Patents

Literature

79results about How to "Increase the flow distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

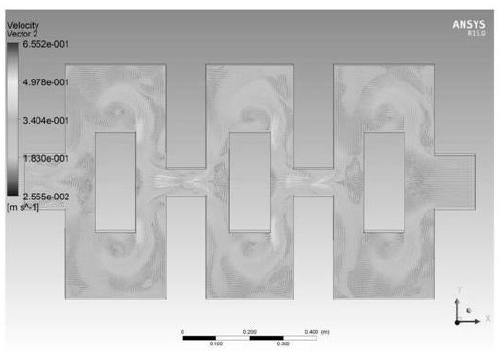

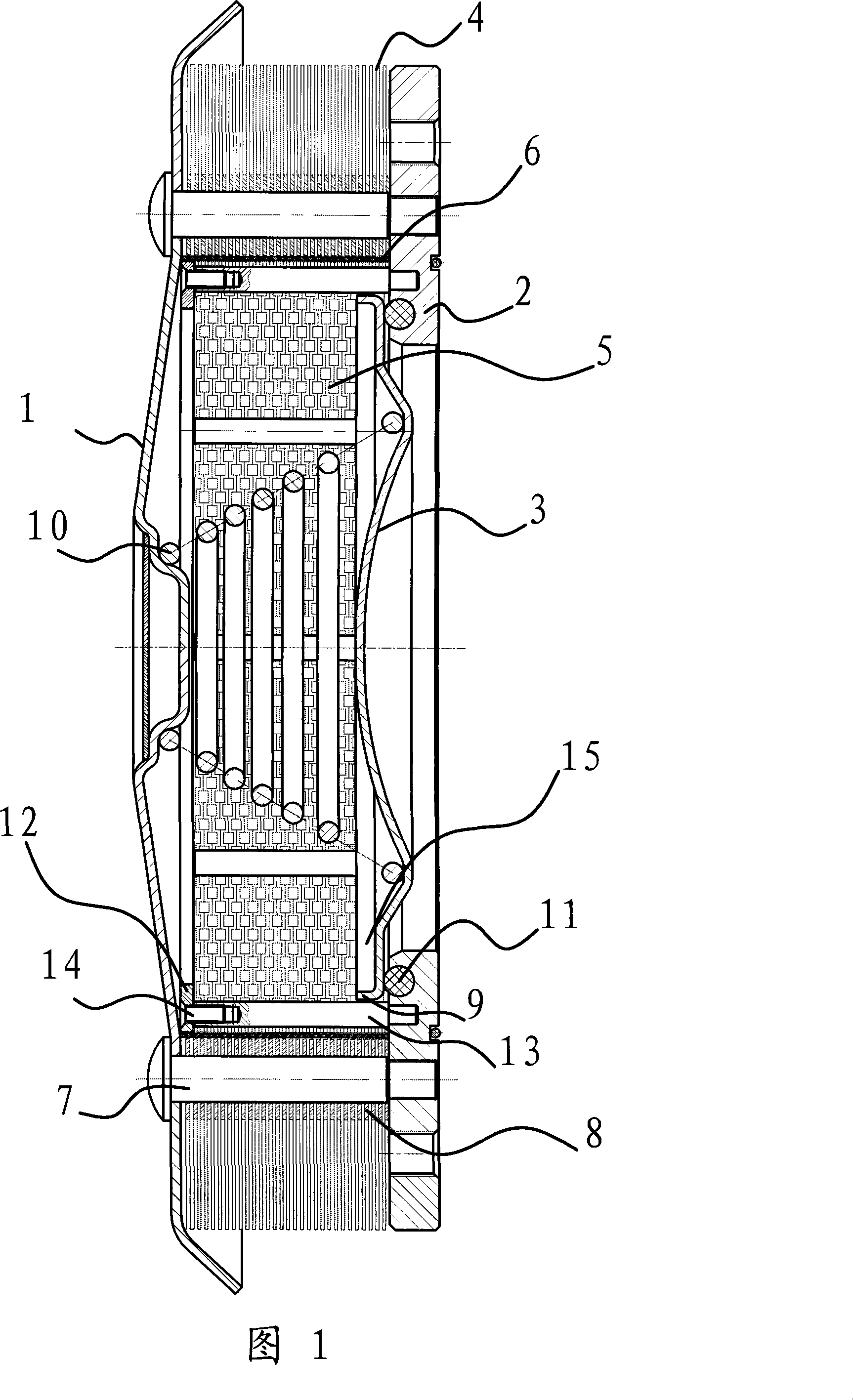

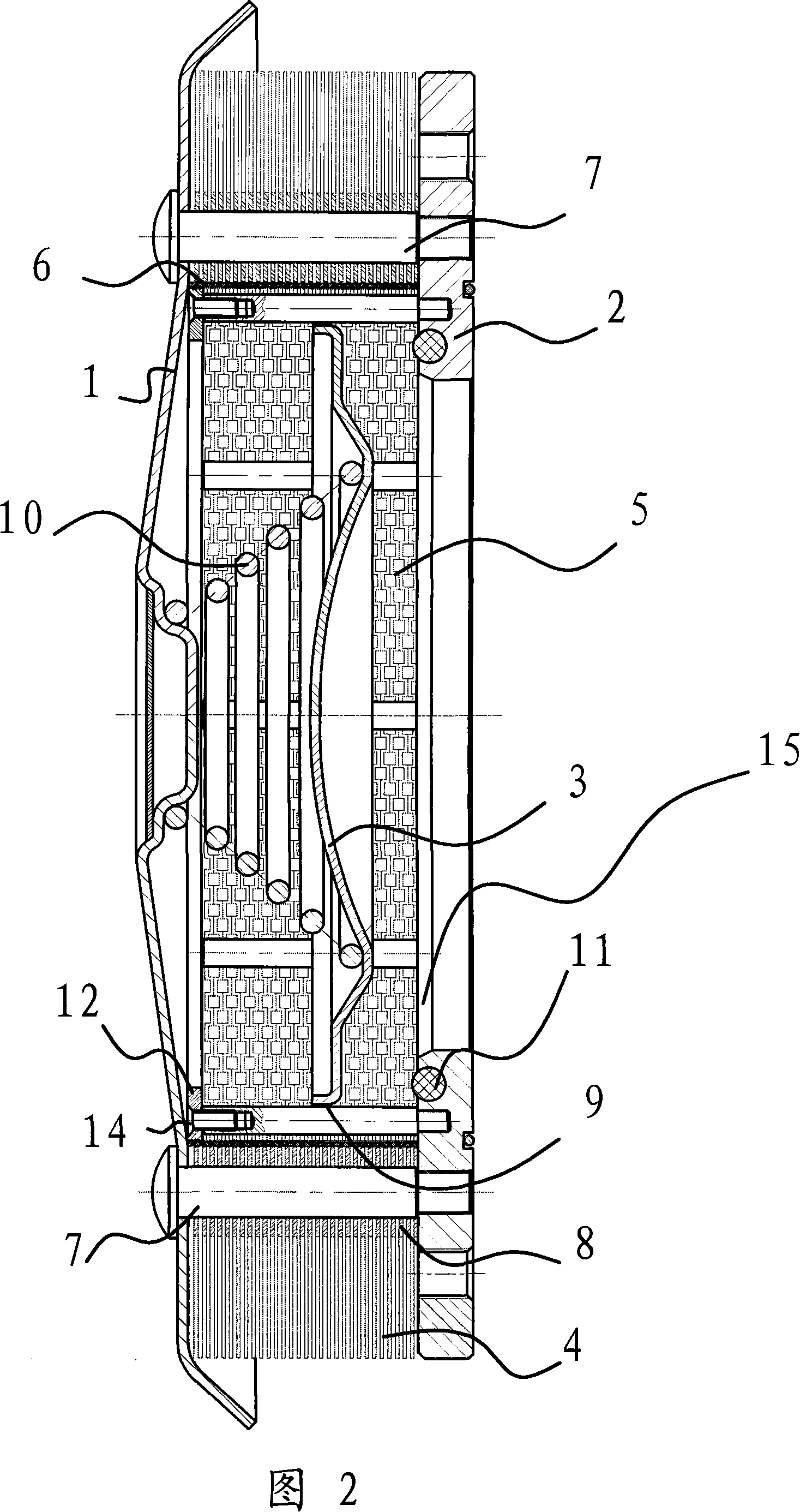

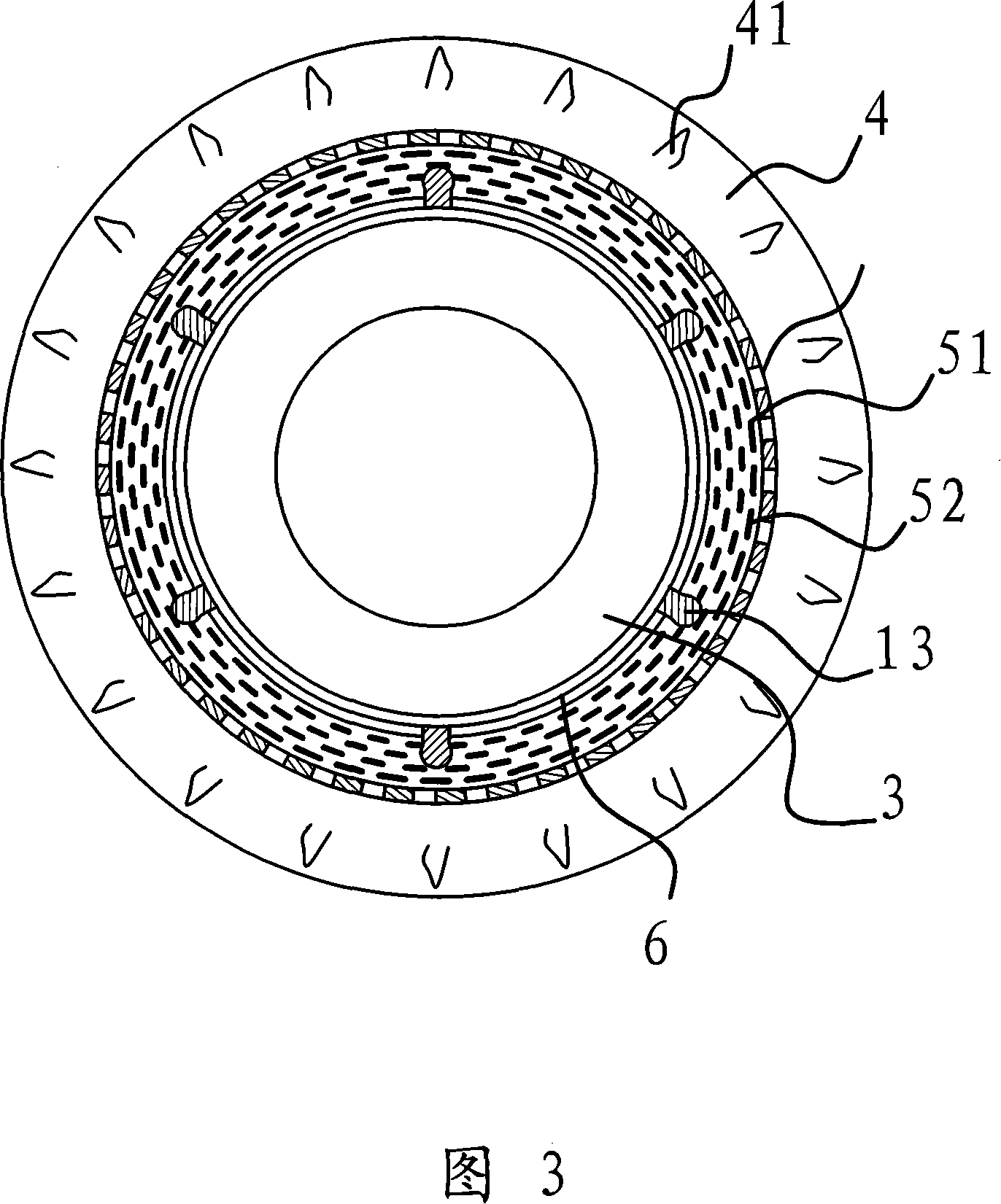

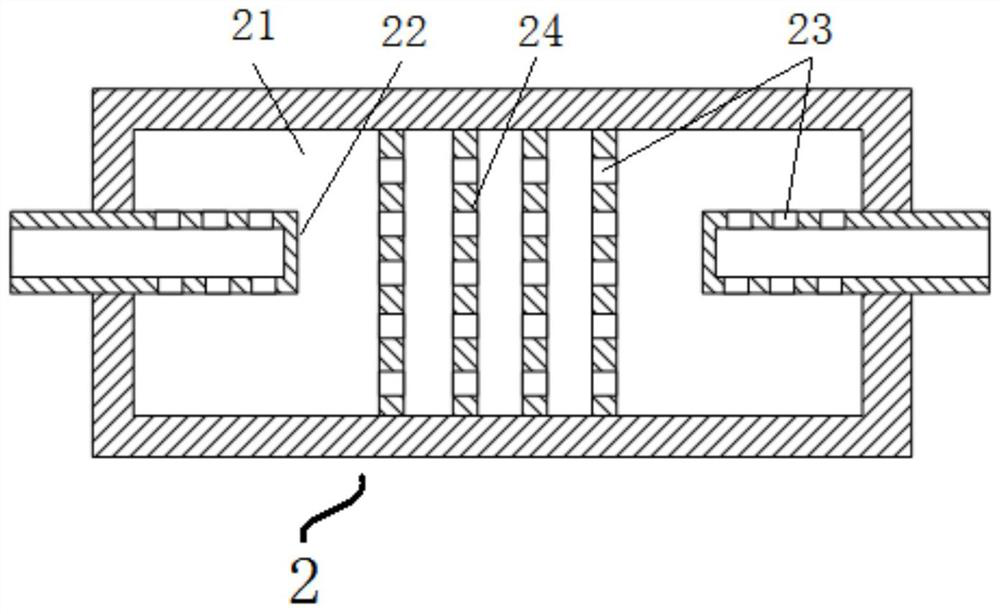

Temperature difference power generation device and vehicle-mounted tail gas waste heat temperature difference power generation system

InactiveCN103904949AIncrease profitImprove power generation efficiencyInternal combustion piston enginesExhaust apparatusTemperature differenceEngineering

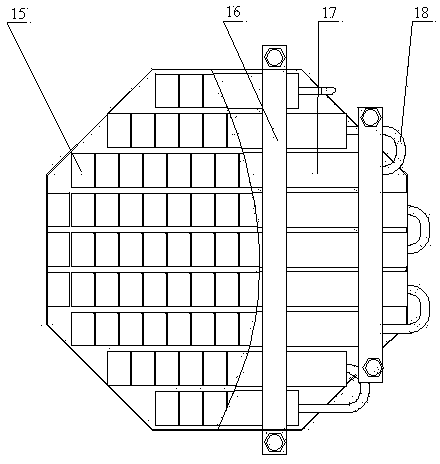

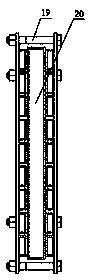

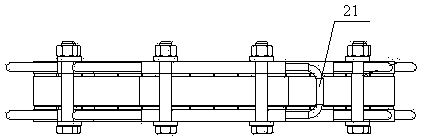

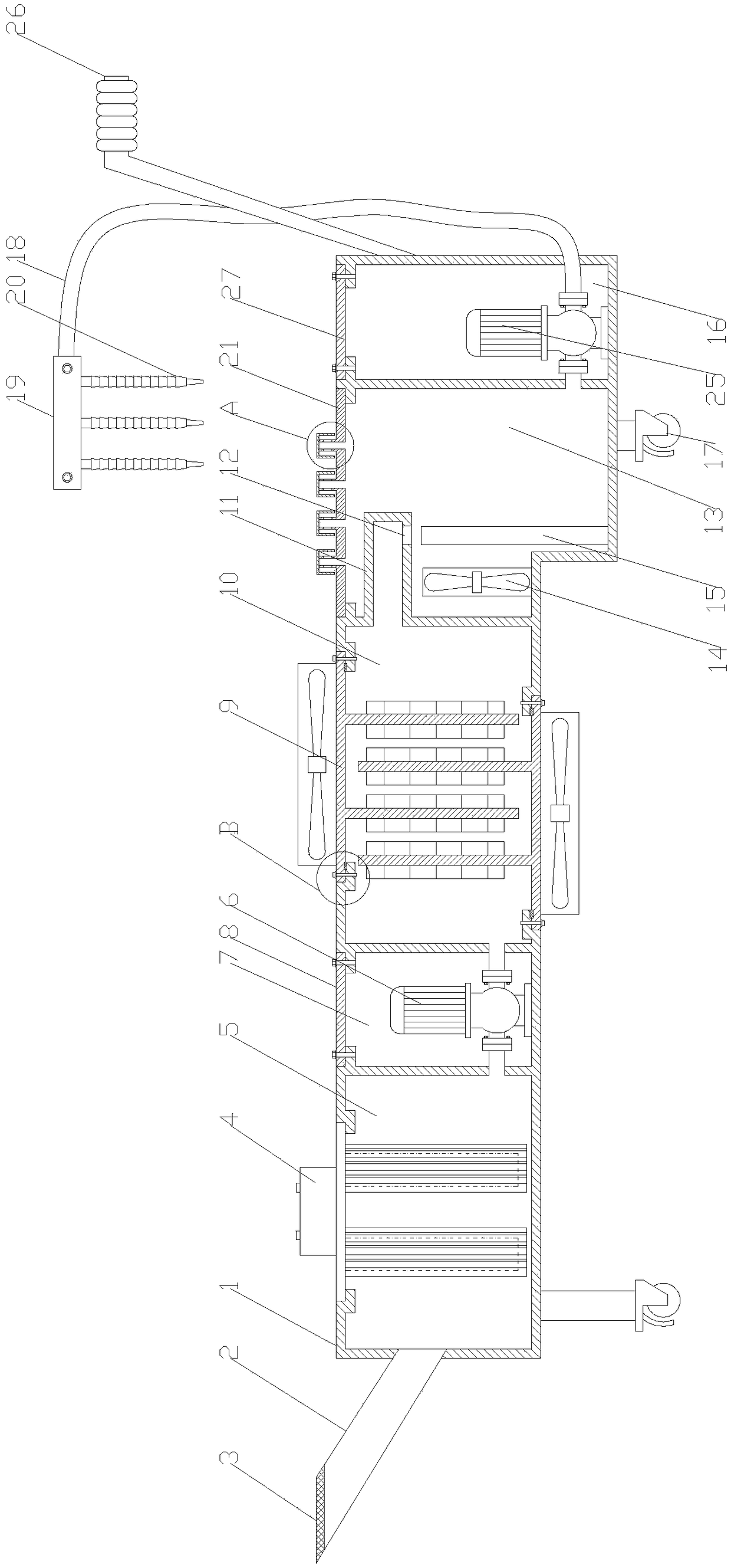

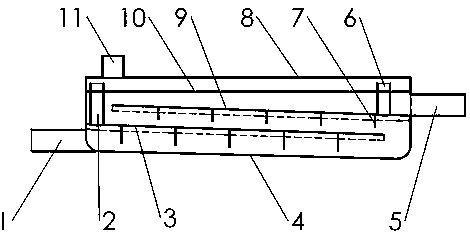

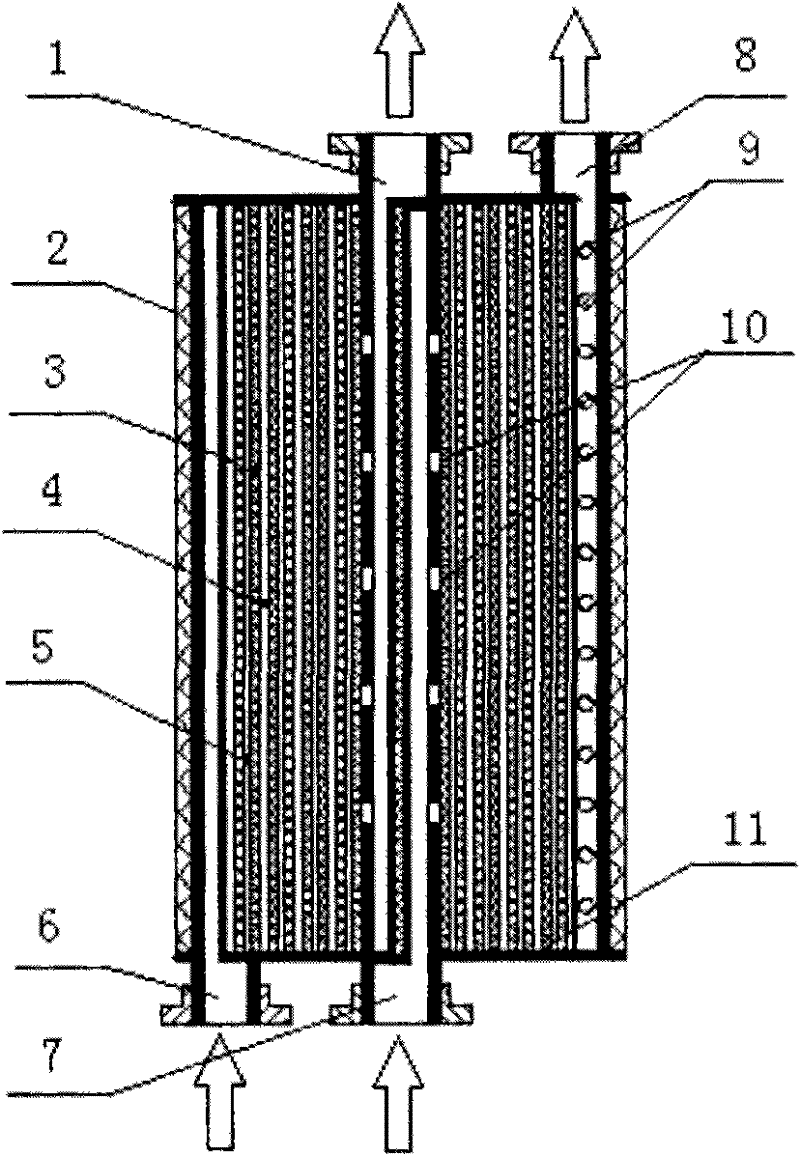

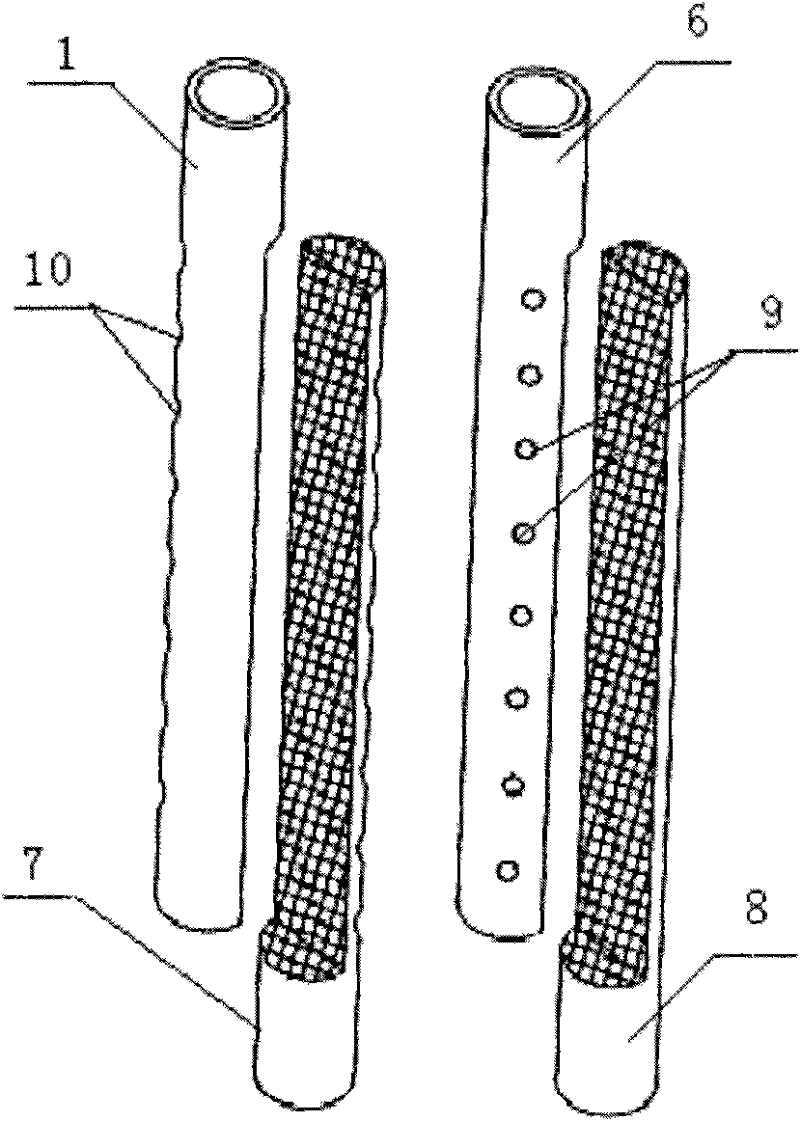

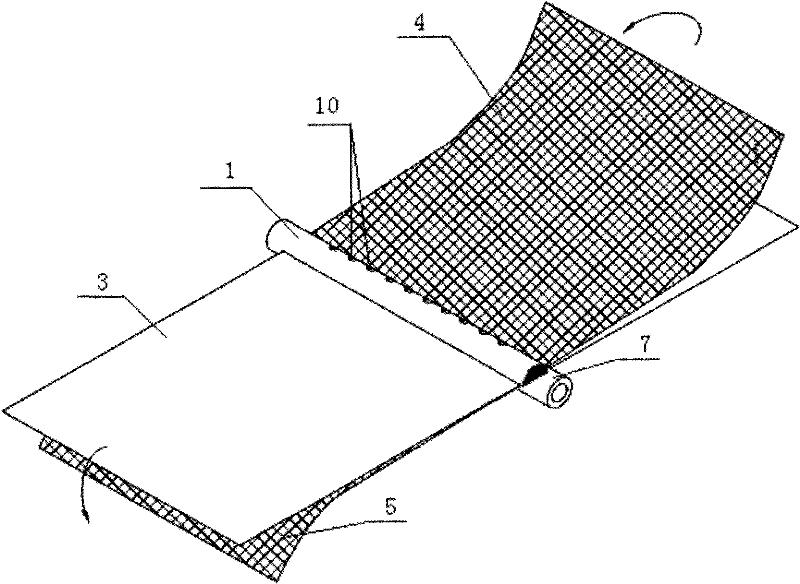

The invention discloses a temperature difference power generation device which comprises a tail gas tank, a cooling water tank assembly, a temperature difference power generation module assembly and a clamping plate. The two ends of the tail gas tank are provided with an intake manifold and an exhaust manifold respectively, and the tail gas tank comprises a gas tank body, a shunt fin, a flow guide fin and an afflux fin; the two ends of the cooling water tank assembly are provided with a water inlet manifold and a water outlet manifold respectively, the cooling water tank assembly comprises multiple cooling water tanks, and each cooling water tank comprises a water tank body and a flow guide plate; the hot end of the temperature difference power generation module assembly is attached to the two sides of the tail gas tank, the cold end of the temperature difference power generation module assembly is attached to one side of the cooling water tank assembly, and the temperature difference power generation module assembly comprises multiple temperature difference power generation modules; the clamping plate is arranged outside the cooling water tank assembly, and the two ends of the clamping plate are locked through bolts. The structure of the temperature difference power generation device is optimized and improved, power generation efficiency is improved, and the aim of improving the energy utilization rate is achieved.

