Patents

Literature

51results about How to "Manufactured very thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

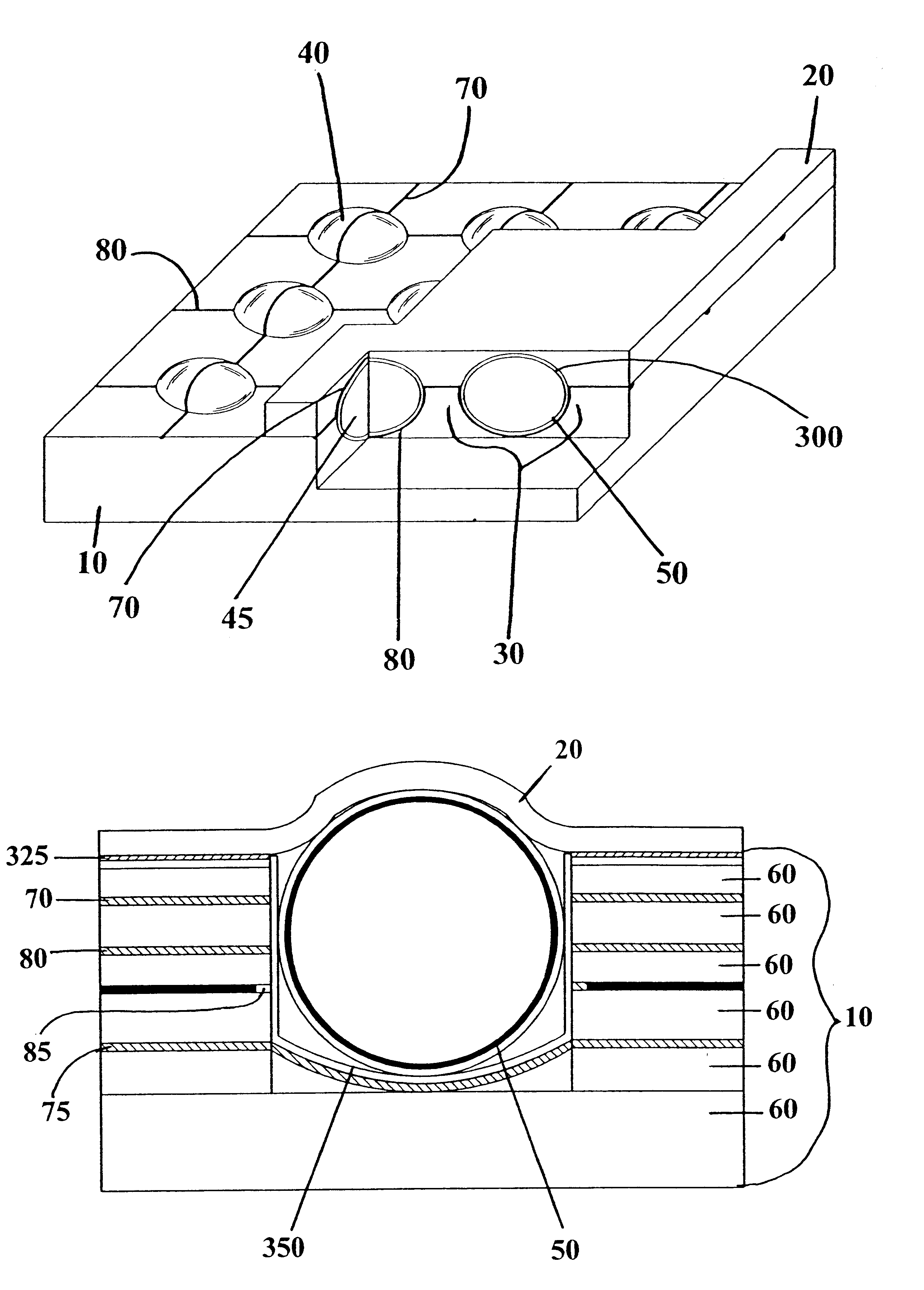

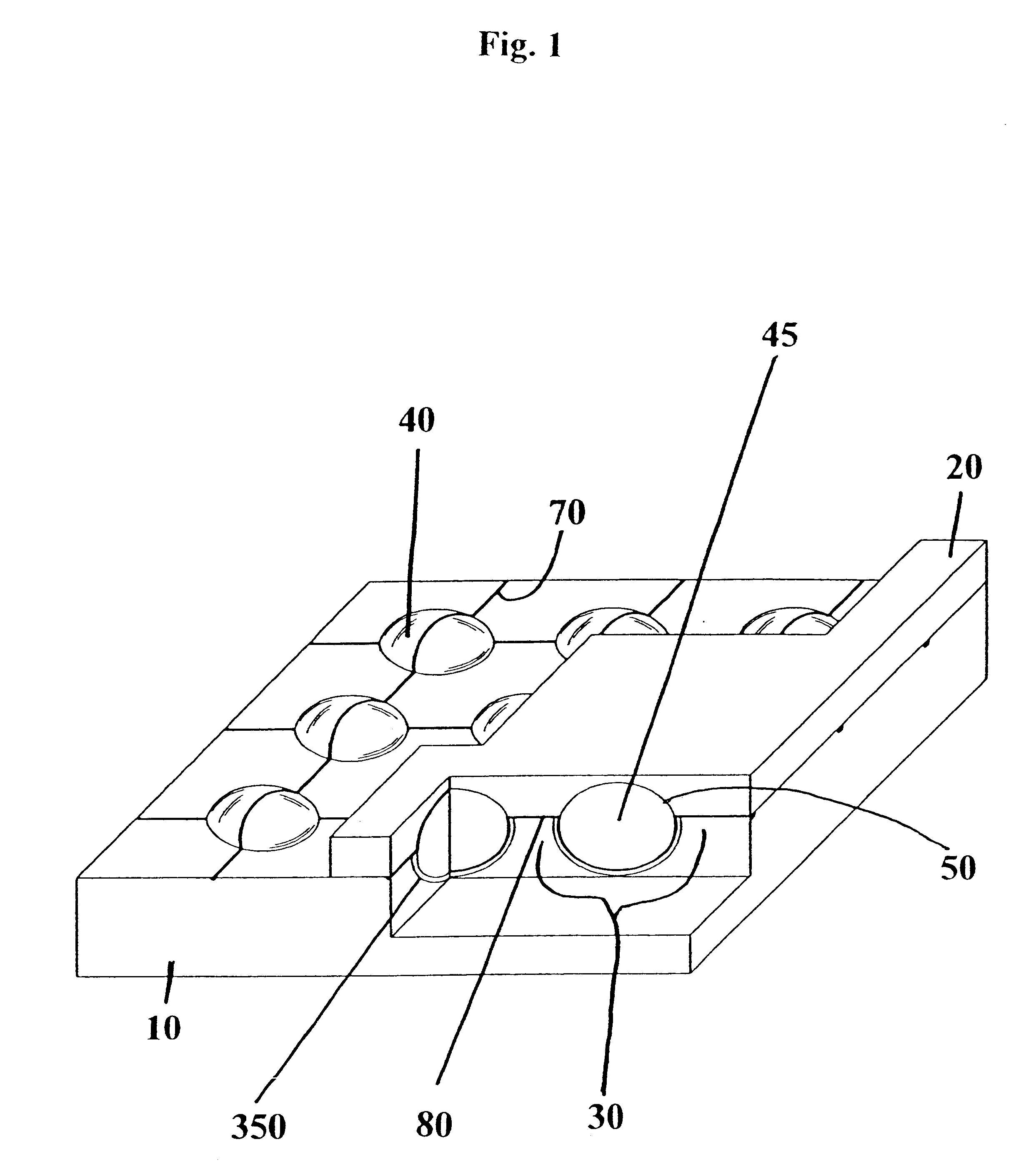

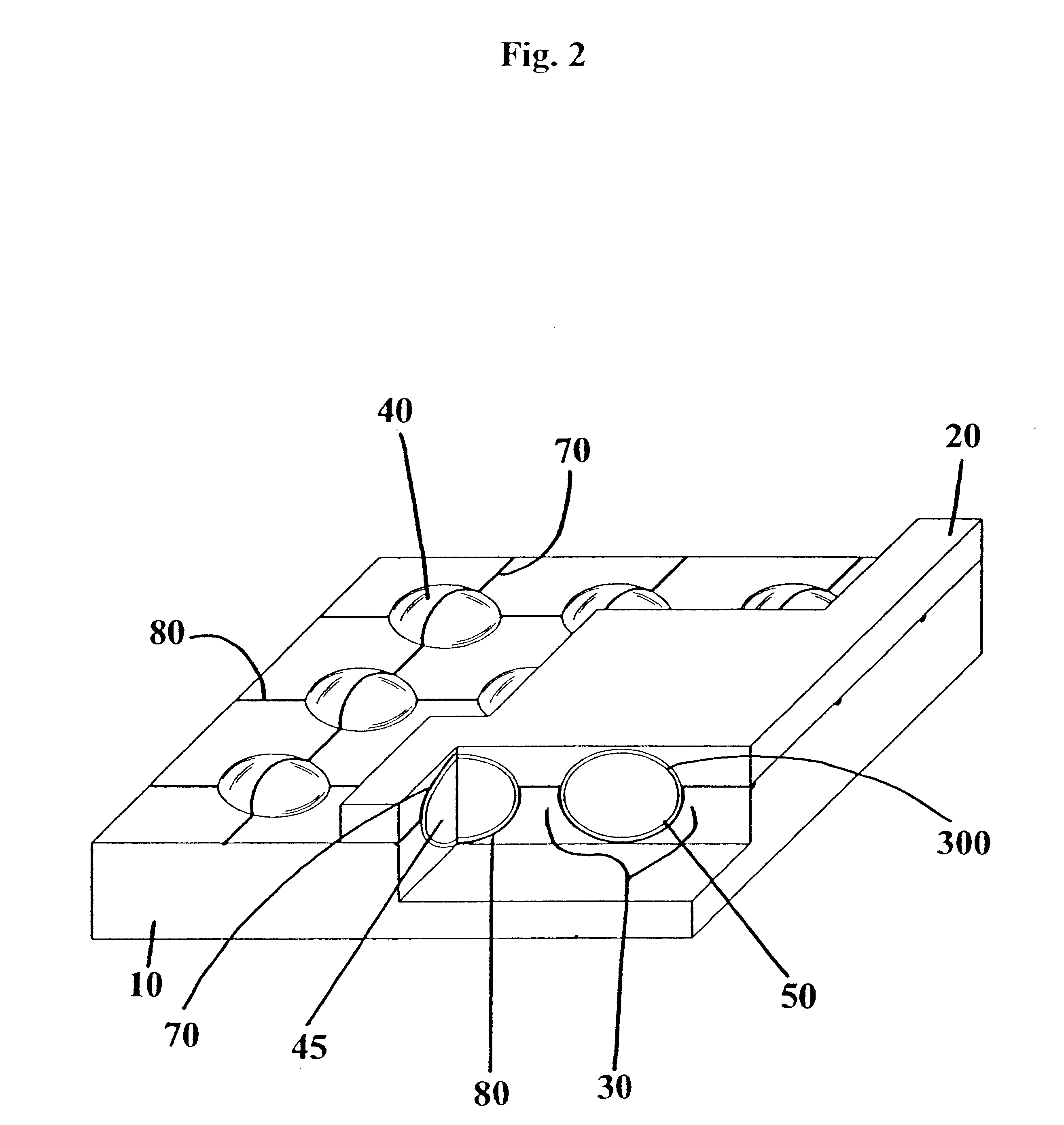

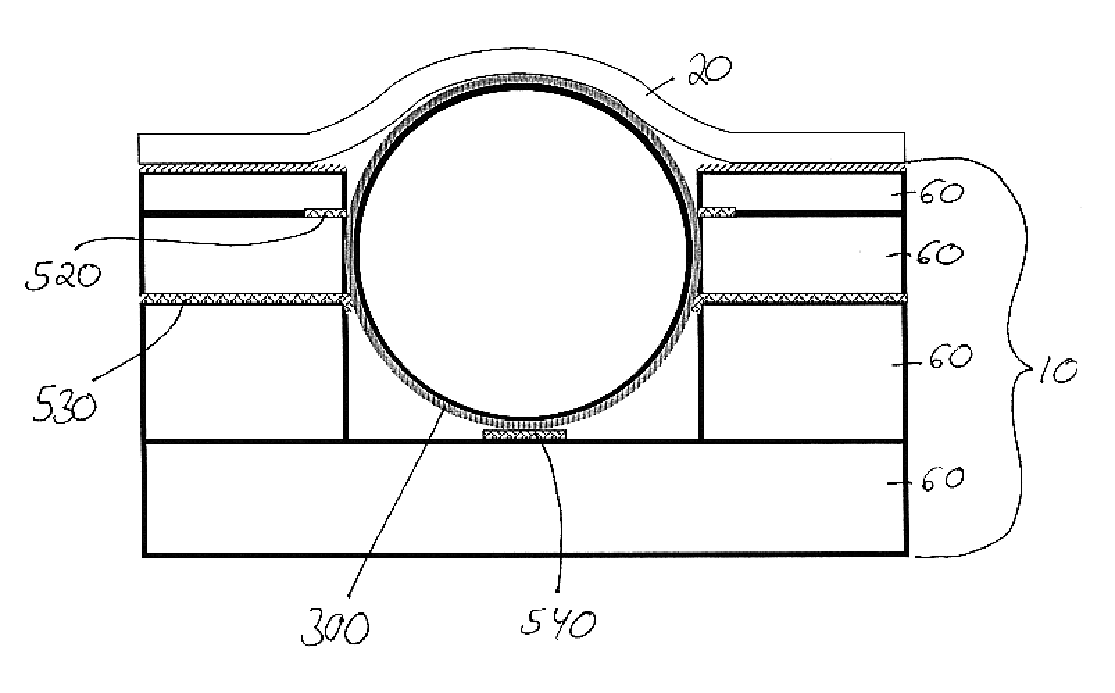

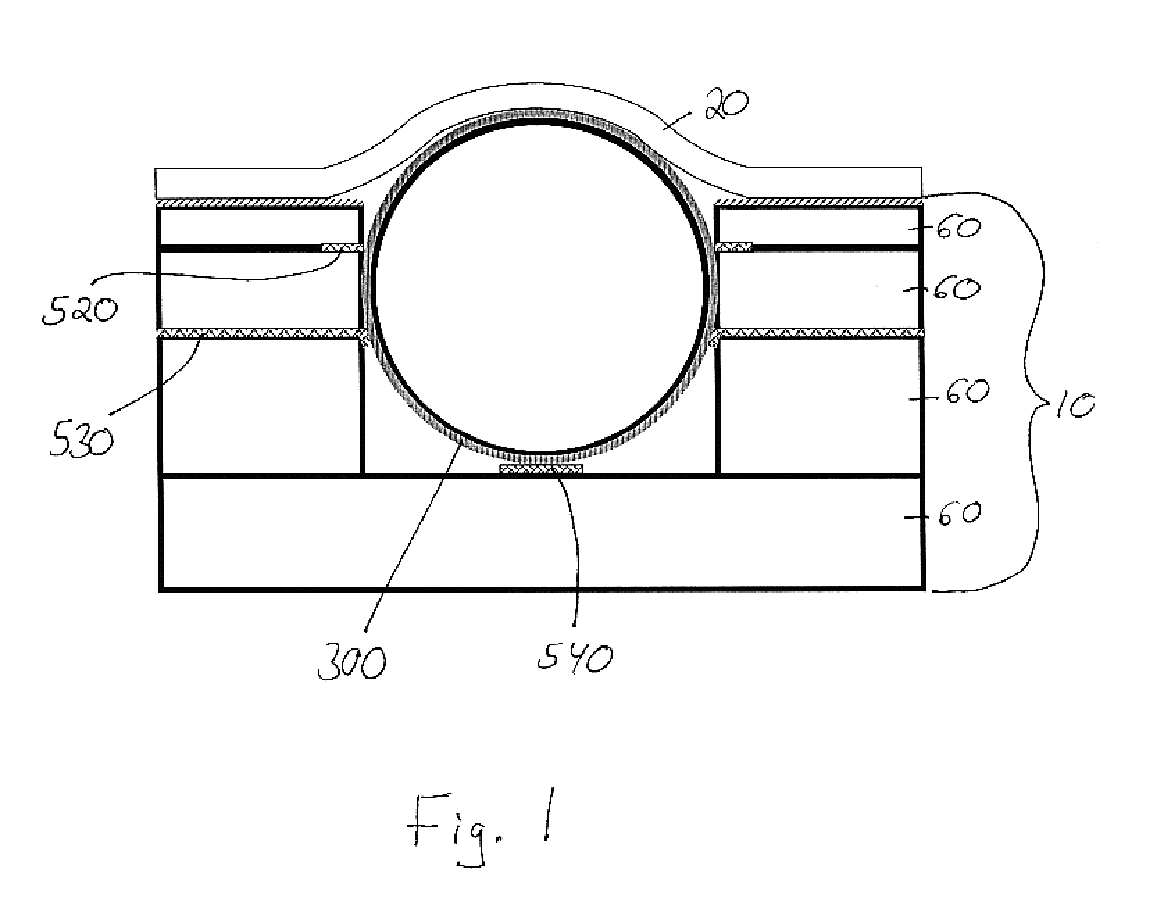

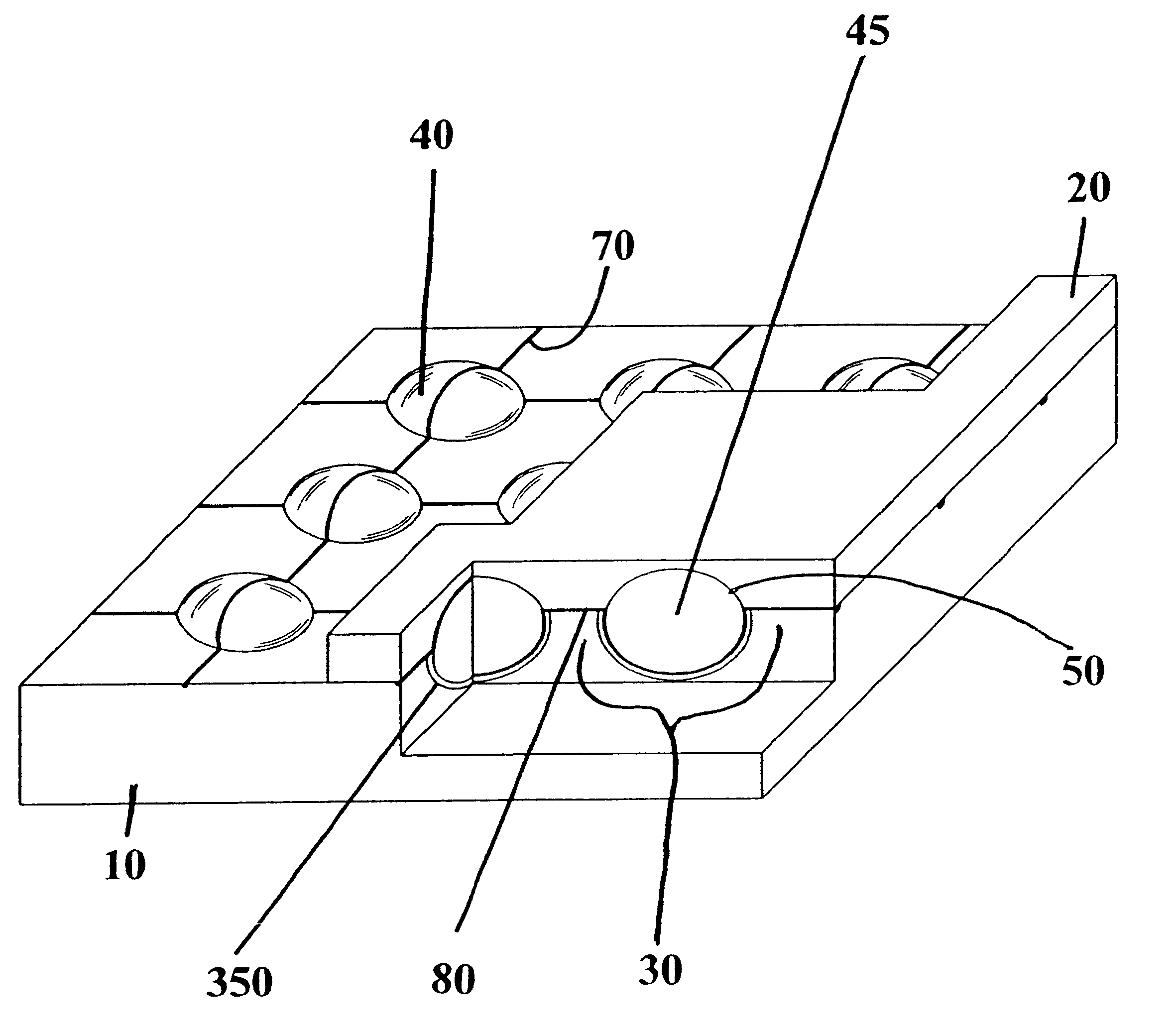

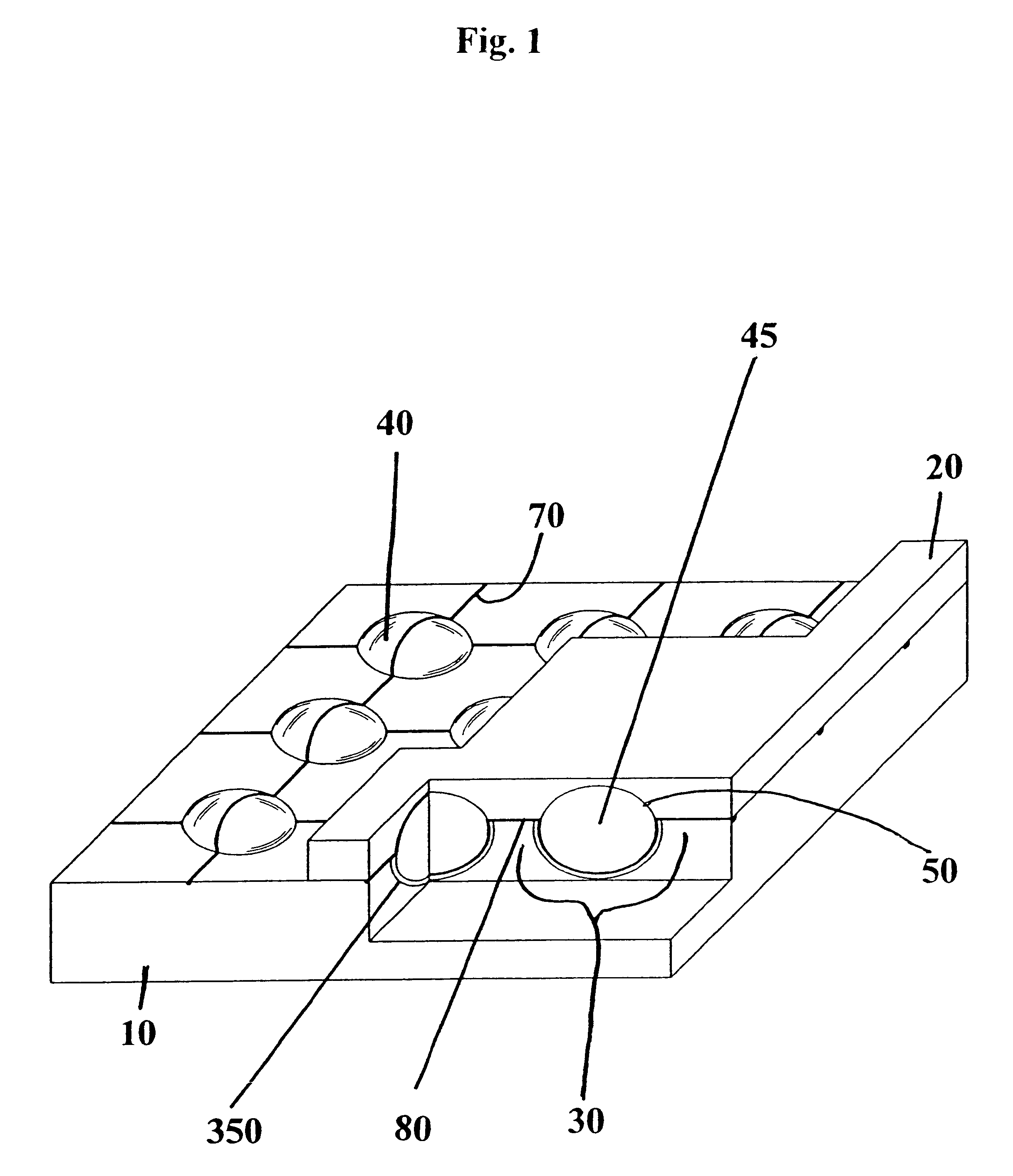

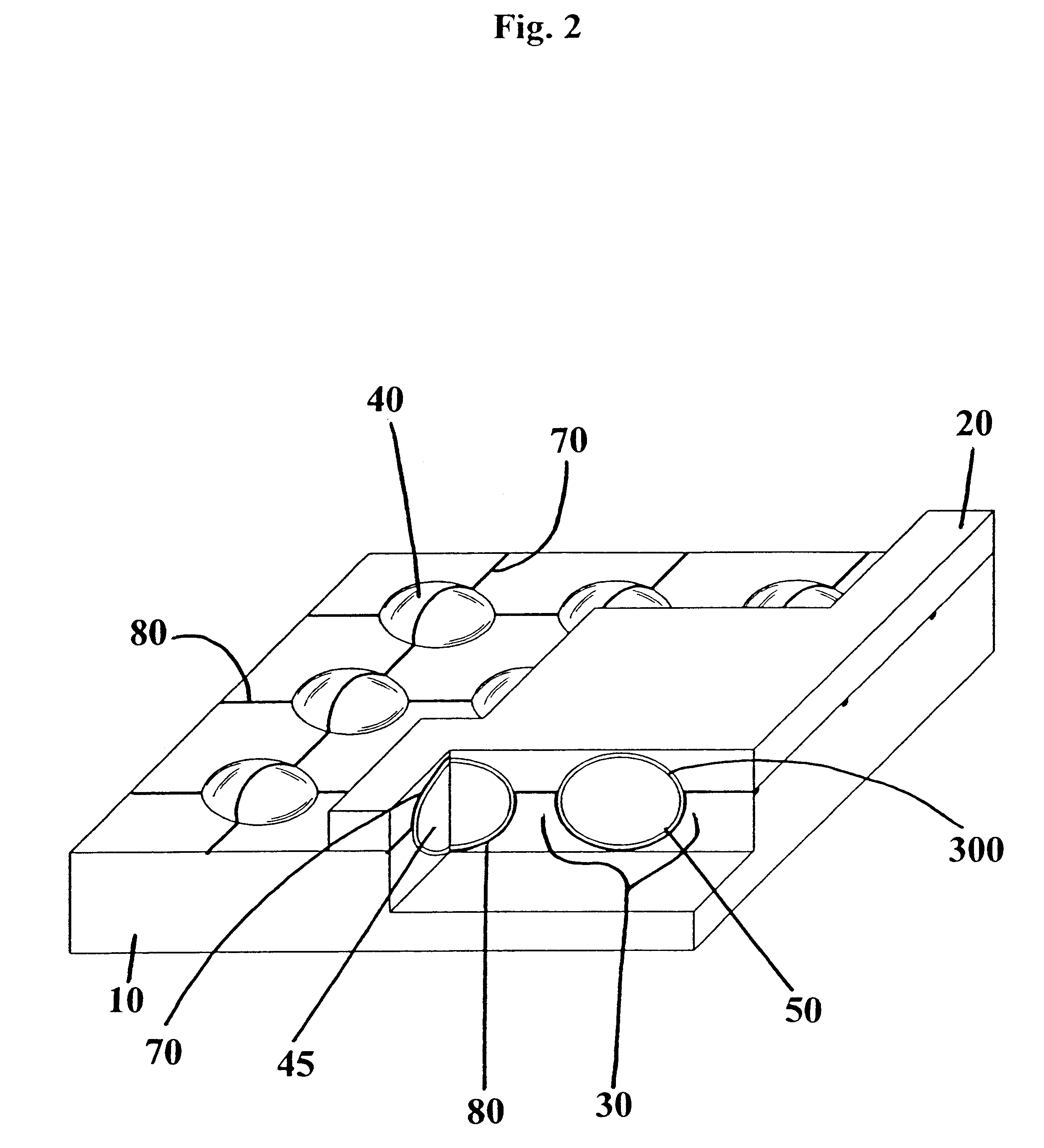

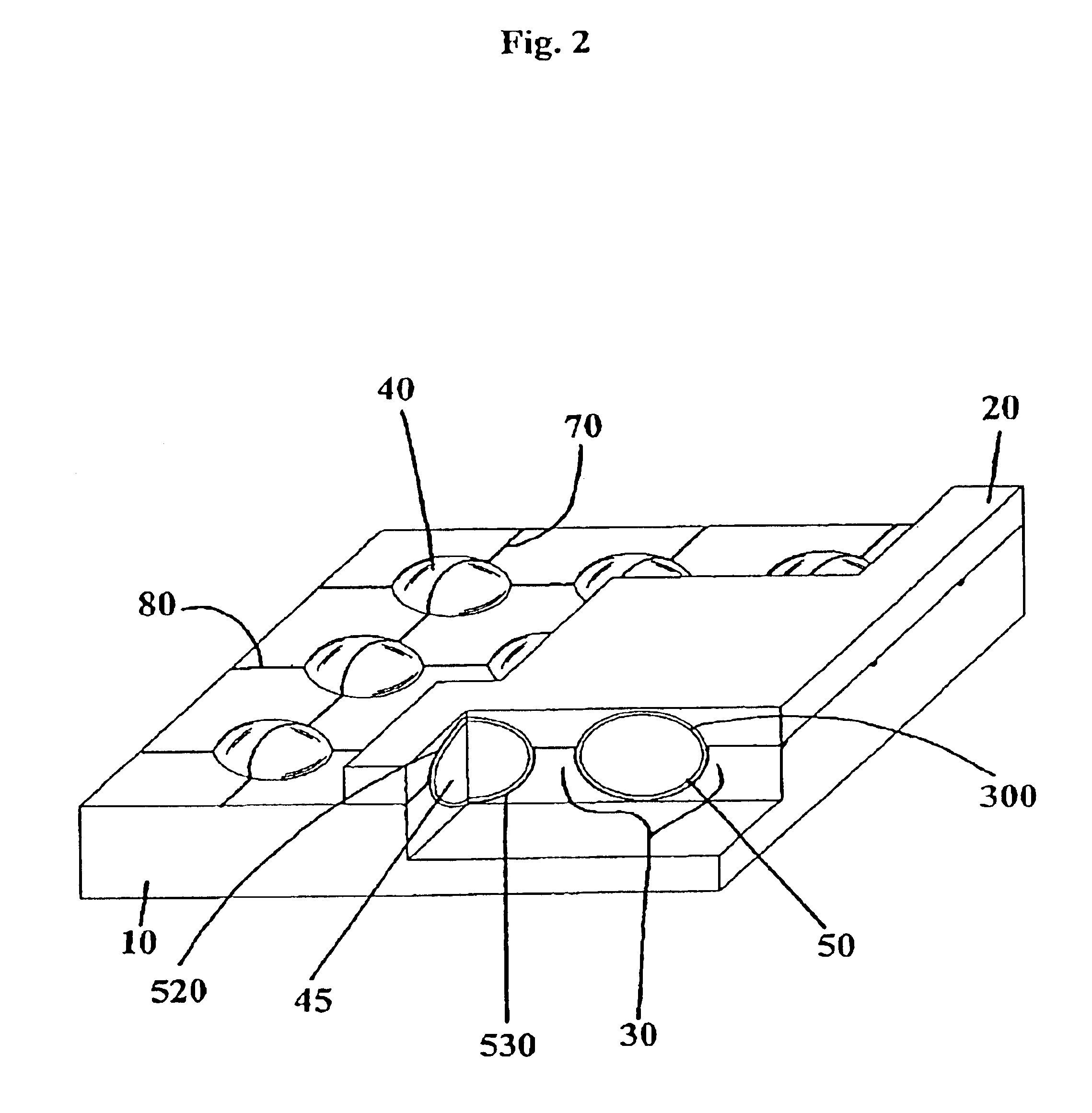

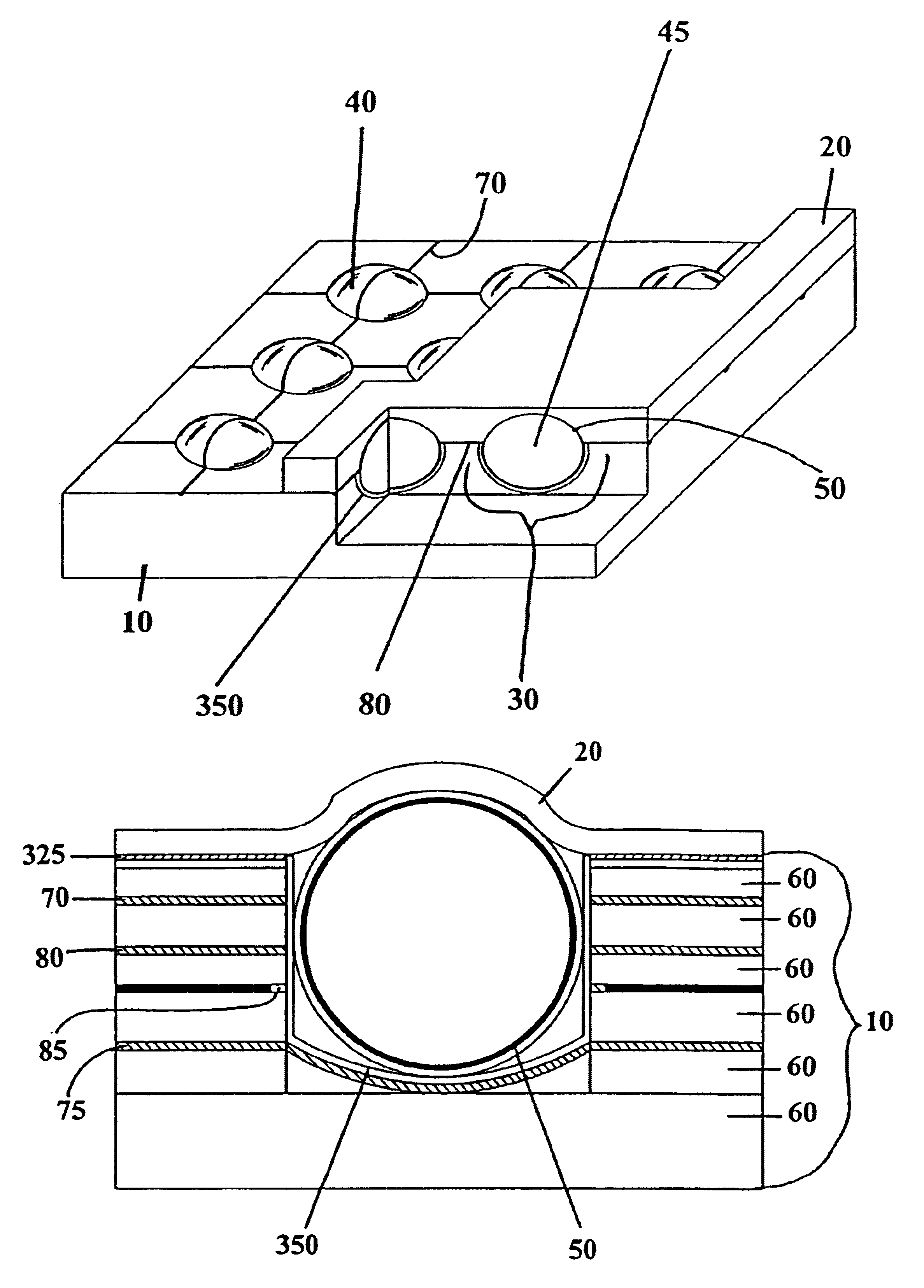

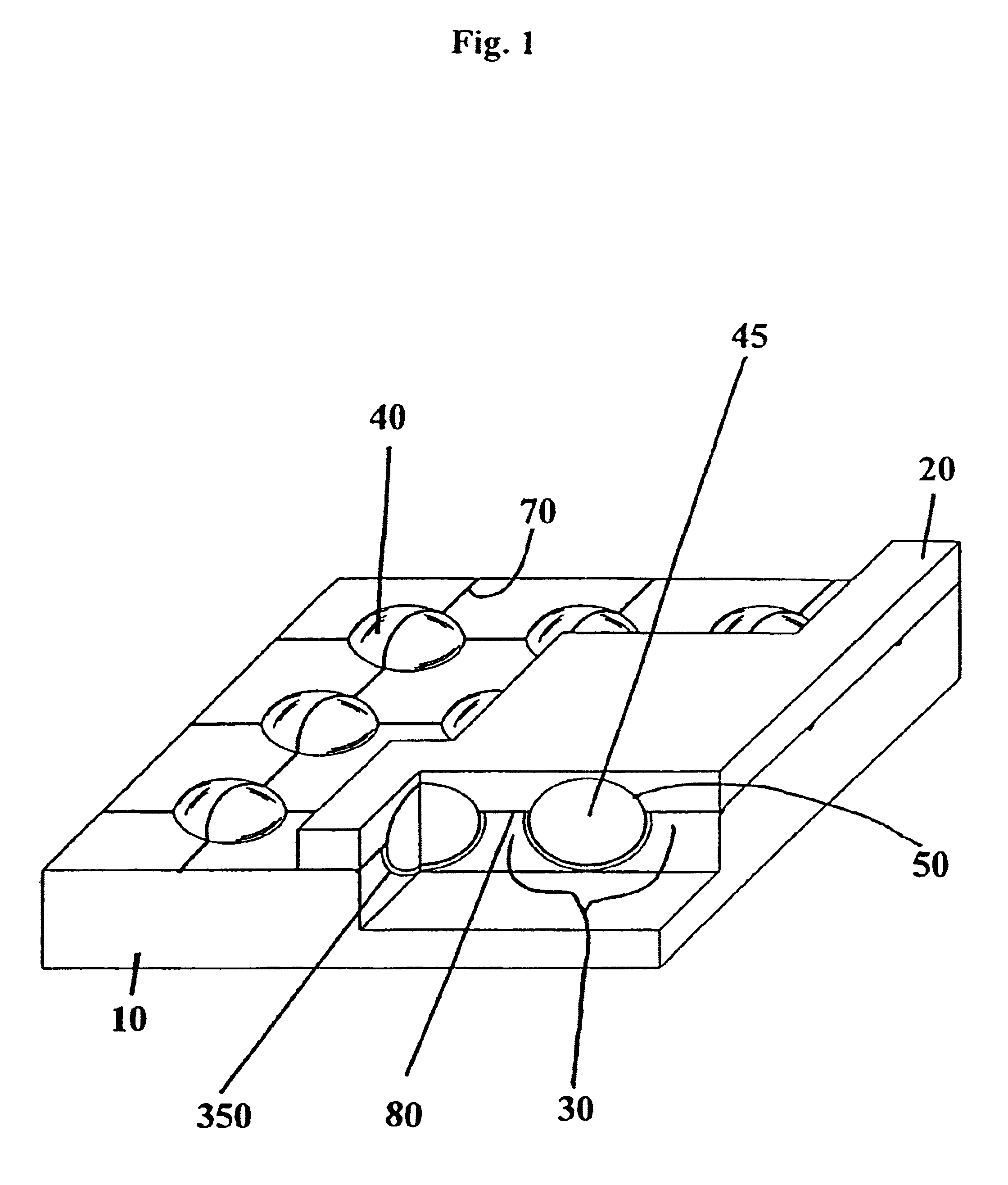

