Device and process for mass transfer process for treating wastewater through supergravity enhanced electric Fenton method

A technology for treating wastewater and mass transfer process, applied in the field of water treatment, can solve problems such as limited mass transfer, achieve the effects of reducing mass transfer resistance, eliminating concentration polarization, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

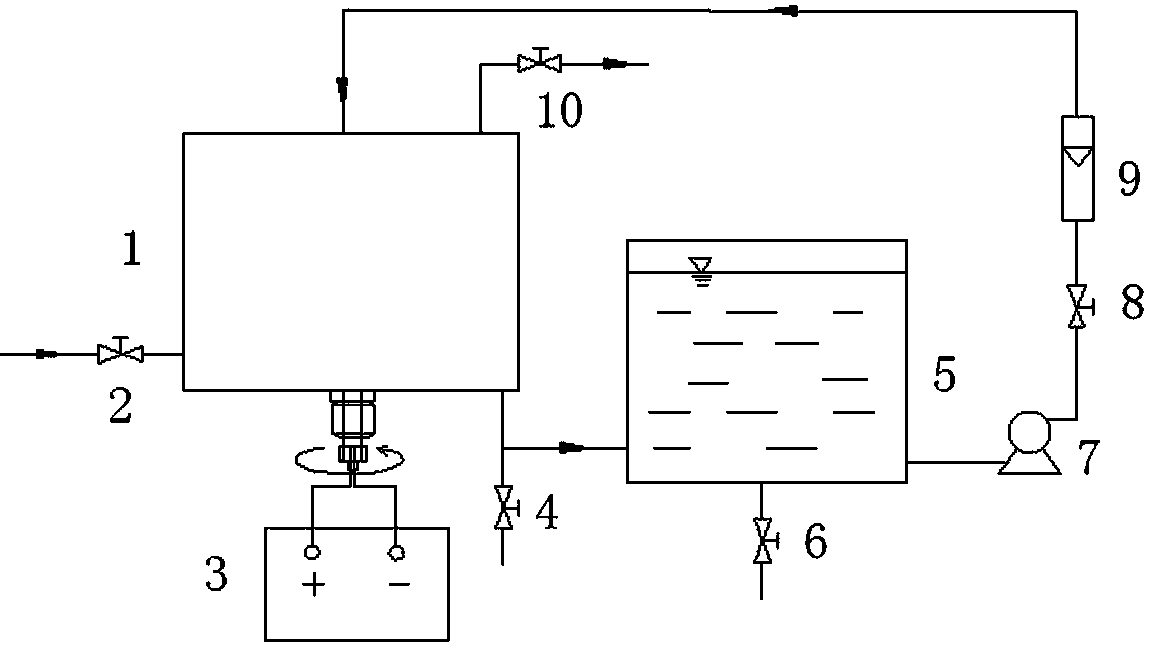

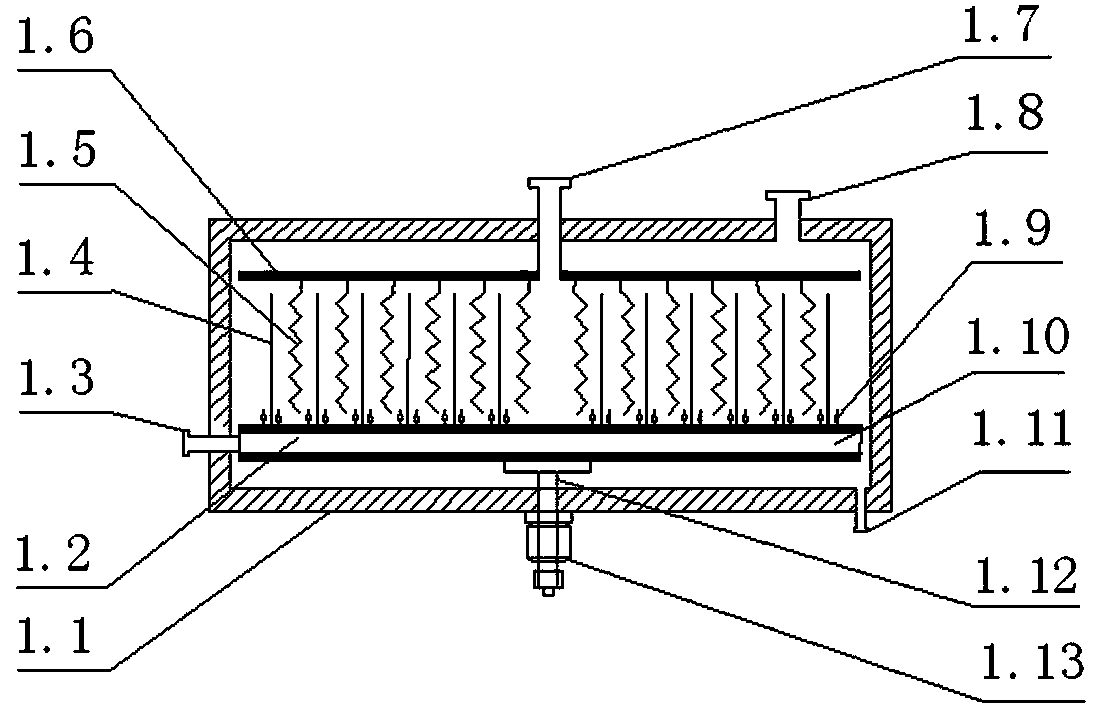

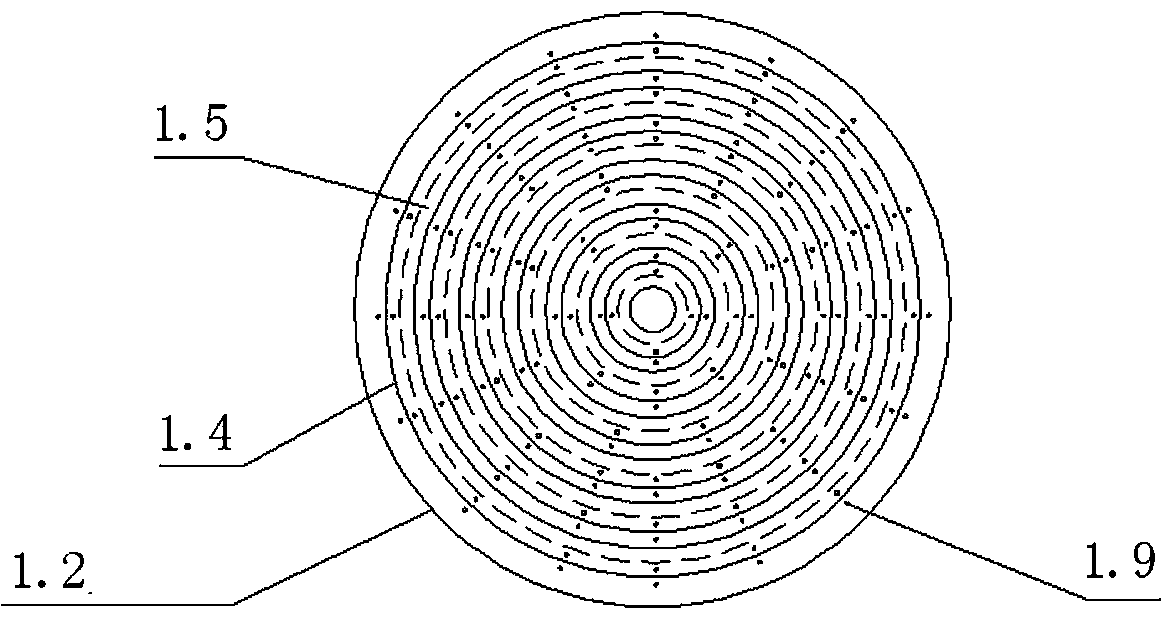

[0053] Example 1: Treatment of nitrobenzene wastewater by the Fenton method of high-gravity electricity.

[0054] The outer casing of the hypergravity electric Fenton reaction device is made of stainless steel and is lined with an insulating layer. The inner diameter is 300mm and the height is 200mm. The anode material of the concentric corrugated cylinder is iron, the cathode material of the concentric cylinder is graphite, the distance between the cathode and anode electrodes is 5mm, the number of cathode or anode electrodes is 6, and the electrode height is 100mm. The distance between the connection pads is equal to 10mm.

[0055] The initial COD content in nitrobenzene wastewater was 2740mg / L. Dosing H into the wastewater storage tank before treatment 2 SO 4 The solution adjusts the initial pH of the wastewater to 3. Turn on the DC stabilized power supply, and the waste water enters the supergravity electric Fenton reaction device through the waste water inlet pipe....

example 2

[0056] Example 2: Treatment of waste water containing organophosphorus pesticides by the Fenton method of high-gravity electricity.