Owner:WUHAN UNIV OF TECH

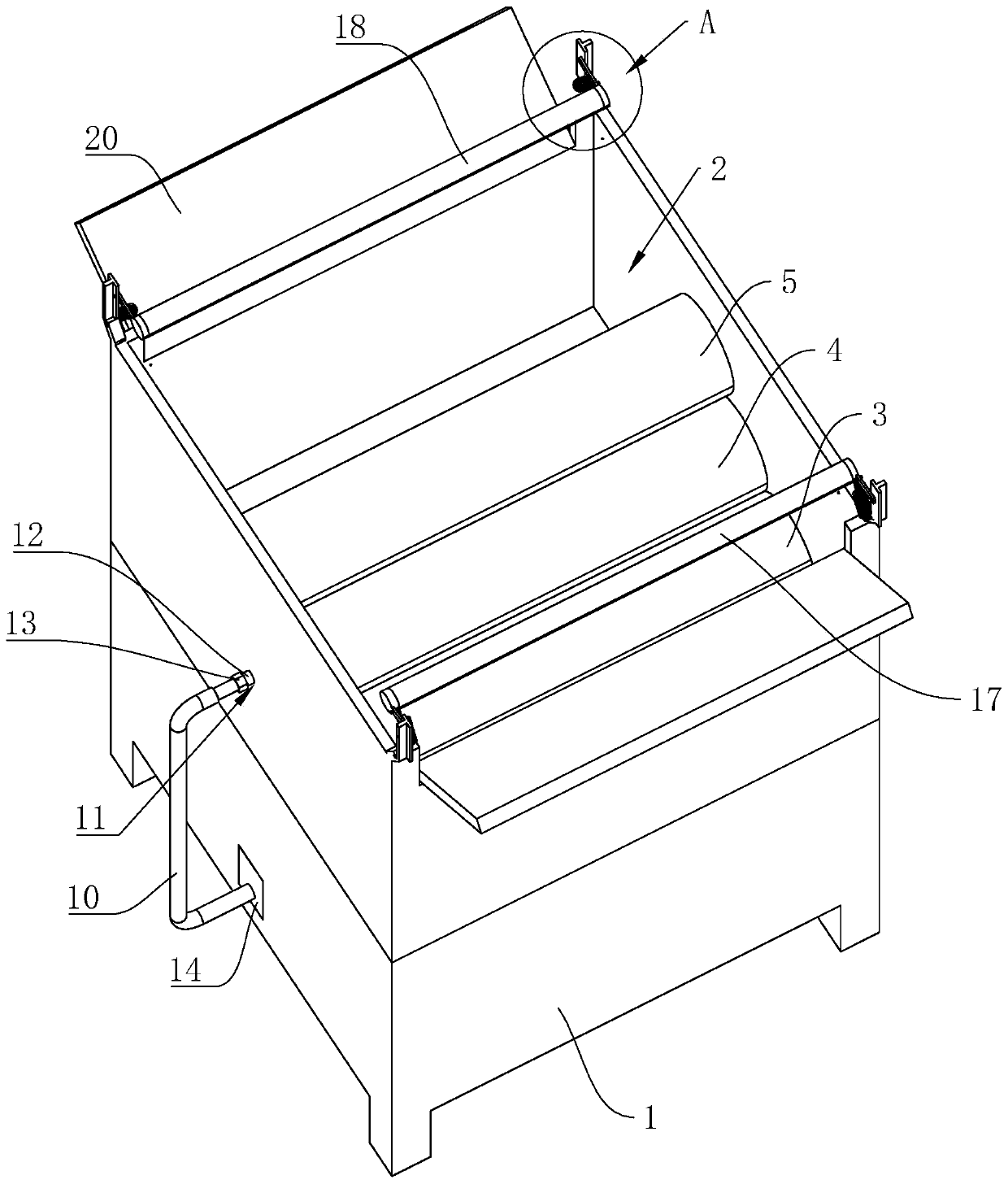

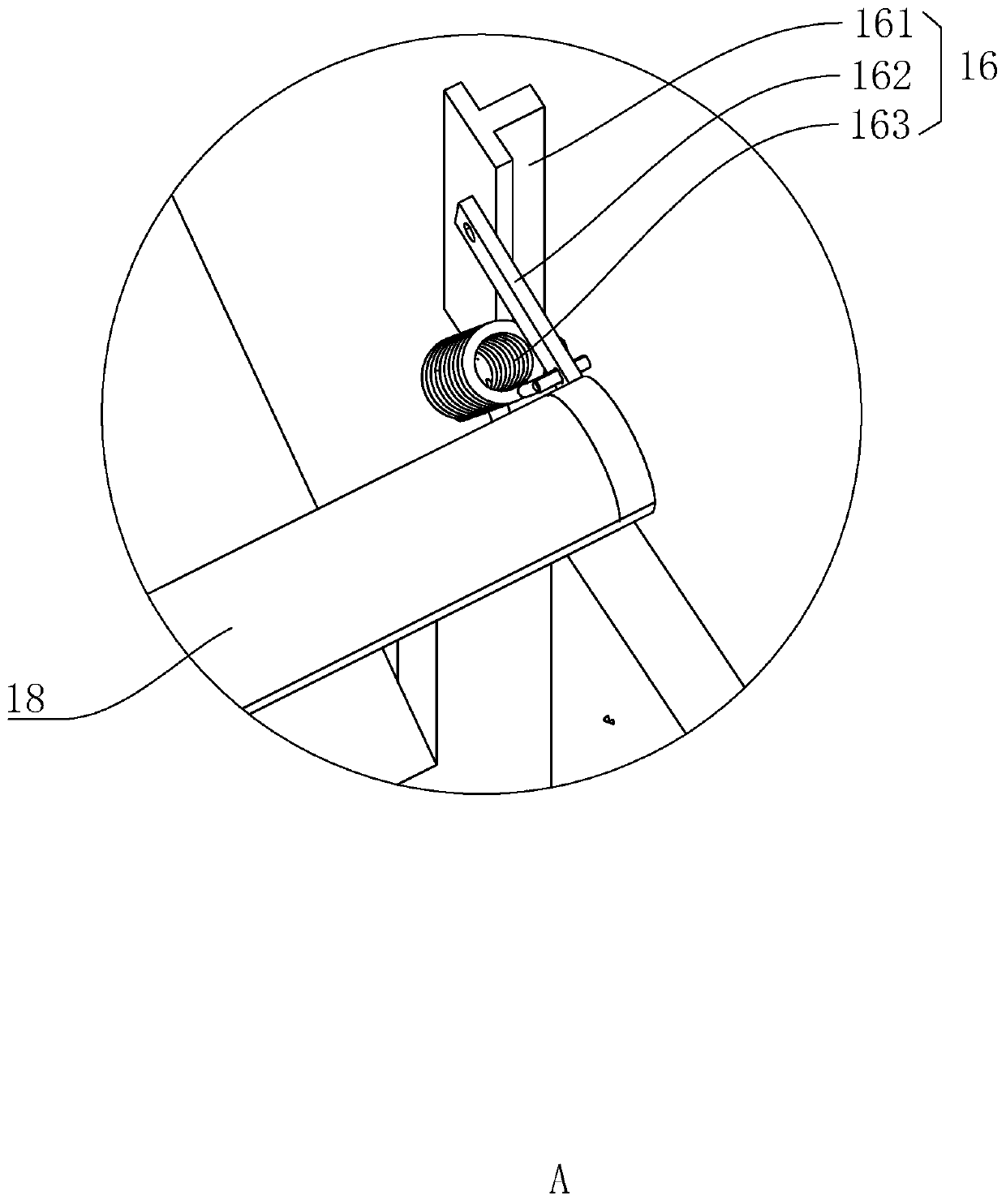

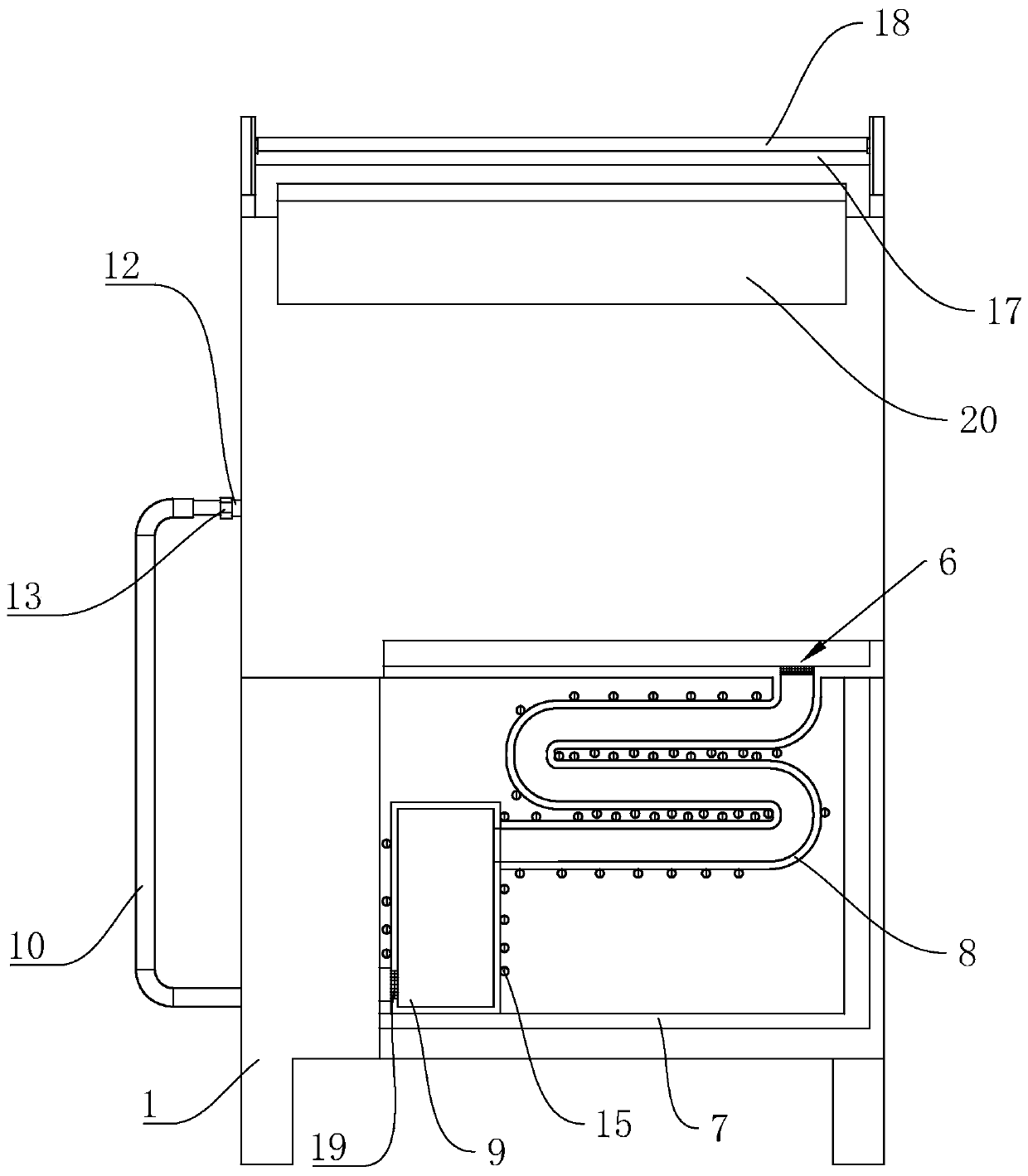

Processing cooling device of numerical control center

ActiveCN109048487ASpeed up the flowIncrease the flow distanceMaintainance and safety accessoriesNumerical controlCooling effect

The invention discloses a processing cooling device of a numerical control center. The device comprises a cooling box; the cooling box is provided with an adsorption chamber, a placement chamber 1, acooling chamber 1, a cooling chamber 2 and a placement chamber 2 from left to right; the left side of the cooling box is provided with an inlet pipe communicating with the adsorption chamber; an adsorption device is arranged at the upper end of the adsorption chamber; a water pump 1 is arranged in the placement chamber; the water inlet end of the water pump 1 is connected with the adsorption chamber, and the water outlet end is connected with the cooling chamber 1; the upper end and the lower end of the cooling chamber 1 are provided with heat dissipating devices; the cooling chamber 1 communicates with the upper end of the cooling chamber 2; a water pump 2 is arranged in the placement chamber 2; the water inlet end of the water pump 2 is communicates with the lower end of the cooling chamber 2; the water outlet end of the water pump 2 is provided with a connecting tube; the front end of the connecting pipe is provided with a water pipe seat; and the lower end of the water pipe seat isprovided with a plurality of universal pipes. The device recovers the cooling liquid when working in the numerical control center, separates the processing waste in the cooling liquid, and cools thecooling liquid, so that a coolant can be recycled and maintains a good cooling effect.

Owner:安庆市基丞精密机械有限公司

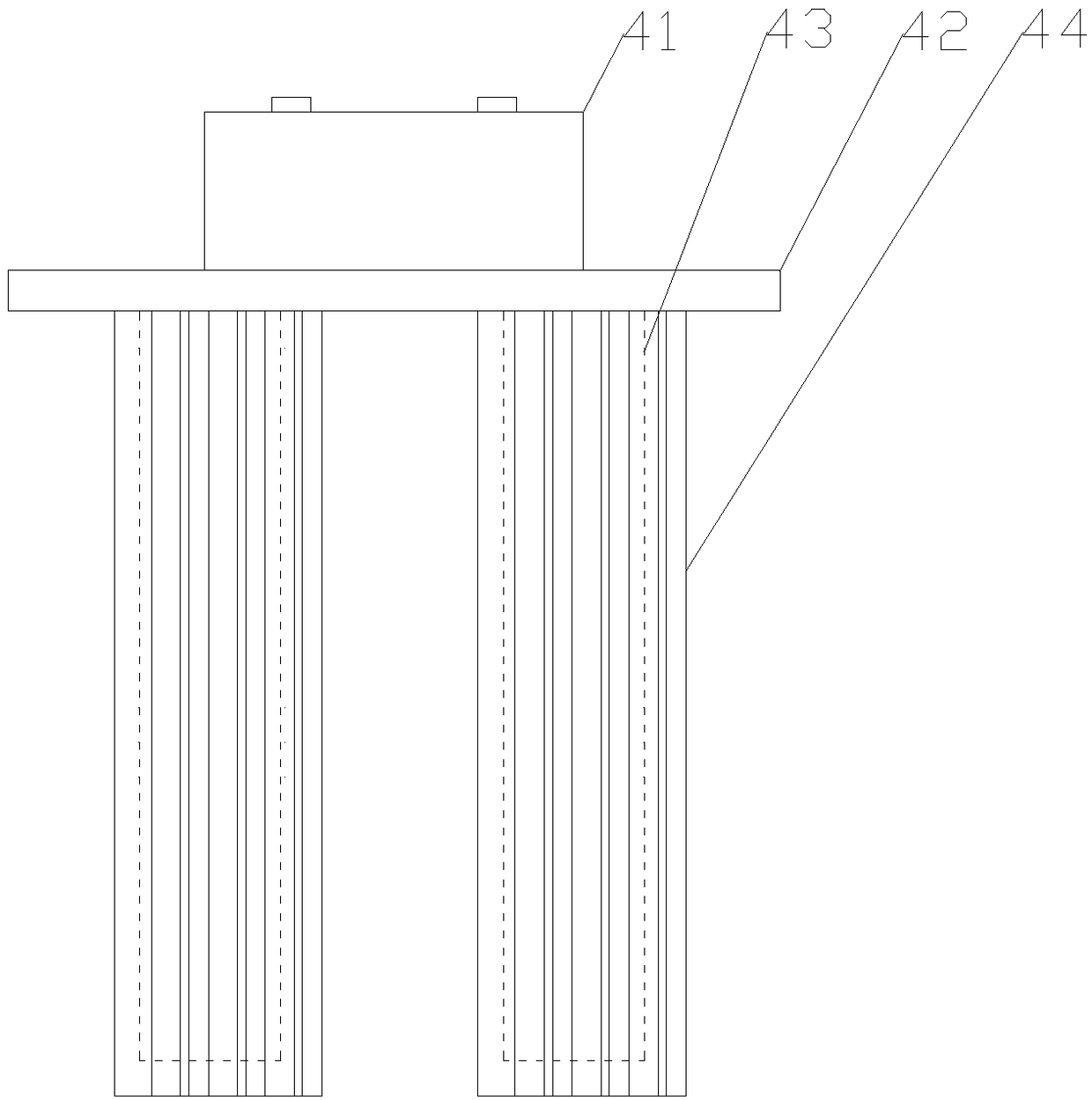

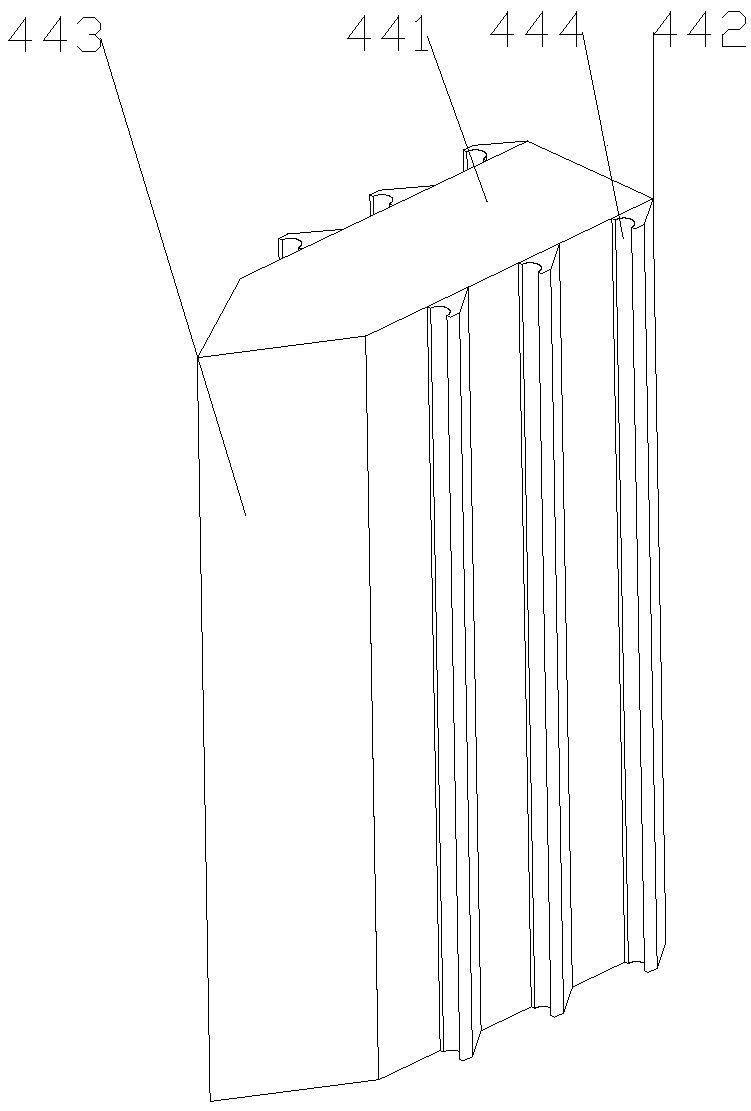

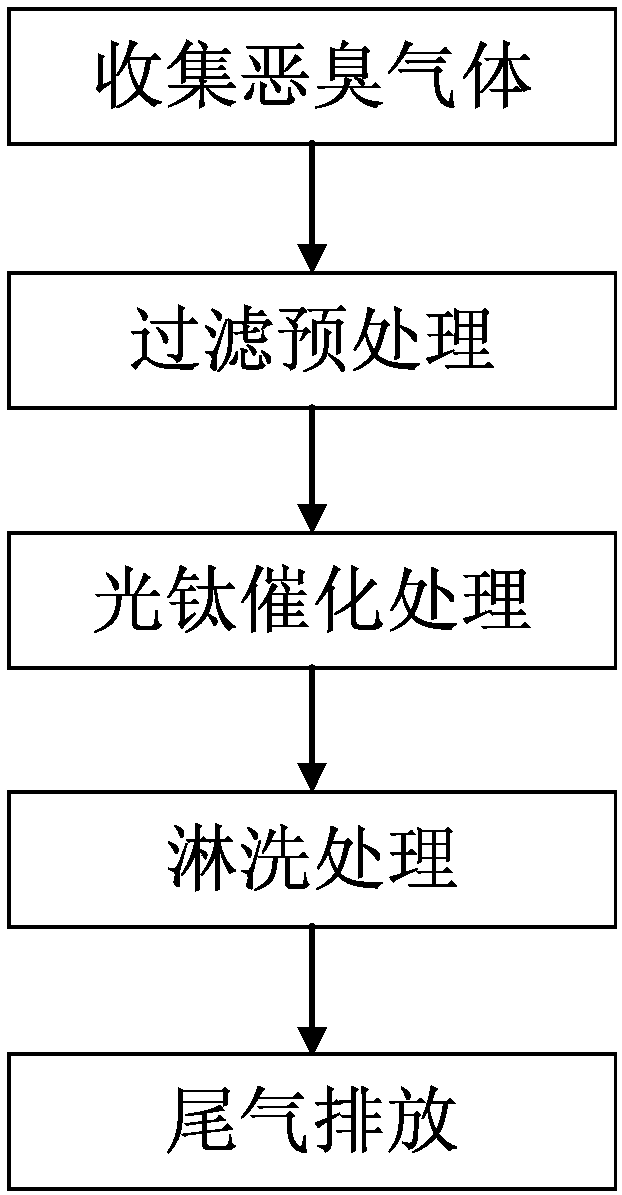

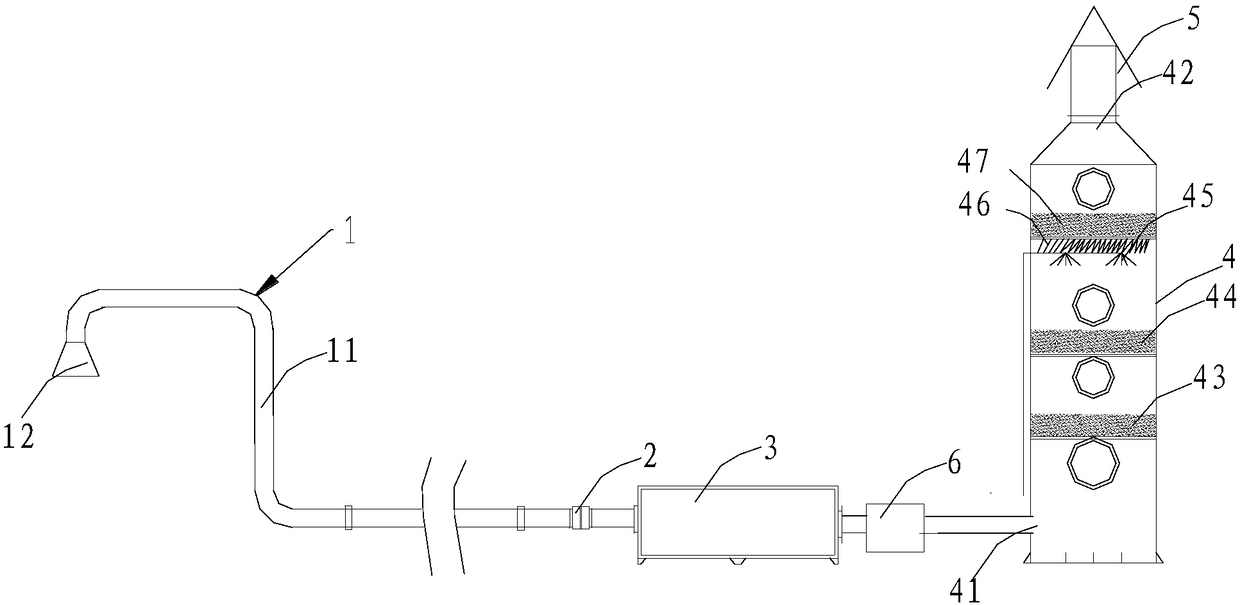

Treatment process for malodorous gas of municipal wastewater treatment plant

ActiveCN108554021AIncreased turbulenceImprove the effectGas treatmentDispersed particle filtrationChemistrySewage treatment

The invention discloses a treatment process for malodorous gases of a municipal wastewater treatment plant. The treatment process comprises the following steps: collecting malodorous gases, and carrying out filtering pretreatment; introducing into a photonic titanium catalysis device, and carrying out photonic catalysis treatment; introducing the gases after photonic catalysis treatment into a catalysis purification tower, carrying out catalytic drip washing, and discharging gases. With the combination of photonic catalysis and drip washing, the outer circumference of an ultrasonic lamp tube is covered by a photocatalyst net cover inside the photonic titanium catalysis device to form a photonic titanium catalysis module, so that the malodorous gases fed into the cover sufficiently contactthe inner wall of the photocatalyst net, and thus the photonic catalysis time and routes can be prolonged; in addition, due to adoption of alternatively arranged photonic titanium catalysis modules, specific gas channels can be formed inside the device, so that the photonic catalysis time and gas flowing routes can be also prolonged, the deodorization capability and the sterilization capability ofthe device can be enhanced, and the removal efficiency of hydrogen sulfide, ammonia gases, volatile organic compounds and odor in the malodorous gases can be improved.

