Patents

Literature

135results about How to "Improve ejection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

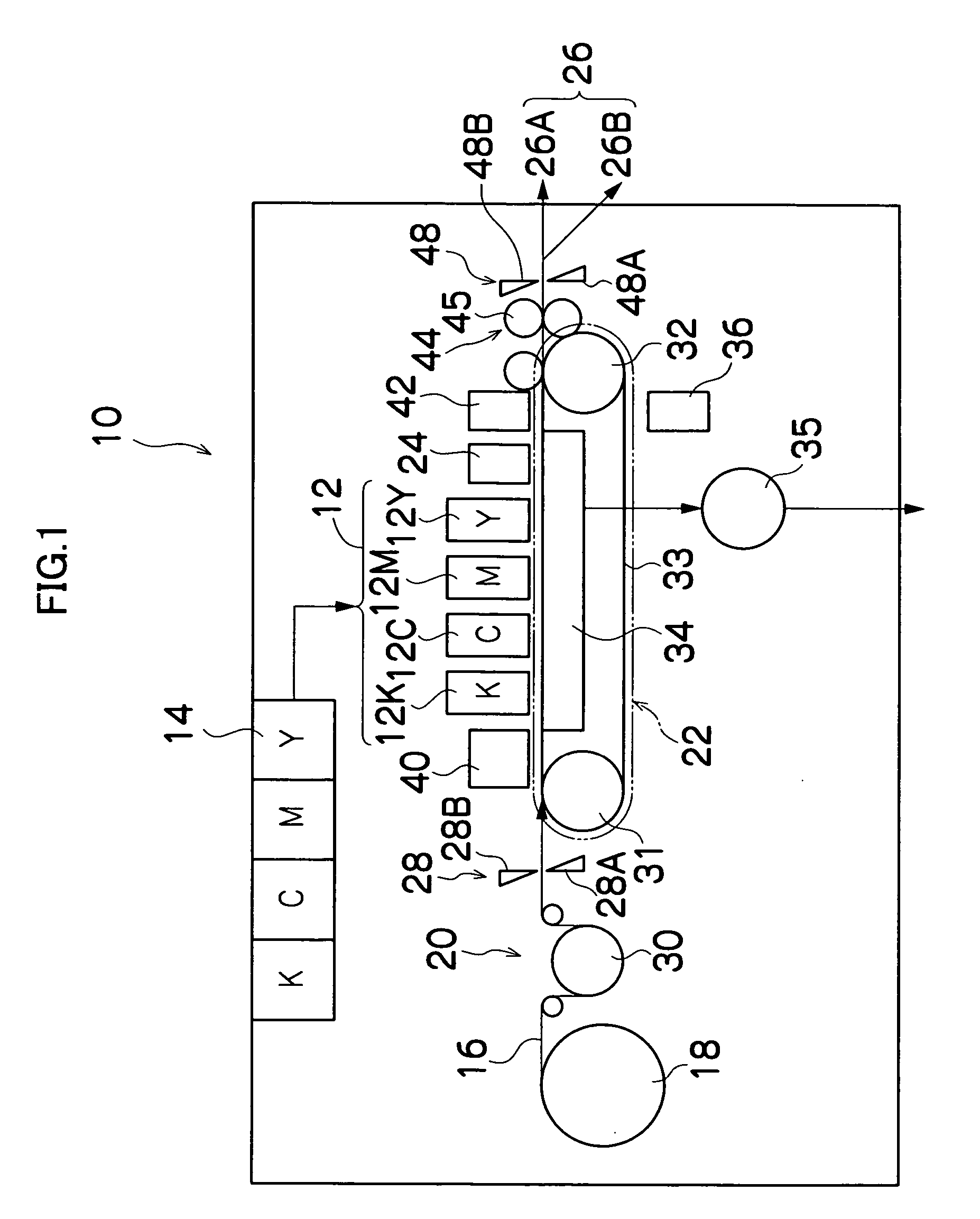

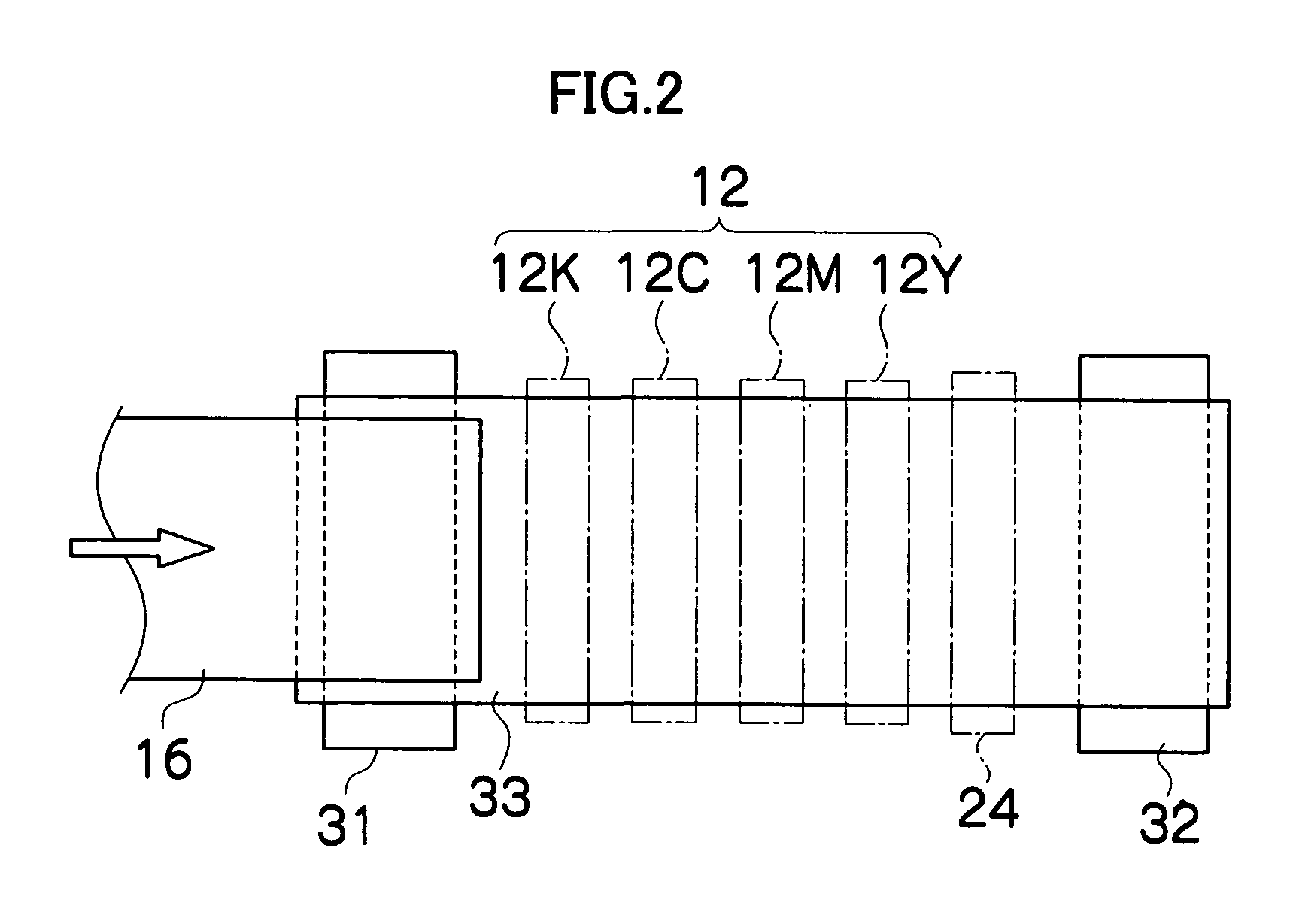

Obtaining tandem mass spectrometry data for multiple parent ions in an ion population

ActiveUS7157698B2Improve performanceImprove ejection efficiencyStability-of-path spectrometersTime-of-flight spectrometersNarrow rangeIon trap mass spectrometry

