Patents

Literature

38results about How to "Increase the degree of blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

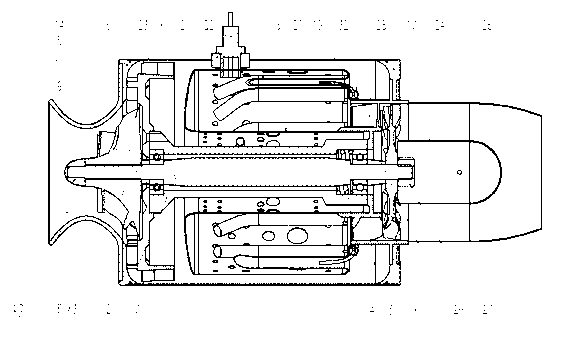

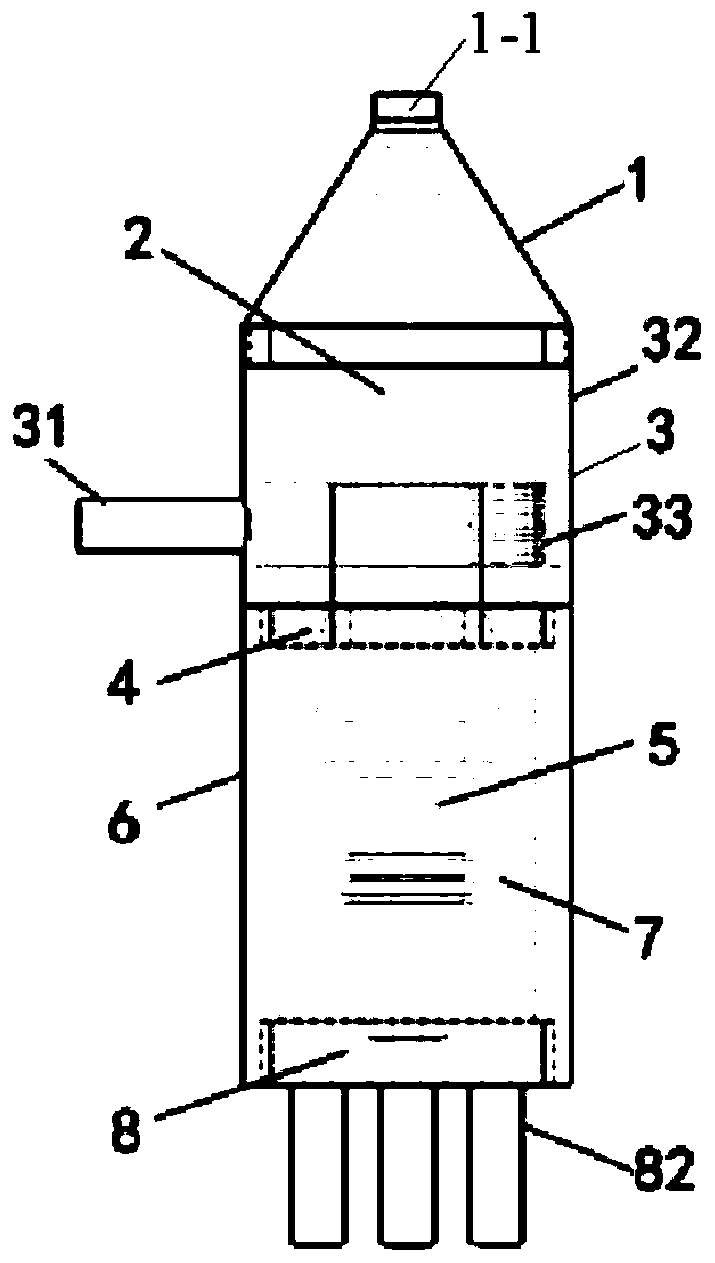

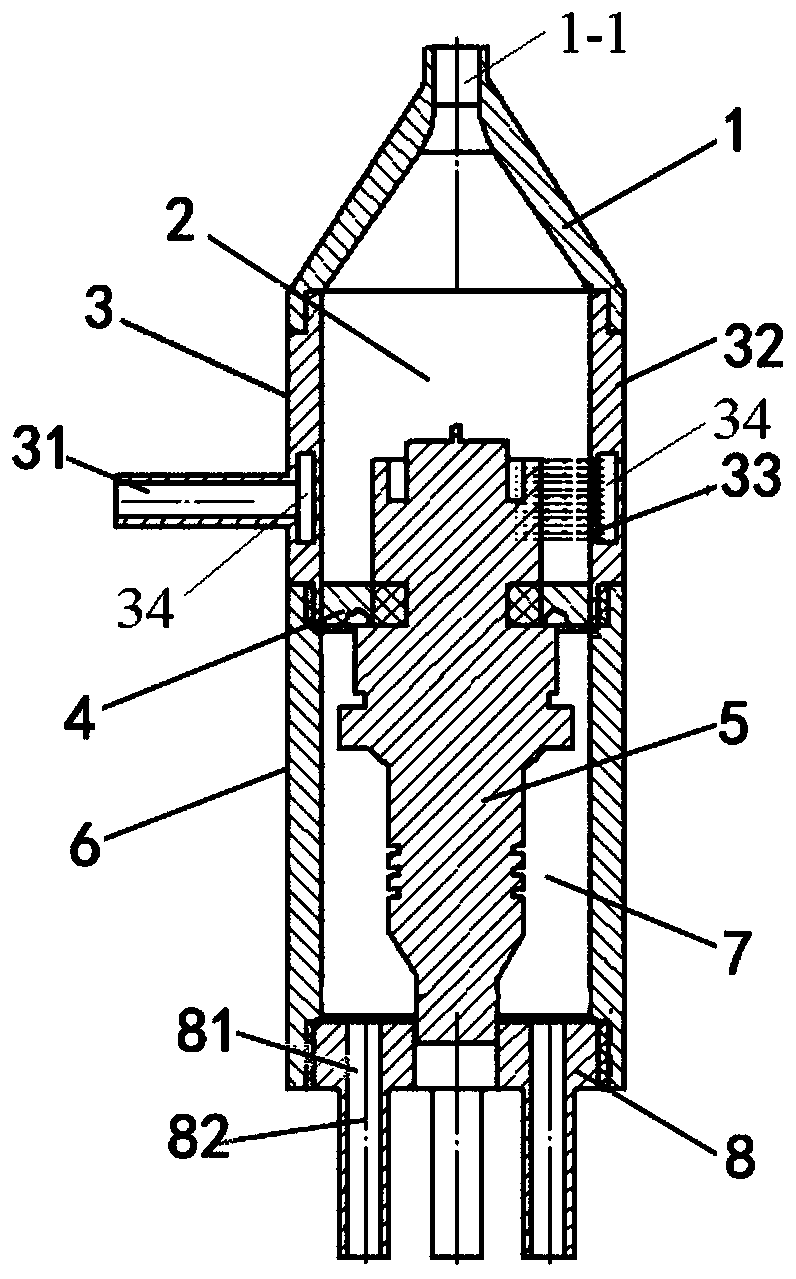

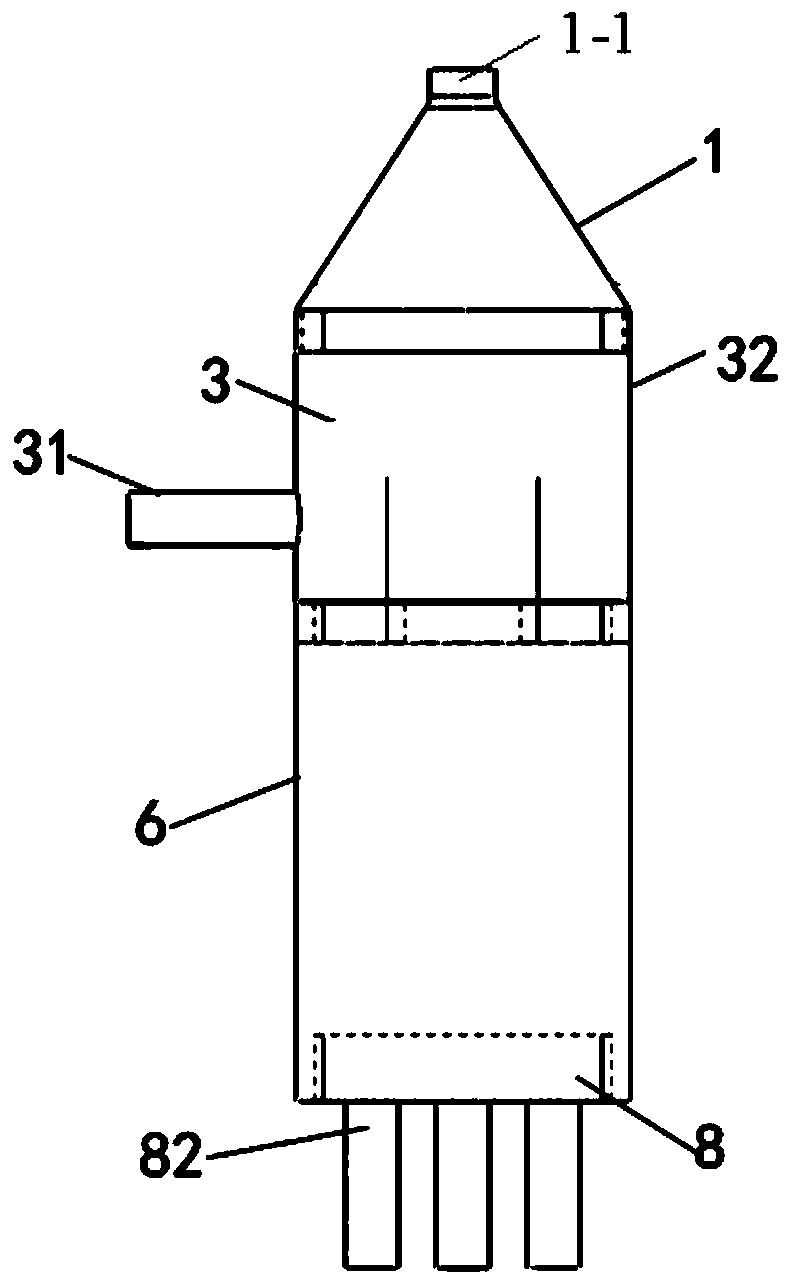

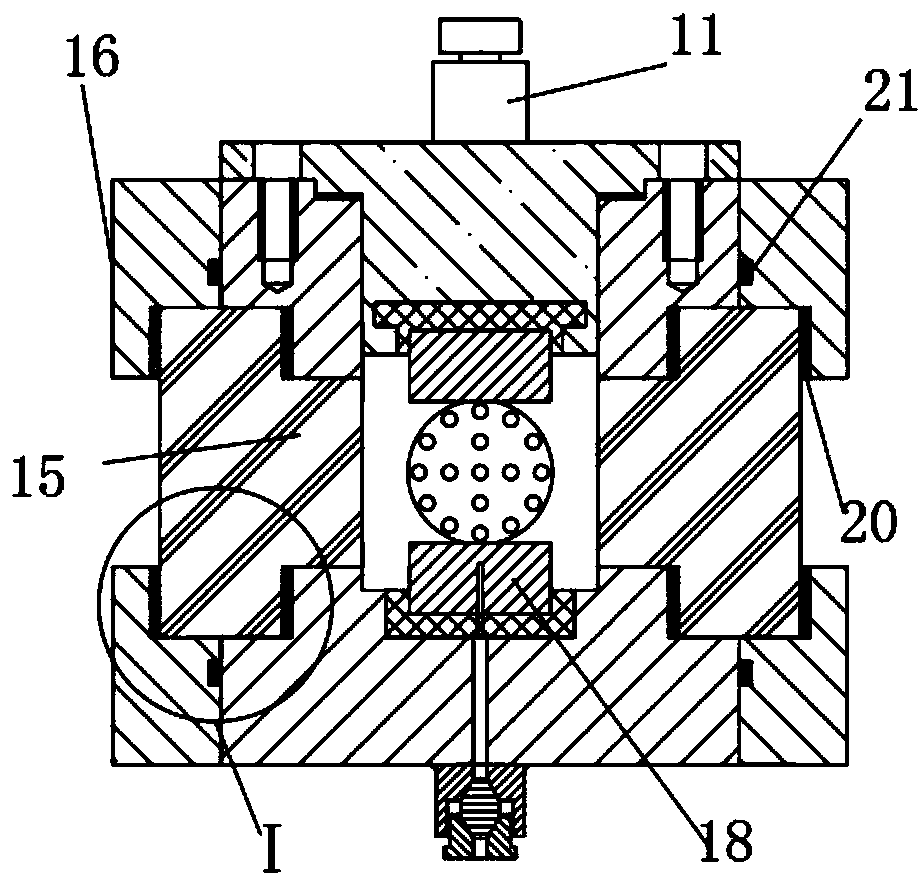

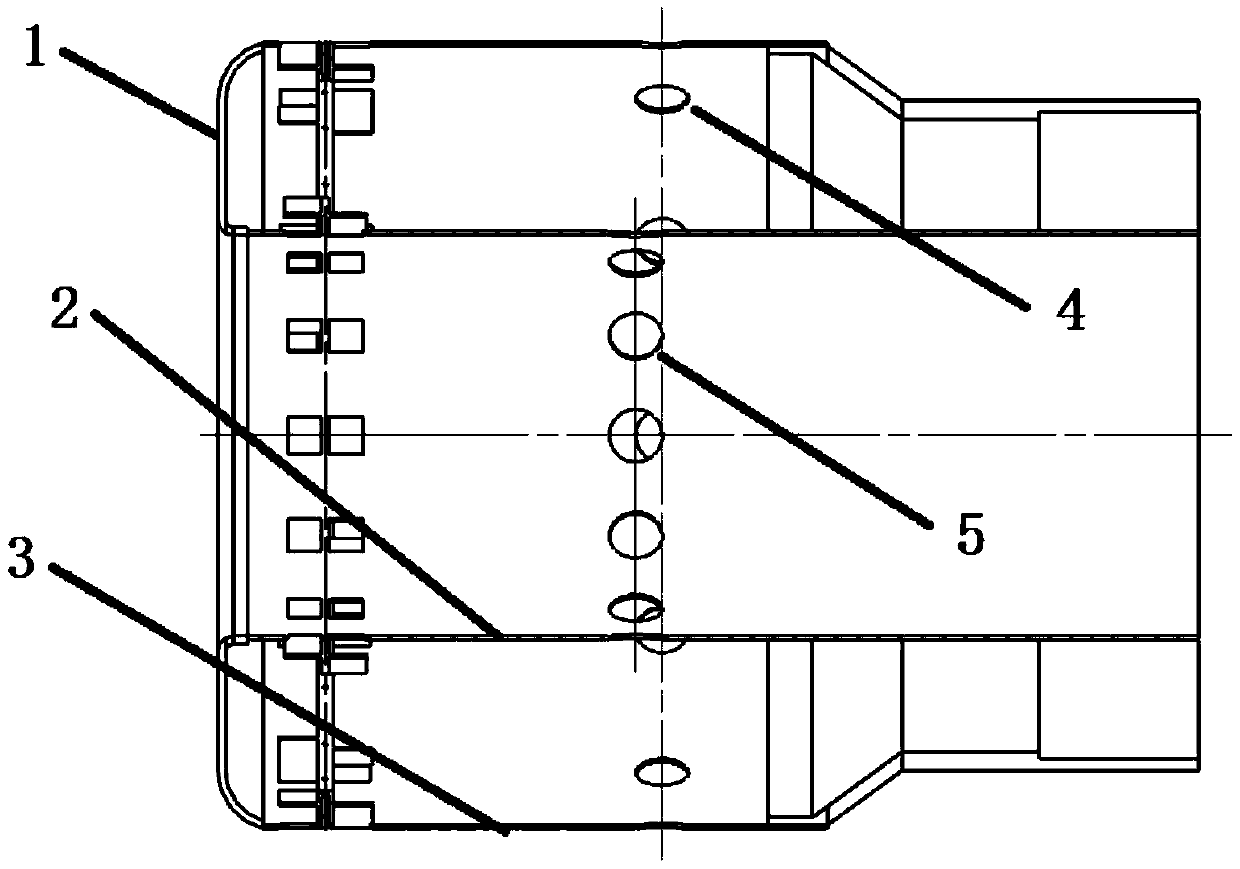

Countercurrent tangential type micro turbojet engine

InactiveCN103216333AImprove utilization efficiencyImprove combustion efficiencyTurbine/propulsion fuel supply systemsGas turbine plantsJet engineWorking life

The invention discloses a countercurrent tangential type micro turbojet engine. The countercurrent tangential type micro turbojet engine comprises a rotor system, a shell, a flame tube, a diffuser, a turbine guider, a fuel supply system, a lubricating system, a starting gas path and an exhaust system, wherein for the overall direction of the entire device, the position of the diffuser is defined as the left end direction of the entire device, the position of the turbine guider is defined as the right end direction of the entire device, by taking the rotor system as the center, the diffuser is fixed at the front end of the rotor system, the turbine guider is fixed at the right end of the rotor system, the exhaust system is positioned at the right end of the turbine guider, the flame tube is concentric with the rotor system and contains the rotor system, the fuel supply system and the starting gas path are fixed on the wall surface of the outer side of the flame tube, and the lubricating system is fixed on the outer side of the rotor system, positioned between the inner side of the flame tube and the rotor system and fixed with the shell of the micro turbojet engine through the diffuser and the turbine guider. The countercurrent tangential type micro turbojet engine reduces the pollutant discharge, and can effectively reduce the carbon deposition of the flame tube, so that the working life of the engine is prolonged.

Owner:NANJING UNIV OF SCI & TECH

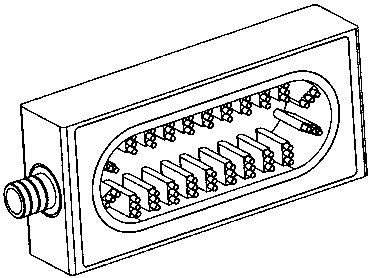

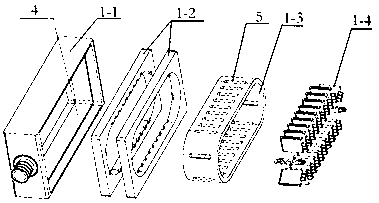

Solid fuel diffusive combustion fine diagnosis combustor

InactiveCN110259603AIncrease the degree of blendingIncrease profitRocket engine plantsGlass coverCombustion chamber

The invention provides a solid fuel diffusive combustion fine diagnosis combustor which comprises a combustion chamber, a combustion chamber top cover and an ignition seat device. A first stepped through hole is formed in the gas inlet wall face of the combustion chamber and used for installing a gas inlet cavity in a coaxial mode. A second stepped through hole is formed in the gas outlet wall face of the combustion chamber and used for installing an effuser. Windows are formed in the wall faces on the two sides of the combustion chamber. Quartz glass is fixed to the windows of the combustion chamber through glass cover plates and used for observing the combustion process of a rocket engine in real time. Both the bottom face of the combustion chamber and the combustion chamber top cover are provided with filling grooves. Second heat insulating layers are arranged in the two filling grooves. Solid fuel is fixed to the second heat insulating layers. The filling grooves are additionally formed in the combustion chamber, the mixing degree between an oxidizing agent and the fuel is improved, and the oxygen utilization ratio in the combustion process is increased; and an effuser throttling device is additionally arranged, effusers with different throat diameters are changed according to different requirements, and the effect of combustion chamber pressure on solid fuel diffusive combustion can be effectively analyzed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

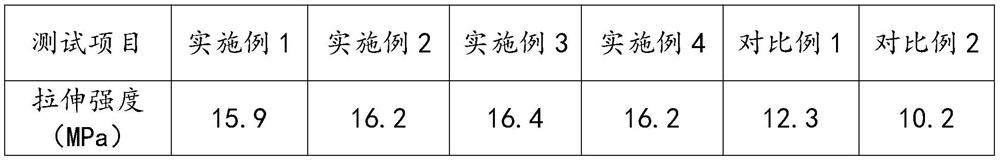

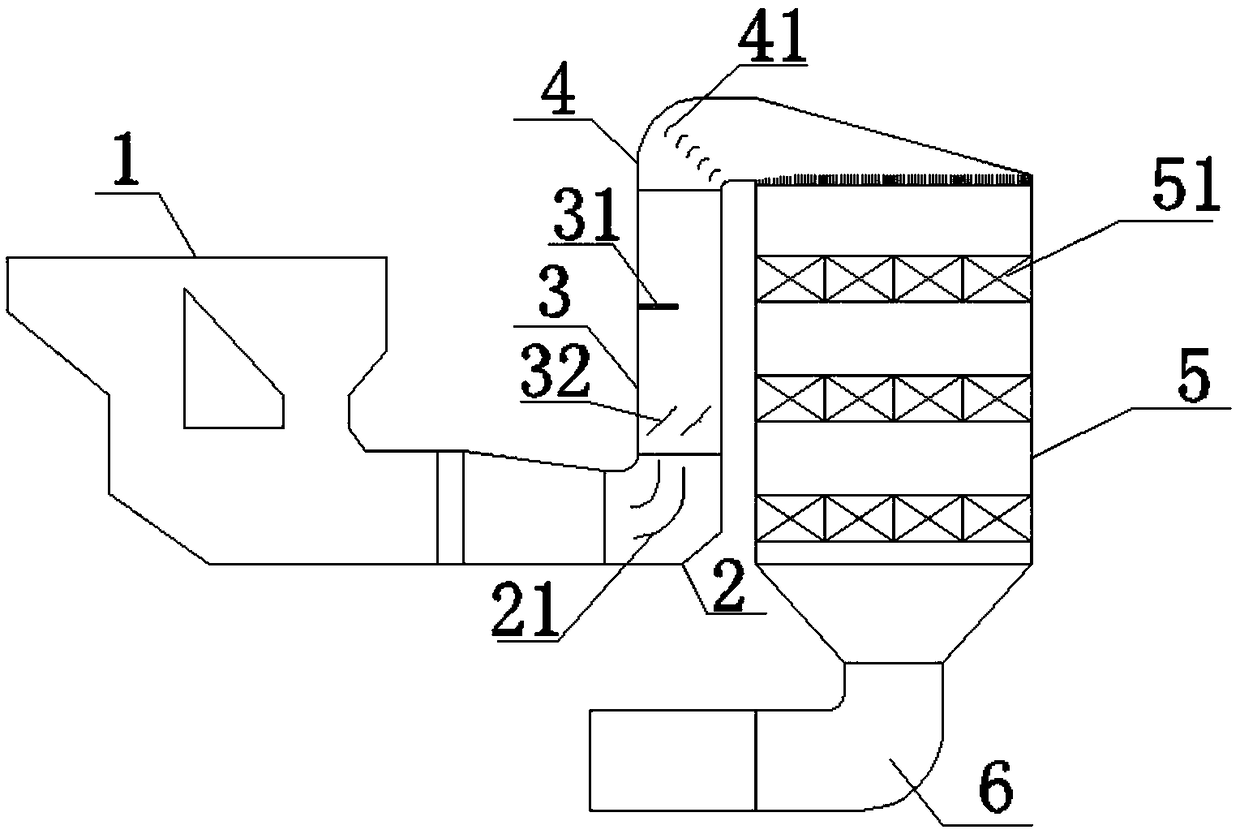

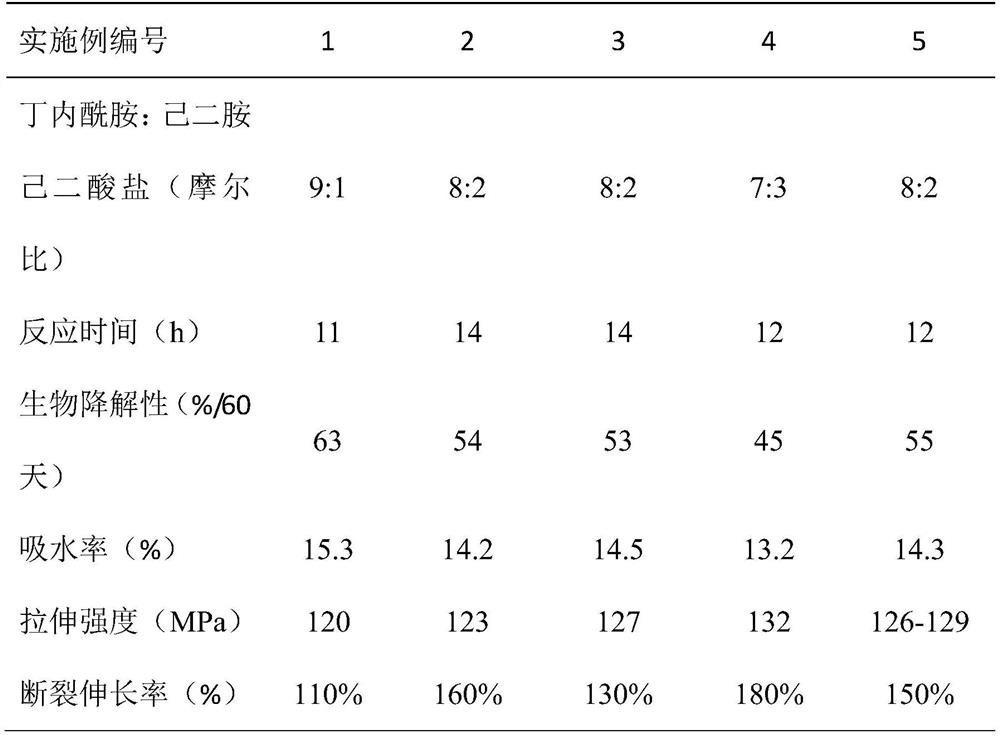

PA6-56 copolymerized material and preparation method thereof

The invention relates to the field of polymer materials, and discloses a PA6-56 copolymerized material and a preparation method thereof. The PA6-56 copolymerized material is prepared through blend polymerization of liquid caprolactam and a water solution of pentamethylene diamine adipate, wherein the molar ratio of the liquid caprolactam to the pentamethylene diamine adipate is 7:3-9:1. The methodcomprises the following steps: mixing the liquid caprolactam, the water solution of the pentamethylene diamine adipate and other reaction raw materials according to a certain proportion, carrying outstirring in a reactor under the protection condition of inert gas, and carrying out a polycondensation reaction at a temperature of 150-300 DEG C, so as to obtain the PA6-56 copolymer material. According to the invention, PA6 monomer caprolactam is mainly copolymerized with PA56 monomer pentamethylene diamine adipate to prepare the PA6-56 copolymer material, and the material not only has the advantages of high strength, wear resistance, acid and alkali resistance of PA6, but also has better hygroscopicity and dyeability, so that better wearing comfort and more abundant color are provided to the textiles.