Owner:浙江华木环境工程有限公司

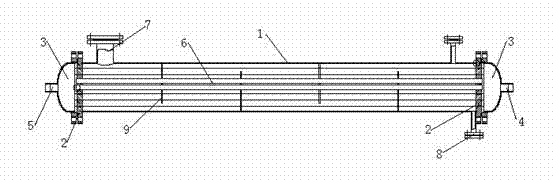

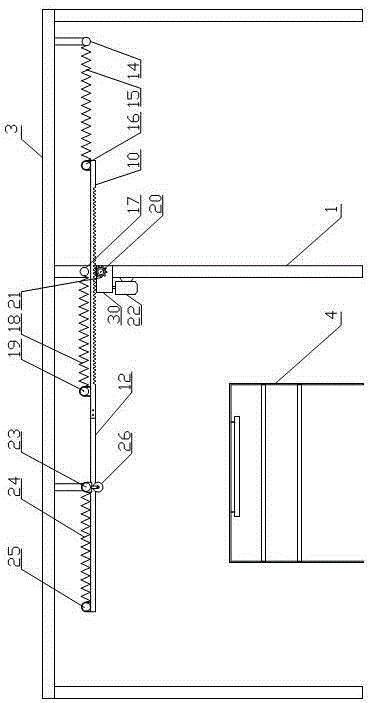

Easily cleaned condenser

InactiveCN102778136AEasy to cleanImprove cooling effectSteam/vapor condensersHeat exchanger casingsCooling effectPulp and paper industry

The invention belongs to the technical field of spice production, and particularly relates to an easily cleaned condenser. The easily cleaned condenser comprises a shell, wherein baffle plates for sealing the shell are arranged at two ends of the shell and respectively connected with end sockets; a water inlet is formed in one of the end sockets, and a water outlet is formed in the other end socket; a heat exchange pipe communicated with the water inlet and the water outlet is arranged in the shell; a steam inlet is formed in the upper part of the shell; a condensation liquid outlet is formed in the lower part of the shell; and baffles for extending a steam flow path are arranged between the steam inlet and the condensation liquid outlet in the shell in a staggering manner. By the easily cleaned condenser, the condenser can be well cleaned, and an ideal cooling effect can be achieved.

Owner:浙江诺睿特生物科技有限公司

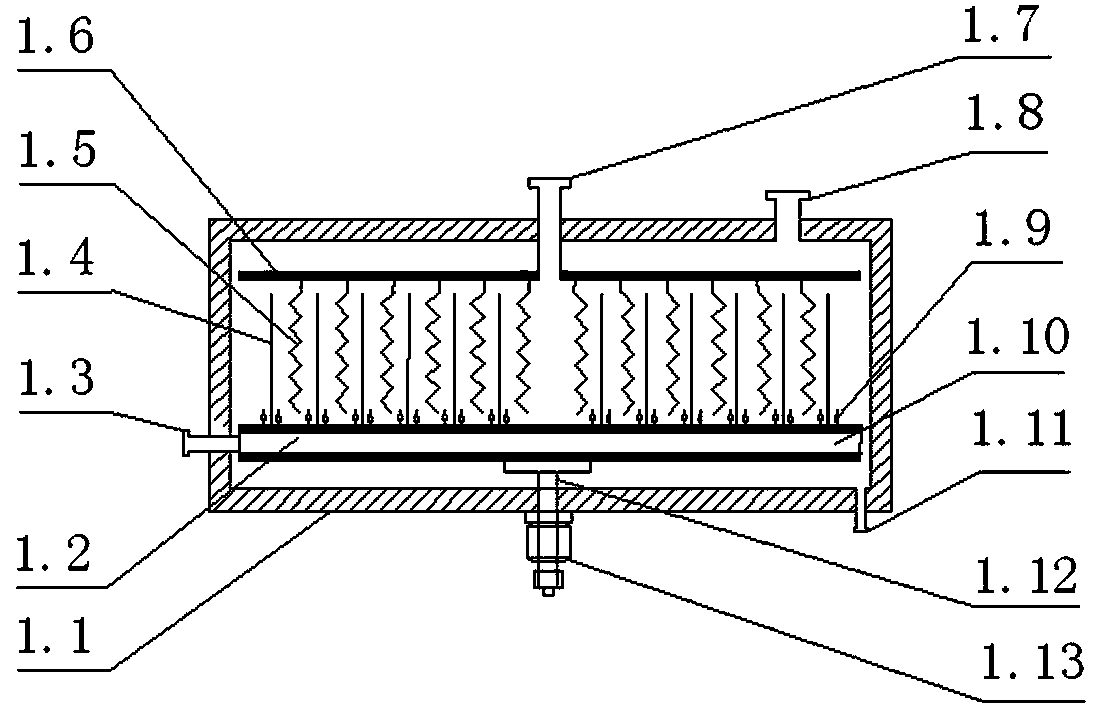

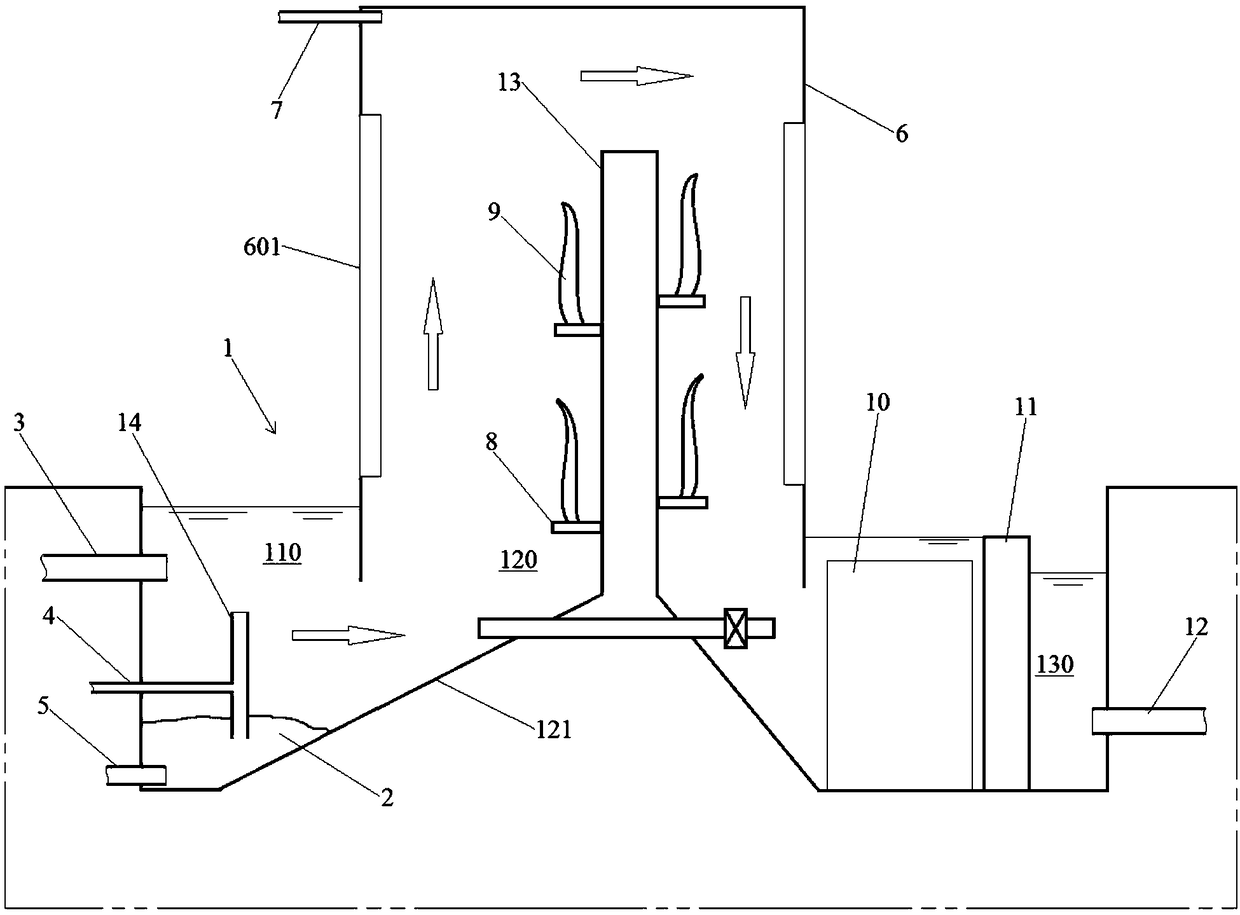

Device and process for mass transfer process for treating wastewater through supergravity enhanced electric Fenton method

ActiveCN103145277BImprove processing efficiencyReduce mass transfer resistanceMultistage water/sewage treatmentWastewaterEngineering

The invention belongs to the technical field of water treatment, and in particular relates to a device and a process for a mass transfer process for treating wastewater through a supergravity enhanced electric Fenton method, aiming at solving the problem of limited mass transfer while treating wastewater through the conventional electric Fenton method. The device comprises a plurality of cylinder cathodes and cathode connecting discs as well as a plurality of corrugated cylinder anodes and anode connecting discs, wherein the corrugated cylinder anodes and the anode connecting discs are static relatively to a shell; the centers of the cathode connecting discs are connected with rotating shafts; intake holes are distributed on the cathode connecting discs; and gas circulating chambers are arranged at the bottoms of the cathode connecting discs. According to the process, a supergravity electric Fenton reaction system is formed through the rotating cathode connecting discs and cylinder cathodes as well as the static anode connecting discs and cylinder anodes, and inflated oxygen. The device and the process disclosed by the invention not only solve the problem of limited mass transfer in the conventional sacrificial anode electric Fenton technology application process, so as to improve treatment efficiency, but also the device is low in liquid holdup, low in load, small in equipment and low in energy consumption.

Owner:ZHONGBEI UNIV

Dust removal and desulphurization tower

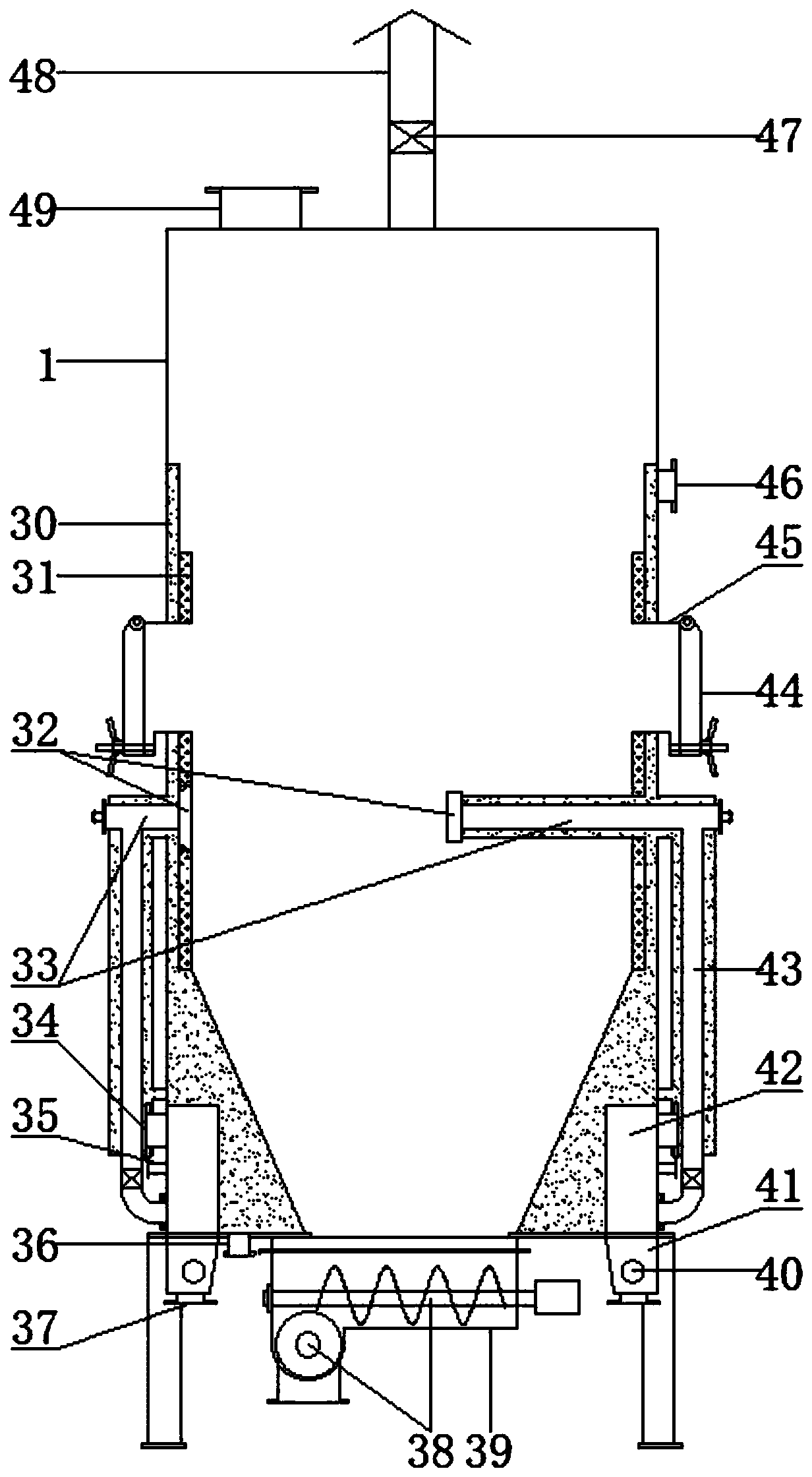

InactiveCN108744885AFully removeIncrease the flow distanceDispersed particle filtrationDrive shaftEngineering

The invention belongs to the technical field of waste gas cleaning, and specifically discloses a dust removal and desulphurization tower. The dust removal and desulphurization tower comprises a dust removing tower and a desulphurization tower, wherein the desulphurization tower comprises an outer tower and an inner tower; an air channel is formed between the inner tower and the outer tower; an annular sliding plate is glidingly connected to the air channel; a first spray head is arranged in the inner tower; a second spray head is arranged in the outer tower; a communication pipe which is communicated with the upper part of the inner tower is connected to the dust removing tower; a motor and a transmission shaft are arranged at the upper part of the dust removing tower; a cam is fixed to the transmission shaft; a first piston barrel is arranged at the lower part of the cam; a first piston is glidingly connected into the first piston barrel; a first pushing rod is fixed to the first piston; a dust removing mechanism is arranged in the dust removing tower; a pushing plate is glidingly connected into the dust removing tower; a second piston barrel is arranged below the pushing plate; asecond piston is glidingly connected into the second piston barrel; a second pushing rod is fixed to the second piston; a single-control switch and a third piston barrel are arranged in the dust removing tower. The dust removal and desulphurization tower is simple in inner structure, and is capable of fully performing desulphurization.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

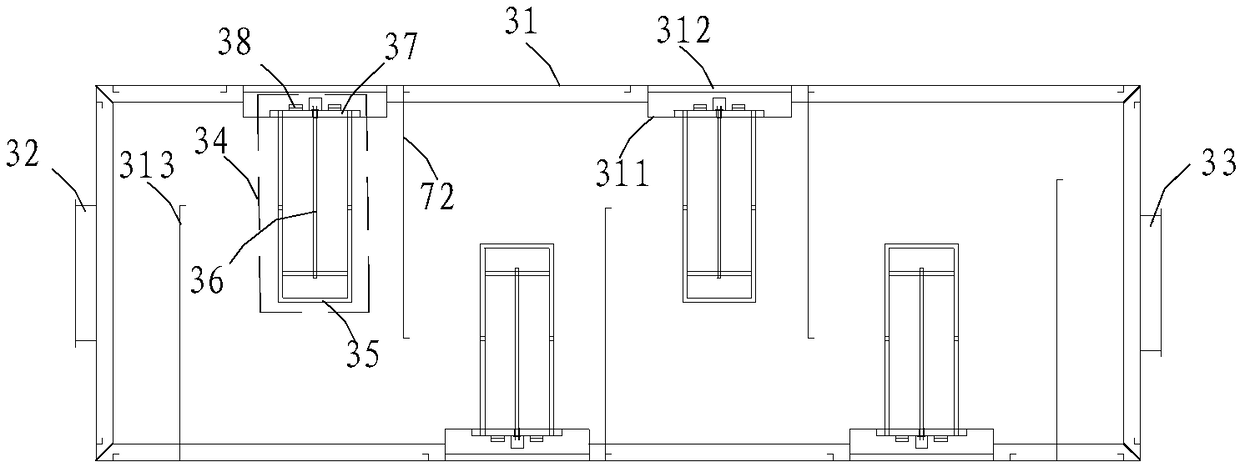

Electromagnetic energy buffering flowing chute device for aluminum alloy grain refinement

The invention discloses an electromagnetic energy buffering flowing chute device for aluminum alloy grain refinement, and relates to the technical field of metallurgy and metal material preparation. Aplurality of electromagnetic energy grain refinement devices are arranged above a buffering flowing chute, a chute body of the buffering flowing chute comprises a bottom plate and side enclosing plates fixed to the upper part of the bottom plate, a flowing chute inlet and a flowing chute outlet are correspondingly formed in the two ends of the side enclosing plates, a plurality of side baffles are fixed to the inner walls of the side enclosing plates, intervals exist between two any side baffles, a plurality of middle baffles are fixed to the middle of the bottom plate, intervals exist between two any middle baffles, and intervals exist between any one middle baffles and any one of side baffles. The electromagnetic energy grain refinement devices comprise iron cores and wire coils, the wire coils are wound on the iron cores, the two adjacent turns of wire coils are mutually insulated, and the wire coils and the iron cores are mutually insulated. The electromagnetic energy buffering flowing chute device can ensure aluminum alloy melt magnetic field processing time, effectively reduce the ingot casting grain size, and improve the product quality.

Owner:包头铝业有限公司 +1

Heat dissipation device of computer case heating parts

InactiveCN106873741AImprove cooling efficiencyImprove cooling effectDigital data processing detailsEngineeringComputer engineering

The invention belongs to the field of computers, and particularly discloses a heat dissipation device of computer case heating parts. The heat dissipation device includes a heat dissipation fan arranged in a case; an air collection groove is arranged on an air outlet part of the heat dissipation fan; an air pipe communicates with the air collection groove; a heat dissipation mechanism is opposite to a position of the air outlet part of the air pipe; the heat dissipation mechanism includes a plurality of heat dissipation units arranged on heating parts; the rotation shaft is connected between the heat dissipation units; a plurality of rotation blades are coaxially arranged on the rotation shaft. The scheme can performing first heat dissipation, second dissipation, and third dissipation on the case heating parts, can greatly improve the heat dissipation efficiency of the case heating parts, and is excellent in heat dissipation effect.

Owner:仁怀市云侠网络科技有限公司

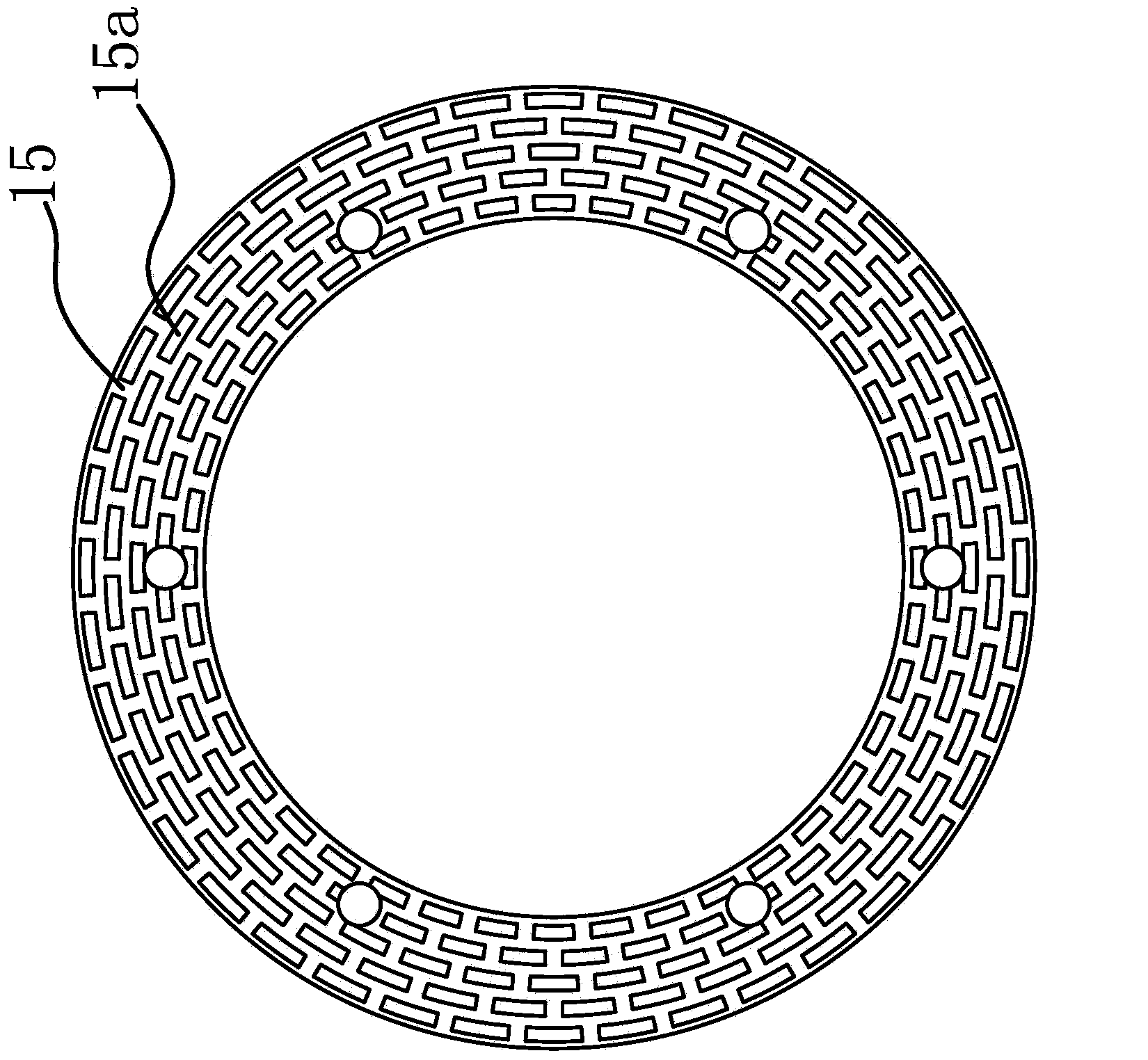

Explosion-proof valve

InactiveCN101187336AReduce airflowGood flame extinguishing performanceMachines/enginesEngine componentsHigh pressureBlow out

The invention provides an explosion-proof valve, belonging to the machinery technology field, which solves the problems that a current explosion-proof valve can not completely blow out flame in the explosion-proof valve, and the effect of reducing high pressure air flow in explosion is not favorable. The explosion-proof valve comprises a ring-shaped seat board, a panel which is fixed with the seat board, a plurality of ring-shaped flame-proof sheets which are fixed between the panel and the seat board. The ring-shaped flame-proof sheets form a valve cavity by superposing layer upon layer, and a gap is left between two adjacent flame-proof sheets. A movable closing plate of a valve orifice is arranged in the valve cavity, a spring whose two ends are respectively pressed on the panel and the closing plate of the valve orifice are arranged between the panel and the closing plate of the valve orifice of the valve, and a ring-shaped flame-proof device is sleeved on the outside of the closing plate of the valve orifice. The ring-shaped flame-proof device is formed by the superposition of a plurality of sheets of flame-proof device, buckling passages are formed between the two adjacent sheets of flame-proof device, and a guiding structure which plays a guiding role for the closing plate of the valve orifice is arranged on the flame-proof device. The invention has the advantages of safe use, wonderful flame blow-out performance, sensitive closure and starting, and long service lift.