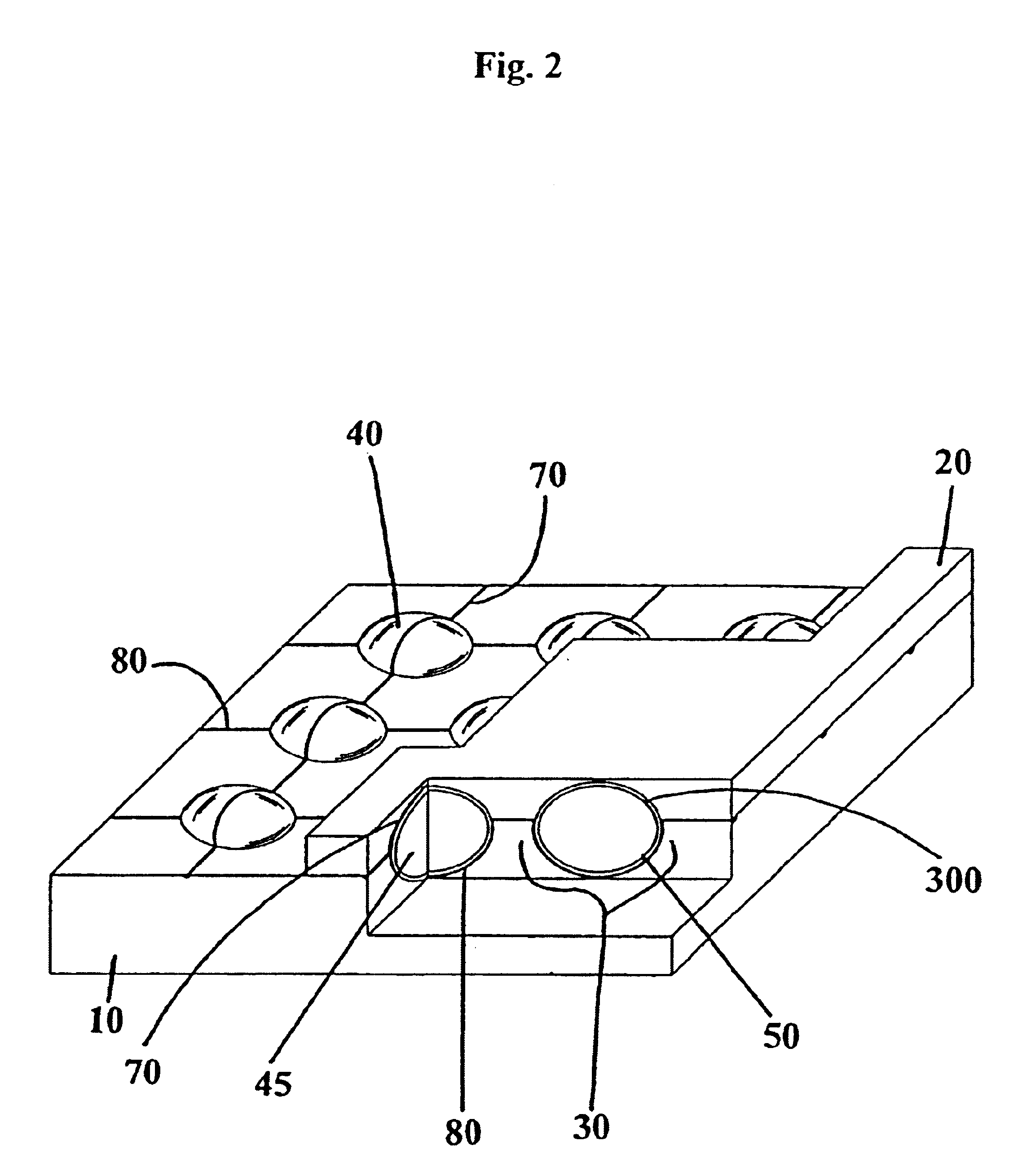

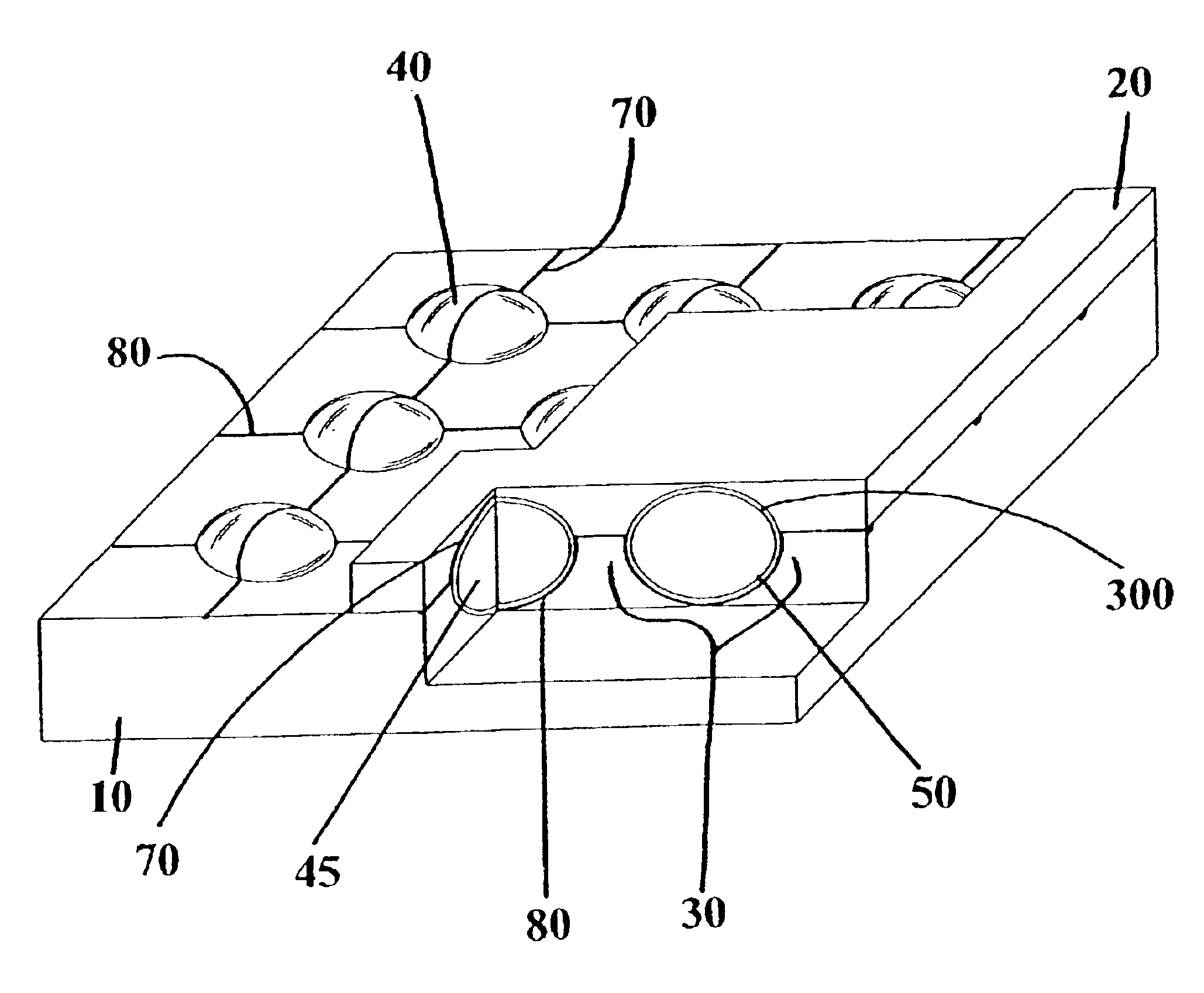

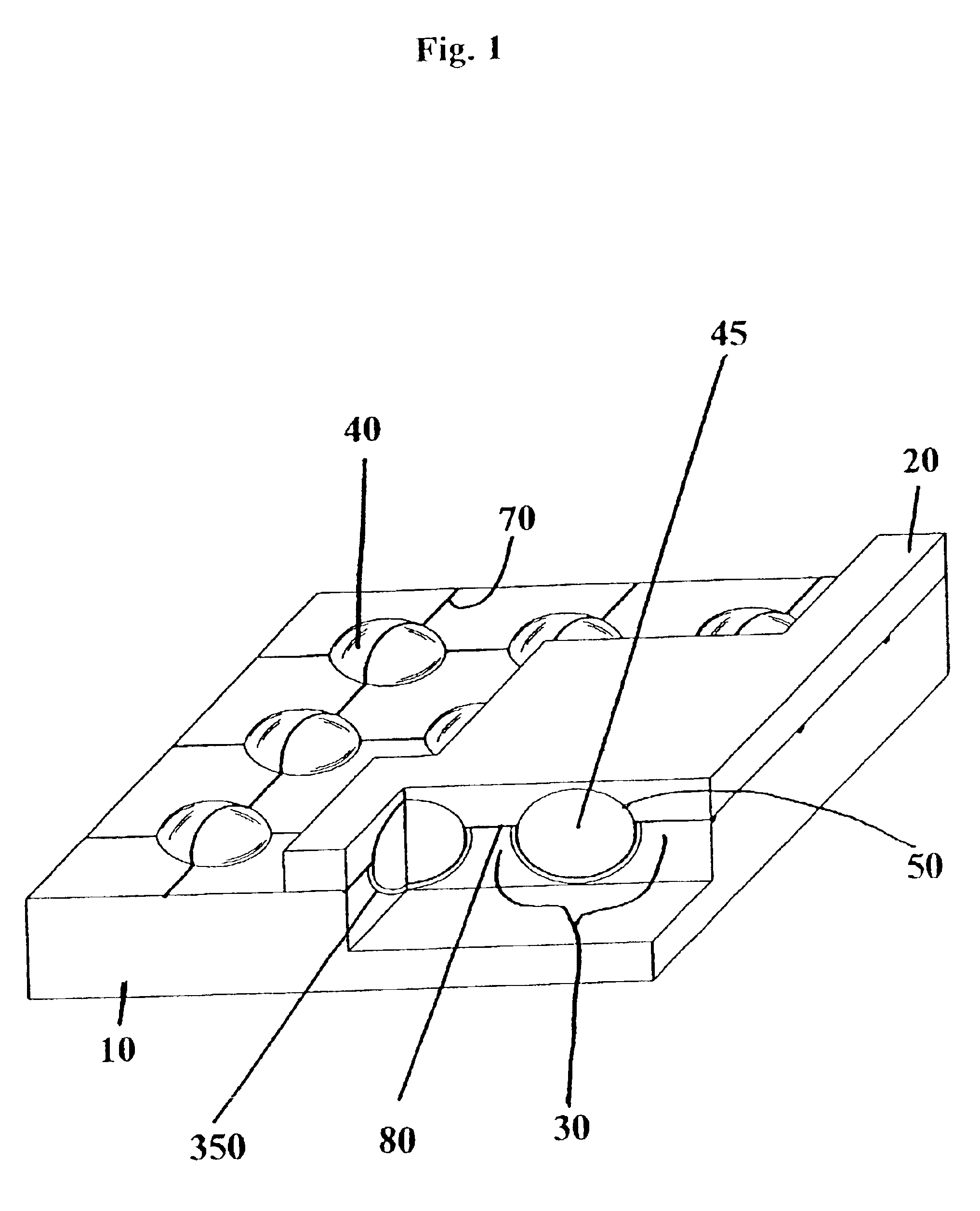

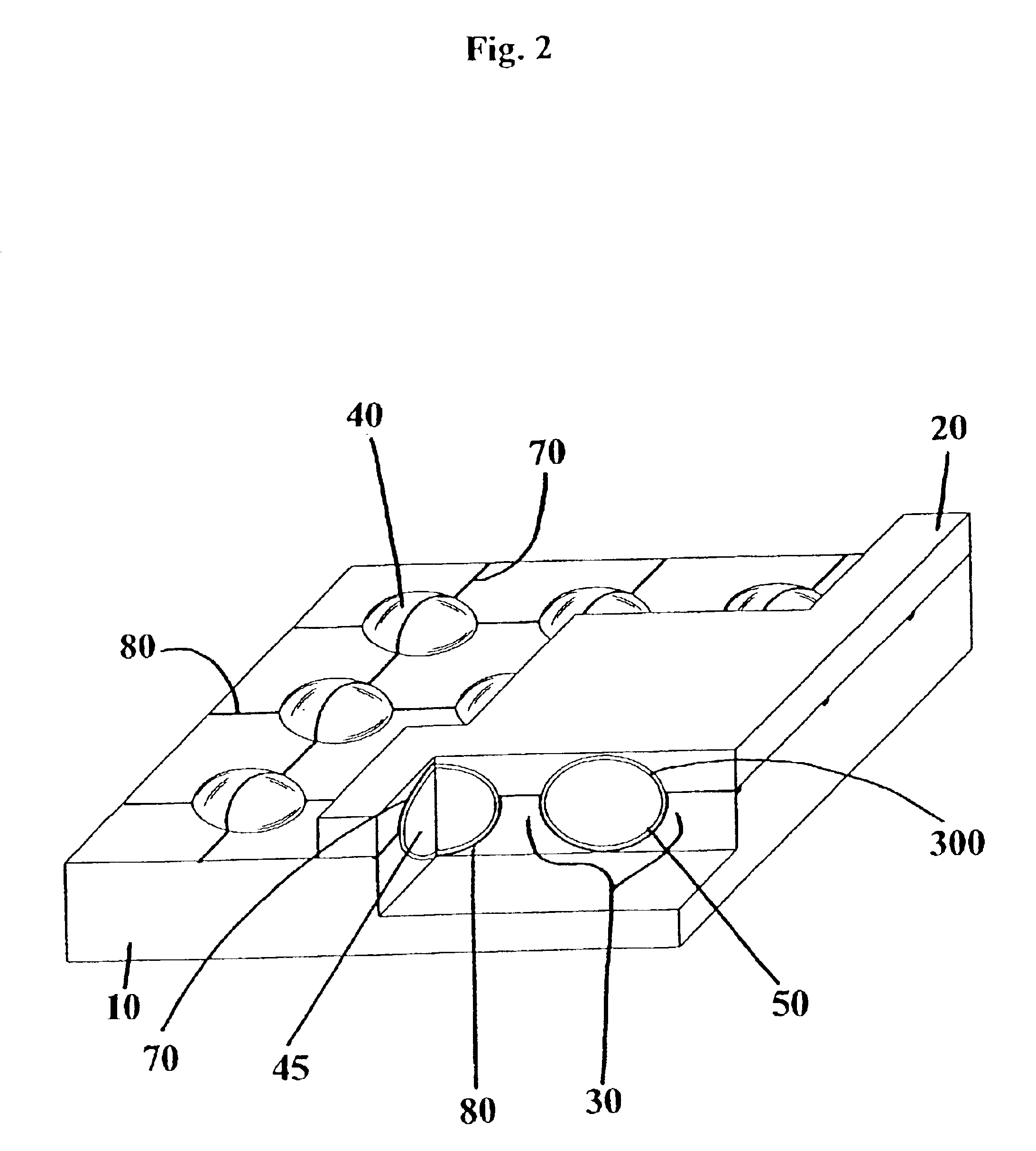

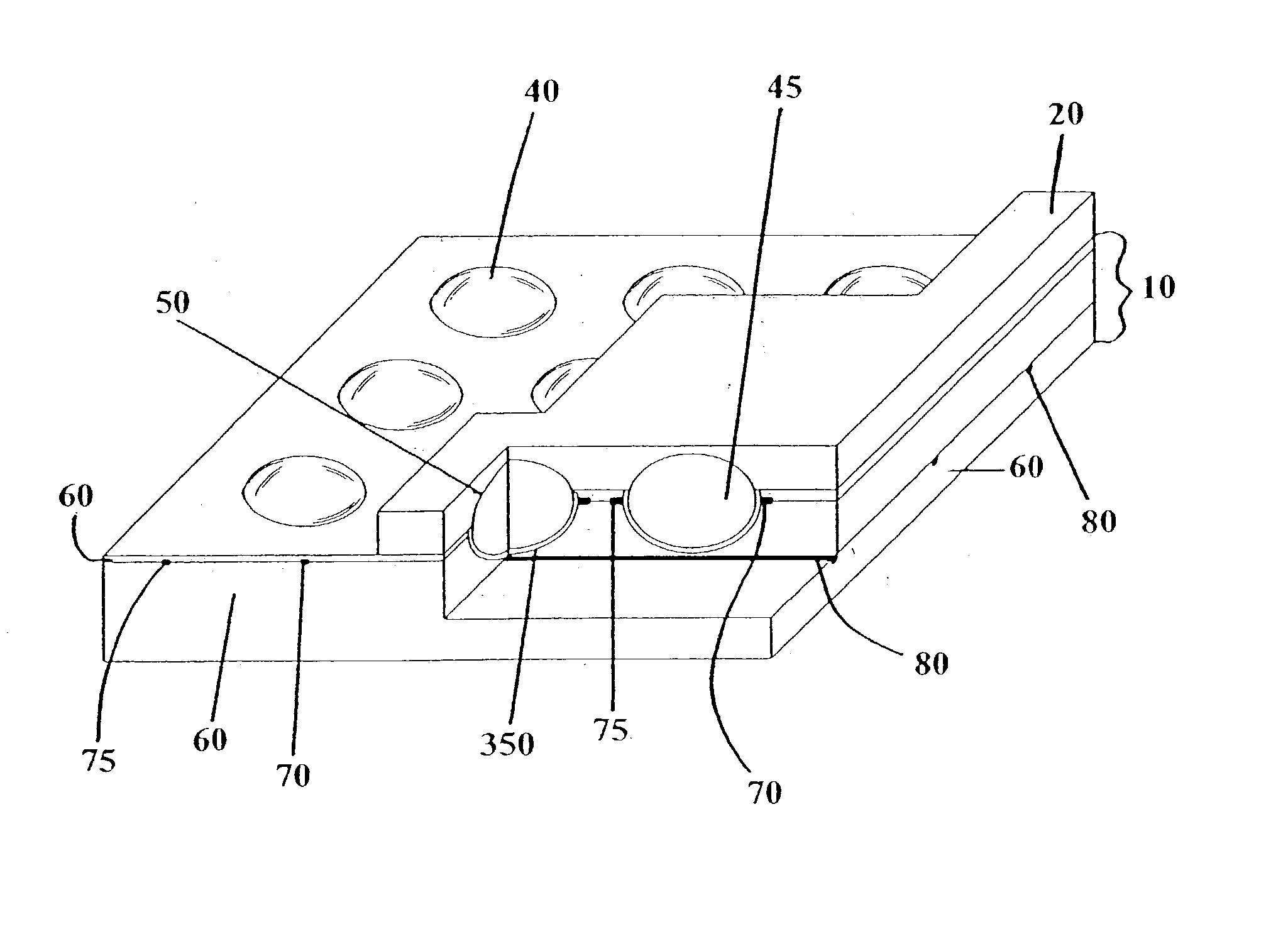

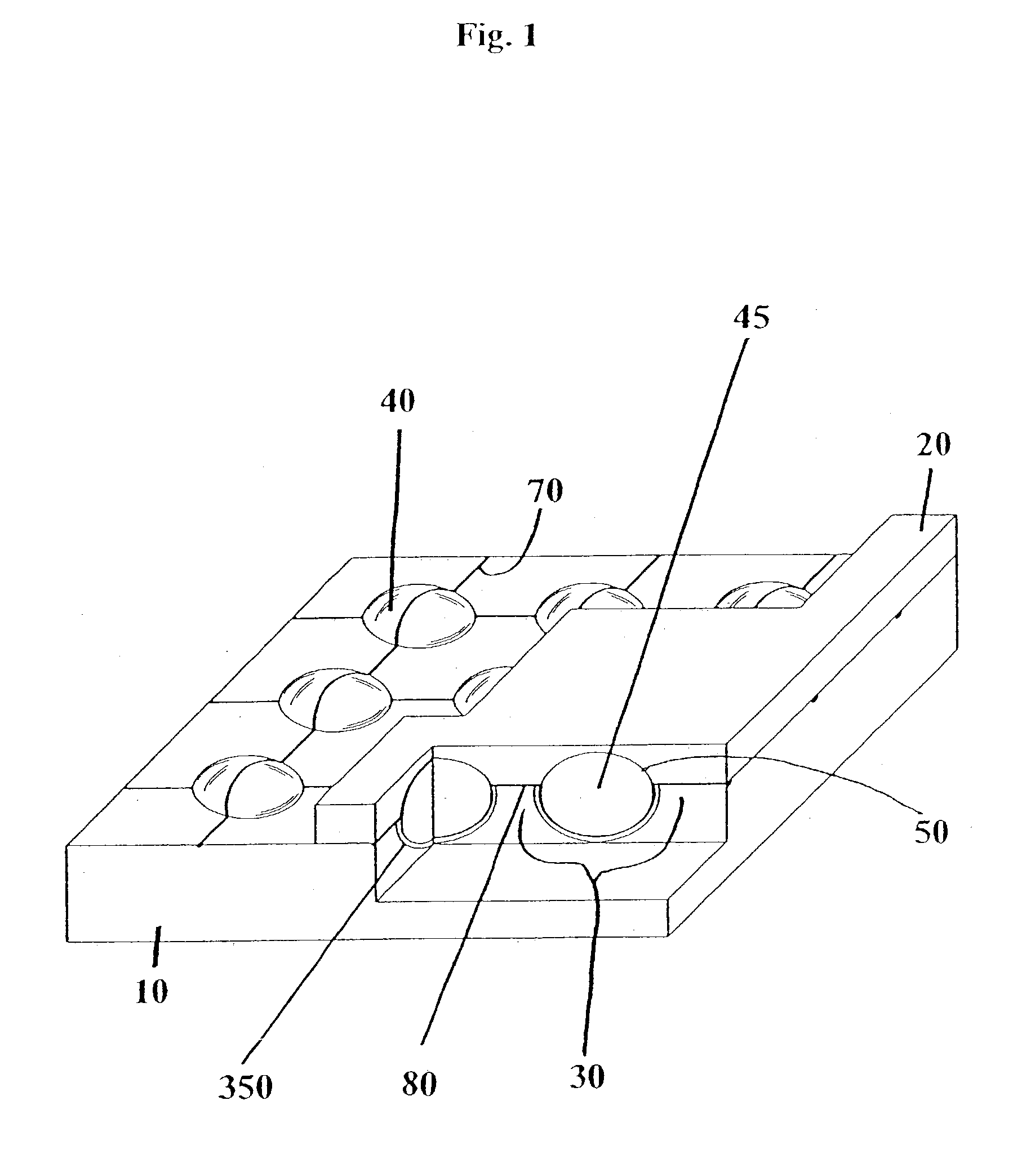

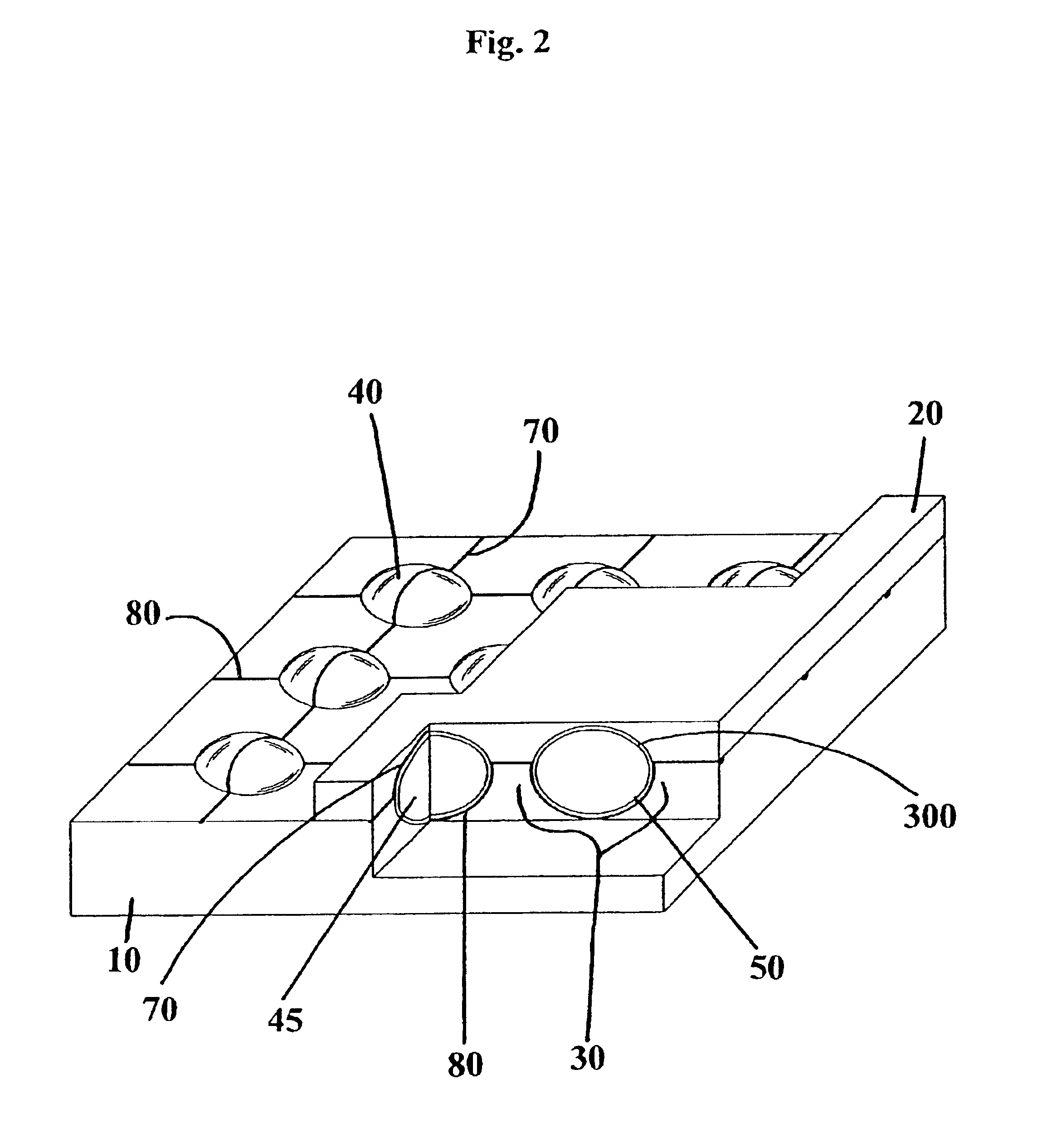

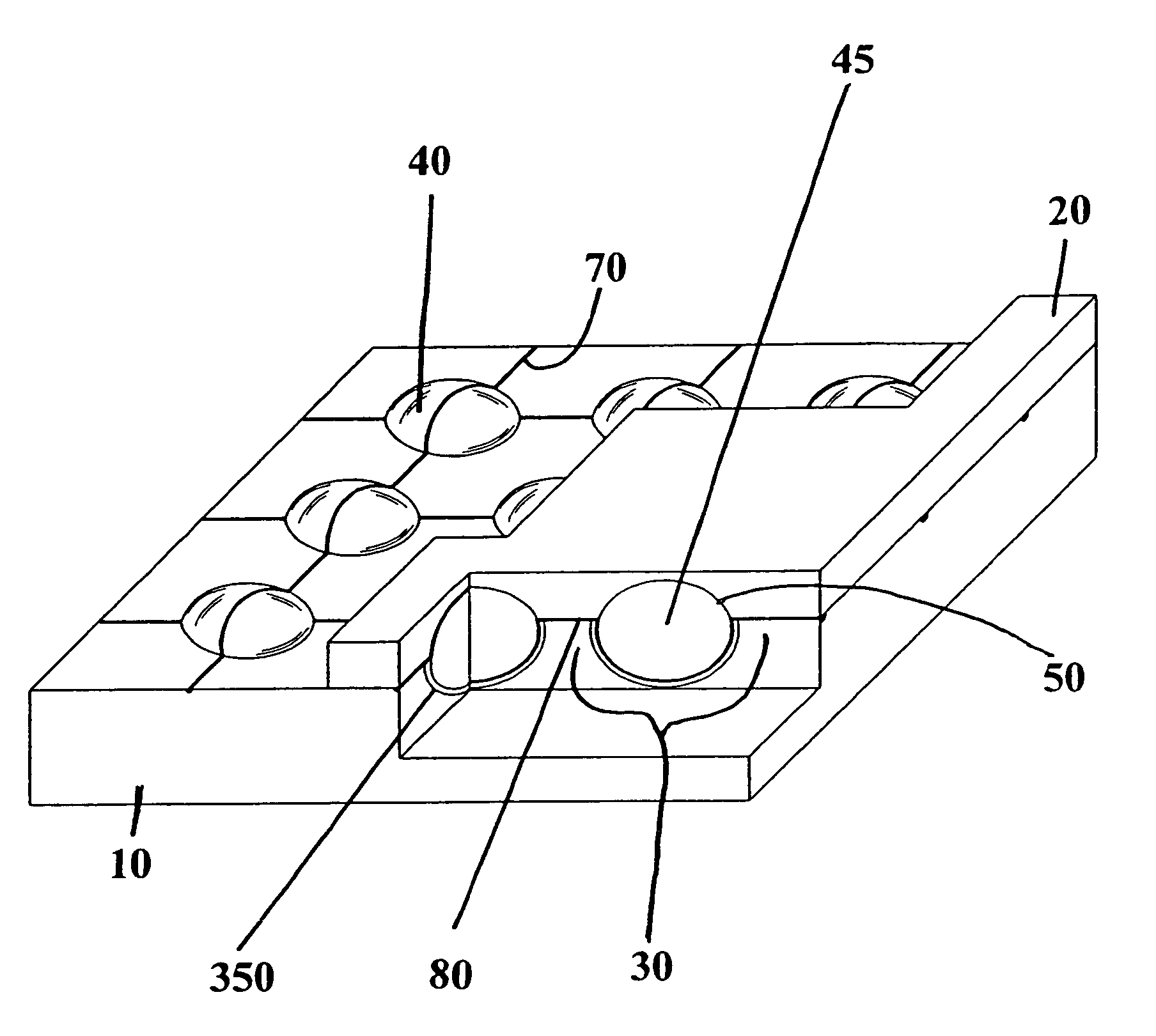

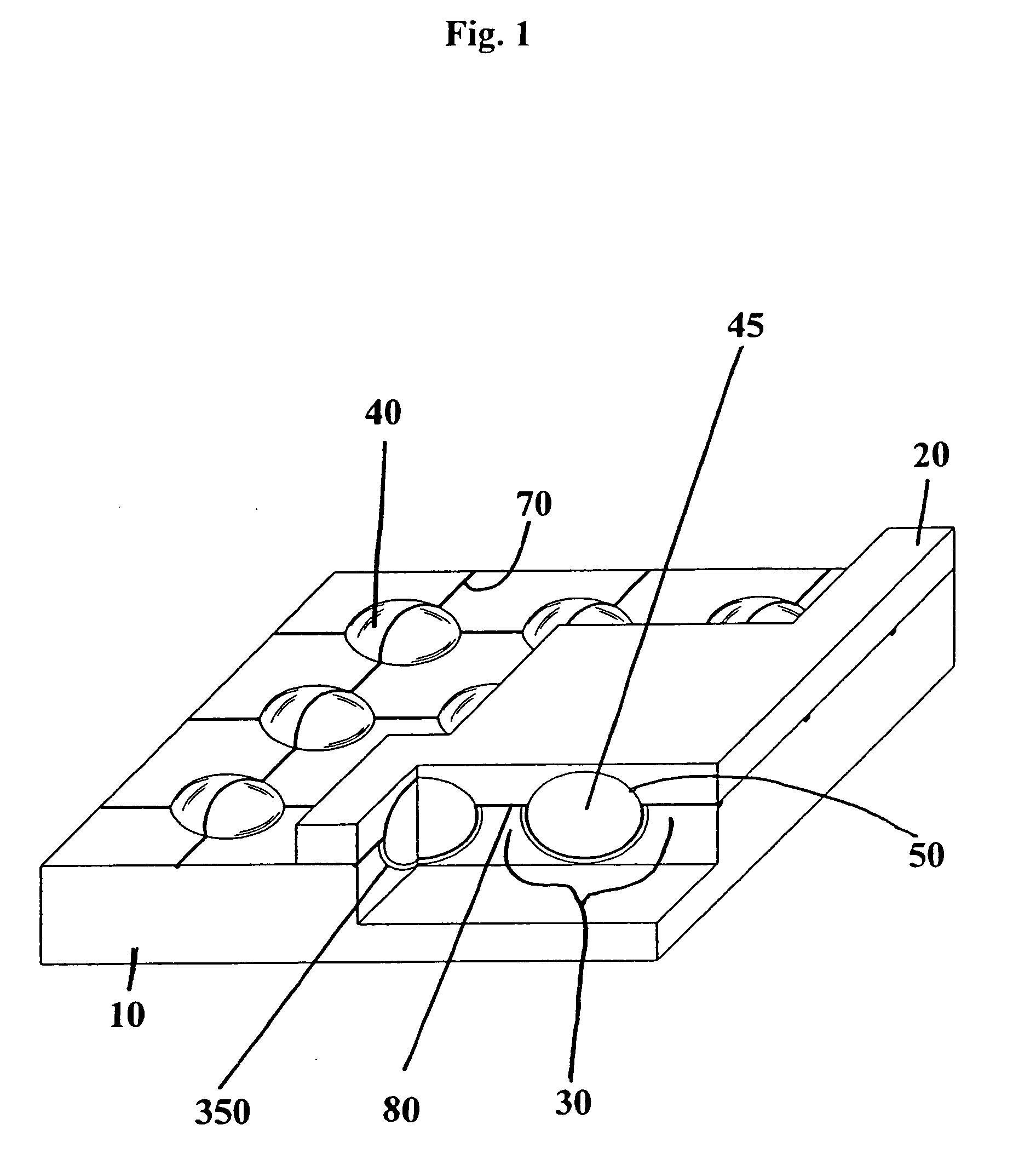

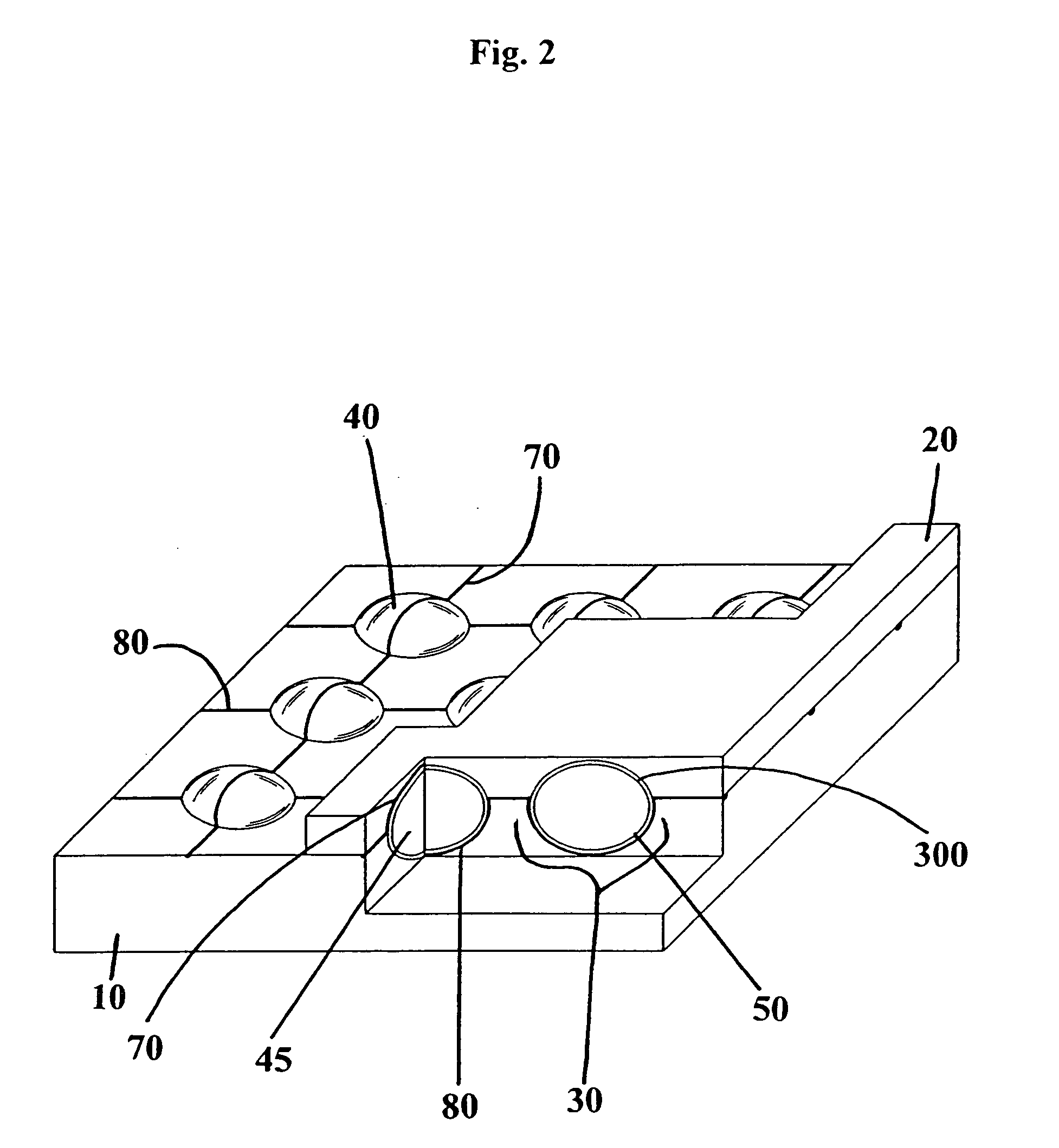

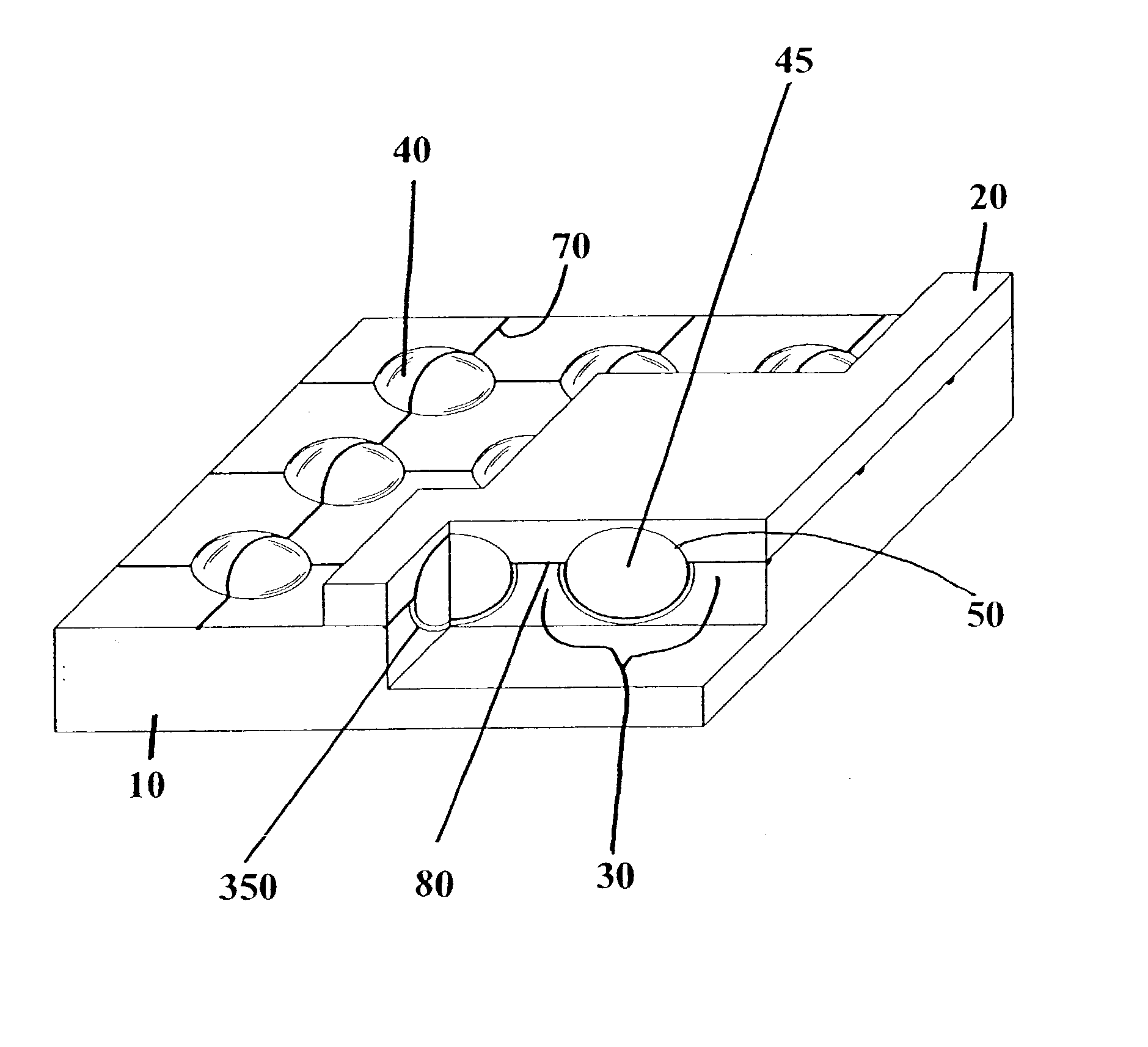

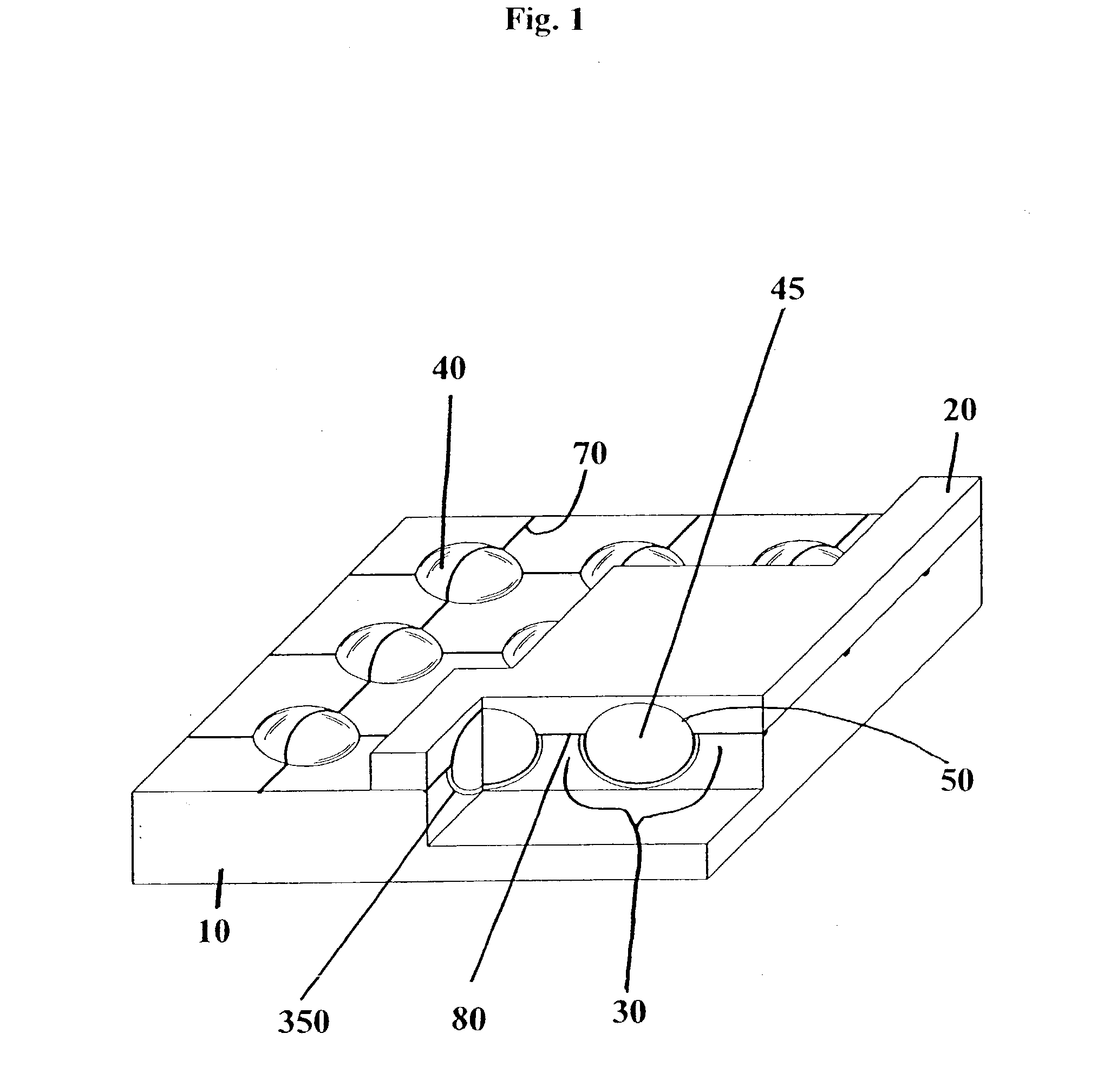

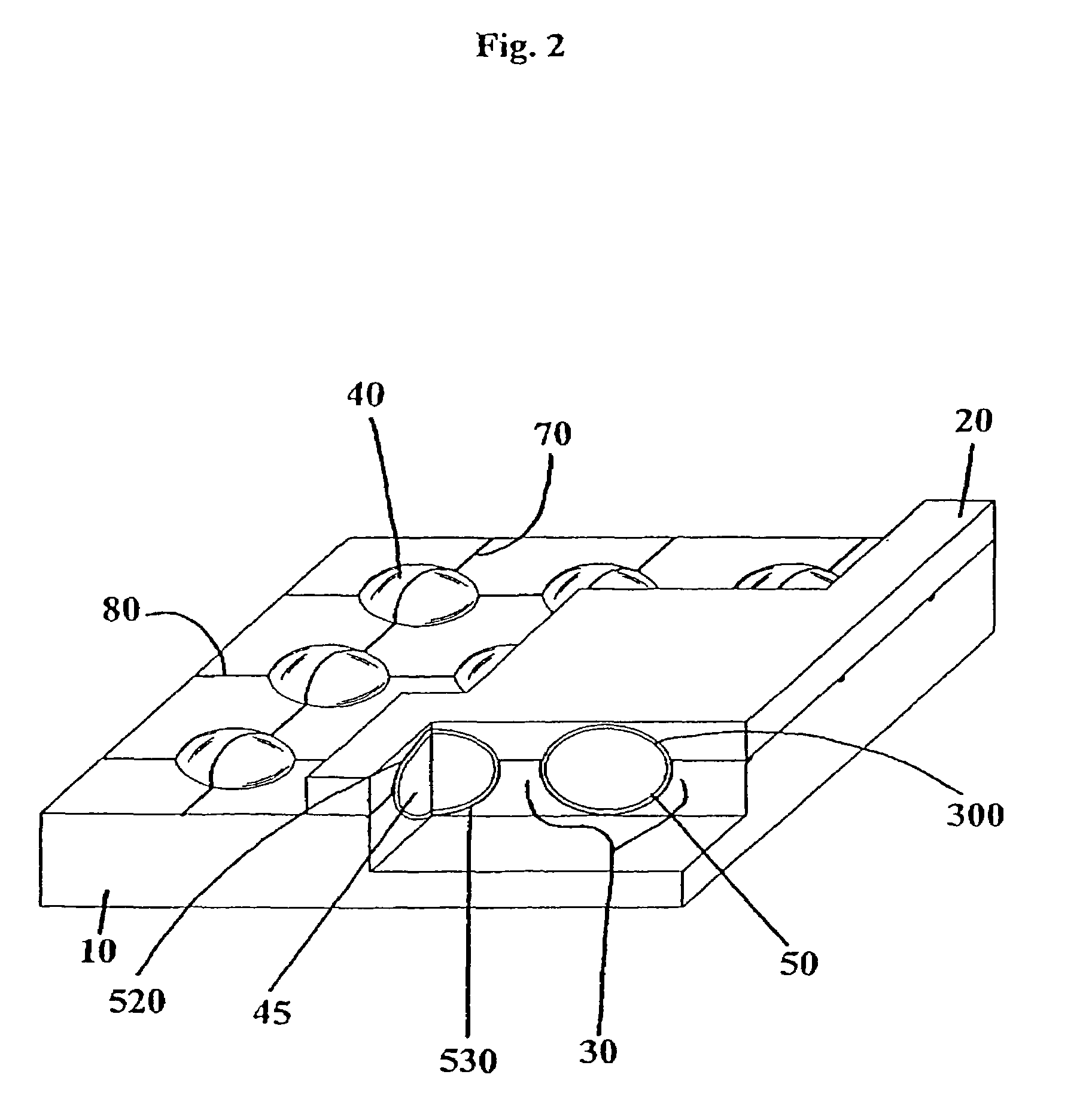

