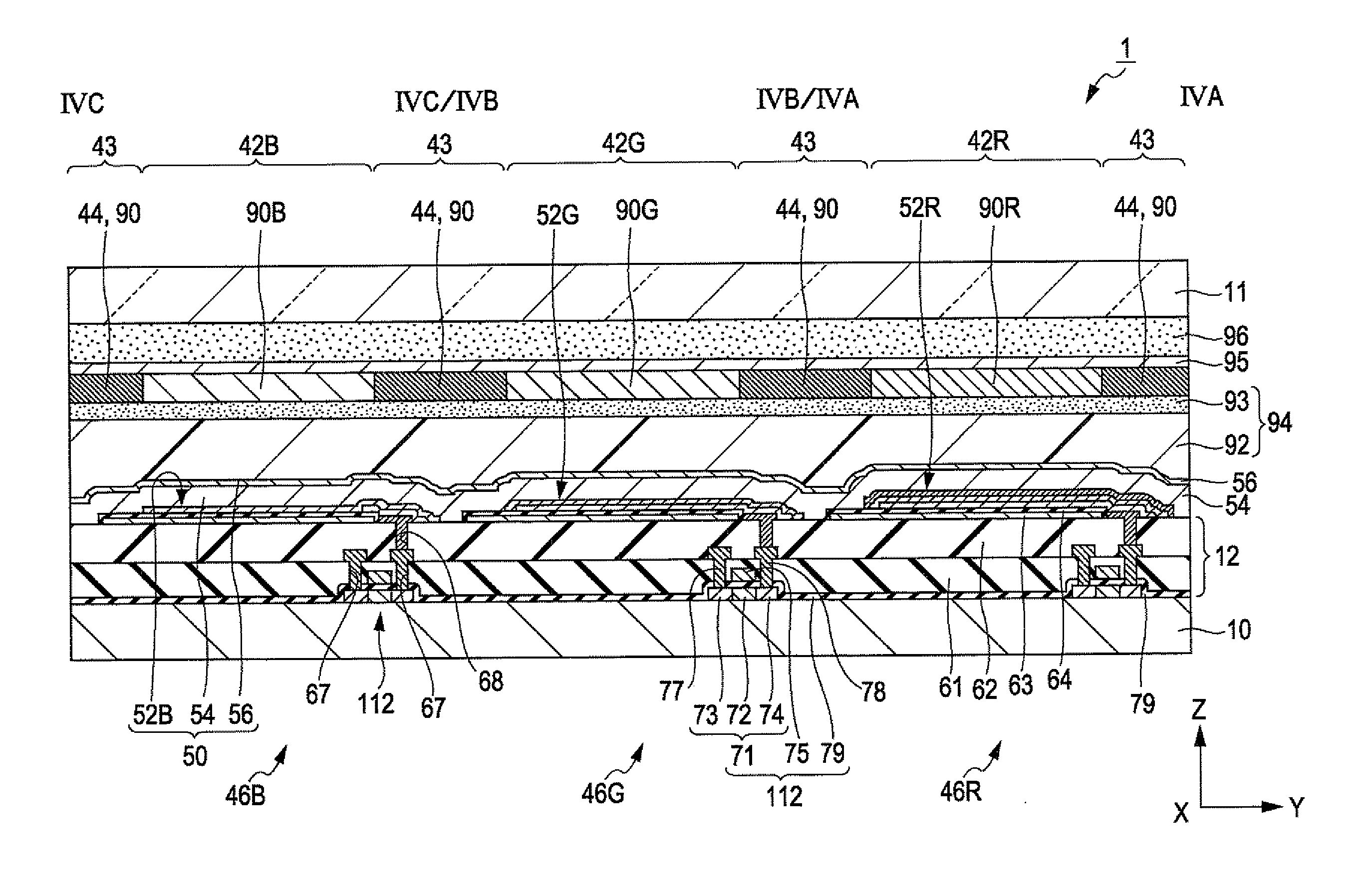

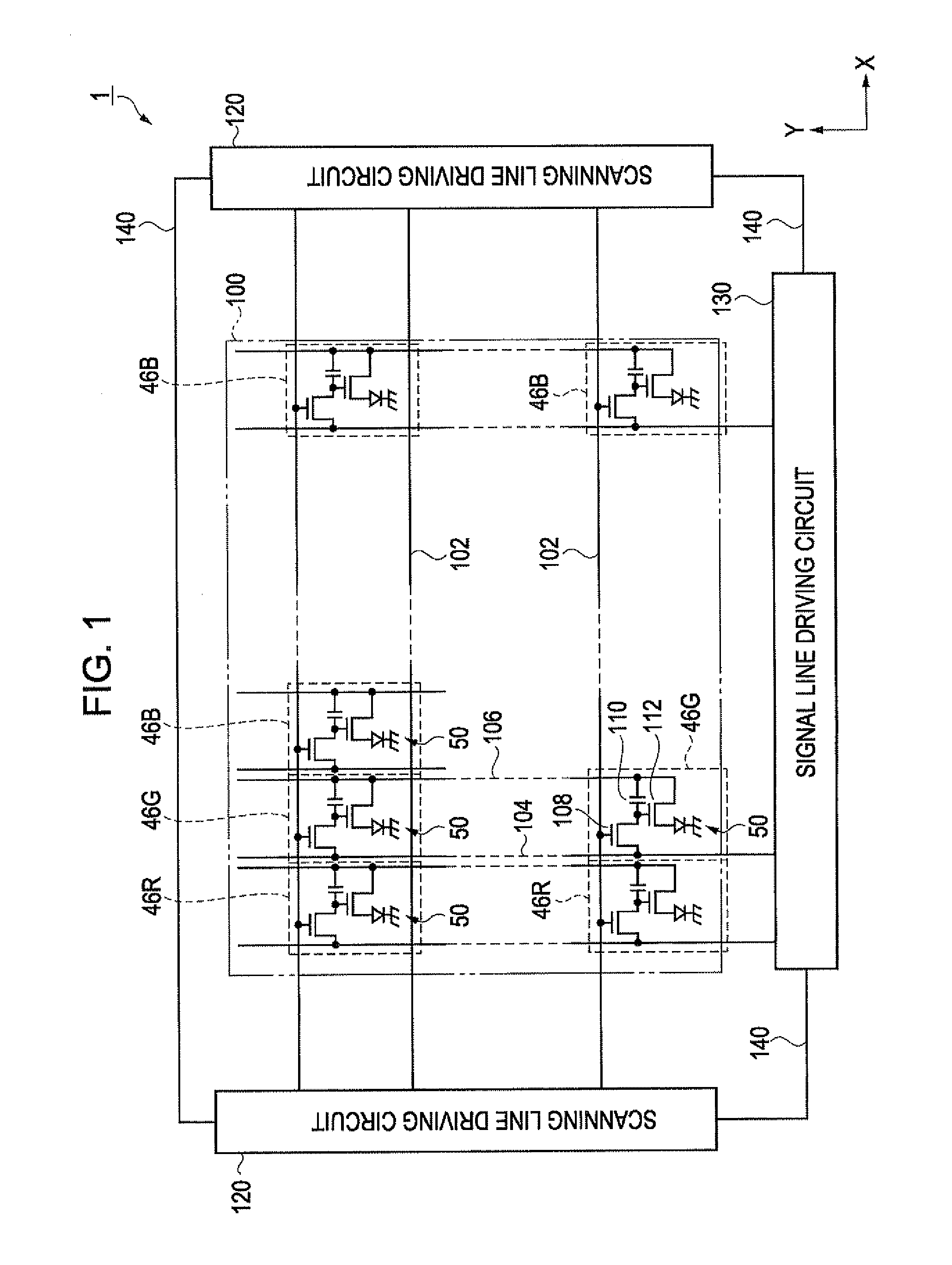

Organic el device, method of producing organic el device, and electronic apparatus

ActiveUS20120038267A1Reducing light emissionImprove display qualityDischarge tube luminescnet screensLamp detailsElectronElectrode

An organic EL device includes a substrate, an organic EL element that is formed on the substrate and is provided with a first electrode, a light emitting functional layer, and a second electrode having transparent conductivity to emit light to the second electrode side, a color filter that is formed on the second electrode side in a pixel area where the organic EL element emits the light, and a partition that is formed in a light shielding area that is an area other than the pixel area. The color filter is provided with any one of a red color filter, a green color filter, and a blue color filter. At least one color filter of the three color filters constitutes at least a part of the partition.

Owner:SEIKO EPSON CORP

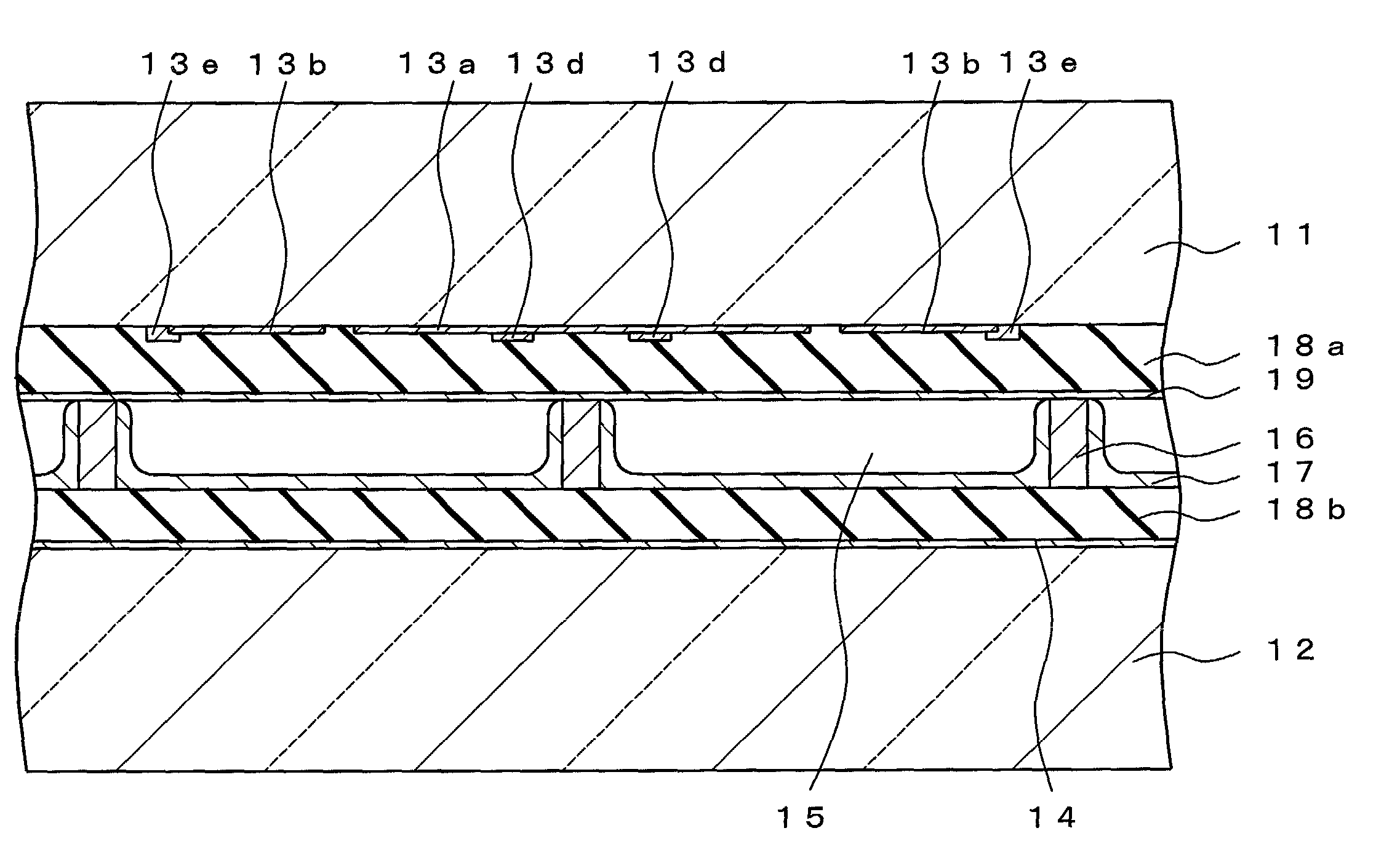

Flat display device and method for making the same

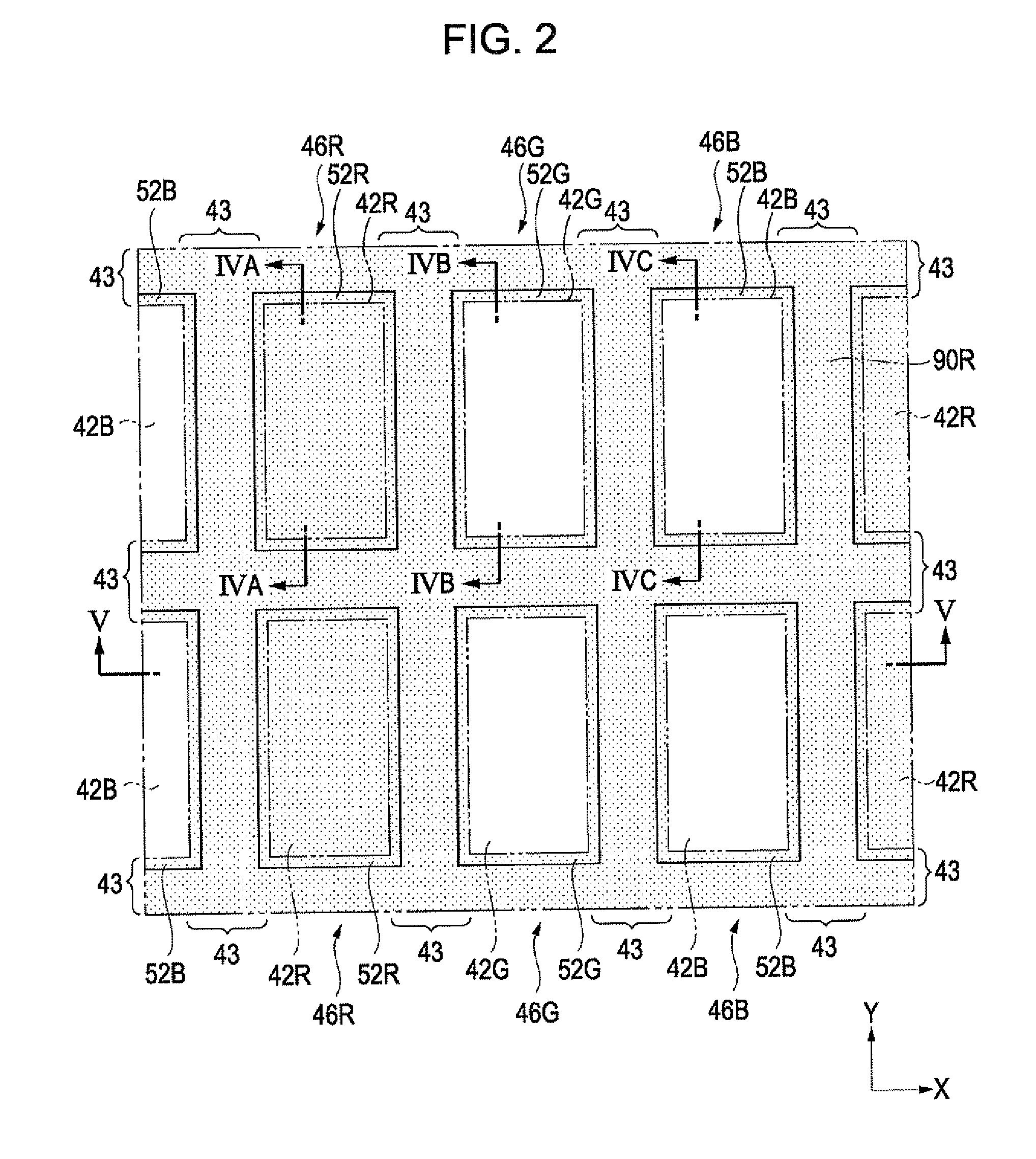

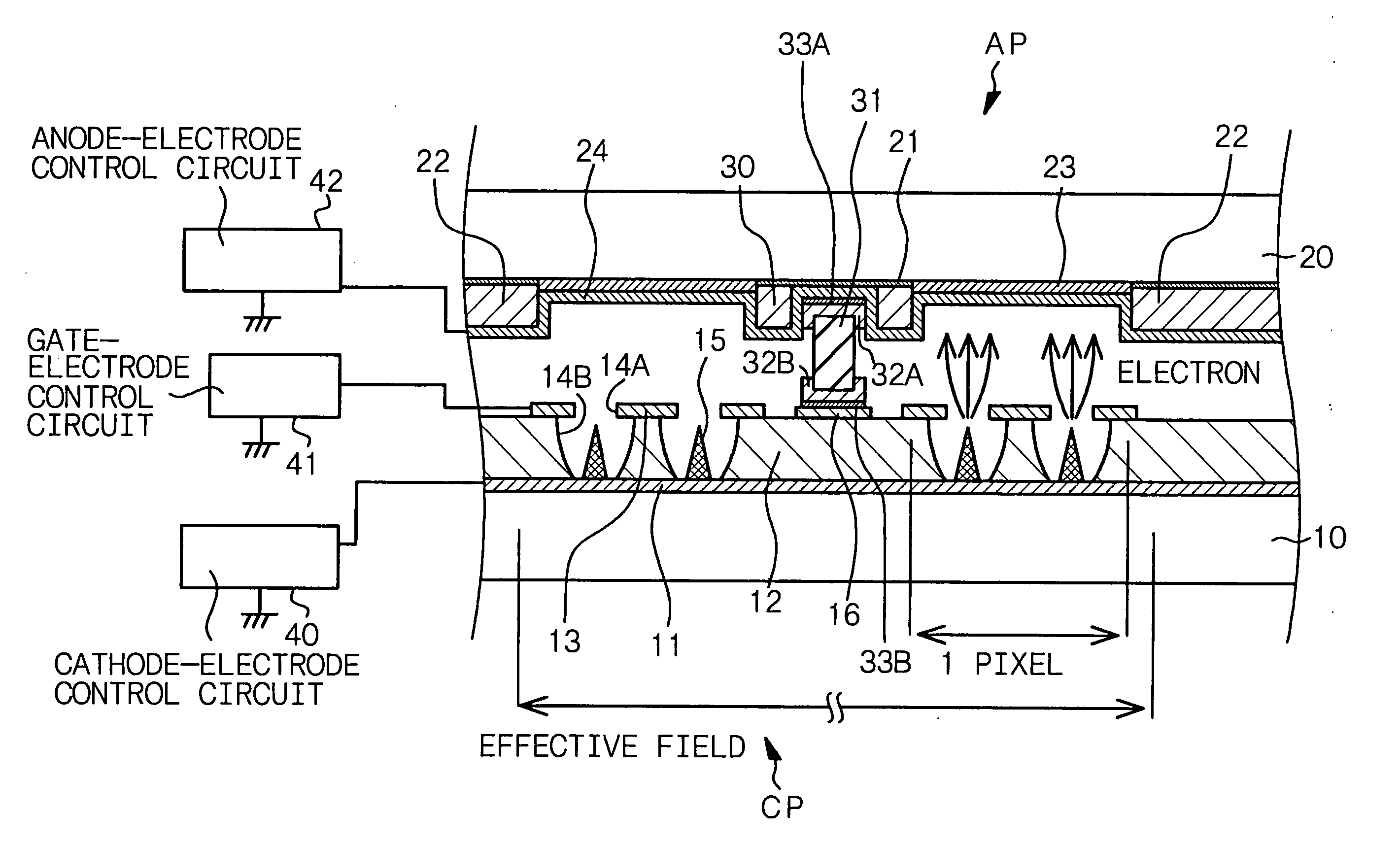

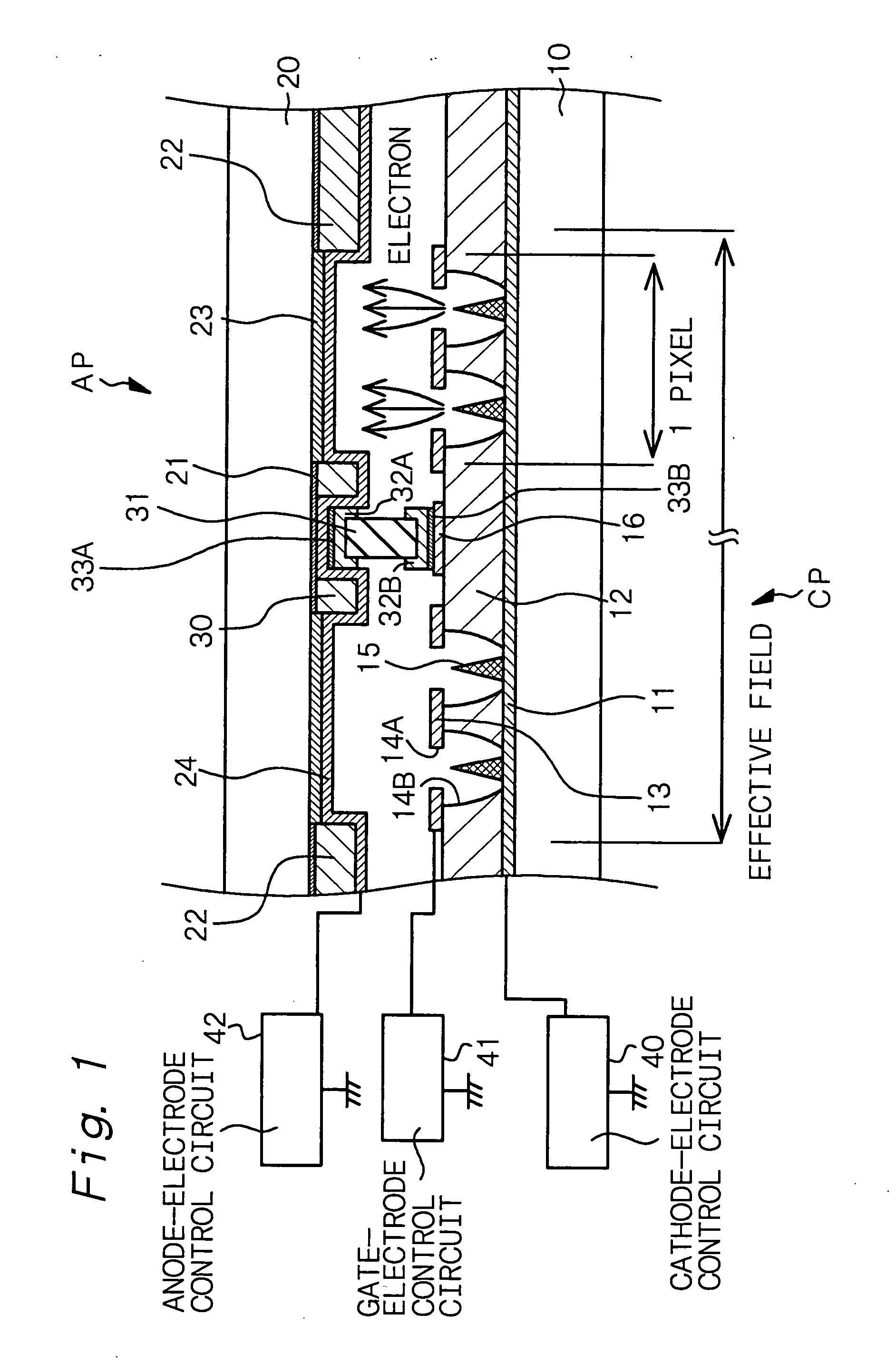

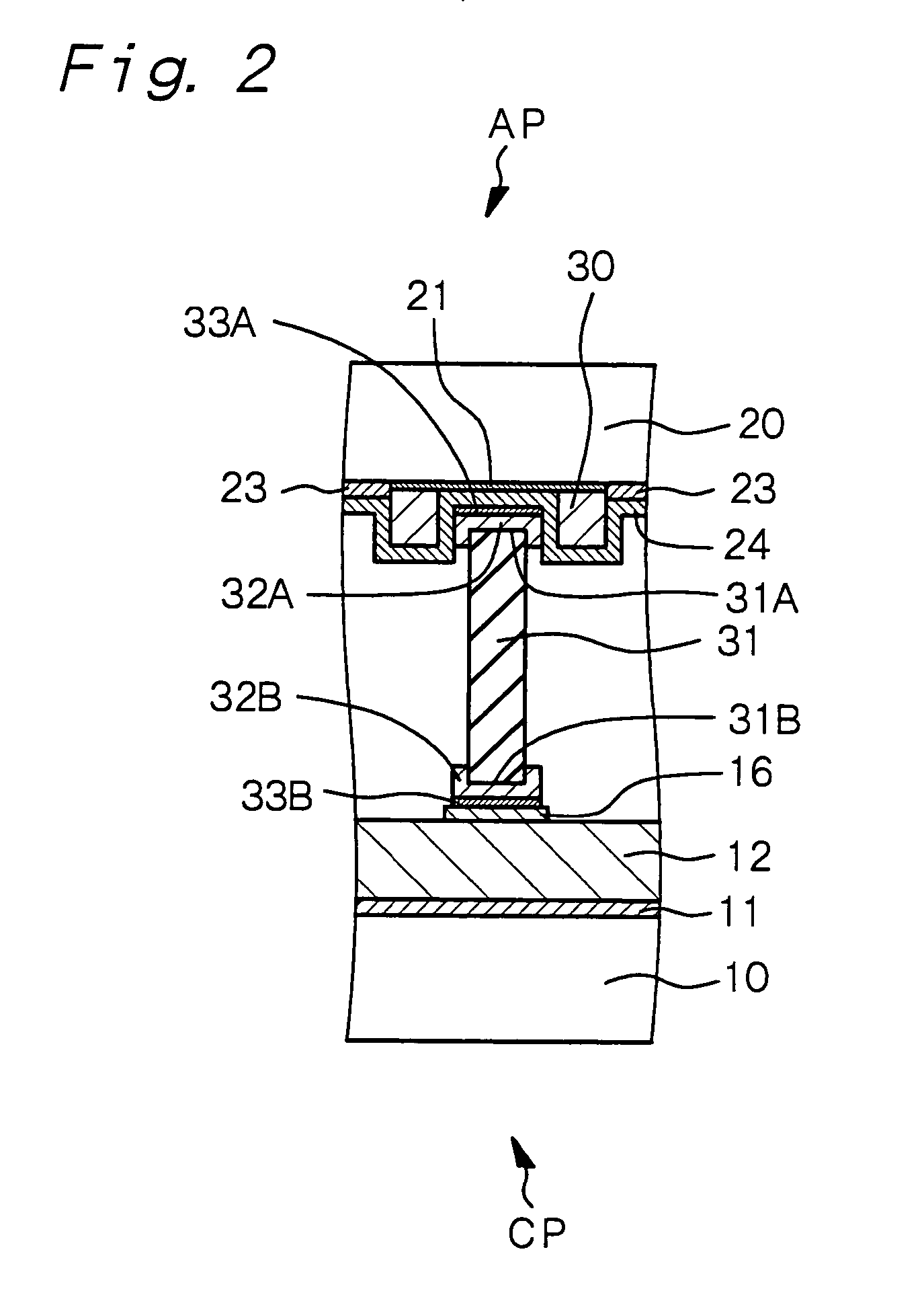

InactiveUS20060091780A1Falling or tilting of the spacer can be reliably preventedElectrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportDisplay deviceEngineering

A flat-type display comprising a first panel AP and a second panel CP which are bonded to each other in their circumferential portions and having a space between the first panel AP and the second panel CP, the space being in a vacuum state, a spacer being disposed between a first panel effective field and a second panel effective field that work as a display portion, said spacer being fixed to the first panel effective field and / or the second panel effective field with a low-melting-point metal material layers 33A and 33B.

Owner:SONY CORP

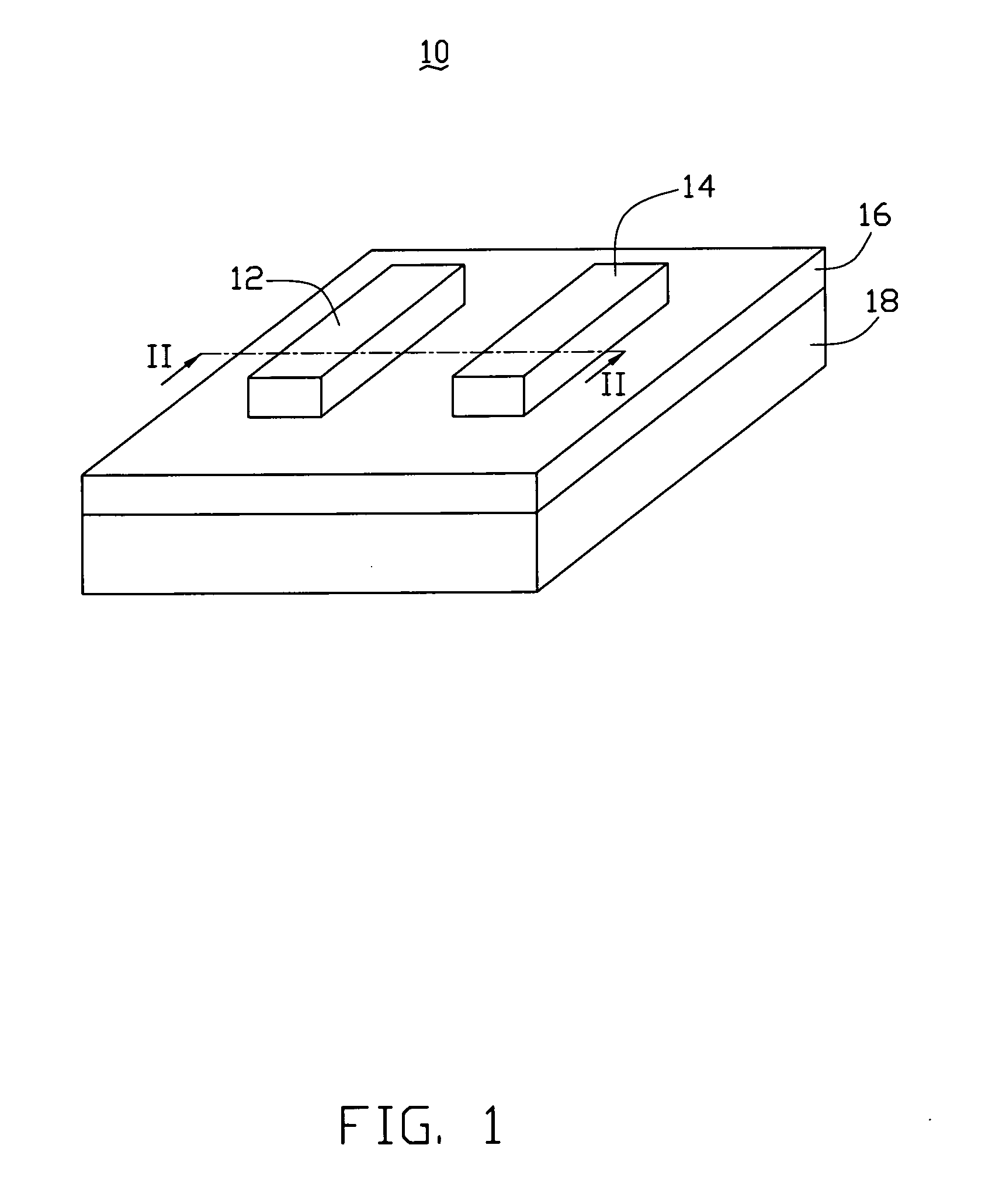

Printed active device

ActiveUS20150270089A1Reduce manufacturing costLow costAdditive manufacturing apparatusControl electrodesElement spaceElectrical connection

Owner:BRITISH TELECOMM PLC

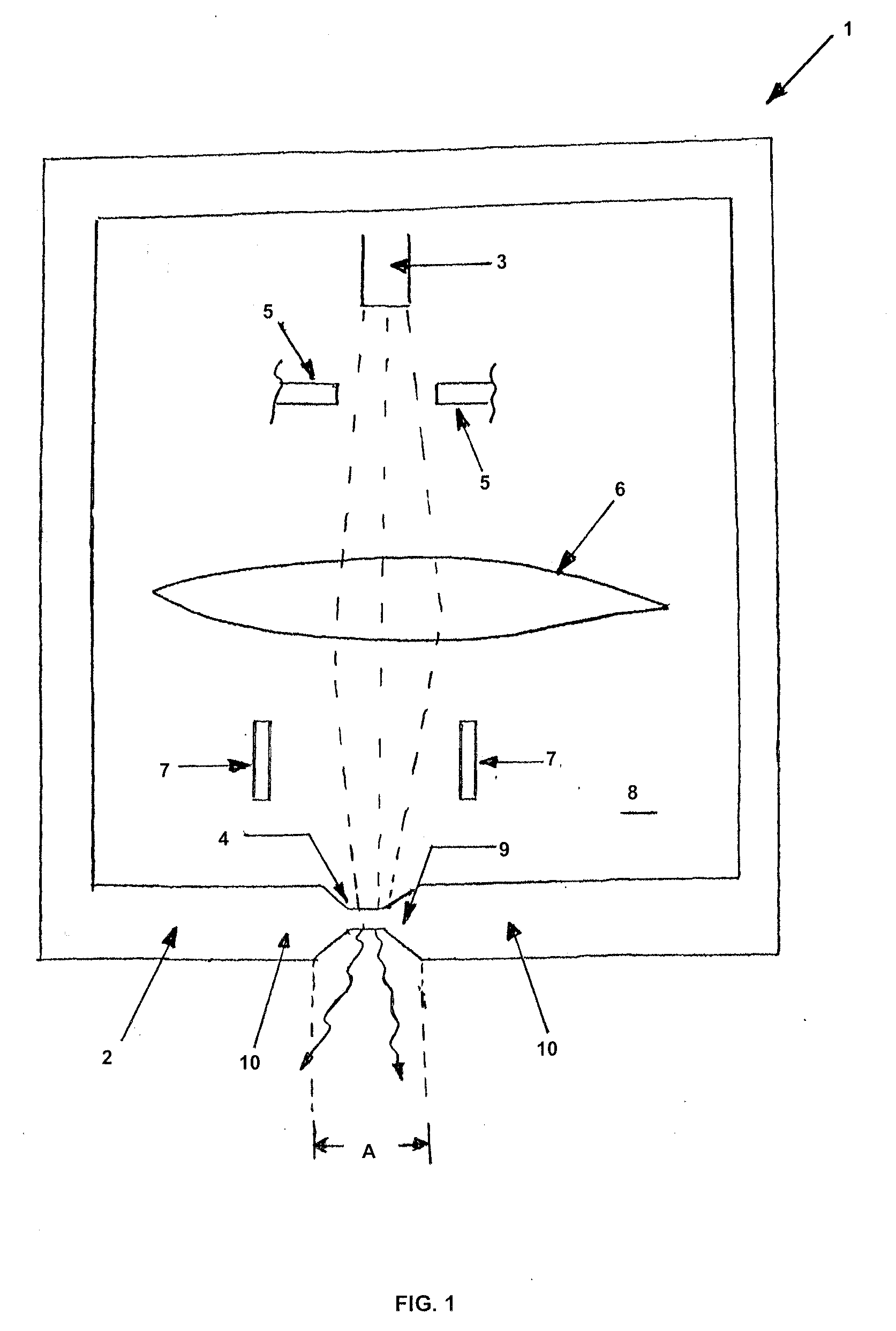

Micro x-ray source

InactiveUS20080170668A1Avoid divergenceHigh resolutionX-ray tube electrodesCathode ray concentrating/focusing/directingElectron sourceMetal foil

A micro X-ray source comprising a target acting as anode, and a cathode, which during operation interacts with the target and functions as electron source, wherein the target is embodied as a metal foil possessing a spot where the electrons from the electron source arrive, and the metal foil being locally thinner at the spot.