Owner:李潘宝

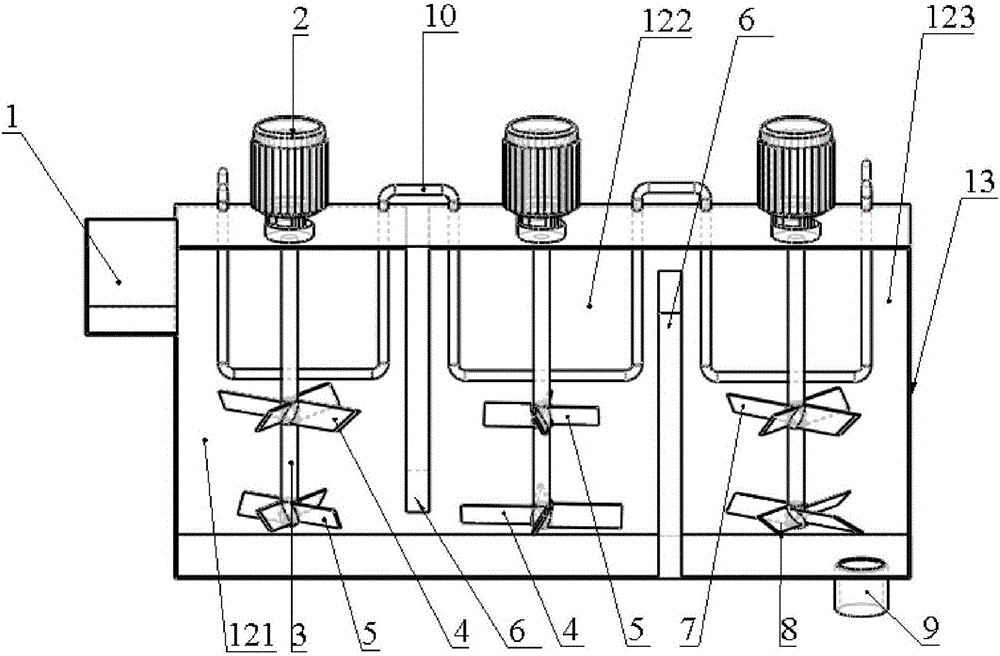

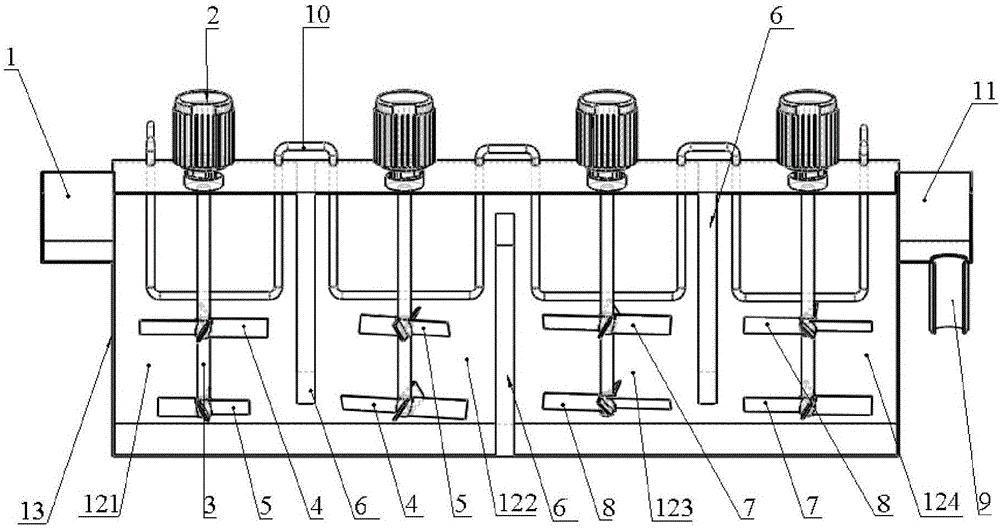

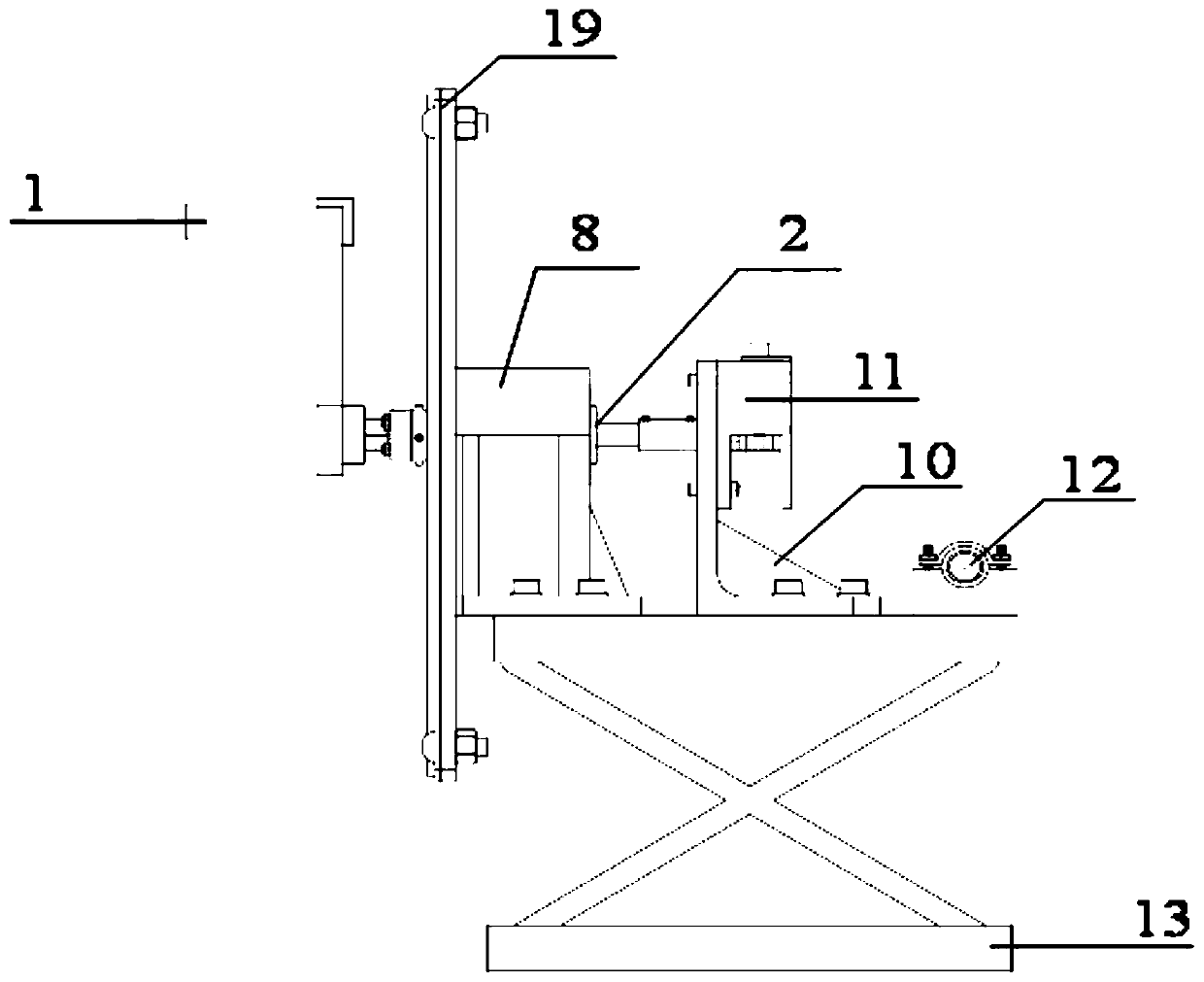

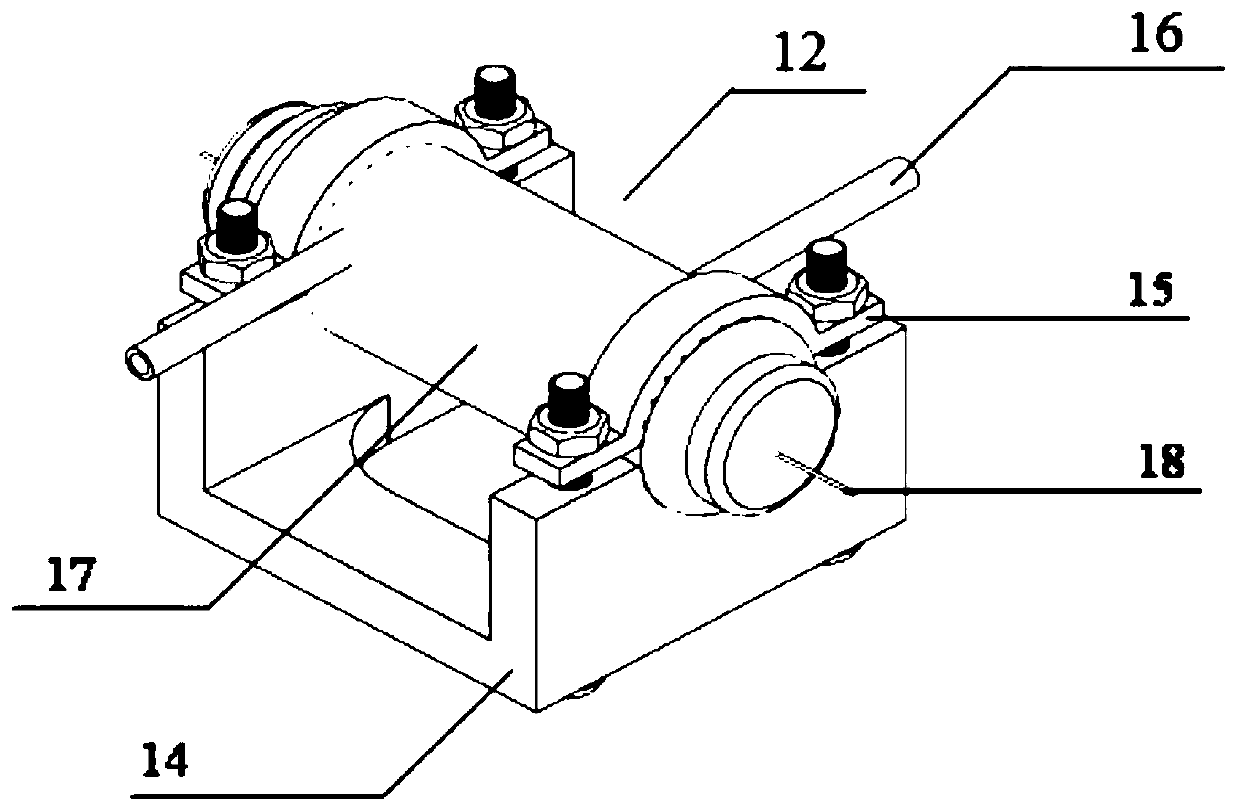

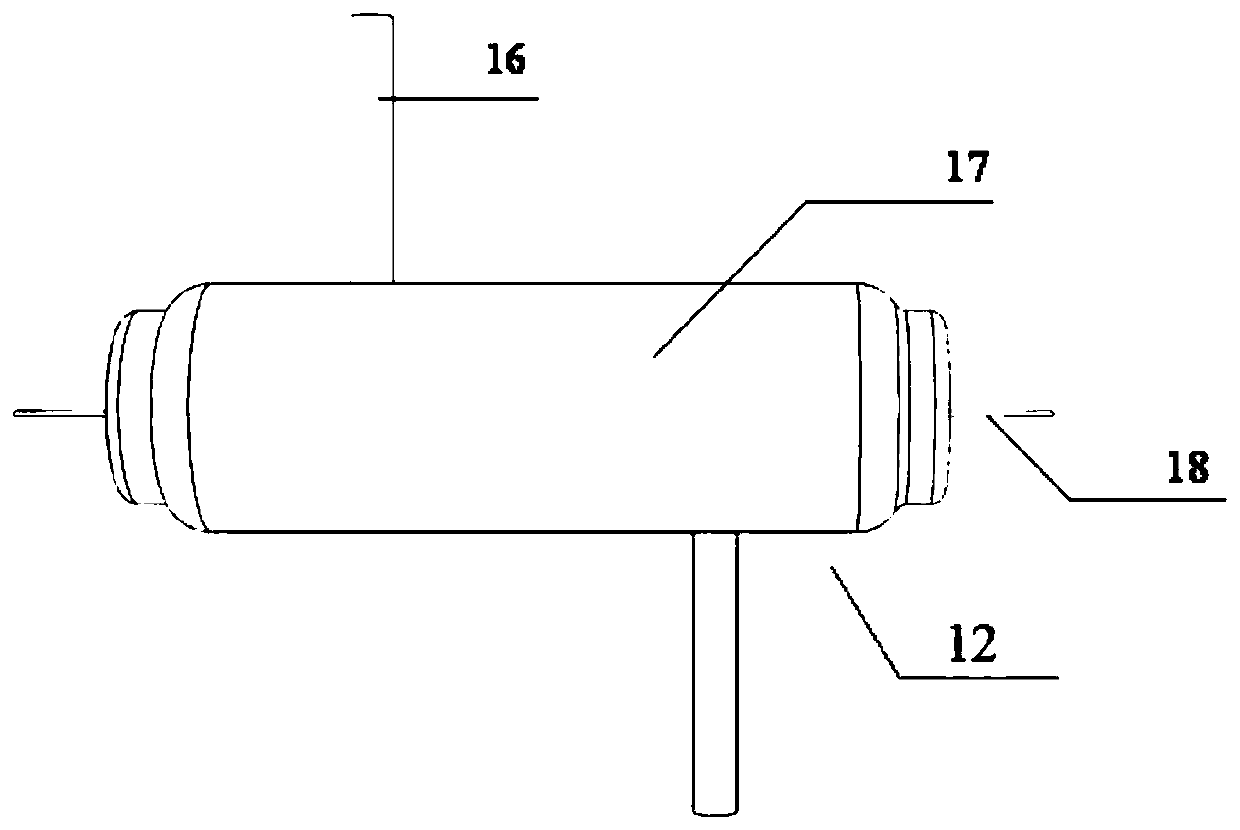

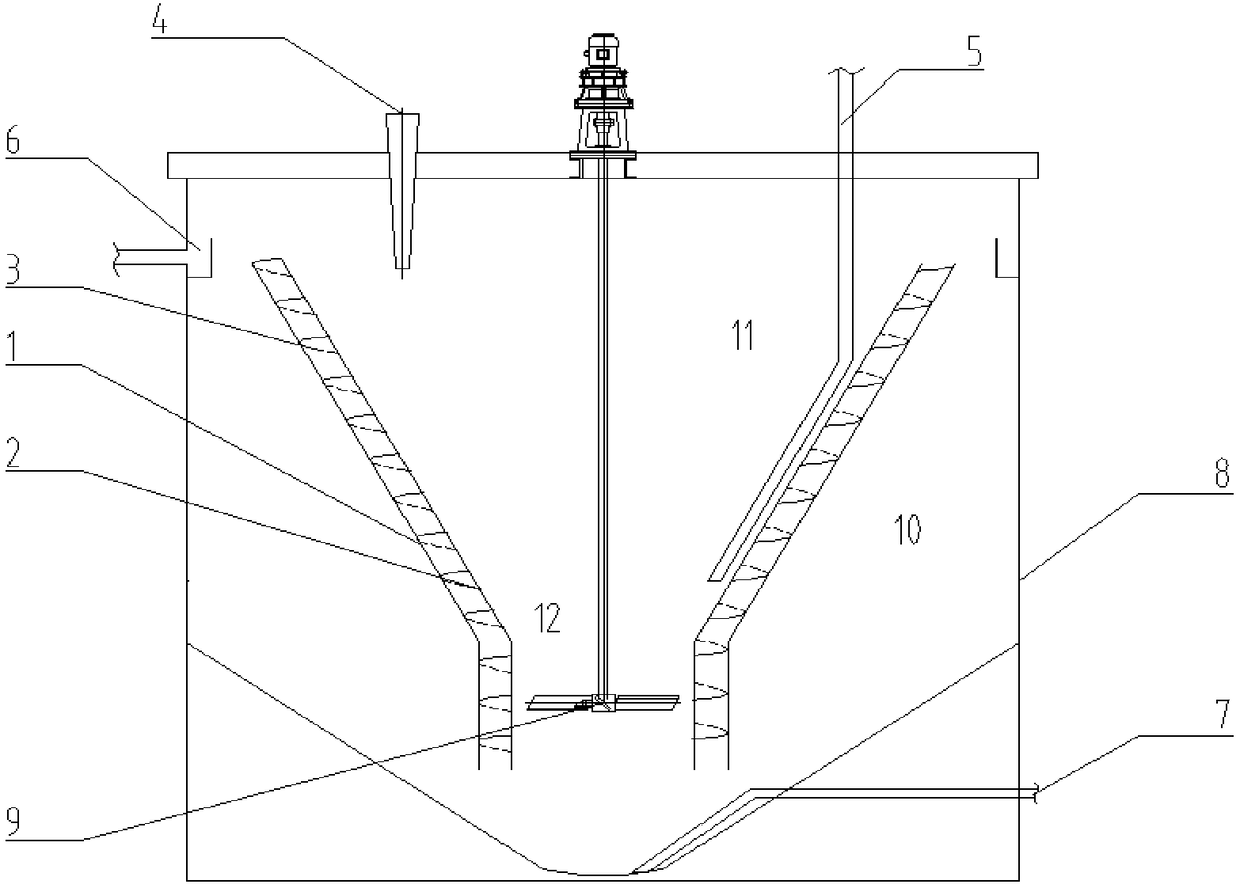

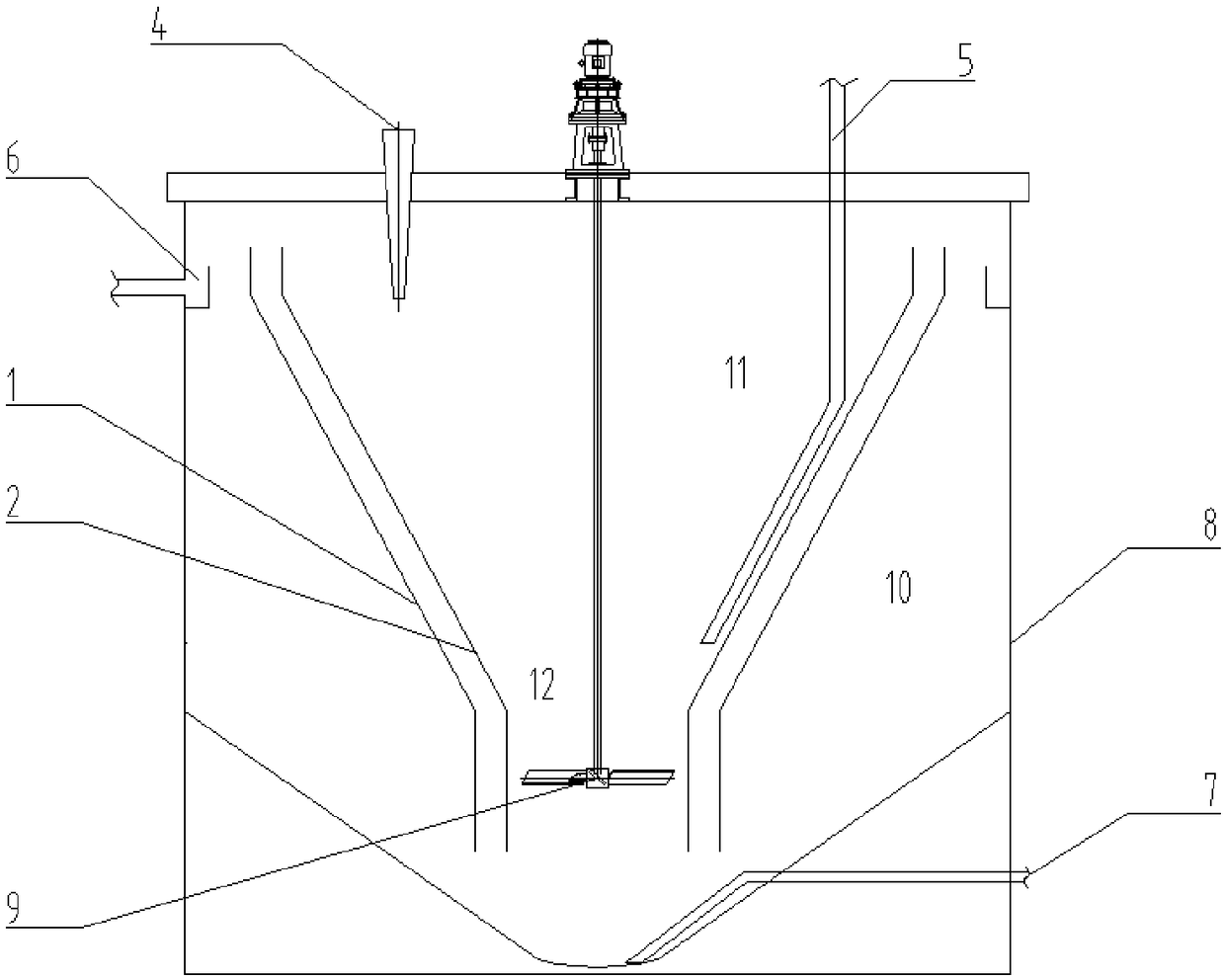

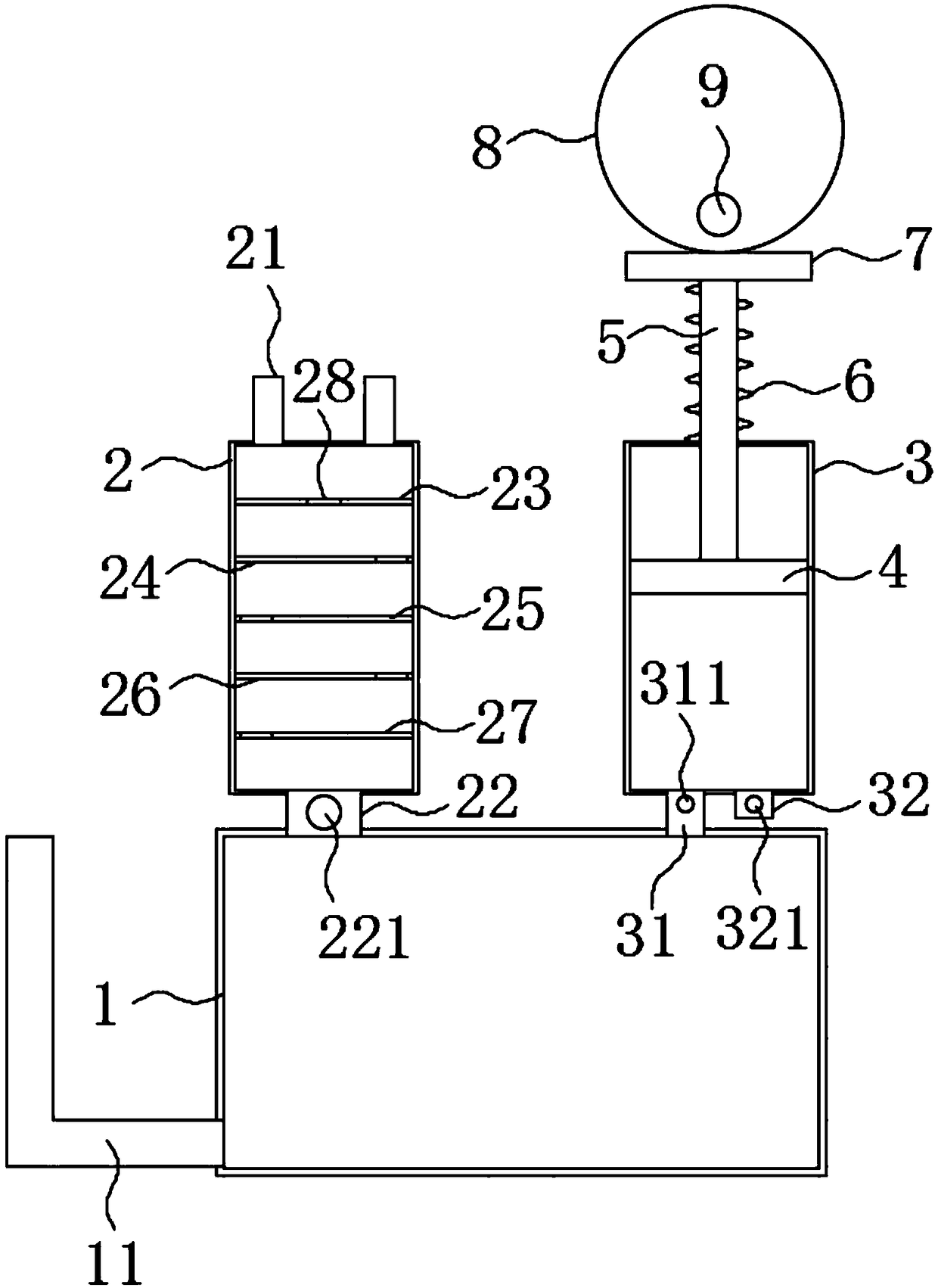

Quicklime slaking apparatus and method used for coke oven flue gas desulphurization

PendingCN106582422AImprove digestibilityIncrease the flow distanceGas treatmentTransportation and packagingFlueProcess engineering

The invention relates to a quicklime slaking apparatus and method used for coke oven flue gas desulphurization. The apparatus comprises a slaking tank, a motor, stirring shafts, blades, a temperature control device and separator plates, the separator plates are arranged in the slaking tank to separate the inner cavity of the slaking tank into a plurality of areas, one stirring shaft is arranged in every separated area, every stirring shaft is provided with two groups of blades, the groups of the blades have opposite tilting directions, the diameter / propeller pitch angle of one group of the blades is more than that of the remaining group, and the temperature control device is also arranged in the slaking tank. The temperature change of a liquid in the tank is controlled in the invention, so the quicklime slaking rate is improved. Arrangement of the flow of a lime slurry in the tank is helpful for proceeding a slaking reaction and enhances solid and liquid mixing. A guiding flow flows according to a required path, so deposition at the bottom of the tank is reduced, the stirring capacity is enhanced, the particle size of the solid is refined, the slaking reaction is promoted, pipeline obstruction is reduced, and the desulphurization technology effect is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Ultraviolet water sterilization device realizing electrification with friction

ActiveCN110182892ATo achieve the purpose of water sterilizationAchieve transformationWater/sewage treatment by irradiationSpecific water treatment objectivesNanogeneratorNoble gas

The invention provides an ultraviolet water sterilization device realizing electrification with friction. The device comprises a mechanical energy input device, a planet gear speed increaser, a friction nanogenerator, a water pump and an ultraviolet lamp, wherein the output end of the mechanical energy input device is connected with an input shaft of the planet gear speed increaser and a rotor ofthe friction nanogenerator, and an output shaft of the planet gear speed increaser is connected with an input shaft of the water pump through a coupler; the ultraviolet lamp adopts a screw type or overflowing type and comprises a lamp tube, water pipes and first and second wire electrodes connected with first and second output ends of the friction nanogenerator, one end of each water pipe serves as a water inlet to be communicated with a water outlet of the water pump, and to-be-sterilized water is introduced into a water inlet of the water pump. the ultraviolet lamp and the friction nanogenerator are combined, high enough voltage is produced by collected mechanical movement under the effect of electrification with friction, rare gas in the ultraviolet lamp tube is broken down, the ultraviolet lamp tube emits ultraviolet, conversion from mechanical energy to light energy is realized, and the device is simple and portable.