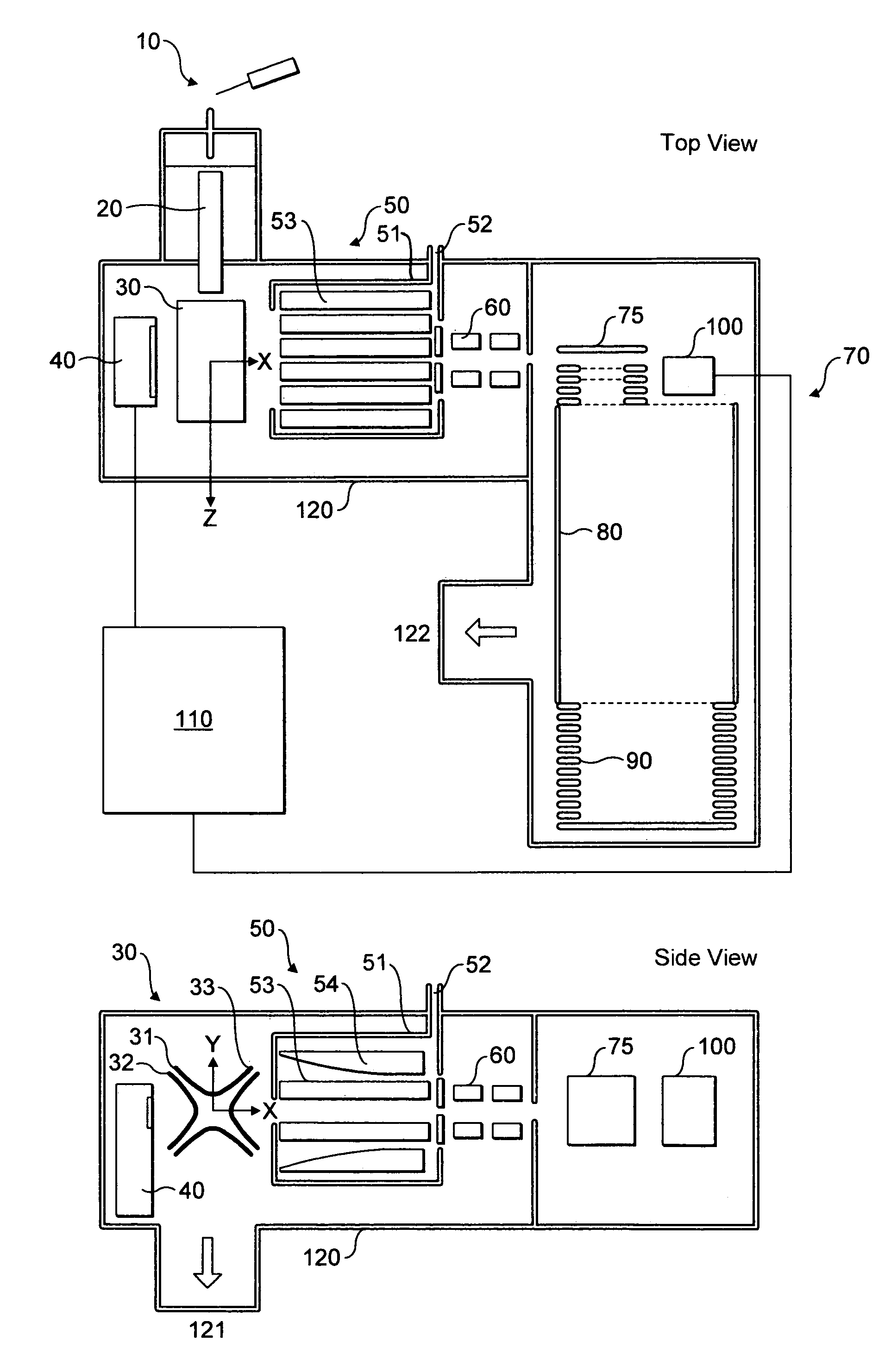

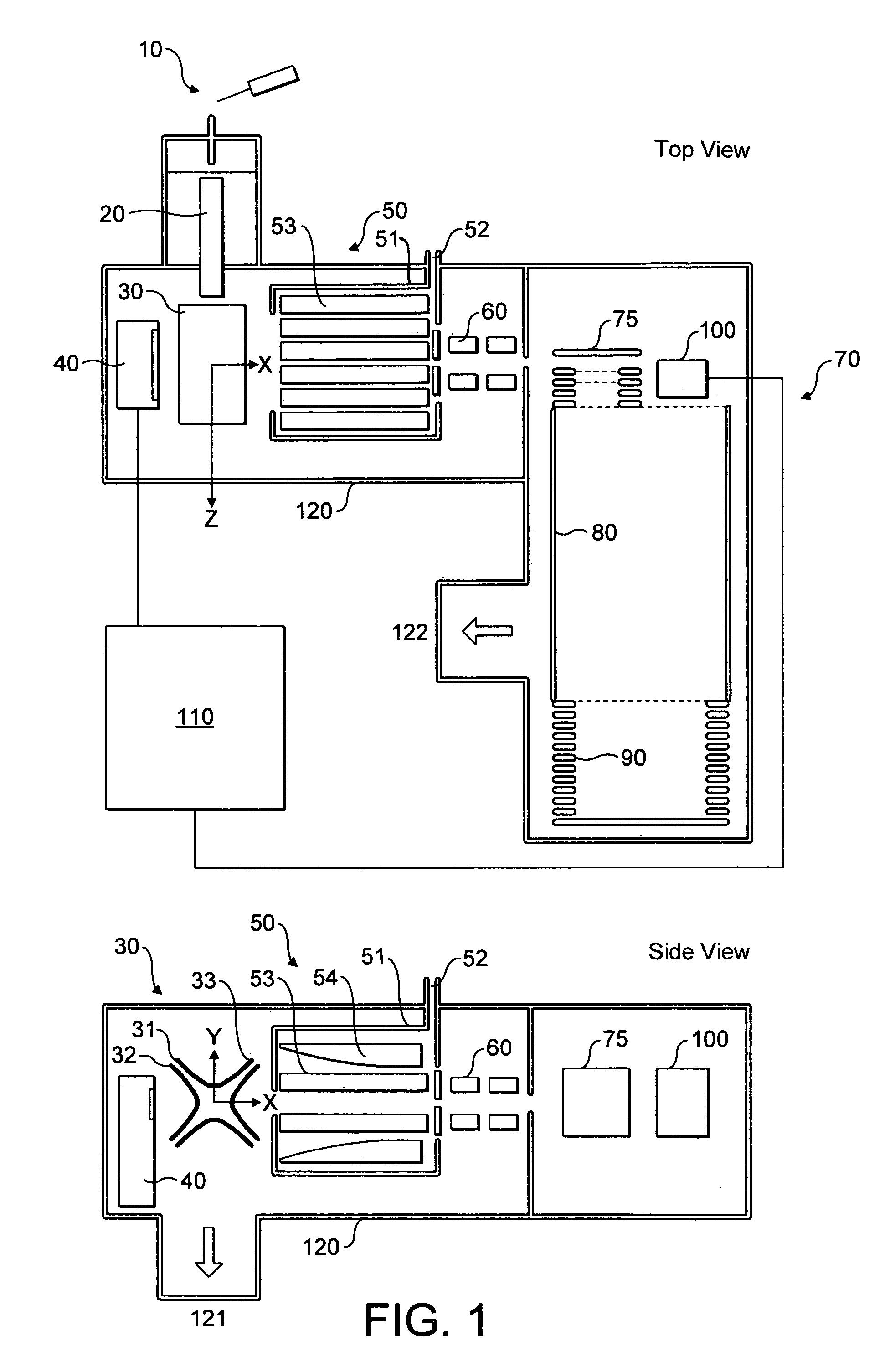

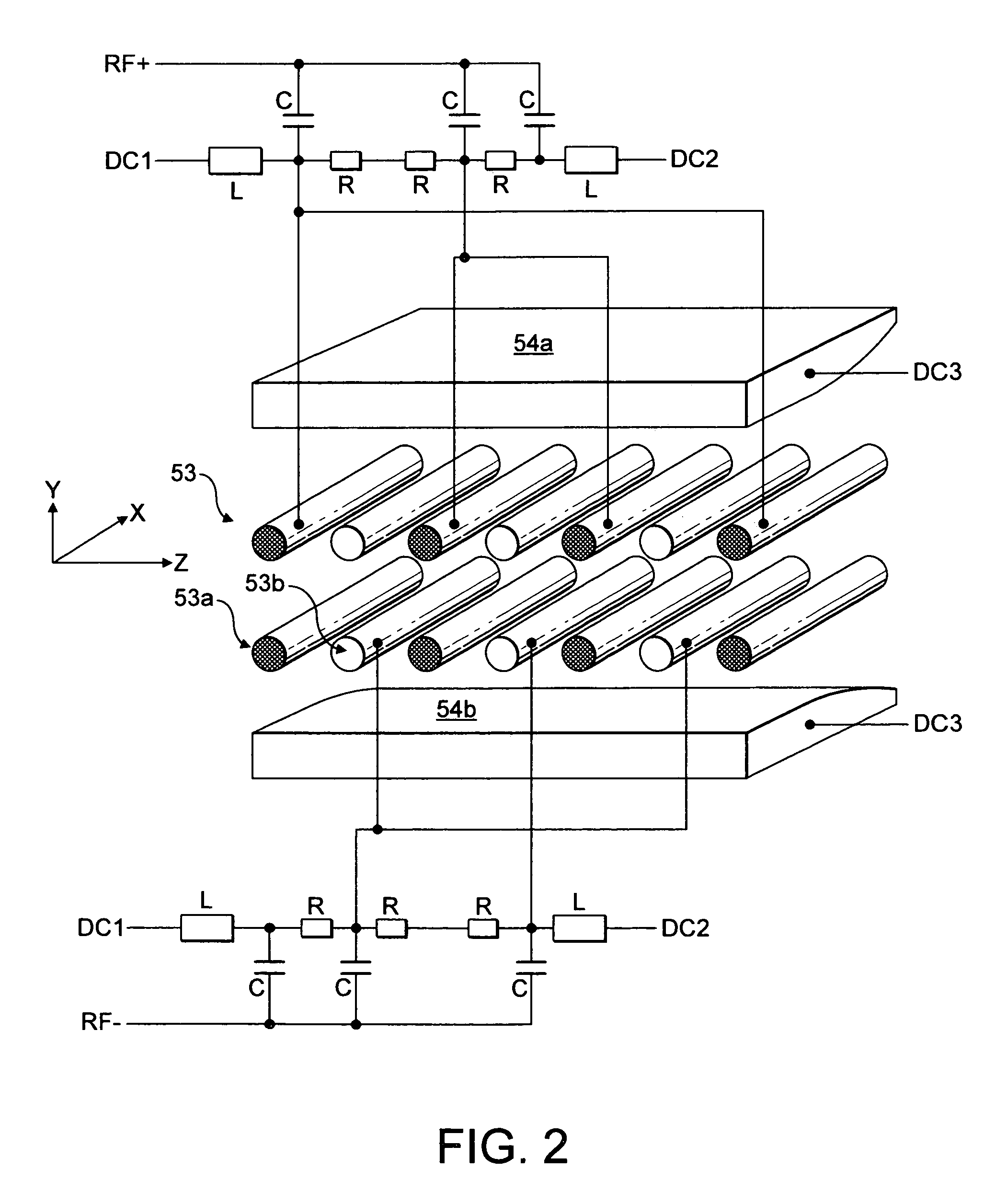

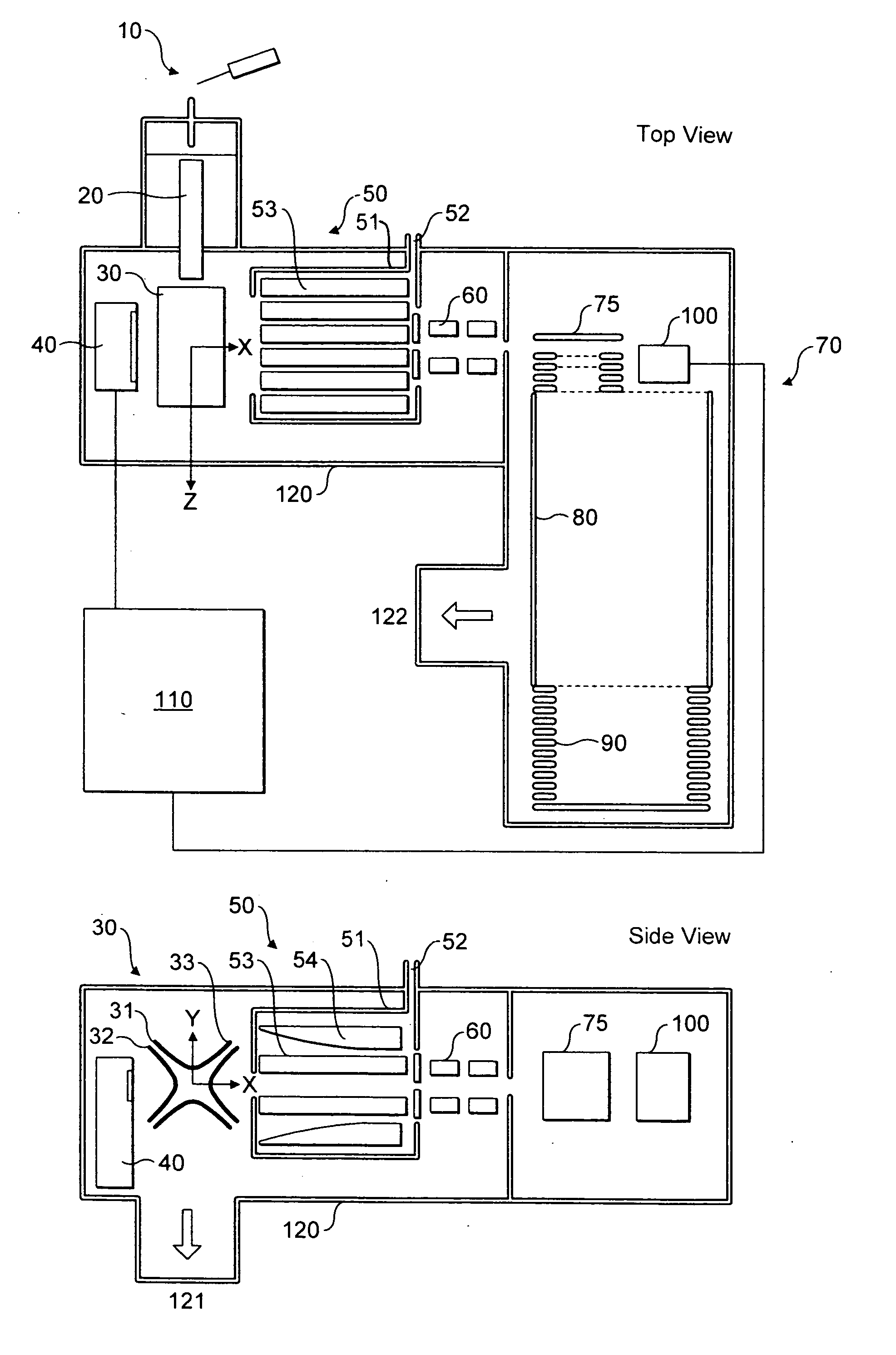

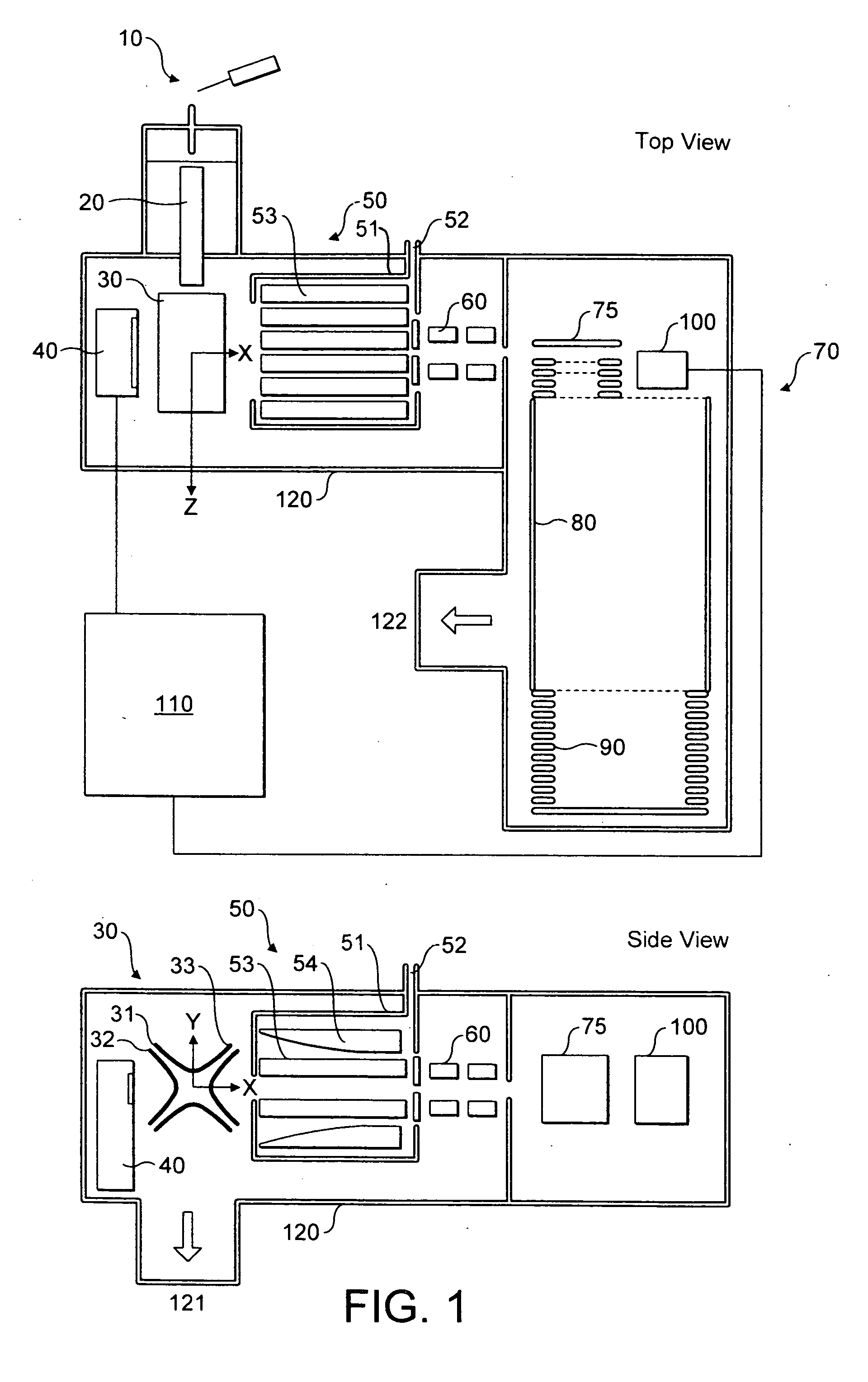

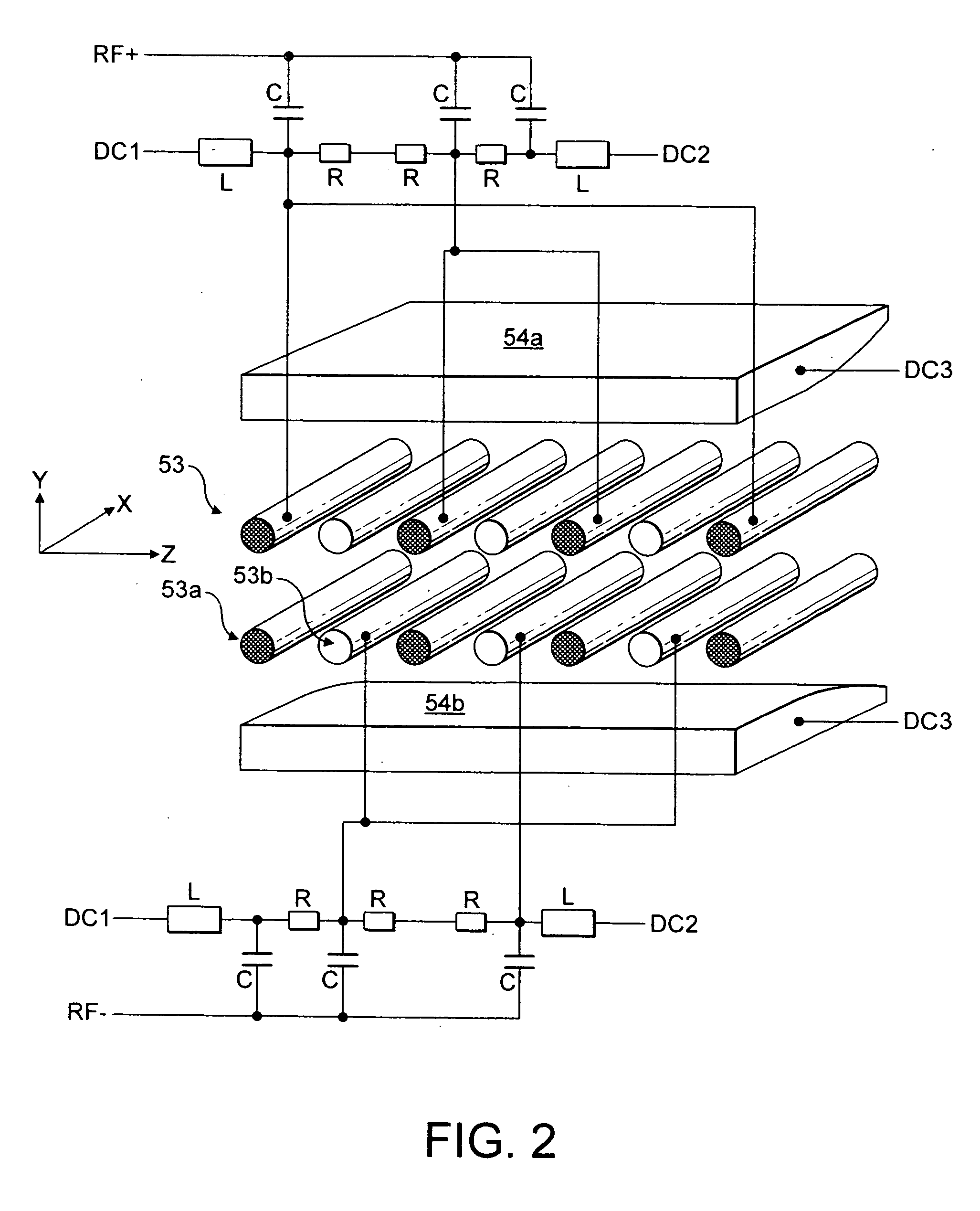

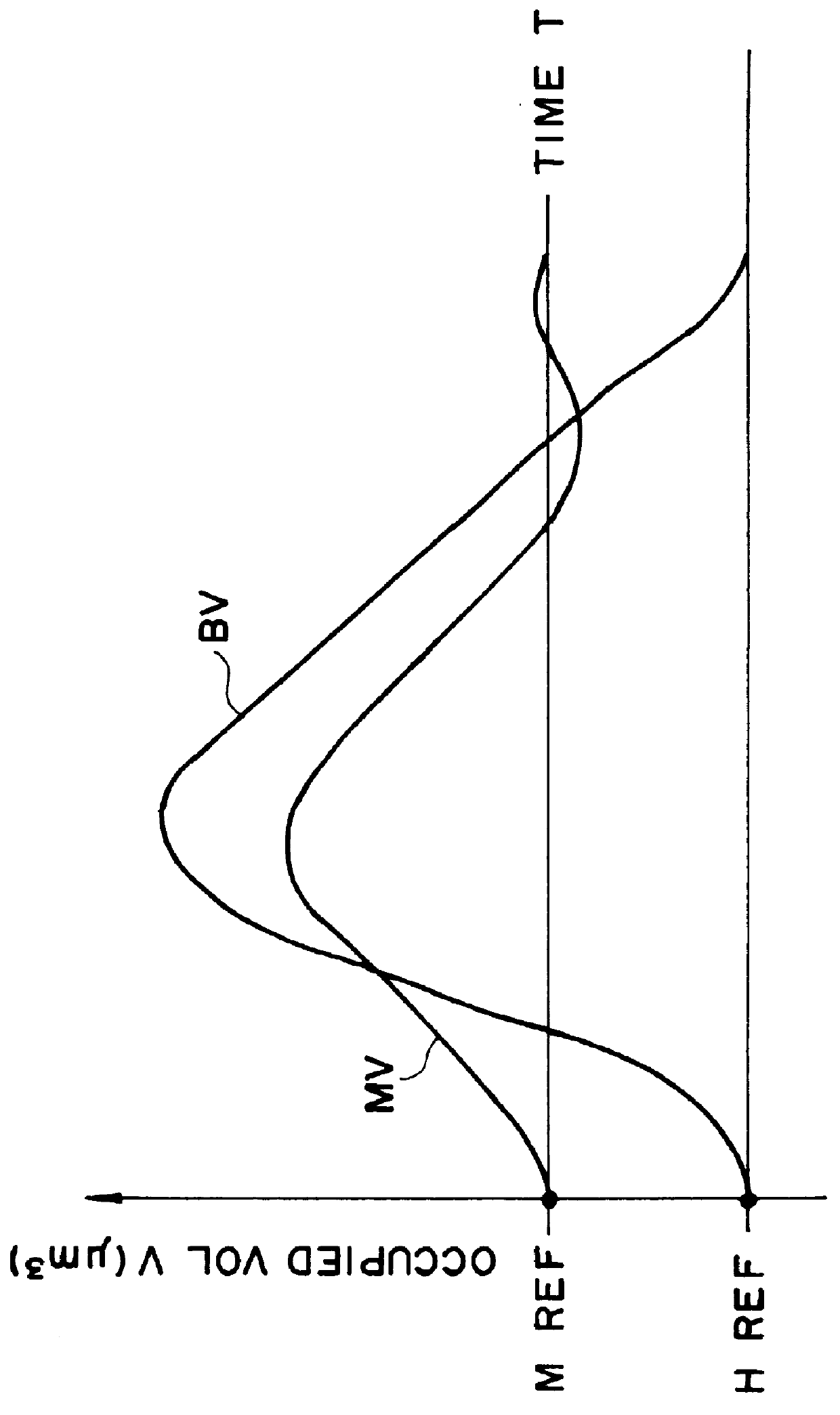

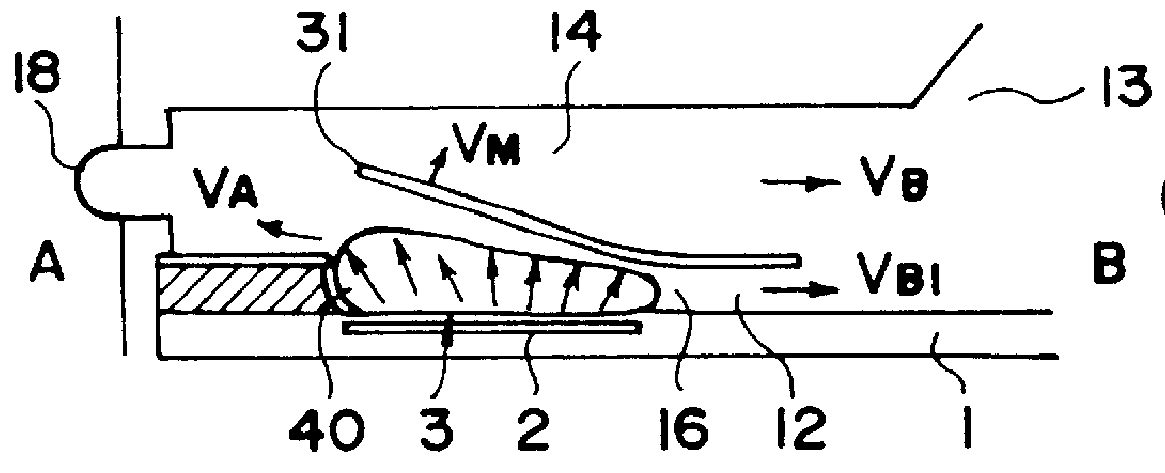

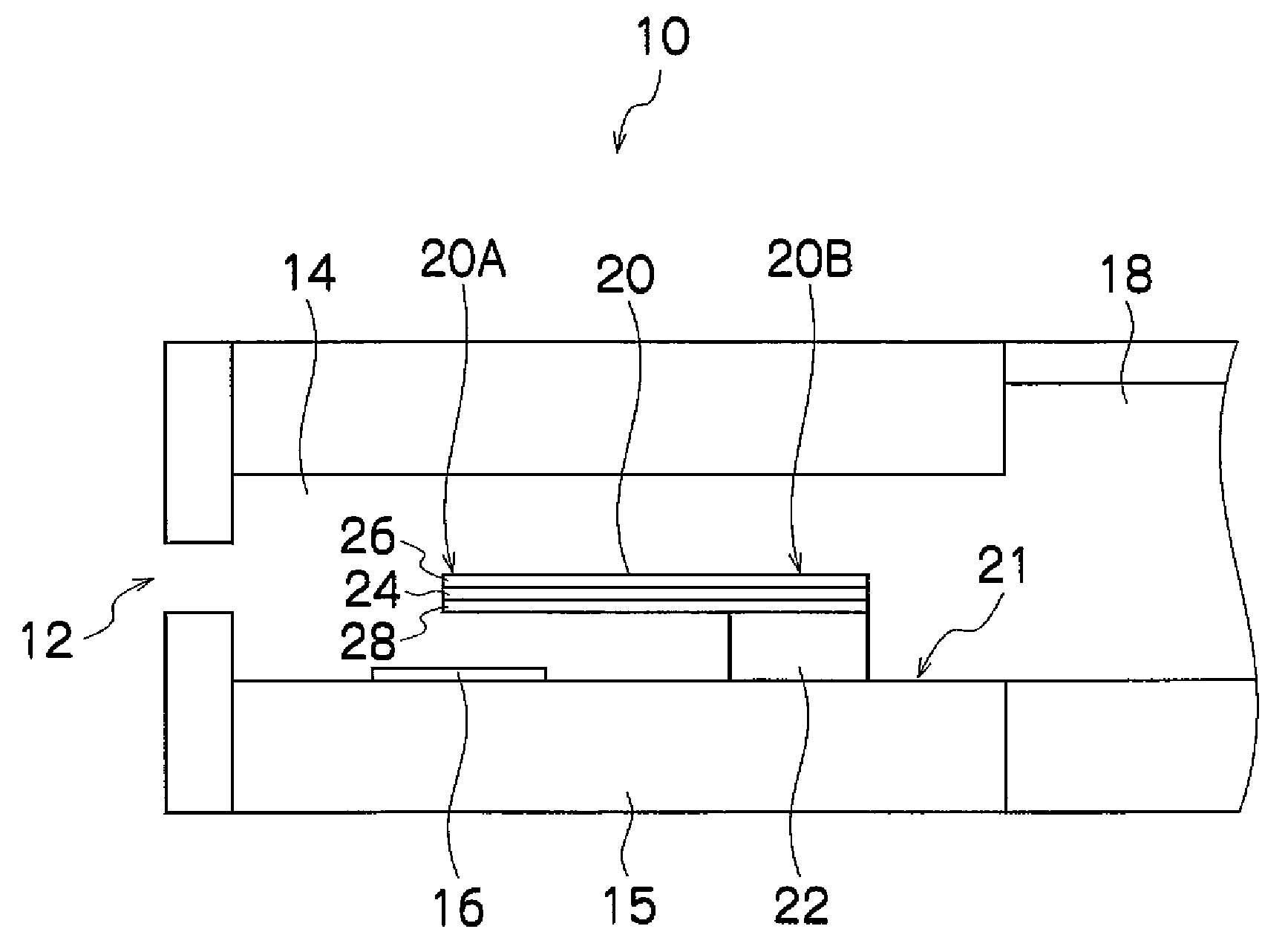

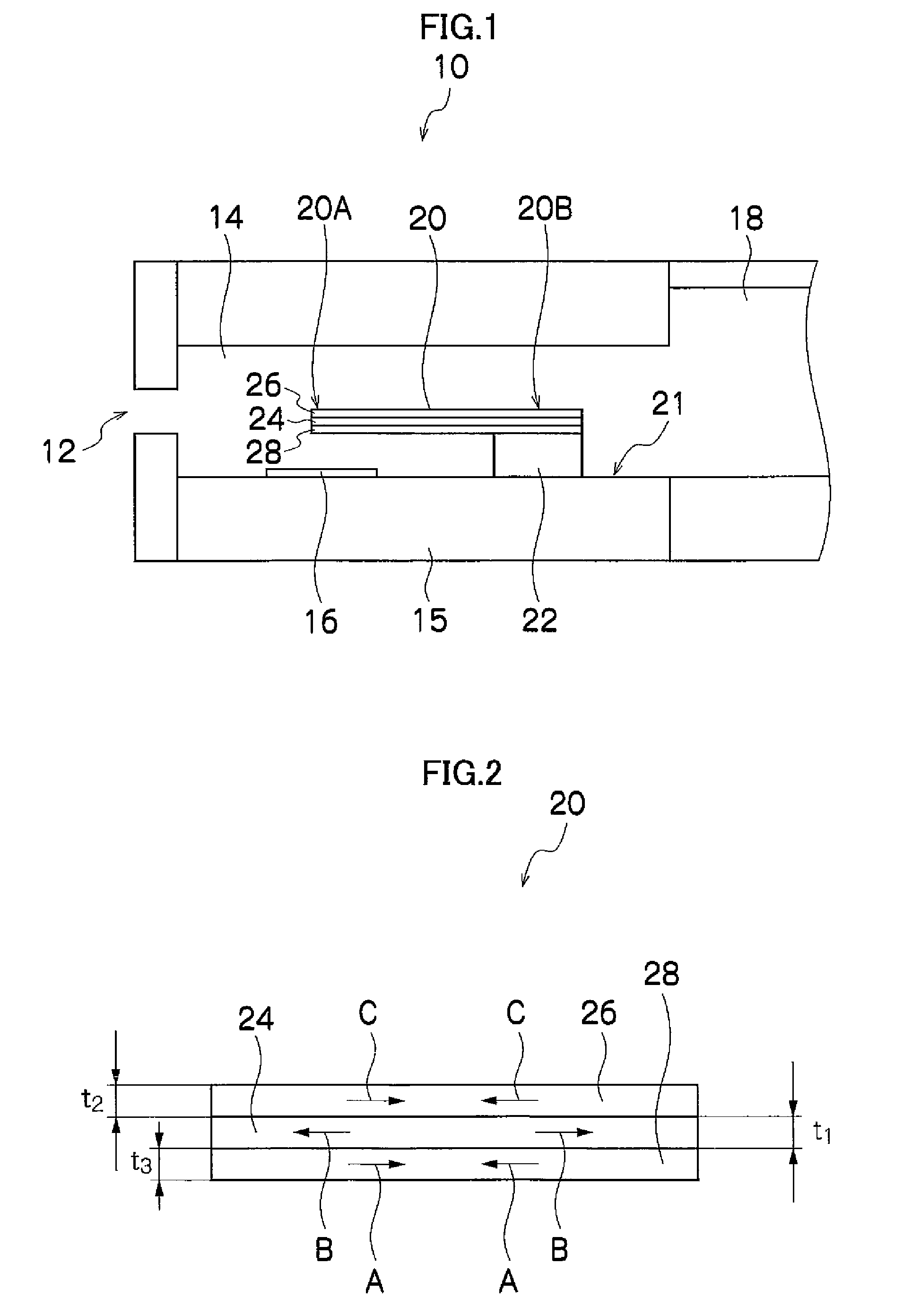

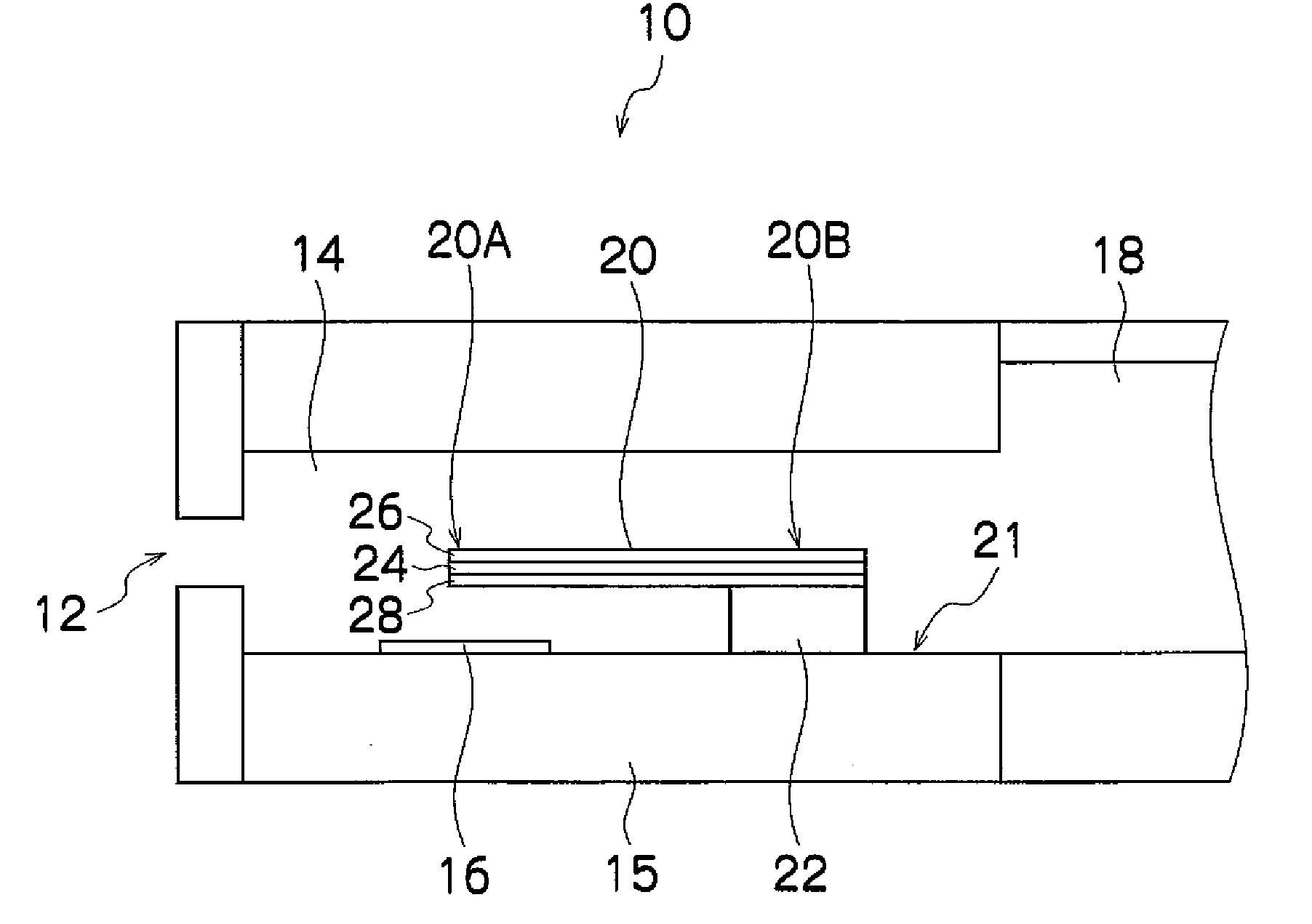

This invention relates to tandem mass spectrometry and, in particular, to tandem mass spectrometry using a linear ion trap and a time of flight detector to collect mass spectra to form a MS / MS experiment. The accepted standard is to store and mass analyze precursor ions in the ion trap before ejecting the ions axially to a collision cell for fragmentation before mass analysis of the fragments in the time of flight detector. This invention makes use of orthogonal ejection of ions with a narrow range of m / z values to produce a ribbon beam of ions that are injected into the collision cell. The shape of this beam and the high energy of the ions are accommodated by using a planar design of collision cell. Ions are retained in the ion trap during ejection so that successive narrow ranges may be stepped through consecutively to cover all precursor ions of interest.

Owner:THERMO FINNIGAN

Obtaining tandem mass spectrometry data for multiple parent ions in an ion population

ActiveUS20060284080A1Addressing slow performanceImprove performanceStability-of-path spectrometersTime-of-flight spectrometersNarrow rangeIon trap mass spectrometry

This invention relates to tandem mass spectrometry and, in particular, to tandem mass spectrometry using a linear ion trap and a time of flight detector to collect mass spectra to form a MS / MS experiment. The accepted standard is to store and mass analyze precursor ions in the ion trap before ejecting the ions axially to a collision cell for fragmentation before mass analysis of the fragments in the time of flight detector. This invention makes use of orthogonal ejection of ions with a narrow range of m / z values to produce a ribbon beam of ions that are injected into the collision cell. The shape of this beam and the high energy of the ions are accommodated by using a planar design of collision cell. Ions are retained in the ion trap during ejection so that successive narrow ranges may be stepped through consecutively to cover all precursor ions of interest.

Owner:THERMO FINNIGAN

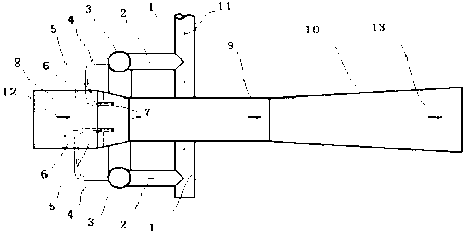

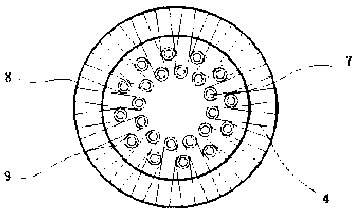

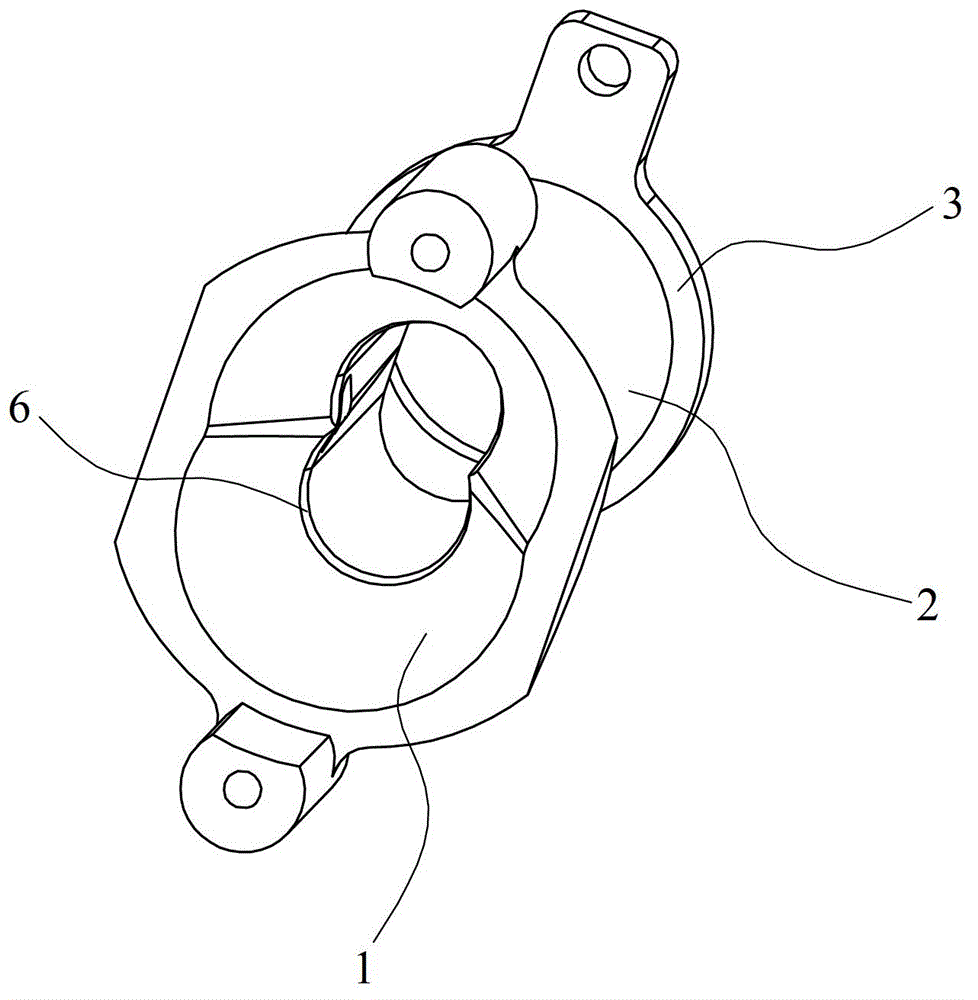

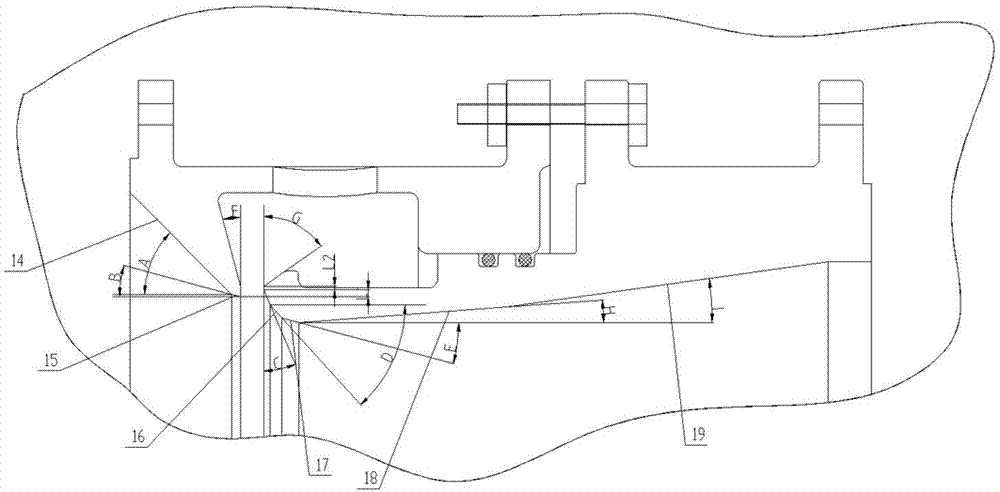

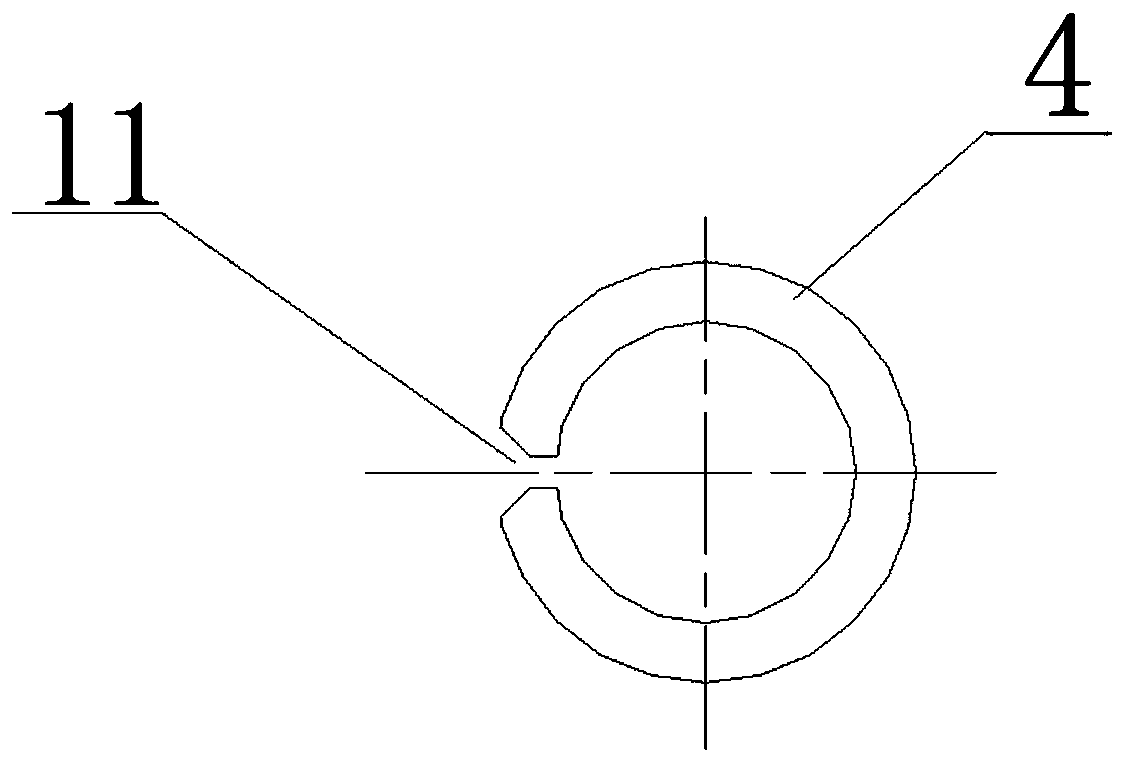

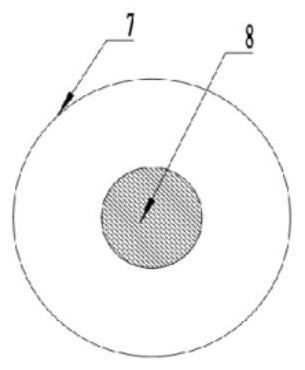

Ejecting pipe

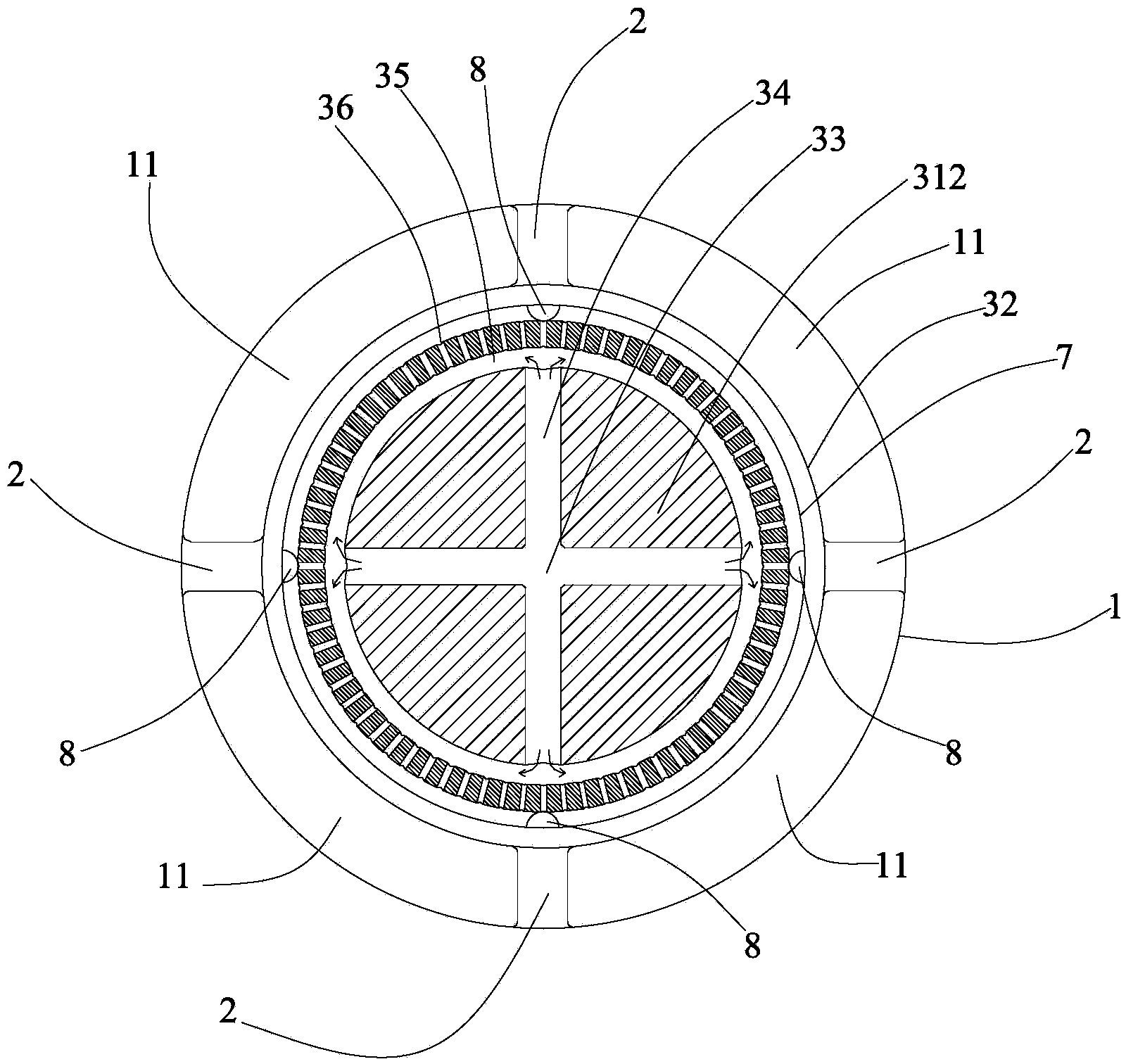

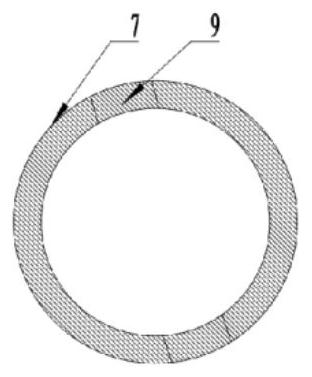

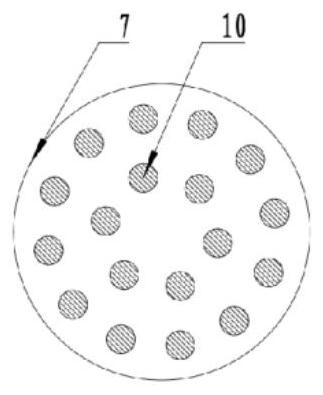

ActiveCN103234201AImprove ejection abilityAvoid mutual interferenceGaseous fuel burnerCombustorEllipse

The invention relates to an ejecting pipe. A horn section, a transition section and a tail interface which is matched with a combustor furnace head are sequentially arranged in an internal chamber of the ejecting pipe along the direction from an inlet to an outlet. A throat opening is formed between the horn section and the transition section; an outer contour of the horn section is formed by a plurality of circles or a plurality of ellipses in an intersecting mode; the ellipses are approximate to circles; centers of the circles or centers of the ellipses are arranged in a same first circle and are uniformly distributed relative to a center of the first circle; nozzles which are matched with the ejecting pipe are arranged on centers of the circles or centers of the ellipses; the number of the nozzles is equal to the number of the circles or the number of the ellipses; a cross section of the horn section is gradually decreased; a shape of a cross section of the throat opening is the same with that of the horn section; the cross section area of the transition section is gradually increased from a cross section area the same as that of the throat opening to a cross section area the same as that of the tail interface. The ejecting pipe has the advantages of avoiding mutual interferences among airflows at the beginning of ejection, adding primary air supplementary amount, promoting mutual mixing of the airflows entering into the internal chamber of the ejecting pipe and the air, improving primary air coefficient, increasing ejecting capability and accordingly improving energy efficiency of a combustor.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Efficient slotted multi-nozzle enhancing mixing ejector

InactiveCN103133430AImprove ejection efficiencyReduce energy consumptionJet pumpsMachines/enginesSpray nozzleEngineering

The invention discloses an efficient slotted multi-nozzle enhancing mixing ejector. The efficient slotted multi-nozzle enhancing mixing ejector is characterized by comprising an inject gas inlet main pipe, an inject gas inlet flow dividing pipe, a gas collecting chamber, an inject nozzle gas inlet pipe, a back rectifying plate, a front rectifying plate, an inject nozzle, a straight slotted section of the inject nozzle, injected air flow gas inlet pipe, a mixing chamber and a diffuser. The efficient slotted multi-nozzle enhancing mixing ejector has the advantages of being high in inject efficiency, relatively small in energy consumption, relatively small in length, relatively low in noise and manufacturing difficulty, capable of using high-temperature etchant gas and the like.