Owner:TECH UNIV DELFT

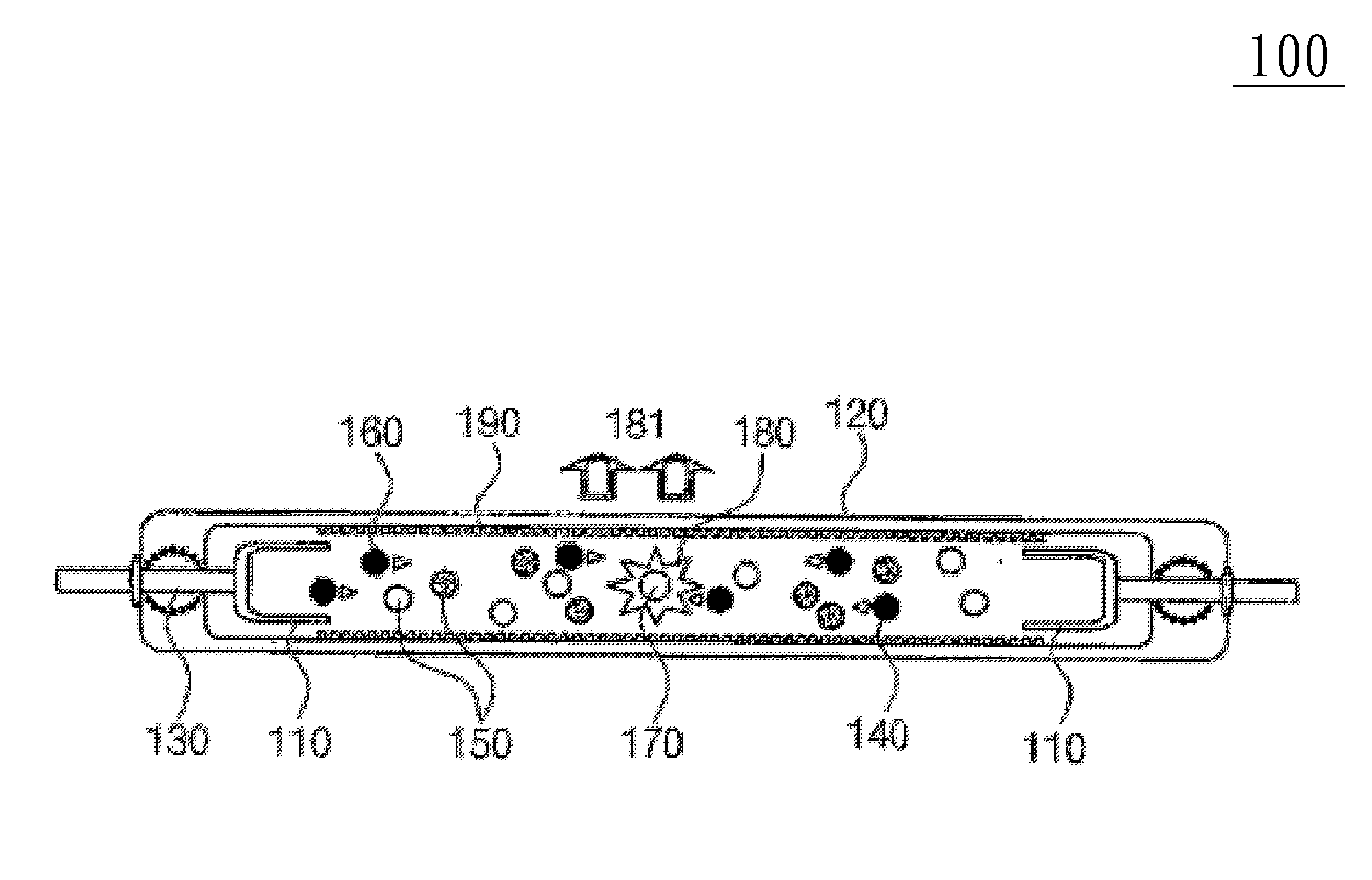

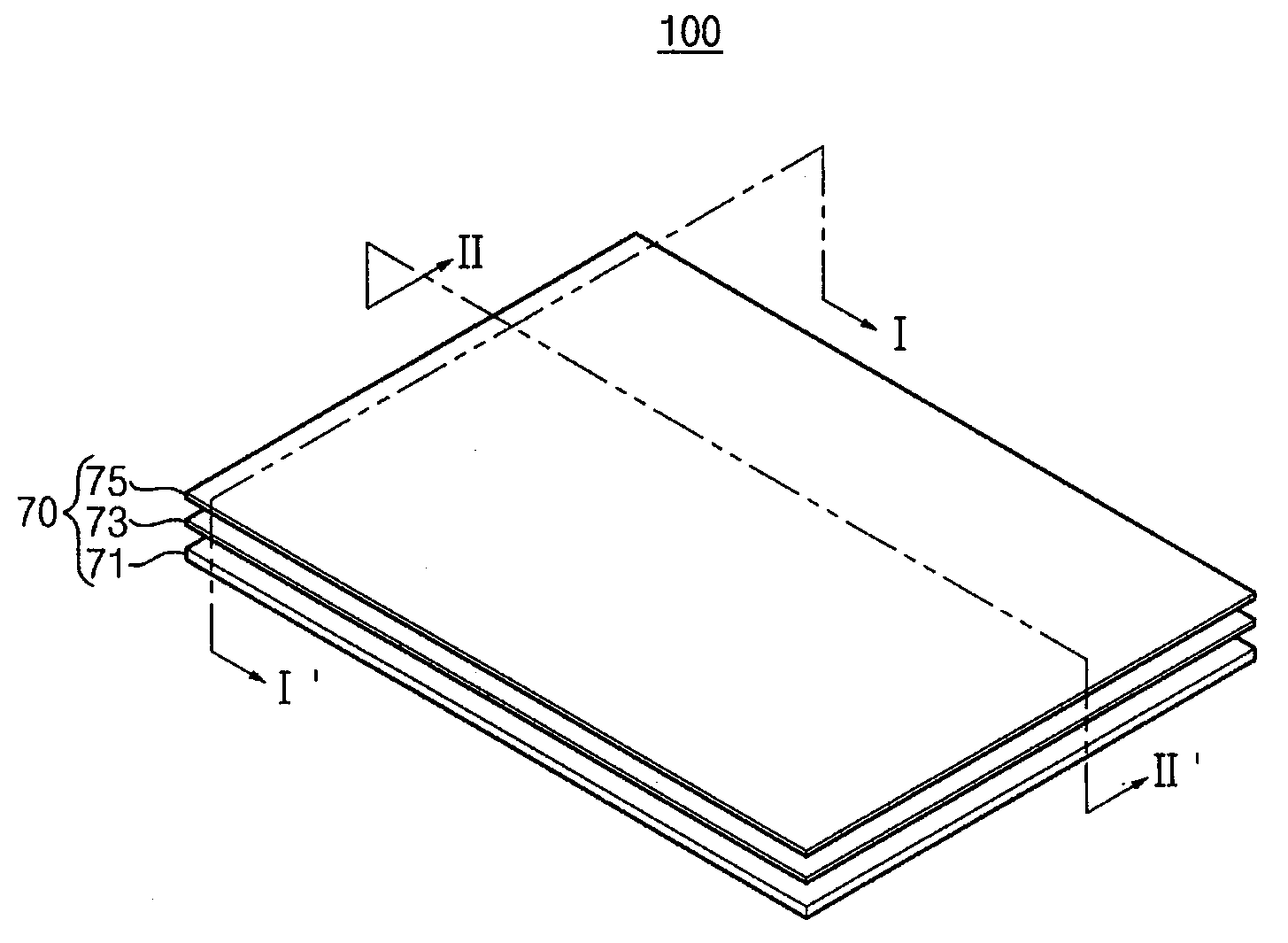

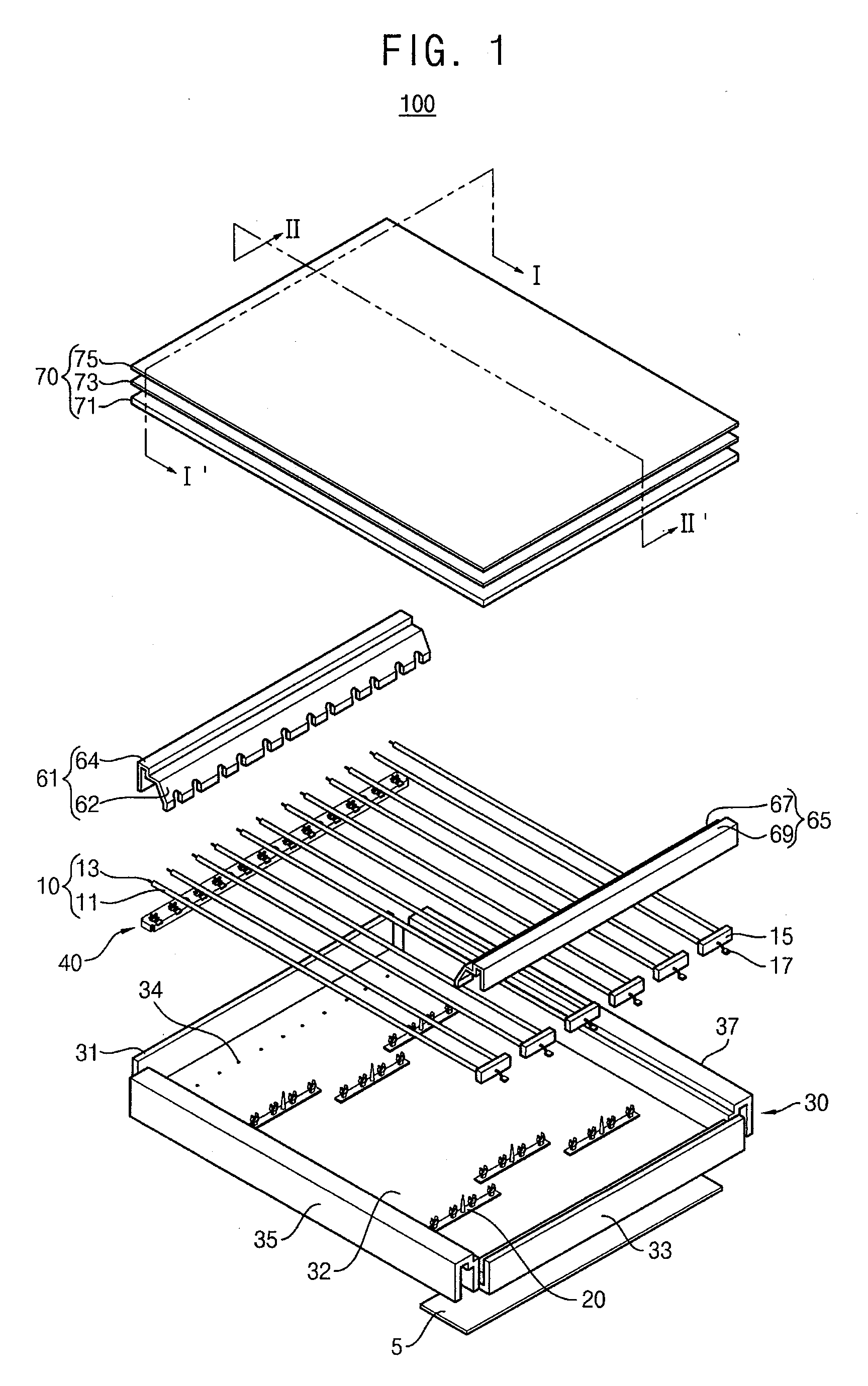

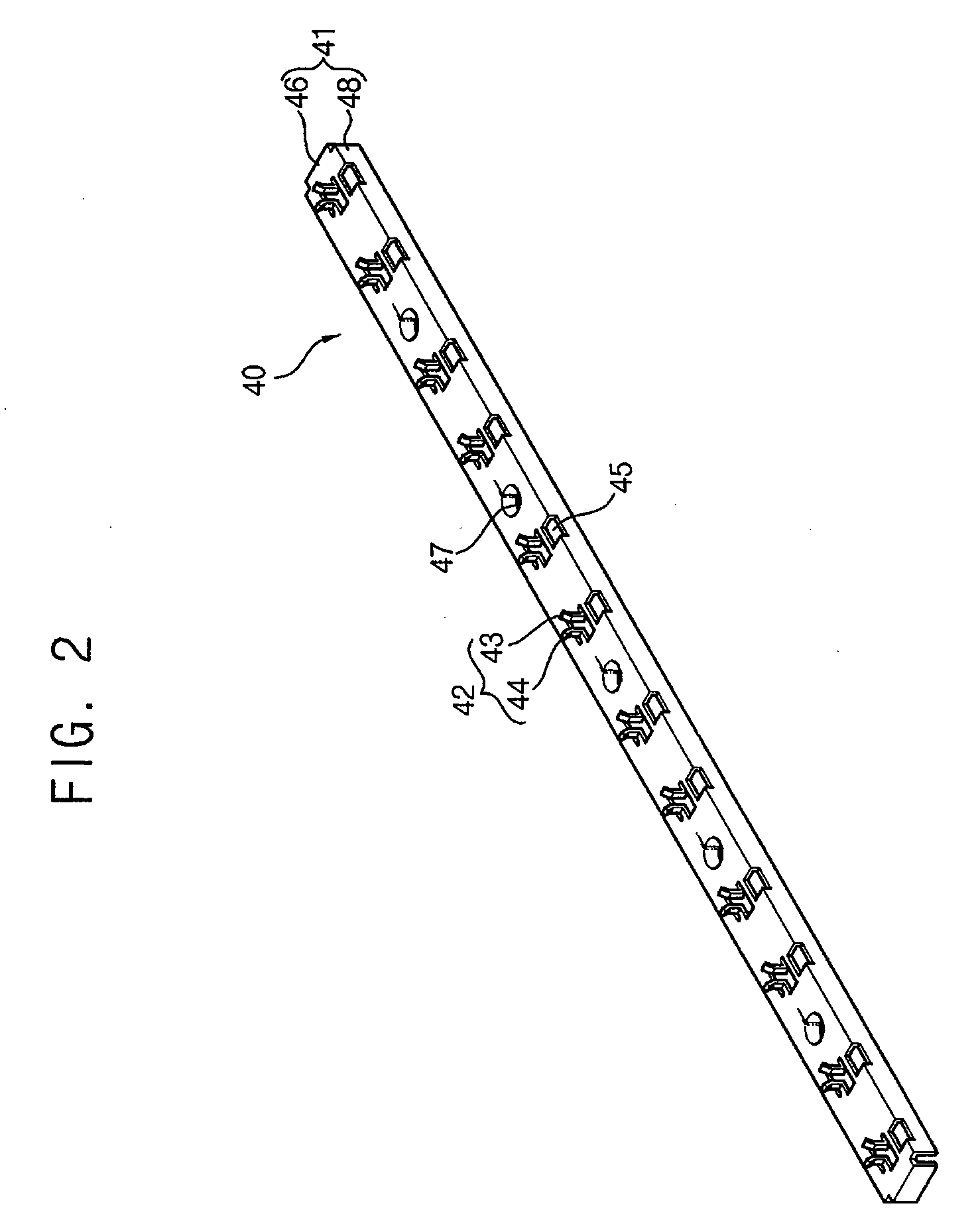

Backlight assembly and method for assembling the same

InactiveUS20080084696A1Easy to assembleReduce the number of partsLighting support devicesElectric lightingEngineeringGround plate

A backlight assembly and a method of assembling the backlight assembly that includes a plurality of lamps having first and second electrodes, a receiving container and a lamp ground member. The receiving container has a bottom plate over which the lamps are disposed, and a side wall extending from the bottom plate to form a receiving space. The lamp ground member includes a ground plate grounded to the bottom plate, and a plurality of electrode ground portions protruded from the ground plate and making contact with the first electrode thereby eliminating the need for a separate part for grounding the first electrode of the lamp and permitting easier assembly of the backlight assembly.

Owner:SAMSUNG ELECTRONICS CO LTD

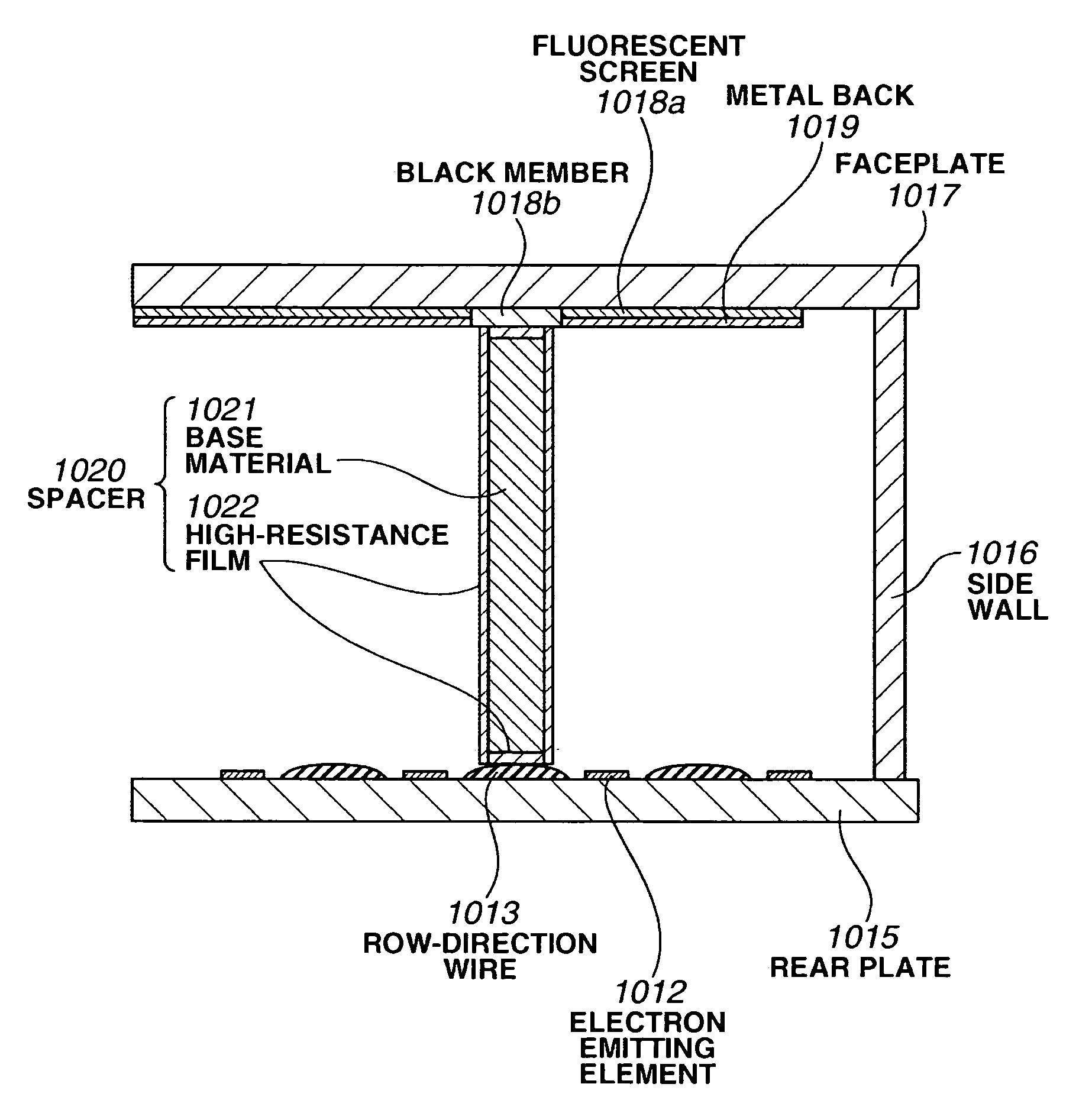

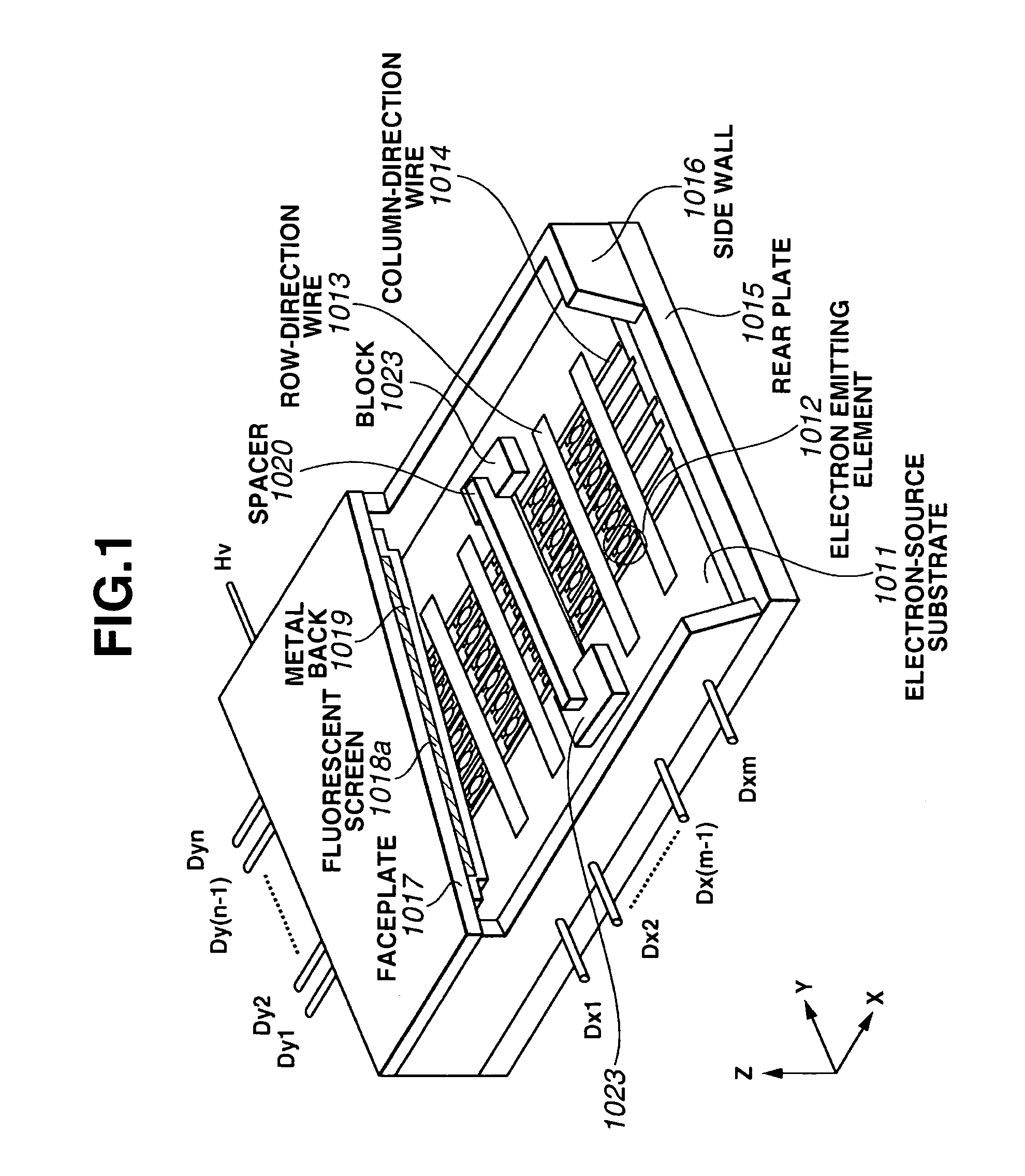

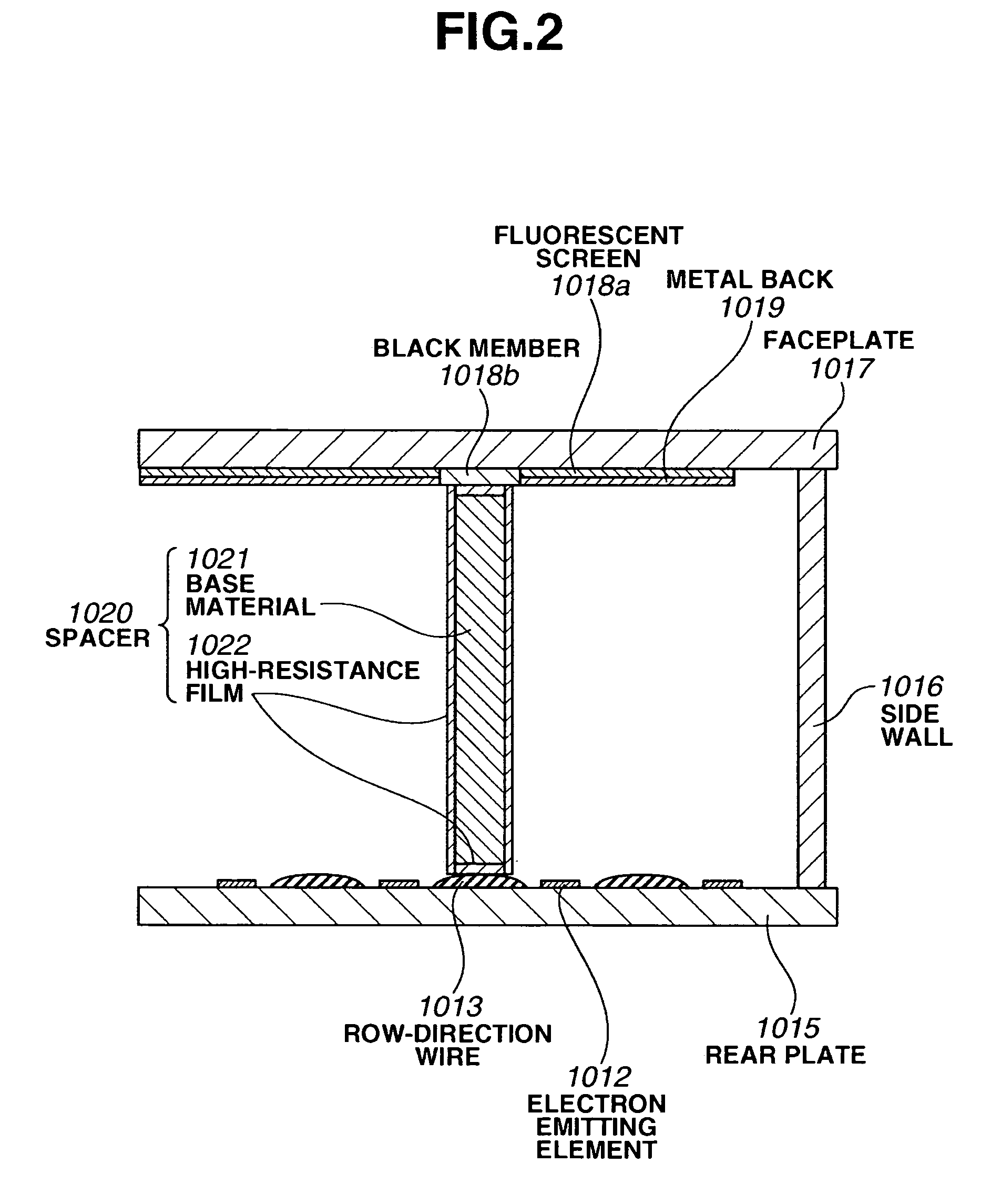

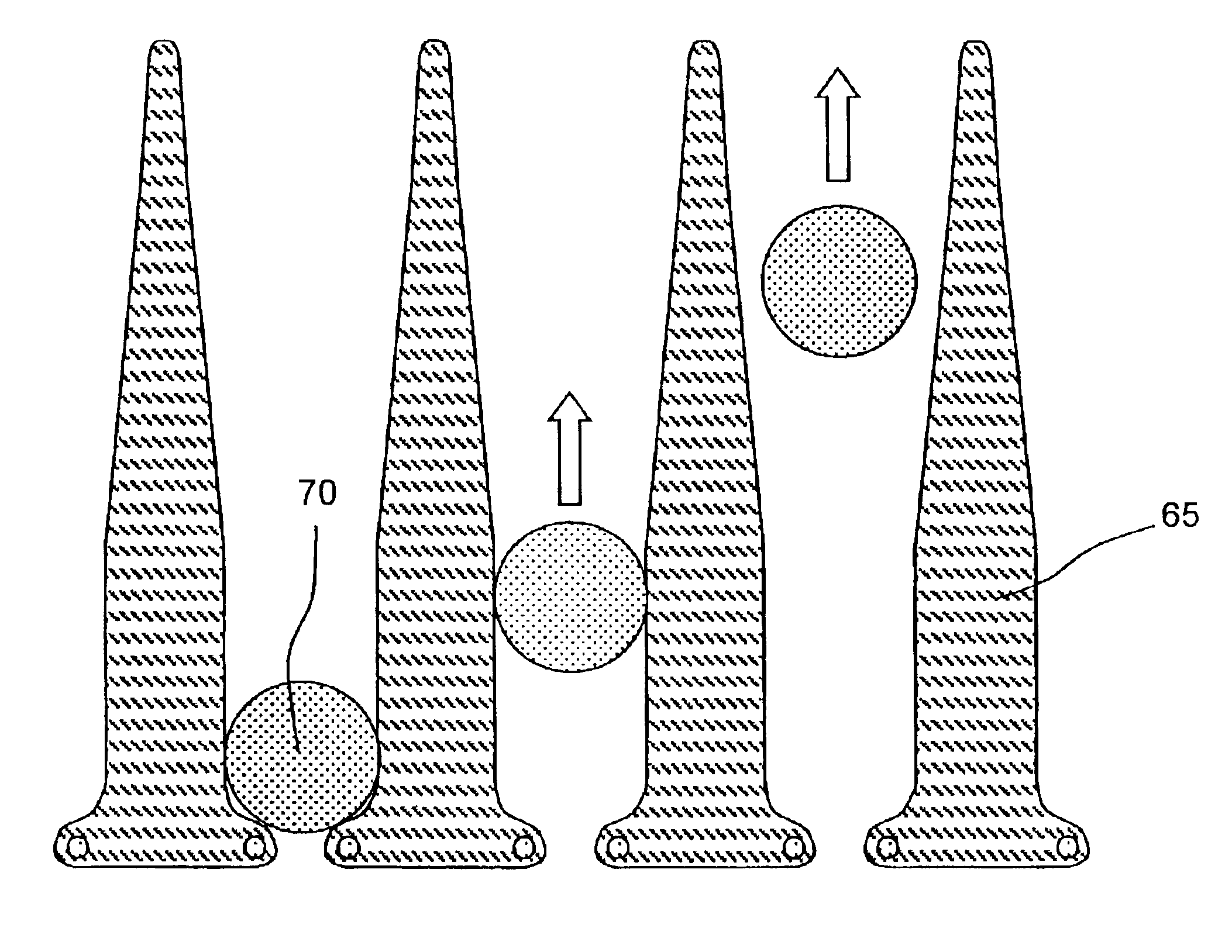

Electron beam apparatus, having a spacer with a high-resistance film

InactiveUS7053537B2Electrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportHigh resistanceElectron

An electron beam apparatus in which a spacer having a high-resistance film coating a surface of a base material is inserted between a rear plate having electron emitting elements and row-direction wires, and a faceplate having a metal back. The row-direction wires and the metal back are electrically connected via the high-resistance film. An electric field near an electron emitting element near the spacer is maintained to substantially constant irrespective of the positional relationship between the spacer and the electron emitting element near the spacer. When a sheet resistance value of the high-resistance film on a first facing surface of the spacer that faces a row-direction wire is represented by R1, and a sheet resistance value of the high-resistance film on a side surface adjacent to the electron emitting element is represented by R2, R2 / R1 is 10 to 200.