Owner:TSINGHUA UNIV

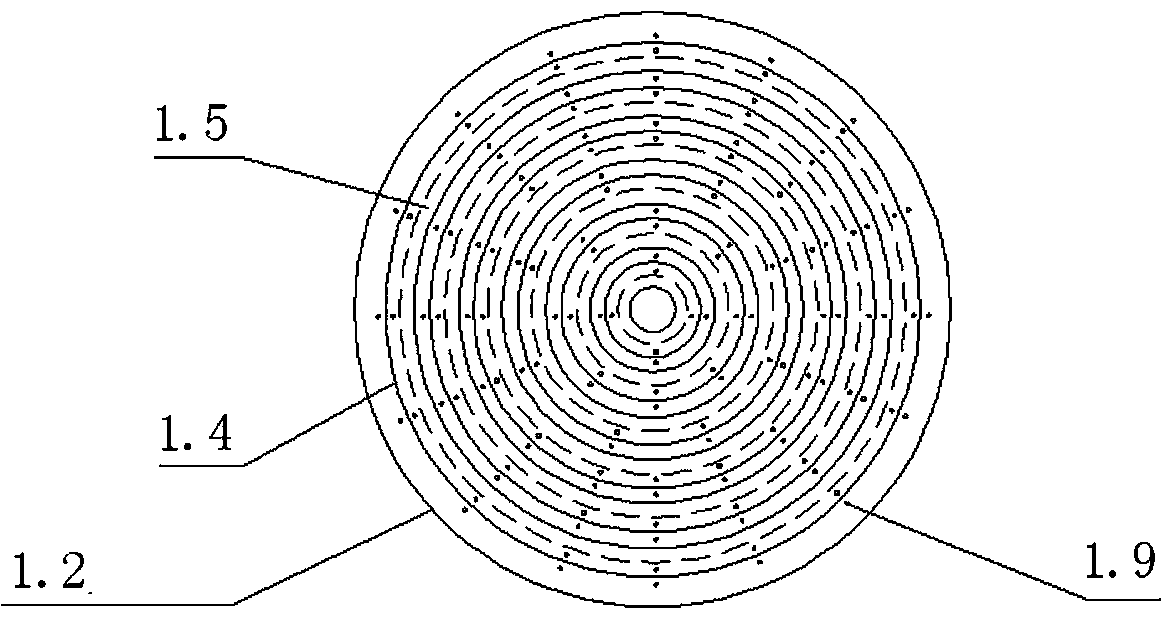

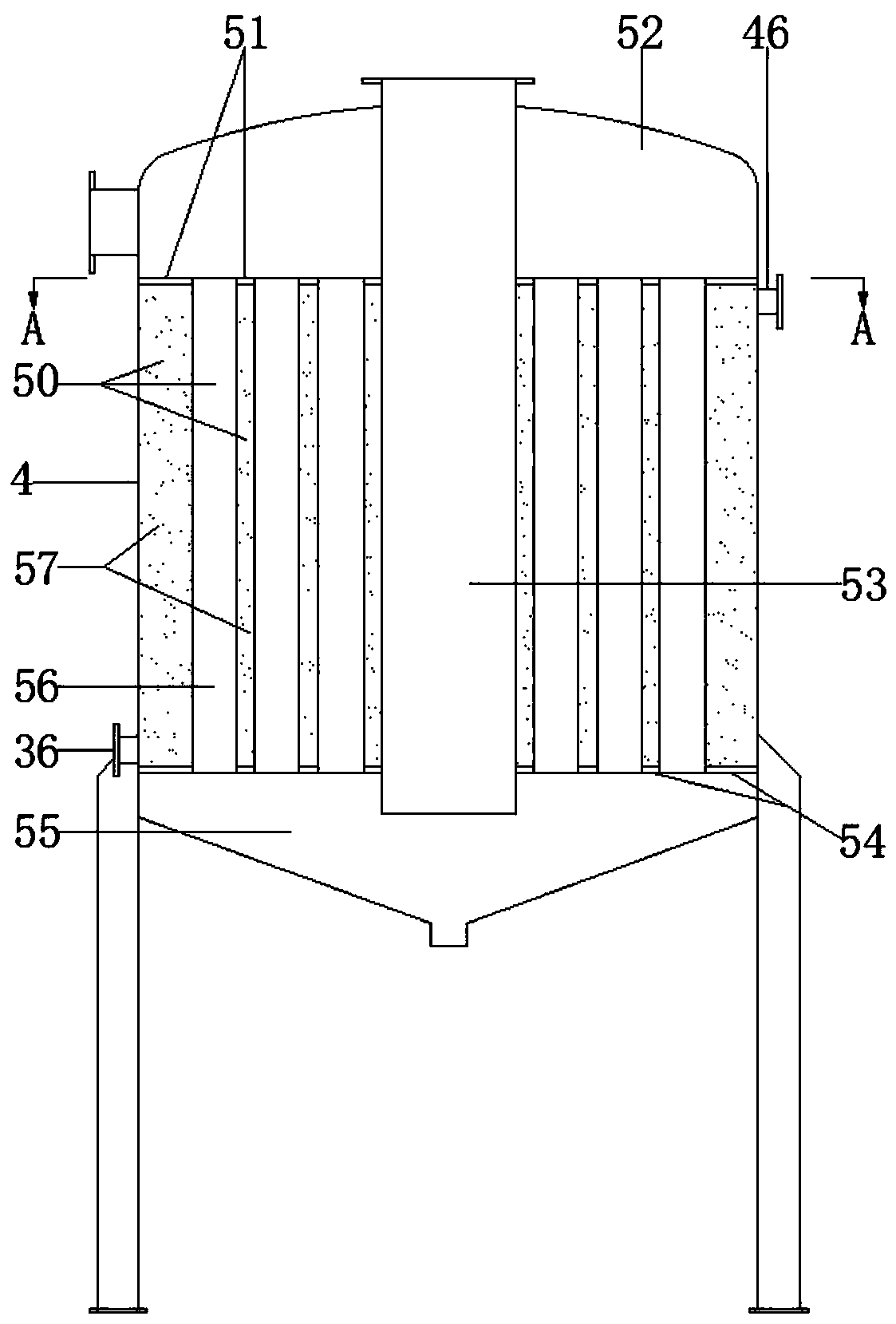

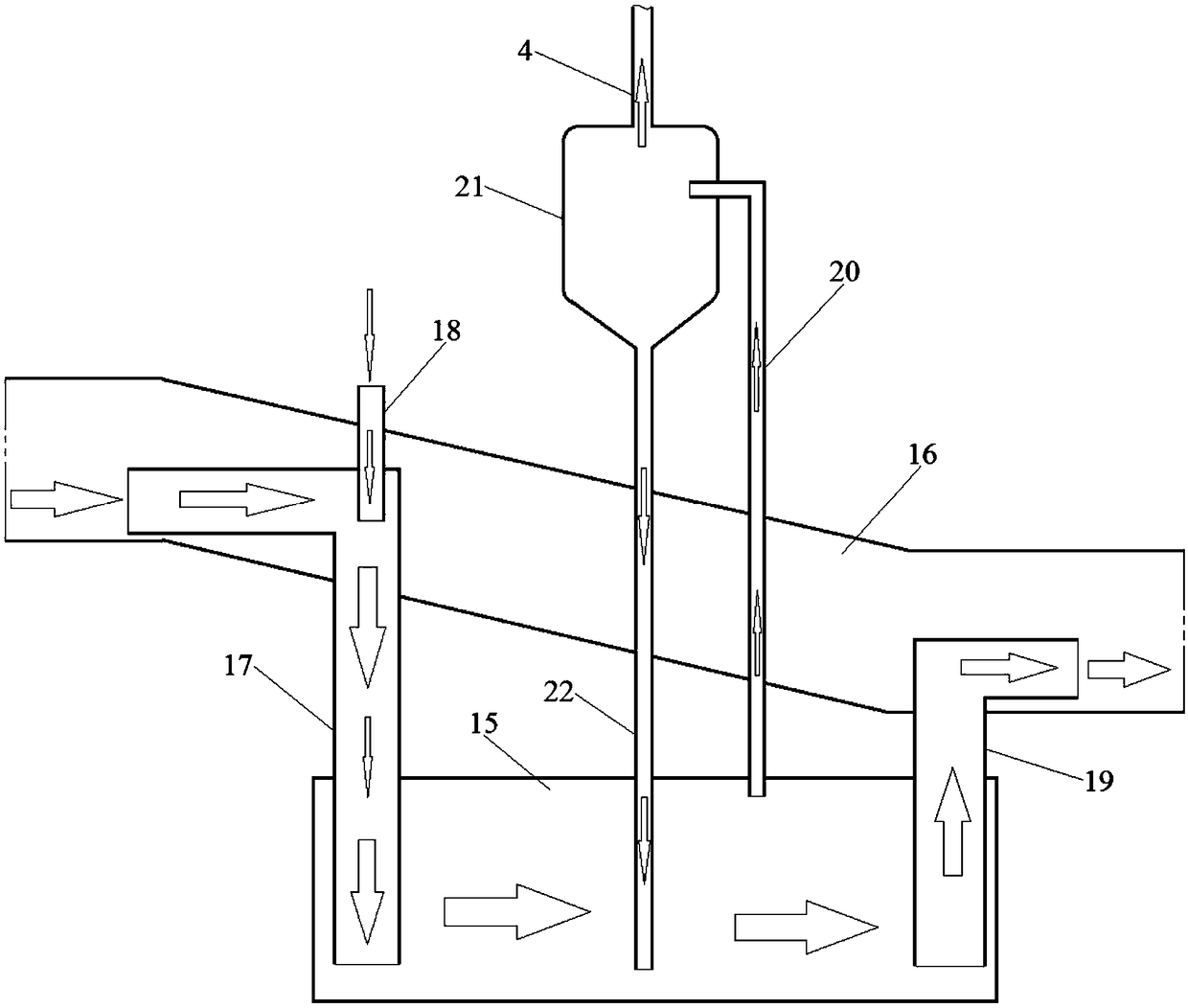

Crystallizer for hydrolyzing carnallite to prepare potassium chloride

PendingCN109173327AIncrease the flow distanceExtended staySolution crystallizationAlkali metal chloridesChloride potassiumDecomposition

The invention provides a crystallizer for hydrolyzing carnallite to prepare potassium chloride. The crystallizer comprises a cylindrical shell, an inner cylinder and an outer cylinder which are coaxial are arranged in the shell, and an annular interlayer is formed between the inner cylinder and the outer cylinder, wherein a plurality of spiral flow guiding plates are arranged in the interlayer atintervals to make a plurality of spiral flow guiding channels formed in the interlayer. The crystallizer is provided with the spiral flow guiding channels, so the flow path of carnallite and a decomposition mother liquor is significantly increased, thereby the residence time is greatly prolonged, and the sufficient hydrolysis of the carnallite, especially large-particle size carnallite, is facilitated; and when the potassium chloride is produced by using the crystallizer, the materials can simultaneously have two modes of full mixed flow and plug flow, so the production efficiency of the crystallizer and the recovery rate of potassium chloride are improved, and the consumption of raw materials and energy in the production process is reduced.

Owner:北京恩泽佳立科技有限公司

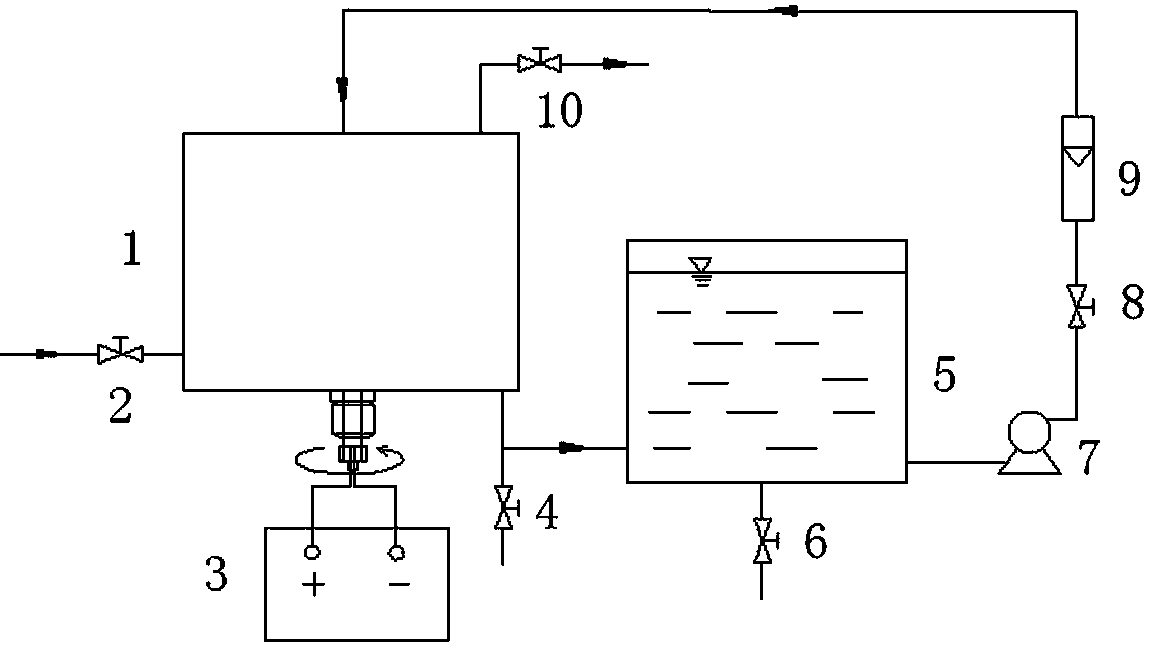

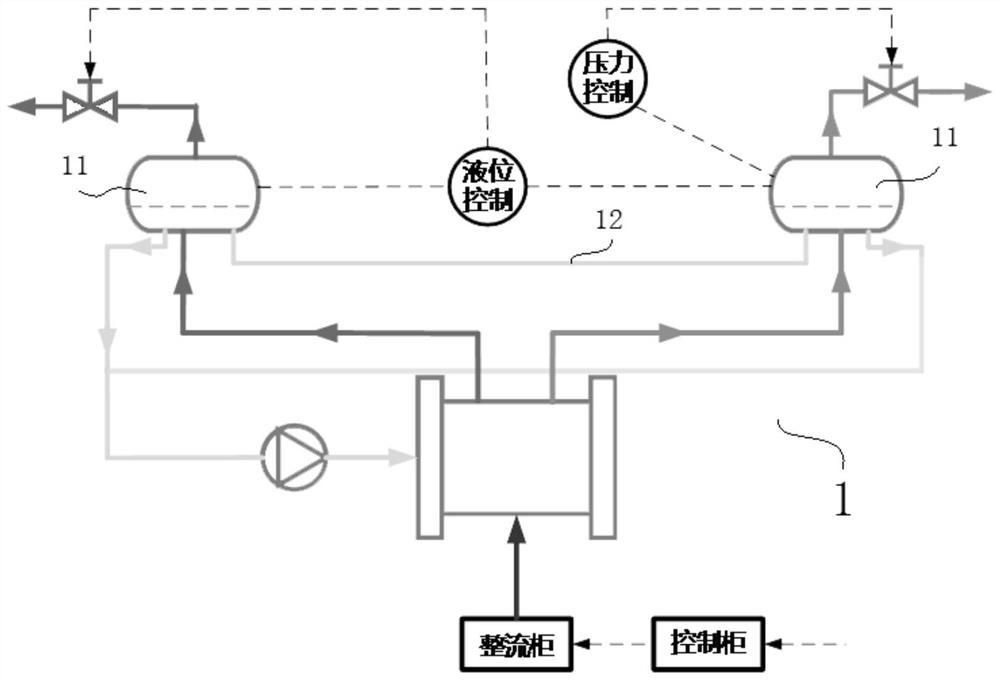

Device and method for maintaining liquid level balance of alkaline electrolysis system and inhibiting blow-by risk

ActiveCN113621975AImproving the safety performance of off-grid hydrogen productionPrevent inflowElectrolysis componentsEnergy inputVapor–liquid separatorElectrolysis

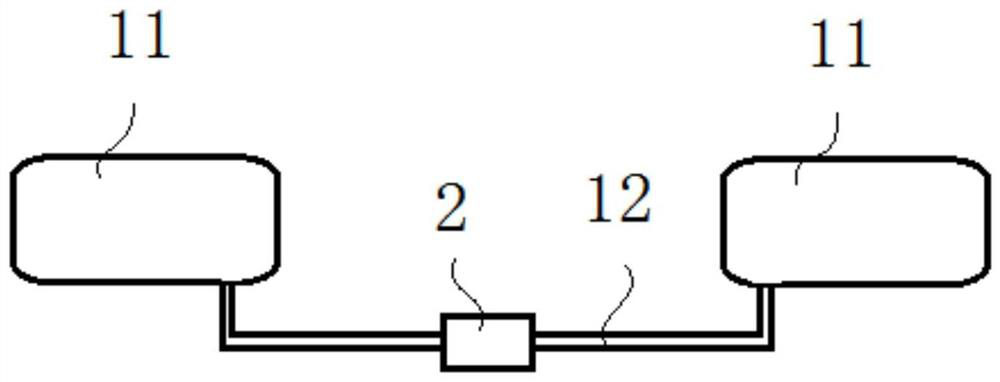

The invention discloses a device and a method for maintaining liquid level balance of an alkaline electrolysis system and inhibiting a blow-by risk. The method comprises the step of installing a safety device for inhibiting the blow-by risk on a U-shaped pipe between two gas-liquid separators in the alkaline electrolysis system. The mode for restraining the blow-by risk of the two gas-liquid separators in the alkaline electrolysis system through the safety device comprises at least one of slowing down the flowing speed of liquid in the U-shaped pipe, increasing the flowing path of the liquid in the U-shaped pipe and reducing the flow of the liquid in the U-shaped pipe passing through the safety device. According to the invention, when the electrolysis power is changed, the alkali liquor in the gas-liquid separator on one side can be effectively prevented from carrying hydrogen or oxygen to flow into the other side under the action of pressure, so that the blow-by risk caused by breaking the liquid level balance is avoided, and the safety problem under the condition of off-grid hydrogen production of the fluctuating renewable energy source is solved; and the off-grid hydrogen production safety performance of the alkaline electrolysis system is improved.

Owner:TSINGHUA UNIV

Planter and cultivation module applicable to ships

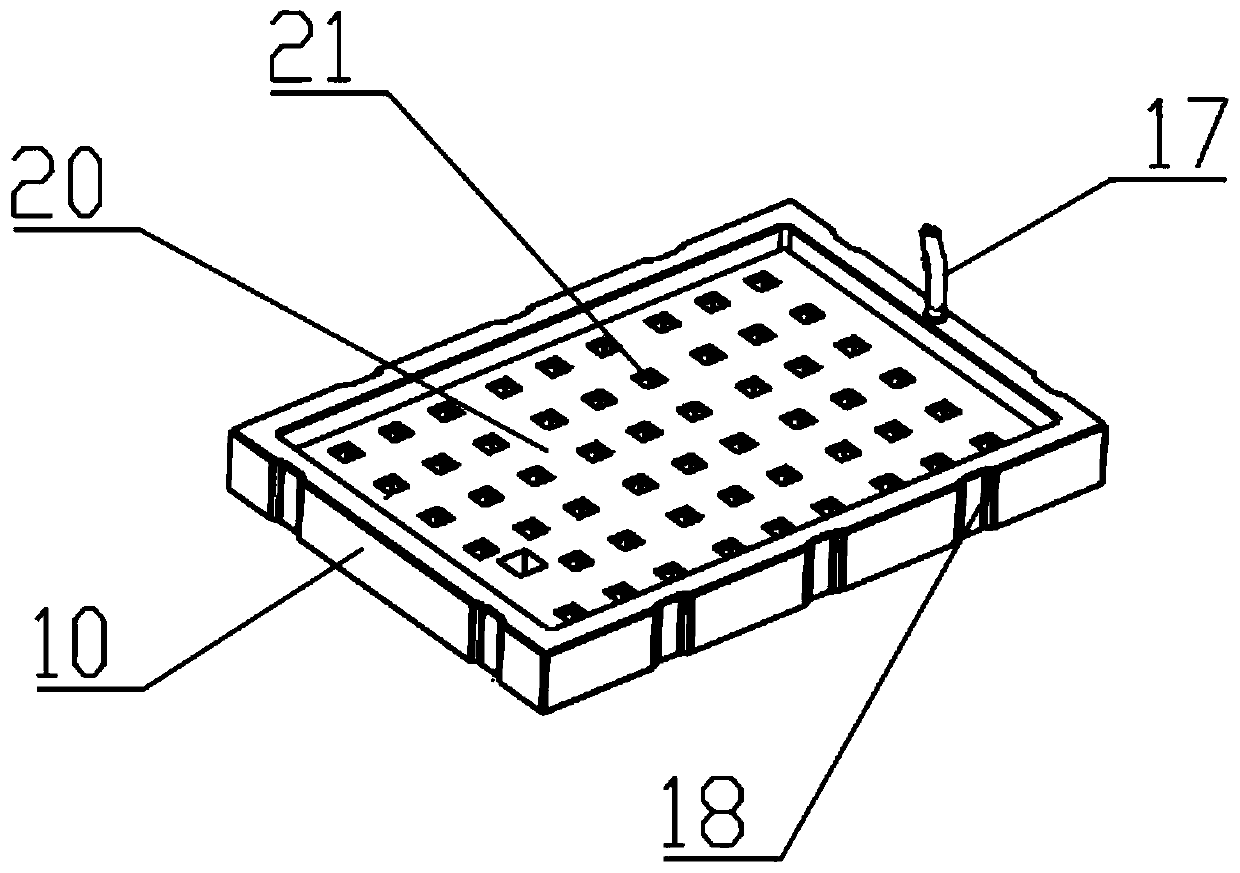

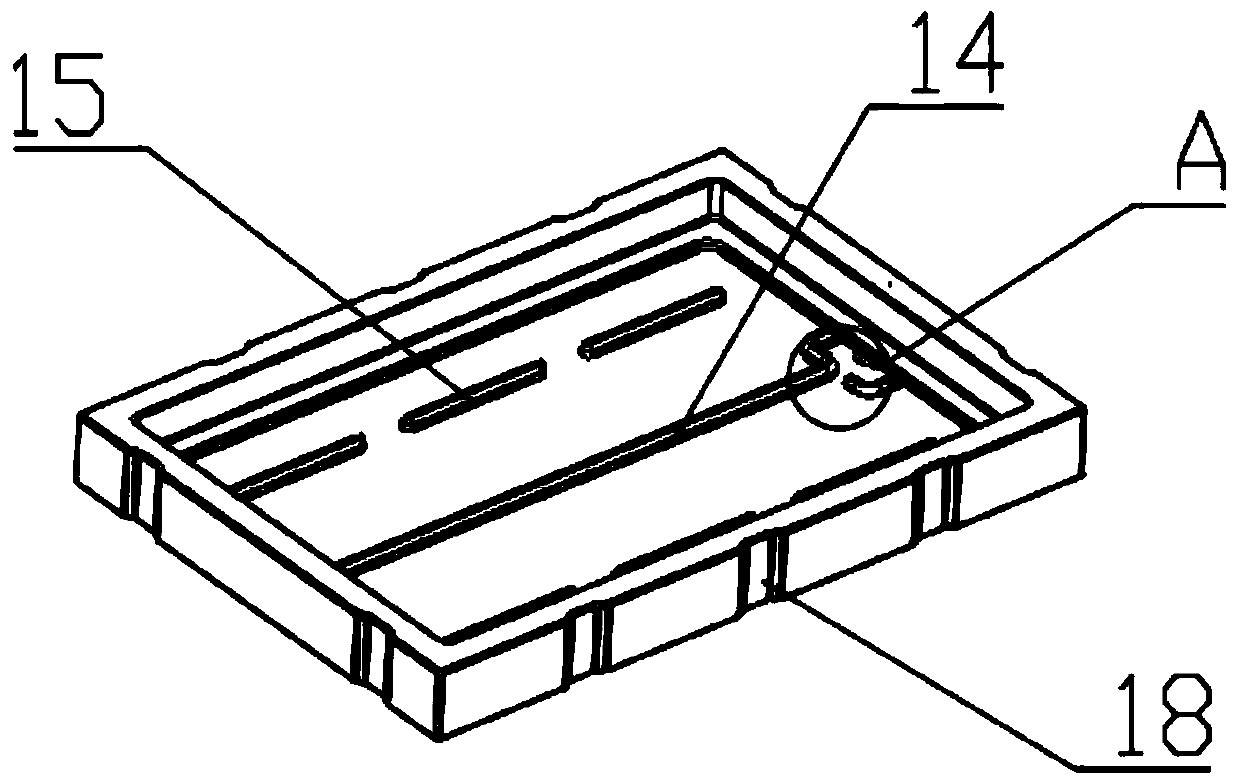

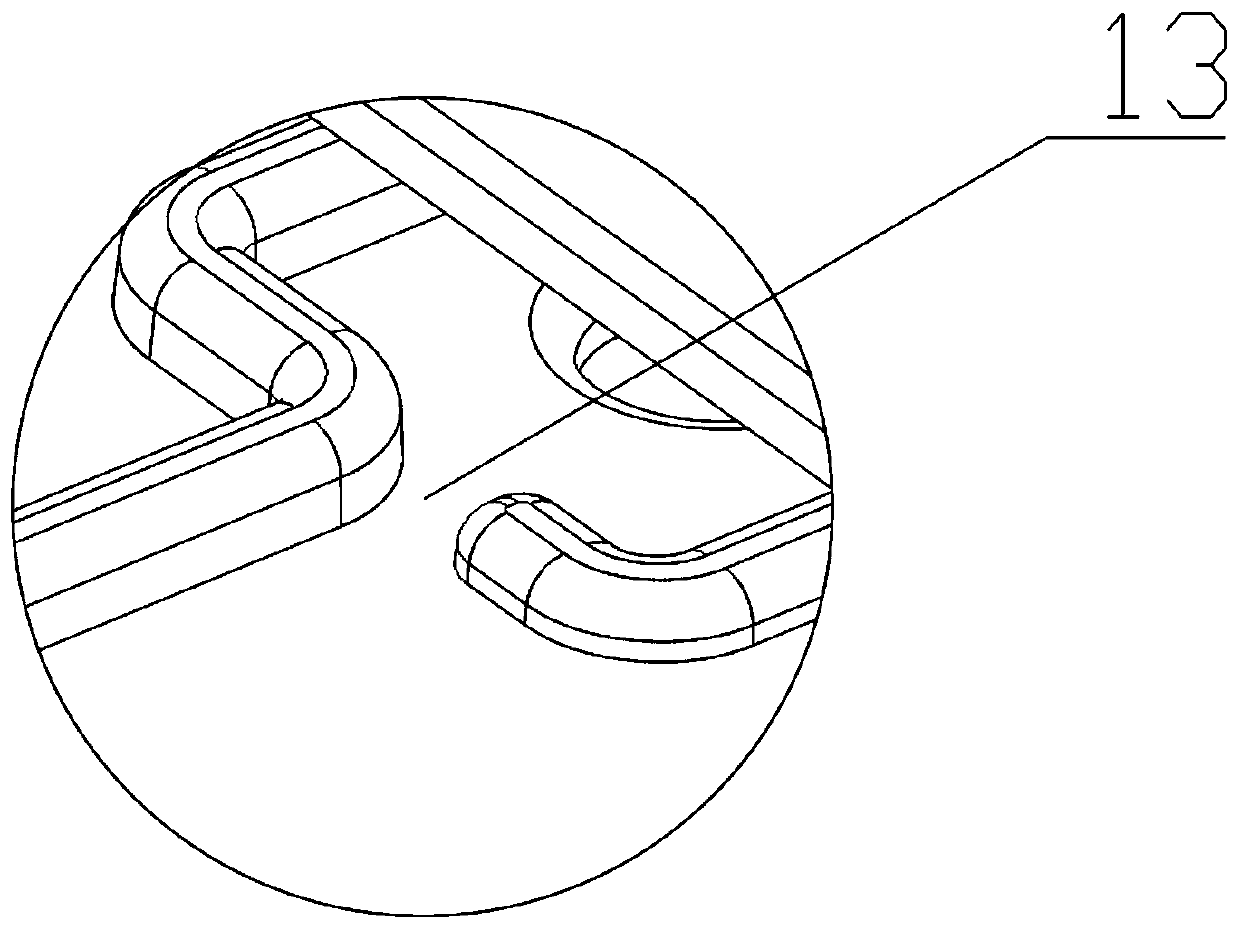

PendingCN111528079AHas water storage capacityIncrease water flowAgriculture gas emission reductionCultivating equipmentsWater storageWater flow

The invention relates to the field of plant-cultivating equipment and discloses a planter applicable to ships. The planter includes a field planting board and a cultivating tank. The cultivating tankis arranged with a water inlet and a water outlet. The cultivating tank includes a base plate and lateral plates surrounding and enclosing the base plate. The top of each of the lateral plates bends inward and extends to form a supporting platform. Water-storing space is formed between the supporting platform and one of the lateral plates. A water flow channel is formed between the supporting platform and the base plate. The water-storing space is communicated with the cultivating tank through the water flow channel. The field planting board is arranged on the supporting platform. The invention also discloses a cultivation module applicable to the ships. The plant-cultivating equipment provided by the invention can ensure that nutrient solution does not spill and plants can grow normally in a moving or shaking environment of conducting scientific investigation and moving equipment in places like oceangoing vessels, long-distance transport vehicles and remote and insecure regions.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

Clarifying device and clarifying method for glass

InactiveCN107827338AIncrease the flow distanceAvoid flowGlass furnace apparatusBiochemical engineeringOptical glass

