Surface heat light source, preparation method thereof and method for heating object using the same

一种热光源、物体的技术,应用在光源、电光源、欧姆电阻加热等方向,能够解决面热光源热辐射及光辐射不均匀、热辐射传递距离近、热辐射效率低等问题,达到良好导电性能以及热稳定性、热辐射传递距离远、热辐射效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

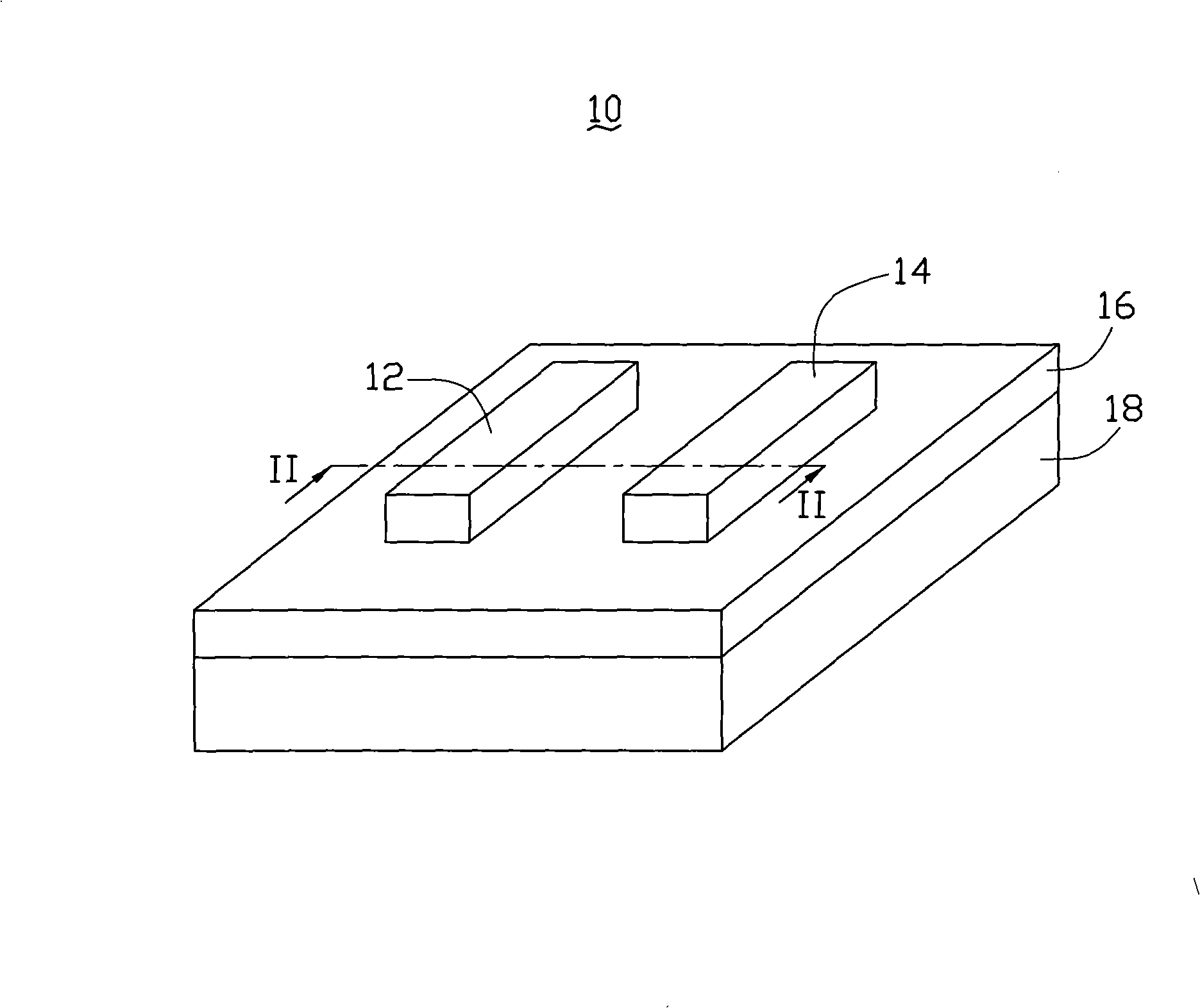

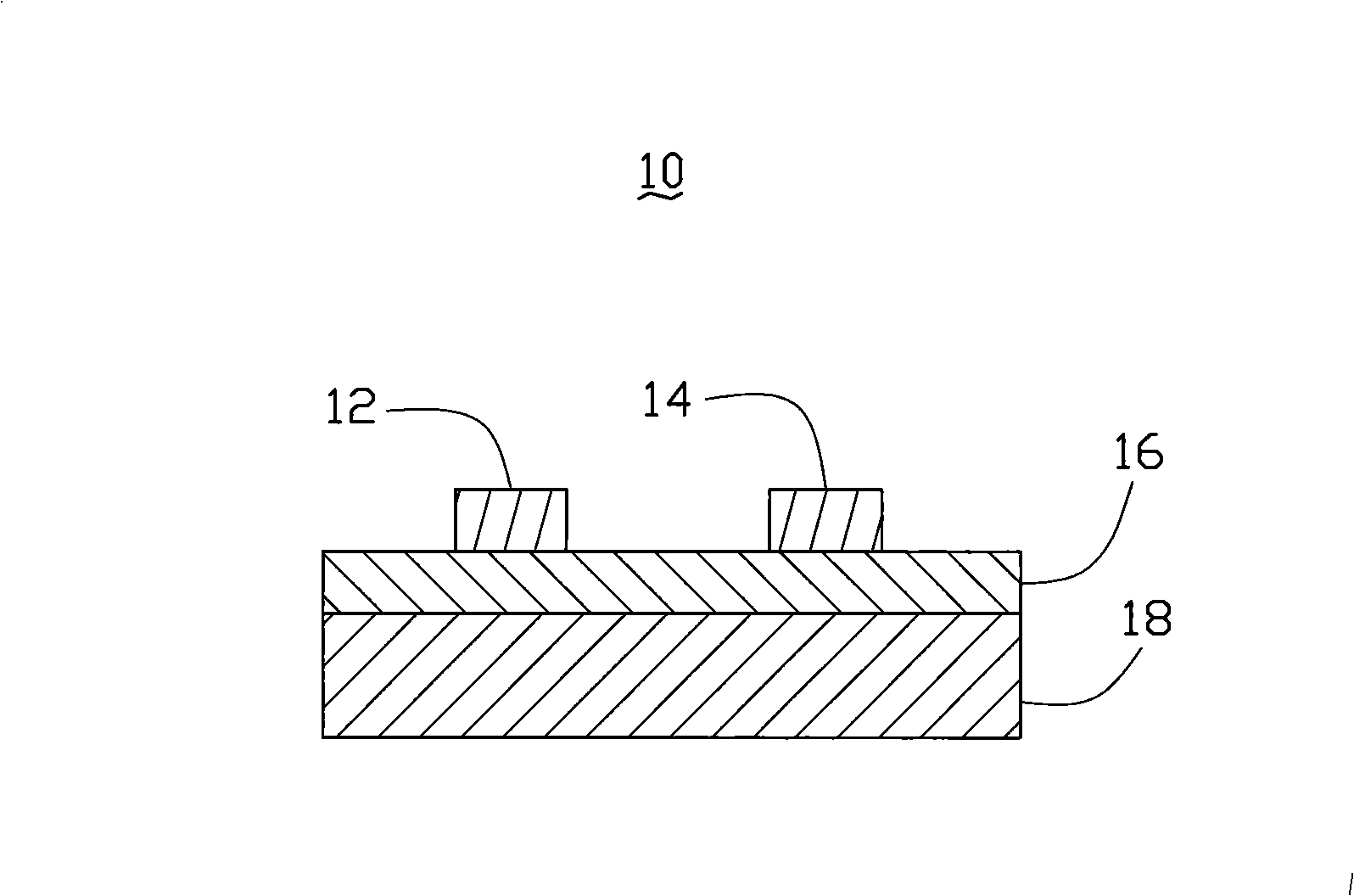

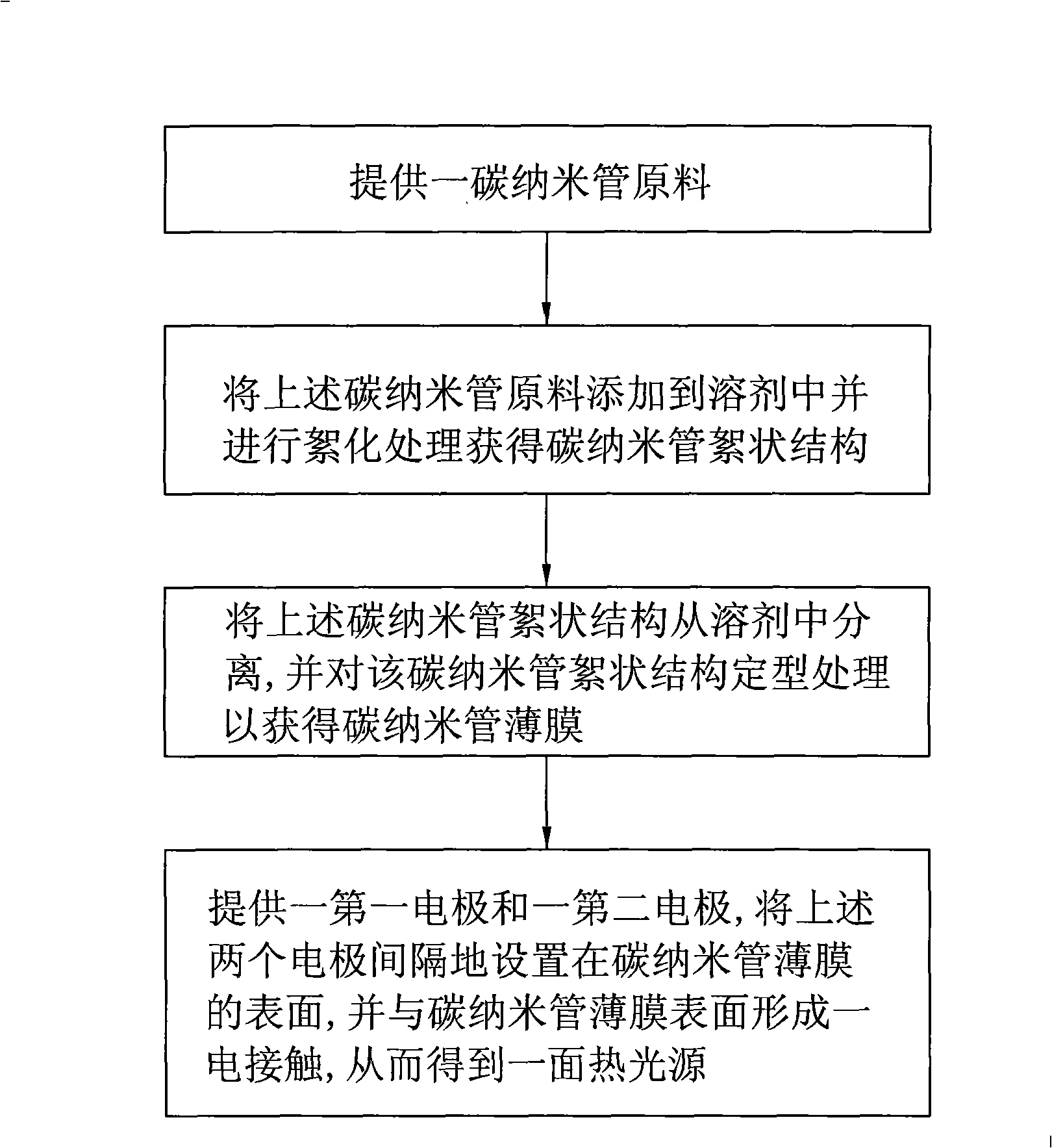

[0019] The surface heat light source of the technical solution, its preparation method and its application method for heating objects will be described in detail below in conjunction with the accompanying drawings.

[0020] see figure 1 and figure 2 The embodiment of the technical solution provides a surface heat light source 10 , the surface heat light source 10 includes a first electrode 12 , a second electrode 14 , a carbon nanotube film 16 and a support 18 . The carbon nanotube film 16 is disposed on the support 18 . The first electrode 12 and the second electrode 14 are disposed on the carbon nanotube film 16 , with a certain distance between the first electrode 12 and the second electrode 14 , and are in electrical contact with the surface of the carbon nanotube film 16 .

[0021] Further, the carbon nanotube film 16 includes intertwined carbon nanotubes, and the carbon nanotubes attract and intertwine with each other through van der Waals force to form a network stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com