Owner:CANON KK

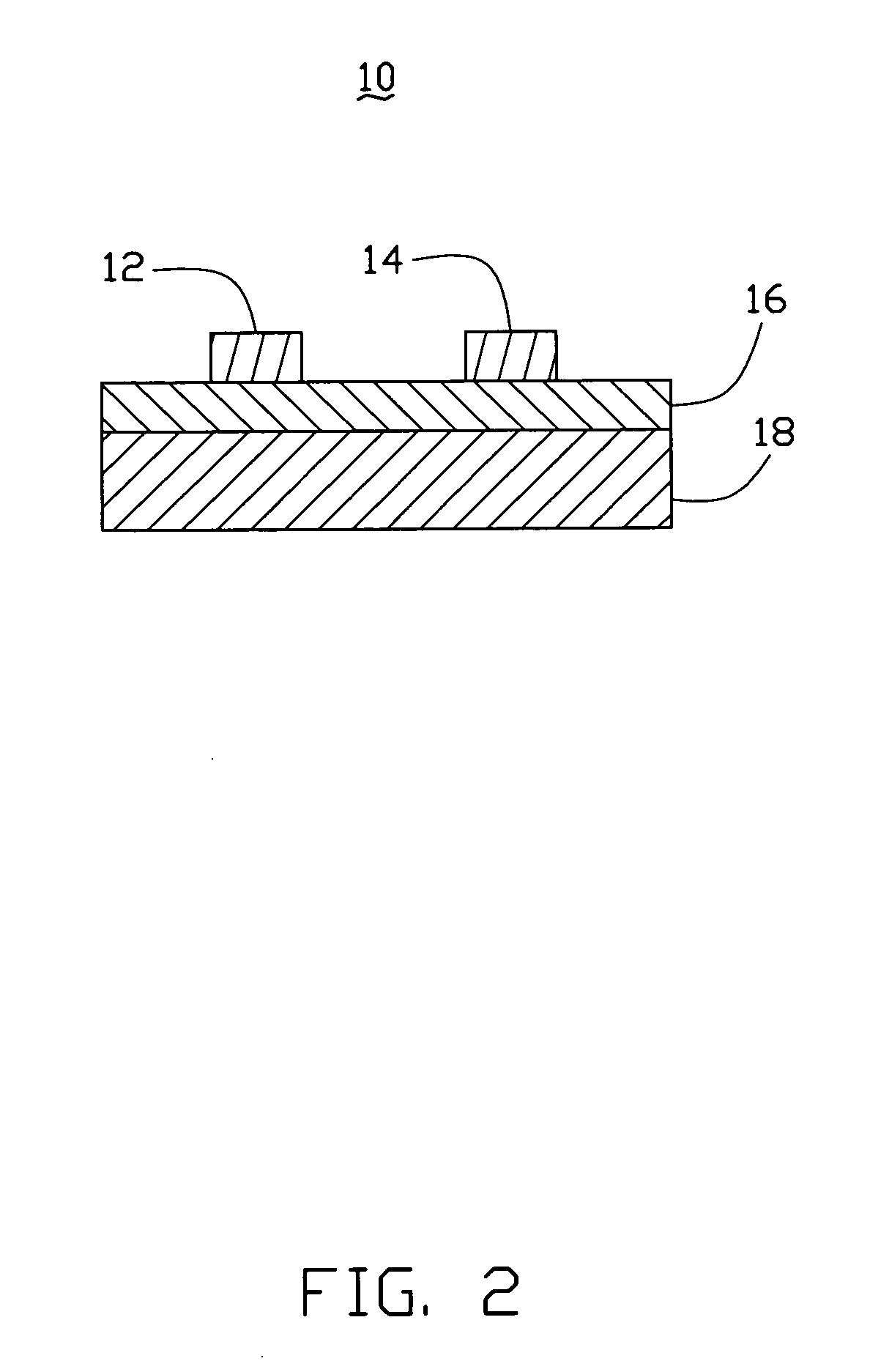

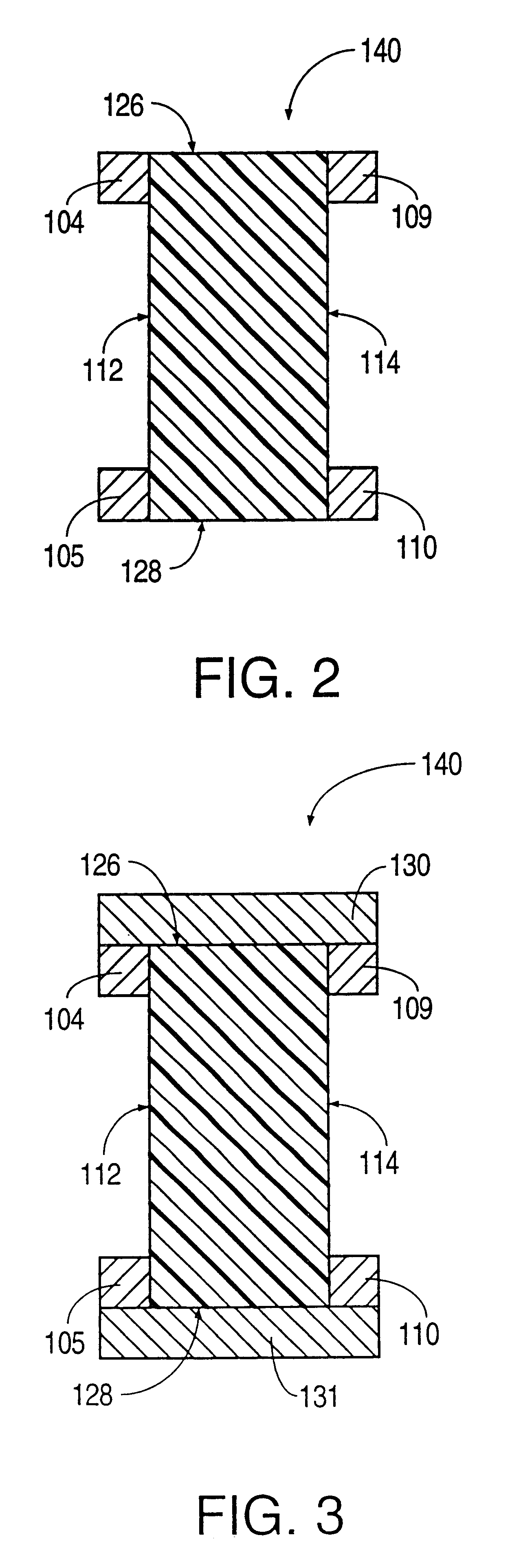

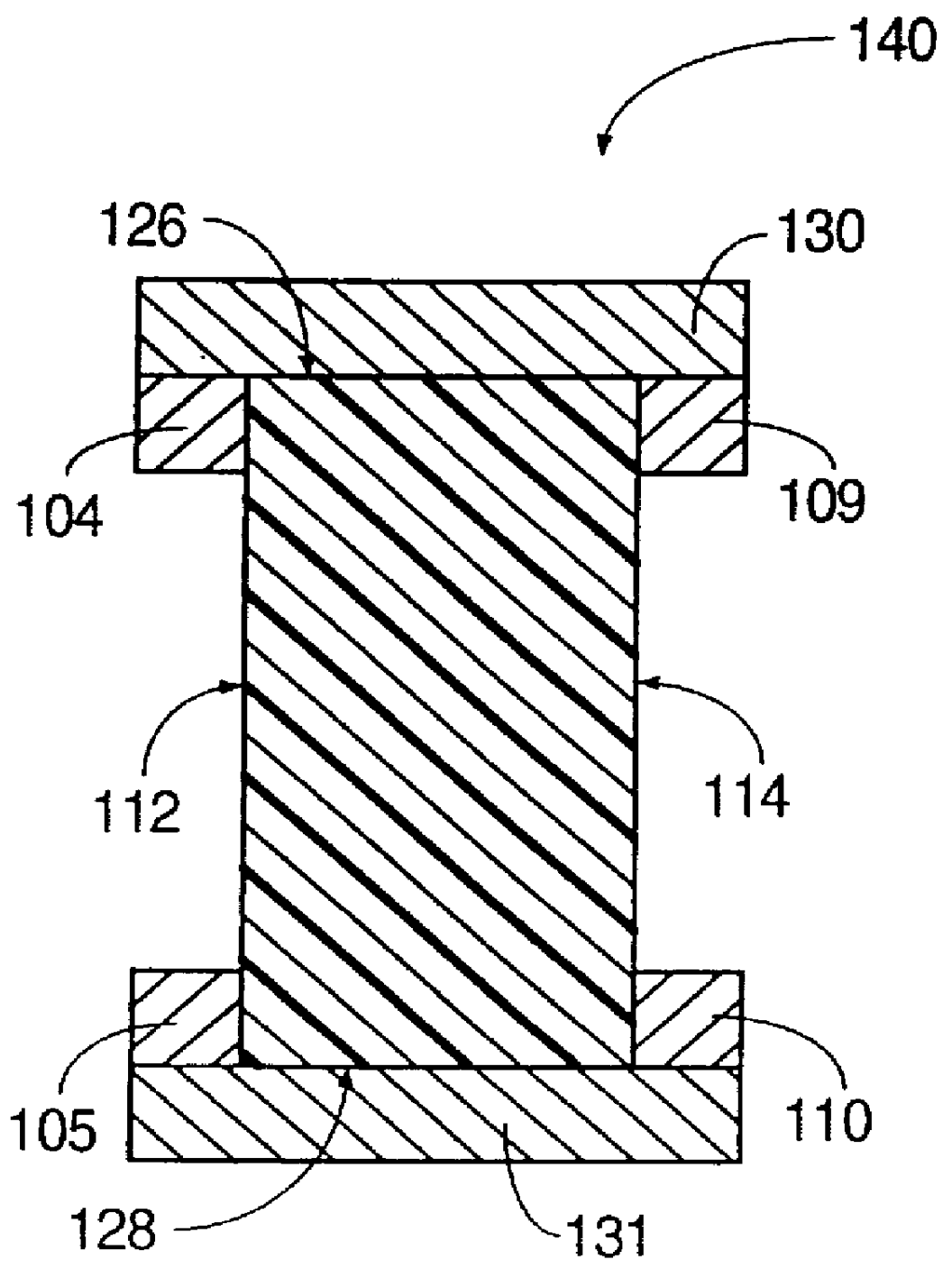

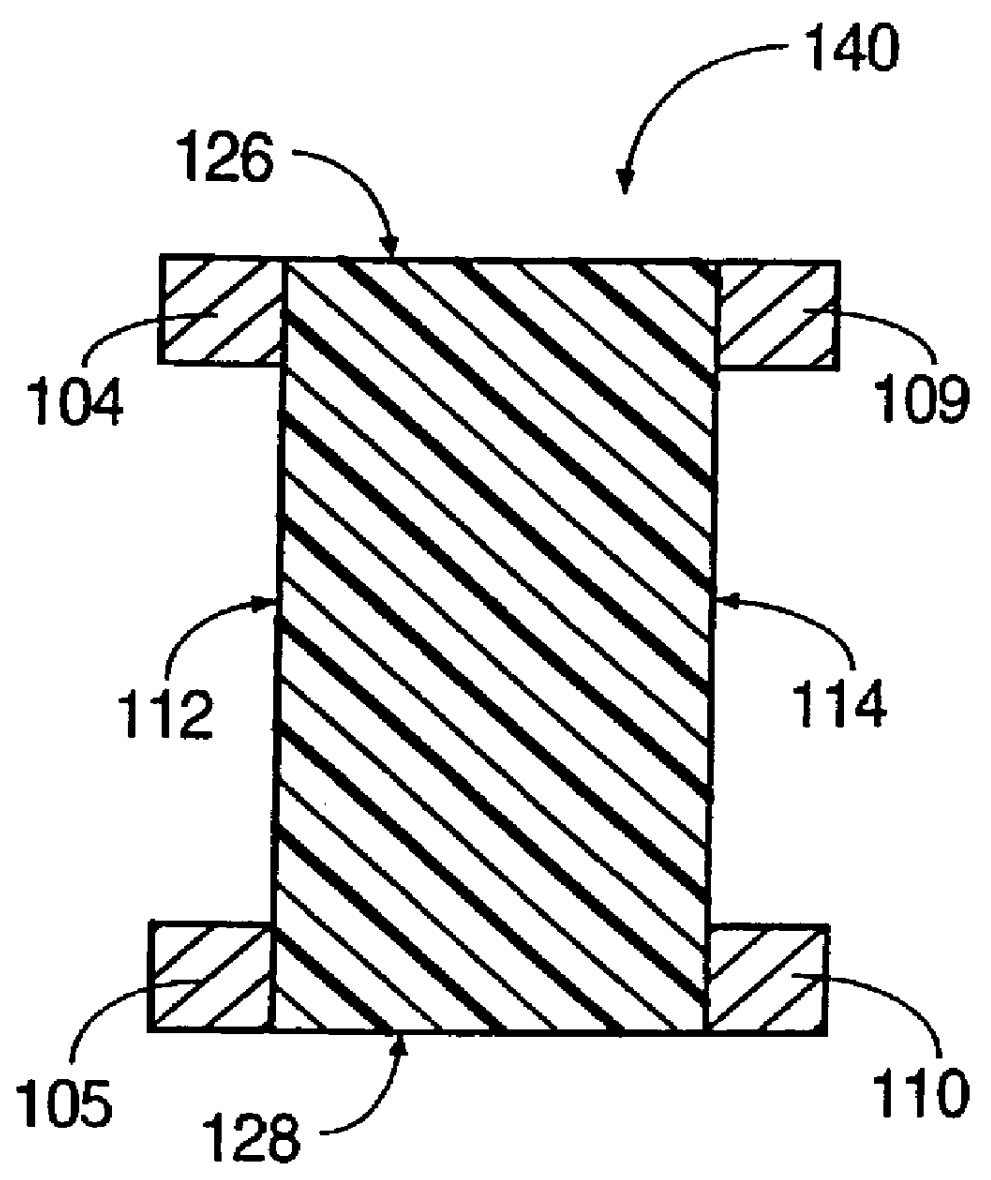

Spacer suitable for use in flat panel display

InactiveUS6489718B1Pigmenting treatmentCathode-ray/electron-beam tube vessels/containersElectrical resistance and conductanceDisplay device

A spacer (140) suitable for use in a flat panel display is formed with ceramic, transition metal, and oxygen. At least part of the oxygen is bonded to the transition metal or / and constituents of the ceramic to form a uniform electrically resistive material having a resistivity of 105-1010 ohm-cm and a secondary electron emission coefficient of less than 2 at 2 kilovolts.

Owner:CANON KK

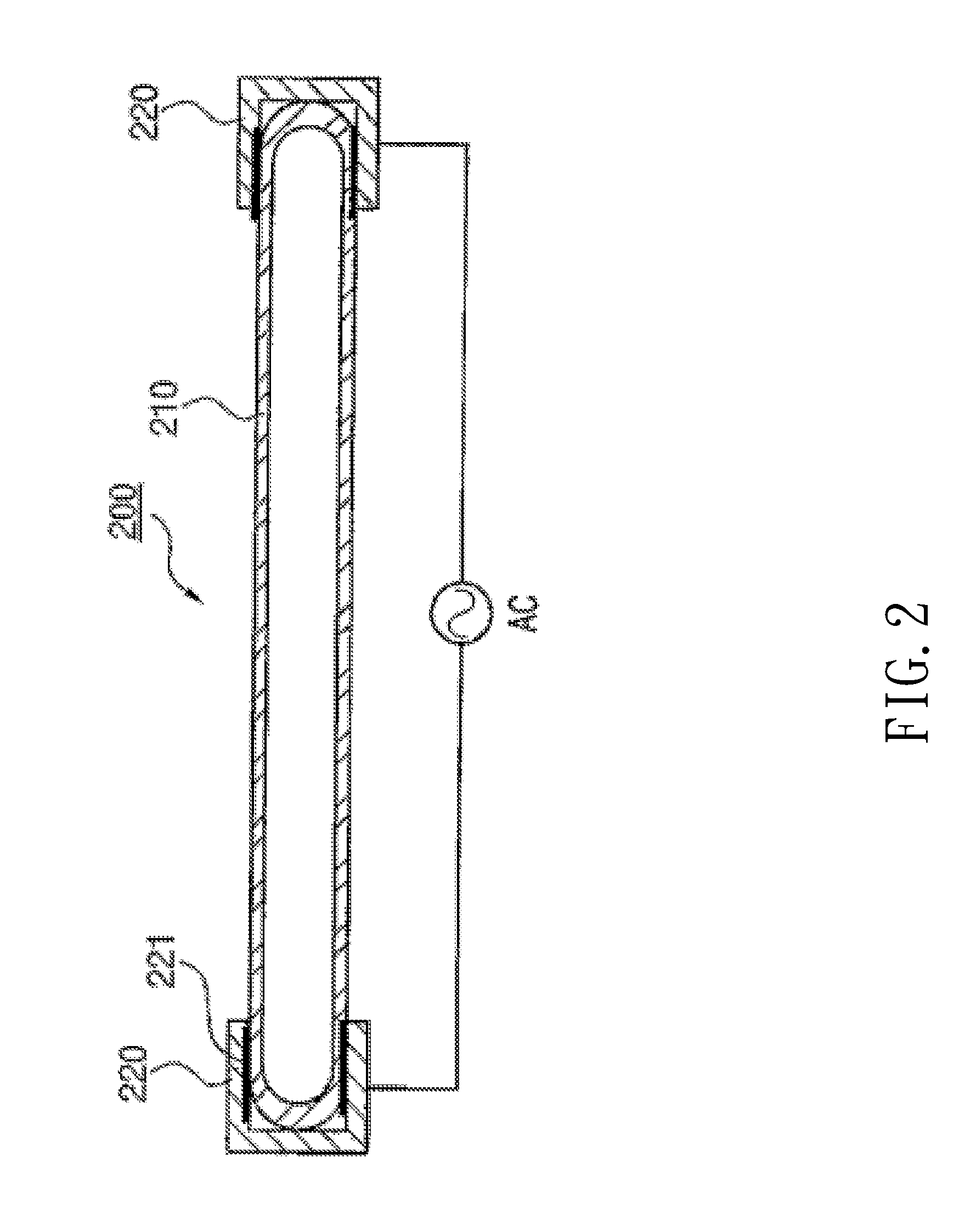

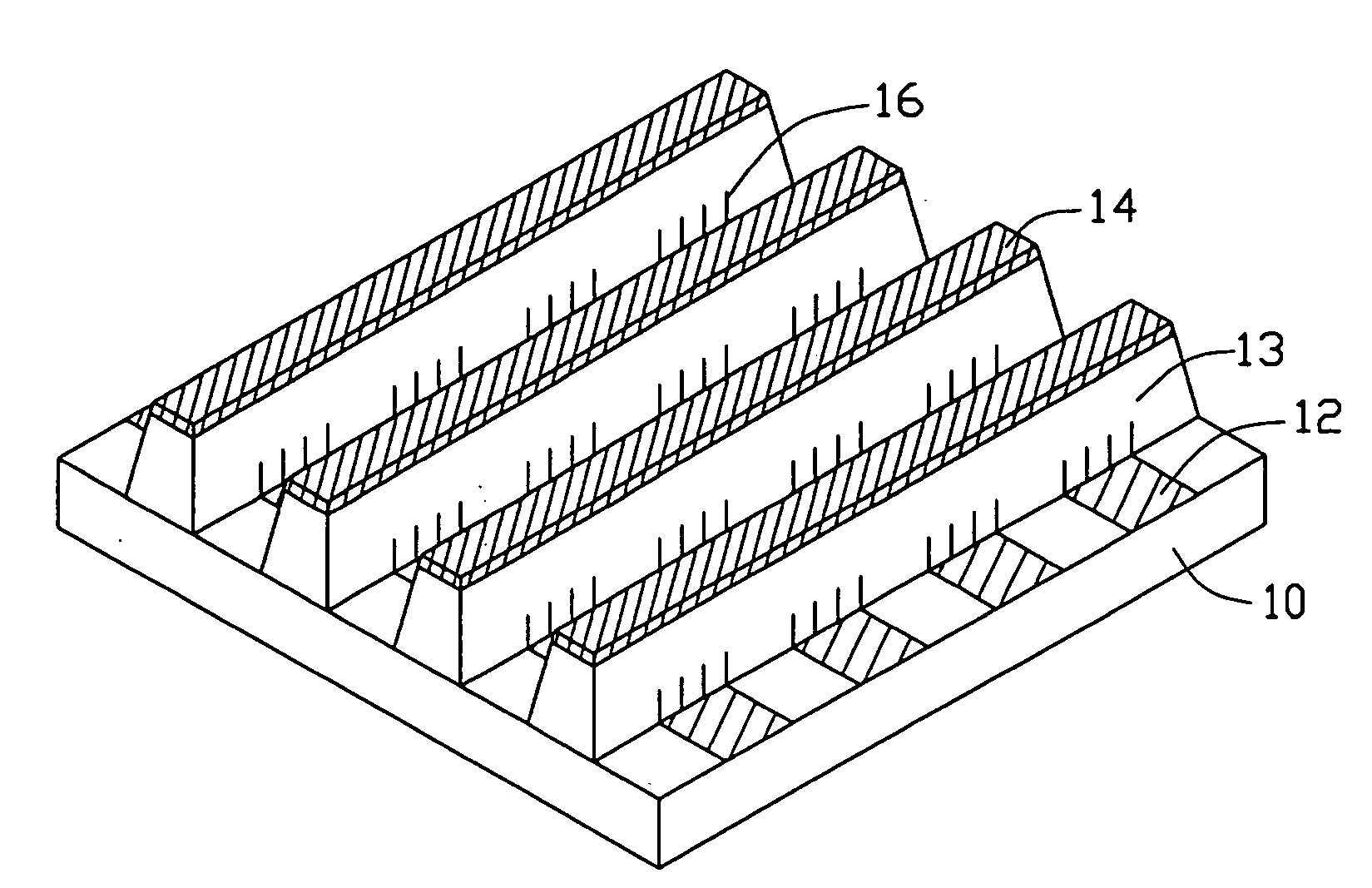

Method for manufacturing carbon nanotube field emission display

ActiveUS20050266766A1High resolutionImprove display qualityNanoinformaticsVessels or leading-in conductors manufactureCarbon nanotubeDisplay device

A method for manufacturing a carbon nanotube field emission display includes the steps of: (a) dispersing a plurality of carbon nanotubes on an array of cathode electrodes formed on an insulative substrate; (b) forming an array of insulation beams on the array of cathode electrodes, the insulation beams being perpendicular to a lengthways direction of the cathode electrodes; (c) forming a plurality of gate electrodes on tops of the insulation beams; (d) making the carbon nanotubes located near opposite sides of each gate electrode stand vertically on the cathode electrodes; and (e) packing and sealing a phosphor screen and side walls. The gate electrodes have the dual functions of driving electron emission and focusing emitted electrons. Thereby the carbon nanotube field emission display has high resolution and good display quality.