The invention provides a clarifying device and a clarifying method for glass, belonging to the technical field of manufacturing of optical glass. The invention is to solve the problems of excessivelylong clarifying groove, easy damage of a platinum product and low clarifying efficiency for optical glass. The clarifying device is mainly characterized by comprising an inlet pipe, a clarifying groove, an outlet pipe and a chimney, wherein the clarifying groove is a cavity with a cuboid shape or a covered U-shaped groove shape; the front end and the rear end of the clarifying groove are respectively welded with the inlet pipe and the outlet pipe which are respectively used as an inflow channel and an outflow channel for liquid glass; the interior of the clarifying groove is provided with partition plates which are used for up-down separation, so independent separate layers with a plurality of layers in communication are formed, and the flowing route of the liquid glass in the clarifying groove is prolonged; a groove cover and the clarifying groove are seal-welded; and the chimney is arranged at the top part of the clarifying groove and used for discharging gas in the clarifying groove. The clarifying device provided by the invention has the characteristics of high efficiency and small size, and is mainly used for clarifying the optical glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

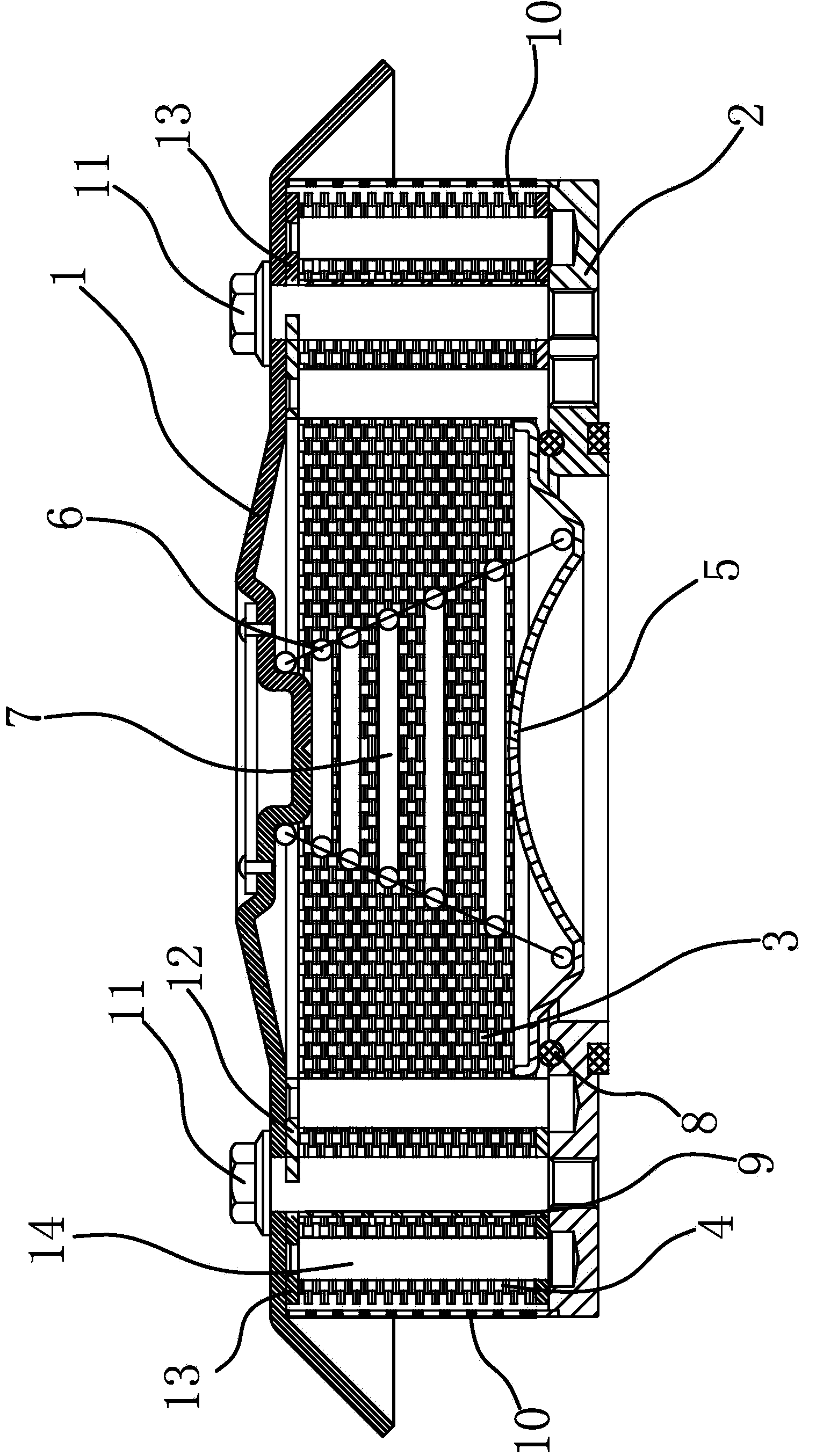

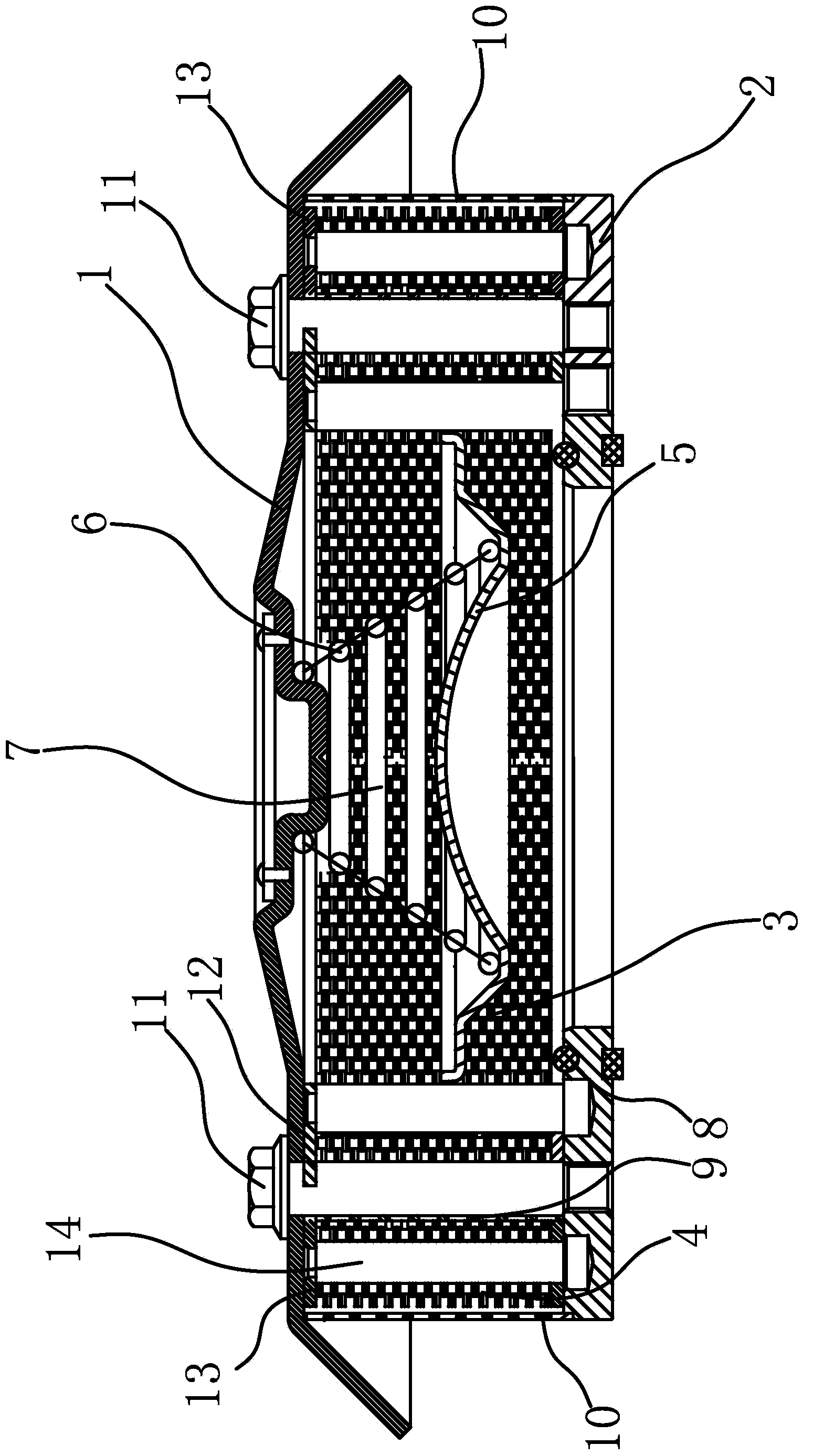

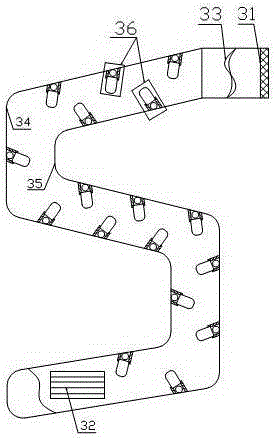

Spiral coil type diffusion dialysis membrane assembly and preparation method thereof

ActiveCN101983756BImprove performanceIncrease the average concentration differenceDialysisDialysis membranesCounter flow

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

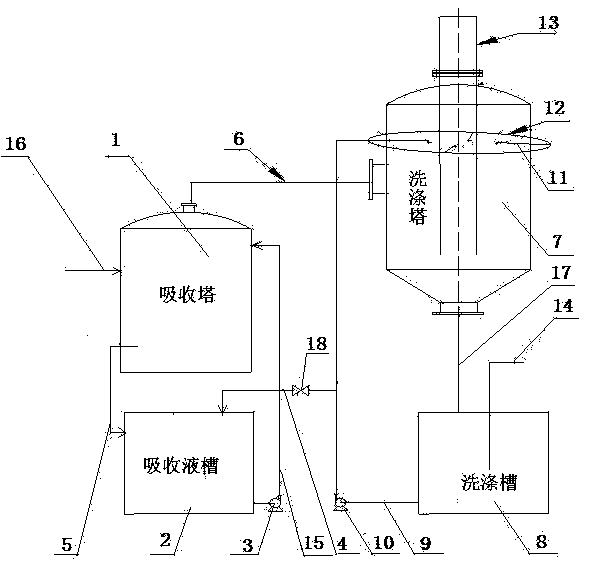

Device and method for increasing absorption rate of iodine-containing tail gas

InactiveCN104190211AImprove absorption ratePromote absorptionDispersed particle separationAbsorption columnEconomic benefits

The invention discloses a device and a method for increasing the absorption rate of iodine-containing tail gas. The device comprises an absorbing liquid tank, a washing tower and a washing tank, wherein absorbing liquid in the absorbing liquid tank is pumped into an absorbing tower, flows through the absorbing tower and then returns into the absorbing liquid tank by another pipeline; the top end of the absorbing tower is provided with a gas escaping hole which is connected with the washing tower by a pipeline; the bottom part of the washing tower is communicated with the washing tank by a pipe section; the side part of the washing tower is communicated with the washing tank by a pumping pipeline; a branch pipeline is arranged on the pumping pipeline and leads into the absorbing liquid tank. The device and the method disclosed by the invention have the advantages that by adoption of a two-stage circulating system, iodine absorption is facilitated, and iodine steam discharged to the outside is reduced to be 4mg / L, so that the environment-protecting requirement is met, and the effect is obvious; the iodine absorption rate is increased to be 80% and economic benefit is improved.

Owner:GANSU WENGFU CHEM

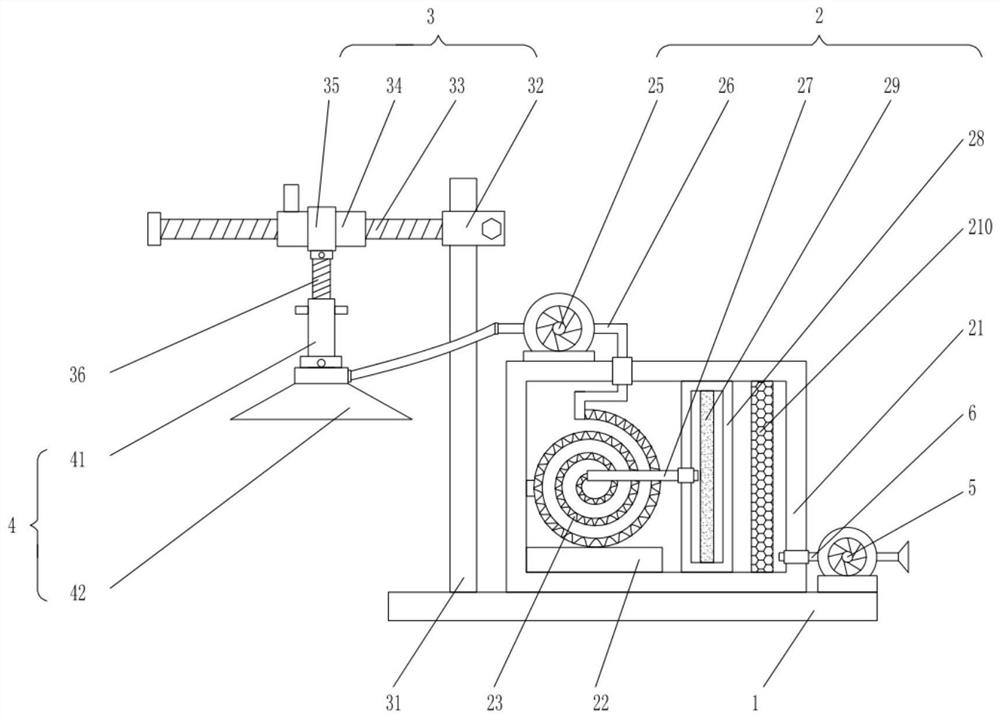

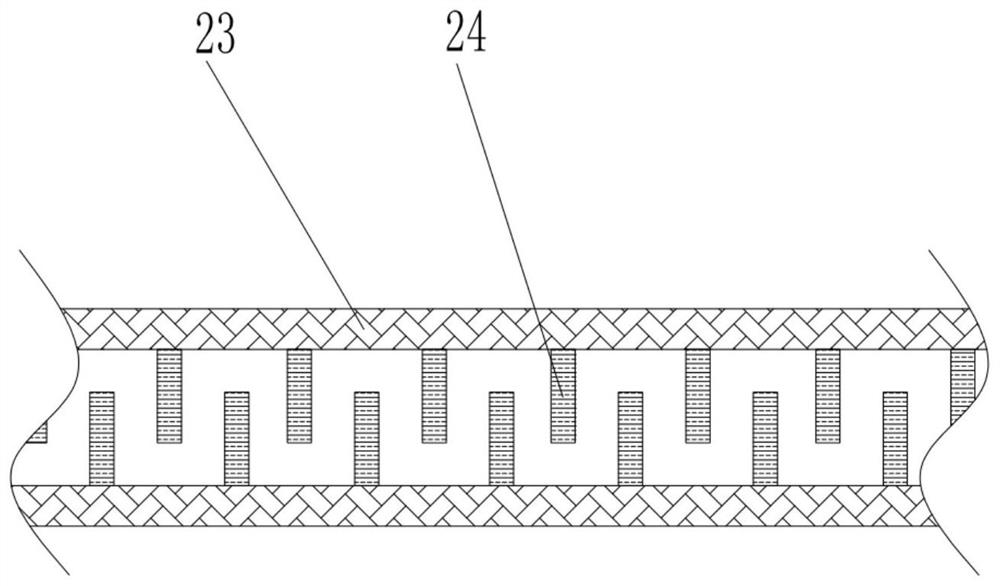

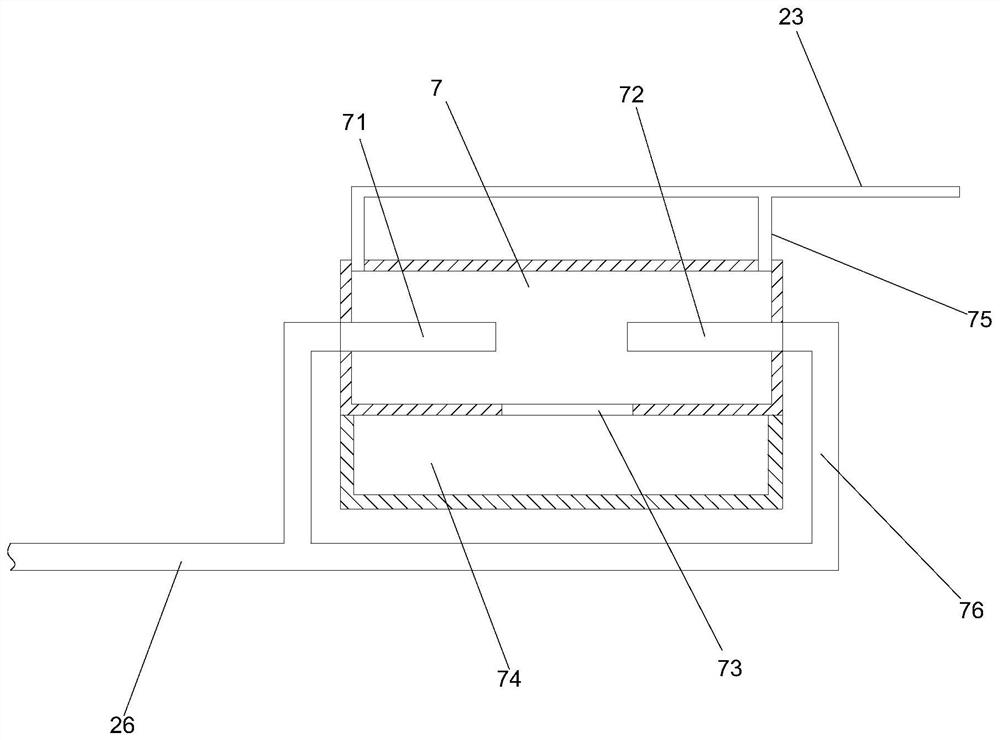

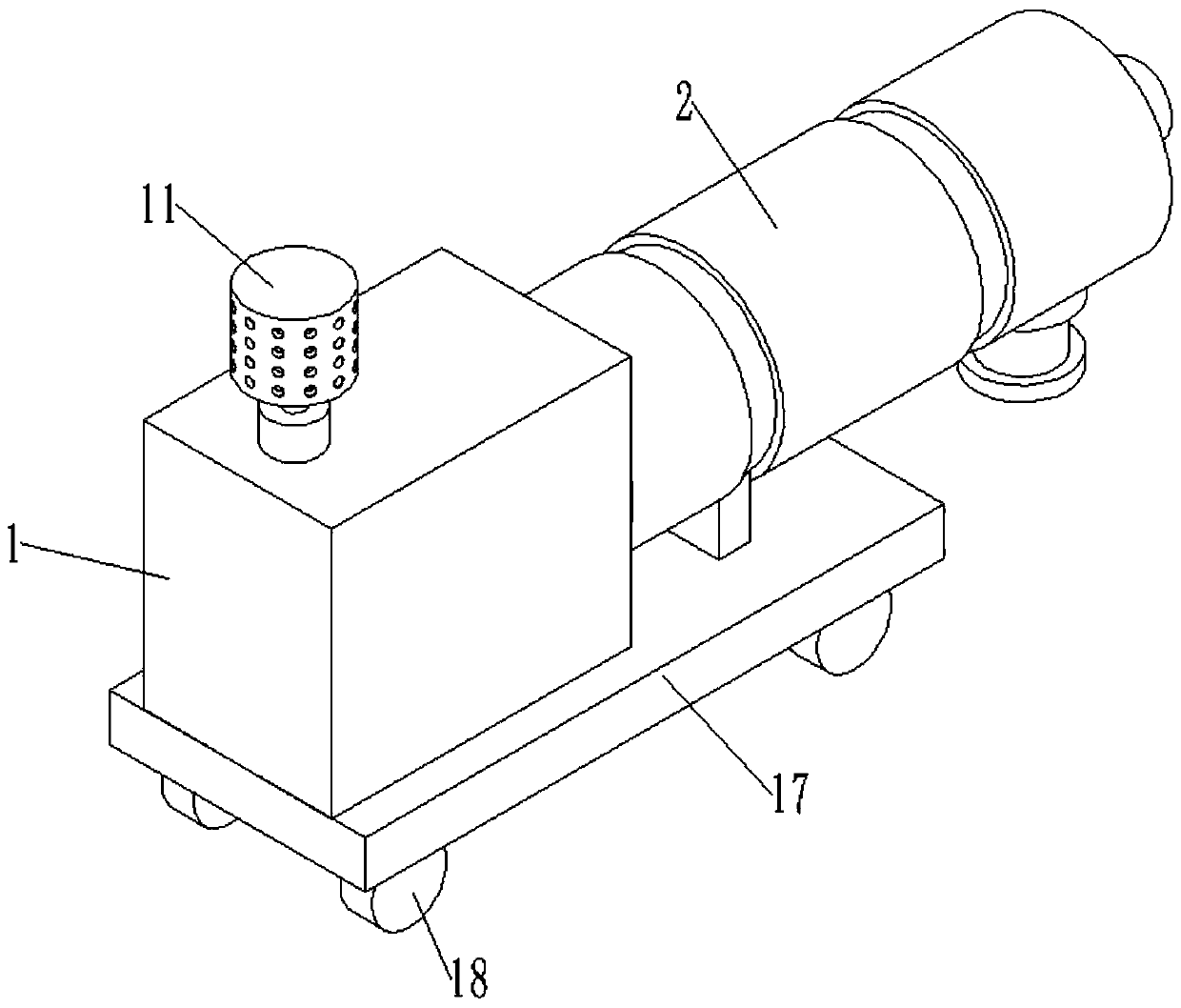

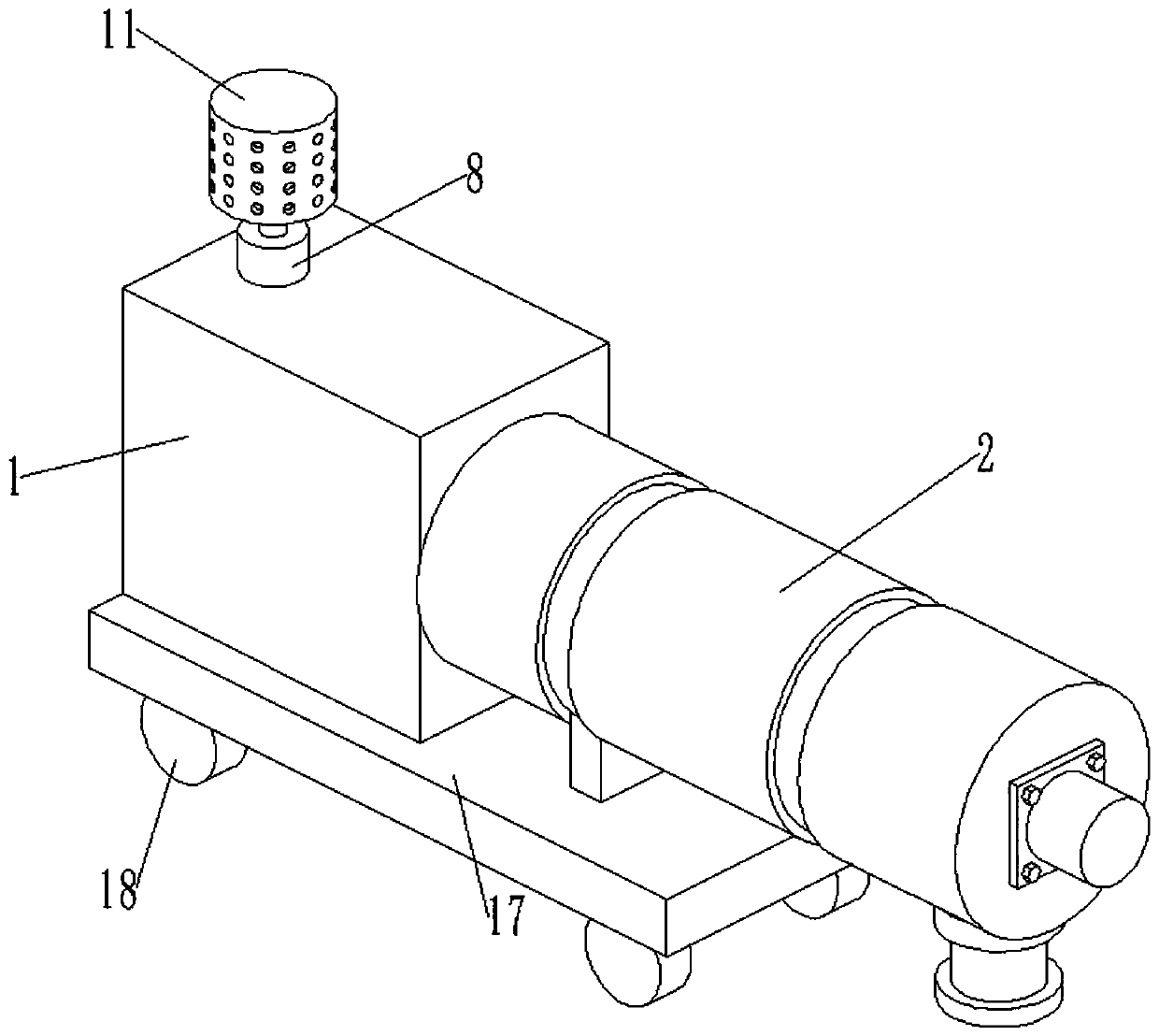

Waste gas treatment device for welding equipment

InactiveCN111672256AIncrease the flow distanceExtended processing timeCombination devicesActivated carbonProcess engineering

The invention provides a waste gas treatment device for welding equipment. The device comprises a machine frame, a gas collecting mechanism and a purifying mechanism are arranged on the machine frame,the purifying mechanism comprises a purification box, a filtering curved pipe, a filtering box and a filtering plate are arranged in the purification box, an exhaust pipe is arranged at one end of the purification box, the gas collecting mechanism is connected with an inlet end of the filtering curved pipe through a gas collecting pipe, the outlet end of the filtering curved pipe is connected with the filtering box through a conveying pipe, the filtering box, the filtering plate and the exhaust pipe are sequentially arranged, a plurality of filter short plates which are arranged in a staggered manner are arranged on the inner wall of the filtering curved pipe, and an activated carbon plate is arranged in the filtering box. Waste gas generated by welding sequentially passes through the filtering curved pipe, the filtering box and the filtering plate, so that the flowing path of the waste gas is increased and the waste gas treatment time is prolonged. The treatment effect is improved through multiple times of filtering or adsorption.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