Owner:浙江恒逸锦纶有限公司

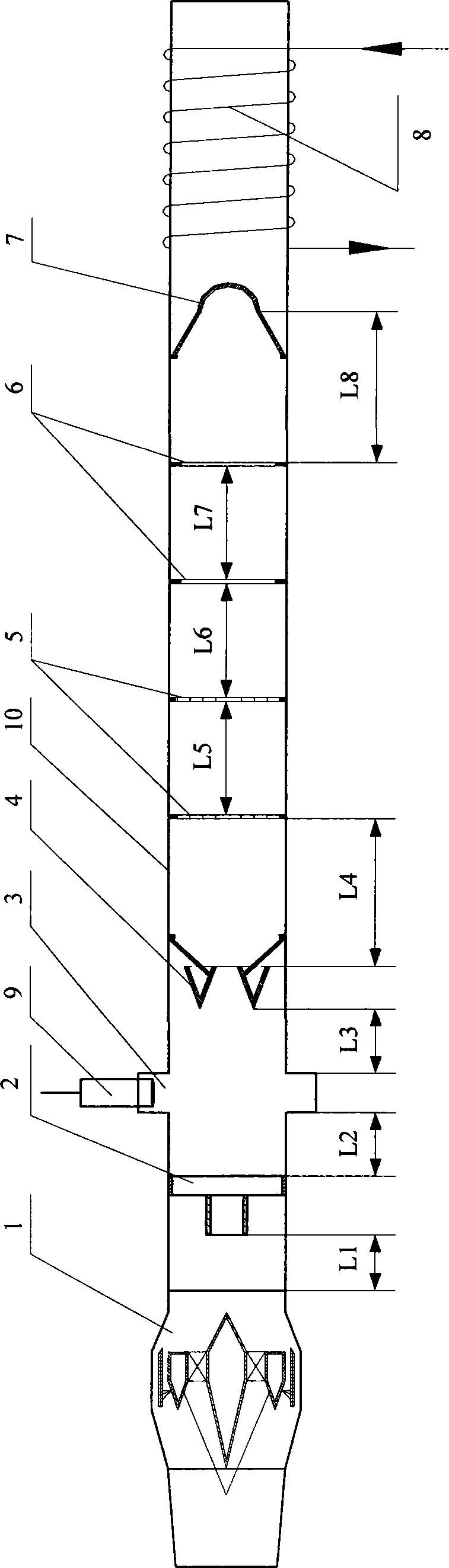

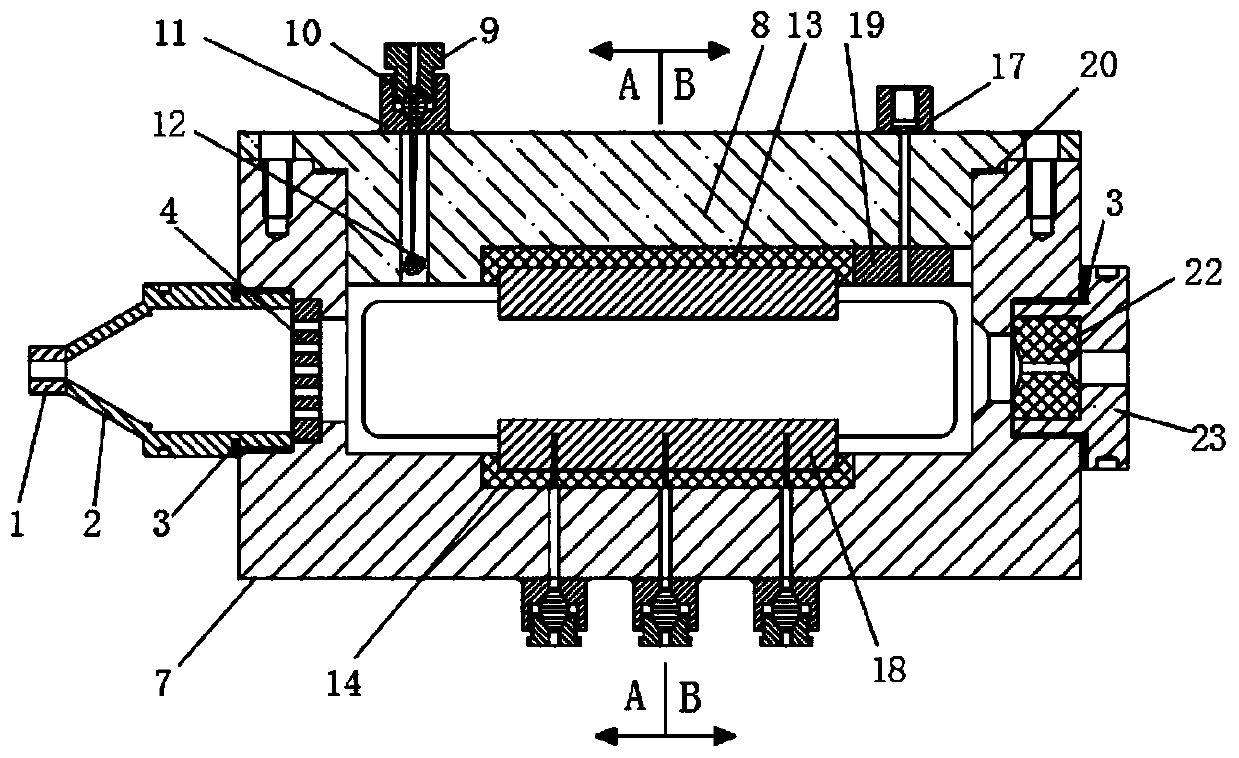

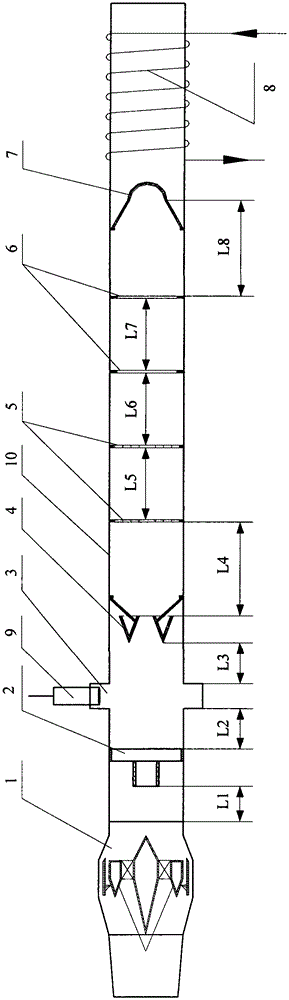

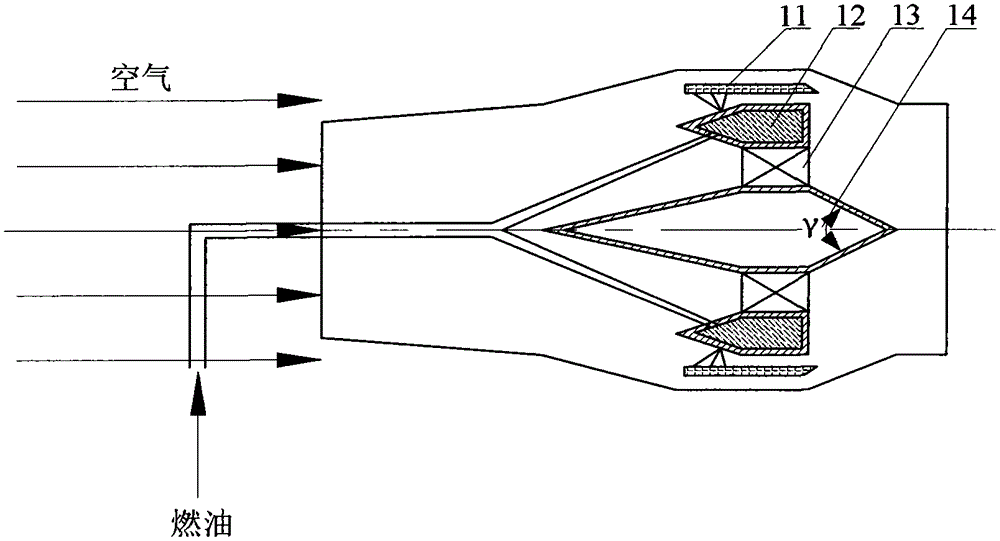

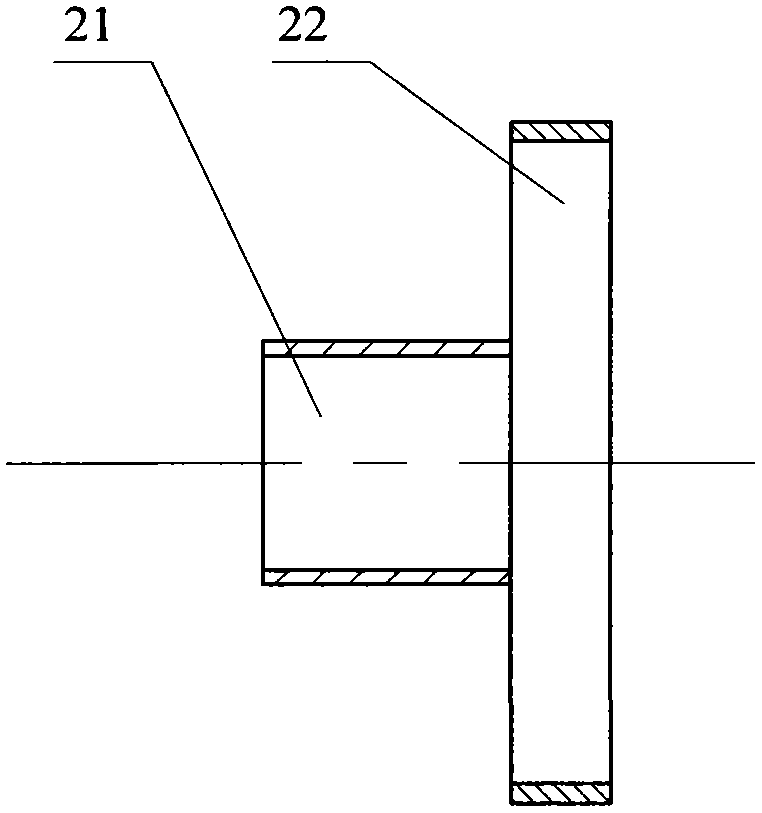

Two-phase high-frequency pre-detonator

ActiveCN103867338ASimple partsOptimize the installation positionIntermittent jet plantsShock waveDetonator

The invention provides a two-phase high-frequency pre-detonator. The two-phase high-frequency pre-detonator comprises a pneumatic valve and a detonation duct, wherein a fuel and air distribution and mixing device, a flame diffusion device, an intensified combustion device A, an intensified combustion device B and a shock reflection device are sequentially installed in the denotation duct along the flowing direction of air and fuel, the distance L1 between the front end surface of the fuel and air distribution and mixing device and the front end surface of the denotation duct is 1.0-2.0D, an ignition groove is processed on the wall surface of the denotation duct between the fuel and air distribution and mixing device and the flame diffusion device, the distance L2 between the rear end surface of the fuel and air distribution and mixing device and the front end surface of the ignition groove is 0.5-0.7D, and the distance L3 between the rear end surface of the ignition groove and the front end of the flame diffusion device is 1.0-1.2D. The two-phase high-frequency pre-detonator has the advantage that the conversion from slow combustion to denotation is realized in a short distance by reasonably designing the internal structure of a denotation chamber, optimizing all major parts and installation positions and adopting a combined method of intensified combustion and shock reflection.

Owner:BEIJING POWER MACHINERY INST

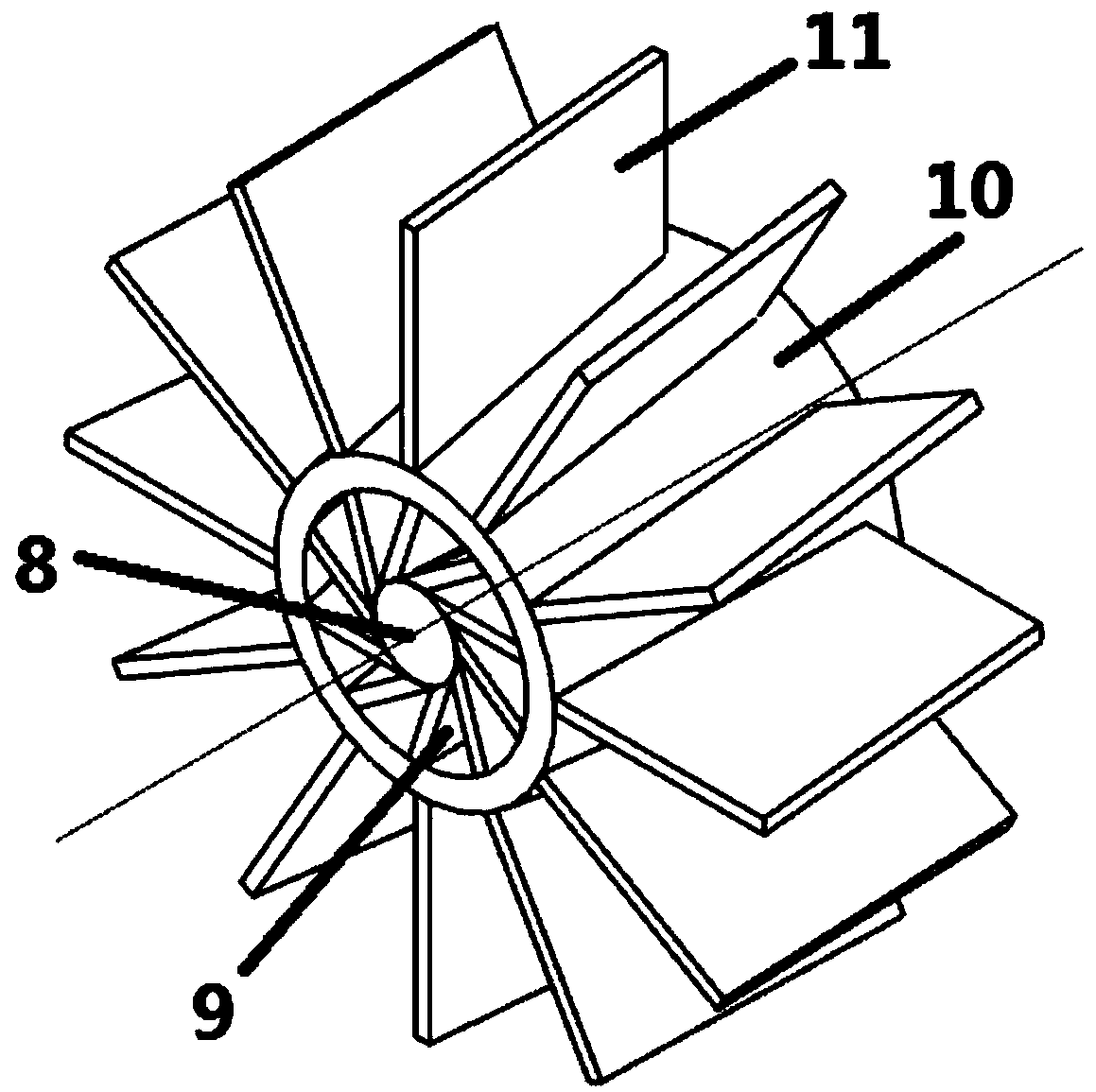

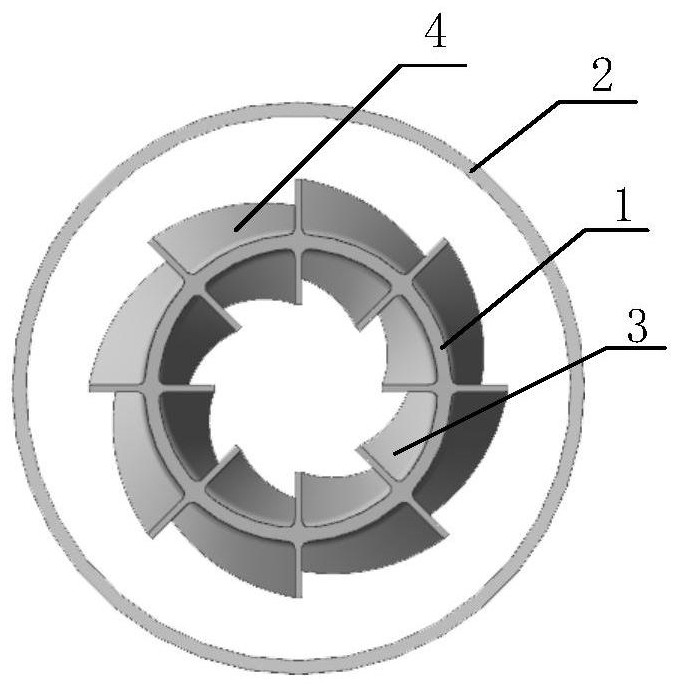

Trapped-vortex combustor with swirlers

InactiveCN108758692AIncrease the degree of blendingStable high temperature heat sourceContinuous combustion chamberCombustion chamberCombustor

The invention provides a trapped-vortex combustor with swirlers. The swirlers which are matched with the combustor are arranged on the rear wall faces of concave cavities of the trapped-vortex combustor, two-stage blades of each swirler have a certain angle, after the oil gas in a trapper-vortex region passes through the swirlers, the flow state can be changed, rotational flow can be formed, and therefore flow return regions with the high strength are formed in the concave cavities, the influence of the main air flow on the flow of the concave cavities is reduced, and a stable high-temperatureheat source is provided for a main combustion region. Meanwhile, due to the fact that the two-stage blades of each swirler are opposite in rotating direction, the high shear force exists between theair flow ejected from the two-stage blades, the atomization degree of fuel oil of the trapped-vortex region and the oil and gas mixing degree can be greatly improved, and the combustion efficiency isimproved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Processing technology of instant tea tree flower food

InactiveCN111000239AEliminate bitternessGreat tasteFood preservationNatural extract food ingredientsInstant teaBitter taste

The invention discloses a processing technology of an instant tea tree flower food, wherein the tea tree flower food is prepared from tea tree flowers, lotus leaves, white kidney beans, opuntia ficus-indica, burdock and purple sweet potatoes. The preparation method comprises the following steps: 1, preparing an additive solution; 2, cooking tea tree flowers; 3, continuously beating and mixing theadditive solution and the cooked tea tree flowers by adopting a specially-made mixing device; and 4, freeze-drying, sterilizing and packaging the mixture. According to the invention, tea tree flowersare cooked and scientifically matched with lotus leaves, white kidney beans, opuntia ficus-indica, burdock, purple sweet potatoes and the like, so that the original bitter taste of the tea tree flowers can be removed, and good mouth feel of the instant tea tree flowers is formed; the finished product is directly prepared through a freeze-drying technology, so that the functional components of thetea tree flowers are completely reserved, and the instant tea tree flowers have all nutritional components and health-care functions of the tea tree flowers; and the instant tea tree flower food withgood taste, nutrition and health care is obtained.

Owner:宣城市合力生态农业有限公司

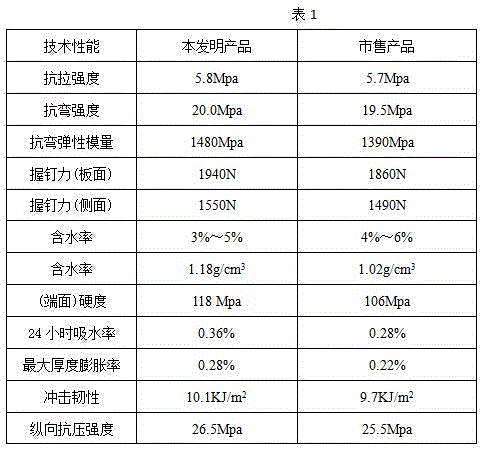

Wood-plastic plate and preparation method thereof

InactiveCN104910640AIncrease the degree of blendingImprove adhesionCarboxymethyl starchPolymer science

The invention discloses a wood-plastic plate and a preparation method thereof to solve the problems that the existing straw plate is poor in water resistance, high in water expansion rate, easy to deform, poor in screw holding capability and high in gel content. The wood-plastic plate comprises the following raw materials in parts by weight: 70-90 parts of fine straw powder, 0.5-1 part of diphenylmethane diisocyanate and 10-30 parts of polylactic acid and carboxymethyl composite starch, wherein during the preparation of the polylactic acid and carboxymethyl composite starch, the added amount of the polylactic acid is 6-10 times of the mass of carboxymethyl starch. The preparation method of the wood-plastic plate comprises the steps of pretreating straws, preparing a single-layer straw composite plate, and preparing a three-layer straw composite plate. The wood-plastic plate disclosed by the invention has performance advantages of woods and plastics, and product materials are biodegradable materials and do not contain harmful substances including formaldehyde and the like to human bodies. The product is high in hardness, high in strength, difficult in deformation and strong in load bearing capacity.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

