Two-phase high-frequency pre-detonator

A pre-explosion, high-frequency technology, applied in intermittent injection devices, mechanical equipment, etc., can solve the problems of large flow resistance, complex detonation tube structure, difficult to trigger large-diameter PDE detonation, etc., and achieve high-frequency stable explosion. The effect of shock combustion, good oil and gas distribution, and improving the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

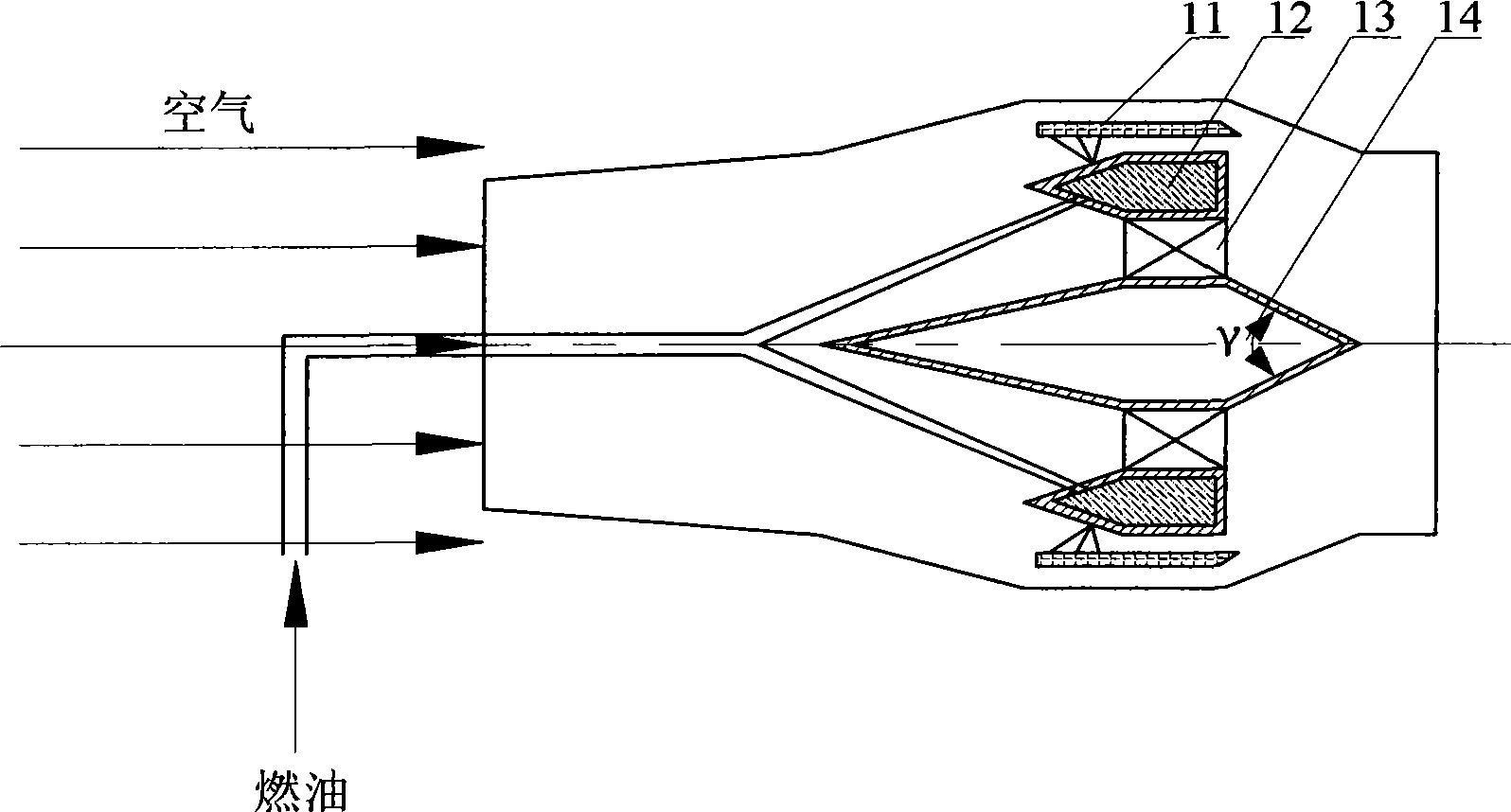

[0030] The design principle of the present invention: the key to successfully realizing high-frequency detonation lies in the following aspects: 1) forming a relatively uniform explosive gas mixture in a relatively short period of time; 2) timely and reliable ignition, effective tissue rapid combustion, and release a large amount of chemical Reaction heat; 3) Using the shock wave formed by the superposition of combustion waves, through reasonable structural design, the gas mixture in the local confined space in the detonation tube will undergo a micro-scale explosion under the action of the shock wave, thereby triggering the formation of the detonation wave.