Owner:TSINGHUA UNIV +1

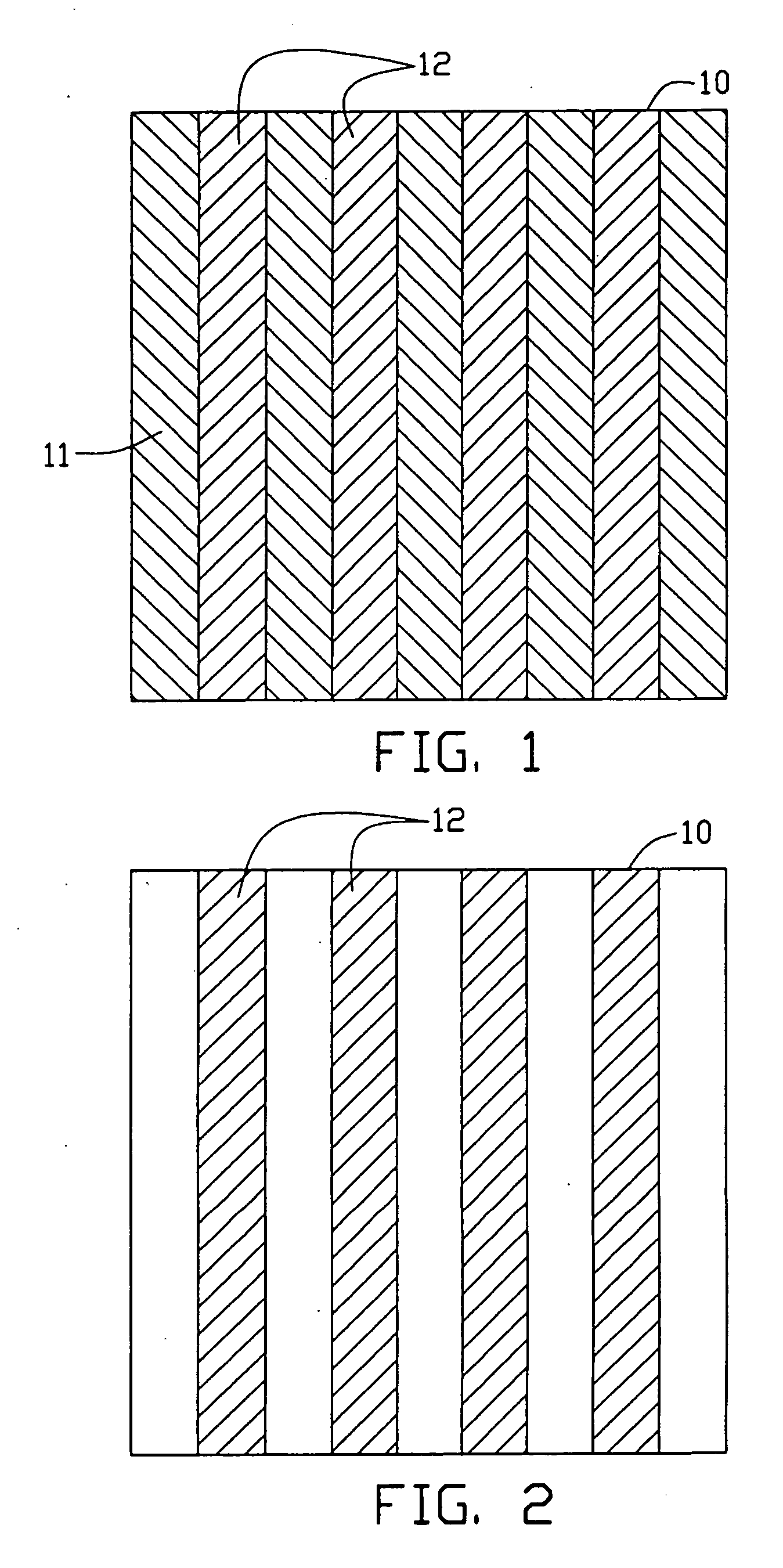

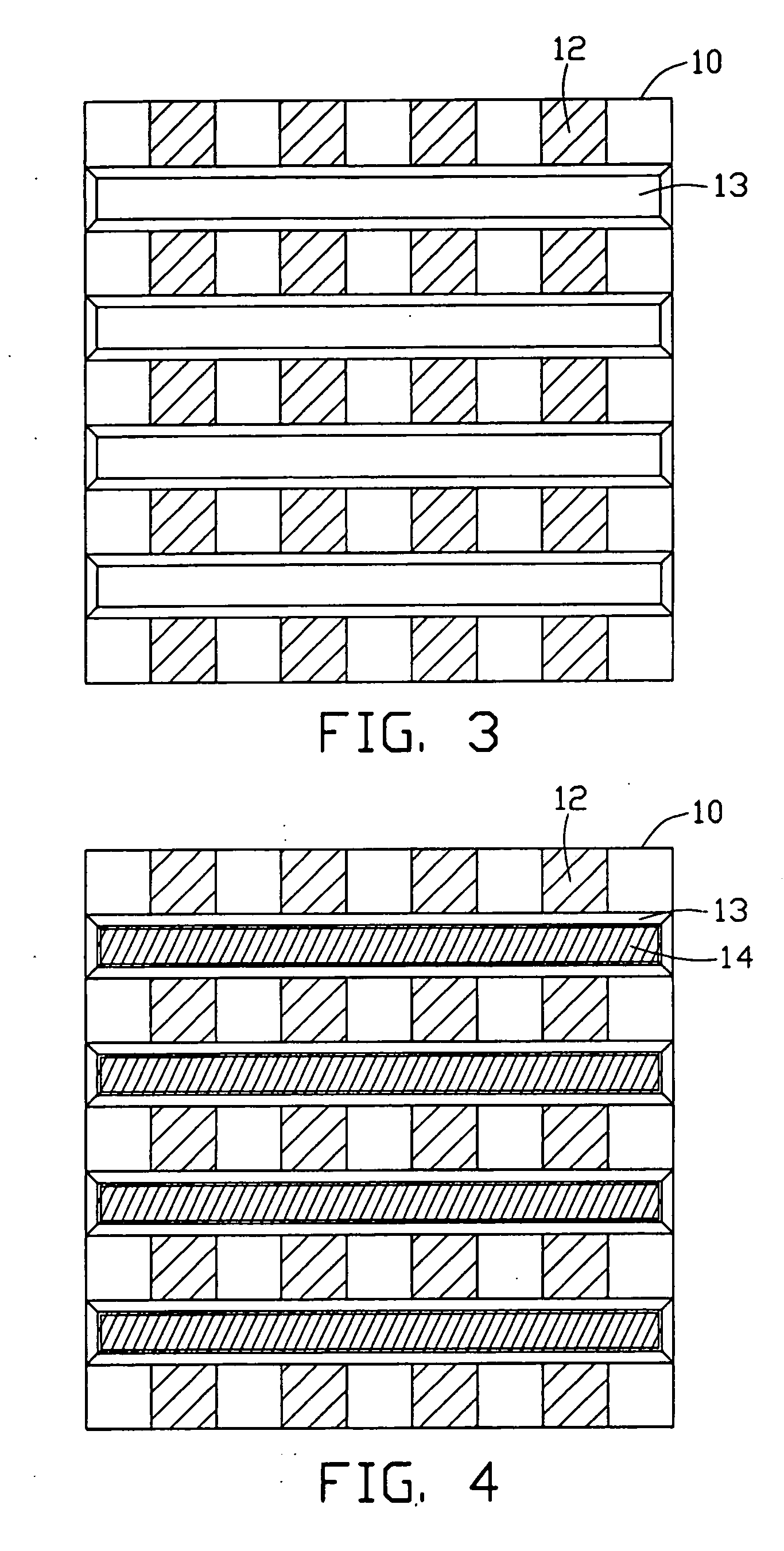

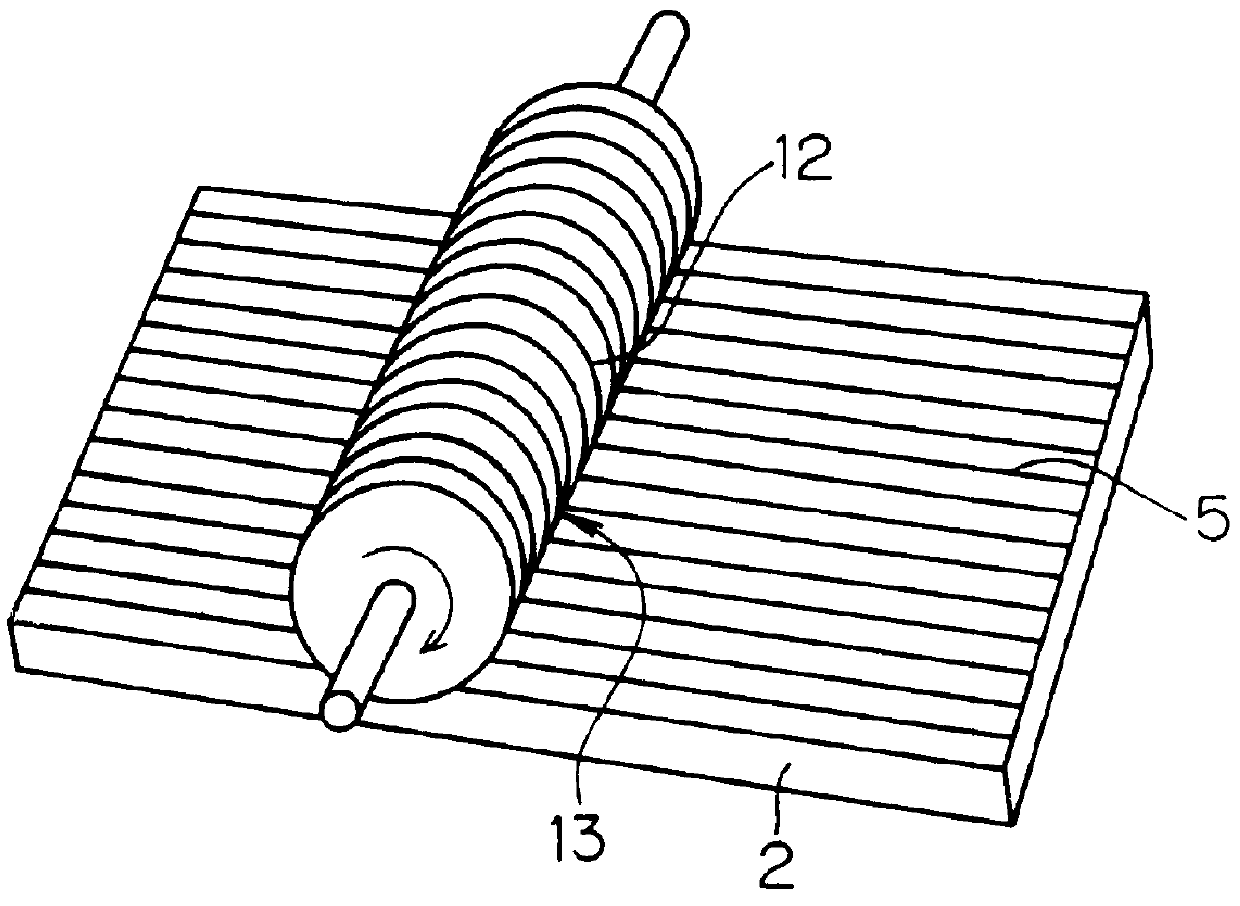

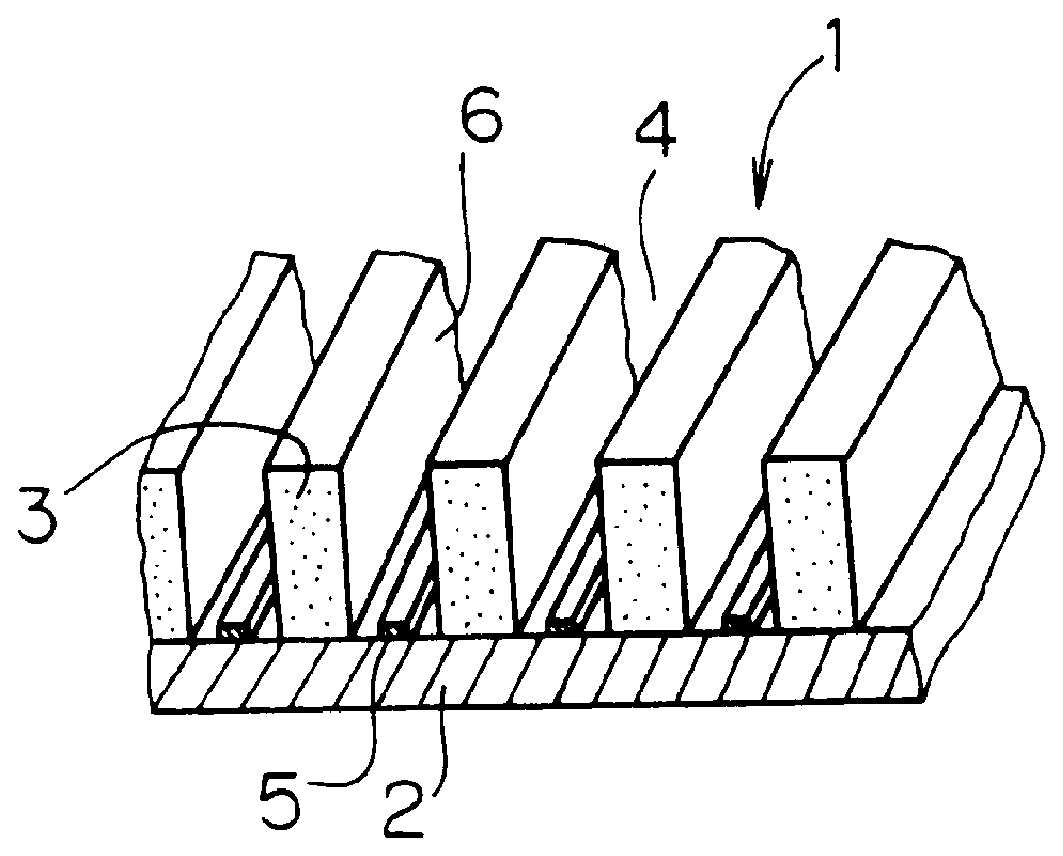

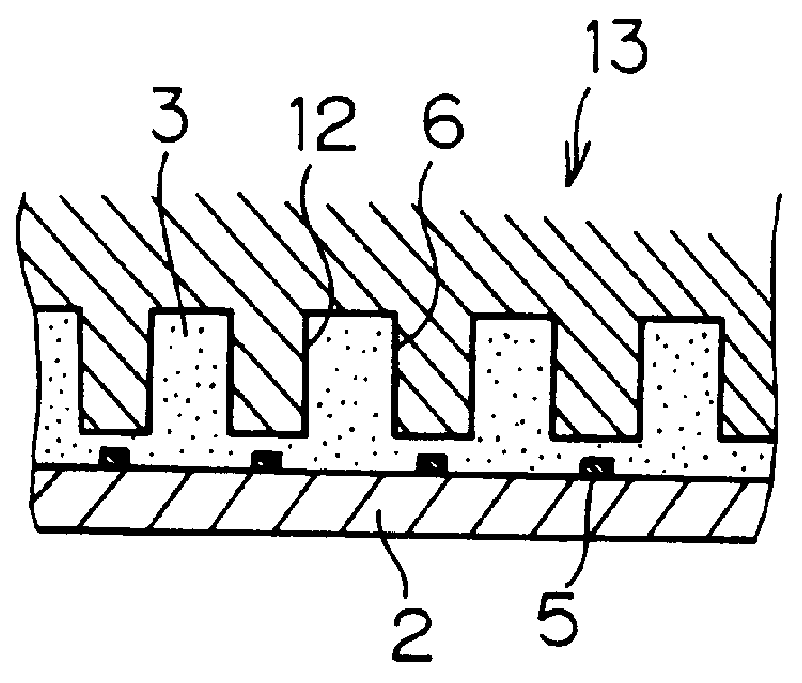

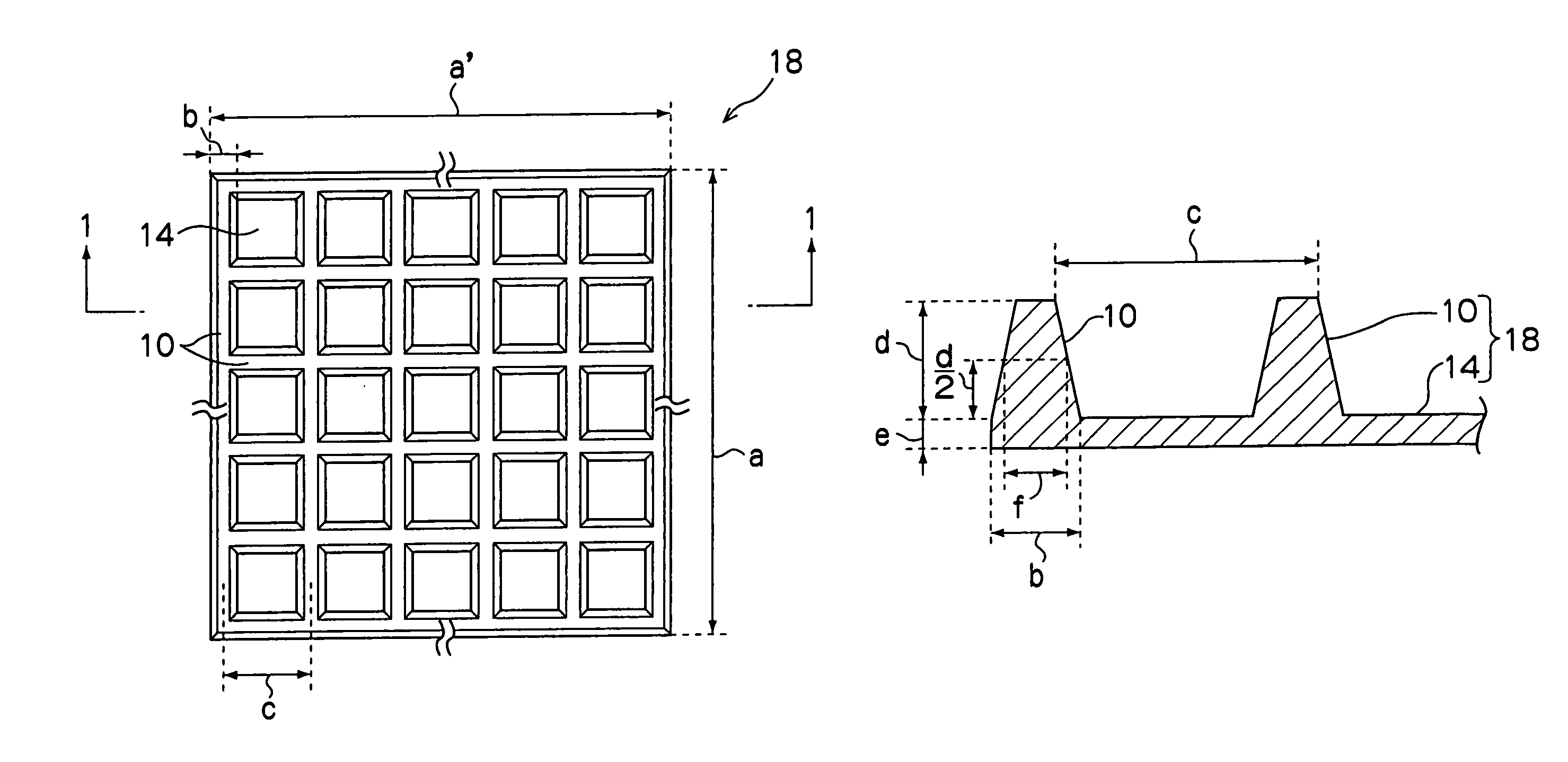

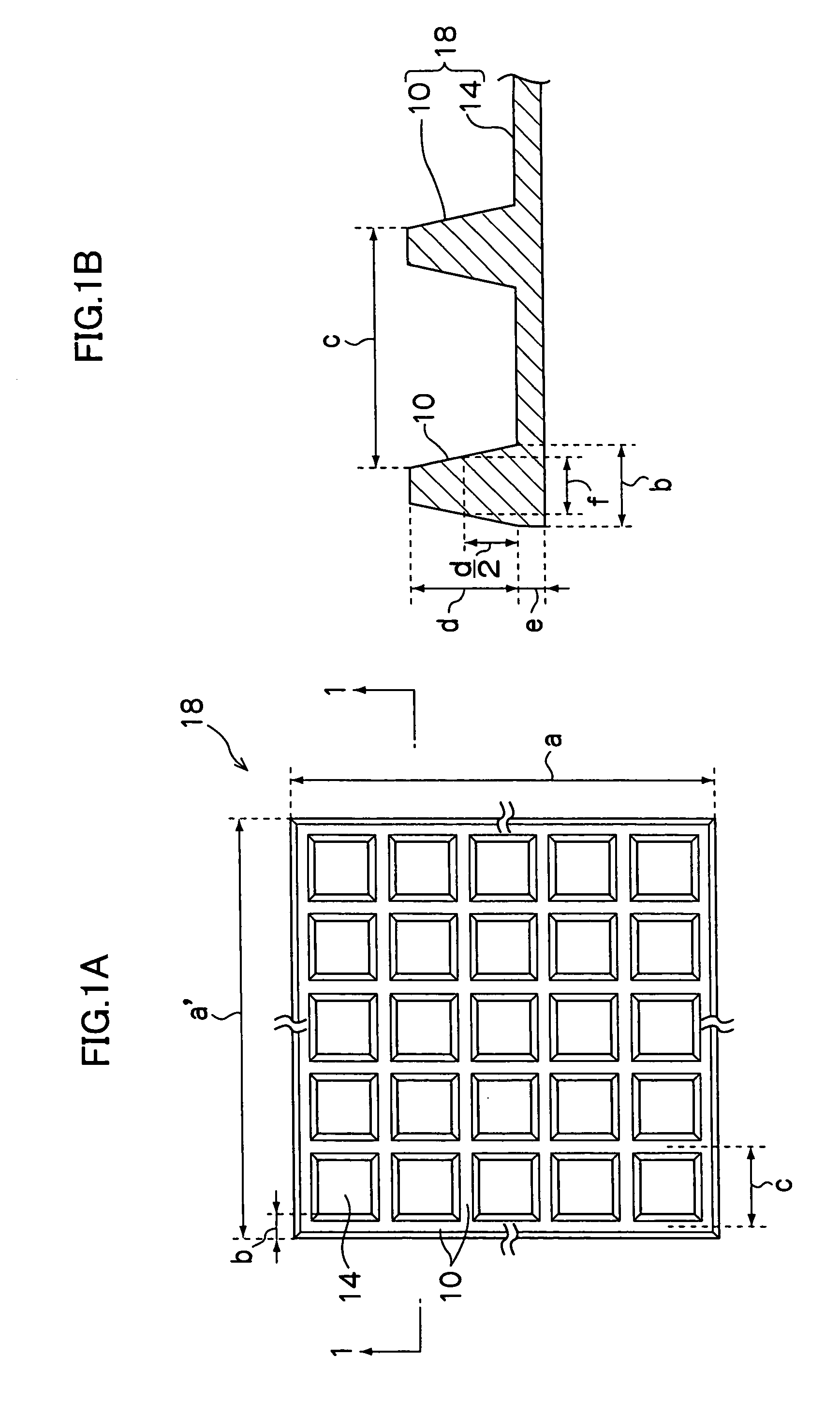

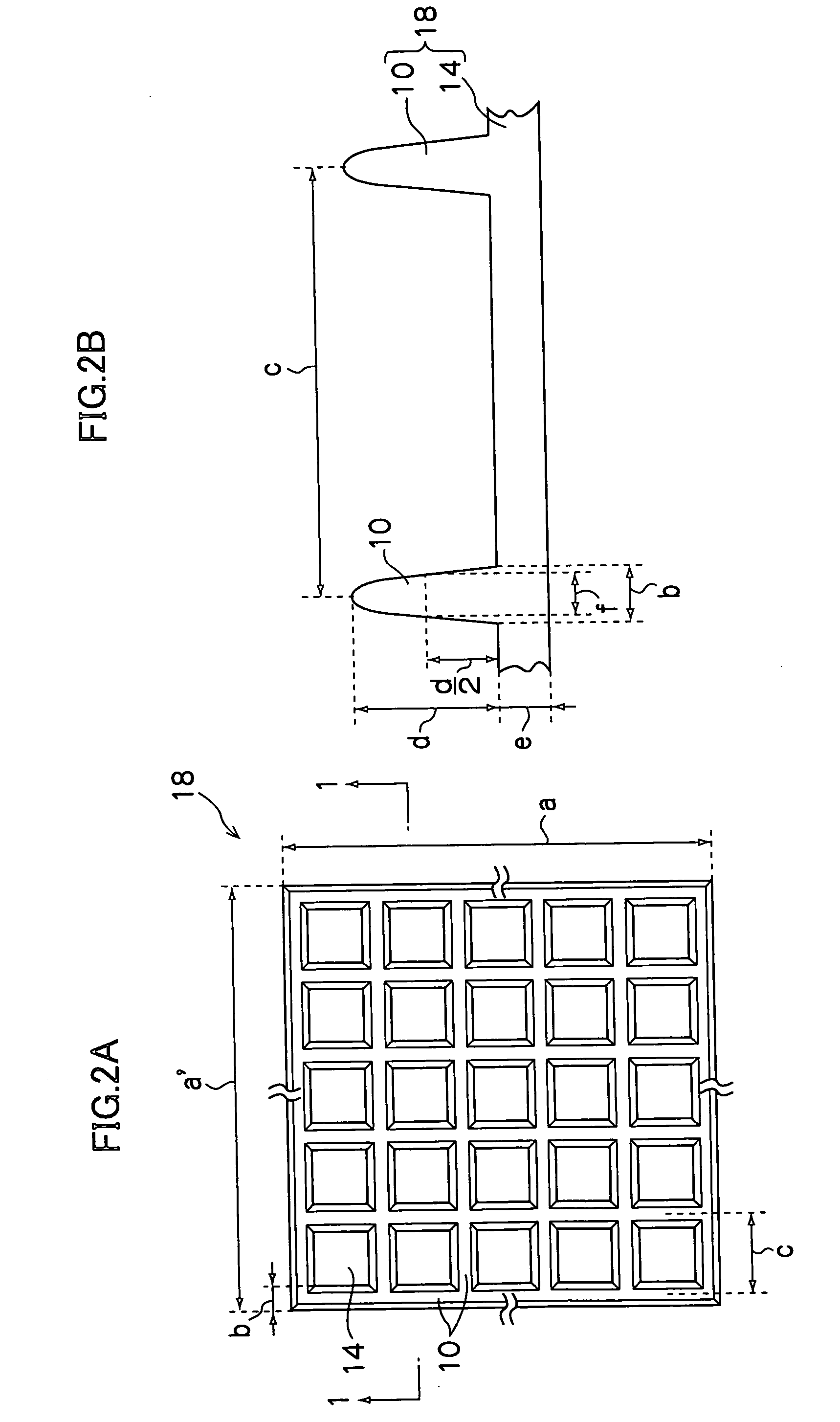

Method for manufacturing flat plate with precise bulkhead, flat plate with precise bulkhead, method for manufacturing plasma display unit substrate and plasma display unit substrate

InactiveUS6149482AGas discharge vessels/containersAlternating current plasma display panelsMoistureCeramic

A method for manufacturing plasma display unit substrates having bulkheads by applying a mixture of ceramic powder or glass powder and a binder to a back face plate made of ceramics or glass. Bulkheads are formed on the back face plate by rolling a roll, having a plurality of grooves on its surface, over the mixture-applied surface of the back face plate while applying pressure to the surface with the roll. Alternatively, the grooves on the surface of the roll may be pre-filled with the moisture and rolled over the surface of a back face plate, thereby forming bulkheads.

Owner:LG ELECTRONICS INC

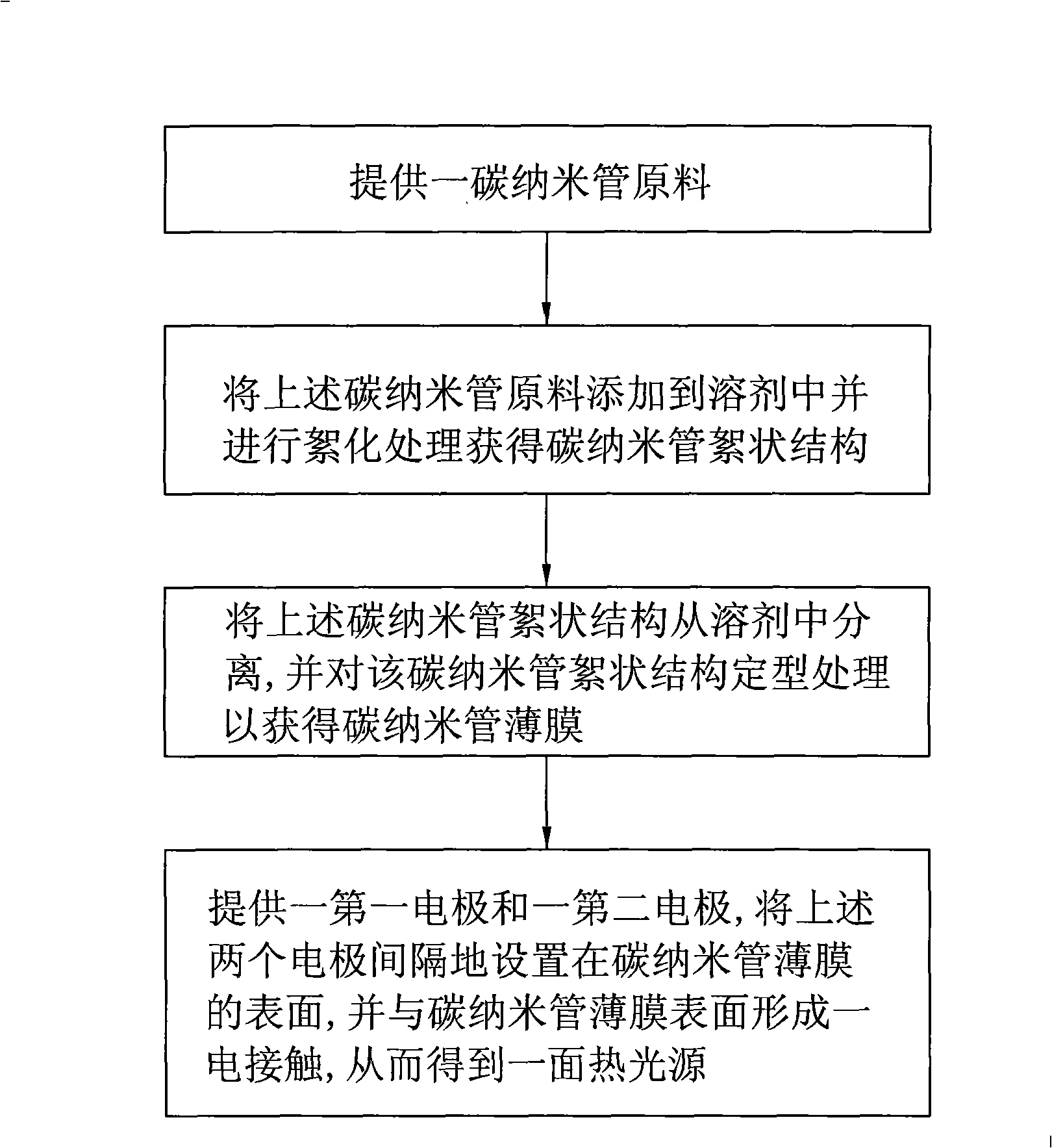

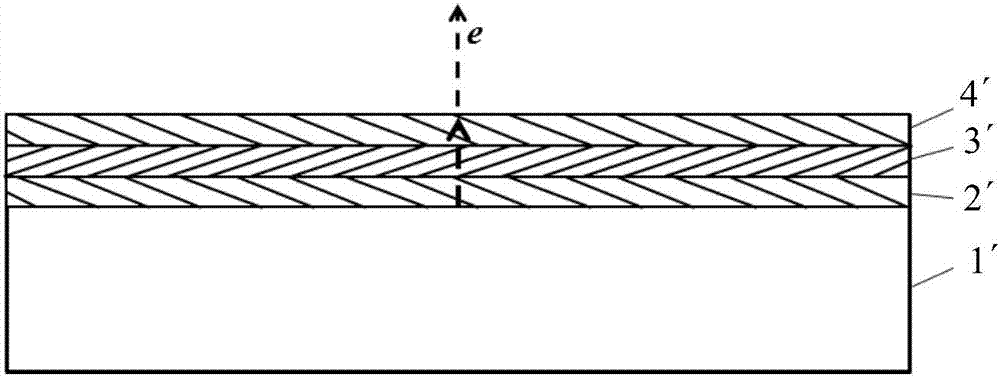

Surface heat light source, preparation method thereof and method for heating object using the same

ActiveCN101409961AImprove conductivityImprove thermal stabilityNanotechCathode ray tubes/electron beam tubesSolventNanotube

The invention relates to a surface heating light source, comprising a first electrode, a second electrode and a carbon nano-tube film; the first electrode and the second electrode are arranged on the carbon nano-tube film; the first electrode and the second electrode have a certain distance and electrically contact with the surface of the carbon nano-tube film; the carbon nano-tube film internally comprises carbon nano-tubes which enwind each other. The invention also relates to a preparation method used for preparing surface heating light source, comprising the steps as follows: carbon nano-tube raw material is provided; the carbon nano-tube raw material is added in solvent and carries out flocking disposal, thus gaining a carbon nano-tube floceulent structure; the carbon nano-tube floceuelent structure is separated from the solvent and shapes the carbon nano-tube floceulent structure so as to gain a carbon nano-tube film; the first electrode and the second electrode are provided; the first electrode and the second electrode are intermittently arranged on the surface of the carbon nano-tube film and form electric contact on the surface of the carbon nano-tube, thus gaining a surface heat light source. The invention also relates to a method used for heating the article by adopting the surface heat light source and comprises the steps as follows: an article to be heated is provided; the article is provided with a surface; the carbon nano-tube film in the surface heat light source is arranged closely to the surface of the article to be heated; voltage is applied to the electrodes in the surface heat light source so as to heat the article.

Owner:TSINGHUA UNIV +1

LED device having improved contrast

ActiveUS20080303435A1Increase ambient contrastImprove light outputDischarge tube luminescnet screensLamp detailsContrast enhancementLight-emitting diode

A light-emitting diode (LED) device includes a reflective electrode and a transparent electrode having one or more light-emitting layers formed there-between. A contrast-enhancement element is located on a side of the transparent electrode opposite the light-emitting layer. The contrast-enhancement element has a first reflected-light absorbing layer and a second layer including transparent areas and reflective areas. The second layer is between the first reflected-light absorbing layer and the reflective electrode. A patterned light-scattering layer is located between the reflective areas of the second layer and the reflective electrode.

Owner:GLOBAL OLED TECH

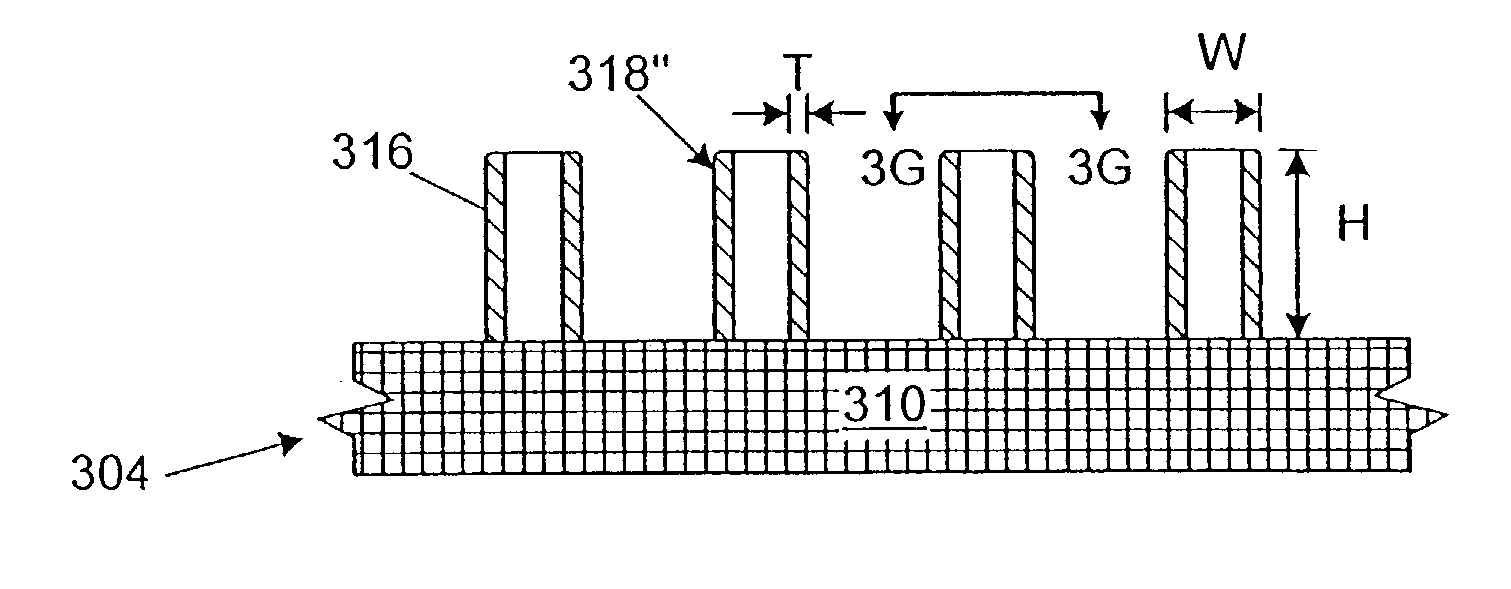

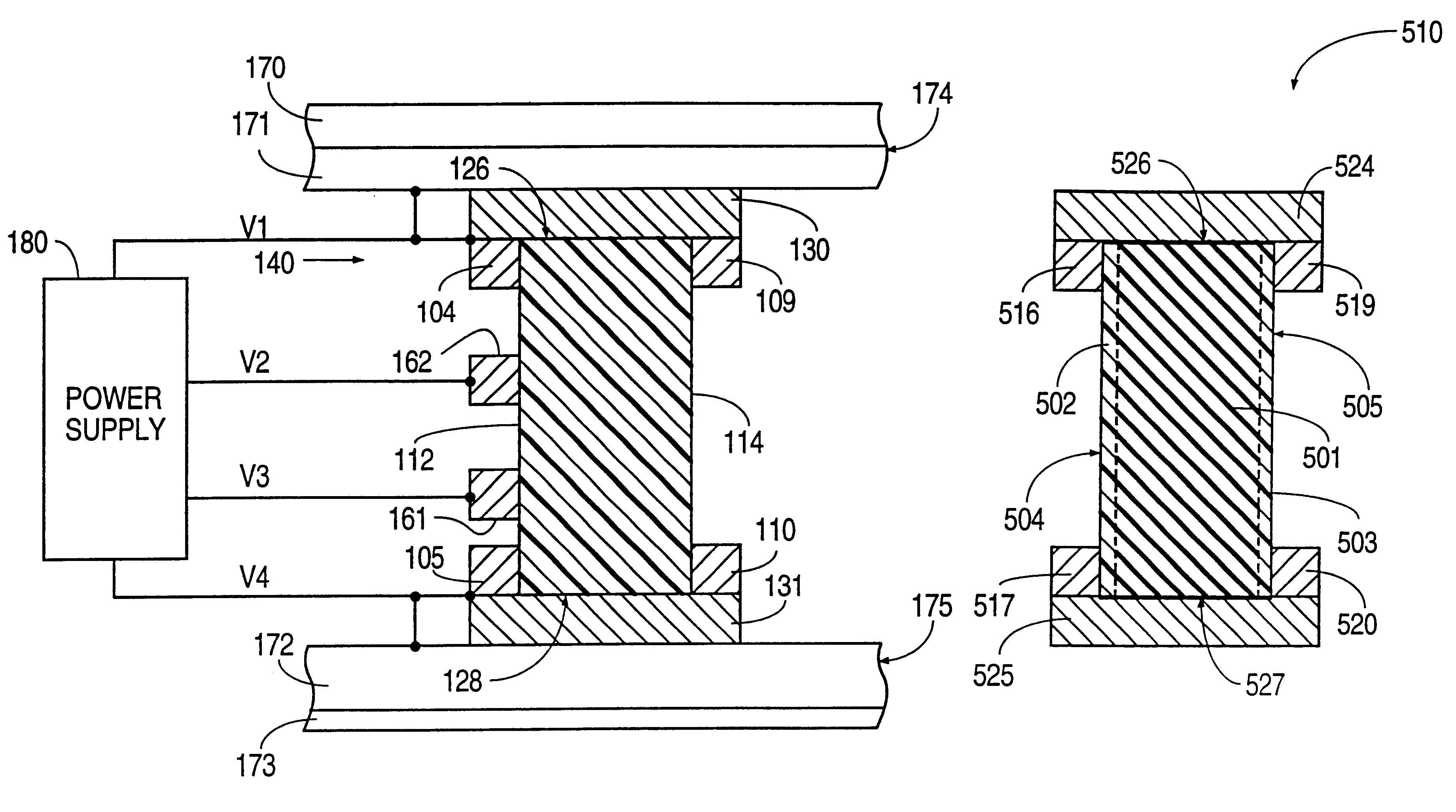

Flat panel display typically having transition metal oxide in ceramic core or/and resistive skin of spacer

InactiveUS6157123ACathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsDisplay deviceEngineering

A flat panel display contains a faceplate structure (174 or 350), a backplate structure (175 or 351), and a spacer (140, 340, 0r 341). A light-emitting structure (171 or 306) is located along a faceplate (170 or 302) in the faceplate structure. An electron-emitting structure (172 or 305) is located along a backplate (173 or 303) in the backplate structure. The spacer is situated between the light-emitting and electron-emitting structures. Transition metal oxide or transition metal in oxide state is present in a ceramic core (401, 501, 0r 601) or / and a resistive skin (402, 403, 502, 503, 602, or 603) of the spacer.

Owner:CANON KK

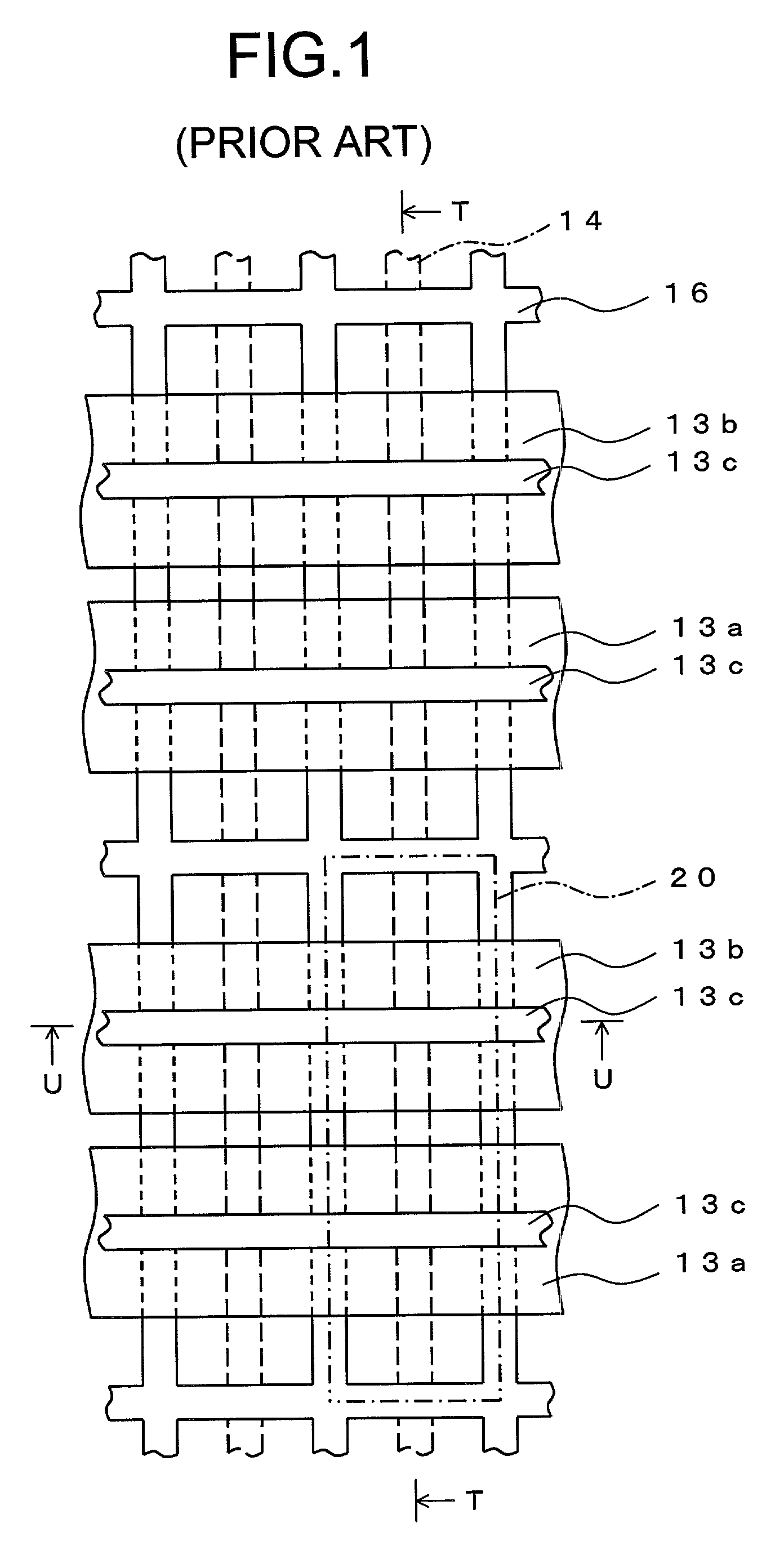

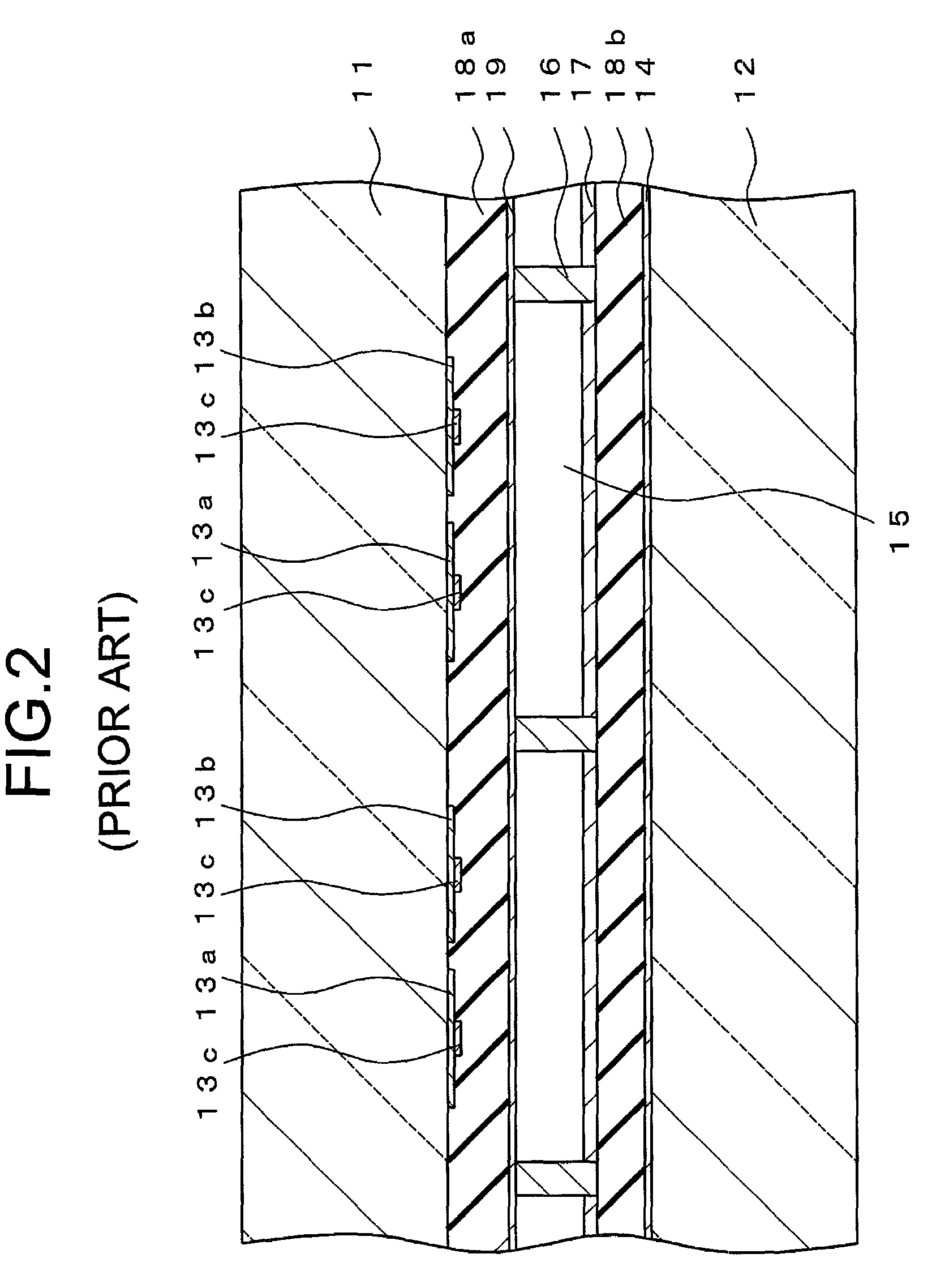

Plasma display panel and method for fabricating the same

InactiveUS7002296B2Improve efficiencyLess power consumptionAddress electrodesSustain/scan electrodesEngineeringPlasma display

Ribs for defining pixel cells are formed in the shape of a lattice, and sustain electrodes and scan electrodes are disposed near the ribs. The electrodes are spaced apart in each pixel cell, and the sustain electrode and the scan electrode are each cut away between pixel cells arranged in the row direction to provide each pixel cell with individually separated electrodes. In addition, between pixel cells adjacent to each other in the row direction, the sustain electrodes and the scan electrodes are connected to each other by means of a sustain-side bus electrode and a scan-side bus electrode, respectively. This makes it possible to provide a high luminous efficiency.