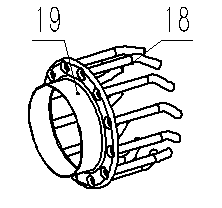

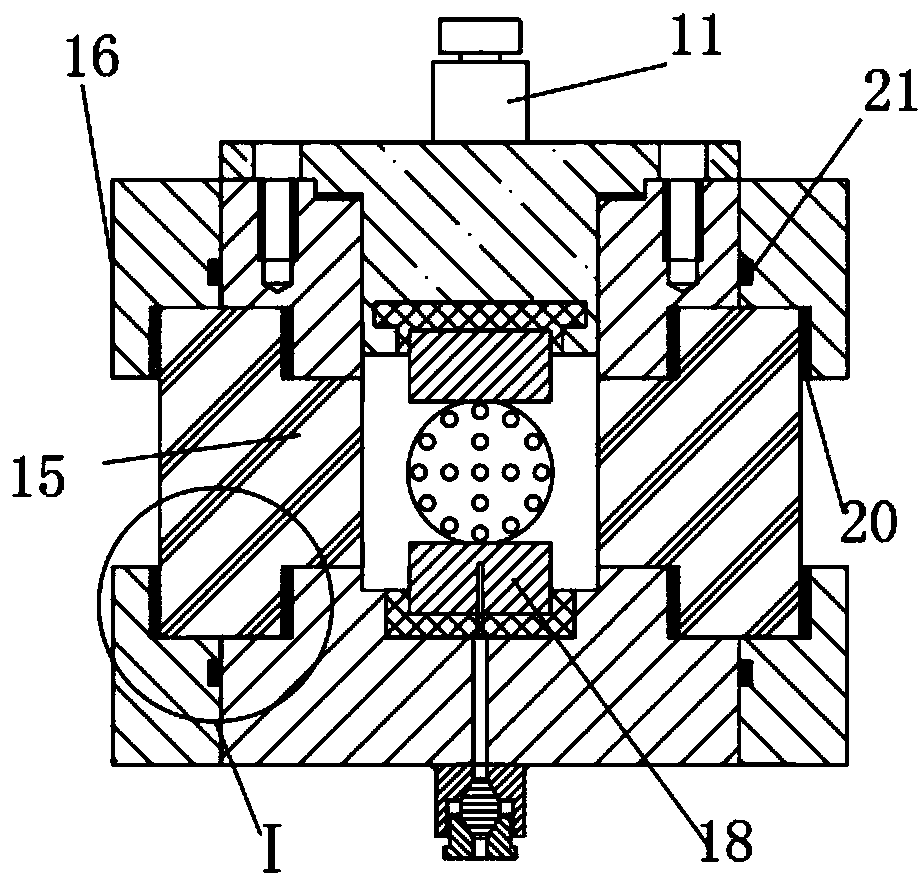

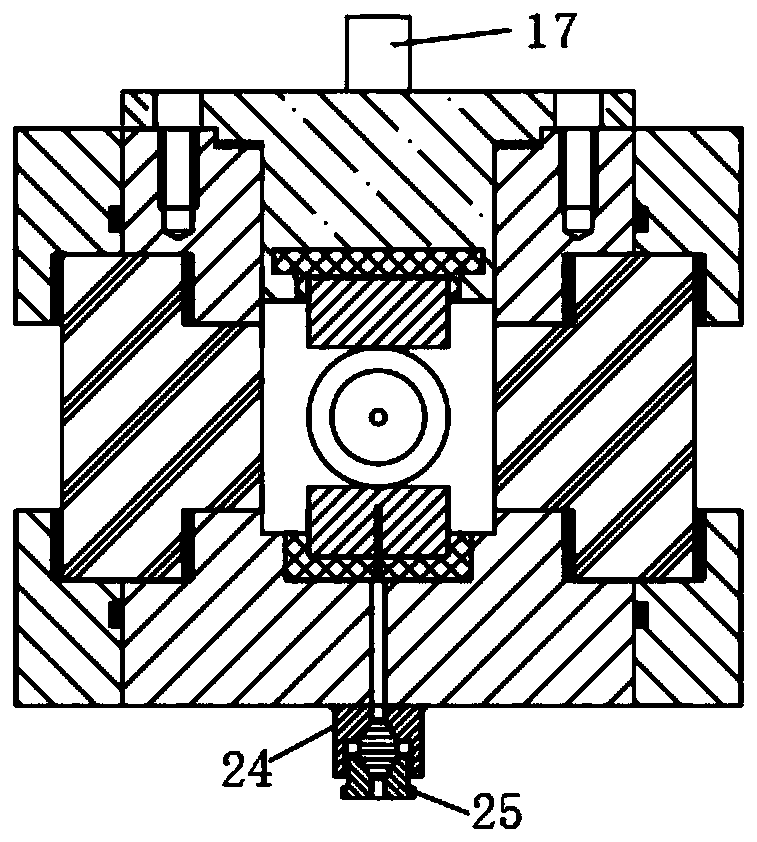

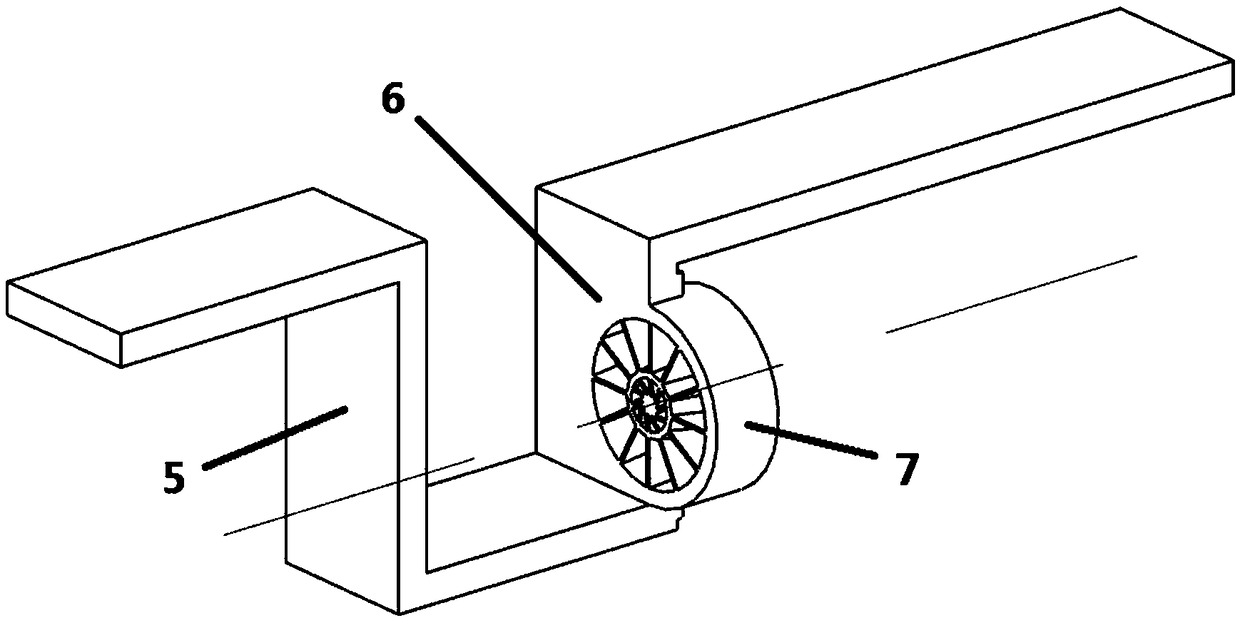

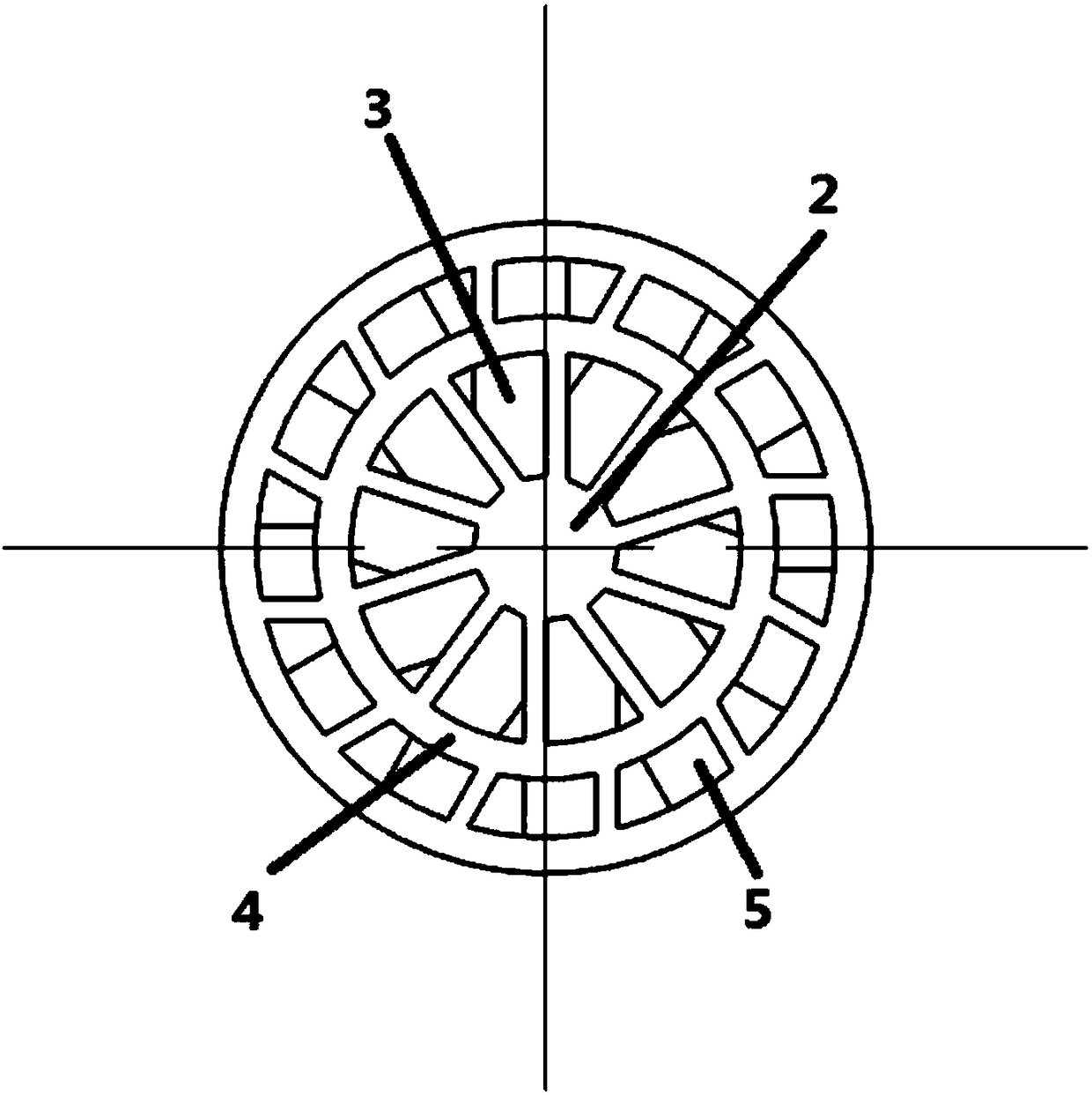

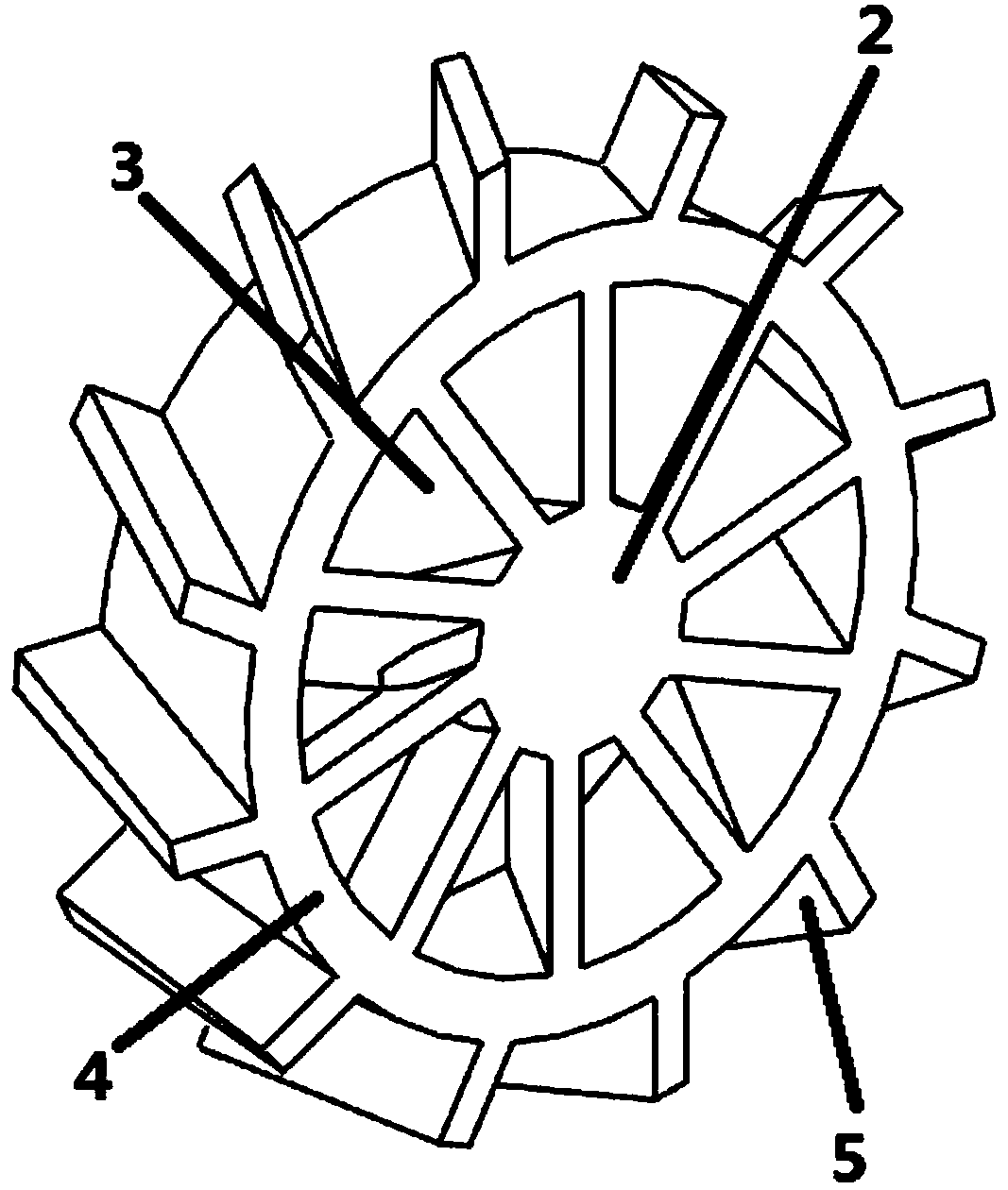

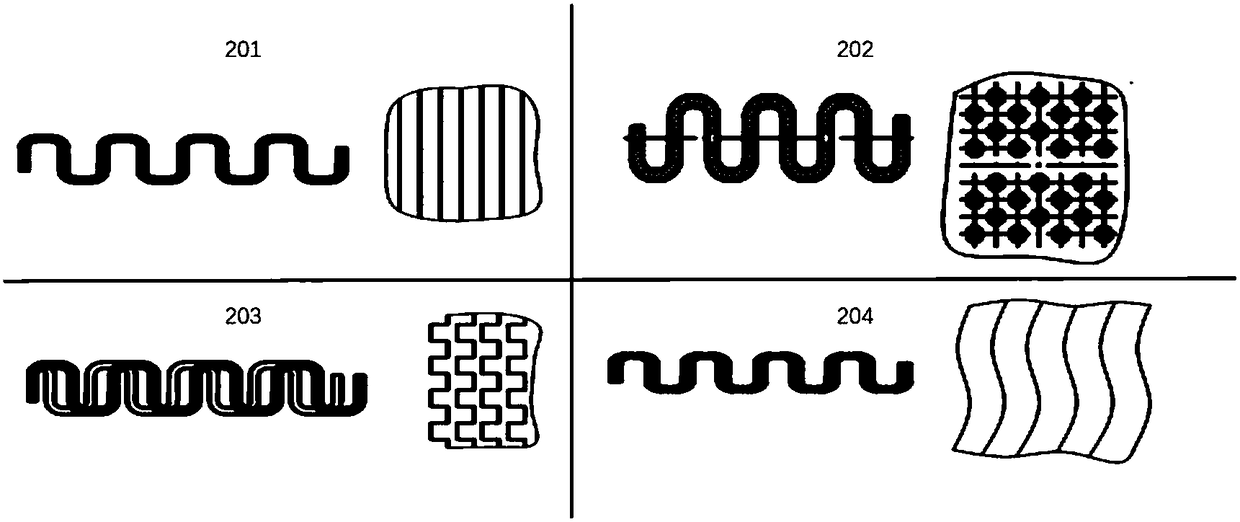

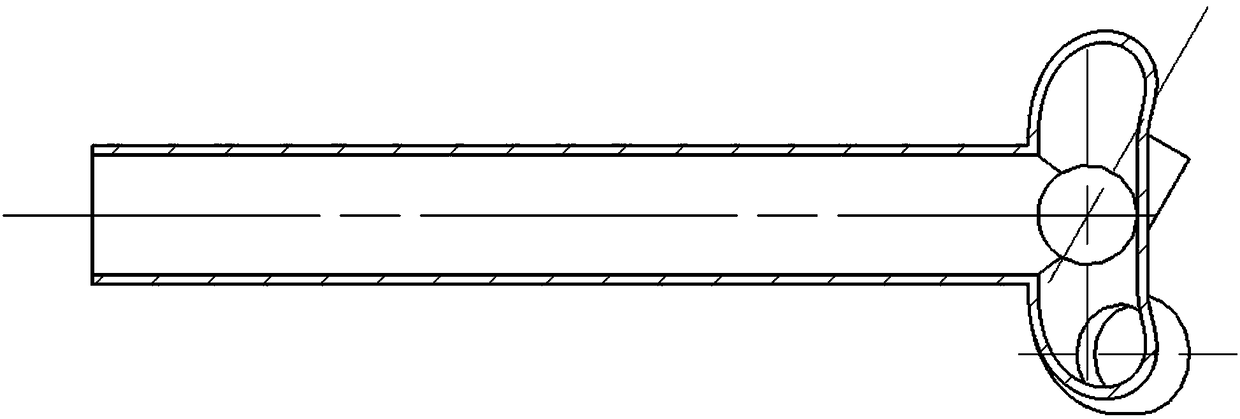

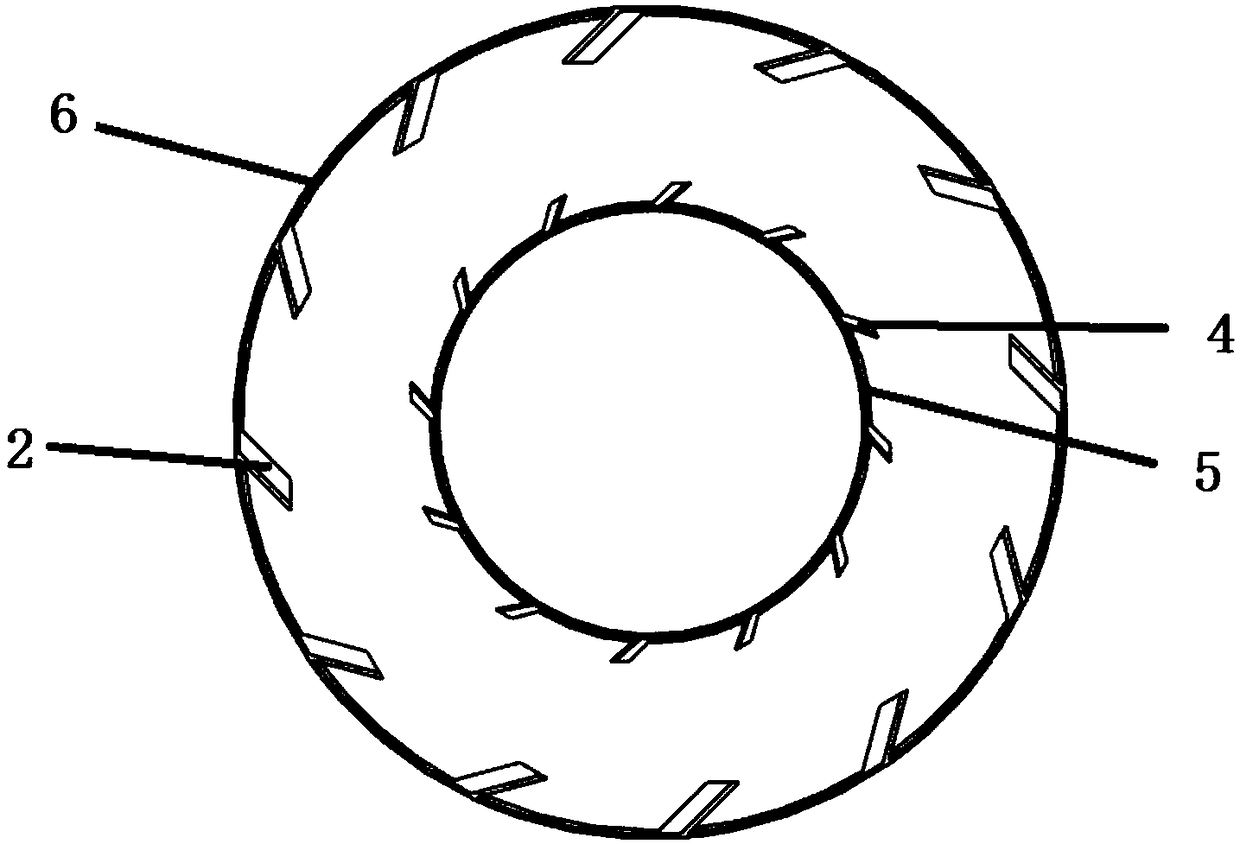

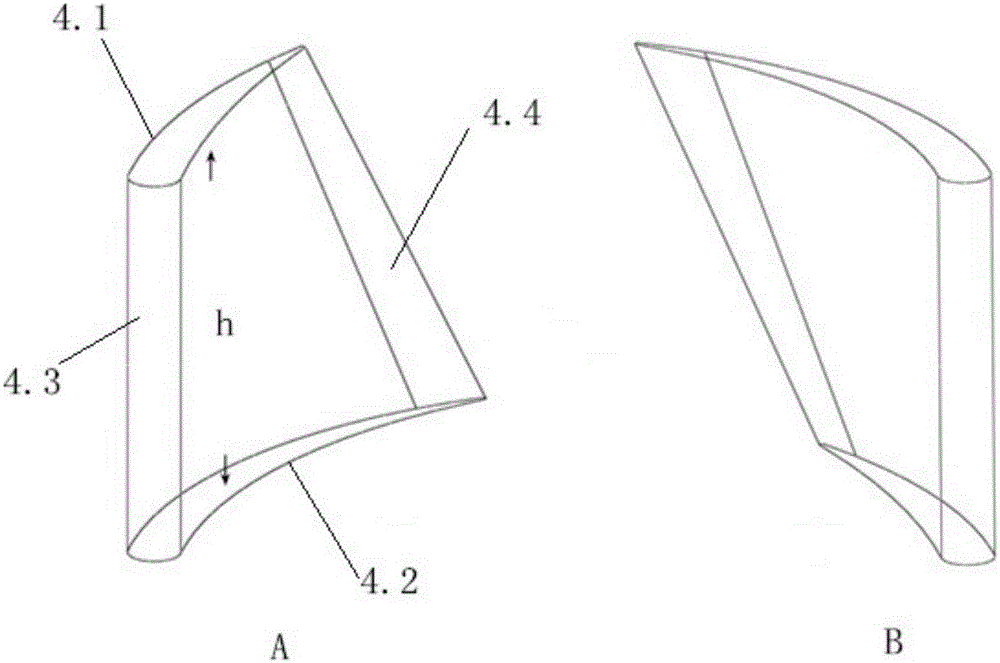

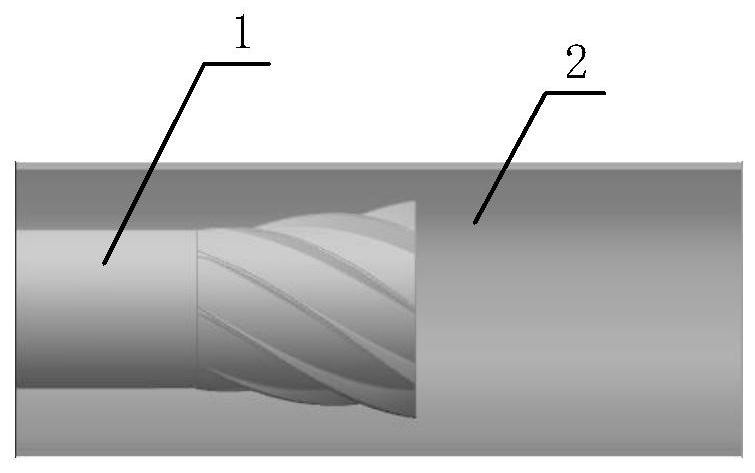

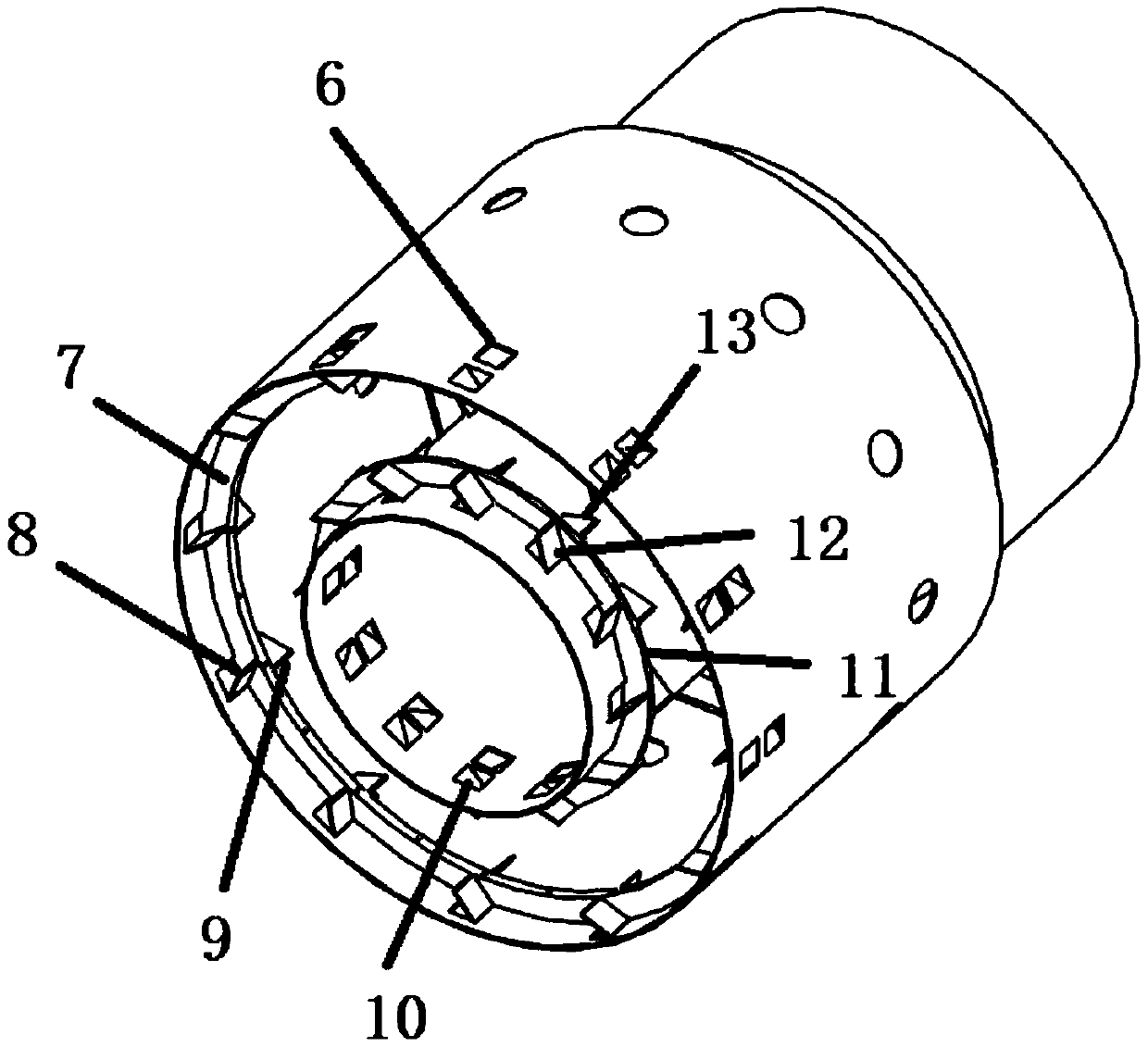

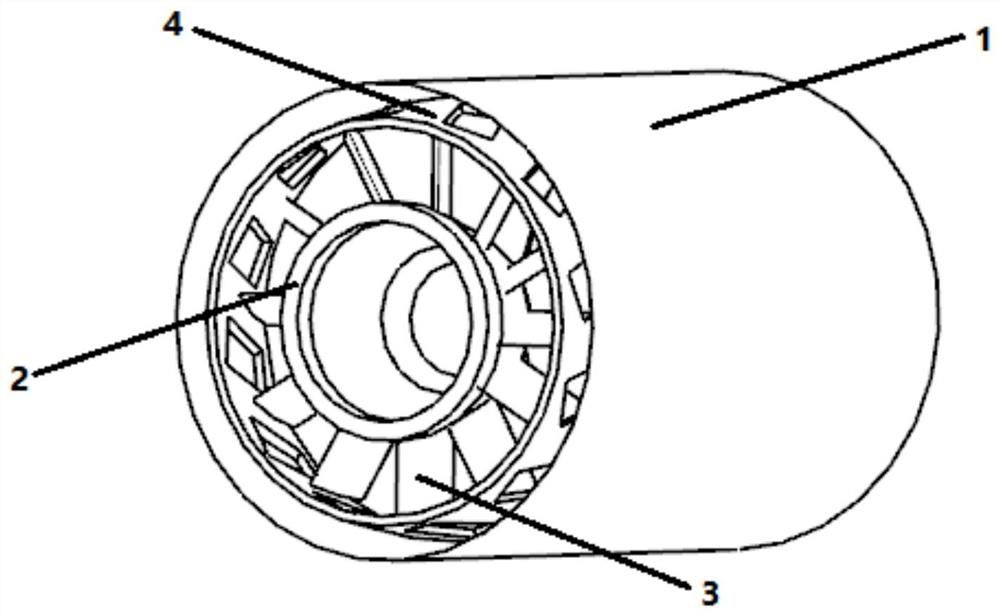

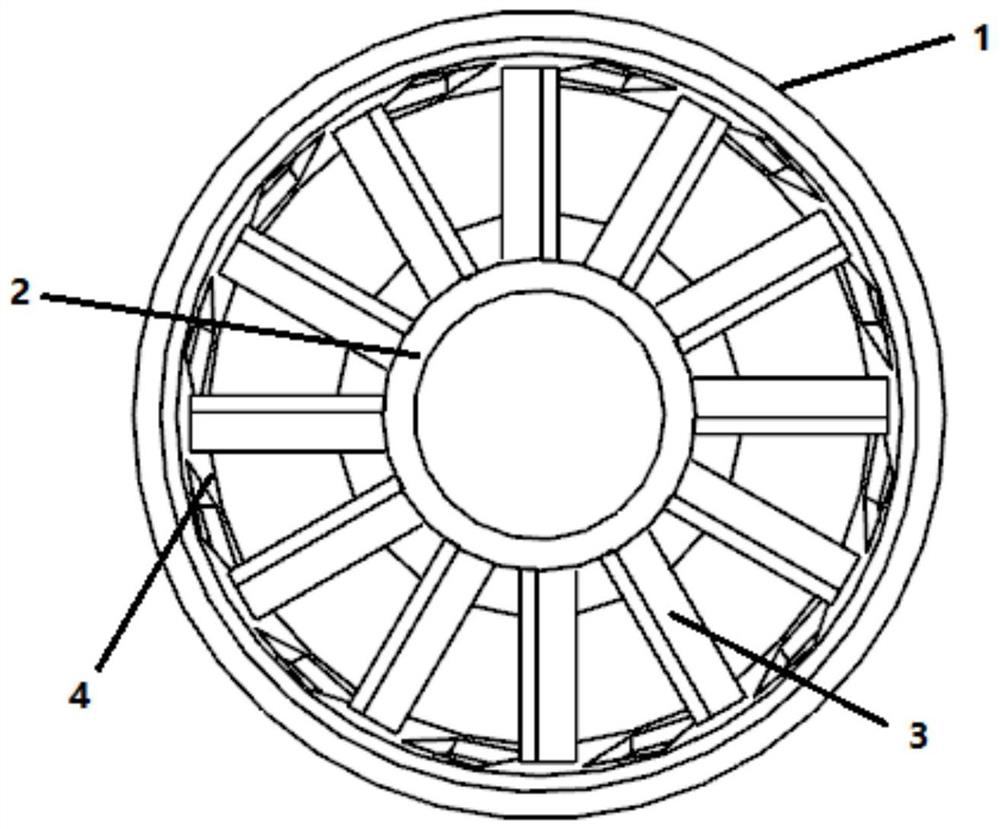

Mini type engine combustion chamber evaporation pipe structure with whirlcone

InactiveCN108151063AImprove the rotation effectIncrease the degree of blendingContinuous combustion chamberCombustion chamberEvaporation

The invention provides a mini type engine combustion chamber evaporation pipe structure with a whirlcone. By means of the structure, the mixing degree between fuel oil in a mini type combustion chamber and air can be effectively improved, forming of a backflow area is facilitated, and accordingly the combustion efficiency and the combustion stability are improved. A double-level whirlcone structure is additionally arranged at a tail end outlet of an evaporation pipe, and due to the fact that a certain angle is formed by each of a first-level whirlcone blade and a second-level whirlcone blade and the axis of the evaporation pipe, after the mixed airflow of the fuel oil and air passes through the first-level whirlcone blade and the second-level whirlcone blade, the flowing state changes, rotational flow is formed, and the oil-gas mixing degree is improved; and a certain backflow area can be formed in the combustion chamber through the rotational flow, accordingly airflow is stabilized, flames are more stable, and better combustion is promoted. On the other hand, due to the fact that the first-level whirlcone blade and the second-level whirlcone blade are opposite in rotation direction, large shear force can be generated between two-level ejected airflow, later fuel oil liquid drops and evaporated fuel oil liquid drops in the evaporation pipe can be better atomized, the oil-gas mixing degree can be better improved, and the combustion efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