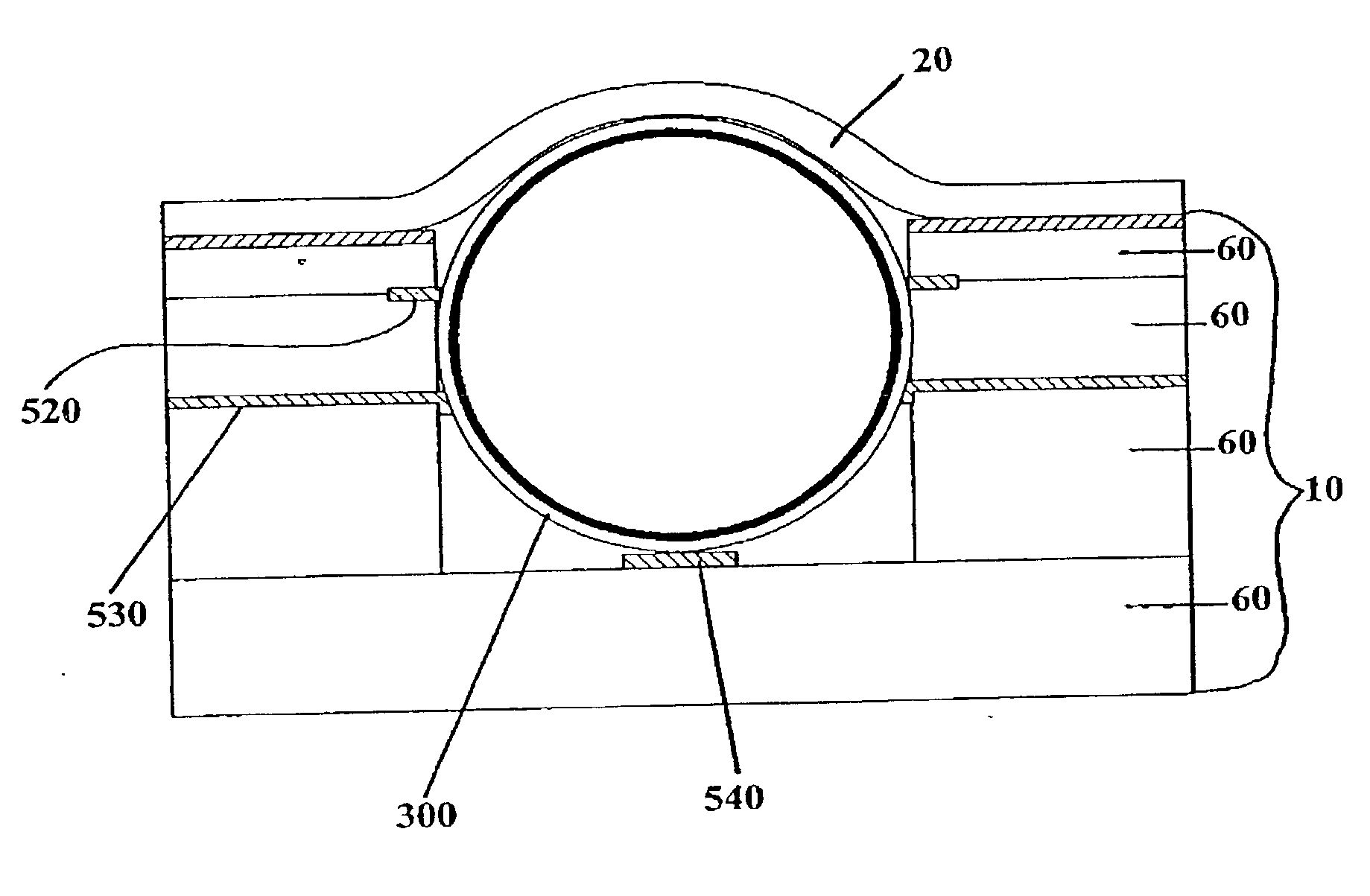

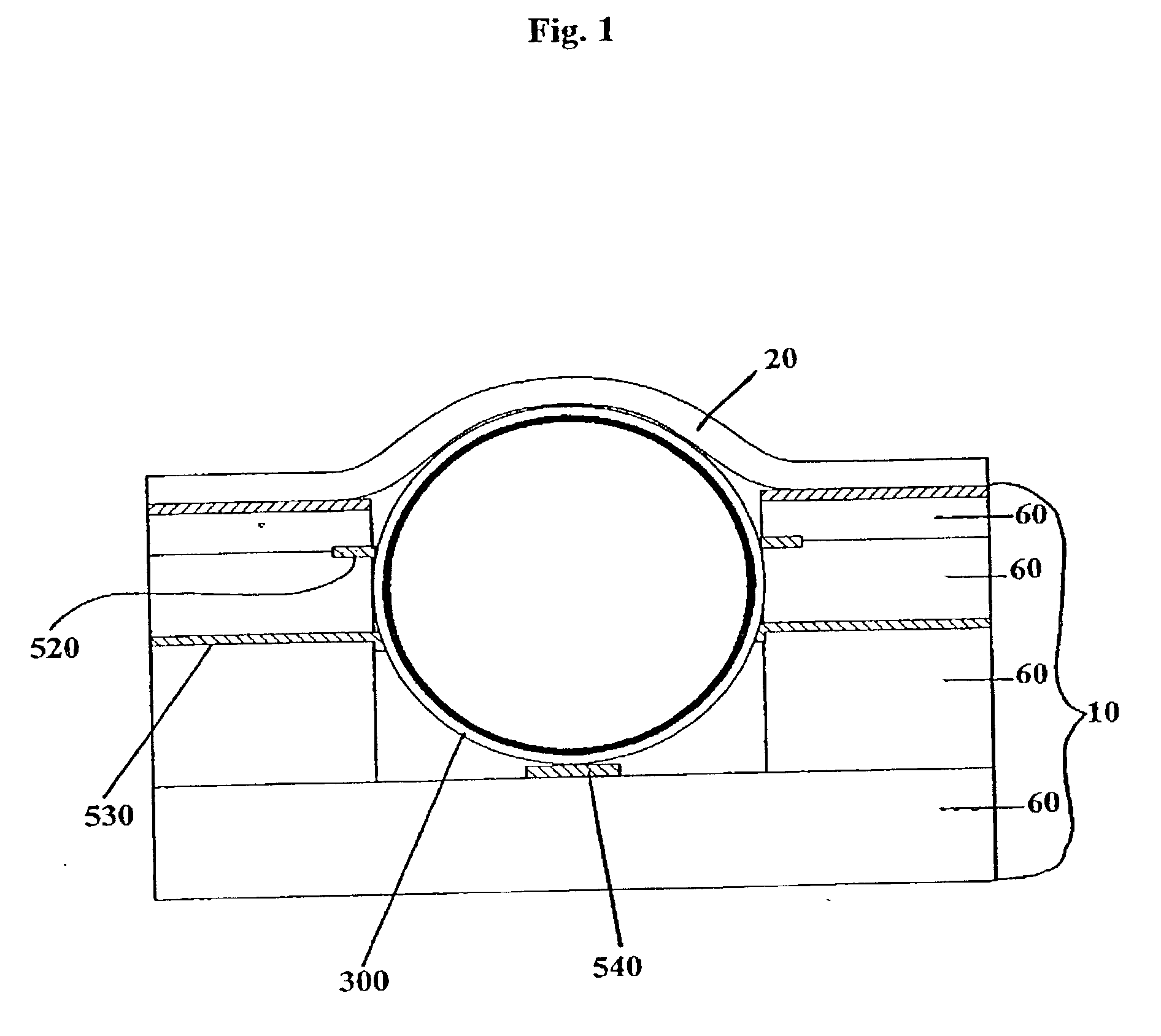

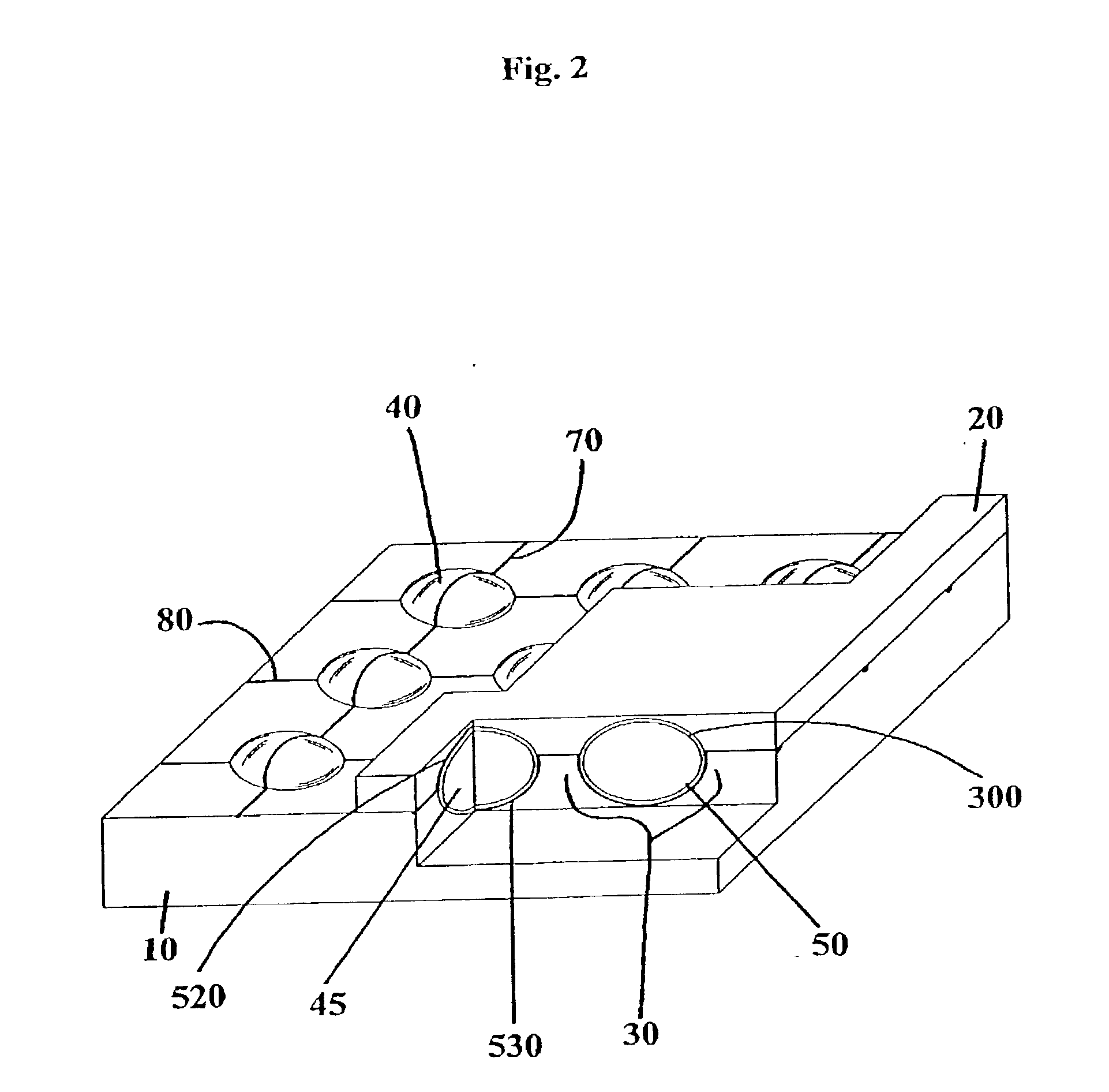

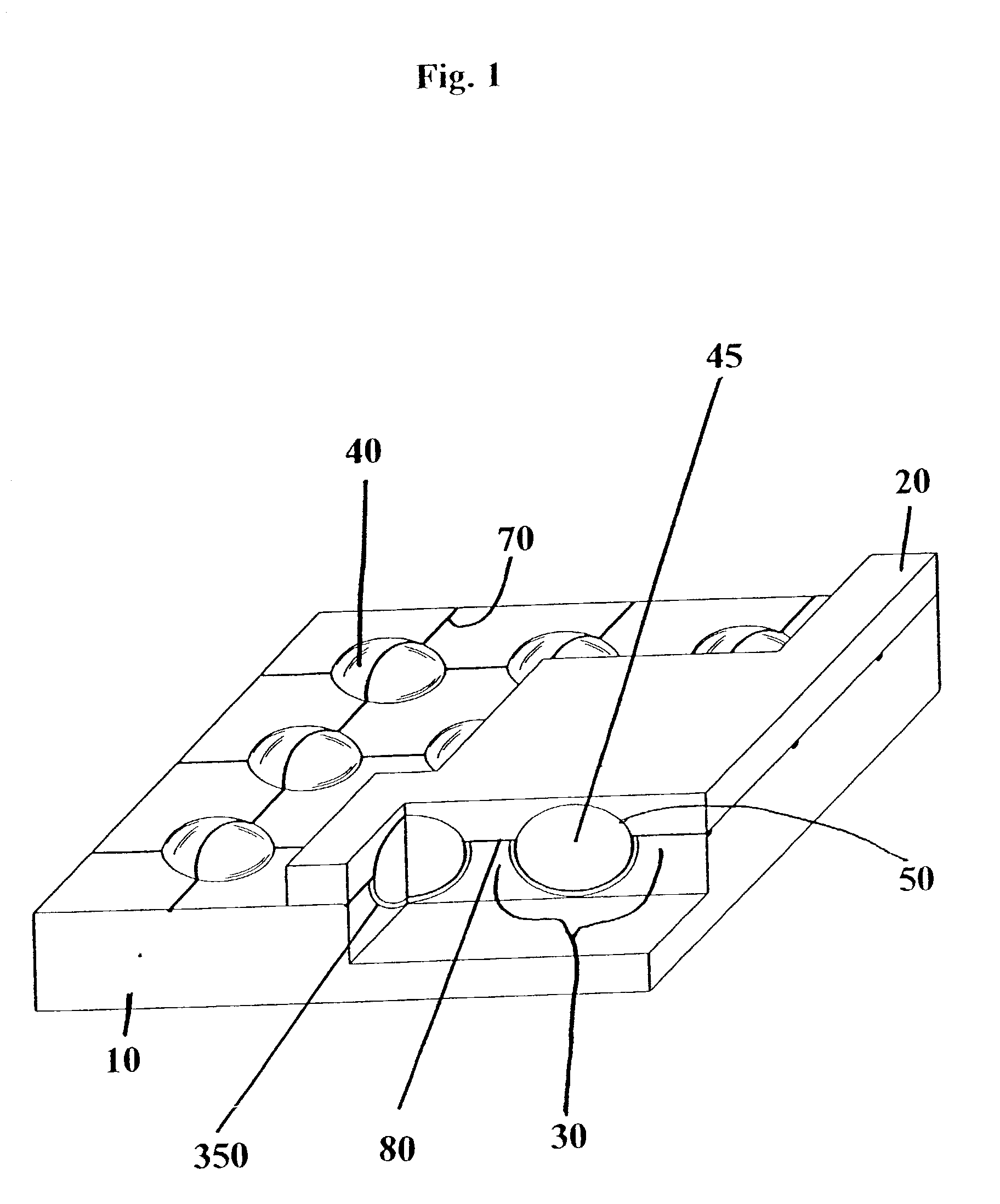

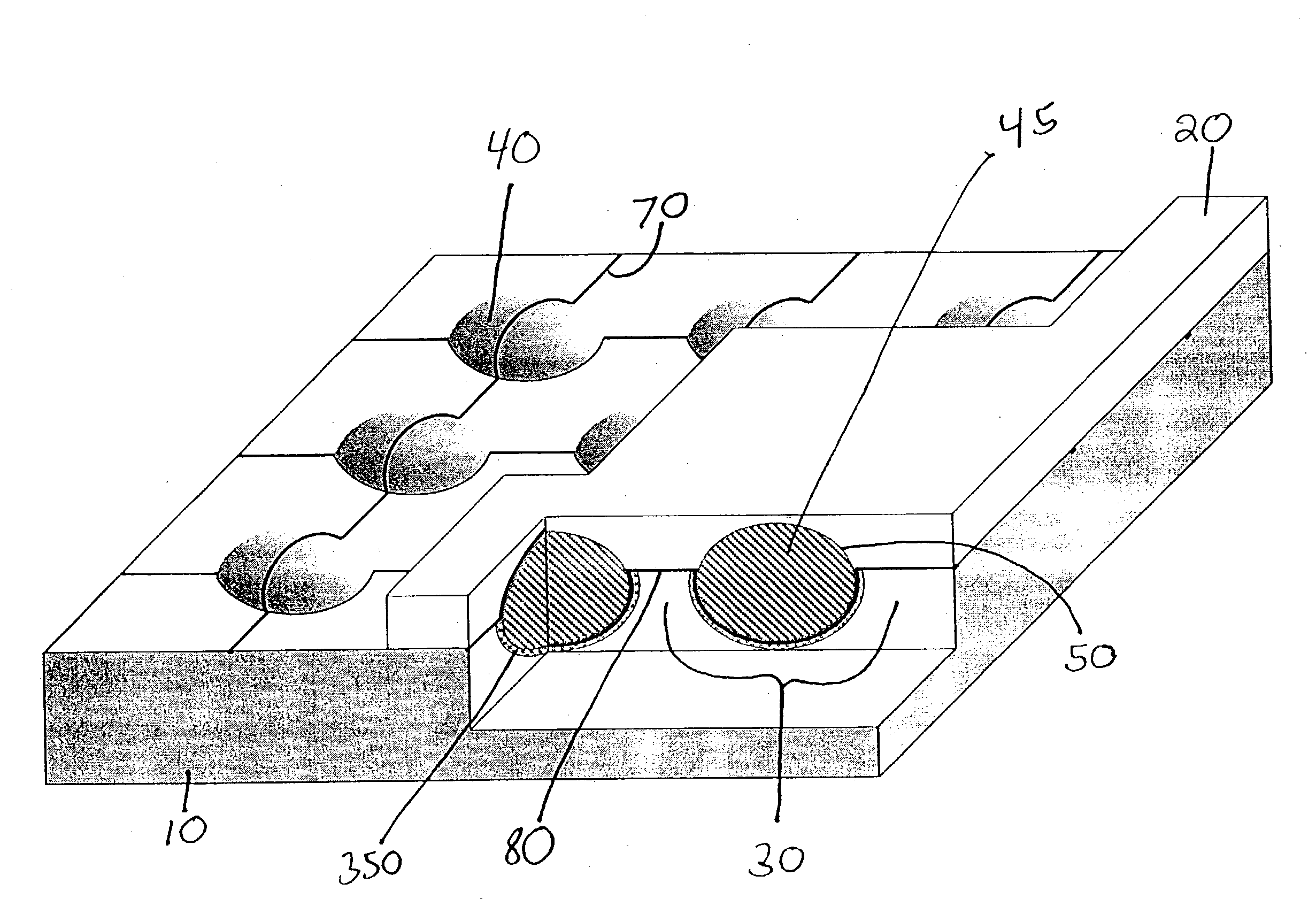

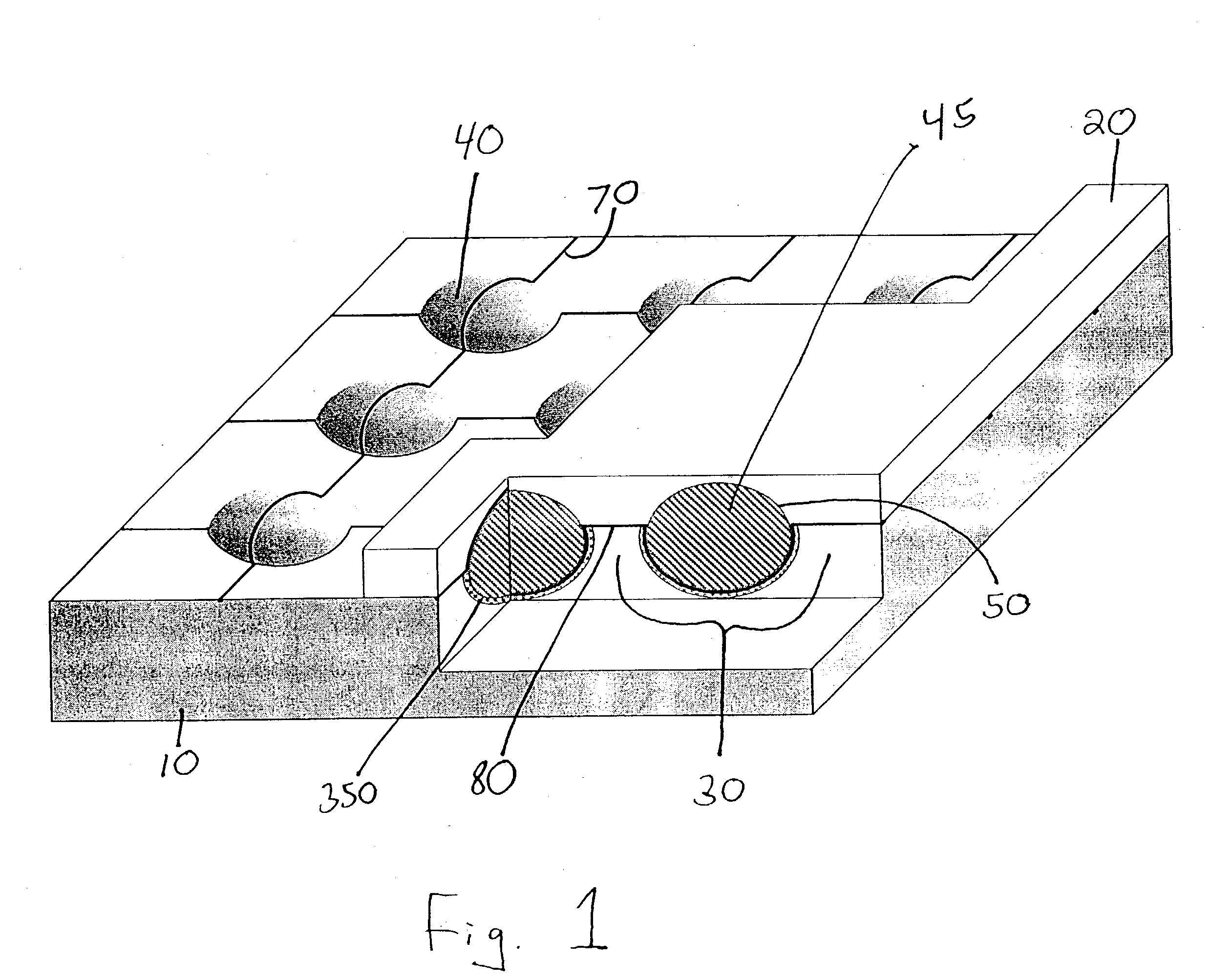

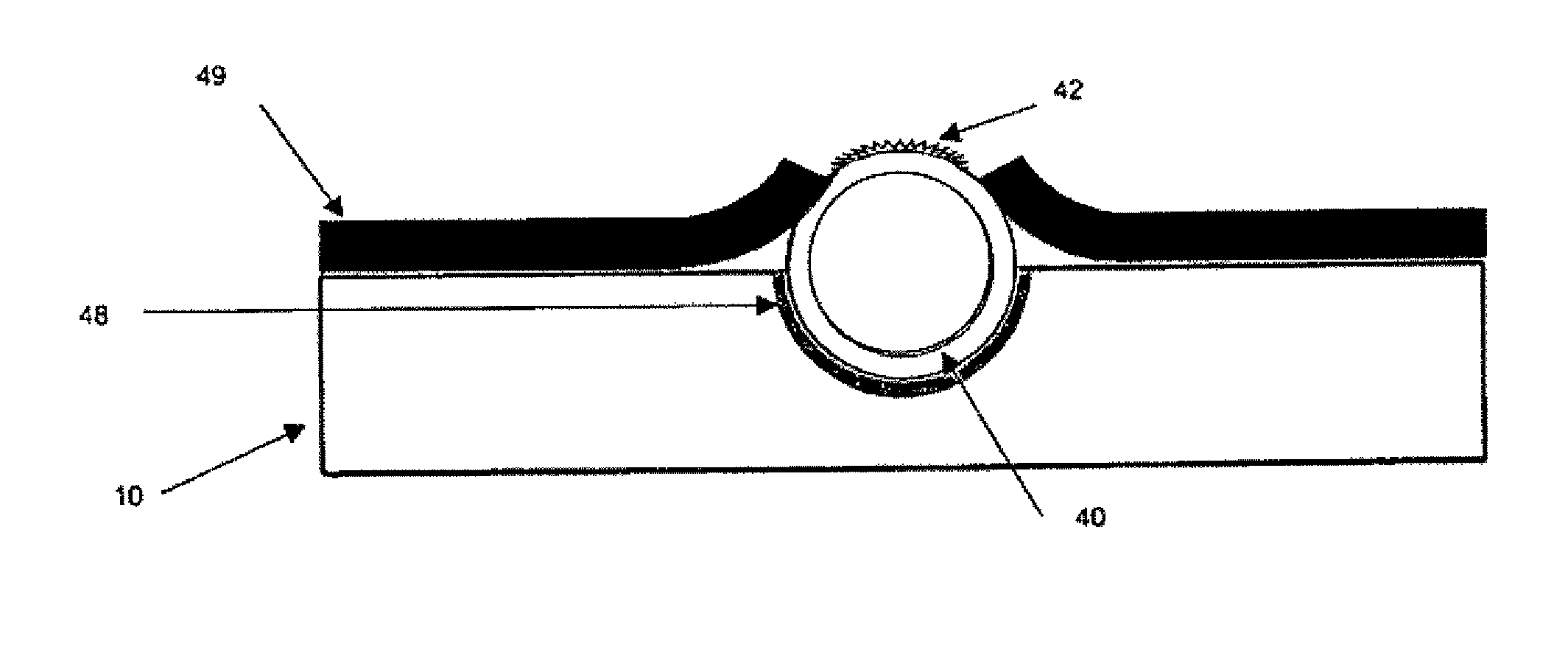

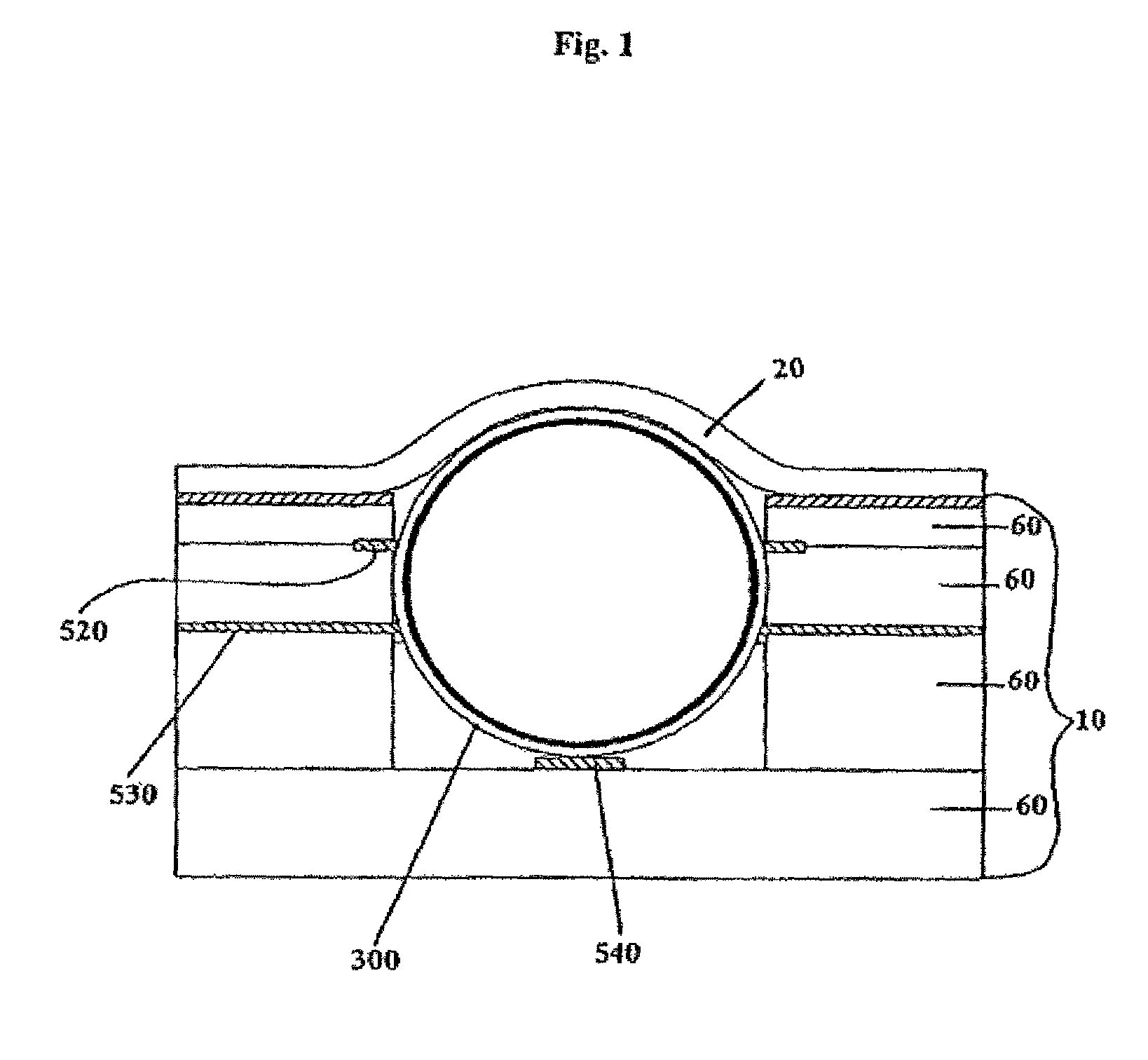

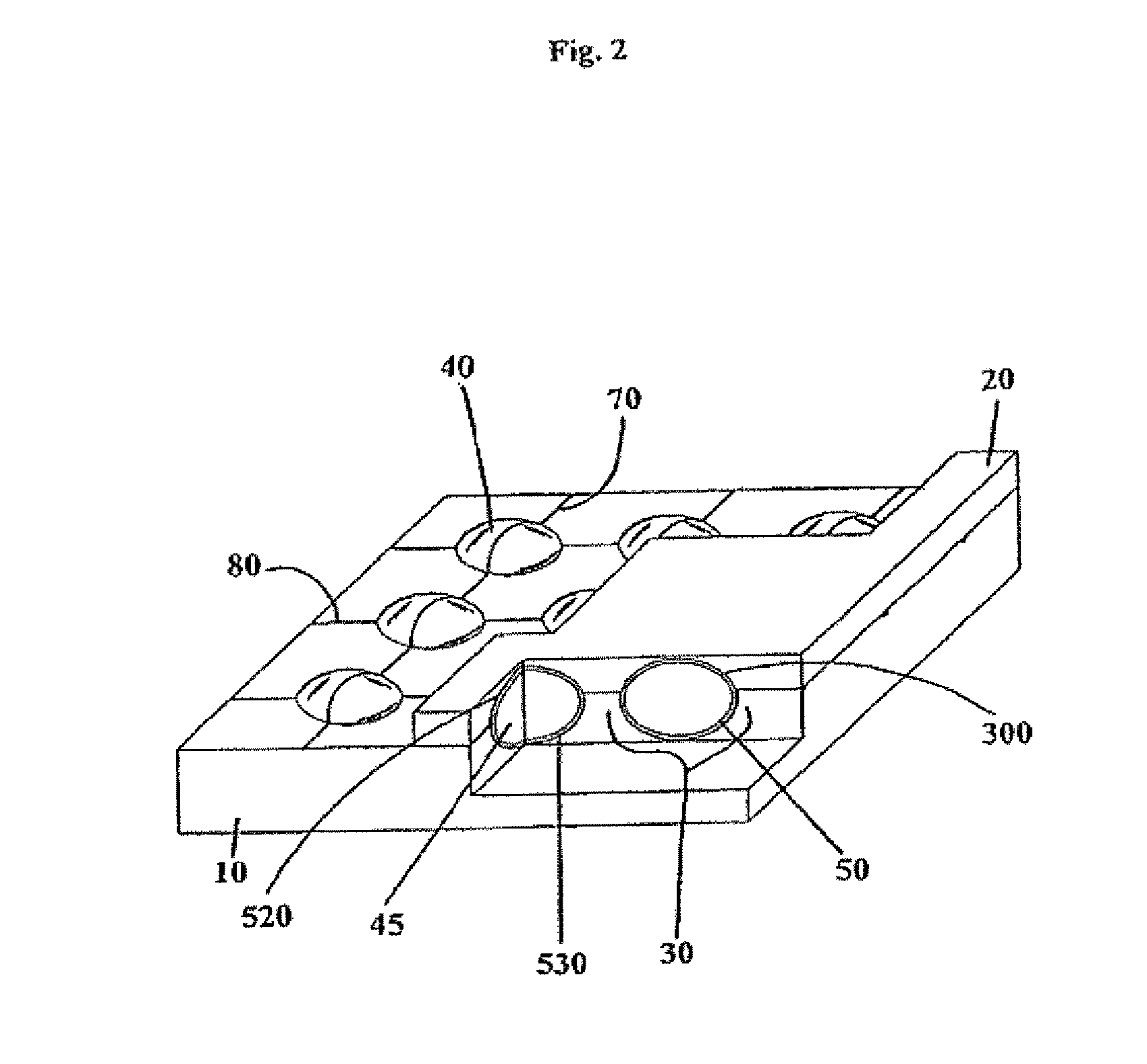

Socket for use with a micro-component in a light-emitting panel

InactiveUS6545422B1Sufficient resolutionManufactured very thinEmission spectroscopyStatic indicating devicesIonizationVoltage