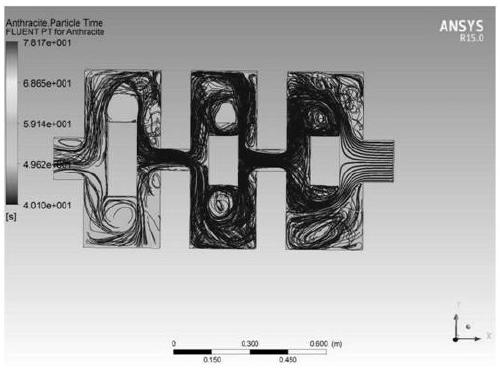

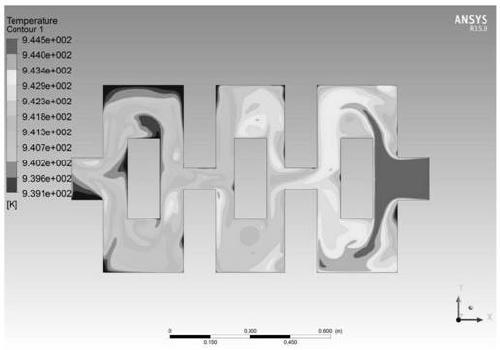

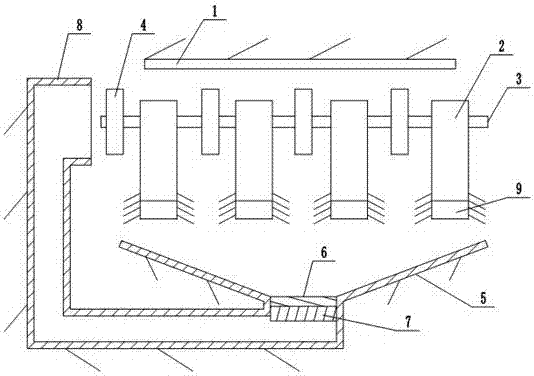

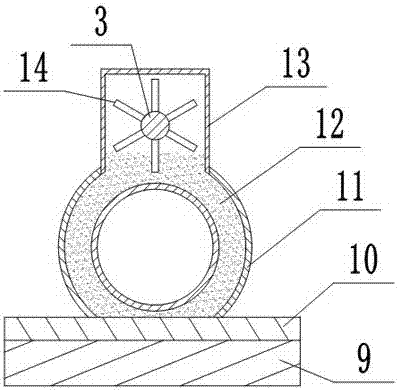

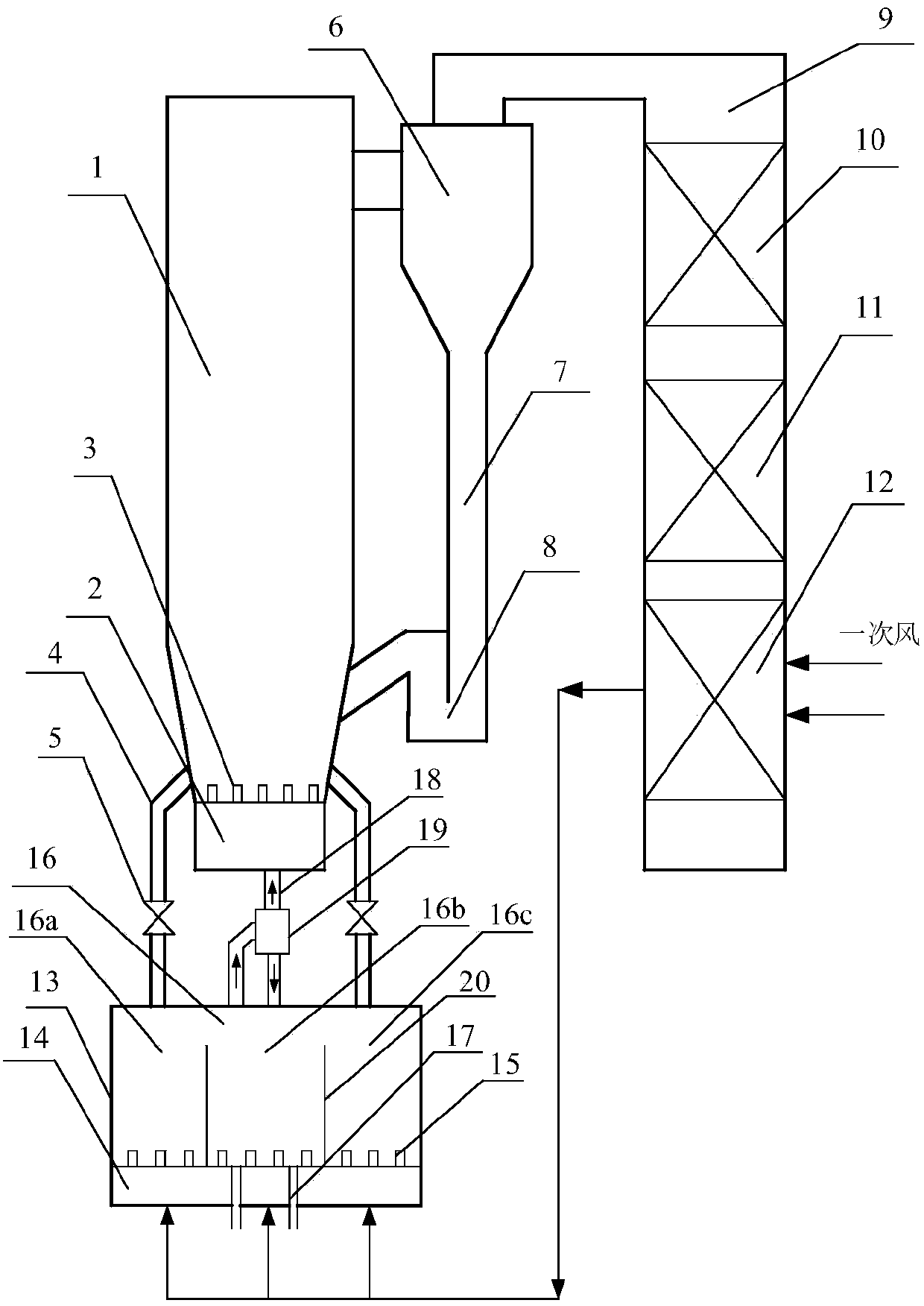

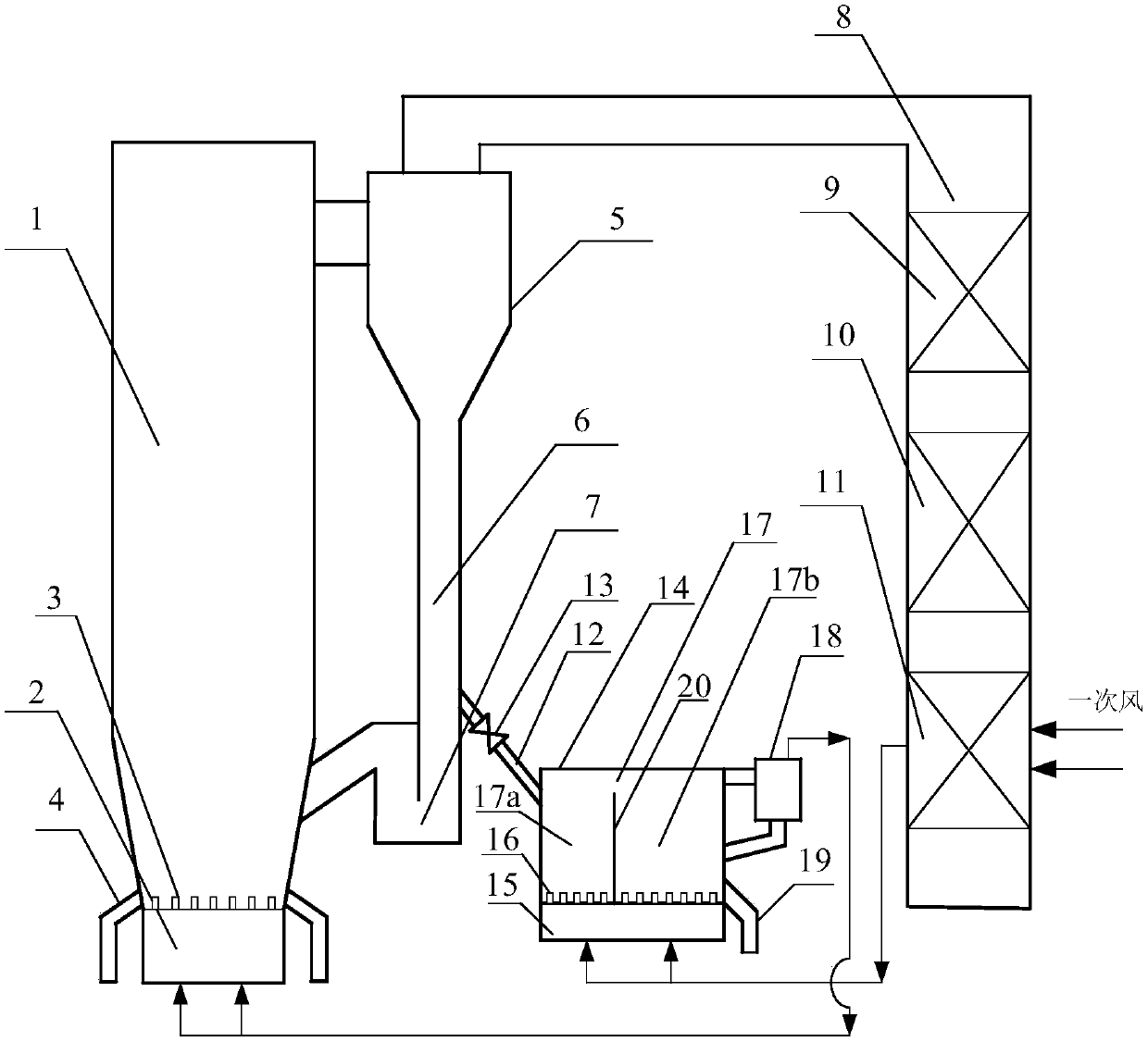

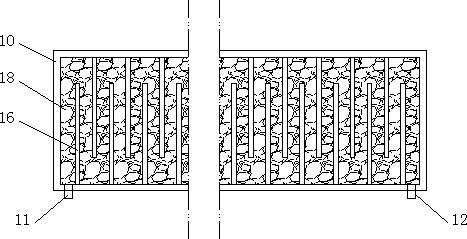

Circulating fluidized bed boiler for burning low-heat-value high-ash fuel

PendingCN107631294AHigh thermal efficiencyIncrease the flow distanceFluidized bed combustionIndirect carbon-dioxide mitigationAir preheaterSlag

A circulating fluidized bed boiler for burning low-heat-value high-ash fuel contains a hearth, a primary air chamber, a cyclone separator, a cyclone separator, a charge leg, a return valve, a slag discharge pipe, a tail flue and a gas-solid heat exchange bed. The gas-solid heat exchange bed is arranged below the primary air chamber and connected with the hearth through a connection pipe and a gas-solid separation device. The hearth is connected with the gas-solid heat exchange bed through the slag discharge pipe. The gas-solid heat exchange bed comprises a heat exchange bed air chamber, a heatexchange bed air cap, a heat exchange bed heat exchange chamber and a heat exchange bed slag discharge pipe. The heat exchange bed air chamber is connected with an air preheater through a gas pipeline. A large quantity of high-temperature ash residues in the hearth are discharged into the gas-solid heat exchange bed through the slag discharge pipe, and primary air is heated by the air preheater,is led into the gas-solid heat exchange bed and then enters the primary air chamber. By means of the circulating fluidized bed boiler, the temperature of the primary air can be greatly improved, and the requirement for stable burning of the low-heat-value high-ash fuel is met; and on the other hand, the heat of the large quantity of ash residues of the high-ash fuel can be recycled, the slag discharge heat loss is reduced, and thus the overall heating efficiency of the boiler is improved.

Owner:TSINGHUA UNIV

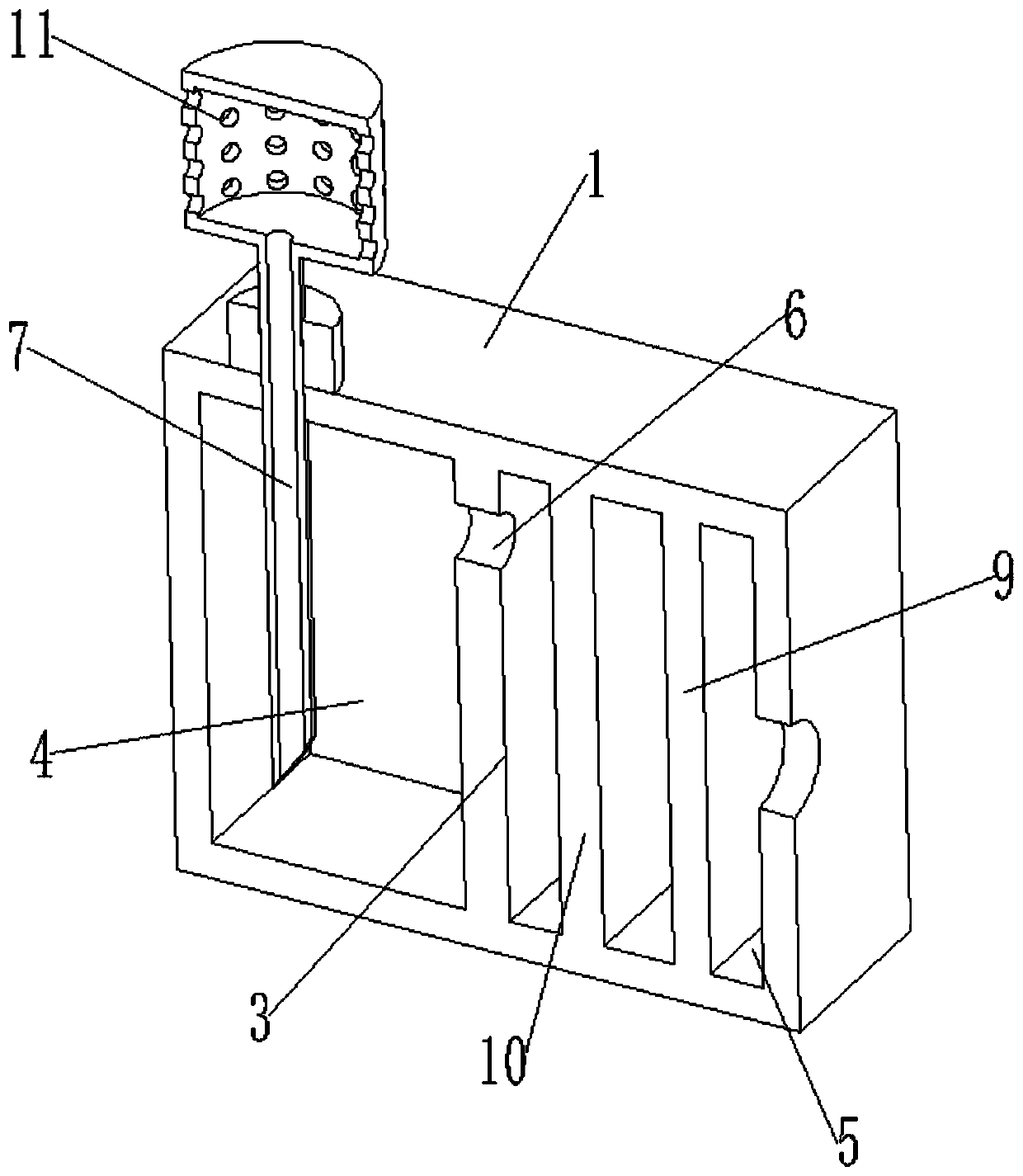

Crankcase anti-explosion valve

InactiveCN103711586AReduce maintenance difficultyEasy to findMachines/enginesEngine componentsCrankcaseMechanical engineering

The invention provides a crankcase anti-explosion valve, and belongs to the technical field of machines. The crankcase anti-explosion valve solves the problem that the assembling process of an existing anti-explosion valve is complex. An elastic earpiece with an improved structure comprises an annular base plate and a face plate fixedly connected with the base plate, the base plate is parallel to the face plate, a valve plate and a spring are fixed between the base plate and the face plate, an inner antiflaming block and an outer antiflaming block are further fixed between the base plate and the face plate, the inner antiflaming block and the outer antiflaming block are annular, and the inner antiflaming block is sleeved with the outer antiflaming block. The crankcase anti-explosion valve has the advantages that production efficiency is high, and the inner antiflaming block and the outer antiflaming block are convenient to replace.

Owner:李潘宝

Circulating fluidized bed boiler for burning low-heat-value high-ash fuel

PendingCN107606609ASufficient heat exchangeExtend heat exchange timeFluidized bed combustionApparatus for fluidised bed combustionAir preheaterSlag

The invention relates to a circulating fluidized bed boiler for burning low-heat-value high-ash fuel. The circulating fluidized bed boiler comprises a hearth, a primary air chamber, a cyclone separator, a dipleg, a material returning valve, a slag discharging pipe, a gas-solid heat exchanging bed and a tail flue. The tail flue is internally provided with a superheater, an economizer and an air preheater. The gas-solid heat exchanging bed is connected with the dipleg through an ash discharging pipe. A part of high-temperature returning ash in the dipleg enters into the gas-solid heat exchangingbed. The gas-solid heat exchanging bed comprises a heat exchanging bed air chamber, a heat exchanging bed air cap, a heat exchanging bed heat exchanging chamber, a heat exchanging bed gas-solid separation device and a heat exchanging bed slag discharging pipe. A gas outlet in the top of the heat exchanging bed gas-solid separation device is connected with the primary air chamber of the boiler through a gas pipeline. The heat exchanging bed air chamber is connected with the air preheater through the gas pipeline. According to the circulating fluidized bed boiler, on the one hand, partial ash cooling and slag discharging are realized by utilizing the gas-solid heat exchanging bed, the ash slag heat is fully recovered, the heat loss of slag discharging is reduced, and the heat efficiency ofthe boiler is improved; and on the other hand, primary air temperature can be greatly improved, and stable burning of the low-heat-value high-ash fuel is facilitated.

Owner:TSINGHUA UNIV

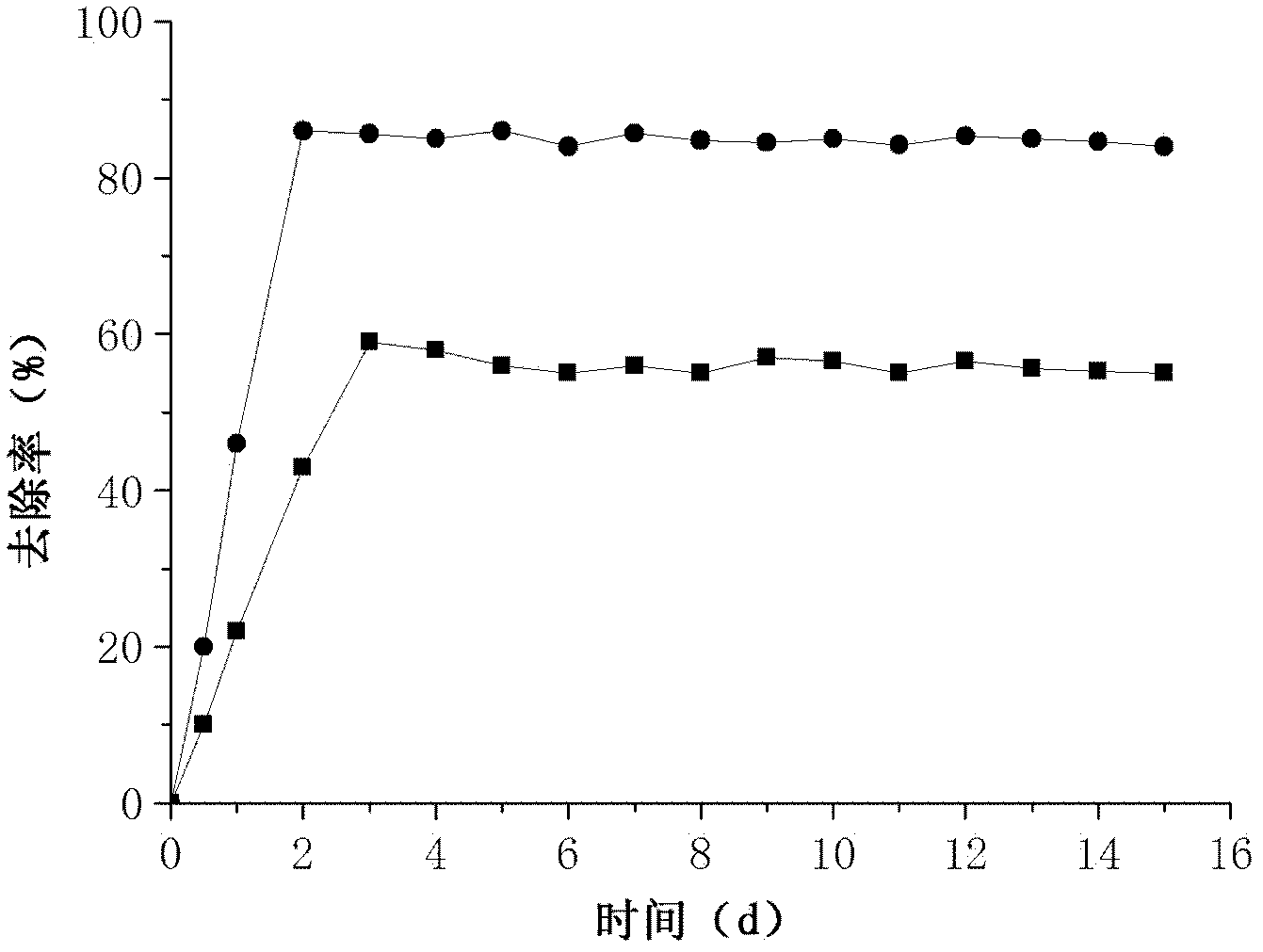

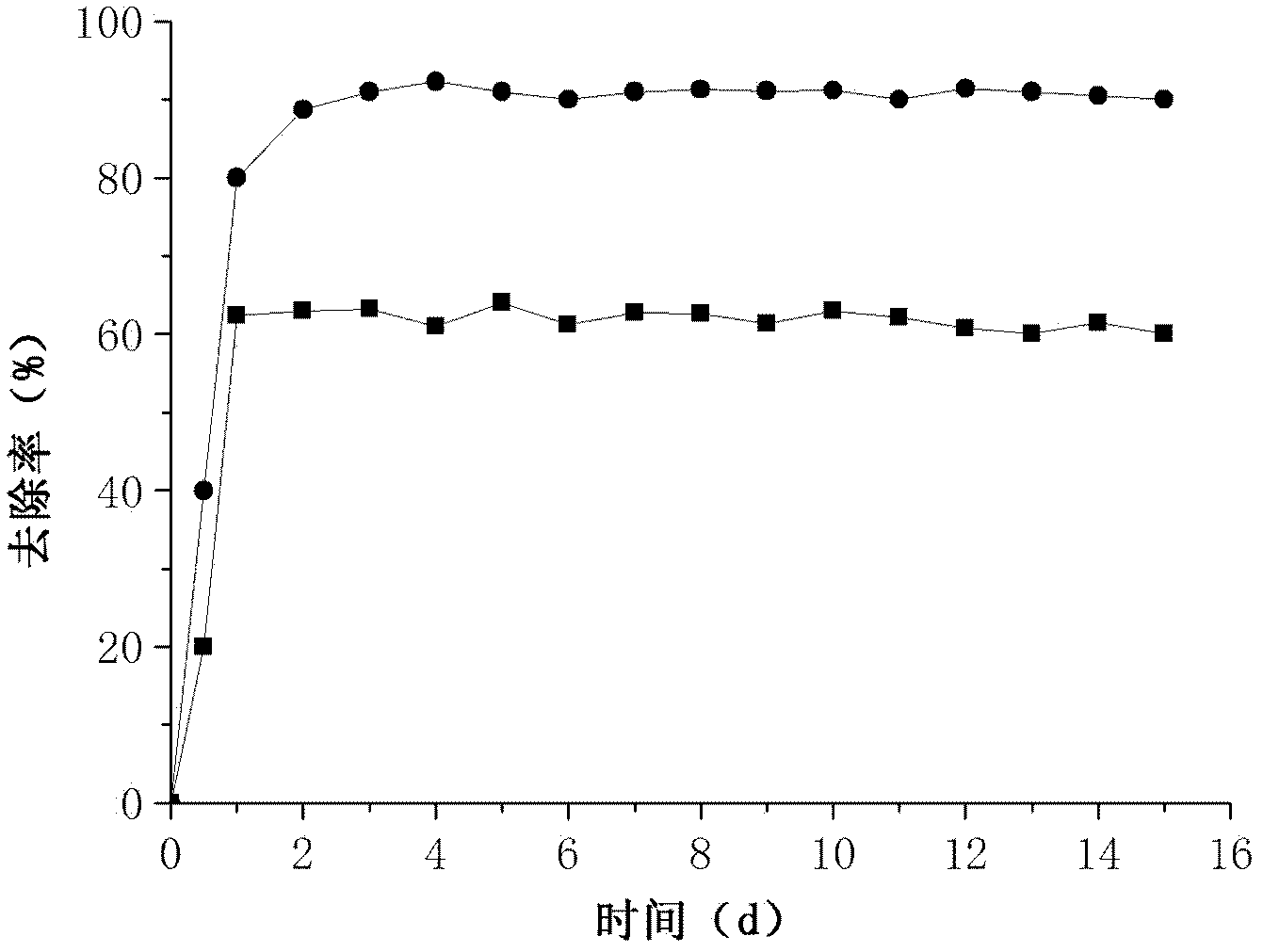

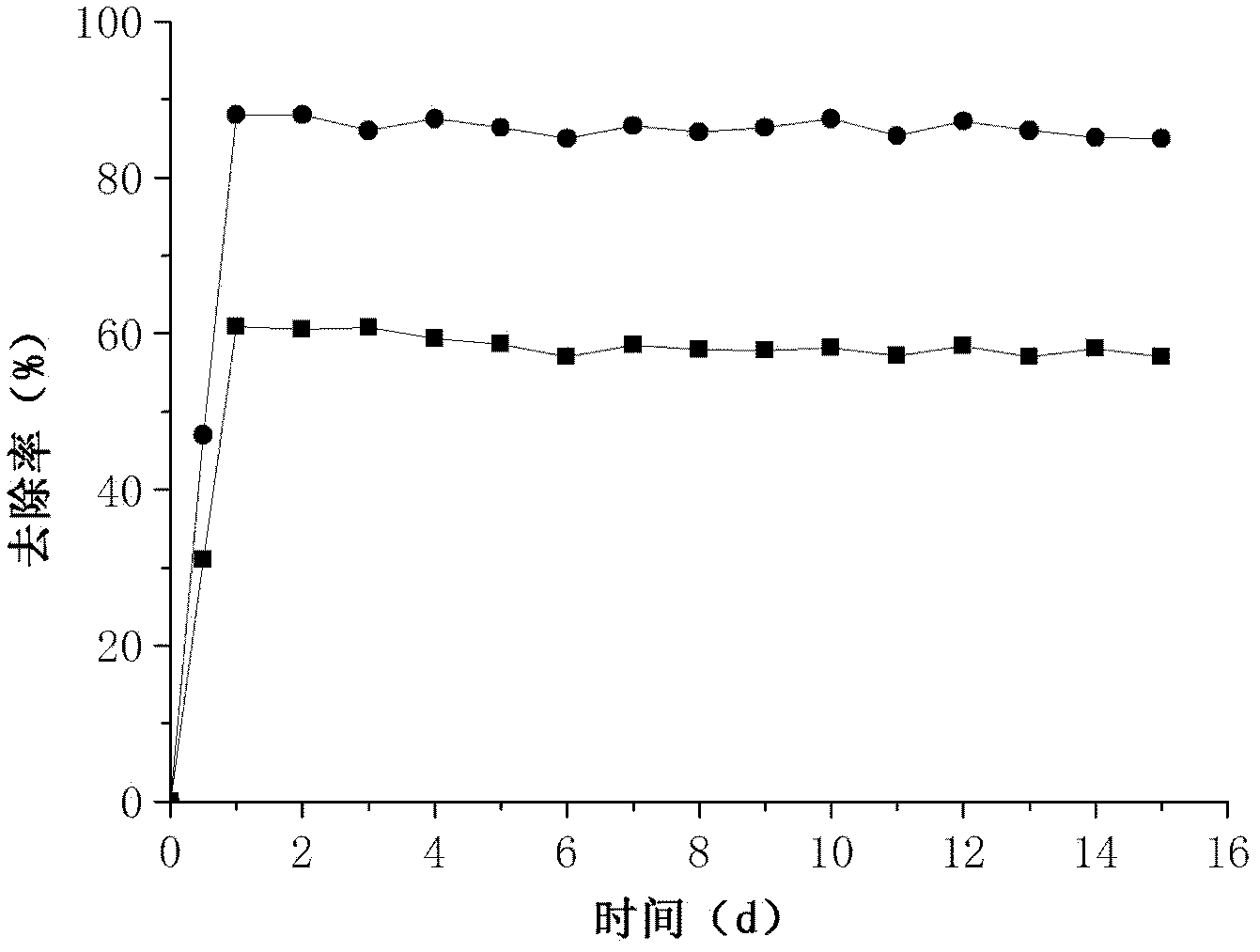

Microbial fuel cell three-level continuous type waste water nitrogen-removing treatment method and device