Owner:中国空气动力研究与发展中心设备设计及测试技术研究所

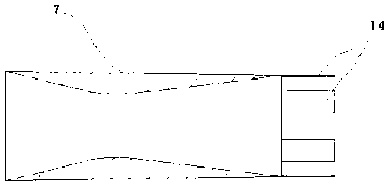

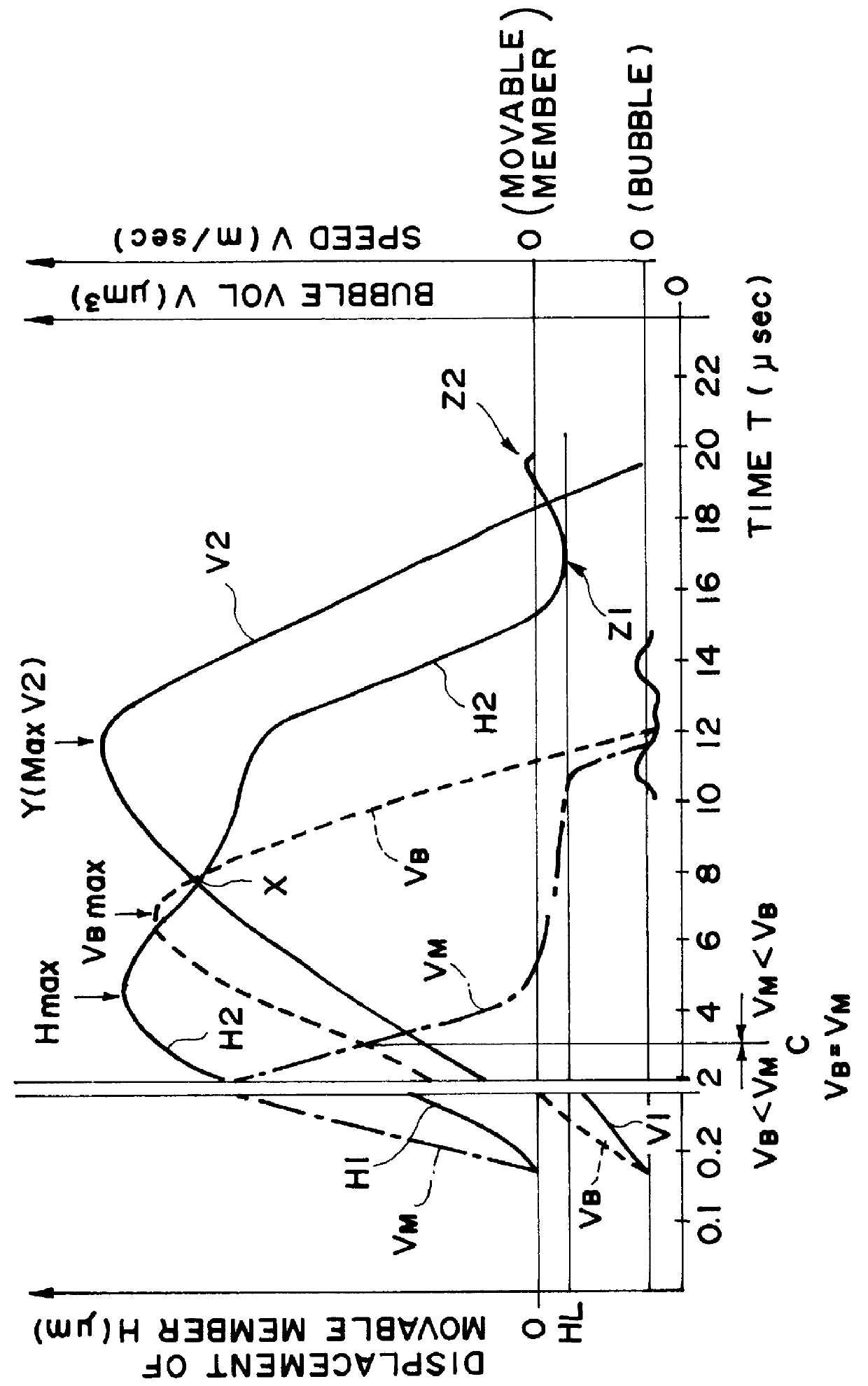

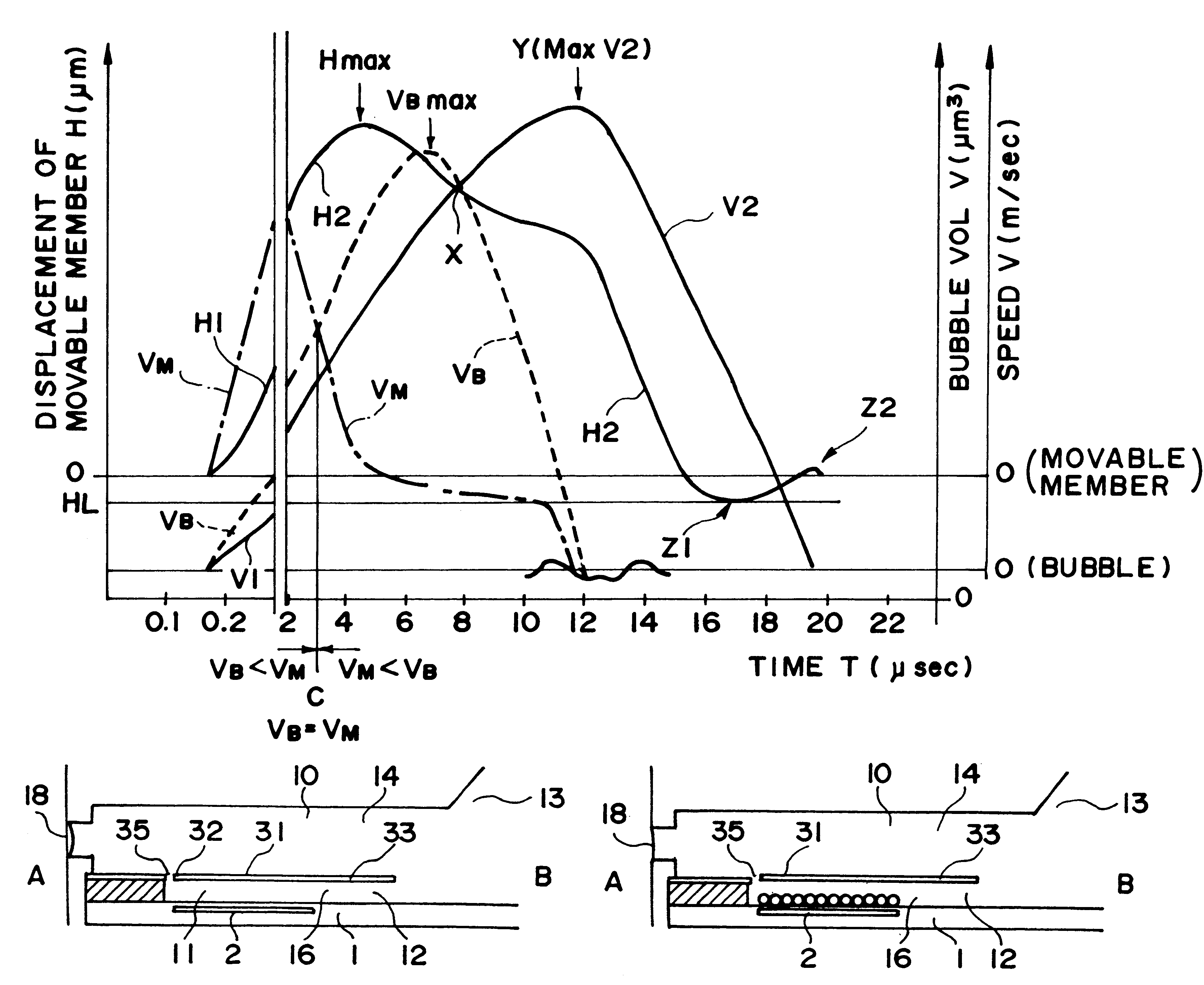

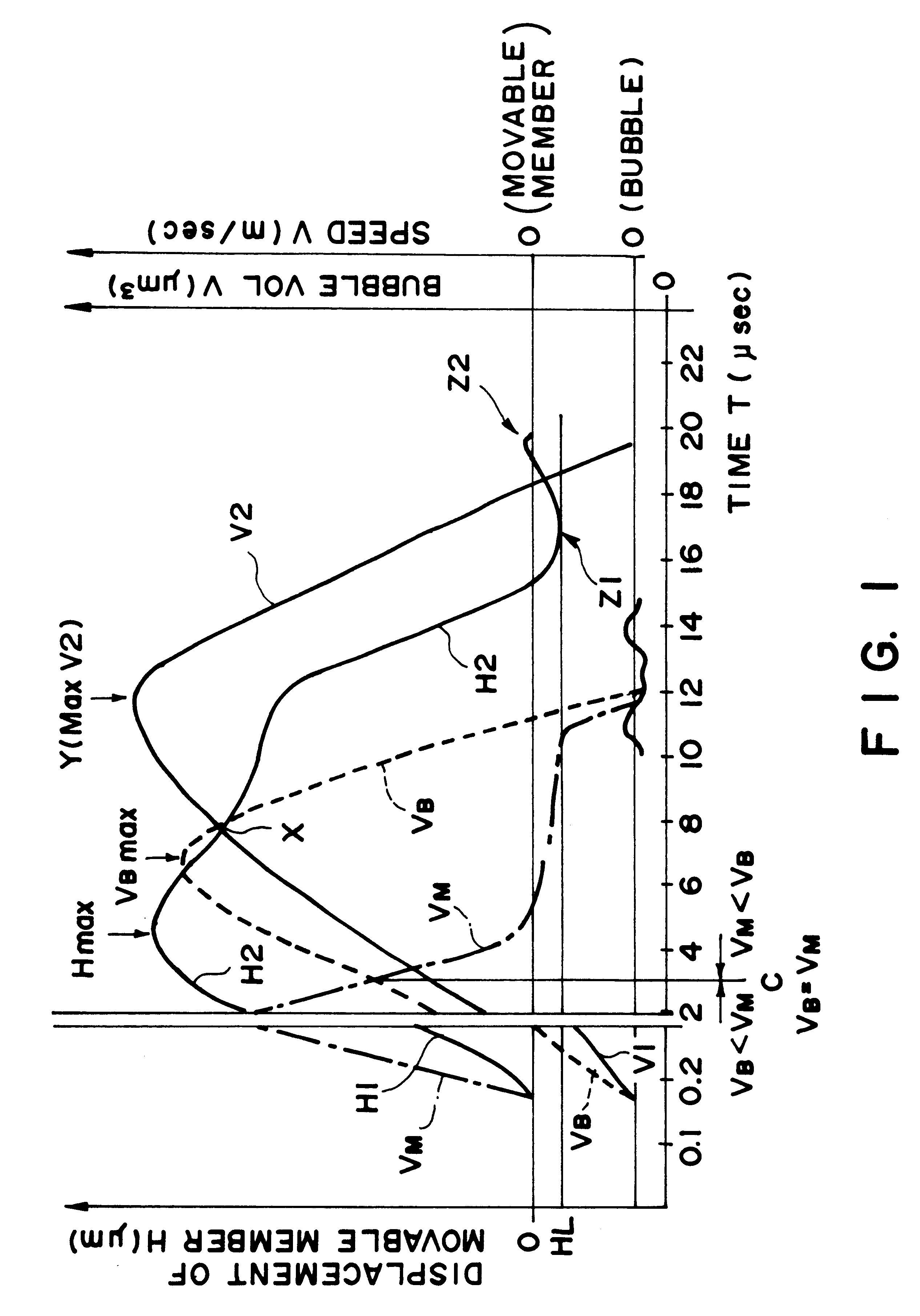

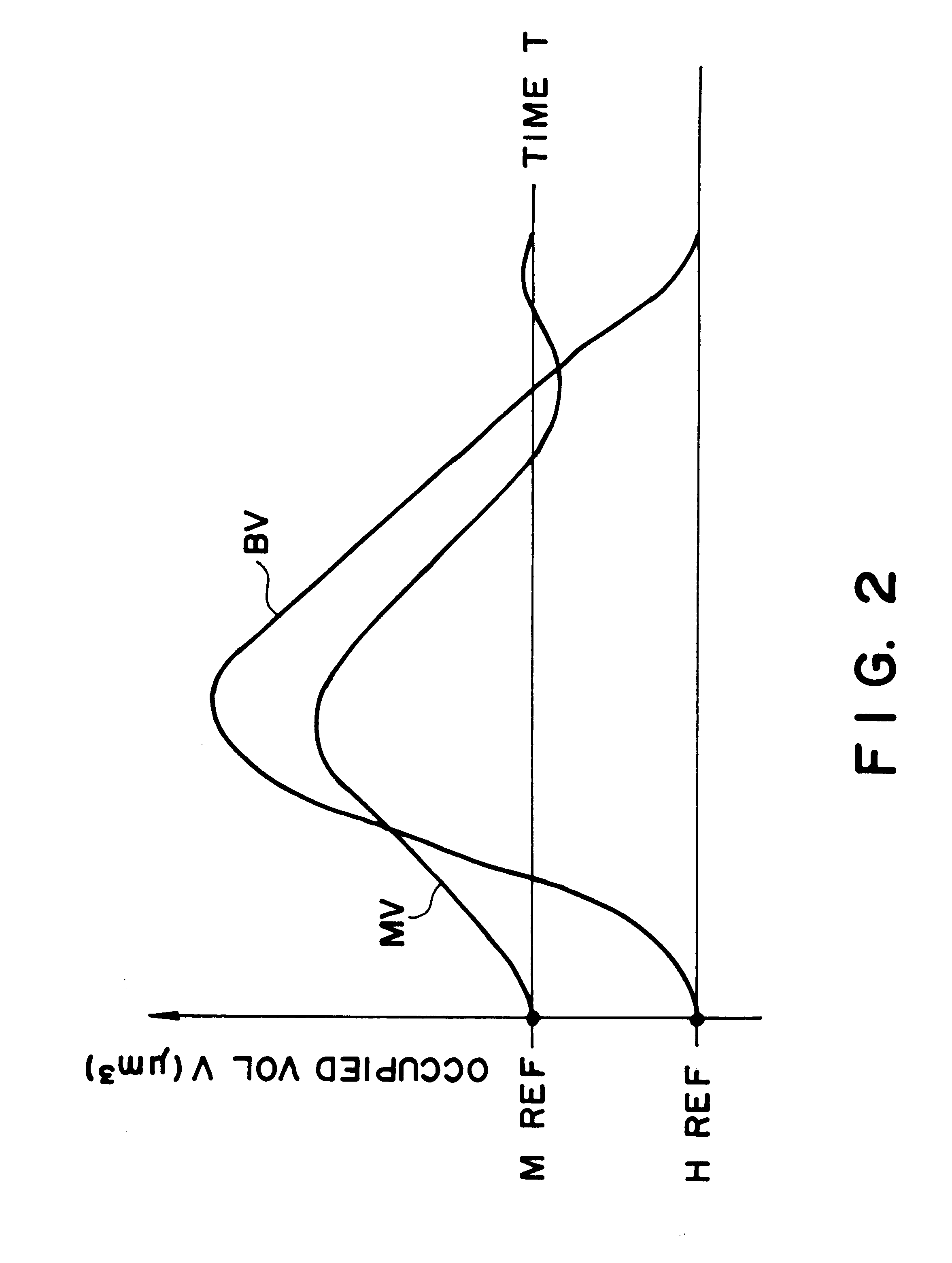

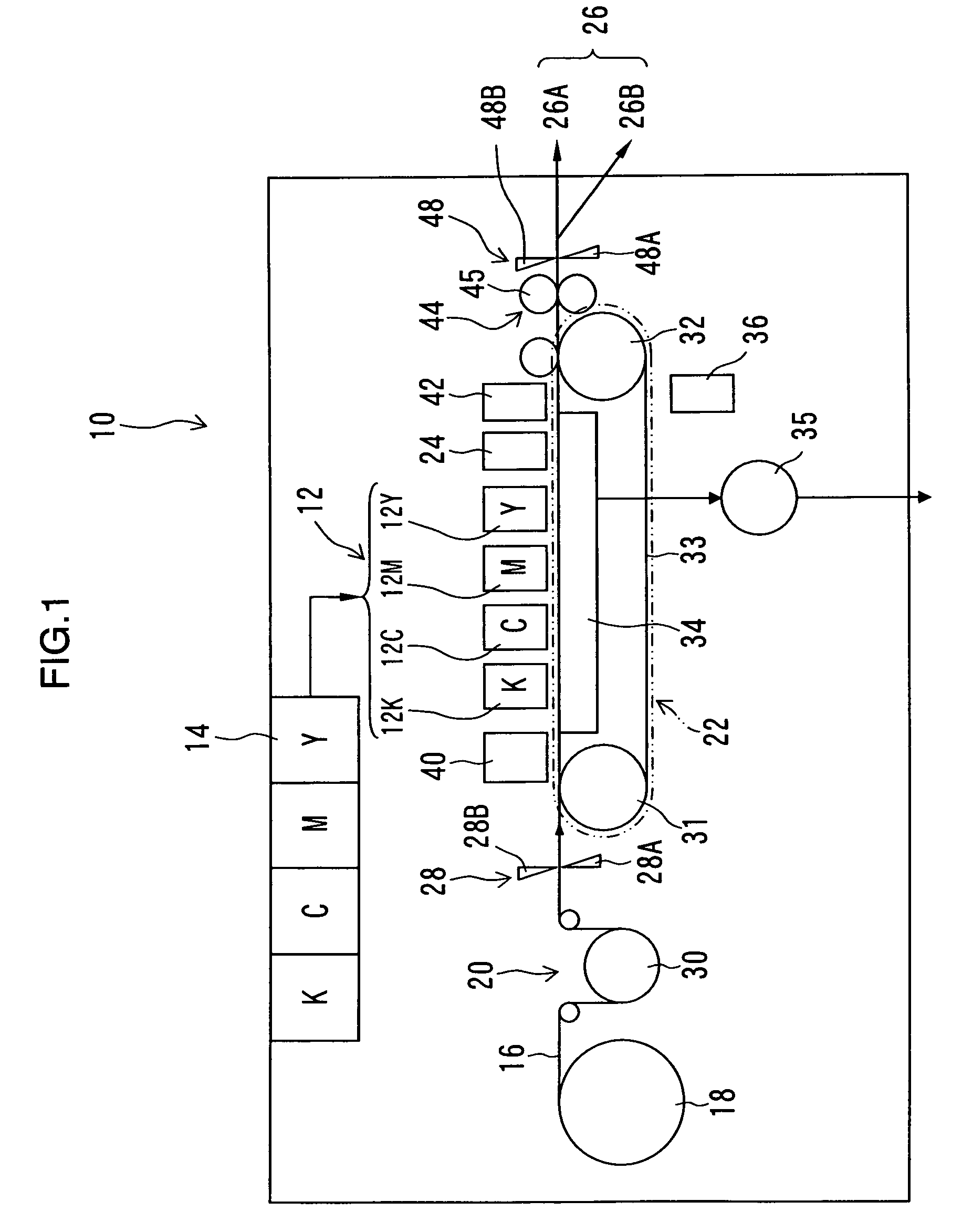

Liquid ejecting method, liquid ejecting head, head cartridge and liquid ejecting apparatus using same

A liquid ejecting method includes displacing a movable member having a free end by bubble generation in a bubble generating region; the improvement residing in: that a fulcrum of said movable member is disposed adjacent to one side of a displacement region where the free end of said movable member displaces, and an ejection outlet through which the liquid is ejected is disposed adjacent to the opposite side of the displacement region; that there is provided a first period in which a displacing speed of the free end of the movable member is higher than a growing speed of the bubble generated in the bubble generating region toward the movable member, before the bubble reaches its maximum size.

Owner:CANON KK

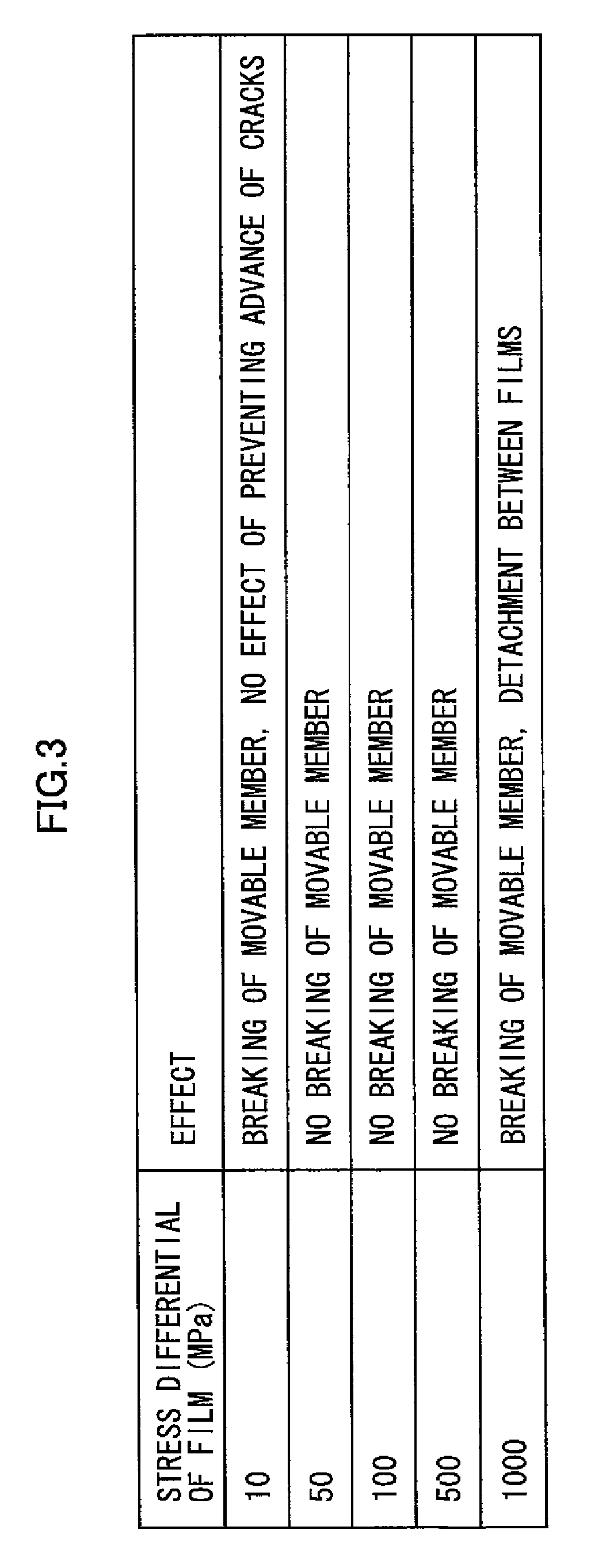

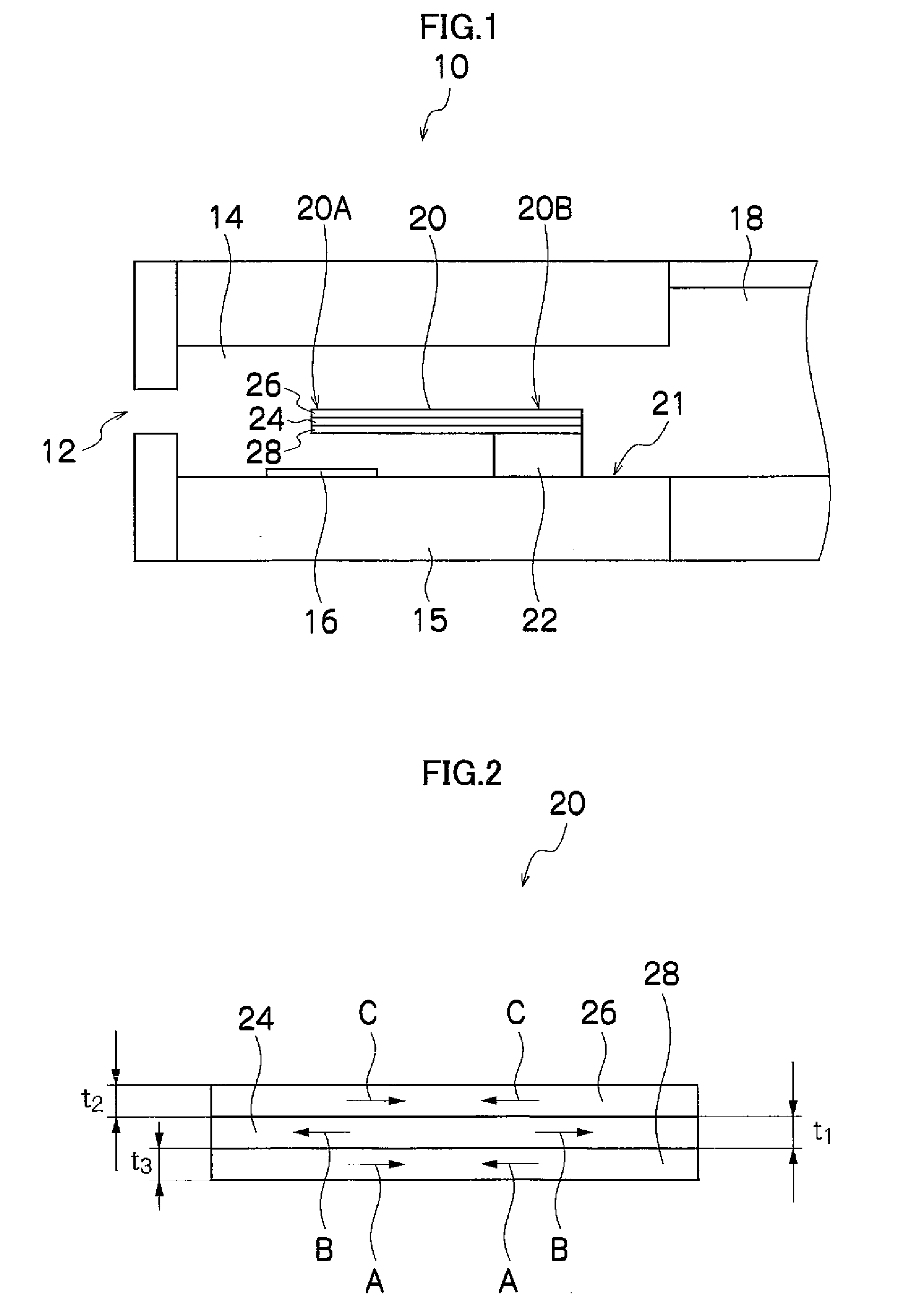

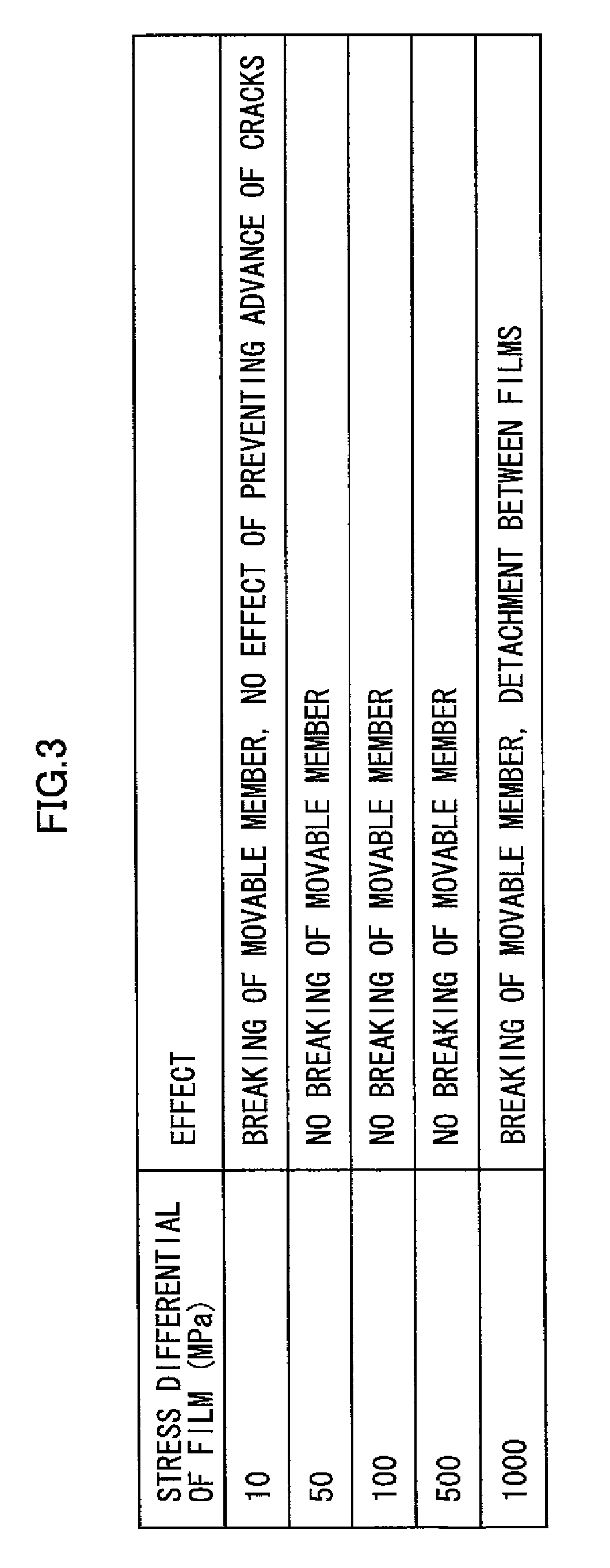

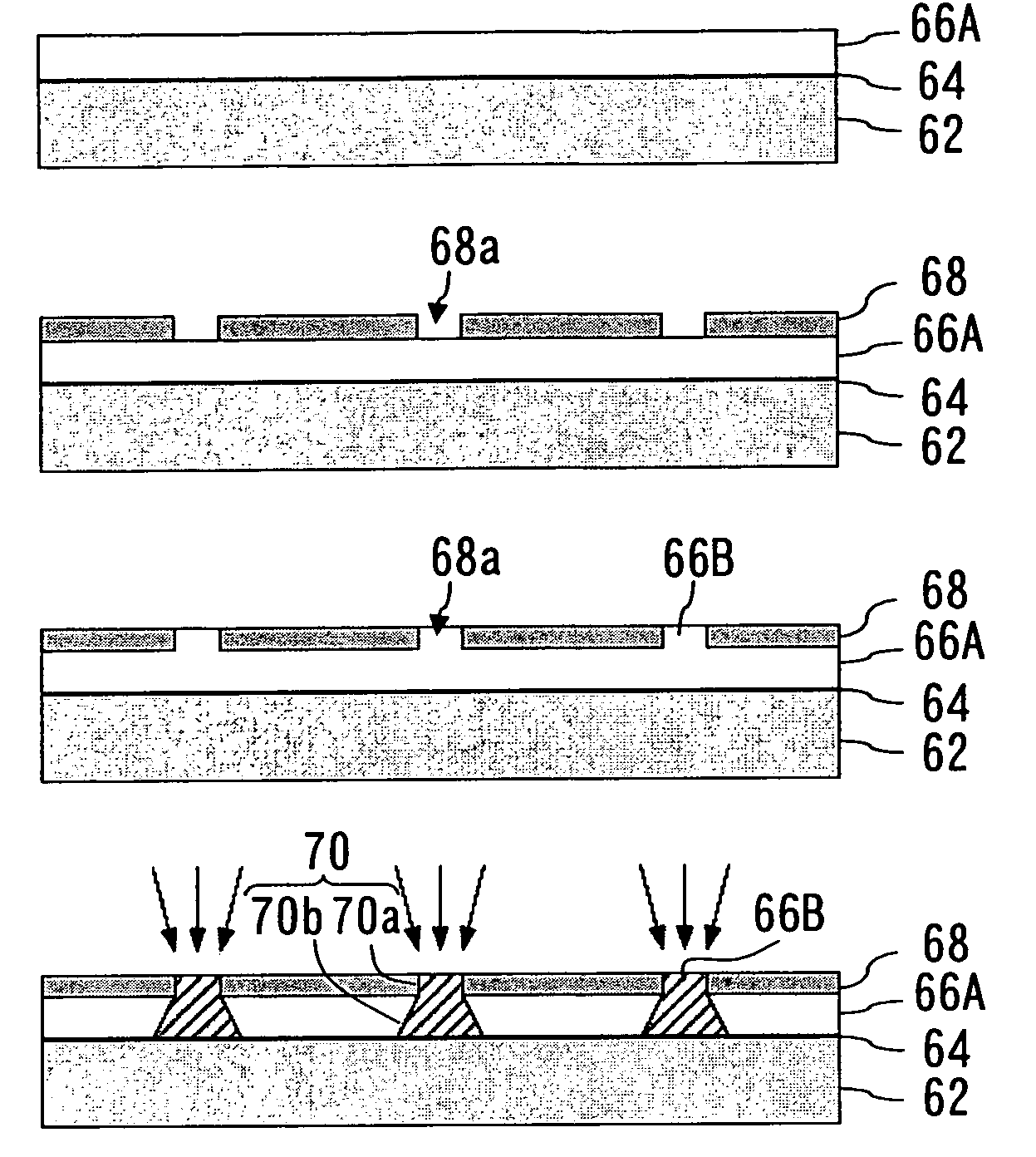

Liquid ejection head, liquid ejection apparatus and method of manufacturing liquid ejection head