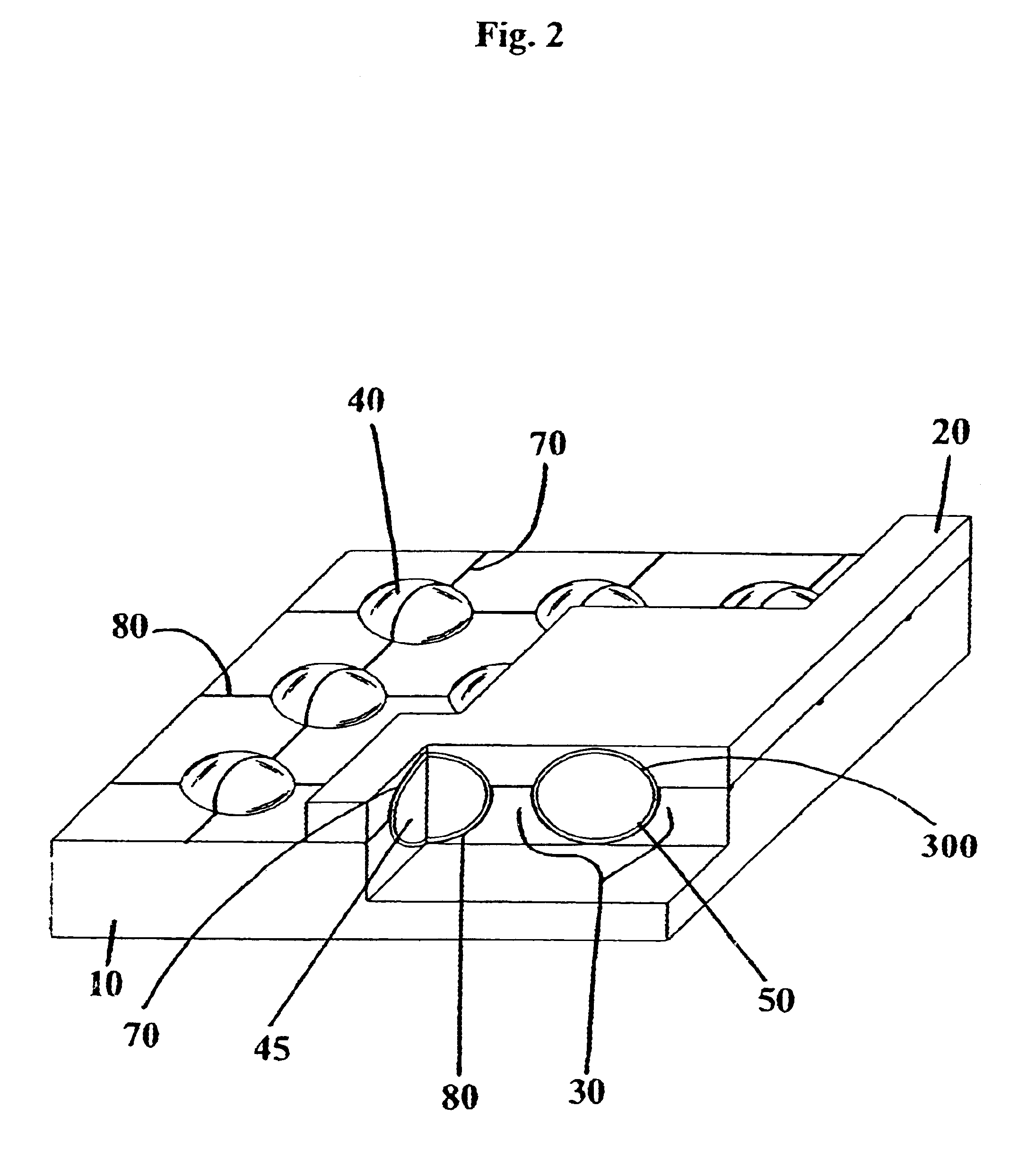

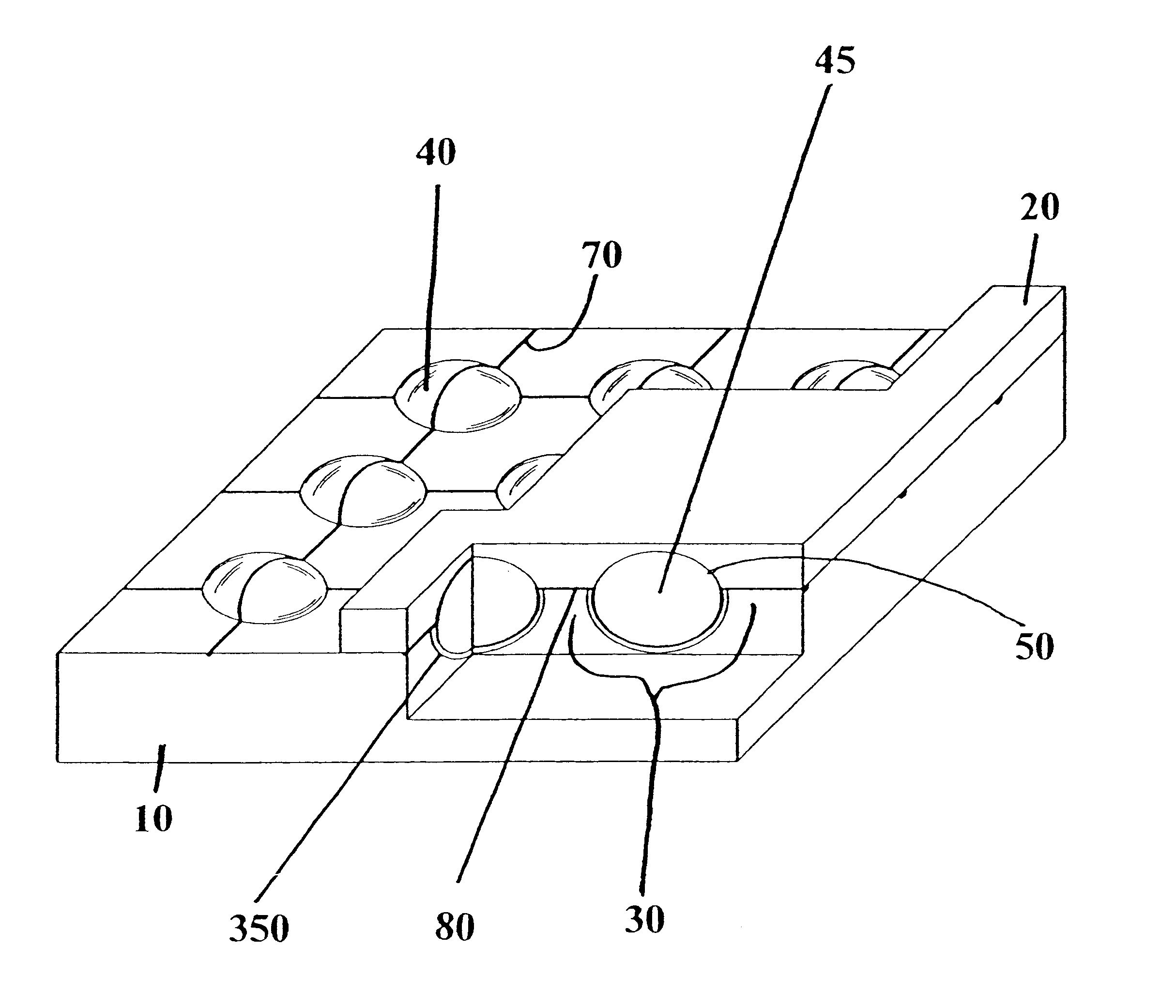

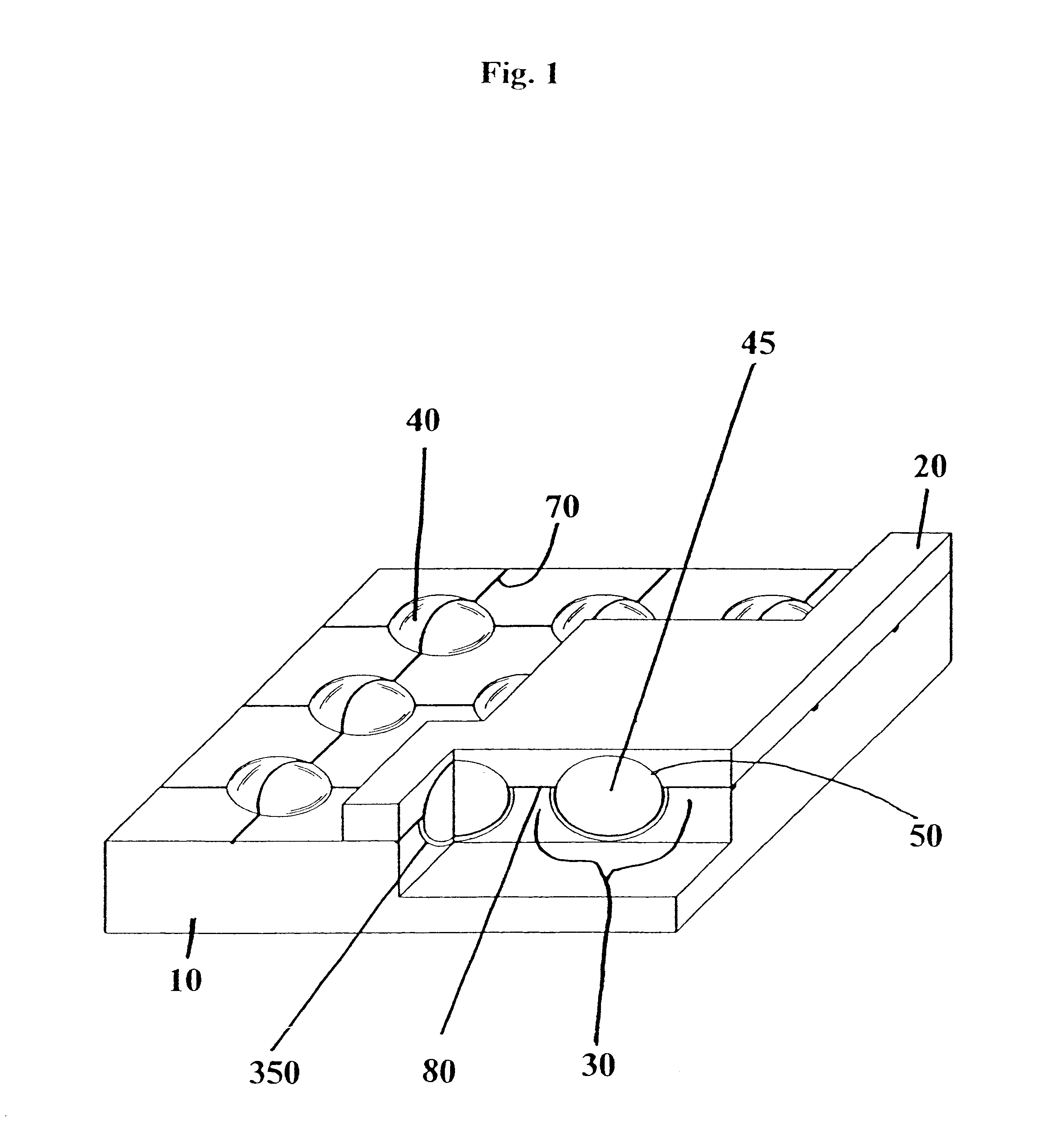

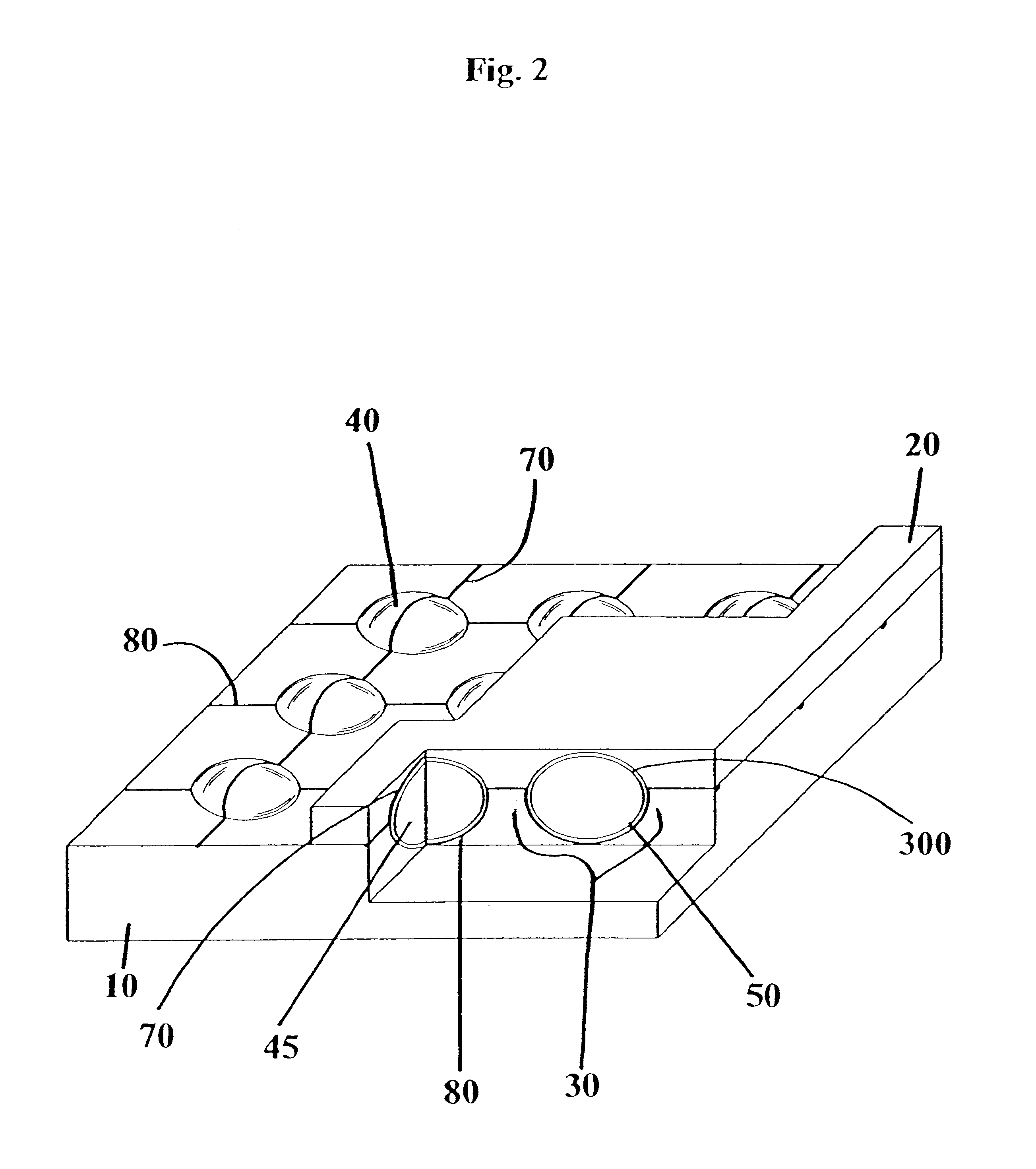

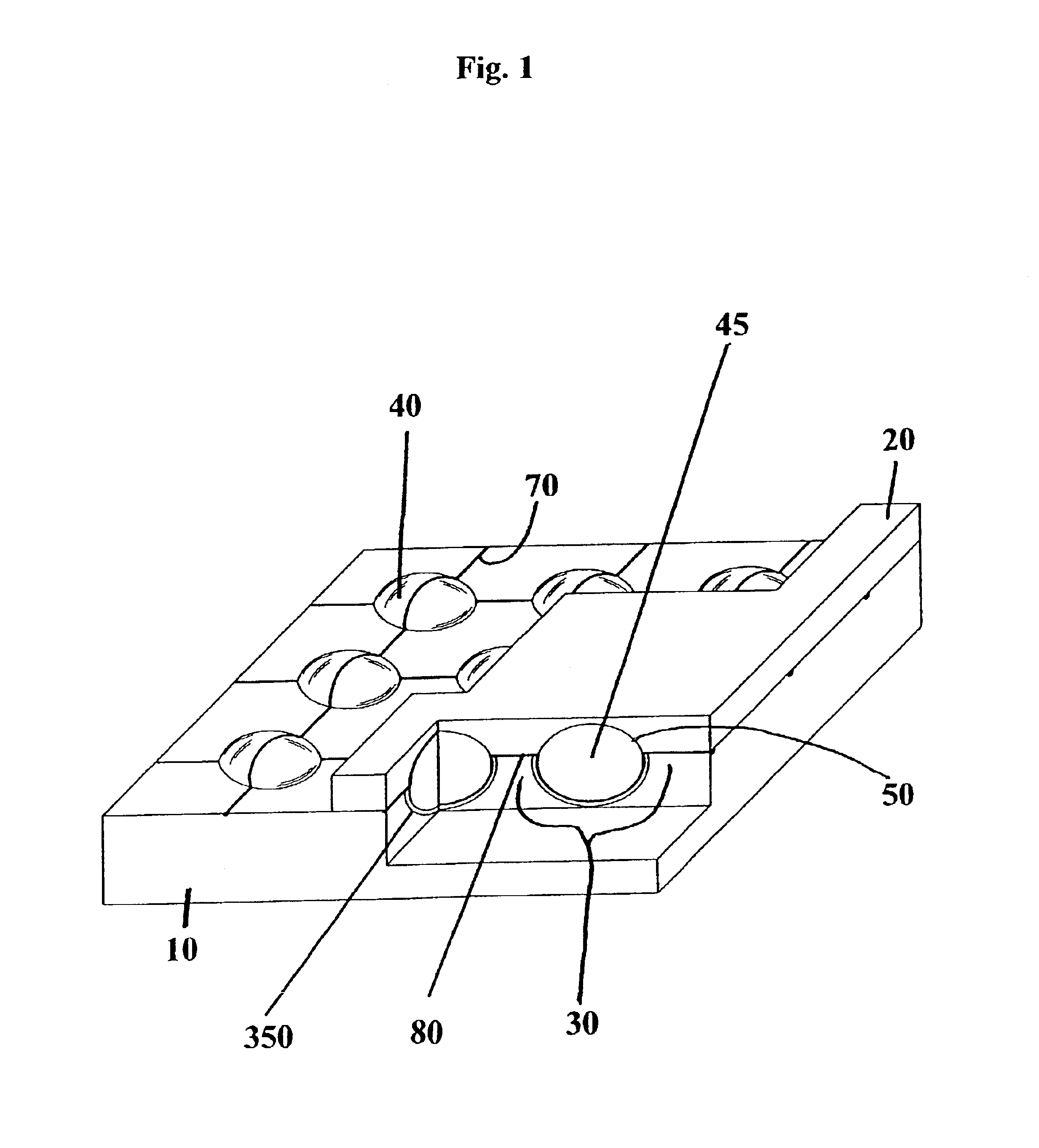

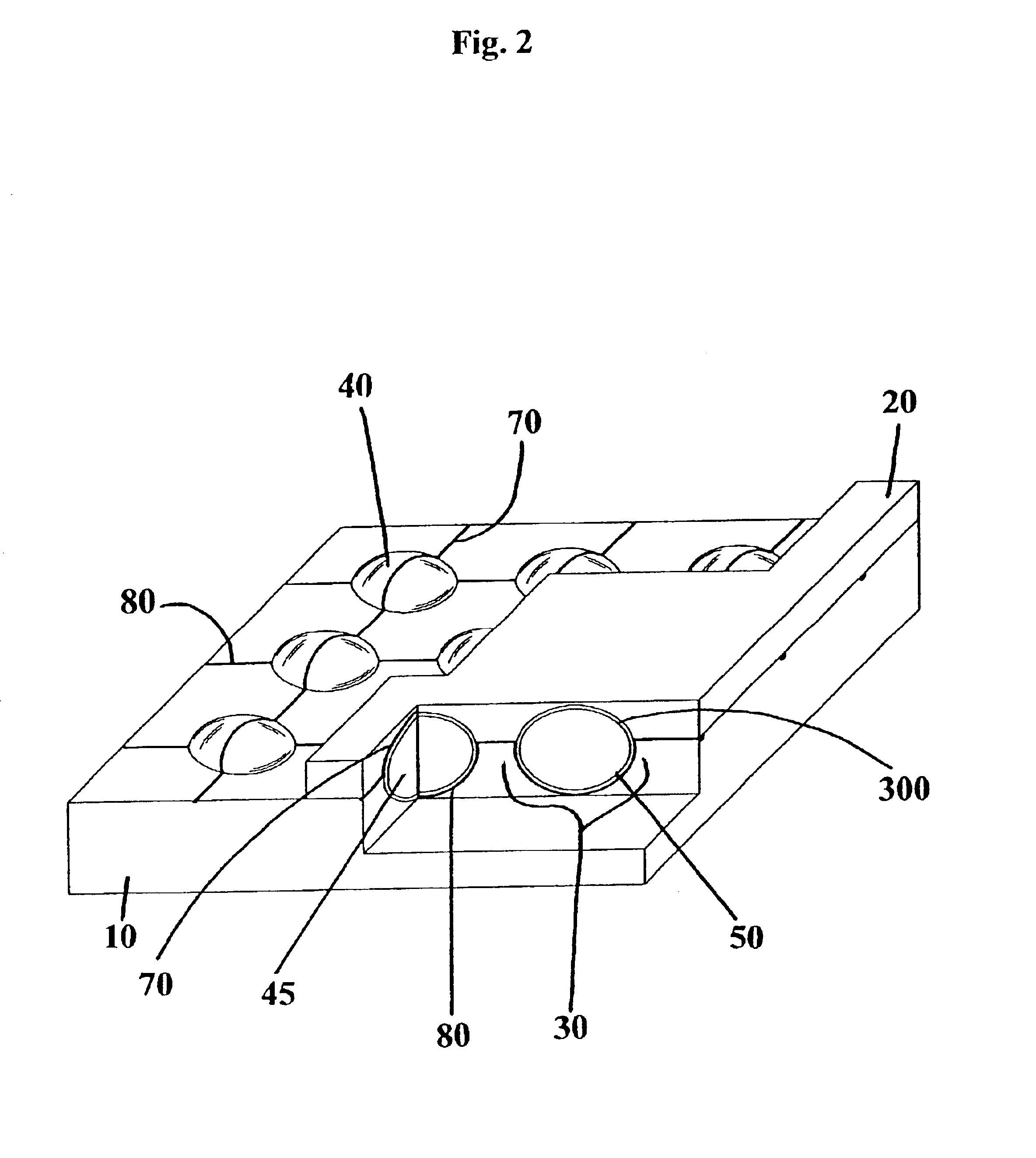

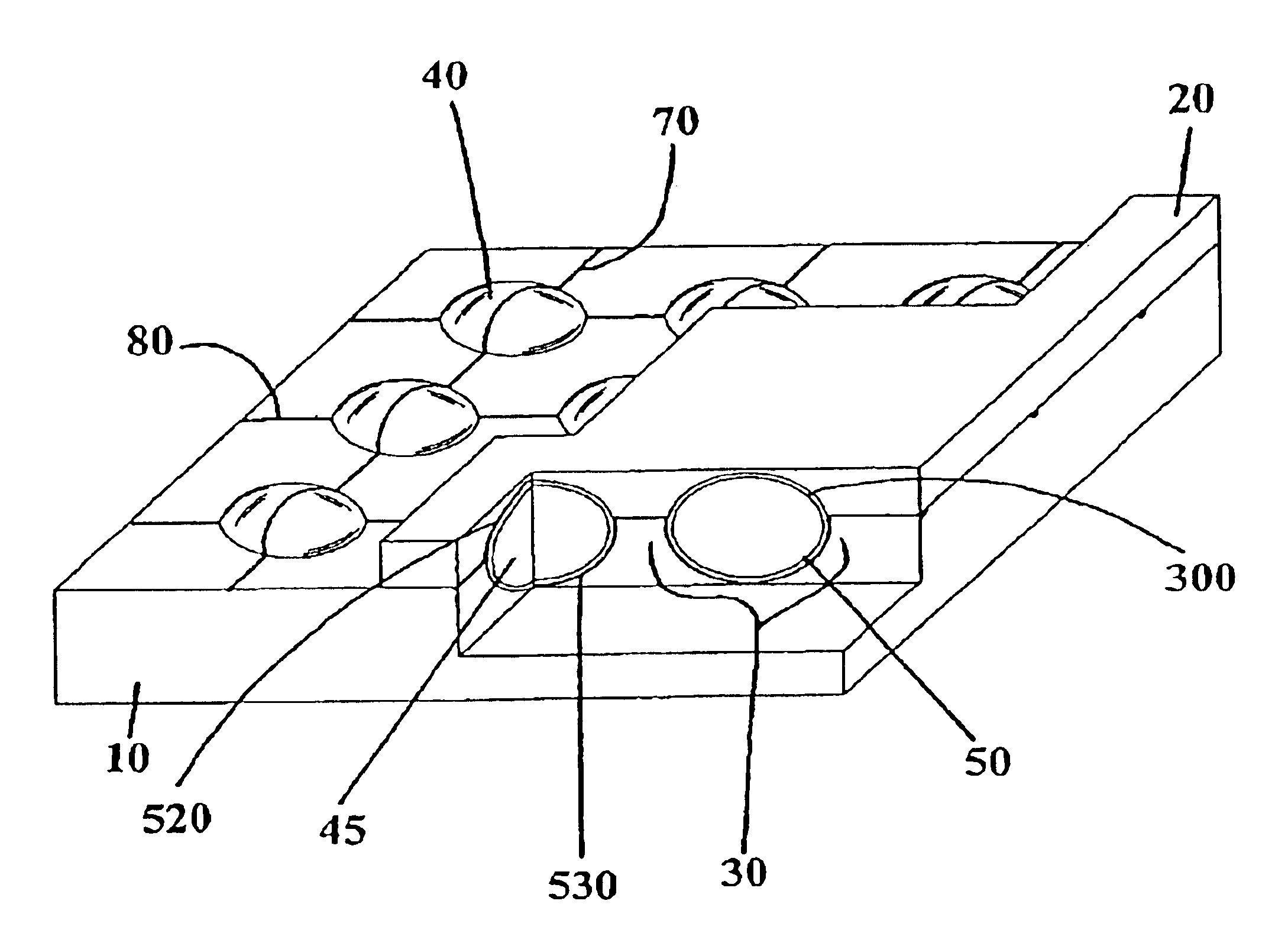

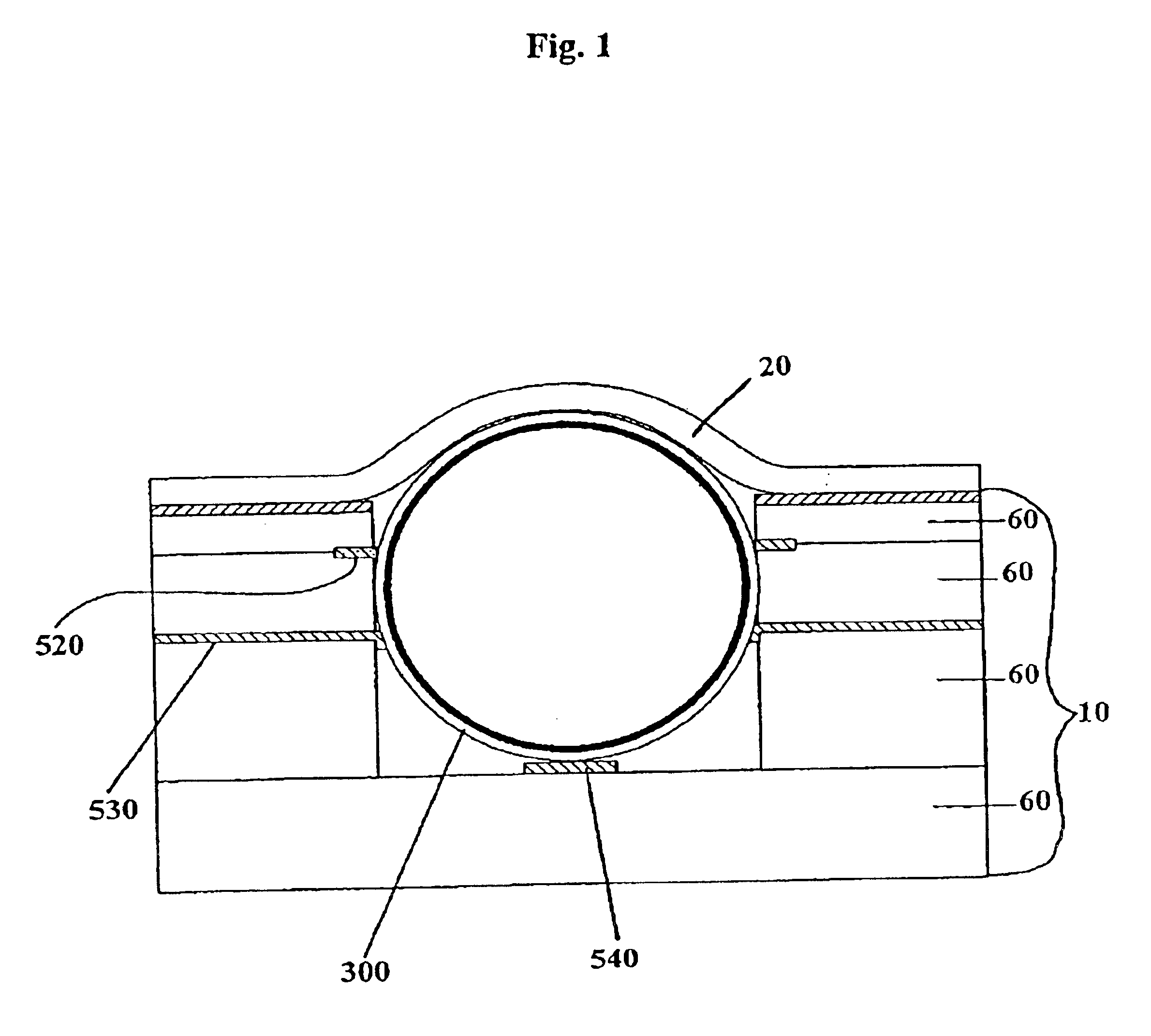

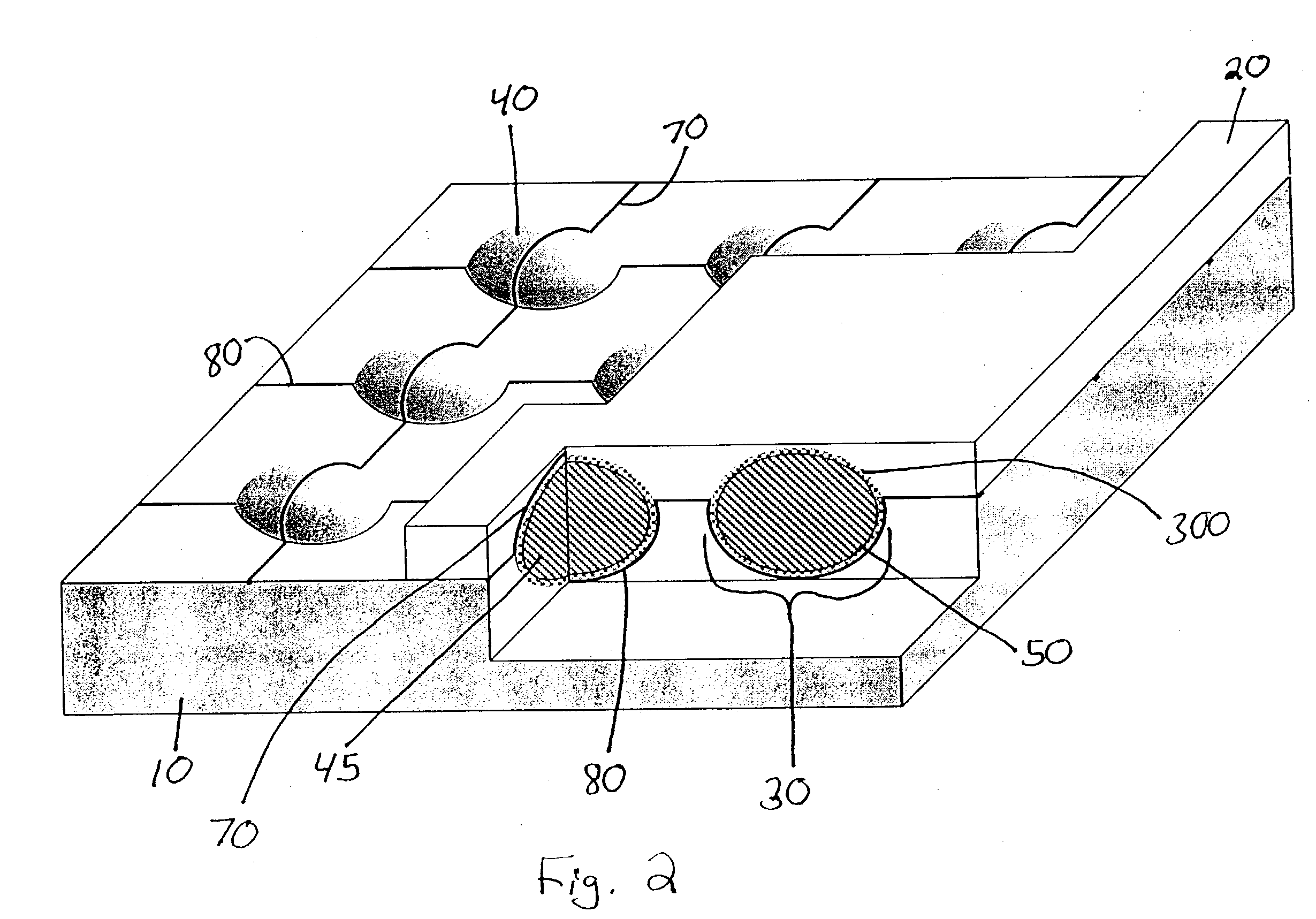

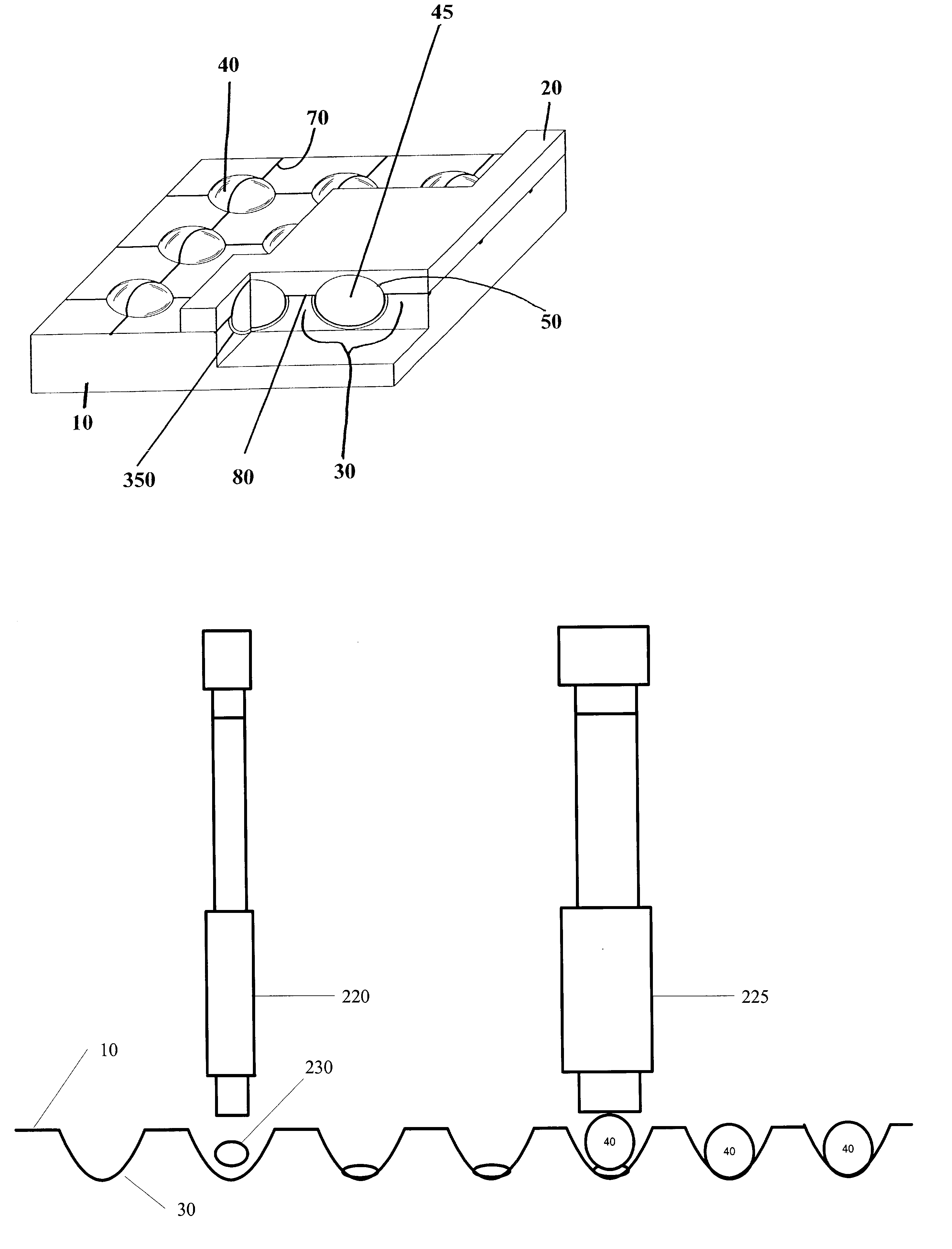

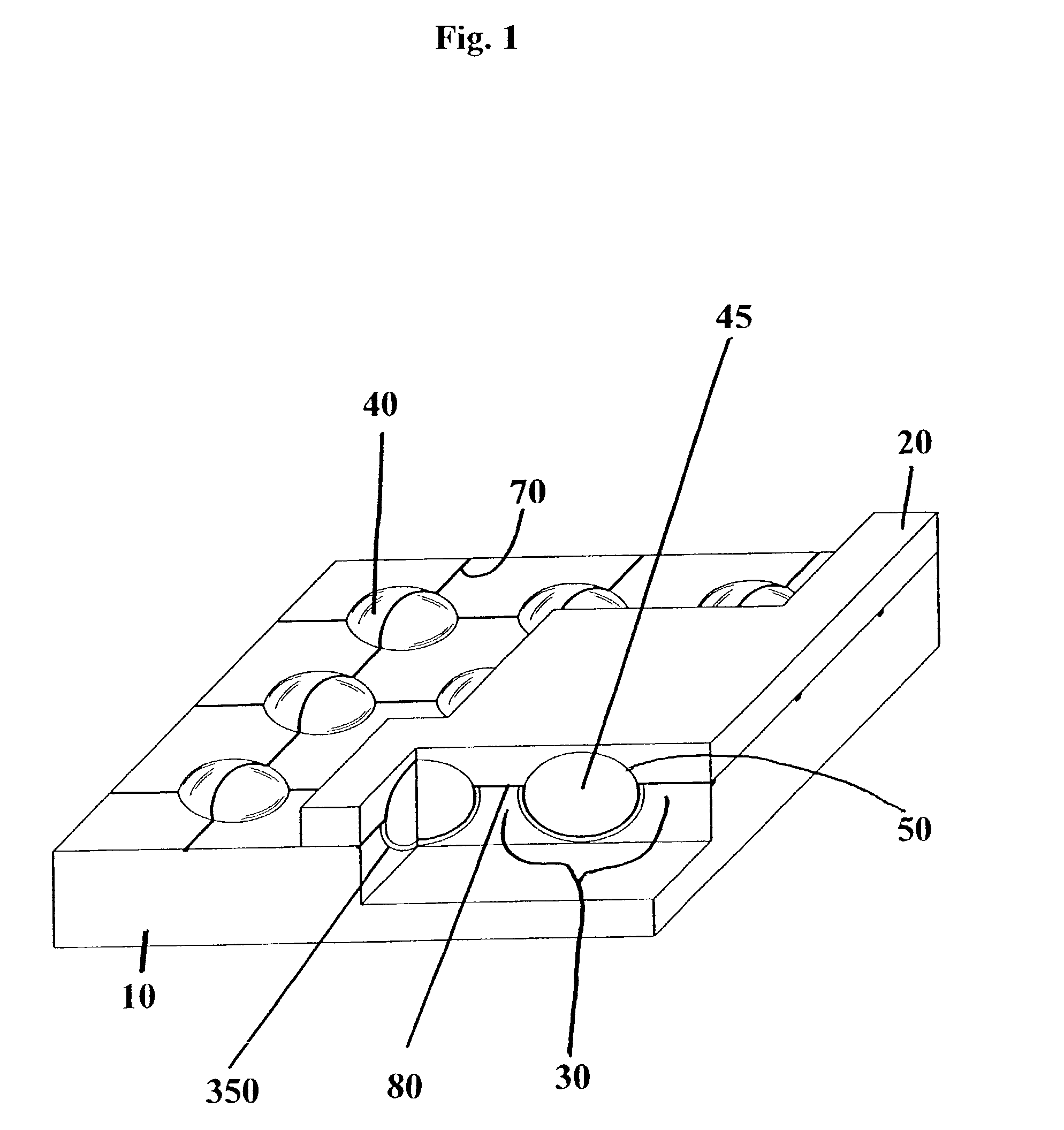

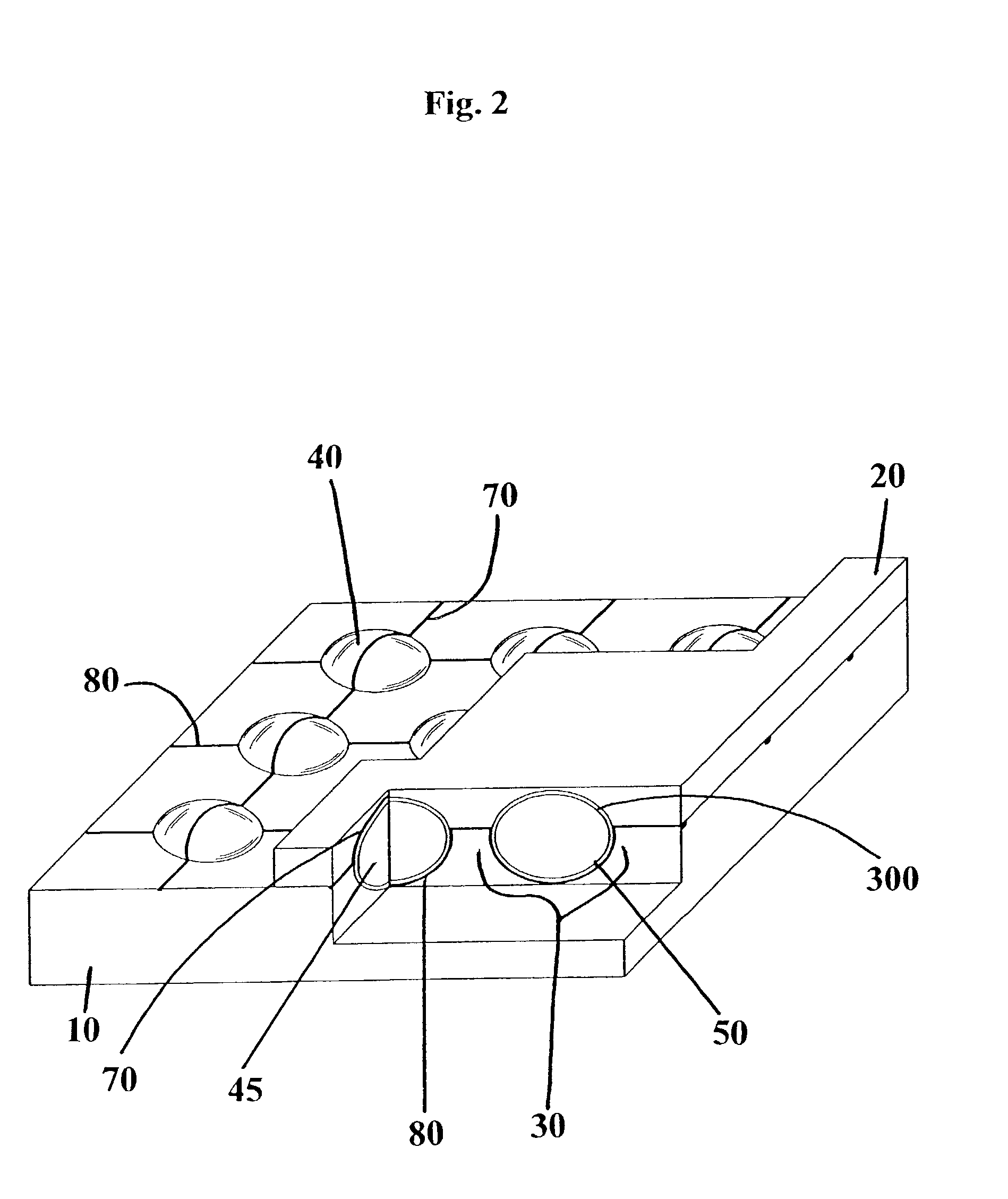

An improved light-emitting panel having a plurality of micro-components at least partially disposed in a socket and sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes.