Owner:PANASONIC CORP

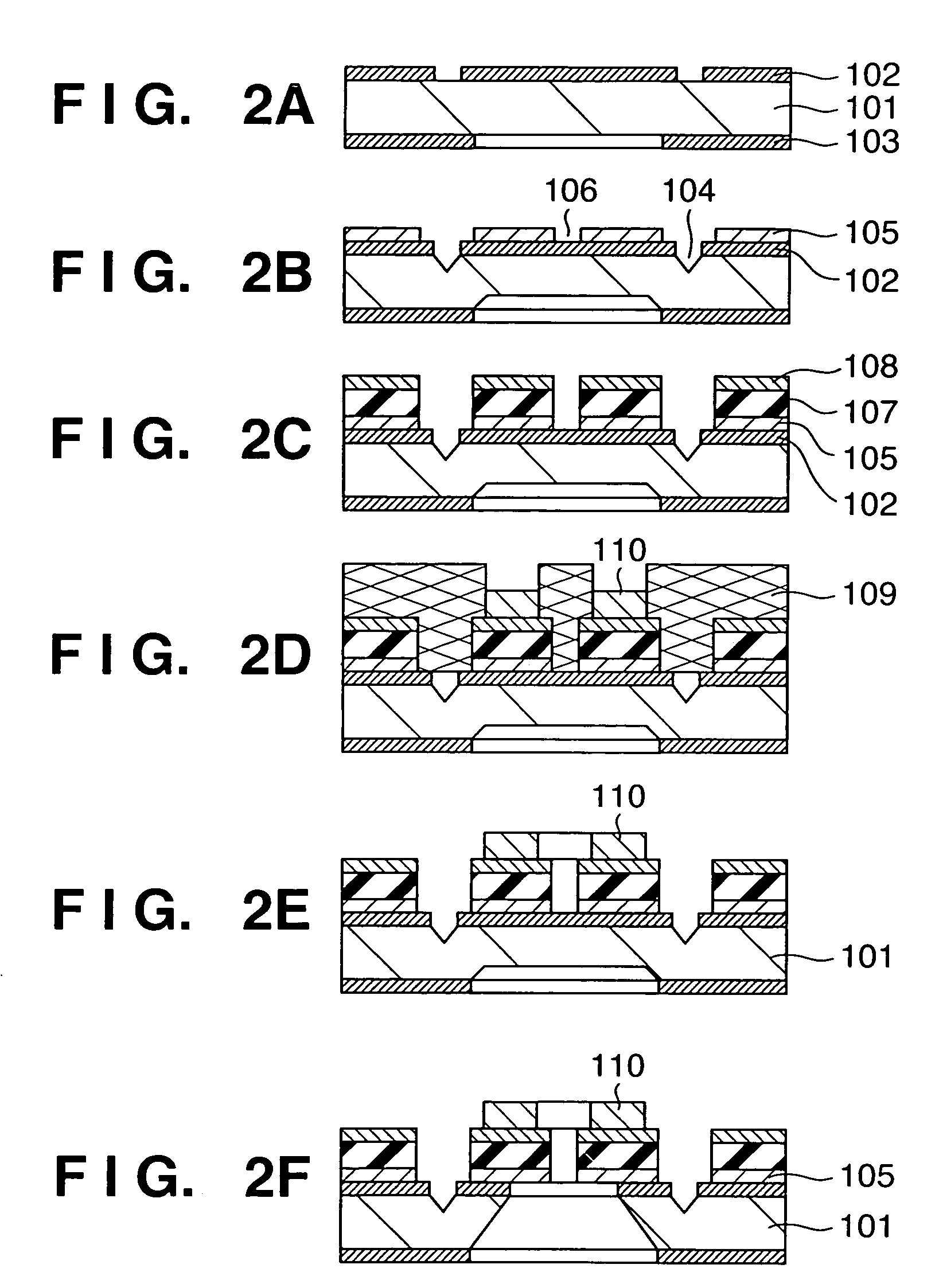

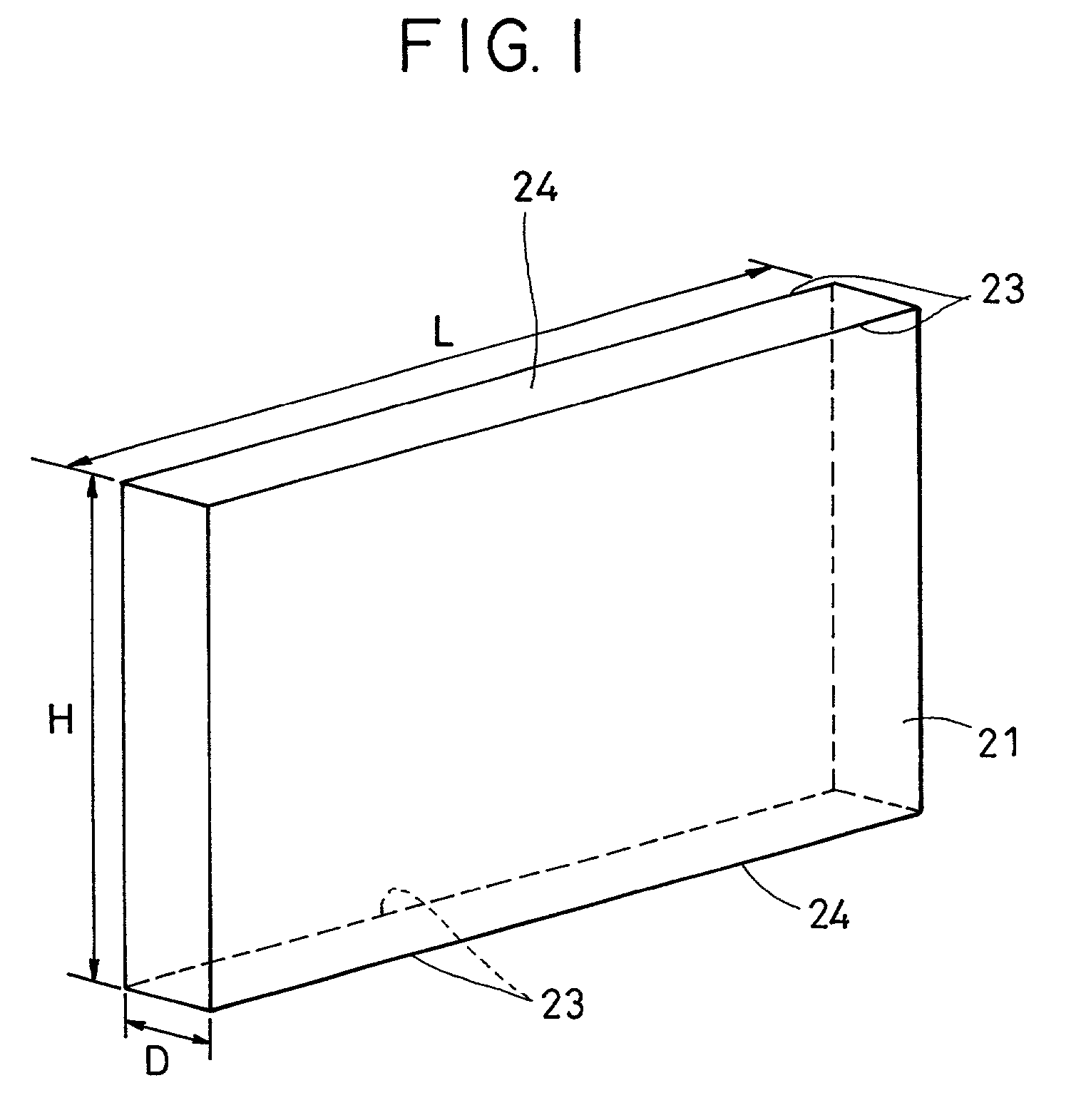

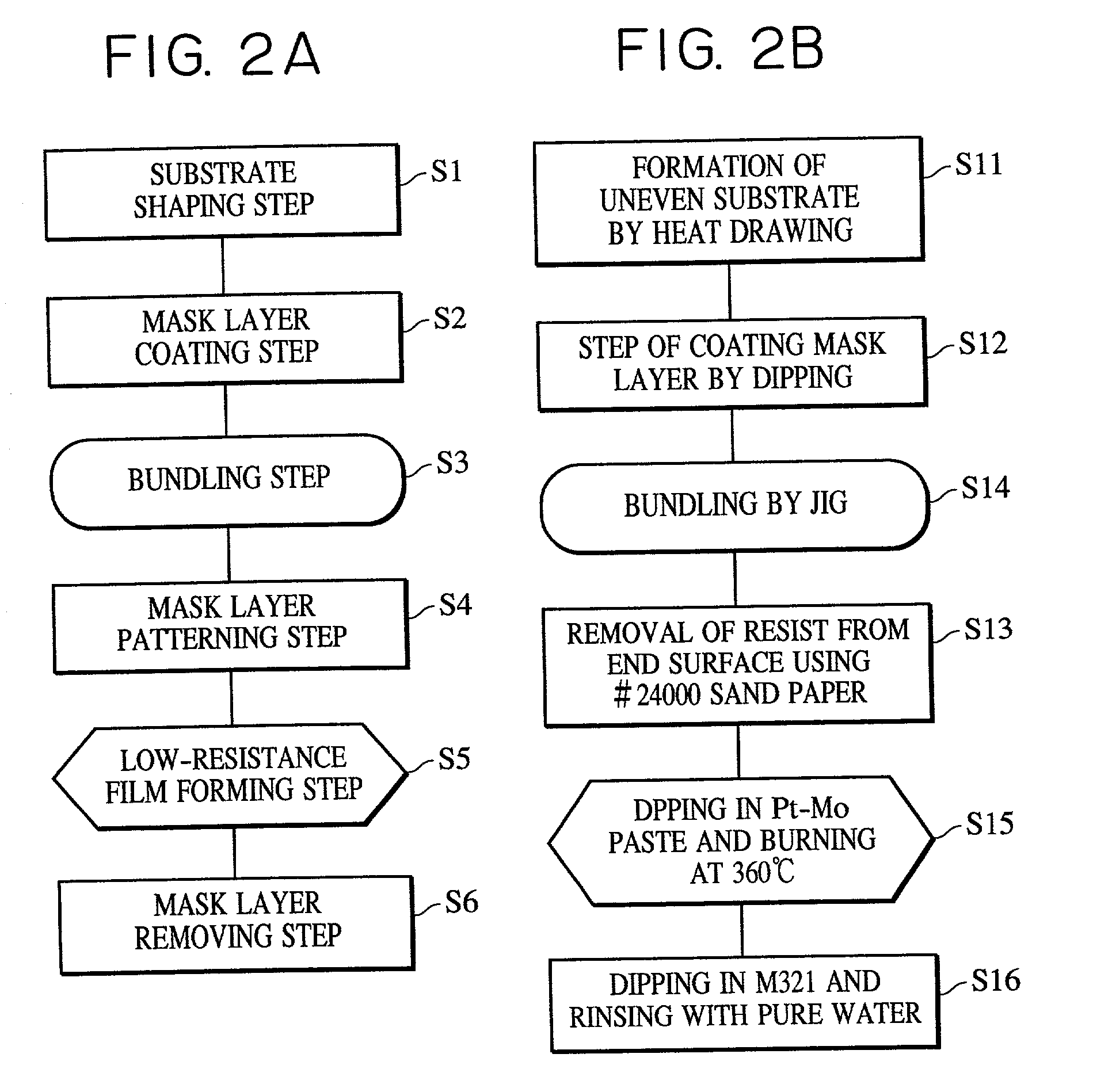

Method of producing spacer and method of manufacturing image forming apparatus

InactiveUS20020031974A1Cathode-ray/electron-beam tube vessels/containersVessels or leading-in conductors manufactureEngineeringFilm material

The present invention provides a method of producing a spacer provided between a first substrate and a second substrate on which an electron emitting device is arranged, the method including the step of forming a film on at least a portion of at least one surface of the spacer. The film forming step includes the step of preparing a bundle of a plurality of spacer base members, and the step of coating a film material on the bundle, and wherein the bundle on which the film material is coated has a mask layer for covering at least a film non-formation portion near the film formation portion of each of the plurality of spacer base members of the bundle.

Owner:CANON KK

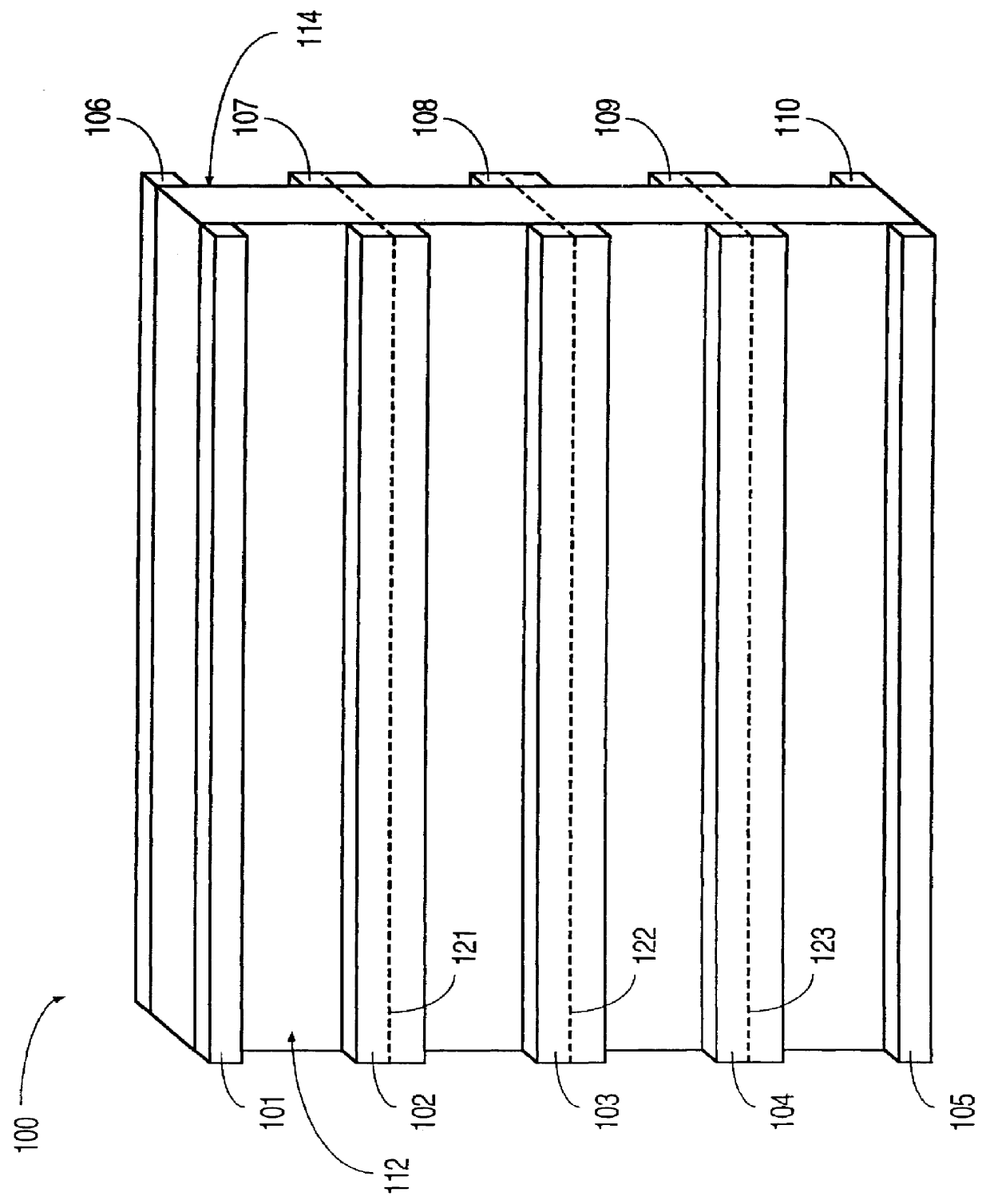

Fiber-based field emission display

InactiveUS6917156B2Increase vacuumGas filling substance selectionCathode-ray/electron-beam tube vessels/containersFiberPhosphor

The invention relates to a field emission display constructed using an array of fibers and an orthogonal array of emitter electrodes. Each fiber in the fiber array contains an extraction electrode, spacer, a high voltage electrode and a phosphor layer. The array of emitter electrodes consists of carbon nanotube emitters attached to conductive electrodes. The emitter electrodes are separated using non-conductive fibers. A getter material in the form of a wire is placed within the array of emitter electrodes to maintain a high vacuum within the display.

