Air-lubricating oil surface type radiator

A radiator and oil surface technology, which is applied in the field of air-sliding surface radiators, can solve the problems of large thermal resistance on the oil side and poor heat dissipation effect of air-sliding radiators, and achieve low thermal resistance and good comprehensive heat exchange Performance, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

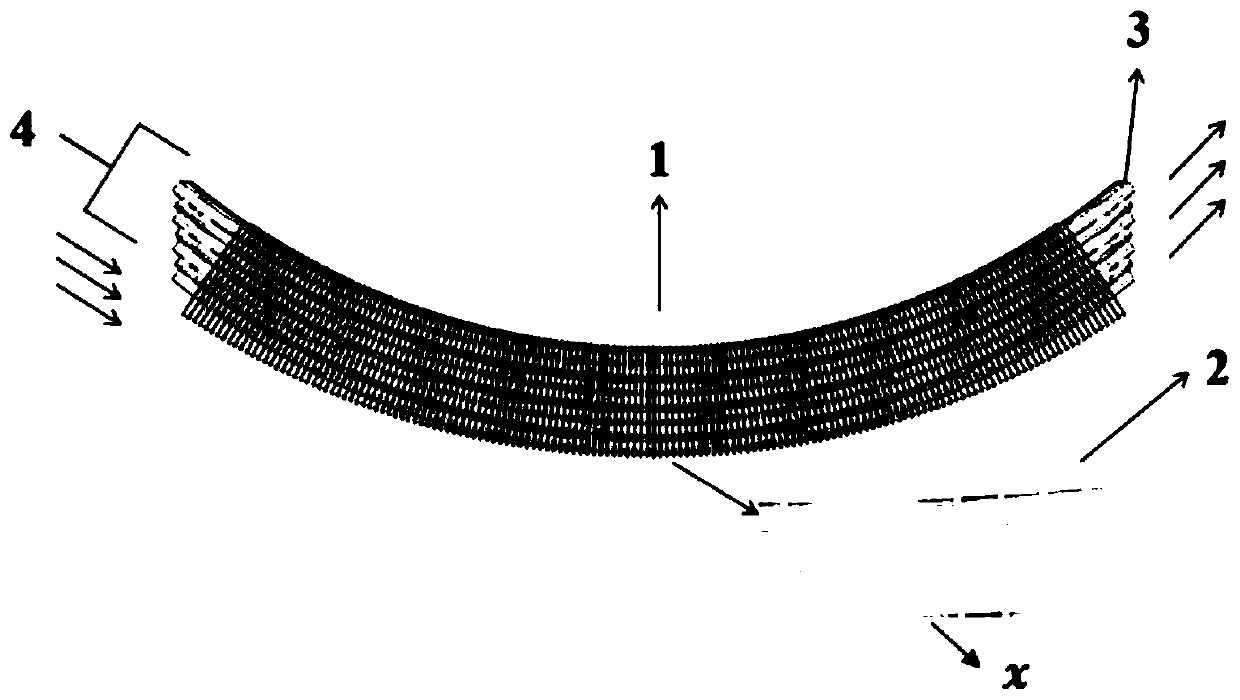

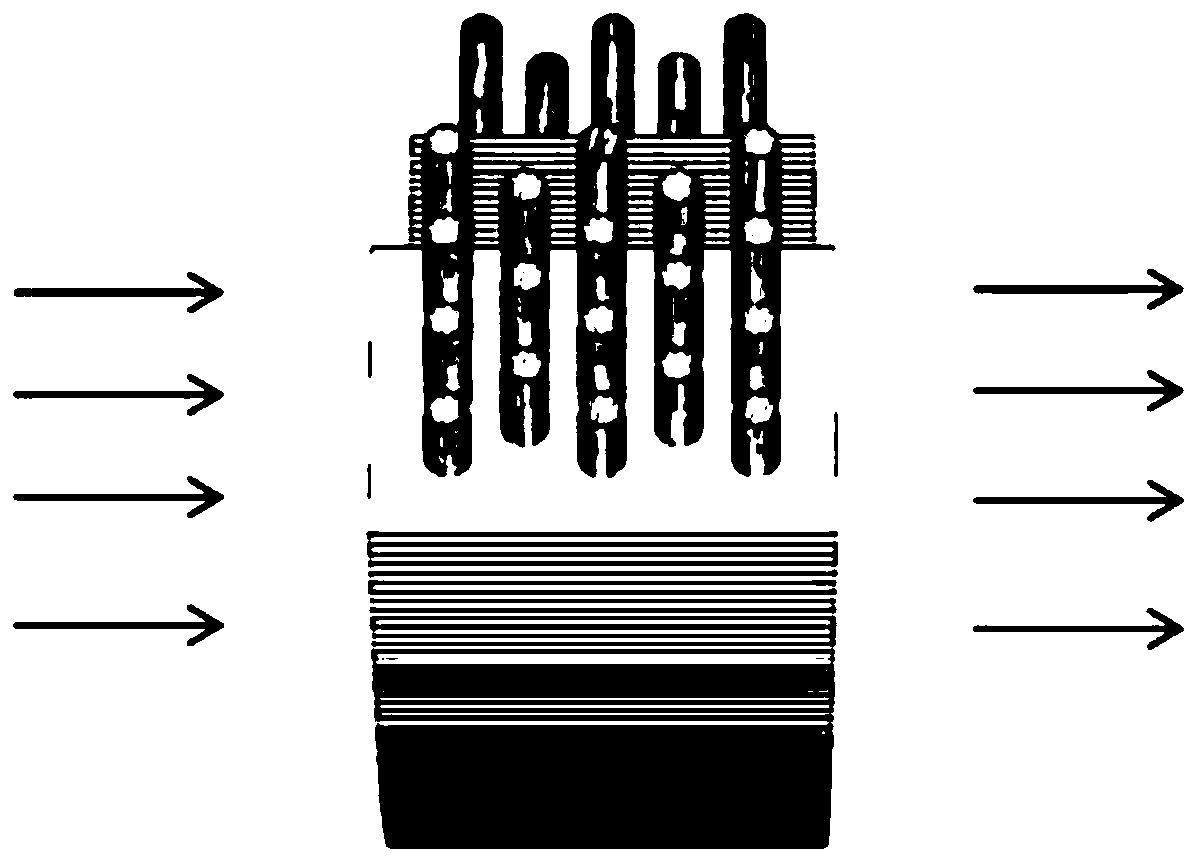

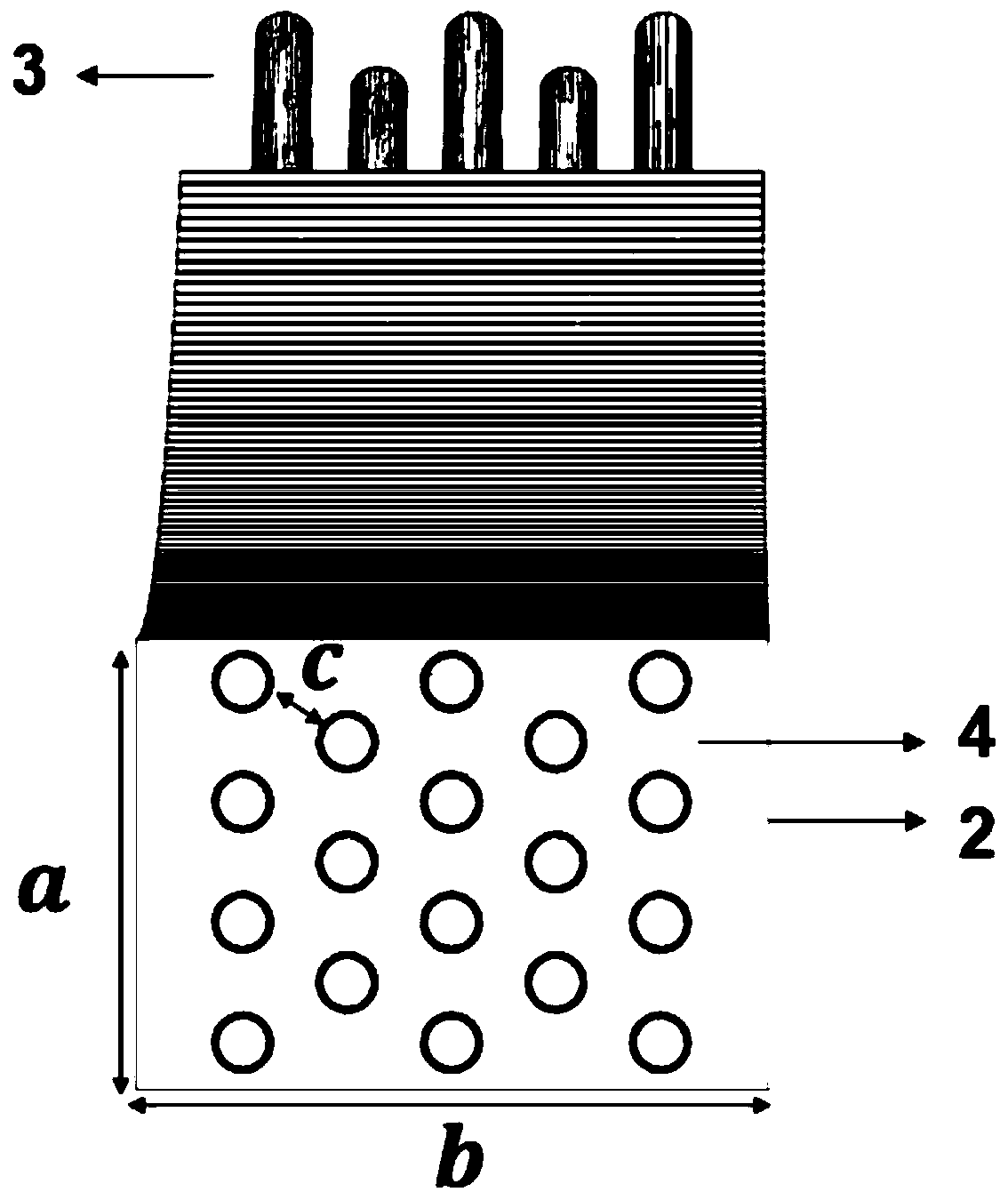

[0024] Such as figure 1 As shown, the lubricating oil radiator body 1 includes a heat exchange tube bundle 4 arranged by several heat exchange tubes 3 , and the outer wall of the heat exchange tube bundle 4 is provided with rectangular fins 2 . The heat exchange tube bundle 4 is annular. The lubricating oil radiator body 1 is mounted on a place with abundant cold air inlet, specifically mounted on the air intake section of the outer duct.

[0025] The outer diameter of the heat exchange tube 3 is D 0 , the inner diameter is D 3 , Wall thickness S, with obvious grain structure on the inner and outer walls of the tube, high-intensity heat exchange can be performed both inside and outside the heat exchange tube. The outer wall of the heat exchange tube 3 is provided with an axially developed axial keyway 5 , and the inner wall is provided with a fixed twist distance d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com