Owner:LEIDOS

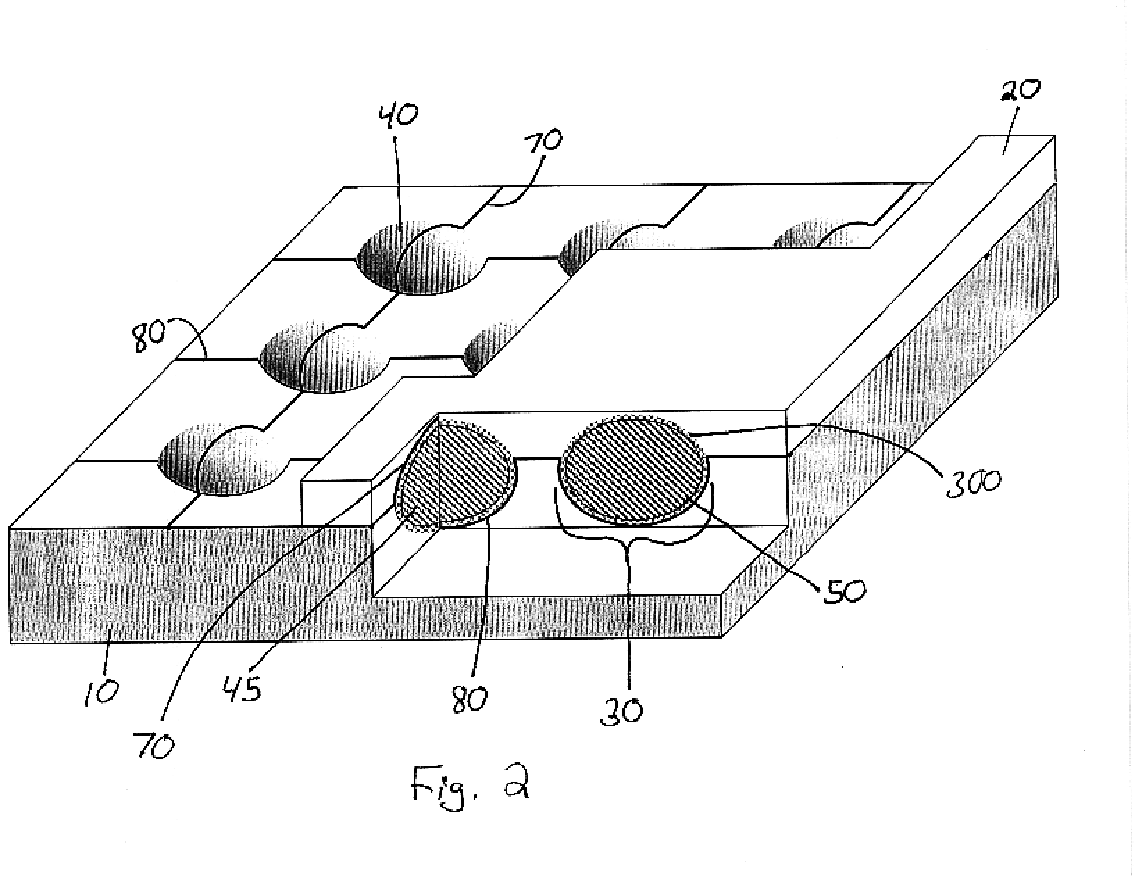

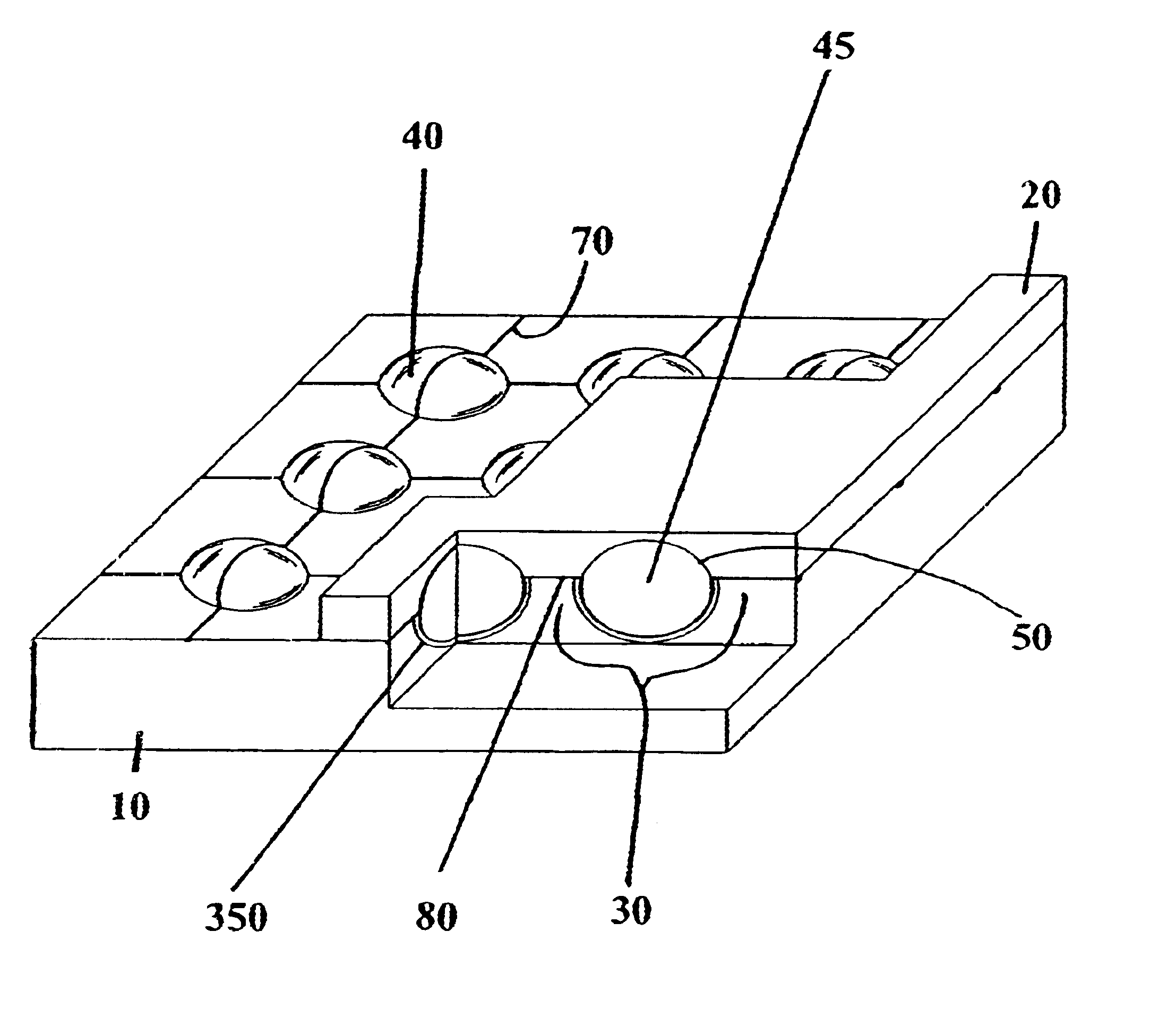

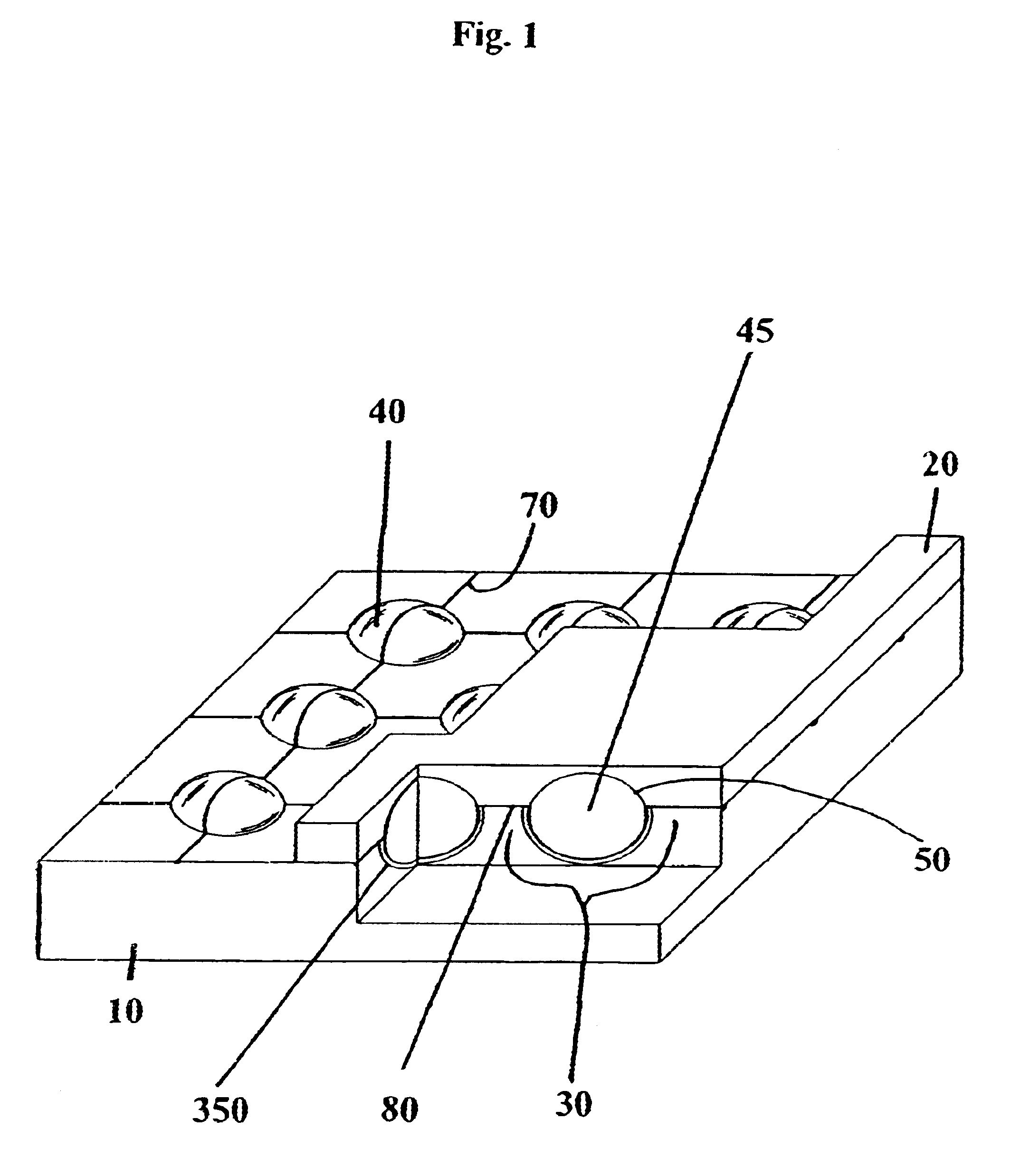

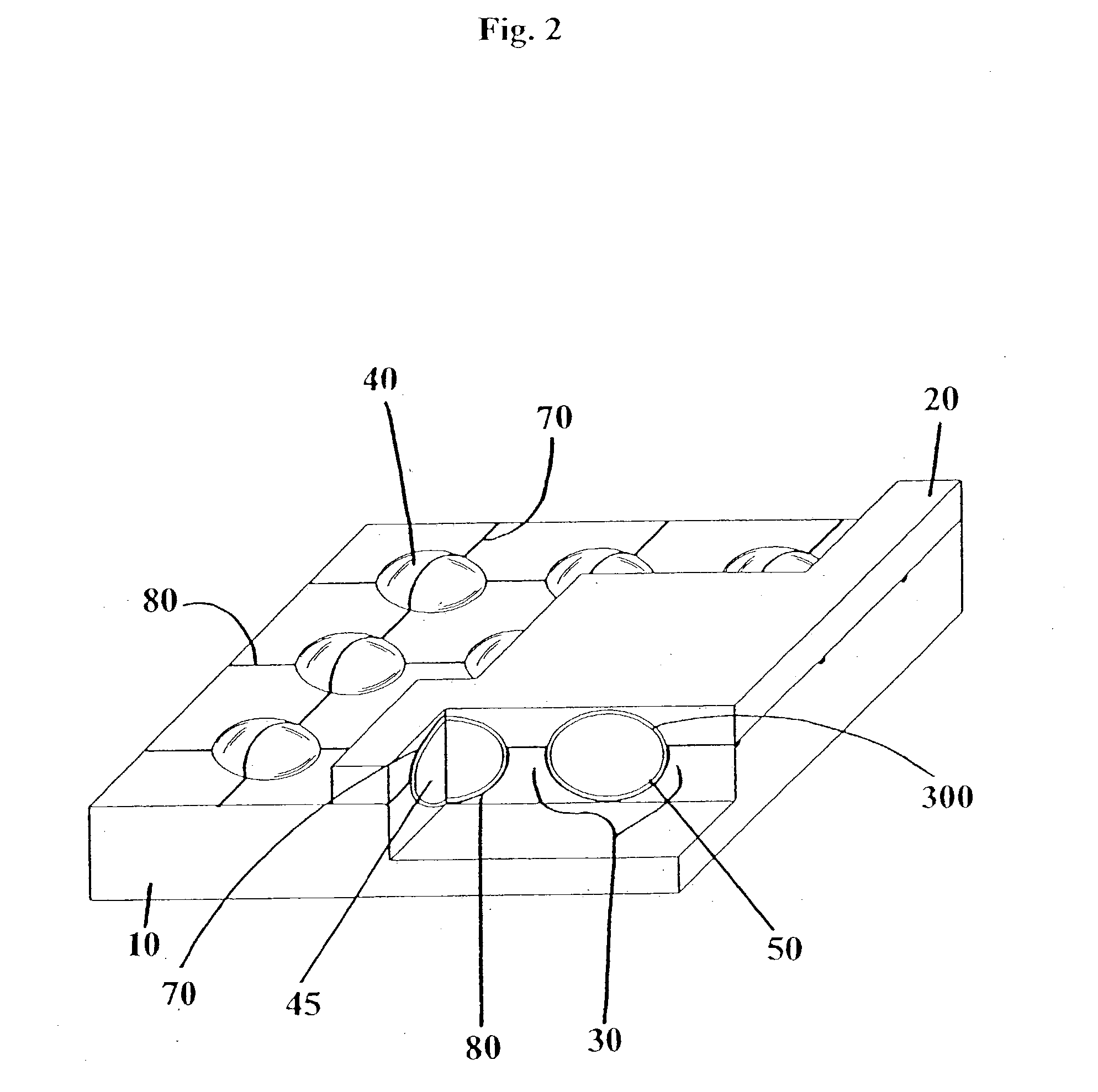

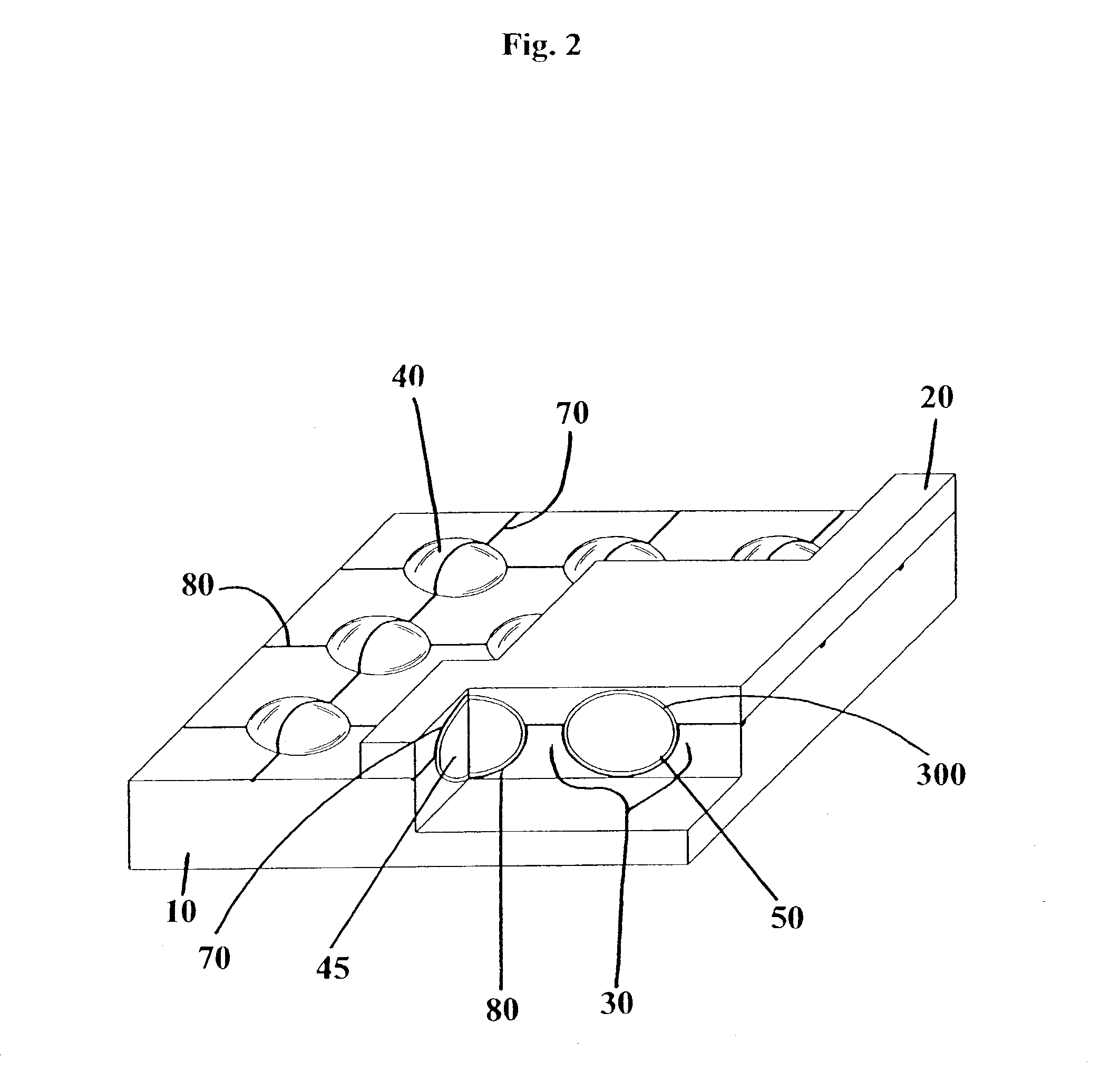

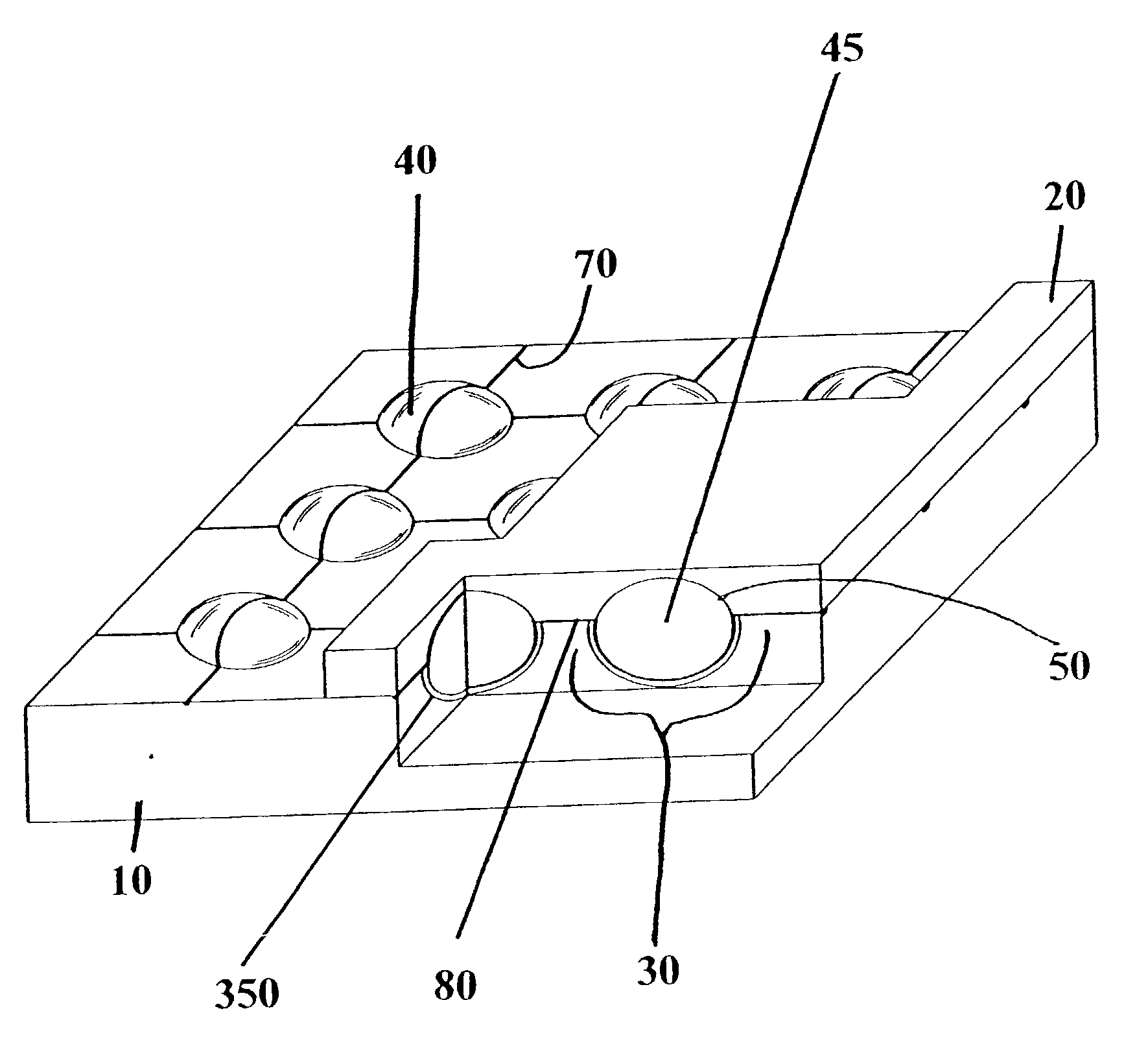

Micro-component for use in a light-emitting panel

InactiveUS6762566B1Sufficient resolutionManufactured very thinMechanical apparatusVolume/mass flow by thermal effectsEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. Several improved methods of forming micro-components are also disclosed.

Owner:LEIDOS

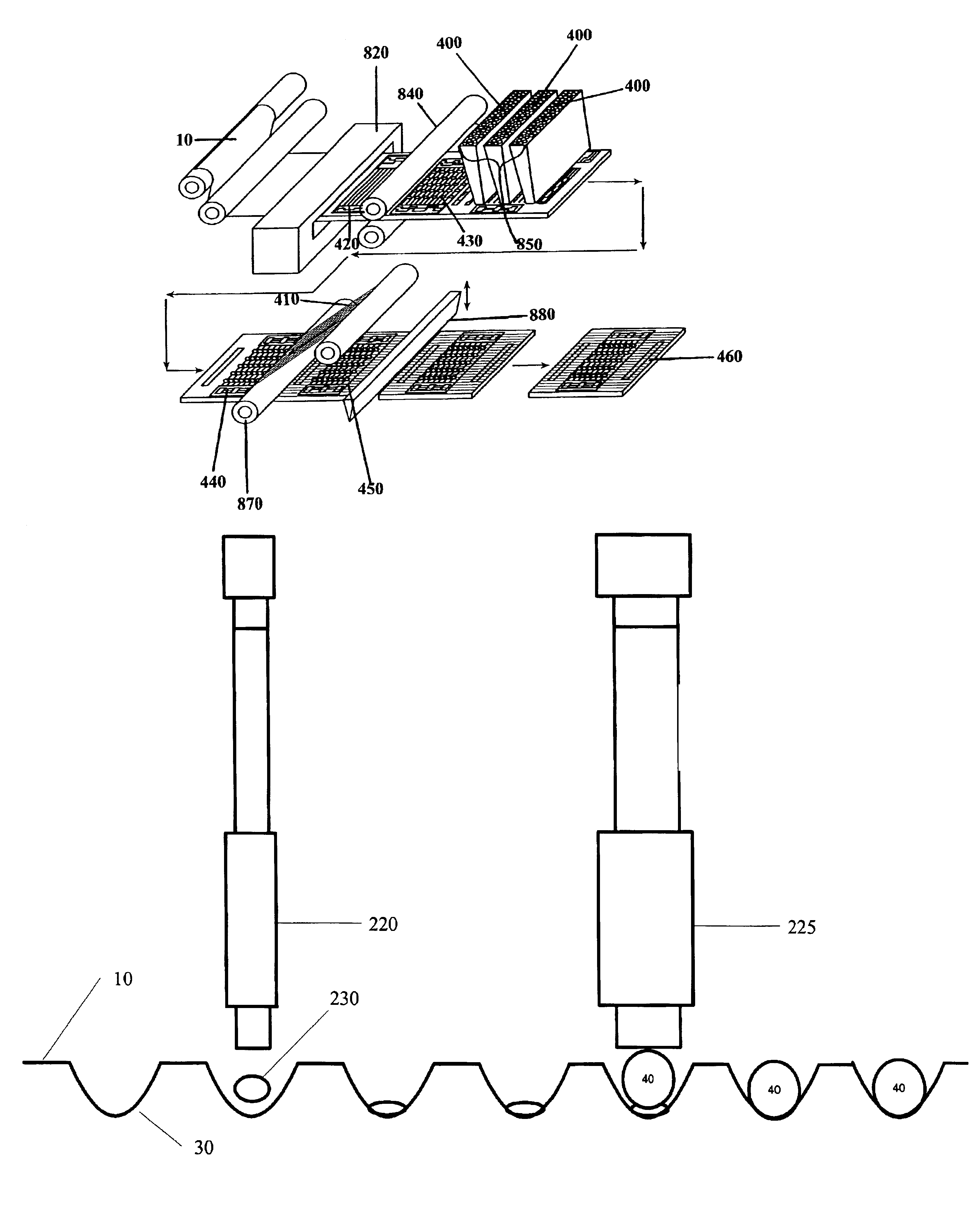

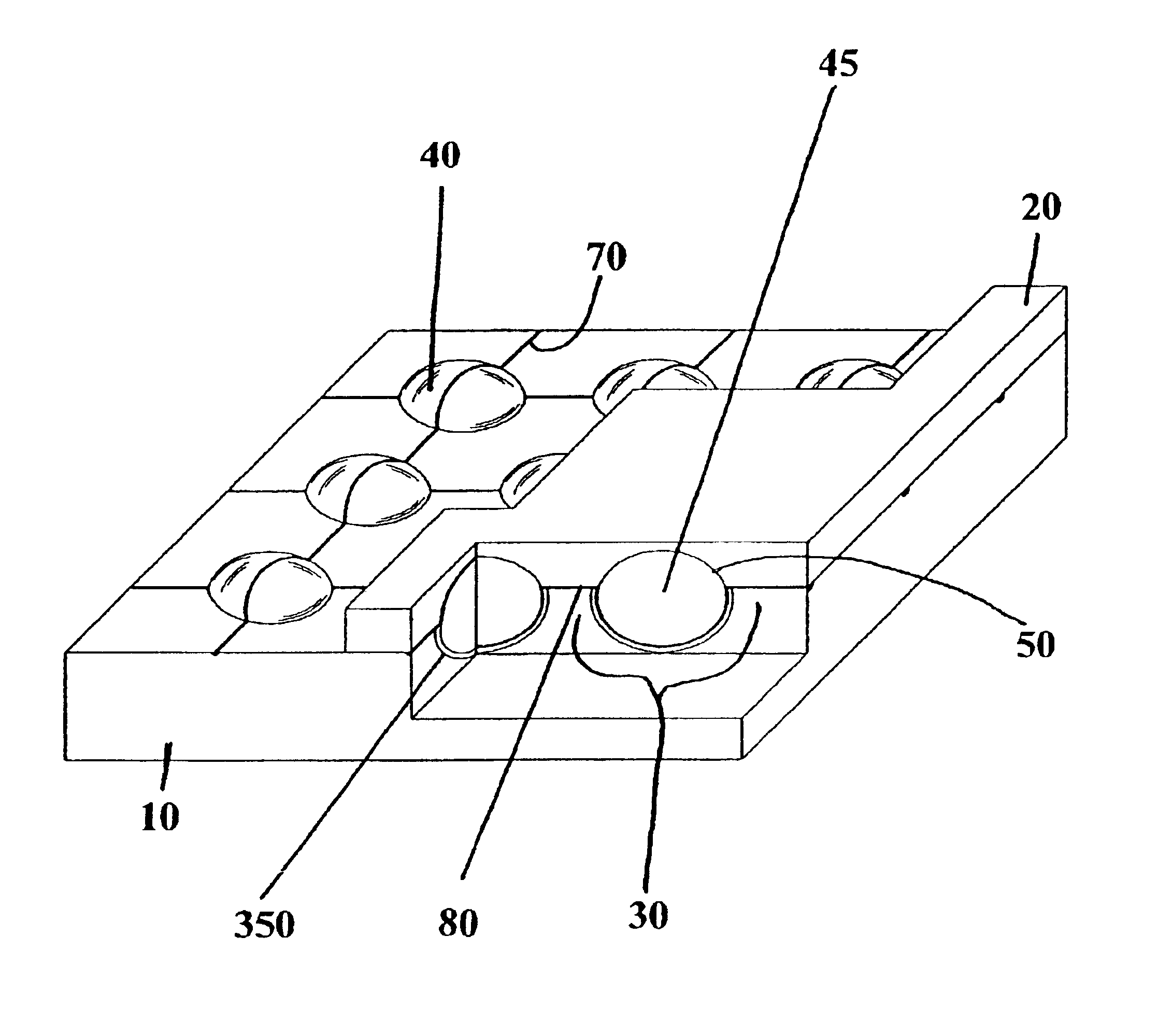

Method for making a light-emitting panel

InactiveUS6612889B1Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusProduct gasEngineering

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

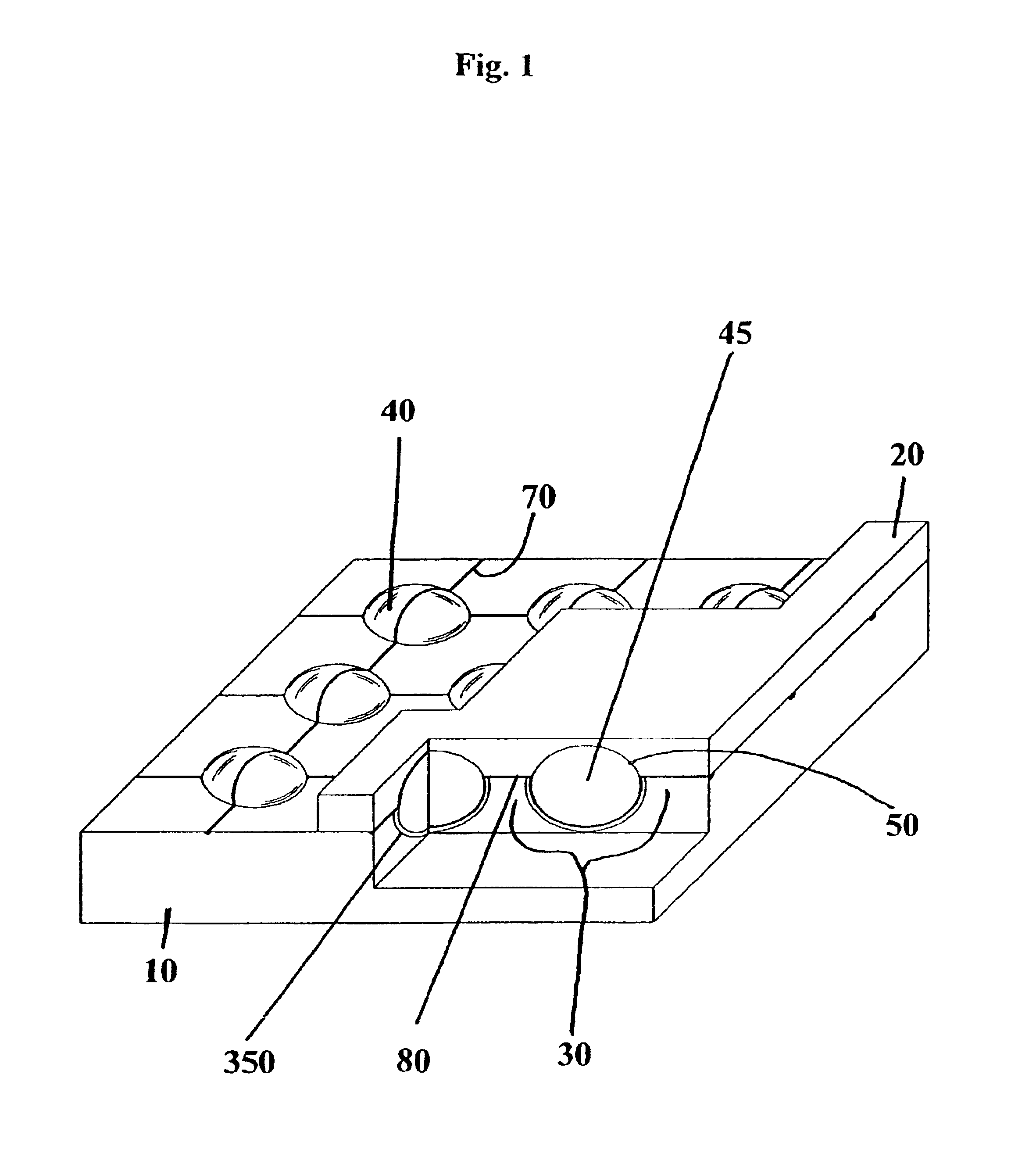

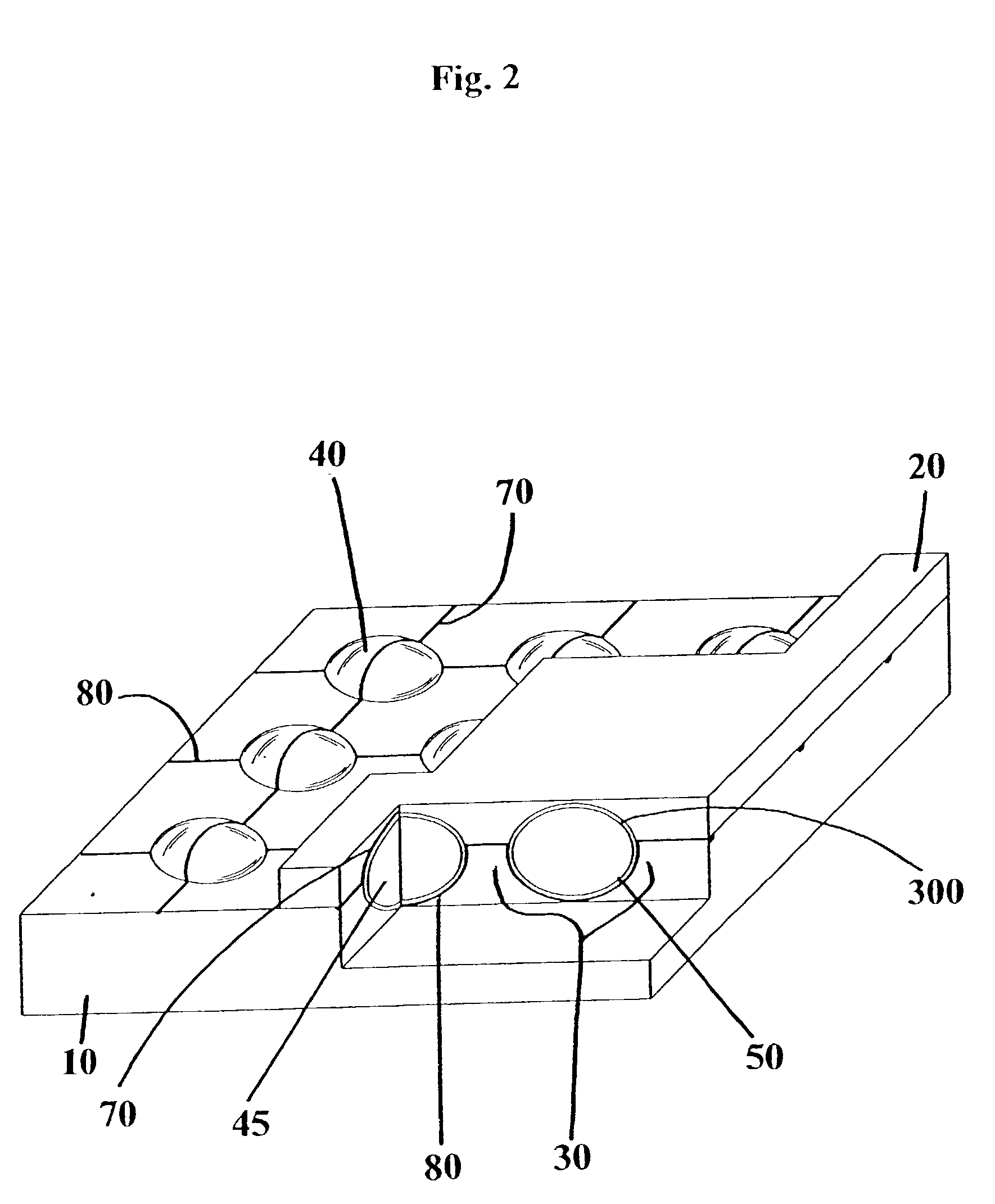

Method and system for energizing a micro-component in a light-emitting panel

InactiveUS6570335B1Sufficient resolutionManufactured very thinPoint-like light sourceStatic indicating devicesEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of energizing a micro-component is also disclosed.