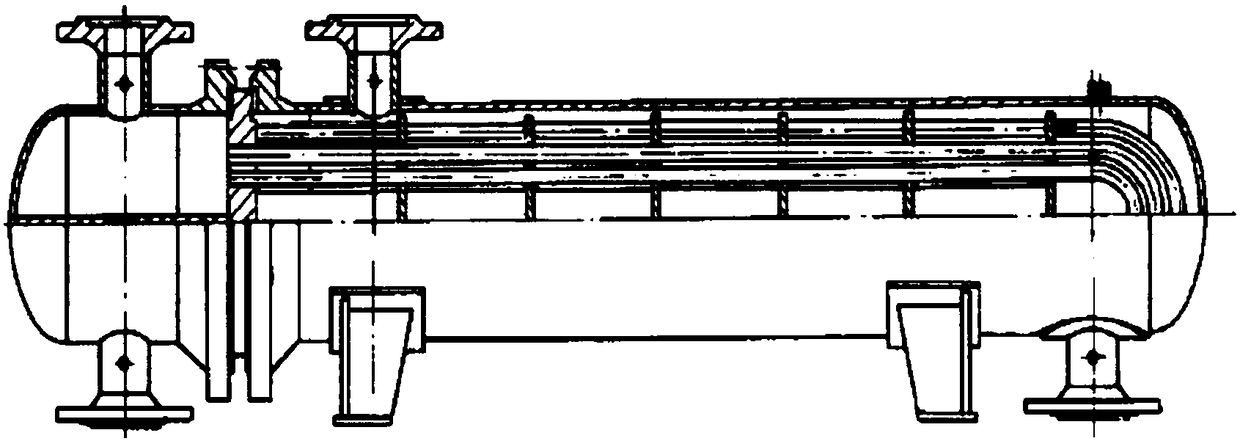

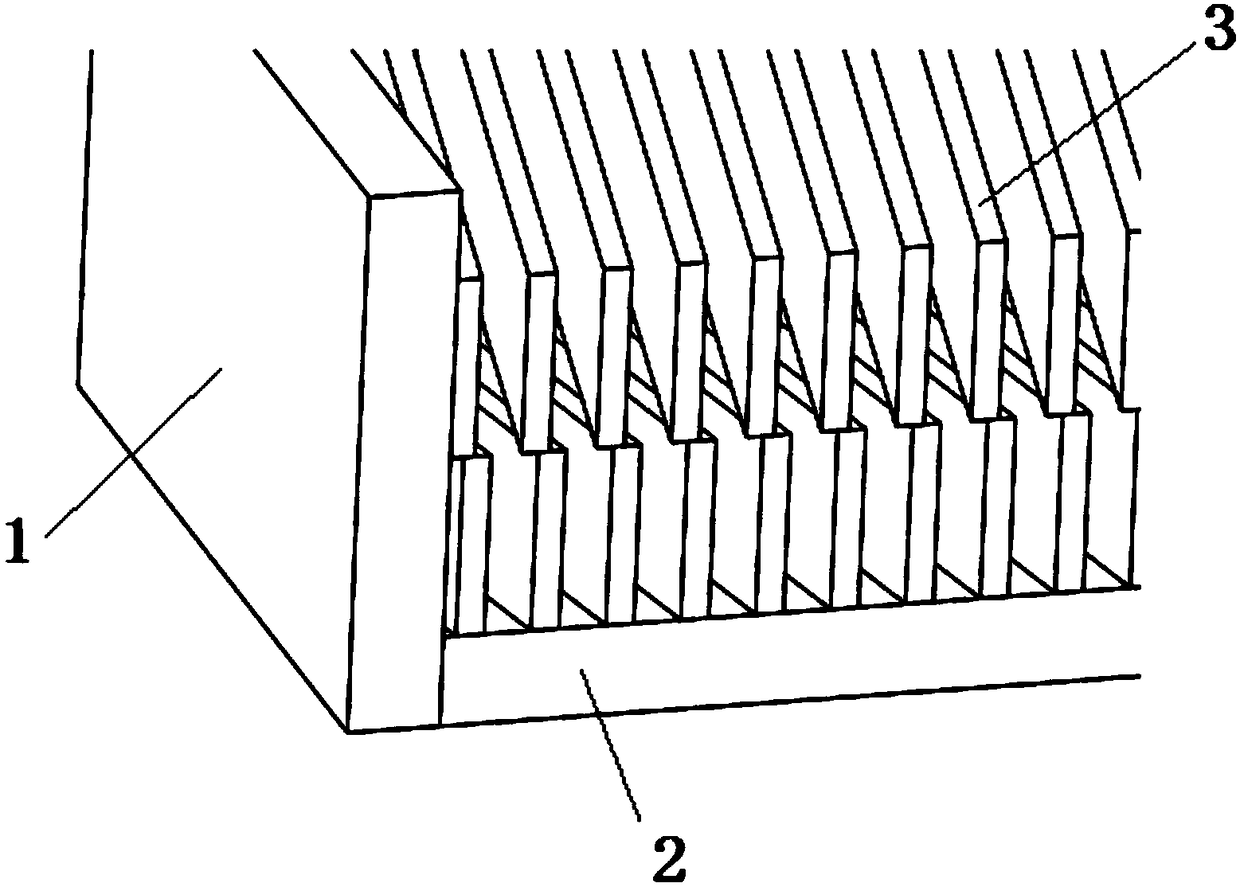

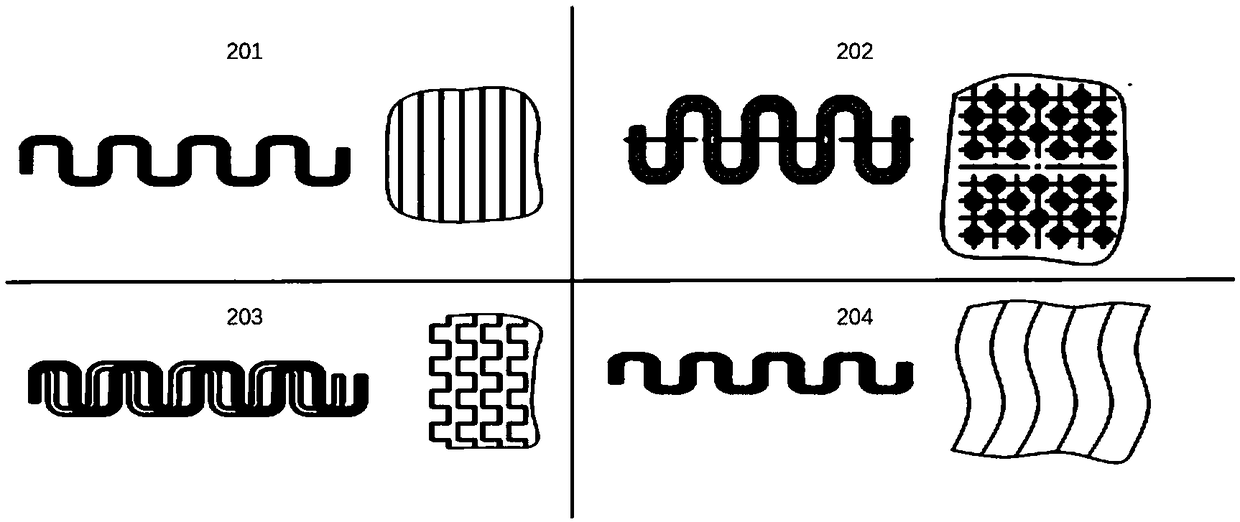

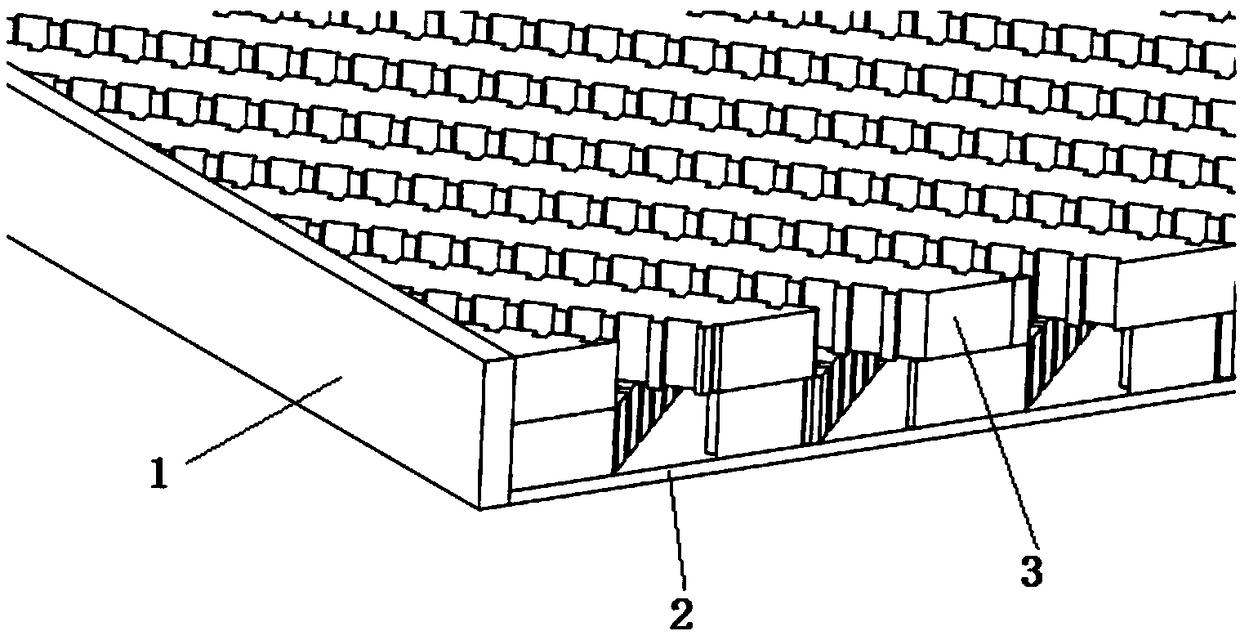

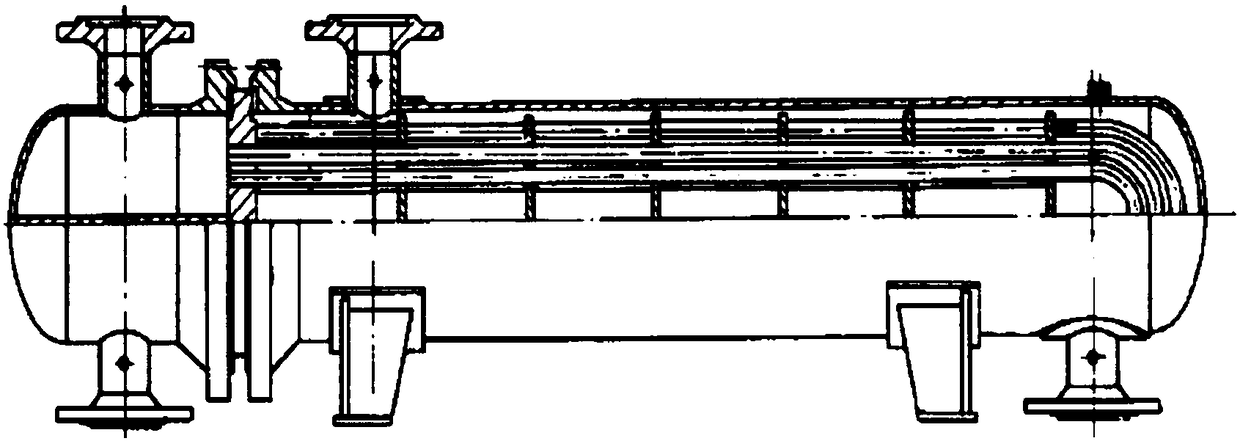

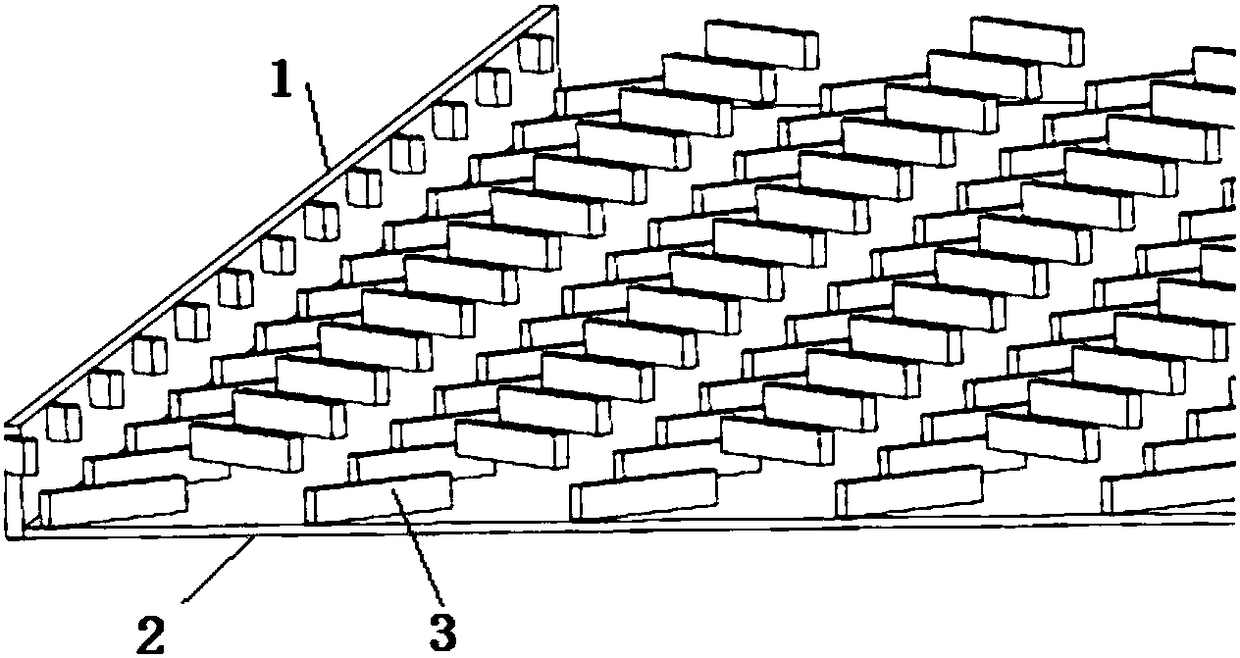

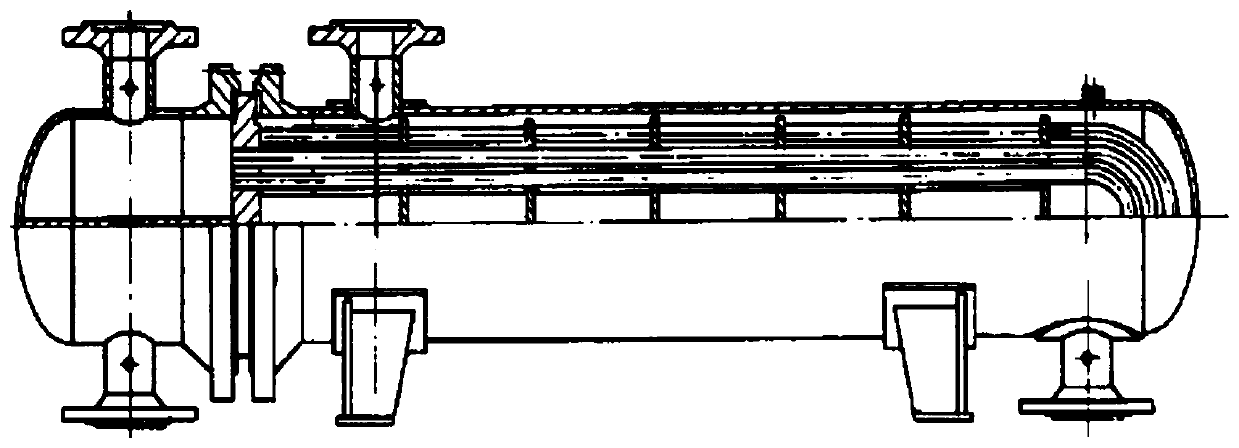

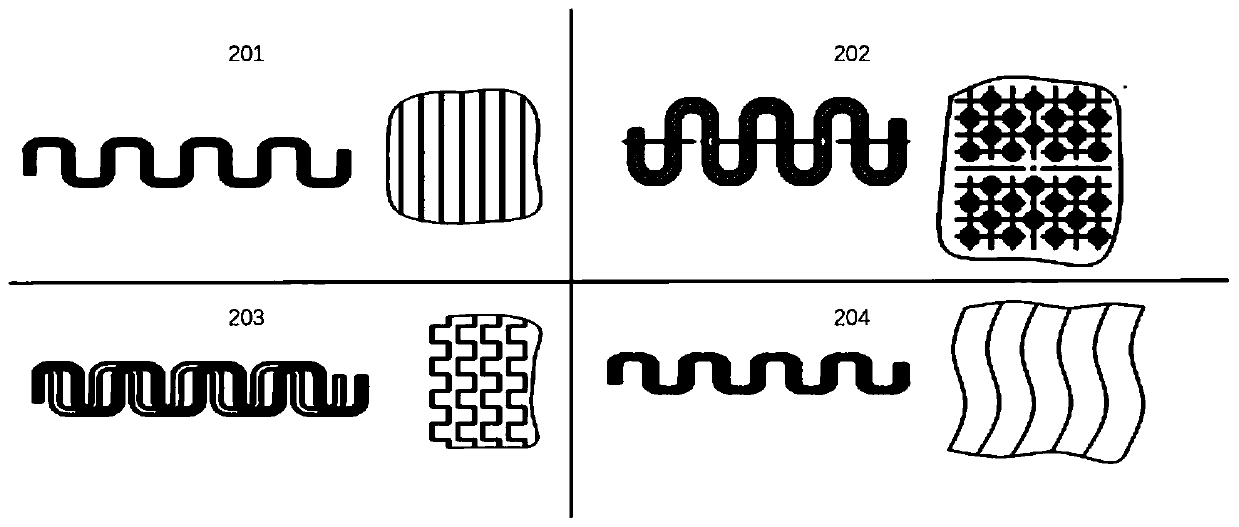

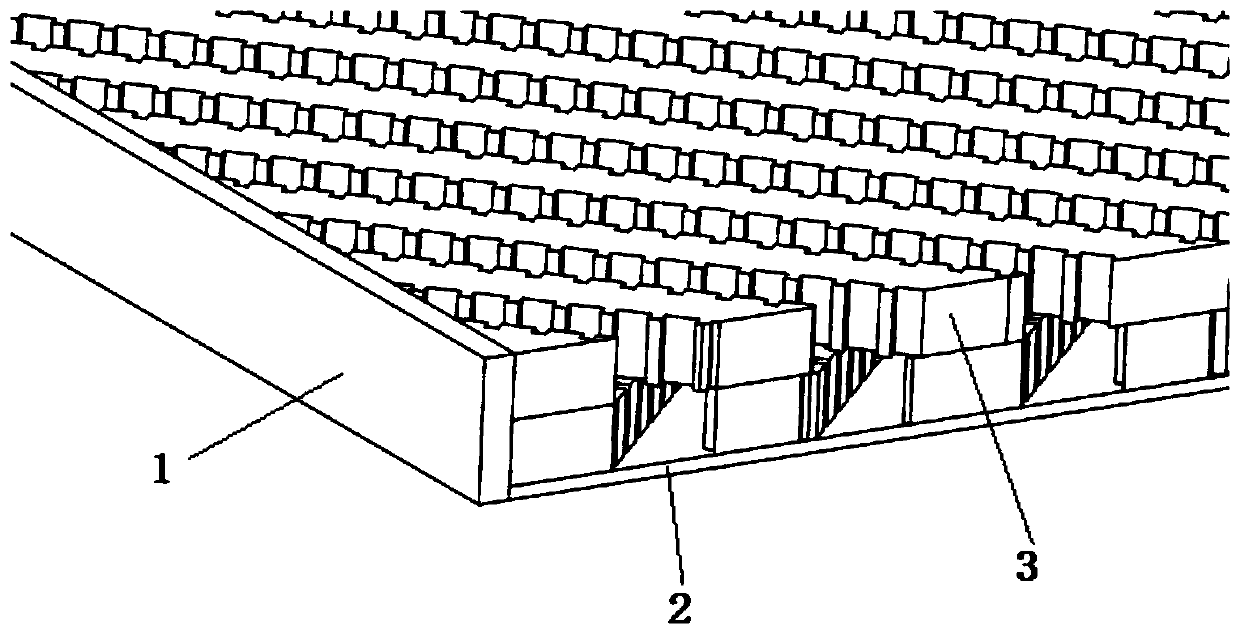

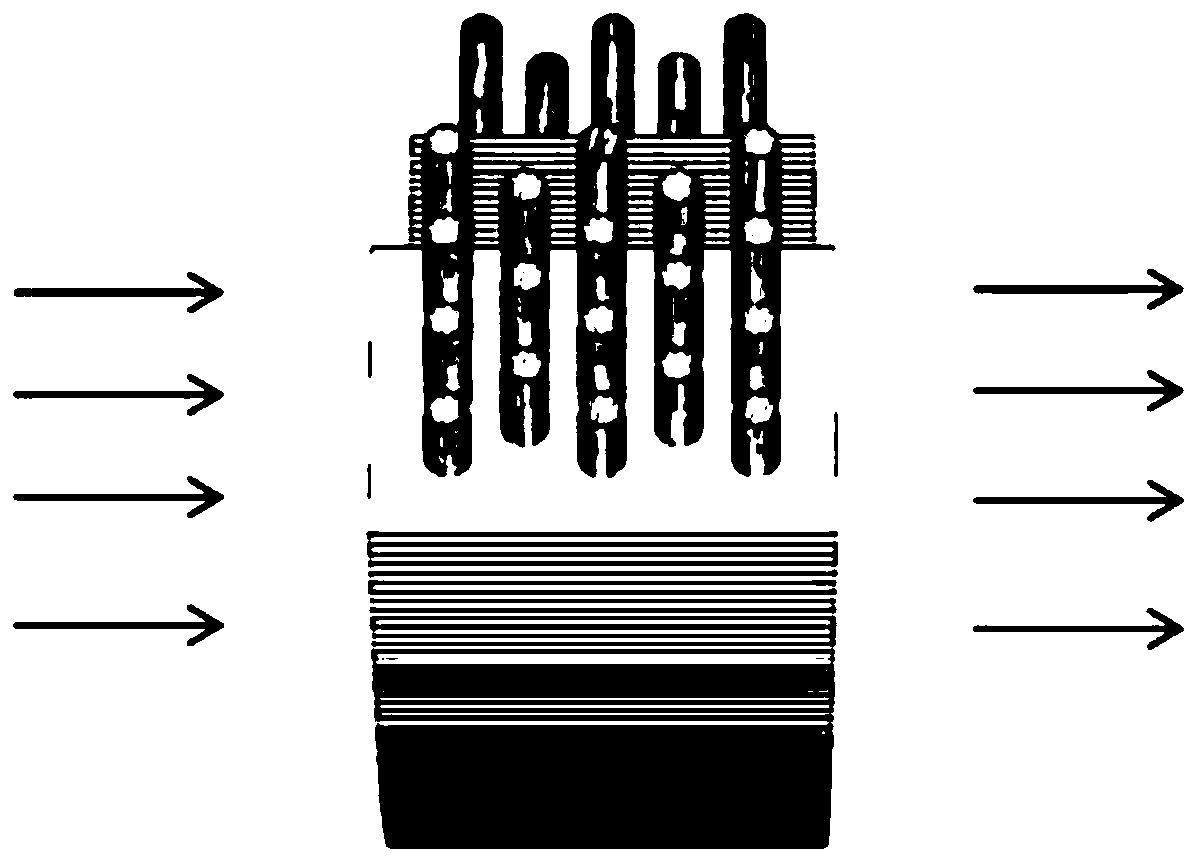

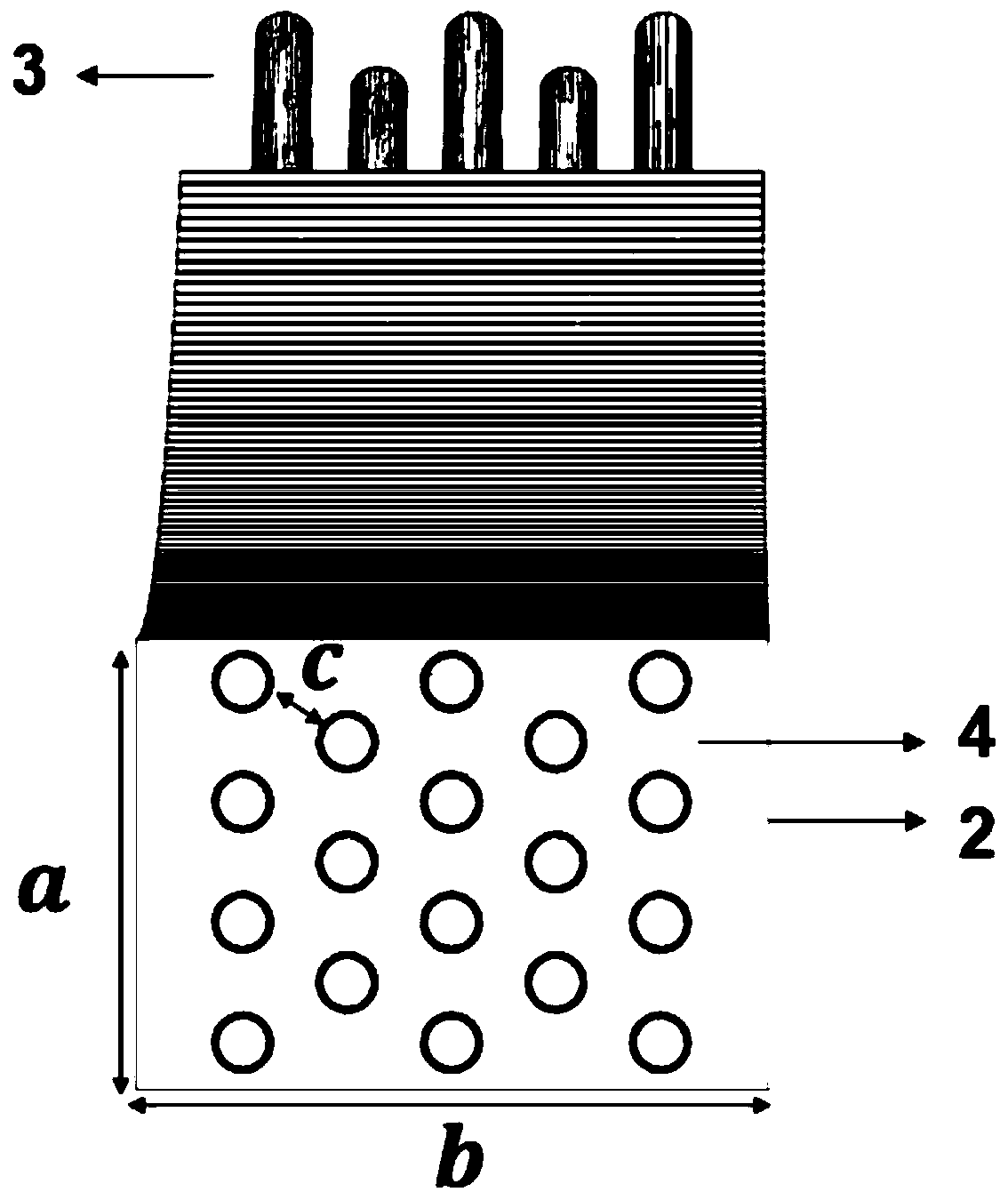

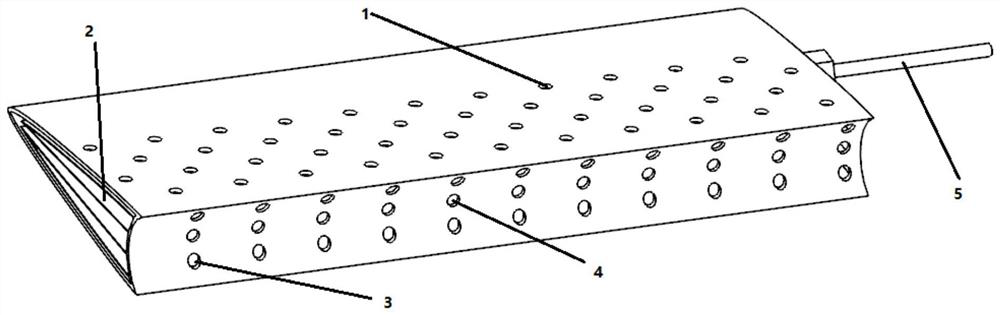

Bionic straight-line-rib-row type tiny staggered alveolar heat exchanger core and heat exchanger

InactiveCN108548435AImprove performanceAvoid cloggingHeat exchanger casingsStationary tubular conduit assembliesEngineeringMicro heat exchanger

The invention discloses a bionic straight-line-rib-row type tiny staggered alveolar heat exchanger core. The core comprises at least two layers of medium flowing cavities separated by a heat exchangeplate, at least two layers of straight-line type rib rows are arranged in each layer of medium flowing cavity, each straight-line type rib row is composed of a plurality of straight-line rib strips parallel to each another, and every two adjacent layers of straight-line rib strips are staggered. Bionic elements are integrated into the design of the heat exchanger to design the tiny staggered alveolar heat exchanger, the structure improves the performance of the heat exchanger from two aspects including the heat transfer coefficient and the heat transfer area, the structure is light and simpleand convenient, and the core is suitable for an aerospace heat exchanger.