A liquid ejection head includes: an ejection port through which liquid is ejected; a liquid chamber which is connected to the ejection port, the liquid chamber being filled with the liquid; a pressurization device which is arranged on a wall of the liquid chamber, the pressurization device pressurizing the liquid in the liquid chamber; and a movable member which has a free end on a side of the ejection port and a fixed end on a side opposite to the ejection port, the free end being arranged at a prescribed distance from the wall of the liquid chamber so as to face the wall of the liquid chamber, the movable member including a first layer that is an internal layer, and second and third layers that are respectively arranged on both surfaces of the first layer, the second and third layers having a stress lower than the first layer.

Owner:FUJIFILM CORP

Ejecting pipe

ActiveCN103234201BImprove ejection abilityAvoid mutual interferenceGaseous fuel burnerCombustorEllipse

The invention relates to an ejecting pipe. A horn section, a transition section and a tail interface which is matched with a combustor furnace head are sequentially arranged in an internal chamber of the ejecting pipe along the direction from an inlet to an outlet. A throat opening is formed between the horn section and the transition section; an outer contour of the horn section is formed by a plurality of circles or a plurality of ellipses in an intersecting mode; the ellipses are approximate to circles; centers of the circles or centers of the ellipses are arranged in a same first circle and are uniformly distributed relative to a center of the first circle; nozzles which are matched with the ejecting pipe are arranged on centers of the circles or centers of the ellipses; the number of the nozzles is equal to the number of the circles or the number of the ellipses; a cross section of the horn section is gradually decreased; a shape of a cross section of the throat opening is the same with that of the horn section; the cross section area of the transition section is gradually increased from a cross section area the same as that of the throat opening to a cross section area the same as that of the tail interface. The ejecting pipe has the advantages of avoiding mutual interferences among airflows at the beginning of ejection, adding primary air supplementary amount, promoting mutual mixing of the airflows entering into the internal chamber of the ejecting pipe and the air, improving primary air coefficient, increasing ejecting capability and accordingly improving energy efficiency of a combustor.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Nozzle for high-speed jetting devices

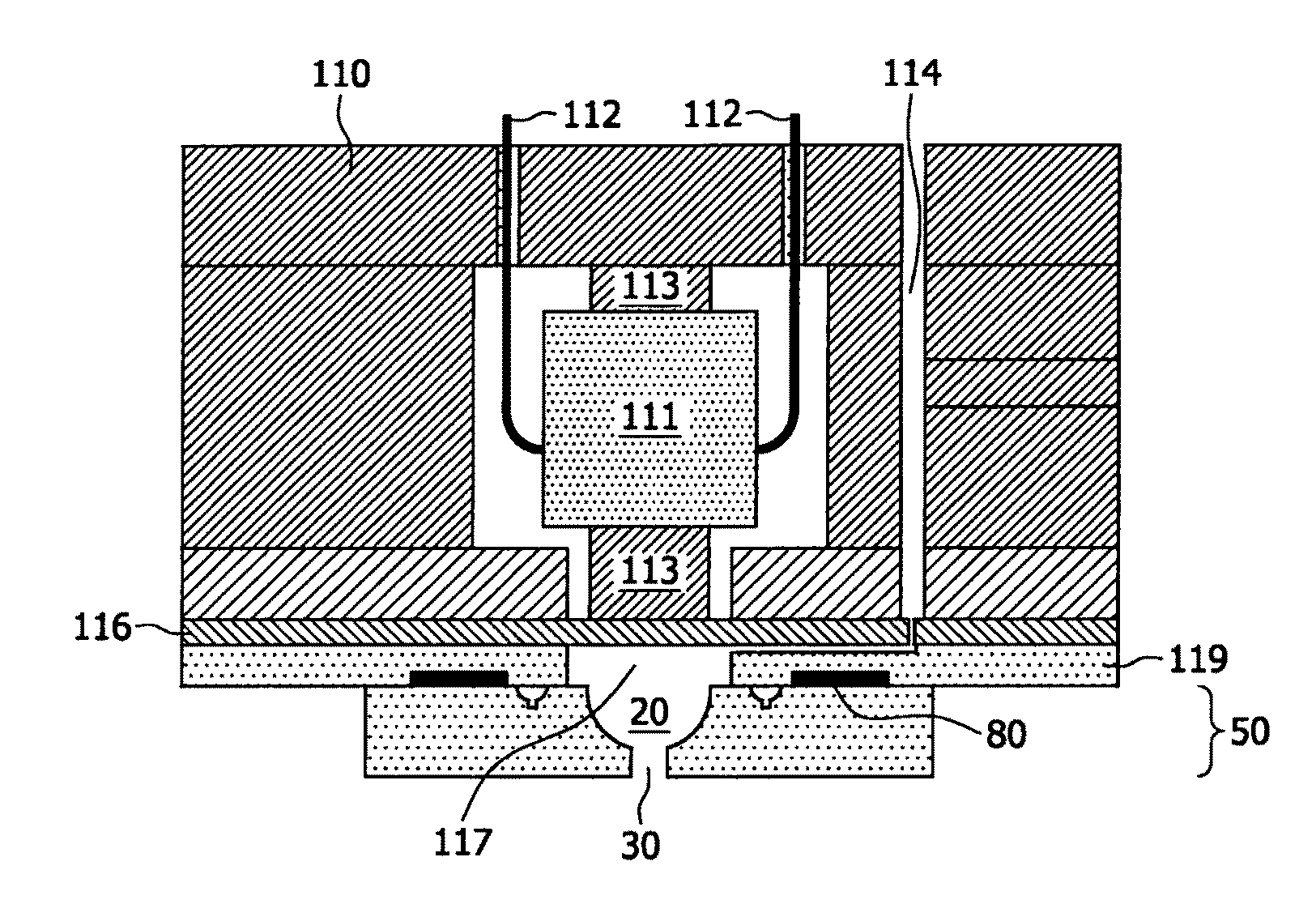

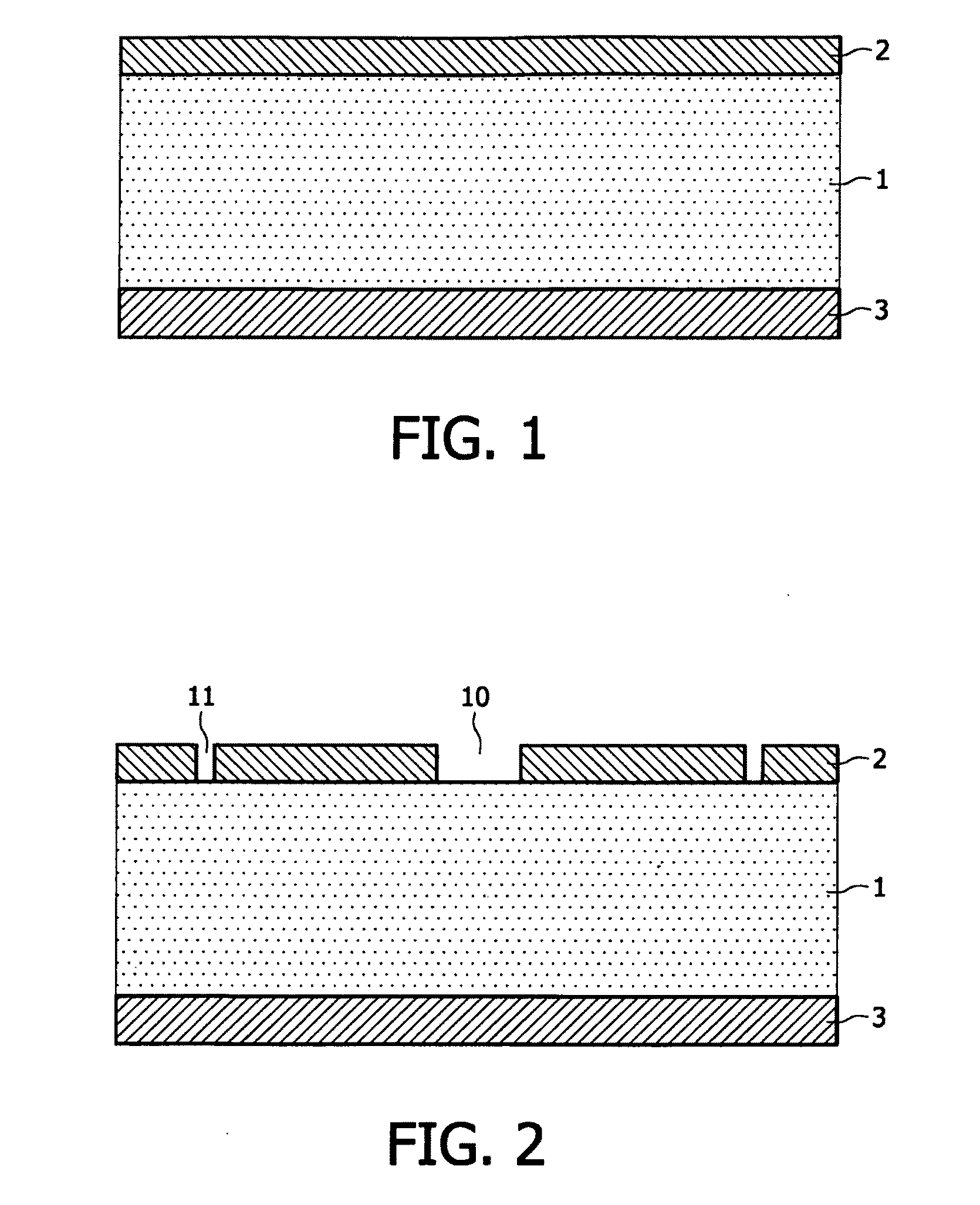

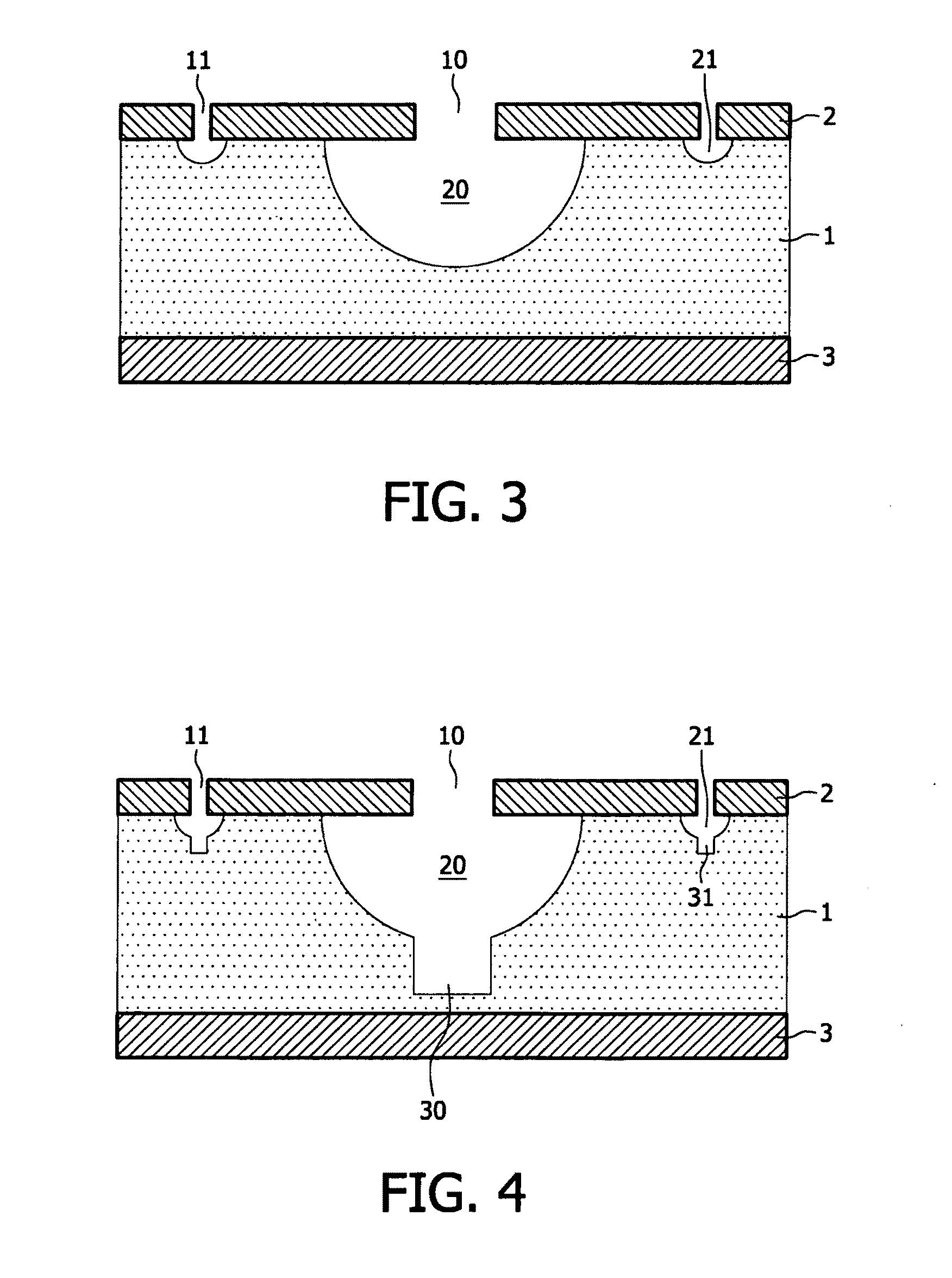

InactiveUS20100331769A1Reduce turbulenceImprove ejection efficiencyJet injection syringesEnemata/irrigatorsAnisotropic etchingIsotropic etching

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

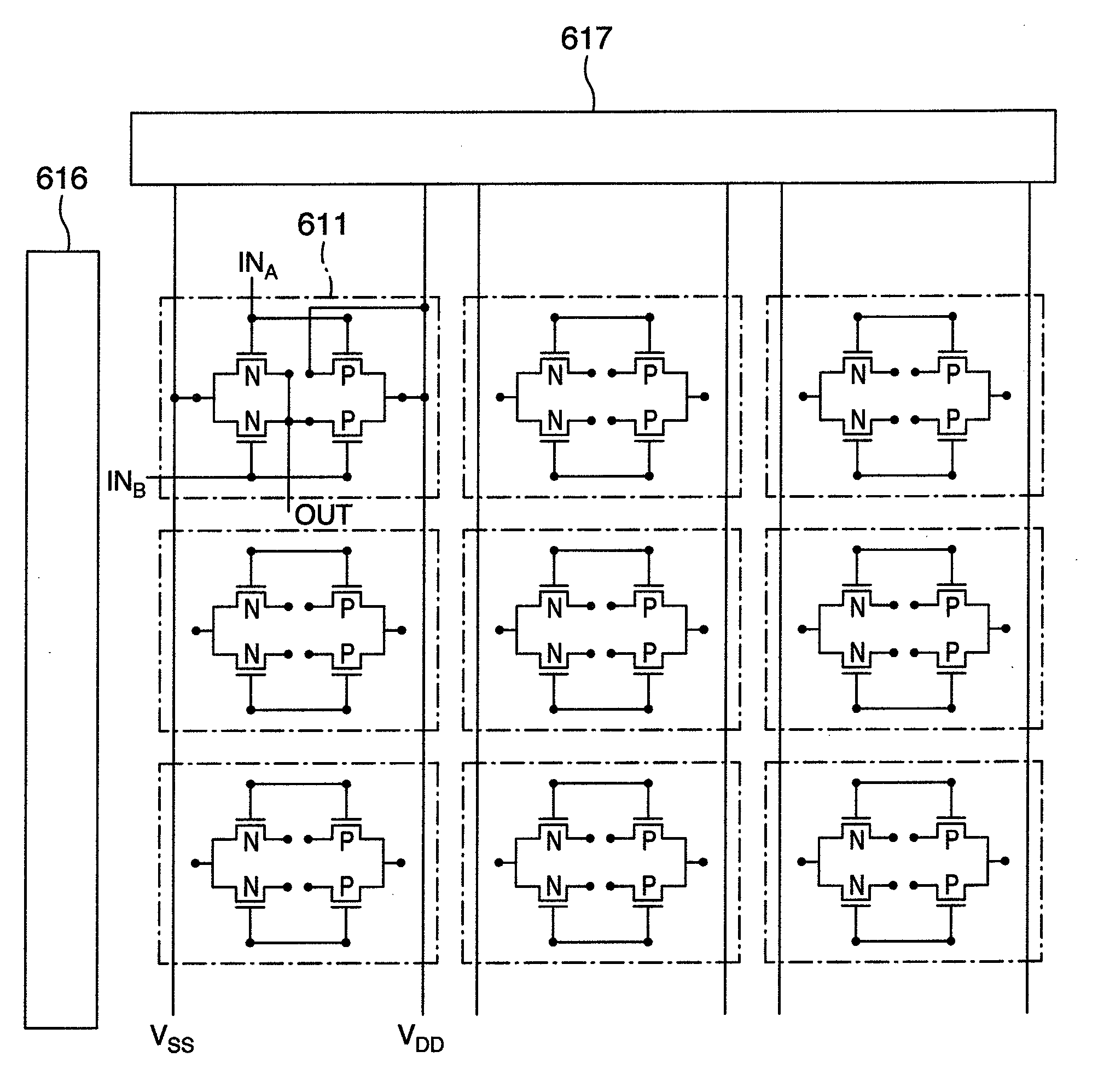

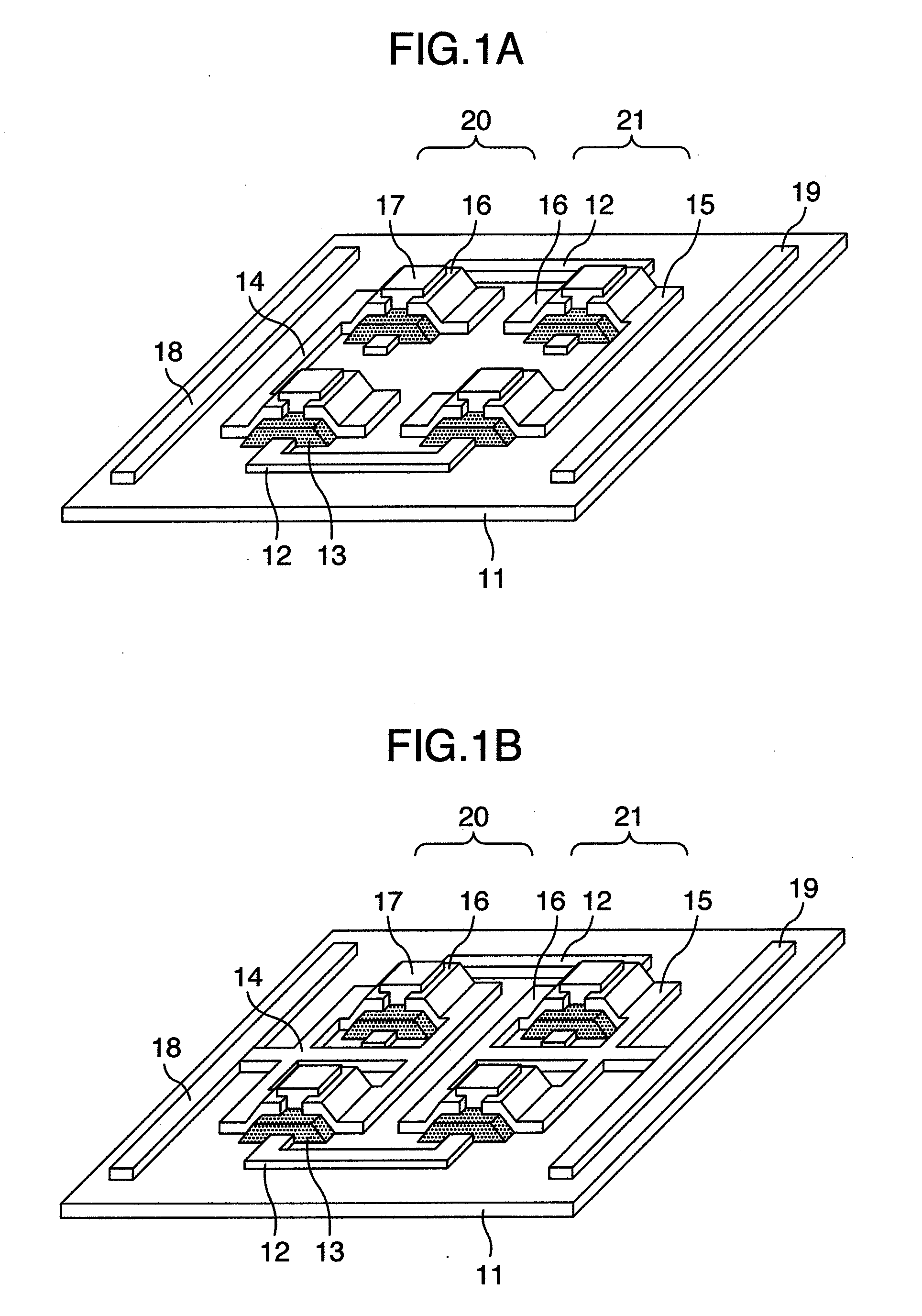

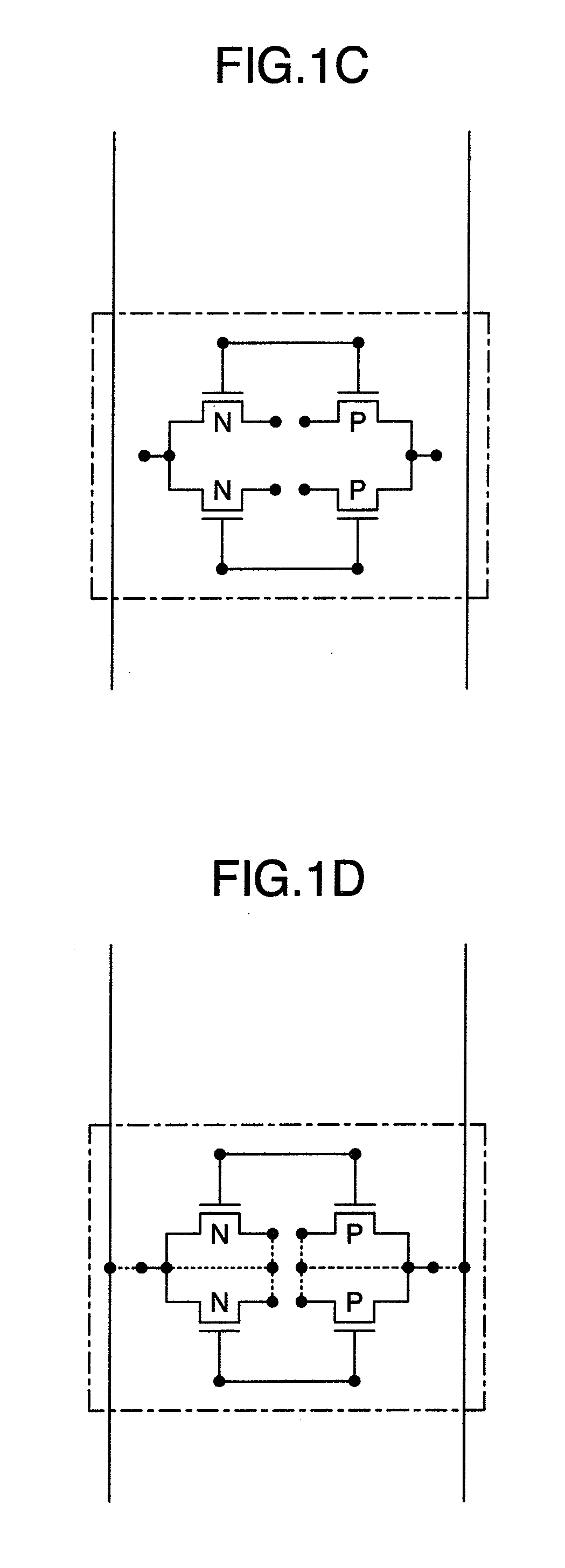

Organic Thin Film Transistor Array and Method of Manufacturing the Same

InactiveUS20080315191A1Manufactured very thinImprove ejection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLaser exposureEngineering

An n-type TFT and a p-type TFT are realized by selectively changing only a cover coat without changing a TFT material using an equation for applying the magnitude of a difference in the Fermi energy between an interface of semiconductor and an electrode and between an interface of semiconductor and insulator. At this time, in order to configure a predetermined circuit, the process is performed, as a source electrode and a drain electrode of the p-type TFT and a source electrode and a drain electrode of the n-type TFT being connected all, respectively, and an unnecessary interconnection is cut by irradiating light using a scanning laser exposure apparatus or the like.