Owner:LEIDOS

Method for testing a light-emitting panel and the components therein

InactiveUS6620012B1Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringIonization

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. A method of testing a light-emitting panel and the component parts therein is also disclosed, which uses a web fabrication process to manufacturing light-emitting panels combined with inline testing after the various process steps of the manufacturing process to produce result which are used to adjust the various process steps and component parts.

Owner:LEIDOS

Use of printing and other technology for micro-component placement

InactiveUS6796867B2Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS6822626B2Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

Socket for use with a micro-component in a light-emitting panel

InactiveUS6646388B2Sufficient resolutionManufactured very thinEmission spectroscopyStatic indicating devicesEngineeringMaterials science

An improved light-emitting panel having a plurality of micro-components at least partially disposed in a socket and sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes.

Owner:LEIDOS INC

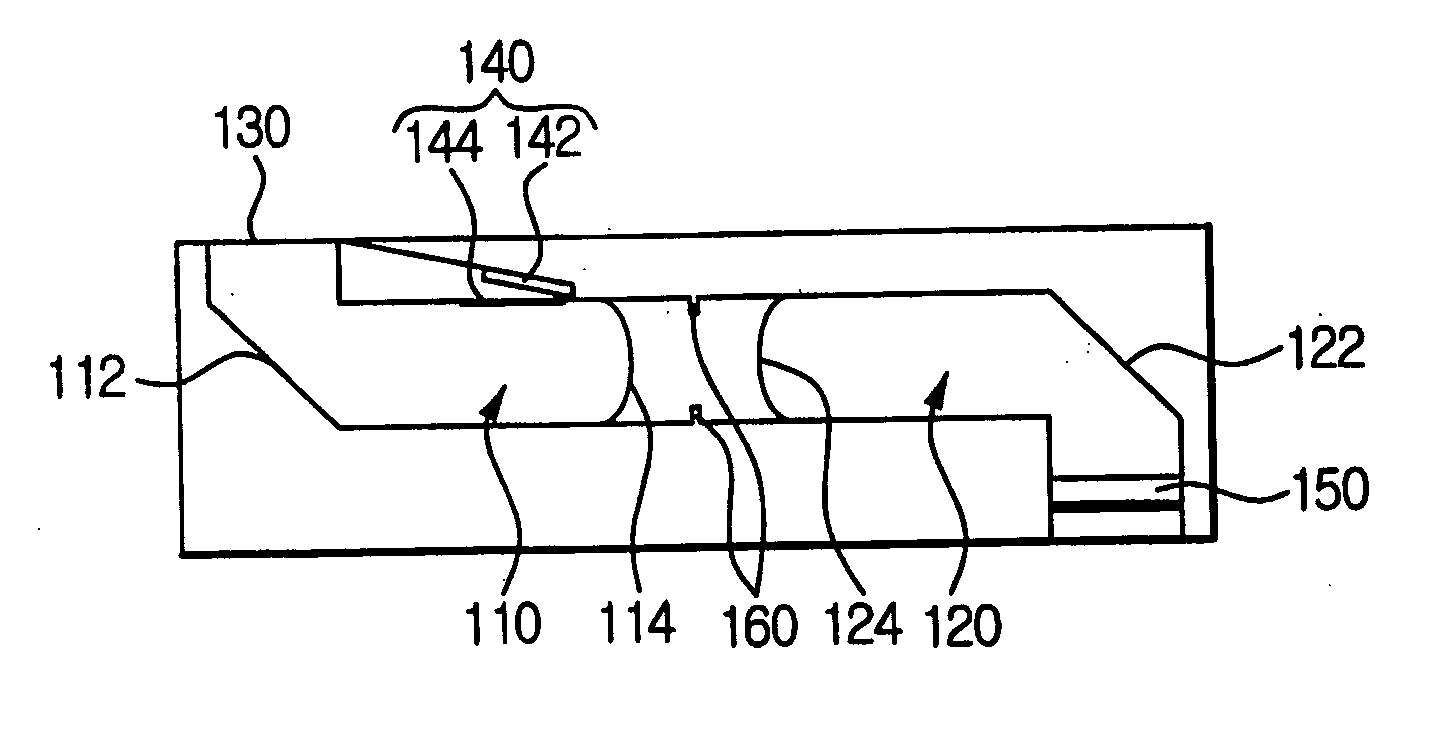

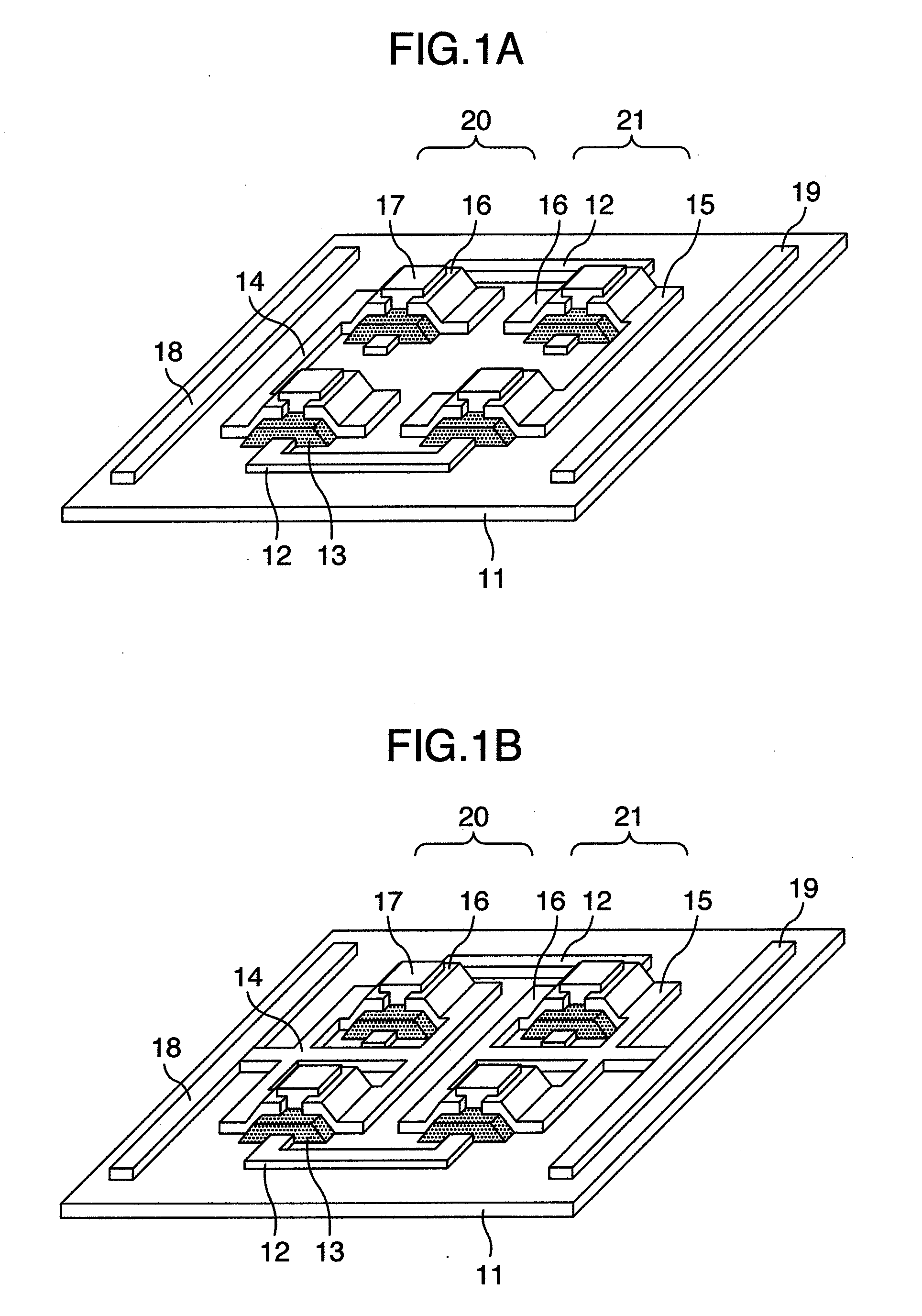

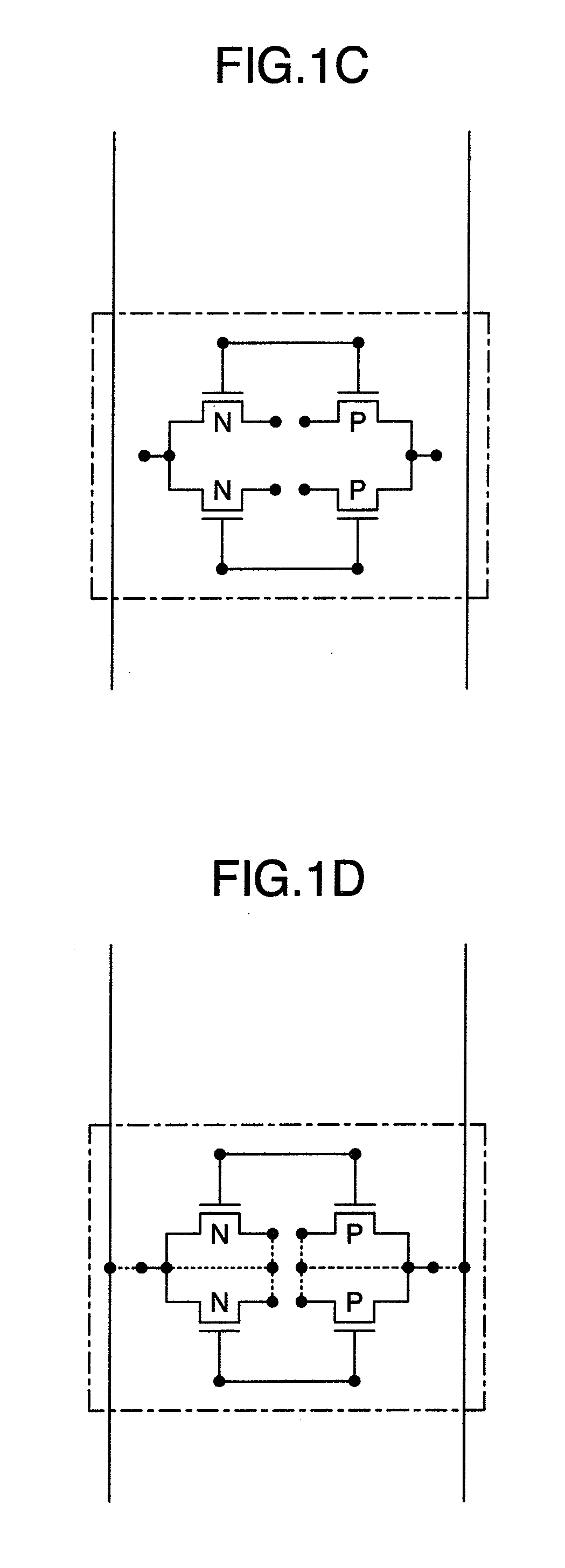

Method and apparatus for addressing micro-components in a plasma display panel

InactiveUS6801001B2Sufficient resolutionManufactured very thinPoint-like light sourceStatic indicating devicesDisplay deviceAlternative methods

An improved light-emitting display having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large trigger voltage is supplied across the micro-component by up to two triggering electrodes and ionization can be maintain by a sustain voltage supplied by up to two sustain electrodes. The display is further divided into a plurality of panels that can be individually addressed in parallel, preferably directly through the back of the panels and can include voltage multiplying circuitry to decrease the power demands for addressing circuitry. Alternative methods of addressing the micro-components include the use of directed light and arrangements of electrodes to address multiple micro-components with a single electrode.

Owner:LEIDOS

Light-emitting panel and a method for making

InactiveUS20030164684A1Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusProduct gasEngineering

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS INC

Method for on-line testing of a light emitting panel

InactiveUS6935913B2Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringLight-emitting diode

Owner:LEIDOS

Method for testing a light-emitting panel and the components therein

InactiveUS20040063373A1Sufficient resolutionManufactured very thinStatic indicating devicesAlternating current plasma display panelsIonizationVoltage

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. A method of testing a light-emitting panel and the component parts therein is also disclosed, which uses a web fabrication process to manufacturing light-emitting panels combined with inline testing after the various process steps of the manufacturing process to produce result which are used to adjust the various process steps and component parts.

Owner:SCI APPL INT CORP

Light-emitting panel and a method for making

InactiveUS20030094891A1Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusProduct gasEngineering

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

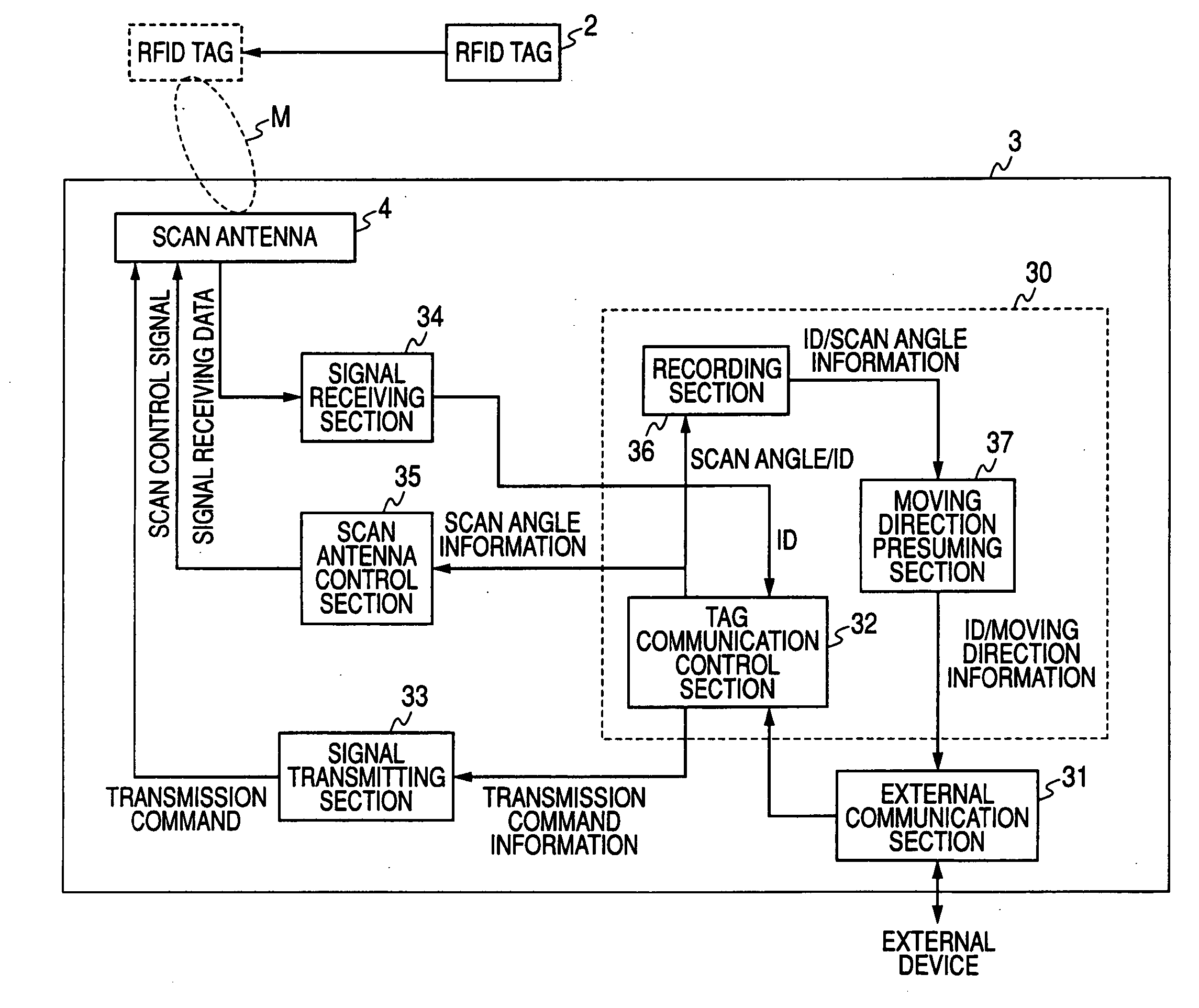

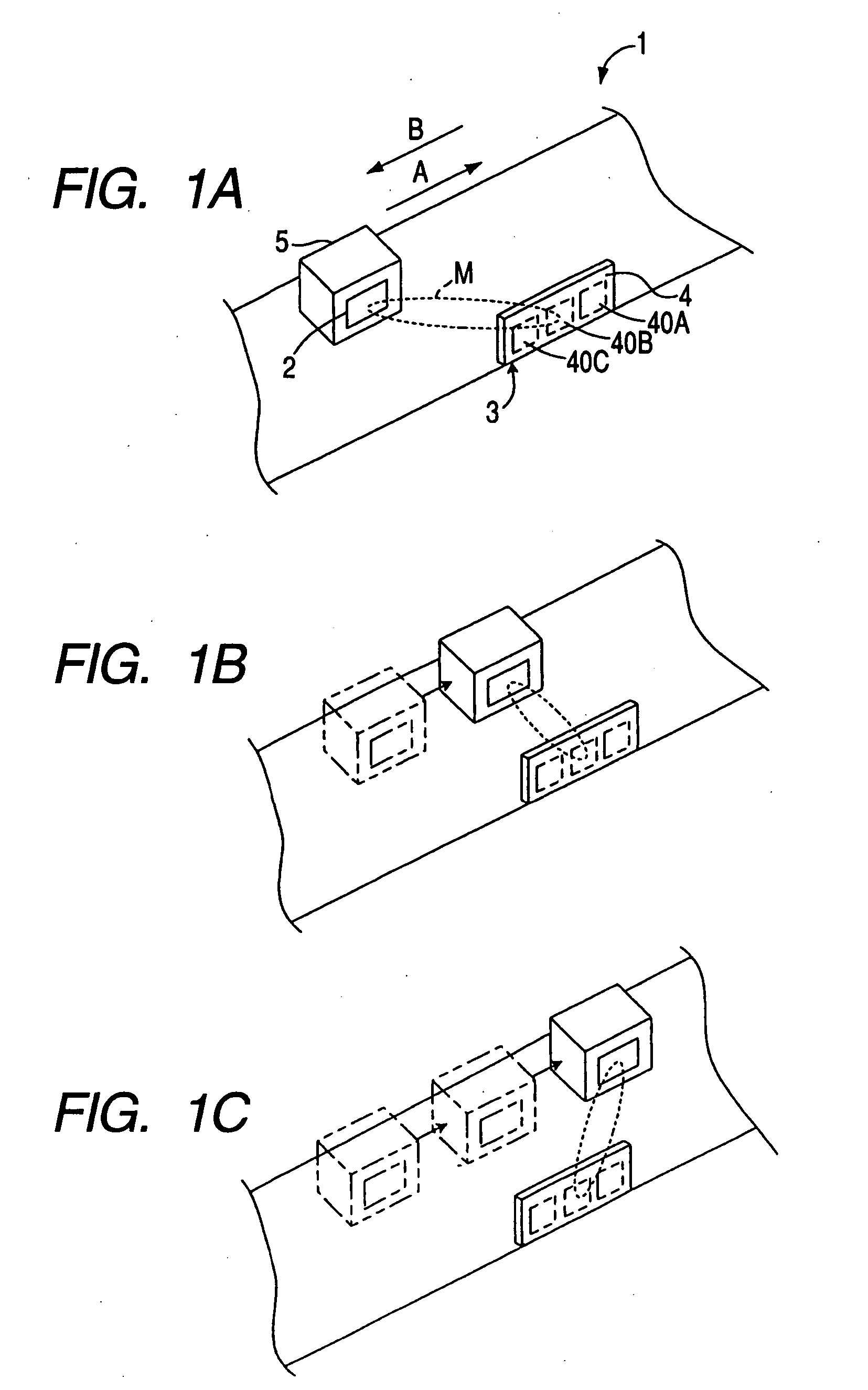

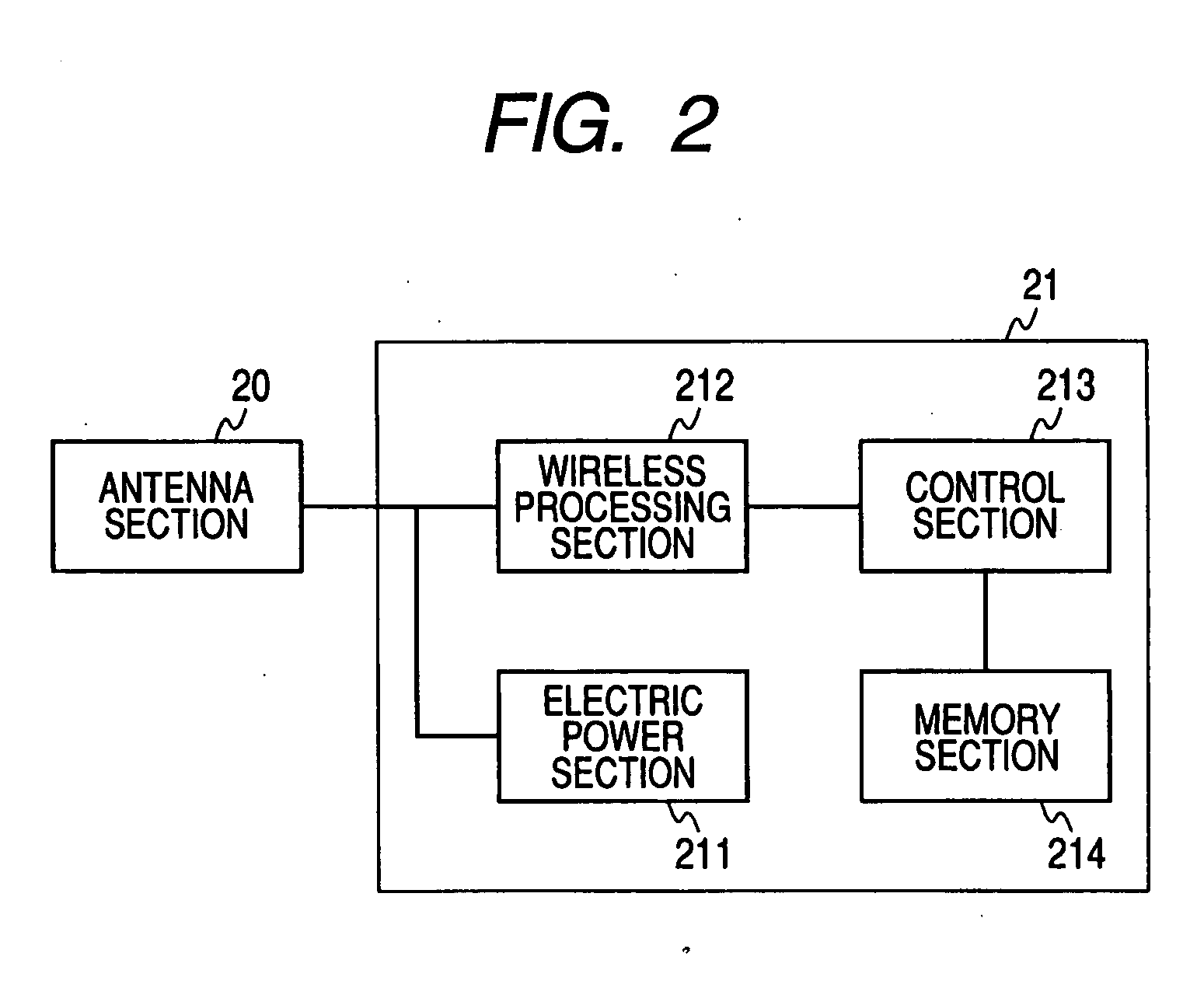

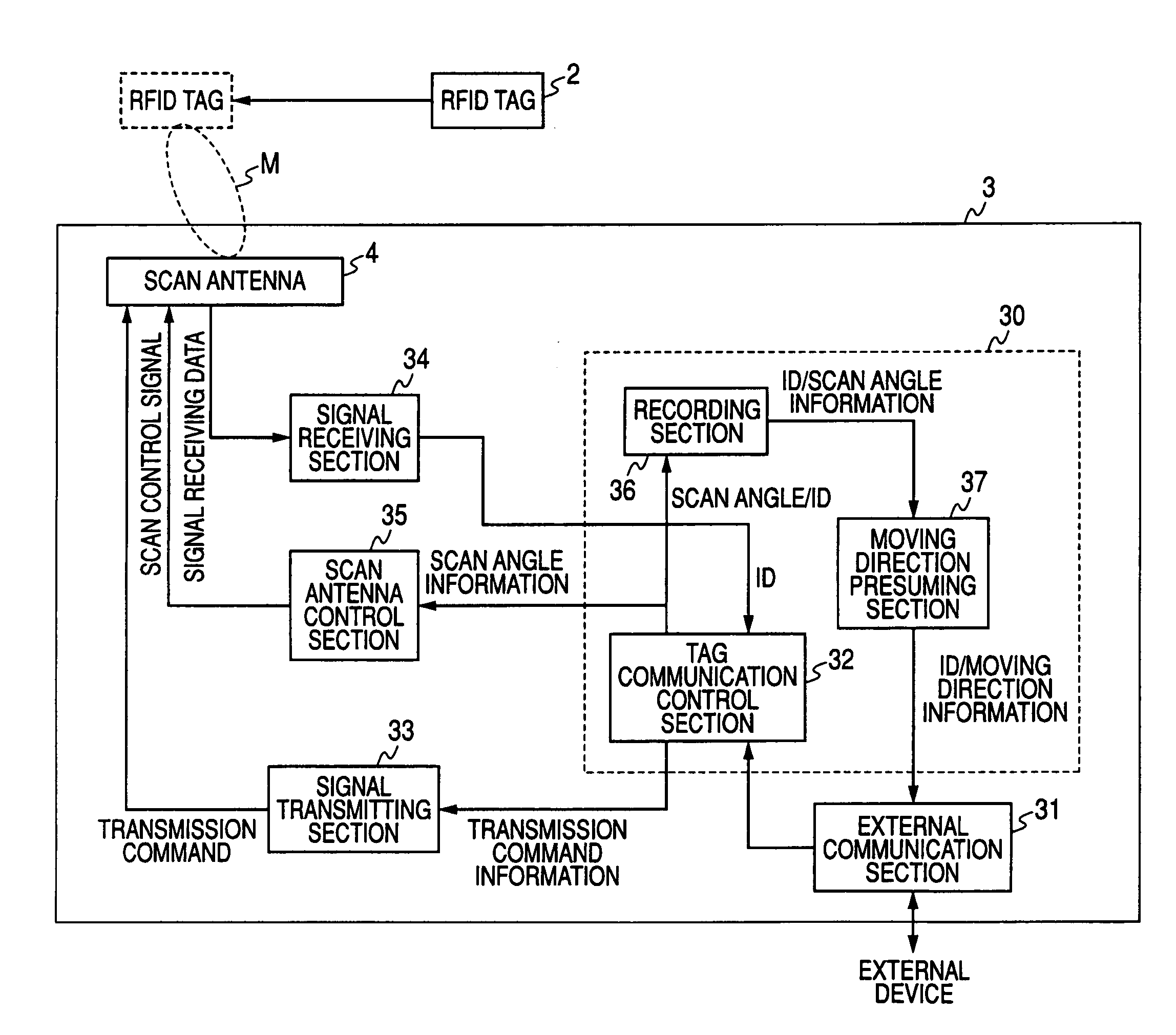

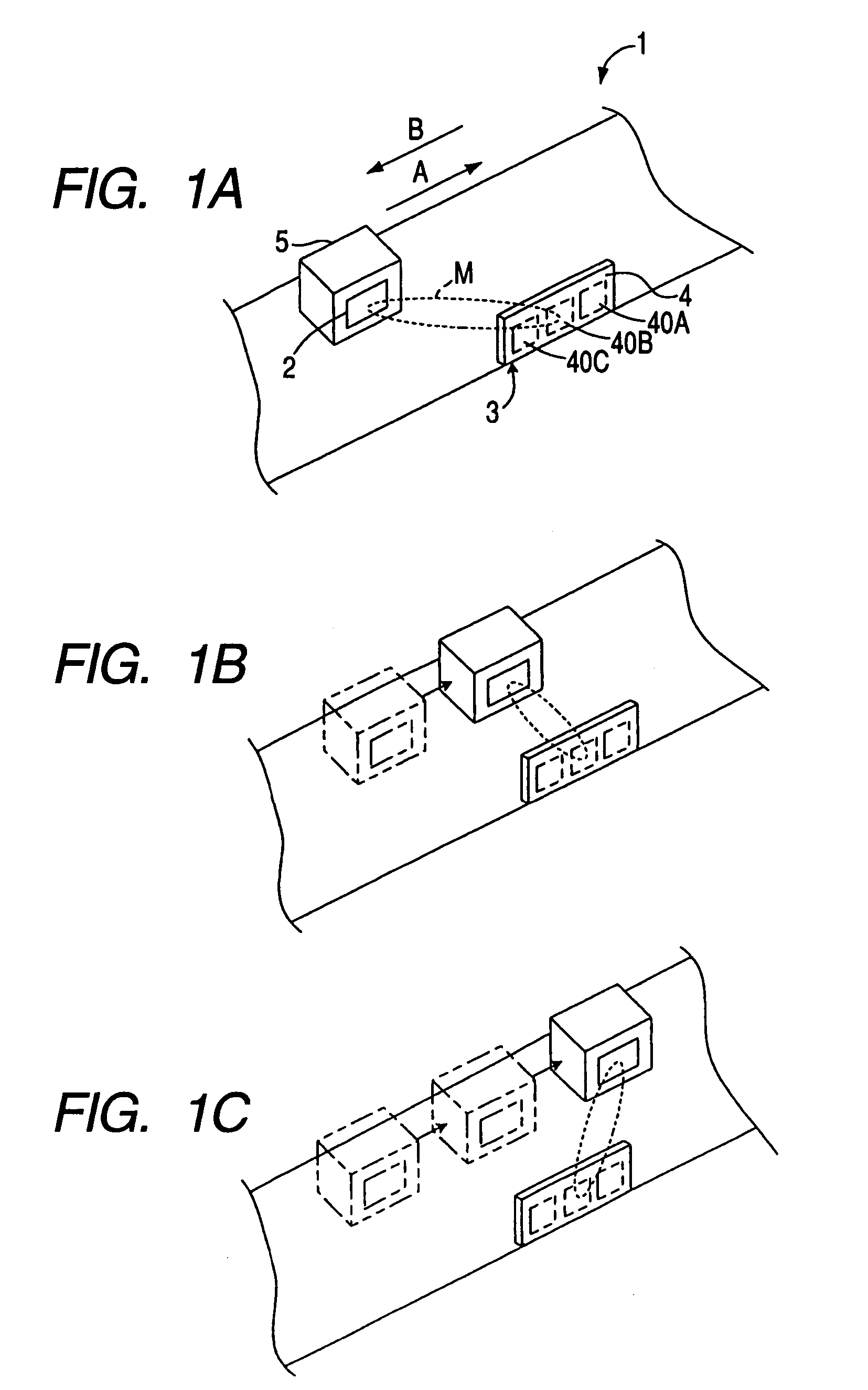

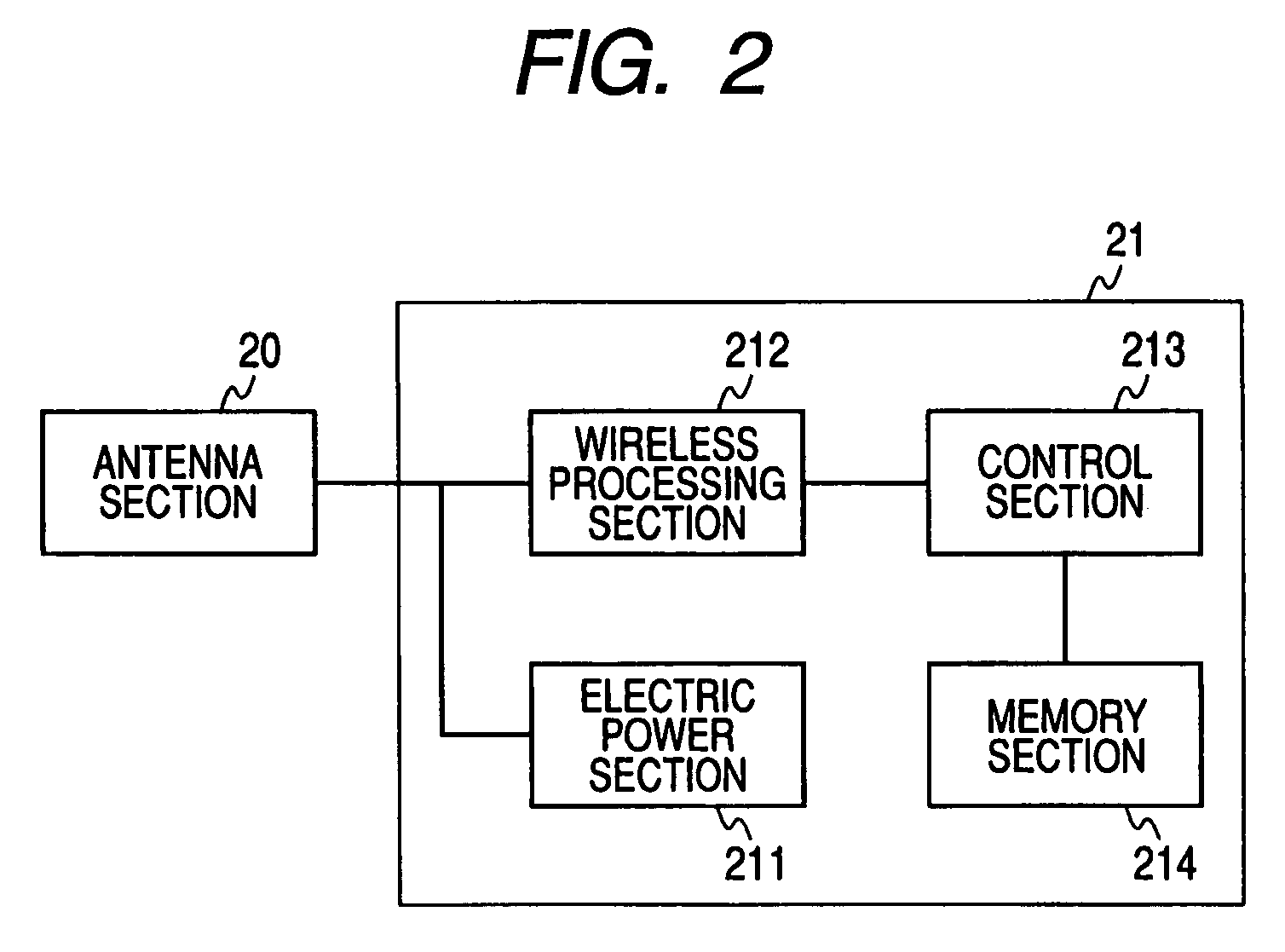

Tag communication device, tag moving direction detecting system and tag moving direction detecting method

ActiveUS20070273530A1Simple processEasy to detectSubscribers indirect connectionBurglar alarm by hand-portable articles removalLinear approximationDirection detection

The invention provides a tag communication device, a tag moving direction detecting system and a tag moving direction detecting method able to detect the moving direction of a moving body attaching a RFID tag thereto by simple processing, and able to easily detect the moving direction even when its moving speed is increased. A scan antenna scans a beam of a transmitted radio wave toward a belt conveyer for conveying baggage with a RFID tag. ID is read from the RFID tag, and reading NO. and a scan angle are related and recorded to a measuring data table, and plot data are generated. These plot data are plotted in an XY coordinate system, and a plot graph is generated. Further, a linear approximate straight line is calculated from this plot graph, and a moving direction of the baggage is detected from an inclination value of the linear approximate straight line.