Owner:陕西益信伟创智能科技有限公司

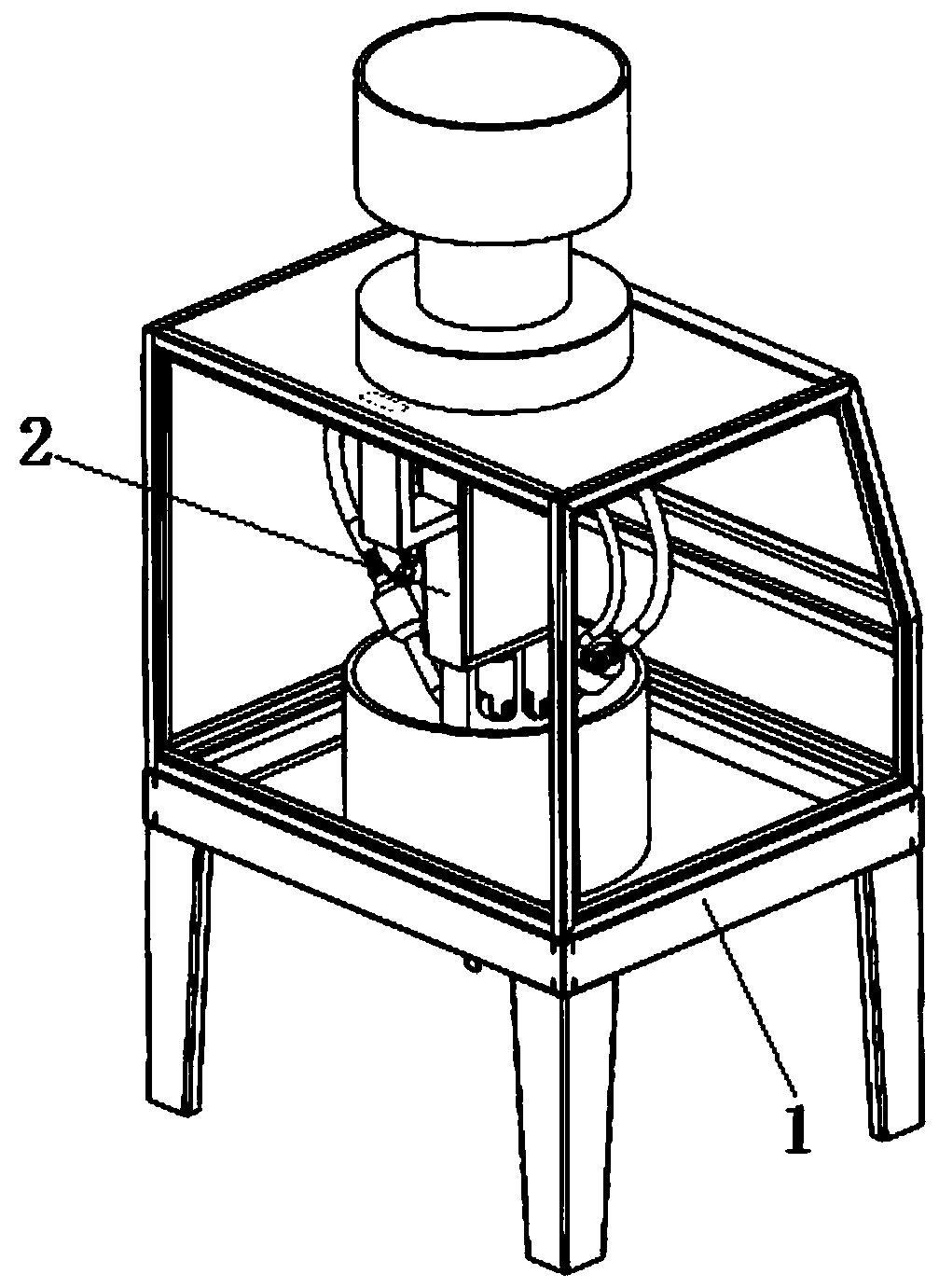

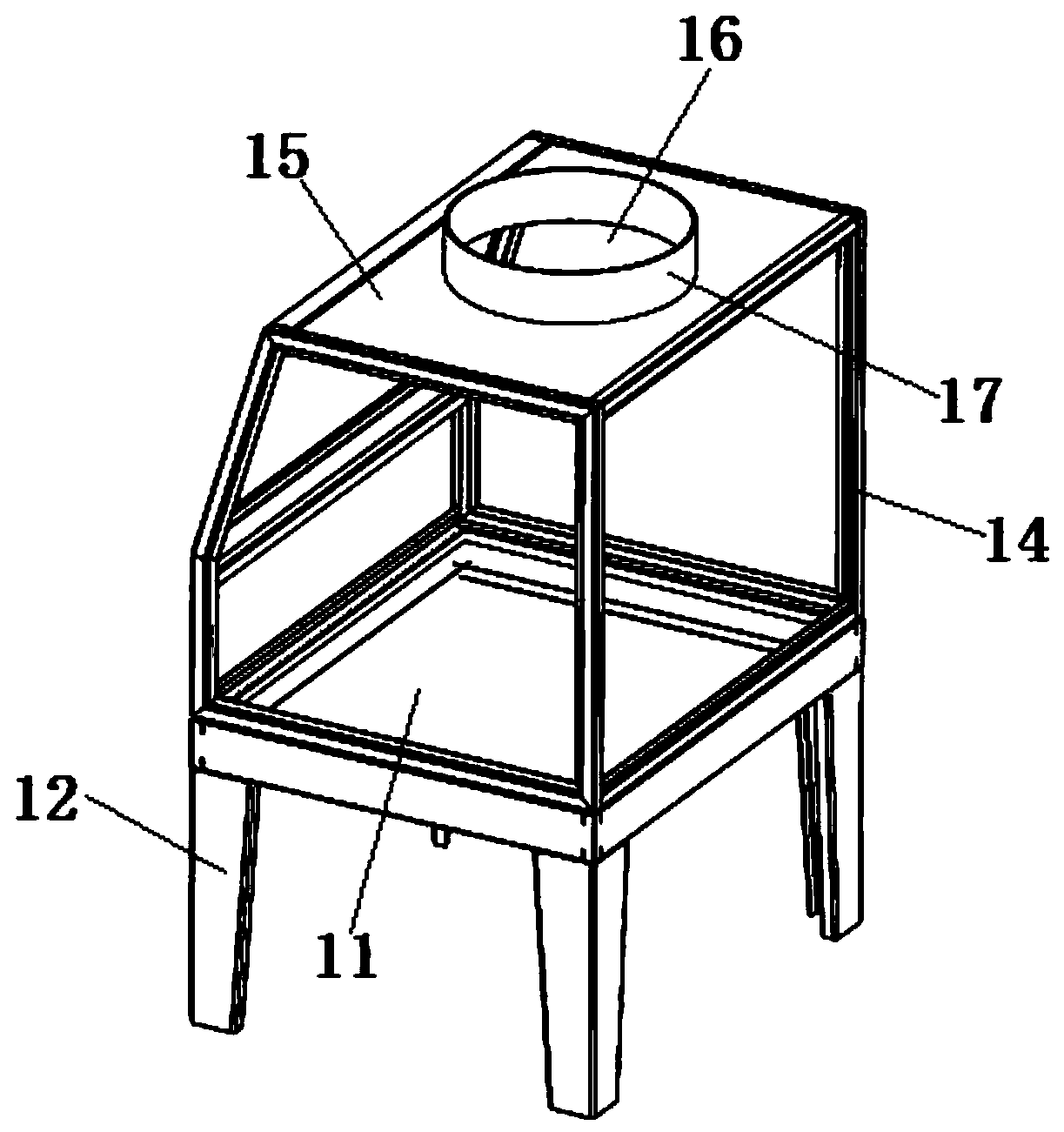

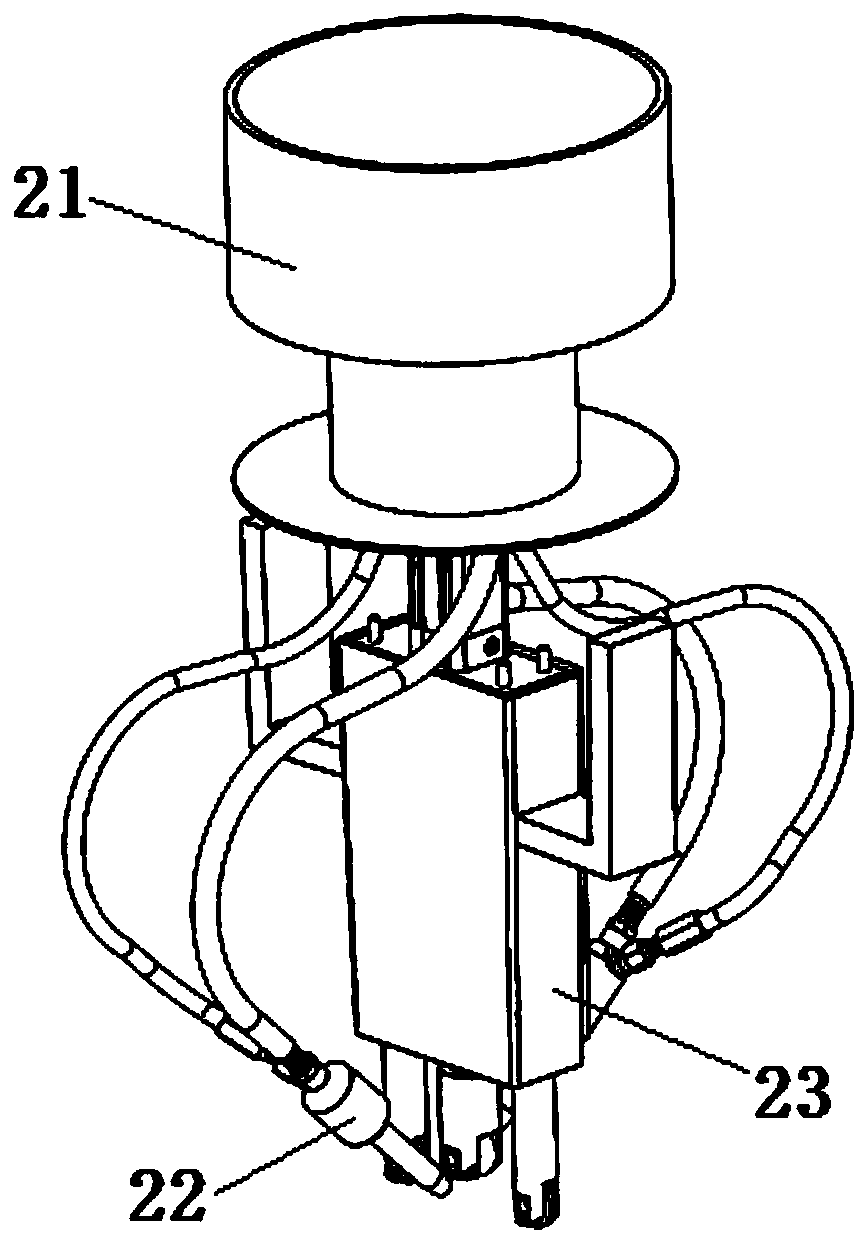

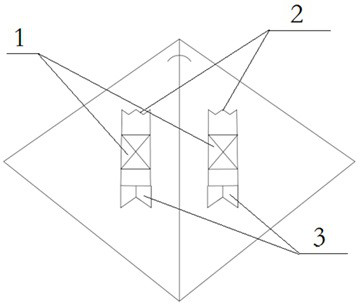

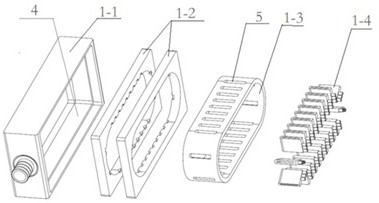

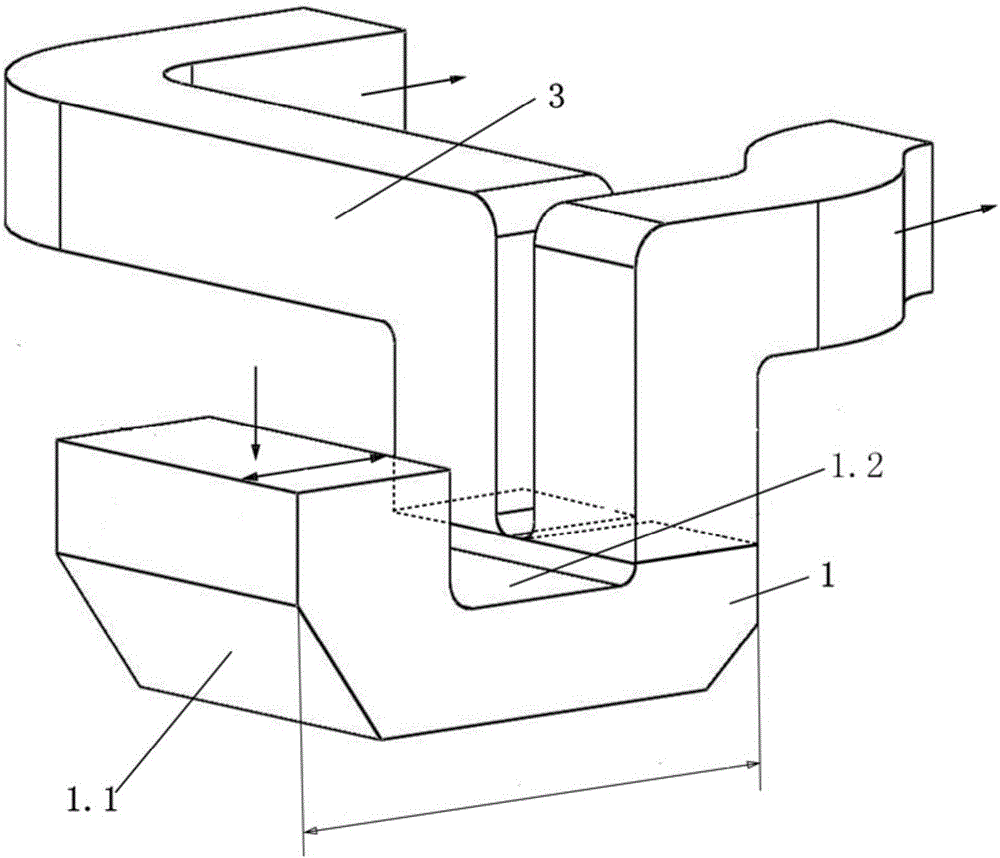

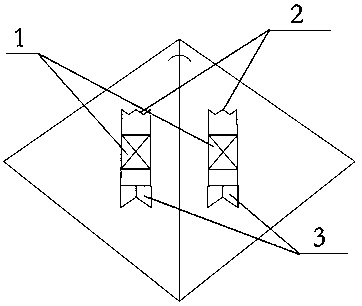

An ejector module used in low-speed wind tunnel aircraft intake and exhaust simulation tests

ActiveCN110411704BCompact structureIncrease the degree of blendingAerodynamic testingFlight vehicleHigh energy

The invention discloses an ejector module used for an intake-exhaust simulation experiment of a low-speed wind tunnel aircraft. The ejector module comprises an outer frame, a middle frame and an innerframe in sequence from outside to inside, wherein the outer frame, the middle frame and the inner frame are mutually connected to form a sealed cavity; the outer frame is provided with a gas inlet communicated with the sealed cavity, the inner frame is provided with a plurality of nozzle rakes, one end of each nozzle rake is communicated with the sealed cavity, and the other ends of the nozzle rakes are provided with nozzles. An injector is designed into a module of a model structure, and the injector is integrated with the model; the injector module uses a discrete multi-nozzle distributiontype injection mode, and the structure is compact. The discrete multi-nozzle distribution type injection mode greatly increases the mixing degree between high-energy compressed gas and injected low-energy gas, and the injection efficiency is obviously improved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