Owner:HITACHI LTD

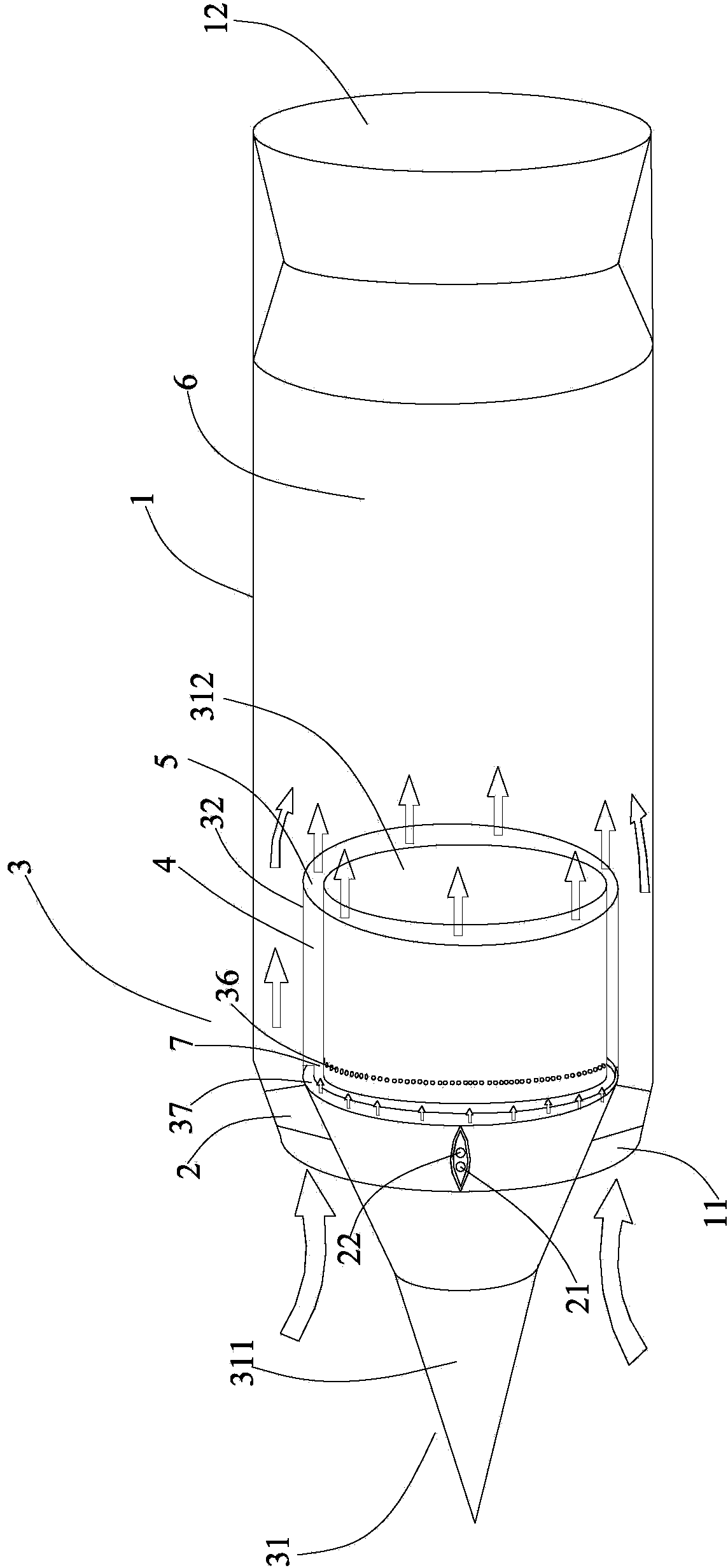

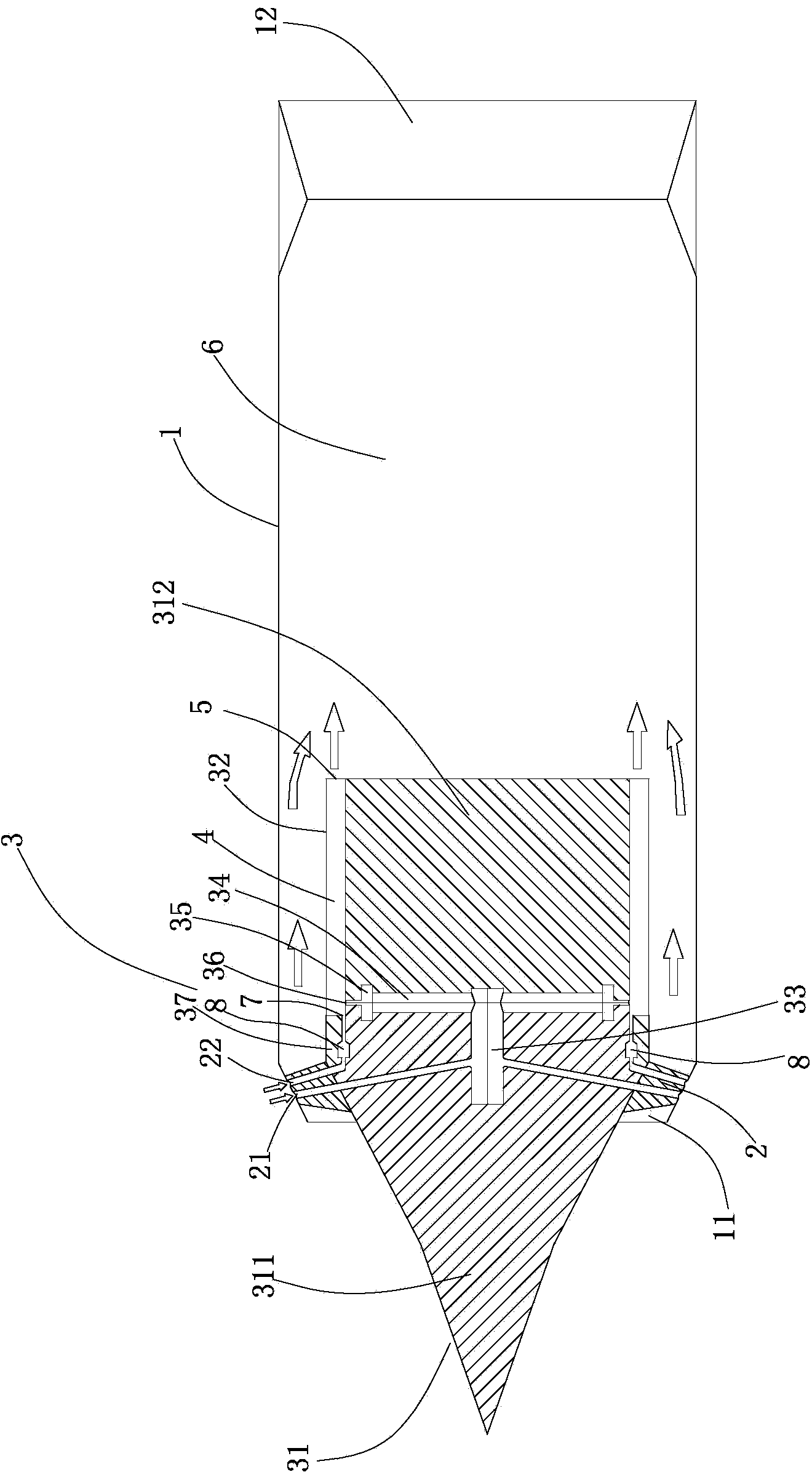

Combined cycle engine

ActiveCN104110325AImprove combustion efficiencyImprove thermodynamic efficiencyJet propulsion plantsCombustion chamberContinuous rotation

The invention provides a combined cycle engine. The combined cycle engine comprises a casing, a fixing guide column and a continuous rotation knock engine as an ejecting device. The casing is provided with an air inlet and a supersonic nozzle. The fixing guide column is provided with a fuel inlet and an oxidant inlet. The continuous rotation knock engine comprises a central conical body, a fuel collecting pipe, a plurality of fuel conveying channels, a fuel inlet pipe, a plurality of fuel nozzles and a ring-shaped body. The central conical body comprises a front body and a rear body, the casing is fixedly arranged by surrounding the outer surface of the whole rear body and part of the front body, a first combustion chamber extends axially and is defined by the casing, the outer surface of the whole rear body and part of the front body, the tail end of the first combustion chamber, which is in an axial direction, is an outlet, space between the casing and the portion behind the rear body of the central conical body inside the casing forms a second combustion chamber, the first combustion chamber is communicated with the second combustion chamber through the outlet, and the second combustion chamber is communicated with the air inlet. Therefore, the combined cycle engine can improve the ejecting efficiency of the ejecting device and simplify the structure of the ejecting device.

Owner:清航空天(浙江)科技有限公司

Jet pump

InactiveCN102654145ANovel structureUnique structureJet pumpsMachines/enginesSuction forceEngineering

The invention provides a jet pump, and relates to a mixed flow jet apparatus. The jet pump is composed of a current distributing assembly, an inner pipe assembly and an outer sleeve assembly which have a same shaft core, wherein the current distributing assembly and the inner pipe assembly are fixedly connected in series, thereby forming a blind top centre cavity and a centre mixing tube; the outer sleeve assembly is sleeved outside the current distributing assembly and the inner pipe assembly, thereby forming an annular mixing chamber, an annular mixing pipe, a total mixing chamber and a total mixing output pipe; an internal ring nozzle and an external ring nozzle are arranged between the current distributing assembly and the inner pipe assembly, a mainstream body sprayed by the internal ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the centre mixing tube, and the secondary fluid is mixed in the centre mixing tube so as to output a centre mixed flow; a mainstream body sprayed by the external ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the annular mixing pipe, and the secondary fluid is mixed in the annular mixing pipe so as to output an annular mixed flow; and the two mixed flows are mutually injected to enter the total mixing chamber and the total mixing output pipe so as to further output in an isotrope voltage-sharing manner. The jet pump provided by the invention has the advantages of smaller weight and axial direction size, high injection rate, great suction force and good property in large flow.

Owner:韩铁夫

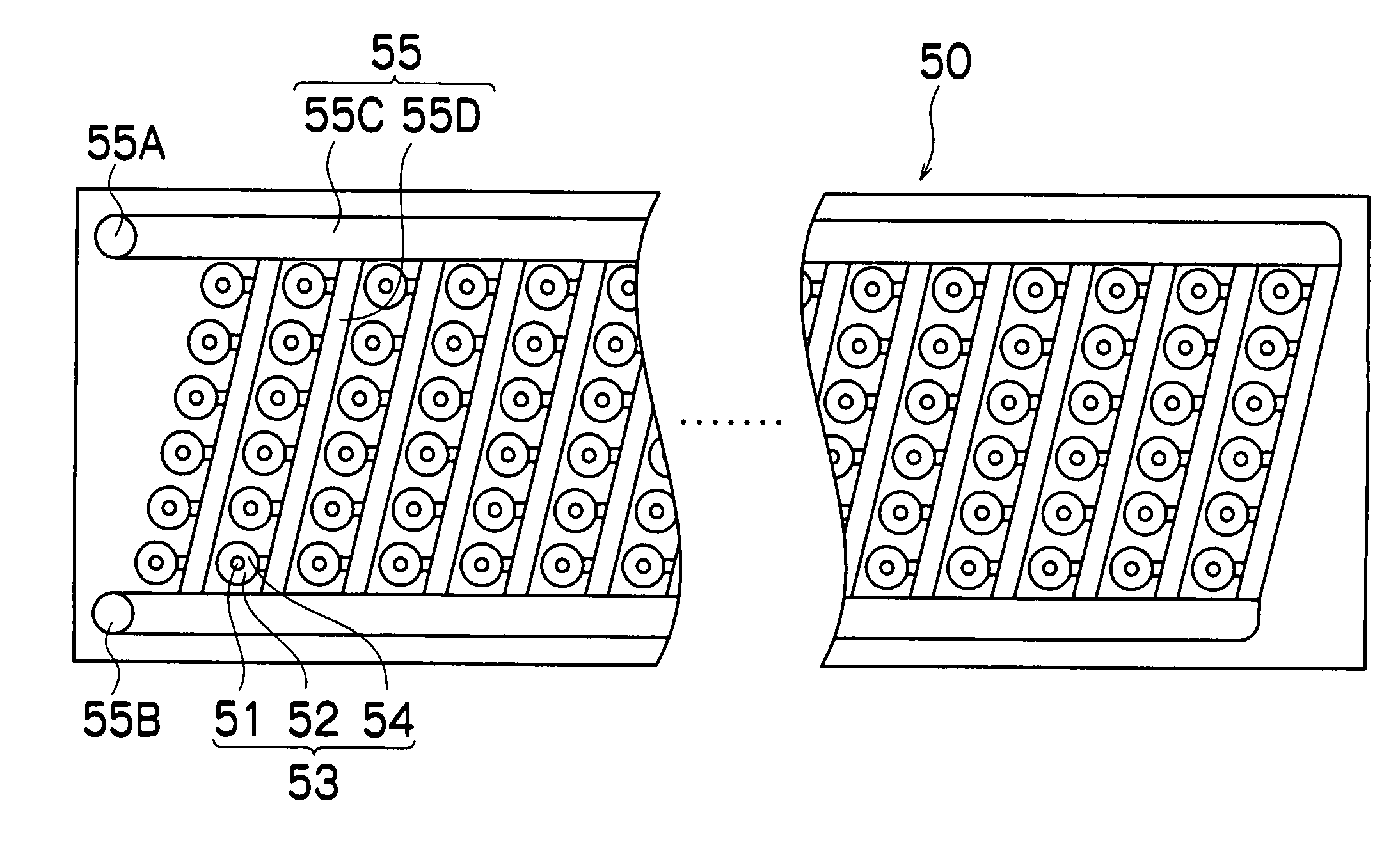

Liquid ejection head, liquid ejection apparatus, and image forming apparatus

InactiveUS20060082617A1Improve ejection efficiencyFunction maximizationInking apparatusLiquid jetEngineering