Owner:ORMON CORP

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS7288014B1Solve the lack of resolutionManufactured very thinMechanical apparatusAlternating current plasma display panelsEngineeringPre testing

Owner:LEIDOS

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS20040175854A1Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

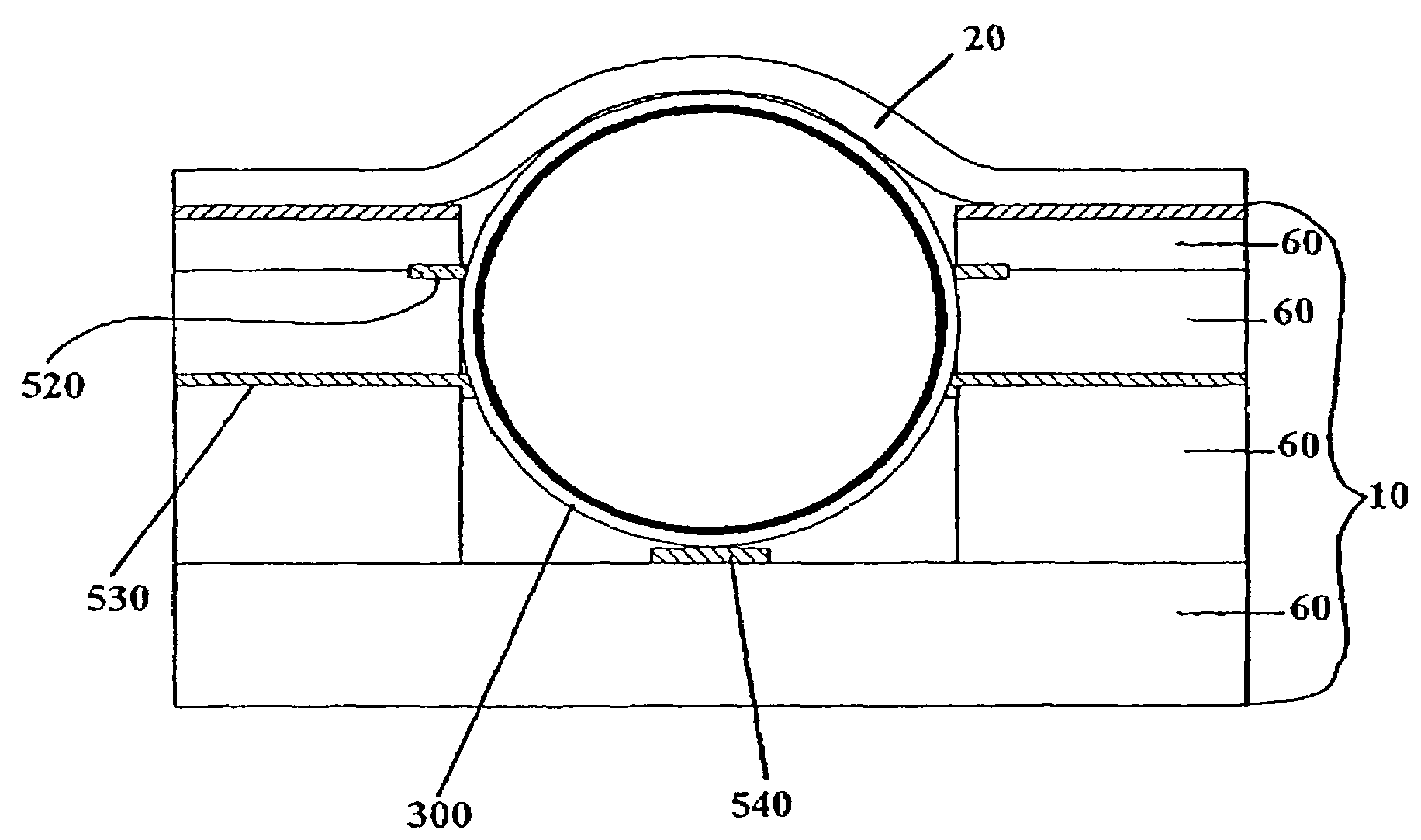

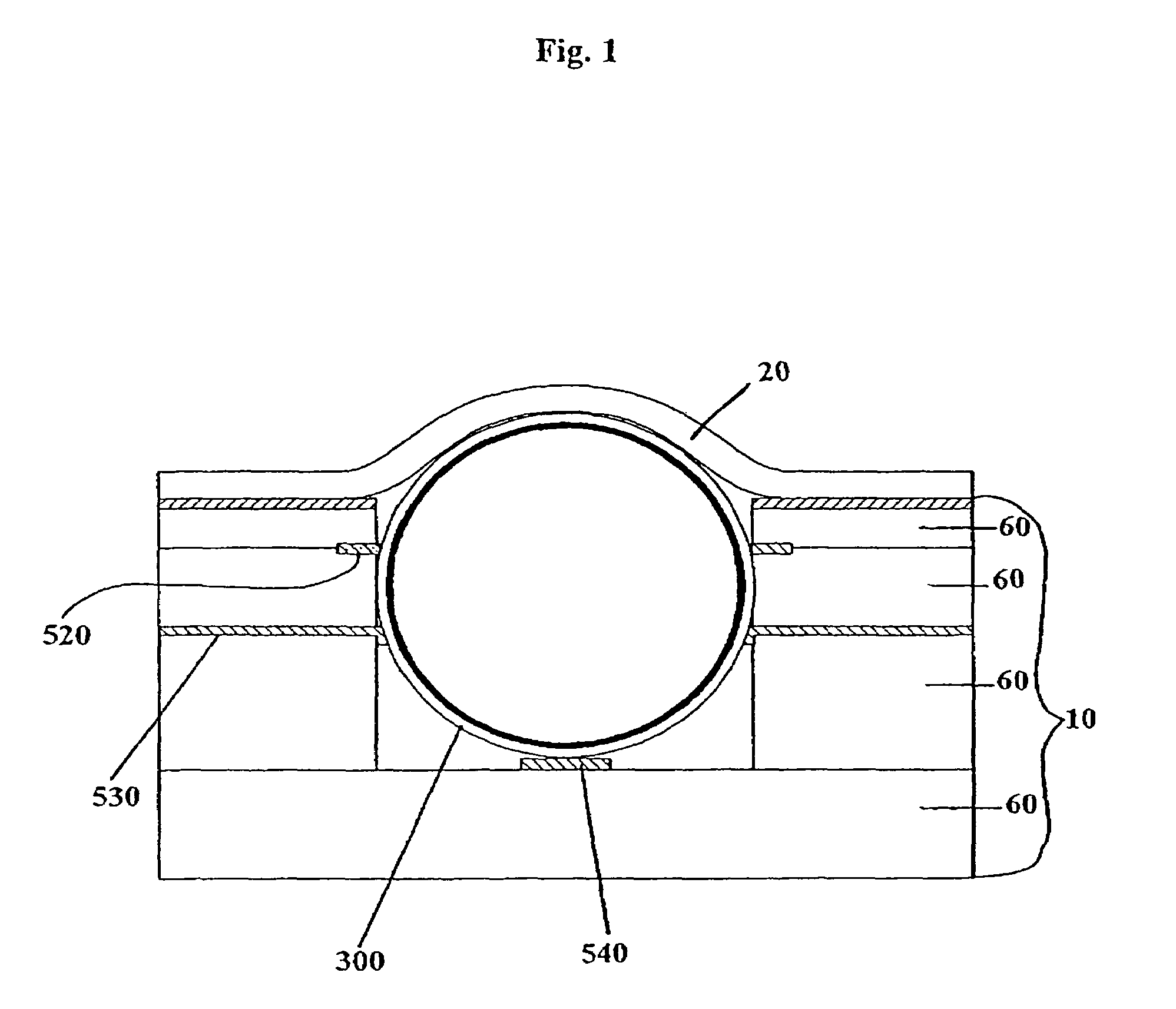

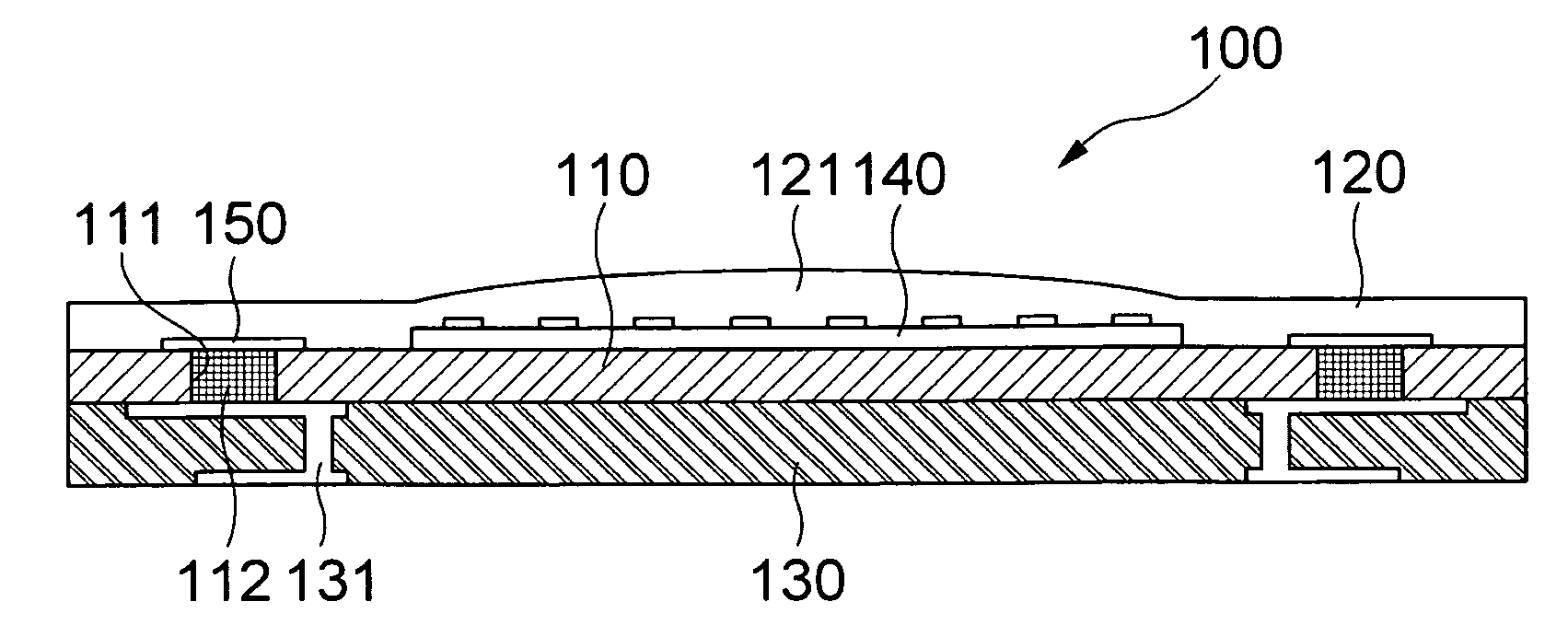

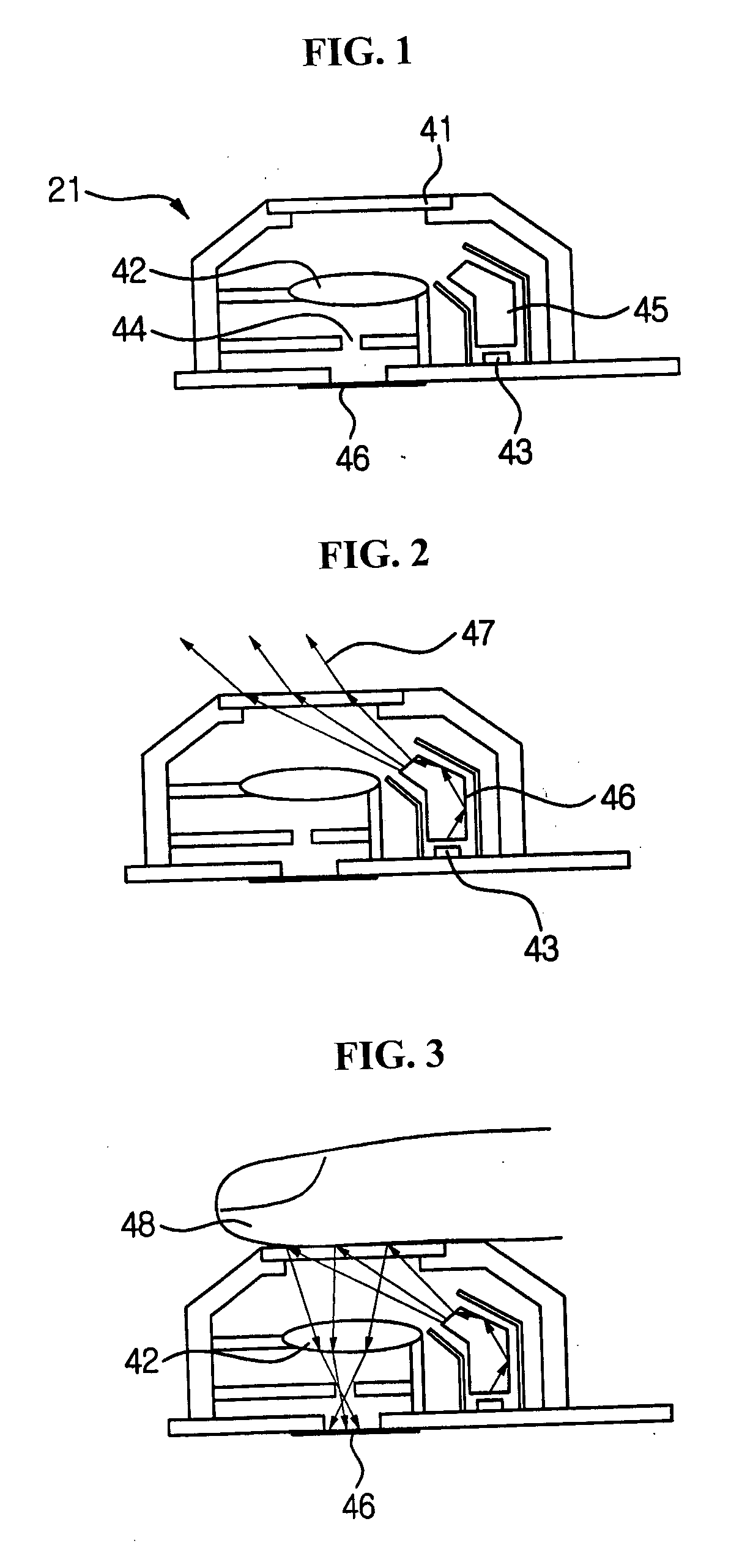

Camera module package and method of manufacturing the same

InactiveUS20080304821A1Prevent penetrationManufactured very thinTelevision system detailsSolid-state devicesComputer moduleCamera module

The present invention relates to a camera module package having flexibility and a method of manufacturing the same. Provided is the camera module package according to the invention including a silicon wafer mounted with the image sensor in the center of a top surface thereof and provided with pads both sides of the image sensor, a lens unit opened to form a convex lens in a mounting portion of the image sensor in an upper part of the wafer, and a flexible board tightly joined to a bottom surface of the wafer and electrically connected to the pads by an internal pattern. The camera module package can be thinly manufactured and since the camera module package has flexibility, the camera module package can be easily attached to a bendable substrate and to the inside an IT apparatus.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method and apparatus for addressing micro-components in a plasma display panel

InactiveUS20030214243A1Sufficient resolutionManufactured very thinPoint-like light sourceStatic indicating devicesDisplay deviceSubstitution method

An improved light-emitting display having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large trigger voltage is supplied across the micro-component by up to two triggering electrodes and ionization can be maintain by a sustain voltage supplied by up to two sustain electrodes. The display is further divided into a plurality of panels that can be individually addressed in parallel, preferably directly through the back of the panels and can include voltage multiplying circuitry to decrease the power demands for addressing circuitry. Alternative methods of addressing the micro-components include the use of directed light and arrangements of electrodes to address multiple micro-components with a single electrode.

Owner:LEIDOS

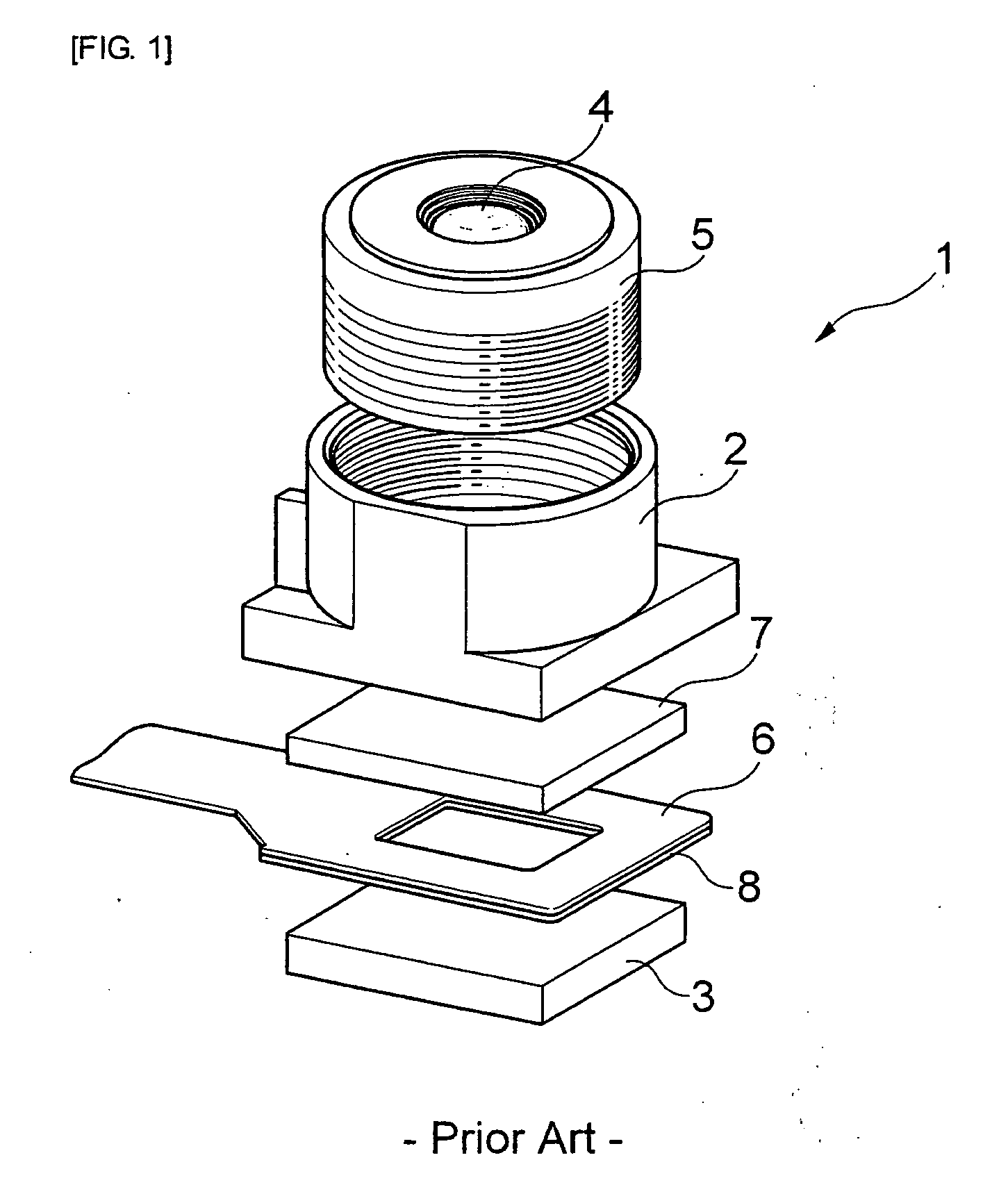

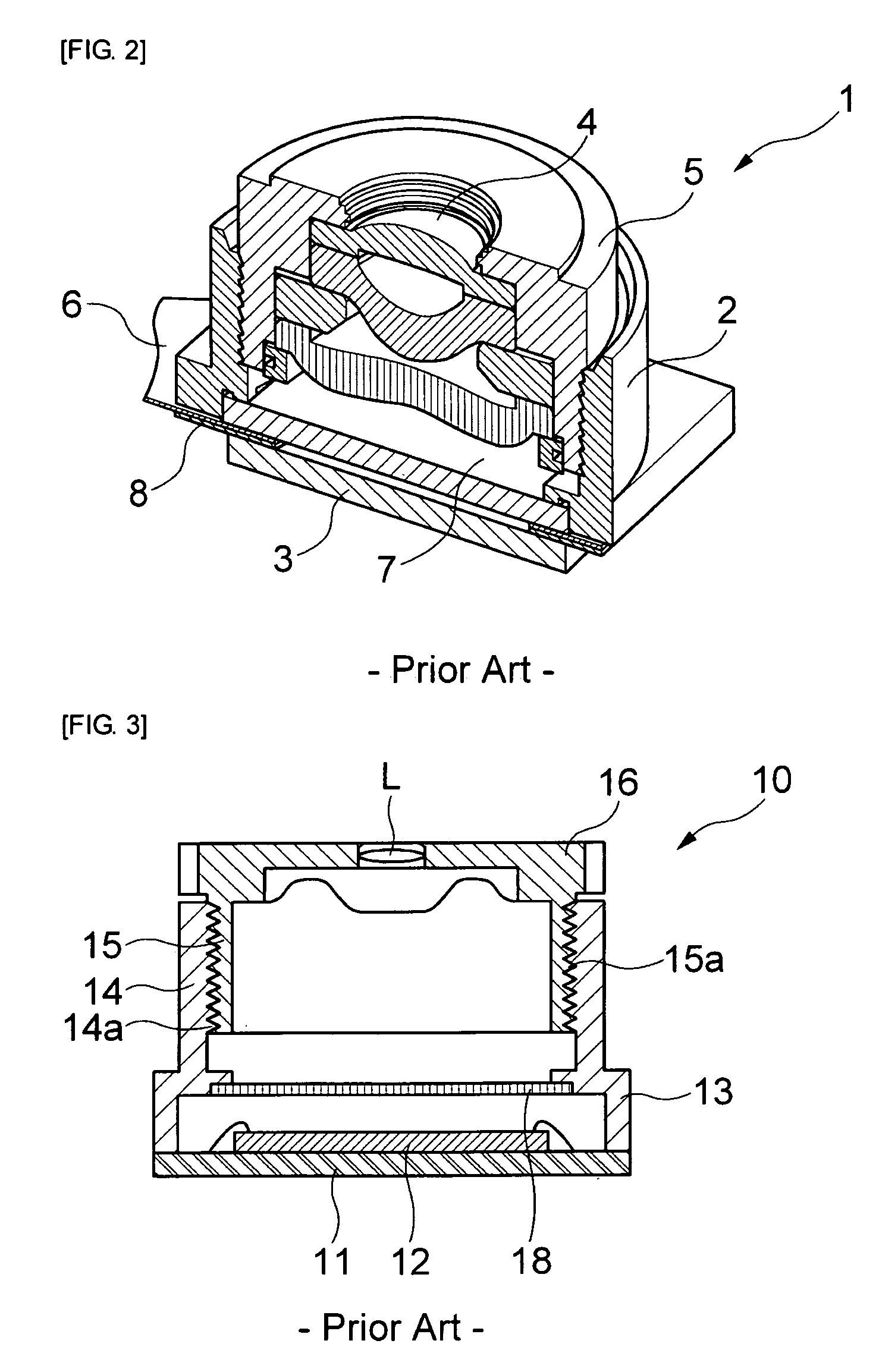

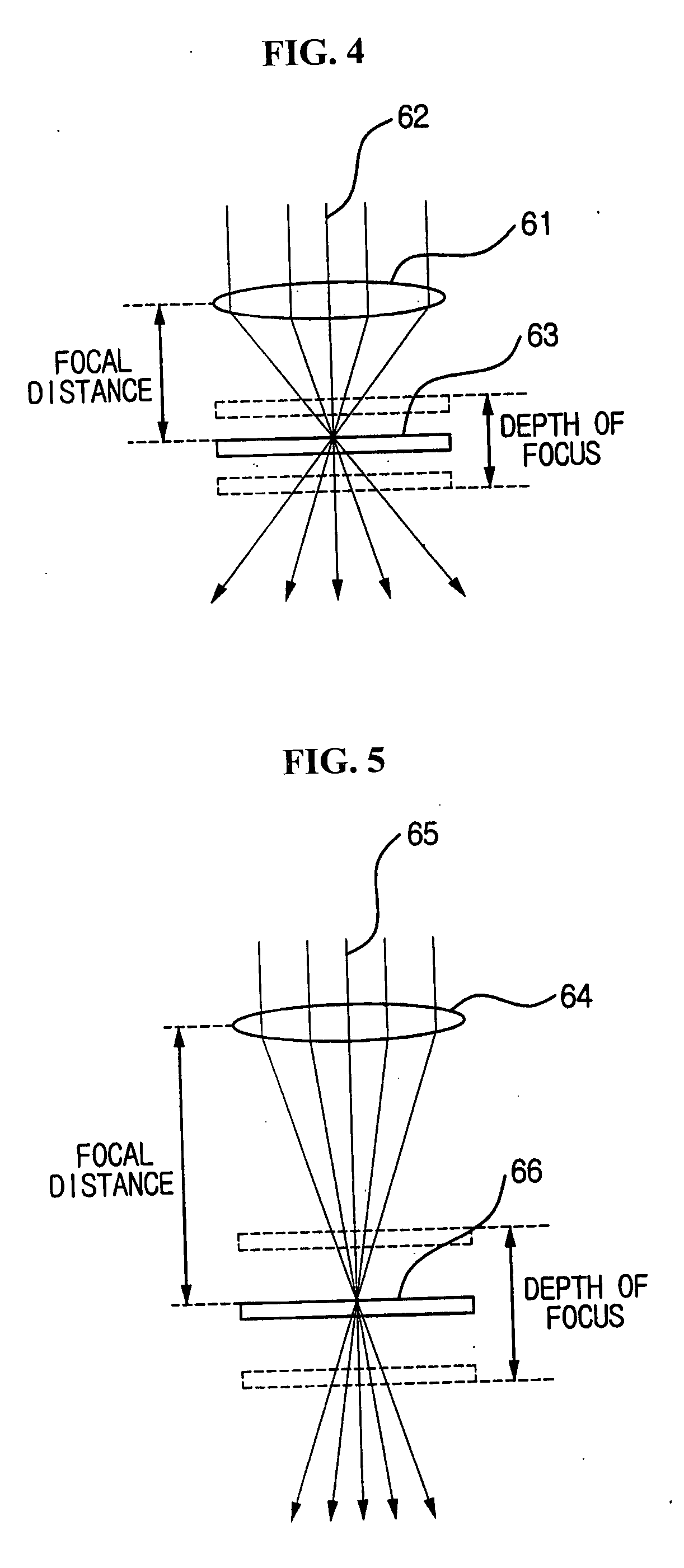

Ultra thin optical joystick and personal portable device having ultra thin optical joystick

InactiveUS20060038776A1Sufficient depth of focusReduce the overall heightCathode-ray tube indicatorsInput/output processes for data processingJoystickWaveguide

An optical joystick includes a first waveguide including a first reflecting surface located below a reading area for sensing the movement of an object and a first plano-convex lens portion condensing light reflected from the first reflecting surface, a second waveguide including a second plano-convex lens portion facing the first plano-convex lens portion and a second reflecting surface for reflecting light refracted at the second plano-convex lens portion, and an image sensor located below the second reflecting surface. The first reflecting surface and the first plano-convex lens portion form a single body, and the second plano-convex lens portion and the second reflecting surface also form a single body. The reflecting surface and the lens portion are in a single body, thereby notably reducing the thickness of the optical joystick. The first and second waveguides are facing each other, thereby improving refraction and condensing light.

Owner:CRUCIALTEC +1

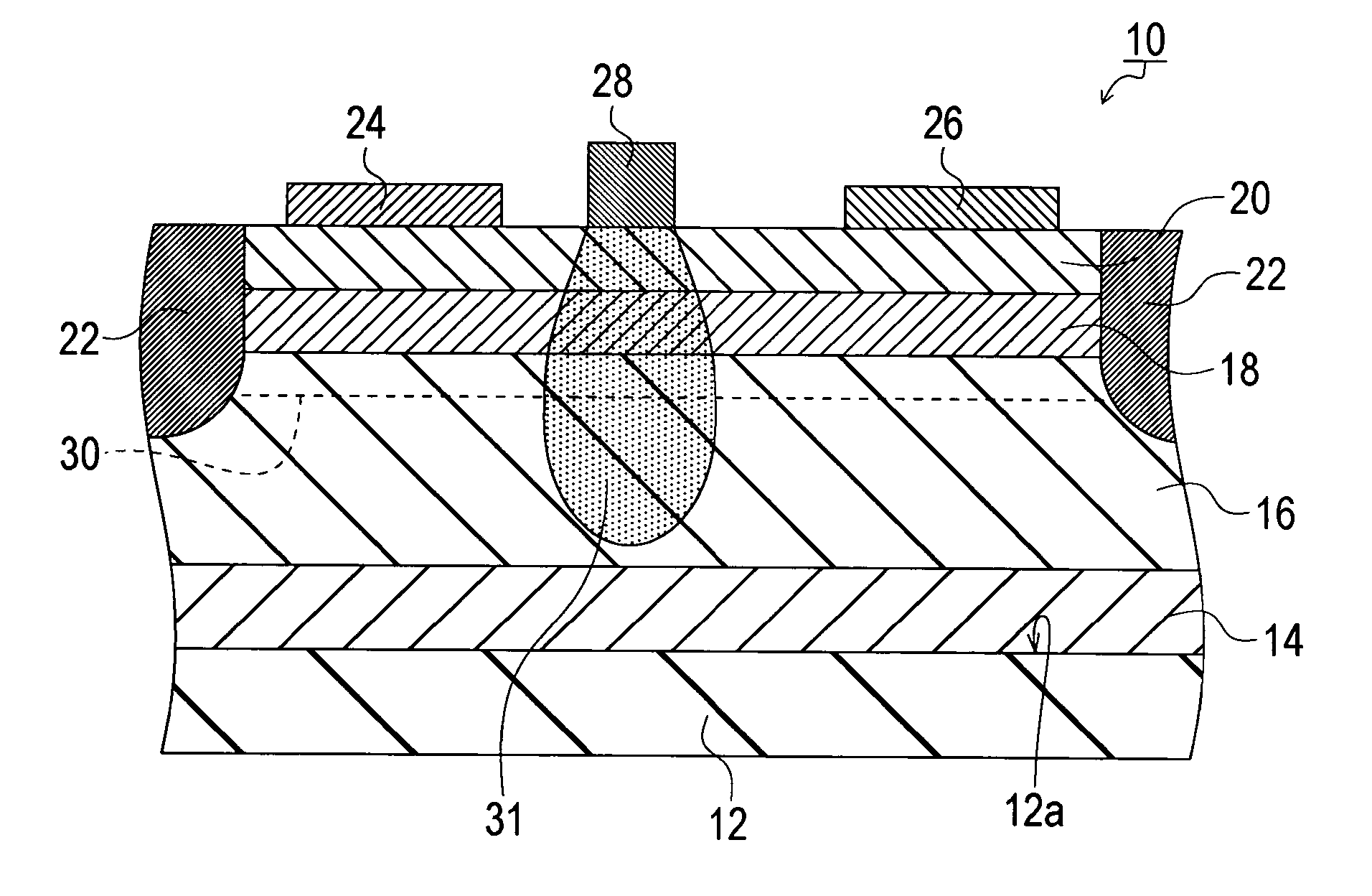

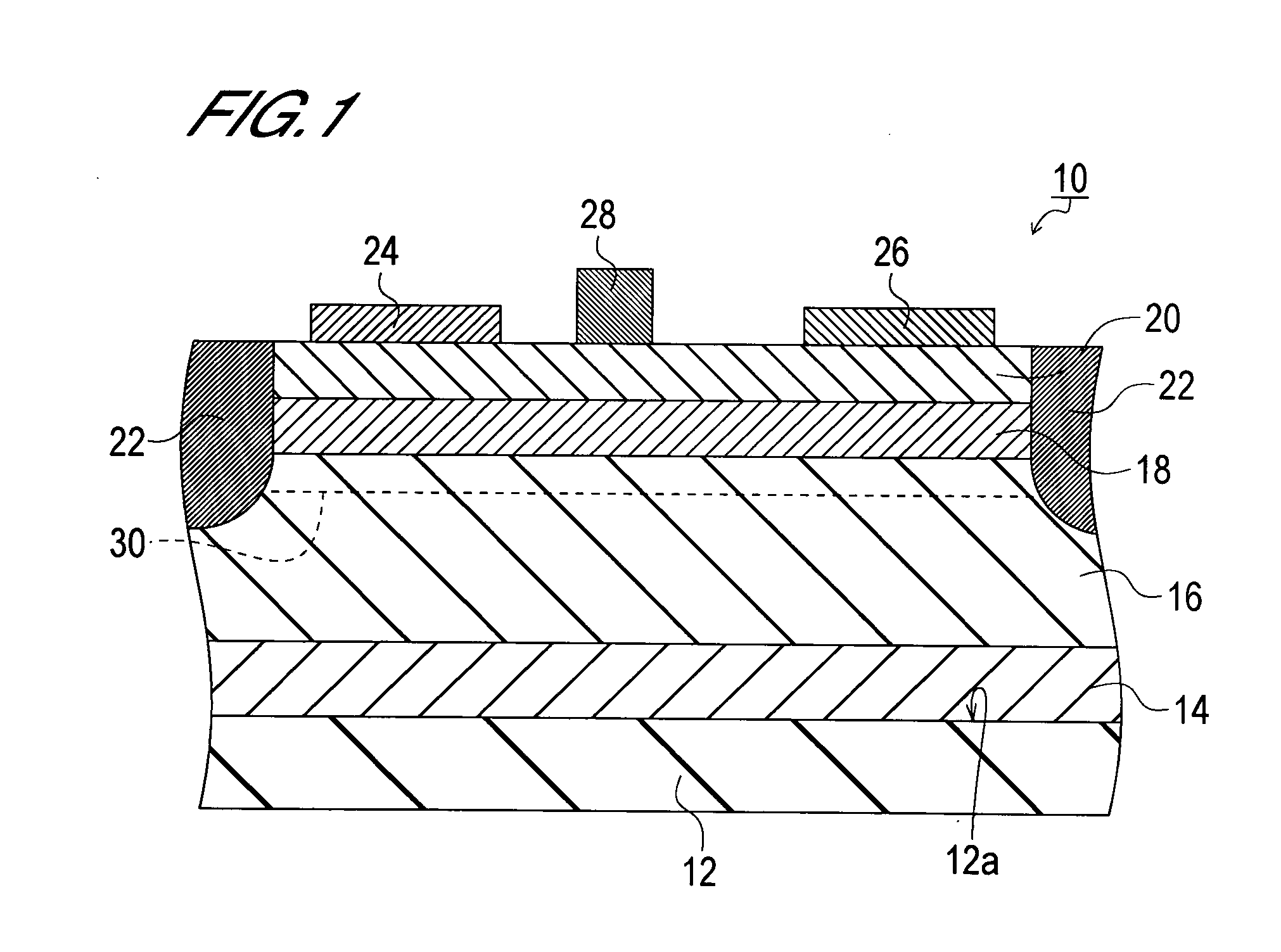

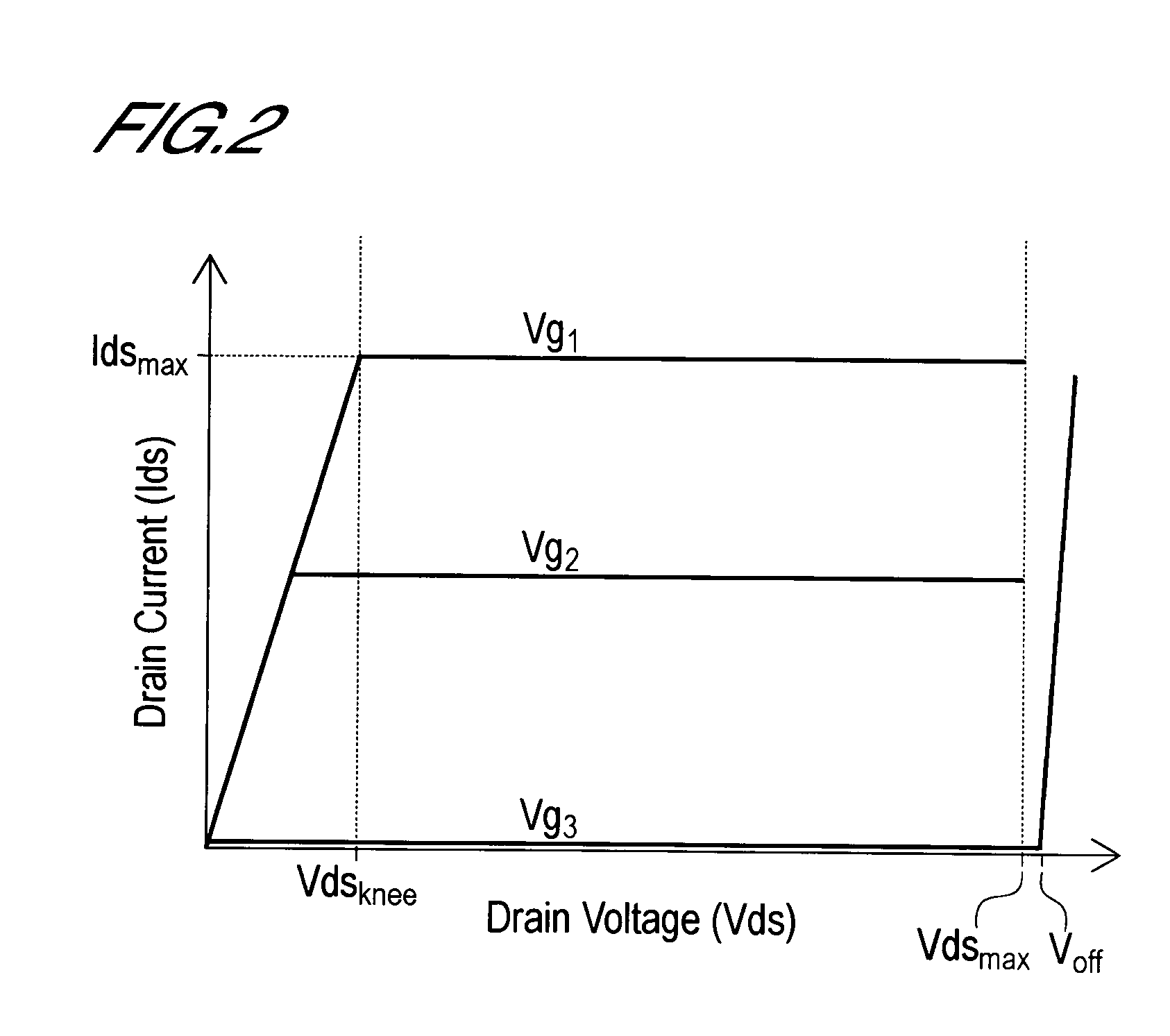

Wafer for semiconductor device fabrication, method of manufacture of same, and field effect transistor

InactiveUS20060214187A1Manufactured very thinImprove off-state breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorSemiconductor

A wafer for semiconductor device fabrication, from which large output power can be obtained by making the off-state breakdown voltage higher than in the prior art. The wafer for semiconductor device fabrication comprises a substrate, GaN electron transit layer formed on the side of the principal surface of the substrate, and AlGaN electron supply layer formed on the electron transit layer. The thickness of the electron transit layer is from 0.2 to 0.9 μm.