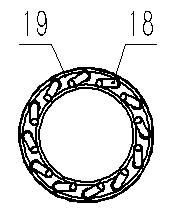

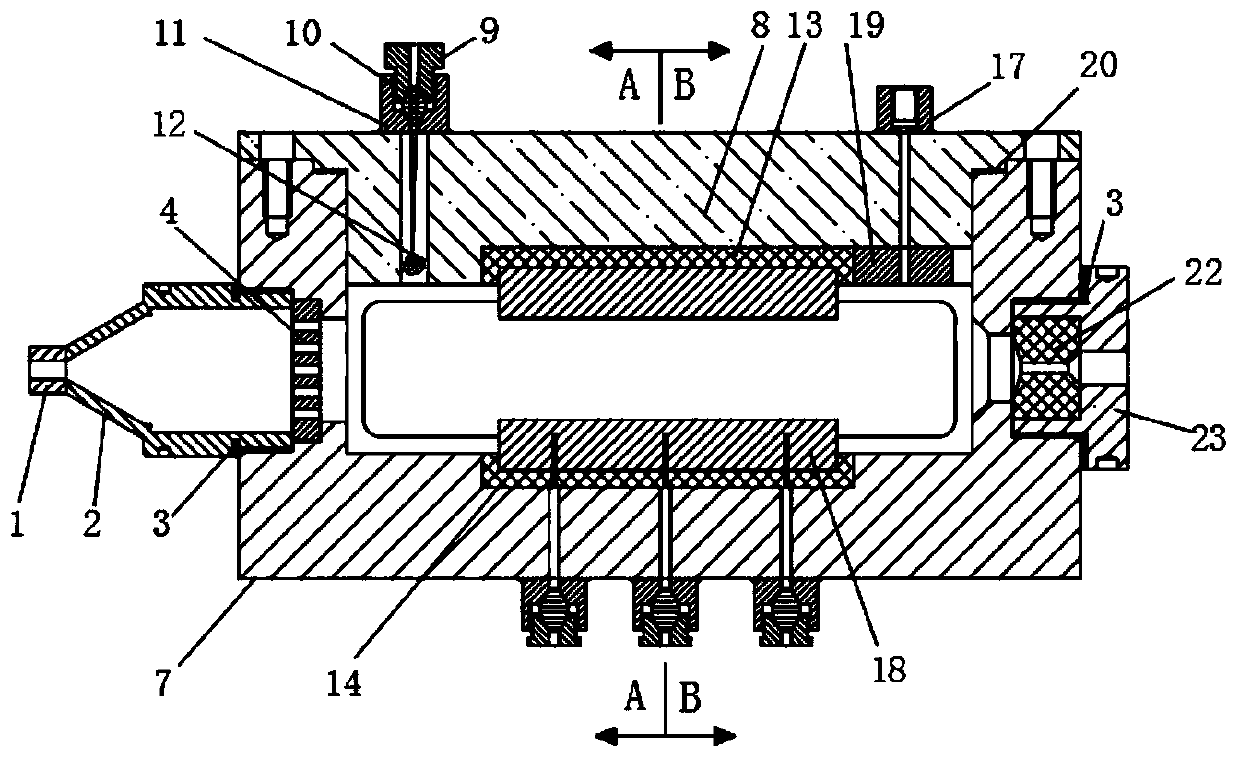

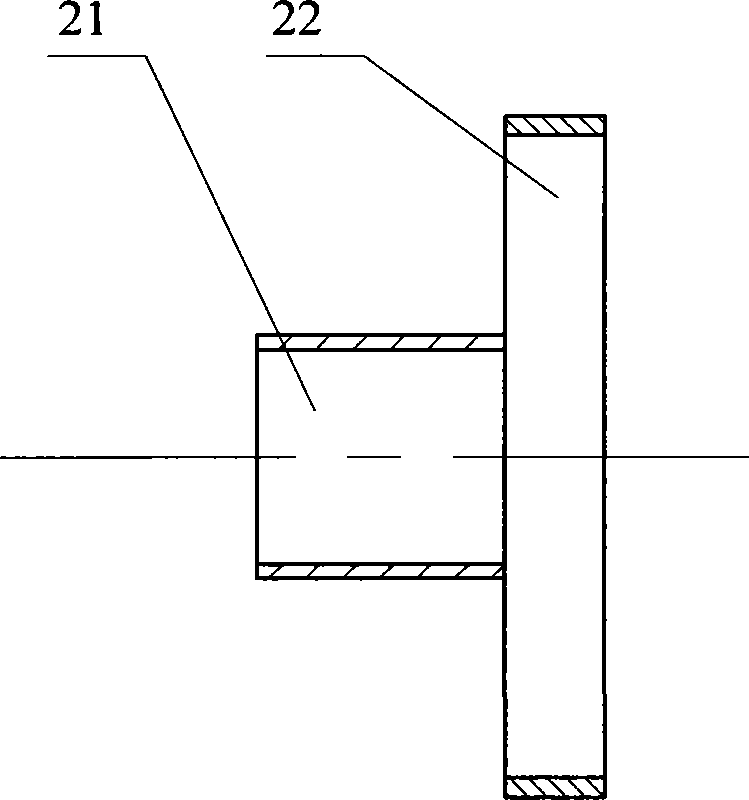

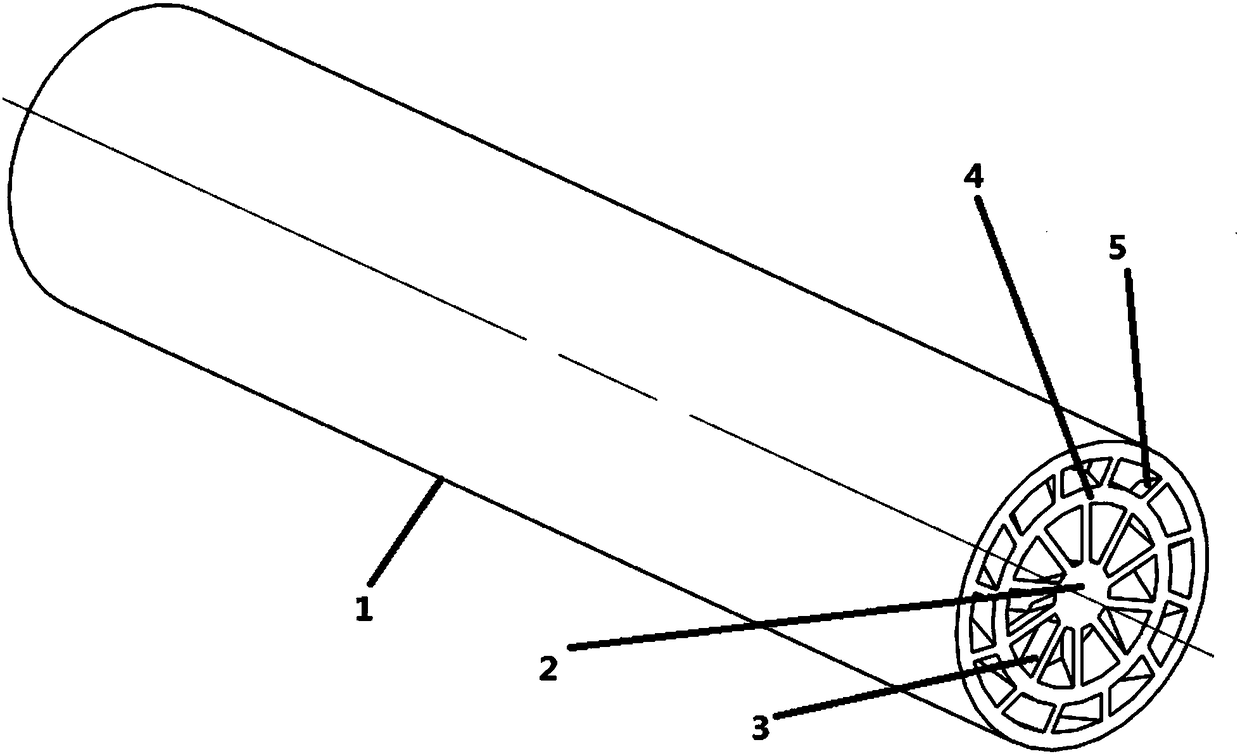

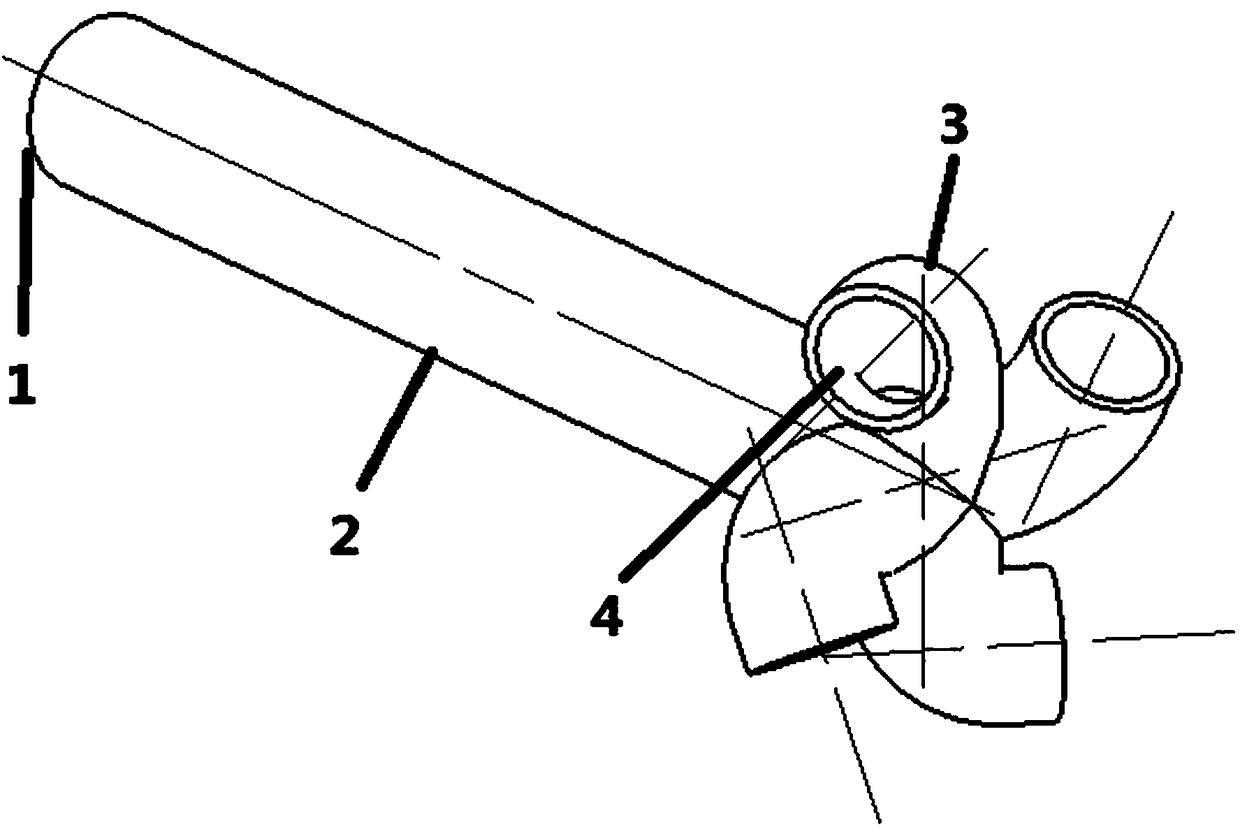

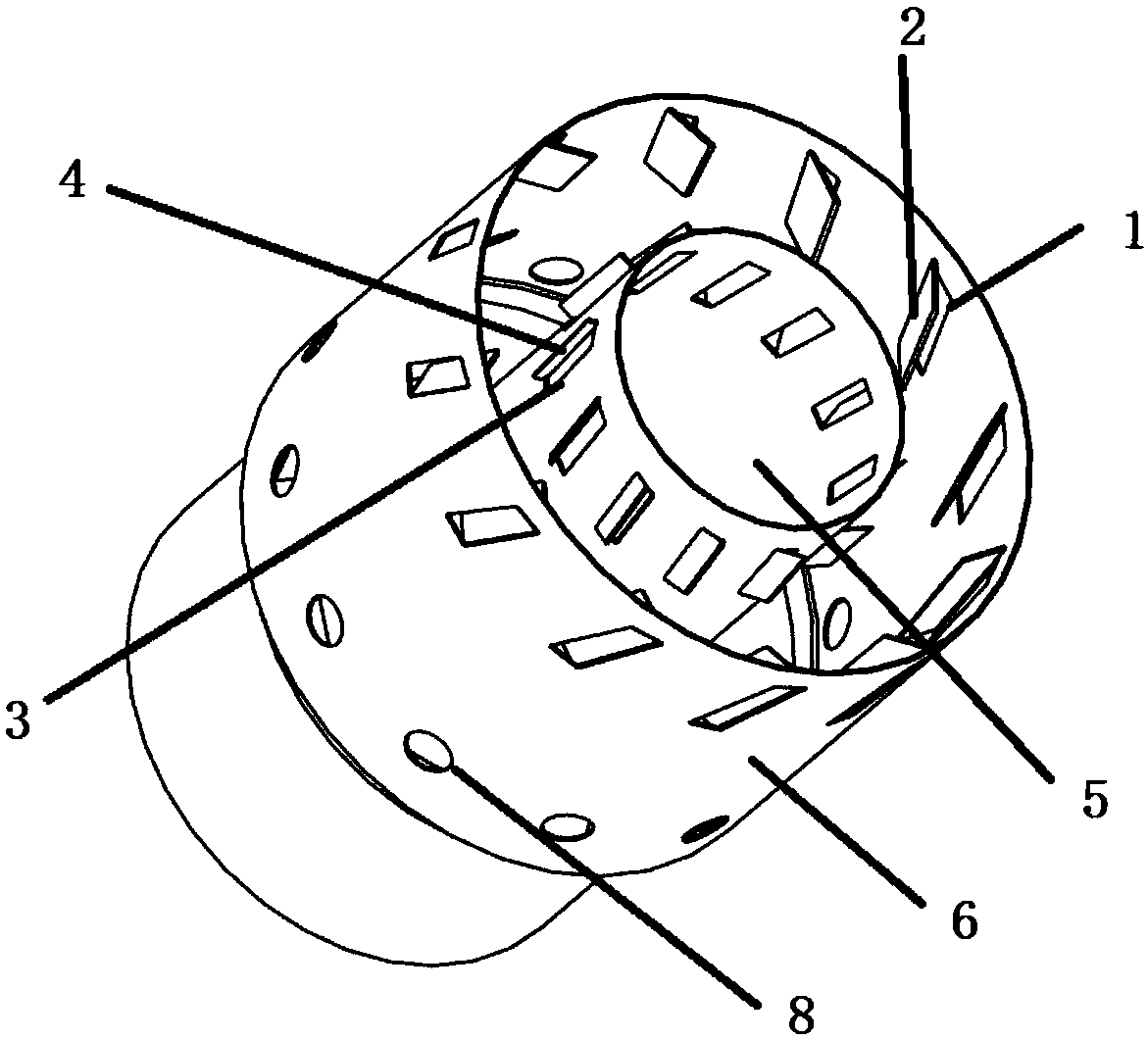

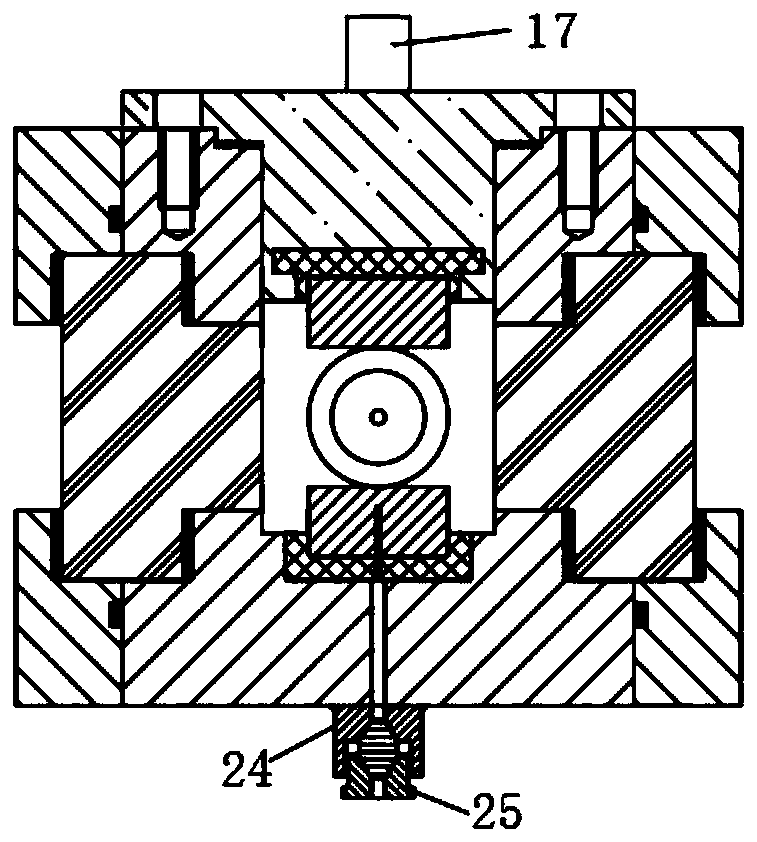

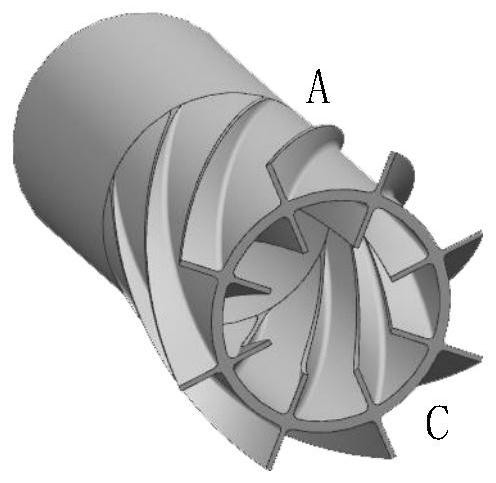

Rotary injection type evaporation tube of combustion chamber of micro engine

InactiveCN108131686AImprove the rotation effectIncrease the degree of blendingContinuous combustion chamberCombustion chamberAirflow

The invention provides a rotary injection type evaporation tube structure of a combustion chamber of a micro engine. The structure can effectively improve the mixing degree of fuel in the micro combustion chamber and air, so that fuel distribution is more uniform, combustion is more sufficient, and the combustion efficiency is improved. By using four rotating branch pipeline structures at the tailend of an evaporation tube, air flows are sprayed out simultaneously from outlets of the four rotating branch pipeline structures and have evaporation tube axial speed and radial speed, the four airflows act on one another to form a rotational flow, and then the fuel-air mixing degree is improved; besides, a certain backflow area can be formed in the combustion chamber so that the air flows canbe stabilized, flame is more stable, and better combustion is promoted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

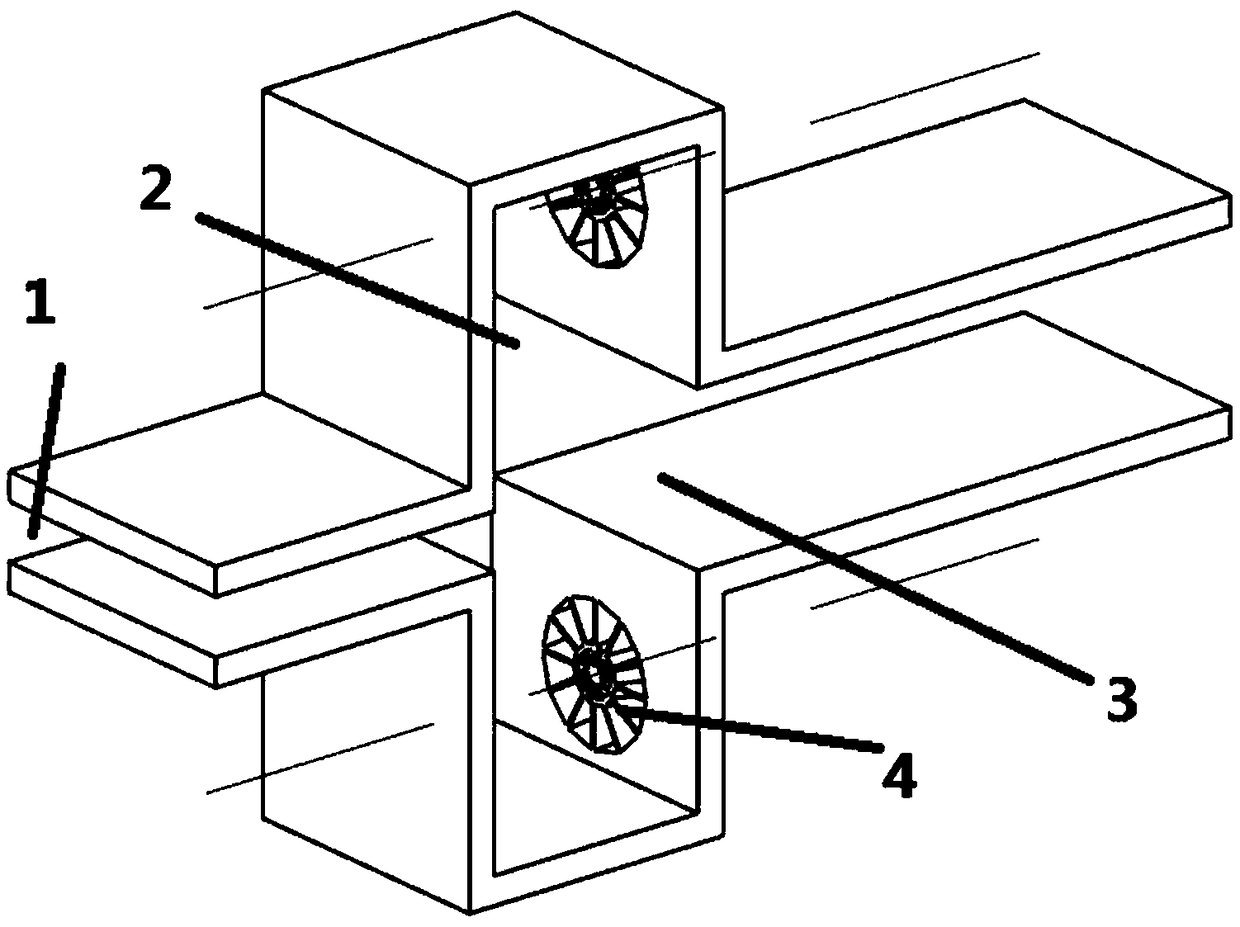

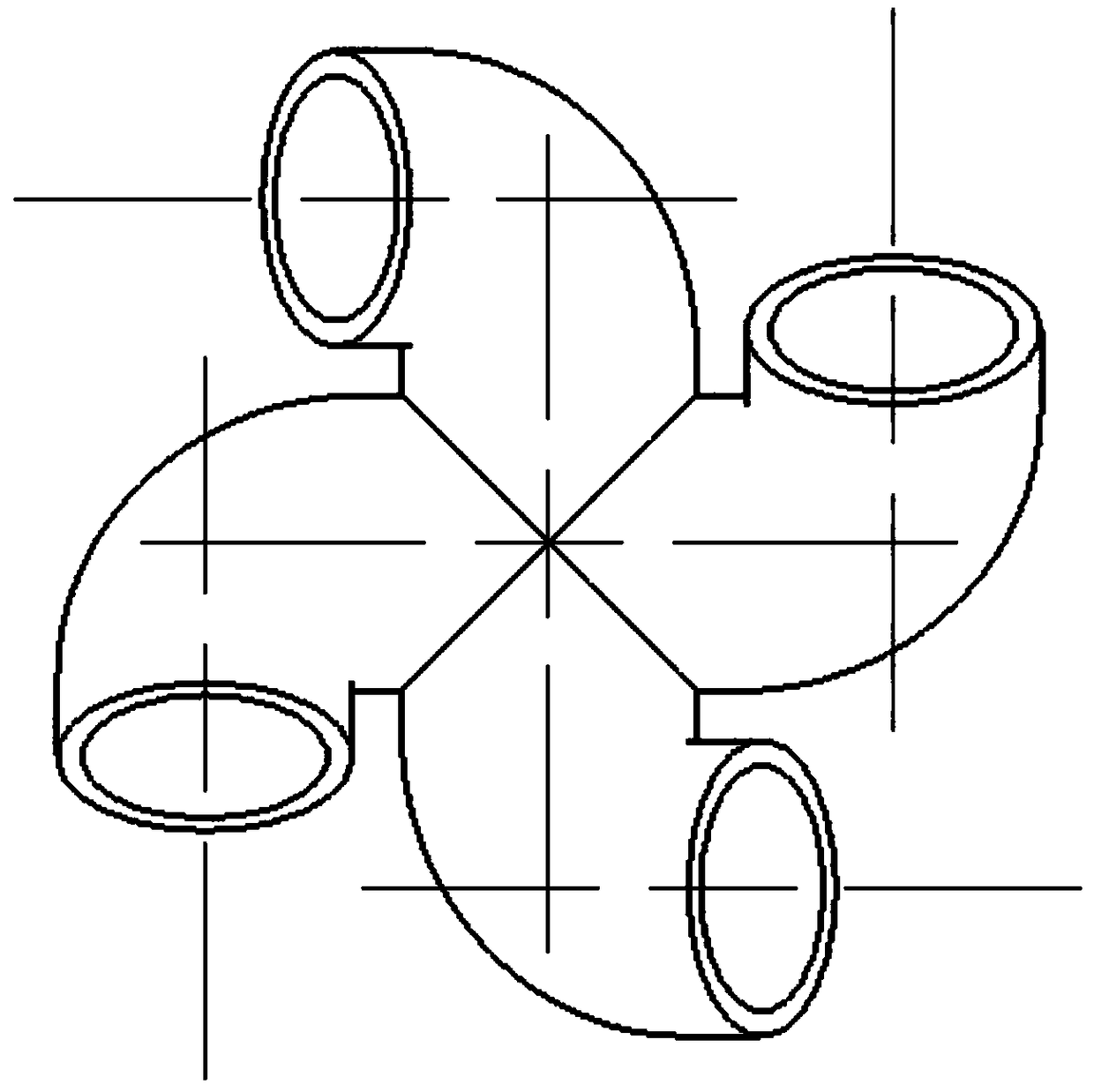

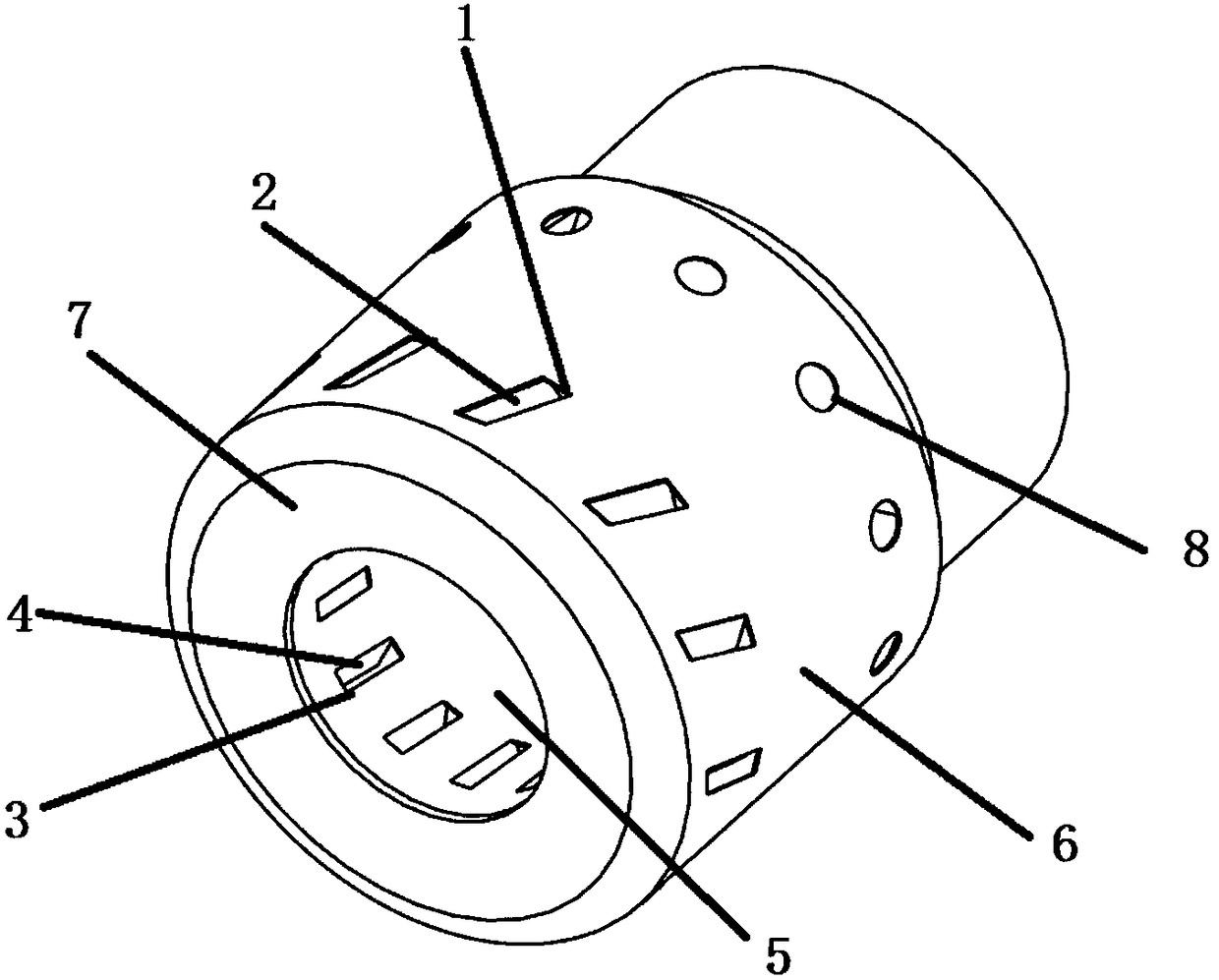

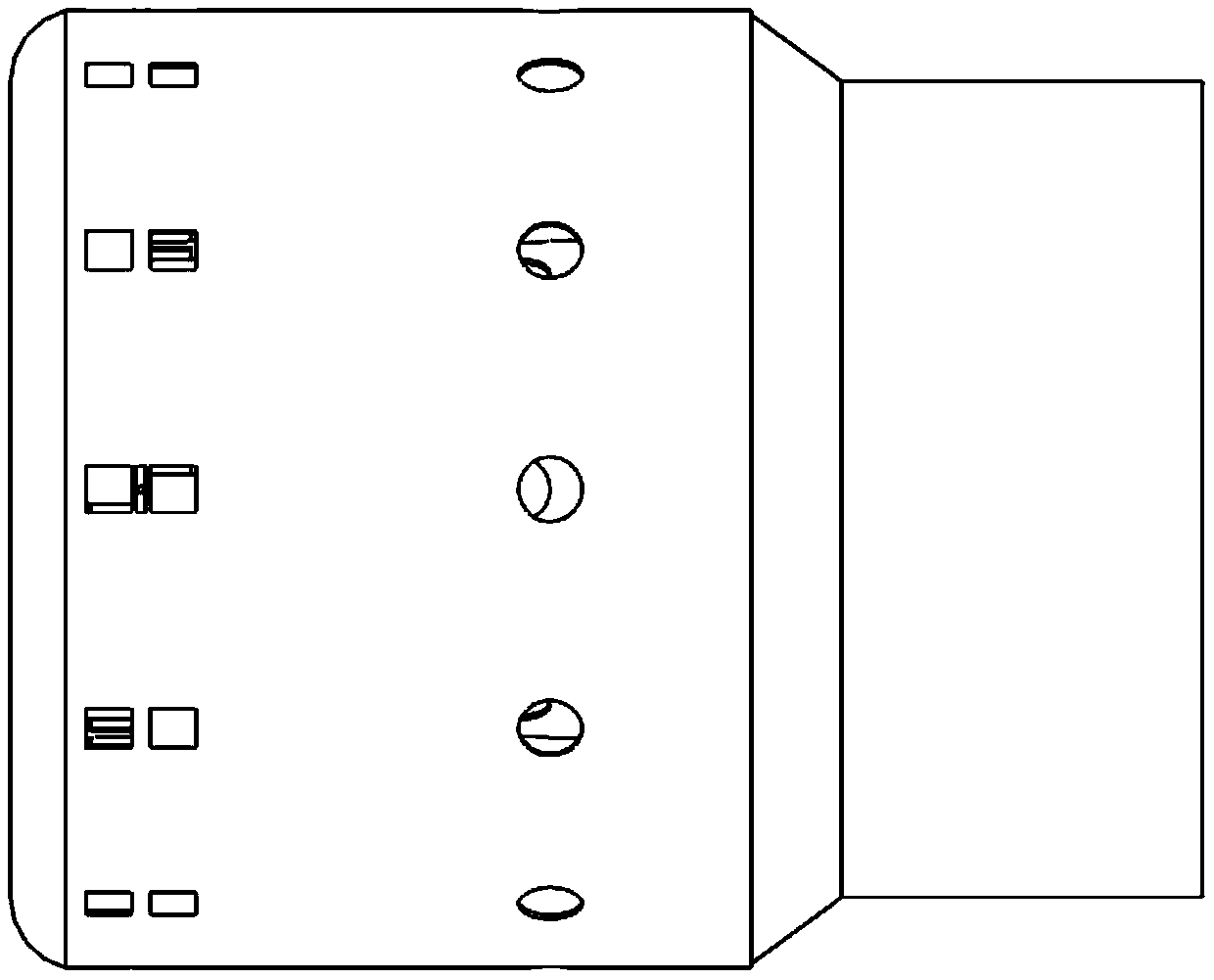

Micro engine flame tube with internal and external hedging guide vane

InactiveCN108131687AExtended stayIncrease the degree of blendingContinuous combustion chamberCombustionFuel oil

The invention provides a structural design scheme of a micro engine flame tube with internal and external hedging guide vanes. Compared with a traditional micro engine flame tube, by arranging the internal guide vanes and the external guide vanes on the portions, close to the front end of the flame tube, of an inner shell and an outer shell of the flame tube, airflow entering the flame tube from an external primary hole becomes rotating inward airflow with three kinds of component velocities in the axial direction, the tangent direction and the radial direction, the velocity of the airflow entering the flame tube from an internal primary hole adopts outwards rotating, and the internal airflow and the external airflow are encountered and subjected to hedging in the flame tube; on one hand,the airflow velocity is lowered to form a low velocity zone, the internal airflow structure of the flame tube is improved, and then stable combustion is achieved; on the other hand, the hedging area has very high scale of turbulence, fuel oil is sprayed into the area to be better mixed with air, and combustion is more thorough.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-temperature-resistant water-based environment-friendly adhesive and preparation method thereof

InactiveCN112980381ALow viscosityHigh bonding strengthPolyureas/polyurethane adhesivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention discloses a high-temperature-resistant water-based environment-friendly adhesive and a preparation method thereof. The high-temperature-resistant water-based environment-friendly adhesive comprises the following raw materials in parts by weight: 60-80 parts of a modified polyurethane prepolymer, 30-40 parts of a modified acrylic resin, 10-20 parts of a coupling agent, 15-20 parts of polyvinyl alcohol, 20-30 parts of a cross-linking agent and 300-400 parts of deionized water. The preparation method comprises the following steps: S1, preparing a modified polyurethane base material; and S2, carrying out a cross-linking reaction by using deionized water as a solvent to obtain the high-temperature water-based environment-friendly adhesive. According to the invention, a modified polyurethane prepolymer containing a large number of benzene rings and silicon-oxygen bonds is prepared, so that the prepared adhesive has relatively large crosslinking density, relatively high bond energy and relatively good thermal stability; and the problem that in the prior art, the bonding strength of a waterborne polyurethane adhesive is reduced under the high-temperature condition is solved.