ActiveCN102557272BEfficient recyclingReduce startup timeFinal product manufactureFuel cell auxillariesThree levelPseudomonas putida

The invention relates to a microbial fuel cell three-level continuous type waste water nitrogen-removing treatment method and a microbial fuel cell three-level continuous type waste water nitrogen-removing treatment device. The method is characterized by comprising the following steps: immobilizing the immobilized pseudomonas putida novel anode, which is obtained through manufacturing and pretreatment of an anode plate and immobilization of pseudomonas putida, in an anode chamber for treating ammonia nitrogen waste water; immobilizing the manufactured and pretreated cathode plate into a cathode chamber for treating nitrate nitrogen waste water, wherein the flow velocity is 0.4 to 0.8 mL / min; continuously treating at the temperature of 15 and 35 DEG C for 15 days; monitoring the output voltage of a microbial fuel cell on time through an electrochemical work station; and measuring the change of the ammonia nitrogen content of the ammonia nitrogen waste water and the change of the nitrate nitrogen content of the nitrate nitrogen waste water every other 24 hours, wherein the output voltage of the cell always ranges from 1.583 v to 1.867 v, the ammonia nitrogen removal rate of the nitrate nitrogen waste water always ranges from 55.6 to 64.7 percent, and the nitrate nitrogen removal rate of the nitrate nitrogen waste water always ranges from 84.6 to 92.3 percent. The pseudomonas putida is derived from the China General Microbiological Culture Collection Center.

Owner:杭州唯铂莱生物科技有限公司

Lipid-decreasing functional peptide by using silkworm chrysalis as raw material

InactiveCN108220375AHigh yieldReduce lossesHydrolysed protein ingredientsMetabolism disorderFood additiveUltrafiltration

The invention discloses lipid-decreasing functional peptide by using silkworm chrysalis as raw material. The molecular weight of the lipid-decreasing functional peptide is 620 to 1200Da. A preparationmethod of the functional peptide comprises the following steps of pretreatment of silkworm chrysalis powder: adding a mixed solution of n-hexane and petroleum ether into the silkworm chrysalis powder, heating and refluxing, so as to obtain silkworm chrysalis protein; adding distilled water into the silkworm chrysalis protein powder, uniformly mixing, adding alkaline protease and papain, then adding D-carnitine, hydrolyzing by enzyme, deactivating enzyme, cooling, and then centrifuging, so as to obtain a supernatant for further use, namely an enzyme hydrolysis liquid; filtering the enzyme hydrolysis liquid by an ultrafiltration film, so as to obtain an ultrafiltration enzyme hydrolysis liquid; sequentially performing gel column chromatography, ion exchange resin chromatography, and high performance liquid chromatography purification on the ultrafiltration enzyme hydrolysis liquid, so as to obtain the lipid-decreasing functional peptide. The lipid-decreasing functional peptide has the beneficial effects that most of lipid forming genes can be regulated down, the stacking of lipid is decreased, the lipid-decreasing function is realized, and the lipid-decreasing functional peptide canbe developed into lipid-decreasing medicines, health-care products and food additives.

Owner:海盐县凌特生物科技有限公司

Back coating device and compound machine using same

ActiveCN111304963AIncrease heatAvoid condensationPaper/cardboardPulp material addition processesCoatingElectric heating

The invention relates to a back coating device. The back coating device comprises a box body, and a back coating groove is formed in the box body. A hydrophilic roller in contact with back coating liquid, a coating roller propped against the hydrophilic roller and an auxiliary roller playing a propping role are mounted in the back coating groove. A back coating tank is mounted in the box body. A water outlet communicated with the back coating tank is formed in the bottom of the back coating groove. A water inlet is formed in the side wall of the back coating tank. A feeding pipe is installed at the water inlet, and the feeding pipe is communicated with the back coating groove. A water pump used for pumping back coating liquid is installed on the feeding pipe. A coiled pipe is installed inthe back coating tank, one end of the coiled pipe is communicated with the water outlet, the other end of the coiled pipe is communicated with the water inlet, and an electric heating wire used for heating the coiled pipe is wound on the peripheral side wall of the coiled pipe. The back coating device can be prevented from being condensed when used at a low temperature.

Owner:上海鼎韧包装科技有限公司

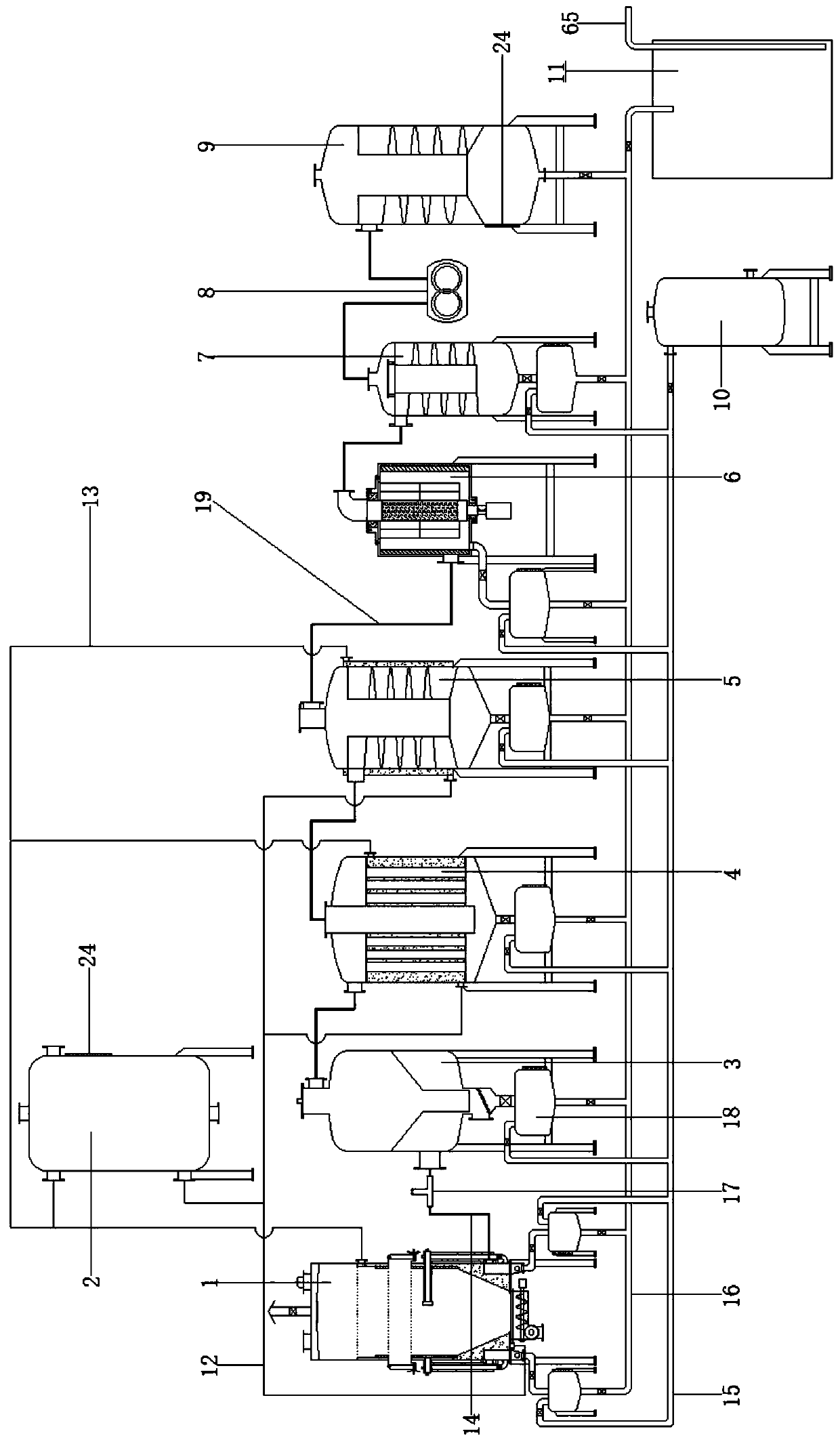

Biomass thermal cracking water-cooling carbon-gas co-production gasification system

PendingCN111500322AImprove purification efficiencyHigh purityGasifier feeding meansGasification processes detailsFiltrationCoke

The invention discloses a biomass thermal cracking water-cooling carbon-gas co-production gasification system which comprises a gasification furnace, a cooling water tank and a plurality of groups ofgas purification systems. Each gas purification system comprises a sand filtration tank, a cooling tank, a filter, a centrifugal separator, a Roots blower and a gas storage tank which are sequentiallyconnected in series by adopting a gas delivery pipe B; a gas outlet of the gasification furnace is connected with a gas inlet of the sand filtration tank through a gas conveying pipe A; a ventilationvalve is arranged on the gas conveying pipe A; a coke outlet of a coke outlet hopper and the bottom ends of the sand filtration tank, the cooling tank, the filter and the centrifugal separator are connected with a liquid accumulation box through liquid discharging pipes respectively, and a liquid changing opening in the bottom of the liquid accumulation box and a liquid releasing opening of the gas storage tank are connected with a liquid storage pool through liquid changing pipelines. According to the biomass thermal cracking water-cooling carbon-gas co-production gasification system, efficient separation of biomass gas generated by the gasification furnace and other impurities is achieved; compared with the prior art, the disclosed system has the following advantages: purification efficiency of the biomass gas is remarkably improved, the purity of the biomass gas is improved, and then the combustion efficiency of the biomass gas is improved.

Owner:王向荣

An automatic liquid mixing and quantitative addition device for industrial production

InactiveCN108993323AOptimize operationSave human effortFlow mixersTransportation and packagingDrive motorEngineering

An automatic liquid mixing and quantitative addition device for industrial production is disclosed. The device includes a liquid storage chamber. The lower part of the left end of the liquid storage chamber is provided with a liquid discharging pipe. The left part of the upper end of the liquid storage chamber is fixedly connected to a liquid adding chamber. First to fifth baffle plats are fixedlymounted in the liquid adding chamber in order from top to bottom in an equally spaced manner. Through arrangement of a quantifying chamber, a first gas conveying pipe, a first check valve, a second gas conveying pipe, a second check valve, a first pushing plate, a push bar, a spring, a second pushing plate, a rotating disk, a drive motor, a switch valve and the liquid discharging pipe, the objective of quantitatively discharging liquid from the liquid storage chamber is achieved, quantitative liquid addition is optimized and labor is saved. Through arrangement of the first to fifth baffle plates and drain holes, the solution flowing path is increased, thus facilitating more uniform solution mixing.

Owner:清远市知途自动化科技有限公司

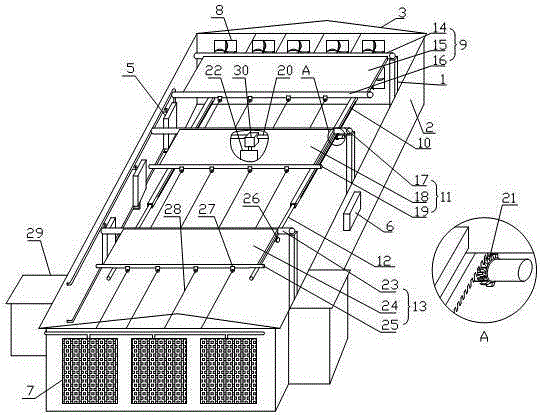

Solar baffling structural container type high-temperature solid heat storing device

PendingCN110118444AIncrease the flow distanceExtension of timeSolar heating energyHeat storage plantsEngineeringHot Temperature

The invention provides a solar baffling structural container type high-temperature solid heat storing device. The device comprises an outer heat insulated protecting housing which is elongated, wherein a heat transferring medium inlet and a heat transferring medium outlet are correspondingly formed in two ends of the outer heat insulated protecting housing; high temperature resistant baffling plates which are staggered at the upper part and the lower part are arranged in the outer heat insulated protecting housing between the heat transferring medium inlet and the heat transferring medium outlet; the bottom part and two sides of the high temperature resistant baffling plate at the lower part are connected to the inner wall of the outer heat insulated protecting housing, and a clearance isreserved between the top part of the high temperature resistant baffling plate at the lower part and the inner wall of the outer heat insulated protecting housing; the top part and two sides of the high temperature resistant baffling plate at the upper part are connected to the inner wall of the outer heat insulated protecting housing; and a clearance is reserved between the bottom part of the high temperature resistant baffling plate at the upper part and the inner wall of the outer heat insulated protecting housing. According to the device, a complete mechanical structure is adopted, so thatthe sealing performance is high; a container type structure is adopted, so that the convenience of conveying, mounting and arranging is ensured; inner parts and rotating parts are saved, so that thefault rate is low, and the maintaining workload is small; and a normal pressure device is provided, so that the cost is low.

Owner:LANZHOU JIAOTONG UNIV

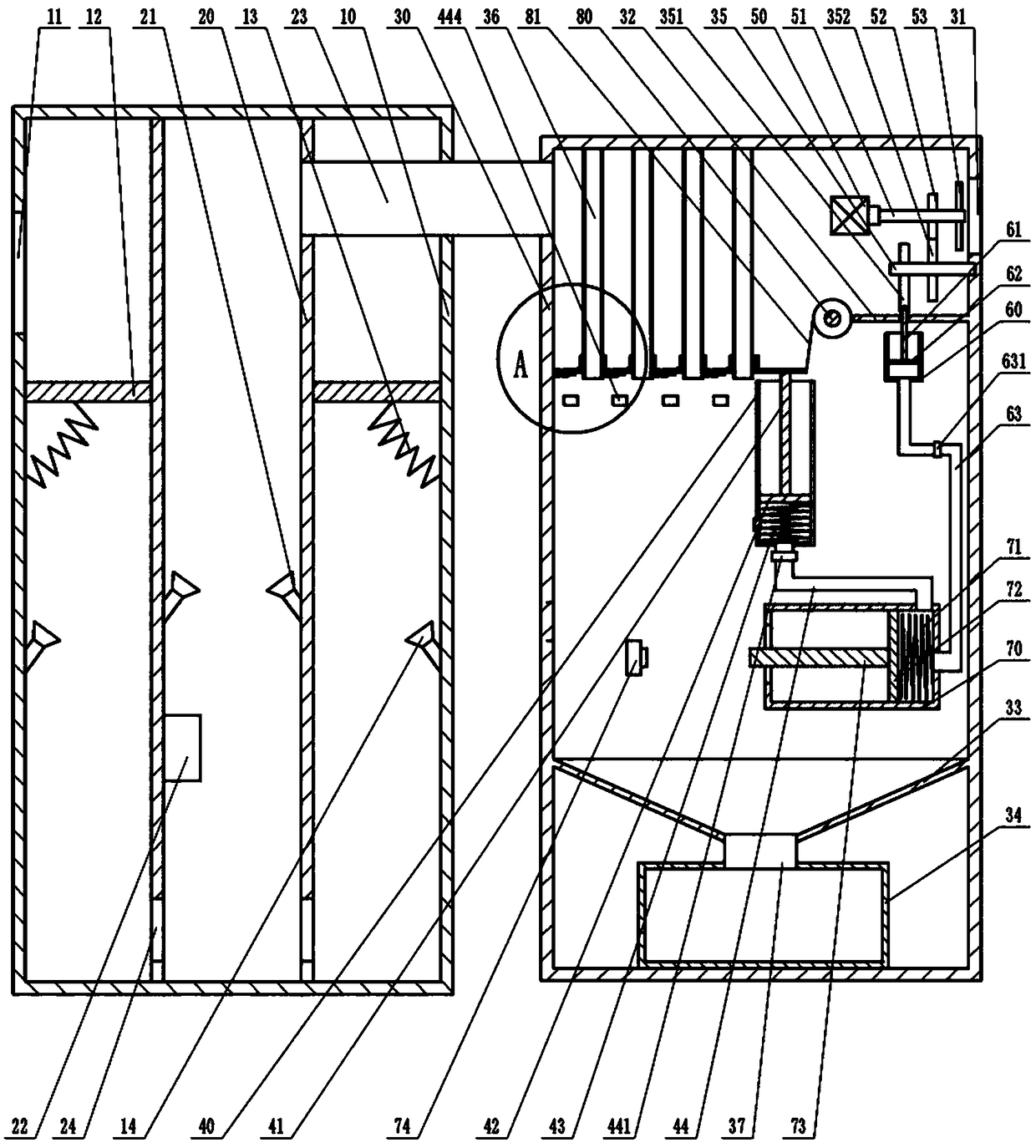

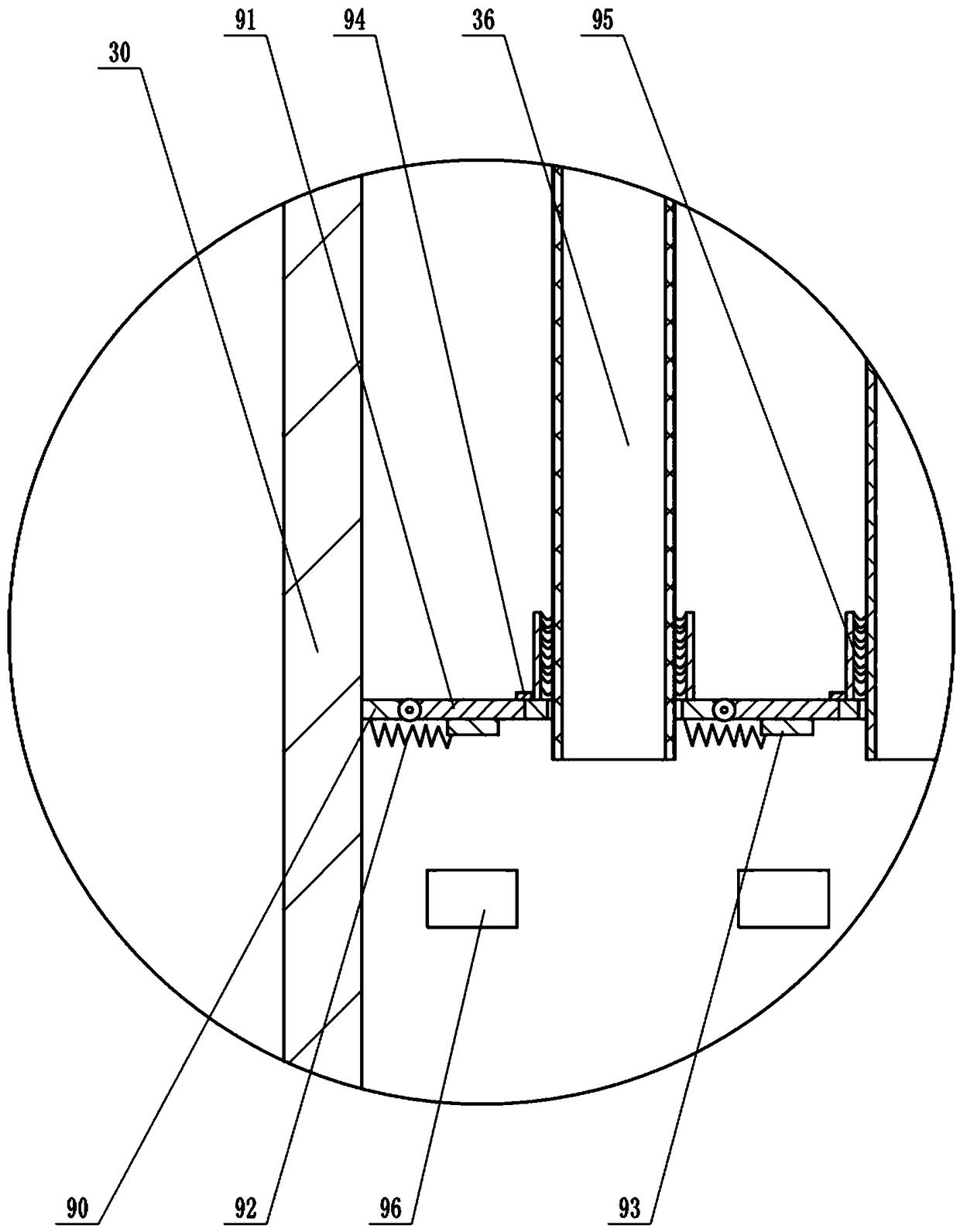

Intensive cultivation chamber for potato seedling cultivation

InactiveCN106561340AReduce the risk of infringementAvoid enteringClimate change adaptationGreenhouse cultivationEngineeringSolanum tuberosum

The invention discloses an intensive cultivation chamber for potato seedling cultivation. The intensive cultivation chamber comprises a bracket. The periphery of the bracket is provided with a side walls. A transparent roof is arranged above the side walls. A sun shading device is arranged below the transparent roof. A seedling placement rack is arranged below the sun shading device. A cultivation space which is surrounded by the side walls is internally provided with a warmer. The warmer is connected with a boiler. The side wall which faces the warmer is provided with a drawing fan. The side wall next to the drawing fan is provided with a water curtain. The side wall which faces the water curtain is provided with a negative-pressure fan. The sun shading device comprises a first sun shading unit which is connected with the head end of a long tooth bar. The long tooth bar is provided with a second sun shading unit. The end of the long tooth bar is connected with the head end of the a sun shading rod. A third sun shading unit is arranged above the sun shading rod. According to the intensive cultivation chamber, the growing condition of the potato seedlings can be set according to a preset experiment condition, thereby realizing fine control. Furthermore the intensive cultivation chamber has advantages of better experiment effect, high convenience in use, labor-saving effect and simple operation.

Owner:GUIZHOU HENGFENG TECH DEV

Negative pressure sewage ecological treatment tank

ActiveCN109292990AIncrease sewage capacityIncrease the flow distanceBiological water/sewage treatmentEmission standardEngineering

The invention discloses a negative pressure sewage ecological treatment tank. The treatment tank comprises a main water tank. The main water tank is divided into a water feeding section, a negative pressure section and a water outlet section. The bottom of the water feeding section is provided with diatomite mud. A water feeding pipe is arranged at the bottom of the water feeding section. The water feeding section is provided with the water feeding pipe, a high pressure gas pipe and a silt discharge pipe. The high pressure gas pipe is connected to a high pressure gas source system. The upper part of the negative pressure section is provided with a negative pressure chamber. A lower port of the negative pressure chamber is below the water level. The top of the negative pressure chamber is connected with an exhaust pipe. A water flow channel is arranged in the negative pressure chamber. An aquatic plant planting rack and aquatic plants are arranged in the water flow channel. Two ends ofthe water flow channel are respectively communicated with the water feeding section and the water outlet section. An adsorption medium, an overflow wall and a water outlet pipe are arranged in the water outlet section. The overflow wall is located between the adsorption medium and an opening of the water outlet pipe. The negative pressure sewage ecological treatment tank has the advantages of small occupied area, large sewage capacity and shallow bottom of the pool, can fully mix the diatomite mud and the sewage, and has a lot of ecological decontamination processes so that the treated sewagecan meet the national emission standards.

Owner:淼汇能源科技(上海)有限公司

Anesthetic waste gas extraction device for anesthesia department

InactiveCN111214942AAchieve purification effectAchieving processing powerDispersed particle separationDirt cleaningAnesthetic departmentEngineering

The invention relates to an anesthetic waste gas extraction device for the anesthesiology department. The anesthetic waste gas extraction device comprises a purification box and a sterilization cylinder; a partition plate is arranged in the purification box and divides the internal space of the purification box into a first chamber and a second chamber; a communicating hole is formed in the partition plate and communicates the first cavity with the second cavity; a sodium hydroxide solution is arranged in the first cavity, a gas inlet pipe is arranged on the purification box, a gas pump is arranged on the gas inlet pipe, one end of the gas inlet pipe is inserted into the sodium hydroxide solution, and an adsorption layer is arranged in the second cavity; and the sterilization cylinder is provided with a sterilization cavity, the sterilization cylinder is provided with a gas inlet and a discharge outlet, the gas inlet and the discharge outlet are both communicated with the sterilizationcylinder, the gas inlet is communicated with the second cavity, the sterilization cylinder is provided with an ultraviolet lamp, and the lamp tube of the ultraviolet lamp is located in the sterilization cylinder and extends in the length direction of the sterilization cylinder.

Owner:李庆磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com