Owner:OKI ELECTRIC IND CO LTD

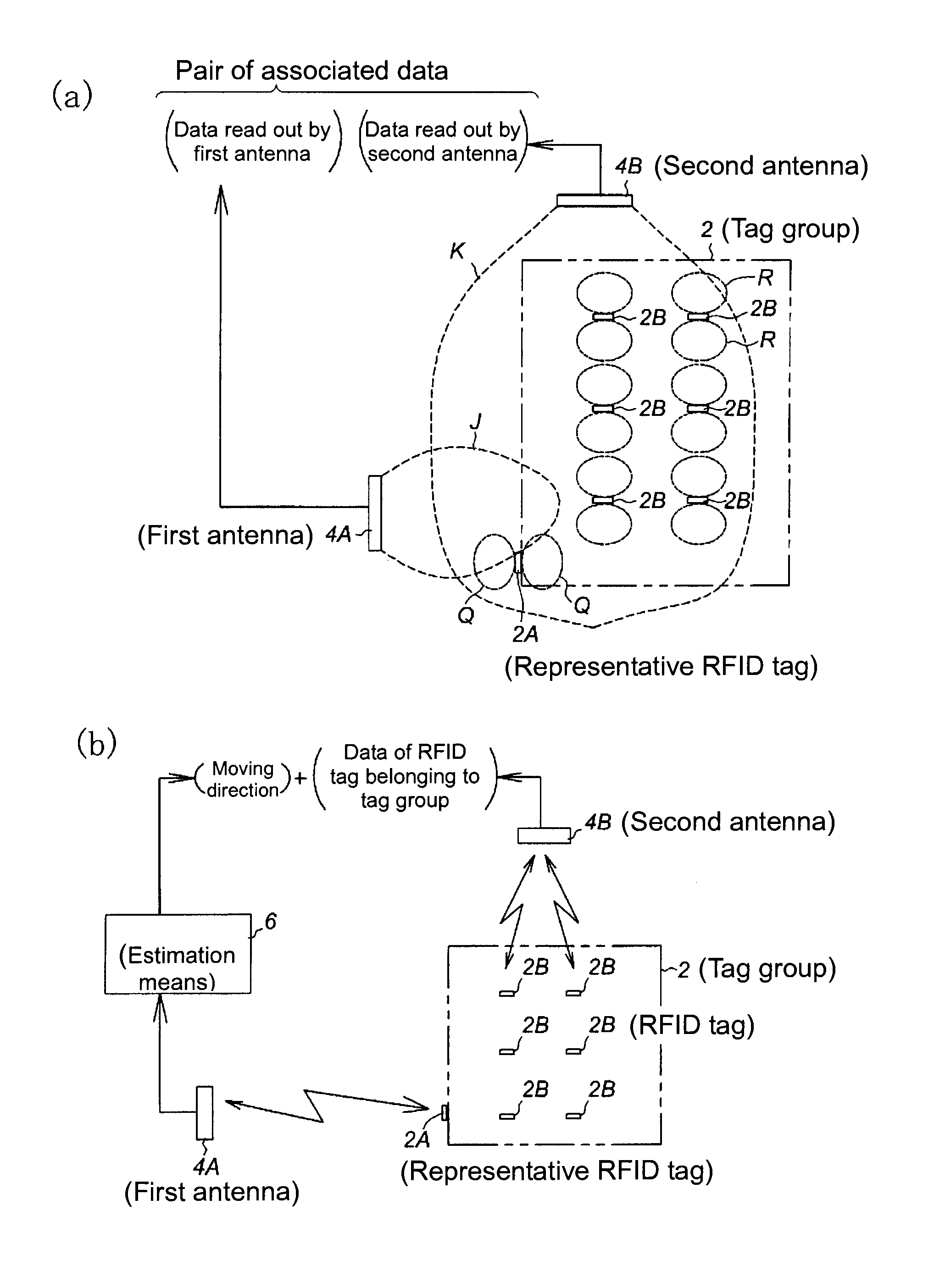

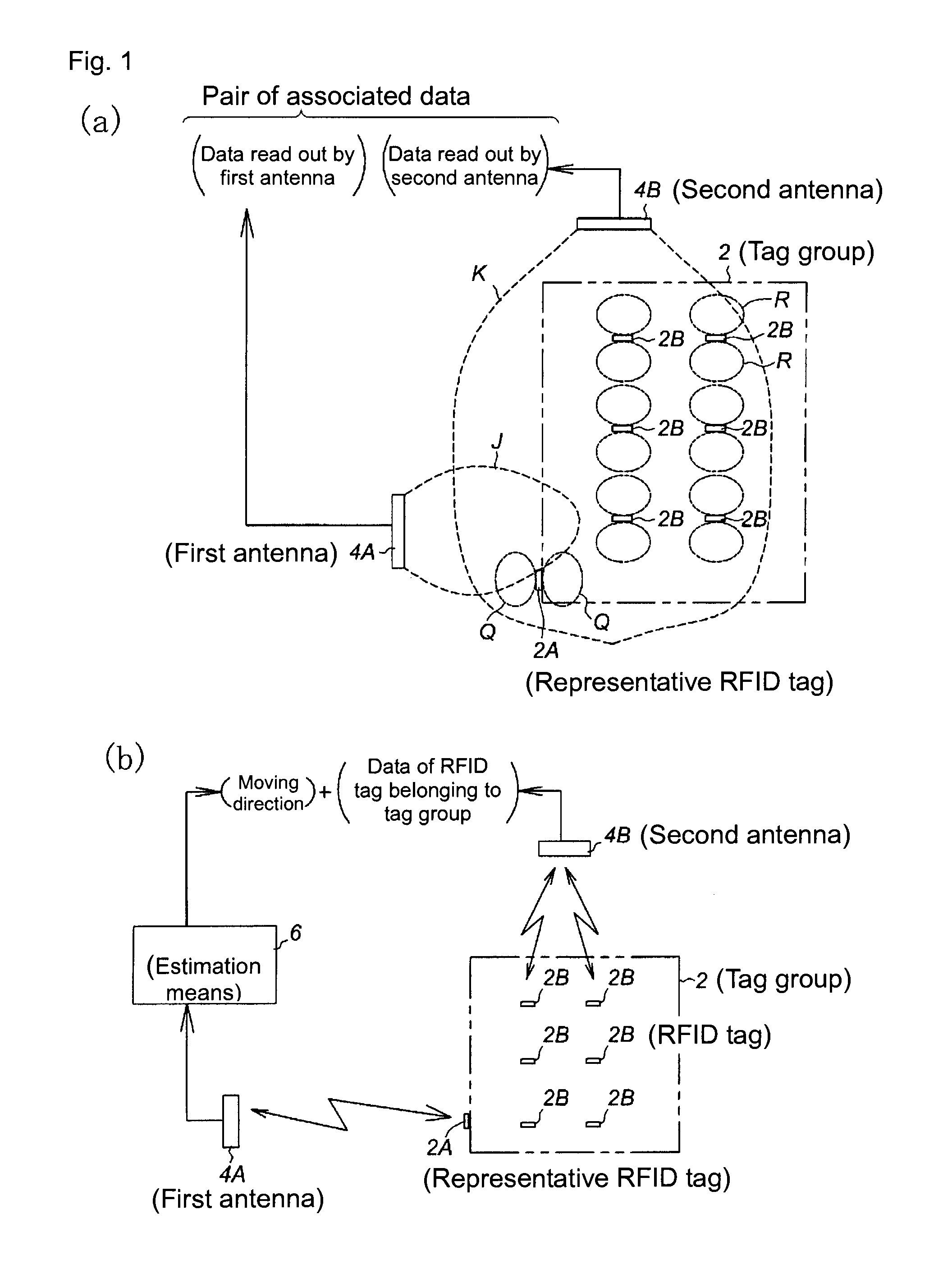

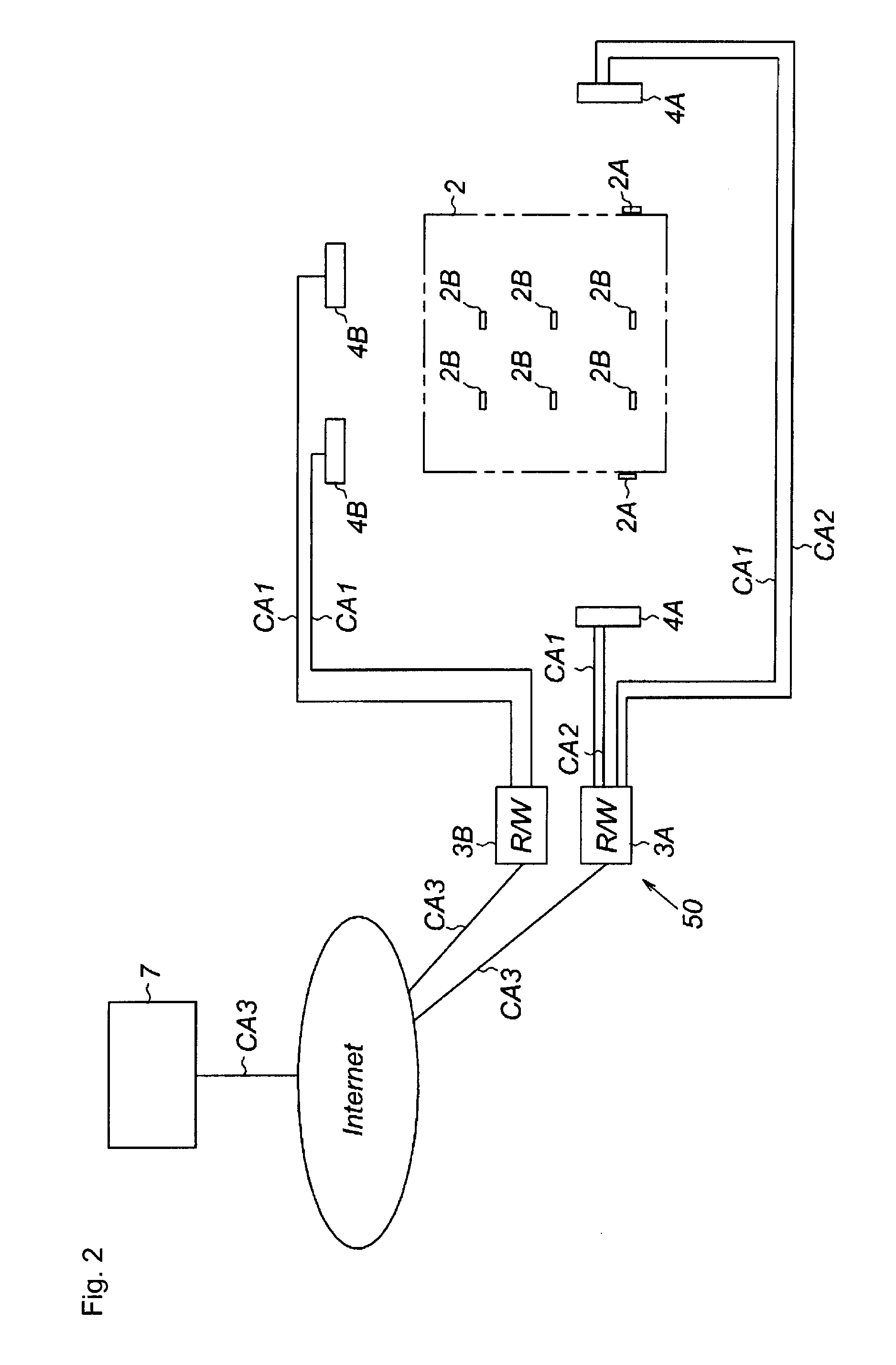

Tag associating system, tag associating method, and tag moving direction detection system

ActiveUS20100237995A1Easy to copyEstimation accuracy loweringCo-operative working arrangementsSensing record carriersDirection detectionWorld Wide Web

[Problems to be Solved] It is an object to provide a tag associating system that, when a plurality of RFID tags are collected to move as a tag group, associates the RFID tags belonging to the tag group with a representative RFID tag ranked as a representative of the tag group; its associating method; etc.[Means for Solving the Problems] The present system associates an RFID tag (2A) ranked as a representative of the tag group (2). A communication area (J) of a first antenna (4A) to read out data from the representative tag group (2A) is arranged to partially overlap with a communication area (K) of a second antenna (4B) to read out data from each RFID tag (2B) of the tag group (2). When the first antenna (4A) reads out a plurality of times data from the representative RFID tag (2A), the second antenna (4B) reads out data from each RFID tag (2B) of the tag group (2), so as to make the data read out from the representative RFID tag (2A) and the data reads out from the RFID tag (2B) of the tag group (2) into a pair of associated data.

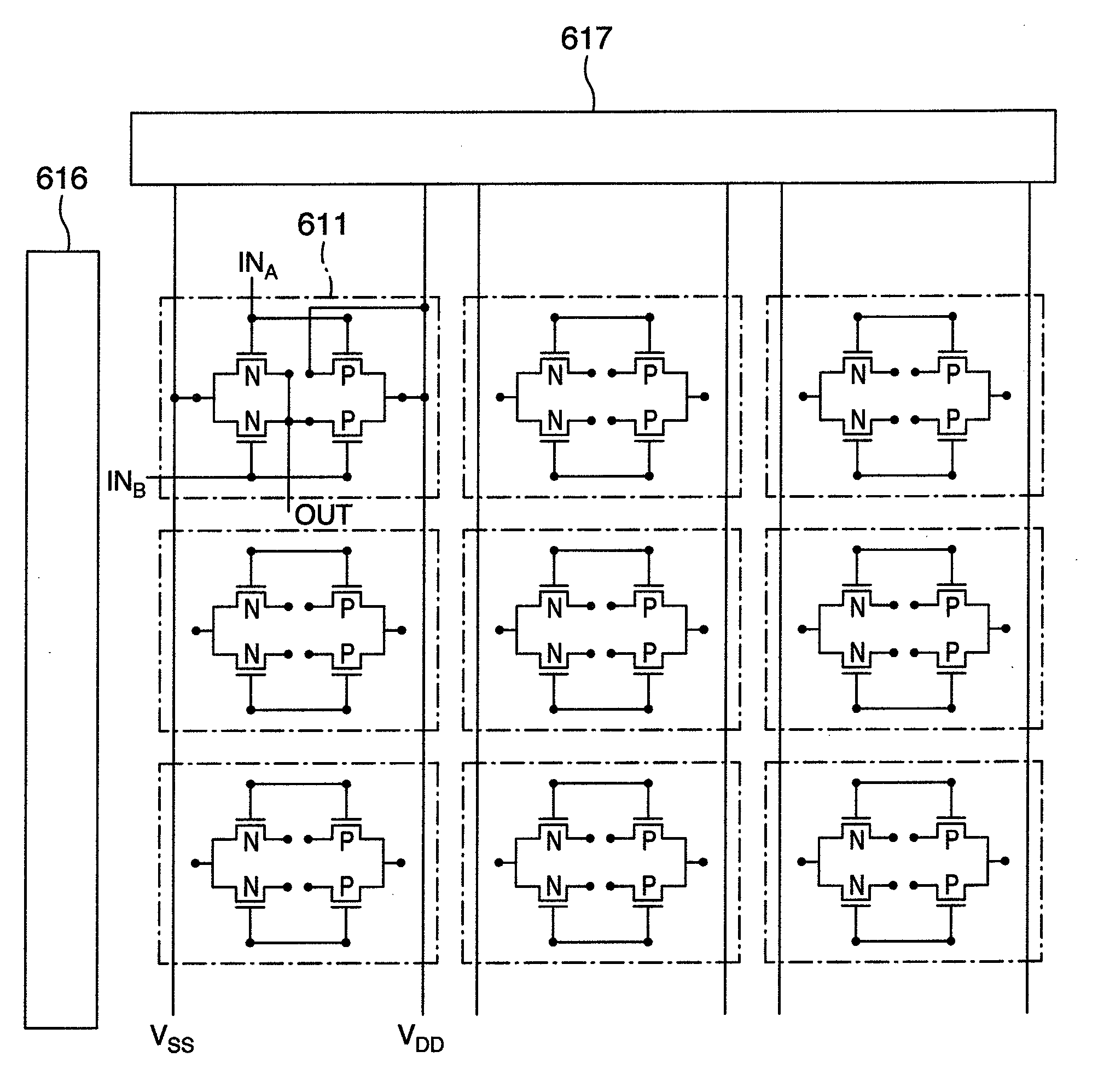

Organic Thin Film Transistor Array and Method of Manufacturing the Same

InactiveUS20080315191A1Manufactured very thinImprove ejection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLaser exposureEngineering

An n-type TFT and a p-type TFT are realized by selectively changing only a cover coat without changing a TFT material using an equation for applying the magnitude of a difference in the Fermi energy between an interface of semiconductor and an electrode and between an interface of semiconductor and insulator. At this time, in order to configure a predetermined circuit, the process is performed, as a source electrode and a drain electrode of the p-type TFT and a source electrode and a drain electrode of the n-type TFT being connected all, respectively, and an unnecessary interconnection is cut by irradiating light using a scanning laser exposure apparatus or the like.

Owner:HITACHI LTD

Acrylic polymer emulsion and glove formed from the same

The present invention provides an acrylic polymer emulsion containing a polymer formed by polymerizing 100% by weight in total of a monodic mixture comprising 50 to 90% by weight of an alkyl acrylate or an alkyl methacrylate, 9 to 49% by weight of a vinyl monomer of which homopolymer having a glass transition temperature Tg is not lower than 80° C., 0.2 to 10% by weight of a vinyl monomer having a carboxyl group and 0.1 to 5% by weight of a crosslinkable monomer having a molecular weight of not less than 280. The acrylic polymer emulasion of present invention provides gloves for home uses, works, examination operations, medical uses and the like which are superior in practical performances such as tensile strength, elongation, alcohol resistance, detergent resistance, oil resistance, recovering property after a stretch and wearing touch.

Owner:SHOWA GLOVE

Method and system for energizing a micro-component in a light-emitting panel

InactiveUS20040004445A1Sufficient resolutionManufactured very thinPoint-like light sourceStatic indicating devicesEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of energizing a micro-component is also disclosed

Owner:LEIDOS

Microporous materials and multi-layer articles prepared therefrom

InactiveUS20090311504A1Improve tensile propertiesIncrease stiffnessSynthetic resin layered productsLabelsPolymer scienceVolumetric Mass Density

A microporous material is provided in the form of a singly extruded microporous sheet having opposing first and second surfaces, comprising:(a) a polymeric matrix component comprising:(i) 25 to 75 weight percent of low melt flow index polypropylene having a melt flow index ranging from 0.1 to 30 grams / 10 minutes;(ii) 12.5 to 25 weight percent of ultrahigh molecular weight polyethylene; and(iii) 0 to 62.5 weight percent of high density polyethylene;(b) a finely divided, inorganic filler component dispersed throughout the polymeric matrix; and(c) a network of interconnecting pores communicating substantially throughout the microporous material, the pores constituting 10 to 80 percent by volume of the microporous material.The sheet typically has a thickness ranging from 3 to 8 mils and a stiffness of greater than 1 g / micron. In certain embodiments, the sheet has a density of greater than 0.75 g / cc. Also provided are multi-layer articles.

Owner:PPG IND OHIO INC

Use of printing and other technology for micro-component placement

InactiveUS20030207645A1Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

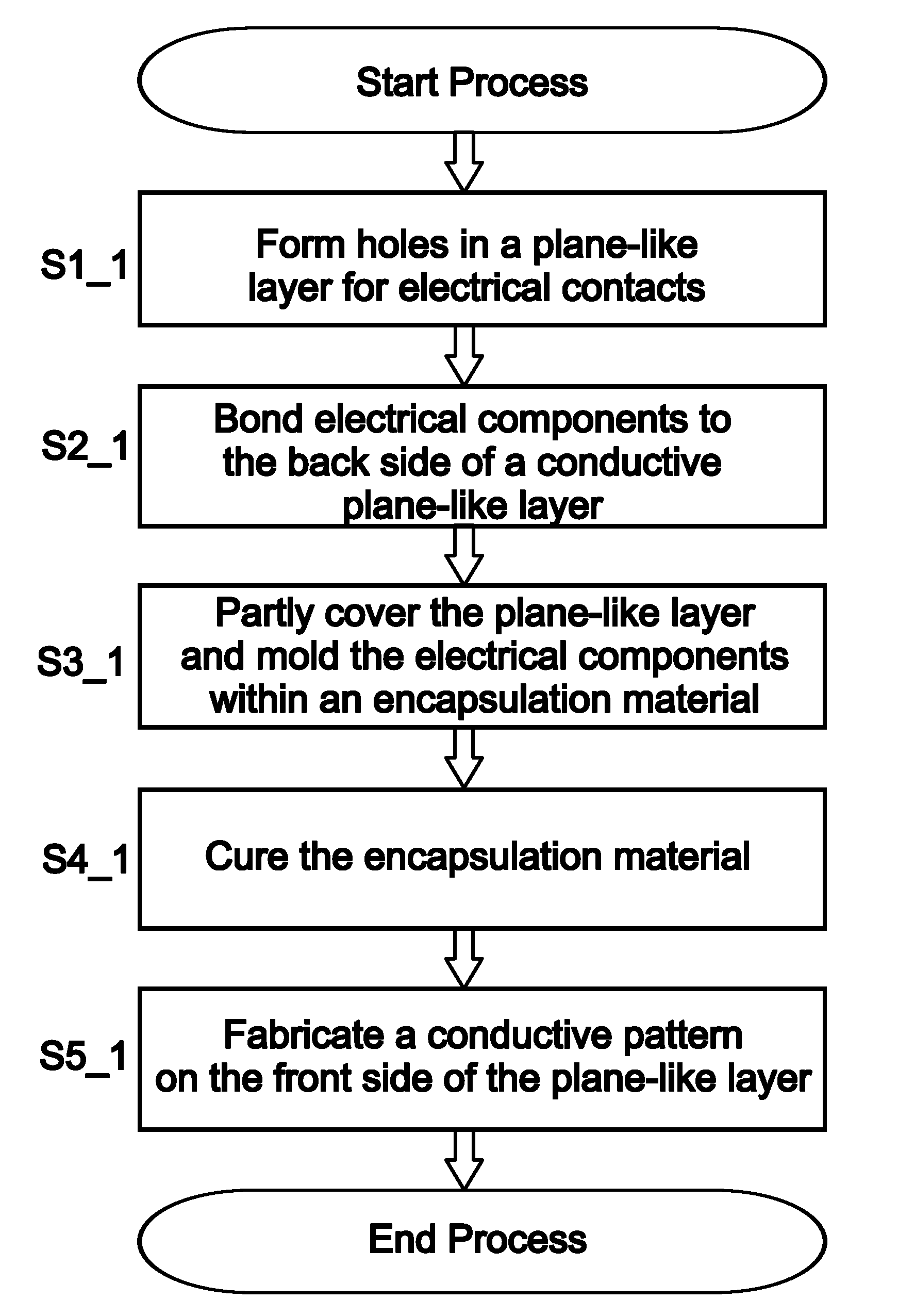

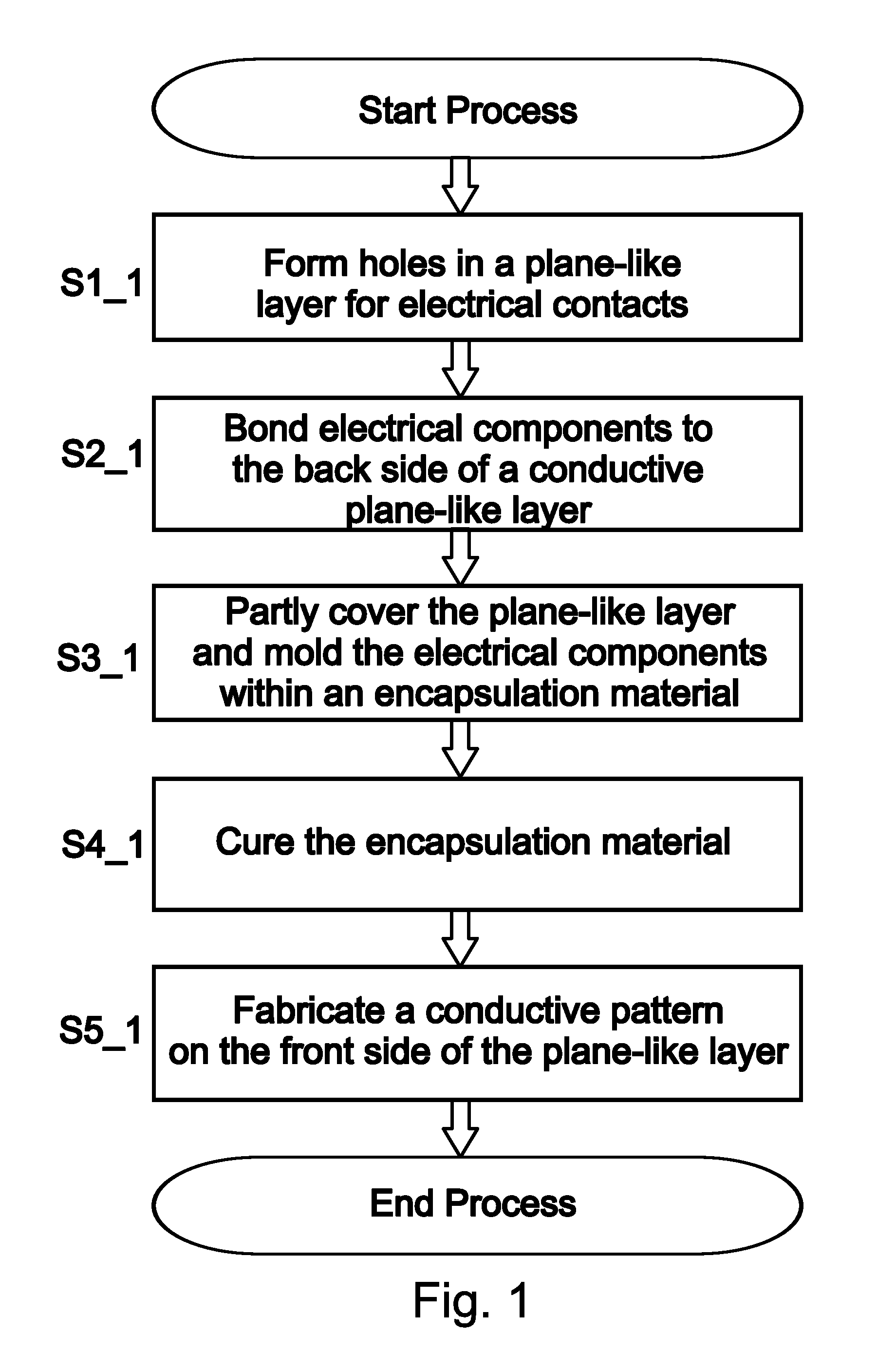

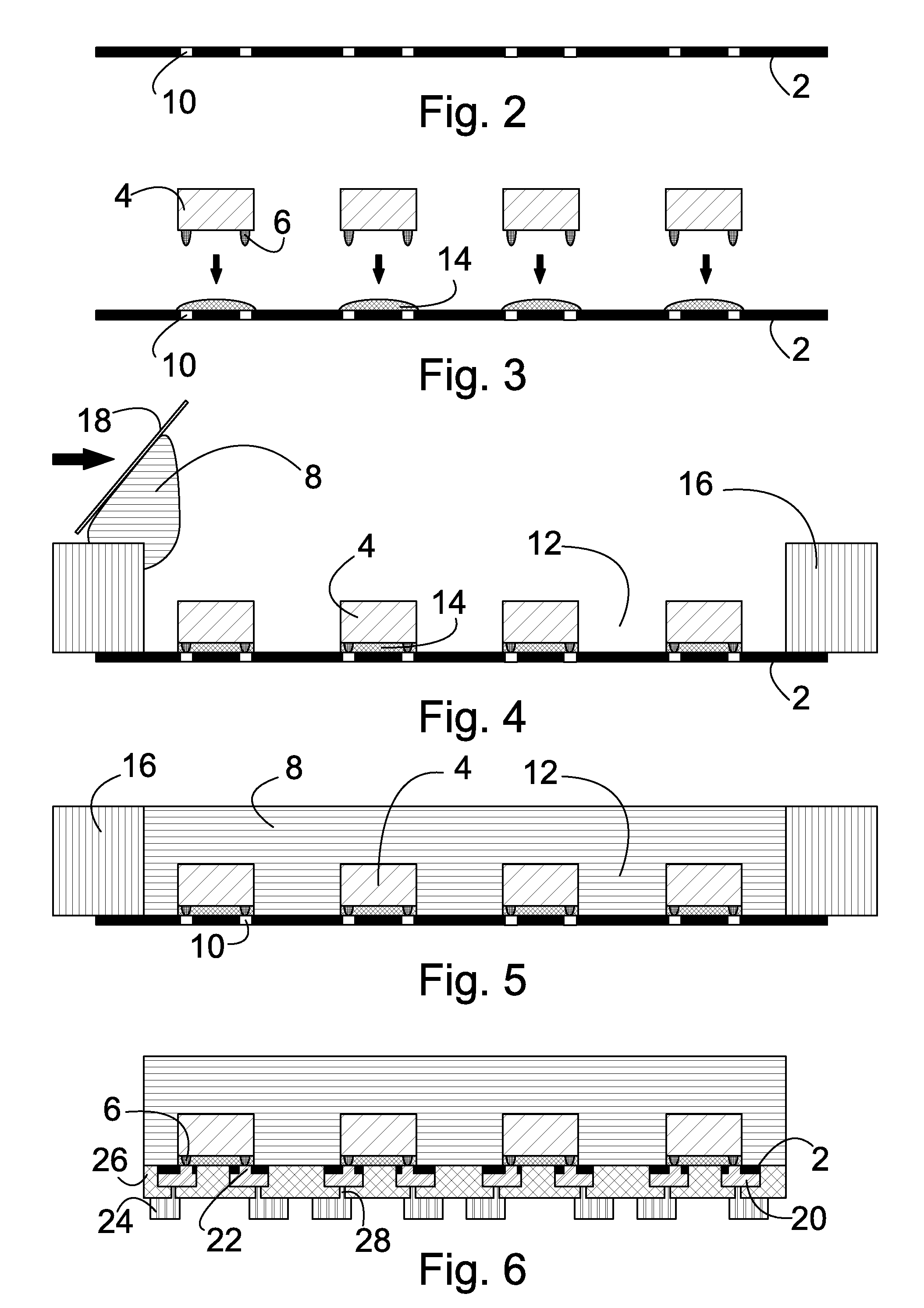

Circuit board structure comprising an electrical component and a method for manufacturing a circuit board structure comprising an electrical component

ActiveUS20100046186A1Precise alignmentReliable and reliablePrinted circuit assemblingSemiconductor/solid-state device detailsElectrically conductiveEngineering

A circuit board structure and a method for manufacturing a circuit board structure comprising an electrical component. The method comprises the steps of fabricating a conductive pattern on the surface of an essentially plane-like layer on the back side of the plane-like layer, and forming an electrical contact between at least one electrical component and the conductive pattern. The method further comprises the steps of attaching at least one electrical component to the back side of the plane-like layer after the fabrication of the conductive pattern, molding encapsulation material on the back side of the plane-like layer so that the encapsulation material at least partly encloses the at least one electrical component attached to the back side of the plane-like layer, and forming holes through the conductive pattern at positions where terminals of the electrical components attached to the back side of the plane-like layer become positioned when the electrical component is attached to the circuit board structure.

Owner:IMBERATEK LLC

Tag communication device, tag moving direction detecting system and tag moving direction detecting method

ActiveUS8115594B2Easy to detectSimple processSubscribers indirect connectionBurglar alarm by hand-portable articles removalDirection detectionLinear approximation

Owner:ORMON CORP

Manufacture of light-emitting panels provided with texturized micro-components

InactiveUS7789725B1Sufficient resolutionManufactured very thinMechanical apparatusVessels or leading-in conductors manufactureEngineeringPre testing

Owner:LEIDOS

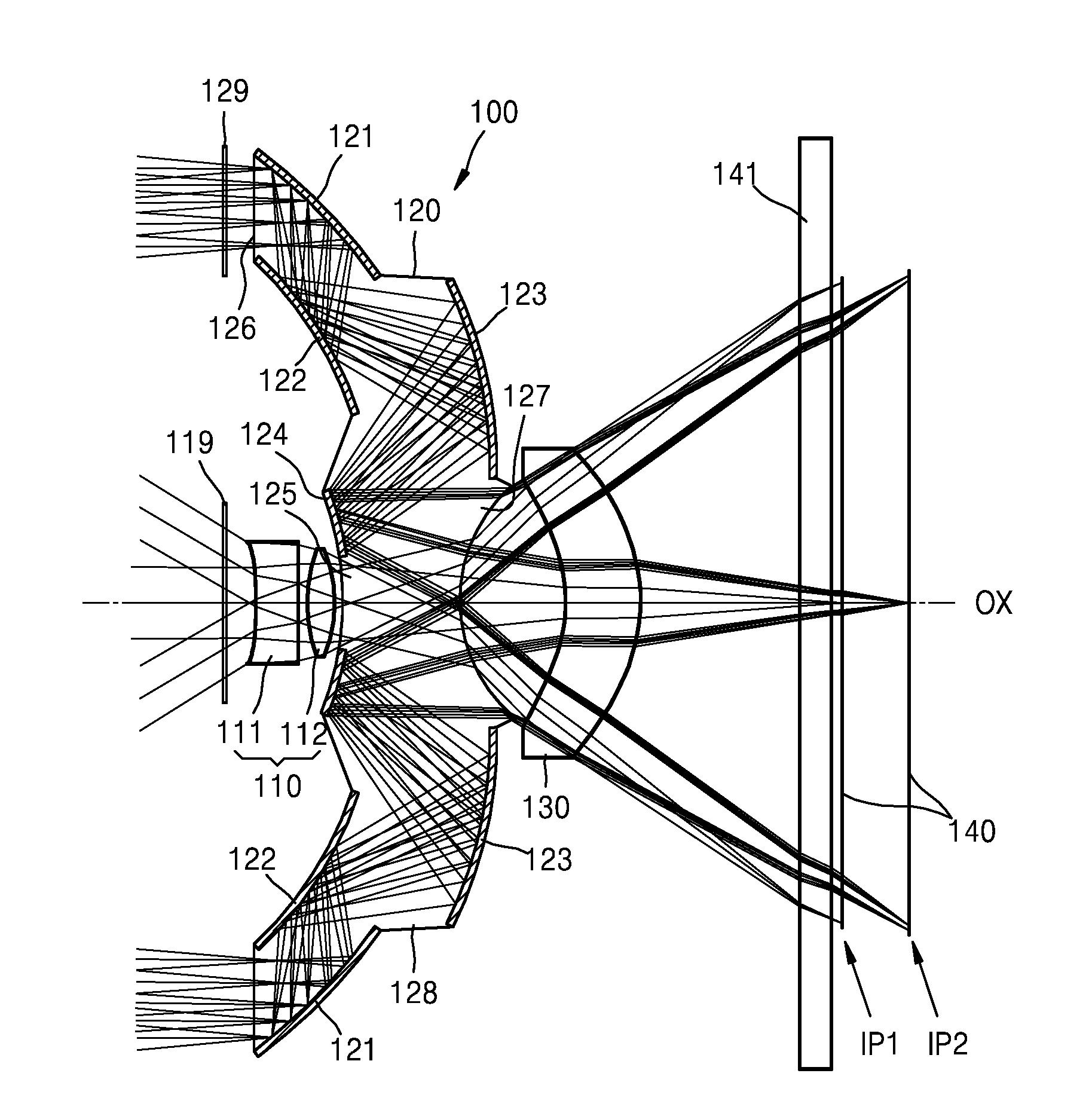

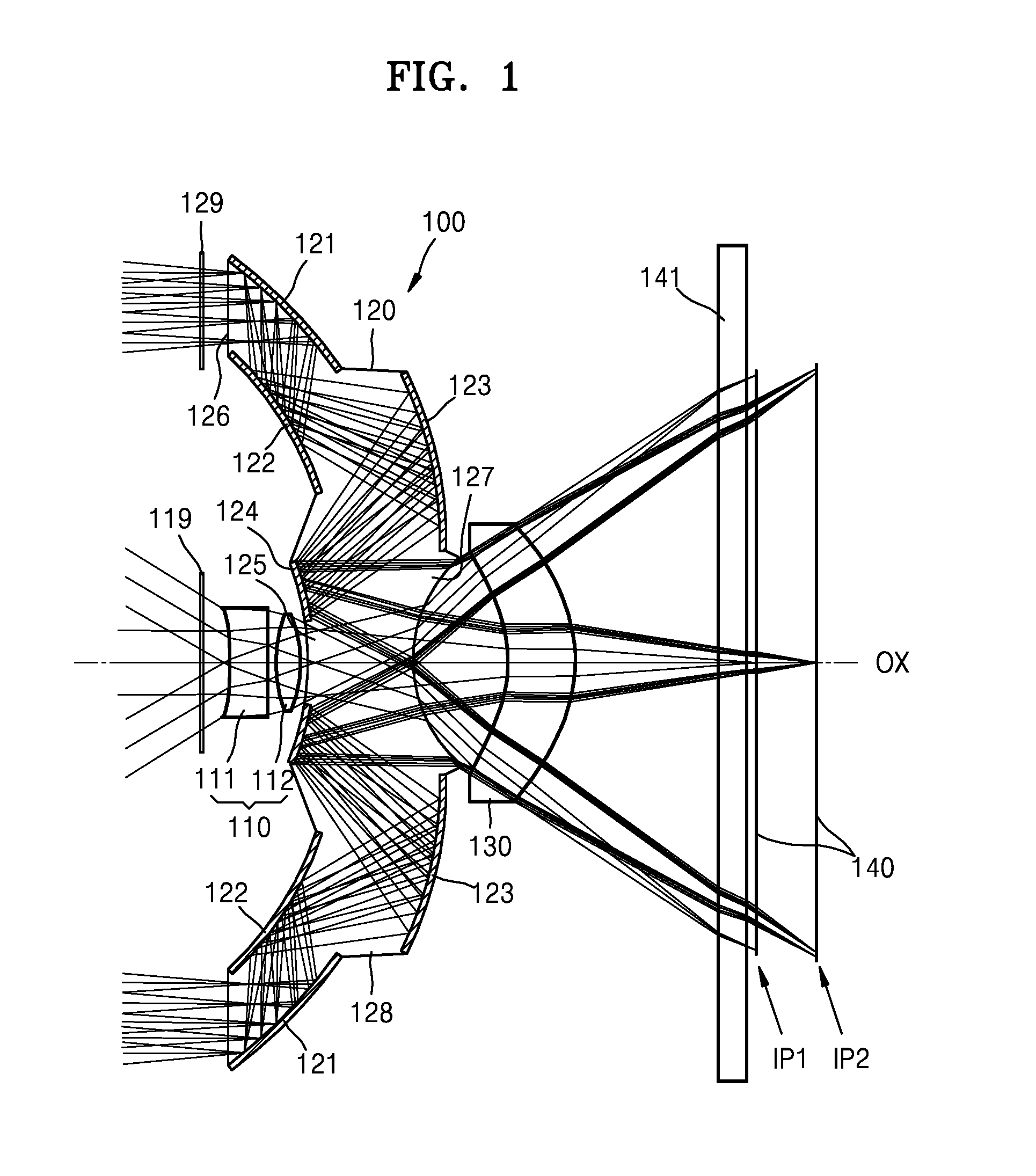

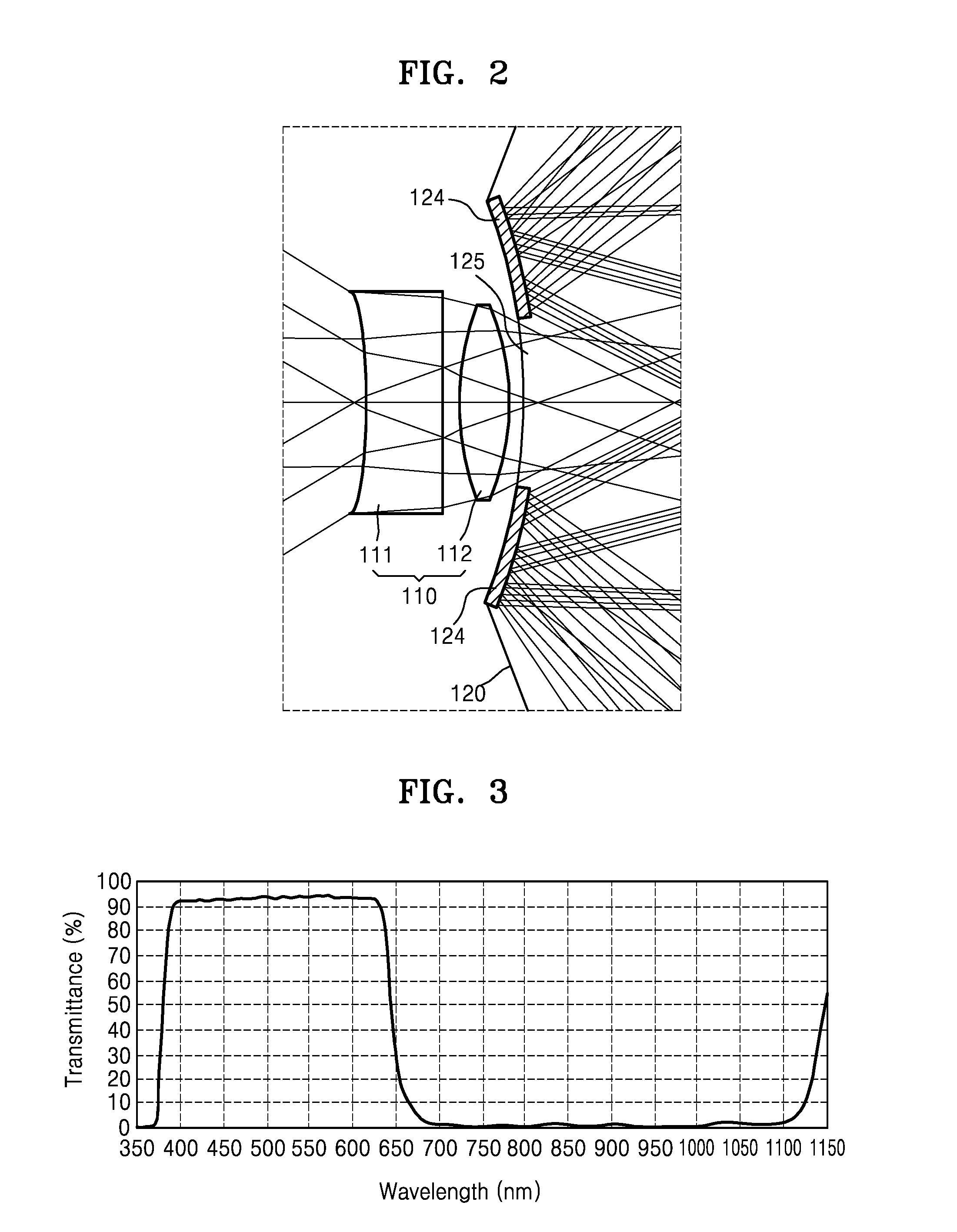

Bifocal lens and imaging device including same

InactiveUS20160377842A1Manufactured very thinTelevision system detailsColor television detailsCatoptricsOphthalmology

Disclosed are a bifocal lens having two focal distances to enable near image capturing and far image capturing and capable of being manufactured to have a thin profile, and an imaging device including same. A bifocal lens according to disclosed embodiments may include: a refractive optical system having at least one refractive lens element and having a first focal distance; and a reflective optical system having multiple reflective surfaces and having a second focal distance that is different from the first focal distance. Because the refractive optical system and the reflective optical system have mutually different focal distances, the bifocal lens according to an embodiment may be capable of both near image capturing and far image capturing.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com