Owner:广州菩曦环保科技有限公司

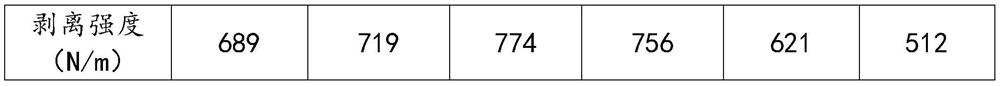

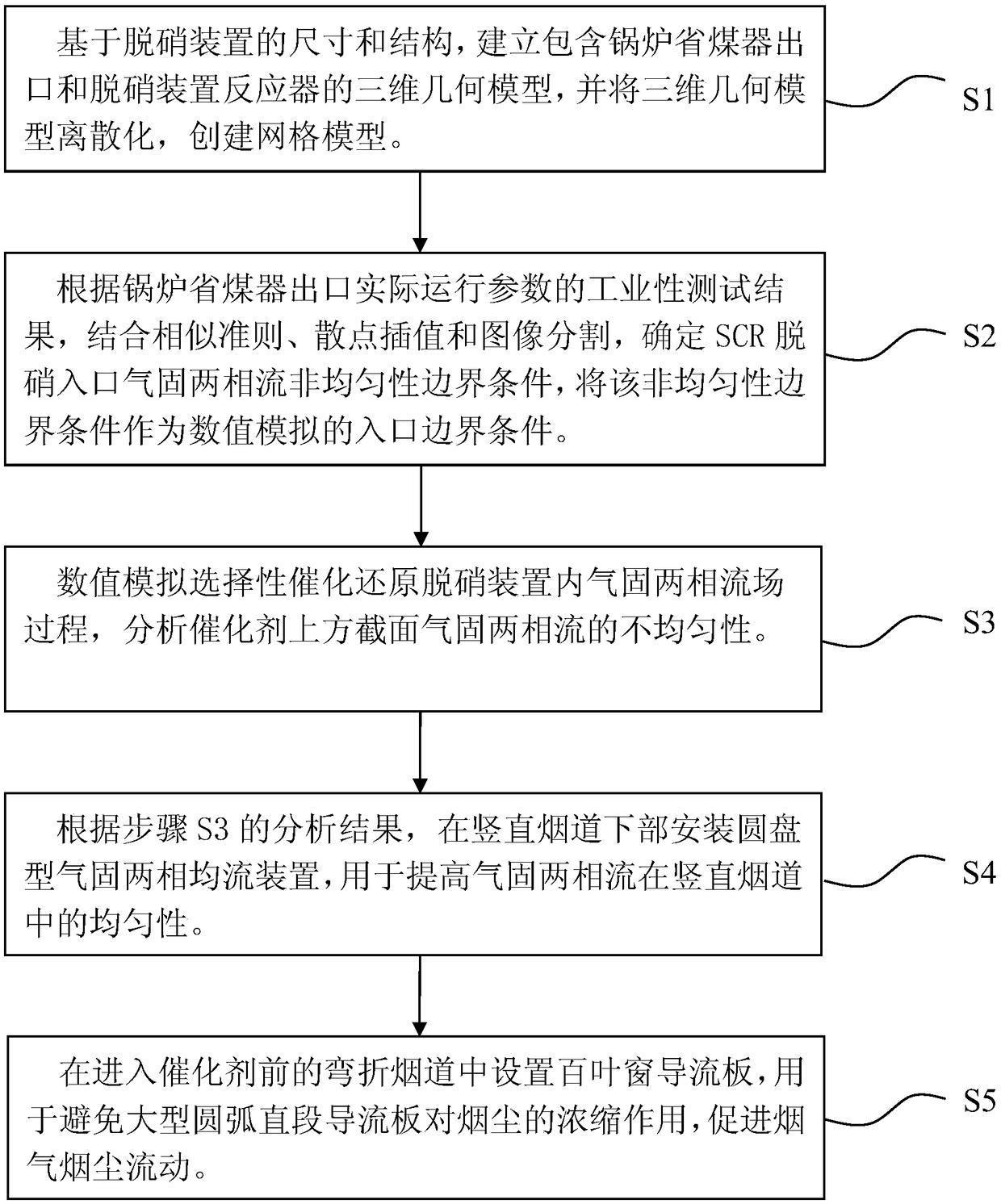

Catalyst anti-wear method for selective catalytic reduction denitration device

InactiveCN109289517AImprove denitrification efficiencyReduce ammonia slip rateGas treatmentDispersed particle separationEscape rateFlue gas

The invention relates to a catalyst anti-wear method for a selective catalytic reduction denitration device. The invention comprises the following steps: based on the size and the structure of the denitration device, establishing a three-dimensional geometric model including a boiler coal economizer outlet and a denitration device reactor, and discretizing the three-dimensional geometric model tocreate a mesh model; determining the non-uniformity boundary condition of the gas-solid two-phase flow at a SCR denitration inlet, and using the non-uniformity boundary condition as an inlet boundarycondition for numerical simulation; performing numerical simulation on a gas-solid two-phase flow field process in the selective catalytic reduction denitration device, and performing analysis on theheterogeneity of the gas-solid two-phase flow above the catalyst; a disc-type gas-solid two-phase flow equalizing device is installed in the lower part of a vertical flue; and a louver baffle is arranged in a bent flue before entering the catalyst. The method solves the problem that the simulation precision of the flue gas field of the selective catalytic reduction denitration device is low, the flow field performance diagnosis and the optimization misalignment, the denitration efficiency of the denitration device is improved, and the ammonia escape rate of the denitration device is reduced.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST +1

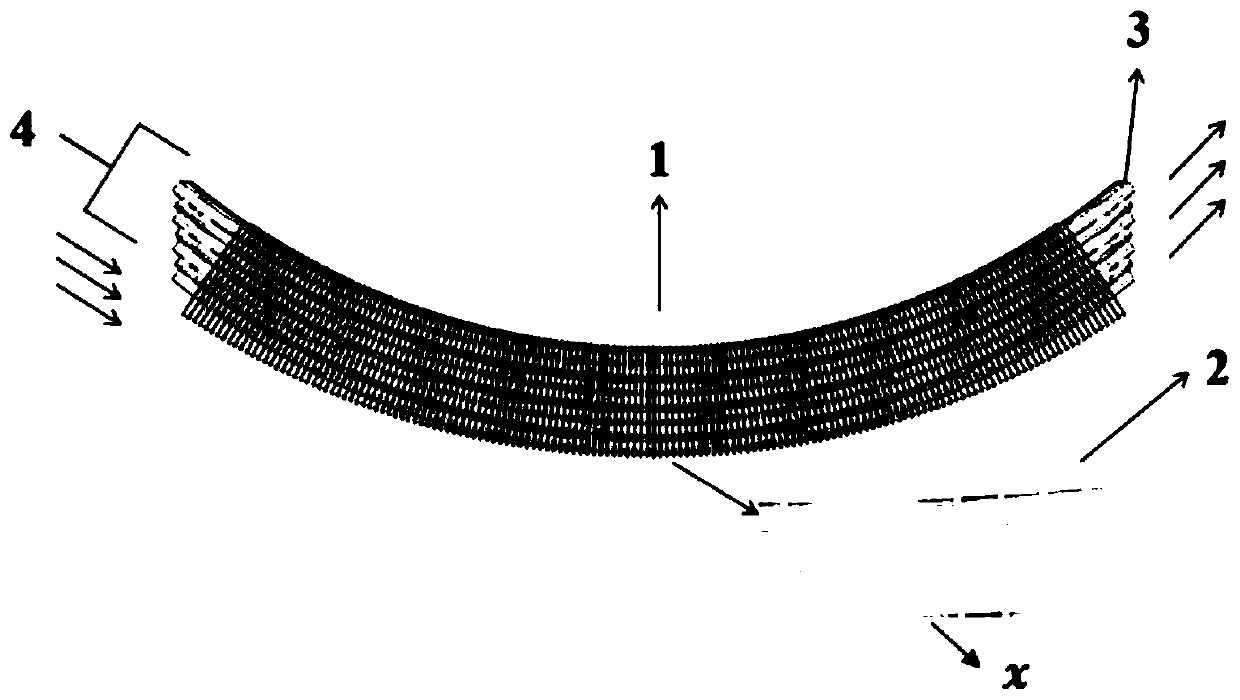

Curve-rib-row-type tiny staggered alveolus heat exchanger core based on bionics, and heat exchanger

ActiveCN108759524AIncrease the degree of blendingImprove performanceLaminated elementsStationary plate conduit assembliesEngineeringExchange coefficient

The invention discloses a curve-rib-row-type tiny staggered alveolus heat exchanger core based on bionics. The curve-rib-row-type tiny staggered alveolus heat exchanger core comprises more than two layers of medium flowing cavities partitioned by heat exchange plates. More than two layers of curve rib rows are arranged in each layer of medium flowing cavity, each curve rib row is composed of a plurality of mutually-parallel curve ribs, and every two layers of curve rib rows are arranged crosswise. Bionic elements are fused into the design of a heat exchanger, and the tiny staggered alveolus heat exchanger is designed; through the structure, the performance of the heat exchange is improved in the two aspects of the heat exchange coefficient and the heat exchange area; and the curve-rib-row-type tiny staggered alveolus heat exchanger core is light, simple and convenient in structure and suitable for an aerospace heat exchanger.

Owner:陕西益信伟创智能科技有限公司

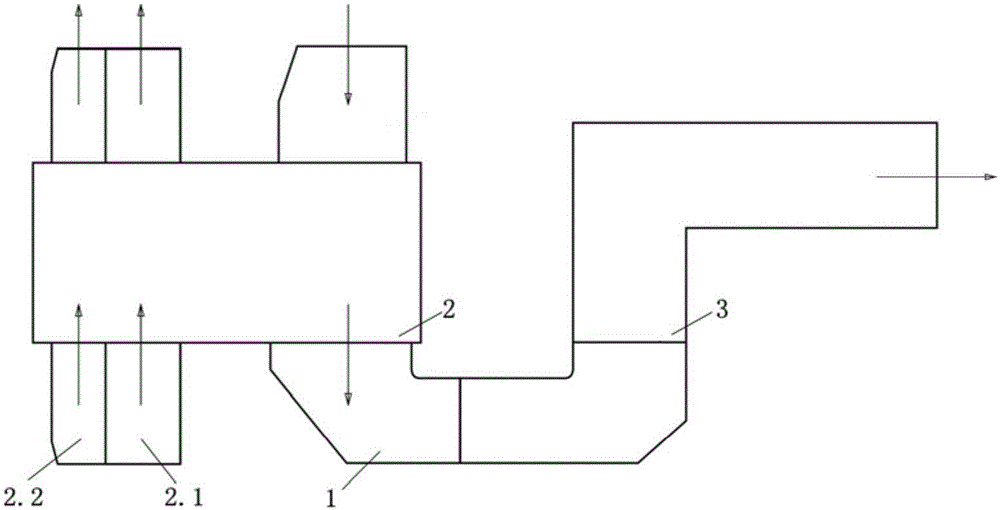

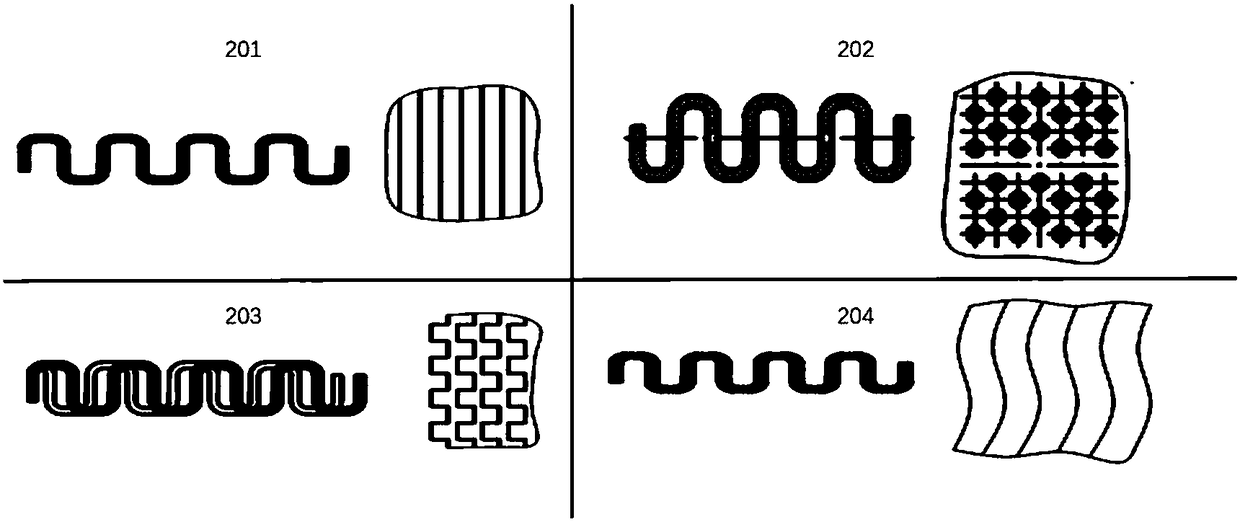

Fume temperature uniform distribution device of rotary air preheater outlet flue

ActiveCN106439898AImprove the problem of uneven smoke temperatureImprove governance effectCombustion processIndirect carbon-dioxide mitigationSocial benefitsAir preheater

The invention discloses a fume temperature uniform distribution device of a rotary air preheater outlet flue. The fume temperature uniform distribution device comprises a U-shaped flue, a flue opening of one end of the U-shaped flue is connected with a rotary air preheater outlet, and two independent deduster connecting pipes are arranged on a flue opening of the other end of the flue side by side. The pipeline of the U-shaped flue is a rectangular channel, the U-shaped flue comprises an outer wall surface and an inner wall surface, and the outer wall surface and the inner wall surface are mutually parallel. A plurality of airfoil blades are arranged on the inner surfaces of the outer wall surface and the inner wall surface in the direction of flue gas emission, and the deflecting directions of the airfoil blades on the outer wall surface and the airfoil blades of the inner wall surface are opposite. According to the fume temperature uniform distribution device of the rotary air preheater exit flue, the problem that fume temperature in an air preheater outlet flue of a power plant is nonuniform is efficiently relieved, the flue gas treatment performance of downstream flue gas treatment devices of the power plant is improved, and great social benefits and economic benefits are predicted to obtain.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

Fishbone-type tiny staggered alveoli heat exchanger core based on bionics and heat exchanger

PendingCN108548437AImprove performanceAvoid cloggingHeat exchanger casingsStationary tubular conduit assembliesEngineeringMicro heat exchanger

The invention discloses a fishbone-type tiny staggered alveoli heat exchanger core based on bionics. The fishbone-type tiny staggered alveoli heat exchanger core comprises a shell. The core in the shell is divided into two layers through a heat exchanging plate. Two layers of fishbone-type rib assemblies are arranged in each layer of cavity, and each layer of fishbone-type rib assemblies is constituted by a plurality of columns of mutually-parallel fishbone-type ribs. Each column of fishbone-type ribs is constituted by a plurality of pairs of short ribs which are arranged in a splay mode, andthe multiple pairs of short ribs of the same column are the same in shape, angle and separation distance. The two layers of fishbone-type ribs do not make contact and are fixed to the inner walls of medium flowing cavities correspondingly. Bionic elements are incorporated into design of a heat exchanger, the tiny staggered alveoli heat exchanger is designed, the properties of the heat exchanger are improved from the two aspects of the heat transfer coefficient and the heat transfer area through the fishbone-type tiny staggered alveoli heat exchanger core, and the fishbone-type tiny staggered alveoli heat exchanger core is light, simple and convenient, and is suitable for being used for the heat exchanger for aerospace.

Owner:陕西益信伟创智能科技有限公司

Ejector module used for intake-exhaust simulation experiment of low-speed wind tunnel aircraft

ActiveCN110411704ACompact structureIncrease the degree of blendingAerodynamic testingLow speedHigh energy

The invention discloses an ejector module used for an intake-exhaust simulation experiment of a low-speed wind tunnel aircraft. The ejector module comprises an outer frame, a middle frame and an innerframe in sequence from outside to inside, wherein the outer frame, the middle frame and the inner frame are mutually connected to form a sealed cavity; the outer frame is provided with a gas inlet communicated with the sealed cavity, the inner frame is provided with a plurality of nozzle rakes, one end of each nozzle rake is communicated with the sealed cavity, and the other ends of the nozzle rakes are provided with nozzles. An injector is designed into a module of a model structure, and the injector is integrated with the model; the injector module uses a discrete multi-nozzle distributiontype injection mode, and the structure is compact. The discrete multi-nozzle distribution type injection mode greatly increases the mixing degree between high-energy compressed gas and injected low-energy gas, and the injection efficiency is obviously improved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

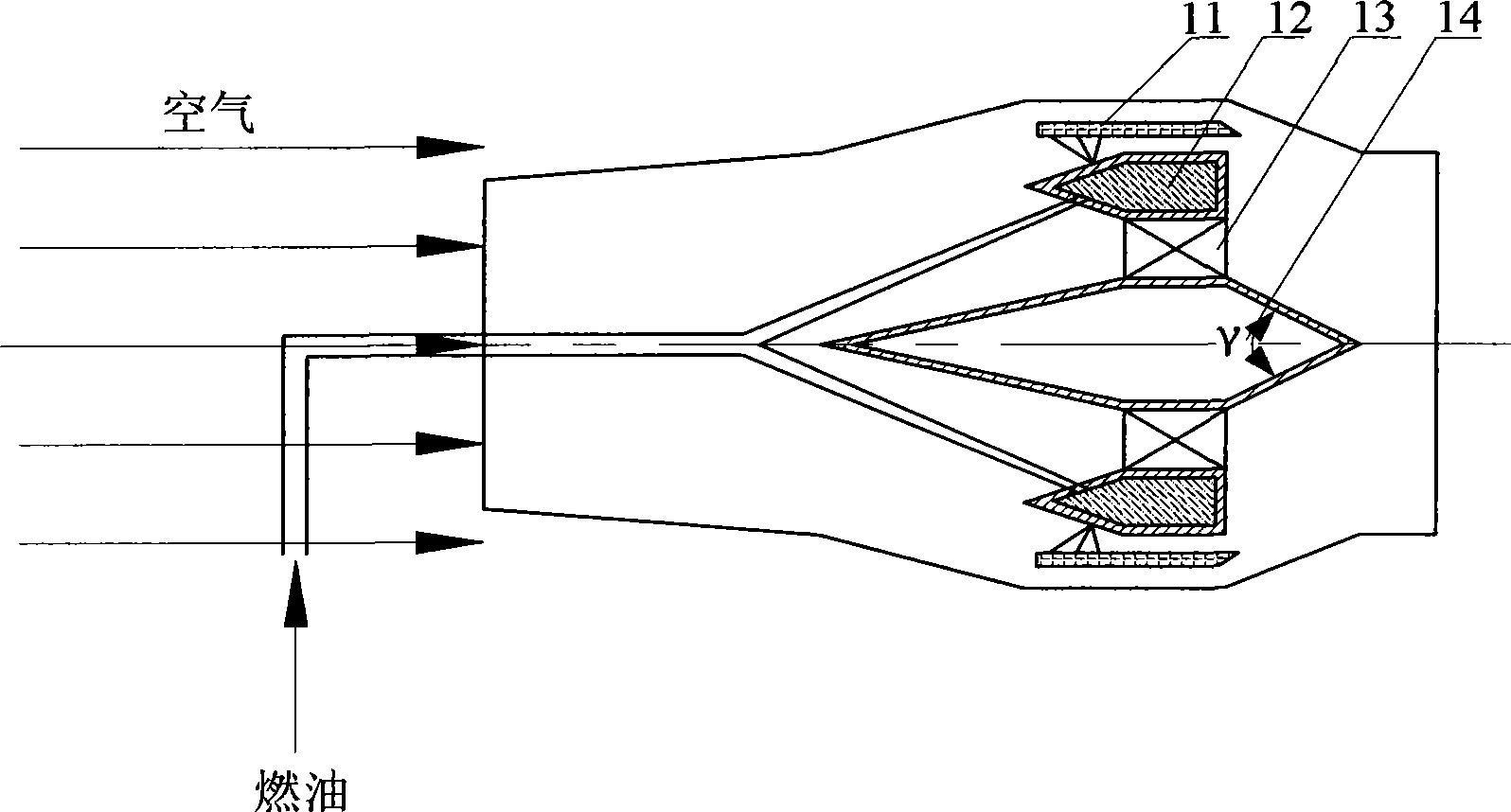

A kind of pre-combustion type plasma igniter and ignition method

ActiveCN107842427BRegion size increasesChemically activeTurbine/propulsion fuel supply systemsGas turbine plantsFuel oilHigh pressure

The invention discloses a pre-combustion type plasma igniter and an ignition method. The pre-combustion type plasma igniter comprises a shell, an oil conveying pipe, a hydrocyclone, a spark plug and agas channel base. A jetting opening is formed in the upper end of the shell. The hydrocyclone is arranged in the shell and connected with the shell. The hydrocyclone divides an inner cavity of the shell into a pre-combustion chamber and a rectification chamber. The spark plug is arranged on the inner cavity of the shell, penetrates the hydrocyclone and is connected with the hydrocyclone, and thehigh-voltage electrode of the spark plug is located in the pre-combustion chamber. An oil conveying cavity is formed in the shell wall of the portion, corresponding to the pre-combustion chamber, of the shell. The oil conveying pipe communicates with the oil conveying cavity. An atomizing hole is formed in the position, corresponding to the pre-combustion chamber, of the inner wall of the shell and communicates with the oil conveying cavity. The atomizing hole is used for atomizing fuel and then spraying the fuel to the pre-combustion chamber. The gas channel base is arranged at the lower endof the shell, connected with the shell, and used for providing combustion-supporting gas for the rectification chamber. A high-pressure lead of the spark plug penetrates the gas channel base and extends out of the shell. The igniter can ignite mainstream fuel oil in the pre-combustion chamber of an aircraft engine, and the reignition height of the aircraft engine is increased.

Owner:XI AN JIAOTONG UNIV

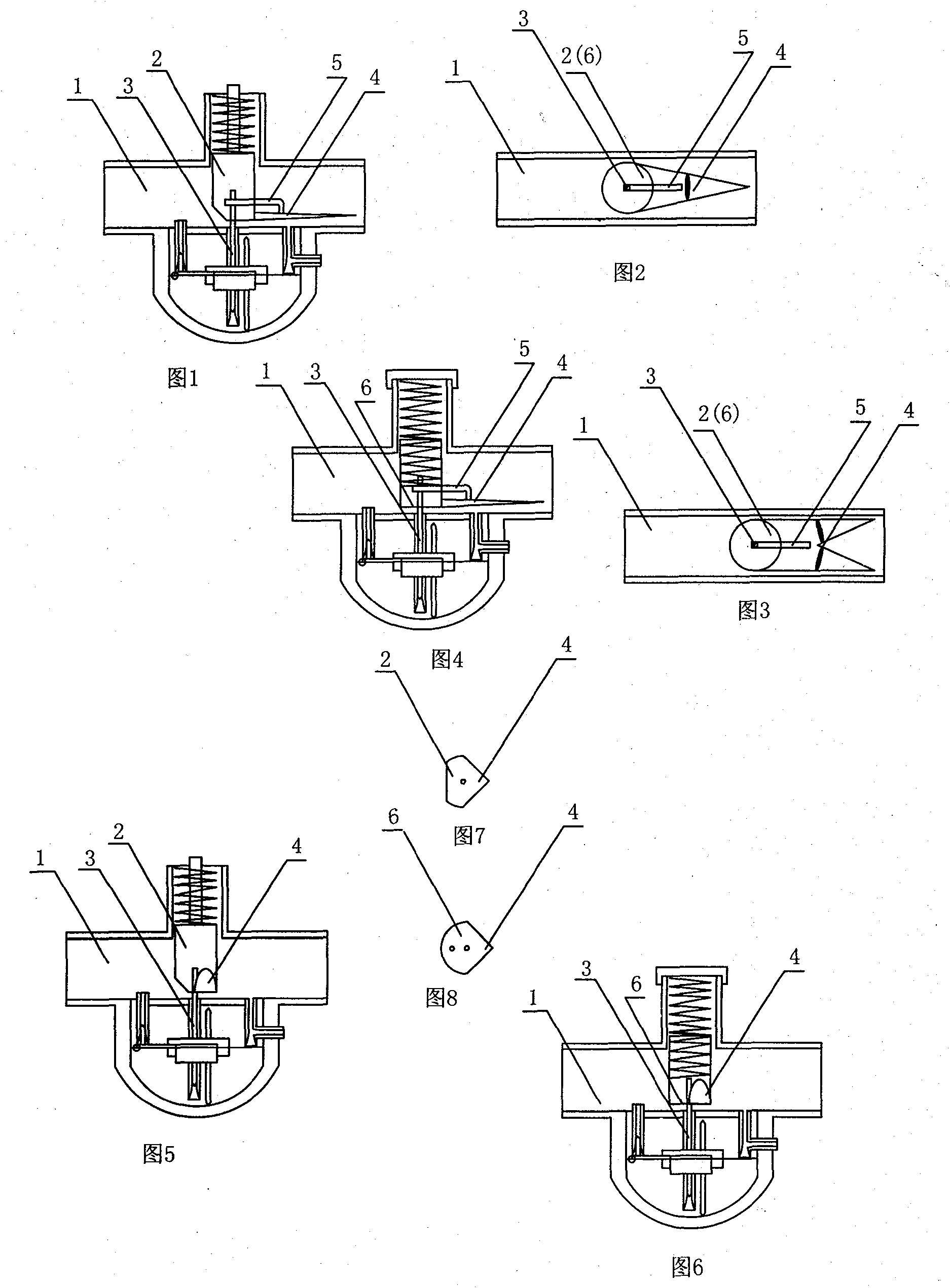

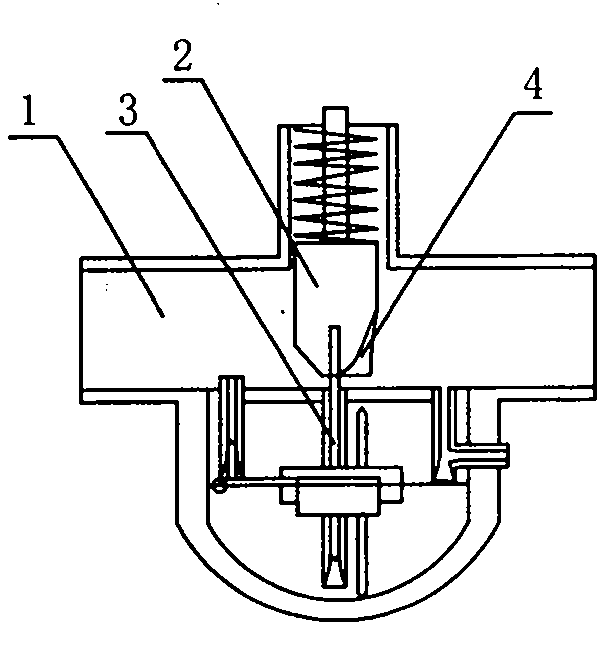

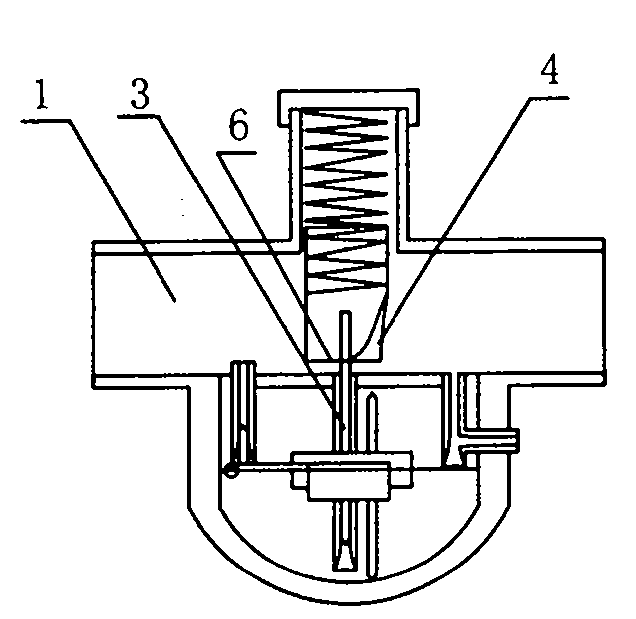

Trapped vortex tail wing carburetor of throttle

InactiveCN101994600AReduce intensityIncrease the degree of blendingMachines/enginesCombustionFuel oil

The invention provides a trapped vortex tail wing carburetor of a throttle. In the invention, a trapped vortex tail wing (4) is additionally arranged below or behind a plunger throttle (2) or a diaphragm throttle (6) in a carburetor body assembly (1), through vortex shedding and the swept effect of a trapped vortex of the trapped vortex tail wing (4) of the throttle, after an air flow flows around to a low pressure region behind the throttle, the loss is lowered, and secondary rotational speed of a mixed gas is formed, thereby increasing the power and the combustion efficiency of an engine, and reaching the purpose of saving fuel oil.