Owner:FUJIFILM CORP

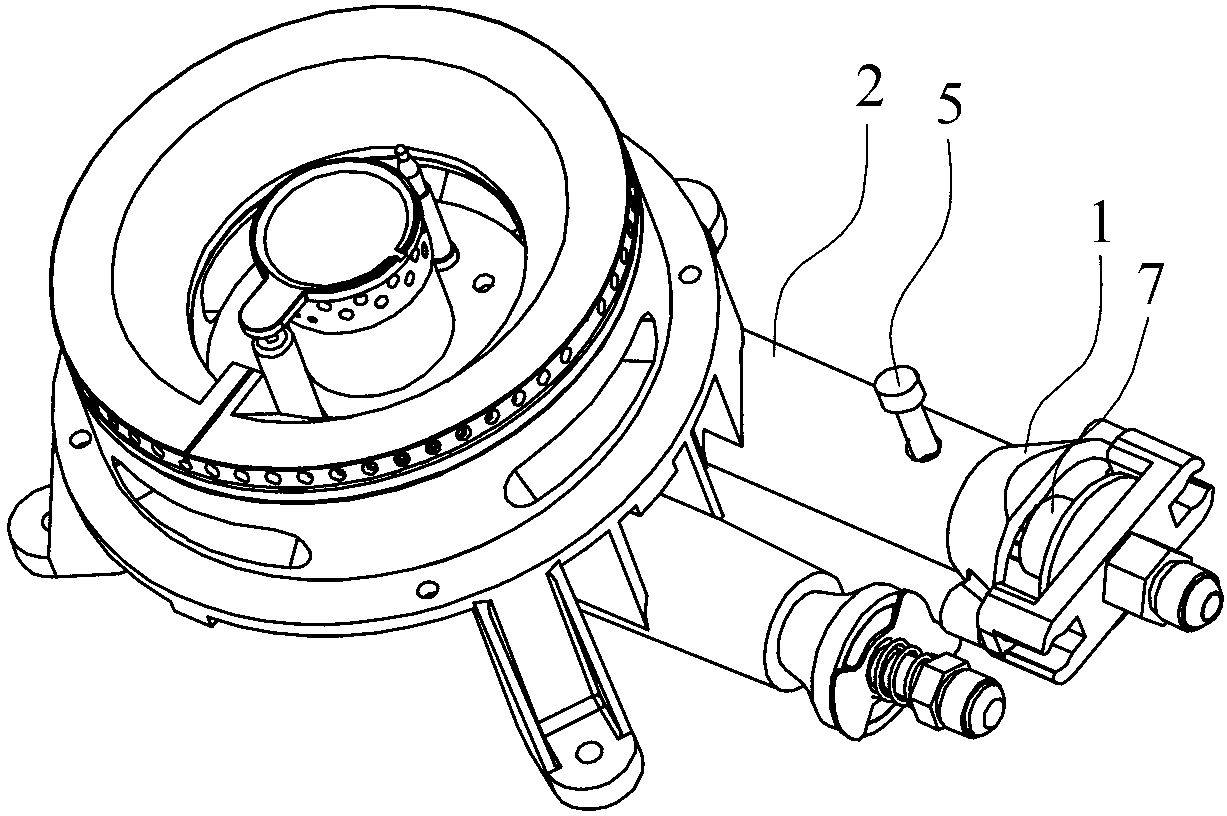

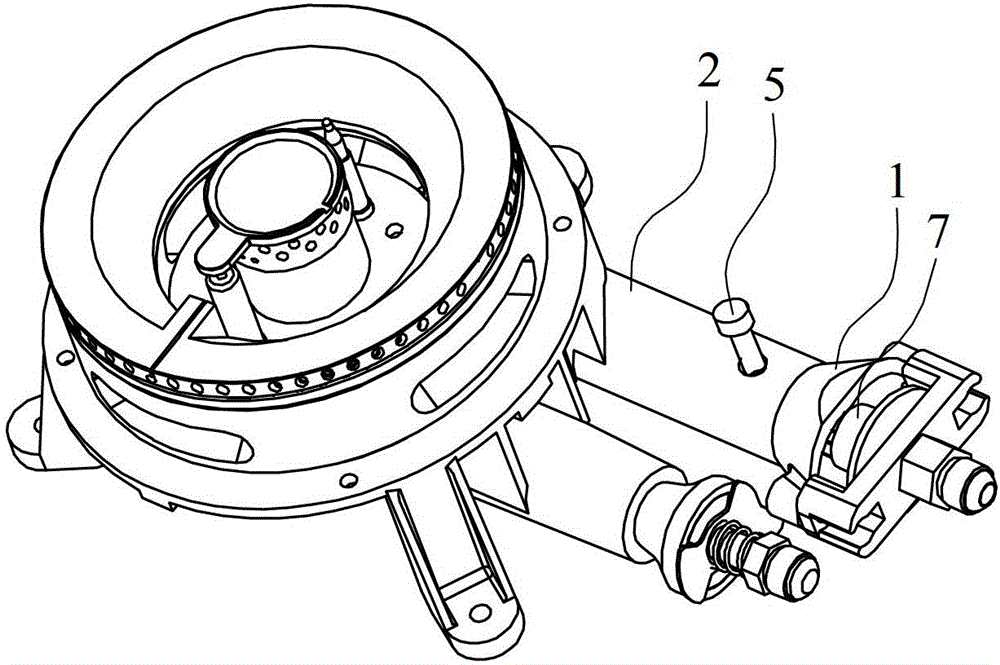

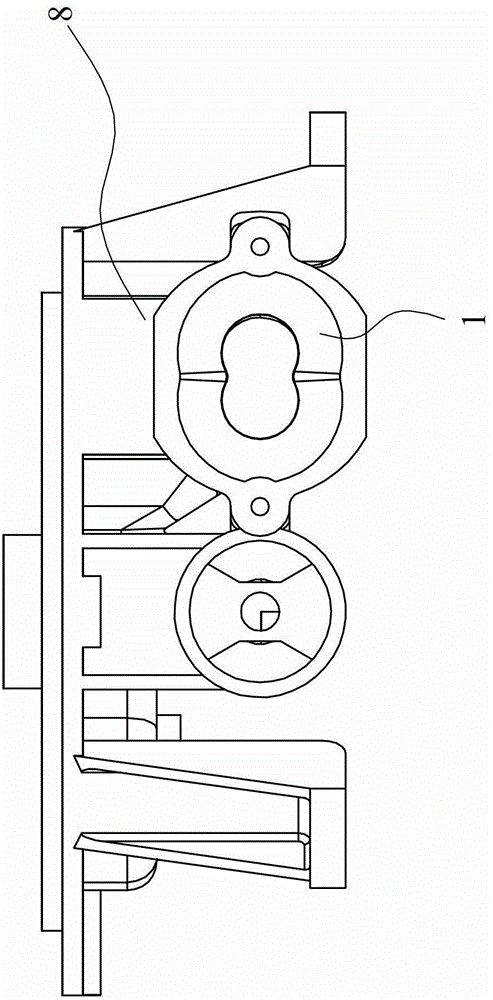

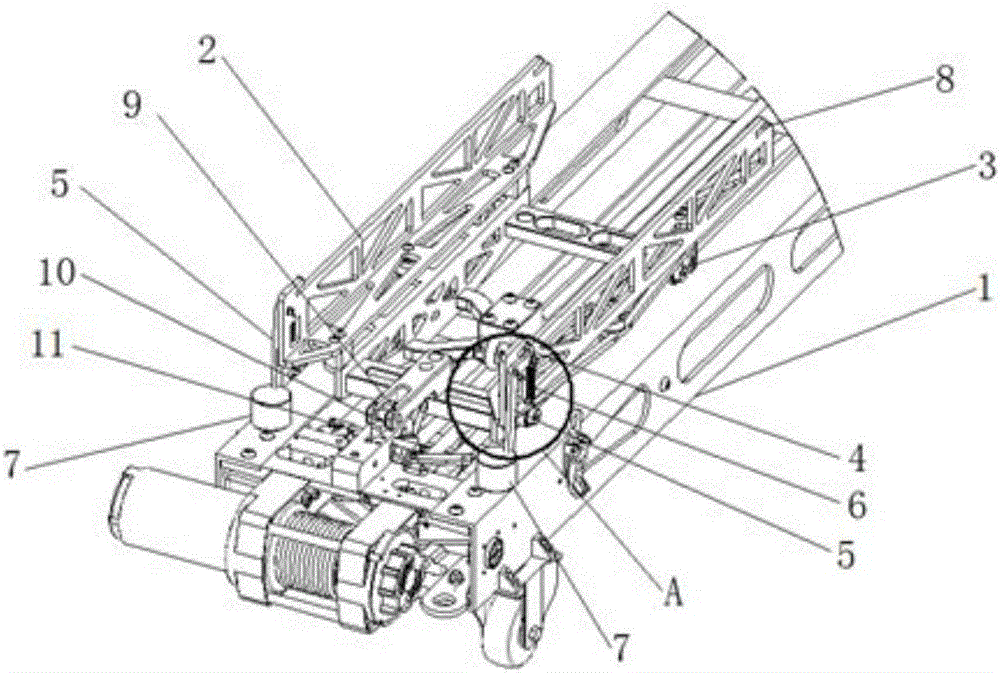

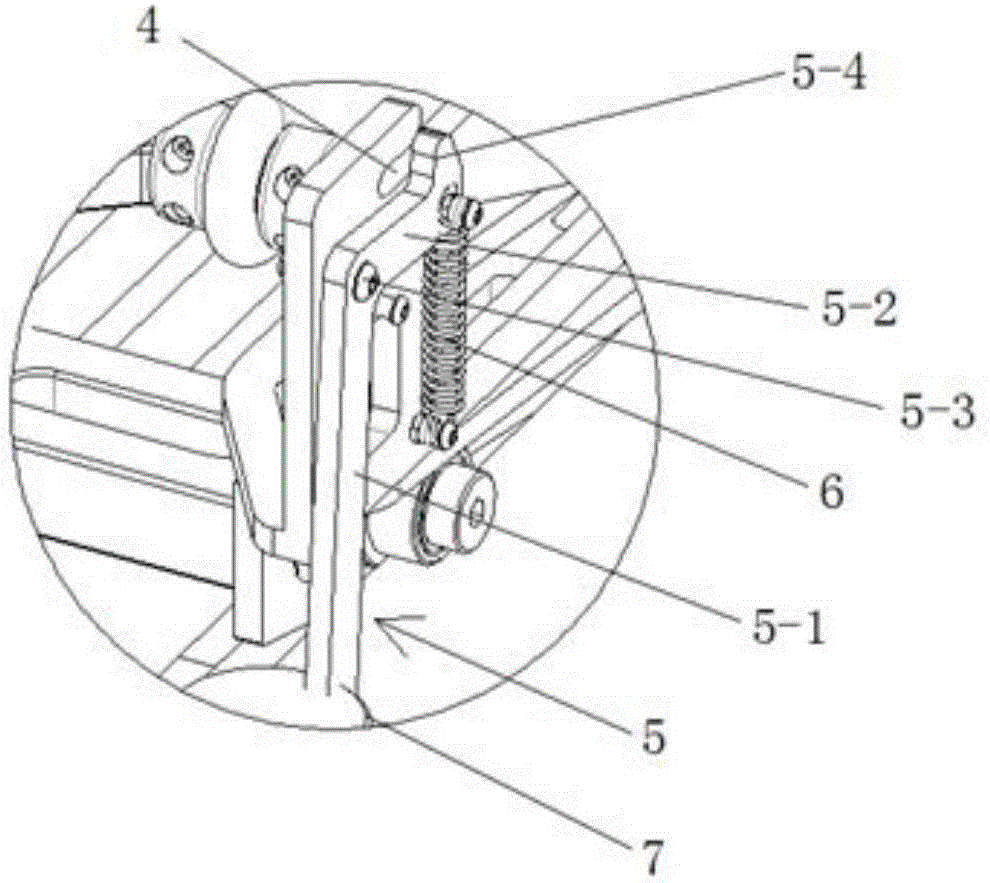

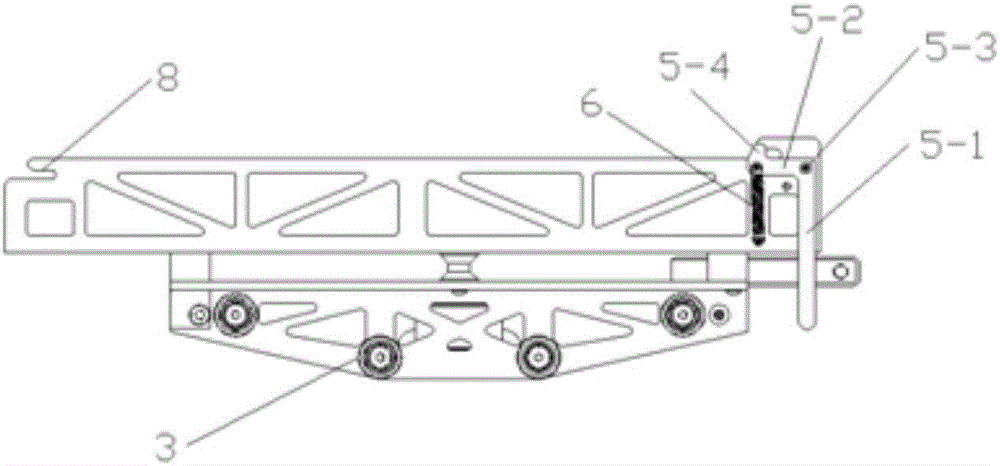

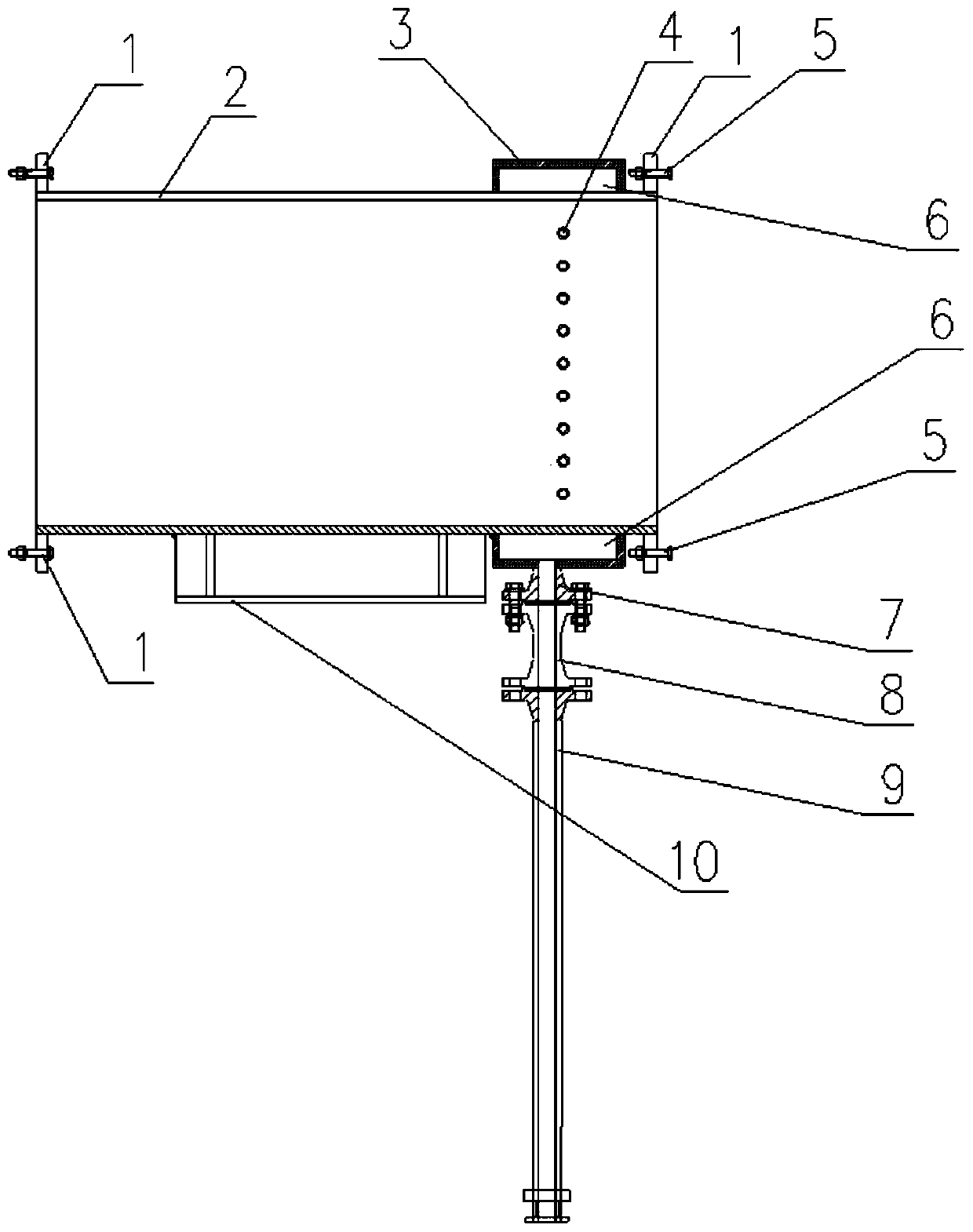

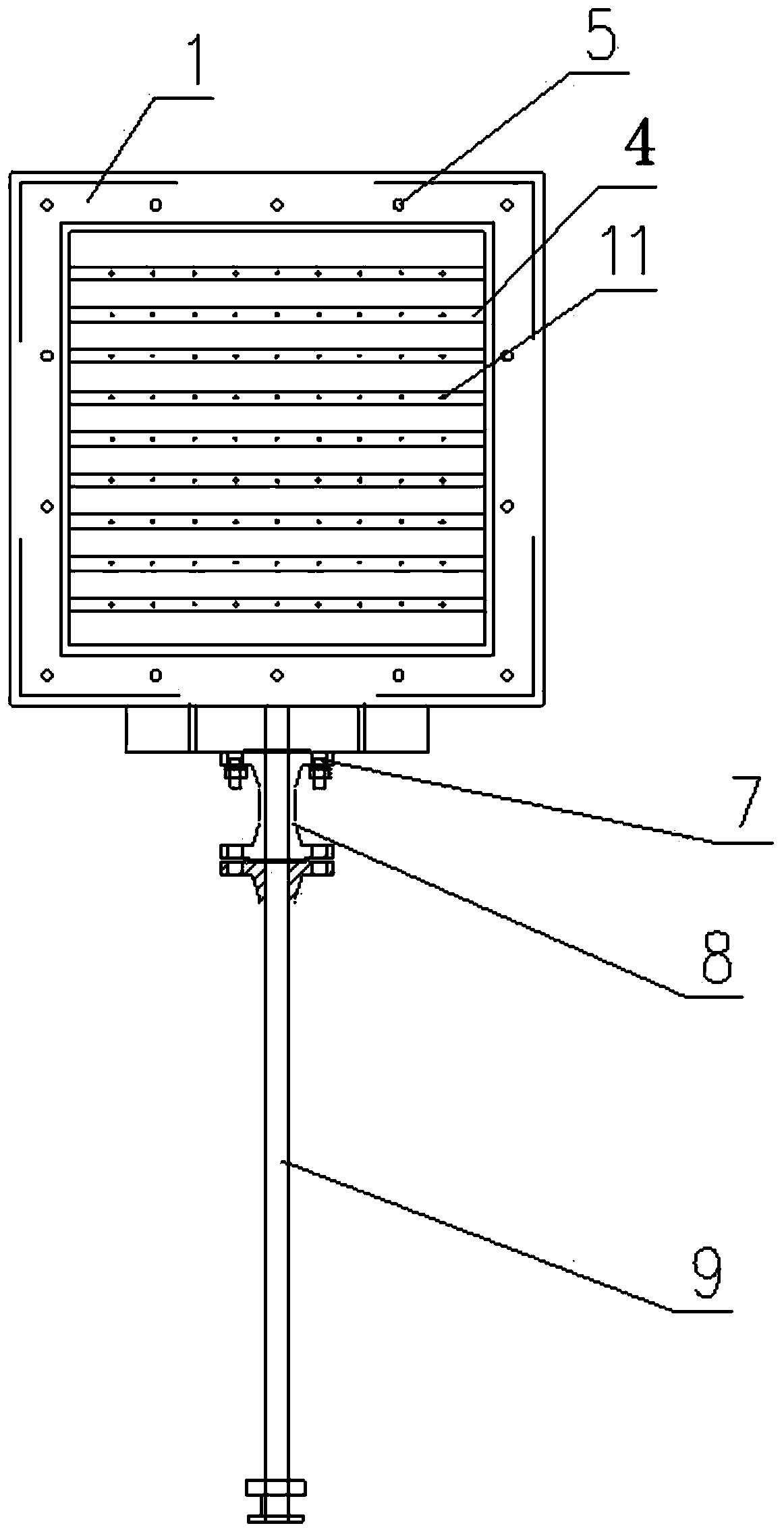

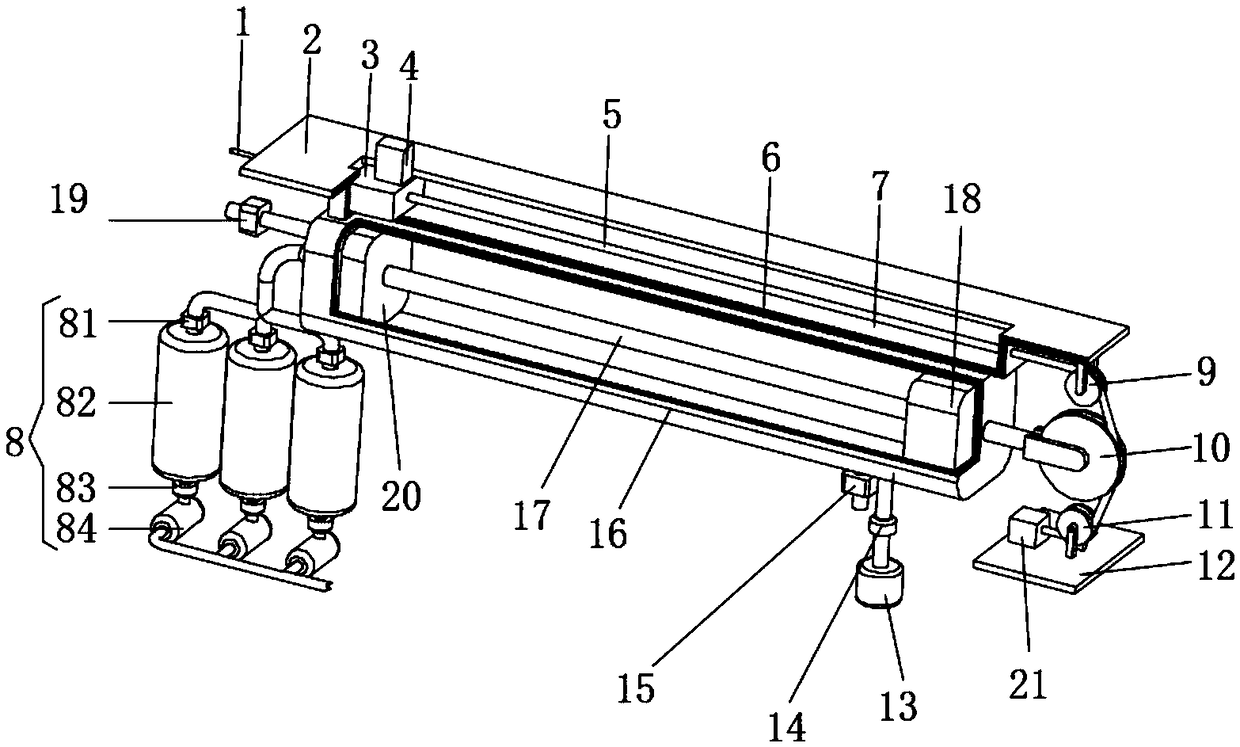

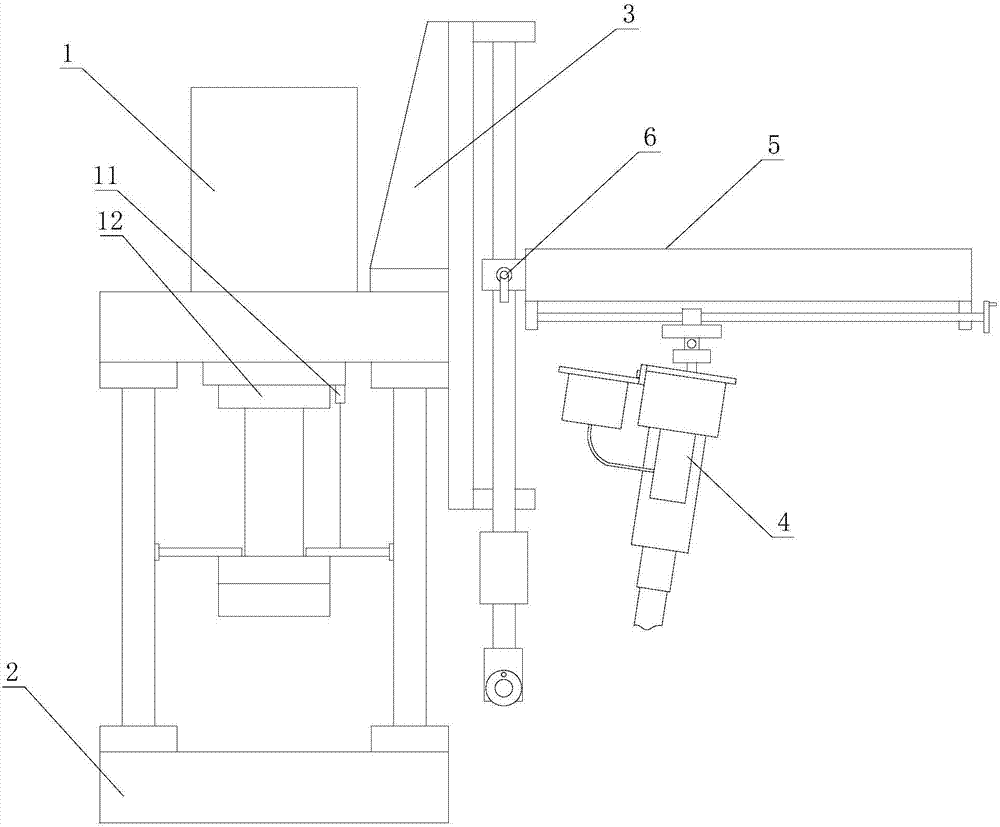

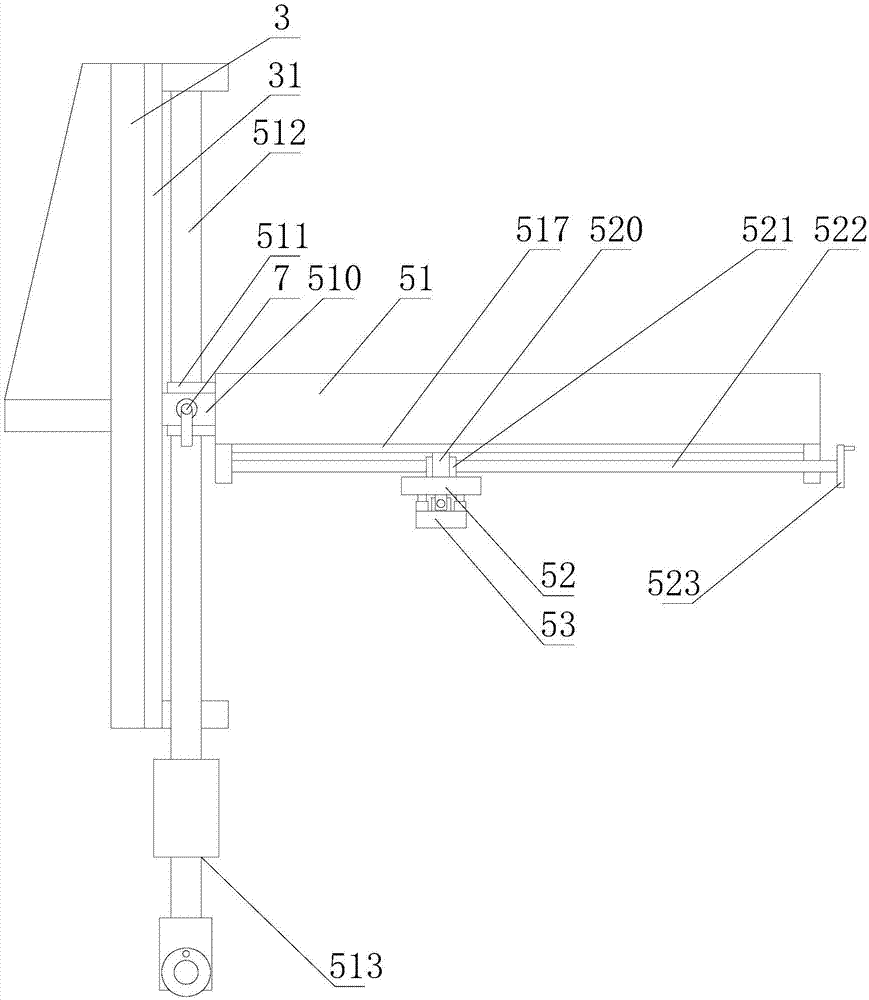

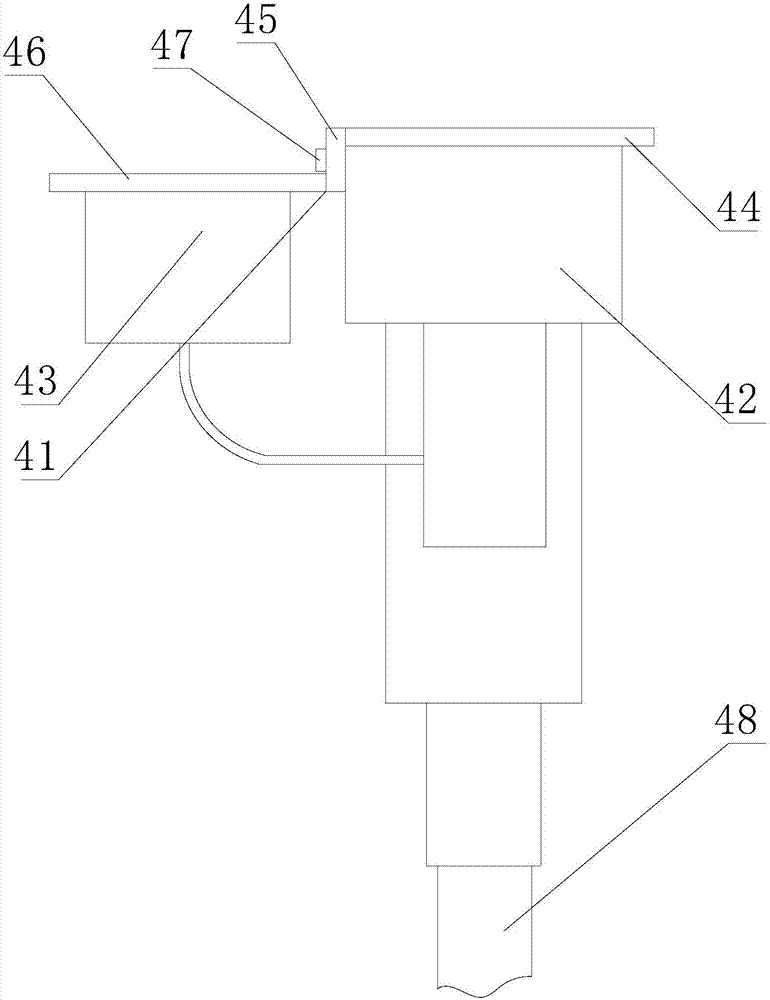

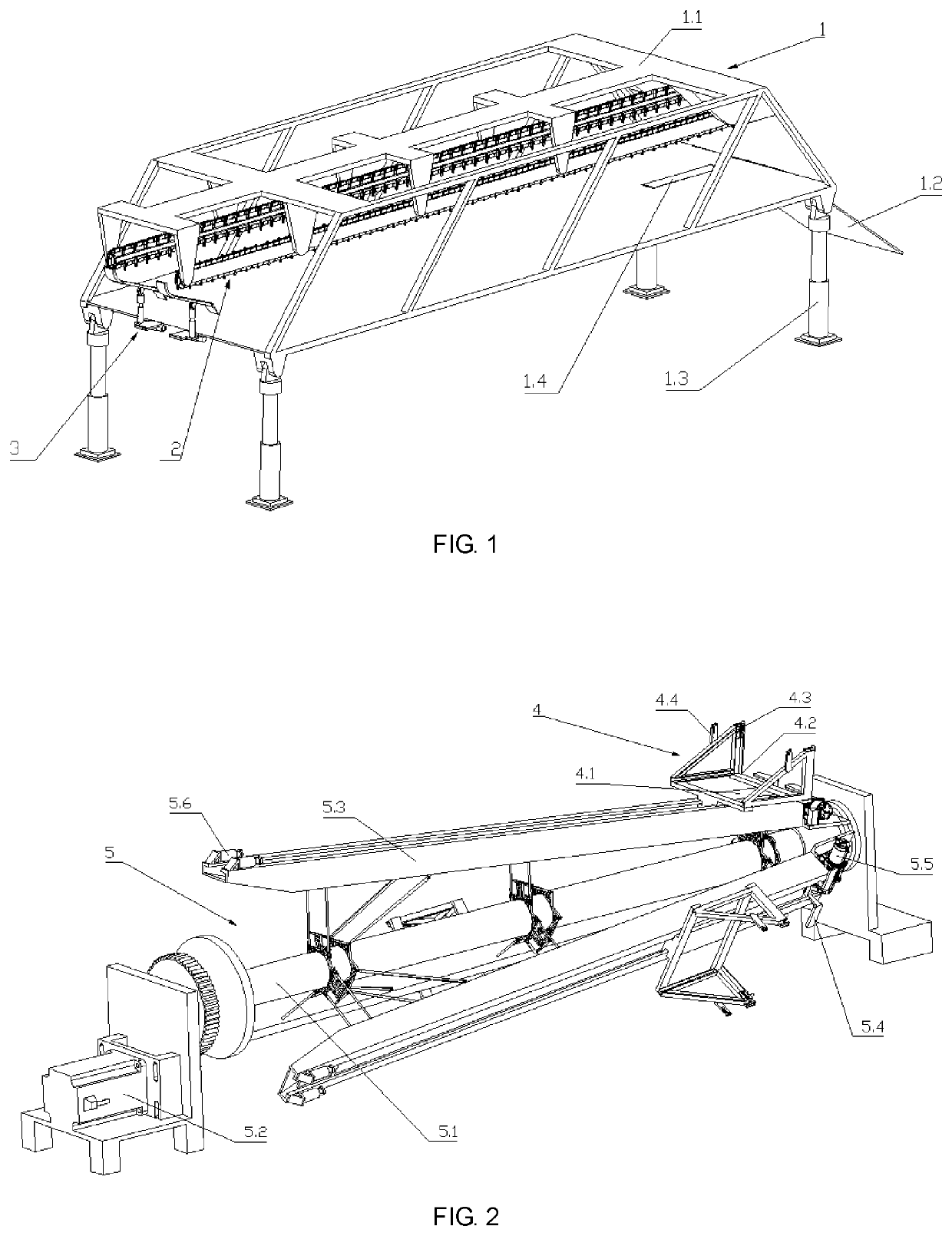

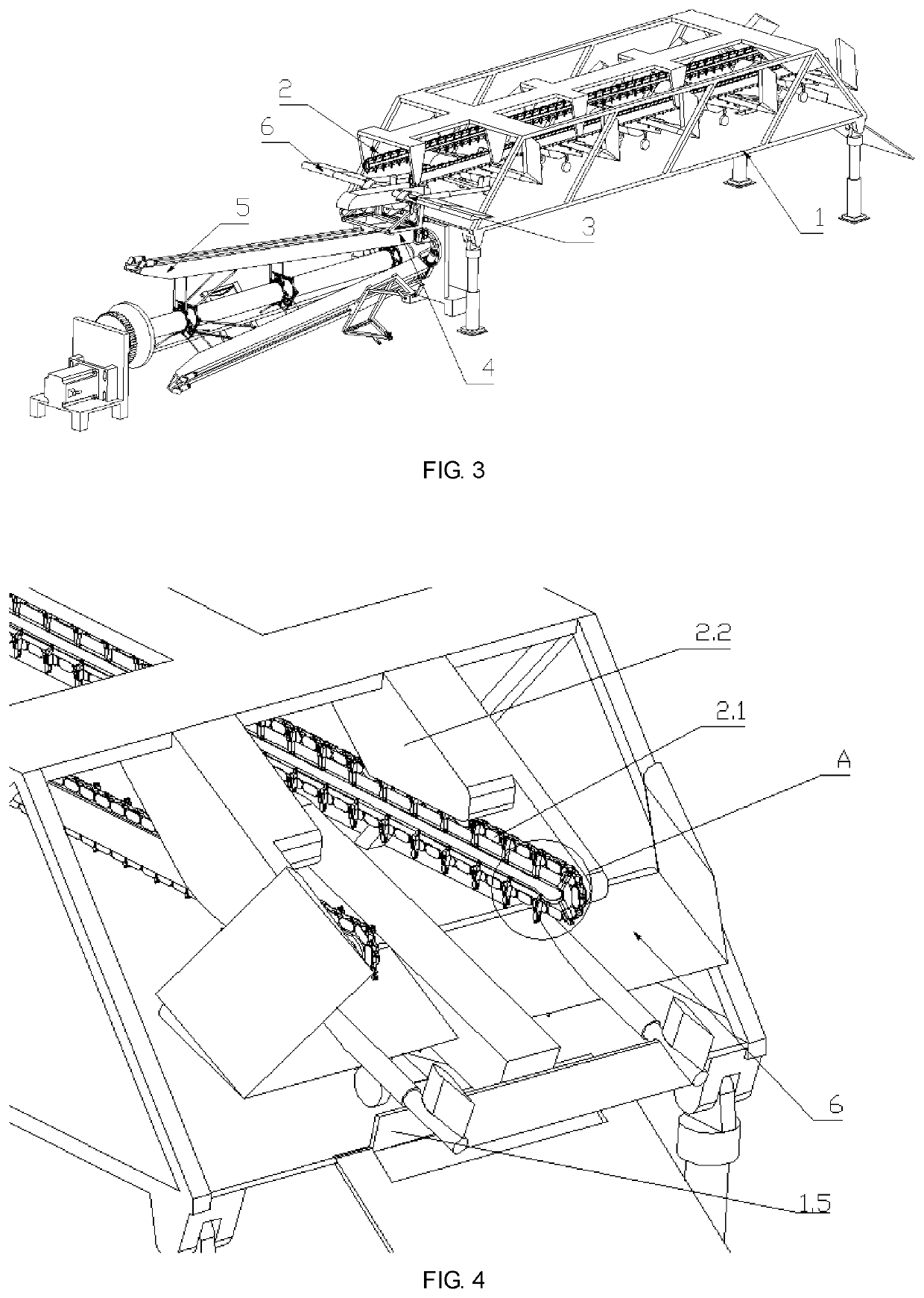

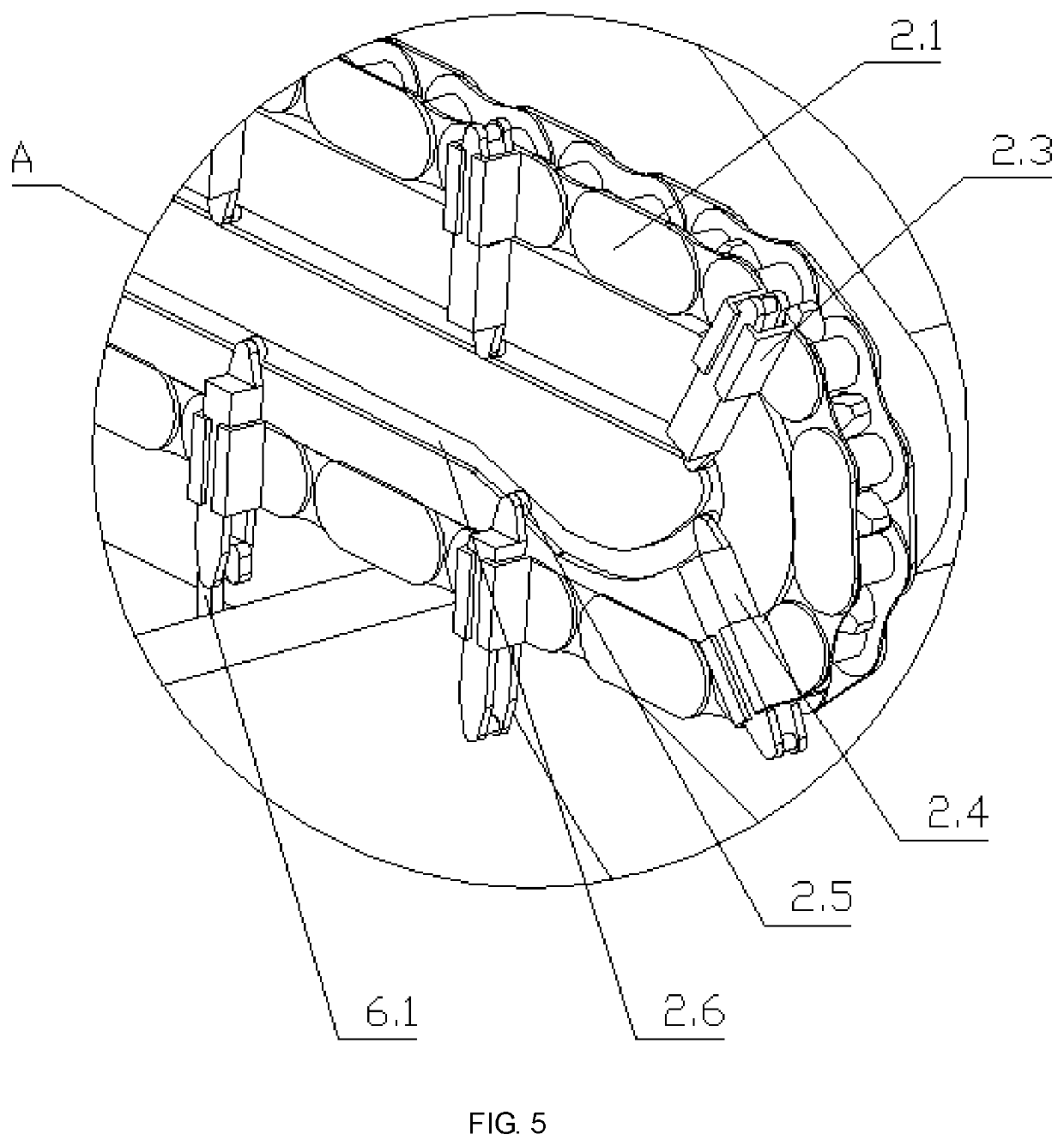

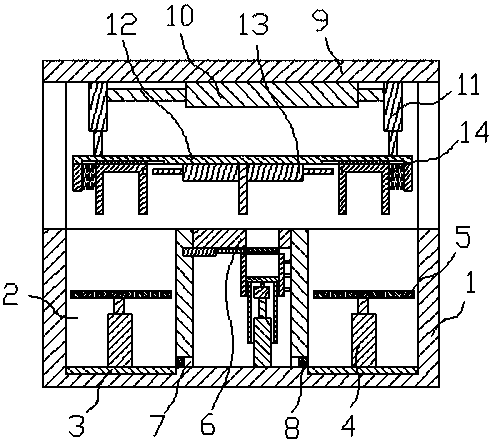

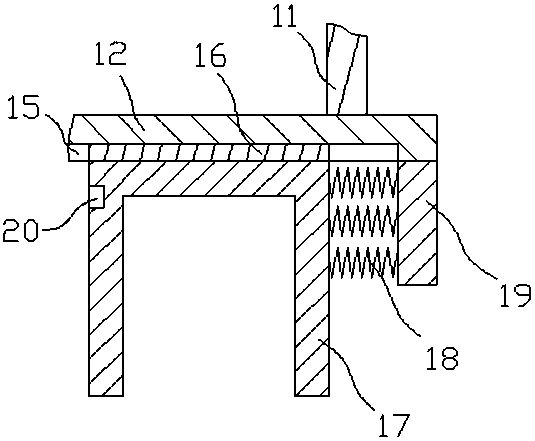

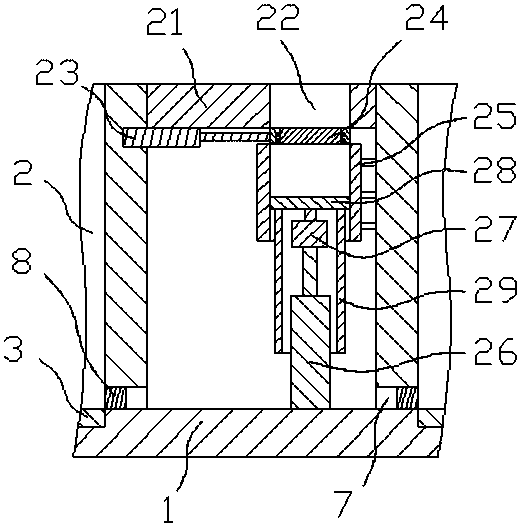

Catapulting rollout device and catapulting system of unmanned aerial vehicle

The invention relates to a catapulting rollout device and a catapulting system of an unmanned aerial vehicle. The catapulting rollout device of the unmanned aerial vehicle is arranged on a catapulting frame and used for bearing the unmanned aerial vehicle and catapulting the unmanned aerial vehicle. The catapulting rollout device comprises a locking mechanism, a rollout frame arranged on a sliding track of the catapulting frame and used for bearing the unmanned aerial vehicle and sliding wheels arranged at the bottom ends of the rollout frame, wherein the locking mechanism is arranged at the end, close to the initial end of the catapulting frame, of the rollout frame and used for locking the unmanned aerial vehicle at the initial end of the catapulting frame and can ensure that the rollout frame slides on the sliding track and accordingly drives the unmanned aerial vehicle on the rollout frame to slide. Direct contact between the unmanned aerial vehicle and the catapulting frame is avoided, it is ensured that the catapulting frame structure is not damaged due to catapulting, and the catapulting rollout device is durable and stable to use and can catapult the unmanned aerial vehicle in a long-time and high-efficiency mode.

Owner:北京韦加智能科技股份有限公司

Circular-seam ejector

ActiveCN107044454AImprove ejection efficiencyReduce volumeJet pumpsMachines/enginesEngineeringGas chamber

The invention relates to a gas-gas ejector device and particularly relates to a circular-seam ejector which is high in ejection efficiency, small in size and convenient to install. The circular-seam ejector comprises an ejector main body, the ejector main body is internally provided with a suction chamber cavity, a pressure expander cavity, a ring-shaped laval nozzle and a ring-shaped gas chamber, the ring-shaped gas chamber communicates with the suction chamber cavity through the ring-shaped laval nozzle, the suction chamber cavity communicates with the pressure expander cavity, and the ejector main body is provided with an ejection gas feeding hole communicating with the ring-shaped gas chamber. An inlet of the laval nozzle is of a gradually-shrunk ring shape, an outlet of the laval nozzle is of a gradually-expanded circular ring shape, the high-speed air flow passing through the ring-shaped laval nozzle is of a circular ring shape, the middle portion of the circular-ring-shaped outlet forms a vacuum environment, the ejected gas is pumped in from the middle to be mixed with the ejection gas, and the mixed gas is discharged through the pressure expander cavity. The pumping capacity of the circular-seam ejector is quite high, efficiency is higher, and the pressure of the gas capable of being pumped can reach -98 KPa at the minimum; and meanwhile, the circular-seam ejector is smaller in size and convenient to install.

Owner:河北恒德环保科技有限公司

Liquid ejection head, liquid ejection apparatus and method of manufacturing liquid ejection head

InactiveUS20090079797A1Control stressIncreased durabilityChemical vapor deposition coatingPrintingLiquid jetEngineering

A liquid ejection head includes: an ejection port through which liquid is ejected; a liquid chamber which is connected to the ejection port, the liquid chamber being filled with the liquid; a pressurization device which is arranged on a wall of the liquid chamber, the pressurization device pressurizing the liquid in the liquid chamber; and a movable member which has a free end on a side of the ejection port and a fixed end on a side opposite to the ejection port, the free end being arranged at a prescribed distance from the wall of the liquid chamber so as to face the wall of the liquid chamber, the movable member including a first layer that is an internal layer, and second and third layers that are respectively arranged on both surfaces of the first layer, the second and third layers having a stress lower than the first layer.