[0057] The outer casing of the hypergravity electric Fenton reaction device is made of stainless steel and is lined with an insulating layer. The inner diameter is 400mm and the height is 240mm. The anode material of the concentric corrugated cylinder is iron, the cathode material of the concentric cylinder is stainless steel covered with activated carbon fiber material, the distance between the cathode and anode electrodes is 5mm, the number of cathode or anode electrodes is 6, and the electrode height is 120mm. The distance between the cylindrical anode and the cathode connection plate is equal to 10mm.

[0058] The initial COD content in the wastewater of organophosphorus pesticides was 4500mg / L. Dosing H into the wastewater storage tank before treatment 2 SO 4 The solution adjusts the initial pH of the wastewater to 3.5. Turn on the D...

example 3

[0059] Example 3: Treatment of petrochemical wastewater containing phenol by the Fenton method of high-gravity electricity.

[0060] The outer casing of the hypergravity electric Fenton reaction device is made of stainless steel and is lined with an insulating layer. The inner diameter is 200mm and the height is 140mm. The anode material of the concentric corrugated cylinder is iron, the cathode material of the concentric cylinder is graphite, the distance between the cathode and anode electrodes is 5mm, the number of cathode or anode electrodes is 4, and the electrode height is 80mm. The distance between the lands is equal to 8mm.

[0061] The initial COD content in petrochemical phenolic wastewater was 640mg / L. Dosing H into the wastewater storage tank before treatment 2 SO 4 The solution adjusts the initial pH of the wastewater to about 2.5. Turn on the DC stabilized power supply, and the waste water enters the supergravity electric Fenton reaction device through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com