Owner:张龙

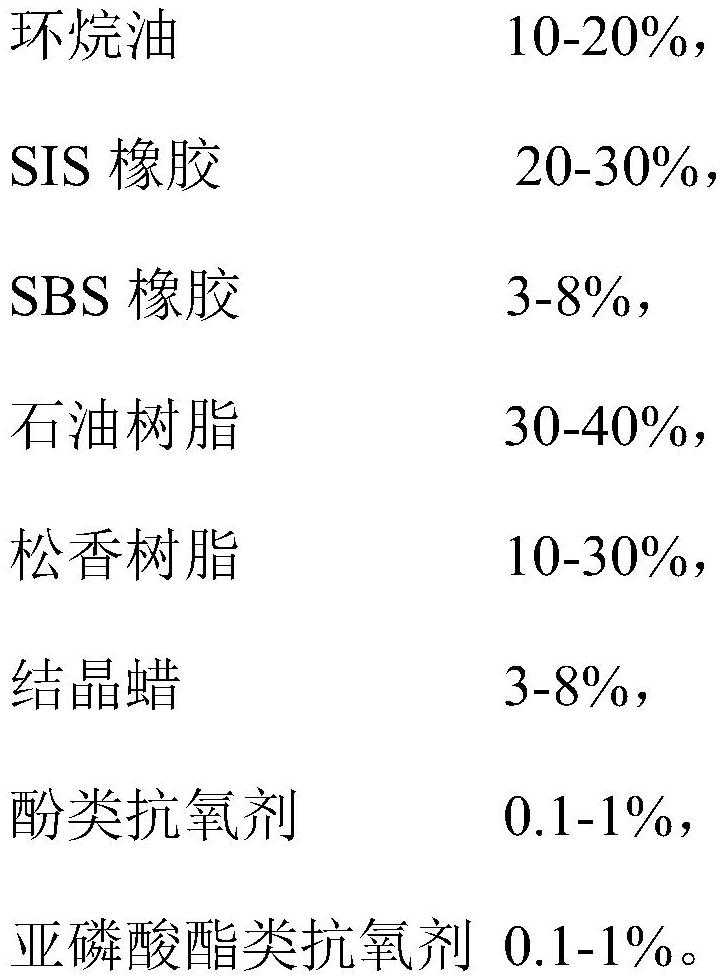

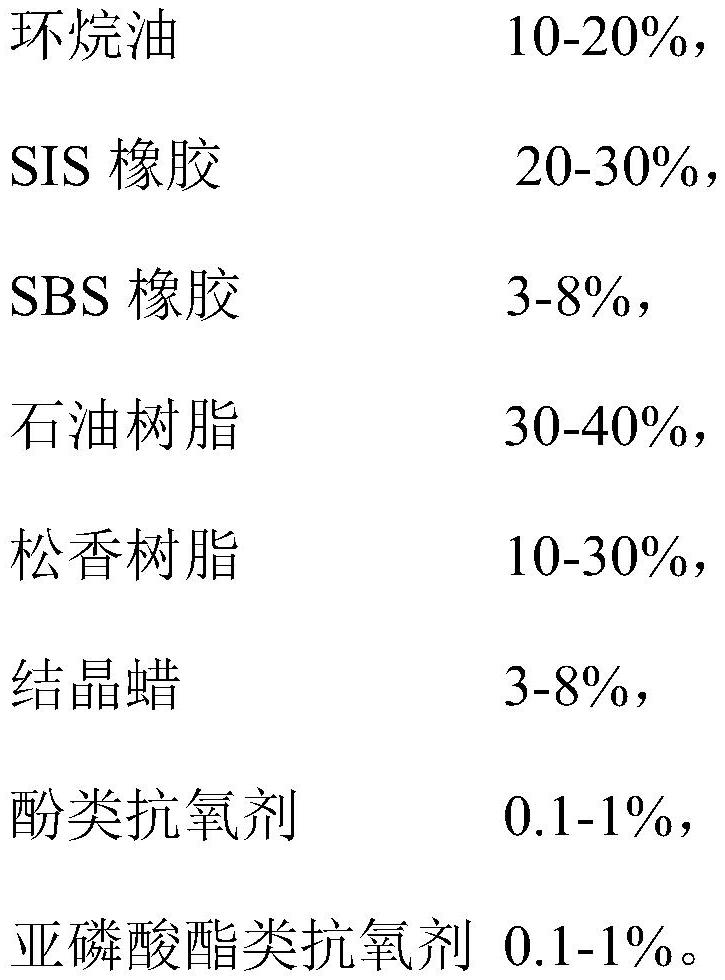

Hot melt adhesive for bonding high-temperature-resistant food bag and preparation method of hot melt adhesive

PendingCN114525094AResist high temperatureHigh temperature food bag bonding resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinPhenolic antioxidant

The invention discloses a hot melt adhesive for bonding a high-temperature-resistant food bag and a preparation method of the hot melt adhesive, and relates to the technical field of hot melt adhesives. Comprising the following components in percentage by weight: 10-20% of naphthenic oil, 20-30% of SIS rubber, 3-8% of SBS rubber, 30-40% of petroleum resin, 10-30% of rosin resin, 3-8% of crystalline wax, 0.1-1% of a phenolic antioxidant and 0.1-1% of a phosphite antioxidant. The SIS rubber and the SBS rubber are adopted as base materials, the content of styrene is increased so as to ensure the high temperature resistance, and meanwhile, the crystalline wax is added, so that the hot melt adhesive can be modified, the high temperature resistance is improved, and the adhesion of the hot melt adhesive can better resist the high temperature of food. Petroleum resin and rosin resin are added as tackifiers, the adhesive force and stability of an adhesive layer are improved, and through reasonable matching of all the components, the hot melt adhesive keeps excellent adhesive force performance at high temperature, has low-temperature wood breaking performance and is safe and non-toxic.

Owner:FOSHAN XINTAO NEW MATERIAL TECH

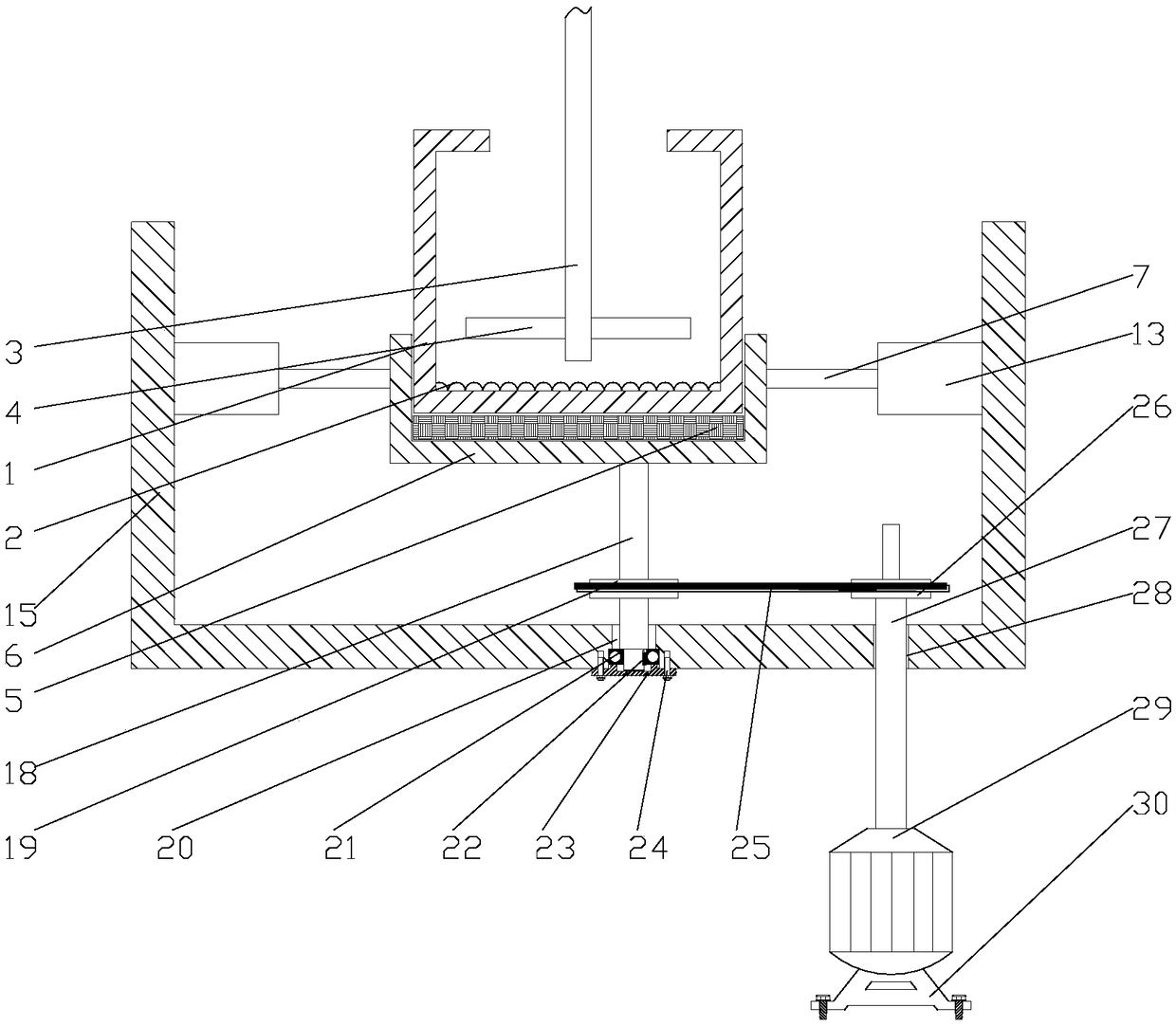

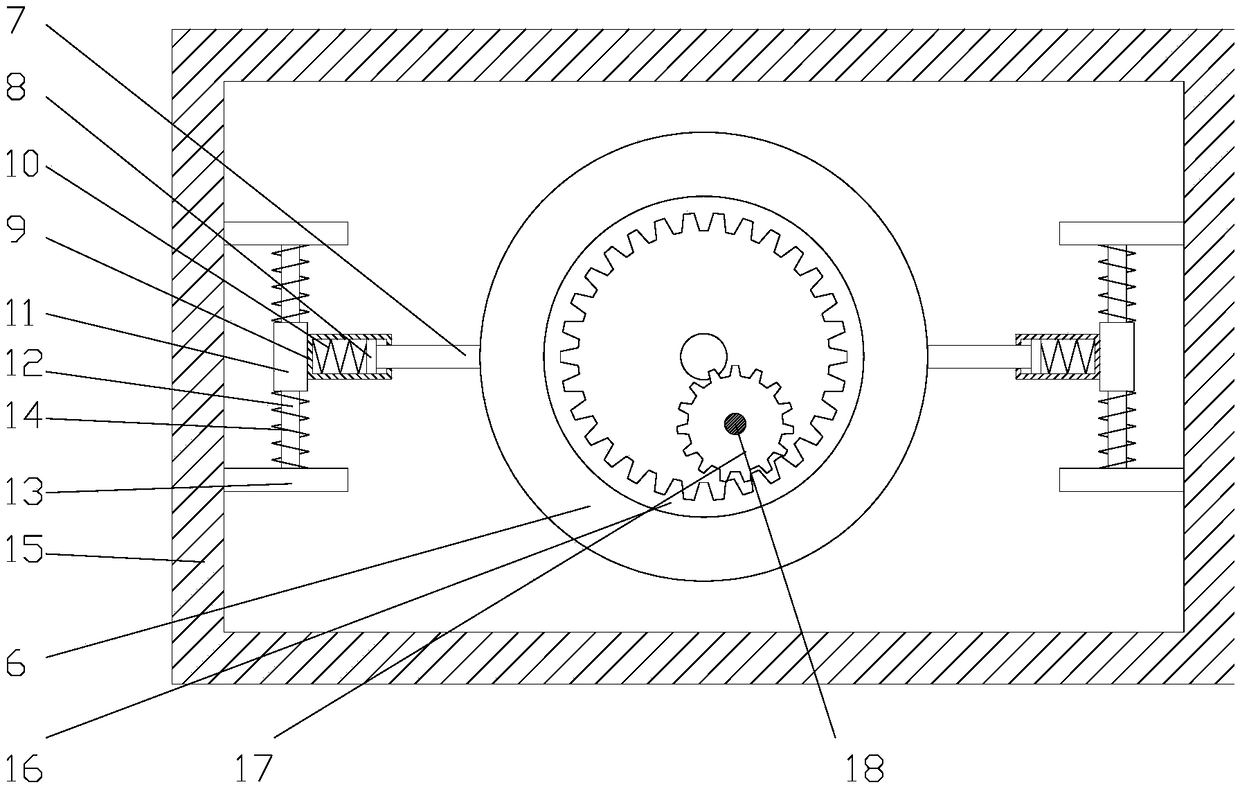

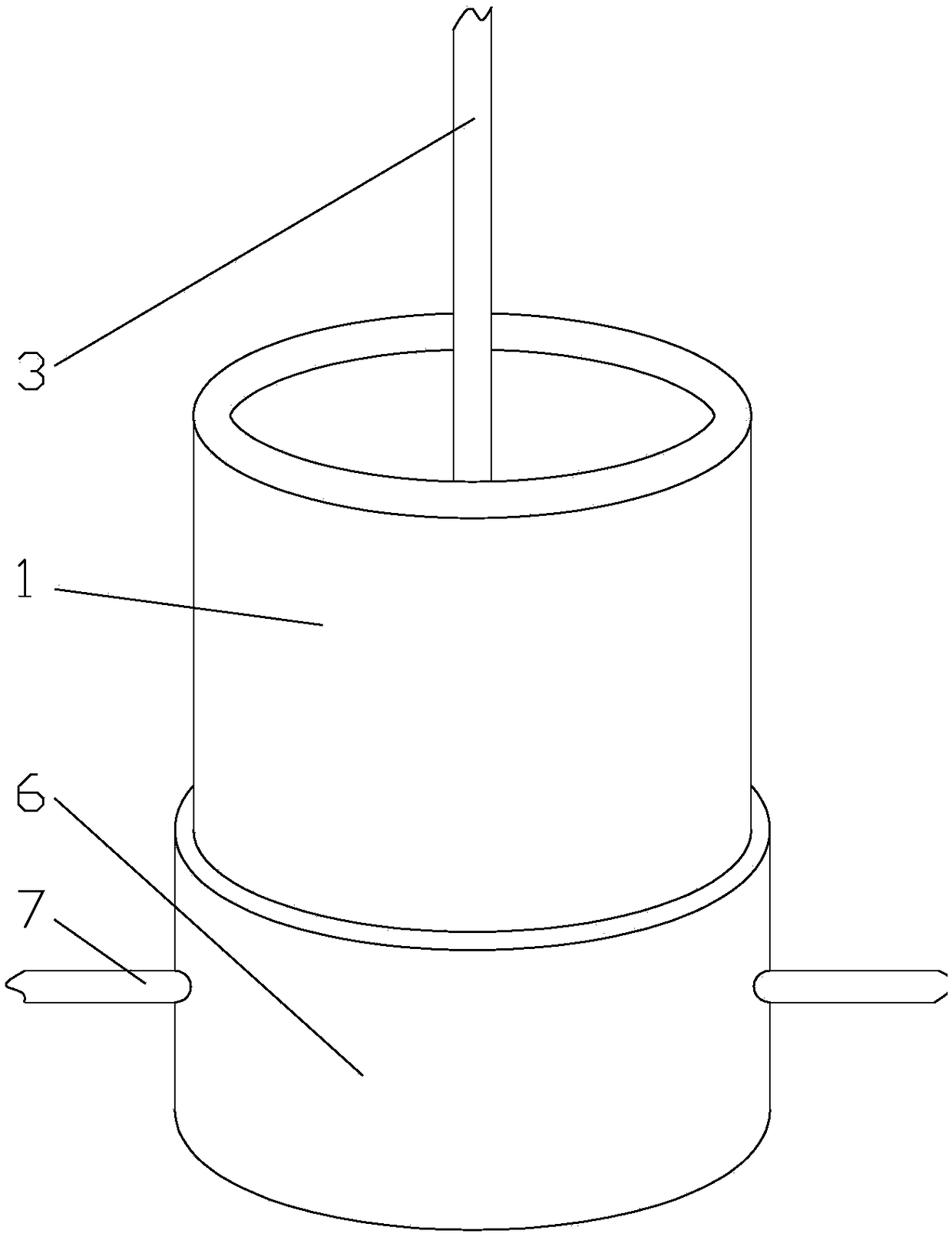

Casting electric furnace good in stirring effect

InactiveCN108844367AAvoid spillingIncrease the degree of blendingTransportation and packagingMixer accessoriesElectric arc furnaceEngineering

The invention discloses a casting electric furnace good in stirring effect. An electric furnace body, an electric heating wire, a stirring shaft and fan blades are included; a heat insulating plate isplaced at the bottom of the electric furnace body, and is placed at the groove bottom position of a rotating table; the rotating table wraps the electric furnace body; a tooth ring is welded and fixed to the bottom of the rotating table; a gear is engaged to the tooth ring; and a gear shaft is installed at the axis position of the gear through a key. The casting electric furnace good in stirringeffect is simple in structure, low in production cost and suitable for transformation on an existing electric furnace, the electric furnace body is made to rotate eccentrically, further sufficient blending of molten metal in the electric furnace body is effectively promoted in the rotating process, and the blending effect is greatly improved; the heat insulating plate avoids damaging and deformingof the tooth ring, the gear and other parts caused by high temperature; a spring A and a spring B have a good buffering shock absorbing effect, splashing leakage of the molten metal is avoided, the potential safety hazards are greatly lowered, and the casting electric furnace good in stirring effect is worthy of using and popularizing.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

Refinement Diagnostics of Solid Fuel Diffusion Combustion Burners

InactiveCN110259603BIncrease the degree of blendingIncrease profitRocket engine plantsCombustion chamberGlass cover

The invention provides a solid fuel diffusive combustion fine diagnosis combustor which comprises a combustion chamber, a combustion chamber top cover and an ignition seat device. A first stepped through hole is formed in the gas inlet wall face of the combustion chamber and used for installing a gas inlet cavity in a coaxial mode. A second stepped through hole is formed in the gas outlet wall face of the combustion chamber and used for installing an effuser. Windows are formed in the wall faces on the two sides of the combustion chamber. Quartz glass is fixed to the windows of the combustion chamber through glass cover plates and used for observing the combustion process of a rocket engine in real time. Both the bottom face of the combustion chamber and the combustion chamber top cover are provided with filling grooves. Second heat insulating layers are arranged in the two filling grooves. Solid fuel is fixed to the second heat insulating layers. The filling grooves are additionally formed in the combustion chamber, the mixing degree between an oxidizing agent and the fuel is improved, and the oxygen utilization ratio in the combustion process is increased; and an effuser throttling device is additionally arranged, effusers with different throat diameters are changed according to different requirements, and the effect of combustion chamber pressure on solid fuel diffusive combustion can be effectively analyzed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

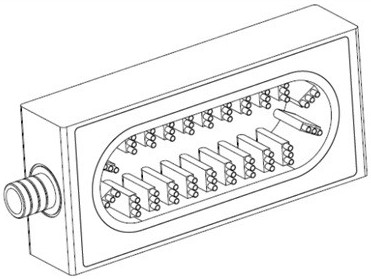

Homodromous reverse spiral mixing device

InactiveCN112808052AReduce torqueIncrease the degree of blendingFlow mixersTransportation and packagingEngineeringMixing effect

The invention discloses a homodromous reverse spiral mixing device.A plurality of spiral flow deflectors are arranged on the inner side of an outlet section of an internal fluid pipeline; and a plurality of reverse spiral outer flow deflectors of which the spiral direction are opposite to the spiral direction of the spiral flow deflectors are arranged on the outer side of the outlet section; when two kinds of fluid in the internal pipeline and an outer pipeline flow in the same direction, under the action of the spiral flow deflectors in the opposite directions, the inner fluid and the outer fluid have a large tangential speed difference at an approximately-annular intersection, then a plurality of slightly-inclined flow direction vortexes are formed, the flow direction vortexes entrain the inner fluid and the outer fluid nearby the flow direction vortexes together to intensively mix the inner fluid and the outer fluid, and the torque borne by the pipelines can be greatly reduced; the inner and outer fluids can also form spanwise vortexes by utilizing the speed difference in the axial direction, so that the mixing degree of the inner and outer fluids is increased; and the two kinds of vortexes interact with each other, and the two fluids are fully mixed through high-speed impact, violent friction, strong extrusion, tearing and crushing between the fluids, so that the mixing effect required by production or test can be met.

Owner:BEIJING POWER MACHINERY INST

A Micro Engine Flame Tube with Two-Stage Guide Vanes

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A two-phase high-frequency pre-explosion device

ActiveCN103867338BSimple partsOptimize the installation positionIntermittent jet plantsDetonatorShock wave

The invention provides a two-phase high-frequency pre-detonator. The two-phase high-frequency pre-detonator comprises a pneumatic valve and a detonation duct, wherein a fuel and air distribution and mixing device, a flame diffusion device, an intensified combustion device A, an intensified combustion device B and a shock reflection device are sequentially installed in the denotation duct along the flowing direction of air and fuel, the distance L1 between the front end surface of the fuel and air distribution and mixing device and the front end surface of the denotation duct is 1.0-2.0D, an ignition groove is processed on the wall surface of the denotation duct between the fuel and air distribution and mixing device and the flame diffusion device, the distance L2 between the rear end surface of the fuel and air distribution and mixing device and the front end surface of the ignition groove is 0.5-0.7D, and the distance L3 between the rear end surface of the ignition groove and the front end of the flame diffusion device is 1.0-1.2D. The two-phase high-frequency pre-detonator has the advantage that the conversion from slow combustion to denotation is realized in a short distance by reasonably designing the internal structure of a denotation chamber, optimizing all major parts and installation positions and adopting a combined method of intensified combustion and shock reflection.

Owner:BEIJING POWER MACHINERY INST

PA4-66 copolymer material and preparation method thereof

The invention belongs to the field of high polymer materials, and discloses a PA4-66 copolymer material and a preparation method thereof. The PA4-66 copolymer material is prepared by copolymerization of a PA4 monomer butyrolactam and a PA66 monomer hexamethylenediamine adipate, and the molar ratio of the butyrolactam to the hexamethylenediamine adipate is (10: 1)-(5: 5). Compared with the prior art, the PA4-66 copolymer material is prepared by copolymerizing the PA4 monomer butyrolactam as a main component and the PA66 monomer hexamethylene adipamide salt, and the material not only has good biodegradability, hydrophilicity and mechanical strength of PA4, but also has greatly improved heat resistance, and can realize melt processing and application in the fields of spinning, engineering plastics and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Bionic-based curvilinear rib-type micro-staggered alveolar heat exchanger core and heat exchanger

ActiveCN108759524BIncrease the degree of blendingImprove performanceLaminated elementsStationary plate conduit assembliesThermodynamicsBionics

The invention discloses a curve-rib-row-type tiny staggered alveolus heat exchanger core based on bionics. The curve-rib-row-type tiny staggered alveolus heat exchanger core comprises more than two layers of medium flowing cavities partitioned by heat exchange plates. More than two layers of curve rib rows are arranged in each layer of medium flowing cavity, each curve rib row is composed of a plurality of mutually-parallel curve ribs, and every two layers of curve rib rows are arranged crosswise. Bionic elements are fused into the design of a heat exchanger, and the tiny staggered alveolus heat exchanger is designed; through the structure, the performance of the heat exchange is improved in the two aspects of the heat exchange coefficient and the heat exchange area; and the curve-rib-row-type tiny staggered alveolus heat exchanger core is light, simple and convenient in structure and suitable for an aerospace heat exchanger.

Owner:陕西益信伟创智能科技有限公司

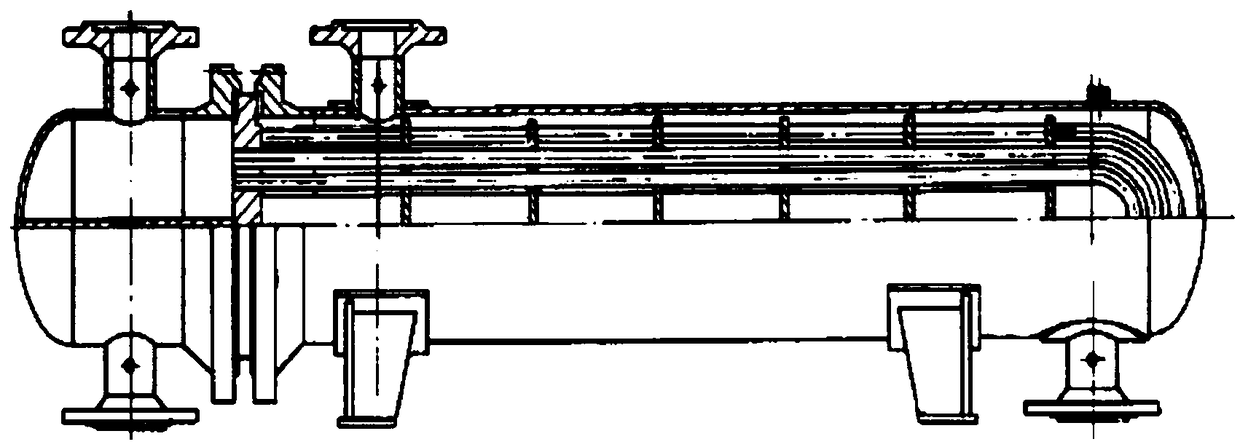

Air-lubricating oil surface type radiator

PendingCN110425570AImprove cooling effectDestroy the boundary layerContinuous combustion chamberStationary conduit assembliesOil pressureSurface type

The invention provides an air-lubricating oil surface type radiator. The inner wall of a heat exchange pipeline of the radiator is provided with rifled threads, and the outer wall surface of the heatexchange pipeline is provided with an axial key groove; and the radiator with an enhanced heat exchange structure is fixed at an air inlet of an engine outer duct and becomes a main radiator in an engine lubricating oil cooling system. According to the air-lubricating oil surface type radiator, by changing the shape of the heat exchange pipeline, the effective heat exchange areas inside and outside the pipeline and the turbulence degree of the flow of fluid inside and outside the pipeline are increased under the condition of minimizing the loss of the lubricating oil pressure inside the pipeline and guaranteeing the quality of the radiator, so that the thermal resistance of the inner wall of the pipeline is effectively reduced, and the integral heat exchange capacity of the radiator is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

An integrated afterburner with adjustable preheating rectifying struts

ActiveCN109539310BImprove combustion efficiencyImprove mixing uniformityContinuous combustion chamberCombustion chamberSpray nozzle

The invention provides an integrated afterburner adopting adjustable preheating struts. Strut flame stabilizers are connected with a central cone body through adjustable bolts, and the deflection angle of each strut flame stabilizer can be adjusted in real time according to actual work conditions. High-temperature mixed gas enters the struts from small intake holes formed in the two side surfacesof each strut flame stabilizer, fuel oil in a fuel oil channel is heated, and then the high-temperature mixed gas is sprayed out towards the center from small spray holes formed in the middle portionof a V-shaped groove of each strut flame stabilizer. After being heated, the fuel oil is sprayed out by direct injection type spray nozzles on the two sides of V-shaped grooves of the strut flame stabilizers, and after being further heated, the fuel oil burns in a low-speed backflow area on the back side. Since being heated, the fuel oil has good atomization and evaporation effects, the oil-gas mixing time in the low-speed area is long, and the oil-gas mixing effect is good, ignition and stable communication can be achieved under the condition of a small oil-gas ratio; and the adjustable strutflame stabilizers can be suitable for work states in larger range, and the performance of an engine is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com