Owner:FUJIFILM CORP

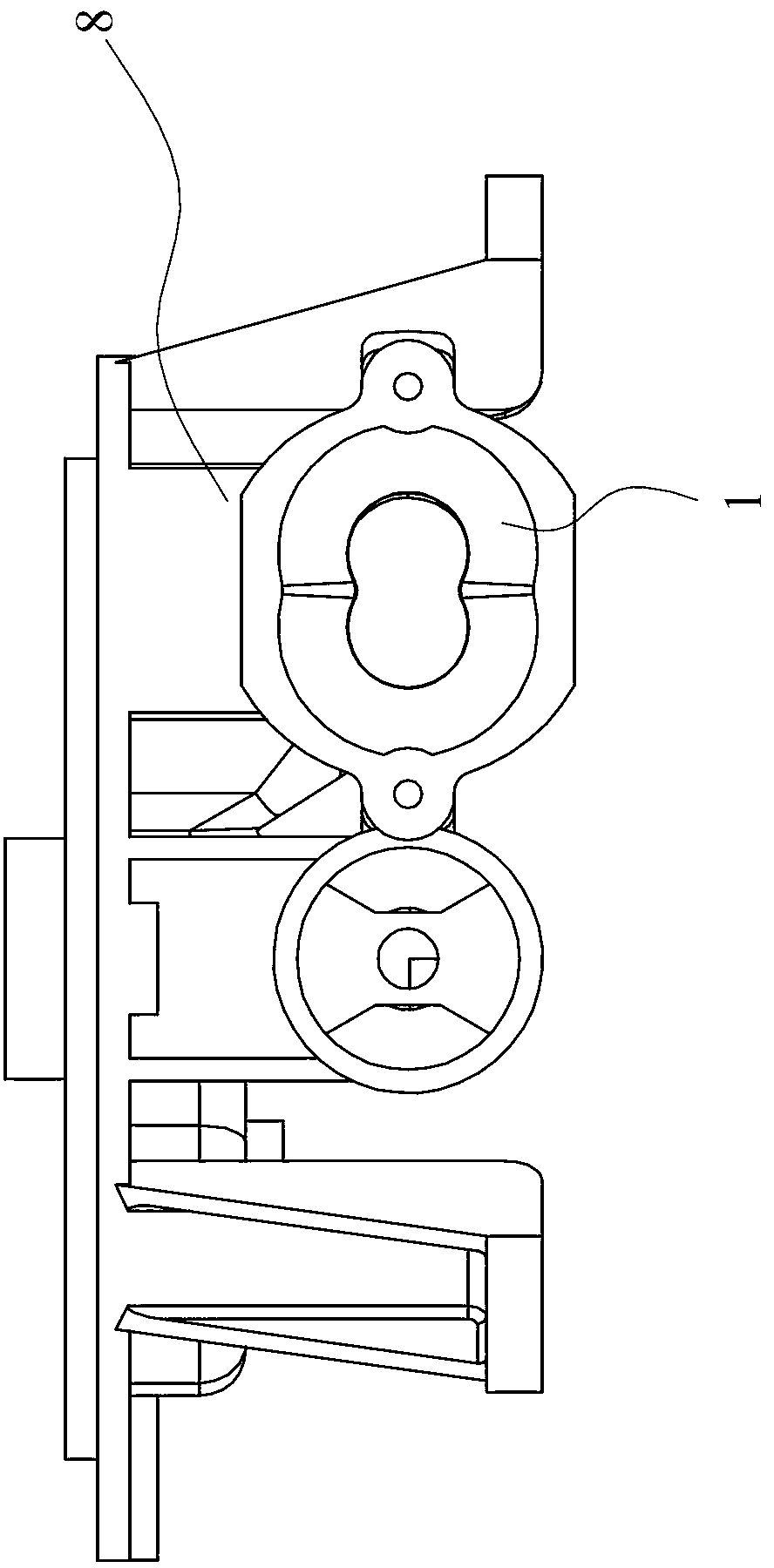

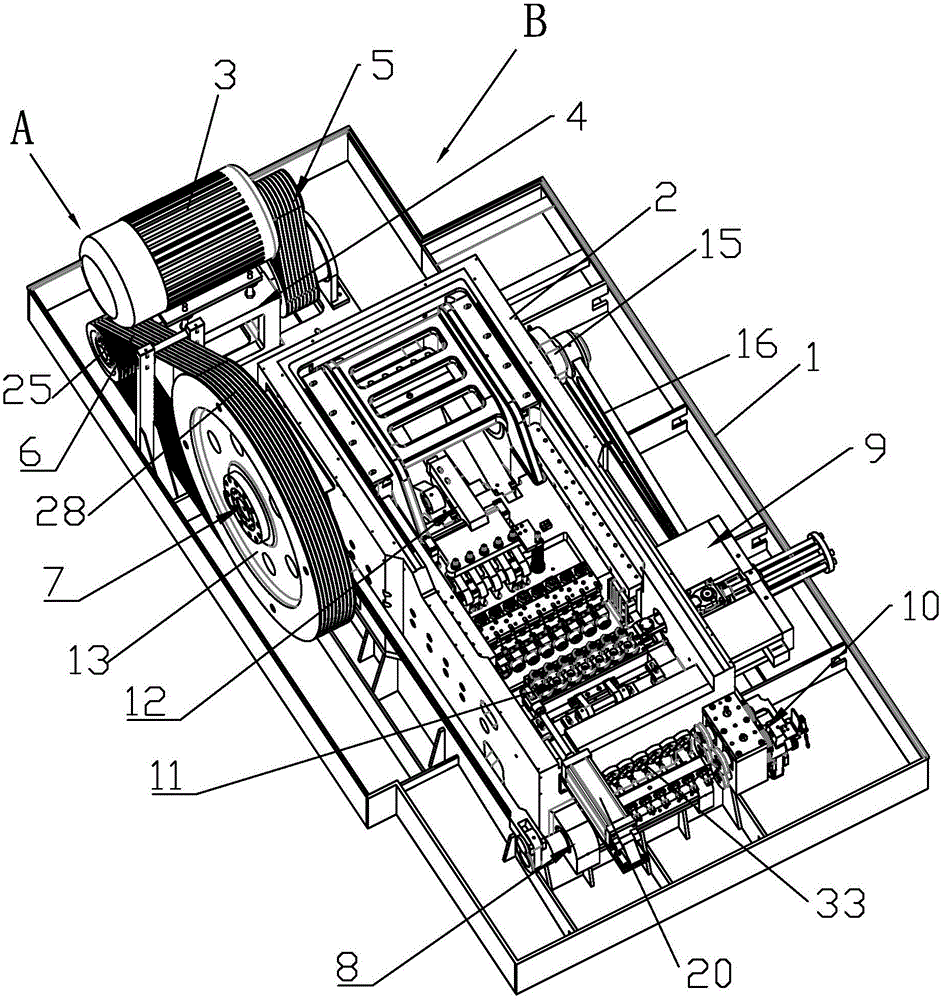

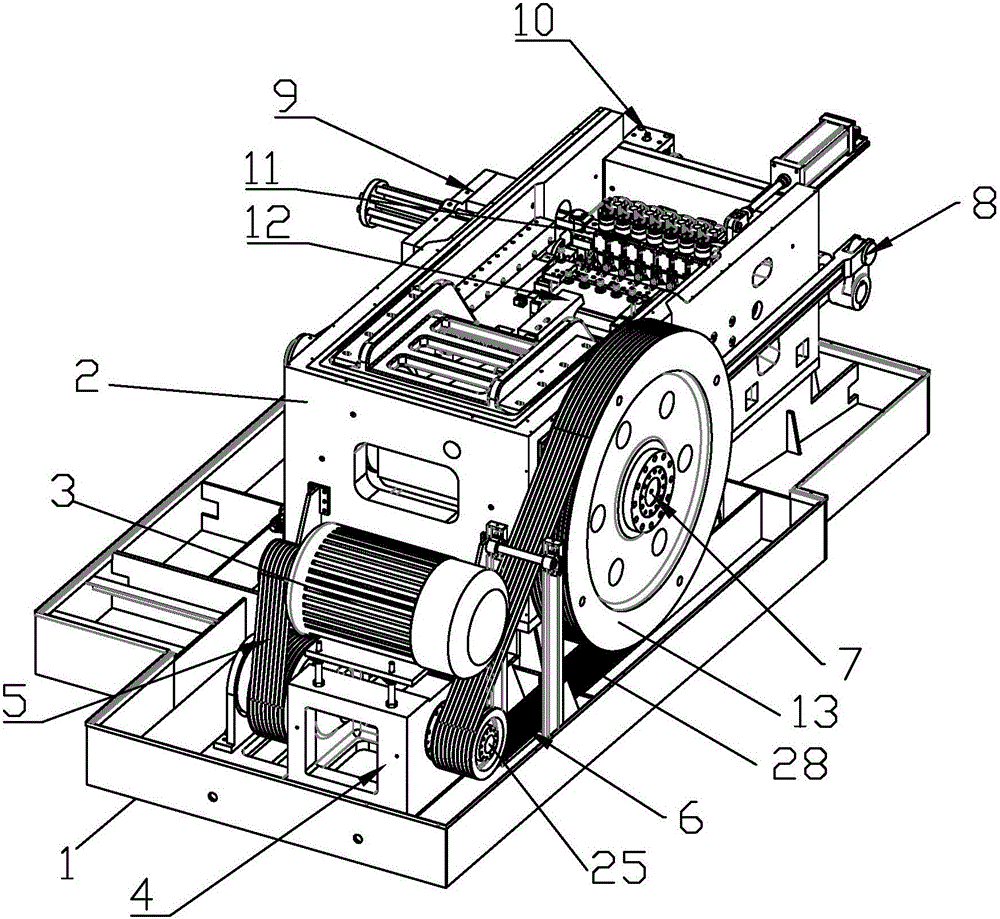

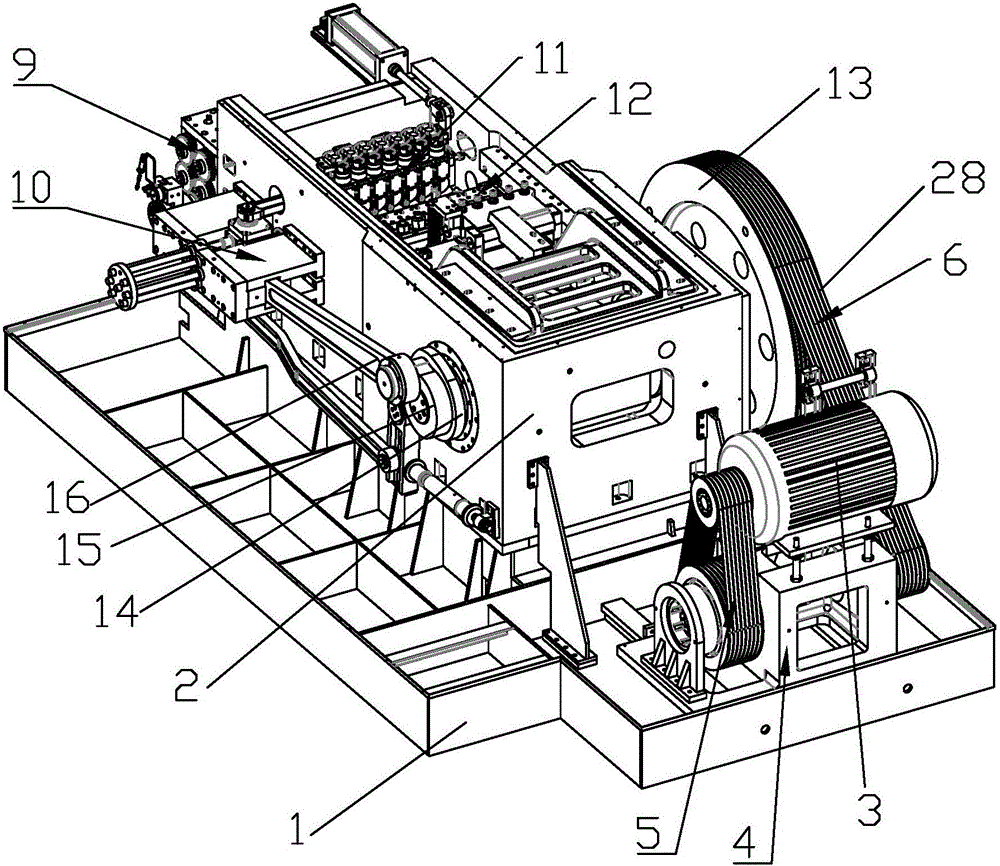

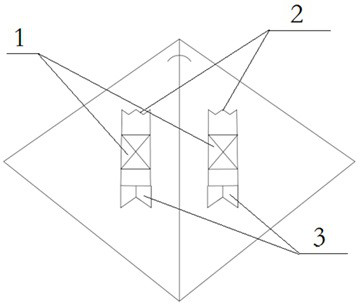

Final assembly mechanism of eight-station cold heading machine

ActiveCN105689616ASimple structureStrong targetingForging/hammering/pressing machinesForging press drivesPunchingReciprocating motion

The invention discloses a final assembly mechanism of an eight-station cold heading machine. The final assembly mechanism comprises a base and a rack, wherein a main motor and a reduction gearbox device are arranged on the base, the main motor is connected with the reduction gearbox device, a main transmission device is connected to the reduction gearbox device, a rear ejection device is connected to one end of the main transmission device, a cutting device and a feeding device are connected to the other end of the main transmission device, the feeding device is connected with the rear ejection device, a clamping device is connected to the cutting device, and a sliding block device is connected to the middle of the main transmission device. According to the final assembly mechanism, the punching operation is completed mainly in the steps that a flywheel is driven to rotate by the main motor by virtue of the reduction gearbox device, so as to drive a crankshaft to rotate, the rear ejection device, the feeding device, the cutting device and the sliding block device are respectively driven to do a reciprocating motion by the crankshaft, all motions are driven by the crankshaft, the workpiece feeding, cutting and clamping are implemented under the action of the crankshaft, and the punching steps can be continuously repeated in sequence.

Owner:浙江东雄机床有限公司

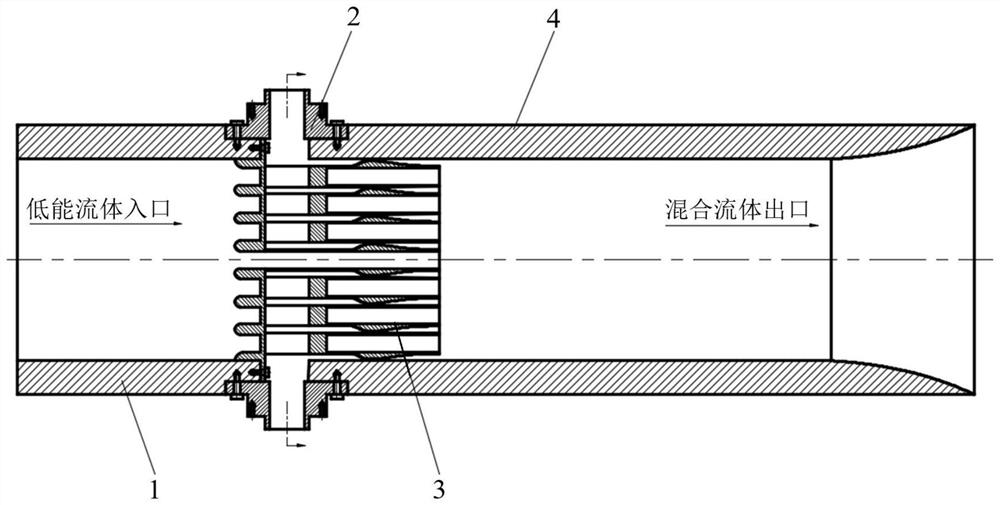

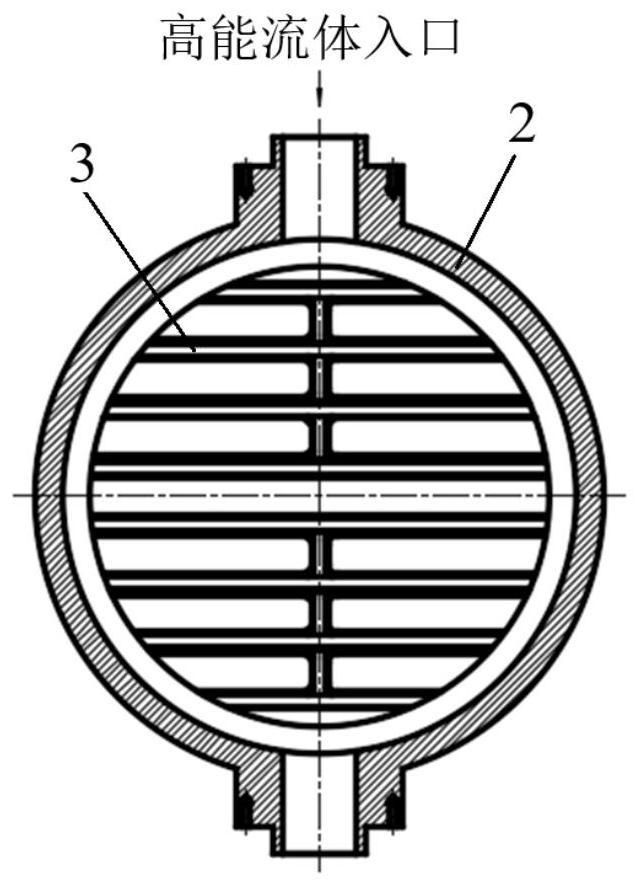

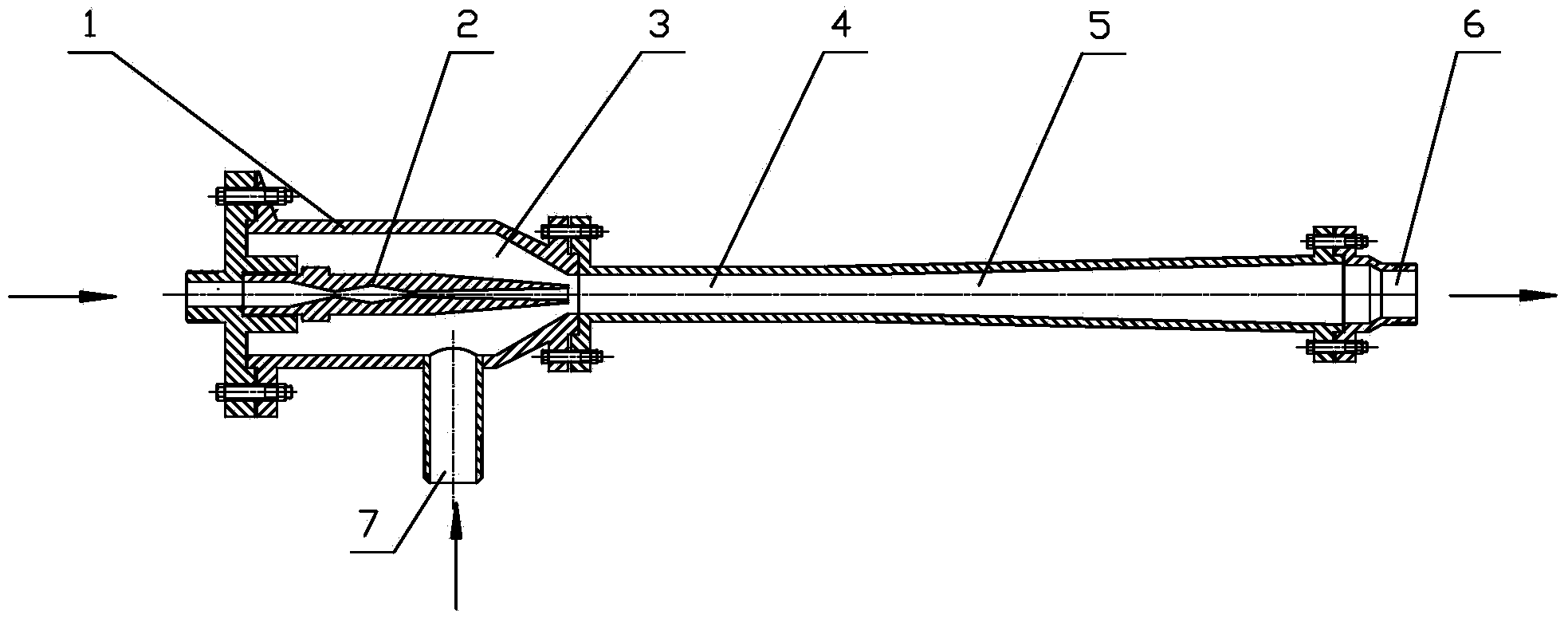

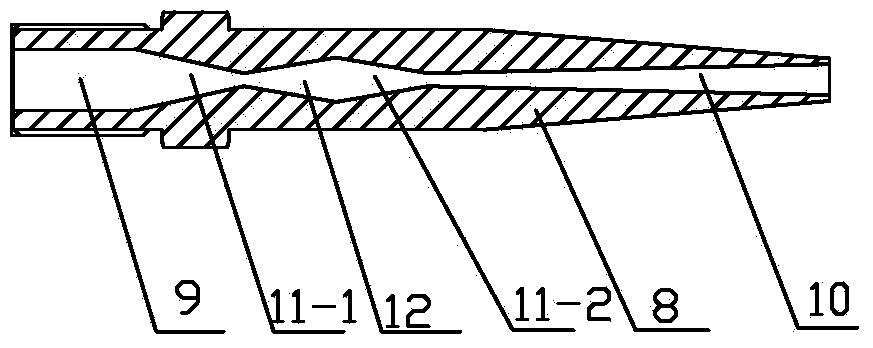

Distributed two-dimensional spray pipe ejector device

ActiveCN111911465AEnough storage spaceIncrease contact surfaceJet pumpsMachines/enginesEngineeringMechanical engineering

The invention discloses a distributed two-dimensional spray pipe ejector device. The distributed two-dimensional spray pipe ejector device uses a pipeline connection mode, and sequentially comprises alow-energy fluid inlet section, a high-energy fluid inlet section and a mixed fluid outlet section which are connected in sequence, wherein an two-dimensional spray pipe ejector is arranged in a pipeline near the high-energy fluid inlet section; a through hole is formed in the surface of the high-energy fluid inlet section and communicates with an external high-pressure tank; the low-energy fluidinlet section, the high-energy fluid inlet section and the mixed fluid outlet section share the same central axis; the two-dimensional spray pipe ejector comprises linear spray pipe unit bodies arranged in parallel; the spray pipe unit bodies are connected through reinforcing ribs; part of the reinforcing ribs are of hollow structures; high-energy fluid enters the spray pipe unit bodies from thethrough hole of the high-energy fluid inlet section and is sprayed out from outlets of the spray pipe unit bodies; and spray pipes are arranged in the spray pipe unit bodies. The distributed two-dimensional spray pipe ejector device is suitable for fluid ejection control of gas and liquid, and has the advantages that the ejection efficiency is improved; the appearance dimension of the ejector device is reduced; and the space installation requirement of the ejector device is lowered.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Liquid ejecting method, liquid ejecting head, head cartridge and liquid ejecting apparatus using same

Owner:CANON KK

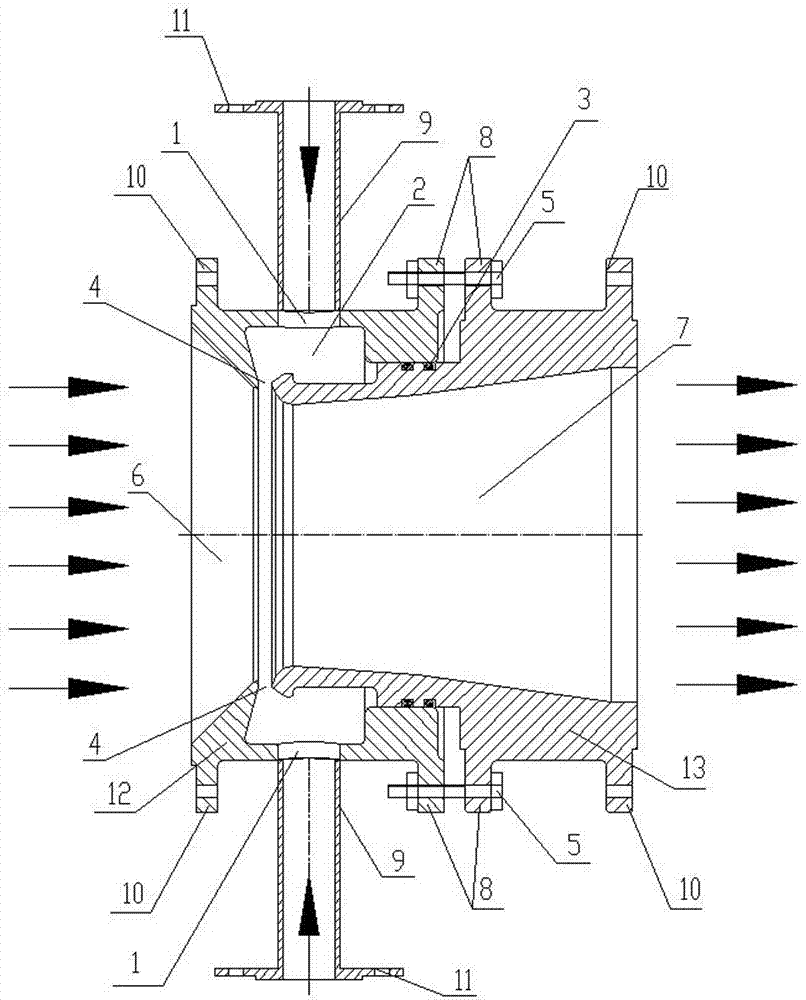

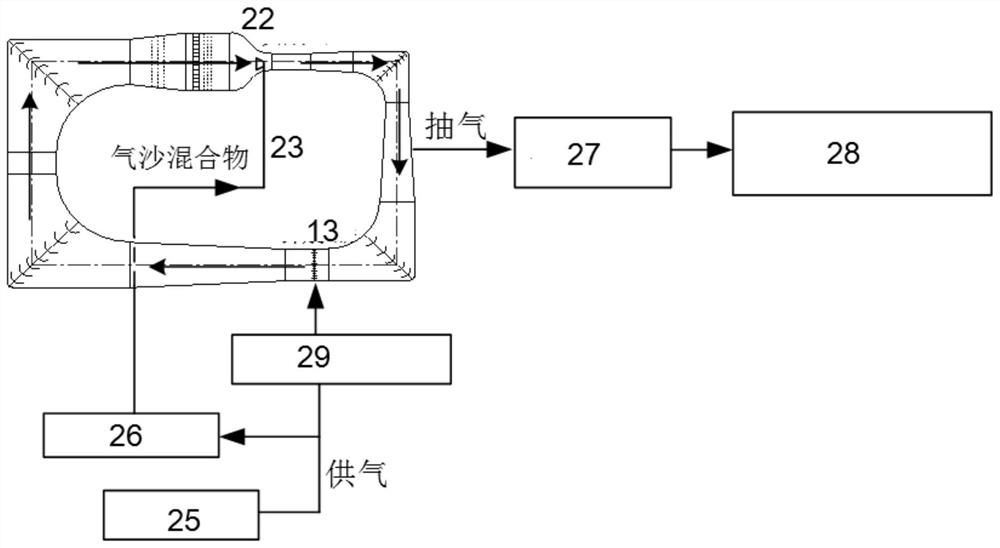

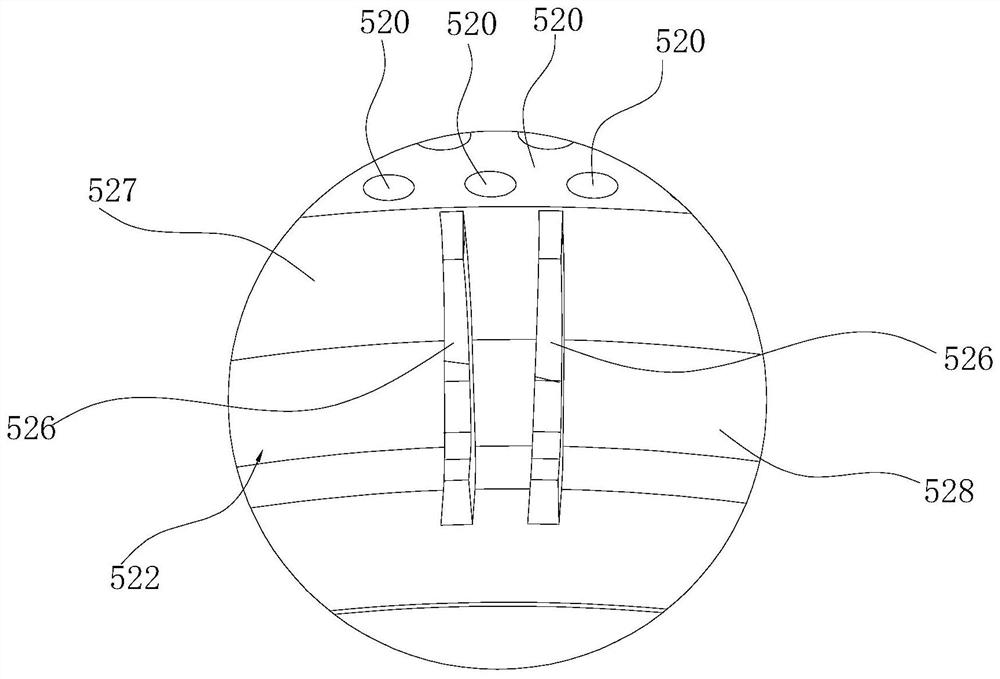

Low-air-pressure ejector device applied to mars wind tunnel

PendingCN111288028ASmall gas consumptionImprove ejection efficiencyAerodynamic testingJet pumpsPhysicsEngineering

The invention aims to provide a low-air-pressure ejector device applied to a mars wind tunnel. The device comprises an ejector shell, an ejector cavity shell, an ejector cavity, multiple of spray pipes and an air supply pipeline; the air supply pipeline communicates with an air source; the ejector cavity shell surrounds the ejector shell for a circle and is connected with the outer wall of the ejector shell in a sealed mode to form the closed ejector cavity, and the air supply pipeline communicates with the ejector cavity; and the multiple of spray pipes are parallel to one another and penetrate through the ejector shell in the radial direction at certain intervals, the heads and the tails of the spray pipes communicate with the ejector cavity, and multiple of nozzles are formed in the parts, positioned in the ejector shell, of the spray pipes. Compared with a conventional ejector of the wind tunnel, the device has the beneficial effects that the ejection efficiency is extremely high,the same wind speed is formed, the gas consumption of the conventional ejector is large, the gas consumption of the device is small, the wind speed can be continuously formed for a long time, and thehighest wind speed can be remarkably increased.

Owner:中国航空工业集团公司哈尔滨空气动力研究所

Method of manufacturing nozzle plate

InactiveUS7255977B2Improve ejection efficiencySteady directionWriting implementsMetal-working apparatusEngineeringLight sensitive

Owner:FUJIFILM CORP

Backflow type wind tunnel device for simulating Mars low-pressure low-density dust storm environment

ActiveCN112649173AImprove ejection efficiencyReduce the cost of vacuumingCosmonautic condition simulationsAerodynamic testingInlet pressureAtmospheric sciences

The invention provides a backflow-type wind tunnel device for simulating a Mars low-pressure low-density dust storm environment. The device comprises a backflow-type wind tunnel, an ejector, and an jetting device; the backflow-type wind tunnel comprises a stable segment, a contraction segment, a test segment, a first diffusion segment, a second diffusion segment, a mixing segment, a third diffusion segment, and a large-angle diffusion segment; a first corner is arranged between the first diffusion section and the second diffusion section in a communicated manner; a second corner is arranged between the second diffusion section and the mixing section in a communicated manner;a third corner and a fourth corner are sequentially arranged between the third diffusion section and the large-angle diffusion section in a communicated manner;a corner flow deflector is arranged in each corner; the ejector is arranged in the mixing section; and the jetting device is arranged in the contraction section. The ejector is combined with the backflow-type wind tunnel, the wind speed required by the test section can be achieved through the small inlet pressure of the ejector; the mode of combining the large contraction ratio and the large-angle diffusion section is adopted, so that the airflow quality is improved, losses are reduced, the overall size of the wind tunnel is reduced, and the vacuumizing cost is reduced.

Owner:HARBIN INST OF TECH

Ejector

PendingCN109018416AImprove ejection efficiencyGuaranteed tightnessLaunching/towing gearHydraulic cylinderSlide plate

The invention discloses An ejector including a deck, the upper surface of the deck is provided with a rectangular sliding hole along the left-right direction, A U-shape sliding plate is fix on that lower surface of the deck corresponding to the rectangular sliding hole, the left and right ends of the U-shaped sliding plate are sealed, and a sliding groove is arranged between the U-shaped sliding plate and the deck, A slide groove and a traction block are slidably connected, A first fixed pulley is mounted on the right end of the lower surface of the deck through a mounting bracket, A hydrauliccylinder block is fixed on the lower surface of the U-shaped sliding plate, the inner wall of the hydraulic cylinder block is slidably connected with the piston side of the hydraulic cylinder, The high-pressure steam pushes the piston of the hydraulic cylinder to move rightward, and the piston of the hydraulic cylinder pushes the pulley to move rightward through the hydraulic cylinder lever, andthe pulley causes the moving speed of the traction block to be twice of the moving speed of the piston of the hydraulic cylinder, thus ensuring the sealing property between the piston of the hydrauliccylinder and the inner wall of the hydraulic cylinder block, and improving the ejection efficiency of the ejector.