Owner:MOORE CHAD BYRON

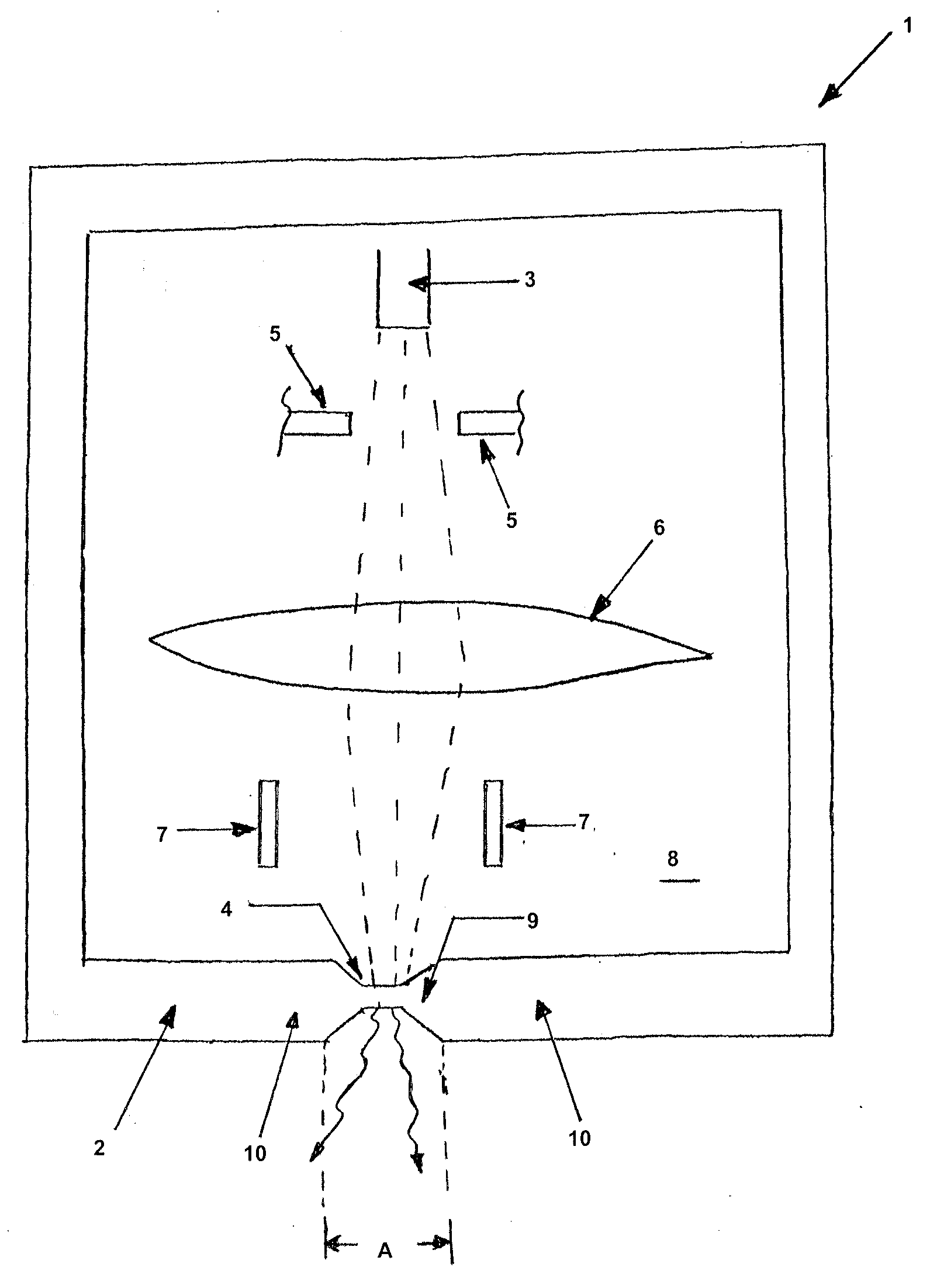

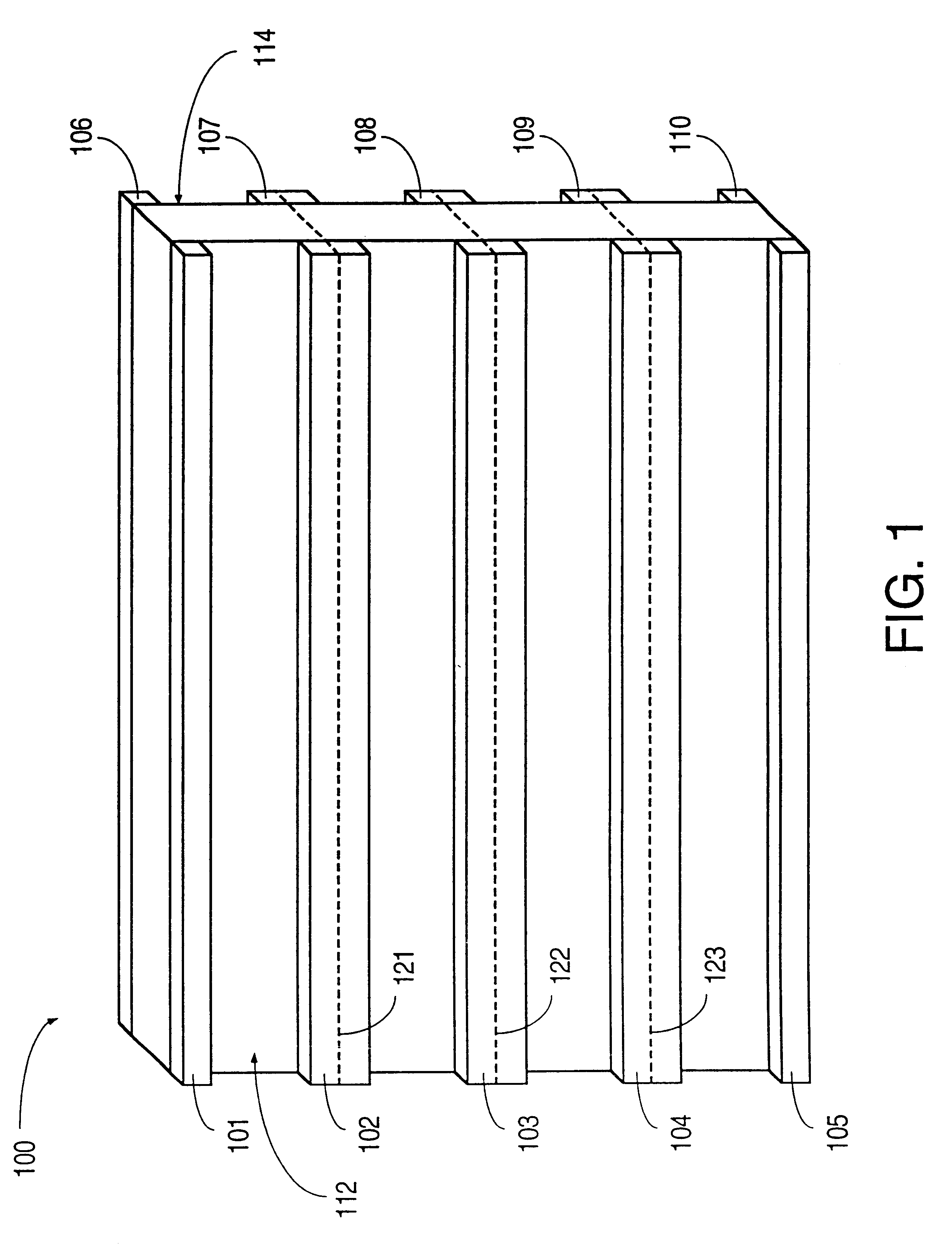

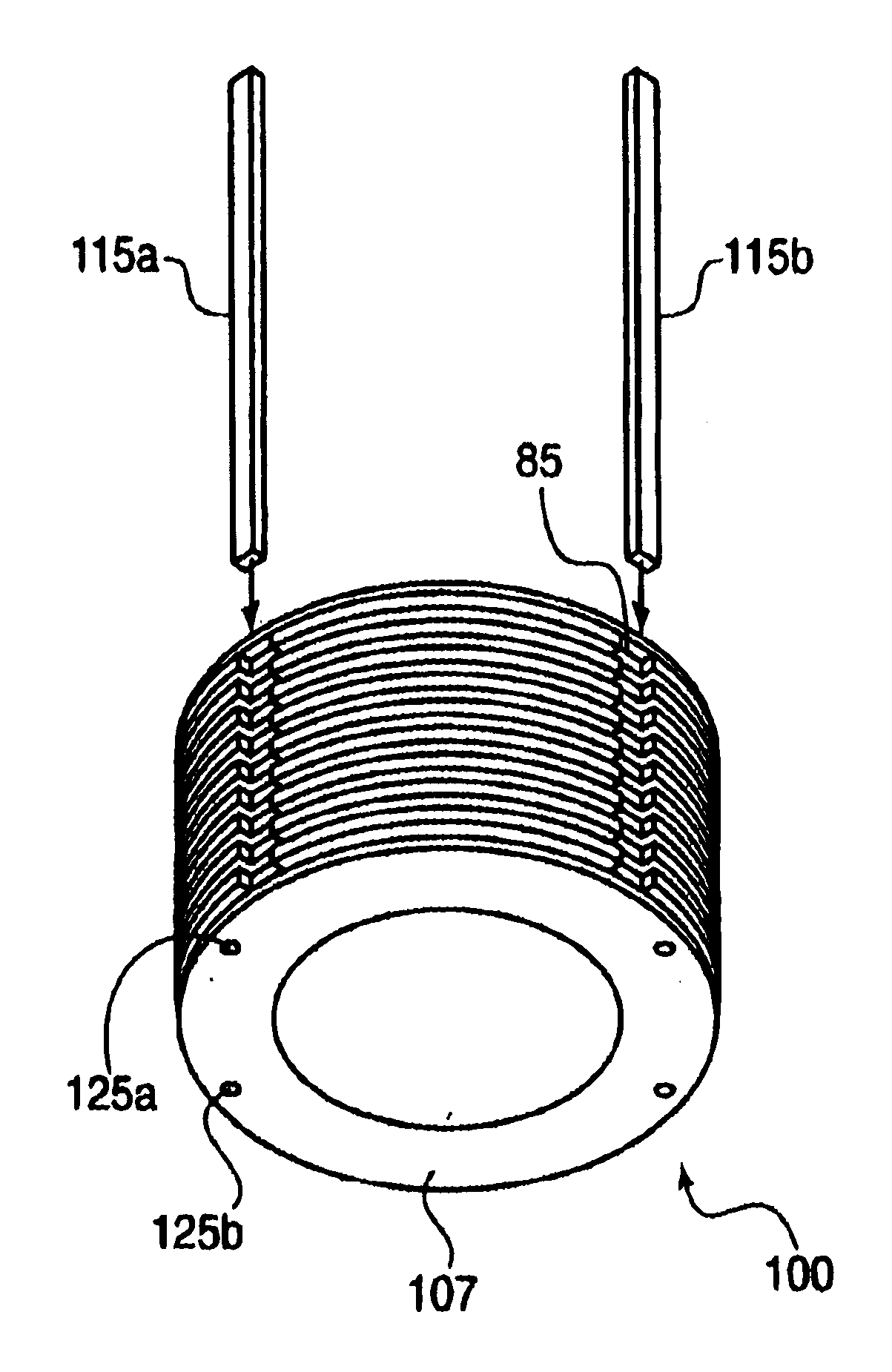

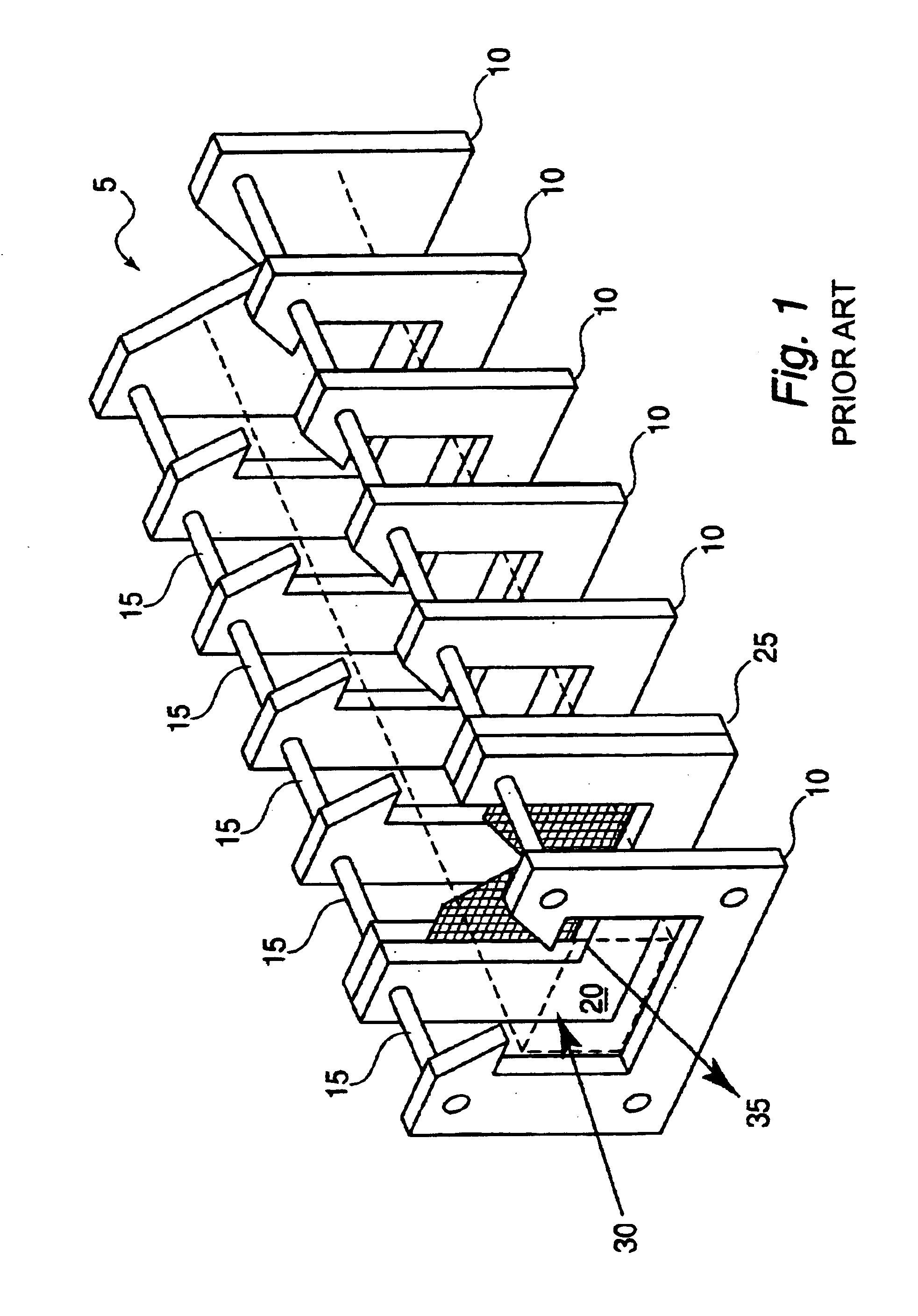

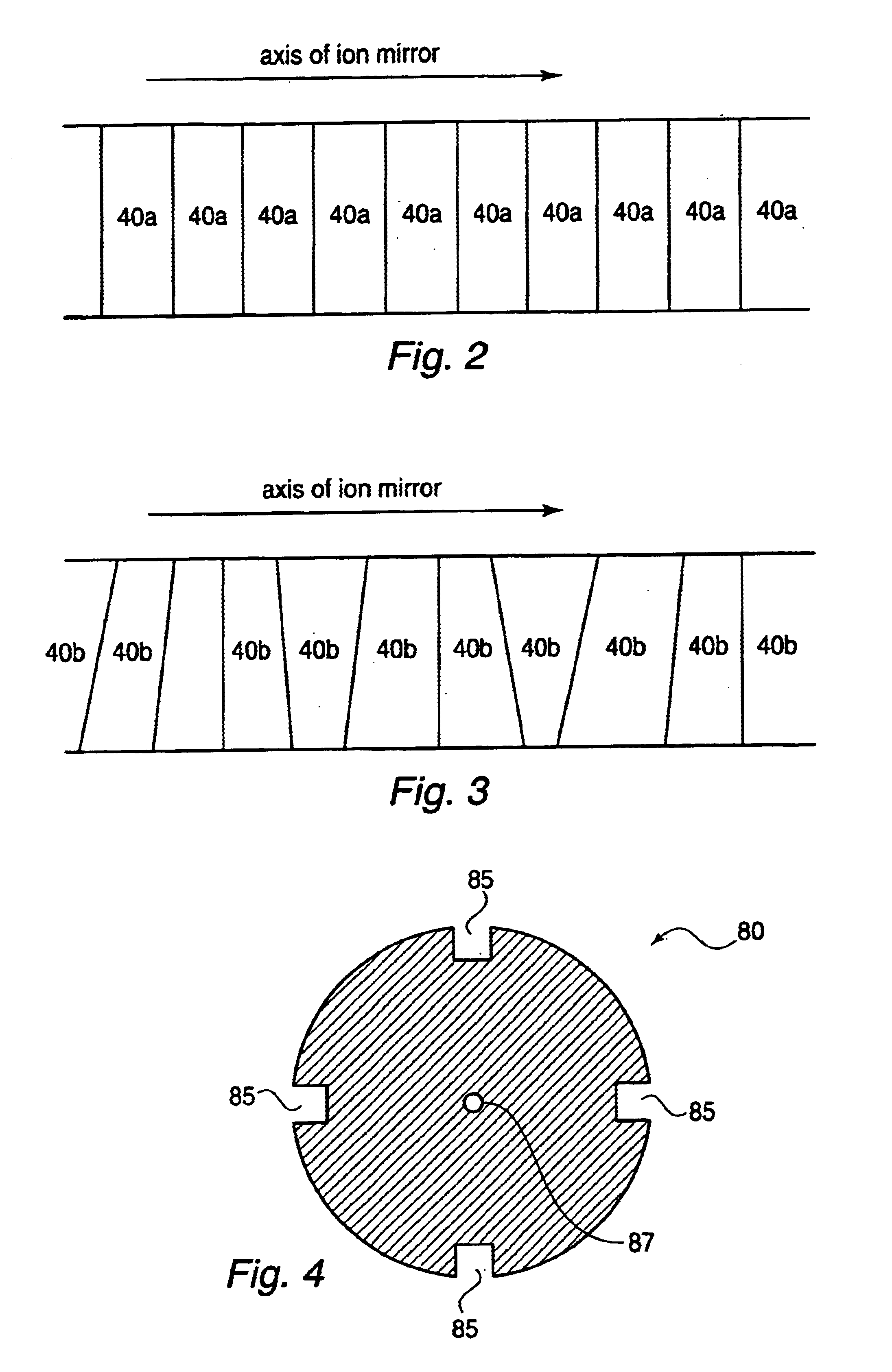

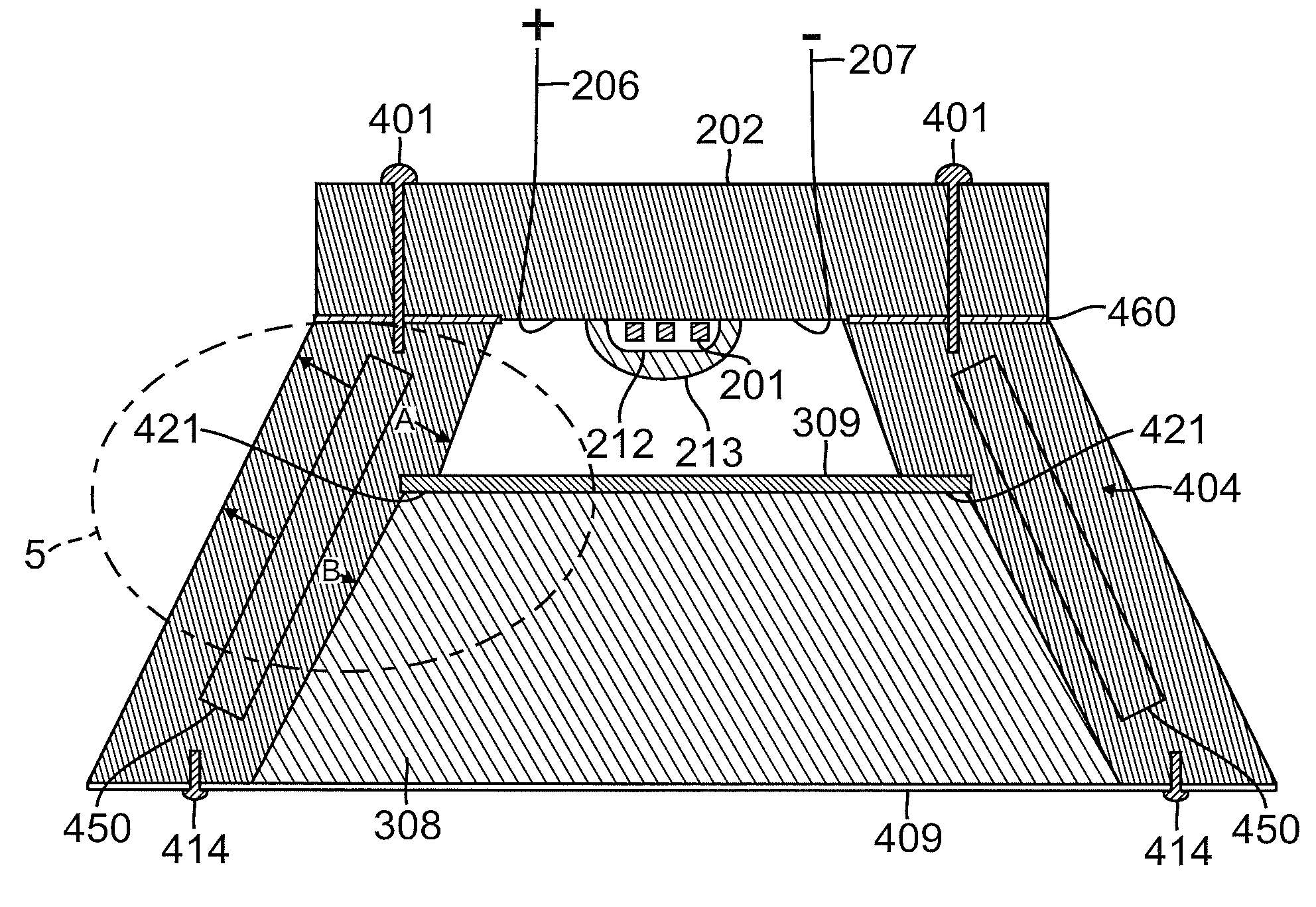

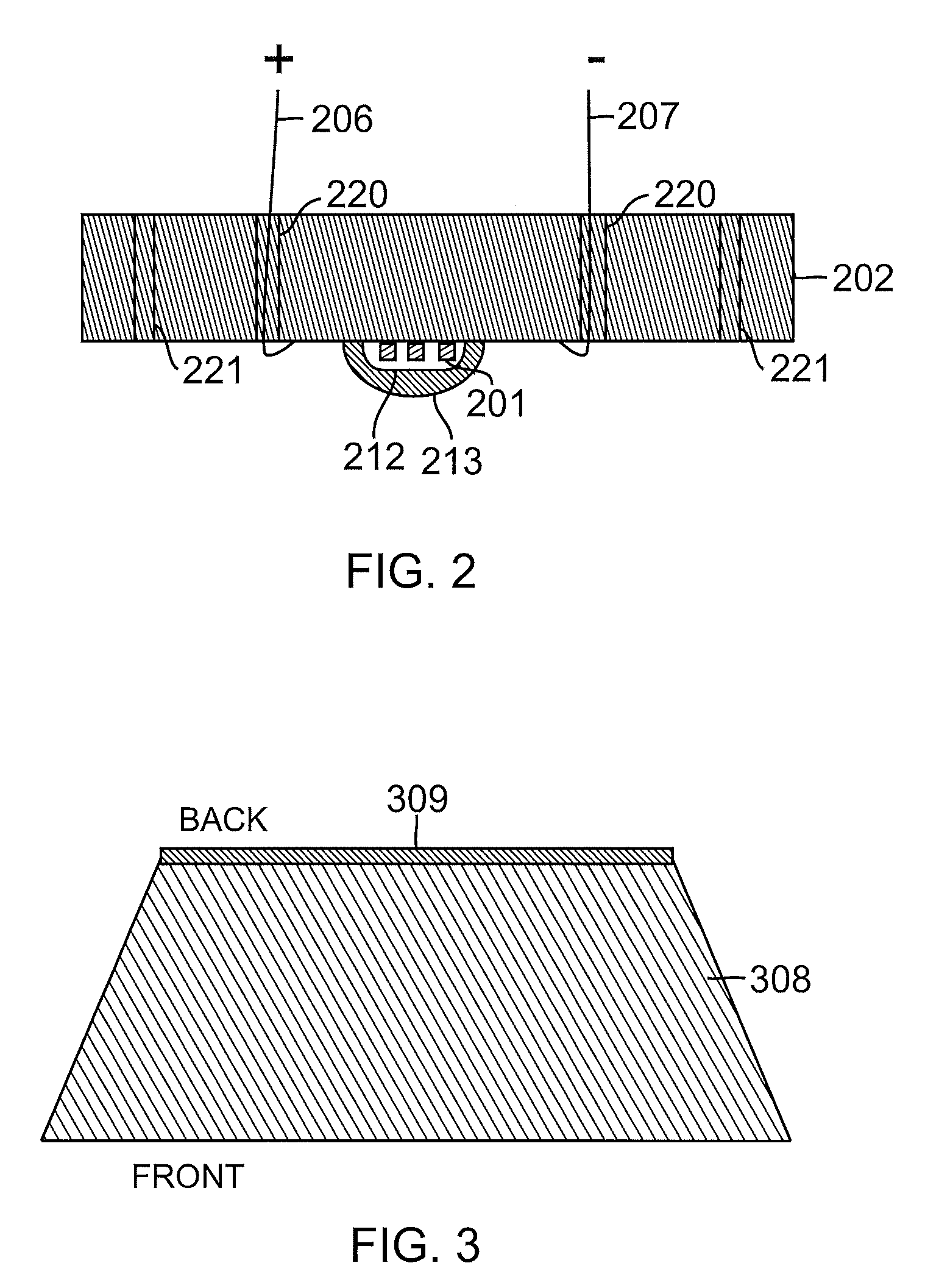

Precision multiple electrode ion mirror

InactiveUS6849846B2Improve parallelismLine/current collector detailsTime-of-flight spectrometersAdhesiveElectronic board

A method of constructing an ion mirror having an axial axis which includes arranging electrode plate elements in parallel alignment along the axial axis and attaching a rigid structure to all of the electrode plate elements with adhesive, thereby fixing the electrode plate elements in their respective axial positions and parallel alignment. In an embodiment of the method, the electrode plate elements are arranged in parallel alignment by turning the electrode plate elements from a single workpiece. In an alternative embodiment, the electron plate elements are arranged in parallel alignment by stacking the electrode plate elements using precisely dimensioned spacers, and the spacers are then removed after attachment of the rigid structure.

Owner:AGILENT TECH INC

Heat sink base for LEDS

ActiveUS20100213808A1Improve cooling effectEasy to operatePoint-like light sourceElectric discharge tubesPhosphorEngineering

An LED assembly can include a heat sink base, at least one LED die attached to the heat sink base, and a lens. One or more layers of phosphor can be formed upon the lens. A heat sink, such as a finned heat sink, can attach the heat sink base to the lens. Heat from the LED die can flow through the heat sink base to the heat sink, from which the heat can be dissipated. Similarly, heat from phosphors can flow through the lens to the heat sink, from which the heat can be dissipated. By removing heat from the LED die, more current can be used to drive the LED die, thus providing brighter light. By removing heat from the phosphors, desired colors can be more reliably provided.

Owner:BRIDGELUX INC

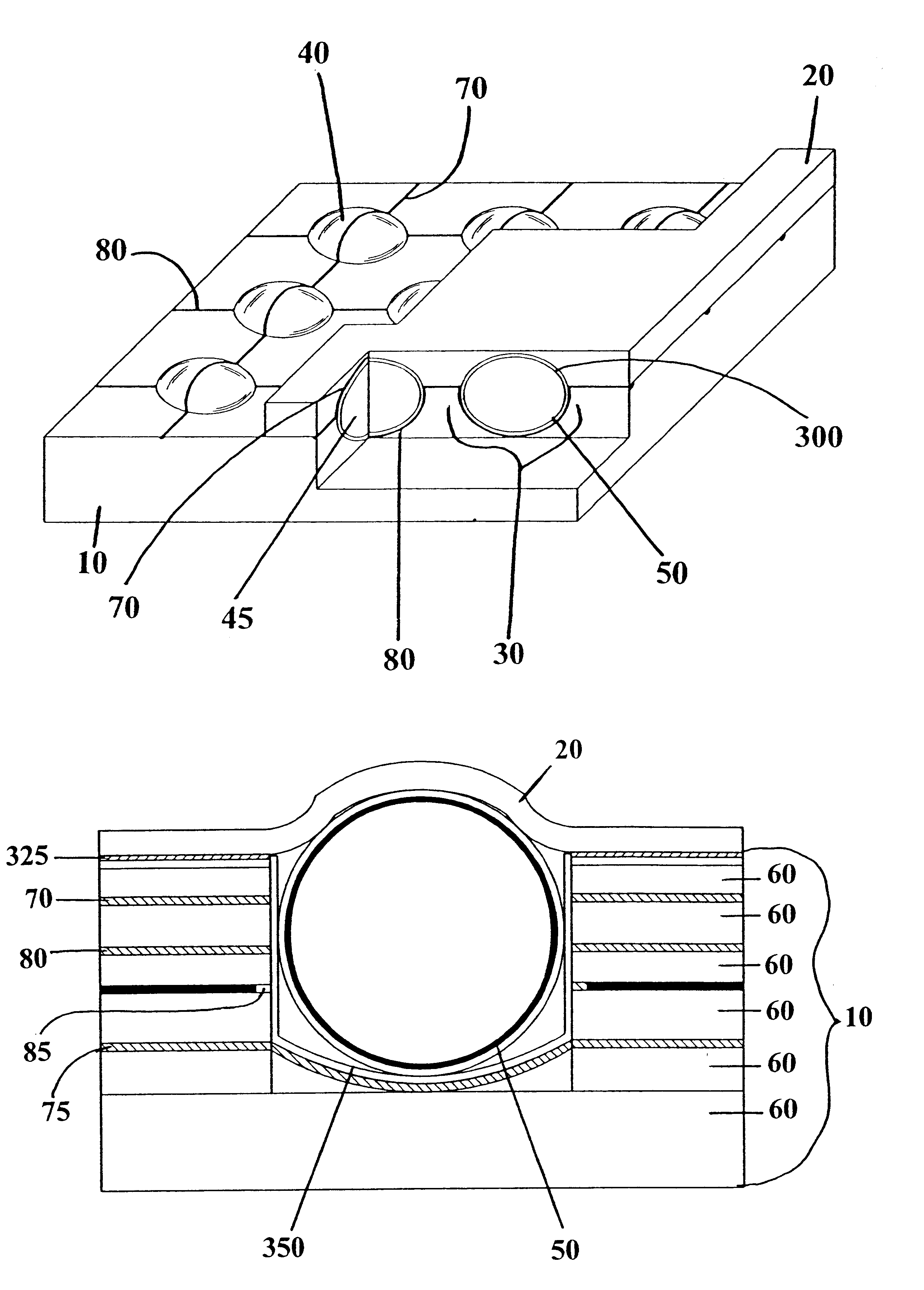

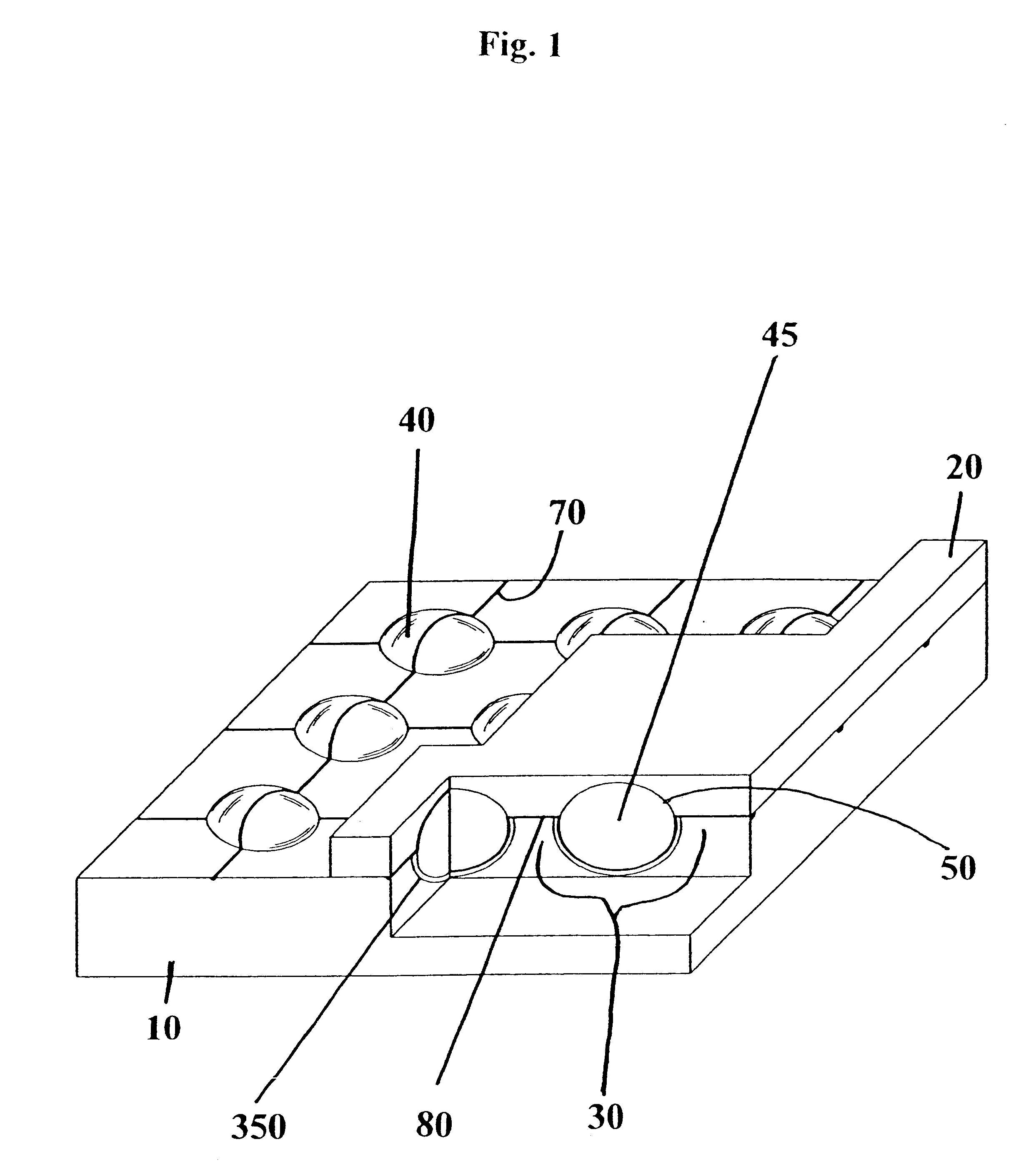

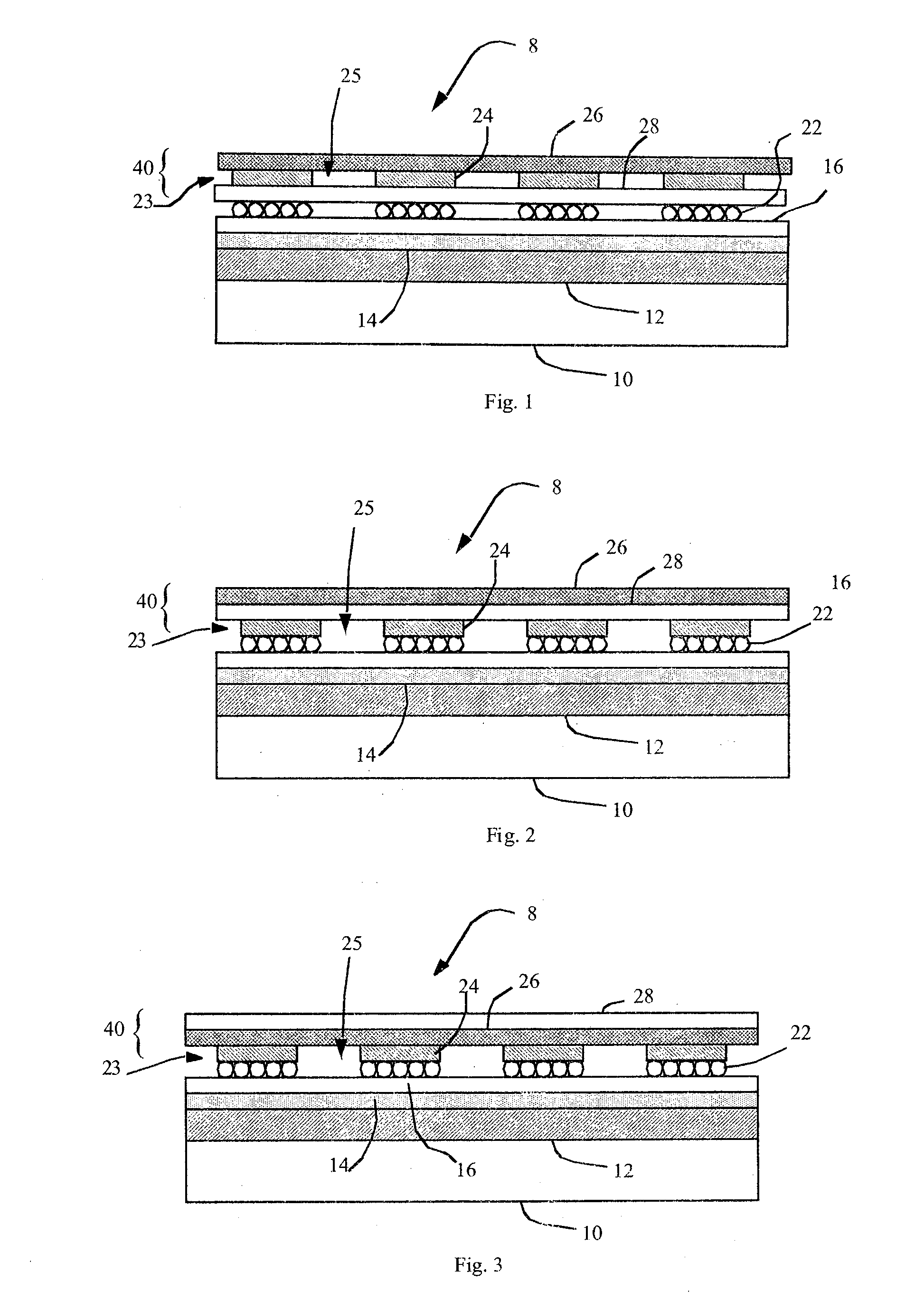

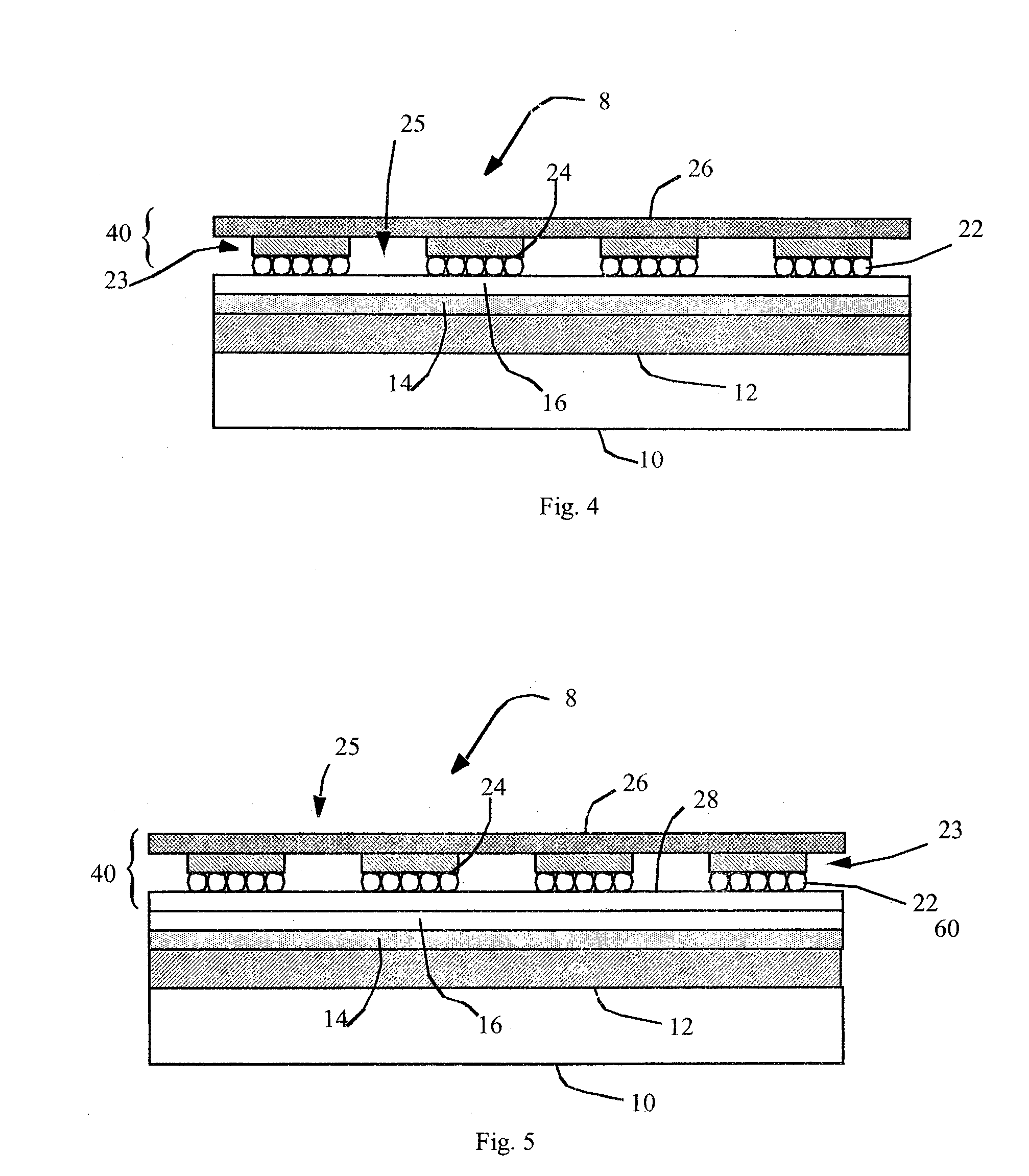

Differential pressure process for fabricating a flat-panel display face plate with integral spacer support structures

InactiveUS6101846ATube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersSilicate glassAmbient pressure

A process for fabricating a face plate for a flat panel display such as a field emission cathode type display, the face plate having integral spacer support structures is disclosed. Also disclosed is a product made by the aforesaid process. The support structures are designed to be load bearing so as to prevent implosion of a planar, transparent face plate toward a parallel spaced-apart base plate when the space between the face plate and the base plate is sealed at the edges of the display to form a chamber, and the chamber is evacuated in the presence of atmospheric pressure outside the chamber. Unlike most spacer support structures proposed for such flat panel displays, the support structures are made from the same material as the substrate from which the face plate is fabricated. For a preferred embodiment of the process, a perforated laminar template is sealably sandwiched between a laminar silicate glass substrate and a manifold block to form a temporary sandwich assembly. The laminar template, preferably formed from a refractory ceramic or graphite material, is perforated with mold holes which are perpendicular to the major planar faces thereof, each hole corresponding to the desired location of a spacer support structure on the substrate. The manifold block has a plurality of mating ports, each such port mating with a major surface of the laminar template, and aligning with at least one mold hole of the template. Each of the mating ports is connected to a main vacuum port via a manifold formed from interconnecting grooves or passageways. After the substrate is heated evenly within a temperature range where the viscosity of the substrate material is greatly reduced, such that the material becomes plastic and readily flowable under pressure, pressure within the mold holes is reduced with respect to ambient pressure. The pressure differential causes the plastic substrate material will flow into the mold holes of the template.