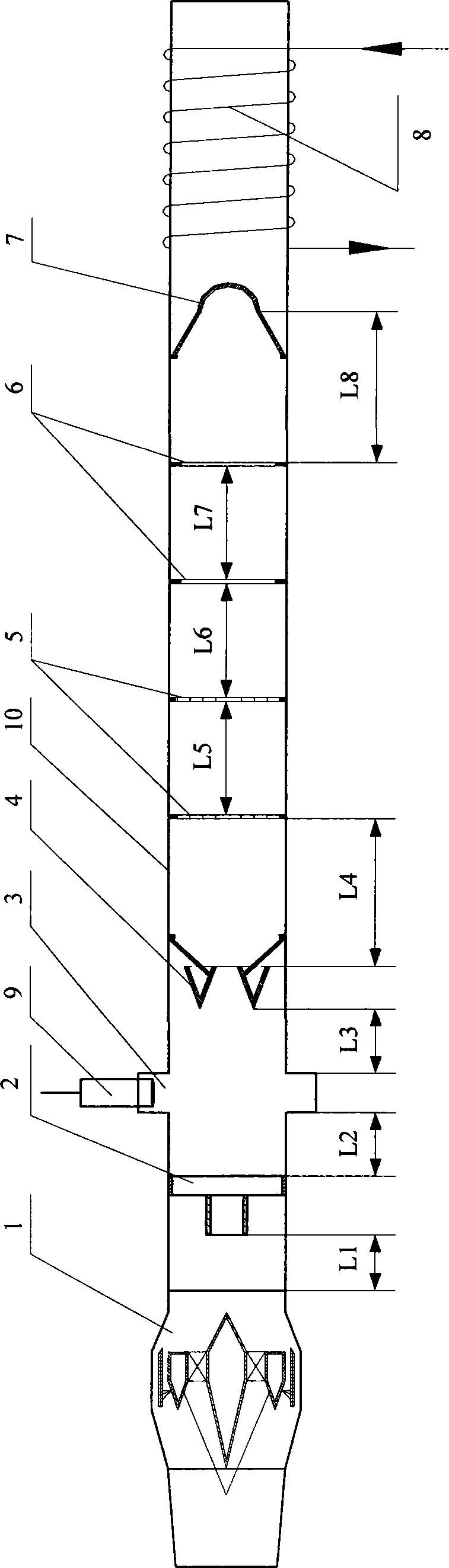

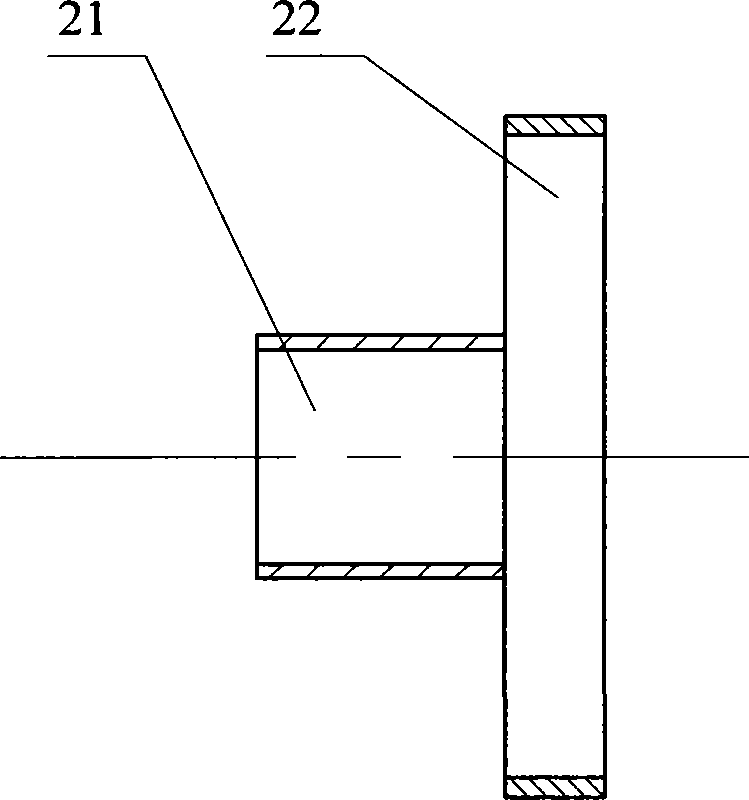

[0031] The present invention as figure 1 As shown, it includes a pneumatic valve 1 and a detonation tube 10. The inside of the detonation tube 10 is installed in sequence along the airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com