Owner:朱建华

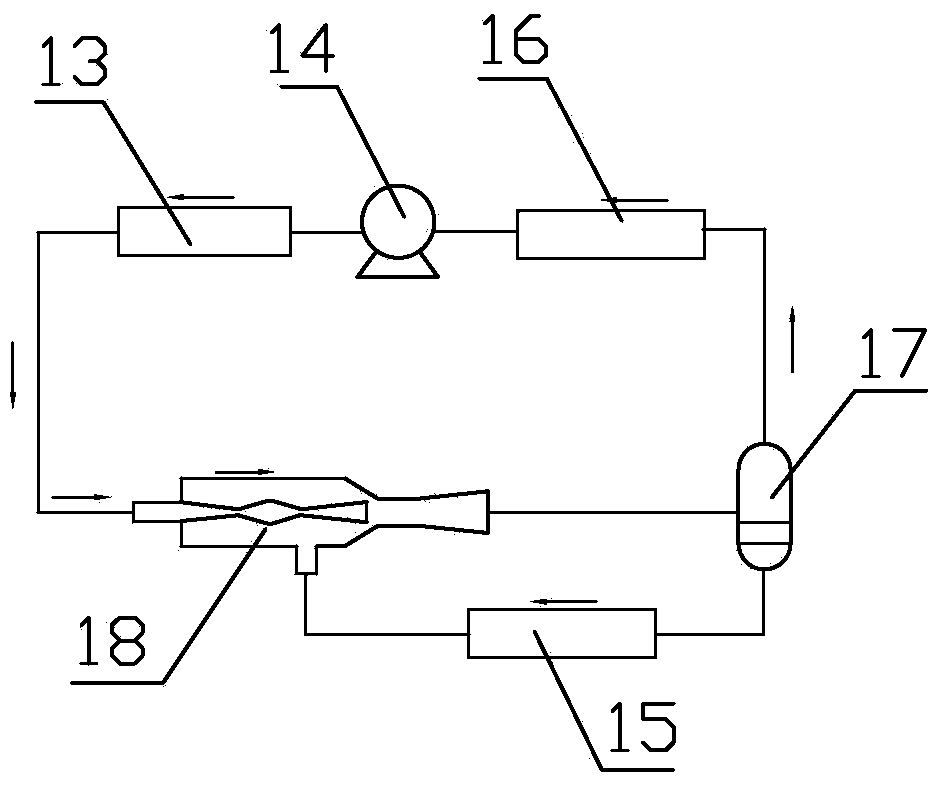

Effect-enhanced serial nozzle two-phase flow ejector and component refrigerating system thereof

InactiveCN103983053AImprove ejection efficiencySimple structureCompressorFluid circulation arrangementEngineeringRefrigerant

The invention discloses an effect-enhanced serial nozzle two-phase flow ejector and a component refrigerating system thereof and aims to improve ejecting efficiency. An ejecting structure is mounted inside an ejector shell and comprises an ejector body, at least two sections of nozzles are serially connected between an ejection inlet end and an ejection outlet end of the ejecting structure, expanding sections are arranged between every two adjacent sections of nozzles, a receiving chamber is formed between the inner wall of the ejector shell and the ejector body, and a mixing chamber and a diffusion chamber are sequentially arranged between the ejection outlet end a eject flow outlet part. Refrigerant is accelerated since pressure in the first section of nozzle is converted into kinetic energy and then is decelerated after flowing to the expansion section; the refrigerant flows to the next section of nozzle to be subjected to acceleration and pressurization for twice or multiple times before entering the mixing chamber and the diffusion chamber together with a eject flow, and finally flows out from the eject flow outlet part; since the refrigerant is close to a homogeneous flow state, an eject ratio and energy efficiency of the refrigerating system are improved.

Owner:TIANJIN UNIV OF COMMERCE

Jack dynamic testing system

PendingCN106969927AImprove ejection efficiencyReduce work intensityStructural/machines measurementClassical mechanicsJackscrew

The invention relates to a jack dynamic testing system comprising a hydraulic constant pressure system and a testboard. The hydraulic constant pressure system is arranged above the testboard, and the hydraulic constant pressure system is provided with a pressure sensor and a displacement sensor. The jack dynamic testing system also comprises a connection support and an operating arm which automatically applies an operating force to a jack, the connection support is arranged on the hydraulic constant pressure system, the connection support is provided with an adjusting device which adjusts the applying angle of the operating arm, and the adjusting device is provided with a self-locking device for locking the adjusting device. The jack dynamic testing system is advantaged in that the operating arm automatically applies the operating force to a jack handle to control ejection of the jack, the jack ejection efficiency is improved, the working intensity of manually cranking the handle to eject the jack is reduced, the safety performance of the jack when the jack is ejected under a load and a constant pressure is improved, the adjusting device adjusts the applying angle of the operating arm to the jack handle, and therefore pressure applied to the jack handle can be effectively adjusted, and the jack dynamic testing system is suitable for testing jacks of different models.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST

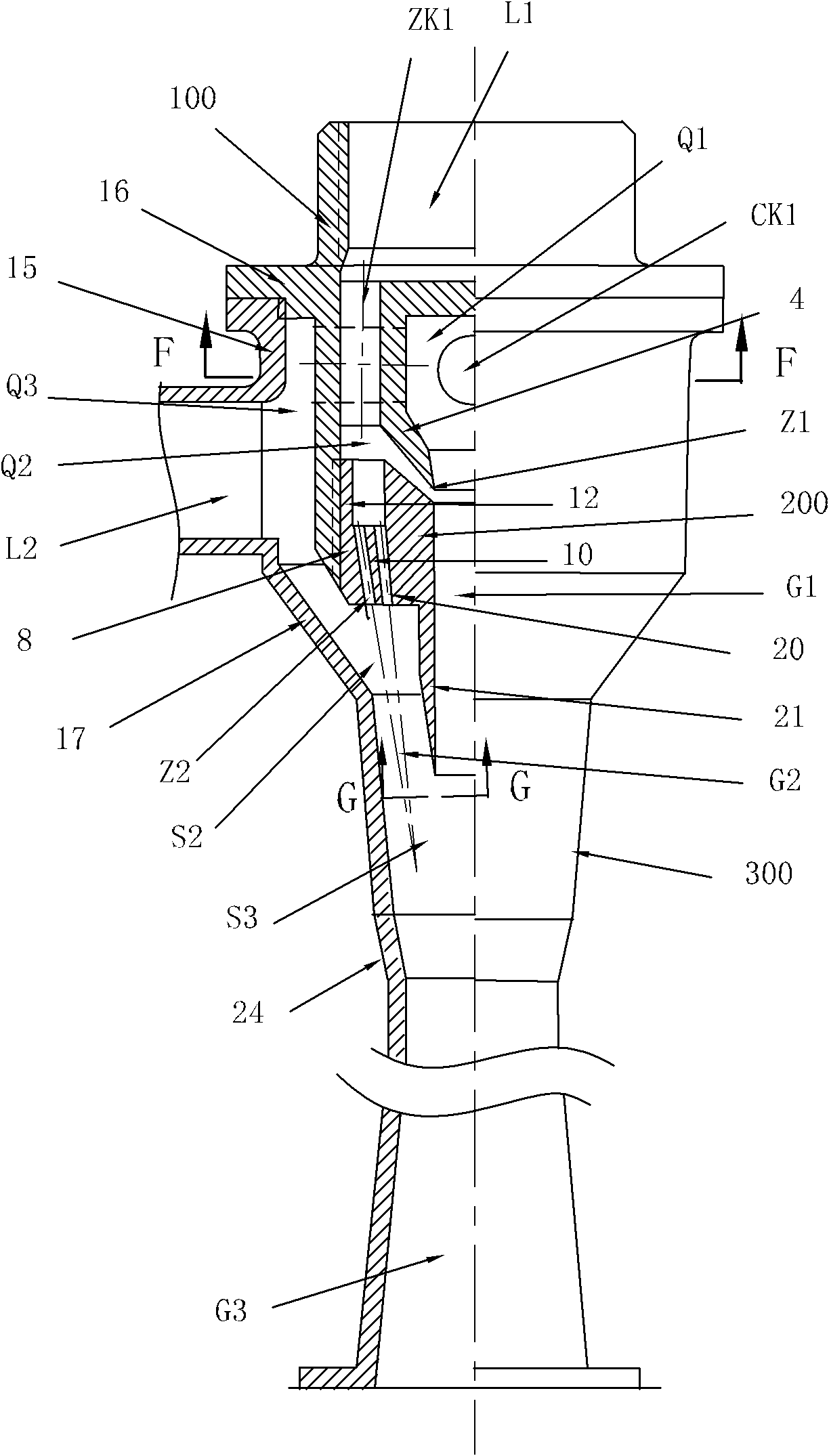

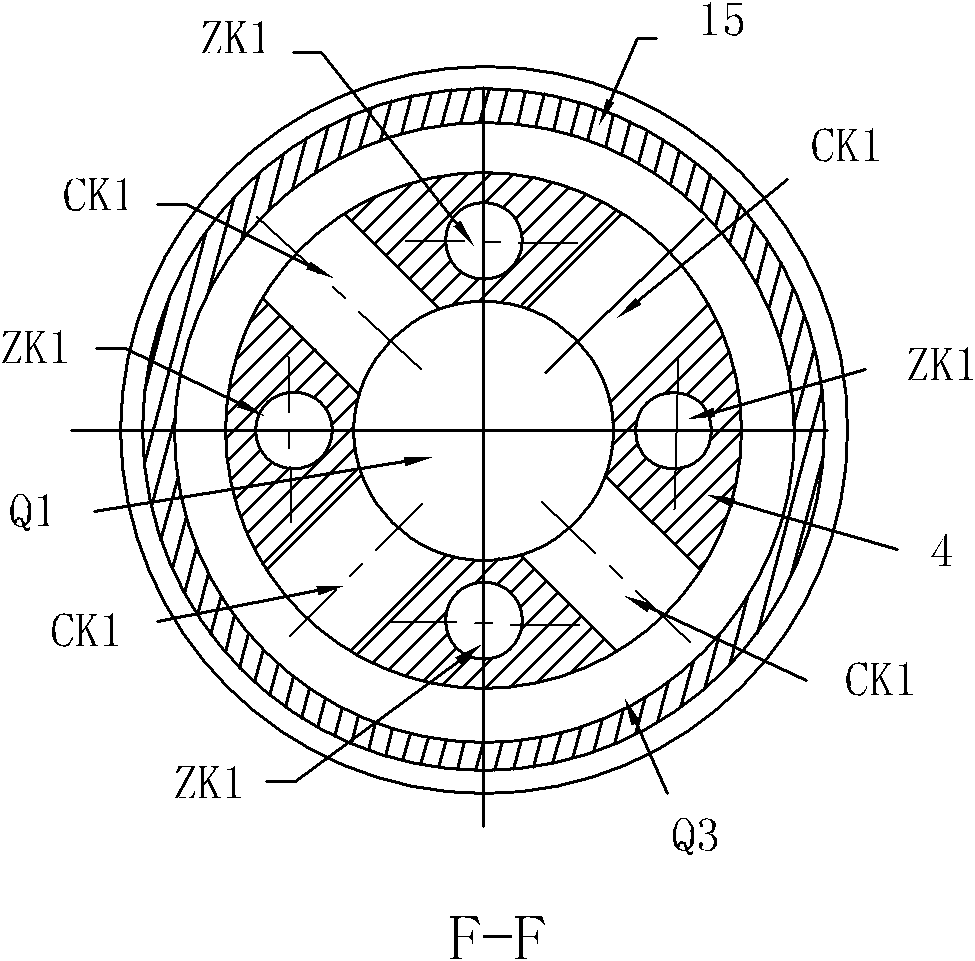

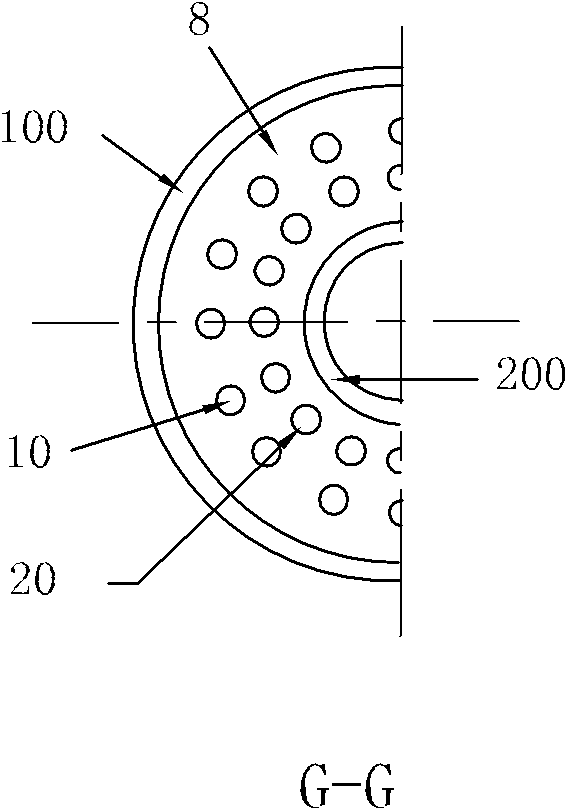

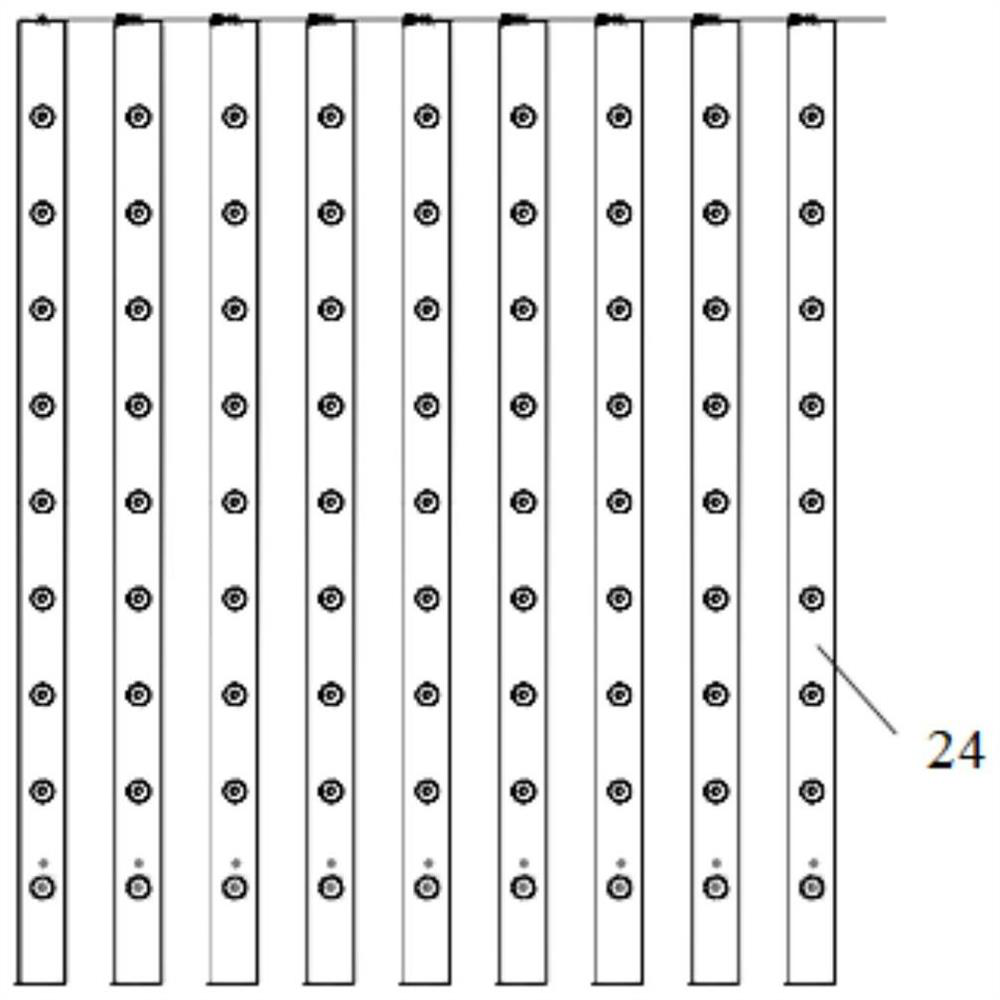

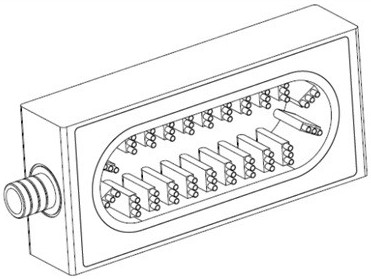

An ejector module used in low-speed wind tunnel aircraft intake and exhaust simulation tests

ActiveCN110411704BCompact structureIncrease the degree of blendingAerodynamic testingFlight vehicleHigh energy

The invention discloses an ejector module used for an intake-exhaust simulation experiment of a low-speed wind tunnel aircraft. The ejector module comprises an outer frame, a middle frame and an innerframe in sequence from outside to inside, wherein the outer frame, the middle frame and the inner frame are mutually connected to form a sealed cavity; the outer frame is provided with a gas inlet communicated with the sealed cavity, the inner frame is provided with a plurality of nozzle rakes, one end of each nozzle rake is communicated with the sealed cavity, and the other ends of the nozzle rakes are provided with nozzles. An injector is designed into a module of a model structure, and the injector is integrated with the model; the injector module uses a discrete multi-nozzle distributiontype injection mode, and the structure is compact. The discrete multi-nozzle distribution type injection mode greatly increases the mixing degree between high-energy compressed gas and injected low-energy gas, and the injection efficiency is obviously improved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

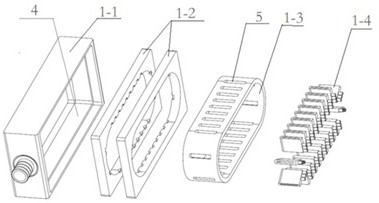

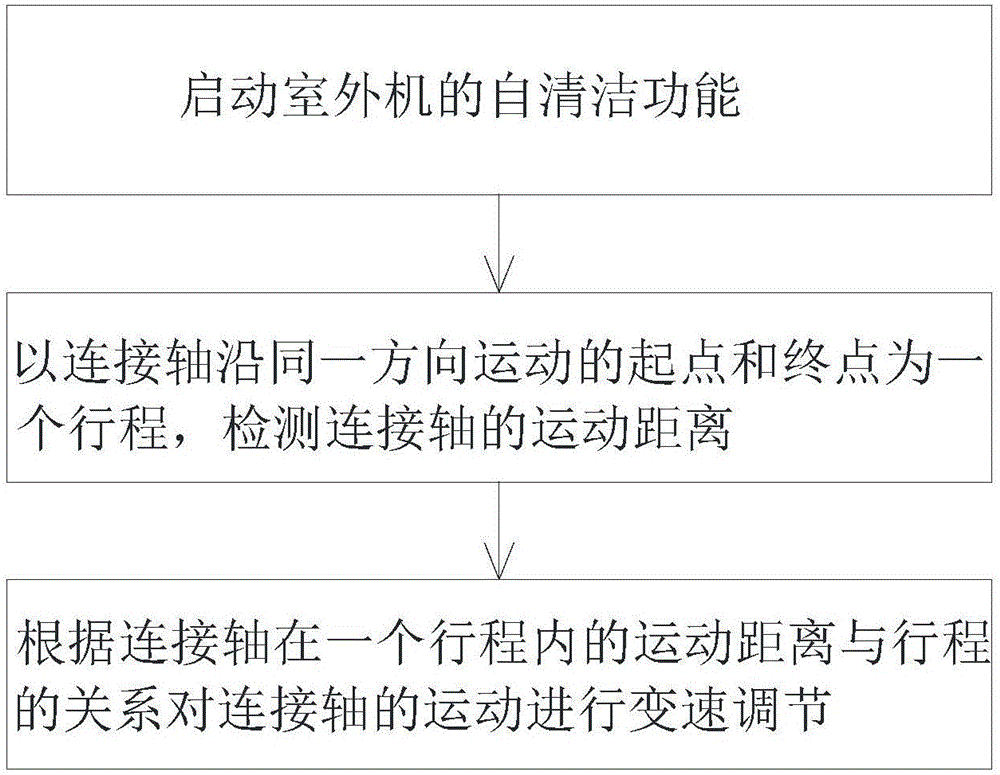

Air conditioner outer unit cleaning method

ActiveCN106225102AImprove ejection efficiencyEnough throw forceMechanical apparatusCondensate preventionEngineeringCondensed water

The invention discloses an air conditioner outer unit cleaning method. An air conditioner outer unit comprises a cleaning device; the cleaning device includes a hollow connecting shaft; the connecting shaft rotates around self rotating shaft in the moving process; a cleaning brush is arranged on the surface of the connecting shaft; and water holes are formed in the peripheral wall of the connecting shaft. The air conditioner outer unit cleaning method comprises the following steps: a self-cleaning function of the outer unit is started; the movement of the connecting shaft from the starting point to the ending point in the same one direction is one travel to detect the moving distance of the connecting shaft; and the speed change adjustment is performed for the movement of the connecting shaft according to the relation between the moving distance of the connecting shaft in one travel and the travel. The air conditioner outer unit cleaning method can solve the problem of lower utilization efficiency of condensed water in the cleaning device in the prior art.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Spray pipe for ejector, ejection unit and air ejector

ActiveCN112461493AImprove integritySimple structureAerodynamic testingWind energy generationEngineeringPlenum chamber

The invention discloses a spray pipe for an ejector, an ejection unit and an air ejector. The spray pipe is horn-shaped and comprises a large-diameter end and a small-diameter end; an annular airflowstanding chamber is arranged in the pipe wall of the spray pipe in the circumferential direction of the spray pipe, an opening is formed in the side, facing the small-diameter end, of the annular airflow standing chamber, and the opening extends to the end face of the small-diameter end. A plurality of air inlets are formed in the large-diameter end of the spray pipe in the circumferential direction of the spray pipe, and each air inlet is connected to the annular airflow plenum chamber through an air inlet channel formed in the pipe wall of the spray pipe. According to the invention, the contact area of the injected airflow and the injected airflow can be increased, the pressure loss is reduced, and the mixing efficiency and the pressurization ratio are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

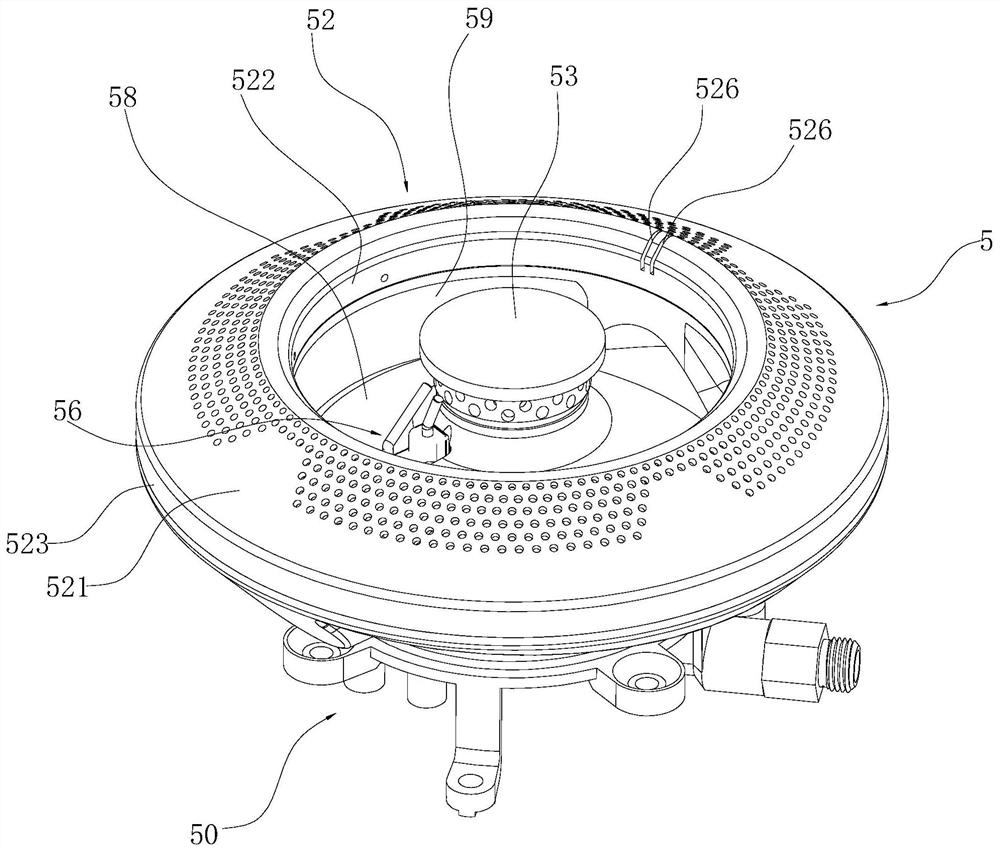

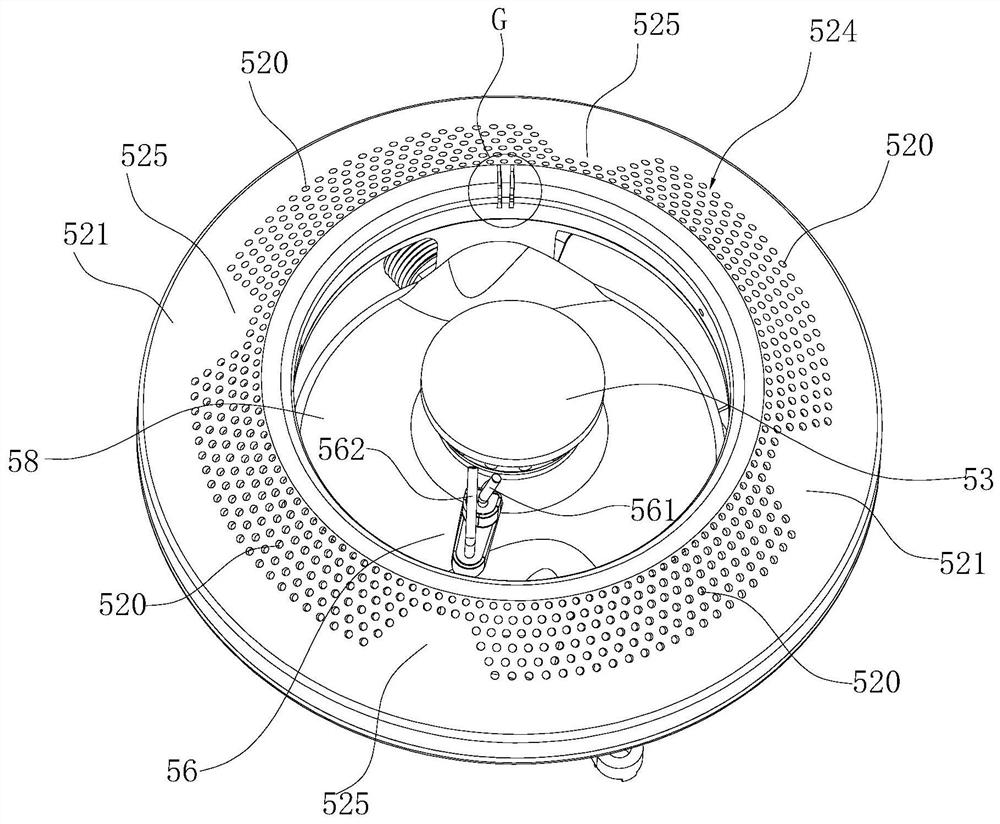

Complete upper air inlet type burner

PendingCN112240549AShorten speedImprove flame stabilityDomestic stoves or rangesAir/fuel supply for combustionThermodynamicsCombustor

The invention relates to a complete upper air inlet type burner. The complete upper air inlet type burner comprises a base, an outer ring fire cover, an inner ring fire cover and outer ring injectionpipes, wherein the base is provided with a center cavity and an annular cavity; the number of the outer ring injection pipes is two; each outer ring injection pipe is communicated with an outer ring gas mixing cavity; the two outer ring injection pipes are transversely and oppositely arranged; gas inlets of the two outer ring injection pipes are staggered; and an annular gap is reserved between the annular cavity and the center cavity, an annular cover body with the center cavity as the center is arranged in the annular gap, the two outer ring injection pipes are arranged at the bottom of thecover body respectively, and therefore secondary air channels defined by the bottom face of the bottom wall of the annular cavity and the upper face of the cover body are arranged in the two sides ofthe bottom of the base respectively. Compared with the prior art, the injection efficiency can be improved, the auxiliary ignition effect can be achieved, primary air and secondary air can be shuntedthrough the arrangement of the cover body, a combusted gas mixture is prevented from being mixed into all the injection pipes, and therefore normal combustion of the burner is guaranteed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Apparatus and method for continuous launching of unmanned aerial vehicles

ActiveUS20200339280A1Improve efficiencyShorten the timeLaunching/towing gearUnmanned aerial vehiclesFlight vehicleUncrewed vehicle

An apparatus and method for continuous catapulting of unmanned aerial vehicles are disclosed, and relate to the technical field of aircraft catapulting and recovery. The apparatus consists of an unmanned aerial vehicle storage apparatus, an unmanned aerial vehicle conveying apparatus, an automatic unmanned aerial vehicle loading apparatus, tackles and a rotary tube-type multi-track unmanned aerial vehicle catapult. The present invention can increase catapulting efficiency of the unmanned aerial vehicles, and is suitable for rapidly forming a cluster of the unmanned aerial vehicles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Water injection detection mechanism

The invention relates to a water injection detection mechanism, comprising a detection frame, wherein two soaking chambers and one dehydrating chamber are formed in the detection frame by two clapboards, the dehydrating chamber is located between the two soaking chambers, a gravity measuring plate is arranged at the inner bottom of each soaking chamber, a soaking lifting cylinder is arranged on the gravity measuring plate, a soaking lifting plate with holes is arranged on the soaking lifting cylinder, an extruded type dehydrating device matched with pork is arranged in the dehydrating chamber,a feeding rack is arranged at the upper part of the detection frame, and a feeding device for realizing transfer of a product in the three chambers is arranged on the feeding rack. The invention aimsat providing the water injection detection mechanism, the detection frame provided with two soaking chambers and one dehydrating chamber is adopted for detecting pork, the relative weight differenceof the two soaking chambers is calculated by weighing liquid in the two soaking chambers, so as to judge whether the pork is water-injected pork; influence cannot be caused to the detected pork duringdetection.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com