Owner:MICRON TECH INC

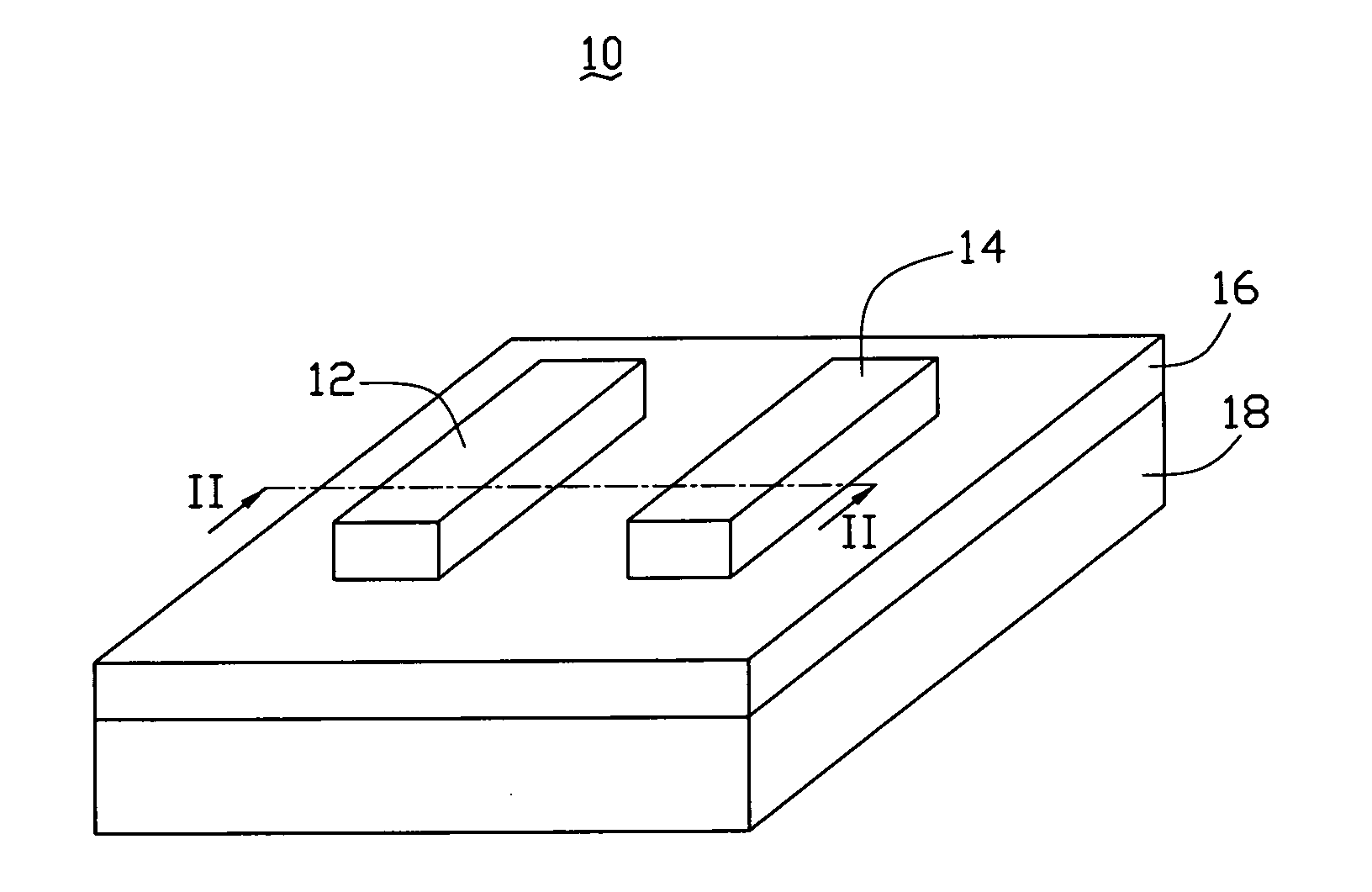

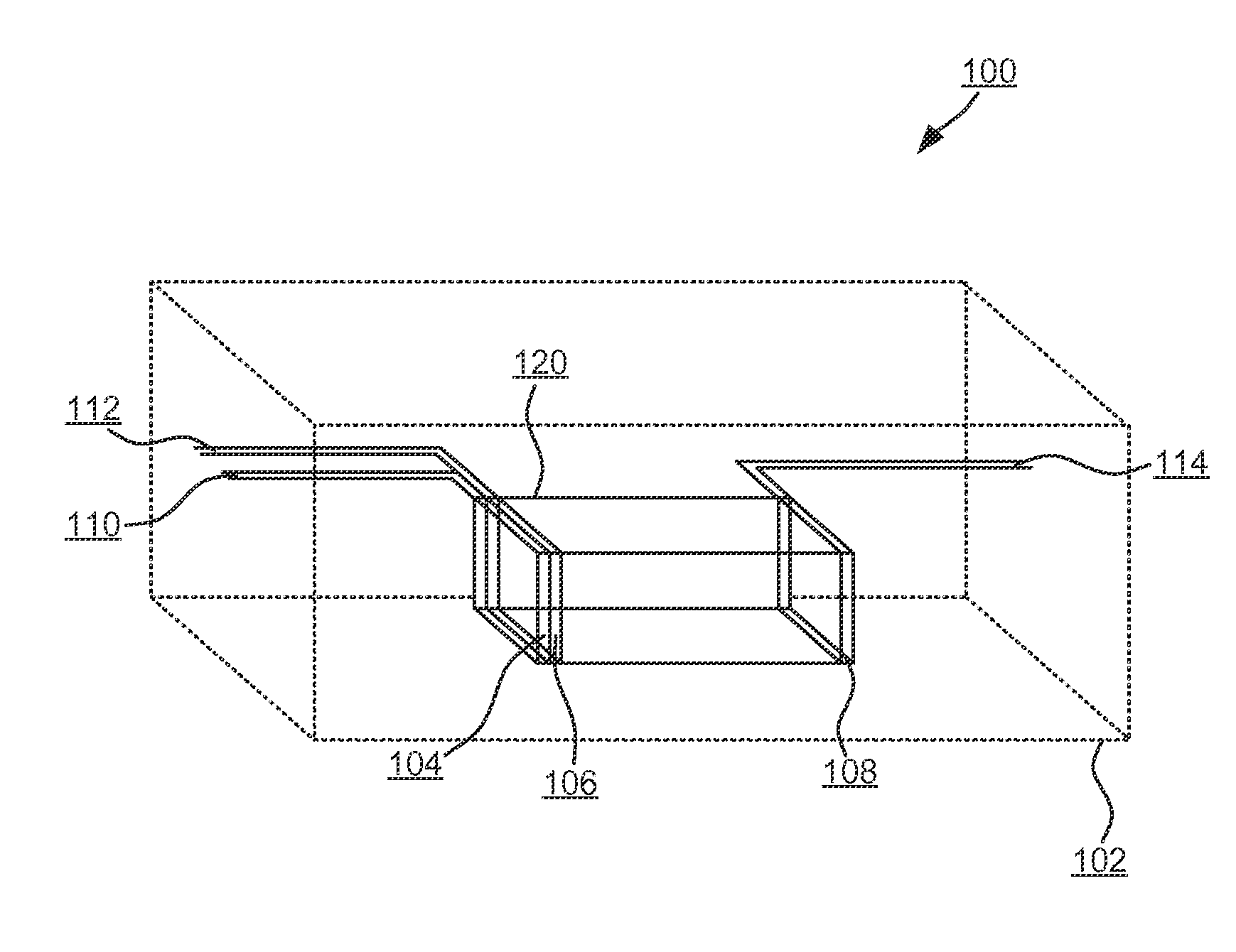

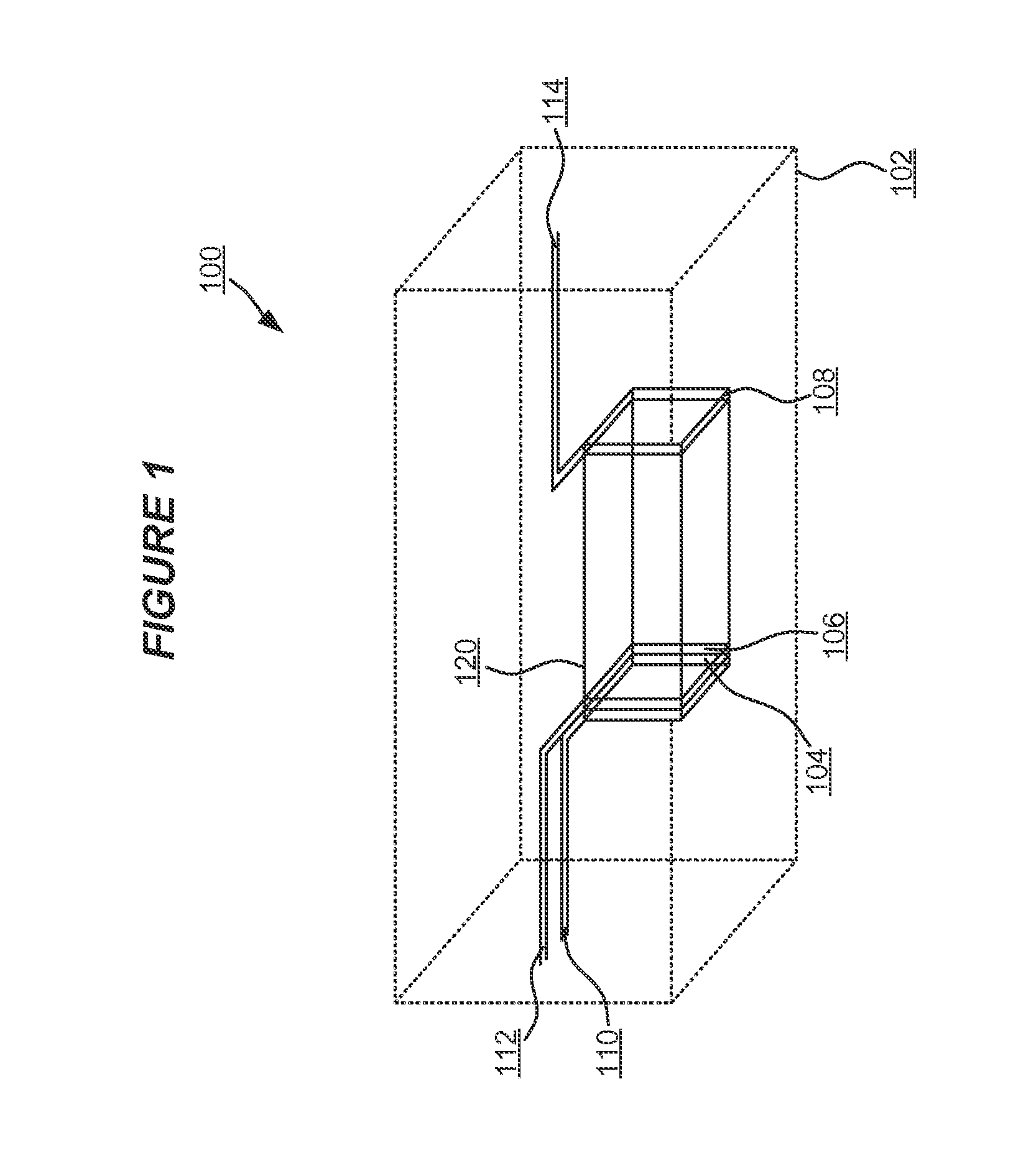

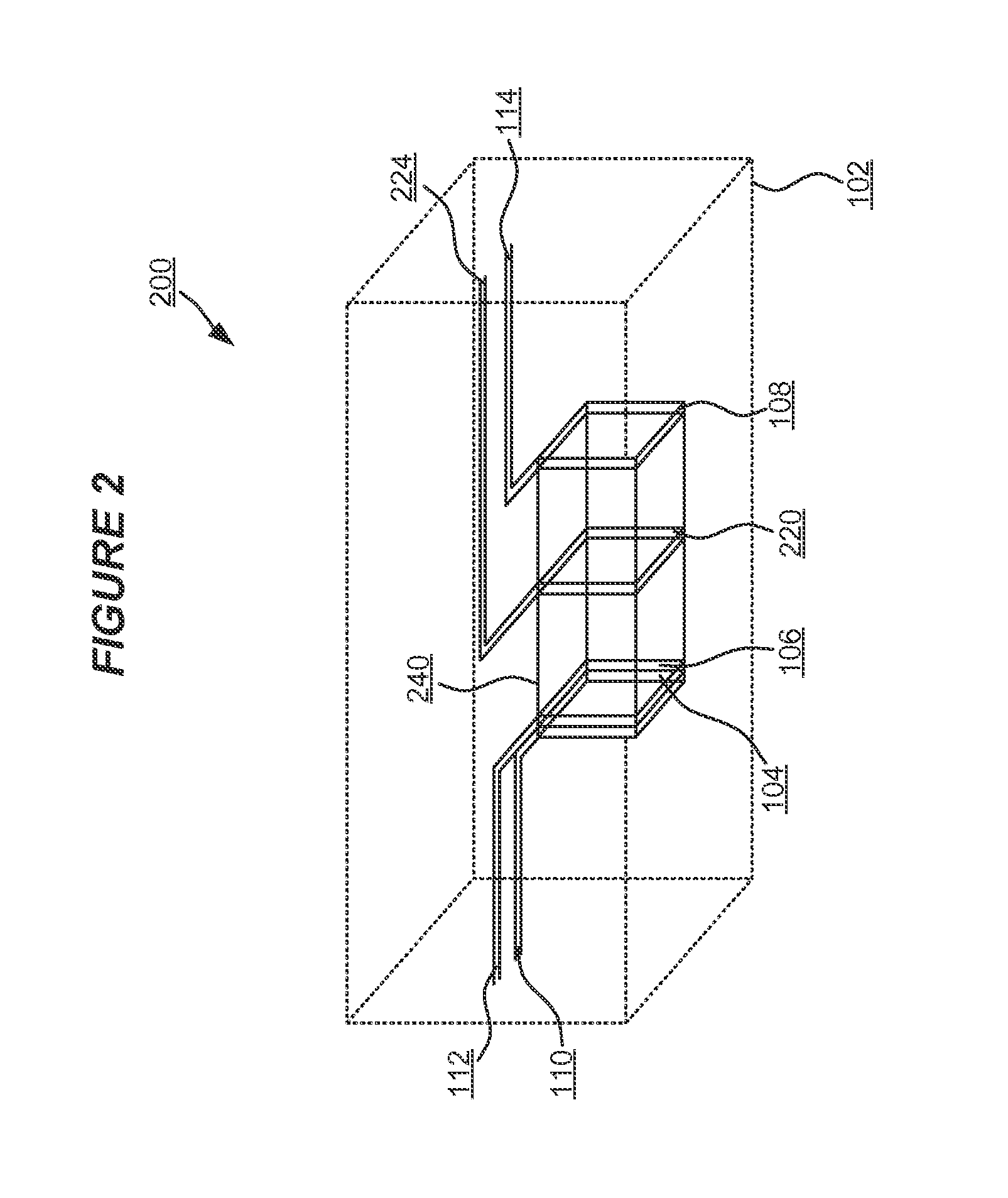

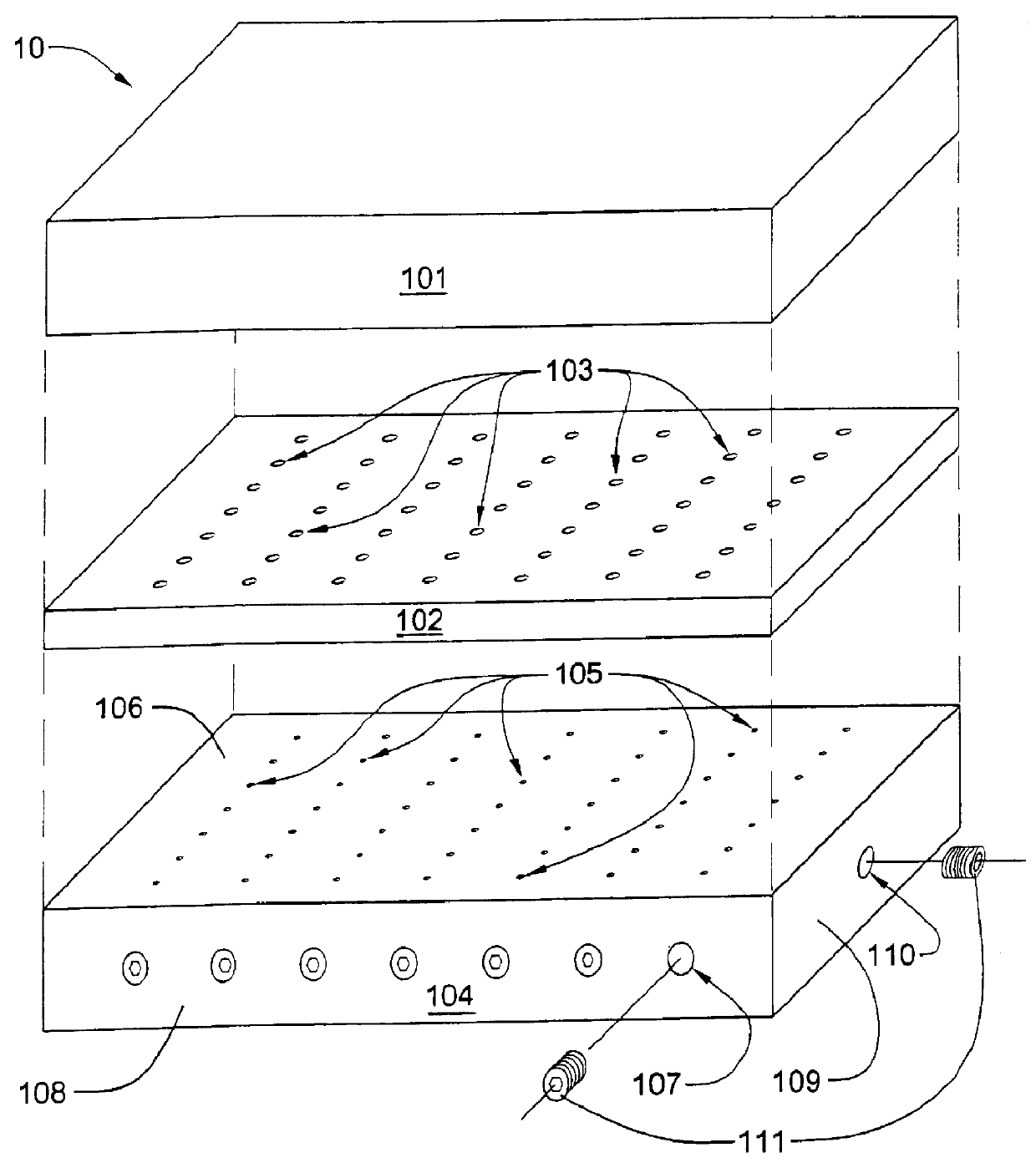

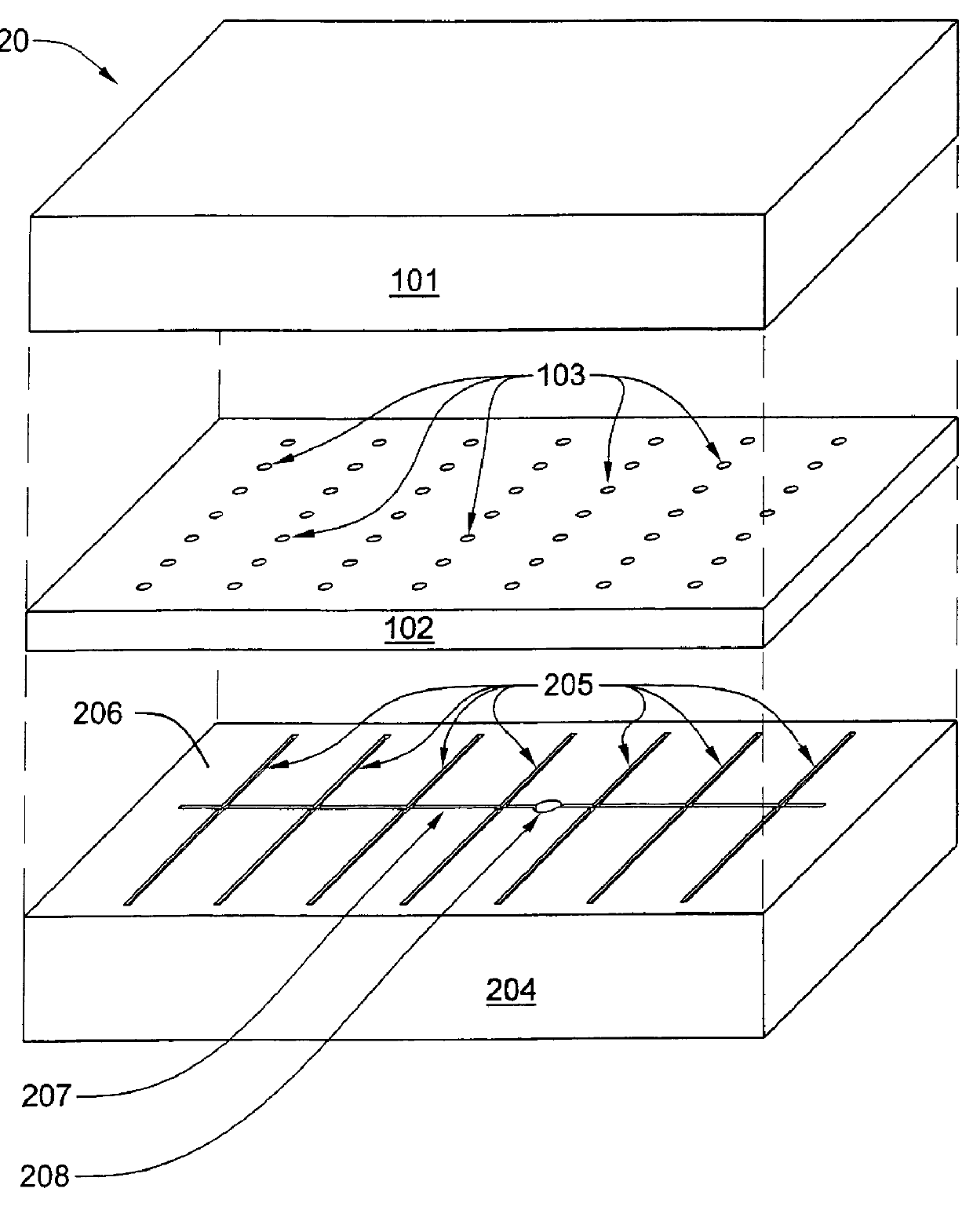

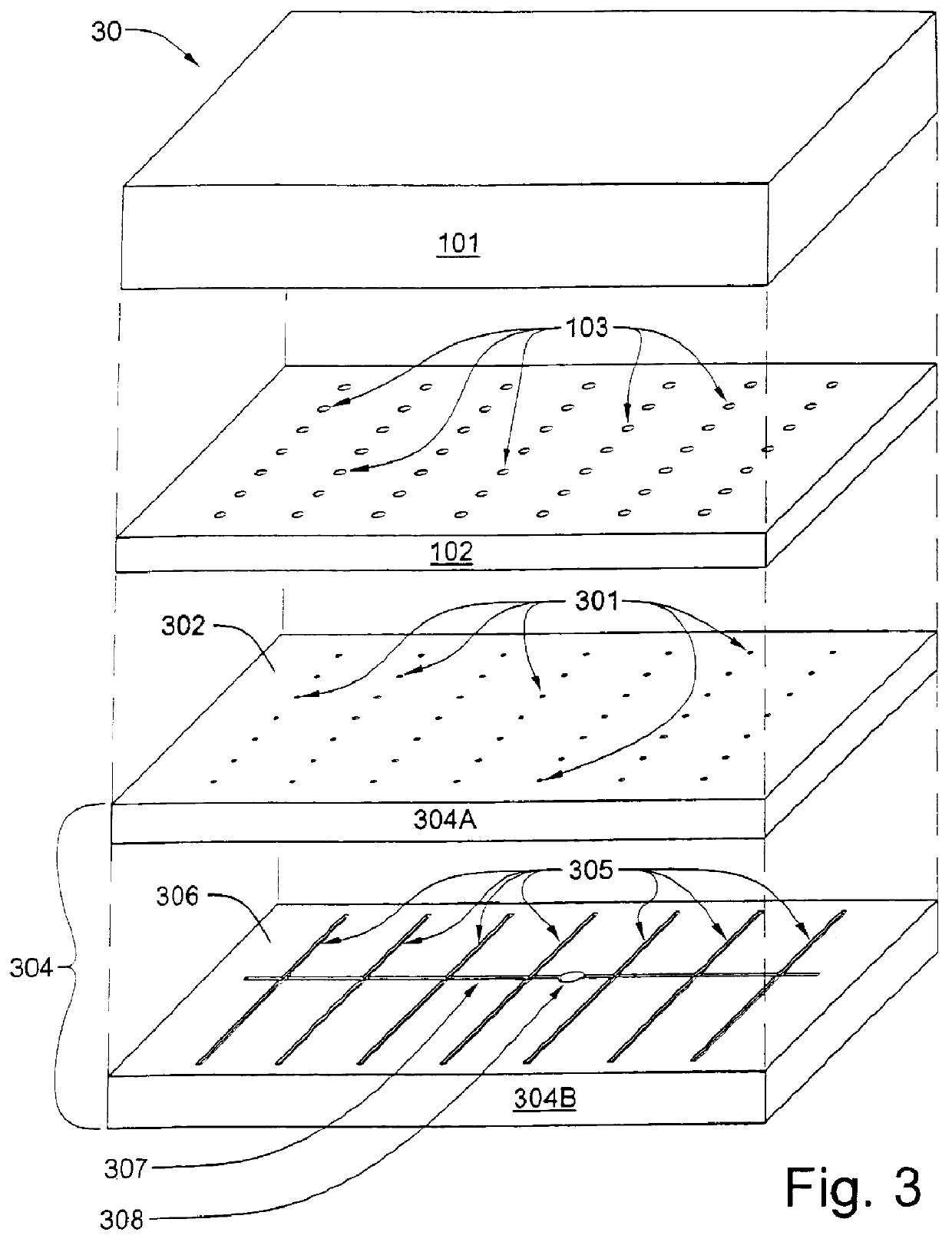

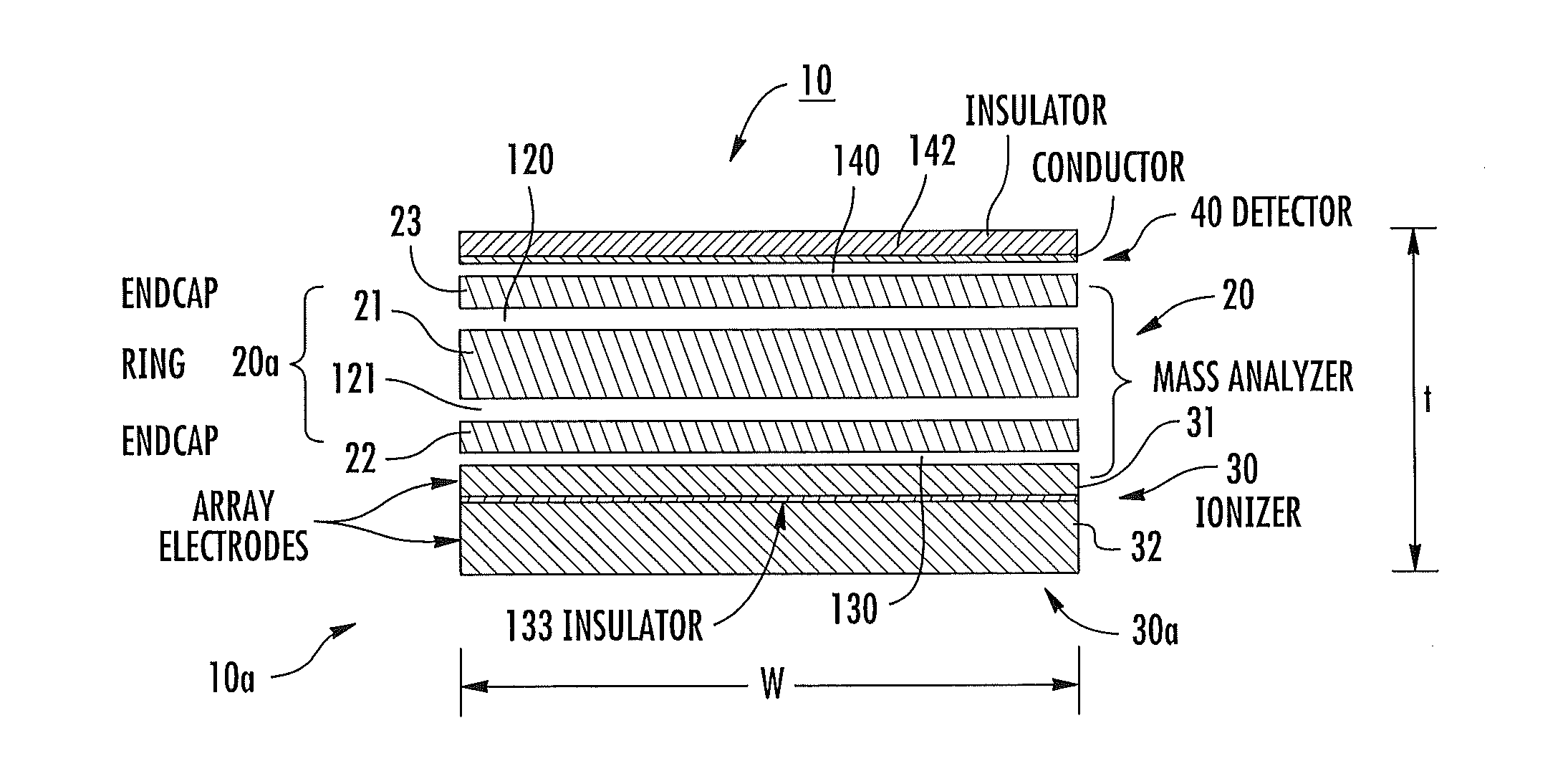

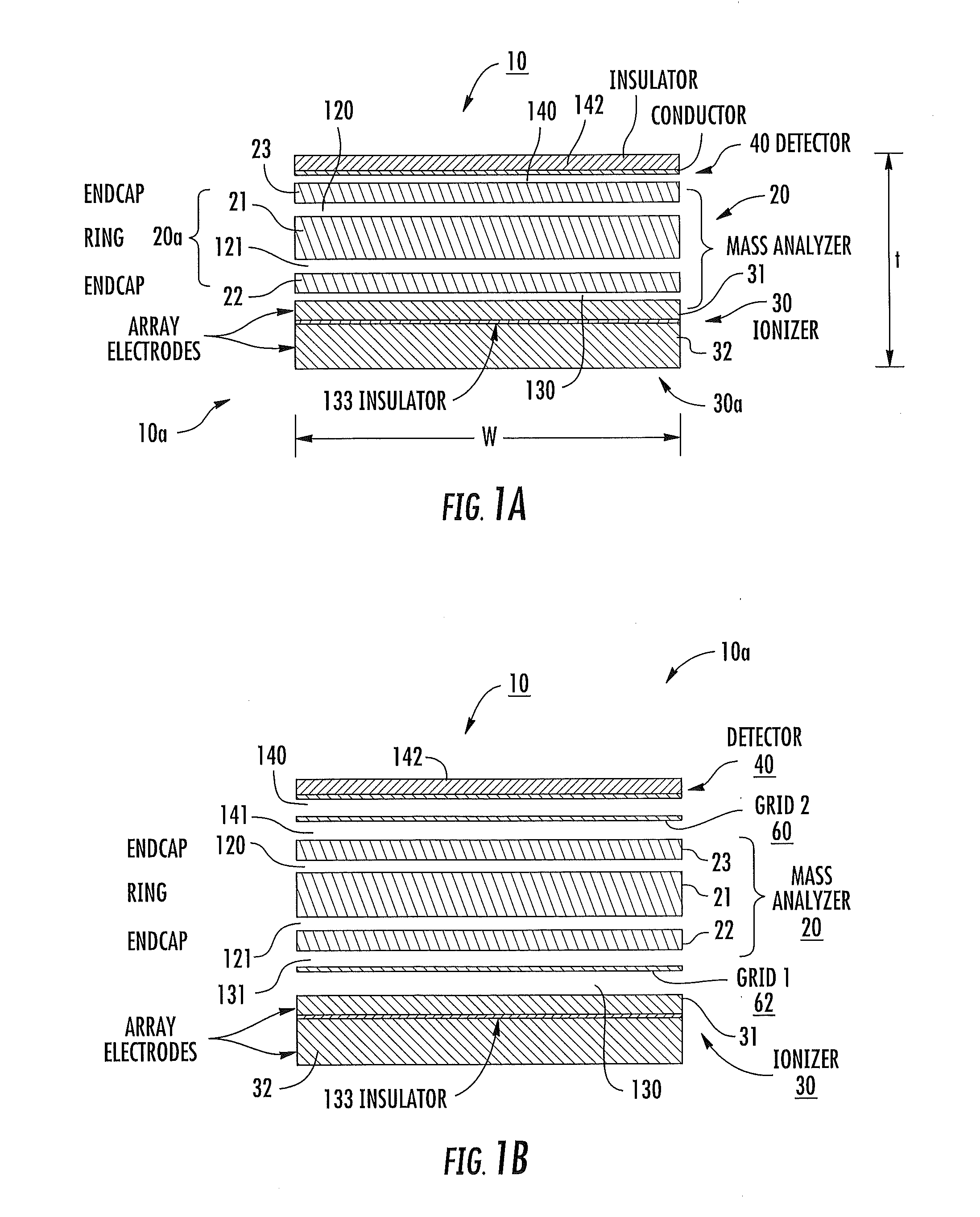

Microscale mass spectrometry systems, devices and related methods

ActiveUS20140263999A1Small sizeReduce weightLine/current collector detailsIon sources/gunsPlanar electrodeElectrical conductor

Mass spectrometry systems or assemblies therefore include an ionizer that includes at least one planar conductor, a mass analyzer with a planar electrode assembly, and a detector comprising at least one planar conductor. The ionizer, the mass analyzer and the detector are attached together in a compact stack assembly. The stack assembly has a perimeter that bounds an area that is between about 0.01 mm2 to about 25 cm2 and the stack assembly has a thickness that is between about 0.1 mm to about 25 mm.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

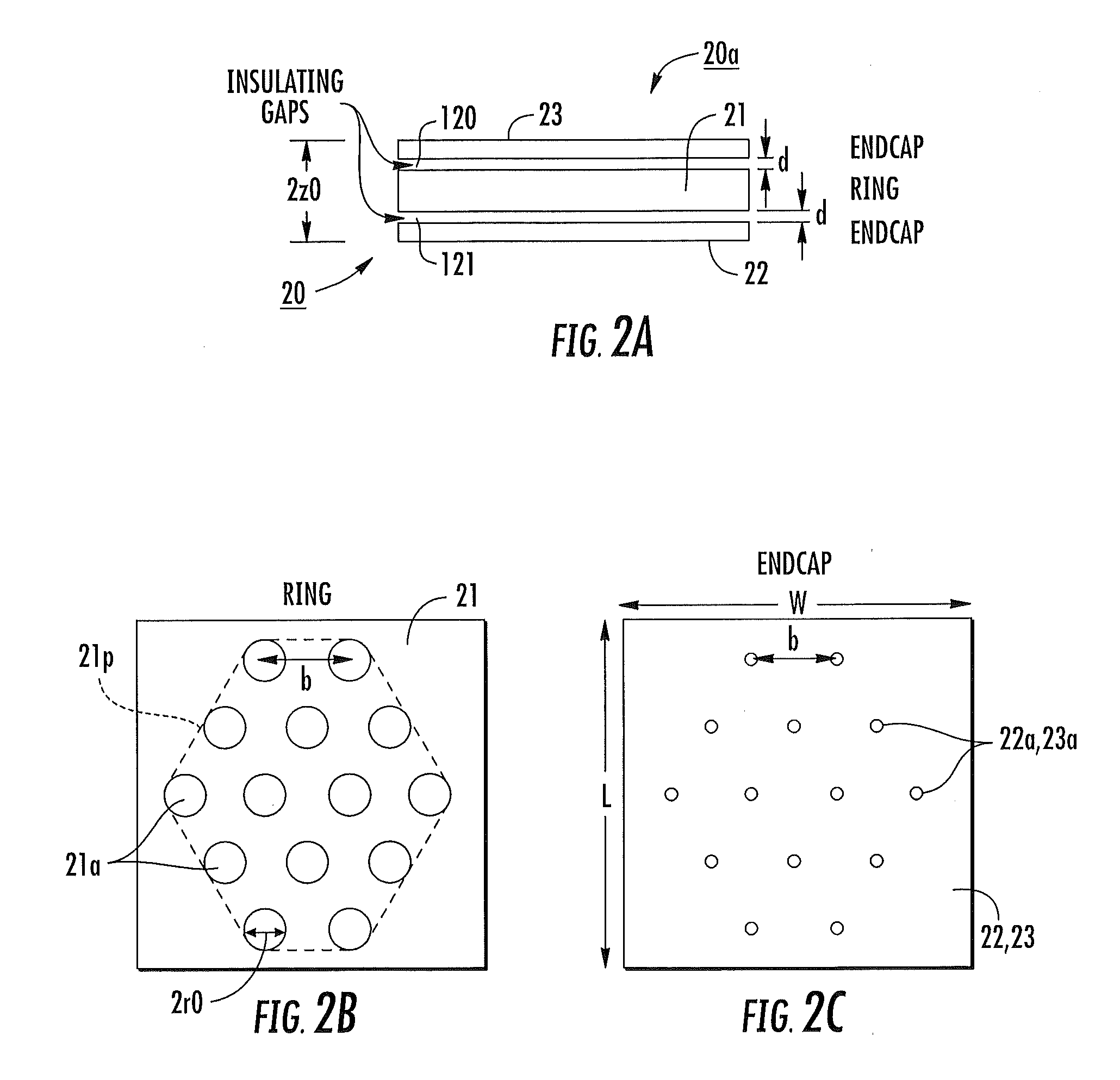

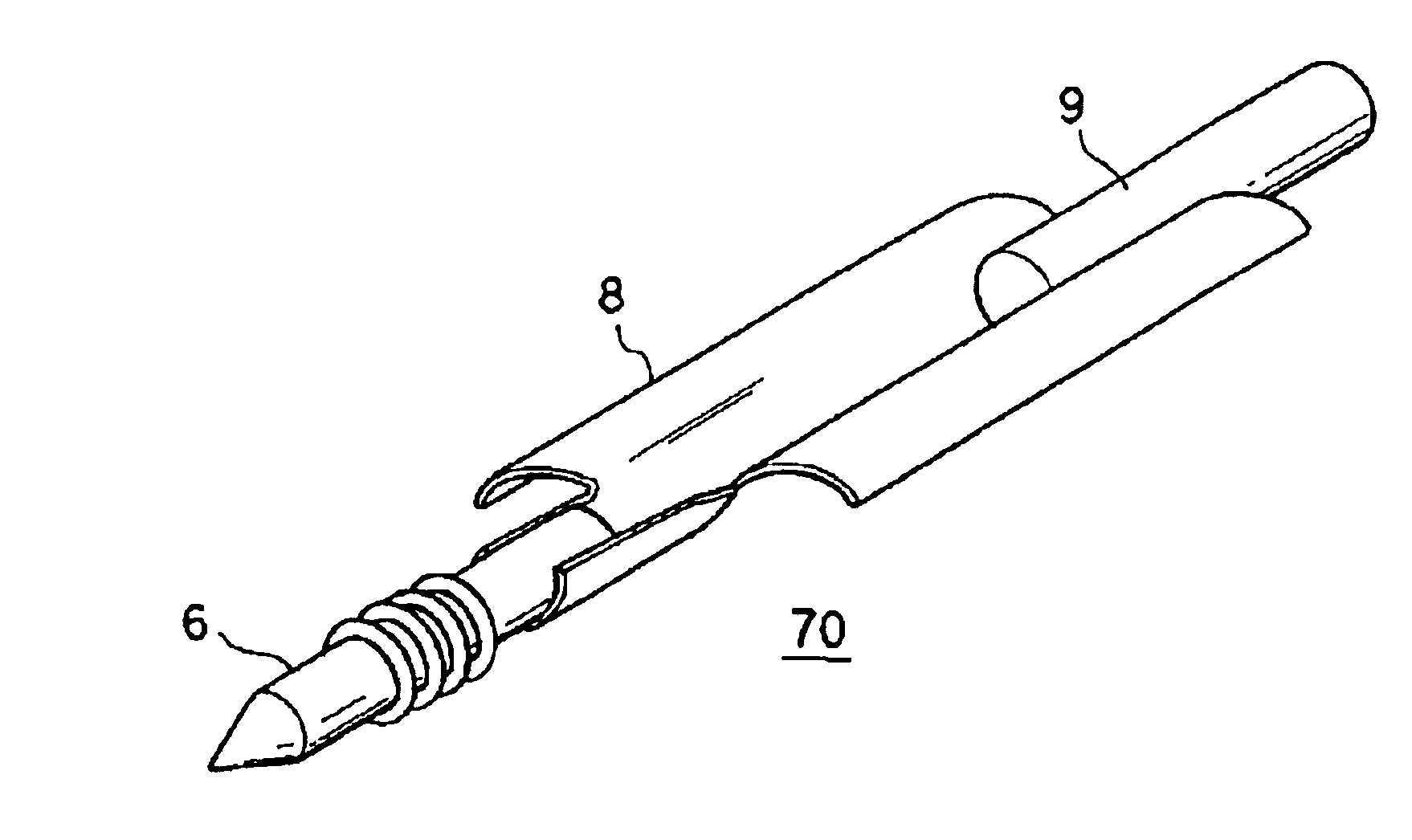

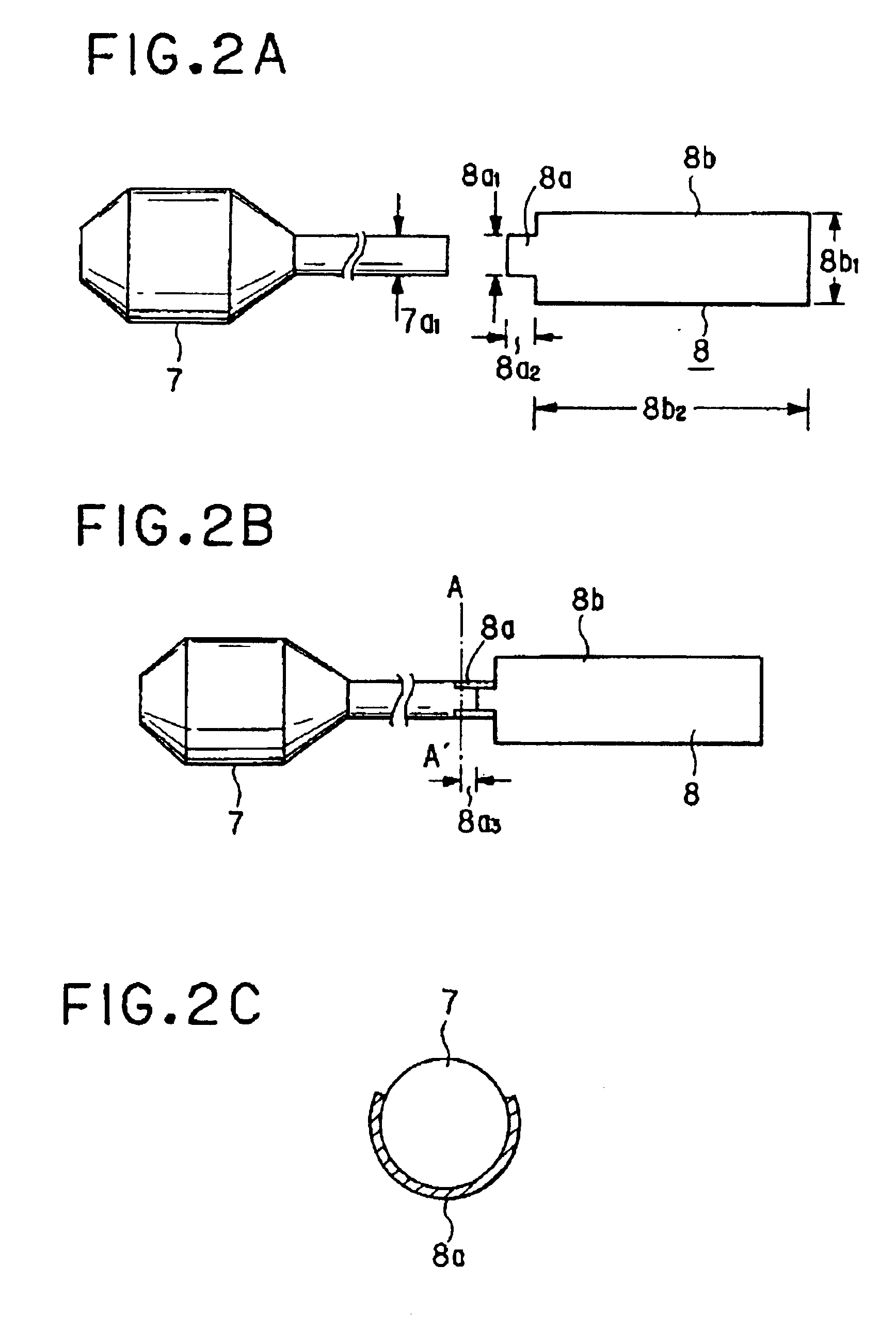

Method of manufacturing a high-pressure discharge lamp

InactiveUS20050003729A1Improve reliabilityEliminate disadvantagesTube/lamp screens manufactureElectroluminescent light sourcesLaser lightLength wave

For manufacturing a high-pressure discharge lamp, a tungsten electrode is welded to a molybdenum foil by bringing a shaft of tungsten electrode into close contact with the molybdenum foil, and by irradiating a laser light, having a metal melting wavelength, to a junction of the molybdenum foil with the tungsten electrode from a location closer to the molybdenum foil to melt both the molybdenum foil and the shaft of the tungsten electrode for bonding.

Owner:USHIO DENKI KK

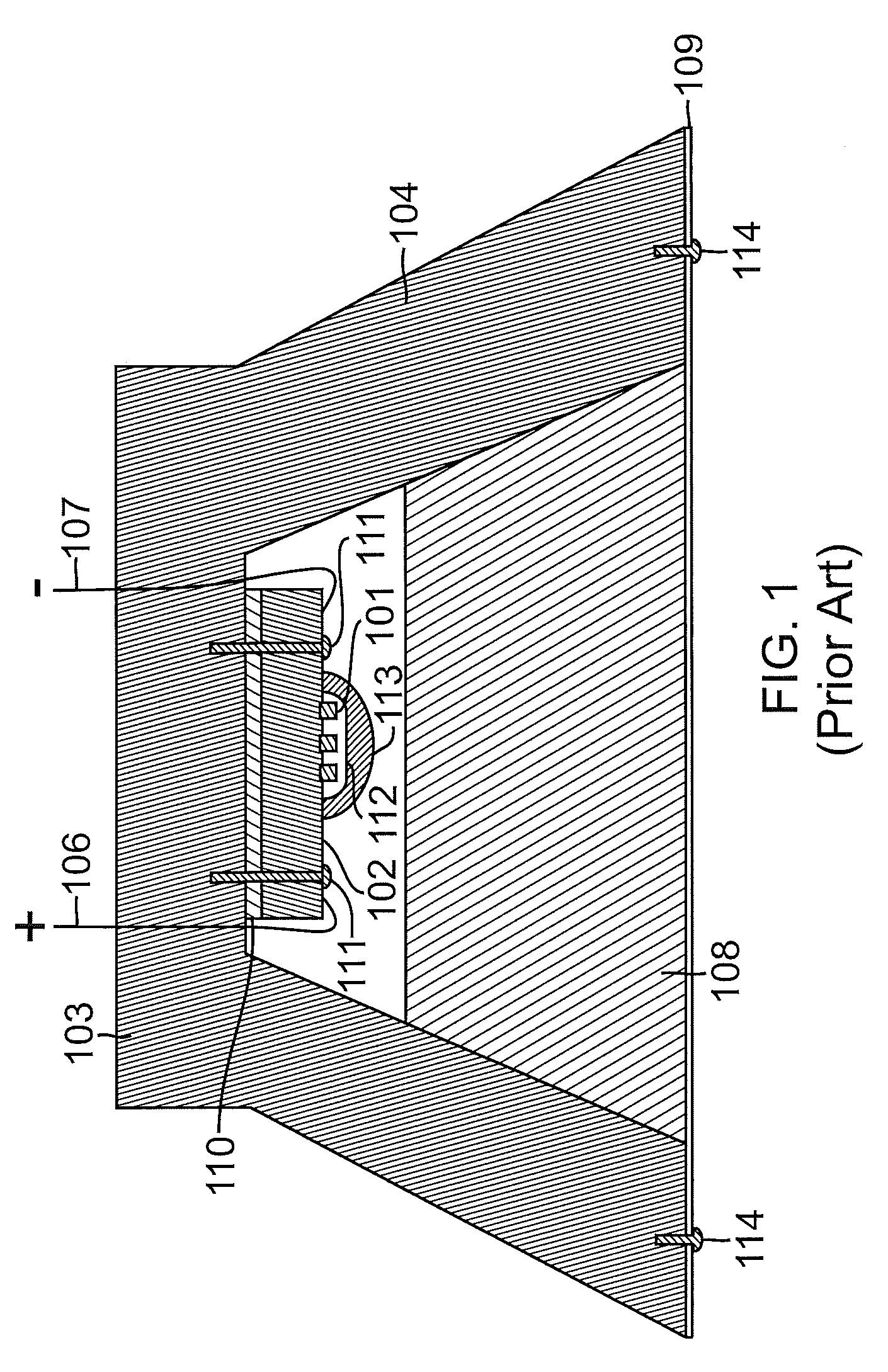

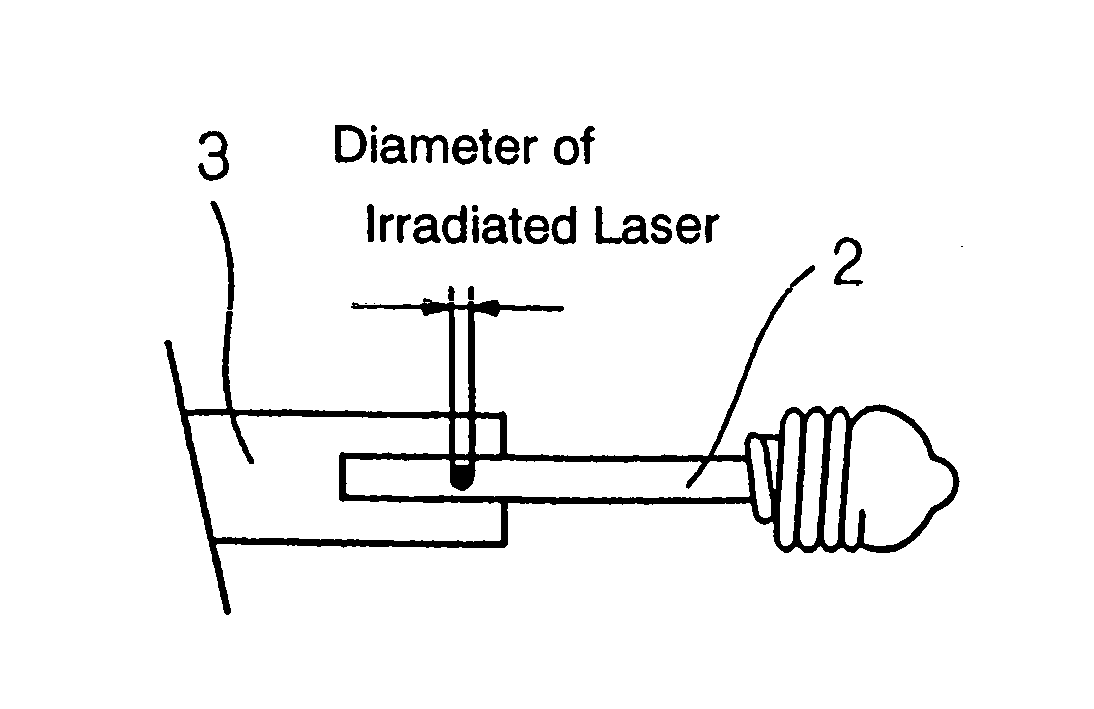

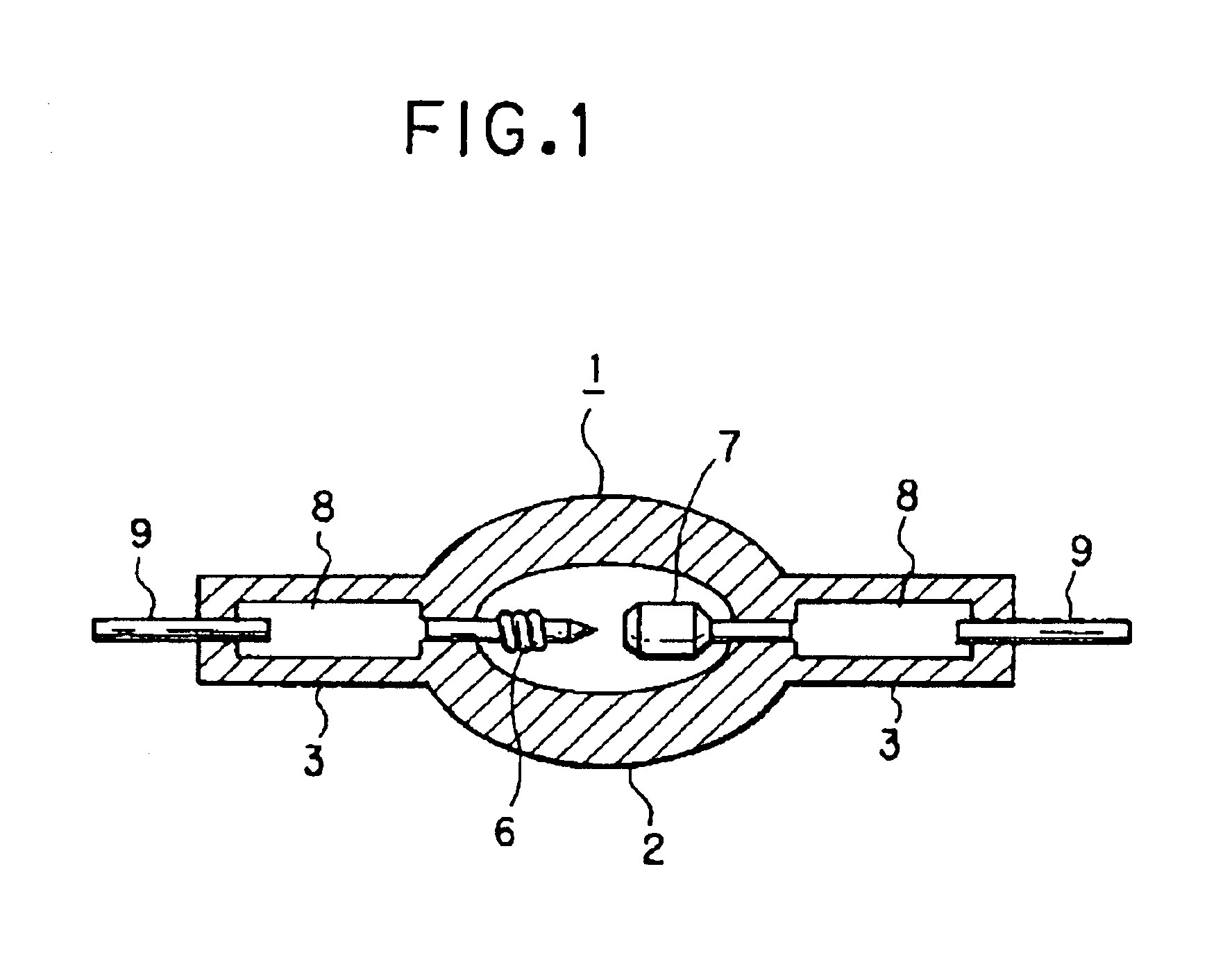

Ultrahigh pressure discharge lamp of the short arc type with improved metal foil to electrode connection arrangement

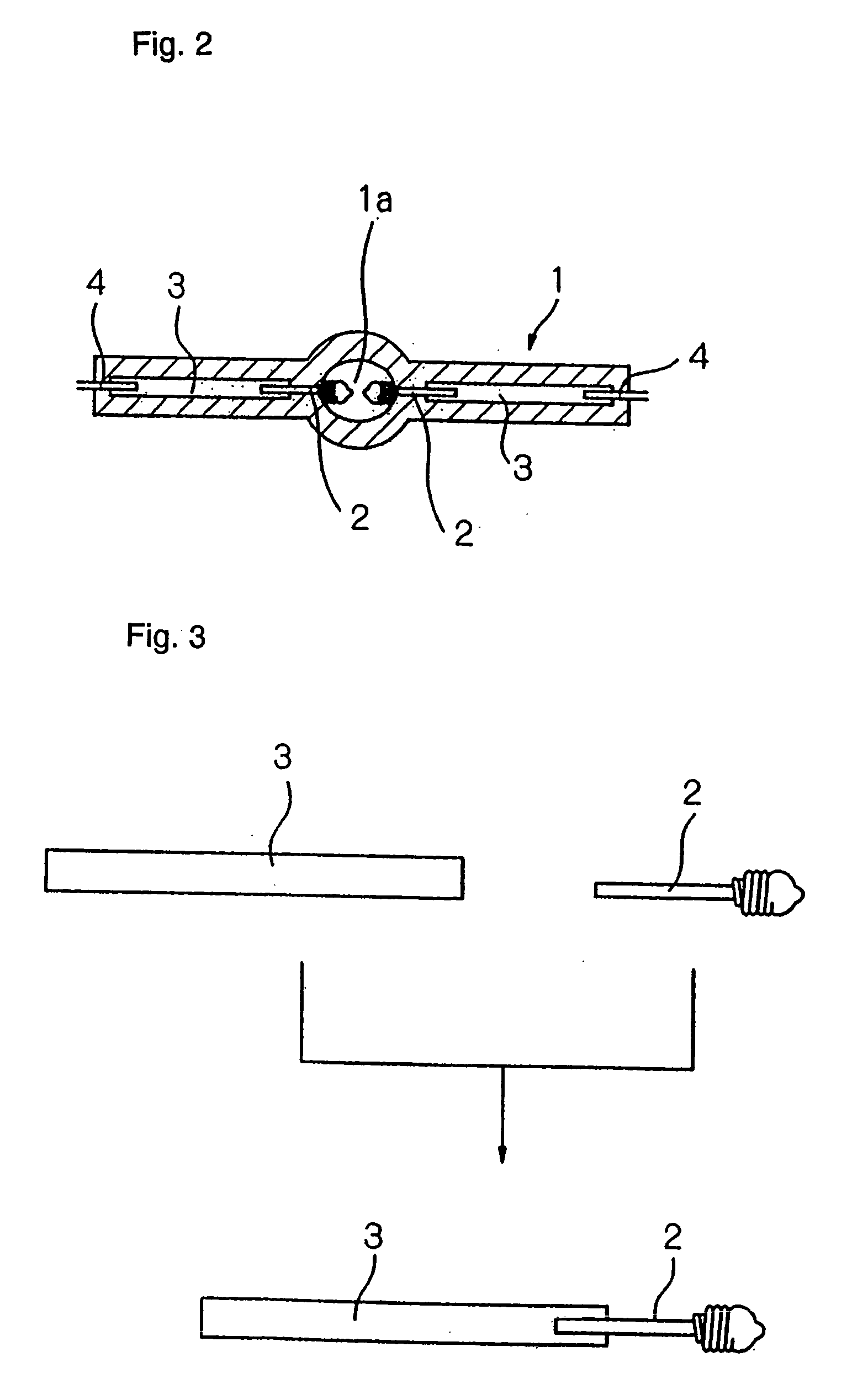

ActiveUS6903509B2Suppress formationSuppress growthElectrode assembly manufactureHigh-pressure discharge lampsMetal foilUltra high voltage

An arrangement with a relatively high pressure tightness in a super-high pressure mercury lamp which is operated with an extremely high mercury vapor pressure is achieved in accordance with the invention in a super-high pressure discharge lamp of the short arc type having a light emitting part in which a pair of electrodes are disposed opposite each other and which is filled with at least 0.15 mg / mm3 mercury; and side tube parts which extend from each side of the light emitting part and in each of which a respective one of the electrodes is partially hermetically sealed and is connected to a metal foil, by the area of the respective metal foil which is connected to the respective electrode has a smaller width than the width in the remaining area of the metal foil, the area with the smaller width wrapping at least partially around the outside surface of the electrode.

Owner:USHIO DENKI KK

Image display medium ribs, production process thereof, and image display medium using the ribs

ActiveUS7157842B2Narrow rib widthImprove picture qualityGas discharge electrodesSolid-state devicesEpoxyComputer graphics (images)

Ribs for an image display medium, which ribs can be retained between a pair of substrates. These image display medium ribs are formed by liquid injection molding (LIM molding), utilizing a heat-curable epoxy resin. In addition, the image display medium ribs are formed so as to have a cell-form arrangement.

Owner:E INK CORPORATION

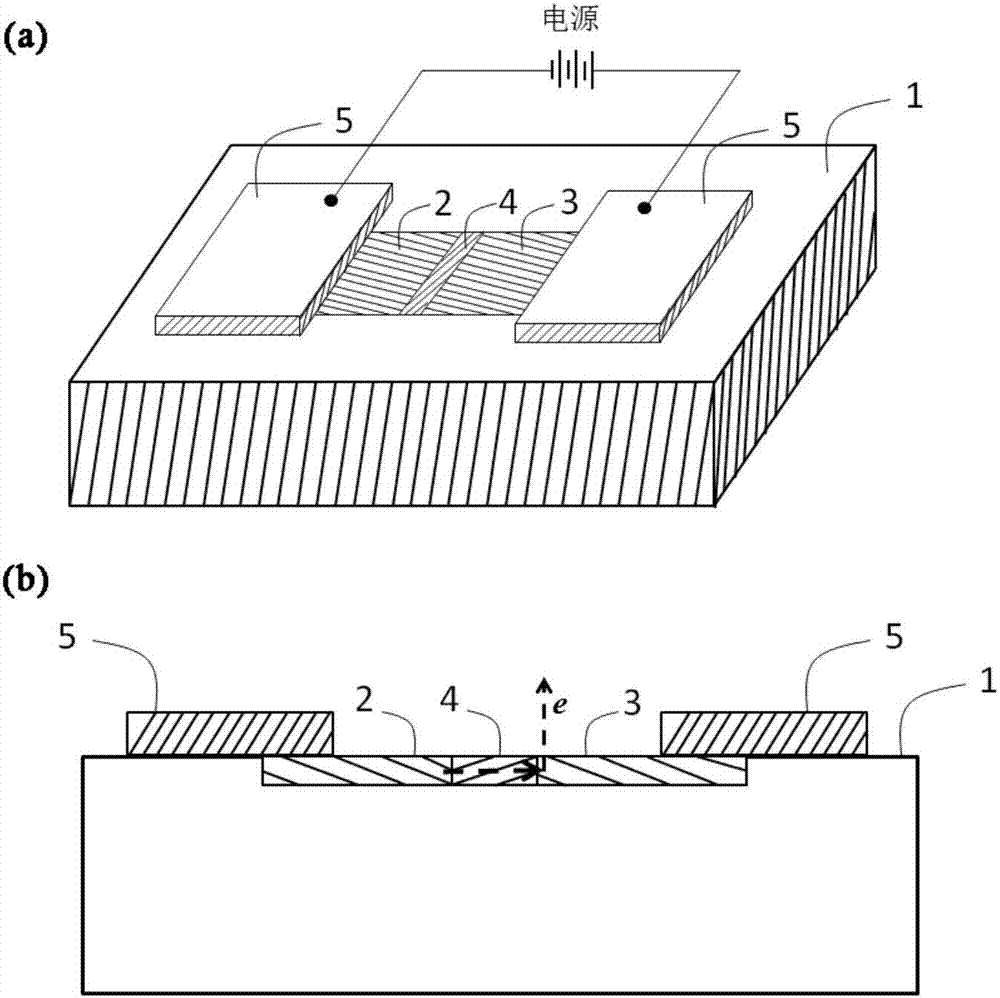

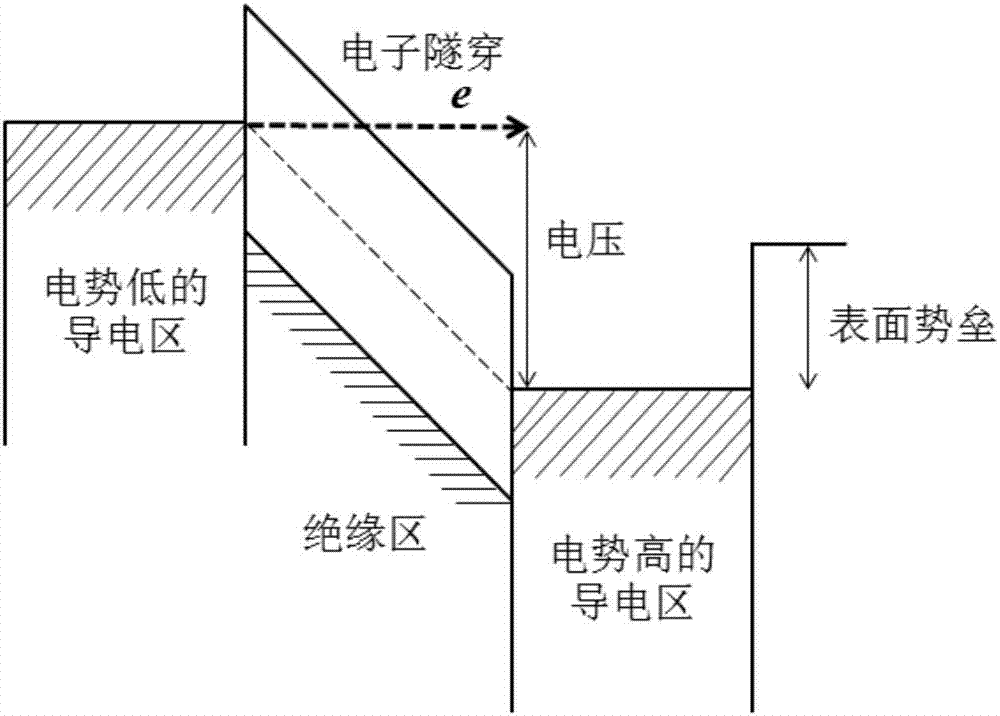

Surface tunneling miniature electron source, array thereof and implementation method of array

ActiveCN107248489ASimple structureImprove electron emission efficiencyCathode ray tubes/electron beam tubesTransit-tube cathodesElectron sourceMicrowave tube

Owner:PEKING UNIV

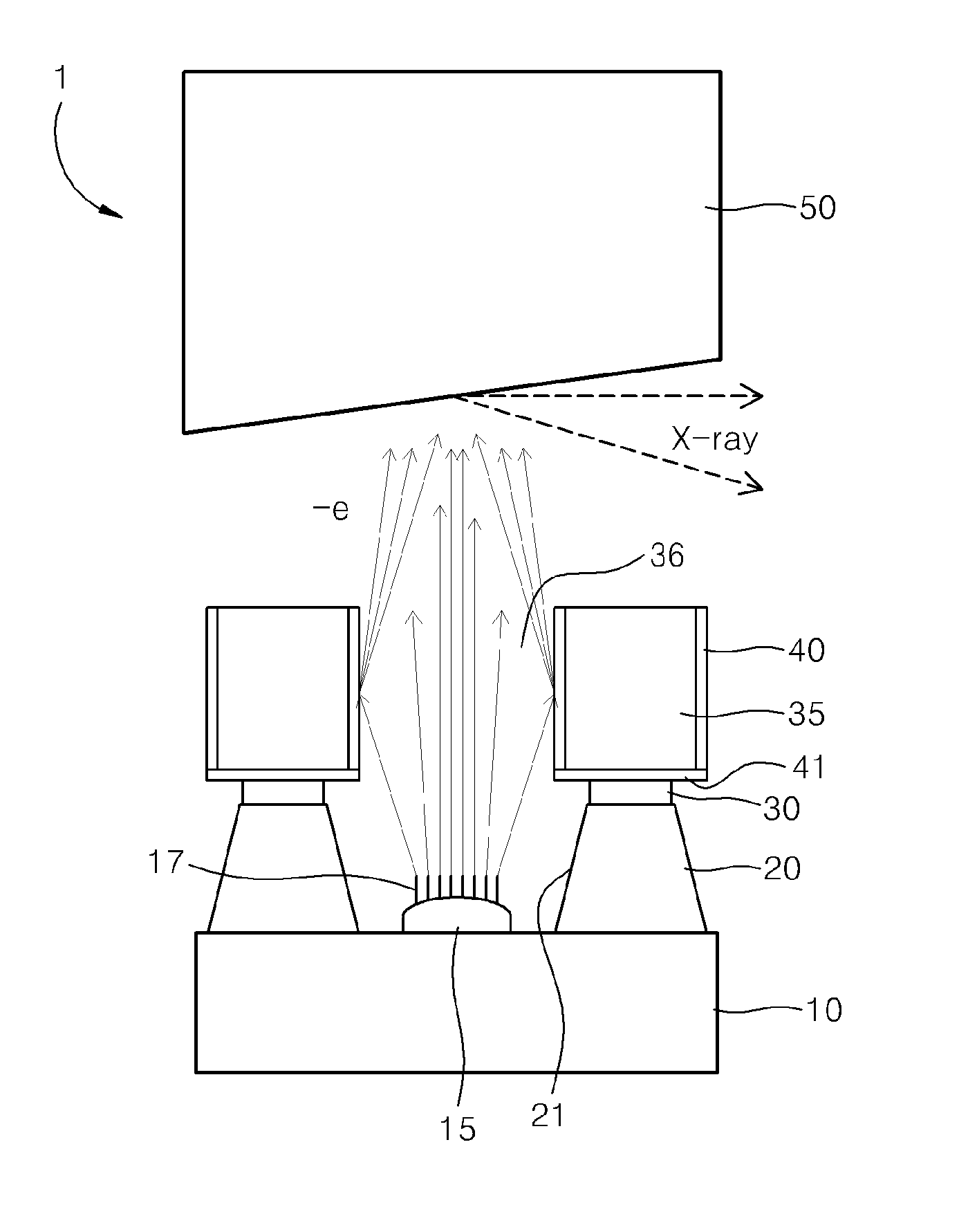

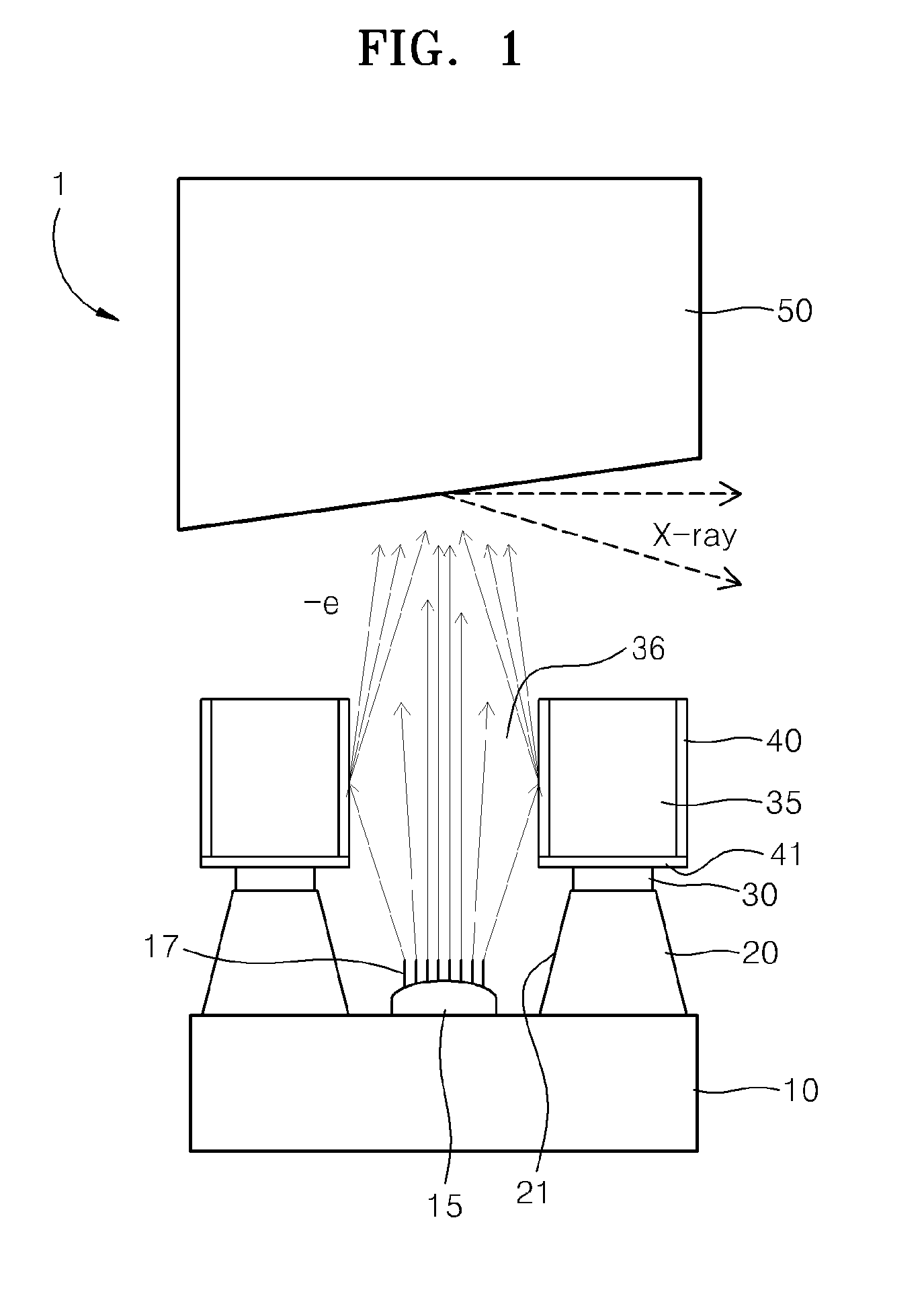

X-ray source device

InactiveUS20130235976A1Reduce widthWidthX-ray tube electrodesDischarge tube/lamp detailsX-raySecondary electrons

An X-ray source device includes a substrate, a cathode electrode on the substrate, an emitter on the cathode electrode, an insulation body around the cathode electrode, a gate electrode on the insulation body, a first secondary electron emission layer at a side wall of the gate electrode and emitting secondary electrons upon collision with an electron beam emitted by the emitter, and an anode electrode separated from the gate electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com